Patents

Literature

613 results about "Cloud point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the petroleum industry, cloud point refers to the temperature below which wax in diesel or biowax in biodiesels forms a cloudy appearance. The presence of solidified waxes thickens the oil and clogs fuel filters and injectors in engines. The wax also accumulates on cold surfaces (producing, for example, pipeline or heat exchanger fouling) and forms an emulsion with water. Therefore, cloud point indicates the tendency of the oil to plug filters or small orifices at cold operating temperatures.

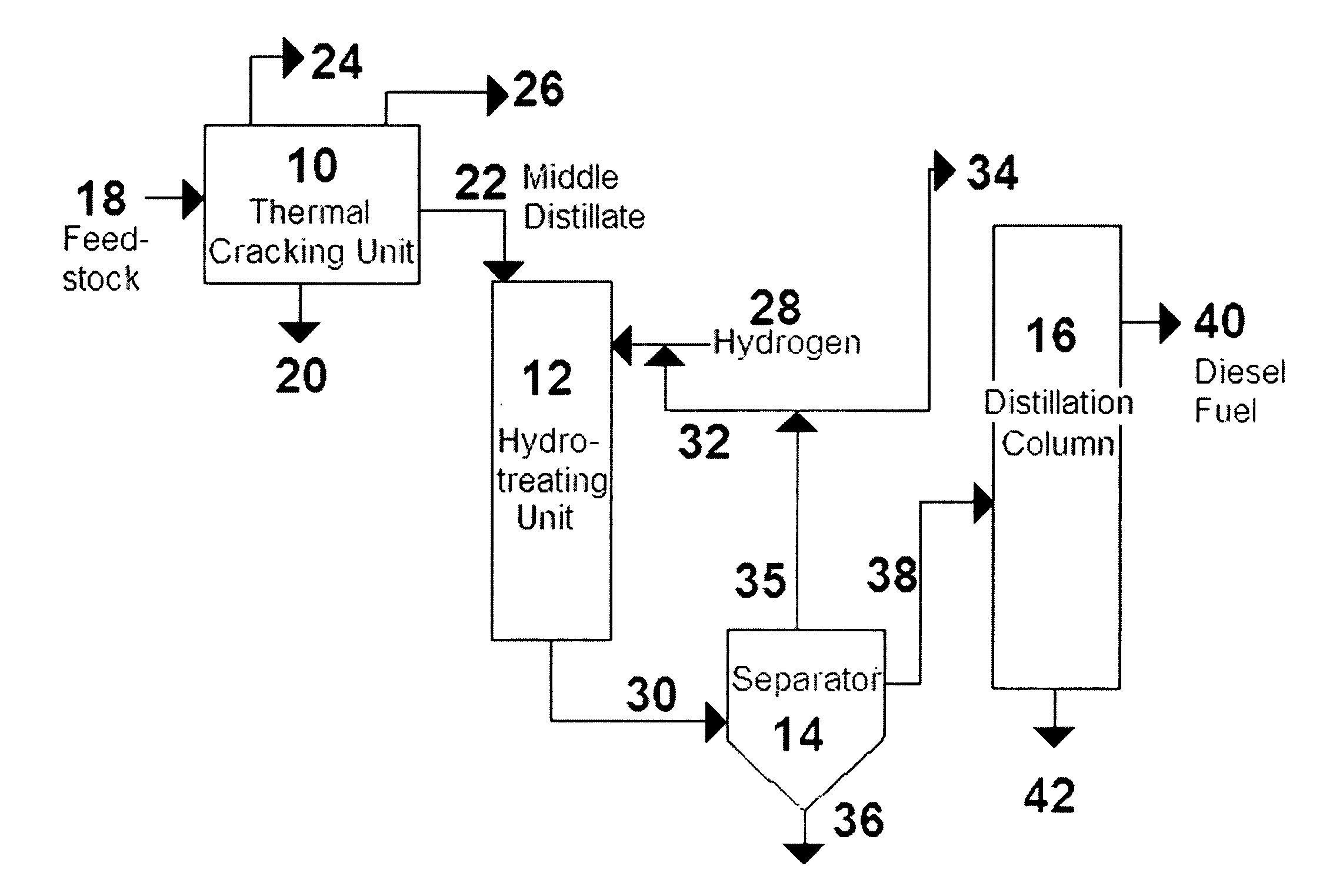

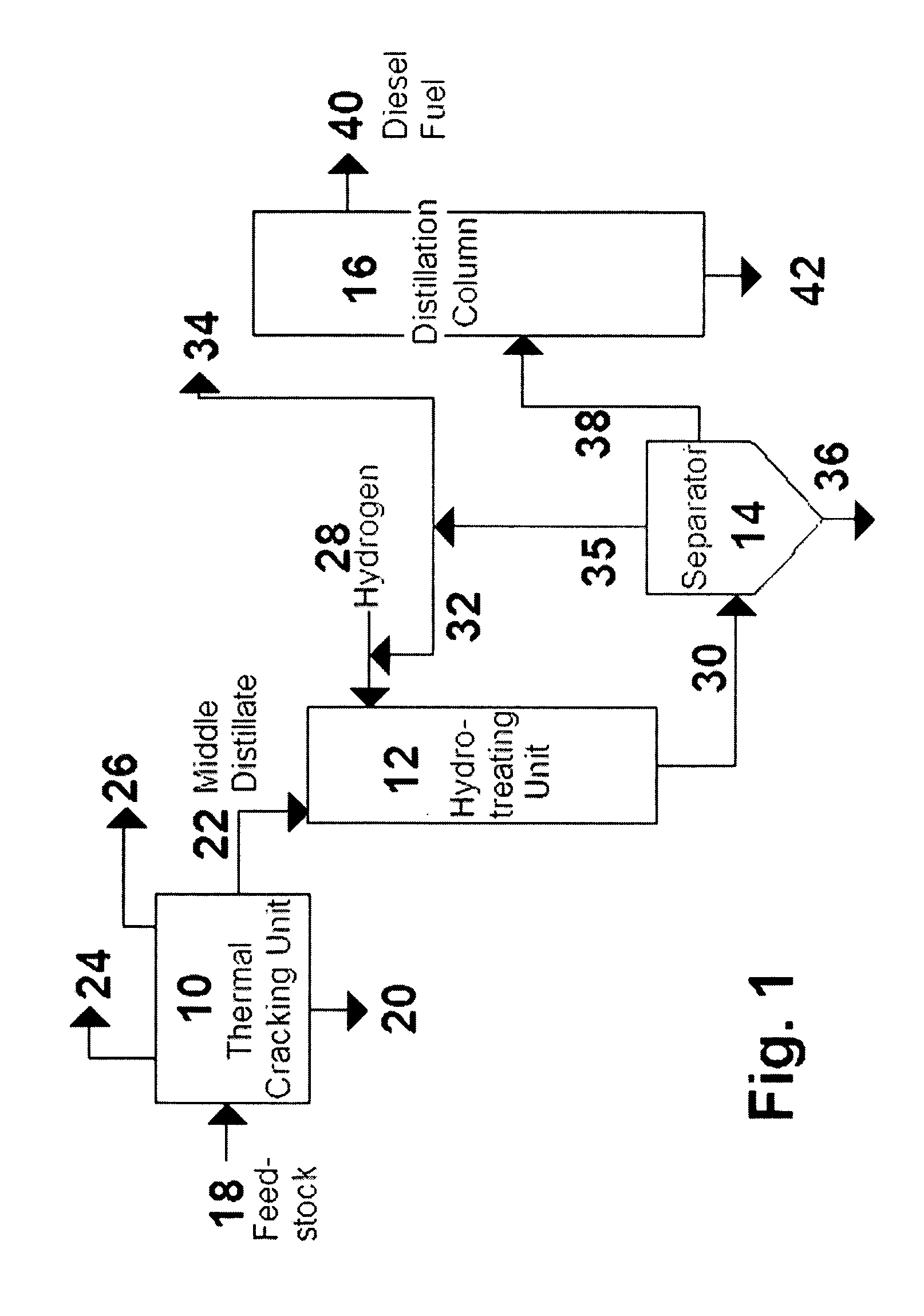

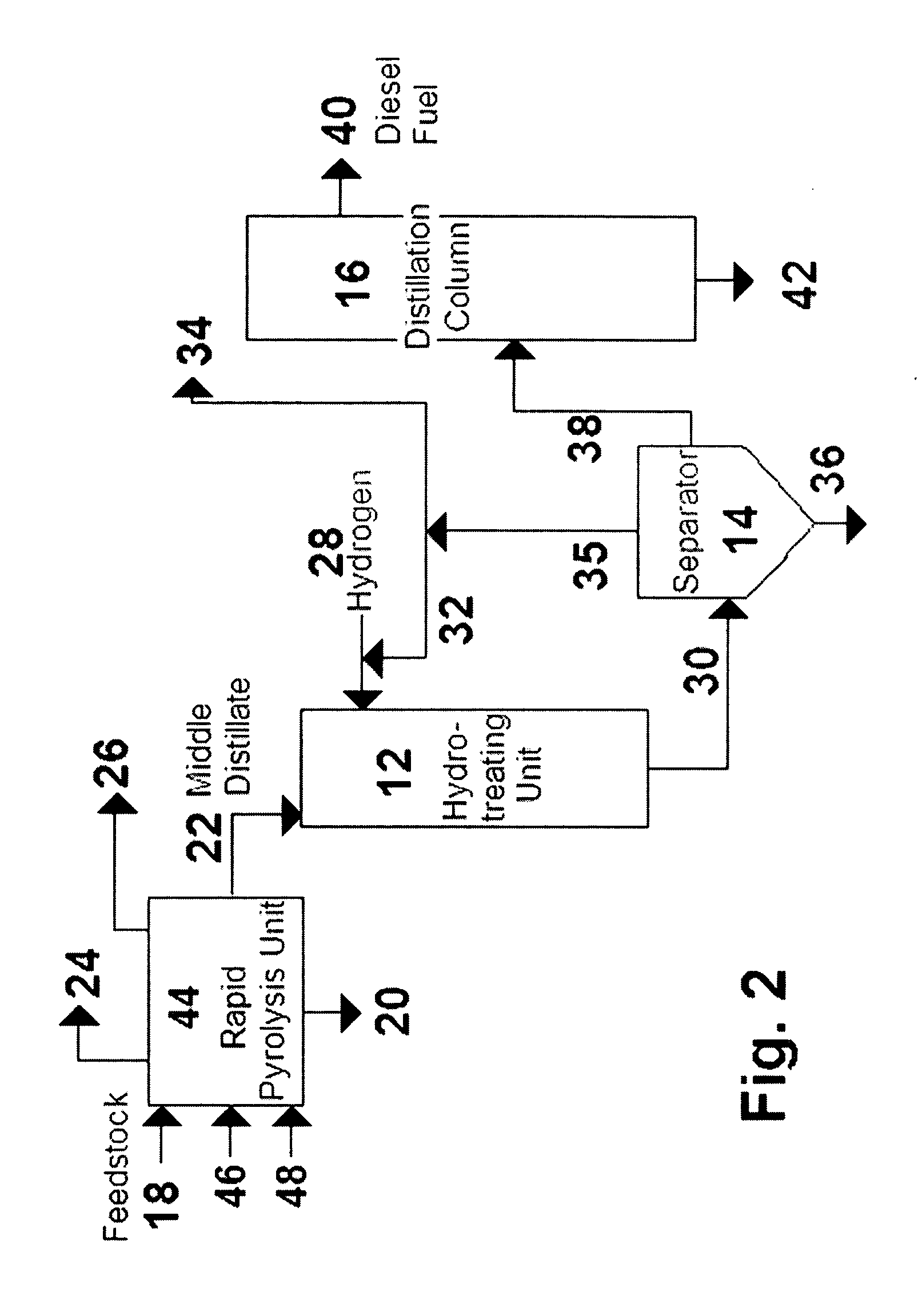

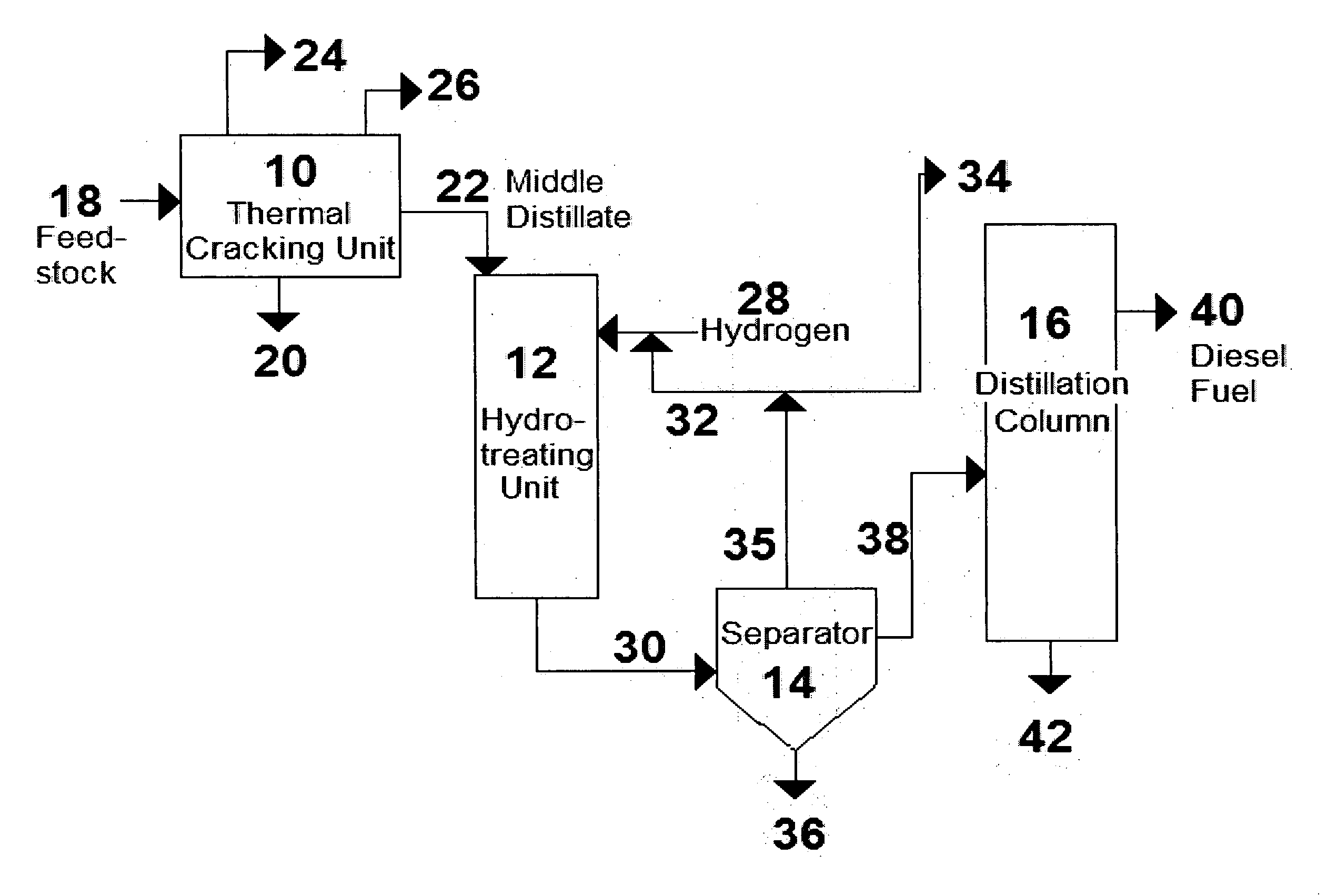

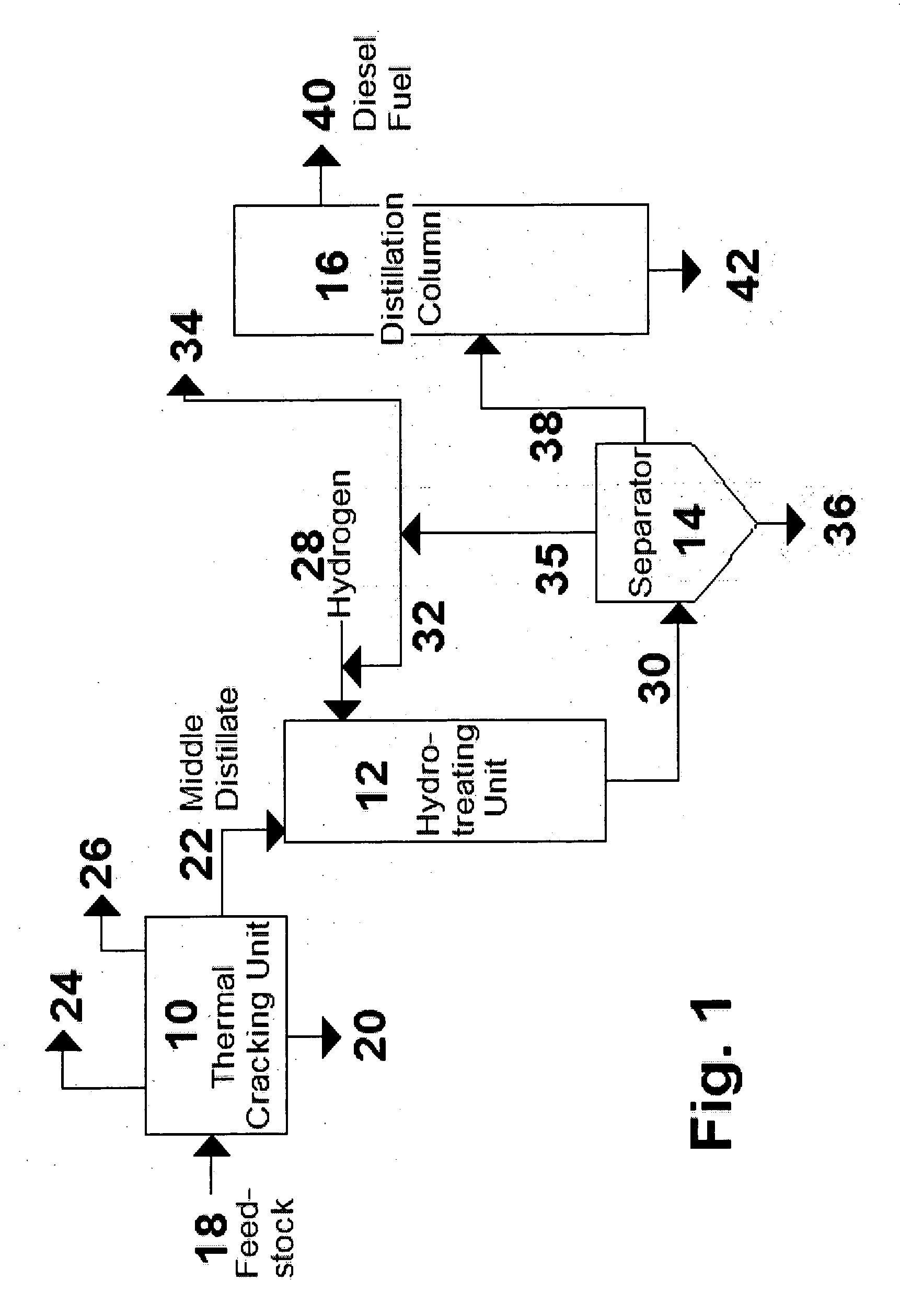

Production of high-cetane diesel fuel from low-quality biomass-derived feedstocks

A method is taught for producing diesel fuels of high cetane value from a triglyceride feedstock, comprising pretreating the triglyceride feedstock by thermal cracking or rapid pyrolysis to partially convert the triglycerides and produce a middle distillates stream, and catalytically hydrotreating the middle distillate fraction to produce high cetane value diesel fuels. A biomass-derived diesel fuel is also taught having sulphur content below 10 ppm, a cetane-value of at least 70, a cloud point below 0° C. and a pour point of less than −4° C. A blended diesel fuel is also taught comprising 5 to 20 vol. % of the biomass-derived diesel fuel of the present invention and 80 to 95 vol. % of a petroleum diesel, based on total volume of the blended diesel fuel.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

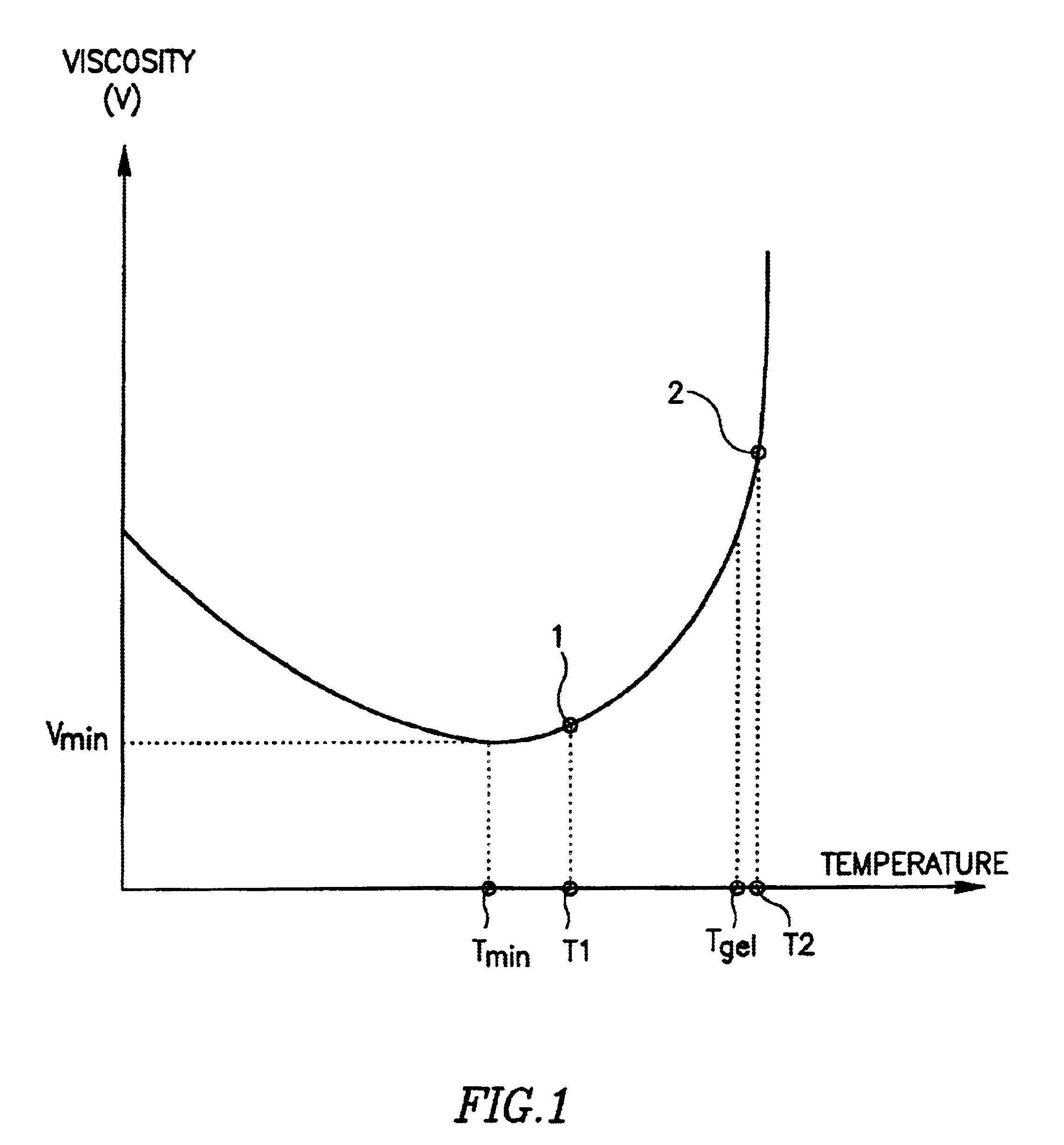

Reverse thermal gels and the use thereof for rapid prototyping

InactiveUS6863859B2Reduce surface tensionHigh strengthAdditive manufacturing apparatusPhotosensitive materialsLower critical solution temperatureWater soluble

