Patents

Literature

1709 results about "Magnetic composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

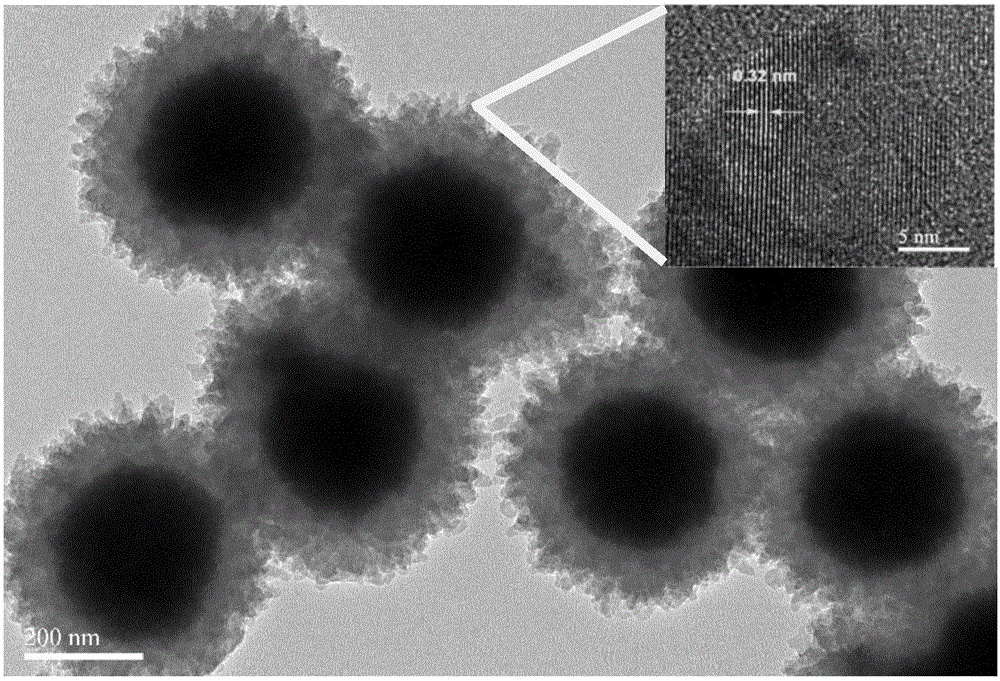

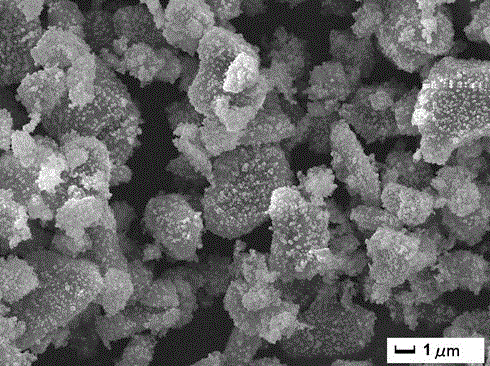

Method for preparing non-metallic element doped carbon coated metal nanoparticle magnetic composite

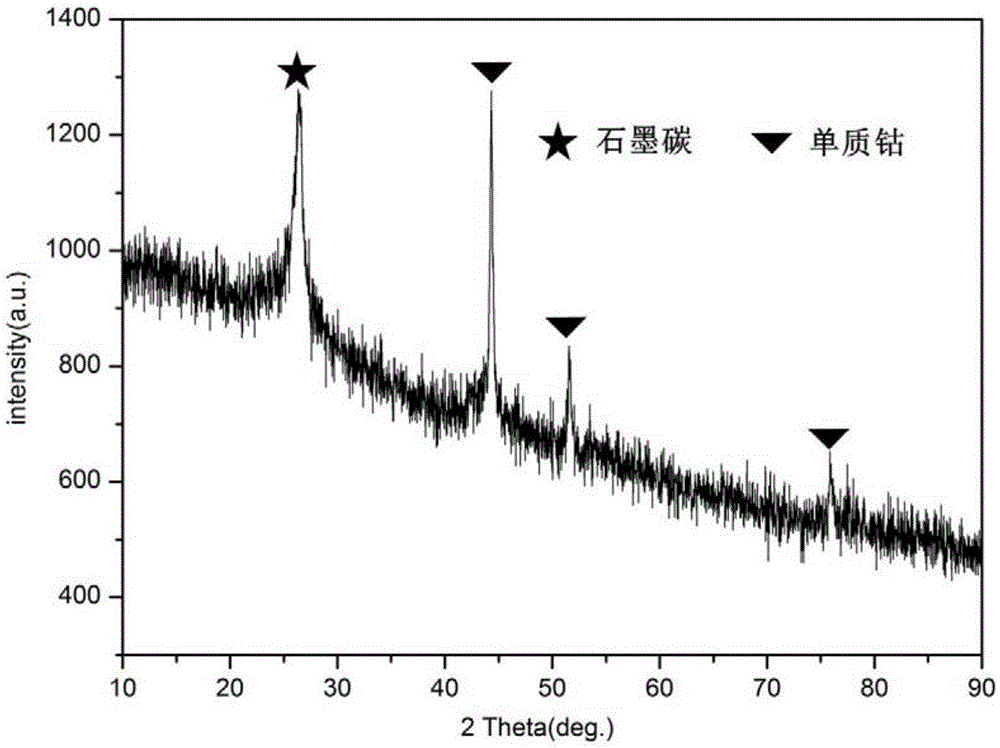

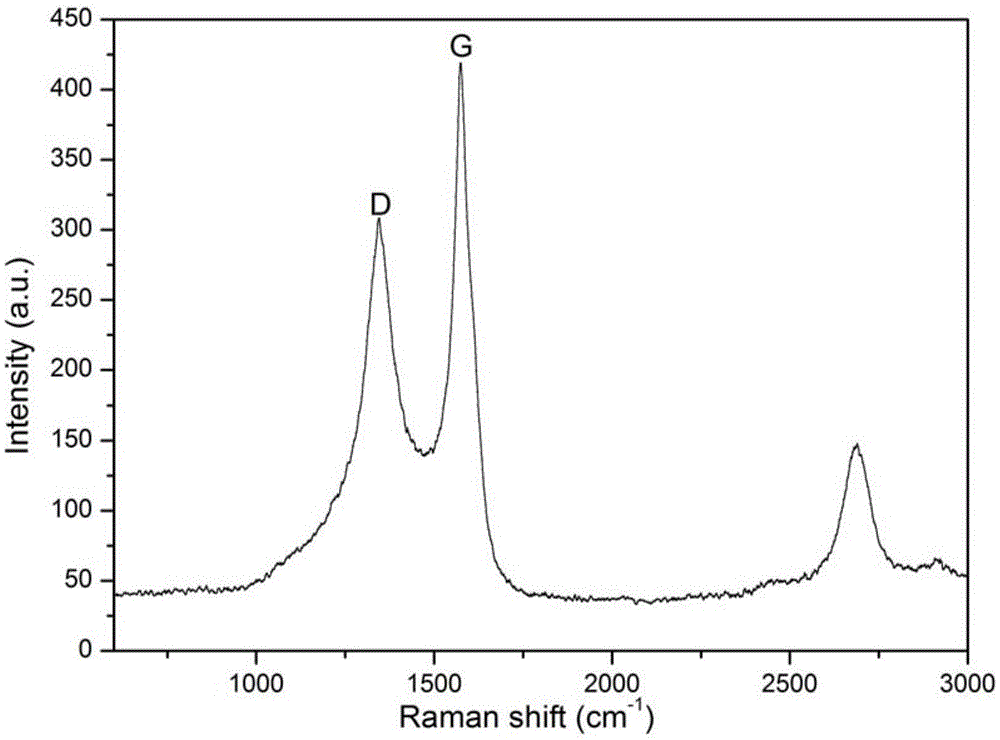

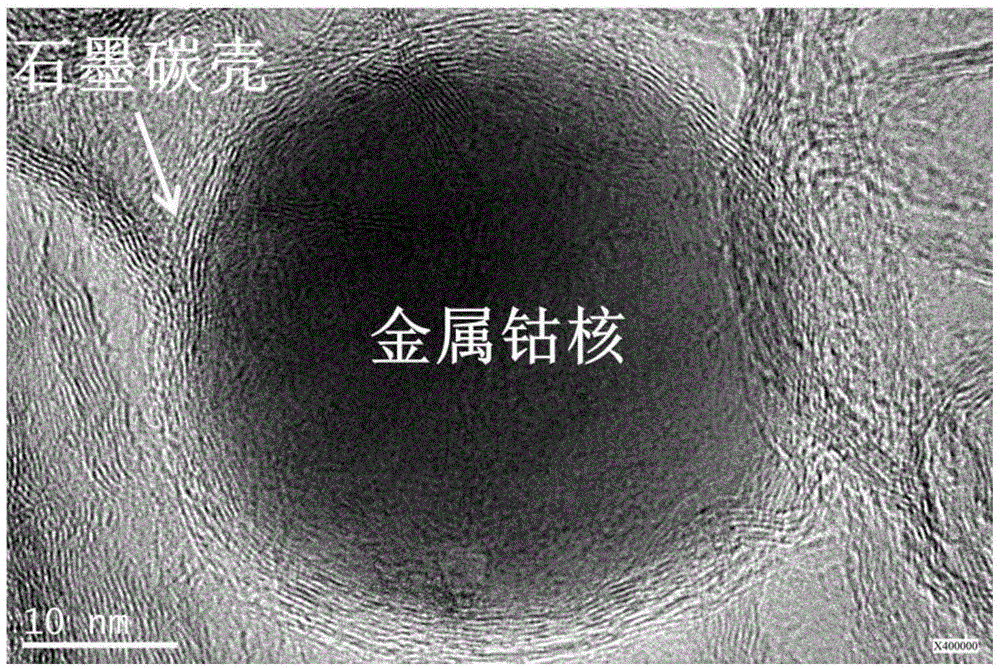

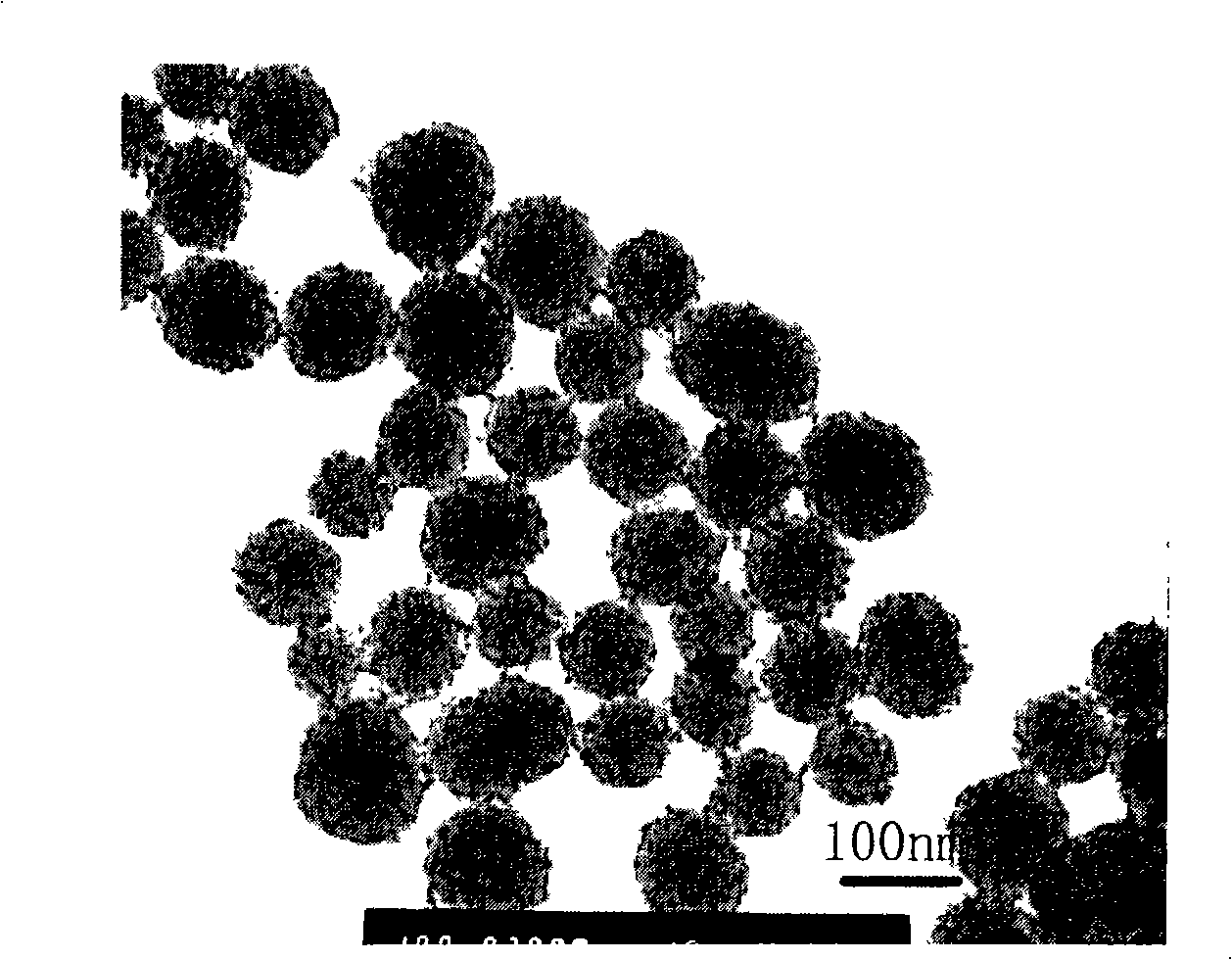

ActiveCN105478755AGood dispersionHigh purityTransportation and packagingMetal-working apparatusDispersityCyanamide compound

The invention discloses a method for preparing a non-metallic element doped carbon coated metal nanoparticle magnetic composite. The method comprises the steps that water-soluble metal divalent salt, a cyanamide compound and a nitrogen or boron or sulfur containing non-metallic compound are added into a methanol solution to be mixed, dissolved, dried and ground, and obtained homogeneous-phase powder is subjected to roasting pyrolysis under the protection of inert gas; and a pyrolysis product is subjected to acid pickling, washing, drying and grinding, and a target product is obtained. According to the whole preparing process of the method, metal ion reduction, metal nanoparticle coating and doping of nitrogen / boron / sulfur and other non-metallic elements are achieved in one step. The composite prepared through the method is high in degree of graphitization, good in dispersity between particles and high in purity, and the preparing method has the advantages that the cost is low, the process is simple, and large-quantity synthesis can be easily achieved.

Owner:合肥庐阳科技创新集团有限公司

Magnetic composite nano microsphere capable of emitting fluorescence and preparation thereof

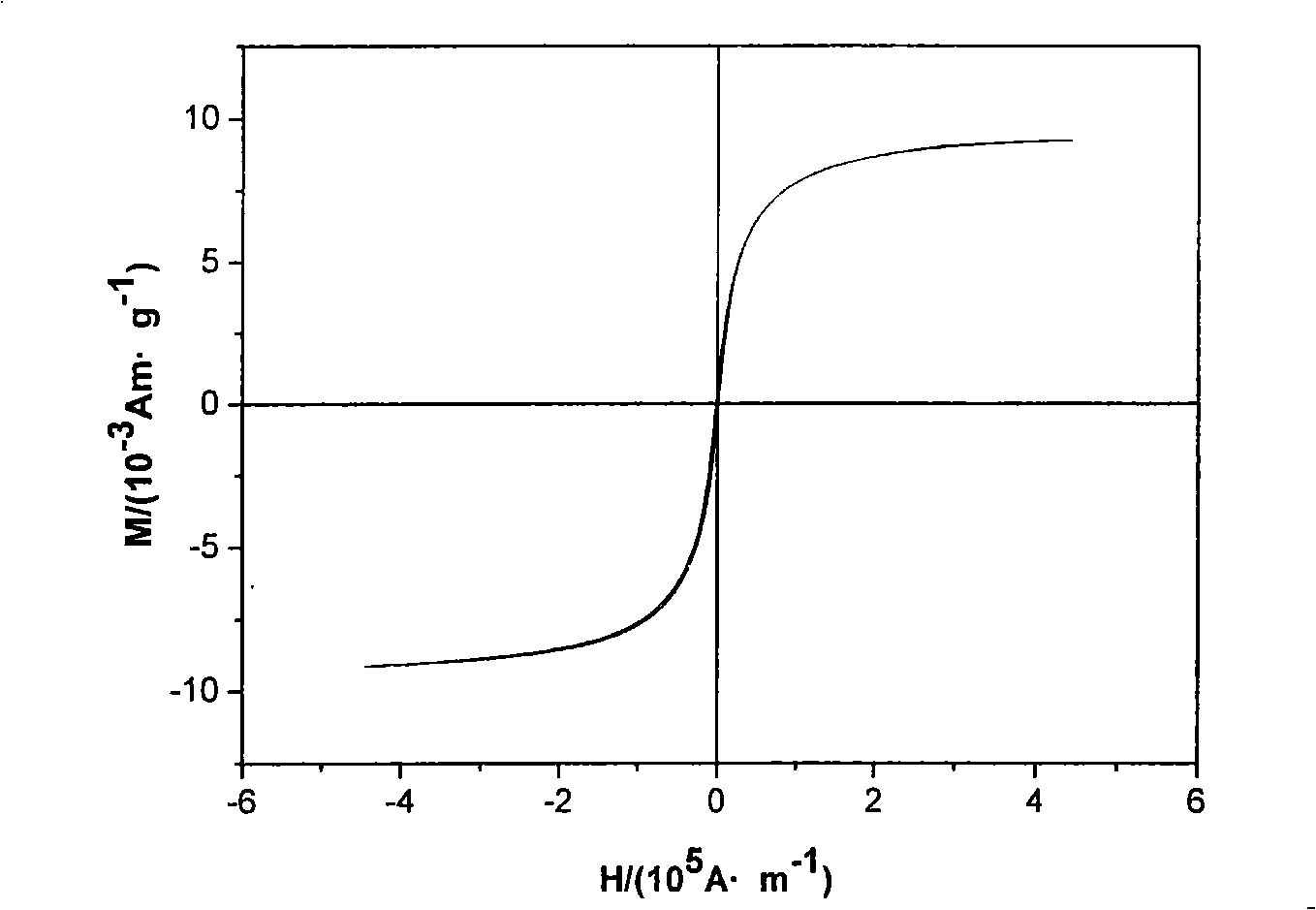

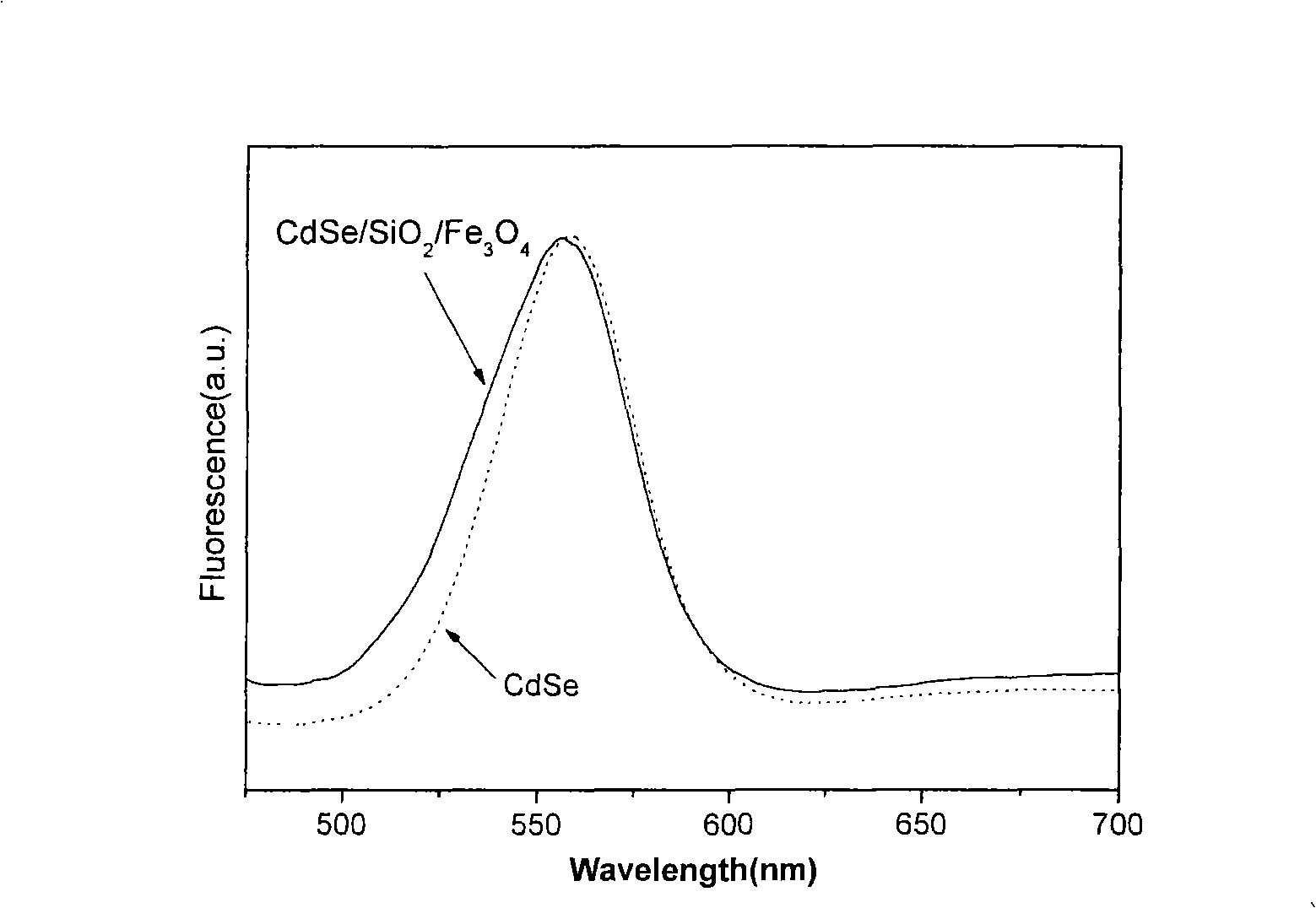

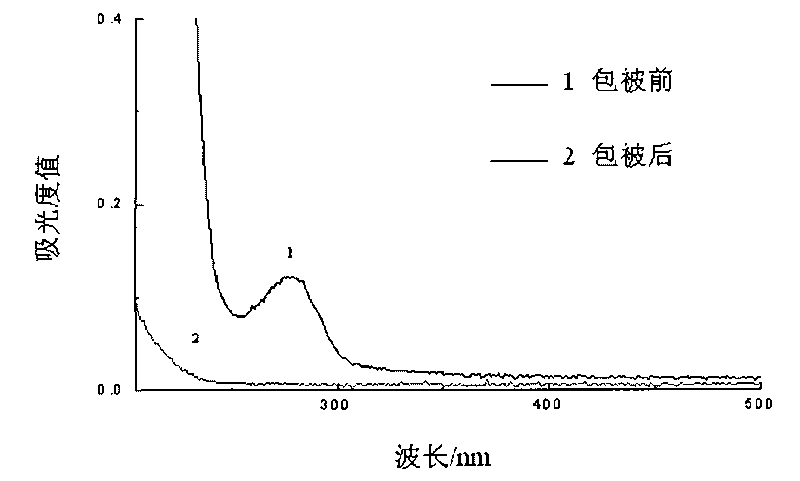

The invention discloses a magnetic composite nano microsphere capable of emitting fluorescent light and a preparation method thereof, which belong to the inorganic nanophase material field. The preparation method comprises the following steps: firstly, the sol-gel method or the reversed phase microemulsion method is adopted for performing base catalysis on alkyl silicate, and a layer of silicon dioxide is uniformly coated on the surface of inorganic magnetic nano particles; secondly, an amino silane coupling agent is adopted for performing surface finish on silicone dioxide; thirdly, semiconductor quantum dots are absorbed on the surface of the silicone dioxide through the electrostatic action between an amino group and a carboxyl group on the surface of the amino silane coupling agent; and fourthly, the magnetic composite nano microsphere with a core-shell structure capable of emitting the fluorescent light is obtained. The preparation method has easy obtained raw materials and low cost. The composite nano microsphere obtained has good stability, controllable grain size, narrow distribution, and has good magnetic responsivity and performance of being capable of emitting the fluorescent light, and the two performances are controllable. The magnetic composite nano microsphere and the preparation method can be applied in the fields of biomedicine, bioengineering, etc. including immunoassay, biological labeling and separation, cell imaging and so on.

