Patents

Literature

71results about How to "Low sulfur and nitrogen content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

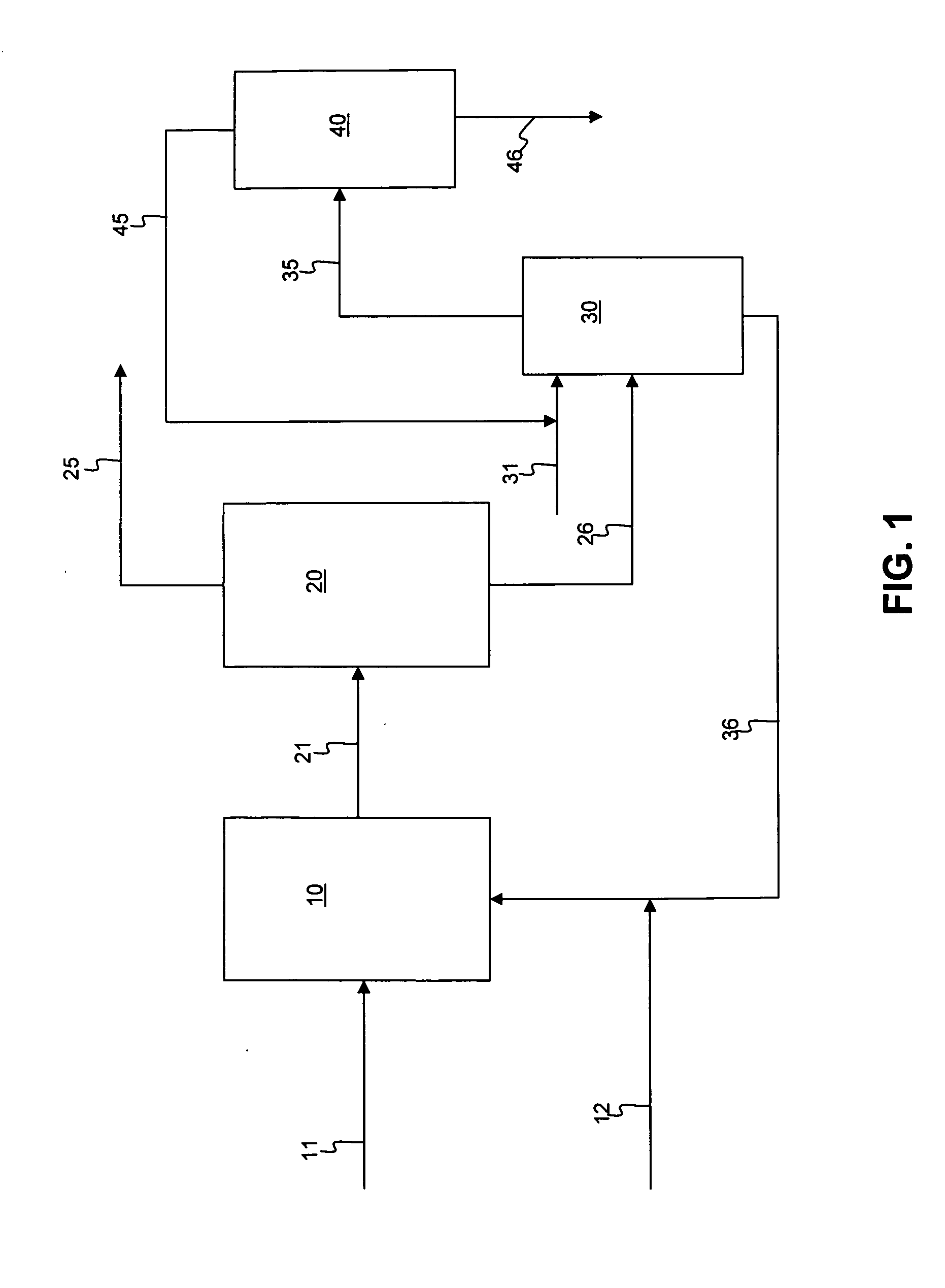

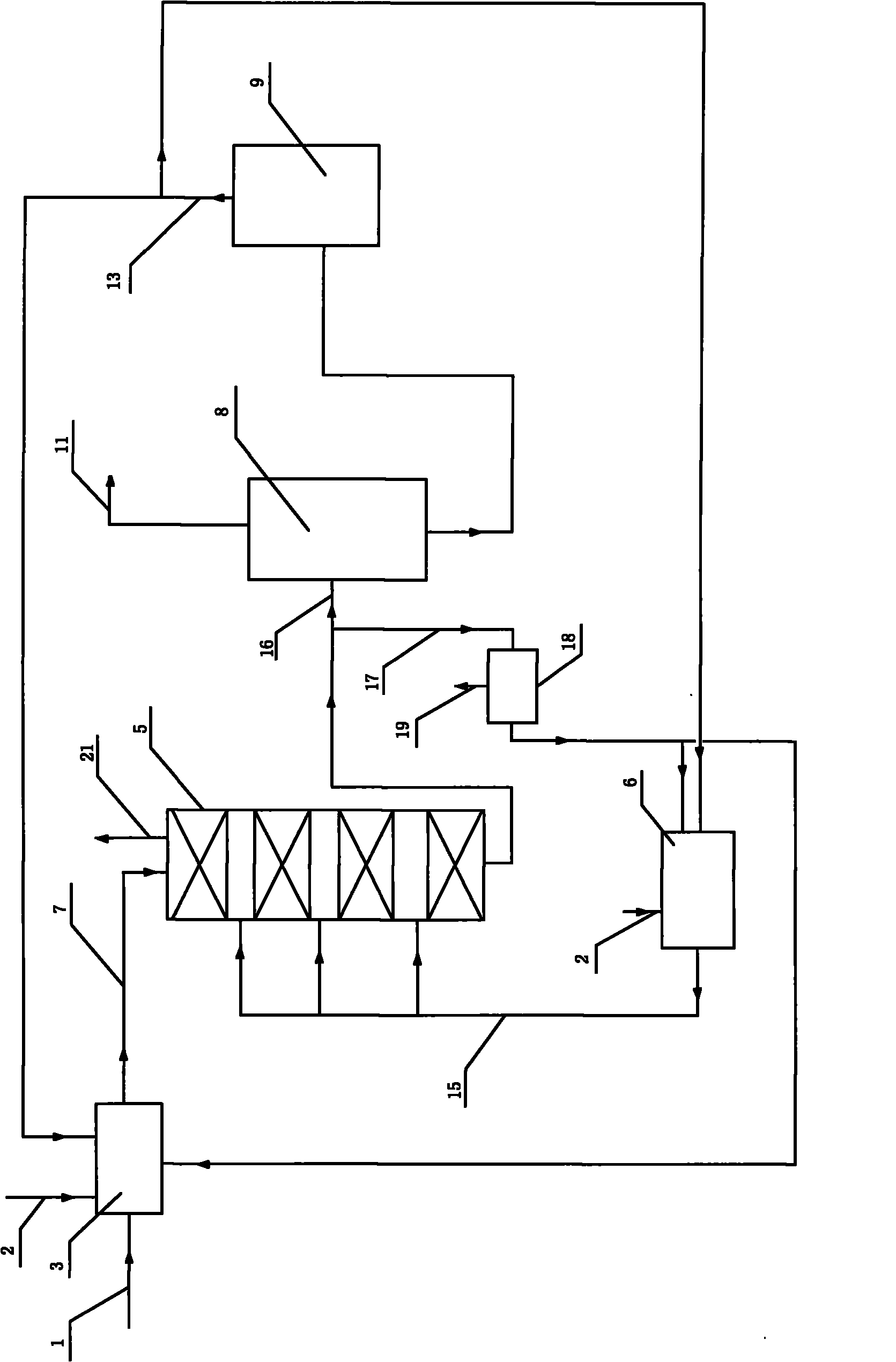

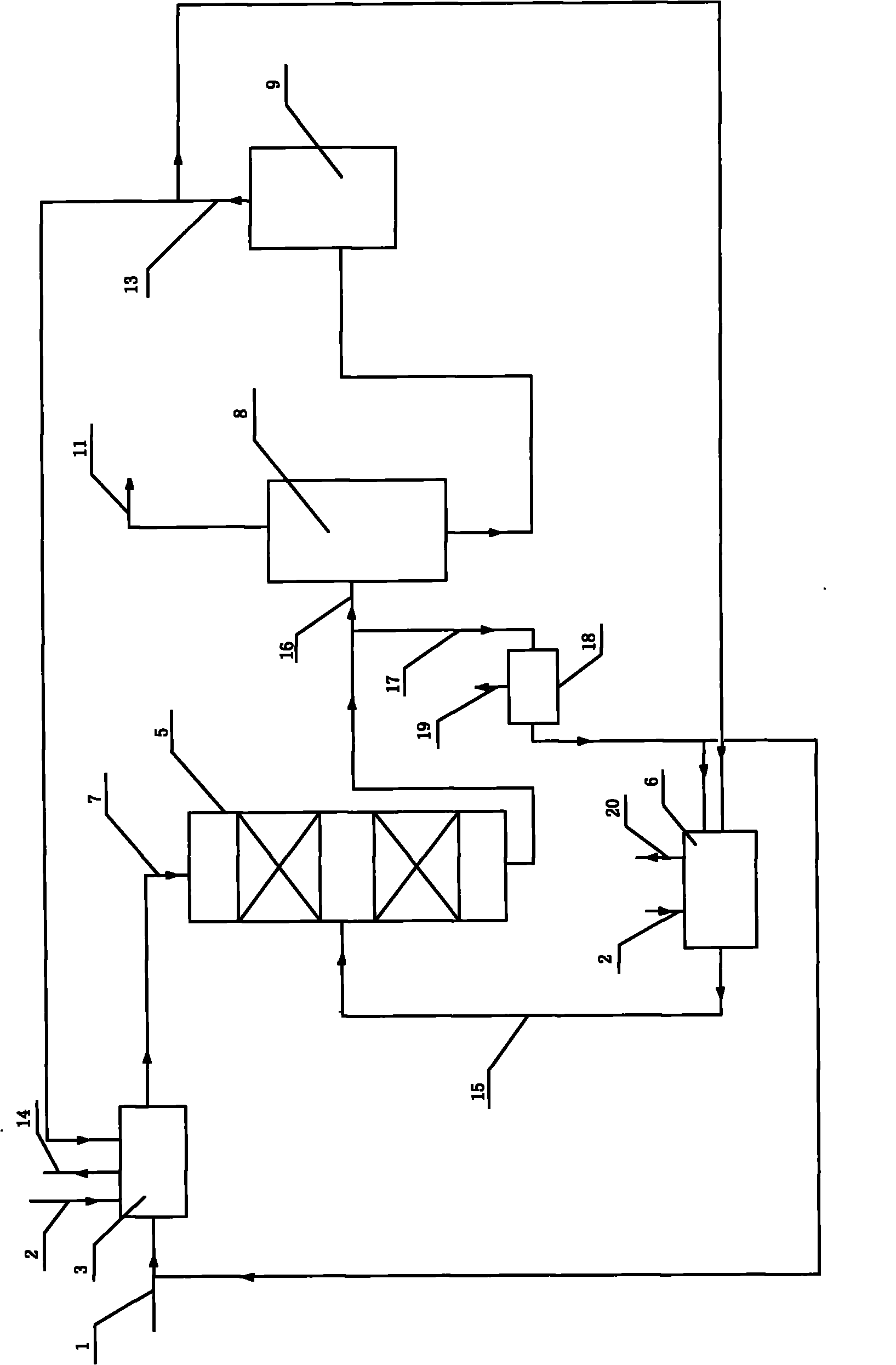

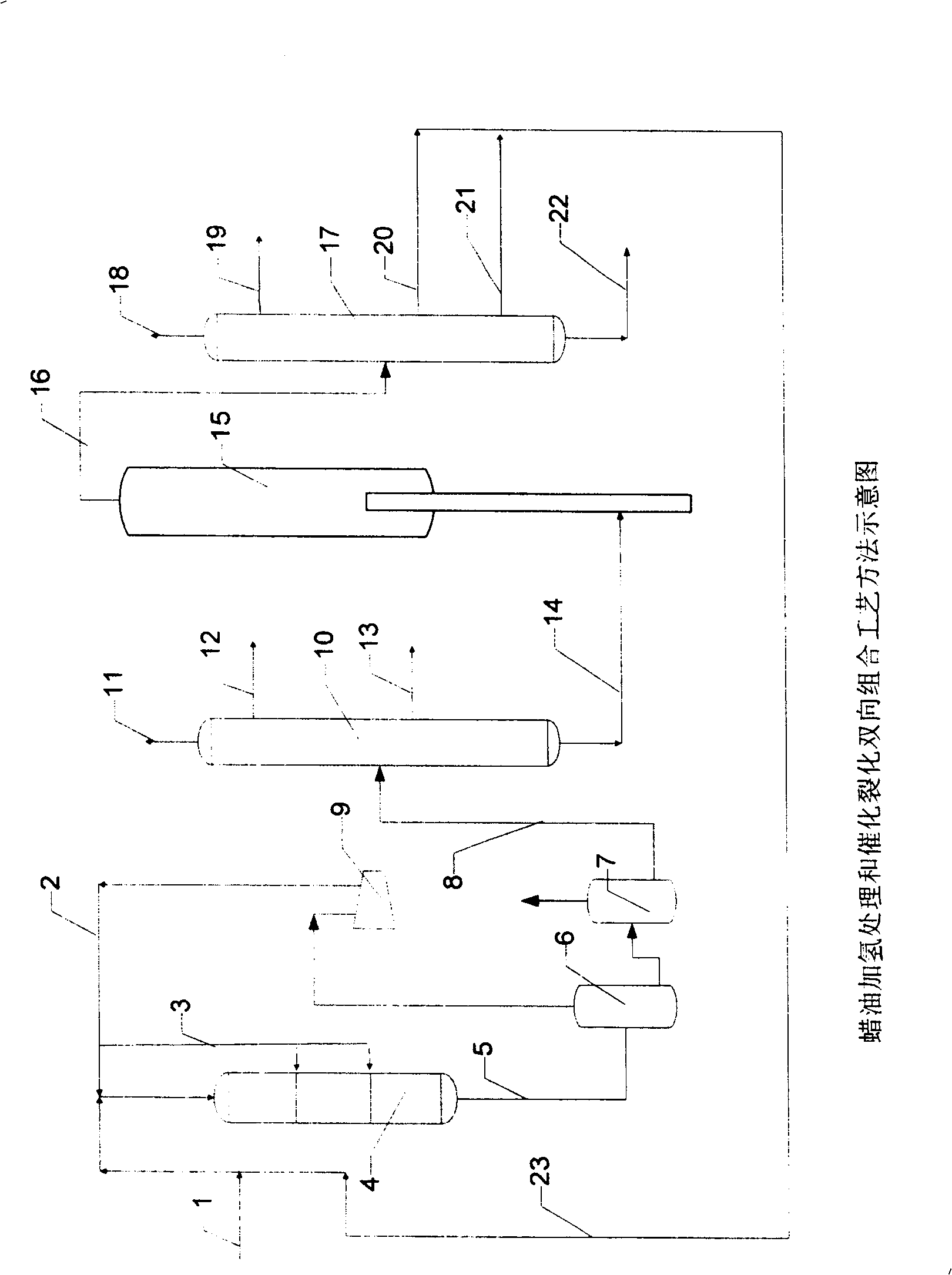

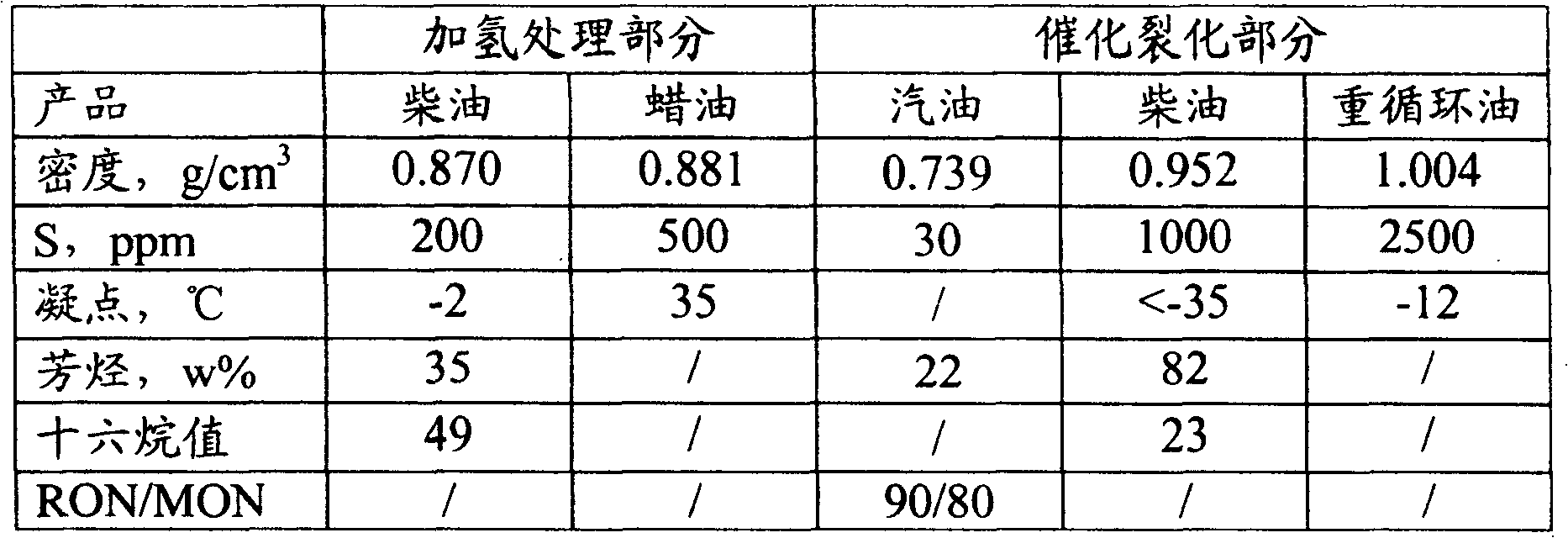

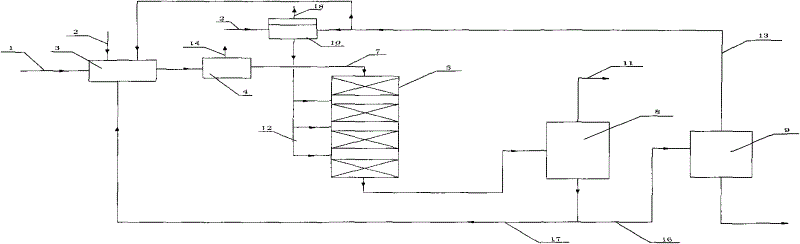

Two-way combined process of wax-oil hydrogenation treatment and catalytic cracking

