Patents

Literature

219results about How to "Realize continuous delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

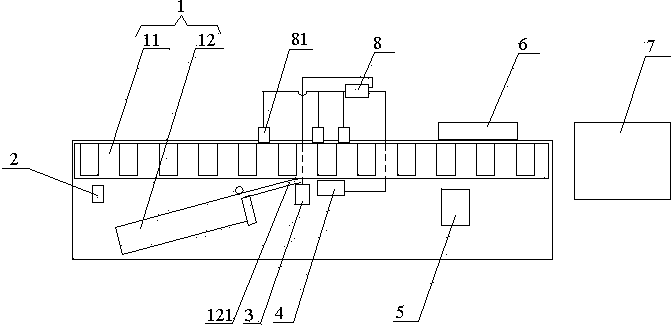

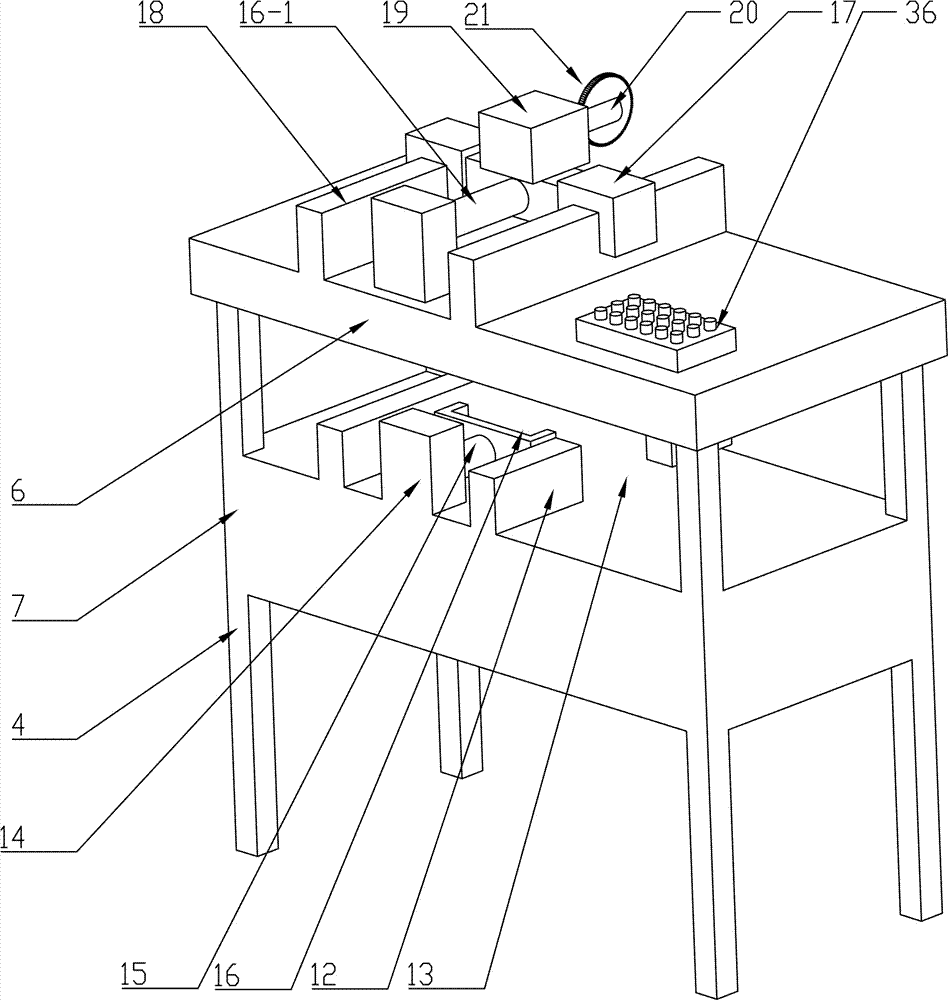

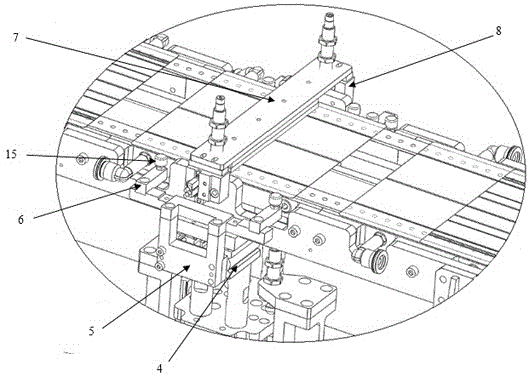

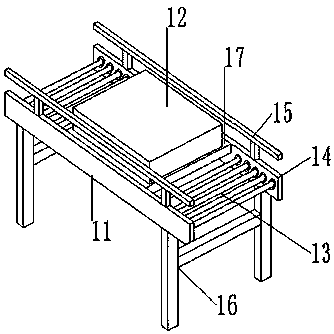

Board splicing machine

The invention discloses a board splicing machine. The board splicing machine comprises a machine frame and a board conveying device installed on the machine frame, wherein the board conveying device comprises a bottom board conveying belt for conveying bottom boards forwards, and a side board conveying groove formed in one side of the bottom board conveying belt, and one side, close to the bottom board conveying belt, of the front end of the side board conveying groove is provided with a side board outlet; a gluing device is arranged beside the inlet end of the bottom board conveying belt; an aligning device corresponding to the side board outlet is arranged in front of the side board outlet, and an induction device corresponding to the aligning device and inducting the positions of the bottom boards is further installed on the portion, beside the bottom board conveying belt, of the machine frame; a nail gun is arranged between the side board outlet and the aligning device; the board conveying device, the aligning device and the nail gun are further connected with a control device, and the input end of the control device is connected with the induction device; a pressing and connecting device for pressing and airing the bottom boards and side boards is arranged in front of the outlet end of the bottom board conveying belt. The board splicing machine is reasonable in structure and convenient to use, the machining efficiency can be substantially improved, consumption of wood can be reduced, and cost can be saved.

Owner:河北简工科技有限公司

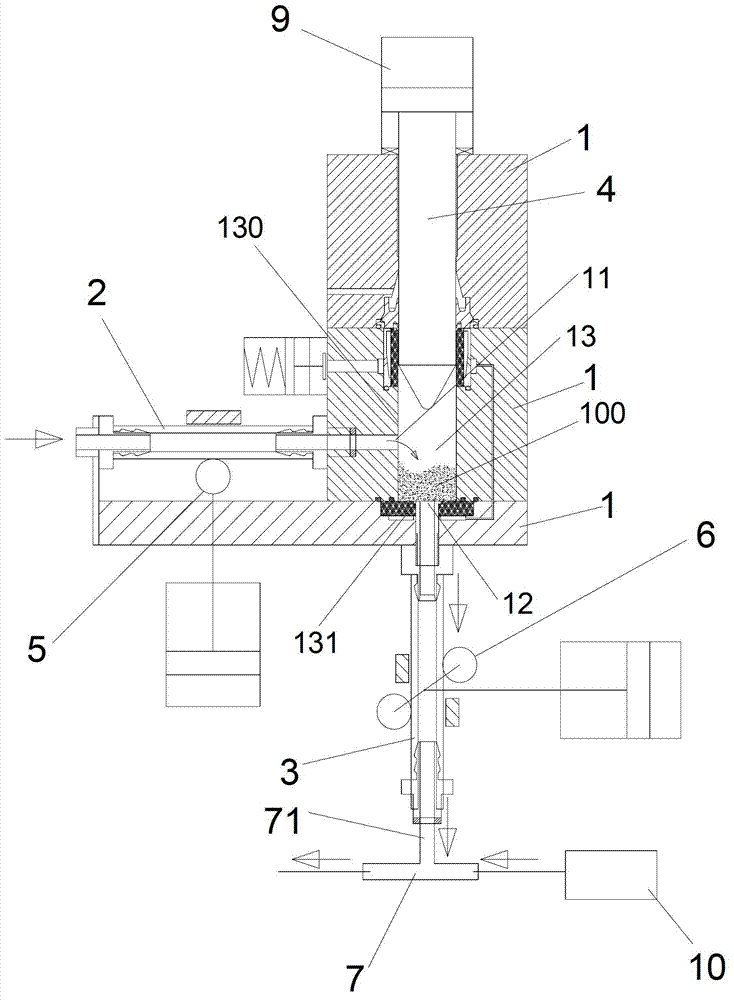

Powder conveyer device

ActiveCN102765604AEasy accessReasonable designBulk conveyorsLiquid spraying apparatusMetallurgyPlunger