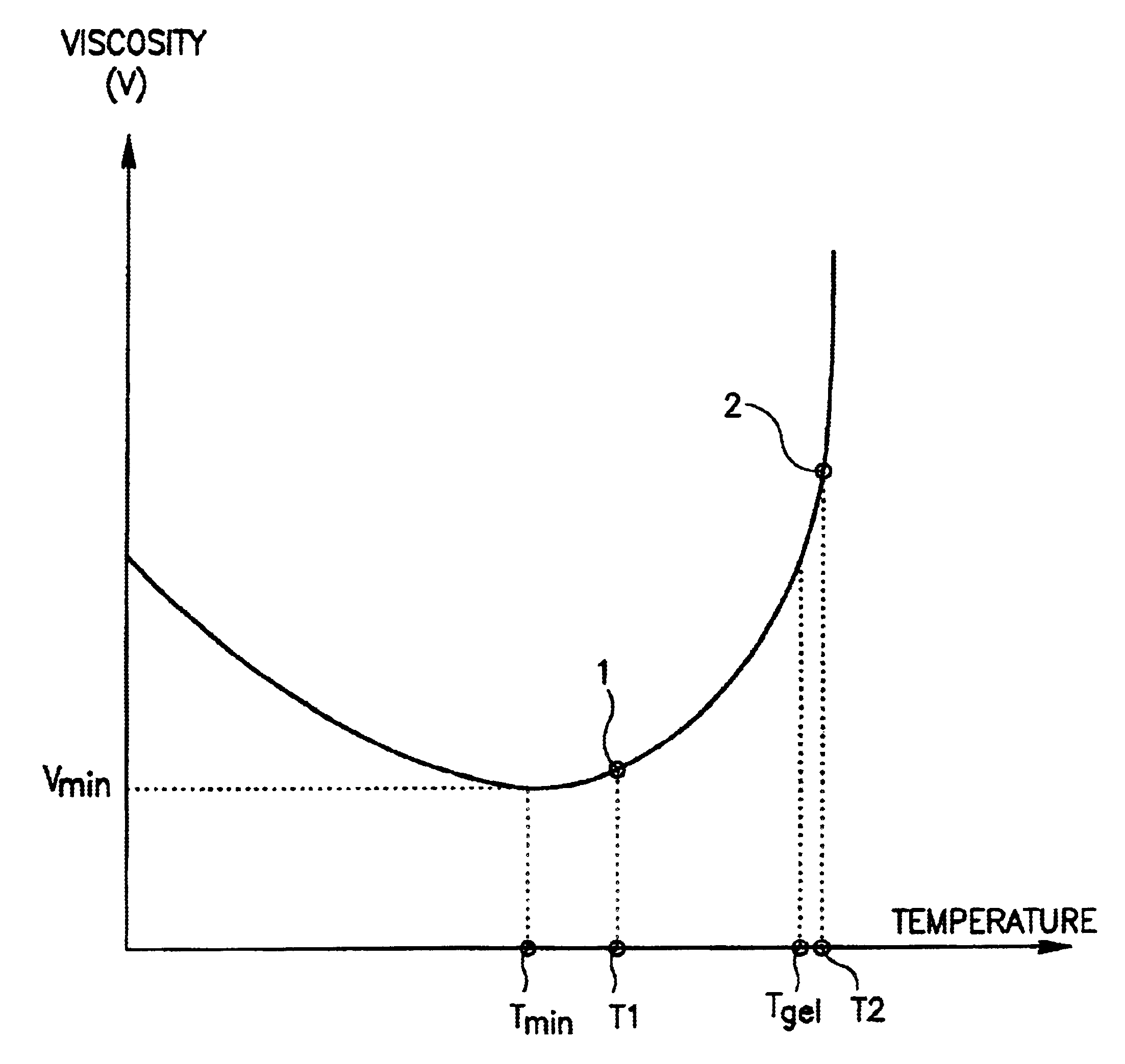

The present invention relates to novel polymeric compositions that exhibit Reverse Thermal Gelation (RTG) properties for use as Support Materials (SM) in the manufacture of three-dimensional objects. These polymers are Temperature Sensitive Polymers that respond with a significant change of properties to a small change in temperature. Temperature Sensitive Polymers exhibit cloud point (CP) or lower critical solution temperature (LCST) in aqueous solutions. Water-soluble Temperature Sensitive Polymers are chosen to give low viscosity liquid at low temperature when dissolved in water and by that to permit easy dispensing at low temperature. Raising the temperature above their gelation temperature (Tgel) will result in solidification of the composition. At its gel position the material has favorable characteristics as a support and building material. The gel layers have the appropriate toughness and dimensional stability to support the model layers during the building process. After the building process is completed the gel can be cooled down to a temperature below its Tgel so the gel can liquefy and be removed easily by rinsing with water.

Owner:STRATASYS LTD

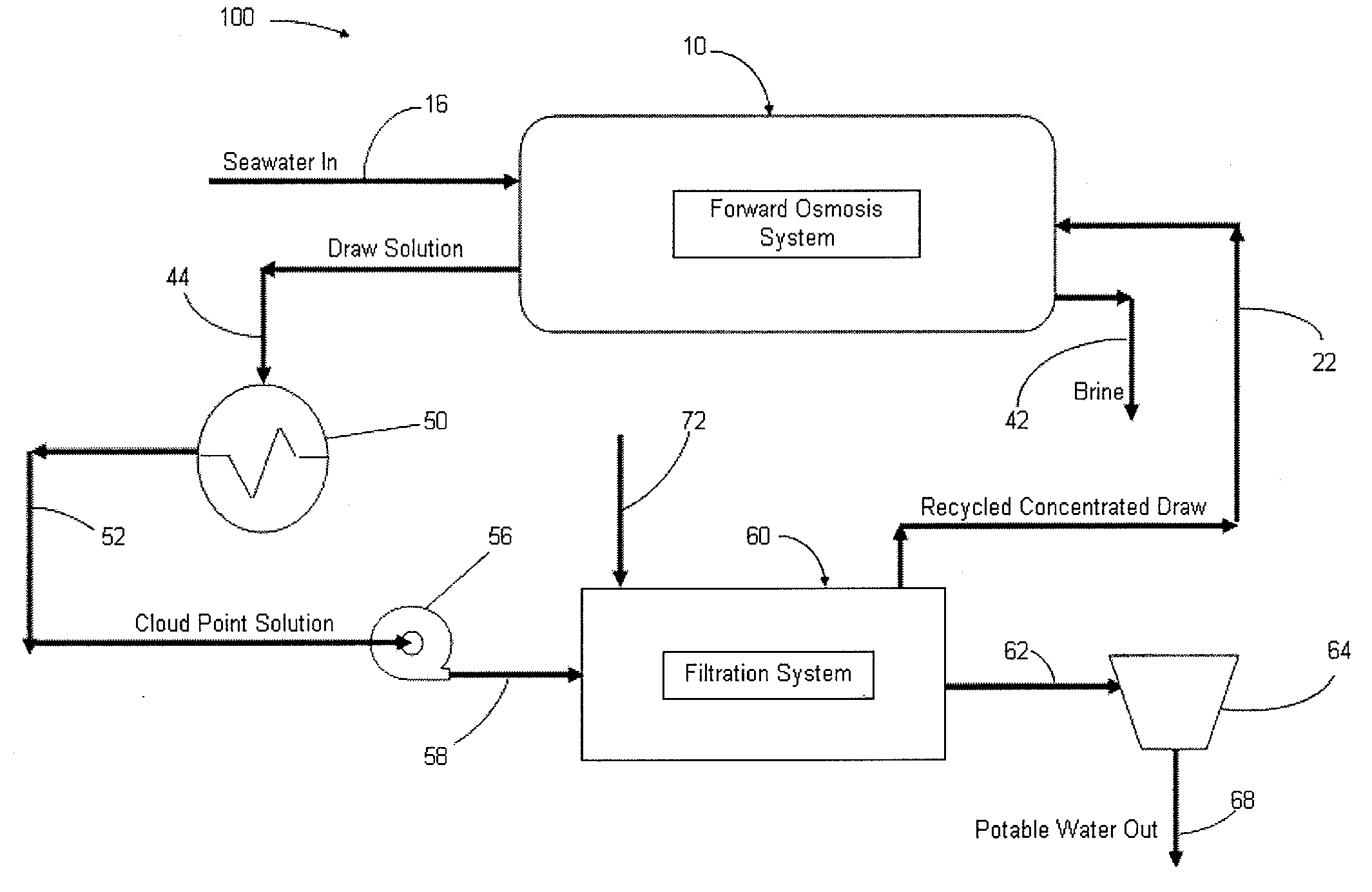

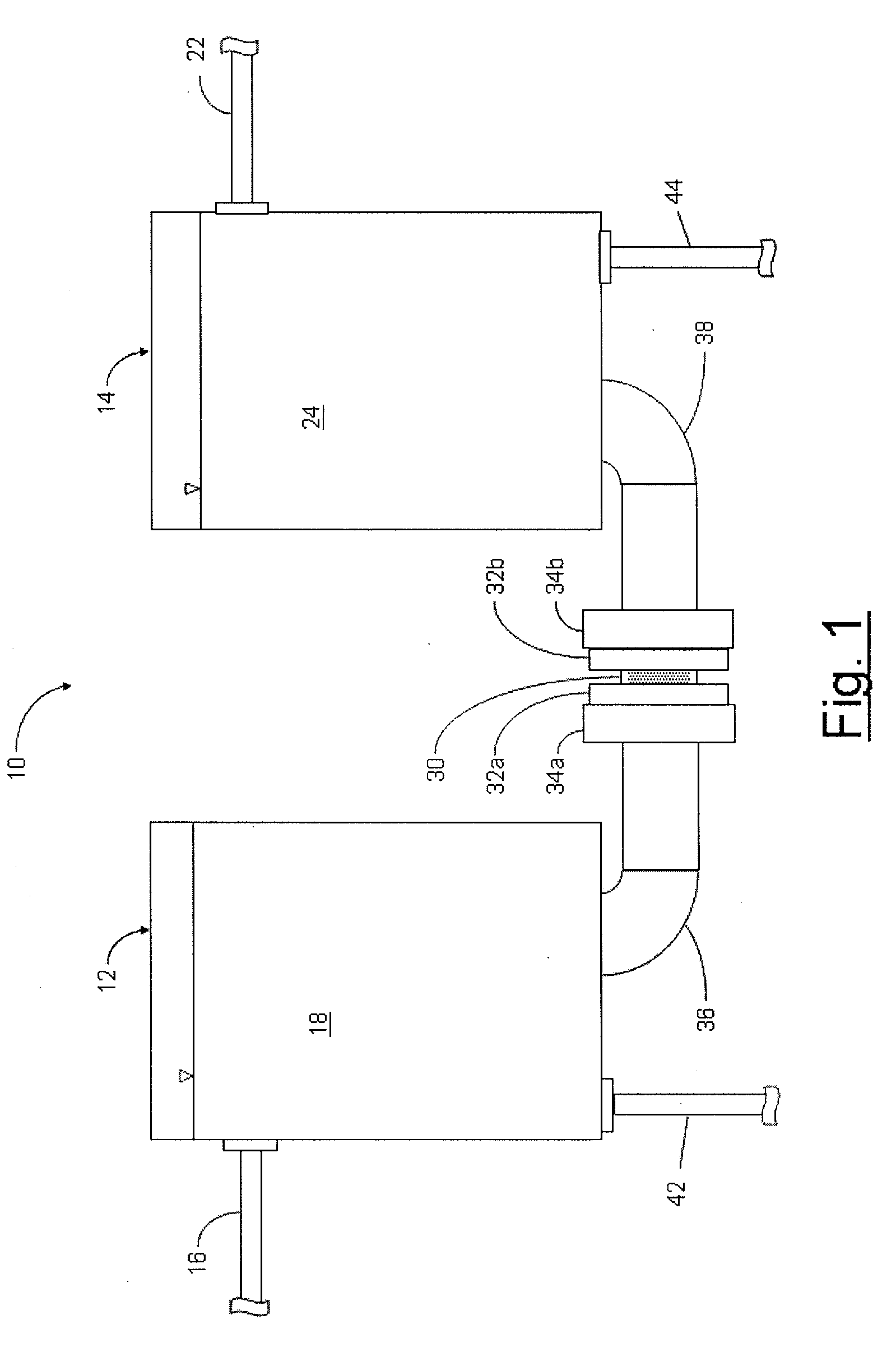

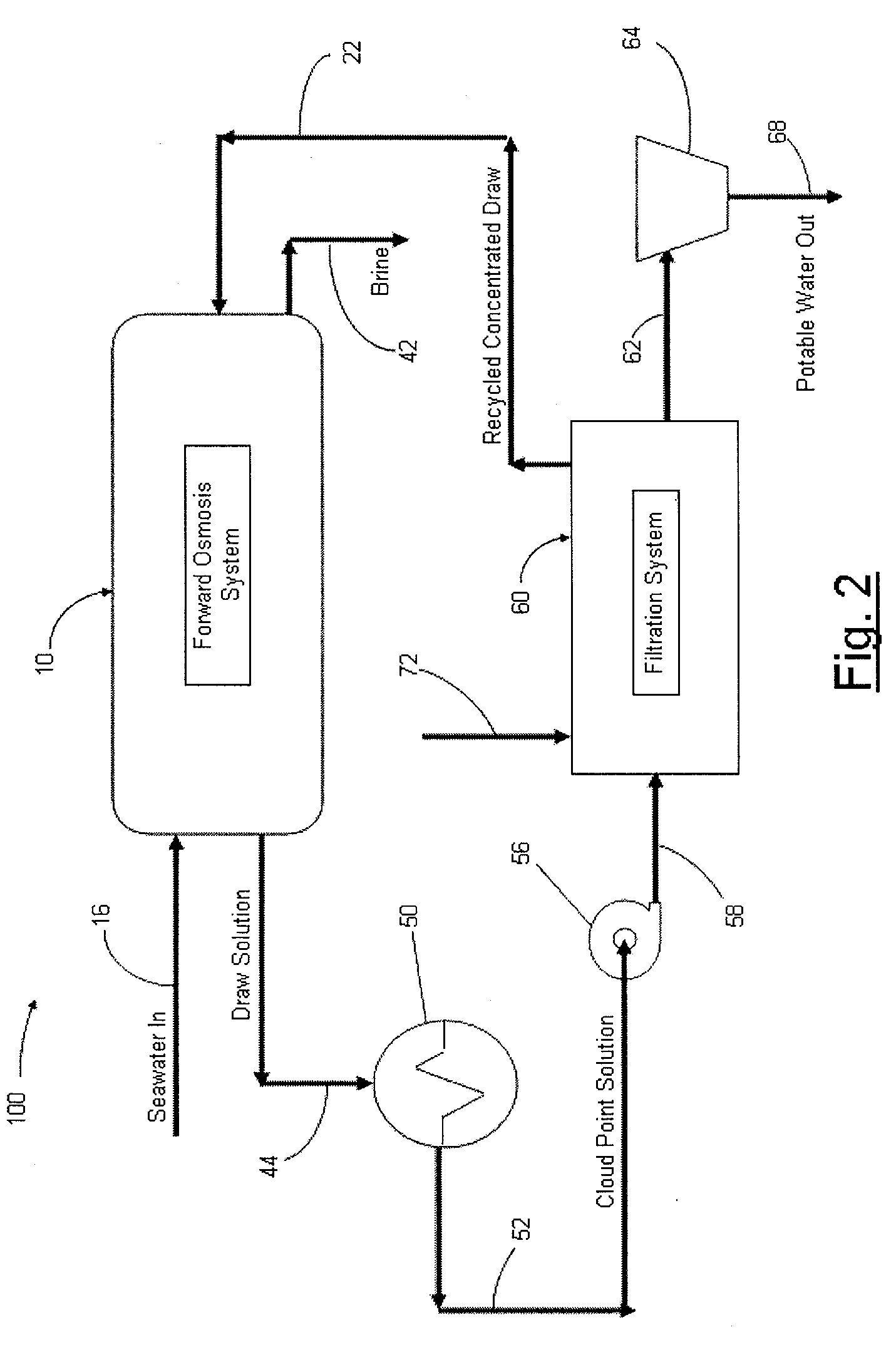

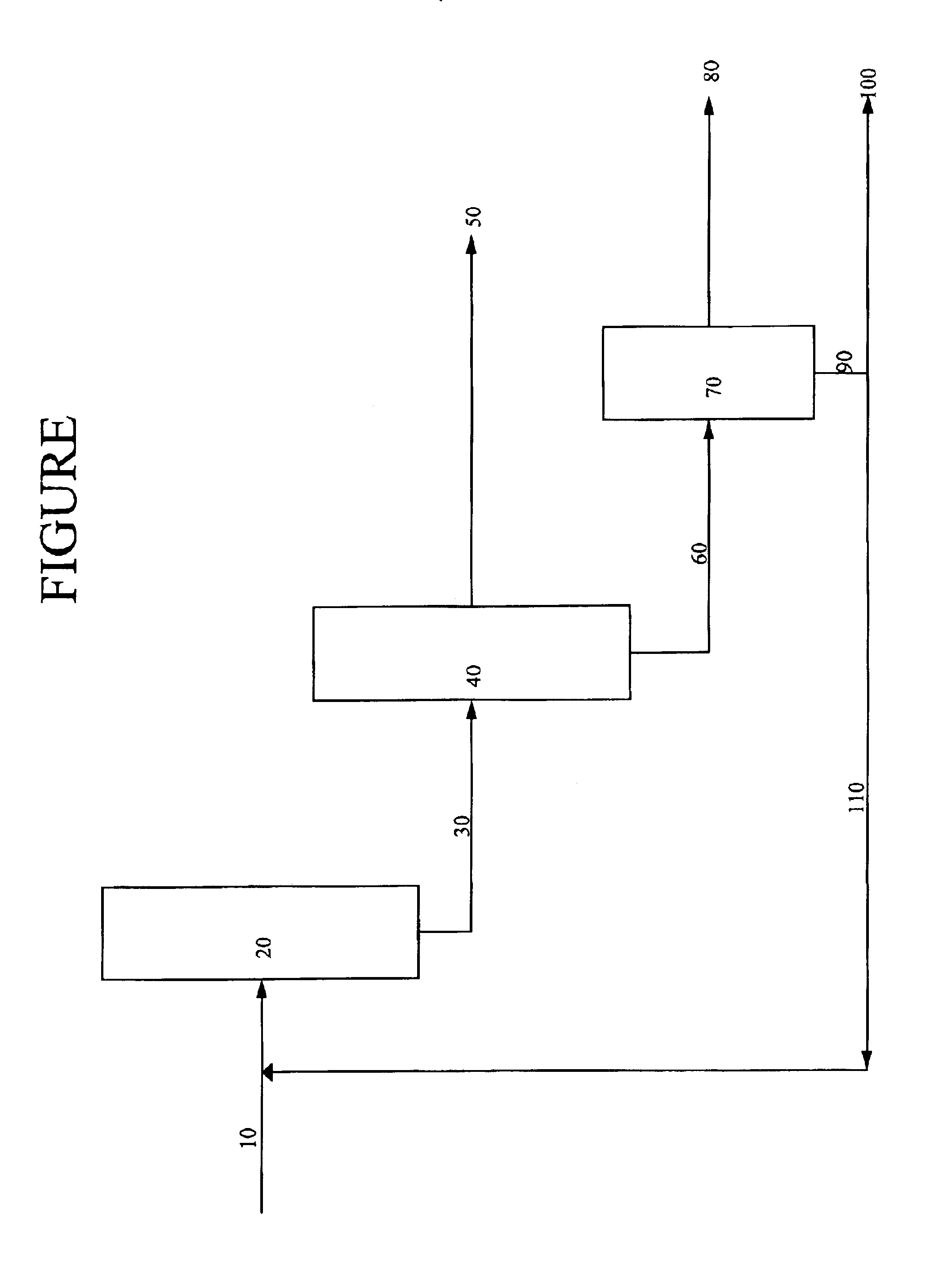

Systems and methods for forward osmosis fluid purification

ActiveUS20100155329A1Improve efficiencyFunction increaseGeneral water supply conservationSeawater treatmentSaline waterDesalination

A process for purification of fluids, for example, desalination of seawater or brackish water, using organic solutes in a concentrated water solution for use in a forward osmosis process, to extract fresh water out of salt water through the forward osmosis membrane, and subsequently separating the organic solutes out of the diluted forward osmosis permeate by cloud point extraction, thereby regenerating a concentrated organic solution for recycling to the forward osmosis process, and fresh water for potable water use.

Owner:JFEENG CORP

Production of high-cetane diesel fuel from low-quality biomass-derived feedstocks

ActiveUS20070068848A1Increase cetane numberBiofuelsLiquid hydrocarbon mixture productionTG - TriglyceridePre treatment

A method is taught for producing diesel fuels of high cetane value from a triglyceride feedstock, comprising pretreating the triglyceride feedstock by thermal cracking to partially convert the triglycerides and produce a middle distillates stream, and catalytically hydrotreating the middle distillate fraction to produce high cetane value diesel fuels. A biomass-derived diesel fuel is also taught having sulphur content below 10 ppm, a cetane-value of at least 70, a cloud point below 0° C. and a pour point of less than −4° C. A blended diesel fuel is also taught comprising 5 to 20 vol. % of the biomass-derived diesel fuel of the present invention and 80 to 95 vol. % of a petroleum diesel, based on total volume of the blended diesel fuel.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

Isomerization/dehazing process for base oils from Fischer-Tropsch wax

InactiveUS7198710B2Hydrocarbon by hydrogenationTreatment with hydrotreatment processesWaxMolecular sieve

A method for producing lubricant base oils is provided comprising the steps of: (a) separating a feedstock into a light lubricant base oil fraction and a heavy fraction; (b) hydroisomerizing the fractions over a medium pore size molecular sieve catalyst under hydroisomerization conditions to produce an isomerized light lubricant base oil fraction having a pour point less than or equal to a target pour point of the lubricant base oils and an isomerized heavy fraction having a pour point of equal to or greater than the target pour point of the lubricant base oils and a cloud point greater than the target cloud point of the lubricant base oils; and (c) dehazing the isomerized heavy fraction to provide a heavy lubricant base oil having a pour point less than or equal to the target pour point of the lubricant base oils and a cloud point less than or equal to the target cloud point of the lubricant base oils.

