Patents

Literature

1640results about How to "Guaranteed rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

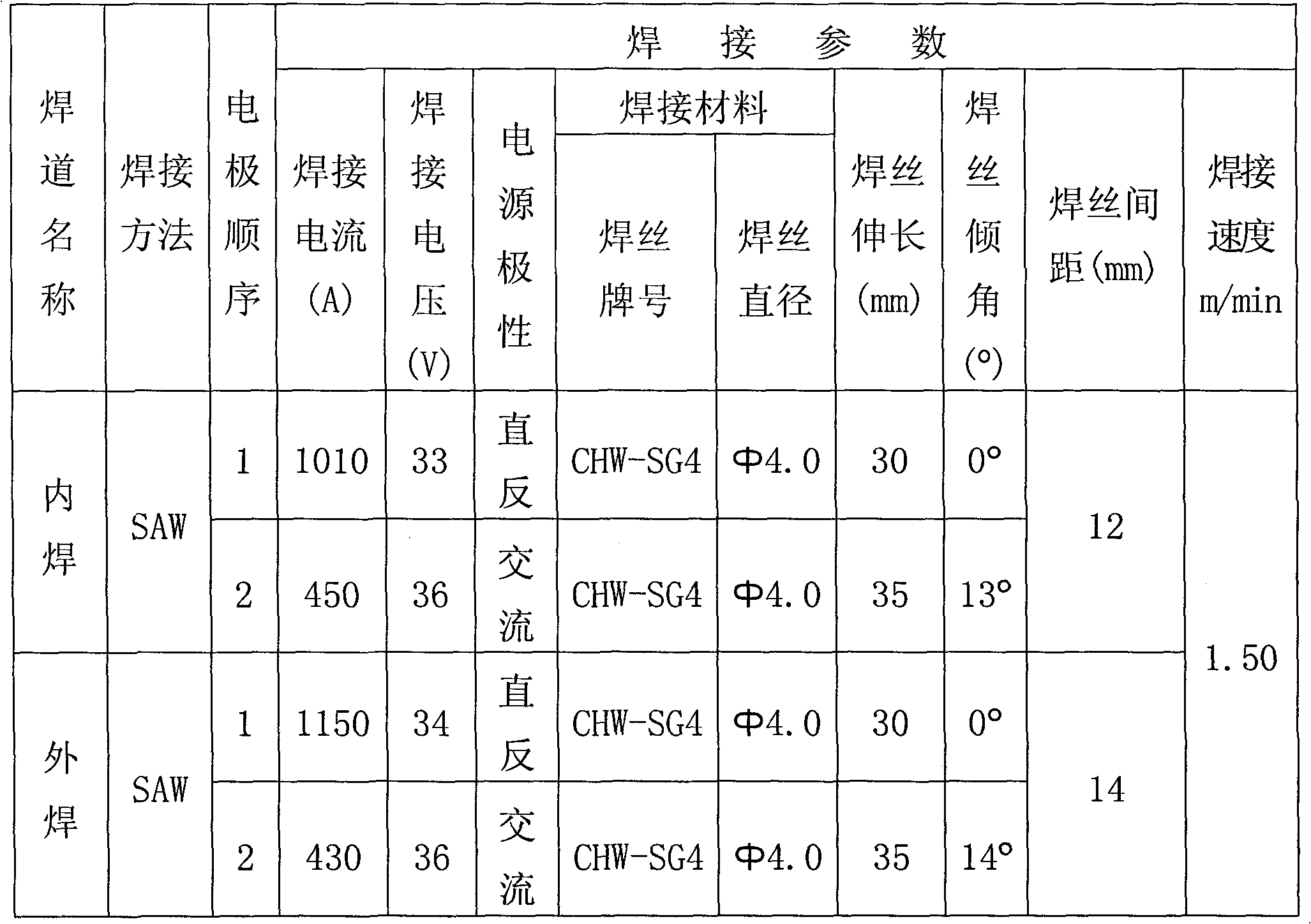

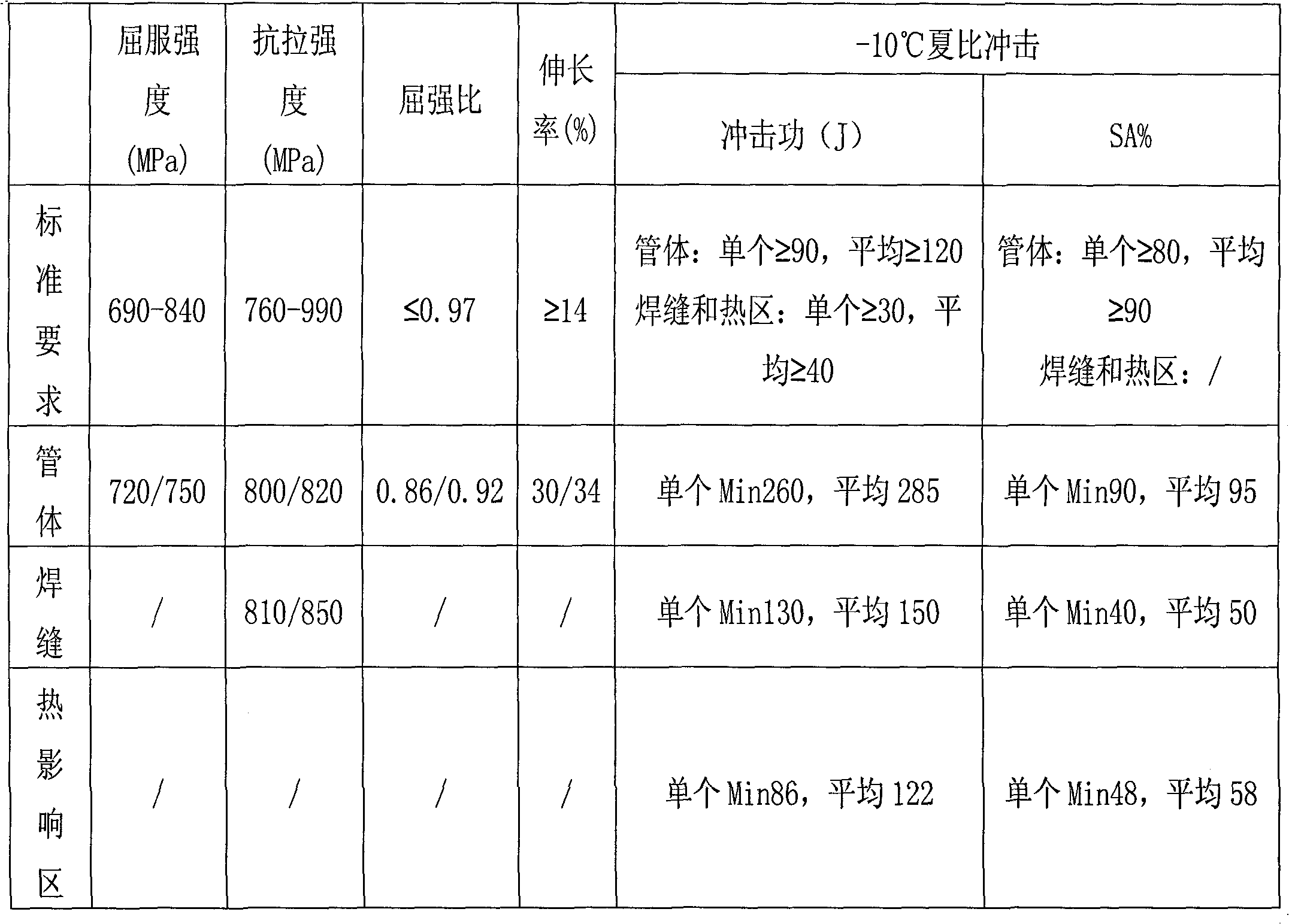

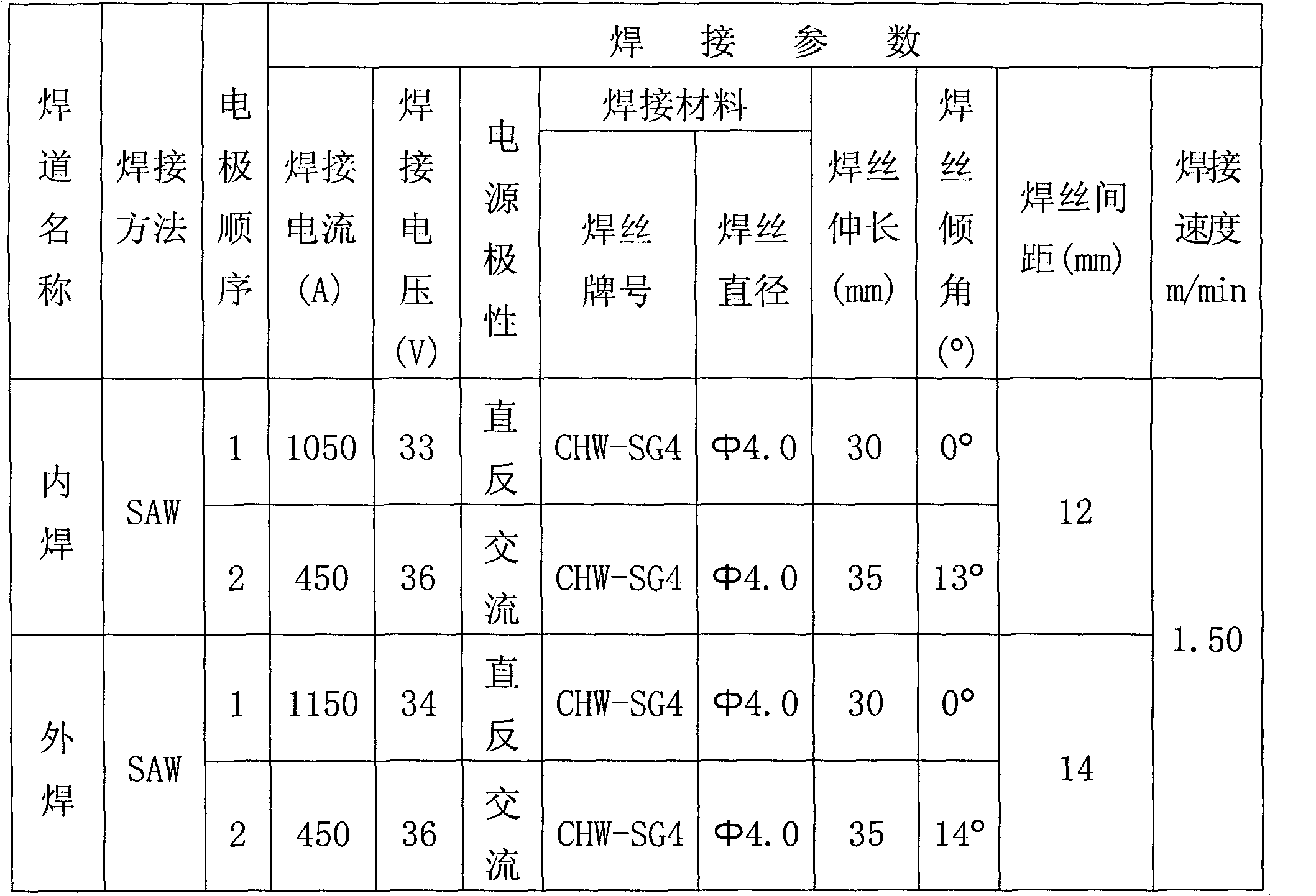

Method for manufacturing high-strength X80 steel spiral welded pipe

InactiveCN101205587AReduced dimensional accuracyImprove docking efficiencyArc welding apparatusWelding/cutting media/materialsUltrasound testSteel plates

The invention discloses a method for manufacturing a high-strength (X 80) steel spiral weld pipe. The weld pipe adopts a parent metal of X 80 rolled steel plate, and the chemical compositions of weld pipe are: 0.02 to 0.09 percent of C, 0.10 to 0.42 percent of Si, 1.50 to 1.85 percent of Mn, less than or equal to 0.022 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.45 percent of Cr, less than or equal to 0.50 percent of Ni, less than or equal to 0.30 percent of Cu, less than or equal to 0.35 percent of Mo, less than or equal to 0.025 percent of Ti, less than or equal to 0.11 percent of Nb, less than or equal to 0.06 percent of V, less than or equal to 0.06 percent of Al, less than or equal to 0.008 percent of N, less than or equal to 0.0005 percent of B, and less than or equal to 0.23 percent of Pcm. The manufacturing procedures includes: decoiling, leveling, edge milling, prebending, molding, internal welding, external welding, pipe end expending, hierarchical ultrasonic examination of parent metal, X-ray examination of welded seam, hydraulic pressure test, ultrasonic examination of welded seam, pipe end chamfering, finished product examination, etc. The (X 80) steel spiral weld pipe( ID: 1219mm, thickness:18.4mm) manufactured by the invention successfully solves the problem of poor stability and unsatisfactory welded seam performance, etc. in the manufacturing process of the high-strength (X 80) steel spiral weld pipe, thereby greatly improving the pass-rate and working efficiency.

Owner:CNPC BOHAI EQUIP MFG +1

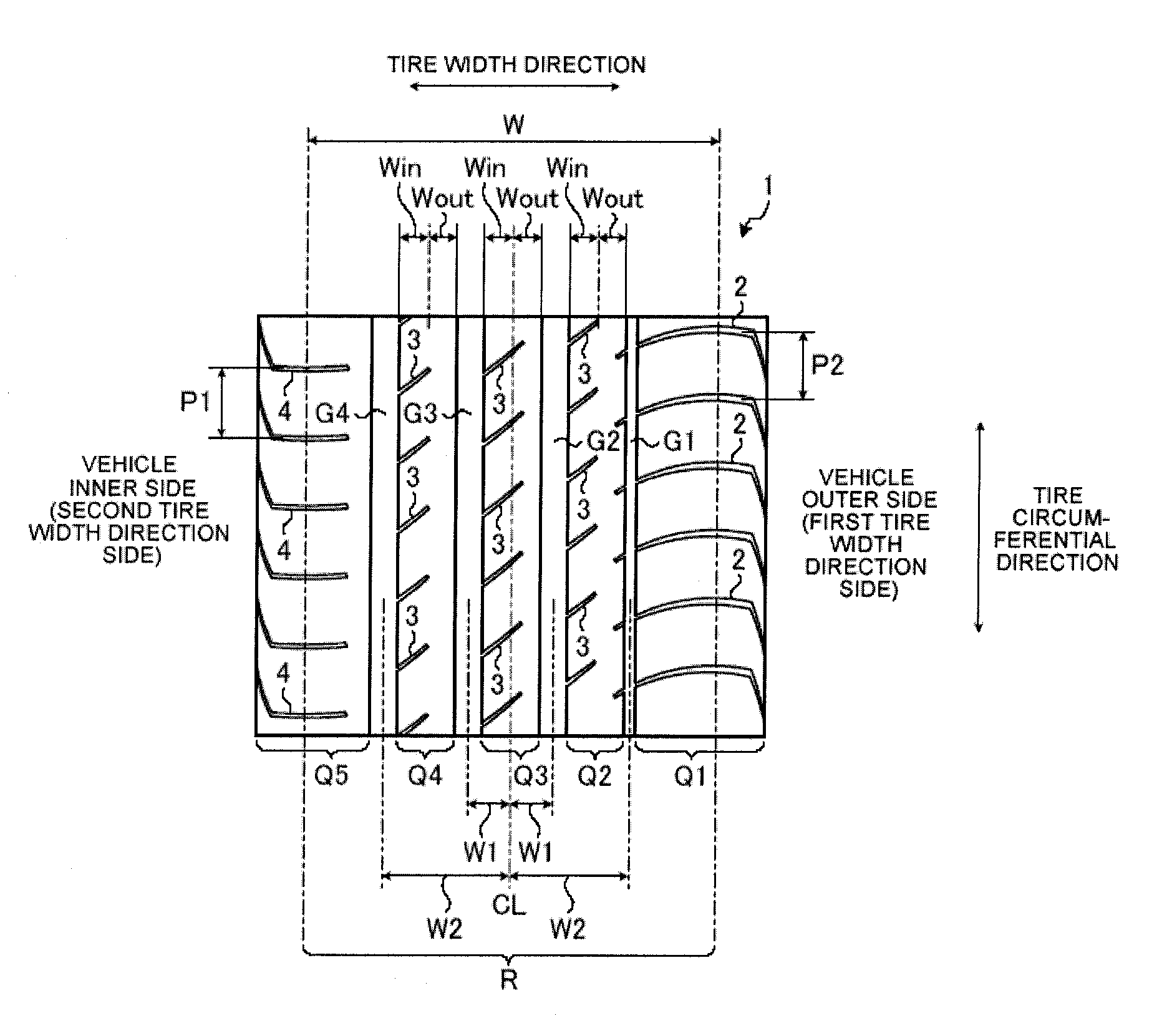

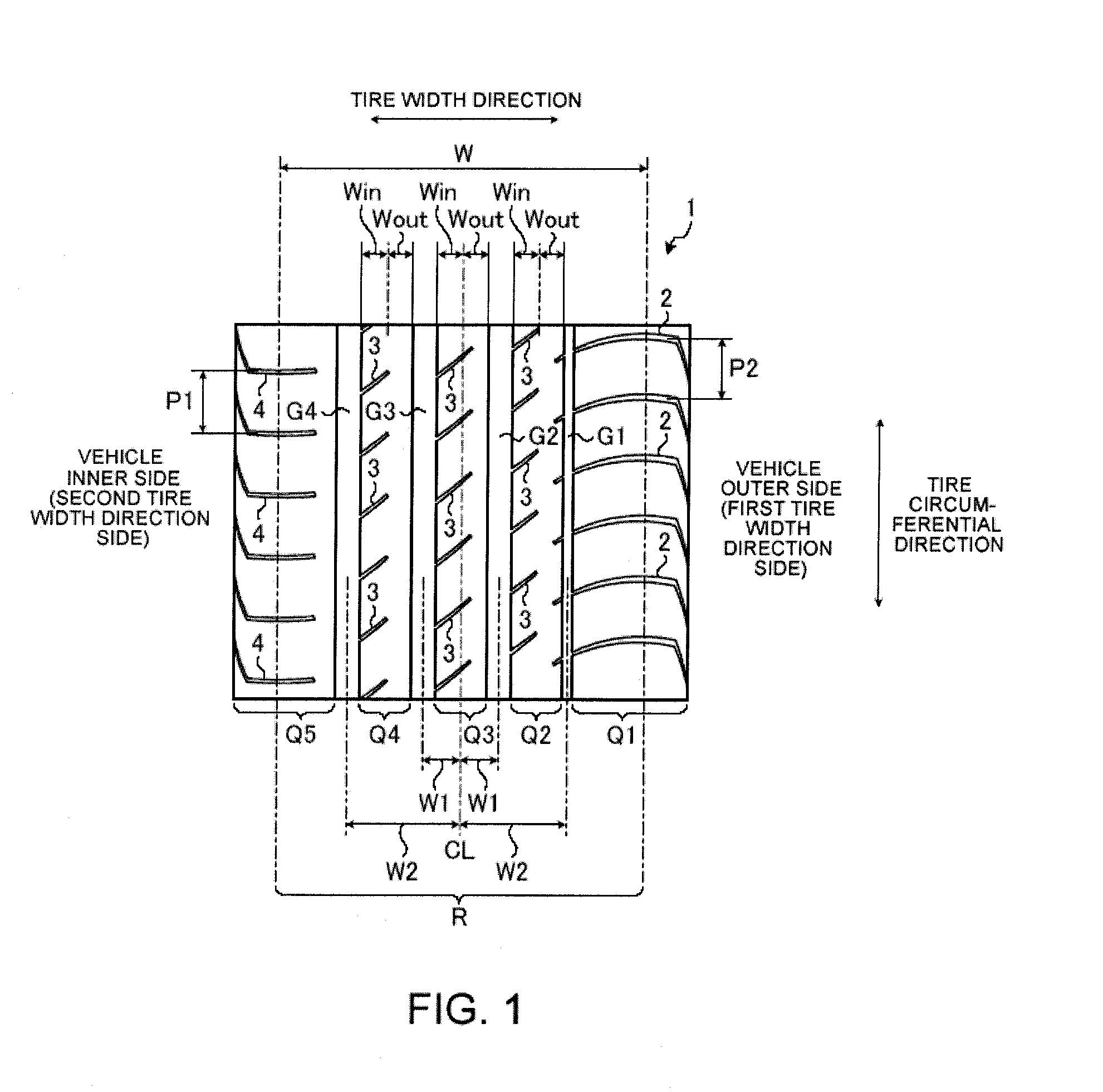

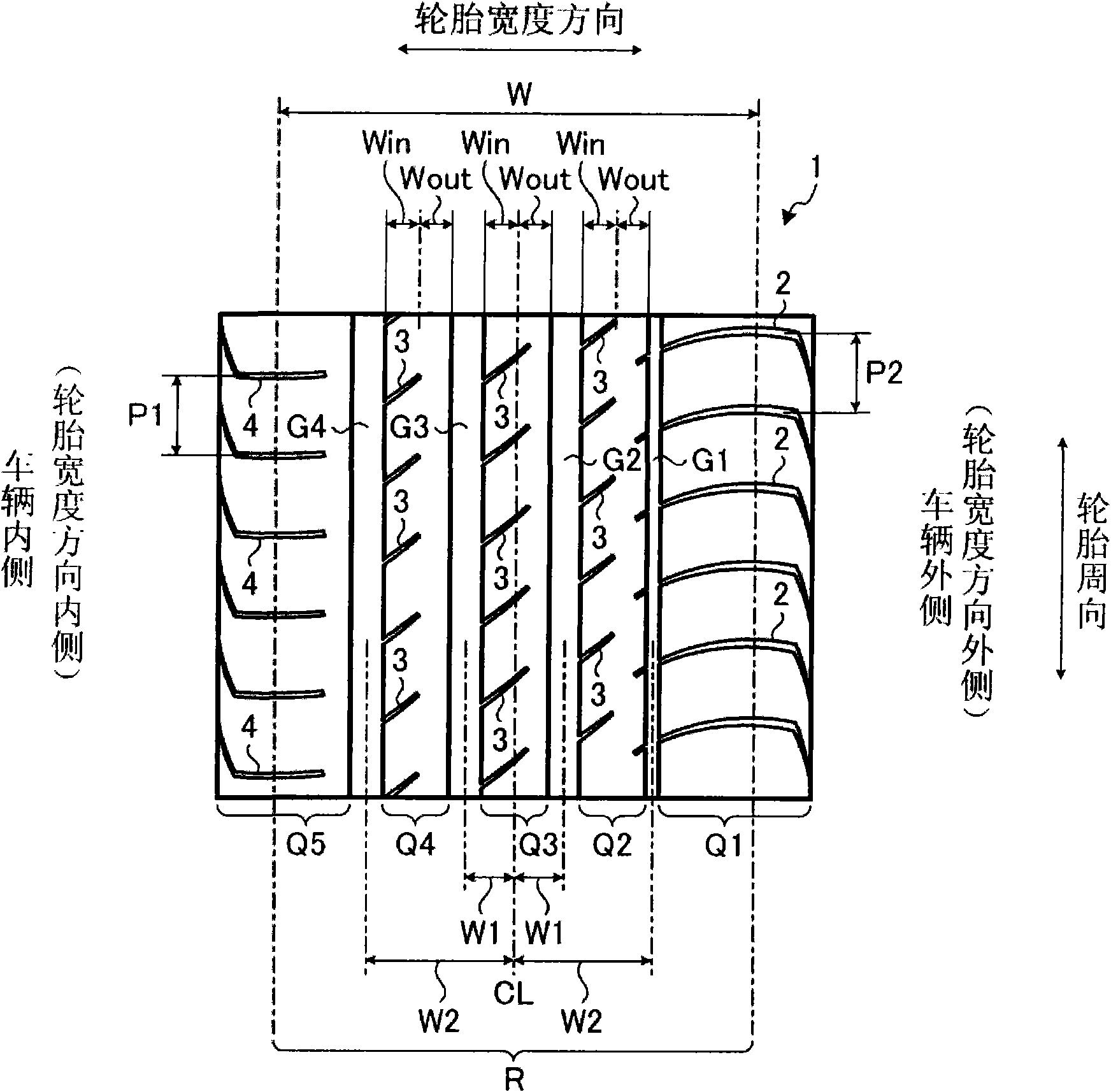

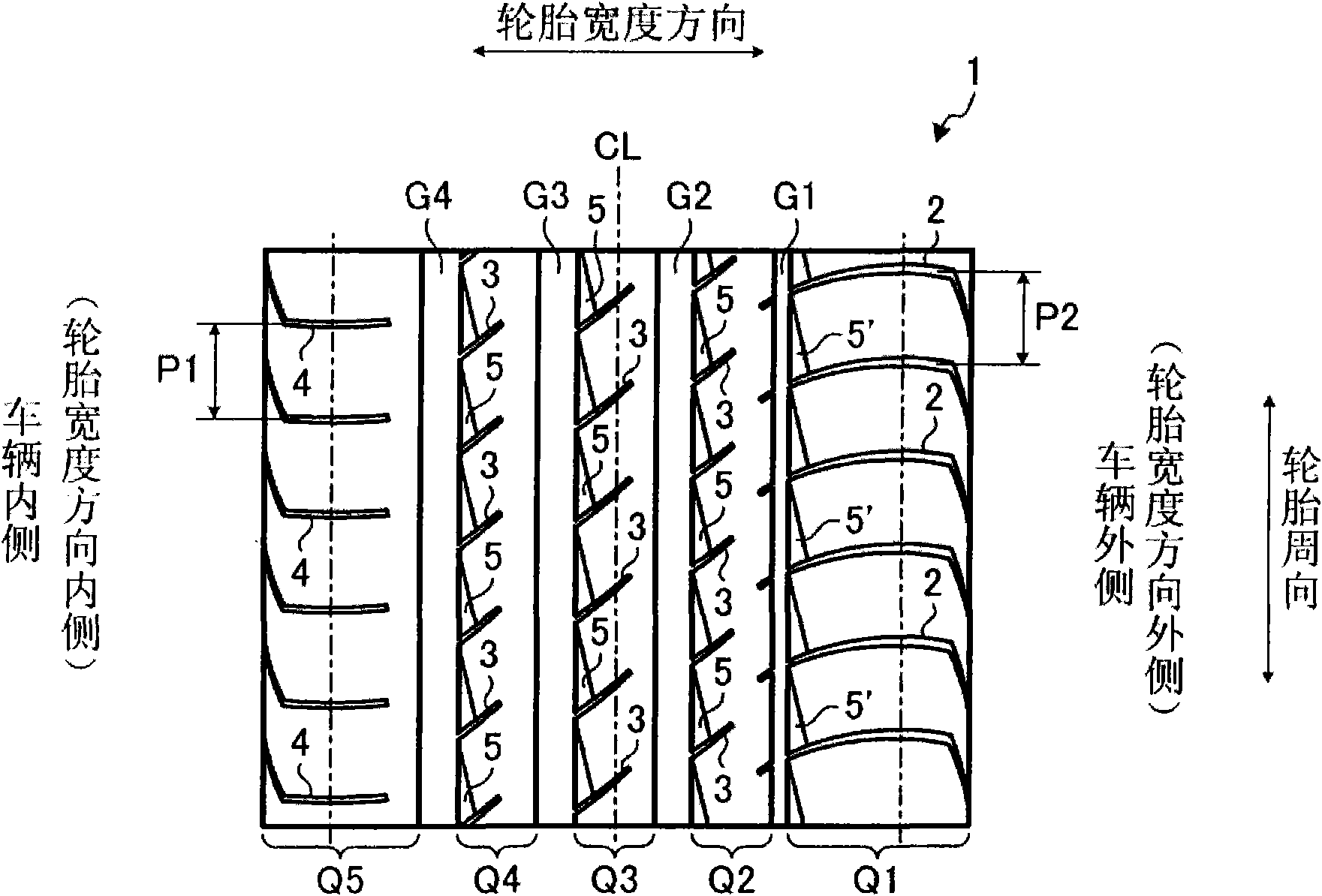

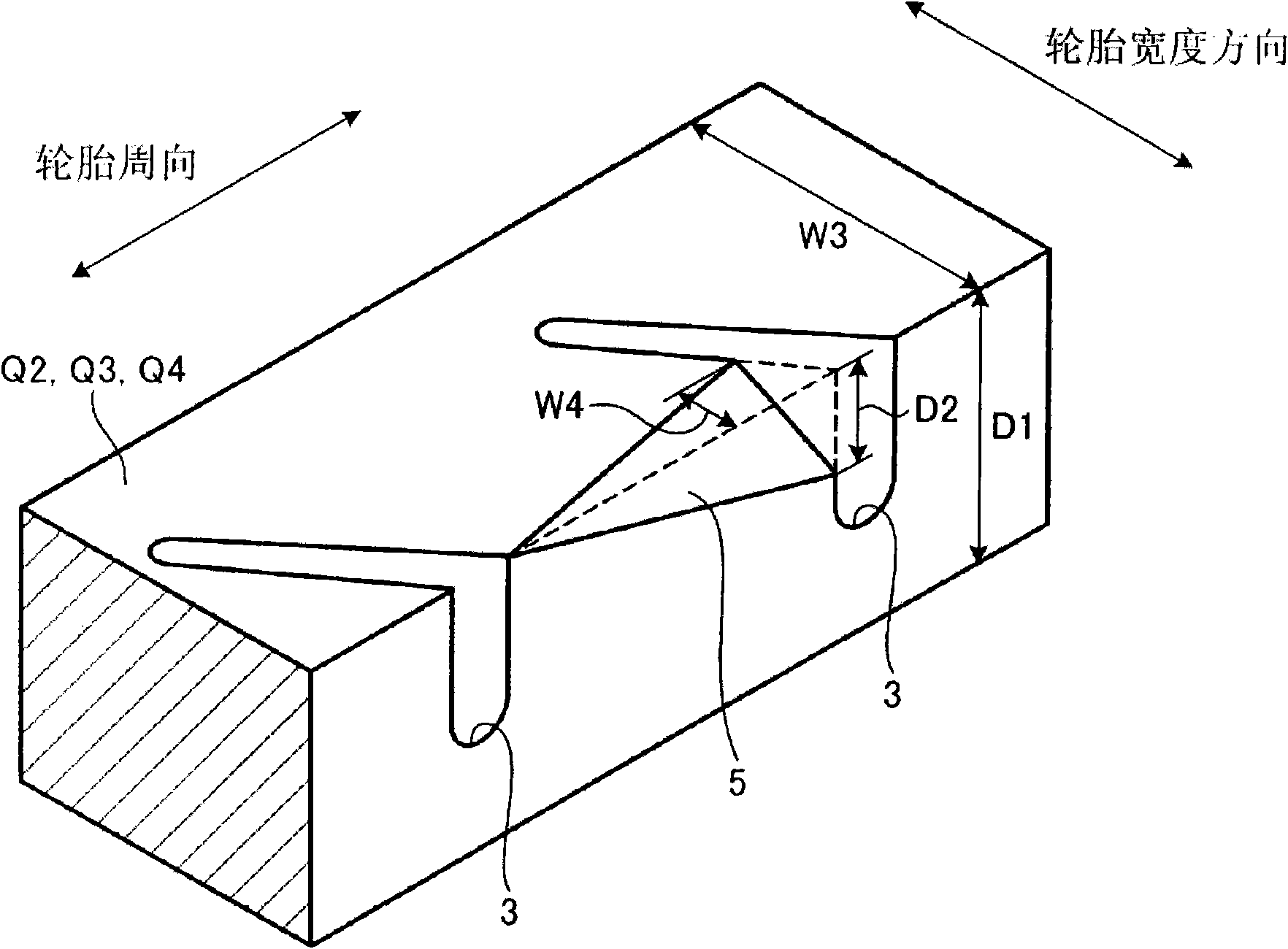

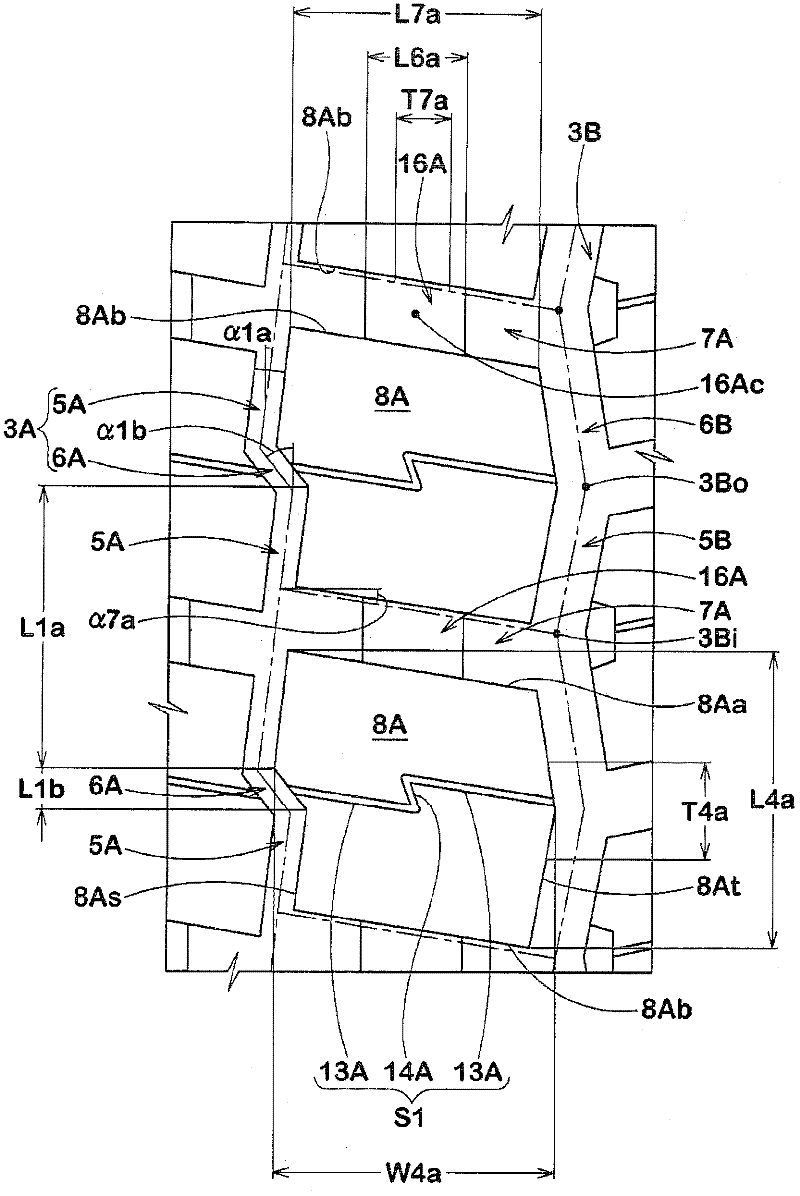

Pneumatic tire

ActiveUS20100212792A1Improve steering stabilityGuaranteed rigidityTyre tread bands/patternsNon-skid devicesGround contactGroove width

A pneumatic tire including five land portions Q1, Q2, Q3, Q4, Q5 in a tread surface 1 by providing four main grooves G1, G2, G3, and G4 in a ground contact region R of the tread surface 1, wherein positions and groove widths of the main grooves G1, G2, G3, and G4 are specified together with only the land portion Q1 positioned outermost on a vehicle outer side when mounted on a vehicle being formed into a block row, and the other land portions Q2, Q3, Q4, and Q5 being formed into ribs, and a groove area proportion of the tread surface 1 is larger on a vehicle inner side than the vehicle outer side with a tire equator CL and center lines of the land portions Q2, Q3, Q4 as boundaries.