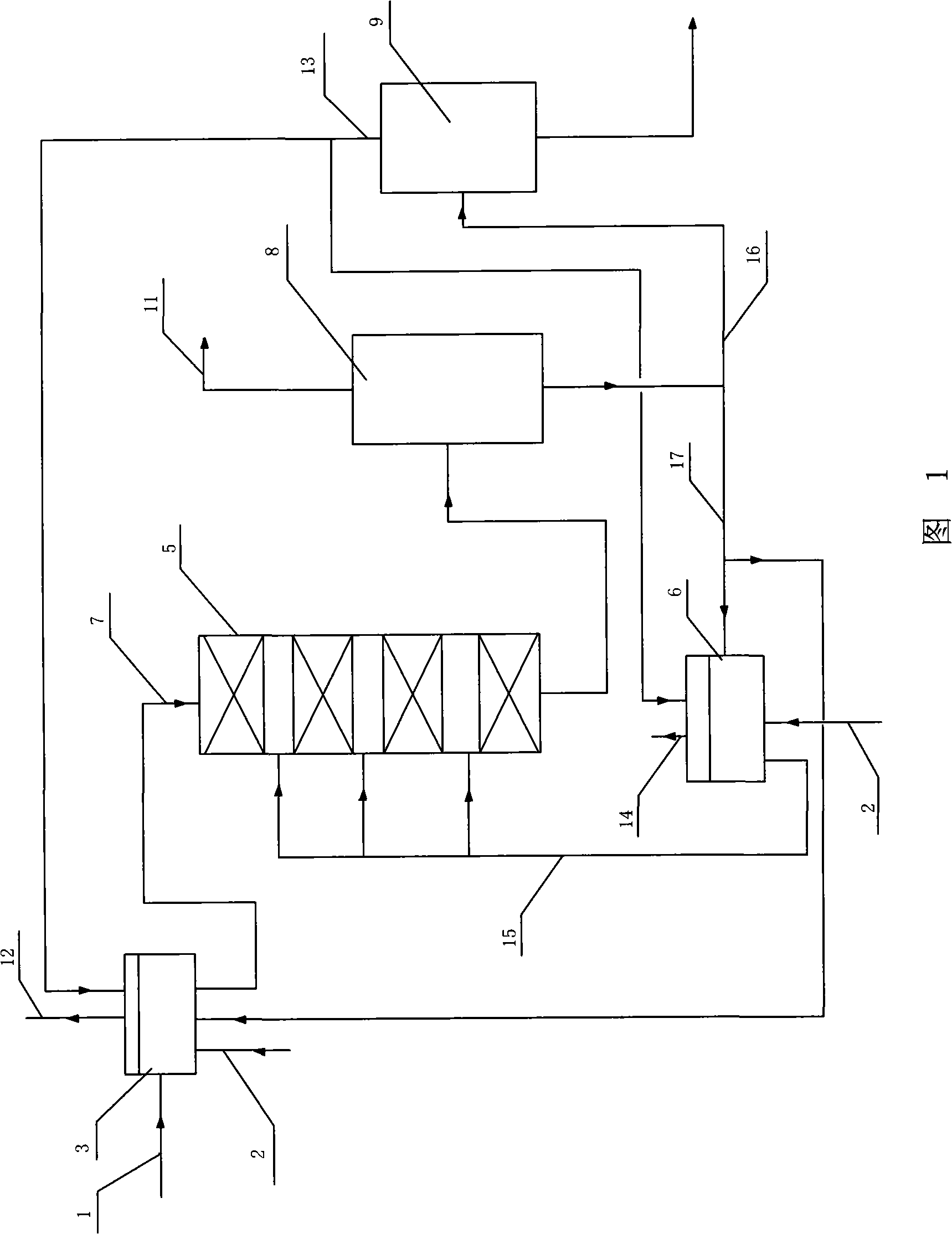

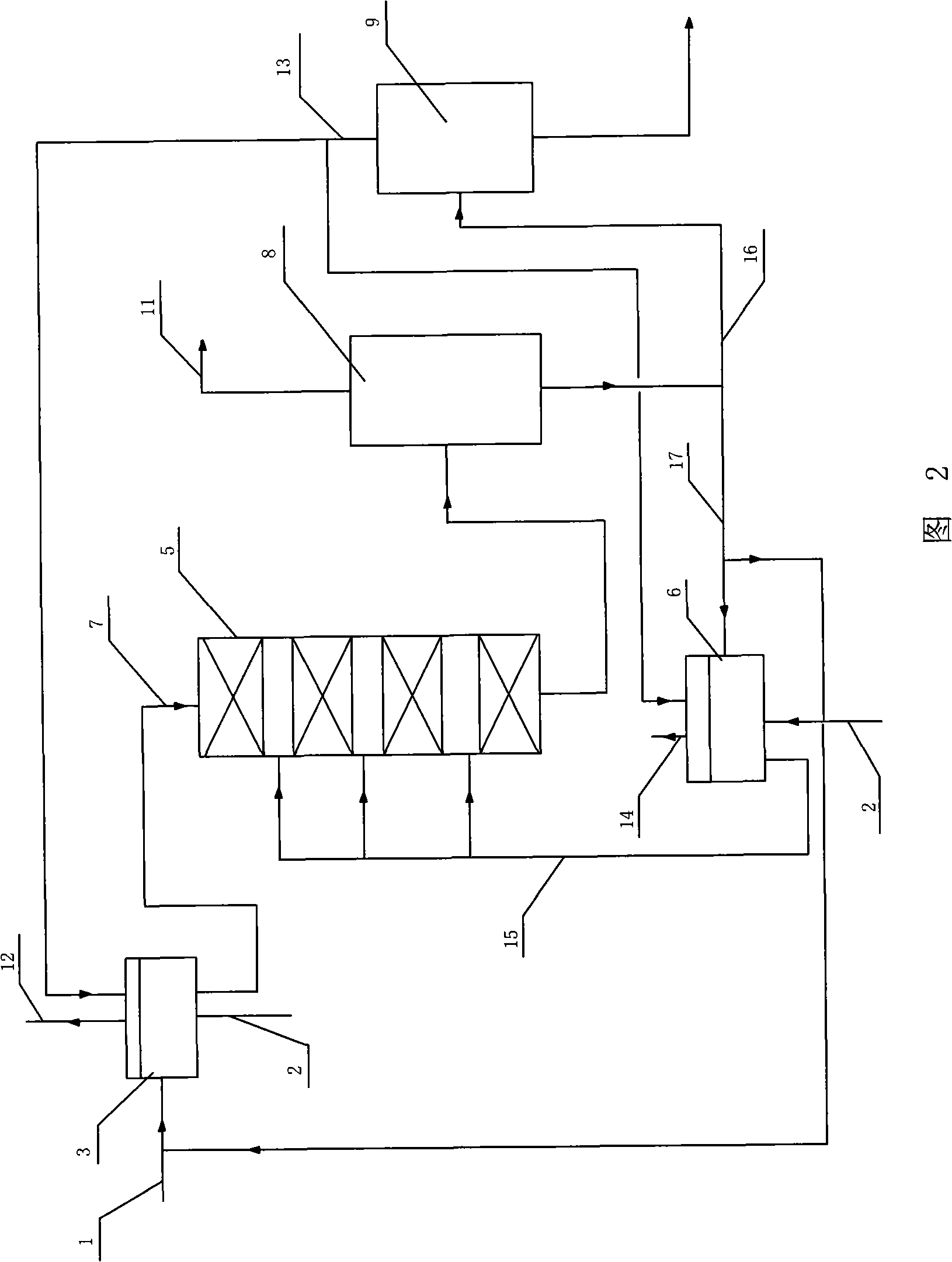

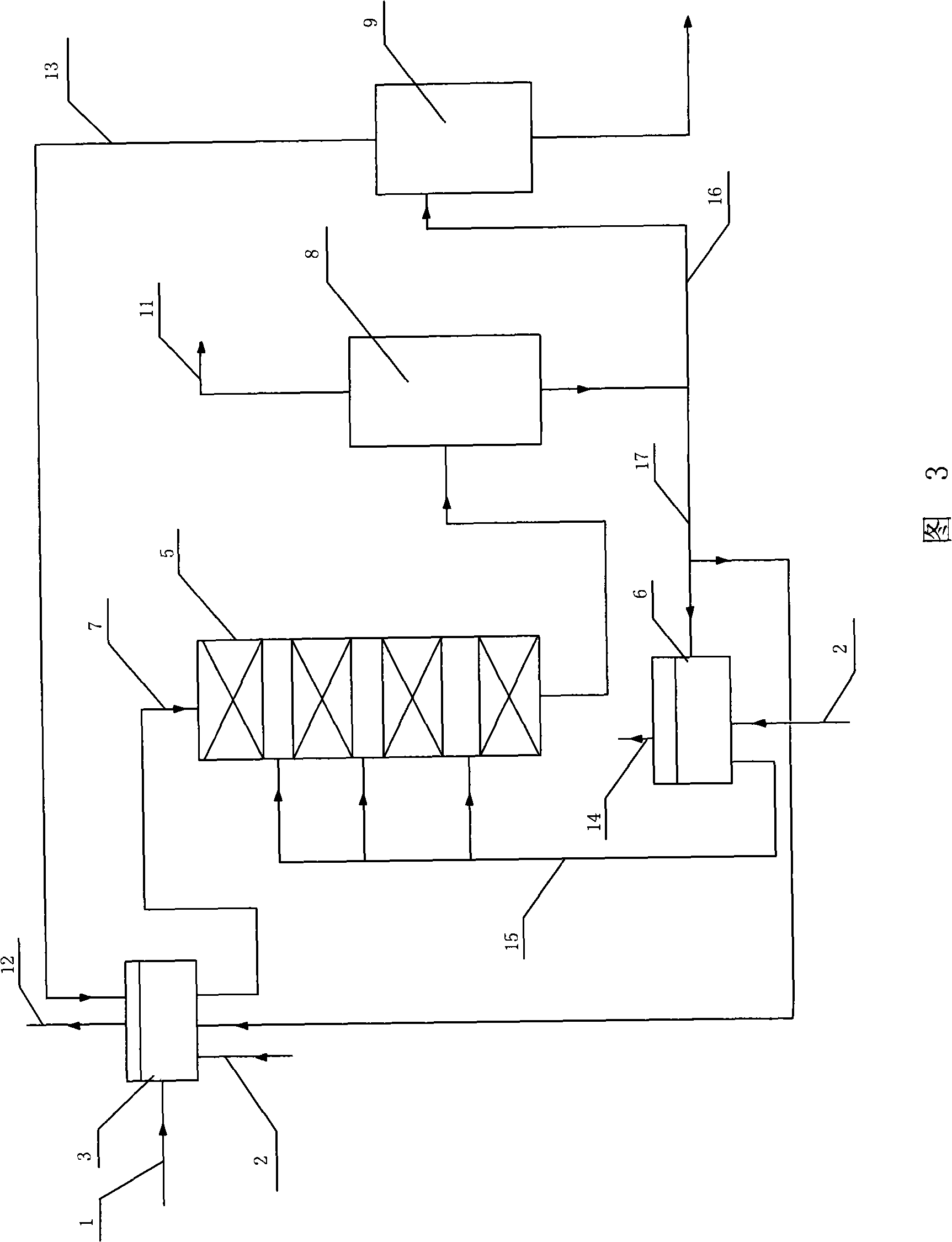

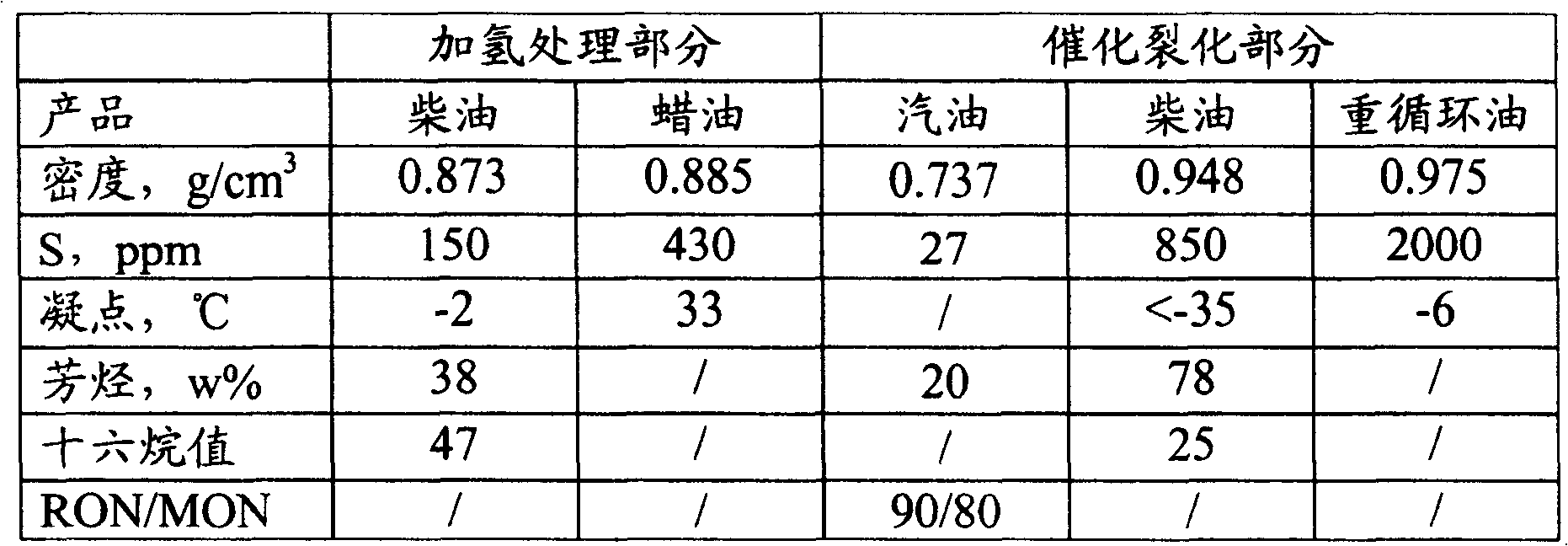

A two-way combined process of wax oil hydro-process and catalytic crack is carried out by entering wax oil, catalytic cracking re-circulating oil and catalytic cracking diesel oil into hydro-processor, hydrogenation reacting under existence of hydrogen and hydrogenation catalyst, separating for reactant to obtain gas, hydrogenation naphtha oil, hydrogenation diesel oil and hydrogenation tail oil, entering hydrogenation tail oil into catalytic cracker, crack reacting under existence of catalytic cracking agent, separating to obtain dry gas, liquefied gas, catalytic cracking gasoline, catalytic cracking diesel oil and catalytic cracking re-circulating oil and oil slurry, and circulating for catalytic cracking diesel oil and catalytic cracking re-circulating oil to hydro-processor. It has higher recovery rate and cetyl value, less sulfur content, arene content and coke output.

