Carrying device

A technology for handling equipment and motion control, which is used in transportation and packaging, conveyors, mechanical conveyors, etc., and can solve problems such as large damping, tire and ground damage, inability to achieve any angle, zero damping, and in-situ steering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

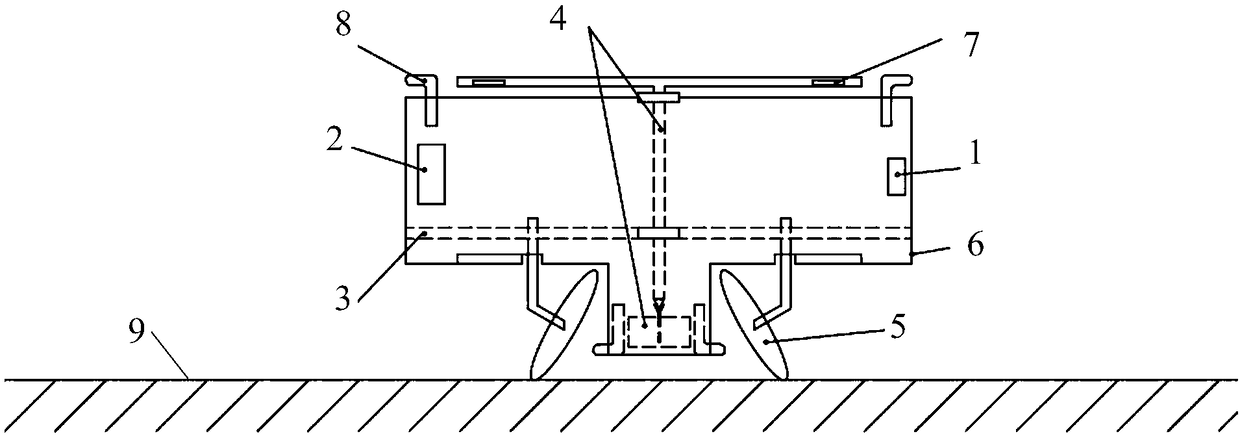

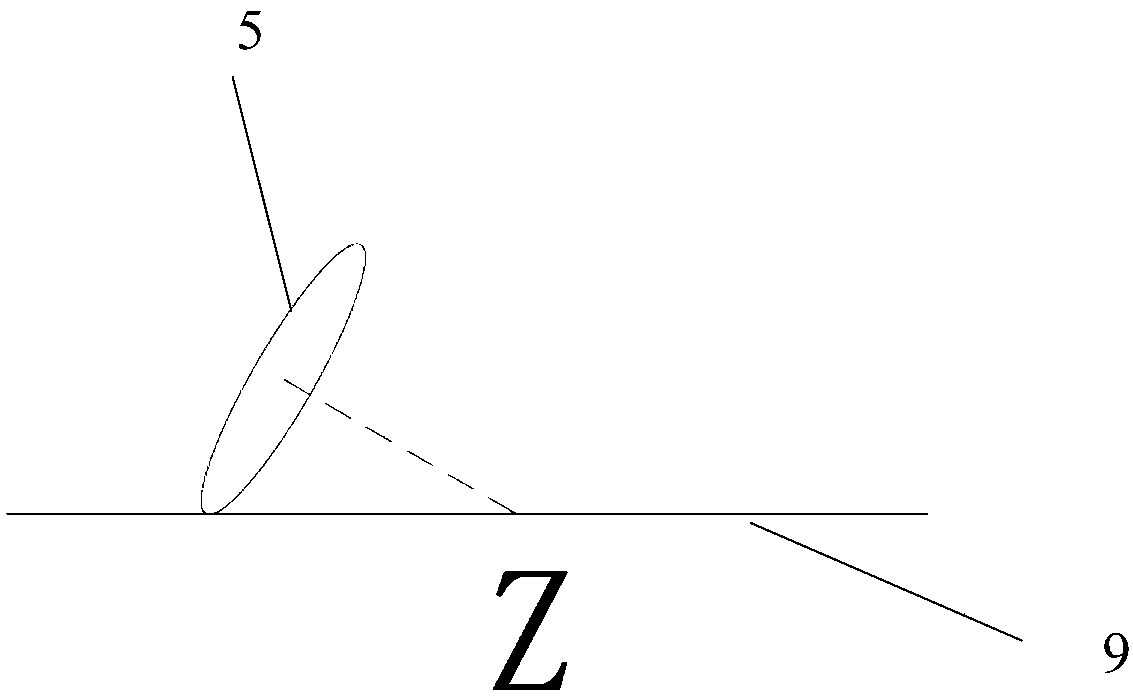

[0077] Such as figure 1 As shown, the present invention provides a handling device, including: a car body 6, a navigation assembly 1 fixed on the car body 6, a motion control assembly 2, a guide assembly 3, a lifting assembly 4 and four in-wheel motors that walk on the ground 9 5. The four in-wheel motors 5 are inclined towards each other, and the angle between each in-wheel motor 5 and the ground is greater than or equal to 45 degrees and less than 90 degrees. Connect with lifting assembly 4, wherein,