Owner:YOKOHAMA RUBBER CO LTD

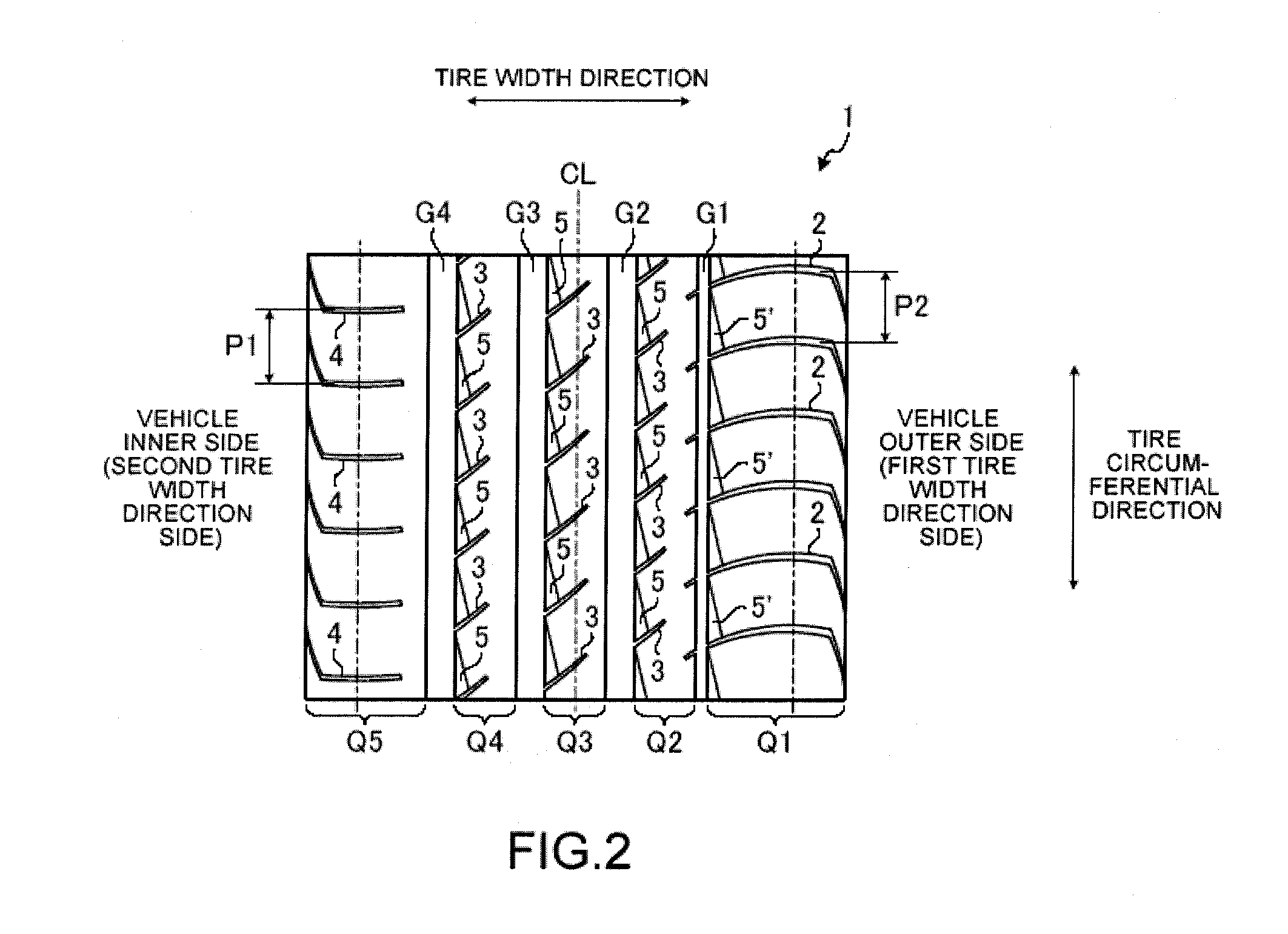

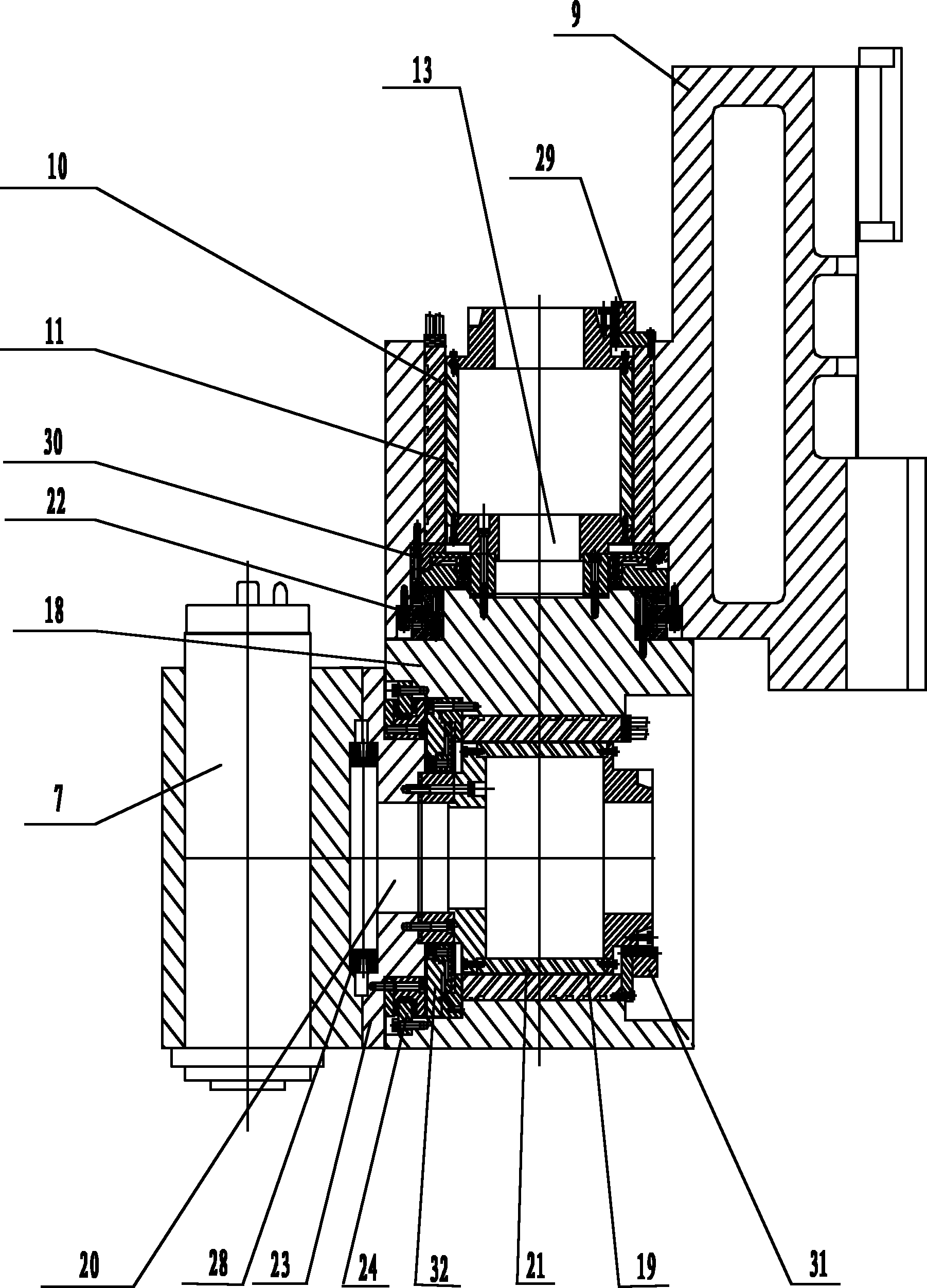

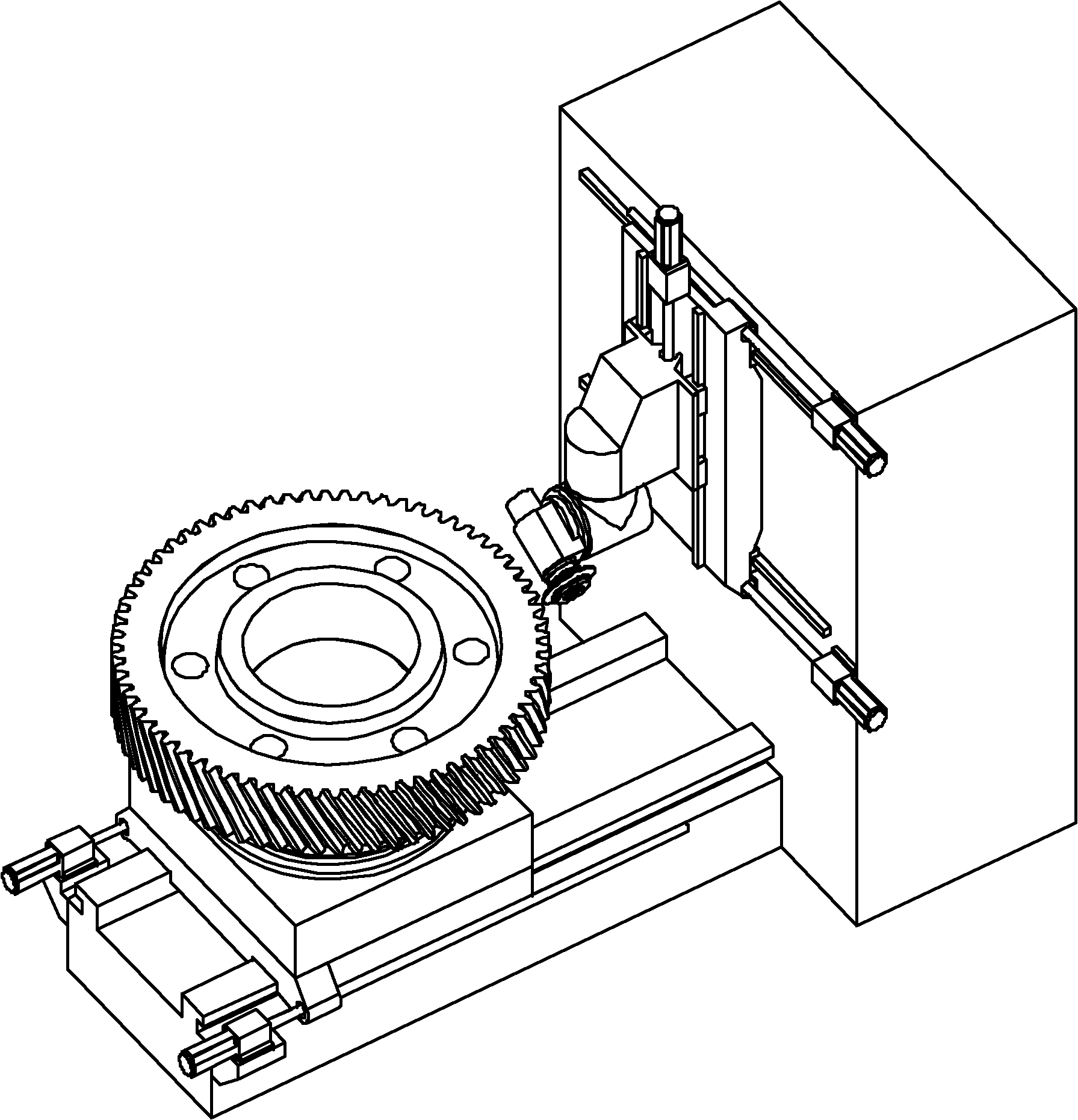

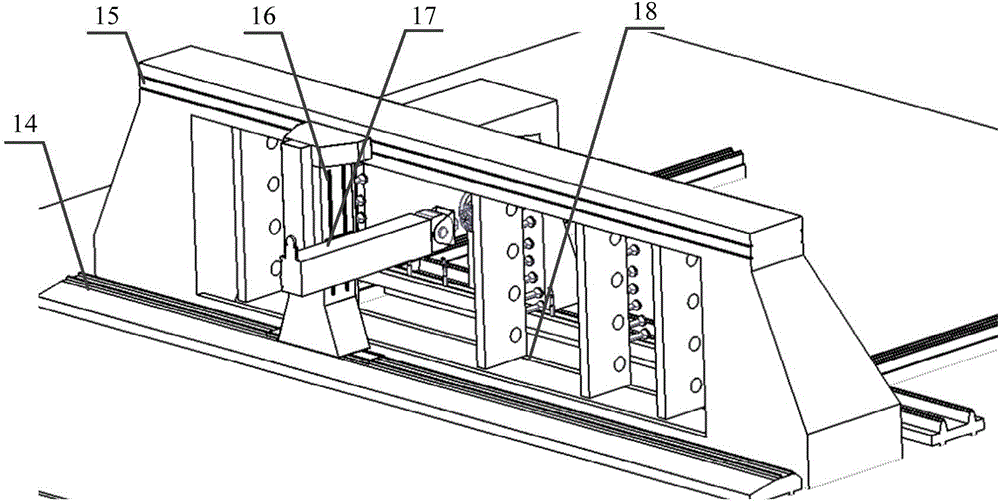

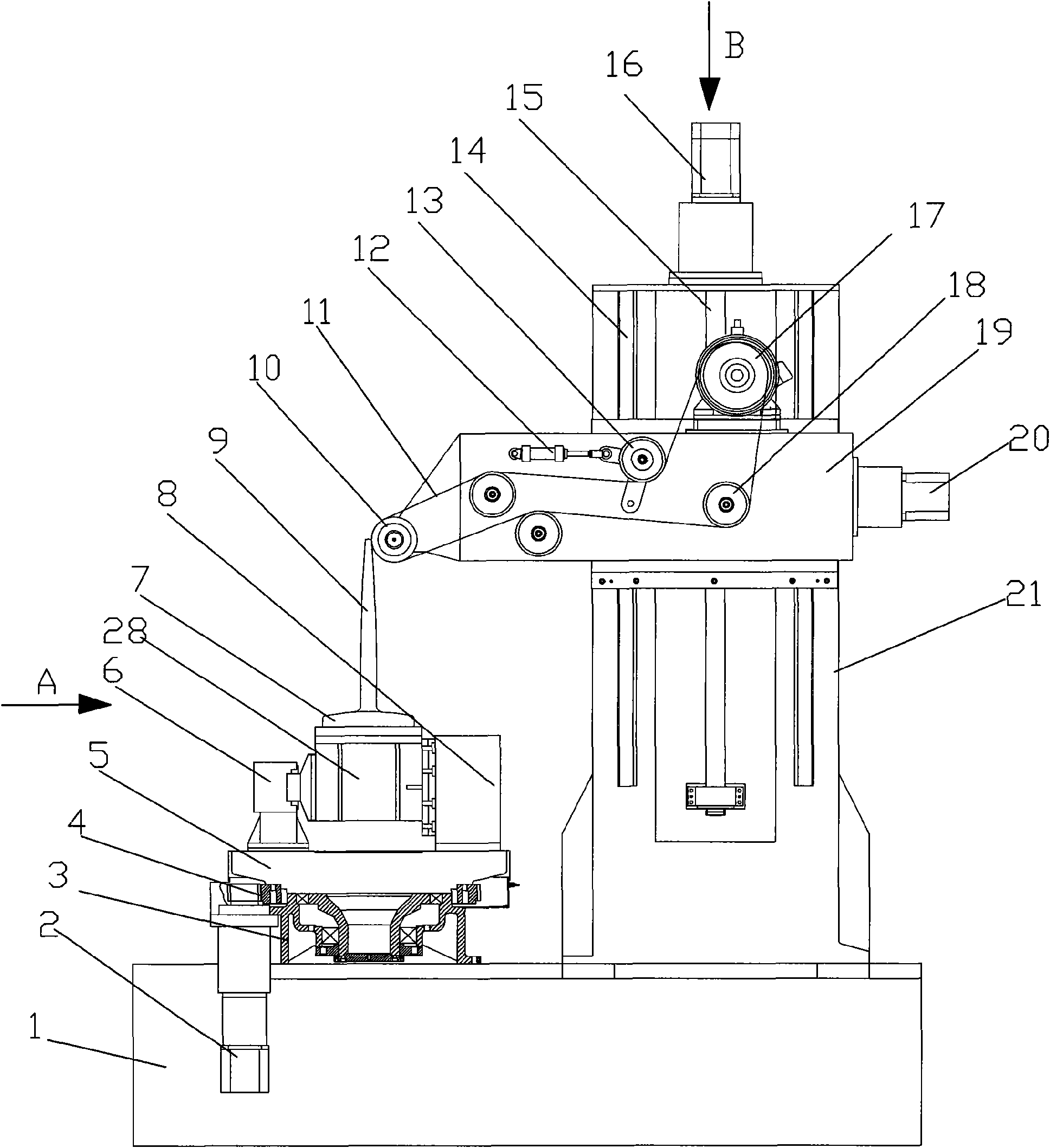

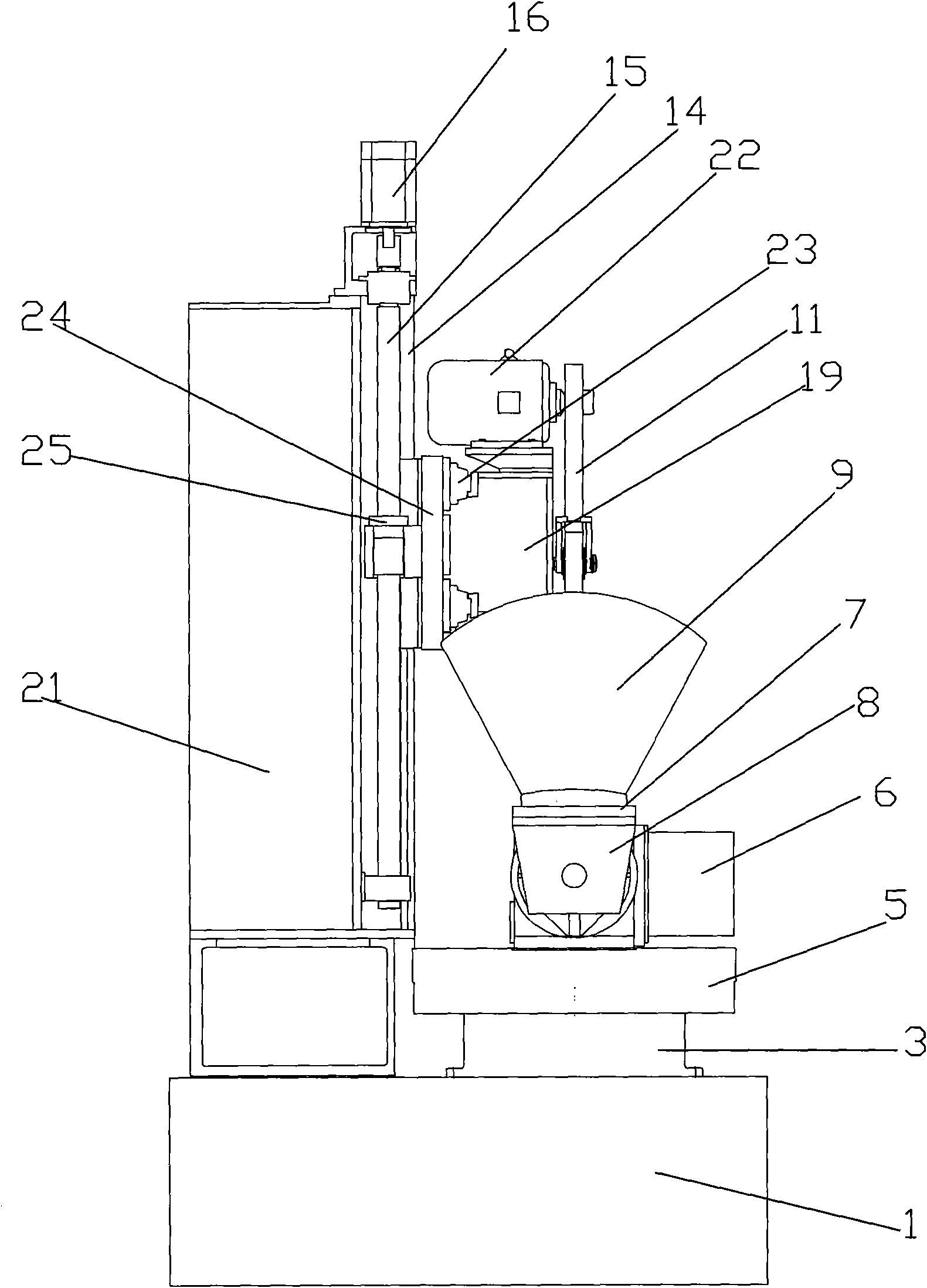

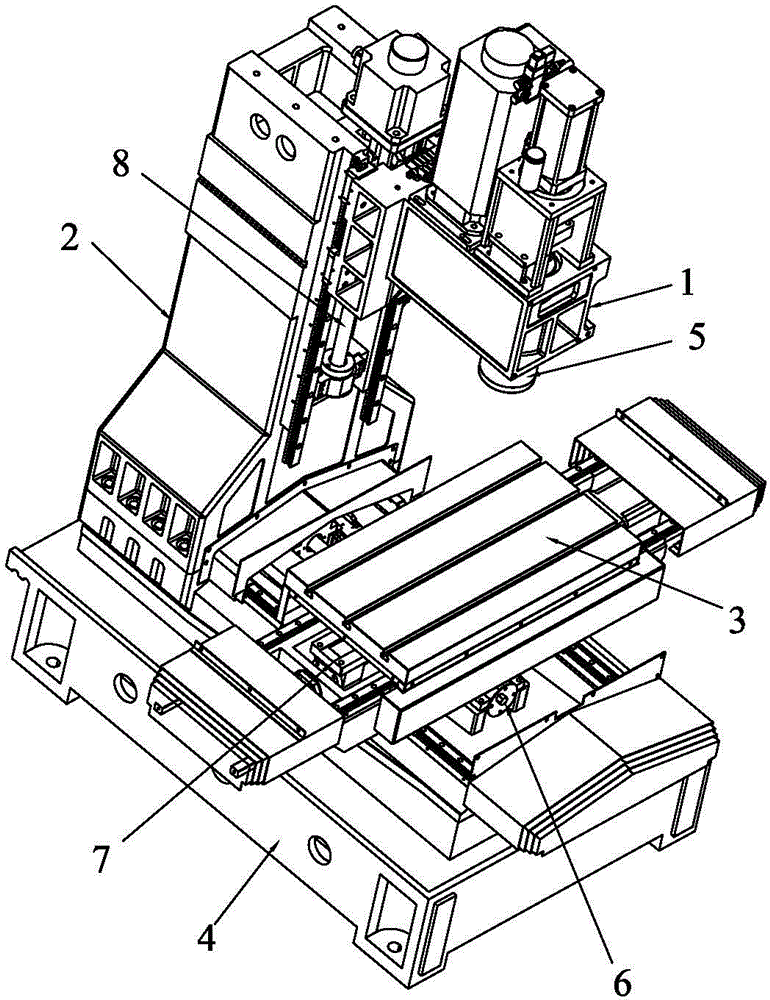

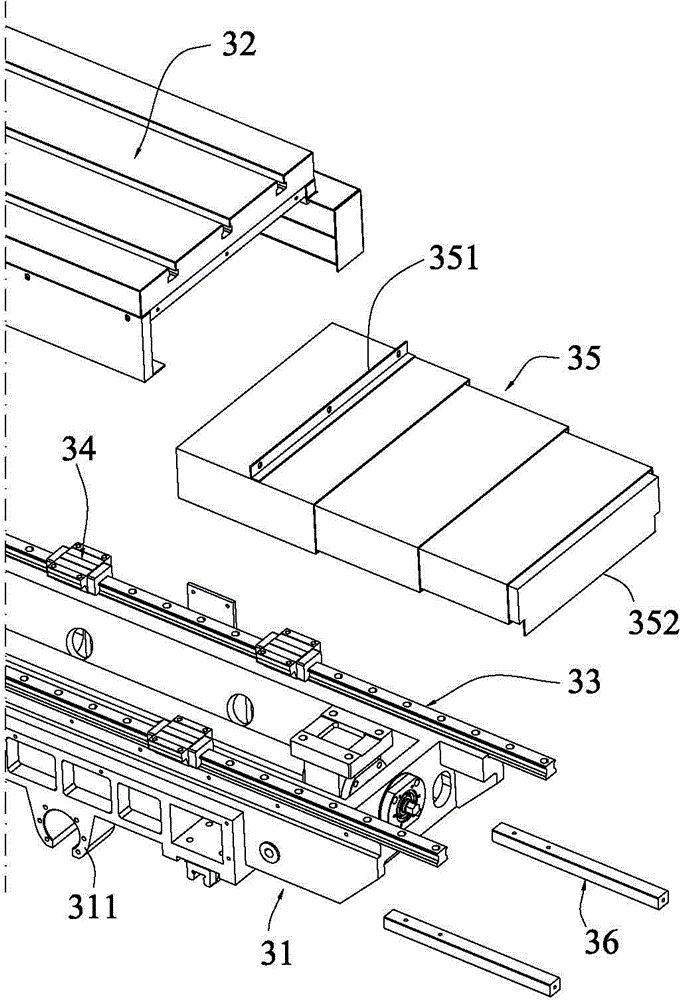

Large-scale numerical control gear machining machine tool

ActiveCN102151909AImprove machining accuracyImprove processing efficiencyLarge fixed membersDriving apparatusLinear motionImpeller

The invention provides a large-scale numerical control gear machining machine tool which has six numerical control coordinate axes, namely X, Y, Z, A, C1 and C2 and adopts a two plus four layout manner. A workpiece has two freedom motion, namely linear motion along the X axis and rotational motion around the C1 axis; and a tool has four freedom motion, namely linear motion along the X axis and the Z axis and rotational motion around the A axis and the C2 axis. The large-scale numerical control gear machining machine tool adopts a six-axis (X, Y, Z, A, CI and C2 axis) five-linkage (X, Y, Z, A and C2 axis linkage) structure; the five numerical control coordinate axes, namely the X, Y, Z, A and C2 axes carry out interpolation motion; and the indexing movement of the workpiece is controlled by the C1 axis to process all tooth surfaces. The rotational axis of the workpiece, namely the C1 axis only finishes the indexing movement and does not participate in the interpolation motion formed bythe tooth surfaces so as to improve the processing precision and the processing efficiency of a large-scale gear. The large-scale numerical control gear machining machine tool can be constructed intoa gear miller or a gear grinder, thereby realizing the curved surface machining of a cylindrical gear, a bevel gear, an impeller and others with the indexing features.

