Patents

Literature

281results about How to "Large transmission torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

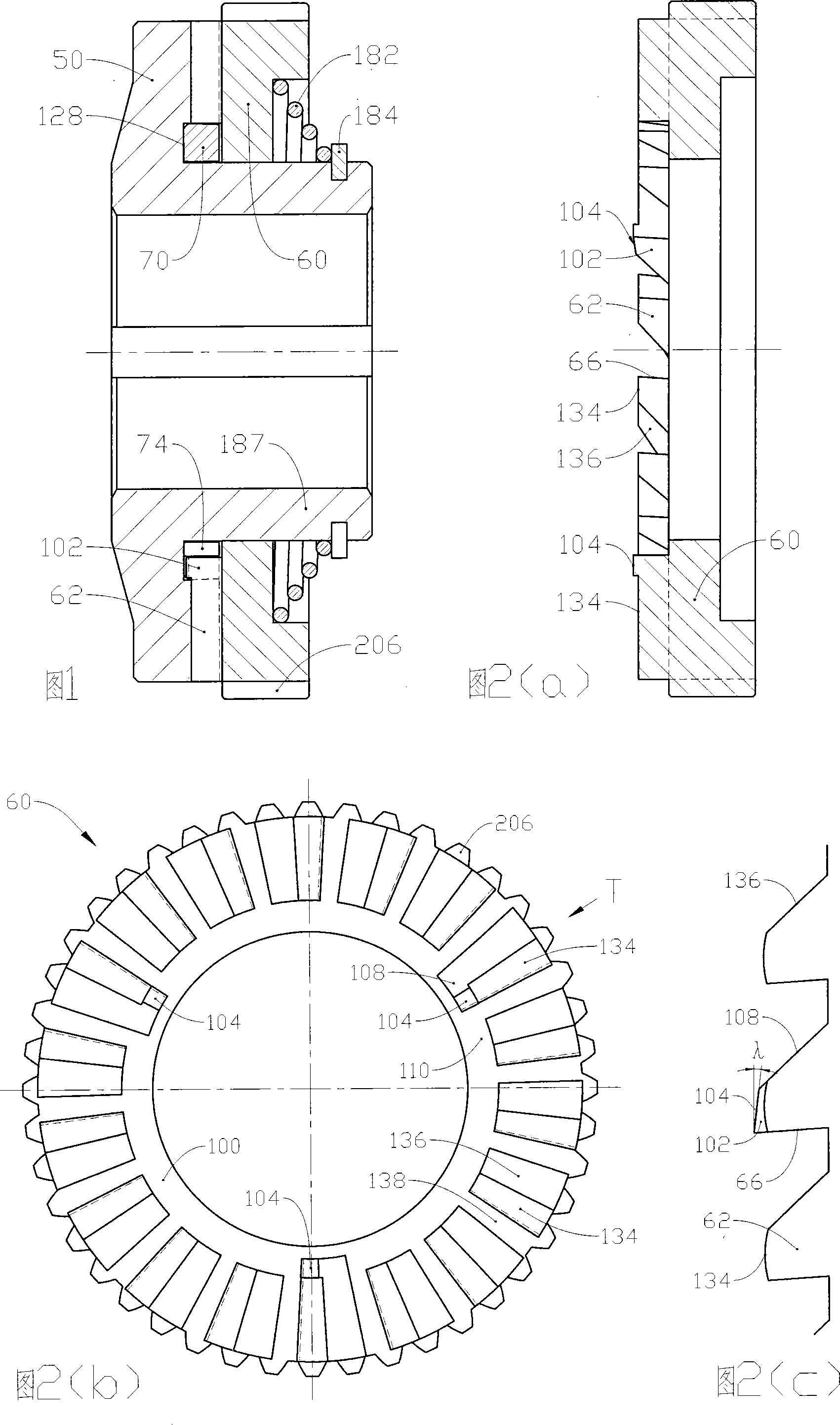

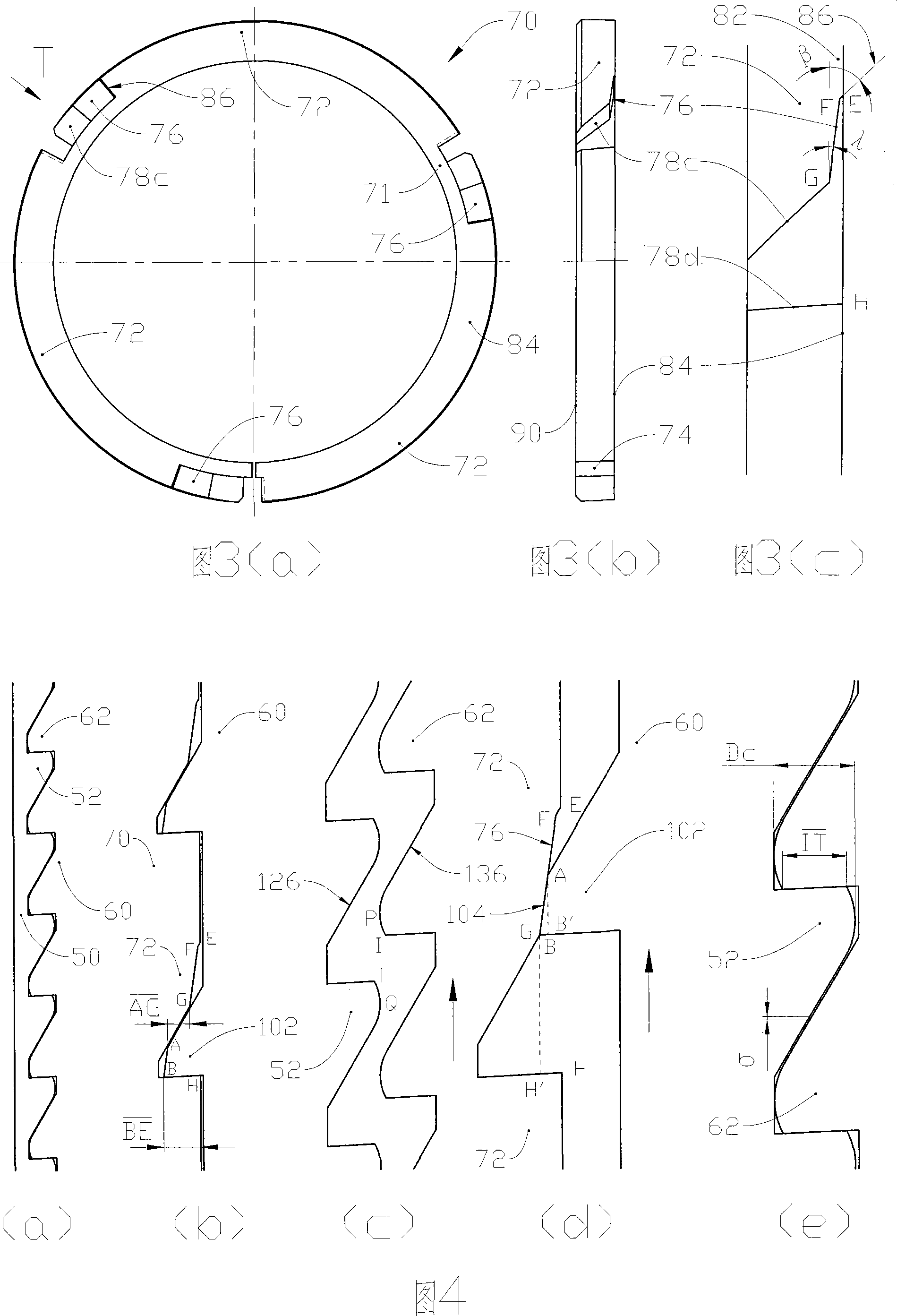

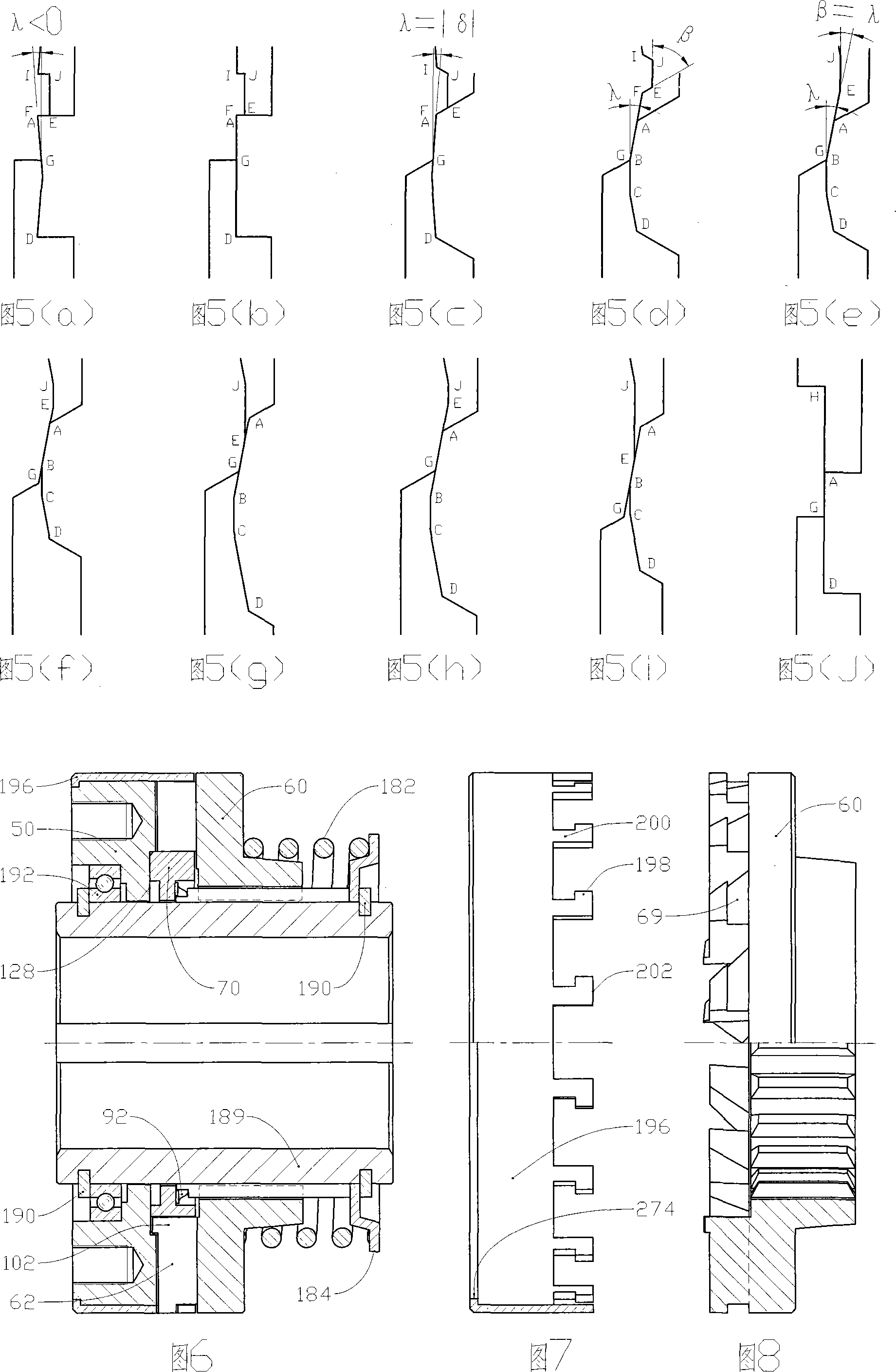

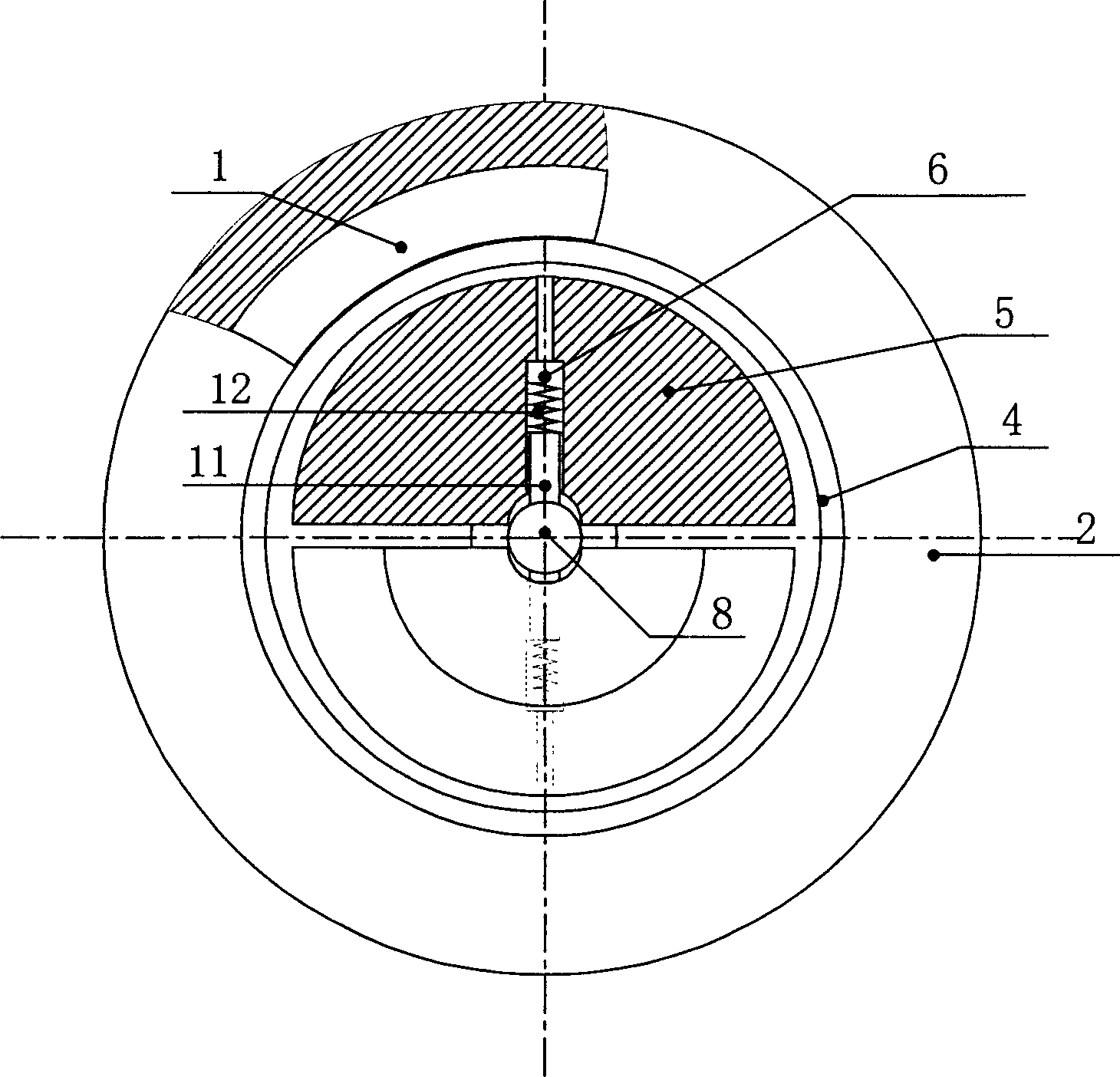

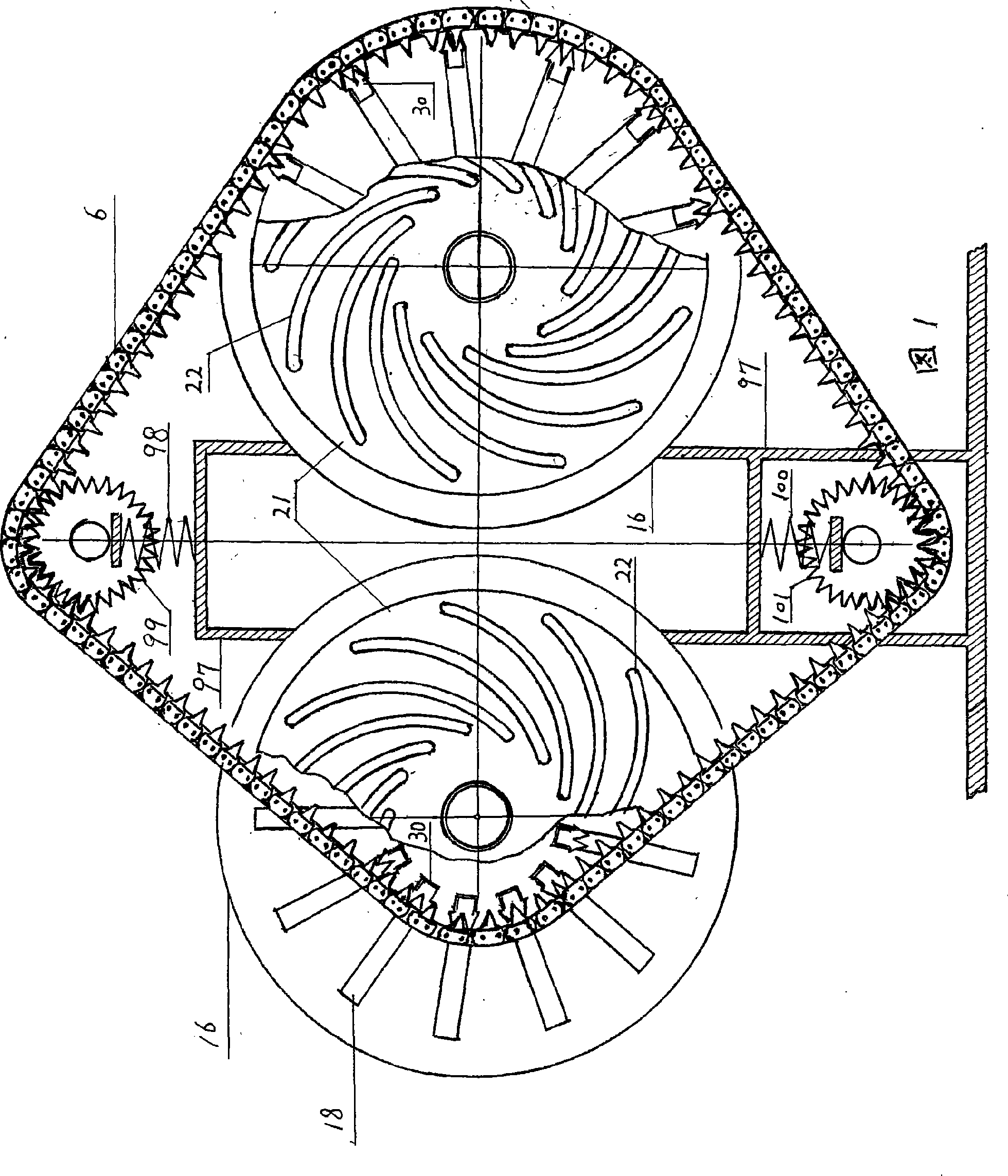

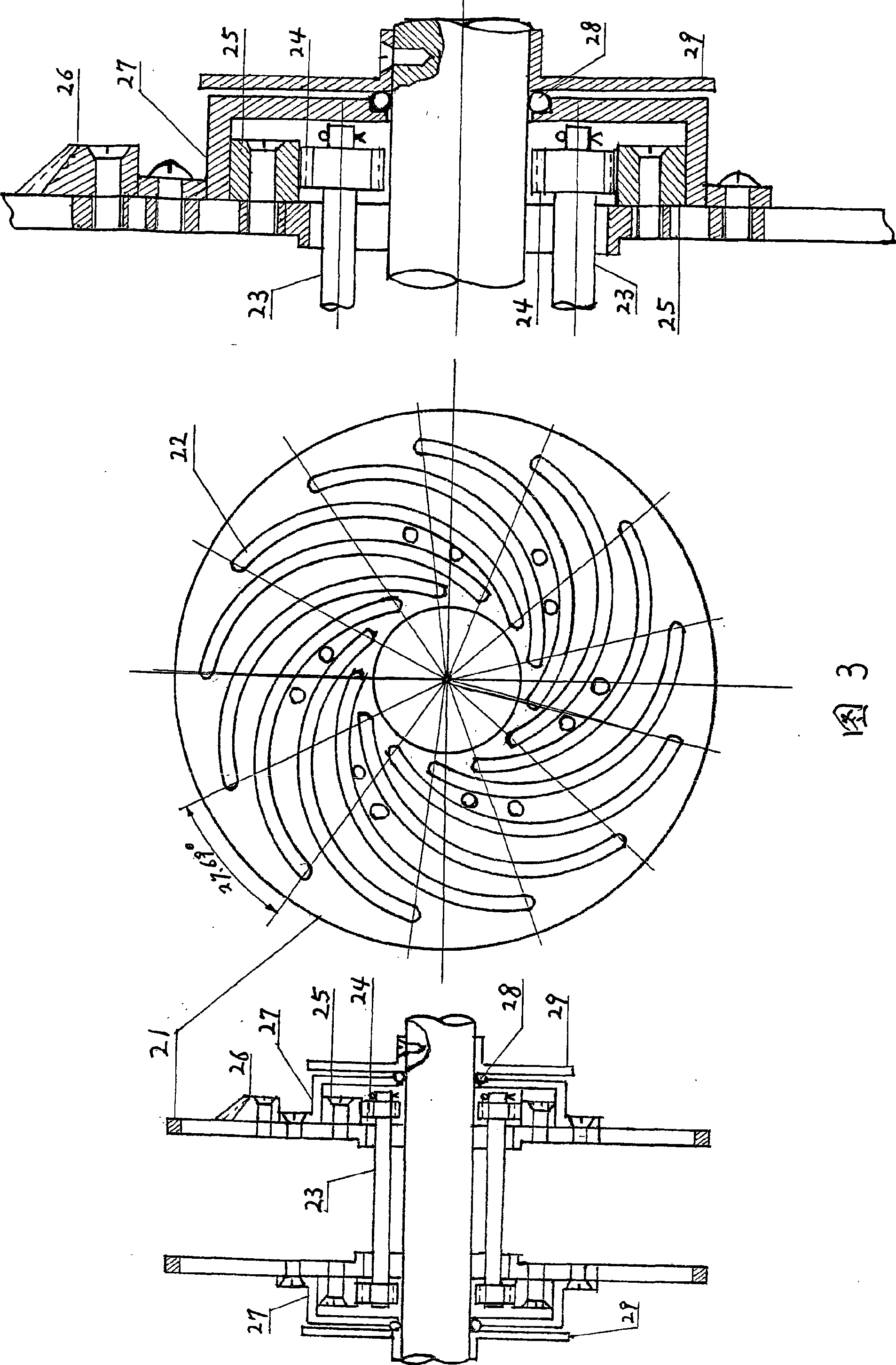

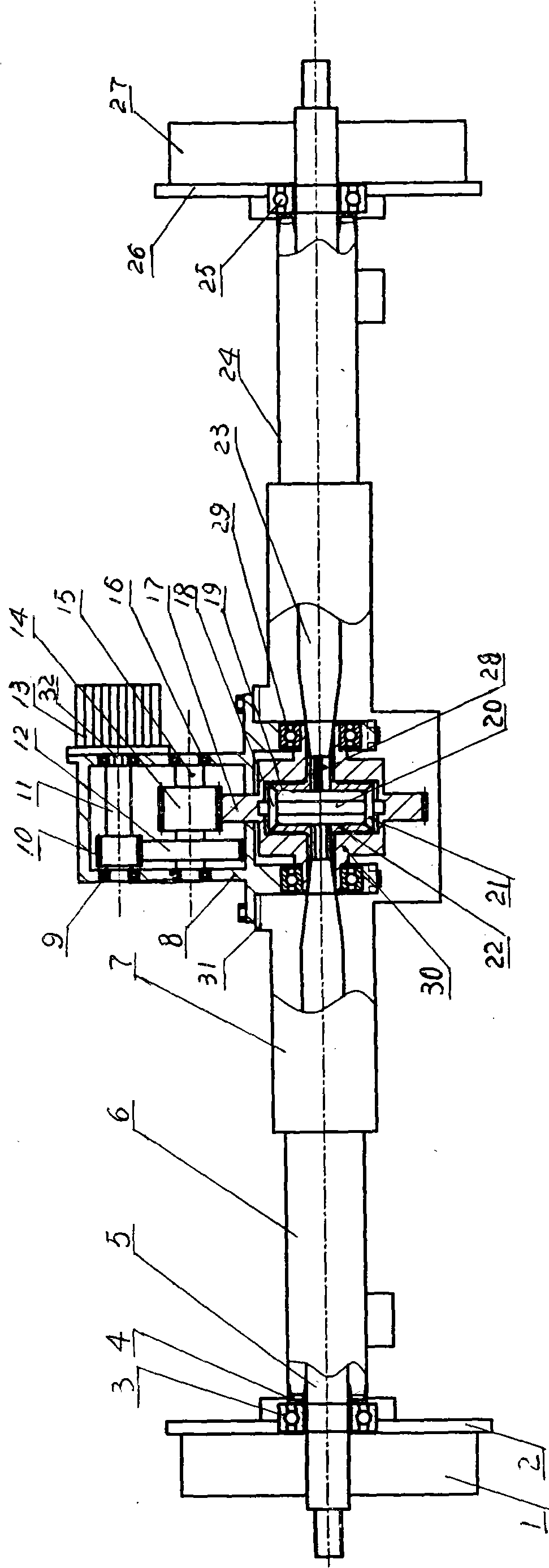

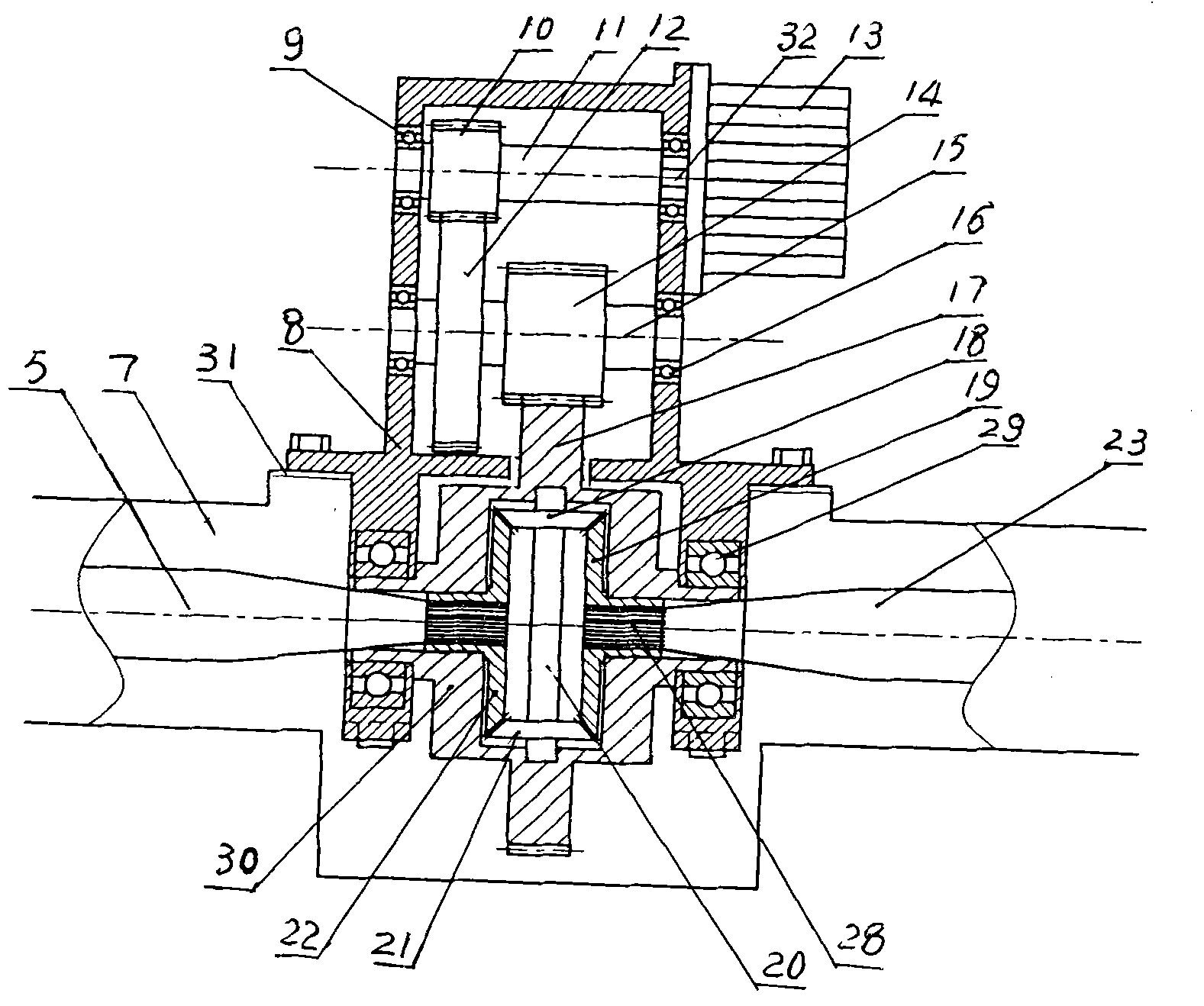

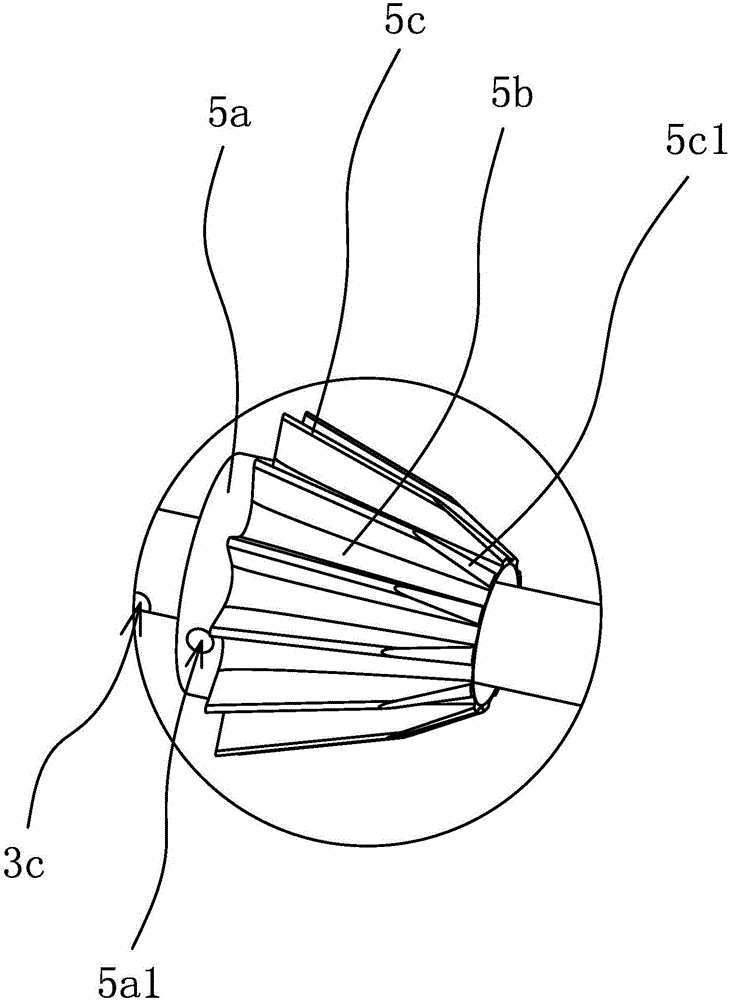

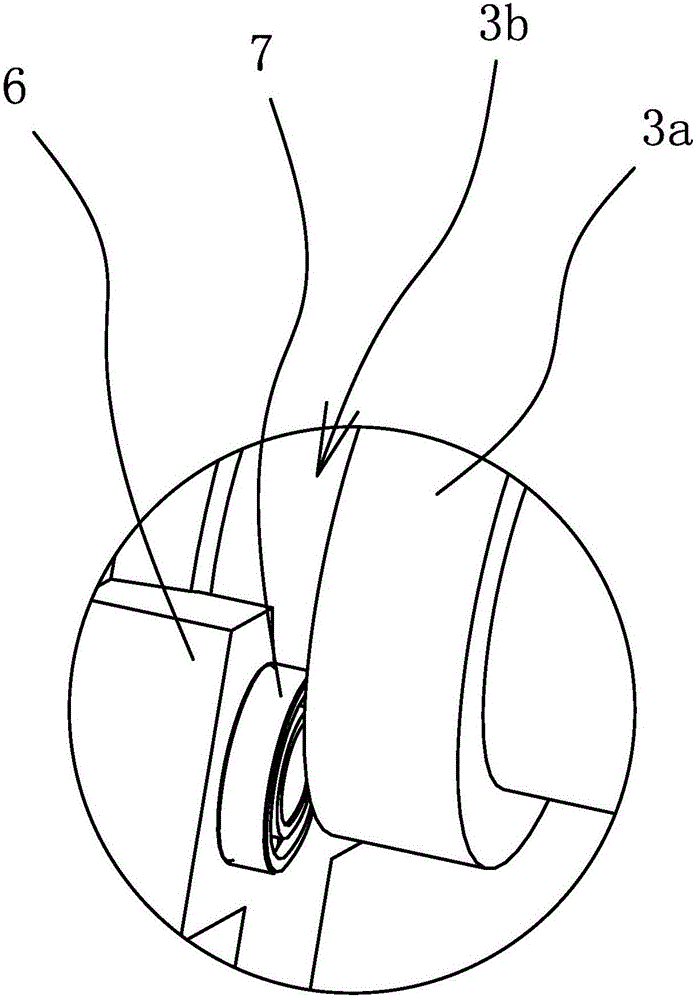

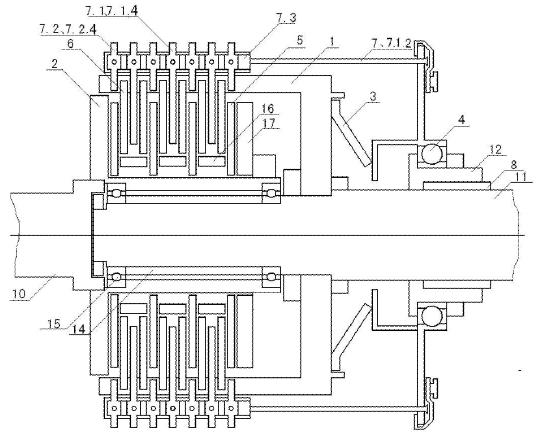

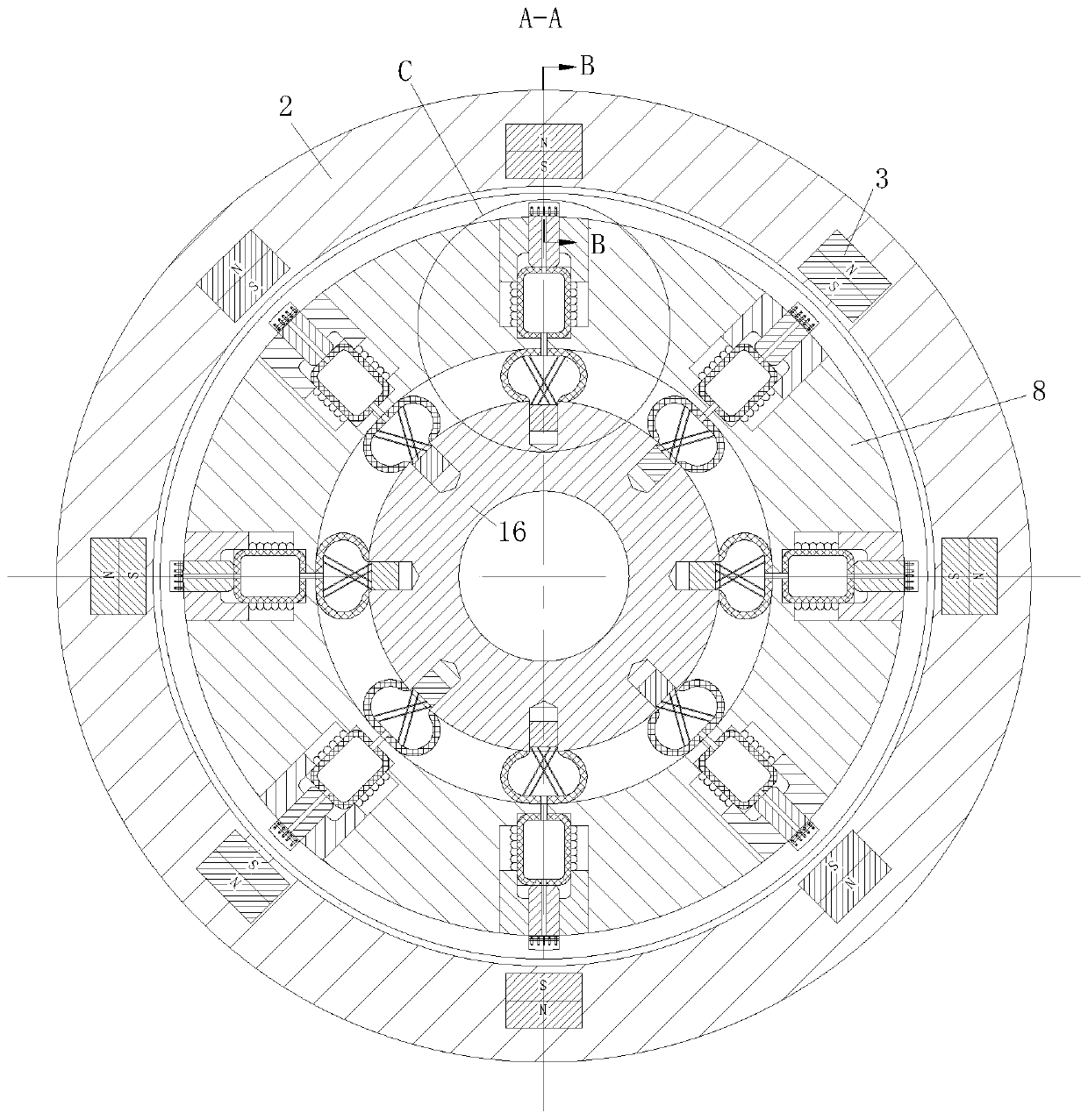

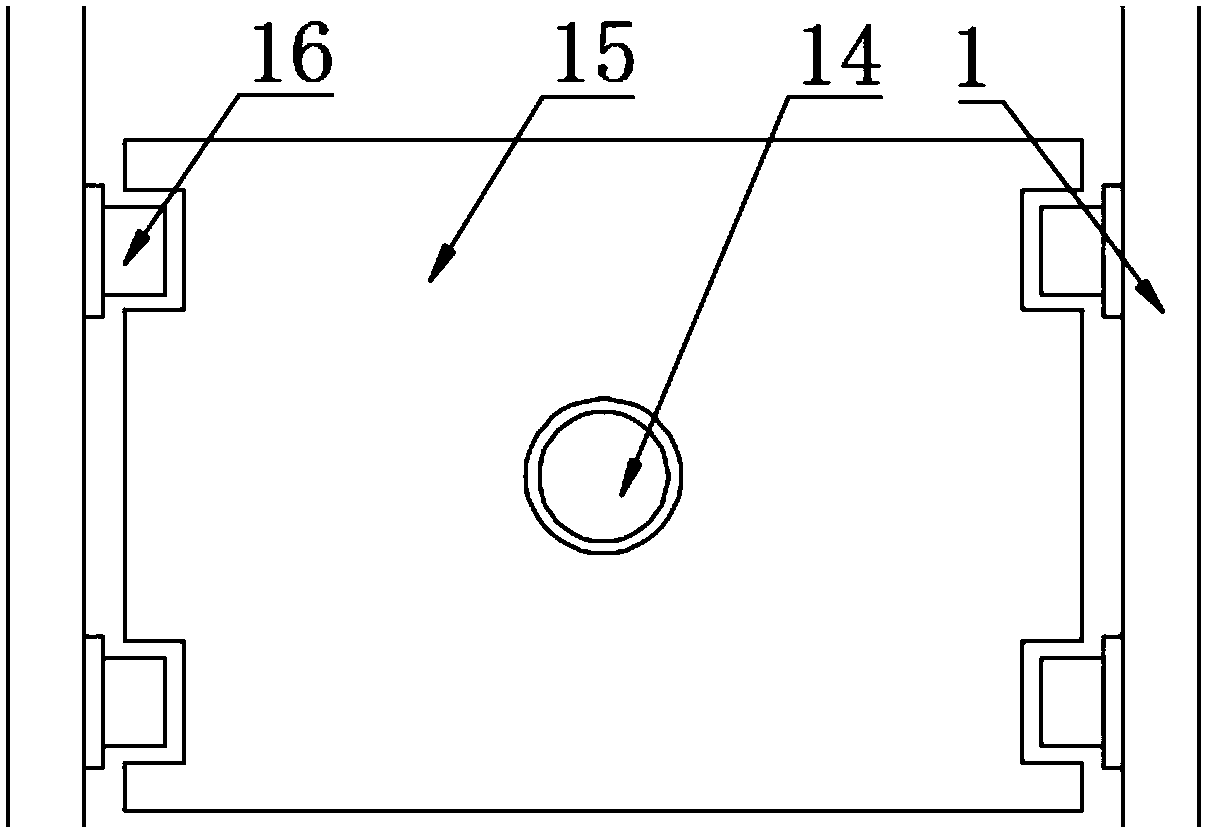

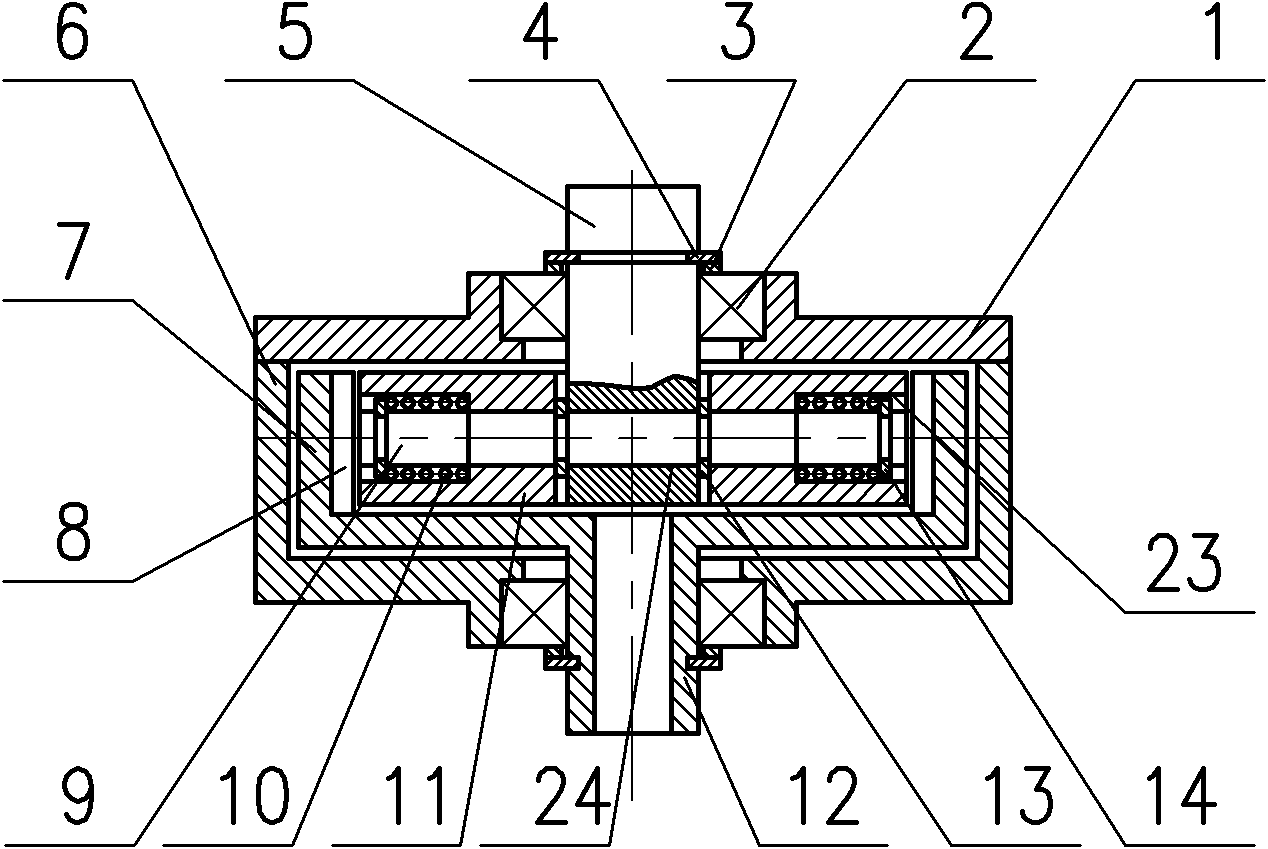

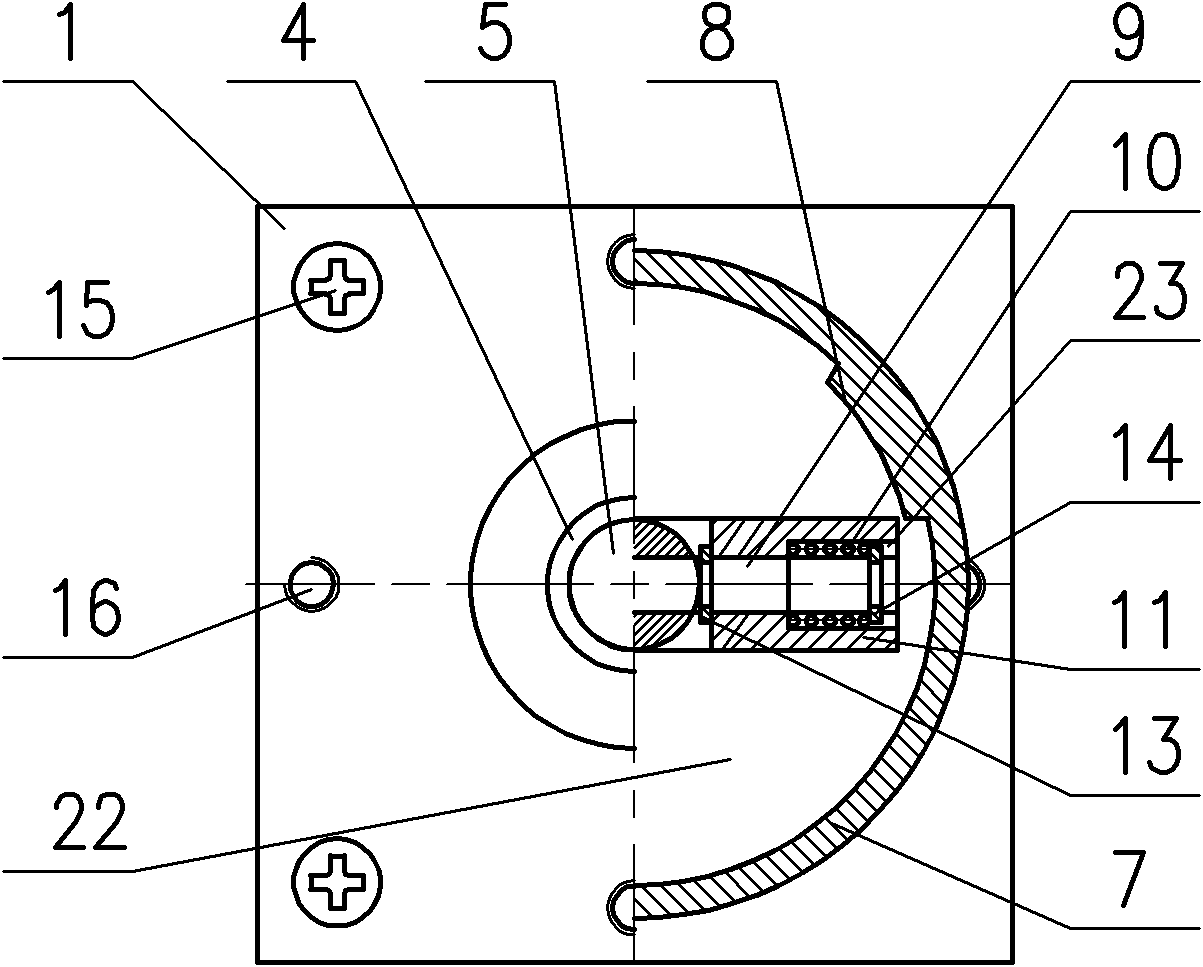

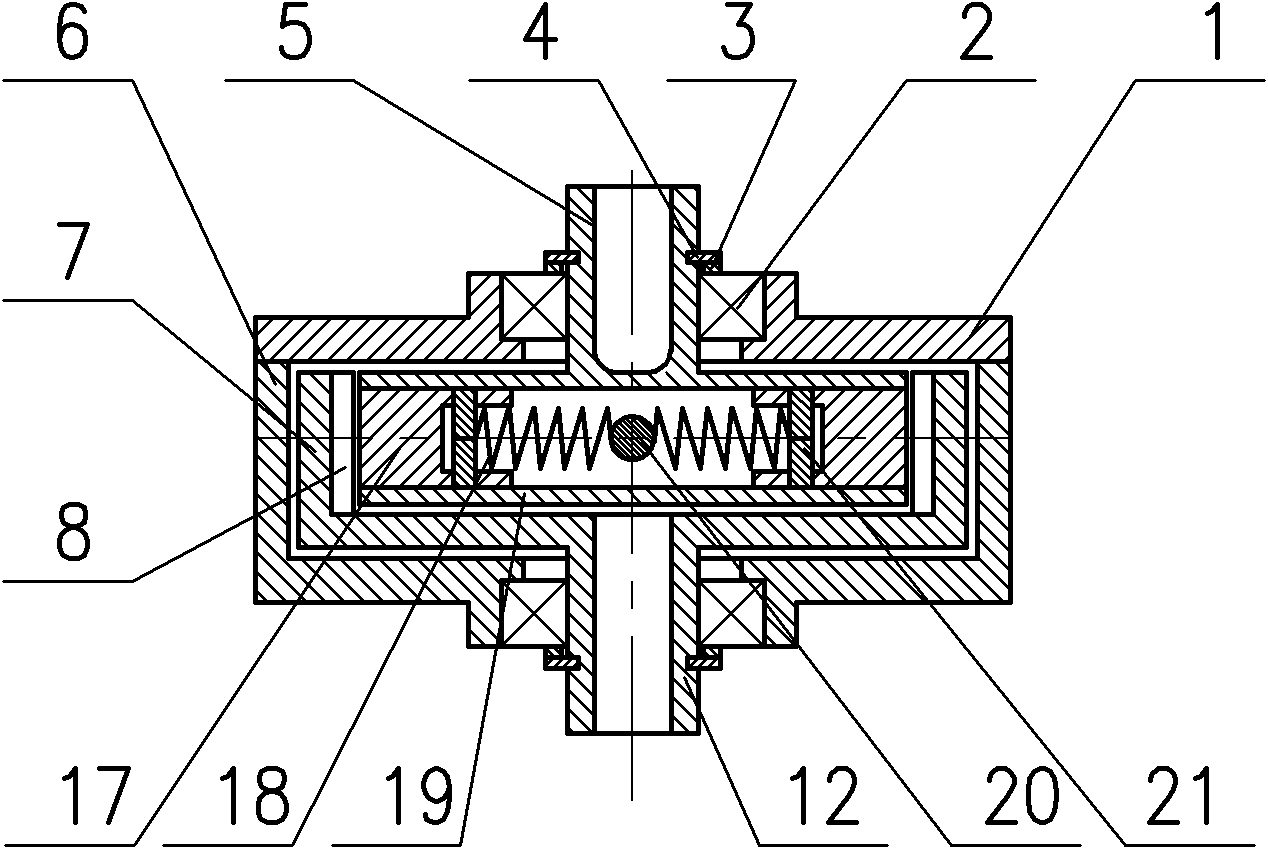

Stitching type jaw single and bidirectional over running clutch

The present invention discloses a press-fitting type jaw overrunning clutch, which can be used as a single or double direction overrunning clutch or a single and double direction controllable glider, and has the characteristics of huge transmissible torque, high rotating speed, no collision, small volume, large impact resistance, simplicity and reliability, and long service life. The present invention is characterized in that the press-fitting type jaw overrunning clutch is provided with a blocking embedding mechanism preventing two embedding mechanisms of a force transmission embedding mechanism and a separation embedding mechanism from being embedded under the overrunning separating condition, the mechanism on the axial direction is positioned in the two mechanisms, and the mechanism on the radial direction is positioned in the two mechanisms, between the two mechanisms or outside the two mechanisms; a lift angle of both sides blocking the working surface is formed to enough ensure the friction self-locking collided on the both sides and the stability of the blocking operating condition, in order that the lift angle has the capabilities that the adaptive axle base is changed and the abrasion is automatically compensated; no collision characteristic of the overrunning operating condition of the two embedding mechanisms is maintained for a long time, and the separating block process and the embedding return process of the embedding mechanism are absolutely reliable. In addition, the direction control mechanism and the condition control mechanism are simple and reliable, the clutch manufacture is relatively easy, the assembly is simple, and the interchangeability of an old part and a new part is strong.