Owner:CHEVROU USA INC

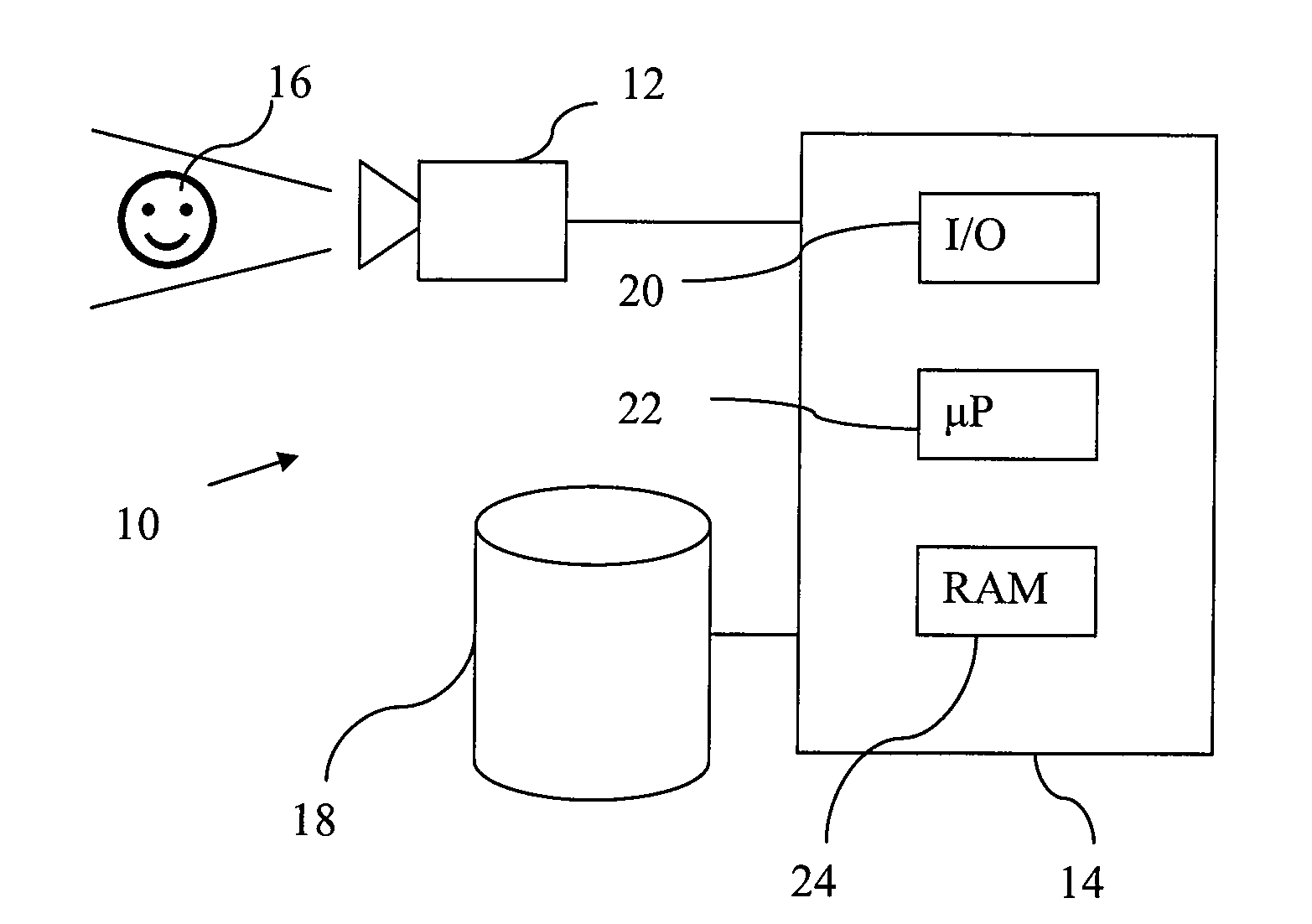

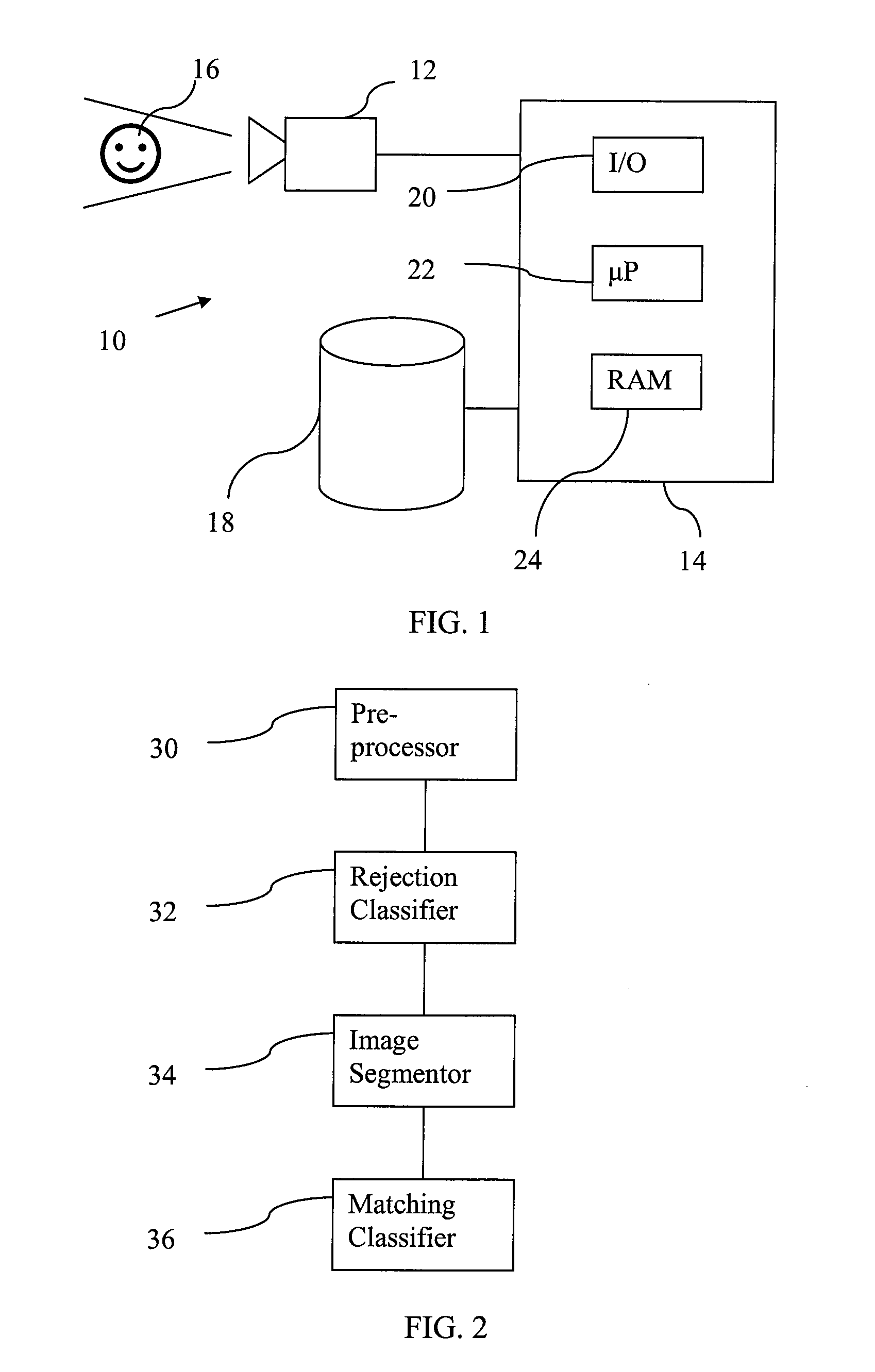

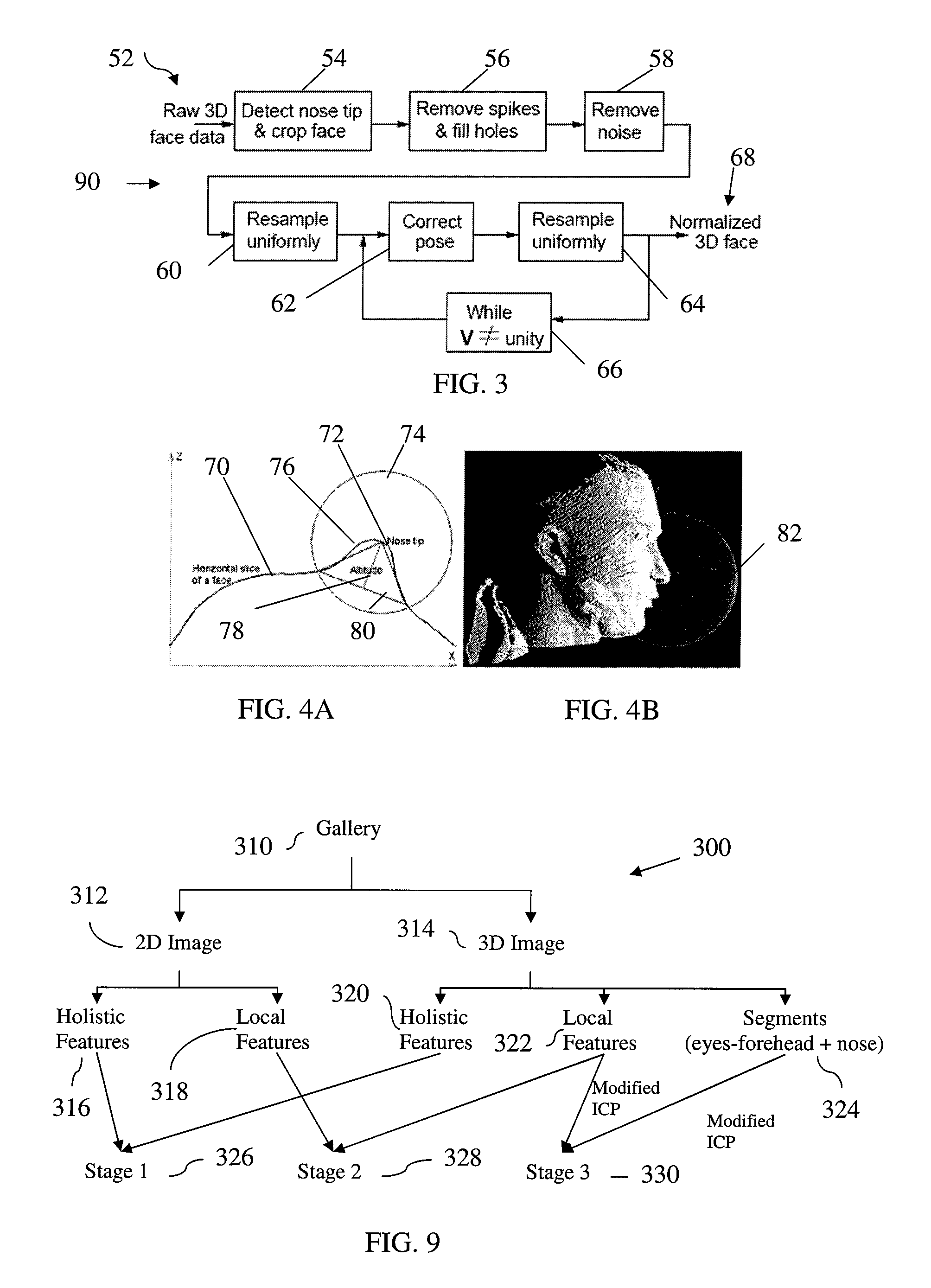

Image recognition

An image recognition method and system (10) comprises receiving at an input (12) a first image set to be recognized, wherein the image set comprises a 3-D image comprising 3-D cloud-points of an observed surface and a registered 2-D image comprising textured pixels. A gallery of image sets is provided in a storage (18) for comparison. A rejection classifier (32) performs a rejection comparison for rejecting image sets in the gallery that do not match the first image set with a high likelihood. A matching classifier (36) performs a matching comparison for identifying an image set of the non-rejected gallery image sets which matches the first image set with a high likelihood.

Owner:UNIV OF WESTERN AUSTRALIA

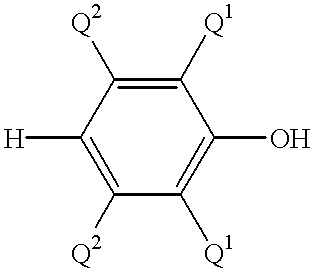

Method of preparing a poly(arylene ether), and a poly(arylene ether) prepared thereby

A method of preparing a poly(arylene ether) includes oxidatively polymerizing a monohydric phenol in solution, concentrating the solution by removing a portion of the solvent to form a concentrated solution having a cloud point, Tcloud, and combining the concentrated solution with an anti-solvent to precipitate the poly (arylene ether), wherein the concentrated solution has a temperature of at least about (Tcloud-10° C.) immediately before it is combined with the anti-solvent. The method reduces the formation of undesirably fine particles in the product poly(arylene ether).

Owner:SHPP GLOBAL TECH BV

Process for isomerization dewaxing of hydrocarbon streams

InactiveUS20030168379A1Yield maximizationReduce pointsMolecular sieve catalystsHydrocarbon by hydrogenationMolecular sieveIsomerization

A process for isomerization dewaxing of a hydrocarbon feed which includes contacting the hydrocarbon feed with a large pore size, small crystal size, crystalline molecular sieve and an intermediate pore size, small crystal size, crystalline molecular sieve to produce a dewaxed product with a reduced pour point and a reduced cloud point. In a preferred embodiment, the feed is contacted with the molecular sieves sequentially, first with the large pore sieve followed by the intermediate pore sieve.

Owner:EXXON RES & ENG CO

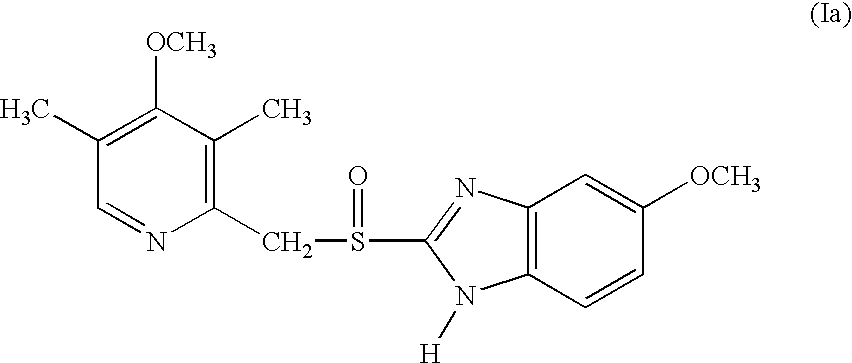

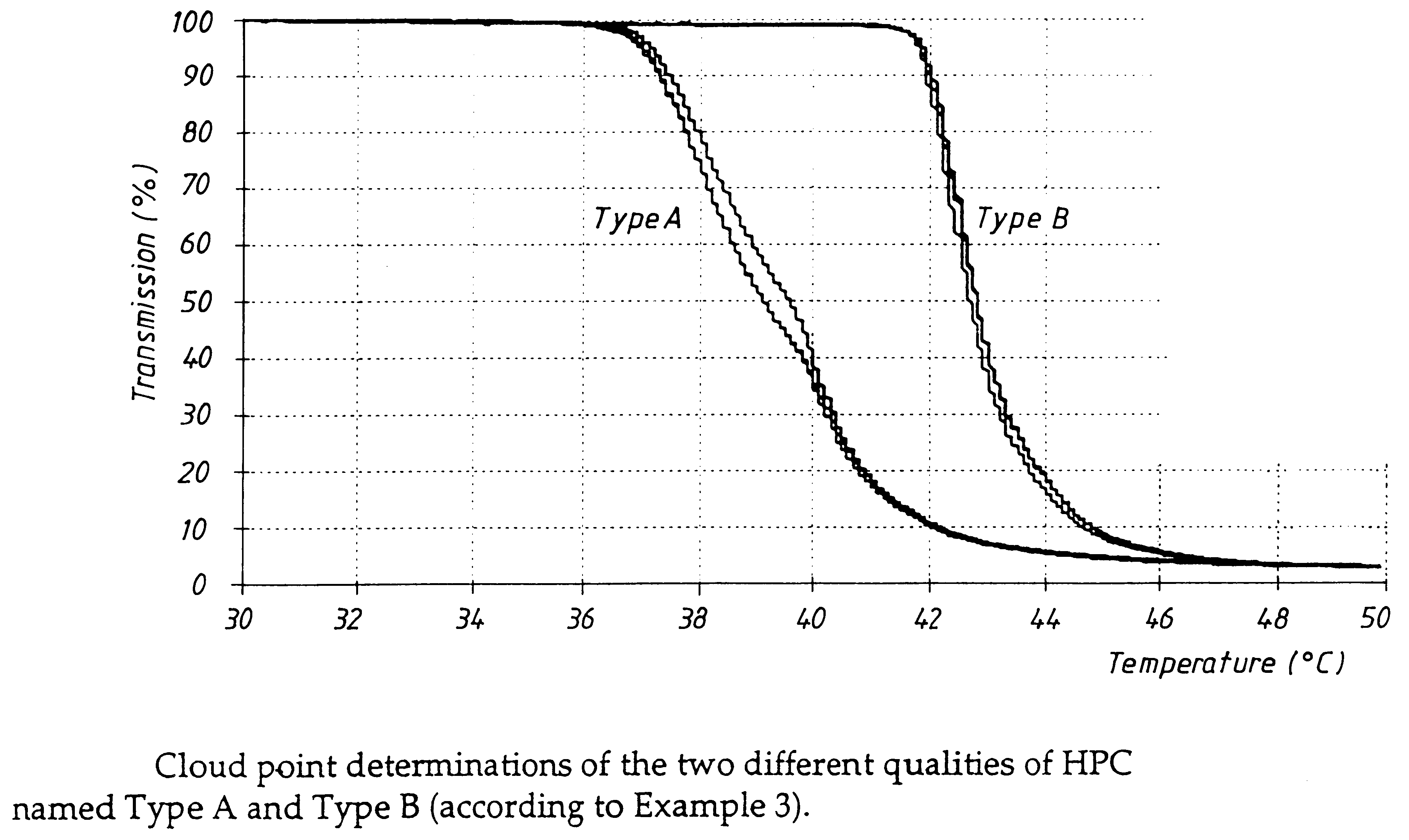

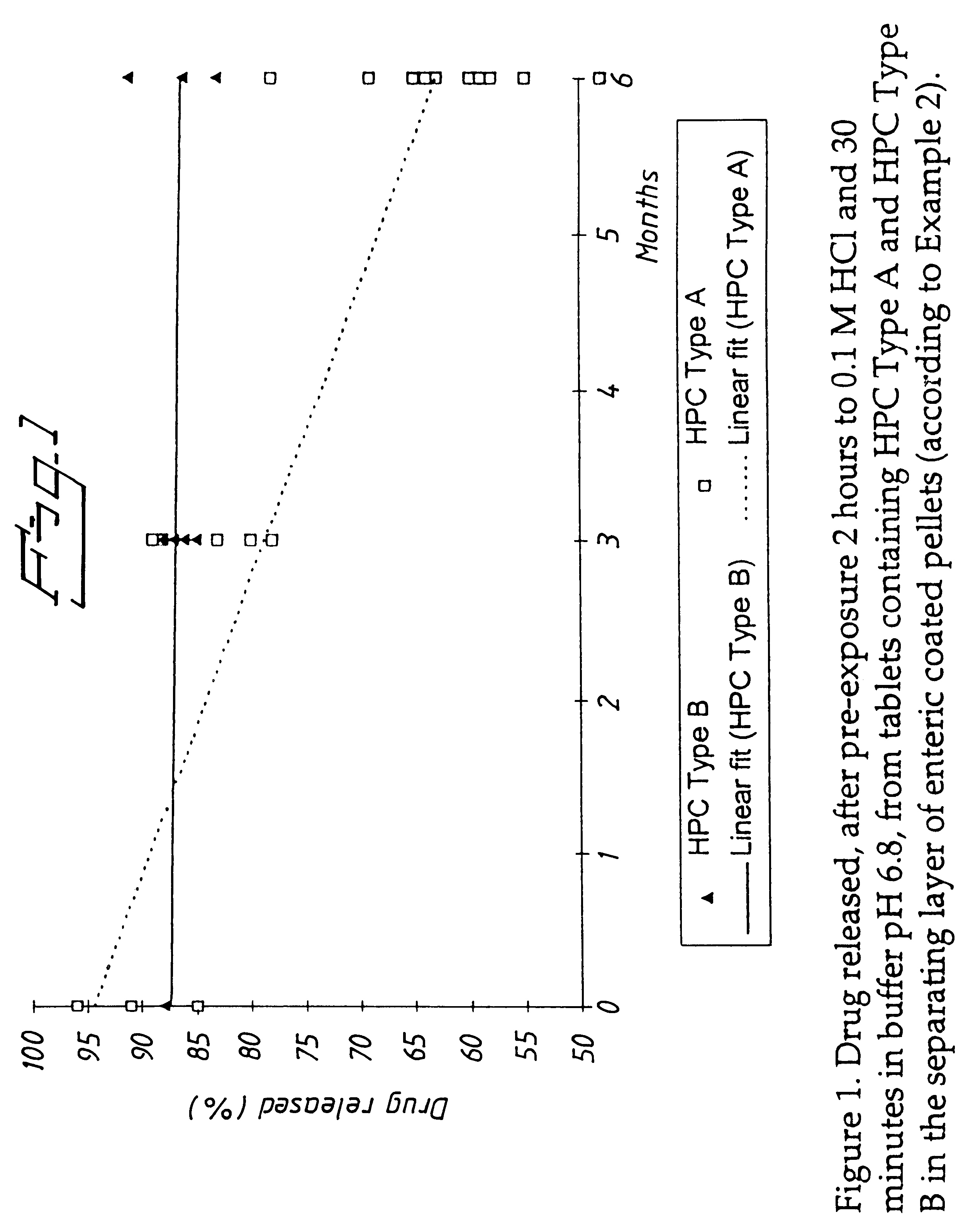

Pharmaceutical formulation comprising omeprazole

InactiveUS6428810B1Reduce diffuseHigh film thicknessOrganic active ingredientsOrganic chemistryEnantiomerOmeprazole