Owner:CHINA PETROLEUM & CHEM CORP +1

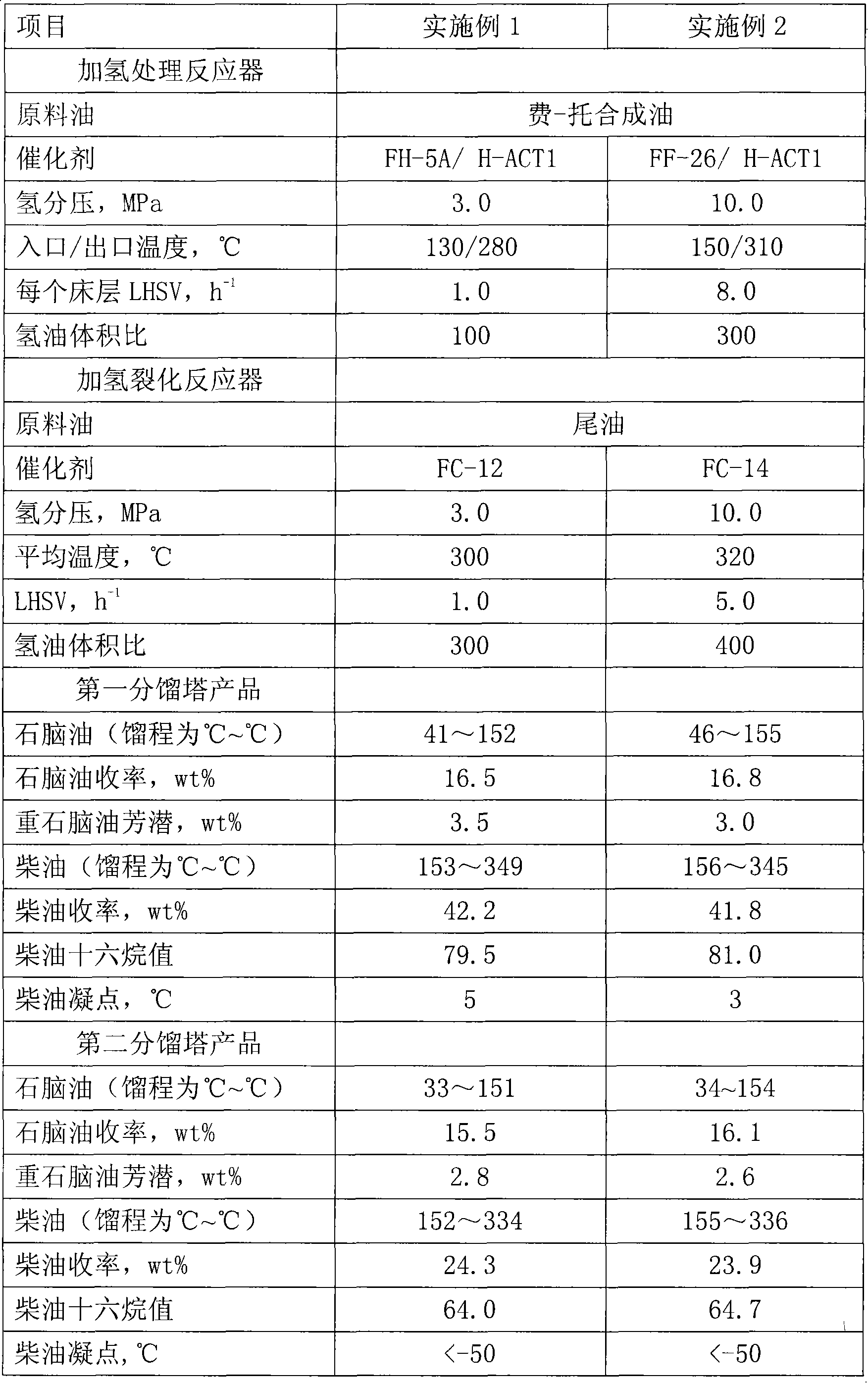

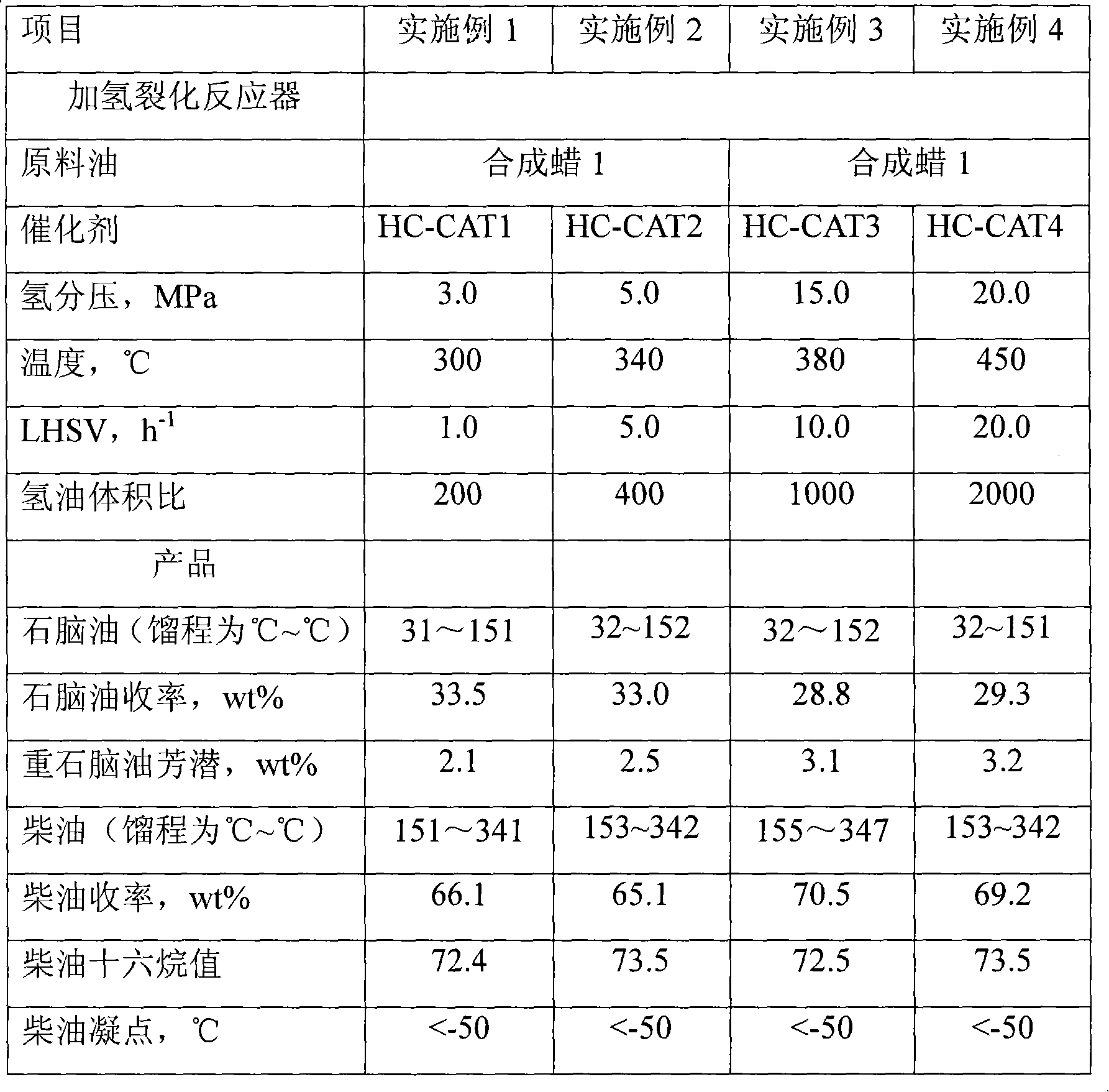

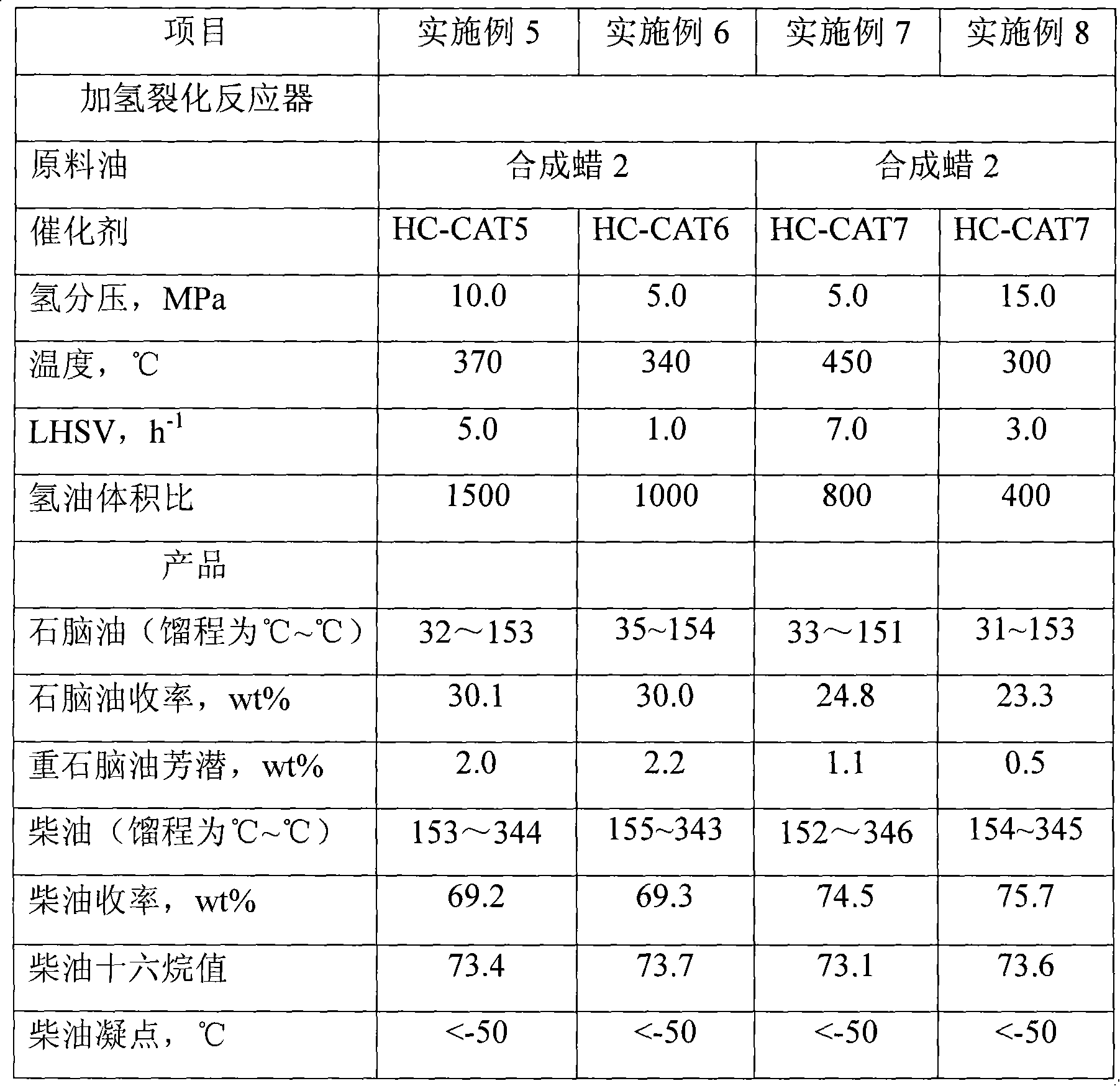

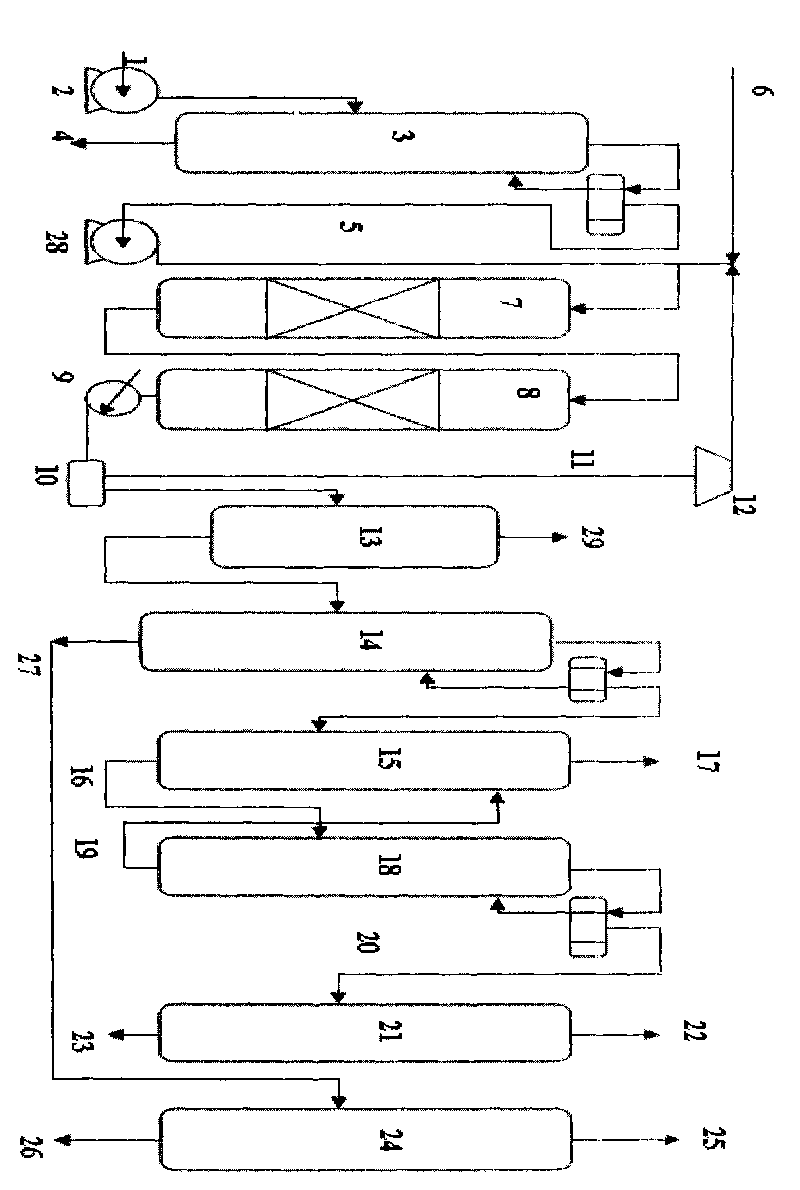

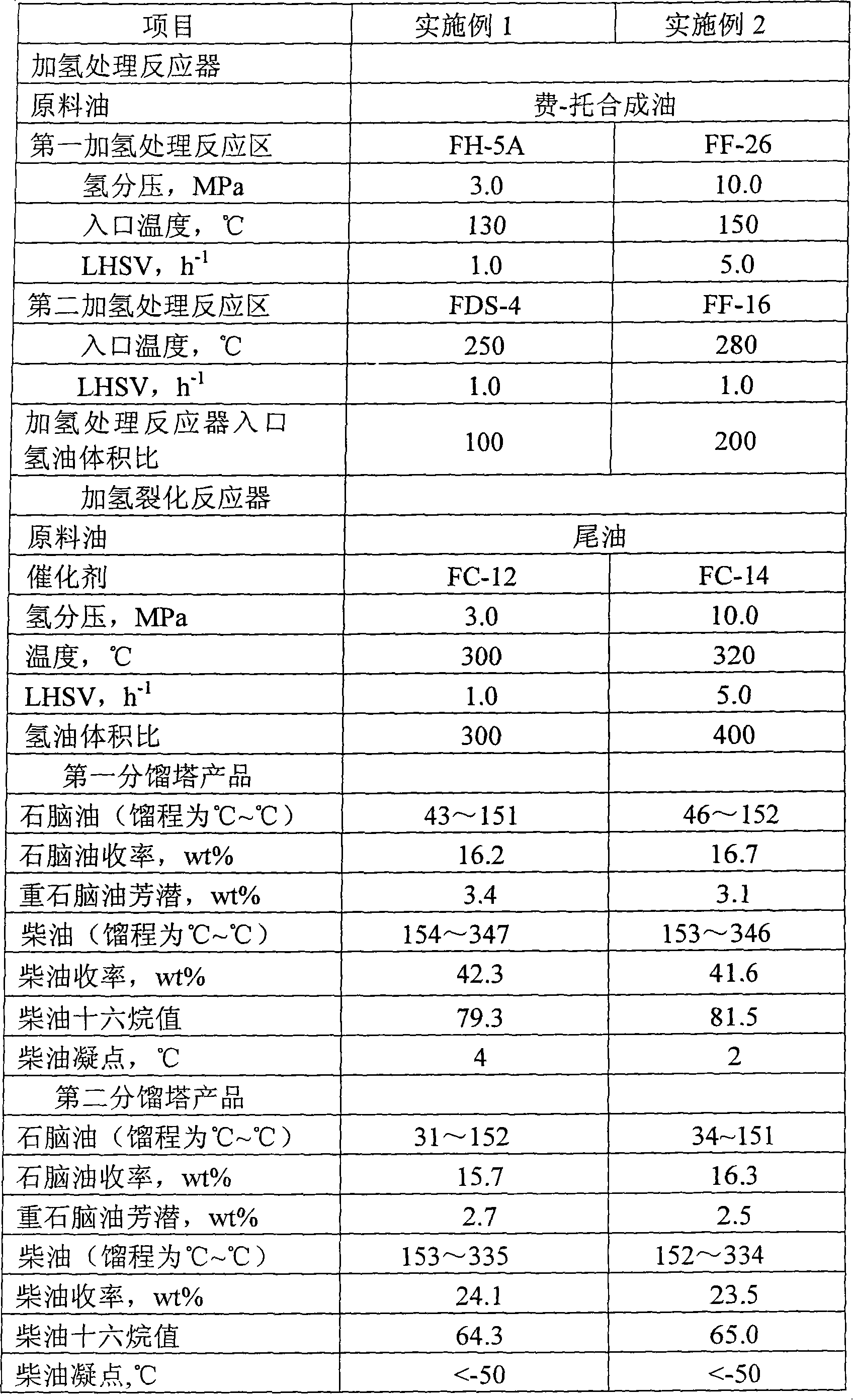

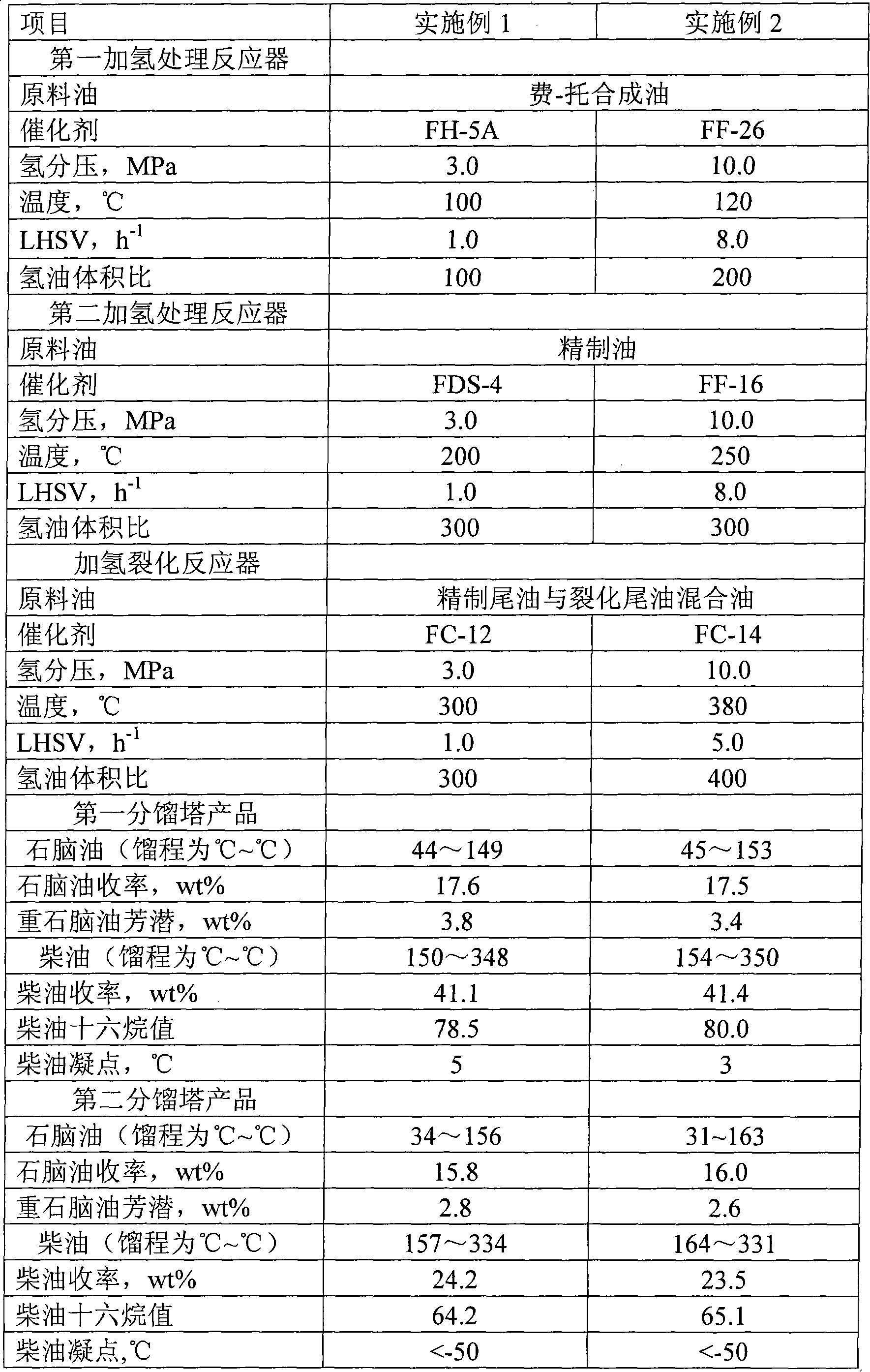

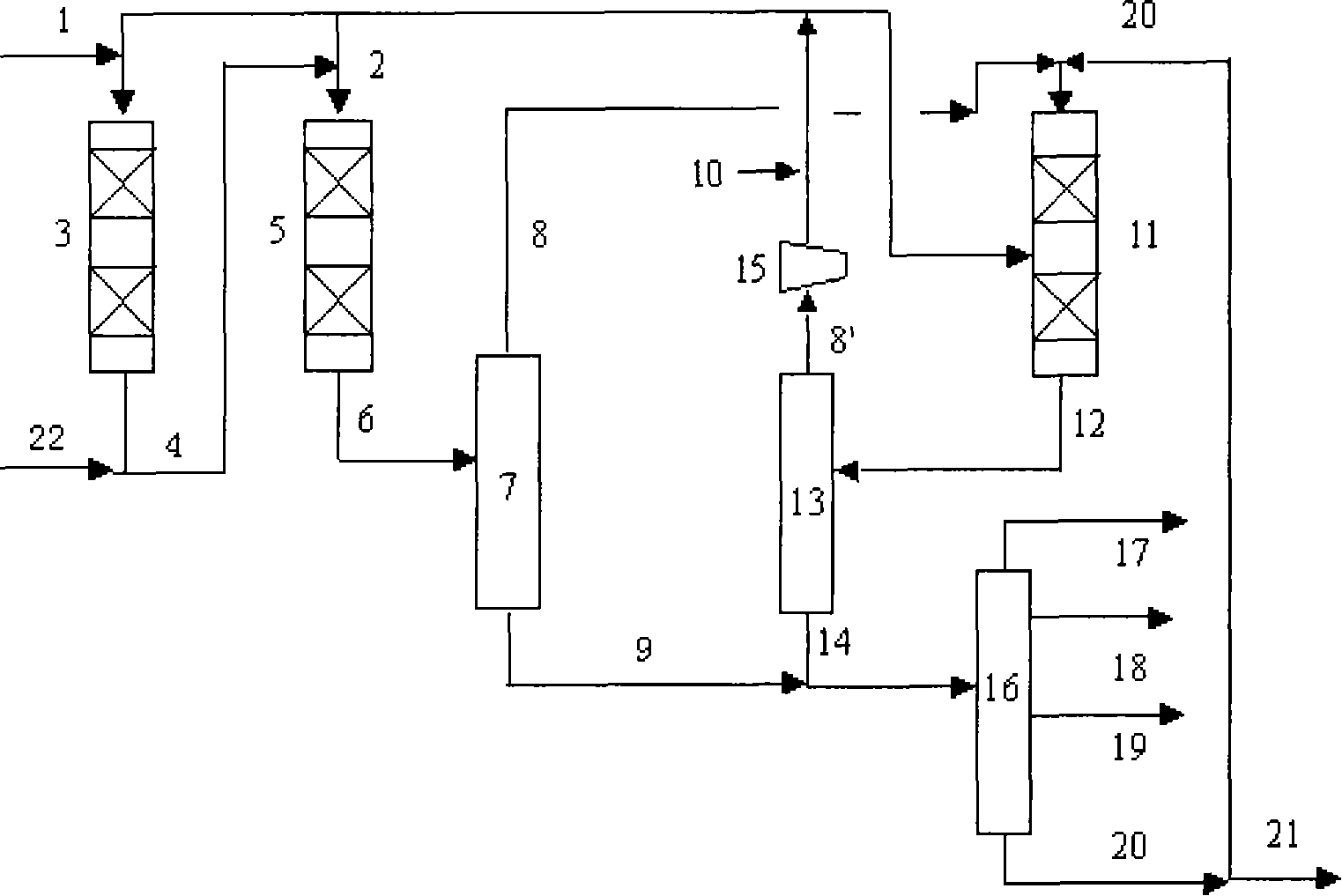

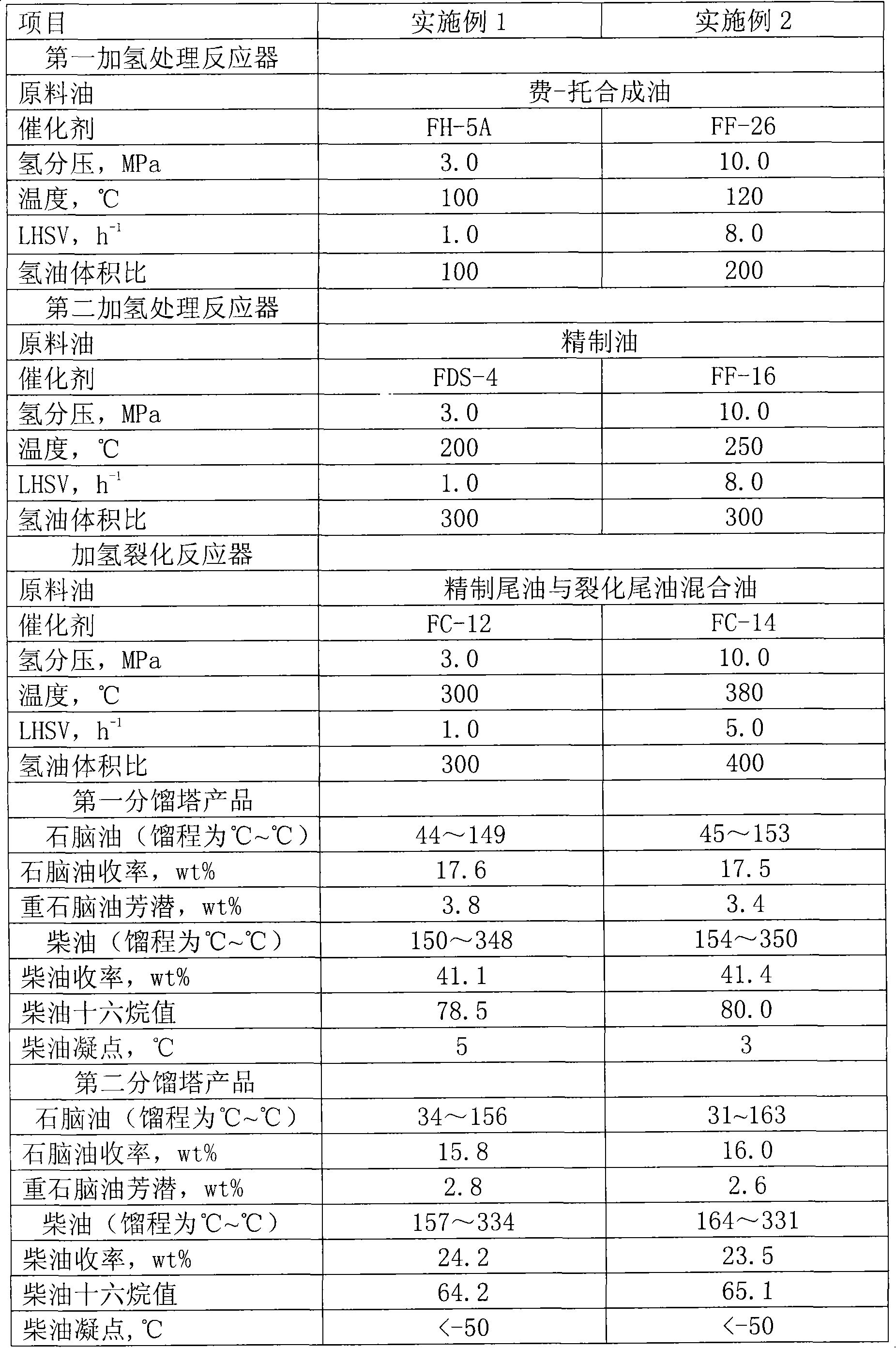

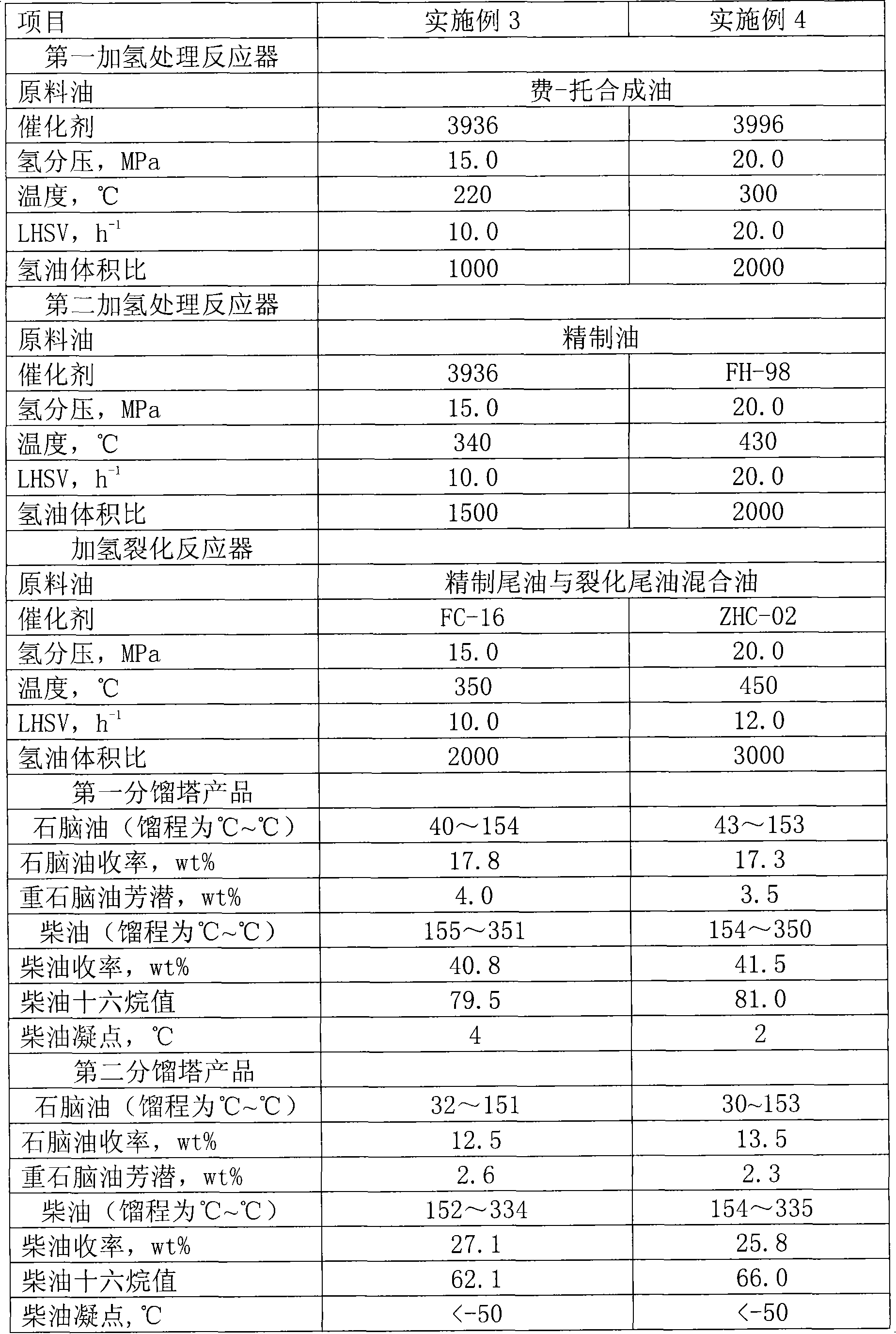

Hydrogenation processing method for f-t synthetic oil

ActiveCN101177625AEffective hydrotreatingReduce the impactTreatment with hydrotreatment processesHydrogenNaphtha

The invention discloses a hydrogenation processing method of Fischer-Tropsch synthetic oil, particularly, the method of the invention is that raw naphtha cut, raw diesel oil cut, mixed cut of raw naphtha and raw diesel oil or Fischer-Tropsch synthetic full cut oil in liquid-phase products acquired from Fischer-Tropsch synthetic process are treated by hydrogenation processing. The method comprises steps that raw material of the Fischer-Tropsch synthetic oil goes through at least two sections of hydrogenation processing catalyst bed layers with different activation for hydrogenation processing and then tail oil acquired from separation after hydrogenation processing is subjected to hydrogen cracking and then hydrogenation processing products and hydrogen cracking products are sent into different fractionating systems for separating. The method of the invention can acquire high-quality clean diesel oil with cetane value higher than 75 and excessively low-freezing clean oil with solidifying point lower than 50 DEG C below zero, meanwhile, the naphtha acquired is high-quality raw material used for producing ethylene by steam cracking.

Owner:SYNFUELS CHINA TECH CO LTD

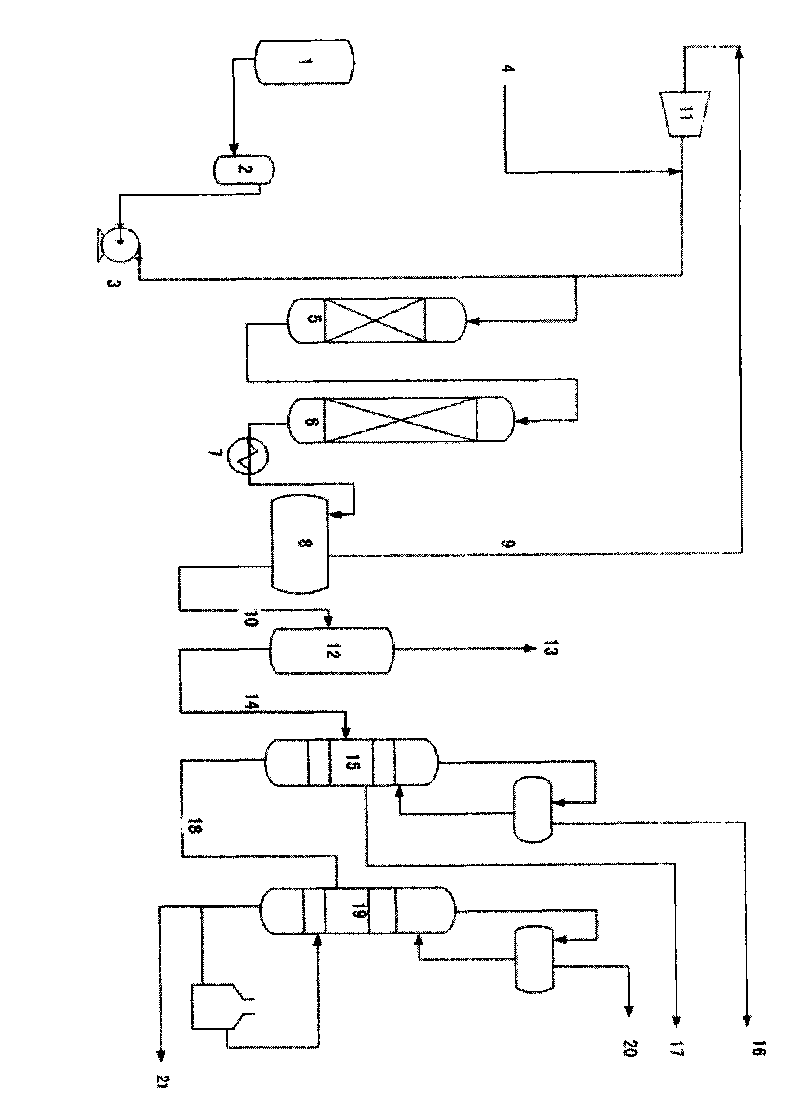

Hydrofining technology of heavy benzol

ActiveCN101712888ANot easy to cokeExtended operating cycleDistillation purification/separationTreatment with hydrotreatment processesBenzeneHydrogen

The invention discloses a hydrofining technology of heavy benzol, which is characterized in that heavy benzol is filtered and is mixed with hydrogen to successively enter a fixed bed pre-hydrogenation reactor and a fixed bed main hydrogenation reactor for selective hydrofining; the obtained hydrogenated oil is converted into solvent oil and industrial naphthalene after cooling, gas stripping, distillation, rectification and the like. The heavy benzol has favourable quality, high additional value and small pollution to environment when the heavy benzol is used, the device has long operation period, and the invention provides a new path for effectively using heavy benzol.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

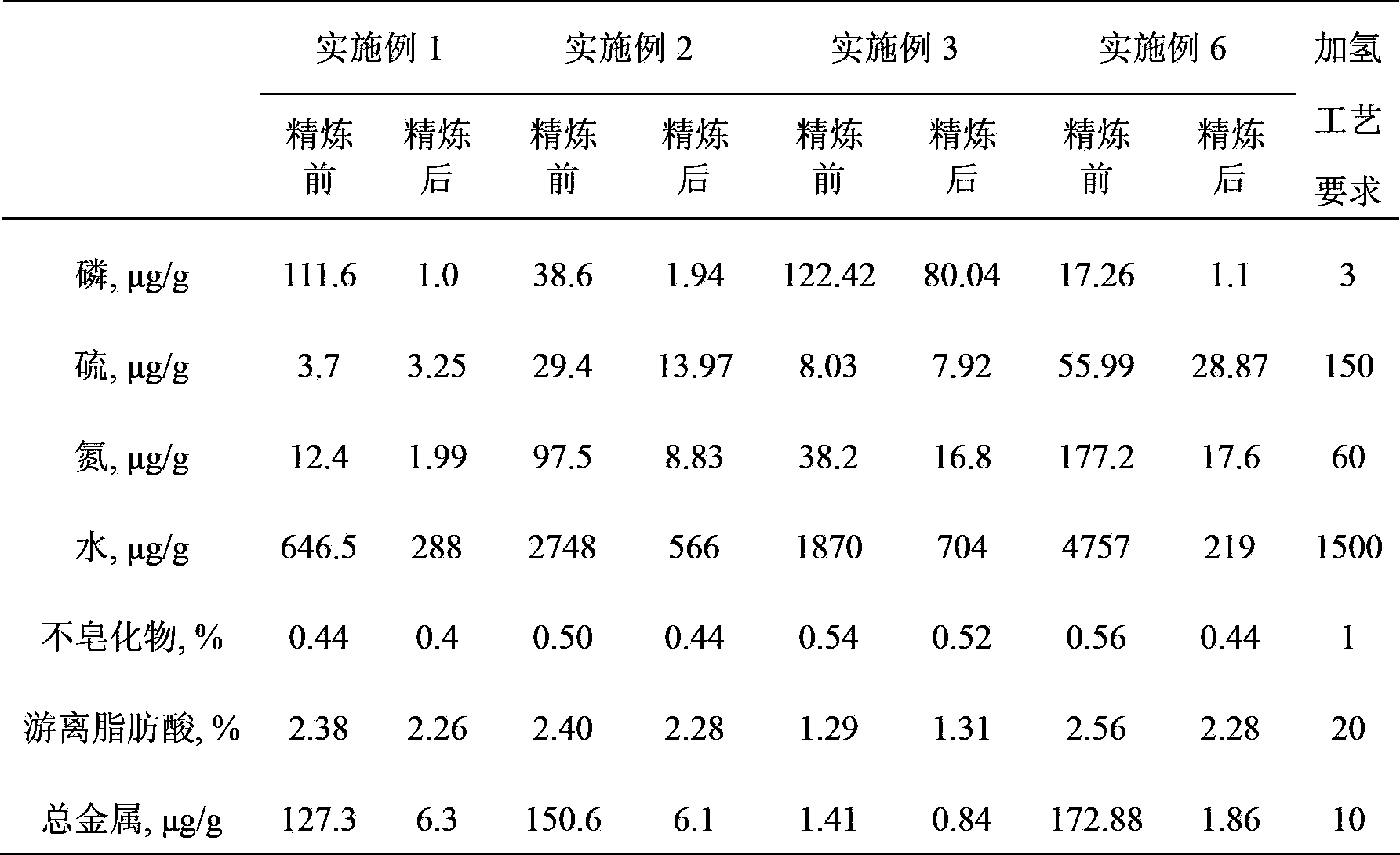

Method for production of diesel oil fraction and aviation fuel fraction by use of animal and plant oils and fats

The invention relates to a method for production of a diesel oil fraction and an aviation fuel fraction by use of animal and plant oils and fats, and the method comprises the following steps: a) performing refining processing on the animal and plant oils and fats; b) performing catalytic hydrogenation and deoxidation to obtain saturated linear alkanes and propane; c) performing hydroisomerization and hydrocracking processing to obtain an alkane material flow with higher branched chain degree; d) separating to obtain liquid hydrocarbons and gaseous hydrocarbons with the boiling point within the boiling point range of diesel oil, aviation fuels and naphtha; e) directly collecting the diesel oil fraction as a product, or cycling in whole or in part to continue isomerization and cracking reaction to increase production of the aviation fuel fraction; and f) mixing propane gaseous hydrocarbon and naphtha for steam reforming hydrogen production reaction, separating and purifying the obtained hydrogen to enter into a circulating hydrogen system; the method is used in the production of the renewable diesel oil and aviation fuels with excellent combustion performance and cold flow performance, and meanwhile efficient utilization of by-products and in-system supplement of hydrogen consumption can be realized.

Owner:PETROCHINA CO LTD

Method for regenerating desulfurizing and denitrogenating adsorbant

InactiveCN101069839AAchieve recyclingDoes not affect the natureDispersed particle separationCombustible gas purificationOrganic sulfide compoundSorbent

The present invention relates to a regeneration method of desulfurizing denitrifying adsorbent. Said method includes the following steps: adding the adsorbent adsorbed organic sulfide and organic nitride into a mixed system formed from water phase and oil phase containing desulfurizing and denitrifying microbial cellulae, making regeneration reaction at 30deg.C, filtering, drying and roasting so as to obtain the regenerated adsorbent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

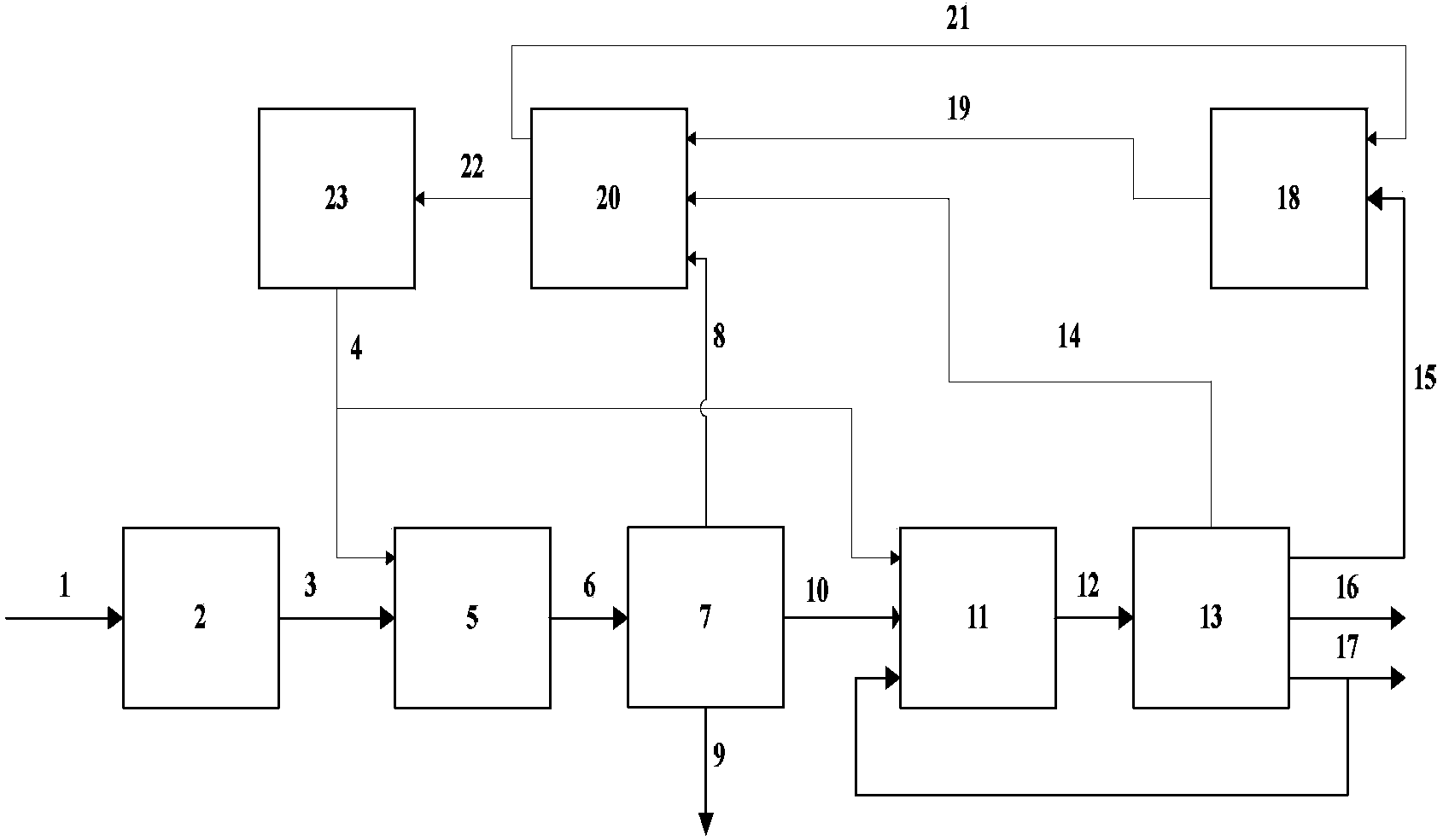

Process for upgrading hydrocarbon feedstocks using solid adsorbent and membrane separation of treated product stream

ActiveUS20090321309A1Level of impurity be lowerLow sulfur and nitrogen contentRefining with non-metalsOther chemical processesChemistryActivated carbon

A process for upgrading crude oil fractions or other hydrocarbon oil feedstreams boiling in the range of 36° to 520° C., and preferably naphtha and gas oil fractions boiling in the range of 36° to 400° C., employs a solid adsorption material to lower sulfur and nitrogen content by contacting the hydrocarbon oil, and optionally a viscosity-reducing solvent, with one or more solid adsorbents such as silica gel or silica, silica alumina, alumina, attapulgus clay and activated carbon in a mixing vessel for a predetermined period of time; passing the resulting slurry to a membrane separation zone, optionally preceded by a primary filtration step (i.e., single stage or multiple stages), to separate the solid adsorption material with the adsorbed sulfur and nitrogen compounds from the treated oil; recovering the upgraded hydrocarbon product having a significantly reduced nitrogen and sulfur content as the membrane permeate; mixing the solid adsorbent material with one or a combination of aromatic solvents such as toluene, benzene, the xylenes and tetrahydrofuran to remove and stabilize the sulfur and nitrogen compounds; transferring the solvent to a fractionation tower to recover the solvent, which can be recycled for use in the process; and recovering the hydrocarbons that are rich in sulfur and nitrogen for processing in a relatively small high-pressure hydrotreating unit or transferring them to a fuel oil pool for blending.

Owner:SAUDI ARABIAN OIL CO

Method for producing diesel oil and chemical materials by f-t synthetic wax

InactiveCN101177619ALowering the freezing pointHigh activityHydrocarbon oil crackingGasoline stabilisationWaxNaphtha

The invention discloses a method for producing chemical raw material and diesel oil by Fischer-Tropsch synthetic wax and the method is that the Fischer-Tropsch synthetic wax and hydrogen gas contact with hydrogen cracking catalyst under hydrogen cracking condition and then the reaction products are treated by fractionation; diesel distillate obtained is the clean diesel with a low freezing point, while the naphtha cut obtained is high-quality raw material used for cracking of steam to ethane, and distillation range is higher than the hydrogen cracking of tail oil circulation of the diesel oil, wherein, the hydrogen cracking catalyst is the hydrogen cracking catalyst containing Beta zeolite and the weight content of the Beta zeolite in the catalyst is 0.5 percent to 60 percent; the Beta zeolite has properties that SiO2 / Al2O3 molar ratio is 20 to 150 and Na2O less than or equal to 0.2w percent. The method of the invention can prepare the Fischer-Tropsch synthetic wax into the clean diesel oil with a low freezing point and high-quality raw material used for producing ethylene by steam cracking.