Owner:洪涛

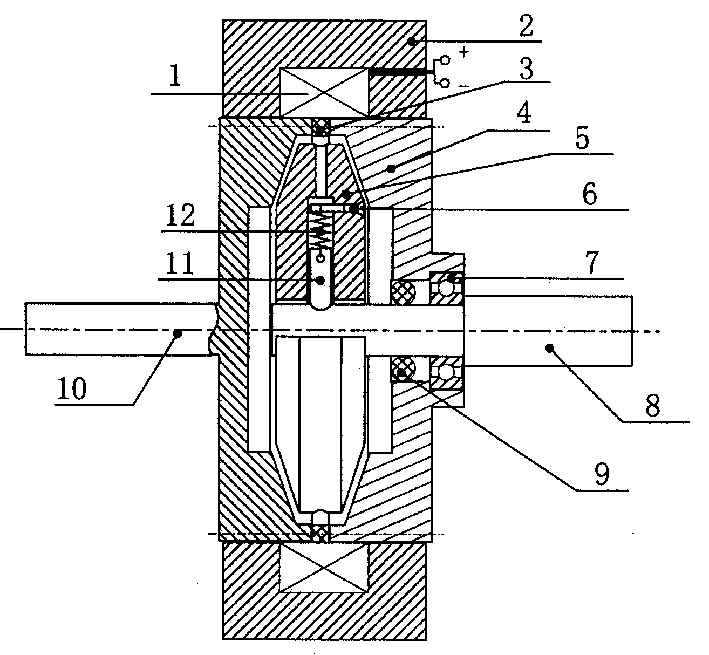

Centrifugal magnetofluid clutch

The clutch of magnetohydrodynamics in centrifugal type is composed of input shaft, output shaft, magnetohydrodynamics, electromagnetic coil and clutching body, which consists of dish shell and sliding bock which can slide along radial direction under the action of centrifugal force to create effects of self-pressurizing for making shearing stress of magnetohydrodynamics a quite great increase. It has the characteristics of big driving torque and less power consumption comparing with the existing clutch of magnetohydrodynamics.

Owner:UNIV OF SCI & TECH OF CHINA

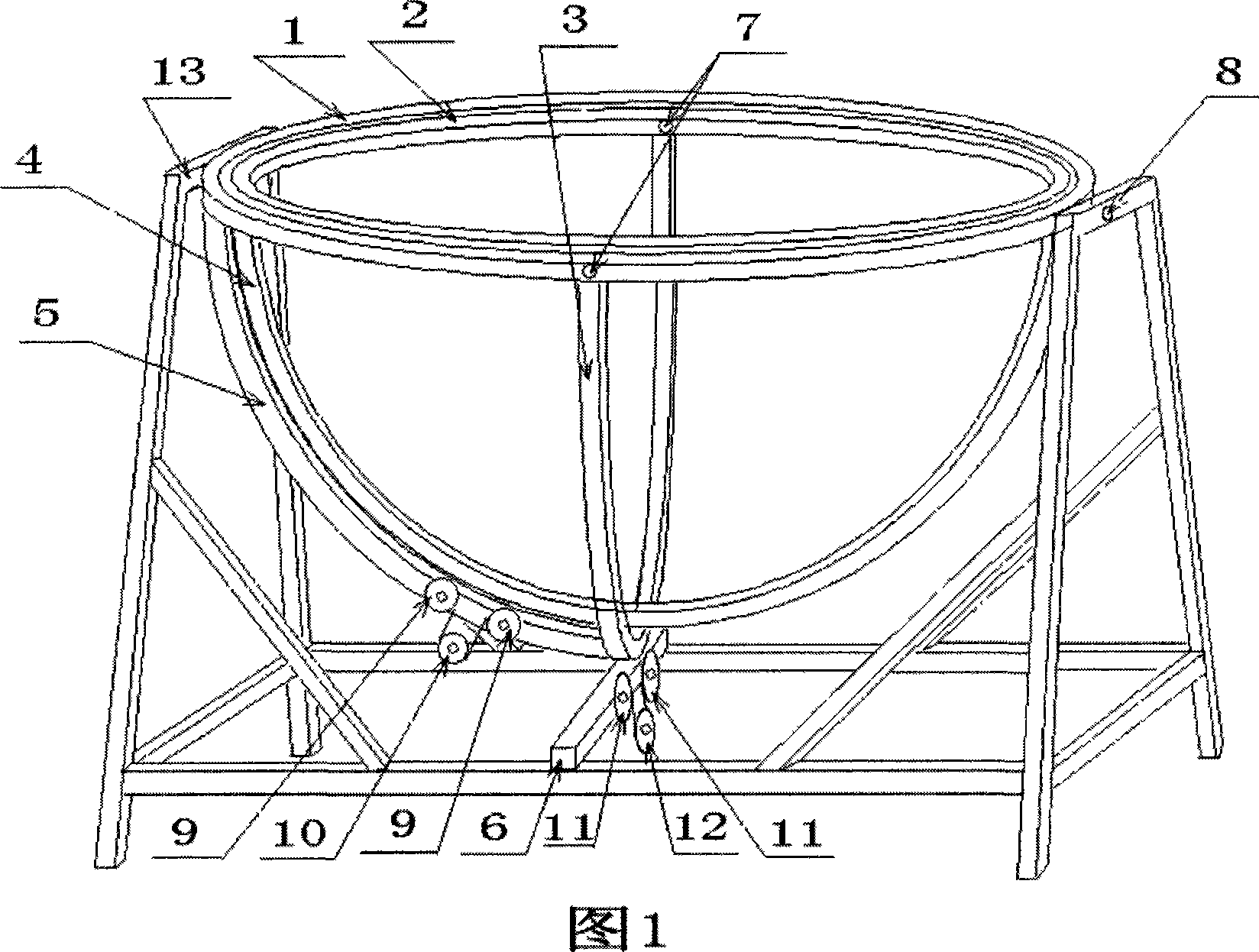

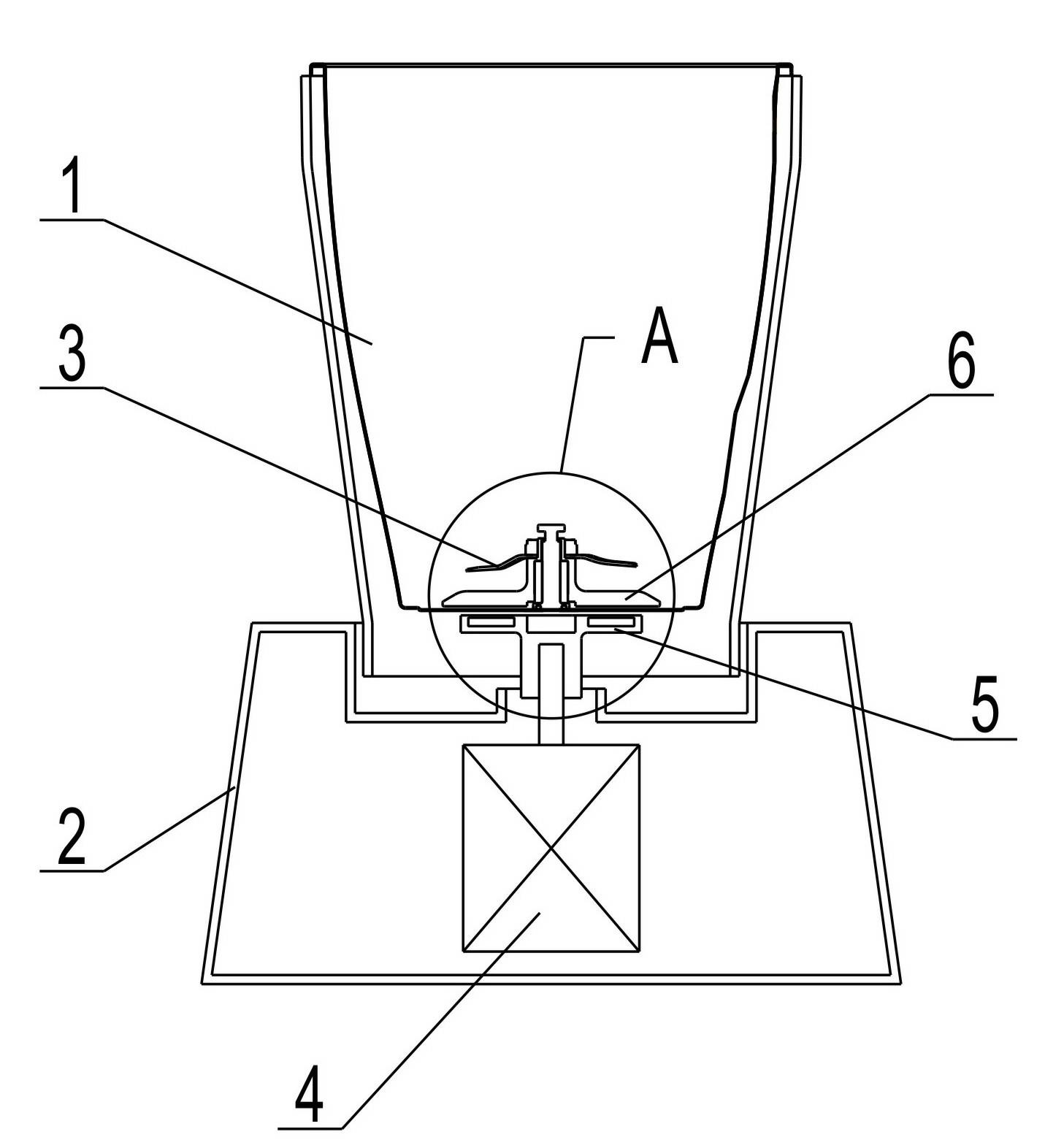

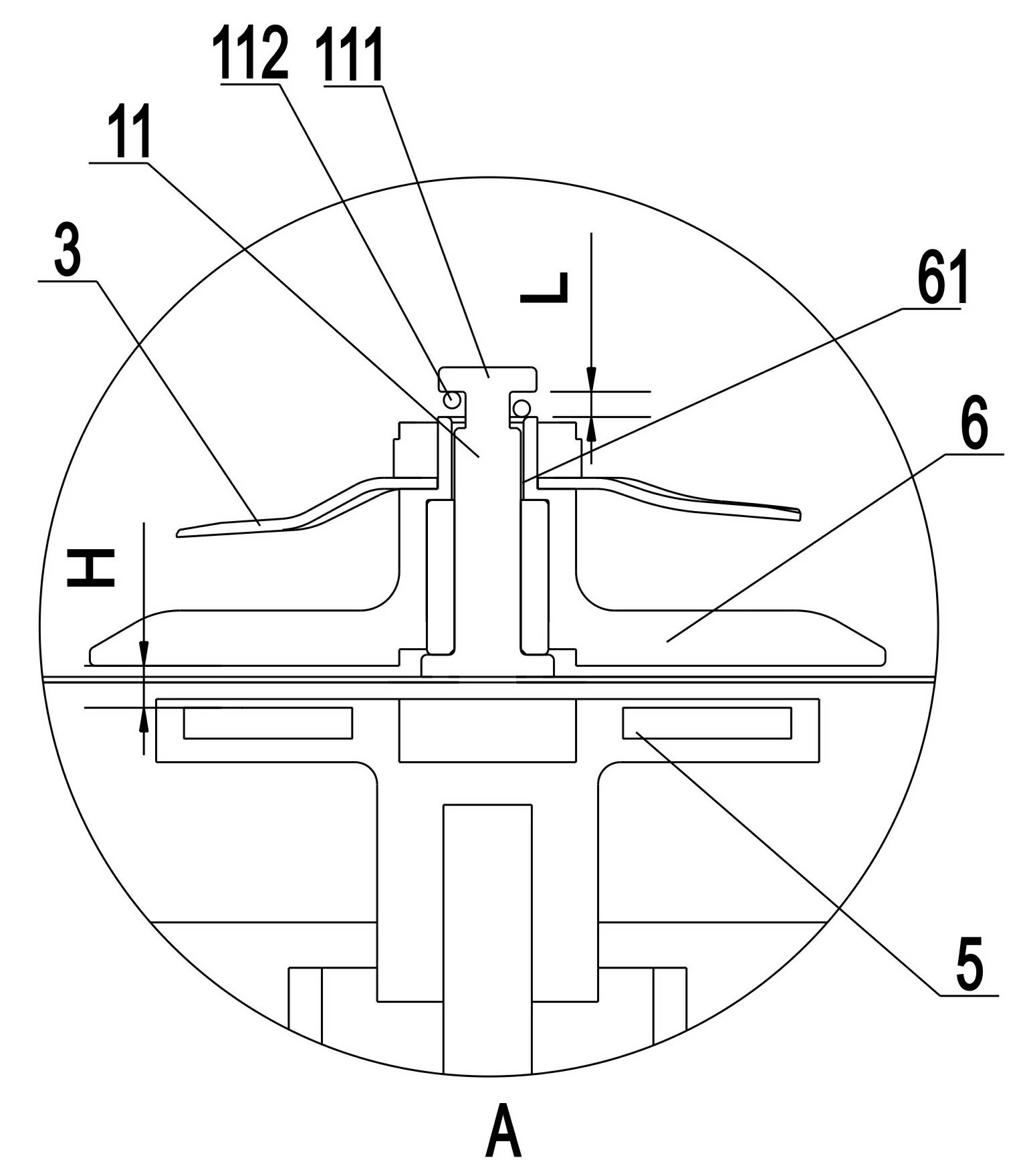

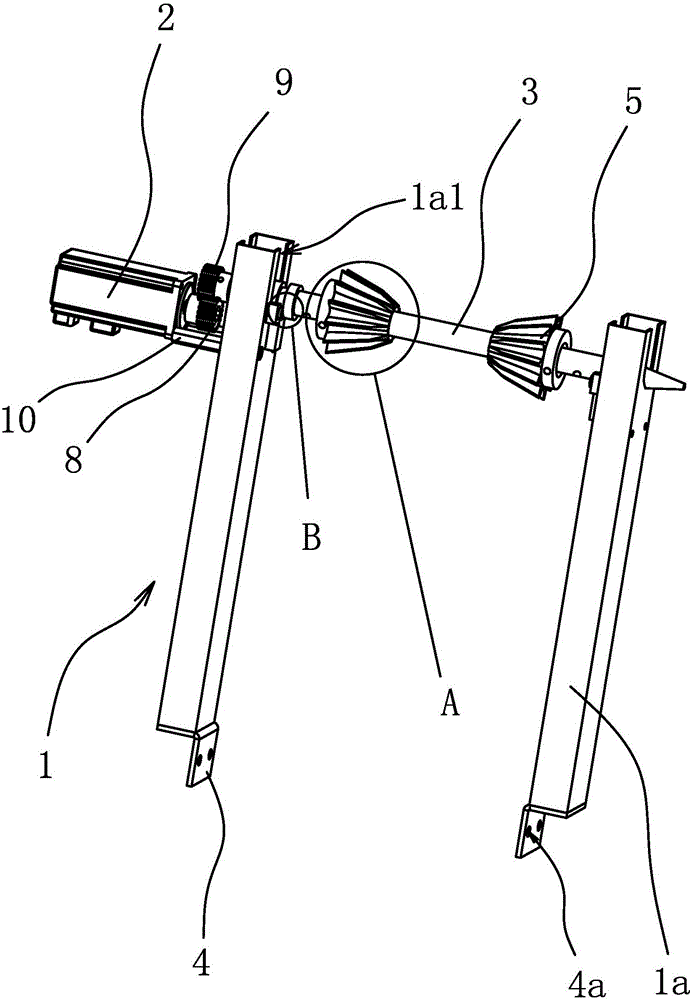

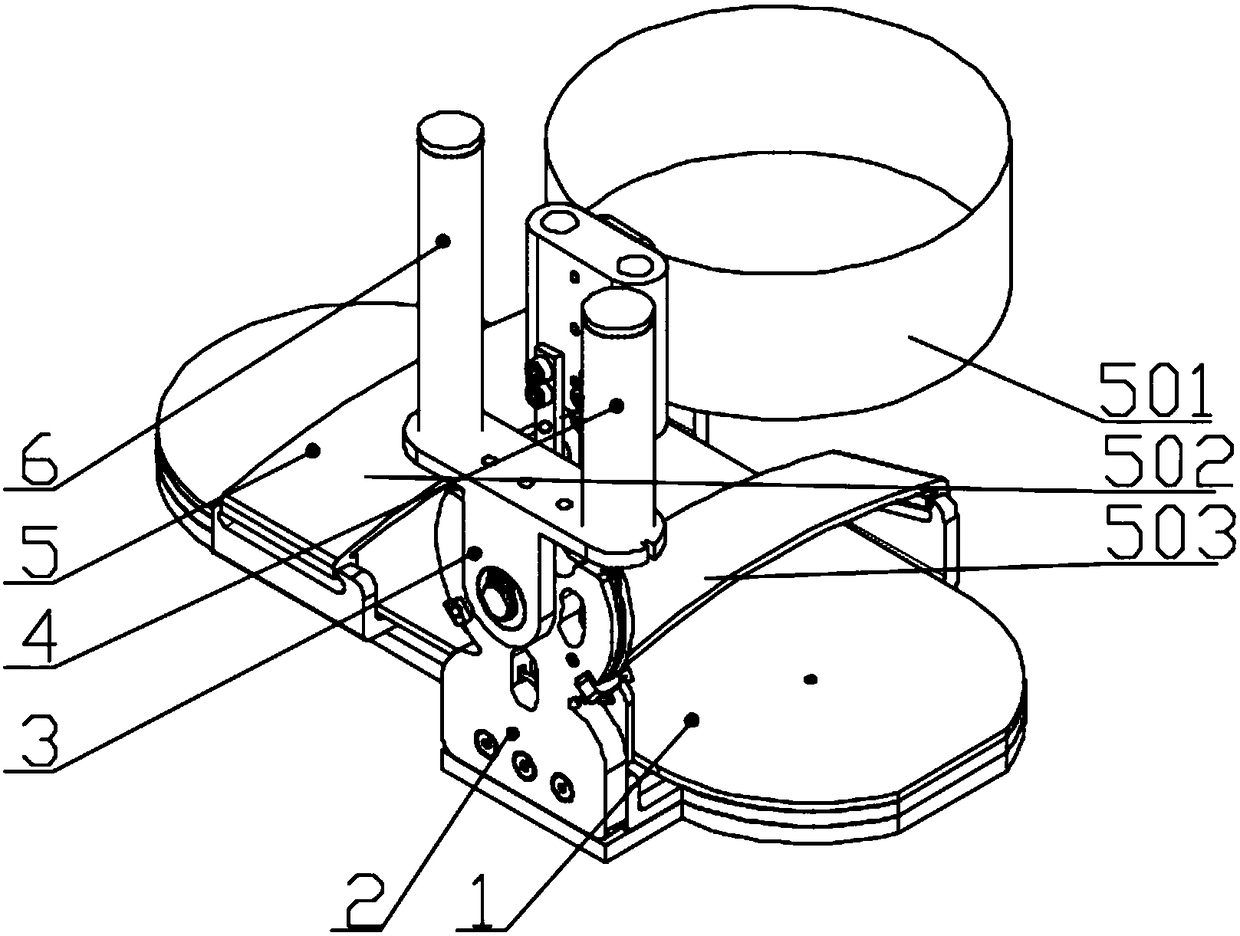

Sun tracing apparatus

InactiveCN101173826AEasy to realize real-time program controlReduce the impact of errorsPhotovoltaic supportsSolar heating energyEffect lightEngineering

The invention provides a sun-tracking device with an external rotating angle and an internal rotating angle, belonging to the technical field of solar energy utilization and track. The invention is characterized in that: an inner gimbal rotating shaft is connected with the outer gimbal, the outer gimbal rotating shaft is connected with a bracket; the inner gimbal, the outer gimbal and a fixed bolster are connected with each other through a shafting forming an outer gimbal rolling shaft which can rotate as the external rotating angle, the inner gimbal can rotate as the internal rotating angle and the external rotating angle, moreover; a rotating half wheel and a rotating driving bracket are arranged on the inner gimbal and the outer gimbal respectively, controlling the tracking trajectory in a hemispheric spherical surface range. The invention has the advantages of simple structure, low cost, strong wind resistance, suitability for concentrating light, lighting, fixing sun and other kinds of tracking, and suitability for tracking control of optics and real-time programs.

