Novel transverse flux motor

A transverse flux motor, a new type of technology, is applied in the directions of magnetic circuit static parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., which can solve the problem of poor magnetic performance, limit the electromagnetic performance of transverse flux High iron eddy current loss and other problems, to achieve the effect of convenient processing and manufacturing, simple assembly and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

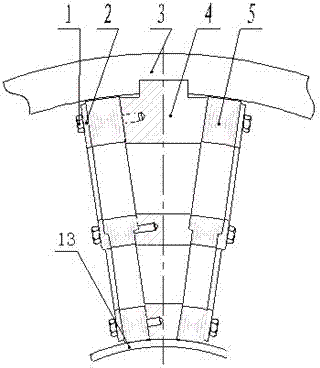

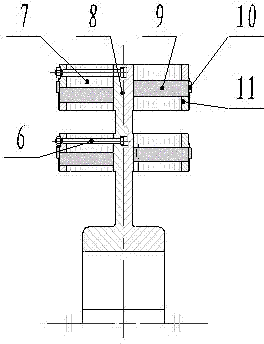

[0022] A new type of transverse flux motor, comprising a stator disk hollow frame 3 and a number of stator pole units (such as figure 1 , 3 shown) constitutes at least one layer of annular stator poles; it also includes a rotor mother plate 8 and a number of rotor pole units (such as figure 2 , 4 shown) constitutes at least one layer of annular rotor poles.

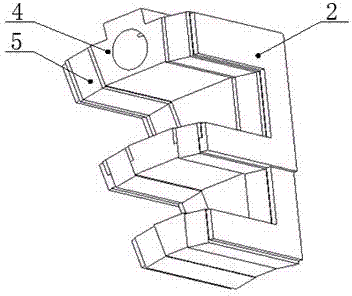

[0023] Such as figure 1 , image 3 As shown, the stator pole unit includes a stator core fixing bolt 1 , a magnetic pole pressure plate 2 , a magnetic pole base plate 4 and a stator core 5 . One end of the magnetic pole base plate 4 is vertically fixed to the hollow base of the stator disk 3, the stator core 5 is fixed on one side of the magnetic pole base plate 4 through the stator core fixing bolt 1, and the stator cores are fixed on both sides of the magnetic pole base plate 4 5. There is also a magnetic pole clamping plate 2 between the stator core 5 and the stator core fixing bolt 1. The stator core fixing bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com