Owner:RAMSEIER KOATINGS ZHONGSHAN PAINTING EQUIP

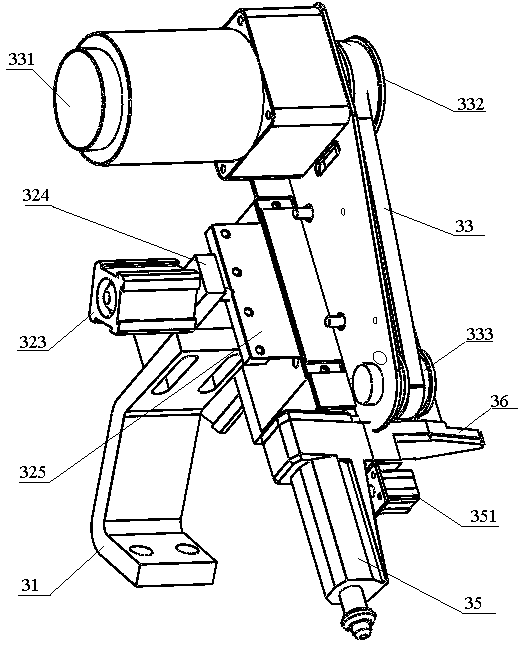

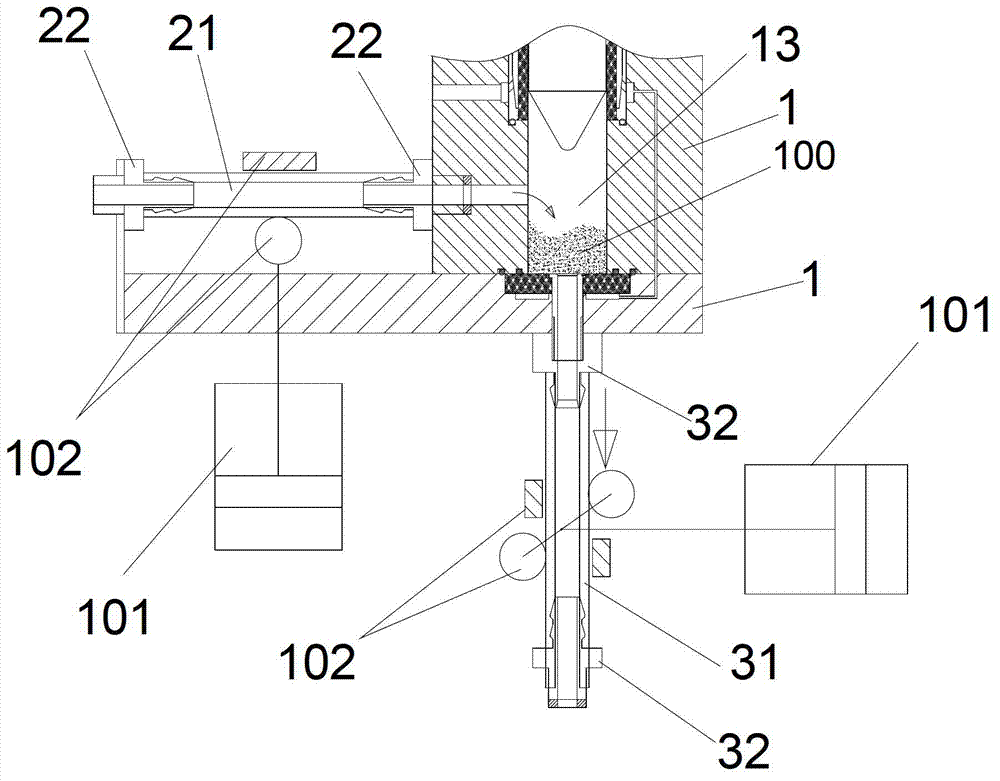

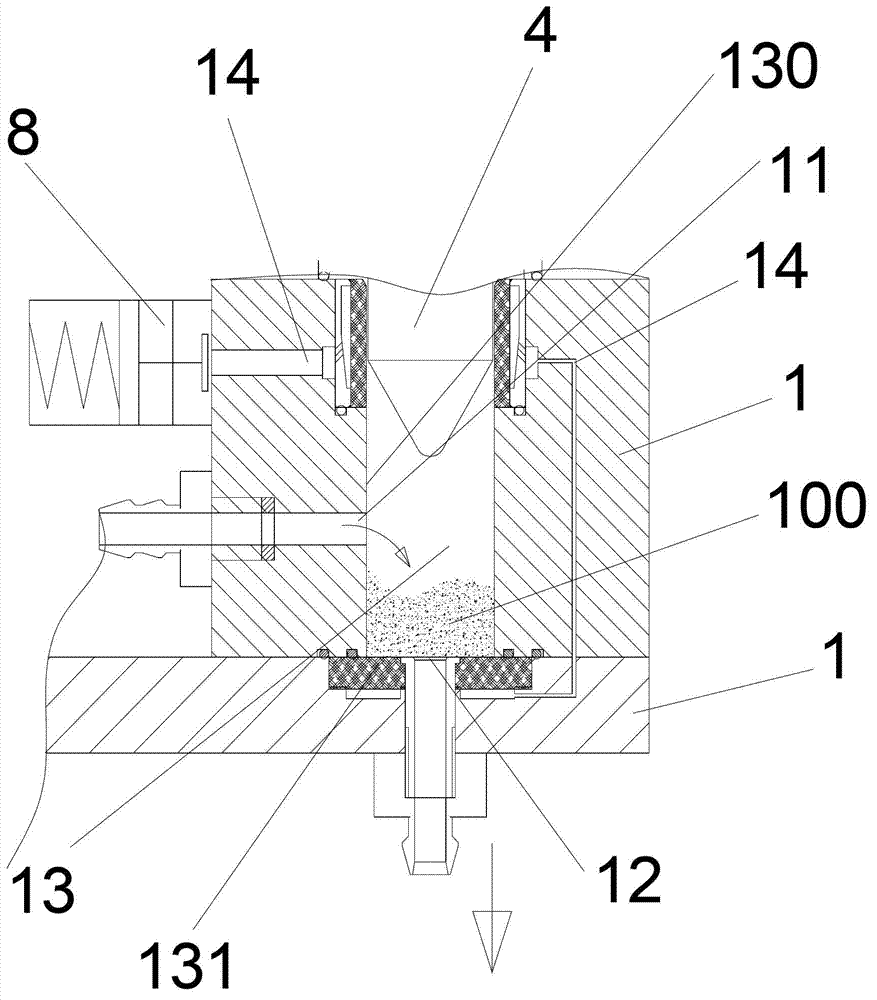

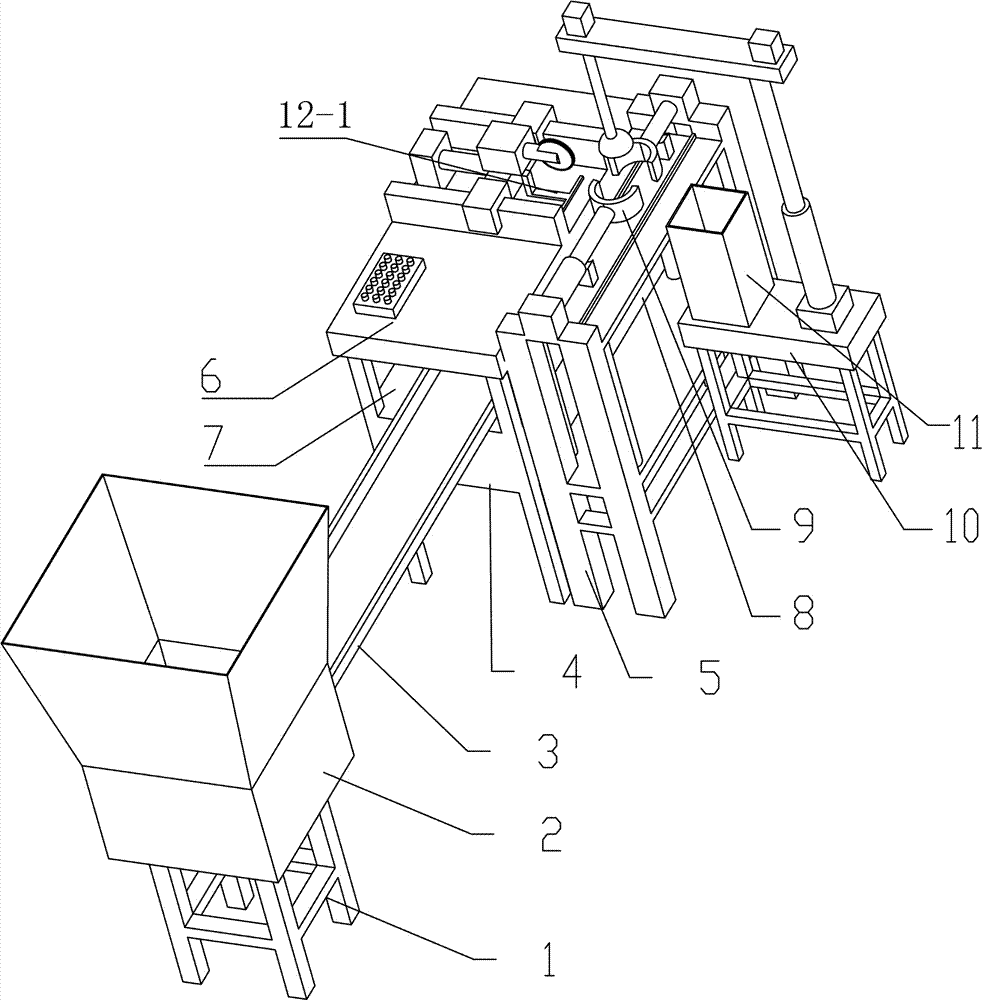

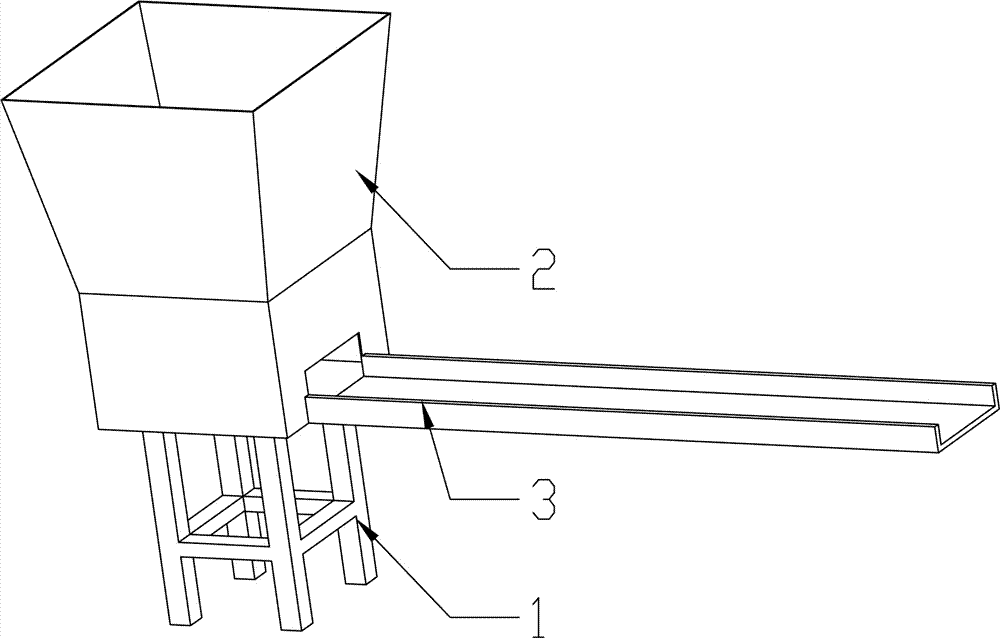

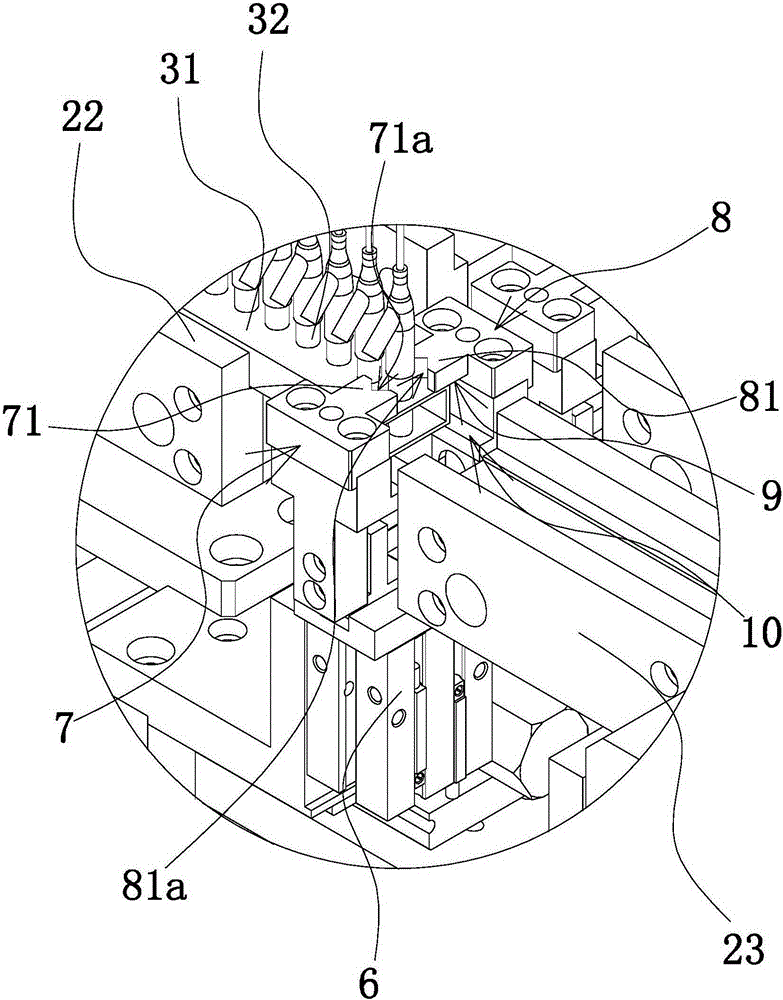

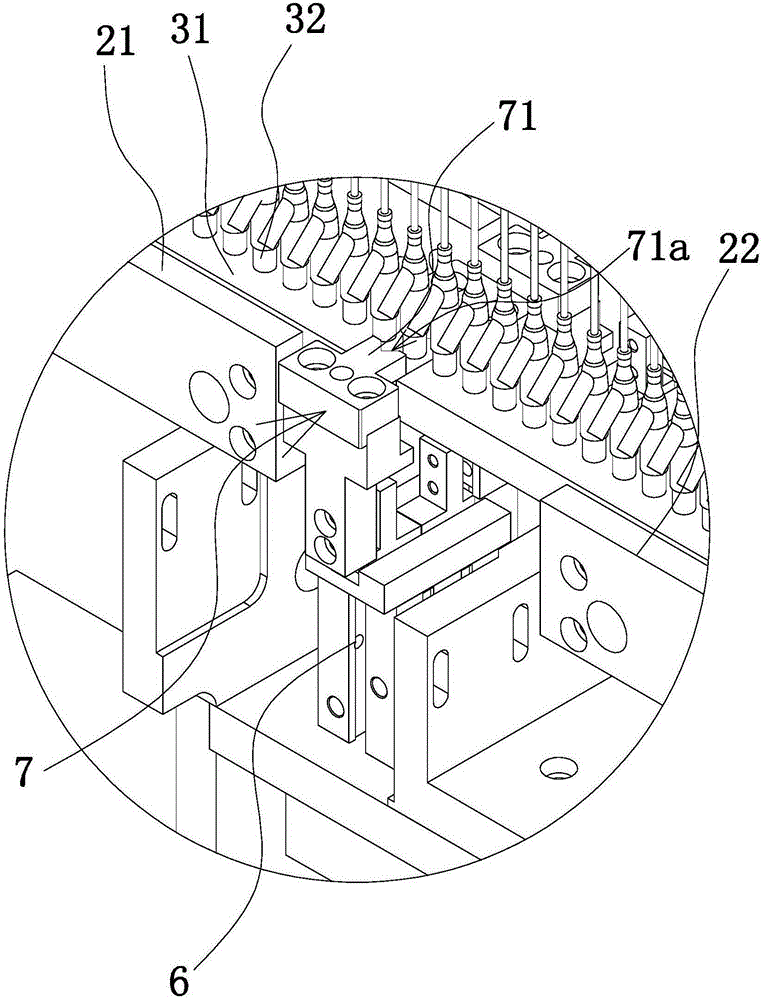

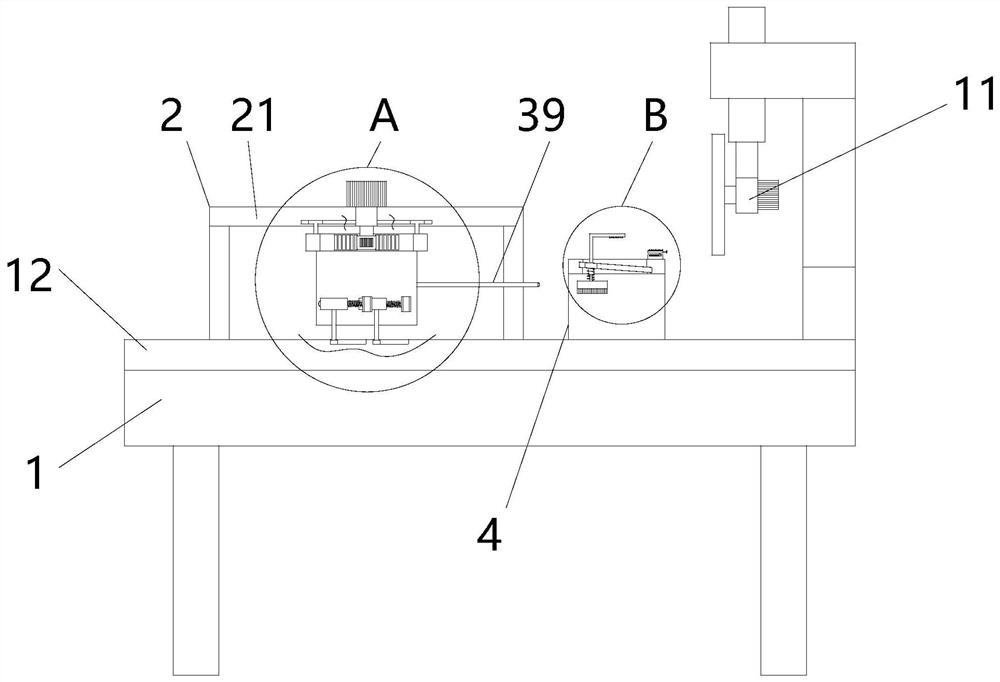

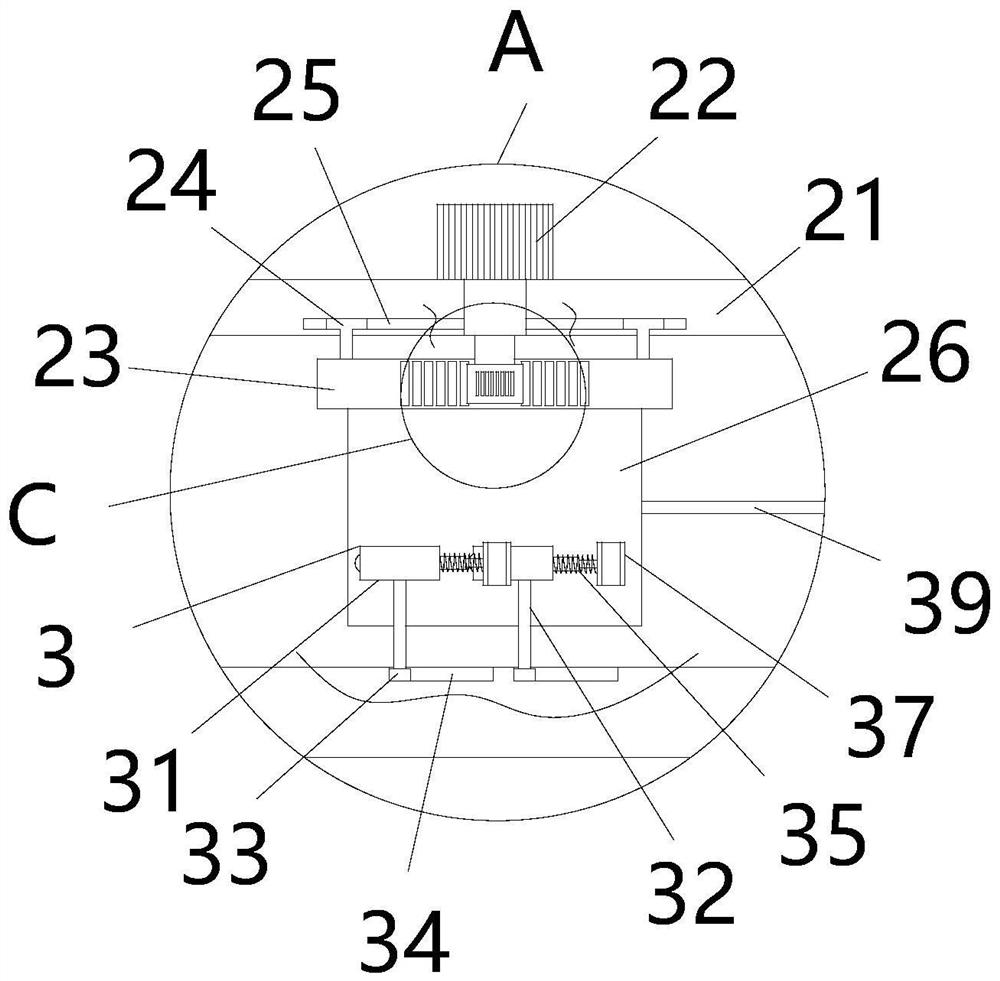

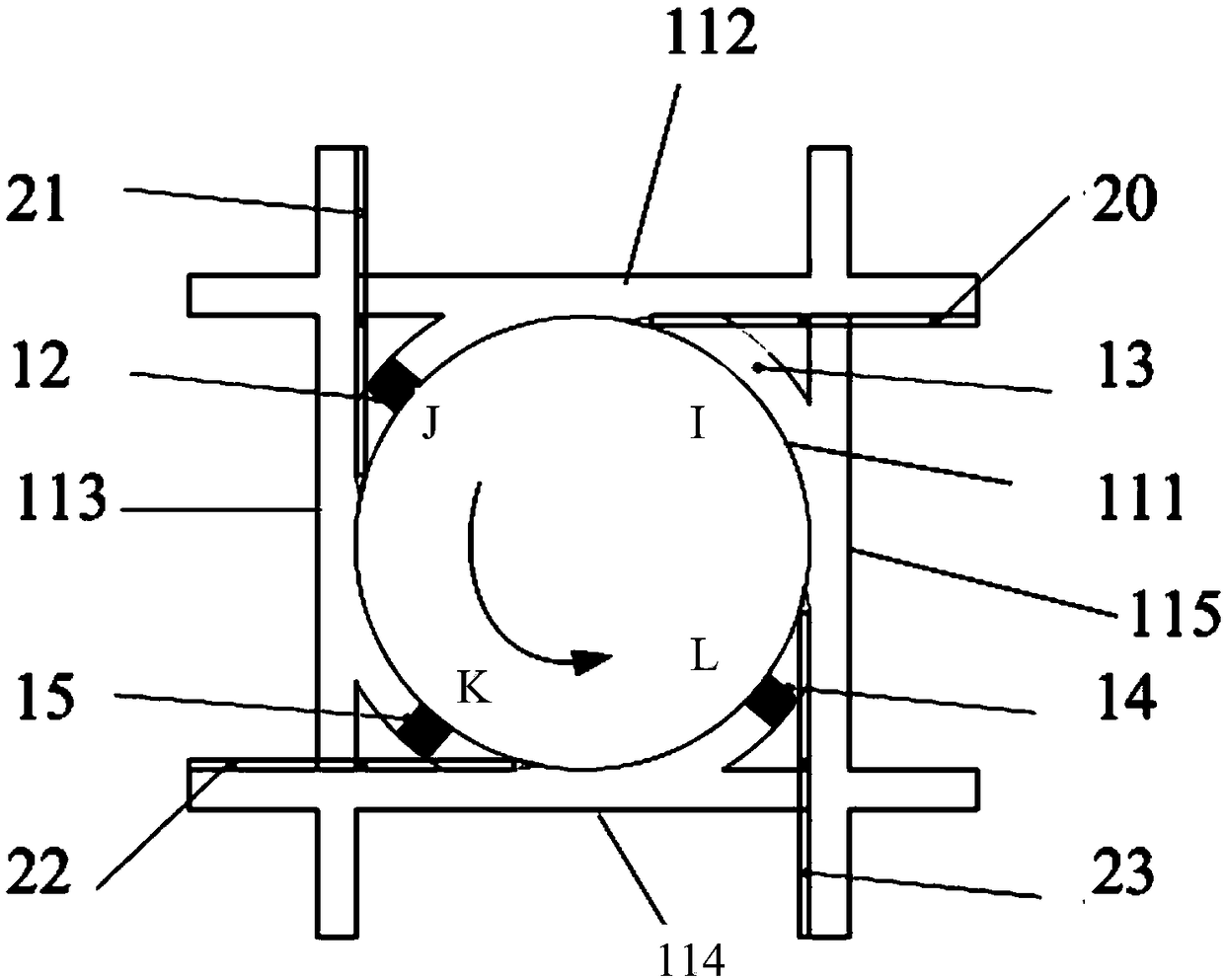

Chestnut thorny-shell removing apparatus and chestnut thorny-shell removing method

ActiveCN106954865ARealize continuous deliveryAchieve circumferential rotationHuskingHullingConveyor belt

The invention discloses a chestnut thorny-shell removing apparatus and a chestnut thorny-shell removing method. The invention mainly relates to the chestnut thorny-shell removing apparatus which comprises a material feeding device, a clamping and cutting device, and a material fetching device; second material feeding is carried out by the material feeding device through a conveyor belt and a material pushing mechanism; the clamping and cutting device pushes a sawtooth cutter to an appropriate position via a telescopic cutting mechanism, and is in cooperation with clamping and circumferential rotation of a clamping mechanism so as to realize circumferential cutting; and separated chestnuts and thorny shell are then pushed into a material receiving box via a pusher. The chestnut thorny-shell removing apparatus and the chestnut thorny-shell removing method provided by the invention realize continuous cutting of thorny chestnut balls by carrying out conveying, clamped cutting and pushing so as to further achieve highly efficient operations.

Owner:CHINA THREE GORGES UNIV

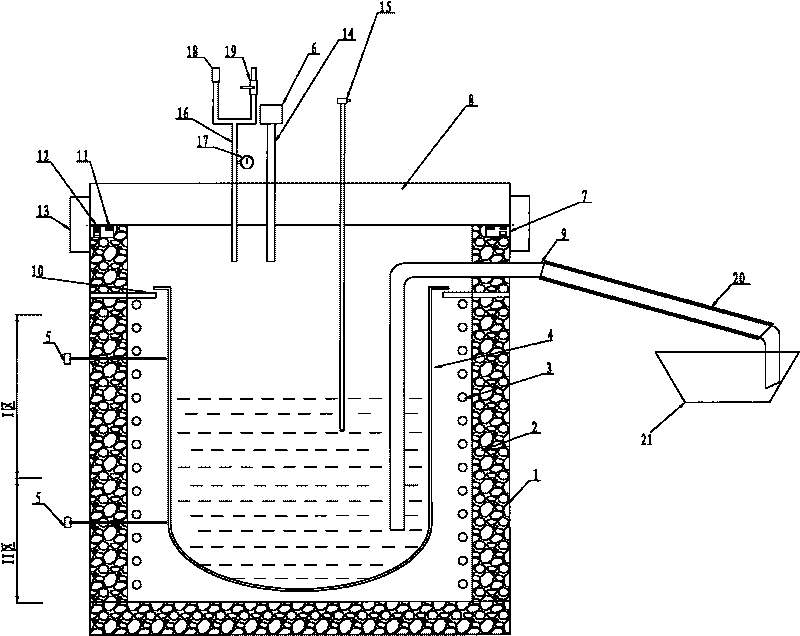

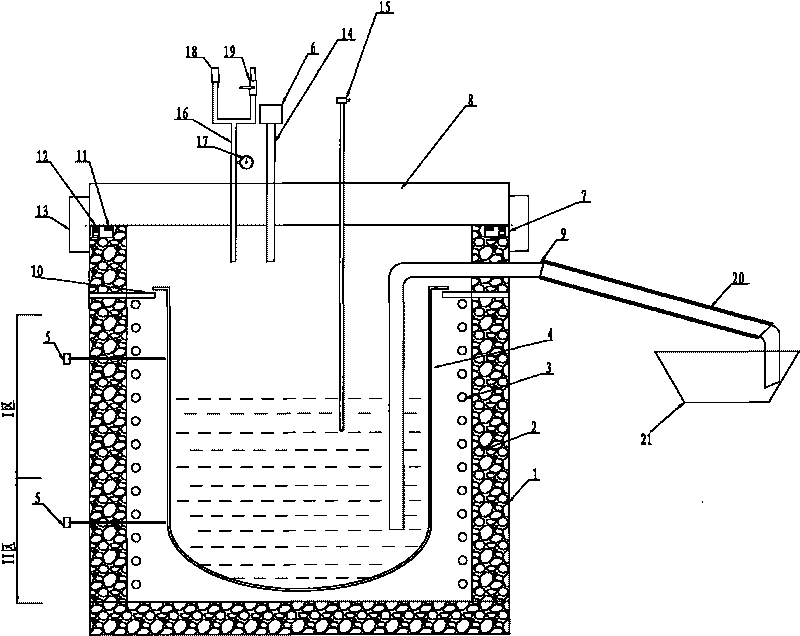

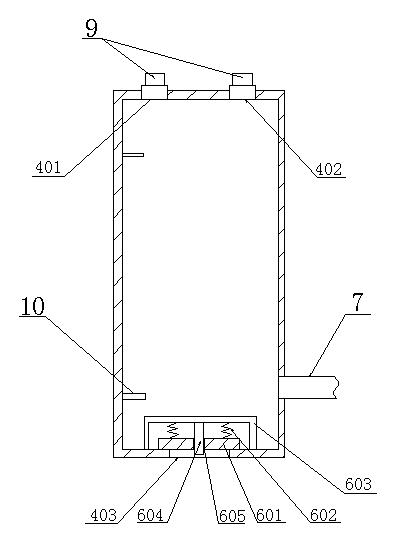

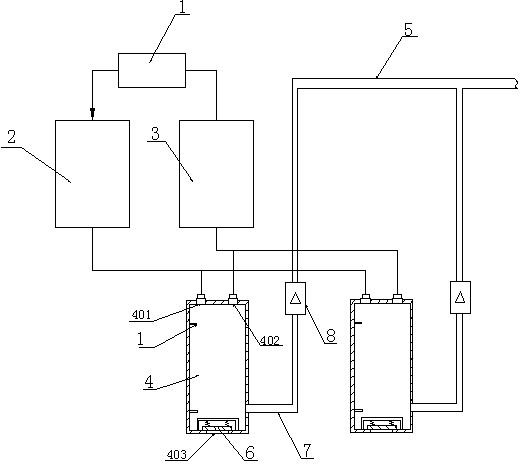

Pressure-flow-type magnesium alloy smelting heat insulating furnace

InactiveCN101706205AHighlight substantive featuresSignificant progressCrucible furnacesExhaust valveHearth

The invention relates to a pressure-flow-type magnesium alloy smelting heat insulating furnace which comprises a furnace body provided with a heat insulating layer, a crucible arranged inside a hearth, a heating element, a temperature measuring device and a furnace cover, wherein the furnace body comprises a furnace shell and a furnace liner; a water-cooling flange is arranged at a position where the upper part of the furnace body is matched with the furnace cover, and internally provided with high temperature resistant and fire-resistant filler material and a silicon rubber sealing ring; the water-cooling flange is internally filled with circulating cooling water; the furnace cover is locked with the furnace body by a compressing mechanism; a temperature thermocouple and a protection gas input pipeline extend into the furnace through inserting holes of the furnace cover, a pressure release pipe is arranged on the furnace cover, and the top of the pressure release pipe is provided with a safety valve and an exhaust valve; and a transfer pipette is introduced into the hearth through the furnace body. The furnace integrates the functions of smelting, heat insulating and melt transmission, accurately controls the flow rate of magnesium alloy melt, extracts the purer magnesium alloy melt at the middle part of the crucible, realizes continuous transmission with fixed flow rate, and prevents oxidation and combustion of the magnesium alloy. Furthermore, by combining corresponding foundry equipment, the magnesium alloy product with high quality can be prepared, and the equipment can be safe in use as well as simple and convenient for operation.

Owner:苏州有色金属研究院有限公司

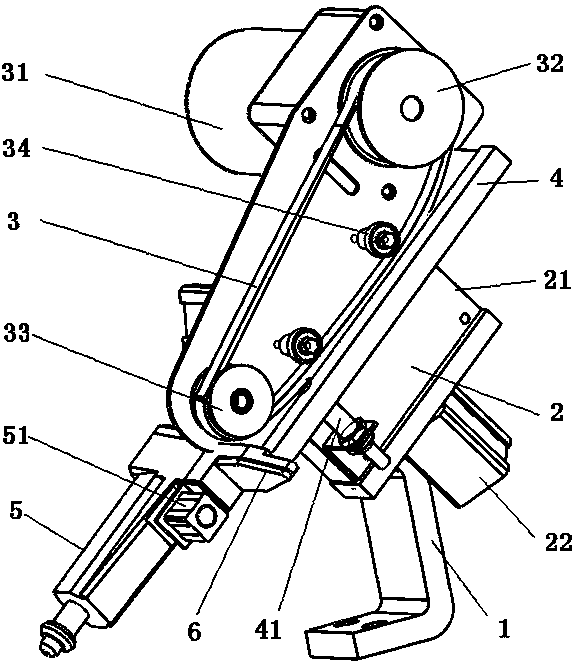

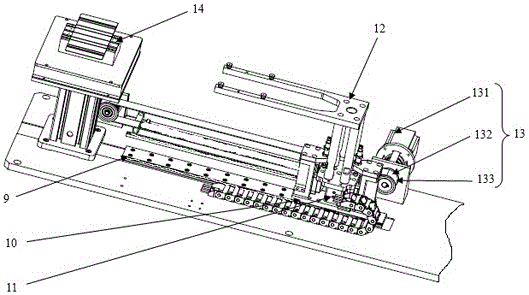

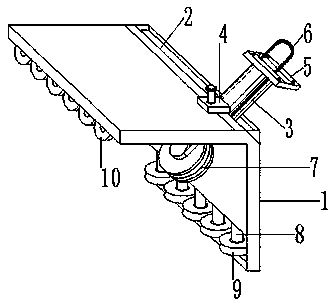

Nail gun

The invention discloses a nail gun which comprises a gun shell, a nailing end with a nail placement gap in the gun shell, a power part, a nail conveying part and a control part, wherein the nail conveying part comprises a nail bin for accommodating rows and stocks of straight nails, and a conveying mechanism, and a nail loading opening is formed in the sidewall of the nail bin; a jacking device for gradually jacking a single row of straight nails in the nail bin to a nail outlet in the top of the nail bin is arranged at the bottom of the nail bin; a lateral pushing device for laterally pushing the single row of straight nails at the nail outlet out of the nail bin is arranged on the upper part of the nail bin; the conveying mechanism comprises a conveying plate and a conveyor belt; the conveying plate is used for receiving the single row of straight nails pushed by the lateral pushing device; the conveyor belt is positioned above the conveying plate, and is matched and contacted with the conveying plate to load the single row of straight nails into the nail placement gap in the tail conveying end of the conveyor belt. The nail gun has the advantages of reasonable structure, stability in conveying, small size, convenience in operation and control and capability of continuously conveying the nails.

Owner:河北简工科技有限公司

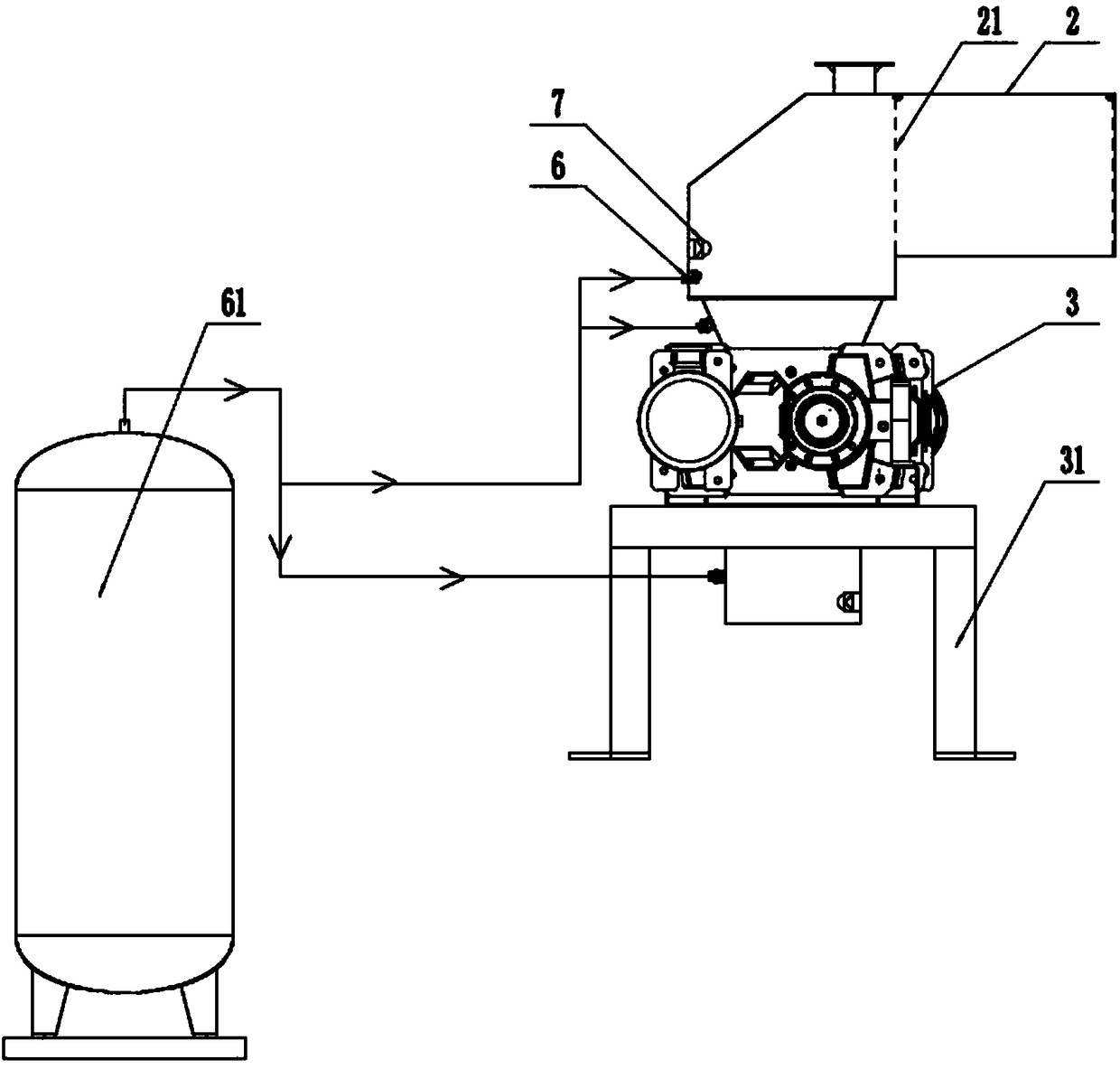

Lithium battery and lithium battery module crushing method

ActiveCN108417924AAvoid burning and explosionImprove securitySolid waste disposalReclaiming serviceable partsGas protectionElectrical and Electronics engineering

The invention discloses a lithium battery and lithium battery module crushing method which includes the steps: 1) turning on a gas protection device, leading flame-retardant gas into a crushing box and reducing oxygen concentration; 2) placing a battery onto a feeding mechanism and starting the feeding mechanism when the oxygen concentration in the crushing box is reduced to below 16%; 3) conveying the lithium battery and a lithium battery module to the crushing box and disassembling and crushing the lithium battery and a lithium battery module; 4) turning off the gas protection device and stopping leading in the flame-retardant gas when the oxygen concentration is lower than or equal to 4%, and turning on the gas protection device and leading in the flame-retardant gas when the oxygen concentration is higher than or equal to 15.5%; 5) discharging the crushed lithium battery and the crushed lithium battery module to a material receiving device and performing a next procedure; 6) stopping leading in the flame-retardant gas after production, discharging exhaust in the crushing box by an exhaust emission channel as soon as possible and enabling the oxygen concentration to return to normal. The lithium battery and the lithium battery module can be crushed and disassembled without discharging, personnel security is ensured, and working efficiency is greatly improved.

Owner:哈尔滨巴特瑞资源再生科技有限公司

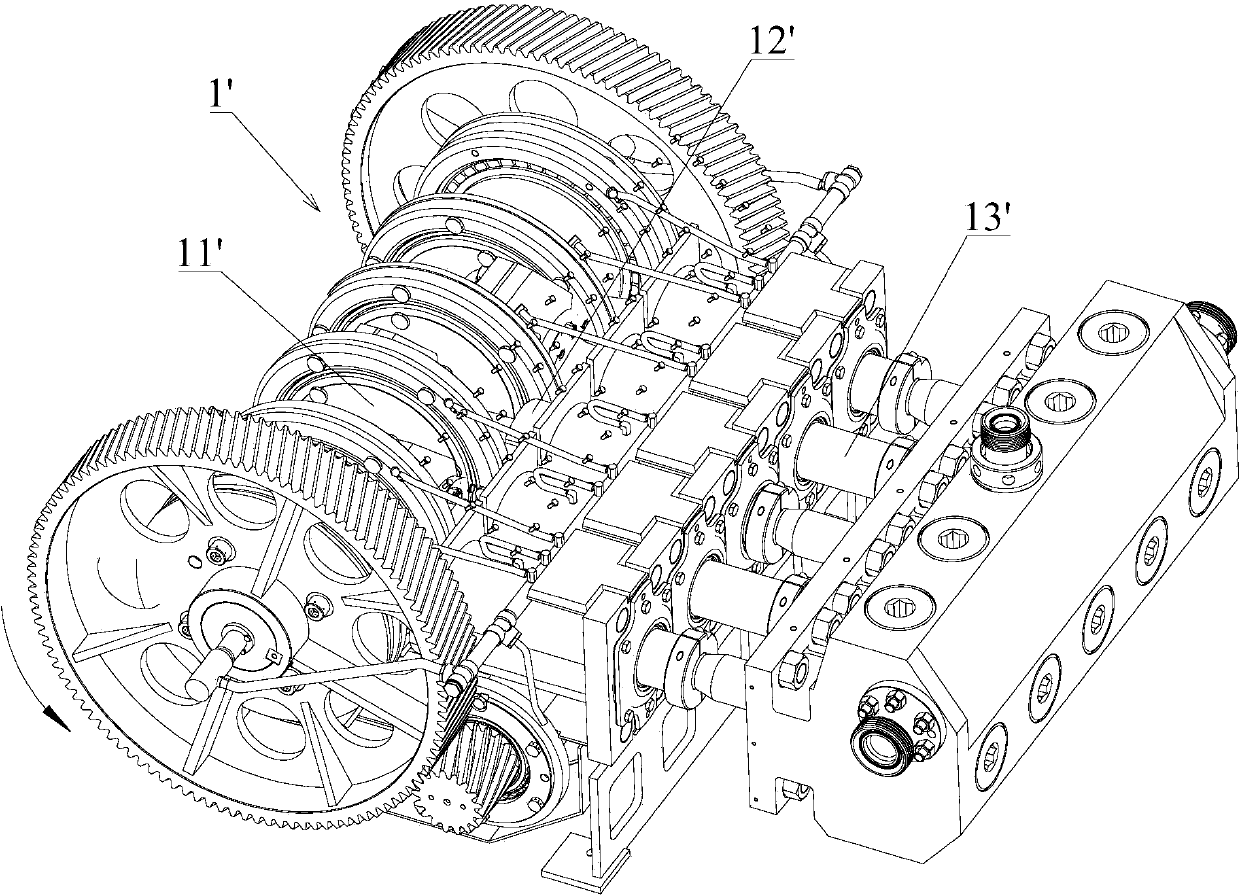

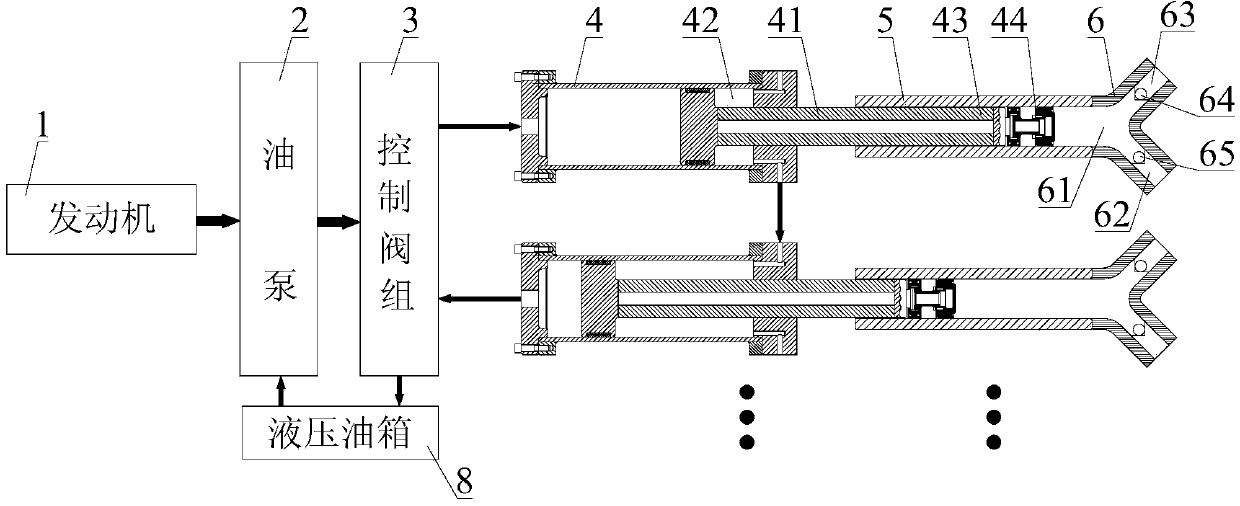

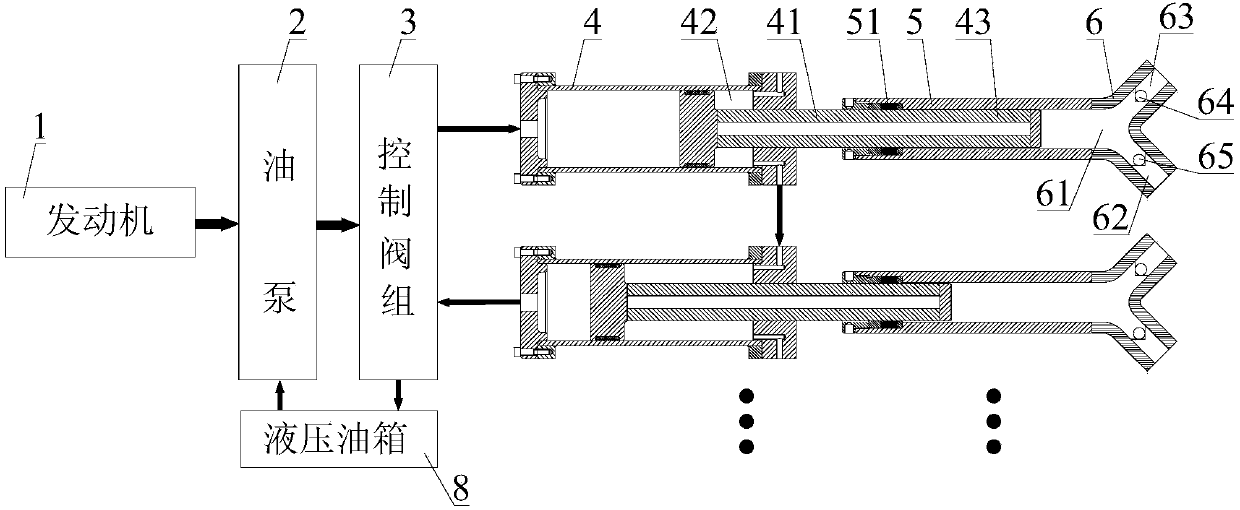

Fracturing pump system and fracturing truck

ActiveCN103742381AFlexible arrangementSimple structureFluid removalPiston pumpsEngineeringControl valves

The invention discloses a fracturing pump system and a fracturing truck. In the fracturing pump system, a first conveying mechanism and a second conveying mechanism comprise oil cylinders, supercharging cylinders and distribution valves. Each distribution valve comprises a first channel, a second channel and a third channel, wherein the first ends of the first channel, the second channel and the third channel are connected, a suction valve is arranged in the second channel, and a discharge valve is arranged in the third channel. Plug bodies are arranged at the extending end of piston rods of the oil cylinders and movably arranged in the supercharging cylinders, and outlets of the supercharging cylinders are connected with the second end of the first channel. An engine is used for driving an oil pump. A control valve group is used for controlling oil inlet and return states of the oil cylinders. By using the fracturing pump system, a stroke can be effectively increased, stoke times can be decreased, the service life of easily damaged parts can be prolonged, an output pressure and flow coverage range can be effectively widened, the structural complexity can be effectively reduced, the cost can be saved, and the lubrication and cooling requirements can be effectively reduced.