Owner:TONGJI UNIV

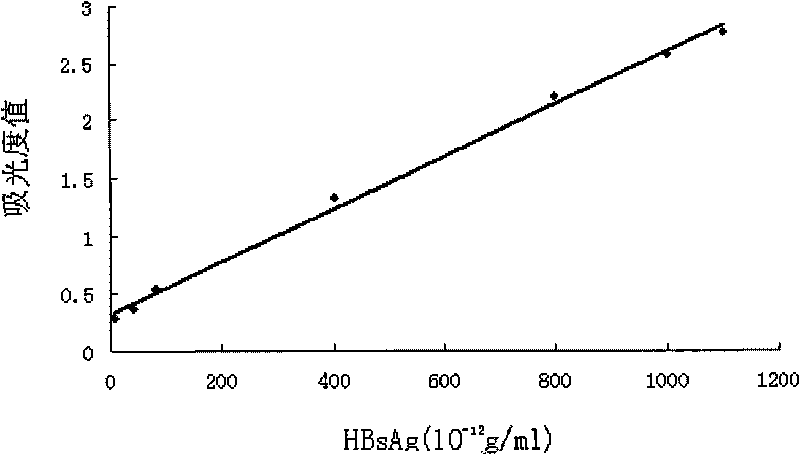

Method for performing immunological test on biomolecules by avidin/streptavidin magnetic composite particles

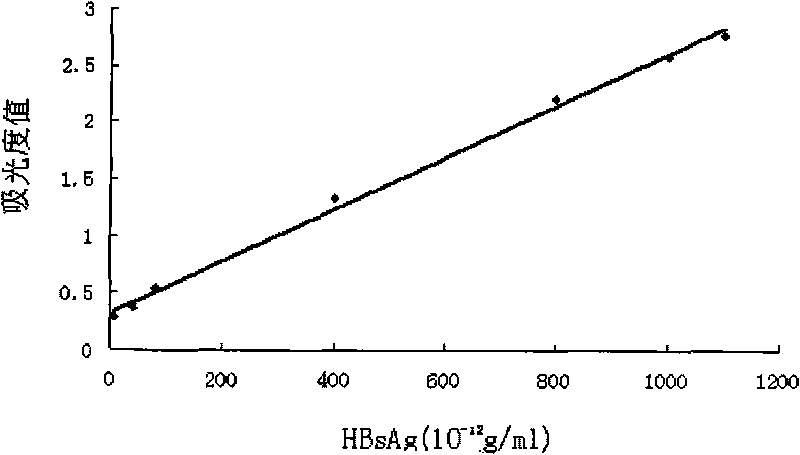

ActiveCN101713779ALarge coupling capacityImprove suspension stabilityMaterial analysisBiotin-streptavidin complexStrong binding

The invention relates to the immune analysis field, in particular relating to a method for performing an immunological test on biomolecules by avidin / streptavidin magnetic composite particles, which takes avidin / streptavidin magnetic composite particles as carriers, and comprises the following steps:, coating biotinylated antibody or antigen, adding a specimen to be tested and enzyme labeled antibody / enzyme labeled antigen / enzyme labeled anti-antibody, adding chromogenic substrate and testing.Biotin and avidin / streptavidin has strong binding capacity, can fix the antigen / antibody labeled by the biotin through the avidin / streptavidin labeled on the surface of the magnetic composite particles so as to use the system to test specific antibody / antigen. The test system has the advantages of high sensitivity, high specificity, high stability, strong adaptability and the like.

Owner:XIAN GOLDMAG NANOBIOTECH

Magnetic composite microsphere with nucleocapsid structure and method for producing the same

InactiveCN101220187AHigh magnetic contentNarrow particle size distributionInorganic material magnetismMicrosphereMagnet

The invention belongs to the technical field of bioseparation material, in particular to a magnetic composite microsphere with nucleocapsid structure and a preparation method thereof. Nano ferroferric oxide decorated by oleic acid is firstly used as raw material, and is polymerized through template fine emulsion so as to prepare the monodisperse magnetic composite microsphere with high magnet content; and then the monodisperse micosphere is polymerized through seed emulsion and is added with different amount of shell monomer to prepare the magnetic composite microsphere with the nucleocapsid structure and the magnet content of 20wt percent to 80wt percent. The grain size of nucleocapsid composite microsphere is in narrow distribution, and the magnet content of the microsphere is controllable and the surface has functional reactive group; therefore, the microsphere of the invention can be surface-modified into a magnetic carrier of biological active molecule by chemical crosslinking to be applied in the biomedicine field. The method of the invention can be simply operated and the process of which can be controlled, thus having industrialized prospect.

Owner:FUDAN UNIV

Novel magnetic Fe / C@ MOF composite absorbent and preparation method thereof

InactiveCN104096542AWide variety of sourcesLow priceOther chemical processesAlkali metal oxides/hydroxidesOrganic dyeMaterials science

The invention provides a novel magnetic porous metal-organic skeleton (Fe / C@ MOF) composite absorbent and a preparation method thereof. Biomaterials which are extensive in source and low in price are served as the carbon source; the Fe<3+> ions are served as the precursor of the magnetic material; under the microwave-assisted condition, magnetic Fe / C material is quickly synthesized; then, the method of self-assembly layer by layer is adopted, so as to alternately deposit metal central ions and organic ligands on the surface of the magnetic Fe / C material and achieve the in-situ synthesis of the MOF; the magnetic Fe / C@ MOF composite is prepared. The preparation method provided by the invention is simple in the preparation technology; moreover, the prepared magnetic Fe / C@MOF composite has the advantages of large specific surface area, high adsorption capacity, capability of magnetic separation, reutilization and the like. The prepared composite simultaneously has the capability of adsorbing and removing organic dye and heavy metal ions. Therefore, the prepared composite has favorable application prospects in the fields of environmental remediation, wastewater treatment, separation science and the like.

Owner:GUANGXI NORMAL UNIV

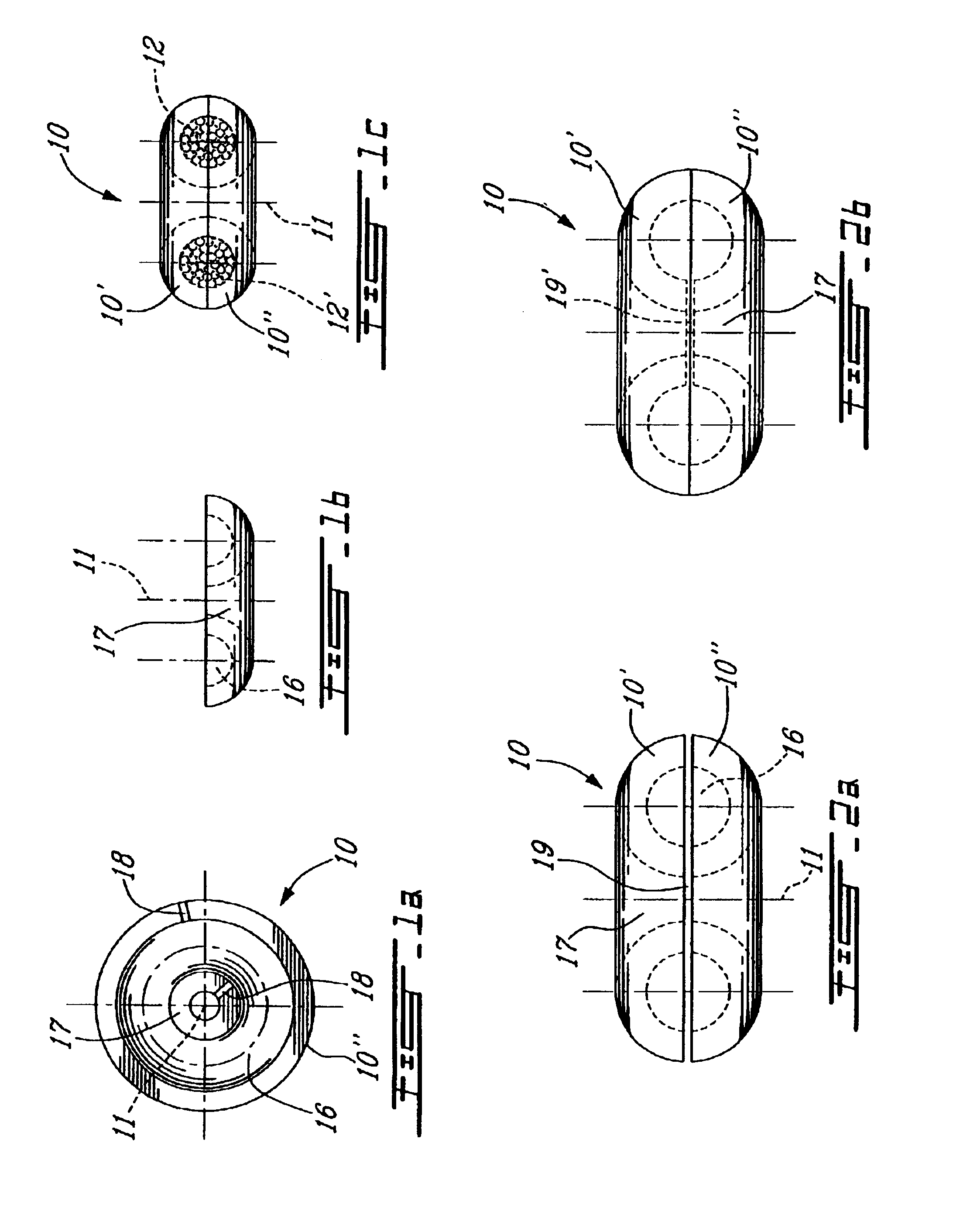

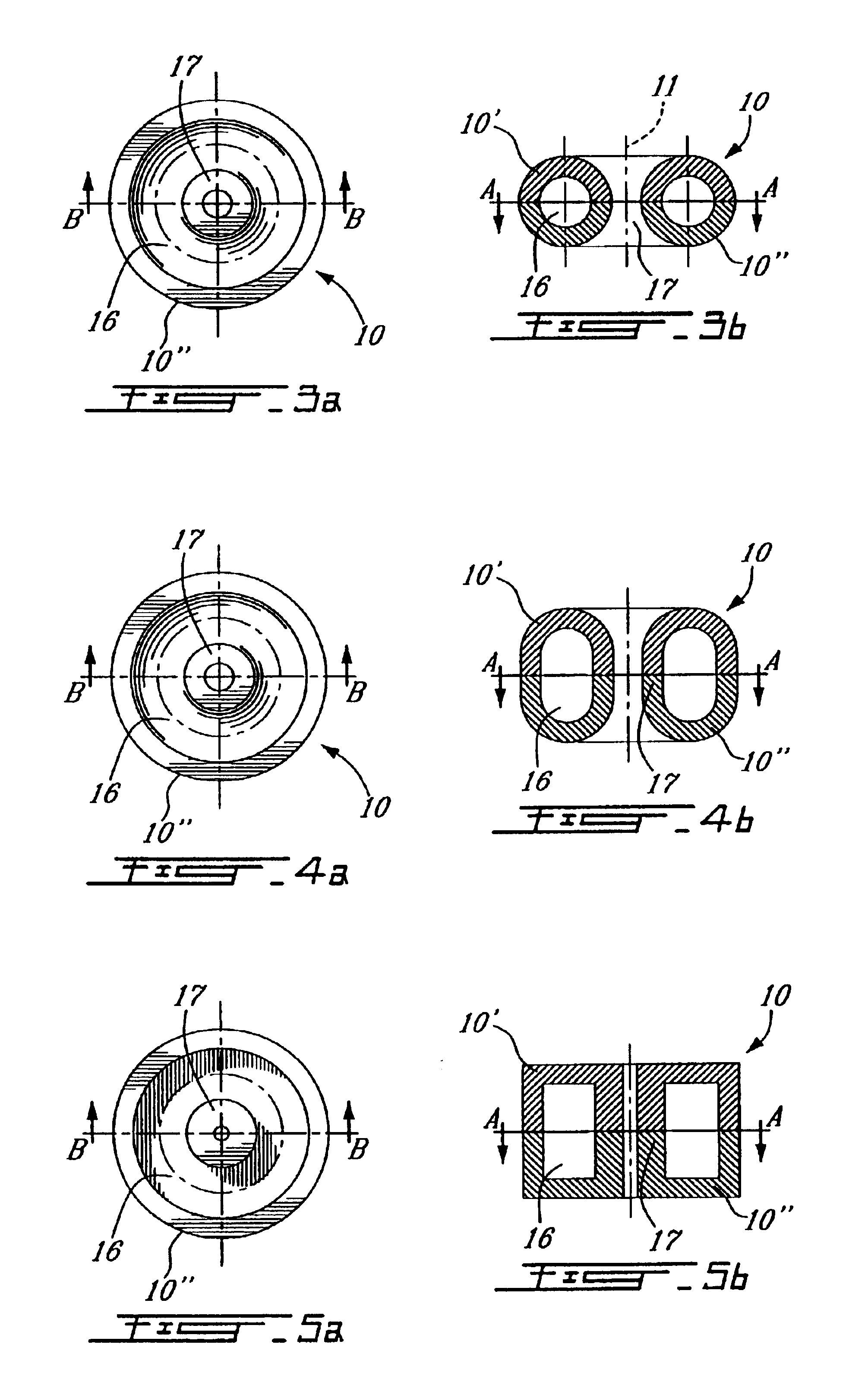

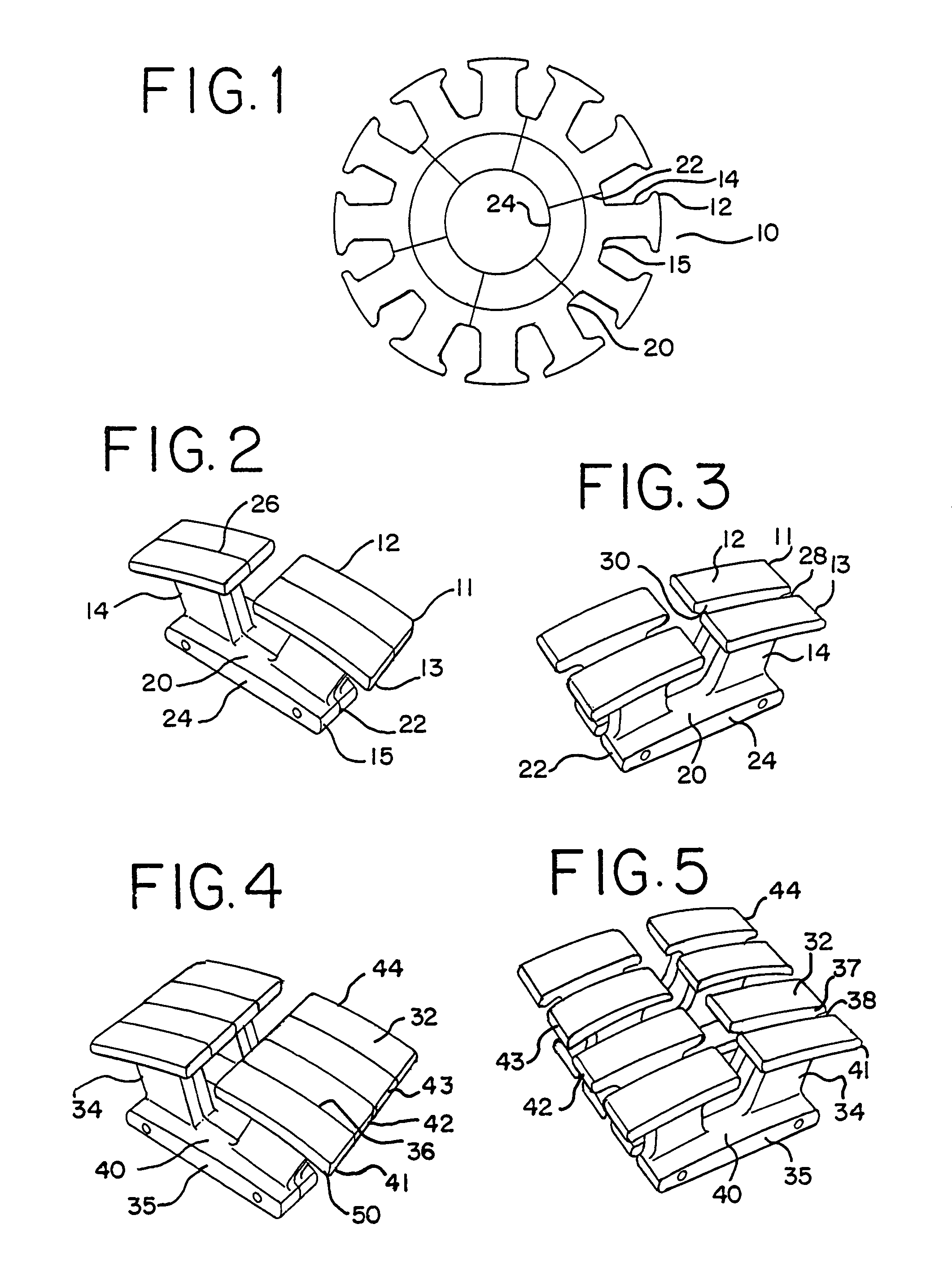

Power transformers and power inductors for low-frequency applications using isotropic material with high power-to-weight ratio

InactiveUS6879237B1Increase power to weightTransformers/inductances coolingTransformers/inductances coils/windings/connectionsBi-isotropic materialTransformer

A transformer for low frequency applications of from 50 Hz to 1000 Hz is described. The transformer comprises a core having a cylindrical symmetry around a main revolution axis. The core is formed of a soft isotropic magnetic composite material composed of iron and resin. Windings are enclosed in the magnetic core and disposed about a central column of the magnetic core and magnetically coupled with the inductor for low frequency applications, DC to 1000 Hz of similar construction is also described, the inductor comprises a core having a cylindrical symmetry around a main revolution axis. The core is formed of a soft isotropic magnetic composite material composed of iron and resin. Winding is enclosed in the magnetic core and disposed about a central column of the magnetic core and magnetically coupled with the magnetic core. The core is formed by core sections.