Owner:秦川机床工具集团股份公司

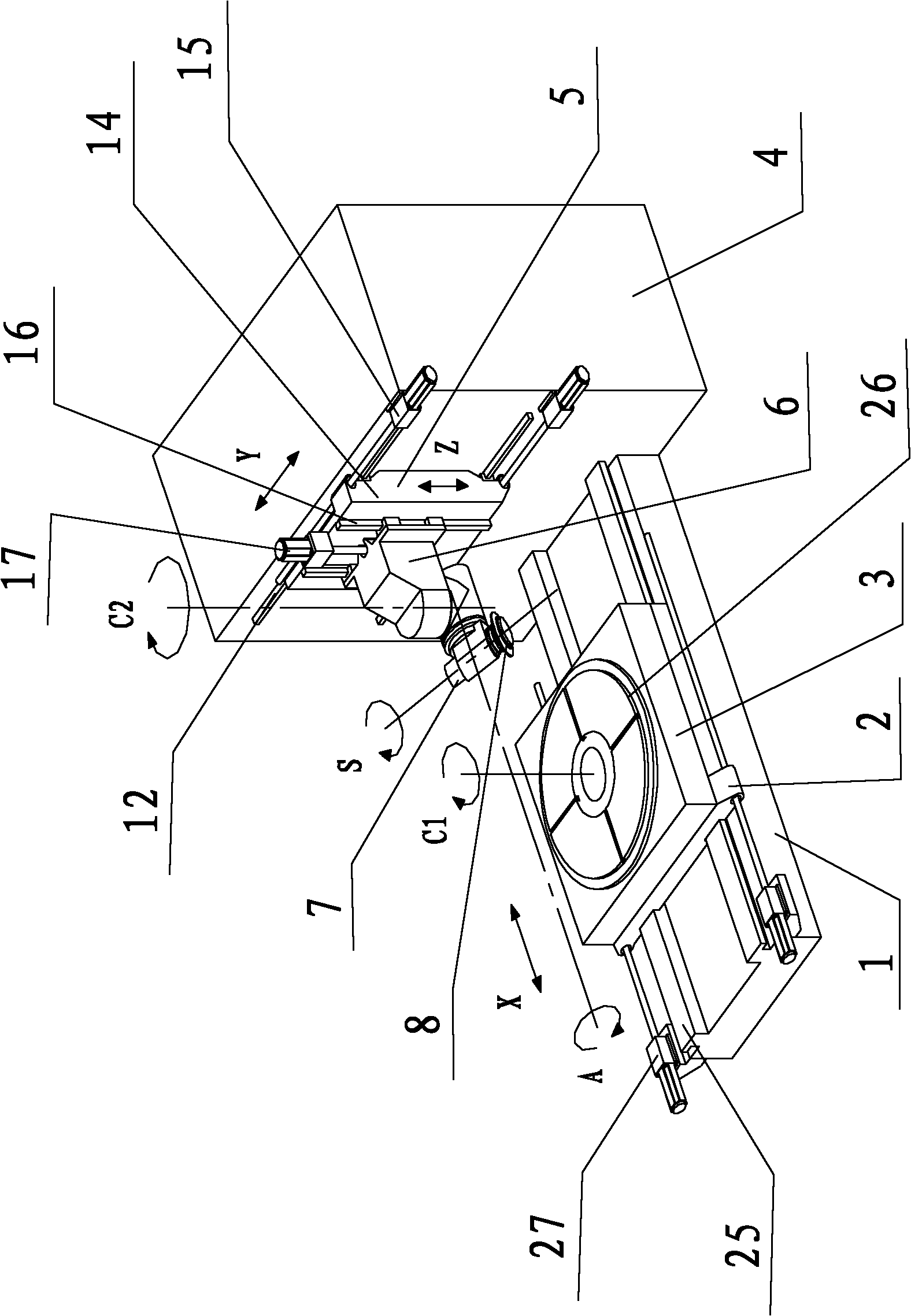

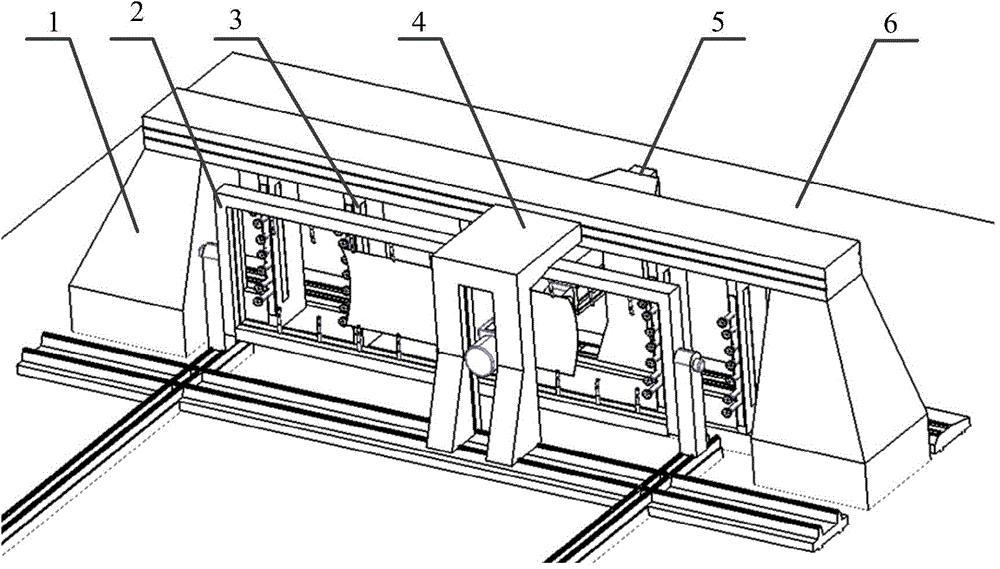

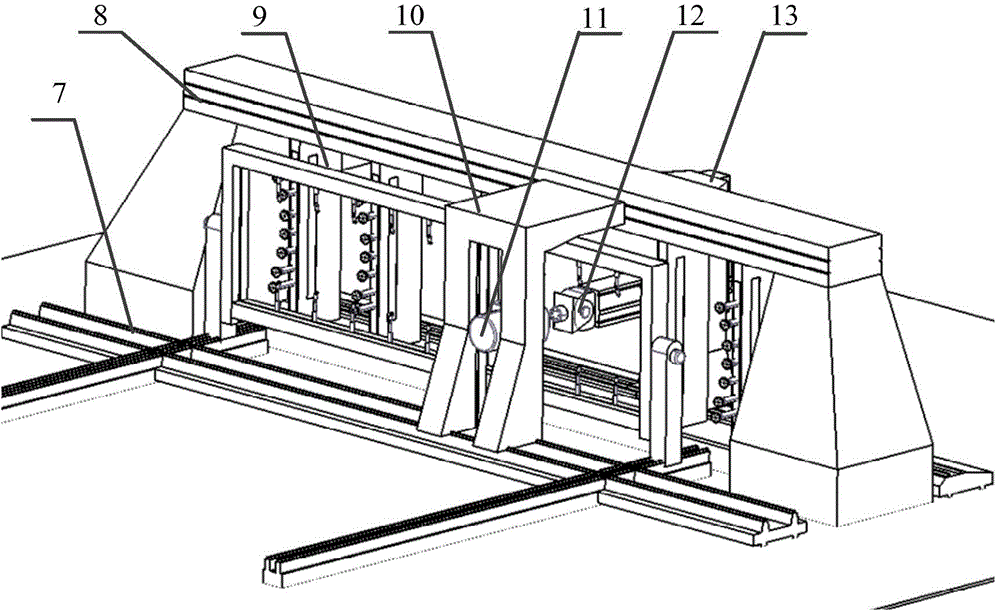

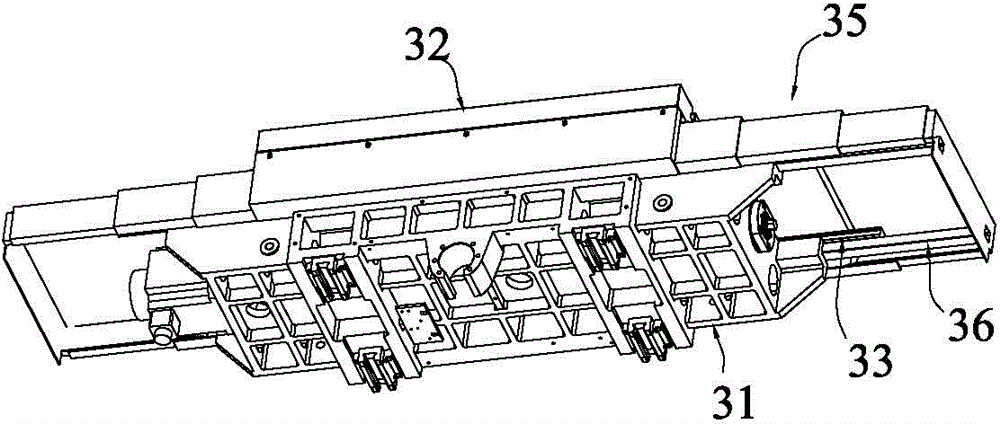

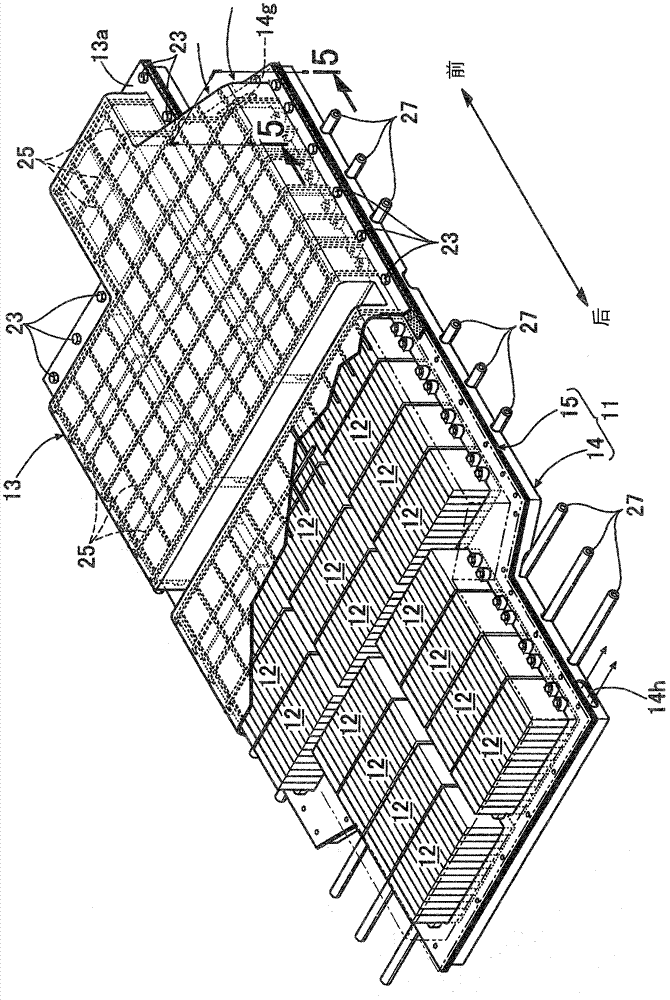

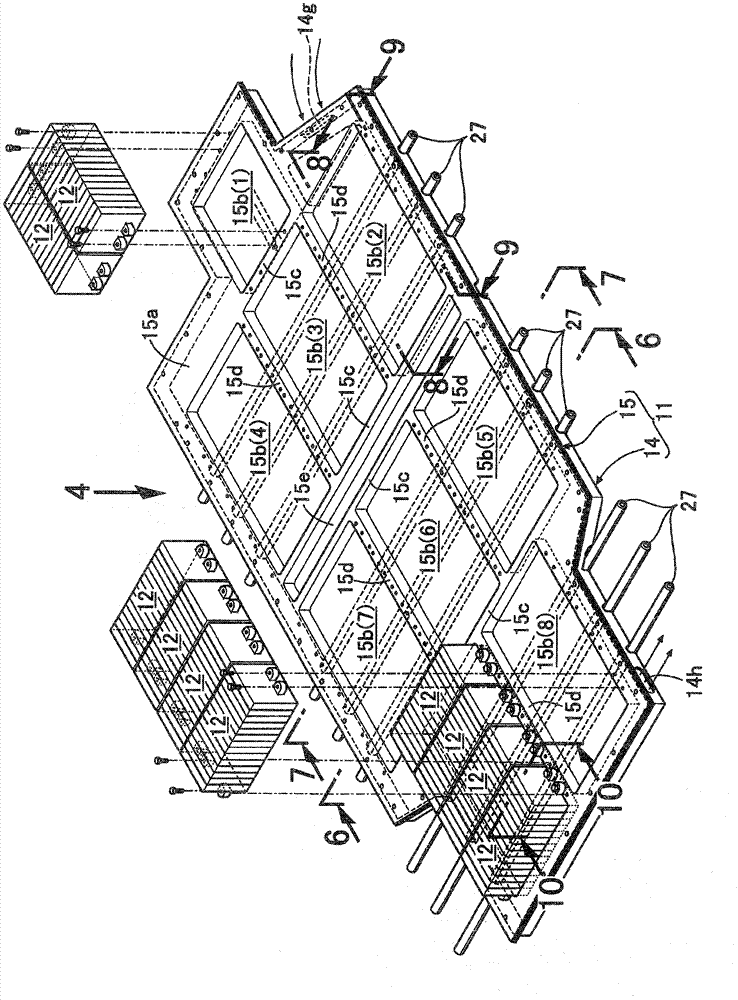

Aircraft skin mirror milling method and aircraft skin mirror milling device

ActiveCN104400086AReal-time thicknessReal-time thickness compensationAutomatic control devicesWorkpiecesSelf adaptiveAirplane

An aircraft skin mirror milling method and an aircraft skin mirror milling device. The device is characterized by mainly comprising a machine tool main framework, a milling apparatus, a vertical-horizontal conversion apparatus, a lug piece holding apparatus, a flexible adsorption apparatus, a top-shore apparatus, a detection apparatus and a thickness measuring apparatus. In the device, an aircraft skin is vertically clamped by the vertical-horizontal conversion apparatus for increasing the clamping efficiency of the aircraft skin and a positioning precision of the aircraft skin is further improved with combination of a vacuum adsorption apparatus so that deformation caused by gravity can be avoided. On the basis of on-line detection by a laser displacement sensor, actual curve surface of the aircraft skin can be detected before processing and aircraft skin processing tool path can be adjusted according to an actual clamping situation for achieving self-adapting numerically-control processing. The top-shore apparatus can support the aircraft skin from backside during a milling process of the aircraft skin, thereby avoiding vibration during processing and improving stability of processing. On-line monitoring of the thickness can be achieved during the processing and thickness compensation can be provided. By means of an integrated control system, cooperative operation of units in the machine tool can be ensured and interference can be avoided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

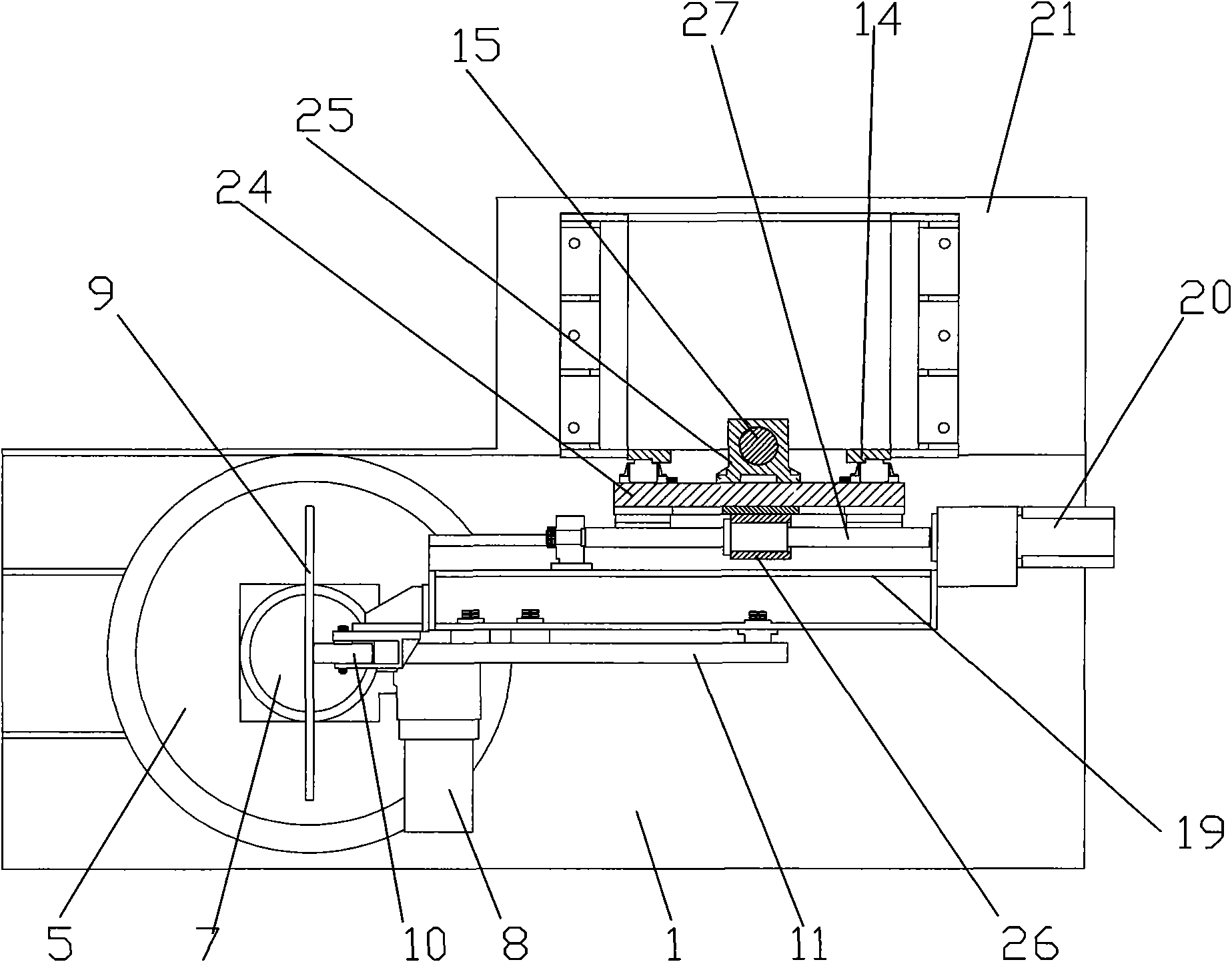

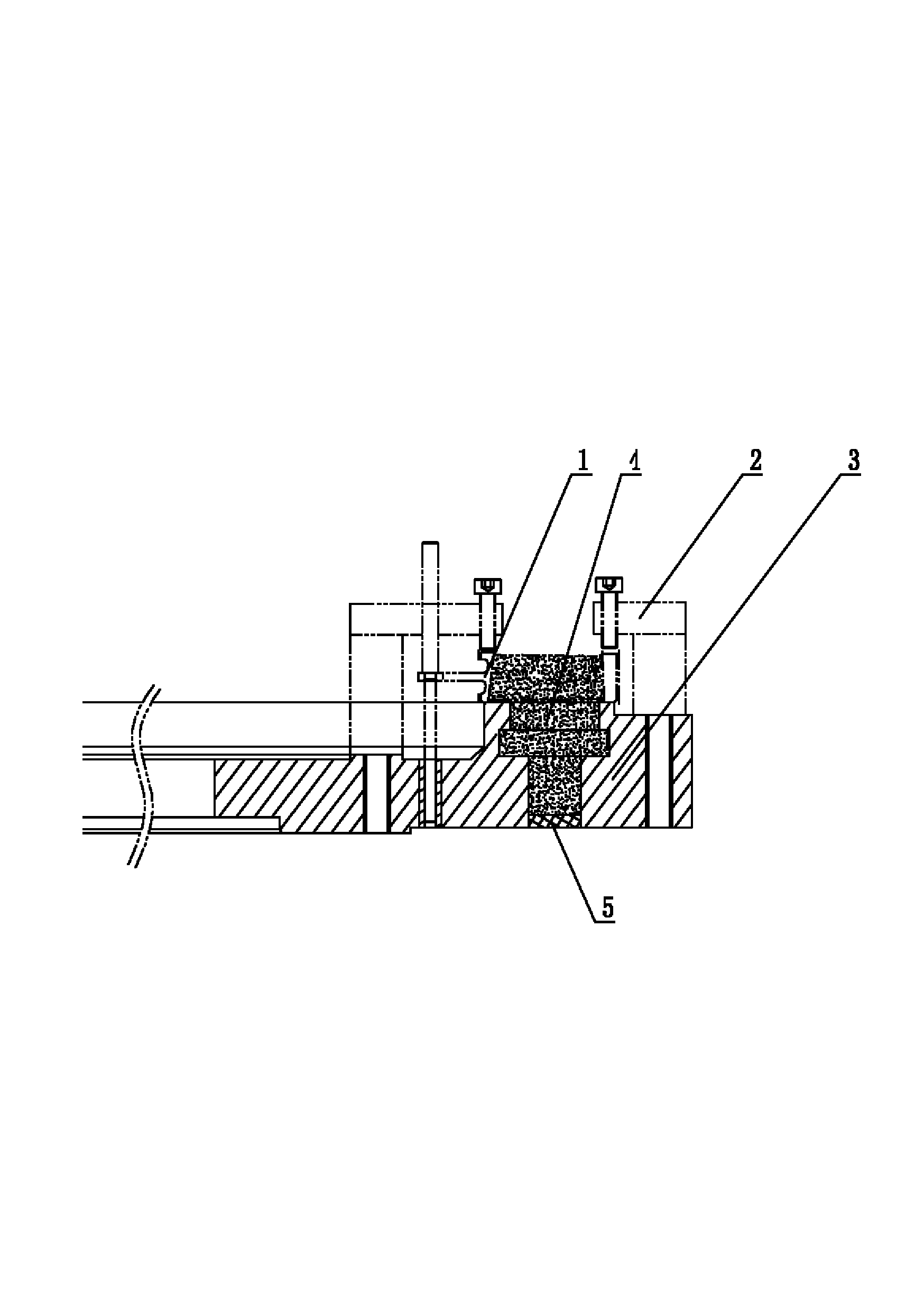

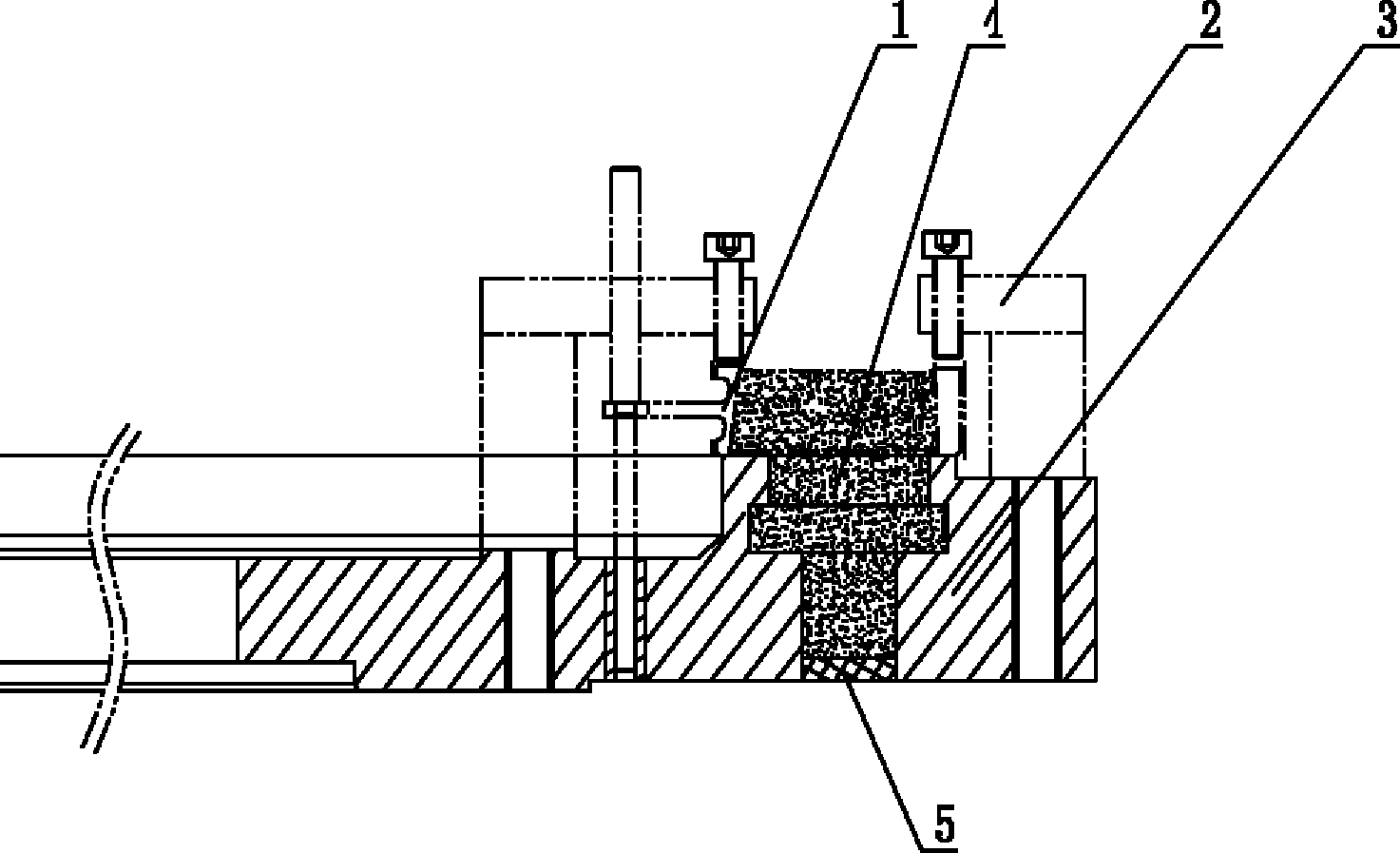

Coated abrasive grinder of propeller blade

InactiveCN101664897AGuaranteed rigidityGuaranteed machining dimensional accuracyBelt grinding machinesDrive wheelPropeller

The invention discloses a coated abrasive grinder of a propeller blade, which comprises a grinder body, a grinding head mechanism, a grinding head feeding mechanism and a workpiece position adjustingmechaism, wherein the grinding head mechanism comprises an abrasive belt, a driving wheel, a contact wheel, a tensioning wheel and a grinding head drive motor; the grinding head feeding mechanism comprises an axial feed mechanism and radial feed mechanism relative to the workpiece; the coated abrasive grinder realizes combination of four degree of freedom of space by reasonable distribution of grinding head feeding and adjustment of the angle of the workpiece position as well as a shorter drive chain, guarantees the rigidity of the grinding head mechanism and a workpiece clamping mechanism, ensures the contact stabiltiy between the contact wheel and the workpice when the contact wheel rotates with a high speed, and improves work efficiency simultaneously when guaranteeing the process sizeprecision of a complex curve workpiece; and thickness is even in curve polishing, the quality of profiles is ensured, the qualificaiton rate of finished products is improved, the labor intensity of workers is reduced, and the management and production cost is decreased.