Owner:SANY PETROLEUM INTELLIGENT EQUIP CO LTD

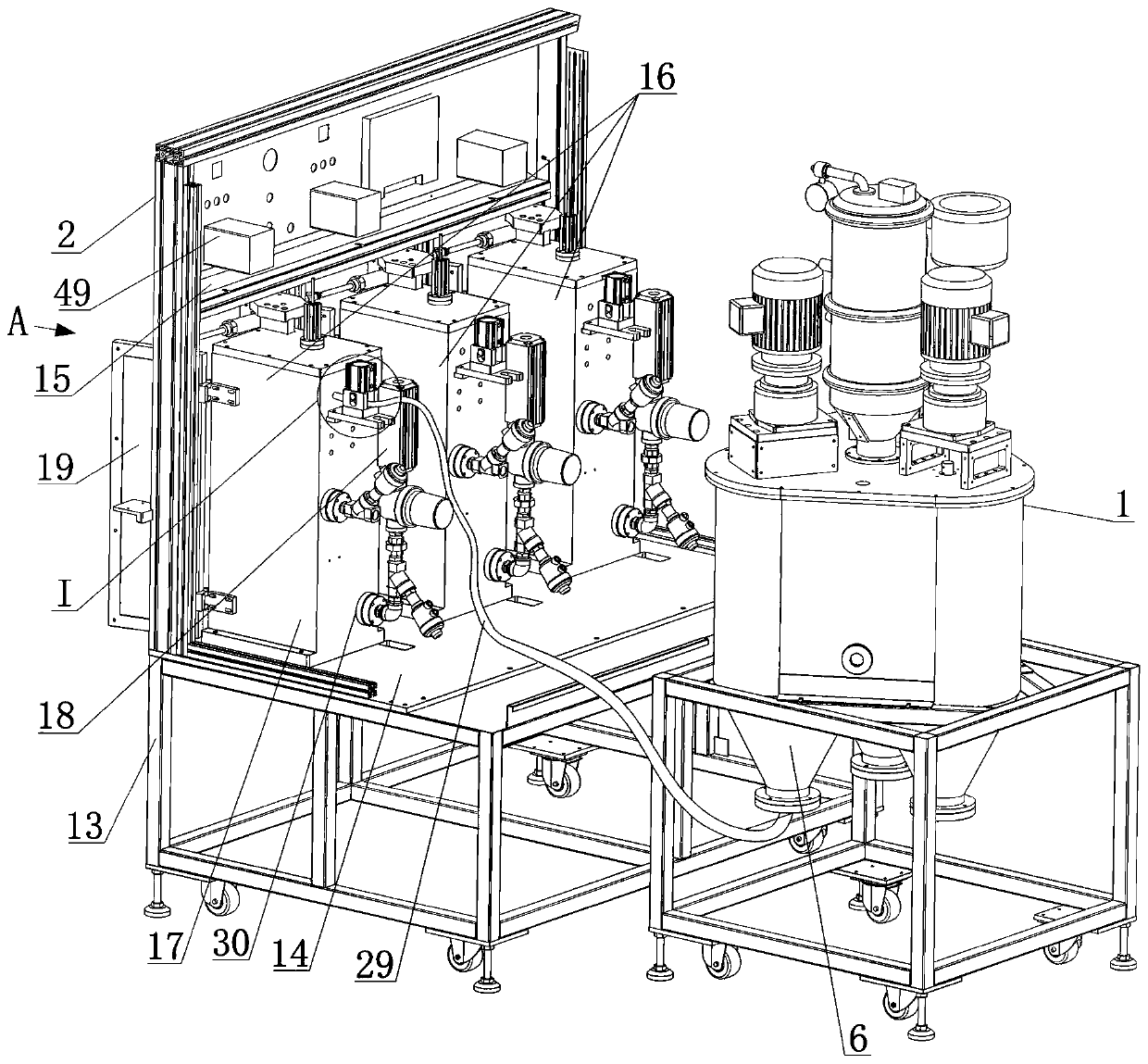

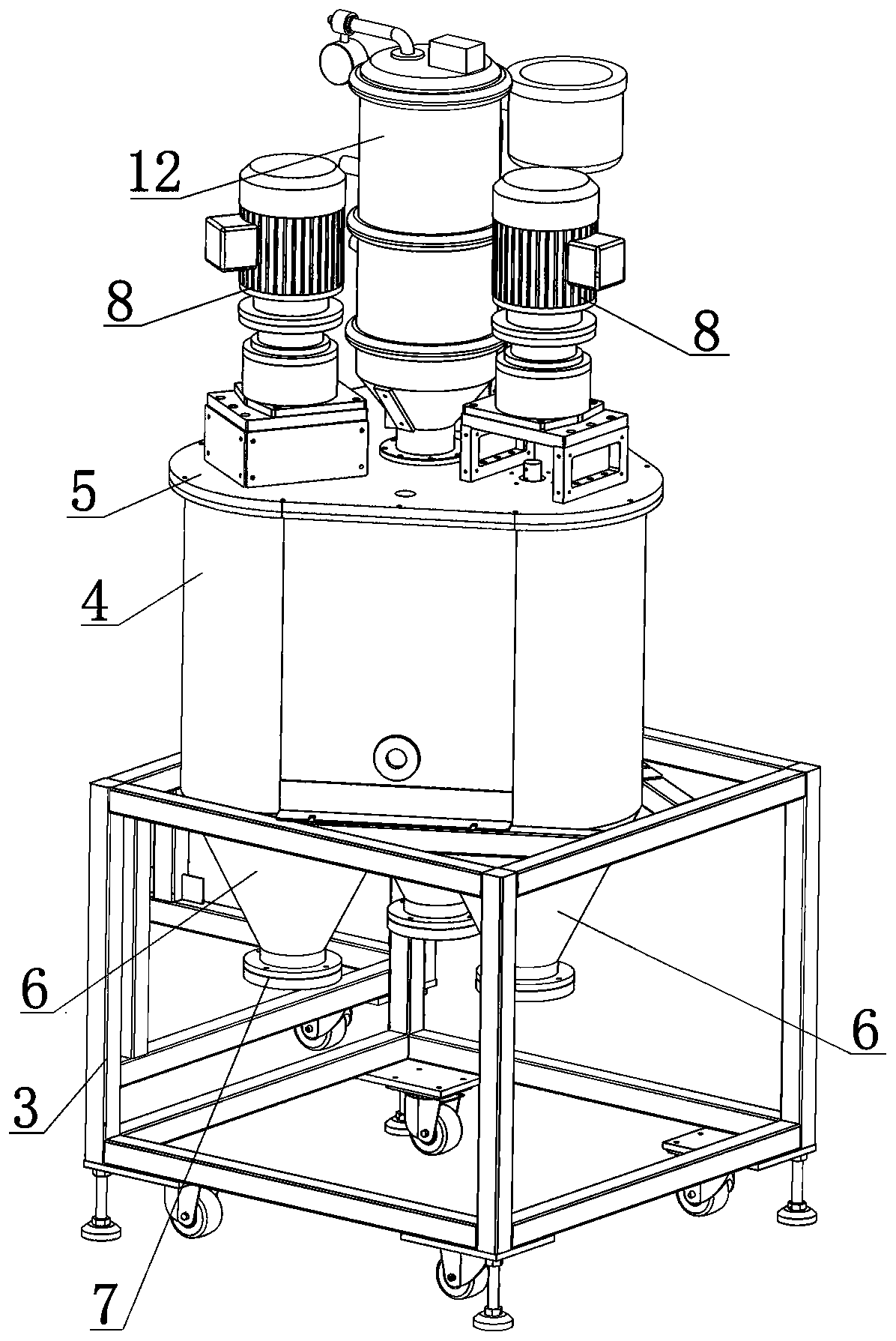

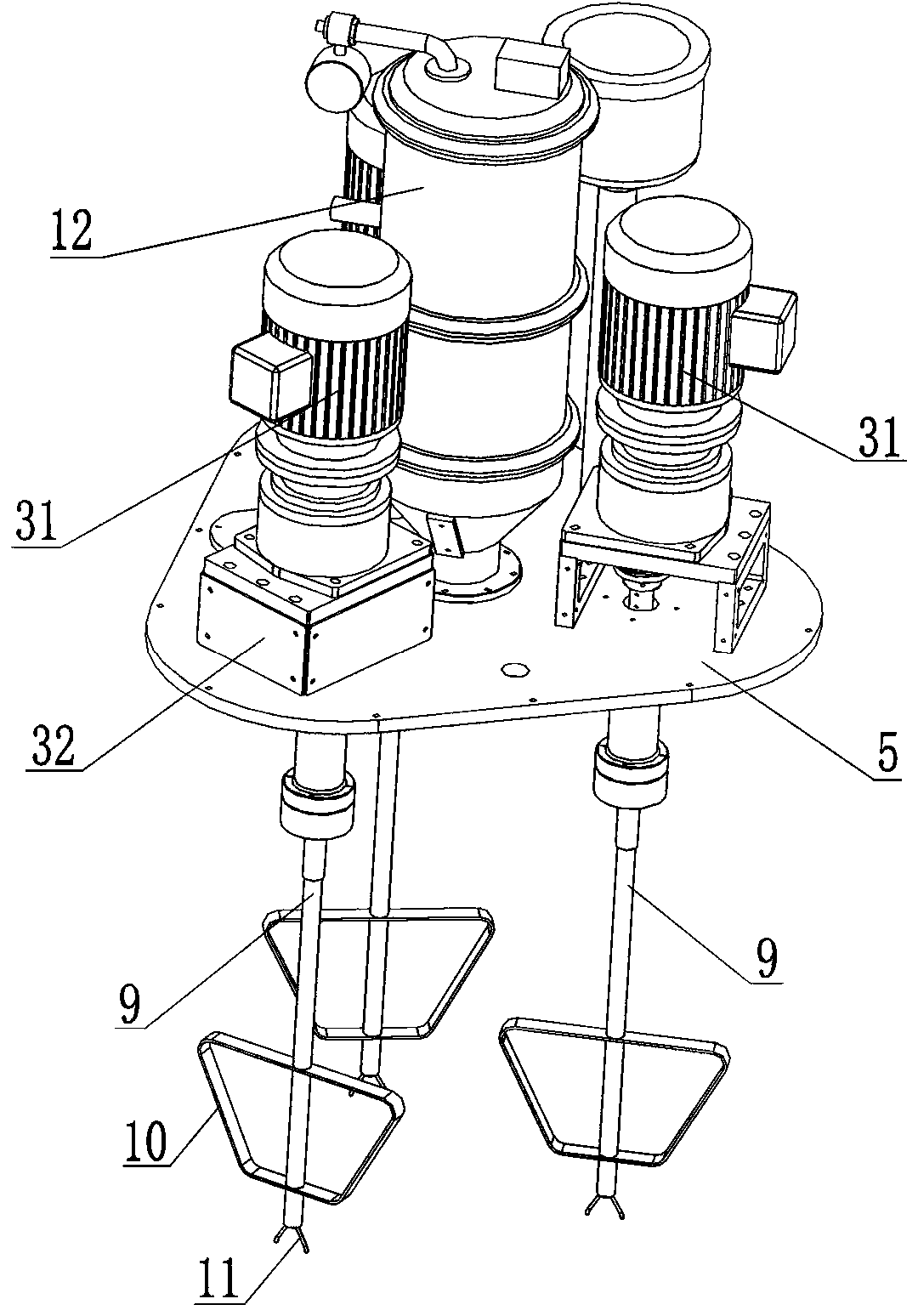

Efficient and precision vacuum powder filling machine

PendingCN111453017AStir wellAvoid stickingLarge containersPackaging under vacuum/special atmosphereClosed cavity

The invention discloses an efficient and precision vacuum powder filling machine. The efficient and precision vacuum powder filling machine comprises a carbon powder storage device and a carbon powderfilling device. The carbon powder storage device comprises a supporting frame, a feeding bucket and an upper cover fixedly arranged at the top of the feeding bucket. The feeding bucket is fixedly arranged on the supporting frame, and multiple conical barrels are arranged at the bottom of the feeding bucket in the circumferential direction. A vacuum conveyor communicating with the feeding bucket is fixedly arranged at the top of the upper cover. The carbon powder filling device comprises a supporting rack, a tabletop plate fixedly arranged at the top of the supporting rack and a portal frame fixedly arranged at the top of the tabletop plate. Multiple carbon powder filling units located below a cross beam of the portal frame are fixedly arranged at the top of the tabletop plate, and each carbon powder filling unit comprises a vacuum box, a vacuum generator, a door plate, a weighing device arranged in a closed cavity of the vacuum box, and a rotary air cylinder A fixedly arranged at thetop of the vacuum box. The efficient and precision vacuum powder filling machine has the advantages that the powder filling efficiency is improved, the purity of poured carbon powder is improved, thelabor intensity of workers is reduced, the weighing precision is improved, and the efficient and precision vacuum powder filling machine is suitable for filling powder boxes of different heights.

