Patents

Literature

721results about How to "Increase cetane number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

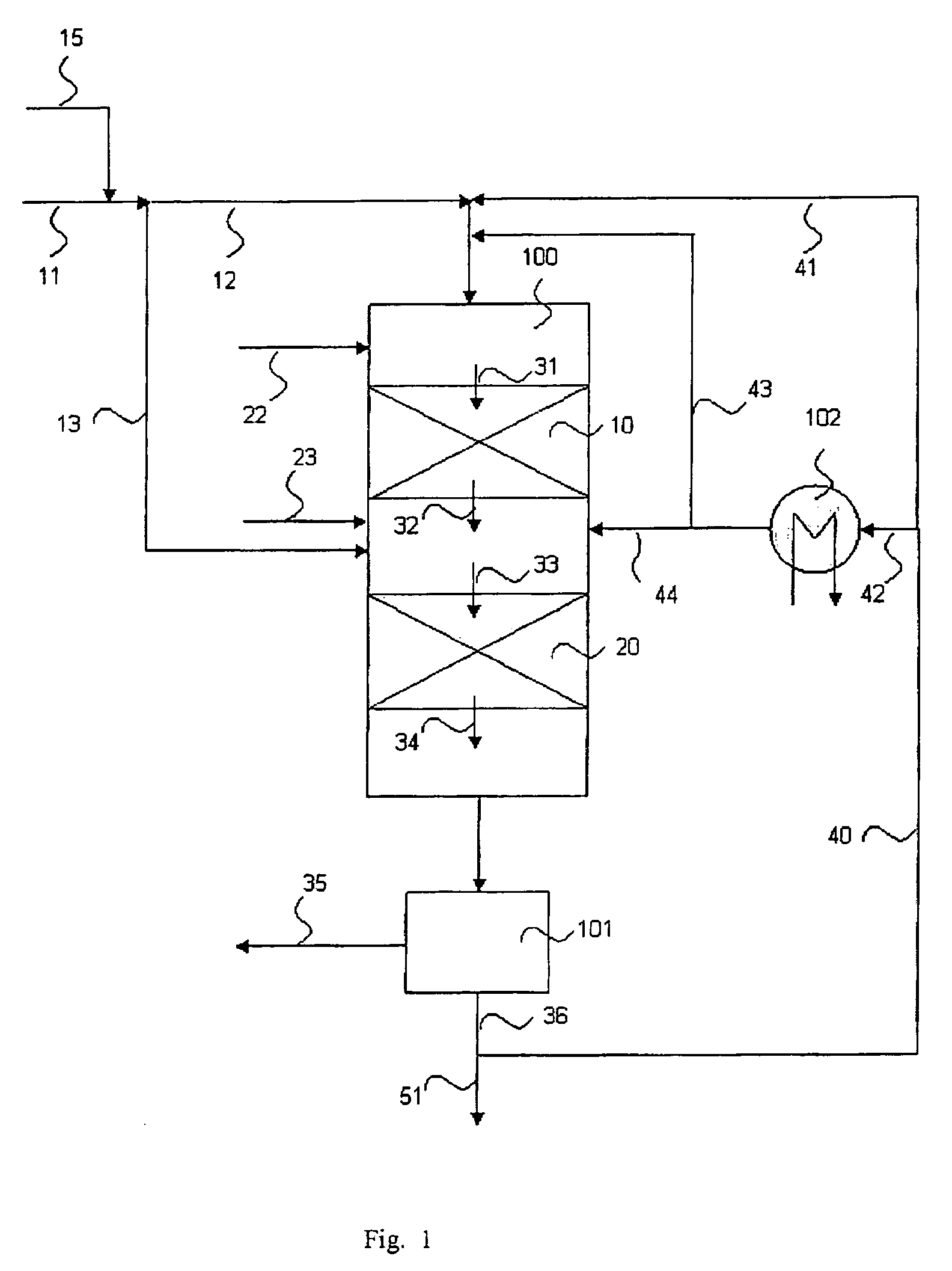

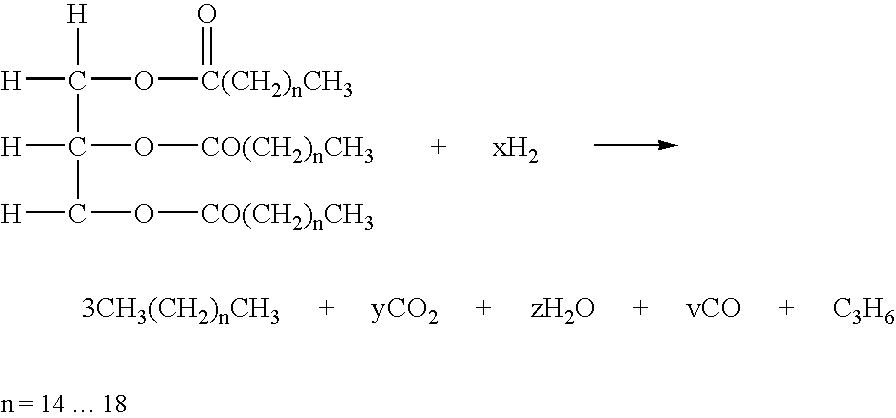

Process for the manufacture of diesel range hydro-carbons

ActiveUS20070006523A1Improve low temperature performanceBig ratioBiofuelsLiquid carbonaceous fuelsChemical industryAlkane

The invention relates to chemical industry and is directed to the production of middle distillate from vegetable oils. In the first step of the production method, the fatty acids or triglycerides of said vegetable oils are hydrogenated to give n-paraffins, and in the second step, the n-paraffins are catalytically converted to paraffins with branched chains. Using this process having two steps, a high-quality middle distillate useful as a component of diesel fuels without any particular specifications may be produced.

Owner:NESTE OIL OY

Process for converting triglycerides to hydrocarbons

ActiveUS20070175795A1High reaction yieldIncrease cetane numberBiofuelsLiquid carbonaceous fuelsBoiling pointHydrocotyle bowlesioides

Processes for the conversion of hydrocarbons boiling in the temperature range of from about 80° F. to about 1000° F. to diesel boiling range hydrocarbons, and processes for increasing the cetane number and amount of n-C17 hydrocarbon products in such processes. Diesel boiling range hydrocarbons may be produced by contacting a hydrocarbon boiling in the above-mentioned boiling range with a triglyceride-containing compound to form a mixture, and then contacting the mixture with a hydrotreating catalyst under suitable reaction conditions.

Owner:PHILLIPS 66 CO

Fuel composition for a diesel engine

InactiveUS20040055209A1Meet quality requirementsImprove low temperature performanceSolid fuelsLiquid carbonaceous fuelsProcess engineeringDiesel engine

The invention is directed to a fuel composition for diesel engines. The fuel composition comprises 0.1-99% by weight of a component or a mixture of components produced from biological raw material originating from plants and / or animals and / or fish. The fuel composition comprises 0-20% of components containing oxygen. Both components are mixed with diesel components based on crude oil and / or fractions from Fischer-Tropsch process.

Owner:NESTE OIL OY

Process for converting triglycerides to hydrocarbons

ActiveUS7550634B2High reaction yieldIncrease cetane numberBiofuelsSolid fuelsBoiling pointTG - Triglyceride

Processes for the conversion of hydrocarbons boiling in the temperature range of from about 80° F. to about 1000° F. to diesel boiling range hydrocarbons, and processes for increasing the cetane number and amount of n-C17 hydrocarbon products in such processes. Diesel boiling range hydrocarbons may be produced by contacting a hydrocarbon boiling in the above-mentioned boiling range with a triglyceride-containing compound to form a mixture, and then contacting the mixture with a hydrotreating catalyst under suitable reaction conditions.

Owner:PHILLIPS 66 CO

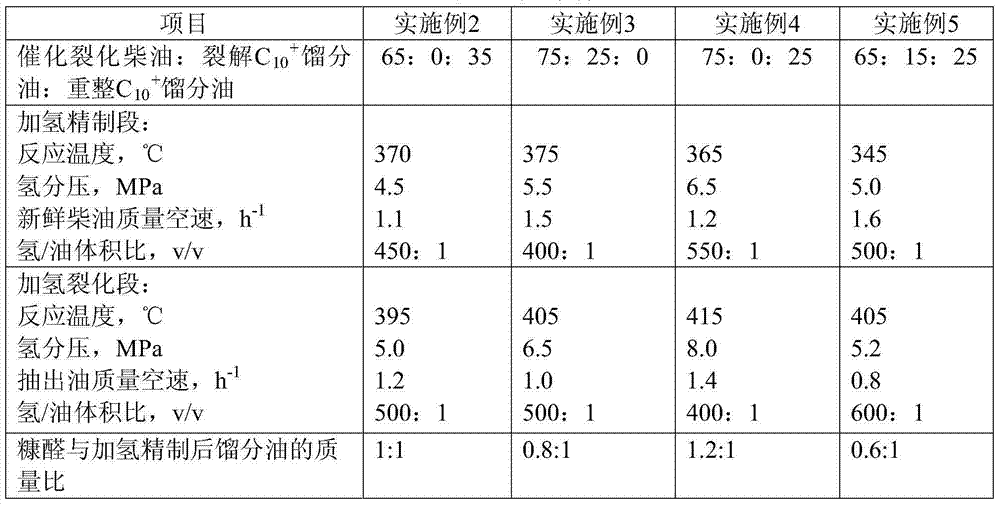

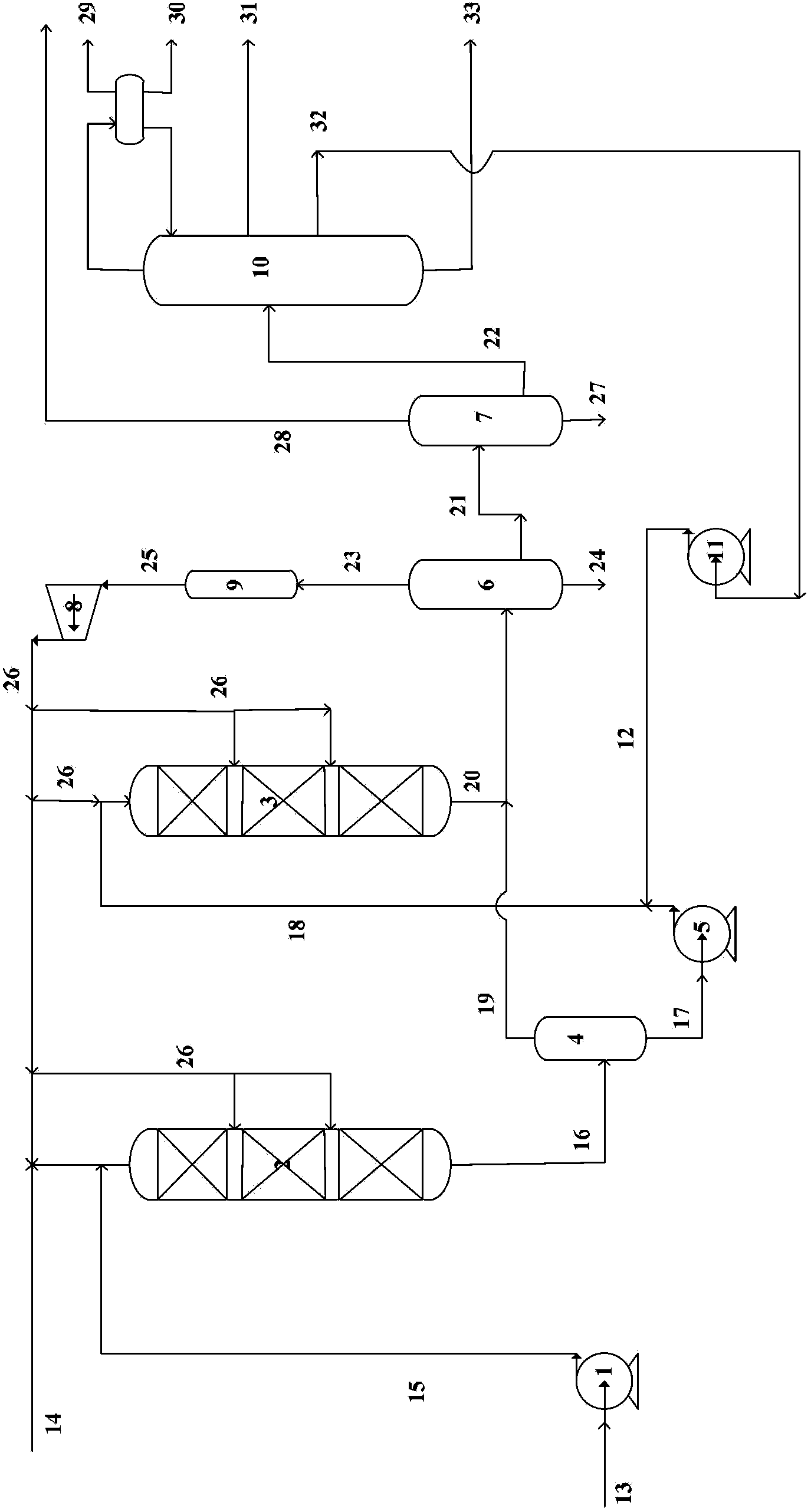

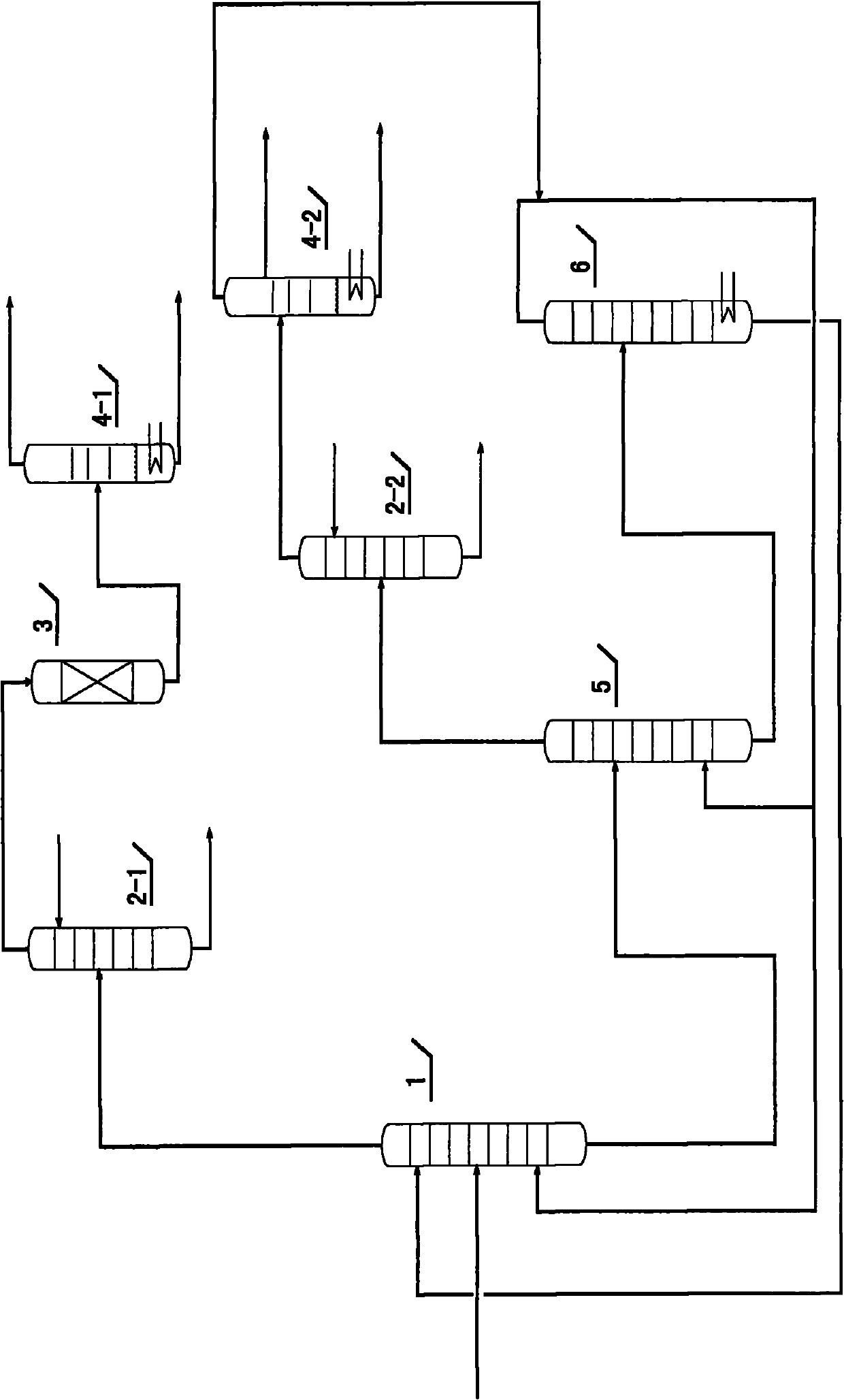

Combined hydrogenation method of producing diesel oil with high cetane number and low solidifying point

InactiveCN1417298AIncrease cetane numberLowering the freezing pointNaphtha reformingChemistryProduct gas

The combined hydrogenation method of producing diesel oil with high cetane number and low solidifying point includes contacting the raw material oil and hydrogen with hydrogenating upgrading catalystor hydrogenating cracking catalyst first, contacting the unseparated reaction effluent with pour point reducing hydrocatalyst feeding the cooled reaction product into high pressure separator to separate liquid product further flowing to the fractionating system and returning the hydrogen-rich gas to reactor. The said method can raise the cetane number of diesel oil and lower the solidifying pointsimultaneously in the same equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation modifying catalyst for poor ignition quality fuel and its preparing process

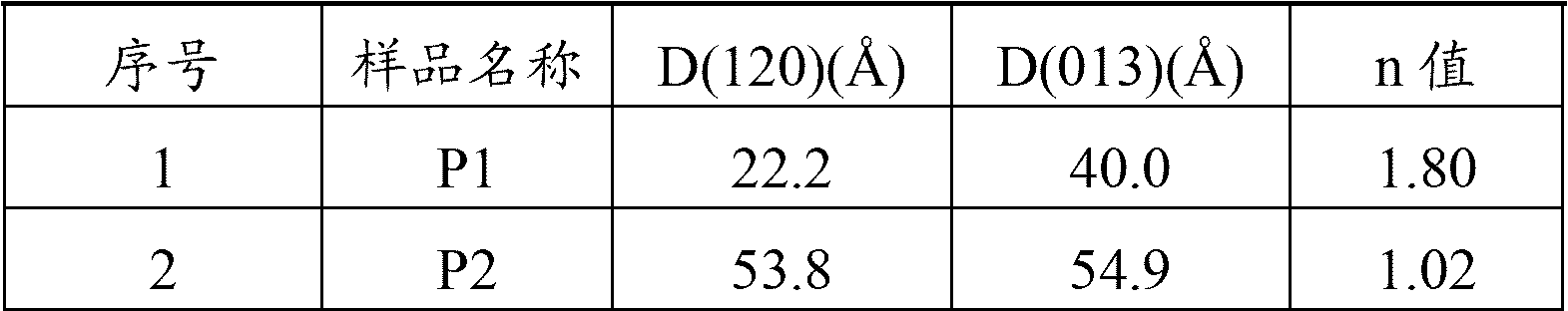

ActiveCN101463271AIncrease cetane numberImprove desulfurizationHydrocarbon oils refiningMolecular sieveSilicon oxide

The invention discloses a hydro-upgrading catalyst for inferior diesel and a preparation method thereof. The preparation method comprises the steps of: mixing, forming and roasting silicon oxide-alumina, alumina and / or a precursor of the alumina and Y-shaped molecular sieve, then introducing an effective dose of metallic components selected from at least one Group VII and at least one Group VI into the roasted forming composition; the preparation method is characterized in that the silicon oxide-alumina is selected from at least two the silicon oxide-alumina having different N values, the difference between the N values of the silicon oxide-alumina is 0.02-0.2. Compared with the prior art, the catalyst provided by the invention method has better upgrading performance for the inferior diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

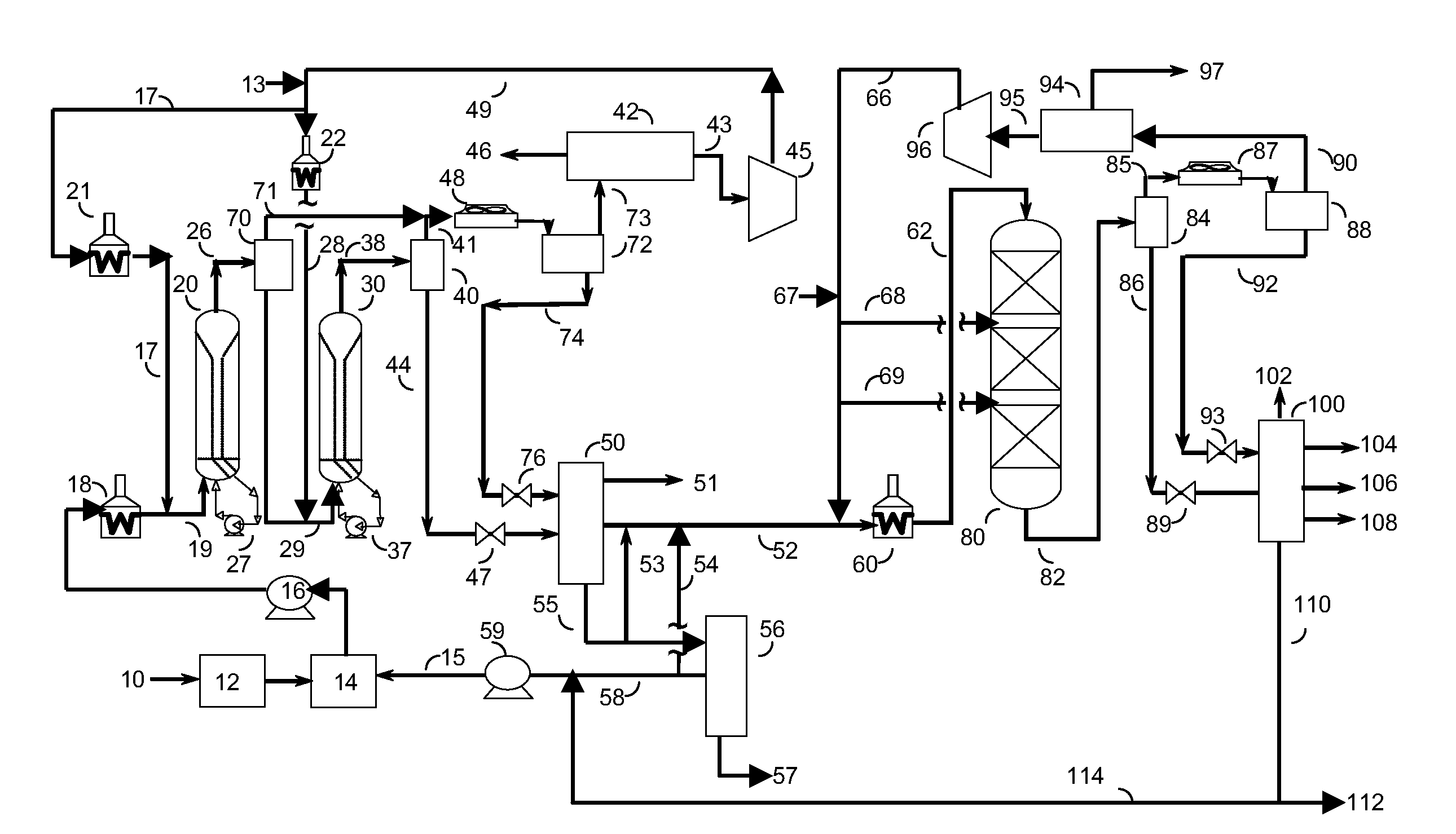

Two-way combined process of wax-oil hydrogenation treatment and catalytic cracking

A two-way combined process of wax oil hydro-process and catalytic crack is carried out by entering wax oil, catalytic cracking re-circulating oil and catalytic cracking diesel oil into hydro-processor, hydrogenation reacting under existence of hydrogen and hydrogenation catalyst, separating for reactant to obtain gas, hydrogenation naphtha oil, hydrogenation diesel oil and hydrogenation tail oil, entering hydrogenation tail oil into catalytic cracker, crack reacting under existence of catalytic cracking agent, separating to obtain dry gas, liquefied gas, catalytic cracking gasoline, catalytic cracking diesel oil and catalytic cracking re-circulating oil and oil slurry, and circulating for catalytic cracking diesel oil and catalytic cracking re-circulating oil to hydro-processor. It has higher recovery rate and cetyl value, less sulfur content, arene content and coke output.

