Patents

Literature

202results about How to "Improve liquid yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

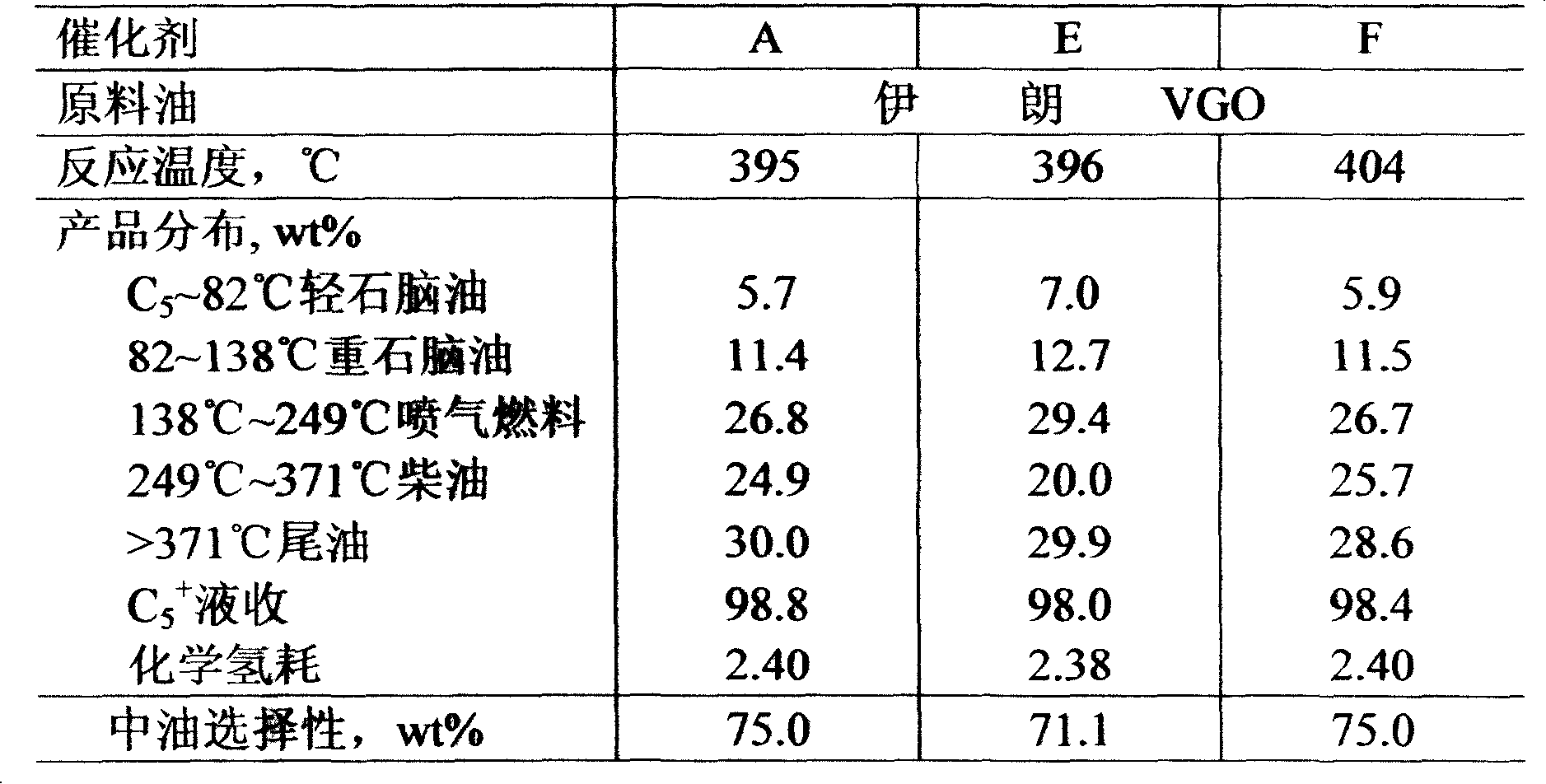

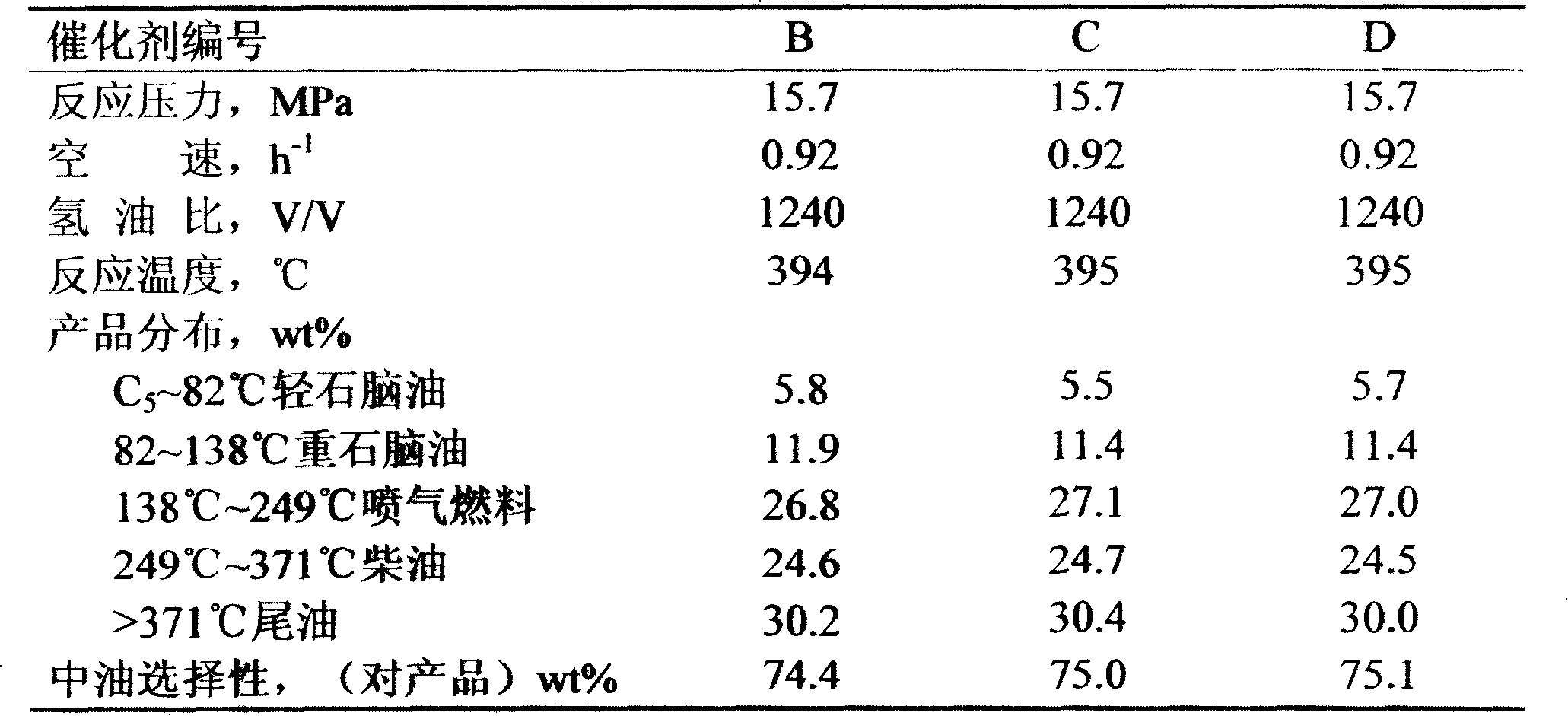

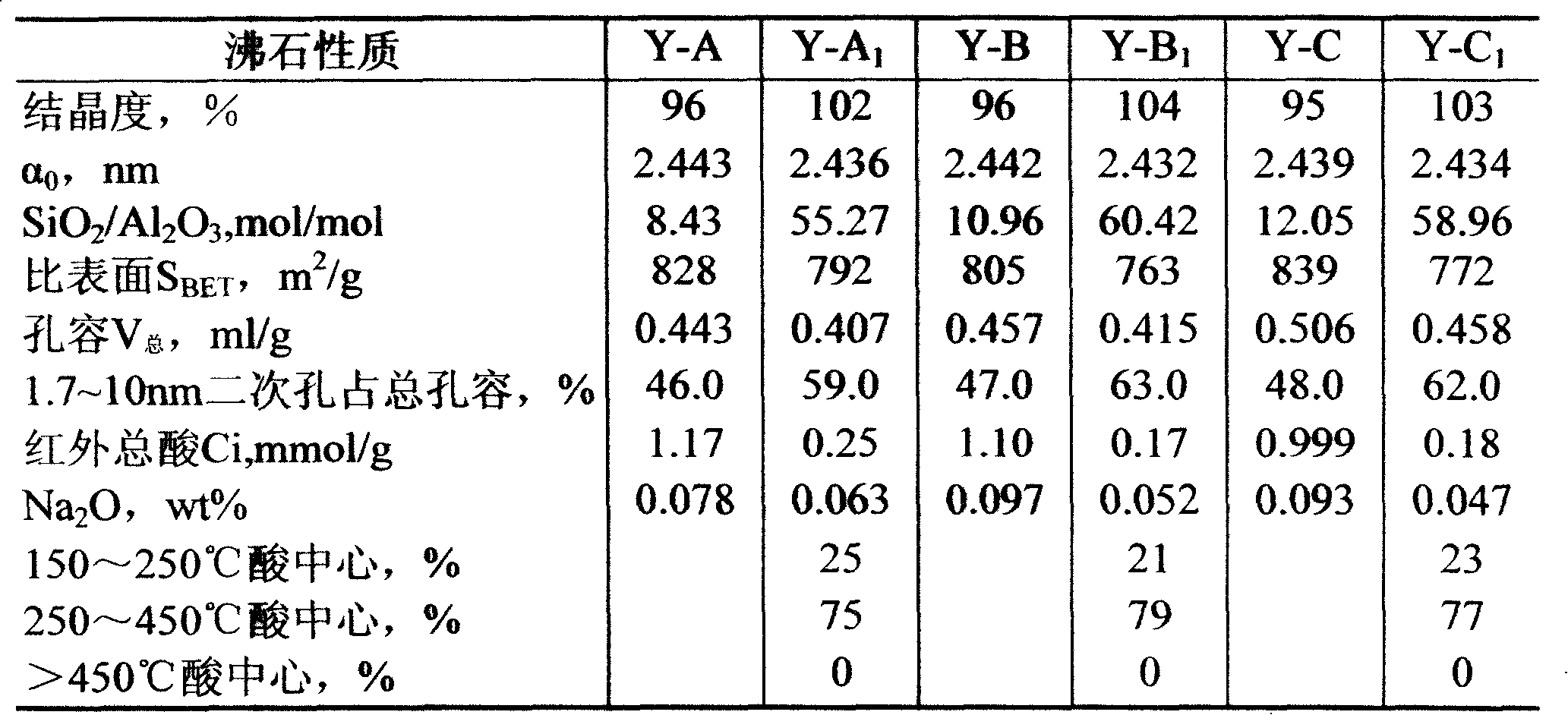

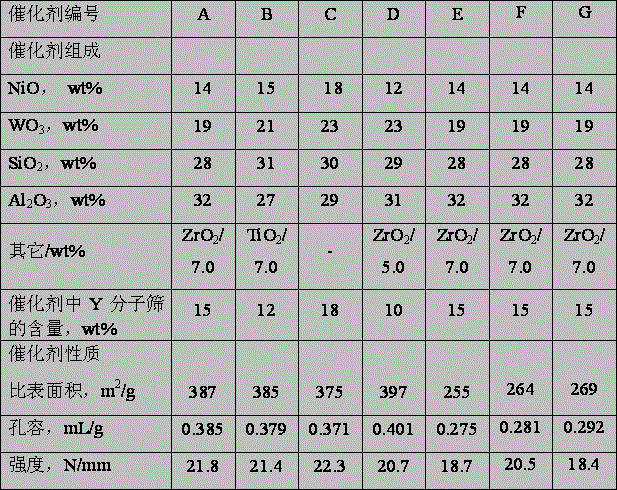

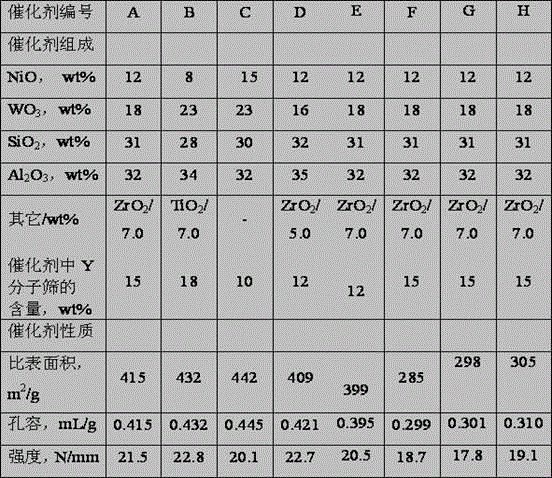

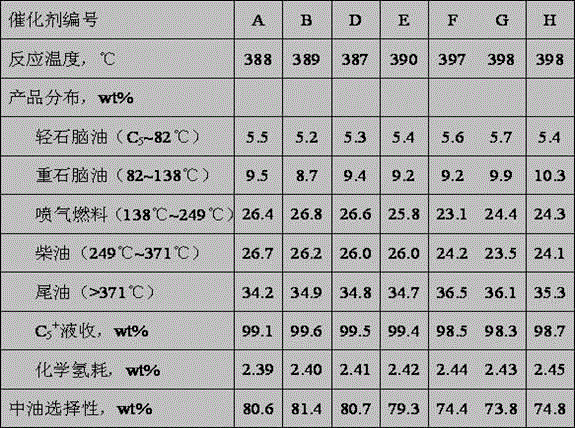

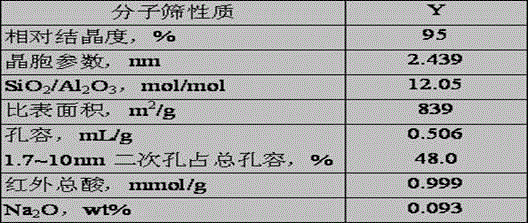

High active high medium oil selective hydrocracking catalyst and preparation thereof

ActiveCN101239324AHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSingle stage

The present invention provides a hydrocracking catalyst having high activity, high medium oil selectivity, catalyst constitute uses amorphous silica-alumina as a carrier, Y type molecular sieve processed by special modification is an acidity component, the molecular sieve has a high crystallinity and a lower cell parameter, a plenty quadric hole, larger surface, in addition, has a small acid center, even distribution, no strong acid center, 70-80% is moderate intensity acid center, 20-30% is weak acid center, and the molecular sieve also has a strong anti-nitrogen ability and better damaging ability, the hydrocracking catalyst using the molecular sieve has a better hydrocracking activity, and a higher medium oil selectivity, and a strong anti-nitrogen ability at the same time. The invention uses heavy hydrocarbon single stage or single stage serial hydrocracking process generate midbarrel oil product, and has better activity and medium oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst

ActiveCN103055923AUnlimited capacityGood dispersionMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveDispersity

The invention discloses a preparation method of a hydrocracking catalyst. The method comprises the steps of preparing an acidic mixed solution A containing hydrogenation reactive metals and silicon, preparing a sodium metaaluminate alkaline solution B, and then adding the acidic mixed solution A, the alkaline solution B and CO2 to a reaction tank filled with clear water in parallel to prepare gel; and then adding turbid liquid of a Y type molecular sieve, mixing the substances uniformly, filtering, drying and forming the mixture, and then washing, drying and roasting the product, thus preparing the hydrocracking catalyst. The method has the beneficial effects that a clean preparation method is adopted, so not only can the catalyst be easily formed and the strength of the catalyst be improved, but also the pore volume and specific surface area of the catalyst can be increased and the dispersity of metals in the catalyst can be improved, thus the catalyst has higher hydrocracking activity, middle oil selectivity and stability; and the catalyst prepared by the method can be used for a single-section hydrocracking process of a non-refining section or a one-section serial hydrocracking process of a refining section.