Owner:刘奇灵

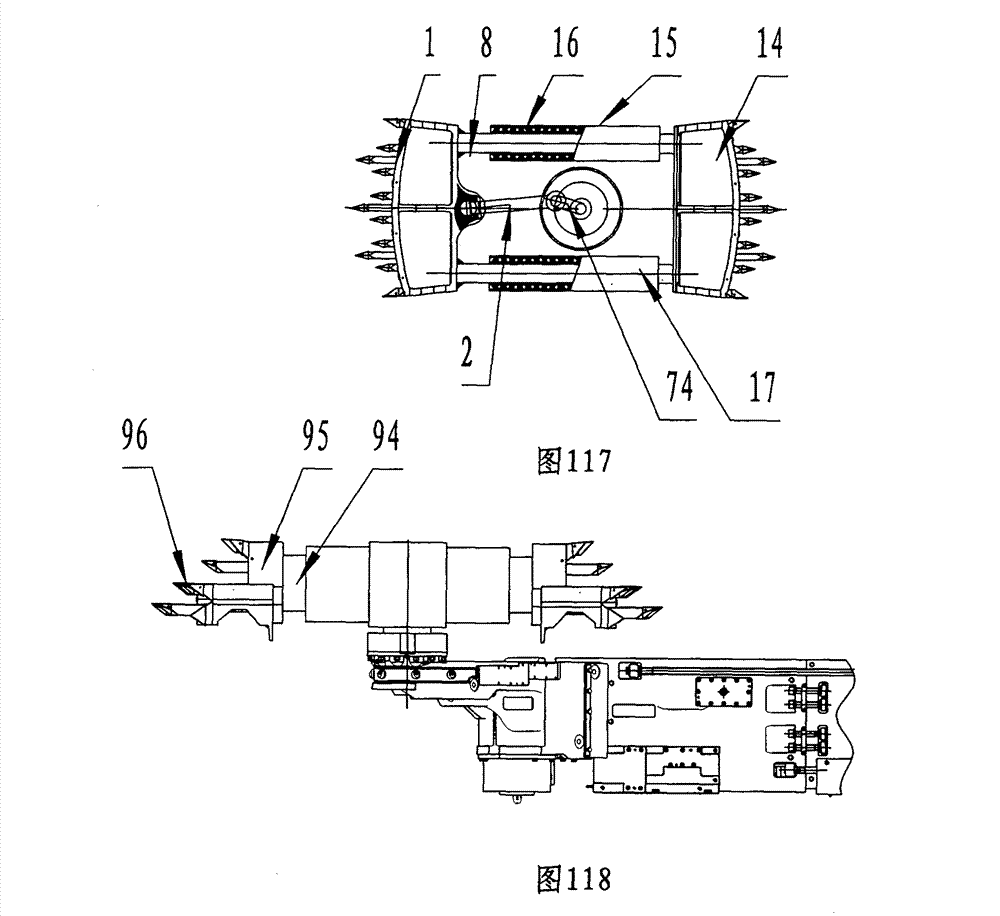

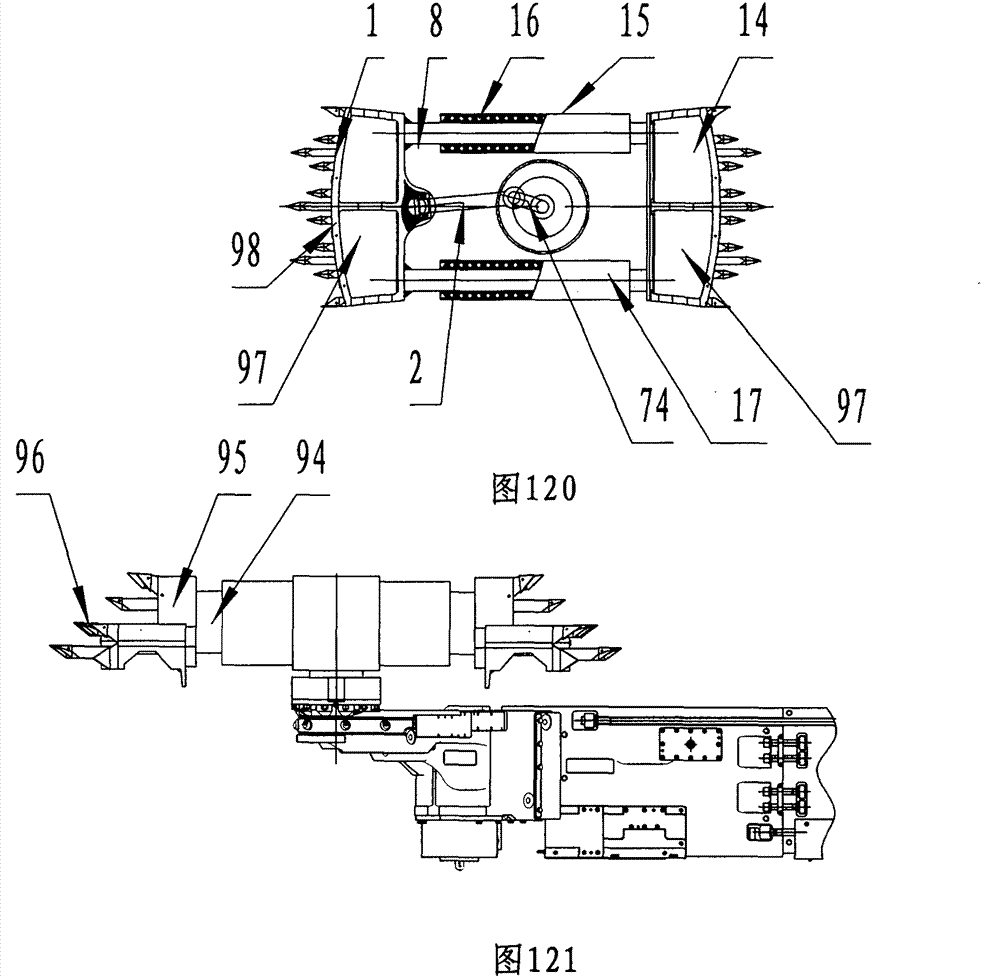

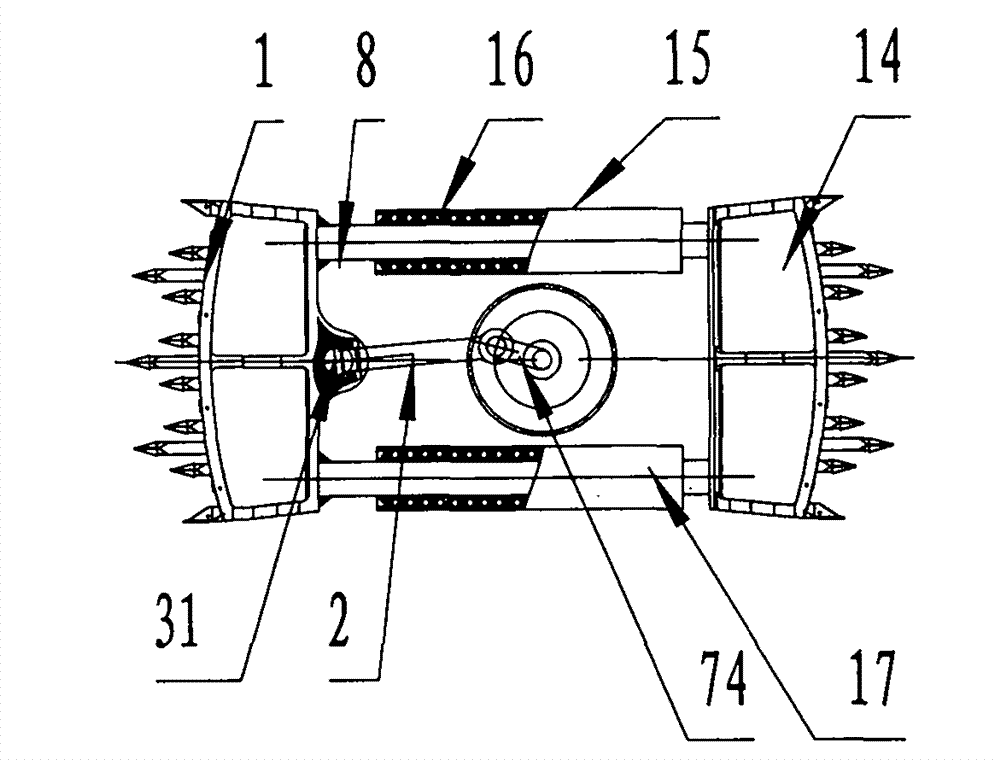

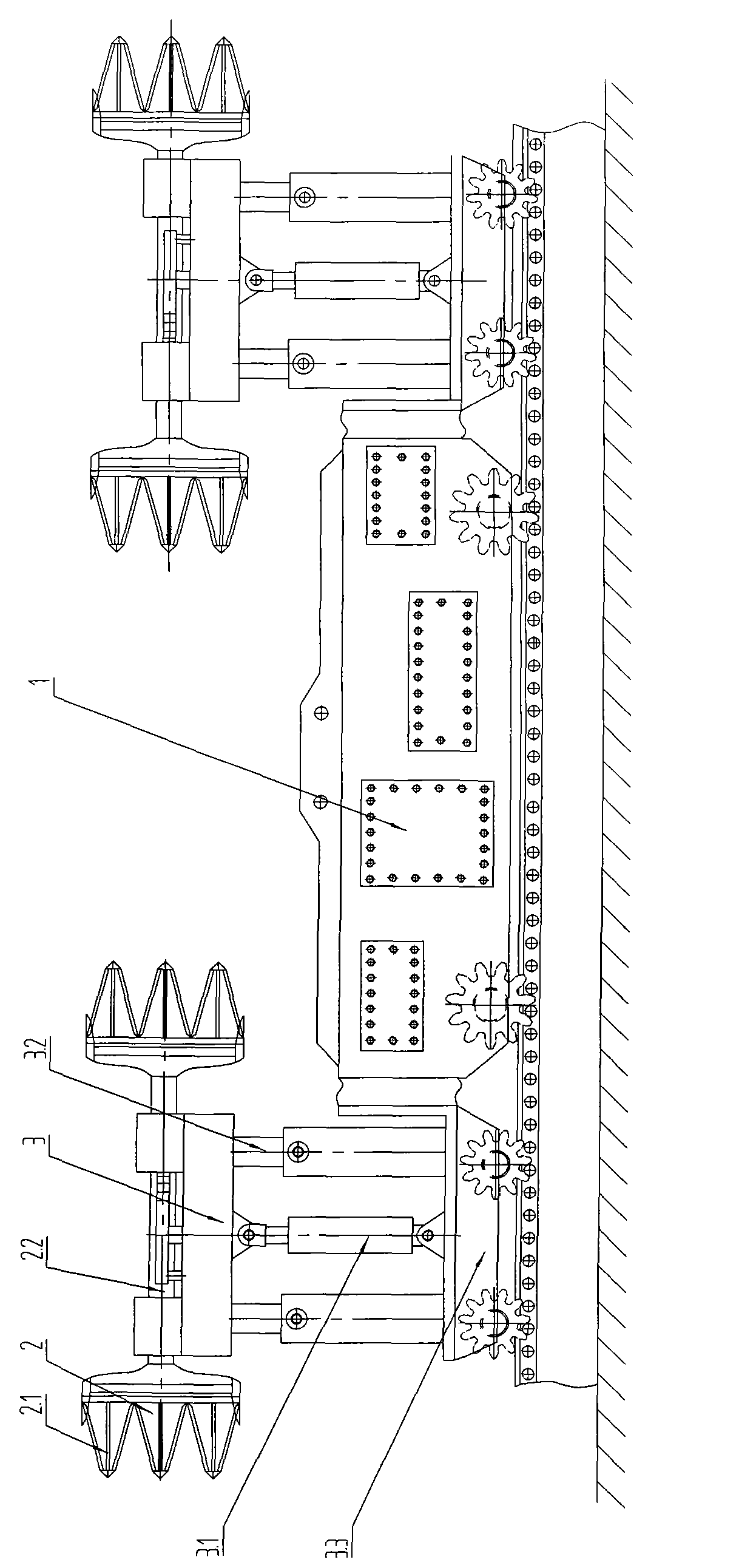

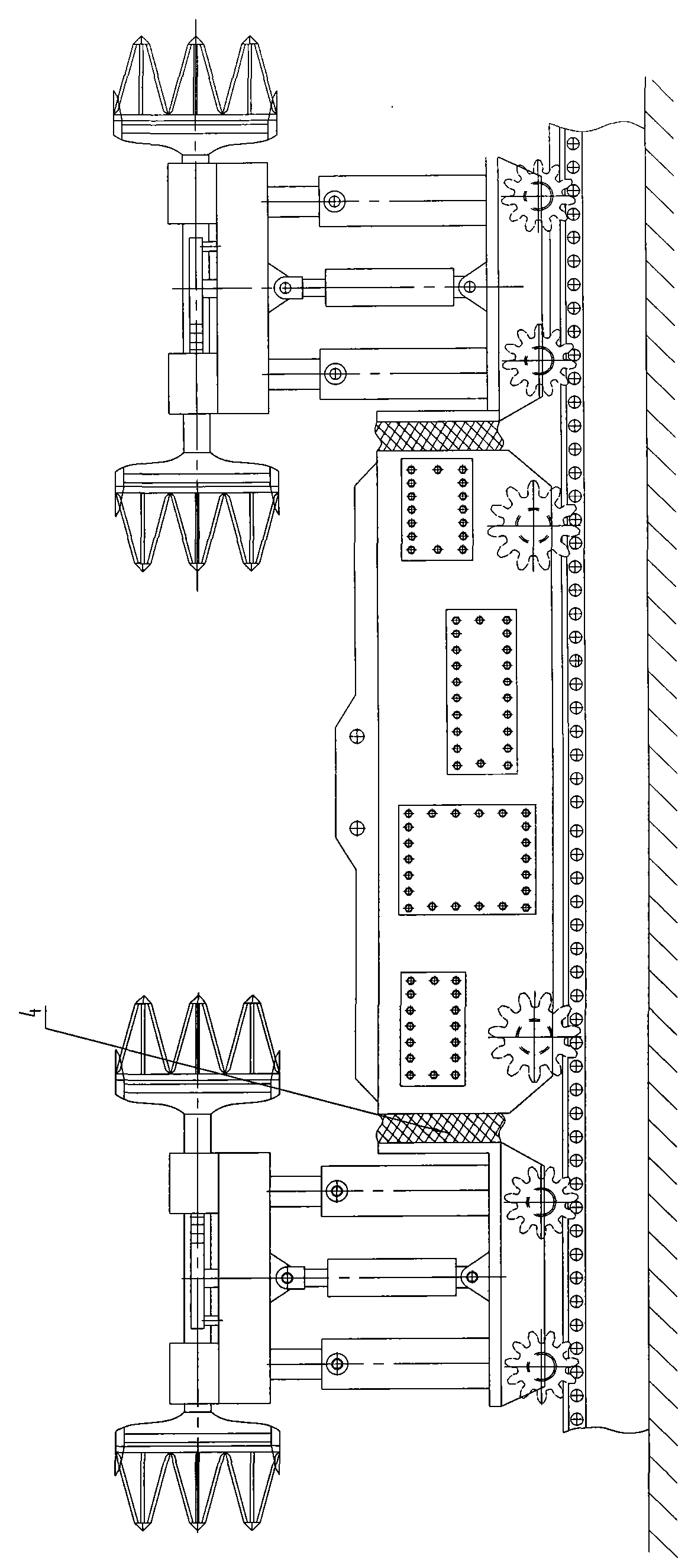

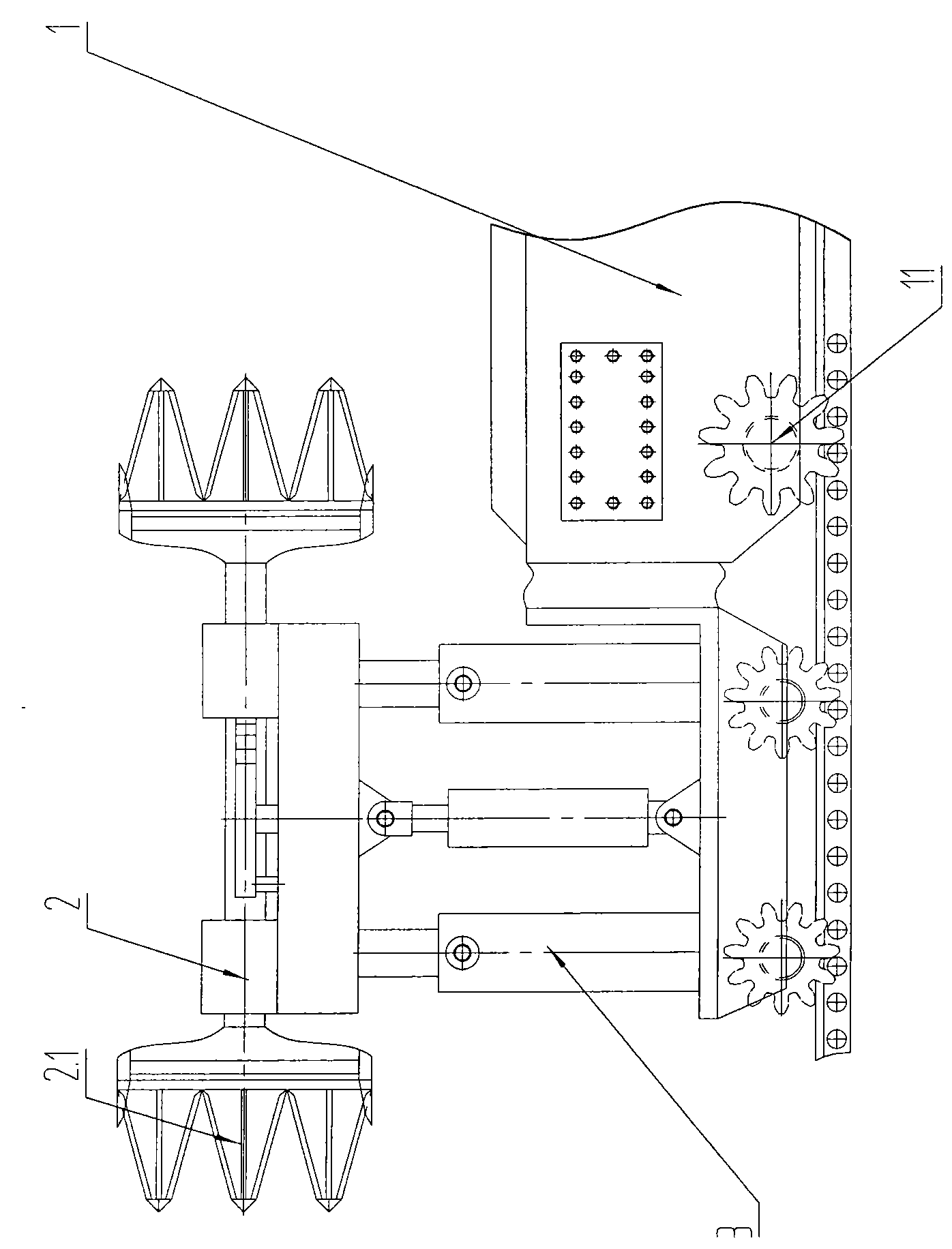

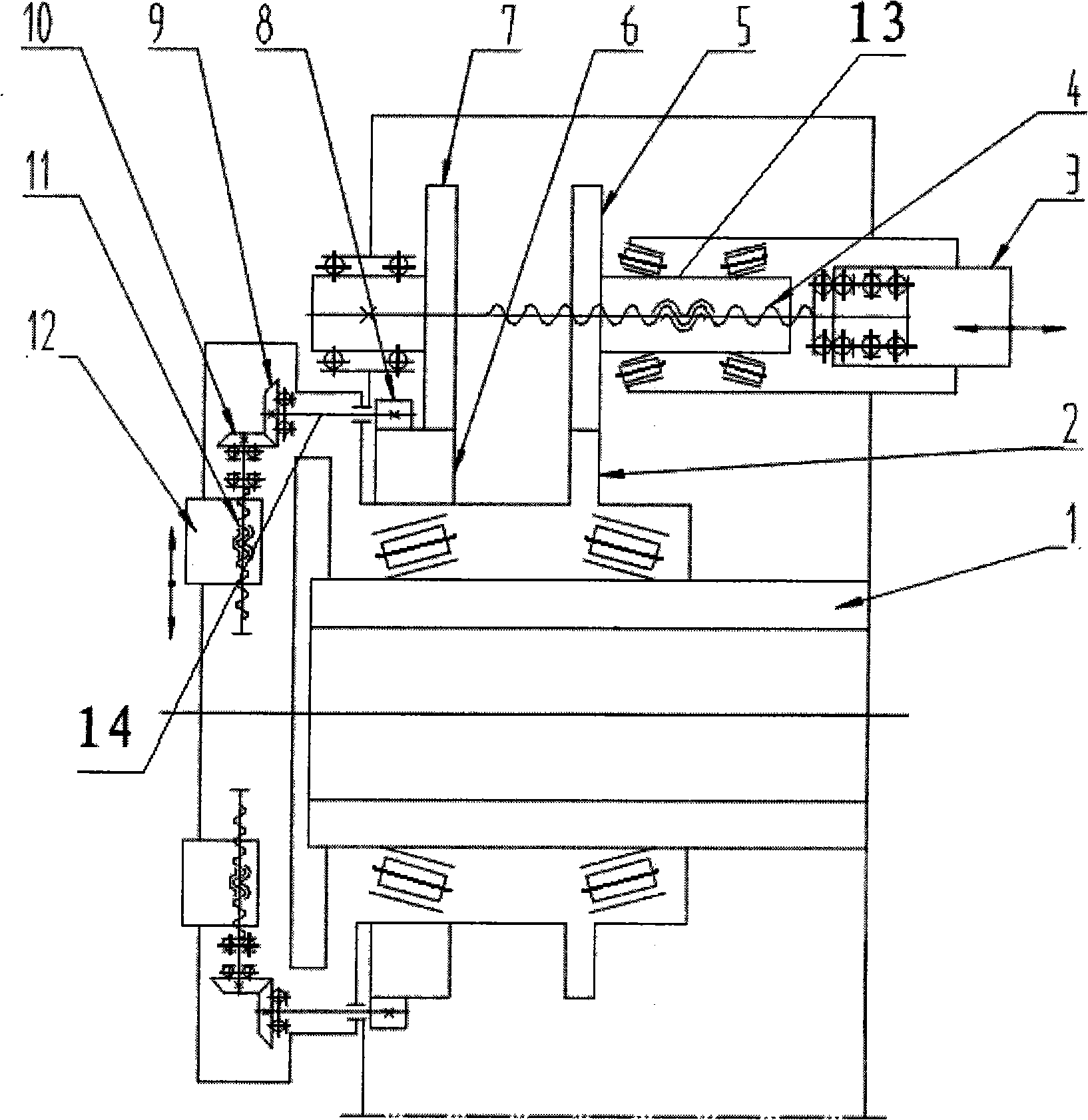

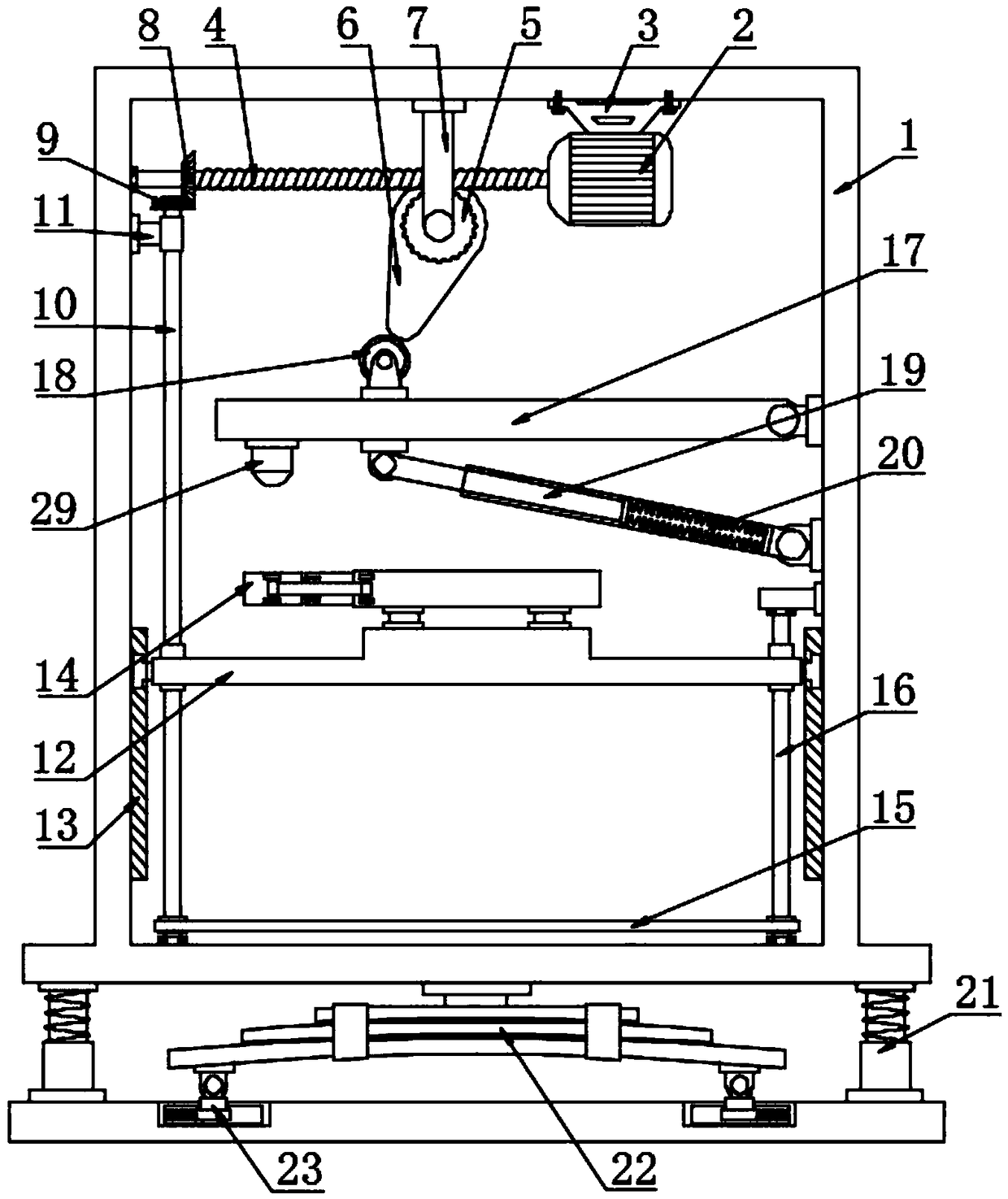

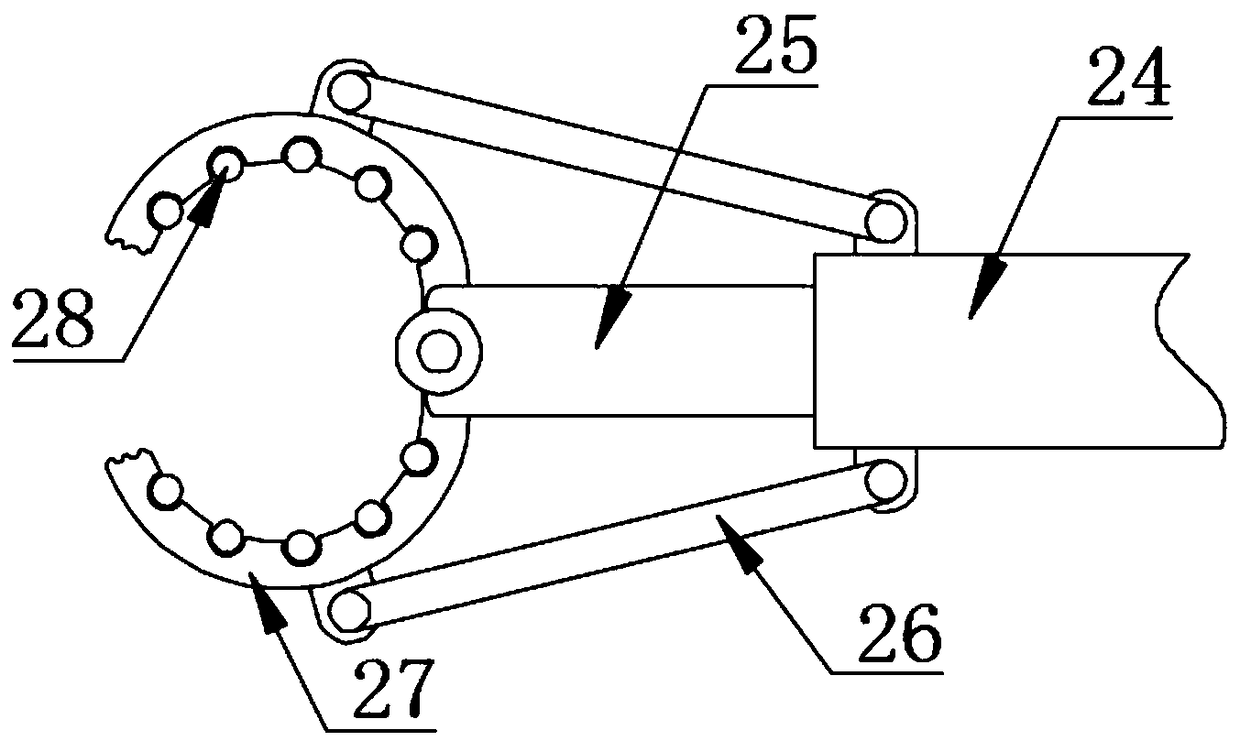

Bidirectional pounding and cutting excavating method and bidirectional pounding and cutting excavator for implementing same

ActiveCN103089259AReduce the number of adjustmentsExtend your lifeDriving meansReciprocating motionEngineering

The method provided by the invention comprises the following steps: a machine body, a walking part, a lifting part, a reciprocating pounding part and the like are arranged; a pounding guide element and the like are arranged on a pounding guide device; pounding heads are arranged at two ends of the pounding guide element, so that a power pounding element drives the pounding guide element; the reciprocating pounding part is arranged on the lifting part; the lifting part is arranged on the machine body; and the walking part drives the machine body to move ahead and retreats so as not to turn the machine body to excavate and drop materials forward and backward. Equipment provided by the invention comprises the machine body, the walking part, the lifting part, the reciprocating pounding part and the like; the reciprocating pounding part comprises the pounding guide device, the pounding driving device and the like; the pounding heads are both arranged at two ends of the pounding guide element; the pounding driving device comprises the power pounding element and the like; the power pounding element drives the pounding guide element to move in a reciprocating mode; the pounding guide element drives the pounding heads to pound; the reciprocating pounding part is arranged on the lifting part; the lifting part is arranged on the machine body; the walking part drives the machine body to move ahead and retreat so as not to turn the machine body to excavate and drop materials forward and backward.

