Preparation method of bright oil

A technology for bright oil and deasphalted oil, which is applied in the recovery/refining of mineral wax, petroleum industry, and treatment of hydrocarbon oil. Effects of utilization, reduced solvent consumption, and reduced quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

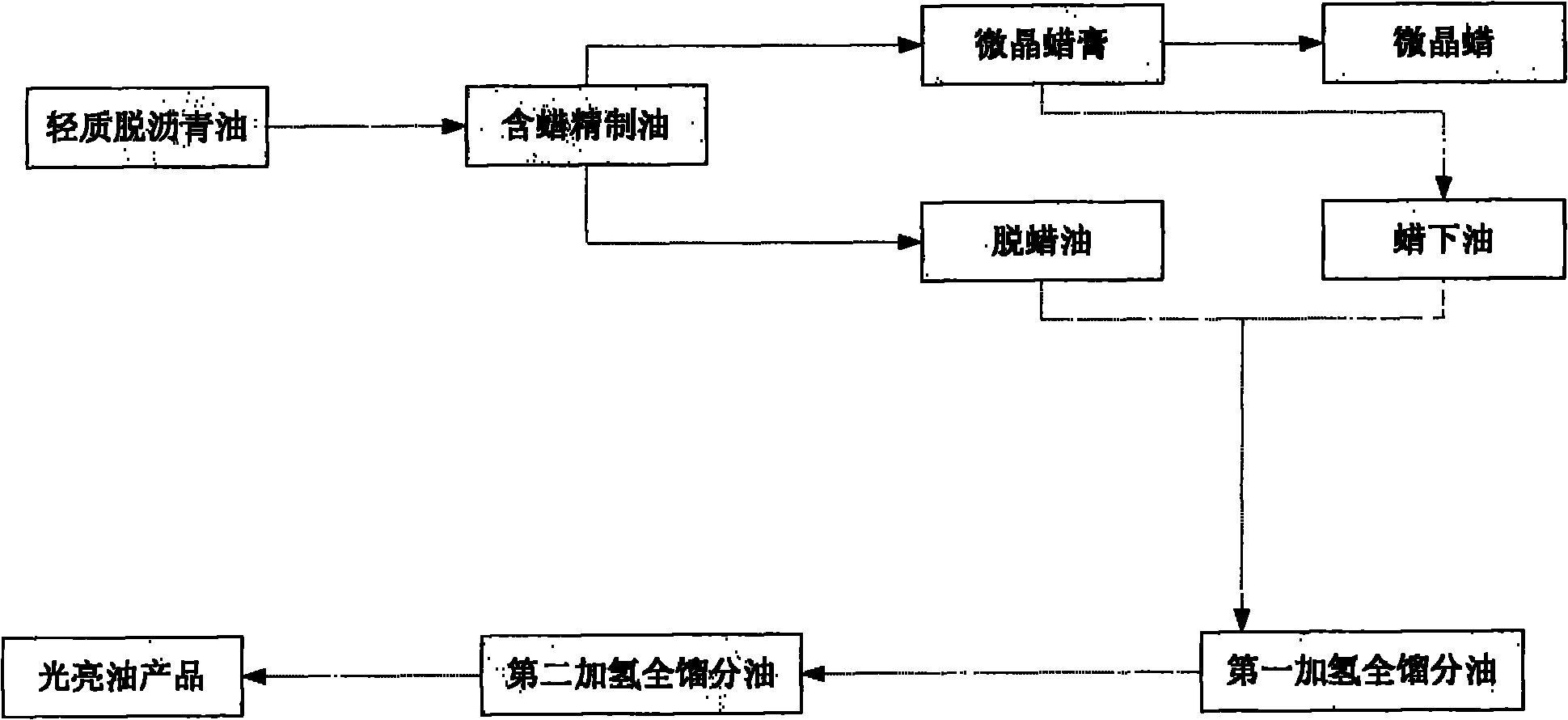

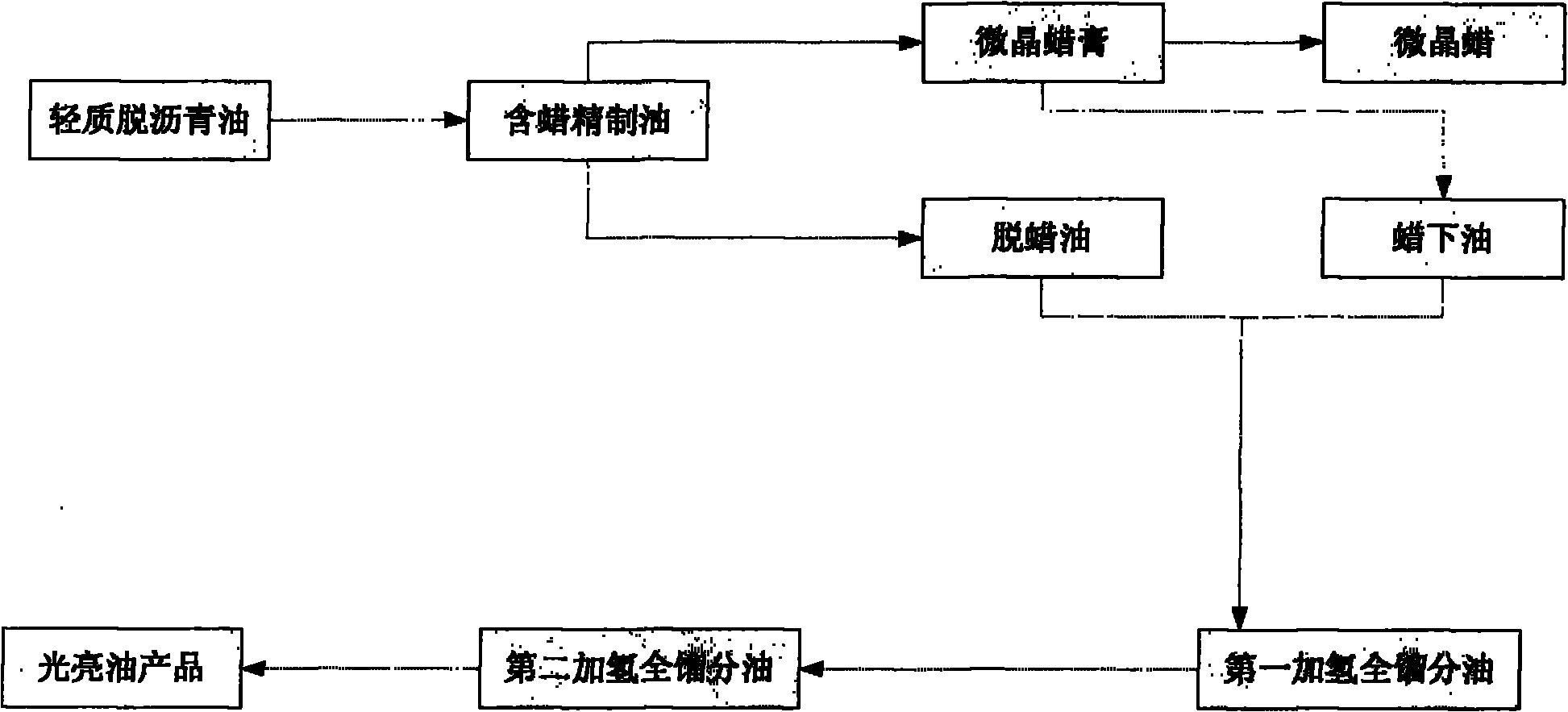

[0023] Such as figure 1 Shown, the preparation method of bright stock provided by the invention comprises the following steps:

[0024] (1) Contacting the light deasphalted oil with a solvent that has selective solubility for macromolecular polycyclic aromatic hydrocarbons, at least removing part of the macromolecular polycyclic aromatic hydrocarbons, and obtaining macromolecular polycyclic aromatic hydrocarbons with a content of less than 30% by weight Refined waxy oil; the macromolecular polycyclic aromatic hydrocarbons refer to polycyclic aromatic hydrocarbons with a number of benzene rings greater than 3, the carbon residue content of the light deasphalted oil is not higher than 2.5% by weight, and the chroma is not greater than No. 8, positive The content of heptane insoluble matter is not more than 100ppm, and the dry point is not more than 700°C;

[0025] (2) Contacting the above-mentioned waxy refined oil with a dewaxing solvent to separate oil and wax to obtain dewax...

