Copper-based catalyst for ammonia selective catalytic reduction of NOx and preparation method of copper-based catalyst

A copper-based catalyst and selective technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of complex catalyst composition and narrow applicable temperature of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

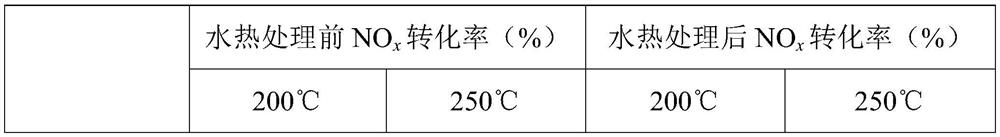

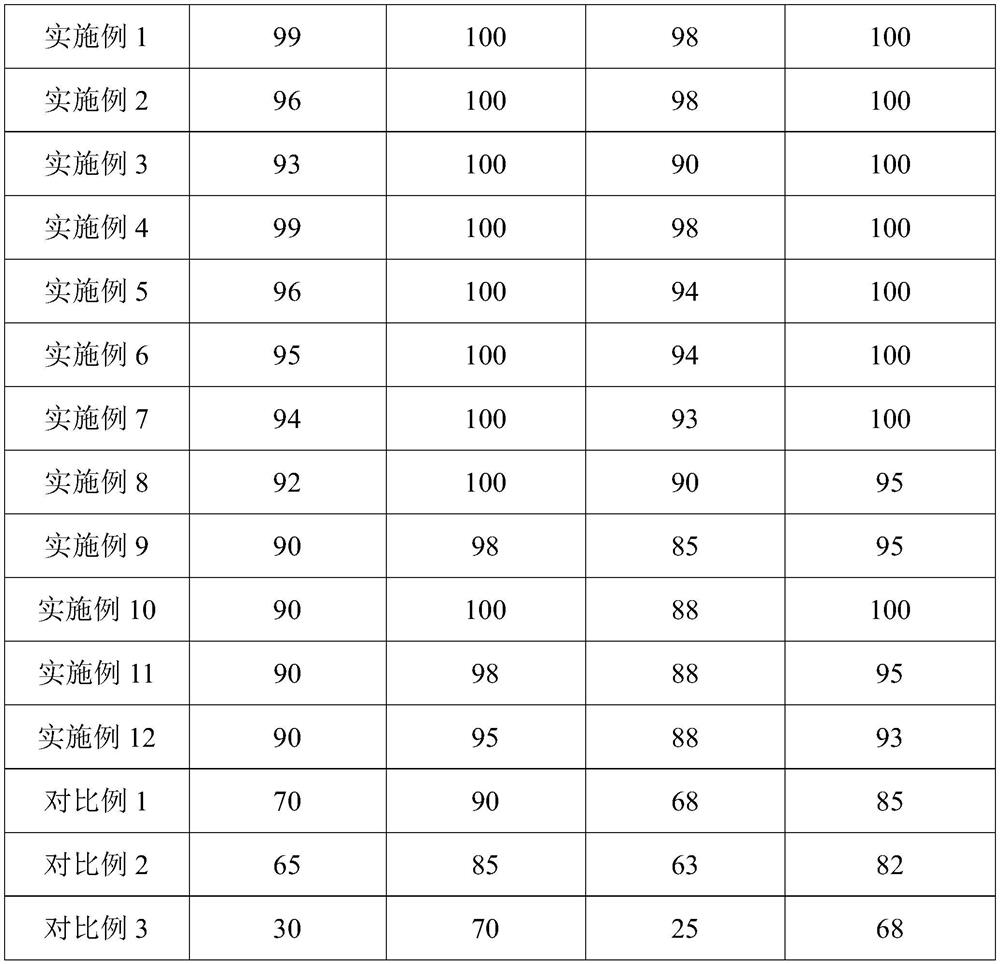

Examples

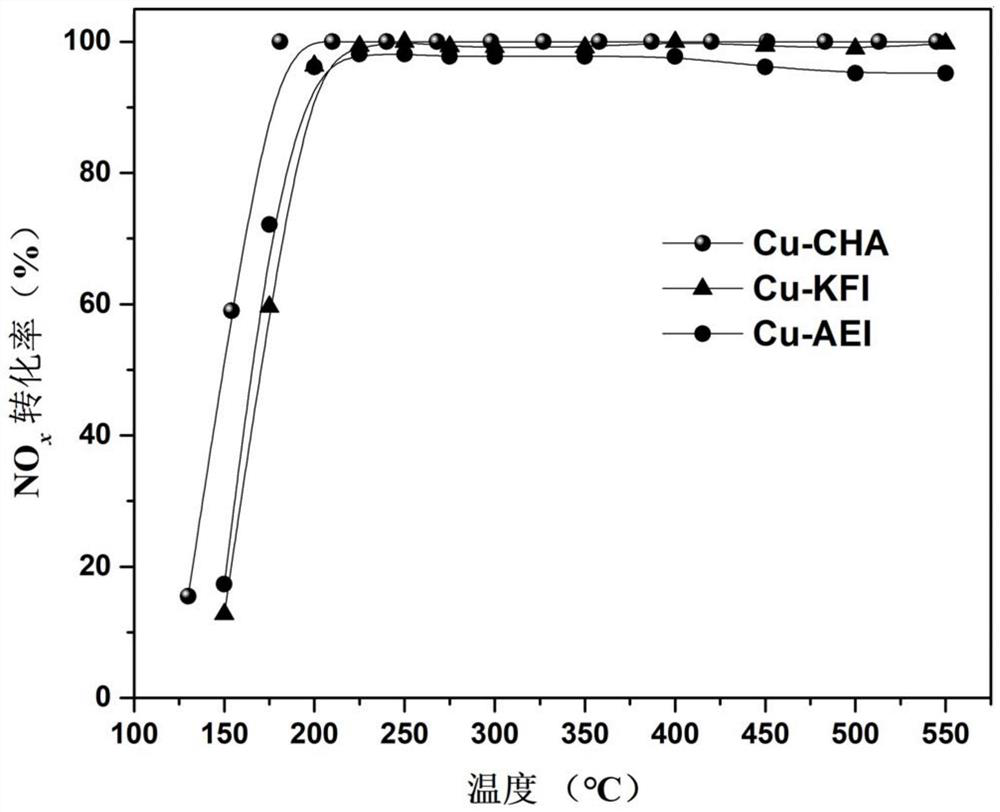

Embodiment 1

[0080] This embodiment provides a Cu-CHA catalyst, the copper-based catalyst of the Cu-CHA includes a CHA molecular sieve with a silicon-to-aluminum ratio of 4.2, and a copper active component loaded on the CHA molecular sieve; the molecular sieve has an aperture of The loading amount of copper in the copper-based catalyst is 4.0wt.%.

[0081] This embodiment also provides the preparation method of described Cu-CHA catalyst, and described preparation method comprises the following steps:

[0082] (1) First, 1.542g NaAlO 2 Completely soluble in 14.166g H 2 O, then add 2.298g CuSO 4 ·5H 2 O, after stirring for 1 h, add 2.139 g of TEPA dropwise, then add 1.1 g of NaOH, and after stirring for 3 h, add 10 mL of silica sol (30 wt %); put the completely mixed gel into a 100 mL hydrothermal reaction kettle, and Crystallization reaction at 120°C for 5 days to obtain a crystallized product;

[0083] (2) Suction filter the crystallized product with deionized water, wash it, and the...

Embodiment 2

[0085] The present embodiment provides a kind of Cu-AEI catalyst, and the copper-based catalyst of described Cu-AEI comprises the AEI molecular sieve that silicon-alumina ratio is 7.3, and the copper active component loaded on AEI molecular sieve; The aperture of described molecular sieve is The loading amount of copper in the copper-based catalyst is 2.8wt.%.

