Molecularly imprinted magnetic microsphere, preparation method and application thereof

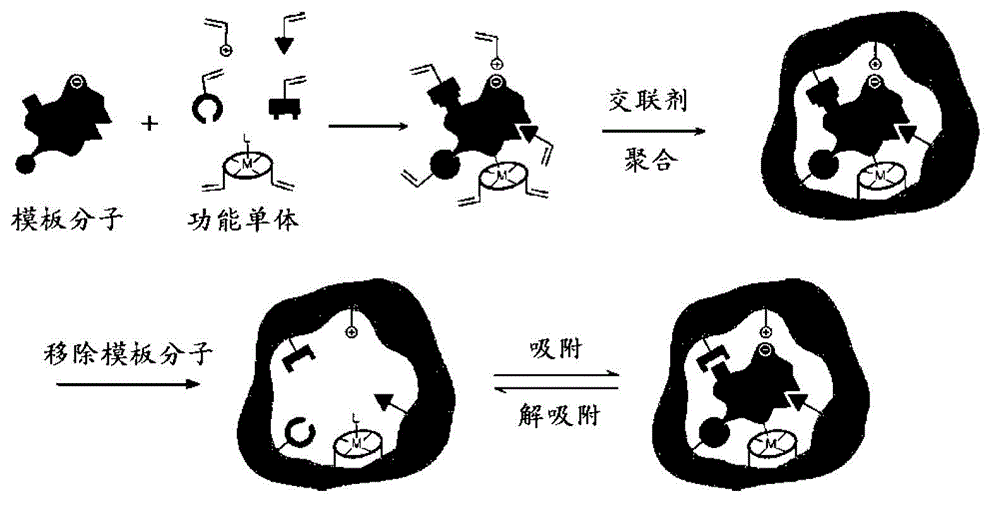

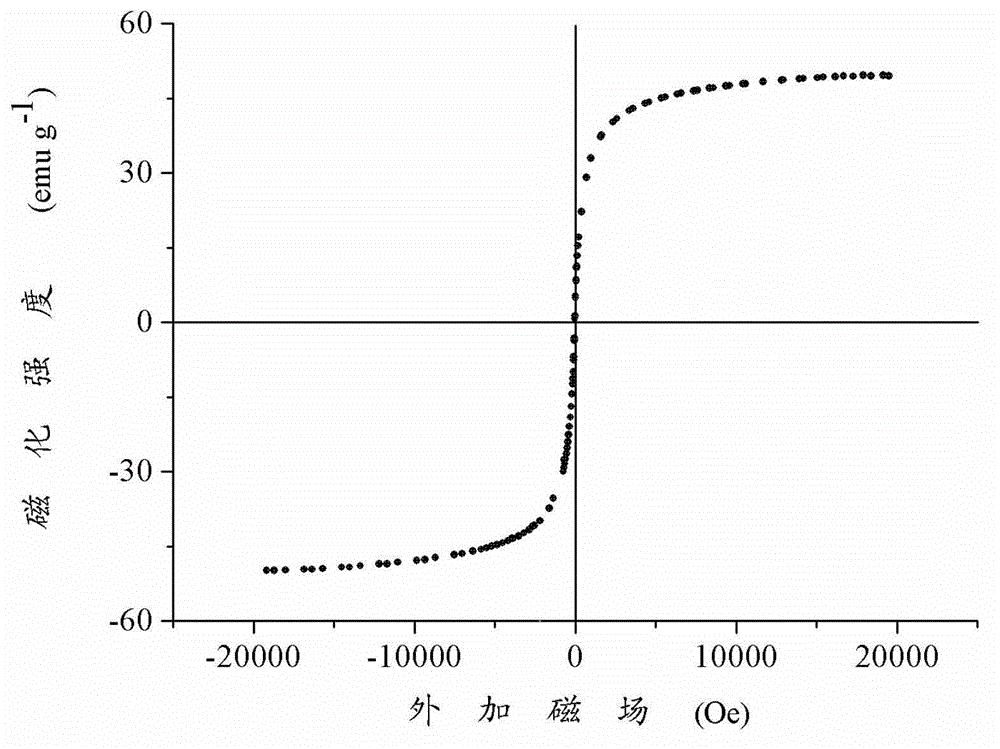

A molecular imprinting and magnetic microsphere technology, applied in the fields of organic chemistry and analytical chemistry, can solve the problems of trace analysis errors, slow elution, and incomplete elution of template molecules in environmental samples, and achieve excellent superparamagnetic properties and excellent selection. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