Owner:CHONGQING SAMHIDA GRINDING MACHINE

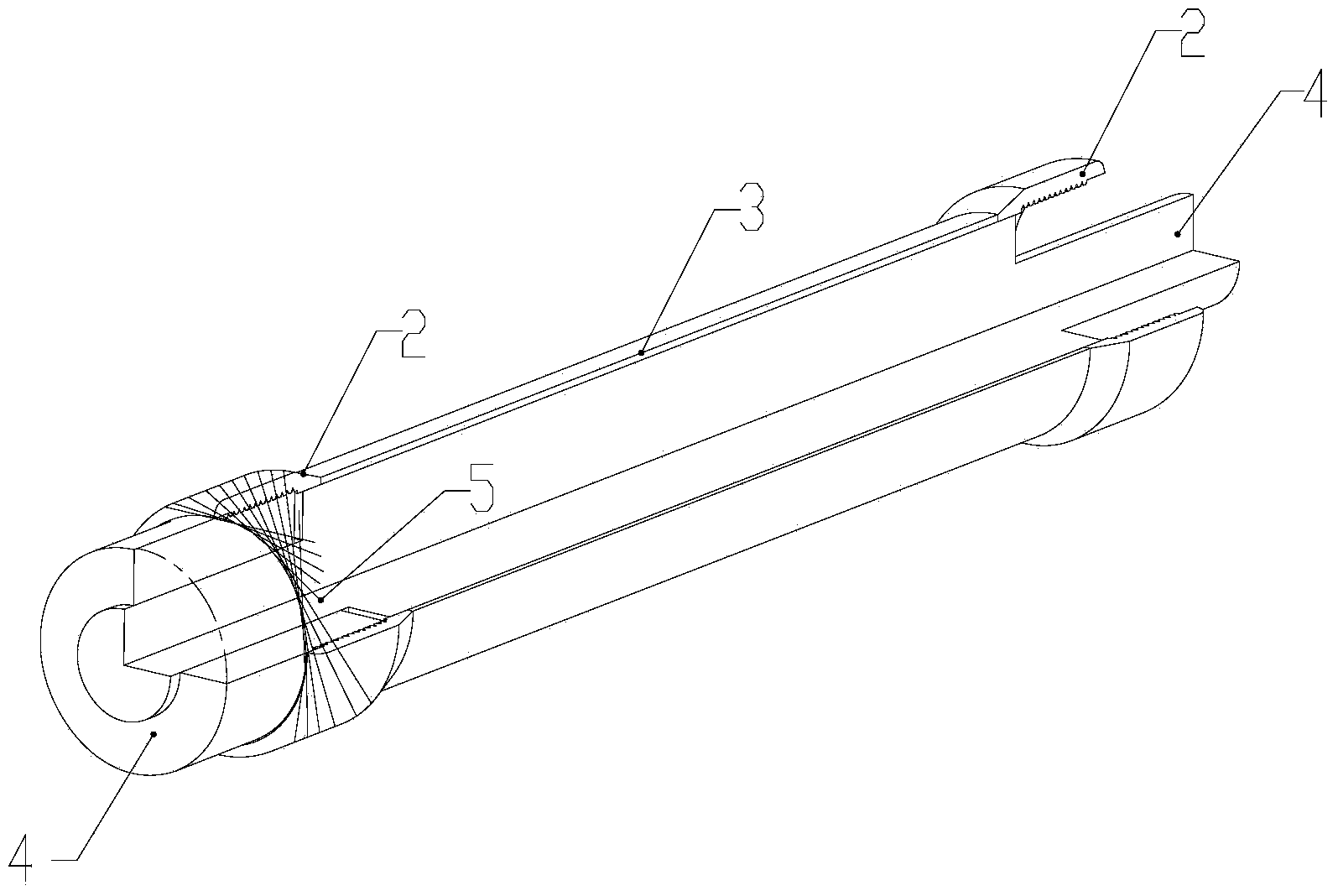

Vehicular suspension arm

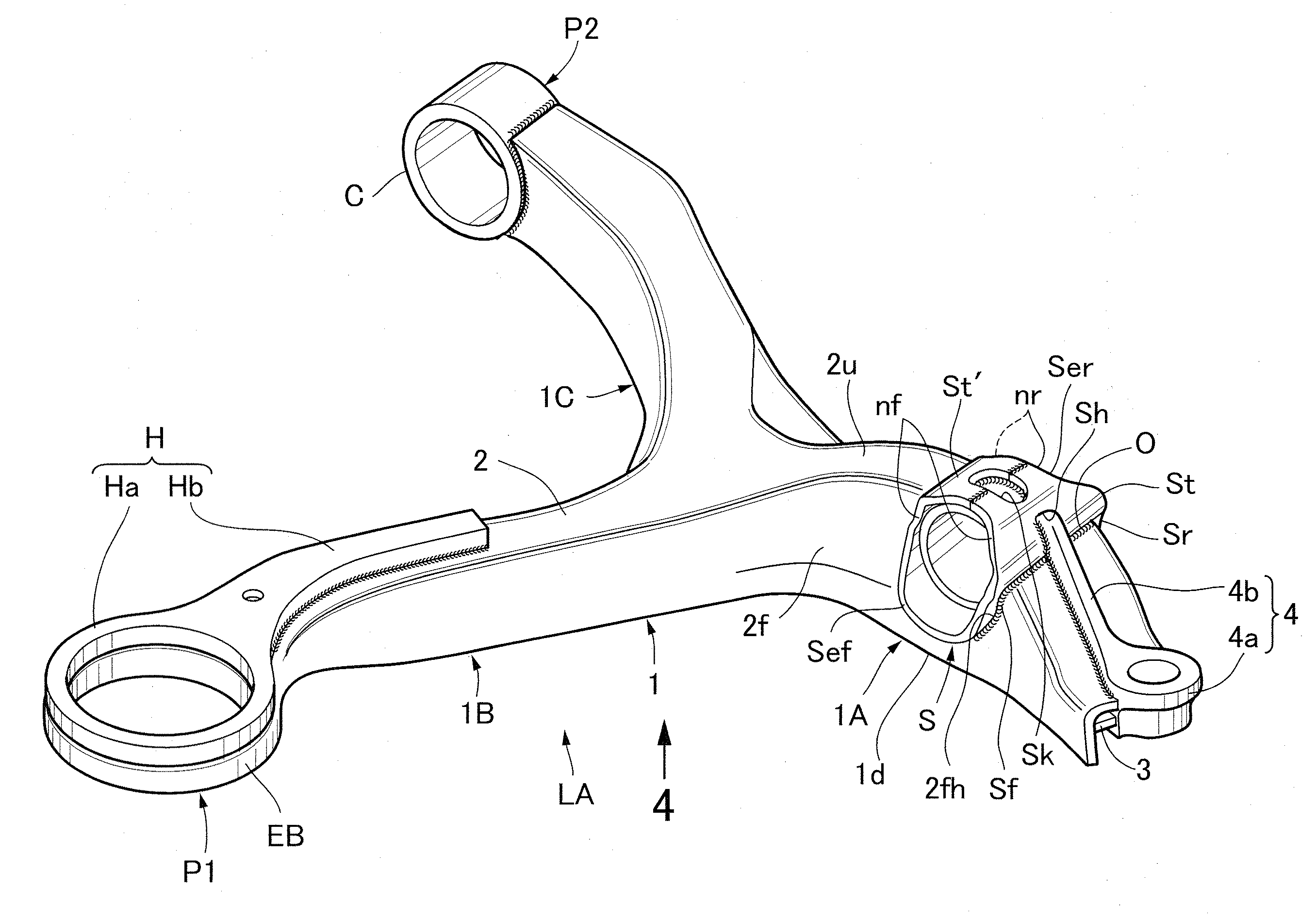

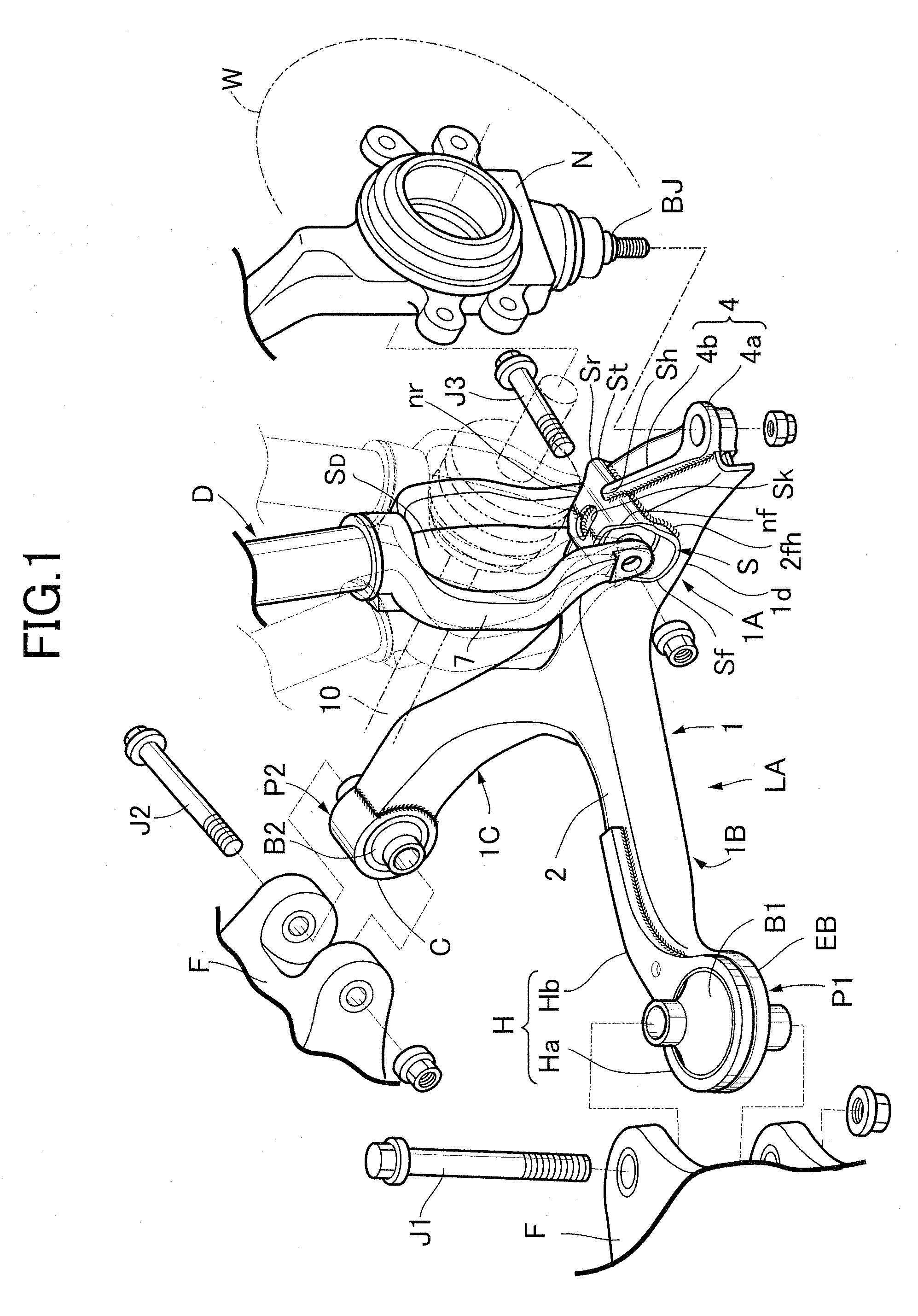

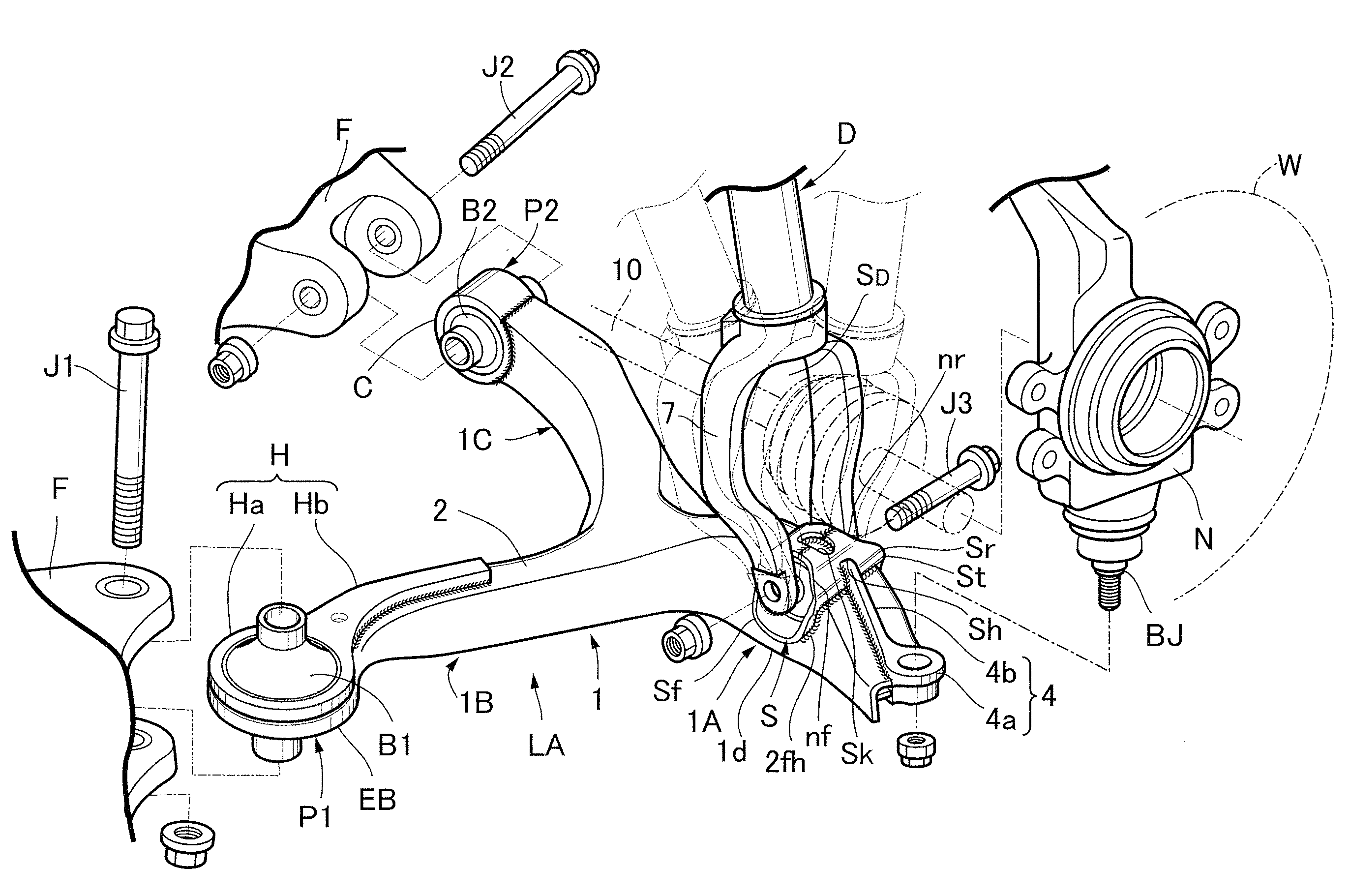

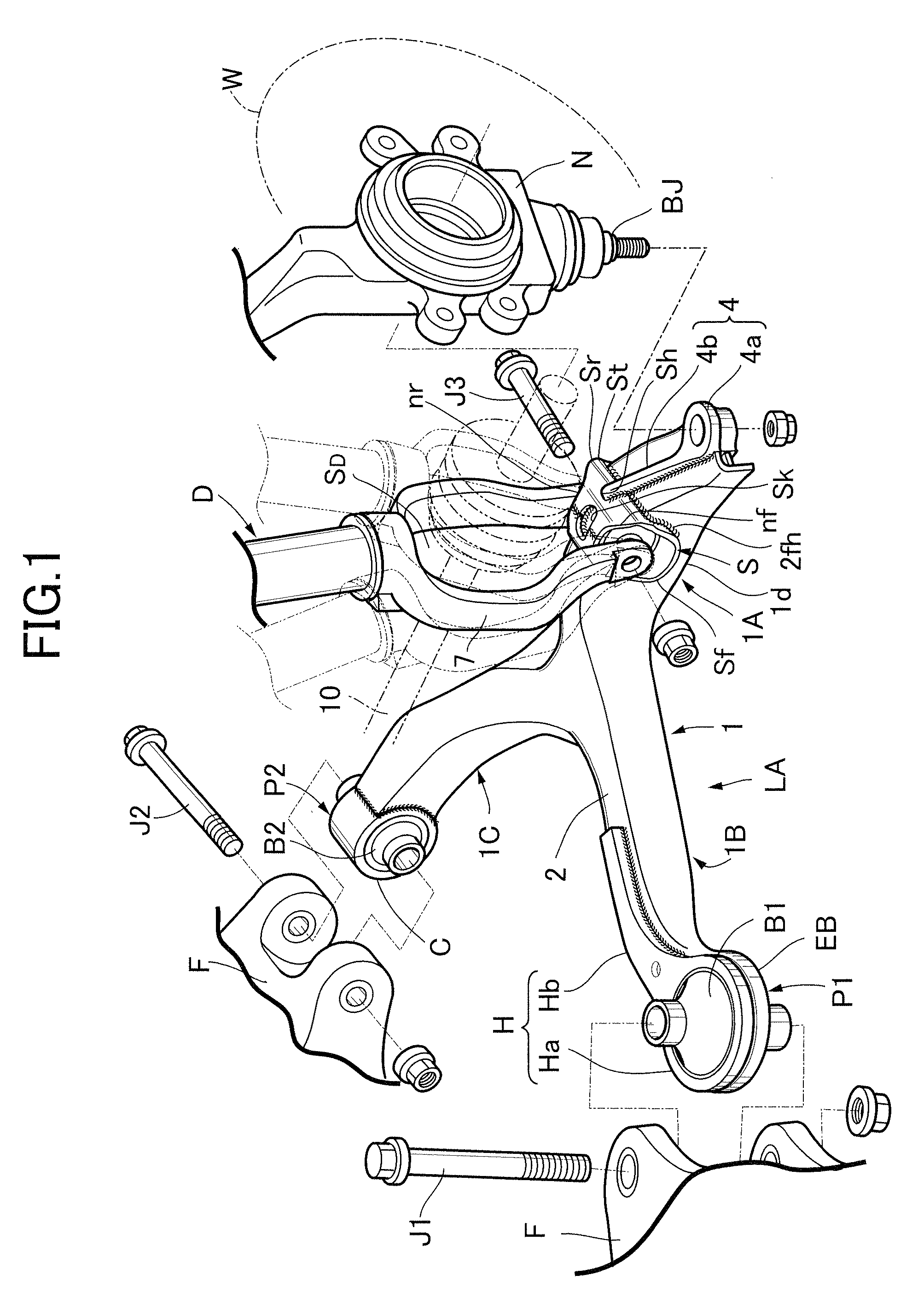

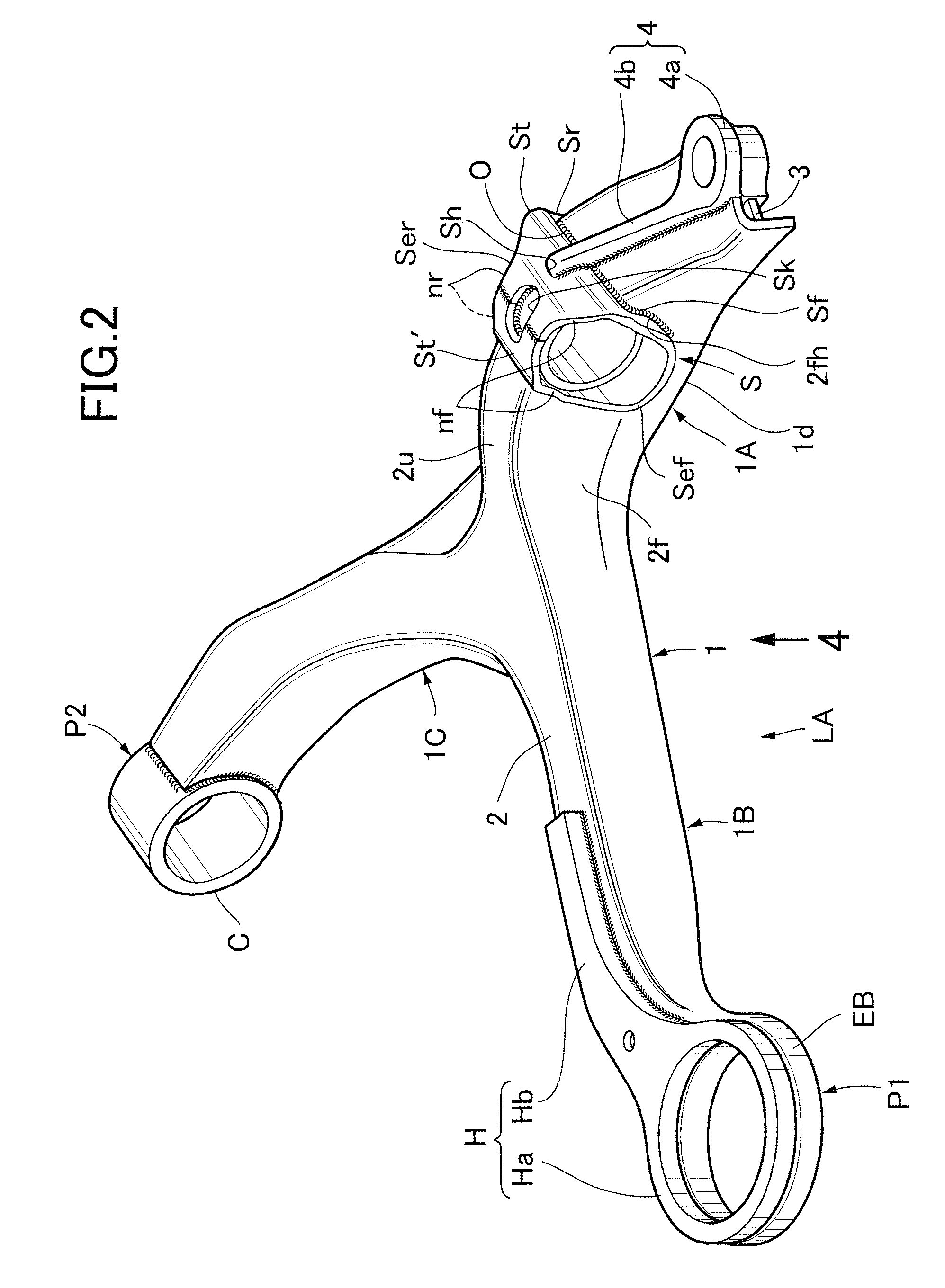

InactiveUS20090295113A1Increased strengthRigidity and strengthTractor-trailer combinationsResilient suspensionsFlangingLower face

A vehicular suspension arm is provided in which an arm main body (1) includes a main plate (2) press-formed as a main part of the arm main body and having a short cylindrical part (EB) provided integrally with one end by flanging, and a reinforcing plate (H) superimposed on one of upper and lower faces of the main plate (2) and reinforcing the main plate (2). The reinforcing plate (H) has an eye-shaped head part (Ha) formed in an annular shape and arranged coaxially with the short cylindrical part (EB), and a tail part (Hb) extending integrally from the eye-shaped head part (Ha) along the longitudinal direction of the main plate (2), is formed from a single plate material that is thicker than the main plate (2), and has at least the tail part (Hb) welded to the main plate (2). A bush press-fit portion (P1) is formed from an inner peripheral face of the eye-shaped head part (Ha) and an inner peripheral face of the short cylindrical part (EB). This ensures that the cross-sectional shape of a transition section from the bush press-fit portion to the plate-type arm main body is adequate, thus enabling the rigidity and strength required for the transition section to be easily guaranteed and, furthermore, it becomes possible to meet a requirement for increasing the strength of the arm without specially increasing the space around the outer periphery of the bush press-fit portion.

Owner:F TECH INC +1

Method for manufacturing high-strength X100 steel grade spiral seam submerged arc welded pipe

ActiveCN101797600ATo achieve effective detectionFully automatedArc welding apparatusMilling equipment detailsProduct inspectionX-ray

The invention discloses a method for manufacturing a high-strength X100 steel grade spiral seam submerged arc welded pipe. The method comprises the following steps: uncoiling, flattening, edge milling, pre-springing, molding, inside welding, outside welding, pipe end belling, base metal layering ultrasonic examination, weld seam X ray inspection, hydrostatic test, weld seam ultrasonic inspection, pipe end chamfering and finished product inspection. In the technical steps of the preparation method, double edge milling process, pre-springing process and pipe end belling process are added so as to successfully solve the technical problems that the high-strength X100 steel grade spiral seam submerged arc welded pipe has poor molding stability, the welding joint performance cannot meet technical requirement and the like.

Owner:NORTH CHINA GASOLINEEUM STEEL PIPE +3

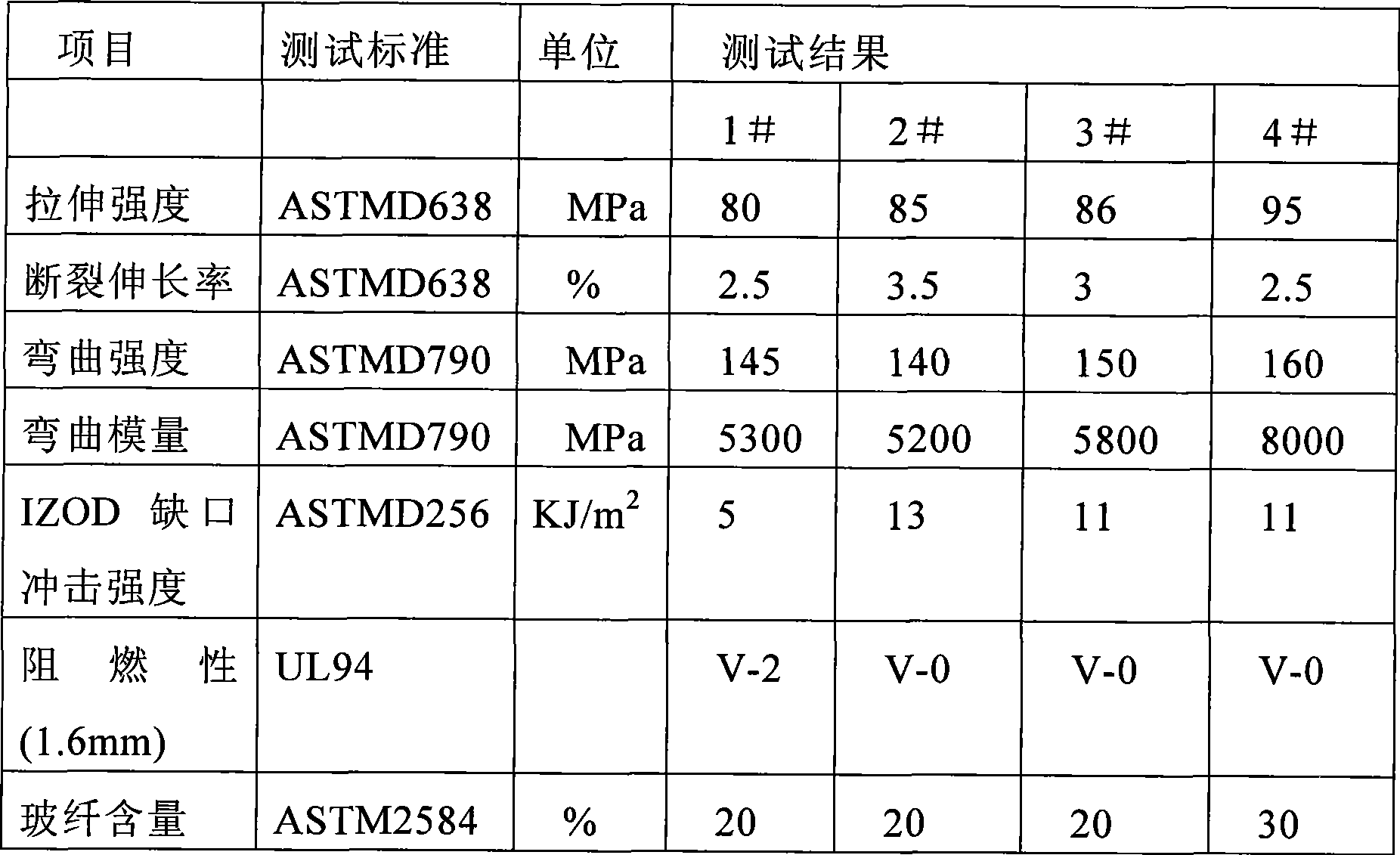

High tenacity halogen-free flame-retardant glass fiber reinforced polycarbonate composition

InactiveCN101469112AImprove mechanical propertiesImprove notched impact strengthPolycarbonateHalogen

The invention relates to a high-tenacity, halogen-free and flame-retardant fiber glass reinforced polycarbonate composition, which comprises the following components by weight portion: 300 to 800 portions of polycarbonate, 100 to 400 portions of fiber glass, 30 to 150 portions of toughening compatilizer, 10 to 100 portions of organosilicon flame retardant, 10 to 150 portions of nano silicic acid inorganic substances, 1 to 10 portions of antioxidant A, 1 to 15 portions of antioxidant B, 1 to 15 portions of coupling agent, and 0 to 20 portions of other assistants. Compared with the prior art, the composition has the characteristics of good processing property, high impact strength, environmental protection due to free halogen and flame retardance, and the like.

Owner:HEFEI GENIUS NEW MATERIALS

Pneumatic tire

ActiveCN101890881AGuaranteed rigidityImprove driving stabilityTyre tread bands/patternsGround contactGroove width

A pneumatic tire including five land portions Q1, Q2, Q3, Q4, Q5 in a tread surface 1 by providing four main grooves G1, G2, G3, and G4 in a ground contact region R of the tread surface 1, wherein positions and groove widths of the main grooves G1, G2, G3, and G4 are specified together with only the land portion Q1 positioned outermost on a vehicle outer side when mounted on a vehicle being formed into a block row, and the other land portions Q2, Q3, Q4, and Q5 being formed into ribs, and a groove area proportion of the tread surface 1 is larger on a vehicle inner side than the vehicle outer side with a tire equator CL and center lines of the land portions Q2, Q3, Q4 as boundaries.

Owner:THE YOKOHAMA RUBBER CO LTD

High-precision vertical type machining center

ActiveCN104802038AReasonable structural designImprove rigidity and stabilityLarge fixed membersMetal working apparatusAutomatic controlProcessing accuracy

The invention discloses a high-precision vertical type machining center comprising a pedestal, an upright column, a worktable, a spindle case, a PLC controller, a machining spindle component, a Y-axis movement mechanism, an X-axis movement mechanism and a Z-axis movement mechanism. The worktable comprises a saddle, a worktable plate, a telescopic protecting cover, and a sliding rail extension bracket. The saddle is installed on the Y-axis movement mechanism. The X-axis movement mechanism comprises a linear sliding rail and a sliding block. One end of the telescopic protecting cover is connected with the worktable plate; the other end is connected with the sliding rail extension bracket. The high-precision vertical type machining center is reasonable in structural design. An automatic control is conducted by the PLC controller, and the purpose of the automatic machining can be achieved by clamping once, with fast machining speed, high precision and good working stability. Moreover, by reasonably designing the worktable, the rigidity and the stability of the entire structure are increased, thereby effectively reducing the vibration. With the high machining precision, the stable running, and the good protecting effect, the cutting chips or other foreign materials are effectively prevented from dropping onto the guide rail, thus the service life is long.

Owner:普锐米勒机床(东莞)有限公司

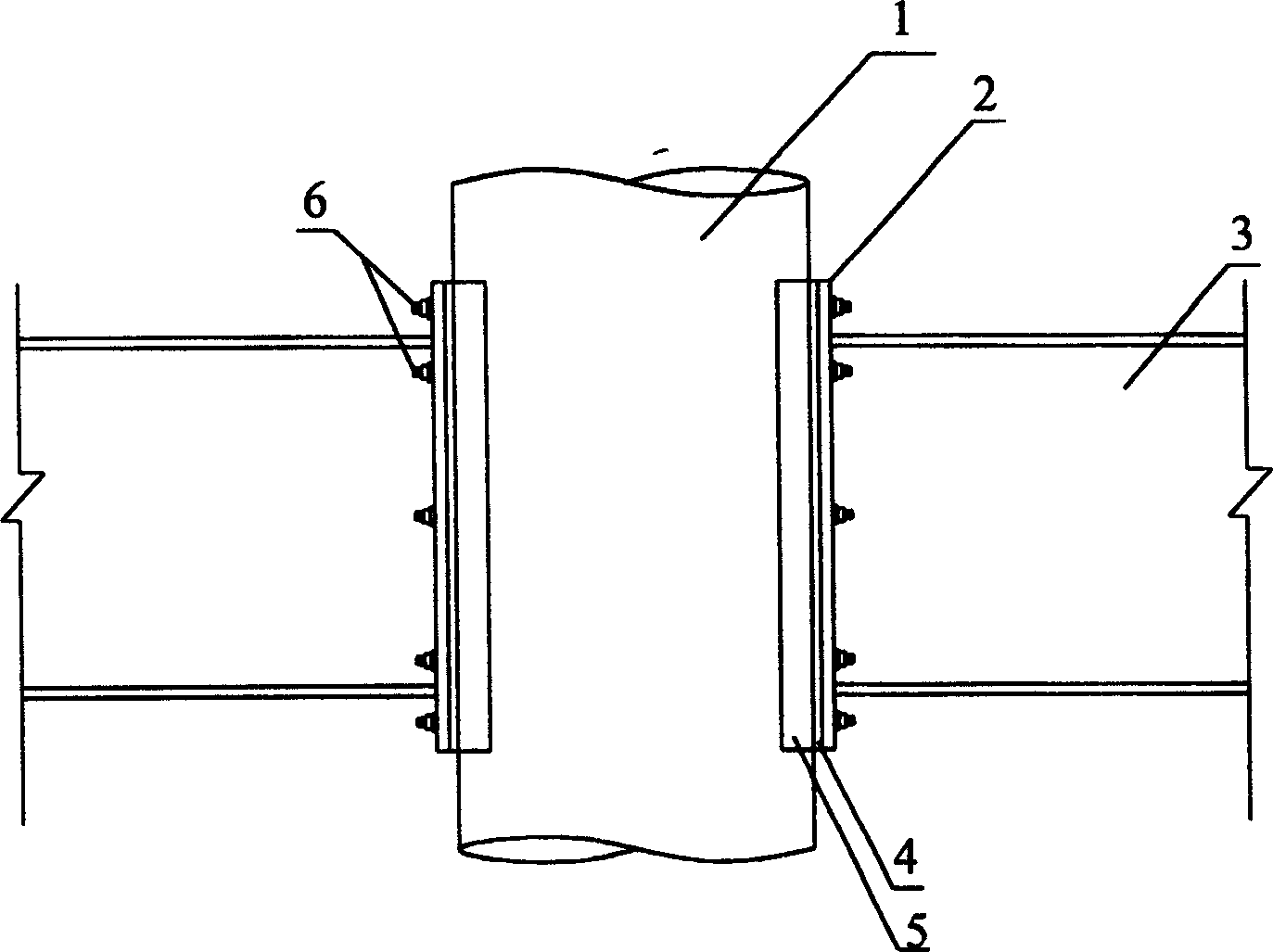

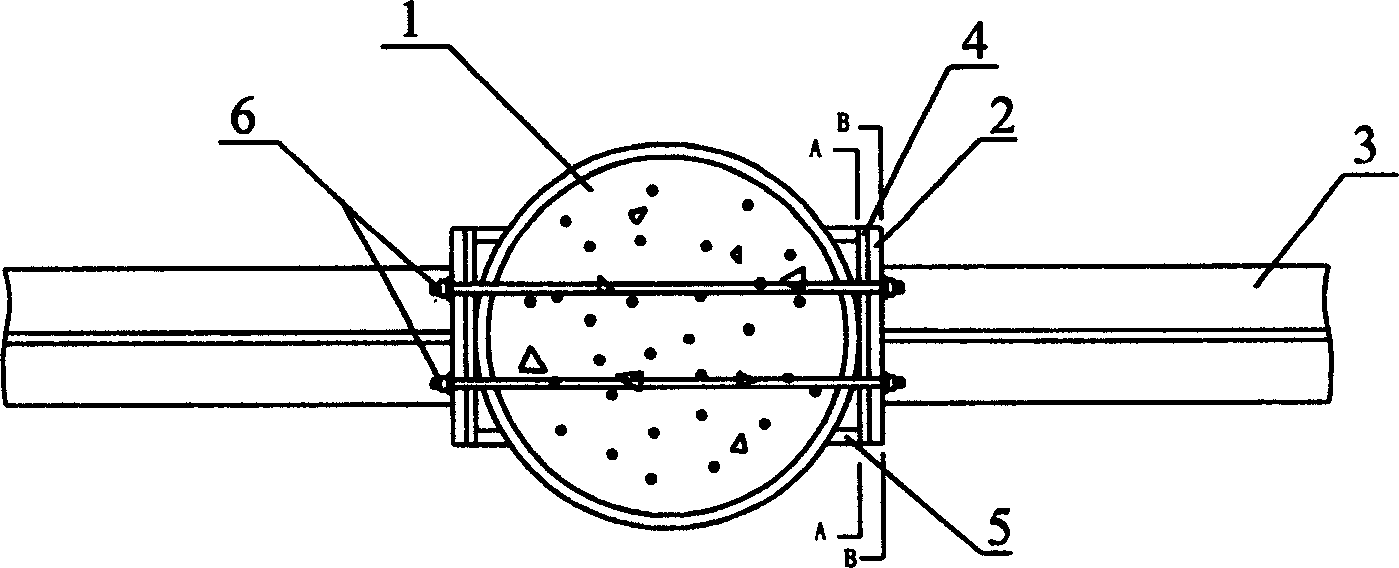

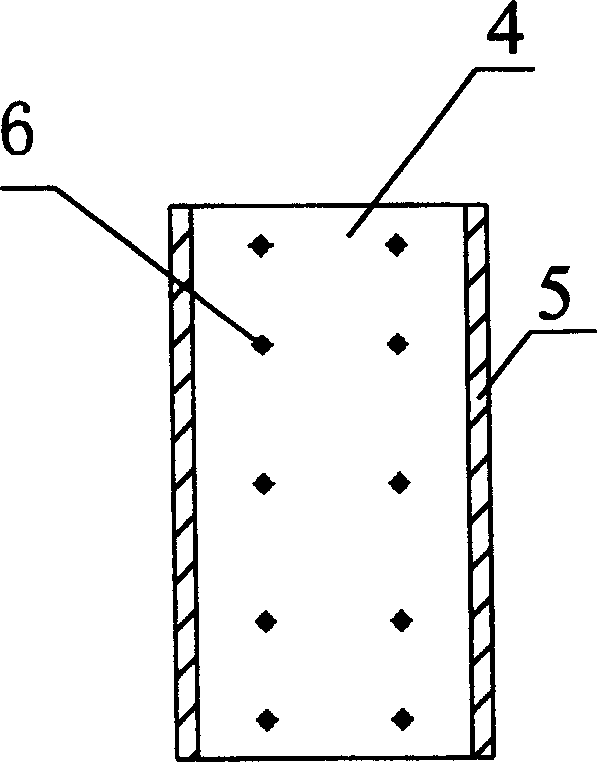

Round steel pipe concrete column joint for beam column connection and method for manufacturing the same

The invention discloses a kind to use in beam column the connection round steel pipe coagulation earth pyramid pitch point and its the manufacture method, it mainly included the round steel pipe coagulation earth pyramid and the steel girder which connected with this column, the round steel pipe coagulation earth pyramid and filled in in this round steel pipe including the round steel pipe the concrete, in carried with steel pipe coagulation earth pyramid connection steel girder Liang is equipped with an end board, this steel pipe coagulation earth pyramid with stated between the end board to be equipped with the belt rib level the steel plate, level the steel plate solidified on the round steel pipe, carried the board, level the steel plate as well as the round steel pipe through as soon as passed through core excels in the bold fastening in together. The invention cost inexpensive, mechanics performance good, design succinct convenient, the construction difficulty is small, also can avoid the scene welding, improves the connection quality and the construction benefit.

