Patents

Literature

138results about How to "Guide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

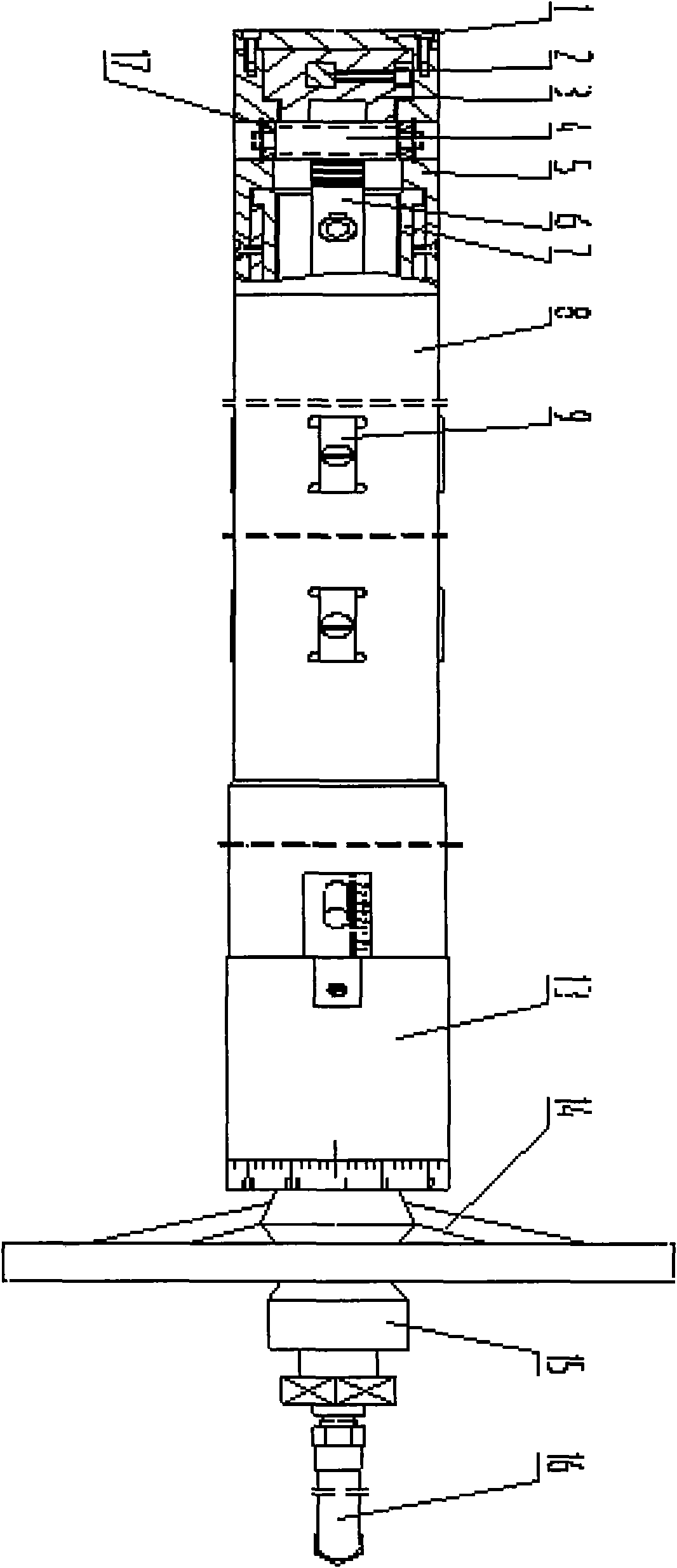

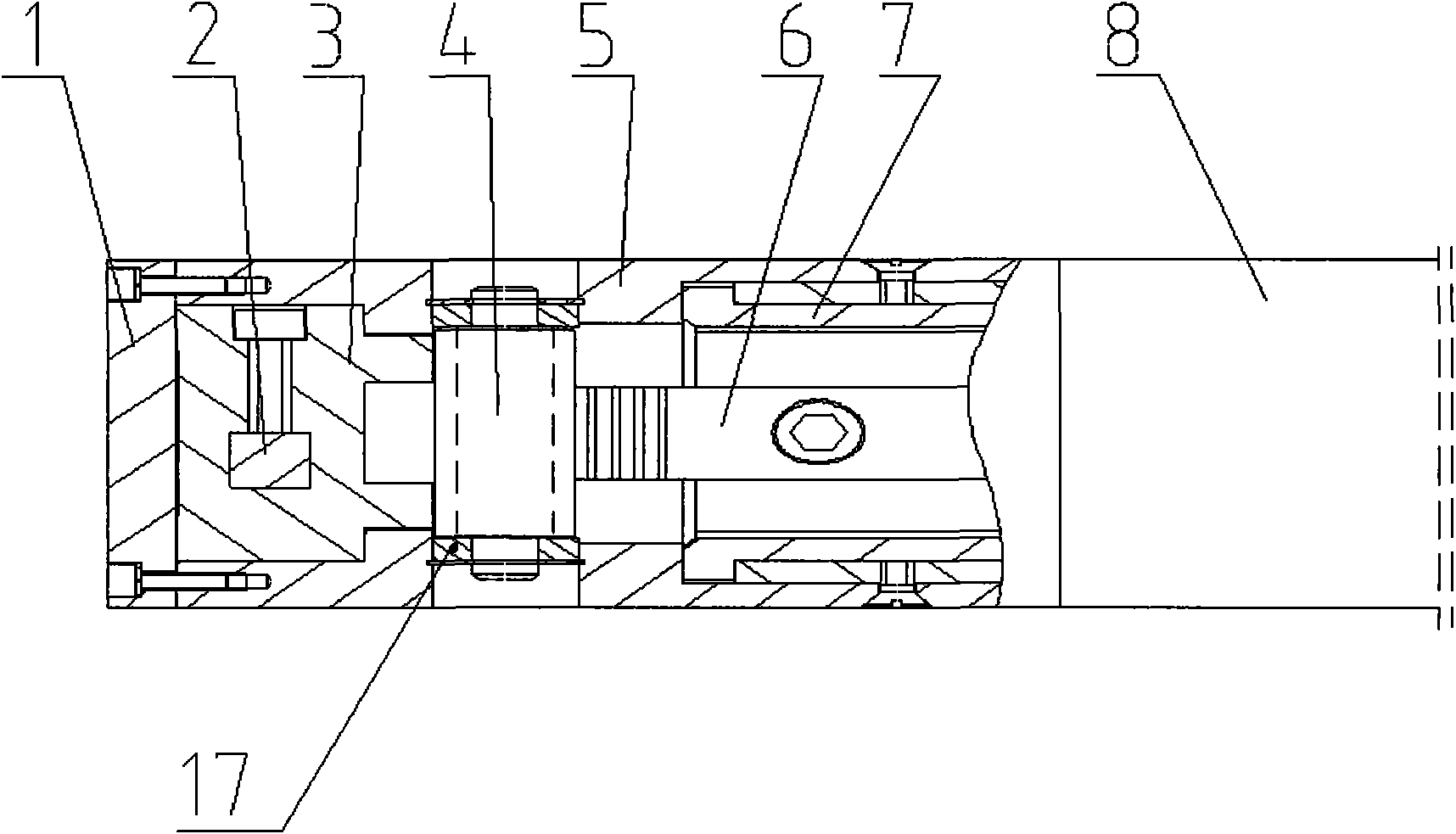

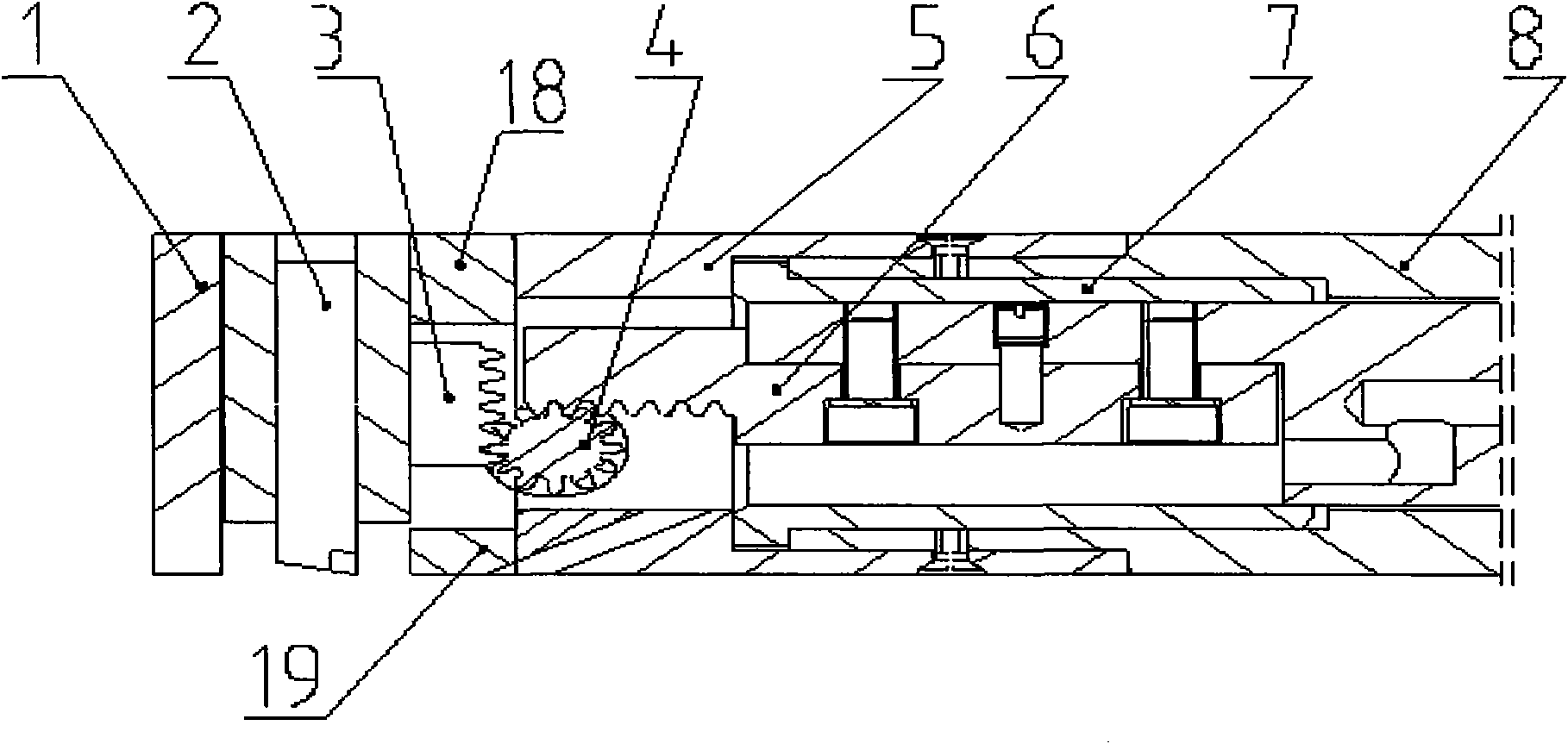

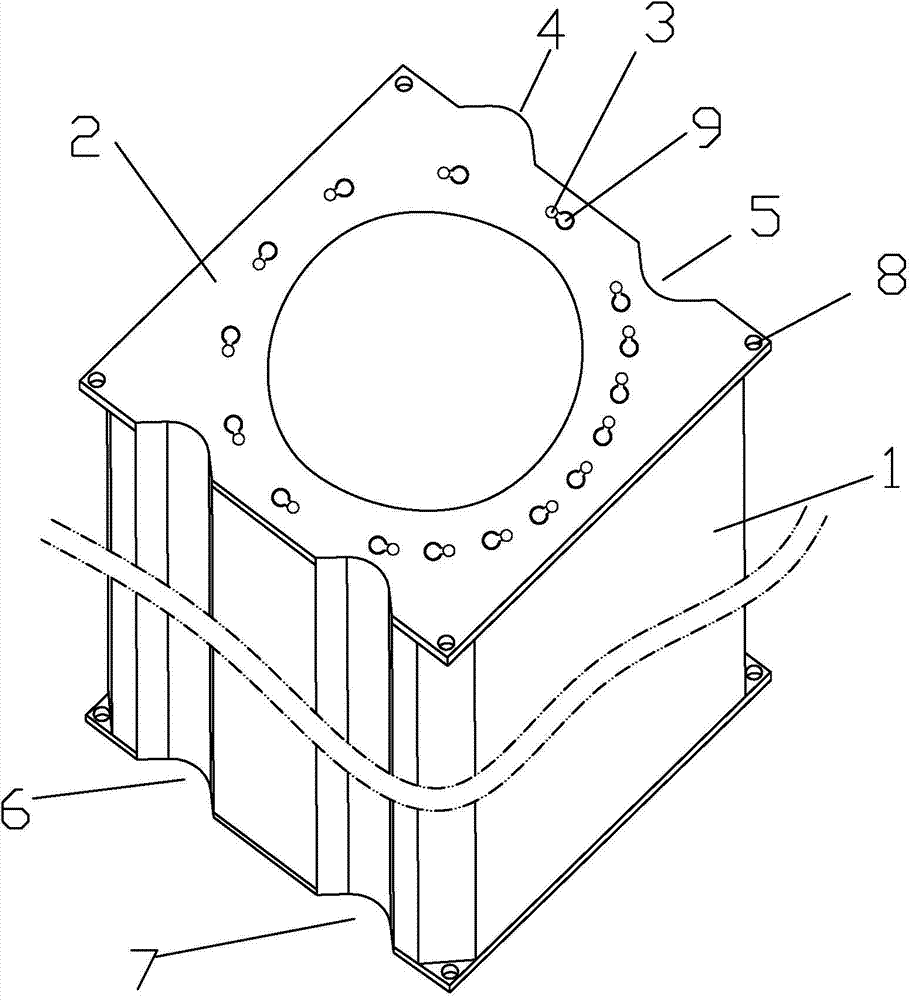

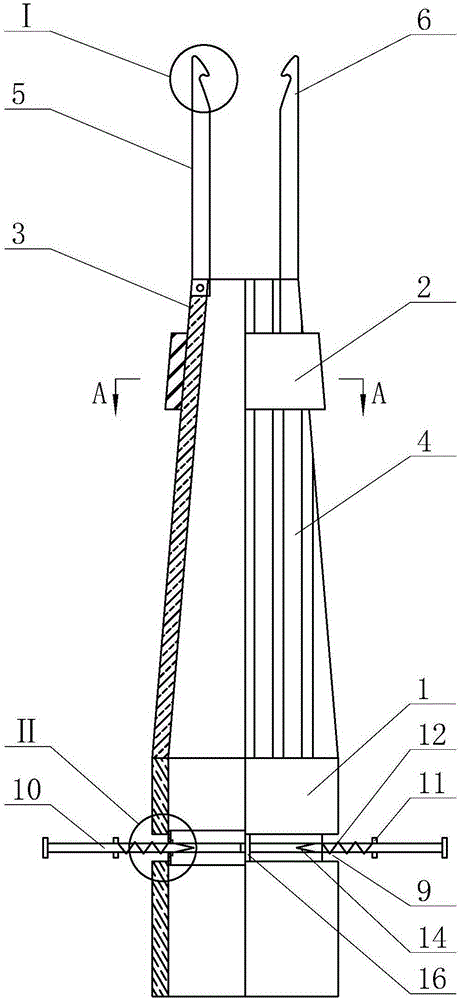

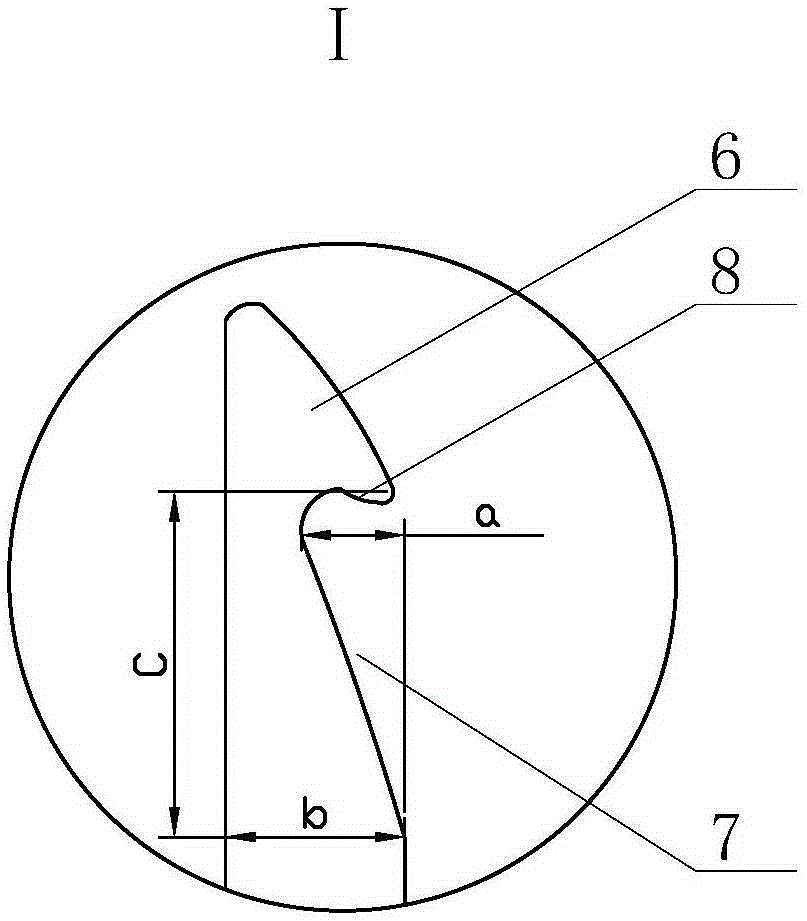

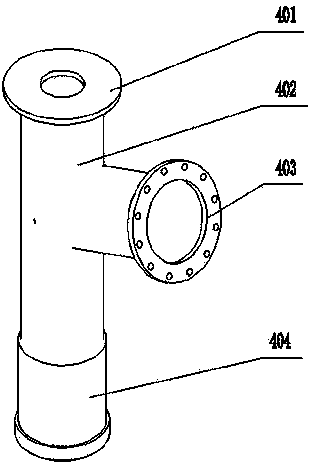

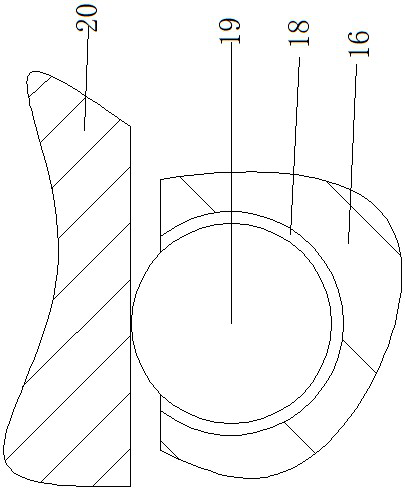

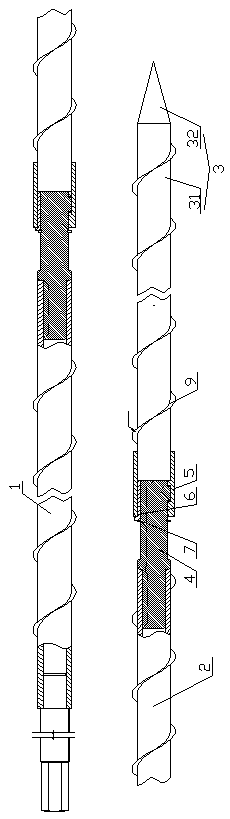

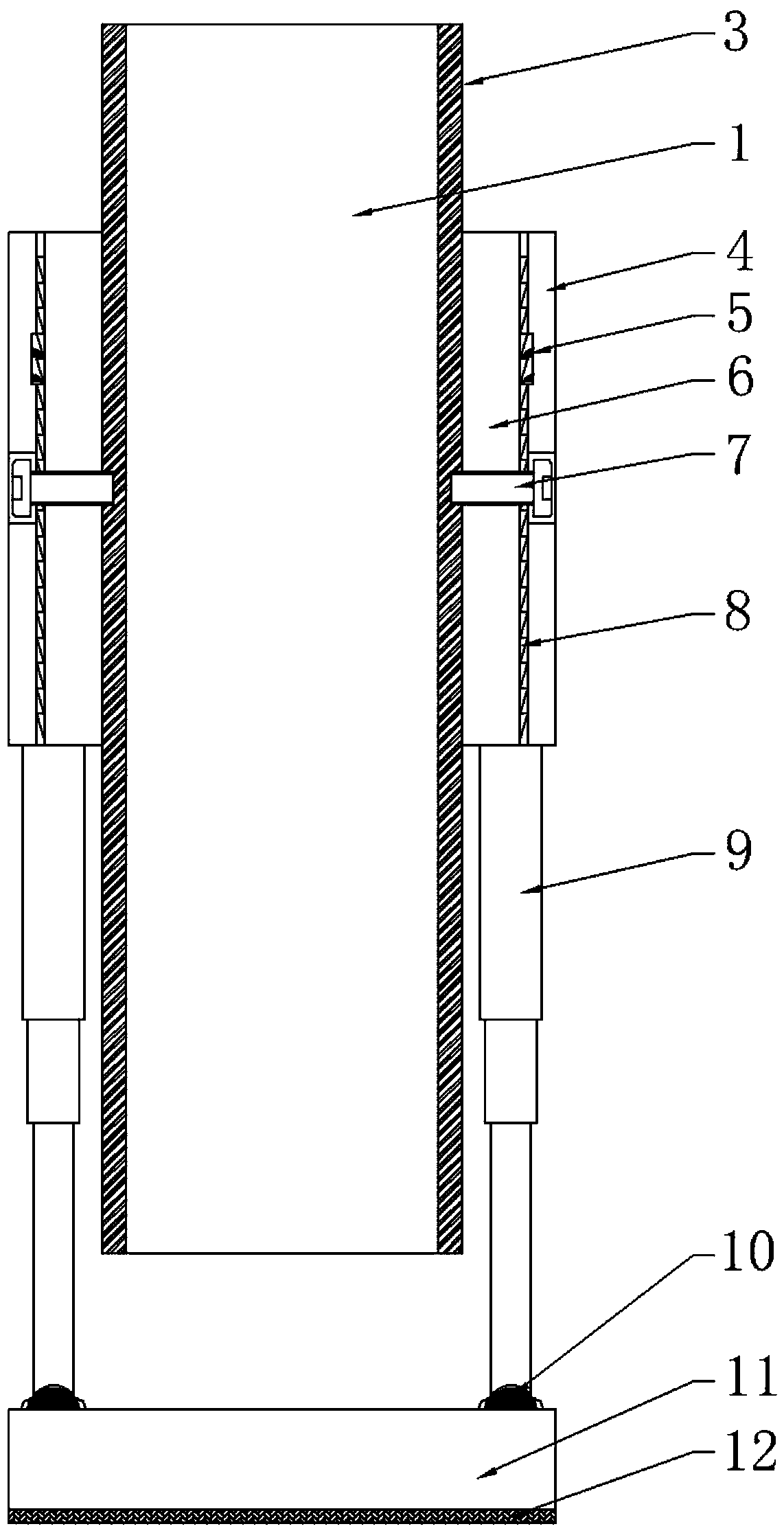

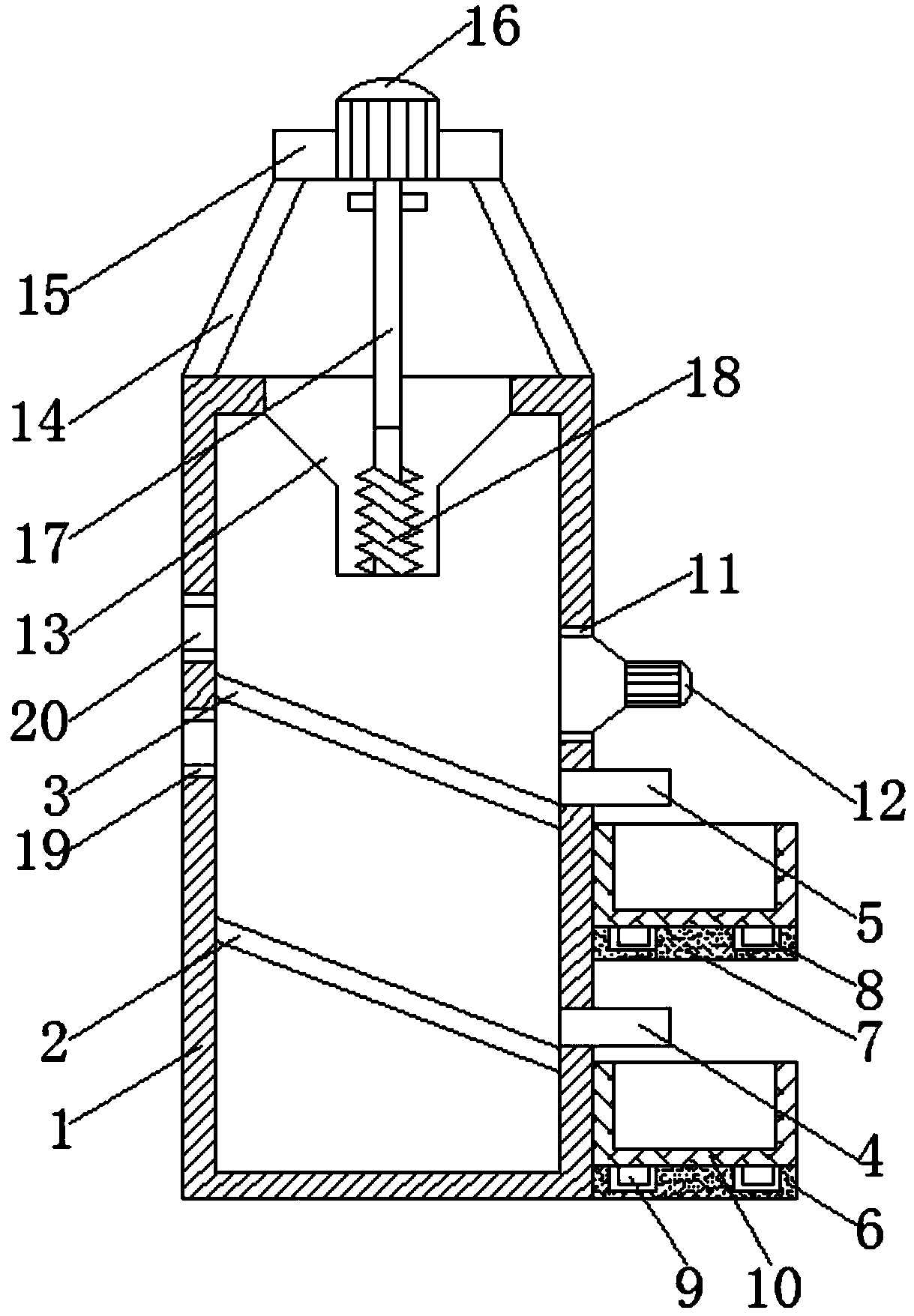

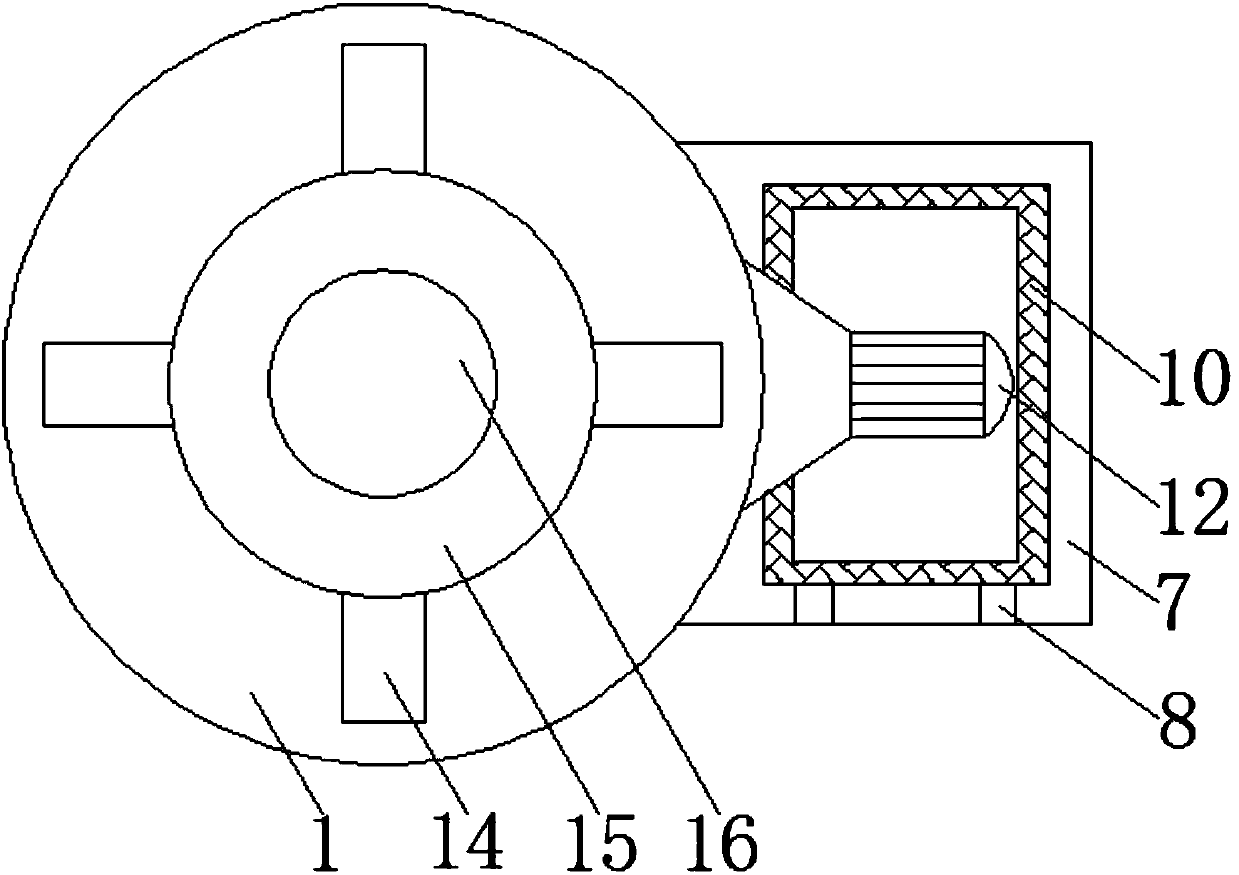

Tip-extension type deep hole boring cutter rod

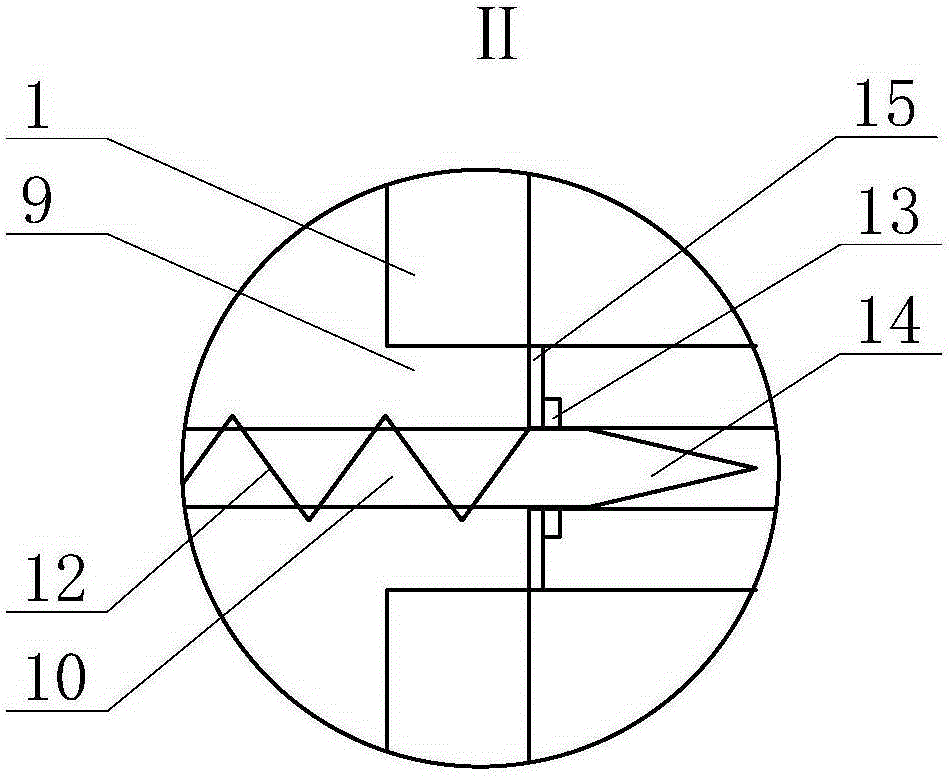

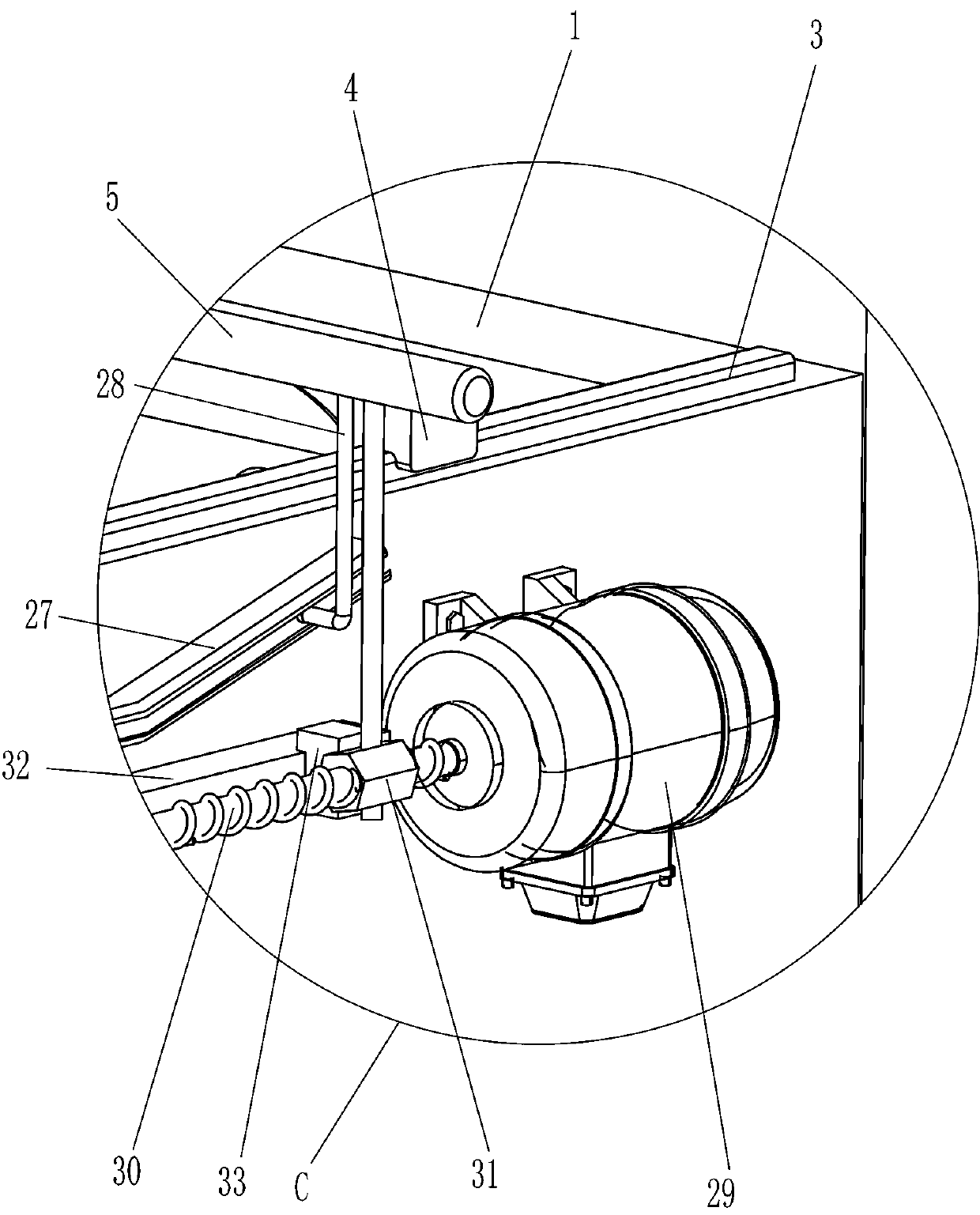

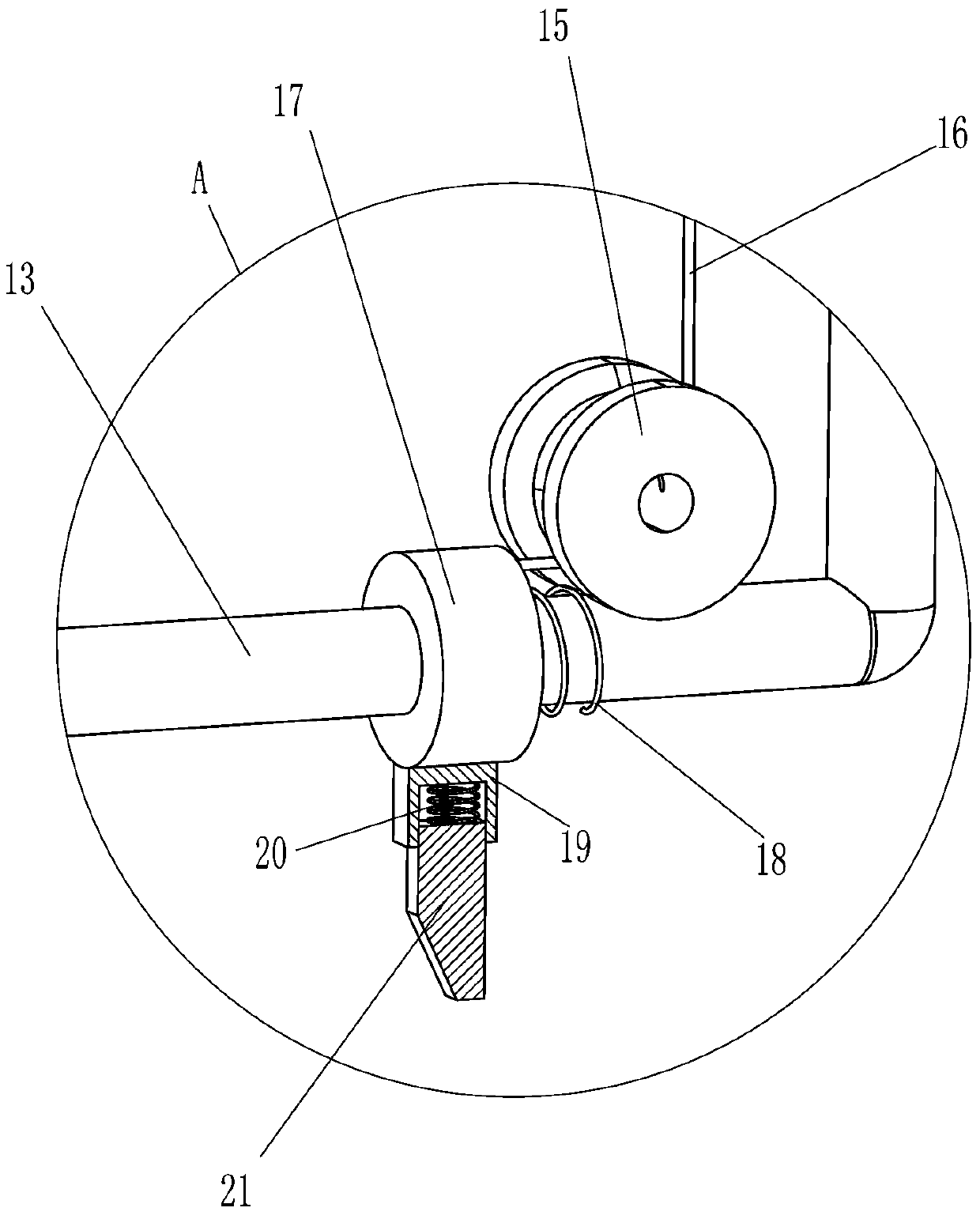

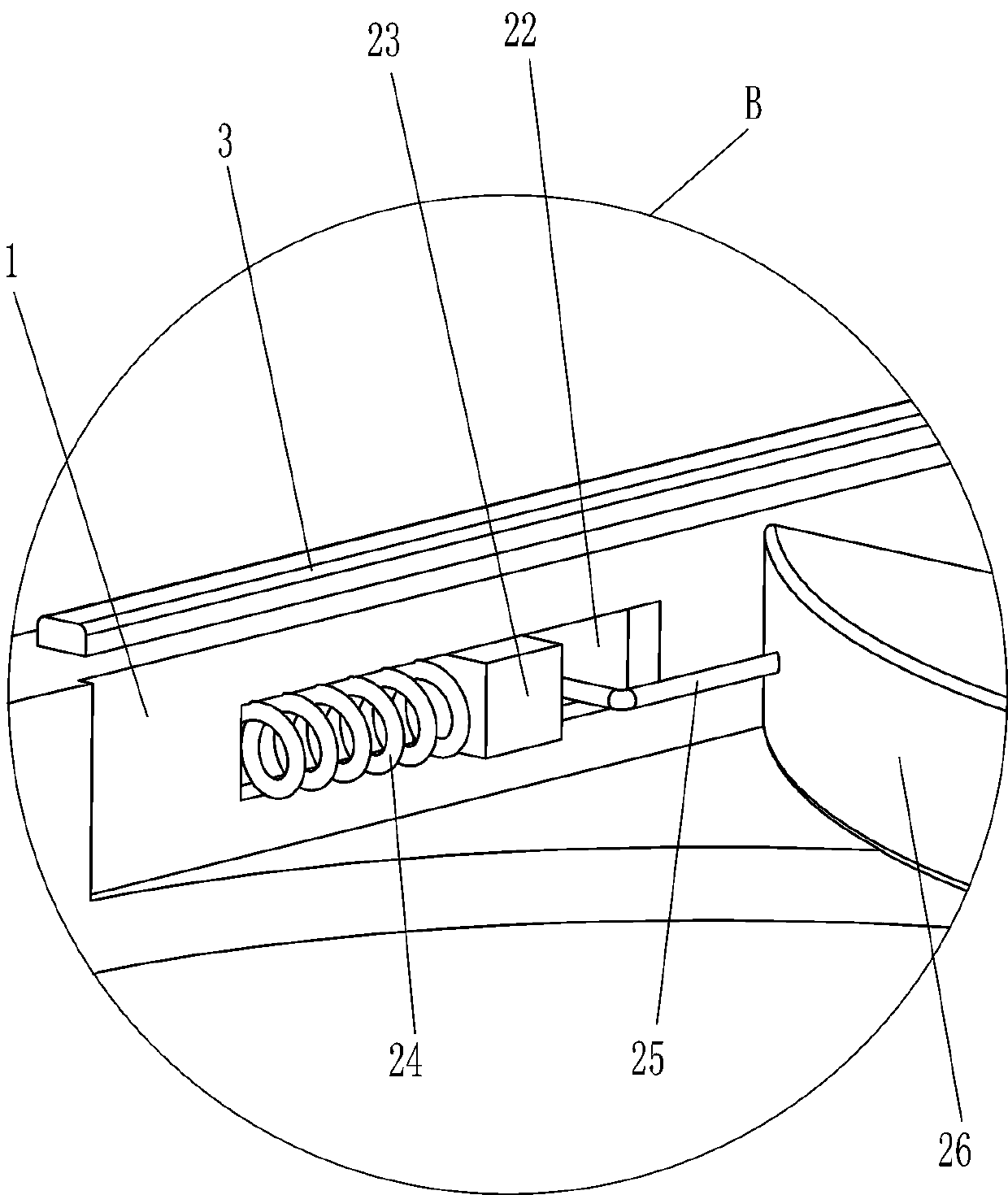

The invention relates to a tip-extension type deep hole boring cutter rod. A cutter seat (3) is positioned in a cavity between a press cover (1) and a gear installing seat (5), and a screw rod (11) connected with one end of a core shaft (10); a rack (6) is installed in a slot on one end of the core shaft (10); one inner edge of a cutter installing hole needs to be coincide with the symmetric center surface of double-row teeth; a cutter (2) is positioned in the cutter installing hole, and a tip is positioned on a center line of a processed hole; and gears (4) are respectively meshed with the double-row teeth of the rack and the cutter seat. The screw rod is rotated by rotating a handle (14) on the screw rod (11) to drive the core shaft (10) to move, and then the cutter tip is extended by the transmission among a thread pair, the rack, gears and the rack. When retracting, the tip enters the end part of an inner hole of a part; and when the tip extends out, the middle of the part is processed. By adopting a guiding block (9), the rigidity of the cutter rod is ensured, and the cutter rod is provided with axial scales and circumferential scales. The tip-extension type deep hole boring cutter rod is suitable for processing deep holes on both ends of a long-shaft part, wherein the deep holes have small inner diameters at two ends, large inner diameters in the middles and larger difference of diameter sizes.

Owner:AECC AVIATION POWER CO LTD

Prestressed concrete precast pile

ActiveCN103572755ANot easy to tiltImprove bending abilityBulkheads/pilesSquare cross sectionPre stress