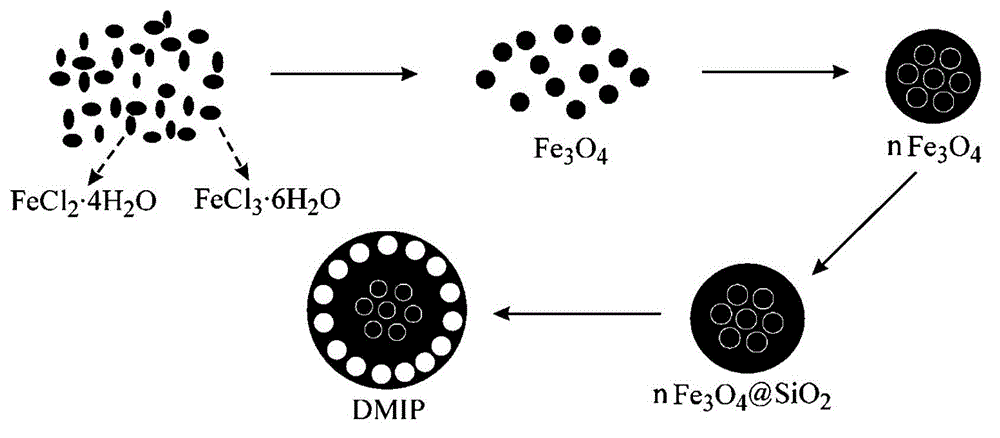

[0029] According to a typical embodiment of the present invention, such as figure 2 As shown, the preparation method of molecularly imprinted magnetic microspheres based on alternative templates includes the following steps: S1, the preparation of Fe by co-precipitation 3 o 4 nanoparticles; S2, utilizing Fe by microemulsion polymerization 3 o 4 Nanoparticles to prepare magnetic composite microspheres; S3, using sol-gel method to grow SiO on the surface of magnetic composite microspheres 2 , to obtain core-shell magnetic spheres; S4, grafting C=C double bonds on the surface of core-shell magnetic spheres; S5, performing molecular imprinting operations on the surface of core-shell magnetic spheres grafted with C=C double bonds , to obtain molecularly imprinted magnetic microspheres.

[0030] The present invention prepares Fe by adopting coprecipitation method 3 o 4 nanoparticles, using Fe 3 o 4 Magnetic composite microspheres (nFe 3 o 4 ), and using the sol-gel method...

Embodiment approach

[0031] According to a preferred embodiment of the present invention, utilize coprecipitation method to prepare Fe 3 o 4 The steps of the nanoparticles include: mixing a salt solution containing ferrous ions and ferric ions, heating, and stirring to obtain a mixed solution of iron ions; adding ammonia water and a surfactant to the mixed solution of iron ions, and stirring to obtain Fe 3 o 4 Nanoparticles. Adding a surfactant during the preparation process is to make the prepared nano-scale Fe 3 o 4 Particles are well dispersed and agglomeration is reduced. In the present invention, oleic acid is preferred as the surfactant, but not limited thereto. Further preferably, the salt containing ferrous ions is FeCl 2 4H 2 O, the salt containing ferric ion is FeCl 3 ·6H 2 O.

[0032] Utilization of Fe by microemulsion polymerization 3 o 4 The steps for preparing magnetic composite microspheres from nanoparticles include: Fe 3 o 4 Ultrasonic dispersion of nanoparticles, add...

Embodiment 1

[0043] 1) Synthesis of Fe 3 o 4 Nanoparticles

[0044] Take 6mM (1.24g) FeCl 2 4H 2 O and 12mM (3.24g) FeCl 3 ·6H 2 O was added to 150mL of ultrapure water degassed by ultrasound, vacuumed to remove oxygen with N2, heated to 50°C, and 15mL of NH was quickly added under the condition of stirring at 300rpm and nitrogen. 3 ·H 2 O, add 0.5 mL of oleic acid after reacting for 5 min, and react for 2.5 hours under the conditions of nitrogen flow and stirring. The obtained black oily precipitate was washed three times with absolute ethanol and dispersed in cyclohexane.

[0045] 2) Preparation of nFe 3 o 4

[0046] 1.2g oleic acid modified Fe 3 o 4 Ultrasonic dispersion of nanoparticles in 2mL cyclohexane, adding 4mL styrene and MPS mixture (styrene / MPS=7 / 3, v / v) to form a stable oil phase, ultrasonic 10min; 0.320g dodecyl Sodium sulfonate (SDS), 0.150g Na 2 HPO 4 , 0.096g NaH 2 PO 4 ·H 2 O was dissolved in 120mL of water, and the pH of the aqueous solution was adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetic strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com