Speed reducer with 2K-H type low-range magnetic gear

A magnetic gear and reducer technology, applied in the direction of permanent magnet clutch/brake, electric brake/clutch, electromechanical device, etc., can solve the problems of long design cycle, high design cost, cumbersome design steps, etc., and achieve low machining accuracy requirements , The effect of improving stability and controllability, simplifying the structure of the reducer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings.

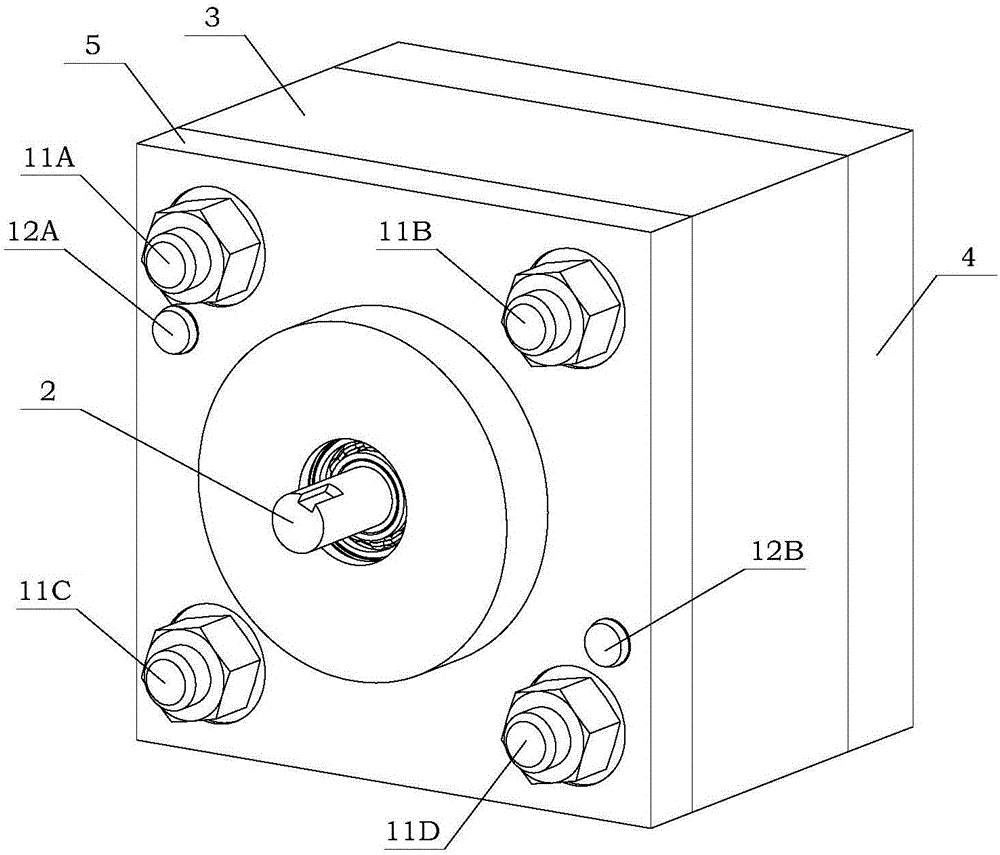

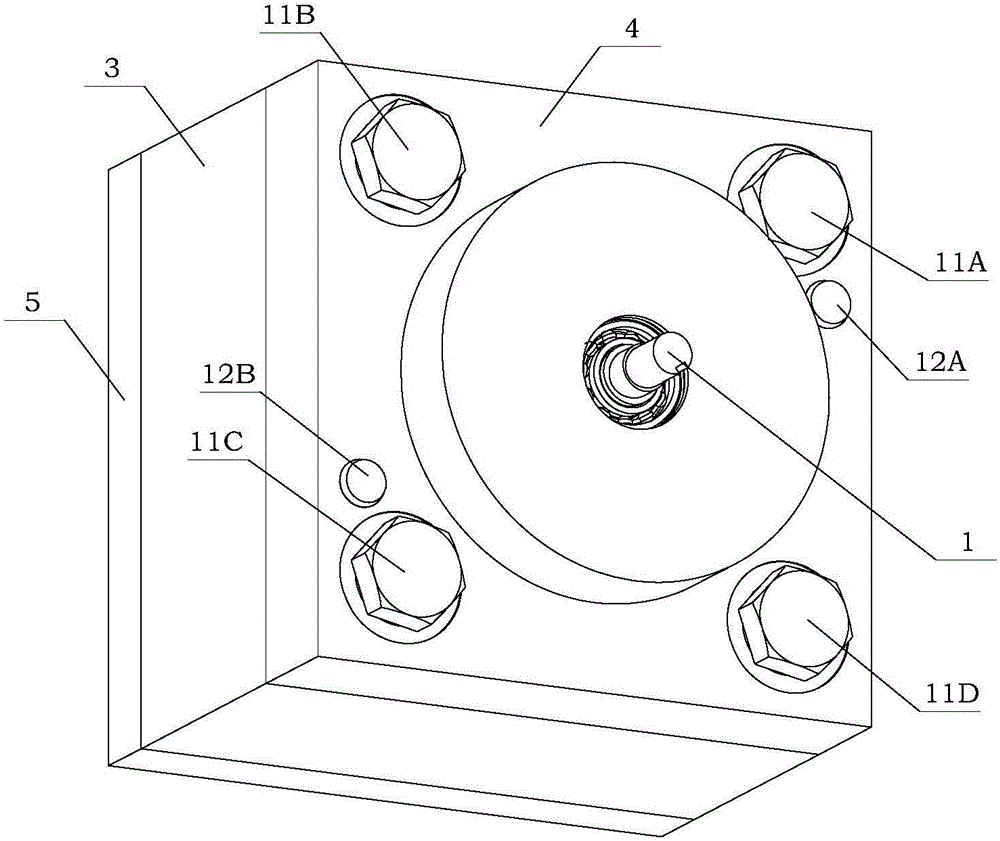

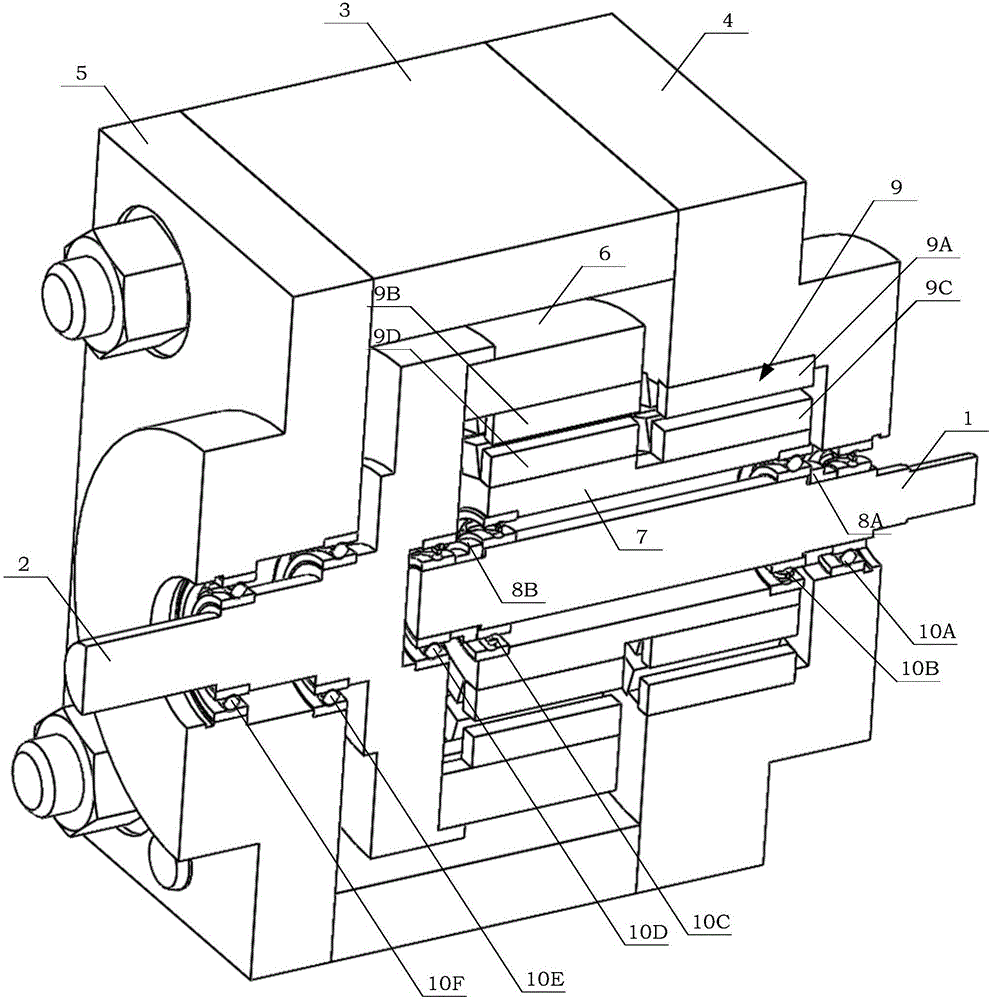

[0050] see figure 1 , Figure 1A , Figure 1B , Figure 1C As shown, the present invention designs a kind of reducer with 2K-H type few extreme difference magnetic gear, and it comprises input shaft 1, output shaft 2, housing 3, end cover (4,5), fixed ring 6, Duplex sleeve 7, shaft sleeves (8A, 8B), magnetic pole assembly 9, deep groove ball bearings (10A-10F), threaded rods (11A-11D) and pins (12A, 12B). In the present invention, the input shaft 1, the output shaft 2, the fixed ring 6, the duplex sleeve 7, the bushings (8A, 8B), the magnetic pole assembly 9 and the deep groove ball bearings (10A-10F) form a deceleration unit. The input shaft 1, the output shaft 2, the casing 3 and the B end cover 5 are processed by metal materials, such as aluminum alloy and stainless steel. A end cap 4, fixed ring 6 and duplex sleeve 7 are processed with magnetically p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com