Owner:威海弘锐机电科技有限公司

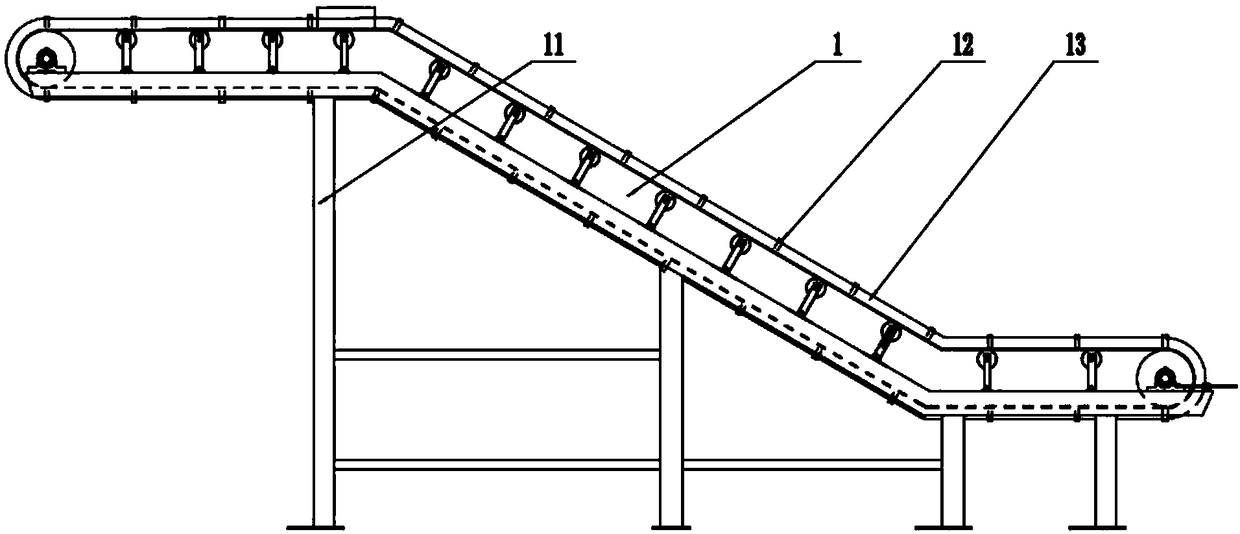

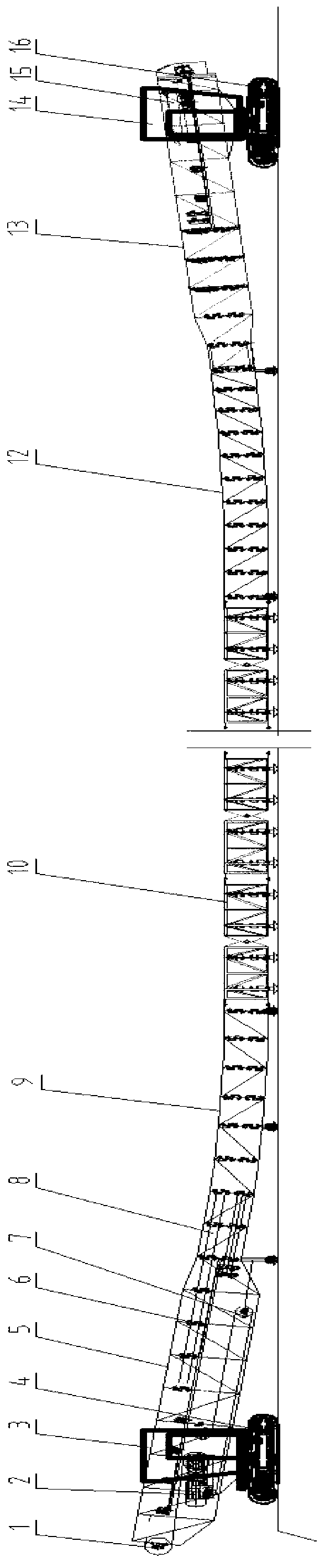

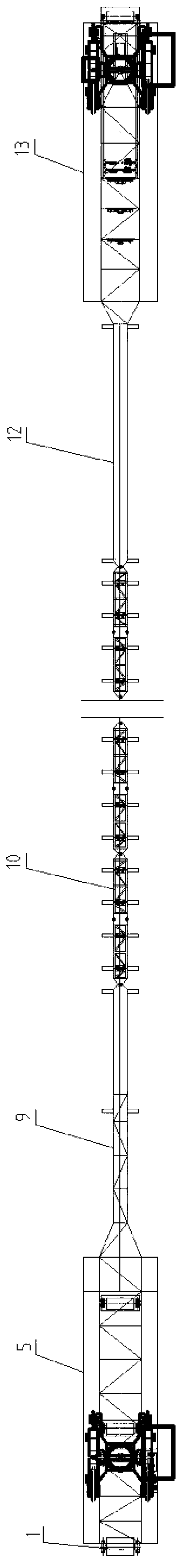

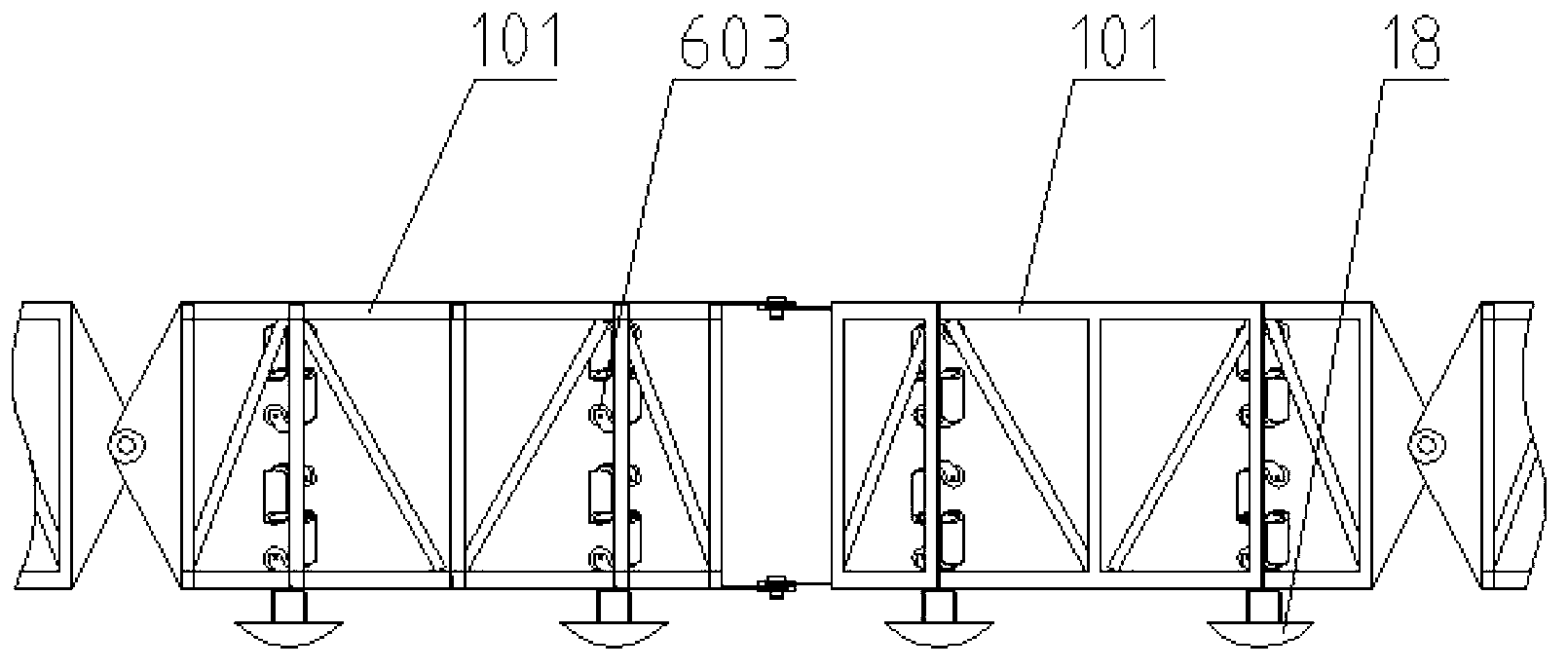

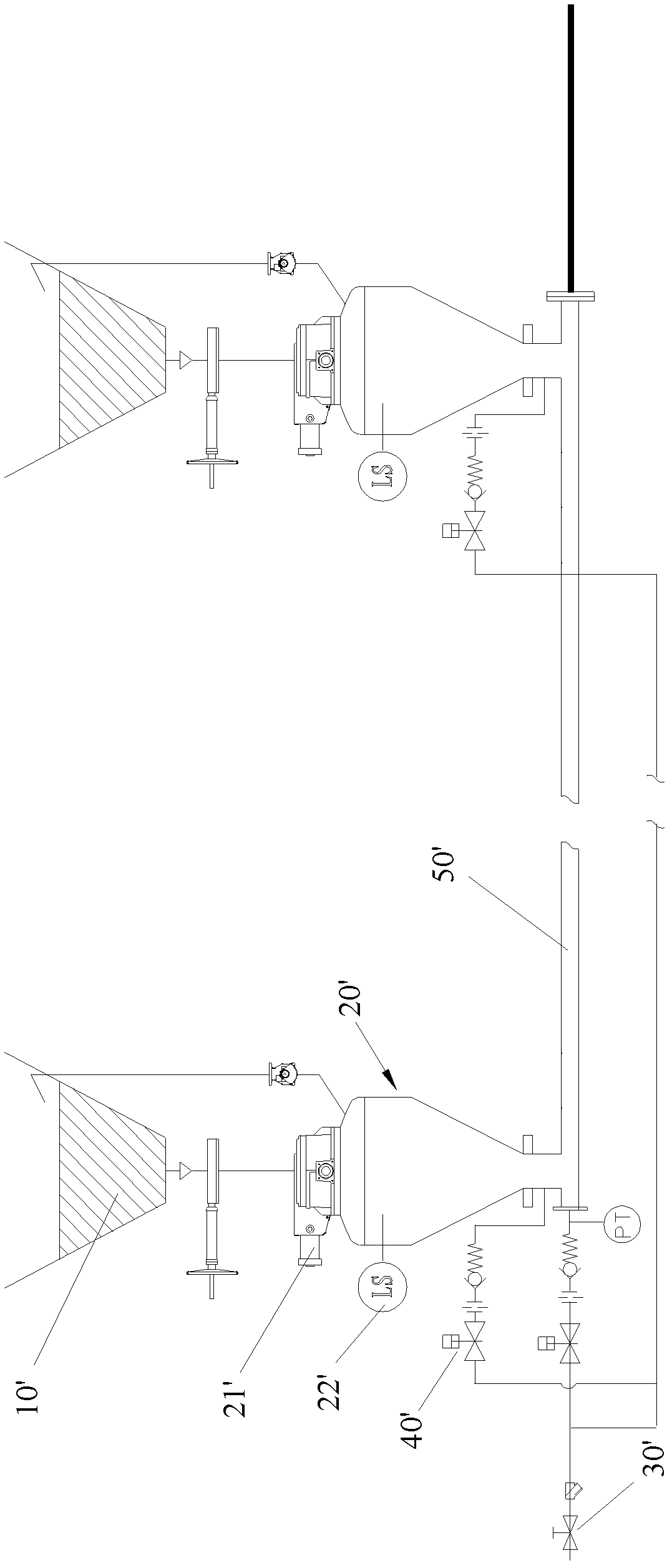

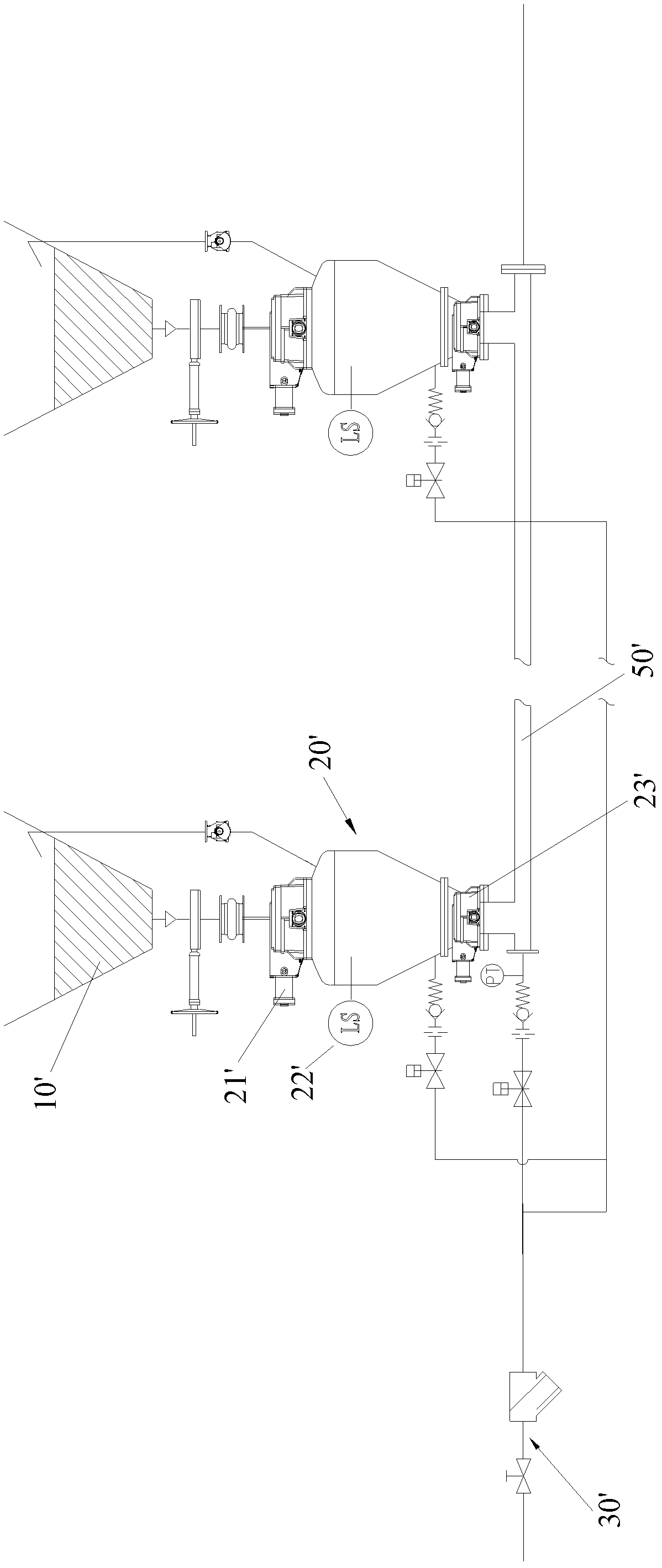

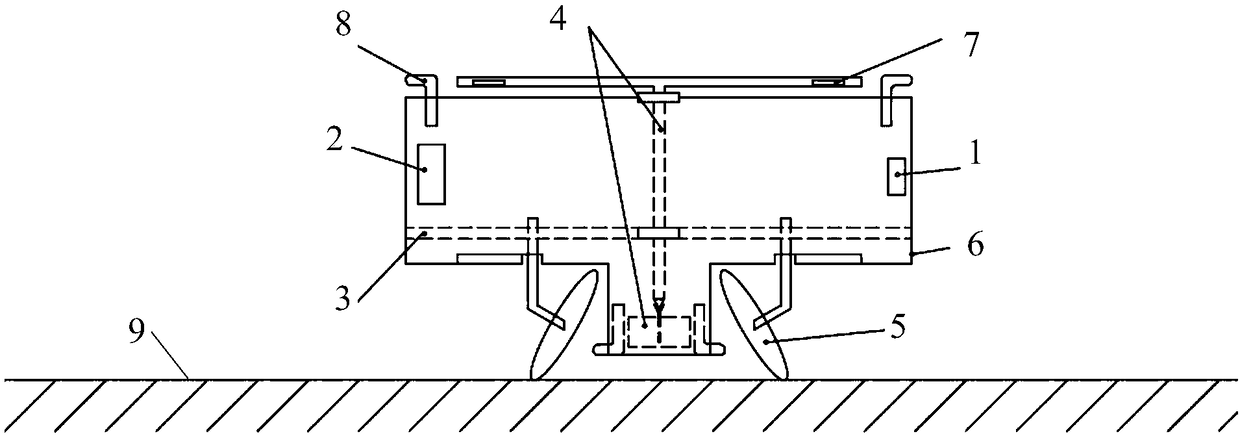

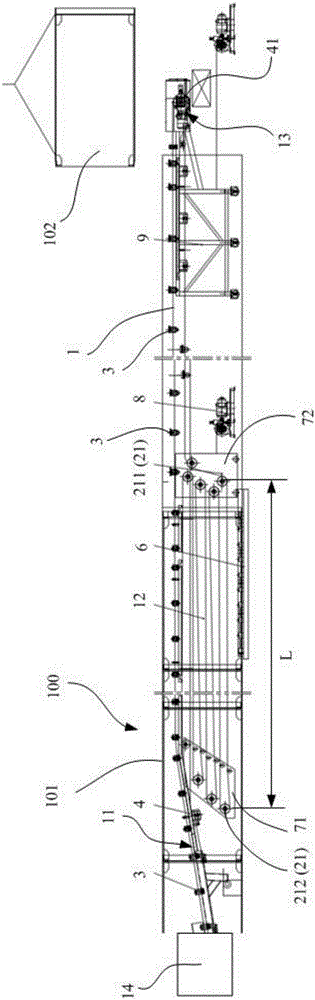

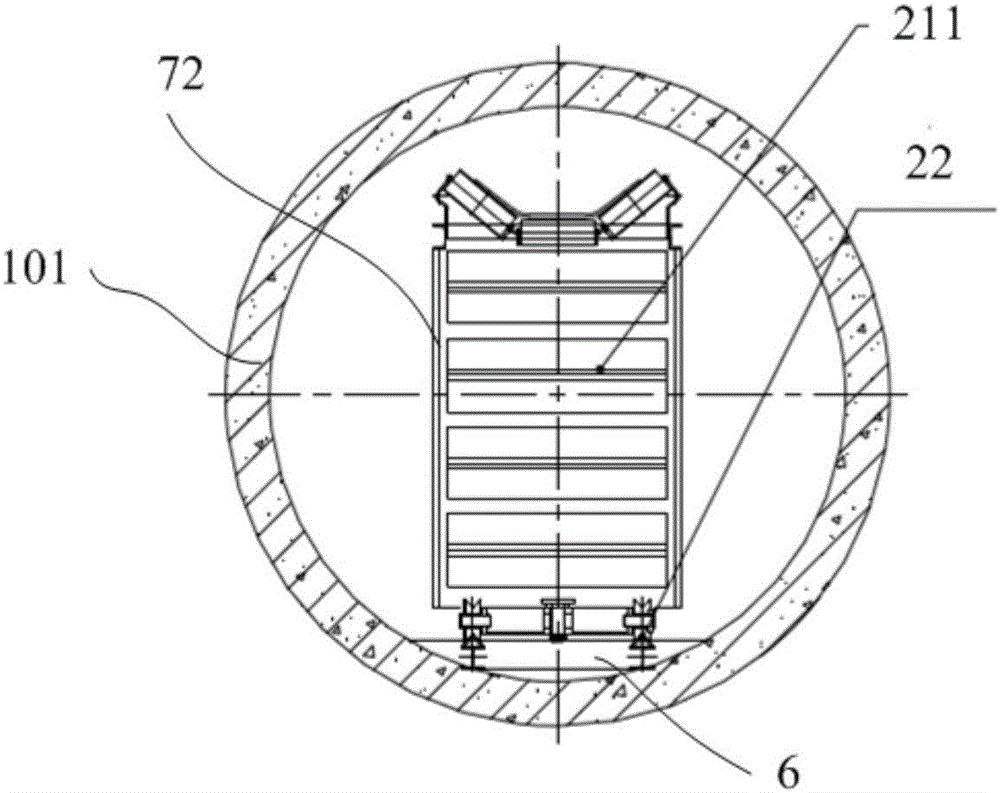

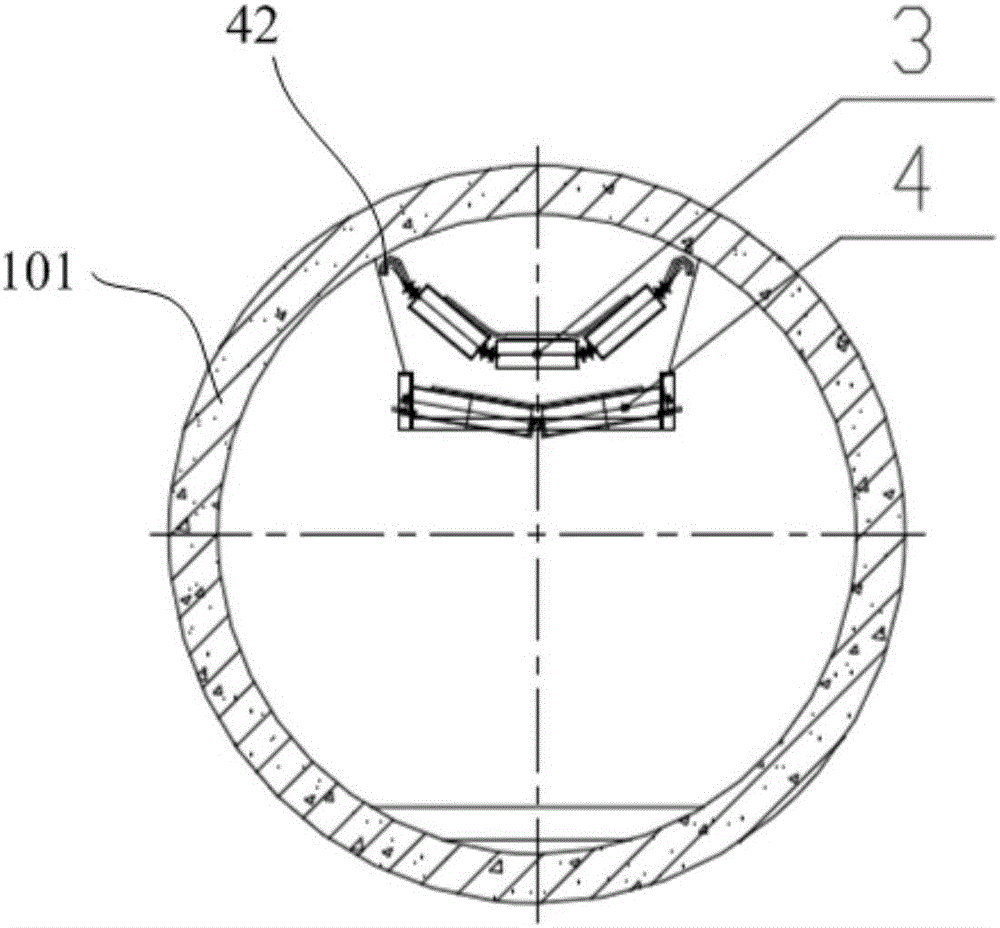

Movable type tubular belt conveyor

ActiveCN103241494ARealize continuous deliveryImprove efficiencyConveyorsSupporting framesTerrainVertical plane

The invention belongs to the field of continuous operating tubular belt conveyors, and particularly relates to a movable pipe belt conveyor. The movable pipe belt conveyor has the technical essentials that, running gears are arranged on the head and the tail of the pipe belt conveyor and enable both the head and the tail of the pipe belt conveyor to perform movements of loading points and emptying points according to practical situations on site, simultaneously middle adjustment machine frames are arranged between the head and the tail of the pipe belt conveyor, the middle adjustment machine frames are all composed of machine frame units and are respectively connected in mode of hinging horizontal planes and vertical planes, slide blocks or universal wheel devices are arranged on the lower portions of the machine frames, and therefore the machine frames can be bent in any horizontal plane, vertical plane and space in a certain bending radius range according to terrain, and materials can be conveyed in a plurality of ranges. The movable pipe belt conveyor can achieve continuous conveying, and thereby is high in efficiency; can effectively restrain dust rising for materials with high dust, and thereby is environment-friendly; and can adapt to topographic change to the upmost, and thereby is strong in adaptability.

Owner:TIDFORE HEAVY IND

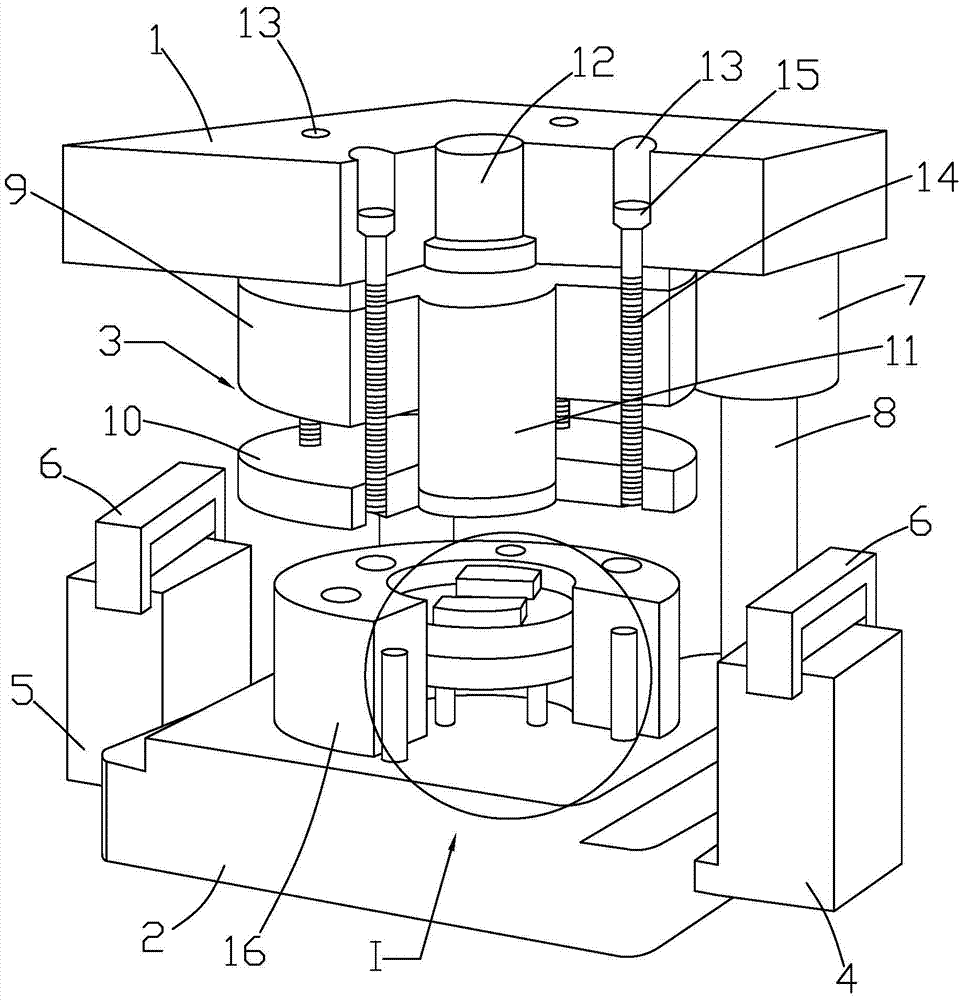

Silicon steel sheet punching machine for production of fan motor rotor

InactiveCN105449946AReduce impactAffect the service lifeMetal-working feeding devicesManufacturing stator/rotor bodiesHydraulic cylinderPunching

The invention discloses a silicon steel sheet punching machine for production of a fan motor rotor. The silicon steel sheet punching machine comprises an upper top plate, a base, a stamping mechanism, a feeding box body and a discharging box body, wherein a main hydraulic cylinder is arranged on the upper top plate, at least two lifting hydraulic cylinders are arranged on the bottom surface of the upper top plate and connected onto the top surface of the base via a piston rod, a punching processing table is arranged at the center of the top surface of the base and fixedly connected onto the base via a limitation rod, a stamping through hole is formed in the center of the punching processing table, a buffer mechanism is arranged in the stamping through hole, the feeding box body and the discharging box body are respectively arranged at the two sides of the base, and feeding positioning devices are arranged on the top surfaces of the feeding box body and the discharging box body. The silicon steel sheet punching machine is simple in structure and has high practicability, continuous transmission of silicon steel sheets can be fulfilled, and the transmission efficiency of the silicon steel sheets is improved; and moreover, the punching process of the silicon steel sheets with different sizes and types can be met, the silicon steel sheets after being punched are automatically stacked and formed, and the production process of the rotor is simplified.

Owner:SHENGZHOU BEIYULING MOTOR FACTORY

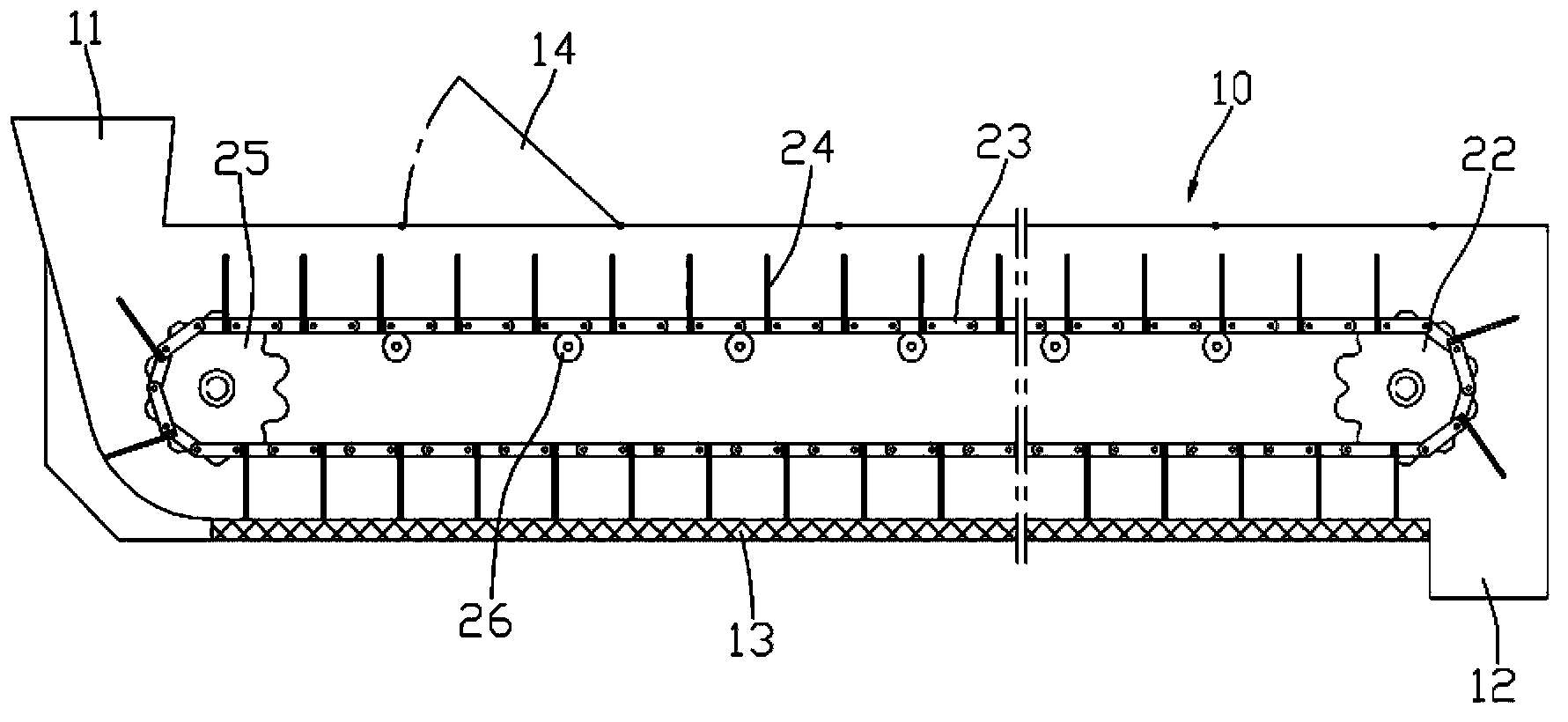

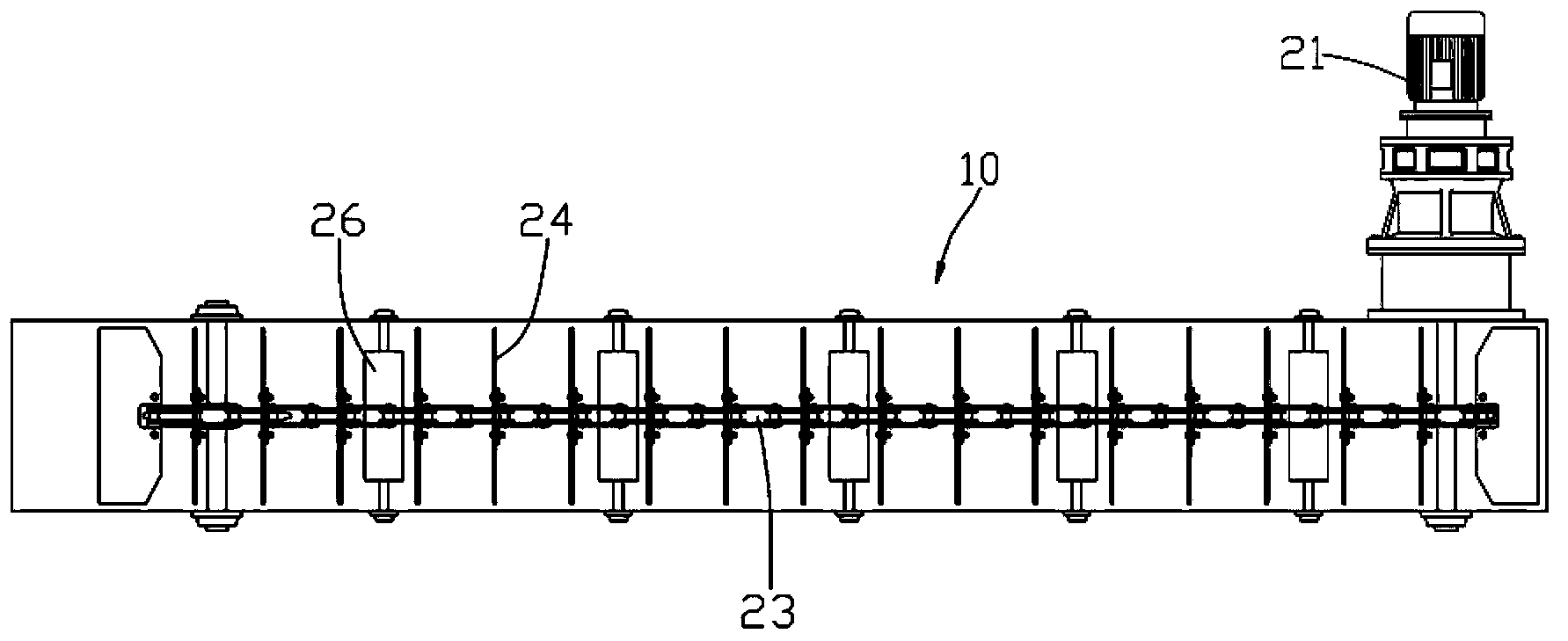

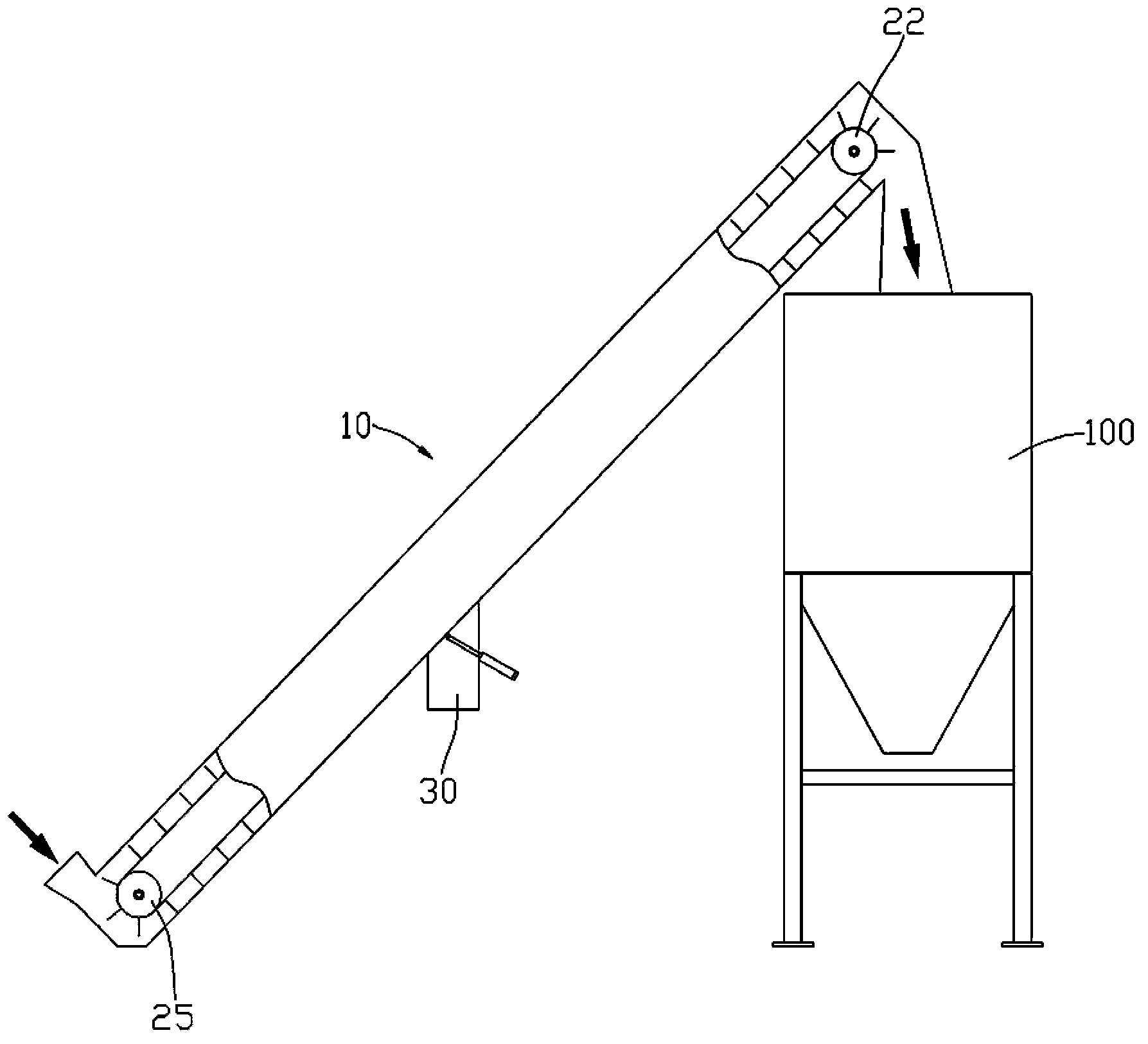

Continuous conveyer for asphalt mixture

The invention discloses a continuous conveyer for asphalt mixture. The continuous conveyer comprises a box provided with a feed hole and a discharge hole. The discharge hole inner end of the box is provided with two coaxial driving sprockets driven by a reducer. The two driving sprockets drive two conveyer chains. A plurality of scraper plates are disposed at intervals on the conveyer chains synchronously. The inner feed end of the box is provided with two driven sprockets used for adjusting tension of the conveyer chains. The middle of the box is provided with a middle discharge door. The continuous conveyer is simple and compact in structure, convenient to maintain and available for continuous conveying of the asphalt mixture; accordingly, work efficiency is improved greatly.

Owner:杨林江

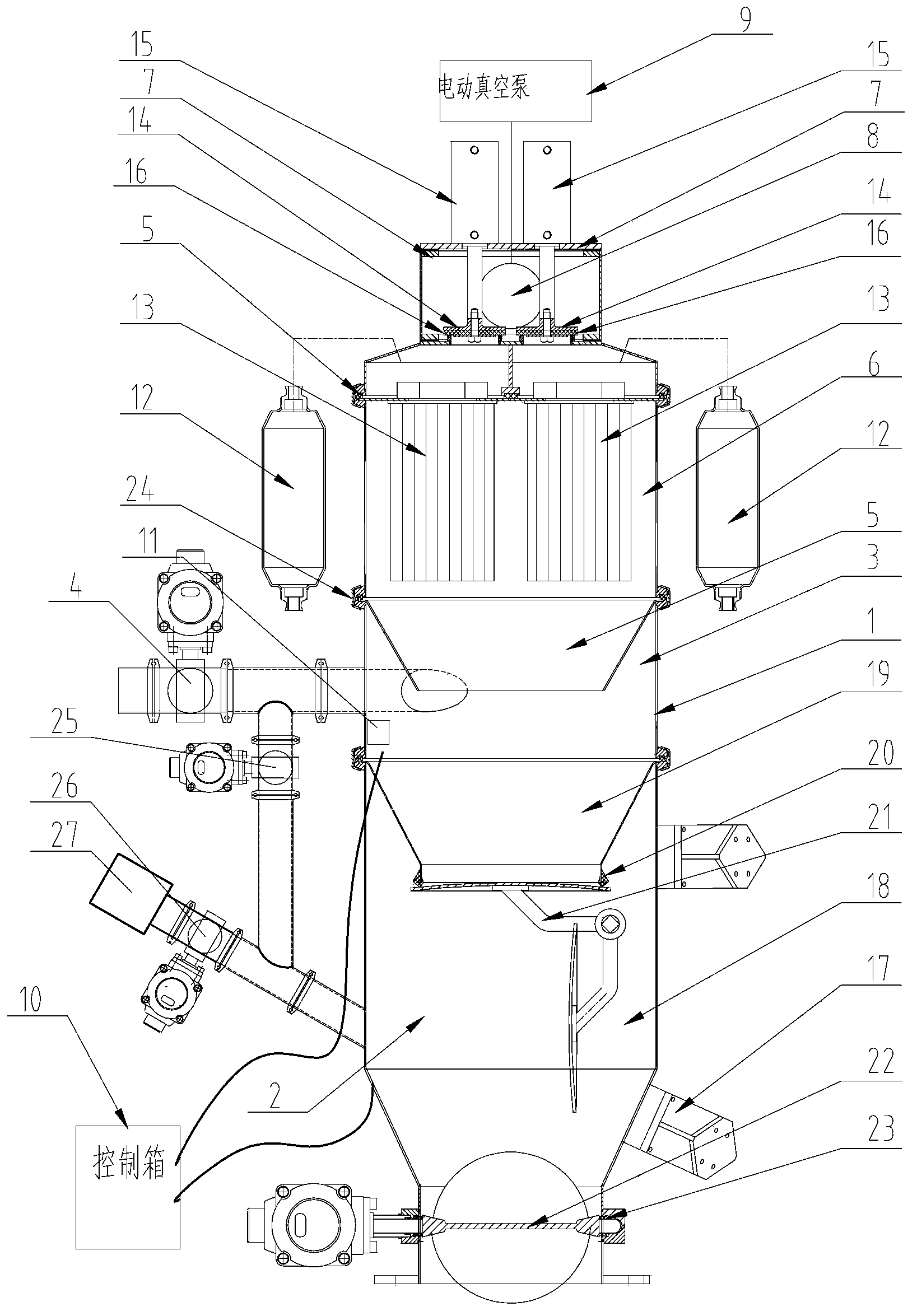

Clearance arrangement type continuous vacuum feeding machine

The embodiment of the invention discloses a clearance arrangement type continuous vacuum feeding machine which comprises a feeding device and a discharging device below the feeding device. The feeding device comprises a feeding bin, a pneumatic material suction butterfly valve, a separation cone hopper, a filer bin and air channel mechanisms, the pneumatic material suction butterfly valve is arranged on the side wall of the feeding bin and used for carrying out feeding, the separation cone hopper is arranged in the feeding bin, the filter bin is arranged above the feeding bin, the air channel mechanisms are arranged above the separation cone hopper and are arranged in a bilateral symmetry mode, the structures of the air channel mechanisms are identical, and the two air channel mechanisms are connected with an electric vacuum pump through vacuum pipes. The electric vacuum pump is electrically connected with a control box. Through the clearance arrangement type continuous vacuum feeding machine, the aim of continuously and permanently conveying materials in a vacuum mode can be achieved without distance limits, the clearance arrangement type continuous vacuum feeding machine has the advantages of being high in conveying efficiency and high in vacuum source utilization rate, meanwhile, material suction and discharging can be kept smooth at constant speed, and dust leakage and potential safety hazards can be eliminated.

Owner:欧才权

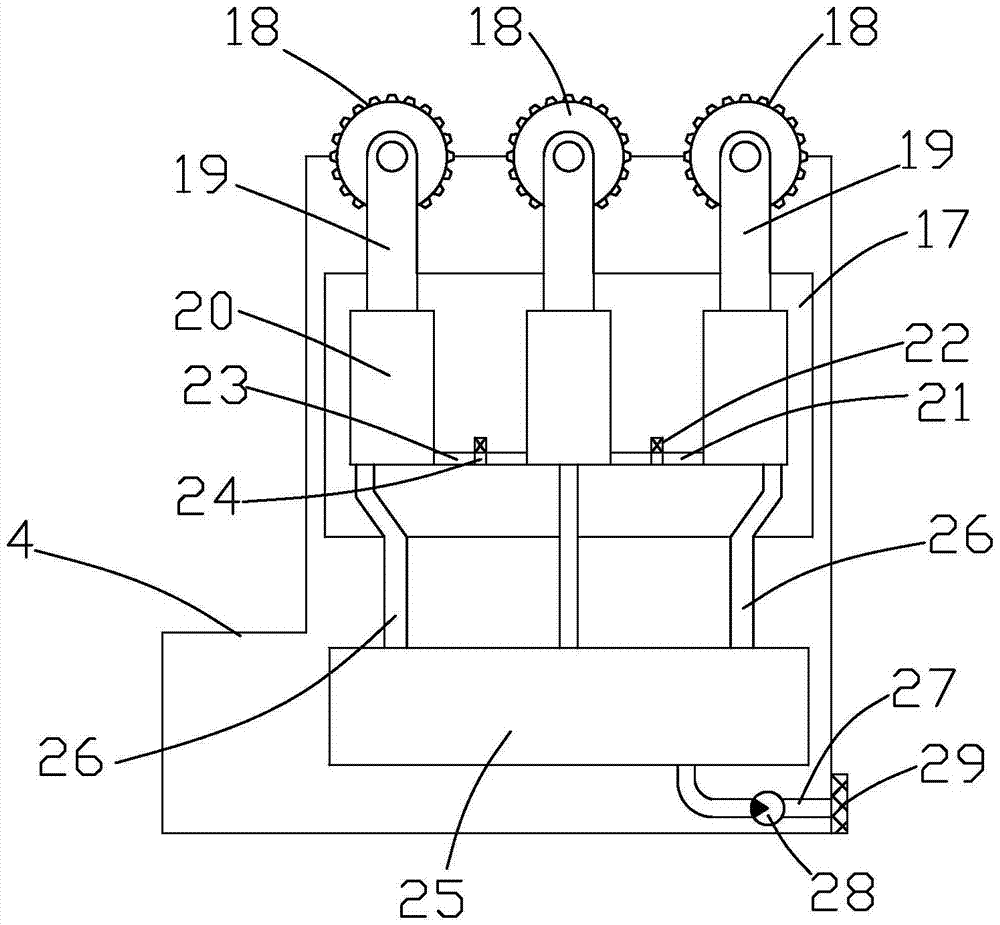

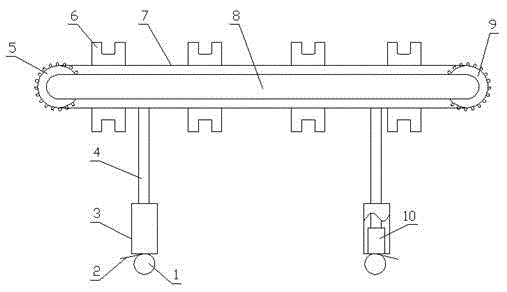

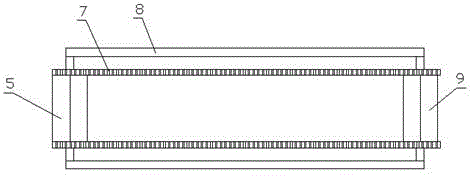

Cloth conveying device for textiles

InactiveCN105584787ARealize continuous deliveryImprove work efficiencyConveyorsSupporting framesHydraulic cylinderEngineering

The invention relates to the field of textiles, in particular to a cloth conveying device for textiles. The cloth conveying device has a continuous conveying function, can improve the conveying efficiency and reduce the transporting safety risk of workers, and is suitable for various conveying heights. The cloth conveying device is characterized by comprising a rack, wherein a driven chain wheel and a driving chain wheel are respectively fixed at the two ends of the rack; a ring-shaped dynamic chain is meshed between the driven chain wheel and the driving chain wheel; a plurality of positioning teeth are arranged on the upper surface of the dynamic chain; the rack is propped against the ground through an upper bracket and a lower bracket fixed on the lower surface of the rack; a hydraulic cylinder is arranged inside the lower bracket; and the top end of the hydraulic cylinder is in contact with the bottom end of the upper bracket. The cloth conveying device is stable to work, convenient to maintain, long in service life and applicable to conveying of textile fabric rolls.

