Chestnut thorny-shell removing apparatus and chestnut thorny-shell removing method

A technology of chestnut and thorn shell, applied in the field of chestnut processing equipment, can solve the problems of complexity, high energy consumption, thorn ball damage and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

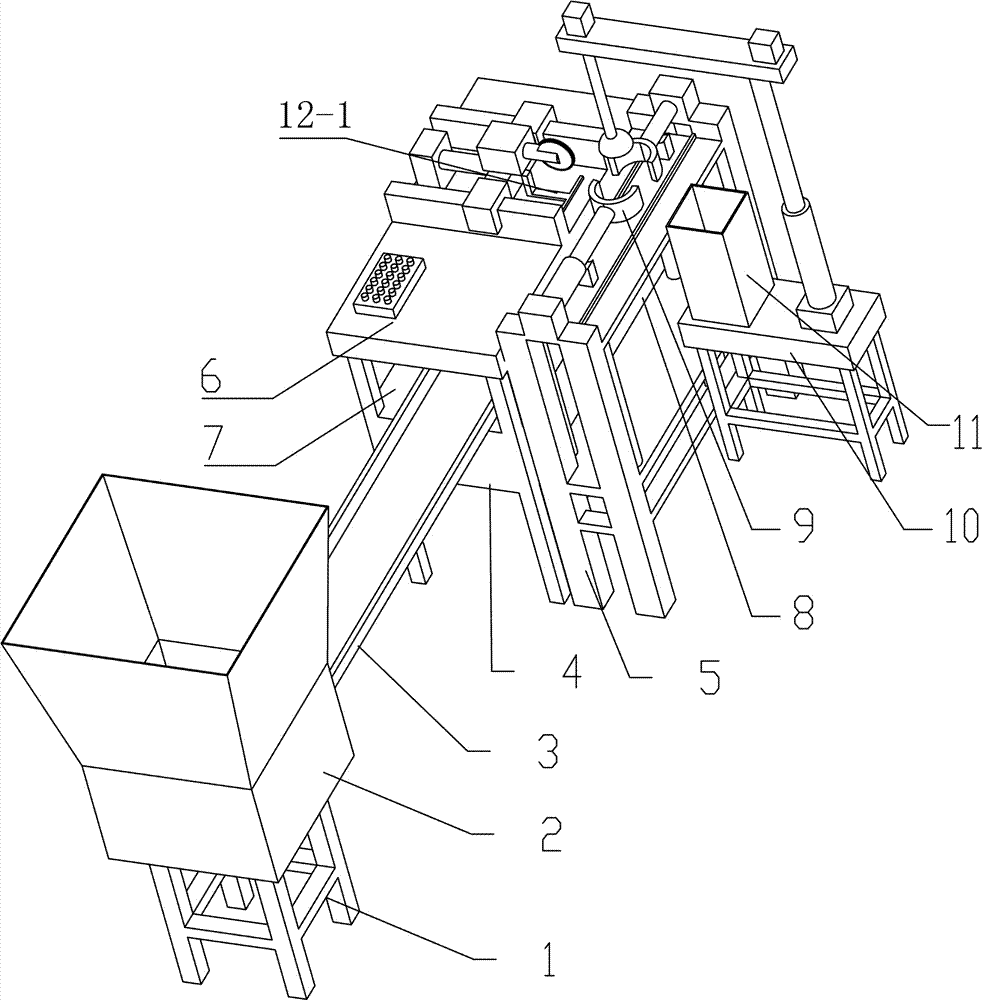

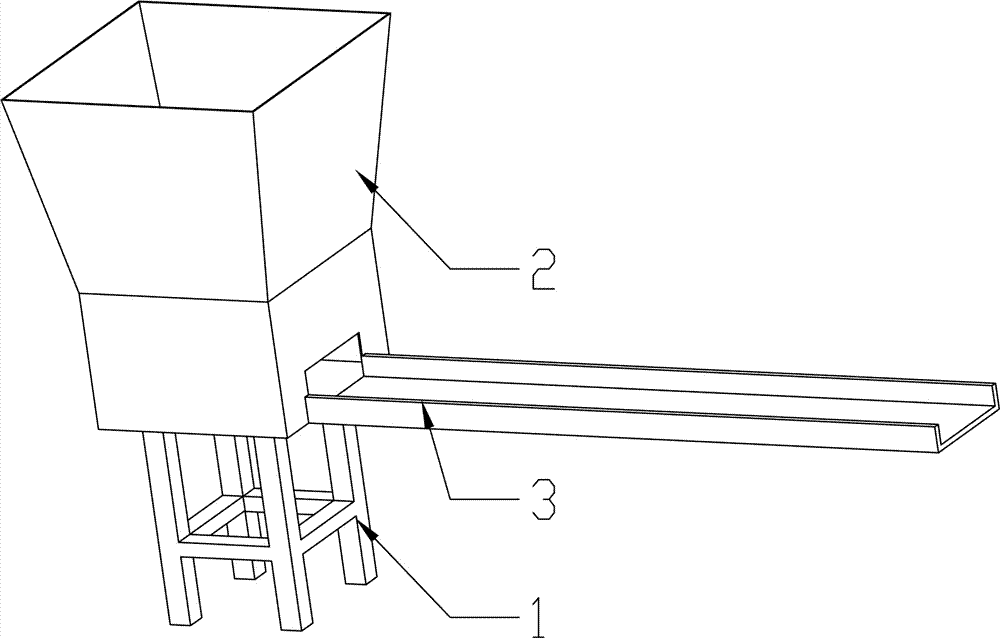

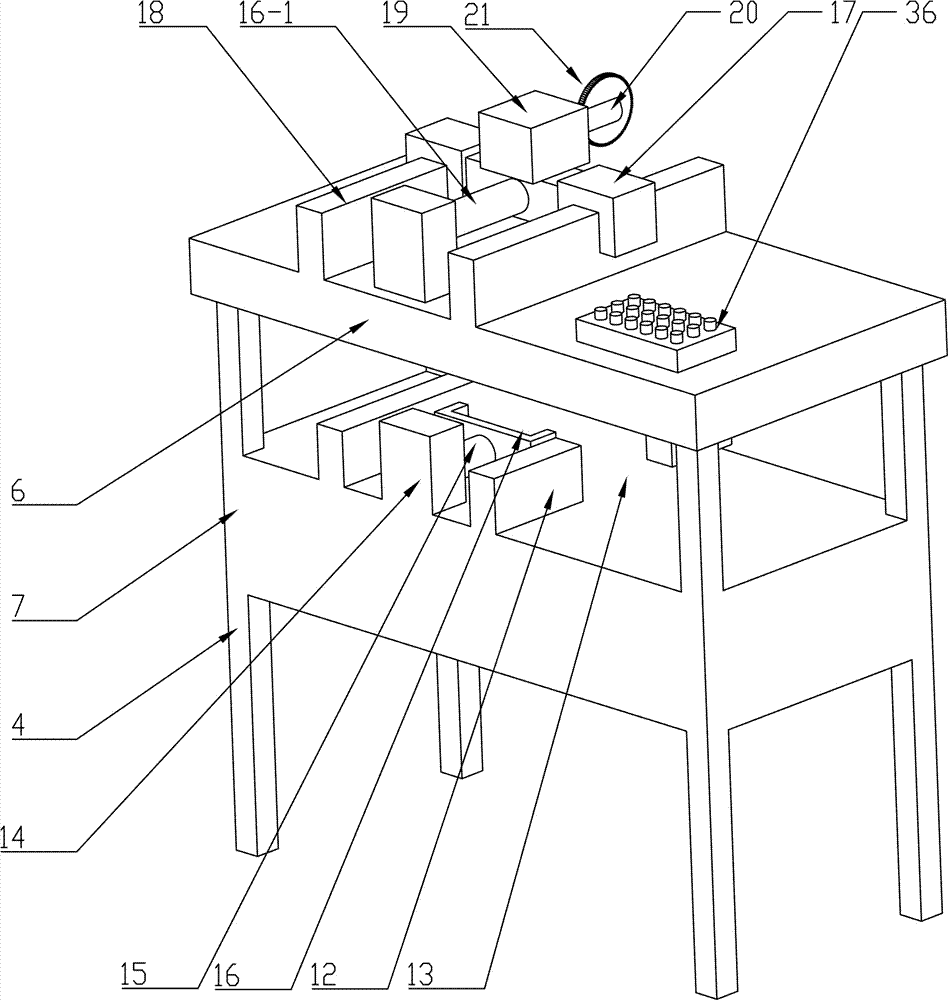

[0037] like Figure 1-2 As shown, a chestnut deburring device includes a feeding device, a clamping and cutting device and a reclaiming device;

[0038] The feeding device includes a feeding frame 1 on which a vibrating box 2 is installed. The front end of the vibrating box 2 is provided with an opening, the opening is connected to one end of the conveyor belt 3, and the other end of the conveyor belt 3 is connected to the clamping and cutting device, thereby completing the initial feeding.

[0039] In order to achieve one-time feeding without clogging and continuity, an arc-shaped opening slightly larger than the size of chestnut with thorn shell can be set at the discharge port of vibrating box 2. The upper opening is hinged with a limit rod, and the limit rod has a small elastic force. the return spring. The chestnut with barbed shell will rush out of the limit bar on the arc opening under vibration, and the subsequent chestnut with barbed shell will be restrained by the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com