Owner:刘素华

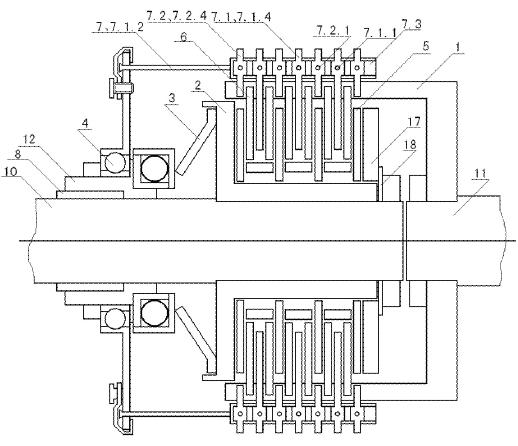

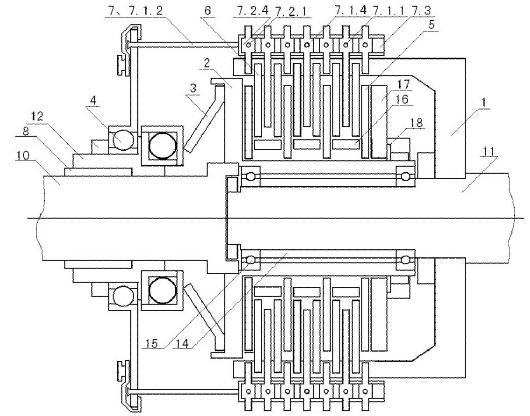

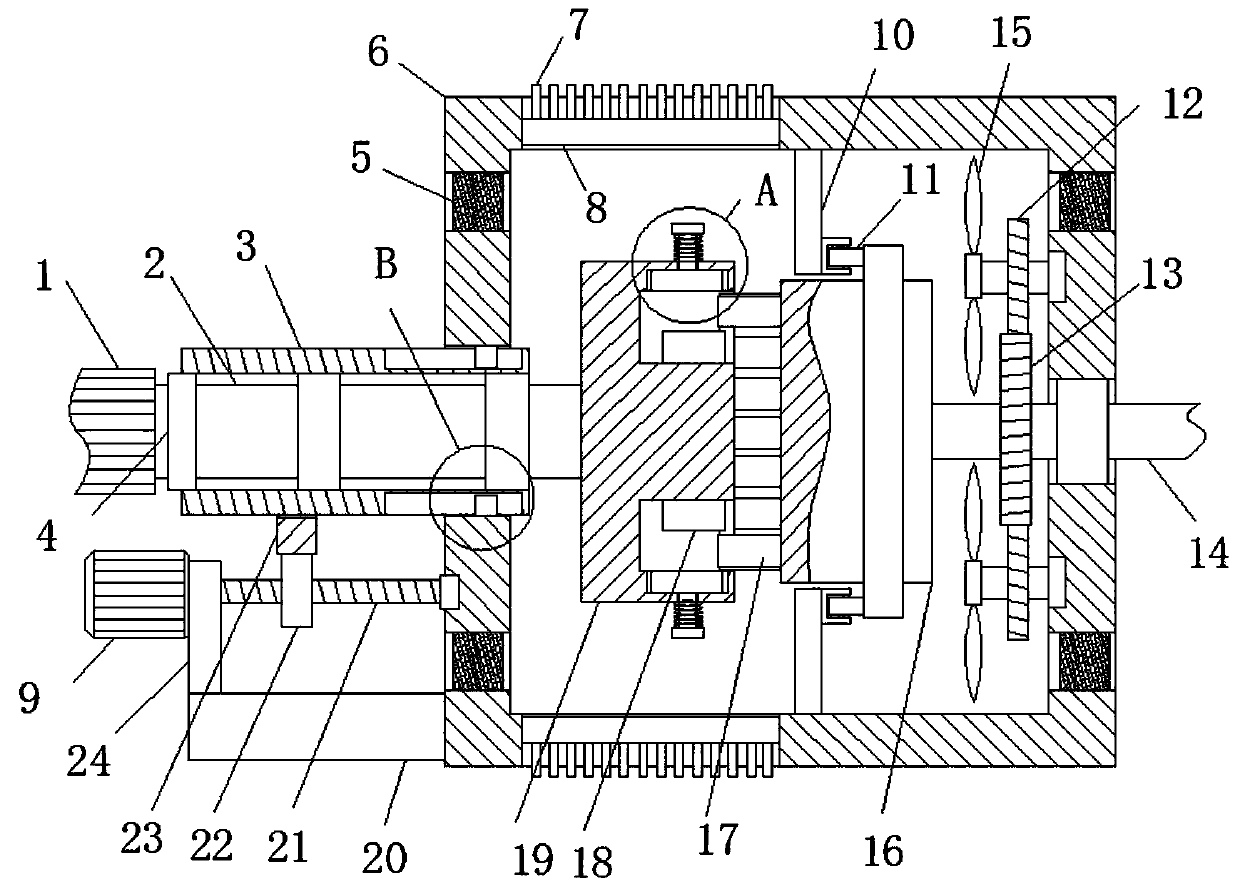

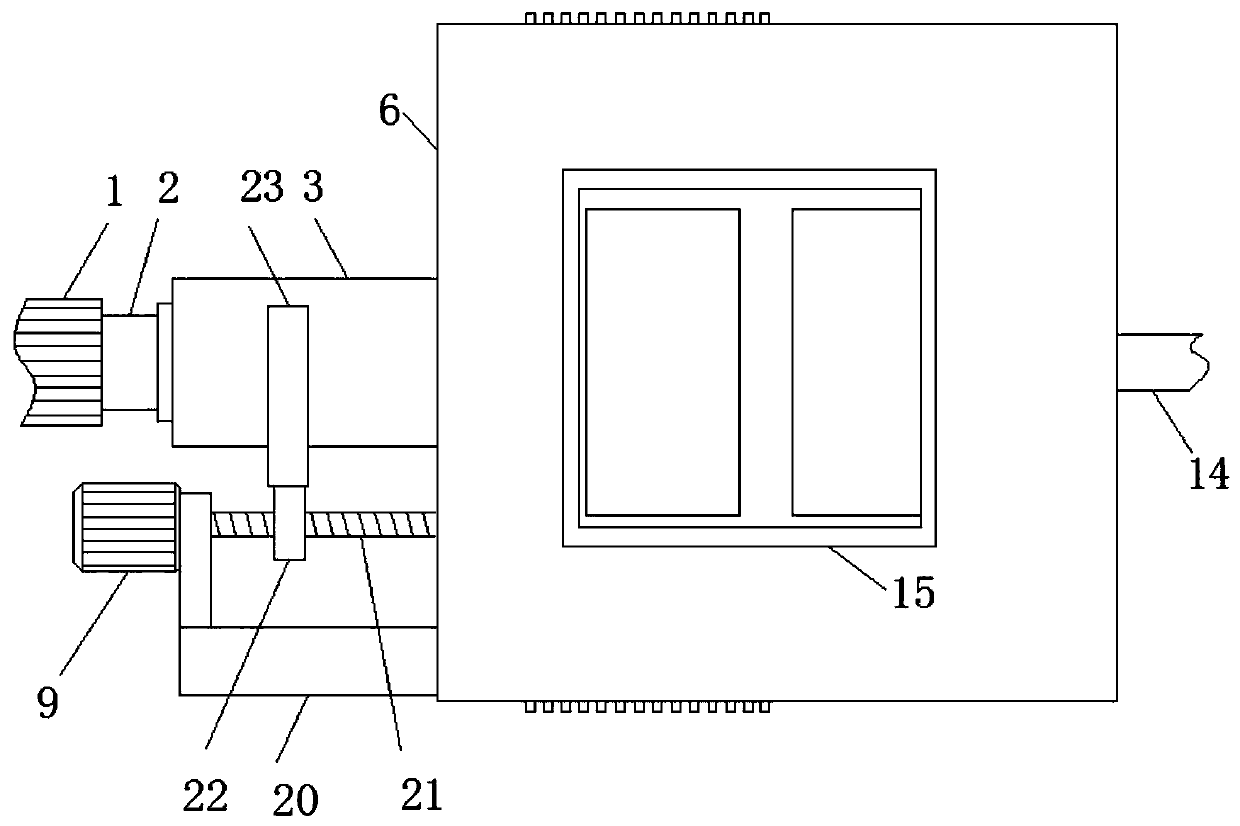

Gear engaging drive stepless speed changer

InactiveCN101435493ANo shifting noiseLarge transmission torqueGearingPortable liftingEngineeringControl theory

The invention relates to a mechanical type continuously variable transmission device. In the tooth meshing transmission non-stage transmission, two increasing-decreasing gears with gear diameters which are variable as required are used as speed ratio changers, when the gear diameter of one increasing-decreasing gear increases, the gear diameter of the other increasing-decreasing gear decreases the same length correspondingly at the same time, and the two gears are driven by the meshing of a toothed chain. The non-stage transmission overcomes the defects of the friction type continuously variable transmission (CVT) such as small drive moment, chain and wheel slippage, small starting moment, high gear shift power consumption, and really realizes the stepless speed change of tooth meshing transmission. The tooth meshing transmission non-stage transmission has the advantages of big drive torsional moment, small volume, and simple structure, and can be applied to various large and small-sized machines in large and small-sized vehicles or fixed occasions.

Owner:金哲根

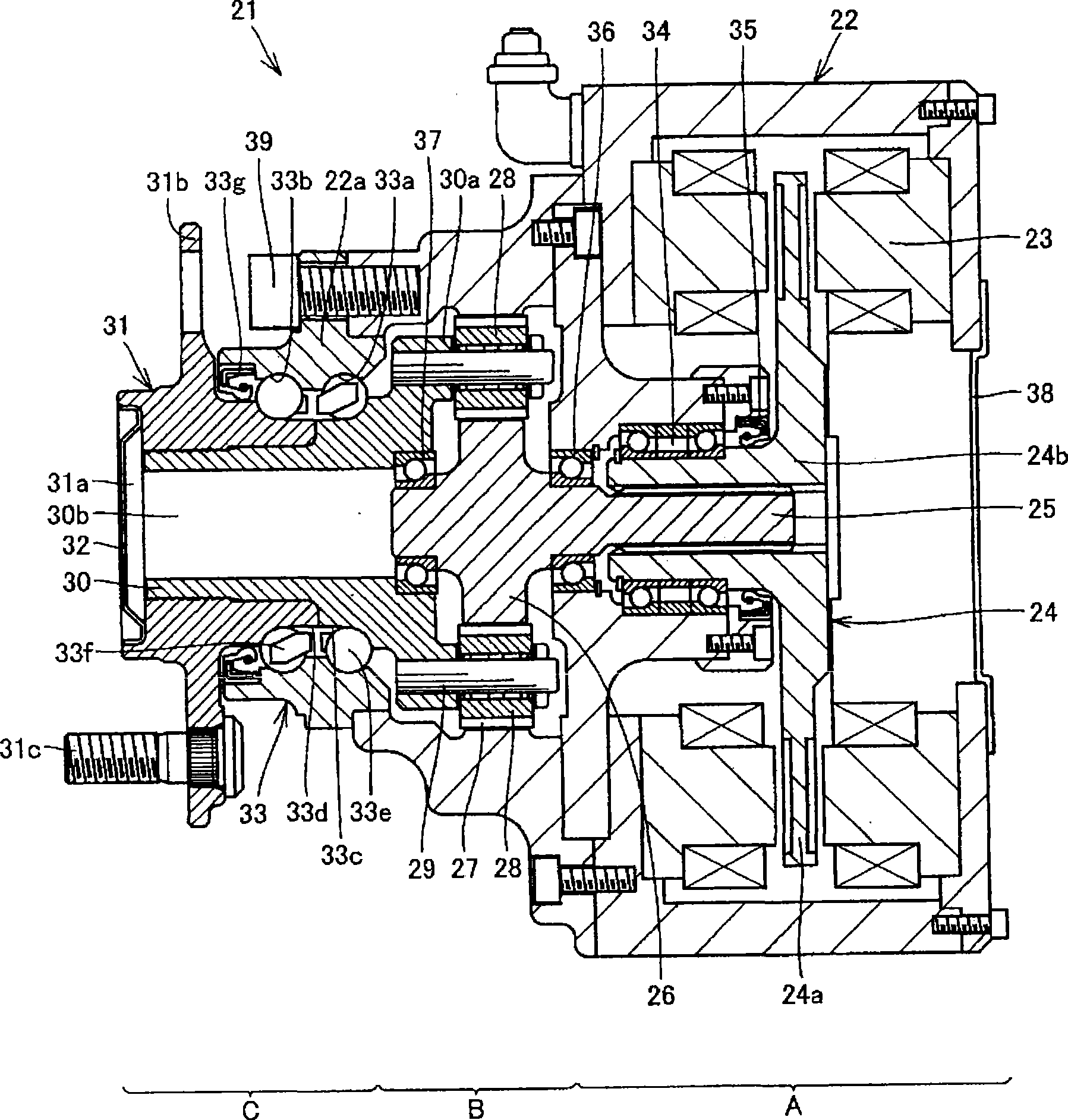

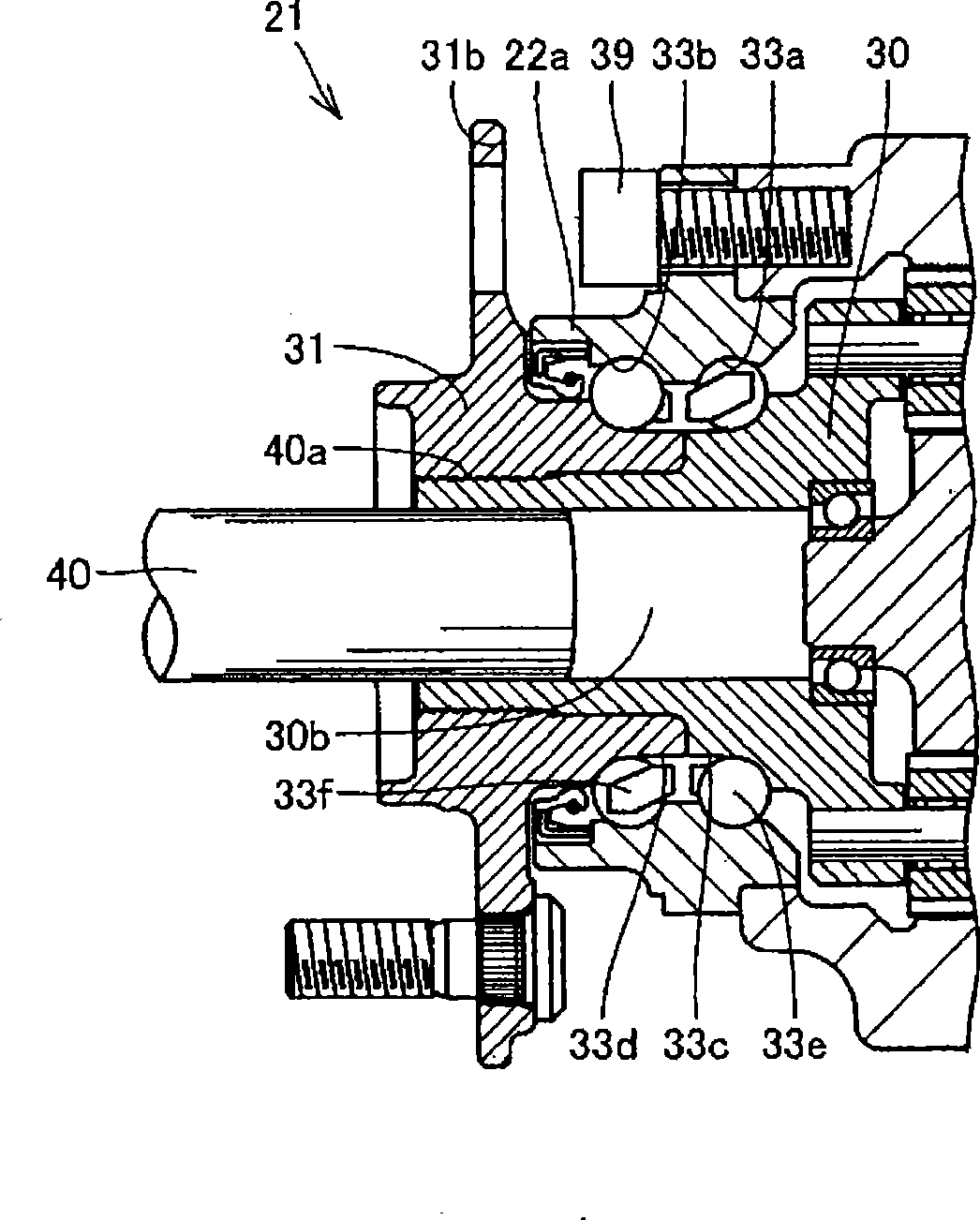

In-wheel motor drive unit

InactiveCN101395404ALarge transmission torqueRolling contact bearingsToothed gearingsEngineeringMotor Drive Unit

An in-wheel motor drive unit (21) comprising a casing (22), a motor unit (A), a decelerating unit (B), a wheel hub (31), and a wheel hub bearing (33) for rotataly supporting the wheel hub (31) on the casing (22). The wheel hub bearing (33) includes first and second outside raceway surfaces (33a, 33b) provided on the inner diameter surface of the casing (22), a first inside raceway surface (33c) provided on the outer diameter surface of a wheel-side rotating member (30) to face the first outside raceway surface (33a), a second inside raceway surface (33d) provided on the outer diameter surface of the wheel hub (31) to face the second outside raceway surface (33b), and a plurality of rolling elements (33e) disposed between the outside raceway surfaces (33a, 33b) and the inside raceway surfaces (33c, 33d).

Owner:NTN CORP

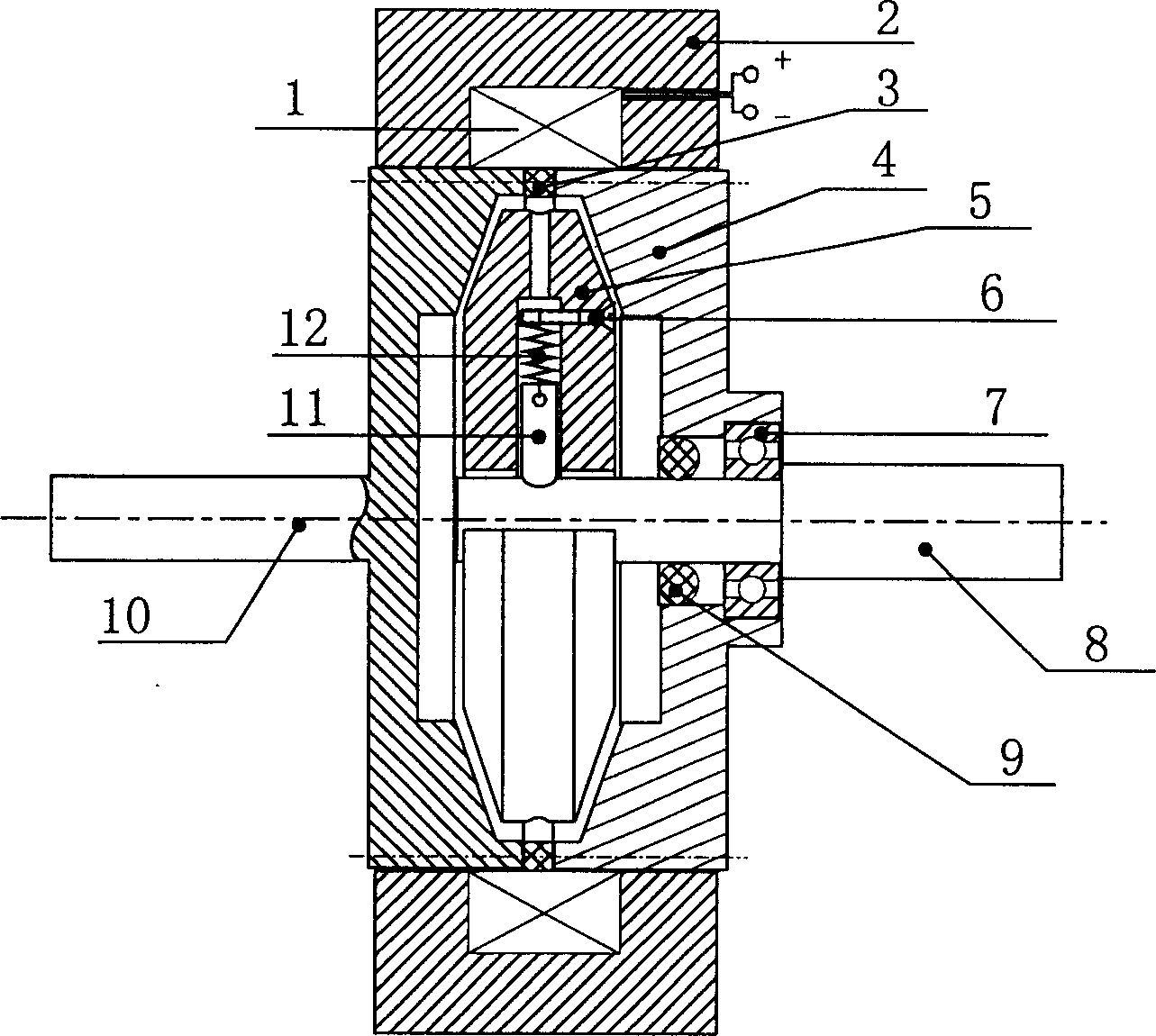

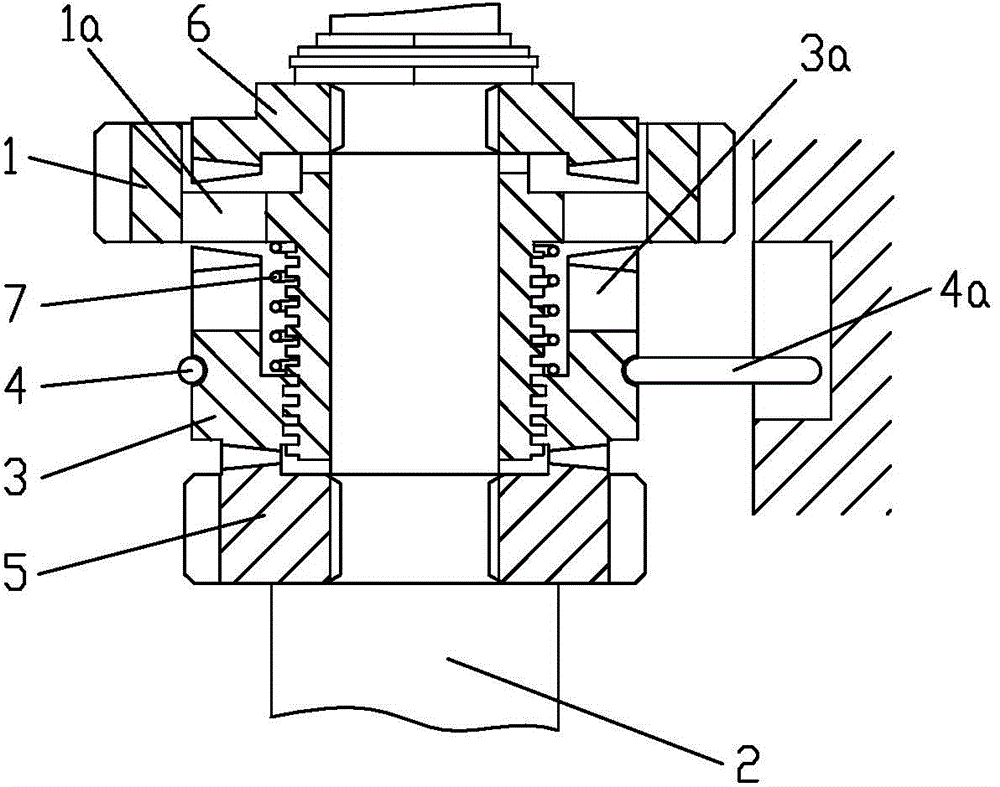

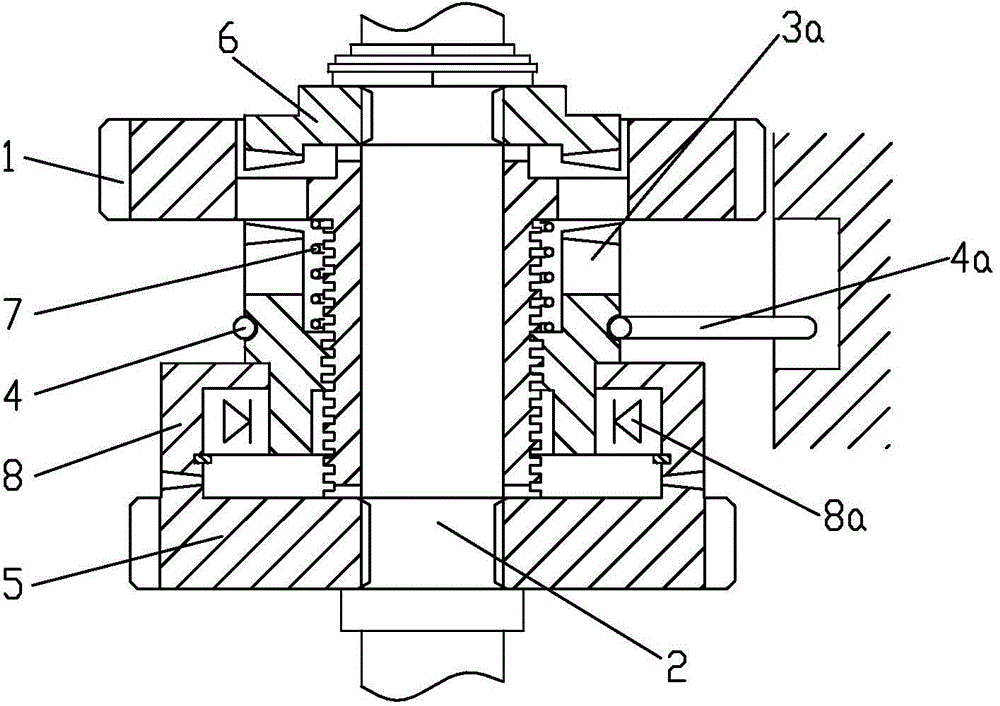

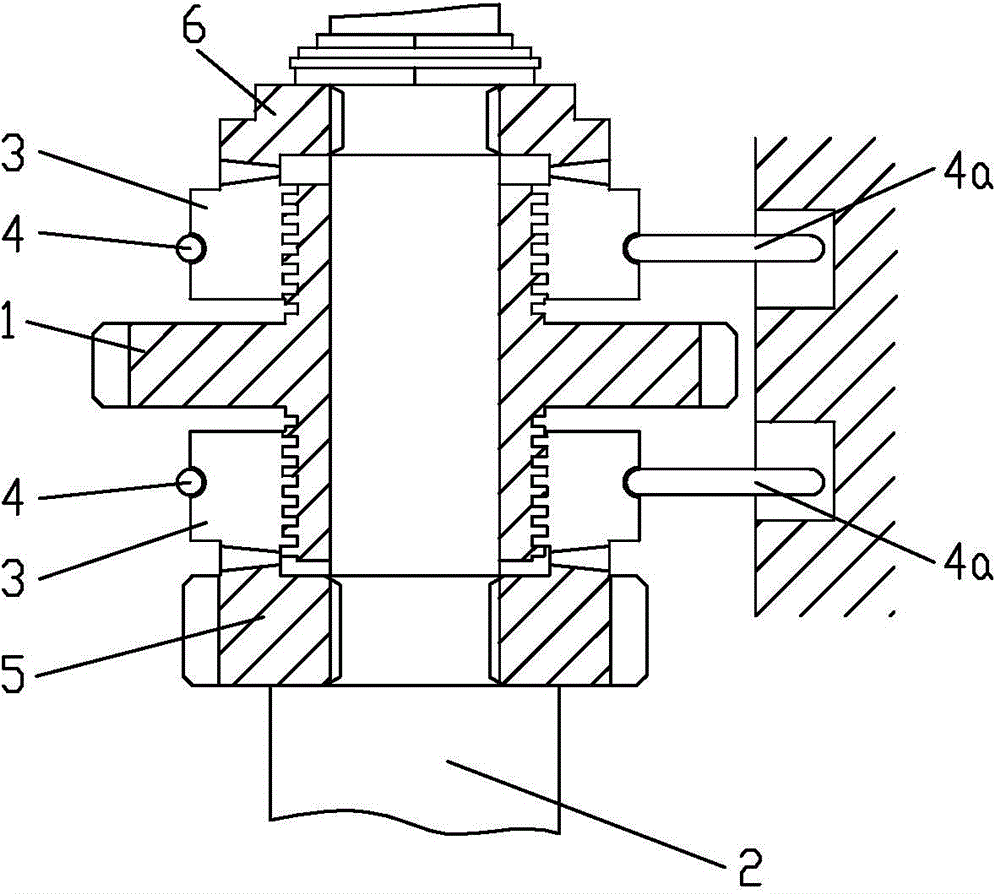

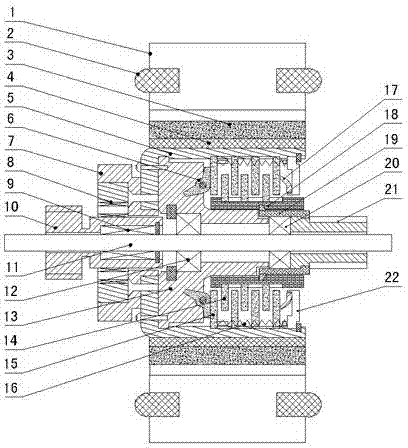

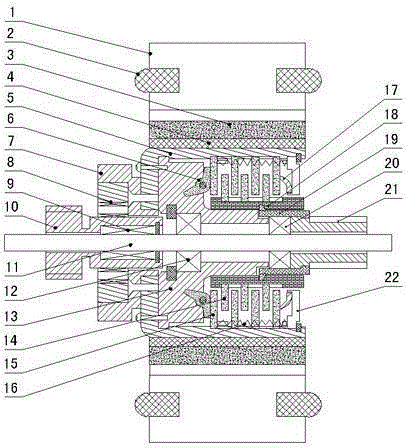

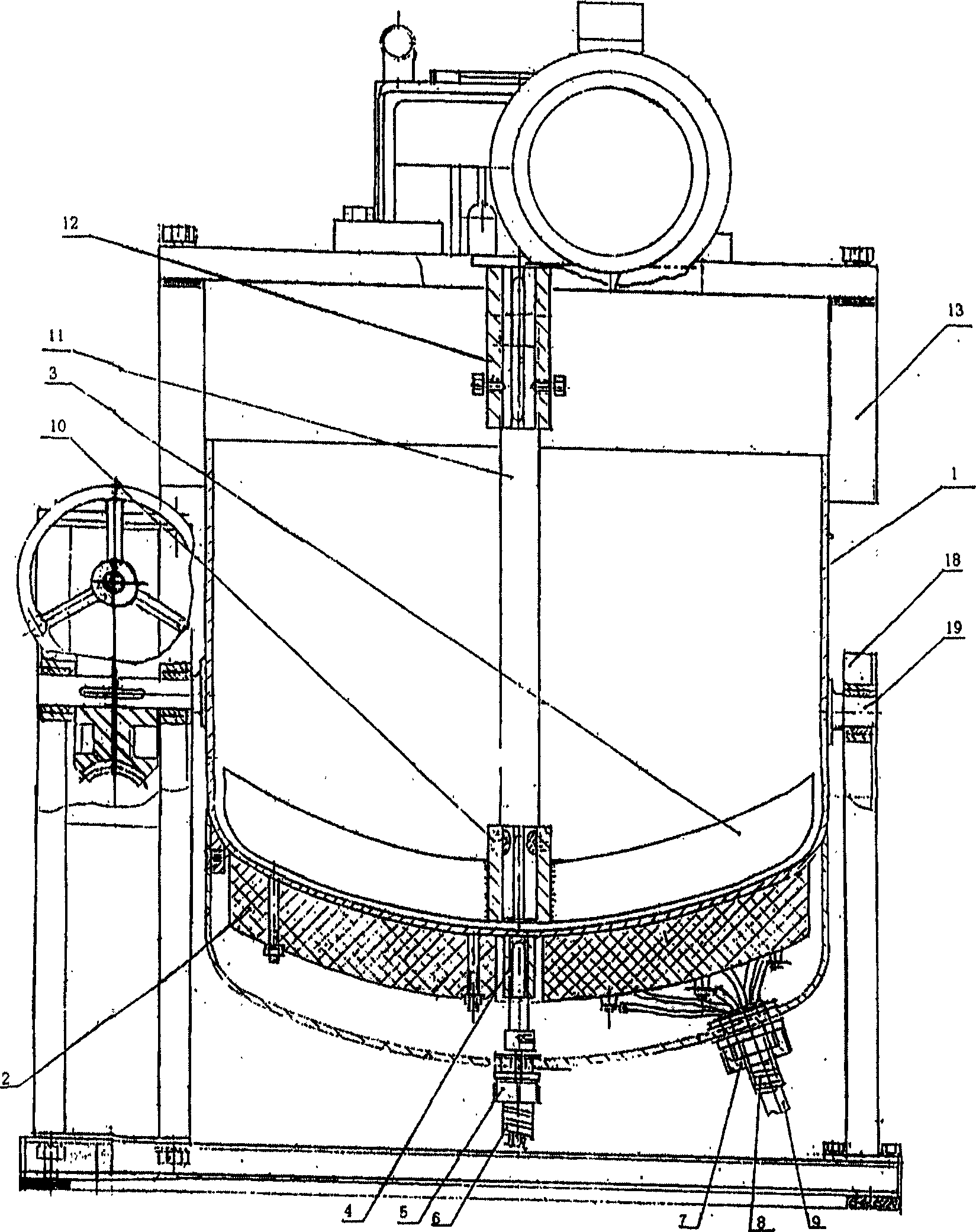

End Tooth Electromagnetic Clutch

InactiveCN102287458AQuick conversionAccurate conversionMagnetically actuated clutchesElectromagnetic clutchTorque transmission

The invention belongs to the technical field of electromagnetic clutches, and relates to an end tooth electromagnetic clutch. The end-tooth electromagnetic clutch includes a driving part and a driven part. The clutch claw, armature flange, and spring are composed of an end gear ring, a magnetic isolation ring, and a core shaft to assemble an end gear shaft, which is set in two 6807 bearings, axially positioned by a retaining ring, and assembled in the inner hole of the yoke. The coil wrapped by insulating paper is placed in the coil groove of the yoke; the armature flange is riveted in the end tooth clutch claw with a hollow pin, and the spring is set on the screw. The end-tooth electromagnetic clutch adopts end-tooth gear connection to transmit power. It has the advantages of simple structure, convenient installation and maintenance, and high transmission ratio precision, which effectively ensures the fast and accurate conversion of mechanical energy in industrial production and the transmission of torque.