Owner:QUEBEC METAL POWDERS

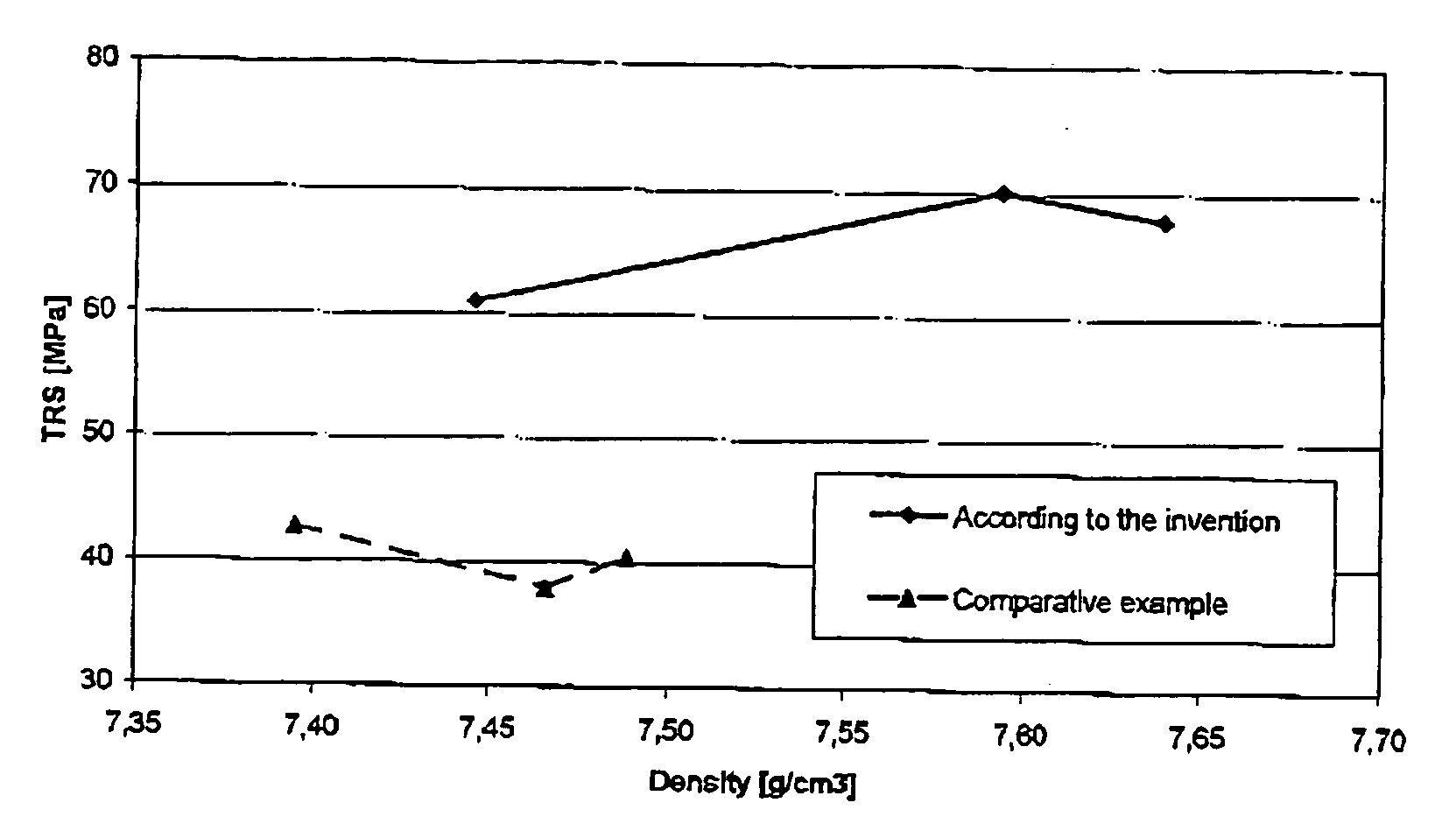

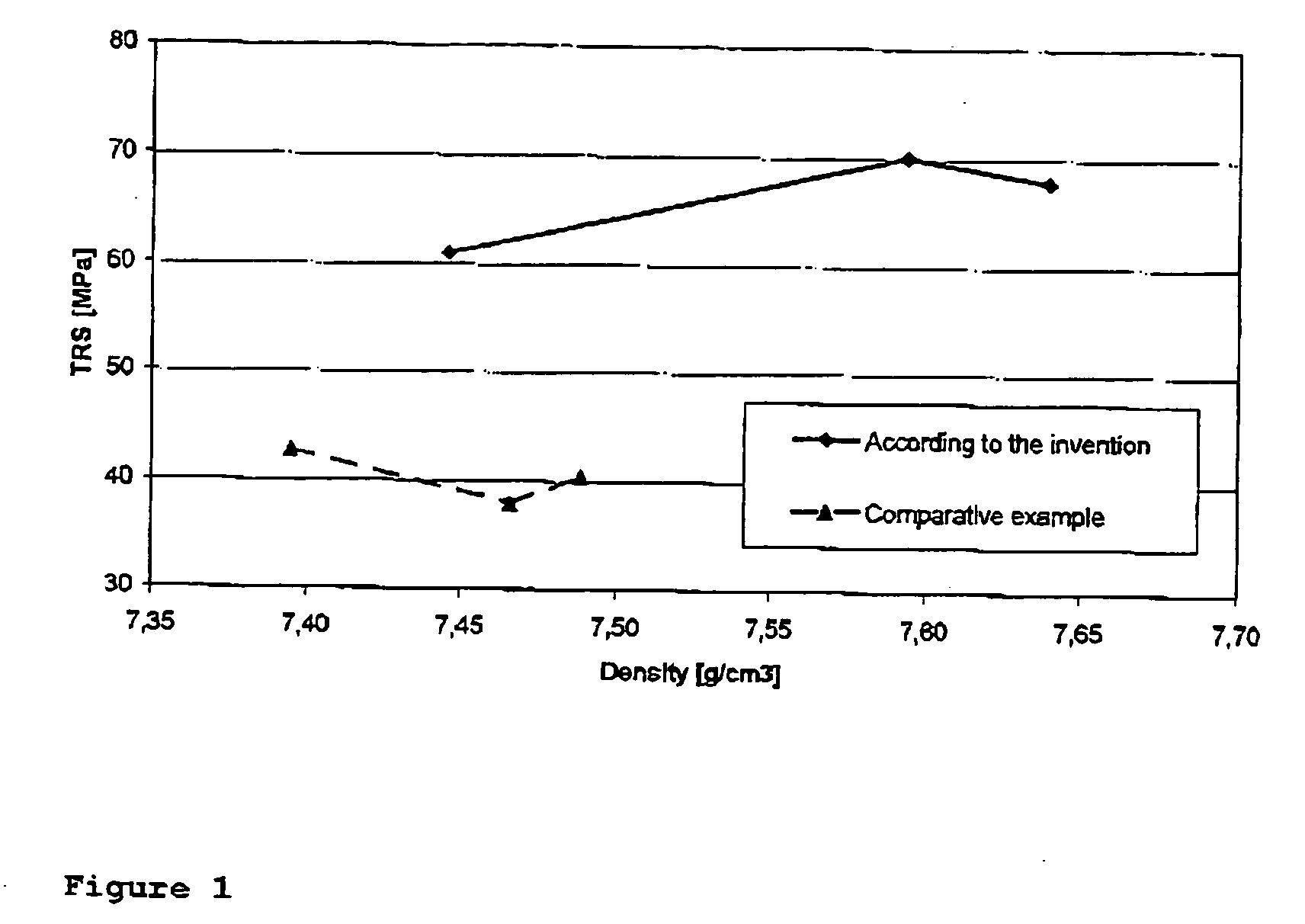

Iron-based powder

ActiveUS20040191519A1High wear of dieLess shiny and deterioratedSynthetic resin layered productsMetal-working apparatusSilanesZirconate

The present invention concerns a new ferromagnetic powder composition comprising soft magnetic iron-based core particles wherein the surface of the core particles are surrounded by an insulating inorganic coating, and a lubricating amount of a compound selected from the group consisting of silanes, titanates, aluminates, zirconates, or mixtures thereof. The invention also concerns a process for the preparation of soft magnetic composite materials using the new powder composition.

Owner:HOGANAS AB

Polymeric resin bonded magnets

Briefly, in accordance with one embodiment of the present invention, a process for making a magnetic composite which comprises providing a polymeric resin and a magnetic powder, the magnetic powder having a mean particle size with a value for standard deviation that is less than the value for the mean particle size of the said magnetic powder, the said magnetic composite being made by mixing said magnetic powder with said polymeric resin and molding the said mixture into a desired shape and a size and said magnetic composite having a magnetic permeability between 30 and 50. In another embodiment the present invention is a composition for a magnetic composite comprising a polymeric resin and a magnetic powder, the said powder having a mean particle size with a value of standard deviation that is less than the value of the mean particle size of the magnetic powder, wherein said magnetic composite has a magnetic permeability between about 30 and about 50.

Owner:SABIC INNOVATIVE PLASTICS IP BV

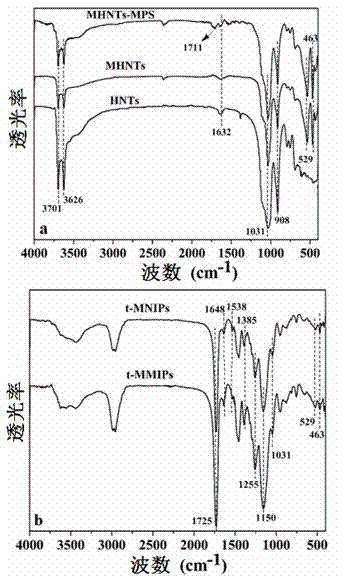

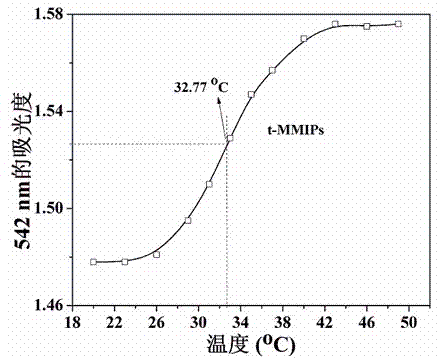

Magnetic composite material surface imprinting thermosensitive adsorbent, and preparation method and application thereof

InactiveCN102527349AHigh mechanical strengthImprove adsorption capacityOther chemical processesSolid sorbent liquid separationMethacrylateMagnetic stability

The invention relates to the technical field of preparation of environment functional materials, in particular to a magnetic composite material surface imprinting thermosensitive adsorbent, and a preparation method and the application thereof. The method comprises the following steps that: firstly, a ferroferric oxide / nerchinskite nanotube magnetic composite material is prepared by a solvent thermal synthesis method; secondly, the magnetic composite material is modified on ethenyl by using 3-(methacrylo) propyltrimethoxyl silane; and finally, the nerchinskite nanotube magnetic composite material is prepared by using the ethenyl-modified magnetic composite material as a substrate material, 2, 4, 5-trichlorophenol as a template molecule, methacrylate as a functional monomer, N-isopropylacrylamide as a thermosensitive functional monomer, ethylene glycol dimethacrylate as a cross-linking agent, and 2,2'-azodiisobutyronitrile as an initiator. The prepared thermosensitive imprinting adsorbent is obvious in thermal stability and magnetic stability, sensitive in magnetic effect and thermosensitive effect, relatively high in adsorption capacity, obvious in reversible absorption / release function along with temperature and obvious in tertiary calcium phosphate (TCP) molecule recognition performance.

Owner:JIANGSU UNIV

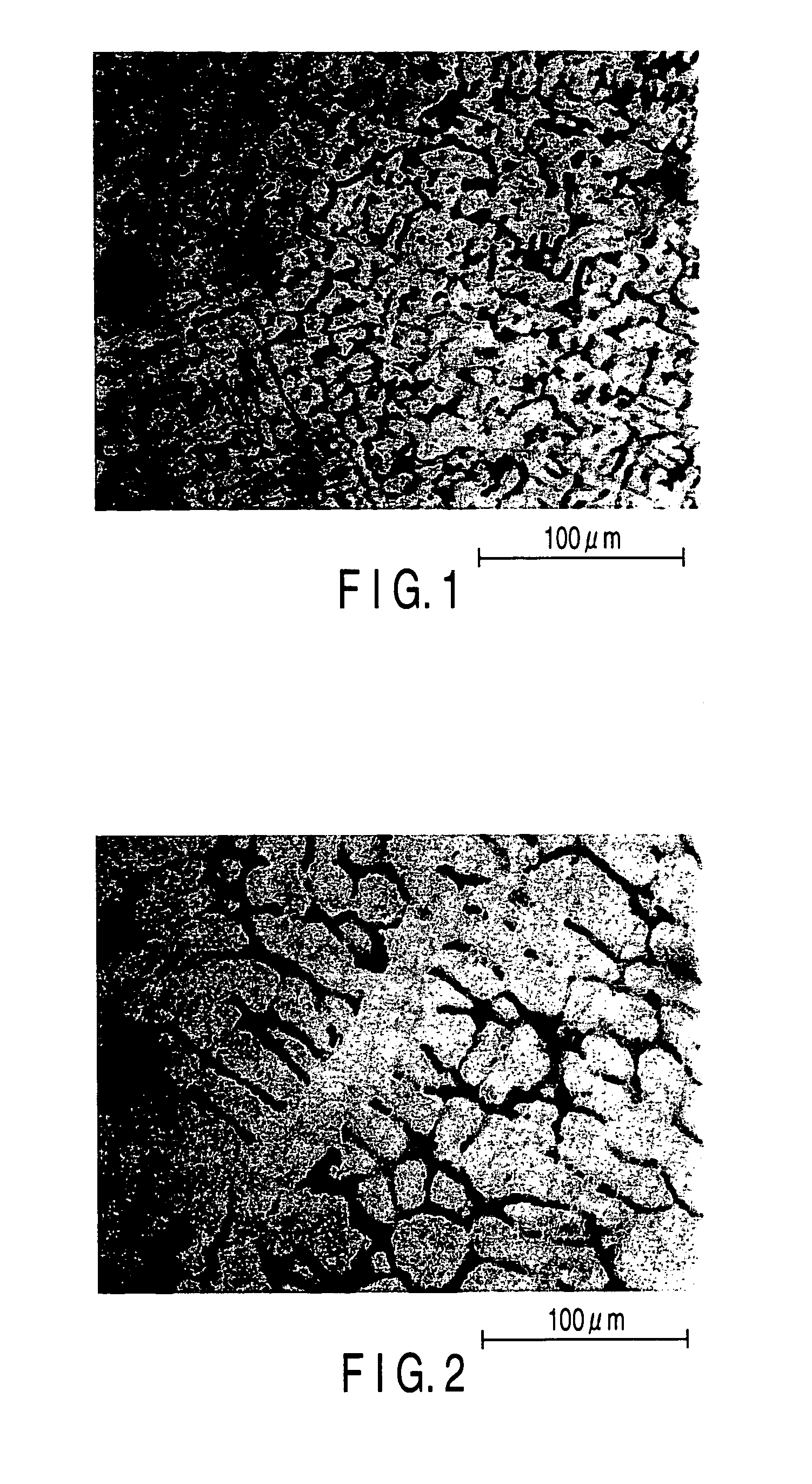

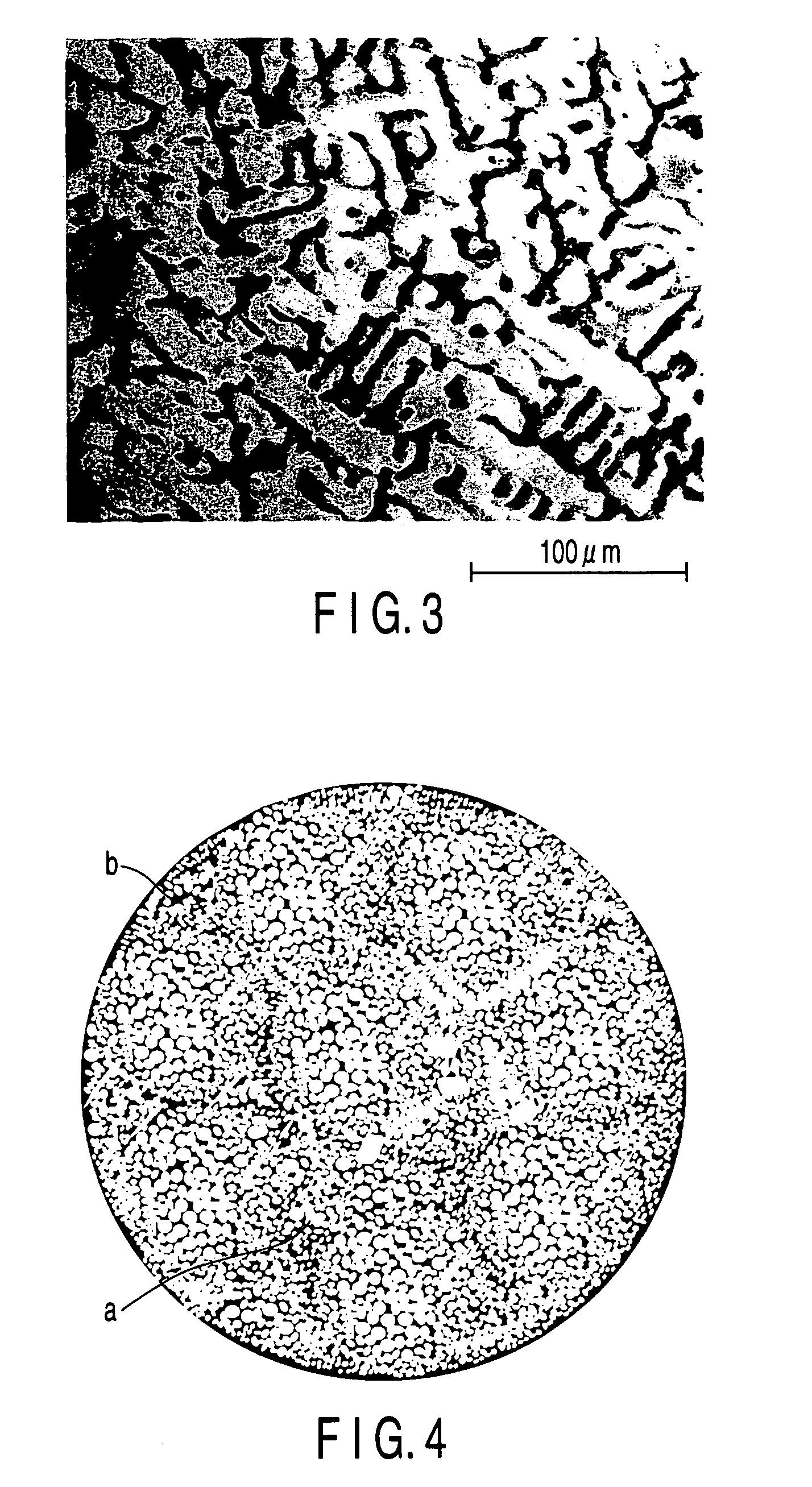

Magnetic composite material and method for producing the same

ActiveUS7168255B2Reduce generationSuppress pressure lossEnergy efficient heating/coolingInorganic material magnetismCrystal structureMagnetic refrigeration

The magnetic composite material of the present invention is used as a working substance in the magnetic refrigeration system and comprising at least two phases, including, a first phase composed of an intermetallic compound represented by a general formula: La(Fe(Co, Ni)Si)13, having an NaZn13 type crystal structure, and a second phase is composed of an iron alloy containing Si. The first phase is precipitated in an expansion size of 100 μm or less in average. Preferably, the magnetic composite material contains Fe as a principal component, La in an amount from 4 atomic % to 12 atomic %, Si in an amount from 2 atomic % to 21 atomic %, and Co and Ni in a total amount from 0 atomic % to 11 atomic %, and the total amount of Fe, Co and Ni being from 75 atomic % to 92 atomic %.

Owner:KK TOSHIBA

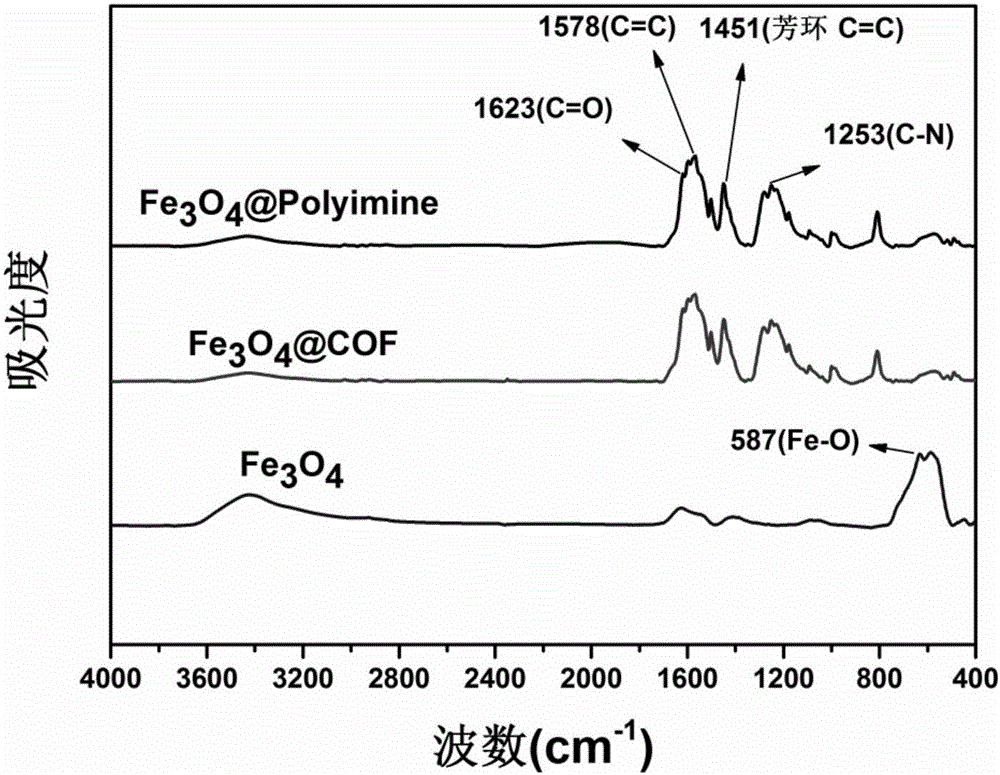

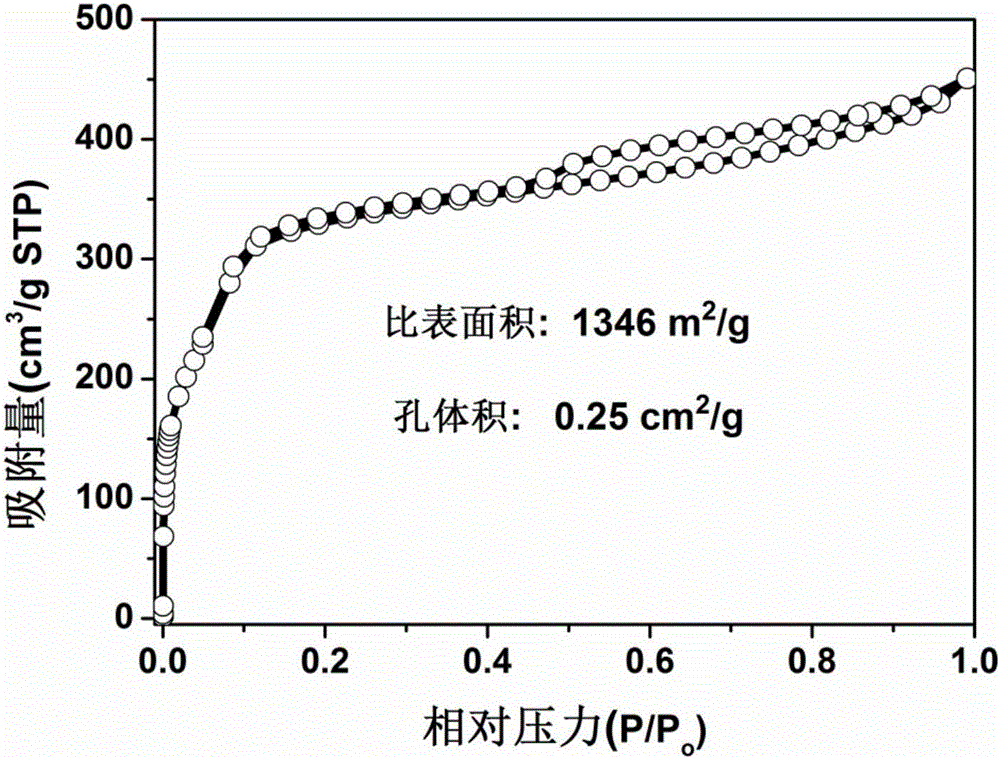

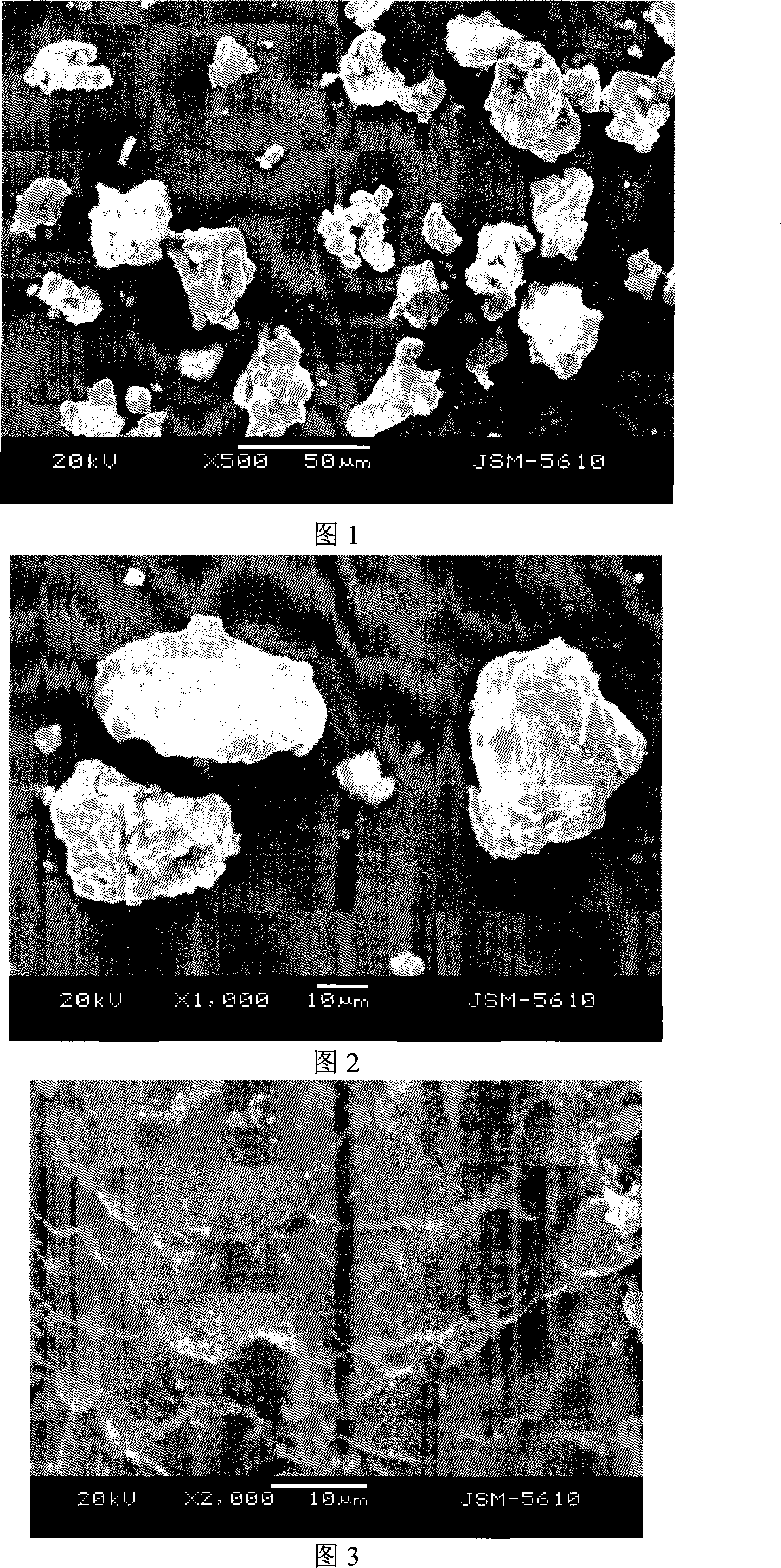

Covalent organic frame magnetic composite microspheres of core-shell structure and preparation method of microspheres