The invention discloses a prestressed concrete precast pile. The prestressed concrete precast pile comprises a precast pile body with a square cross section, wherein the precast pile body comprises two end plates, a pile body and prestressed reinforcements, the pile body is arranged between the two end plates, and the prestressed reinforcements are arranged in the pipe body and connected with the two end plates; bulge rib which longitudinally extends to an end and a first groove which longitudinally extends and penetrates through the end are arranged on an outer side surface of the precast pile body; and a second groove and a third groove which are corresponding to positions of the bulge rib and the first groove respectively, matched in shape and size and longitudinally extend and penetrate through an end of the precast pile body are formed in one outer side surface which is not adjacent to the outer side surface. According to the prestressed concrete precast pile, the construction is convenient, the engineering cost can be reduced, the water stopping effect is enhanced, and the prestressed concrete precast pile has good bending and shearing resistance.

Owner:宁波中淳高科股份有限公司

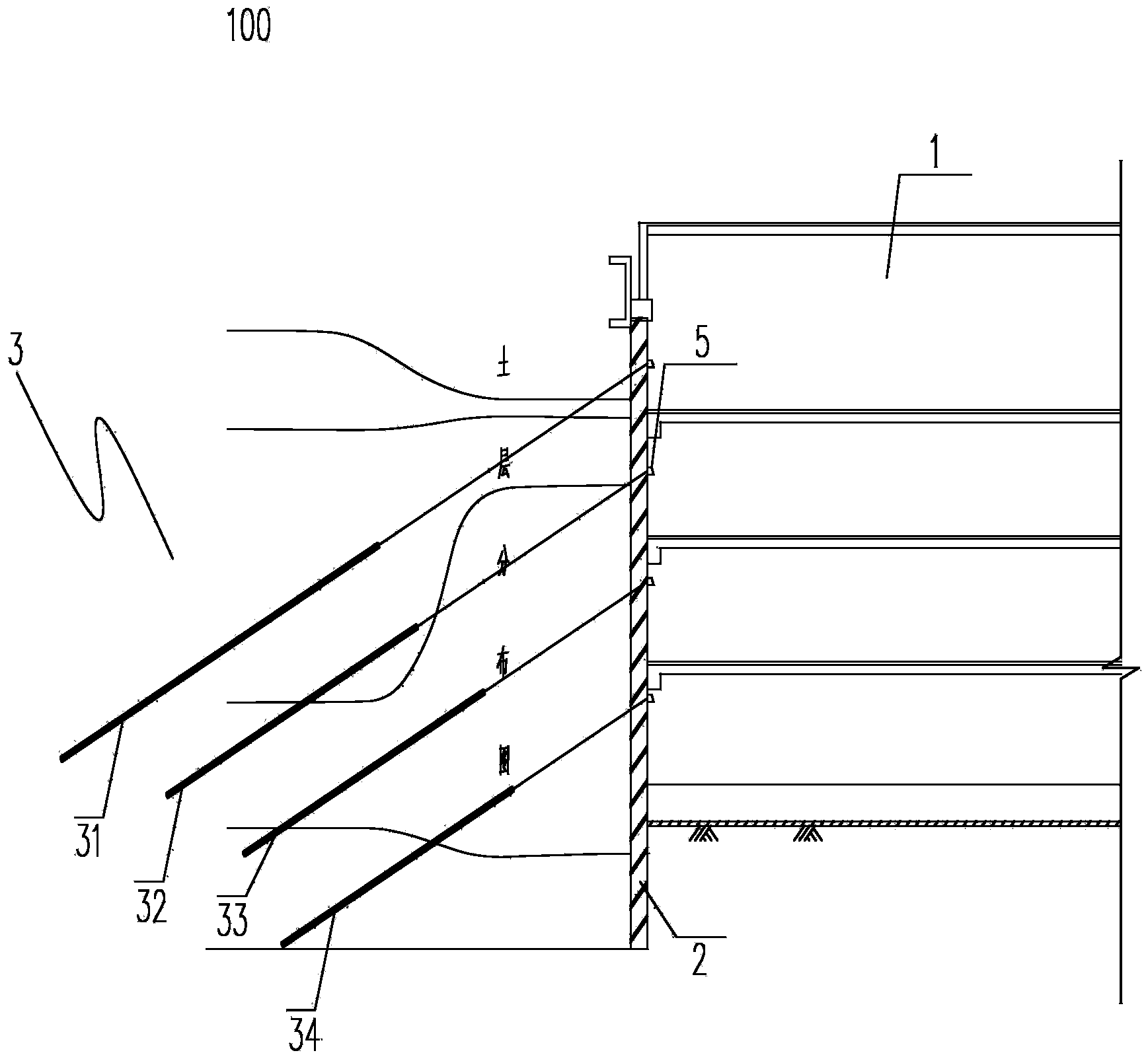

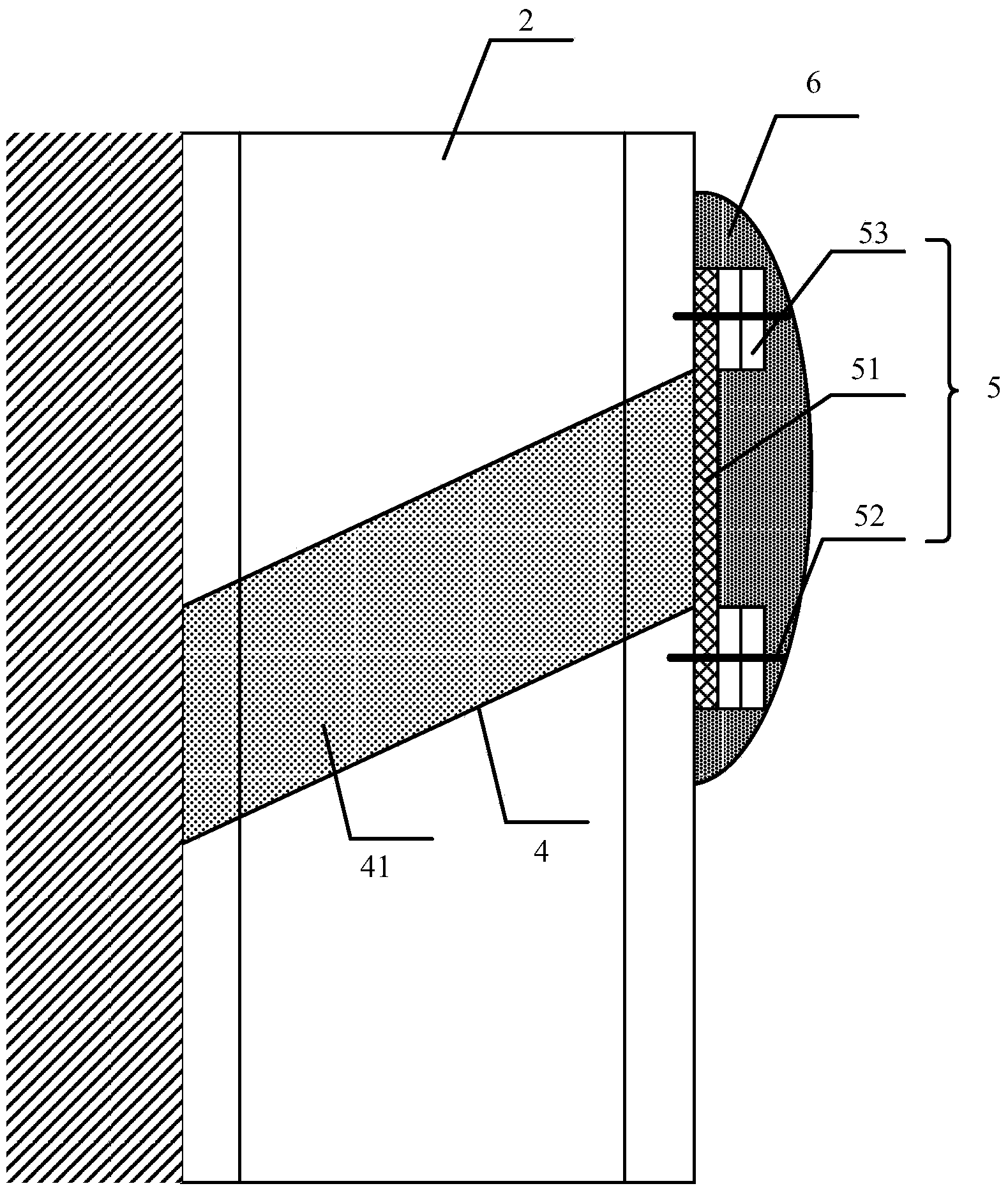

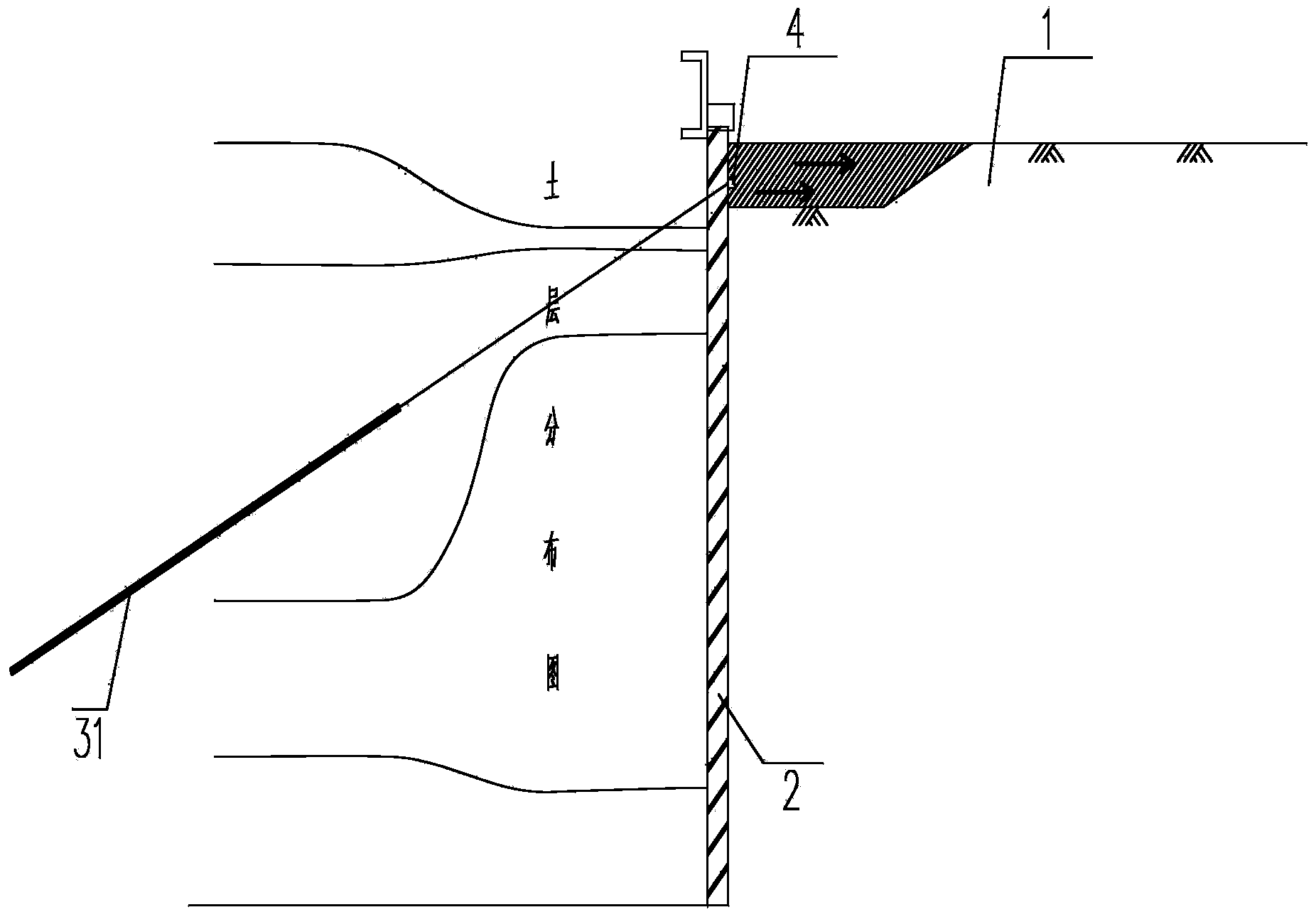

Offshore deep foundation pit supporting structure and construction method thereof

ActiveCN103726495AGood waterproofImprove waterproof performanceExcavationsBulkheads/pilesSlurry wallBuilding construction

The invention provides an offshore deep foundation pit supporting structure and a construction method of the offshore deep foundation pit supporting structure, and belongs to the technical field of deep foundation pit construction. The offshore deep foundation pit supporting structure comprises a plurality of underground continuous walls, a plurality of anchor ropes and anchors, wherein the underground continuous wall is located on the outer edge of a deep foundation pit and connected end to end in a surrounding mode, a plurality of sleeves are embedded into each underground continuous wall, one end of each anchor rope is fixed to the corresponding underground continuous wall through the corresponding anchor, the other end of each anchor rope penetrates through the corresponding sleeve and is fixed into soil outside the deep foundation pit, each anchor comprises a rubber sealing plate and a plurality of expansion bolts, a pipe opening in the side, close to the deep foundation pit, of each sleeve is covered with the corresponding rubber sealing plate, and each rubber sealing plate is fixed to the corresponding underground continuous wall through the corresponding expansion bolts. The offshore deep foundation pit supporting structure has a quite excellent water stopping effect.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