Owner:CHINA PETROLEUM & CHEM CORP +1

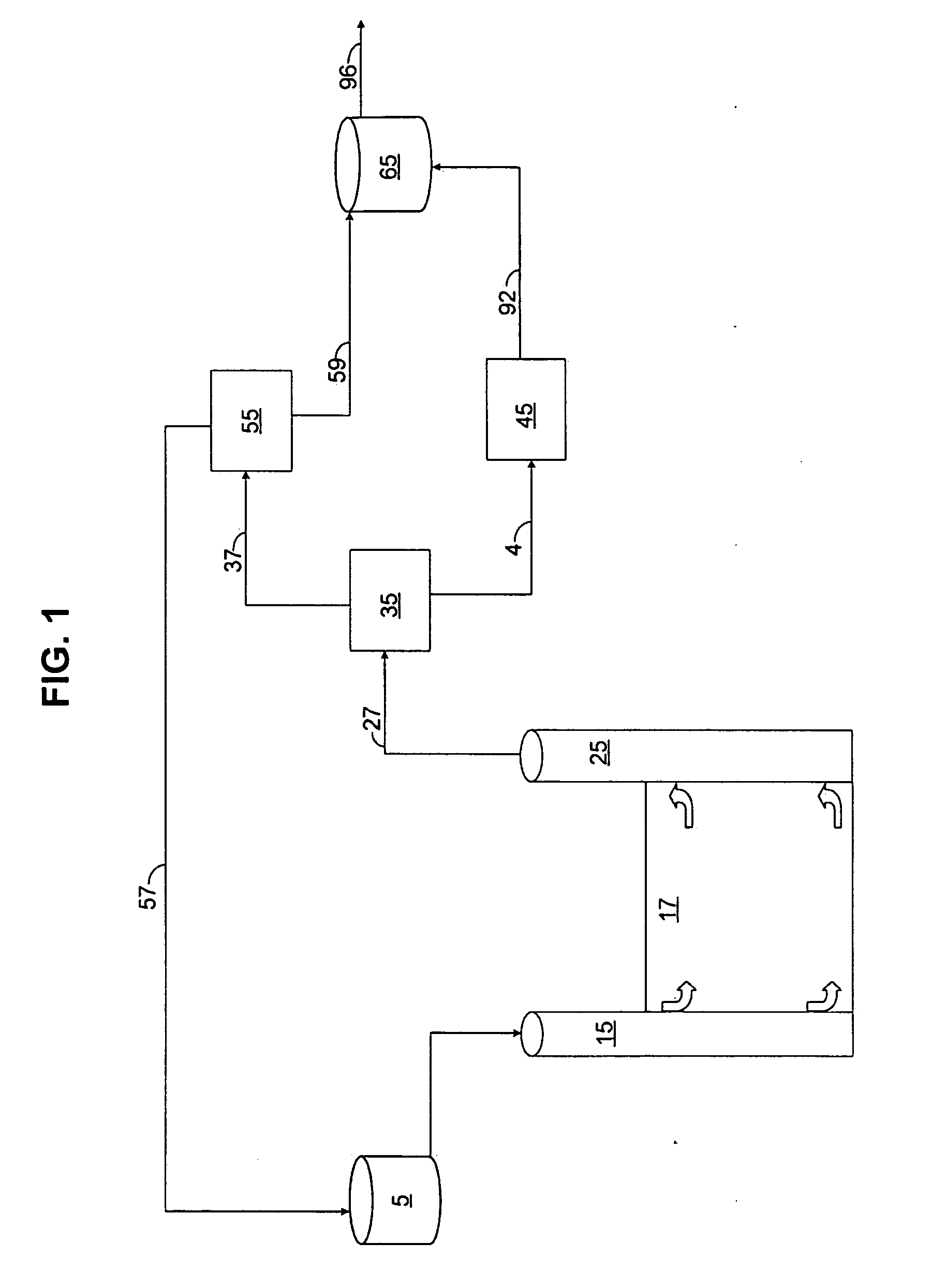

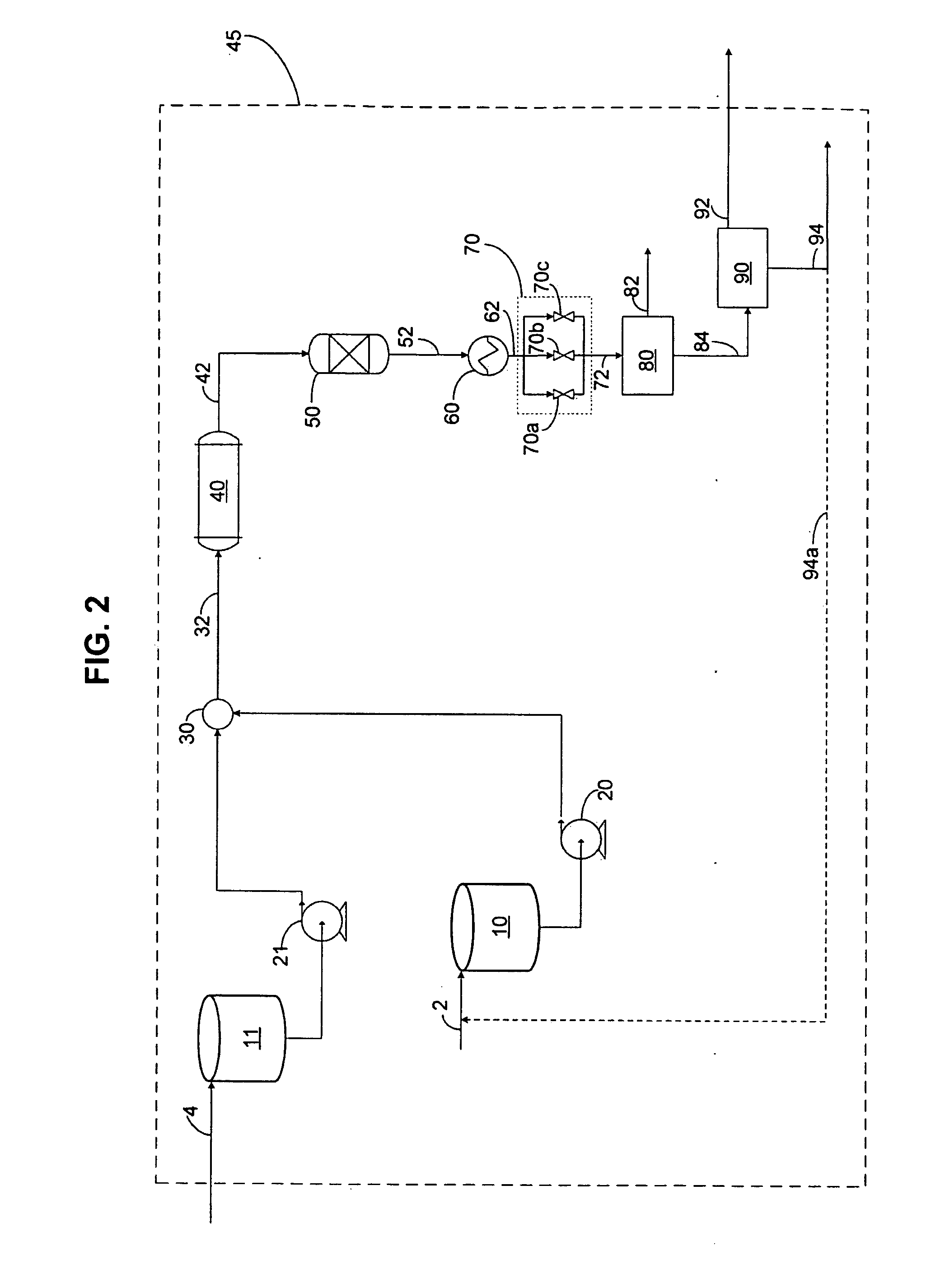

Process to upgrade whole crude oil by hot pressurized water and recovery fluid

ActiveUS20090139715A1Upgraded more easilyLess coke formationThermal non-catalytic crackingRefining by water treatmentSulfurLow nitrogen

A process for upgrading whole crude oil utilizing a recovery fluid, depressurizing an extracted whole crude oil / recovery fluid mixture in a step-wise fashion, and subsequently contacting at least a portion of the whole crude oil with supercritical water fluid to produce high value crude oil having low sulfur, low nitrogen, and low metallic impurities for use as hydrocarbon feedstock.

Owner:SAUDI ARABIAN OIL CO

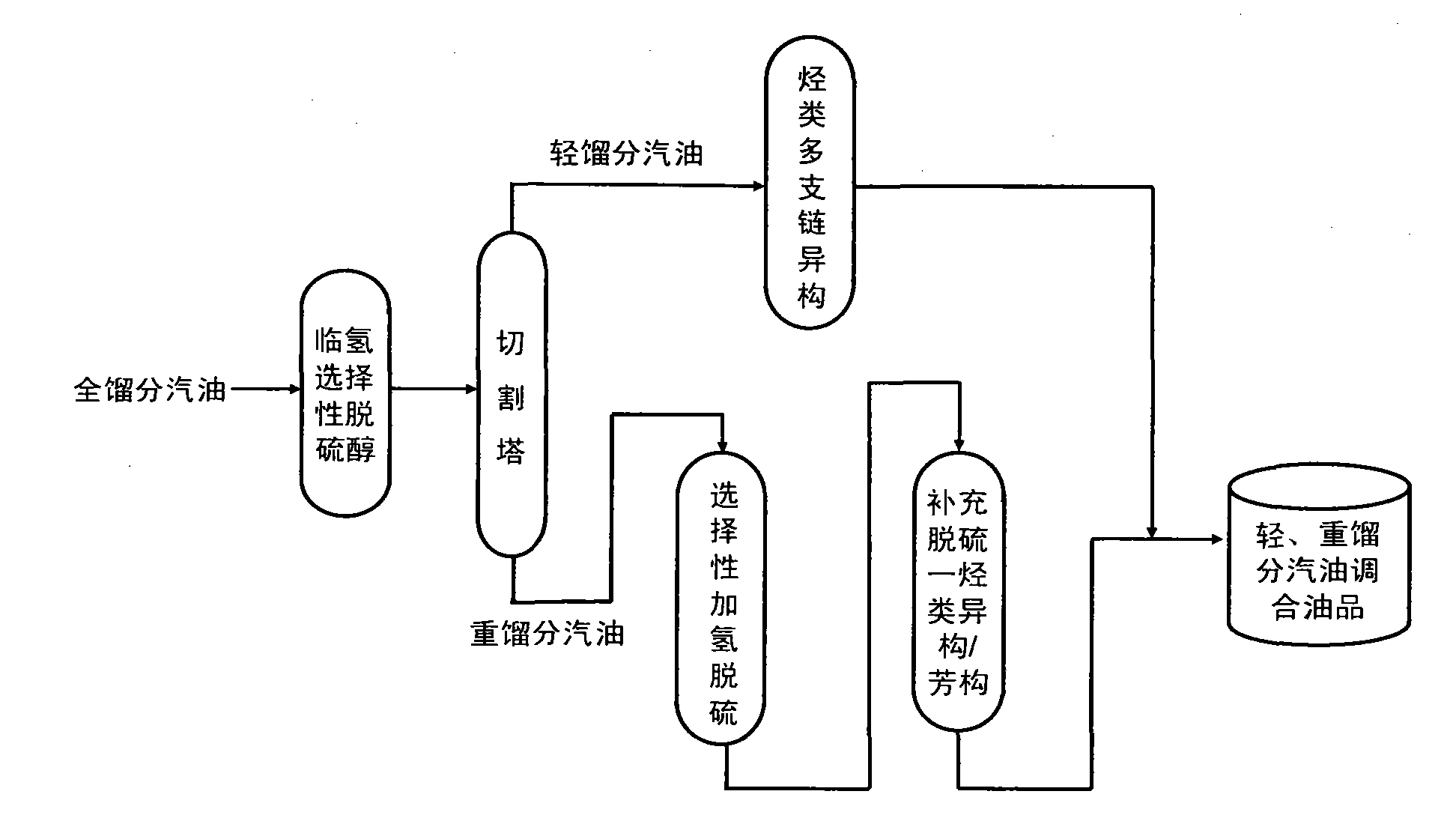

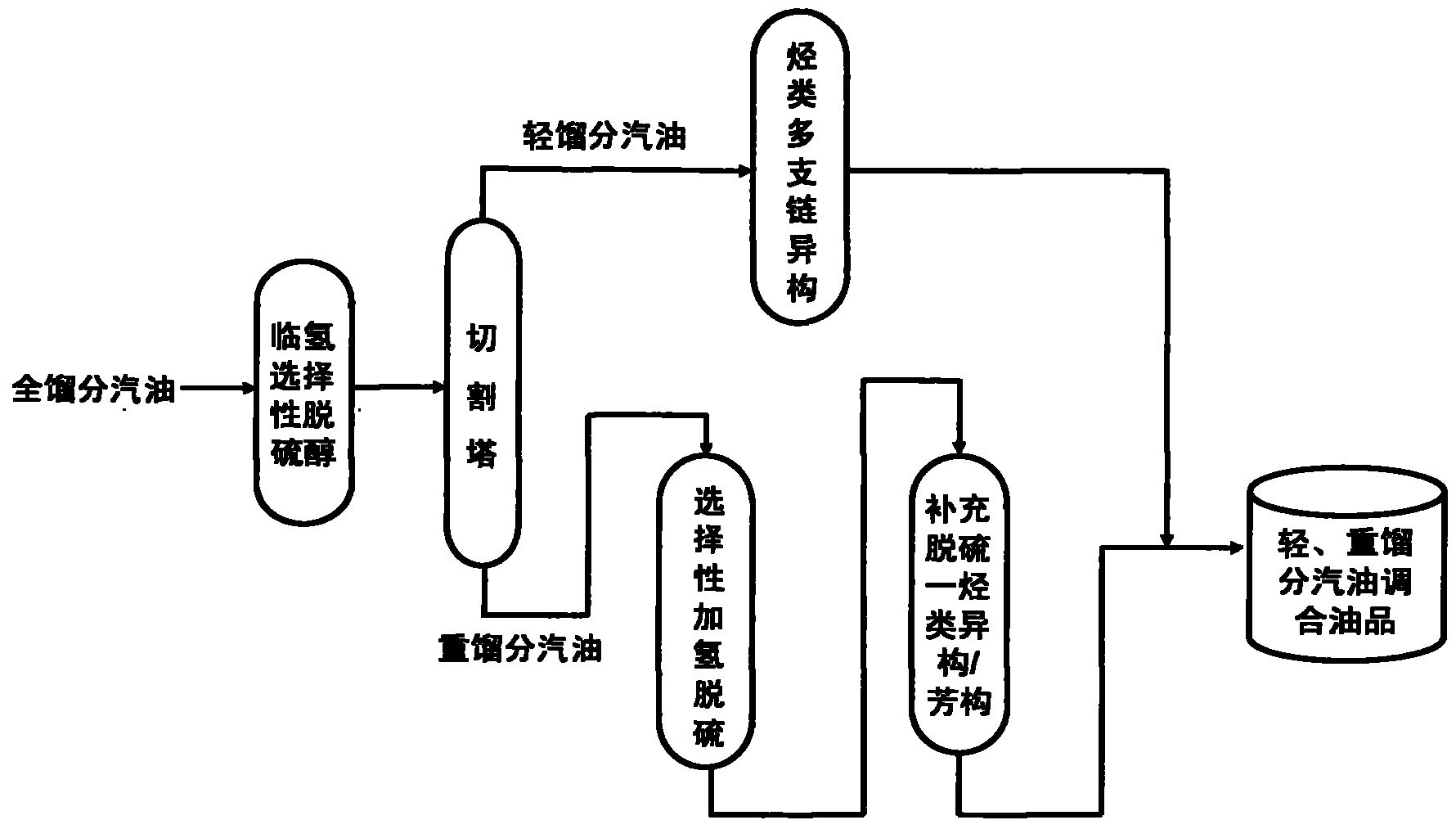

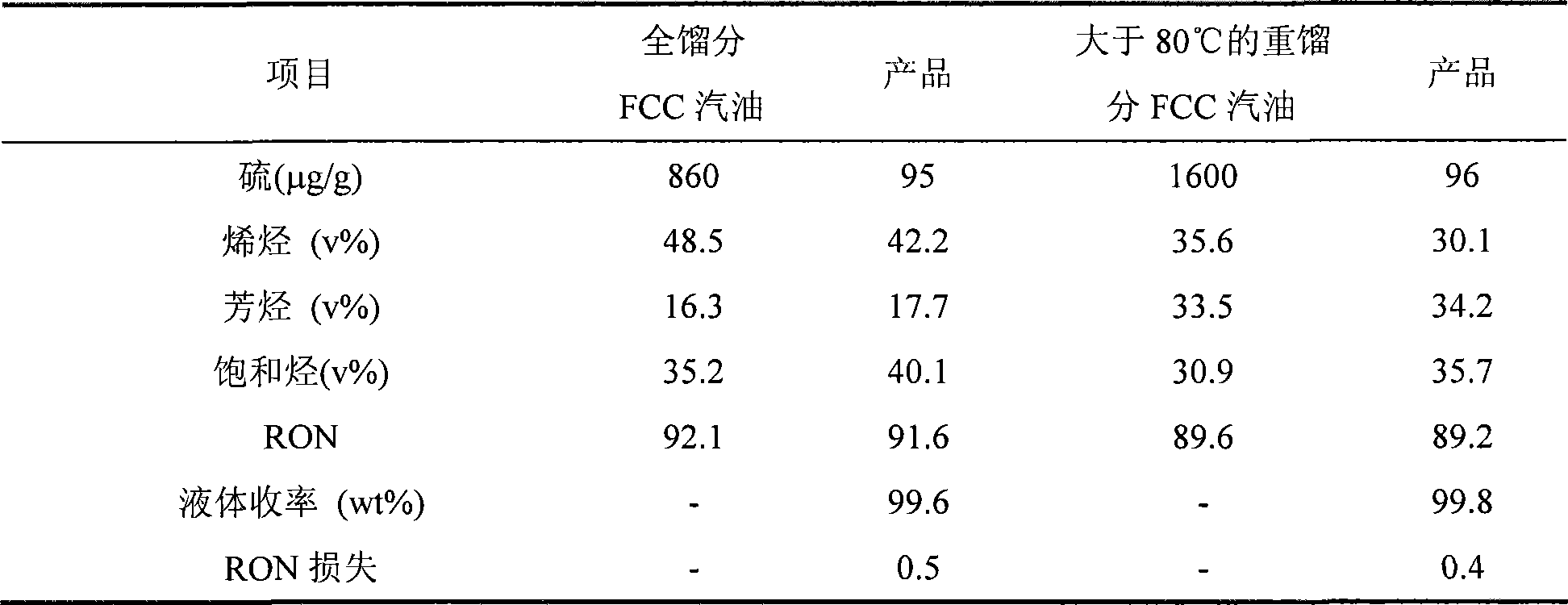

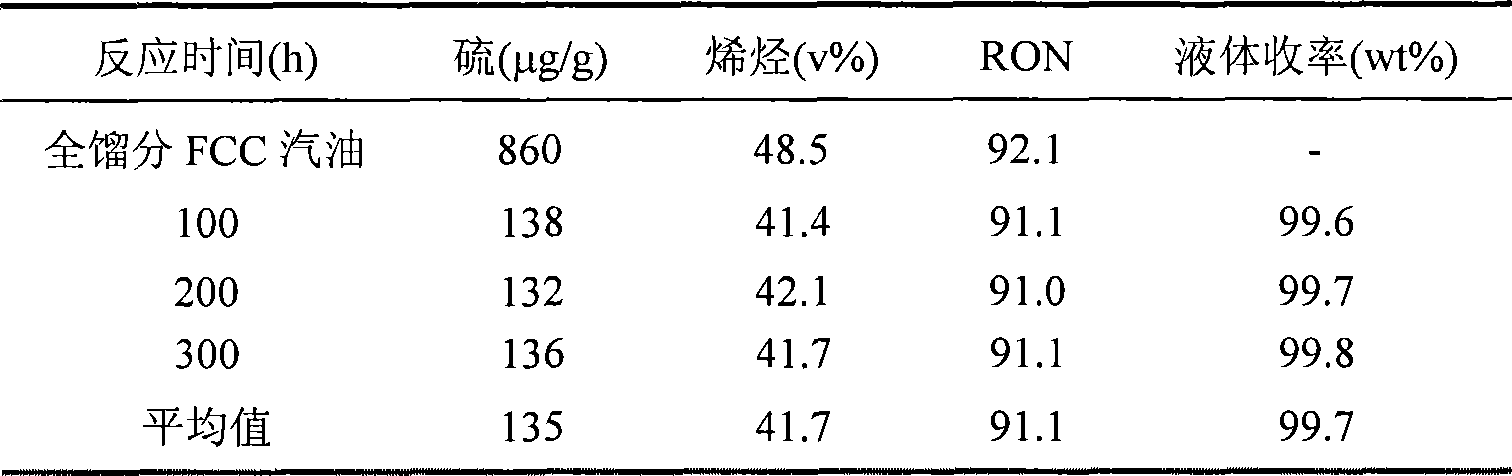

Efficient coupling hydro-upgrading method for producing gasoline with ultra-low sulfur and high octane number

ActiveCN101885983AImprove octaneOctane recoveryTreatment with hydrotreatment processesIsomerizationAlcohol

The invention relates to an efficient coupling hydro-upgrading method for producing gasoline with ultra-low sulfur and a high octane number. The method comprises the following steps of: distilling inferior full cut gasoline at 50-90 DEG C to obtain light cut gasoline and heavy cut gasoline; making the light cut gasoline contact with a hydrocarbon multi-branched isomerization catalyst; making the heavy cut gasoline contact with a selective hydrogenation desulfurization catalyst and a complement desulfurization isomerization / aromatization catalyst sequentially; and finally, mixing the treated light cut gasoline with the treated heavy cut gasoline to obtain the gasoline with the ultra-low sulfur and the high octane number. The method further comprises the step of: before the distillation, making the inferior full cut gasoline contact with a hydro-selective desulfurization alcohol catalyst, or, before making the light cut gasoline contact with a hydrocarbon multi-branched isomerization catalyst, making the light cut gasoline contact with the hydro-selective desulfurization alcohol catalyst. The efficient coupling hydro-upgrading method is suitable for the hydro-upgrading treatment of inferior gasoline with ultrahigh sulfur and high olefin, reduces the sulfur content after the upgrading treatment to below 5mu g / g (no sulfur substantially) and can maintain the octane number and higher yield of products.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