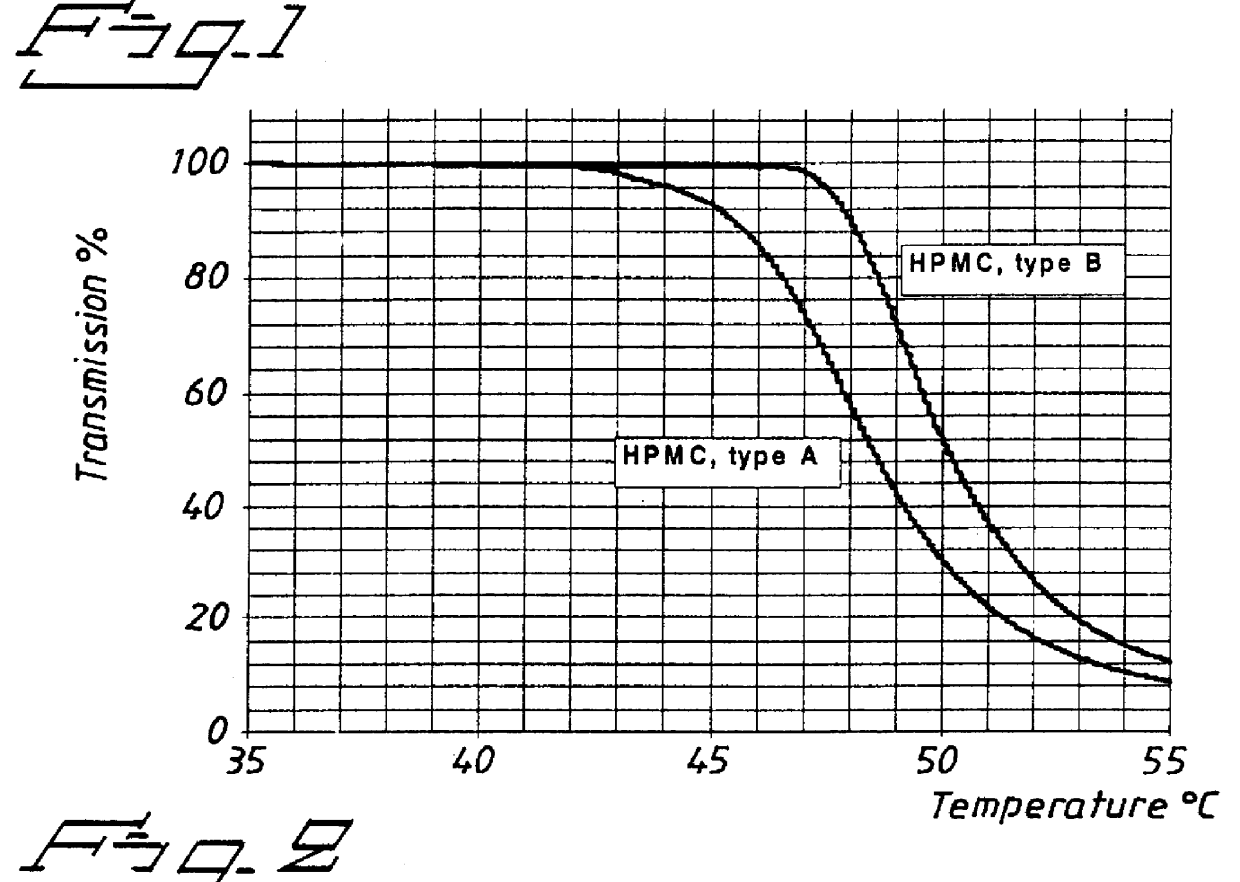

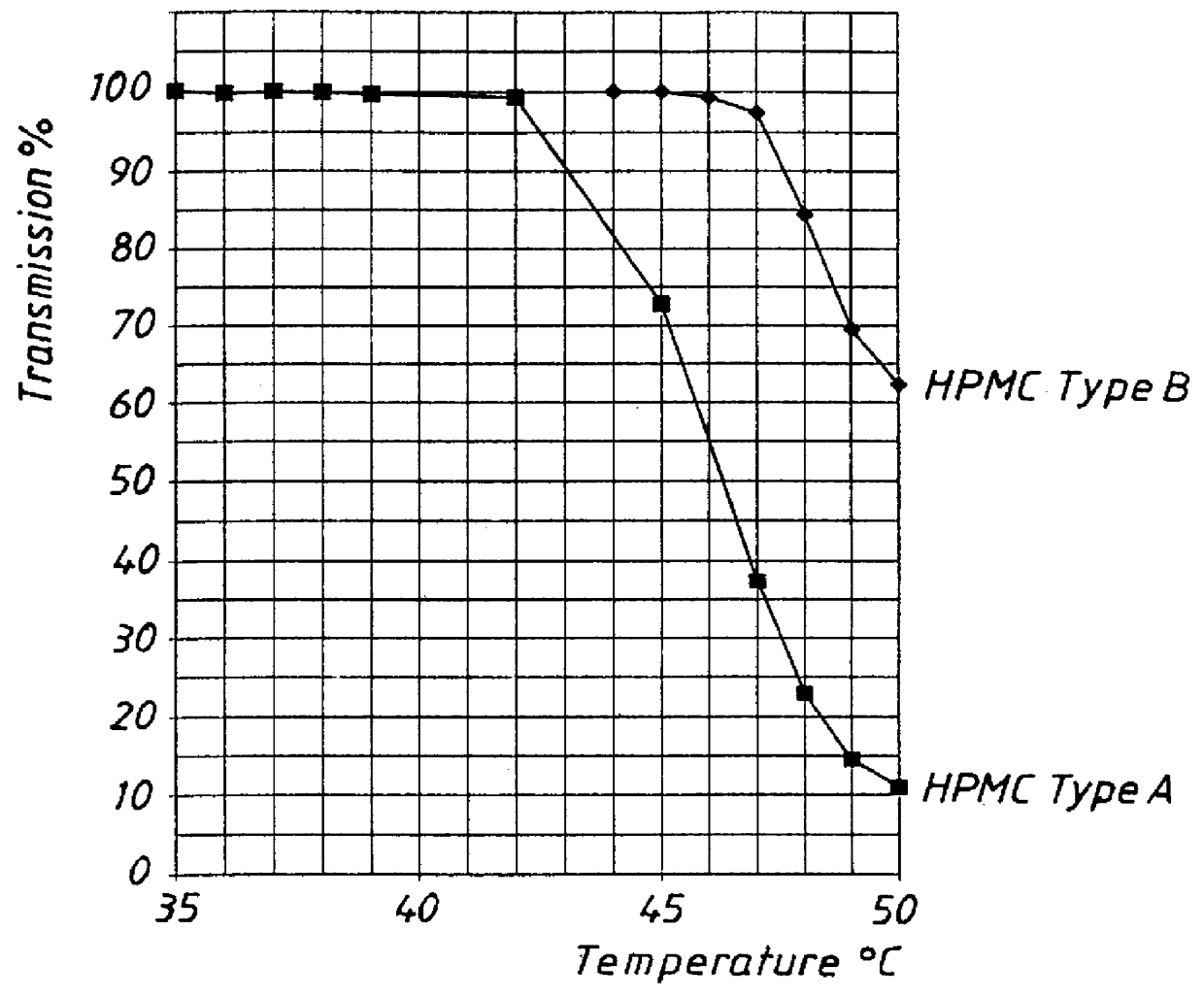

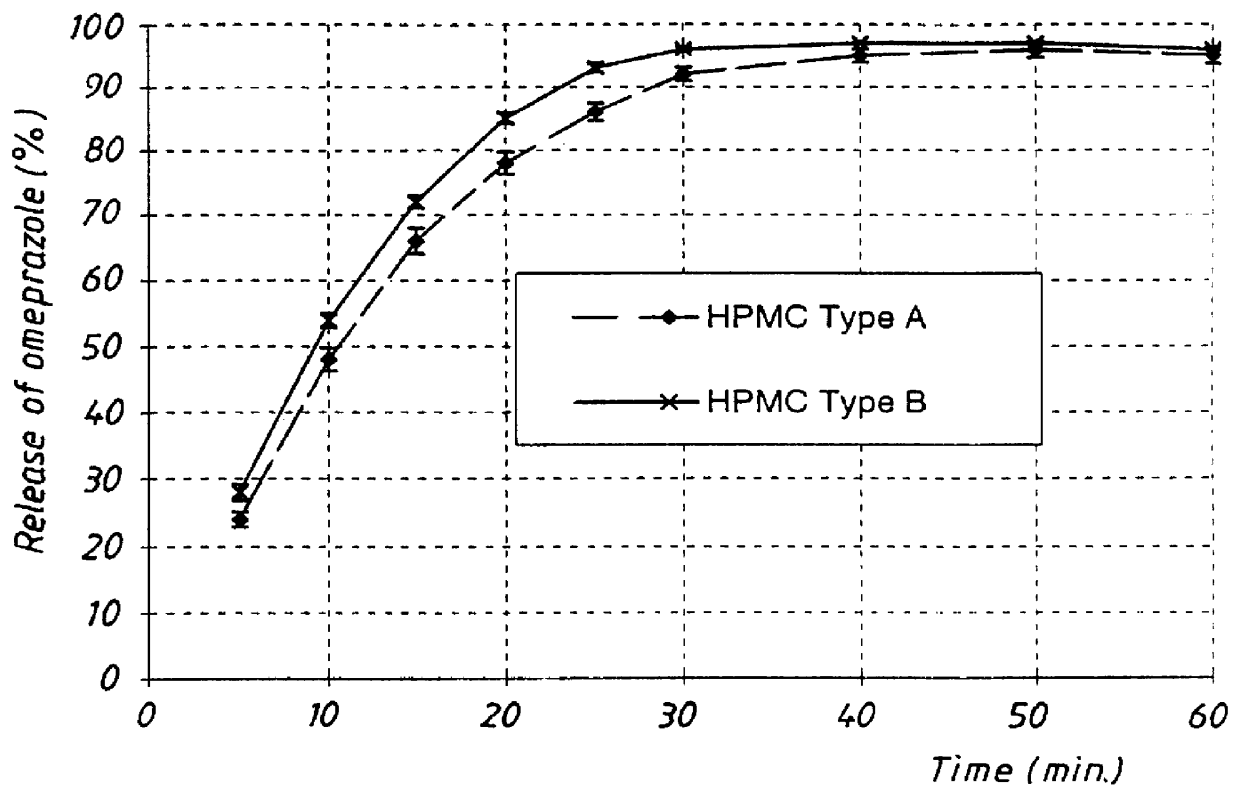

An enteric coated oral pharmaceutical formulation comprising as active ingredient a compound selected from the group of omeprazole, an alkaline salt of omeprazole, one of the single enantiomers of omeprazole and an alkaline salt of one of the single enantiomers of omeprazole, wherein the formulation comprises a core material that comprises the active ingredient and optionally an alkaline reacting compound, the active ingredient is in admixture with a pharmaceutically acceptable excipient, such as for instance a binding agent, and on said core material a separating layer and an enteric coating layer. A hydroxypropyl cellulose (HPC) with a specific cloud point is used in the manufacture of the claimed pharmaceutical formulations. Furthermore, the application describes the processes for their preparation and the use of the claimed formulations in medicine.

Owner:ASTRAZENECA AB

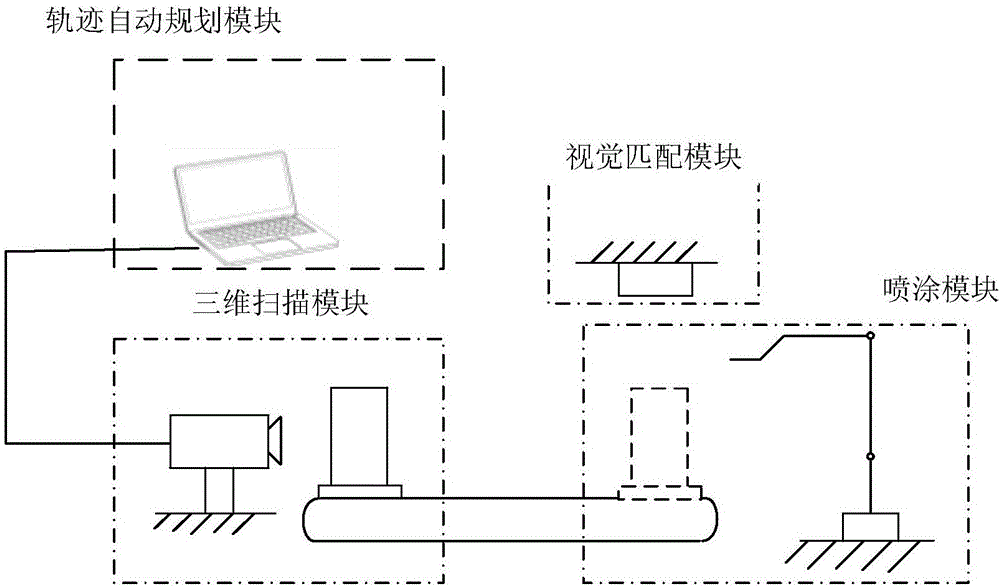

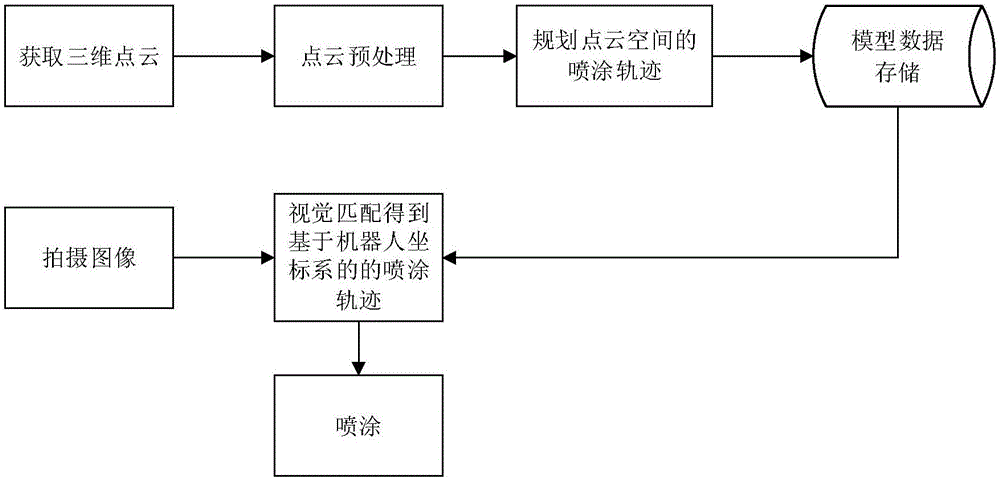

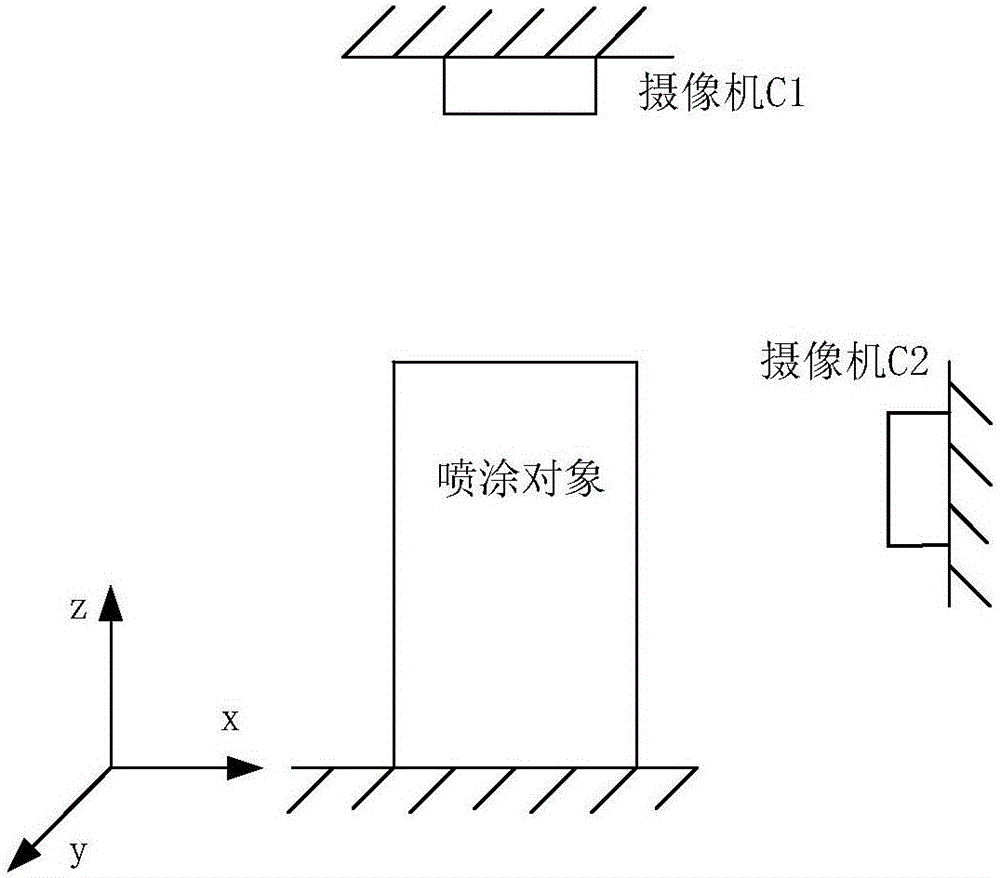

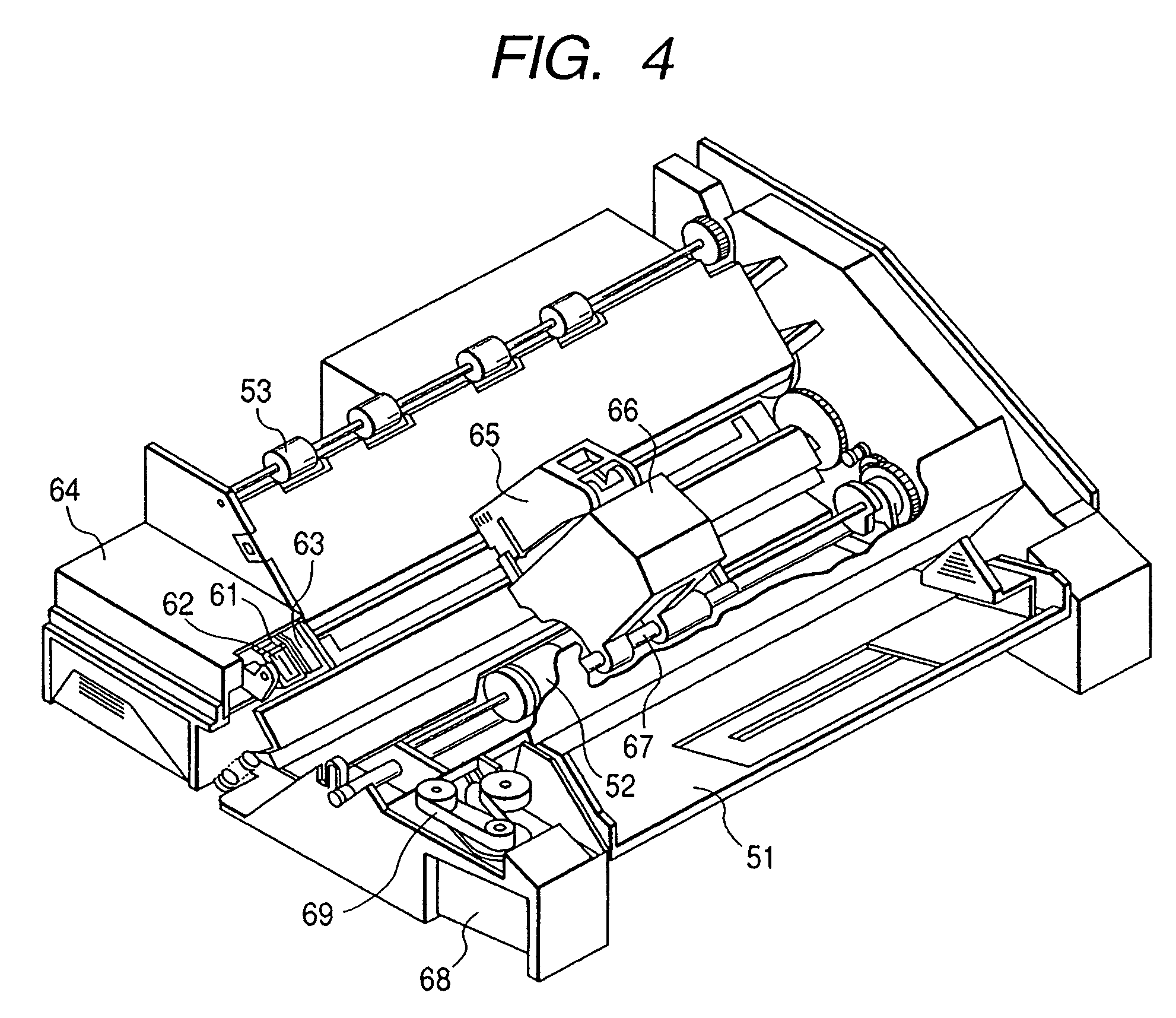

Automatic spraying system and automatic spraying method based on point cloud and image matching

ActiveCN106423656AReduce difficulty of useRealization of automatic sprayingSpraying apparatusVisual matchingPoint cloud

The invention provides an automatic spraying system based on point cloud and image matching. The automatic spraying system comprises a three-dimensional scanning module, an automatic trajectory planning module, a visual matching module and a spraying module. The three-dimensional scanning module is used for scanning a spraying object and acquiring a point cloud model according to scanned three-dimensional point cloud data; the automatic trajectory planning module is used for planning spraying trajectories in a point cloud space; the visual matching module is used for acquiring a transformational relation between a point cloud coordinate system and a spraying robot coordinate system; the spraying module is used for automatically spraying the spraying object. The automatic spraying system has the advantages that an algorithm is planned automatically according to a robot spraying path of the point cloud coordinate system, the point cloud coordinate system is correlated with the robot coordinate system according to the cloud point and image matching algorithm, and accordingly, automatic spraying of the spraying object is realized; on the basis of guaranteeing spraying efficiency, the spraying quality is improved greatly, calculation quantity for trajectory planning is reduced, and trajectory planning quality is improved.

Owner:CHONGQING UNIV

Process for treating an oil well

InactiveUS6939832B2Reduce riskOther chemical processesTransportation and packagingDemulsifierWater dispersible

Method of treating a subterranean formation, comprising (A) injecting down a well bore into the formation an admixture of (a) an emulsion having an internal aqueous phase comprising a water-soluble oil of gas field chemical or an aqueous dispersion of a water-dispersible oil or gas field chemical and an external oil phase comprising a liquid hydrocarbon and an oil-soluble surfactant and (b) a demulsifier comprising a solution of a surfactant having a cloud point temperature of above 40° C. Alternatively, the method comprises separately injecting down a well bore into the formation emulsion (a) and demulsifier (b) and generating an admixture of emulsion (a) and demulsifier (b) within the formation.

Owner:BP EXPLORATION OPERATING CO LTD

Method of preparing a poly (arylene ether) and a poly (arylene ether) prepared thereby

A method of preparing a poly(arylene ether) includes oxidatively coupling a monohydric phenol in a reaction solution at a reaction temperature that exceeds the cloud point temperature of the reaction solution. The oxidative coupling occurs in the presence of a metal complex catalyst, and when the catalyst includes an amine ligand, the method facilitates incorporation of the amine ligand into the poly(arylene ether) resin. The amine-incorporated poly(arylene ether) resins prepared by the method are useful in the preparation of higher molecular weight poly(arylene ether) resins and compatibilized blends of poly(arylene ether) resins with other thermoplastics.