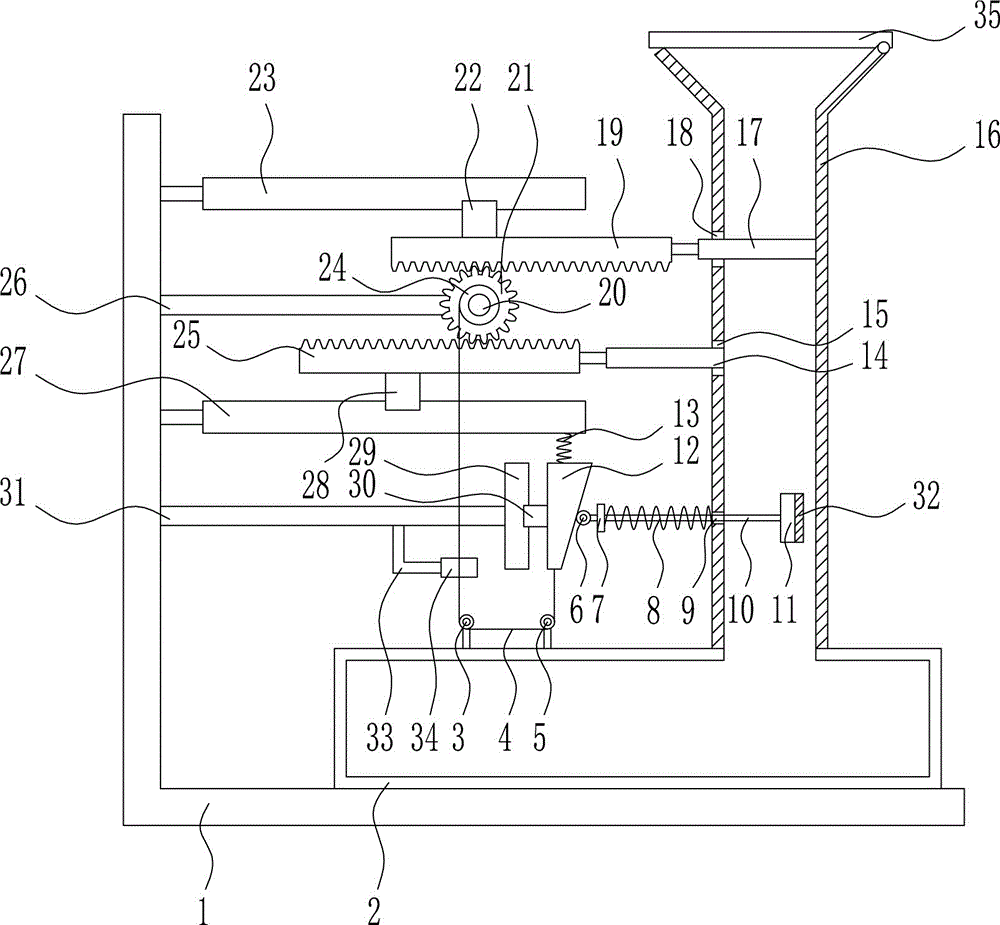

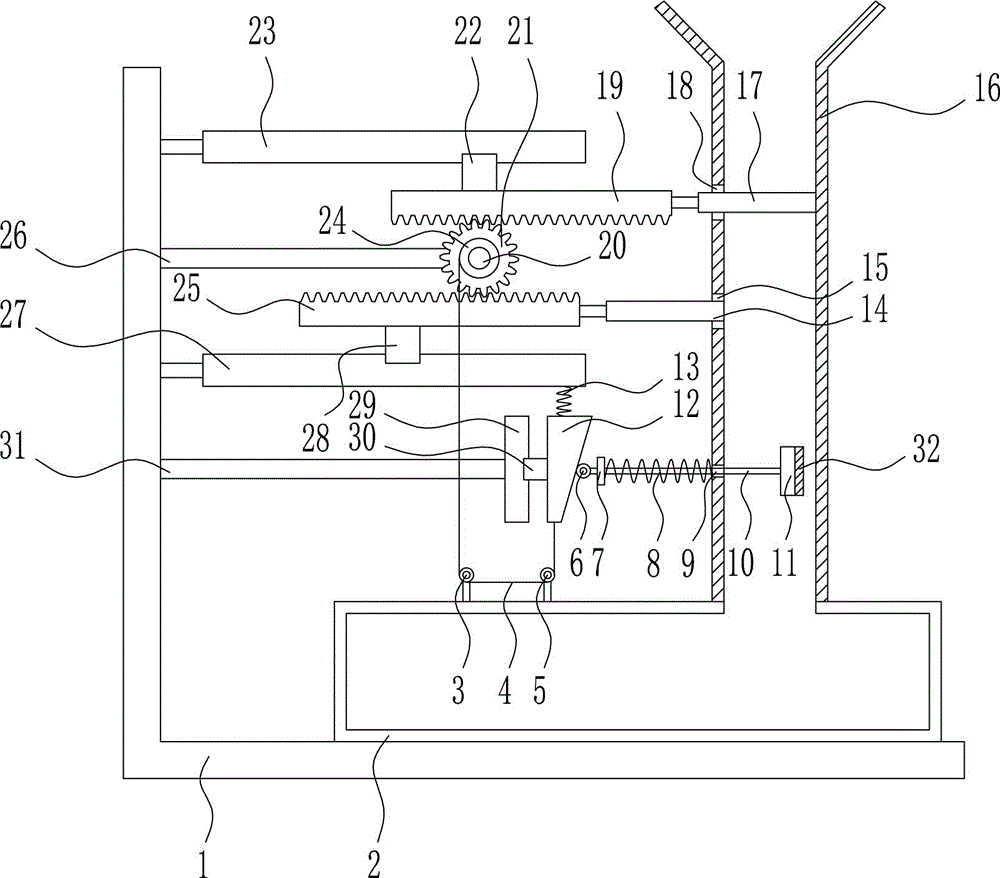

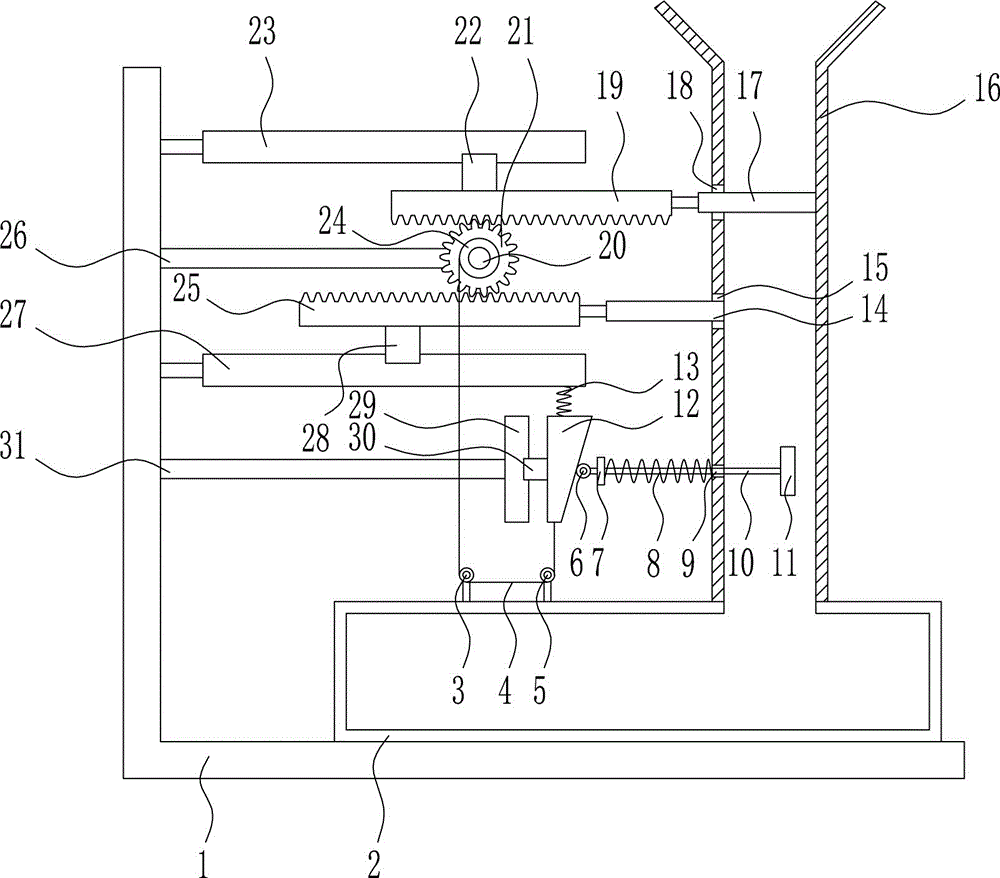

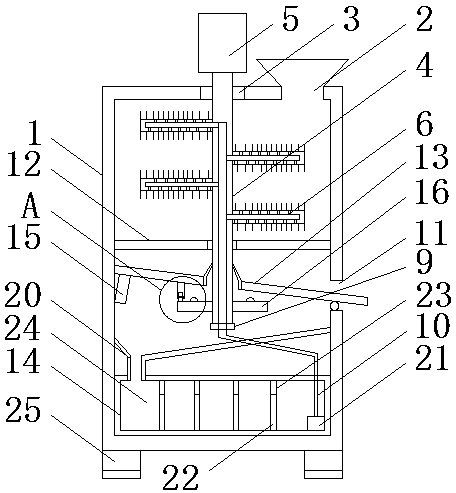

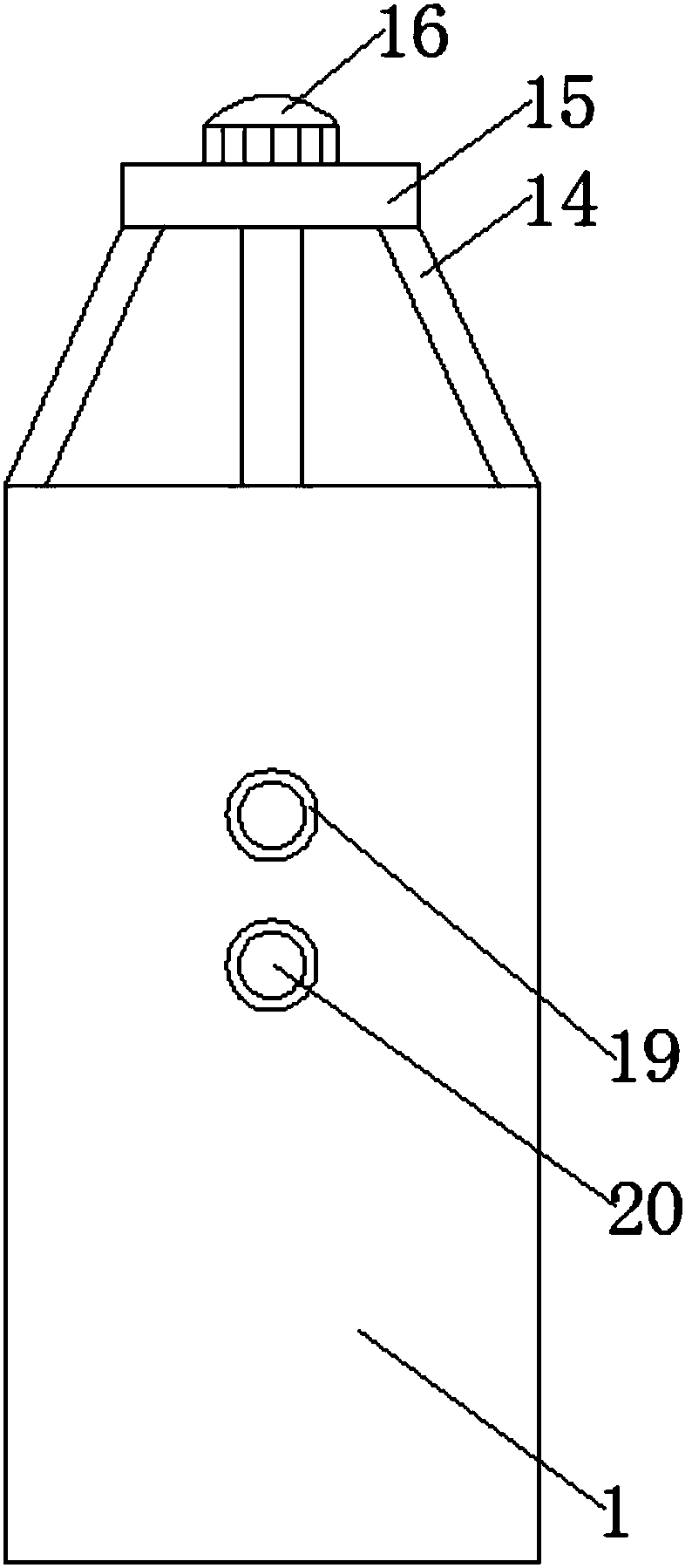

Industrial raw material quantitative charging device

InactiveCN106629108AExtended service lifeActing as a force bufferLoading/unloadingSmall holeLeft wall

The invention relates to a quantitative charging device, in particular to an industrial raw material quantitative charging device. The technical effect that the industrial raw material quantitative charging device which is small in industrial raw material charging amount deviation is provided is achieved. In order to achieve the technical effect, the provided industrial raw material quantitative charging device comprises a support, a processing box, a first pulley, a stay cord, a second pulley, a contact wheel, a fixing block, a second spring, a lifting rod, a knocking block, a wedge block, a first spring and the like. The first pulley, the second pulley and a feed hopper are sequentially arranged at the top of the processing box from left to right. A first small hole, a second small hole and a third small hole are sequentially formed in the left wall of the feed hopper from top to bottom. The purposes of the precise industrial raw material charging amount and no waste of industrial raw materials are achieved, and meanwhile, the problems that manual industrial raw material charging is not precise and the industrial raw materials are harmful to human body surface skins are solved.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

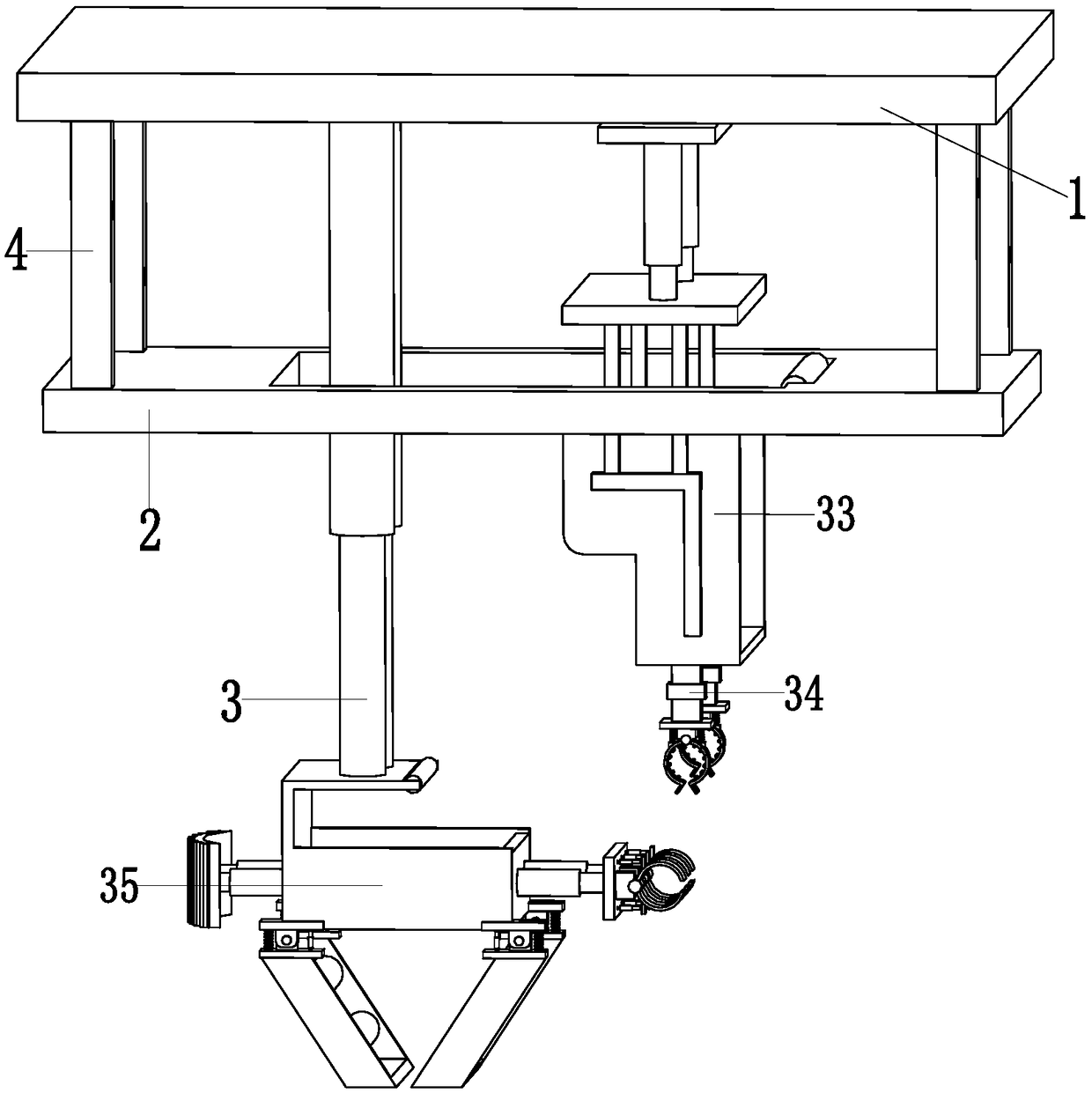

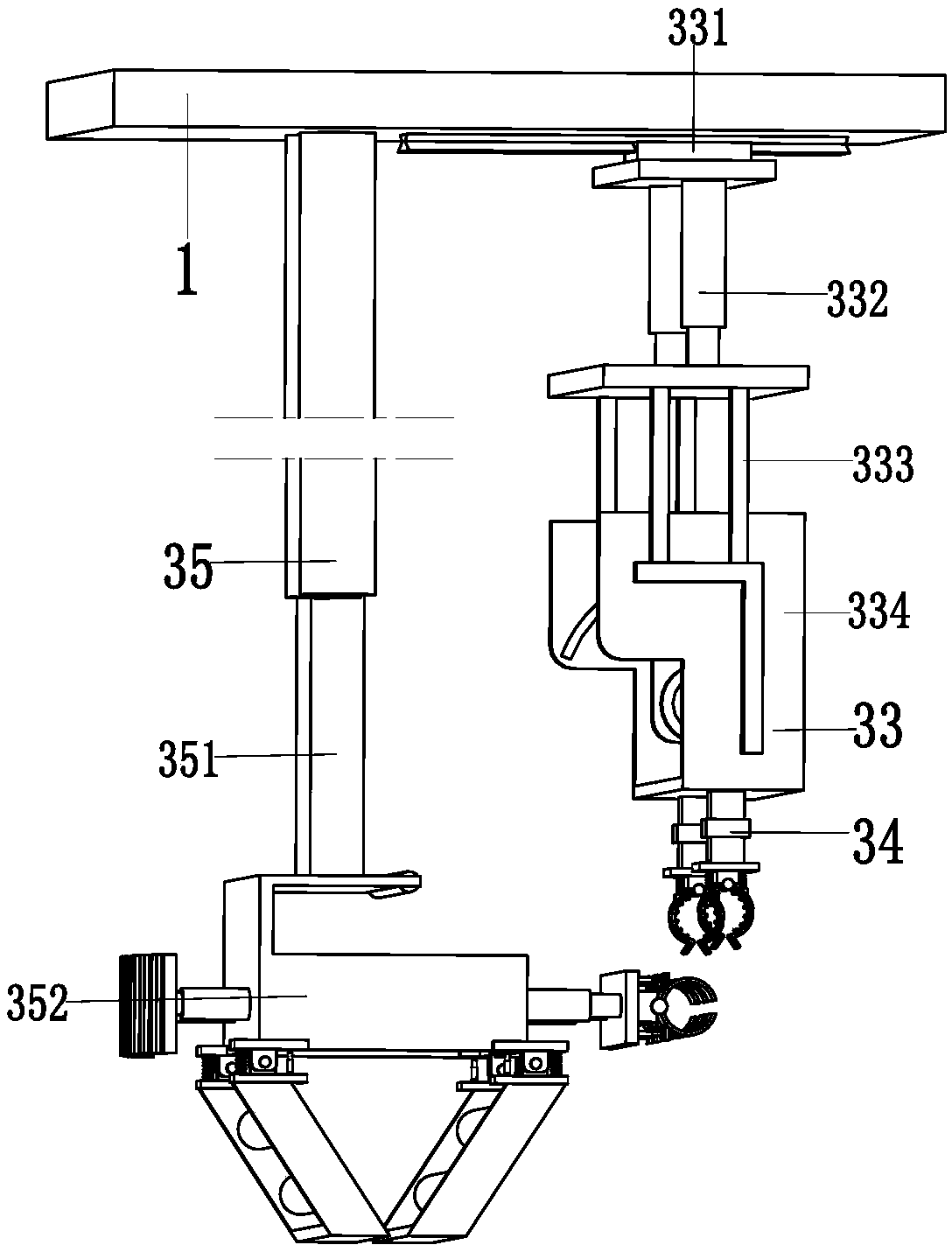

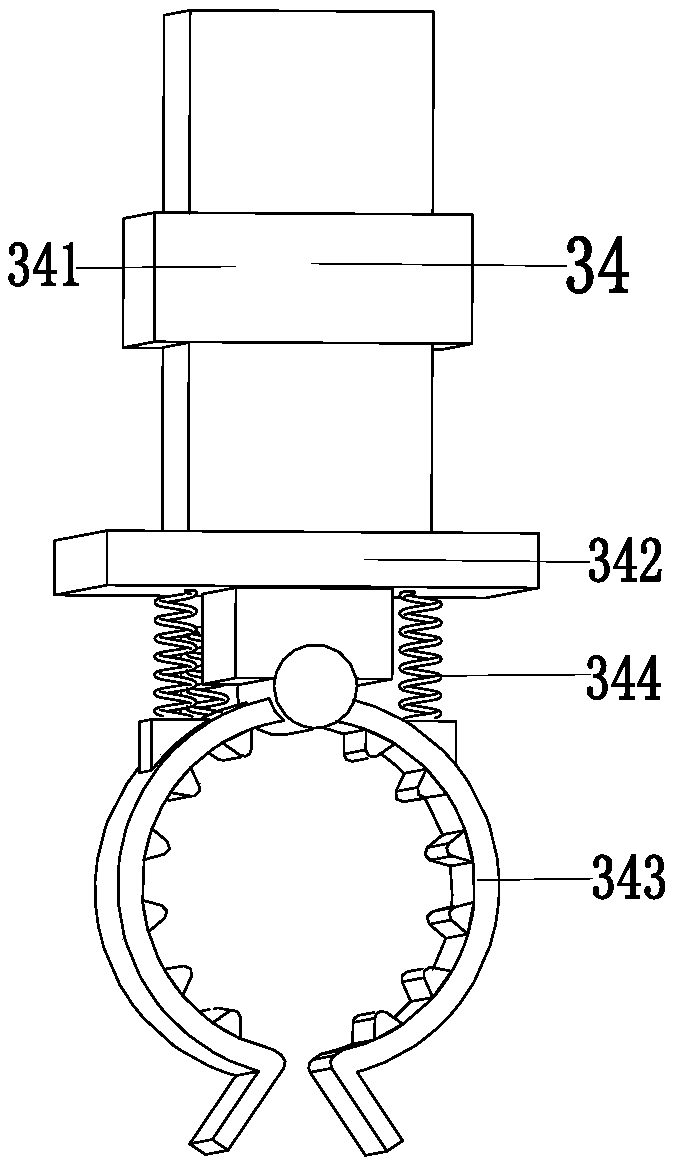

Cable multi-angle laying scaffold

ActiveCN108711787AEliminate damage to cablesAvoid shakingFilament handlingApparatus for laying cablesEngineering

The invention relates to a cable multi-angle laying scaffold. The cable multi-angle laying scaffold comprises a support roof, a support bottom plate, a paying-off device and a support connecting column; a square slot is arranged in the middle part of the support bottom plate, the support roof is arranged on the top of the support bottom plate through the support connecting column, and the paying-off device is connected with the bottom of the support roof; the paying-off device comprises a guiding mechanism, a clamping mechanism and a distributing mechanism; the clamping mechanism comprises a clamping telescopic column, a clamping connecting rack, a clamping claw and a clamping spring. The problems that the cable can produce friction with the sidewall of a cable well when the existing cablerack performs the cable pay-off, the cable has the hidden danger of twisting on the escalator of the cable well, the twining can occur when the cable is conveyed in two directions, and a transmissionrack can shake when the cable is conveyed in the cable well can be solved, and the function of performing angle-adjustable conveying of the cable in the cable well can be realized.

Owner:湘潭潭州电力建设有限公司

Protection cable skinning knife

InactiveCN105244816AEasy to holdEasy to apply forceLine/current collector detailsApparatus for removing/armouring cablesConical formsSkin effect

Owner:STATE GRID SHANDONG ELECTRIC POWER CO YUNCHENG POWER SUPPLY CO

Automatic chalk production machine

The invention relates to a production machine, particularly relates to an automatic chalk production machine, and aims to provide the automatic chalk production machine which can automatically and quantitatively pour out gypsum liquid, automatically scrape and flatten the gypsum liquid and improve the working efficiency. The automatic chalk production machine comprises a support, wherein a storagebarrel is arranged on the right side of the top of the support, a scraping flattening assembly for scraping flattening in a sliding mode is arranged on the top of the support, a quantifying assemblyfor quantifying in a lifting mode is arranged between the support and the storage barrel, a discharging assembly for discharging in a moving mode is arranged on the quantifying assembly, and a chalk manufacturing template is arranged in the support. According to the automatic chalk production machine, through cooperation of a push rod and a scraping plate, the gypsum liquid can be rapidly and evenly pushed into the chalk manufacturing template, through cooperation of a lower plug and a quantifying barrel, the gypsum liquid flowing out can be quantitatively controlled, and through cooperation of a wedge-shaped block and the push rod, automatic discharging can be achieved in the movement process of the push rod.

Owner:日照市昱岚新材料有限公司

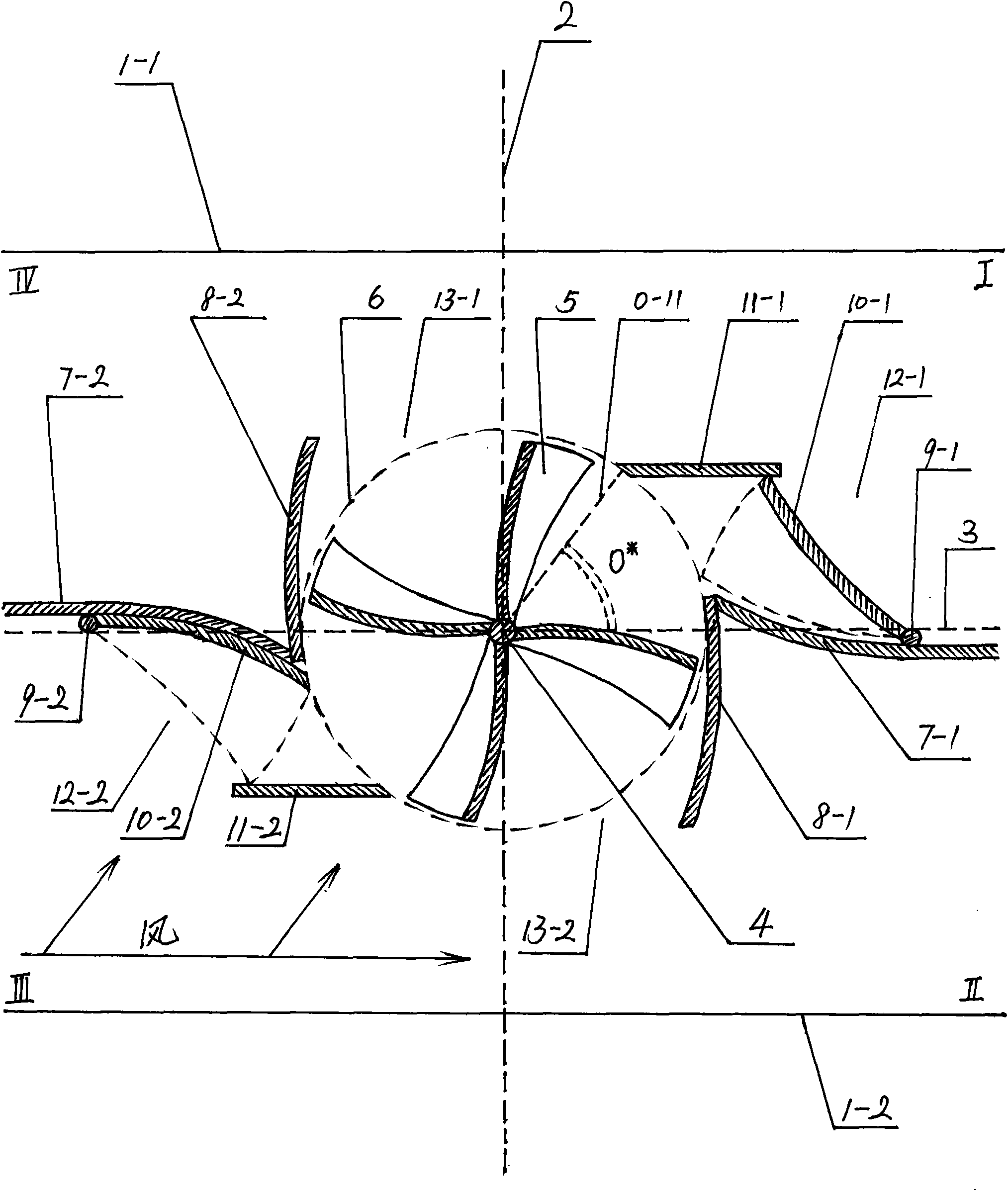

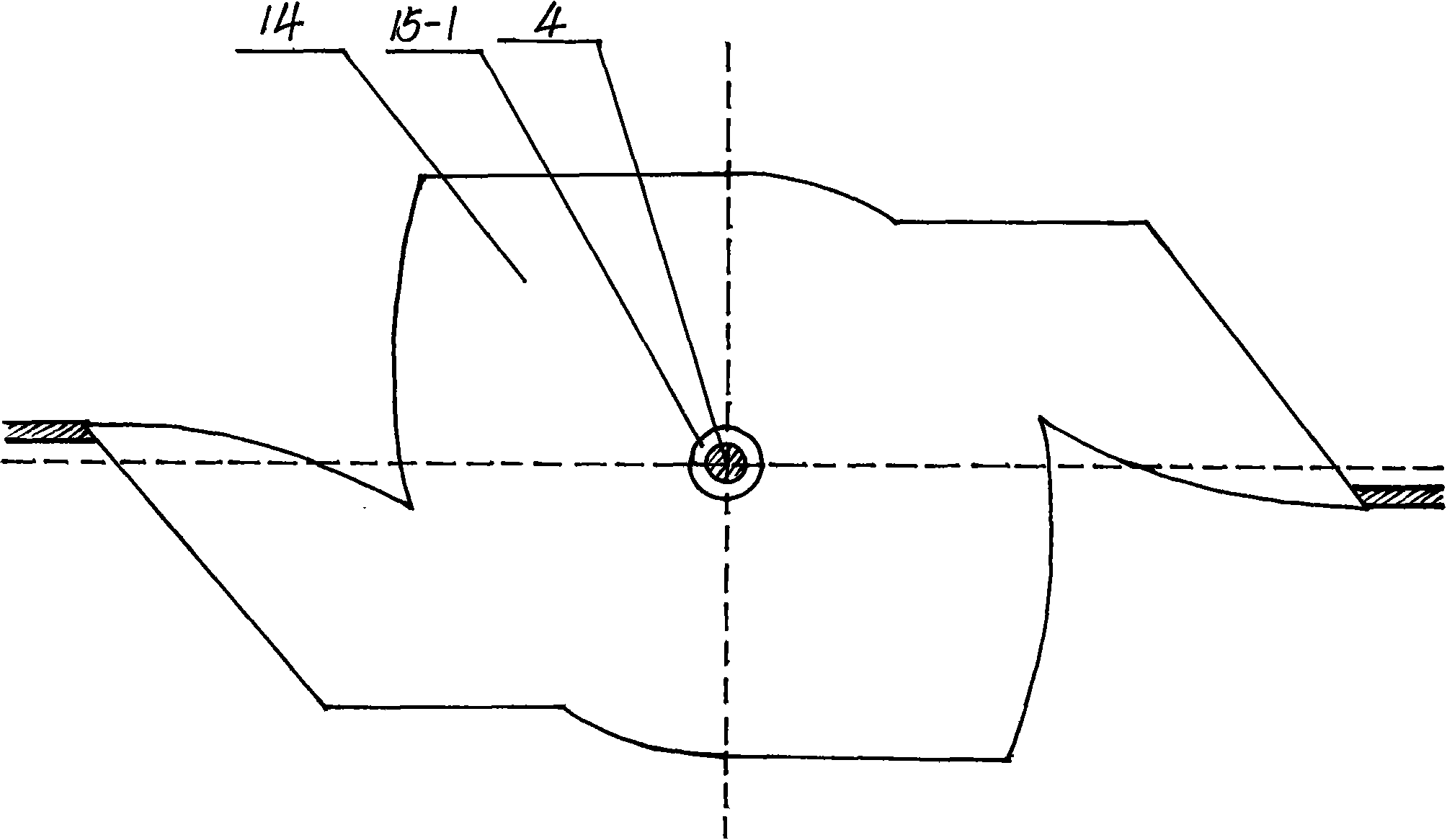

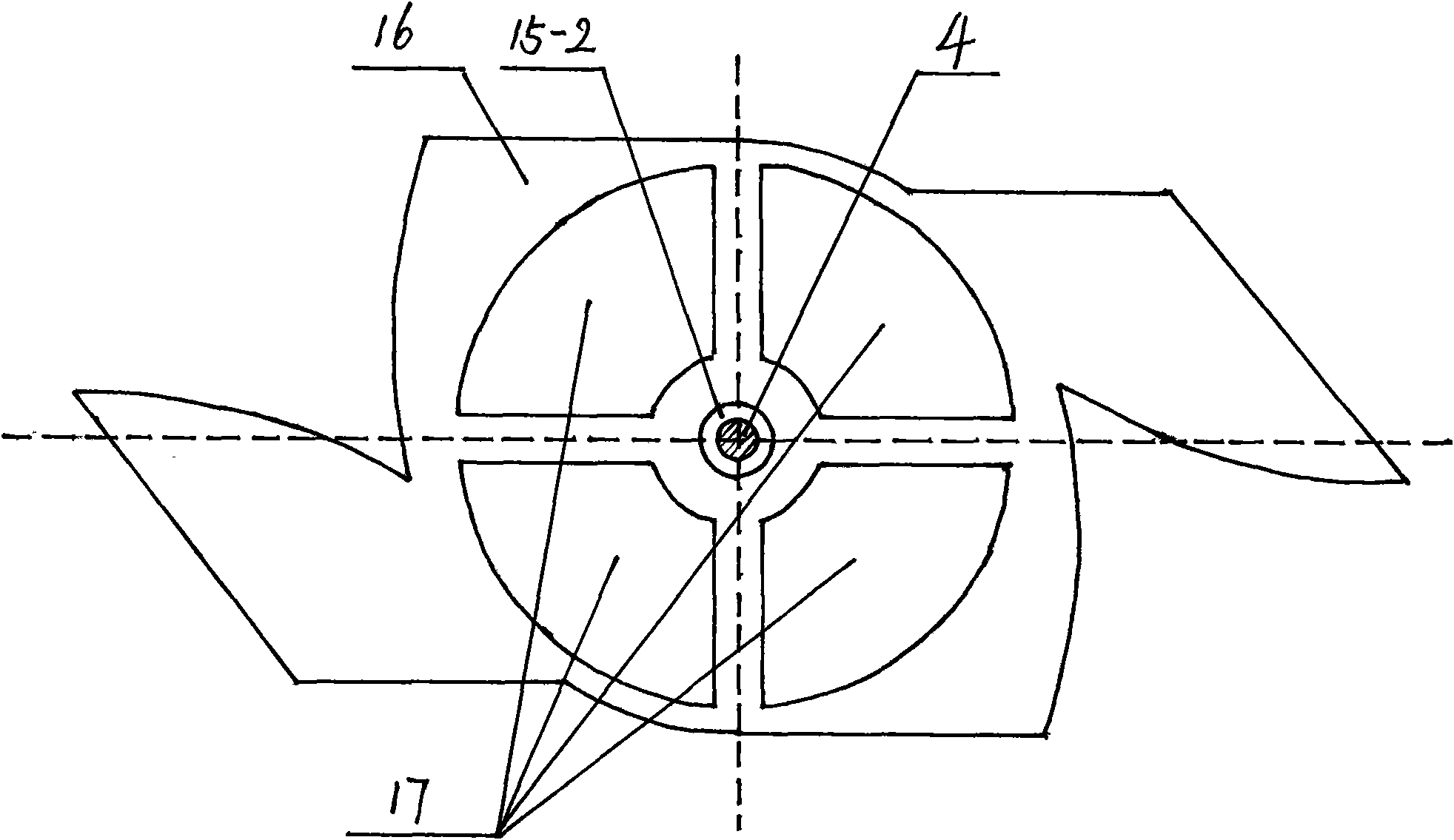

Road wind generator

InactiveCN101672250APrevent force reversalGuideMachines/enginesWind motor combinationsWind drivenElectricity

The invention relates to a road wind generator, which belongs to the field of wind driven generators. The road wind generator has three mounting position modes on railways, express highways, subway tunnels and the like for land transport devices, and the three mounting position modes include the lateral surface on one side of a driveway, the lateral surface in the middle of opposite running driveways, and the top part in the middle of the opposite running driveways; a wind axle vertical to an opposite surface in a driving direction is arranged on the road wind generator and is connected with afan blade, and a one-way bearing is connected with a top cover and a bottom cover; a valve is connected with an air deflector through a door spindle, and the air deflector is connected with the top cover and the bottom cover; a gear is connected with the wind axle and is in meshed connection with a speed changer, and the speed changer is in meshed connection with a generator rotor shaft; and a supporting rod is connected with and fixes a machine body. The road wind generator uses the wind energy generated by the land transport devices of trains, automobiles, subway locomotives and the like inmoving, changes the wind energy into electric energy to change the waste into valuable, and can use natural wind energy to generate electricity so that the road wind generator accords with a nationalpolicy for environmental protection, energy-saving and emission reduction; besides, the road wind generators can be continuously arranged along the driveway direction to form generating sets for providing electric power for stations, towns and countries and parallel power supply on the way and providing electric power for electric locomotives and motor train units.