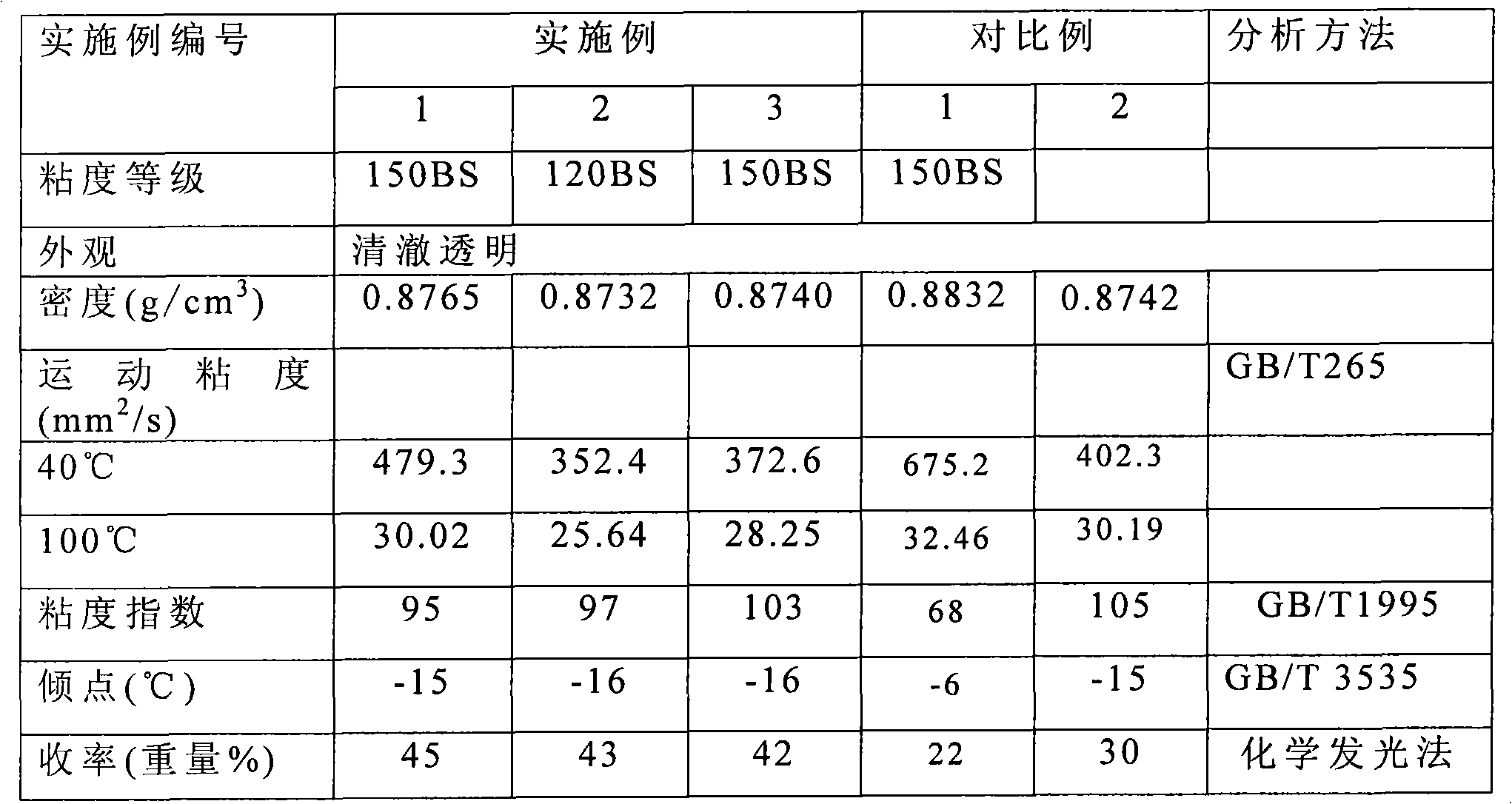

Embodiment 1

[0057] This example is used to illustrate the preparation method of the bright stock provided by the present invention.

[0058] according to figure 1 The described procedure produces bright stock.

[0059] (1) Using the vacuum residue obtained by distillation of intermediate base crude oil as raw material, carry out propane deasphalting in a propane deasphalting device including an extraction tower and a settling tower to obtain light deasphalting oil. The operating conditions are as follows: the temperature of the raw material entering the tower is 95°C, the temperature of the solvent entering the tower is 38°C, the volume ratio of solvent to oil is 5.0; the temperature of the extraction tower is 40-65°C, the temperature of the settling tower is 65-76°C, and the deasphalting solvent is A mixing vessel of propane and pentane, with a propane content of 94.2% by weight. Under the above conditions, the yield of light deasphalted oil was 21% by weight. The properties of the li...

Embodiment 2

[0081] This example is used to illustrate the preparation method of the bright stock provided by the present invention.

[0082] according to figure 1 The described procedure produces bright stock.

[0083] (1) The light deasphalted oil obtained according to the method described in Example 1 is contacted with N-methylpyrrolidone in an extraction tower to obtain a waxy refined oil. The temperature at the top of the extraction tower is 115°C, the temperature at the bottom of the tower is 90°C, the weight ratio of N-methylpyrrolidone and light deasphalted oil is 1.5:1, and the contact time is 35 minutes; the properties of the waxy refined oil are as follows: As shown in Table 1, the yield of the waxy refined oil was 85% by weight.

[0084] (2) The above-mentioned waxy refined oil is contacted with a dewaxing solvent in a dewaxing solvent device to separate the oil and wax, and the yields are respectively 58% by weight of dewaxed oil and 42% by weight of microcrystalline wax pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com