Owner:SABIC INNOVATIVE PLASTICS IP BV

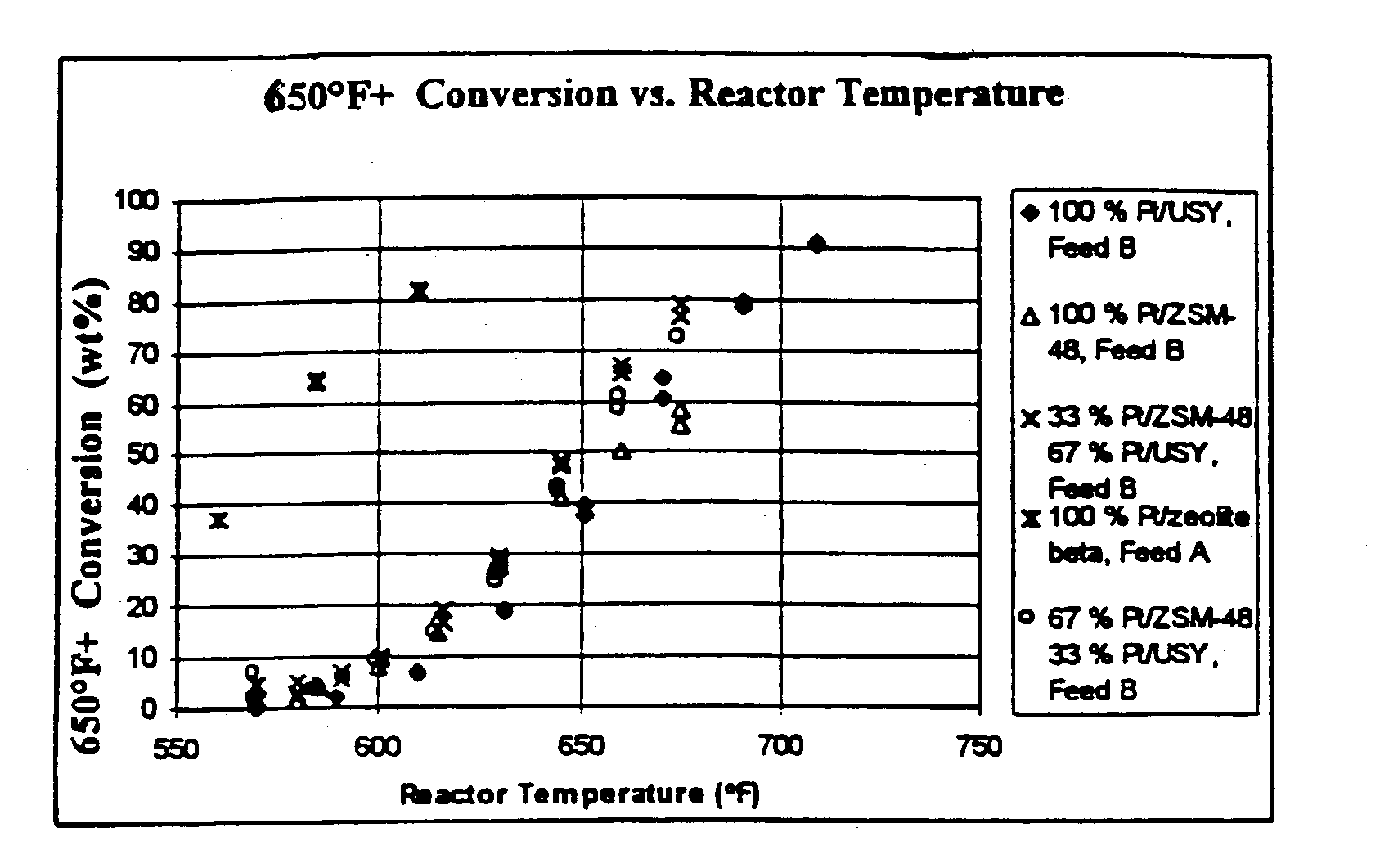

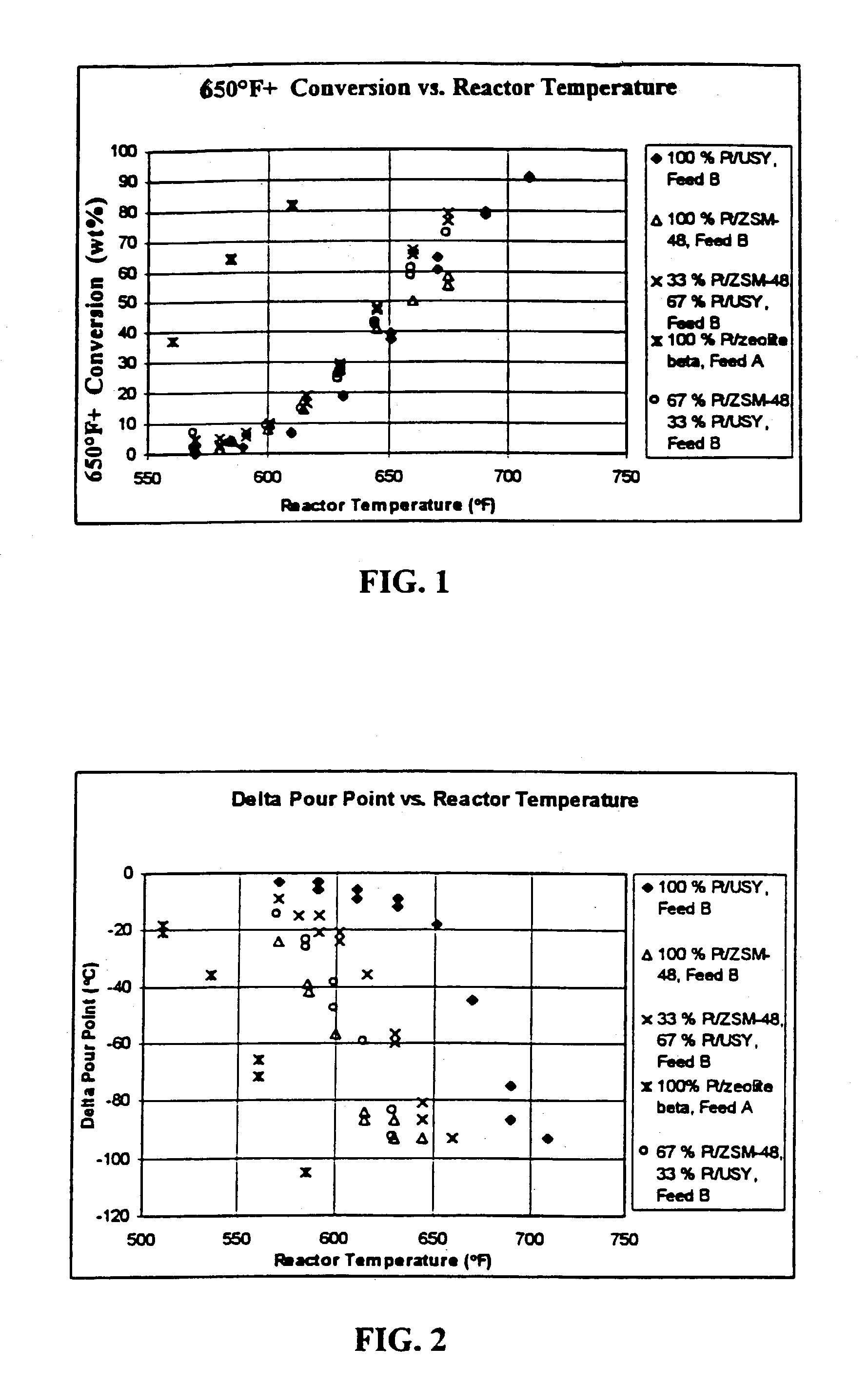

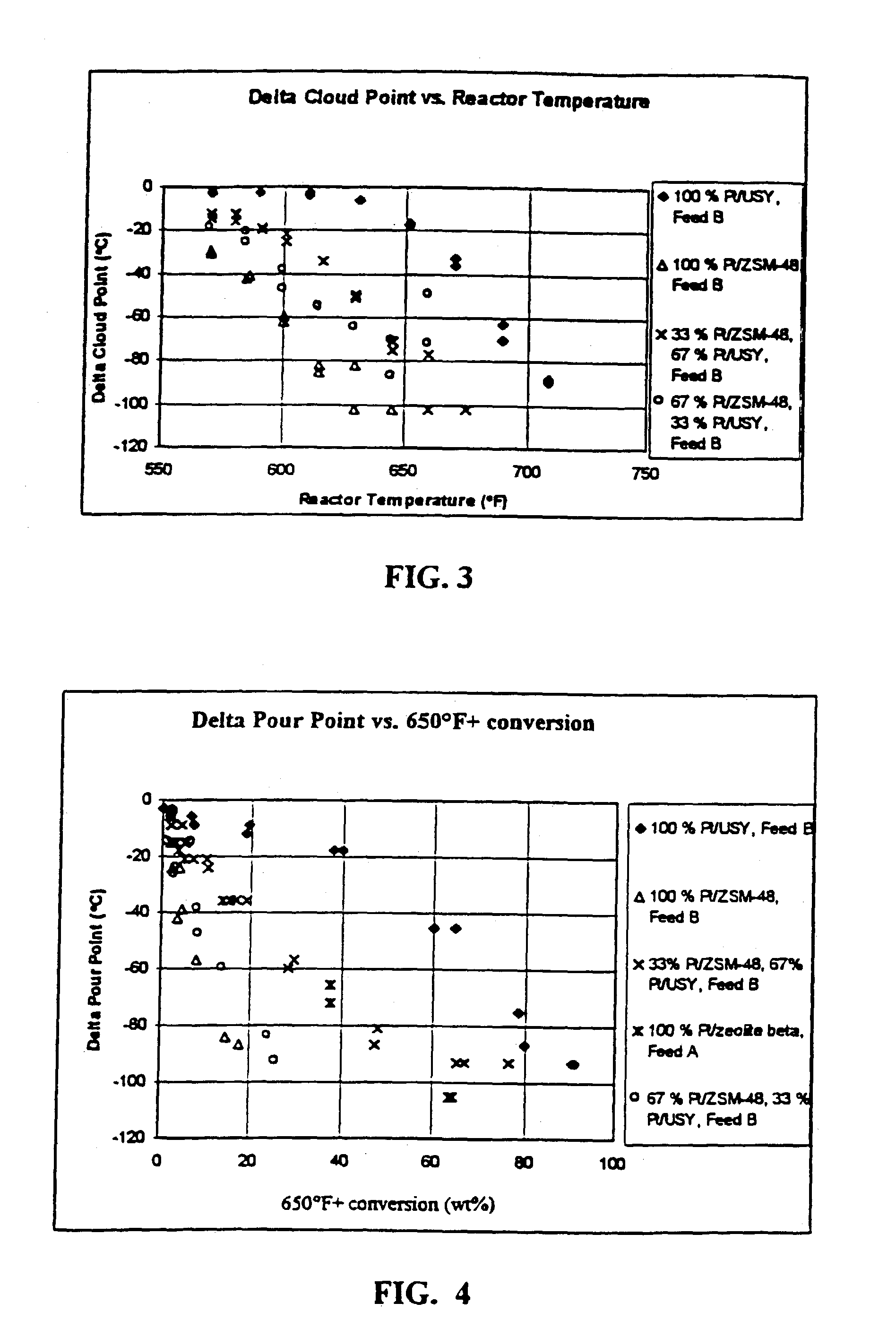

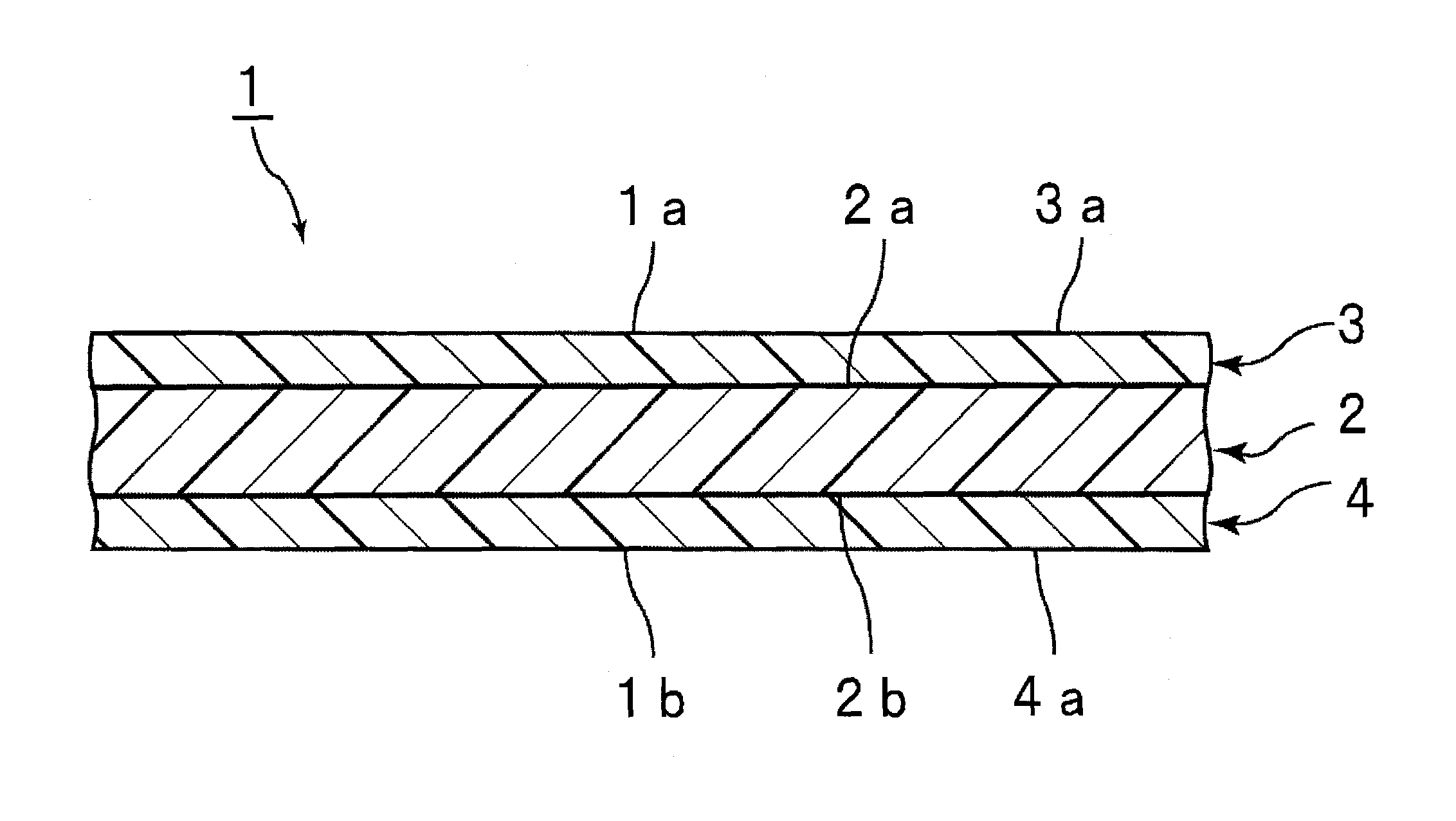

Process for catalytic dewaxing and catalytic cracking of hydrocarbon streams

InactiveUS7261805B2Reducing pour point pointReducing point cloud pointTreatment with plural serial cracking stages onlyCoke ovensWaxIsomerization

A process for upgrading a hydrocarbon feedstock containing waxy components and having an end boiling point exceeding 650° F., which includes contacting the feedstock at superatmospheric hydrogen partial pressure with an isomerization dewaxing catalyst that includes ZSM-48 and contacting the feedstock with a hydrocracking catalyst to produce an upgraded product with a reduced wax content. Each catalyst is present in an amount sufficient to reduce the cloud point and the pour point of the feedstock at a conversion of greater than about 10%, and an overall distillate yield of greater than about 10% results from the process.

Owner:EXXON RES & ENG CO

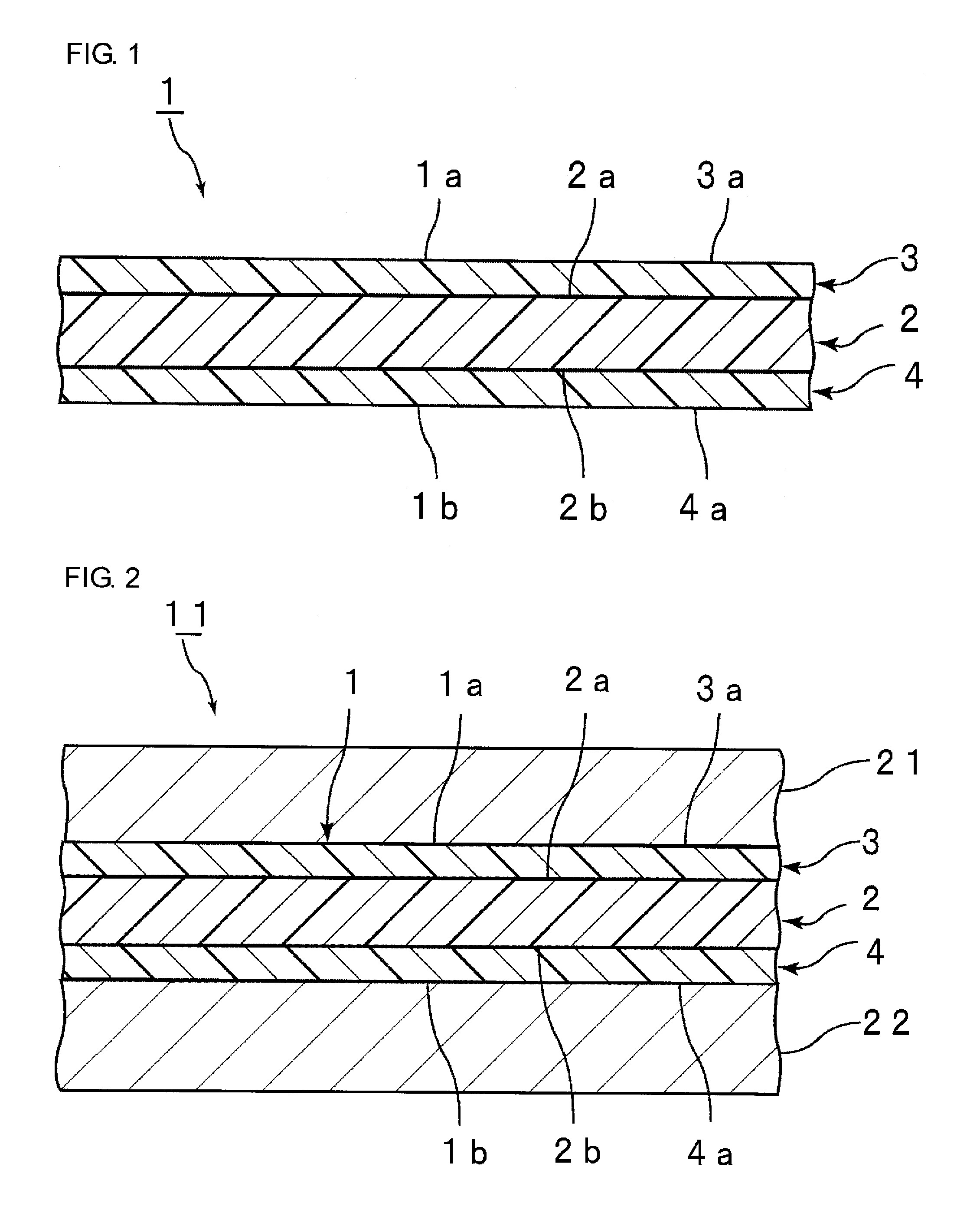

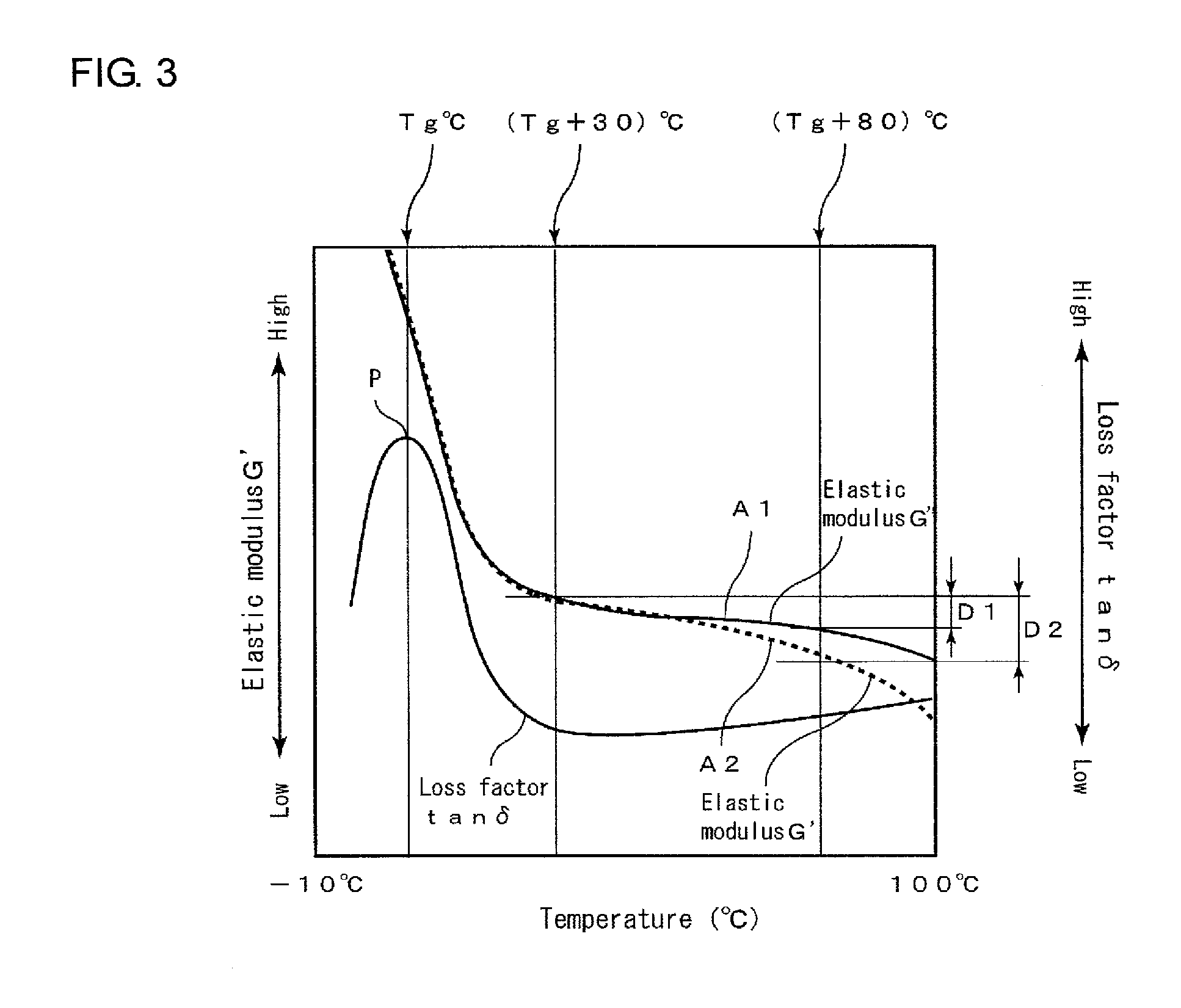

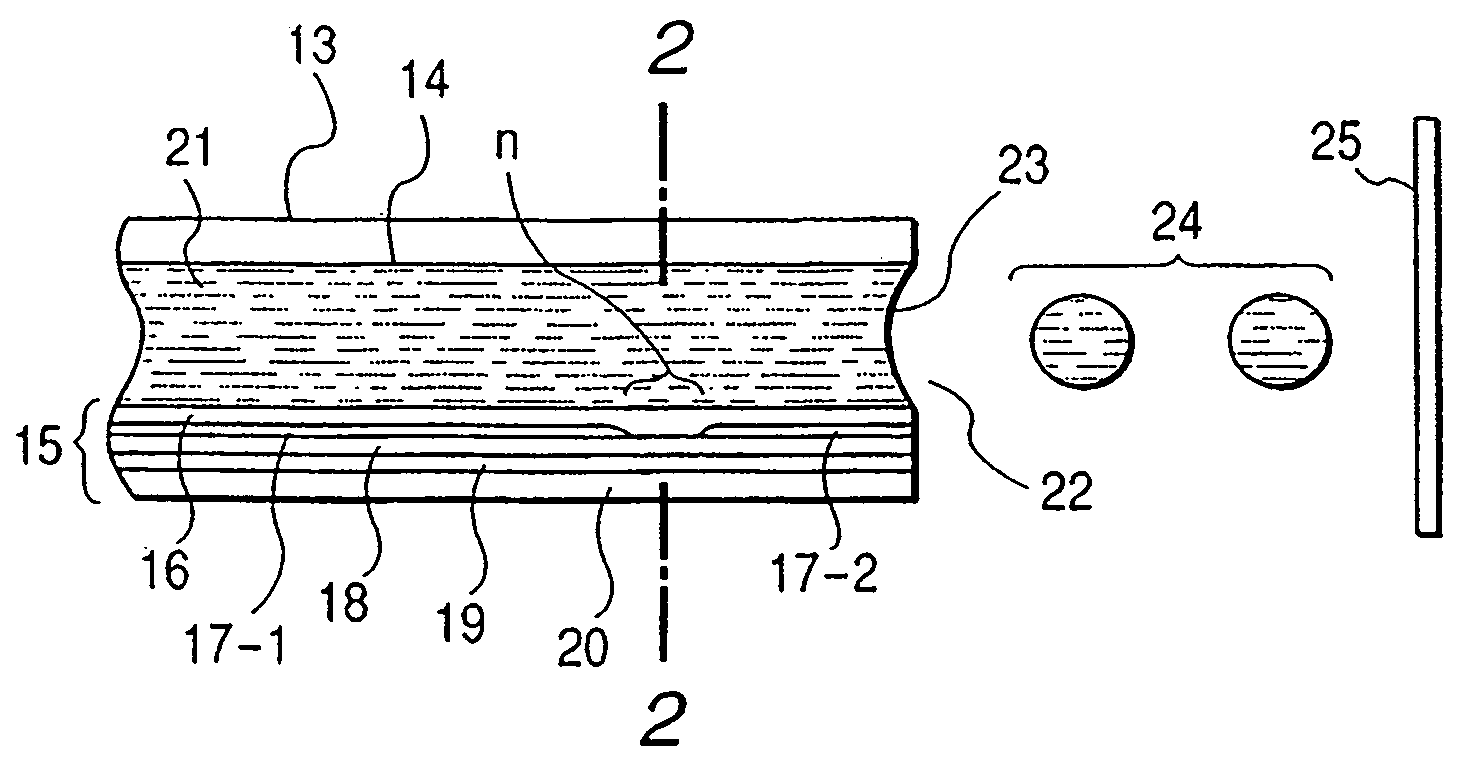

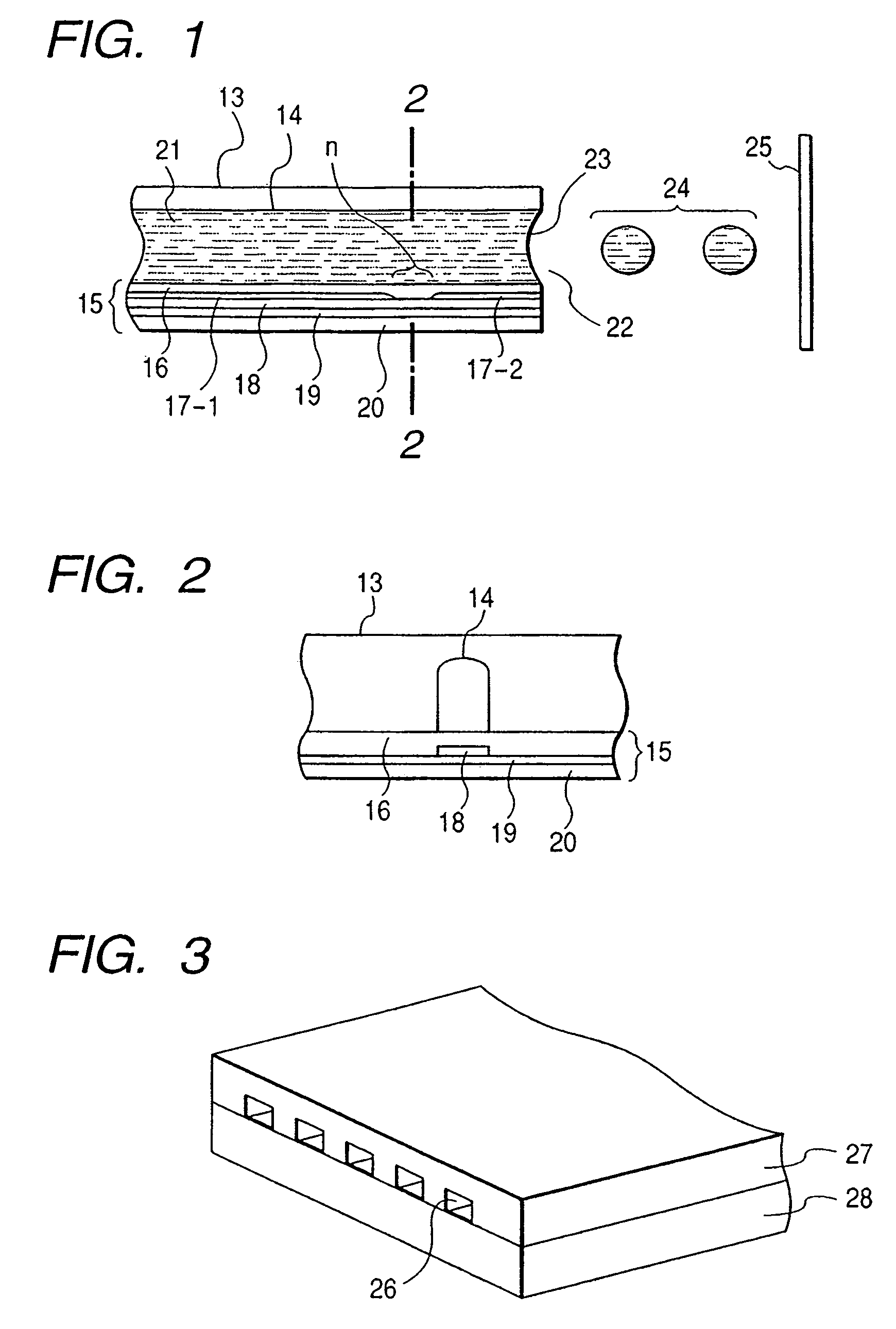

Laminated glass interlayer and laminated glass

ActiveUS8741439B2Improve sound insulationAntiglare equipmentSynthetic resin layered productsPlasticizerPolyvinyl alcohol

The present invention aims to provide an intermediate film for laminated glass which, in the case of being used for constituting a laminated glass, enables to improve the sound-insulating property of the obtained laminated glass, and a laminated glass. The intermediate film 1 for laminated glass of the present invention comprises a first layer 2 which contains a polyvinyl acetal resin and a plasticizer, and the polyvinyl acetal resin and the first plasticizer are a polyvinyl acetal resin and a first plasticizer which have a cloud point of 5° C. or lower when the cloud point is measured using a solution prepared by dissolving 8 parts by weight of the polyvinyl acetal resin in 100 parts by weight of the first plasticizer; and the laminated glass 11 of the present invention comprises first and second components for laminated glass, and the intermediate film 1 for laminated glass sandwiched between the first and second components for laminated glass.