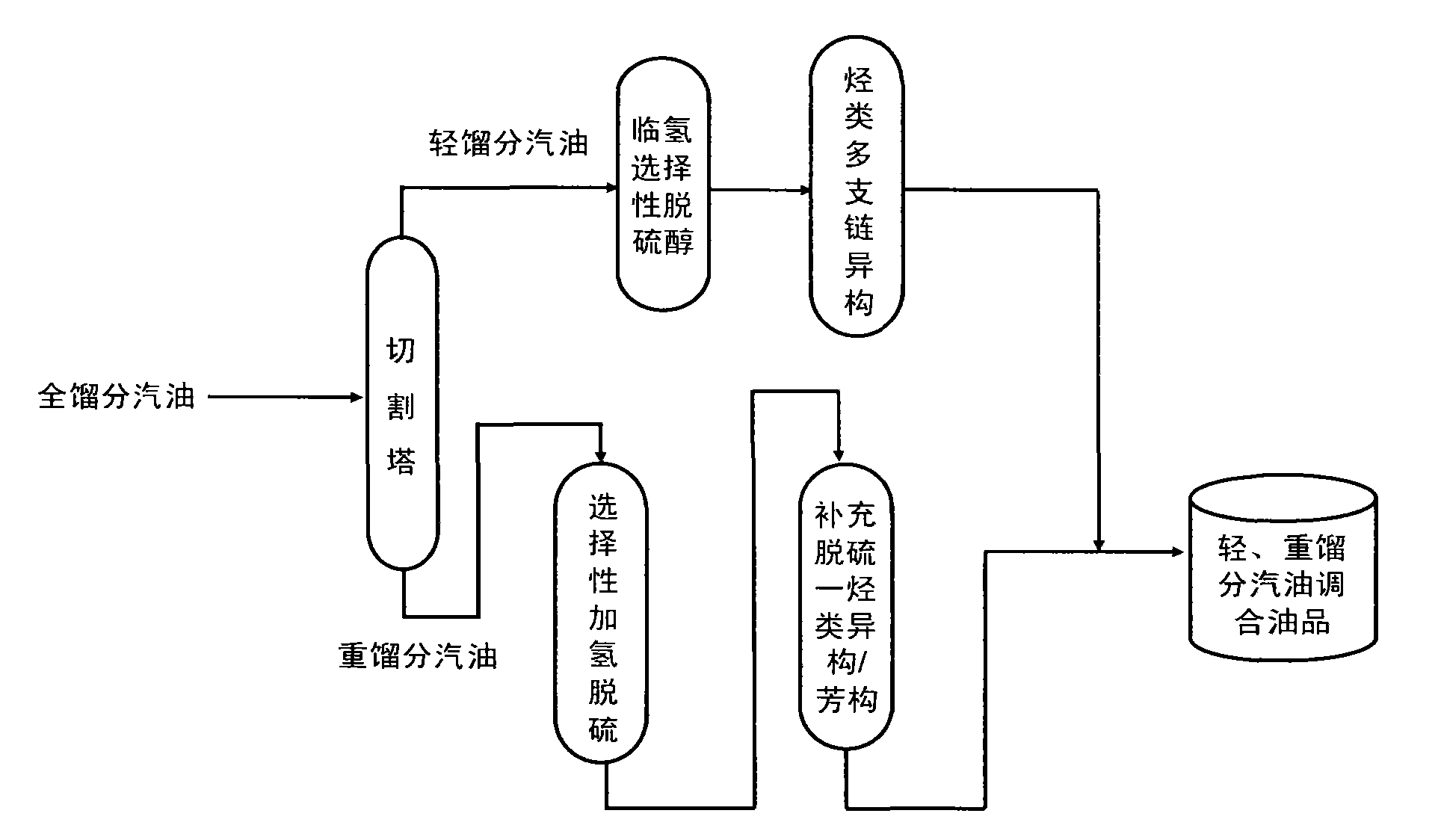

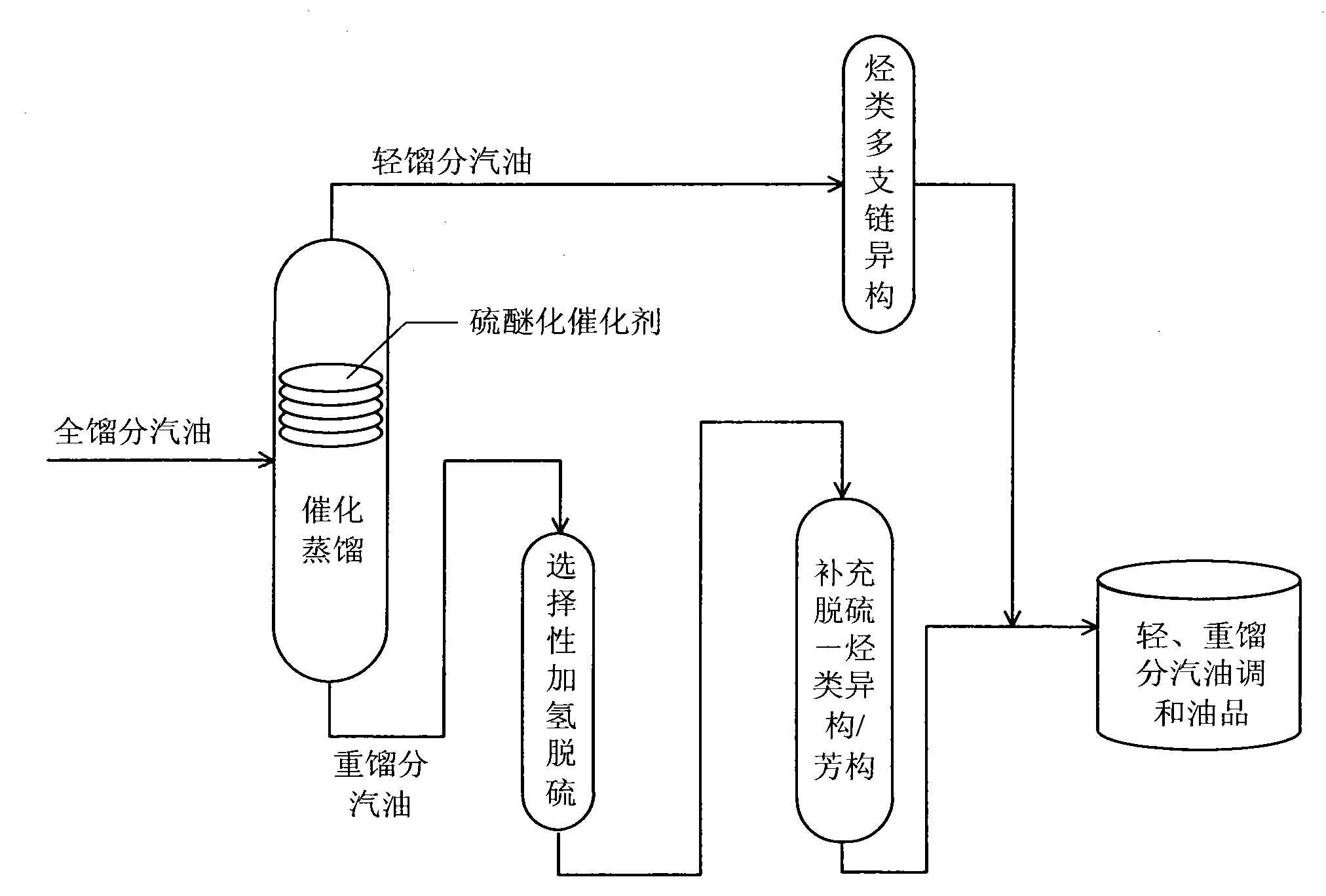

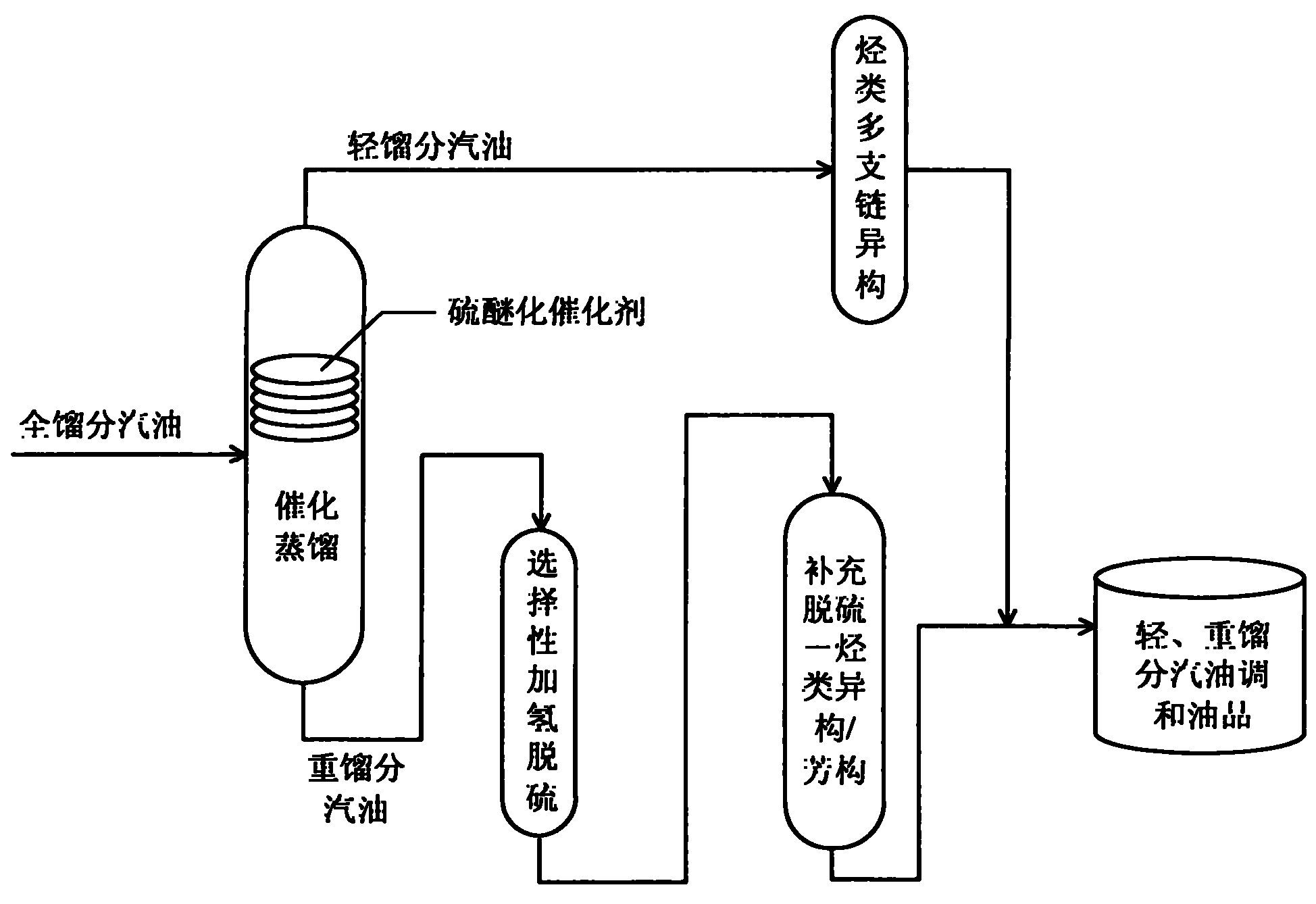

Production method for ultra-low sulfur and high-octane number gasoline

ActiveCN101885985ATake advantage ofIncrease temperatureTreatment with hydrotreatment processesIsomerizationHydrodesulfurization

The invention relates to a production method for ultra-low sulfur and high-octane number gasoline. The method comprises the following steps of: filling a poor-quality full range gasoline raw material in a reaction distillation column to contact the material with a sulfoether catalyst to perform a sulfur ether reaction and fraction cutting so that low-boiling point sulfides, such as thiol and thiophene, are converted into high-boiling point sulfoether which is then transferred into heavy fraction gasoline, wherein the cutting fractionation temperature of light fraction gasoline and the heavy fraction gasoline is 50 to 90 DEG C; contacting the light fraction gasoline with a hydrocarbon highly branched isomerization catalyst; contacting the heavy fraction gasoline with a selective hydrodesulfurization catalyst and a desulfurization-hydrocarbon isomerization / aromatization catalyst; and mixing the treated light fraction gasoline and the heavy fraction gasoline to obtain the ultra-low sulfur and high-octane number gasoline. The method is suitable for modifying poor-quality gasoline, can reach better desulfurization and olefin reduction effects on ultra-high sulfur and high-olefin poor-quality catalytic gasoline, and can maintain or increase the octane number of the product and keep a higher product yield after reaction.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