Owner:HUNAN UNIV

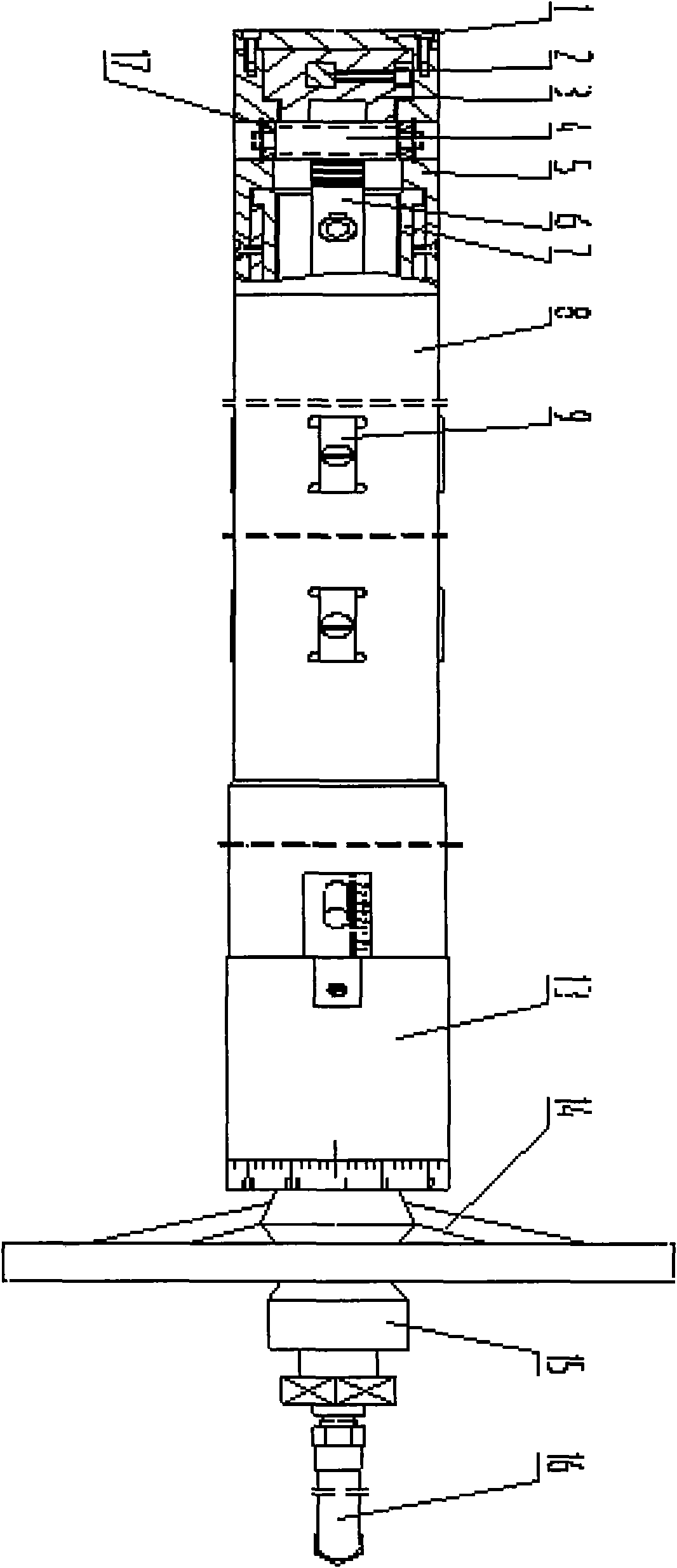

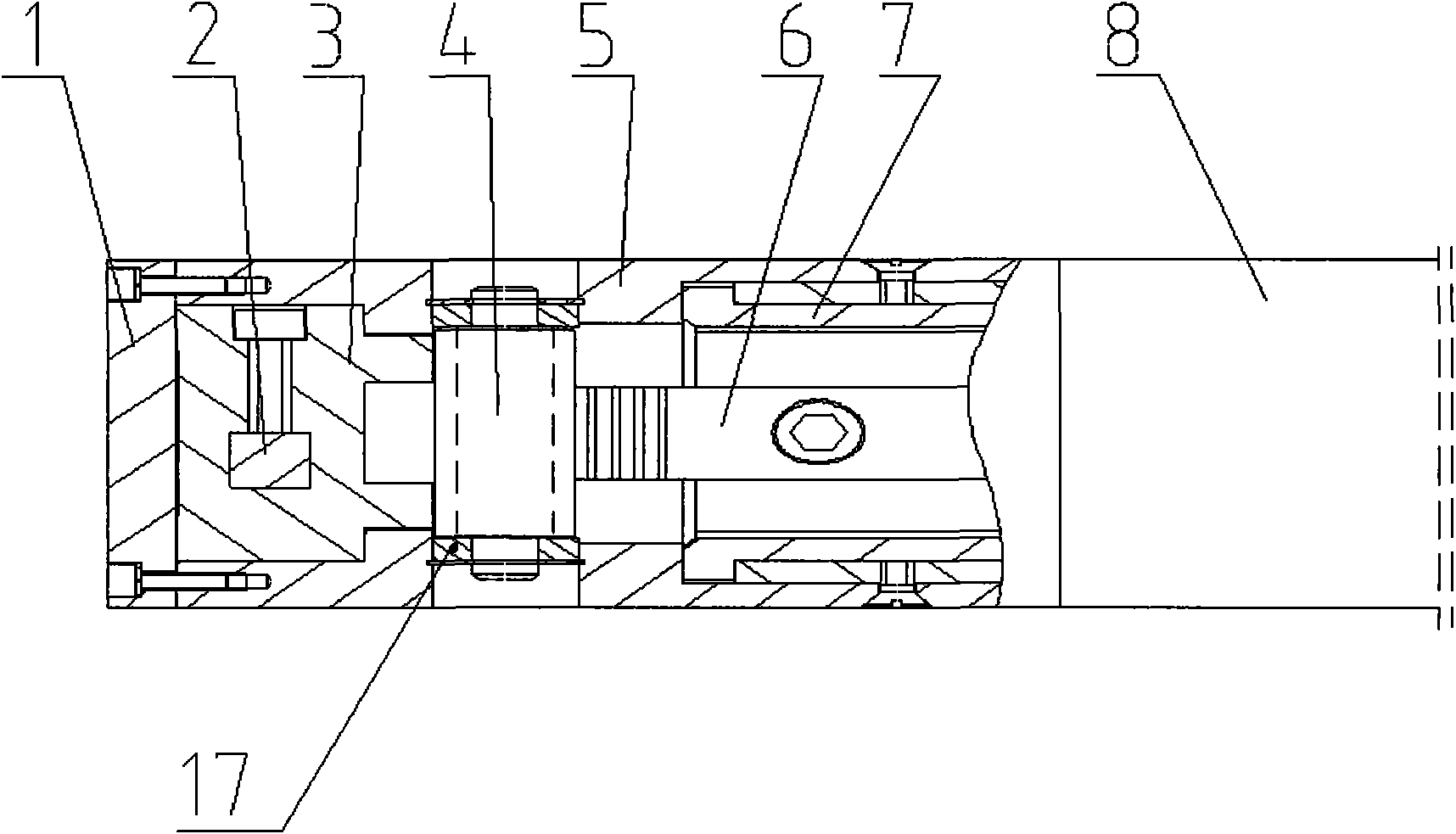

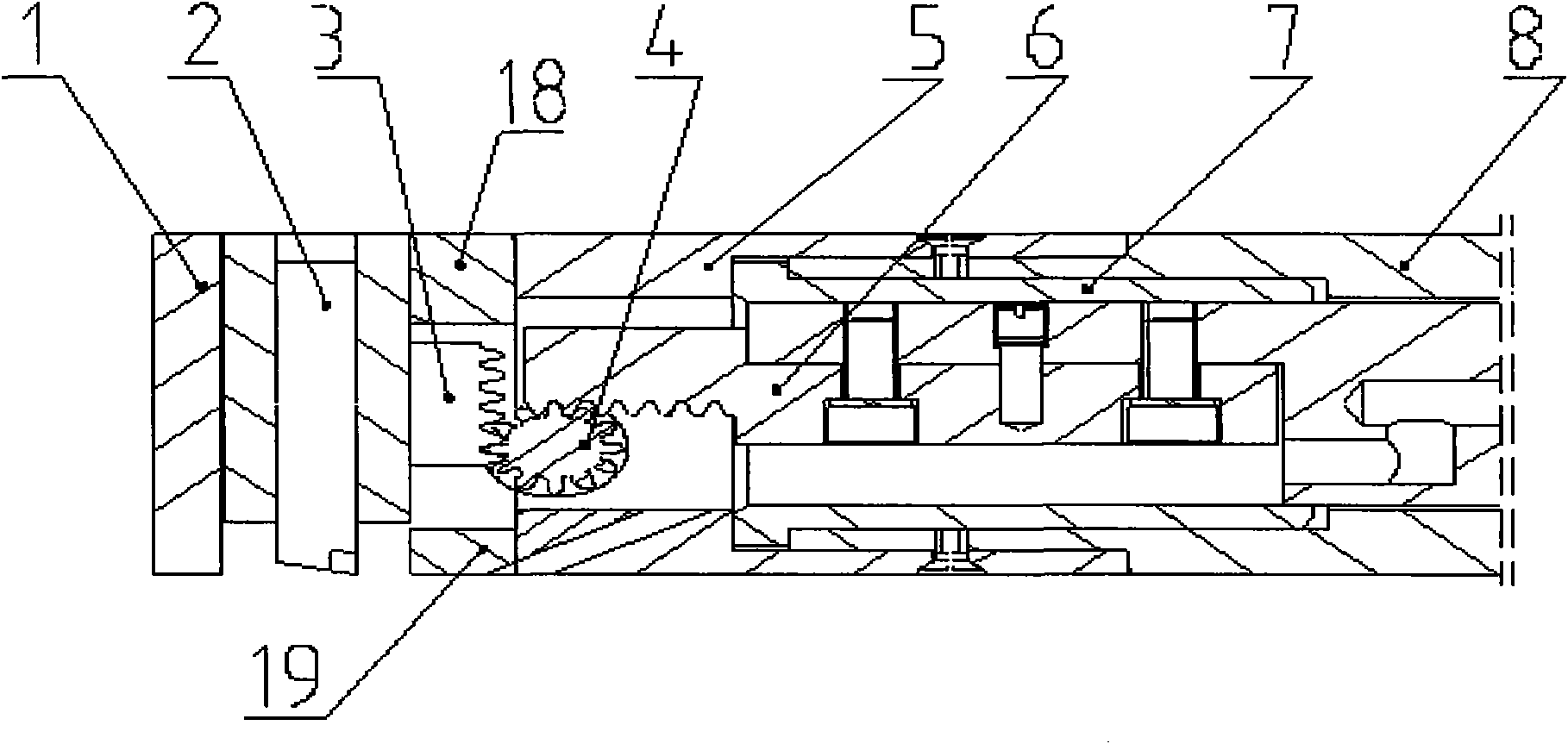

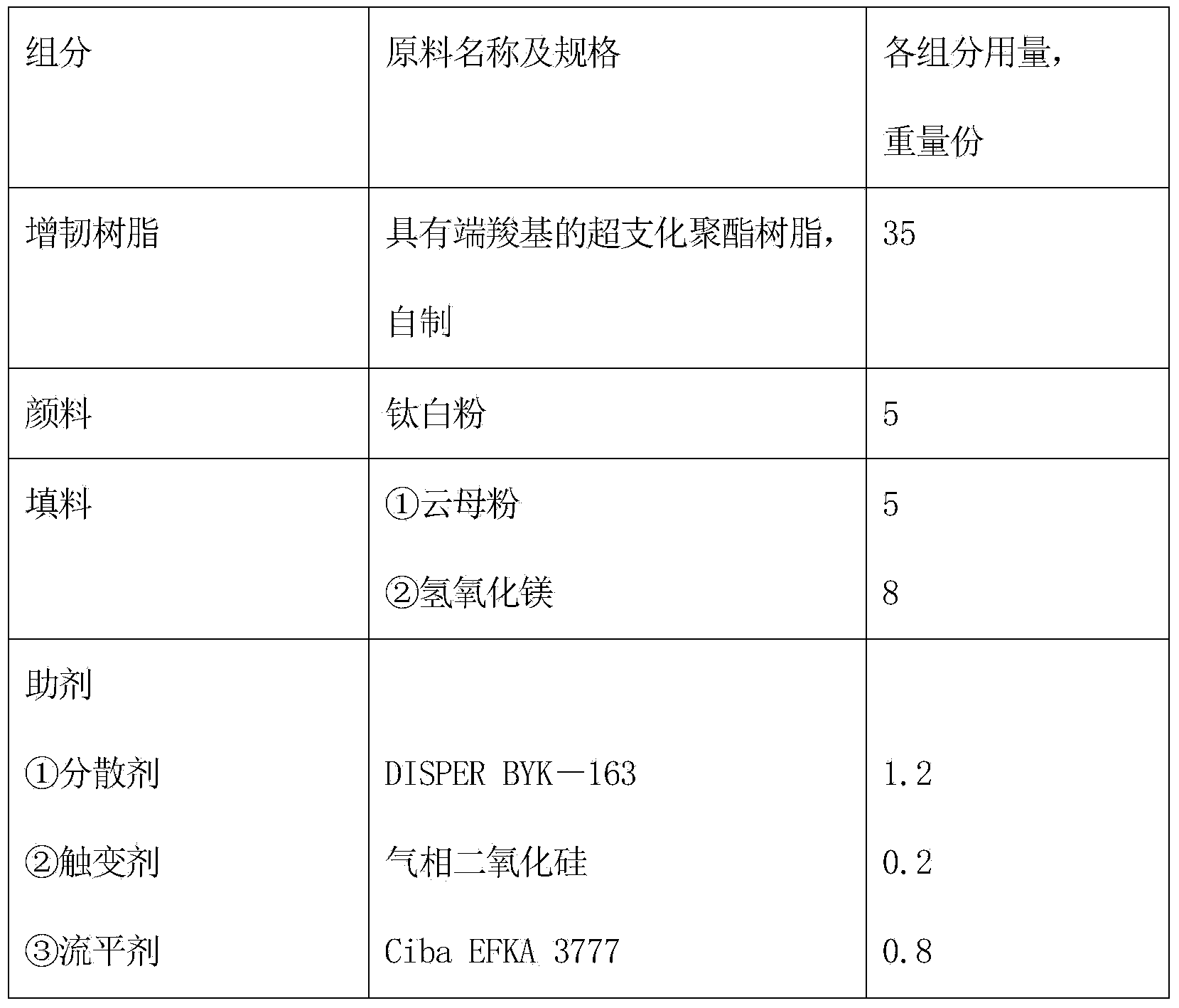

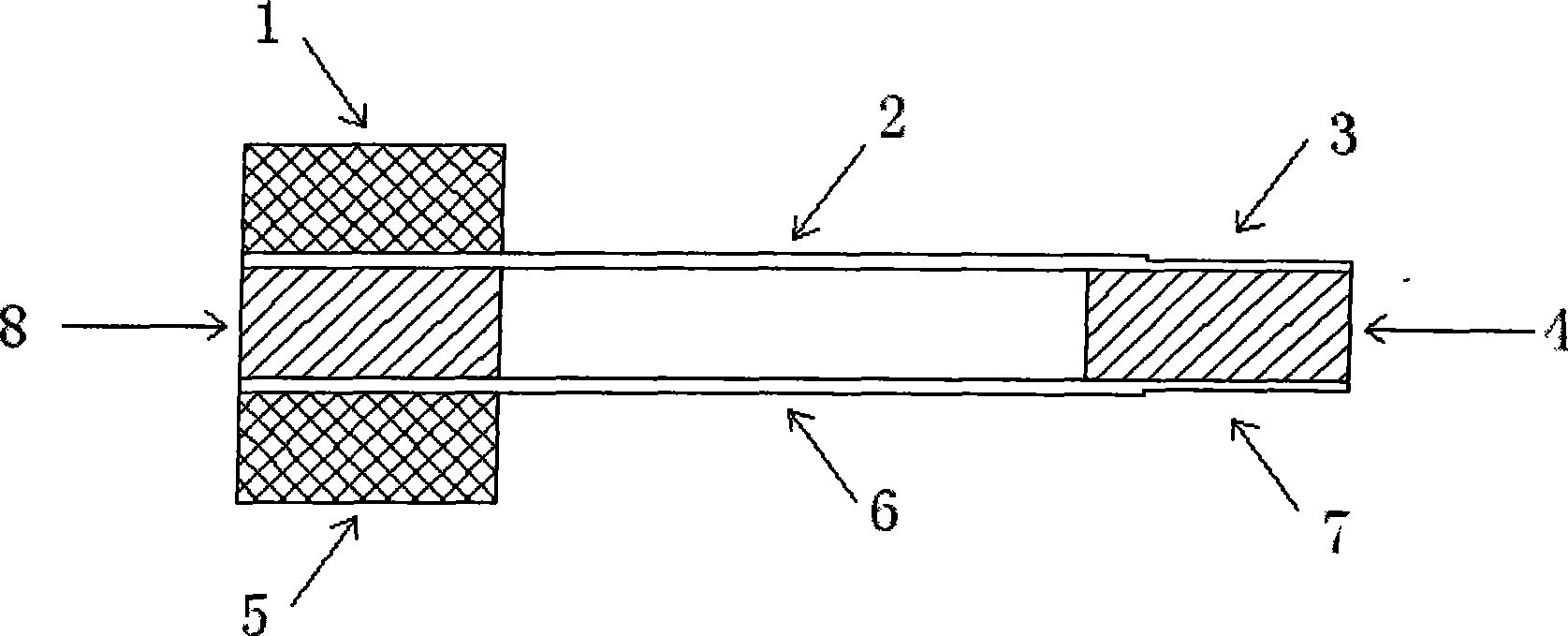

Tip-extension type deep hole boring cutter rod

The invention relates to a tip-extension type deep hole boring cutter rod. A cutter seat (3) is positioned in a cavity between a press cover (1) and a gear installing seat (5), and a screw rod (11) connected with one end of a core shaft (10); a rack (6) is installed in a slot on one end of the core shaft (10); one inner edge of a cutter installing hole needs to be coincide with the symmetric center surface of double-row teeth; a cutter (2) is positioned in the cutter installing hole, and a tip is positioned on a center line of a processed hole; and gears (4) are respectively meshed with the double-row teeth of the rack and the cutter seat. The screw rod is rotated by rotating a handle (14) on the screw rod (11) to drive the core shaft (10) to move, and then the cutter tip is extended by the transmission among a thread pair, the rack, gears and the rack. When retracting, the tip enters the end part of an inner hole of a part; and when the tip extends out, the middle of the part is processed. By adopting a guiding block (9), the rigidity of the cutter rod is ensured, and the cutter rod is provided with axial scales and circumferential scales. The tip-extension type deep hole boring cutter rod is suitable for processing deep holes on both ends of a long-shaft part, wherein the deep holes have small inner diameters at two ends, large inner diameters in the middles and larger difference of diameter sizes.

Owner:AECC AVIATION POWER CO LTD

Display device

InactiveCN101842826AImprove rigidityImprove retentionNon-linear opticsIdentification meansDisplay deviceMechanical engineering

Owner:SHARP KK

PPR (polypropylene randon coplymer) pipe material with excellent low-temperature toughness and preparation method thereof

The invention relates to a PPR (polypropylene randon coplymer) pipe material with excellent low-temperature toughness. The PPR pipe material is prepared from the following raw materials in parts by mass: 100 parts of polypropylene randon coplymer, 0.1 to 5 parts of coupling agent, 1 to 20 parts of toughening agent, 1 to 20 parts of crystal whisker loaded beta nucleating agent, 0.1 to 3 parts of antioxygen, and 0.1 to 5 parts of color master batch. The PPR pipe material provided by the invention has excellent low-temperature toughness, and has better rigidity, strength and pressure resistance at the same time; according to the PPR pipe material with the excellent low-temperature toughness provided by the invention, the reliability in transporting and applying the pipe material in a low-temperature environment is improved.