Owner:王川

Plastic product sand removal device and method

InactiveCN108437280ASimple structureEasy to usePlastic recyclingCleaning using liquidsBristleShake up

The invention discloses a plastic product sand removal device and method in the technical field of plastic product sand removal. The device comprises a box body, a rotating rod is inserted in an innercavity of a bearing, cleaning rods are evenly arranged on the left side and the right side of the rotating rod, a first filter net, a second filter net, a hopper and a water box are sequentially arranged in an inner cavity of the box body from top to bottom, cleaning liquid is sprayed out through a water outlet hole through a water pump, plastic product surfaces are washed, the cleaning rods rotate to drive bristles to brush the plastic product, the first filter net separates the cleaning liquid mixed up with gravel and the plastic product, the second filter net separates the cleaning liquidand the gravel, the second filter net shakes up and down, filtering and cleaning of the gravel are facilitated, the cleaning liquid mixed up with fine gravel and dust is precipitated in a precipitation chamber, a mesh-free filter layer filters fine gravel and dust mixed up in the cleaning liquid, through layer-by-layer filtering of the cleaning liquid, circular utilization of the cleaning liquid is achieved, and resource waste is reduced.

Owner:CHENGDU PUJIANG KEXIAN TECH

Coarse coal slime sorting machine

The invention belongs to the field of coal mine mechanical equipment and particularly relates to a coarse coal slime sorting machine, which comprises an electric actuating mechanism. The electric actuating mechanism is sequentially connected with an adjustable feeding device and a cyclone interference device of a pipe structure. The cyclone interference device is arranged in a water tank and comprises a plurality of arc-shaped plates. A movable casing can be in close contact with the arc-shaped pates on the cyclone interference device during field installation to guarantee materials to fully flow along the direction of the arc-shaped plates. The cyclone interference device in the coarse coal slime sorting machine enables the materials to forcibly form rotational flow under the effect of the arc-shaped plates on the cyclone interference device to enable the materials to be evenly scattered, so that the sorting effect can be improved by approximate 10 percent. The coarse coal slime sorting machine can still reach a better scattering effect under the situation that the materials flow naturally, the feeding pressure is not required to be increased and the construction cost and the production process cost are reduced.

Owner:苏州玛瑞麦精密机械有限公司

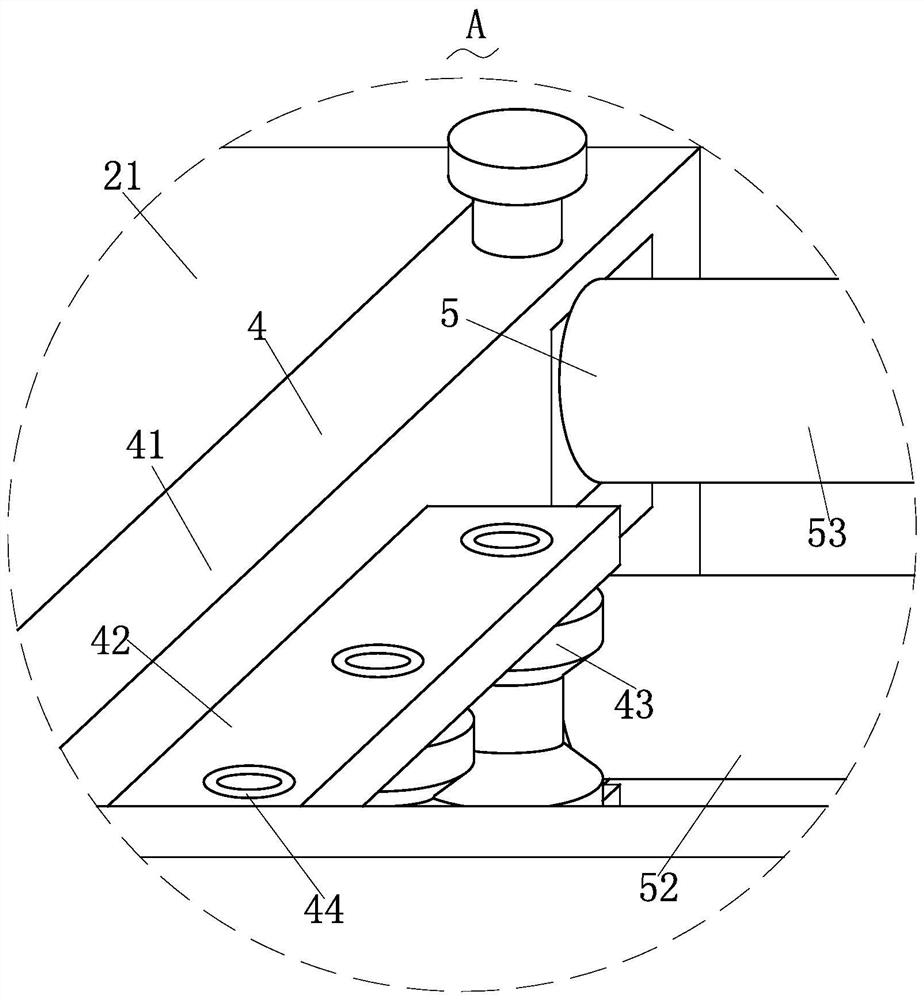

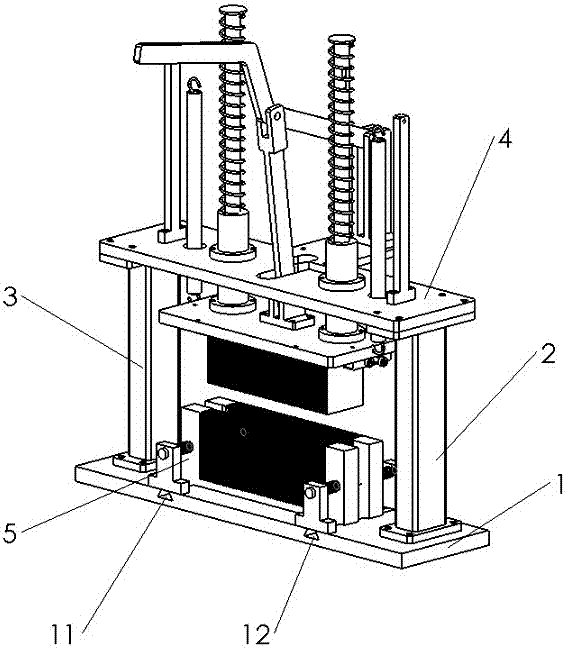

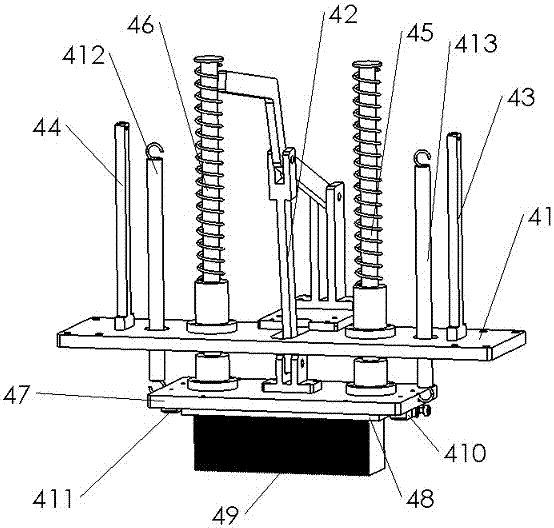

Stamping head lubricating mechanism

ActiveCN111957814AReduce frictionTo avoid glitchesShaping toolsMetal-working feeding devicesStructural engineeringMetal sheet

The invention relates to the field of stamping dies, in particular to a stamping head lubricating mechanism. The stamping head lubricating mechanism comprises a base, a stamping structure, a lubricating structure, a guide structure, a feeding structure, a cleaning structure and a pressing structure. Through the arrangement of the stamping structure, long sheet materials can be stamped into required round parts one by one, the lubricating structure can be synchronously driven to work while the stamping structure carries out stamping work, and through work of the lubricating structure, oil injection lubrication work can be automatically carried out on assemblies in the stamping structure during stamping, so that the friction force between the stamping assembly and the sheet materials can bereduced, the situation that burrs appear on the periphery of a stamped finished product part can be avoided, and thus the effect of greatly improving the production quality is achieved; and the cleaning structure can be synchronously driven to work while the feeding structure works, dust and chippings on the metal sheet materials to be punched can be blown off, and therefore the dust and the impurities can be prevented from being punched along with the metal sheet materials.

Owner:浙江艾信汽车零部件股份有限公司

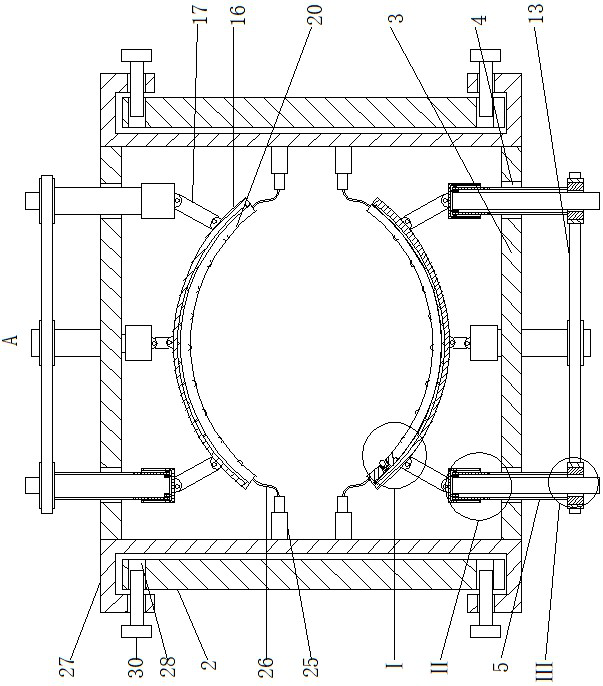

Corn stigma peeling device

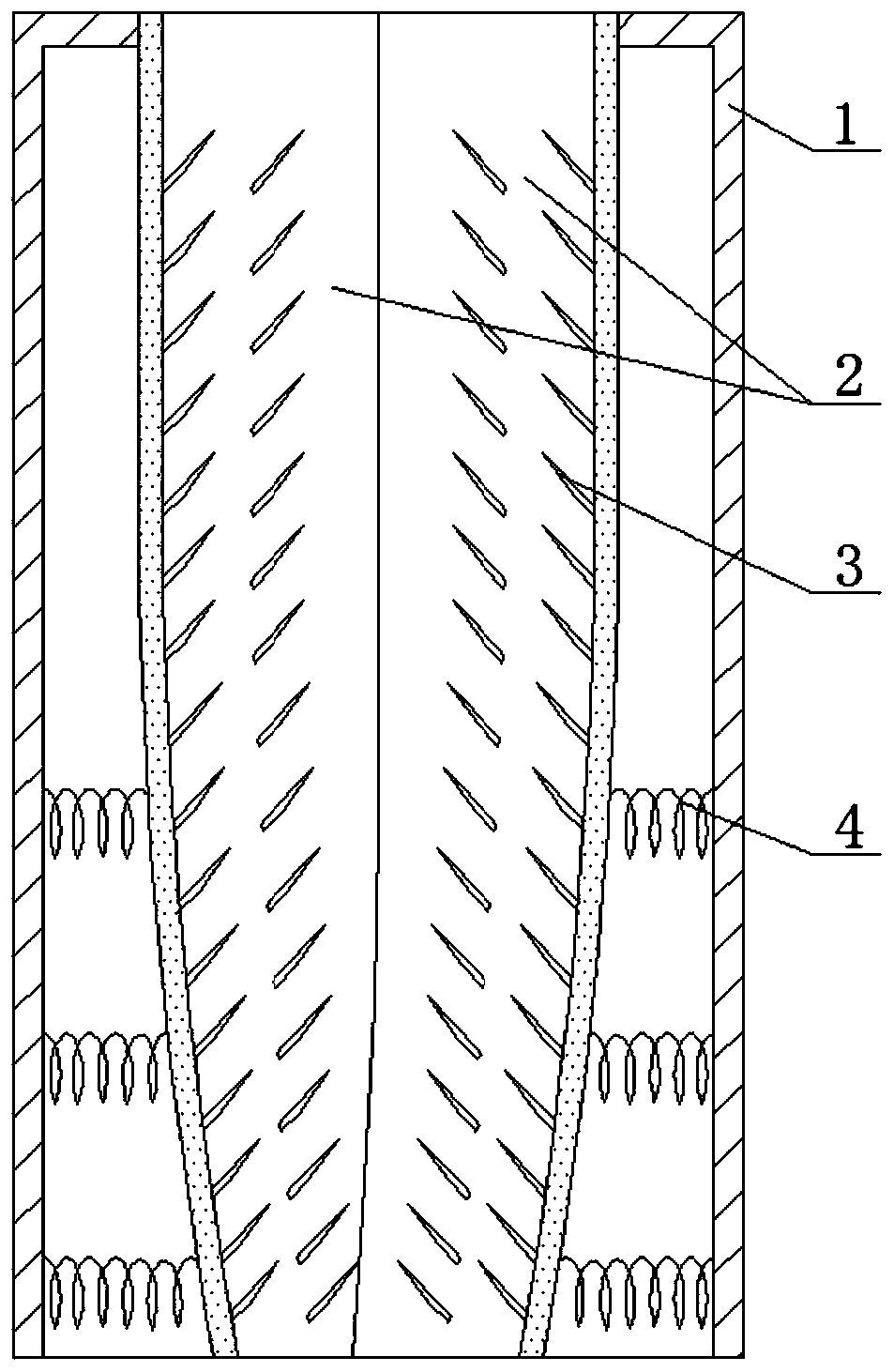

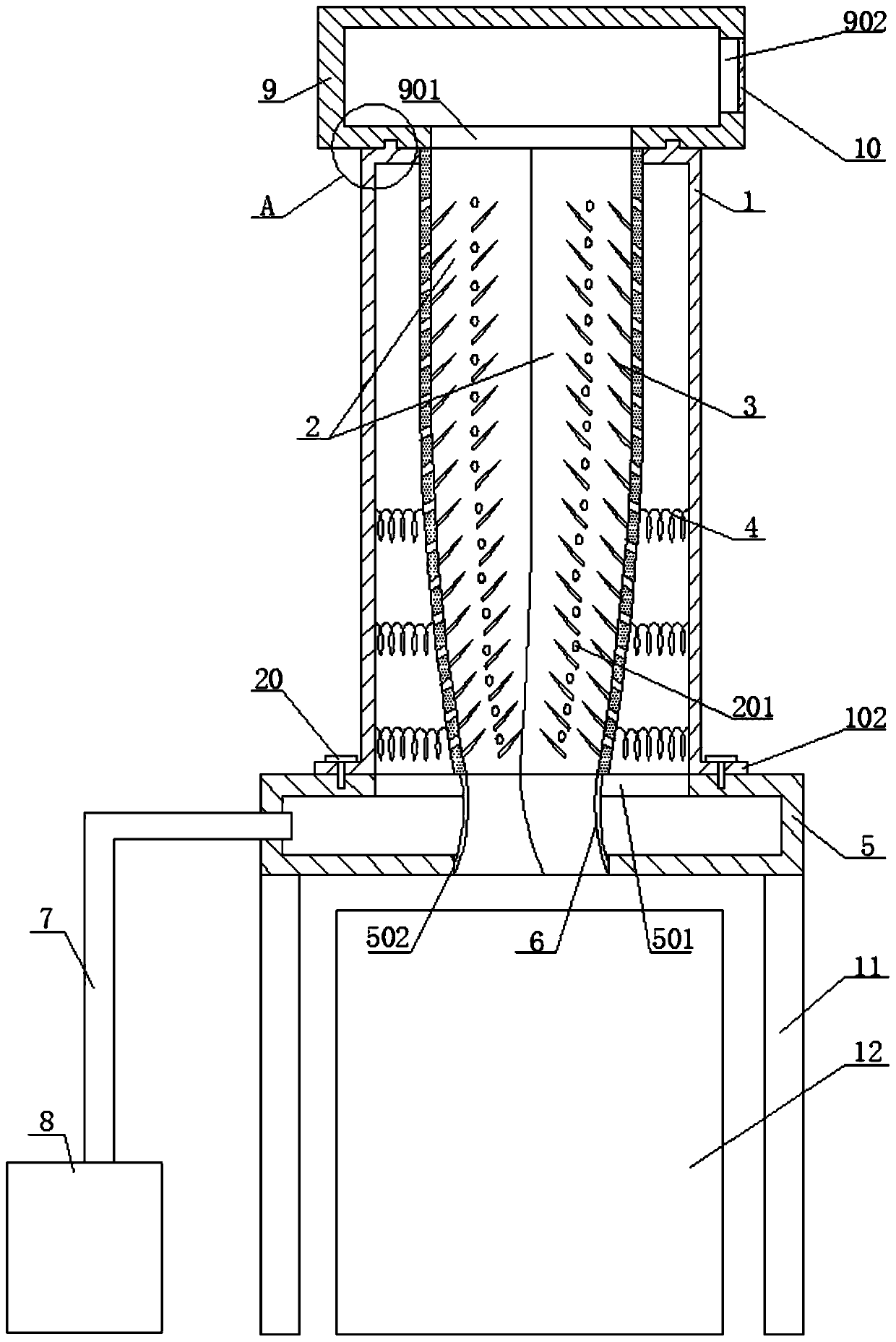

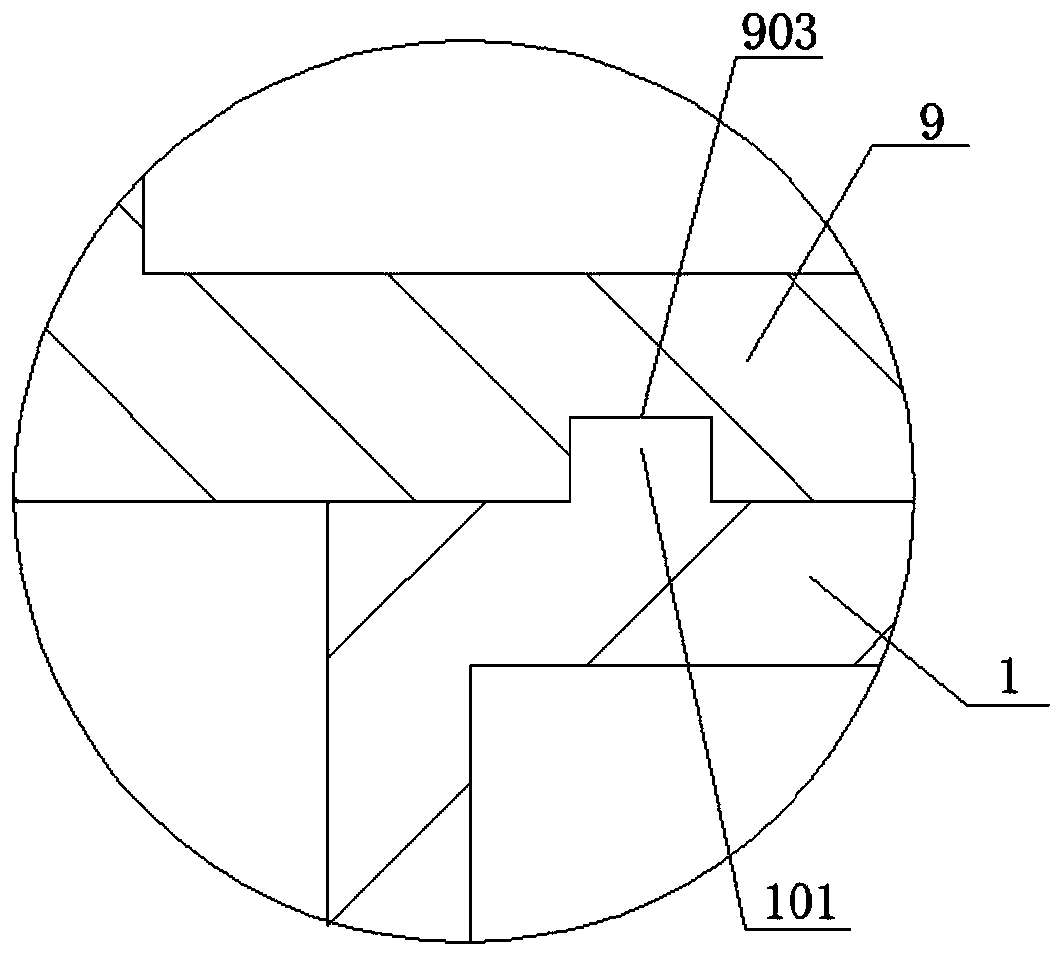

ActiveCN109716924AGood peeling effectImprove air drying effectHarvestersElastic componentWater vapor

The invention discloses a corn stigma peeling device, and belongs to the technical field of corn processing equipment. The corn stigma peeling device comprises a peeling barrel, a support barrel, a plurality of spikes and elastic components. The peeling barrel is of a barrel structure formed by a plurality of arc-shaped plates in an enclosed manner, the support barrel sleeves the peeling barrel, the upper end of the support barrel is connected with the upper ends of the arc-shaped plates, the corresponding spikes are arranged on the side, which is far away from the support barrel, of each arc-shaped plate and are connected with the arc-shaped plate, the end, which is close to the corresponding arc-shaped plate, of each spike is lower than the end, which is far away from the arc-shaped plate, of the spike, the multiple spikes are uniformly distributed on the arc-shaped plates, the elastic components are arranged between the support barrel and the arc-shaped plates, the end, which is close to the support barrel, of each elastic component is connected with the lower portion of the support barrel, and the end, which is close to the corresponding arc-shaped plate, of each elastic component is connected with the lower end of the arc-shaped plate. The corn stigma peeling device has the advantages that corn stigmas on corn cobs can be effectively removed by the corn stigma peeling device, accordingly, corn cob air drying effects can be improved for the corn cobs in stacking and air drying procedures in later periods, the problem of vulnerability to rotting and mildew of existing corn cobs due to the fact that water vapor can be easily stored in existing corn stigmas can be solved, and the shelf lives of the corn cobs can be prolonged.