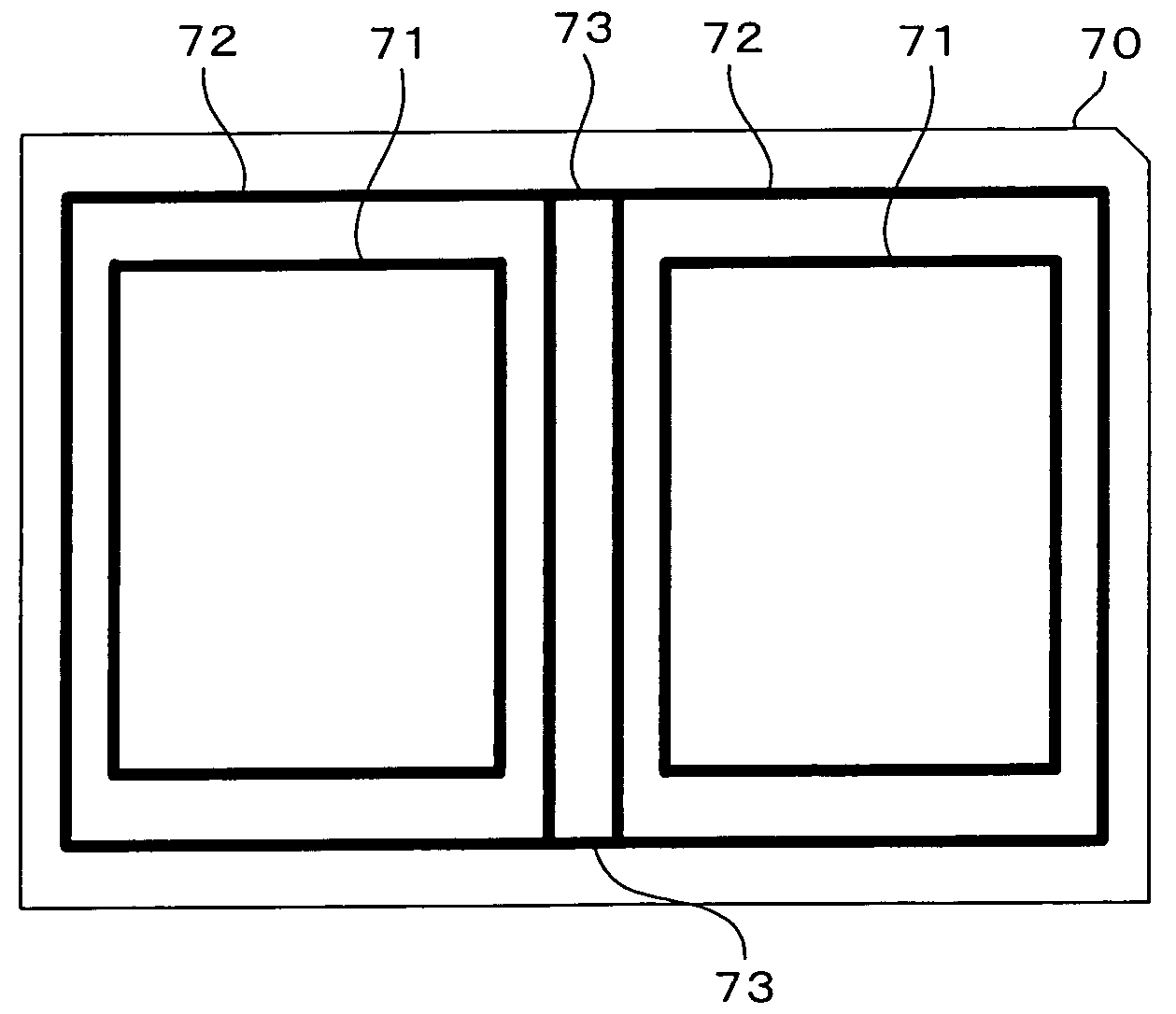

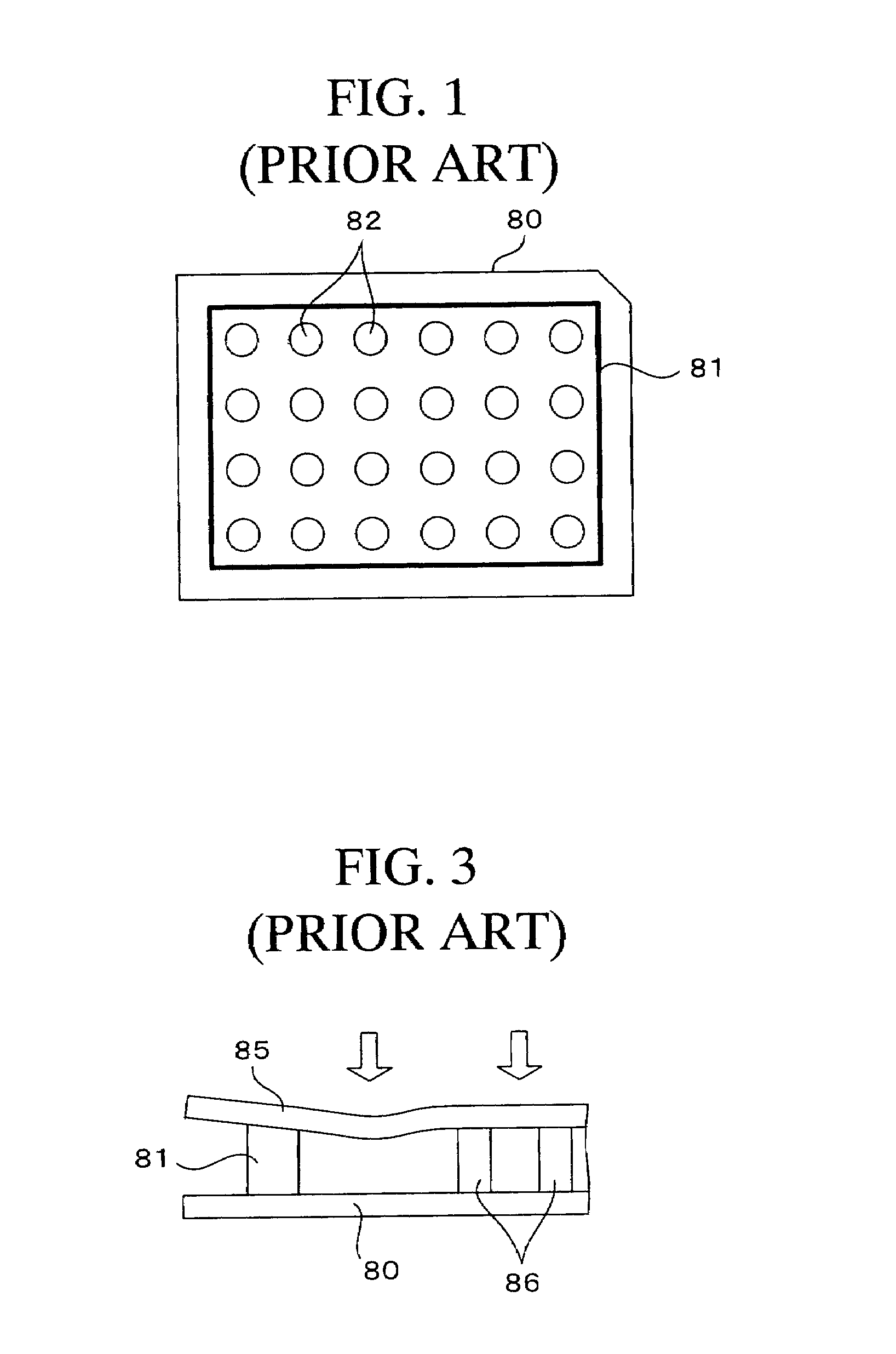

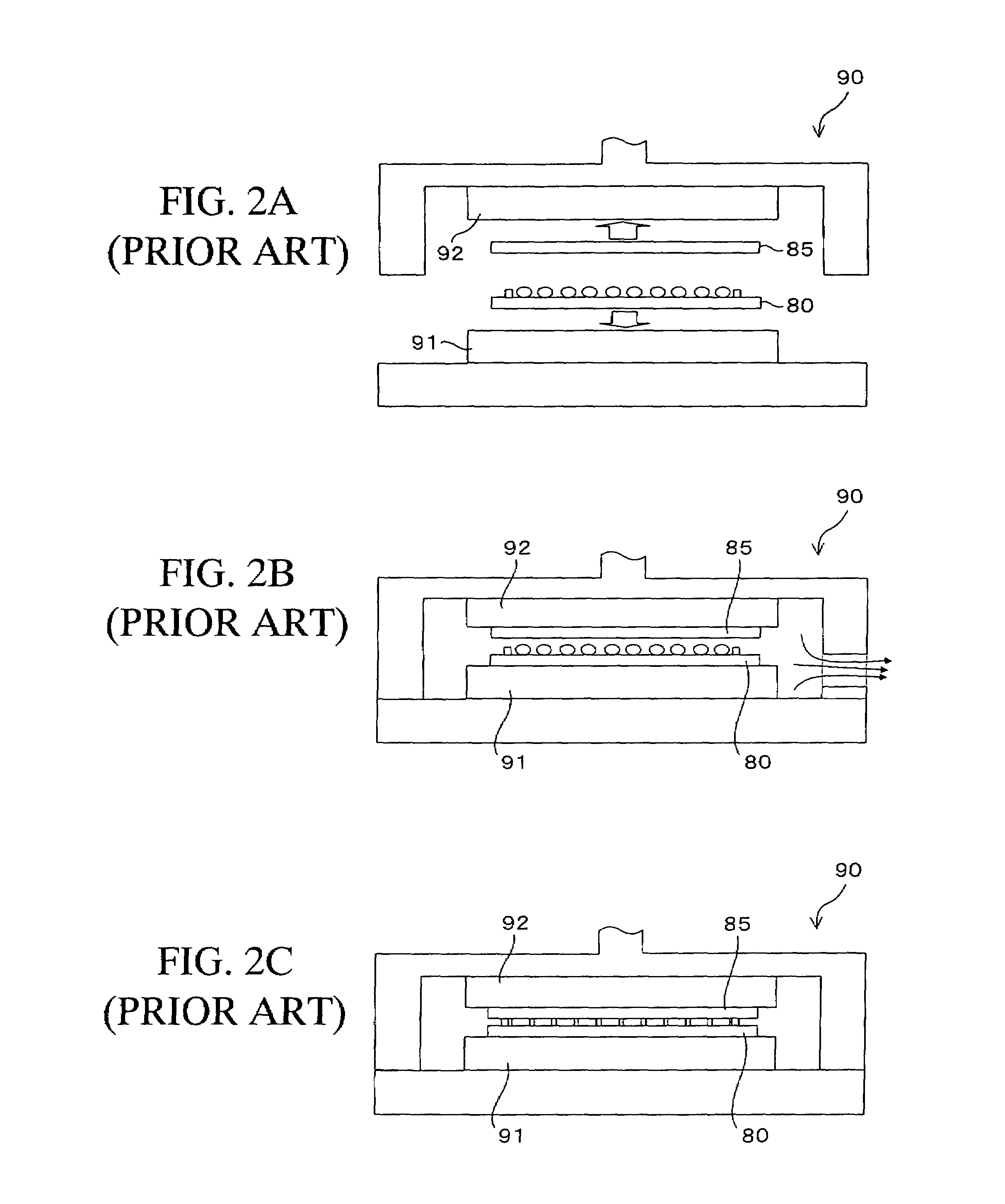

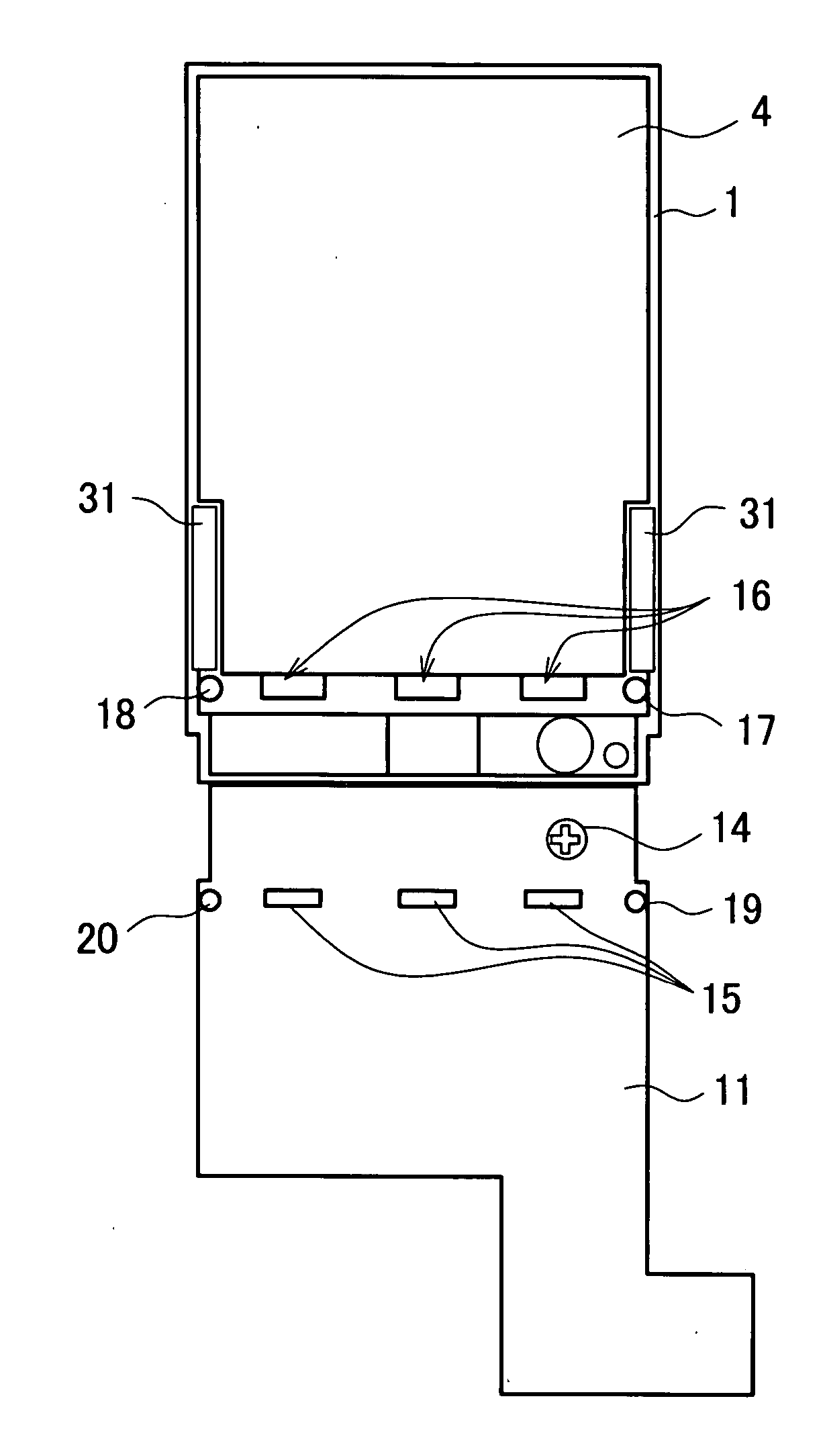

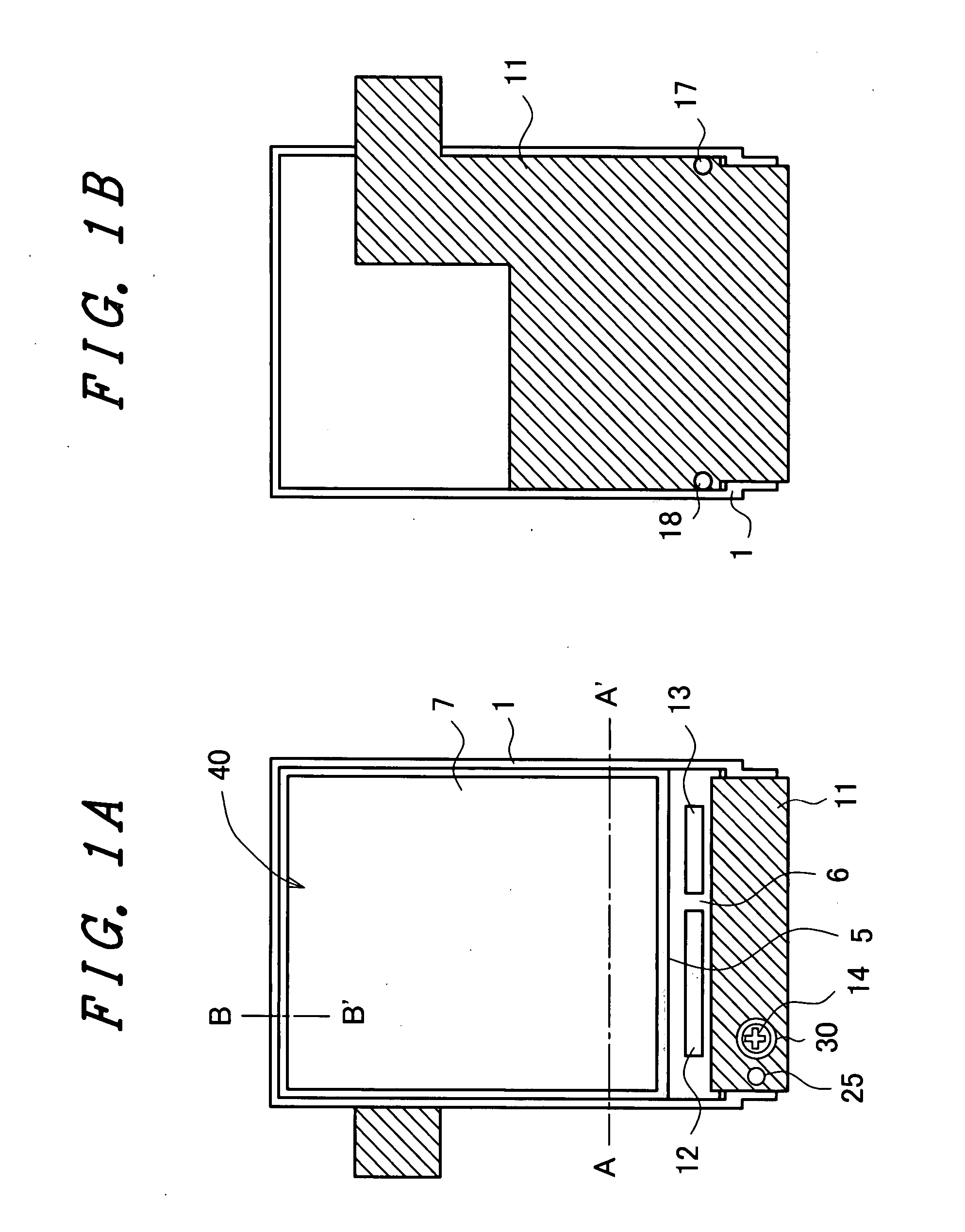

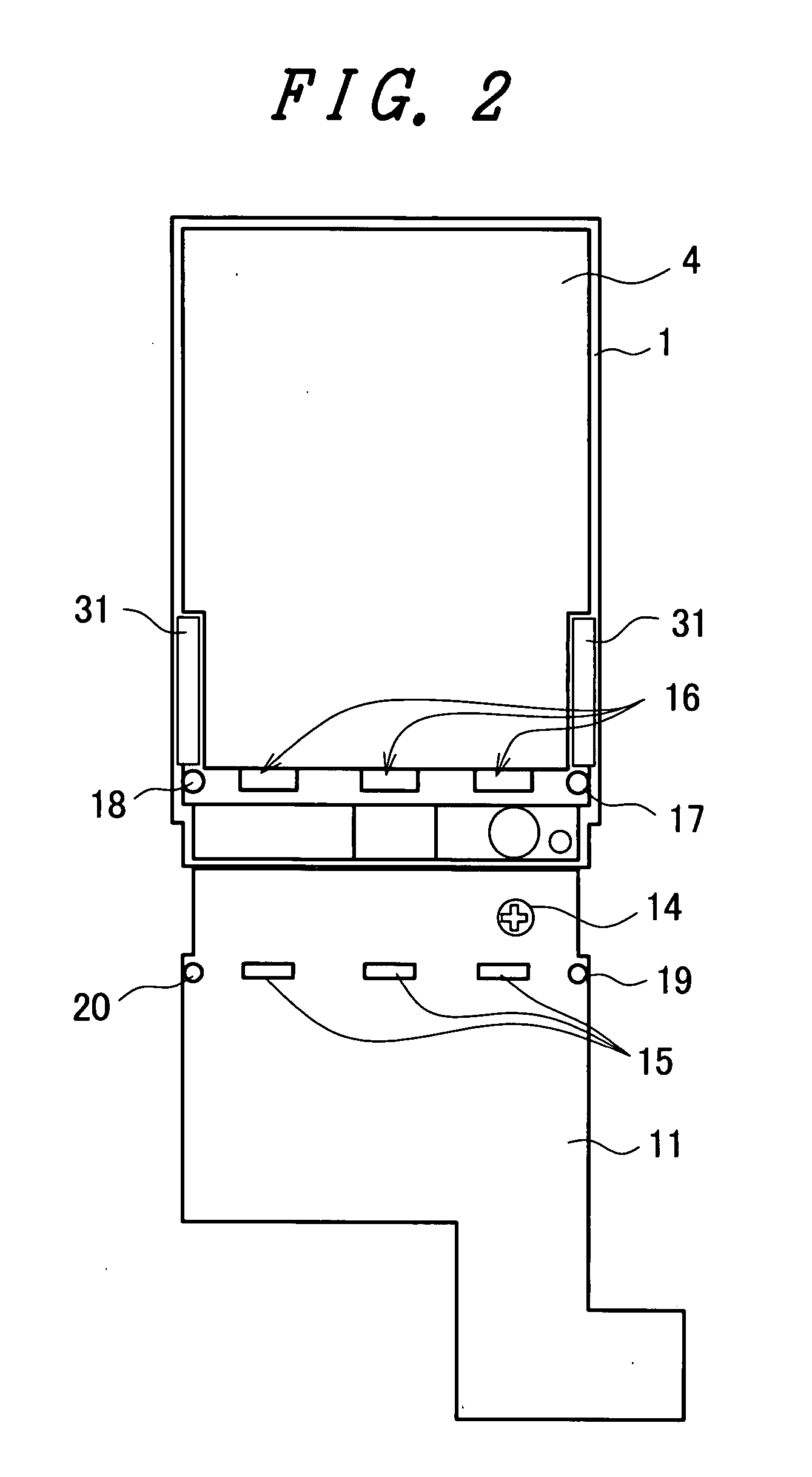

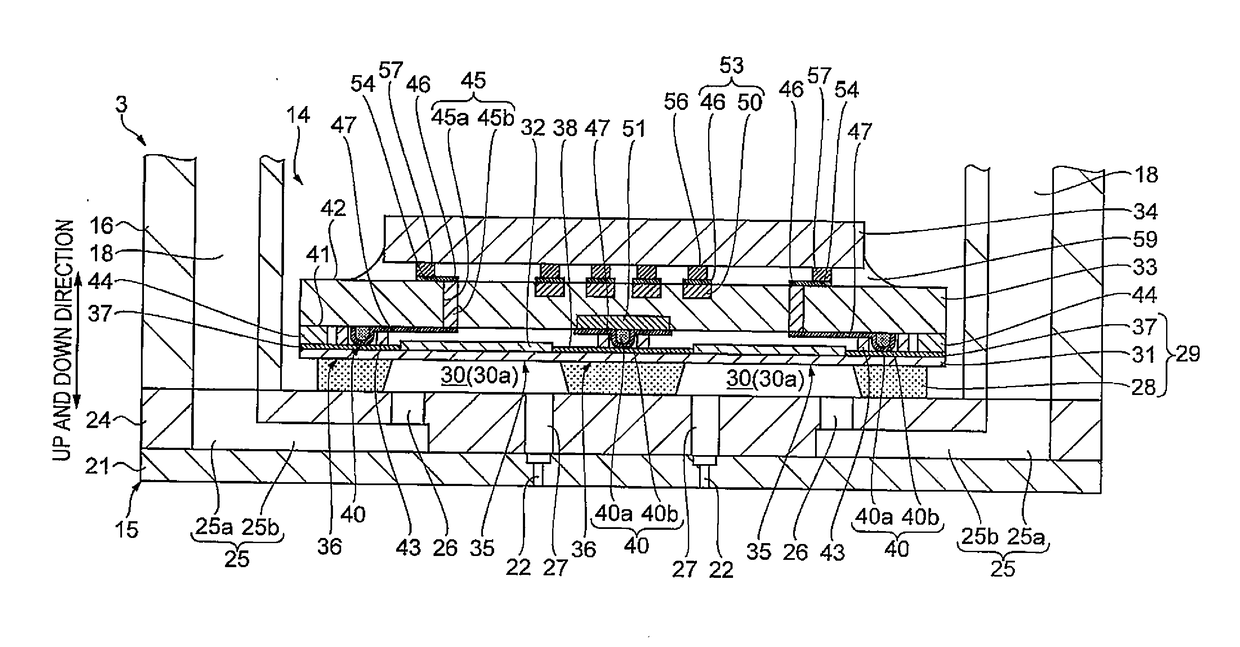

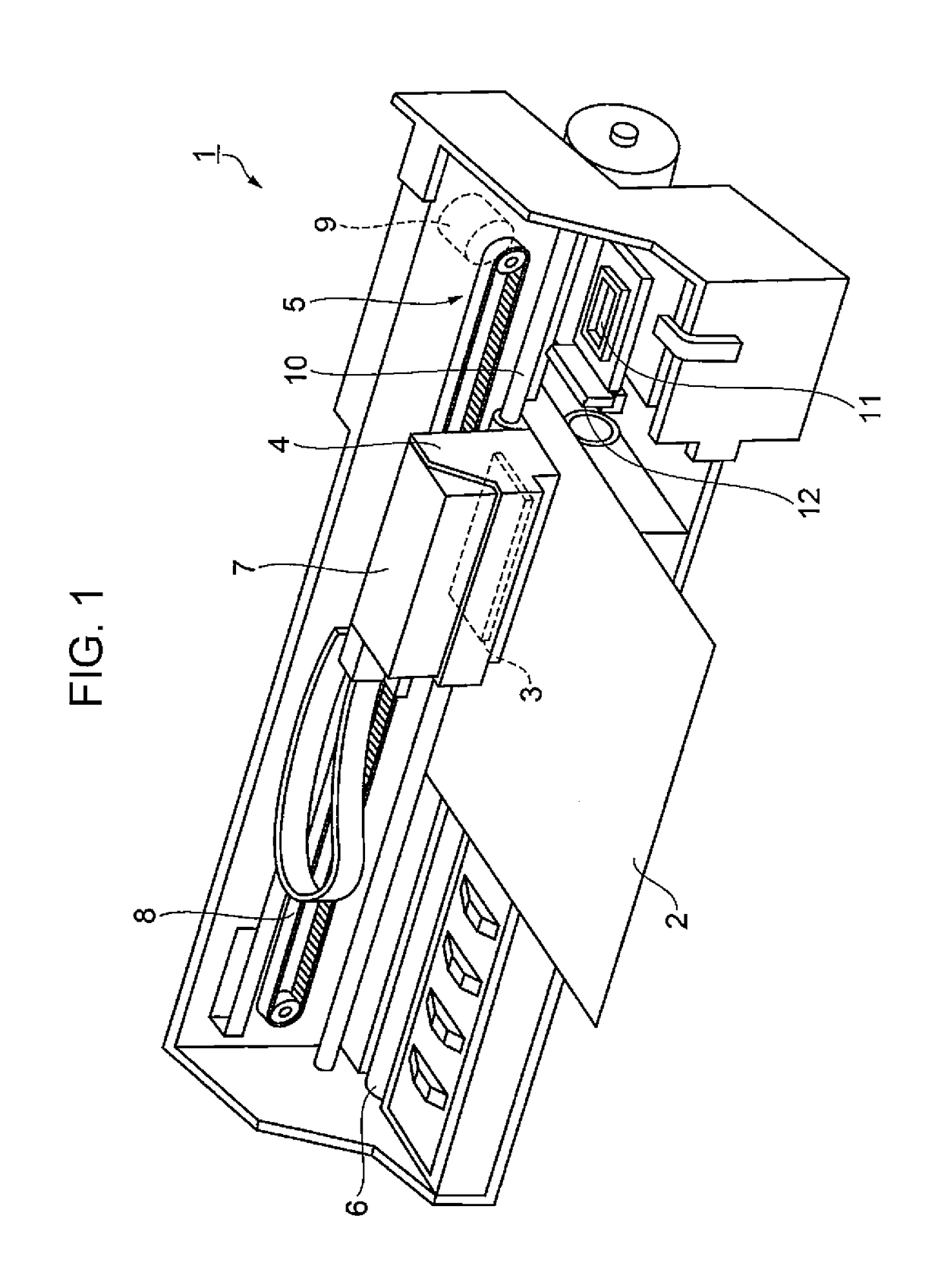

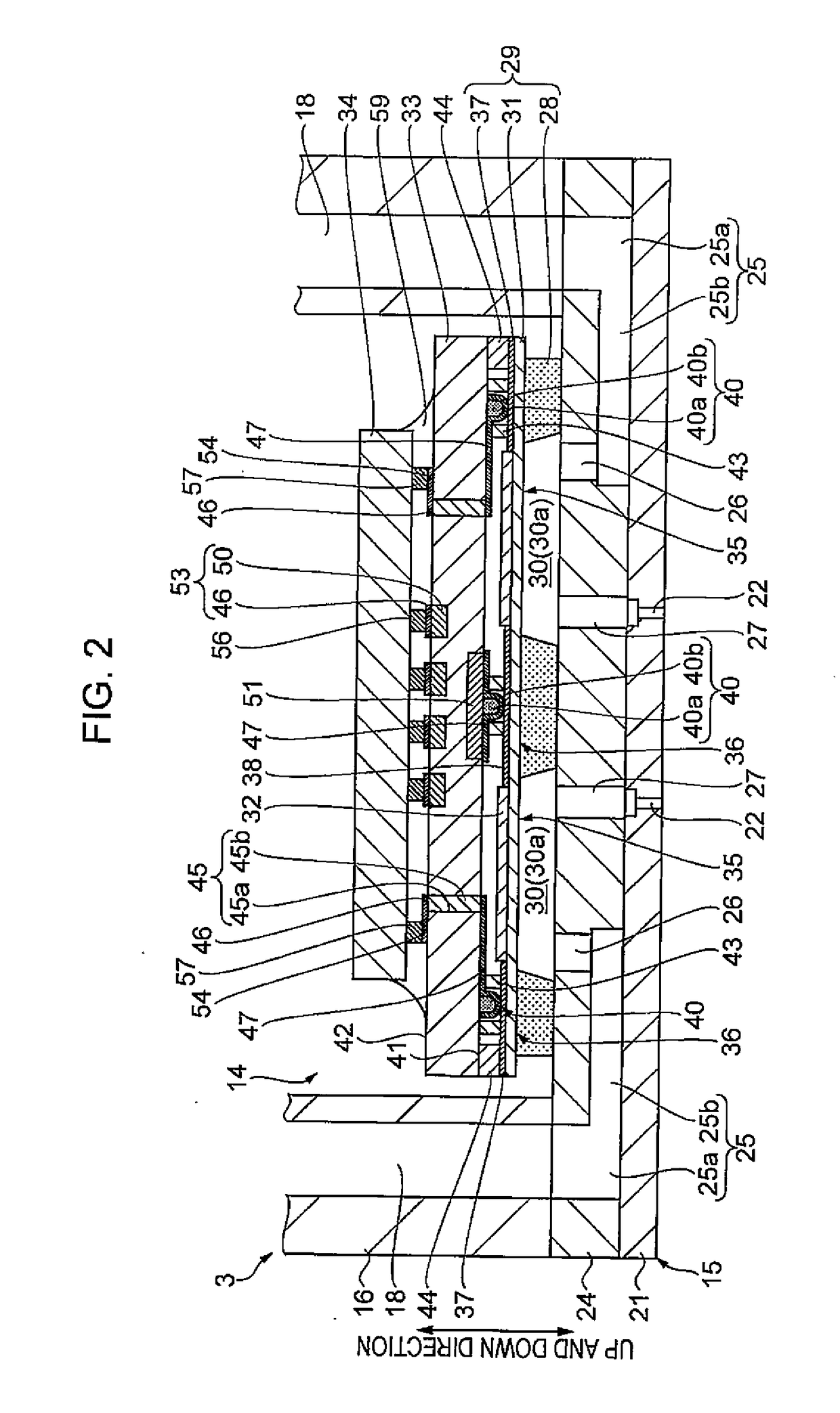

Method of manufacturing liquid crystal display device

InactiveUS6970227B2Improve display qualityHigh yieldNon-linear opticsLiquid-crystal displayVacuum level

A plurality of main seal patterns and dummy seal patterns are formed by a sealant on one of substrates. The plurality of main seal patterns individually enclose each of a plurality of display areas. The dummy seal patterns individually enclose the plurality of main seal patterns, and sides of the dummy seal patterns facing sides of the one substrate are all interconnected. These formations enable constant vacuum levels to be maintained the inside and the outside of the main seal patterns when the inside of a chamber of an assembling device is recovered to atmospheric pressure. Therefore, distortion of substrates is impeded in the vicinity of the main seal patterns, and degradation of display quality can be prevented.

