Bidirectional pounding and cutting excavating method and bidirectional pounding and cutting excavator for implementing same

A technology of fuselage and guide parts, applied in the field of machinery, can solve the problems of increasing power consumption, consuming a lot of manpower, material resources and time, and reducing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

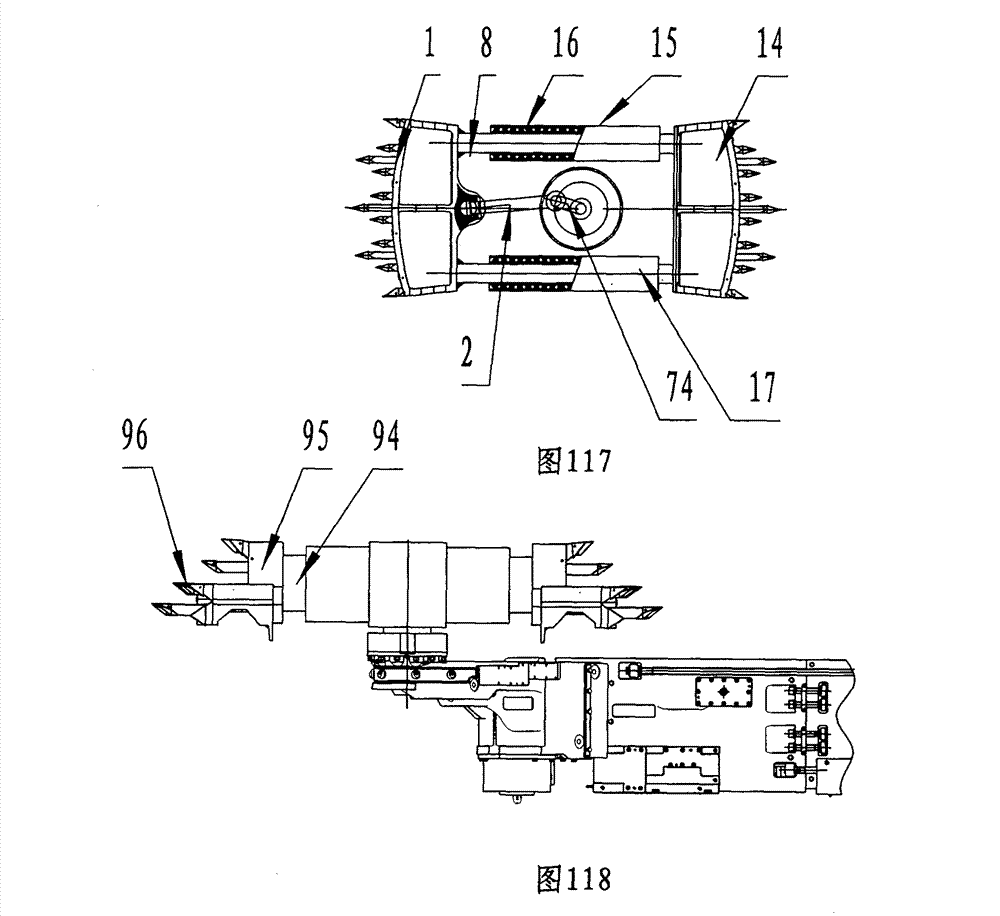

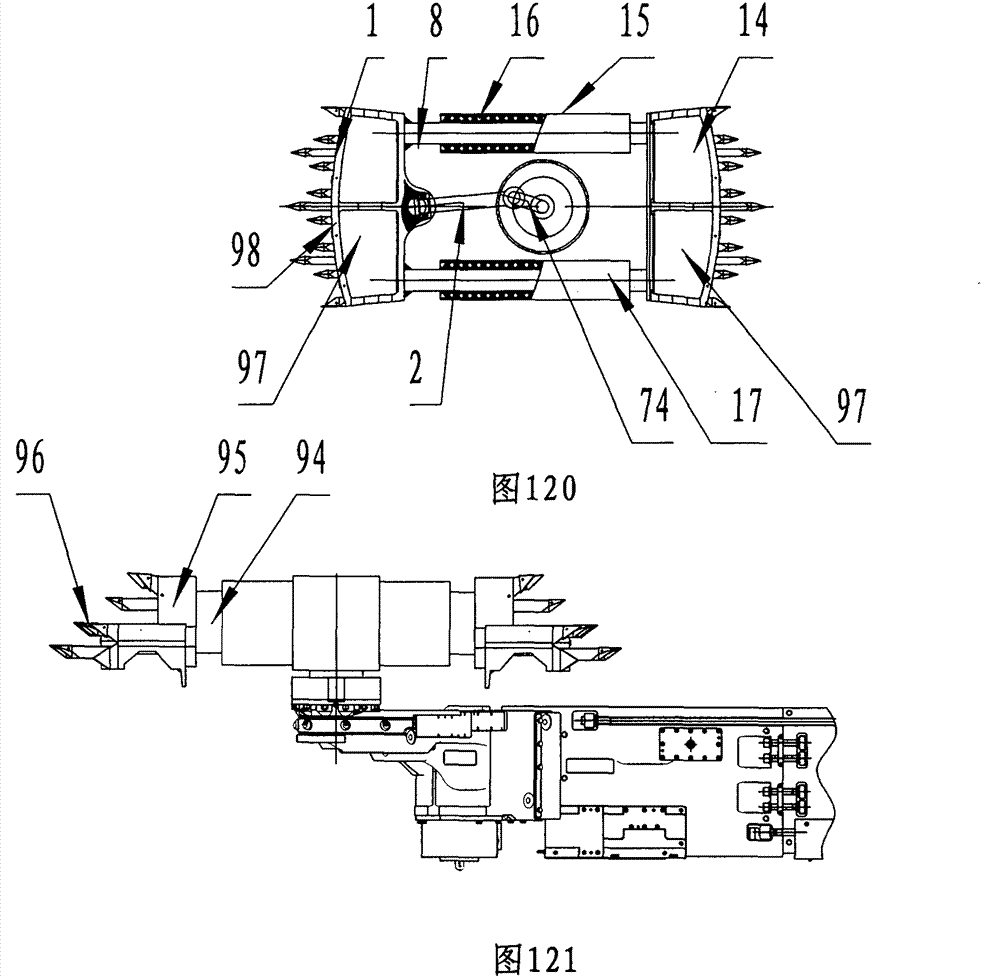

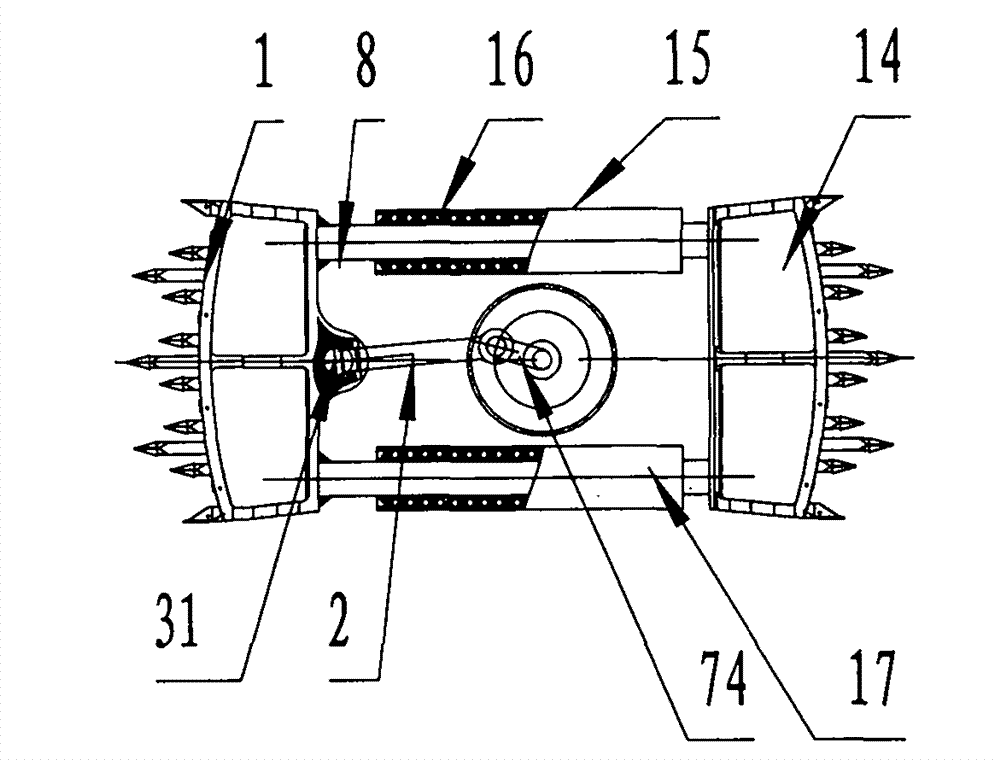

Embodiment 1

[0634] Figure 1 to Figure 3 It is the two-way punching mining machine described in Embodiment 1. The two-way punching mining machine includes a fuselage 6, a walking part 5, a lifting part 4, a reciprocating impact part 3, etc., and the reciprocating impact part 3 includes an impact guide 8, etc. Both ends of the impact guide 8 are provided with an impact head 1, etc., the reciprocating impact part 3 also includes an impact drive device 7, etc., the impact drive device 7 includes a crank impact drive device 17, etc., and the crank impact drive device 17 includes a power impact member 2, etc. The power impact part 2 drives the impact guide part 8 to reciprocate, and the impact guide part 8 drives the impact head 1 to impact the coal seam mining material. The power impact part 2 and the impact guide part 8 are separated or integrated, and the reciprocating impact part 3 is arranged in the lifting part 4, the lifting part 4 is arranged on the fuselage 6, and the running part 5 i...

Embodiment 2