Owner:CHINA PETROLEUM & CHEM CORP +1

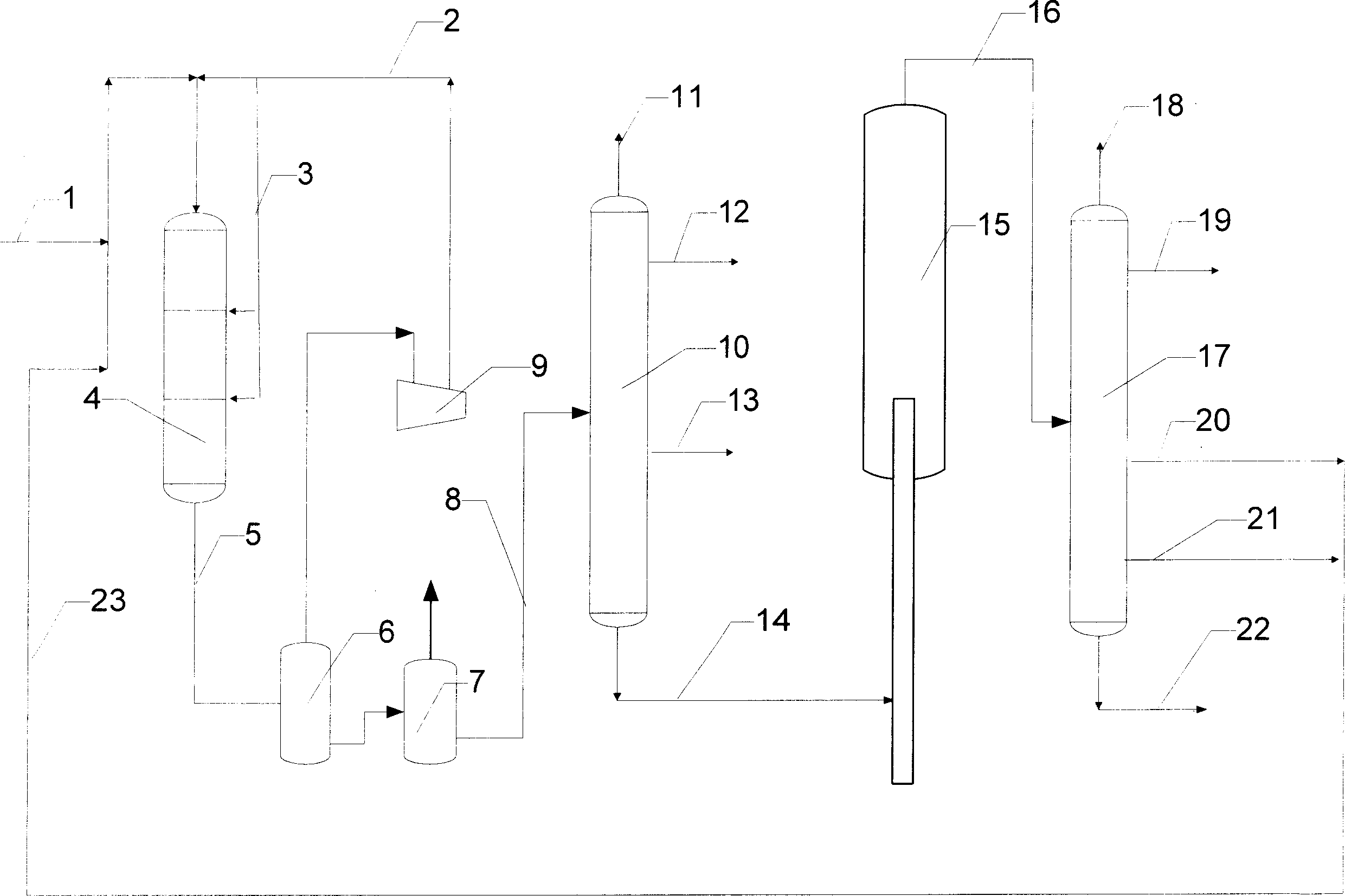

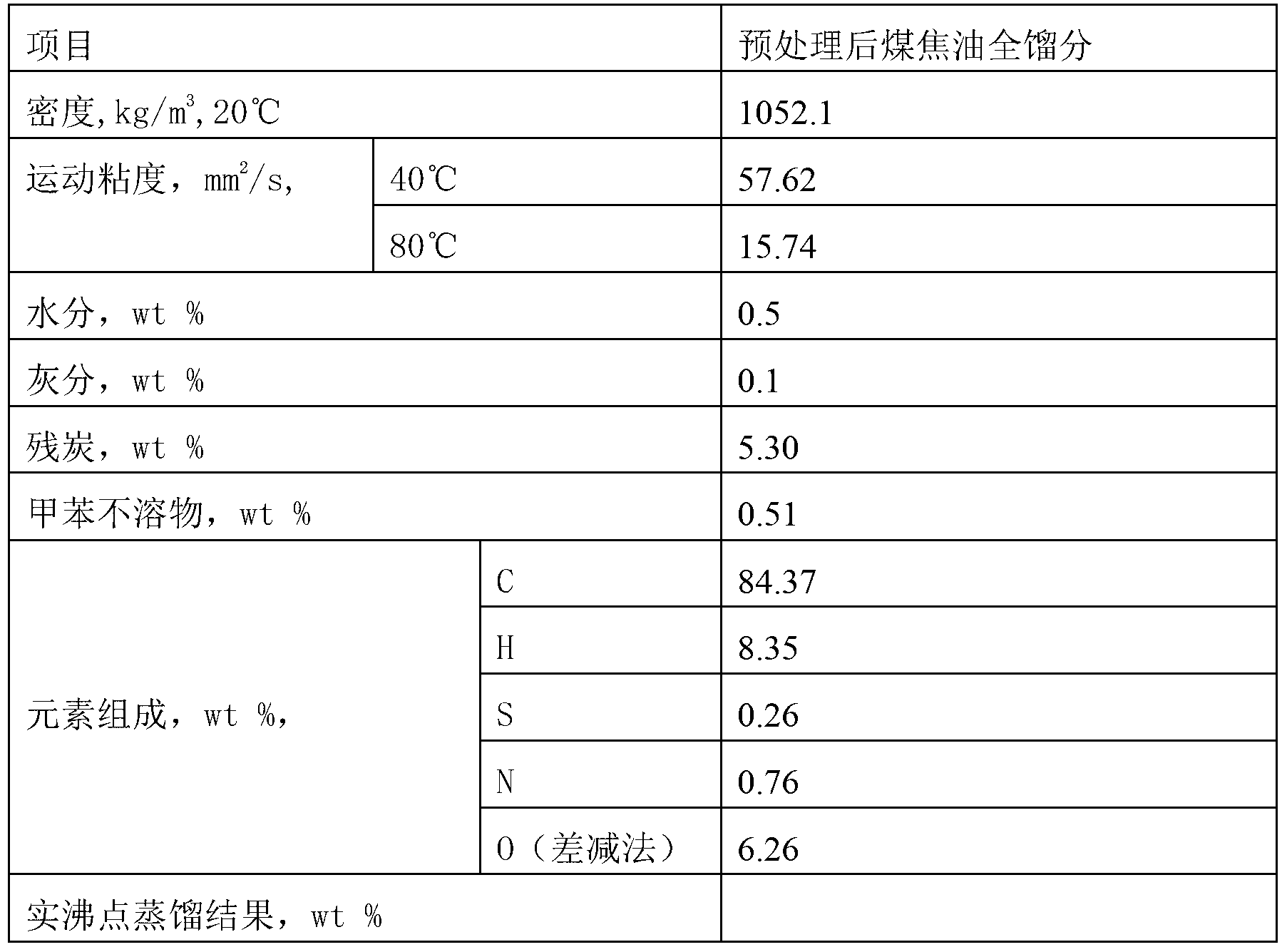

Heterogeneous coal tar suspension bed hydrogenation method

ActiveCN103265971AReduce processing stepsSolve delivery problemsLiquid hydrocarbon mixture productionHydrocarbon oil crackingSlurryFuel oil

The invention discloses a heterogeneous coal tar suspension bed hydrogenation method which comprises the following steps: mixing catalyst oil slurry with full fraction or heavy fraction oil of coal tar and catalyst-containing circulating oil, adding into a suspension bed hydrogenation reactor, and performing hydrocracking reaction, wherein the catalyst is a powdery particle coal tar suspension bed hydrogenation catalyst containing a single-metal active component or composite multi-metal active component of molybdenum, nickel, cobalt, tungsten or iron; separating out light oil from the hydrogenation reaction product, and then directly circulating a large amount of the tail oil containing the catalyst to the suspension bed reactor; and performing catalyst removal treatment on a small amount of the tail oil, recirculating to the suspension bed reactor, and performing further light fraction conversion. The heavy oil is wholly or maximally circulated to realize the maximal, convenient and flexible light oil production from the coal tar having different characteristics and the cyclic utilization of the catalyst, thus greatly improving the utilization efficiency and operating flexibility of the raw materials and the catalyst.

Owner:CCTEG CHINA COAL RES INST

Inferior diesel hydrogenation catalyst

InactiveCN1778873AHigh yieldWeak ring opening cracking performanceRefining to eliminate hetero atomsLanthanumChemistry

A hydrotreating catalyst of inferior diesel consists of alumina 20.0í½80.0wt% and molecular sieve 3.0í½60.0w%. The catalyst is prepared by loading at least one Fe, Co and Ni metal of ó° family and MO and W metal of ó÷B family as metal active component and adding one or above oxide or fluorinated compound of titanium, magnesium, zirconium, lanthanum, iron, phosphorus, silicon and boron as active auxiliaries. It can decrease content of sulfur and arenes and increase cetyl value in products. It can be used for cryogenic hydrogenation desulfurization, denitridation and hydrogenation dearomatization.

Owner:PETROCHINA CO LTD +1

Coal tar hydrogenating modified method by two-stage method

ActiveCN101307257AGood Ring Opening Cracking PerformanceGood nitrogen resistanceTreatment with hydrotreatment processesGas phaseDistillation

The invention discloses a two-stage method coal tar hydro-upgrading method. Coal tar is subject to the atmospheric distillation and / or the reduced pressure distillation and is cut into coal tar light cut and coal tar heavy cut; after the coal tar light cut and optional distillate oil are mixed with hydrogen, the mixture enters a first hydrogeneration reaction zone and performs the contact reaction with hydrorefining catalyst; gas phase impurities of a reaction effluent is removed through an intermediate flash distillation column or a high-pressure stripping tower, and then the reaction effluent enters a second hydrogeneration reaction zone to perform the contact reaction with the hydro-upgrading catalyst or the hydrocracking catalyst; and the obtained reaction effluent is cooled, separated and fractionated to produce diesel fraction and naphtha cut. The invention provides a clean and effective coal tar processing and utilizing method, the coal tar light cut is hydro-upgraded to produce diesel oil for vehicles, the sulfur content of the obtained diesel product is less than 50 mu g / g, the content of polycyclic aromatic hydrocarbon is less than 11 weight percent, and the diesel oil cetane number of the product is improved by not less than 20.

Owner:CHINA PETROLEUM & CHEM CORP +1

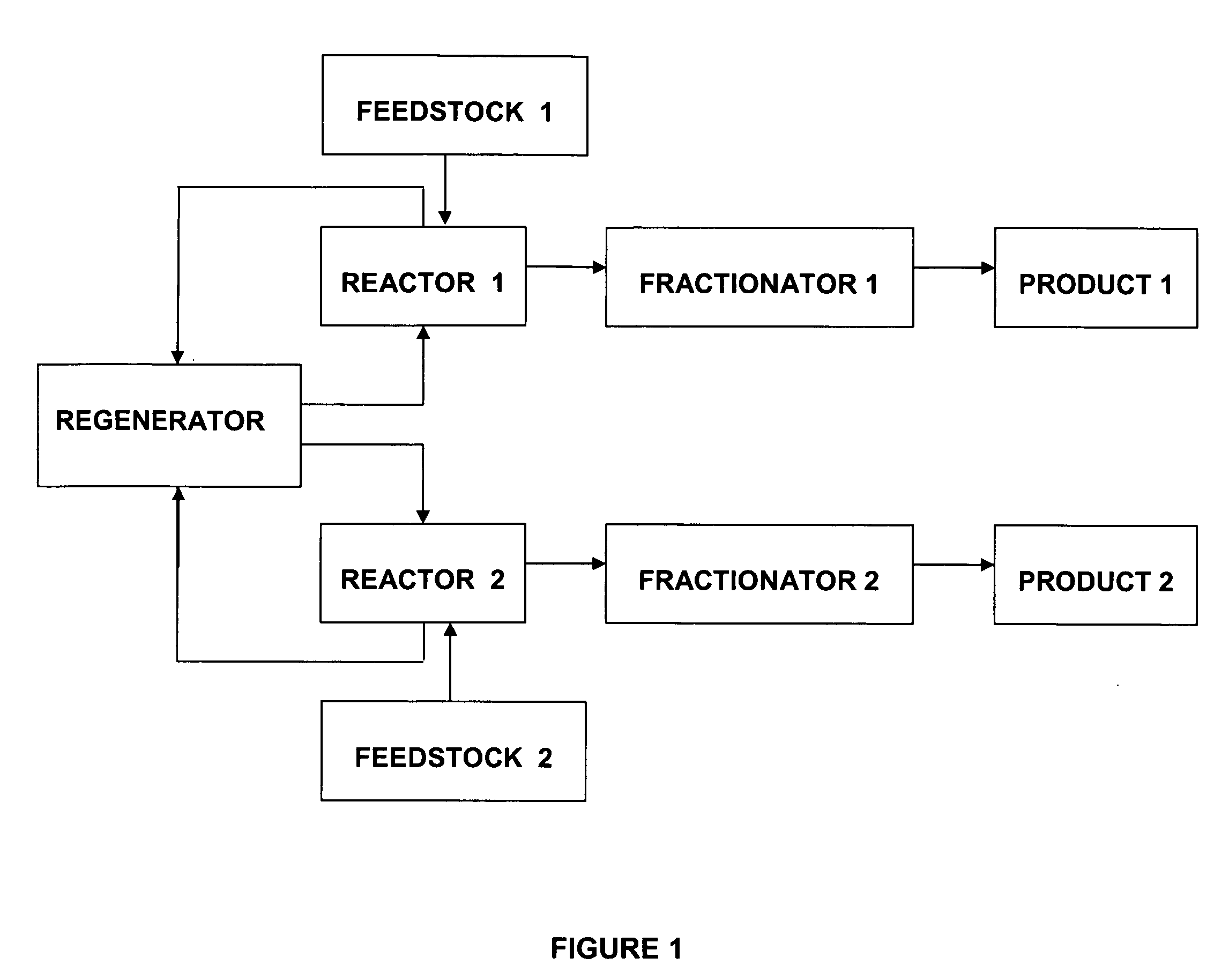

Catalytic cracking process for the production of diesel from vegetal oils

ActiveUS20070007176A1Increase cetane numberCatalytic crackingCatalytic naphtha reformingHydrocotyle bowlesioidesTransesterification

The present invention comprises a thermo catalytic process to produce diesel oil from vegetal oils, in refineries which have two or more Catalytic Cracking (FCC) reactors. At least one reactor processes heavy gasoleum or residue in conventional operation conditions while at least one reactor processes vegetal oils in proper operation conditions to produce diesel oil. This process employs the same catalyst employed in the FCC process, which processes conventional feedstocks simultaneously. This process transforms high heat content raw materials into fuel hydrocarbons. It shows excellent efficiency for the obtention of highly pure products and do not yield glycerin, one by-product of the transesterification process. The diesel oil produced by said process presents quality superior and cetane number higher than 40. Once cracking reactions occur at lower temperatures, it forms less oxidized product, which is consequently purer than those obtained by existent technology are.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