Owner:SHARP KK

System for display images

InactiveUS20130003006A1Improve the bonding force between layersBlock display panelNon-linear opticsComputer science

A system for displaying images including a display panel is provided. The display panel has a display area and a peripheral area. The display panel includes a metal layer disposed on a first substrate. A patterned planarization layer is disposed on the metal layer, having at least one opening corresponding to the peripheral area, wherein a portion of the metal layer is exposed through the opening. A second substrate is disposed opposite to the first substrate. A seal is disposed at the peripheral area and between the first and the second substrates, wherein the seal covers the metal layer through the opening of the patterned planarization layer.

Owner:INNOLUX CORP +1

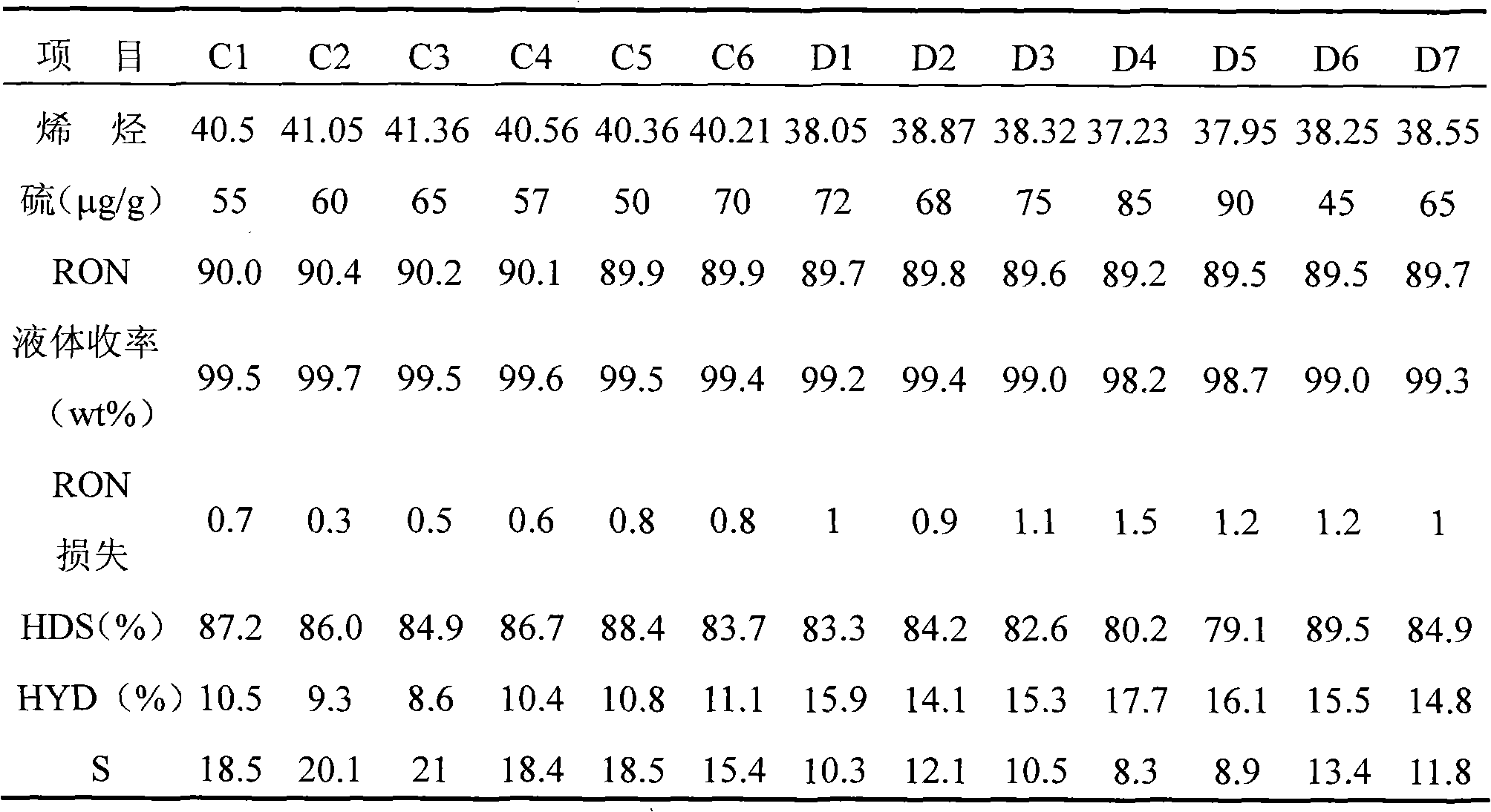

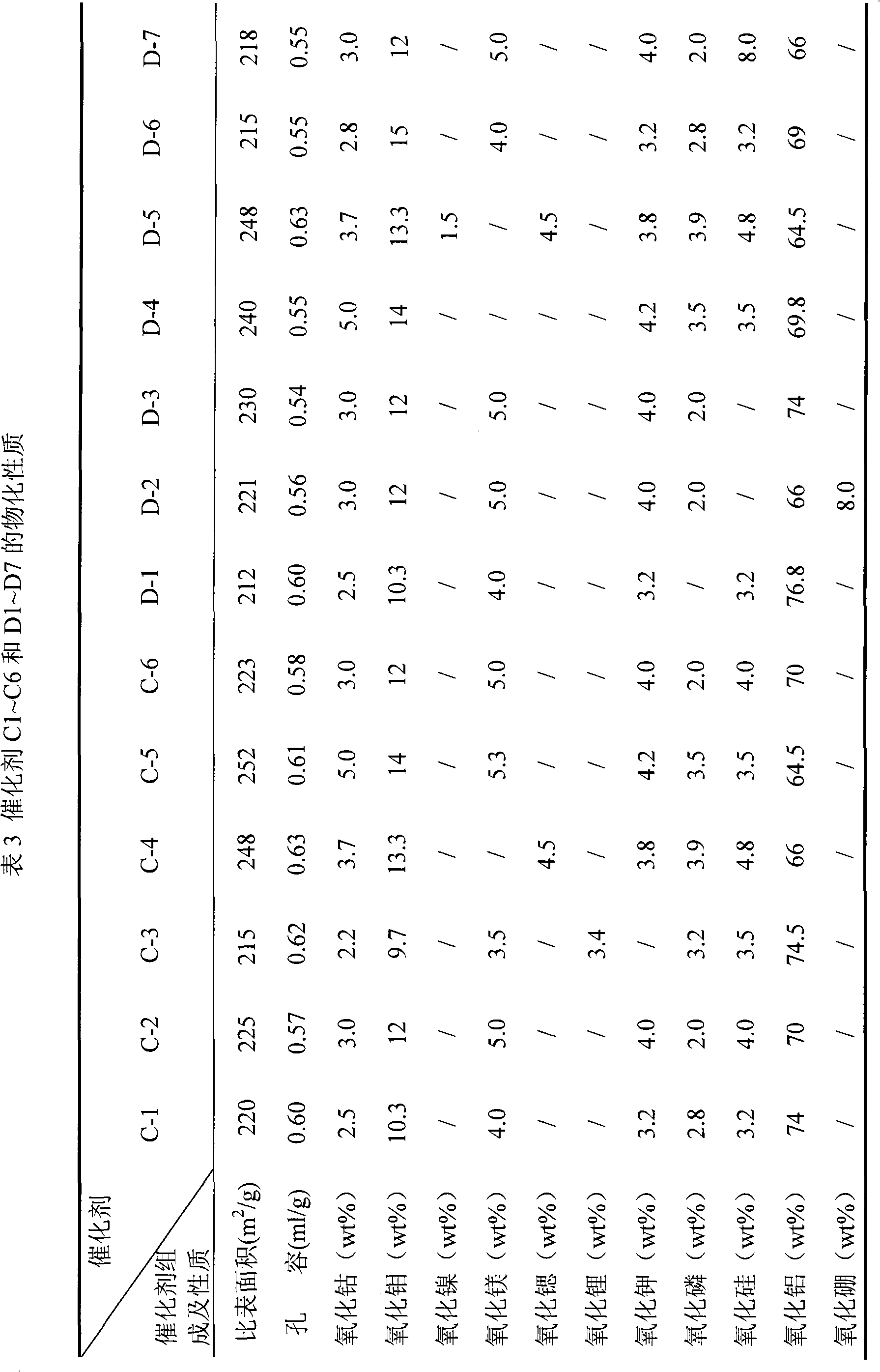

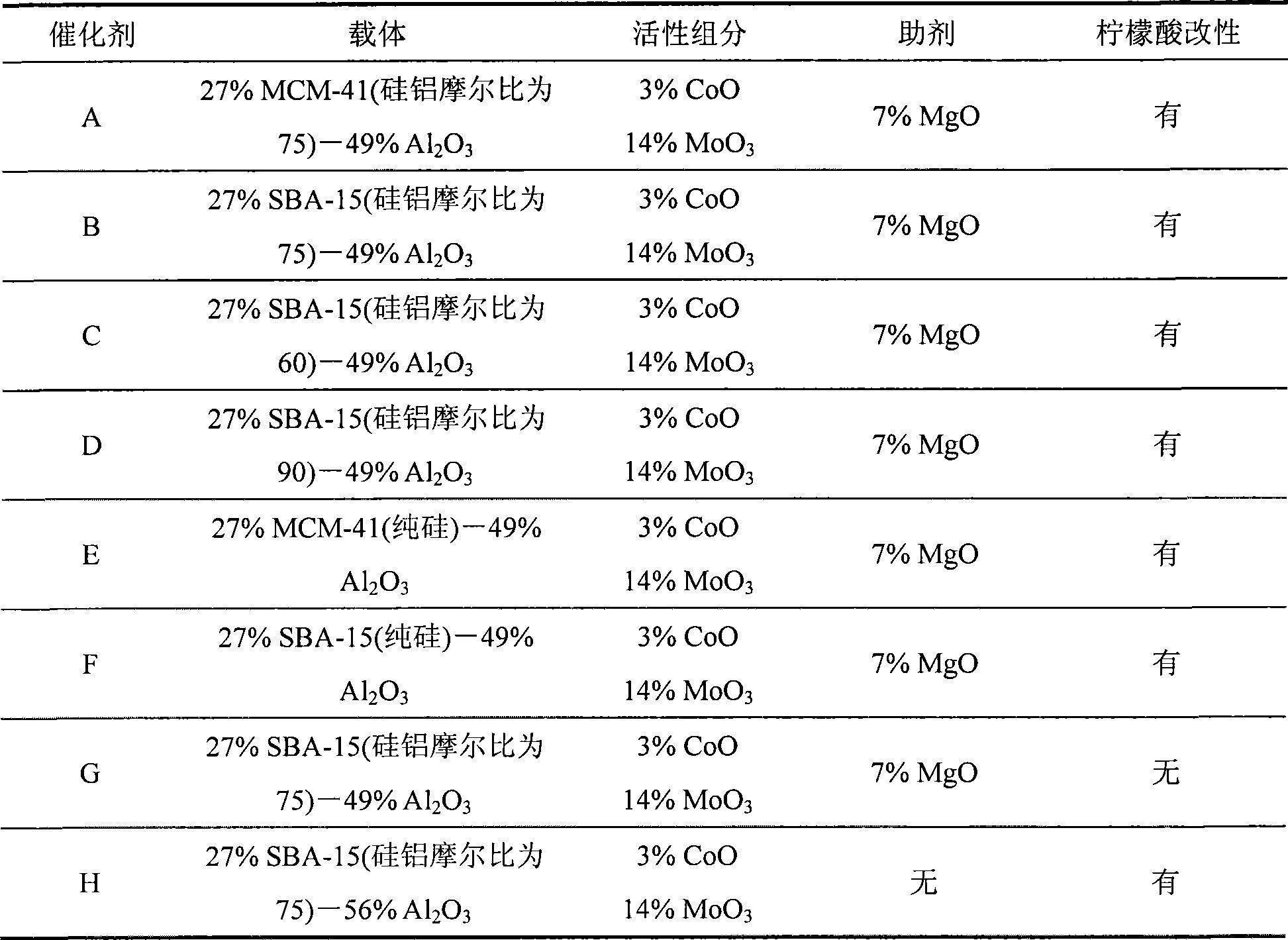

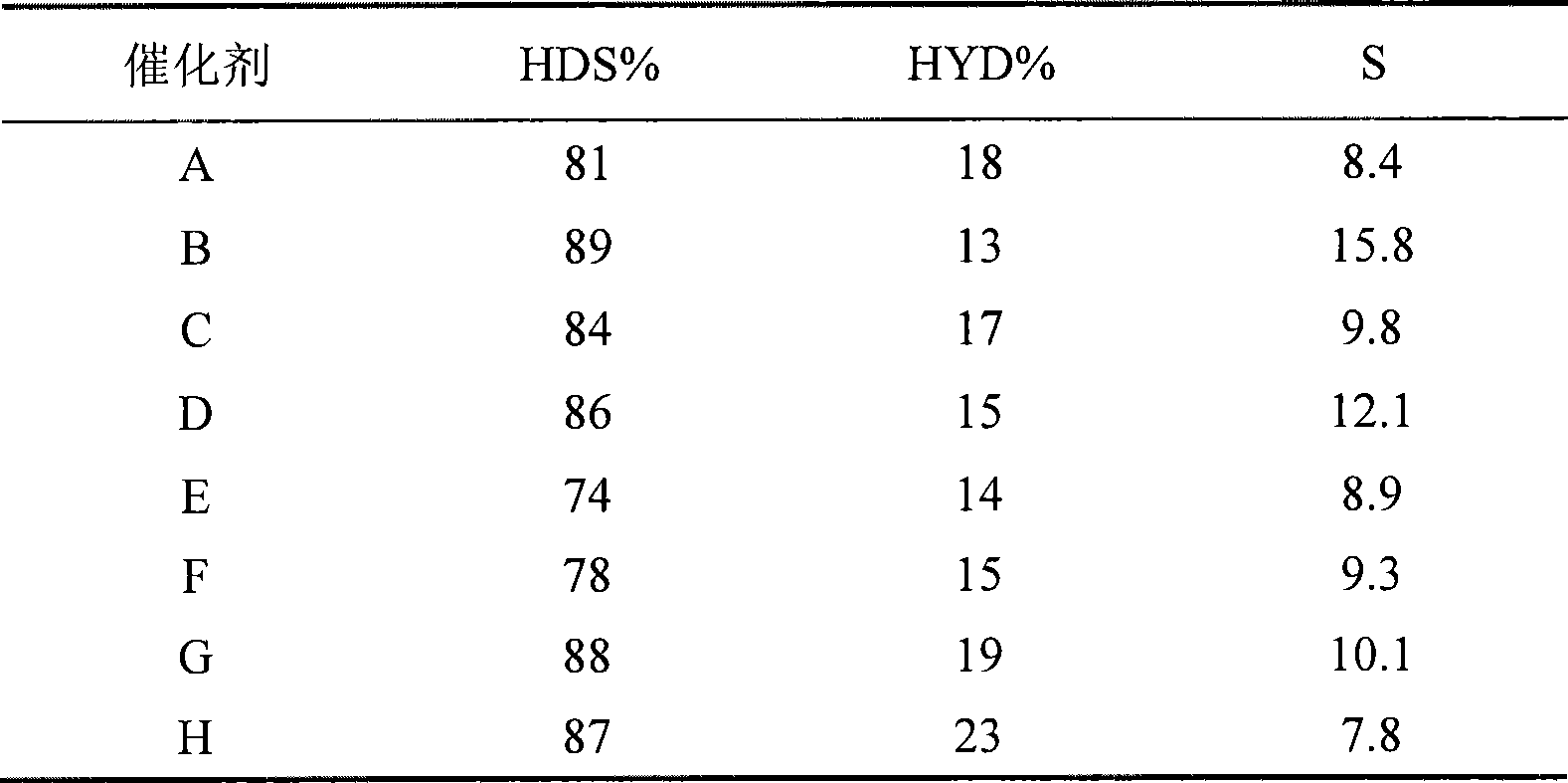

Selective hydrodesulfurization catalyst and preparation method thereof

ActiveCN102335612AReduce acid strengthEnhance the interaction strengthMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAlkaline earth metalHydrodesulfurization

The invention relates to a selective hydrodesulfurization catalyst contains cobalt and molybdenum as active components. The selective hydrodesulfurization catalyst is characterized in that silicon oxide and aluminum oxide are used as carriers of the catalyst; based on the total weight of 100%, the catalyst comprises 2-6wt% of cobalt oxide, 9-15 wt% of molybdenum oxide, 2-8wt% of alkaline earth metal oxide, 2-6wt% of phosphorus oxide, 3-5wt% of alkali metal oxide, 2-6wt% of silicon oxide and 54-80 wt% of aluminum oxide; and the catalyst has the specific surface area of 200-300m<2> / g and the pore volume of 0.5-0.7mL / g. The catalyst has high hydrogenation activity and selectivity, good stability, low research octane number loss and high liquid yield. The catalyst is suitable for selective hydrodesulfrization of low-quality gasoline and is particularly suitable for selective hydrodesulfrization of low-quality FCC (Family Car China) gasoline.

