Mg-Al hydrotalcite-like compound catalyst for treating residual oil and extra heavy oil material and preparation method of Mg-Al hydrotalcite-like compound catalyst

A hydrotalcite and catalyst technology, applied in the field of Mg-Al hydrotalcite catalyst and its preparation, can solve problems such as difficulty and achieve the effects of strong hydrothermal resistance, high liquid yield, and realization of resource value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1, co-precipitation method prepares Mg-Al hydrotalcites

[0077] (1) Mg(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O is formulated as an aqueous solution at a Mg / Al molar ratio of 3:1.

[0078] (2) Weigh a certain amount of Na 2 CO 3 and NaOH dissolved in deionized water to form a mixed solution, where n(CO 3 2- ) / n(A1 3+ )=2, n(NaOH) / n(Mg 2+ +Al 3+ )=2, n refers to the number of moles.

[0079] (3) Pour the above two solutions into deionized water evenly, keep the temperature at 70° C., stir vigorously, and keep the pH at 11.

[0080] (4) Continue aging at 70° C. for 16 hours, filter and wash until the pH value is 7.

[0081] (5) Dry at 80°C for 12 hours to obtain the Mg-Al hydrotalcite-like material.

[0082] (6) Pour 75g of aluminum sol and 25g of kaolin into a 1000ml beaker to mix, add 500g of deionized water to make a slurry, and stir evenly; then slowly and uninterruptedly pour 36ml of 34% nitric acid, continue to stir for 1 hour, and then sta...

Embodiment 2

[0085] Embodiment 2, preparation of Mg-Al hydrotalcites by hydrothermal method

[0086] Steps (1)-(3), (6)-(8) are the same as in Example 1, except that:

[0087] (4) Crystallize the reaction slurry obtained above in a high-pressure reactor at a temperature of 115° C. for 24 hours, filter and wash until the pH value is 7.

[0088] (5) Dry at 80°C for 12 hours to obtain Mg-Al hydrotalcite-like material.

[0089] The catalyst obtained in this example is designated as Cat-II.

Embodiment 3

[0090] Embodiment 3, the Cat-1 catalyst prepared by embodiment 1 is used to treat Daria vacuum residue

