Patents

Literature

1038results about "Driving means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

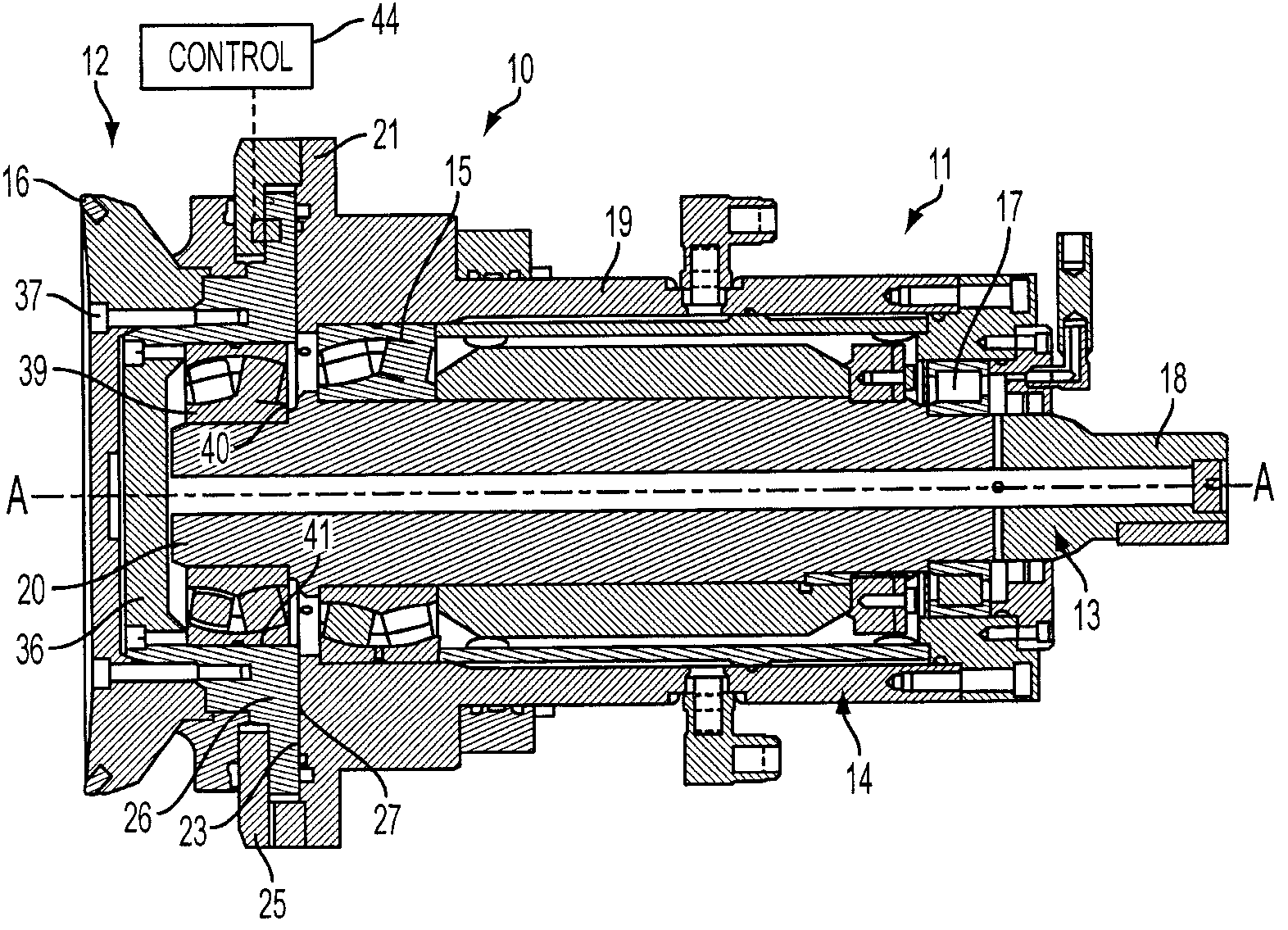

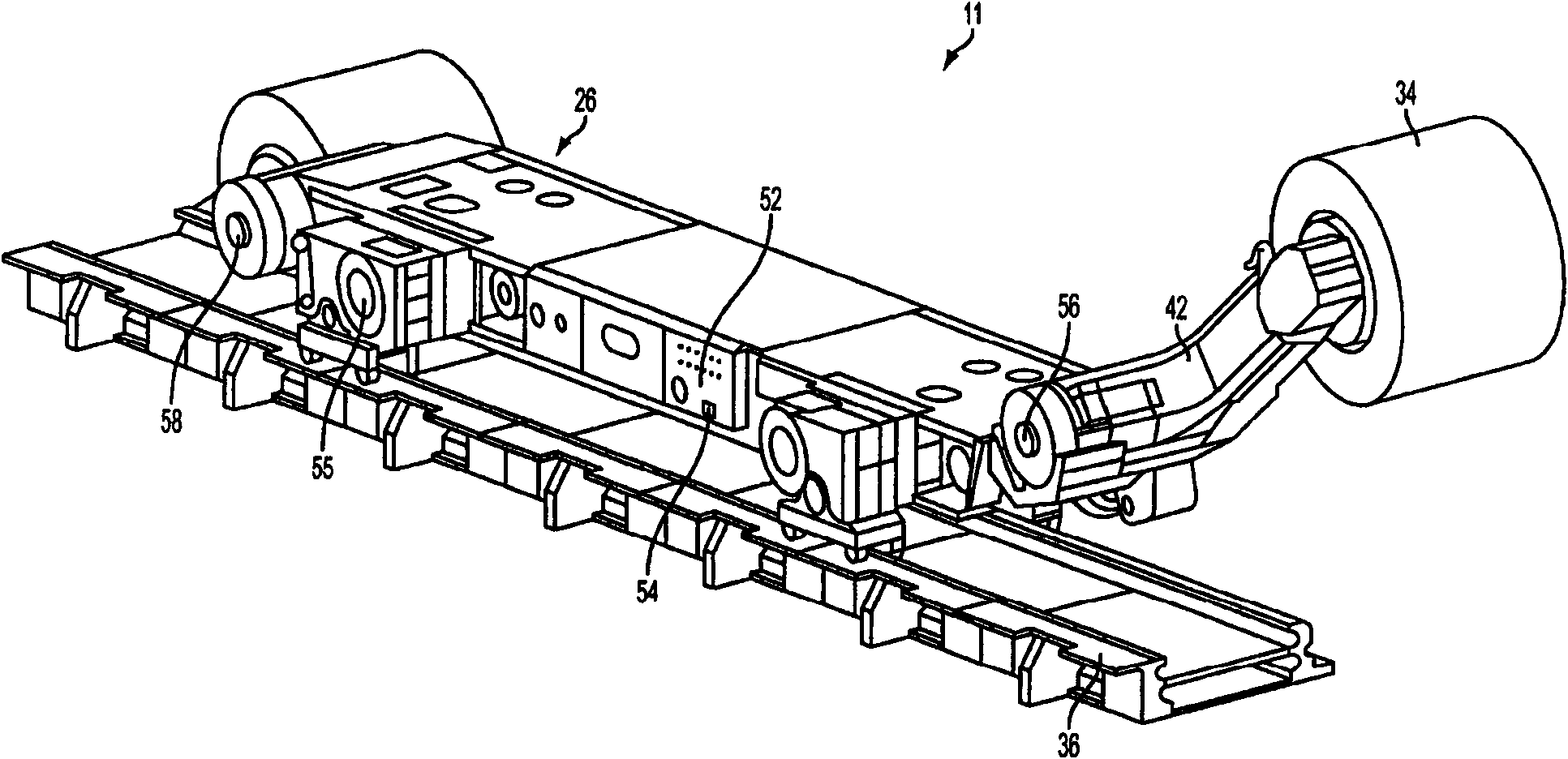

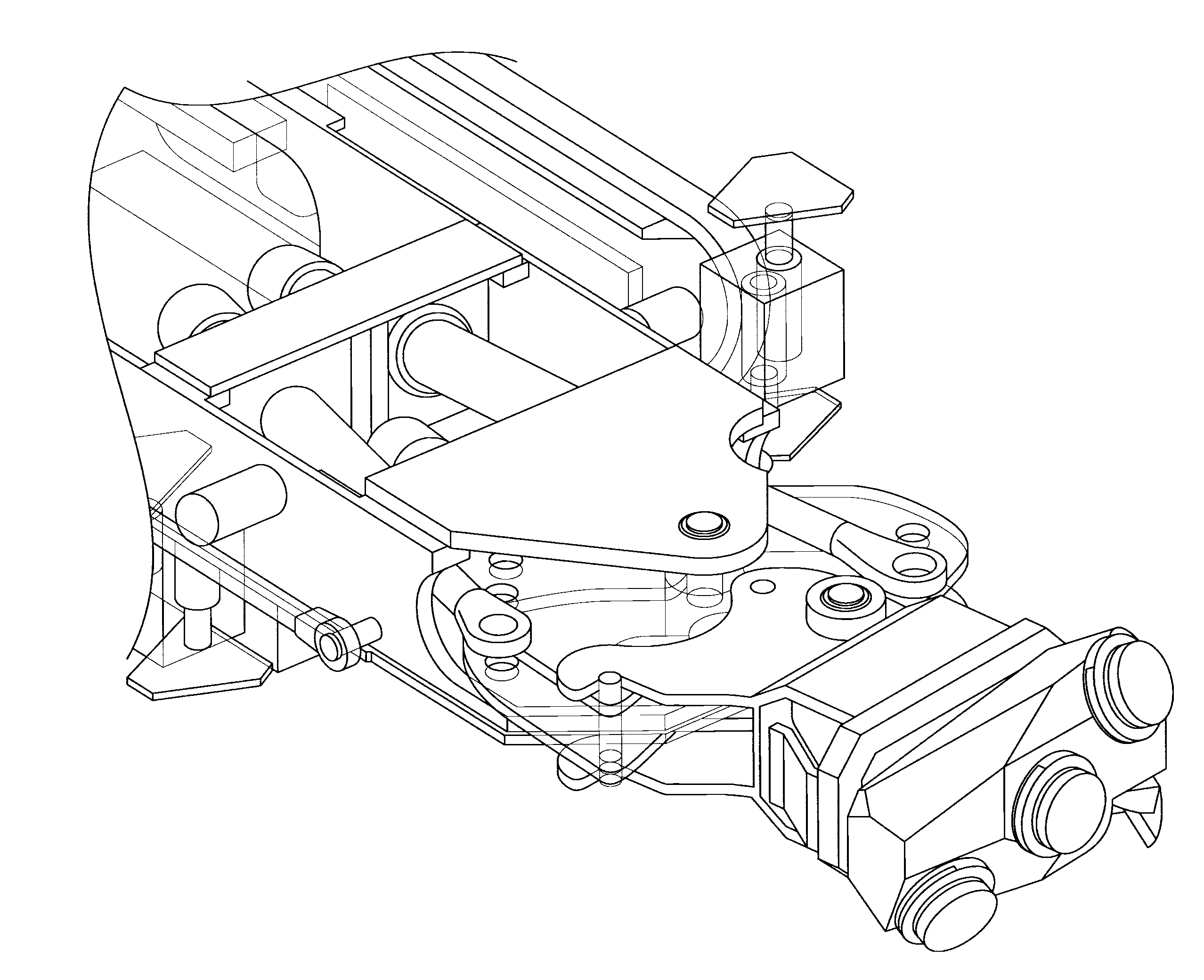

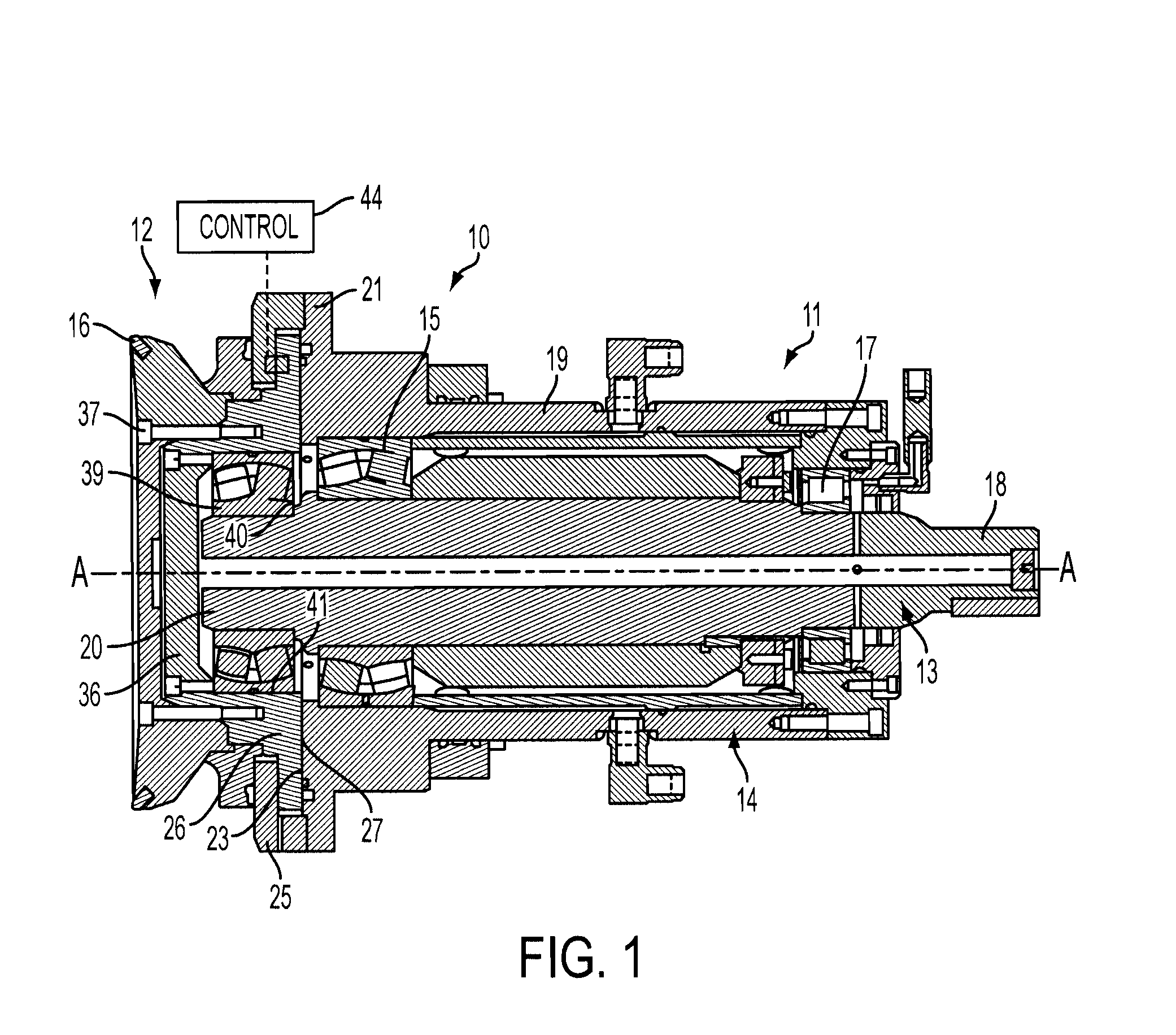

Mining machine with driven disc cutters

A mining machine includes a cutting mechanism with an arm, and a substantial weight of more than a thousand pounds attached to the arm. The mining machine also includes a first disc cutter adapted to engage the material to be mined and mounted on a first disc cutter assembly for eccentrically driving the first disc cutter, the first disc cutter assembly being mounted within the substantial weight. The mining machine also includes at least a second disc cutter spaced apart from the first disc cutter assembly and adapted to engage the material to be mined, and mounted on a second disc cutter assembly for eccentrically driving the second disc cutter, the second disc cutter assembly being mounted within the substantial weight.

