Automatic chalk production machine

An automatic production and chalk technology, which is applied to ceramic molding machines, unloading devices, manufacturing tools, etc., can solve problems such as low work efficiency and difficulty in controlling the pouring amount of gypsum liquid, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A chalk automatic production machine, such as Figure 1-4 As shown, it includes a support 1, a storage barrel 2, a scraping assembly, a chalk making template 8, a quantitative assembly and a blanking assembly. A scraping assembly for scraping by sliding. A quantitative assembly for quantification by lifting is provided between the support 1 and the storage tank 2. A blanking assembly for unloading by moving is provided on the quantitative assembly. Support 1 There are 8 chalk making templates inside.

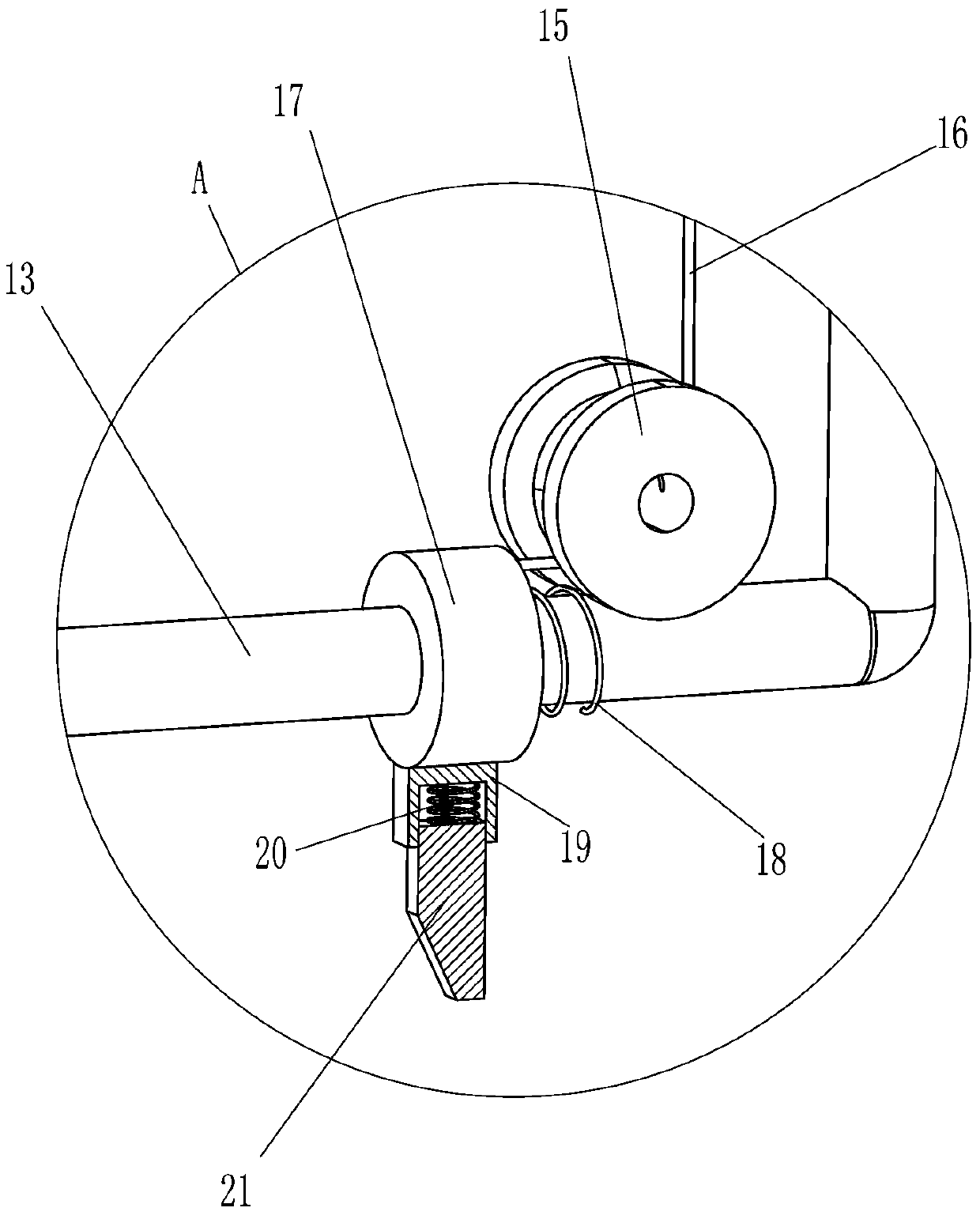

[0024] Such as figure 1 As shown, the scraping assembly includes a first slide rail 3, a first slide block 4, a push rod 5, a scraper 6 and a push block 7, and the front and rear sides of the top of the support 1 are fixed with the first slide rail 3 by screws. , the first sliding rail 3 is provided with a sliding first slider 4, the push rod 5 is welded between the tops of the first slider 4, the lower part of the push rod 5 has elasticity, and the bottom of the push r...