Owner:SEKISUI CHEM CO LTD

Ultra-high loading glyphosate concentrate

ActiveUS20090318294A1Much cycle timeMuch efficient productionBiocideDead animal preservationHigh concentrationActive agent

This invention relates to a storage stable, aqueous, herbicidal formulation containing an ultra-high concentration of glyphosate in the isopropylamine, potassium or mixed salt form in combination with a surfactant system, to a method of making the formulation, and to a method of treating unwanted vegetation employing the formulation. The surfactant system employed in the concentrate comprises dialkoxylated alkylamine, water miscible solubilizer and amine oxide. The surfactant system unexpectedly permits the formulation of storage stable, ultra-high loaded aqueous glyphosate salt concentrates possessing high or no cloud points.

Owner:STEPAN COMPANY

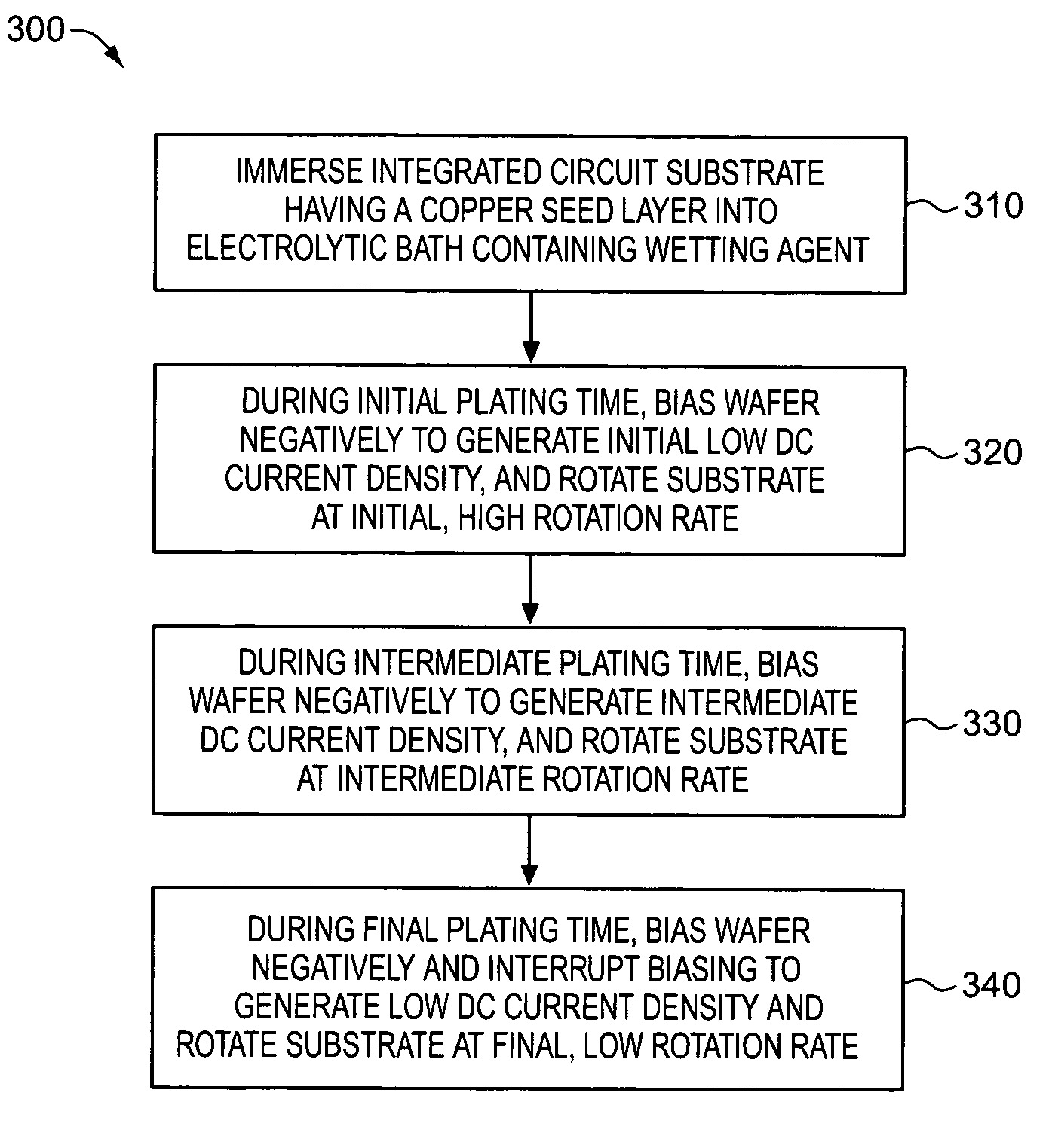

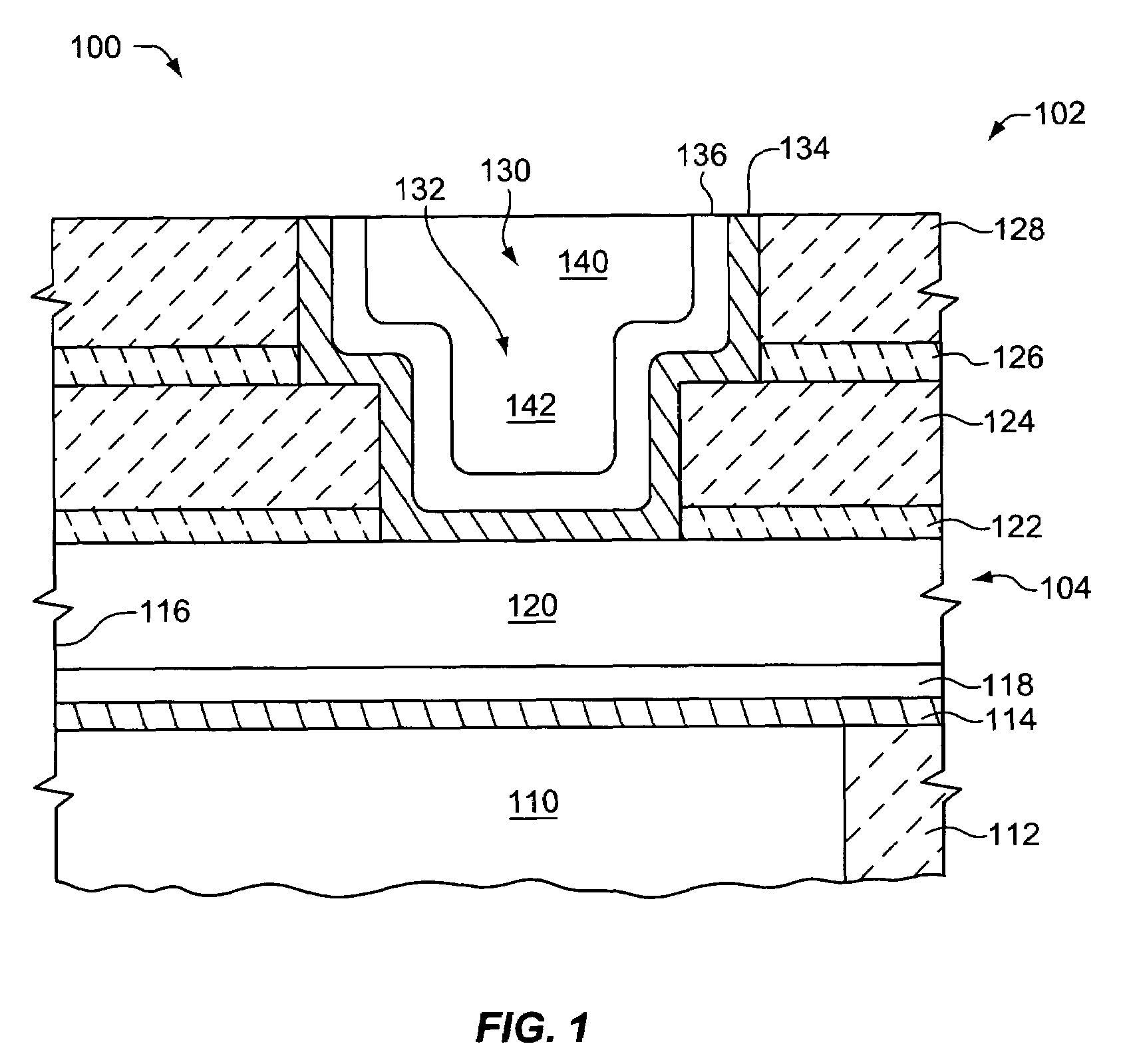

Electroplating bath containing wetting agent for defect reduction

InactiveUS7232513B1Wetting of substrate surfaceReducing pit defectSemiconductor/solid-state device manufacturingSuppressorDyne

An electroplating solution contains a wetting agent in addition to a suppressor and an accelerator. In some embodiments, the solution has a cloud point temperature greater than 35° C. to avoid precipitation of wetting agent or other solute out of the plating solution. In some embodiments, the wetting agent decreases the air-liquid surface tension of the electroplating solution to 60 dyne / cm2 or less to increase the wetting ability of the solution with a substrate surface. In some embodiments of a method for plating metal onto substrate surface, the electroplating solution has a measured contact angle with the substrate surface less than 60 degrees.

Owner:NOVELLUS SYSTEMS

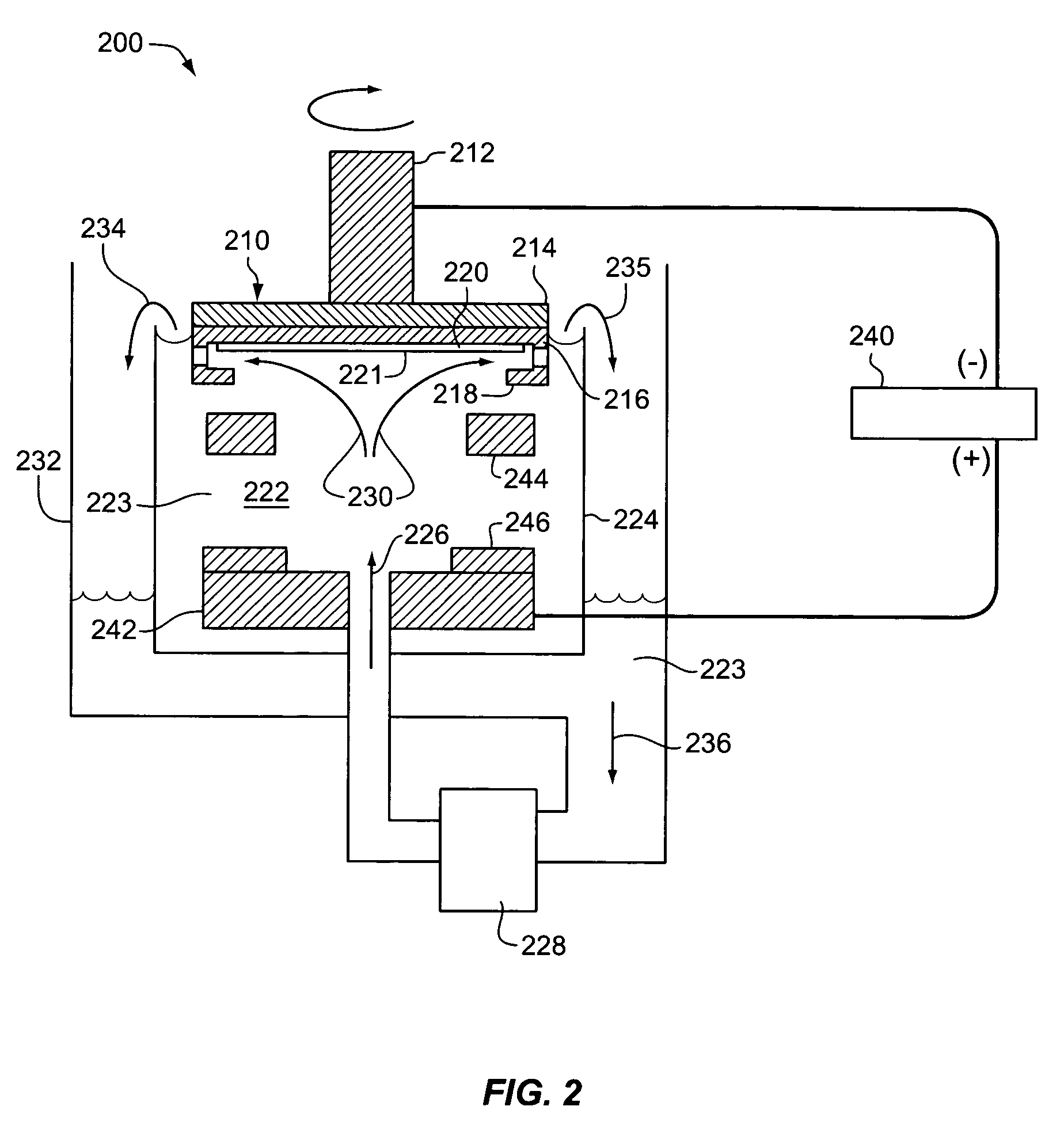

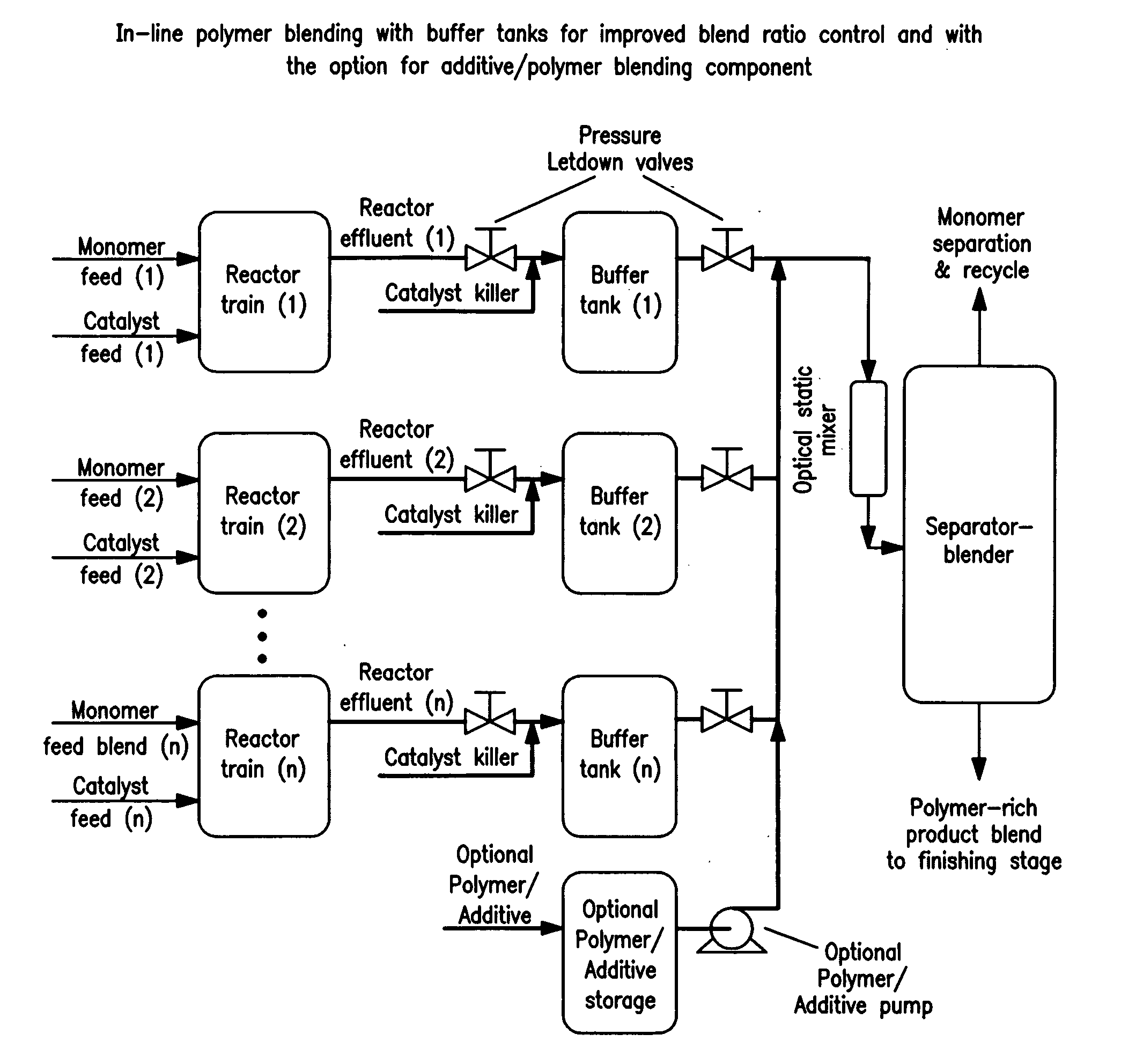

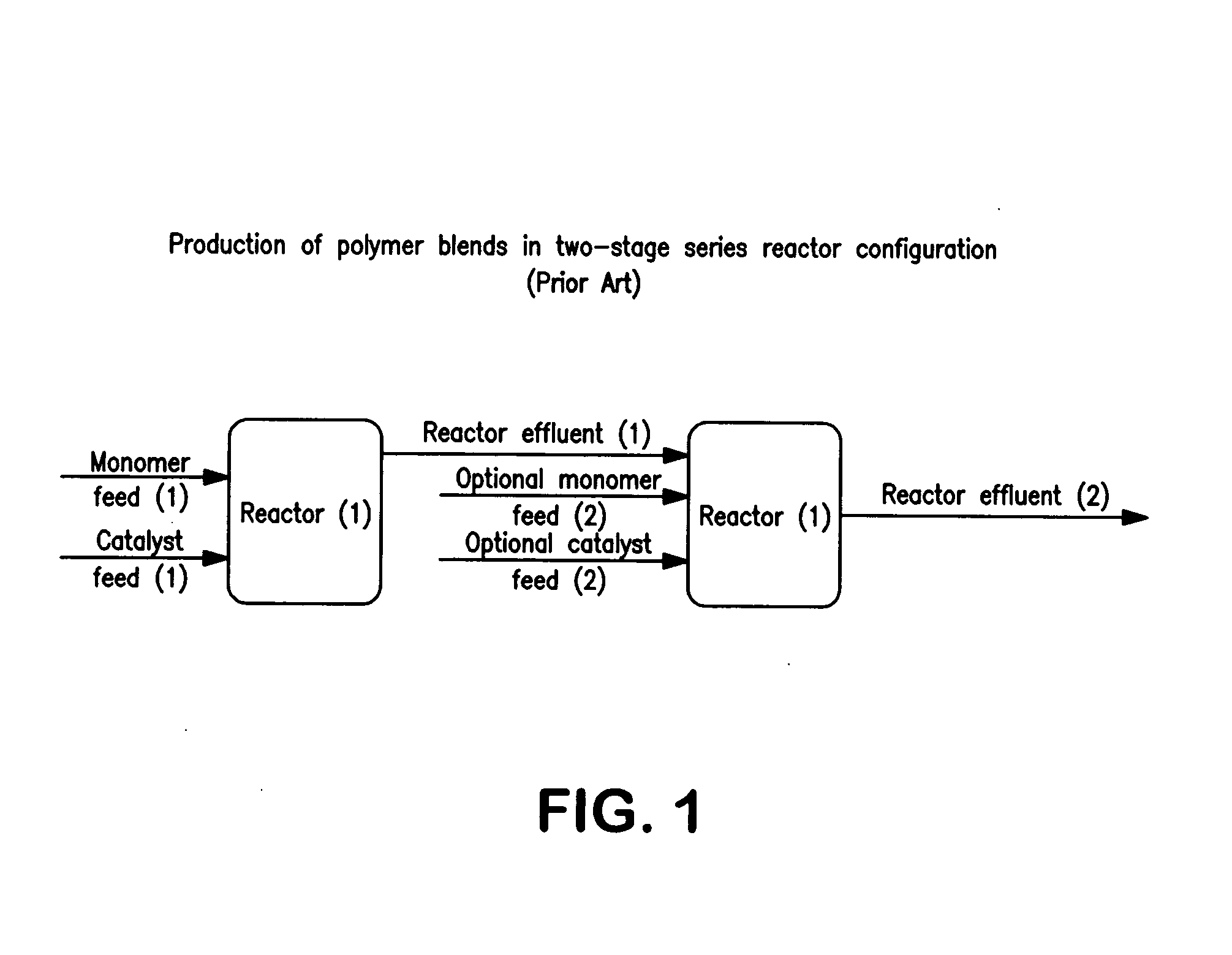

Process for fluid phase in-line blending of polymers

ActiveUS20080234443A1Maintain temperatureSpecial tyresChemical/physical/physico-chemical stationary reactorsScavengerSolvent

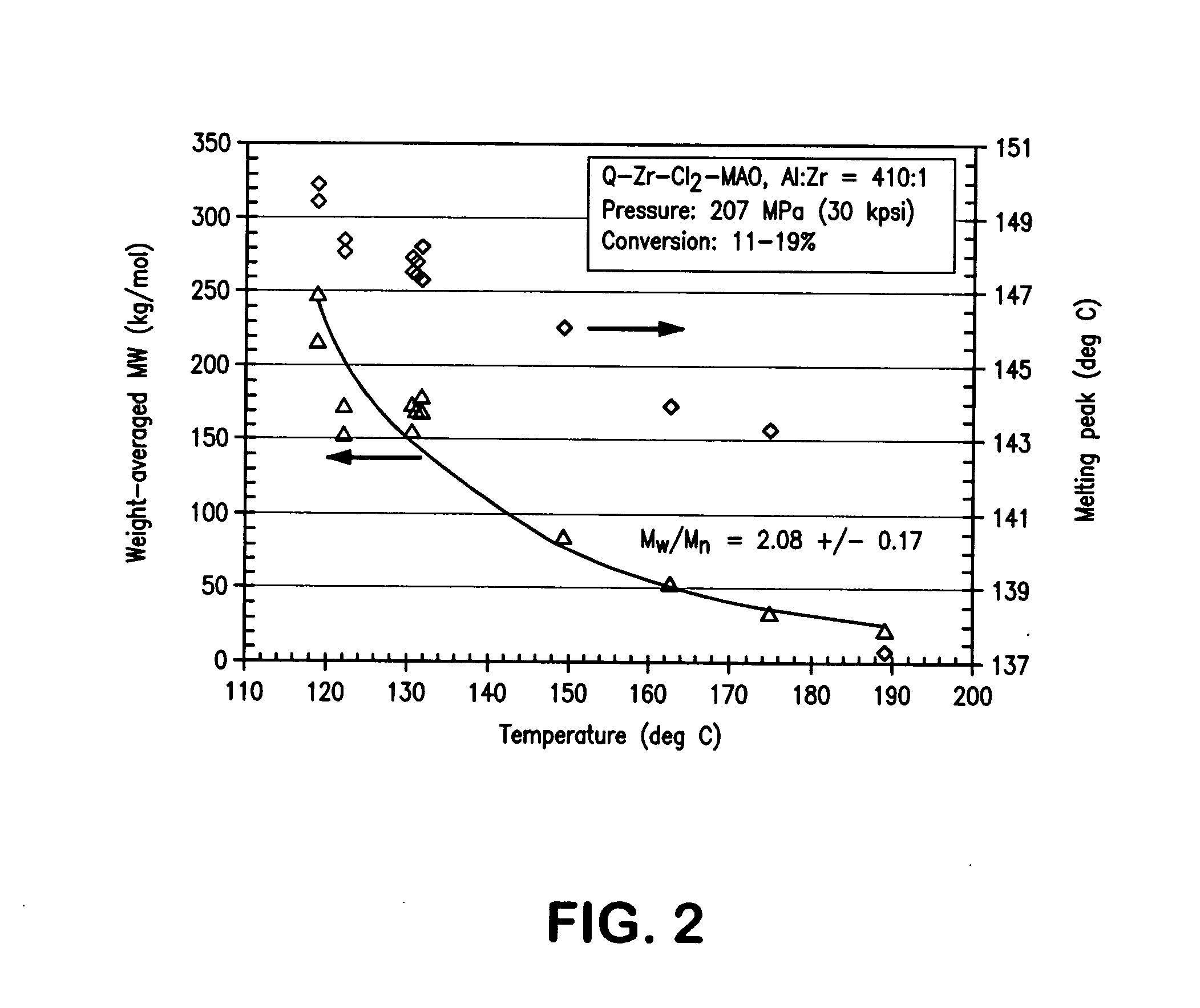

A process for fluid phase in-line blending of polymers. The process includes providing two or more reactor trains configured in parallel and a separator for product blending and product-feed separation; contacting in at least one of the parallel reactor trains olefin monomers having three or more carbon atoms, catalyst systems, optional comonomers, optional scavengers, and optional inert diluents or inert solvents, at a temperature above the solid-fluid phase transition temperature of the polymerization system and a pressure no lower than 10 MPa below the cloud point pressure of the polymerization system and less than 1500 MPa; forming a reactor effluent including a homogeneous fluid phase polymer-monomer mixture in each parallel reactor train; combining the reactor effluent from each parallel reactor; passing the combined reactor effluent through the separator; maintaining the temperature and pressure within the separator above the solid-fluid phase transition point but below the cloud point pressure and temperature to form a fluid-fluid two-phase system including a polymer-rich blend phase and a monomer-rich phase; and separating the monomer-rich phase from the polymer-rich blend phase. The separated monomer-rich phase is recycled to the polymerization reactor bank. The polymer-rich blend phase is conveyed to a downstream finishing stage for further monomer stripping, drying and / or pelletizing to form a polymer product blend.