Owner:GUANGDONG LIANSU TECH INDAL

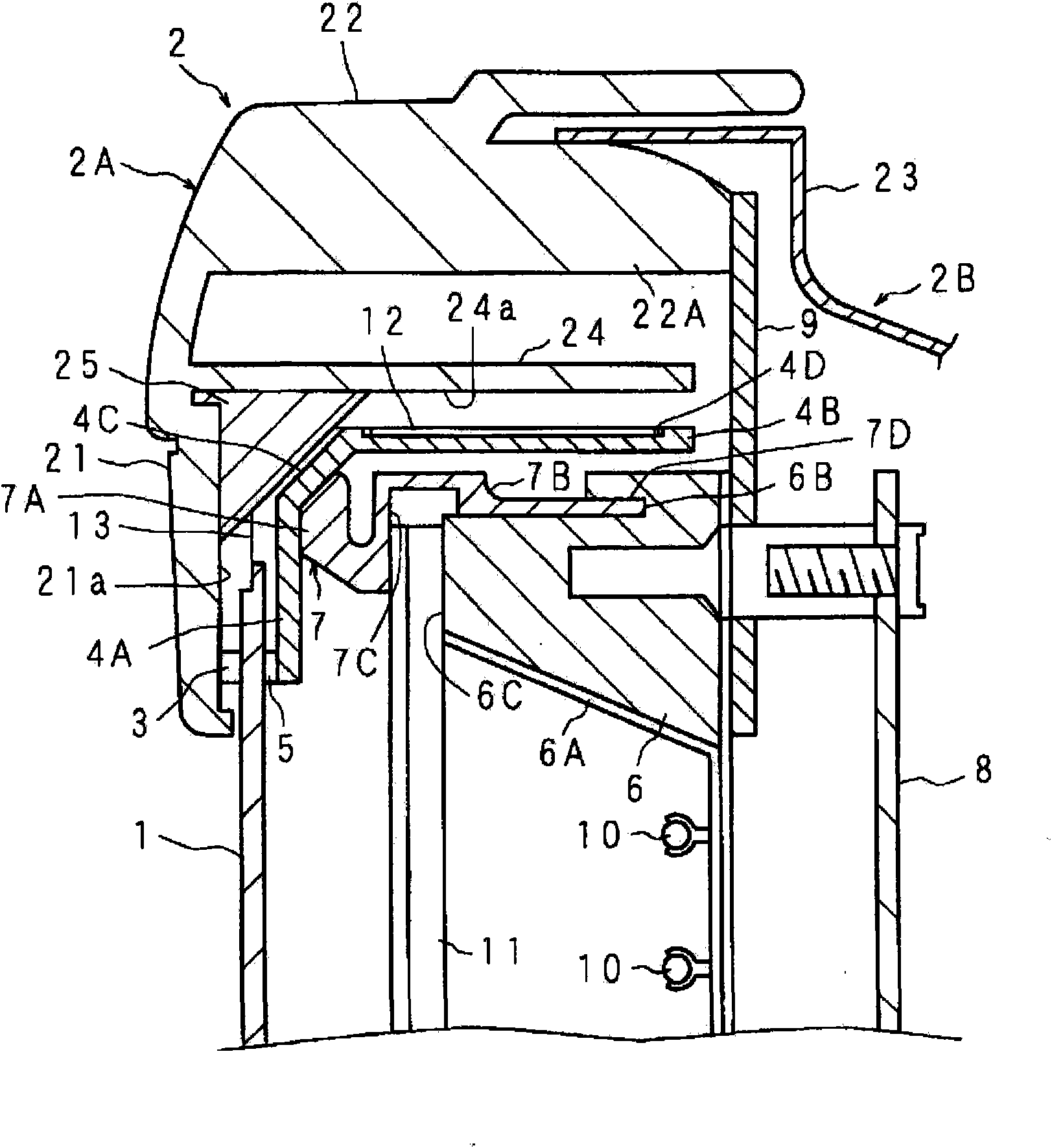

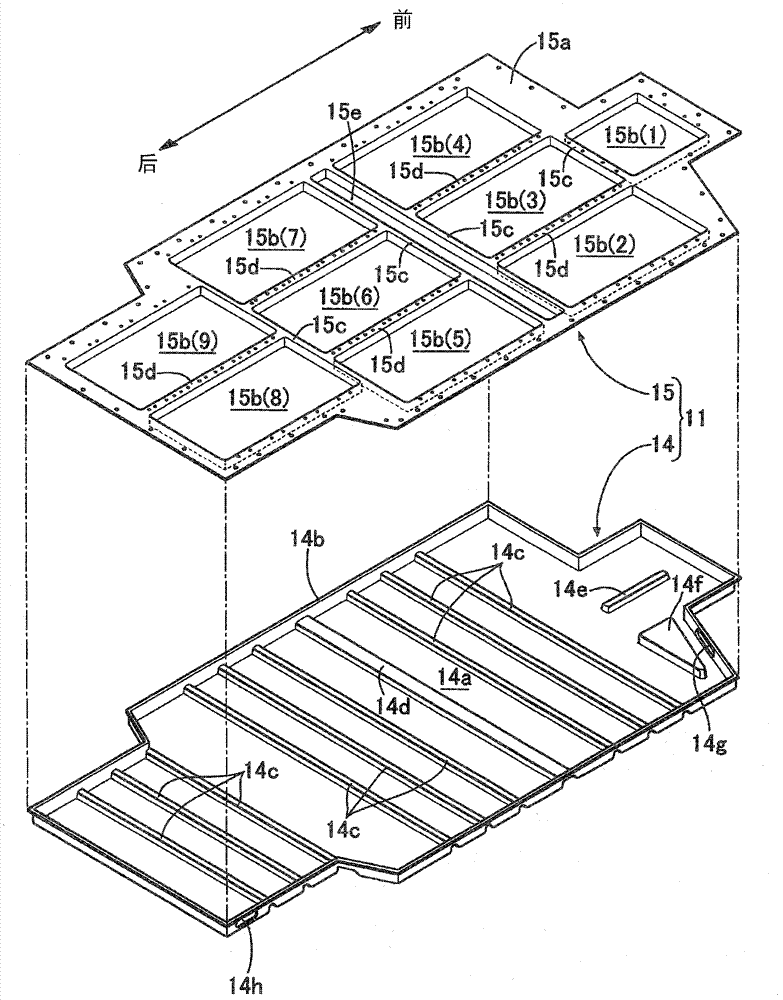

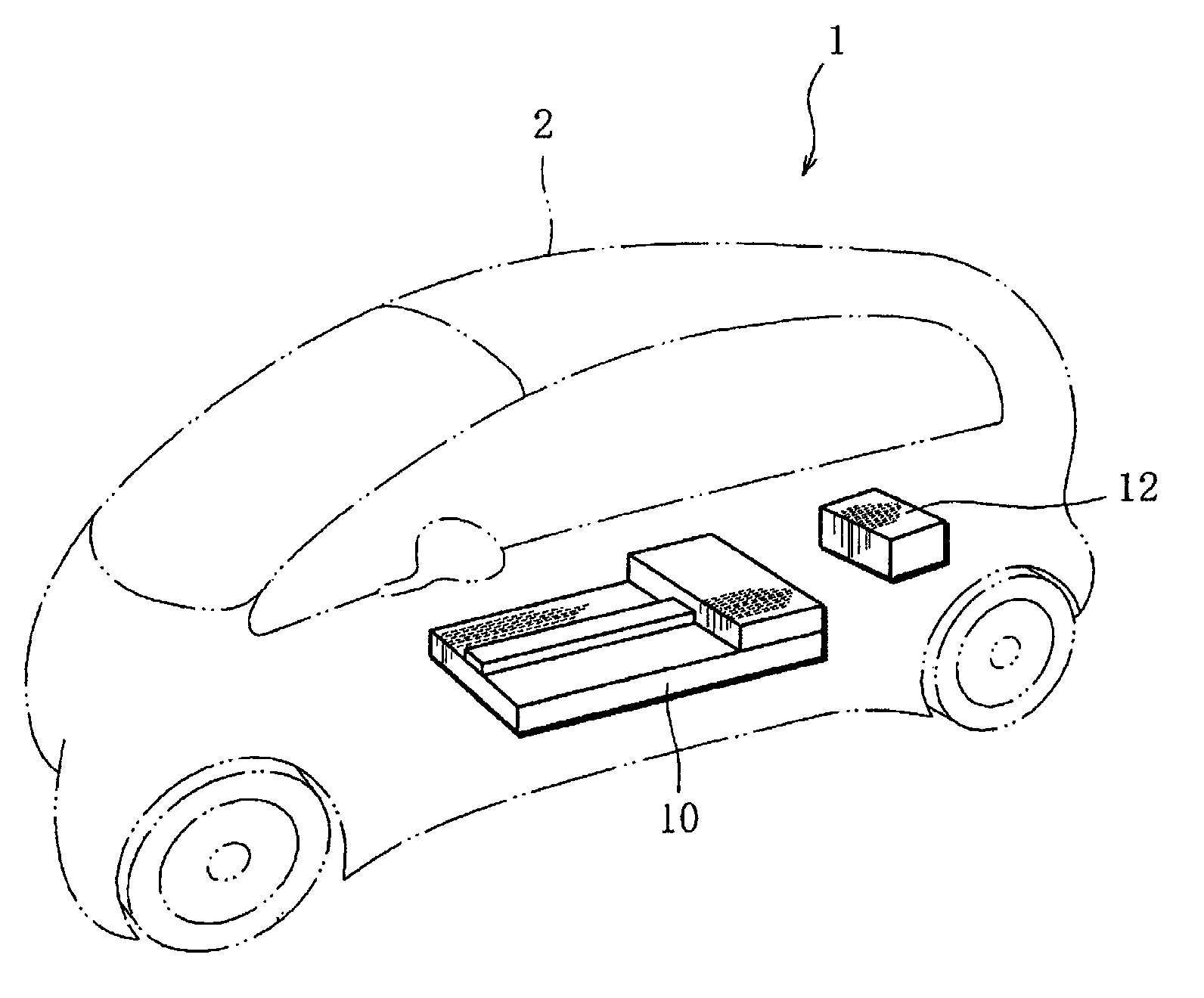

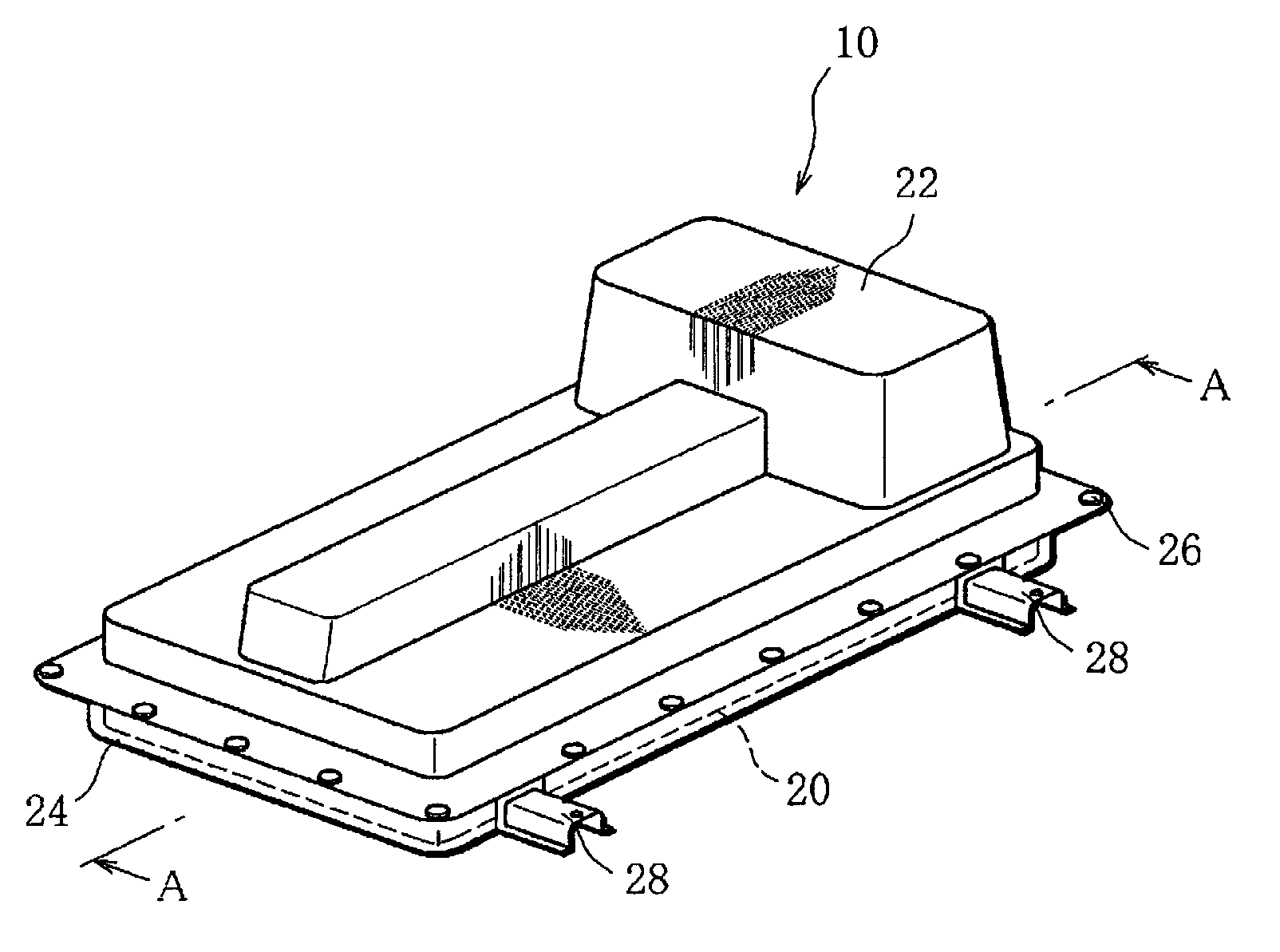

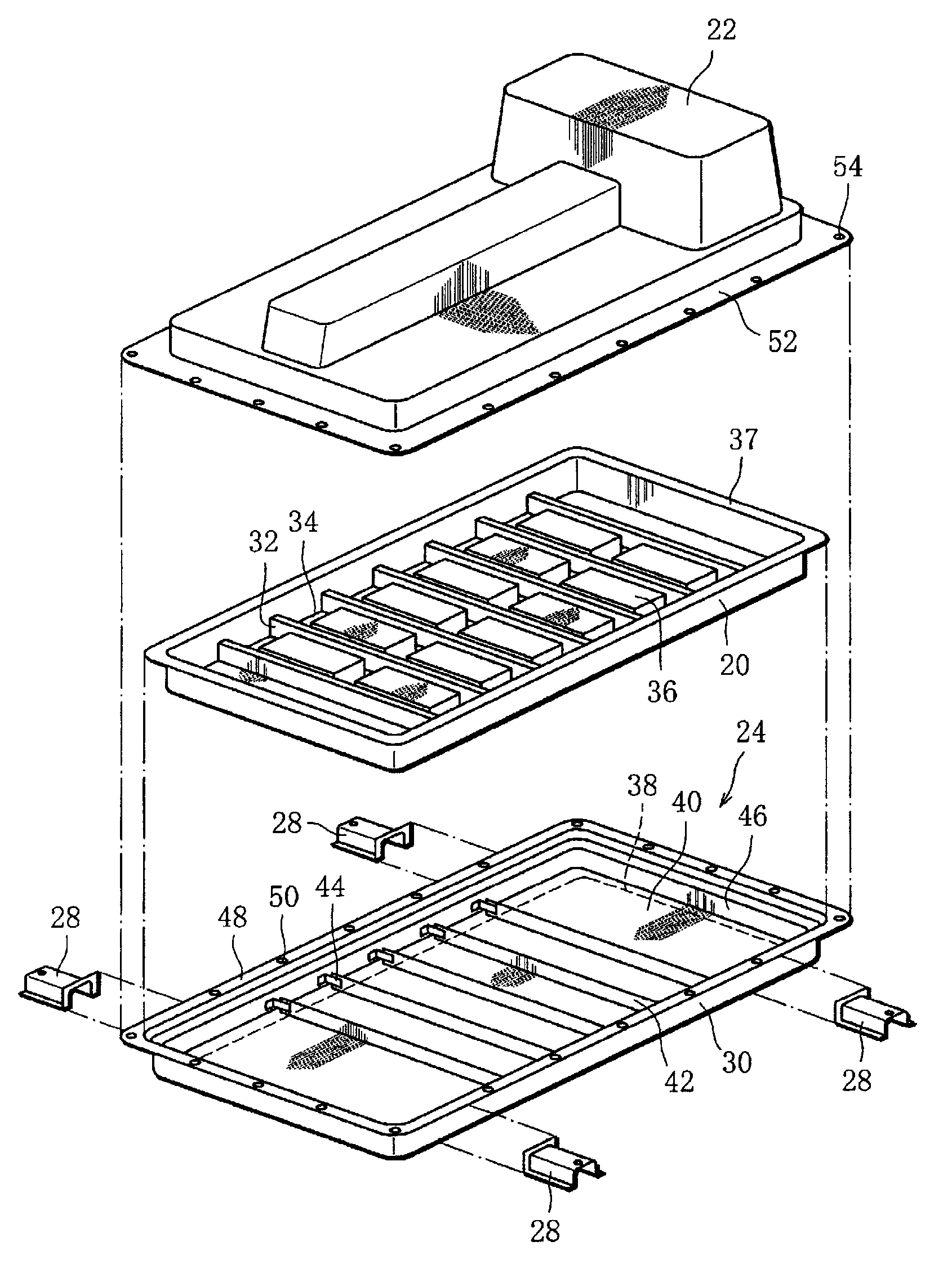

Power supply apparatus for vehicle

ActiveCN102820439AGuaranteed Cooling PerformanceGuaranteed rigidityCell temperature controlElectric propulsion mountingEngineeringCoolant flow

The invention provides a power supply apparatus for a vehicle, wherein the rigidity and the cooling performance of the support plate which supports and cools the battery modules. The support plate 11 supports the battery modules and includes a first plate (15) and a second plate (14). The first plate (15) thermally contacts bottom surfaces of the battery modules. The second plate (14) is placed on a bottom surface of the first plate to define cooling spaces where a coolant flows. The first reinforcing projections (14c, 14d) project into the cooling spaces and extend in in a flow direction of the coolant. The plurality of second reinforcing projections (15d) is provided on a top surface of the first plate (15) and extending in a direction crossing the flow direction of the coolant. Rigidity against bending of the support plate in two directions can be secured by the first reinforcing projections and the second reinforcing projections, and the first reinforcing projections projecting into the cooling spaces extend in the flow direction of the coolant, and the second reinforcing projections project out of the cooling spaces, and the second reinforcing projections (15d) project out of the cooling spaces. Therefore the first and second reinforcing projections do not interfere with the flow of the coolant, thereby securing the cooling performance.

Owner:HONDA MOTOR CO LTD

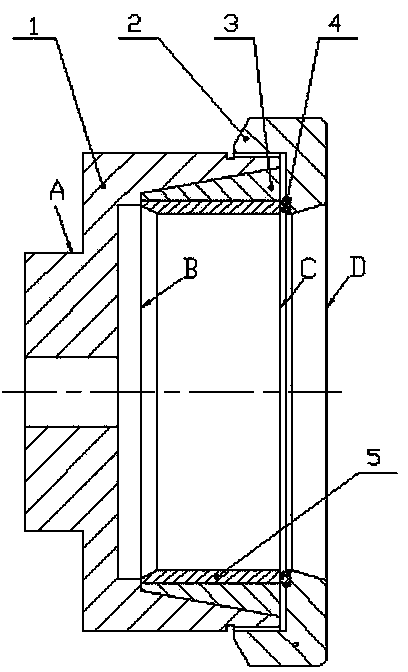

Thin-wall sleeve inner hole finish machining clamp and inner hole machining method

InactiveCN103419051AGuaranteed rigidityAvoid deformationPositioning apparatusMetal-working holdersEconomic benefitsCircular cone

The invention relates to a thin-wall sleeve inner hole finish machining clamp and an inner hole machining method. A locating base is composed of a small cylinder A and a big cylinder in an integrated mode. The right end of an inner cavity of the big cylinder is a circular conical surface. The left end of the inner cavity of the big cylinder is a round hole. A transition step surface B is arranged between the round hole formed in the left end and the circular conical surface at the right end. The right end of the big cylinder is provided with external threads. An outer circular conical surface of an elastic lining and the right end of an inner cavity of the locating base 1 are mutually matched at the taper of 1:10. A thin-wall sleeve is arranged in an elastic lining cylindrical surface inner hole. The elastic lining and the left end of the thin-wall sleeve abut against the transition step surface B. A rubber gasket is installed at the right end of the thin-wall sleeve. Inner threads of an end cap are matched with fine pitch external threads at the right end of the locating base. The thin-wall sleeve is pressed tightly through the rubber gasket. A cut being 2mm is formed in the side wall of the elastic lining. When the thin-wall sleeve inner hole finish machining clamp is applied to the machining of a thin-wall inner hole, the rigidity of the thin-wall sleeve is guaranteed when inner hole fine machining is conducted, deformation generated in the process of clamping and machining is avoided, the product percent of pass reaches over 95%, the production cost is reduced, the production efficiency is improved, and economic benefits are increased.

Owner:JIANGXI HONGDU AVIATION IND GRP

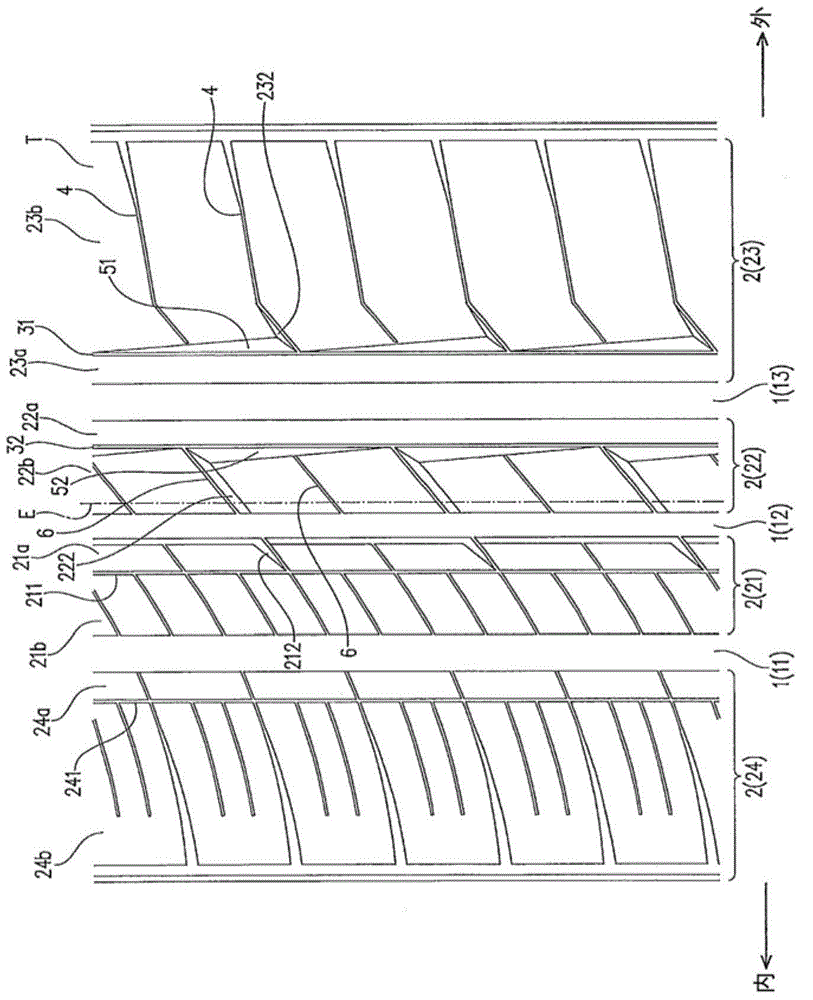

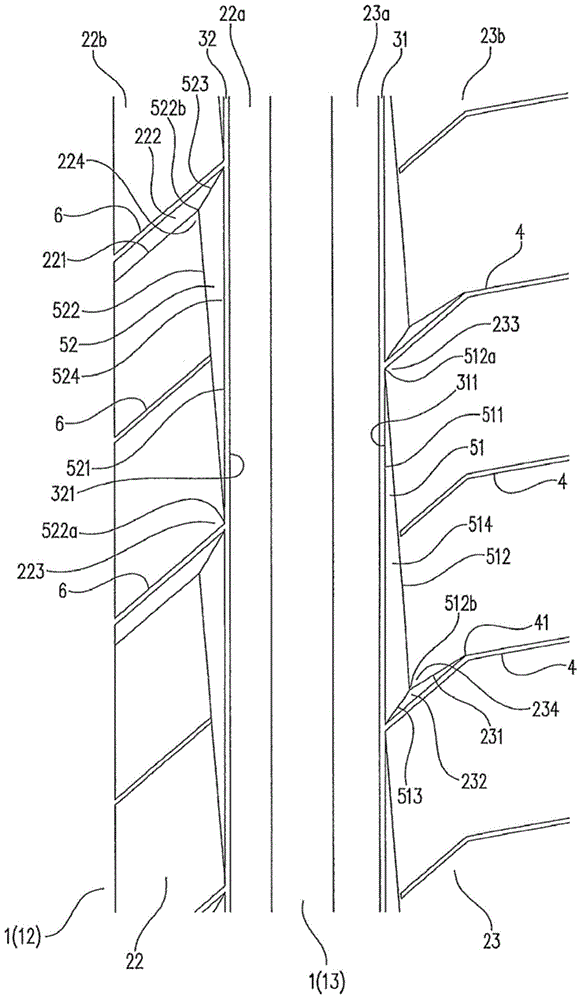

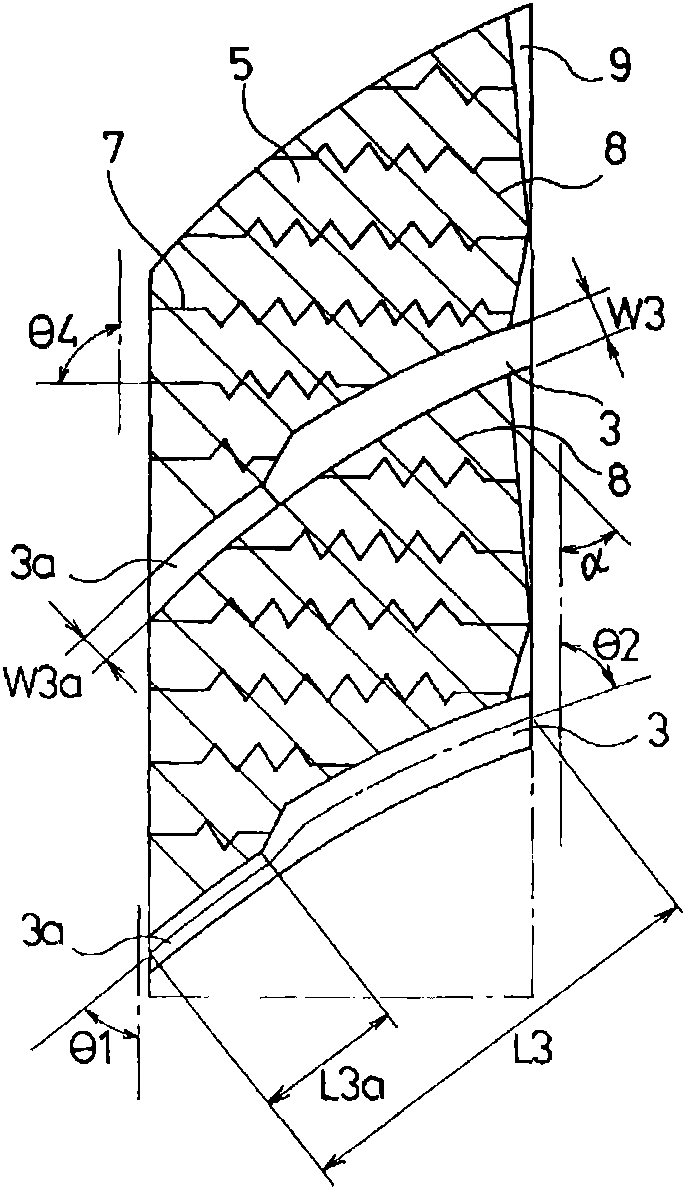

Pneumatic tyre

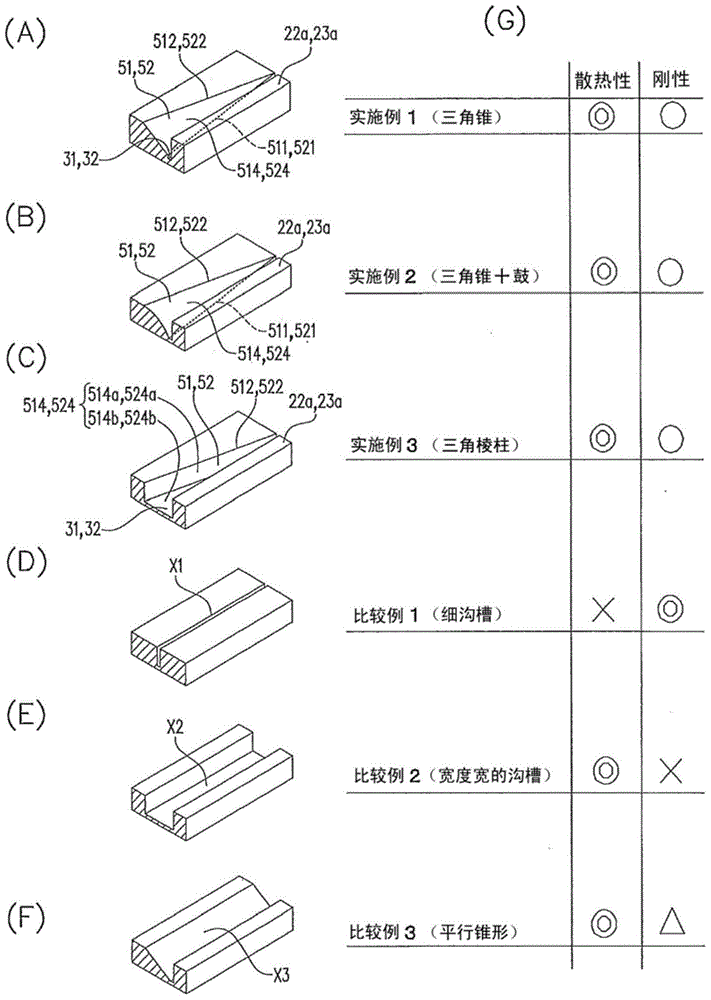

ActiveCN104417282AGuaranteed rigidityImprove cooling effectTyre tread bands/patternsEngineeringMechanical engineering

The invention provides a pneumatic tyre. The tread surface (T) is provided with at least one main groove (13) extending the circumferential direction of the tyre and at least one fine groove (31, 32) parallelly opposite to main groove (13), thin stripes (23a, 22a) which extend along the circumferential direction of the tyre and is located among the main groove (13) and the thin grooves (31, 32). Thick stripes (23b, 22b) are located at the sides opposite to the thin stripes (23a, 22a) in the width direction of the tyre of the thin grooves (31, 32) and provided with multiple notch portions (51, 52) adjacently connected to the thin grooves and arrayed along the circumferential direction of the tyre. The shapes of the multiple notches (51, 52) are characterized in that one end portion of each notch portion in the circumferential direction of the tyre has the large width in the width direction of the tyre and the other end portion of each notch portion has the smaller width in the width direction. The invention helps to ensure rigidity and obtain excellent heat dissipation performance.

Owner:TOYO TIRE & RUBBER CO LTD

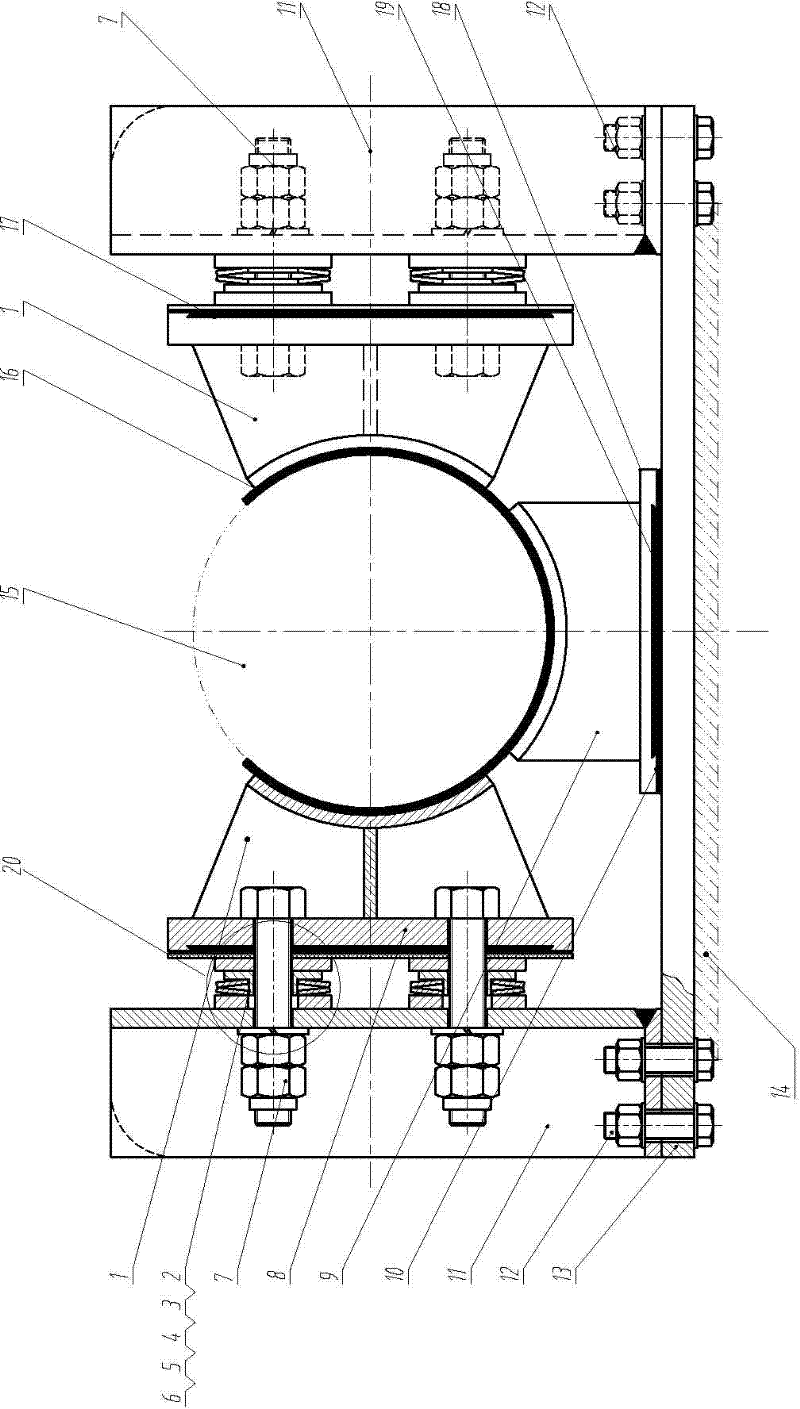

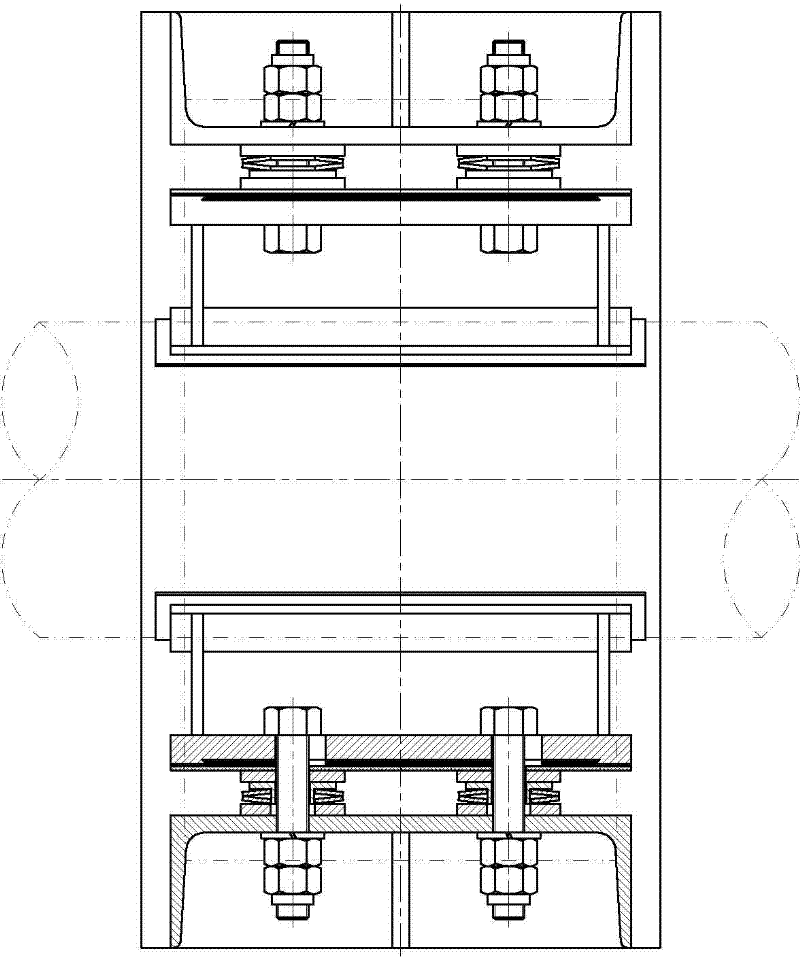

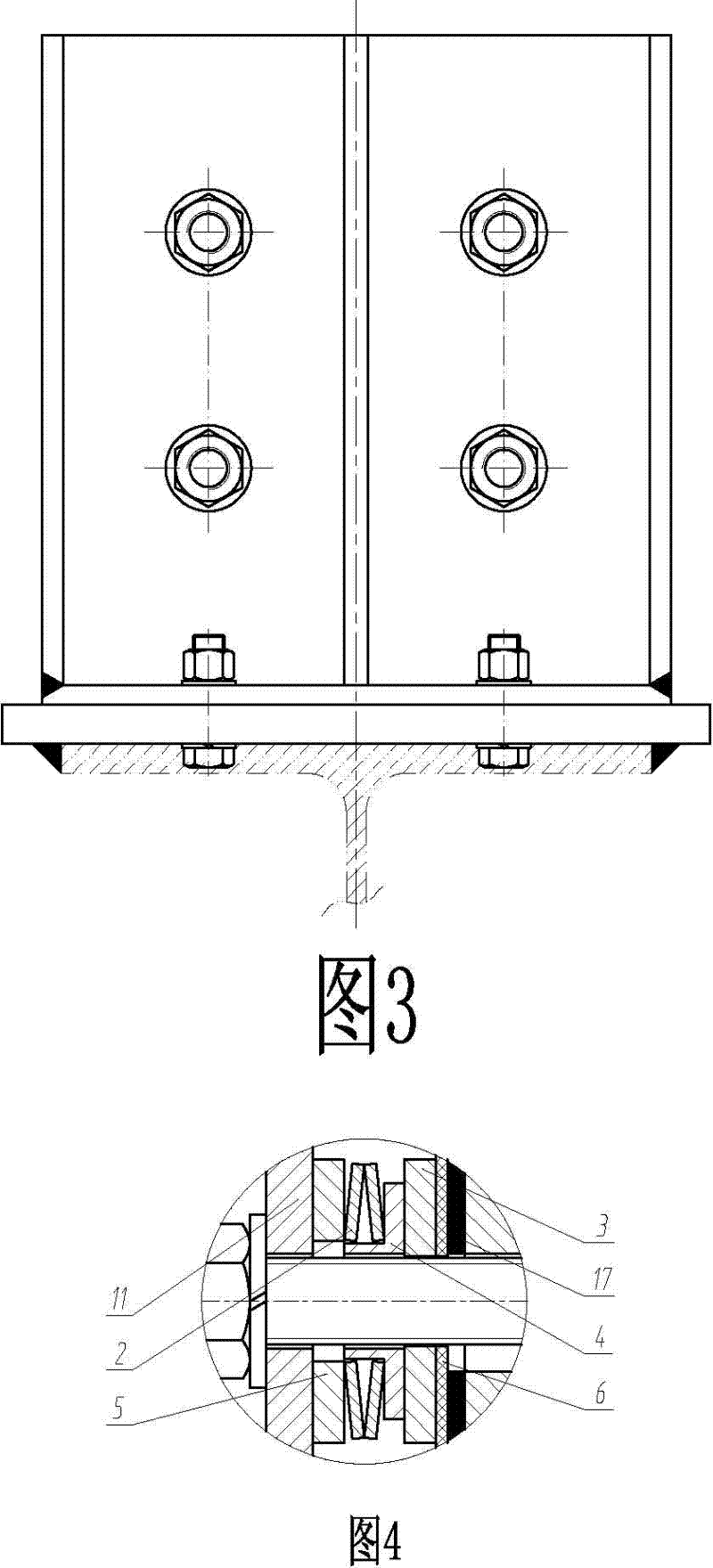

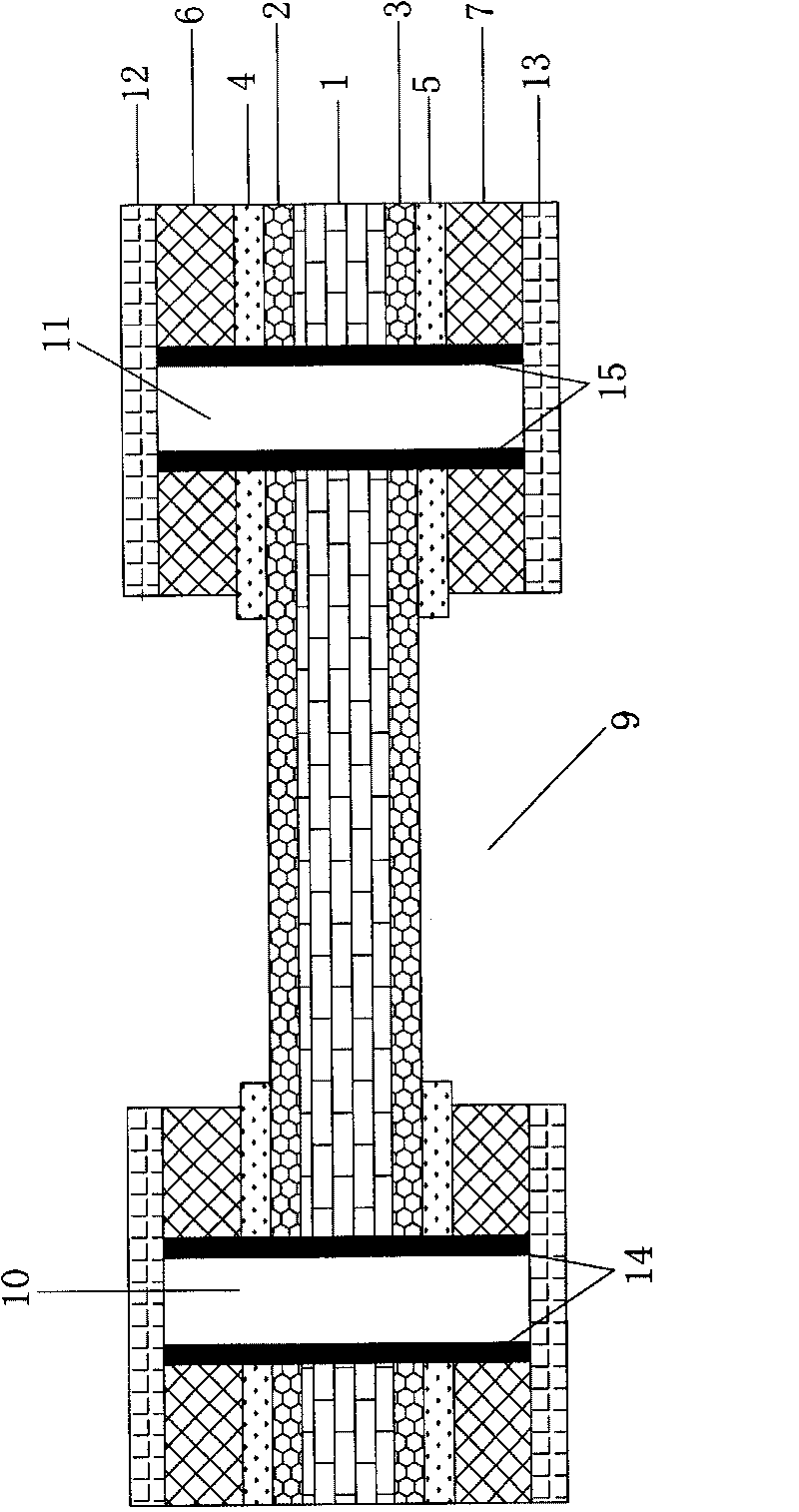

Pressure pipe radial vibration damping force stilling support

ActiveCN102297291AVibration stress reliefGuaranteed rigidityPipe supportsRadial vibrationPressure pipe

The invention relates to a radial vibration-reducing stress-dissipating bracket for a pressure pipeline. The radial vibration-reducing stress-dissipating bracket for the pressure pipeline comprises a lower supporting block (9) and a lower bottom plate (13); the pressure pipeline (15) is supported on the lower supporting block (9); and the lower supporting block (9) is supported on the lower bottom plate (13). The radial vibration-reducing stress-dissipating bracket for the pressure pipe is characterized in that vertical type fixing brackets (11) are symmetrically arranged at two sides of the lower bottom plate (13); two radial clamping blocks (1) which are matched with the two sides of the pressure pipeline (15) are respectively connected with corresponding supporting plates (8); the supporting plates (8) are connected with corresponding vertical type fixing brackets (11) through respective fastening connecting pieces (7); and elastic supporting assemblies (20) are mounted on the fastening connecting pieces (7) and between the vertical type fixing brackets (11) and the supporting plates (8). With the adoption of the radial vibration-reducing stress-dissipating bracket for the pressure pipe, the rigidity of a piping system can be maintained and a vibrating stress generated in the radial direction of the piping system can be eliminated, thus the requirement of vibration-reducingsupport for the pressure pipeline can be satisfied.