Owner:吴江市盛泽信达绸厂

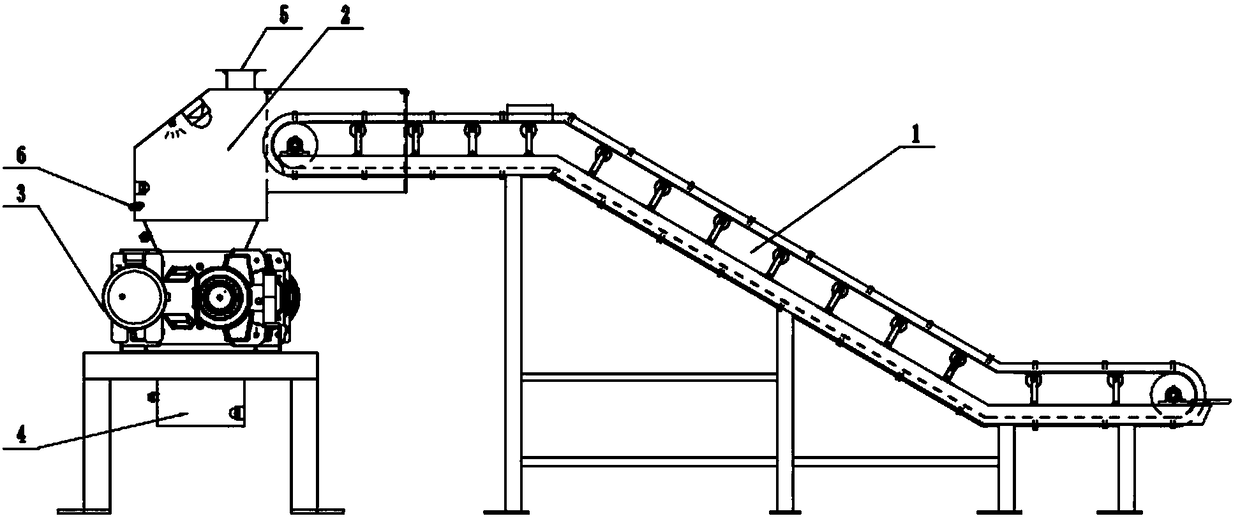

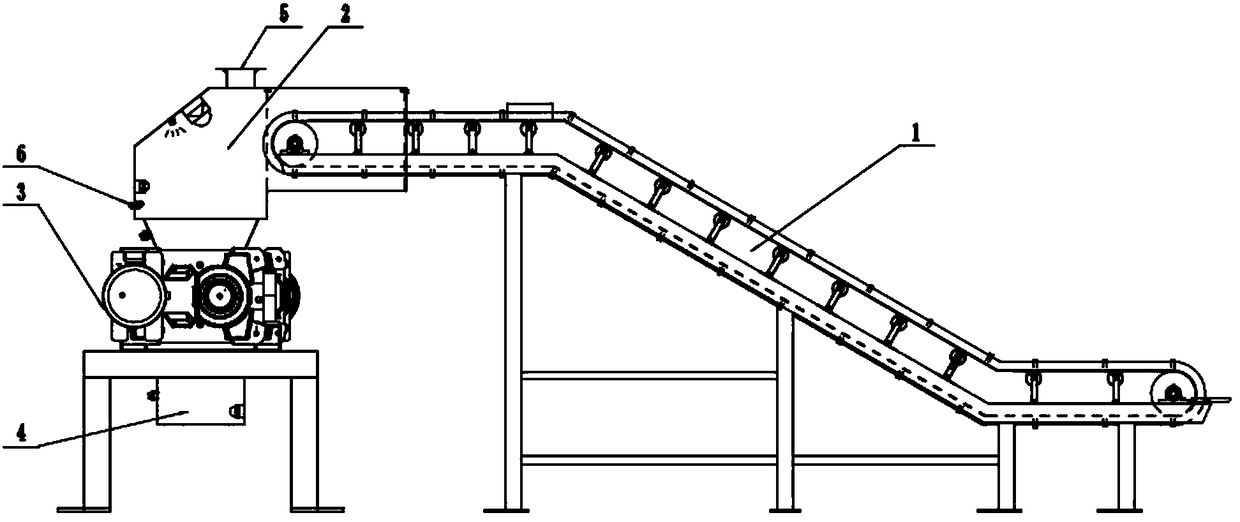

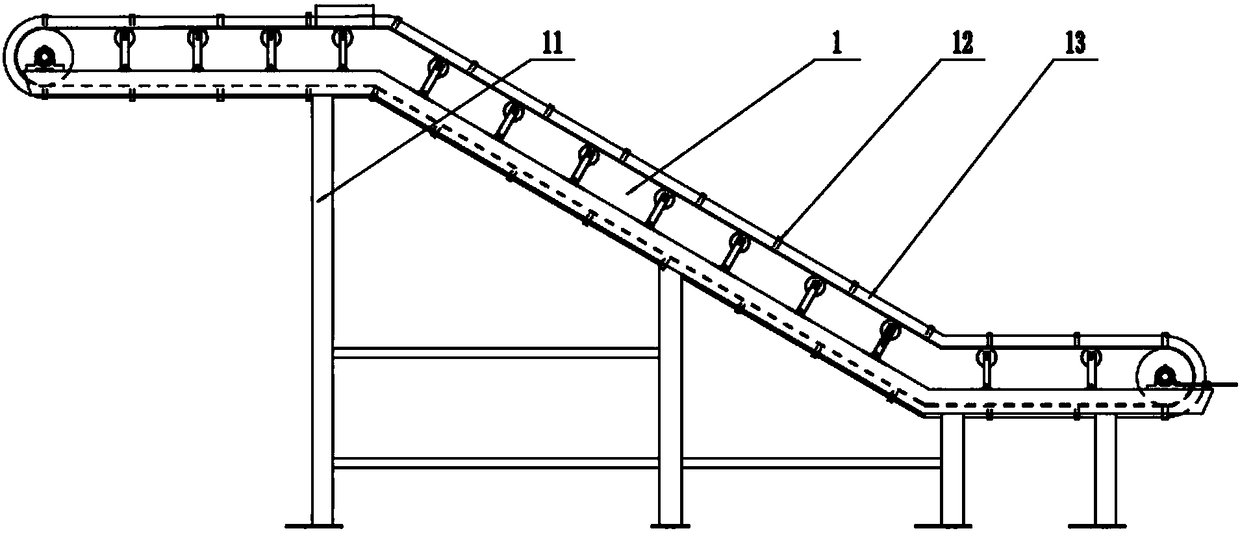

Electrified lithium battery and lithium battery module breaking system

PendingCN108452933AAvoid burning and explosionReduce oxygen concentrationFire rescueDirt cleaningElectrical batteryEngineering

The invention discloses an electrified lithium battery and lithium battery module breaking system and belongs to the technical field of lithium battery and lithium battery module breaking. The electrified lithium battery and lithium battery module breaking system comprises a feeding box, a breaking box, a discharging hopper and a material conveying mechanism, wherein an inlet of the feeding box isconnected with the material conveying mechanism, an outlet of the feeding box is connected with the top of the breaking box, a breaking device for breaking batteries is arranged in the breaking box,the bottom of the breaking box is connected with the discharging hopper, a waste gas discharging pipeline is connected to the feeding box, and a gas protection device is further arranged on the feeding box. The electrified lithium battery and lithium battery module breaking system disclosed by the invention avoids discharge in disassembling lithium batteries and lithium battery modules, saves a lot of time and cost and reduces safety and environment-friendly problems caused by discharge; meanwhile, the electrified lithium battery and lithium battery module breaking system is safe in a breakingprocess, fire explosion is prevented from happening, work efficiency is greatly improved by full-automatic breaking and disassembling, and the sealed system ensures environmental friendliness.

Owner:哈尔滨巴特瑞资源再生科技有限公司

Carrier conveying device

ActiveCN105197577AContinuous deliveryStable and precise deliveryConveyor partsEngineeringMechanical engineering

The invention provides a carrier conveying device and belongs to the technical field of medical accessory assembling machines. The technical problem that an existing carrier conveying device is low in conveying precision is solved. The carrier conveying device comprises a machine frame and a guide rail arranged on the machine frame and extending in the linear direction. The guide rail is provided with a plurality of carriers which can horizontally move along the guide rail. The carriers are sequentially arranged in the length direction of the guide rail. The machine frame is provided with a first clamping jaw capable of being opened and closed. The first clamping jaw can achieve relative positioning with one carrier when closed. The machine frame is provided with a pushing mechanism capable of pushing the other carriers towards the first clamping jaw. The machine frame is further provided with a first driving mechanism capable of driving the first clamping jaw to move back and forth in the length direction of the guide rail. The carrier conveying device has the advantages of being high in conveying precision, compact in structure and the like.

Owner:MAIDER MEDICAL IND EQUIP

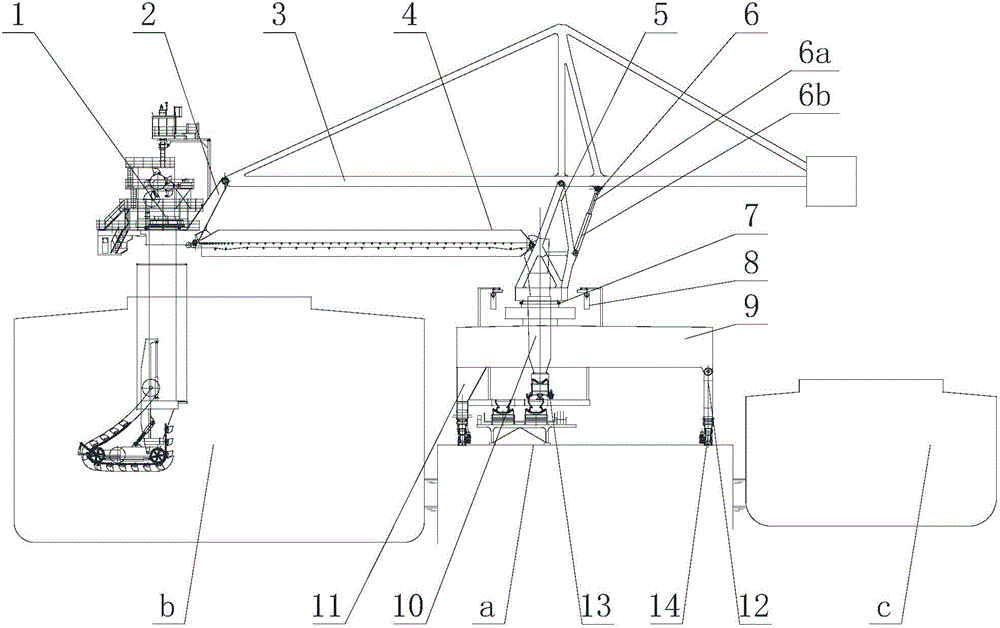

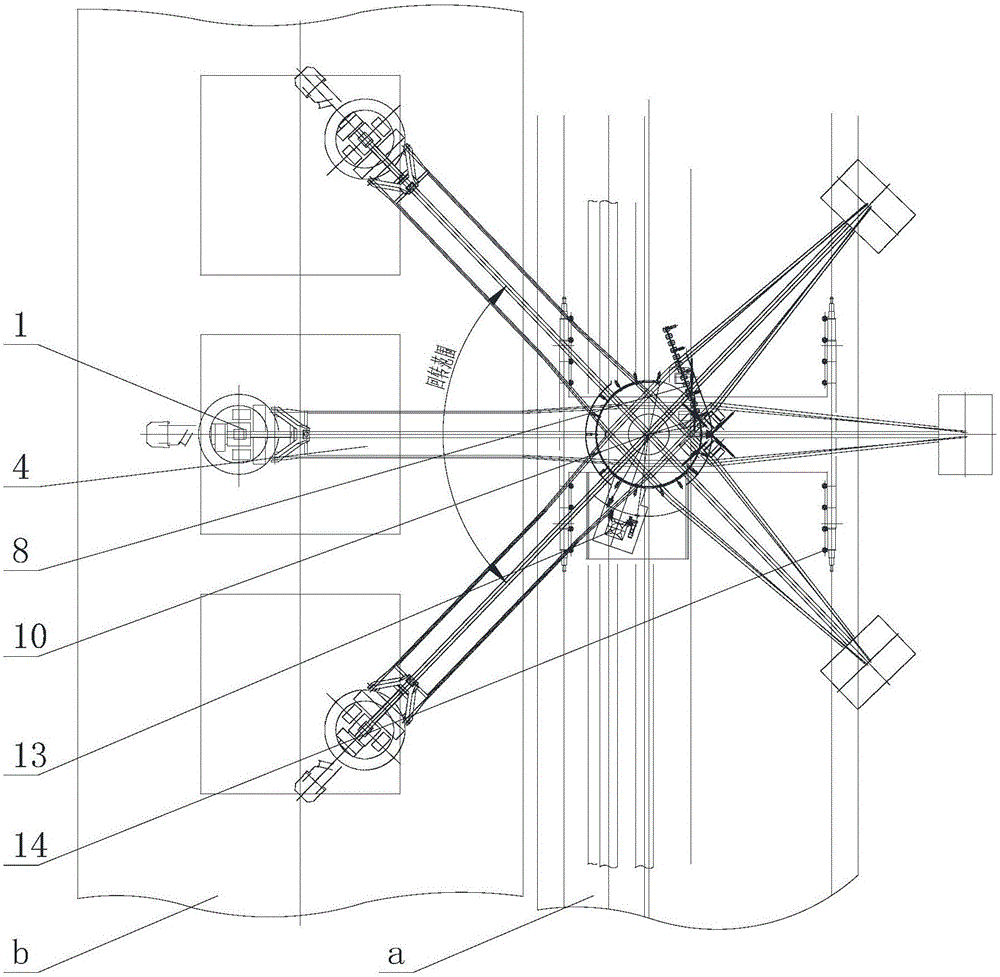

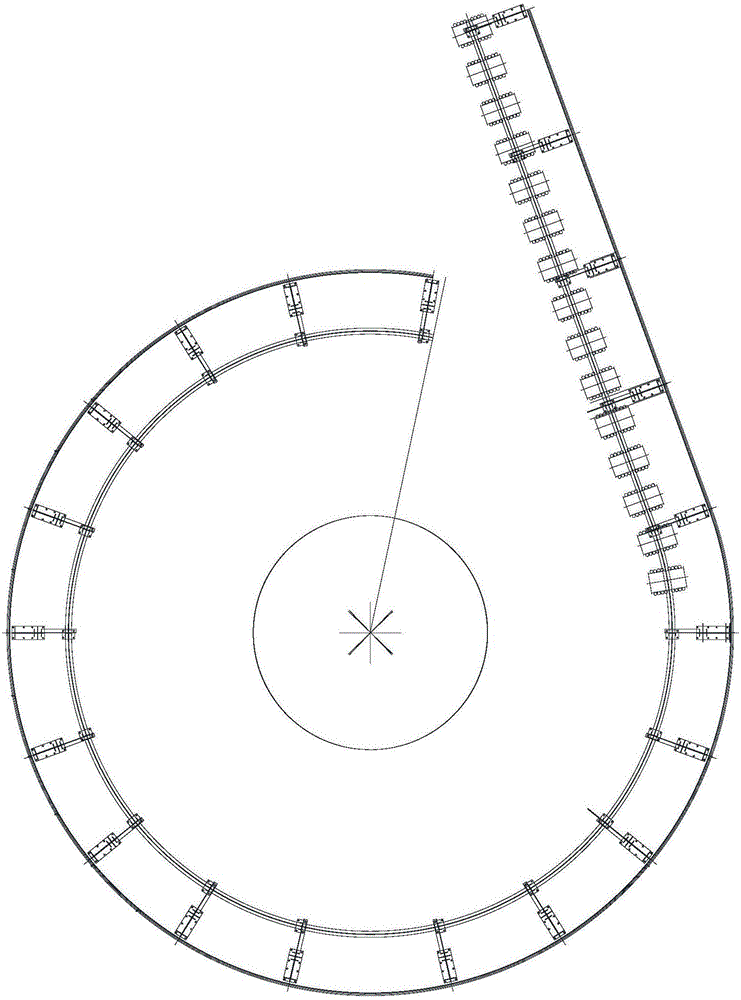

Continuous unshipping machine capable of realizing unshipping from two sides and unshipping method

PendingCN106800195ARotary realizationRealize unloadingLoading/unloadingMaterial scatteringEngineering

The invention discloses a continuous unshipping machine capable of realizing unshipping from two sides and an unshipping method. The continuous unshipping machine comprises a portal frame, wherein a sea-side supporting column and a land-side supporting column are respectively mounted on two sides of the bottom of the portal frame; a rotary frame is mounted at the upper part of the portal frame through a rotary bearing; the rotary frame is of a truss structure, and a central sliding tube for receiving a material is arranged in the center of the rotary frame; a balance beam is arranged at the upper part of the rotary frame; the front end of the rotary frame is connected with a material taking and lifting system for extracting the material through a horizontally arranged boom system; and a belt conveyer system for conveying the material is arranged in the boom system. According to the continuous unshipping machine capable of realizing unshipping from two sides and the unshipping method which are disclosed by the invention, the whole continuous unshipping machine is in a sealed state; in the whole material conveying process, the phenomena of dust flying and material scattering are avoided, so that an extremely good environmental protection effect is achieved; furthermore, the continuous unshipping machine is compact in structure, high in practicability, energy-saving and efficient; all the used components are independently manufactured, and convenient to machine and assemble; and one set of equipment can realize unshipping from the sea side and the land side, thus realizing a strong function.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

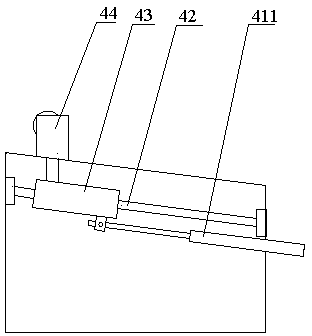

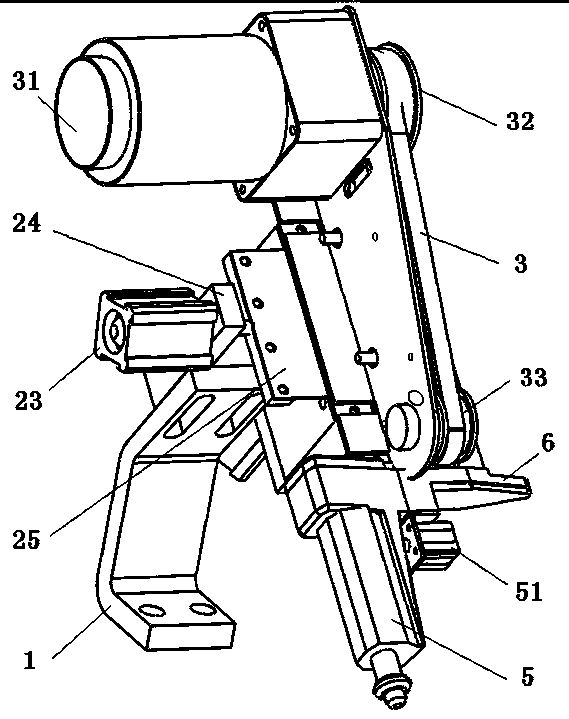

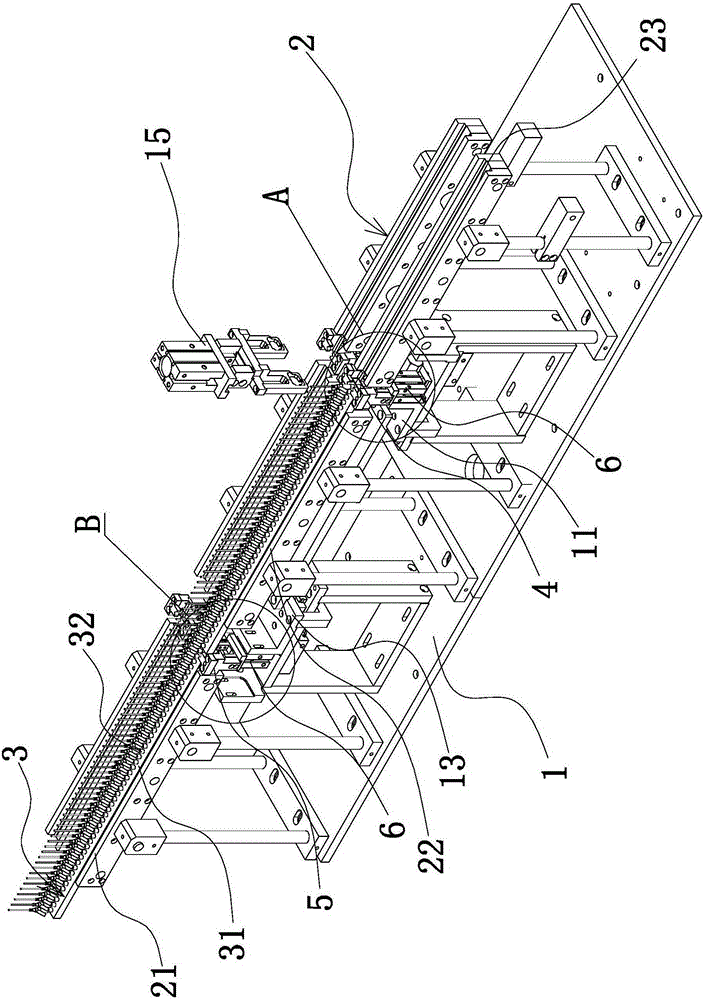

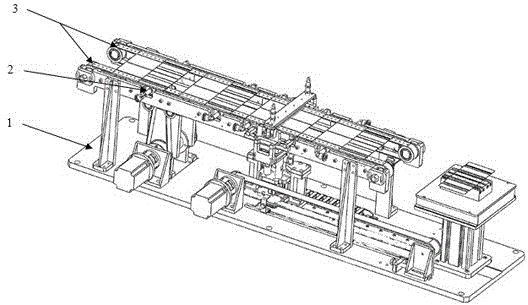

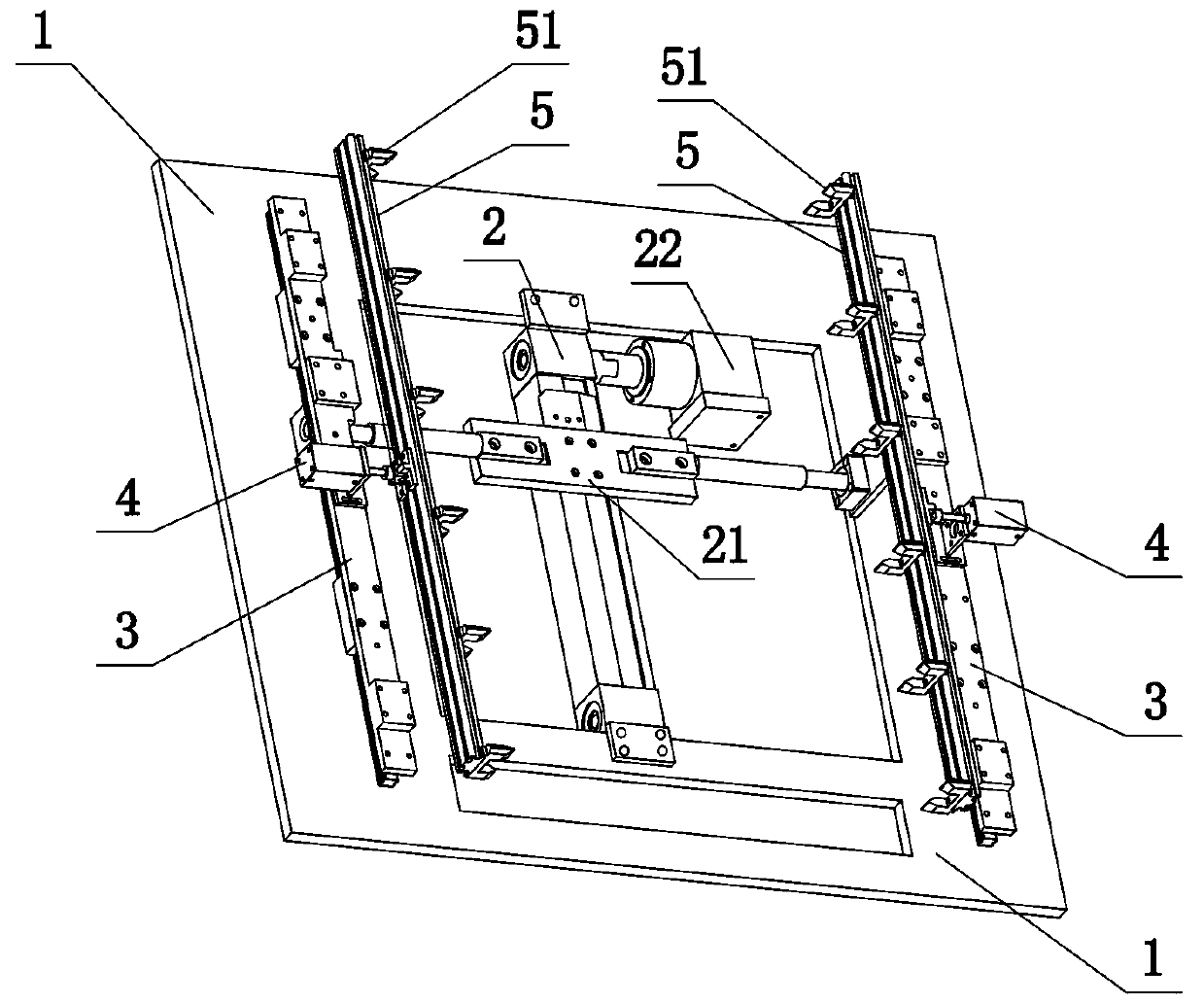

Battery piece conveying mechanism for automatic series welding machine

ActiveCN105598612AAbsorb stableRealize continuous deliveryWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to a battery piece conveying mechanism for an automatic series welding machine. The mechanism comprises a conveying device, adjusting devices and a discharging device, wherein the discharging device comprises a guiding device installed on a base plate, the guiding device is parallel to a conveyer belt, a movable device is installed on the guiding device, a lifting device is installed on the movable device, a piece taking support is installed on the lifting device, and the movable device is driven by a power device. Continuous conveyance is achieved through belt conveyance, and conveying efficiency is improved; meanwhile, by arranging the adjusting devices on the two sides of a conveying support, battery pieces can be adjusted during conveyance, so that time is saved and conveying efficiency is improved; battery pieces which are out of position during conveyance can be adjusted by the adjusting devices, battery pieces which arch up are pressed flat through a pressing plate, so that the discharging device can absorb the battery pieces more stably, and then the battery pieces are effectively prevented from falling off during conveyance.

Owner:WUXI AUTOWELL TECH

Stainless steel pipe production and machining equipment

ActiveCN112059280ARealize continuous deliveryImprove cutting efficiencyTube shearing machinesMetal working apparatusMechanical engineeringMachining

The invention relates to the technical field of stainless steel pipe production and machining, and discloses stainless steel pipe production and machining equipment. The stainless steel pipe production and machining equipment comprises a workbench, a cutting machine is fixedly installed at the top of the right side of the workbench, a pushing mechanism is arranged on the left side of the top of the workbench and comprises a fixing frame, the side walls, close to a containing groove, of two pushing plates are each provided with two extrusion mechanisms correspondingly, and each extrusion mechanism comprises an extrusion plate. According to the stainless steel pipe production and machining equipment, steel pipes can be continuously conveyed through work of a power source servo motor, so thatthe labor intensity of workers is reduced, and the steel pipe cutting efficiency is improved; and meanwhile, through cooperative use of the extrusion mechanisms, a fixing device and a limiting device, the pushed steel pipes can be automatically fixed, the stability during steel pipe cutting is improved, the steel pipes are prevented from shaking and shifting in the cutting process, and the steelpipe cutting efficiency is further improved.