Owner:EXXONMOBIL CHEM PAT INC

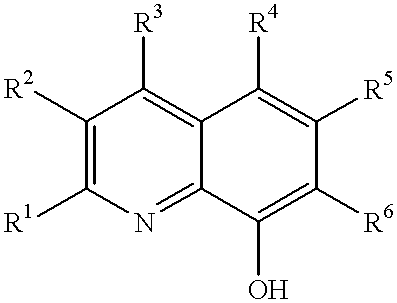

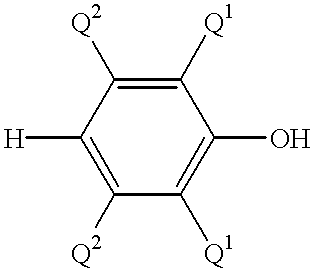

Polymer production at supercritical conditions

InactiveUS20060293474A1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSolventCloud point

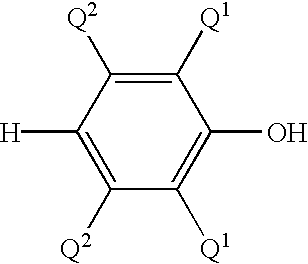

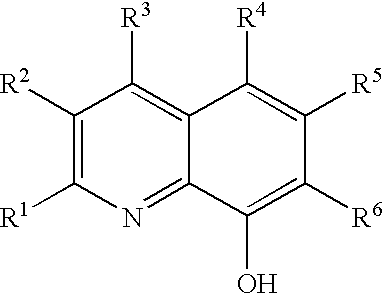

This invention relates to a process to polymerize olefins comprising contacting, in a polymerization system, olefins having three or more carbon atoms with a catalyst compound, activator, optionally comonomer, and optionally diluent or solvent, at a temperature above the cloud point temperature of the polymerization system and a pressure no lower than 10 MPa below the cloud point pressure of the polymerization system, where the polymerization system comprises any comonomer present, any diluent or solvent present, the polymer product, where the olefins having three or more carbon atoms are present at 40 weight % or more, wherein the metallocene catalyst compound is represented by the formula: where M is a transition metal selected from group 4 of the periodic table; each R1 is independently selected from the group consisting of hydrogen, hydrocarbyl, substituted hydrocarbyl and functional group, and any two R1 groups may be linked, provided that if the two R1 groups are linked, then they do not form a butadiene group when M is Zr; each R2 is independently selected from the group consisting of hydrogen, hydrocarbyl, substituted hydrocarbyl or a functional group, and two or more R2 groups may be linked together to form an aliphatic or aromatic ring; R3 is carbon or silicon; R4 is hydrogen, hydrocarbyl, substituted hydrocarbyl or a functional group; a is 0, 1, or 2; R5 is hydrogen, hydrocarbyl, substituted hydrocarbyl or a functional group, R4 and R5 may be bound together to form a ring, and R5 and R3 may be bound together to form a ring; b is 0, 1, or 2; R6 is carbon or silicon; and R4 and R6 may be bound together to form a ring; each R7 is independently selected from the group consisting of hydrogen, hydrocarbyl, substituted hydrocarbyl and a functional group; each R8 is independently selected from the group consisting of hydrogen, hydrocarbyl, substituted hydrocarbyl and a functional group, and R7 and R8 may be linked together to form an aliphatic or aromatic ring; each R9 is independently selected from the group consisting of hydrogen, hydrocarbyl, substituted hydrocarbyl and a functional group, and two R9 groups may be linked together to form a ring, R9 and R8 may be linked together to form a ring, R9 and R16 may be linked together to form a ring, R9 and R11 may be linked together to form a ring; c is 0, 1 or 2; R10 is -M2(R16)h- where M2 is B, Al, N, P, Si or Ge, h is an integer from 1 to 2, such that the valence of M2 is filled, and R16 is hydrogen, hydrocarbyl, substituted hydrocarbyl or a functional group, and two R16 groups may be linked together to form a ring; d is 0, 1, or 2; each R11 is independently selected from the group consisting of hydrogen, hydrocarbyl, substituted hydrocarbyl and a functional group, and two R11 groups may be linked together to form a ring. R11 and R8 may be linked together to form a ring. R11 and R16 may be linked together to form a ring; e is 0, 1, or 2; where the sum of c, d, and e is 1, 2 or 3; R12 is carbon or silicon; R13 is hydrogen, hydrocarbyl, substituted hydrocarbyl or a functional group, and R13 and R14 may be bound together to form a ring, and R13 and R15 may be bound together to form a ring, when g is 0; f is 0, 1, or 2; R14 is hydrogen, hydrocarbyl, substituted hydrocarbyl or a functional group, and R14 and R12 may be bound together to form a ring, when f is 0; g is 0, 1, or 2; and R15 is carbon or silicon.

Owner:EXXONMOBIL CHEM PAT INC

Process for producing synthetic naphtha fuel and synthetic naphtha fuel produced by that process

InactiveUS6475375B1Treatment with plural parallel cracking stages onlyTreatment with plural parallel stages onlyNaphthaEngineering

The invention provides a process for the production of a synthetic naphtha fuel suitable for use in compression ignition (CI) engines, the process including at least the steps of hydrotreating at least a fraction of a Fischer-Tropsch (FT) synthesis reaction product of CO and H2, or a derivative thereof, hydrocracking at least a fraction of the FT synthesis product or a derivative thereof, and fractionating the process products to obtain a desired synthetic naphtha fuel characteristic. The invention also provides a synthetic naphtha fuel made by the process as well as a fuel composition and a Cloud Point depressant for a diesel containg fuel composition, said fuel composition and said depressant including the synthetic naphtha of the invention.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD +1