ActiveCN106117474AThickness is easy to controlAvoid defects such as poor dispersionInorganic material magnetismMicroballoon preparationDispersityPorosity

The invention belongs to the technical field of functional materials and particularly relates to covalent organic frame magnetic composite microspheres of core-shell structure and a preparation method of microspheres. Cores of the core-shell type composite microspheres are ferroferric oxide magnetic particles, and shells are covalent organic frames of ordered porous structures. The preparation method includes the steps that the ferroferric oxide magnetic particles are prepared through the solvothermal method; core-shell type magnetic composite microspheres are obtained through aldimine condensation reaction; under the solvothermal condition, the core-shell type magnetic composite microspheres in a formless and disordered channel state are induced to be converted into highly crystallized covalent organic frames with ordered channels, and the covalent organic frame magnetic composite microspheres with the excellent porous property are obtained. The composite microspheres have the advantages of being uniform in size, high in dispersity, high in mangnetic responsiveness, high and ordered in porosity and the like. The preparation method is simple, the process is controllable, and the size and the appearance of the composite microspheres are kept unchanged. The composite microspheres and the preparation method have wide application prospects in the fields of catalysis, drug loading, molecular sensing, energy storage and the like.

Owner:FUDAN UNIV

Soft magnetic composite organically/inorganically compound insulation coating powdered iron and preparation method thereof

InactiveCN101226807ASolve densityAddress mechanical propertiesInorganic material magnetismInductances/transformers/magnets manufactureIron powderSilicon dioxide

The invention relates to a soft magnetic composite material, in particular to a soft magnetic composite material of organic / inorganic insulator-coated ferrous powder and a process for preparation by sol-gel. In the soft magnetic composite material of organic / inorganic insulated-coated ferrous powder, the soft magnetic composite material comprises insulation material coated ferrous powder, wherein the quantity of the insulation material is 0.05%-1.5% of quality of the coated ferrous powder according to percentage by weight, the insulation material uniformly and dispersedly compounded by materials containing sol and polymer of silicon dioxide, and the polymer is 5%-30% of the insulation material in accordance with percentage by weight. The invention has the advantages that 1) the sol of silicon dioxide is generated in-situ of the solution and coated on the surface of the ferrous powder, 2) by employing the organic / inorganic insulator to coat the ferrous powder, combining the advantages of organic and inorganic coatings, the coating effect and mechanical property of insulated layers is excellent, and 3) the technique is simple and cost is low.

Owner:ZHEJIANG KEDA MAGNETOELECTRICITY

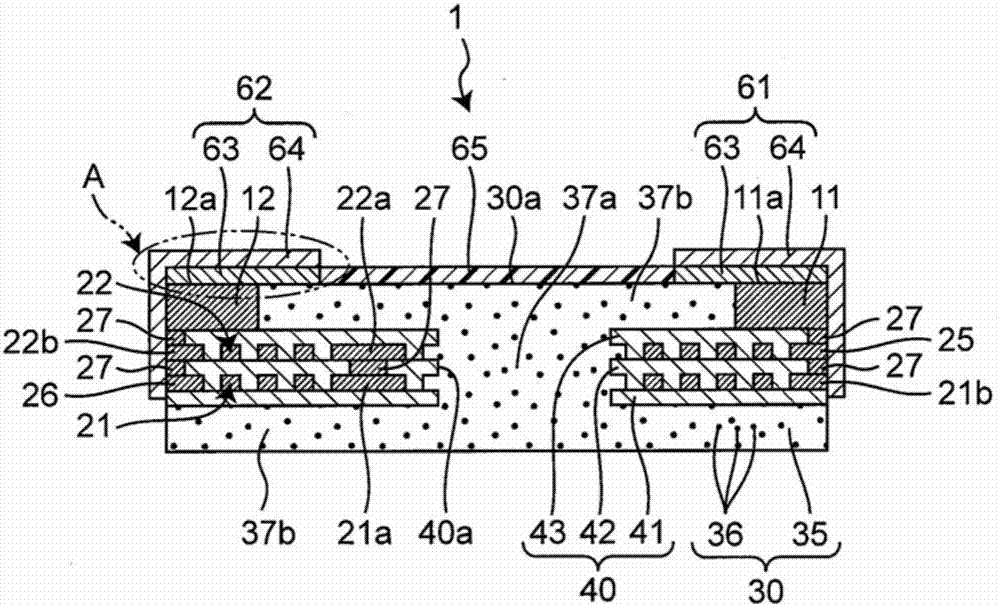

Inductor component

ActiveCN107039144APostural stabilityImprove installation stabilityTransformers/inductances coils/windings/connectionsCoils manufactureInductorMaterials science

An inductor component has a plurality of layers of spiral wirings a magnetic composite body directly or indirectly covering the plurality of layers of spiral wirings and made of a composite material of a resin and a metal magnetic powder with an average particle diameter of 5 mum or less an internal electrode embedded in the magnetic composite body with an end surface exposed from an outer surface of the magnetic composite body, the internal electrode being electrically connected to the spiral wirings, and an external terminal disposed on the outer surface of the magnetic composite body and electrically connected to the internal electrode.