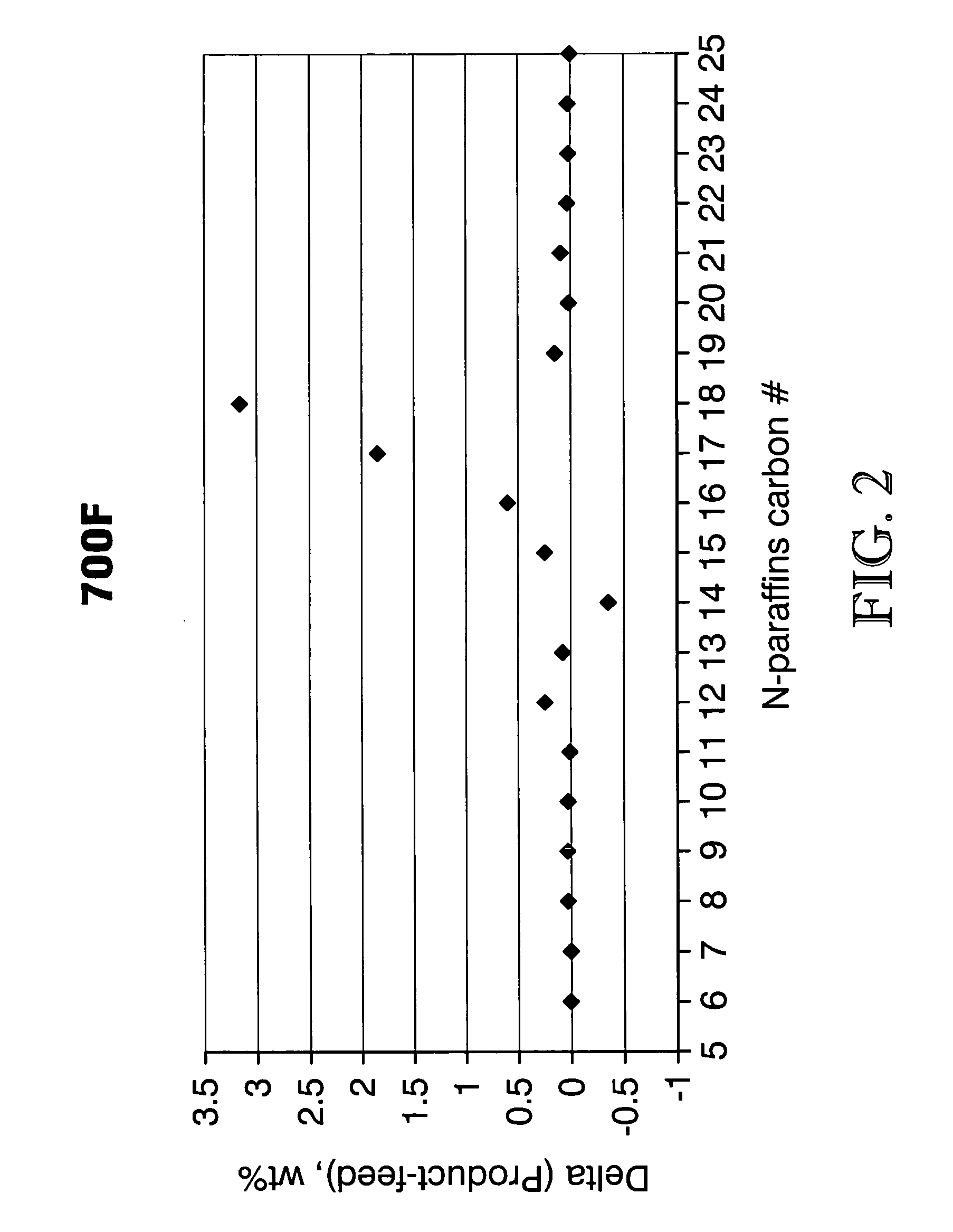

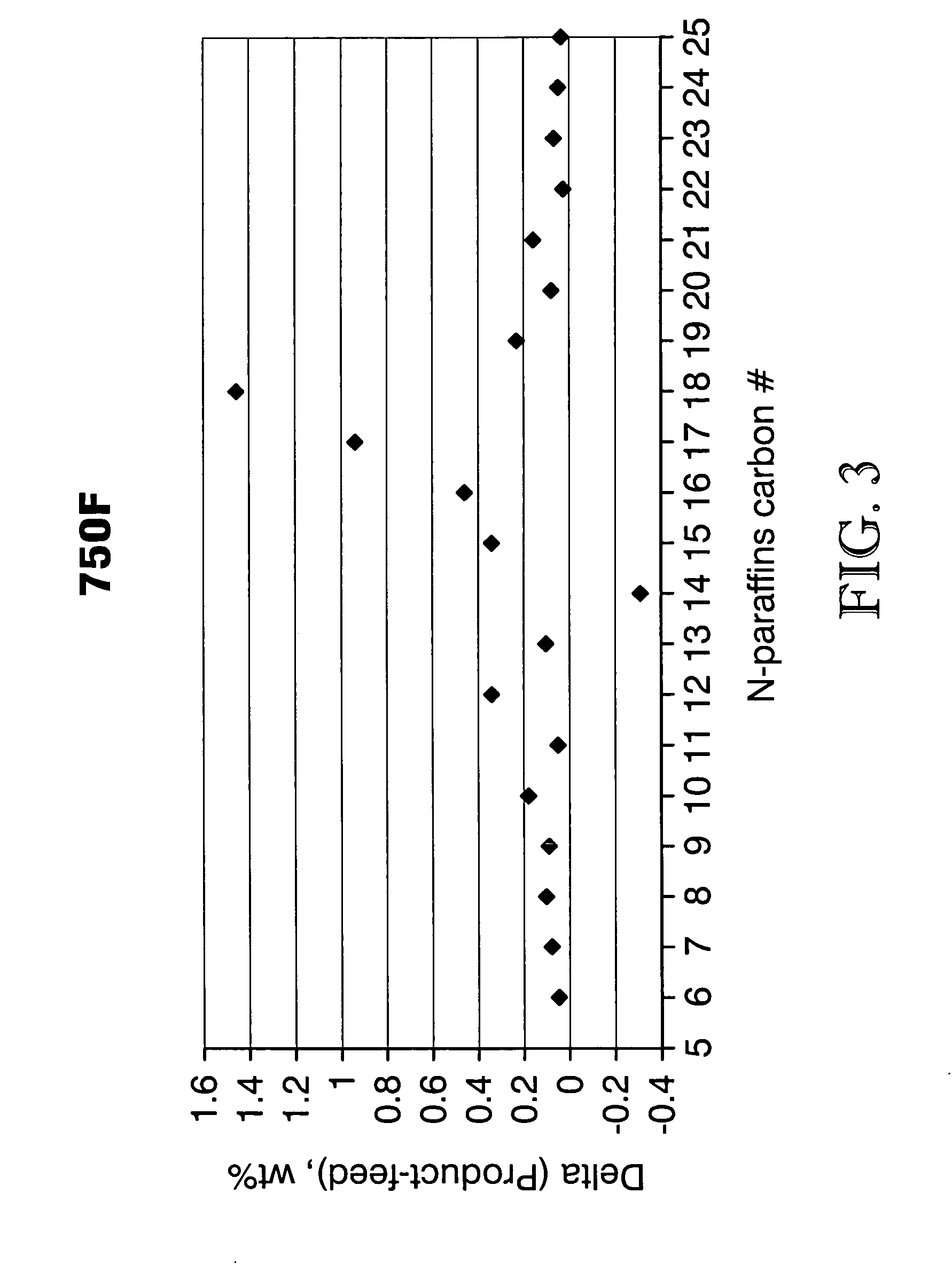

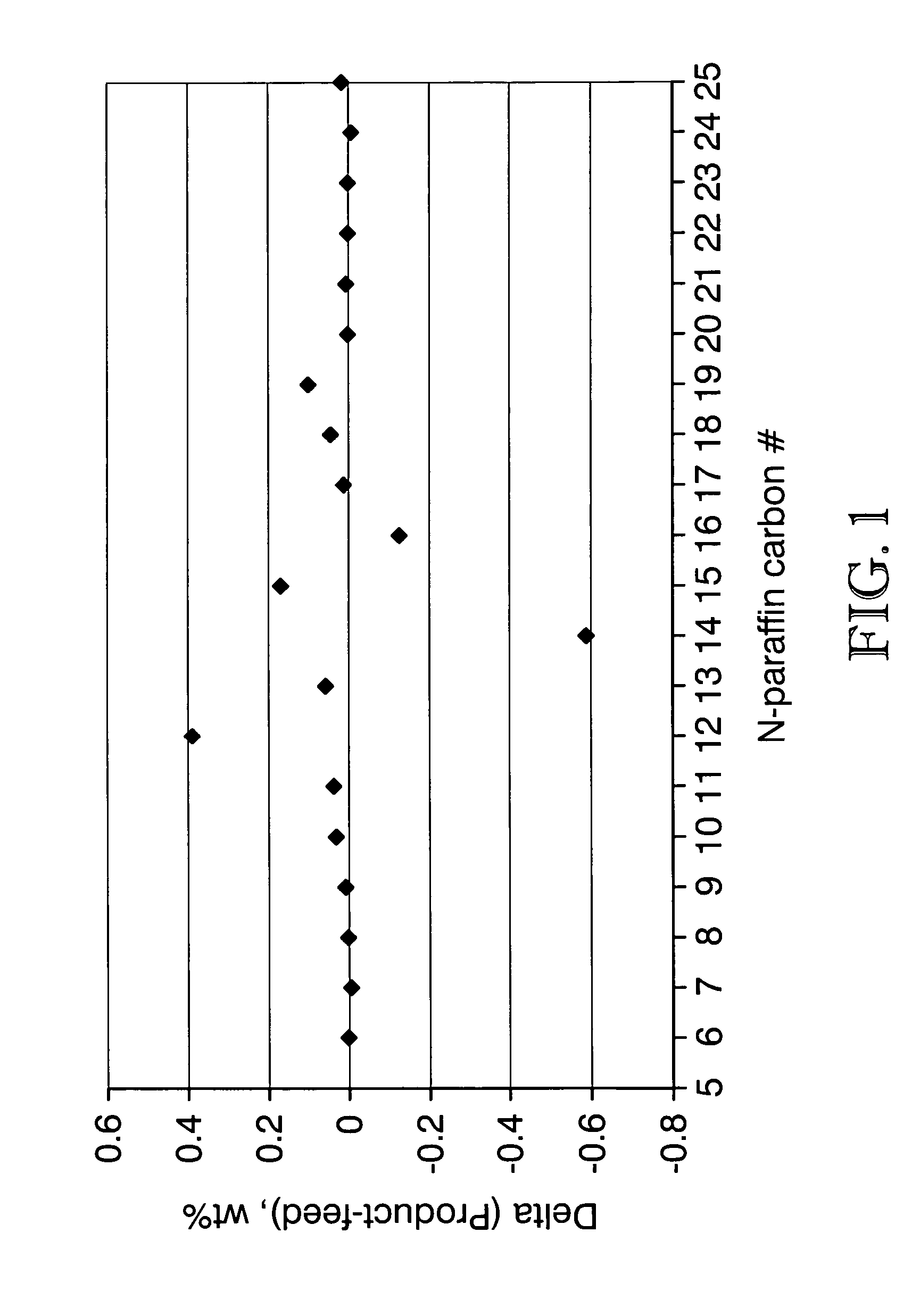

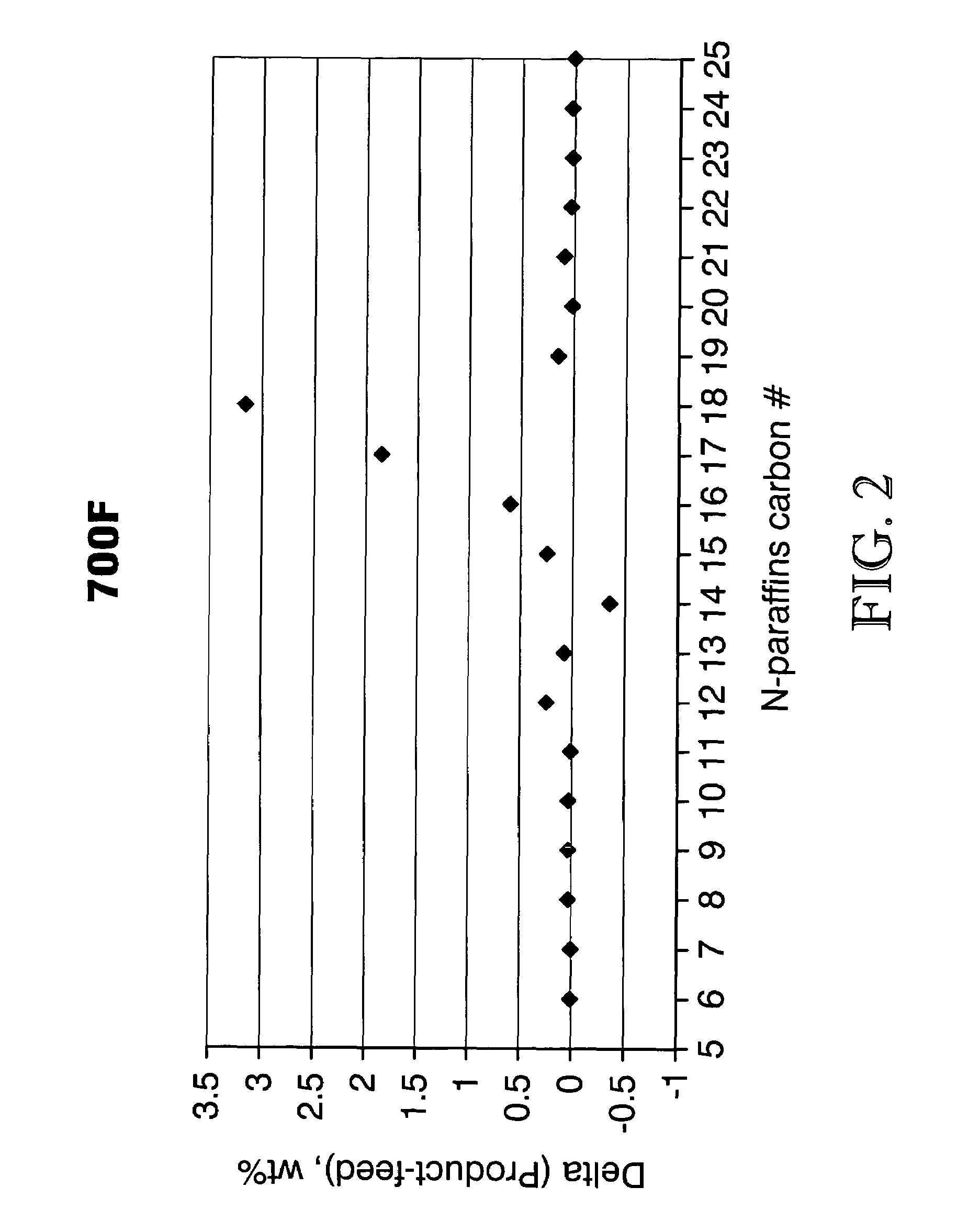

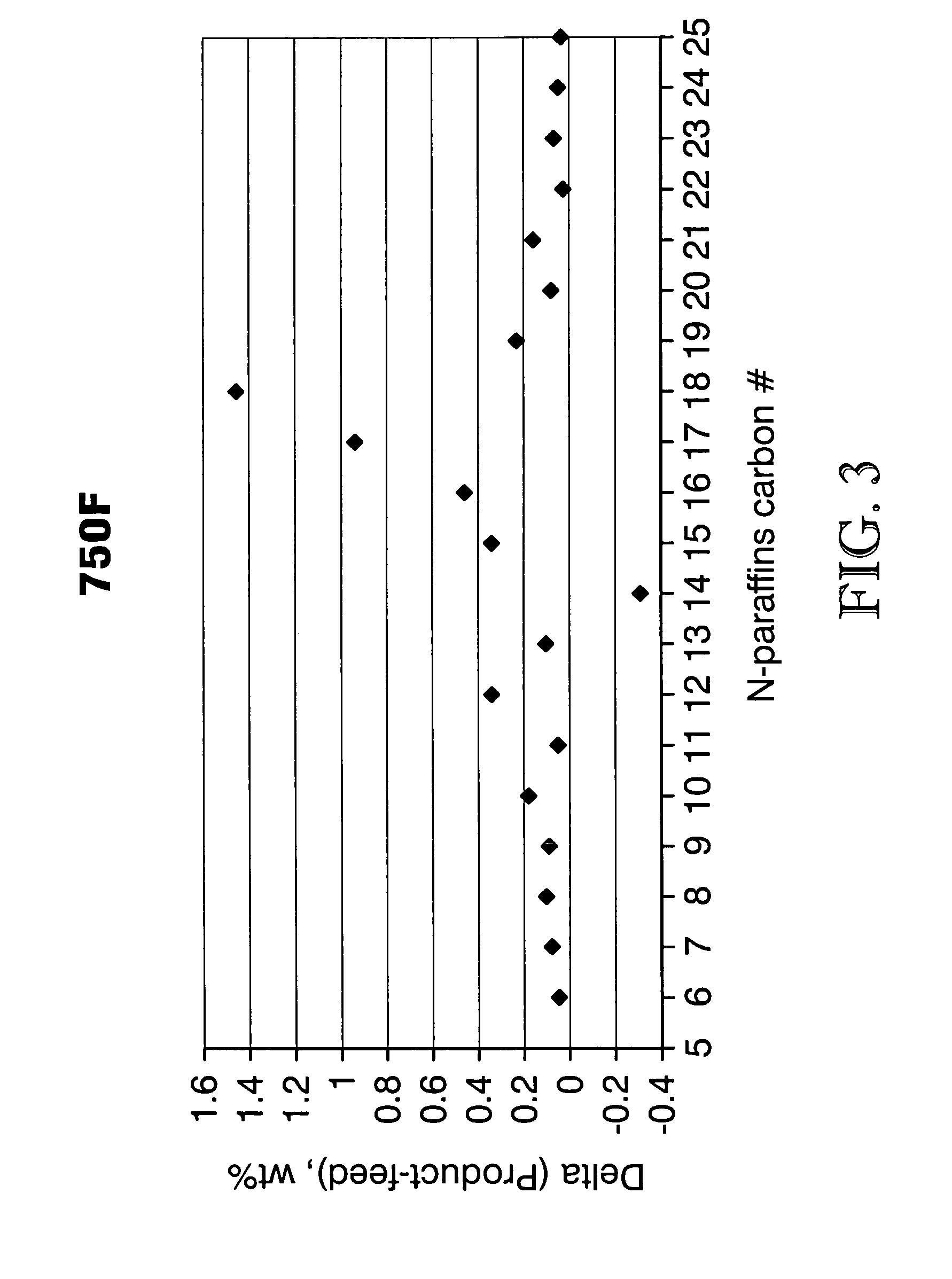

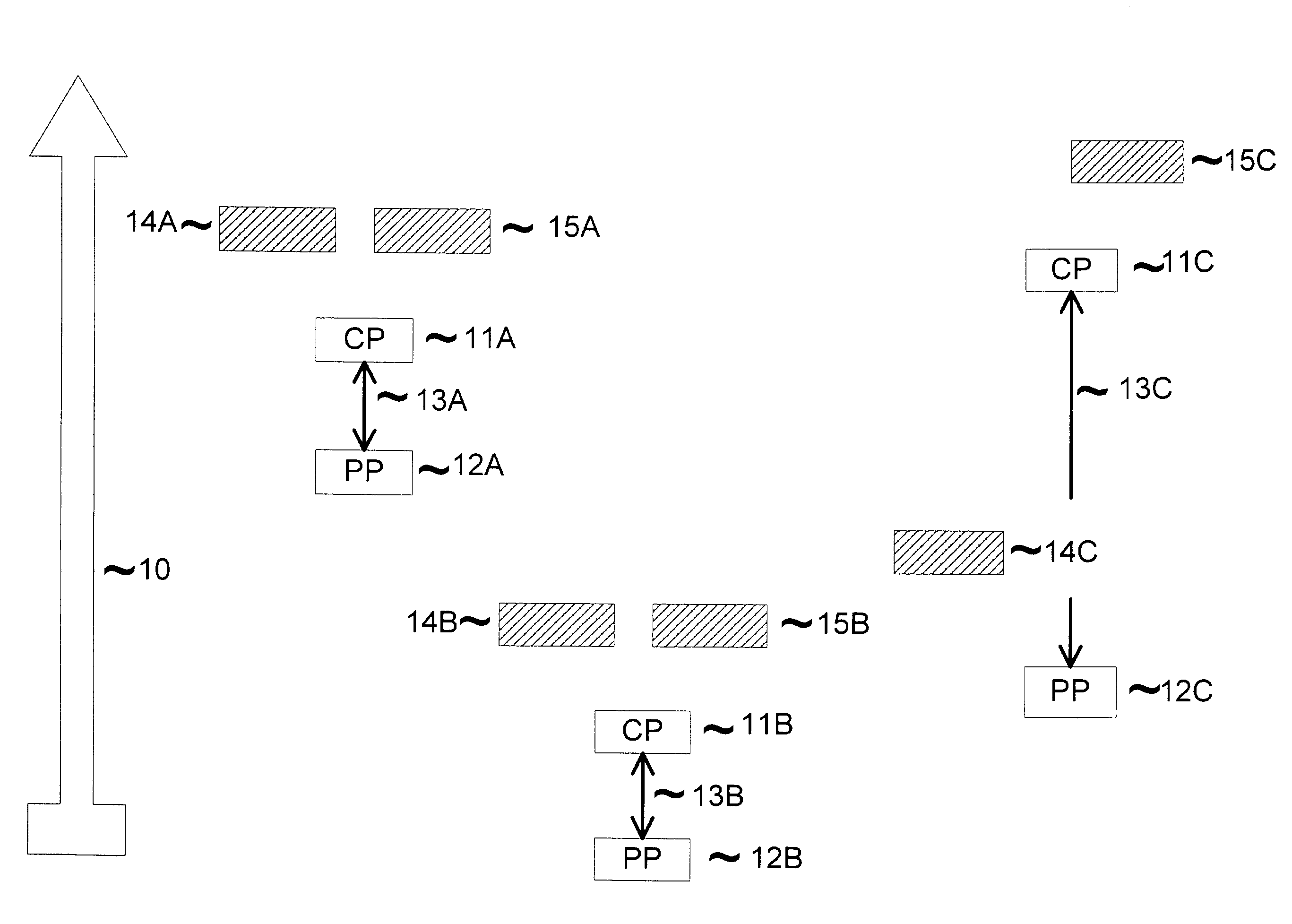

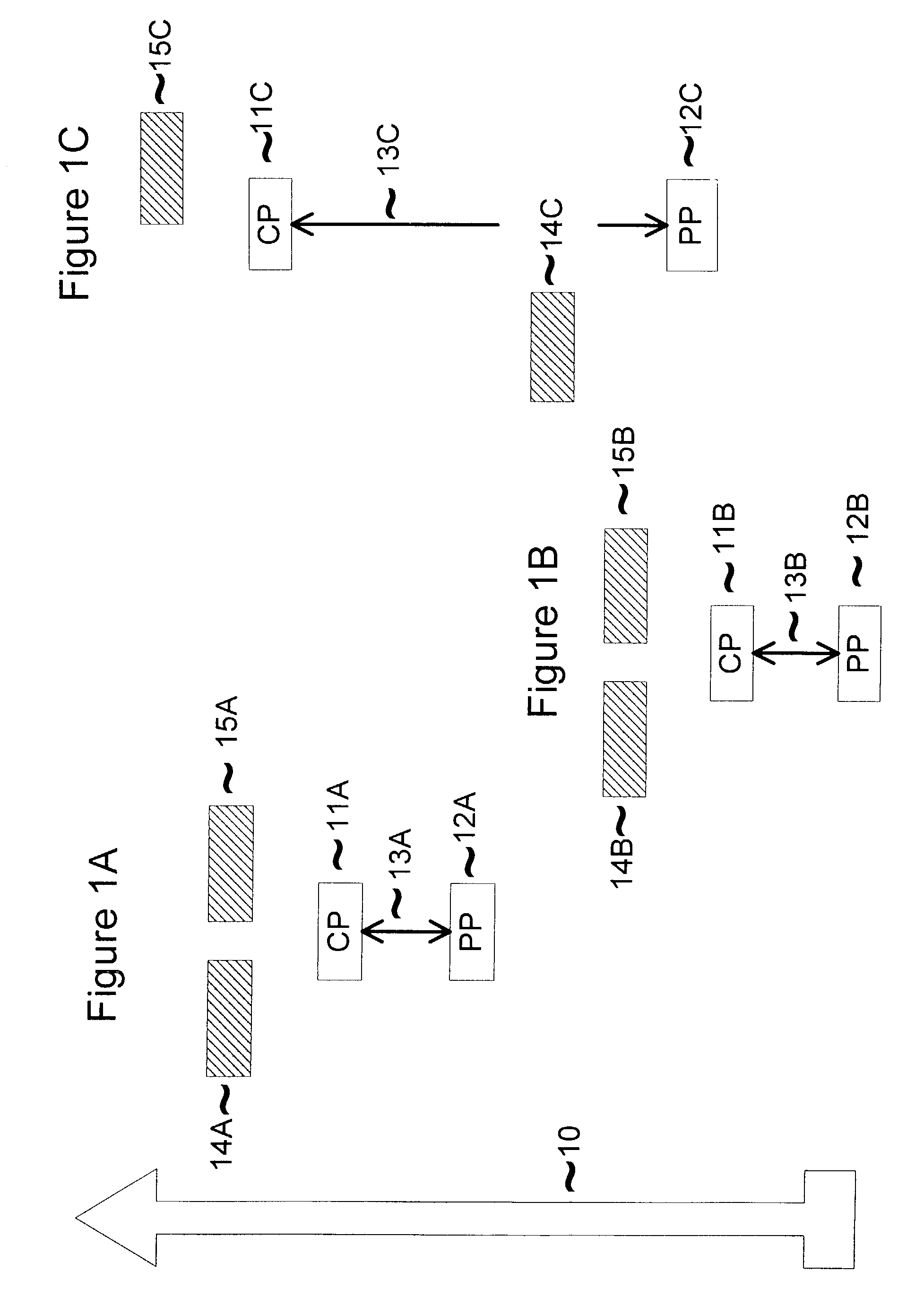

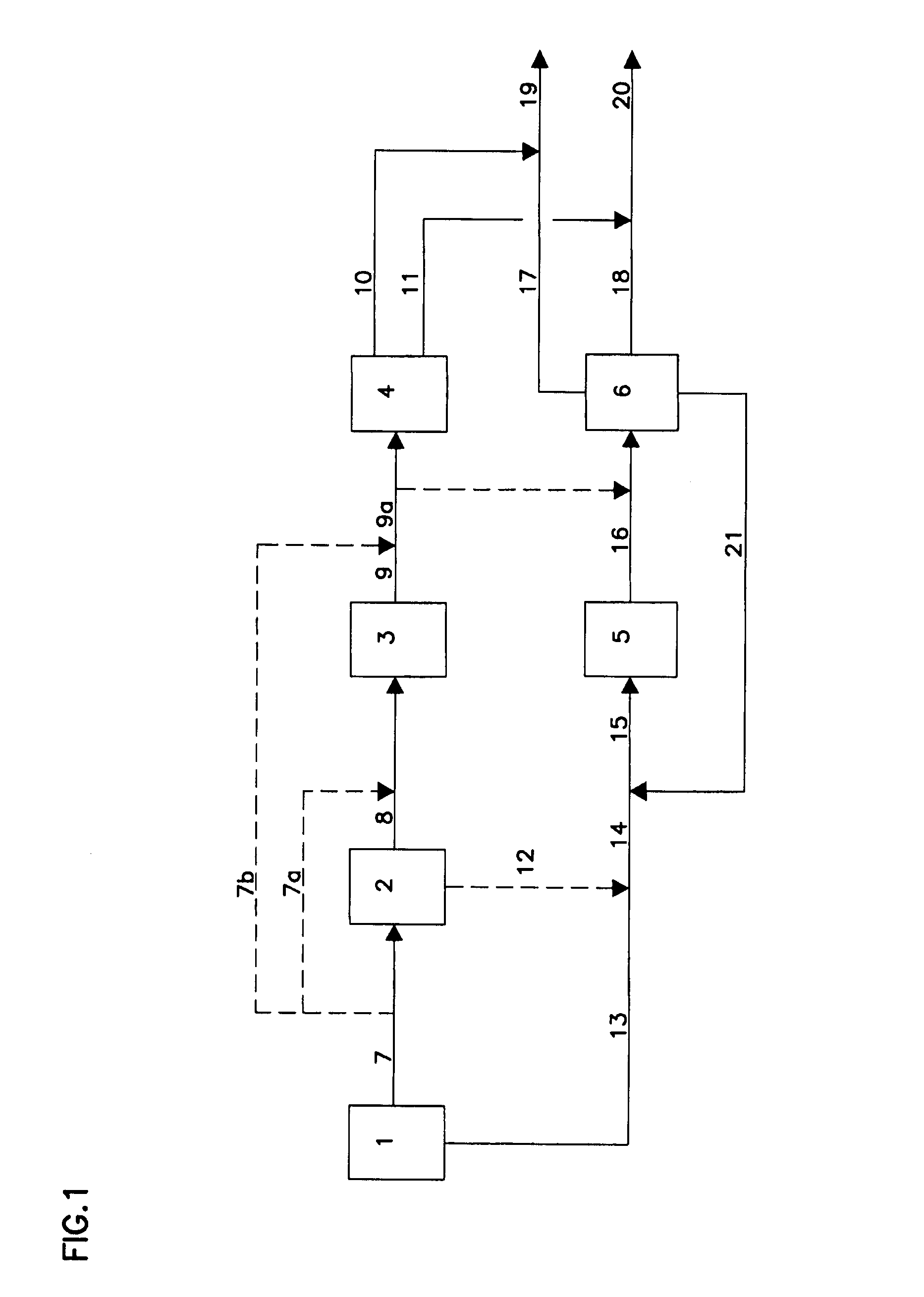

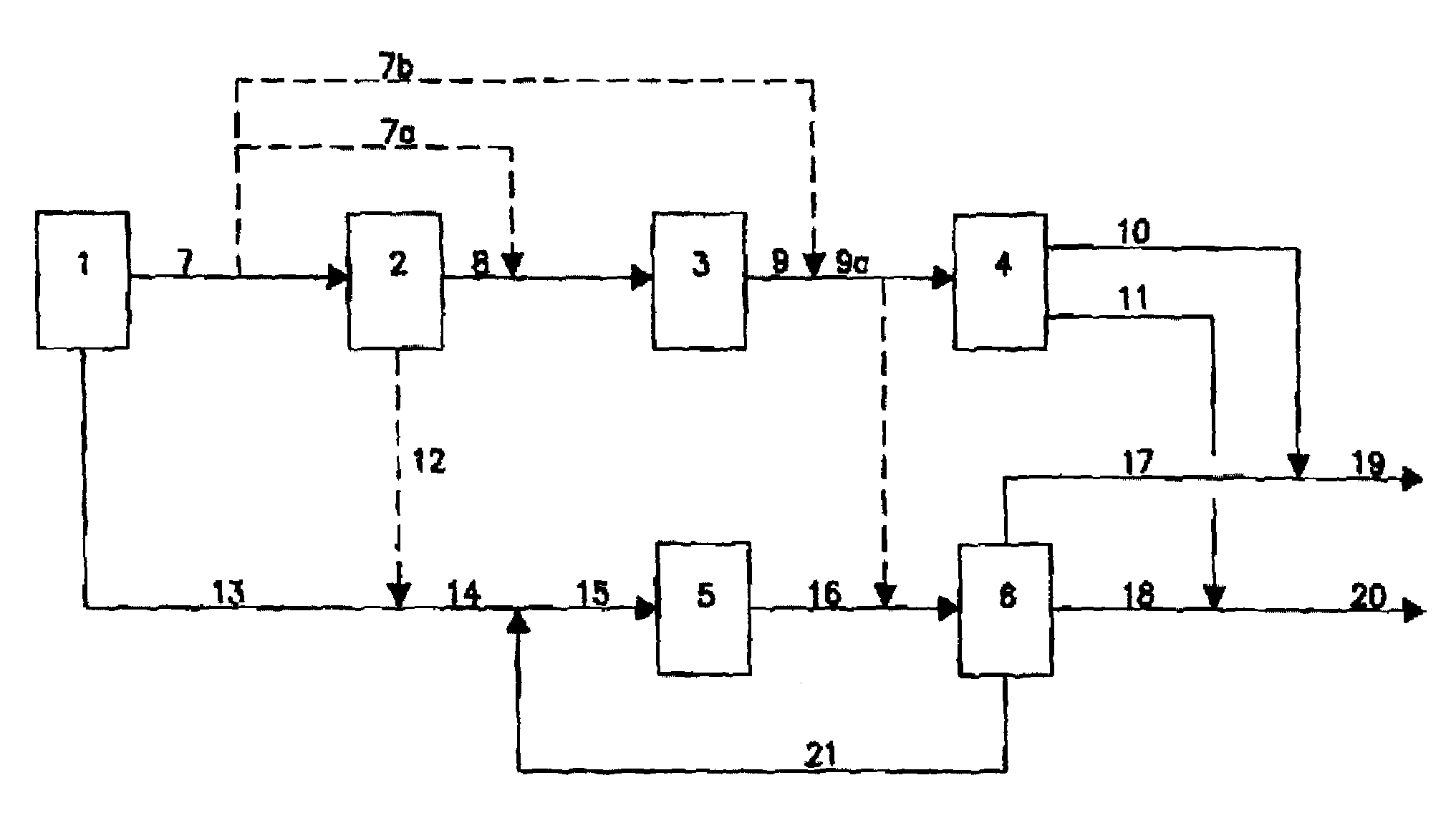

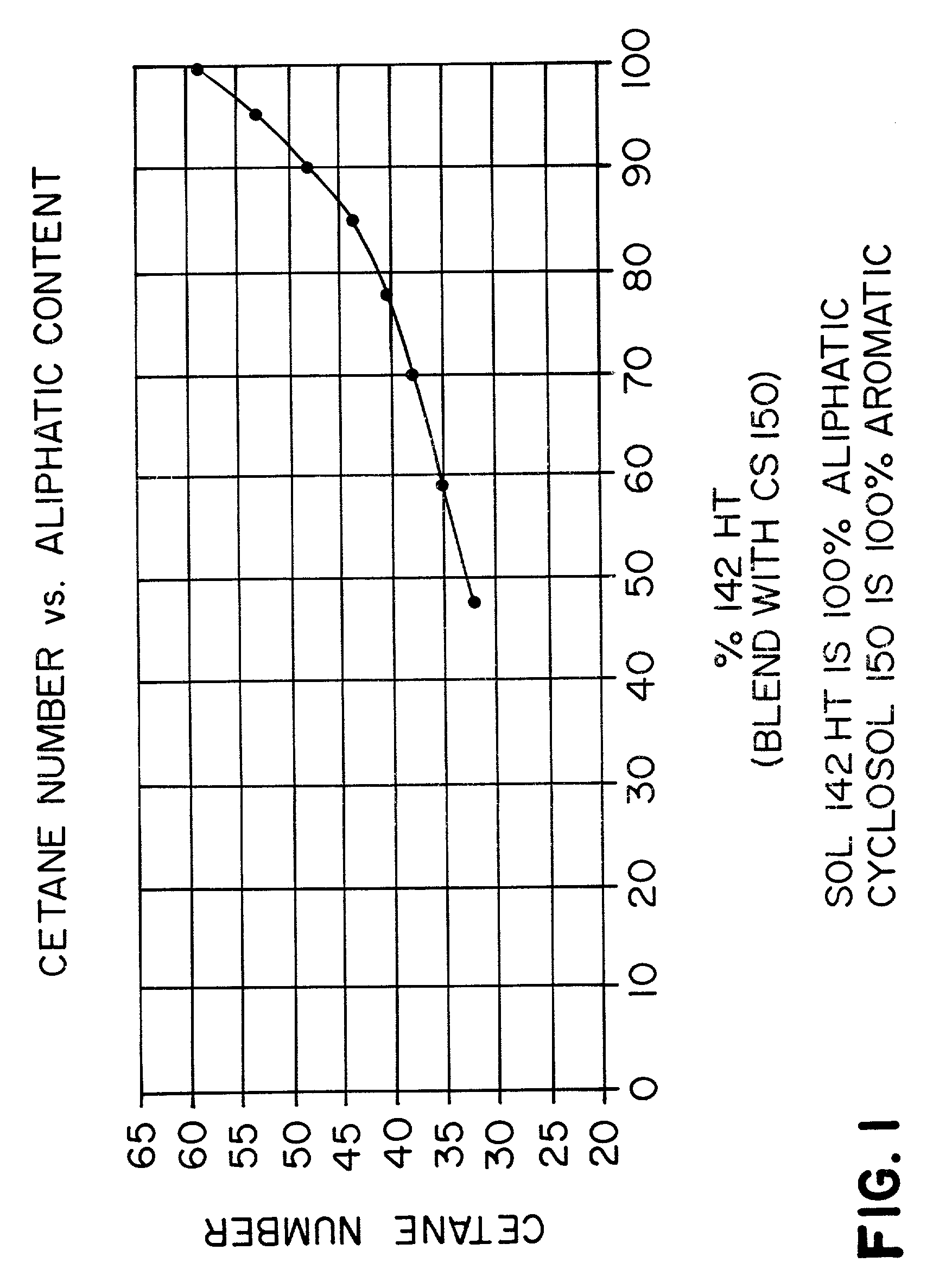

Systems and methods of improving diesel fuel performance in cold climates

InactiveUS7354462B2Reduce yieldIncrease cetane numberNon-fuel substance addition to fuelCombustion enginesParaffin waxPetroleum product

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Coal conversion process and products, comprising two direct ebullated bed liquefaction stages and a fixed bed hydrocracking stage

ActiveUS20110230688A1High yieldEasy to transportWaste based fuelLiquid carbonaceous fuelsKeroseneFixed bed

A process for the conversion of coal into fuel bases comprises two successive direct liquefaction stages in ebullated bed reactors followed by a fixed bed hydrocracking stage. This process can produce excellent quality fuel bases (kerosene and diesel).

Owner:INST FR DU PETROLE

Alumina supporter containing modified gamma zeolite and its preparation method

ActiveCN1765492ALowering the freezing pointReduce crackingMolecular sieve catalystsCatalyst activation/preparationIon exchangeMetal

The invention discloses an alumina support containing Y zeolite and relative preparing method. The carrier utilizes the Y zeolite and alumina as carriers, while the property of zeolite can be changed via changing the metallic positive ions between the VIB group and / or VIII group to adjust the acid distribution, especially the proportion of B acid and L acid. The invention can be used a carrier of hydro-treating catalyst to fraction prepare the winter cleaning diesel fuel from poor diesel fuel.