Owner:SYNFUELS CHINA TECH CO LTD

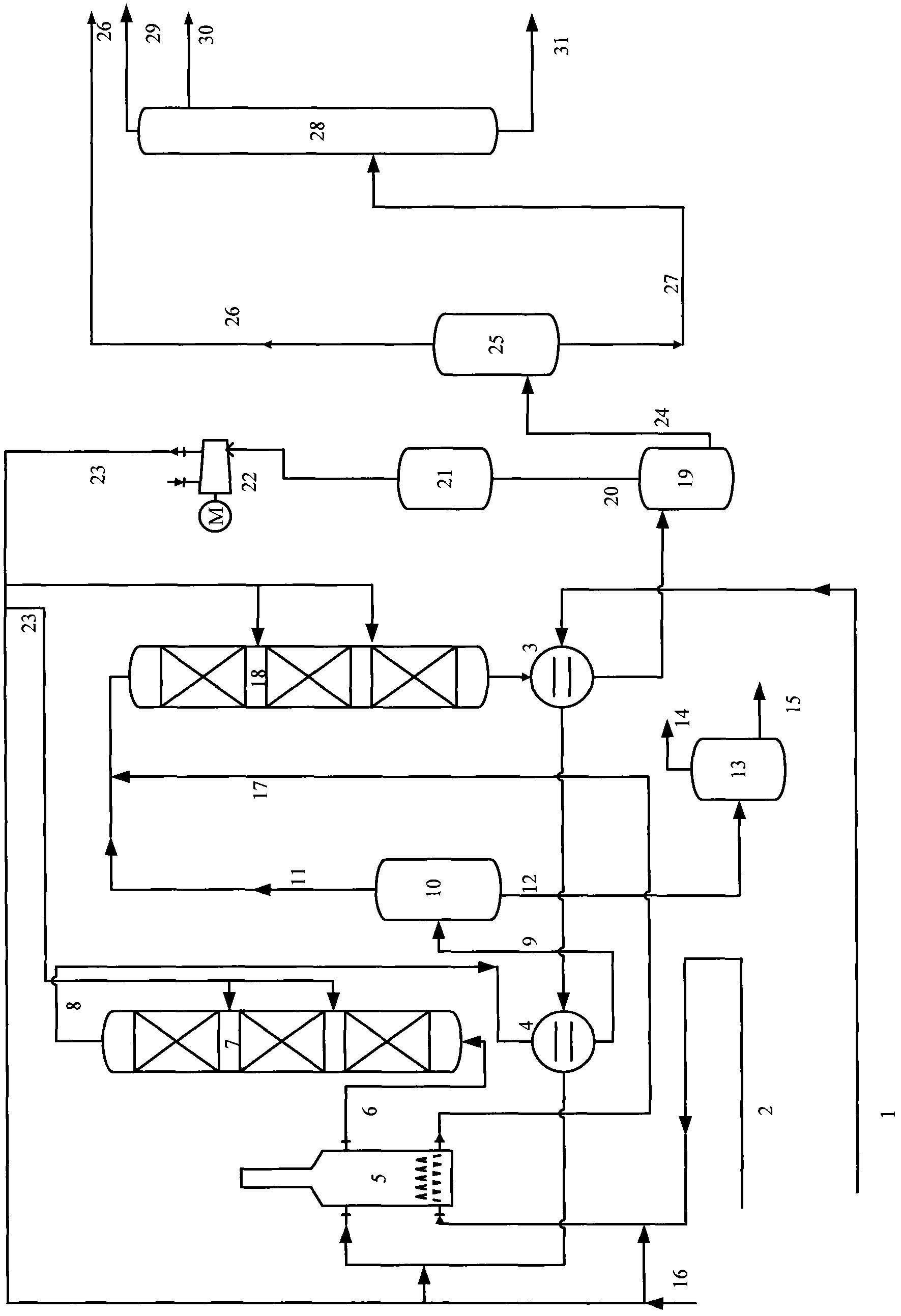

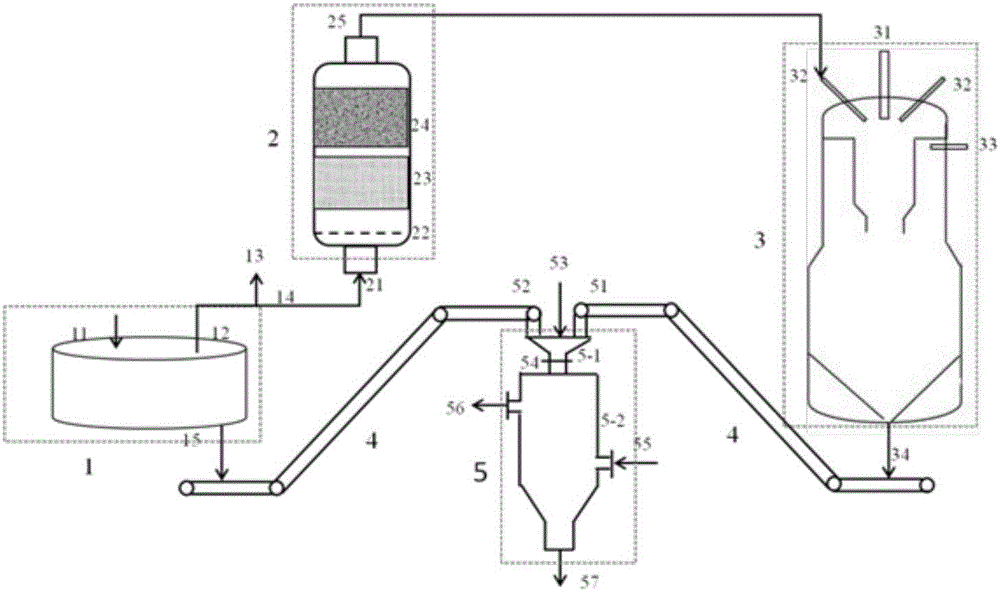

Liquid phase hydrogenating method of hydrocarbon oil

InactiveCN101993720AReduce dosageReduce lossesHydrocarbon oils refiningHydrocarbon oils treatmentSolubilityHydrogen

The invention discloses a liquid phase hydrogenating method of hydrocarbon oil. In the method, recycle hydrogen and a recycle hydrogen compressor are cancelled; hydrogen reacts with fresh raw oil and partial recycle oil in the presence of a solvent or a diluent to form a mixture flow, and the mixture flow enters a reactor to contact with a catalyst; the other part of or all recycle oil is mixed with hydrogen, and an obtained mixture enters the reactor by a path or branches from spaces between catalyst bed layers of the reactor; partial reaction effluent is subjected to hydrogen sulfide removal and then used as recycle oil, and the other part enters a separator; and the solubility of the hydrogen in the solvent or the diluent is larger than that in the mixture of the fresh raw oil and the solvent or the diluent.

Owner:CHINA PETROCHEMICAL CORP +1

Two-phase hydrogenation process

InactiveCN101338219AReduce dosageReduce lossesHydrocarbon oils refiningLiquid productHydrogenation process

The present invention discloses a biphase hydrogenation method, which cancels circulating hydrogen and a circulating hydrogen compressor. Hydrogen is mixed with fresh crude oil and circulating oil under the existence of a solvent or a diluting agent so as to form a mixture flow; the mixture flows into a reactor to contact a catalyst; after the other part of the circulating oil is mixed with hydrogen for gas discharging, a circuit or a shunt circuit enters the reactor between reactor catalyst bed layers; after the solvent or the diluting agent is mixed with hydrogen for gas discharging, a circuit or a shunt circuit enters the reactor between reactor catalyst bed layers; the reacted effluent is used for gas-liquid separation and the liquid phase further separates the solvent or the diluting solvent for recycling use; a part of the separated liquid product is used as the product and the other part is used as the circulating oil.

Owner:CHINA PETROCHEMICAL CORP +1

Method for preparing light aromatics from coal tar

ActiveCN101712889AGood product qualityReduce manufacturing costTreatment with hydrotreatment processesTar working-up by distillationSolventCoal tar

The invention discloses a method for preparing light aromatics from coal tar. The method is characterized by comprising the following steps of: cutting the coal tar into light oil fraction lower than 200 DEG C and heavy oil fraction higher than 200 DEG C; sequentially enabling the light oil fraction lower than 200 DEG C to enter two fixed-bed hydrogenation reactors for selective hydrogenation refining; stripping and pre-distilling the obtained hydrogenated generating oil; and extracting, distilling and finely distilling the solvent to obtain light aromatic products, such as benzene, toluene, xylene, and the like and byproducts, such as non-aromatics and solvent oil. The invention has wide raw material resources, low production cost, long device-running period and good aromatic product quality.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Hydrocarbon oil hydrogenation technique

The present invention discloses a hydrocarbon oil-hydrogenating technique. The technique is free from circulating hydrogen and a circulating hydrogen compressor; with solvent or diluting agent, hydrogen is mixed with fresh raw oil and part of circulating oil to form mixed material flow, which enters into a reactor to be contacted with catalyst; another part or all of circulating oil is mixed with hydrogen; one route or branch passes between the catalyst beds of the reactor to enter into the reactor; one part of reaction outflow is used as circulating oil, and the other part is used as the product after the gas and the solvent or the diluting agent are separated out; and the dissolubility of hydrogen in the solvent or the diluting agent is larger than the dissolubility of hydrogen in the mixture of the fresh raw oil and the solvent or the diluting agent.

Owner:CHINA PETROCHEMICAL CORP +1

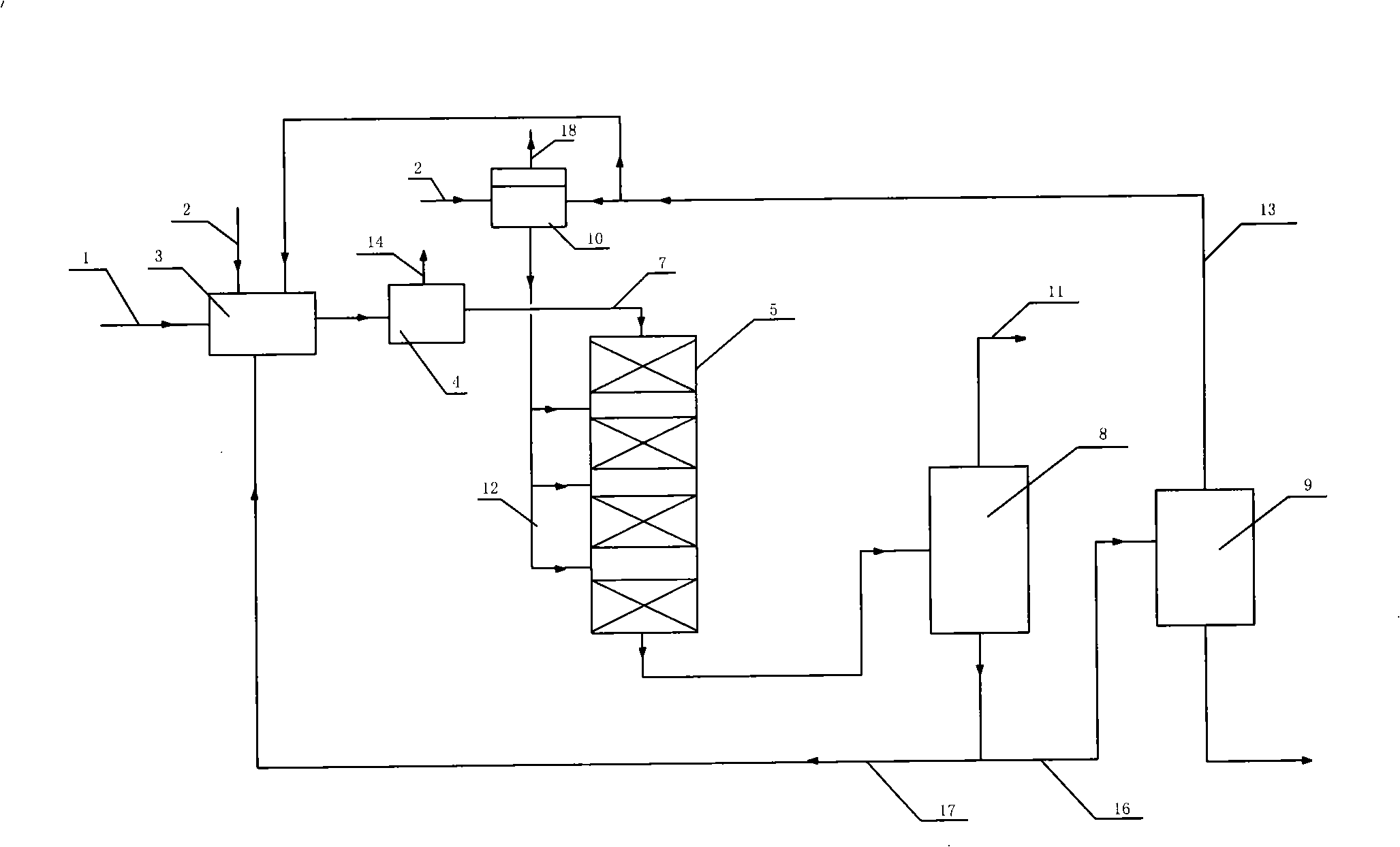

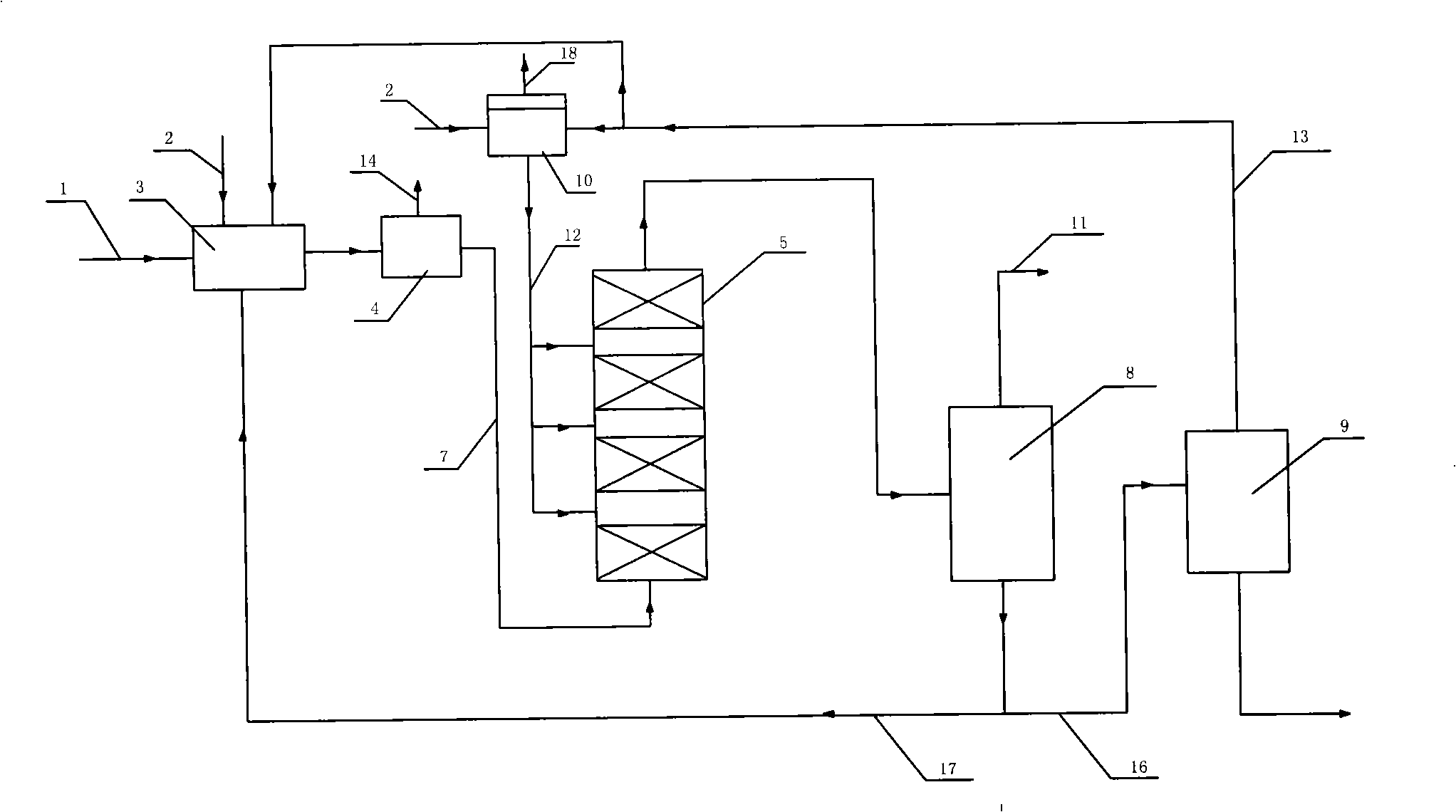

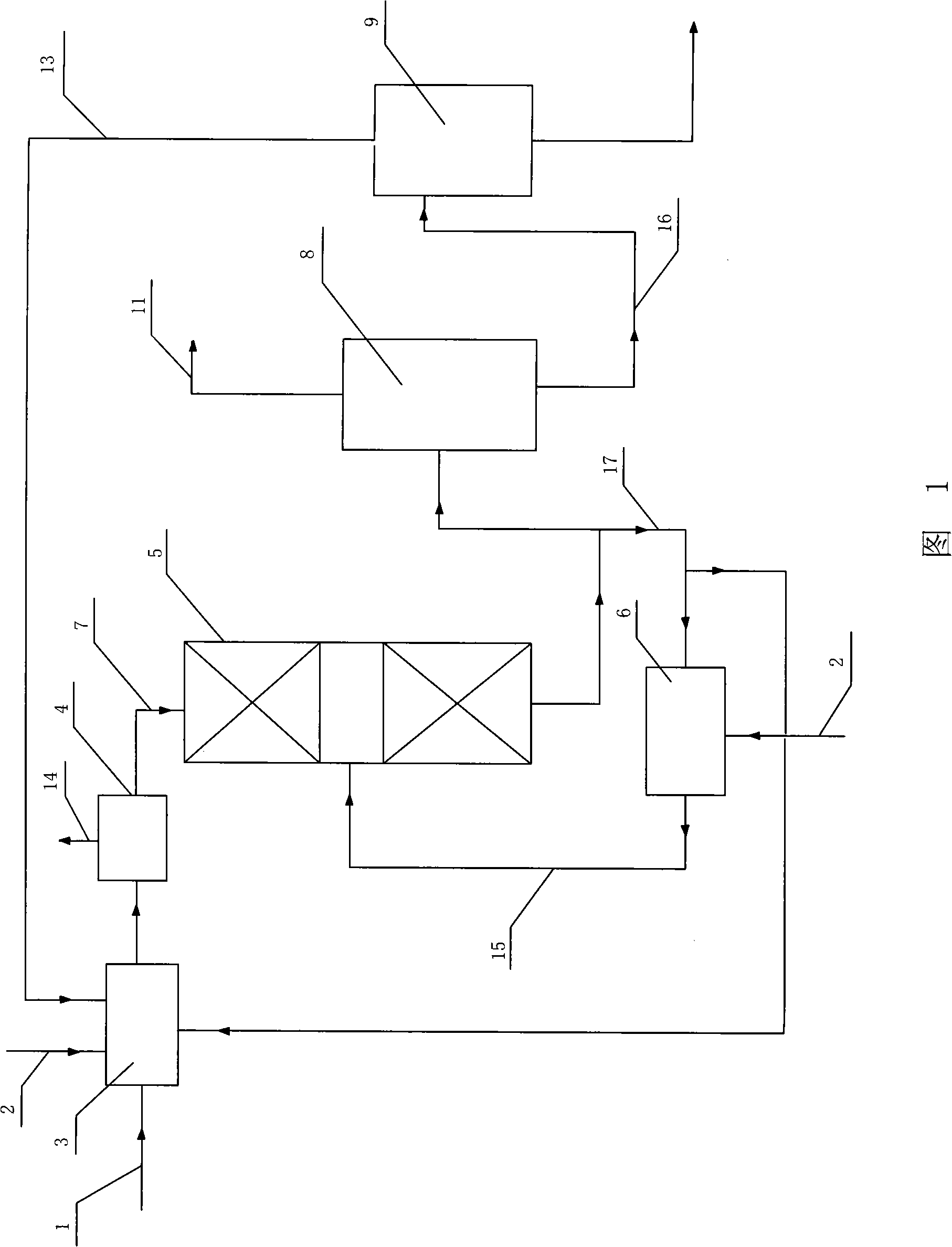

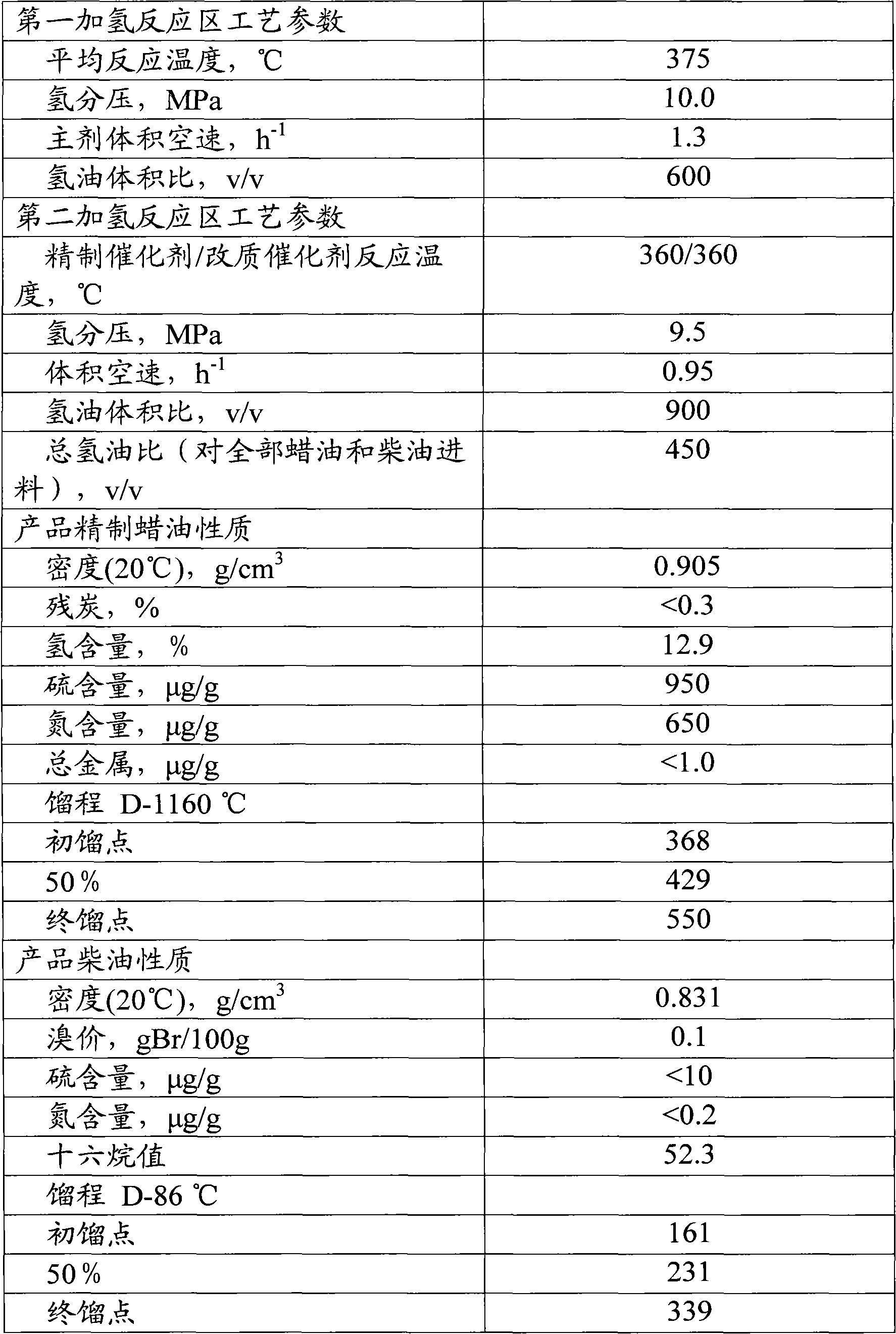

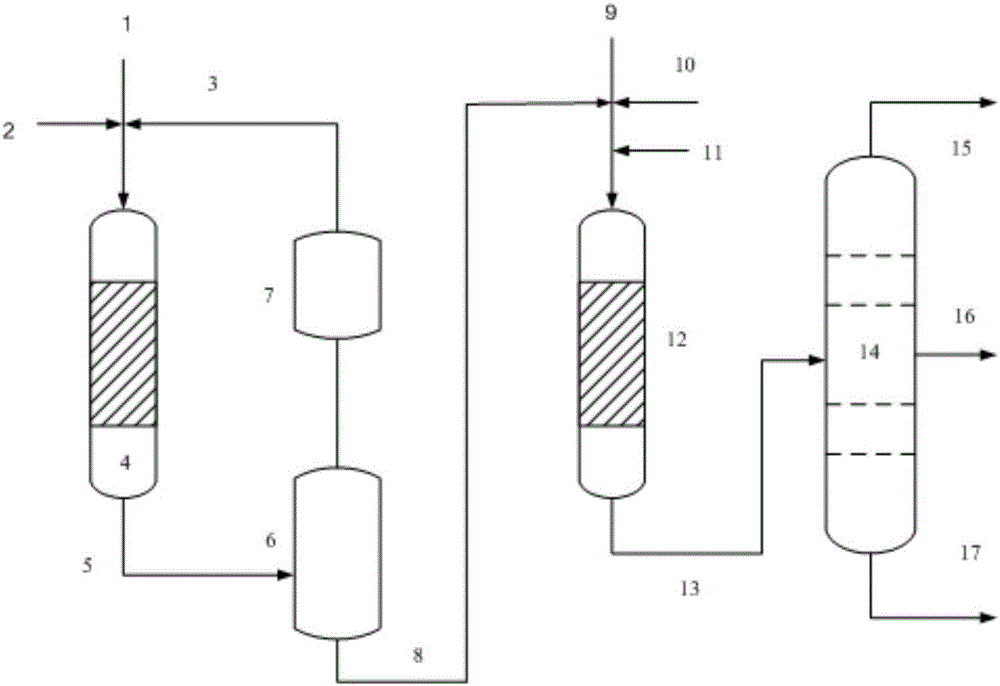

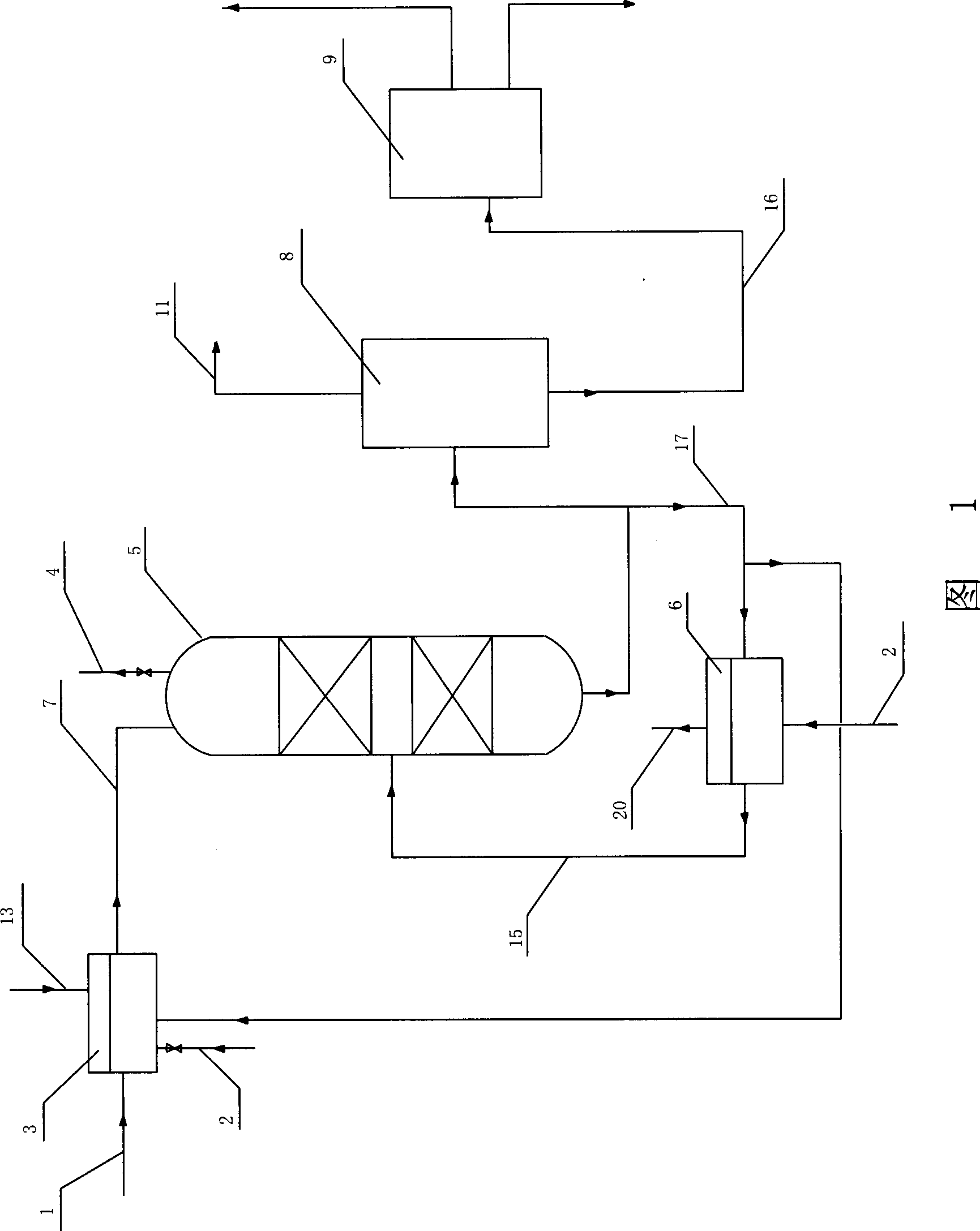

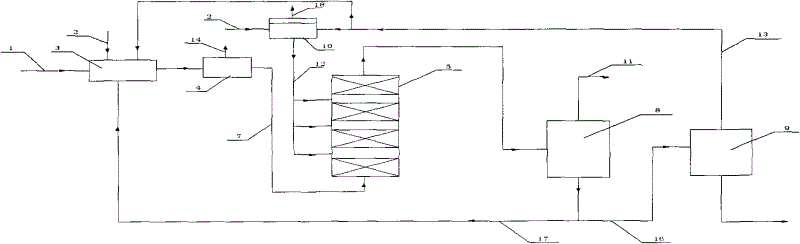

Combined hydrotreating method

InactiveCN103074103AIncrease cetane numberImprove energy efficiencyTreatment with hydrotreatment processesWaxProcess economics

The invention relates to a combined hydrotreating method. According to the method, a wax oil raw material enters a first hydrogenation reaction zone with an up-flow manner, such that a hydrotreating reaction is carried out; a reaction effluent from the first hydrogenation reaction zone enters a thermal high pressure separator; liquid-phase material flow from the bottom of the thermal high pressure separator is further separated by a thermal low pressure separator, such that dissolved gas is separated, and the material is directly used as a feed for a catalytic cracking device; hydrogen-rich gas and hydrocarbon fraction separated from the top of the thermal high pressure separator are mixed with a fresh diesel raw material; the mixture is subjected to a hydrogenation modification reaction in a second hydrogenation reaction zone; a reaction effluent from the second hydrogenation reaction zone is separated, such that a hydrogen-rich gas is obtained; and the hydrogen-rich gas is compressed, and is circulated back to the first hydrogenation reaction zone and the second hydrogenation reaction zone. With the method provided by the invention, device equipment investment and operation cost can be effectively reduced, and oil refining process economic efficiency can be improved to a maximal extent.