Owner:王万年

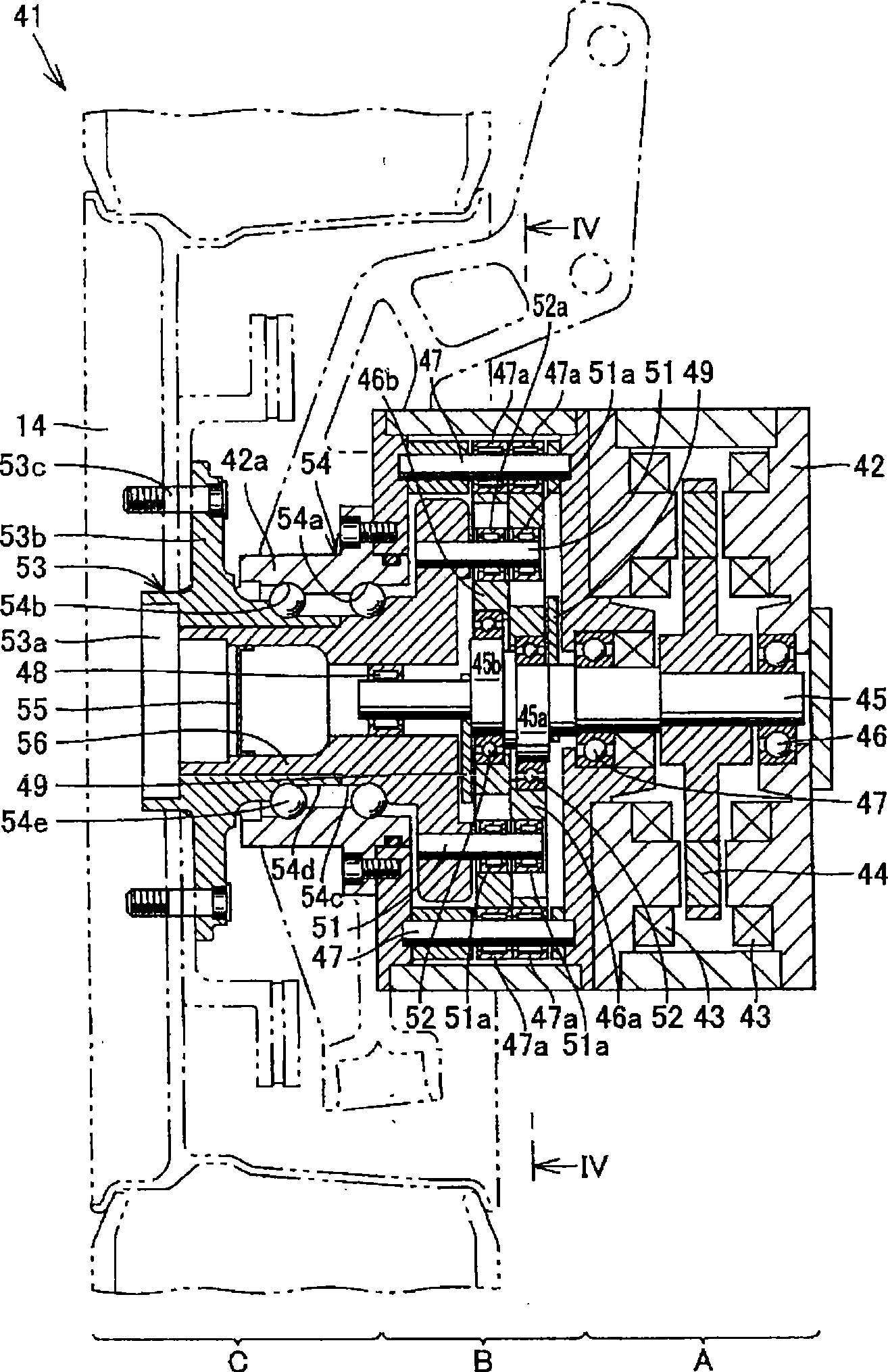

Bidirectional overrunning clutch, speed control device and automatic speed control system

ActiveCN104806656ASmall cross-sectional sizeImprove transmission efficiencyToothed gearingsFreewheel clutchesLow speedAutomatic transmission

The invention discloses a bidirectional overrunning clutch, a speed control device and an automatic speed control system. The bidirectional overrunning clutch comprises a disc-shaped driving part, wherein the disc-shaped driving part can rotatably sleeve a shaft-shaped driven part; a spiral spline sleeve is in spiral spline fit with a journal of the driving part, and a braking device which is used for applying frictional resistance to the spiral spline sleeve is connected to the spiral spline sleeve; a first end surface engagement clutch structure and a second end surface engagement clutch structure are formed between the spiral spline sleeve and the driven part, and the first end surface engagement clutch structure and the second end surface engagement clutch structure are respectively used only for the spiral spline sleeve to drive the driven part to synchronously rotate clockwise and anticlockwise; a bidirectional clutch structure is formed between high and low-speed driven gears of the speed control device and the automatic speed control system. The bidirectional overrunning clutch has the beneficial effects of small cross-sectional dimension, convenience in application, high mechanical efficiency, strong loading capability and long service life; two-gear automatic transmission and reverse output can be realized by the speed control device.

Owner:傅元才

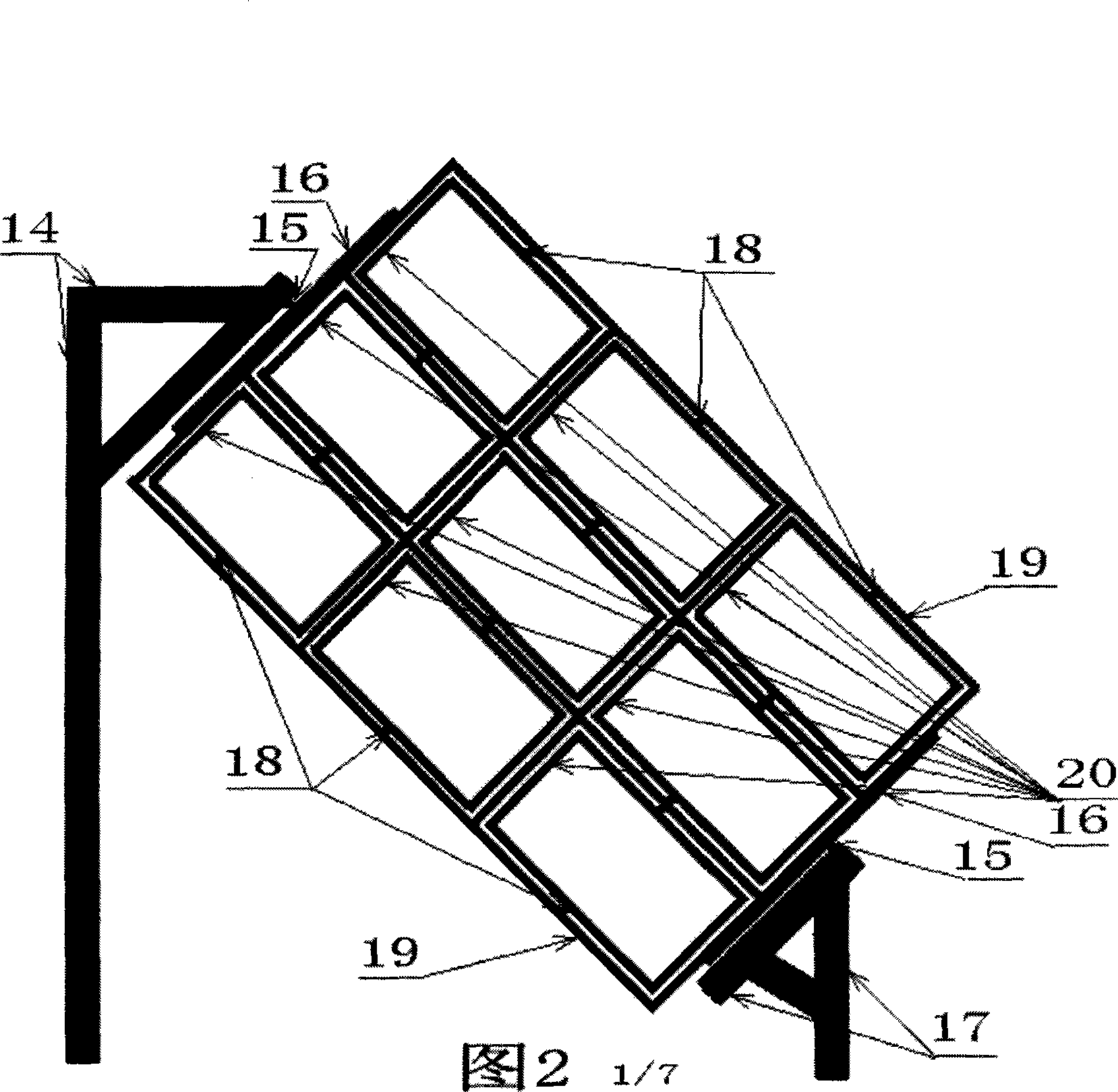

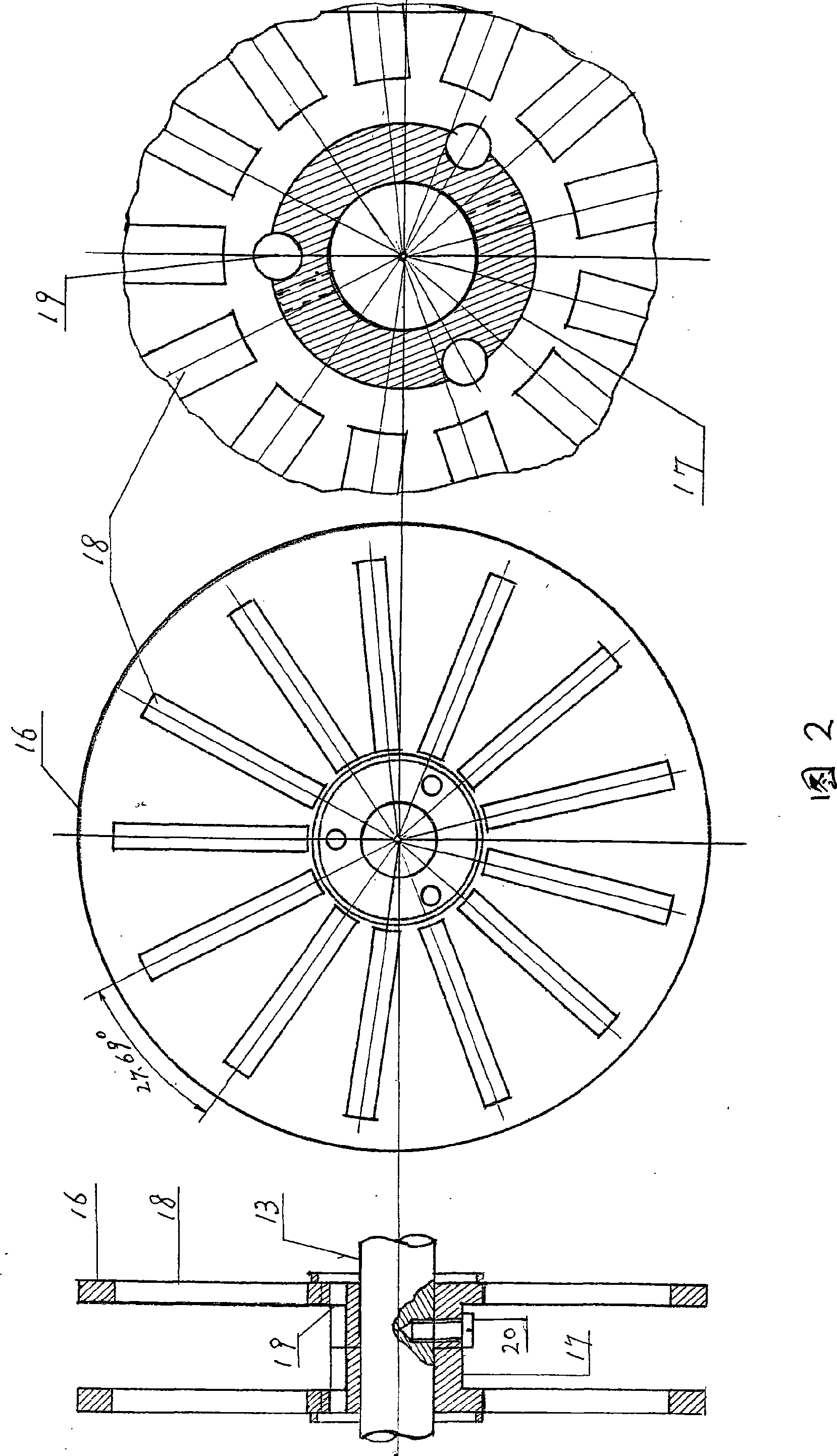

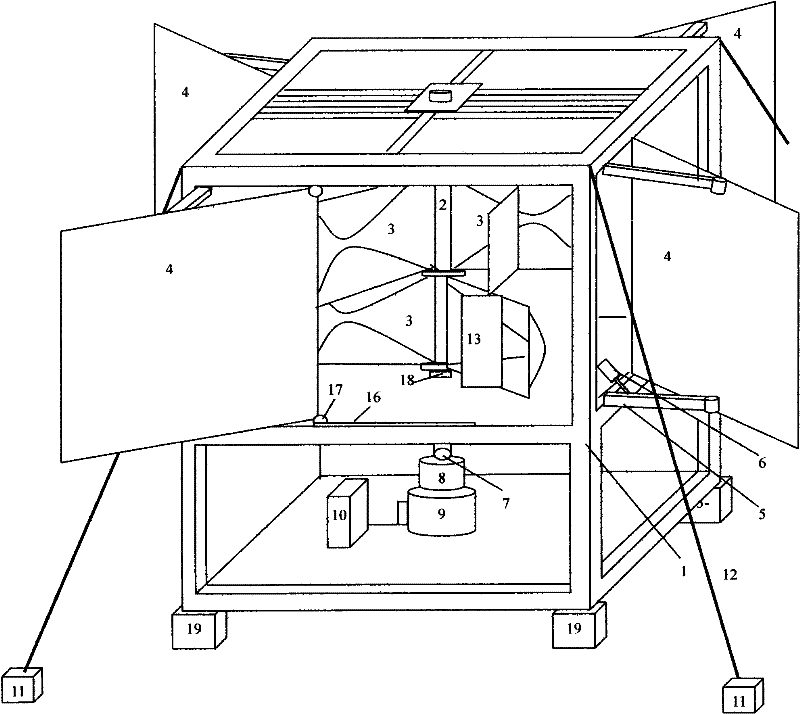

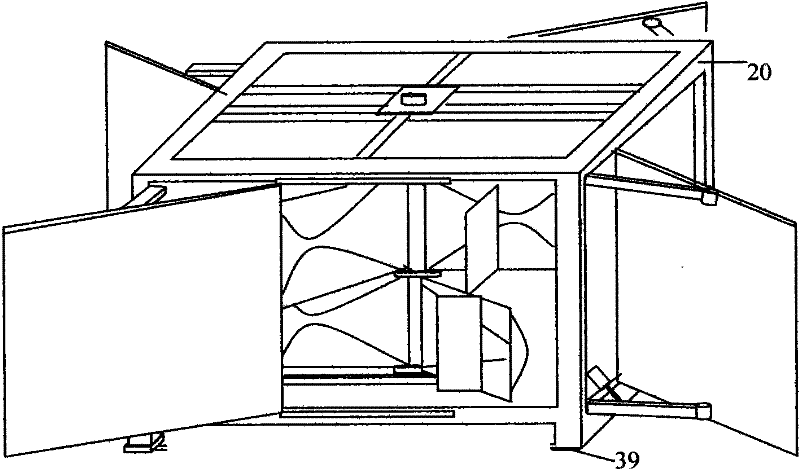

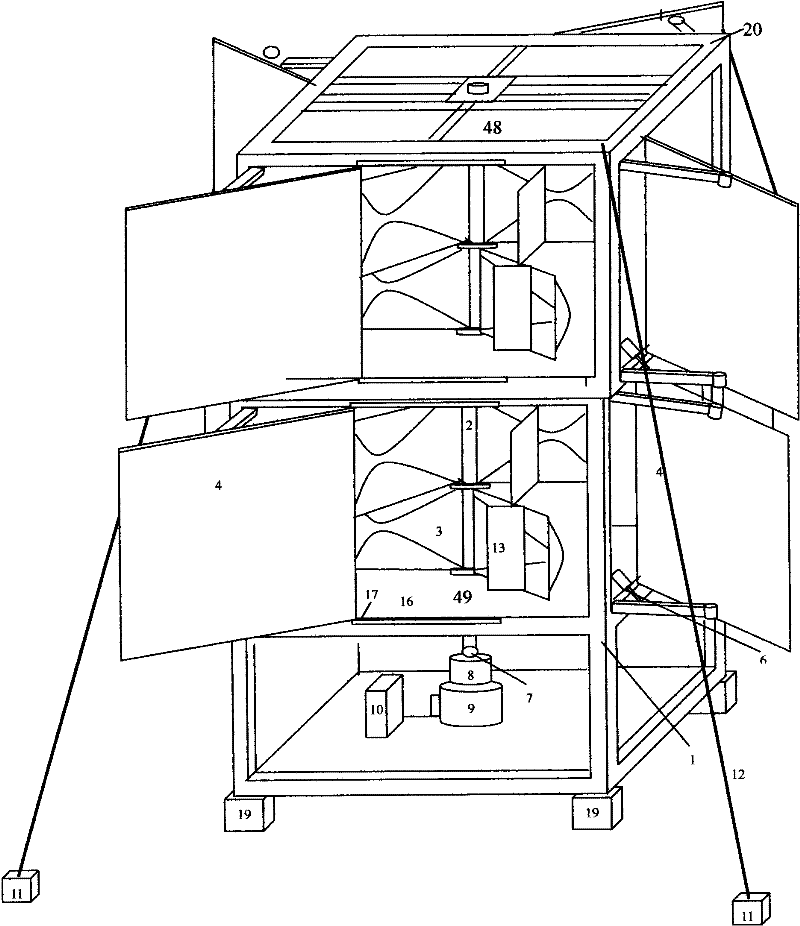

Multilayer stacking combined vertical type wind power generation system

InactiveCN102128138AReduce deformationReduce vibrationYielding couplingEngine fuctionsCouplingFan blade

The invention discloses a multilayer stacking combined vertical type wind power generation system, which comprises multi-section combined crankshafts, multilayer stacking combined vertical type wind power systems and a multilayer stacking combined type frame, wherein each layer of wind power system has a box frame structure and comprises a fan blade system, a wind collection and protection system, a double-speed increasing device and a multi-winding electrode variation generator system; each layer of wind power system individually forms an independent wind power system for operation or all layers of wind power systems are fixed together by vertical posts at all corners; a detachable combined coupling is used for connecting all layers of fan blade crankshafts into a whole, so that synchronous turning moment can be generated by each layer of fan blades; and the lower shaft end of a fan blade crankshaft on the lowermost layer of the multilayer wind power system is connected with the double-speed increasing device and the multi-winding electrode variation generator system together through the detachable combined coupling. In the invention, the wind power generation system is decomposed into a plurality of layers of combined structures, is convenient to manufacture, transport, mount, assemble and maintain, has a small volume and high performance and can form a high-capacity power generation system.

Owner:HARBIN POWER VERTICAL WIND POWER EQUIP ENG TECH RES CENT

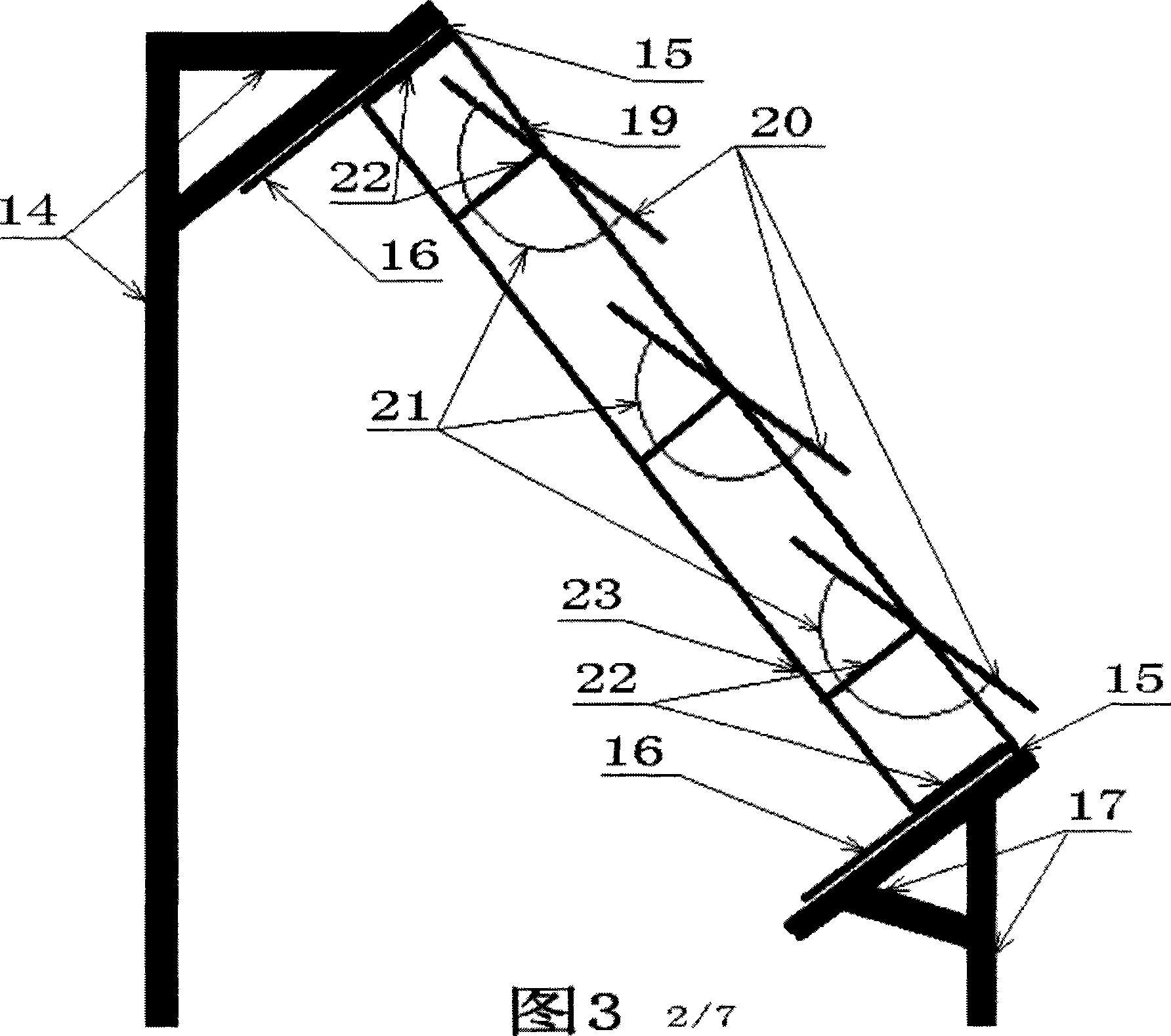

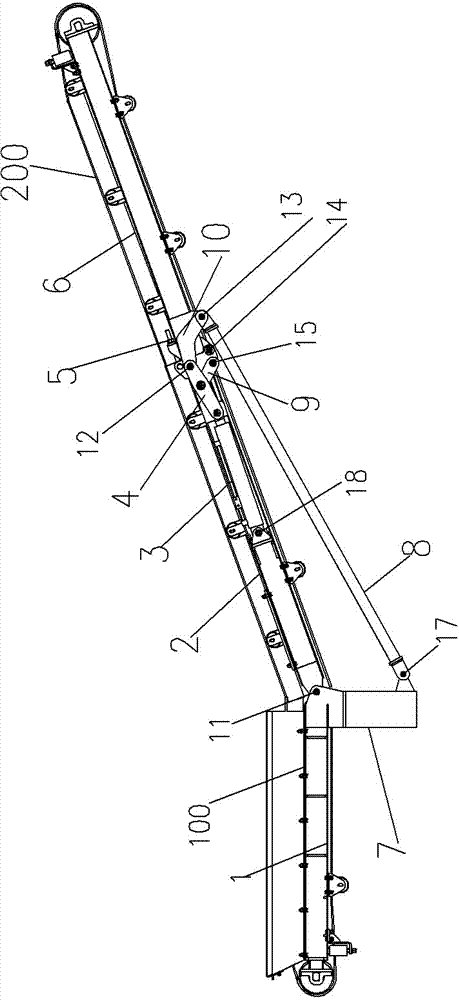

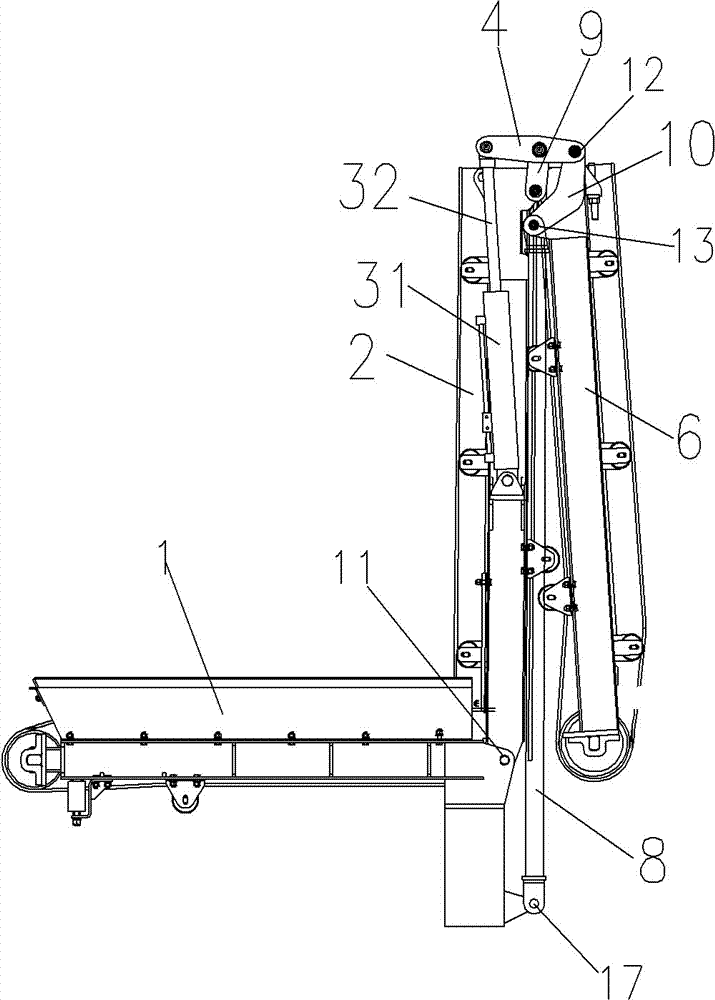

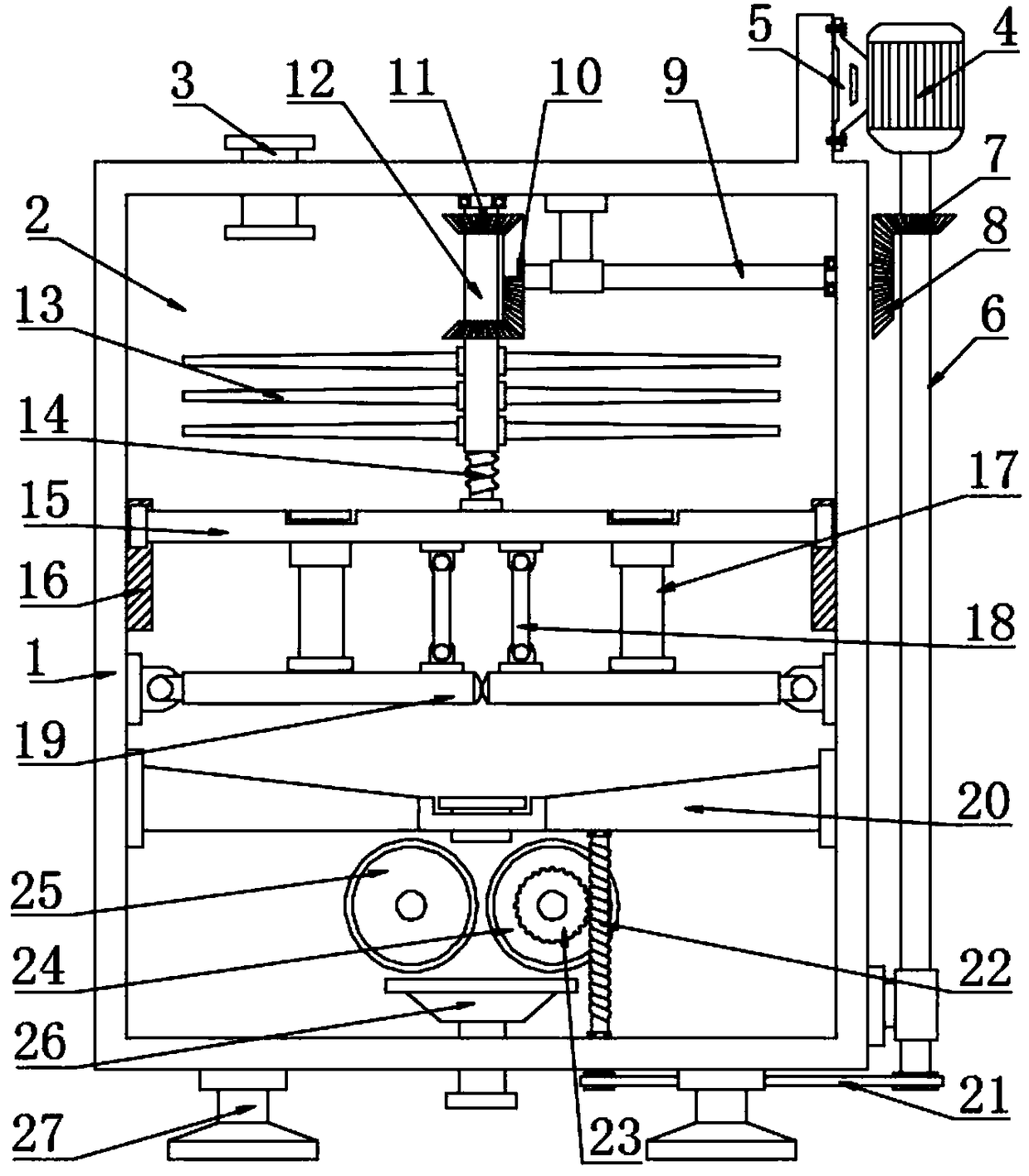

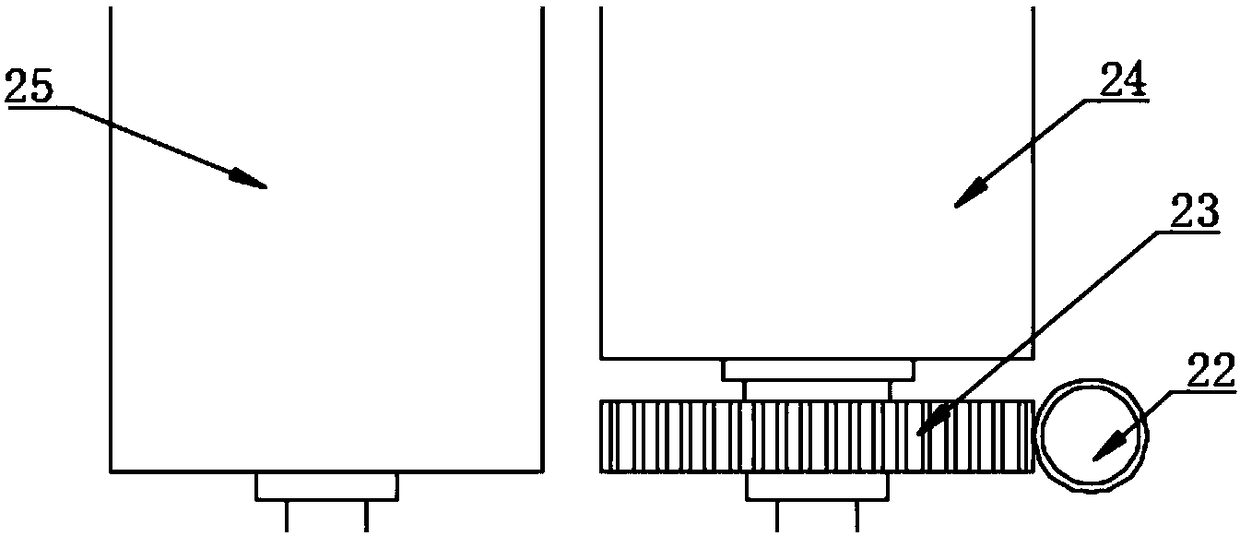

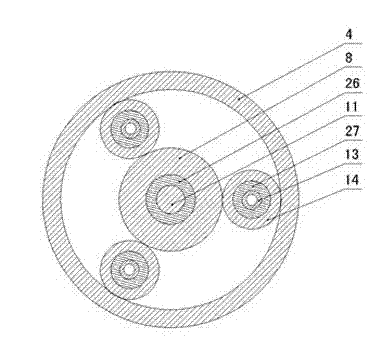

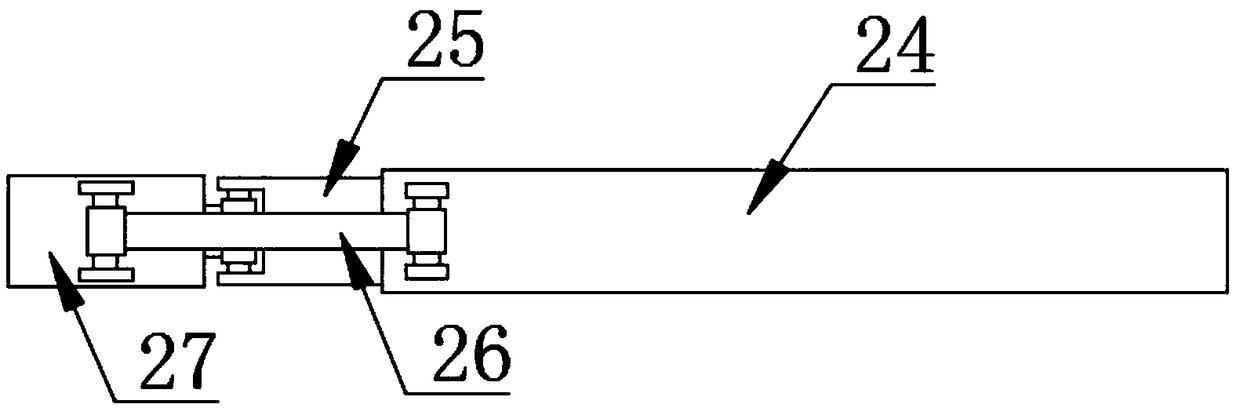

Method for retaining vertical impact of impacting mechanism and vertical-lift impact-cutting digger implementing same

InactiveCN103206213AIncrease arm lengthReduce farewellDriving meansCutting machinesEngineeringFuselage

The invention specifically relates to a method for retaining vertical impact of an impacting mechanism and a vertical-lift impact-cutting digger implementing the method, belonging to the field of machinery, especially to the field of mining. The digger comprises a body, the impacting mechanism and a vertical lift mechanism, wherein the impacting mechanism comprises a guiding member and an impacting head, the vertical lift mechanism comprises a vertical lift driving unit, a lifting and moving part, a supporting seat and the like, the lifting and moving part is movably connected with the supporting seat, the supporting seat is connected with the body, the impacting mechanism is arranged on the lifting and moving part, the vertical lift driving unit drives the lifting and moving part to vertically move up and down, and the lifting and moving part drives the impacting mechanism to vertically rise and fall. The digger provided by the invention has the advantages of a long service life, a small amount of maintenance, high work efficiency, shortened body length and applicability to a complex usage occasion.

Owner:刘素华

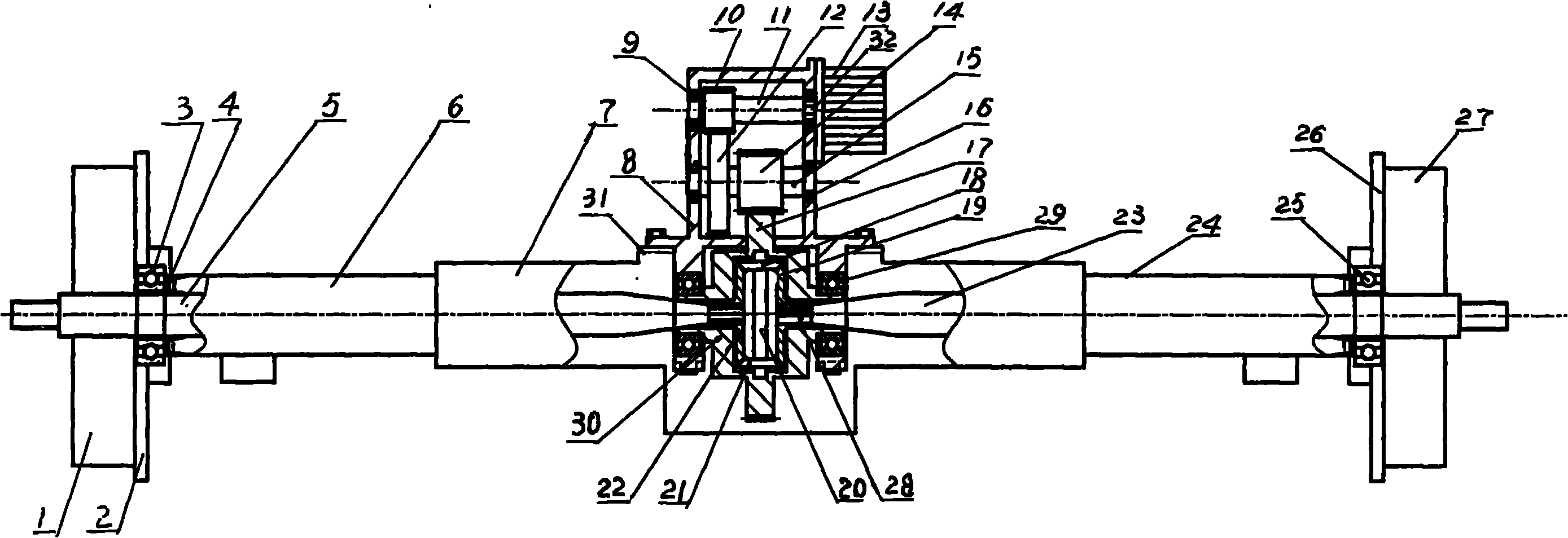

Electric vehicle deceleration and differential integrated rear axle assembly

The invention relates to an electric vehicle reduction and differentiation integrated rear axle assembly which is an integrated assembly of a motor, a reducing mechanism, a differential mechanism and a rear axle of an electric vehicle. The integrated assembly is applied to rear axle drive systems of freight vehicles, passenger vehicles, electric three-wheeled vehicles, electric four-wheeled vehicles and the like. The integrated assembly comprises the motor, the reducing mechanism, the differential mechanism, a reduction and differential case and the rear axle. The rear axle comprises a rear axle stand, a first drive half-axle, a second drive half-axle, a first braking fixed plate, a second braking fixed plate, a brake block, a brake cam, a first hub and a second hub. The reduction and differential case is installed on the rear axle stand and is fixed by screws; the reducing mechanism comprises a reducing gear shaft, a reduction transition gear and a reduction transition pinion; and the differential mechanism comprises a differential mechanism housing, a differential gear, a first satellite gear, a second satellite gear, a satellite gear shaft, a first spline gear, a second spline gear and a fifth bearing. The differential mechanism housing is installed below the reduction and differential case through the fifth bearing and a bearing support, and the differential gear is arranged outside the differential mechanism housing.