Owner:CHINA PETROLEUM & CHEM CORP +1

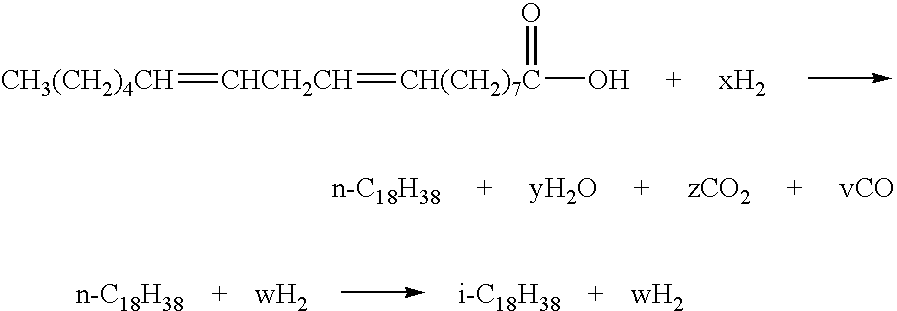

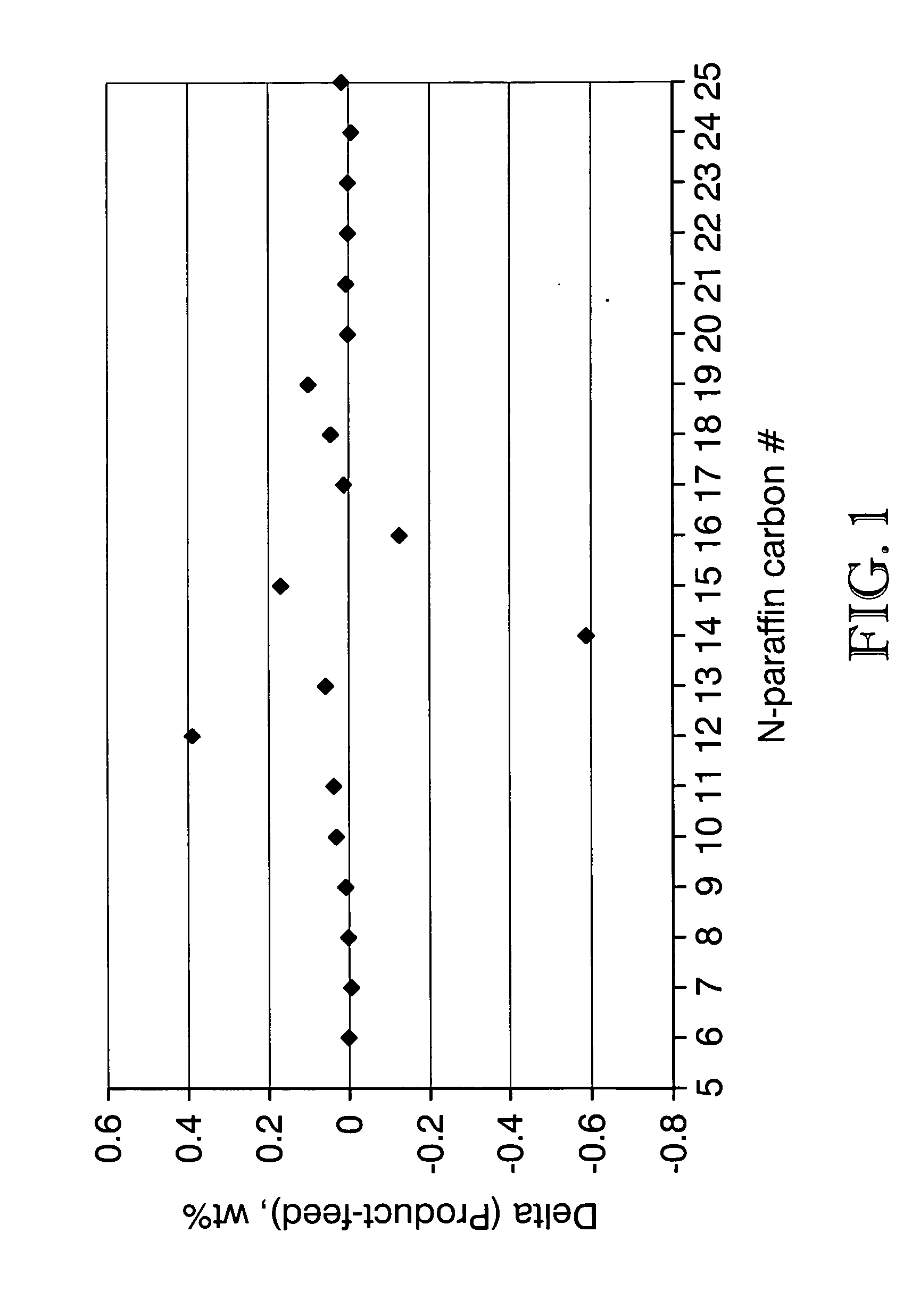

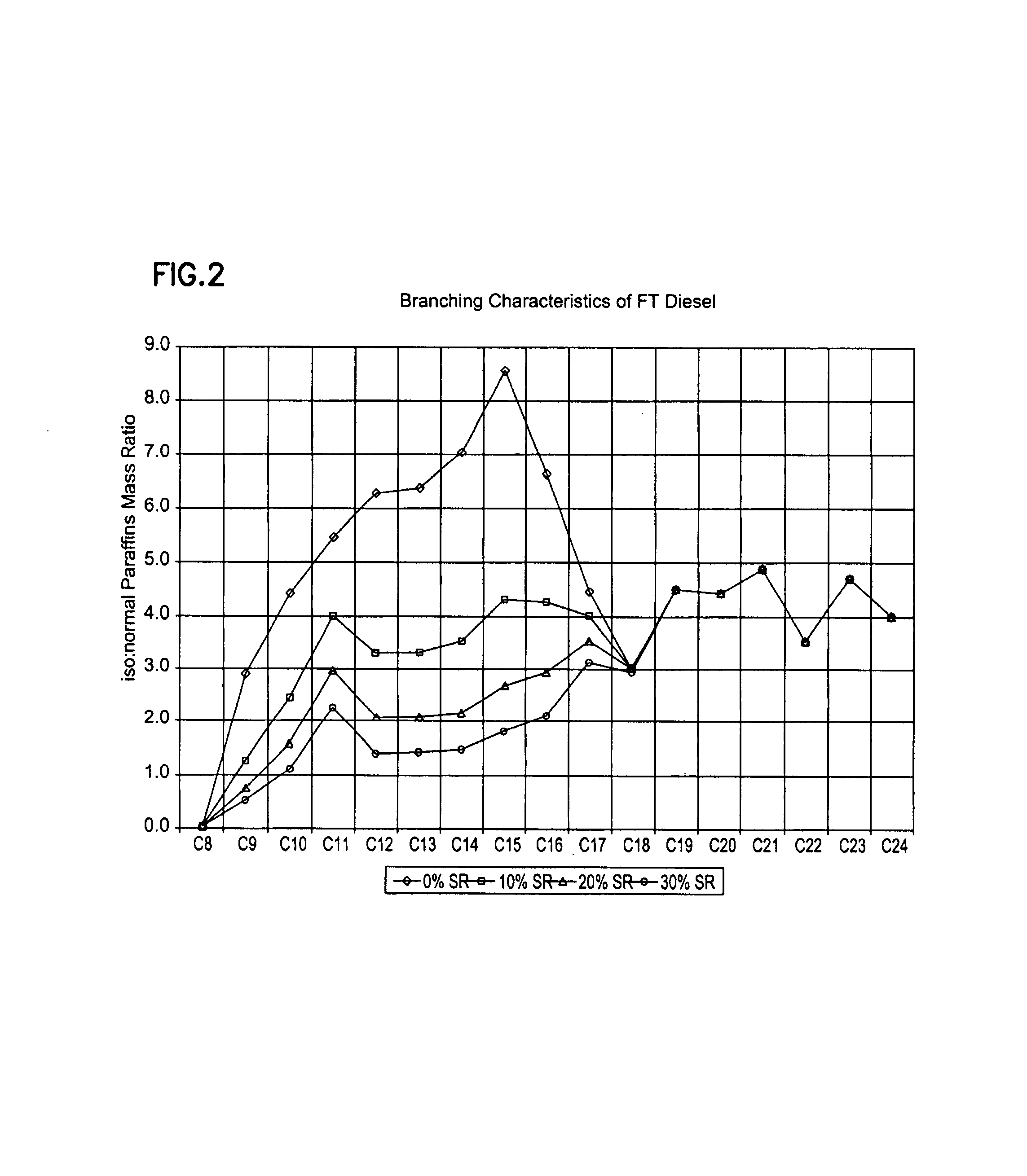

Process for producing middle distillates

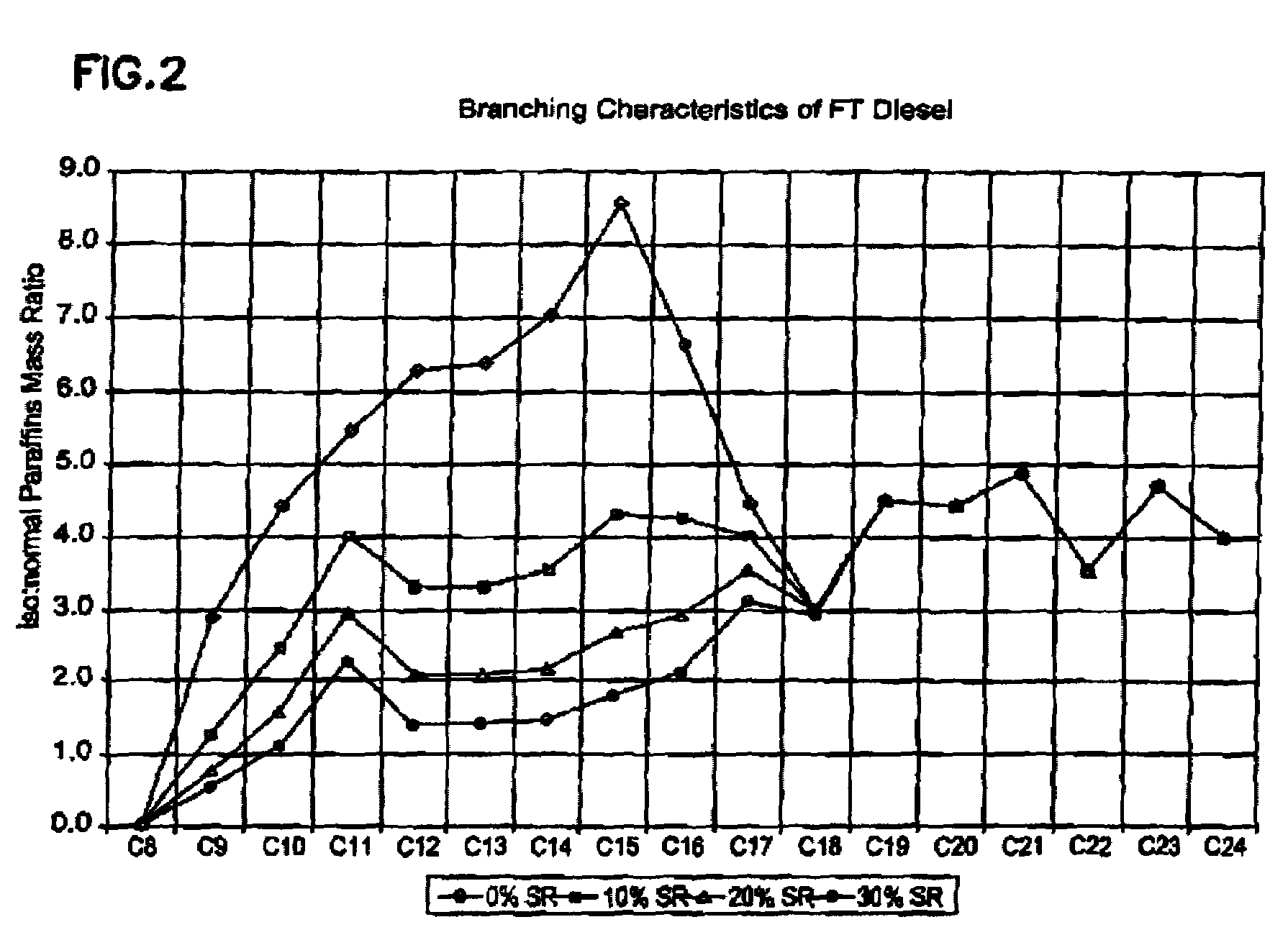

InactiveUS7294253B2Increase cetane numberImprove cold flowOrganic compounds purification/separation/stabilisationOrganic compound preparationAlkanePolymer science

This invention relates to process for producing middle distillates having good cold flow properties, such as the Cold Filter Plugging Point (CFPP) measured in accordance with the IP method 309, and a high Cetane number, as well as to a process for production of such distillates. More particularly, this invention relates to a process in which middle distillates are produced from a mainly paraffinic synthetic crude which is produced by the reaction of CO and H2, typically by the Fischer-Tropsch (FT) process. The middle distillates produced by the process of the invention are predominantly isoparaffinic, the isoparaffins being methyl, ethyl and / or propyl branched.

Owner:SASOL TECHNOLOGY (PTY) LTD

Process for producing middle distillates and middle distillates produced by that process

InactiveUS7217852B1Increase cetane numberImprove cold flowHydrocarbon by hydrogenationHydrocarbon distillationAlkaneCold filter plugging point

This invention relates to middle distillates having good cold flow properties, such as the Cold Filter Plugging Point (CFPP) measured in accordance with the IP method (309), and a high Cetane number, as well as to a process for production of such distillates. More particularly, this invention relates to middle distillates produced from a mainly paraffinic synthetic crude which is produced by the reaction of CO and H2, typically by the Fischer-Tropsch (FT) process. The middle distillates of the invention are predominantly isoparaffinic, the isoparaffins being methyl, ethyl and / or propyl branched. The invention also provides a diesel fuel composition including the middle distillates in accordance with the invention. A process for preparing the middle distillates is also included in the invention.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Process for Producing Hydrorefined Gas Oil, Hydrorefined Gas Oil, and Gas Oil Composition

InactiveUS20080308459A1Increase cetane numberSufficient efficiencyTreatment with hydrotreatment processesRefining by aromatic hydrocarbon hydrogenationDistillates petroleumMolecular sieve

A process of the present invention for producing a hydrotreated gas oil has a step for obtaining a product oil having a total aromatic content of 3% by volume or less by hydrogenating a hydrotreated oil including 95% by volume or more of fraction having a boiling point range of 150-380° C., a sulfur content of 2-15 ppm by mass, a total aromatic content of 10-25% by volume, and a naphthene of 20-60% by volume in the presence of a hydrogenation catalyst; and a step for obtaining, by hydrogenating the above-described product oil in the presence of a hydrogenation catalyst containing a crystalline molecular sieve component, a product oil satisfying the conditions that the content of petroleum fraction having a boiling point range of lower than 150° C. is 16% by volume or less, and the sum of the total aromatic content and the total naphthene content is 80% or less relative to the sum of these in the hydrotreated oil.