[0078] The guide assembly 1 includes:

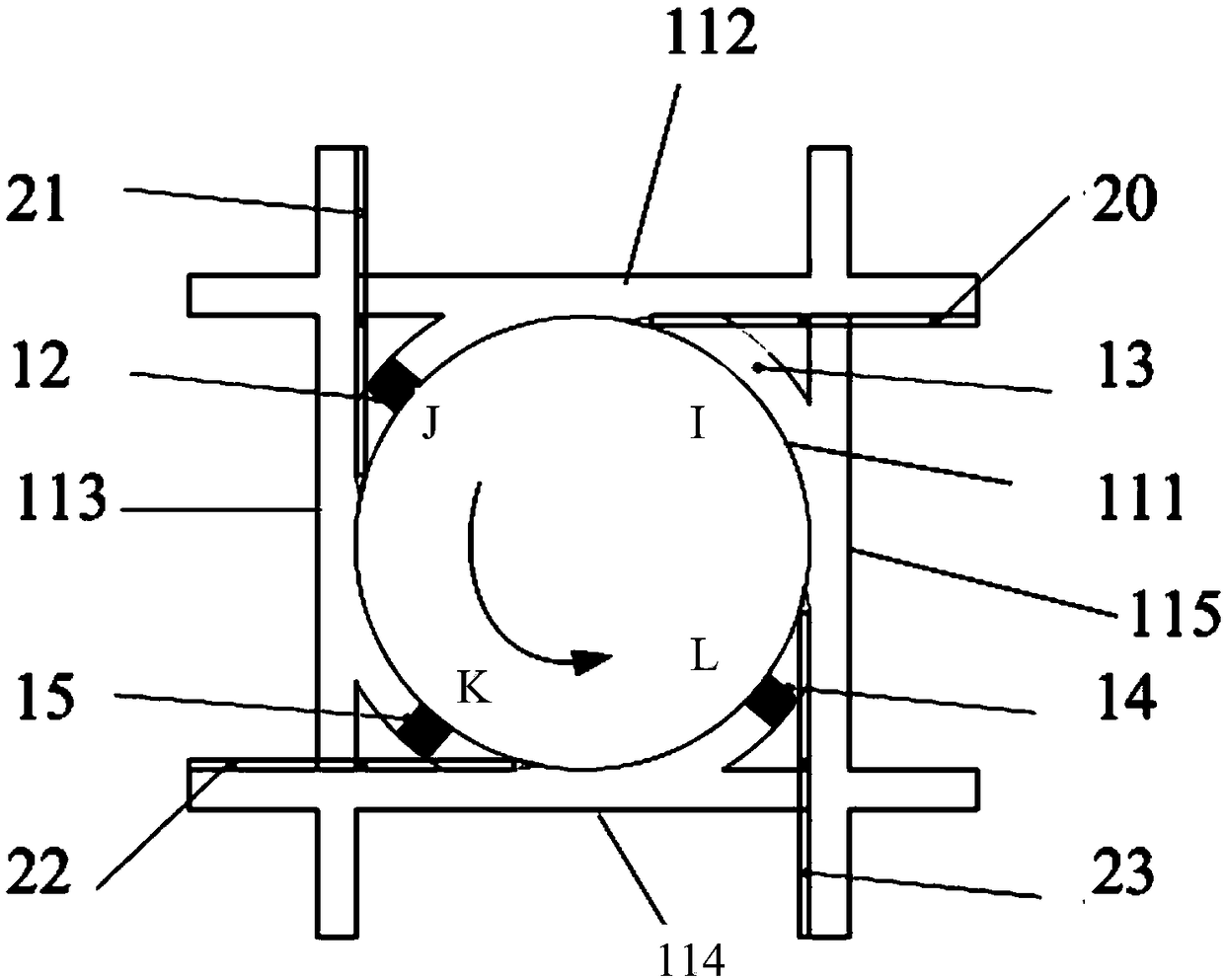

[0079] Such as image 3 Shown, guide track 11, described guide track comprises circular track 111 and the well-shaped track that is surrounded by four linear tracks 112,113,114,115 two by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com