Owner:扬州市凯峰达物资有限公司

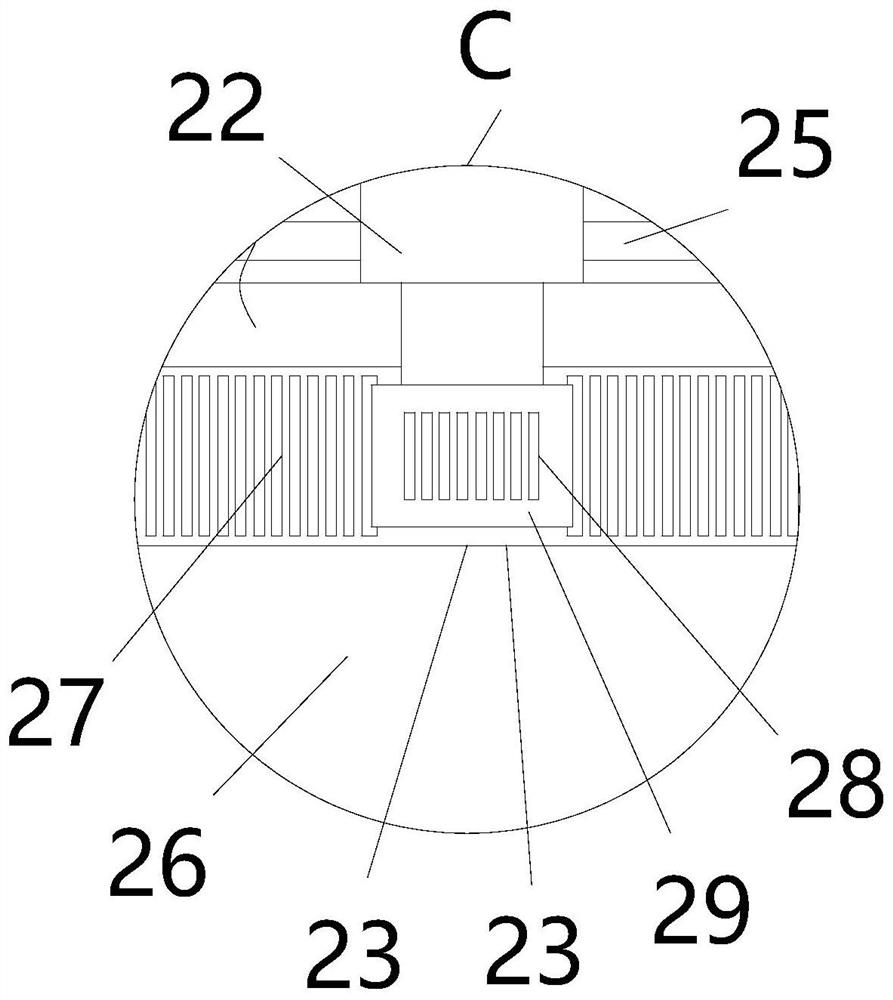

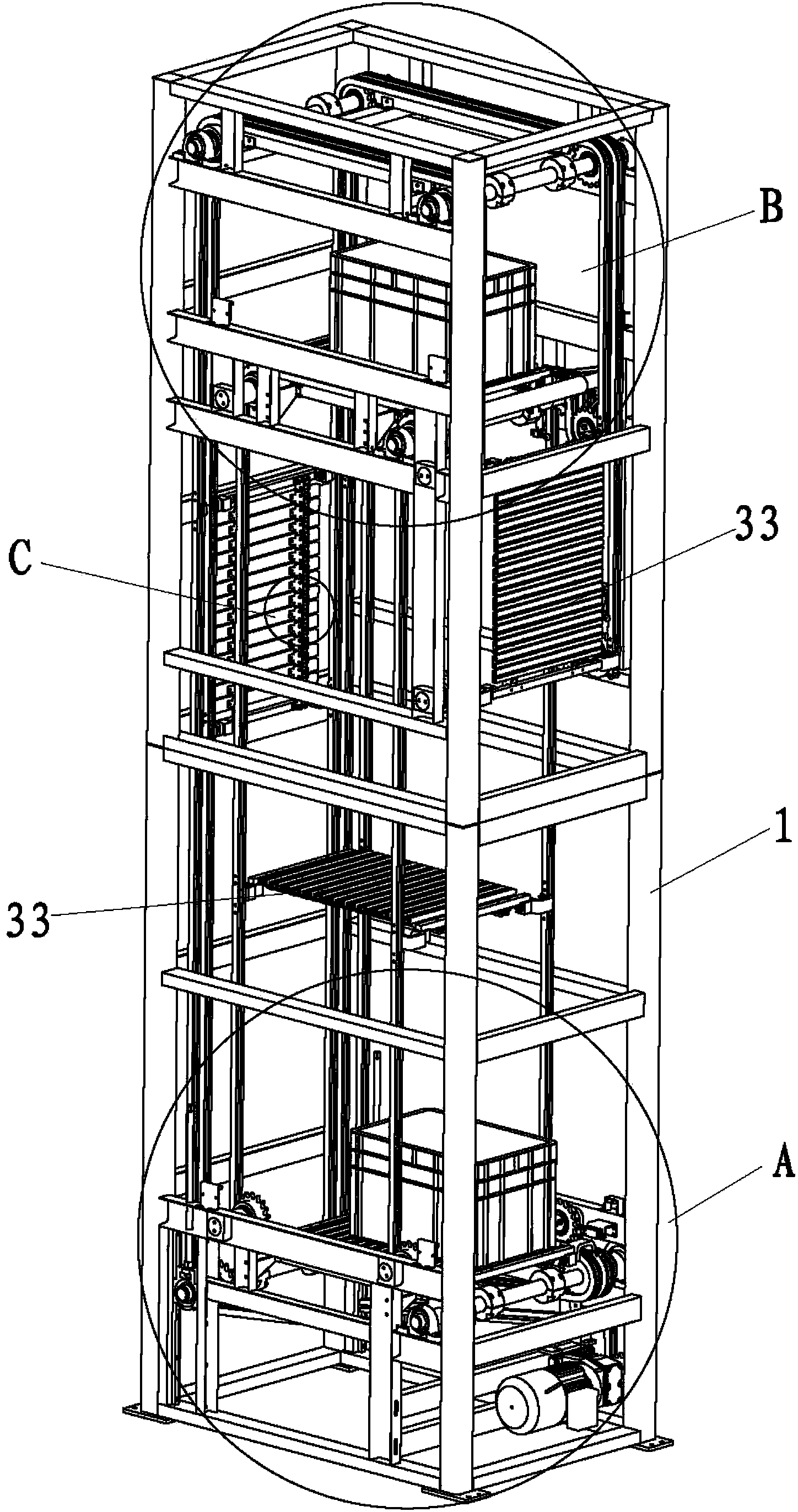

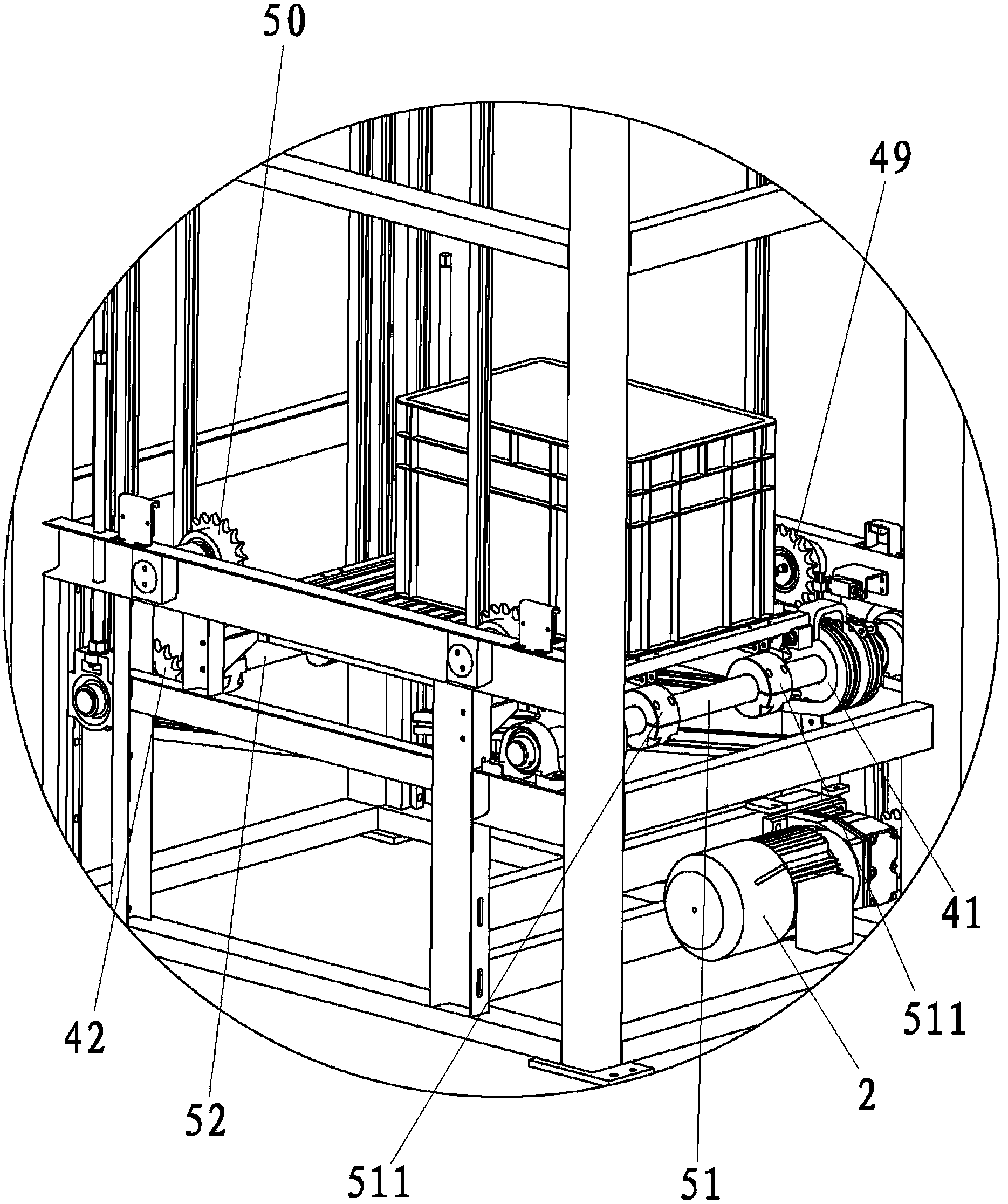

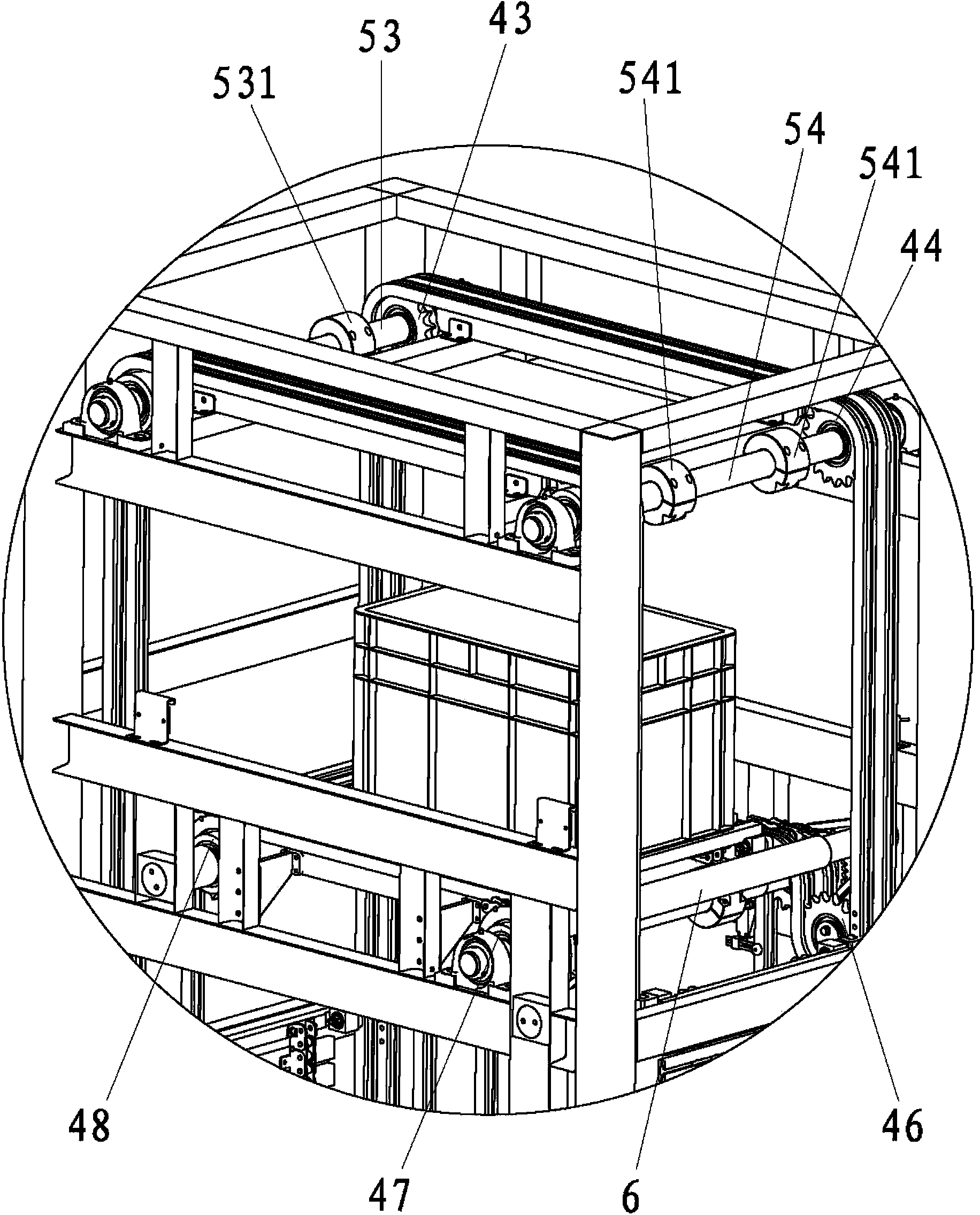

C type continuous elevator

The invention relates to the field of machines, in particular to a C type continuous elevator. According to the technical scheme, the C type continuous elevator comprises a machine frame, a driving device and a chain assembly. The machine frame is provided with an upper entrance and a lower entrance. The chain assembly comprises two first chains, two second chains and a conveyor belt, wherein the two sides of the front end of the conveyor belt are connected to the side walls of the corresponding first chains in a rotating mode respectively, and the two sides of the rear end of the conveyor belt are connected to the side walls of the corresponding second chains in a rotating mode respectively. The upper entrance and the lower entrance are located in the same side of the machine frame. The conveyor belt comprises a plurality of battens which are connected with one another in a rotating mode. The upper entrance and the lower entrance are located on the same side of the machine frame, and therefore after the elevator is matched with other devices, the goods displacement is relatively short, and the space utilization ratio of a whole logistics device is high.

Owner:HUZHOU RIGOR TECH

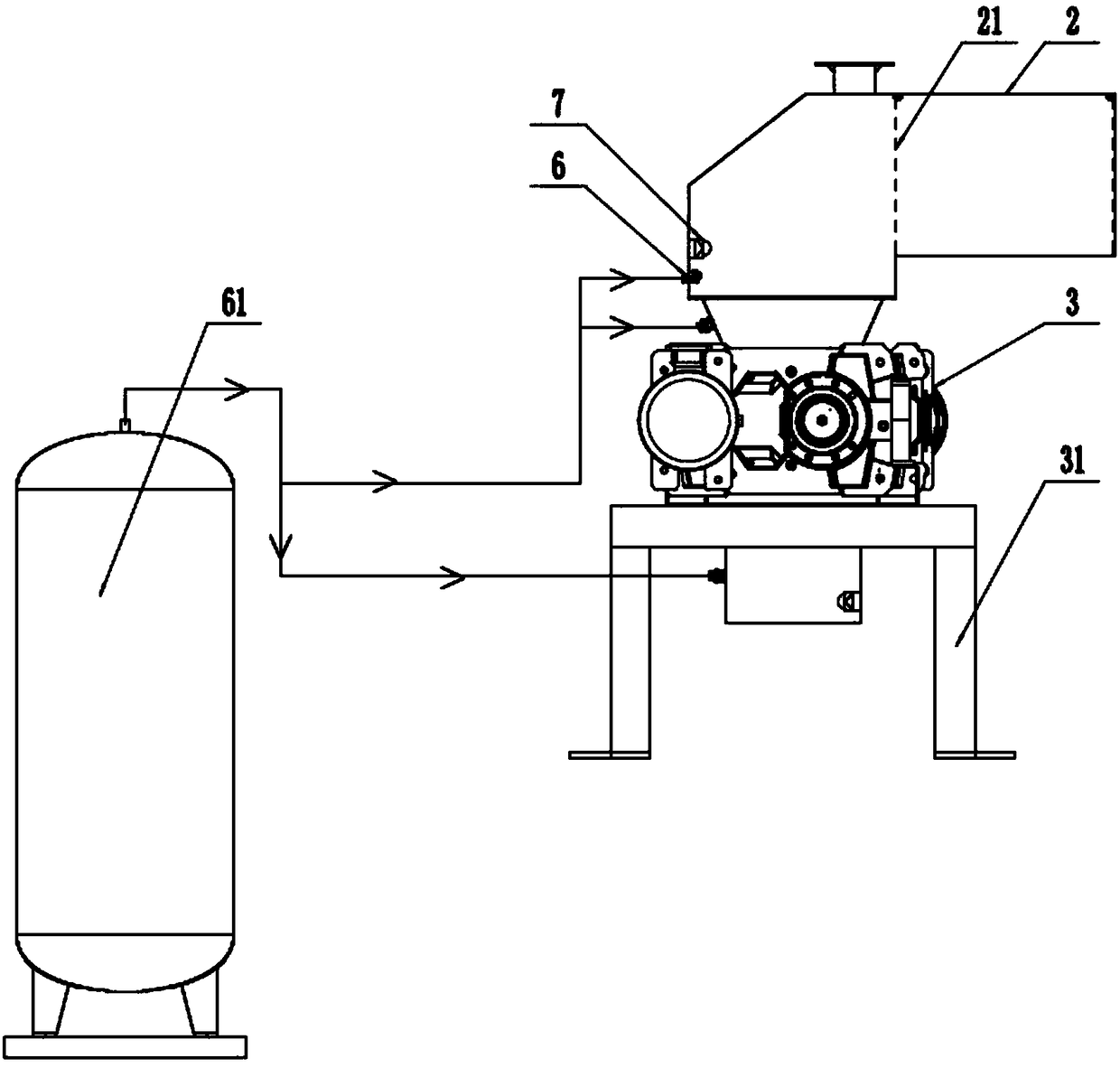

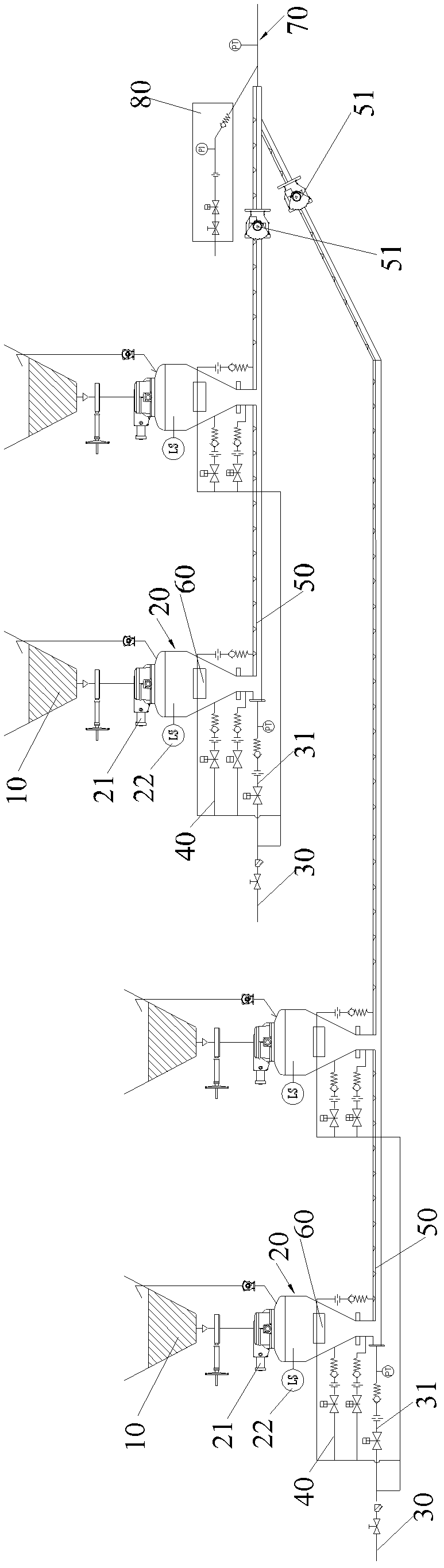

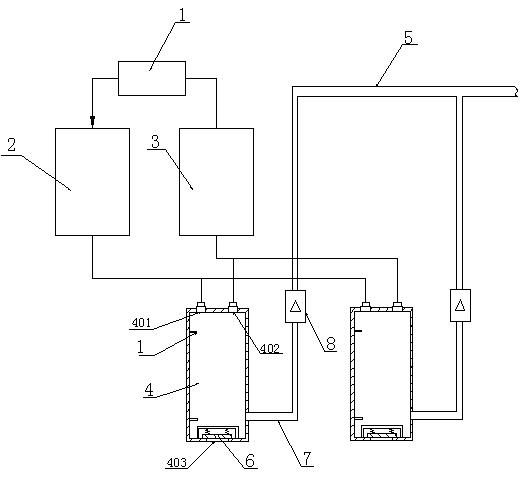

Positive pressure pneumatic transmission system and method

ActiveCN102491093AImprove delivery efficiencyImprove stabilityBulk conveyorsTransmission systemSystem stability

The invention provides a positive pressure pneumatic transmission system and a method. The positive pressure pneumatic transmission system comprises an air inlet pipeline (30), a delivery pipeline (50), a plurality of warehouse pumps (20) and a material adjuster (60). The first end of the air inlet pipeline is communicated with a first compression air source. The delivery pipeline is provided with a first end communicated with the air inlet pipeline (30). The lower ends of the warehouse pumps (20) are communicated with the delivery pipeline (50). The material adjuster (60) is arranged in the warehouse pumps (20) and comprises a flow stopping blocking body (61) arranged in the warehouse pumps (20). The lower ends of the warehouse pumps (20) have cone segments. The material adjuster (60) is arranged in an extension-type manner in the cone segments of the warehouse pumps (20) along axial direction of the warehouse pumps (20). The positive pressure pneumatic transmission method includes the following steps: feeding materials in the plurality of warehouse pumps, enabling the materials to drop into the delivery pipeline through the material adjuster and introducing compression air in the air inlet pipeline with the air quantity ranging from 0 to a rated value. The positive pressure pneumatic transmission system and the method resolve the problem of difficulty in coarse ash delivery, enable continuous delivery of coarse ash to be achieved, improve delivery efficiency of the delivery system, improve system stability and overcome the shortcomings of high valve cost of large warehouse pumps and high equipment cost.

Owner:克莱德贝尔格曼华通物料输送有限公司

Binding type multilevel-pneumatic water pump

InactiveCN102213239AImprove pumping efficiencySimple electrical structurePressure pumpsMachines/enginesPositive pressure ventilationWater pipe

The invention discloses a binding type multilevel-pneumatic water pump which comprises an air pump, a positive pressure cabin, a negative pressure cabin, a water pipe and at least one water uptake cabin, wherein the positive pressure cabin is connected with the air outlet of the air pump, the negative pressure cabin is connected with the bleeding point of the air pump, the upper end of the water uptake cabin is respectively provided with a positive pressure air port and a negative pressure air port, the positive pressure air port and the negative pressure air port are provided with control valves, the positive pressure air port is connected with the positive pressure cabin, the negative pressure air port is connected with the negative pressure cabin, the lower end of the water uptake cabin is arranged on a water inlet, the water inlet is provided with a water valve, the lower part of the water uptake cabin is connected with the water pipe through an outlet pipe with a check valve. The positive pressure cabin and negative pressure cabin in the invention can be connected with multiple water uptake cabins simultaneously, and the water uptake cabins operates alternately, thus the continuous water flow transmission is realized and the water drawing efficiency is greatly improved.

Owner:袁兴立

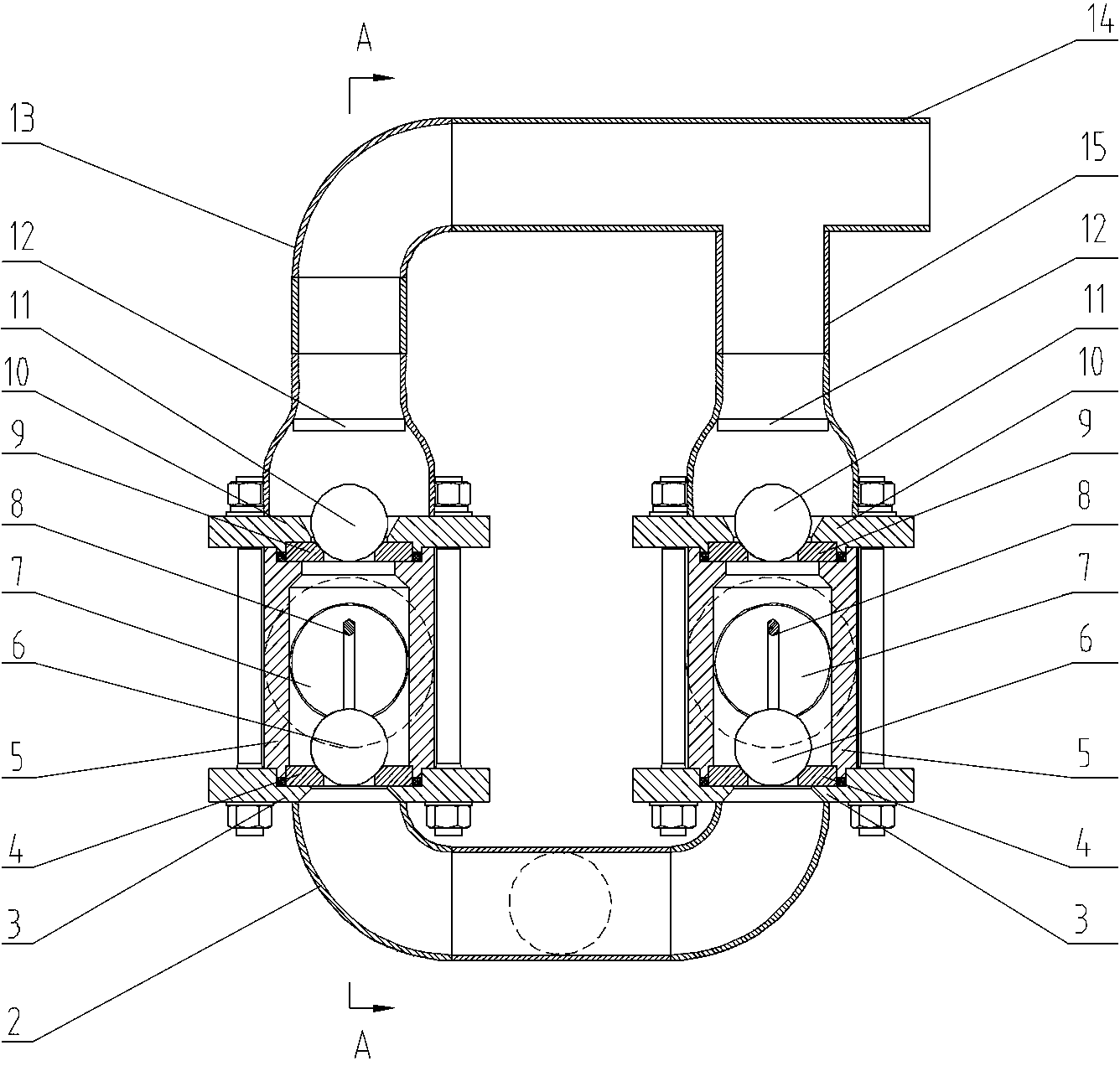

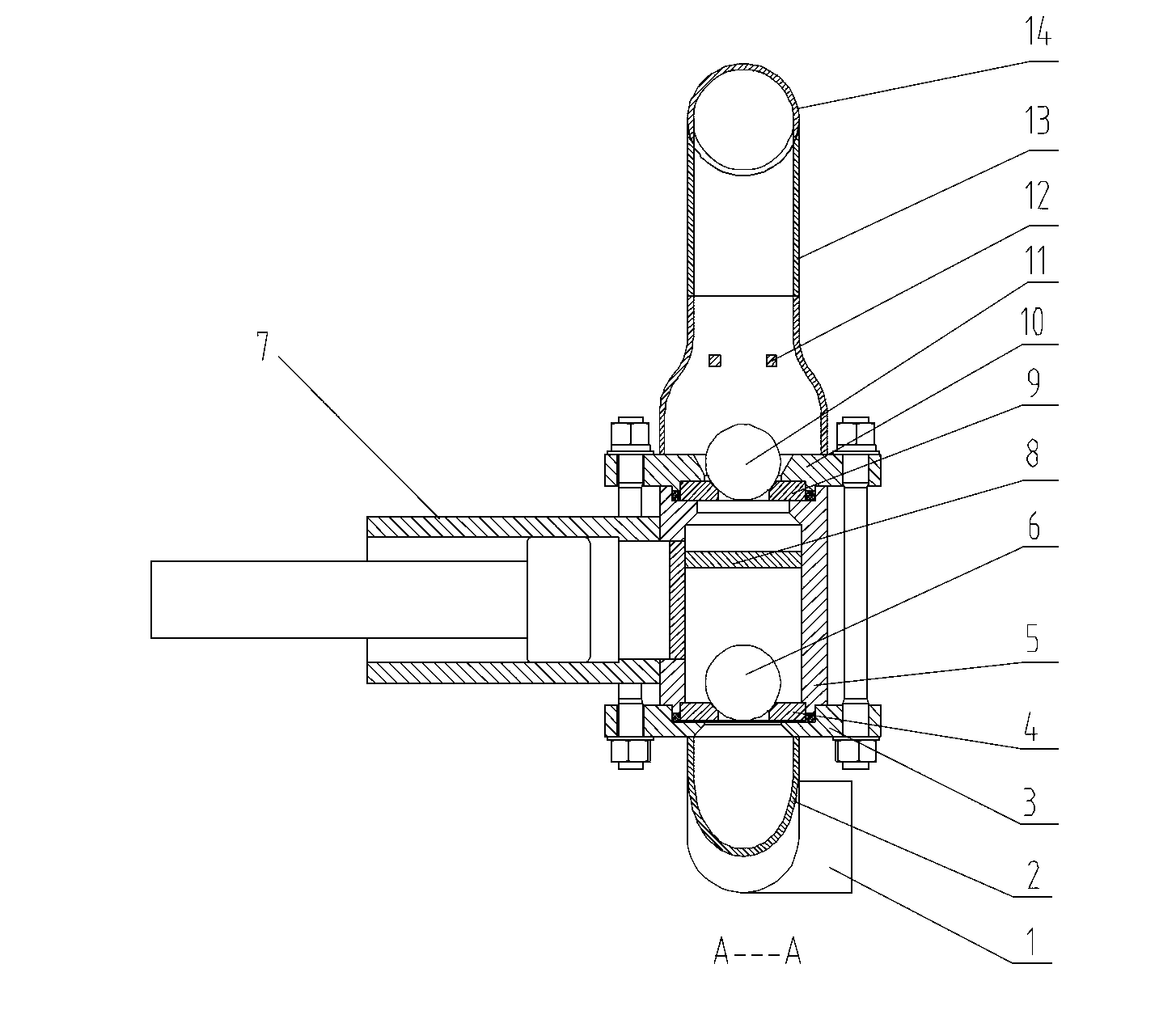

Ball valve type mortar pump

InactiveCN102852754ARealize continuous deliveryLow flow resistancePositive displacement pump componentsPumpsSpray coatingEngineering

A ball valve type mortar pump is suitable for conveying and spray coating construction operation of various mortar pumps. The ball valve type mortar pump comprises a feeding pipe assembly, a discharging pipe, a left ball valve, a right ball valve and a conveying cylinder, wherein the feeding pipe assembly comprises a conveying pipe and a feeding pipe which is vertically connected at the middle part of the conveying pipe; each ball valve comprises a lower fixing plate, a lower ball valve seat, a valve body, a lower ball valve core, a lower stop lever, an upper ball valve seat, an upper fixing plate and an upper bal valve core; an upper-left transitional pipe and an upper-right transitional pipe which are connected onto the discharging pipe in parallel are respectively arranged on the left and right ball valves; lower ends of the upper-left transitional pipe and the upper-right transitional pipe are respectively and fixedly arranged on the fixing plates of the left and right ball valves; and two parallel upper stop levers are respectively arranged at the lower parts of the upper-left transitional pipe and an upper-right transitional pipe. Due to the adoption of a structure comprising two sets of ball valves and the conveying cylinders, the continuous conveying of mortar is realized. The ball valve type mortar pump has the advantages of simple structure, long service life, high reliability, favorable sealing property and favorable conveying continuousness.