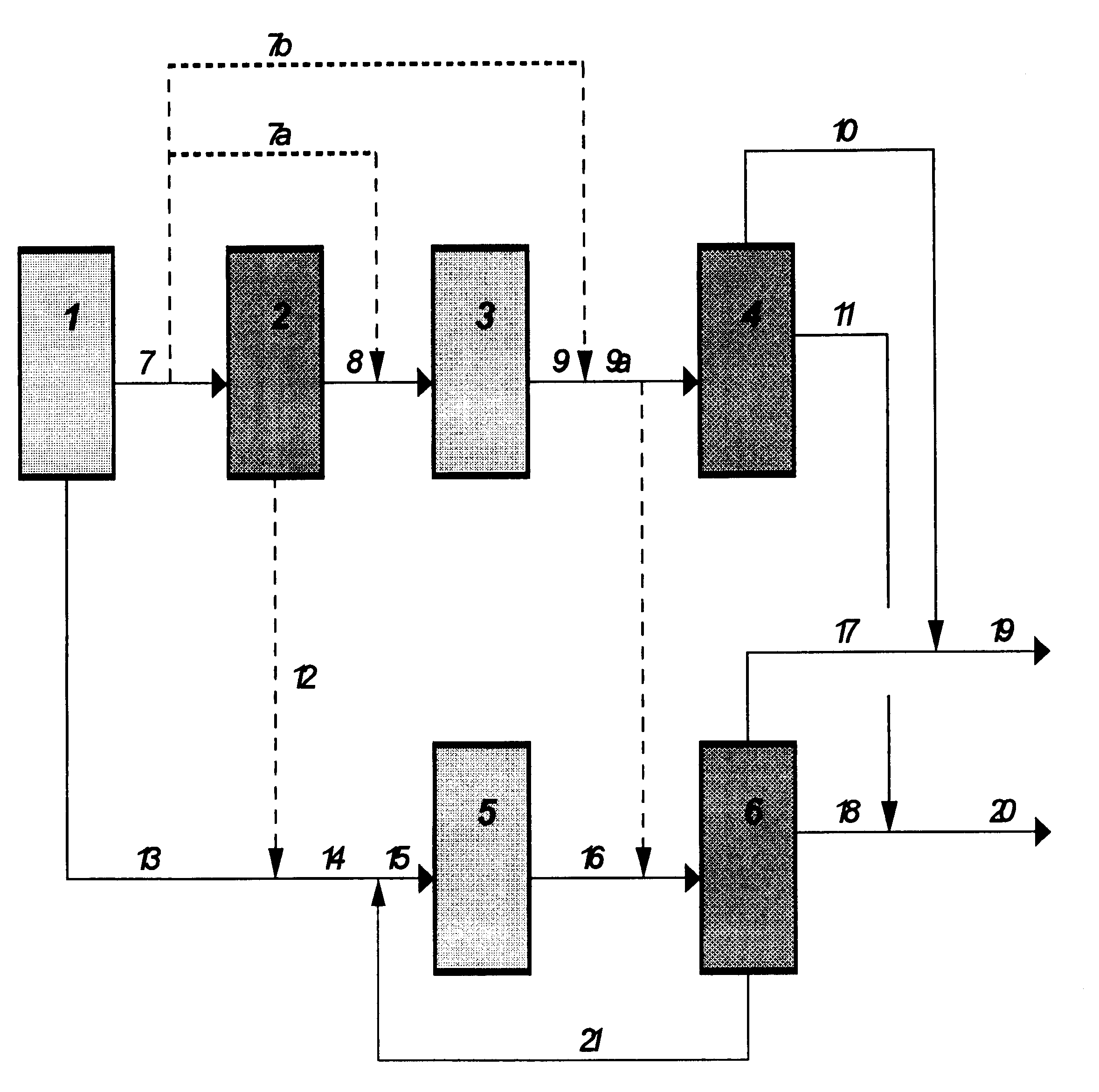

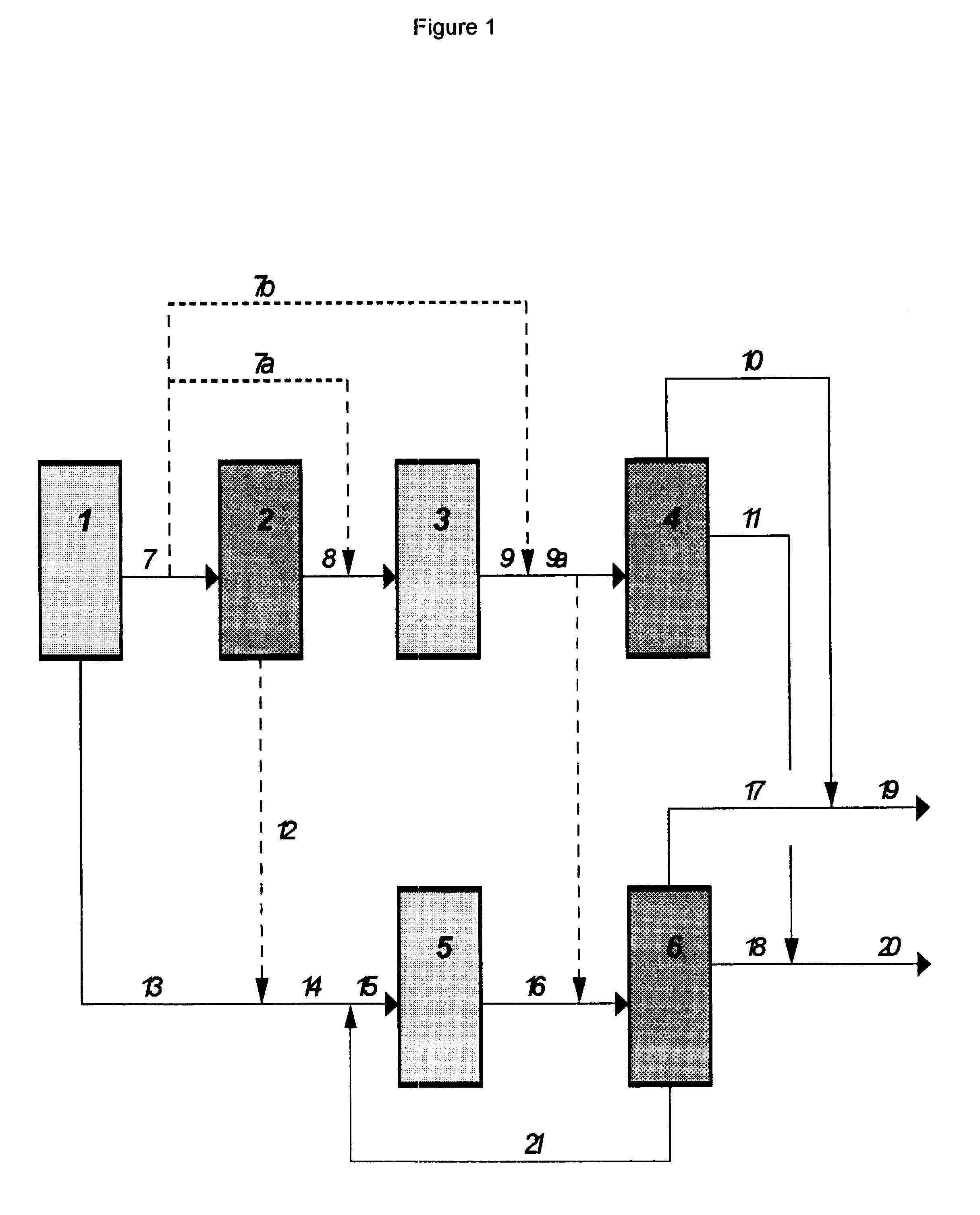

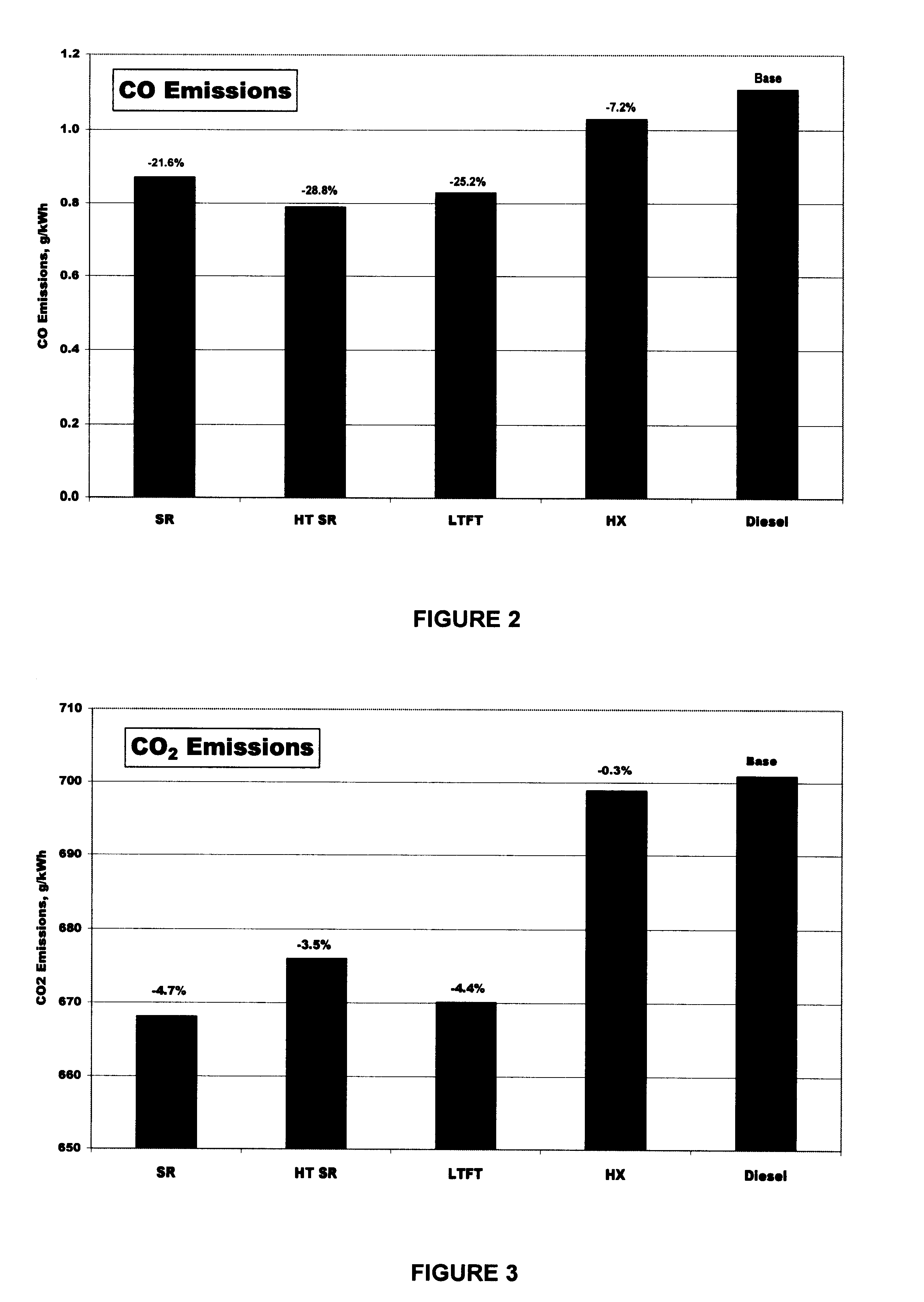

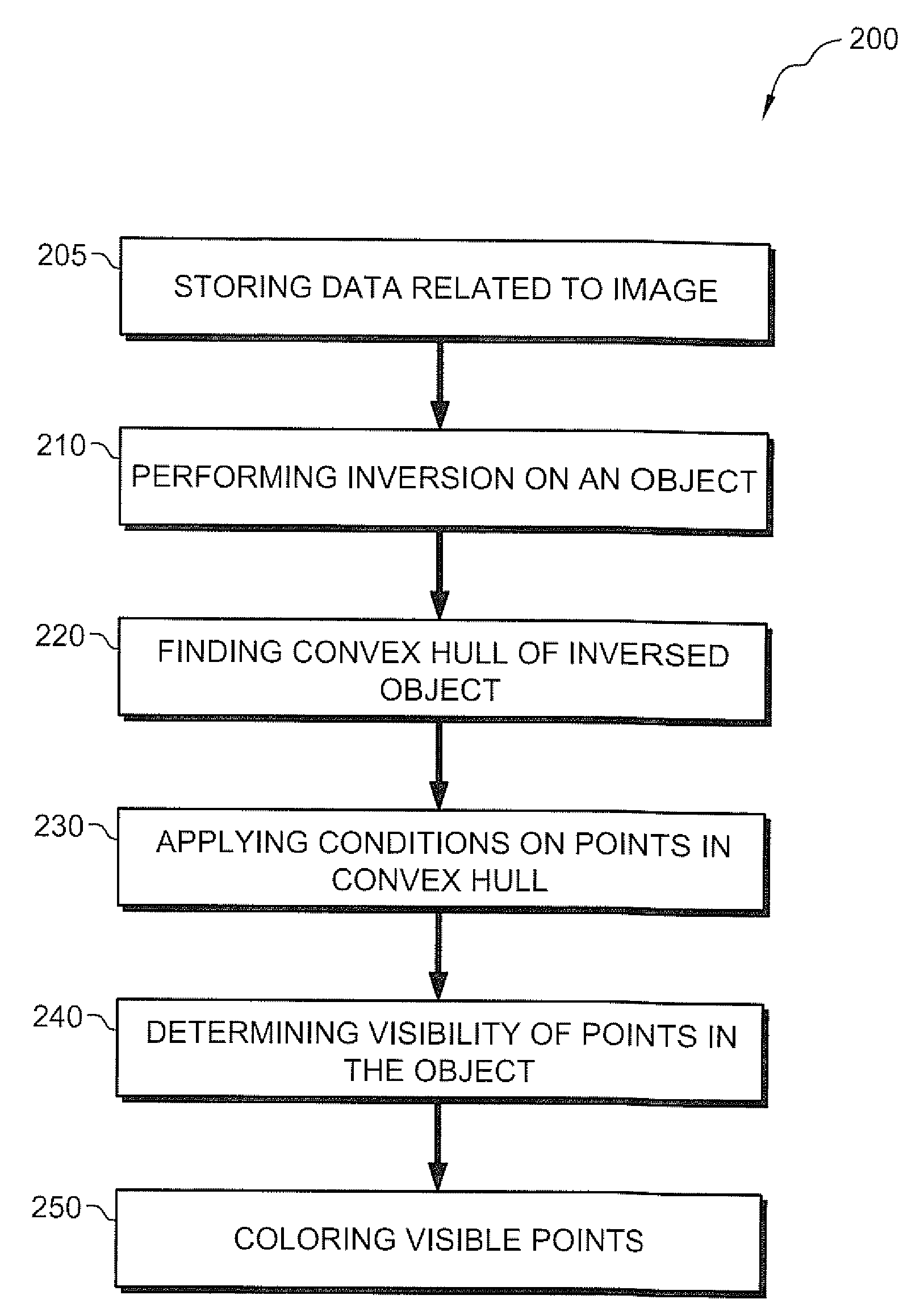

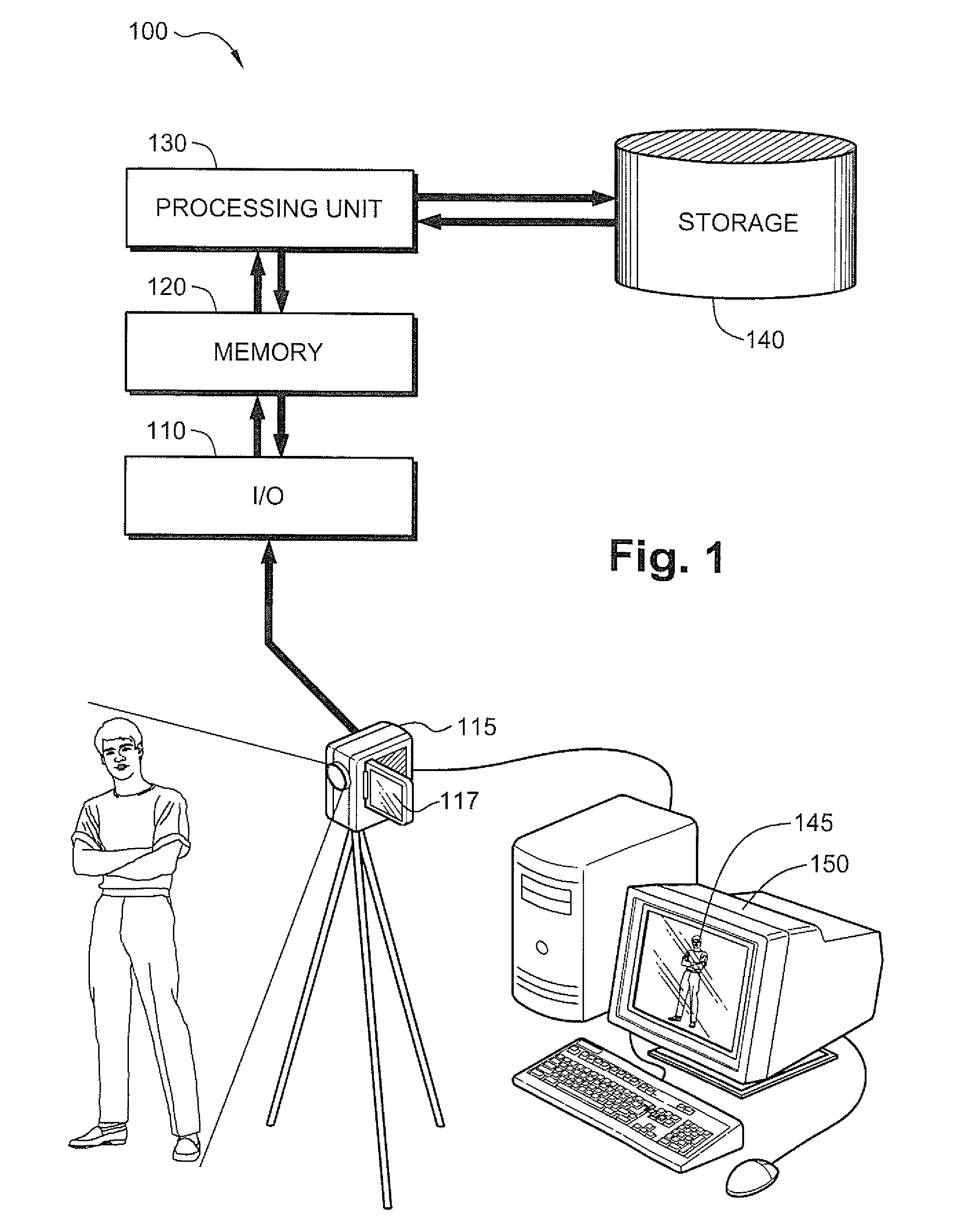

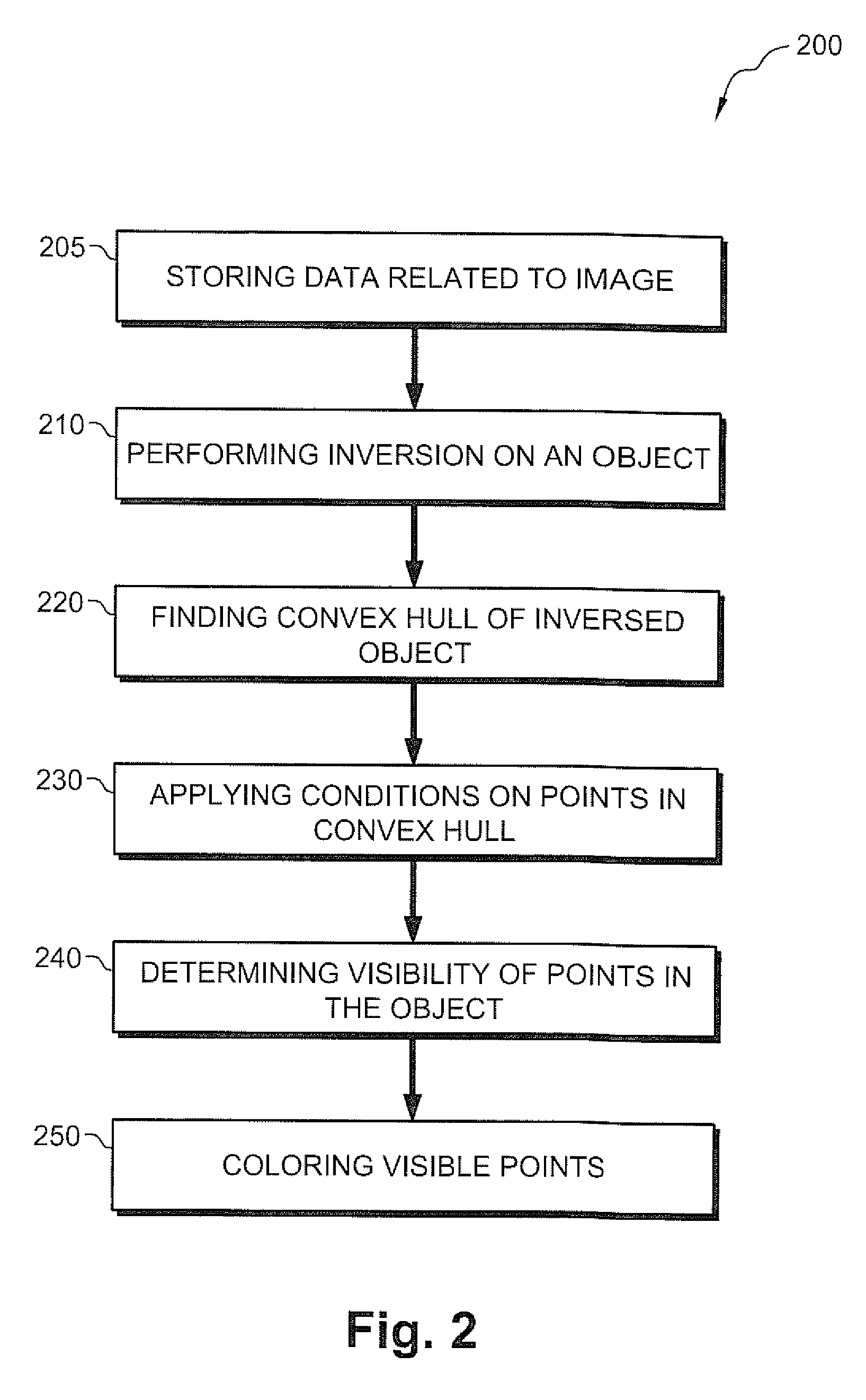

Apparatus and method for finding visible points in a cloud point

ActiveUS20100295850A1Increase the number ofImage generation3D-image renderingPoint cloudSubject matter

The subject matter discloses a method of determining whether a point in a computerized image is visible from a viewpoint; said image is represented as a point cloud, the method comprising: performing inversion on a the vicinity of the point thus creating a computerized inversed objects each point in the vicinity of the point is related to a parallel point in the computerized inversed object and obtaining a convex hull of the inversed object; the point is likely to be visible from the viewpoint in case it belongs to the point set composing the convex hull. The method is also useful for shadow casting and for determining the location of an image-capturing device within a volume

Owner:TECHNION RES & DEV FOUND LTD

Method for producing a plurality of lubricant base oils from paraffinic feedstock

InactiveUS6962651B2Refining to change hydrocarbon structural skeletonHydrocarbon by hydrogenationAlkaneMolecular sieve

A method for producing lubricant base oils is provided comprising the steps of: (a) hydroisomerizing a feedstock over a medium pore size molecular sieve catalyst under hydroisomerization conditions to produce an isomerized product having a pour point of greater than a target pour point of the lubricant base oils; (b) separating the isomerized product into at least a light lubricant base oil having a pour point less than or equal to the target pour point of the lubricant base oils and a heavy fraction having a pour point of equal to or greater than the target pour point of the lubricant base oils and a cloud point greater than the target cloud point of the lubricant base oils; and (c) dehazing the heavy fraction to provide a heavy lubricant base oil having a pour point less than or equal to the target pour point of the lubricant base oils and a cloud point less than or equal to the target cloud point of the lubricant base oils.

Owner:CHEVROU USA INC

Rinse-aid composition

InactiveUS20060189508A1Suitable stabilityPossibility of corrosionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsRoom temperatureNon ionic

Rinse-aid composition comprising a polyalkoxylated trisiloxane surfactant and a non-ionic solubilising system having a cloud point above room temperature and an acidifying agent wherein the rinse-aid composition has a pH of from about 1 to about 4.5.

Owner:THE PROCTER & GAMBLE COMPANY

Process for isomerization dewaxing of hydrocarbon streams

InactiveUS6652735B2Yield maximizationReduce pointsHydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonMolecular sieveIsomerization

A process for isomerization dewaxing of a hydrocarbon feed which includes contacting the hydrocarbon feed with a large pore size, small crystal size, crystalline molecular sieve and an intermediate pore size, small crystal size, crystalline molecular sieve to produce a dewaxed product with a reduced pour point and a reduced cloud point. In a preferred embodiment, the feed is contacted with the molecular sieves sequentially, first with the large pore sieve followed by the intermediate pore sieve.

Owner:EXXON RES & ENG CO

Foam control formulations

ActiveUS20150080273A1Lower Level RequirementsInhibition formationDewatering/demulsification with chemical meansDefoamers additionProcedure AgentsWater insoluble

The invention provides a foam control formulation in the form of a microemulsion, the formulation comprising: (a) from S to 70% w / w of primary surfactant, this surfactant having an HLB of from 1 to 12 and / or a cloud point of from 20 to 70° C.; (b) from 2 to 40% w / w of water-insoluble organic carrier liquid; and (c) water. Also provided is the use of this formulation to prevent and / or reduce foam in a fluid system, or as a processing aid to control foam production in a fluid system. The formulation may be used in an aqueous fluid system, such as an oilfield.

Owner:ENERGY SOLUTIONS (US) LLC

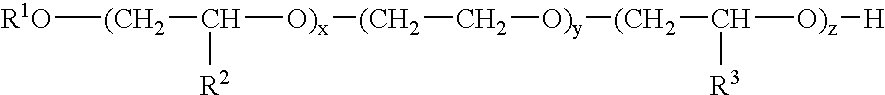

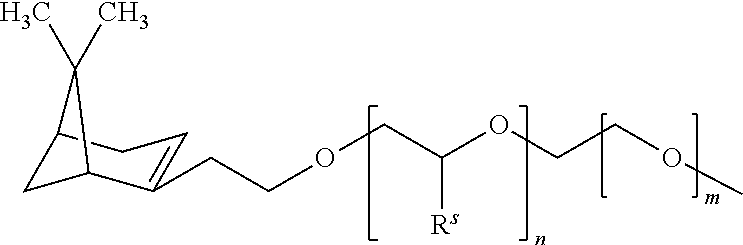

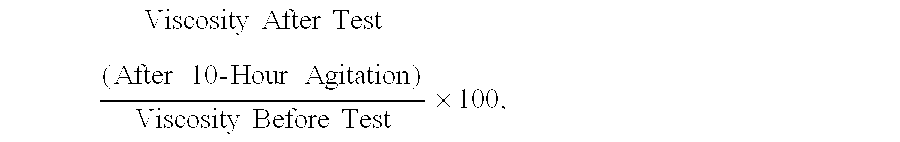

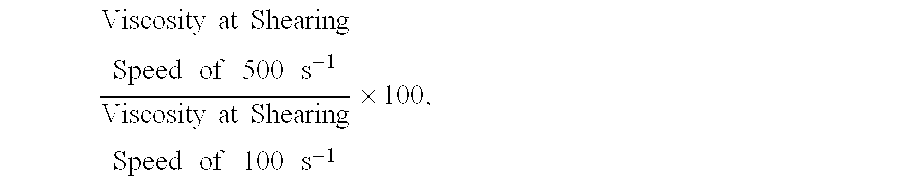

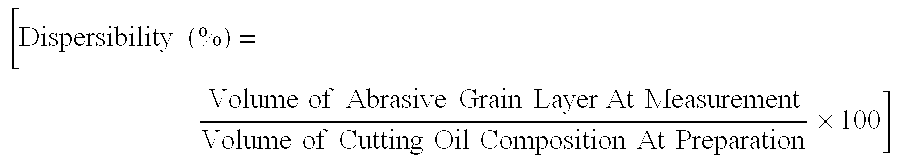

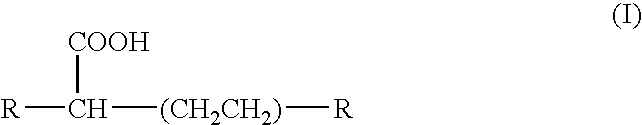

Cutting oil composition

InactiveUS6383991B1Good dispersionEasy to cleanWork treatment devicesAdditivesHydrogen atomChemical composition

The present invention relates to a cutting oil comprising (a) a polyether compound represented by the formula (I):wherein each of R1 and R2, which may be identical or different, is hydrogen atom or a hydrocarbon group having 1 to 24 carbon atoms, at least one of which is a hydrocarbon group; EO is oxyethylene group; AO is an oxyalkylene group having 3 or 4 carbon atoms; and each of m and n is 1 to 50, wherein a sum of m and n is from 4 to 100; a cutting oil composition comprising the above cutting oil and an abrasive; a cutting method using the above cutting oil composition; and a process of cleaning a wafer, comprising the steps of cleaning a wafer obtainable by cutting an ingot with a wire saw using the above cutting oil composition; heating the resulting waste water to a temperature equal to or higher than a cloud point of a polyether compound represented by the formula (I) contained in the waste water, to allow separation into an oil phase and an aqueous phase; and removing the oil phase comprising the polyether compound from the waste water. According to the present invention, there can be obtained excellent dispersibility of the abrasive, and excellent re-dispersibility, cutting performance and workability when sedimented, and the object to be cut obtained after cutting can be easily cleaned.

Owner:KAO CORP

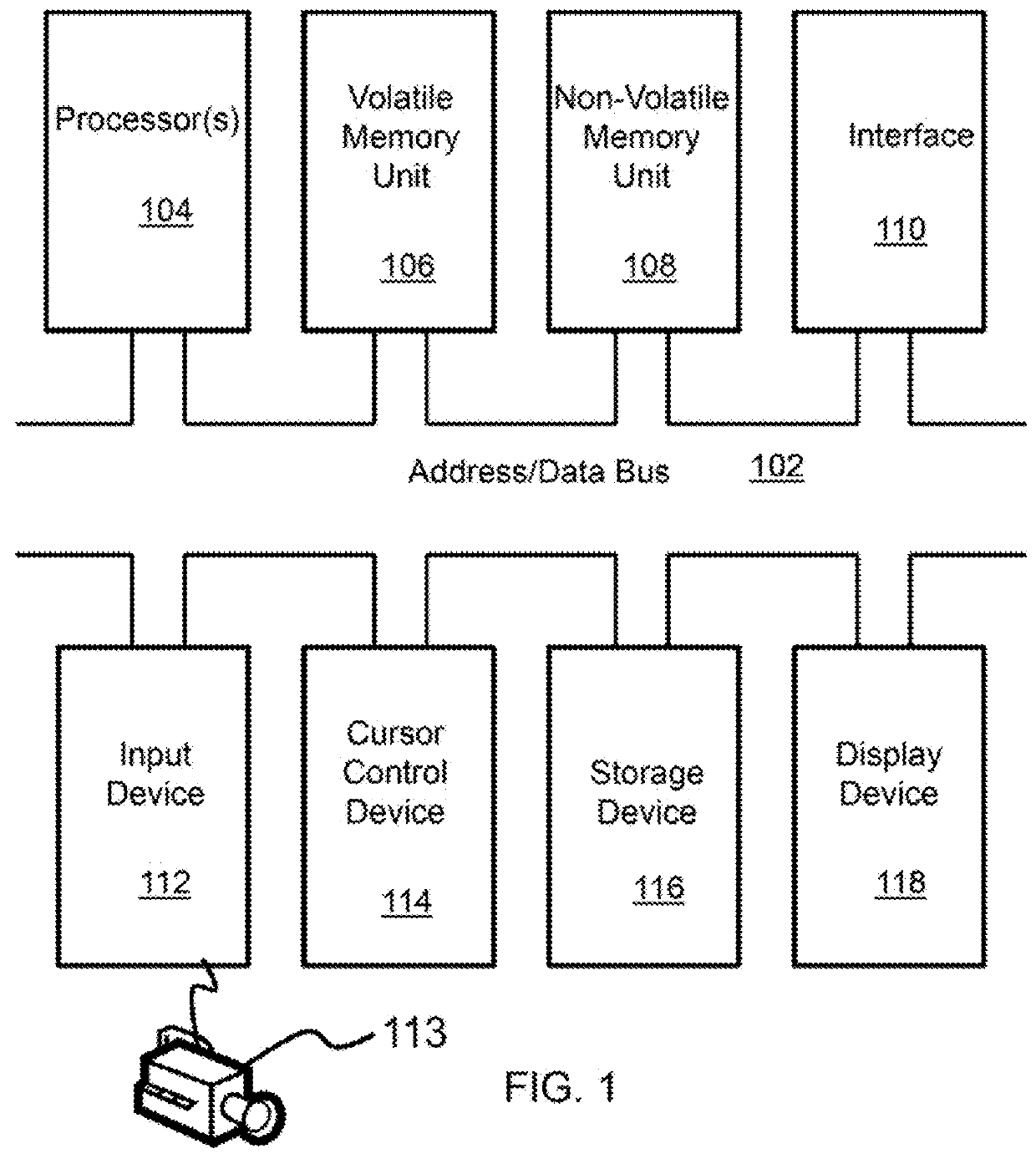

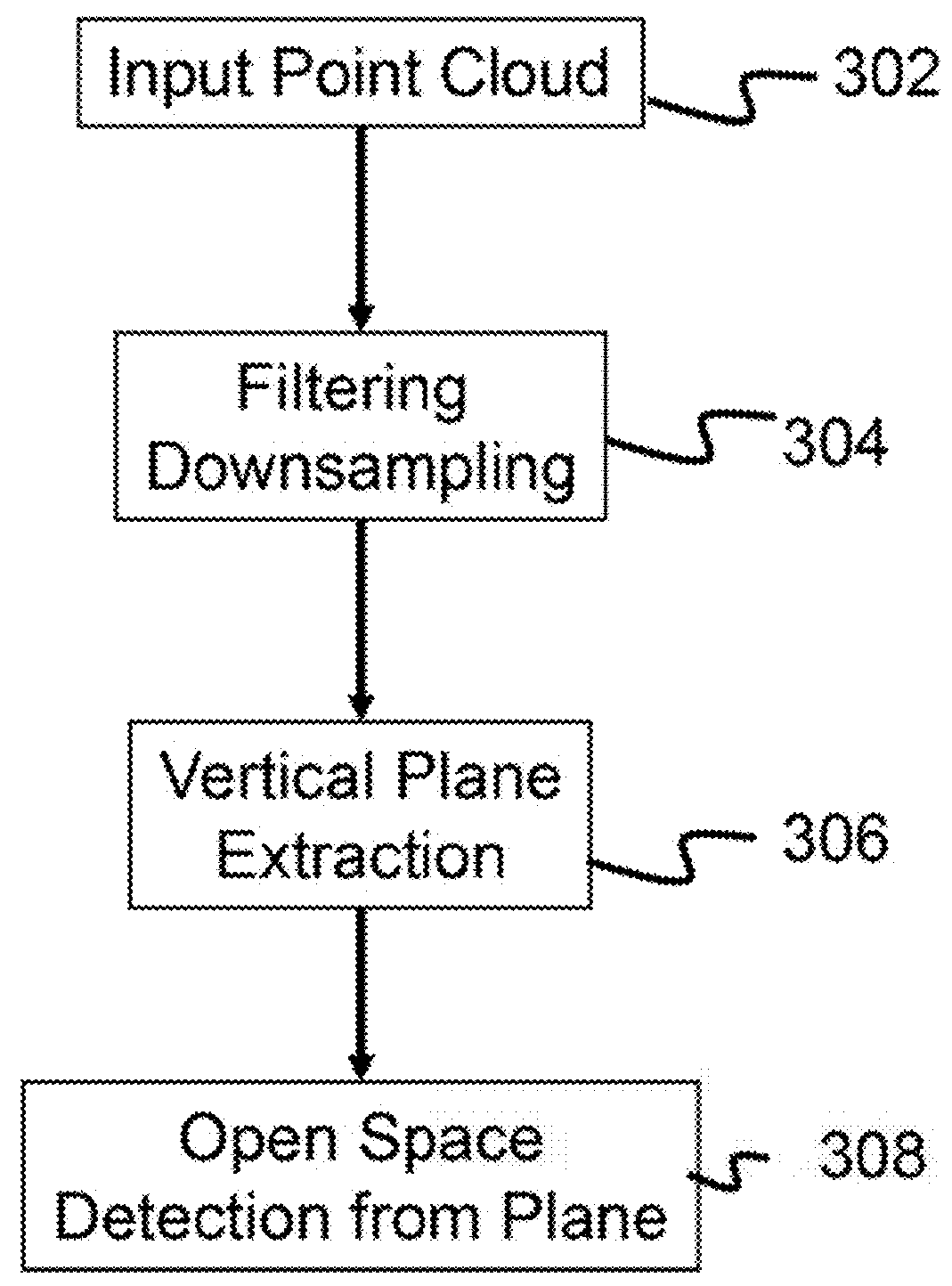

Fast open doorway detection for autonomous robot exploration

Described is a system for open doorway detection for autonomous robot exploration, the system includes an onboard range sensor that is operable for constructing a three-dimensional (3D) point cloud of a scene. One or more processors that receive the 3D point cloud from the range sensor. The 3D point cloud is then filtered and downsampled to remove cloud points outside of a predefined range and reduce a size of the point cloud and, in doing so, generate a filtered and downsampled 3D point cloud. Vertical planes are extracted from the filtered and downsampled 3D point cloud. Finally, open doorways are identified from each extracted vertical plane.

Owner:HRL LAB

Pharmaceutical formulation of omeprazole

PCT No. PCT / SE98 / 00922 Sec. 371 Date Jun. 8, 1998 Sec. 102(e) Date Jun. 8, 1998 PCT Filed May 18, 1998 PCT Pub. No. WO98 / 53803 PCT Pub. Date Dec. 3, 1998An enteric coated oral pharmaceutical formulation comprising as active ingredient a compound selected from the group of omeprazole, an alkaline salt of omeprazole, the (-)-enantiomer of omeprazole and an alkaline salt of the (-)-enantiomer of omeprazole, wherein the formulation comprises a core material of the active ingredient and optionally an alkaline reacting compound, the active ingredient is in admixture with a pharmaceutically acceptable excipient, such as for instance a binding agent, and on said core material a separating layer and an enteric coating layer. A hydroxypropyl methylcellulose (HPMC) of low viscosity with a specific cloud point is used in the manufacture of pharmaceutical formulations. Furthermore, the application describes the processes for their preparation and the use of the claimed formualtions in medicine.

Owner:ASTRAZENECA AB

Ink-jet recording method and ink-jet ink

InactiveUS7195340B2Good inkjet effectExcellent ejection stabilityMeasurement apparatus componentsPrintingThermal energyEngineering

Disclosed herein is an ink-jet recording method comprising a step of applying thermal energy to an ink to generate bubbles thereby ejecting the ink from an ejecting portion to record, wherein the relationship among a cloud point (T) of a liquid obtained by removing coloring material from the ink, a temperature T0 of the ink before formation of the bubbles in a portion in which the bubbles are generated and a temperature T1 of a part of the ink, which includes a portion in contact with the bubbles and surrounds the bubbles, satisfies T0<T<T1.

Owner:CANON KK

Liquid ester compositions and cosmetic compositions containing the same

ActiveUS20070110702A1Sustain feelingImprove gloss feelingCosmetic preparationsHair cosmeticsIsostearic acidOctanoic Acids

The present invention provides a liquid ester composition which is obtained by esterifying a branched isostearic acid such as 2-(1,3,3-trimethyl)butyl-5,7,7-trimethyl octanoic acid with dipentaerythritol, and said liquid ester composition having a viscosity at 25° C. of 100,000 to 2,000,000 mPa·s; hydroxyl value of 10 to 160; and cloud point of less than 5° C. This liquid ester composition has pigment dispersibility and hydrating ability that polybutene, which is one of the raw materials of oil compositions for cosmetic compositions, does not have, together with their abilities to sustain feeling of cosmetic film and improve gloss and moisture feeling of cosmetic compositions and shape retaining ability of lipsticks and the like equal to those containing polybutene.

Owner:THE NISSHIN OILLIO GRP LTD

Transfer ink jet recording aqueous ink

ActiveUS20110269885A1Inhibit deteriorationExcellent ejection stabilityFilm/foil adhesivesInksIntermediate imageEther

An aqueous ink for a transfer ink jet recording method including applying to an intermediate transfer member a reaction liquid which forms an increased viscosity ink image by coming into contact with a coloring material in the ink, applying the ink to the intermediate transfer member by an ink jet device to form an intermediate image, and bringing a printing object into contact with the intermediate transfer member to transfer the image to the object. The aqueous ink contains a coloring material which is a polymer dispersion pigment dispersed in the aqueous medium with a polymer having a hydroxyl group in its structure as a dispersant, a nonionic surfactant which is an alcohol ether surfactant a 1% aqueous solution of which has a cloud point of 33° C. or less and which has a C4-C30 alkyl group and a propyleneoxy group in its structure, and an aqueous medium.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com