Owner:MURATA MFG CO LTD

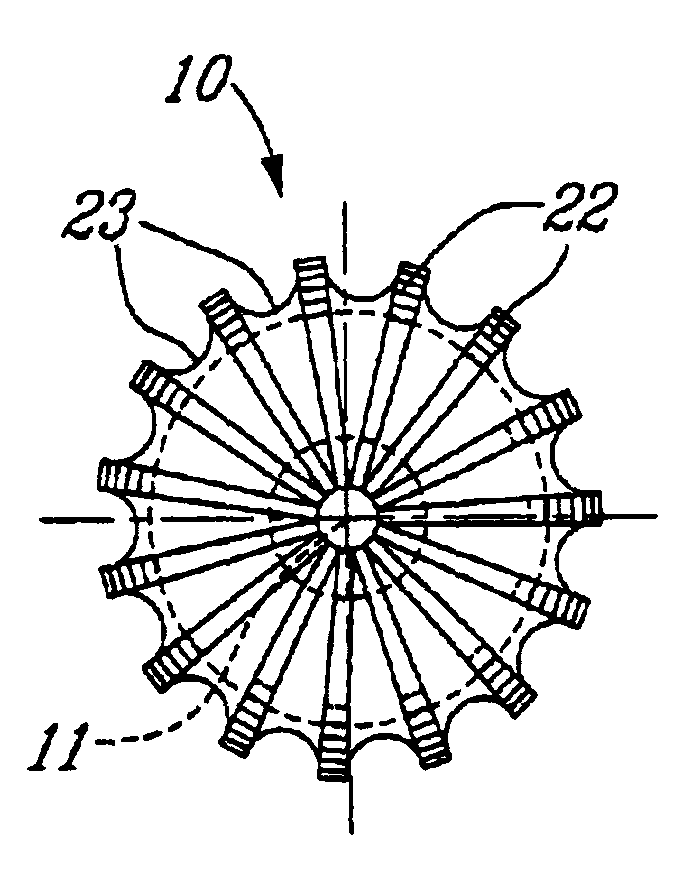

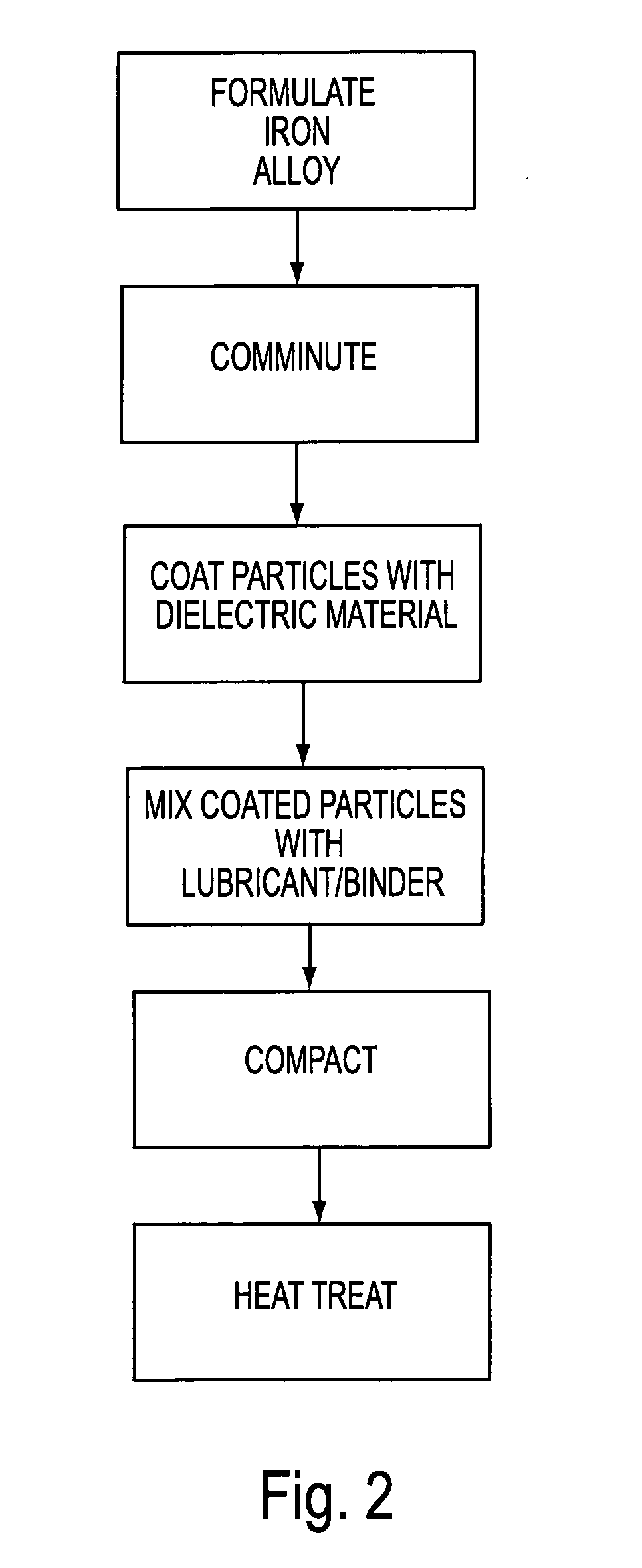

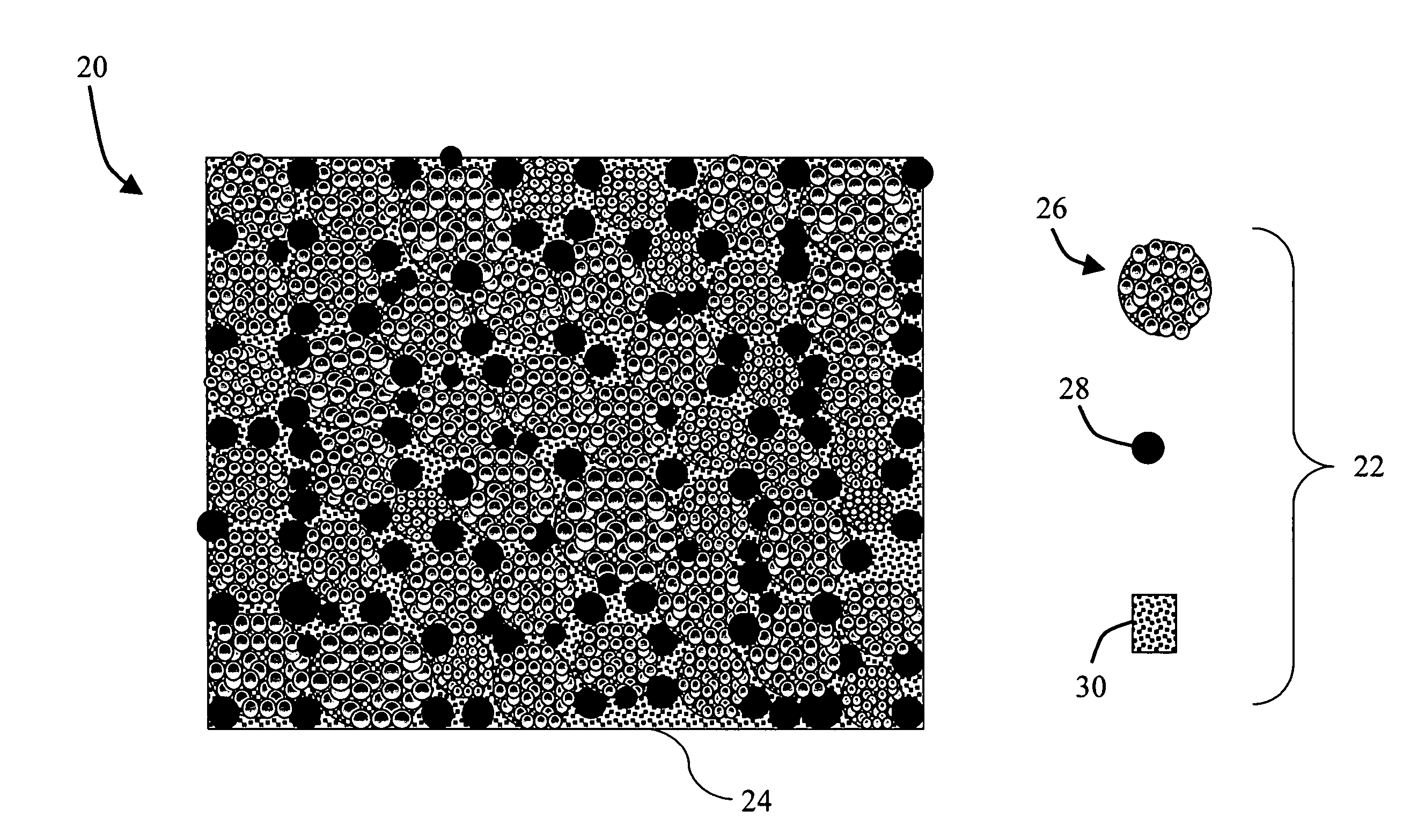

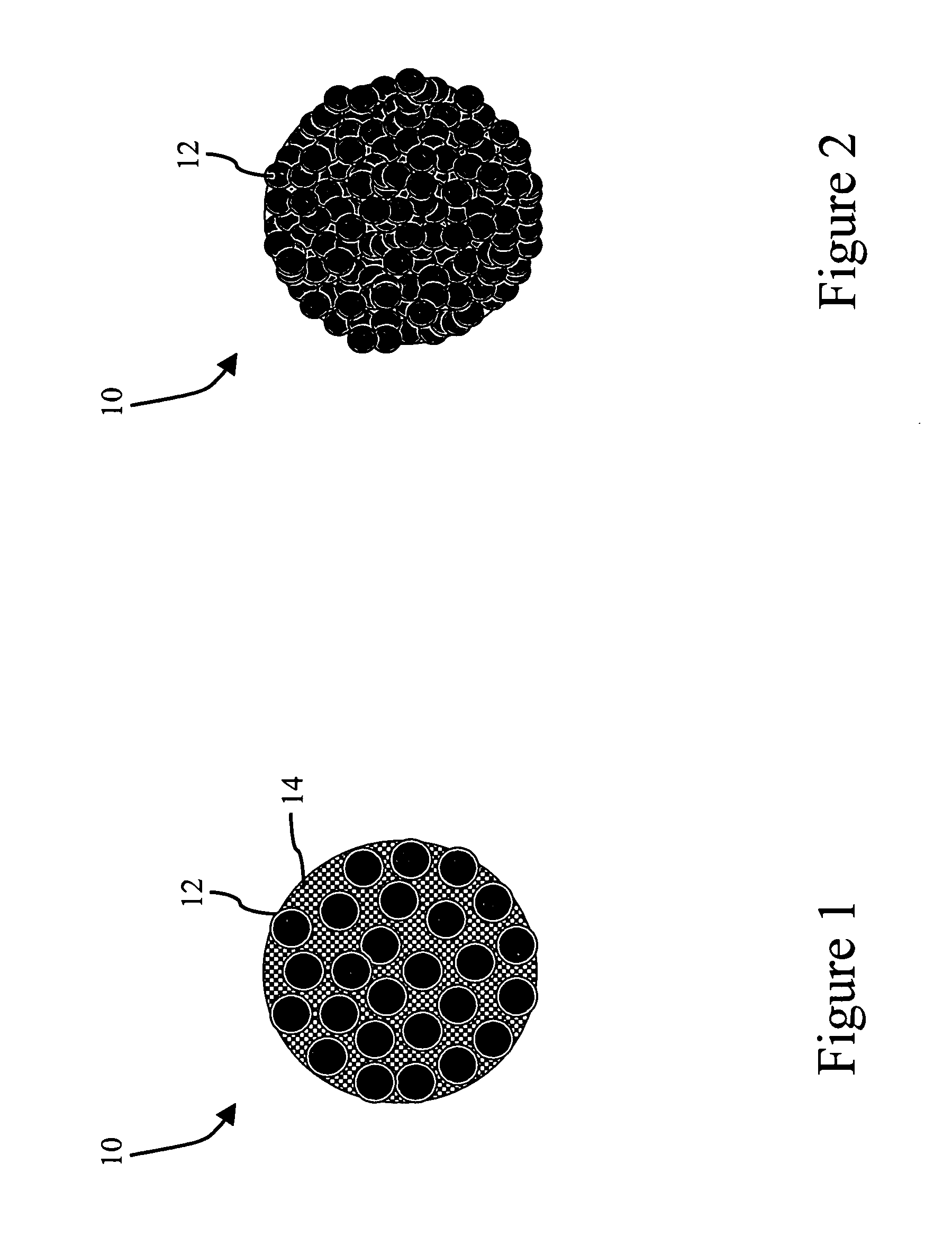

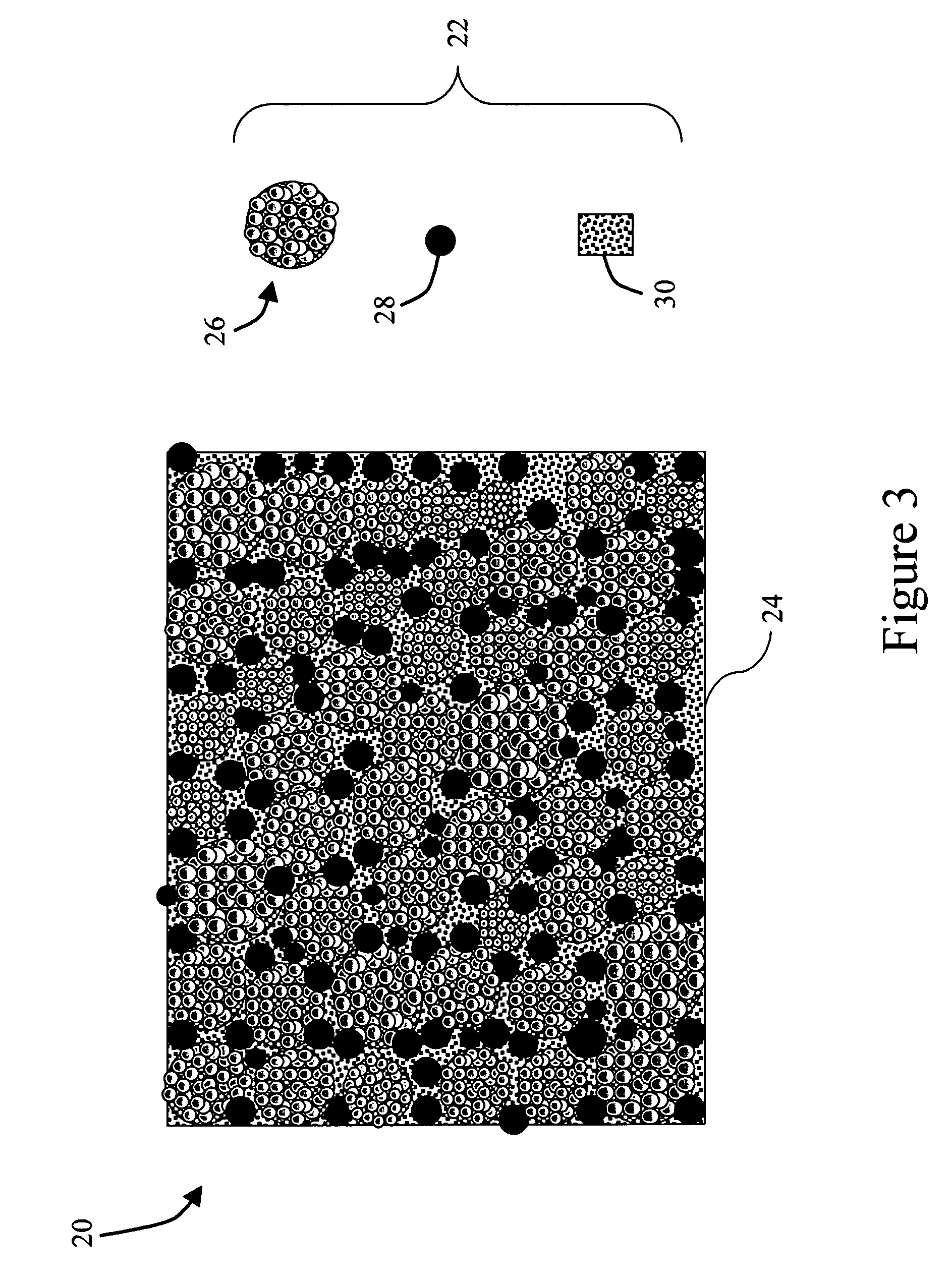

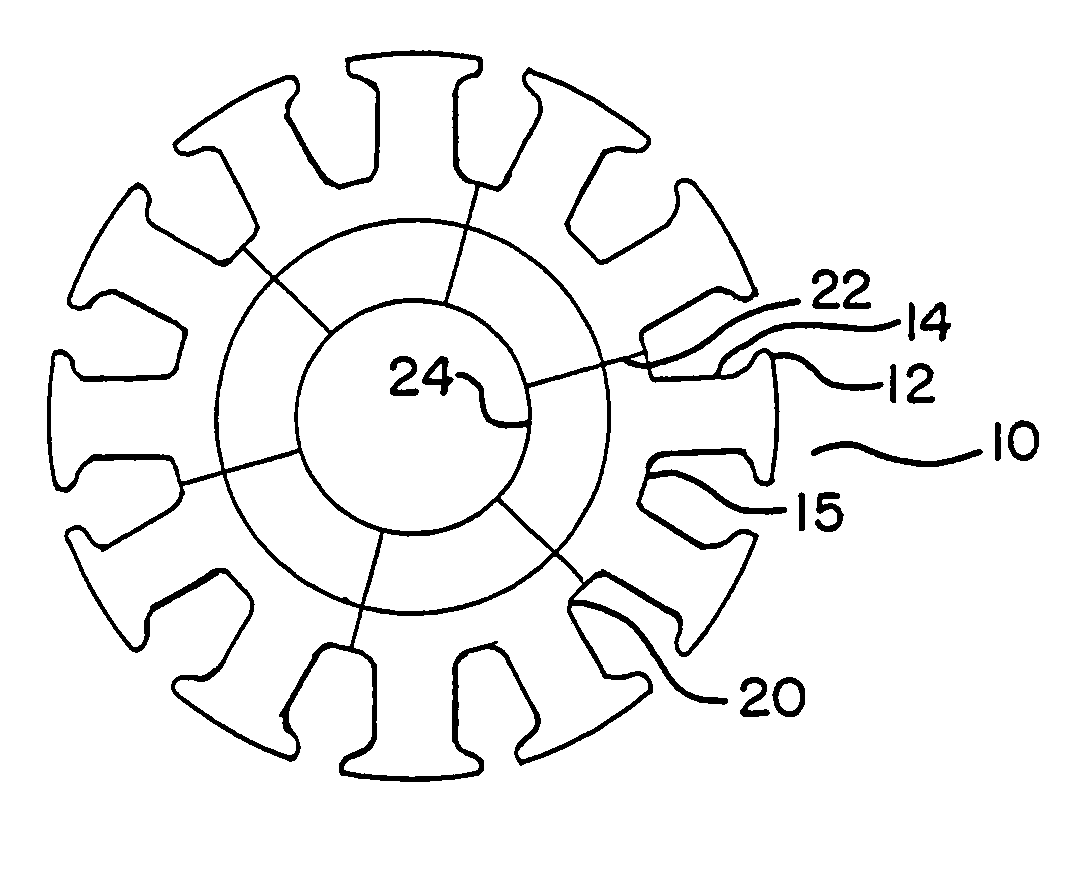

Soft magnetic composites

InactiveUS20050162034A1Readily apparentMagnetic circuit rotating partsMagnetic circuit stationary partsOperation modeIron alloys

Electric motor components, such as a plurality of electromagnetic poles of an annular stator, are formed of soft magnetic composites comprising compacted, electrically isolated iron alloy particles. Embodiments comprise predetermining particular alloy compositions and processing conditions, such as compaction pressures and temperatures, and post compaction heat treating temperatures and atmospheres, for an intended mode of operation, thereby improving manufacturing efficiency and reliability in tailoring soft magnetic composite components for particular design situations.

Owner:MATRA MFG & SERVICES

Magnetic composites and methods of making and using

Disclosed herein is a magnetic paste that generally includes a magnetic component and a liquid organic component. The magnetic component includes a plurality of discrete nanoparticles, a plurality of nanoparticle-containing assemblies, or both. Magnetic devices can be formed from the magnetic paste. Methods of making and using the magnetic paste are also described.

Owner:INFRAMAT CORPORATION

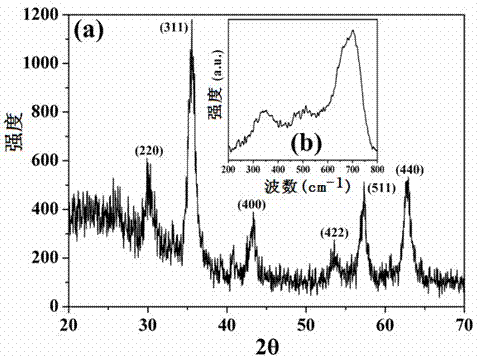

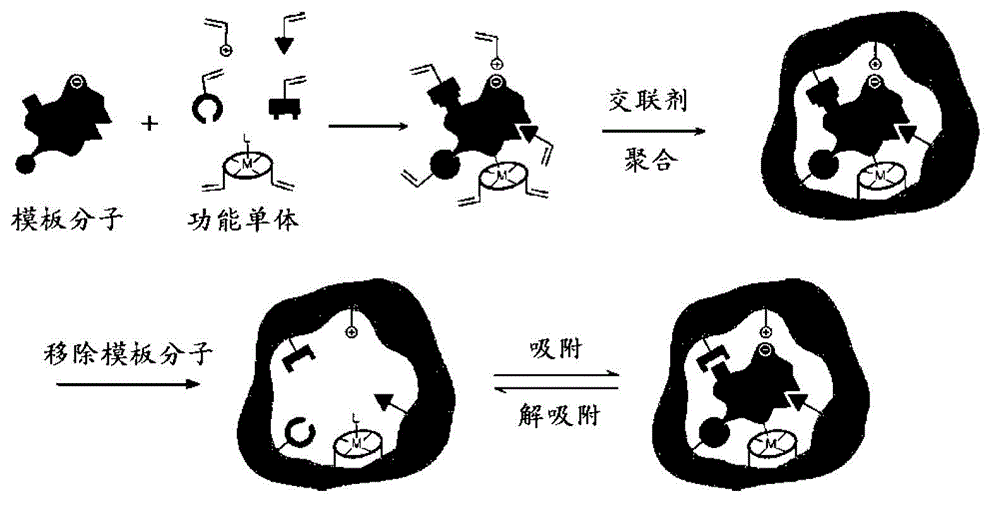

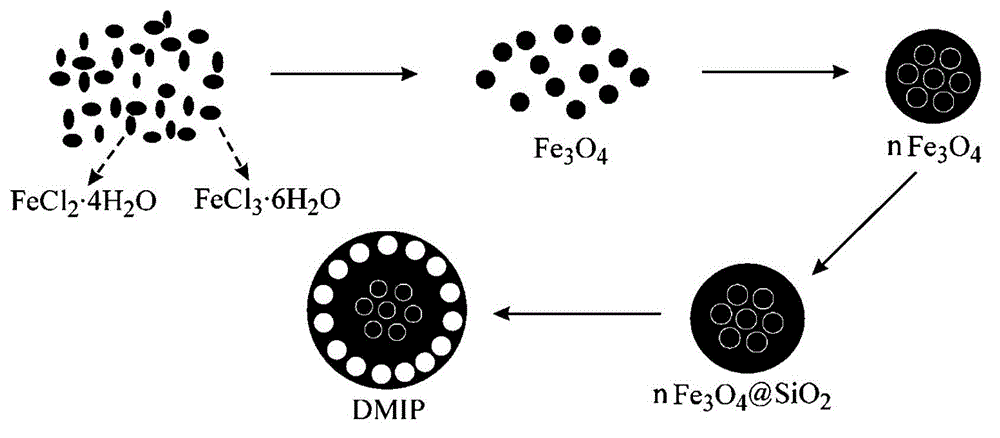

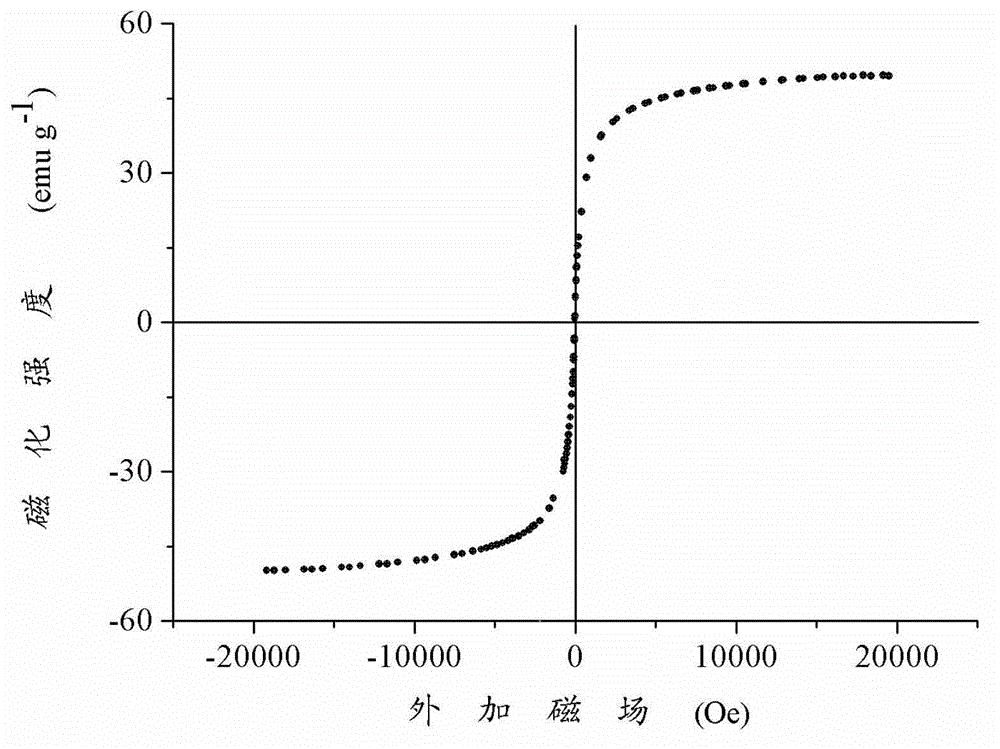

Molecularly imprinted magnetic microsphere, preparation method and application thereof

ActiveCN102977288AGood superparamagneticGood choiceOther chemical processesAlkali metal oxides/hydroxidesMicrosphereSuperparamagnetism

The invention discloses a molecularly imprinted magnetic microsphere, a preparation method and an application thereof. The preparation method comprises the following steps: S1, adopting a coprecipitation method to prepare Fe3O4 nanometer particles; S2, adopting a microemulsion polymerization method to prepare a magnetic composite microsphere by virtue of the Fe3O4 nanometer particles; S3, adopting a sol-gel method to grow SiO2 on the surface of the magnetic composite microsphere to obtain a core-shell microsphere; S4, grafting C=C double bond on the surface of the core-shell magnetic microsphere; and S5, adopting a substitution template method on the surface, which is grafted with the C=C double bond, of the core-shell microsphere to carry out molecular imprinting operation to obtain the molecularly imprinted magnetic microsphere. DMIP (Dimethyl Isophthalate) prepared by the method provided by the invention has excellent superparamagnetism and excellent selectivity for target molecules.

Owner:WENZHOU MEDICAL UNIV

Magnetic nano T102 composite photocatalysis and preparation method

InactiveCN1562464ANot easy to interactReduce interactionPhysical/chemical process catalystsMethyl orangeMagnetic field

A magnetic composite nano-TiO2 photocatalyst able to be recovered magnetically is prepared by sol-gel method. It is composed of Fe3O4 as core, SiO2 as isolating layer and TiO2 as coated layer. It has excellent soft magnetic property, high photocatalyst activity, and high degradability to methyl orange.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