Owner:JOY GLOBAL UNDERGROUND MINING LLC

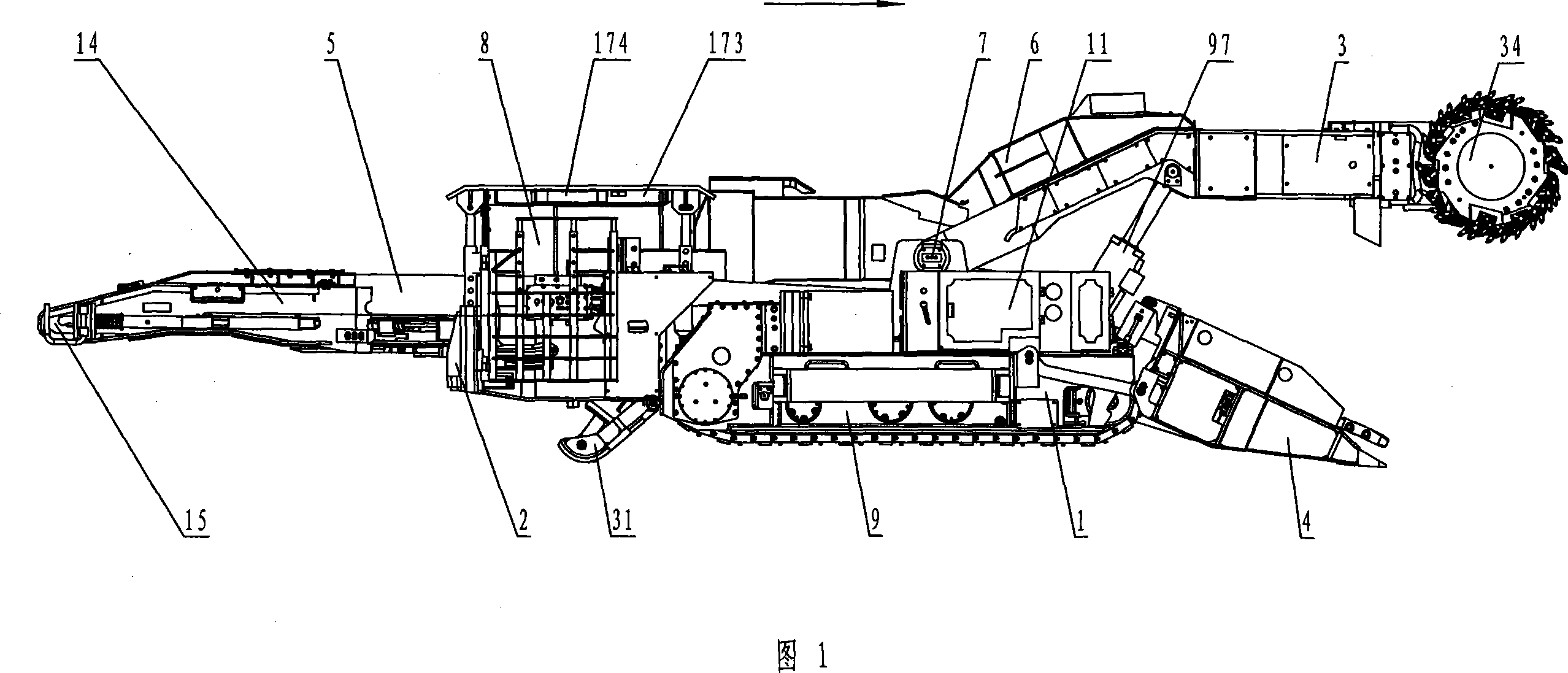

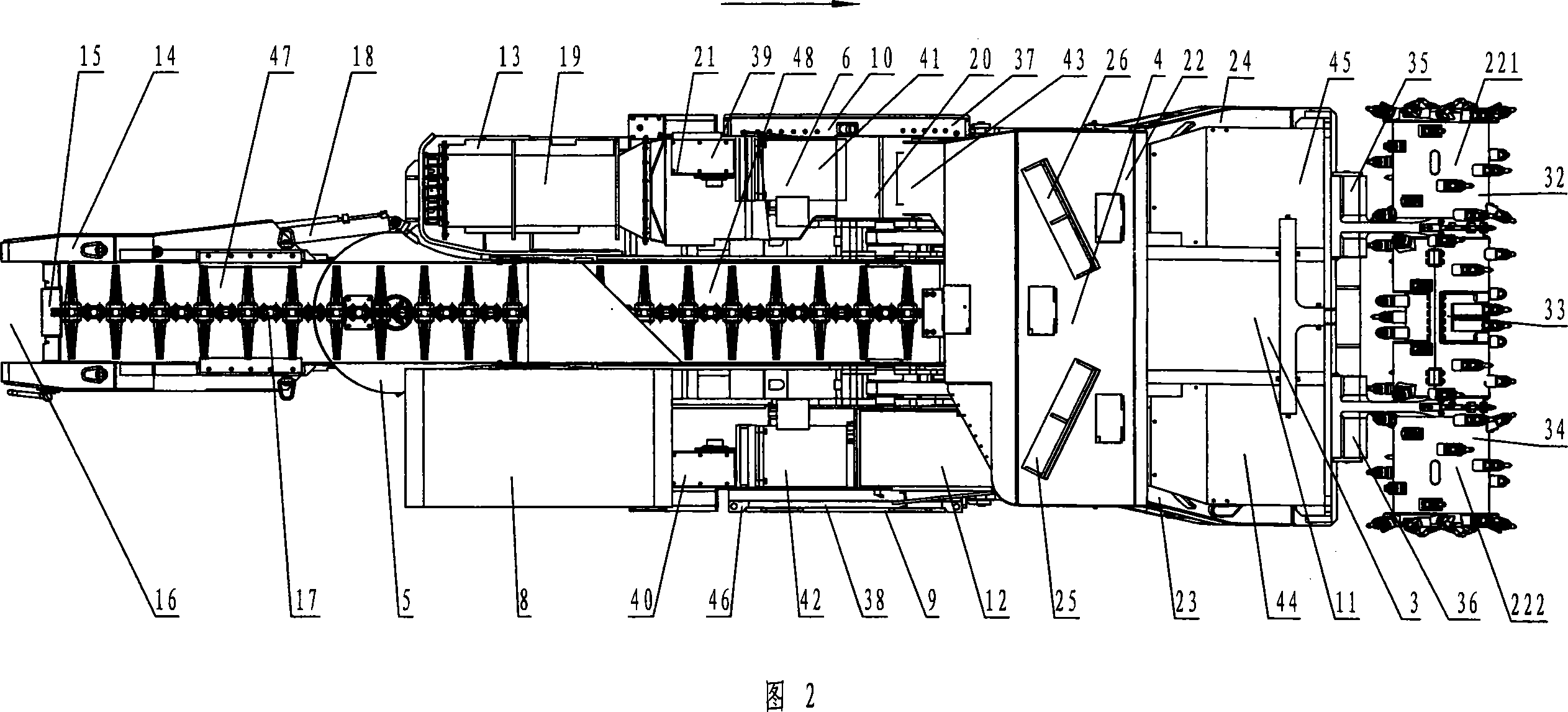

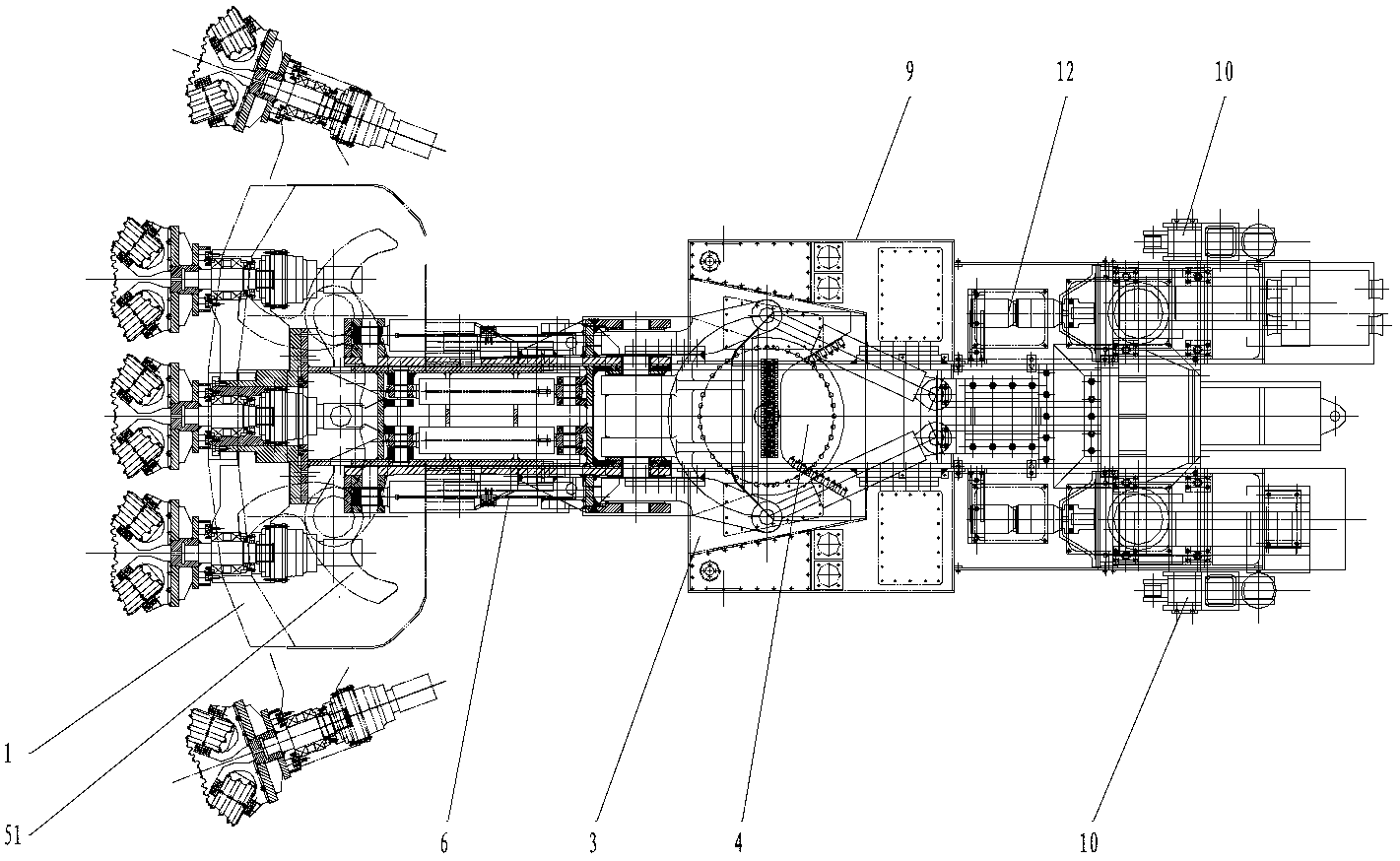

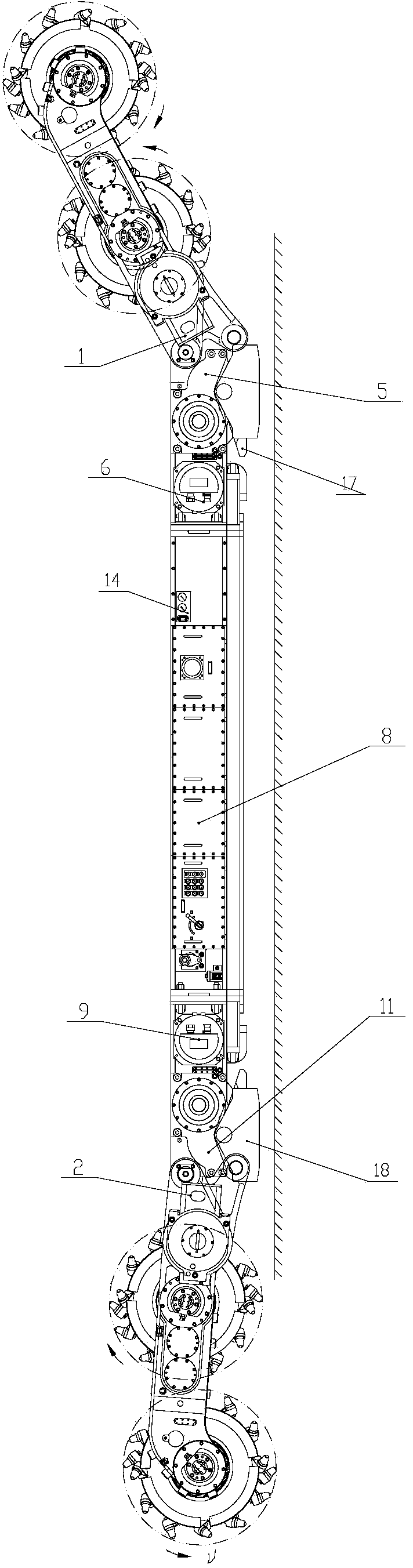

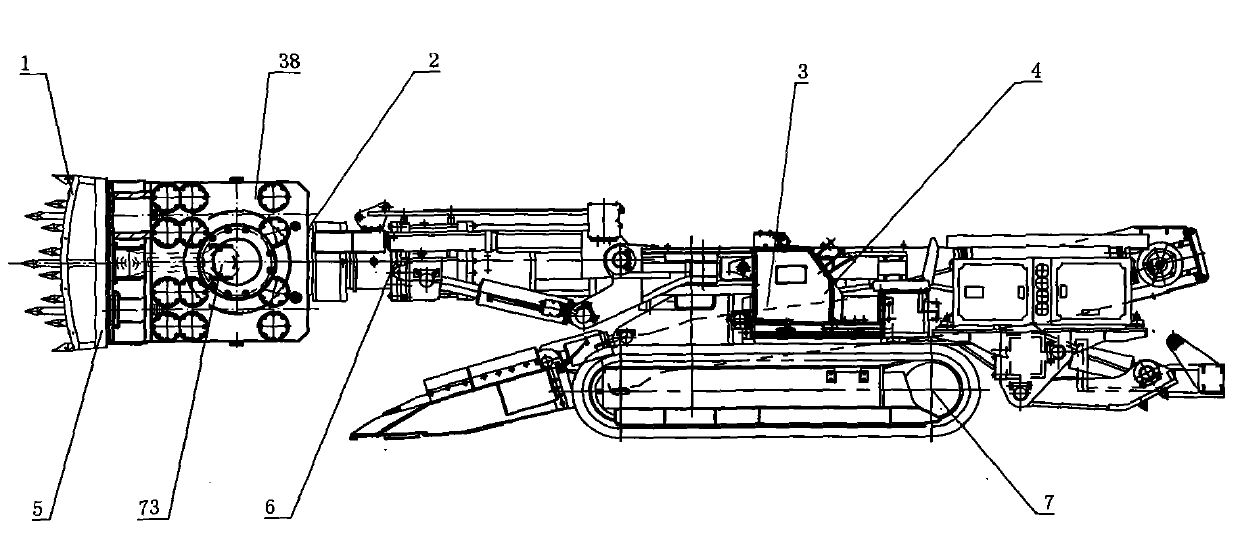

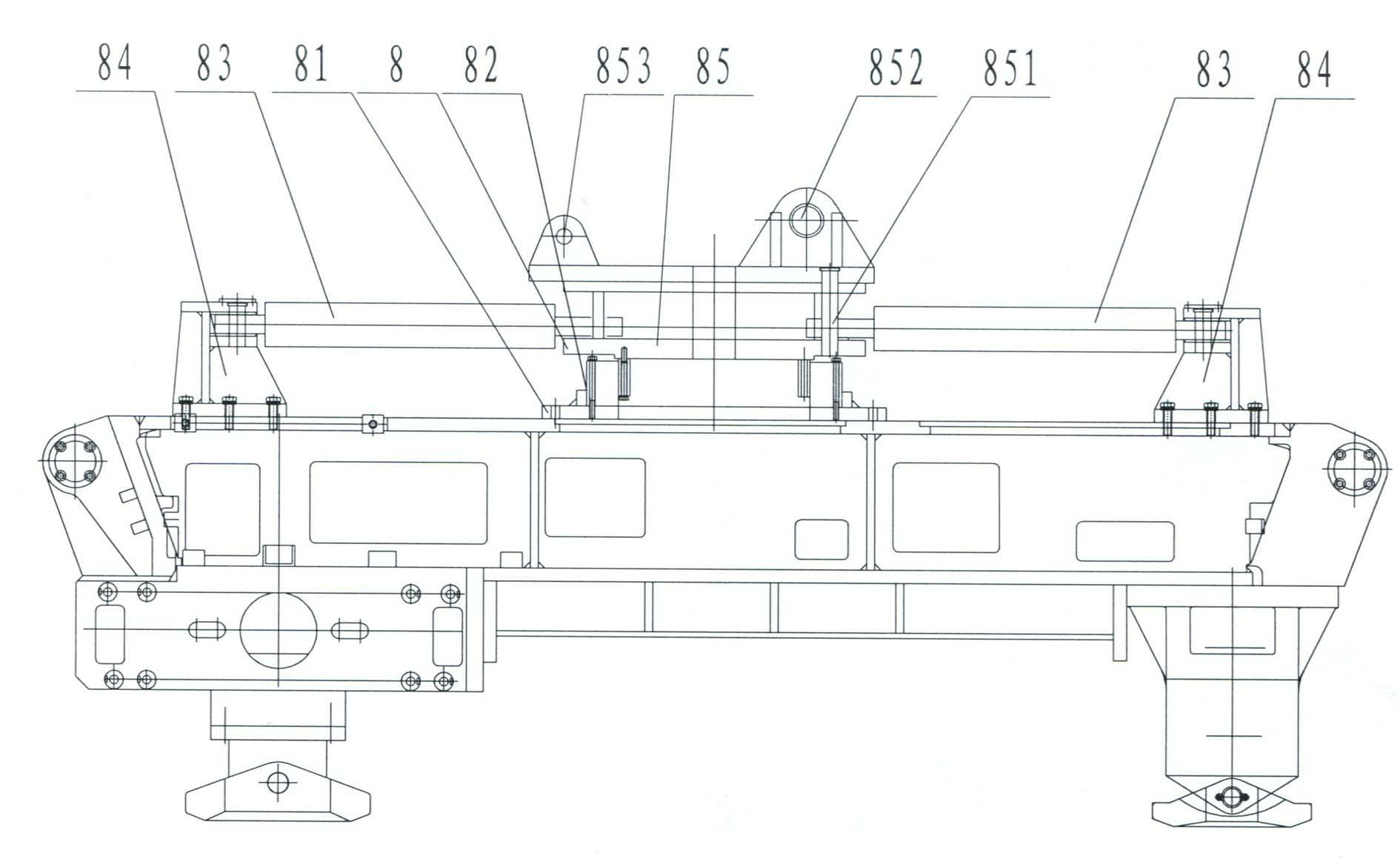

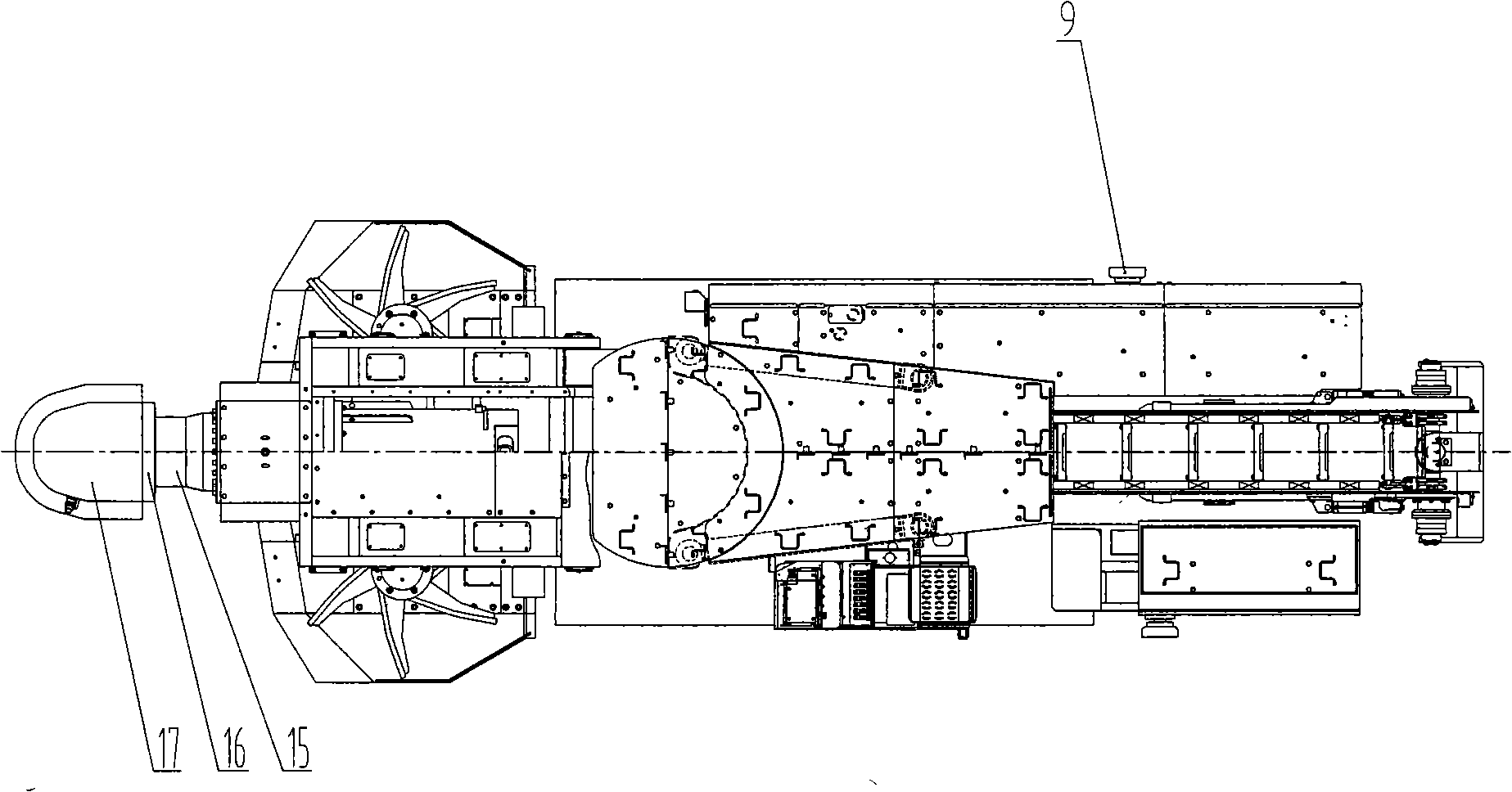

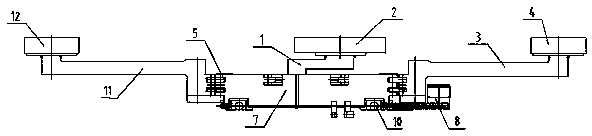

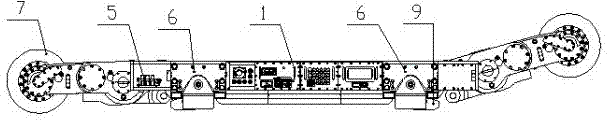

Underground continuous tunnelling machine

ActiveCN101050703AAdvancedFill the research gapDriving meansPropulsionAgricultural engineeringElectric control

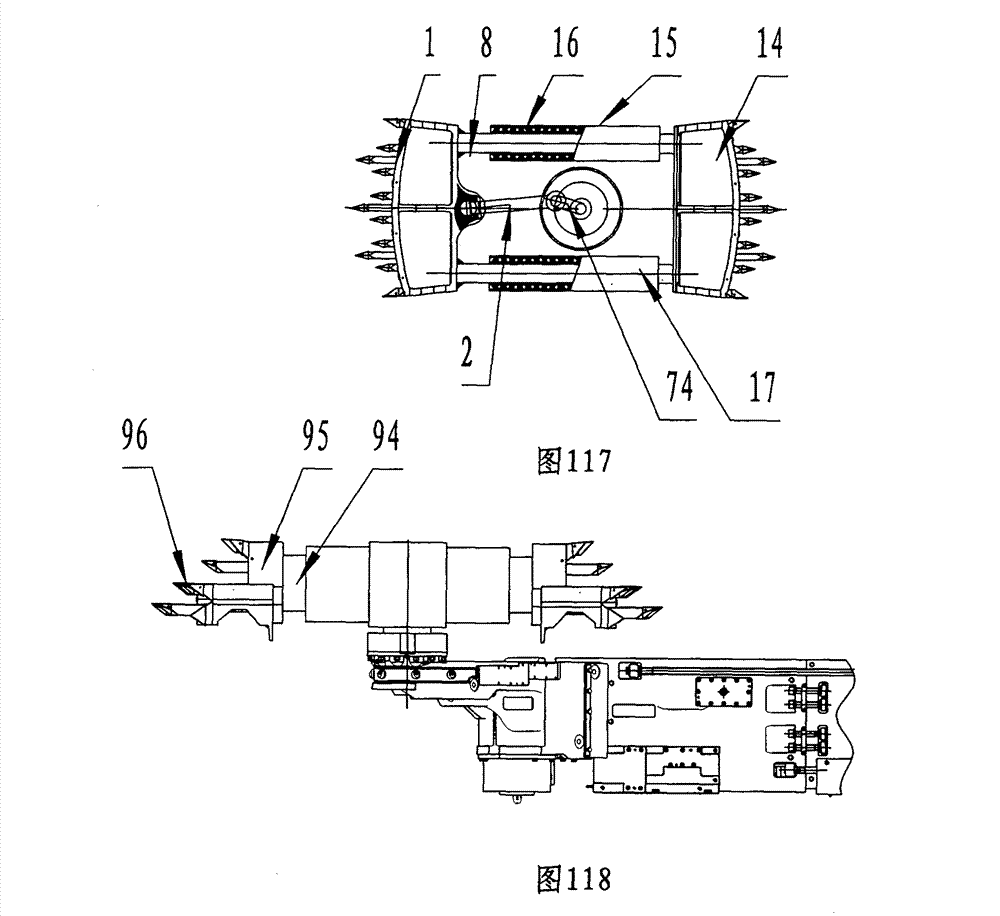

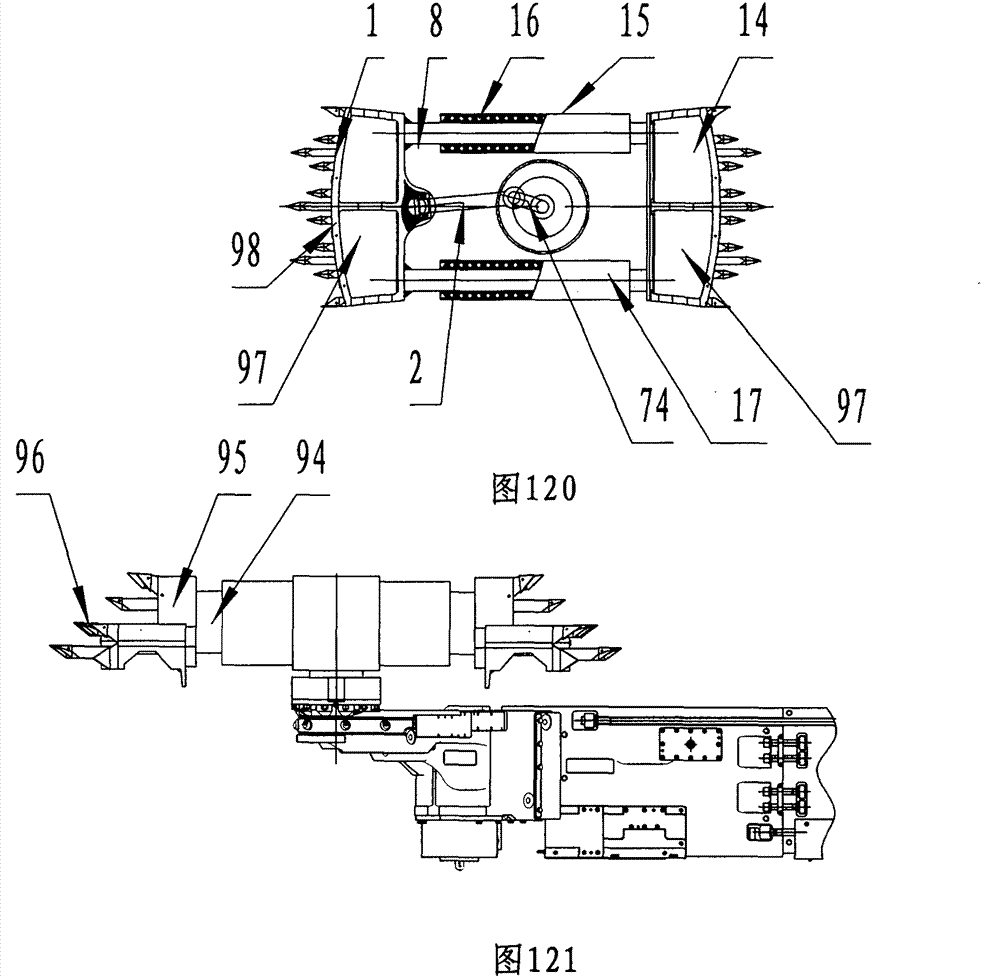

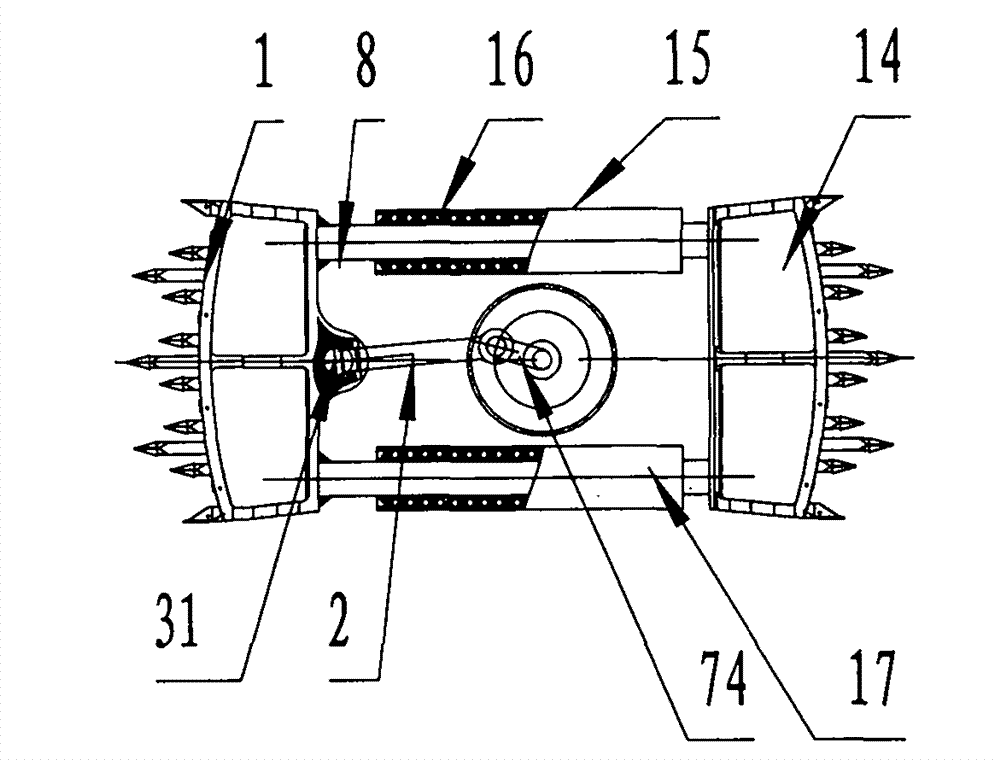

The present invention relates to a coal mine underground continuous excavating machine. Its main mechanism includes the following several portions: main machine frame, rear machine frame, cutting mechanism, scooping plate mechanism, conveying mechanism, dust-removing mechanism, traveling mechanism, driving mechanism, hydraulic mechanism, electric control circuit and stable mechanism. Said invention also provides the connection mode of all the above-mentioned portions, and also provides the working principle of said excavating machine and its operation method.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

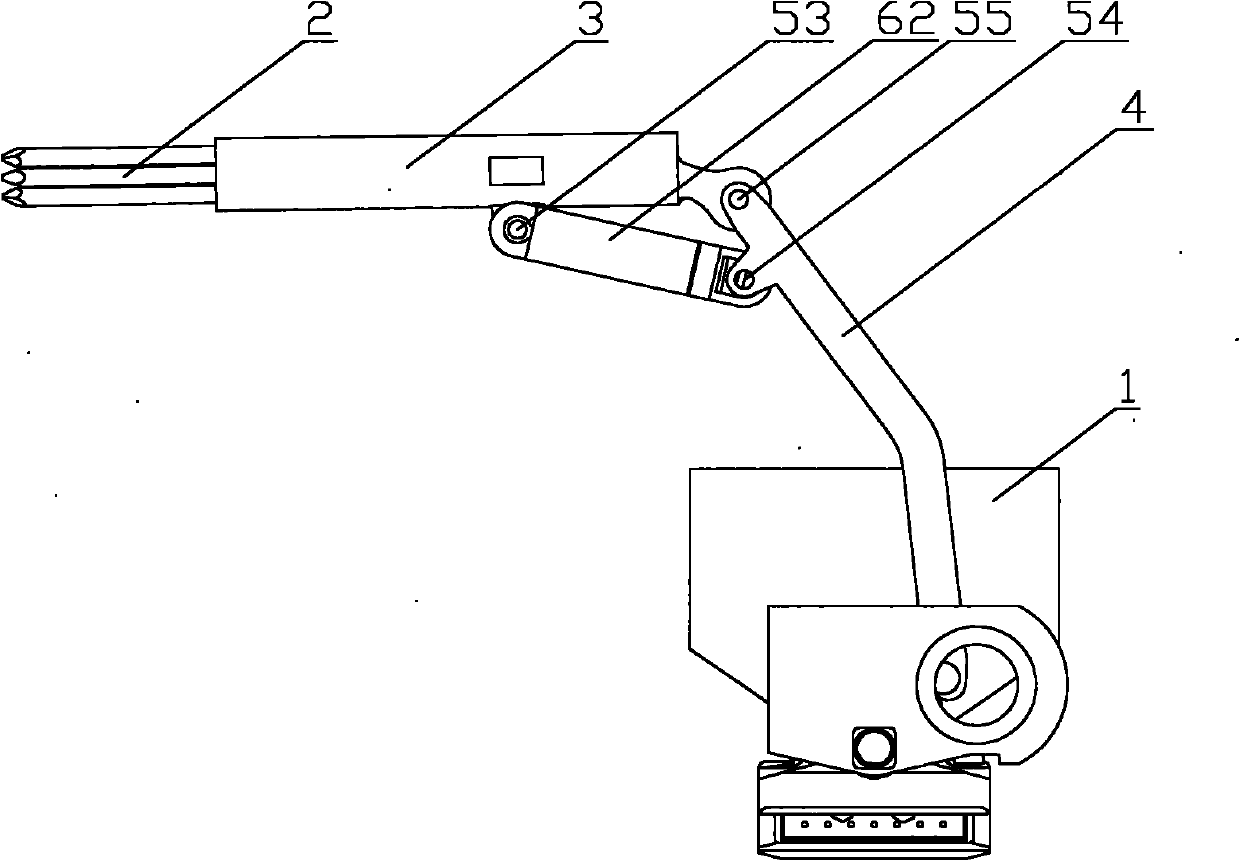

Coal mining device and crushing mechanism thereof

InactiveCN101906969AImprove crushing efficiencyPrevent flying outDriving meansEngineeringCentrifugal force

The invention discloses a crushing mechanism for a coal mining device, comprising a main body part (1), a power component installed on the main body part (1) and a work component (2) driven by the power component, wherein the power component is used for driving the work component (2) to do the reciprocating straight line motion. In the work process of the crushing mechanism, the straight line motion does not generate a centrifugal force, thereby preventing the crushed coals from flying out in crushing process and guaranteeing the personal safety of the staffs in the tunnel; meanwhile, the coal crushed by the straight line motion is not cut into powders so as to prevent coal dusts from flying in the tunnel and to improve the air quality in the tunnel; in addition, the single motion stroke of the straight line motion is large so as to improve the crushing efficiency of the crushing mechanism. The invention further discloses a coal mining device including the crushing mechanism.