Owner:PETROCHINA CO LTD

Hydrocracking catalyst containing compound molecular sieve and preparing method thereof

InactiveCN1488726AImprove nitrogen resistanceHigh hydrocracking activityHydrocarbon oil crackingMolecular sieveNitrogen

The present invention relates to a hydrocracking catalyst containing compound molecular sieve and its preparation method. Said catalyst composition uses amorphous aluminosilicate and a compound molecular sieve as carrier, in which the amorphous aluminosilicate content is 30-60% of catalyst weight, compound molecular sieve content is 1-20% of catalyst weight, and is the mixture of modified Y molecular sieve and SAPO molecular sieve, VIB group metal oxide content is 10-40%, VIII group metal oxide content is 1-20% of IVB group metal oxide content is 1-10%. Said invented catalyst is prepared by adopting co-precipitation method, and its strength and performance can be raised and improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

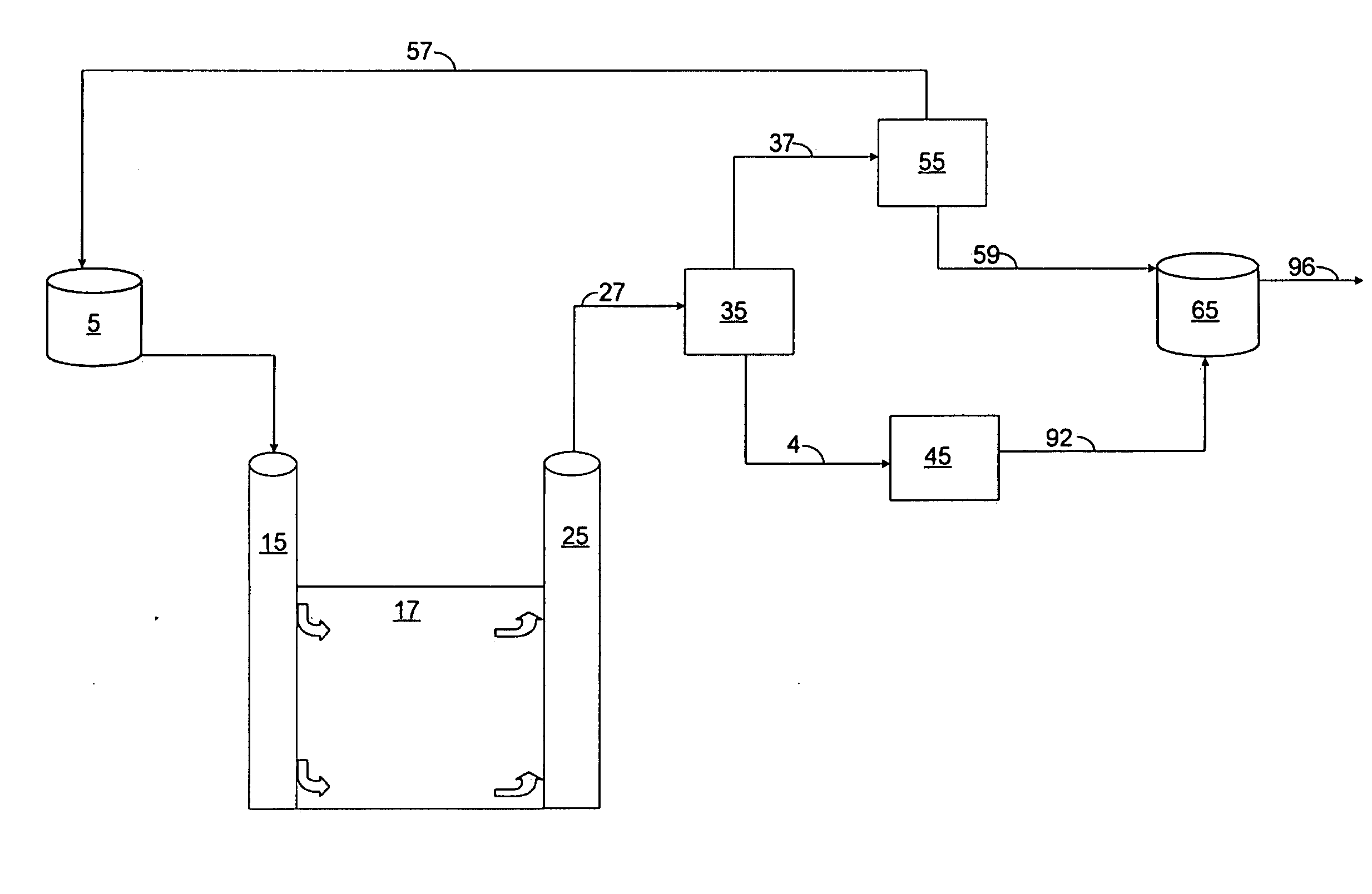

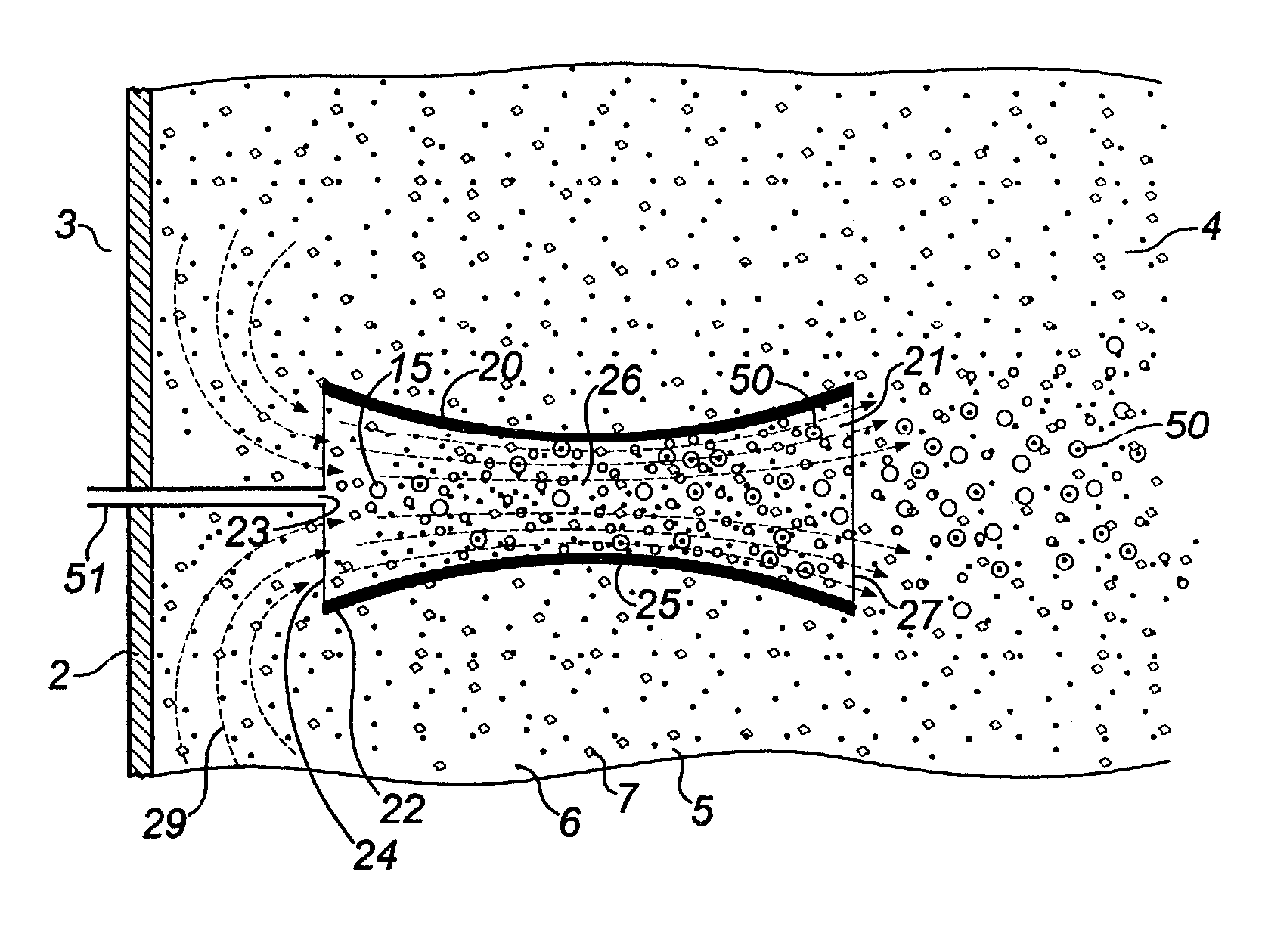

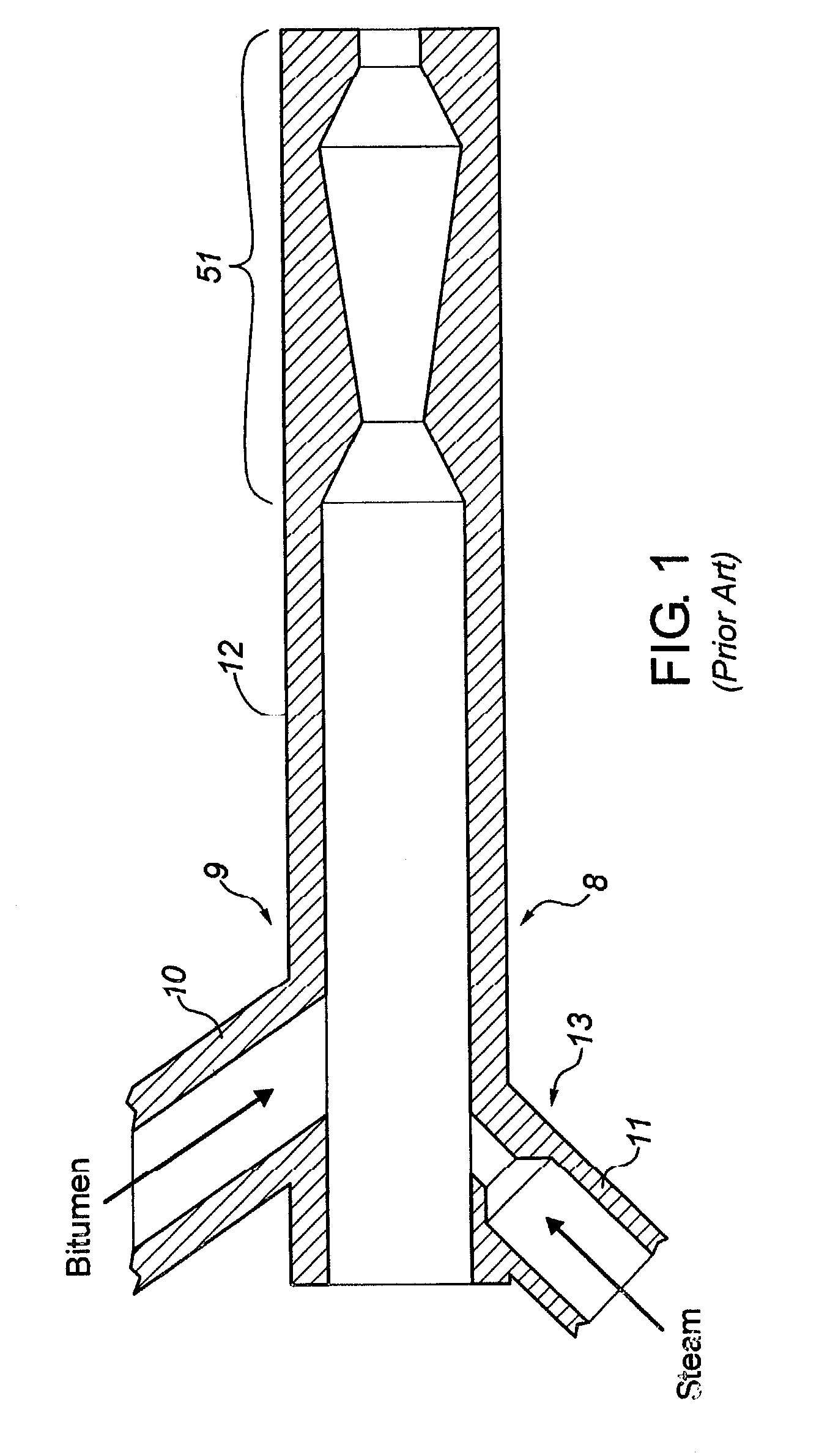

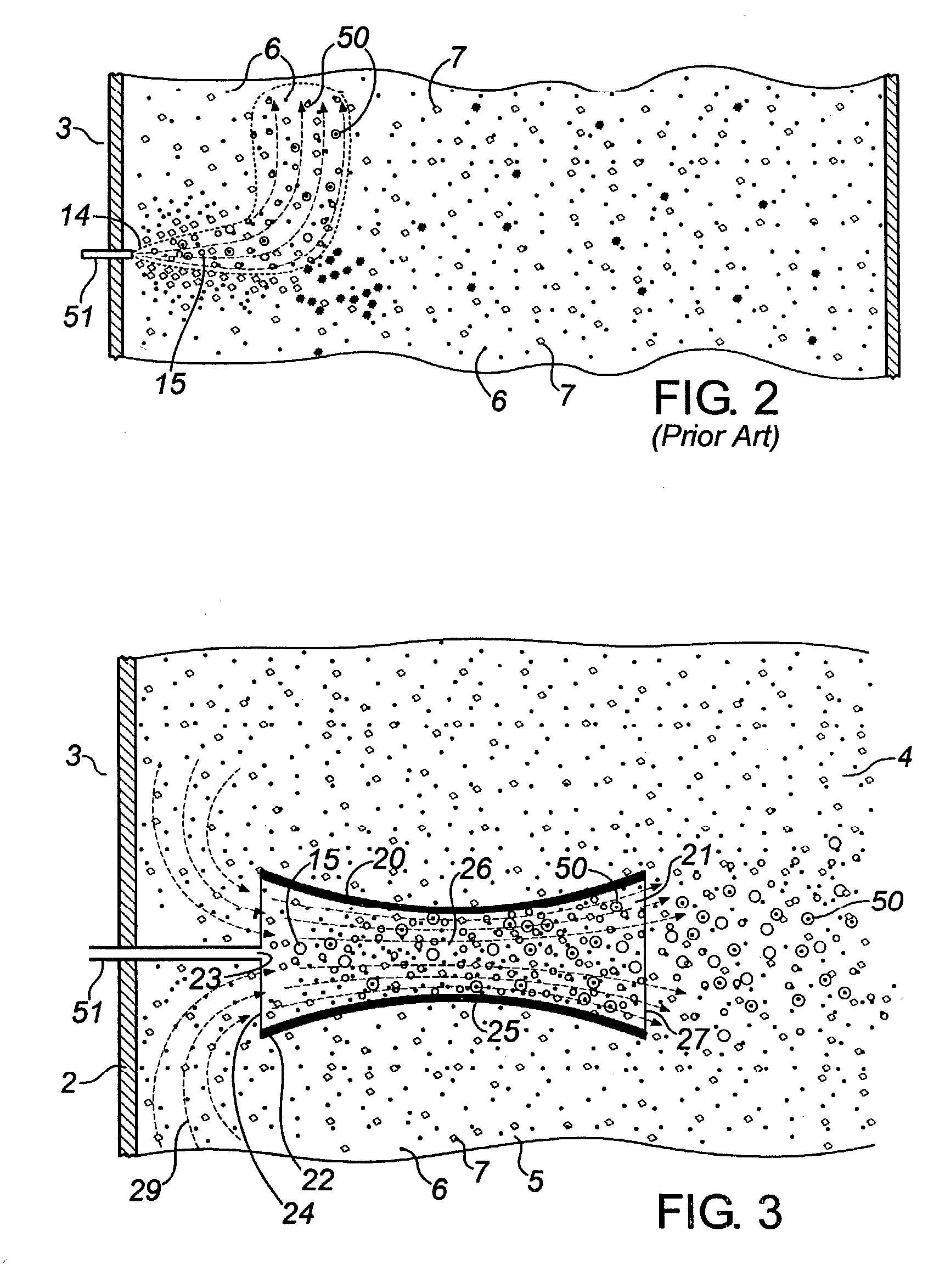

Nozzle/mixer assembly

InactiveUS7025874B2Increase probabilityImprove liquid yieldThermal non-catalytic crackingFlow mixersJet flowFluidized bed

A bitumen / steam pre-mixer and atomizing nozzle combine to produce a jet of minute liquid droplets (bitumen) in carrier gas (steam). The jet is injected into a draft tube mixer positioned in a fluid bed of hot coke particles suspended in steam and contained within a fluid coking reactor. The movement of the jet through the draft tube passageway induces a stream of coke particles in steam to be drawn into the passageway, where the jet and stream mix vigorously and bitumen droplets have an enhanced probability of contacting coke particles.

Owner:AEC OIL SANDS

Hydrocracking catalyst preparation method

ActiveCN104588082AEasy to useControl distributionMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveHigh activity

The invention discloses a preparation method of a hydrocracking catalyst. According to the method, a nickel and aluminum precipitate is prepared with a straight addition method; a tungsten, silicon and aluminum precipitate is prepared with a parallel flow precipitation method; the two precipitates are mixed, and a suspension liquid of Y type molecular sieve is added, such that the catalyst is prepared. With the method, the distributions of different hydrogenation active metals can be controlled; high-activity phase can be formed among active metals tungsten and nickel; and the interaction between active metals and the carrier can be improved. Therefore, the hydrogenation activity and the cracking activity of the obtained hydrocracking catalyst can cooperate well, and the application performance of the hydrocracking catalyst can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Selective hydrodesulfurization catalyst containing mesoporous molecular screen and preparation method thereof

ActiveCN101439293ALow mechanical strengthImprove performanceMolecular sieve catalystsHydrocarbon oils refiningHydrodesulfurizationCobalt

The invention relates to a selective hydrodesulfurization catalyst and a preparation method thereof. The catalyst takes alumina and a silicon-aluminum mesoporous molecular sieve containing an ordered mesoporous structure as carriers, takes cobalt and molybdenum as the active components and takes magnesium as an addition agent. The preparation method of the catalyst comprises: mixing the alumina and the silicon-aluminum mesoporous molecular sieve; adding sesbania powder and nitric acid, then carrying out mixing kneading, shaping, drying and baking on the mixture to prepare the compound of the alumina and the silicon-aluminum mesoporous molecular sieve; then the compound is treated by organic acid and loaded with the addition agent of magnesium as well as the active components of cobalt and molybdenum, then, aging, drying and baking are carried out on the mixture to prepare the catalyst. The catalyst shows excellent gasoline selectivity and hydrodesulfurization activity, low loss of product researching octane number and high liquid yield by inducing the porous structure and acidity of the modulating catalyst of the ordered mesoporous molecular sieve, inducing the acidity of a magnesium modulating catalyst and inducing the manual effect between an organic acid modulating carrier and the active components.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Reforming method for coking gasoline

ActiveCN1715372ABoost octaneExtended operating cycleTreatment with hydrotreatment processesHydrogenDistillation

The coker gasoline reforming process includes the following steps: 1. hydrorefining coker fraction oil, cutting the fraction of distillation range 70-175 deg c for reforming and pre-refining to eliminate impurity and dewatering to material water content below 5ppm; and 2. making the dewatered material to contact with the reforming catalyst for reaction at 470-540 deg c and 0.2-2.0 MPa in the presence of hydrogen, circulating un-reacted hydrogen and controlling water content in circulated hydrogen within 5-20ppm. The said process has effectively raised octane number of the coker gasoline and prolonged service life of the reforming catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