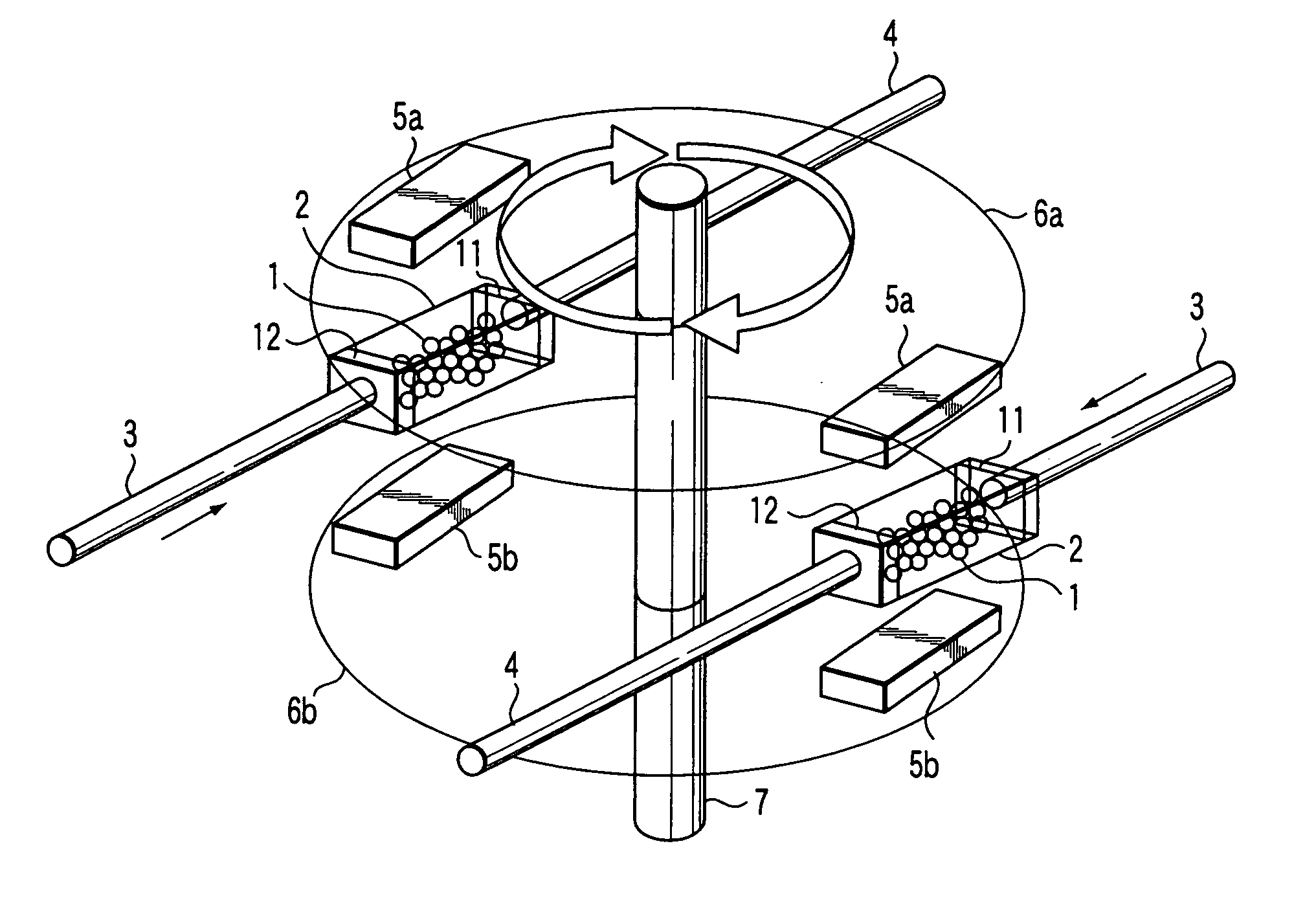

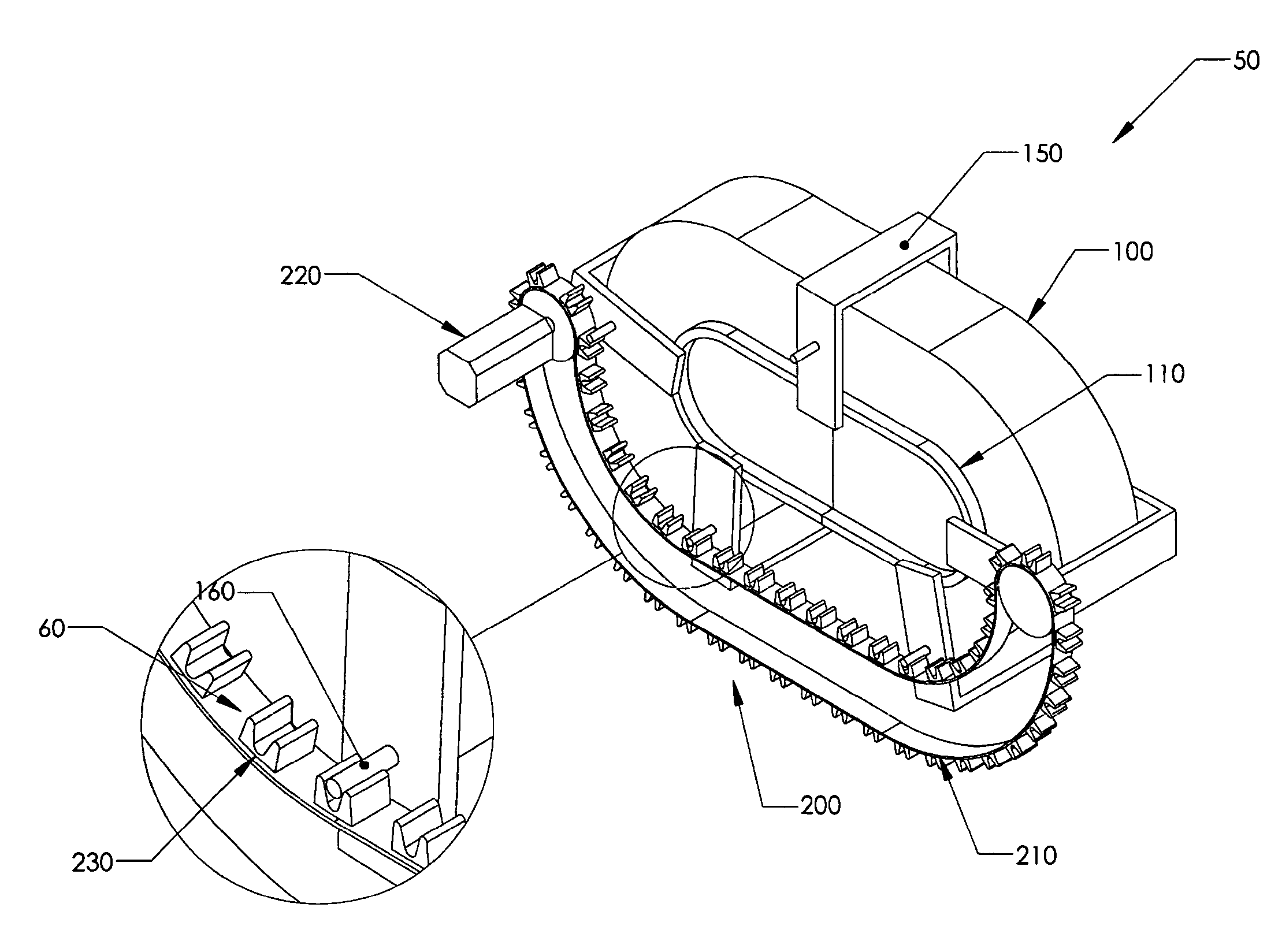

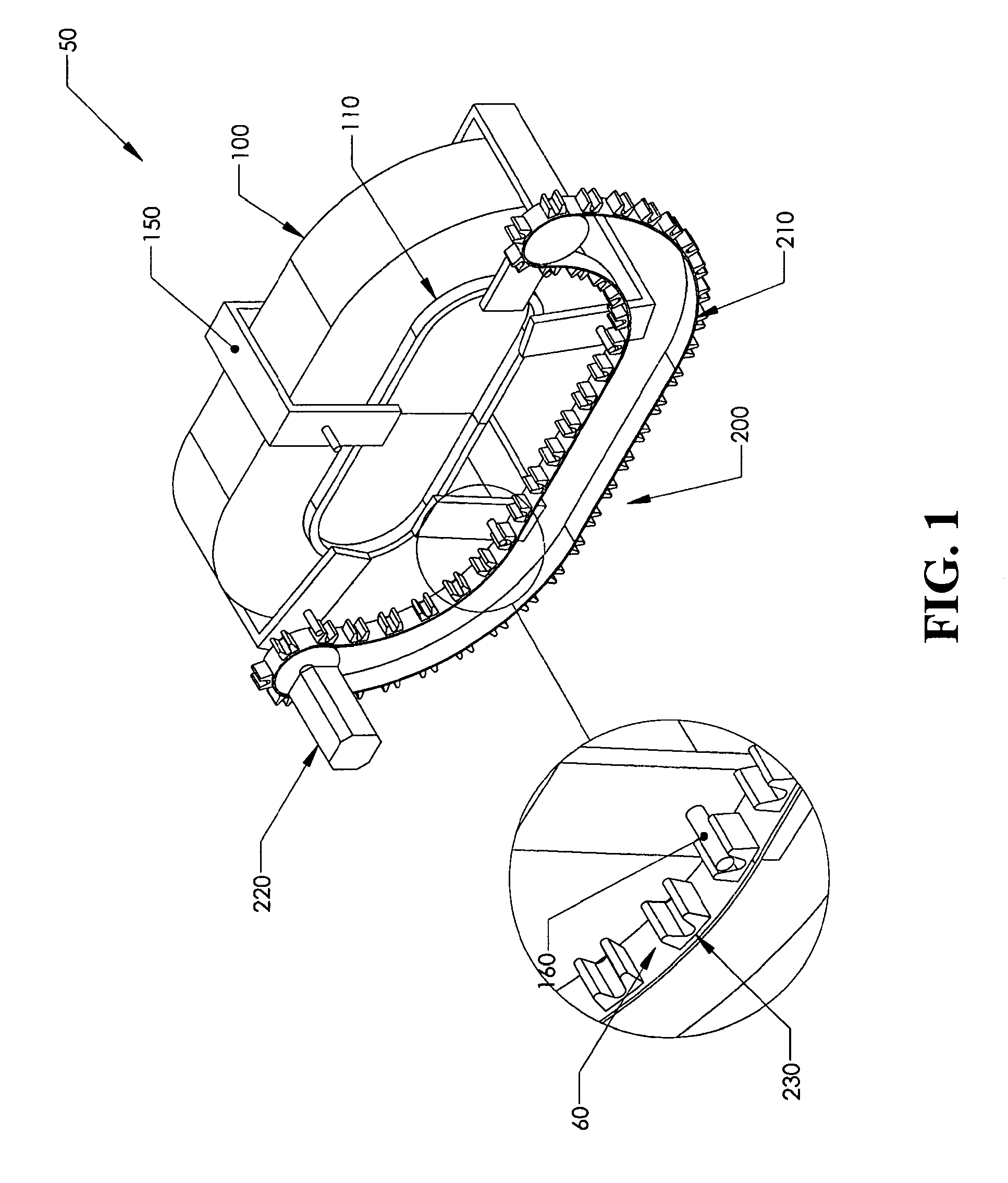

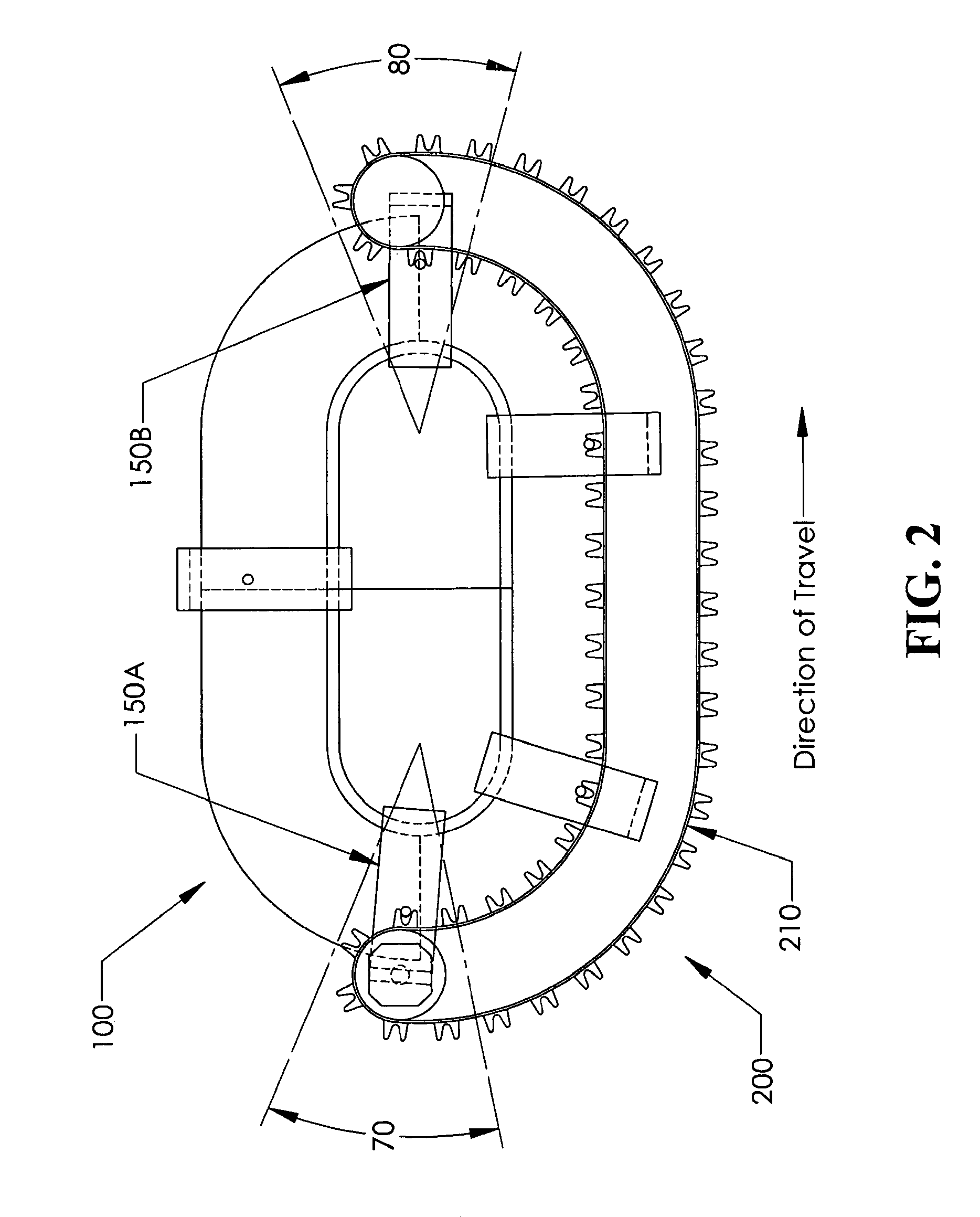

Controlled motion system

ActiveUS7859139B2Lower assembly costsMotor/generator/converter stoppersDC motor speed/torque controlPositive controlEngineering

A controlled motion system with movers mounted on a hybrid track system comprised of at least one smart section and at least one dumb section. The smart sections control each mover independently, while the dumb sections drive all movers at the same speed. The transition between these sections is characterized by positive control of the movers at all points in the transition. A soft magnetic composite core for the smart sections is disclosed. Also, a single-sided mover for smart sections that is constrained against loads in all direction, except for the direction of motion, is disclosed.

Owner:ROCKWELL AUTOMATION

Emergency restoring process for pollution of water body, substrate sludge and mud flat by heavy metal

InactiveCN101786713ALow costSolve secondary pollutionWater contaminantsWater/sewage treatment by flocculation/precipitationSludgeLiving environment

The invention discloses an emergency restoring process for pollution of a water body, substrate sludge and a mud flat by heavy metal. A complex agent is first added to the water body, and most heavy metal ions in ionized and absorbed states are converted into dissolved complex ions; short fibers and a heavy metal capturing agent are added to the water body so as to convert the heavy metal complex ions into suspended matters, and then a flocculating agent is added to flocculate the suspended matters; a flocculation assisting agent is added to the water body to form a fiber enhanced flocculating body; an Mg / magnetic composite material prepared by magnetic substances and magnesium powder in advance is thrown into the water body so as to lead the fiber enhanced flocculating body to capture air bubbles and float to the water surface; finally, the fiber enhanced flocculating body is captured to carry out emergency restoration. The emergency restoring process is convenient for in-situ emergency restoration of the stormy wavy water body in a large scale, so as to avoid the disadvantages that the present biological restoring method leads to slow treatment and is limited by the biological living environment in the aspect of the application range, thereby not only solving the problem of secondary sedimentation pollution caused by the present chemical restoring method, but also solving the bottleneck problem that the present dissolved air floatation process cannot carry out entire water-area pipe laying operation.

Owner:QUANZHOU NORMAL UNIV

Preparation method for inorganic-organic composite adhesive-coated soft magnetic composite

ActiveCN104070161AImprove composite effectGood coating effectInorganic material magnetismAdhesiveInorganic organic

The invention discloses a preparation method for inorganic-organic composite adhesive-coated soft magnetic composite. The preparation method for the inorganic-organic composite adhesive-coated soft magnetic composite includes steps that (1) mixing metal magnetic powder according to particle size distribution; (2) passivating the prepared magnetic powder of the step (1) through passivator; (3) using the adhesive composed of organic adhesive and inorganic adhesive to coat the passivated magnetic powder particles of the step (2); (4) pressing the bonded magnetic powder of the step (3) to obtain a magnetic powder core; (5) carrying out heat treatment on the pressed magnetic powder core of the step (4), and spraying to obtain a target product. The preparation method for the inorganic-organic composite adhesive-coated soft magnetic composite enables the compounding effect of the organic adhesive and inorganic adhesive to be improved and integrates advantages of the organic adhesive and inorganic adhesive; the inorganic-organic composite adhesive-coated soft magnetic composite is reasonable in component selection, is good in use effect and has good insulating bonding effect for iron-base metal soft magnetic powder, nickel-base metal soft magnetic powder and other metal soft magnetic powder with other components. The magnetic powder core made from the inorganic-organic composite insulating adhesive has excellent magnetic property and mechanical performance.

Owner:ZHEJIANG UNIV

Soft magnetic composite powder metal cores

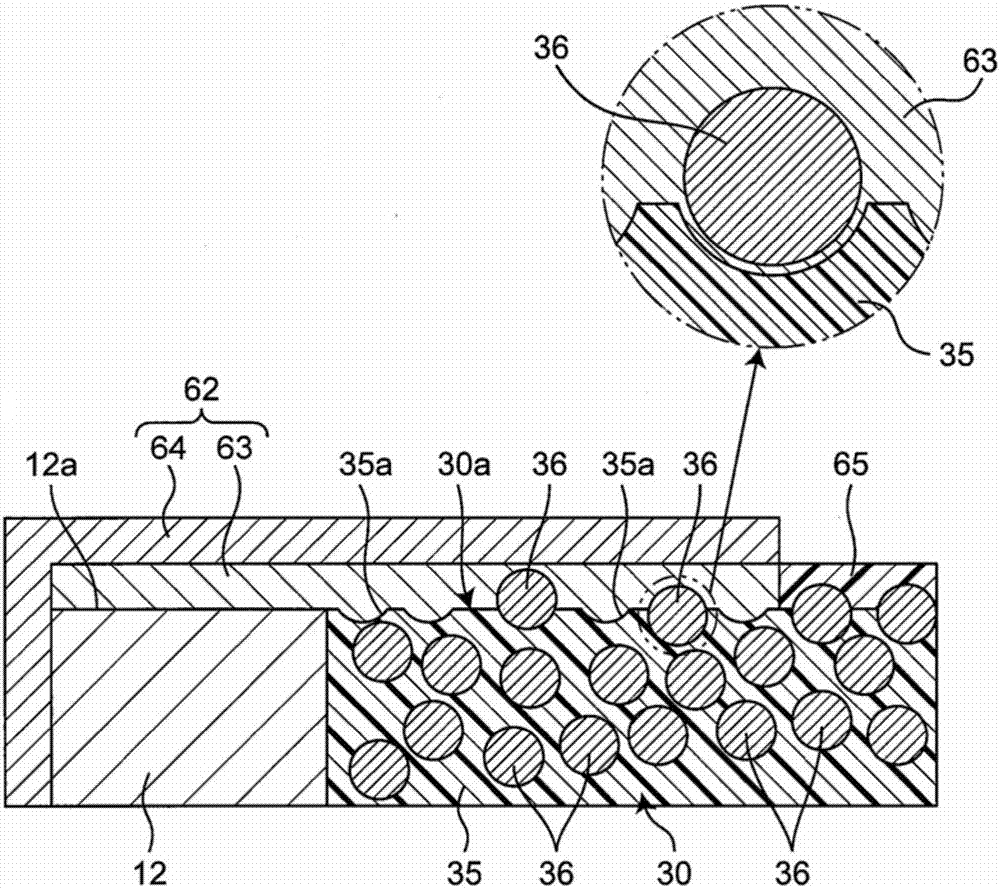

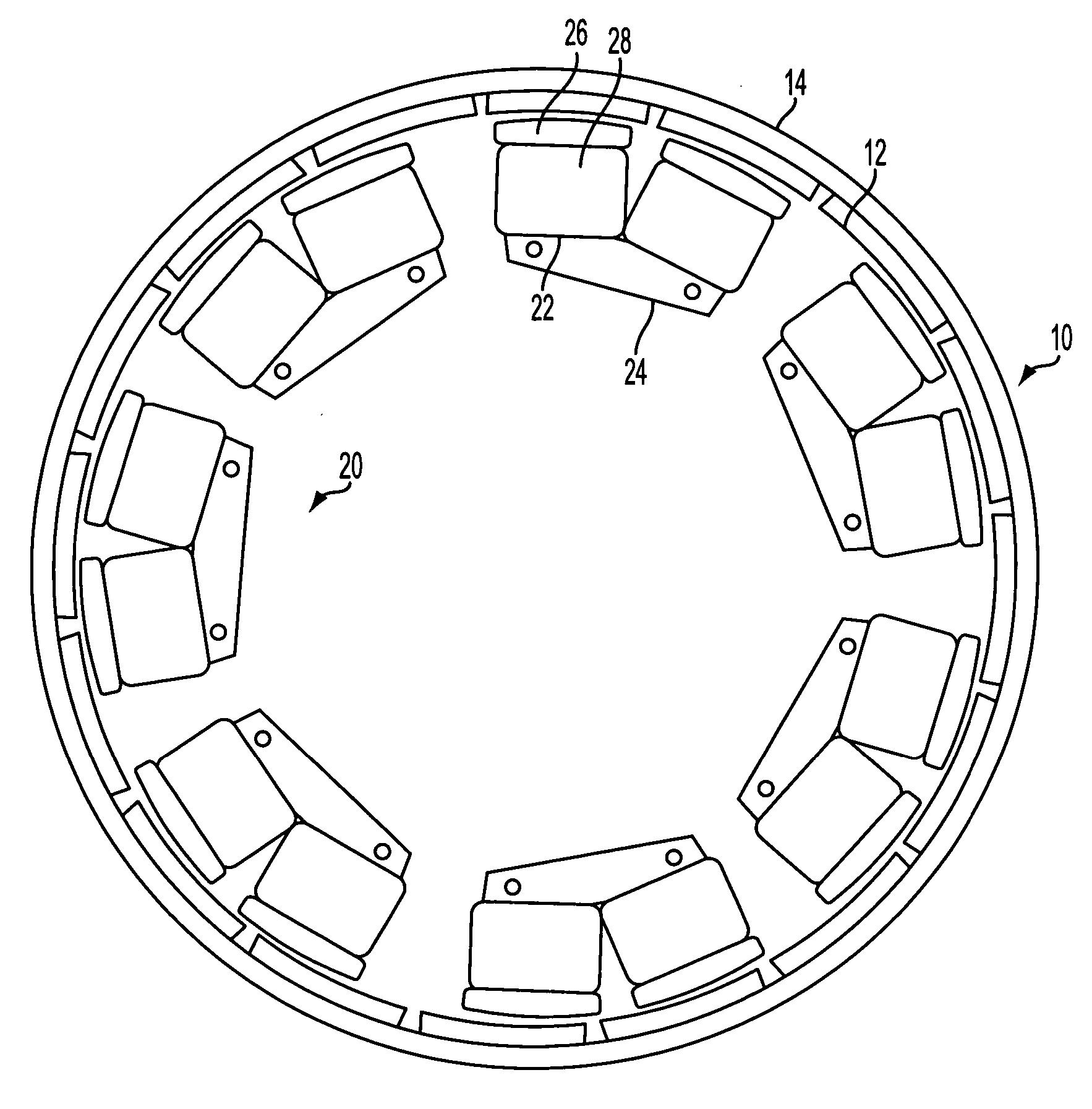

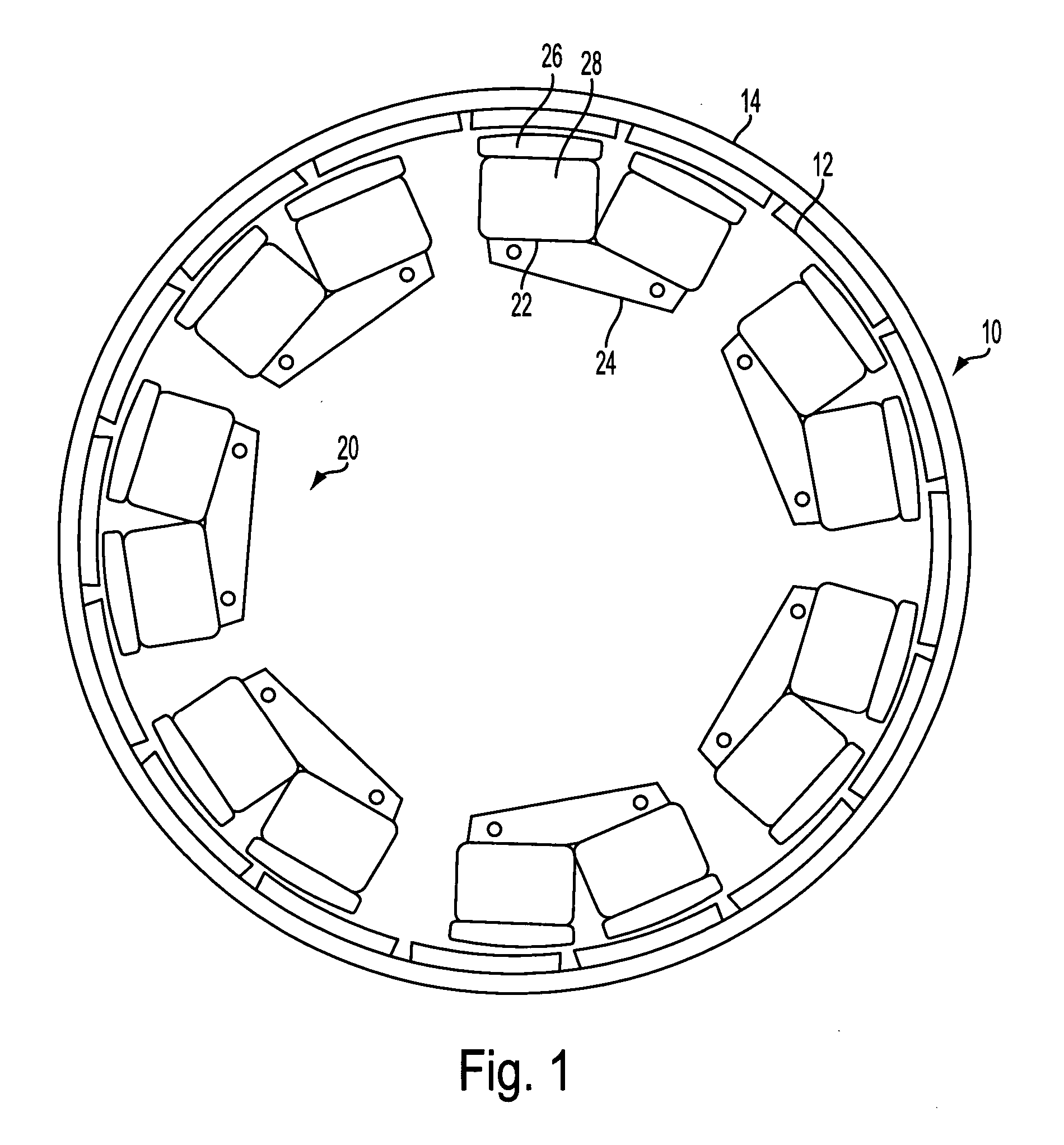

ActiveUS6956307B2Reduced eddy current lossImprove performanceWindingsMagnetic circuit rotating partsNuclear engineeringCore component

A stator core assembly for use in an electrical machine is provided. The stator core assembly includes a plurality of core components. Each core component forms an arcuate section of the stator core assembly. Each core component is comprised of at least two core component sections, with each core component section adjacent another core component section. Each core component section is formed of a ferrous magnetic powder metal particles which are generally mutually insulated. Such ferrous magnetic powder metal particles are pressure formed into the core component section.

Owner:BURGESS NORTON MFG

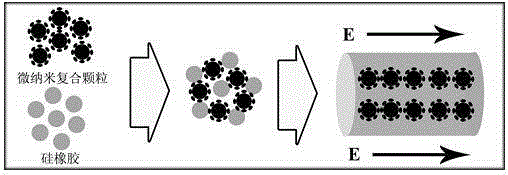

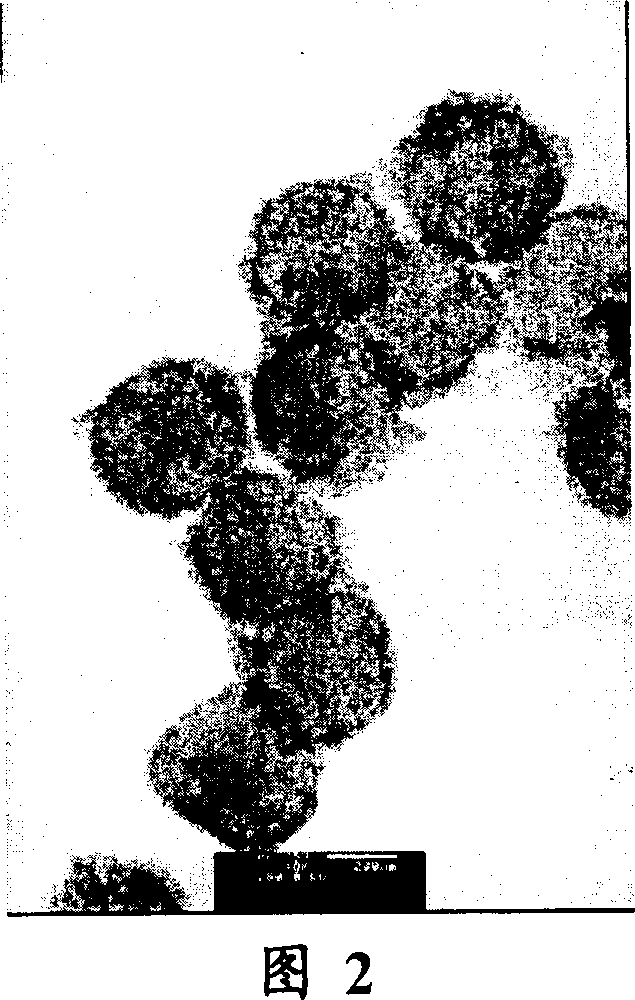

Preparation method of magnetic micro/nano composite filler/silicon rubber heat-conducting composite material

The invention belongs to the field of polymer-base heat-conducting composite materials, and relates to a preparation method of a heat-conducting high-polymer composite material, particularly a preparation method of a magnetic micro / nano composite filler / silicon rubber heat-conducting composite material. Magnetic nano metal particles are dispersed and compounded to the micron-sized heat-conducting filler surface to obtain a magnetic composite heat-conducting filler; by using the magnetic response caused by micro / nano compounding, an external magnetic field is utilized to regulate the orientation of the micro / nano composite filler in the silicon rubber base so as to implement orientated arrangement of the composite heat-conducting filler in the silicon rubber base, thereby preparing the heat-conducting anisotropic high-heat-conductivity silicon rubber composite material under the condition of low filling percent of the filler. Besides, the micro / nano composite filler is prepared by coating the magnetic nano metal particles on the heat-conducting filler, thereby avoiding the problems of low dispersion tendency and high aggregation tendency of the nano metal particles in the polymer base, and indirectly implementing uniform dispersion of the micro / nano particles in the polymer base.