Owner:SANY HEAVY EQUIP

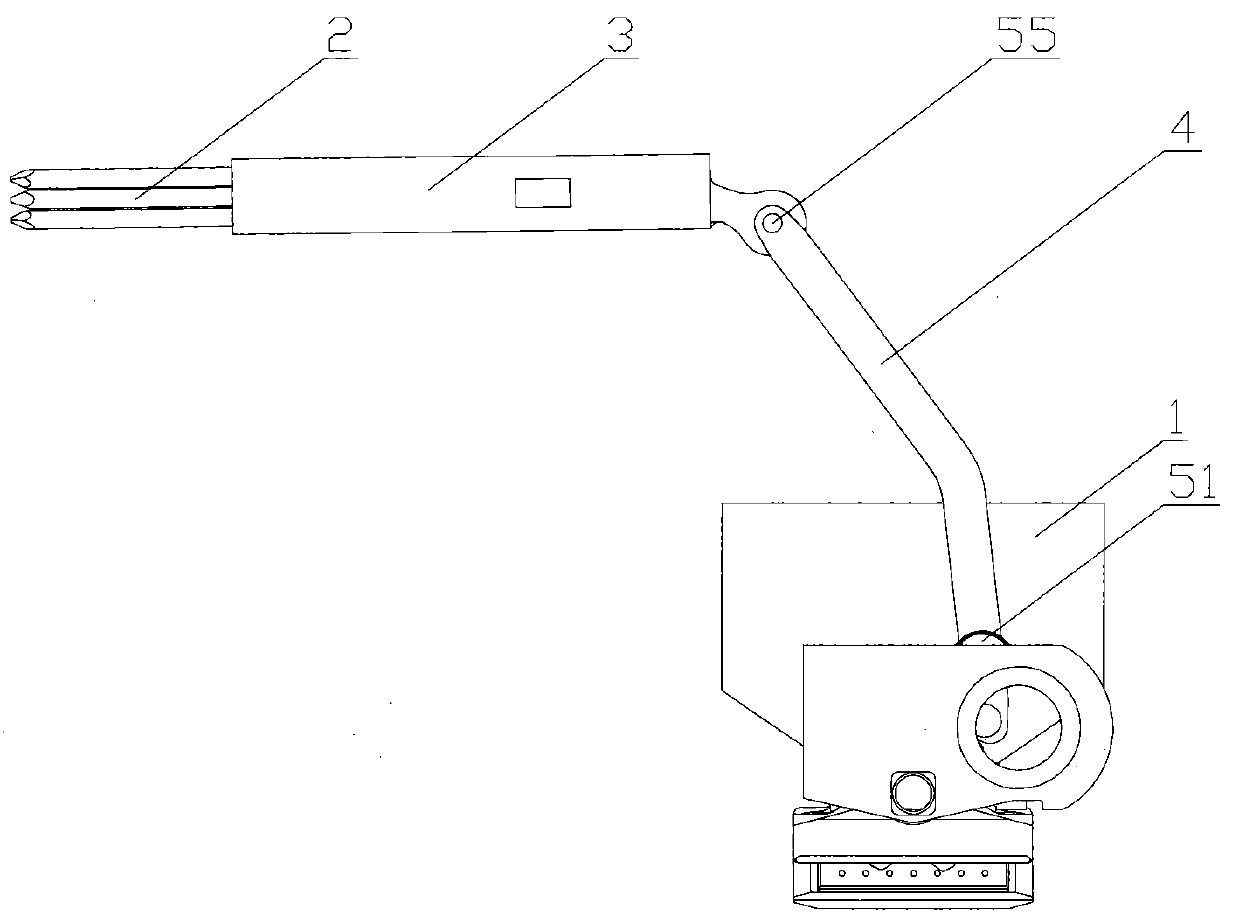

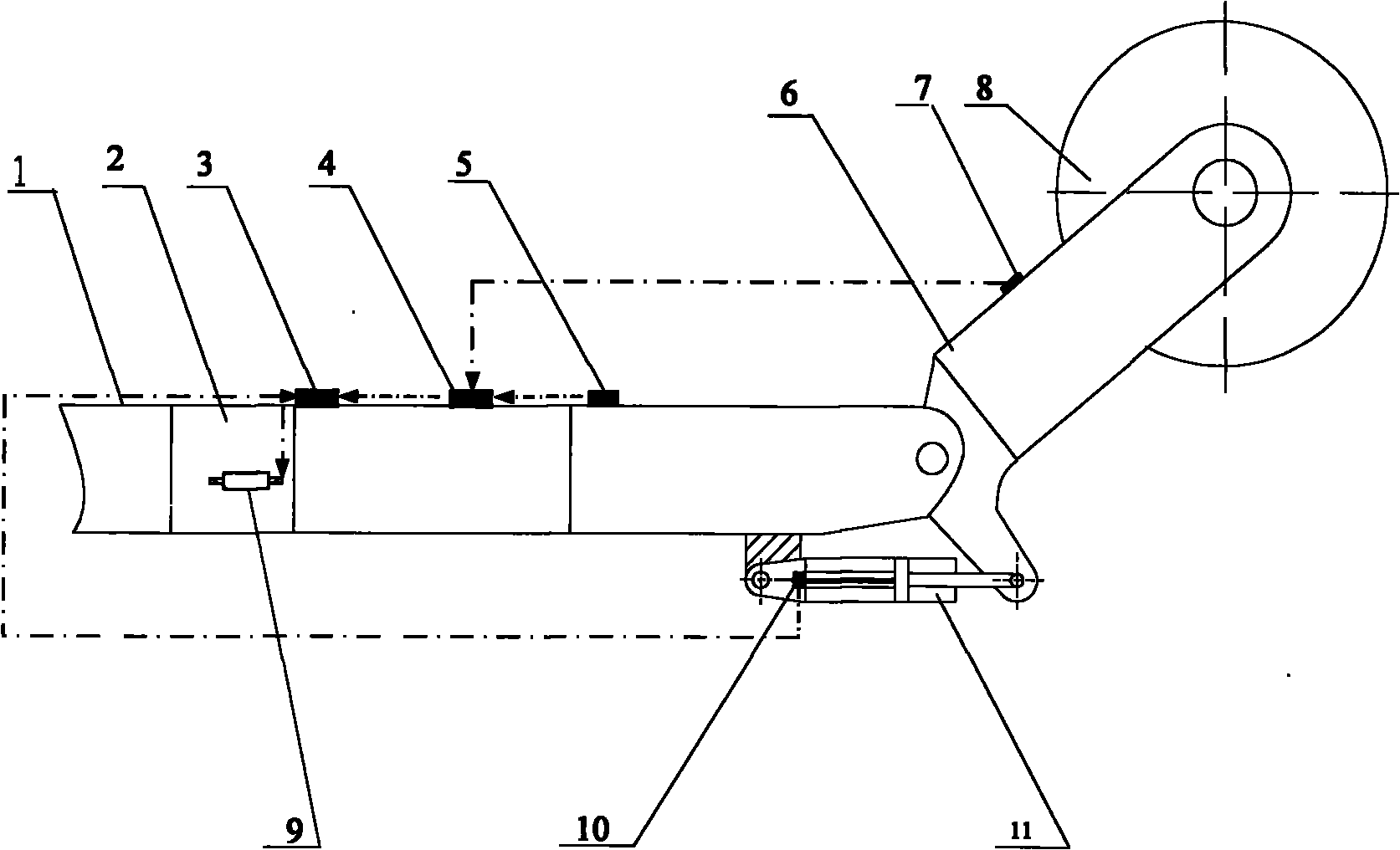

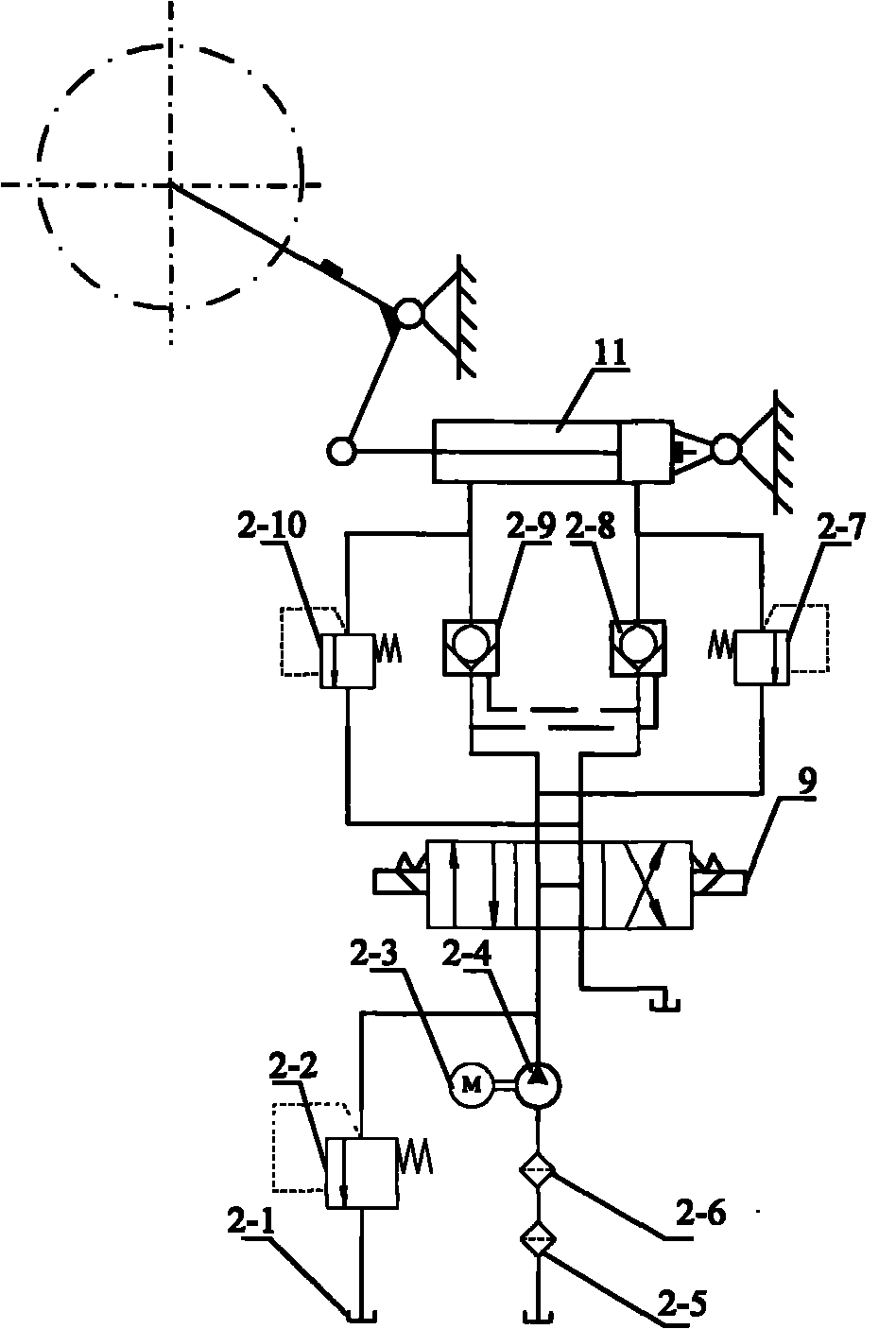

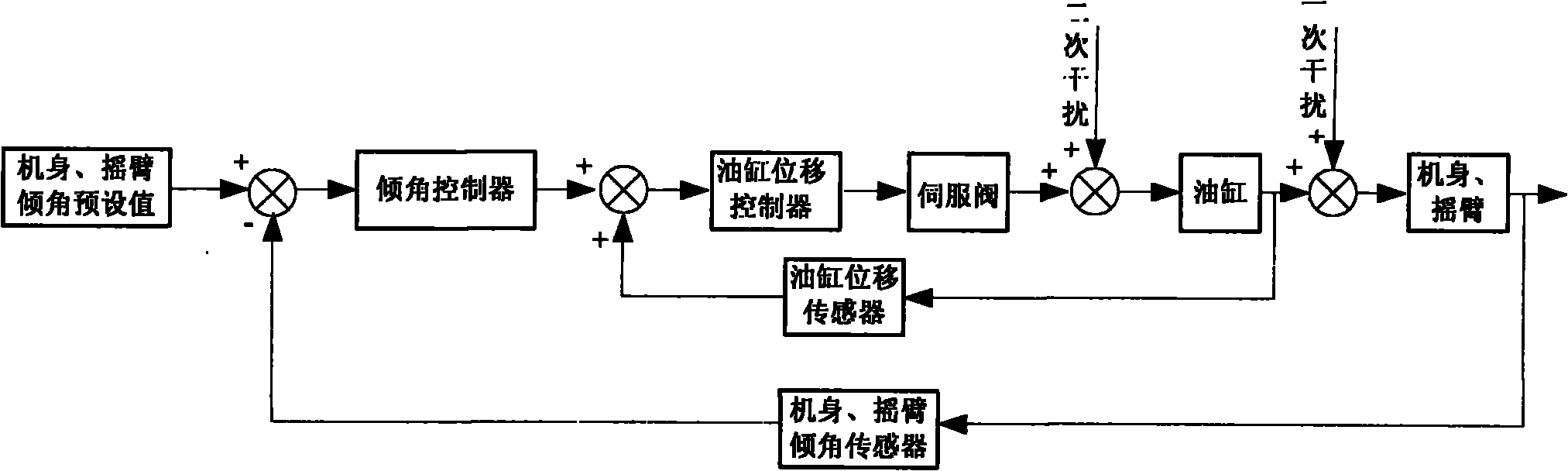

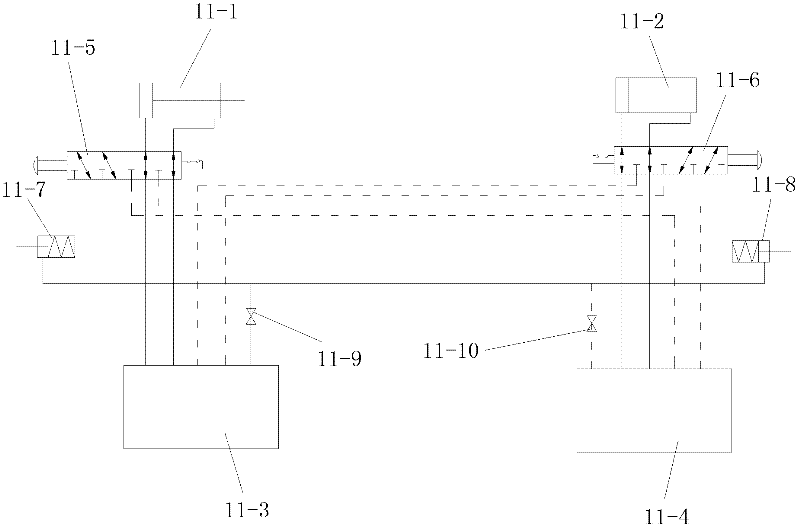

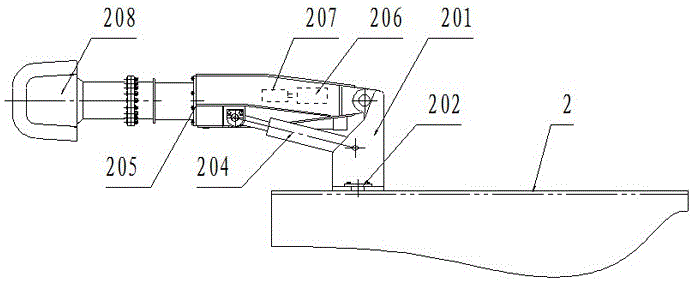

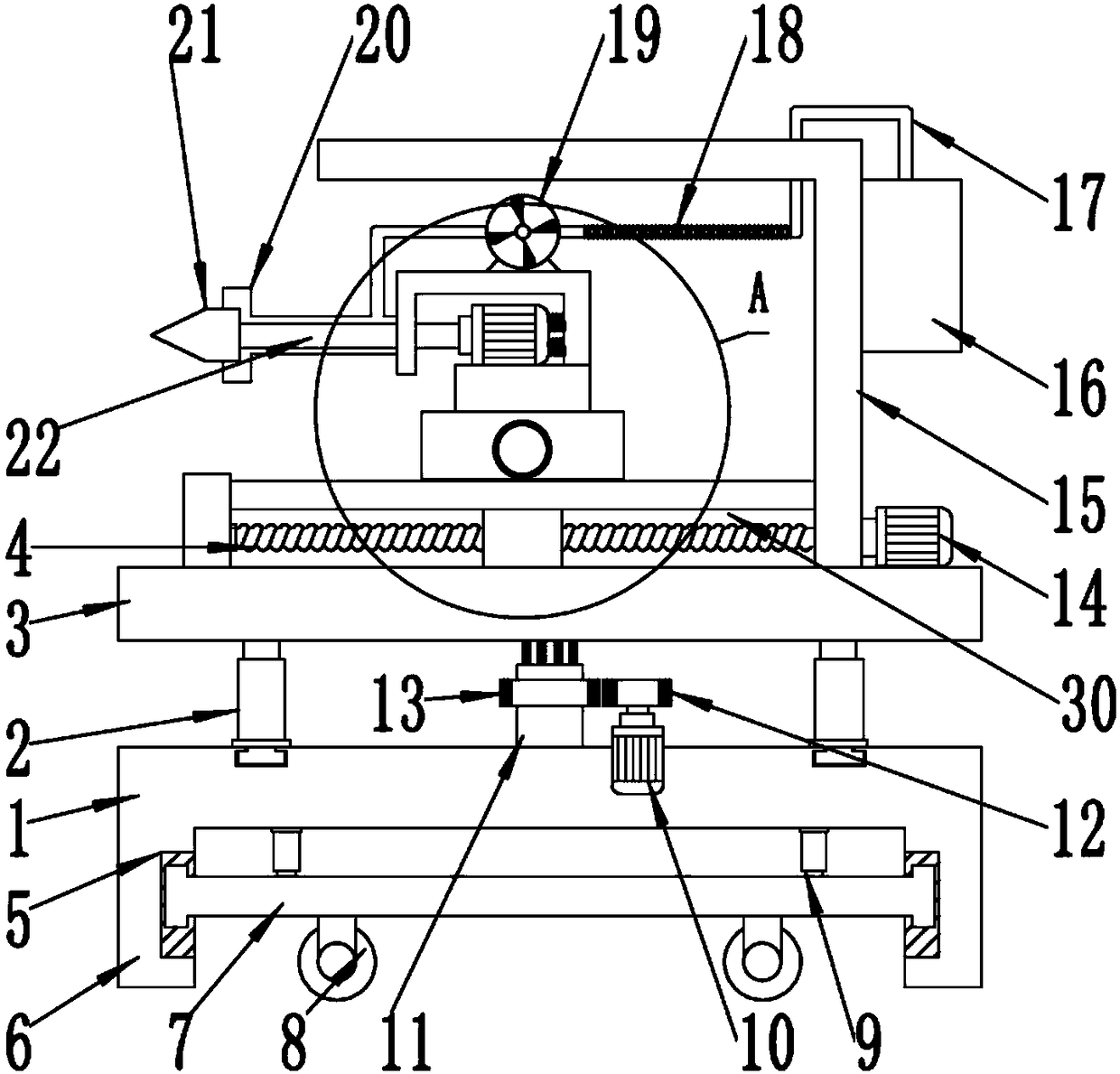

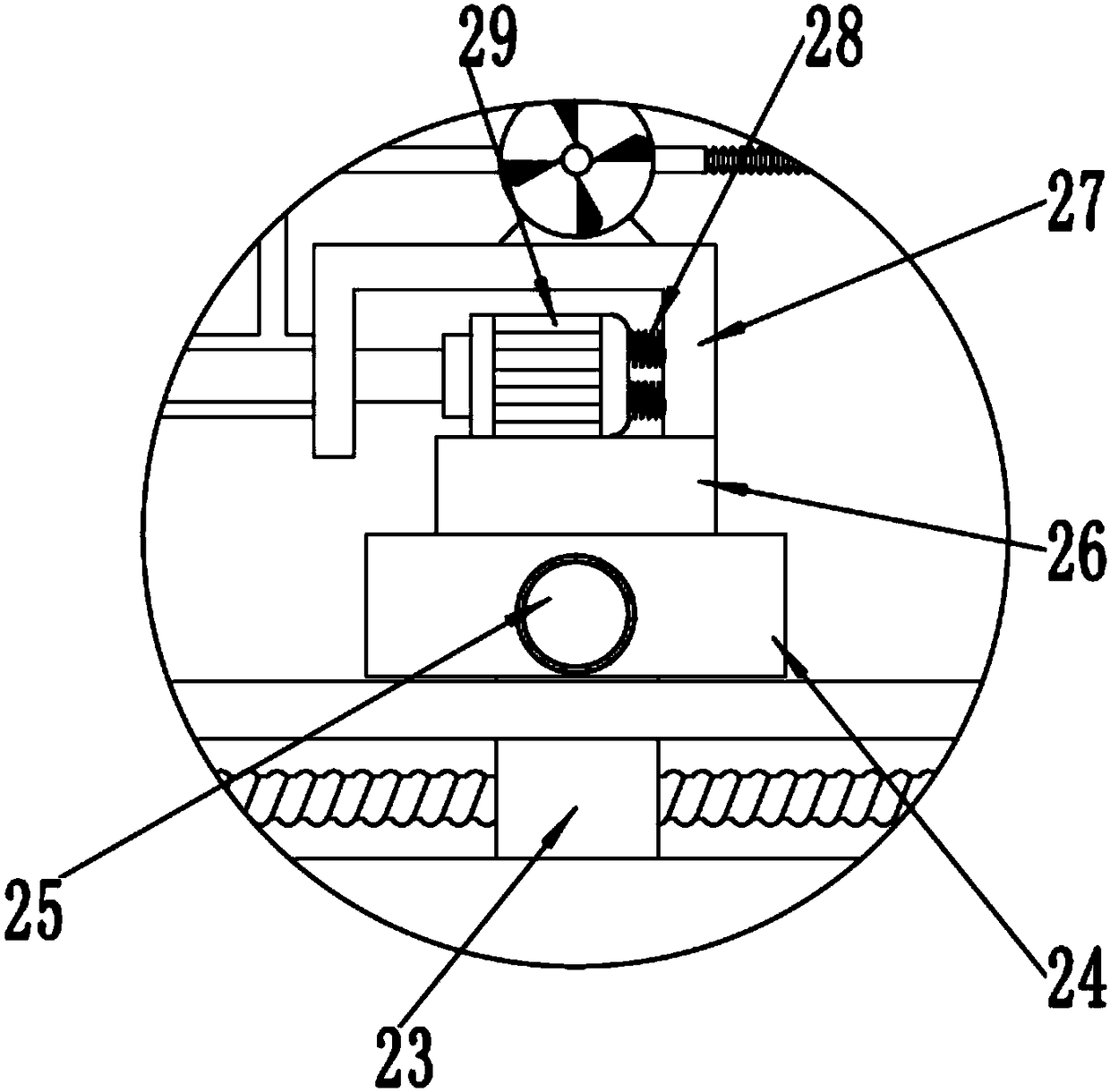

Automatic height-adjusting test device of coal mining machine roller and control method

InactiveCN101887273ATurn up fastImprove precisionControl using feedbackDriving meansDisplacement controlFuselage

The invention relates to an automatic height-adjusting test device of a coal mining machine roller and a control method. The device comprises a device body, a rocker arm, a roller, a height adjusting pump station, sensors, an inclined angle controller and a displacement controller, wherein the device body is articulated with the rocker arm; the output end of the rocker arm is connected with the roller; the height adjusting pump station is used for driving the rocker arm and the roller to move by an oil cylinder and simulating the running condition of a coal mining machine; the inclined angle sensors are arranged on both the device body and the rocker arm; the displacement sensor is arranged on the oil cylinder; the output of the inclined angle sensors on the device body and the rocker arm is compared with a corresponding inclined angle preset value, and an error is used as the input of the inclined angle controller; the output of the inclined angle controller is used as a preset value of the oil cylinder displacement controller and compared with the output data of the oil cylinder displacement controller, and an error is transmitted to the oil cylinder displacement controller; and the output of the oil cylinder displacement controller is used for controlling the opening and the direction of a servo valve and realizing the height adjustment of the roller. The invention is used for a test for researching the change of a cutting medium on the performance requirement of the roller height adjusting device and a test for researching the influence of oil cylinder displacement fluctuation on the height of the roller.

Owner:CHINA UNIV OF MINING & TECH

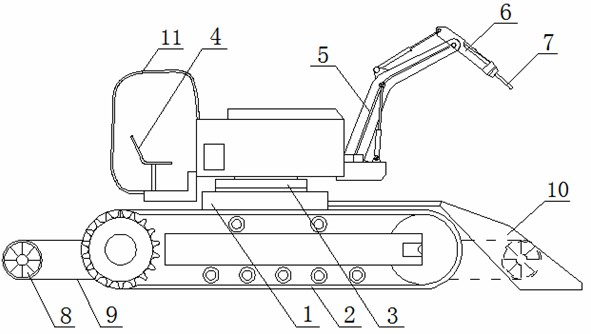

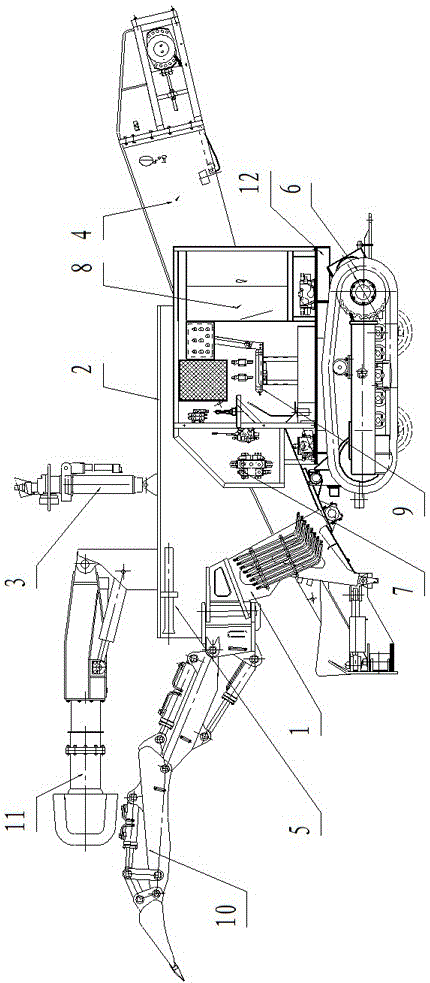

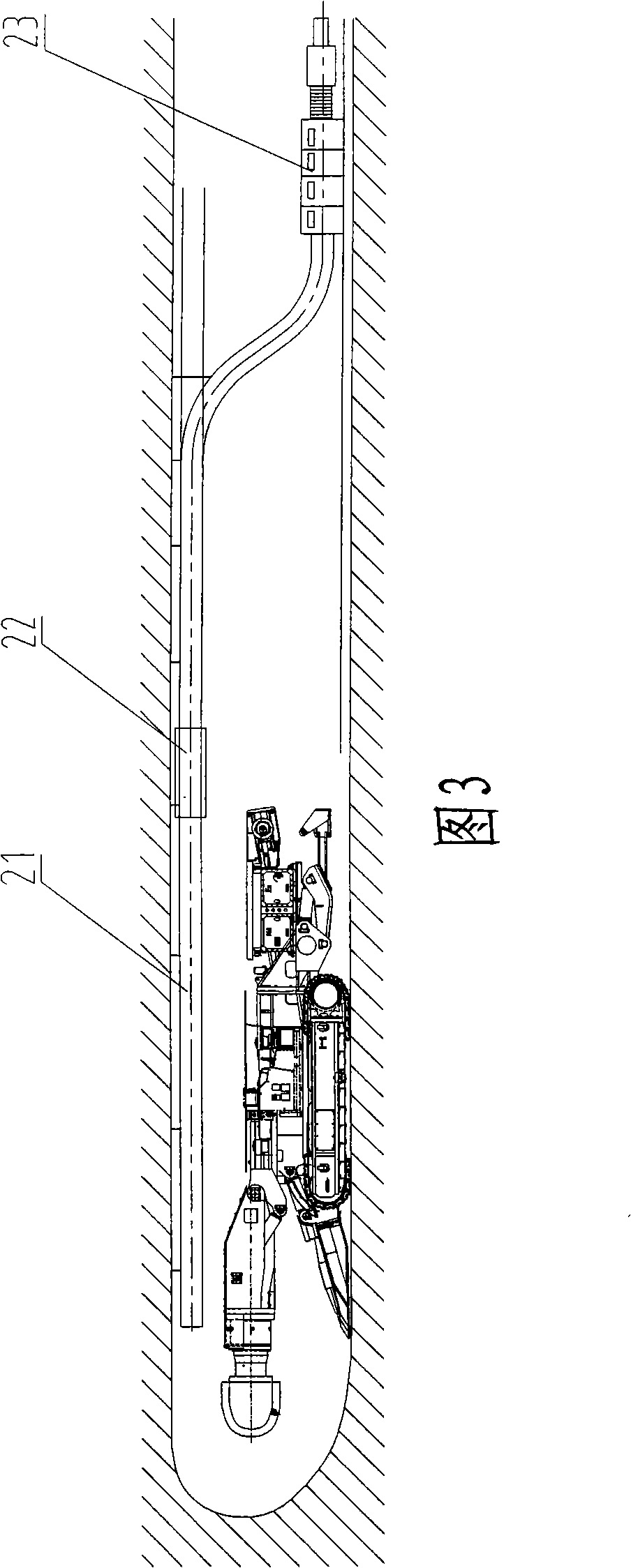

Tunnel mining machine

The invention provides a tunnel mining machine, which belongs to mining tunneling equipment. The tunnel mining machine comprises a chassis (1), a crawler travel mechanism (2), a rotary base (3), a large arm (5), a mining mechanism (6) and an operation device, wherein the rotary base (3) is arranged on the chassis (1); a main machine is driven by a power unit which is a motor; the power of the whole machine is supplied by an external power distribution device; an ore conveying channel is arranged under the chassis (1) or an ore conveying mechanism is arranged above the crawler of the crawler travel mechanism (2); and the mining mechanism (6) is arranged on the large arm (5). The tunnel mining machine has a simple structure, facilitates ore conveying, saves a working space when mining in a tunnel, can freely walk and move and be remotely controlled, and realizes integrated uninterrupted mining operation with high mining efficiency.

Owner:张元杰

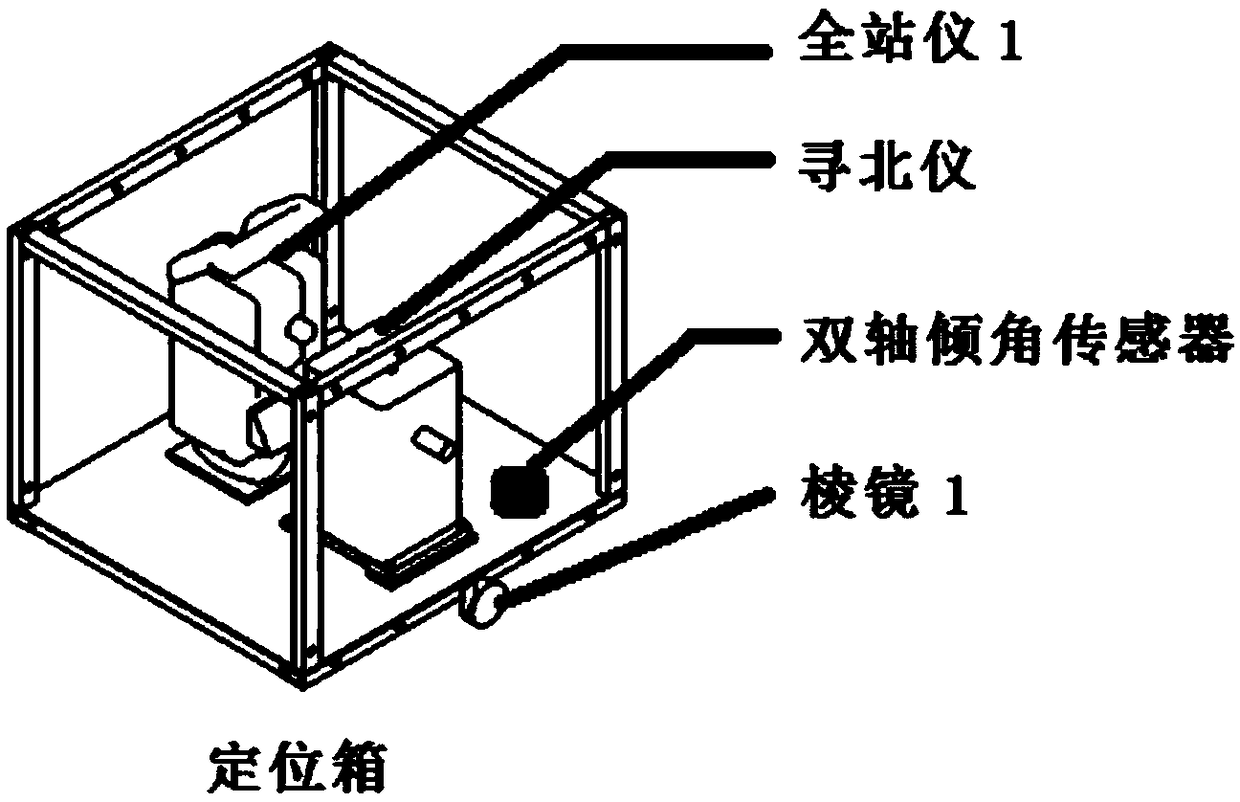

Roadheader, system and method

ActiveCN109356608AAchieve positioningSolve the fast-moving puzzleMining devicesTesting machinesAutomatic controlRemote control

The invention provides a roadheader, a system and a method. According to the roadheader, the system and the method, three-dimensional space coordinates of the roadheader can be tracked and measured inreal time to realize the millimeter levelpositioning accuracy of the set distance within the visual range, remote control operation and automatic control over the roadheader are facilitated, and themovement path and the speed of a cutting head as well as the direction, position and posture of a roadheader body can be automatically adjusted according to the position change of the roadheader and the rock wall hardness change of a heading working face roadway.