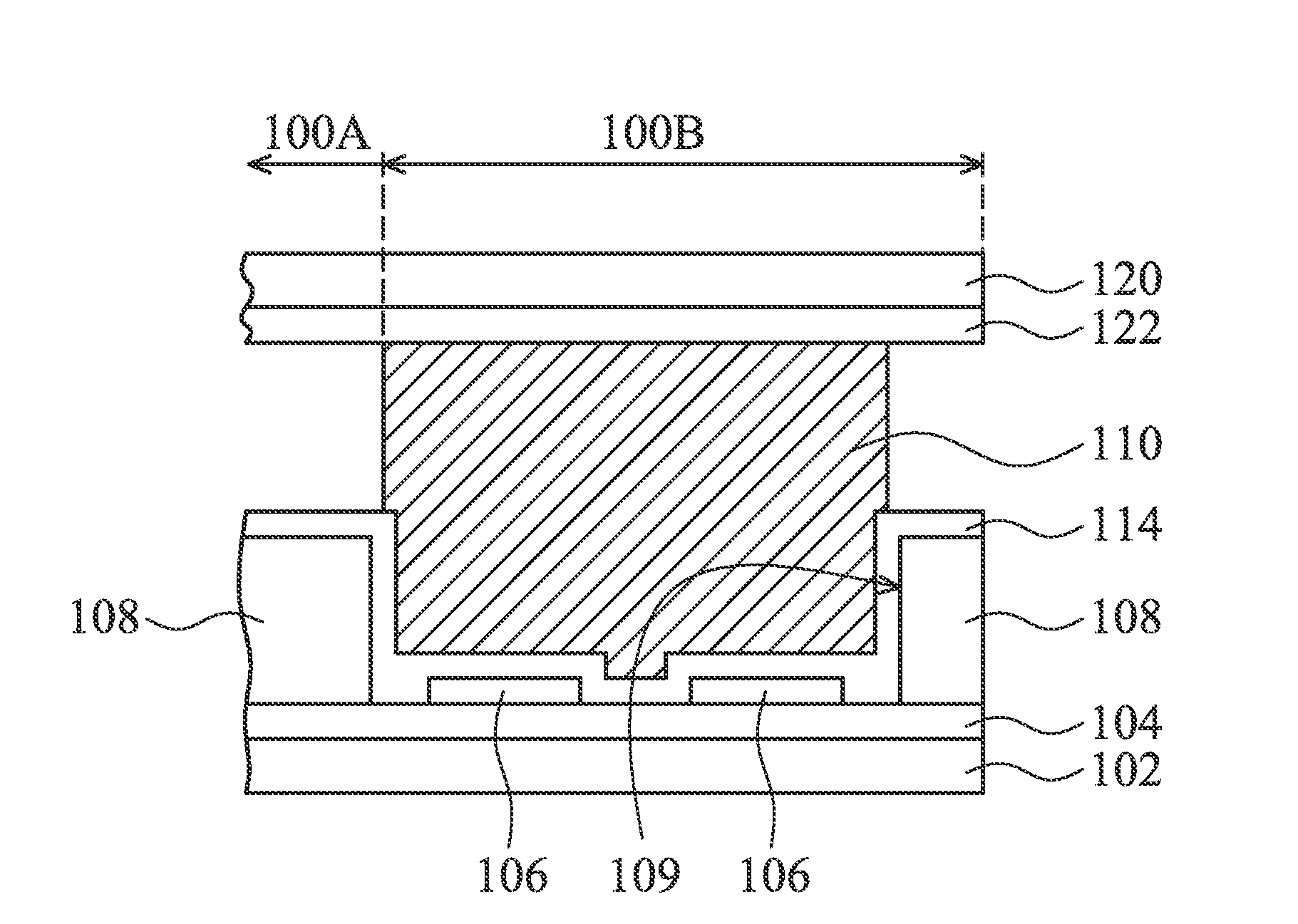

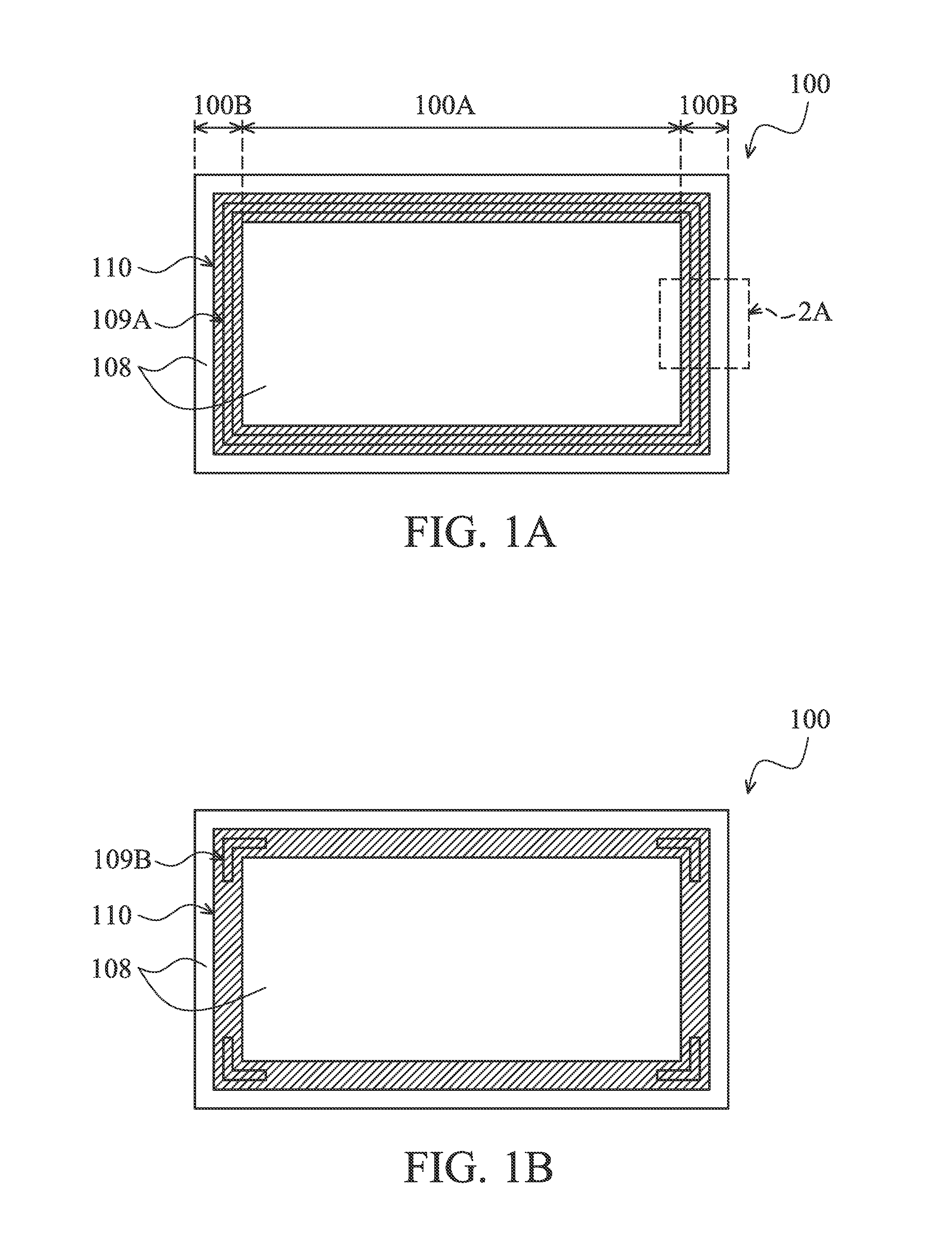

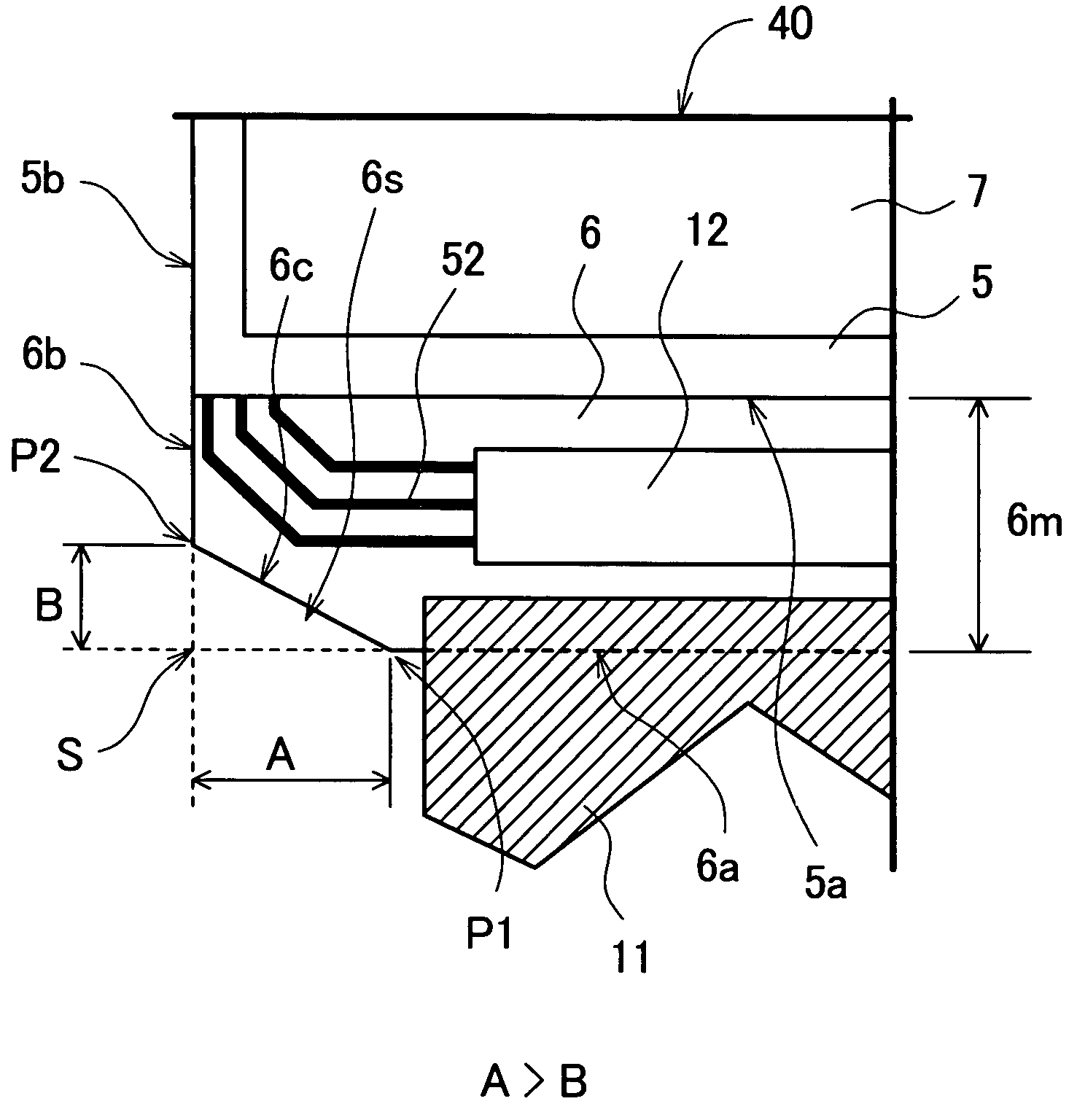

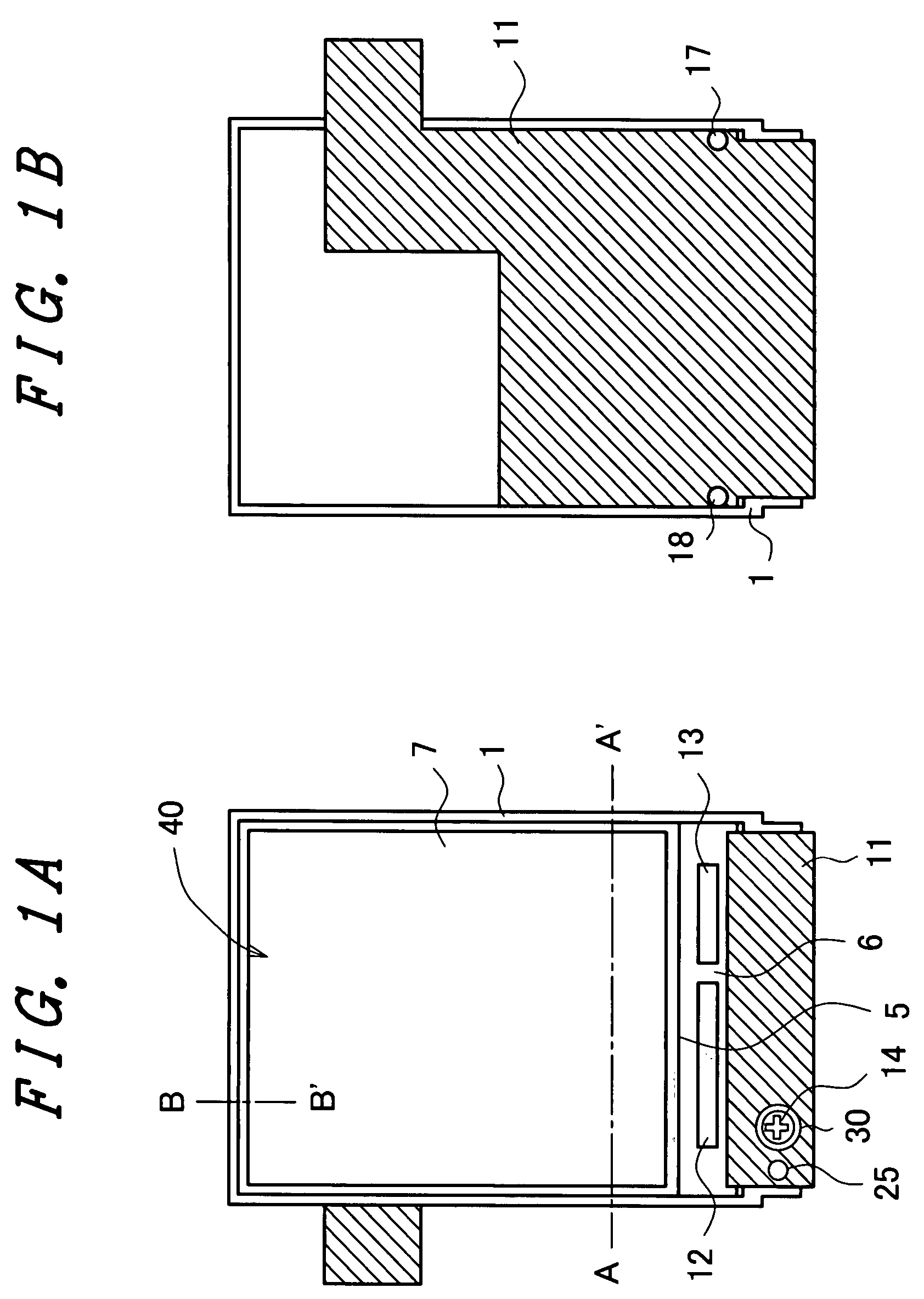

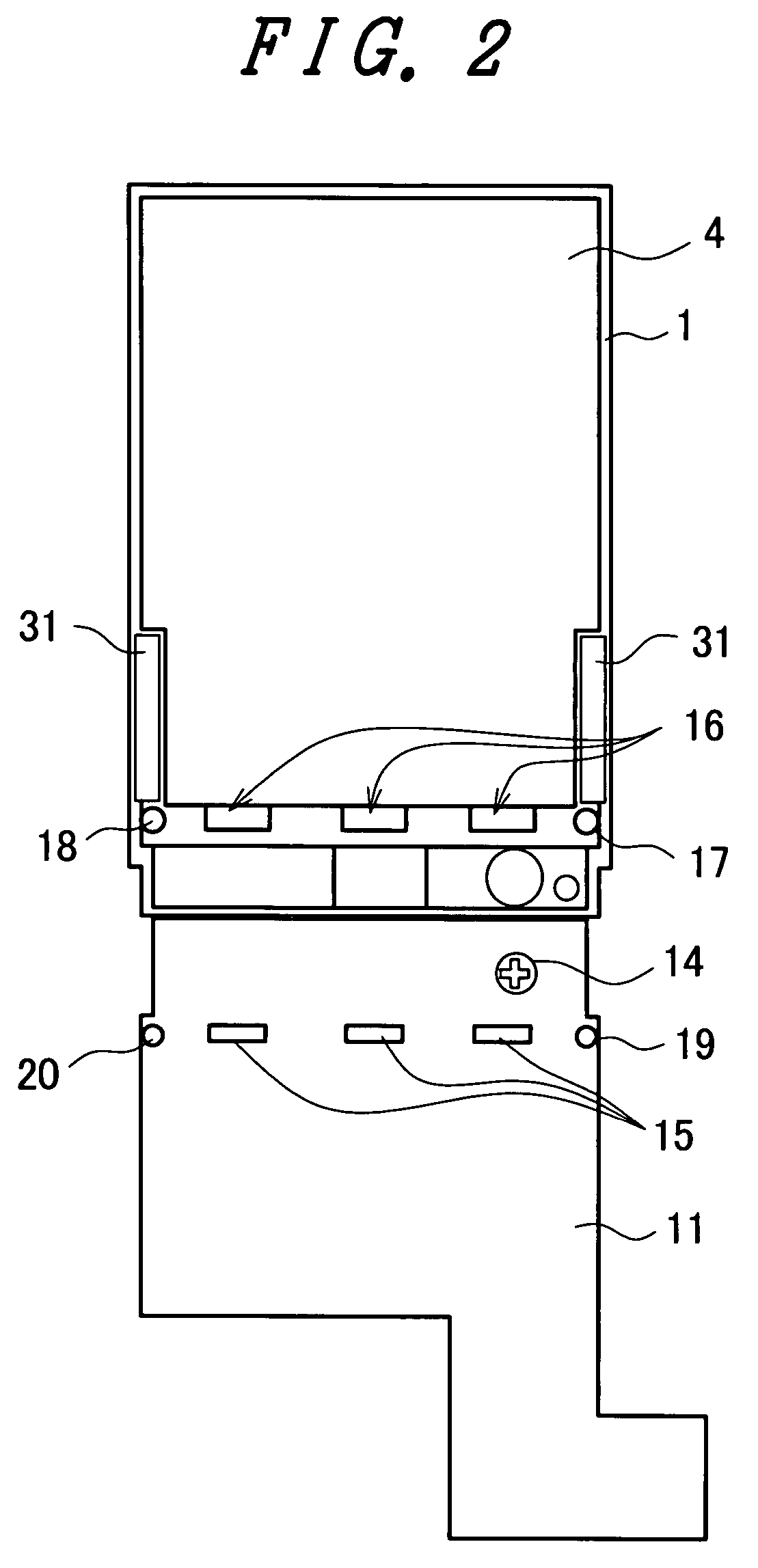

Liquid crystal display device

ActiveUS20080088765A1Improve liquid yieldImprove manufacturing yieldNon-linear opticsLiquid-crystal displayEngineering

The liquid crystal display (LCD) device of the present invention includes a LCD panel and a resin-molded frame that houses the LCD panel, the LCD panel including first and second substrates, and a liquid crystal layer sandwiched between the first and second substrates. The two-dimensional shapes of the first and second substrates are rectangles having longer and shorter sides, the longer side of the first substrate being longer than that of the second substrate. The first substrate has a non-overlapping area that does not overlap with the second substrate. Among the four corners of the first substrate, the non-overlapping area of the first substrate has two corners adjacent to each other. At least one of the two corners forms a chamfered structure having a diagonal side that intersects the longer and shorter sides of the first substrate with the diagonal side inclined to the longer and shorter sides.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