Owner:薛建南

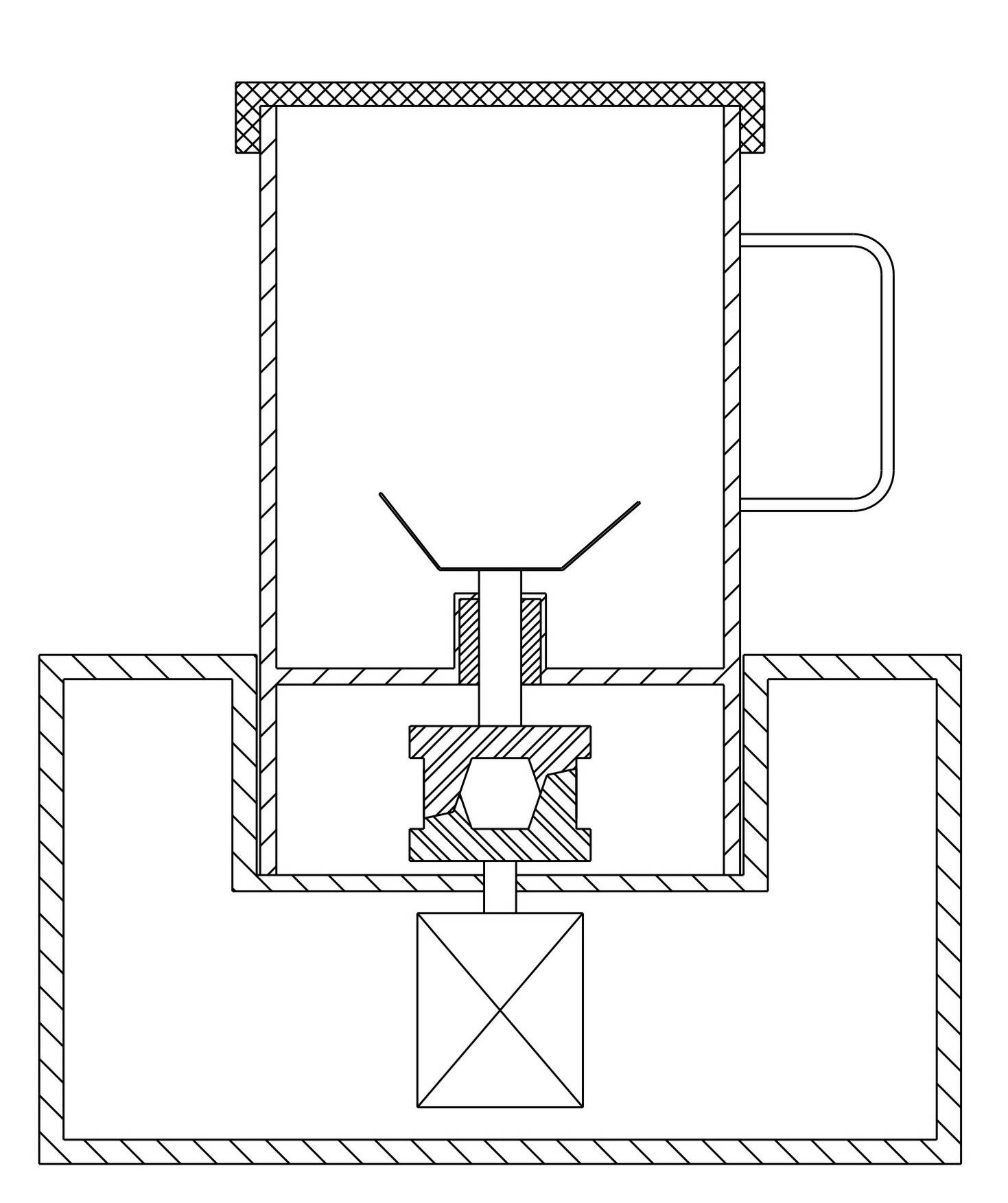

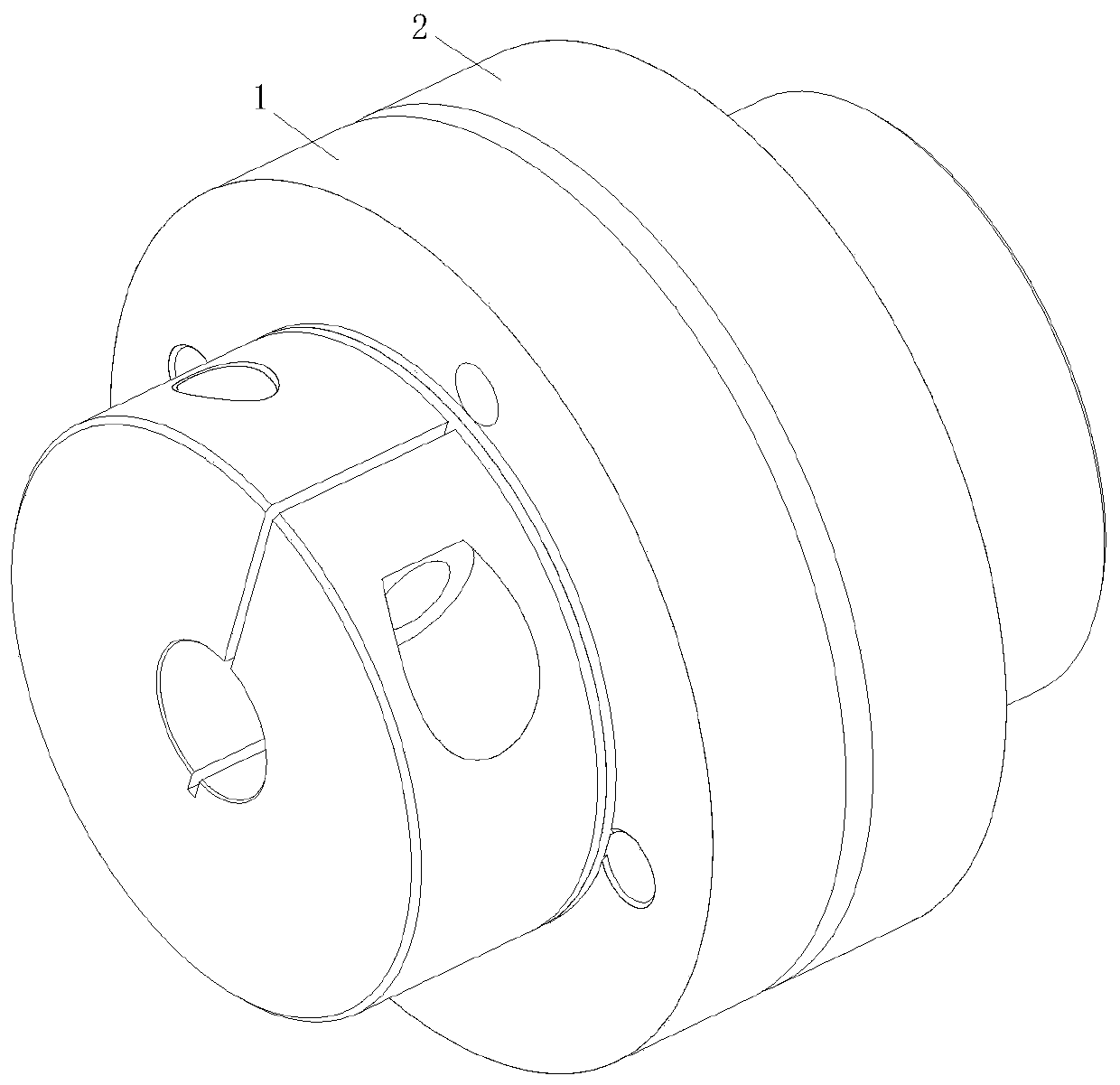

Indirectly driven food processor

ActiveCN102217905ANo wear and tearReduced concentricity requirementsKitchen equipmentWater leakageDrive shaft

The invention discloses an indirectly driven food processor, which comprises a container, a crushing cutter arranged in the container, a motor, a base internally provided with the motor, a driving shaft coupling arranged on a power output shaft of the motor, and a driven shaft coupling connected with the crushing cutter. The indirectly driven food processor is characterized in that: the driving shaft coupling and the driven shaft coupling are in non-contact connection. The driven shaft coupling can be rotatablely arranged in the container and is arranged in a floating mode relative to the container. The driving shaft coupling is made of magnet and the driven shaft coupling is made of metal. The driving shaft coupling and the driven shaft coupling are in non-contact transmission, which caneffectively solve the problem of abrasion between the driving shaft coupling and the driven shaft coupling; the container needs no cutter shaft hole, and sealing to thoroughly solve the problem of container water leakage; vibration and noise can be effectively relieved; the driven shaft coupling is arranged in a floating mode, which can effectively solve the problem of cutter blockage; and the driven shaft coupling and the crushing cutter are dismountable so that the container can be cleaned conveniently.

Owner:JOYOUNG CO LTD

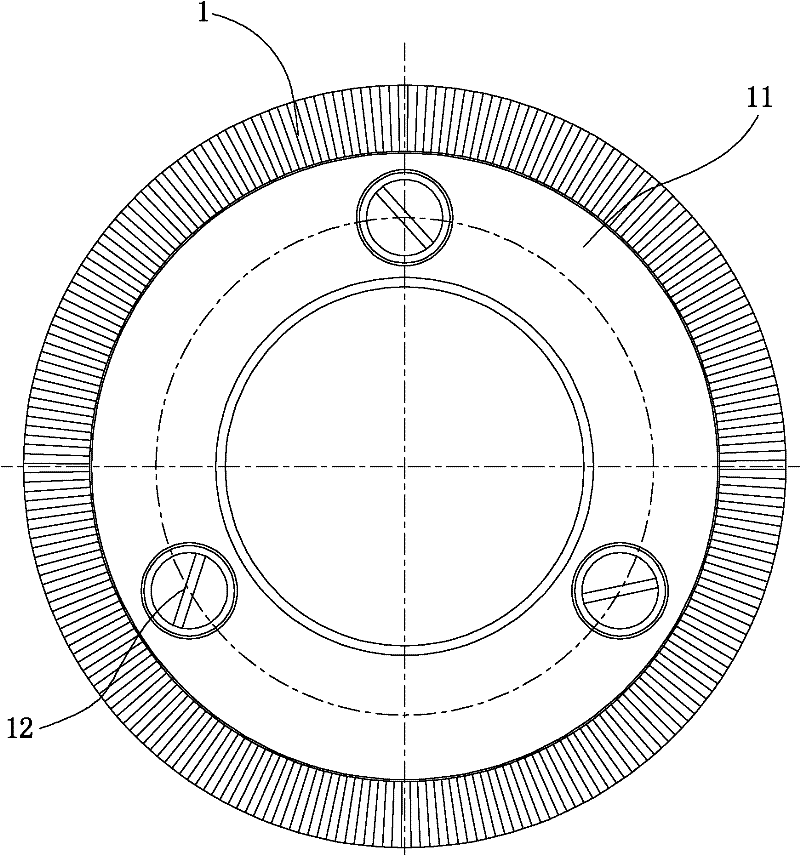

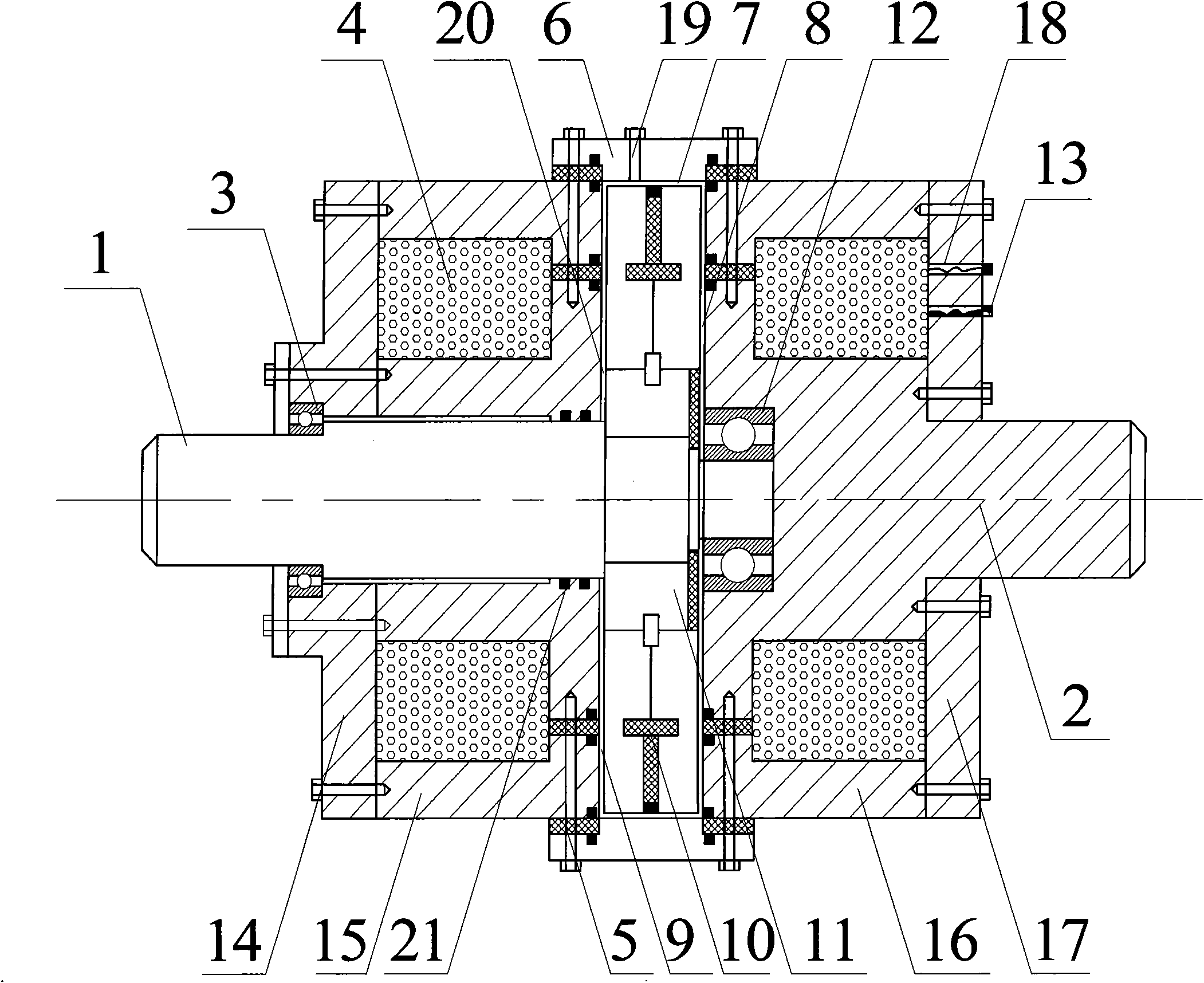

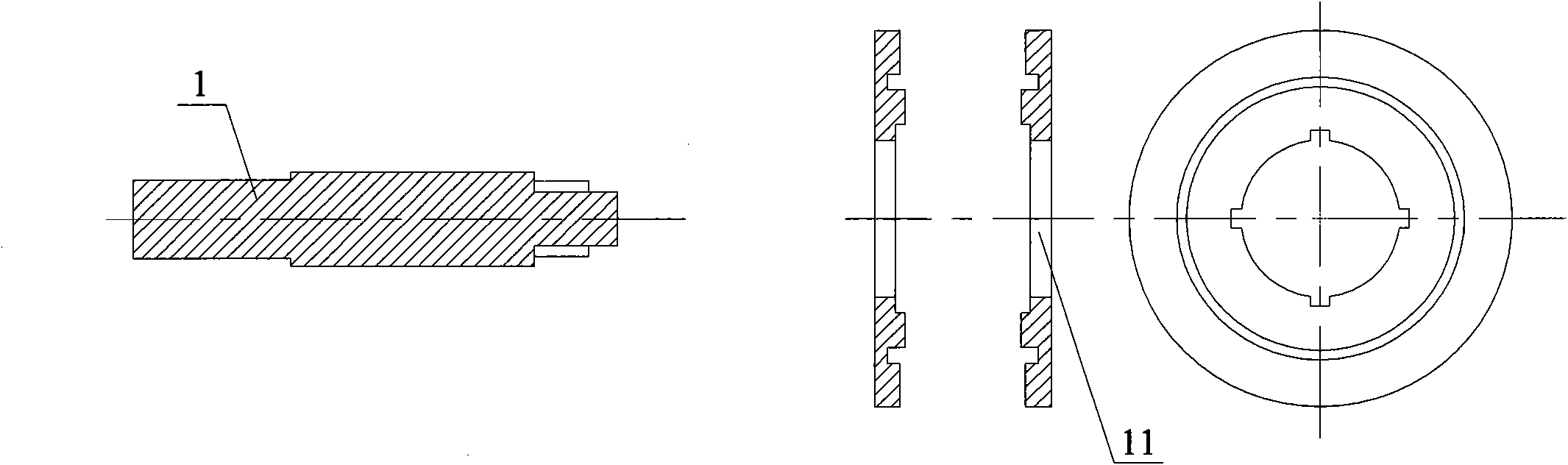

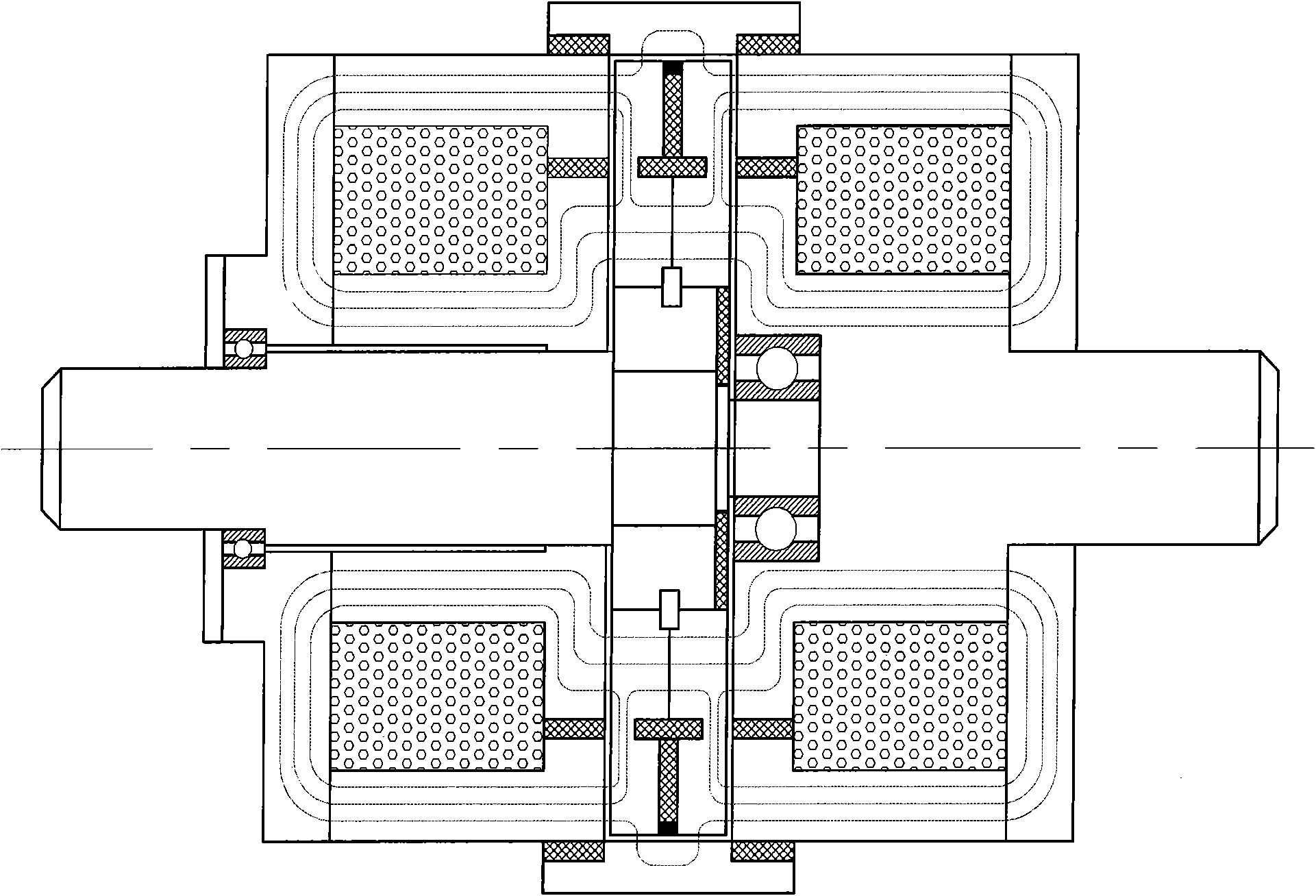

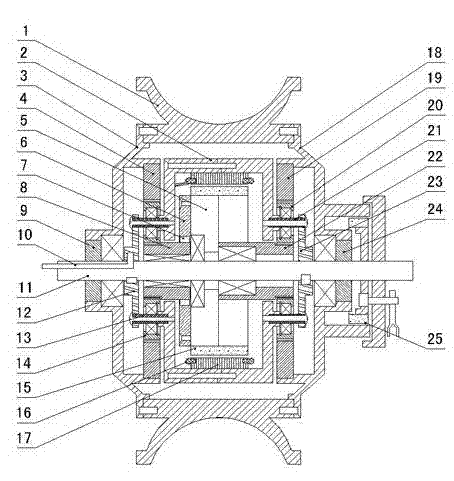

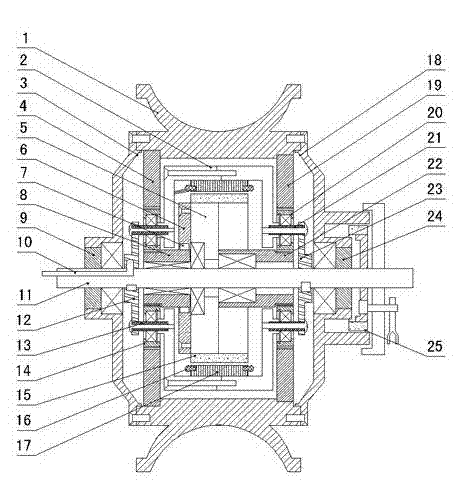

Uniwafer three-disk magnetic rheological clutch

The invention discloses a uniwafer three-disk magnetic rheological clutch which comprises a drive shaft (1), a driven shaft (2), a drive disk (11), a magnet exciting coil (4), a magneto rheological left disk channel (9), a magneto rheological right disk channel (8), a magneto rheological circular channel (7), a left shell (14), a left driven member (15), a right shell (17), a right driven member (16), a drive disk magnetism-isolating copper ring (10), a driven member magnetism-isolating copper ring (5), an angle contact ball bearing (3), a thrust ball bearing (12), a magneto rheological liquid (20) and a sealing device, wherein the drive disk (11) is positioned in a cavity surrounded by the left driven member (15), the right driven member (16) and a driven connecting member (6), and the magneto rheological liquid is filled in the cavity; and magnetic fields vertical to three disk surfaces of the drive disk (11) pass through the same, which can more effectively develop magneto rheological effect. The invention overcomes the defects of slow response, easy abrasion, large noise, more heat generation, unstable control and the like of the traditional clutch, and has the advantages of smaller volume, bigger drive torque, simpler structural design and less power consumption compared with the traditional magneto rheological clutch.

Owner:HOHAI UNIV

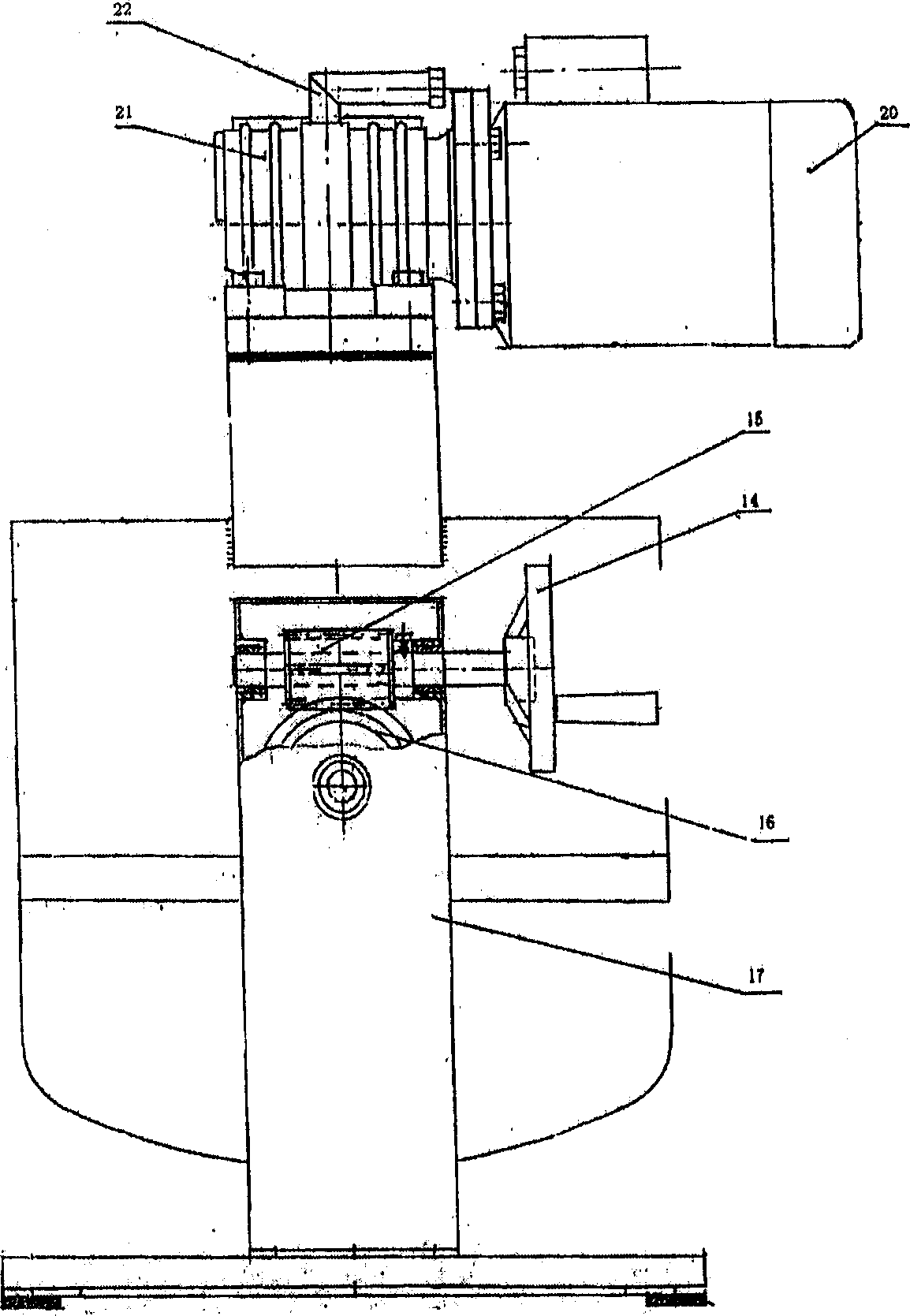

Auxiliary transmission mechanism for fabric roll of fabric spreading machine

The invention provides an auxiliary transmission mechanism for a fabric roll of a fabric spreading machine, belongs to the technical field of machinery, and aims at solving the problems of an existing fabric spreading machine which is not applicable to large, thin and smooth fabrics and is low in generality. The auxiliary transmission mechanism comprises a supporting frame, a driving motor and a transmission shaft, wherein a mounting seat is arranged at the bottom part of the supporting frame; the supporting frame is detachably connected to a main engine of the fabric spreading machine through the mounting seat; the driving motor is fixed to one side of the supporting frame; the transmission shaft, which is in transmission connection with the driving motor, is rotatably and detachably connected to the supporting frame; two clamping wheels are arranged on the transmission shaft in a sleeving mode and can slide along the transmission shaft; the fabric roll can be positioned and clamped to the transmission shaft through the clamping wheels. According to the auxiliary transmission mechanism for the fabric roll of the fabric spreading machine, the fabric roll is arranged on the transmission shaft, and two ends of the fabric roll are clamped through the corresponding clamping wheels; the clamping wheels can be adjusted according to the size of the fabric roll; the driving motor can actively drive the fabric roll to rotate, thus a fabric can be easily released without tensile force, and as a result, the generality of the fabric spreading machine can be improved.

Owner:BULLMER ELECTROMECHANICAL TECH

A New Type of Friction Clutch and Its Separation and Combination Device

InactiveCN102278383AImprove transmission efficiencyStable clutch functionFriction clutchesFailure rateDrive shaft

The invention provides a friction clutch, comprising an externally moving disc cover, an internally moving disc, a separating bearing, internal friction sheets, external friction sheets, a driving shaft, and a driven shaft, the externally moving disc cover is in a sleeve joint on the driving shaft, the separating bearing is in a sleeve joint at the external of a sliding sleeve, the sliding sleeve is in a sleeve joint at the external of a lining, the sliding sleeve and the lining sleeve the driving shaft or the driven shaft, the external friction sheets are connected with the externally moving disc cover, and disposed between two adjacent internal friction sheets, and a thick gasket is disposed between the two adjacent internal friction sheets, a separating and combining device is connected on the separating bearing, the separating and combining device comprises a fixed connecting mechanism and a combining mechanism composed of a big connecting rod, a small connecting rod, porous connecting plate and shafts, and a separating mechanism, wherein the combining mechanism and the separating mechanism are respectively connected with the fixed connecting mechanism. The friction clutch is advantageous in that: clutch function is stable, transmission torque is big, wear is little, transmission efficiency is high, heat radiation performance is good, failure rate of a separator is low, and radial space is small; when the friction clutch is used, a current manual operating system or a pedal operating system can be used to complete combining and separating functions.

Owner:姜成立

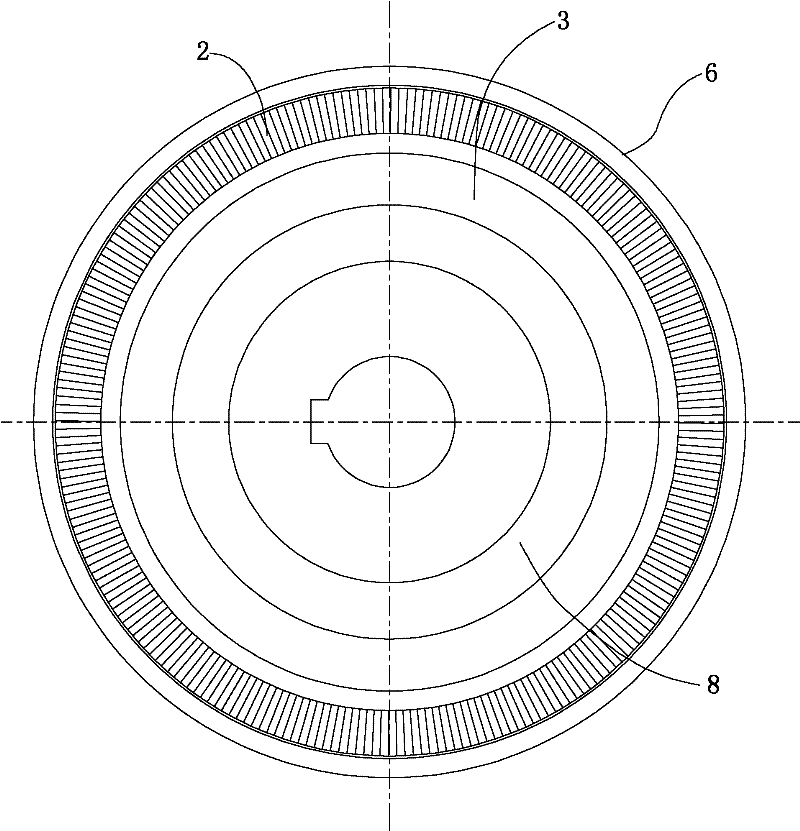

Automatic clutch type direct-current brushless motor stator

InactiveCN102710038AStable jobImplement automatic conversionMagnetic circuit rotating partsMechanical energy handlingBrushless motorsAutomatic transmission

The invention discloses an automatic clutch type direct-current brushless motor stator which comprises a main shaft (11), an automatic clutch, rotor magnetic steel (3) and a magnetic separation sleeve (4), wherein the automatic clutch is arranged on the main shaft (11) in a rotating way, the magnetic separation sleeve (4) is fixed on a shell (5) of the automatic clutch, the rotor magnetic steel (3) is uniformly distributed on the magnetic separation sleeve (4), an isolator seat (7) is fixedly arranged on the end surface of the shell (5) of the automatic clutch, an isolator (8) is fixedly arranged on the isolator seat (7), a low-speed central gear (10) is arranged on the main shaft (11) in the rotating way, an inner ring of the isolator (8) is matched with the low-speed central gear (10), and a high-speed central gear (21) which is matched with the automatic clutch is arranged on the main shaft (11). By adopting the structure, the automatic clutch type direct-current brushless motor stator has the advantages of being simple and compact in structure, small in volume, large in transmission torsion, low in accuracy requirement, long in service life, and good in university and having the capability of automatic transmission and the like.