Owner:JIANGSU UNIV

Sandwich structure magnetic composite micro ball with functional shell layer, its preparing method and use

The invention discloses a type of sandwich structure magnetic composite microspheres with functional shells. Said magnetic composite microspheres in structure is characterized by the whole body is as sandwich structure, kernel is as macromolecule microspheres, the middle layer is as magnetic nanoparticles, the external layer is as functional shells of certain thickness.

Owner:BEIJING NORMAL UNIVERSITY

Magnetic composites

InactiveUS20080044680A1Improve magnetic strengthReduce materialConfectioneryInorganic material magnetismEpoxyMagnetite Nanoparticles

The present invention discloses methods and magnetic material composites capable of withstanding one or more loads without the need for a substructure to provide structural support thereto. The magnetic composites are formable from composites such as epoxies, resins, plastics and the like together with rare earth or other magnetic or magnetizable compounds, or magnetic nano-particles to form structural magnetic composites. The magnetic composites have one or more portions with an aggregation of the magnetic material and one or more portions free of or substantially free of the magnetic material. The magnetic composites are suitable for use to form components of electrical motors, generators, pumps, fans, paints, coatings and parts or derivatives thereof.

Owner:MAGLEV TECH LLC

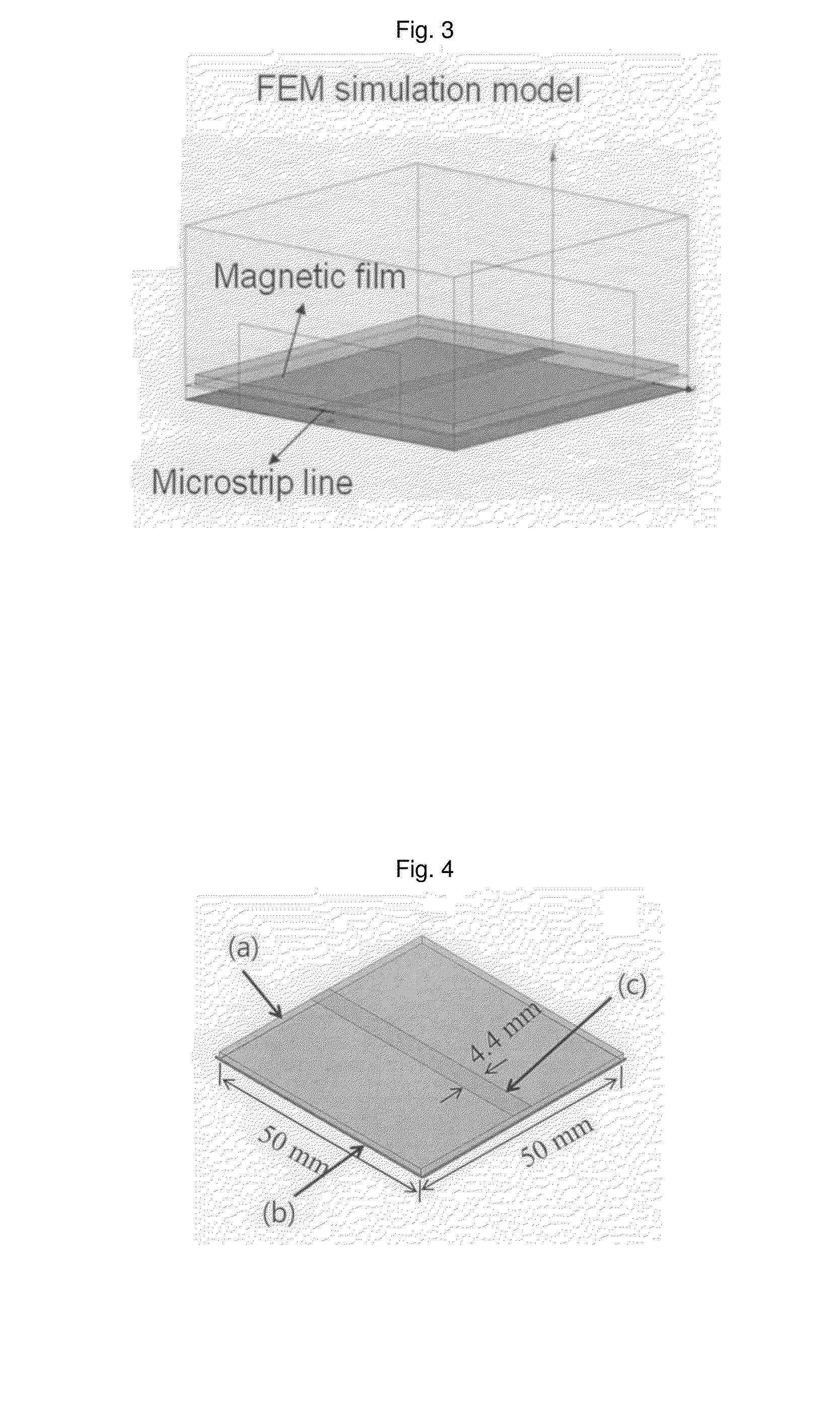

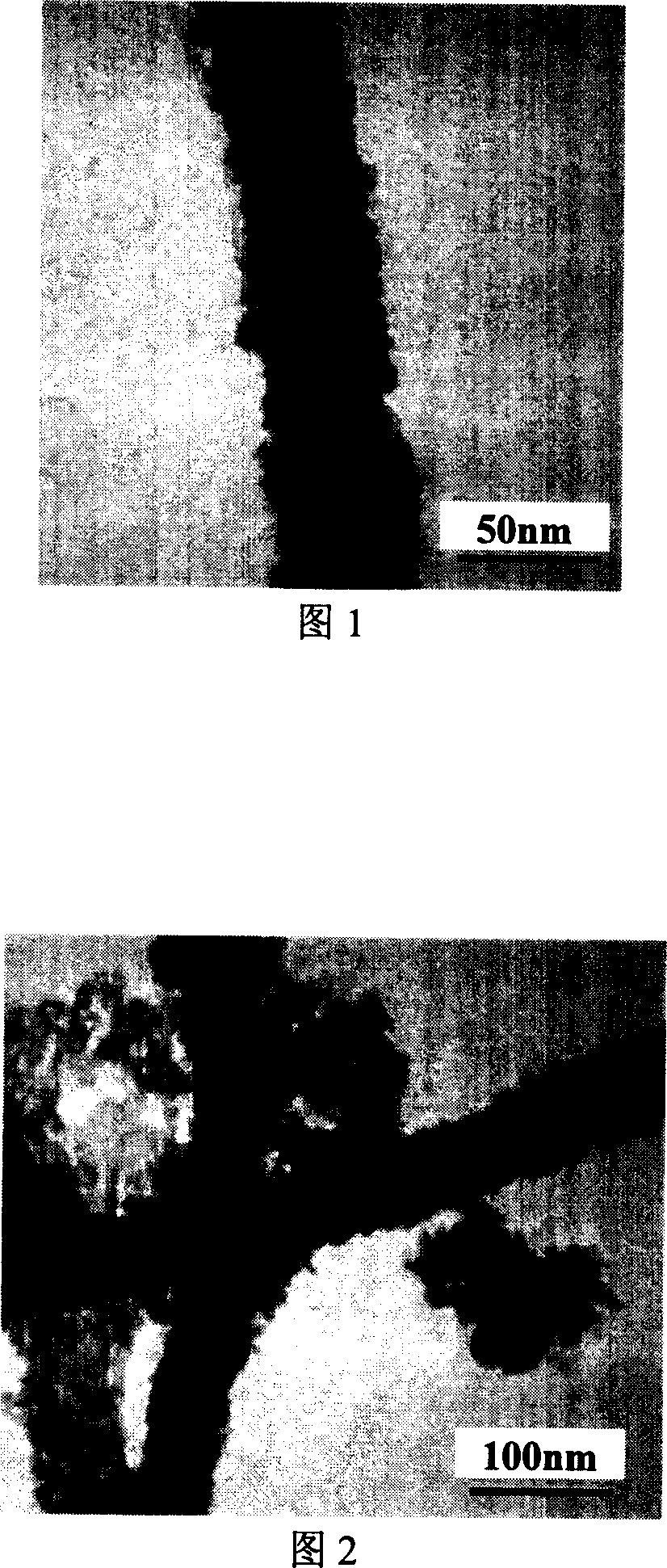

Waveband electromagnetic wave absorber and method for manufacturing same

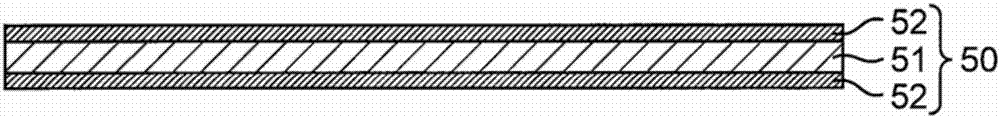

ActiveUS20130140076A1Effective absorptionAvoid interferenceLine/current collector detailsMagnetic/electric field screeningElectromagnetic wave absorberPolymer resin

Provided is a wideband electromagnetic wave (EMW) absorber including a magnetic composite having a structure in which magnetic particles are dispersed in a polymer resin, and a plurality of conductive lines arranged in the magnetic composite, and a method of manufacturing the same. The wideband EMW absorber can be used for a device configured to emit EMWs and effectively absorb wideband EMWs.

Owner:KOREA INST OF MATERIALS SCI

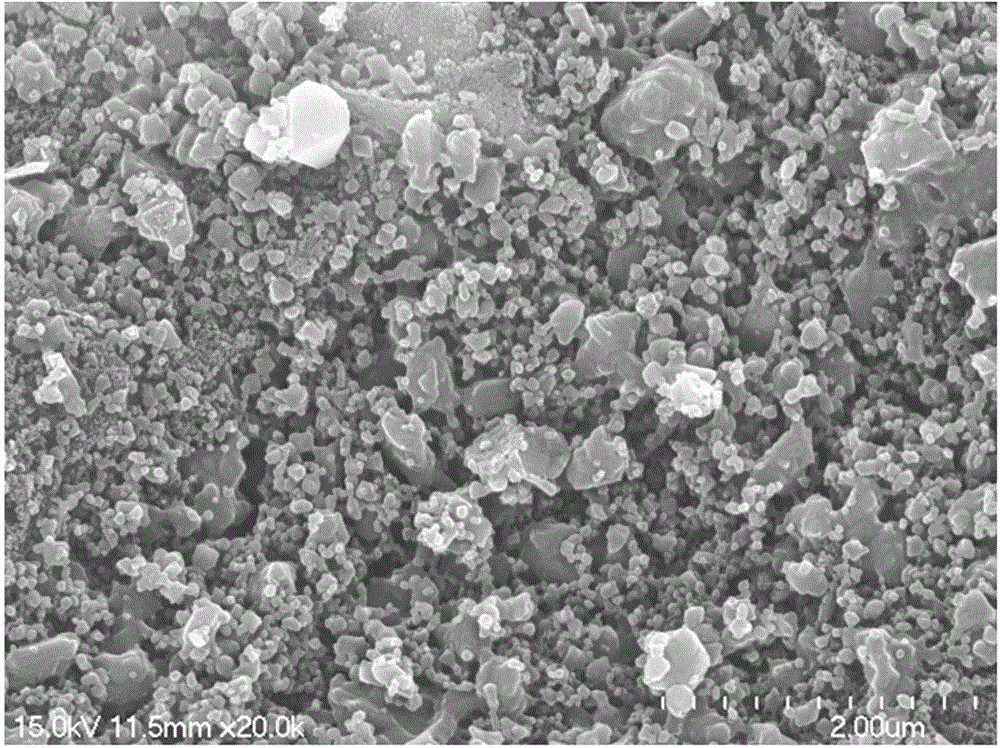

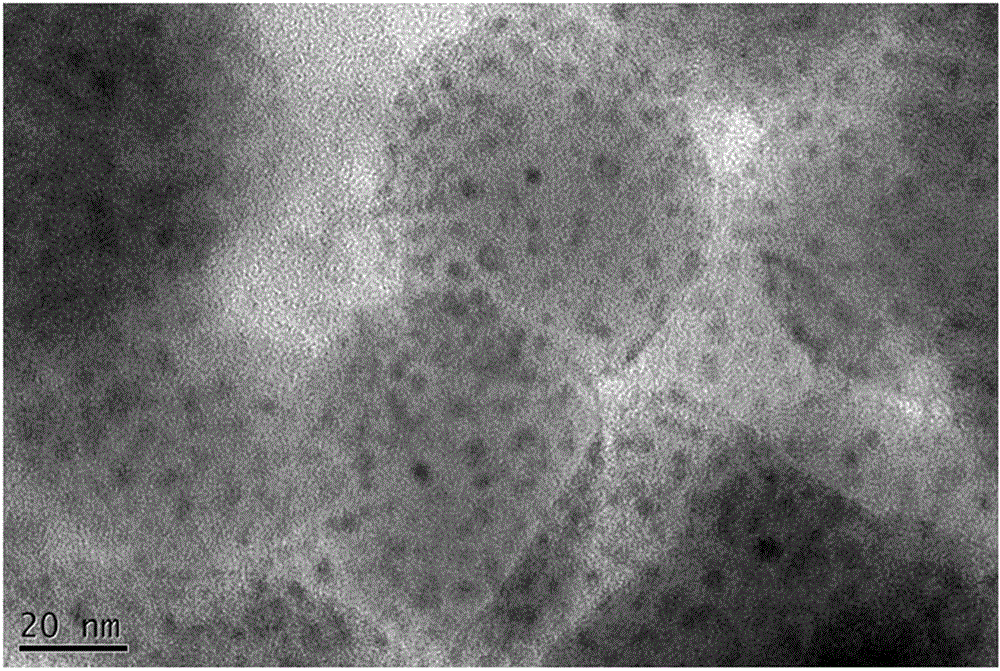

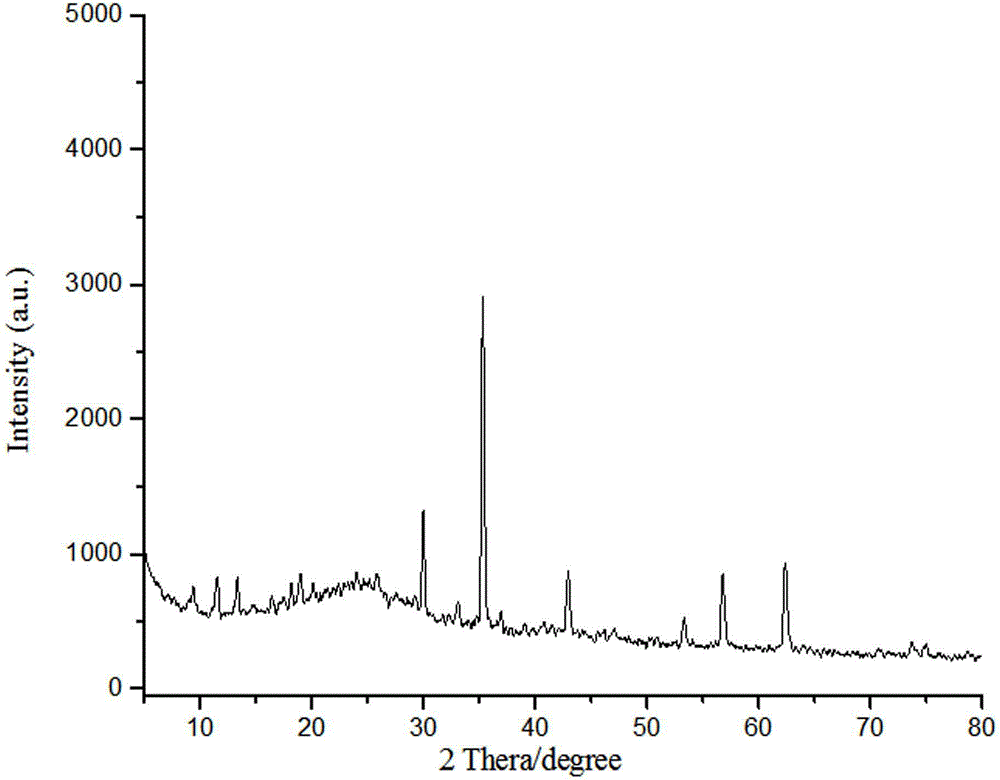

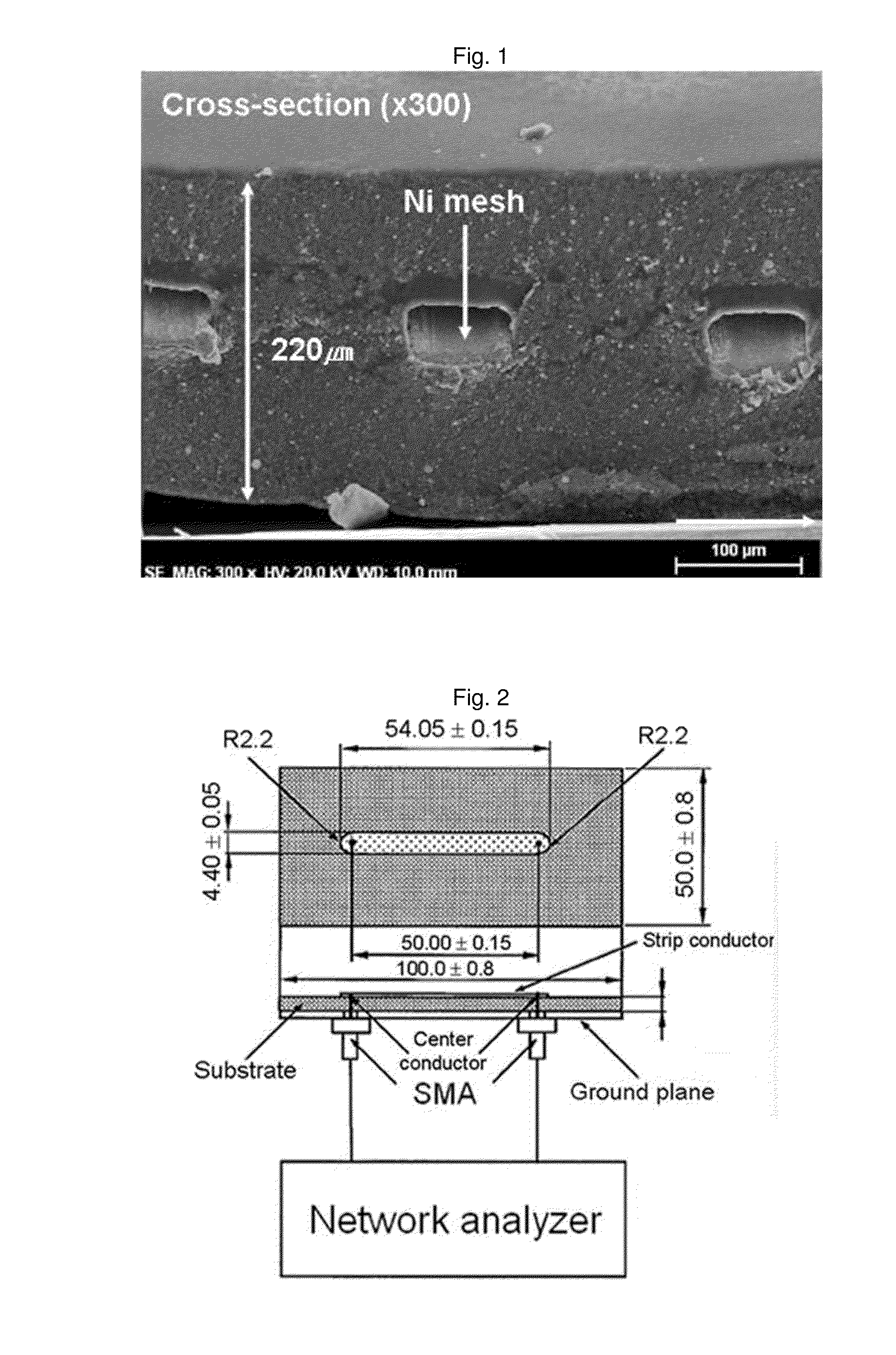

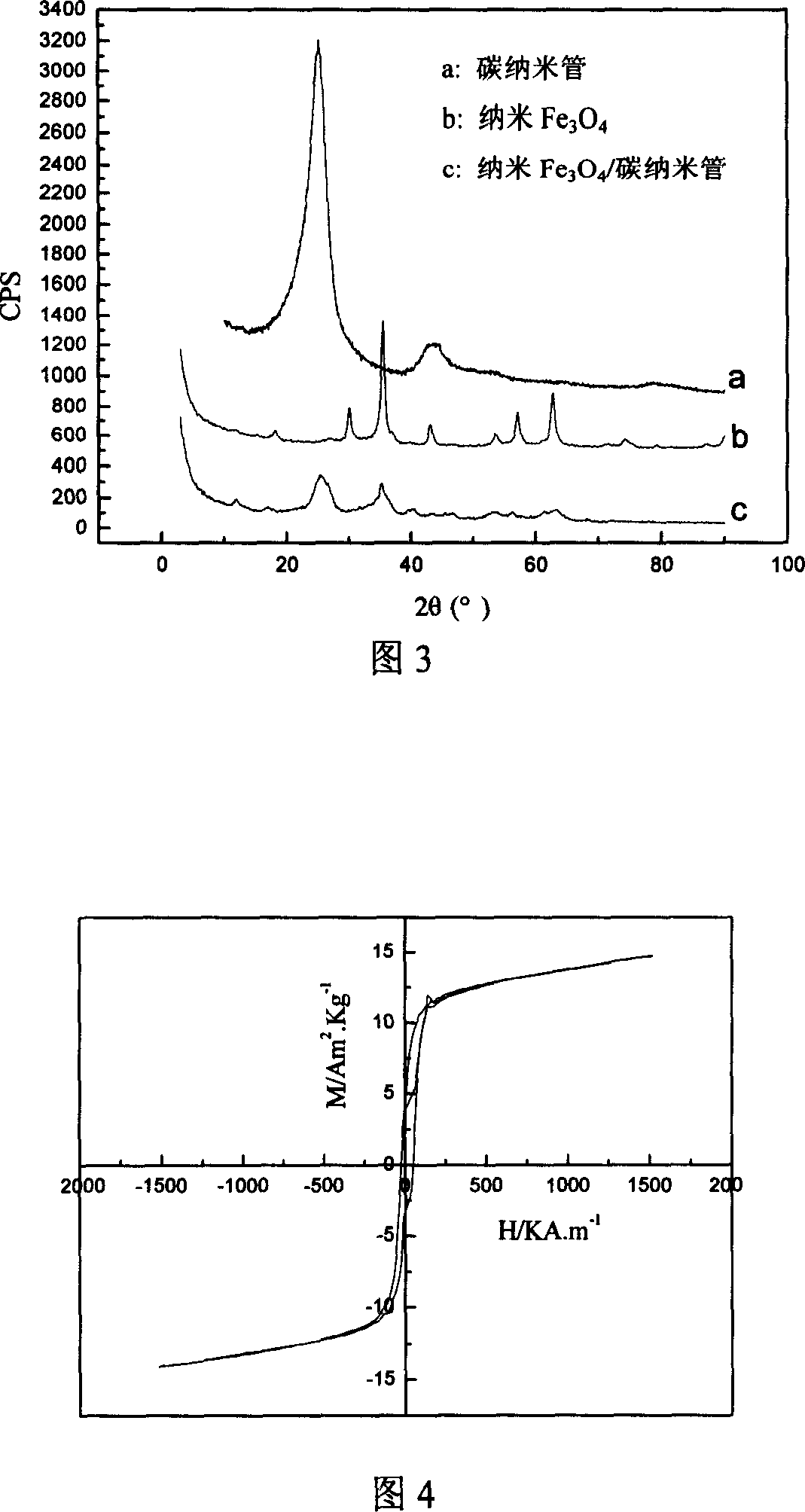

Preparing method of nano-Fe3O4 coating carbon nanotube magnetic composite material