Owner:JINAGSU SUNPOWER PIPELINE ENG TECH CO LTD

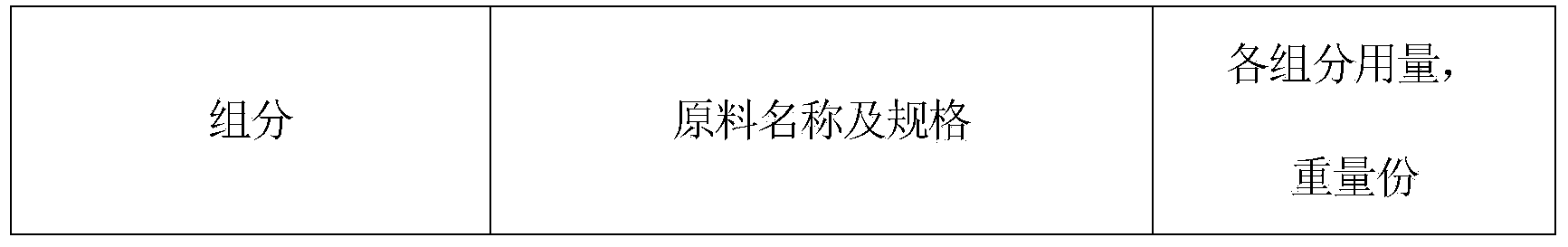

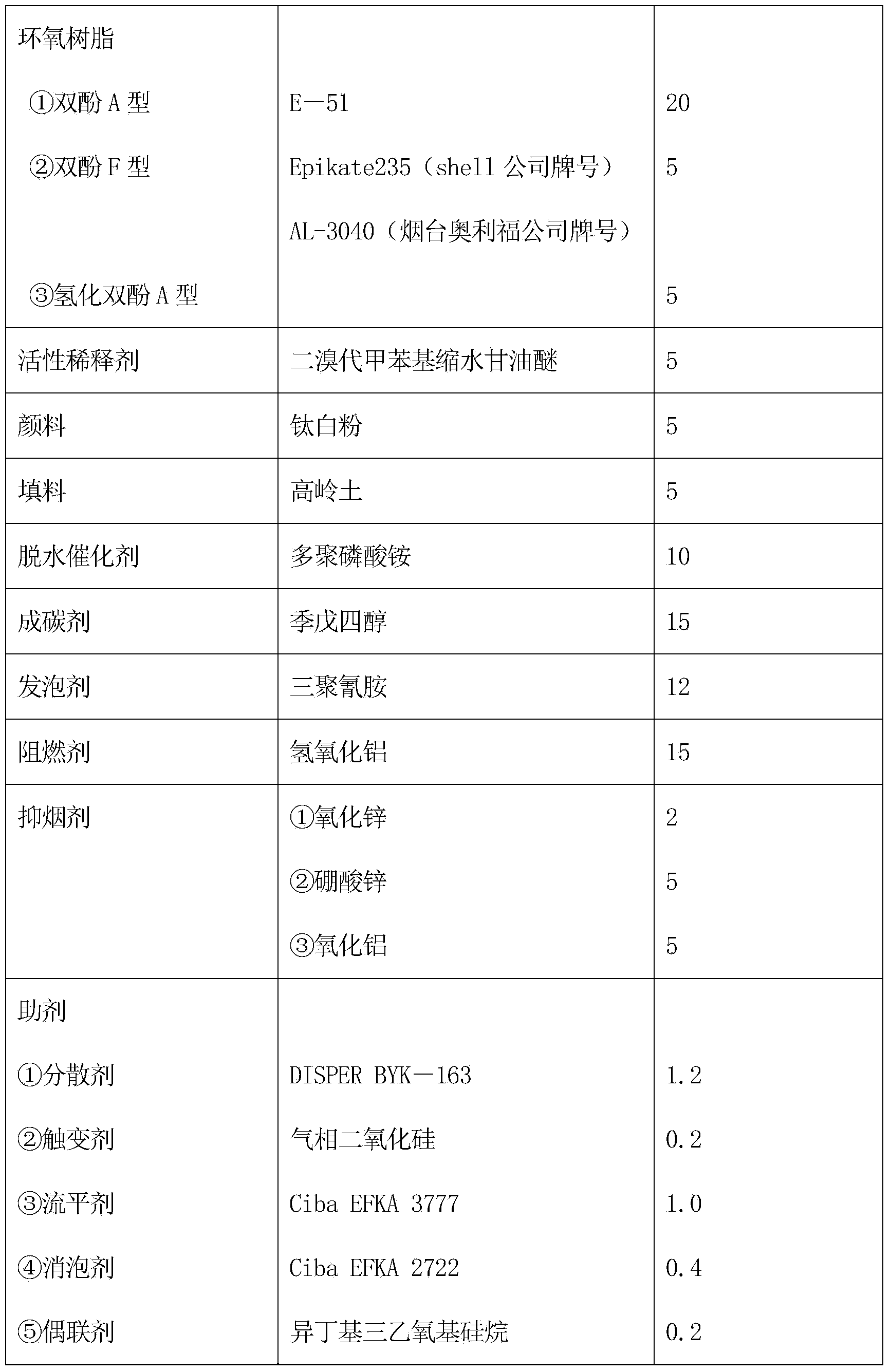

Fire retardant coating for steel structure surface of nuclear power plant

InactiveCN103709899AChemically resistantFlame retardantFireproof paintsEpoxy resin coatingsFoaming agentHyperbranched polyester

The invention relates to a fire retardant coating for a steel structure surface of a nuclear power plant. The fire retardant coating consists of components A, B and C at a weight ratio of (4-6): 1: 1, wherein the component A is a mixture composed of 15-35 parts of epoxy resin, 2-10 parts of reactive diluent, 5-15 parts of dehydration catalyst, 10-30 parts of carbonizing agent, 5-20 parts of foaming agent, 15-35 parts of fire retardant, 5-15 parts of smoke inhibitor, 10-30 parts of pigment and filler and 2-10 parts of auxiliaries; the component B is a mixture composed of 10-50 parts of toughened resin, 10-30 parts of pigment and filler and 2-10 parts of auxiliaries; the C component is an amine curing agent; and the toughened resin in the component B is hyper-branched polyester resin with a terminal carboxyl group. The fire retardant coating disclosed by the invention is more excellent than a normal intumescence fire retardant coating in binding strength, freezing and thawing cycle resistance, acid and base resistance, and fire retardant limit, and is specifically up to fire resistance requirements of the steel structure surface of the nuclear power plant.

Owner:CHINA NAT OFFSHORE OIL CORP +3

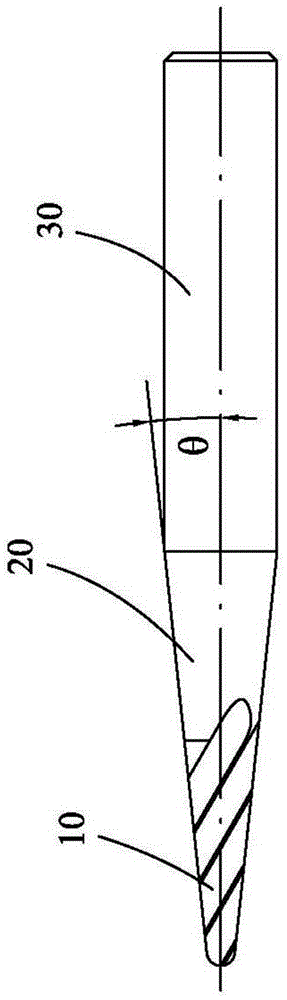

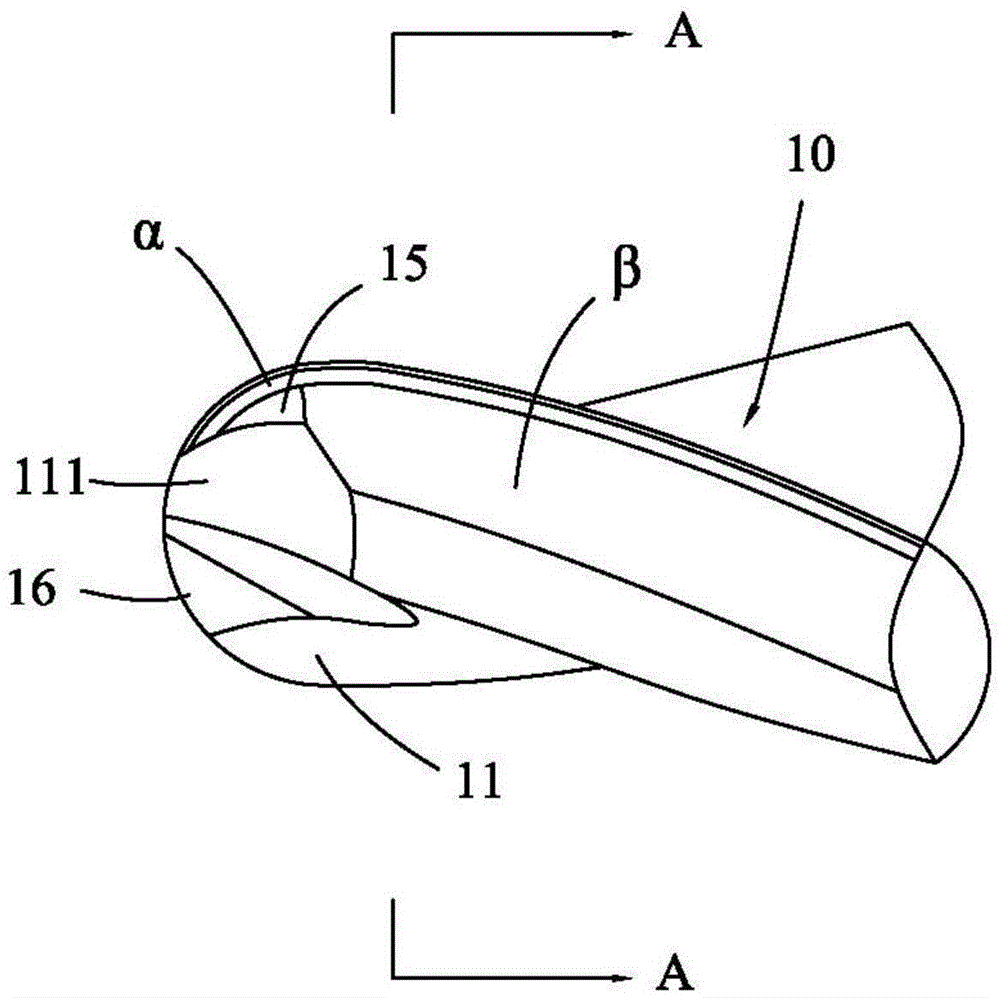

Taper and ball-end milling cutter

InactiveCN105642986AIncrease sharpnessGuaranteed StrengthMilling cuttersMilling cutting insertsMilling cutterNeck parts

The invention provides a taper and ball-end milling cutter. The milling cutter comprises a head part, a neck part connected with the head part, and a handle part connected with the neck part, wherein the head part is provided with a chip removal slot, an entity part used for forming the chip removal slot, and a cutting edge formed at an intersection line between the chip removal slot and the entity part, wherein the cutting edge is provided with a front cutter face and a rear cutter face, the front cutter surface and the rear cutter surface are contacted and form a front angle, and the rear cutter face of the cutting edge and a machining piece are contacted and form two rear angles, including the first rear angle and the second rear angle respectively. According to the taper and ball-end cutter provided by the invention, the front angle and the rear angles are reasonably designed, so that the rigidity of the milling cutter is guaranteed, the sharp degree of the milling cutter is guaranteed at the same time, and the probability of burr generation in a milling process is effectively reduced; the taper and ball-end milling cutter has a long service life and can keep good surface roughness when machining an aluminum alloy pressure wheel.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

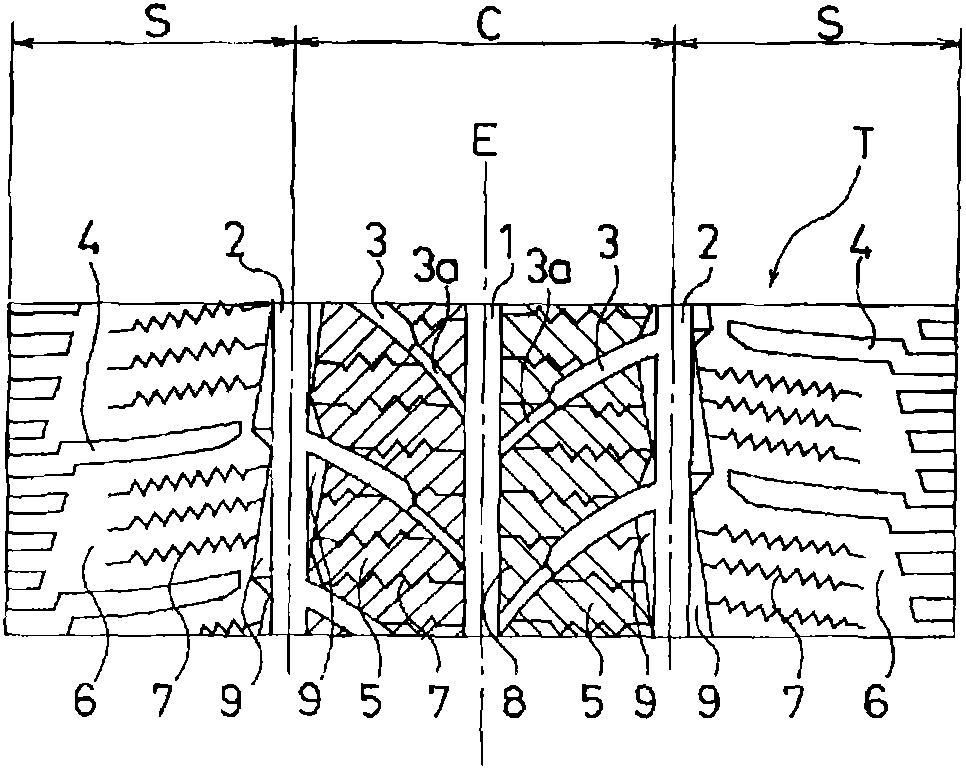

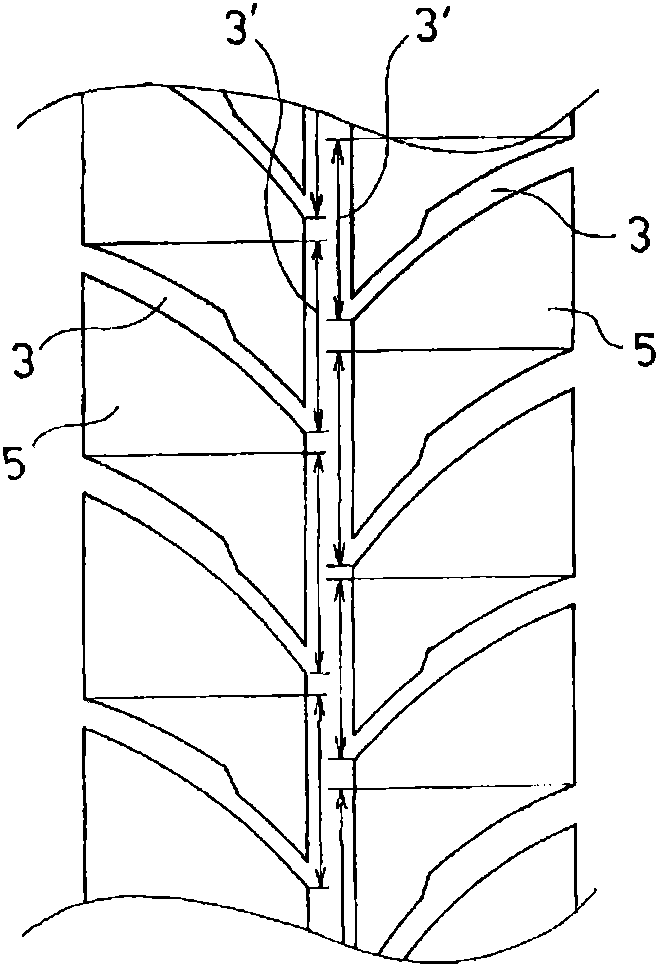

Pneumatic tire

ActiveCN102310723AImprove wetting performanceImprove snow performanceSpecial tyresTyre tread bands/patternsAcute angleTransverse groove

The invention provides a pneumatic tire, which has directional patterns and achieves improved wet performance, snow performance and nonuniform wear resistance. The central portion (C) of the pneumatic tire is divided into multiple pattern blocks (5) via a central main groove (1), outer main grooves (2) and transverse grooves (3). Meanwhile, the strip-shaped patterns (5) at the tire shoulder portion (S) is provided with shoulder pattern grooves (4). The patterns of the pneumatic tire are directional patterns. The transverse grooves (3) are formed at two sides of the central main groove (1) in the tire width direction and is reversely inclined relative to the tire equator, wherein the central inclined angle Theta1 of the transverse grooves (3) is an acute angle. Meanwhile, the transverse grooves (3) are formed at two sides of the central main groove (1) in the tire width direction and the tire circumferential direction in a staggered manner such that the circumferential portion (3') formed by upward projection of the transverse grooves (3) in the tire circumferential direction is provided at the periphery of the tire. In addition, sipes (7) are provided at the pattern blocks (5) and the strip-shaped patterns (6).

Owner:THE YOKOHAMA RUBBER CO LTD

Novel integral turning method of blades

InactiveCN102145460AGuaranteed rigidityGuaranteed pressing forcePositioning apparatusMetal-working holdersAlloyMachining

The invention provides a novel integral turning method of blades, which can effectively solve the problem of insufficient pressing force of the blades during the assembly machining of the blades in the past and also overcome the defect of insufficient rigidity caused by interrupted cutting. The novel integral turning method of the blades is simple and can greatly enhance machining efficiency. The novel integral turning method of the blades is characterized by comprising the following steps of: positioning the blades by simulating an assembling state, and pressing the positioned blades on a turning jig by using a press plate; then pouring a low-melting-point alloy between the blades and the turning jig; disassembling the press plate after the low-melting-point alloy is cooled and solidified; firmly bonding the blades and the turning jig depending on the low-melting-point alloy so that an integral rigid part is formed by the blades and the turning jig, and then carrying out assembly machining on the blades; and after the blades are subjected to the assembly machining, placing the blades and the turning jig into hot water so that the blades and the turning jig are separated because the solid low-melting-point alloy is melted when heated, and therefore the assembly machining of the blades is completed.

Owner:WUXI TURBINE BLADE

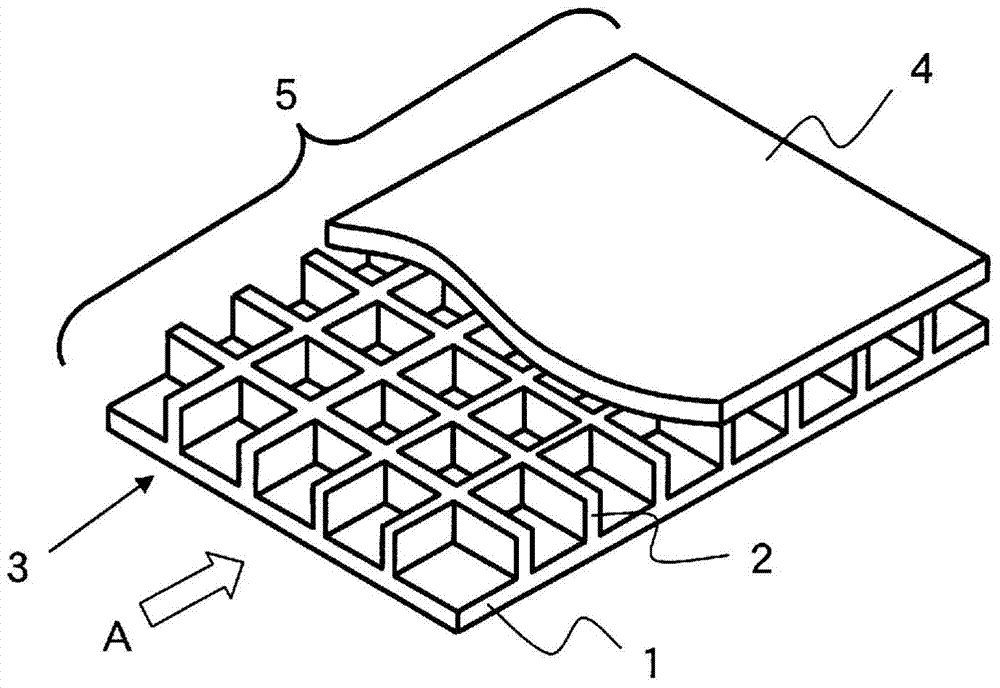

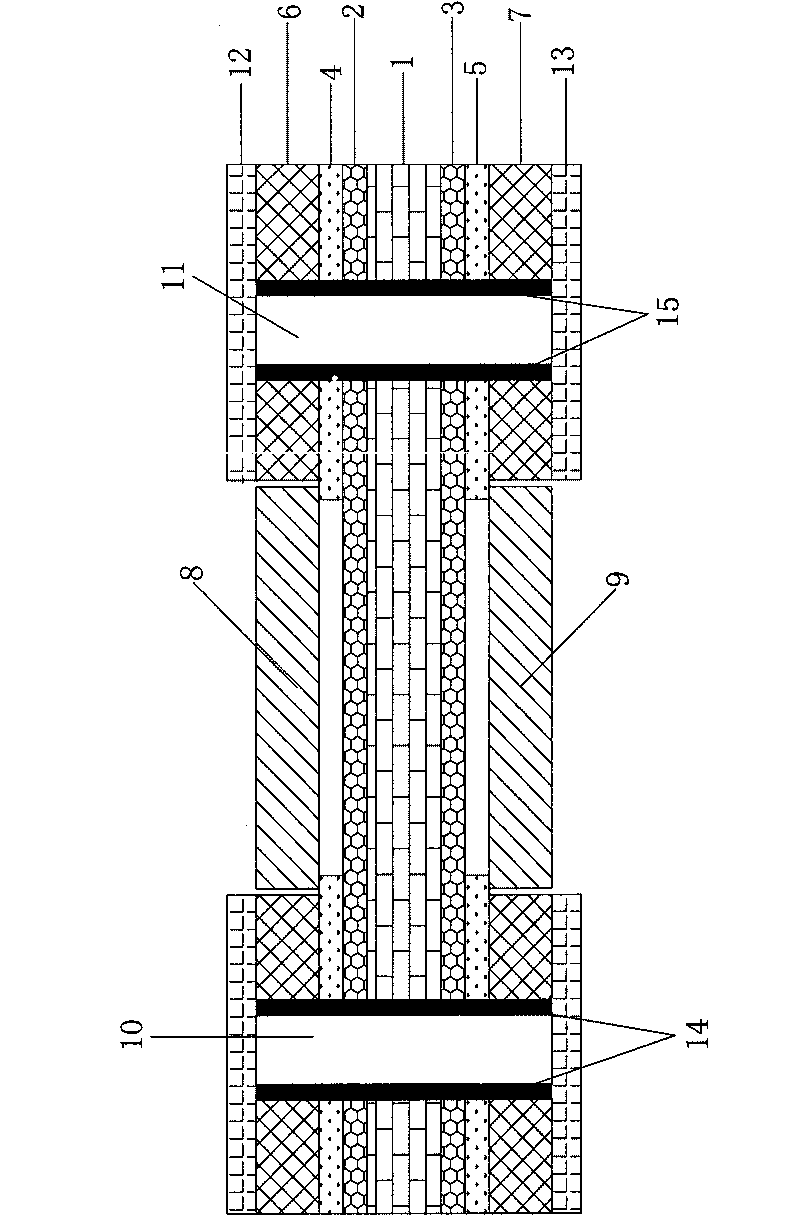

Molded product having hollow structure and process for producing same

ActiveCN104781065AImprove rigidityGuaranteed rigiditySynthetic resin layered productsMedical devicesPolymer sciencePolymer chemistry

A molded product obtained by unifying a first member (I) which is composed of both a plane surface layer part and a protruding core part and a second member (II), wherein: the first member (I) is made of a fiber-reinforced resin (A) which comprises reinforcing fibers (a1) and a matrix resin (a2); the reinforcing fibers (a1) extend across the boundary surface between the surface layer part and the core part: the quantity of reinforcing fibers (a1) extending across the boundary surface is 400 fibers / mm2 or more as observed at the boundary surface; the number-average fiber length (Ln) of the reinforcing fibers (a1) is 1mm or longer; and the core part constitutes a hollow structure. Thus, a molded product and a unified molded product which exhibit satisfactory lightness and meet the rigidity required in the market can be obtained.

Owner:TORAY IND INC

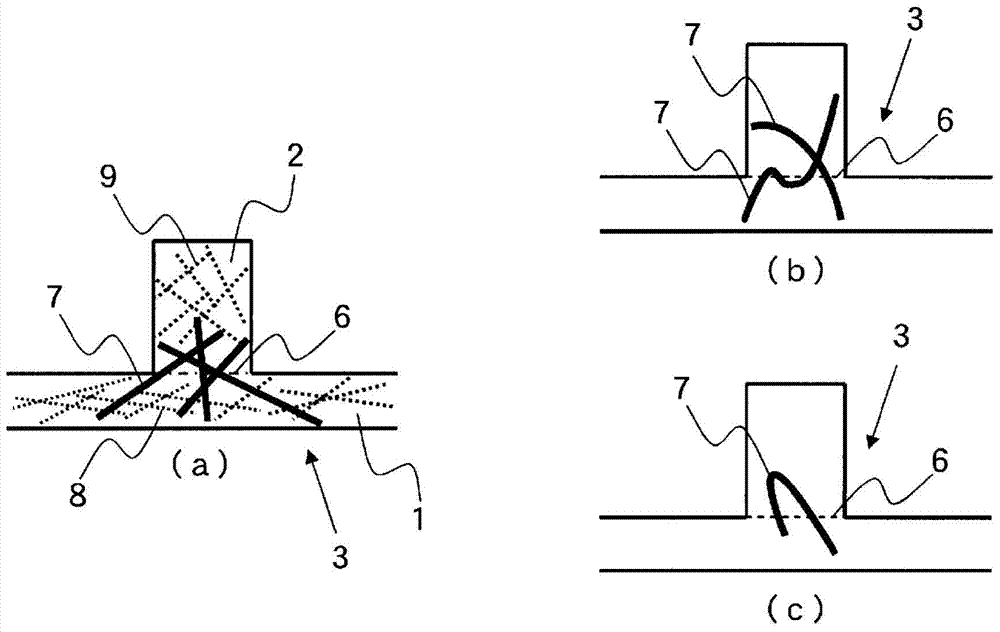

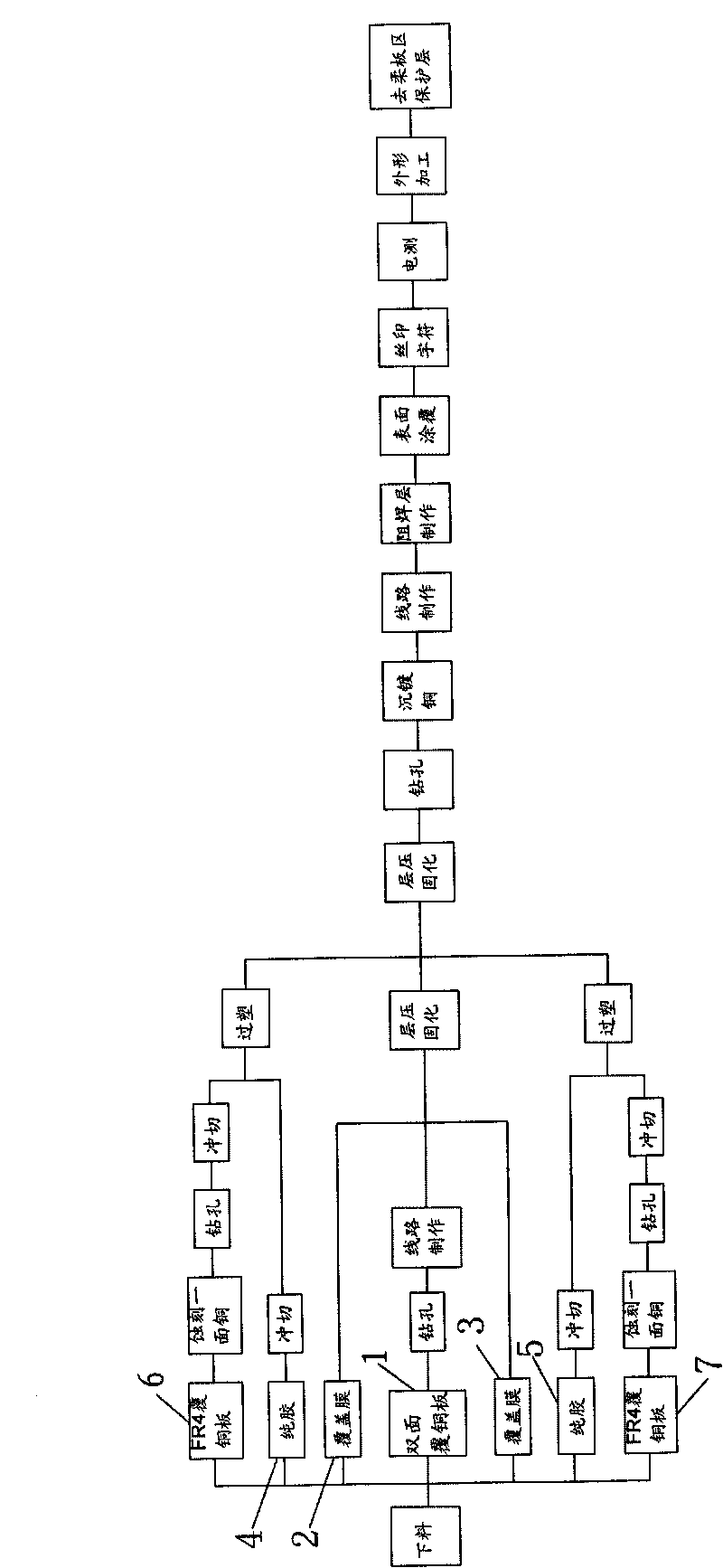

Soft-hard printed circuit board combination process

ActiveCN101720174AControl combination processImprove copper plating performancePrinted circuit assemblingMultilayer circuit manufactureFlexible circuitsEngineering

The invention discloses soft-hard printed circuit board combination process, including that bonding sheets are firstly packaged between inlayer flexible printed circuit boards, the inlayer flexible printed circuit boards are subject to lamination and curing, and then outer flexible printed circuit board is packaged, thus completing forming of soft-hard printed circuit board. PI copper foil used by flexible printed circuit board is more than FR4 copper foil used by hard printed circuit board, thus the hole depth of outer blind hole can be well controlled, the blind hole depth can be controlled to be 40 Mum if 12 Mum no-glue PI copper foil is used, thus greatly improving blind hole copper depositing and plating yield. Thus, the invention can conveniently control the outer blind hole depth while ensuring rigidity and thickness of four-layer HDI soft-hard printed circuit board and improve blind hole copper depositing and plating quality, PI copper foil and PP bonding sheet are adopted, structure is simple and the soft-hard printed circuit board is easy to make, cost is low, and electric performance of product is improved.