Owner:山东新矿信息技术有限公司

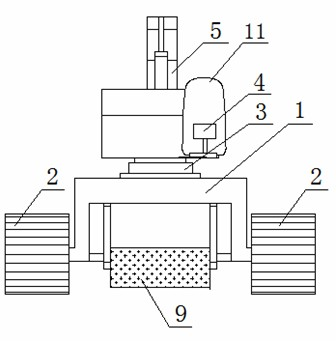

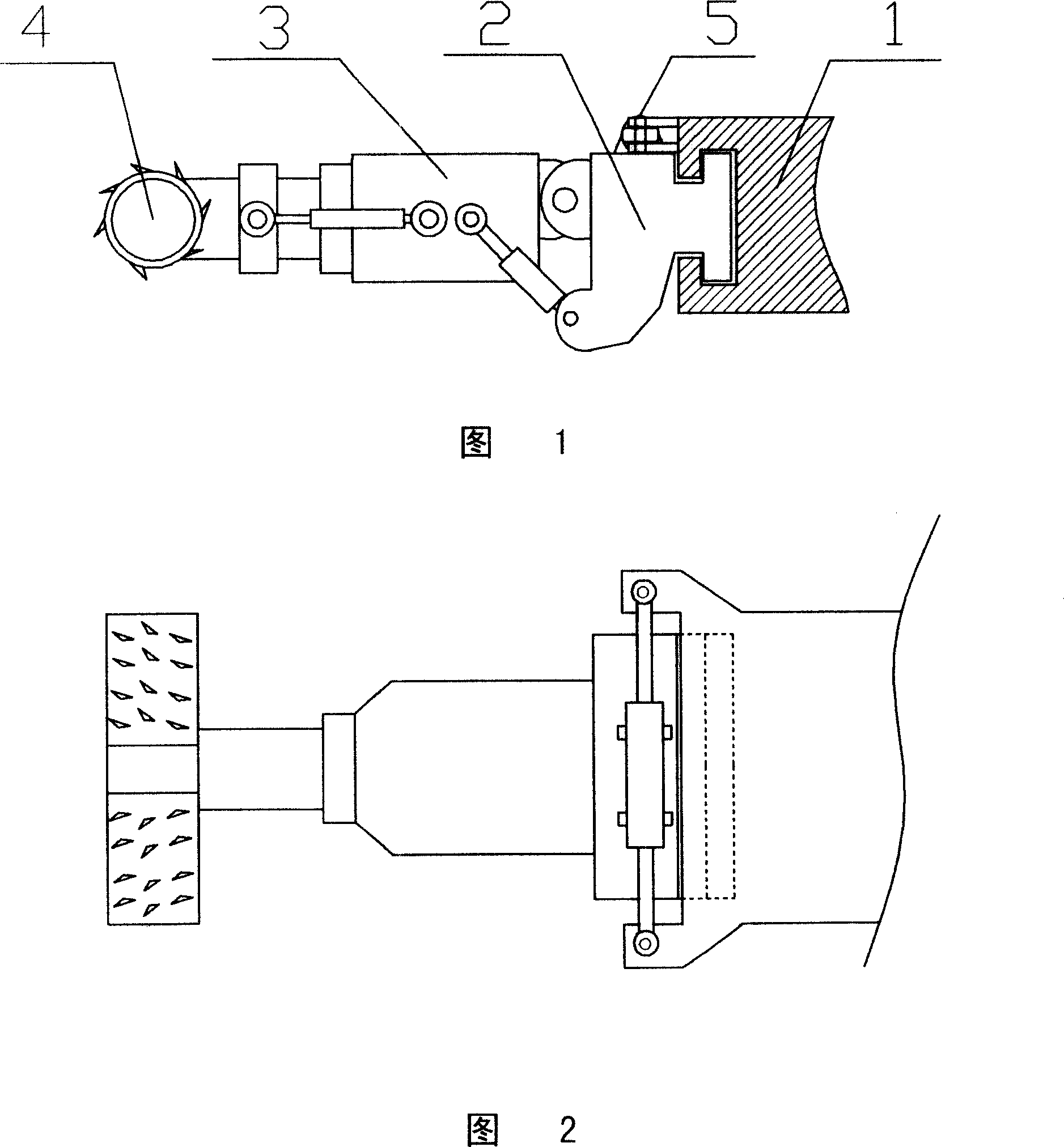

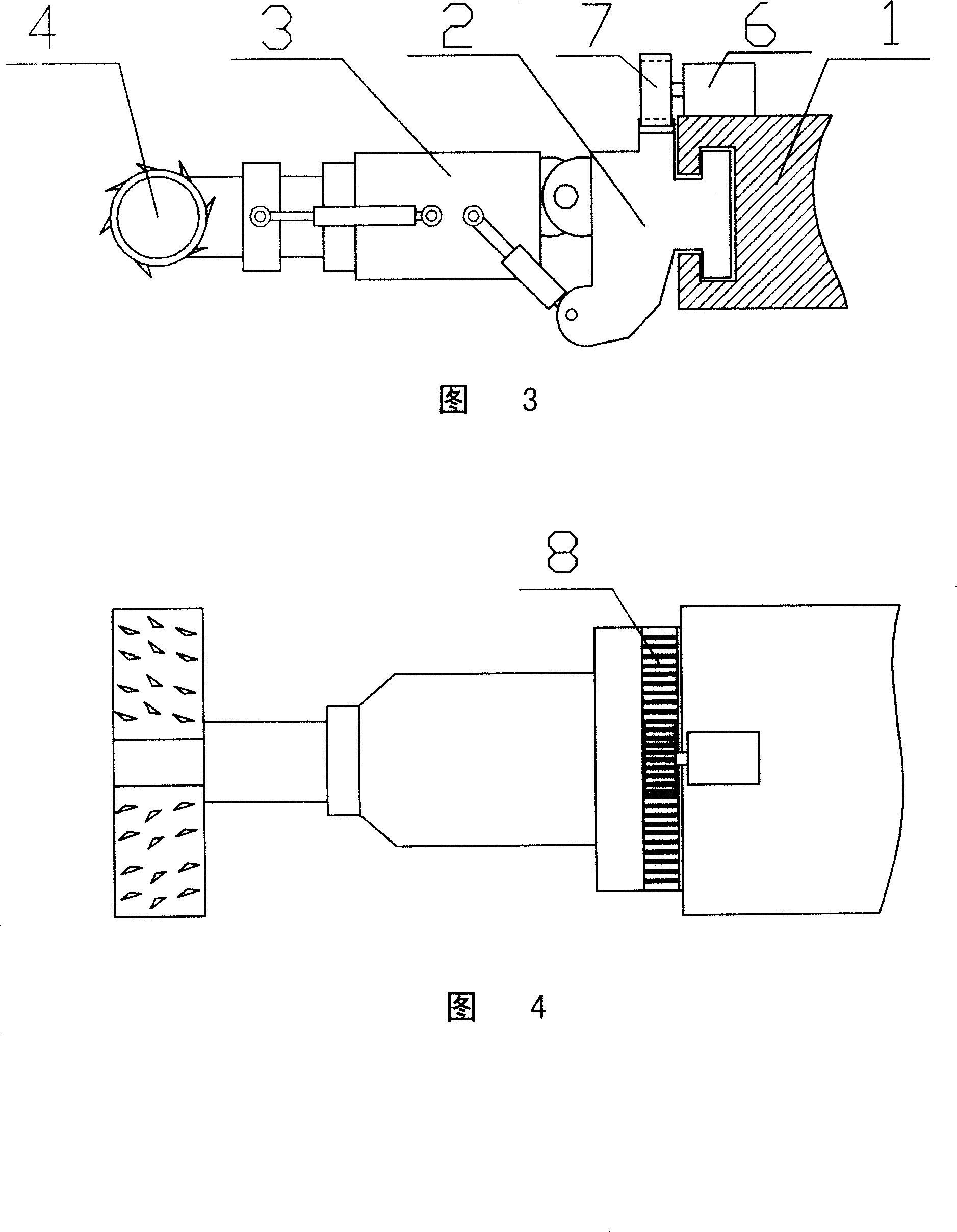

Bidirectional pounding and cutting excavating method and bidirectional pounding and cutting excavator for implementing same

ActiveCN103089259AReduce the number of adjustmentsExtend your lifeDriving meansReciprocating motionEngineering

The method provided by the invention comprises the following steps: a machine body, a walking part, a lifting part, a reciprocating pounding part and the like are arranged; a pounding guide element and the like are arranged on a pounding guide device; pounding heads are arranged at two ends of the pounding guide element, so that a power pounding element drives the pounding guide element; the reciprocating pounding part is arranged on the lifting part; the lifting part is arranged on the machine body; and the walking part drives the machine body to move ahead and retreats so as not to turn the machine body to excavate and drop materials forward and backward. Equipment provided by the invention comprises the machine body, the walking part, the lifting part, the reciprocating pounding part and the like; the reciprocating pounding part comprises the pounding guide device, the pounding driving device and the like; the pounding heads are both arranged at two ends of the pounding guide element; the pounding driving device comprises the power pounding element and the like; the power pounding element drives the pounding guide element to move in a reciprocating mode; the pounding guide element drives the pounding heads to pound; the reciprocating pounding part is arranged on the lifting part; the lifting part is arranged on the machine body; the walking part drives the machine body to move ahead and retreat so as not to turn the machine body to excavate and drop materials forward and backward.

Owner:刘素华

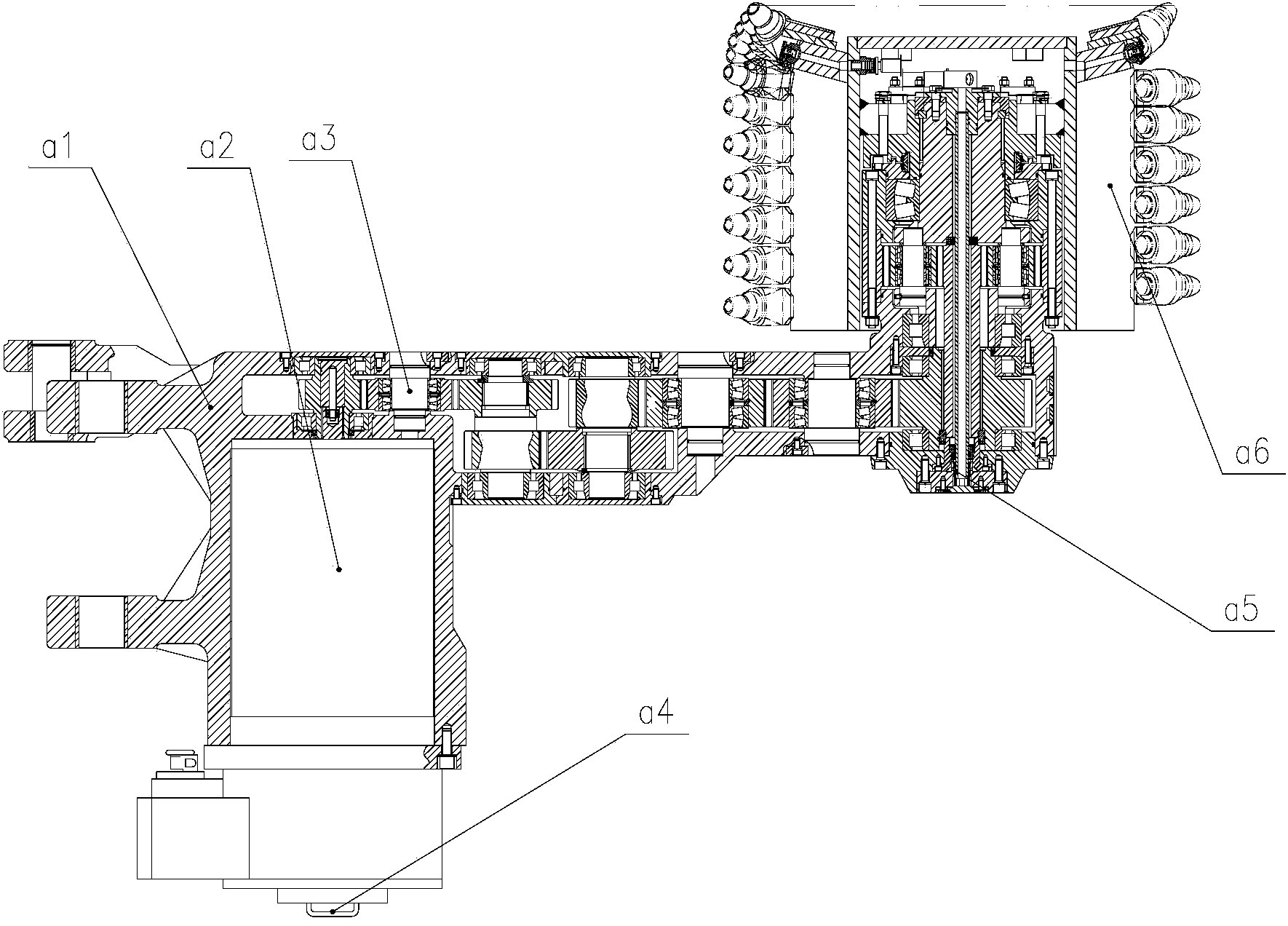

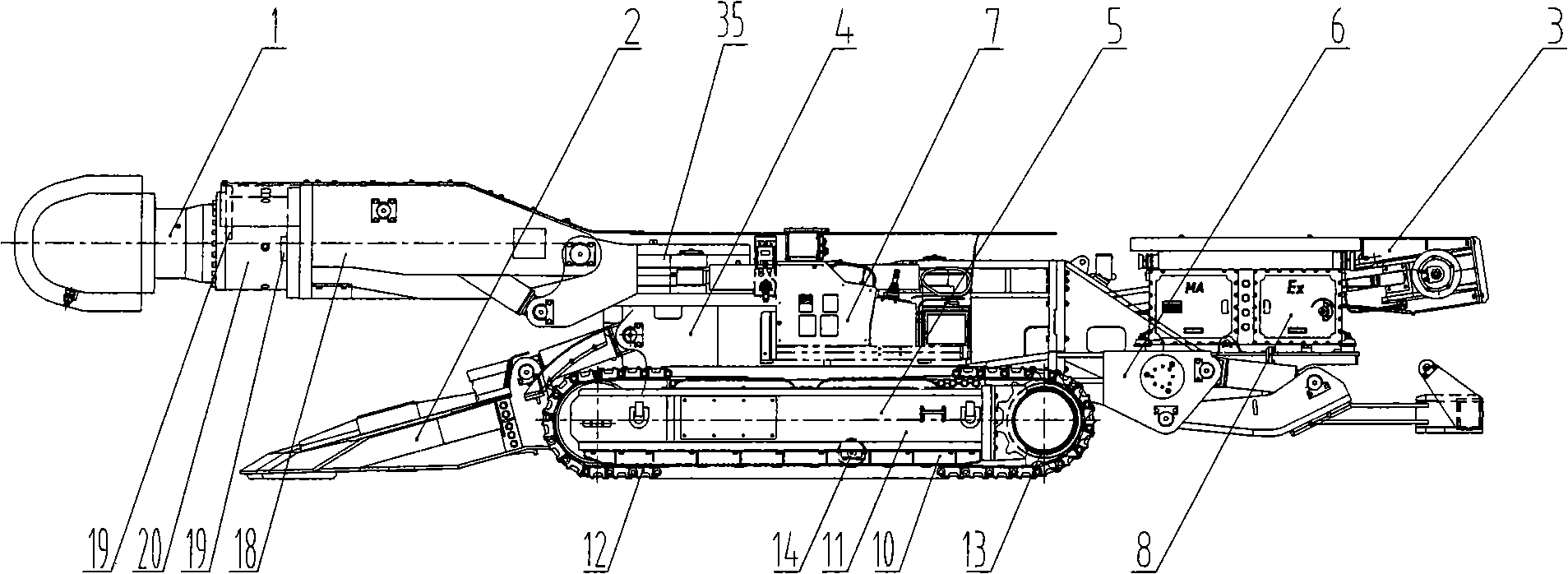

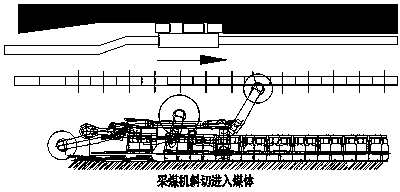

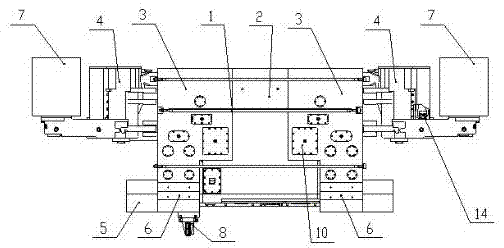

A high-power heavy-duty thin coal seam shearer

ActiveCN102287185AReasonable structural designEasy to operateMechanical energy handlingDriving meansEngineeringElectric control

The invention discloses a high-power heavy low seam mining machine, which comprises a machine body, a left traction part, a right traction part, a left cutting part, a right cutting part, a swinging arm elevating hydraulic system and an electric control system, wherein the electric control system comprises an electric control box and a controller; the left cutting part comprises a left swinging arm, a left roller and left cutting motors; the right cutting part comprises a right swinging arm, a right roller and right cutting motors; the left traction part comprises a left traction motor and a left traction transmission mechanism; the right traction part comprises a right traction motor and a right traction transmission mechanism; the left cutting motors, the right cutting motors, the left traction motor, the right traction motor and swinging arm elevating hydraulic system are controlled by the controller; and two left cutting motors and two right cutting motors are provided. The high-power heavy low seam mining machine has the advantages of reasonable design, high overall power, high mining efficiency, stable and reliable working performance and good using effect, and can be used for solving the problems of low power, low mining efficiency, poor using effect and the like existed in the conventional coal mining machine in the mining process of a low coal seam.

Owner:XIAN COAL MINING MACHINERY

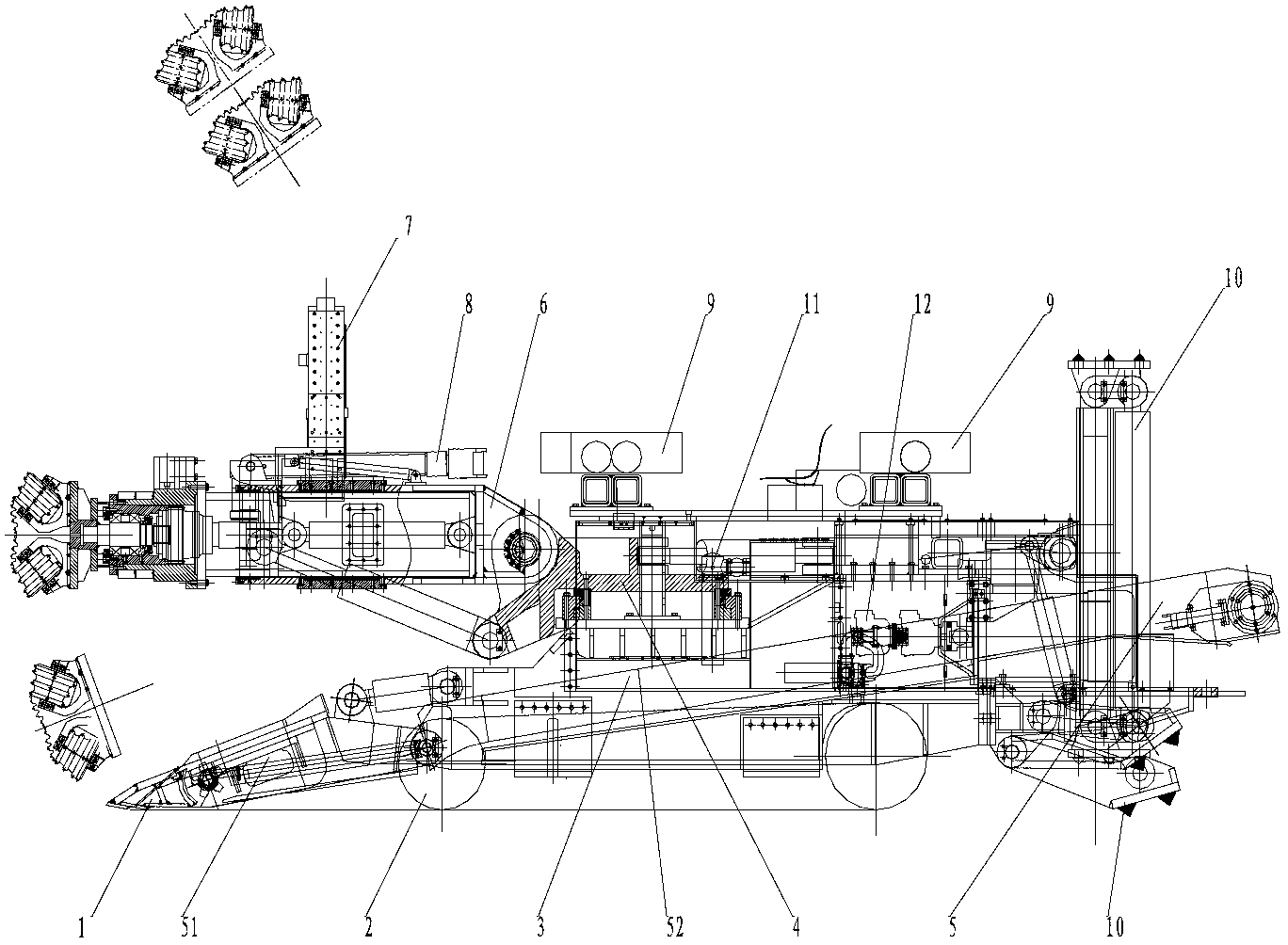

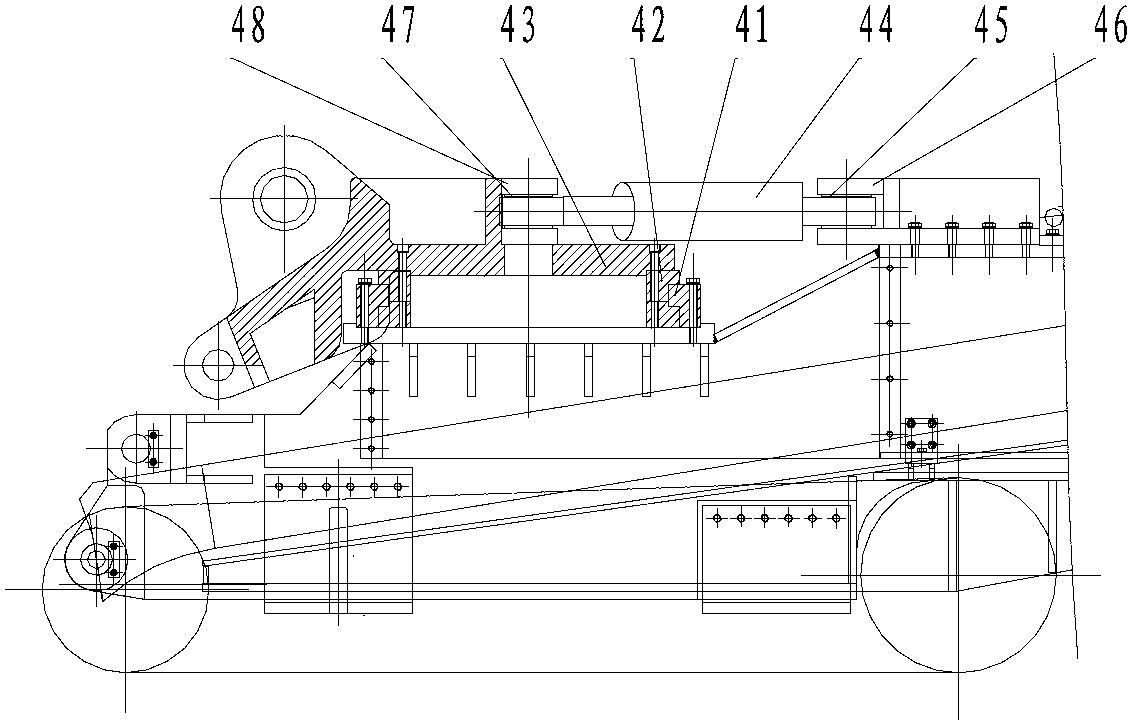

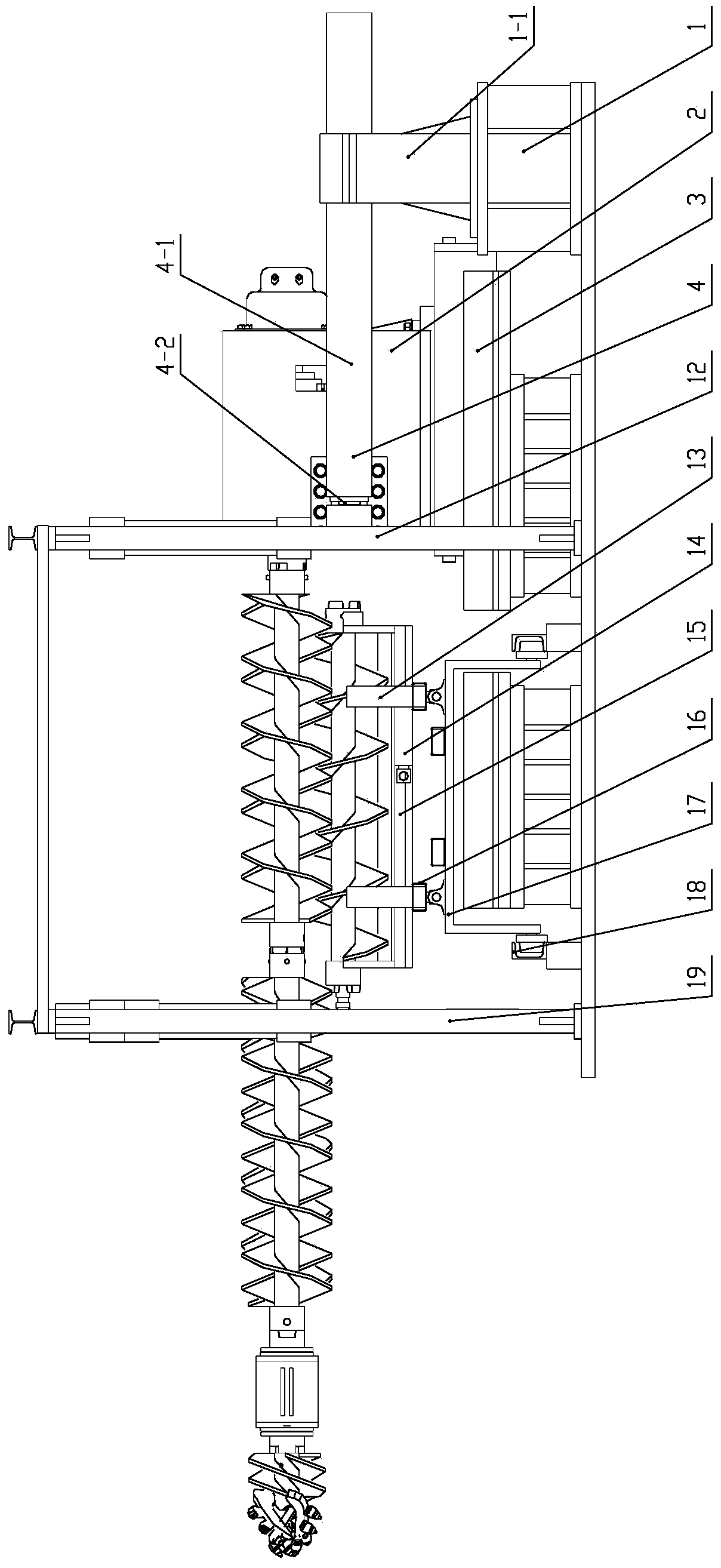

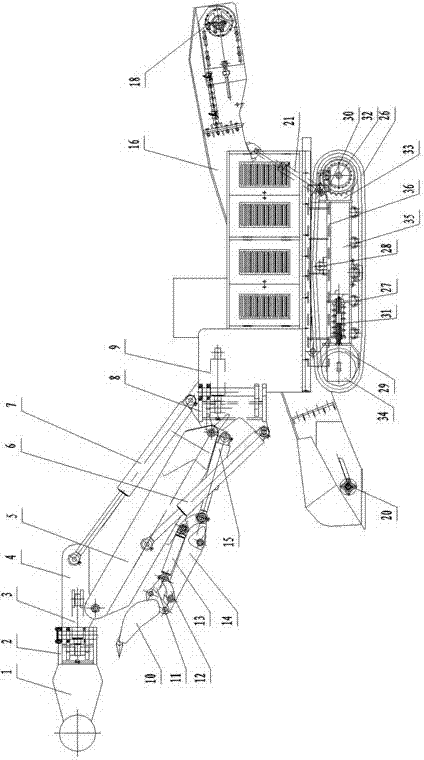

Comprehensive mechanization stone drift heading machine set

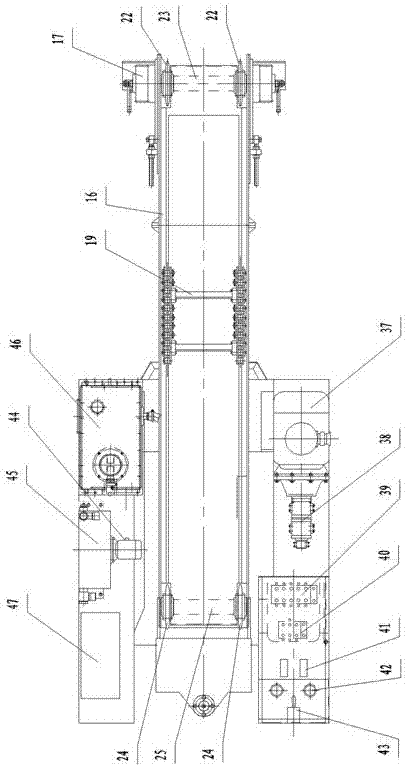

InactiveCN102704927AGuarantee the construction qualityReduce labor intensityMine roof supportsDriving meansControl systemEngineering

The invention relates to a comprehensive mechanization stone drift heading machine set, which comprises a shovel plate part, a caterpillar band travelling part, a rack, a belt conveying part, a flexible cutting part, a hydraulic drilling rig device, an advance support device, a hydraulic control system and an electric control system. The comprehensive mechanization stone drift heading machine set is characterized by also comprising a rotation part, two side supporting devices and top and bottom plate supporting devices. The comprehensive mechanization stone drift heading machine set disclosed by the invention is improved and perfected to enable the structure design to be more reasonable and compact, and the performances, such as working efficiency, stability, reliability, and safety of the set, are improved. Comprehensive mechanization construction equipment is provided for mine underground stone drift heading, and is especially adaptive to the underground stone drift mechanization operation and construction of various big, medium and small mines.

Owner:马晓山

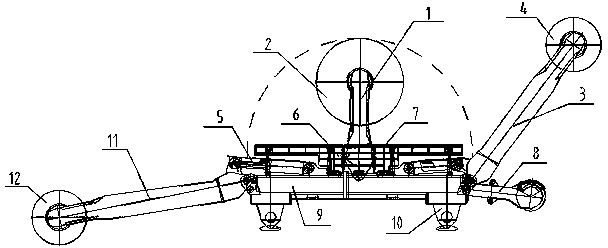

Four-roller coal cutter adopting double-roller cutting parts

ActiveCN103590829AAvoid hurtingPrevent radial projectionDriving meansCutting machinesFailure rateEngineering

The invention discloses a four-roller coal cutter adopting a double-roller cutting parts. The four-roller coal cutter comprises a right cutting part and a left cutting part which have the same structure, a right drawing part and a left drawing part which have the same structure, a right traveling part and left traveling part which have the same structure, as well as a middle control cabinet, wherein each cutting part comprises two cutting rollers, namely a dextrorotary cutting roller and a laevorotatory cutting roller; the rotation directions of each dextrorotary cutting roller and each laevorotatory cutting roller are opposite. According to the coal cutter adopting double- roller cutting part, provided by the invention, the two rollers are arranged on each cutting part, so that the total coal accommodating ratio is increased; the rotation directions of every two cutting rollers are opposite, so that the radial ejection of a coal block can be effectively prevented, and coal charging is further facilitated; the coal cutting and charging efficiency is greatly improved, the cutting teeth utilization ratio is improved, the service life of the whole machine is prolonged, the operation of the whole machine is stable, the coal charging effect is excellent, and the failure rate is low.