Owner:CHINA PETROLEUM & CHEM CORP +1

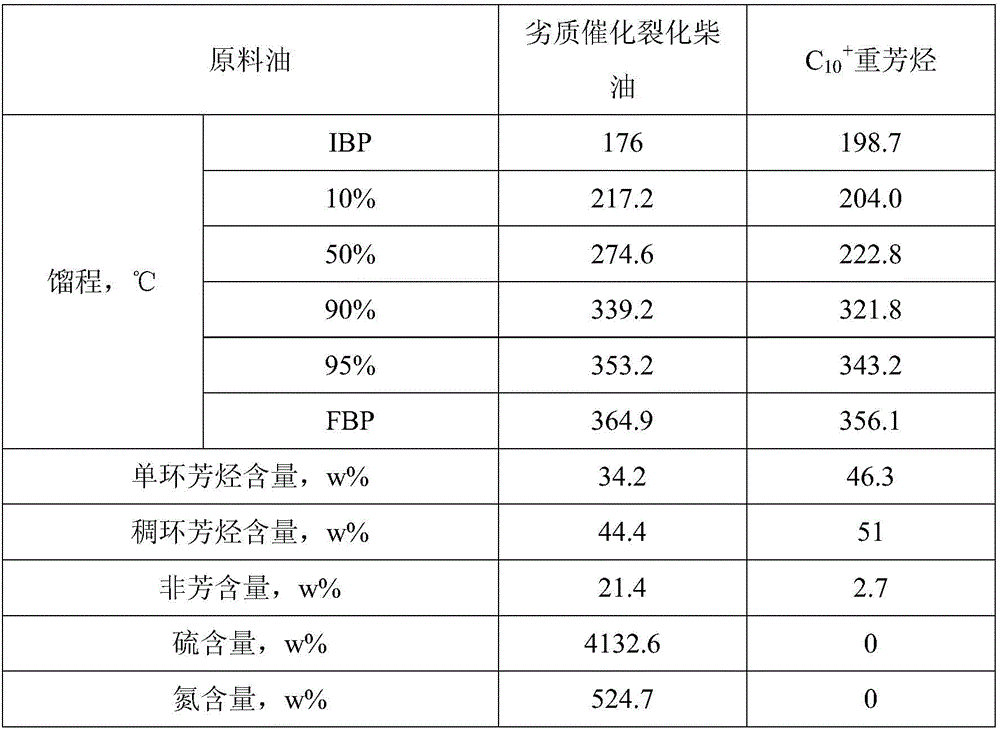

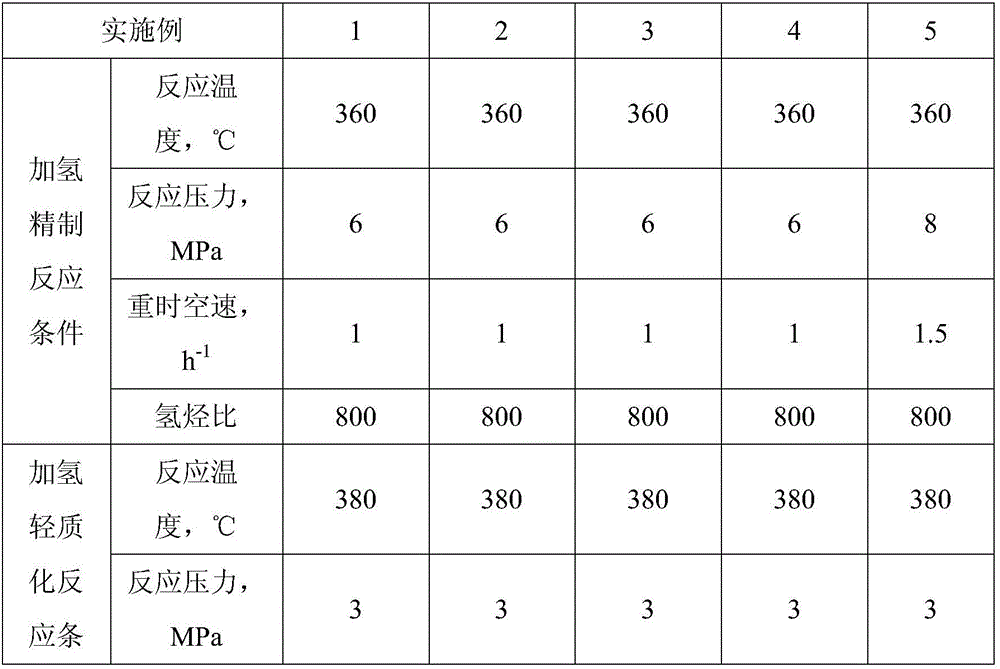

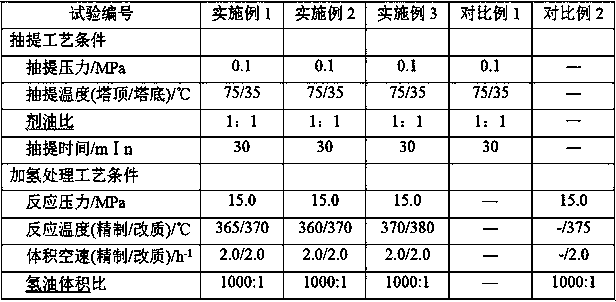

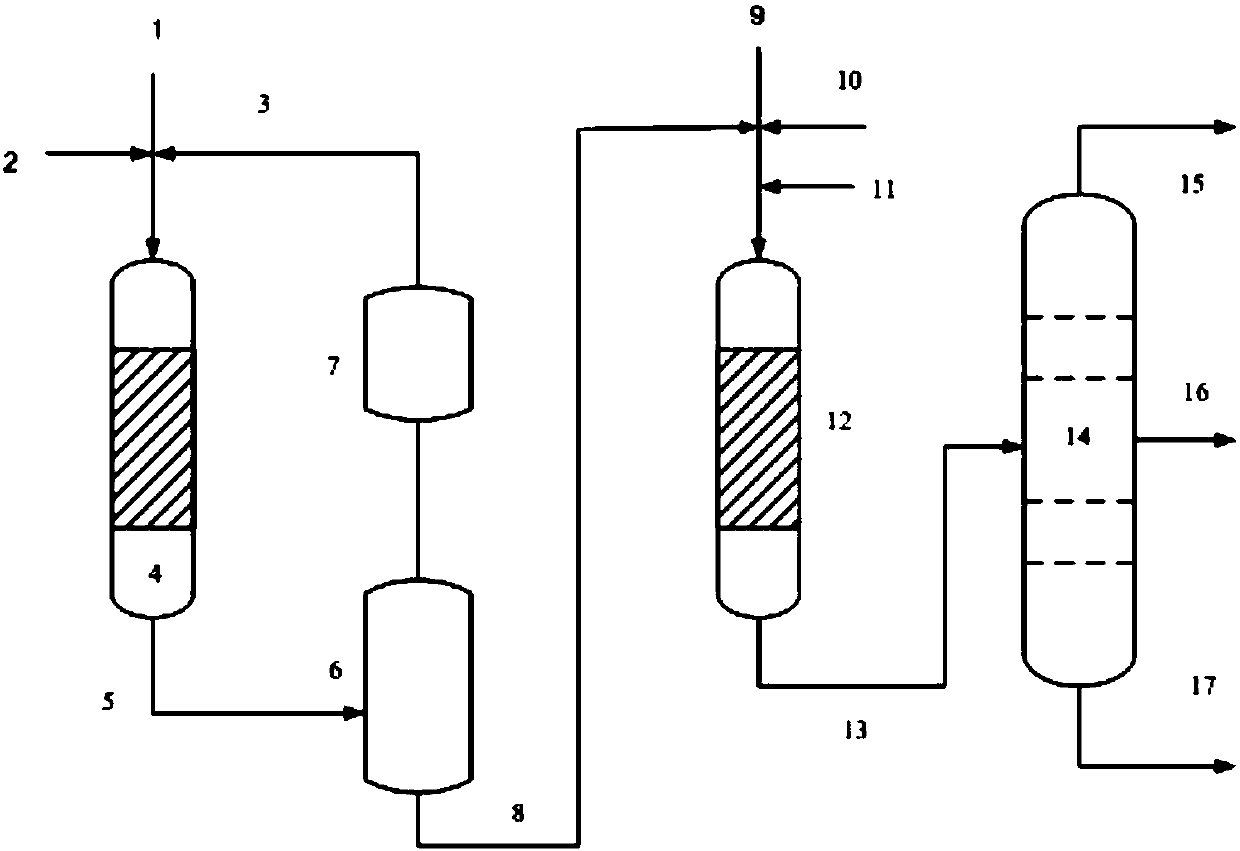

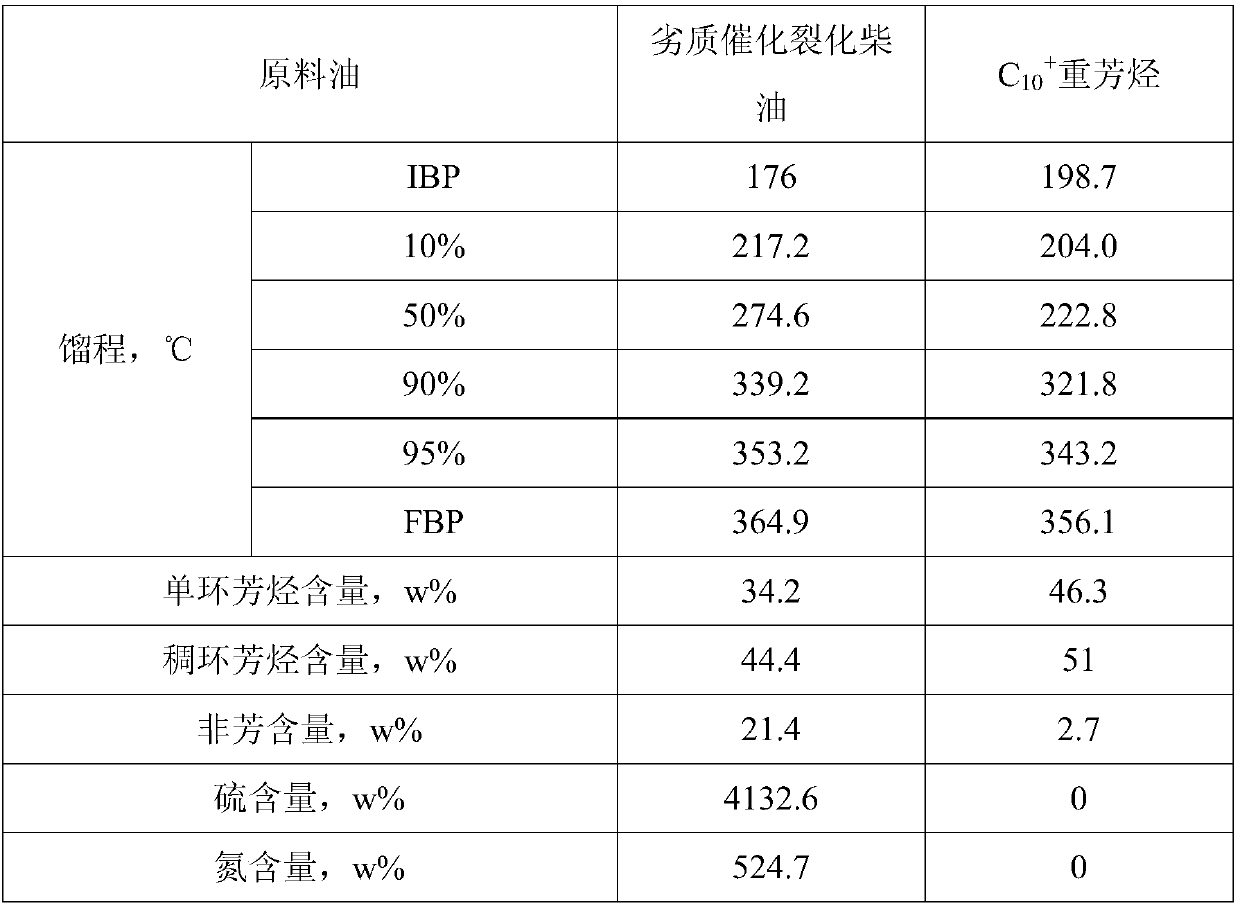

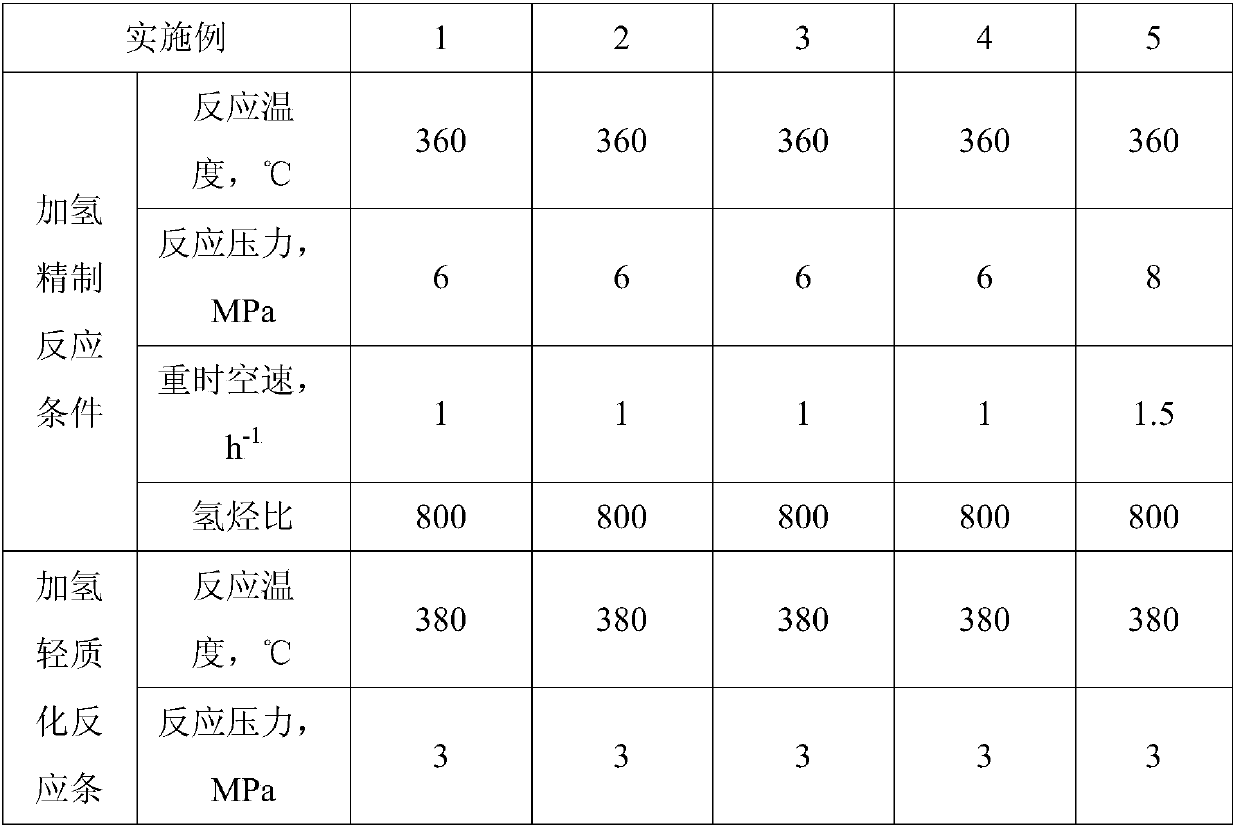

Combined technique for improving yield of high-octane gasoline by using inferior catalytic cracking diesel

ActiveCN106047404AAchieve ultra-deep removalAchieve maximum retentionTreatment with hydrotreatment processesHydrocarbon oils treatment productsPolycyclic aromatic hydrocarbonHydrogen atmosphere

The invention relates to a combined technique for improving yield of high-octane gasoline by using inferior catalytic cracking diesel. The combined technique comprises the following steps: firstly, carrying out polycyclic aromatic hydrocarbon selective hydrogenation, desulfurization and denitrification reaction on the inferior catalytic cracking diesel through a hydrofining reactor at a hydrogen atmosphere and under a relatively gentle refining condition; feeding a refined liquid-phase product into a reactor for conversion to light fraction and filled with a noble metal catalyst and carrying out hydrogenation conversion to light fraction; and finally, achieving the purpose of increasing the yield of the high-octane gasoline. By the technique, the inferior catalytic cracking diesel can be treated, and meanwhile, reforming C10+ heavy aromatics are converted to light fraction; the combined technique has relatively high gasoline fraction yield, gasoline fraction aromatics selectivity and liquid yield, and meanwhile, the inferior catalytic cracking diesel and the C10+ heavy aromatics are utilized effectively at high value.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Liquid-solid two-phase hydrogenation method

ActiveCN101381623AReduce dosageReduce lossesRefining to eliminate hetero atomsSolubilityLiquid product

The invention discloses a solid-liquid two phase hydrogenation method. In the method, the circulating hydrogen and a circulating hydrogen compressor are not used, hydrogen is mixed with fresh raw oil and circulating oil to form mixing material current in the presence of a solvent or a diluent, the mixing material current enters a reactor, a part of or all the circulating oil is mixed with the hydrogen, and enters the reactor from the catalyst bed interlayers through one path or a plurality of branch paths, a part of the reaction effluent is used as the circulating oil, and another part of the reaction effluent is separated to be the solvent or the diluent, the liquid product is the finished product, the gas with the volume percentage of between 0.1 and 15 percent is contained in the reactor according to the total volume of the reactor, and the solubility of the hydrogen in the solvent or the diluent is larger than that in the mixture of fresh raw oil and the solvent or the diluent.

Owner:CHINA PETROCHEMICAL CORP +1

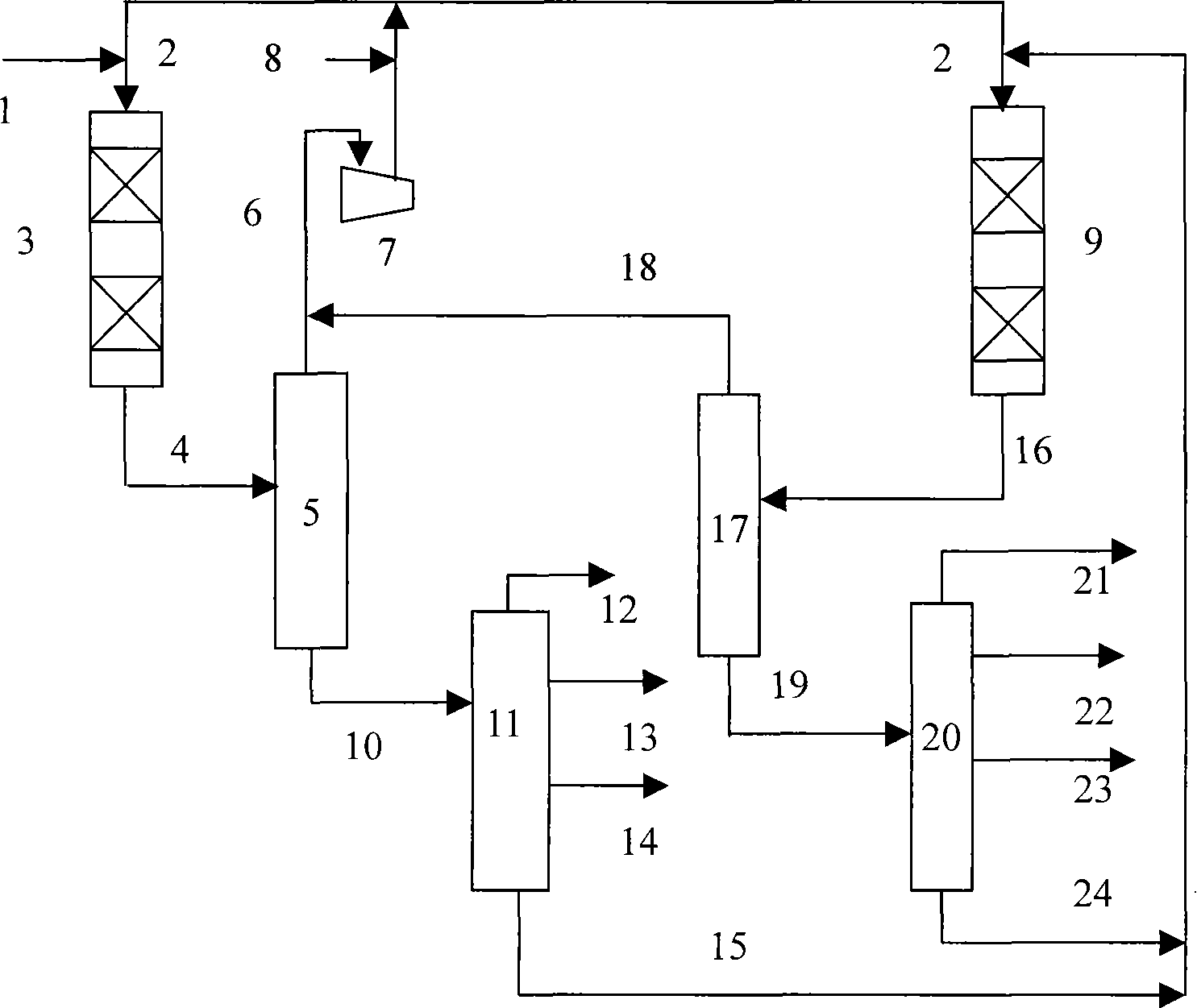

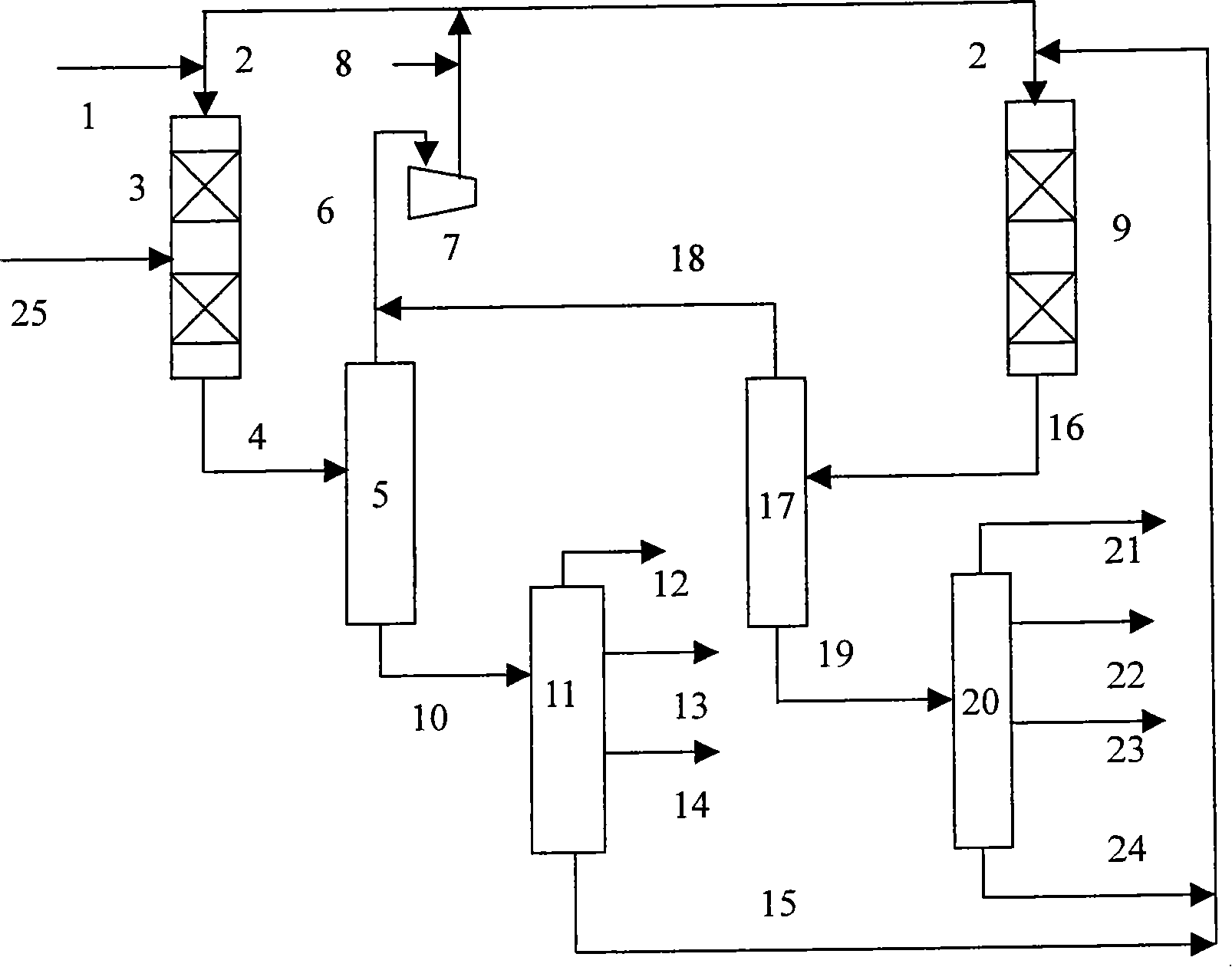

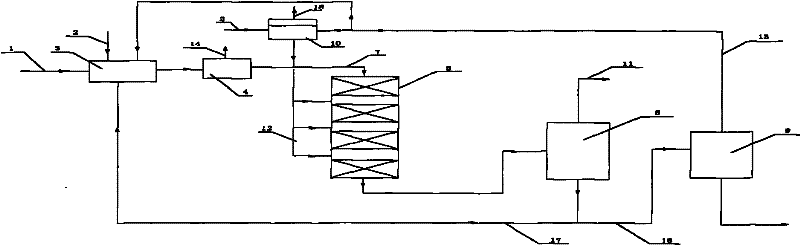

Hydrogenation processing method for f-t synthetic oil

ActiveCN101177626AEffective hydrotreatingGuaranteed long-term operationTreatment with hydrotreatment processesNaphthaHydrogen

The invention discloses a hydrogenation processing method of Fischer-Tropsch synthetic oil and the processing method is that the Fischer-Tropsch synthetic oil is subjected to hydrogenation processing in a plurality of hydrogenation processing reaction zones with different entrance temperatures. The entrance temperatures of hydrogenation processing reaction zones are raised by injecting hot hydrogen. The tail oil separated after hydrogenation processing is subjected to hydrogen cracking. Hydrogenation processing products and hydrogen cracking products enter different fractionating systems. The invention can acquire high-quality clean diesel oil with cetane value higher than 75 and low-freezing clean oil with solidifying point lower than 50 DEG C below zero, meanwhile, naphtha acquired is high-quality raw material used for producing ethylene by steam cracking.