Embodiment 2

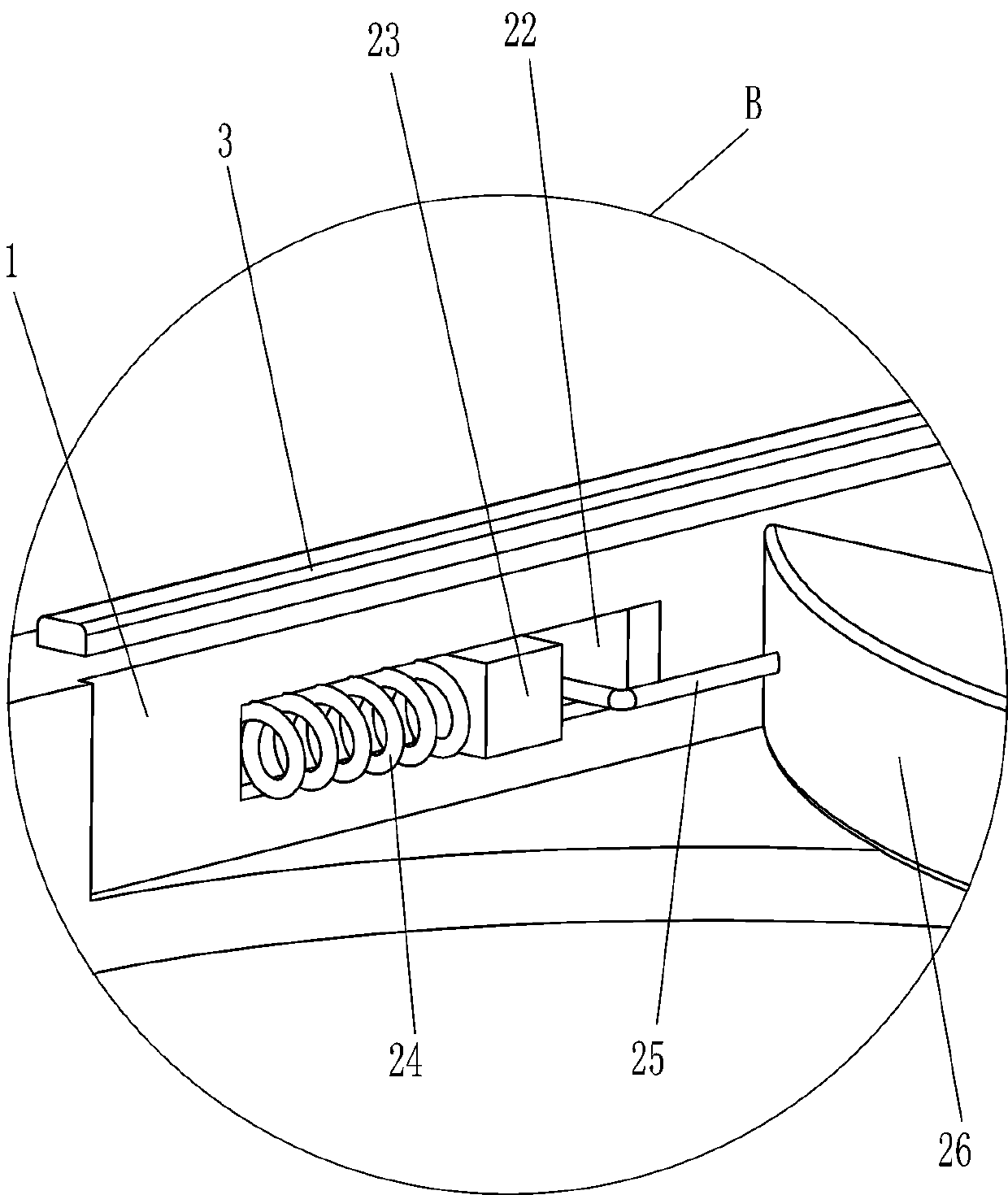

[0032] On the basis of Example 1, such as Figure 5 Shown, in order to improve the quality of chalk making, also comprise the second slide block 23, the 4th spring 24, connecting rod 25 and baffle plate 26, all have chute 22, the chute 22 is provided with the second sliding block 23 that slides left and right, and the fourth spring 24 is welded between the second sliding block 23 and the support 1, and the second sliding block 23 right side is equipped with a connecting rod 25, and the connecting rod 25 A baffle 26 is arranged between, and the baffle 26 cooperates with the push block 7 .