Owner:徐州沃土资产管理有限公司

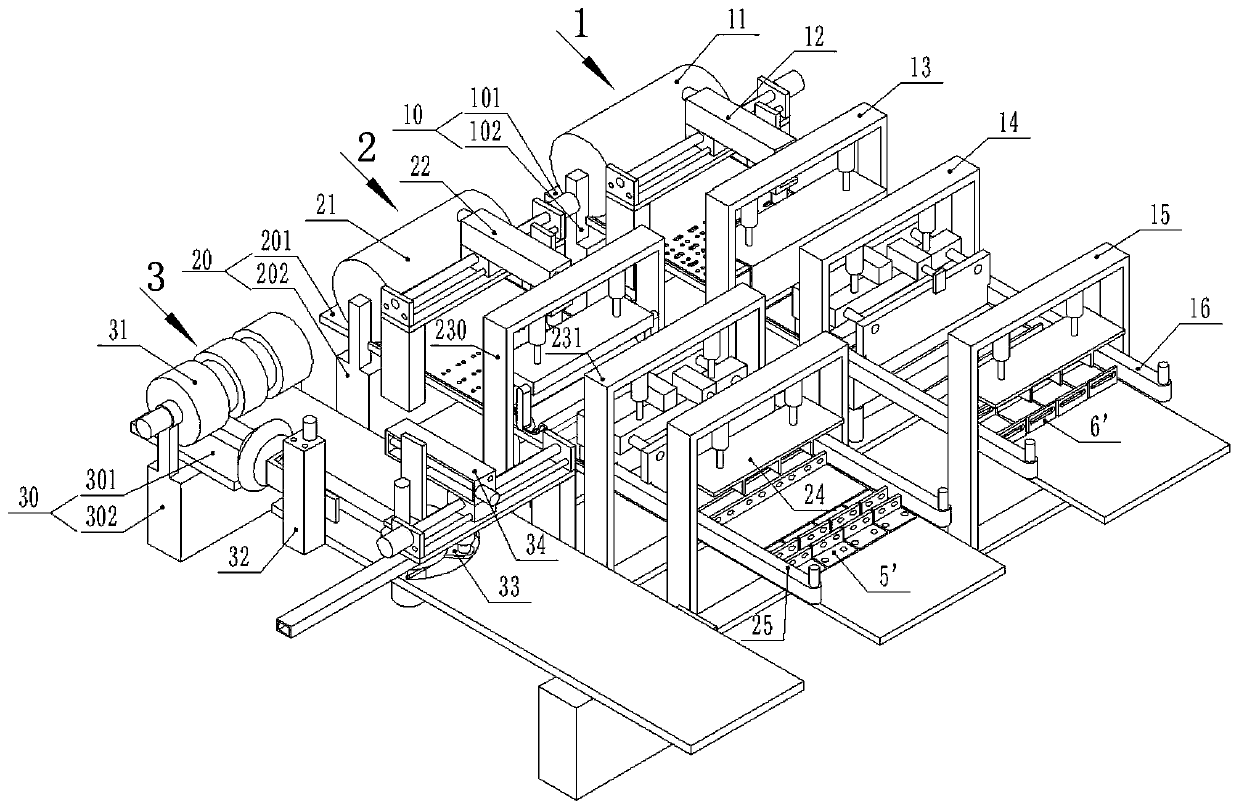

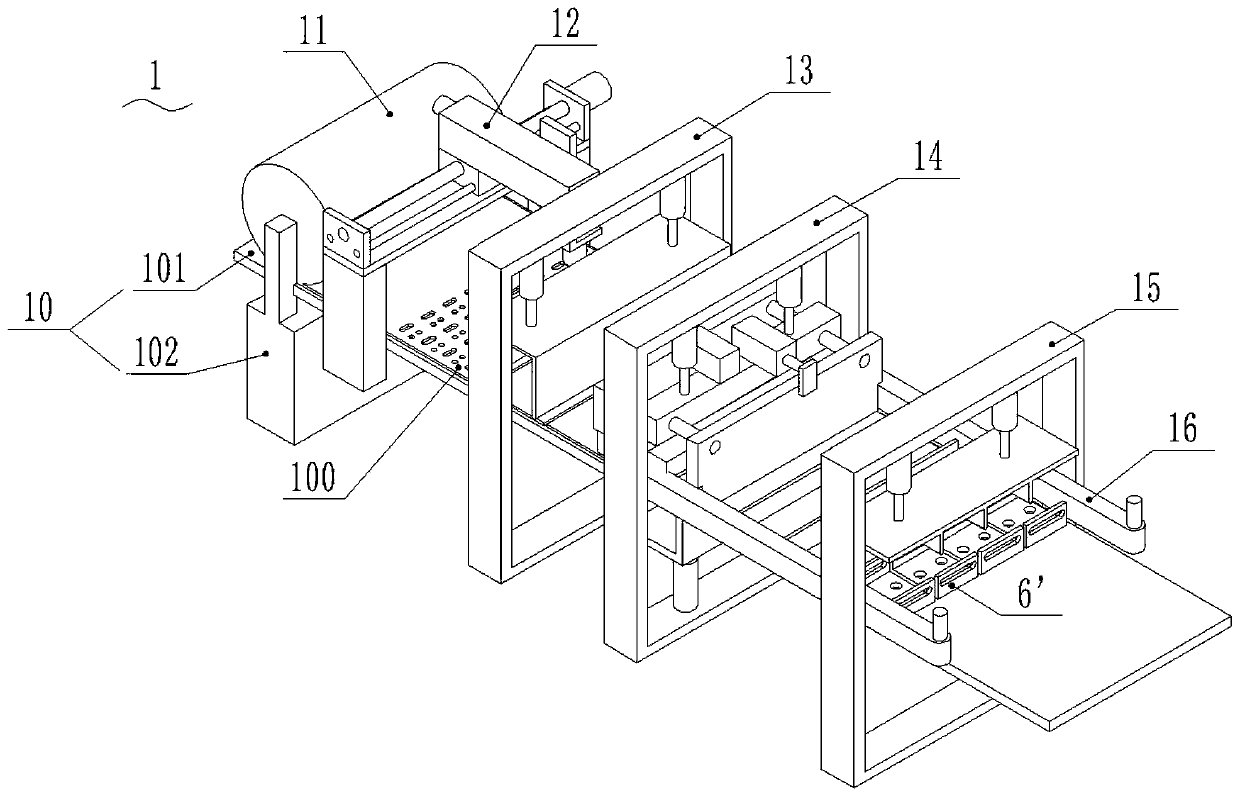

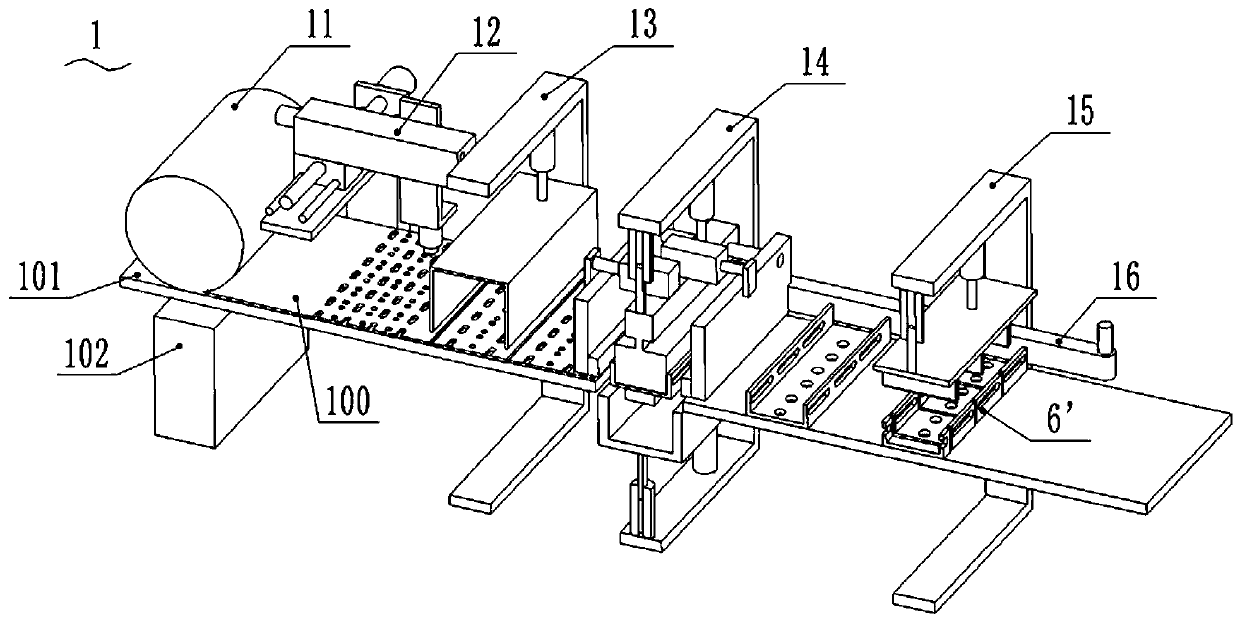

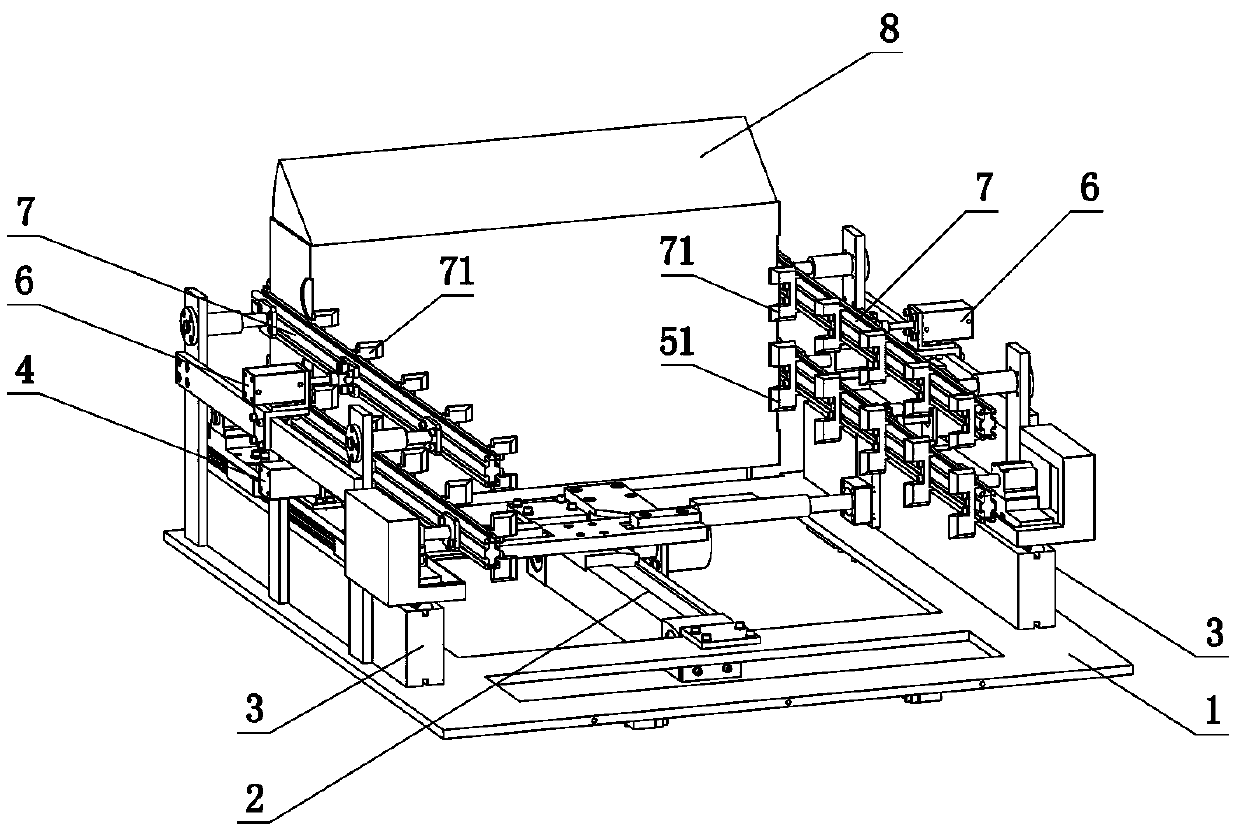

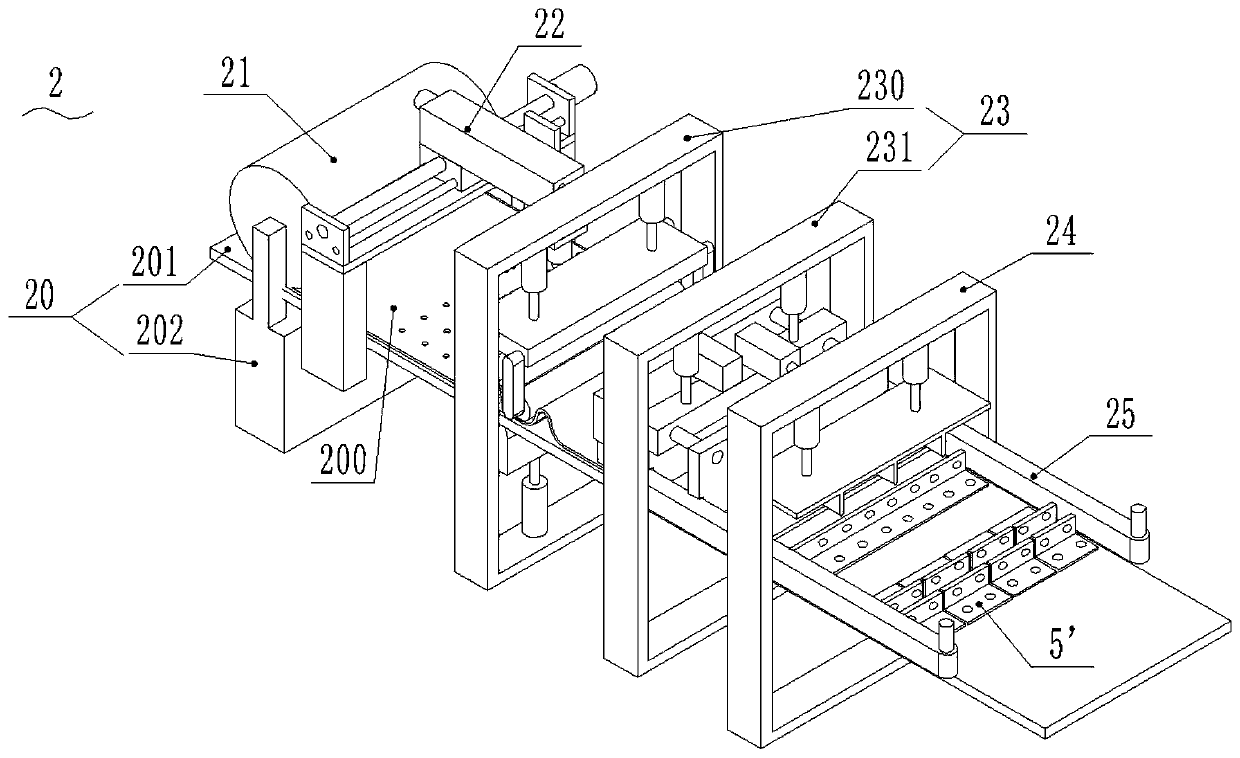

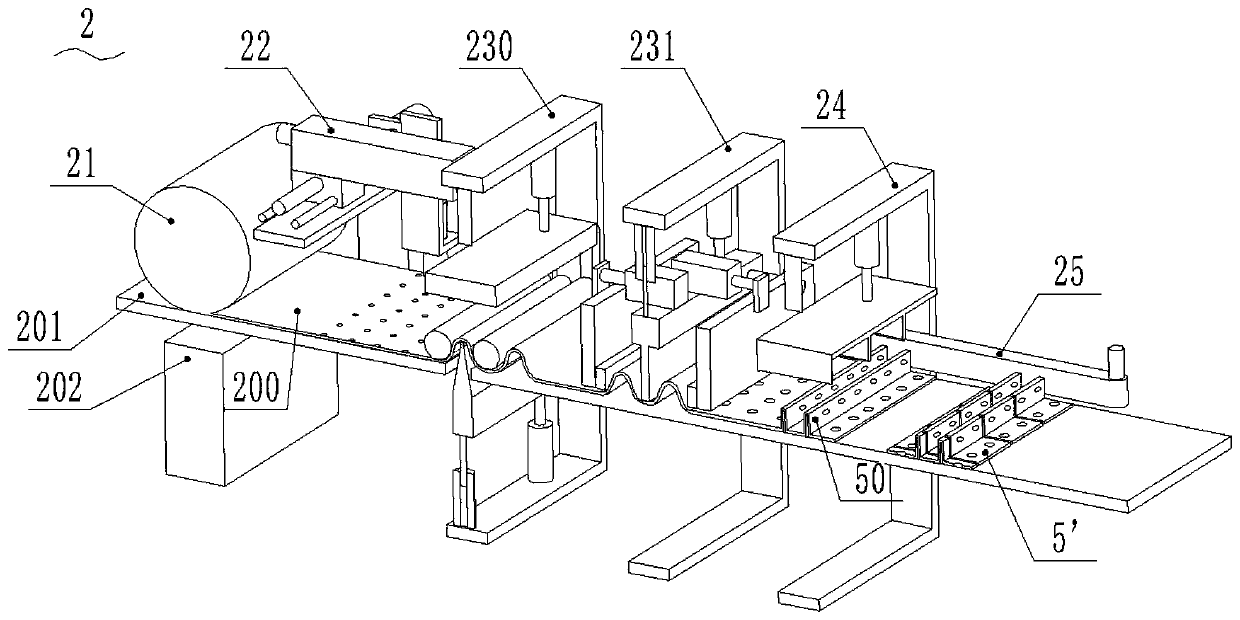

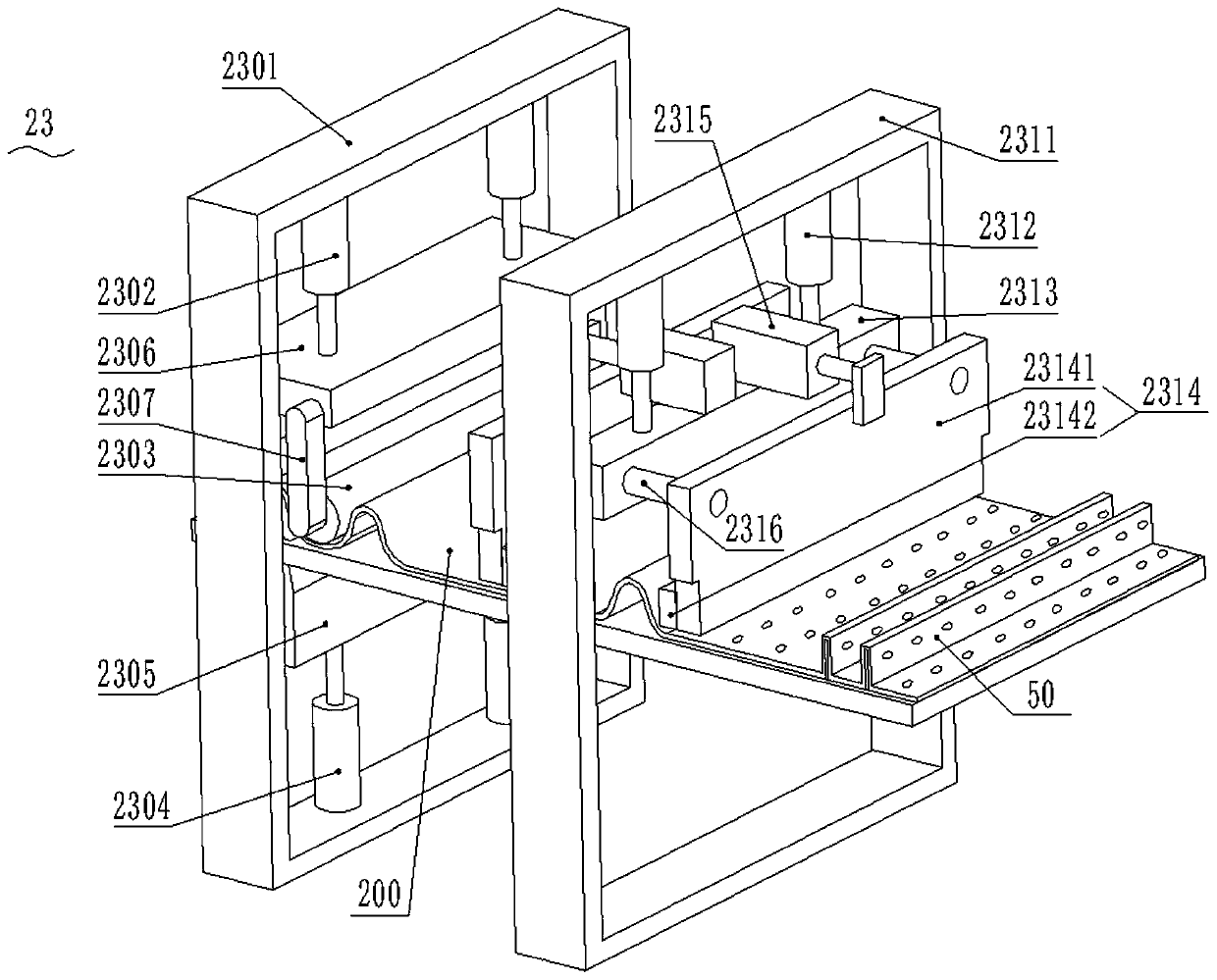

Enclosure mass production processing line and processing method

ActiveCN111496547ARealize continuous deliveryRealize mass productionFencingOther manufacturing equipments/toolsComputer printingIndustrial engineering

The invention discloses an enclosure mass production processing line. An enclosure comprises a mesh plate, a framework, a framework fixing seat, a supporting rod, and a supporting rod fixing seat, andthe framework comprises an outer frame and a plurality of inner reinforcement tubes. The enclosure mass production processing line comprises: a discharging machine for discharging from the mesh plate, the supporting rod and the inner reinforcement tube; an outer frame processing device for processing of the outer frame; a framework fixing seat processing device for processing of the framework fixing seat; a supporting rod fixing seat processing device for processing of the supporting rod fixing seat; a touch welding machine for welding of the outer frame and the inner reinforcement tube and welding of the mesh plate and the framework; a paint spraying machine for paint spraying of the mesh plate, the framework, the framework fixing seat, the supporting rod, and the supporting rod fixing seat; and a UV printer for printing a surface pattern to the mesh plate after paint spraying. The enclosure mass production processing line and the processing method are high in production efficiency,save manpower, and can be applied to mass production.