Owner:国科中迈(徐州)能源科技有限公司

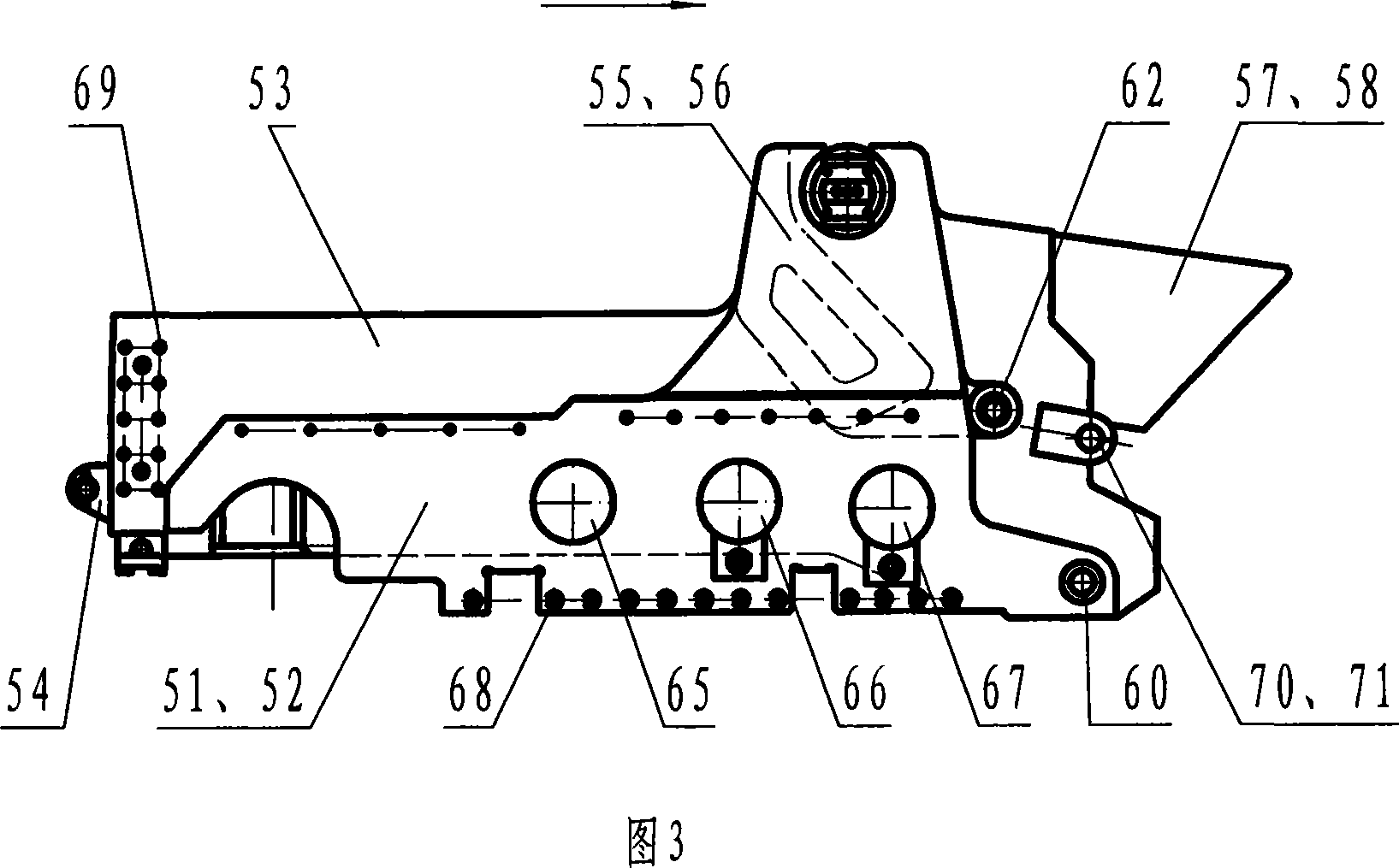

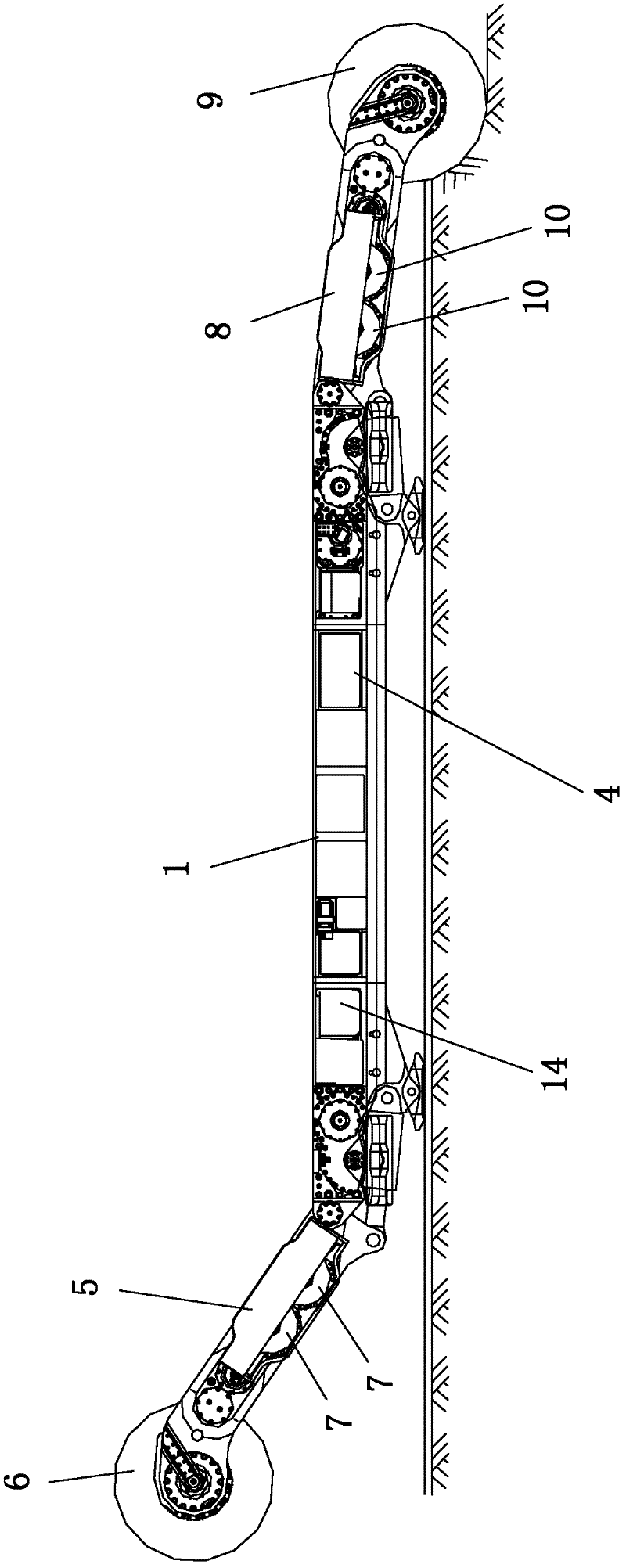

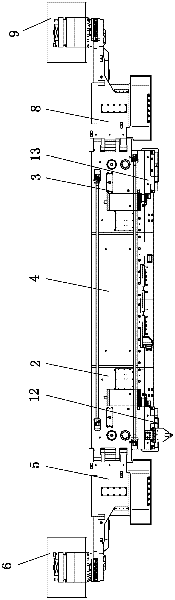

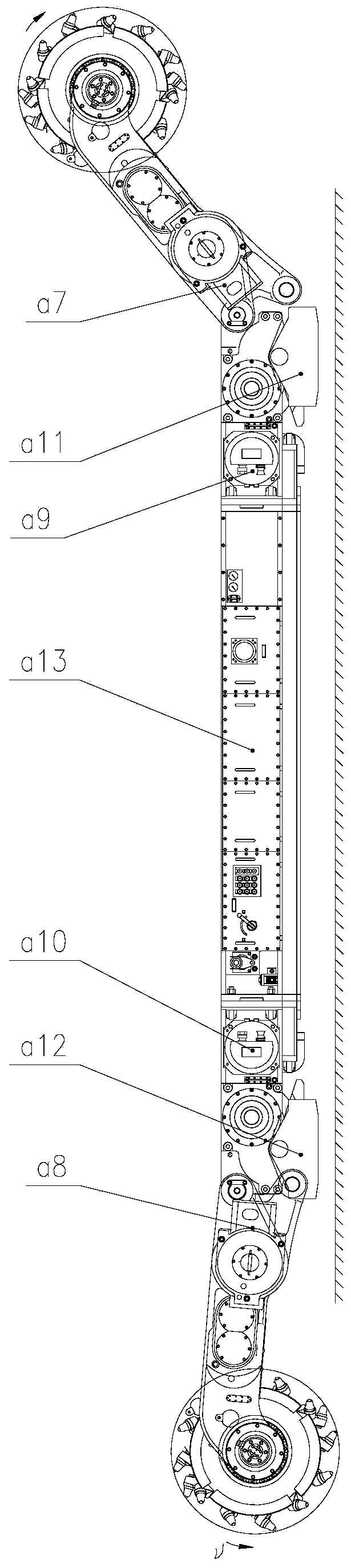

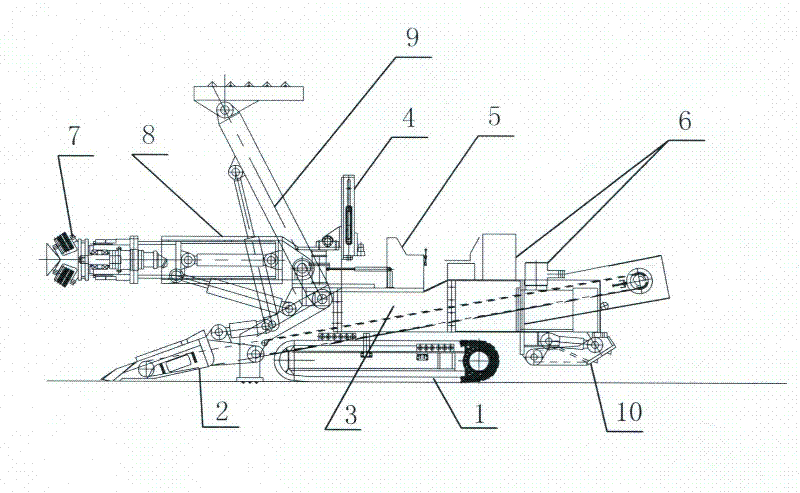

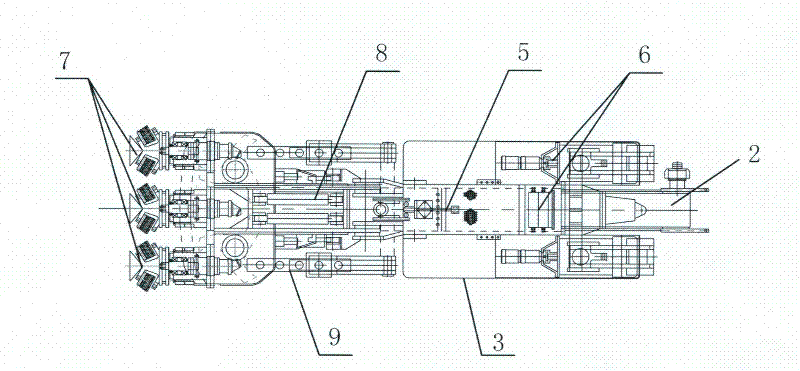

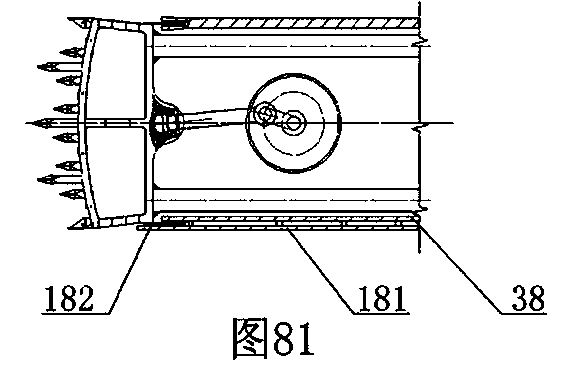

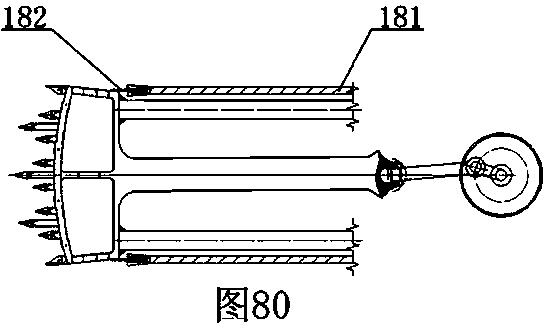

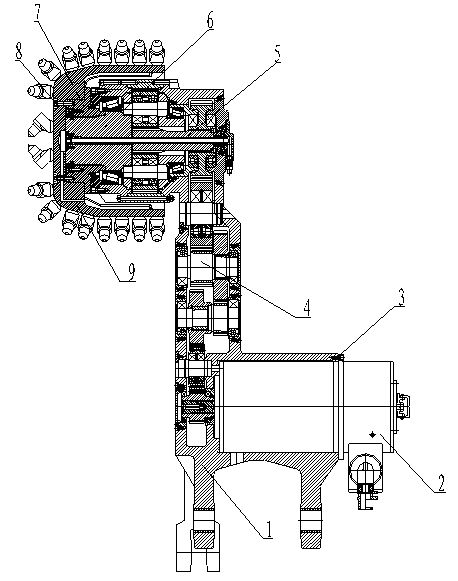

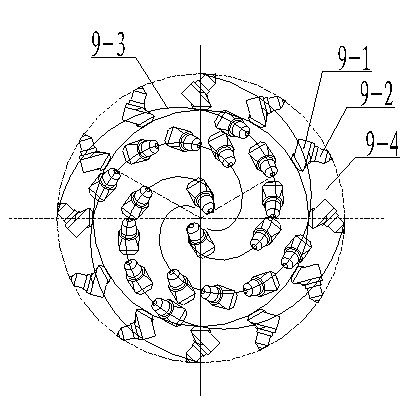

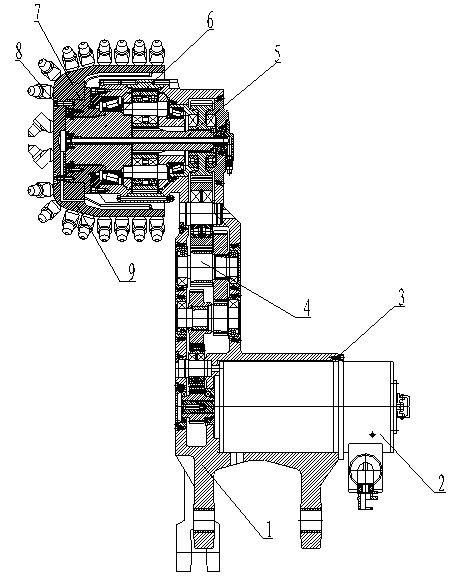

Comprehensive mechanized rock roadway tunneling machine

ActiveCN102364048ASimplify the construction processImprove securityTunnelsDriving meansControl systemUltimate tensile strength

The invention provides a comprehensive mechanized rock roadway tunneling machine, which comprises a caterpillar traveling part, a belt conveyer part, a body mounted on the caterpillar traveling part, a top slope anchor rod anchor cable drill, an operating table and a hydraulic and control system, and is characterized by also comprising at least one cutting device, a vertical swing pushing device, a temporary support, a front fixing device and a rear fixing device, wherein the cutting device is arranged on the vertical swing pushing device and is arranged on the front part of the body; the temporary support and the front fixing device are arranged on the two sides of the front part of the body; the top slope anchor rod anchor cable drill is arranged in the middle of the front part of the body; the operating table and the hydraulic and control system are arranged on the body; and the rear fixing device is arranged in the rear lower space of the body. By using the machine, mechanized construction level is further improved, labor intensity of construction personnel and the construction personnel are reduced, field operation environment is improved, occupational diseases are reduced, and safety and working efficiency are improved; and the machine can be suitable for rock roadway construction of various large, medium and small-sized mines.