Owner:马加良

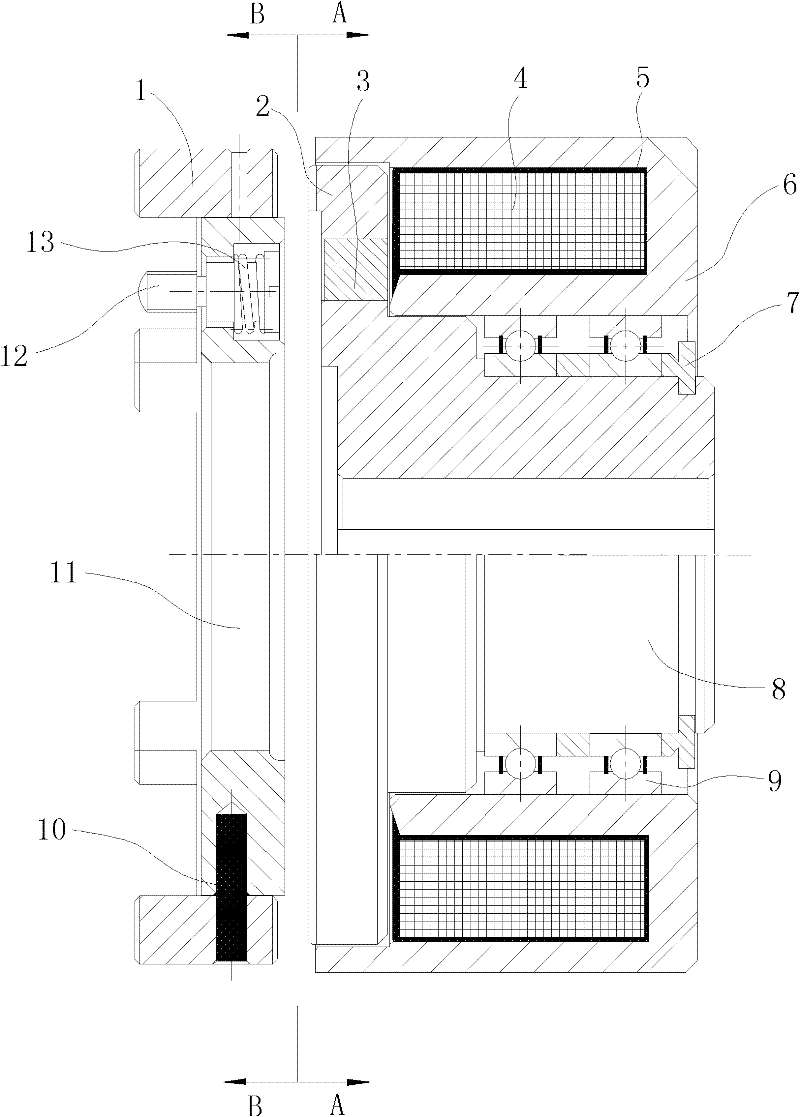

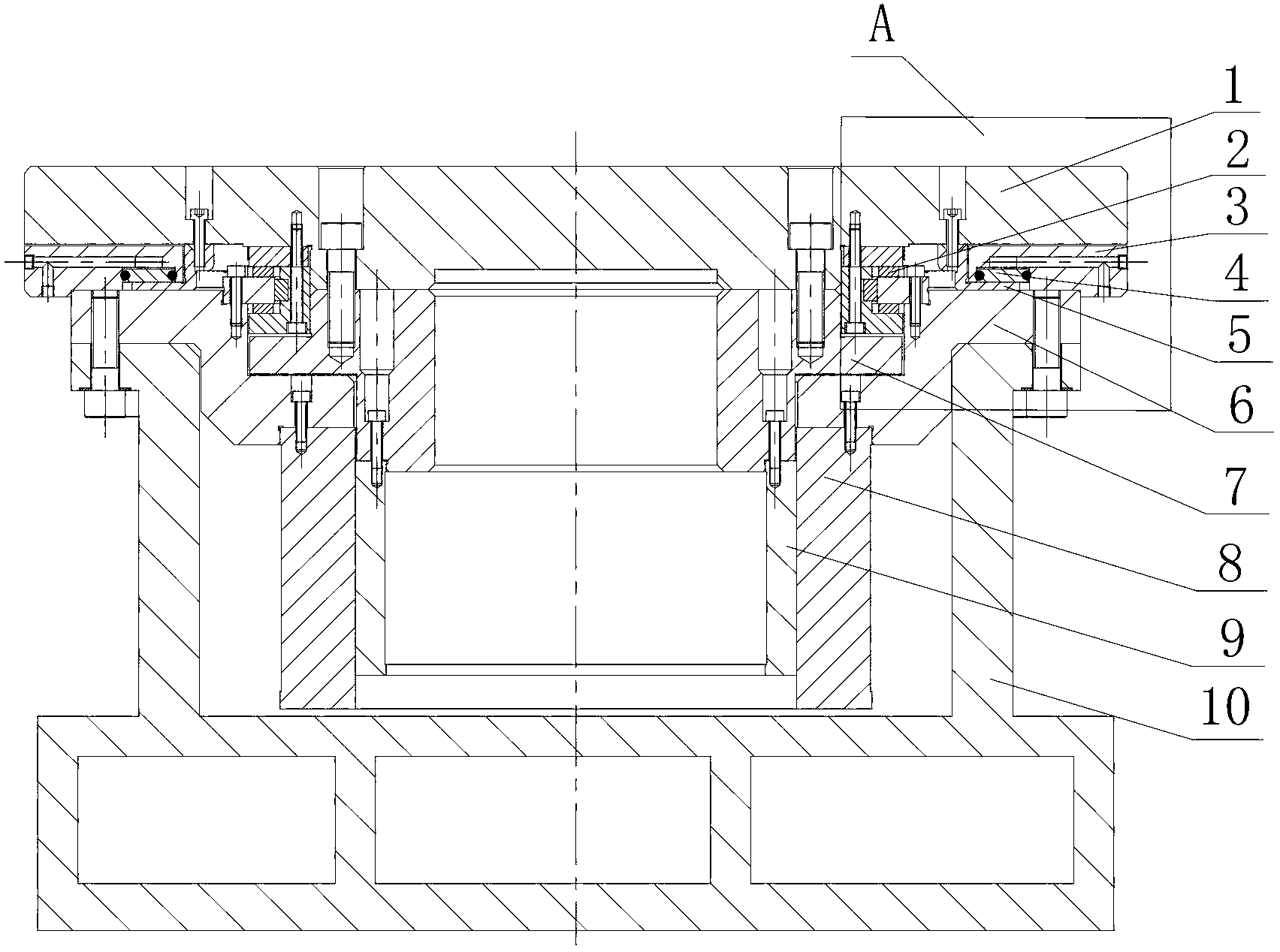

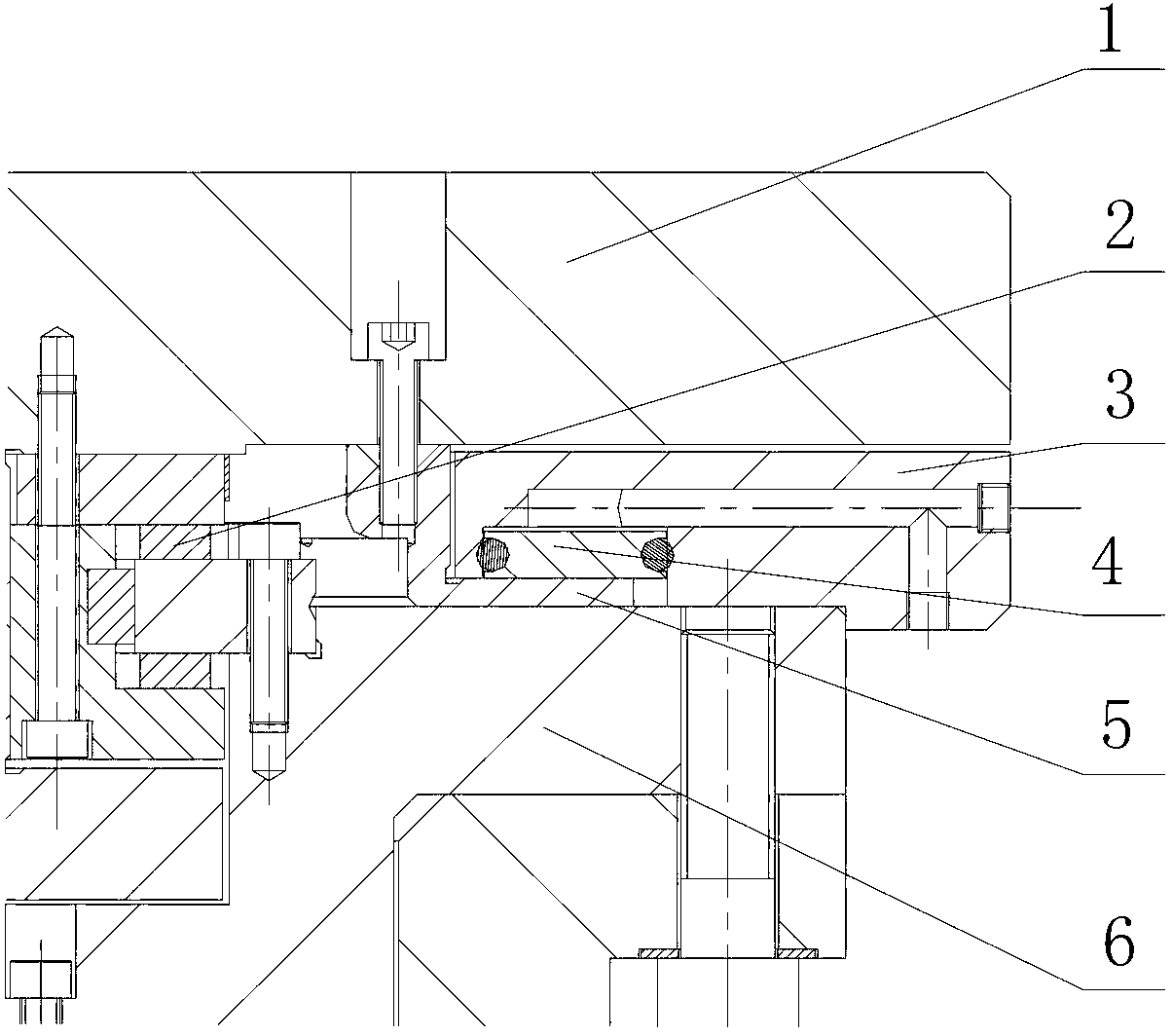

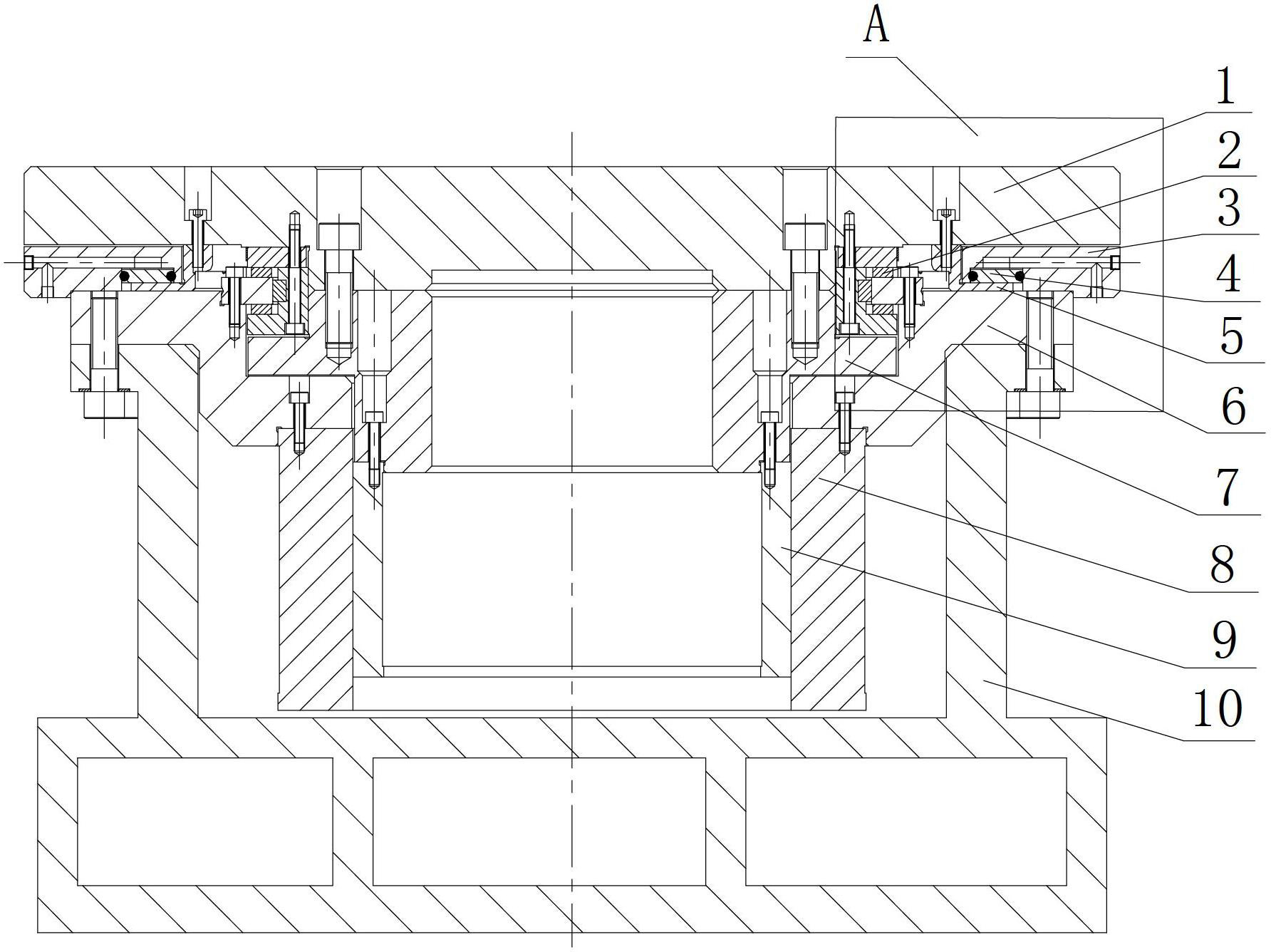

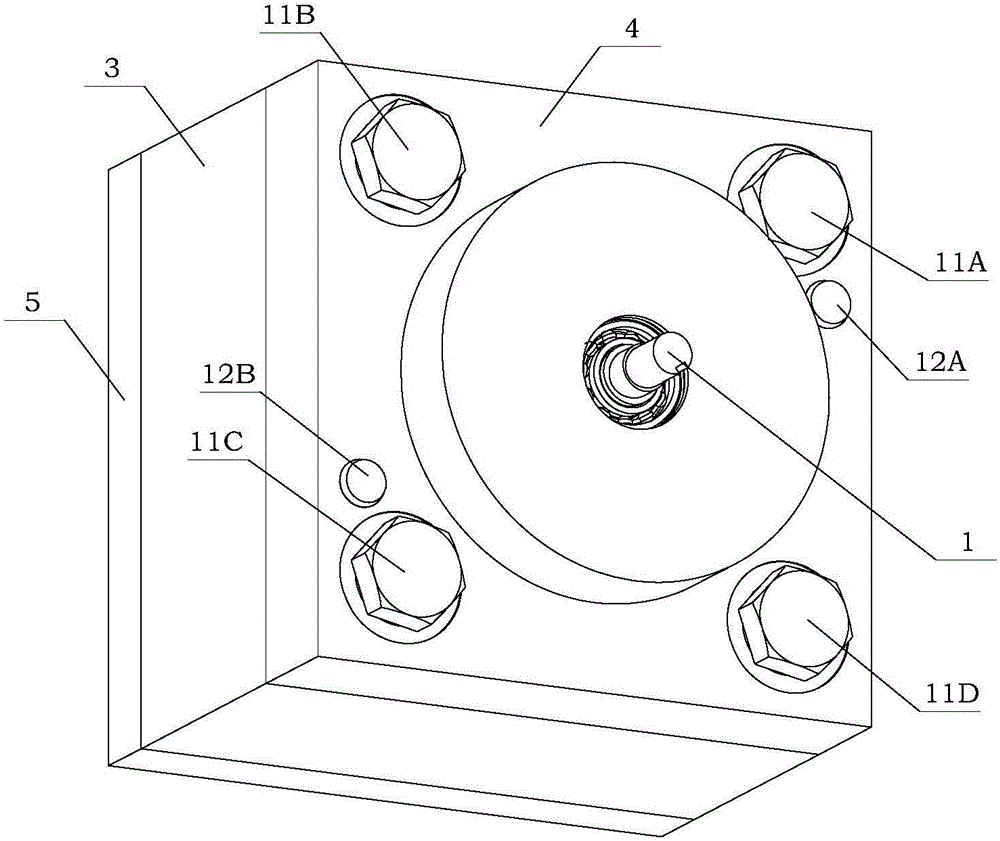

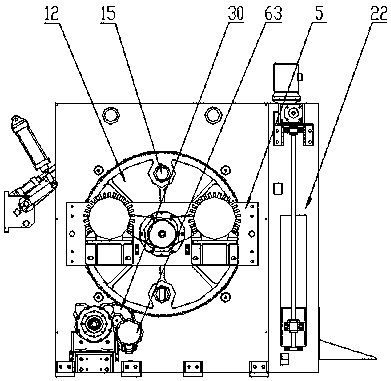

Precision numerical control rotary workbench

InactiveCN102699691AAdd positioning functionLarge transmission torqueLarge fixed membersNumerical controlTorque motor

The invention relates to a precision numerical control rotary workbench which comprises a workbench base, a workbench spindle and a spindle mandrel fixedly connected with the workbench spindle, wherein a support sleeve is fixedly connected on the workbench base, a rotary workbench bearing outer race and a hydraulic clamping cylinder are installed on the support sleeve, a torque motor stator is fixedly connected on the bottom of the support sleeve, the workbench spindle is installed on the inner race of the rotary workbench bearing, a torque motor rotor is connected below the spindle mandrel, a hydraulic clamping cylinder spring compaction sheet is installed below the workbench spindle, a hydraulic clamping cylinder piston is assembled in a groove of the hydraulic clamping cylinder, and the hydraulic clamping cylinder piston is in contact with the hydraulic clamping cylinder spring compaction sheet. The precision numerical control rotary workbench has the advantages of increasing the bench surface precision and the positioning precision of the workbench under the action of unbalance load impact force, the transmission torque is large, and the assembly is simple and reliable; and the precision numerical control rotary workbench has self-locking function, so that the torque motor can work discontinuously, and the electric energy is saved.

Owner:TIANJIN NO 1 MACHINE TOOL WORKS

Energy-saving environment-friendly type permanent magnet speed regulation device

ActiveCN109861496AEffective transmission torqueSave electricityPermanent-magnet clutches/brakesCooling/ventillation arrangementElectrical conductorControl engineering

The invention relates to the technical field of driving speed regulation, and discloses an energy-saving environment-friendly type permanent magnet speed regulation device; the energy-saving environment-friendly type permanent magnet speed regulation device comprises a shell, wherein a rectangular pipe is transversely connected with the left of the shell through a rectangular through hole in a sliding and sleeving mode, and an output shaft is arranged in the rectangular pipe, and two first rolling shafts are fixedly connected to the shaft wall of the output shaft; the outer rings of two firstrolling bearings are fixedly connected with the inner wall of the rectangular pipe, and one end of the output shaft penetrates through the rectangular pipe and is fixedly connected with a mounting block; an annular groove is formed in the right side of the mounting block; a plurality of first magnets are uniformly and fixedly connected to one side of the annular groove, wherein the plurality of first magnets are annularly distributed; and a transverse plate is fixedly connected to the lower end of the left side of the shell. According to the device, the transmission torque between a permanentmagnet rotor and a conductor rotor in the speed regulation device can be effectively increased, so that the driving device is not easy to perform idle rotation, electric energy is saved, and when thepermanent magnet speed regulation device works, the clothes of workers are not prone to being wound so as to avoid dangers.

Owner:MAANSHAN LANXIN ENVIRONMENTAL PROTECTION TECH CO LTD

Folding bracket for conveyor and belt conveyor using same

The invention provides a folding bracket for a conveyor and a belt conveyor using the same. The folding bracket comprises a fixed rear frame, a middle frame and a front frame; the middle frame is provided with a hydraulic cylinder driving mechanism; the power output end of the hydraulic cylinder driving mechanism is in transmission connection with a driving hinged joint so as to apply an applied moment, which forces the front frame to rotate clockwise around a front hinged joint to fold the bracket and forces the front frame to rotate anticlockwise around the front hinged joint to unfold the bracket, to the front frame by the driving hinged joint when a piston rod slides in a cylinder body; a folding strut is arranged between the front frame and the fixed rear frame; the front end of the folding strut is hinged with the front frame by a front supporting hinged joint and the rear end of the folding strut is hinged with the fixed rear frame by a rear supporting hinged joint; the front supporting hinged joint is positioned on the front frame and in front of the front hinged joint; the rear supporting hinged joint is positioned on the fixed bracket and below the rear hinged joint. By adding the folding strut, an effect of controlling folding and unfolding of the front frame and the middle frame by the single hydraulic cylinder driving mechanism is implemented; the bracket has a simple integral structure.

Owner:ZHENGZHOU YIFAN MECHANICAL EQUIP

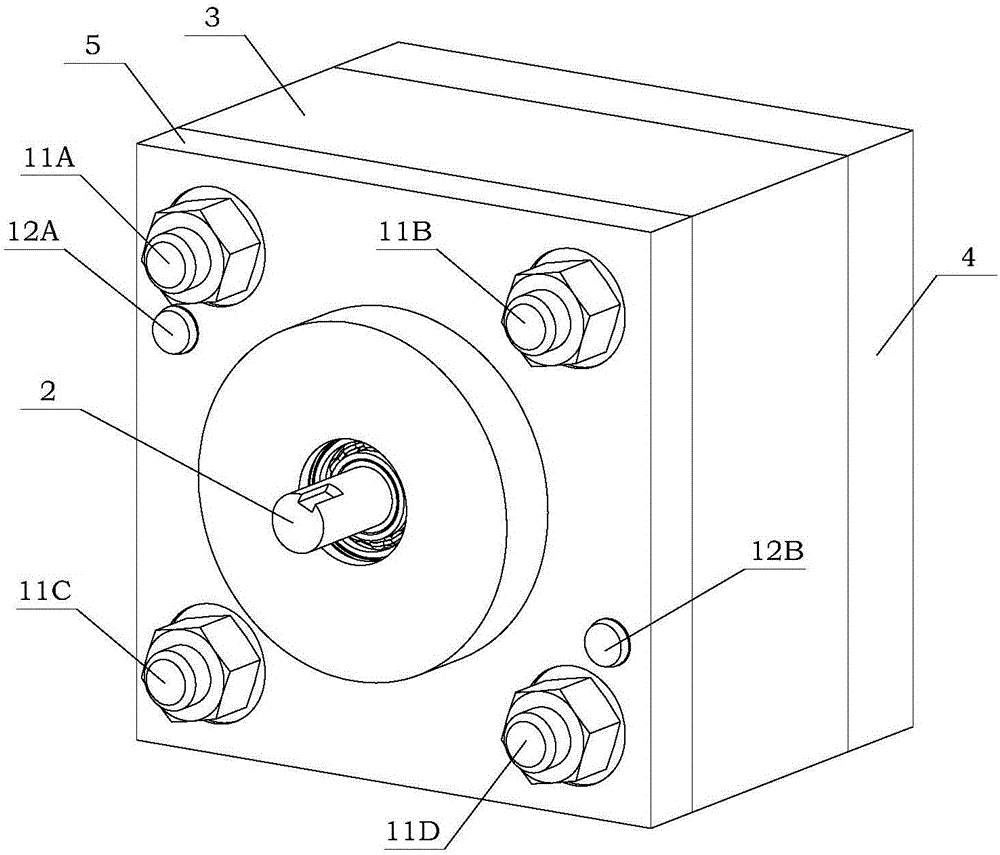

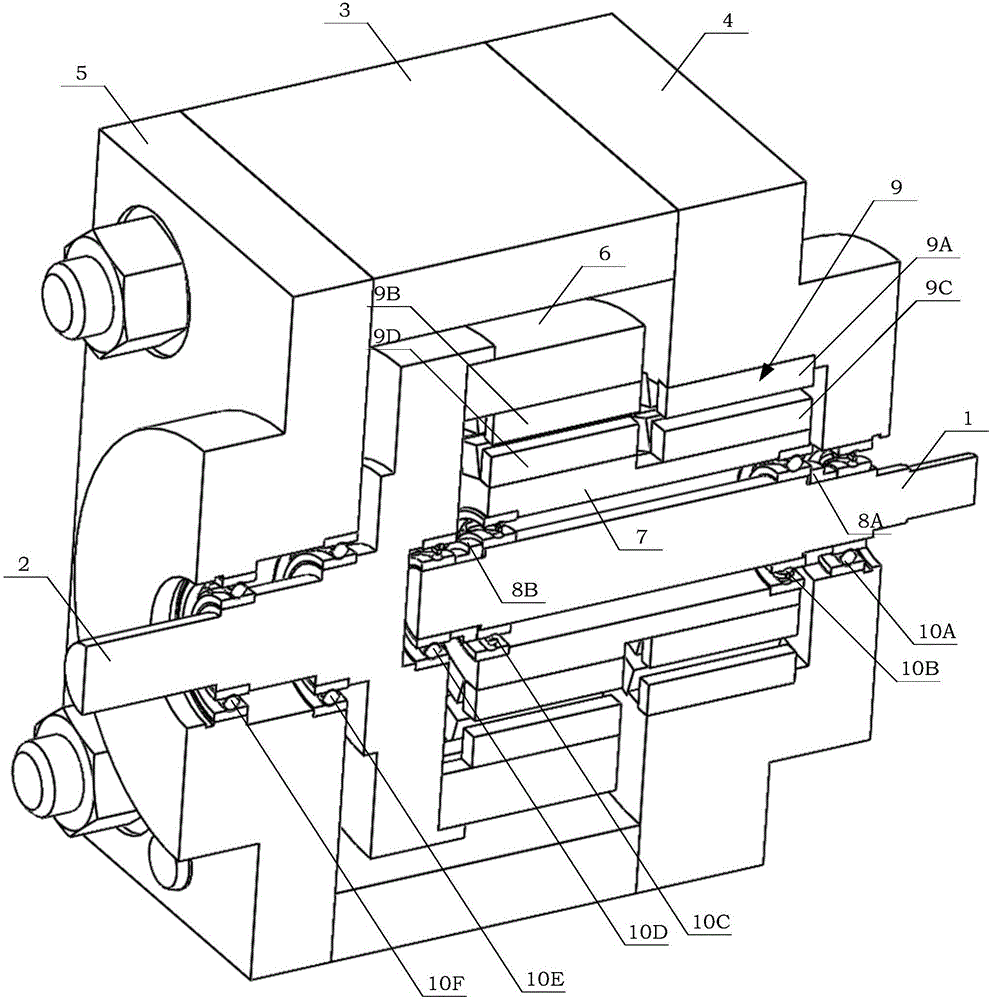

Speed reducer with 2K-H type low-range magnetic gear

ActiveCN106374719AOvercoming lossOvercoming noisePermanent-magnet clutches/brakesBall bearingReduction drive

The invention discloses a speed reducer with a 2K-H type low-range magnetic gear. A duplex sleeve (7) is connected with an input shaft (1) through a deep groove ball bearing; a B end cover (5) is connected with an output shaft (2) through a deep groove ball bearing; a fixed ring (6) is fixed on the shaft disc end part of the output shaft; a shell (3) and end covers (4, 5) are fixed through threaded rods (11A-11D) and pins (12A, 12B); a first-level inner layer magnetic block group (9C) is glued on an A section sleeve (7A) of the duplex sleeve (7); a second-level inner layer magnetic block group (9D) is glued on a B section sleeve (7B) of the duplex sleeve (7); a second-level outer layer magnetic block group (9B) is glued on the inner wall of the fixed ring (6); and a first-level outer layer magnetic block group (9A) is mounted in a central through hole of the A end cover (4). According to the speed reducer, the dual-layer magnetic poles are designed on the circumference of the duplex sleeve (7), so that two-level speed reduction without mechanical contact gear transmission is realized; and in addition, the transmission torque and transmission ratio are both relatively high.

Owner:BEIHANG UNIV

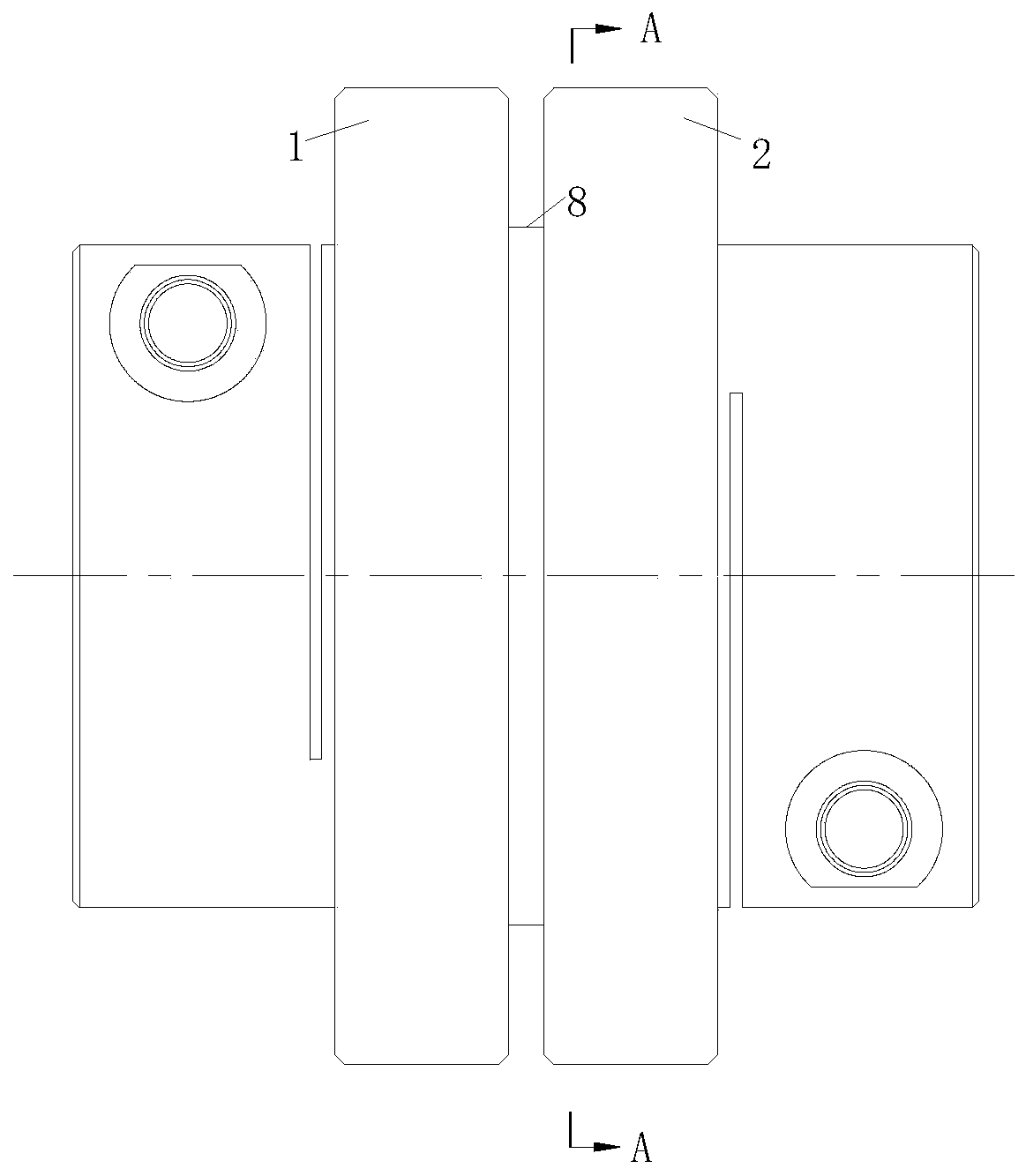

Coupling

ActiveCN110273933AReduce vibration transmissionProtection securityClutchesYielding couplingCopper wireMagnet

The invention belongs to the technical field of mechanical transmission, and particularly relates to a coupling. The coupling comprises a left half coupling, a right half coupling, magnets, air bags, windings, sliding blocks and a groove, wherein the left half coupling is fixedly connected with a driven shaft, the right half coupling is fixedly connected with a driving shaft, a circular groove is formed in the end face, close to the left half coupling, of the right half coupling, a hollow shaft connected with the left half coupling is arranged in the groove, the groups of magnets are uniformly embedded in the inner circumference of the side wall of the groove, mounting holes are formed in the positions, corresponding to the magnets, of the outer edge of the hollow shaft, the air bags are fixedly connected to the bottoms of the mounting holes, the windings formed by winding copper wires are arranged on the peripheries of the air bags, clamping blocks are arranged at the ends, far away from the bottoms of the mounting holes, of the air bags, and the sliding blocks are connected in the clamping blocks in a sliding mode. According to the coupling, magnetic induction lines of the winding cutting magnets generate currents for heating, so that the air bags expand to push the sliding blocks to abut against the side wall of the groove, power is smoothly transferred from the driving shaft to the driven shaft through the friction force between the sliding blocks and the groove, so that the service life of a prime mover is prolonged.

Owner:大庆市富隆达石油工程机械设备有限公司

Fluid-pressure driven differential feeding system

The invention relates to a hydraulic drive differential feed system, which comprises an oil cylinder (3) and a ball screw(4) arranged at the front end of the oil cylinder (3); a third gear (7) is arranged at the front end of the ball screw (4); a first gear (5) is fixed on a nut (13) of the ball screw (4); the first gear (5) is meshed with a second gear (2); a fourth gear (6) is hollowly sheathed on a main shaft (1); the fourth gear (6) is meshed with the third gear (7); a fifth gear (8) is positioned at the left side of the third gear (7) and is meshed with the fourth gear (6); a first bevel gear (9) is meshed with a second bevel gear (10) on which a lead screw (11) is fixed. The differential feed system overcomes the shortcomings of the existing differential feed system of a metal cutting machine tool that not only is the number of the grade limited, but also the amount of feed of the machine tool can not be infinitely regulated and the maintenance cost is high. The hydraulic drive differential feed system has the advantages of large transmission torque and better meeting the requirements of processing and manufacturing industry and that the feed speed can be infinitely regulated.

Owner:应城市华兴机床有限公司

Symmetrical roller type fodder crushing machining device

InactiveCN108325597APrevent solidarity without blankingReduce the phenomenon of slipping and not crushingFeeding-stuffTransportation and packagingDrive shaftEngineering

The invention discloses a symmetrical roller type fodder crushing machining device. The upper portion of a device body is provided with a material bucket, the upper portion of the right side of the device body is provided with a driving motor, and the lower portion of the driving motor is rotationally connected with a driving shaft; the upper portion of the drying shaft is fixedly connected with the first bevel gear; a second bevel gear is fixedly connected with a driven shaft, a driven shaft bearing is rotationally connected with the side wall of the material bucket, and the left end of the driven shaft is fixedly connected with a semi-circular bevel gear; and the left side of the semi-circular bevel gear is provided with two third bevel gears, a toothed part of the semi-circular bevel gear is meshed with the third bevel gears, and the third bevel gears are fixedly connected with a threaded sleeve. According to the symmetrical roller type fodder crushing machining device, the semi-circular bevel gear drives the upper third bevel gear and the lower third bevel gear to rotate forwards and reversely in a reciprocating mode, accordingly, the threaded sleeve is driven to rotate forwards and reversely, the threaded sleeve drives a screw rod and a movable transverse plate to move up and down, partition panels are driven to swing back and forth through connection rods, and accordingly, intermittent discharging is achieved; and a worm drives a worm wheel and a driving roller to rotate for crushing, crushing is more thorough, the transmission torque of the worm and the worm wheel islarge, and the phenomenon that the driving roller slides and cannot crush fodder is avoided.