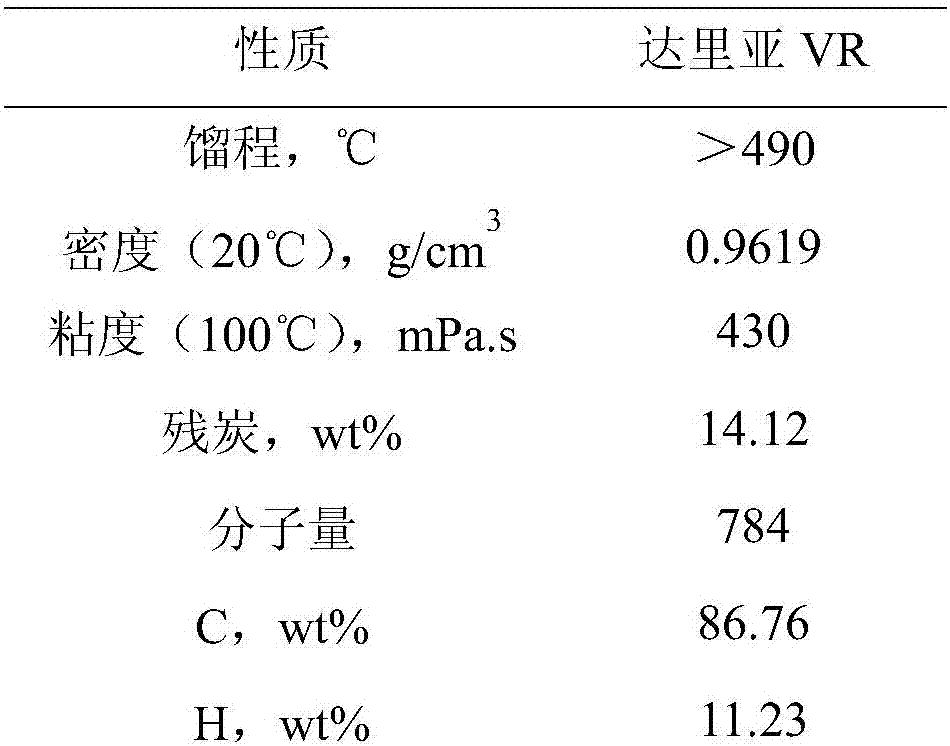

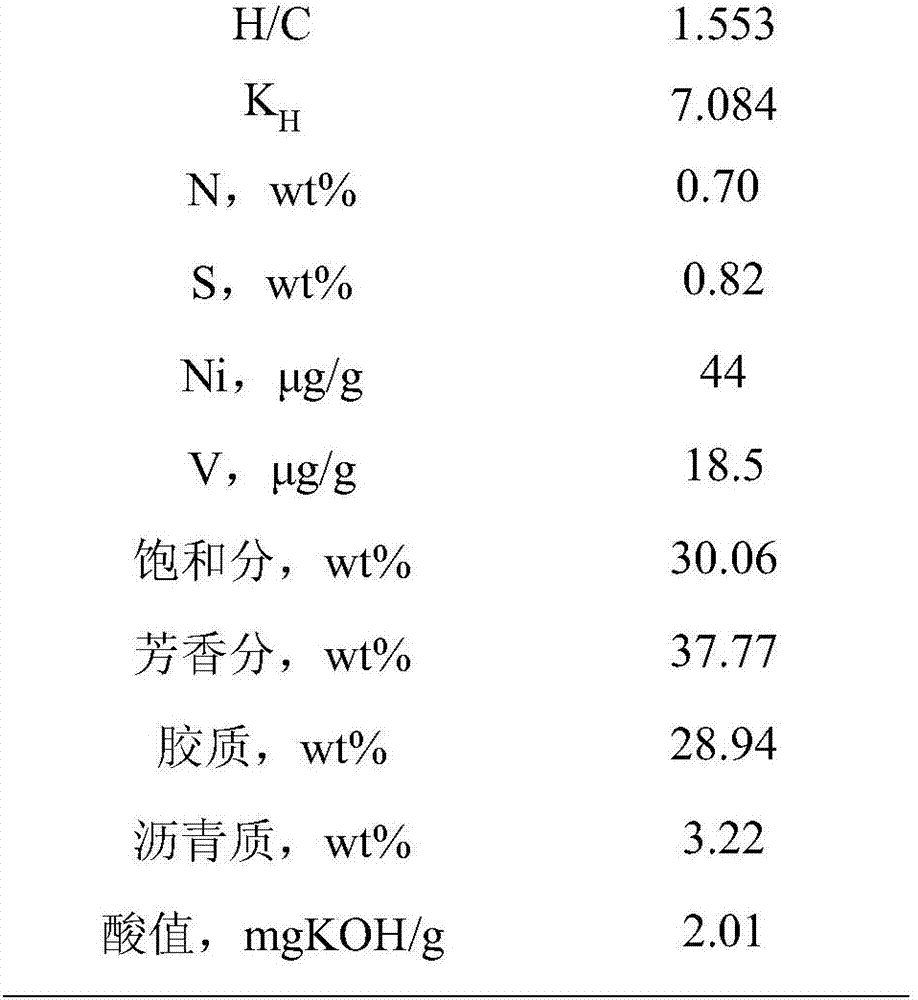

[0091] The basic properties of Daria vacuum residue are shown in Table 1.

[0092] Table 1 Daria Vacuum Residue

[0093]

[0094]

[0095] Proceed as follows:

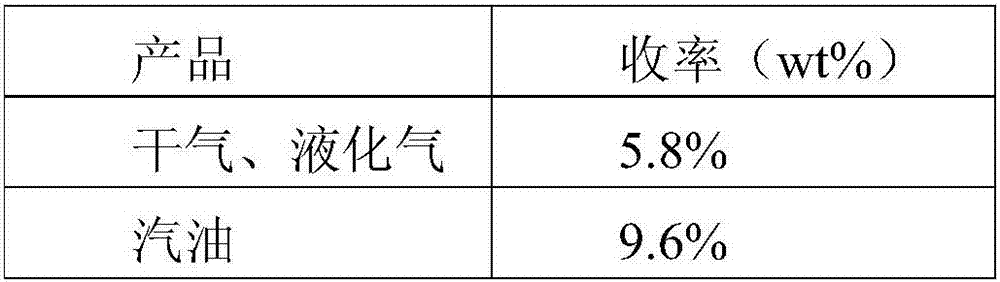

[0096] Use dry gas to lift the vacuum residue, and carry out catalytic cracking in the riser reactor, where the temperature is 525°C, the ratio of agent to oil is 5, and the pressure is 0.2Mpa. Then, the oil and gas in the spent catalyst are stripped through the stripping section, and the oil and gas are separated from the spent catalyst in a settler to obtain the spent catalyst and reaction oil and gas.

[0097] The catalyst to be regenerated enters the regenerator through the inclined pipe to be regenerated. The regeneration gas is a mixture of water vapor and air (the volume ratio of the two is 1:5.5), the temperature is 880 ° C, and the pressure is 0.3 MPa. The regenerated catalyst is regenerated The in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com