Owner:INST OF QUALITY STANDARDS & TESTING TECH FOR AGRO PROD OF SHANDONG ACADEMY OF AGRI SCI

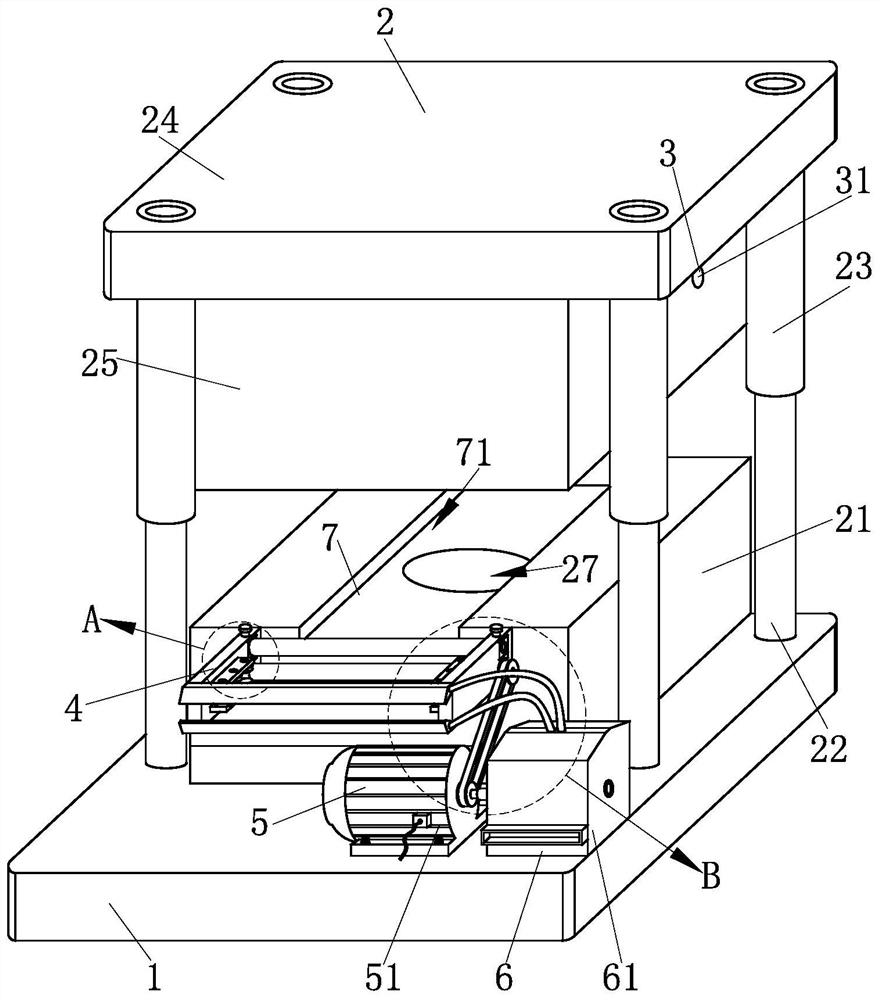

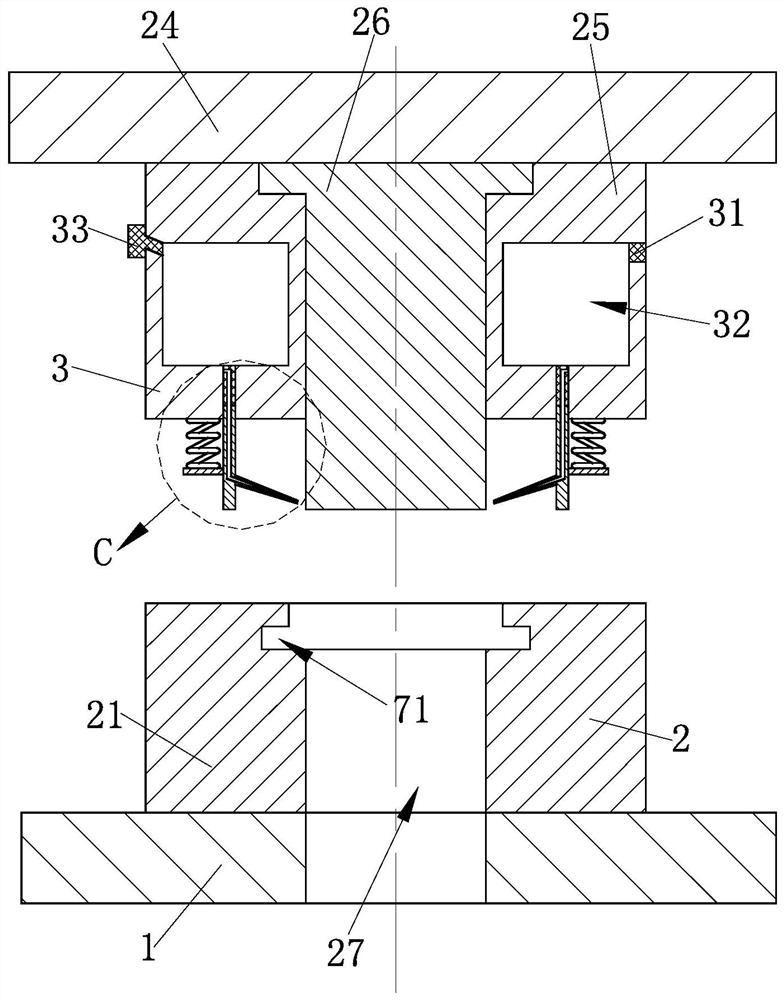

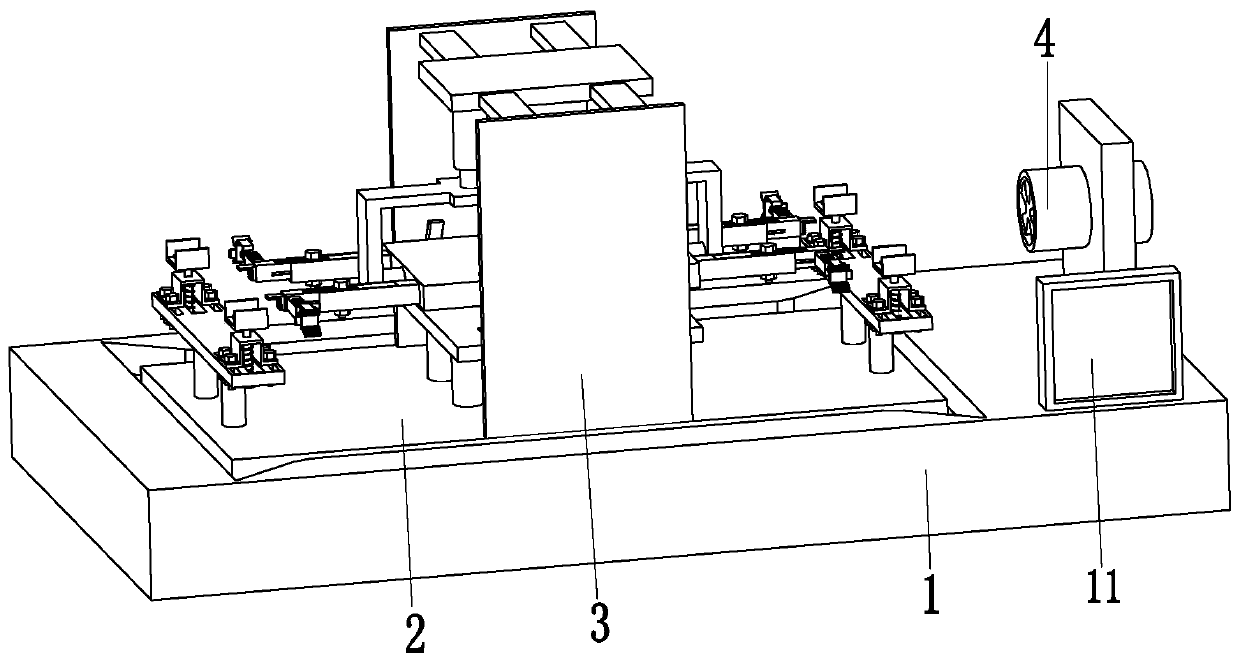

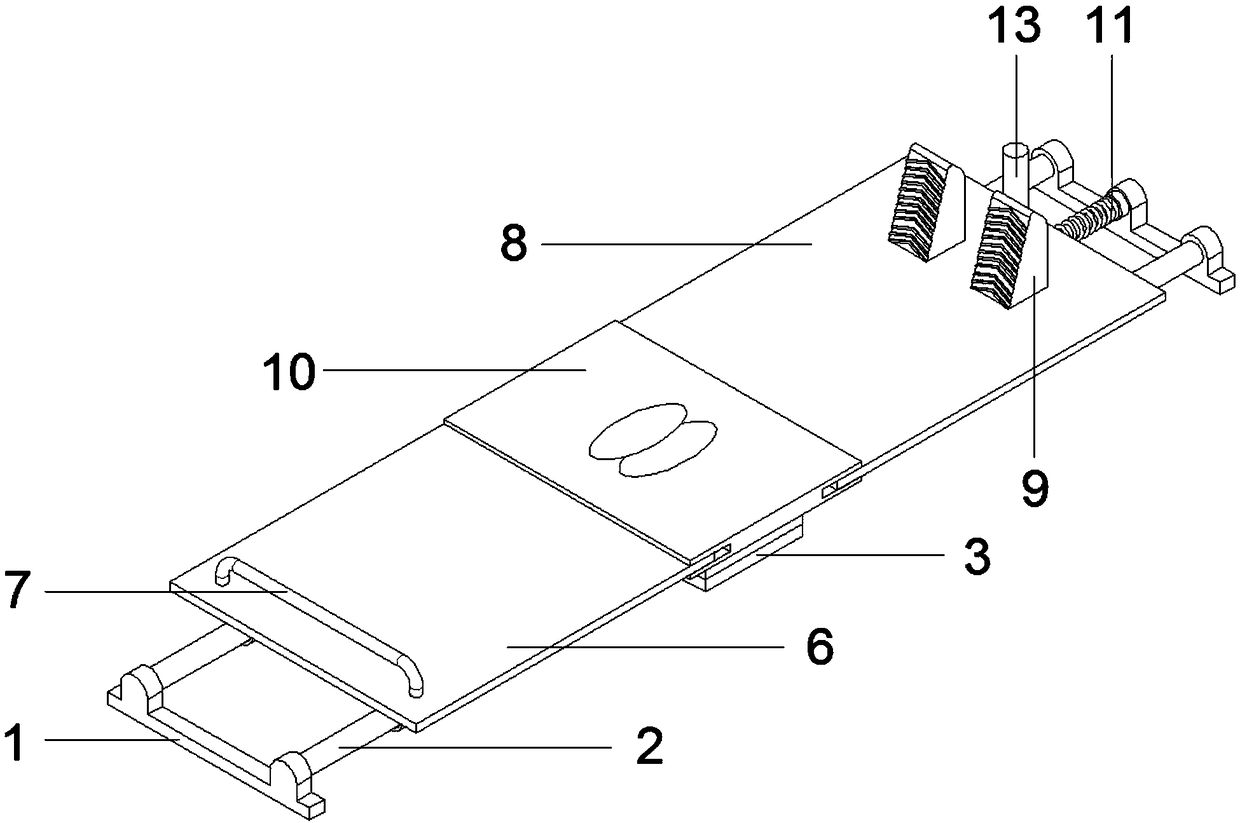

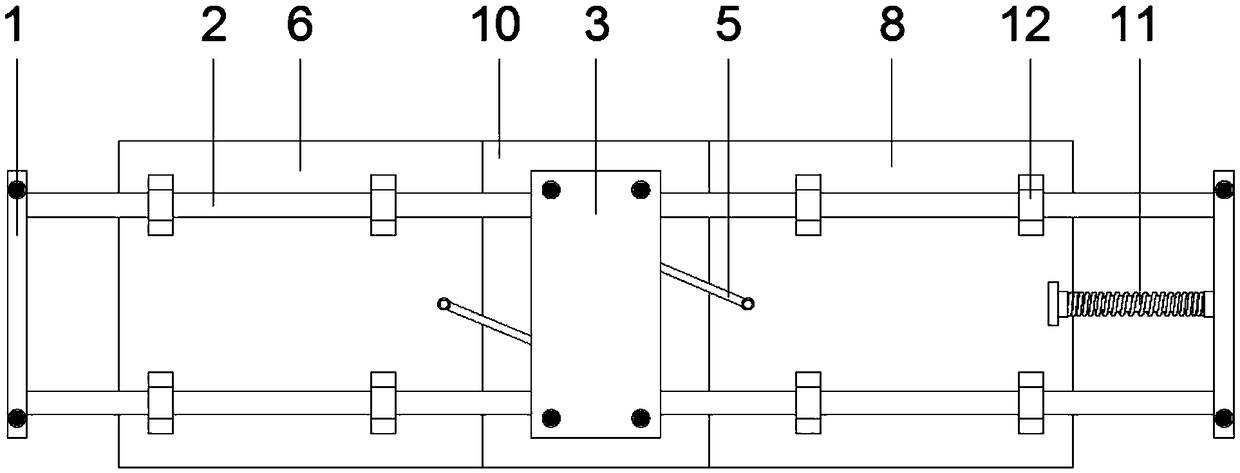

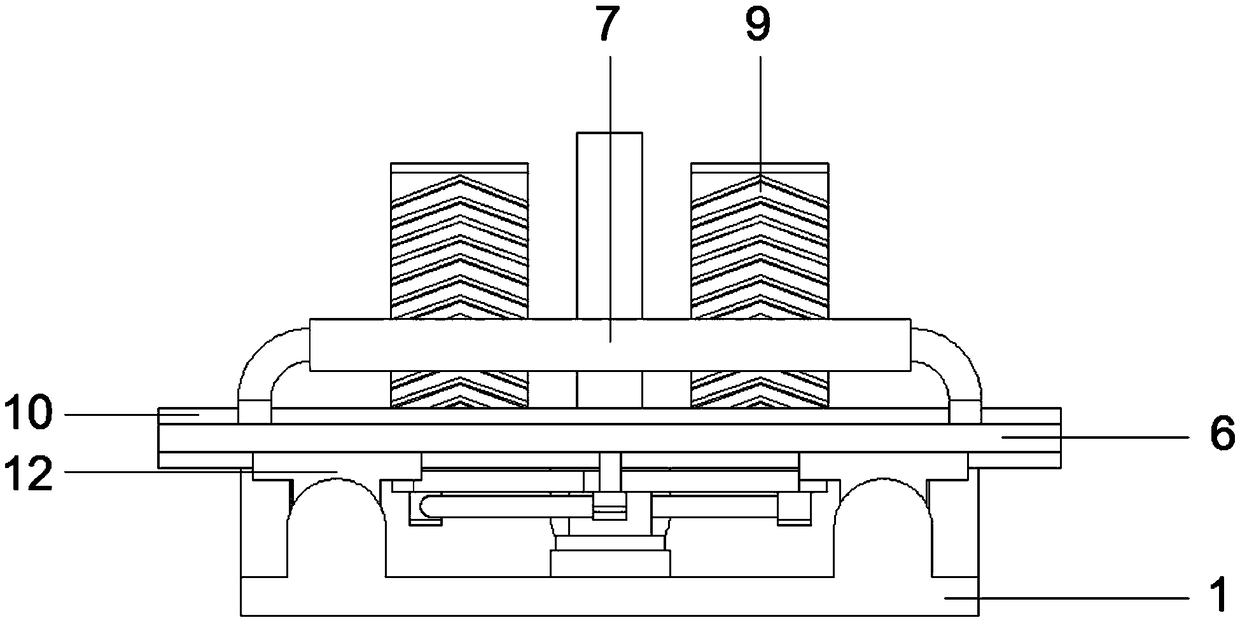

Automobile frame aerodynamics test system and test method

ActiveCN110108436AEasy to moveImprove locking effectVehicle testingAerodynamic testingVehicle frameEngineering

The invention relates to an automobile frame aerodynamics test system and a test method. The automobile frame aerodynamics test system comprises a test base, a supporting device, a locking device anda fan, wherein a square groove is arranged on a middle portion of the test base; the outer end of the square groove of the test base is symmetrically provided with an arc groove; the front side wall of the square groove on the test base is provided with a controller; the square groove of the test base is internally provided with the supporting device; the top part of the supporting device is provided with the locking device; the fan is mounted at the right top part of the test base; and the supporting device comprises a rotating motor, a rotating supporting plate, a rotating sliding column, aguiding cylinder, a guiding mechanism, a supporting cylinder, a supporting connecting plate and a detecting mechanism. The problems that when the existing frame is subjected to aerodynamics test, different types of frames can not be locked, the frame placing position needs to be adjusted and put straight manually, multi-angle aerodynamics test on the frame can not be carried out, detection of theframe aerodynamics test is inaccurate and the like can be solved.

Owner:苏州郅荣软件有限公司

Intelligent pipe burying and wire passing device for water conservancy construction

ActiveCN111987647AGuidePlay a clamping roleApparatus for laying cablesStructural engineeringRelative motion

The invention discloses an intelligent pipe burying and wire passing device for water conservancy construction. The device comprises a mobile device, a ring is fixedly mounted on the left side wall ofthe moving device; a plurality of wire passing devices are mounted at the top of the moving device; each wire passing device comprises two guide columns, two vertical guide columns are fixedly installed on the top of the moving device side by side, the guide columns are sleeved with lifting devices, vertical plates are fixedly installed between the front ends and the rear ends of the two liftingdevices, and three first threaded holes are formed in the front side walls and the rear side walls of the vertical plates in the left-right direction. The device is compact in structure and easy to install and maintain, the first springs are matched with the balls and the arc-shaped elastic friction plates to achieve the damping effect on the passing cable, so that the cable is not prone to damage, and when the two arc-shaped elastic friction plates do relative motion, the cable can be twisted to change the direction so as to bypass obstacles to continue to advance intentionally.

Owner:高龙龙

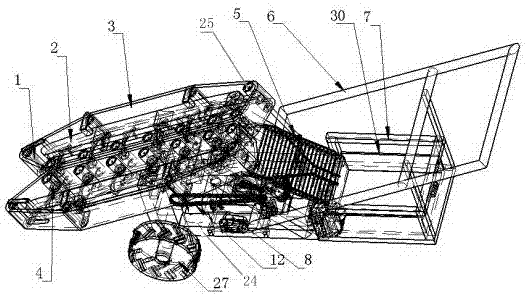

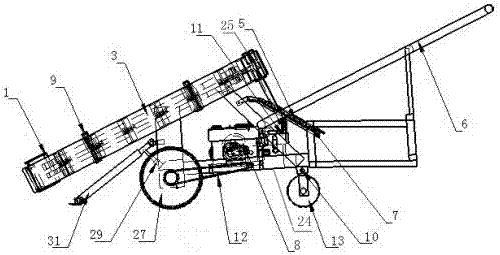

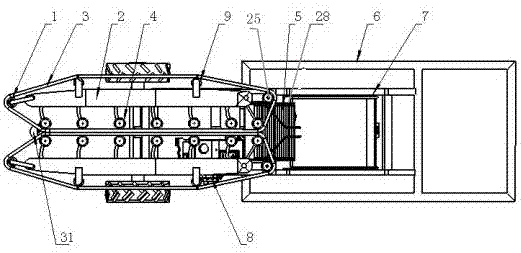

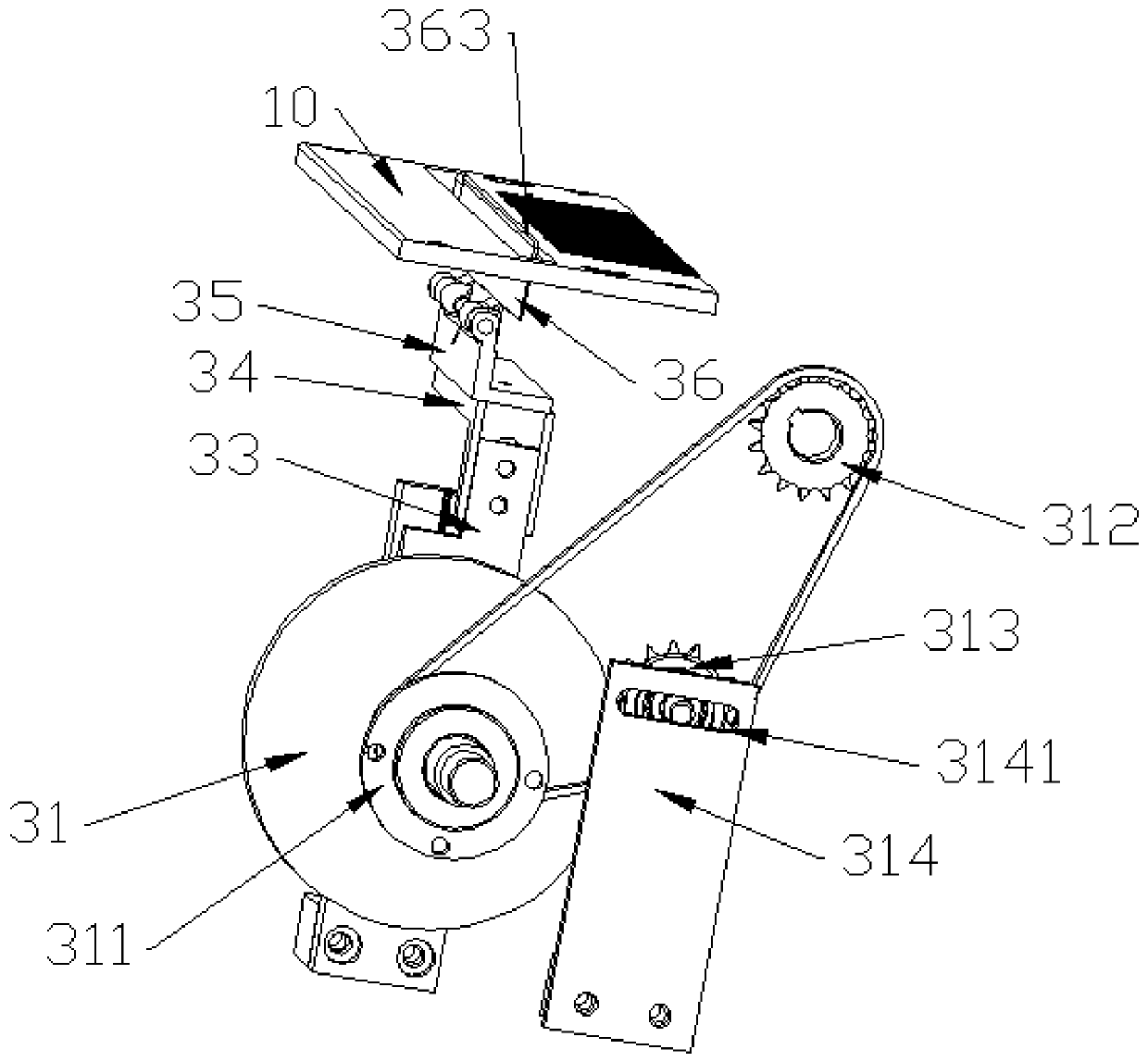

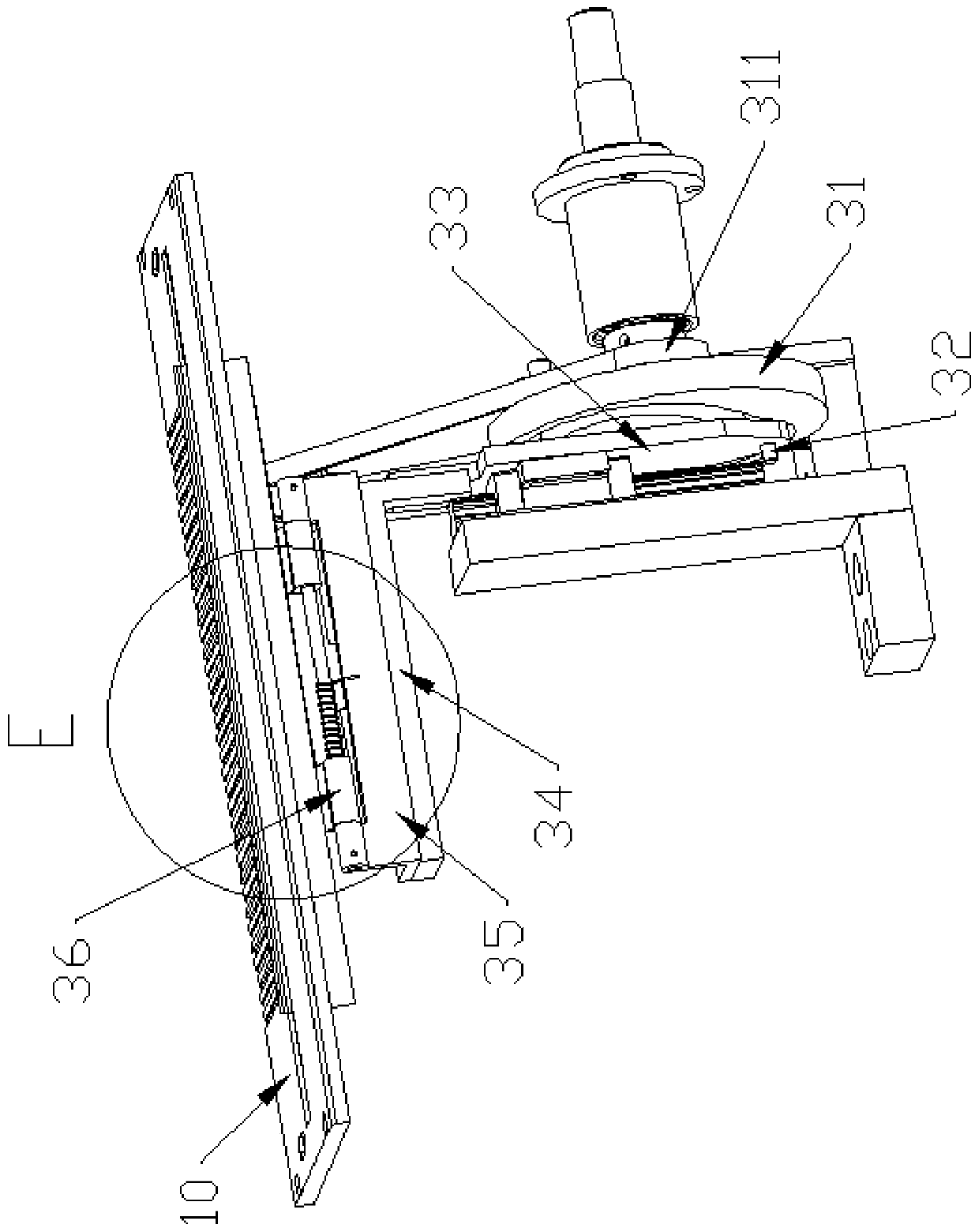

Line-aligning celery harvester and use method thereof

PendingCN107455076AGuaranteed clampingSo as not to damageHarvestersFood treatmentDrive wheelAgricultural engineering

The invention relates to a line-aligning celery harvester which comprises a rack, a power device, a transmission device, a driving device, a root cutting device, a clamping conveyor, a collecting device and a handle. The power device is connected with the driving device and the clamping conveyor through the transmission device and provides power for the driving device and the clamping conveyor; the clamping conveyor comprises two conveying frames fixed side by side in front of the rack and driving wheels respectively arranged behind the conveying frames; each conveying frame is provided with a guide wheel at the front end, the guide wheel and the driving wheel on the same conveying frame are wounded with one conveying belt, and a row of tension devices capable of rotating along a mounting point under the action of force is mounted on each conveying frame; the guide wheel, the conveying belt and the tension device enclose to form a conveying channel with the width gradually decreased from front to back. By the arrangement, damage rate of celery is low, and the harvested celery can be automatically aligned.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

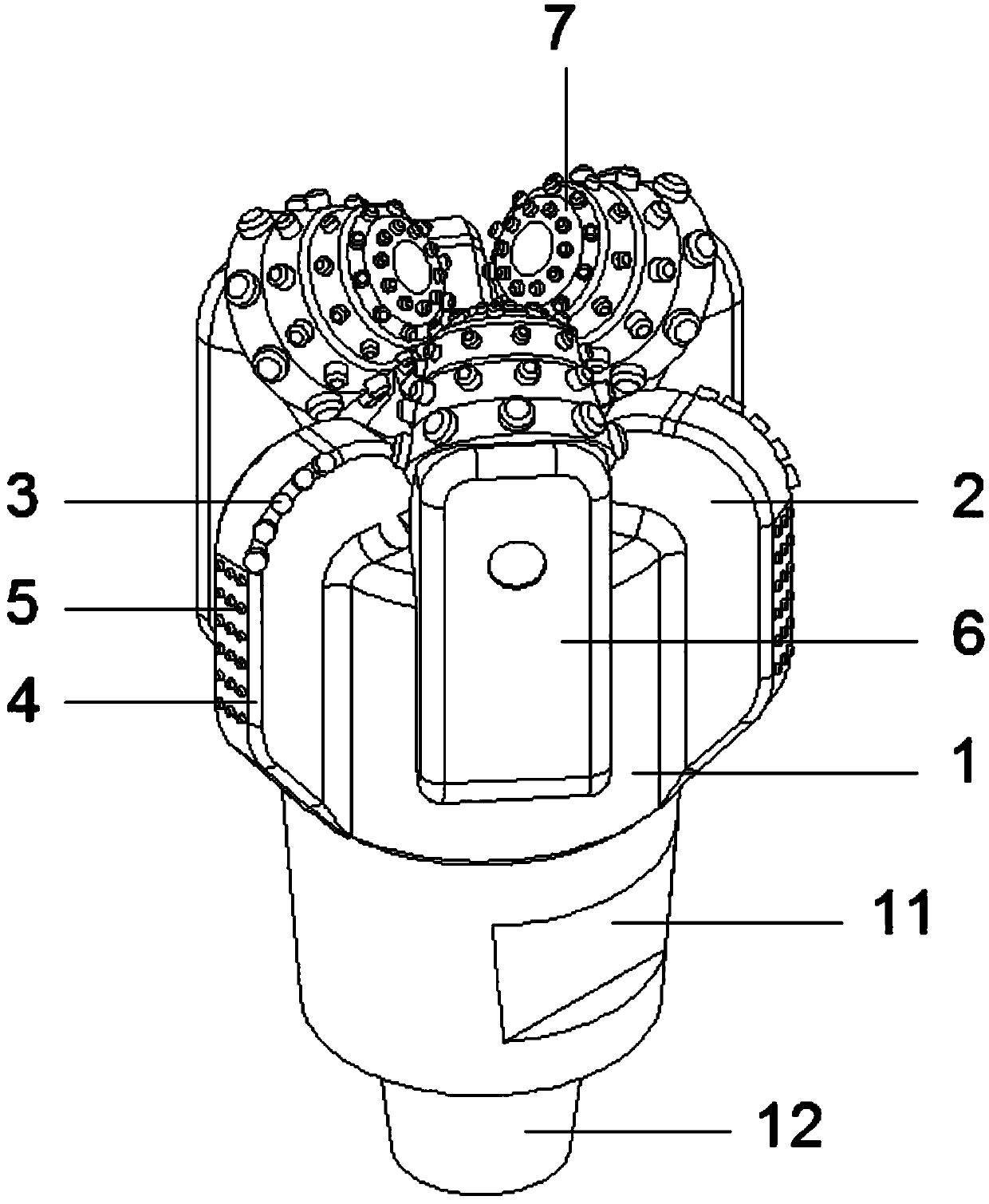

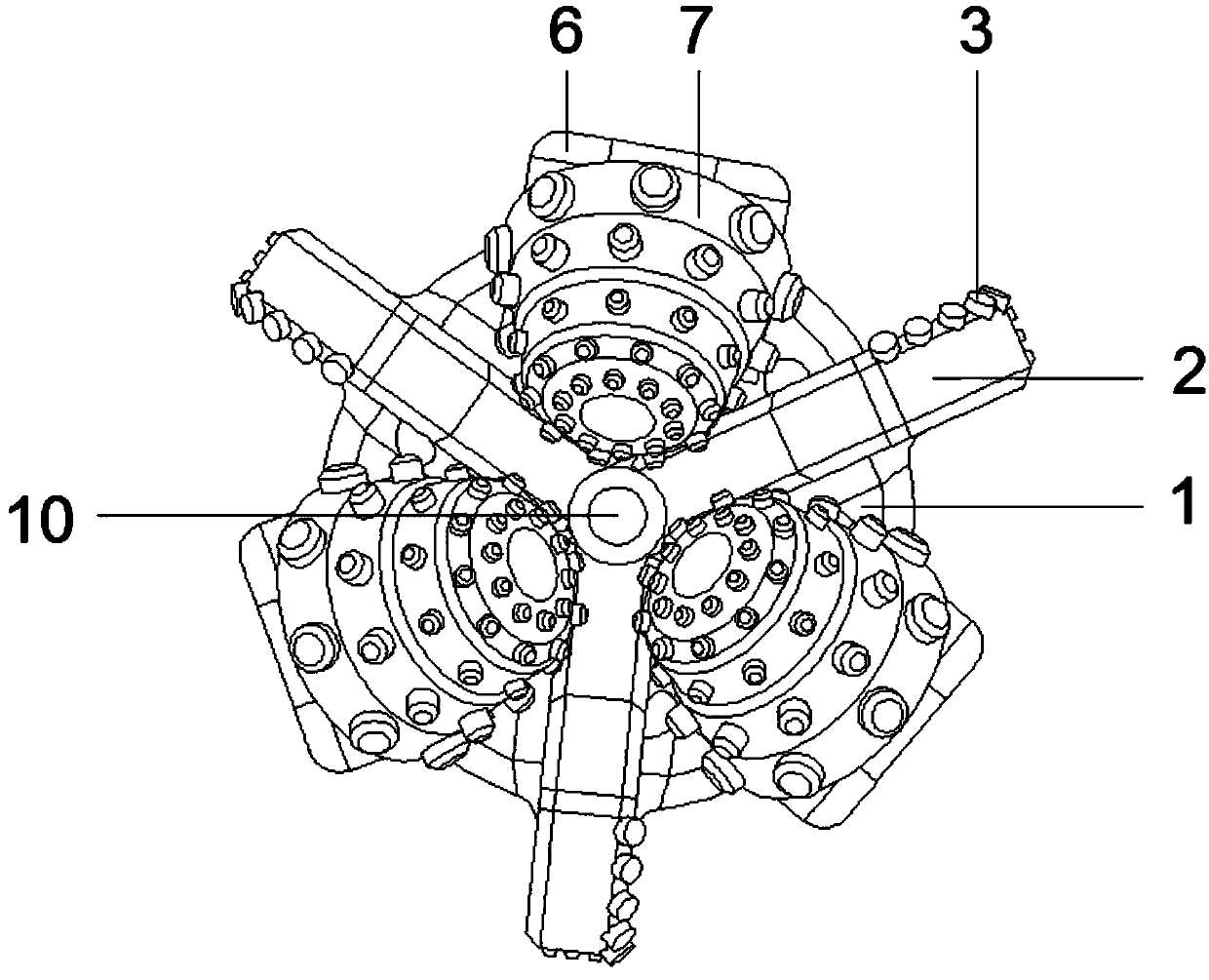

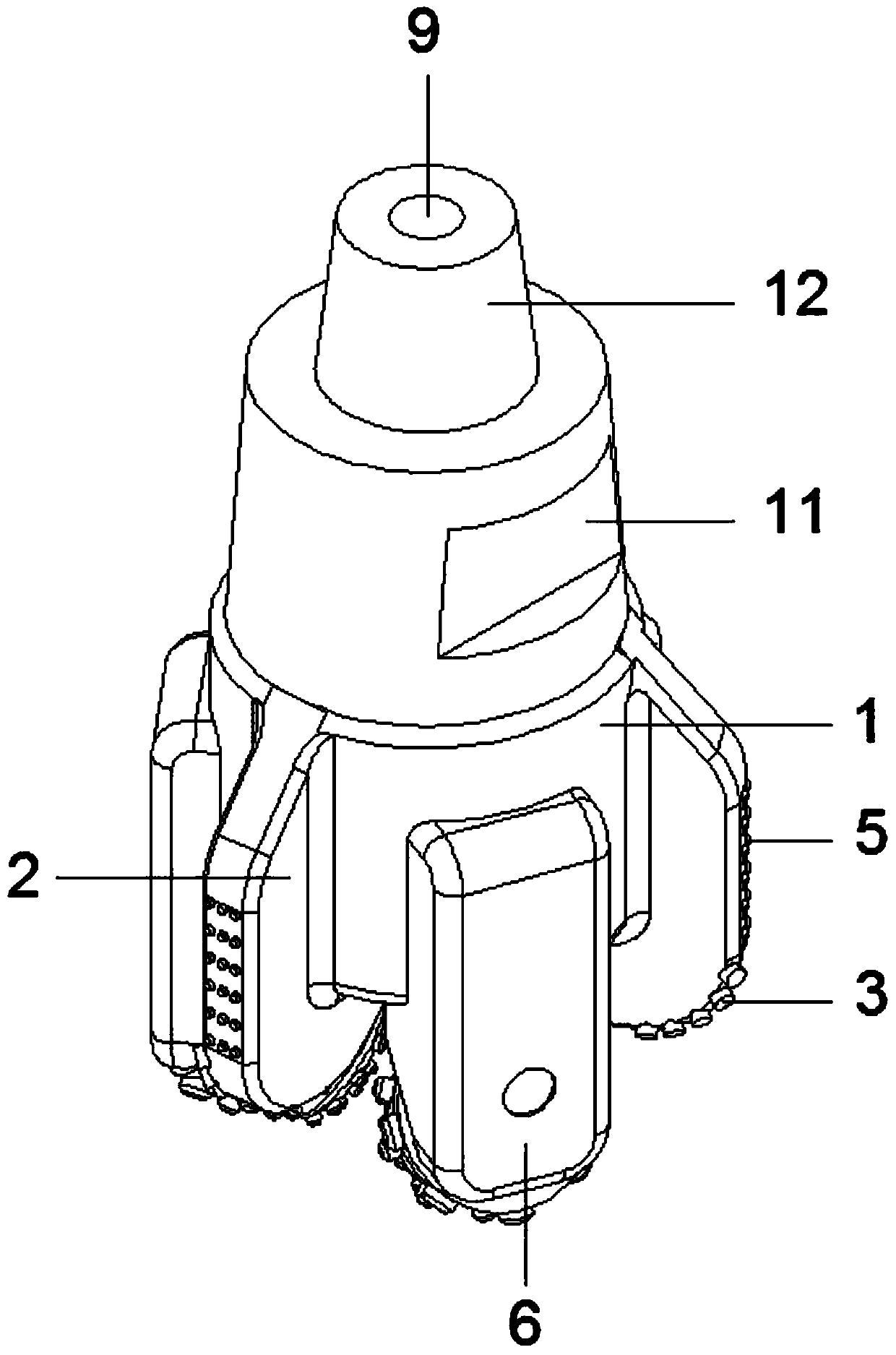

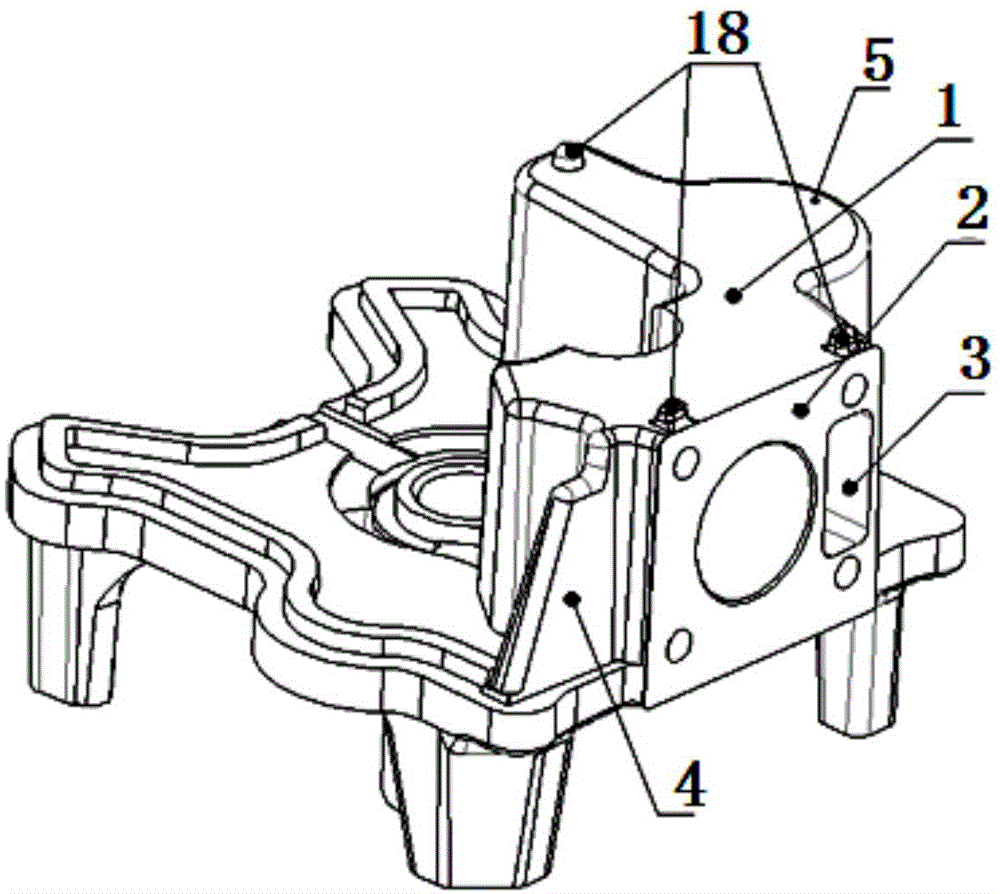

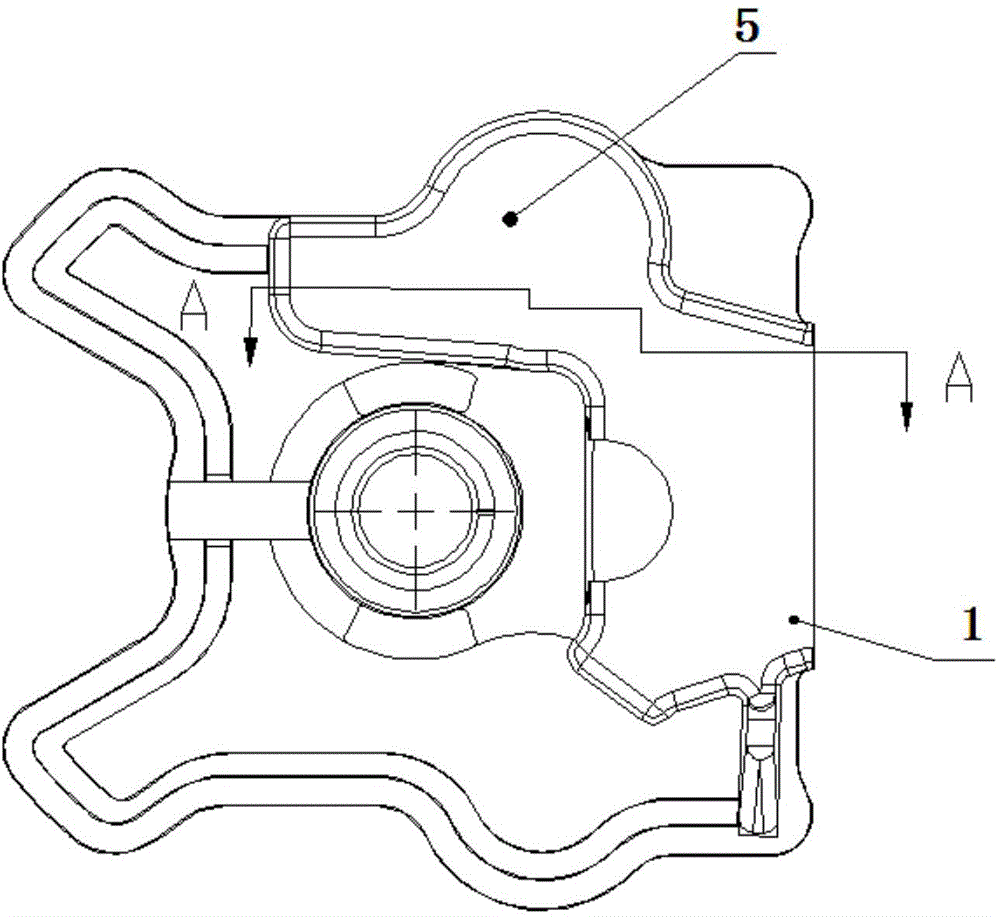

Roller-cone polycrystalline diamond compact (PDC) two-stage cutting compound drill bit

InactiveCN109667545AReduce energy consumptionAvoid recuttingDrill bitsWell drillingPolycrystalline diamond

The invention provides a roller-cone polycrystalline diamond compact (PDC) two-stage cutting compound drill bit, comprising a PDC drill bit body, blade wings and roller cones, wherein the blade wingsare arranged at the top end of the PDC drill bit body, and the blade wings and the PDC drill bit body form an integral structure; cutting teeth are embedded and welded at one sides of the top ends ofthe blade wings; gauge protection parts are arranged at the outer sides of the blade wings, and are connected with the blade wings in a welding way; gauge protection teeth are embedded and welded on the outer walls of the gauge protection parts; an oil storage cavity is arranged at the top end of the PDC drill bit body. By improving a compound drill bit, the roller-cone PDC two-stage cutting compound drill bit has the advantages that the structural design is reasonable, layer-by-layer cutting can be realized, a roller-cone drill bit and a PDC drill bit complement the advantages of each other,and the drill bit is good in guiding effect, high in stability, strong in well deviation control ability, less in local hydraulic loss, low in energy consumption of ground power equipment, high in drilling efficiency, low in drilling cost and high in practicality; therefore, the problems and deficiencies raised in the background technology of the invention are effectively solved.