Owner:IKI HIDESHI +3

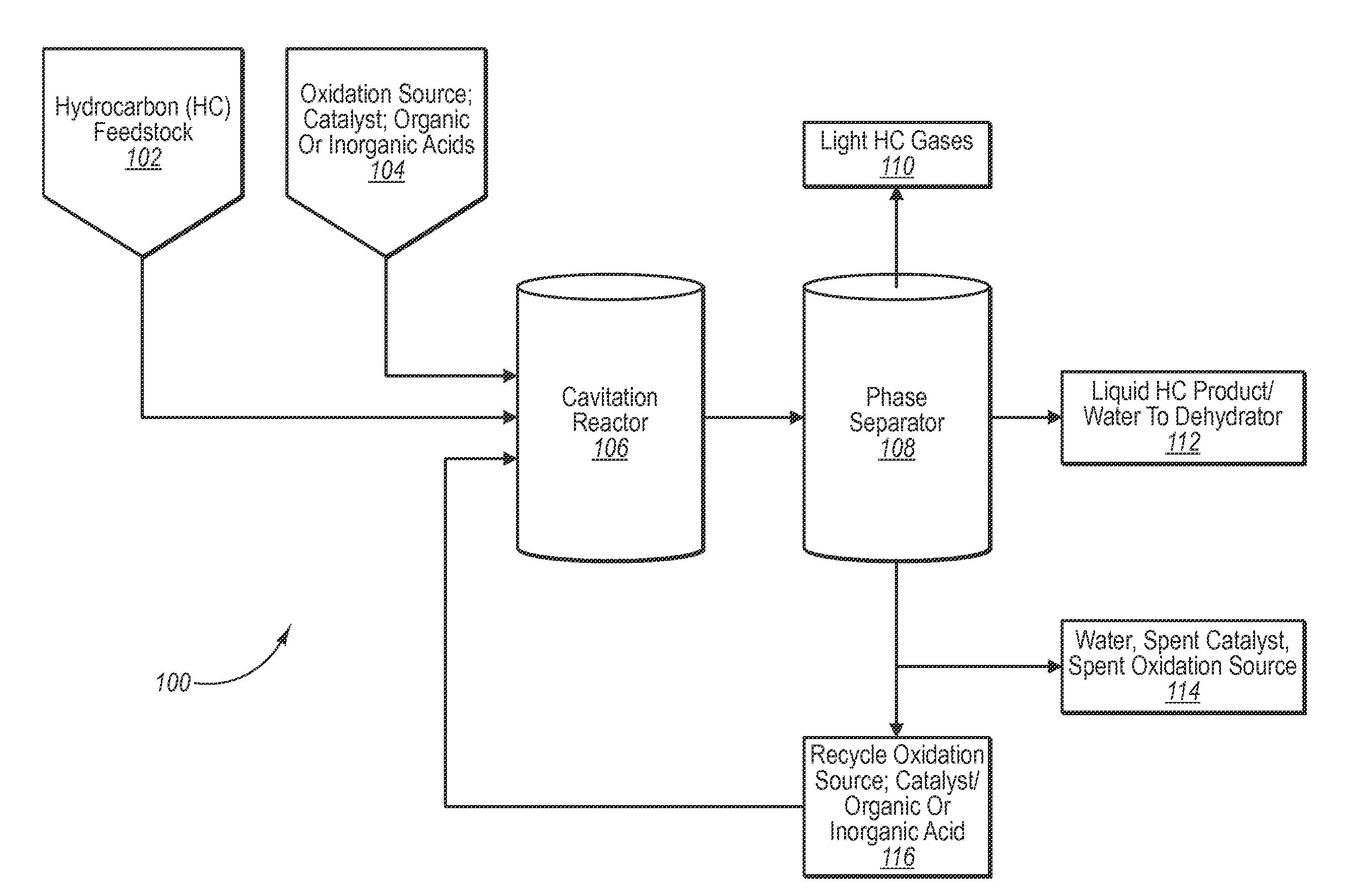

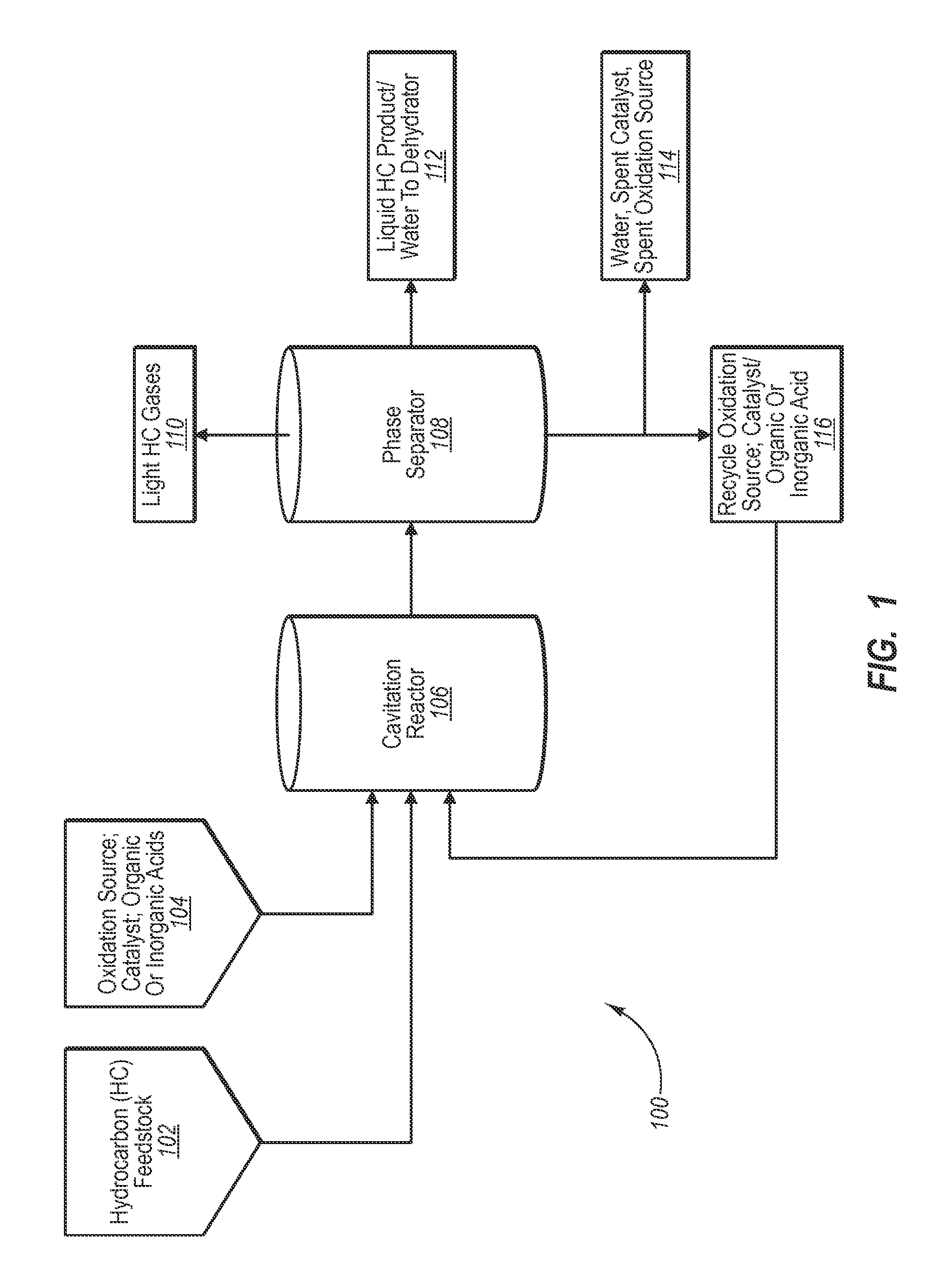

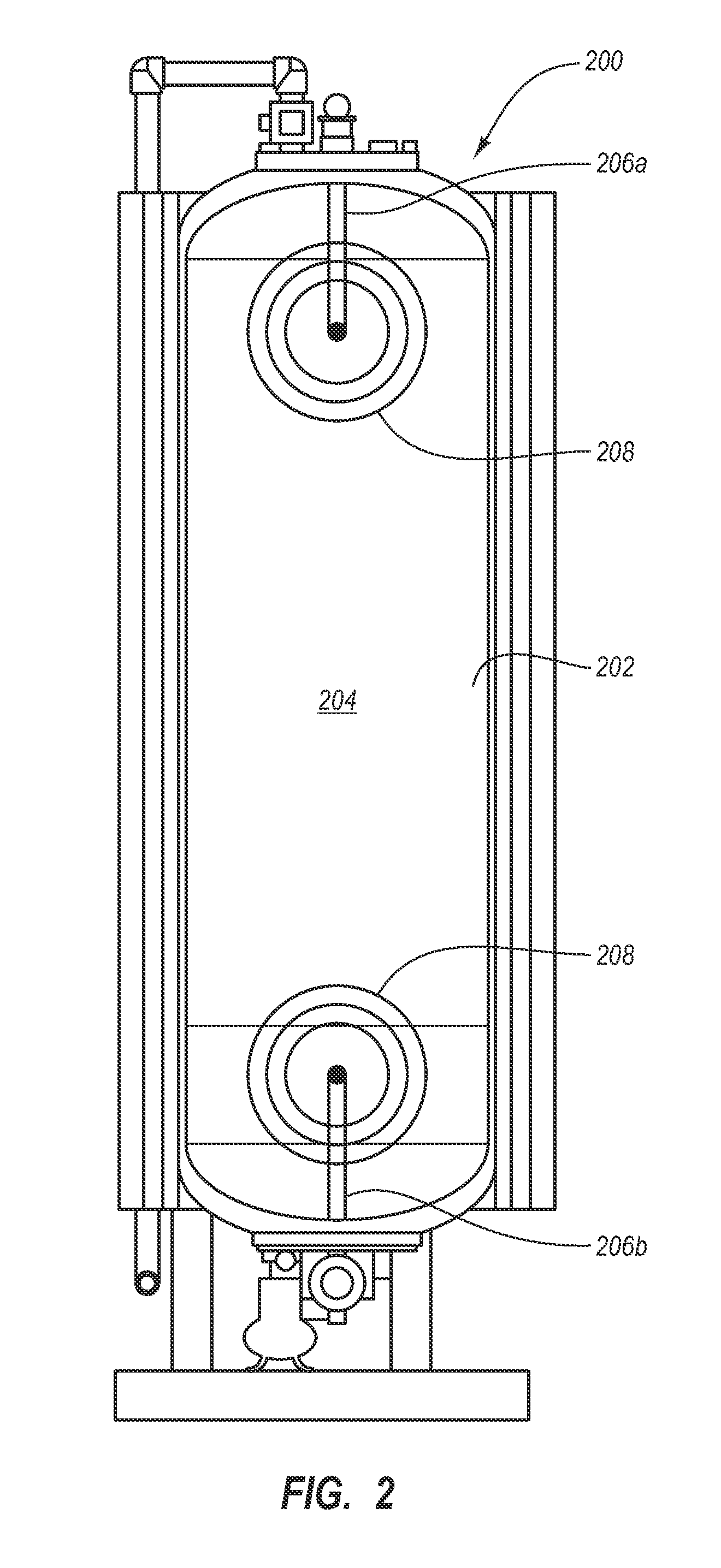

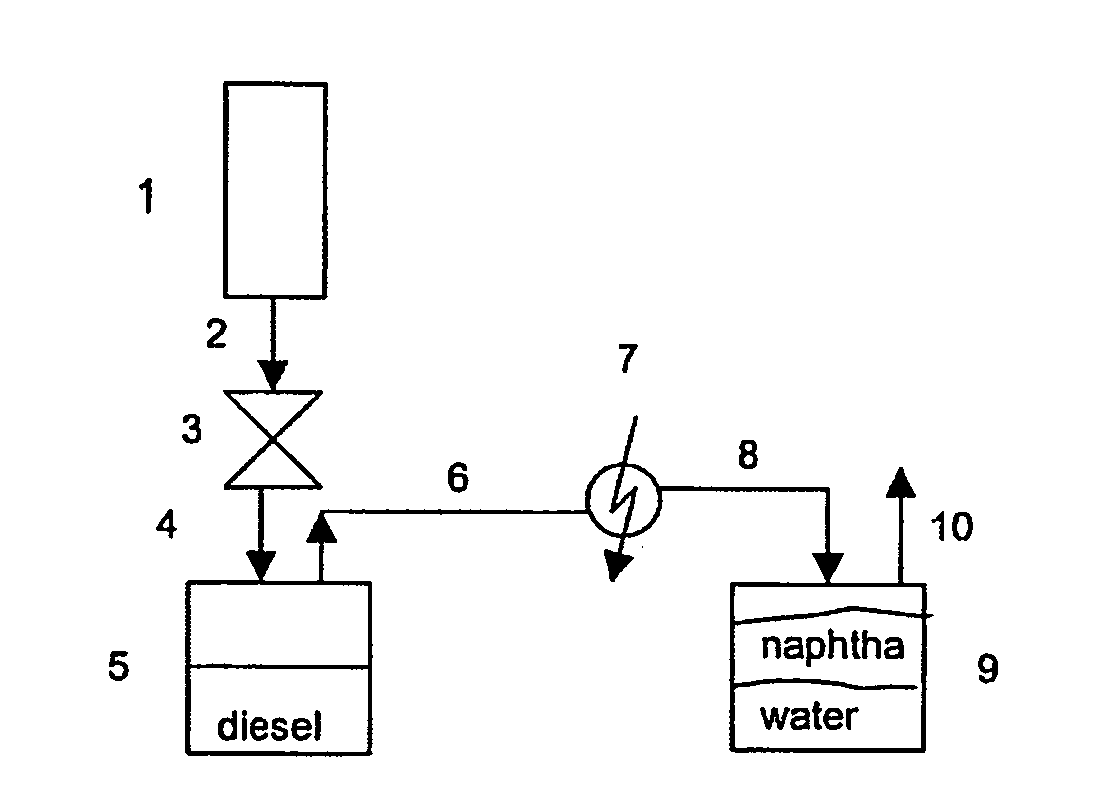

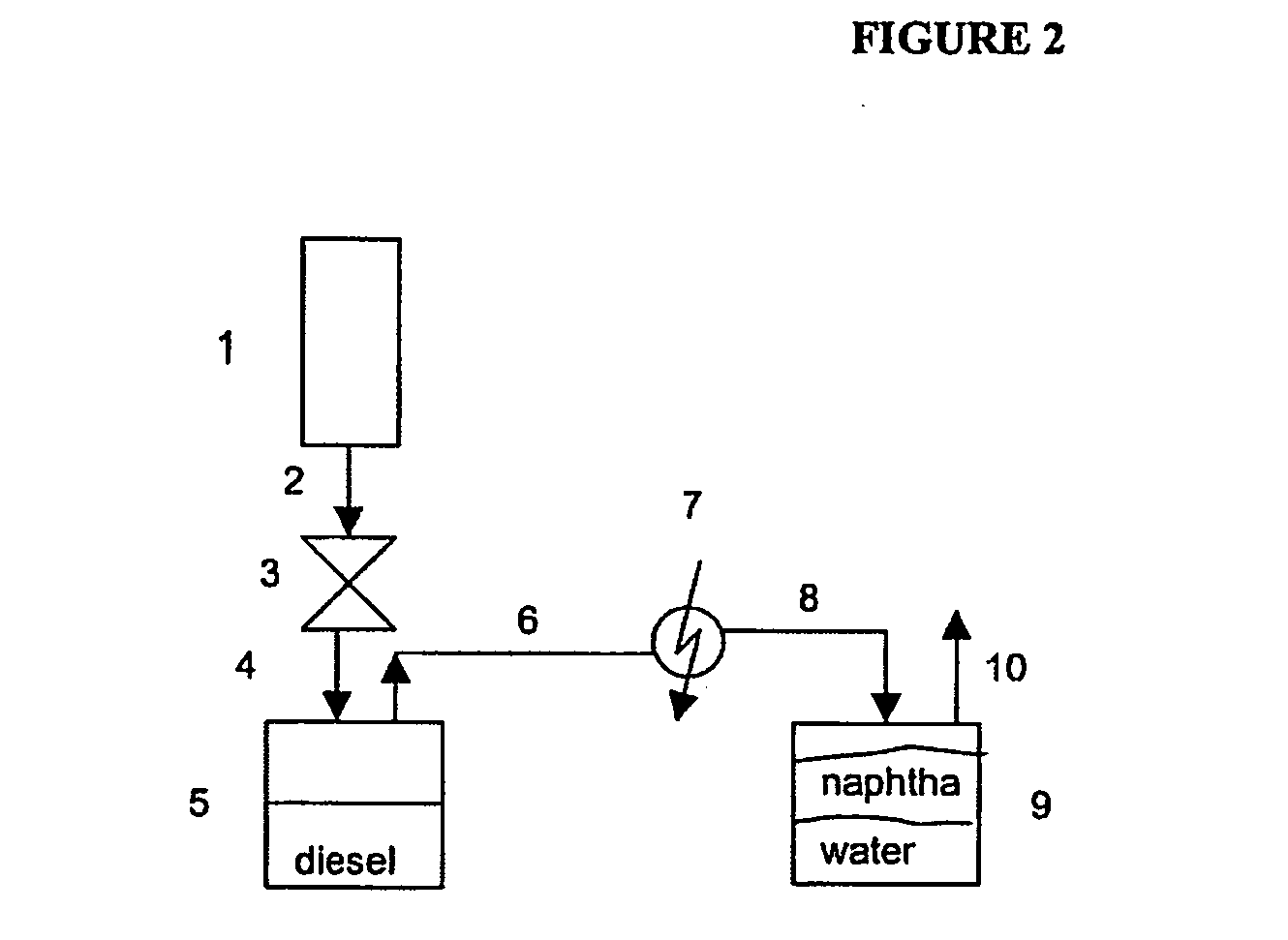

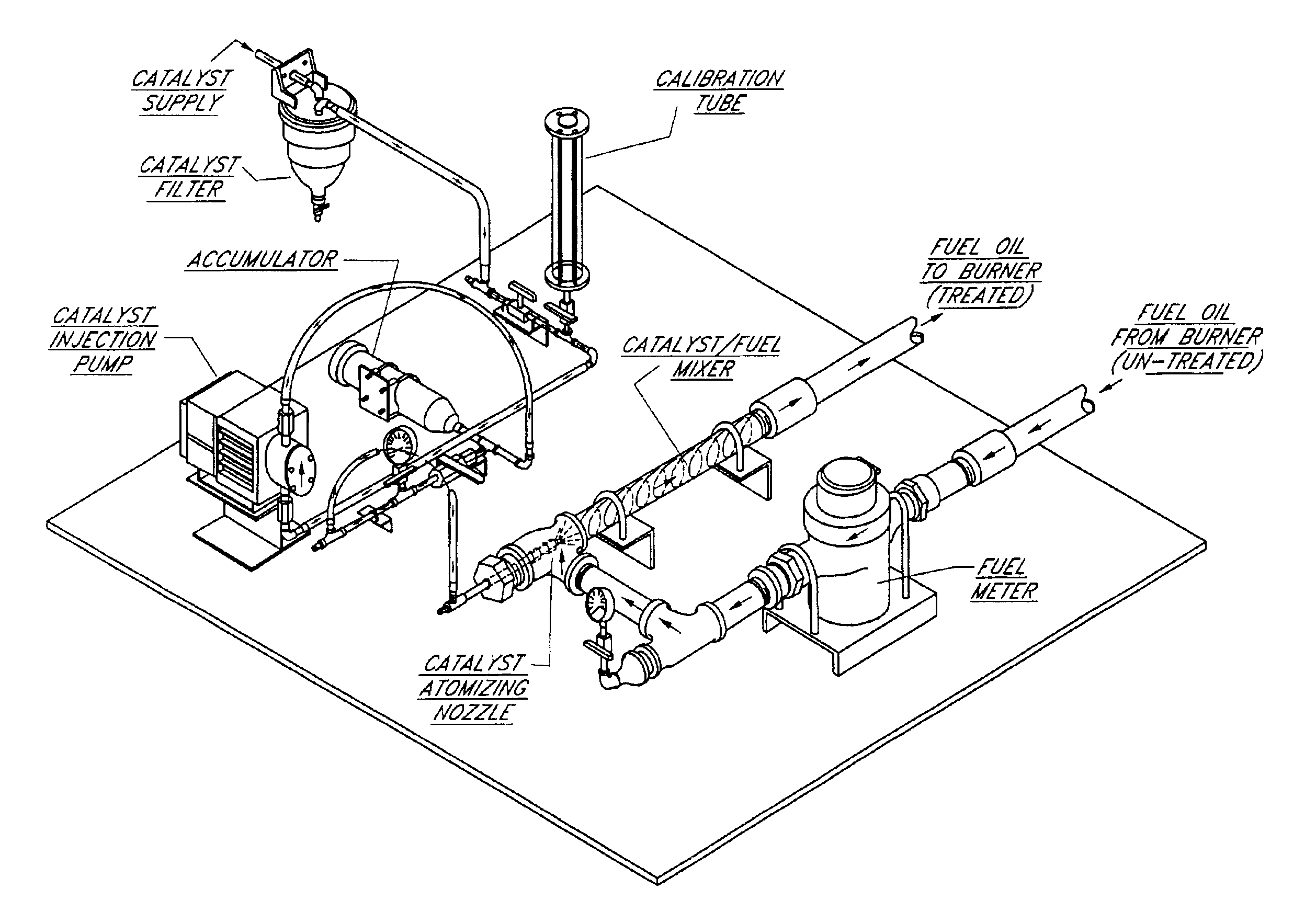

Method and system for oxidatively increasing cetane number of hydrocarbon fuel

InactiveUS20110065969A1Increase heightIntense release of energyRefining with halogen compoundsRefining with oxygen compoundsUltrasonic cavitationHigh energy

High energy (e.g., ultrasonic) mixing of a liquid hydrocarbon feedstock and reactants comprised of an oxidation source, catalyst and acid yields a diesel fuel product or additive having substantially increased cetane number. Ultrasonic mixing creates cavitation, which involves the formation and violent collapse of micron-sized bubbles, which greatly increases the reactivity of the reactants. This, in turn, substantially increases the cetane number compared to reactions carried out using conventional mixing processes, such as simple mechanical stirring. Alternatively, an aqueous mixture comprising water and acid can be pretreated with an oxidation source such as ozone and subjected to ultrasonic cavitation prior to reacting the pretreated mixture with a liquid hydrocarbon feedstock.

Owner:CETAMAX VENTURES

Simple low-pressure fischer-tropsch process

InactiveUS20080108716A1Improve efficiencyImprove cooling effectOrganic compound preparationOxygen compounds preparation by reductionRheniumWax

A process for combing carbon monoxide and hydrogen to form liquid fuels such as diesels, and / or waxes, in a single pass fixed bed reactor, at an operation pressure less than 200 psig. The reactor uses a catalyst with a metallic cobalt loading greater than 5% by weight and a rhenium loading of less than 2% by weight, on an alumina support.

Owner:WM GTL

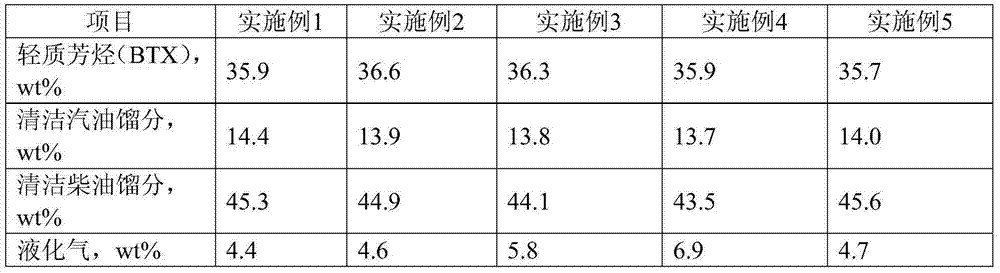

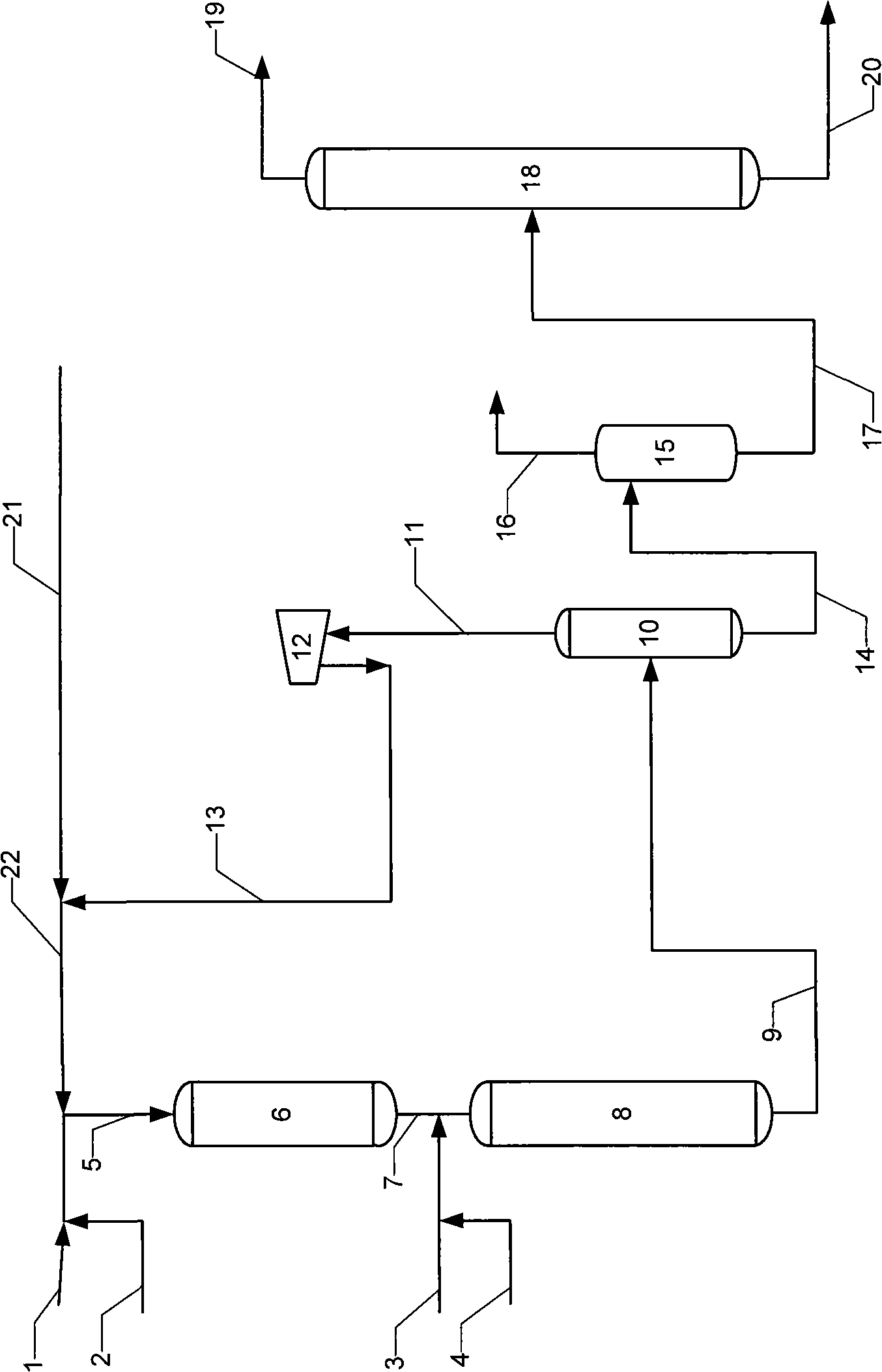

Method for mixed production of light-weight aromatic hydrocarbon by use of catalytic cracking diesel and C10<+> distillate oil

ActiveCN103897731AThe content of sulfur and nitrogen impurities is reducedAchieve enrichmentHydrocarbon by hydrogenationHydrocarbonsAlkaneGasoline

The invention relates to a method for mixed production of light-weight aromatic hydrocarbon by use of catalytic cracking diesel and C10<+> distillate oil. The method comprises the following steps: firstly mixing the catalytic cracking diesel and the C10<+> distillate oil with hydrogen, performing a hydrofining reaction to remove sulfur and nitrogen, saturate olefin and appropriately saturate aromatic hydrocarbon; then, extracting a hydrofining product by using an extraction solvent to obtain extract oil containing rich aromatic hydrocarbon and raffinate oil containing rich alkane; using the raffinate oil as a clean diesel oil concoction component, and performing rectification separation on the extract oil to obtain aromatic hydrocarbon extract oil; performing a hydrocracking reaction on the aromatic hydrocarbon extract oil, performing cutting separation on a hydrocracking product, using a distillate oil product greater than 195 DEG C as the clean diesel oil concoction component, feeding the distillate oil product smaller than 195 DEG C as an aromatic hydrocarbon raw material into an aromatic hydrocarbon treatment device to obtain a light-weight aromatic hydrocarbon product and a clean gasoline concoction component. By adopting the method provided by the invention, the yield of the light-weight aromatic hydrocarbon is increased, and meanwhile high-quality clean fuel oil is obtained and the high additional value utilization of the C10<+> distillate oil is achieved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

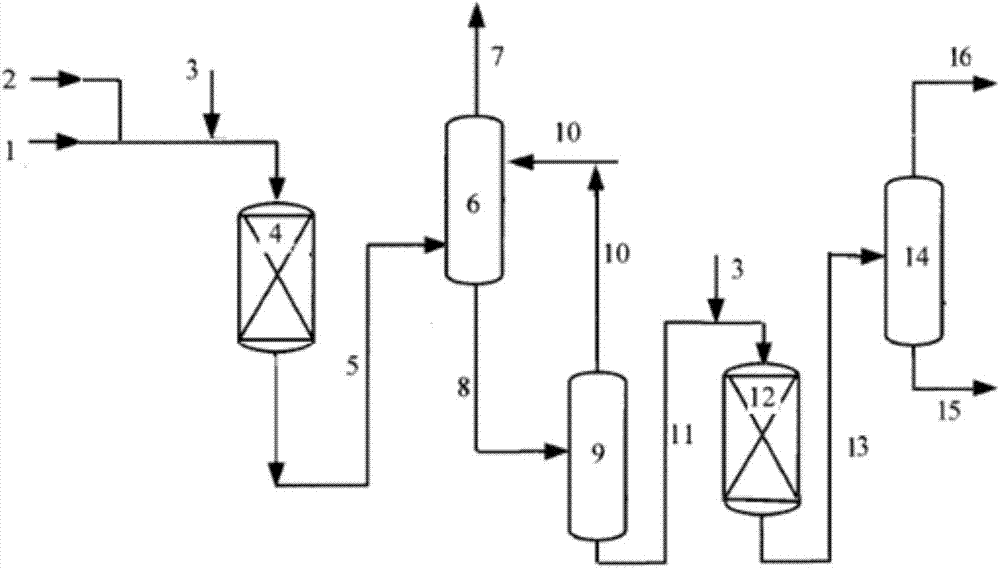

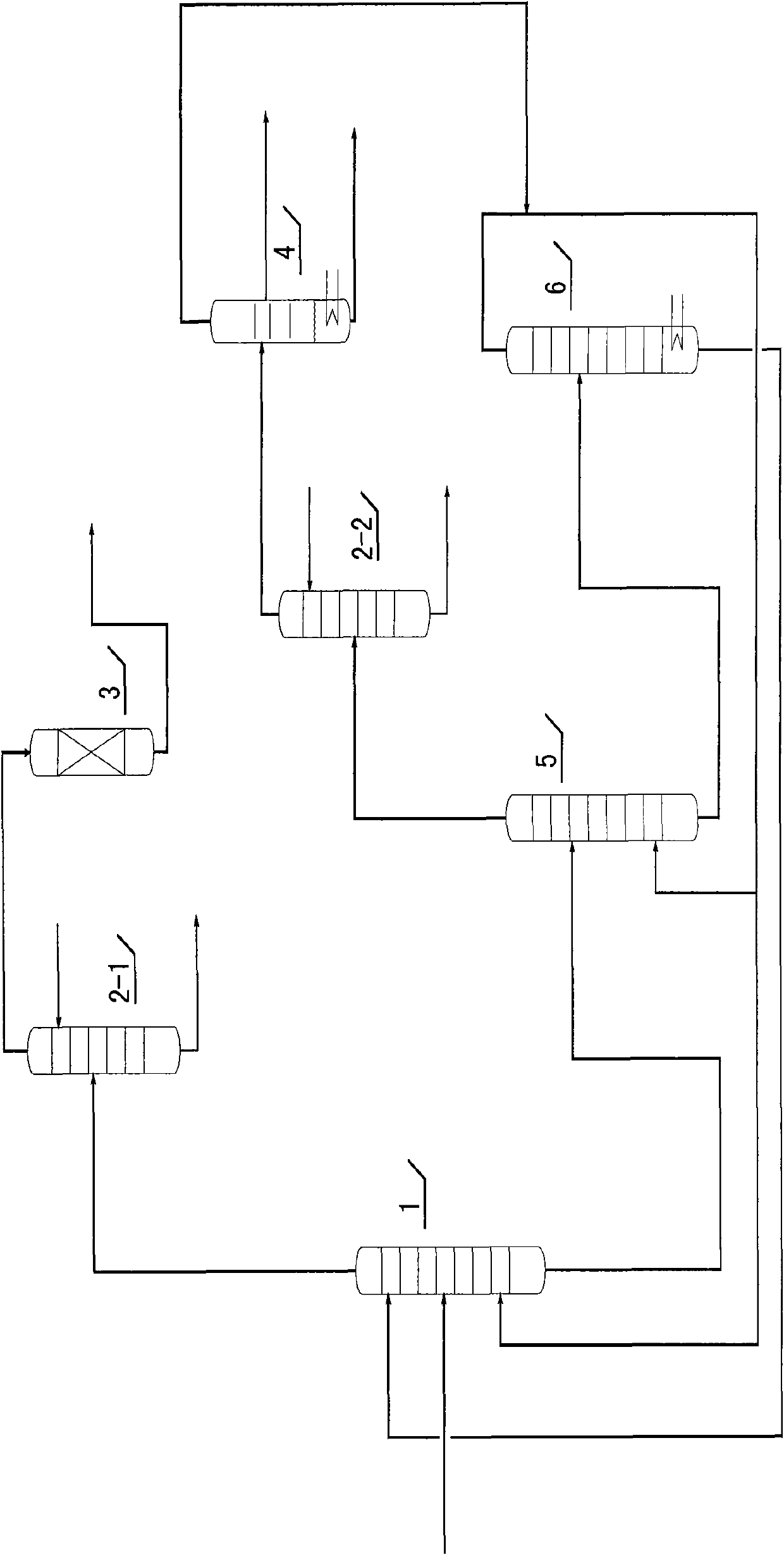

Process for producing ultralow sulfur diesel fuels

ActiveCN101311252AReduce sulfur contentReduce PAH contentTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonNaphtha

The invention relates to a production method for ultra-low sulfur diesel oil; wherein, after mixed with hydrogen, straight-run atmosphere 3rd side cut distillate and (or) diesel oil heavy distillate enter(s) a first hydrogenation reaction zone and reacts under the action of hydro-upgrading catalyst and hydrofining catalyst; after mixed with the reaction effluent of the first hydrogenation reaction zone, straight-run atmosphere 2nd side cut distillate and (or) diesel oil light distillate enter(s) a second hydrogenation reaction zone and reacts under the action of the hydrofining catalyst; the reaction effluent of the second hydrogenation reaction zone is cooled, separated and distilled to obtain naphtha fraction and diesel products. The method provided by the invention can treat the diesel distillate with high sulfur, high nitrogen and high final boiling point, and under mild operating conditions, obtain clear diesel products with low content of sulfur and polycyclic aromatic hydrocarbons as well as high cetane number; meanwhile, the product quality can reach the indexes of the IV European emission standard.