Owner:SYNFUELS CHINA TECH CO LTD

Two-phase hydrogenation method for hydrocarbon oil

The invention discloses a method of hydrocarbon oil liquid-solid two-phase hydrogenation; the method avoids the recycle hydrogen and the recycle hydrogen compressor; hydrogen is mixed with fresh raw oil and a part of recycle oil under the existence of solvent or diluent; after the gas is separated in the mixer, the mixture is fed into the reactor and contacted with the catalyst for reaction; the other part of the recycle oil is mixed with hydrogen and solvent or diluent and the gas is separated; the mixture is all or partially fed into the bed of the catalyst; the effluent of the reaction is discharged from the bottom of the reactor for separation; the separated solvent or the diluent is used for recycle use; the liquid product is used as the product or the recycle oil; the solubility of hydrogen in solvent or diluent is more than the solubility of hydrogen in the mixture of fresh raw oil and solvent or diluent.

Owner:CHINA PETROCHEMICAL CORP +1

Mg-Al hydrotalcite-like compound catalyst for treating residual oil and extra heavy oil material and preparation method of Mg-Al hydrotalcite-like compound catalyst

InactiveCN107115853AStrong water and heat resistanceHigh content of saturated hydrocarbonsCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsWater vaporChemical products

The invention discloses an Mg-Al hydrotalcite-like compound catalyst for treating residual oil and extra heavy oil material and a preparation method of the Mg-Al hydrotalcite-like compound catalyst. The preparation method of the catalyst comprises the following steps: preparing a mixed aqueous solution of magnesium nitrate and aluminum nitrate; preparing an alkaline aqueous solution of sodium carbonate and sodium hydroxide; moreover, adding the mixed aqueous solution and the alkaline aqueous solution into water, stirring under the condition of keeping the pH value to be 9 to 12, and then performing preparation to obtain an Mg-Al hydrotalcite-like material; mixing the Mg-Al hydrotalcite-like material with size of clay and a binding agent, and sequentially performing spray drying and calcination, so as to obtain the Mg-Al hydrotalcite-like compound catalyst. The Mg-Al hydrotalcite-like compound catalyst can be directly used for the production of high quality gasoline and diesel oil through conventional catalytic cracking, is high in water-heat resistance, can be applied to a one-step method diesel oil preparation technology or the production of chemical products, such as olefin or arene, and realizes the maximum utilization of the resource value, moreover, synthesis gas with the H / C ratio being approximately 1 is prepared from a mixture of vapour and water as regeneration gas by adopting a vaporization and regeneration technology.

Owner:CHINA NAT OFFSHORE OIL CORP +2

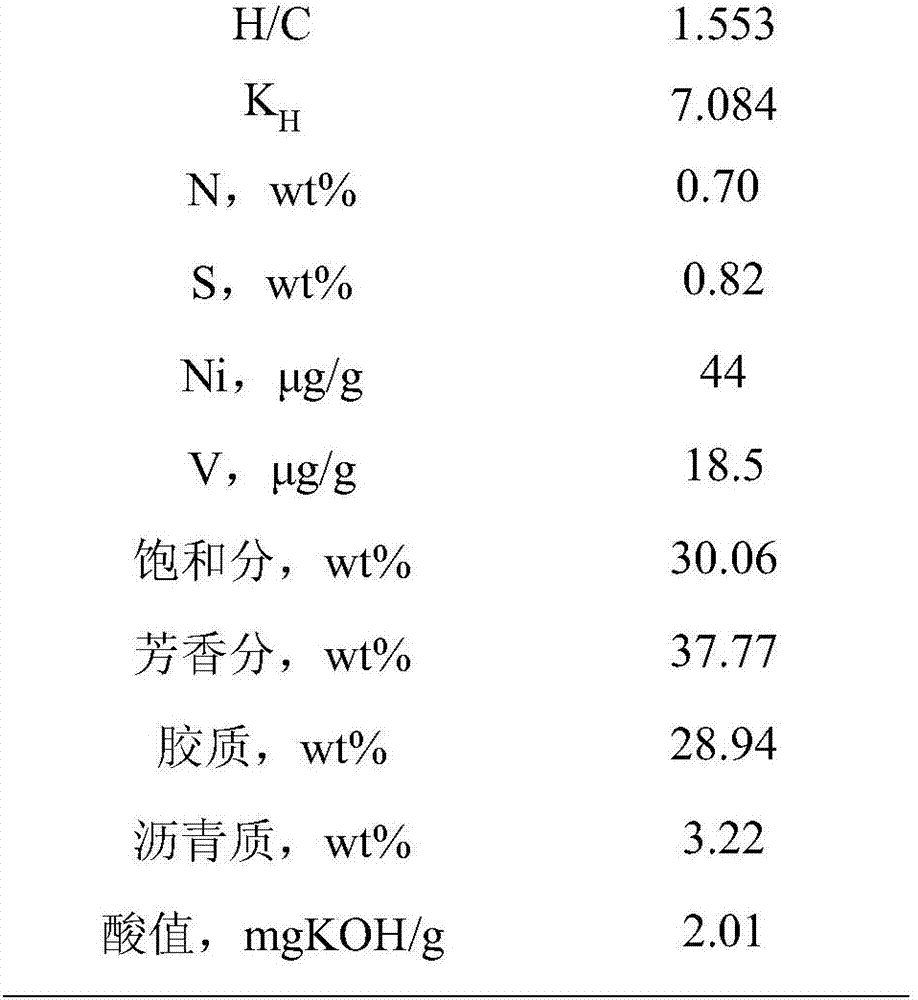

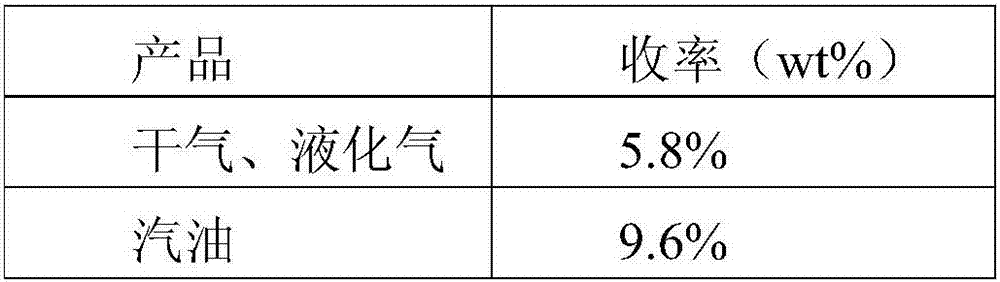

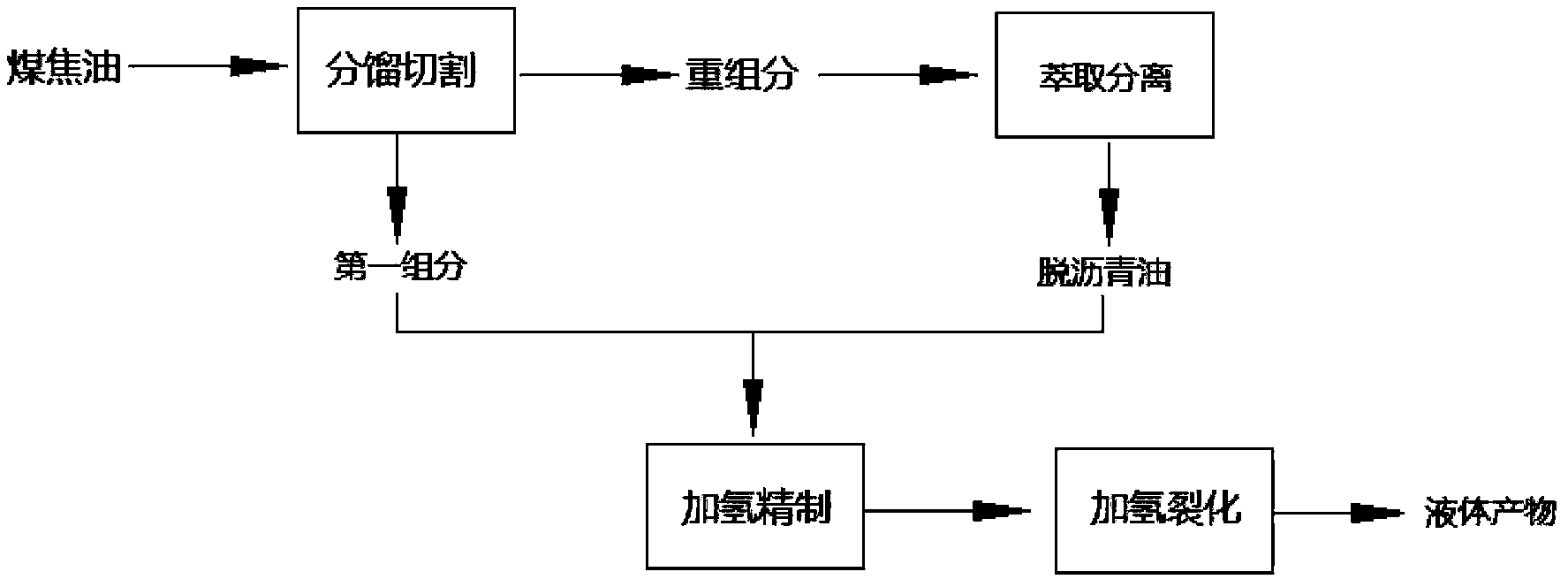

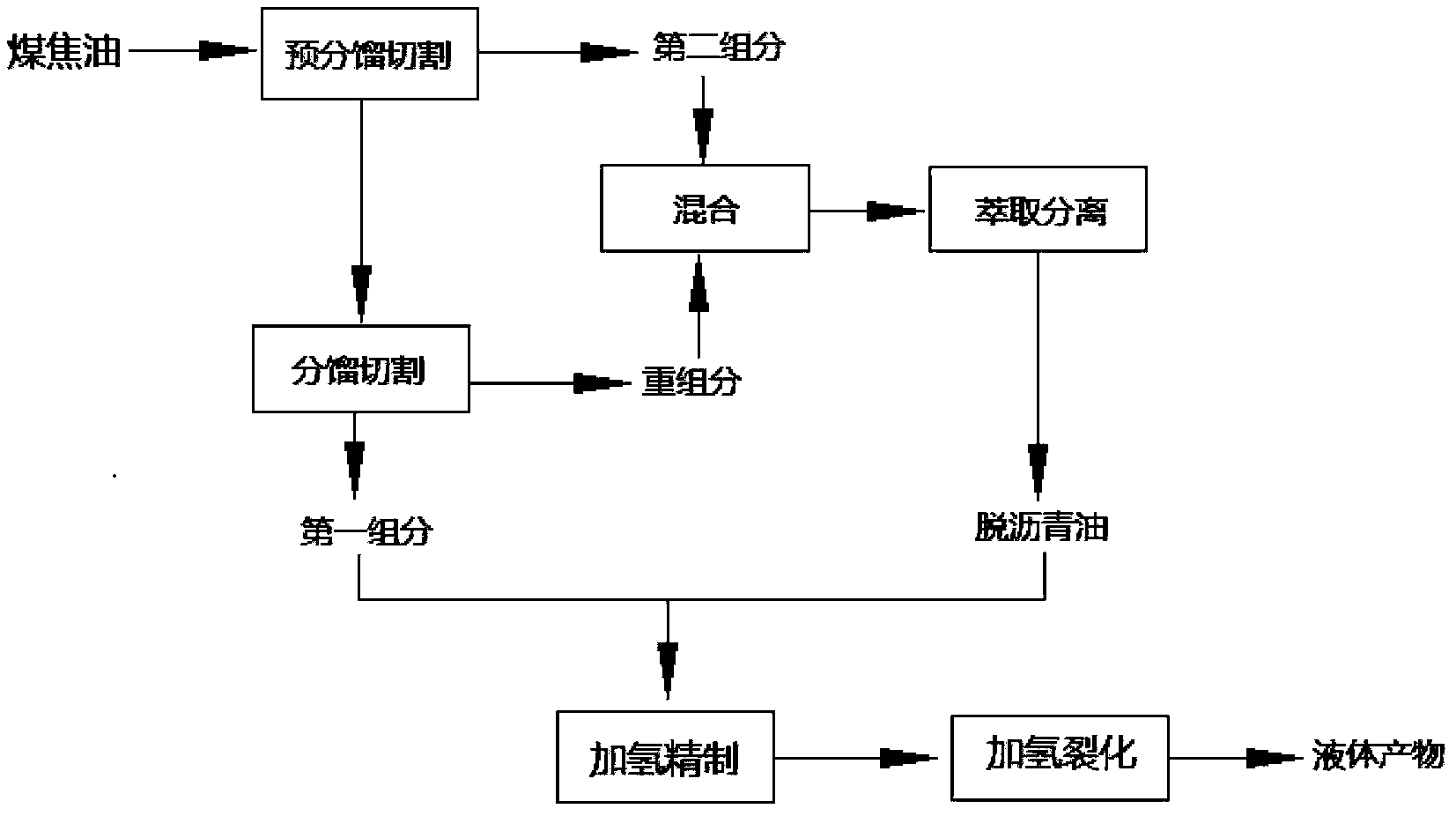

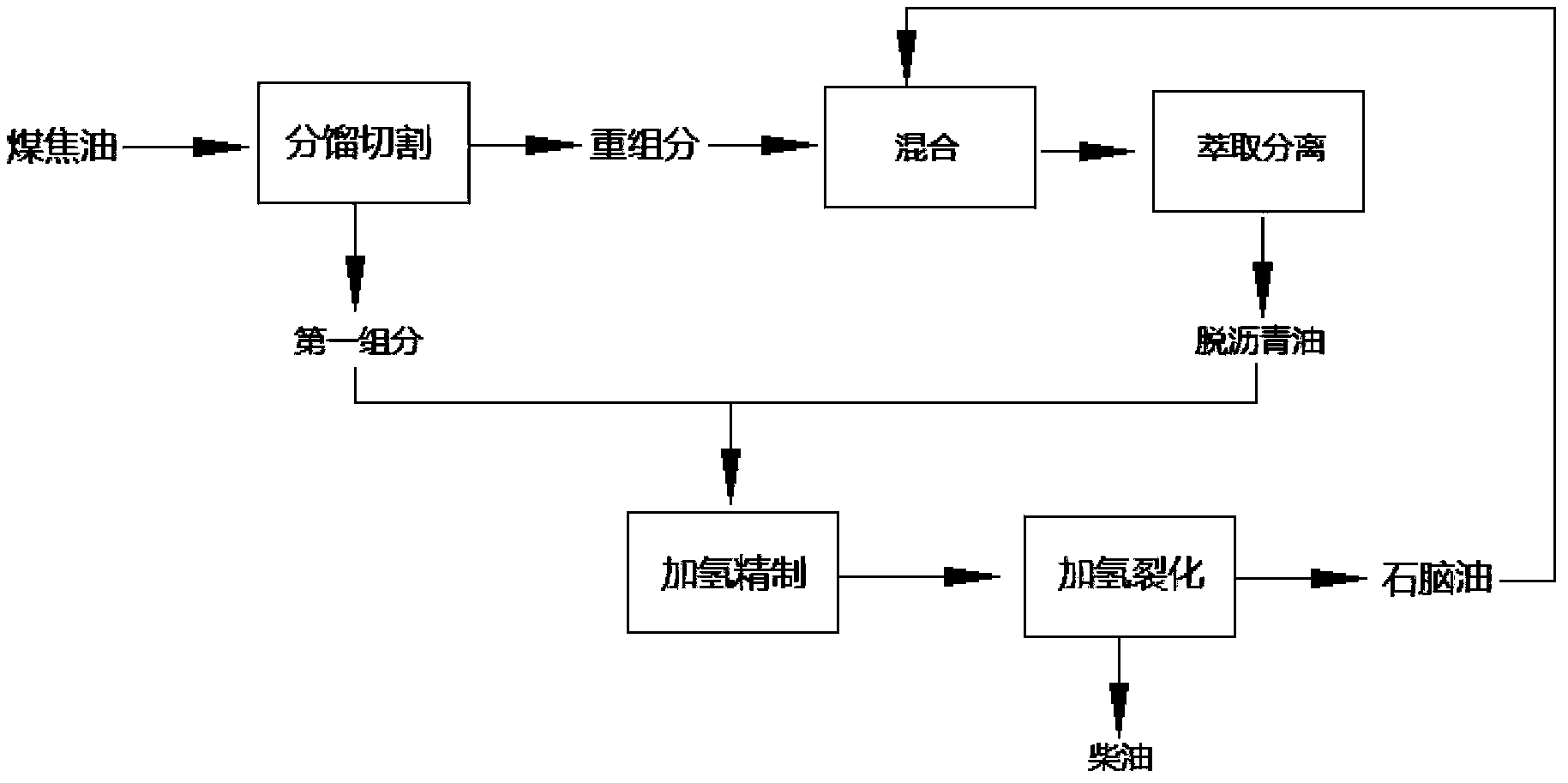

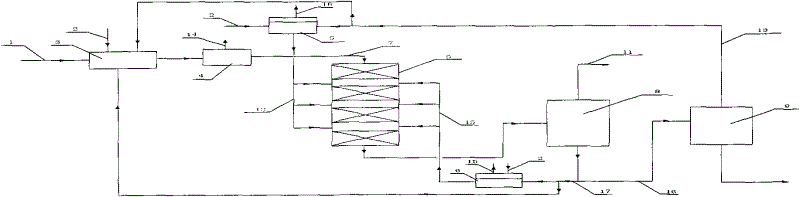

Coal tar hydrogenation upgrading method

ActiveCN104178212AIncrease the amount of hydrogenation feedstockHigh yieldTreatment with hydrotreatment processesChemistryCoal tar

The invention discloses a coal tar hydrogenation upgrading method. The method includes the following steps: carrying out fractionation cutting on coal tar to obtain a first component with the boiling temperature not higher than a cutting temperature of fractionation cutting and a heavy component with the boiling temperature higher than the cutting temperature of fractionation cutting, wherein the cutting temperature of fractionation cutting is not higher than 600DEG C; extracting and separating the heavy component by using an extraction agent to obtain deasphalted oil; and allowing the deasphalted oil and the first component to contact with a hydrogenation catalyst under hydrotreatment conditions. The method effectively improves the quantity of a hydrogenation raw material, increases the yield of each of naphtha and diesel, and can realize the comprehensive utilization of the coal tar. The method also can effectively reduce the amount of coke formed on the surface of the hydrogenation catalyst, prolongs the service life of the hydrogenation catalyst, allows a hydrogenation apparatus to stably run for a long time and naphtha and diesel oil with low sulfur and nitrogen content to be obtained even hydrotreating in a fixed bed reactor, and the obtained diesel has high cetane number.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

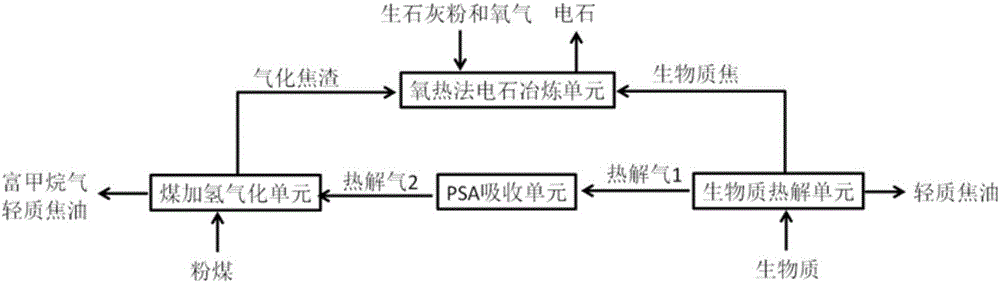

System and method for treating pulverized coal and biomass

InactiveCN106479541AReduce energy consumptionHigh quality pyrolysis gasChemical industryBiofuelsProcess engineeringOxygen

The invention discloses a system and a method for treating pulverized coal and biomass. The system comprises a biomass pyrolysis unit, an oil gas separation unit, a PSA (pressure swing adsorption) absorption unit, a pulverized coal hydrogasification unit and a calcium carbide smelting unit, wherein the biomass pyrolysis unit comprises a biomass inlet, a pyrolysis oil gas outlet and a biomass char outlet; the oil gas separation unit comprises a pyrolysis oil gas inlet, a pyrolysis oil outlet and a pyrolysis gas 1 outlet; the PSA absorption unit comprises a pyrolysis gas 1 inlet and a pyrolysis gas 2 outlet; the pulverized coal hydrogasification unit comprises a pulverized coal nozzle, pyrolysis gas 2 nozzles, a gasification char residue outlet and an oil gas outlet; the calcium carbide smelting unit comprises a biomass char inlet, a gasification char residue inlet, a powdery quick lime inlet, oxygen nozzles, a calcium carbide furnace gas outlet and a calcium carbide outlet. The pyrolysis gas is taken as a hydrogen source for hydrogasification, meanwhile, produced biomass char and gasification char residues obtained through hydrogasification are used for producing calcium carbide, system energy efficiency is improved, and quality-divided gradient utilization of biomass and coal is realized.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

