Fluid-pressure driven differential feeding system

A cutting-feeding and hydraulic technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, feeding devices, etc., can solve the problems of large investment and high maintenance cost of AC servo system, achieve large transmission torque, high degree of automation, and prolong tool life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

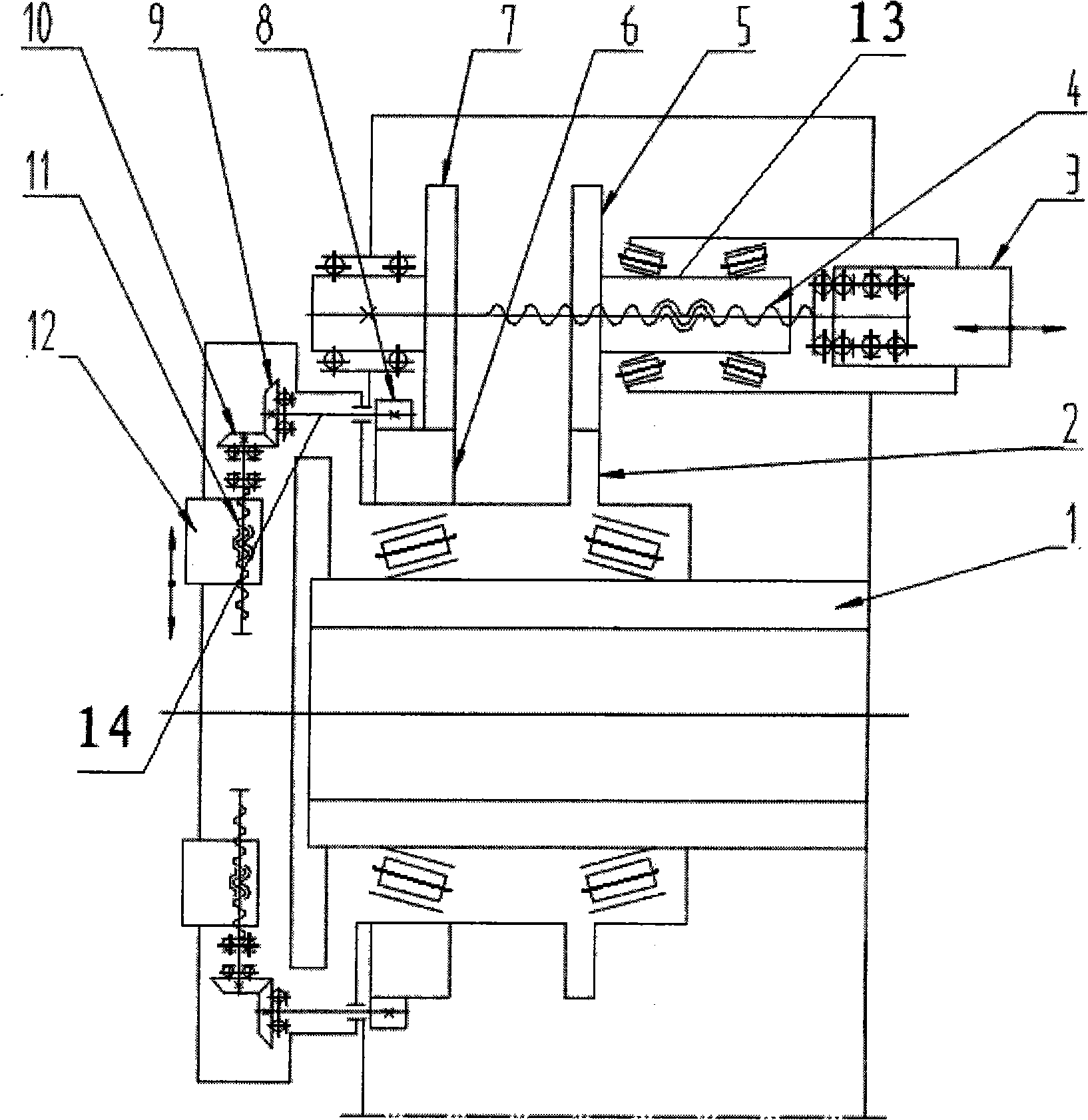

[0012] The implementation of the hydraulically driven differential feed system of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation of the present invention, and are only used as examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

[0013] Referring to the accompanying drawings, it can be seen that the hydraulically driven differential feed system of the present invention includes a main shaft 1, a knife rest 12, a screw mandrel 11 positioned on the knife rest 12, an oil cylinder 3, and a ball screw 4 positioned at the front end of the oil cylinder 3 , the front end of the ball screw 4 has a third gear 7, the first gear 5 is fixed on the nut 13 of the ball screw 4, the first gear 5 meshes with the second gear 2, and the second gear 2 is fixed on the main shaft 1 , the fourth gear 6 is idle on the main shaft 1, the fourth gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com