Owner:CHINA PETROLEUM & CHEM CORP +1

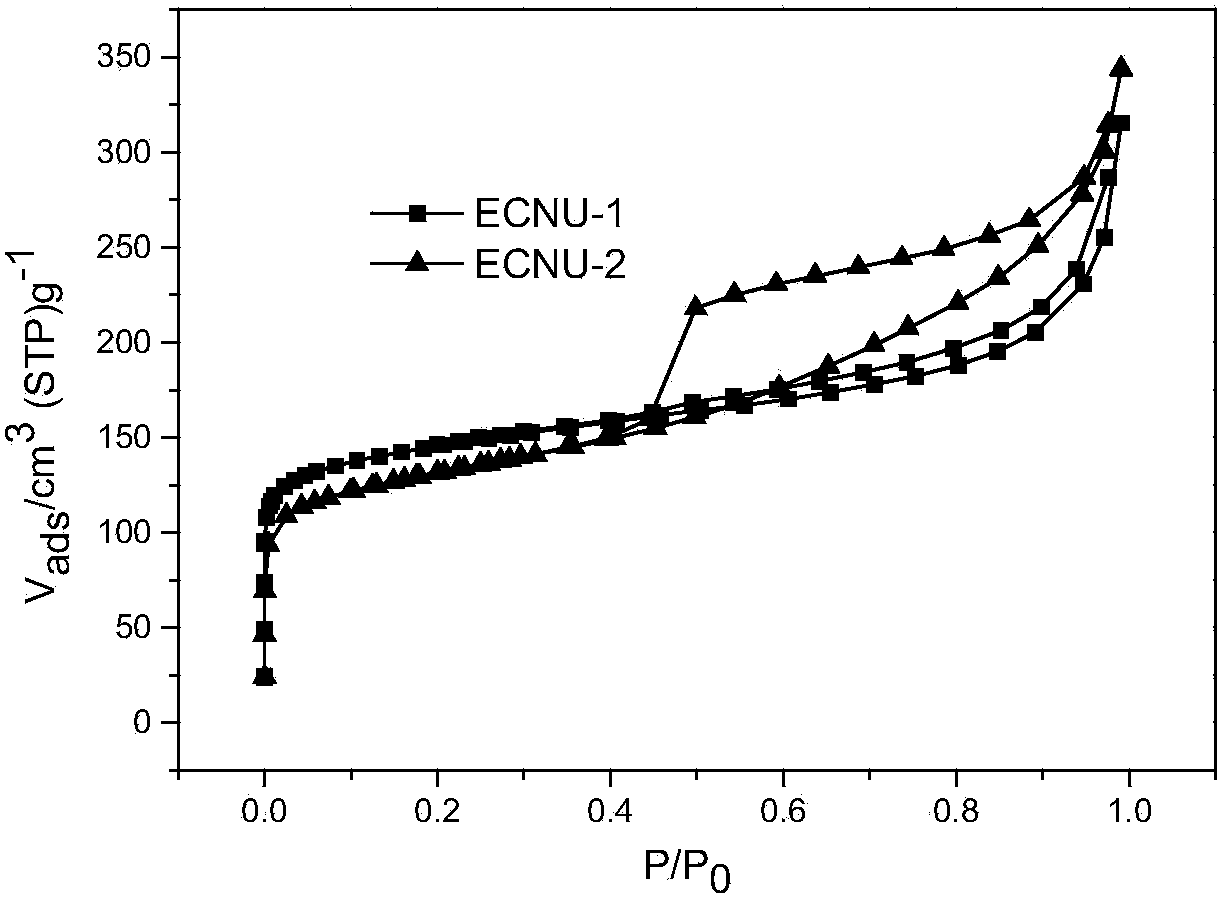

Preparation of hierarchically porous molecular sieve supported metal catalyst and application thereof in grease hydrodeoxygenation

InactiveCN104368381AIncrease the areaLarge hole volumeMolecular sieve catalystsLiquid hydrocarbon mixture productionMolecular sieveMetal catalyst

The invention discloses a hierarchically porous molecular sieve supported metal catalyst, a preparation method thereof and application thereof in grease hydrodeoxygenation. The catalyst comprises a hierarchically porous molecular sieve serving as a supporter and a metal supported by the hierarchically porous molecular sieve; the supporter is a micro-mesoporous composite molecular sieve; the supported metal is one or more of nano-scale transition metals Fe, Co and Ni; and the transition metal is loaded on the supporter in a manner of high supported quantity and high dispersion. The porous molecular sieve supported metal catalyst has the advantages of high activity, long service life, strong inactivation resistance, strong carbon deposition resistance and the like. The production process is simple, environmentally friendly and efficient, the catalyst has strong adaptability to grease raw materials, the quality of a diesel oil product is high, and the catalyst is low in preparation cost, is suitable for industrialized large-scale production and has a wide application prospect.

Owner:EAST CHINA NORMAL UNIV

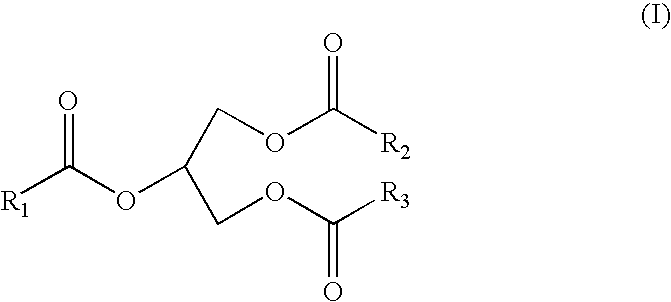

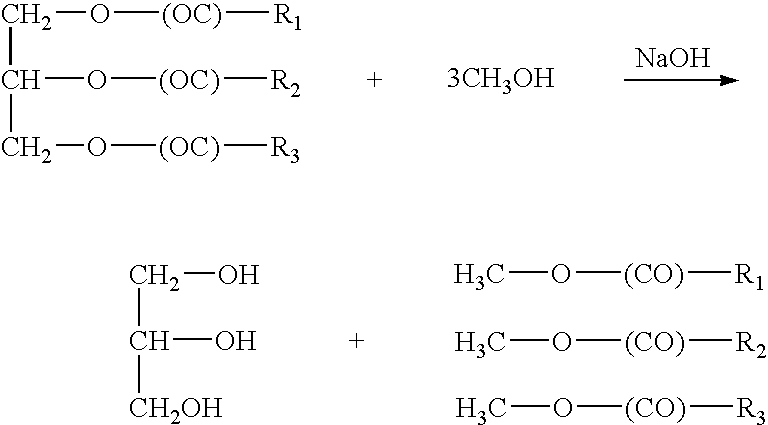

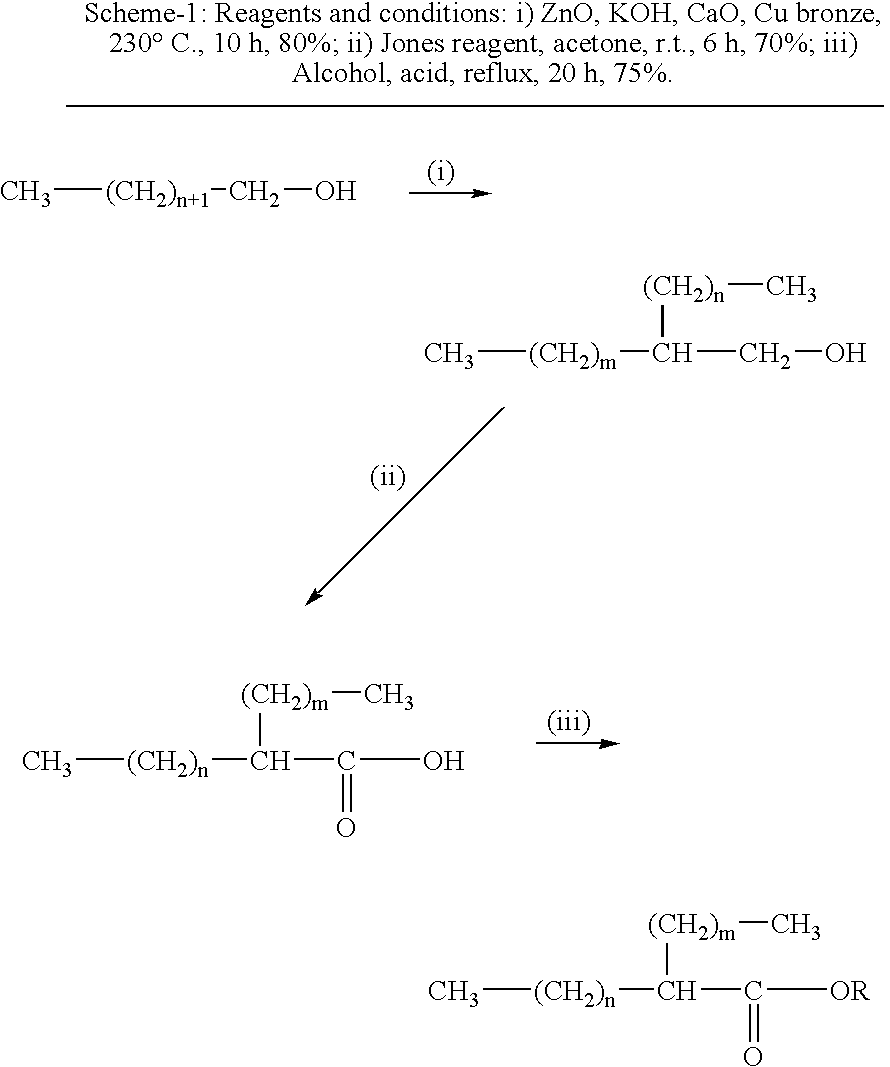

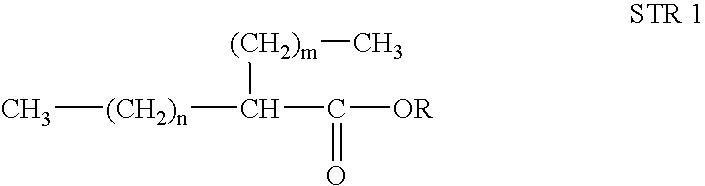

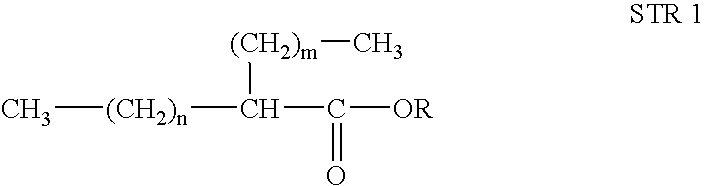

Novel synthetic fuel and method of preparation thereof

ActiveUS20090038211A1Improved diesel fuel propertyExcellent low temperature propertyOrganic compound preparationCarboxylic acid esters preparationOxidation stabilityEngineering

Disclosed is a novel synthetic fuel as alternative to diesel, wherein said synthetic fuel comprises branched esters and wherein the fuel having improved fuel properties such as zero aromatic, zero olefin, zero sulphur, low pour, high cetane diesel fuel with improved lubricity and oxidative stability. Further, the present invention provides a method of preparation of said esters.

Owner:INDIAN OIL CORPORATION

Method for preparing gasoline and diesel by oil washing hydrogenation

InactiveCN101486926ABig increaseLow impurity contentRefining to eliminate hetero atomsCoal tarNaphtha

The invention discloses a method using the washing oil produced by the coal tar to prepare gasoline and diesel with hydrogen, which is essentially characterized in that the washing oil produced during the coal carbonization process is mixed with the hydrogen to obtain the hydrogenation oil through a reactor filled with protective agent, demetalization activator, hydrogenation refined activator and / or hydrogenation modified activator; the hydrogenation oil enters into a high-pressure separator; and the hydrogen obtained at the upper part is recycled to use, and the materials at the lower part are stripped or fractionated to obtain gasoline (naphtha) and diesel. The method can effectively produce high-quality and clean diesel products with washing oil.

Owner:胜帮科技股份有限公司

Diesel fuel for use in diesel engine-powered vehicles

InactiveUS20010001803A1Easy to operateLow levelSolid fuelsLiquid carbonaceous fuelsTruckDiesel engine

Owner:BLOOM LEONARD

Hydrocracking method for catalytic cracking diesel

ActiveCN103773487ASimple compositionHigh yieldTreatment with hydrotreatment processesHydrogenNaphtha

The invention provides a hydrocracking method for catalytic cracking diesel. According to the method, a mixture of the diesel material and hydrogen is in contact reaction with a hydrorefining catalyst in a hydrorefining reactor, liquid efflux from the hydrorefining reactor is not separated and then enters a hydrocracking reactor to be in contact and react with a hydrocracking catalyst, the reaction efflux from the hydrocracking reactor is subjected to separation and fractional distillation to obtain hydrogen-rich gas, then light naphtha fraction, gasoline fraction, recycle fraction and diesel fraction are performed, in the distillation range of the recycle fraction, the temperature is 190 DEG C to 300 DEG C, and the recycle fraction returns to an inlet of the hydrocracking reactor. The method provided by the invention improves the composition of feed hydrocarbon of the hydrocracking reaction region, and the yield and the octane value of the gasoline fraction are effectively increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

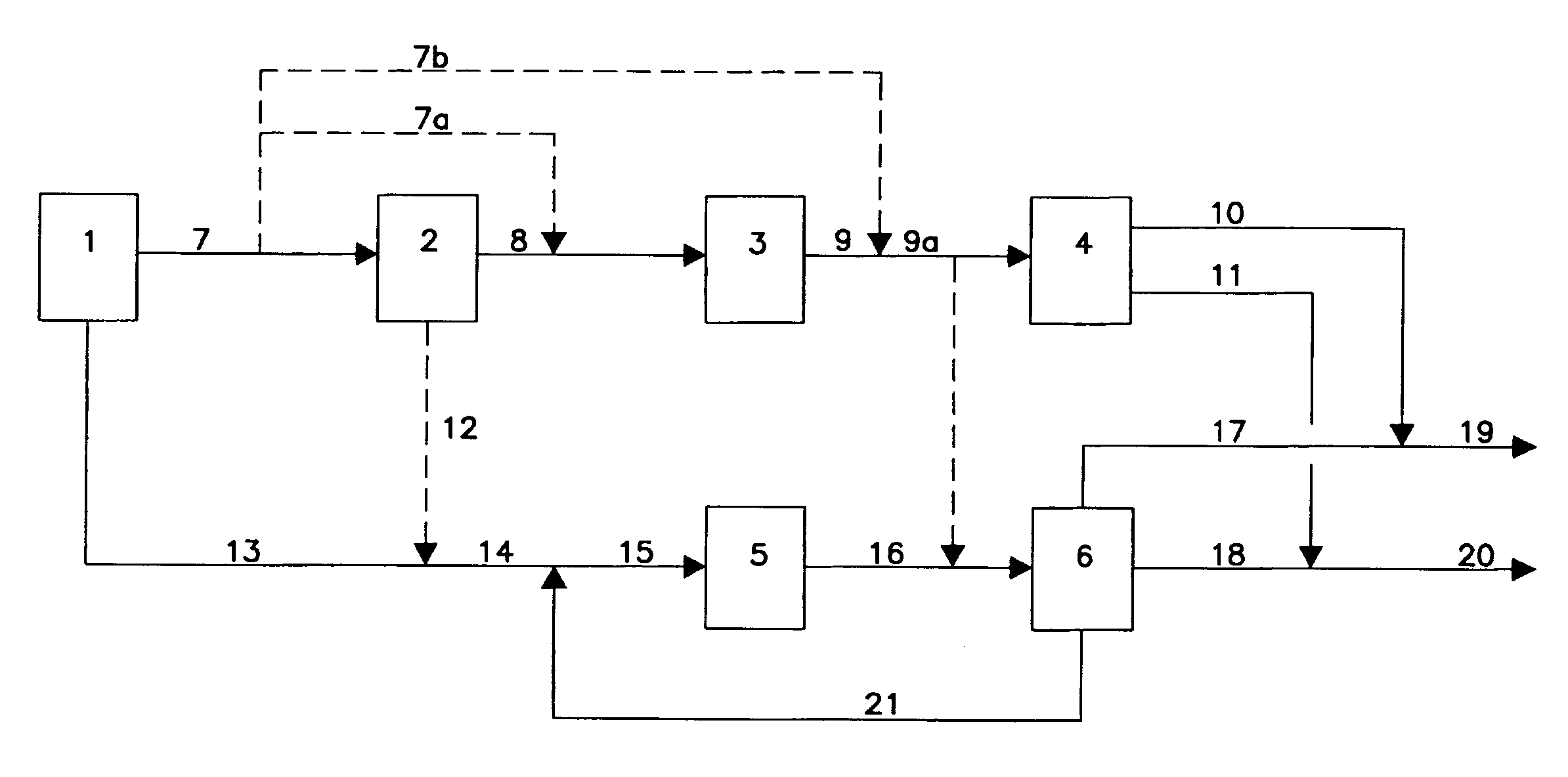

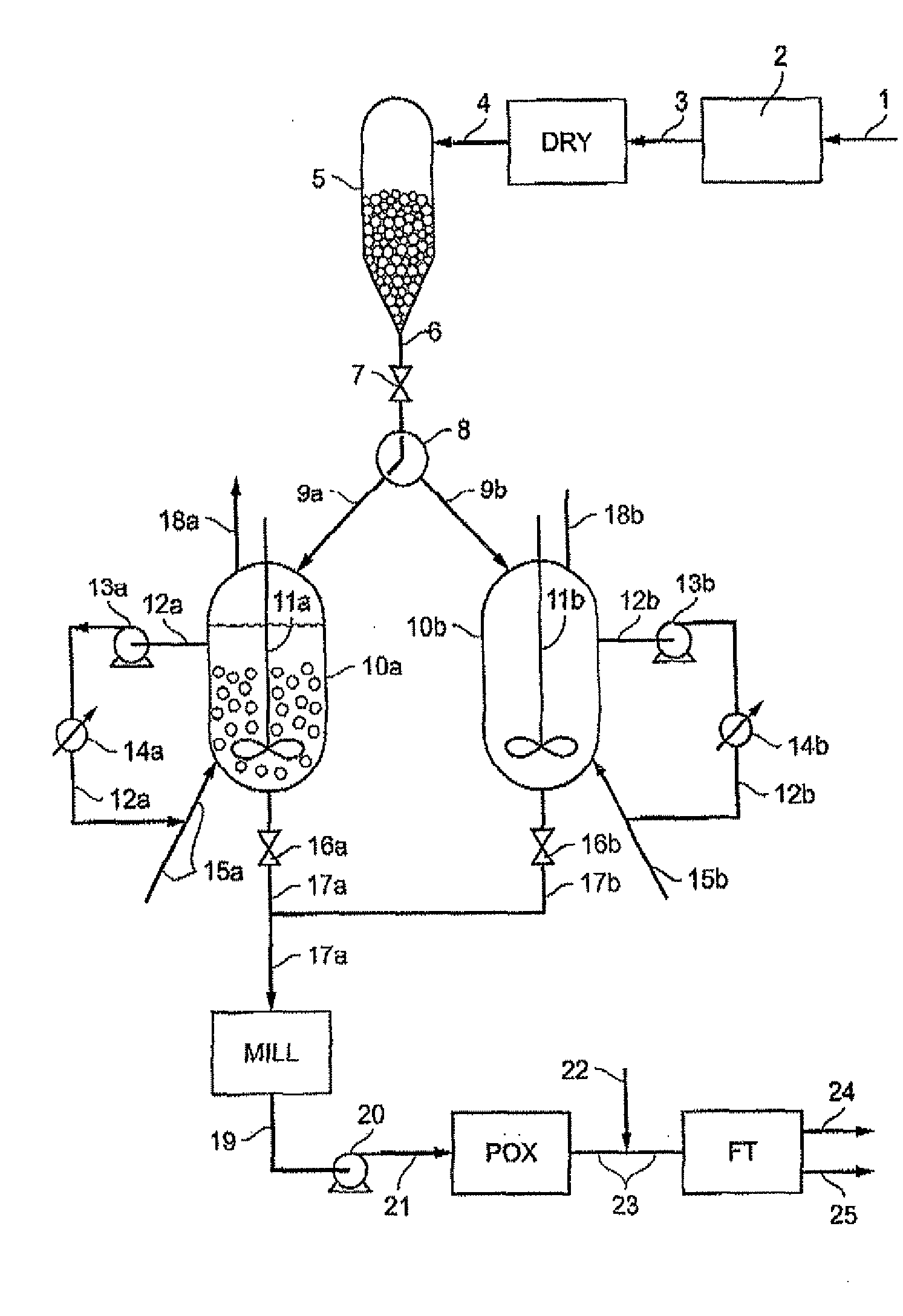

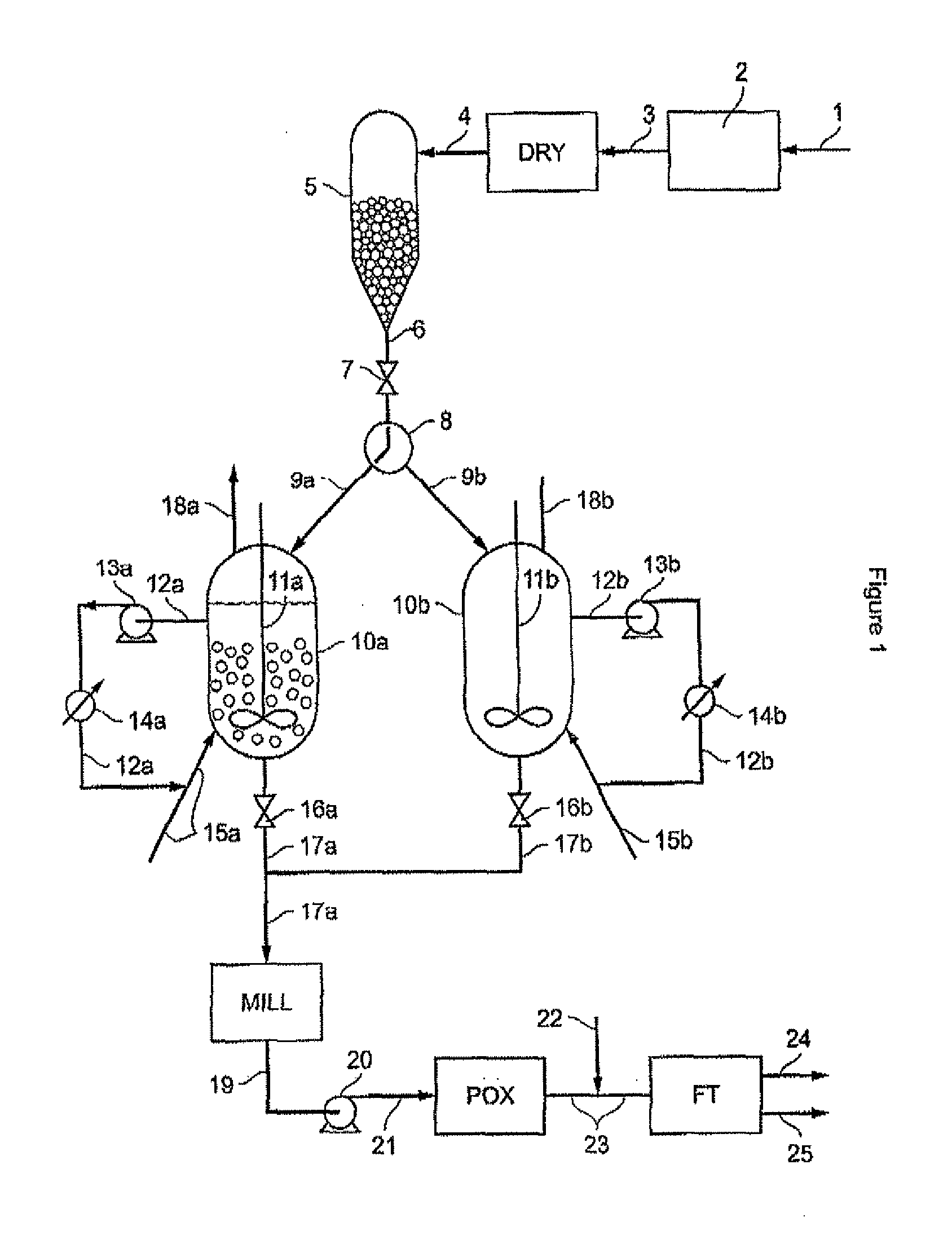

Process for converting biomass to produce synthesis gas

The process of the invention concerns a series of steps for preparing a solid lignocellulosic biomass type feed to supply a unit for gasification of that feed.The process employs at least one step for maturing the feed in the presence of a liquid hydrocarbon phase at a temperature in the range 250° C. to 320° C. for a residence time of at least 10 minutes, and milling the solid fragments which have thus been heat-treated in the presence of liquid hydrocarbon to obtain a suspension of solid in the divided form with a characteristic dimension of less than 150 micrometres.The invention also concerns a device for carrying out the process.