Owner:马晓山

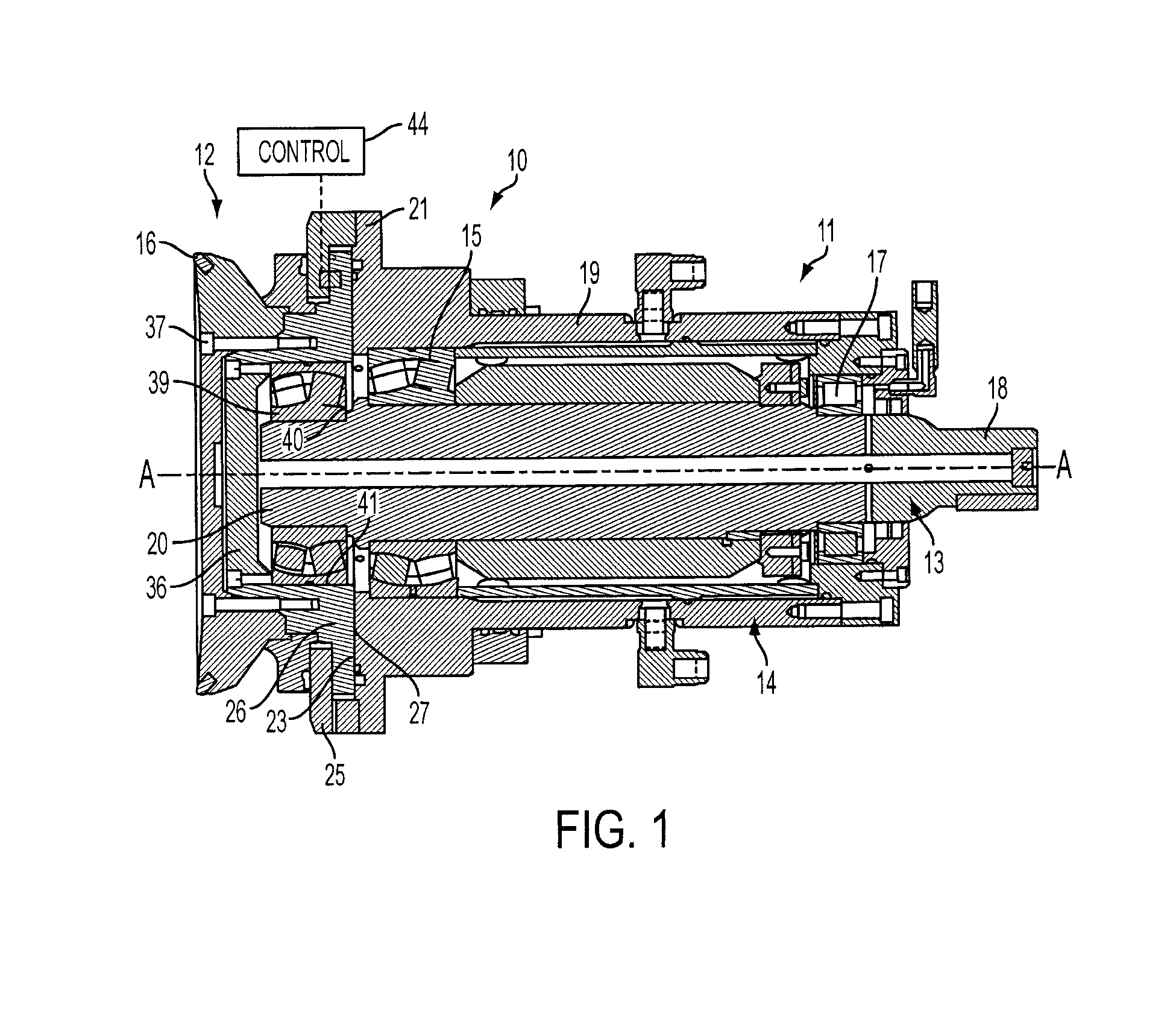

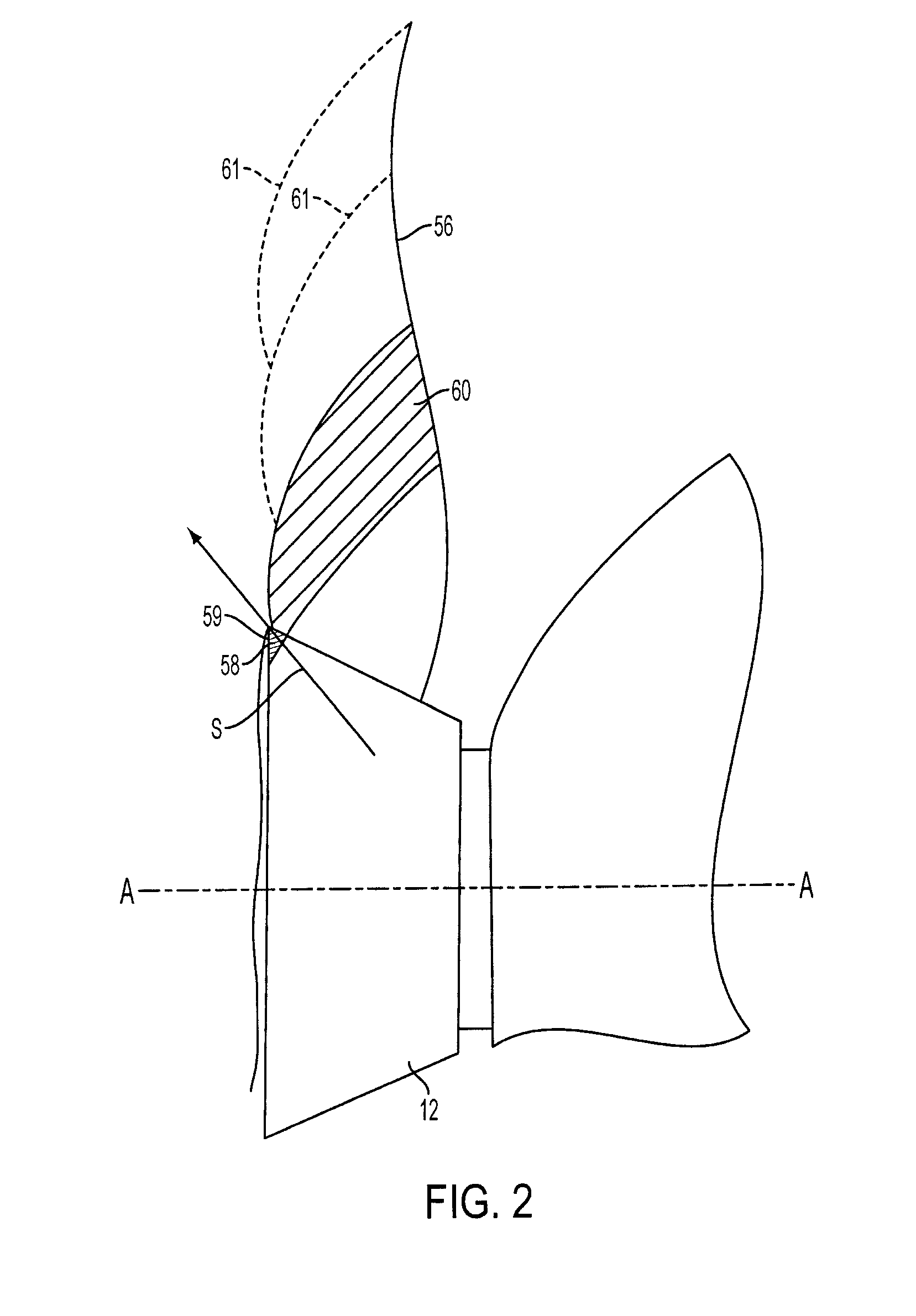

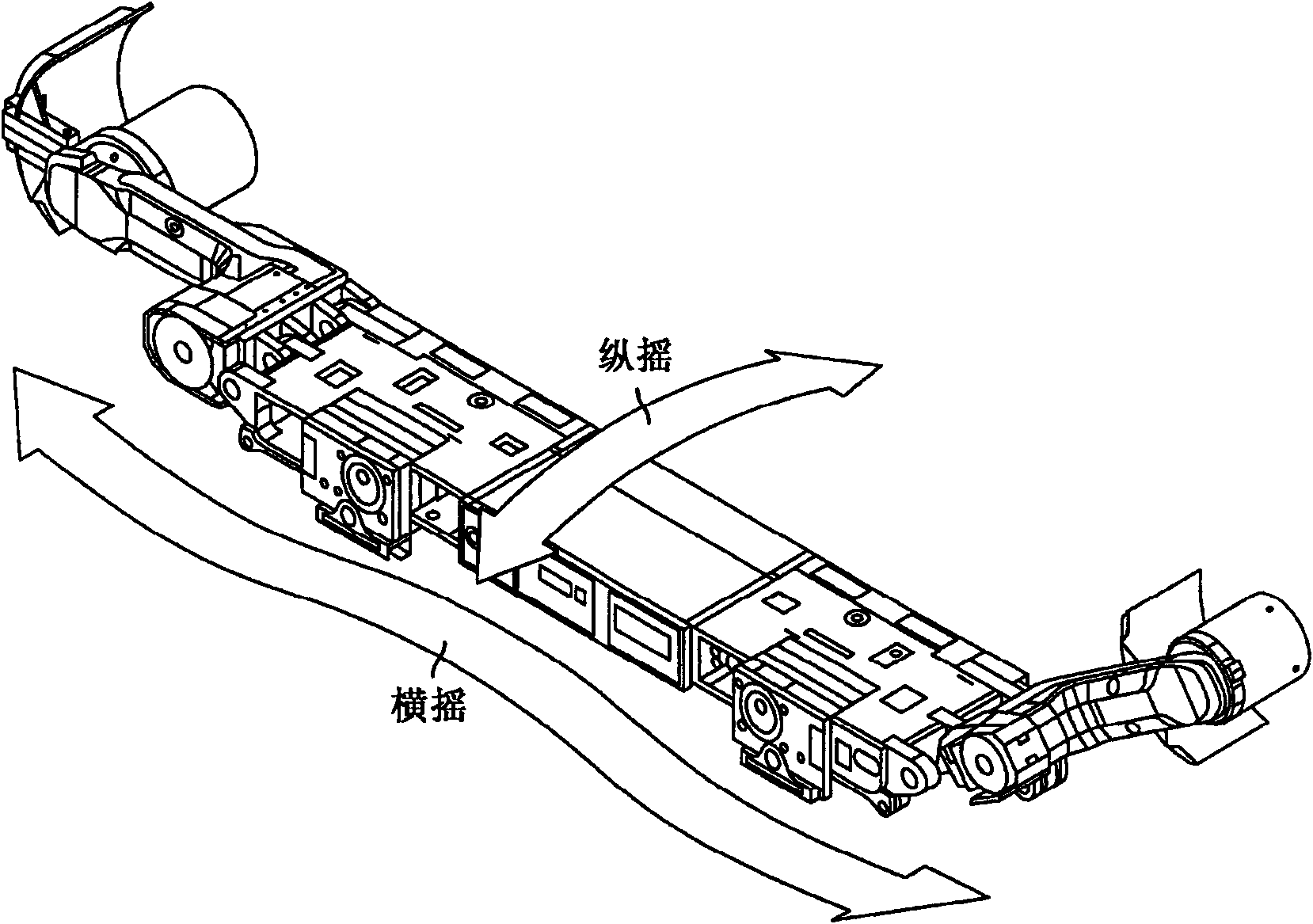

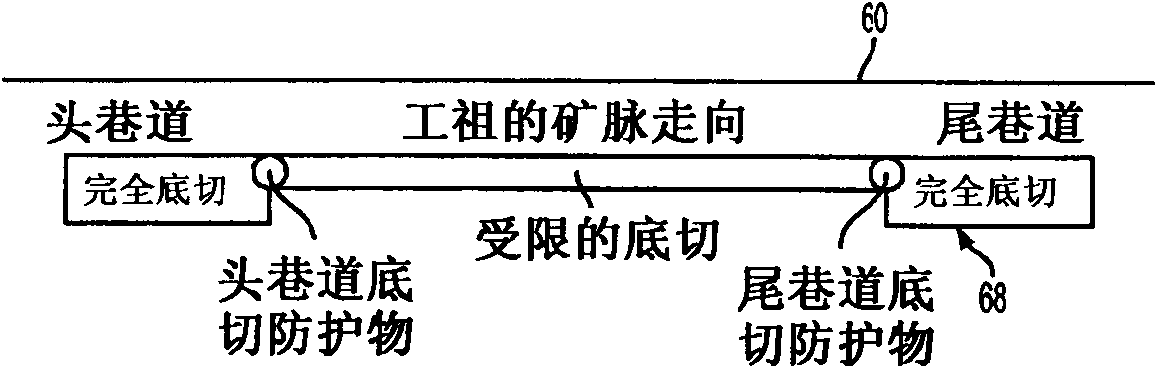

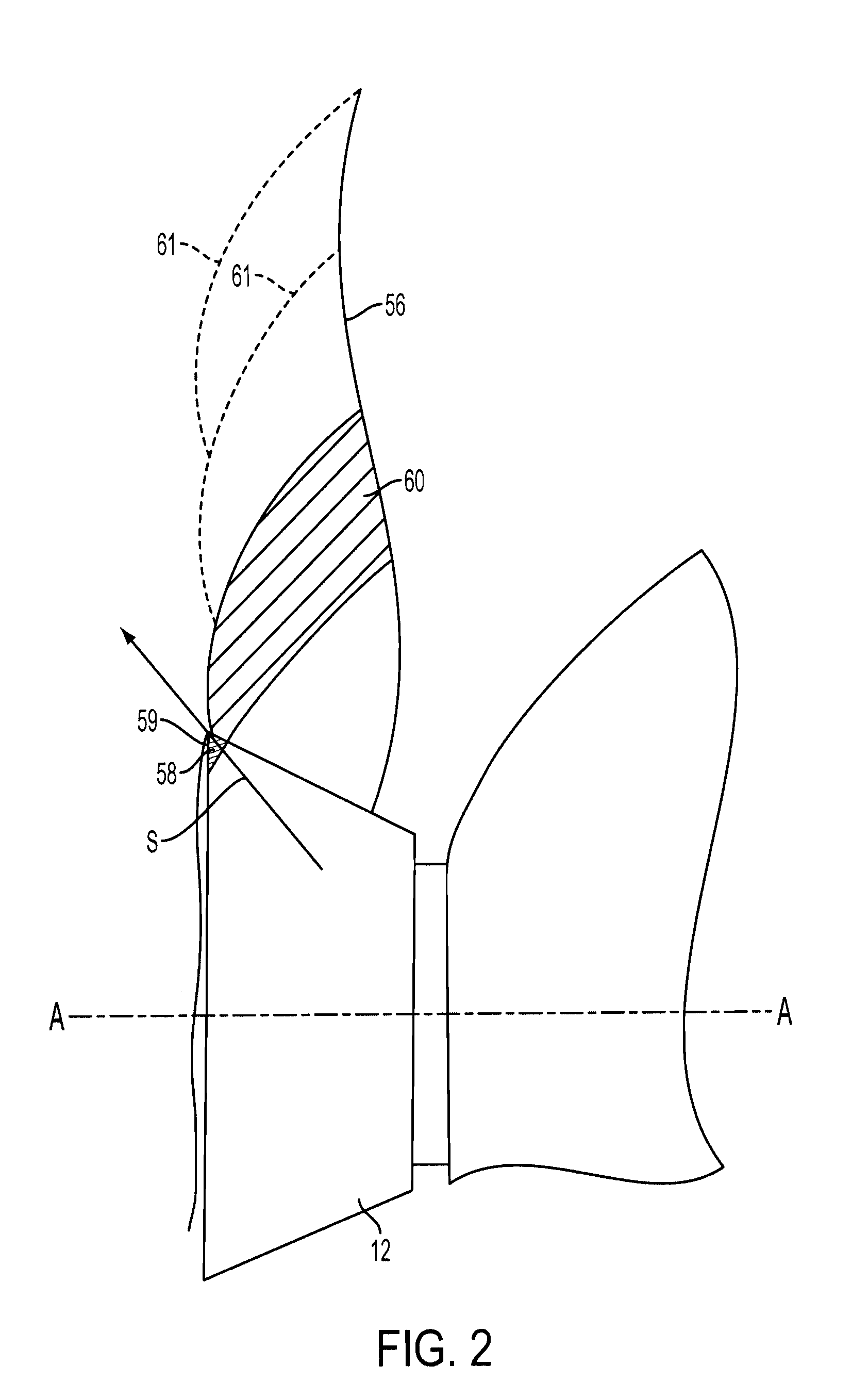

Method for steering a mining machine cutter

Owner:JOY GLOBAL UNDERGROUND MINING LLC

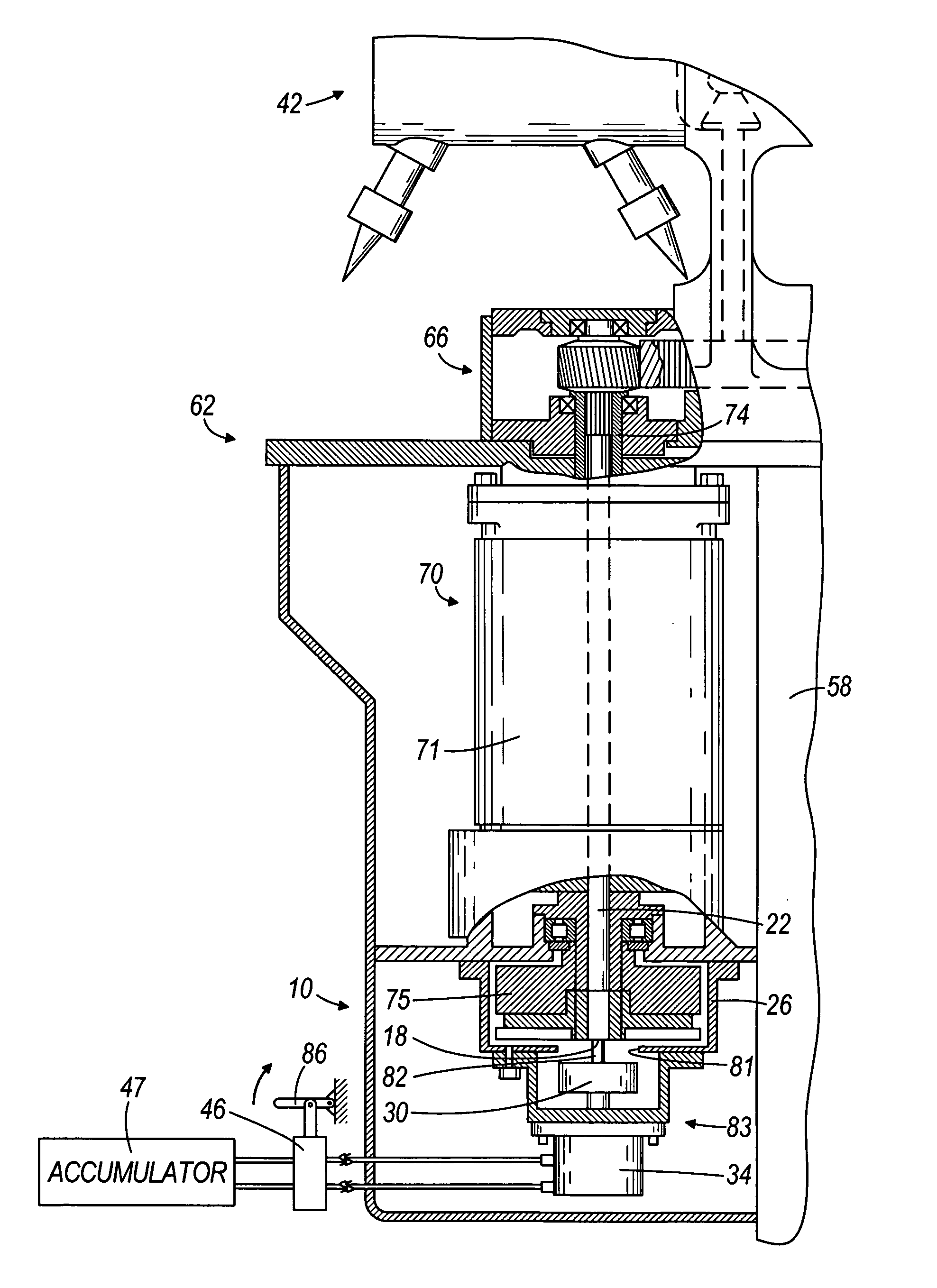

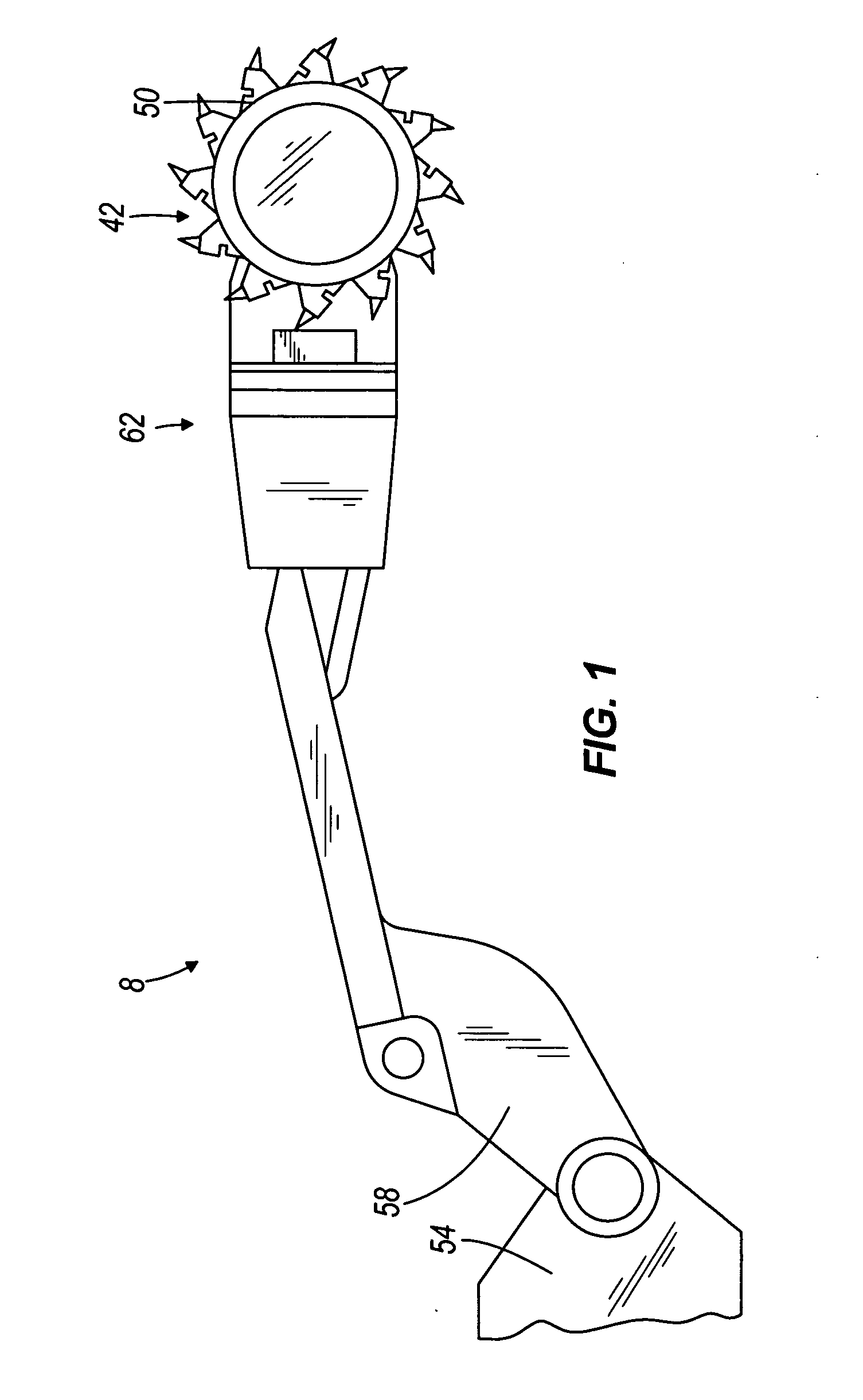

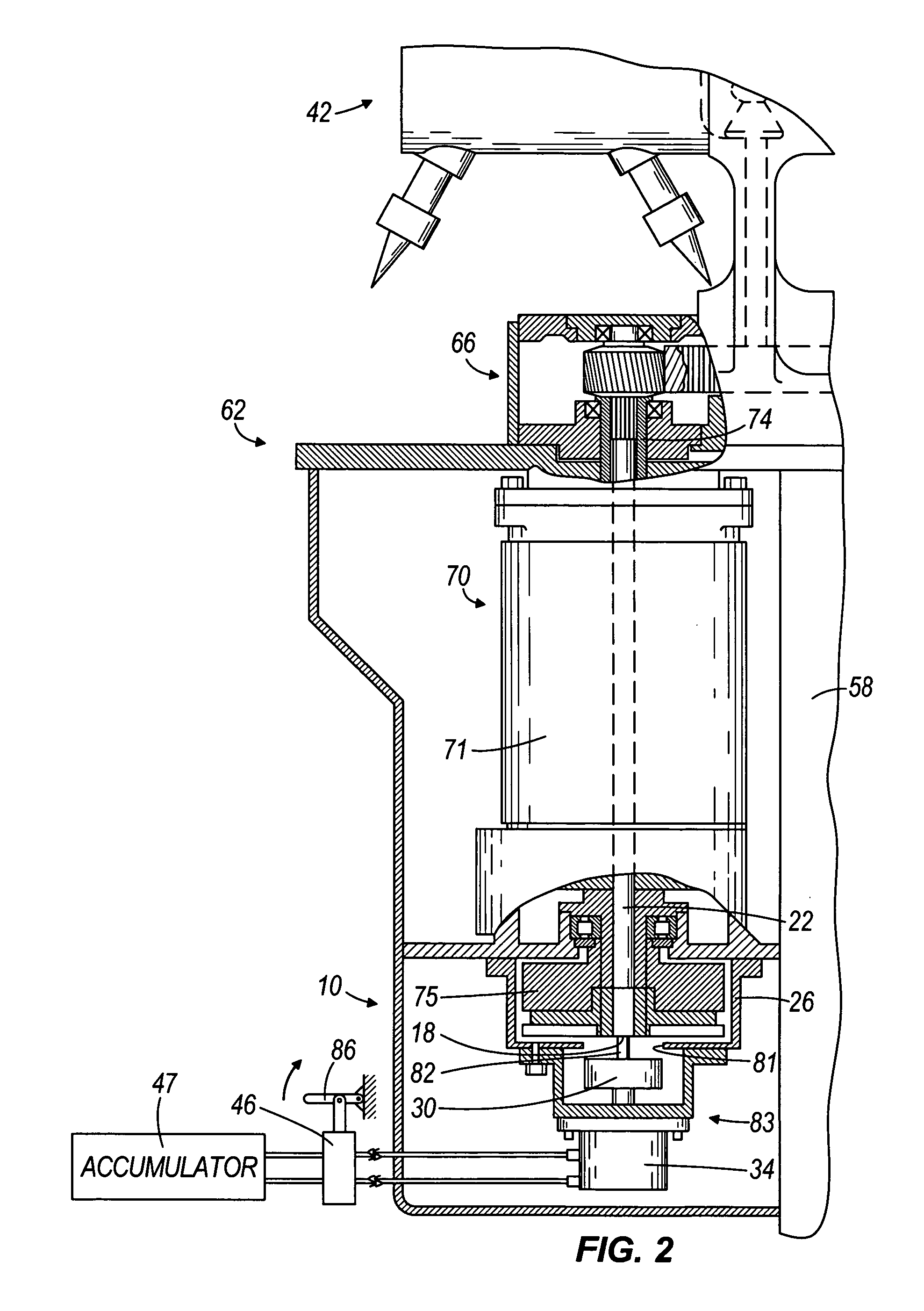

Mining machine with driven disc cutters

A mining machine including a cutting mechanism comprising an arm having an arm end, a disc cutter adapted to engage the material to be mined and mounted on the arm end. The disc cutter is driven by the arm into the material to be mined, and the arm further includes a main portion, and a wrist portion pivotally attached to the main portion.

Owner:JOY GLOBAL UNDERGROUND MINING LLC

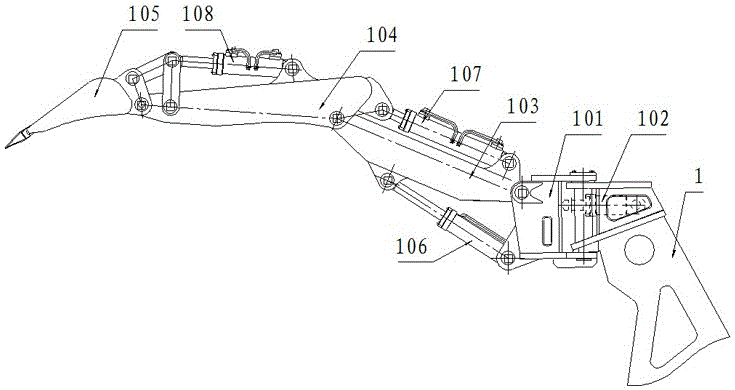

Adaptive excavating integrated machine

ActiveCN106194171AReduce operating proceduresImprove job qualityDriving meansPropulsionEngineeringDrill

The invention discloses an adaptive excavating integrated machine. The adaptive excavating integrated machine comprises a gantry assembly installed on a complete machine underbed, a fixing platform installed on the complete machine underbed, a working mechanism for providing operation, a drill machine supporting mechanism, a conveying mechanism for conveying materials, a laser device, a walking mechanism installed below the underbed and switched between crawler-type walking and wheel-type walking, a hydraulic mechanism, a driving mechanism for providing power for the complete machine and a cab assembly. The working mechanism comprises an excavating working arm mechanism installed at the front end of the gantry assembly and a cutting working arm mechanism installed above the gantry assembly, and the excavating working arm mechanism and the cutting working arm mechanism can be switched for working; the laser device assists the cutting working arm mechanism in rock crushing, and the drill machine supporting mechanism drills anchor rope supporting holes in the top of a roadway. By means of the technical scheme, multiple walking, crushing, cutting, excavating, loading and supporting functions are achieved, continuous excavating, loading and conveying work is achieved, applicability is high, the integrated machine is multipurpose, acquisition cost is saved, the number of operation process workers is reduced, working efficiency is improved, engineering quality is improved, and working safety is ensured.

Owner:安徽宏昌机电装备制造有限公司

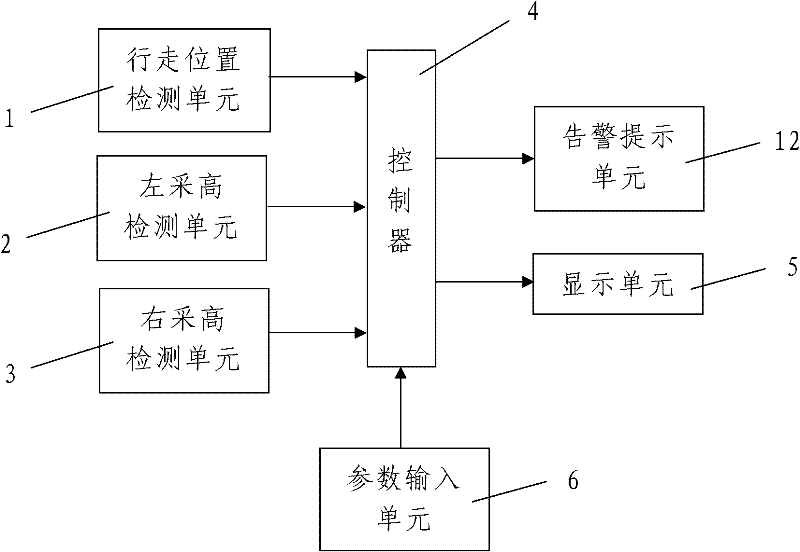

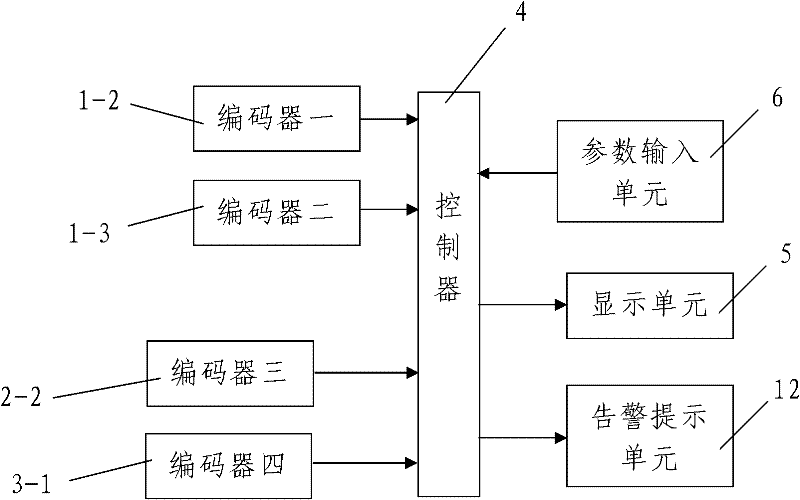

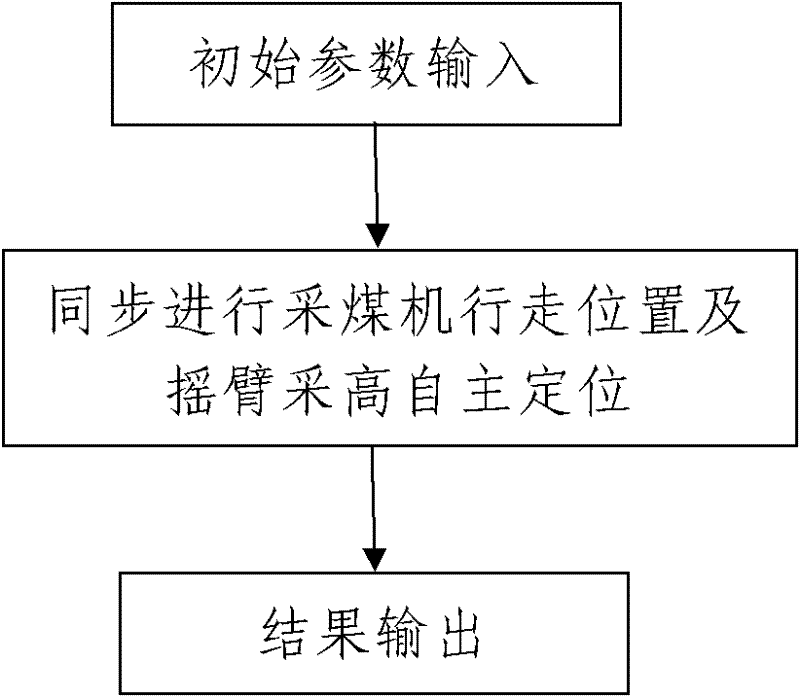

A coal mining machine autonomous positioning system and its autonomous positioning method

ActiveCN102287186AEasy to operateHigh degree of intelligenceMeasurement devicesDriving meansLocation detectionEngineering

The invention discloses a self-positioning system and a self-positioning method for a coal mining machine. The self-positioning system comprises a controller, a walking position detection unit for detecting a walking position of the coal mining machine in real time, a left mining height detection unit for detecting the mining height of a left rocker arm of the coal mining machine in real time, a right mining height detection unit for detecting the mining height of a right rocker arm of the coal mining machine in real time, and a display unit and a parameter input unit which are connected withthe controller. The self-positioning method comprises the following steps of: 1, inputting initial parameters; 2, synchronously performing self-positioning of the walking position of the coal mining machine and the mining heights of the rocker arms; and 3, outputting results. The invention has the advantages that: the self-positioning system is reasonable in design, easy and convenient to use andoperate, convenient to implement, good in using effect and high in positioning accuracy, can automatically accurately position the walking position of the coal mining machine and the mining heights of the rocker arms, and various practical problems that the conventional coal mining machine has low automation and intelligent degrees, does not have self-positioning function, has high labor intensity and poor using effect and the like are effectively solved.

Owner:XIAN COAL MINING MACHINERY

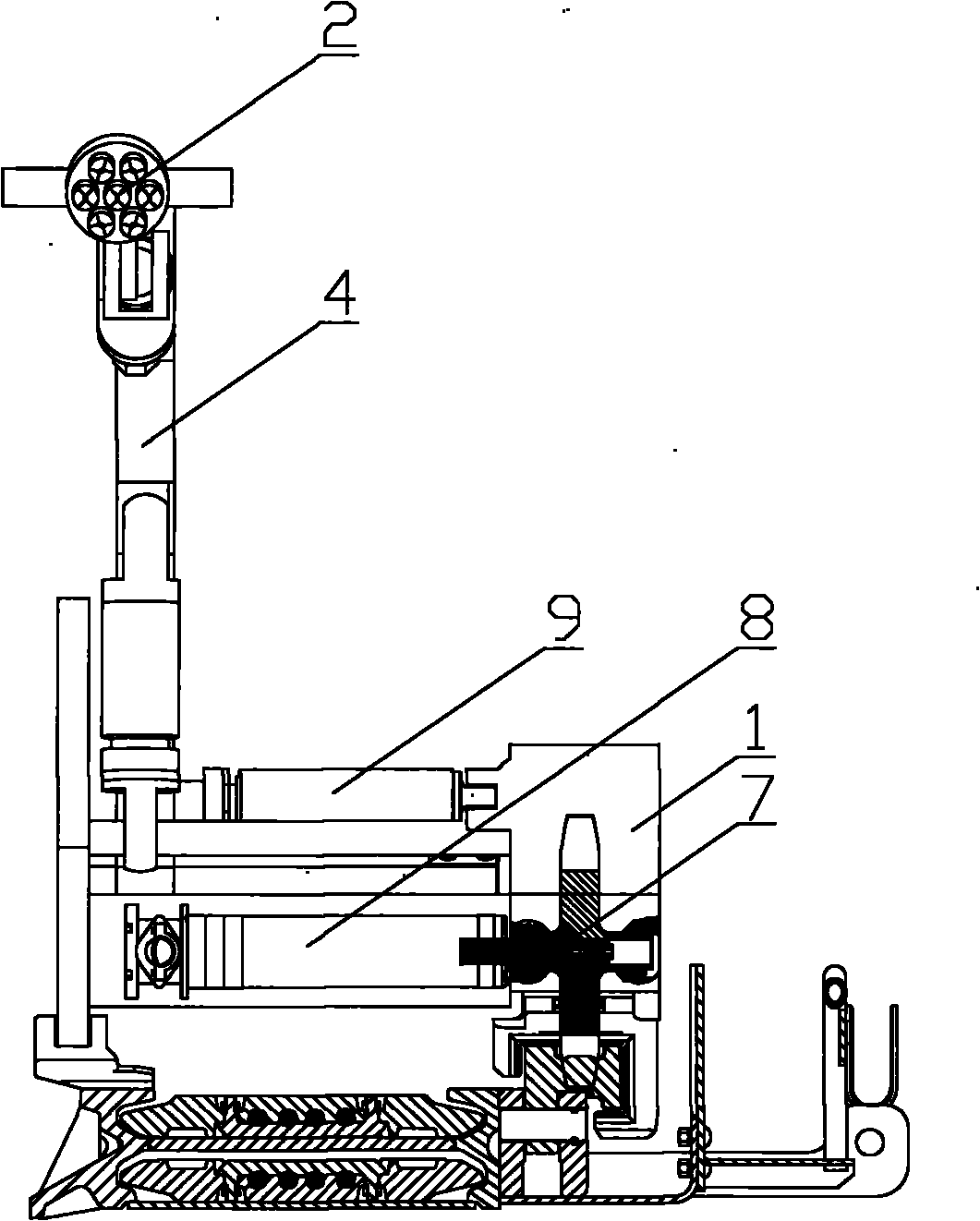

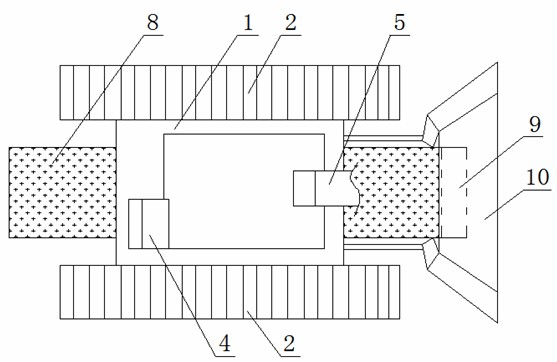

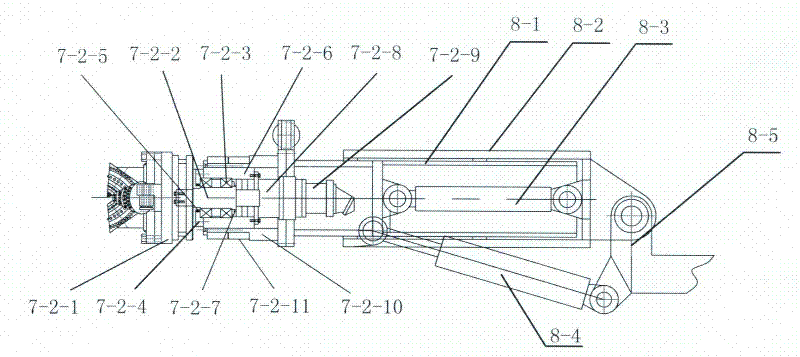

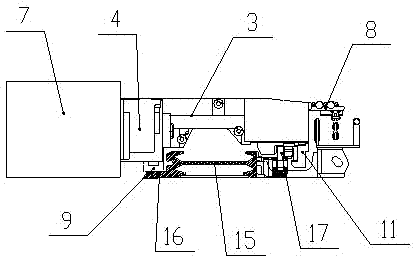

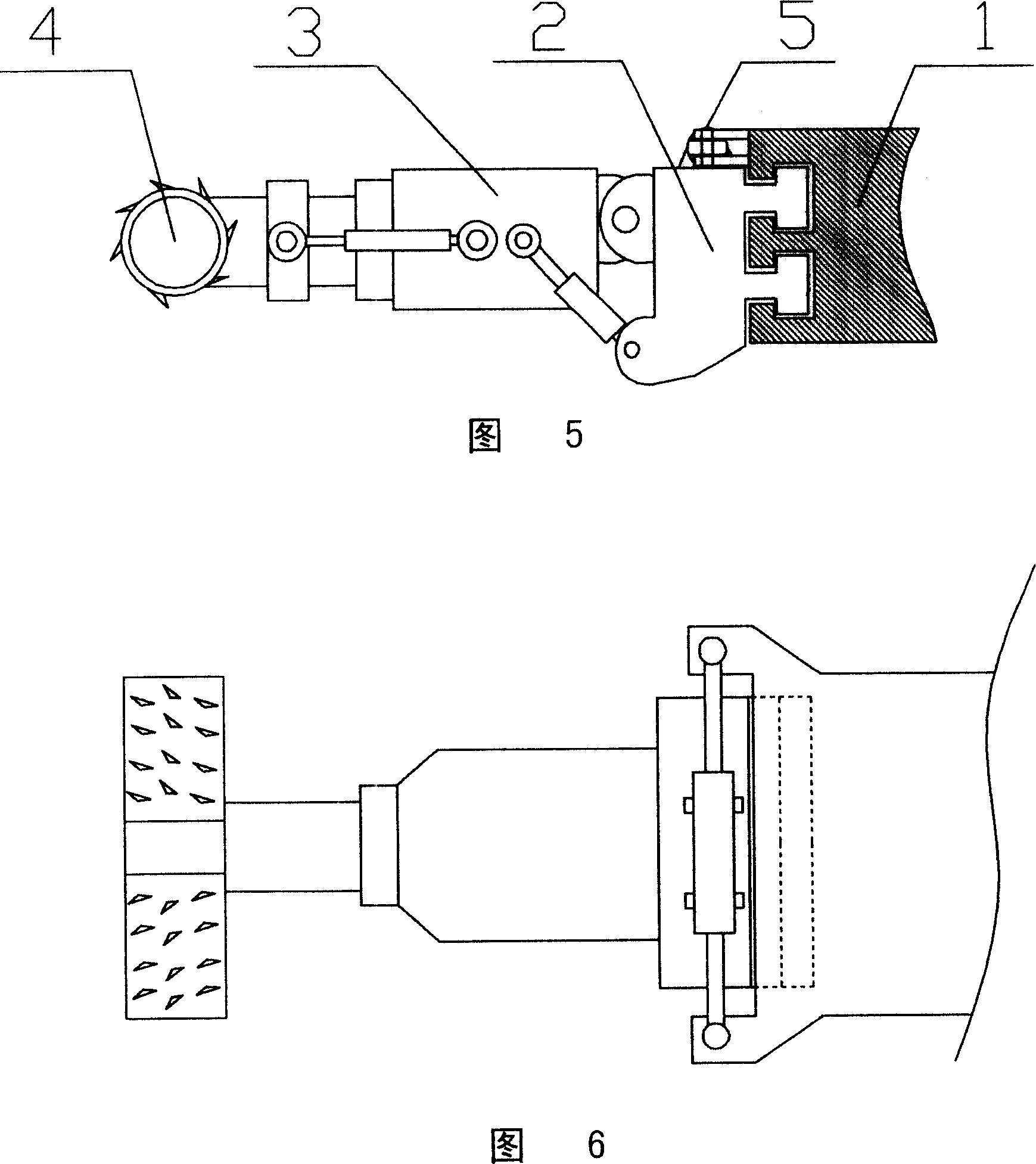

Method and apparatus for converting rotary motion into reciprocating impact motion