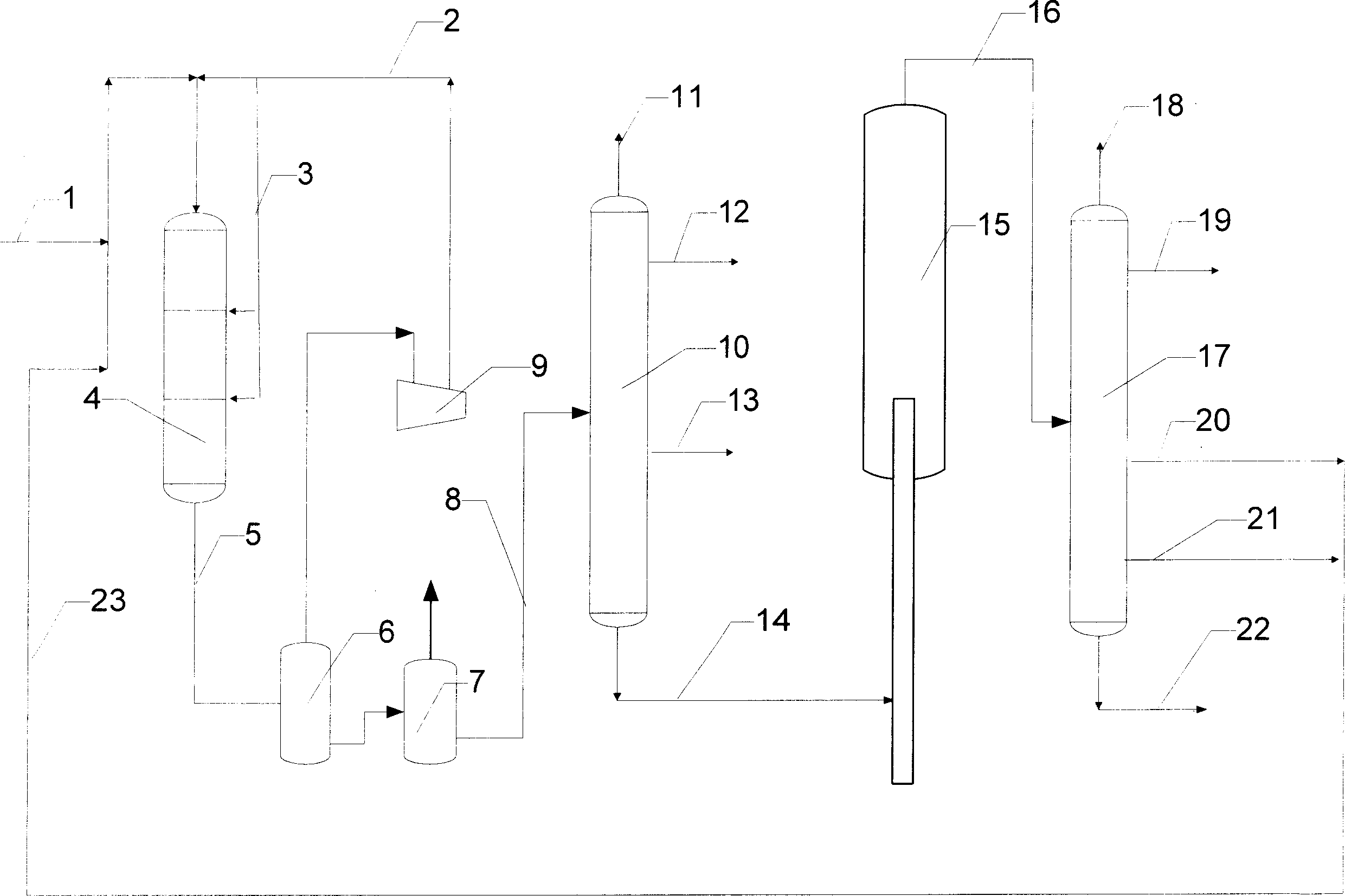

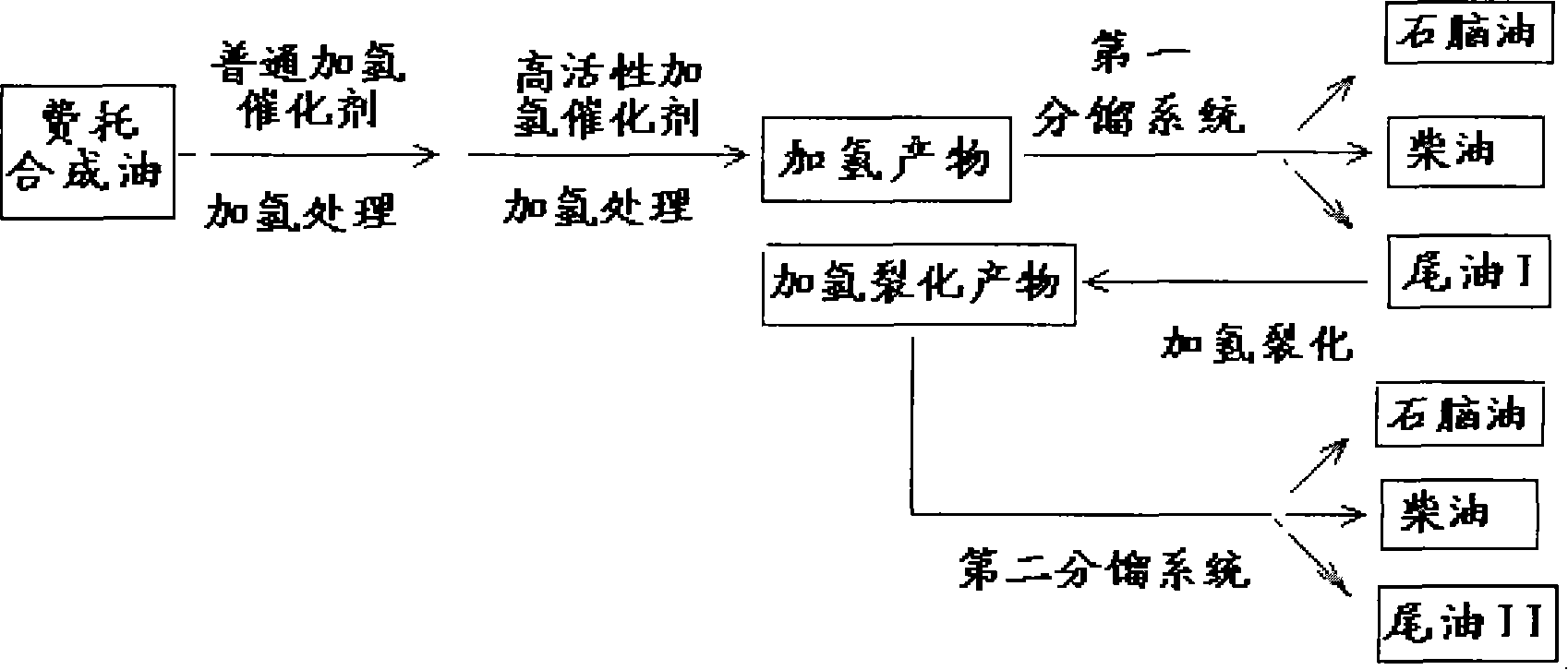

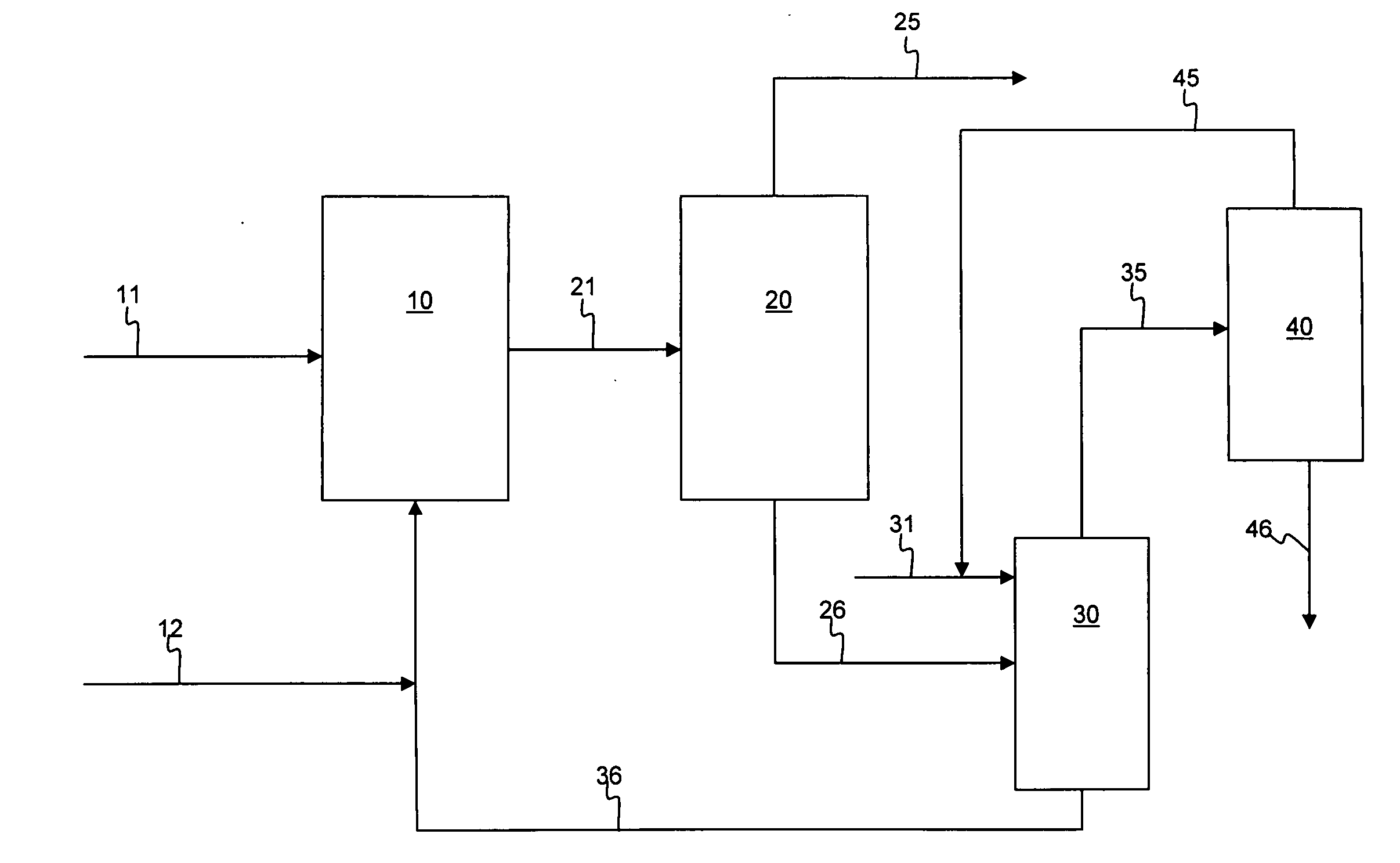

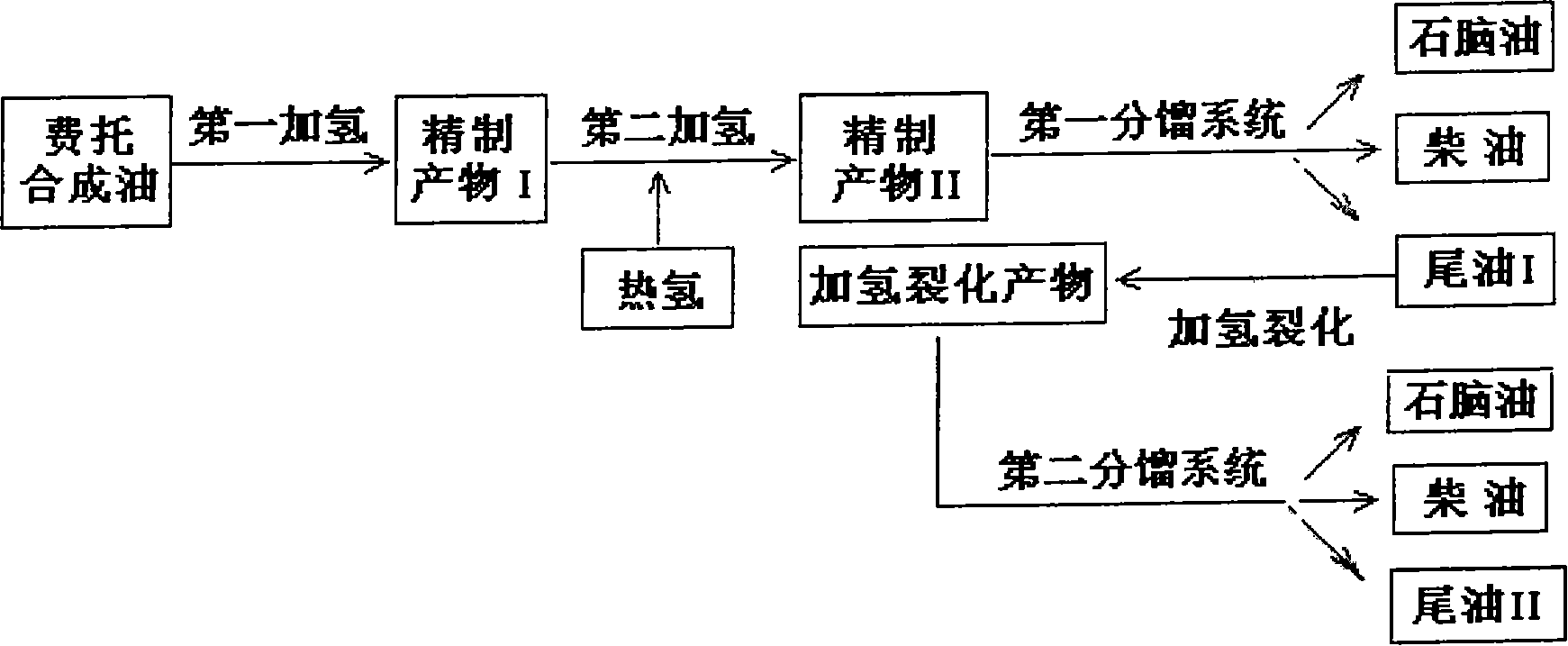

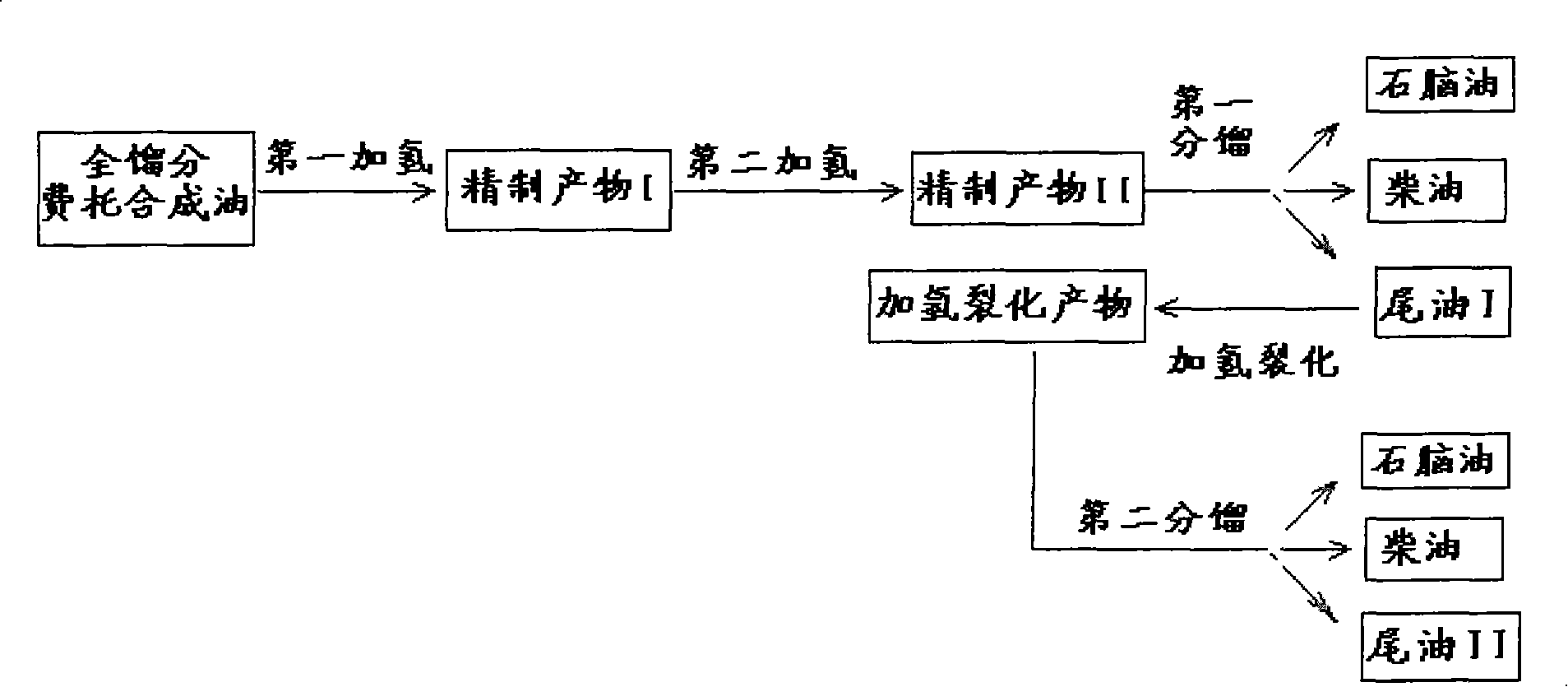

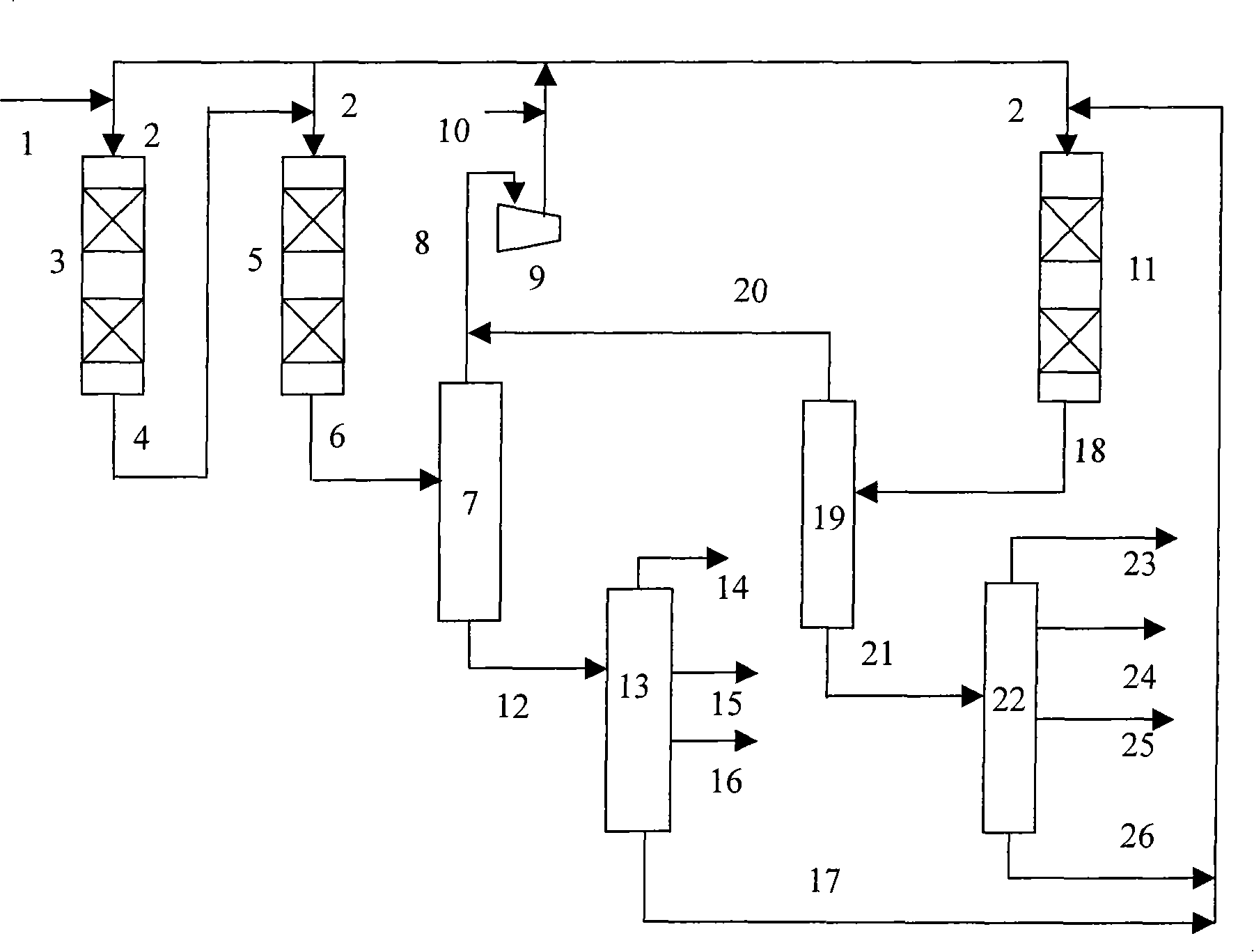

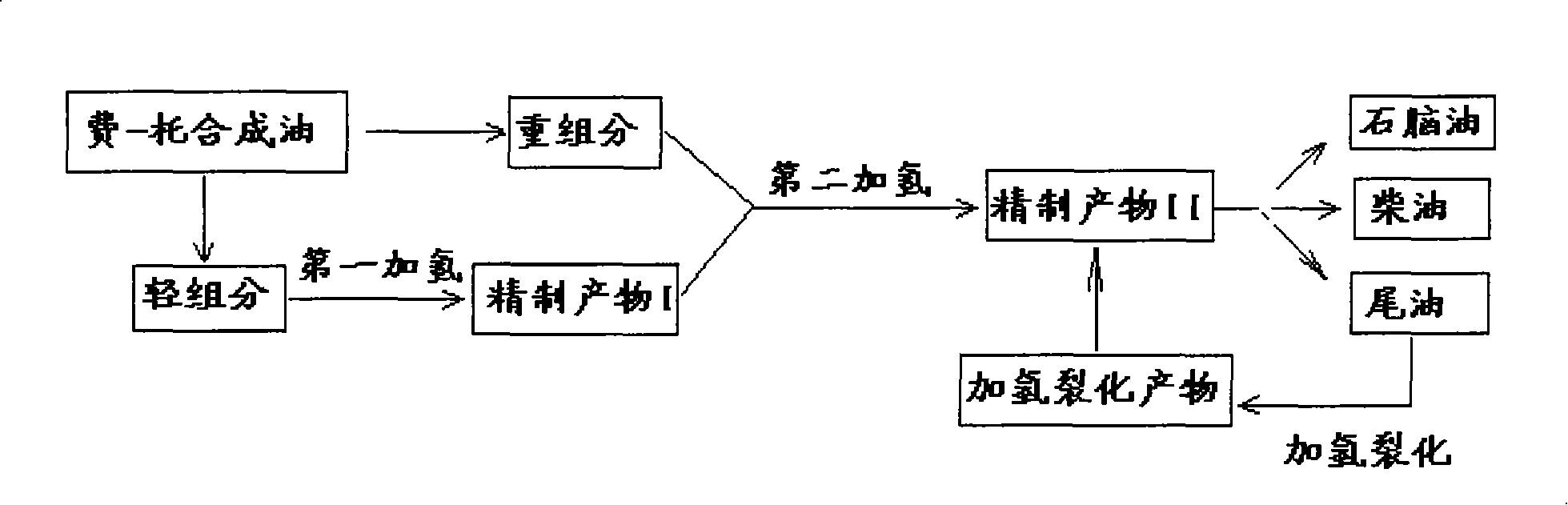

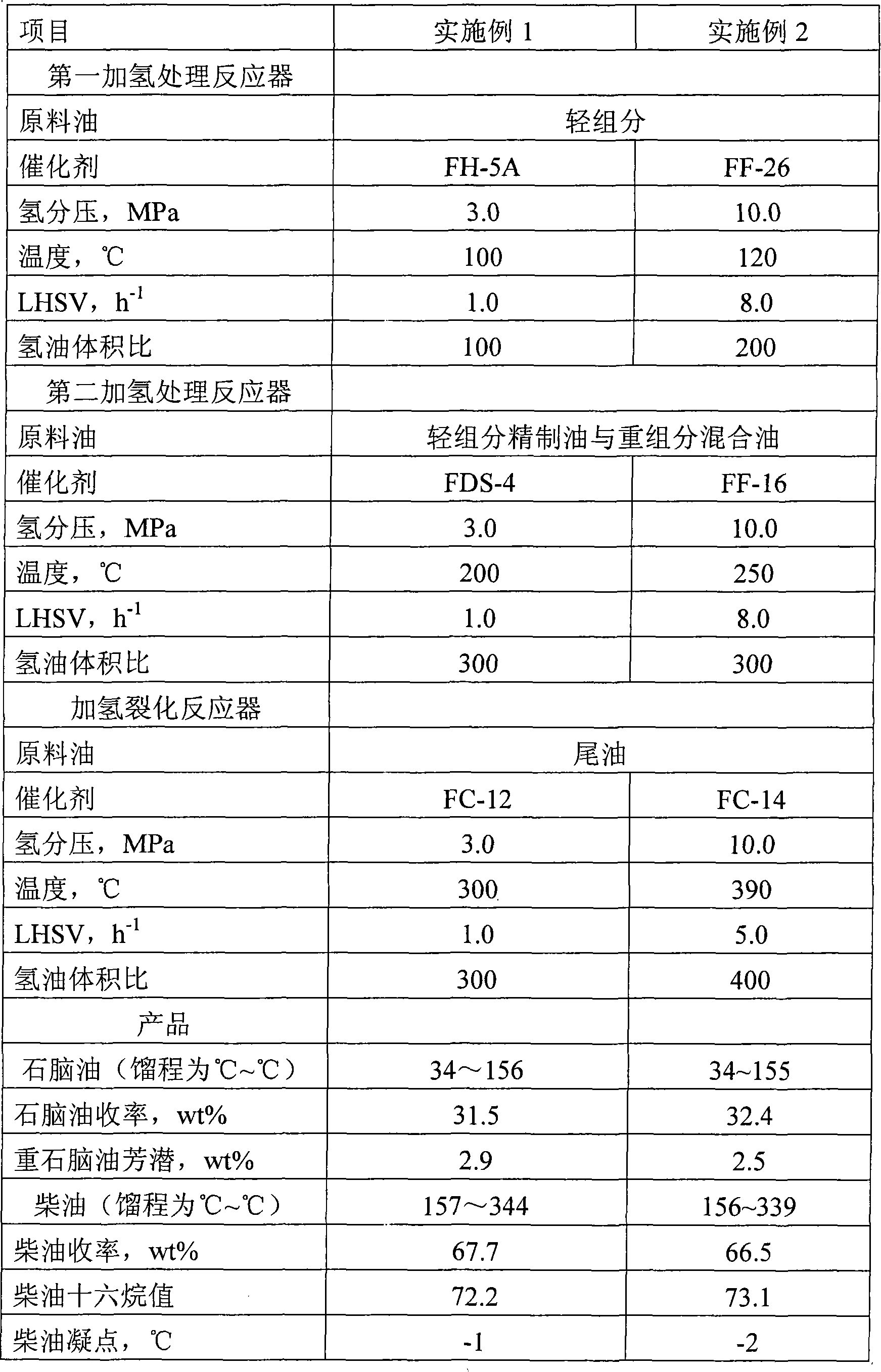

Hydrogenation processing method for full-range f-t synthetic oil

InactiveCN101177621AQuality improvementLow sulfur and nitrogen contentTreatment with hydrotreatment processesHydrogenNaphtha

The invention relates to a hydrogenation processing method of Fischer-Tropsch synthetic oil full cut and the method is that the Fischer-Tropsch synthetic oil full cut is subjected to two-step hydrogenation processing and then enters a first separation system; the tail oil obtained by separation undergoes hydrogen cracking and the hydrogen cracking products acquired enter a second separation system. The invention can acquire high-quality clean diesel oil with cetane value higher than 75 and excessively low-freezing clean oil with solidifying point lower than 50 DEG C below zero, meanwhile, naphtha acquired is high-quality raw material used for producing ethylene by steam cracking.

Owner:SYNFUELS CHINA TECH CO LTD

Double-phase hydrogenating method

The invention discloses a double-phase hydrogenating method. In the double-phase hydrogenating method, recycle hydrogen and a recycle hydrogen compressor are omitted, hydrogen is mixed with fresh raw oil and a part of recycle oil under the action of solvent or diluent to form mixture flow, the mixture flow enters a reactor and contacts with catalyst, after the rest recycle oil and the hydrogen gas are mixed to discharge gas, the gas in one channel or branches enters the reactor from catalyst bed layers of the reactor, the solvent or diluent is mixed with hydrogen gas to discharge gas, and the gas in one channel or branches enters the reactor from the catalyst bed layers of the reactor. Reaction effluence is subjected to liquid gas separation, liquid phase is further separated to obtain solvent or diluents for recycling, and a part of separated liquid products is utilized as products and the other part of separated liquid products is utilized as recycle oil.

Owner:CHINA PETROCHEMICAL CORP +1

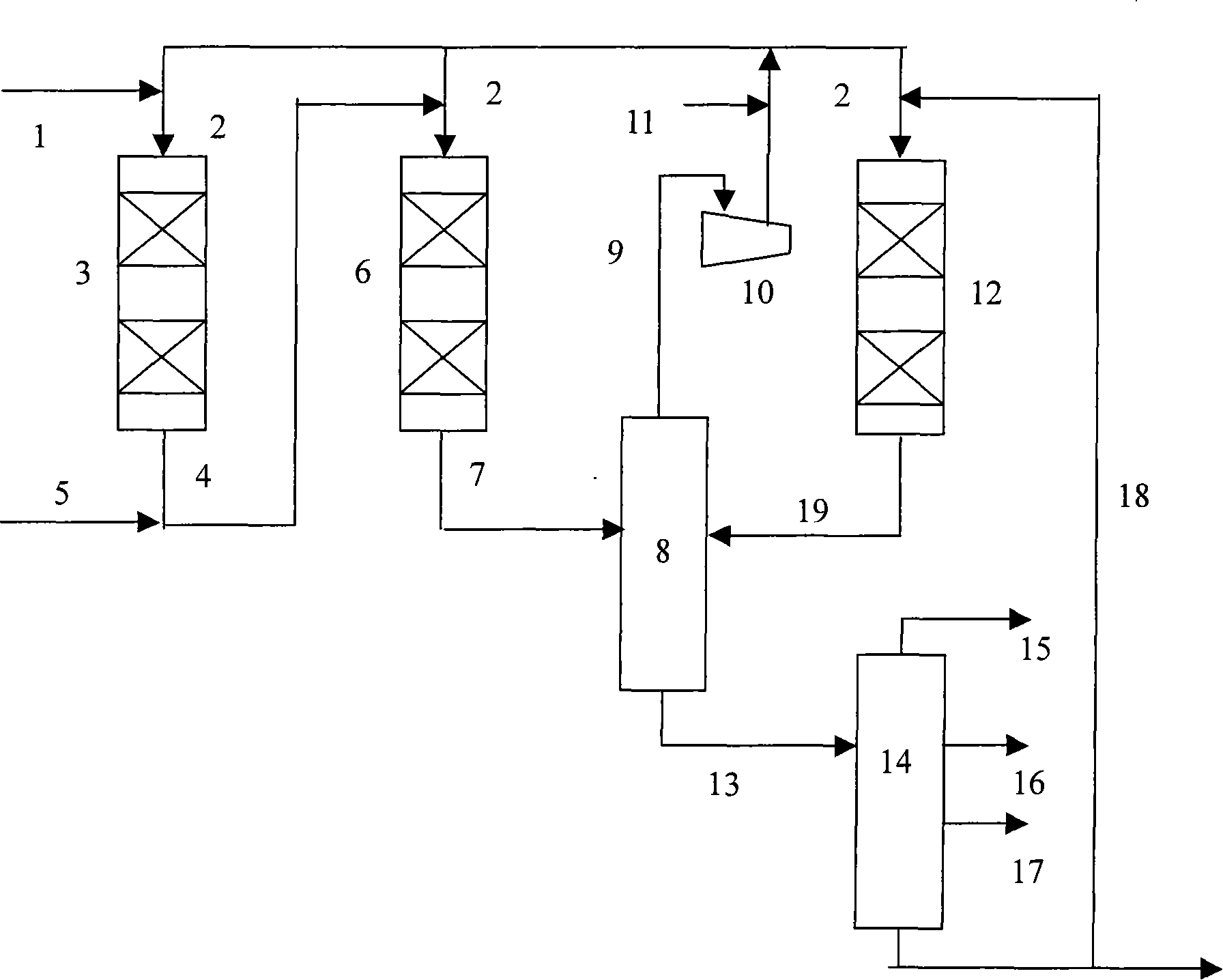

Hydrogenation processing method for f-t synthetic oil

InactiveCN101177627ALowering the freezing pointReduce the impactTreatment with hydrotreatment processesLiquid productHigh pressure

The invention discloses a hydrogenation processing method of Fischer-Tropsch synthetic oil and the method is that the Fischer-Tropsch synthetic oil is divided into lightweight cut and heavyweight cut which are mixed with synthetic wax after prerefining and then are subjected to hydrogenation processing; the products of the hydrogenation processing enter a first high-pressure separator and the liquid products separated enter a fractionating system through a low-pressure separator; the separated hydrogen-rich gas is mixed with heavy component separated from the fractionating system and then is subjected to hydrogen cracking; cracking products enter a second high-pressure separator and the separated liquid products enter the same low-pressure separator and fractionating system with the hydrogenation processing; the separated hydrogen-rich gas is pressurized by a circulating hydrogen compressor and is mixed with new supplementary hydrogen and then enters a hydrogen preprocessing reactor. Cetane value of diesel oil acquired is higher than 70, solidifying point is below 0 DEG C and the content of sulfur and nitrogen is extremely low, meanwhile, naphtha acquired is high-quality raw material used for producing ethylene by steam cracking.

Owner:SYNFUELS CHINA TECH CO LTD

Hydro-cracking method for f-t synthetic oil

InactiveCN101177624AQuality improvementLow sulfur and nitrogen contentTreatment with hydrotreatment processesMineralogyNaphtha

The invention relates to a hydrogen cracking method of Fischer-Tropsch synthetic oil, which divides Fischer-Tropsch synthetic oil cut into light component and heavy component, wherein, the light is subjected to moderate hydrogenation processing; hydrogenation processing products and the heavy component are subjected to a second hydrogenation processing, products of which undergo separation and the separated tail oil is treated with hydrogen cracking, products of which and the products of the second hydrogenation processing enter a same separation system. Cetane value of diesel oil acquired from fractionation of liquid phase by employing the method of the invention is higher than 70, solidifying point is below 0 DEG C and content of sulfur and nitrogen is extremely low; therefore, the diesel oil acquired can produce 0 model high-quality clean diesel oil and can also serve as high-quality harmonic component to promote the cetane value of diesel oil; meanwhile, the naphtha acquired is high-quality raw material used for producing ethylene by steam cracking.