Owner:INST FR DU PETROLE

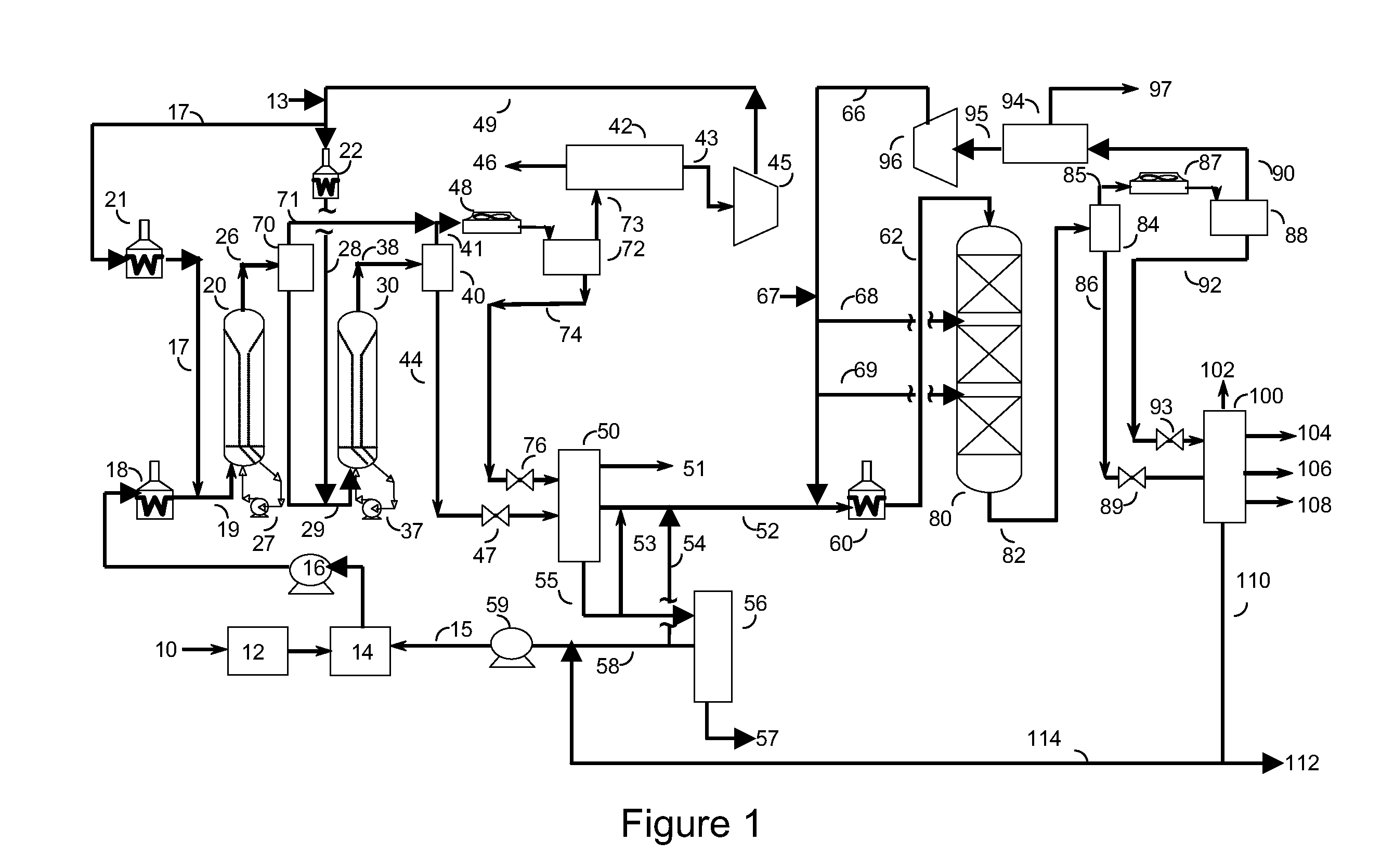

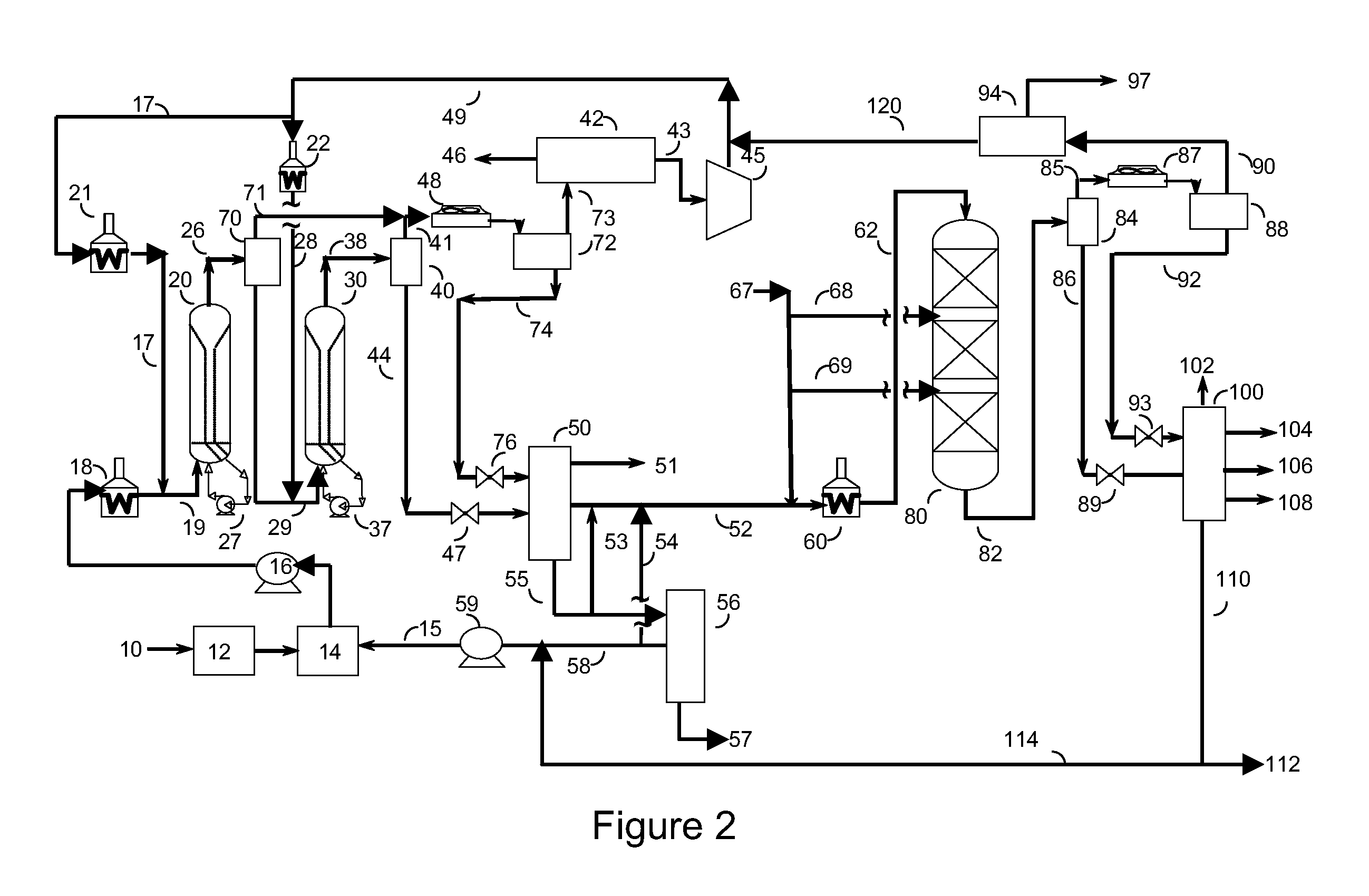

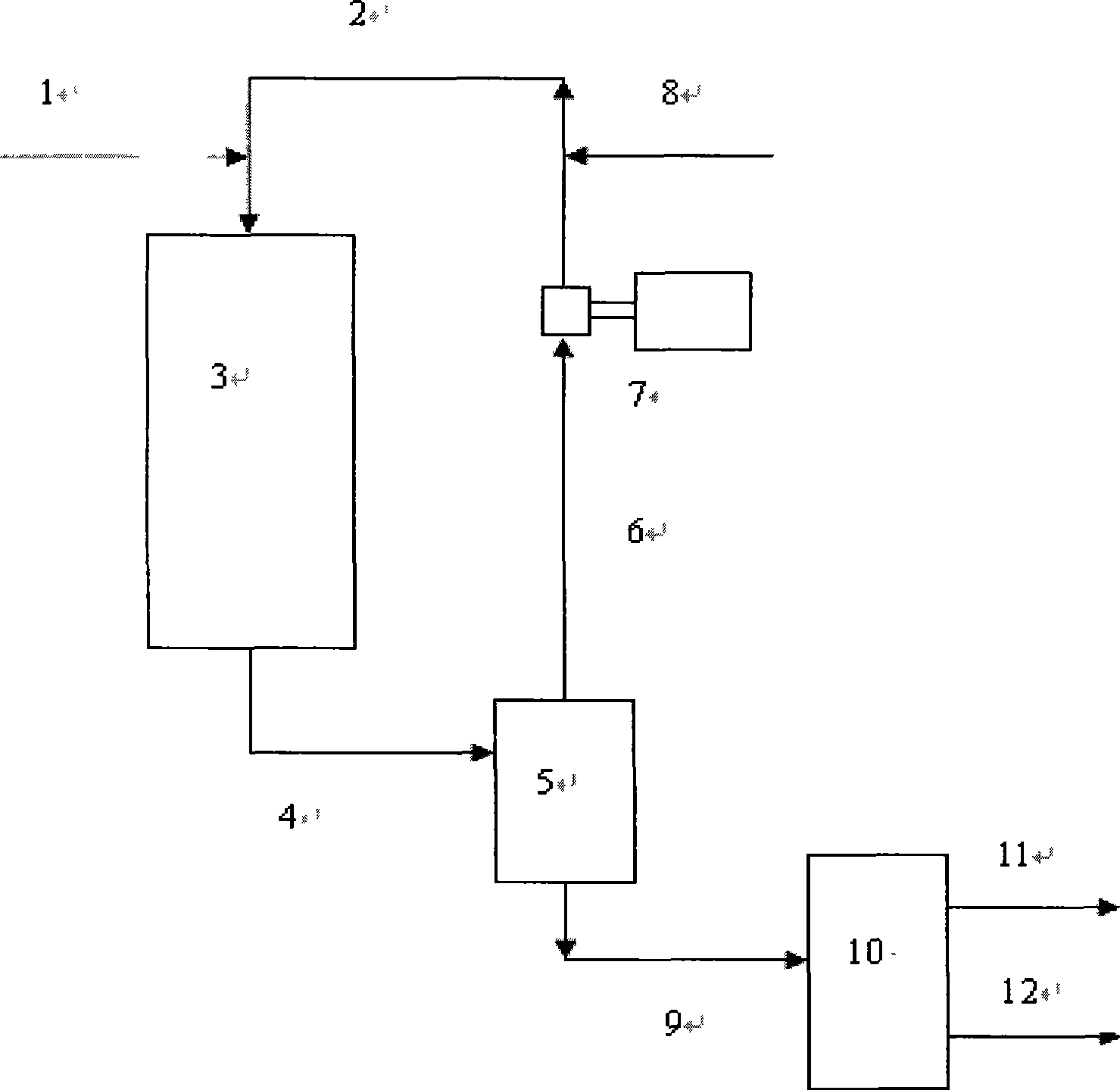

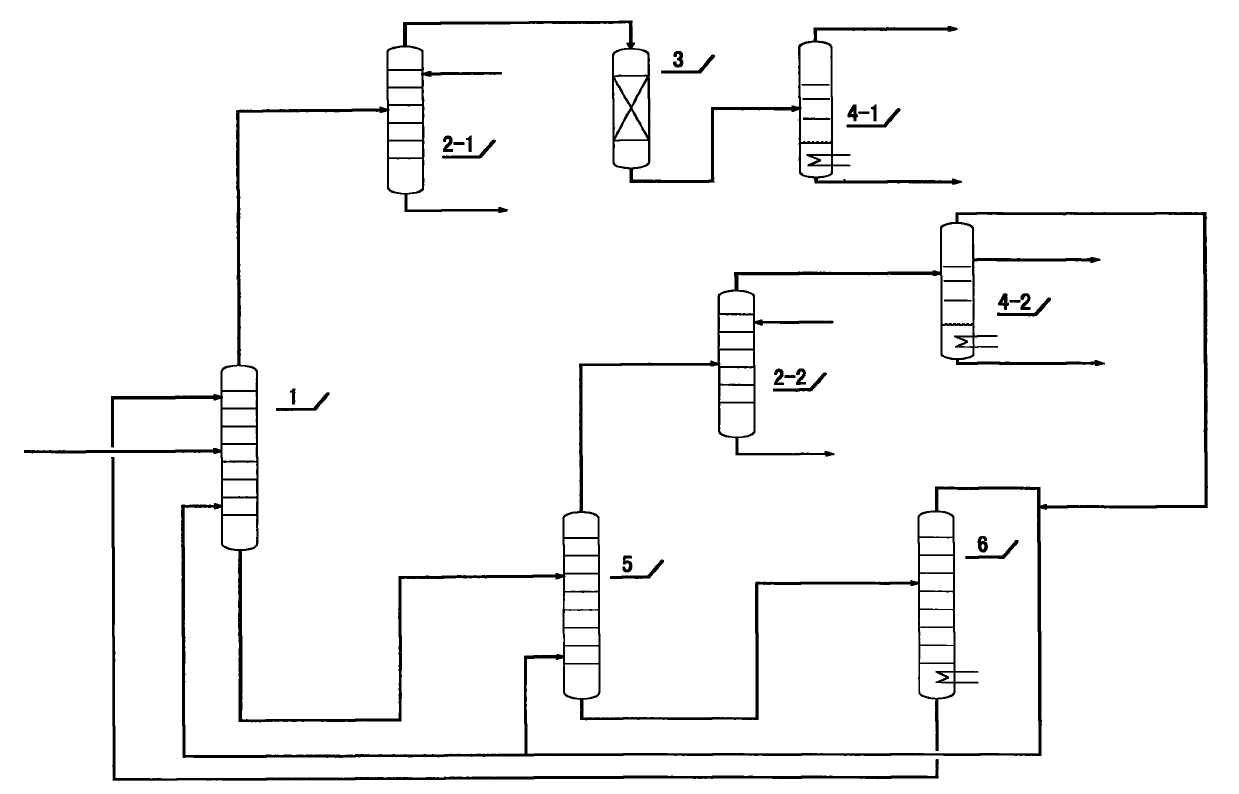

System for producing diesel of high quality and method thereof

ActiveCN102021024AIncrease cetane numberLowering the freezing pointTreatment with hydrotreatment processesHydrogenation reactionPulp and paper industry

The present invention relates to a system for producing diesel of high quality and method thereof. The system comprises an extraction unit. The system is characterized in that the top of the extraction unit is connected with a raffinate-oil washing tower via pipes, the top of the raffinate-oil washing tower is connected with a hydrogenation reaction system via pipes, products are extracted from the bottom of the hydrogenation reaction system via pipes, the bottom of the extraction unit is connected with a return washing tower via pipes, the top of the return washing tower is connected with an extract-oil washing tower via pipes, the bottom of the return washing tower is connected with a recovery tower, the top of the extract-oil washing tower is connected with a extract-oil cutting tower via pipes, the top of the extract-oil cutting tower is connected respectively with the bottom of the extraction unit and connected with the bottom of the return tower via pipes, light aromatic hydrocarbon products are directly extracted out from the side lines of the extract-oil cutting tower via pipes, heavy aromatic hydrocarbon products are directly extracted out from the bottom of the extract-oil cutting tower via pipes, the top of the recovery tower is connected respectively with the bottom of the extraction unit and the bottom of the return tower, and the bottom of the recovery tower is connected with the top of the extraction unit via pipes. The hydrogenation unit is only applied to raffinate oil and extract oil with special requirements, so that the scale is small and the cost is low. Moreover, the diversification of raw materials processed by the system is obvious. Not only can straight-run diesel oil can be processed, but also the catalyzed diesel oil and the coking diesel oil can be processed. In addition, the invention separates aromatic hydrocarbon from diesel oil, therefore the cetane number of the diesel oil is improved greatly.

Owner:BEIJING GRAND GOLDEN BRIGHT ENG & TECH

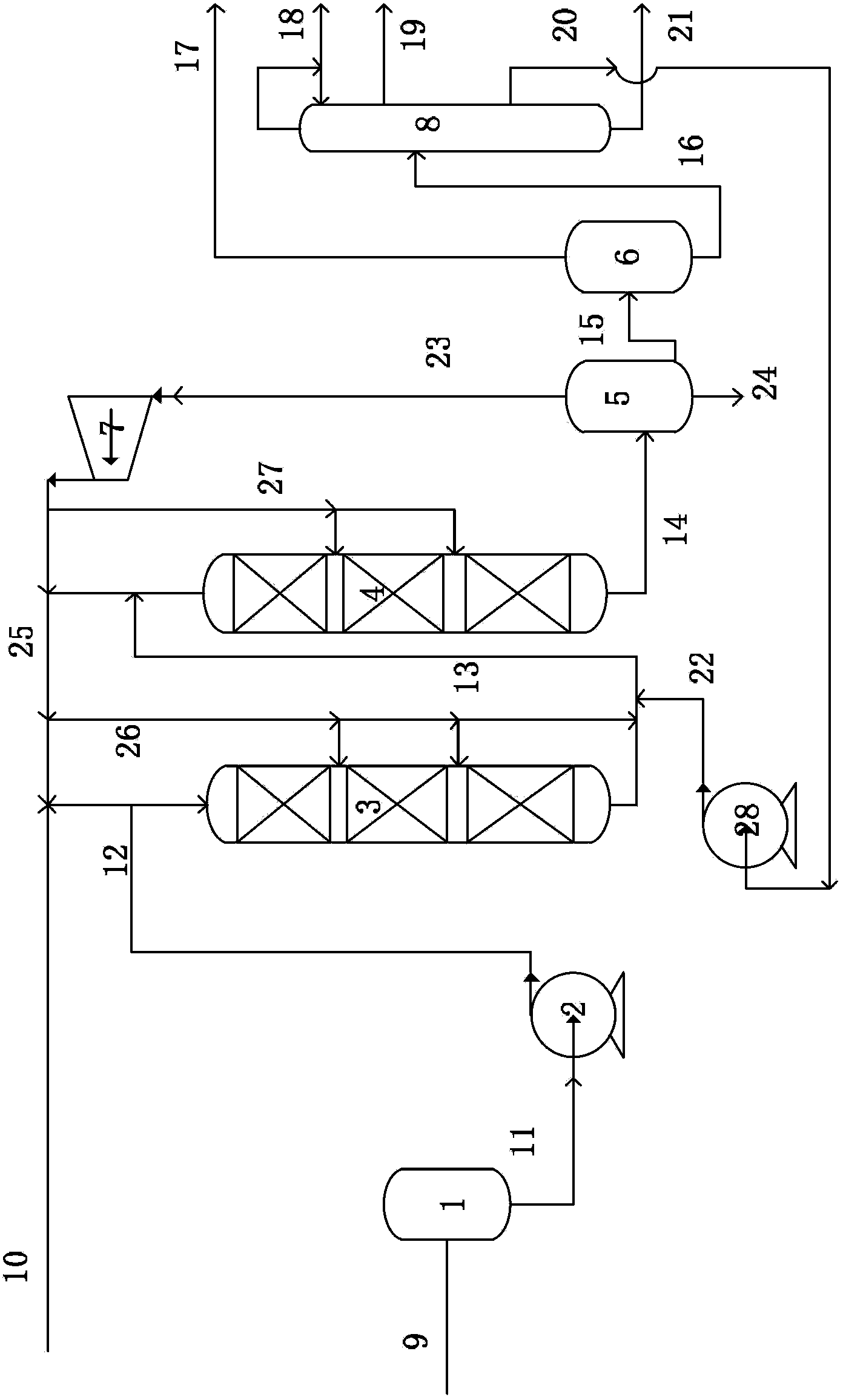

Hydrogenation for producing high-bioctyl-value and low-freezing-point diesel oil

ActiveCN1896187AIncrease cetane numberLowering the freezing pointRefining to eliminate hetero atomsLiquid productHydrogen

Hydrogenation of low-set point and high-cetyl value diesel oil is carried out by contacting raw material oil with hydrogen and hydrogenation refined catalyst in the first reactive area, entering reactant into the second reactive area to contact with hydrogenation modified catalyst, cooling, separating, returning the hydrogen-enriched gas separated into reactor to reuse, and entering the liquid product into fractional system. It has higher recovery rate, more cetyl of diesel oil and lower set point.

Owner:CHINA PETROLEUM & CHEM CORP

Organic cetane improver

InactiveUS7029506B2Reduce pollutant emissionsAvoid equipmentLiquid carbonaceous fuelsFuel additivesChemistryCetane Improver

The present invention relates generally to a composition and method for increasing the amount of cetane in fuel. More specifically, it was discovered that the amount of cetane in fuel can be increased by mixing a fuel additive comprising β-carotene that was prepared in an inert atmosphere.

Owner:AQ

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com