Preparation method and application of catalytic material based on magnetic layered double hydroxides

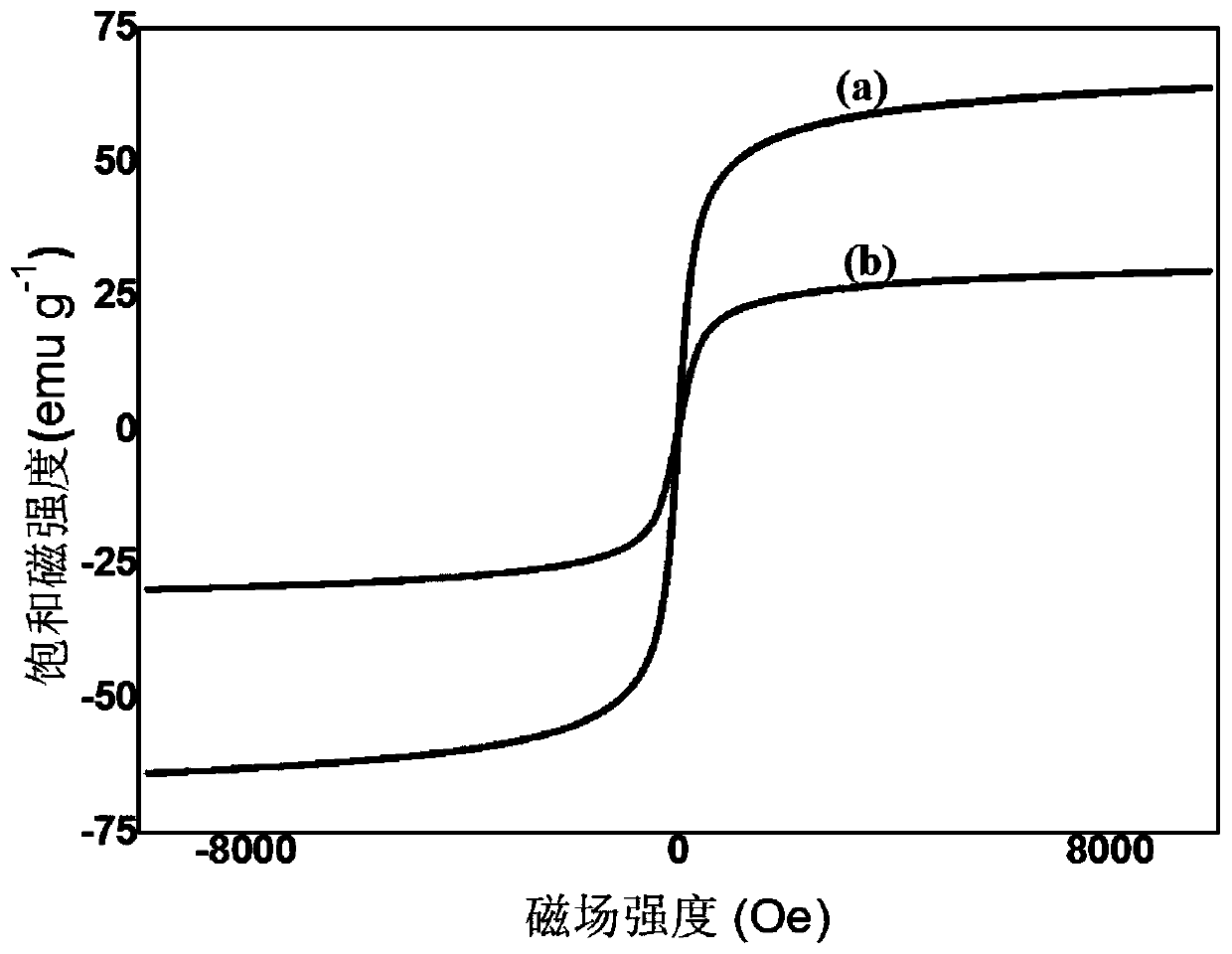

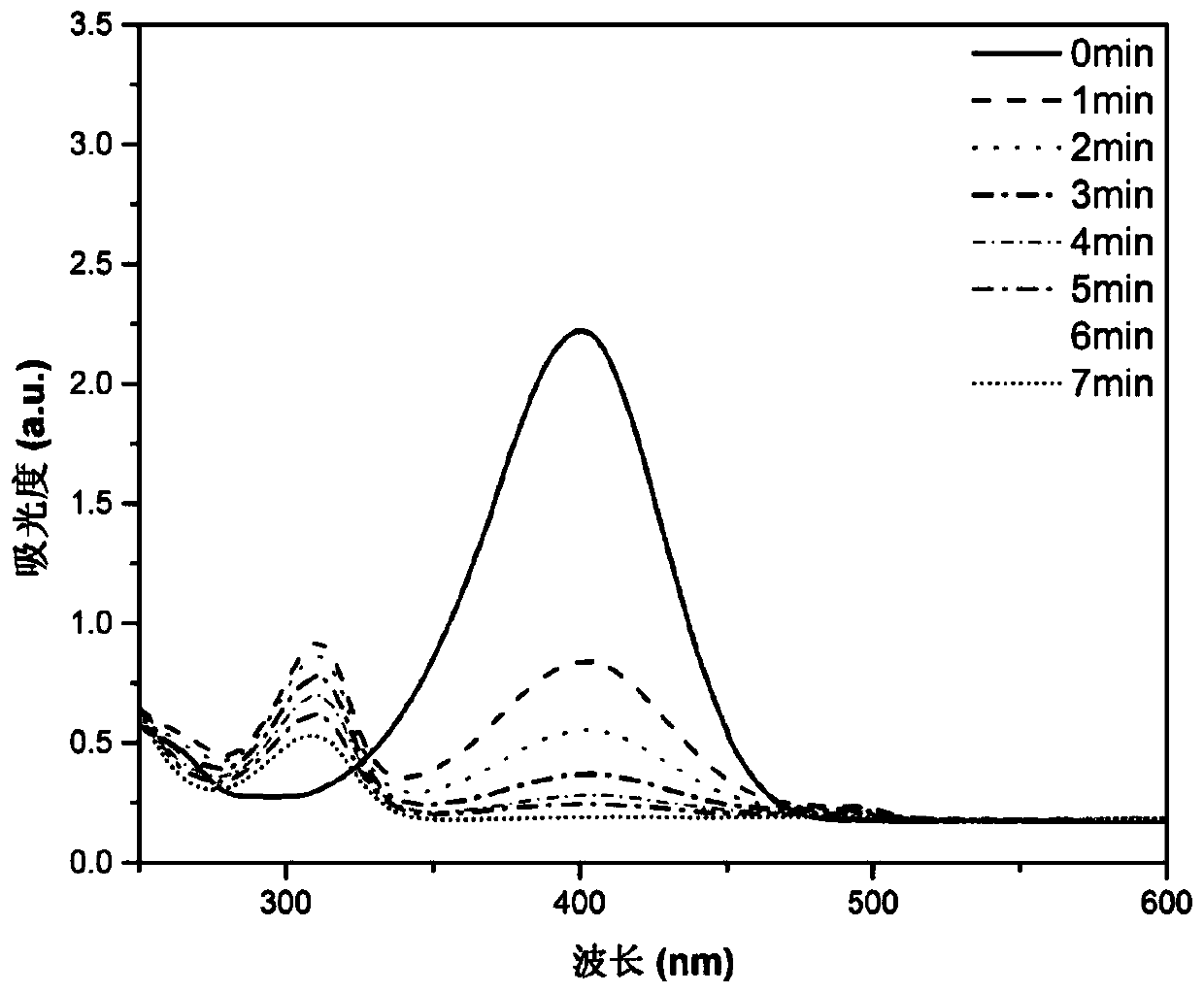

A hydroxide and catalytic material technology, applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problem of poor catalyst recycling effect and low catalytic efficiency , complex preparation process and other problems, to achieve the effect of good catalytic activity and stability, stable structure, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of a catalytic material based on a magnetic layered double hydroxide:

[0046] (1) The preparation method of magnetic layered double metal hydroxide, comprises the following steps:

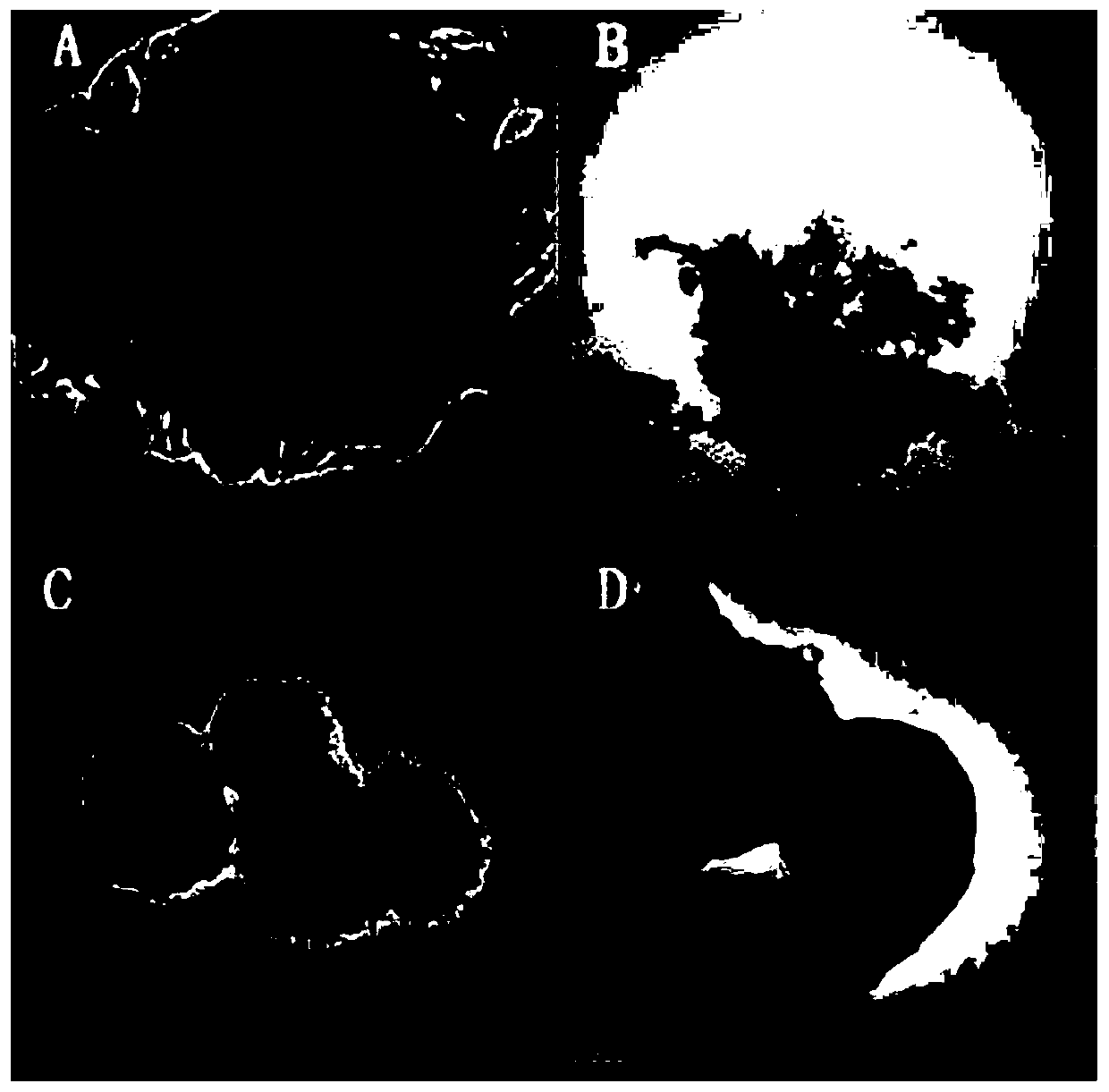

[0047] [1] Mix and stir 5.4g ferric chloride, 9.6g sodium acetate, 2.0g sodium citrate, and 160mL ethylene glycol for 30 minutes to obtain mixture 1;

[0048] [2] The mixture 1 obtained in step [1] is placed in a reactor for reaction, the reaction temperature is 200°C, and the time is 8 hours to obtain ferric oxide;

[0049] [3] After mixing and stirring 0.425g ferric oxide, 100mL ethanol, 25mL deionized water, and 1.8mL ammonia water, add 1.25mL tetraethoxysilane to react at room temperature for 12 hours to obtain magnetic silica gel particles;

[0050] [4] Mix 0.2 g of magnetic silica gel particles with 100 mL of deionized water, adjust the pH of the solution to 10, and obtain an aqueous silica gel solution.

Embodiment 2

[0056] A preparation method of a catalytic material based on a magnetic layered double hydroxide:

[0057] (1) The preparation method of magnetic layered double metal hydroxide, comprises the following steps:

[0058] [1] Mix and stir 5.0g ferric chloride, 9.2g sodium acetate, 1.6g sodium citrate, and 140mL ethylene glycol for 35 minutes to obtain mixture 1;

[0059] [2] The mixture 1 obtained in step [1] is placed in a reactor for reaction, the reaction temperature is 200°C, and the time is 8 hours to obtain ferric oxide;

[0060] [3] After mixing and stirring 0.40g ferric oxide, 80mL ethanol, 20mL deionized water, and 1.6mL ammonia water, add 1.0mL tetraethoxysilane to react at room temperature for 10 hours to obtain magnetic silica gel particles;

[0061] [4] Mix 0.15 g of magnetic silica gel particles with 90 mL of deionized water, adjust the pH of the solution to 9.5, and obtain an aqueous silica gel solution.

[0062] [5] Add 40mL magnesium nitrate and aluminum nitrate...

Embodiment 3

[0067] A preparation method of a catalytic material based on a magnetic layered double hydroxide:

[0068] (1) The preparation method of magnetic layered double metal hydroxide, comprises the following steps:

[0069] [1] Mix and stir 5.8g ferric chloride, 10.0g sodium acetate, 2.4g sodium citrate, and 180mL ethylene glycol for 35 minutes to obtain mixture 1;

[0070] [2] The mixture 1 obtained in step [1] is placed in a reactor for reaction, the reaction temperature is 200° C., and the time is 10 hours to obtain ferric oxide;

[0071] [3] After mixing and stirring 0.45g ferric oxide, 120mL ethanol, 30mL deionized water, and 2.0mL ammonia water, add 1.5mL tetraethoxysilane to react at room temperature for 14 hours to obtain magnetic silica gel particles;

[0072] [4] Mix 0.35 g of magnetic silica gel particles with 110 mL of deionized water, adjust the pH of the solution to 10.5, and obtain an aqueous silica gel solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com