ActiveCN103498673APass smoothlySmooth nestingDriving meansPercussion drillingDrive shaftReciprocating motion

A method and device for converting rotary motion to reciprocating percussion motion. The device comprises a machine body (4), a travel portion (7), and a reciprocating percussion portion (5). The reciprocating percussion portion (5) comprises a percussion drive mechanism (2), a rocker arm (6), and a percussion head (1). The percussion drive mechanism (2) comprises a percussion power source member (11), a transmission component, and a crankshaft (10). The percussion power source member (11) comprises a motor, and the motor comprises a power output shaft (14). The transmission component comprises a power gear (13) and a transmission gear (12). The power gear (13) is mounted on the power output shaft (14). The transmission gear (12) drives the crankshaft (10). The transmission component comprises a transmission shaft. The power output shaft (14) is perpendicular to the rocker arm (6), and is parallel to the transmission shaft and the crankshaft (10) so that the transmission gear (12) drives the crankshaft (10) to convert rotary motion to reciprocating motion; or the power output shaft (14) is parallel to the rocker arm (6), the crankshaft (10) is driven to convert rotary motion to reciprocating motion after the power direction is changed by a power bevel gear and a transmission bevel gear. The crankshaft (10) drives the percussion head (1) to perform reciprocating percussion. The travel portion (7) drives the machine body to travel. The machine body (4) drives the reciprocating percussion portion (5) to move and work continuously. The device applies to the mining field or mechanical engineering field, and has advantages such as strong structural strength and a small amount of maintenance.

Owner:刘素华

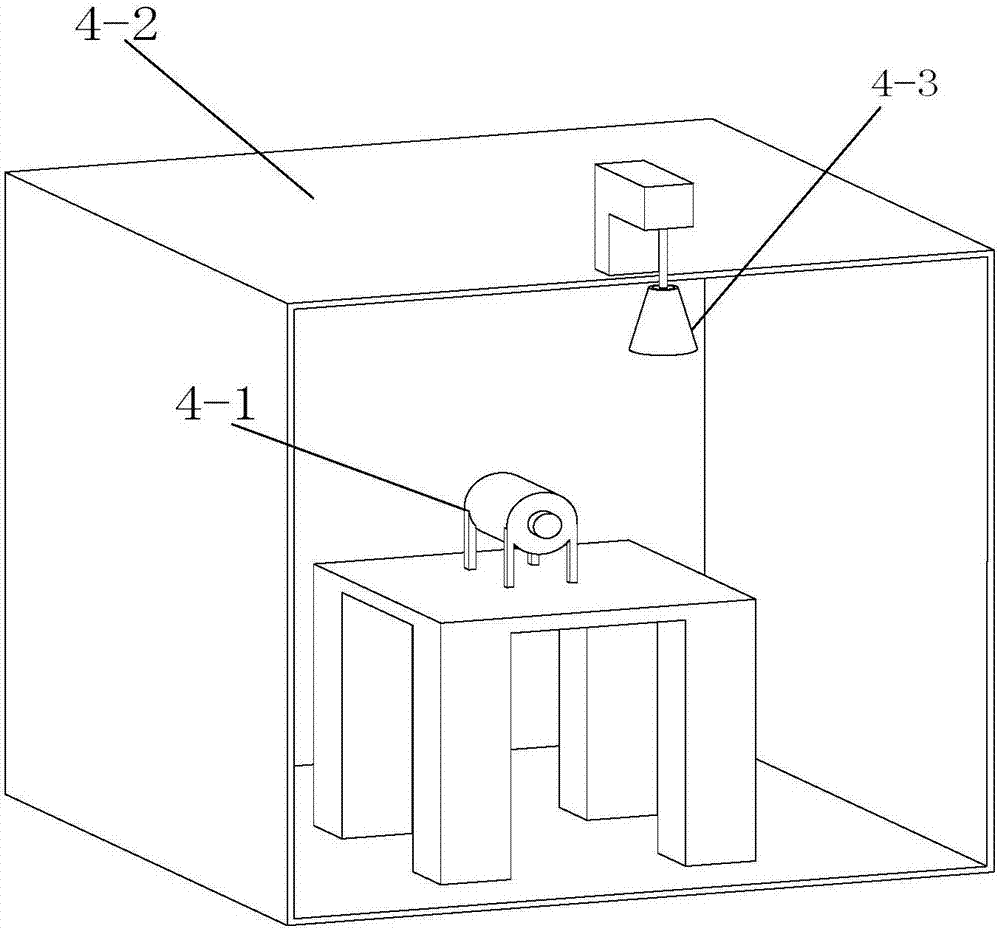

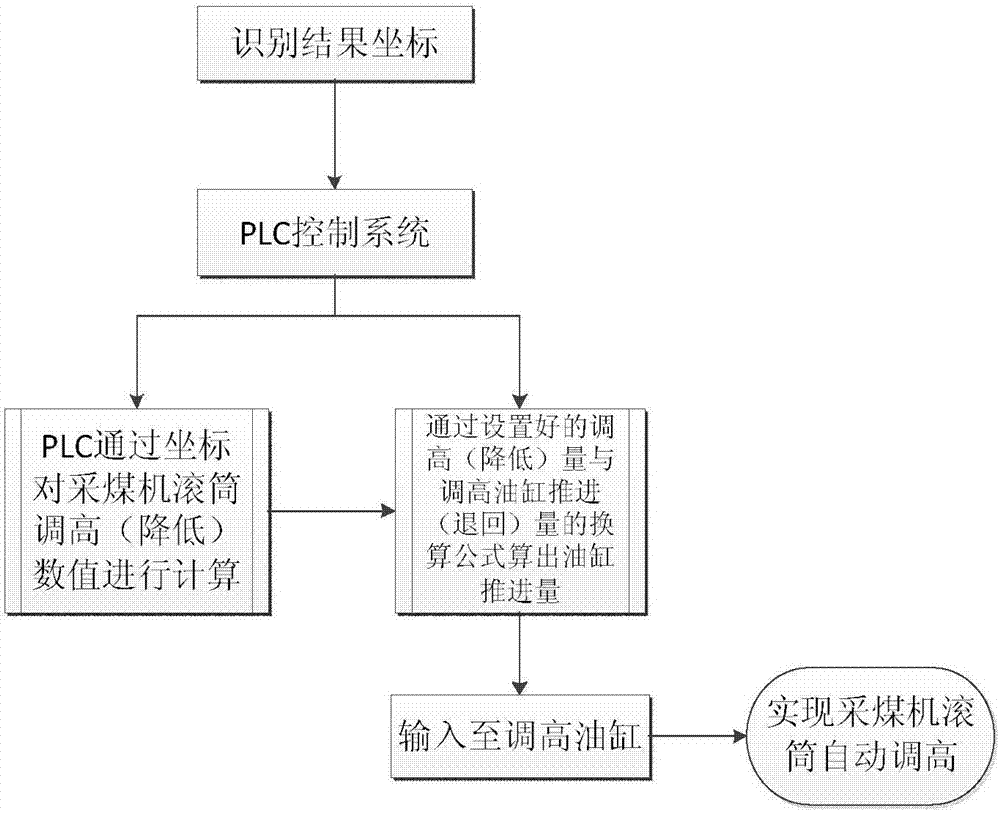

Coal mining machine roller automatic height regulating device and method based on image recognition

ActiveCN107120116AQuick responseRemote monitoring of cutting conditionsDriving meansComputer scienceRocker arm

The invention discloses a coal mining machine roller automatic height regulating device based on image recognition. The device comprises an image pickup module, an image recognition processing module, a coal mining machine rocker arm height regulating module, an image pickup monitoring module and a roller track tracking sensor module, wherein the image pickup module is used for shooting a coal mining working face coal rock image and putting the image into the image recognition processing module and the image pickup monitoring module; the image recognition processing module is used for recognizing the coal mining working face coal rock image boundary, and inputting the recognizing result into the coal mining machine rocker arm height regulating module; the coal mining machine rocker arm height regulating module is used for controlling the automatic height regulation of a coal mining machine roller; the image pickup monitoring module is used for monitoring whether the coal mining machine roller generates contact with rock stratums or not during the whole coal working face cutting; the roller track tracking sensor module is used for performing path detection calculation on a coal mining machine rocker arm, and comparing the fitting degree of the coal rock interface in the collected image. The device has the advantages that the coal mining efficiency is high and the reliability is high.

Owner:江苏中矿汇弘科技有限公司

Flame-resistant anti-static V belt under glue and preparation technique thereof

The invention provides a flame-proof antistatic V-belt rubber, which adopts neoprene adhesive variety which has excellent fire-proof property, adds traditional natural gum, butylbenzene rubber and neoprene adhesive in order to modify process property, then adds various fire retarding agent which has excellent antistatic and fire-proof property, wherein fire-proof property can respectively reach that flame combustion average time is no more than 5 seconds, and flameless combustion average time is no larger than 7 seconds, and simultaneously meets the base process technique property of V-belt and various physical mechanical properties which are required by criterion.

Owner:ZHEJIANG FENFEI RUBBER & PLASTIC PROD CO LTD

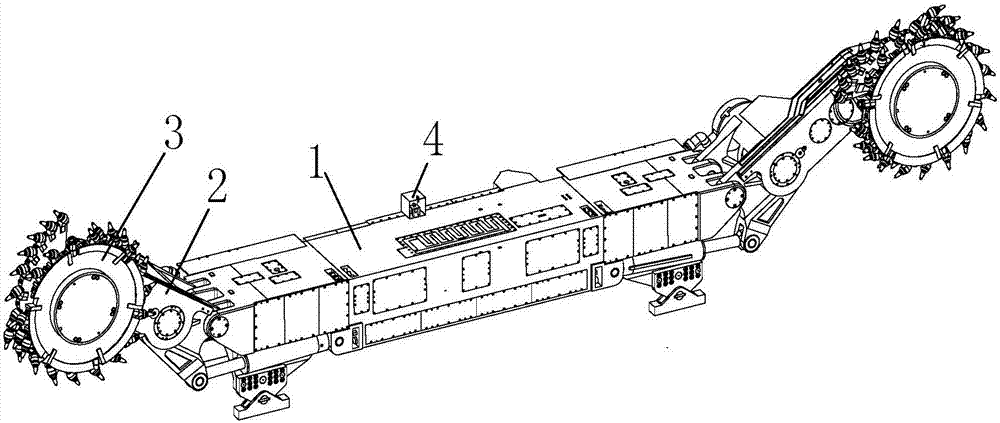

Superposition arm three-roller large-mining-height coal mining machine

InactiveCN102536226ATo achieve the purpose of mining highWide range of height adjustmentDriving meansCutting machinesElectrical controlEngineering

The invention relates to a superposition arm three-roller large-mining-height coal mining machine. The machine mainly comprises a rectangular machine body assembly, a rocker arm device, coal cutting rollers, a traction part, an electrical control system, a hydraulic control system, a rotary part, a development machine type cutting part, a top coal cutting roller and the like, wherein the rotary part is arranged on the top of the machine body assembly; the development machine type cutting part is arranged on the rotary part; the top coal cutting roller is connected to the tail end of the development machine type cutting part in a rotating mode; left and right coal cutting rollers are used for cutting coal bodies below the rotary part together under the driving action of the rocker arm device; the top coal cutting roller is used for cutting partial coal bodies above the rotary part in a lifting and lowering mode through the development machine type cutting part by controlling the extension and the retraction of an up-regulated oil cylinder; and the motion track of the top coal cutting roller is a camber line. Three coal cutting rollers are used for cutting coal layers with the same thickness and have small diameters, so that the machine has a simple manufacturing process and low production cost, and the adaptability of the machine to the variation of the coal layers is improved.

Owner:闫振东

Drum turning mechanism for continuous miners and longwall shearers

A mining machine including a cutting drum, a plurality of bits mounted on the cutting drum, a base, and a boom extending between the base and the cutting drum for mounting the drum on the base. The mining machine further includes a primary cutting drum turning mechanism attached to the boom and in driving connection with the cutting drum for causing cutting movement of the cutting drum at a cutting drum cutting speed, and a secondary cutting drum turning mechanism attached to the boom and in driving connection with the cutting drum for causing turning movement of the cutting drum at a speed much less than the cutting drum cutting speed.

Owner:JOY MM DELAWARE INC

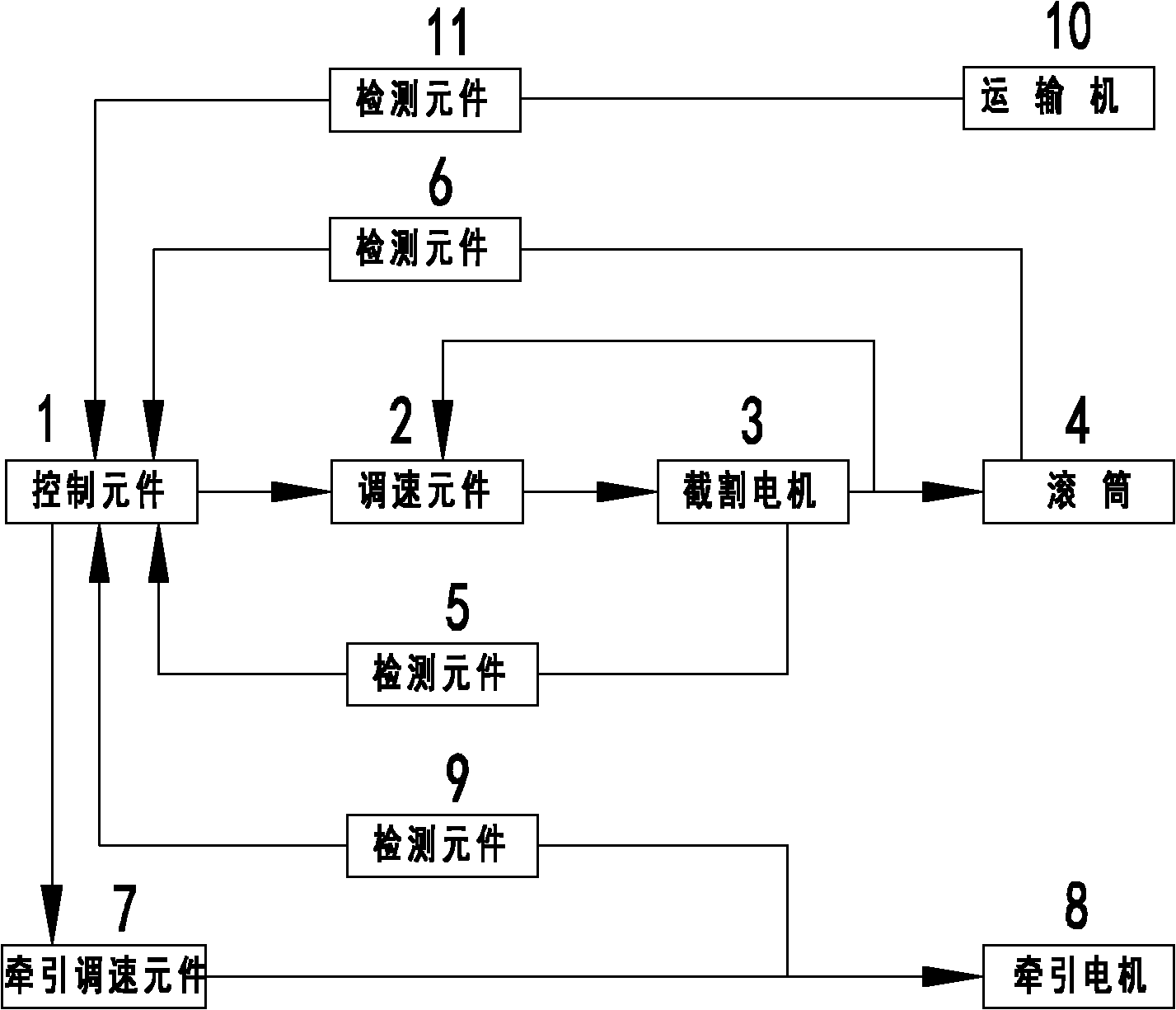

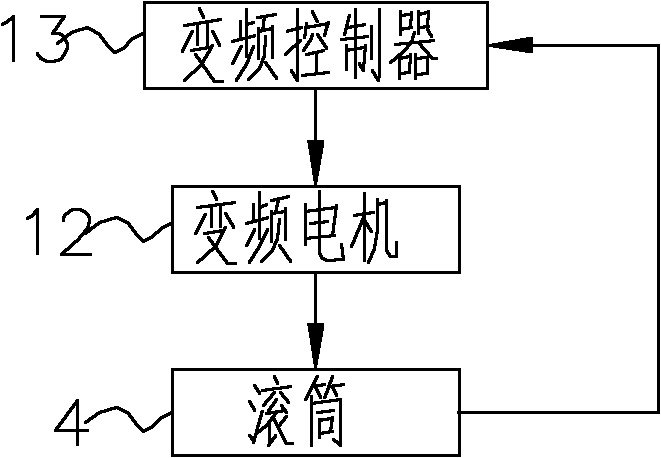

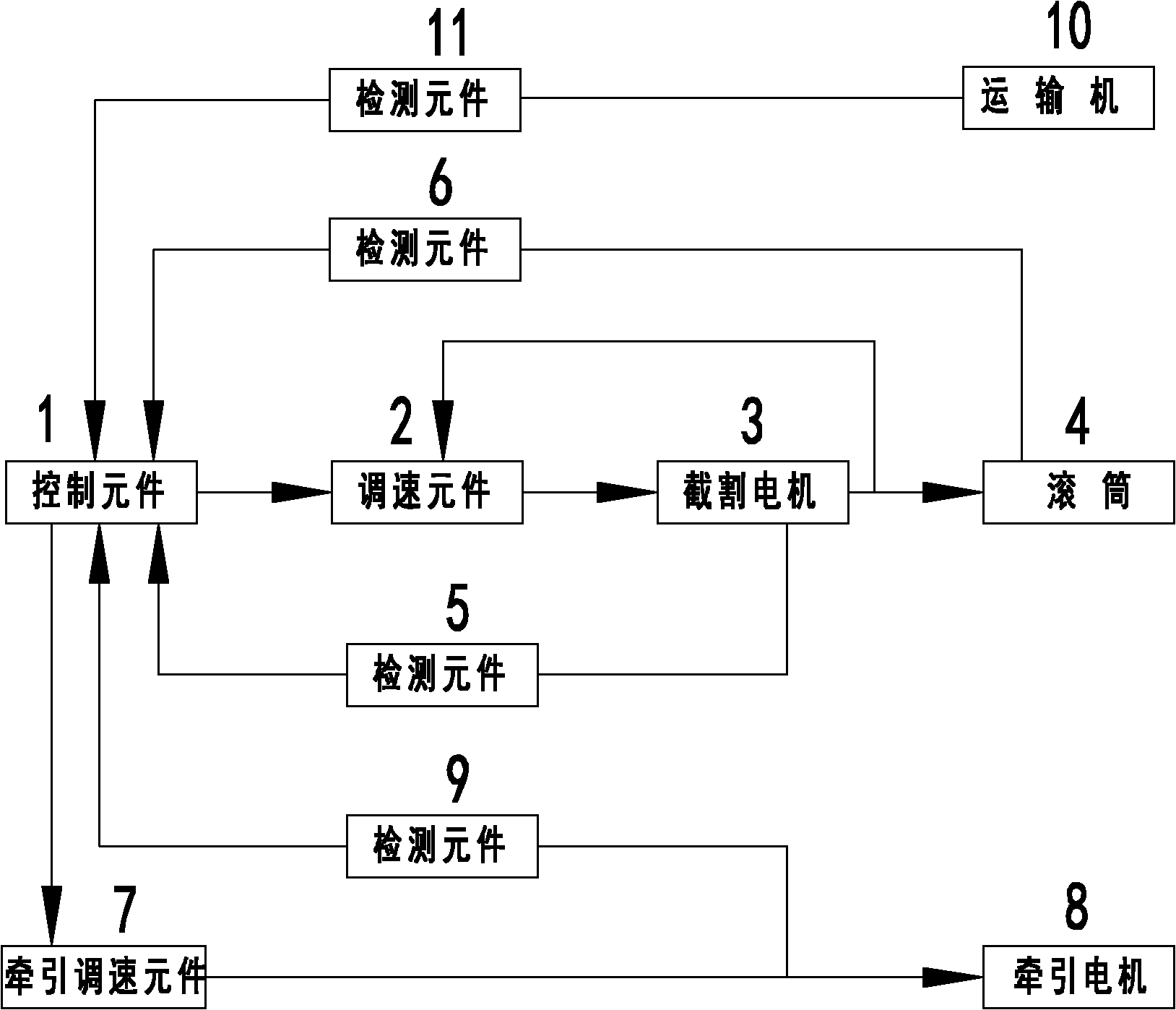

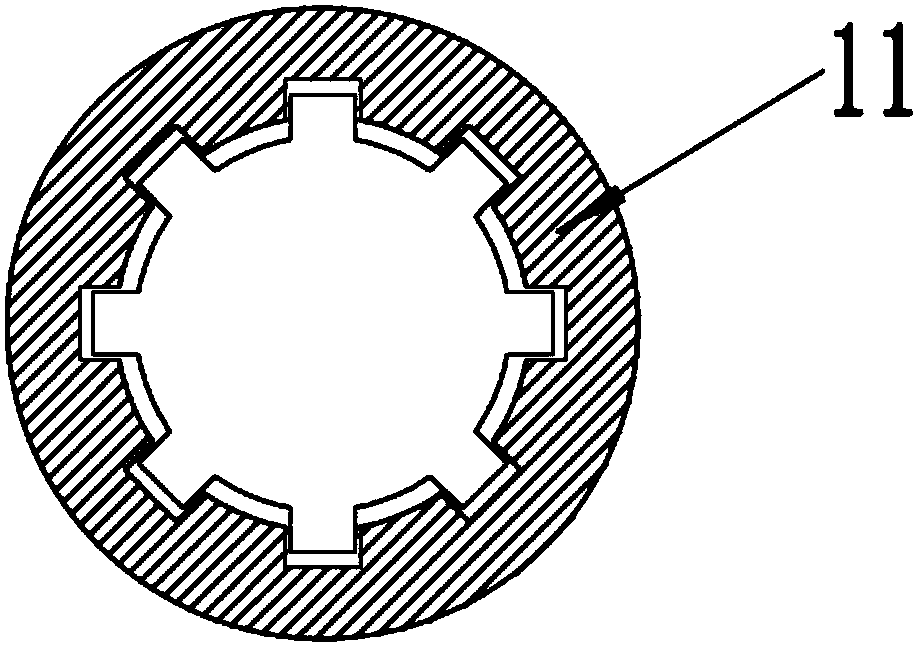

Coal mining equipment and roller electrical speed regulating system

ActiveCN102108862AEnsure coal mining efficiencyIncrease speedEnergy industryDriving meansStress conditionsEngineering

The invention discloses a roller electrical speed regulating system for coal mining equipment, which comprises a first detection element, a control element and a speed regulating element. In the system, the rotation speed of the roller can adapt to randomly changing condition of a coal cutting coal bed, so as to prevent the roller from being damage by an encountered hard coal bed and prolong the service life of the roller; meanwhile, under a normal use condition, for example the coal mining equipment works on a soft coal bed, the roller can rotate at a high speed to ensure the coal mining efficiency of the coal mining equipment. The control element also can regulate a traction speed by the traction speed regulating element, so that the traction speed of a coal mining machine and a cutting speed are consistent enough to realize high-efficiency cutting. The control element also can detect the coal loading effect of the roller and receive the stress condition of a conveyor through the detection element so as to control the cutting and traction speeds of the coal mining machine and ensure the high yield and efficiency of the fully mechanized coal mining equipment. The invention also discloses the coal mining equipment having the roller electrical speed regulating system.

Owner:益阳市科技成果转化服务中心 +1

Hard rock tunneling machine

InactiveCN101289936AImprove structural strengthMajorDriving meansCutting machinesWorking environmentHardness

The invention relates to the coal mine roadway drivage machinery, in particular to a heavy hard rock tunneling machine which can cut a semi-rock roadway and a whole-rock roadway with high hardness. The tunneling machine solves the problem that the prior mole is not suitable for rock roadway drivage, can greatly improve the drivage working efficiency of the whole-rock roadway, and dramatically reduce working intensity of operators. The tunneling machine has an integral structure with high strength, a complete machine with heavy weight, a horizontal side support arranged on the back of the machine, and a device with high stability; the machine is provided with a mighty dust absorption system and an inside and outside spray dust suppression system, which effectively improves working environment of the operators; a traction of the tunneling machine adopts a full-sealed structure to increase traction driving force and improve propulsive force of the cutting; the tunneling machine has a small assembly, a large diameter and an inertia cutting head, adopts a reliable and highly-efficient hydraulic system matched with a high-strength point-attack pick, which greatly improves unidentate cutting force, thereby the tunneling machine has the ability of cutting the semi-rock roadway and the whole-rock roadway with high-hardness (f8).

