A kind of polyamide composite material with good tactility and easy encapsulation and preparation method thereof

A composite material and polyamide technology, applied in the field of polyamide materials, can solve the problems of low efficiency, high cost, large operation workload, etc., and achieve the improvement of surface polarity, good adhesion, and good tear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

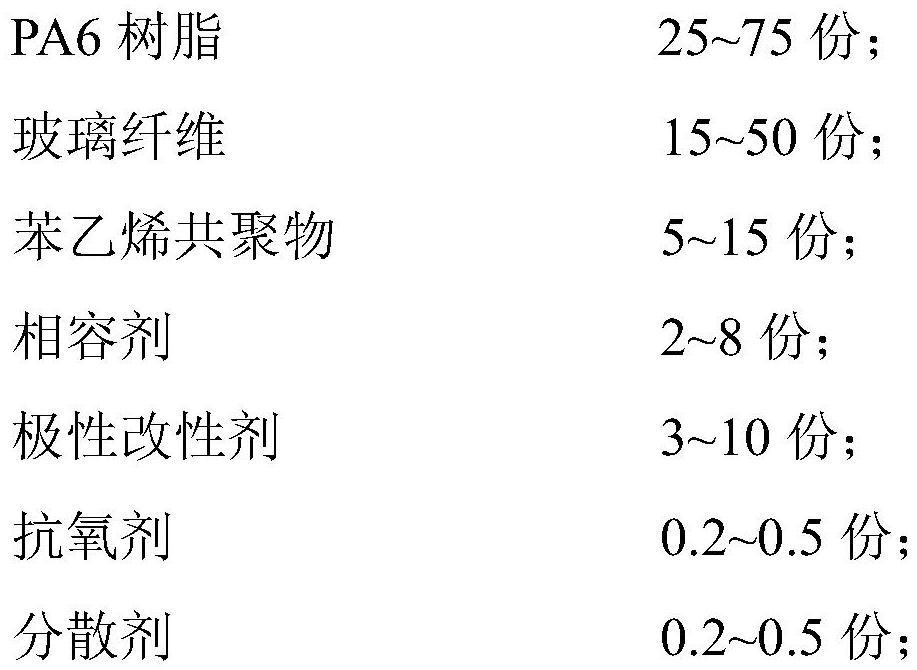

Method used

Image

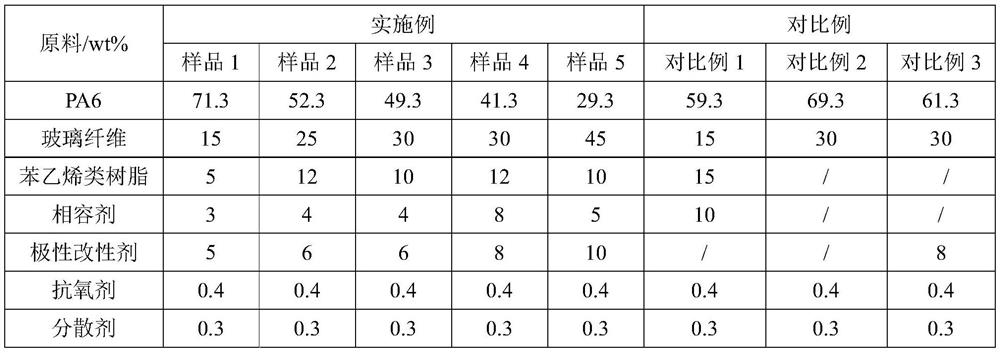

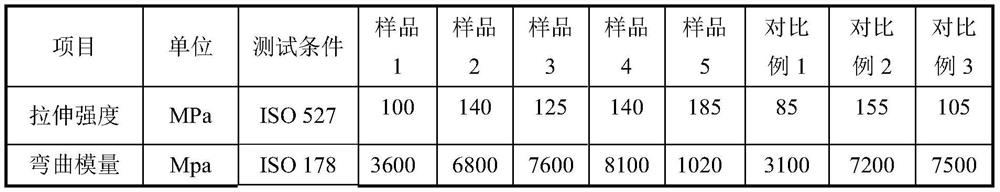

Examples

Embodiment

[0033] Put the other components except glass fiber into the high mixer according to the ratio in Table 1, mix for 5-10 minutes, and then discharge to obtain the mixture, and add it from the main feeding port of the twin-screw extruder, and the glass fiber is fed from the side Then control the processing temperature of the twin-screw extruder to 200-260°C, the screw speed to 180-600 rpm, and put the mixture in the twin-screw extruder to extrude and granulate to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com