Owner:XIAMEN HONGXIN ELECTRON TECH

High-speed low-shrink low-smoke zero-halogen tight-buffered material used for 4G optical cable and preparation method of high-speed low-shrink low-smoke zero-halogen tight-buffered material

ActiveCN103897256AHigh melting pointHigh softening temperatureFibre mechanical structuresLinear low-density polyethyleneFire retardant

The invention discloses a high-speed low-shrink low-smoke zero-halogen tight-buffered material used for a 4G optical cable and a preparation method of the high-speed low-shrink low-smoke zero-halogen tight-buffered material. The tight-buffered material is composed of the following raw materials in parts by weight: 30-60 parts of ethylene-vinyl acetate copolymer, 10-20 parts of linear low density polyethylene, 20-30 parts of high density polyethylene, 10-30 parts of compatilizer, 100-150 parts of filler-type flame retardant, 25-60 parts of synergistic flame retardant, 1-2 parts of silane coupling agent, 2-5 parts of ultra-high molecular weight silicone master batch, 0.5-1 part of amides high-performance lubrication dispersant and 0.2-0.5 part of compound antioxygen through stirring, mixing and extruding steps. The tight-buffered material prepared by elaborate formula selection and processing is low in shrinking percentage, strong in rigidity, high in hardness, high in extrusion molding speed, low in rejection rate and good in high / low temperature cycling resistance. When the tight-buffered material is processed, die orifice stacking and salivation are less, the surface of the optical cable is smooth, fine and particle-free, and the tight-buffered material is easy to peel.

Owner:JIANGSU LINRY NEW MSTAR TECH

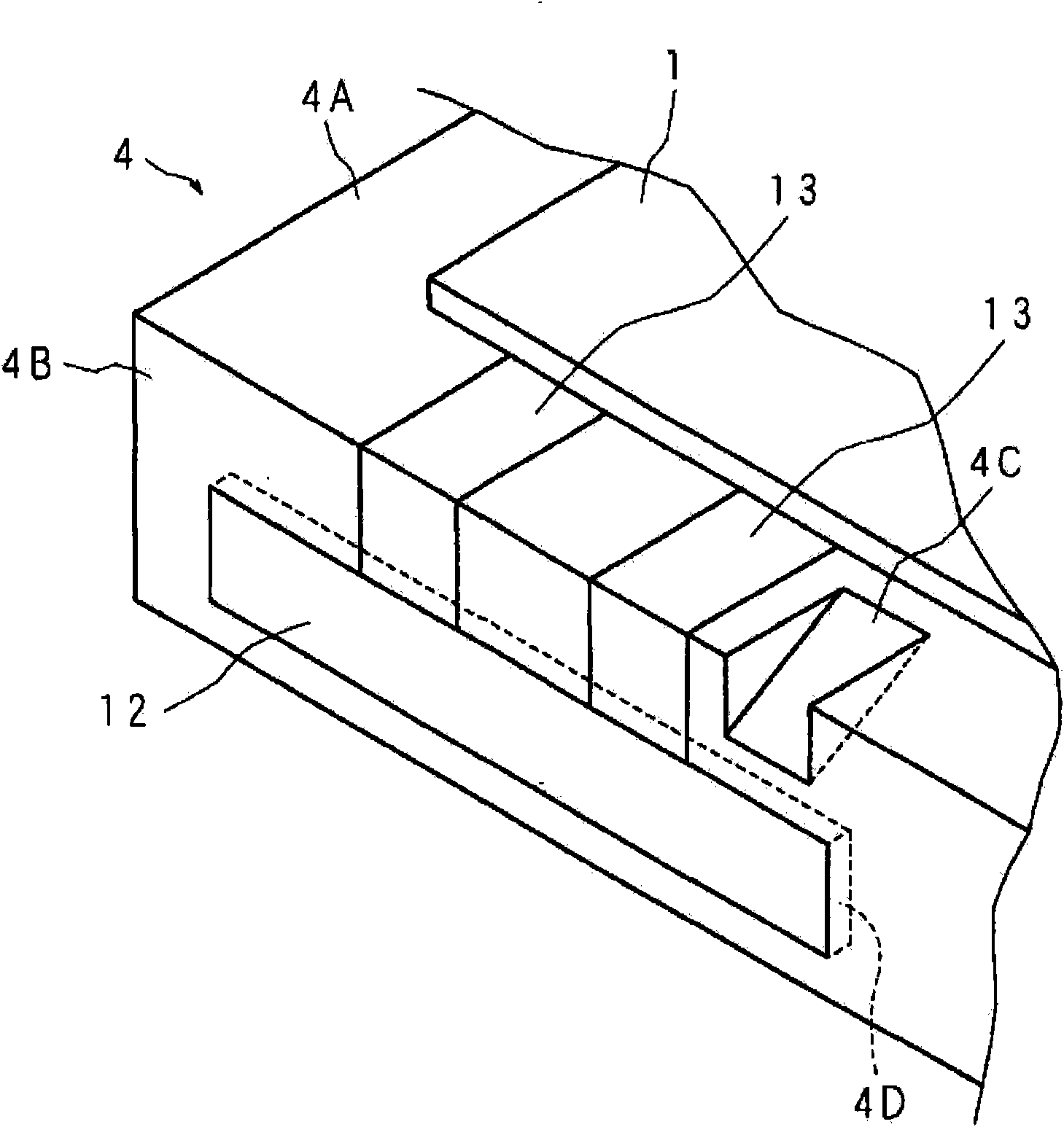

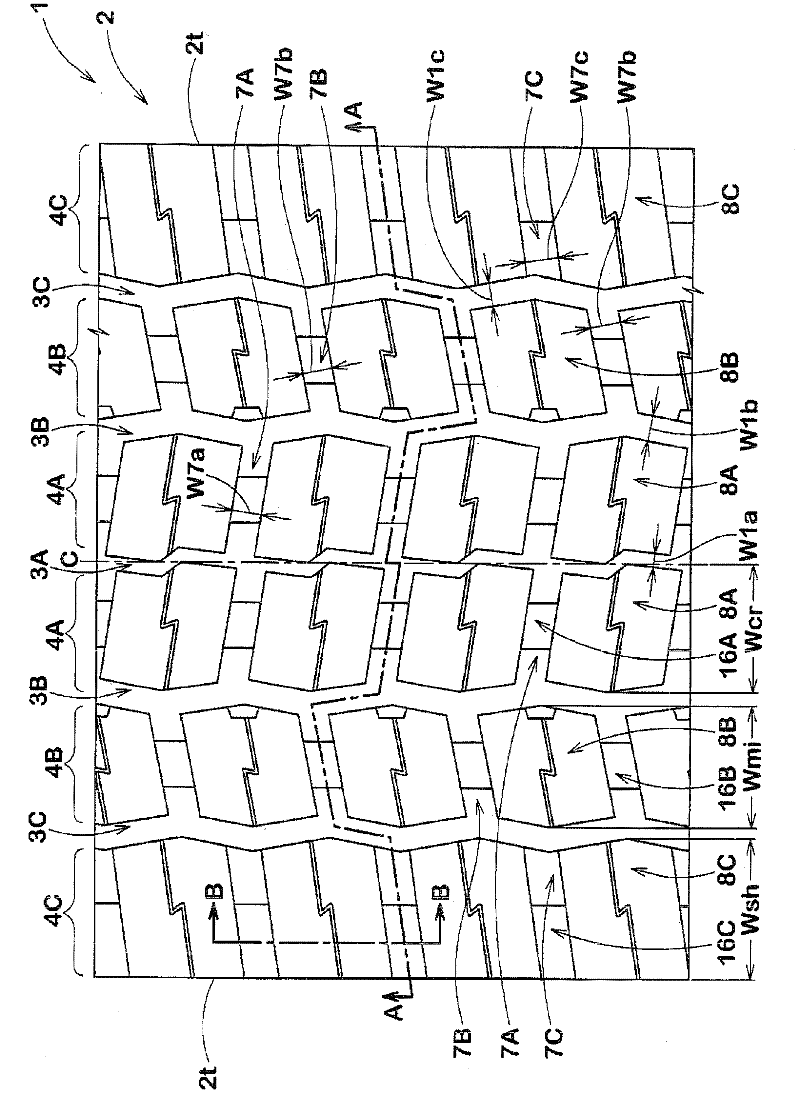

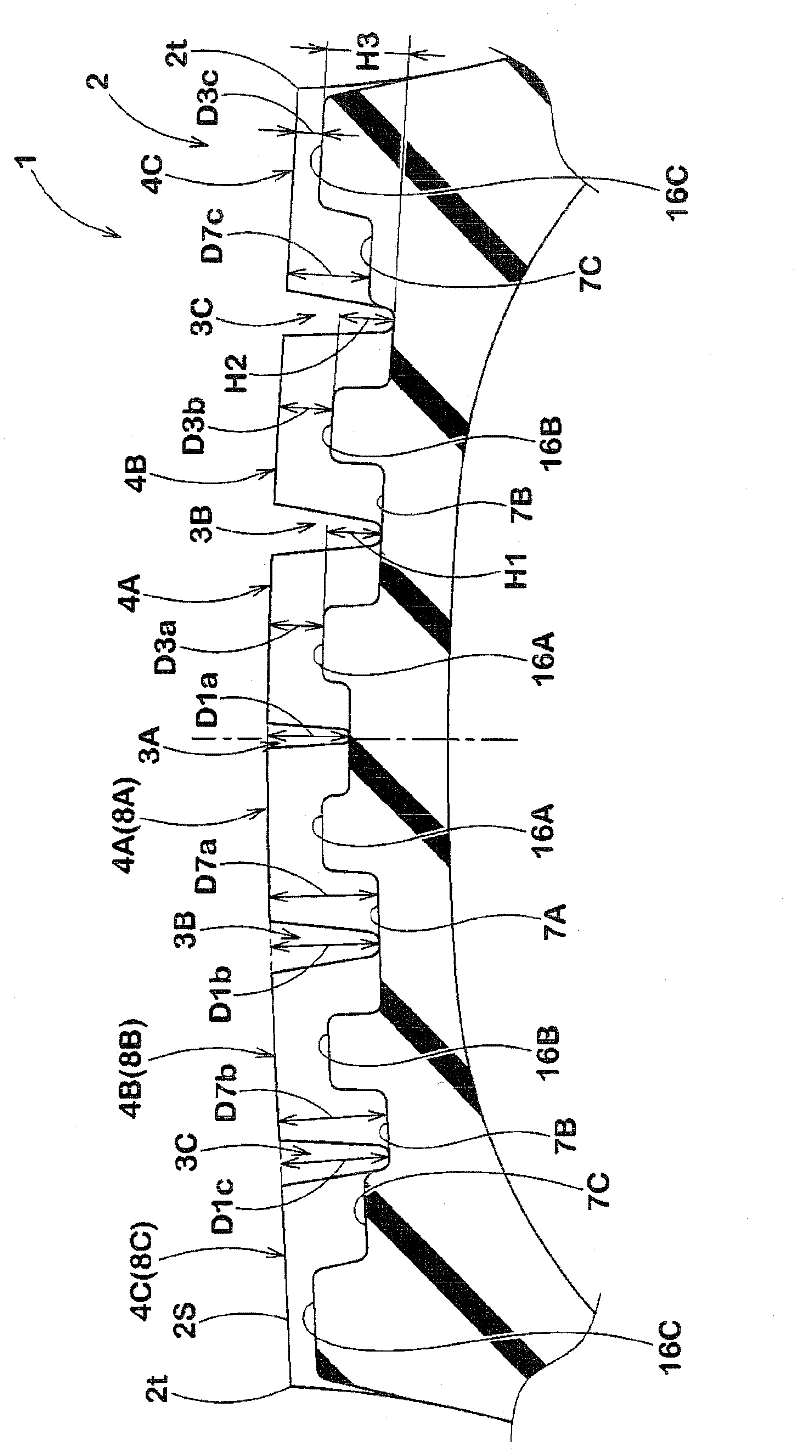

Heavy duty pneumatic tire

ActiveCN102689568AImprove traction performanceEasy to wearHeavy duty tyresHeavy duty vehicleHeel-and-toeEngineering

The invention discloses a heavy duty pneumatic tire. Both of the center wear and heel-and-toe wear can be improved to high levels. A tread portion 2 is divided into a pair of crown land portions 4A, a pair of middle land portions 4B and a pair of shoulder land portions 4C by center main grooves 3A, middle main grooves 3B, and shoulder main grooves 3C. The crown land portions 4A, the middle land portions 4B and the shoulder land portions 4C are divided into crown blocks 8A, middle blocks 8B and shoulder blocks 8C by crown axial grooves 7A, middle axial grooves 7B and shoulder axial grooves 7C. The crown axial groove 7A, the middle axial groove 7B and the shoulder axial groove 7C are provided with a crown tie bar 16A, a middle tie bar 16B and a shoulder tie bar 16C, respectively. The maximum width Wcr of the crown land portion, the maximum width Wmi of the middle land portion, and the maximum width Wsh of the shoulder land portion are set in the preset range.

Owner:SUMITOMO RUBBER IND LTD

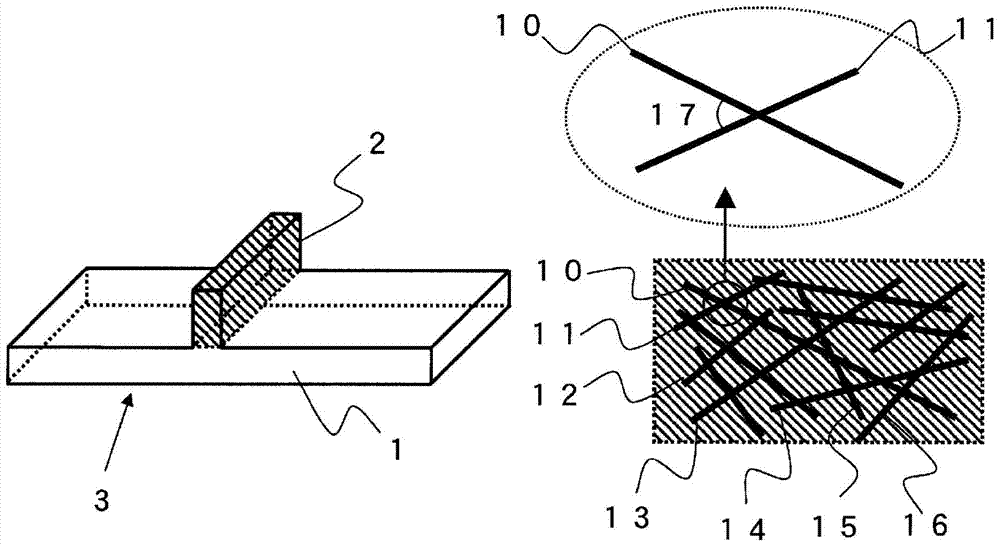

Physical design for four-layer soft and hard combined board

ActiveCN101511147AGuaranteed rigidityGuaranteed flexibilityElectrical connection printed elementsPrinted circuits structural associationsElectrical connectionEngineering

The invention discloses a four-layer rigid- flexible pcb structure, wherein, a double-layer FPC base end connects with a double-face golden finger, but another base end of the double-layer FPC connects with PCB (rigid pcb) mutually, and the double-layer FPC middle forms hollow, the structure makes the golden finger on the FPC base end having certain thickness, keeping strong rigidity, the FPC middle part for connecting the rigid pcb has better flexible, the whole structure can ensure insert and pull out the golden finger on the FPC base end oftenly, electrical connection of the whole product, and keep flexible performance of the FPC middle part.

Owner:SHENZHEN JINGCHENGDA CIRCUIT TECH

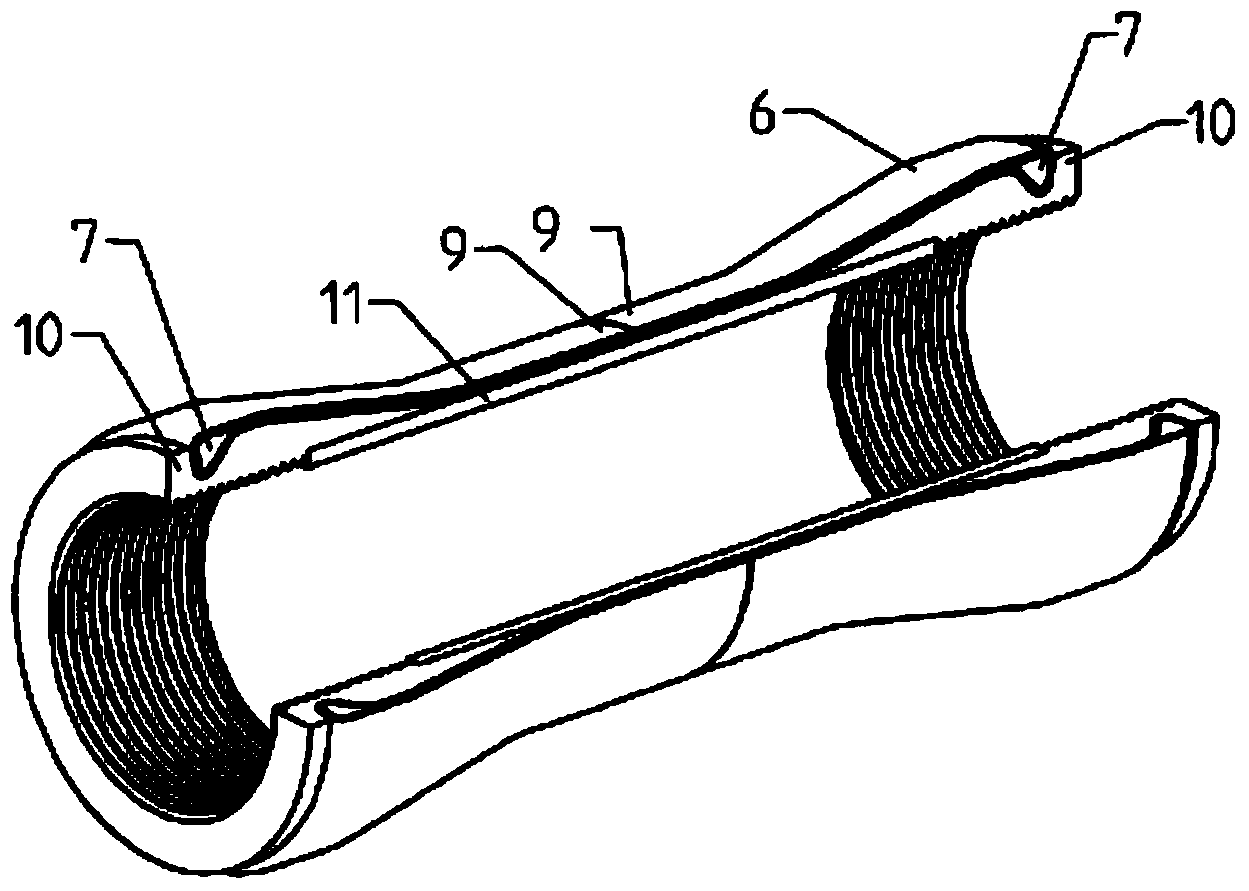

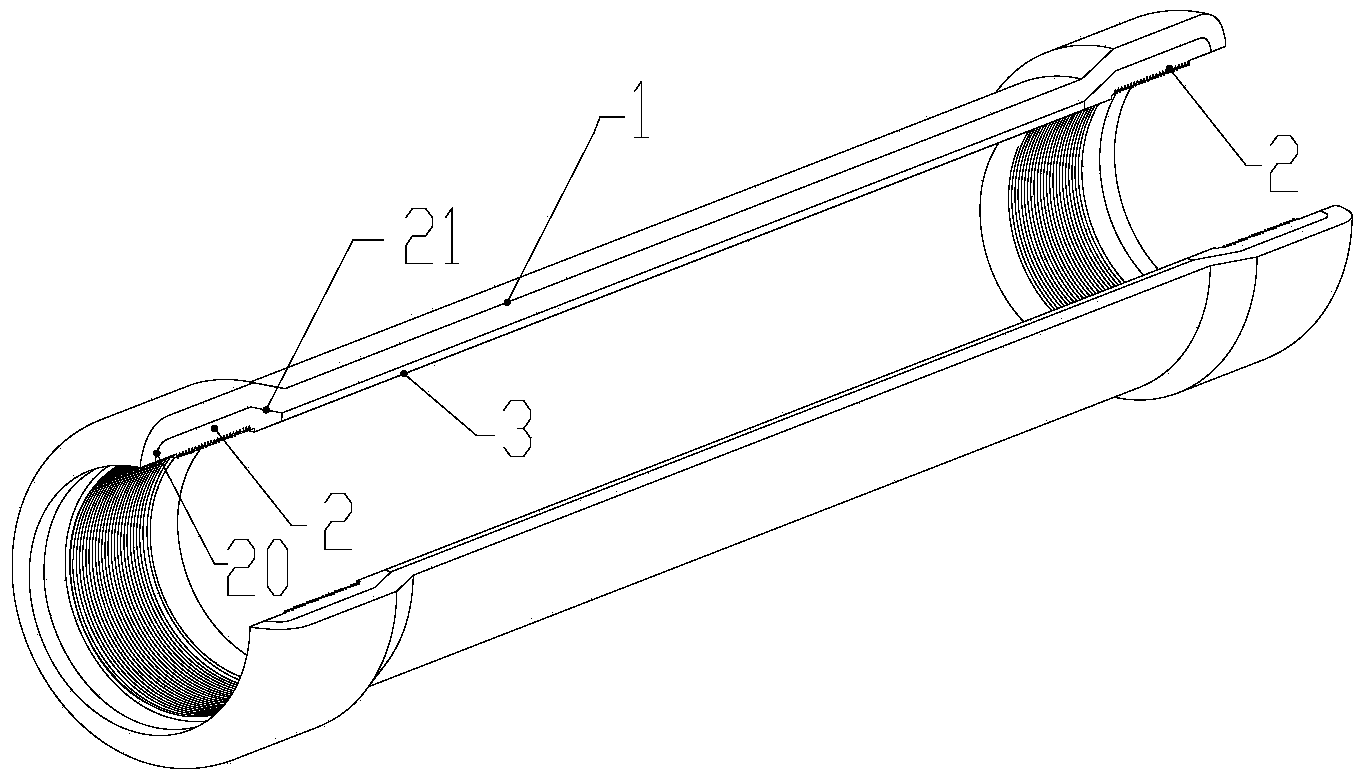

Composite-material tube, manufacturing method, hydraulic cylinder barrel and piston rod

InactiveCN103527549AAvoid interruptionImprove connection strengthFluid-pressure actuatorsHydraulic cylinderFiber

The invention discloses a composite-material tube. Two connecting rings are nested in inner holes in the two end portions of a tube body. The tube body comprises axial strengthening fibers, and the two connecting rings are wound and wrapped with the axial strengthening fibers in a continuous and reciprocating mode with the two ends of the tube body as poles. The invention further discloses a hydraulic cylinder barrel, a piston rod and a manufacturing method of the composite-material tube. According to the composite-material tube, the hydraulic cylinder barrel, the piston rod and the manufacturing method of the composite-material tube, the strength of connection between the connecting rings and the tube body is improved, large axial stretching and compressing loads can be borne, meanwhile, materials of the strengthening fibers are saved, the cost for manufacturing the hydraulic cylinder barrel is reduced, and the production efficiency is improved.

Owner:SANY AUTOMOBILE MFG CO LTD

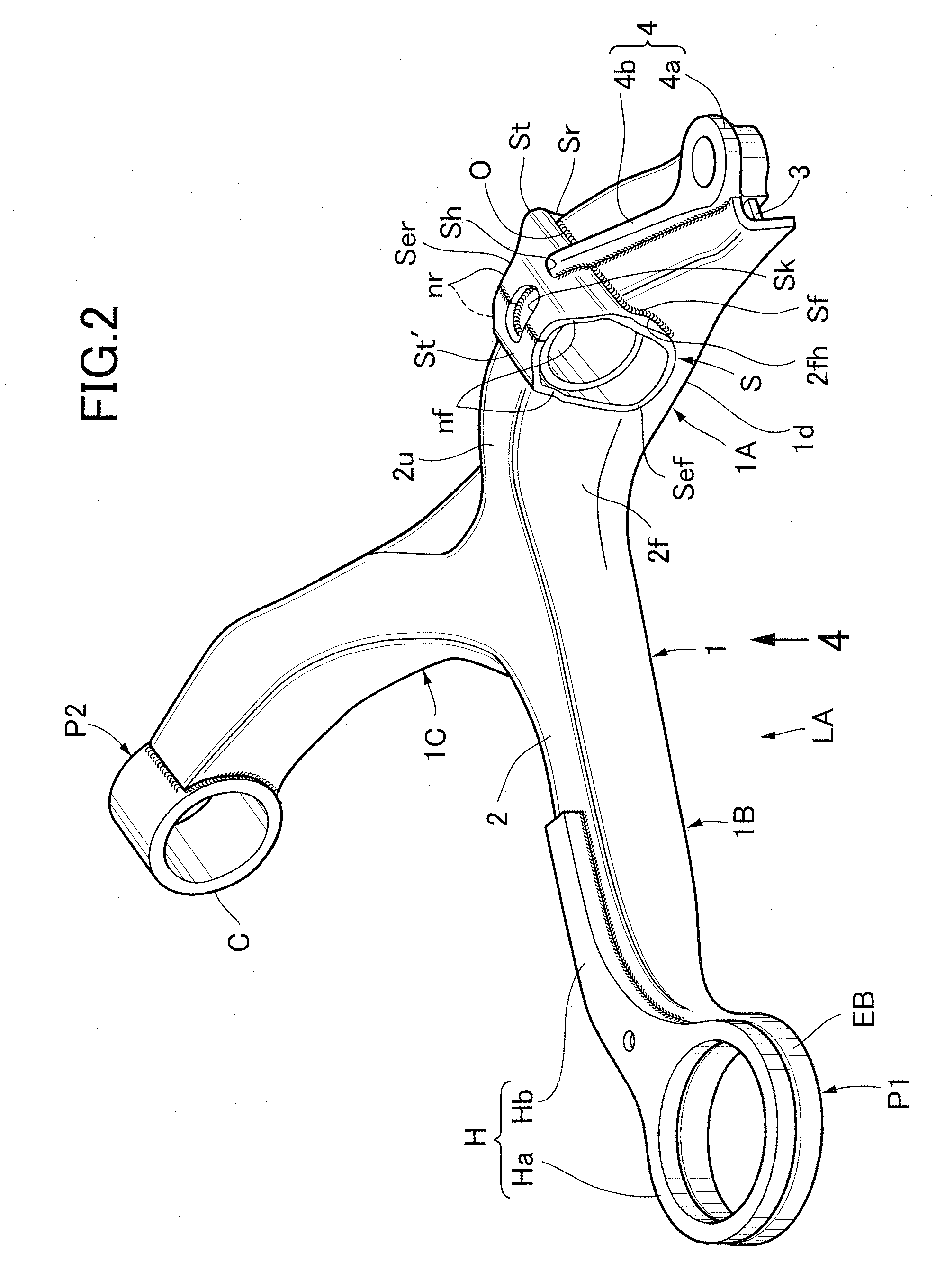

Vehicular suspension arm

InactiveUS7980576B2High strengthStrengthTractor-trailer combinationsResilient suspensionsEngineeringFlanging

A vehicular suspension arm is provided in which an arm main body (1) includes a main plate (2) press-formed as a main part of the arm main body and having a short cylindrical part (EB) provided integrally with one end by flanging, and a reinforcing plate (H) superimposed on one of upper and lower faces of the main plate (2) and reinforcing the main plate (2). The reinforcing plate (H) has an eye-shaped head part (Ha) formed in an annular shape and arranged coaxially with the short cylindrical part (EB), and a tail part (Hb) extending integrally from the eye-shaped head part (Ha) along the longitudinal direction of the main plate (2), is formed from a single plate material that is thicker than the main plate (2), and has at least the tail part (Hb) welded to the main plate (2). A bush press-fit portion (P1) is formed from an inner peripheral face of the eye-shaped head part (Ha) and an inner peripheral face of the short cylindrical part (EB). This ensures that the cross-sectional shape of a transition section from the bush press-fit portion to the plate-type arm main body is adequate, thus enabling the rigidity and strength required for the transition section to be easily guaranteed and, furthermore, it becomes possible to meet a requirement for increasing the strength of the arm without specially increasing the space around the outer periphery of the bush press-fit portion.

Owner:F TECH INC +1

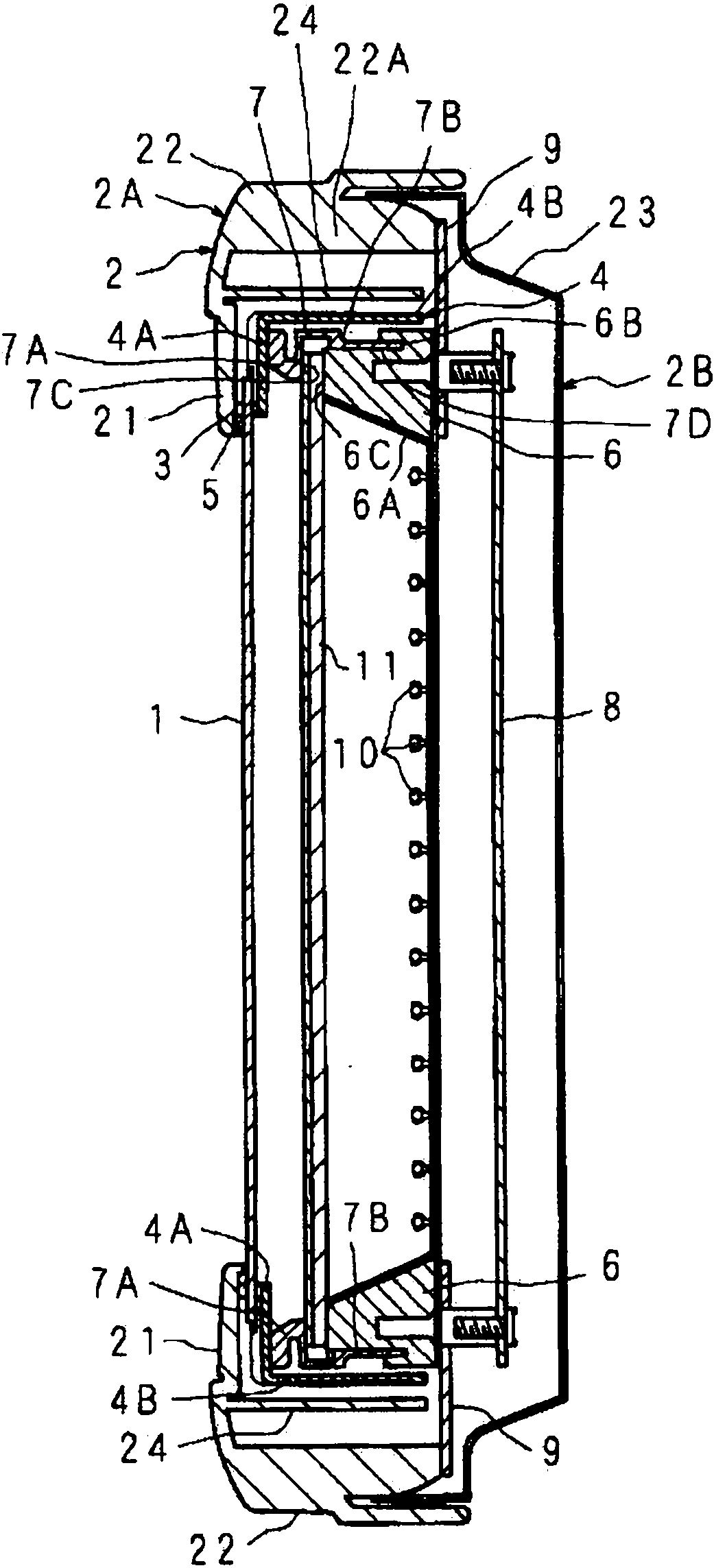

Battery case for vehicle

ActiveCN102714287AGuaranteed rigidityAvoid deflectionElectric propulsion mountingCell component detailsMetalElectrical and Electronics engineering

Disclosed is a battery case for a vehicle, which is provided with: a resin tray member (20), which holds a battery (36), and which has a plurality of protruding sections (32) formed on the bottom portion (34); and a reinforcing tray member, which is disposed on the outer surface of the tray member, and which has at least one reinforcing member (42), which is configured of a metal plate that is provided upright on the side that faces the tray member. On the outer surface of each of the protruding sections, a recessed section (56) is formed, corresponding to at least the reinforcing member, and the reinforcing member is fitted in the recessed section.

Owner:MITSUBISHI MOTORS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com