Owner:赵志坚

Full-automatic bidirectional clutch

The invention relates to a full-automatic bidirectional clutch. The full-automatic bidirectional clutch comprises a shell which is formed by fixedly connecting a front end cover and a back end cover, wherein a driving shaft is fixed to the front end cover rotatably; a driven shaft is fixed to the back end cover rotatably; the shaft end, positioned in the shell, of the driving shaft is provided with a centrifugal sliding pin device; the shaft end, positioned in the shell, of the driven shaft is provided with a driven plate; the plate surface of the driven plate is provided with a first groove; the inner wall surface of the first groove is provided with a boss; and the centrifugal sliding pin device is in clearance fit in the first groove. The full-automatic bidirectional clutch adopts a centrifugal sliding pin spring return structure; the driving shaft and the driven shaft drive through the joint of a driving pin and the boss; and the clutch has the characteristics of simple structure, light weight, short joint time and small inertia, capacity of transmitting bidirectional torque, small appearance size, large transmission torque, no relative sliding between the drive shaft and the driven shaft after jointing, and unchanged drive ratio.

Owner:WUXI KAIXUAN MOTOR

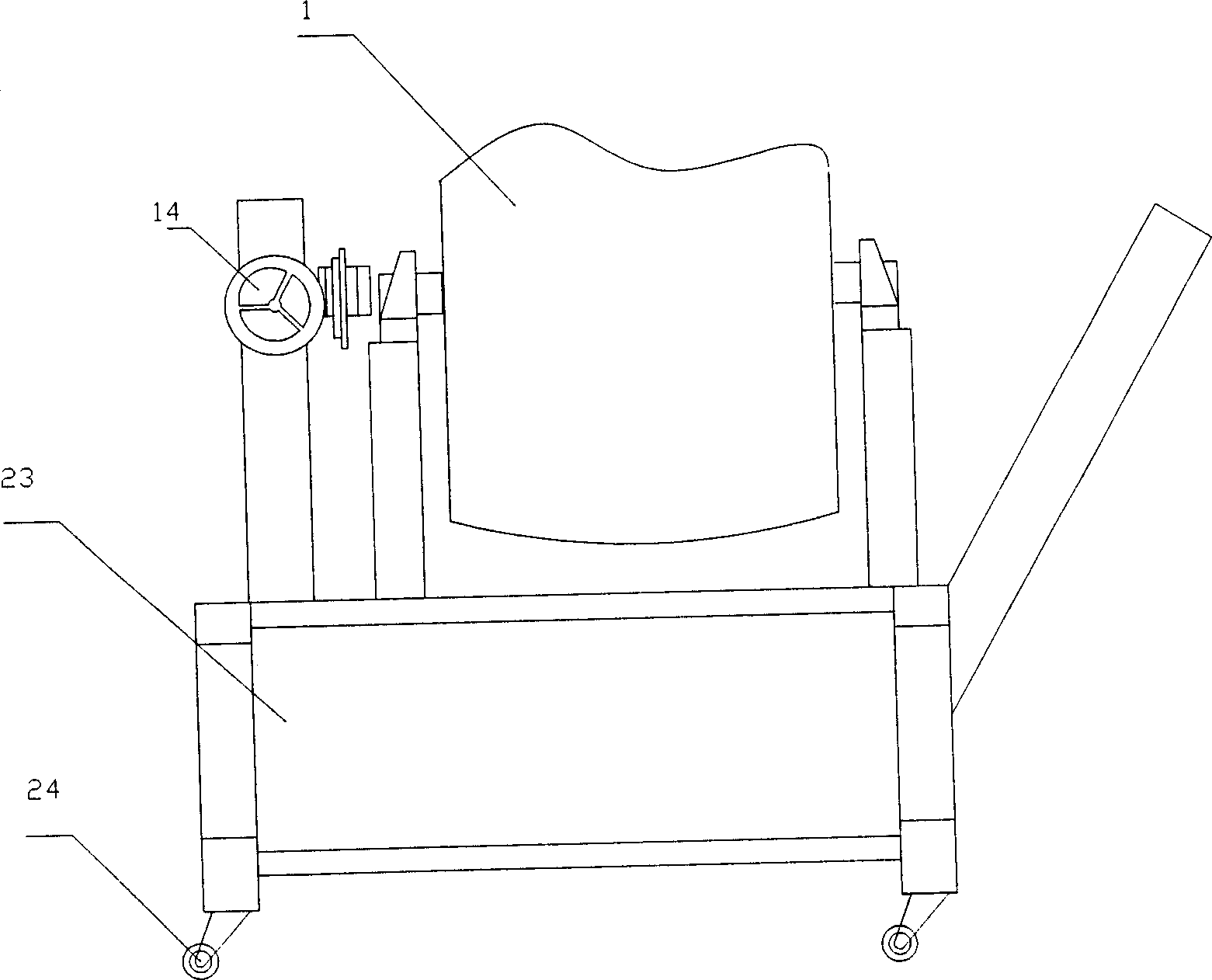

Stainless steel and electric heating type cooker chestnuts roasted in sand with brown sugar

An electrically heating stainless steel cooker for chestnuts roasted in sand with brawn sugar is composed of electric drive system, pot-body, heating assemblage consisting of electric heater and heater unit, and stirrer assemblage with paddles. Its advantages are uniform heating, saving electricity, low service life and no environmental pollution.

Owner:王金波

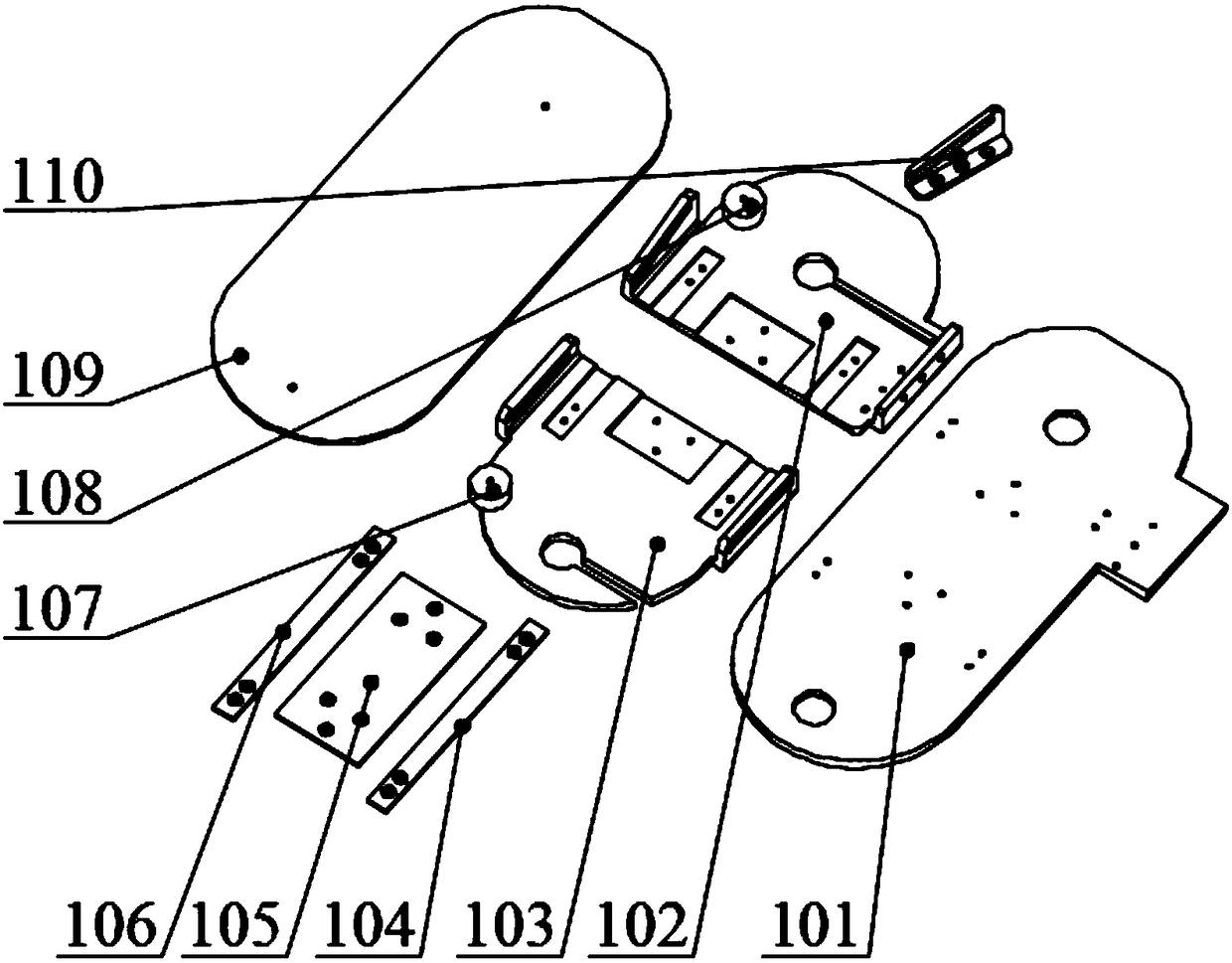

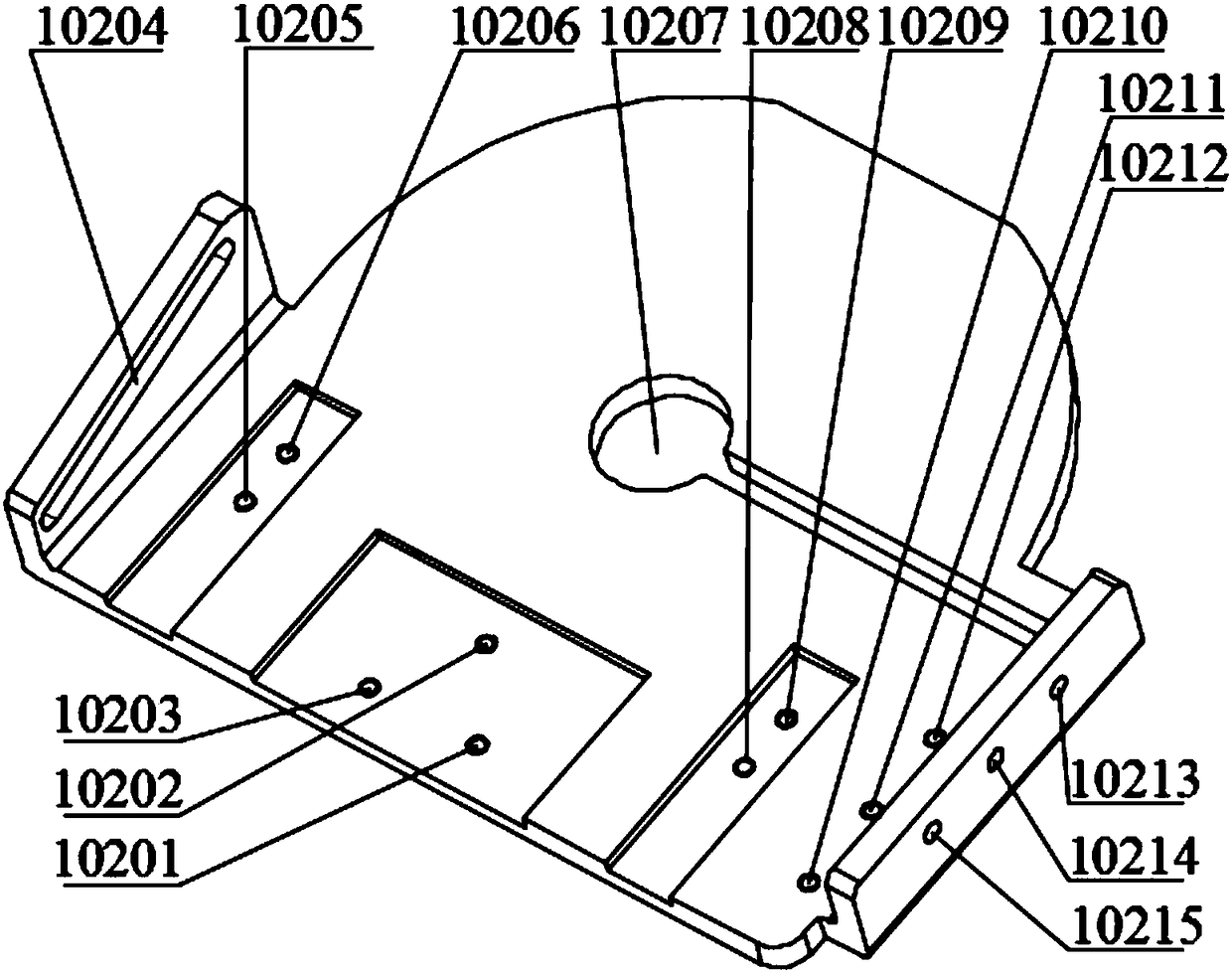

Multi-DOF (degree of freedom) energy-storing foot mechanism

InactiveCN108186287AReduce energy lossLarge transmission torqueChiropractic devicesEnergy lossExoskeleton

The invention discloses a multi-DOF (degree of freedom) energy-storing foot mechanism, comprising a sole unit, a side plate unit, an ankle unit and a binding unit. The ankle unit is releasably connected with the sole unit through the side plate unit; the binding unit is releasably connected with both the sole unit and the ankle unit; the ankle unit includes an ankle support that includes a supportterrace and a hanger lug that are integrated; the hanger lug is provided with a through hole; an ankle toe-flexure dorsal-flexure spindle and a bearing are mounted in the through hole so that the ankle support may be rotationally fitted to the side plate unit; the support is releasably connected with an energy-storing unit. The multi-DOF energy-storing foot mechanism has the advantages that energy loss can be effectively decreased, a multi-direction DOF is achieved, the structure is simple, wearing is facilitated, comfort is better for a wearer, parts are convenient to manufacture and mount,the multi-DOF energy-storing foot mechanism is highly transplantable and may be used with any limb-assistant exoskeleton, and the production cost may be greatly reduced since no drive and control system is provided.

Owner:SOUTHEAST UNIV

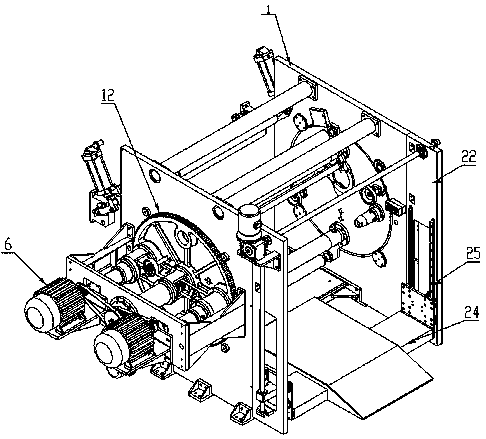

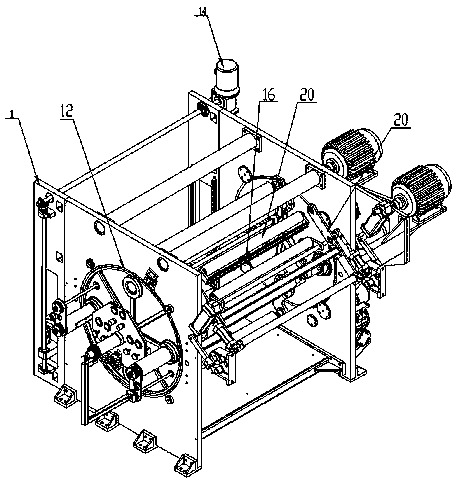

High-speed disc gear non-shaft loading rolling and unrolling device

The invention discloses a high-speed disc gear non-shaft loading rolling and unrolling device which comprises an installation frame, a transmission mechanism, an overturning mechanism, a cutting mechanism and an unrolling lifting mechanism, wherein the transmission mechanism, the overturning mechanism, the cutting mechanism and the unrolling lifting mechanism are installed on the installation frame. Multi-stage transmission of a worm gear reduction motor and a disc large gear is adopted for the overturning mechanism, and a non-shaft loading structure is adopted for the device. By means of thehigh-speed disc gear non-shaft loading rolling and unrolling device, multi-stage transmission of the worm gear reduction motor and the disc large gear is adopted for the overturning mechanism, the transmission torque is large, rigidity is good, the braking capability is high, the problems of jittering, sliding and the like cannot happen in the high-speed material collecting and releasing process,the overturning material changing process and the cutting process of the equipment, and stable running is ensured; and the non-shaft loading structure is adopted, the stretching and contracting distance of end stoppers on the left and right side of the equipment is long, a gas expansion shaft or a mechanical shaft or the like does not need to be additionally arranged for aiding during new materialroll installation, the end stoppers on the two edges directly abut against a material roll paper core, unnecessary parts are reduced, precision is higher, and the labor intensity of workers is also greatly lowered.

Owner:广东汕樟轻工股份有限公司

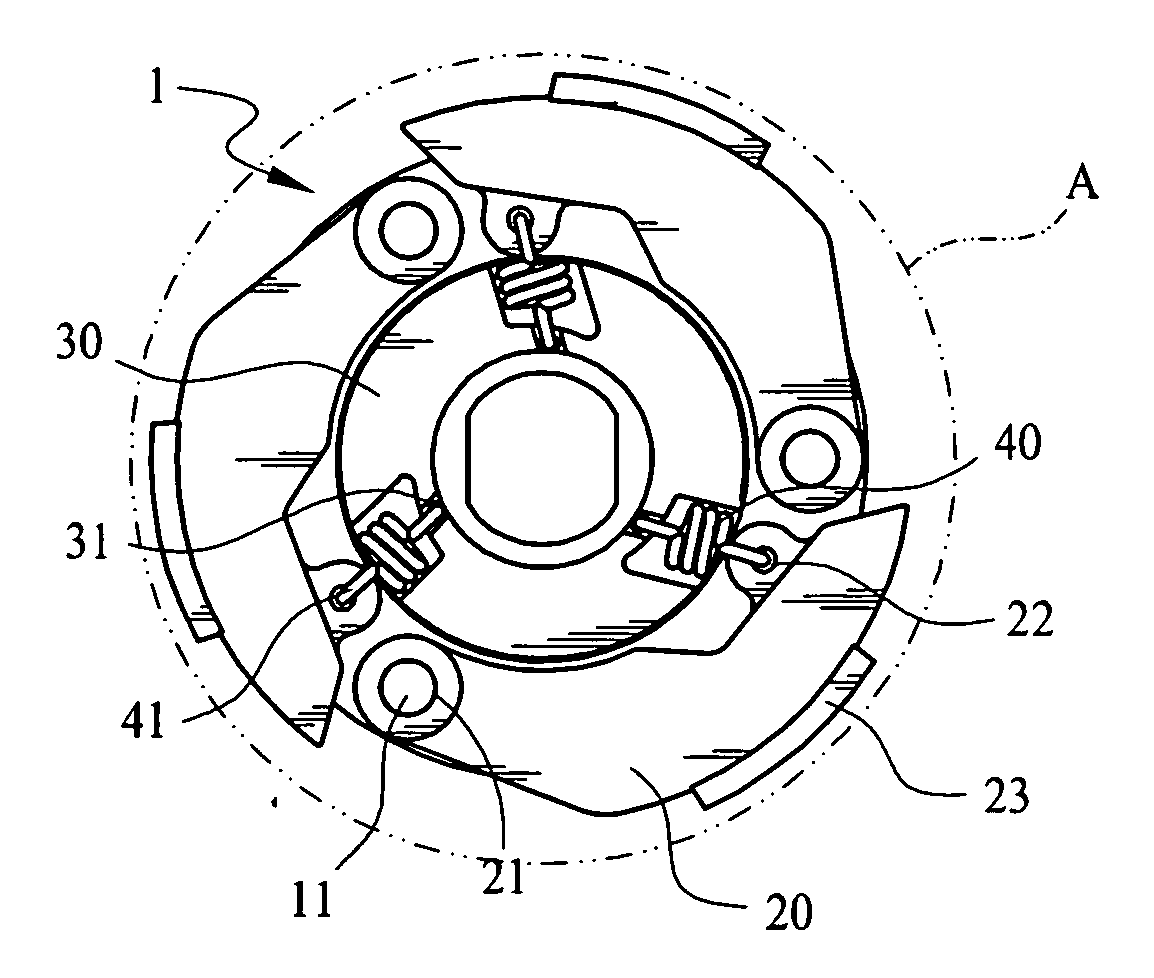

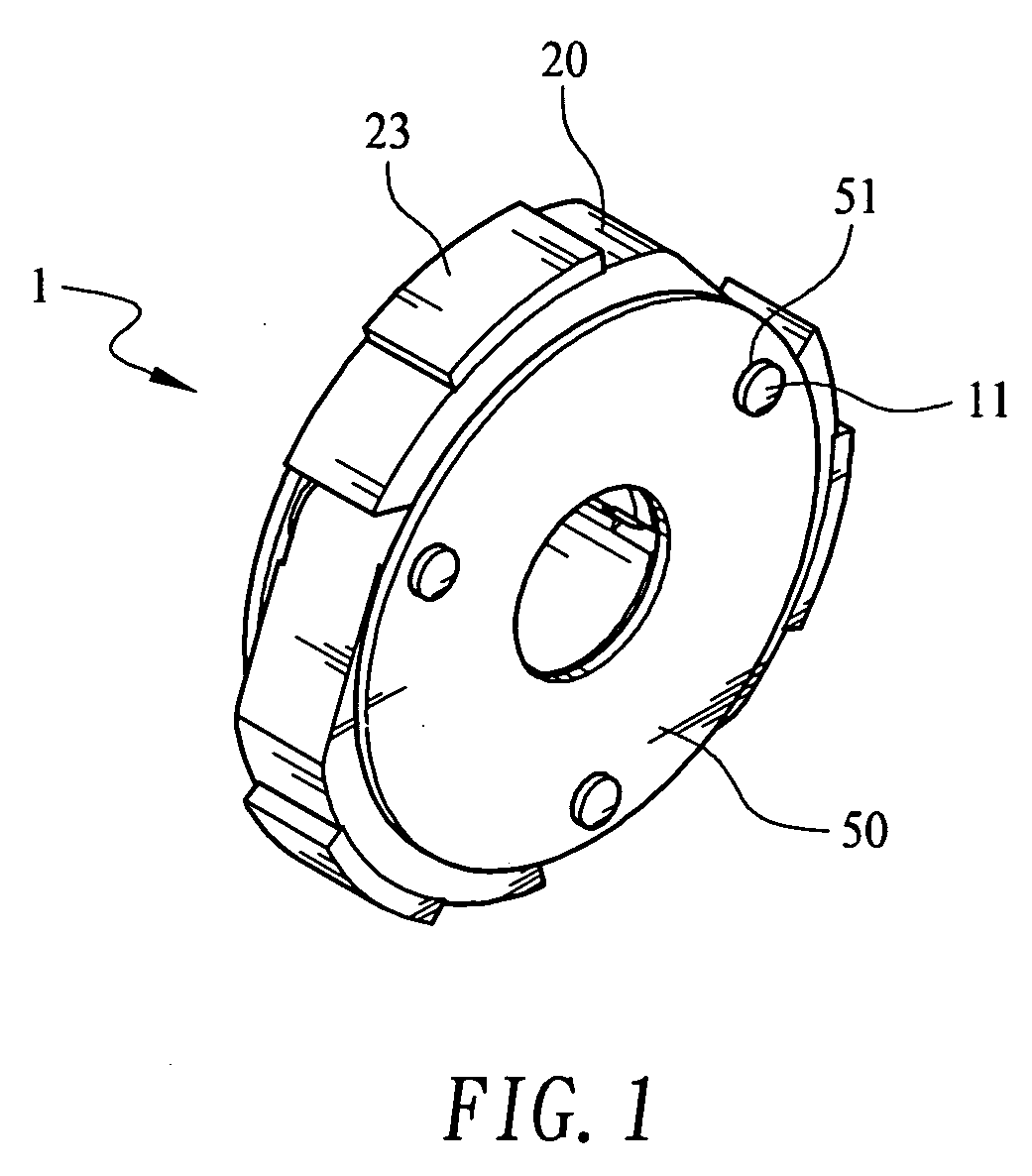

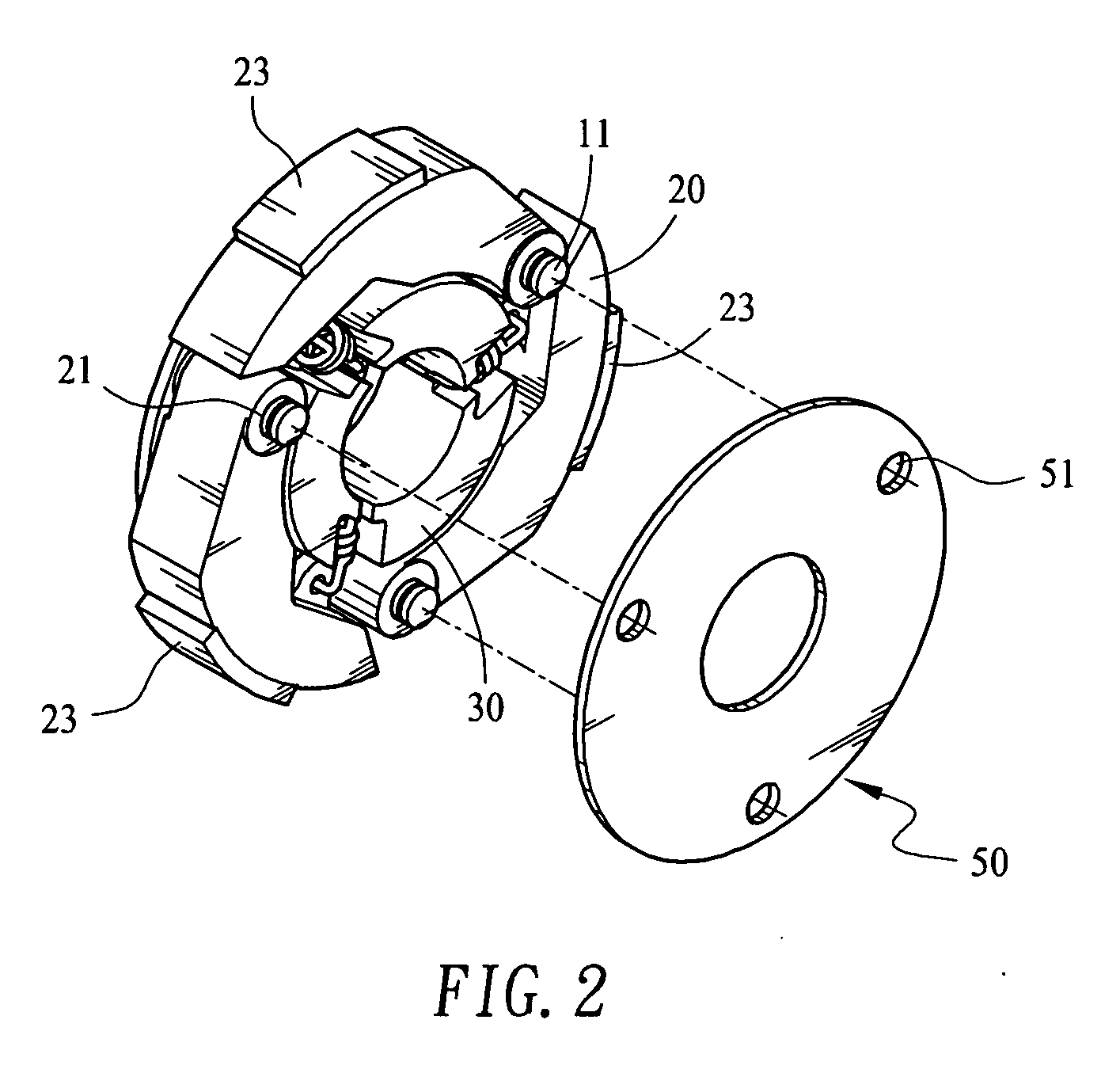

Automatically and continuously adjustable centrifugal clutch

InactiveUS20080060903A1Large startingLarge transmission torqueAutomatic clutchesAcceleration rateCentrifugal clutch

An automatically and continuously adjustable centrifugal clutch has a base plate used to receive a power source; at least one centrifugal weight assembled to the base plate; at least one angular acceleration response assembly connected to the at least one centrifugal weight; and at least one returning element having two ends separately connected to one centrifugal weight and one angular acceleration response assembly. With these arrangements, a relatively high engine revolving speed at clutch engagement may be obtained by an instantaneously quickly increased acceleration rate at starting, so that a mechanism may have a large starting torque and good accelerating ability; and a relatively low engine revolving speed at clutch engagement may also be obtained by slow acceleration at starting to enable smooth starting at reduced fuel consumption.

Owner:WU CHUN YI & PEI HSUAN WU

Automatic gear-shifting wheel-hub motor of electric vehicle

ActiveCN102403833AStable jobImplement automatic conversionElectric machinesToothed gearingsStator coilEngineering

This invention discloses an automatic gear-shifting wheel-hub motor of an electric vehicle, which comprises wheel hubs (1), a left end cover, a right end cover (3, 18), a main shaft (11), and a motor, wherein the left end cover, the right end cover (3, 18) and the wheel hubs (1) compose an airtight shell body and can be rotationally arranged on the main shaft (11); the inner motor is mounted in the shell body; the inner motor comprises an inner shell body (2), an automatic clutch (5), rotor magnetic steels (15), a stator coil (16), and a stator iron core (17); the automatic clutch (5) is rotationally mounted on the main shaft (11); the rotor magnetic steels (15) are evenly distributed on the circumference of the outer shell body of the automatic clutch (5); the stator iron core (17) is fixed on the inner shell body (2) correspondingly to the rotor magnetic steels (15); the stator coil (16) is embedded on the stator iron core (17); two sides of the inner shell body (2) are correspondingly provided with a low-speed rotating mechanism and a high-speed rotating mechanism; by dint of a structure disclosed by this invention, the motor disclosed by this invention has advantages of simple and reasonable structures, large transmission torques, good climbing capacity and overloading capacity, high running efficiency, automatic gear shifting and the like.

Owner:东阳市创升机电有限公司

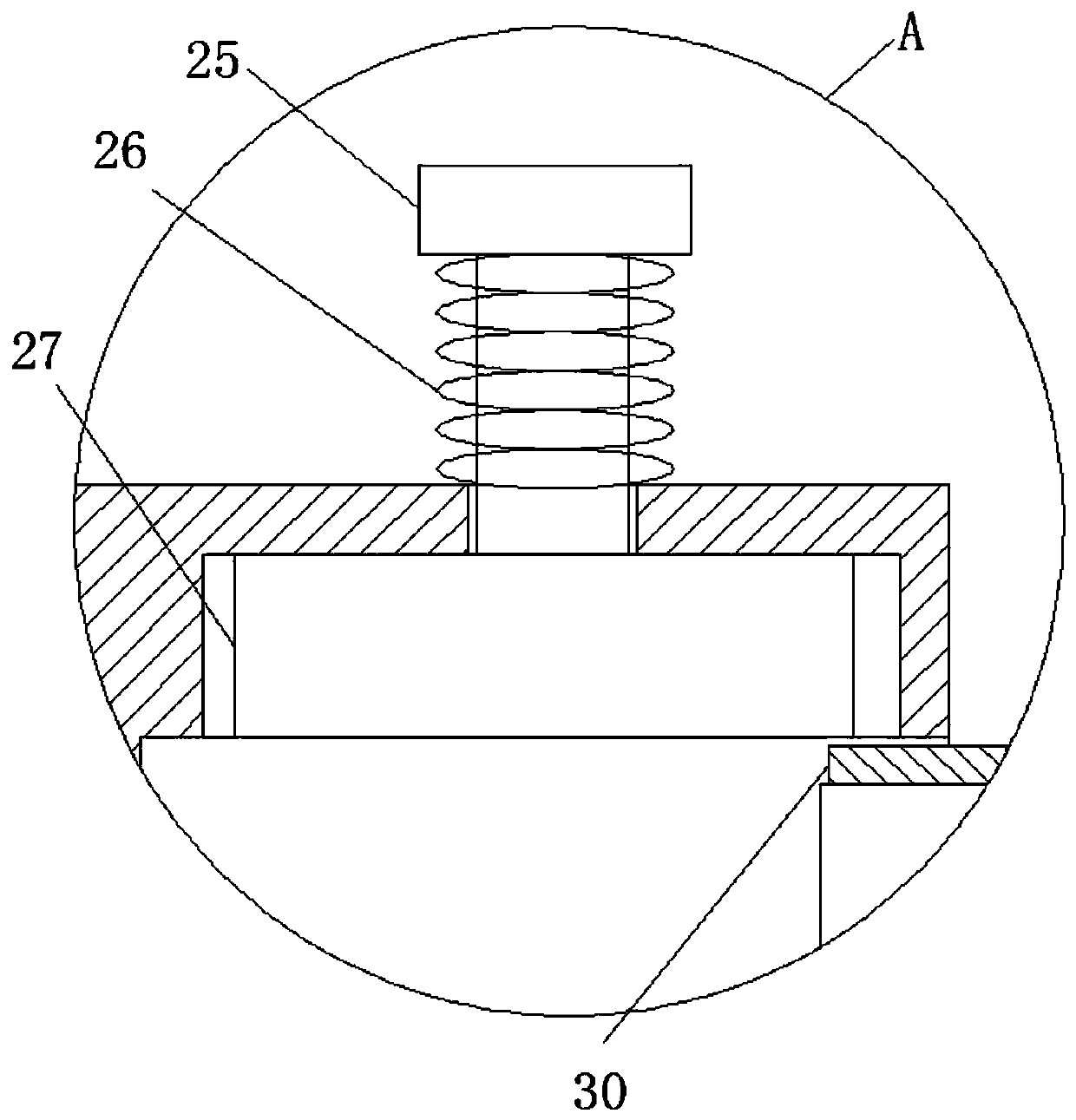

Progressive knocking device for interference fit assembly

ActiveCN108637637ALarge transmission torqueGuaranteed percussion forceMetal working apparatusDrive motorCam

The invention discloses a progressive knocking device for interference fit assembly. The left side of a driving motor is rotatably connected to a worm, the worm is engaged to a worm wheel, the worm wheel is fixedly connected to a cam, a rotating wheel is attached below the cam, the rotating wheel is rotatably connected to the upper surface of a swing arm, the lower surface of the swing arm is rotatably connected to the upper end of a telescopic rod, the lower part of the telescopic rod sleeves the upper part of the sleeve, the lower end of the sleeve is rotatably connected to a device body, ahammer is fixedly connected to the lower surface of the left end of the swing arm, a spring is arranged on the bottom surface in the sleeve, the upper end of the spring leans against the lower end ofthe telescopic rod, and the left side of the worm is fixedly connected to a first bevel gear. The device drives the rotating wheel and the swing arm to swing up and down in a reciprocating manner through the cam, the swing arm drives the hammer head to knock the upper end of a shaft part in the reciprocating manner, so that the shaft part enters a hole part, the worm wheel and worm are great in driving torque, and therefore, the knocking vigor is ensured. A driving lead screw and a driven lead screw drive a worktable, the shaft part and the hole part to move upward continuously while the hammer head knocks to achieve continuous knocking assembly, and meanwhile, a shock absorbing mechanism is also arranged in the bottom of the device body.

Owner:JIANGSU ZHONGZHAN VEHICLE PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com