Owner:LANZHOU CITY UNIV

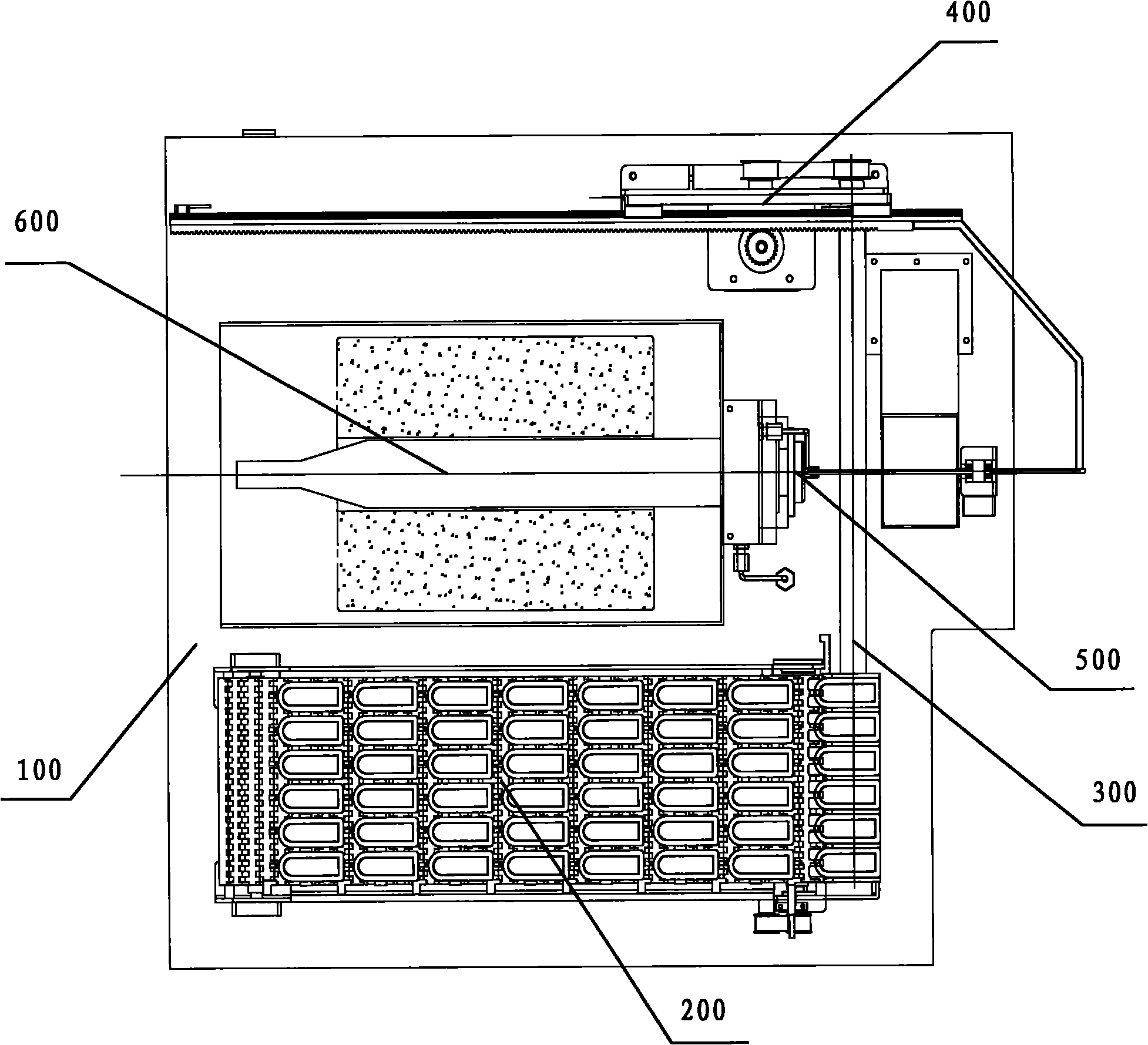

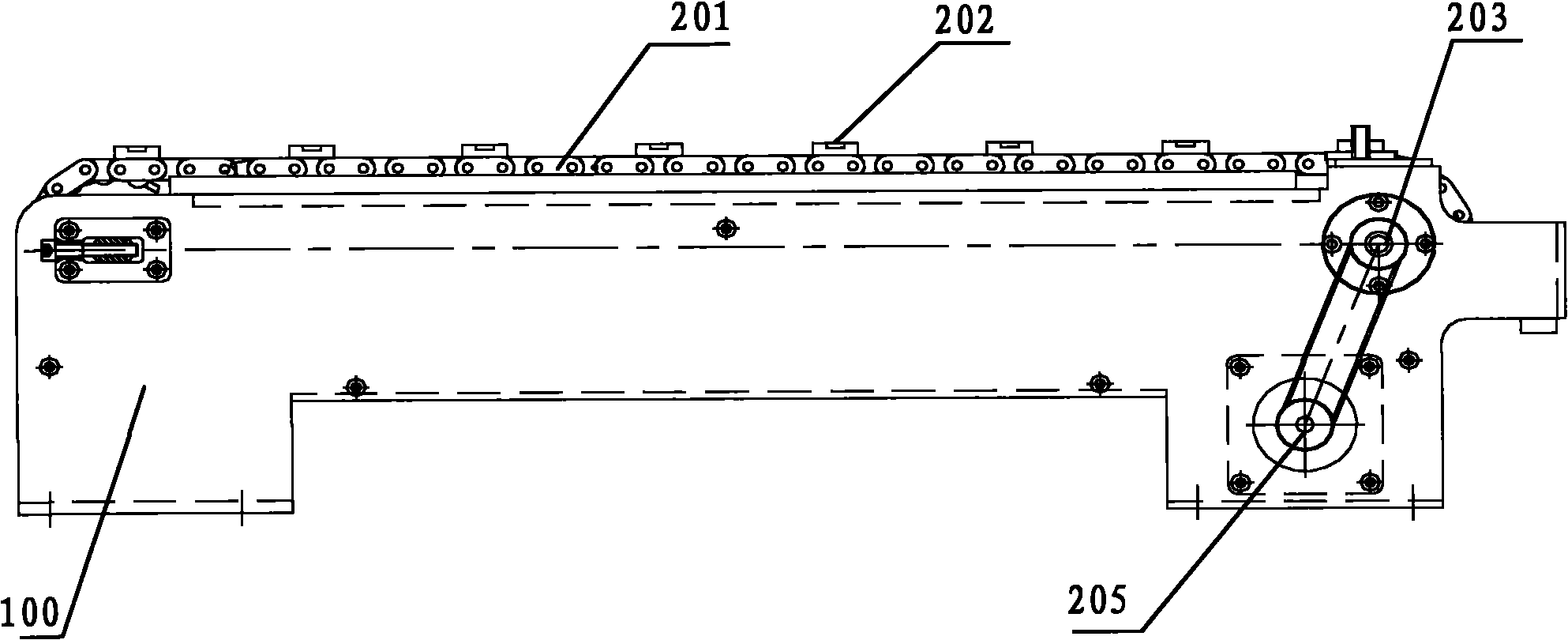

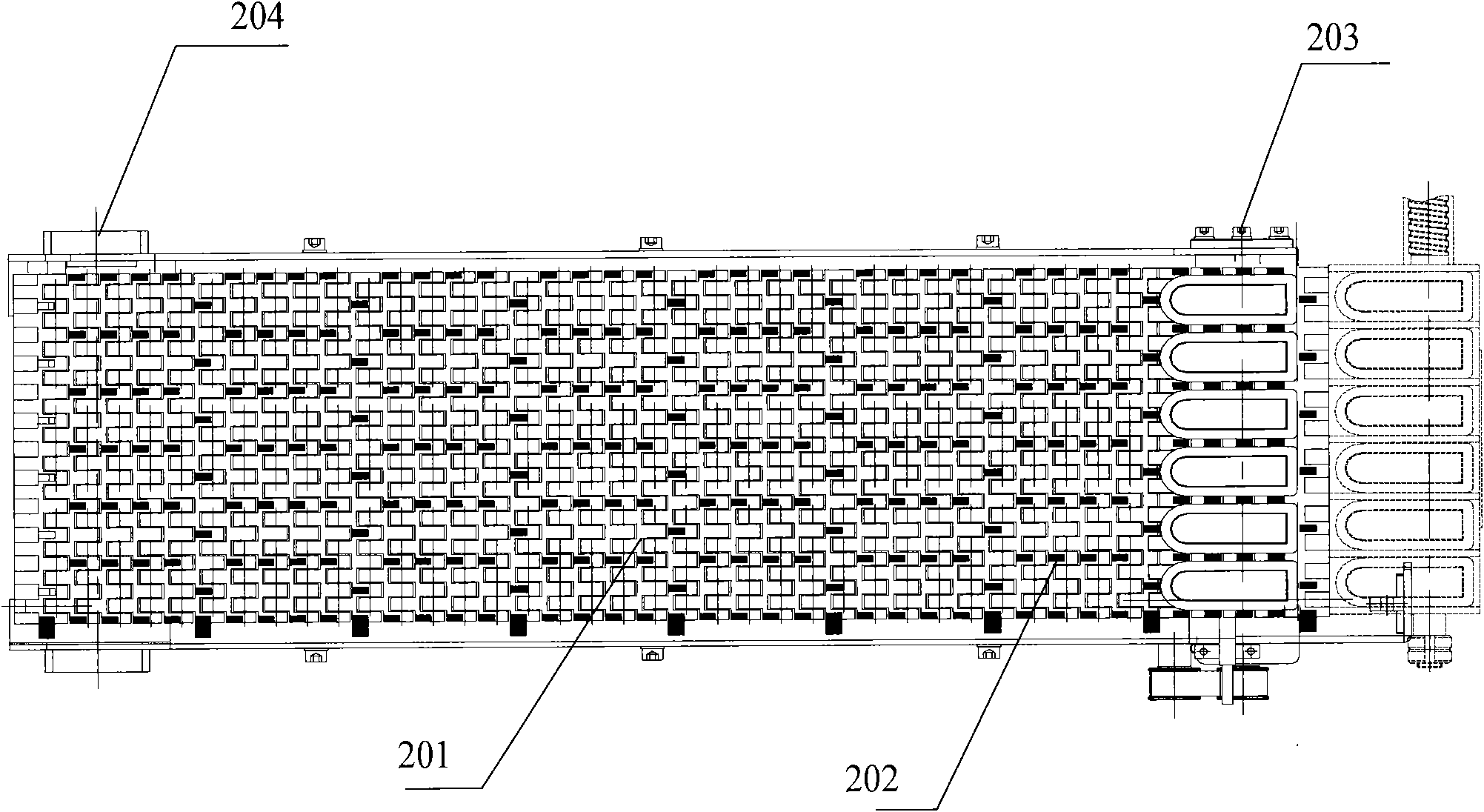

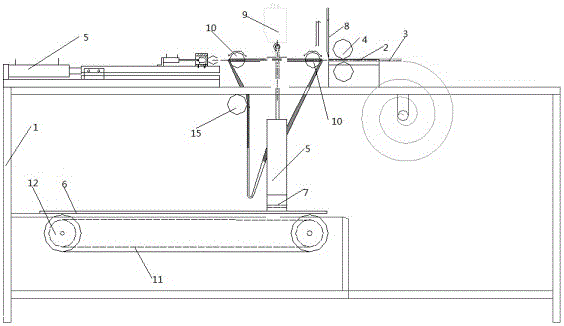

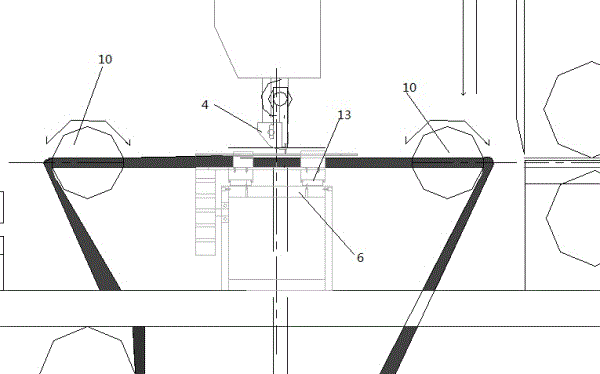

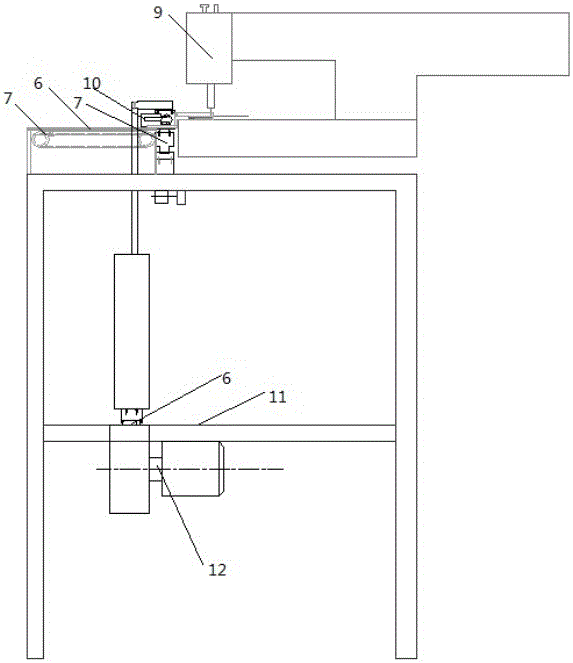

Automatic sample conveying device

InactiveCN101825643ARealize automatic transfer in batchesSimple structureMaterial analysis by optical meansAutomatic controlMechanical engineering

The invention discloses an automatic sample conveying device, which comprises a support frame, a mesh-belt conveying mechanism, a lead-screw conveying mechanism, a push rod mechanism and a furnace opening guide block, wherein the mesh-belt conveying mechanism is arranged on the support frame and is used for placing crucible pots and conveying the crucible pots in batches, the lead-screw conveyingmechanism is arranged on the support frame, and is used for conveying the crucible pots conveyed by the mesh-belt conveying mechanism to a stokehole, the push rod mechanism is arranged on the supportframe, is used for pushing the crucible pots conveyed to the stokehole by the lead-screw conveying mechanism into a furnace cavity, and can pull out the crucible pots out of the furnace cavity, and the furnace opening guide block is arranged at the stokehole and is used for making the push rod mechanism smooth push the crucible pots into the furnace cavity or smoothly pull out the crucible pots. The automatic sample conveying device can automatically control the sample conveyance in batches, the whole process is completely automatic without manual operation, and the labor can be saved. In addition, the conveyance precision is high, and the personal error is reduced.

Owner:CHANGSHA KAIYUAN INSTR

Device for cutting cylindrical vegetable

The invention discloses a device for cutting cylindrical vegetable. The device comprises a bottom plate, wherein a first chute and a second chute are symmetrically formed in the bottom plate; a first supporting leg is arranged at the right half part of the upper surface of the bottom plate, and a second supporting leg is arranged at the left half part of the upper surface of the bottom plate; a lower cutting die set is mounted at the upper ends of the first supporting leg and the second supporting leg; a positioning die set is arranged in the middle part of the upper surface of the bottom plate; a cutter is driven by the lower cutting die set to downwards cut the vegetable; the vegetable to be cut is positioned through the positioning die set. The device has the advantages of being high in safety, time saving, force saving, and high in generality.

Owner:上海老盛昌配送有限公司

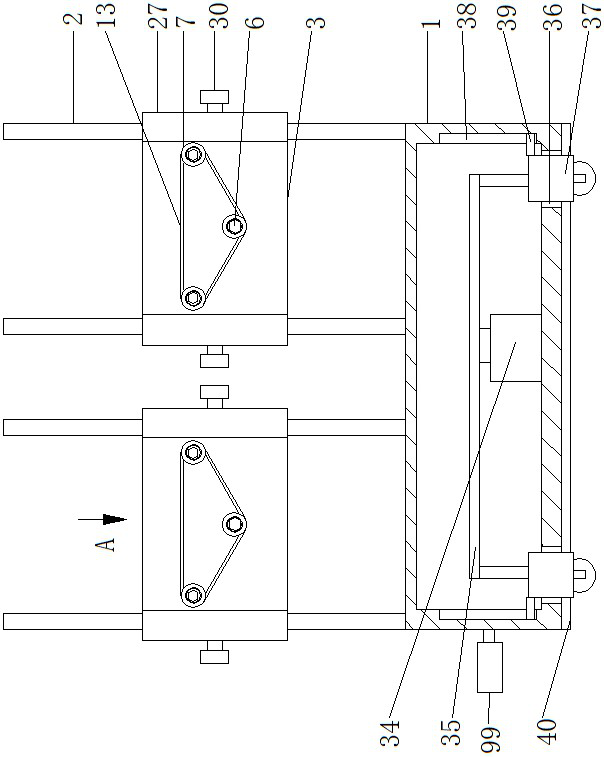

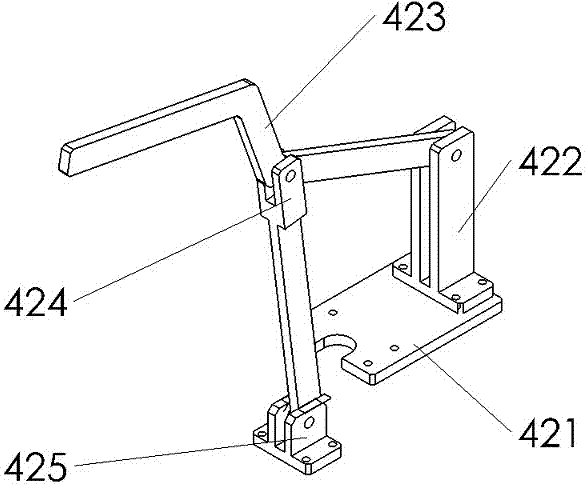

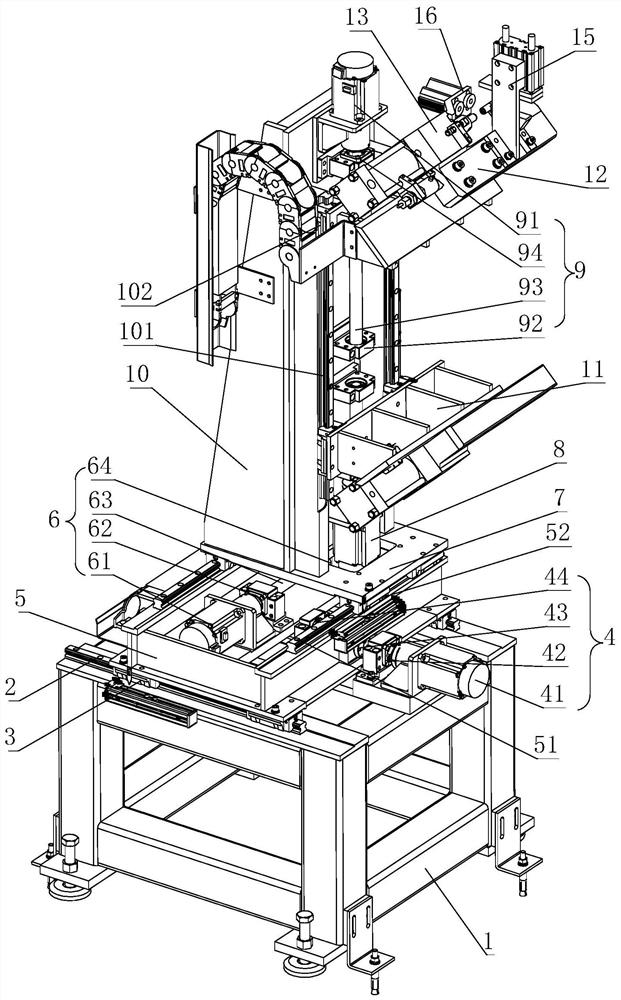

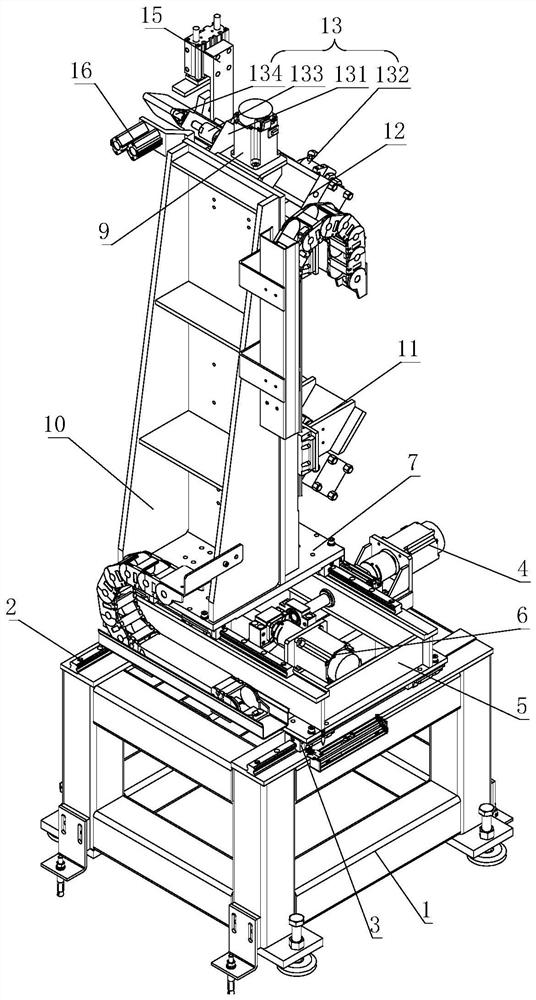

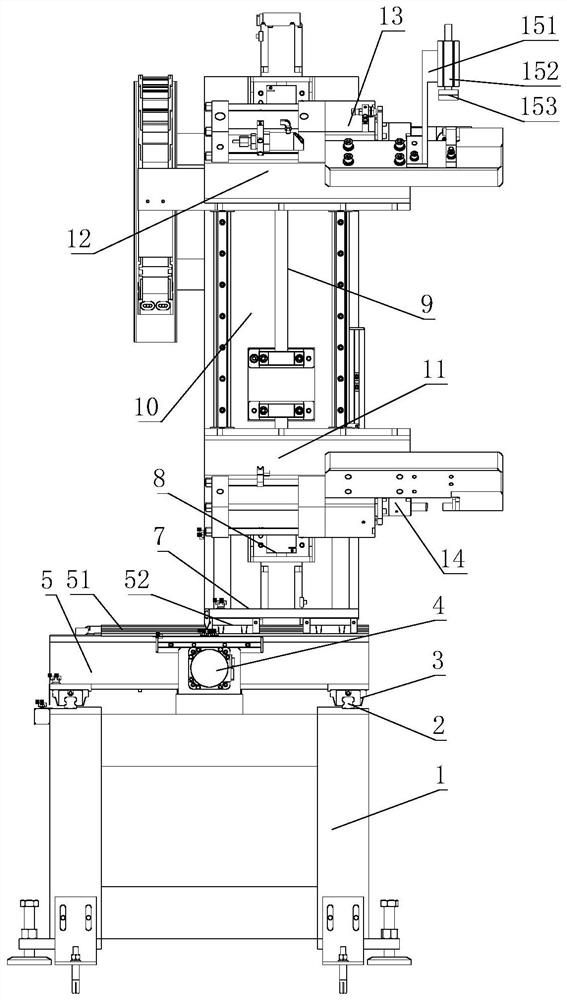

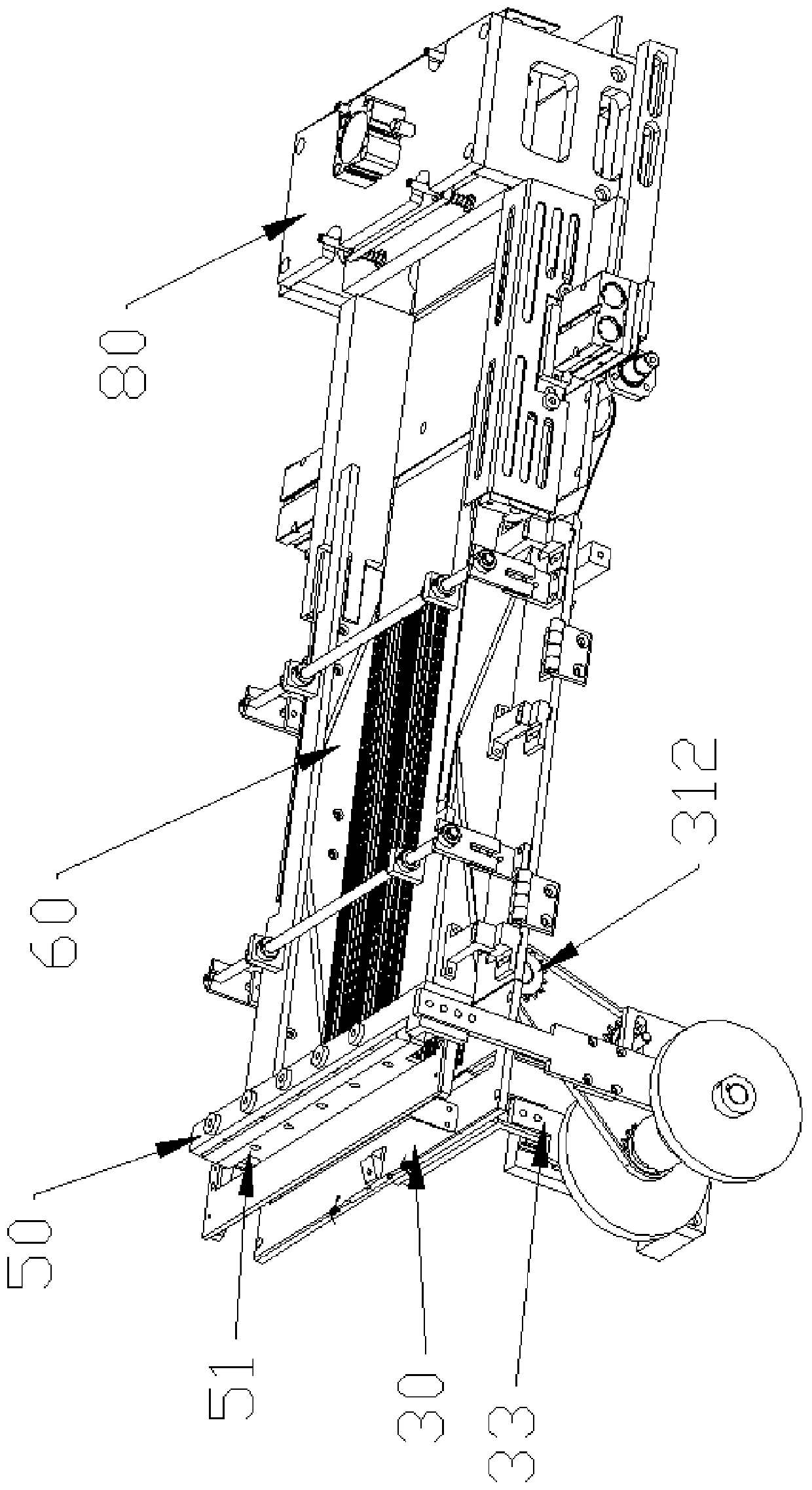

Fully-automatic flexible production equipment and production process of annular lifting belt

InactiveCN105780317AGuidePlay a role in compressingWorkpiece carriersWork-feeding meansEngineeringFully automatic

The invention discloses fully-automatic flexible production equipment and production process of an annular lifting belt.The equipment comprises a base, a flat belt cutting system and a flat belt sewing system, the base is provided with a rotating shaft, the rotating shaft is provided with a rolled flat belt, belt pressing wheels are arranged on the flat belt, the belt pressing wheels press the flat belt tightly, a linear air cylinder is fixedly arranged on the base, the base is provided with a guide rail, the guide rail is provided with a slide block, the slide block can perform linear reciprocating motion relative to the guide rail fixed to the base, a small air cylinder is fixedly arranged on the slide block, and the slide bock drives a gripper at the tail end to be opened and closed through reciprocating linear motion; the flat belt cutting system is composed of a cutter, a horizontal stretching mechanism and a vertical stretching mechanism, the cutter is arranged above the base, and the horizontal stretching mechanism and the vertical stretching mechanism can guarantee sufficient space in the sewing process.