InactiveCN1971780ALight in massStrong magneticNanostructure manufactureInductances/transformers/magnets manufactureCarbon nanotubeElectromagnetic shielding

This invention belongs to nanometer compound materials process and application technique field and to one carbon nanometer tube and ferriferous oxide compound materials process. This invention discloses one nanometer ferriferous oxide to cover carbon nanometer magnetic compound materials. This invention can process carbon nanometer tube in aqua forties for regurgitation and its surface leads in carbonyl, hydroxyl group and carboxyl group function groups, wherein, under outer magnetic field, the groups can be absorbed onto nanometer tube surface Fe3+ and Fe2+ with OH-1 to generate deposition reaction.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing silicon dioxide magnetic composite microballoon with core-shell structure

ActiveCN101707106AThickness is easy to controlNarrow particle size distributionInorganic material magnetismInductances/transformers/magnets manufactureMicrosphereLayer thickness

The invention belongs to the field of the synthesis of magnetic nano materials, and relates to a method for preparing a silicon dioxide magnetic composite microballoon with a core-shell structure. The method comprises the following steps: adding magnetic iron oxide nano particles monodispersed in water into the mixing solution of alcohol and ultrapure water, and stirring for 0.3-2h; then adding 0.01-1ml of tetraethyl silicate in the mixture, and stirring for 0.3-2h; then adding 0.5-5ml of stronger ammonia water, continuing to stir for 2-24h, and obtaining the solution of the silicon dioxide magnetic composite microballoon with the core-shell structure; and using applied magnetic field for separating the microballon from the solution. In the invention, by proportioning the quantity of the reactant reasonably, and setting the reaction conditions reasonably, one or a plurality of the iron oxide magnetic nano particle(s) are covered in each produced silicon dioxide microballoon, and the microballoon has good balling performance and monodispersity, has controllable shell layer thickness and narrow particle size distribution, and is easy to clean, simple and convenient in operation, low in cost, less in waste, and high in productivity.

Owner:XIAN GOLDMAG NANOBIOTECH

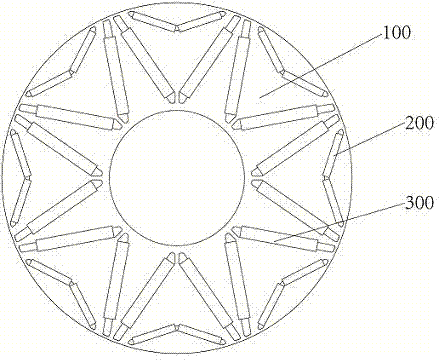

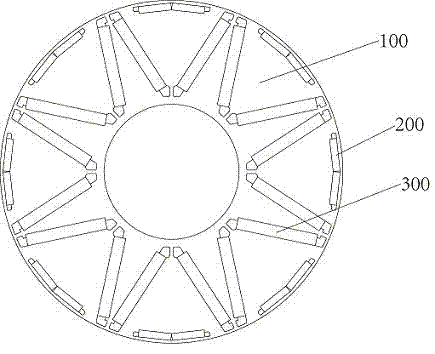

Rotor of permanent magnetic composite excitation synchronous motor

ActiveCN104242509AReduce the effect of the air gap magnetic fieldImproving Salient Pole Torque UtilizationMagnetic circuit rotating partsSynchronous motorTorque density

The invention aims at disclosing a rotor of a permanent magnetic composite excitation synchronous motor. The rotor comprises a double-layer embedded type rotor sheet, first magnetic steel grooves are formed in the outer side of the rotor sheet, second magnetic steel grooves are formed in the inner side of the rotor sheet, magnetic bridges are arranged between the second magnetic steel grooves, and magnetic steel is arranged in the first magnetic steel grooves and the second magnetic steel grooves. Compared with the prior art, different permanent materials are embedded in the rotor sheet according to a certain rule to form the rotor, the usage number of rare-earth permanent magnetic materials is effectively reduced, the effect of the temperature on a motor air-gap magnetic field is reduced, the excitation stability is improved, the utilization rate of salient pole torque of the motor is increased, the torque density of the motor is increased, and the purpose of the rotor is achieved.

Owner:ZHEJIANG LOONGSON ELECTRIC DRIVE TECH CO LTD

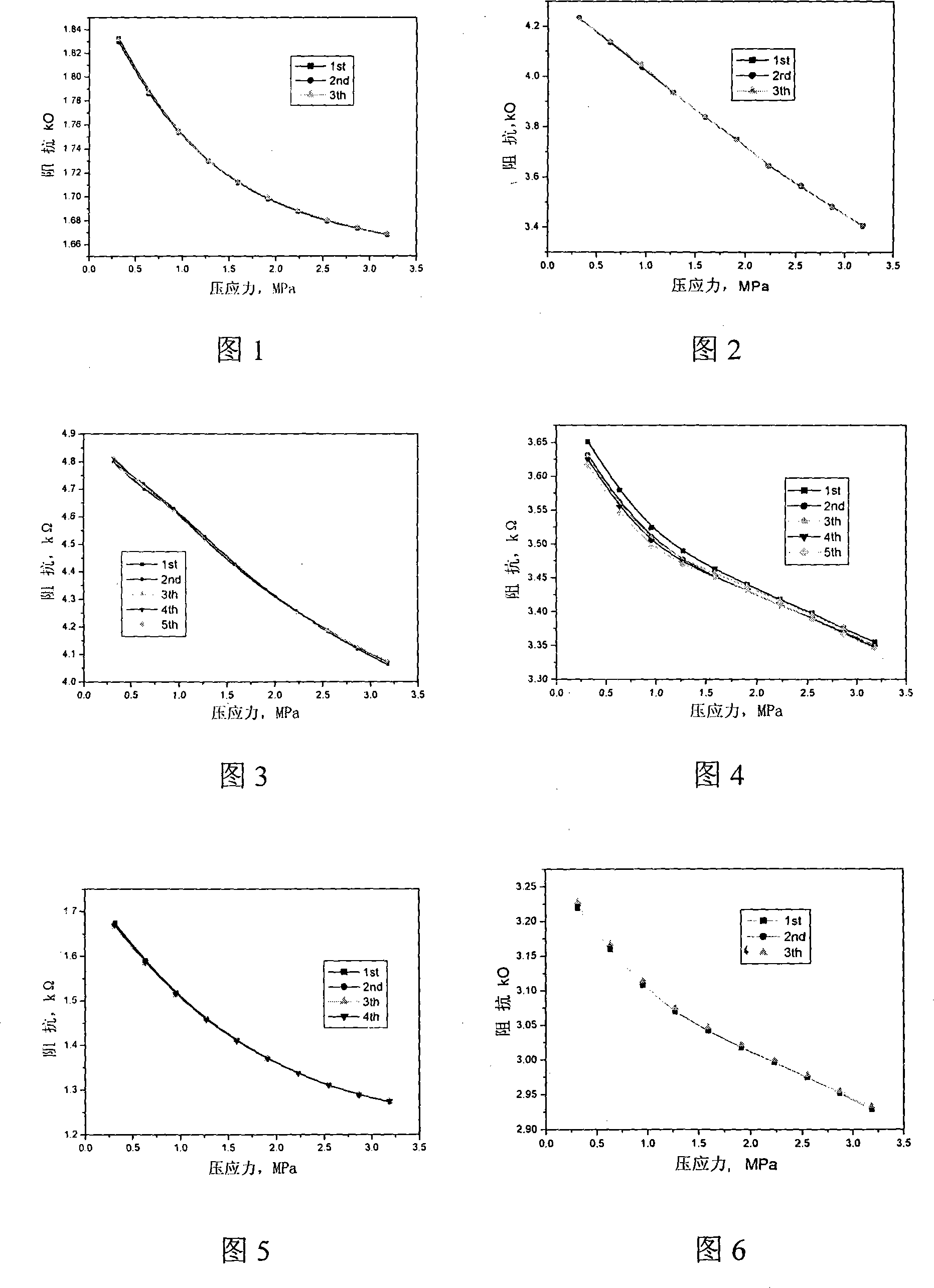

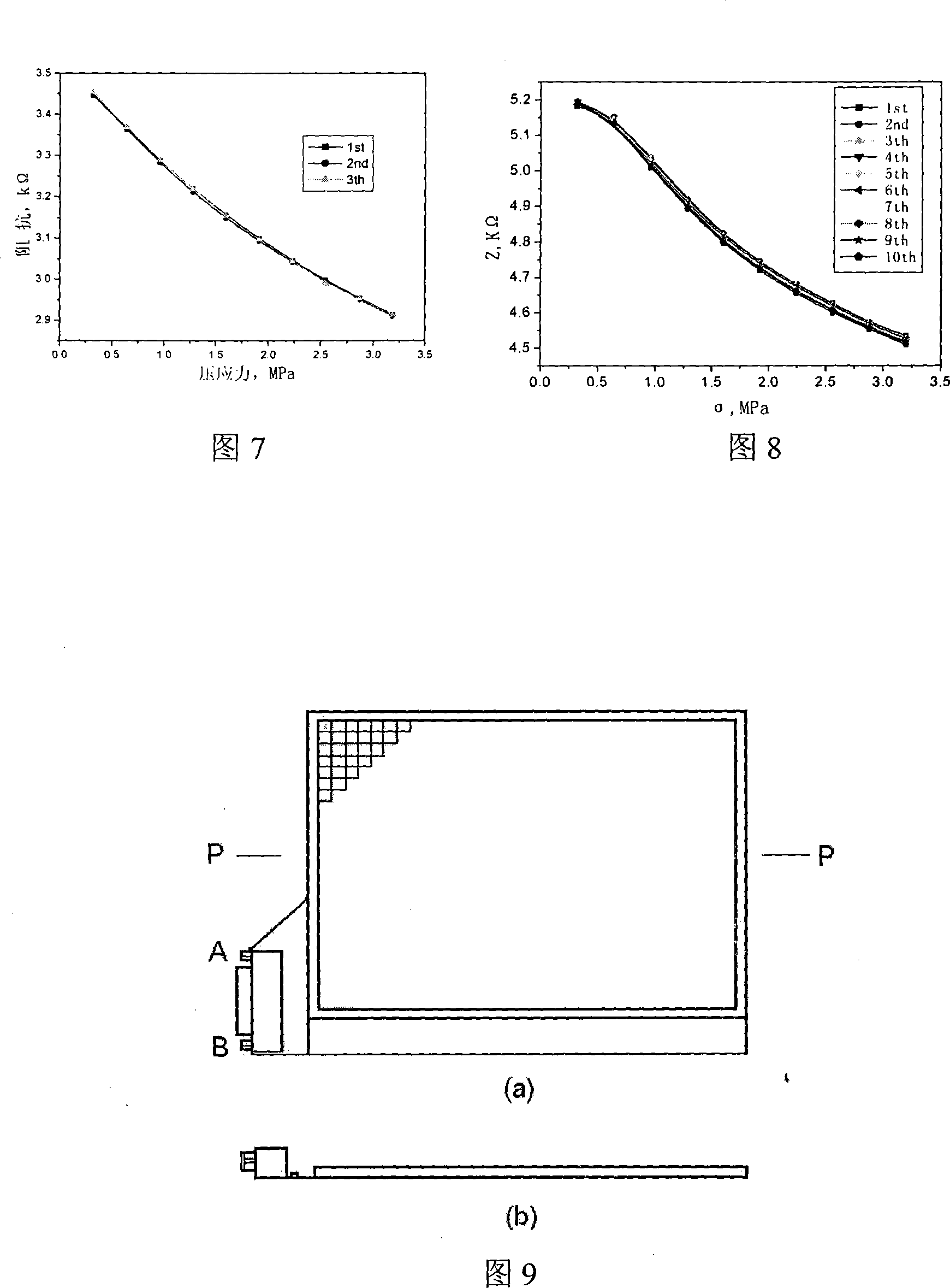

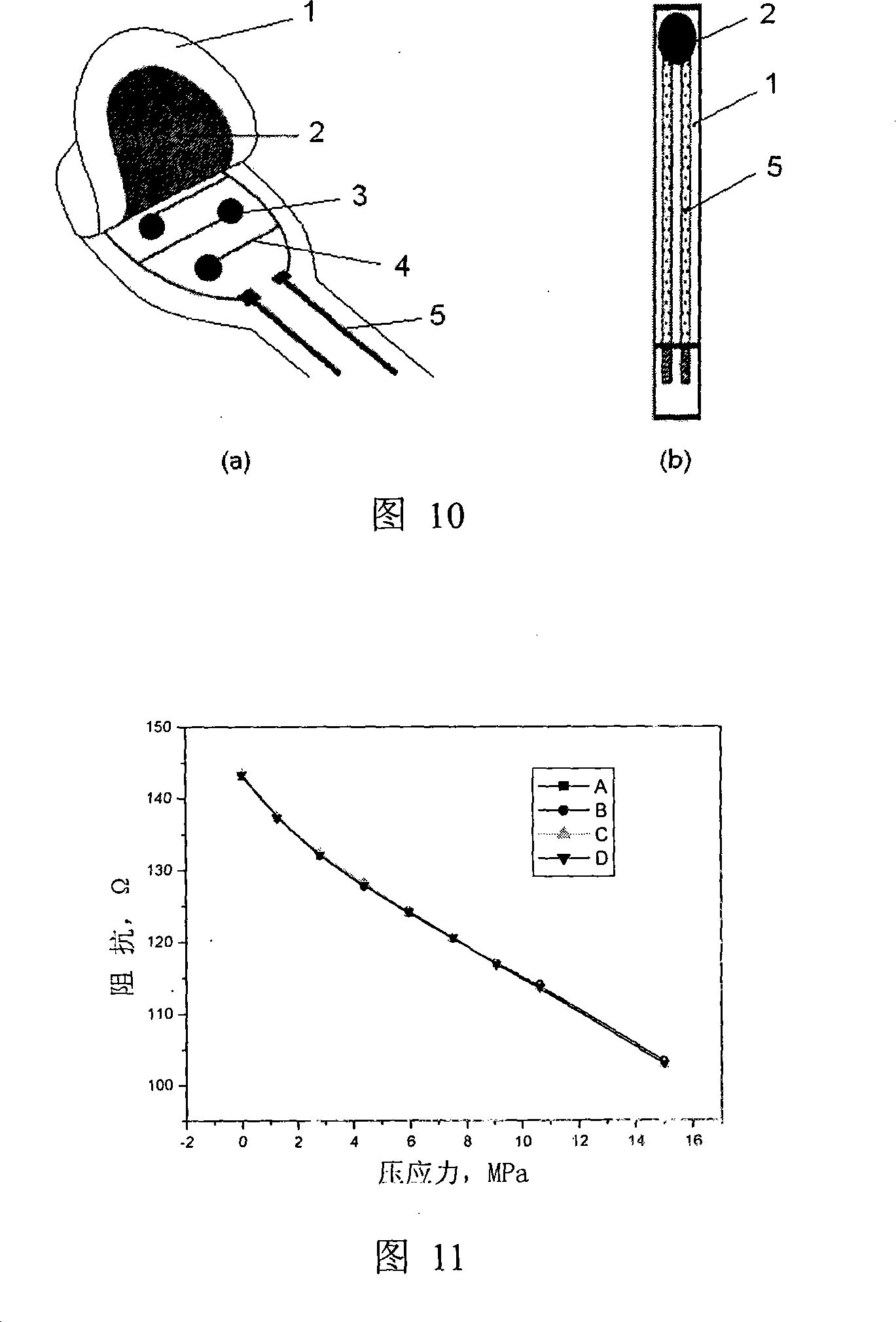

Flexible piezomagnetic composite material and preparation method thereof

InactiveCN101100549ASignificant stress sensitive propertiesNo storage stability issuesInorganic material magnetismForce sensorMaterials science

A flexible piezo-magnetic composite material and its production are disclosed. It consists of non-crystalline and / or nanometer crystal soft magnetic powder material with grain size 0.1-200 mum, flexible polymer and auxiliary additive ingredients. It can be used to inspect contact stress during casing and pipeline assembly curved profiled structure connection and impact process of large equipments and sophisticated engineering; it can be used to real-time monitor usage performance, relating components and functional material ageing and stress of system when they are mounted, stored and transported. It can be used in biological technology, medicine, sports, vehicles and aerospace industries.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

Composite photocatalytic material, preparation method and application thereof

InactiveCN105148968AImprove degradation rateImprove magnetismPhysical/chemical process catalystsWater/sewage treatment by irradiationHydrothermal depositionCalcination

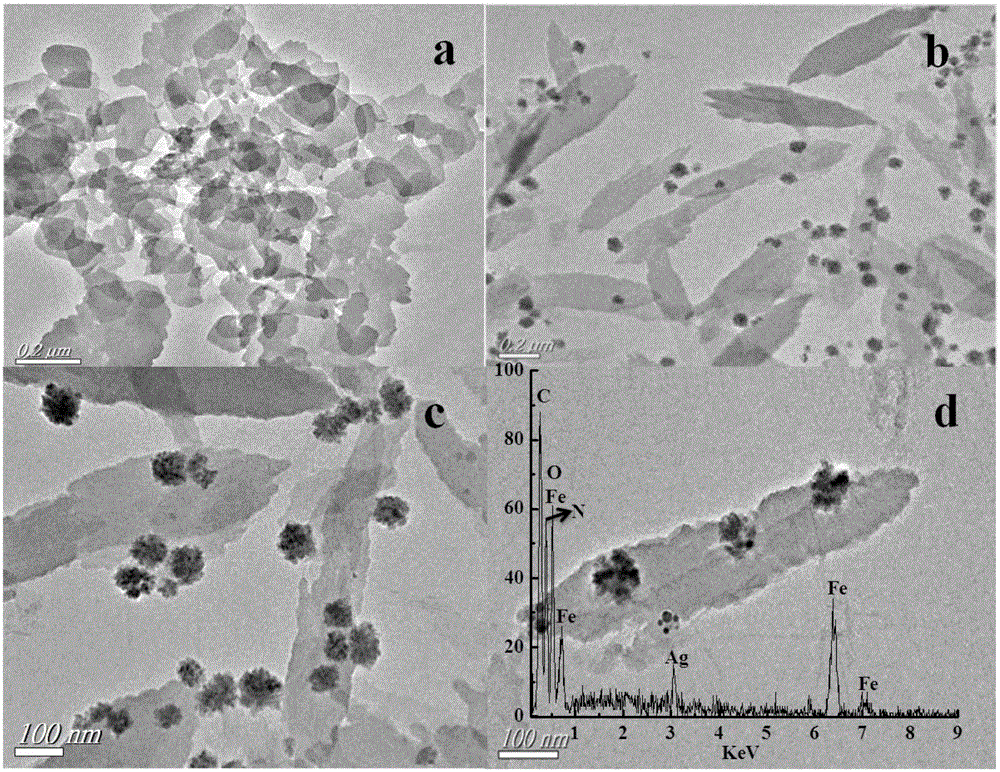

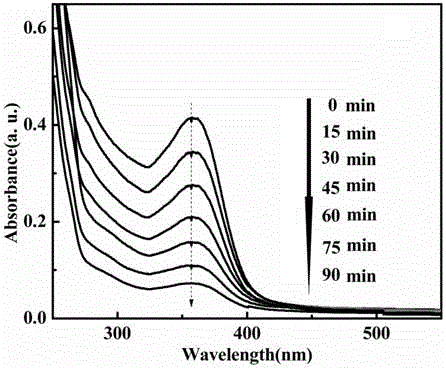

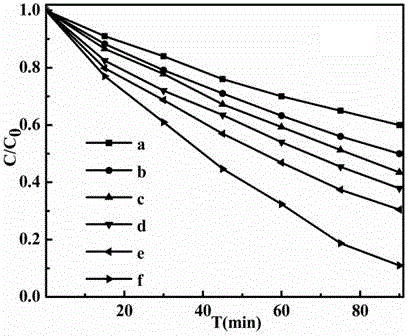

The invention provides a composite photocatalytic material, a preparation method and an application of the composite photocatalytic material. The preparation method comprises: obtaining a precursor of g-C3N4 through high-temperature calcination; preparing a magnetic composite of Fe3O4 / g-C3N4 through hydrothermal deposition; and allowing the magnetic composite to react in a solution of silver nitrate through a thermal photodeposition method to obtain the composite photocatalytic material of Ag / Fe3O4 / g-C3N4. The composite is high in dispersion and activity, can degrade tetracycline in the environment, and has characteristics of simple synthesis and high degradation rate.

Owner:JIANGSU UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com