[0642] Figure 4 It is the two-way punching mining machine described in Embodiment 2. The two-way punching mining machine includes a reciprocating impact part 3 , and the reciprocating impact part 3 also includes an impact driving device 7 , etc., and the impact driving device 7 includes a hydraulic impact driving device 10 . The hydraulic impact driving device 10 includes a hydraulic cavity 11, a piston 12, a hydraulic impact rod 13 and the like.

[0643] The impact driving device 7 can also be a pneumatic impact driving device 54 .

Embodiment 3

[0645] Figure 4 It is the two-way punching mining machine described in Embodiment 2. The two-way punching mining machine includes a running part 5. The running part 5 drives the fuselage 6 to move forward and backward, and the power impact part 2 drives the impact guide part 8 to reciprocate. The impact guide 8 drives the impact head 1 to impact the coal wall or rock wall, so as to complete the forward and backward mining and falling of materials without turning the machine body. The power impact member 2 and the impact guide 8 are separated or integrated.

[0646] The dynamic impact member 2 and the impact guide member 8 can also be of separate structure.

[0647] According to the above structure, the present invention also includes a method for two-way punching and mining, which is realized by the following steps:

[0648] The first step: the walking part 5 drives the fuselage 6 to move forward, the power impact member 2 drives the impact guide 8 to reciprocate, and the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com