Owner:曾庆鹏

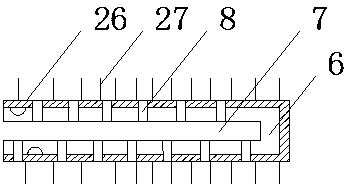

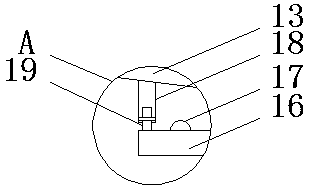

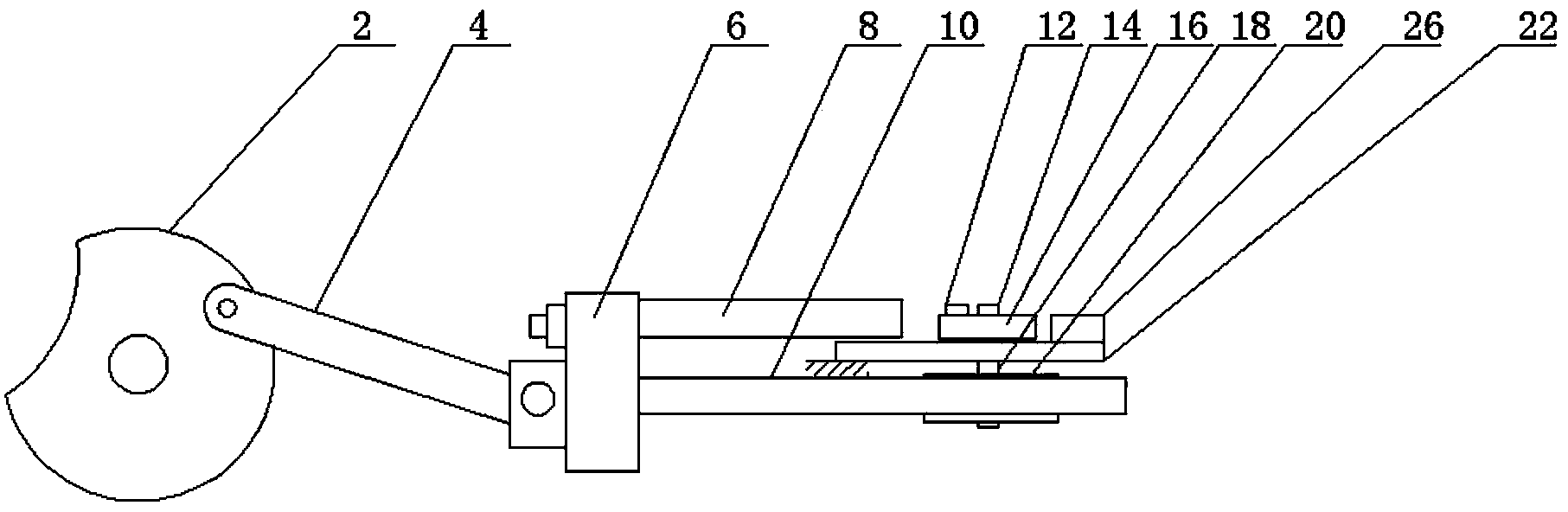

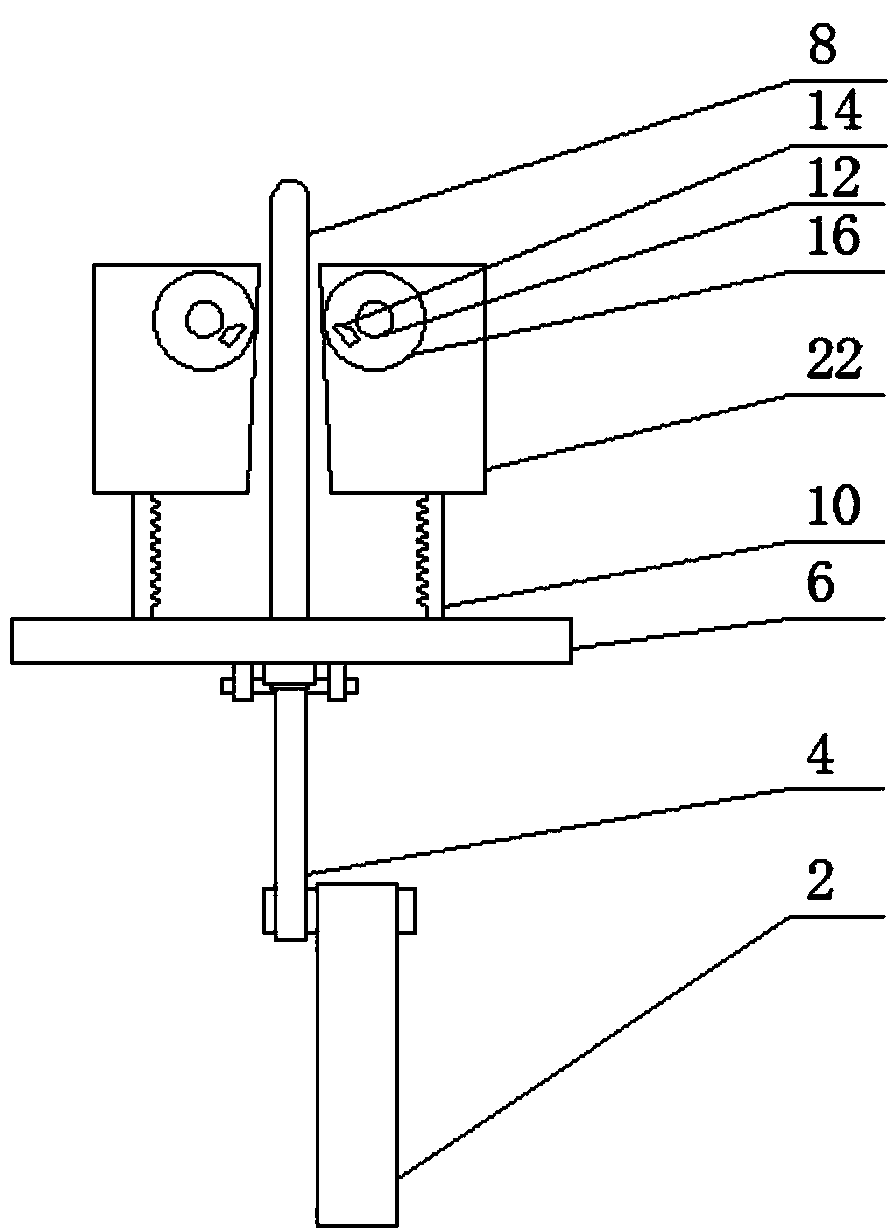

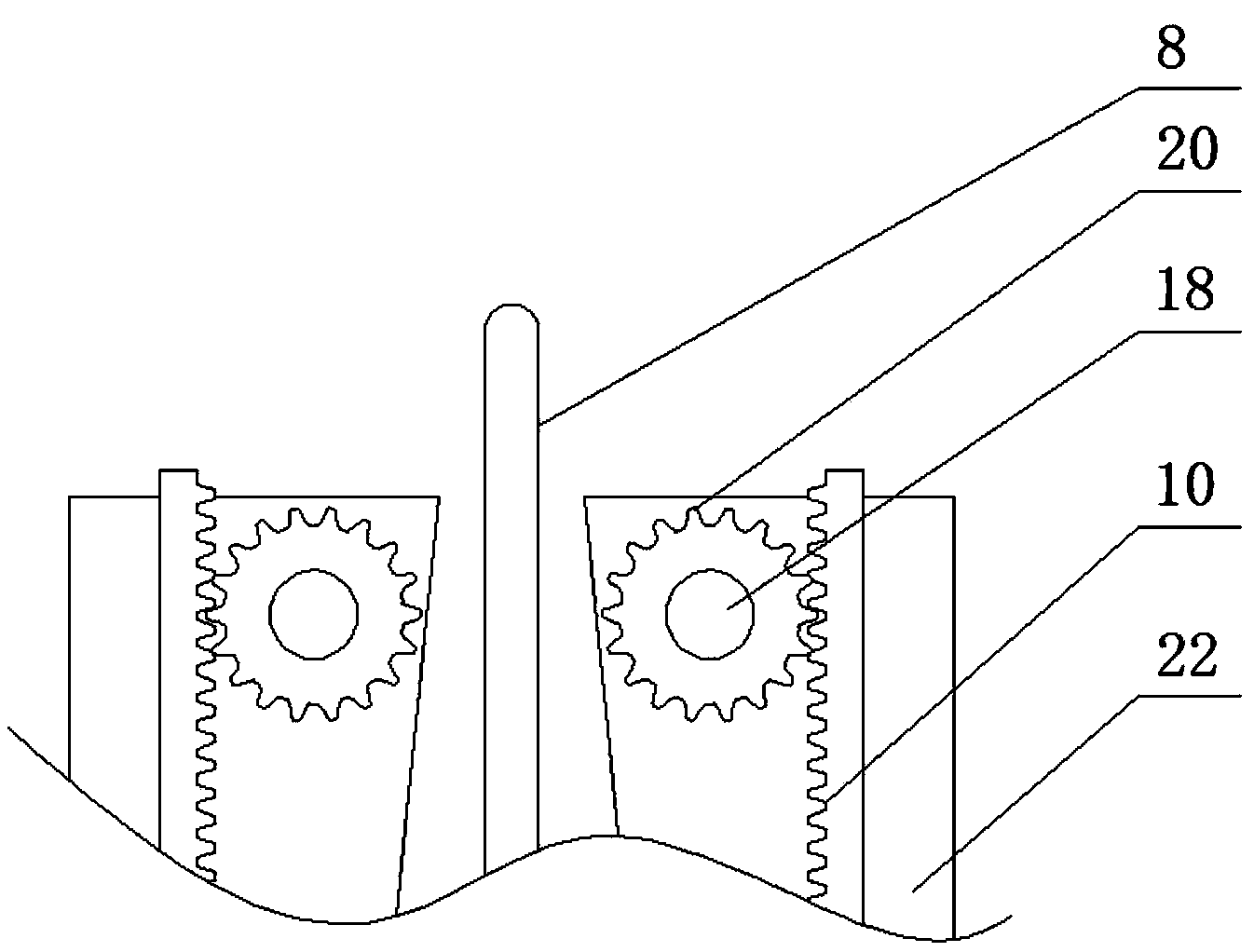

High-efficiency energy-saving bending machine

The invention discloses a high-efficiency energy-saving bending machine, which comprises two horizontal baffles (26) arranged at intervals, wherein a turntable (16) which is driven to rotate by a power unit is arranged behind each baffle (26); the upper surface of each turntable (16) is provided with a first cylindrical lug (14) concentric with the turntable (16) and a second lug (12) eccentrically arranged on the turntable (16); a push rod (18) which is arranged along the symmetry axis of the two turntables (16) is arranged between the two turntables (16). The high-efficiency energy-saving bending machine can bend workpieces twice at the same station, the complicated degree of machining is greatly reduced, and the production efficiency is improved.

Owner:江苏九澍机电科技有限公司

Self-drilling and self-anchoring retractable anchor rod for soil layer and sand layer, and anchoring method of self-drilling and self-anchoring retractable anchor rod

ActiveCN110042835ASave installation timeImprove support efficiencyExcavationsBulkheads/pilesStructural engineeringSelf anchoring

Owner:TAIAN DAIZHONG ELECTROMECHANICAL TECH DEV CO LTD

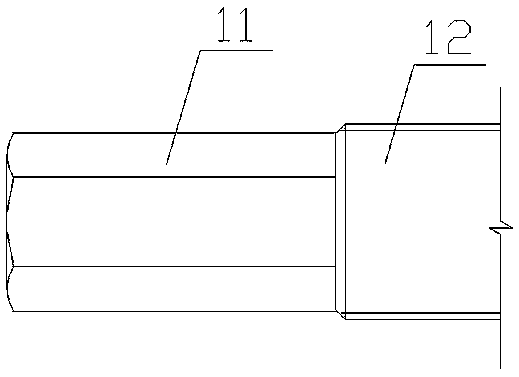

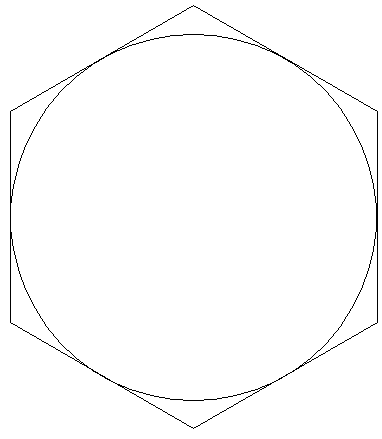

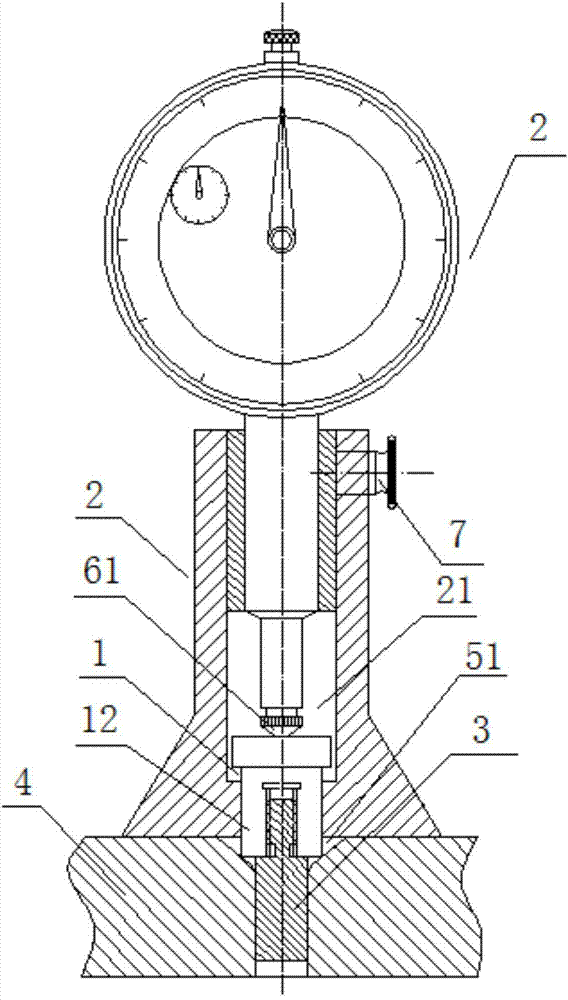

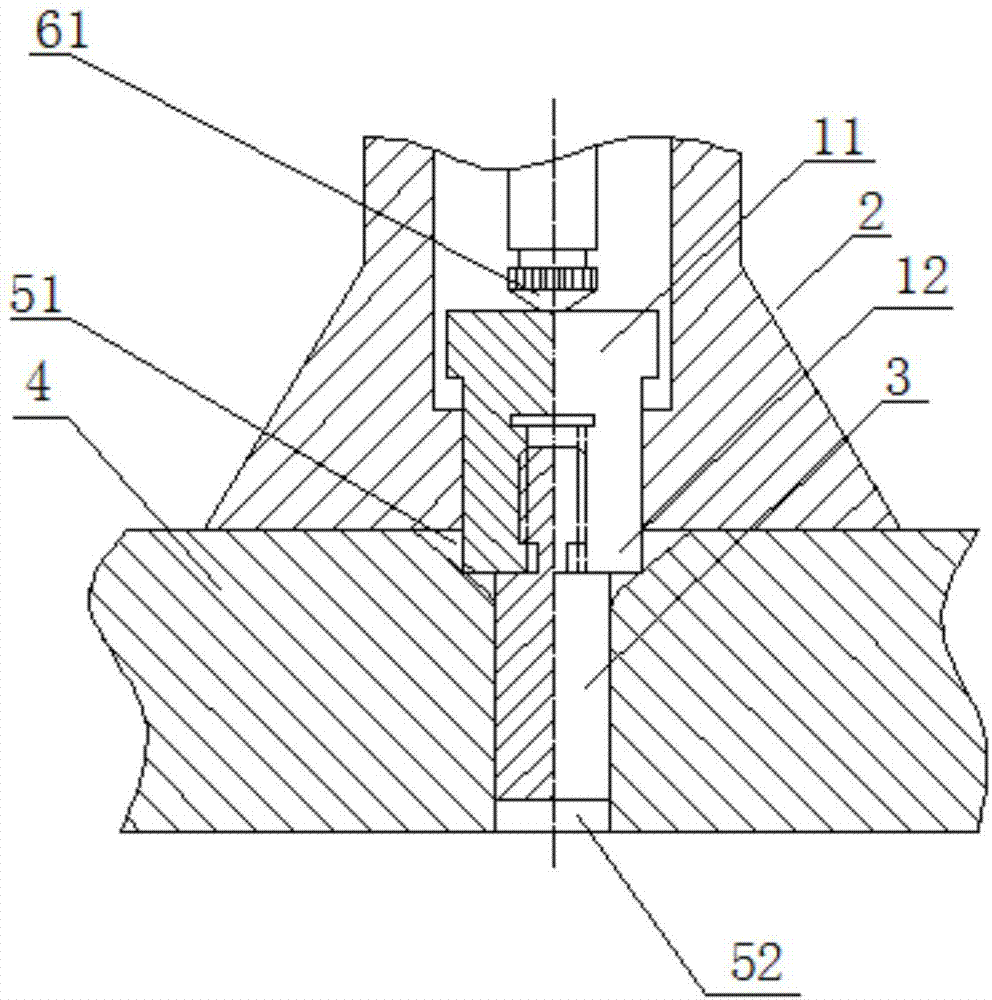

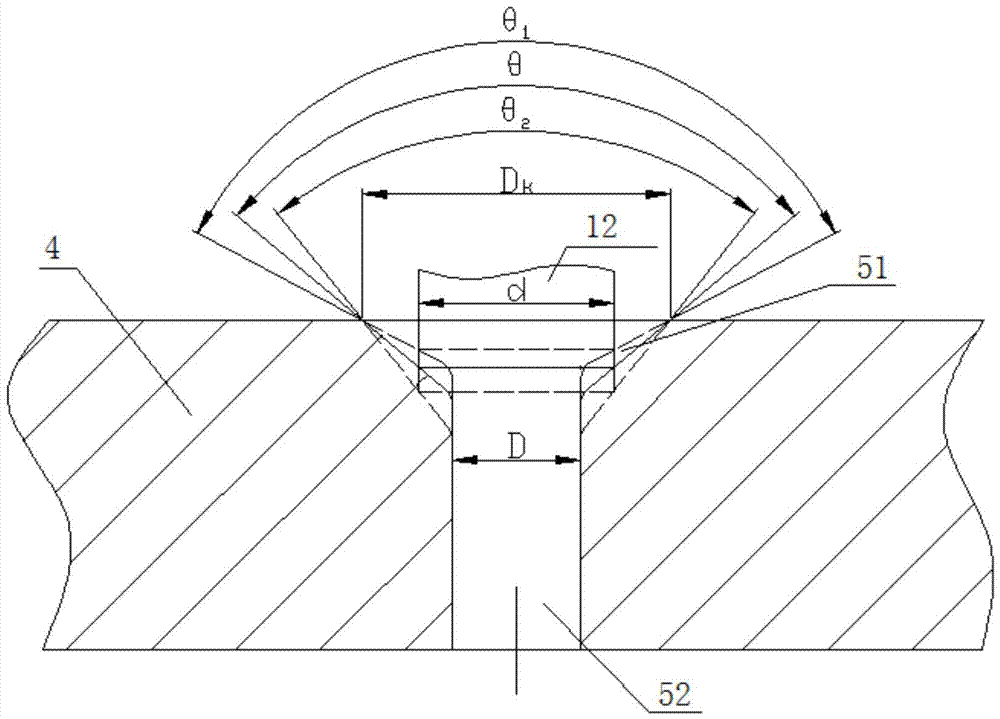

Countersunk head angle gauge for counterbore and measurement method of countersunk head angle gauge

ActiveCN104713458AHigh measurement accuracyImprove stabilityAngles/taper measurementsEngineeringLength measurement

The invention provides a countersunk head angle gauge for a counterbore and a measurement method of the countersunk head angle gauge. The countersunk head angle gauge comprises a dial indicator, a sleeve and a gauge measuring head, wherein the sleeve comprises a hollow cavity; the cavity refers to a sleeve cavity; the gauge measuring head is arranged at the bottom of the sleeve cavity and is in sliding fit with the sleeve cavity; the bottom of the gauge measuring head does a telescopic motion relative to the bottom surface of the sleeve; and when the bottom surface of the gauge measuring head and the bottom surface of the sleeve are positioned on the same horizontal plane, a measuring head of the dial indicator is pressed against the top of the gauge measuring head, and the measuring head is positioned in a compressed state. According to the matched arrangement of the dial indicator, the sleeve and the gauge measuring head, the direct measurement of the countersunk head angle can be converted into length measurement, the efficiency of measuring the countersunk head angle is improved by using the countersunk head angle gauge, and the measurement accuracy is improved.

Owner:AEROSPACE PRECISION PROD INC LTD

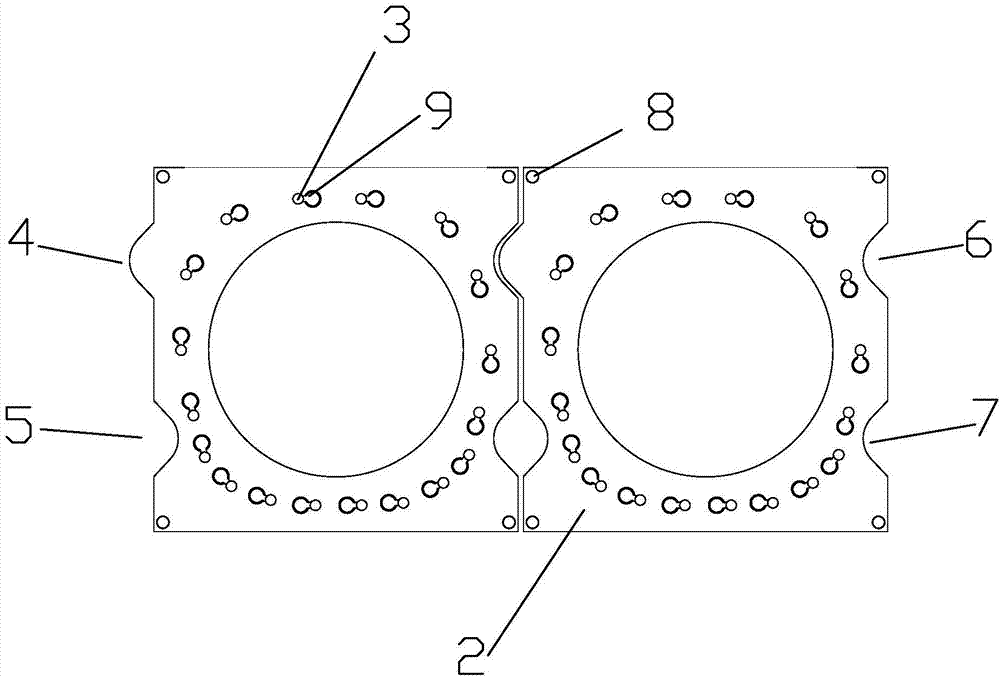

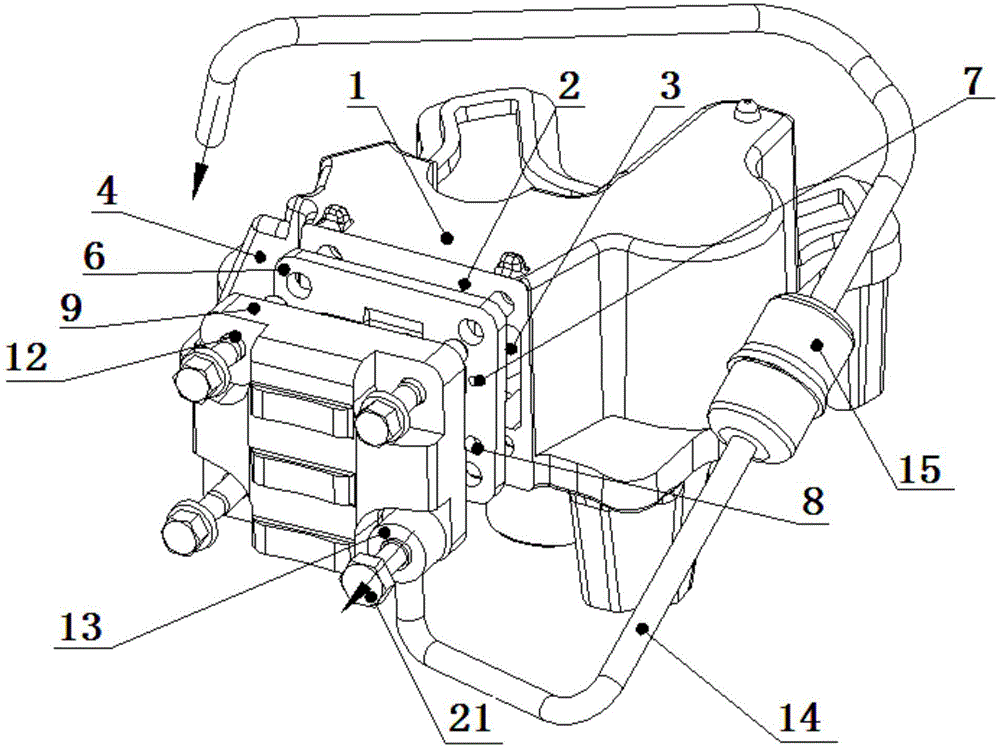

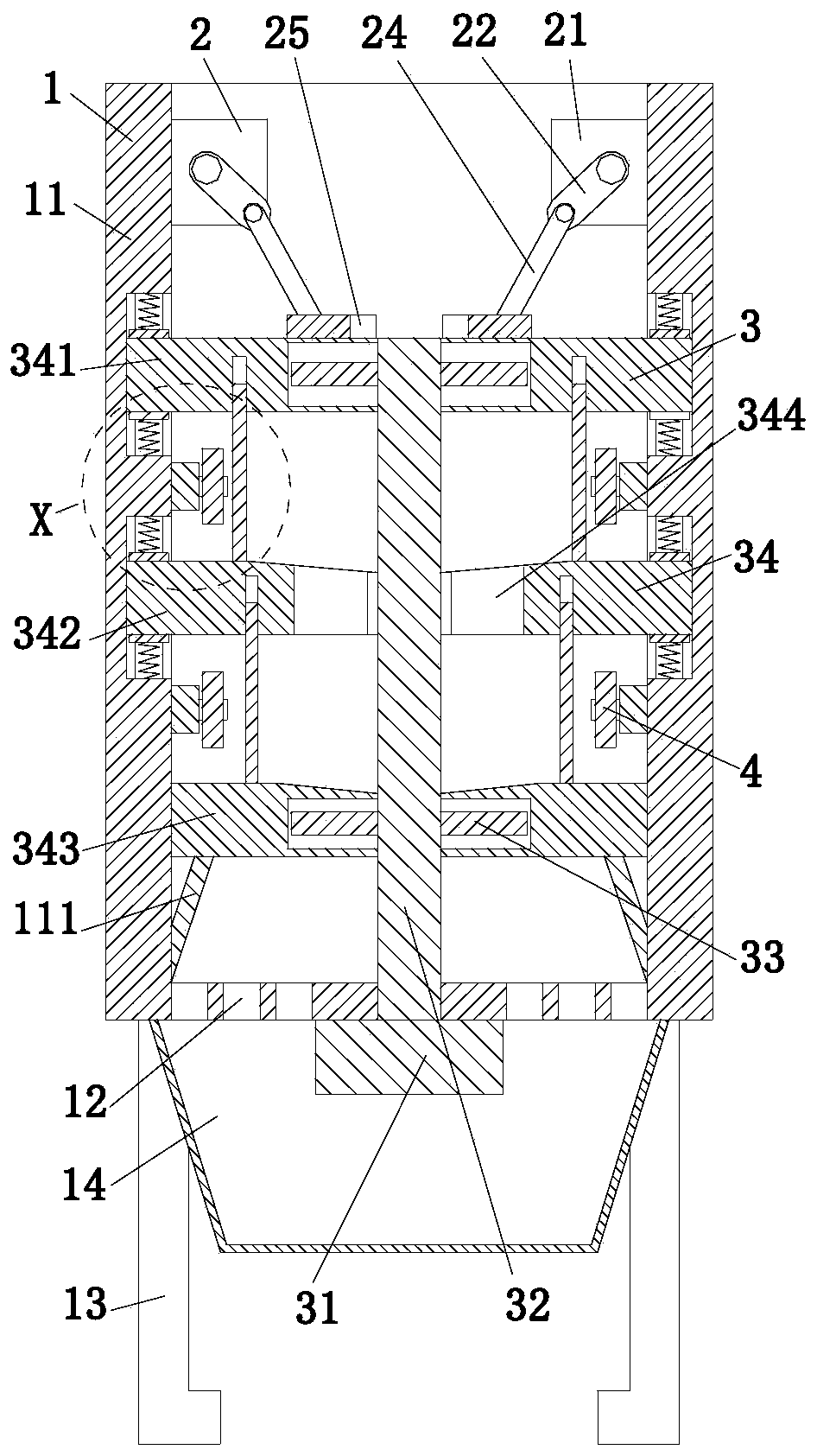

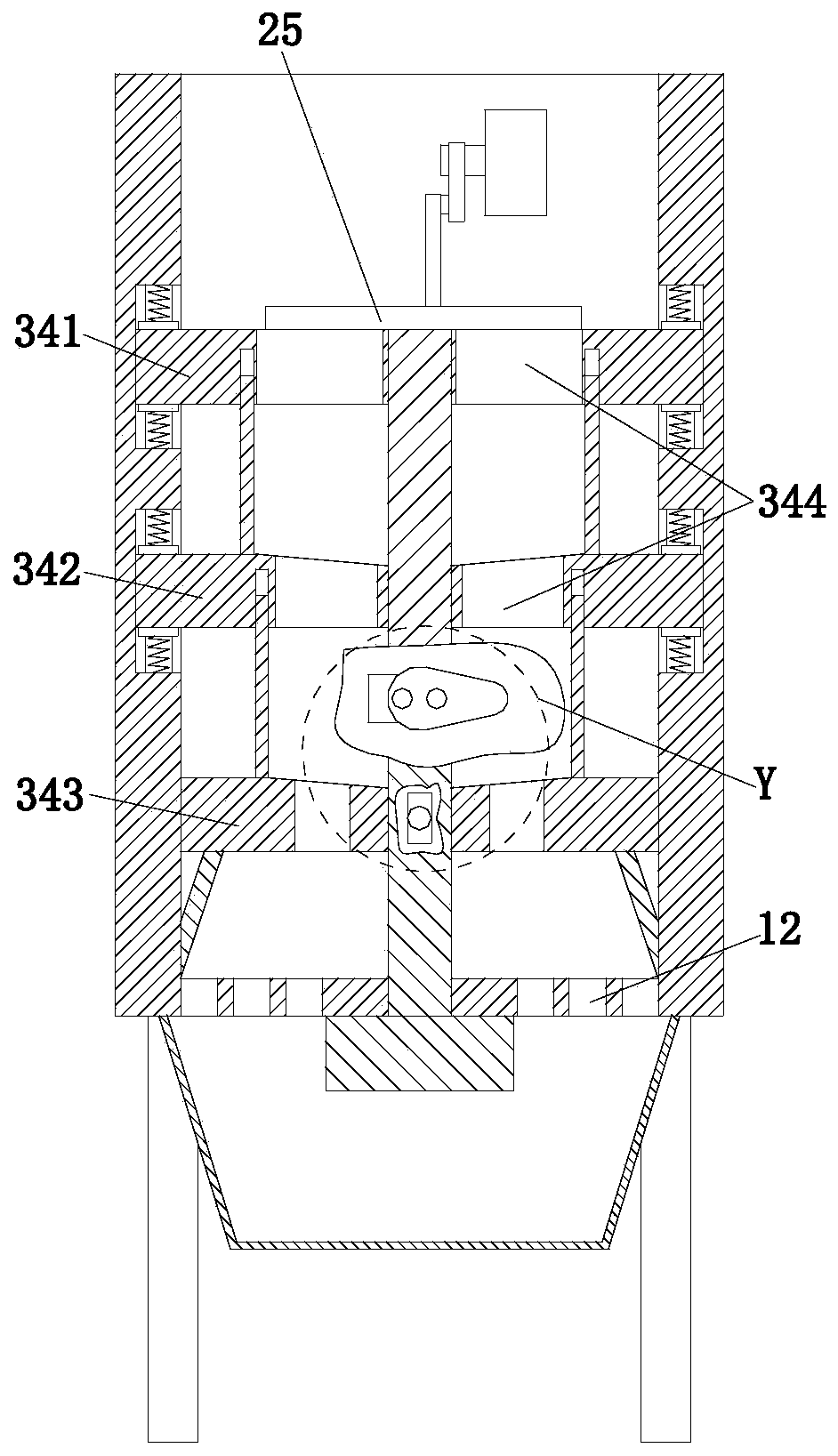

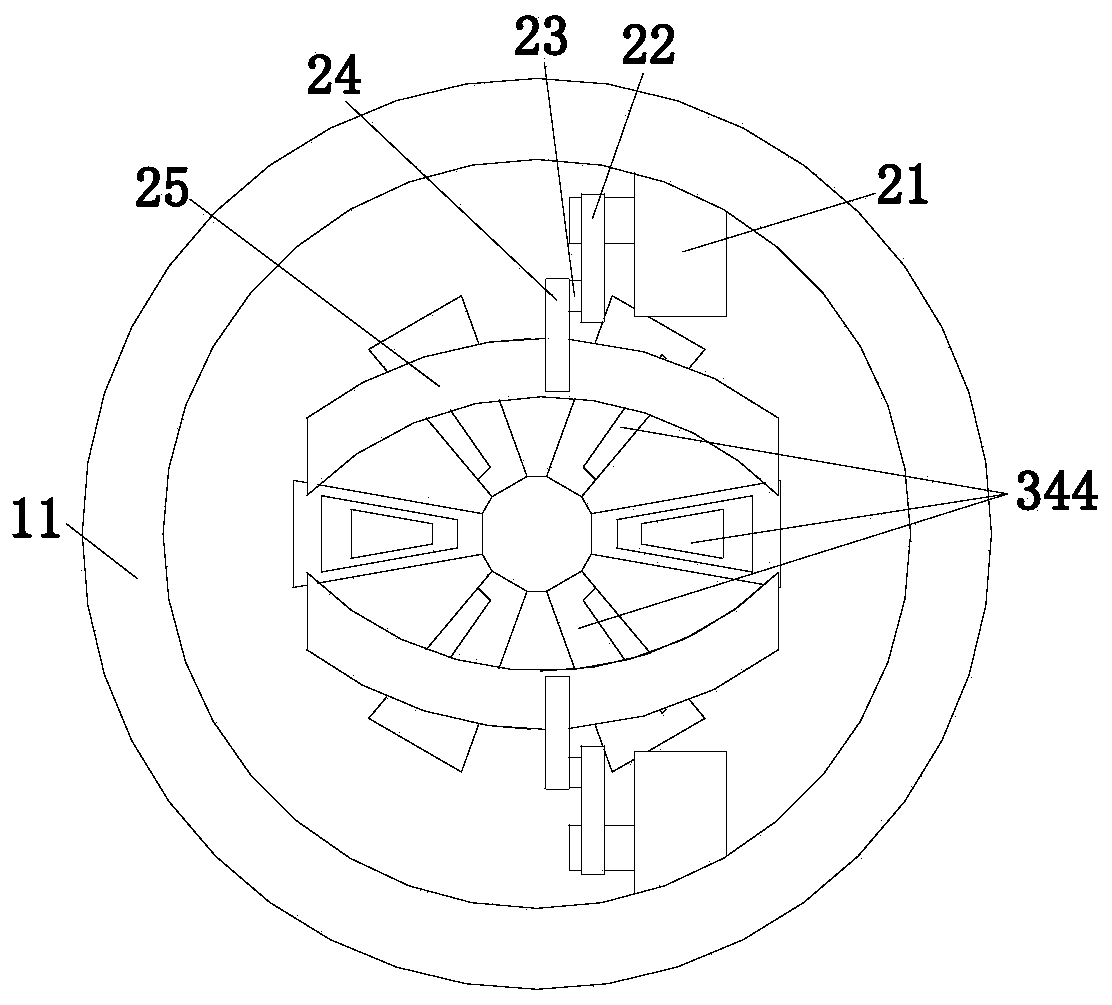

High-efficiency noise reducing and refrigerating compressor

InactiveCN104696194AImprove the noise reduction effectSmooth exhaustPositive displacement pump componentsPositive-displacement liquid enginesRefrigeration compressorManufacturing technology