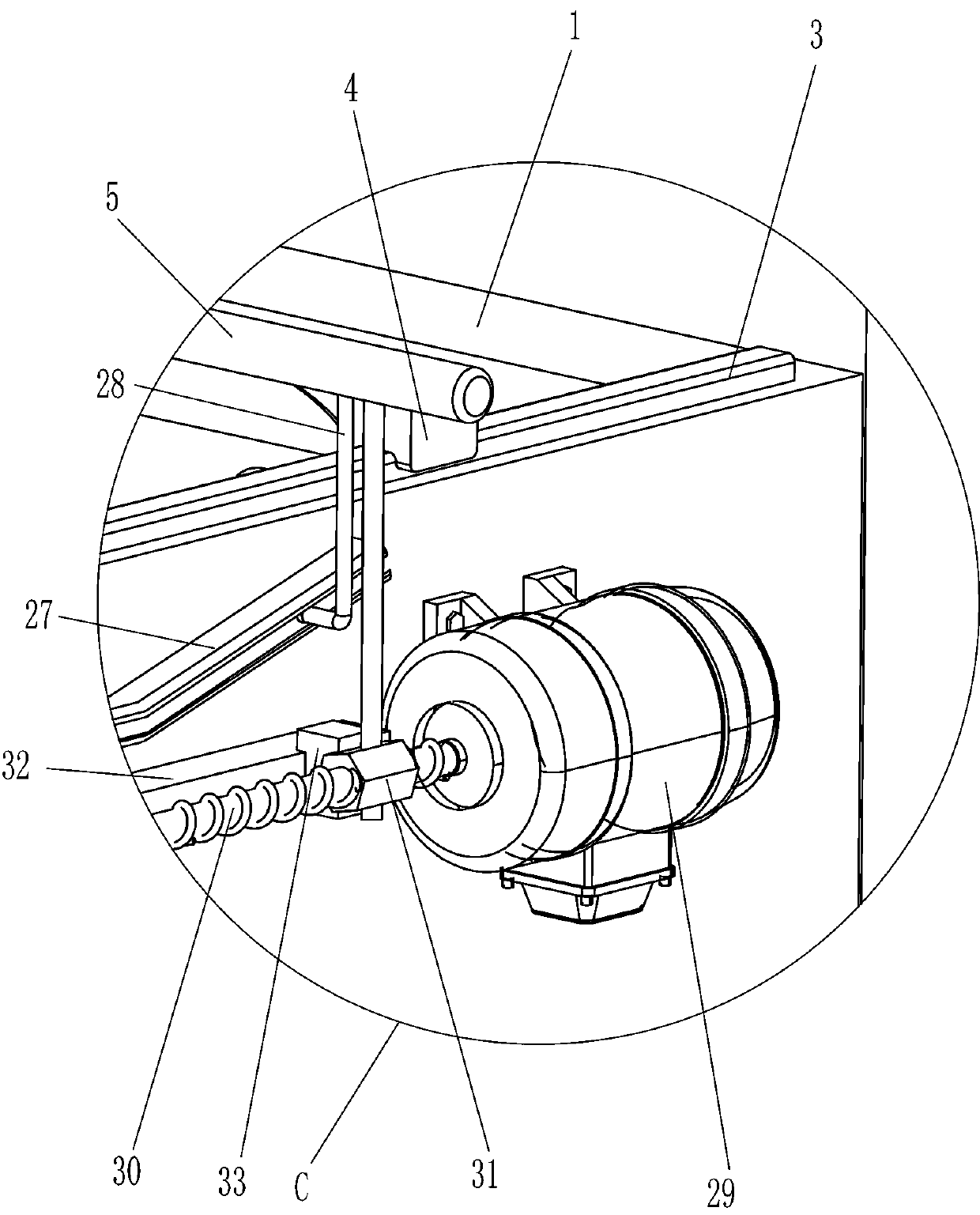

[0033] Such as Figure 6As shown, in order to use the device more conveniently, it also includes a track 27, a slide bar 28, a geared motor 29, a screw mandrel 30 and a nut 31. The sliding type is provided with a slide bar 28, the front and rear sides of the right part of the support 1 are fixedly connected with a deceleration motor 29 by bolts, the output shaft of the deceleration motor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com