Owner:湖南翰坤实业有限公司

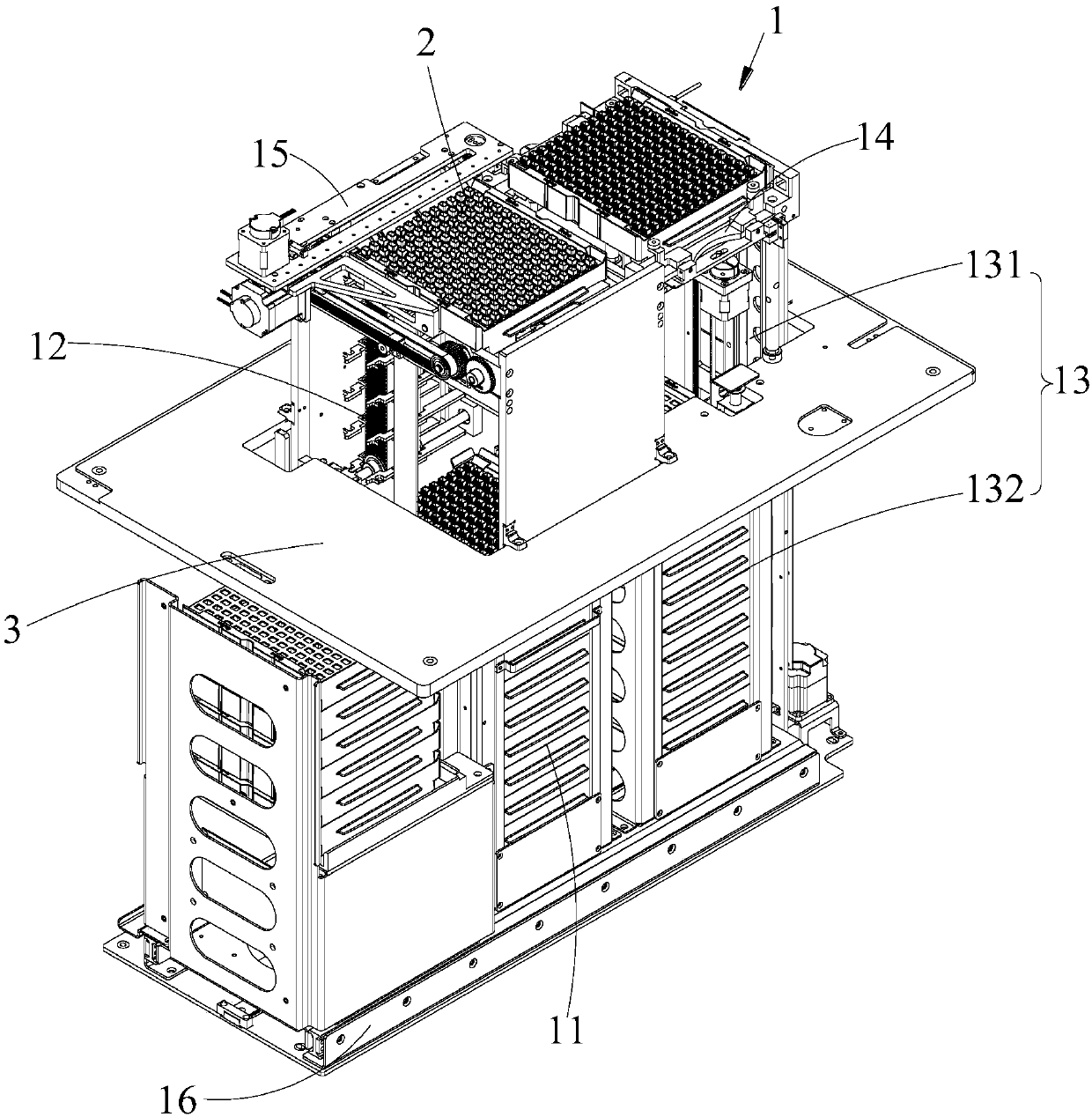

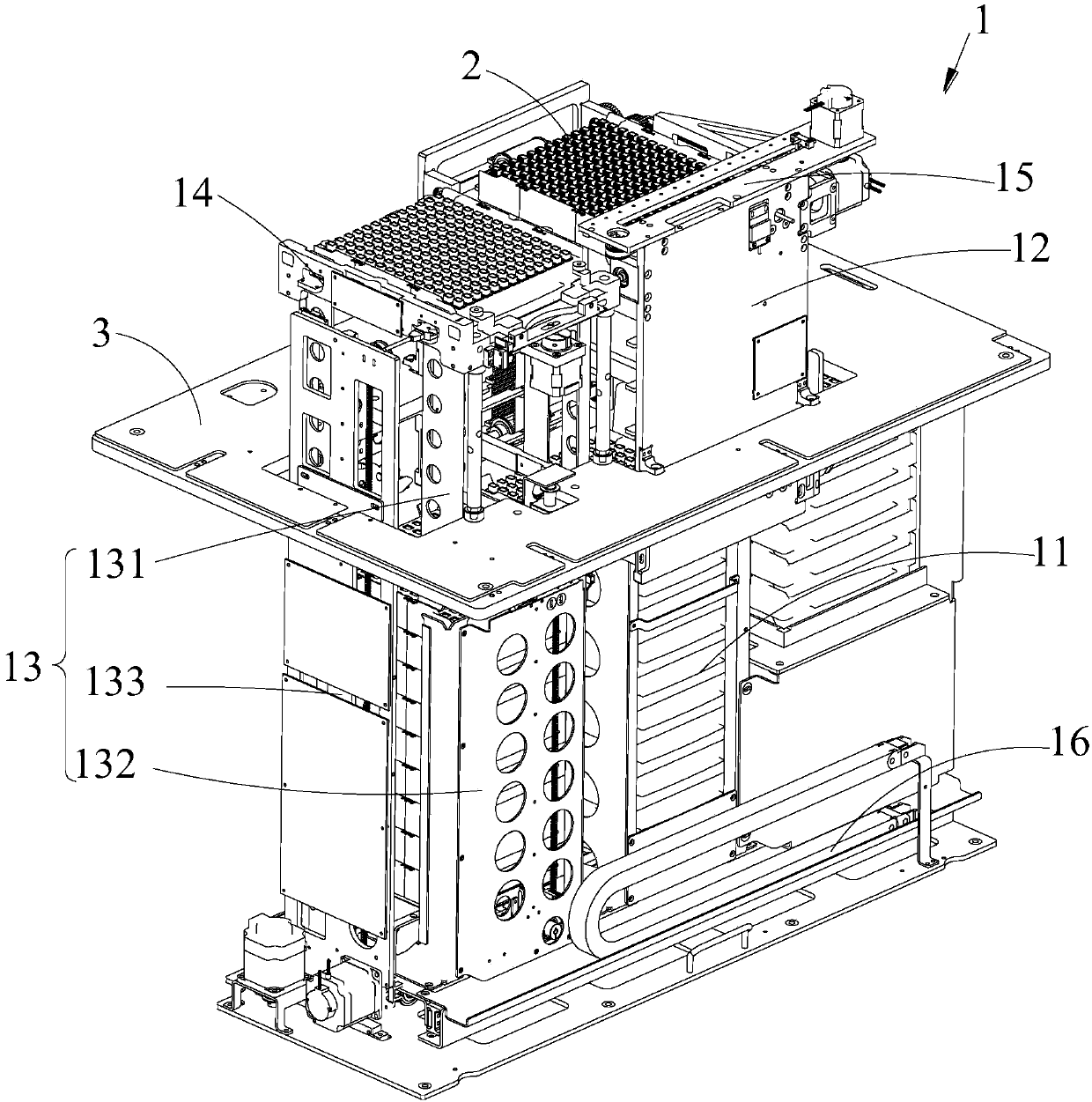

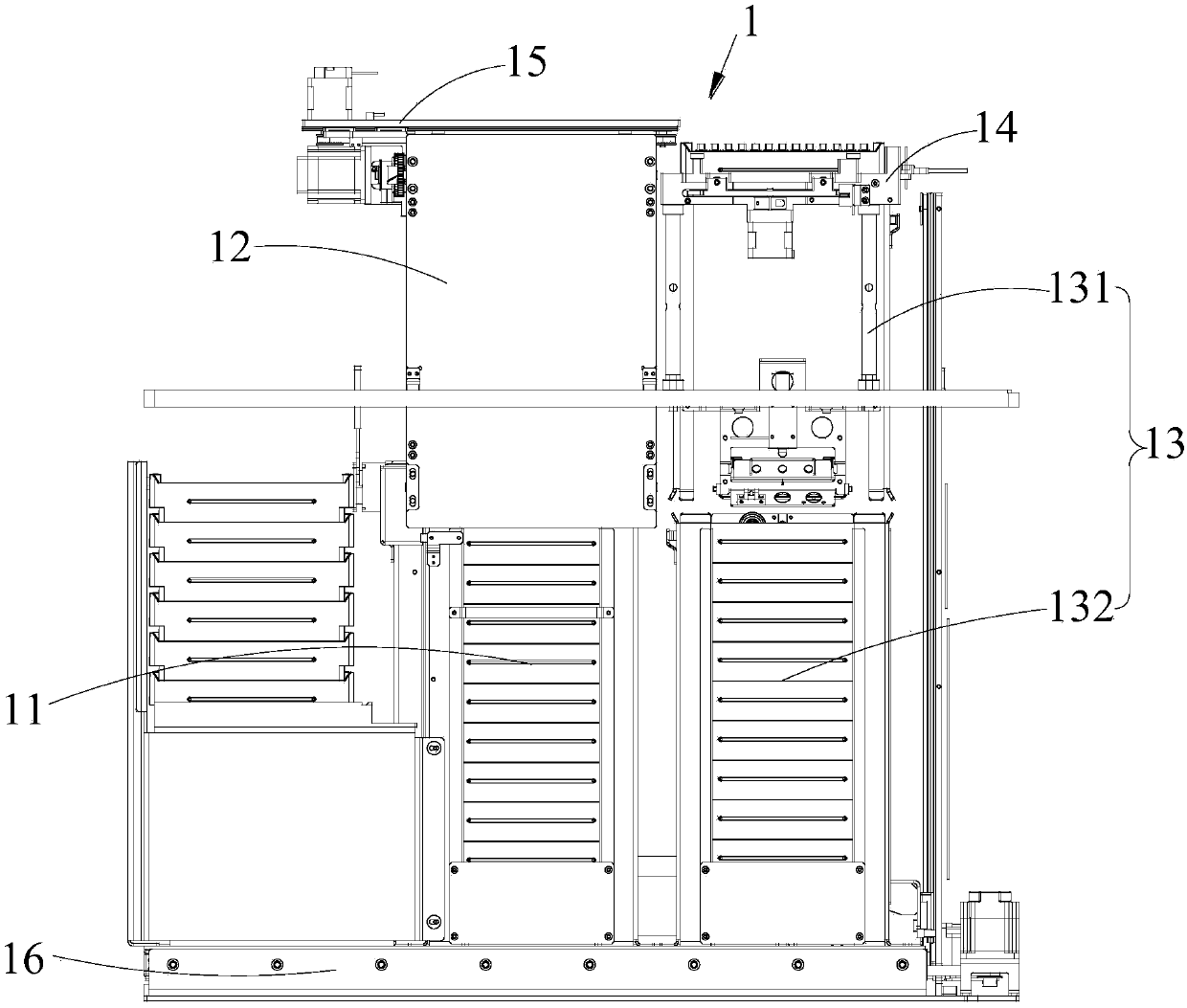

Chemiluminiscence detector, and automatic conveying device and method of consumable boxes

ActiveCN109765217ARealize continuous deliveryWill not affect deliveryChemiluminescene/bioluminescenceBiological testingEngineeringMechanical engineering

The invention provides an automatic conveying device of consumable boxes. The automatic conveying device comprises a consumable box storage mechanism for loading and storing the consumable boxes, anda consumable box lifting mechanism located above the consumable box storage mechanism; the consumable box lifting mechanism can lift the consumable boxes, and the consumable box storage mechanism store and the consumable box lifting mechanism can store and convey the consumable boxes correspondingly; and the consumable box storage mechanism can convey the consumable boxes to the bottom of the consumable box lifting mechanism, and the consumable box lifting mechanism receives the consumable boxes at the bottom and lifts the consumable boxes to the top layer of the consumable box lifting mechanism so that the consumable boxes can be parallelly conveyed. The consumable boxes are continuously conveyed, manual supervision or frequent manual operation is reduced, safety performance of consumablebox conveying is improved, and the detection efficiency is guaranteed. The invention further provides a chemiluminiscence detector and an automatic conveying method of the consumable boxes.

Owner:SHENZHEN NEW INDS BIOMEDICAL ENG

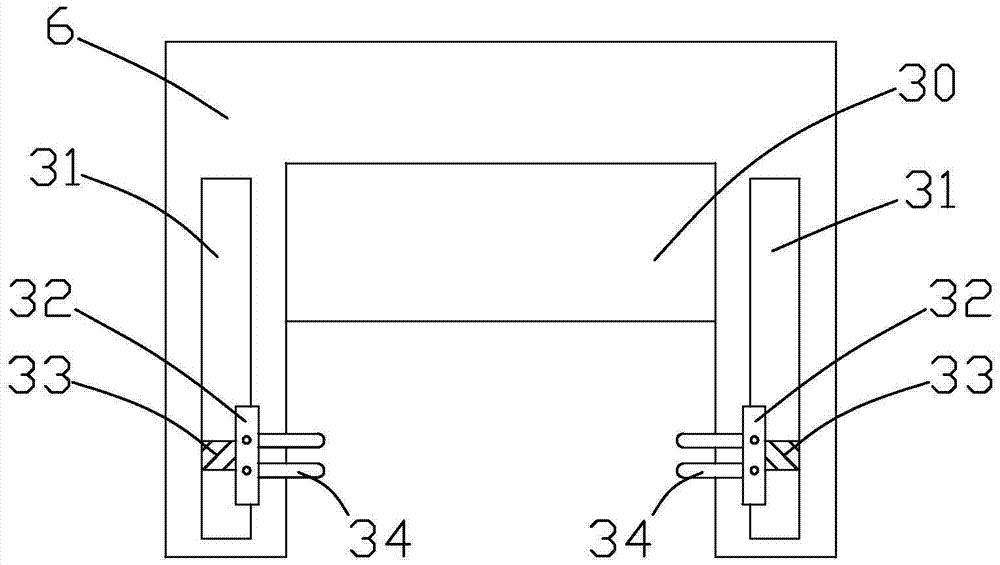

Empty carton delivery device of rod-like material boxing machine and delivery method thereof

ActiveCN104176322APrevent lodgingReduce production processPackaging cigaretteCartoning machineReciprocating motion

The invention provides an empty carton delivery device of a rod-like material boxing machine. The device comprises an underbed, an electric cylinder arranged on the underbed and a servo motor which drives the electric cylinder to work, wherein slide supporting rods parallel to the electric cylinder are respectively arranged on the two sides of the electric cylinder; an empty carton delivery plate parallel to the underbed is mounted on the underbed; an empty carton pushing device is mounted on each slide supporting rod. The invention also provides an empty carton delivery method which comprises steps of carton packaging, carton delivery, backwards movement of the slide supporting rods, and the like; the slide supporting rods can perform reciprocating movement forwards and backwards by operating the steps repeatedly, so that each empty carton delivered to the empty carton delivery plate can move forwards by the distance between two fixing pushing blocks and the empty carton on the rear side of the empty carton delivery plate can be conveyed to downstream equipment, as a result, automatic delivery of empty cartons is realized.

Owner:XUCHANG TOBACCO MACHINERY

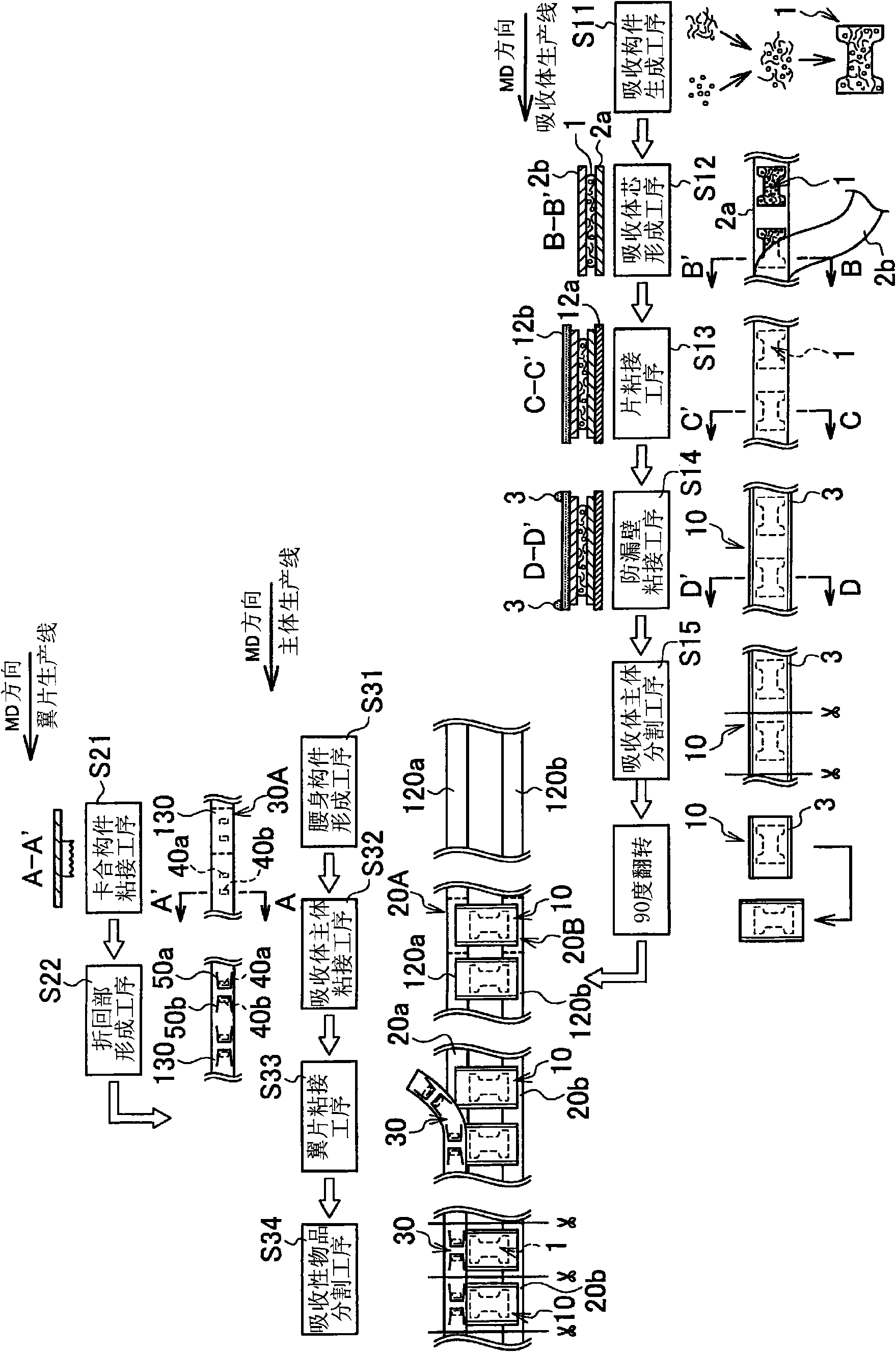

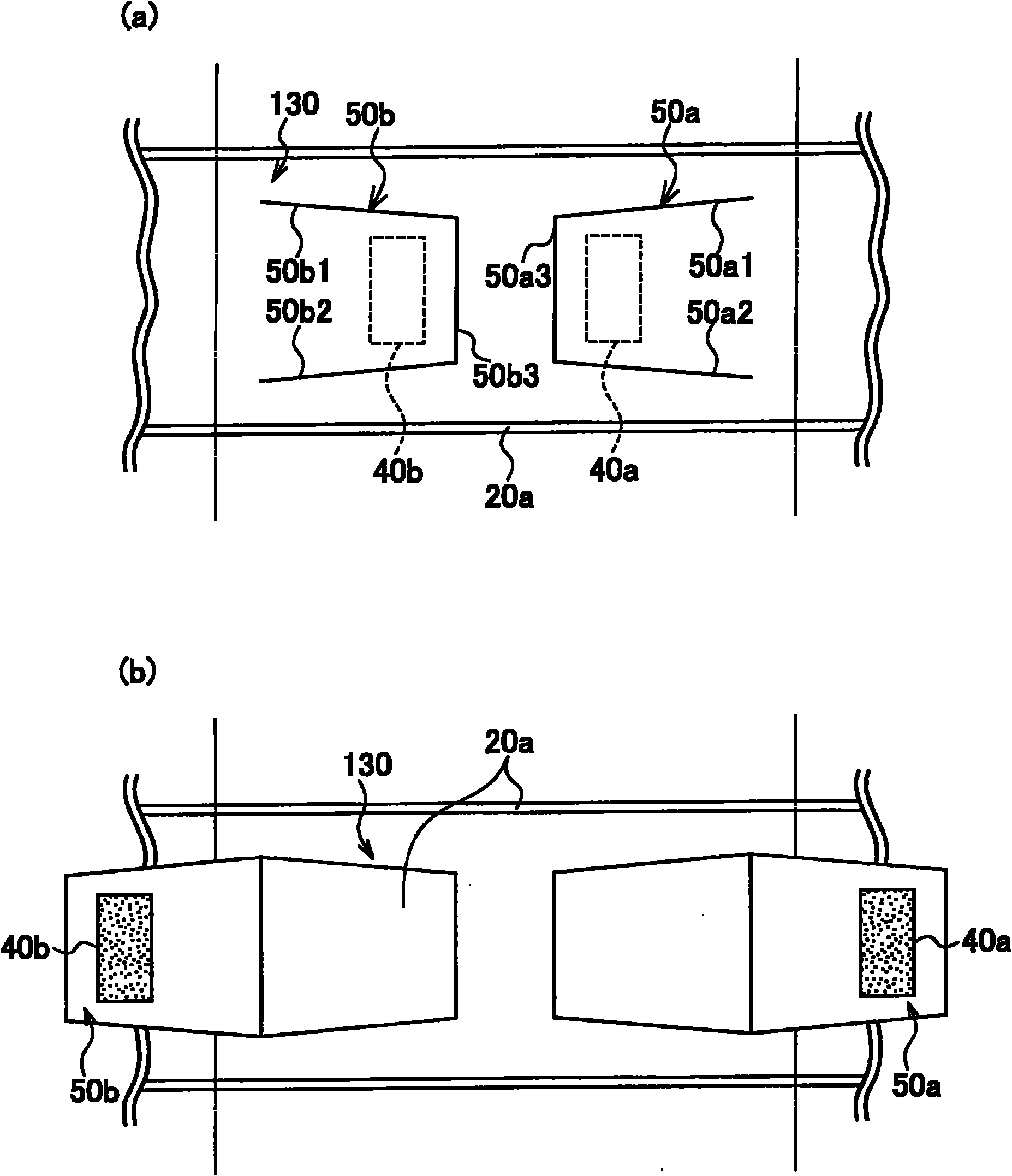

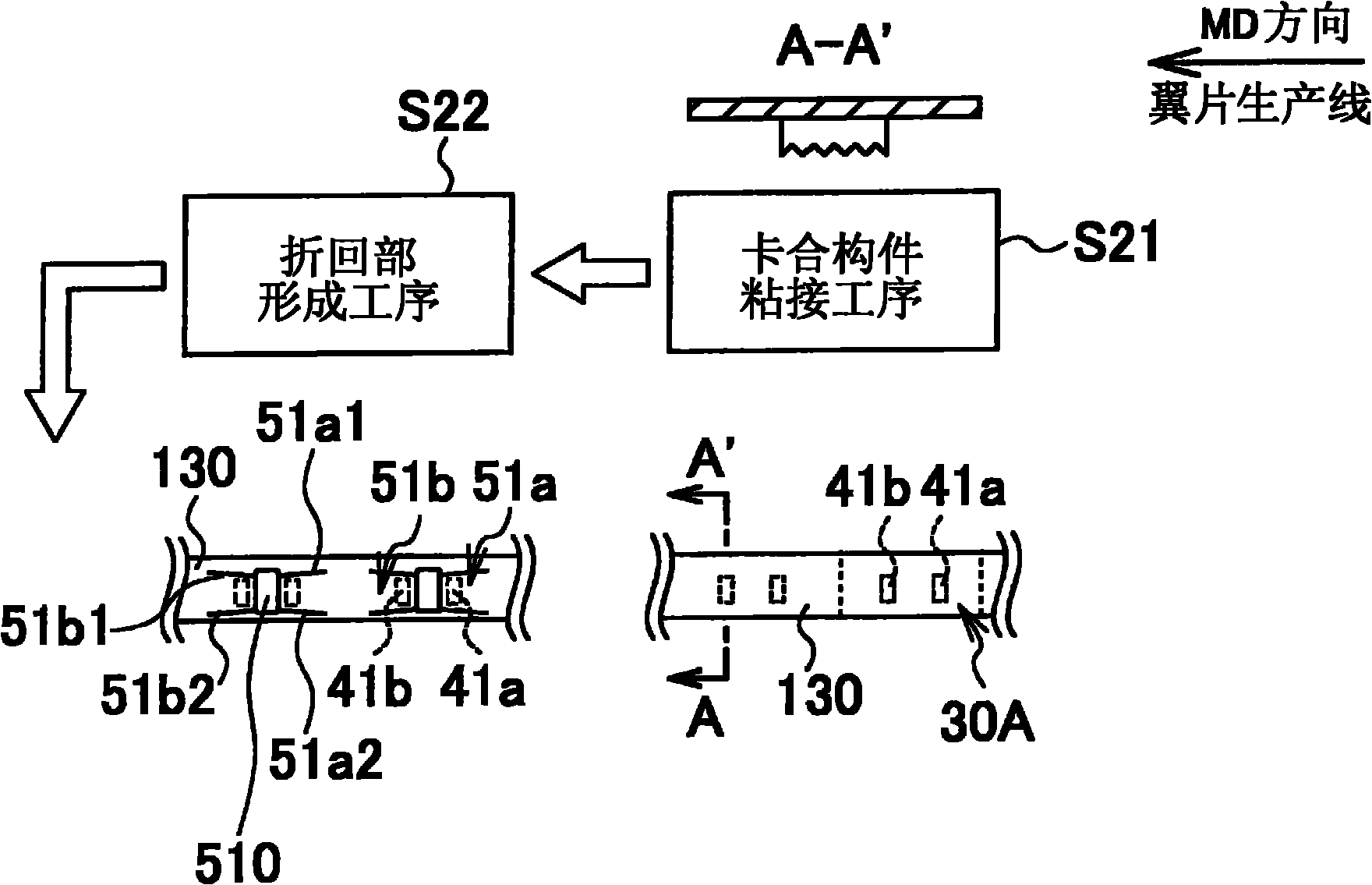

Manufacturing method for absorbent products and manufacturing device for absorbent products

InactiveCN101983045ARealize continuous deliveryAbsorbent padsBaby linensEngineeringMechanical engineering

Provided is a manufacturing method for absorbent products that has a process for forming a pair of fold-over parts (50a, 50b), which can be folded over in the direction of conveyance of a flap line and in the direction opposite said conveyance direction, on portions of areas (30A) that constitute a single flap in connected flaps (130) that are continuously conveyed on the flap line, a process wherein fastening members (40a, 40b), which are fastenable to prescribed areas, are placed on the pair of fold-over parts (50a, 50b), and a process wherein connected flaps (130) are connected with connected front torso-surrounding members or back torso-surrounding members (120a) or (120b) so that each area (30A) that constitutes a single flap, corresponds to areas (20A, 20B), that constitute a singleabsorbent product in connected front torso-surrounding members or back torso-surrounding members (120a) or (120b).

Owner:UNI CHARM CORP

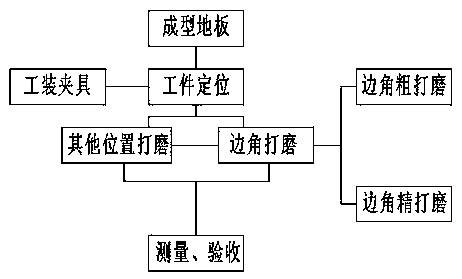

Burr-removal method for wood-plastic floor production

InactiveCN109807718ARealize continuous deliverySolve transportation problemsEdge grinding machinesWood working apparatusWaste productEngineering

The invention discloses a burr-removal method for wood-plastic floor production. The burr-removal method is characterized by comprising a guide blocking plate and a conveyor belt, wherein an includedangle between two side plates on the guide blocking plate is 90 degrees; a regulating slot is formed in a crossed line between the two side plates on the guide blocking plate; two fixed plates which are distributed in parallel and can slide are spliced inside the regulating slot; a positioning plate is welded on the outer wall of one side of one fixed plate; a threaded hole is formed in the outerwall of the top of the positioning plate; the threads of the threaded hole are connected with a positioning bolt; and a connecting plate is welded on the outer walls of ends of the two fixed plates. The burr-removal method realizes continuous conveying for the wood-plastic floor, can achieve the reliable fixing effect for solving the wood-plastic floor conveying problem for people, facilitates grinding burrs of the wood-plastic floor, can effectively control the grinding precision of the wood-plastic floor, is suitable for grinding operation of floor of different specifications, and reduces arejection rate in the wood-plastic floor production.

Owner:安徽锦汇新材料科技有限公司

Carrying device

PendingCN108946015AImplement position conversionAchieve liftingMechanical conveyorsEngineeringFunctional requirement

The invention provides a carrying device. A guiding assembly applies corresponding restraining of first, second, third and fourth walking stoppers and first, second, third and fourth reversing stoppers due to the movement trajectory of a hub motor itself according to the function requirements, so as to achieve reversing in situ and goods lifting in a rotating manner. All power needed for walking,reversing and goods lifting of the carrying device is provided by walking of the hub motor, it is not needed to arrange mechanisms and power for steering and goods lifting, and achieving of reversingwithout damping through walking trajectories of wheels is one of key technologies of the carrying device. Due to the hub motor, the walking power is integrated in the wheels, in this way, the inner space of equipment can be saved. A specific portion of the guiding assembly is provided with a restraining mechanism of the first, second, third and fourth walking stoppers and the first, second, thirdand fourth reversing stoppers, and switching and locking of work modes are achieved in combination with walking of the hub motor.

Owner:倪燕

Frame fixing base machining device and fence machining production line

ActiveCN111346934ARealize continuous deliveryRealize mass productionOther manufacturing equipments/toolsLaser beam welding apparatusMolding machineEngineering

The invention discloses a frame fixing base machining device. The frame fixing base machining device comprises a second working platform, a second winding drum mechanism used for winding a second ironplate, a second extrusion forming mechanism used for extruding two parallel straight plates on the second iron plate, and a third cutting mechanism used for cutting the second iron plate and the twostraight plates, wherein the second winding drum mechanism, the second extrusion forming mechanism and the third cutting mechanism are sequentially arranged on the second working platform; and the frame fixing base machining device further comprises a second conveying mechanism arranged on the second working platform and used for conveying the second iron plate. According to the frame fixing basemachining device, automatic machining of a frame fixing base is achieved, the production efficiency is high, the device can be suitable for batch production, and manpower is saved. The invention further discloses a fence machining production line. The production efficiency of a fence is greatly improved, the fence machining production line is suitable for batch production, the manpower is saved, and the production cost is saved.

Owner:湖南翰坤实业有限公司

Muck transporter used for pipe-jacking construction method

The invention discloses a muck transporter used for a pipe-jacking construction method. The muck transporter comprises a conveyor belt arranged in a tunnel pipeline, and the conveyor belt is tensioned and moves circularly. The conveyor belt extends in the axial direction of the pipeline, and comprises a muck receiving section located in a front area, a winding operation section located in a middle area, and a muck releasing section located in a tail area. Along with advancement of tunnel construction, the muck receiving section also advances forward, and meanwhile, the portion, located in the winding operation section, of the conveyor belt is gradually unfolded. According to the muck transporter, the conveyor belt is used for continuously transporting muck, and the conveyor belt adapts to advancement of tunnel construction. Muck is continuously discharged, and muck accumulation within a tunnel is avoided.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com