The invention discloses a high-efficiency noise reducing and refrigerating compressor. The high-efficiency noise reducing and refrigerating compressor comprises a cylinder seat, wherein a noise elimination cavity is formed in the cylinder seat, and an inlet of an exhaust and noise elimination cavity, communicated with the noise elimination cavity, is formed in the end surface of the front end of the cylinder seat; a valve plate and a cylinder cover which are connected with the cylinder seat are arranged at the front end of the cylinder seat; an exhaust outlet communicated with the inlet of the exhaust and noise elimination cavity is formed in the valve plate; an exhaust and collection cavity communicated with the exhaust outlet is formed in the cylinder cover, a two-stage noise elimination mechanism is arranged at the outlet of the exhaust and collection cavity; after a refrigerant enters the noise elimination cavity from the exhaust and noise elimination cavity and noise elimination is performed, the refrigerant enters the exhaust and collection cavity of the cylinder cover from the exhaust outlet of the valve plate, and the exhaust and collection cavity has the effects of guide and buffering, so that the noise elimination effect and the vibration absorption effect are improved; the refrigerant enters the two-stage noise elimination mechanism from the outlet of the exhaust and collection cavity, and after the two-stage noise elimination is performed, the refrigerant is discharged, so that the purpose of high-efficiency noise reduction is achieved; besides, the high-efficiency noise reducing and refrigerating compressor disclosed by the invention is simple in the noise elimination and vibration absorption structure, simple in manufacture technology and lower in cost.

Owner:WUHU ABAUR MECHANICAL & ELECTRICAL

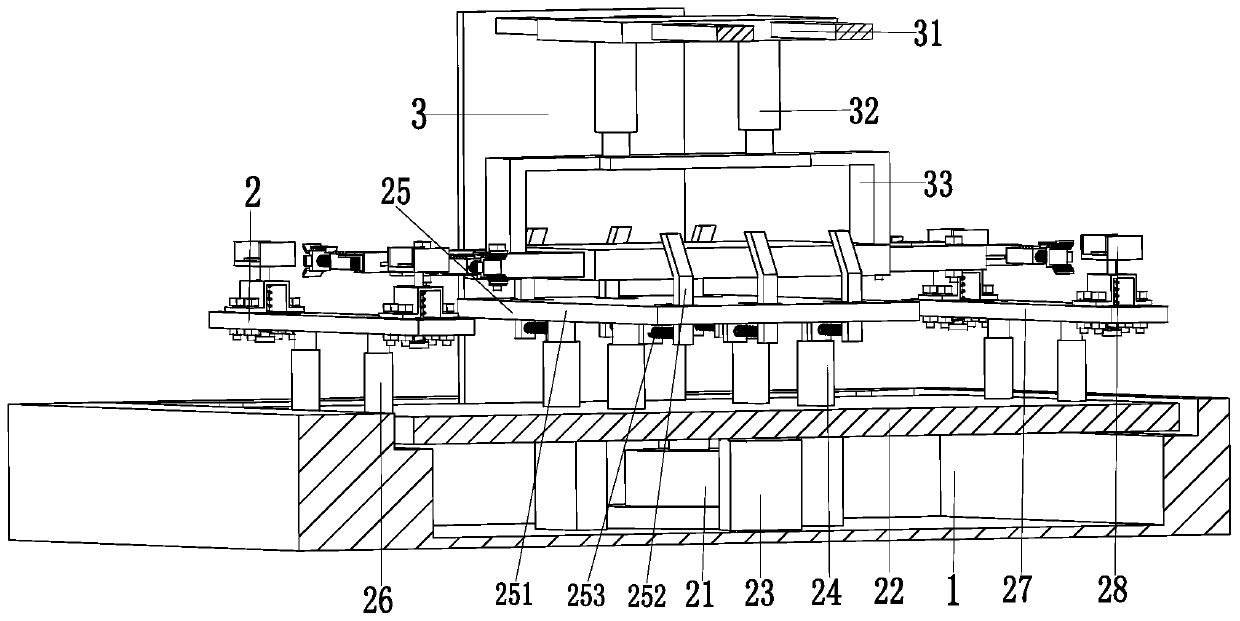

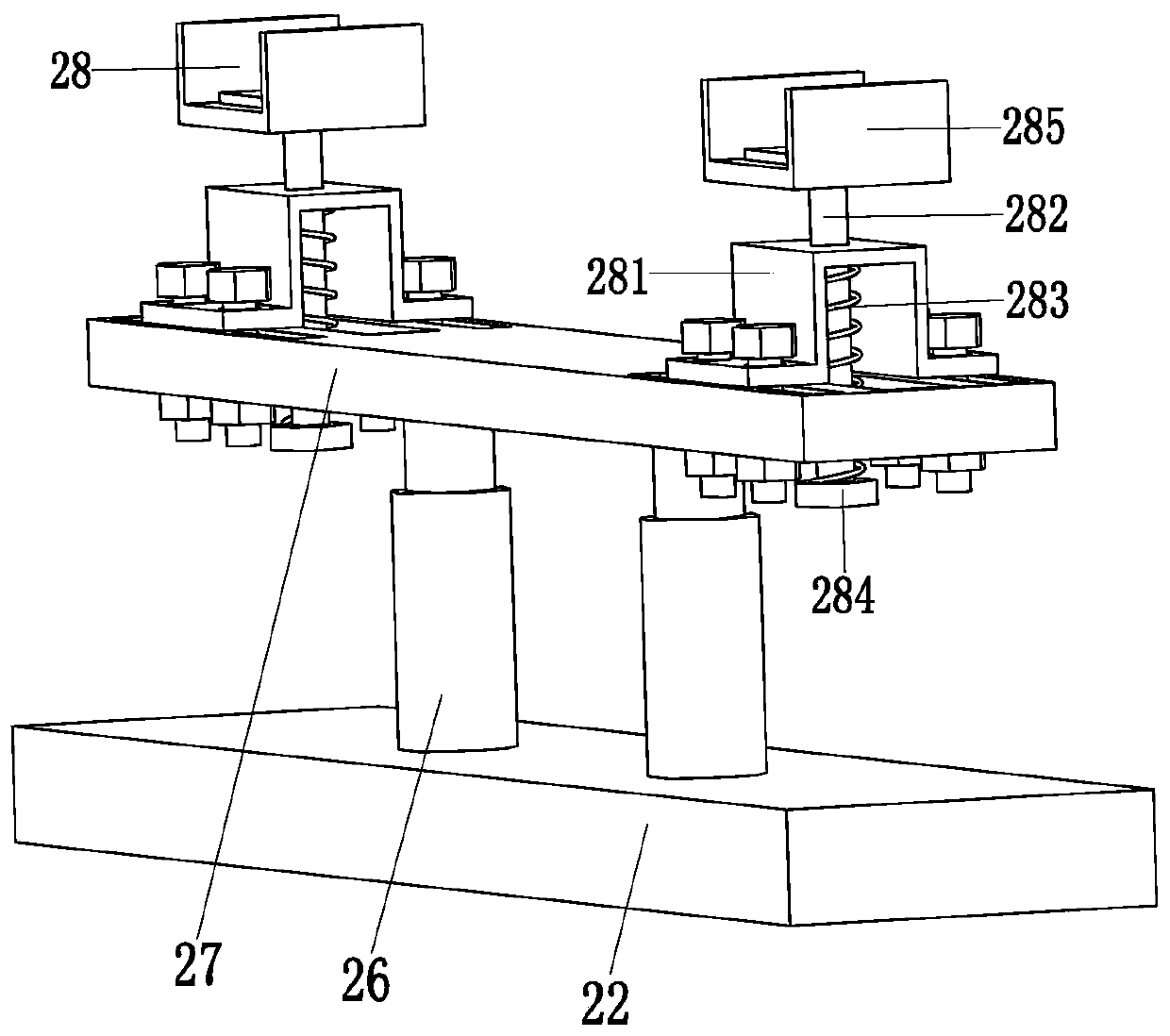

Automatic adjusting device for riveting clamp body of freezer liner

PendingCN113953393AReduce laborImprove processing efficiencyMetal-working feeding devicesPositioning devicesEngineeringMachining

The invention discloses an automatic adjusting device for a riveting clamp body of a freezer liner, which comprises a main body rack, and a first driving assembly used for driving a lower support to move horizontally is installed at the upper end of the main body rack; the lower support is provided with a second driving assembly used for driving a horizontal support to move transversely; a vertical support is fixedly installed on the horizontal support, and a third driving assembly used for driving a lower riveting frame in a lifting mode and a fourth driving assembly used for driving an upper riveting frame in a lifting mode are installed on the vertical support; the lower riveting frame is provided with a lower riveting assembly used for riveting the freezer liner; and an upper riveting assembly used for riveting the freezer liner is installed on the upper riveting frame. The positions of two groups of riveting assemblies in the X-axis direction, the Y-axis direction and the Z-axis direction are adjusted by arranging the four groups of driving assemblies, so that riveting machining is conducted on different positions of the freezer liner, and meanwhile riveting machining of products of different specifications can be met.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

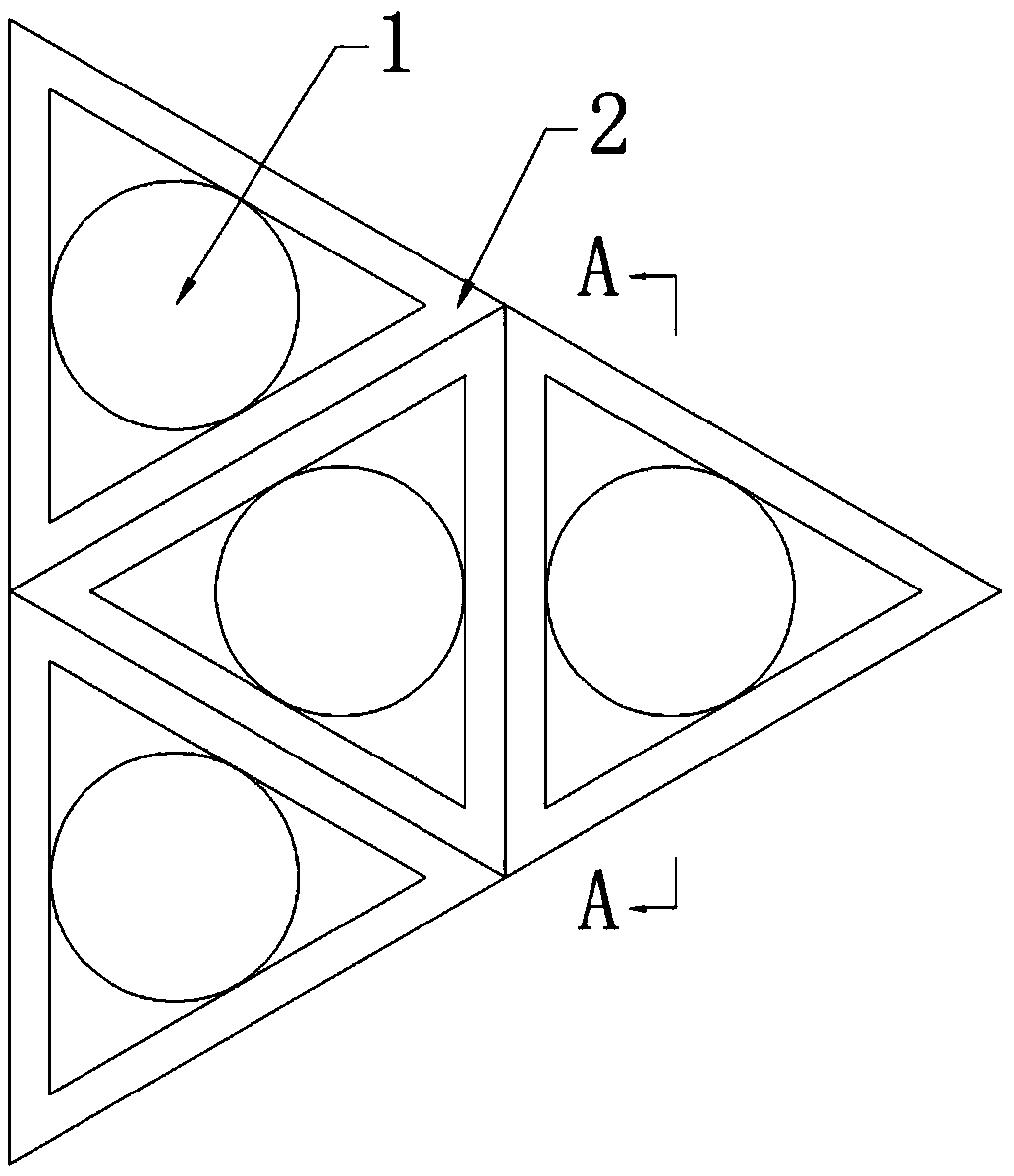

Detection device and detection method for rebound parameter of concrete

The invention discloses a detection device and a detection method for a rebound parameter of concrete. The device comprises a plurality of concrete rebound hammers and a bracket, wherein the bracket comprises a plurality of assembly units; fixing frames are inserted by the assembly units; then, the concrete rebound hammers are fixedly connected and fixed by the fixing frames; the bracket is connected by extension links and universal joints at the bottom of the bracket; and the connected bracket is leveled by the extension links and the universal joints. The detection device performs detectionby arranging the concrete rebound hammers in a detection area in an equilateral triangle or regular hexagon shape; invalid test values are excluded by sequential detection and simultaneous detection;and the difference of individual measurement is reduced to the full extent. The device can continuously detect the rebound parameter of the concrete, is high in detection precision, high in stabilityand convenient to mount, dismount and adjust at the same time.

Owner:湖南长建科技有限公司

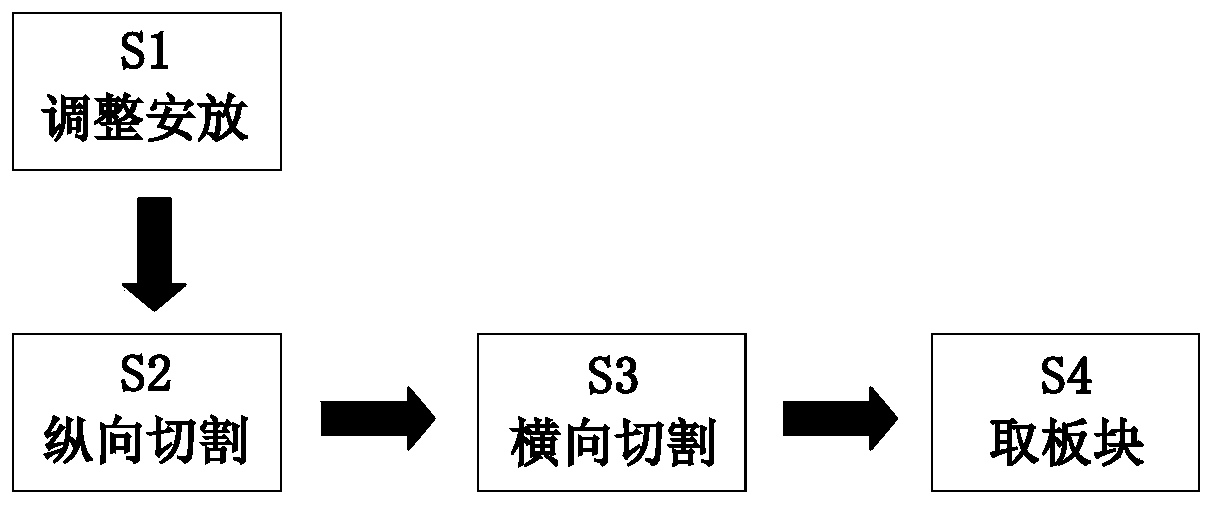

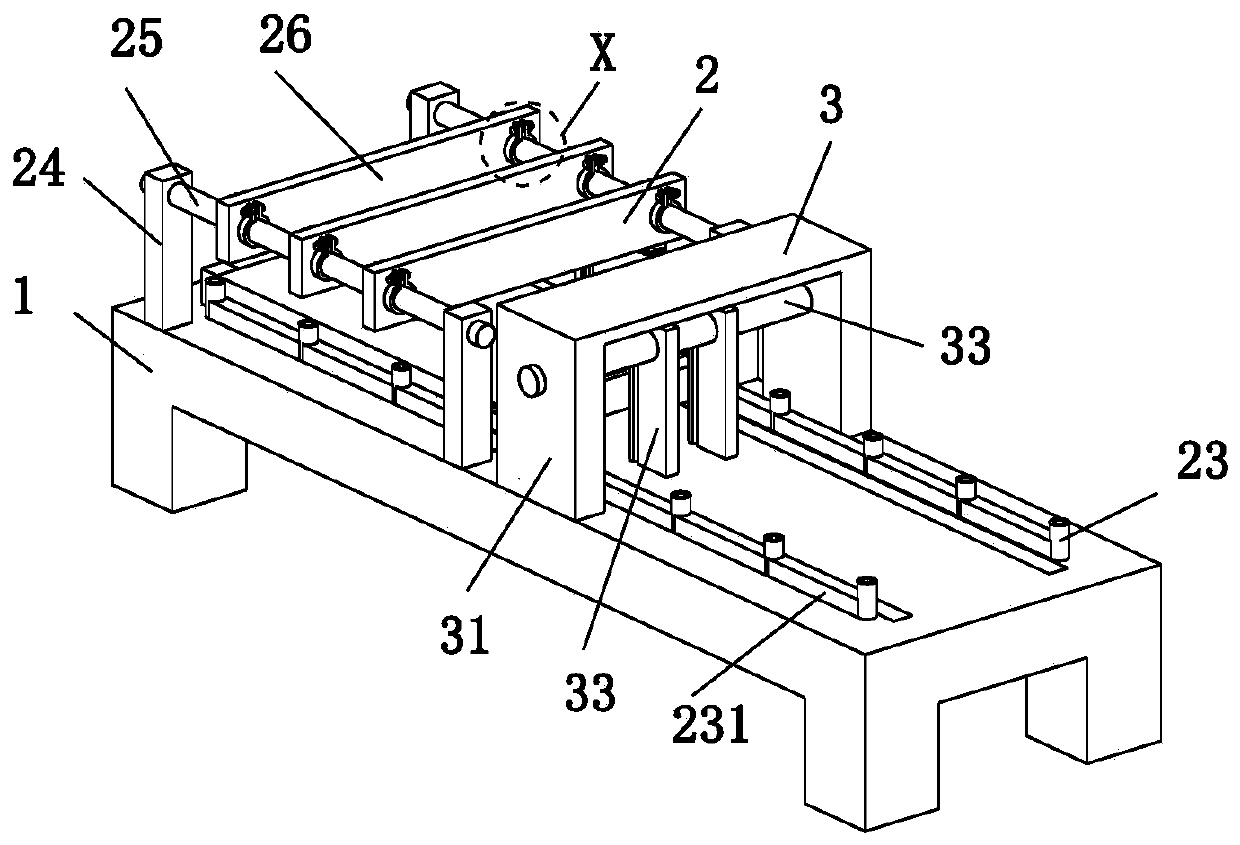

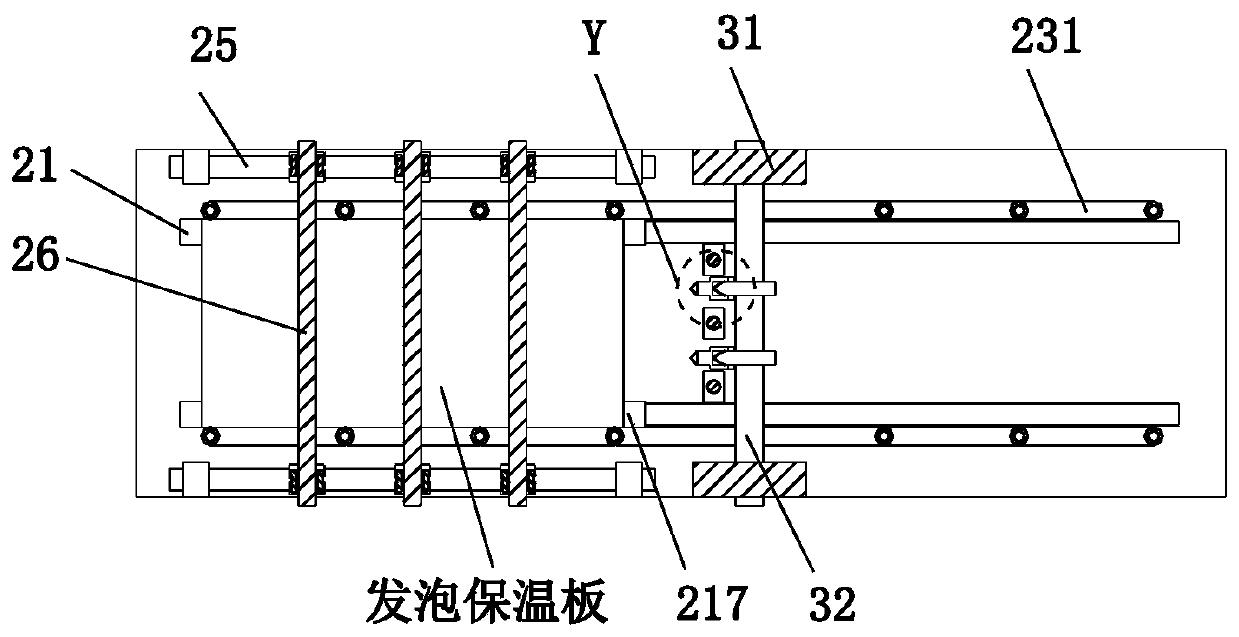

Foaming insulation board cutting and forming process

ActiveCN111421678AReduce cutting stutteringImprove work efficiencyWorking accessoriesStone-like material working toolsWorkbenchIndustrial engineering

The invention relates to a foaming insulation board cutting and forming process. The foaming insulation board cutting and forming process uses a foaming insulation board cutting and forming device. The foaming insulation board cutting and forming device comprises a workbench, a vertical cutting mechanism and a transverse cutting mechanism, the left end of the upper end of the workbench is providedwith the vertical cutting mechanism in a sliding fit mode, the right side of the vertical cutting mechanism is provided with the transverse cutting mechanism, and the lower end of the transverse cutting mechanism is arranged at the upper end of the workbench. The design concept of a longitudinal and transverse continuous cutting structure is adopted for cutting and forming a foaming insulation board, and pre-cutting structures are arranged in the longitudinal cutting process and the transverse cutting process, so that the purposes of reducing the occurrence probability of cutting jamming andimproving the working efficiency are achieved, meanwhile, workers can accurately control the longitudinal cutting forming size and the overall size of the cut foaming insulation board within a certainrange, and the overall application range of the device is further improved.

Owner:江苏特伟尔斯新材料有限公司

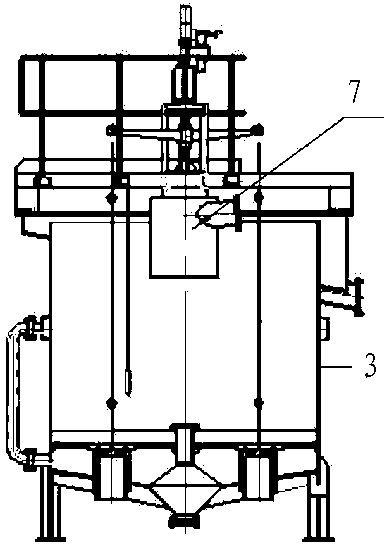

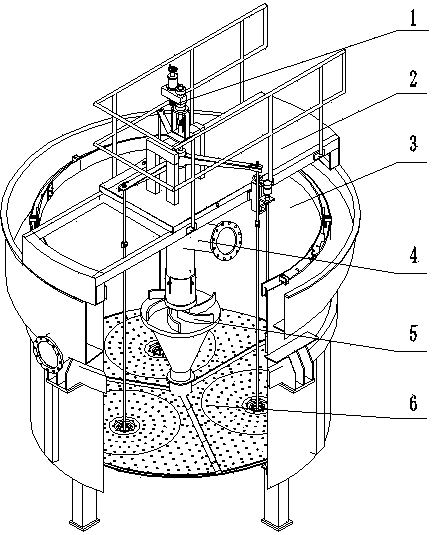

Concrete mixing device

ActiveCN110696187AHigh degree of homogenizationReduce accumulationCement mixing apparatusClassical mechanicsBilateral symmetry

The invention relates to a concrete mixing device. The device comprises a mixing cylinder, raking-out devices, mixing devices and vibrating devices. The raking-out devices are mounted on the upper endof the inner side wall of the mixing cylinder in a bilateral symmetry manner, the mixing devices are arranged below the raking-out devices, the mixing devices are in sliding fit with the inner wall of the mixing cylinder, the vibrating devices are mounted in the middle end of the inner side wall of the mixing cylinder in a bilateral symmetry manner, and the vibrating devices are arranged up and down at equal distances. According to the concrete mixing device, the multi-stage combined design theory is adopted for mixing concrete, mixing is more sufficient and uniform, the mixing effect is improved, the raking-out devices are adopted for pushing the concrete on a pouring opening to the inner side, and the probability of stacking of the concrete can be reduced.

Owner:无锡锦汇建筑科技有限公司

Film laminating and heat sealing integrated production line

ActiveCN109941485ASave on transshipmentSave positioningConveyor wrappingWrapper twisting/gatheringProduction lineAssembly line

The invention provides a film laminating and heat sealing integrated production line, belongs to the field of packaging equipment. The film laminating and heat sealing integrated production line comprises a lower shovel flattening assembly, a corner folding assembly and an end surface flattening assembly which are sequentially arranged along the assembly line, wherein a heat sealing assembly is arranged over the lower shovel flattening assembly, and the heat sealing assembly and the lower shovel flattening assembly share a power source and move up and down relative to the corner folding assembly. A packaging box is coated with a film and then passes through the lower shoveling flattening assembly and the heat sealing assembly for connection after film laminating, the packaging box enters the corner folding assembly for the end face corner folding action and the end face sealing action after corner folding while the packaging box is continuously pushed, then the packaging box enters theend face flattening assembly for flattening and hot covering of the upper and lower sections, and finally the package box is discharged for the next procedure. The film laminating and heat sealing integrated production line integrates film laminating and heat sealing, the intermediate transfer link of the packaging box is omitted, the secondary feeding and repeated positioning are also avoided, therefore, the working efficiency is improved, and the manpower is saved.

Owner:天津树达科技发展有限公司

Non-ferrous alloy crushing device with good separation effects

The invention discloses a non-ferrous alloy crushing device with good separation effects and relates to the technical field of non-ferrous alloy manufacture. The non-ferrous alloy crushing device withgood separating effects comprises a box body, a sloping plate is fixedly connected to the bottom of the inner wall of the box body, a first filter plate is fixedly connected to the top of the inner wall of the box body, one side of the box body above the sloping plate is fixedly communicated with a first discharge pipe, and one side of the box body above the first filter plate is fixedly communicated with a second discharge pipe. According to the non-ferrous alloy crushing device with good separation effects, a blower is started, small non-ferrous alloy particles are fed into a lower discharge box through the first discharge pipe and large non-ferrous alloy particles are fed into an upper discharge box through the second discharge pipe so that it is solved that large non-ferrous alloy particles easily block the filtering plate on the market to influence normal use of the non-ferrous alloy crushing device.

Owner:镇江金鑫有色合金有限公司

Dual-use exercise instrument for people lying on back or front

InactiveCN108704272AHarm Avoidance PhenomenonLess discomfortGymnastic exercisingEngineeringSafety coefficient

The invention provides a dual-use exercise instrument for people lying on back or front. The dual-use exercise instrument comprises supports, guide posts and a bed. The supports are arranged at two ends of the guide posts and are connected with the guide posts in an inserted manner. The bed is mounted in the middle of the guide posts, and sleeves the guide posts. A transmission base is arranged atthe top end of the base, and the bottom of the transmission base is inserted into the bed. Sliders are arranged at the bottom of a push plate as well as the bottom of a carrier plate, and are connected with the push plate through bolts. A push handle is welded to the top end of the push plate. The push plate is connected with the transmission base through a connecting rod. The dual-use exercise instrument for people lying on back or front, which is modified, has the advantages of novel structure, reasonable design, comprehensive function, various exercise modes, improved exercise effect, highcomfortableness, high safety coefficient and high practicability, and effectively solves the problems of the prior art.

Owner:HUIZHOU WULING KANGTAI HEALTH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com