Polyurethane modified acrylic emulsion, preparation method of acrylic emulsion and prepared artificial stone

An acrylic emulsion and polyurethane modification technology, which is applied in the field of artificial stone, can solve the problems of unsatisfactory heat resistance and flame retardancy, poor processing and setting, and large curing shrinkage, and achieve good performance, high molecular weight, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

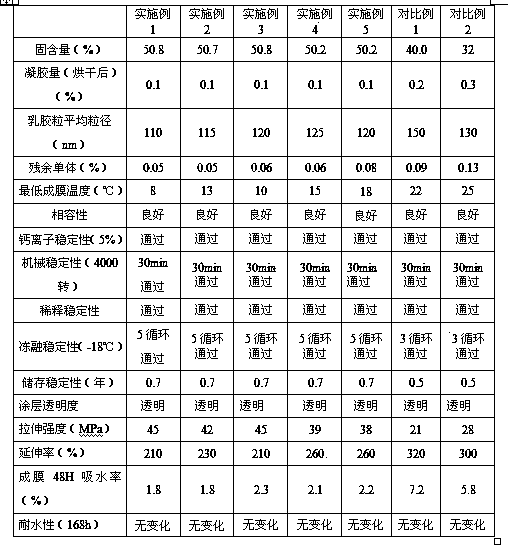

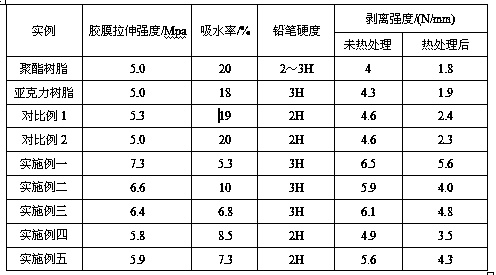

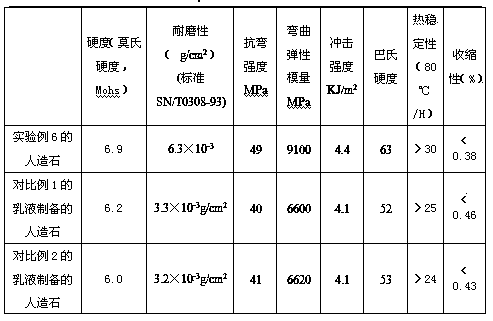

Examples

Embodiment 1

[0068] 1) Preparation of hydroxyacrylate emulsion

[0069] 100 parts by weight of water, 5.5 parts by weight of sodium lauryl sulfate, 2.5 parts by weight of nonylphenol polyoxyethylene ether, 30 parts by weight of styrene, 150 parts by weight of methyl methacrylate, 18 parts by weight of butyl acrylate, acrylic acid 2 parts by weight are stirred evenly to obtain a uniform pre-emulsion;

[0070] Add 300 parts by weight of water to the reactor, raise the temperature to 80°C, add 10% pre-emulsion, 0.5 parts by weight of initiator ammonium persulfate, and react for 35 minutes until the blue light is sufficient; drop the remaining pre-emulsion and 2.0 parts by weight of initiator Ammonium persulfate, dripping time is 3 hours, and the dropwise addition is completed and kept for 30 minutes;

[0071] 150 parts by weight of butyl acrylate, 55 parts by weight of methyl methacrylate, 50 parts by weight of hydroxyethyl acrylate, and 5 parts by weight of acrylic acid are mixed uniformly ...

Embodiment 2

[0079] 1) Preparation of hydroxyacrylate emulsion

[0080] 80 parts by weight of water, 2 parts by weight of sodium lauryl sulfate, 1.5 parts by weight of nonylphenol polyoxyethylene ether, 10 parts by weight of styrene, 100 parts by weight of methyl methacrylate, 10 parts by weight of butyl acrylate, acrylic acid 2 parts by weight were stirred evenly to obtain a pre-emulsion.

[0081] Add 260 parts by weight of water into the reaction vessel, raise the temperature to 70°C, add 4% pre-emulsion, 0.2 parts by weight of ammonium persulfate, and react for 15 minutes until the blue light is sufficient. The dropwise addition of the remaining pre-emulsion and 1.2 parts by weight of ammonium persulfate was started. The dropwise addition time was 2.5 hours, and the reaction was incubated for 30 minutes after the dropwise addition. Mix 140 parts by weight of butyl acrylate, 40 parts by weight of methyl methacrylate, 30 parts by weight of hydroxyethyl acrylate, and 10 parts by weight o...

Embodiment 3

[0088] 1) Preparation of hydroxyacrylate emulsion

[0089] 140 parts by weight of water, 8.5 parts by weight of sodium lauryl sulfate, 6.5 parts by weight of nonylphenol polyoxyethylene ether, 155 parts by weight of styrene, 203 parts by weight of methyl methacrylate, 85 parts by weight of butyl acrylate, acrylic acid 2.5 parts by weight were stirred evenly to obtain a pre-emulsion.

[0090] Add 320 parts by weight of water into the reaction vessel, raise the temperature to 85°C, add 15% pre-emulsion and 0.8 parts by weight of ammonium persulfate, and react for 45 minutes until the blue light is sufficient. The dropwise addition of the remaining pre-emulsion and 2.5 parts by weight of ammonium persulfate was started. The dropwise addition time was 4 hours, and the reaction was incubated for 30 minutes after the dropwise addition. Mix 160 parts by weight of butyl acrylate, 80 parts by weight of methyl methacrylate, 55 parts by weight of hydroxyethyl acrylate, and 5 parts by w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com