[0086] The present embodiment also provides the preparation method of described Cu-AEI catalyst, and described preparation method comprises the steps:

[0087] (1) Dissolve 3gY molecular sieve in 25.5gH 2 O, then add 4.5g 1,1,3,5-tetramethylpiperidine solution (20wt.%), after stirring for 3h, add 0.75g NaOH, continue stirring for 5h. Put the completely mixed solution into a 100mL hydrothermal reaction kettle, and conduct a crystallization reaction at 140°C for 3 days to obtain a crystallized product;

[0088] (2) Suction filter the crystallized product with deionized water, wash it, then put it into a 100°C oven for...

Embodiment 3

[0091] The present embodiment provides a kind of Cu-KFI catalyst, and the copper-based catalyst of described Cu-KFI comprises the KFI molecular sieve that silicon-alumina ratio is 4.2, and the copper active component loaded on KFI molecular sieve; The aperture of described molecular sieve is The loading amount of copper in the copper-based catalyst is 3.0wt.%.

[0092] The present embodiment also provides the preparation method of described Cu-KFI catalyst, and described preparation method comprises the steps:

[0093] (1) 0.327g sodium aluminate (NaAlO 2 ) into 3.8g of deionized water, and stir until evenly mixed; add 0.05g of sodium hydroxide (NaOH), and stir for 1 hour; add 2.5g of potassium nitrate (KNO 3 ), stirred for 1 hour; added 3.2g of silica sol, stirred for 24h; added 0.05g of seed crystal, stirred for 1h. The obtained solution was put into a reaction kettle, and crystallized at 140°C for 3 days to obtain a crystallized product;

[0094] (2) The crystallized pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Molar concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com