Owner:SANY HEAVY EQUIP

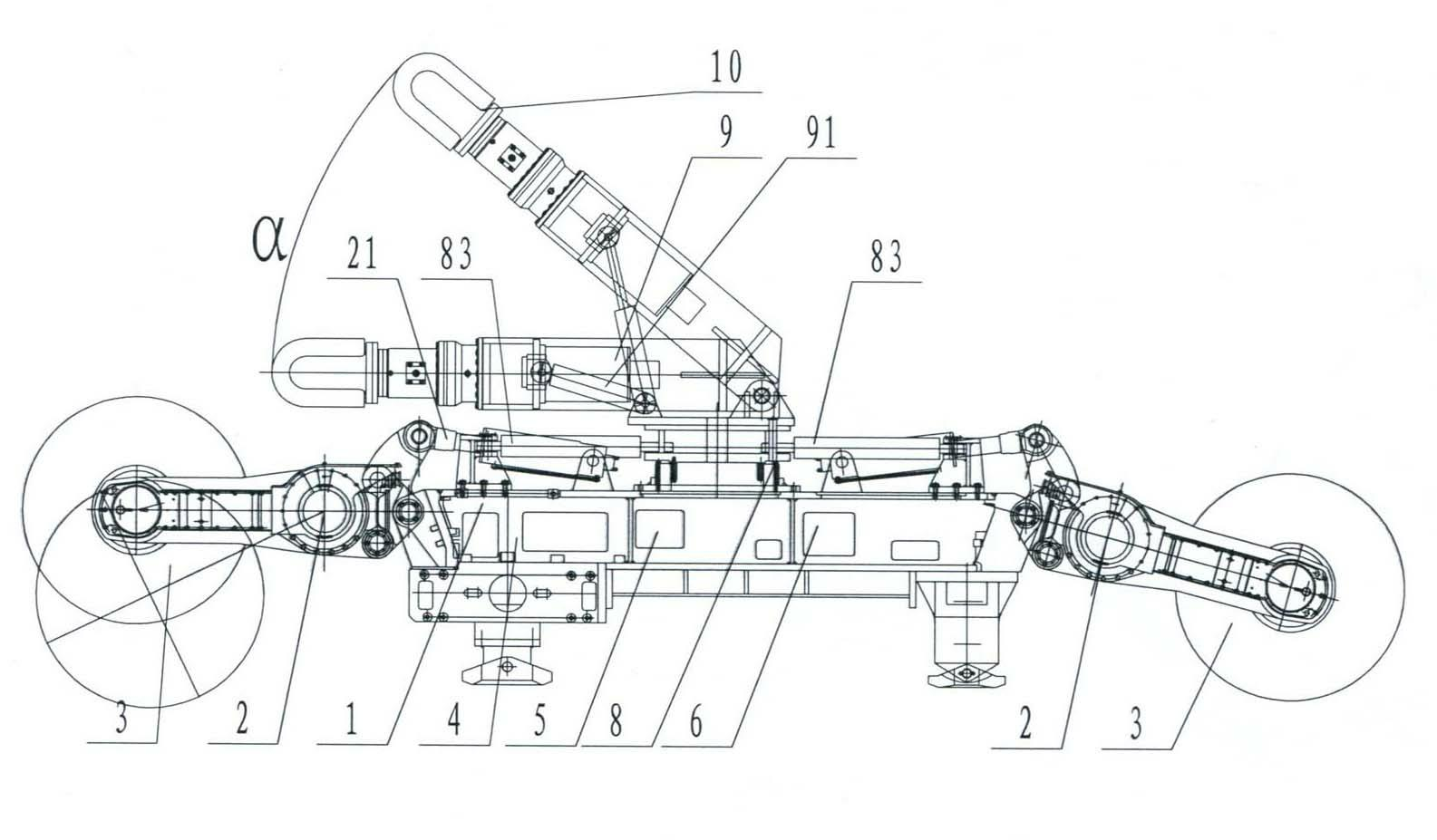

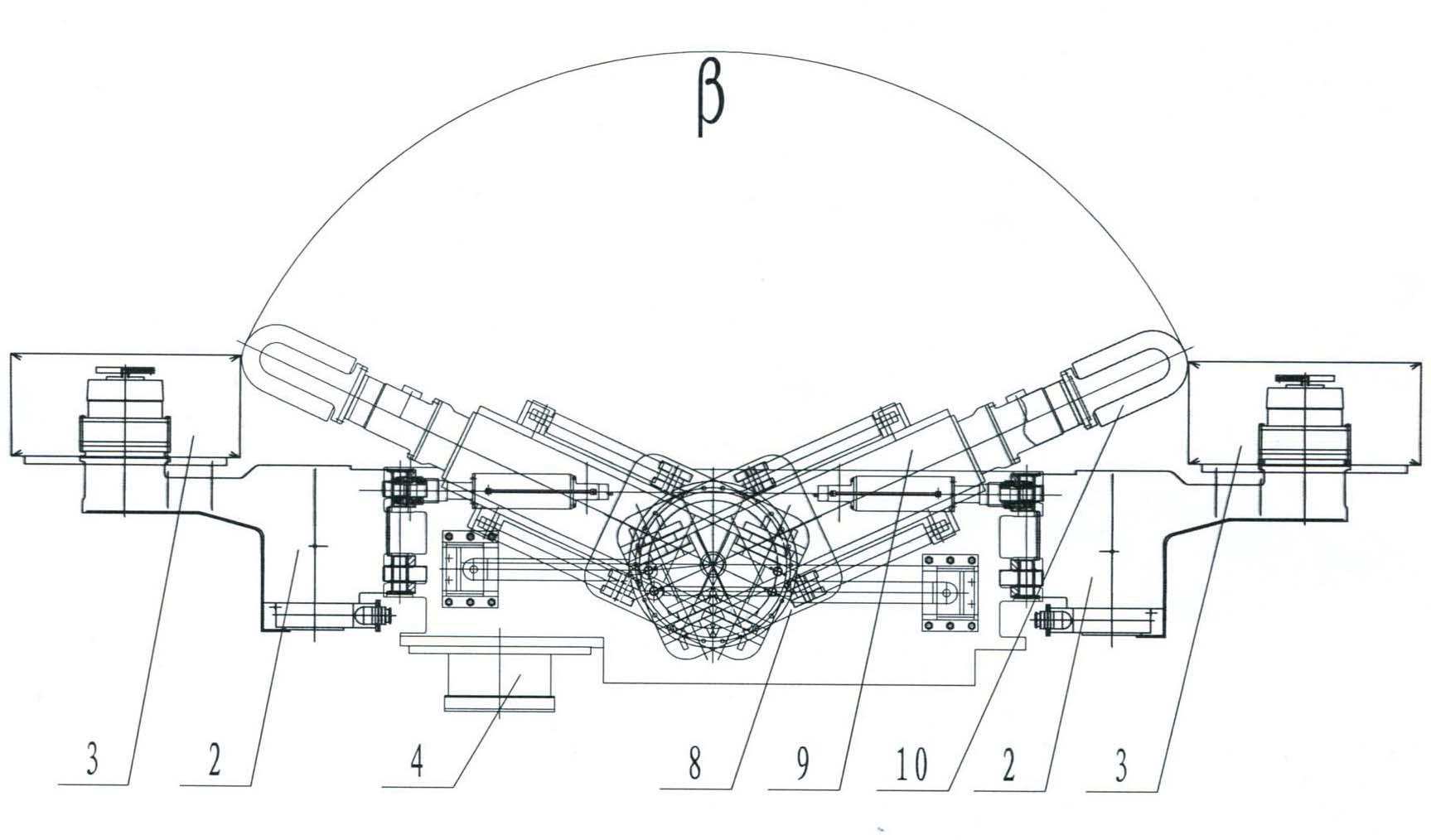

Three-roller coal miner applicable to coal seam with thickness of 7-10m and mining method

ActiveCN104234711AResolve resistanceAddress reliabilityUnderground miningSurface miningMining engineeringCoal

The invention discloses a mining method applicable to full-seam mining with large mining height of a coal seam with the thickness of 7-10m. The coal seam of a working face is divided into an upper part, a middle part and a lower part, and is mined by a three-roller coal miner; two end rollers of the coal miner are mainly used for cutting the upper part and the lower part of the coal seam; a middle roller is used for cutting the middle part of the coal seam; two end parts of the three-roller coal miner are connected with small-diameter rollers via long rocker arms; the middle part of the three-roller coal miner is provided with the large-diameter roller with a short rocker arm; the two end parts of the three-roller coal miner are provided with the equal-diameter rollers with equal long rocker arms; the short rocker arm is arranged on a bottom bracket of the coal miner; the three-roller coal miner is matched with a scraper plate conveyer and an extra large mining height hydraulic support to achieve automatic end part beveling feed. According to the invention, the three-roller coal minder is adopted for full-seam mining with large mining height for the coal seam with the thickness of 7-10m, and can solve the problems of low resource recovery ratio, spontaneous ignition of the coal seam, low efficiency and the like of existing full-mechanized caving mining and layered mining, and the feasible large mining height mining method is provided for the coal seam with the thickness of 7-10m.

Owner:TIANDI SCI & TECH CO LTD

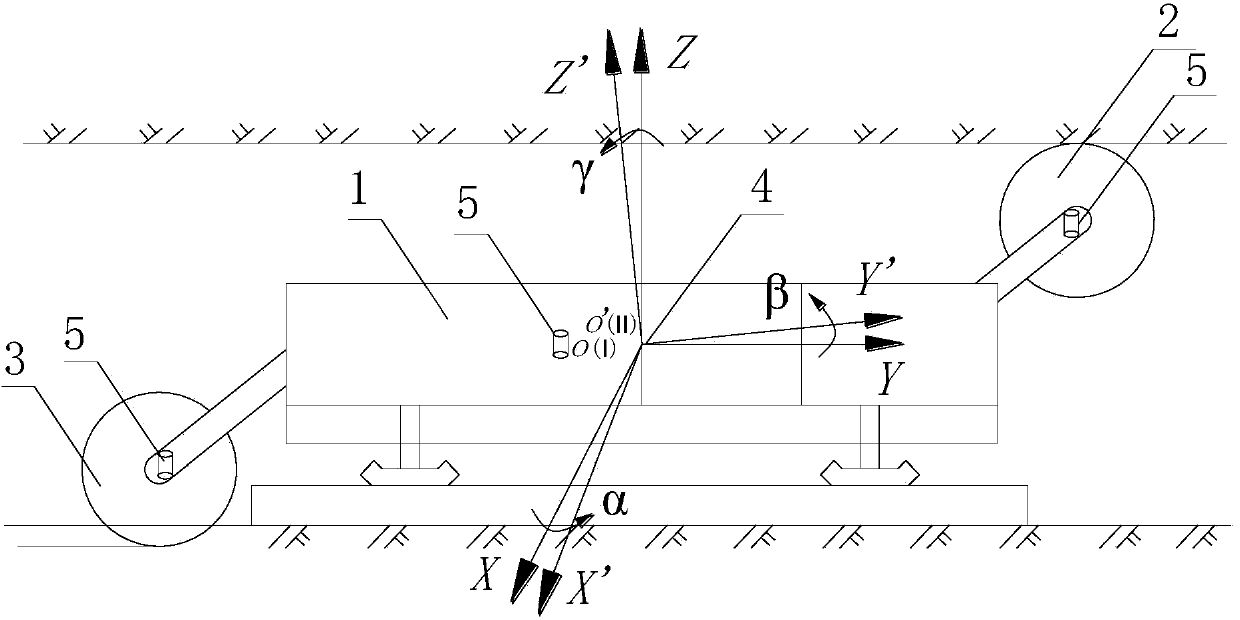

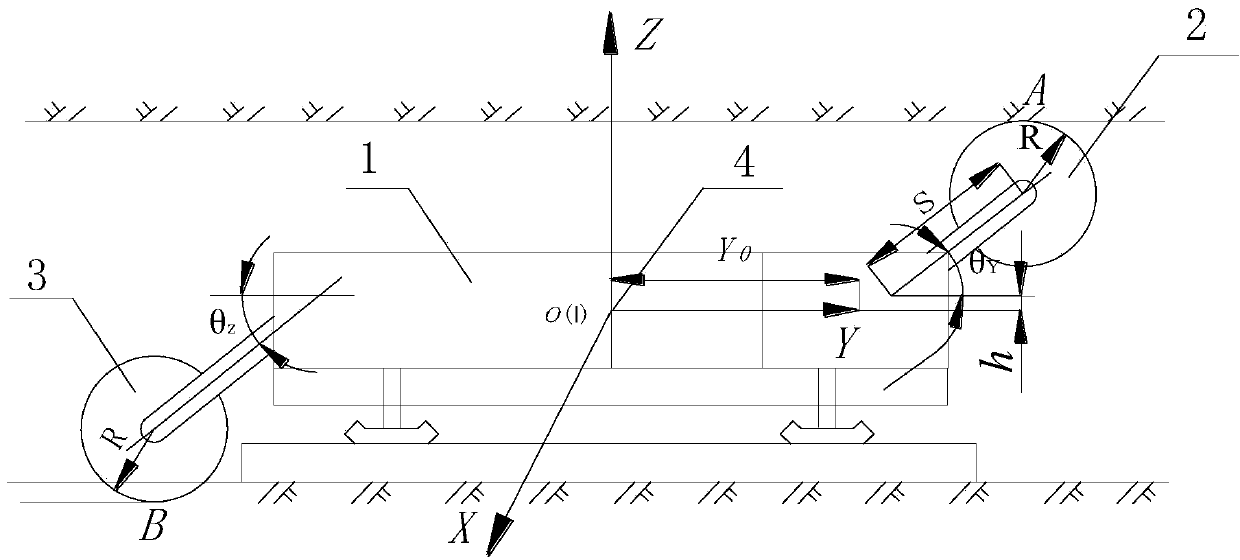

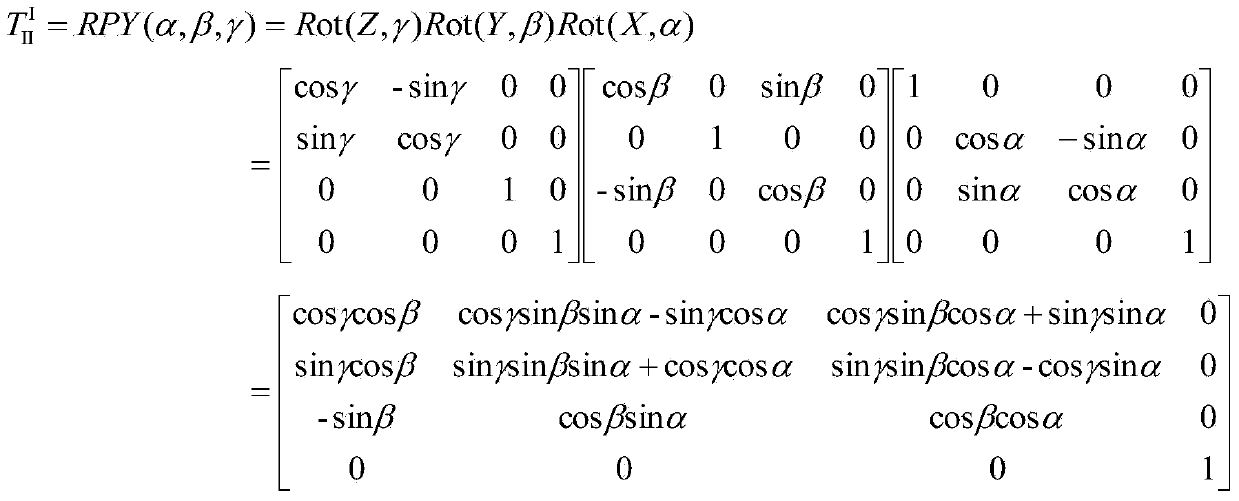

Construction method of attitude angle regulating model of manless working face coalcutter for thin seam

ActiveCN103775080AImprove the design of automated controlsEasy to useDriving meansGyroscopeEngineering

The invention discloses a construction method of an attitude angle regulating model of a manless working face coalcutter for a thin seam, belonging to a construction method of an attitude angle regulating model of a coalcutter. The construction method is characterized in that a situation that gyrocopes are installed on the machine body, the front roller and the rear roller of the manless working face short machine body coalcutter is taken as a basic to construct the attitude angle regulating model of the manless working face coalcutter; when the coalcutter is drawn back and forth to perform automatic memory coal cutting on the manless working face, a primary coordinate system is established in the center of the coalcutter, and an interconversion principle between the primary coordinate system and a space coordinate system is combined, so as to derive the conversion between the moving coordinate system and the primary coordinate system after the attitude angle of the coalcutter is regulated; the inclined angle of the roller rocker is measured after the initial inclined angle and the attitude angle of the coalcutter are regulated through a gyroscope, so as to further construct a control model for attitude angle regulation and automatic roller height adjustment. The construction method disclosed by the invention has the advantages that operation is reasonable, and production benefit, safety and reliability are good; the control model control method improves the automation control of the coalcutter, improves the use performance, enhances the reliability and prolongs the service life of equipment.

Owner:CHINA UNIV OF MINING & TECH

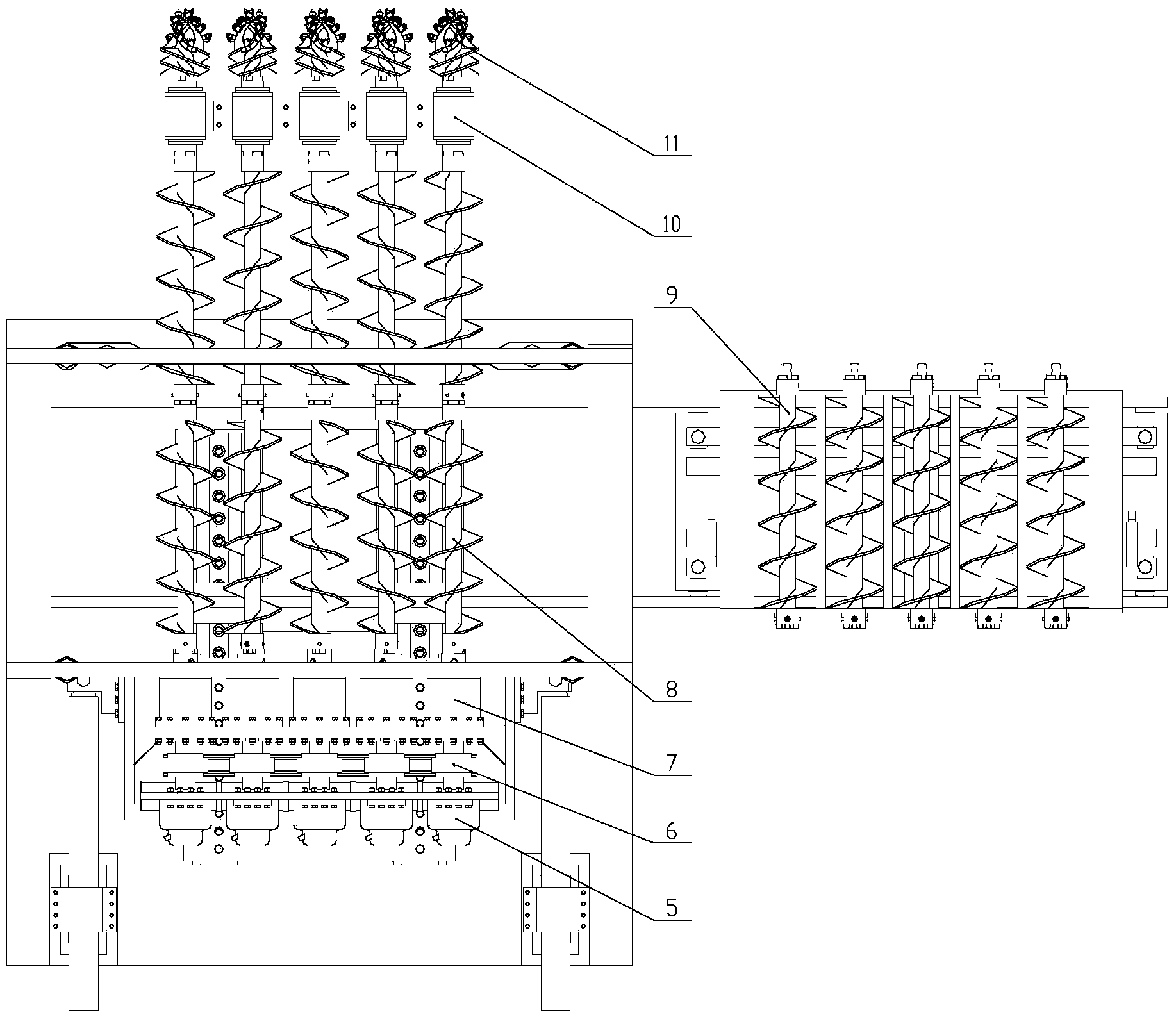

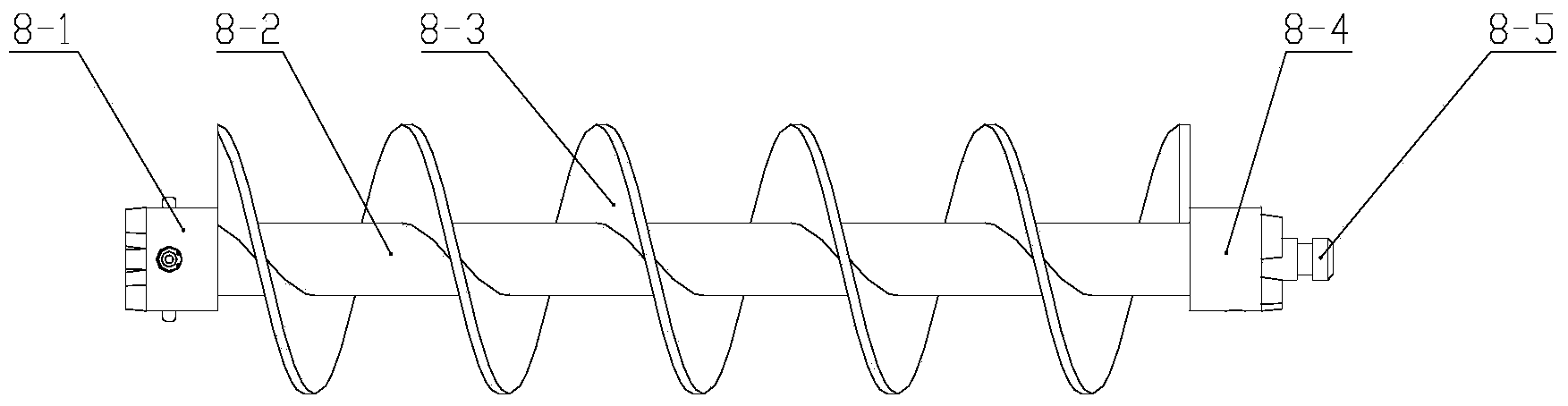

Five-bit spiral-drill coal mining device convenient for switching drilling rods

InactiveCN103470255AReduce replacement timeCompact structureDriving meansHydraulic cylinderCooperative work

The invention discloses a five-bit spiral-drill coal mining device convenient for switching drilling rods. The five-bit spiral-drill coal mining device comprises a supporting frame, a moving frame, a guiding rail, a hydraulic propelling oil cylinder, a hydraulic braking motor, a torque and rotating-speed sensor, a transmission box, the drilling rods, spiral bits, a tightening device, a lifting hydraulic cylinder, an auxiliary hydraulic oil cylinder, a drilling-rod supporting frame, a drilling-rod lifting frame and a drilling-rod bottom supporting frame and the like, wherein the hydraulic braking motor supplies power to the spiral bits and drives the spiral bits to rotate so as to realize cutting of a coal seam. A bit-feeding mechanism transfers the drilling rods to be switched to the switching position, and the automatic switching of the drilling rods is finished by cooperative work of the lifting hydraulic cylinder, the auxiliary hydraulic cylinder, the tightening device and the hydraulic propelling oil cylinder. The five-bit spiral-drill coal mining device disclosed by the invention has the advantages that hydraulic driving is adopted, the structure is simple and compact and the installation and the disassembly are convenient; compared with the prior art, the five-bit spiral-drill coal mining device disclosed by the invention has the beneficial effects that the needed time for switching the drilling rods is greatly reduced, the labor and the materials are saved, the efficiency for switching the drilling rods is improved, and support is provided for safe and high-efficiency mining of underground thin and ultrathin coal seams.

Owner:CHINA UNIV OF MINING & TECH

Cantilever type electric traction coal cutter

InactiveCN102777173ALower the plane heightLow failure rateDriving meansCutting machinesElectricityElectric machinery

The invention discloses a cantilever type electric traction coal cutter, belonging to the field of coal mining machinery. The coal cutter comprises a coal cutter body, a cutting part, a hydraulic device and a towing device, wherein the coal cutter body is in three-section type horizontal arrangement and consists of an electric cabinet, a traction box and a traveling part; the coal cutter body is of a forward-extending type for reducing the height of the coal cutter, and the main parts of the cutting part and the coal cutter body extend to the outer side of a scraper conveyor; and a cutting motor and a traction motor are both horizontally arranged and assembled and disassembled from a coal wall side so as to be disassembled and replaced conveniently. According to the cantilever type electric traction coal cutter, as the main part of the coal cutter body extends to the outer side of the scraper conveyor and goes deep into a coal bed, the height of the coal butter is effectively reduced, and the coal cutter can be used for mining an extremely thin coal bed or thin coal bed which is 0.75-1.3m thick; and travelling wheels of the travelling part reciprocate on pin tracks on the conveyor, so that the coal cutter is driven to reciprocate for coal mining, and the whole coal cutter operates stably with low fault rate.

Owner:JIANGSU ZHONGJI MINE EQUIP

Roadheader

InactiveCN101153540AAdd supportImprove support efficiencyDriving meansCutting machinesEngineeringCantilever

A tunneling machine for tunneling gross section coal drift consists of a cutting unit, a body, a travel unit, a blade, a conveyor and a hydraulic system, etc. The cutting unit consists of a cutting head (4), a cantilever (3), a cutting motor, a cutting reduction gearbox and a telescopic part, etc. The cantilever (3) is connected with the body through a side slip guide mechanism namely a crosshead (2) is hinged onto the rear end of the cantilever (3); a guide body is arranged on the rear end of the crosshead; a guide holder (1) is fixed on the body; a guide groove is arranged on the front end of the guide holder, and the guide body is embedded in the guide groove and is in slide fit with the guide groove; or the two parts are arranged in a reverse way. A driving element or mechanism for driving the crosshead and the cantilever to make lateral movement is arranged between the guide holder and the crosshead. A cantilever tilt cylinder is hinged between the cantilever (3) and the crosshead (2). The wall of the coal drift cut by the tunneling machine is smooth, flat and easy in supporting, thereby improving supporting efficiency and effect. The cutting unit makes a large range of lateral movement, thereby realizing gross section fixed point cutting in a wider coal drift without lateral movement of the whole machine, shortening cycle time, improving tunneling speed and efficiency with great adaptability.

Owner:贾民

Multidirectional adjustment type coal mine tunneling device

InactiveCN108086974AQuality improvementGood for healthDriving meansPropulsionPhysical healthEngineering

The invention discloses a multidirectional adjustment type coal mine tunneling device, which comprises a base, a moving plate, a first transmission cavity, a second transmission cavity and a tunnelingmechanism. Supporting legs are symmetrically mounted at the lower end of the base; the upper end of the base is in rotational connection with the moving plate through a rotating rod; hydraulic telescopic rods A are fixedly mounted at the lower end of the moving plate; an L-shaped plate is fixedly connected with the upper end of the moving plate, and the inner side of the L-shaped plate is provided with a first transmission cavity; a second transmission cavity is arranged above the first transmission cavity, and the lower end of the second transmission cavity is fixedly connected with a firstmoving block; the tunneling mechanism is arranged at the upper end of the second transmission cavity. The multidirectional adjustment type coal mine tunneling device is novel in design, simplicity inoperation, high in operating efficiency and capable of tunneling at different positions in different directions and sucking ash generated in a tunneling process, quality of an operating environment isimproved, and physical health of operators is benefited.

Owner:长沙德科投资管理咨询有限公司

Drum shearer cutting part

InactiveCN102359373AImprove mining efficiencyMeet mining needsDriving meansCutting machinesReduction driveTransmitted power

The invention discloses a drum shearer cutting part which comprises a rocker arm shell, a cutting motor, a rocker arm speed reduction box, a planetary gear mechanism and a cutting drum, wherein the cutting motor is directly and transversely arranged in the rocker arm shell, and the motor is fixed in the rocker arm shell through a bolt. A cutting part mechanical transmission comprises a rocker arm speed reduction box and a planetary gear speed reduction mechanism which are independent transmission parts. When a hard waste rock clamping coal bed shearer cutting part works, an output shaft of the cutting motor transmits power to the rocker arm speed reduction box, the power is transmitted to the cutting drum after subjected to speed reduction through a five-grade cylindrical gear and the planetary gear transmission, the cutting drum is linked with an output shaft of the planetary gear speed reducer by adopting a square connecting sleeve, with the advantages of reliability in linkage and convenience for disassembly. The cutting part has a simple and compact integral structure, strong exploitation capacity due to the adoption of the special strong hard waste coal bed clamping coal bed cutting drum, can be used for exploiting a waste coal clamping coal bed with a coal rock firmness exploitation efficiency f of less than 6 and meets the demands of exploitation of an underground hard waste coal clamping coal bed, thus the exploitation efficiency of the hard waste coal clamping coal bed and the exploitation recovery rate of coal resources are increased.

Owner:CHINA UNIV OF MINING & TECH

Multifunctional mine roadway milling and digging machine

InactiveCN104847347AImprove repair efficiencySimple and fast operationServomotorsDriving meansSlagEngineering

The invention discloses a multifunctional mine roadway milling and digging machine, which comprises a multifunctional work mechanism, a transportation mechanism, a walking device, a hydraulic system and an electric system, wherein the multifunctional work mechanism consists of a milling and digging mechanism and a digging mechanism. The digging mechanism and the digging mechanism are integrated to form the multifunctional work mechanism; the milling and digging mechanism firstly carries out large-range milking restoration, planing and restoration on a blasting dug irregular roadway; then, a large amount of slag and stones are dug through a grab excavator; next, materials are conveyed to the tail part through the self conveying mechanism. The multifunctional mine roadway milling and digging machine adopting the technical scheme has the advantages that the defects in the prior art are overcome, meanwhile, the functions of roadway milling restoration, bottom planing, digging and conveyance are realized; the roadway mining restoration, the bottom planing, the digging and the loading continuous operation can be realized, the operation is simple and convenient, the cost is reduced, the applicability to various complicated work conditions is high, the field applicability is effectively improved, and the roadway restoration efficiency is improved.

Owner:安徽宏昌机电装备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com