Owner:SYNFUELS CHINA TECH CO LTD

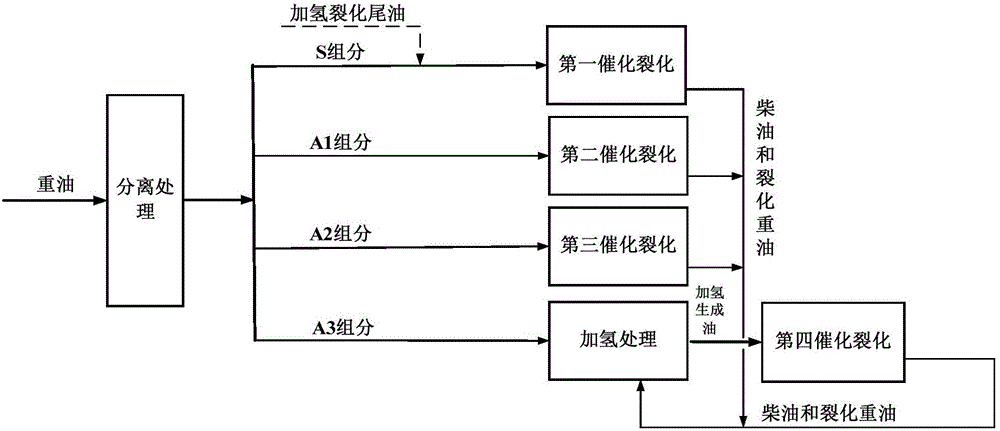

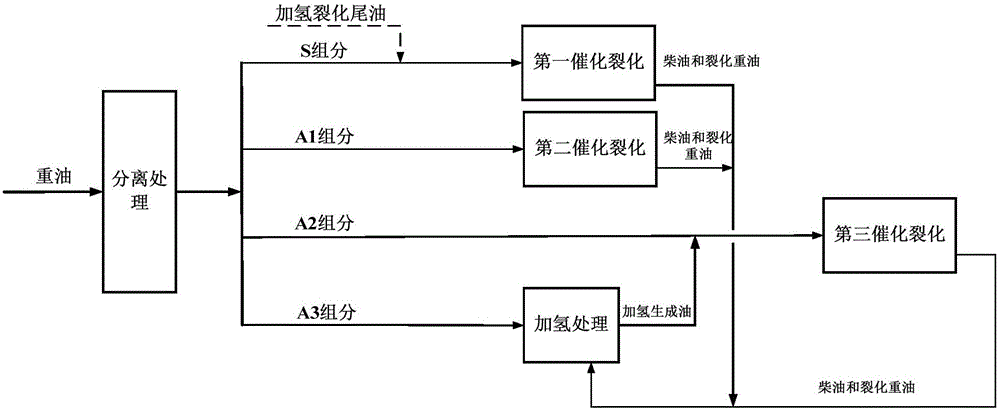

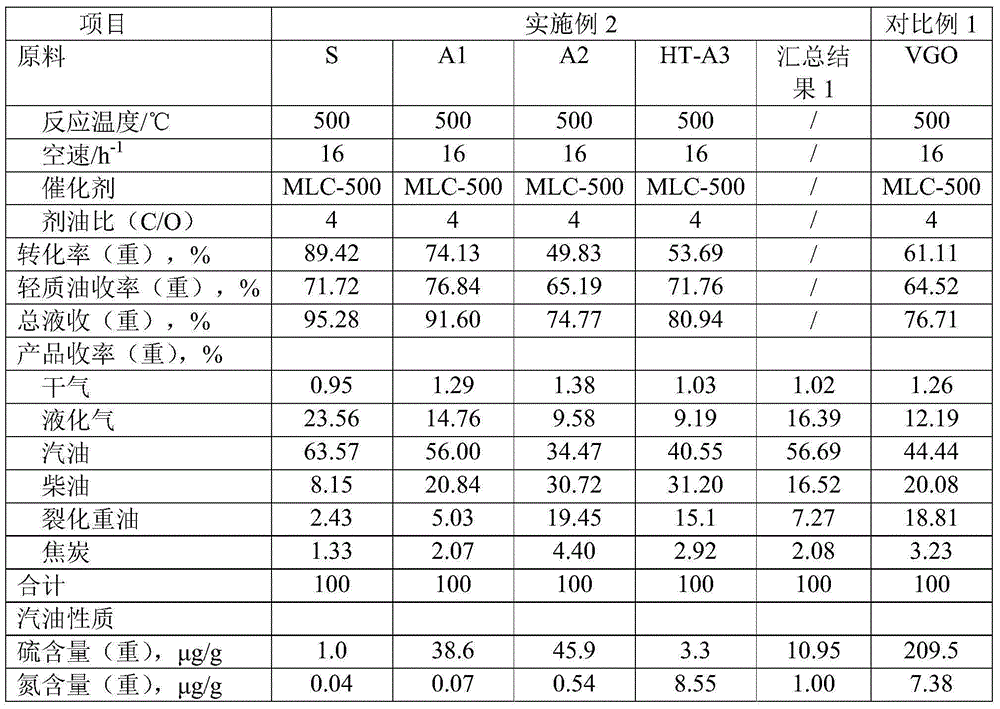

Heavy oil separation-hydrotreatment-catalytic cracking combined method

ActiveCN106467757AEliminate interactionIncrease profitTreatment with hydrotreatment processesSulfurNitrogen

The invention discloses a heavy oil separation-hydrotreatment-catalytic cracking combined method. the method comprises the following steps: a, separating heavy oil to obtain a component S, a component A1, a component A2 and a component A3; and b, carrying out a first catalytic cracking reaction on the component S obtained in the step a, so as to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil; carrying out a second catalytic cracking reaction on the component A1 obtained in the step a, so as to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil; carrying out a third catalytic cracking reaction on the component A2 obtained in the step a, so as to obtain dry gas, liquefied gas, gasoline, diesel oil, coke and cracked heavy oil; and carrying out a hydrotreatment reaction on the component A3 obtained in the step a under the action of a hydrotreating catalyst, so as to obtain hydrogenated oil. In comparison with the prior art, the method for heavy oil treatment and the subsequent catalytic cracking reactions has advantages of higher yield of gasoline and liquefied gas and lower sulfur / nitrogen content of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

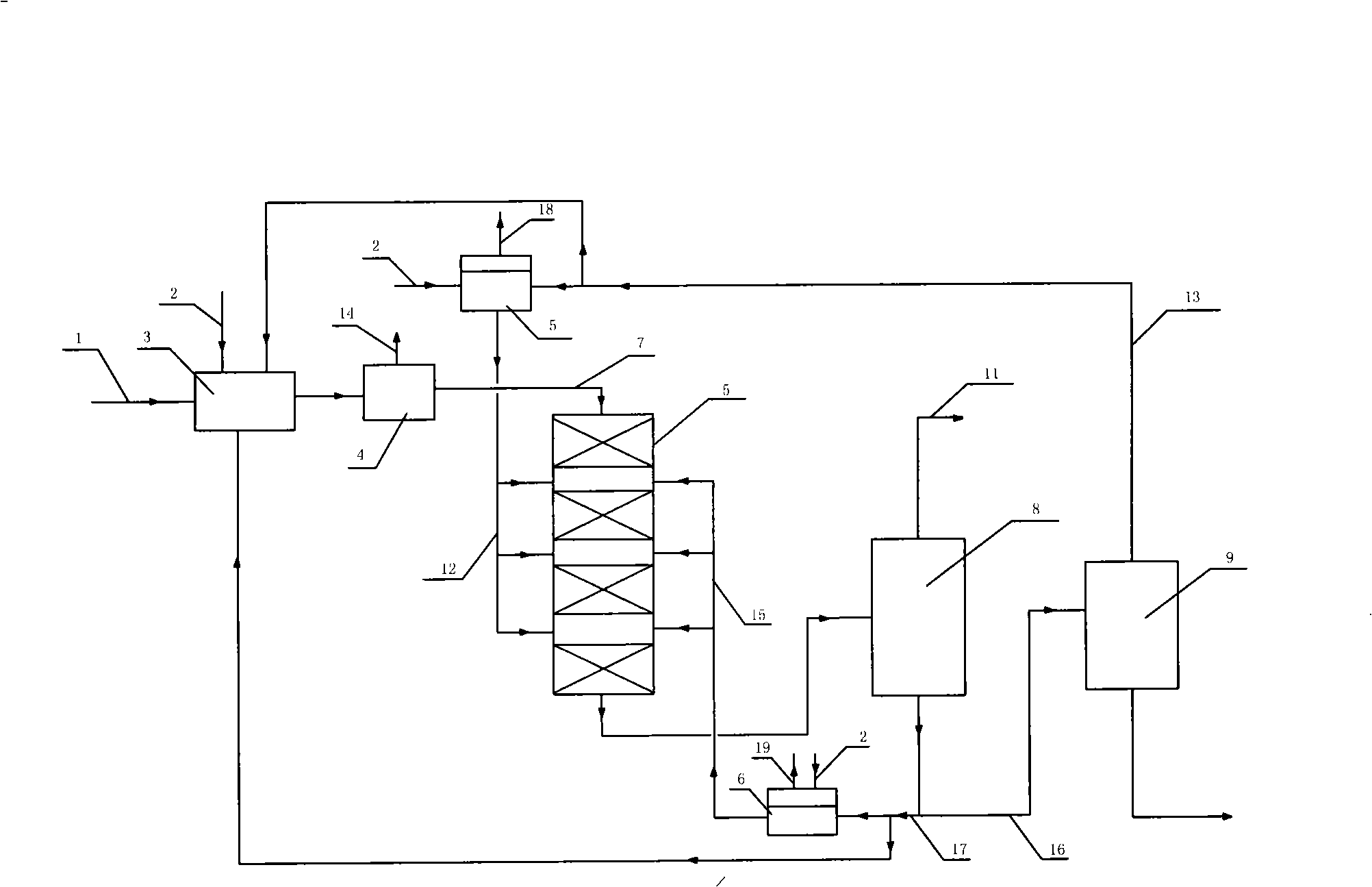

Two-way combined process of wax-oil hydrogenation treatment and catalytic cracking

ActiveCN100434496CLow aromatic contentLow sulfur and nitrogen contentTreatment with hydrotreatment processesWaxNaphtha

A two-way combined process of wax oil hydro-process and catalytic crack is carried out by entering wax oil, catalytic cracking re-circulating oil and catalytic cracking diesel oil into hydro-processor, hydrogenation reacting under existence of hydrogen and hydrogenation catalyst, separating for reactant to obtain gas, hydrogenation naphtha oil, hydrogenation diesel oil and hydrogenation tail oil, entering hydrogenation tail oil into catalytic cracker, crack reacting under existence of catalytic cracking agent, separating to obtain dry gas, liquefied gas, catalytic cracking gasoline, catalytic cracking diesel oil and catalytic cracking re-circulating oil and oil slurry, and circulating for catalytic cracking diesel oil and catalytic cracking re-circulating oil to hydro-processor. It has higher recovery rate and cetyl value, less sulfur content, arene content and coke output.

Owner:CHINA PETROLEUM & CHEM CORP +1

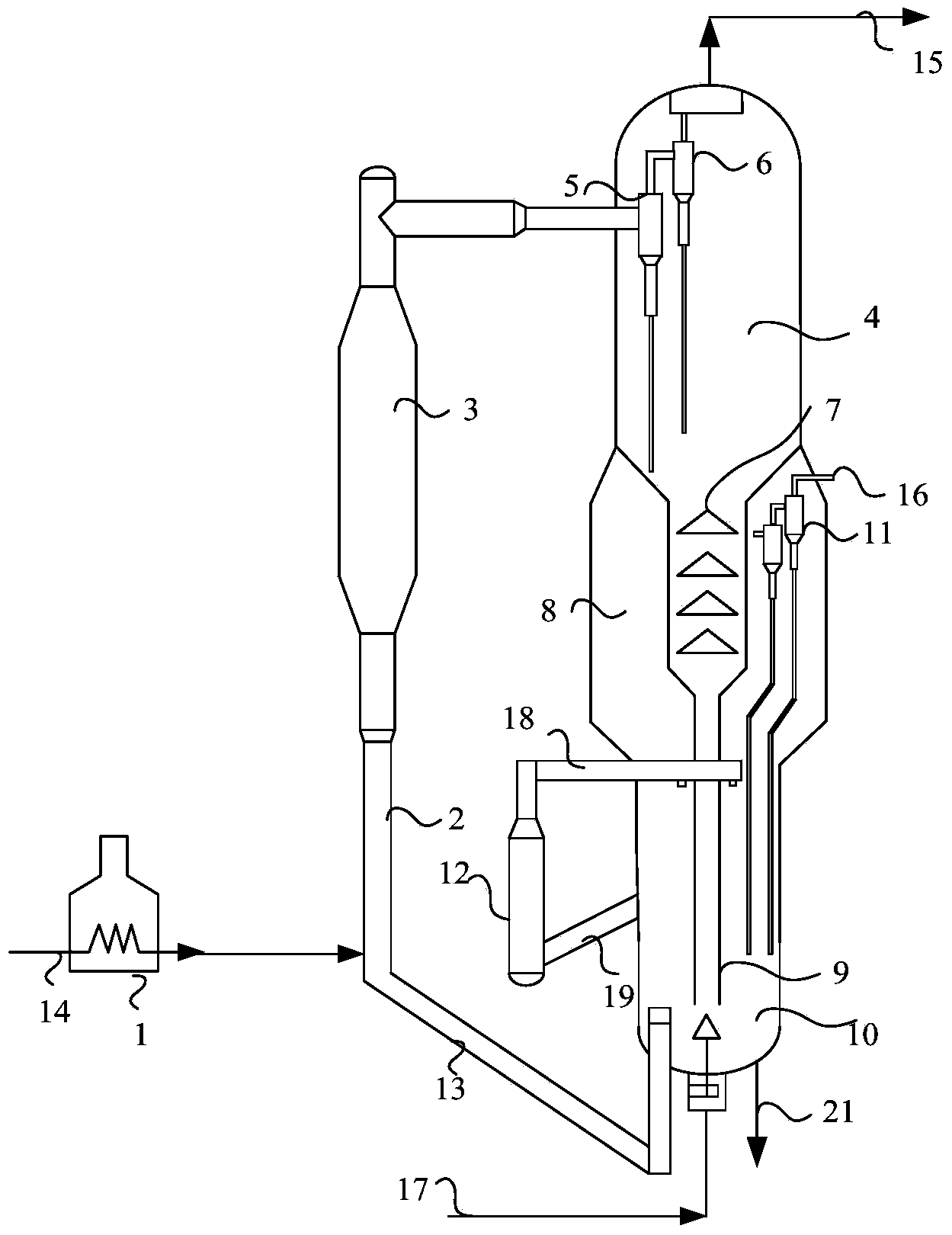

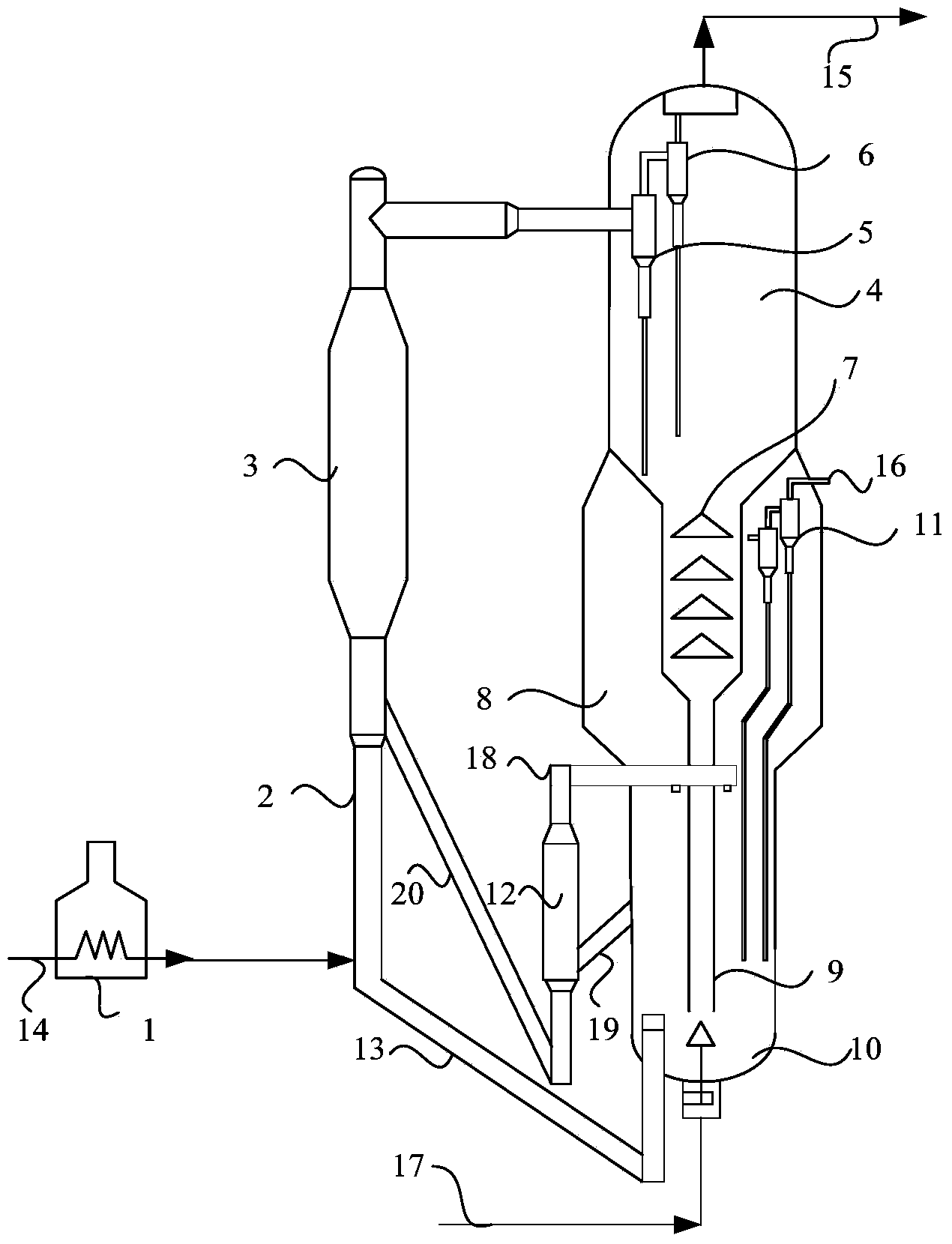

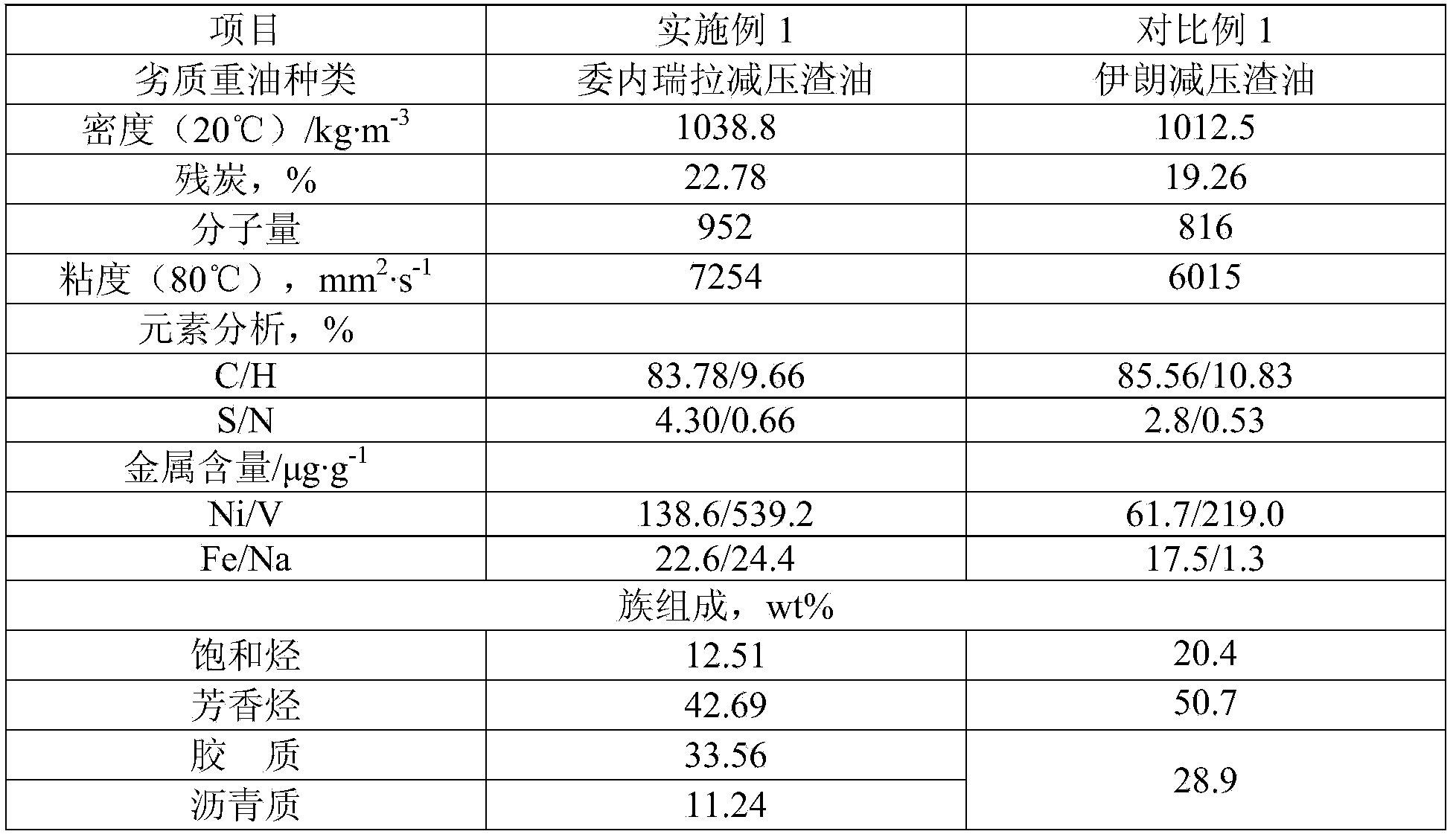

Method for processing inferior heavy oil

ActiveCN103509596AAdvanced removal rateAdvanced carbon removal rateCatalytic crackingTreatment with plural serial stages onlyLiquid productActivity index

The invention provides a method for processing inferior heavy oil. The method comprises the following steps: adopting a riser and a bed reactor to preheat the inferior heavy oil raw material, injecting the preheated raw material in a riser reactor, keeping the raw material in contact with solid catalysis grains in the riser and taking reaction, controlling the riser reaction temperature at 550-610 DEG C, introducing the oil gas after reaction to the upper-layer tandem bed reactor through the riser reactor to continuously react, keeping the bed reactor temperature at 440-520 DEG C, and weight hourly space velocity at 0.5-5 h-1, separating the oil gas after reaction from the contained solid catalysis grains, and sending the oil gas to a fractionating system, wherein the specific surface area of the solid catalysis grains is larger than 80 m<2> . g<-1>; the pore volume is larger than 0.22 ml / g; the abrasion index is smaller than 2.0%; the micro-activity index is 20-50. The method provided by the invention can effectively remove carbon residue, heavy metal, asphaltene and other impurities from the inferior heavy oil, synchronously obtain higher yield of the liquid product, and is simple in the processing technology.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for biphase hydrogenation of hydrocarbon oil

The present invention discloses a method for biphase hydrogenation of hydrocarbon oil. According to the method, recycle hydrogen and a recycle hydrogen compressor are cancelled; hydrogen is mixed with fresh raw oil and one part of recycle oil in the presence of a solvent or a diluent to form a mixture flow, and the mixture flow enters a reactor to contact with a catalyst; after the other part of the recycle oil is mixed with the hydrogen and the gas is discharged, an obtained mixture enters the reactor by a path or branches from spaces between catalyst bed layers of the reactor; after the solvent or the diluent is mixed with the hydrogen and the gas is discharged, an obtained mixture enters the reactor by a path or branches from spaces between catalyst bed layers of the reactor; the reaction effluent is subjected to gas-liquid separation, and the liquid phase is further separated to obtain the solvent or the diluent, wherein the separated solvent or the separated diluent is used for recycle use; and the partial separated liquid product is used as the product, and the partial separated liquid product is used as the recycle oil.

Owner:CHINA PETROCHEMICAL CORP +1

Combined method for producing high-quality lubricant base oil and environment-friendly aromatic hydrocarbon oil

ActiveCN111378499AEliminate steric hindranceImprove denitrification effectTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonEnvironmental engineering

The invention discloses a combined method for producing lubricant base oil and environment-friendly aromatic hydrocarbon oil. API I lubricant base oil with very low polycyclic aromatic hydrocarbon content produced by three old processes is subjected to solvent extraction, and the extraction depth is controlled, so that aromatic hydrocarbon in raffinate oil is further reduced; then through hydrofining and hydro-upgrading, the color and stability are improved, the viscosity index is increased, and the indexes of API III type lubricant base oil are reached; meanwhile, the aromatic hydrocarbon isenriched into the extract oil, so that the content of polycyclic aromatic hydrocarbon (3.0%, aromatic hydrocarbon content) in the extract oil is 20%, and the excellent rubber filling oil for the tireindustry is obtained. According to the method disclosed by the invention, two products with high additional values can be obtained at the same time by modifying the base oil I; and the method has theadvantages of high target product yield, low operation cost and no waste treatment in the processing process.

Owner:CHINA PETROLEUM & CHEM CORP +1

A combined process method for increasing the production of high-octane gasoline by inferior catalytic cracking diesel oil

ActiveCN106047404BAchieve ultra-deep removalAchieve maximum retentionTreatment with hydrotreatment processesHydrocarbon oils treatment productsPolycyclic aromatic hydrocarbonPtru catalyst

The invention relates to a combined technique for improving yield of high-octane gasoline by using inferior catalytic cracking diesel. The combined technique comprises the following steps: firstly, carrying out polycyclic aromatic hydrocarbon selective hydrogenation, desulfurization and denitrification reaction on the inferior catalytic cracking diesel through a hydrofining reactor at a hydrogen atmosphere and under a relatively gentle refining condition; feeding a refined liquid-phase product into a reactor for conversion to light fraction and filled with a noble metal catalyst and carrying out hydrogenation conversion to light fraction; and finally, achieving the purpose of increasing the yield of the high-octane gasoline. By the technique, the inferior catalytic cracking diesel can be treated, and meanwhile, reforming C10+ heavy aromatics are converted to light fraction; the combined technique has relatively high gasoline fraction yield, gasoline fraction aromatics selectivity and liquid yield, and meanwhile, the inferior catalytic cracking diesel and the C10+ heavy aromatics are utilized effectively at high value.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

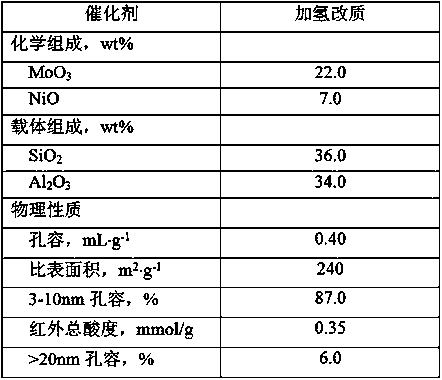

Preparation method of hydrofining catalyst for high-activity coker gasoline

ActiveCN103521236AImprove stabilityInhibit cokingMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsReaction temperatureGasoline

The invention discloses a preparation method of a hydrofining catalyst for high-activity coker gasoline. The preparation method is characterized in that the hydrofining catalyst is prepared by one-time co-impregnation roasting of a TiO2-Al2O3 carrier and an impregnating solution; the carrier employs a TiO2-Al2O3 composite carrier; the impregnating solution contains elements of Mo, Ni, W, Co, P and Mg, and additives; after impregnation roasting, a Mo-Ni-W-Co-Mg-P / TiO2-Al2O3 hydrotreating catalyst with specific surface area of 150-250 m<2> / g, pore volume of 0.3-0.8 ml / g, pore size of 6-11 nm and strength higher than 120 N / cm is obtained. The TiO2, MgO and additives added in the hydrotreating catalyst can enhance dispersion and stability of the active metal elements, so that the catalyst gains high hydrogenation activity, enables the coker gasoline to carry out hydrofining at lower reaction temperature, slows the rate of coking and has good desulfurization and denitrification effects.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com