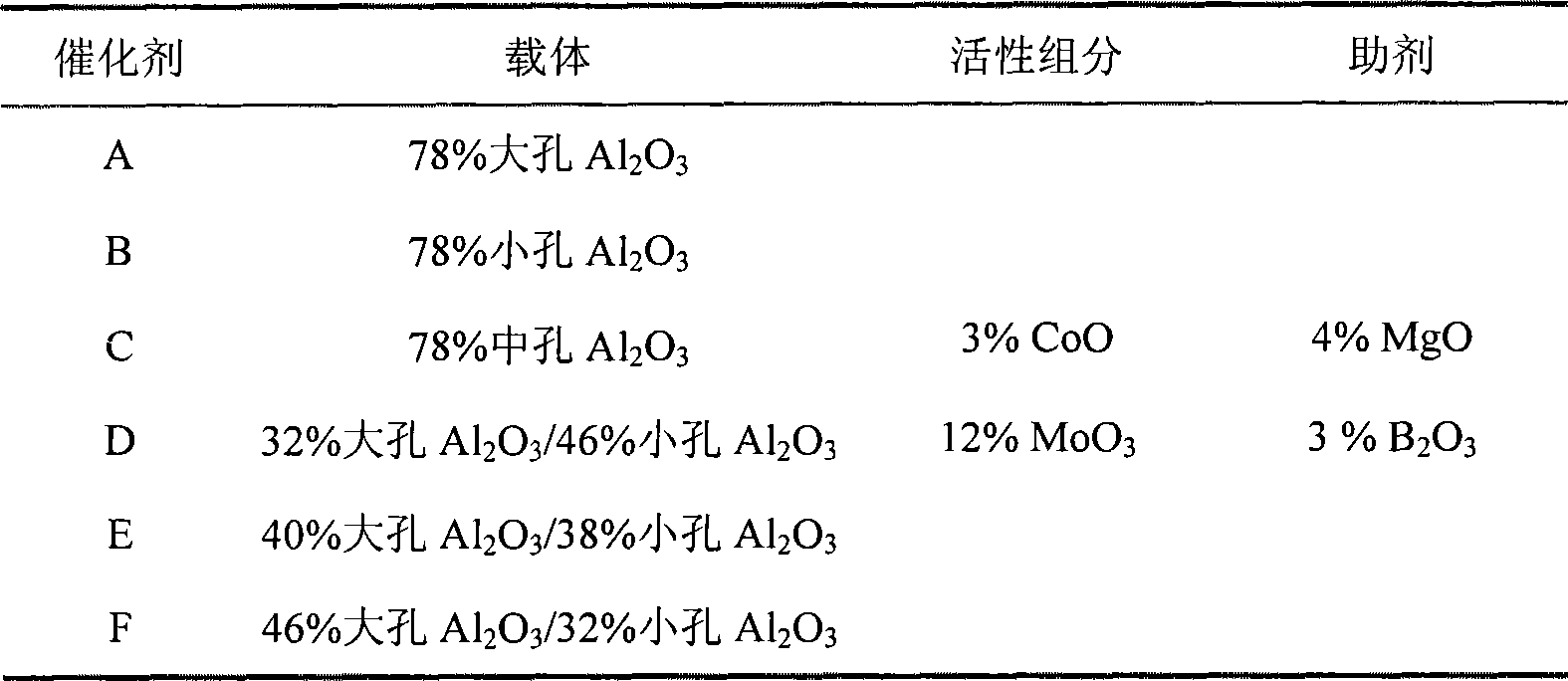

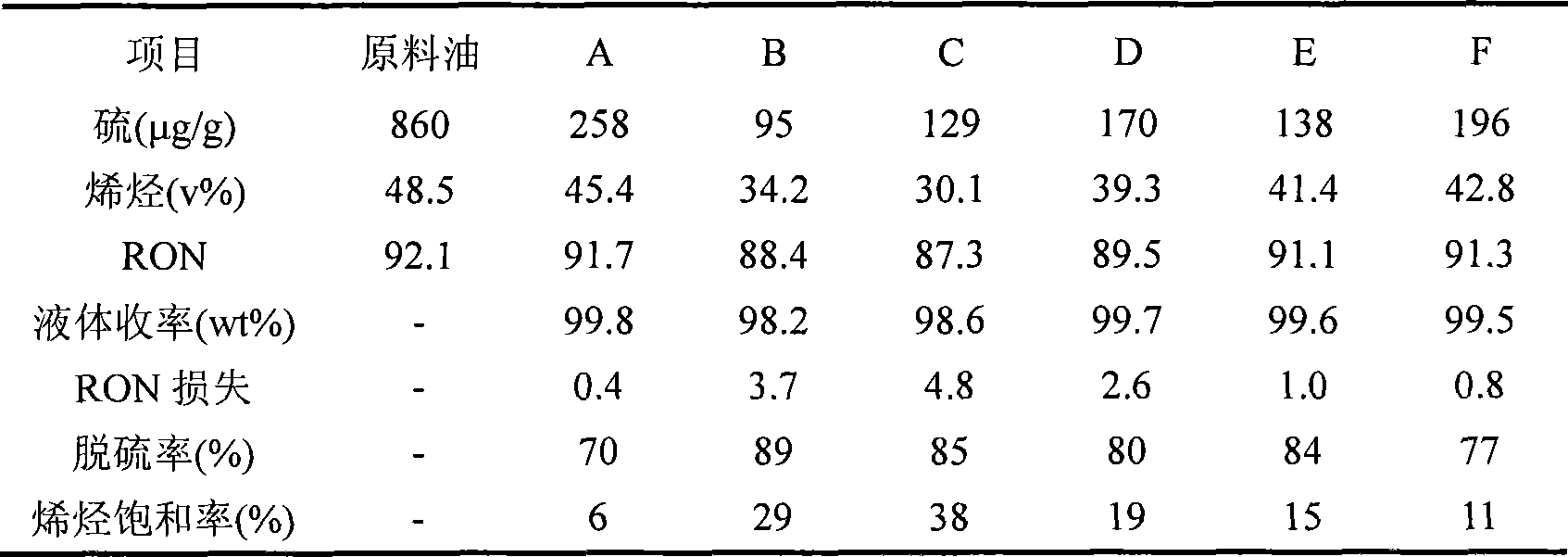

Combined aluminum oxide-based selective hydrodesulfurization catalyst and preparation method thereof

ActiveCN101439288ANo reduction in mechanical strengthImprove performanceMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationActive component

The invention relates to a selective hydrodesulfurization catalyst of a combined alumina base and a preparation method thereof. The carrier of the catalyst is compounded by macroporous alumina with a specific surface of 280-300m<2> / g, and a pore volume of 0.8-0.9mL / g as well as fenestral alumina with a specific surface of 250-280m<2> / g, and a pore volume of 0.3-0.4mL / g; the active components of the catalyst are cobalt and molybdenum; the addition agents of the catalyst are magnesium and boron. The preparation method of the catalyst comprises: mixing the macroporous alumina and the fenestral alumina; adding sesbania powder and nitric acid, then carrying out mixing kneading, shaping, drying and baking on the mixture to prepare the compound carrier of the alumina; then loading the addition agents of magnesium and boron as well as the active components of cobalt and molybdenum in sequence, then carrying out drying and baking on the mixture to prepare the catalyst. The catalyst has excellent gasoline selectivity and hydrodesulfurization activity, low loss of product researching octane number, high liquid yield, and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Liquid crystal display device

The liquid crystal display (LCD) device of the present invention includes a LCD panel and a resin-molded frame that houses the LCD panel, the LCD panel including first and second substrates, and a liquid crystal layer sandwiched between the first and second substrates. The two-dimensional shapes of the first and second substrates are rectangles having longer and shorter sides, the longer side of the first substrate being longer than that of the second substrate. The first substrate has a non-overlapping area that does not overlap with the second substrate. Among the four corners of the first substrate, the non-overlapping area of the first substrate has two corners adjacent to each other. At least one of the two corners forms a chamfered structure having a diagonal side that intersects the longer and shorter sides of the first substrate with the diagonal side inclined to the longer and shorter sides.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

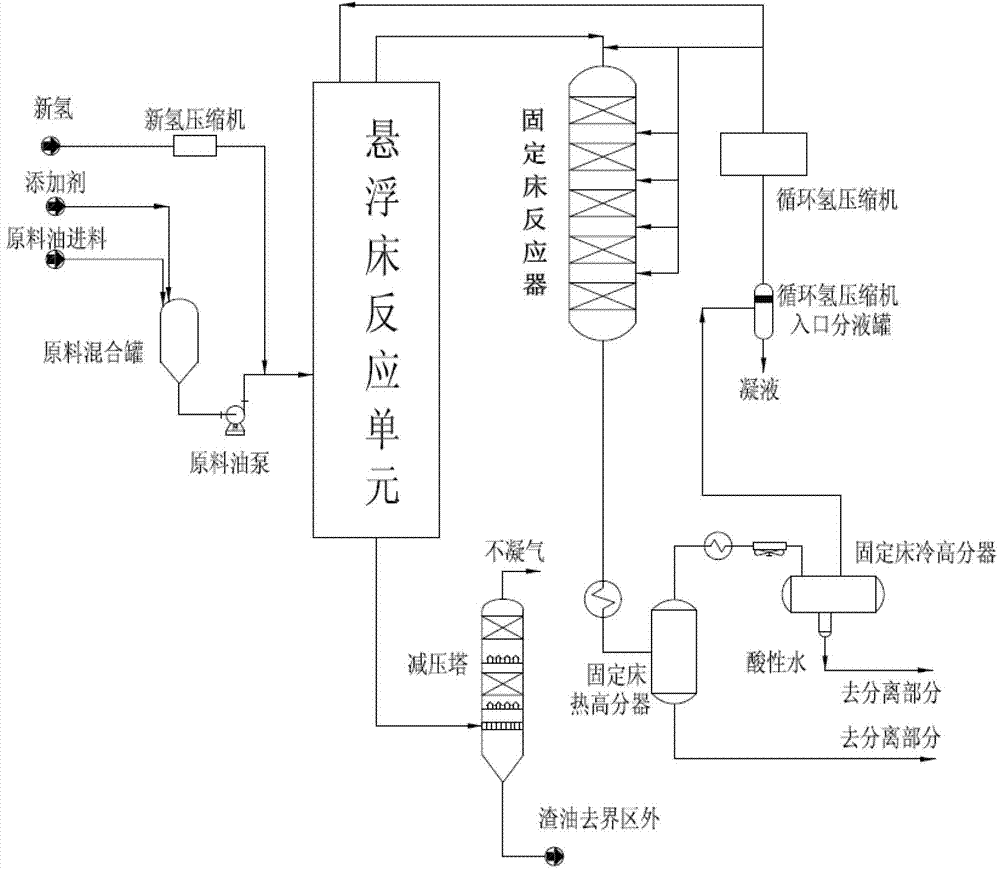

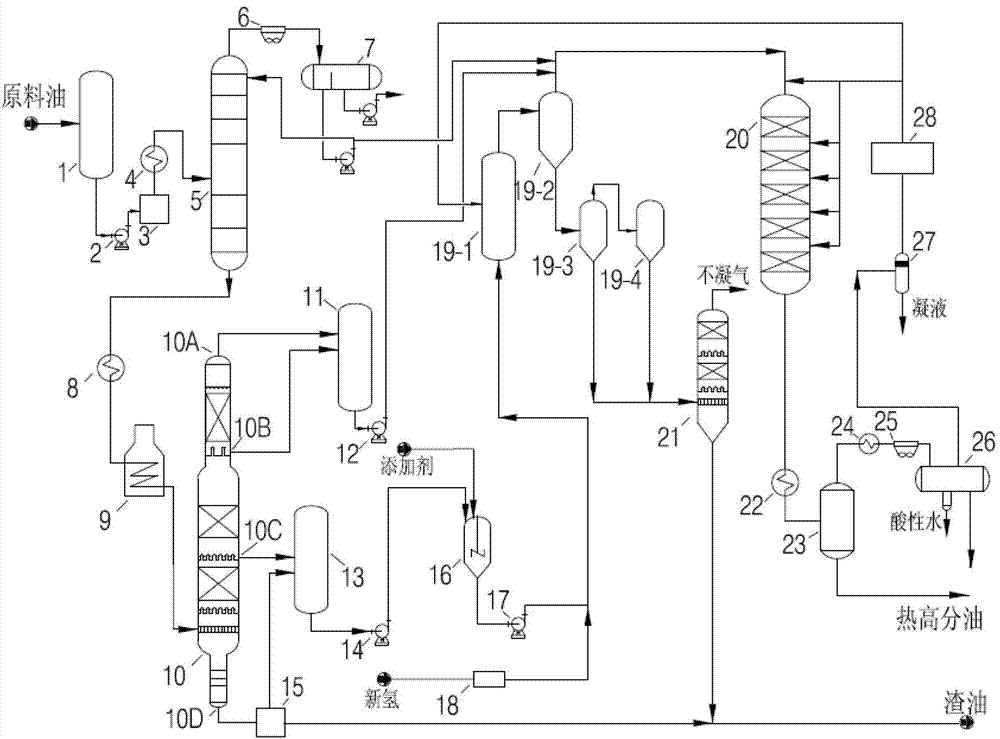

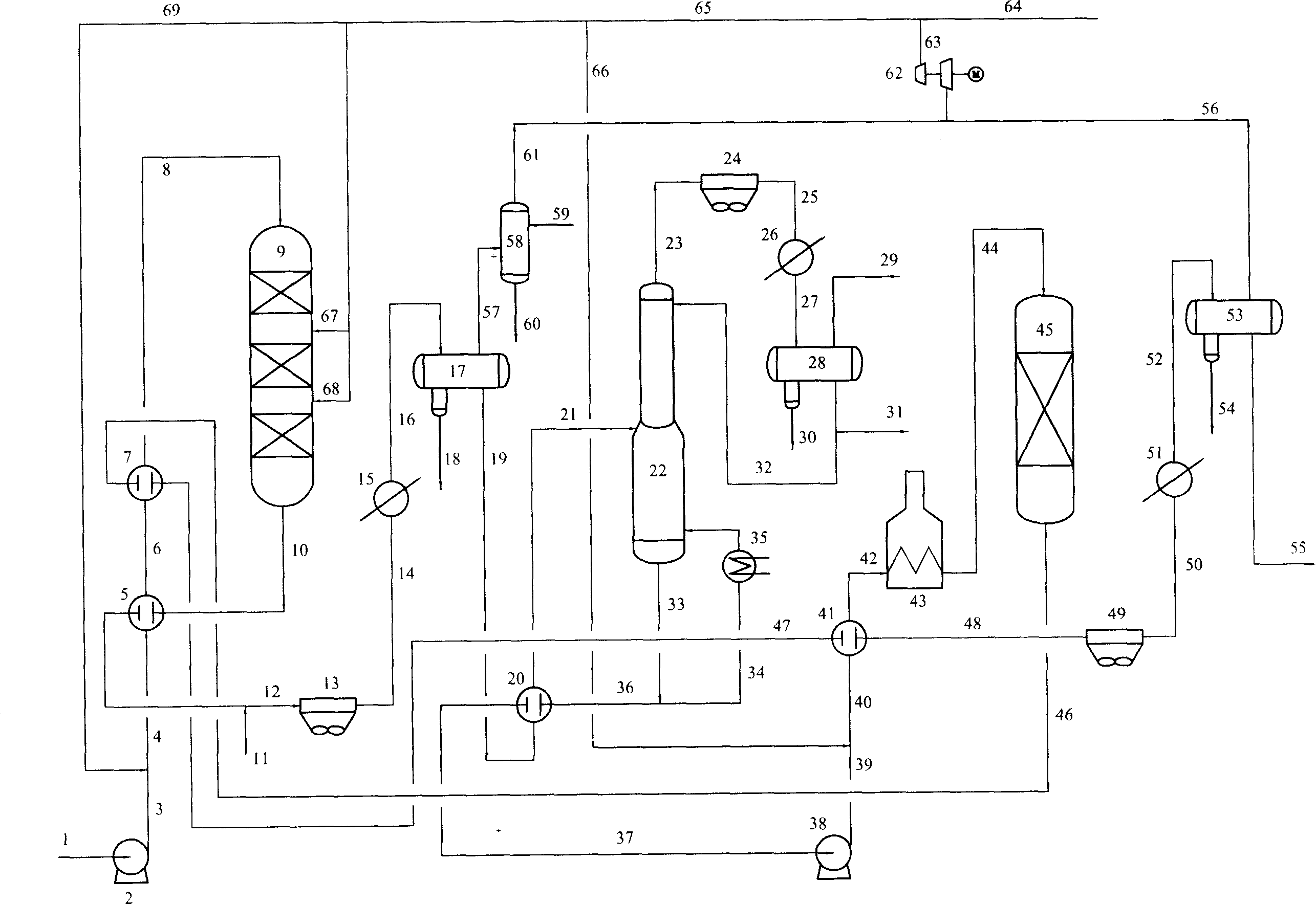

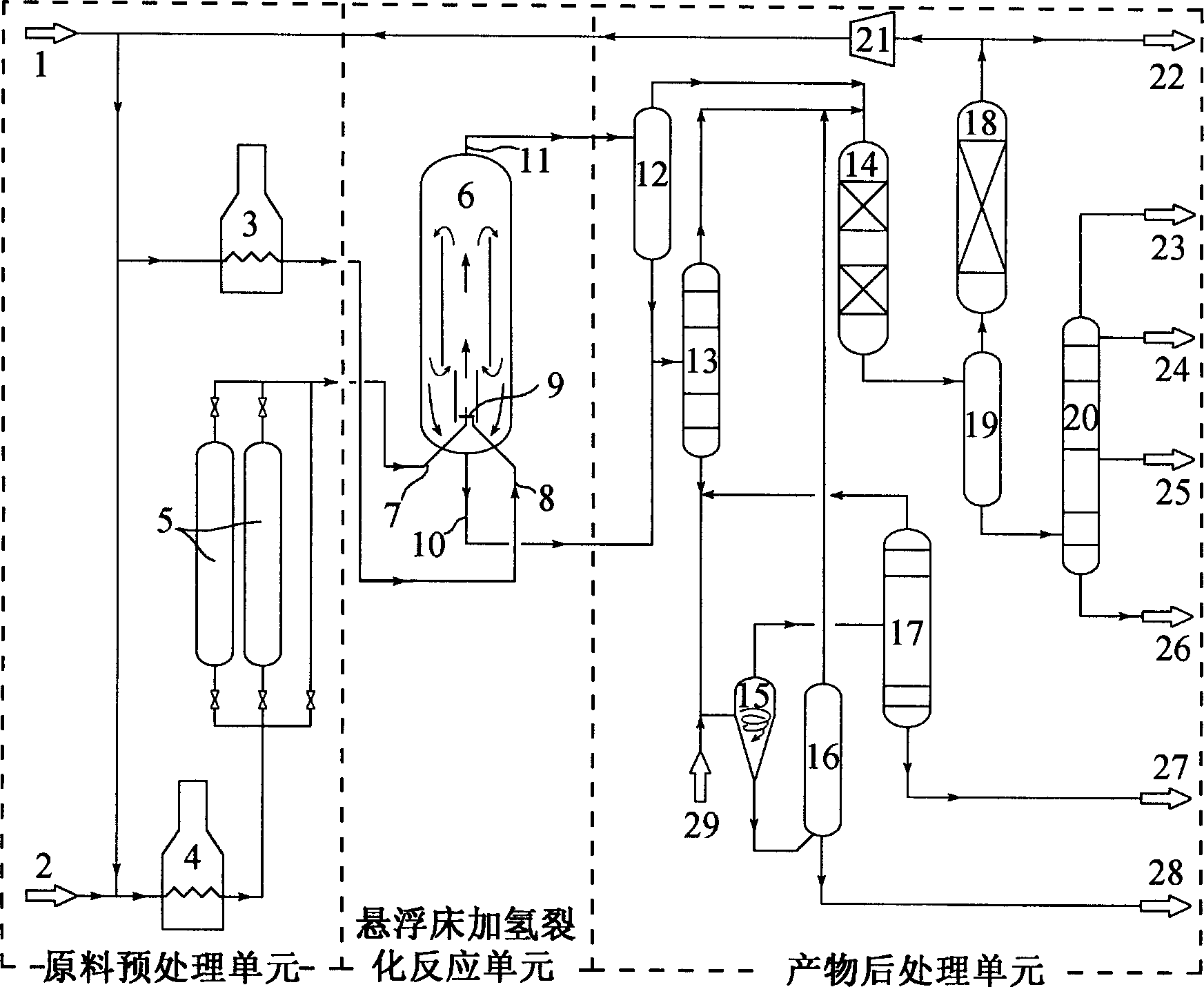

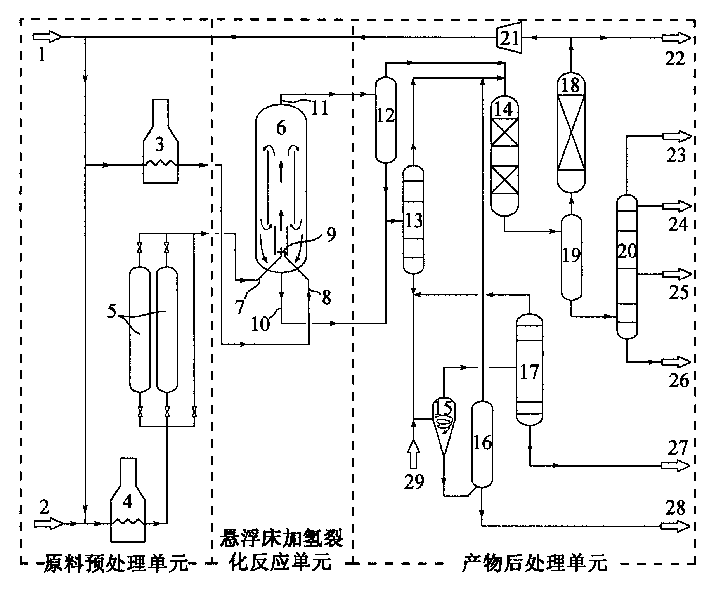

Matching technology method for optimizing feeding of coal tar suspended bed hydrocracker

ActiveCN103484159AAvoid crackingReduce solid particlesTreatment with hydrotreatment processesFiltrationFixed bed

The invention relates to a matching technology method and a treatment system for optimizing feeding of a coal tar suspended bed hydrocracker. The method comprises the following steps: filtration and deslagging of coal tar, dehydration treatment through a dehydrating tower, and deep drawing through a vacuum tower. According to the invention, light oil pumped out from the top of the vacuum tower is mixed with diesel fractions pumped out from the vacuum tower siding to be sent to a fixed bed reactor for hydrocracking treatment; the light oil pumped out from the top of the vacuum tower can also be sent to the fixed bed reactor for hydrocracking treatment, and the diesel distillate pumped out from the siding is sent to a phenol-extracting device to be used as a raw material for extracting phenolic substances; wax oil fractions pumped out from the vacuum tower siding are sent to the suspended bed hydrocracker to be used as a raw material for a hydrocracking reaction; heavy oil pumped out from the bottom of the vacuum tower is subjected to filtration, a filtrate is sent to the suspended bed hydrocracker to be used as a raw material for the hydrocracking reaction, and filter residues are sent to a granulating device for granulating. The invention also provides the treatment system, suitable for the method, of the coal tar.

Owner:BEIJING PETROCHEM ENG

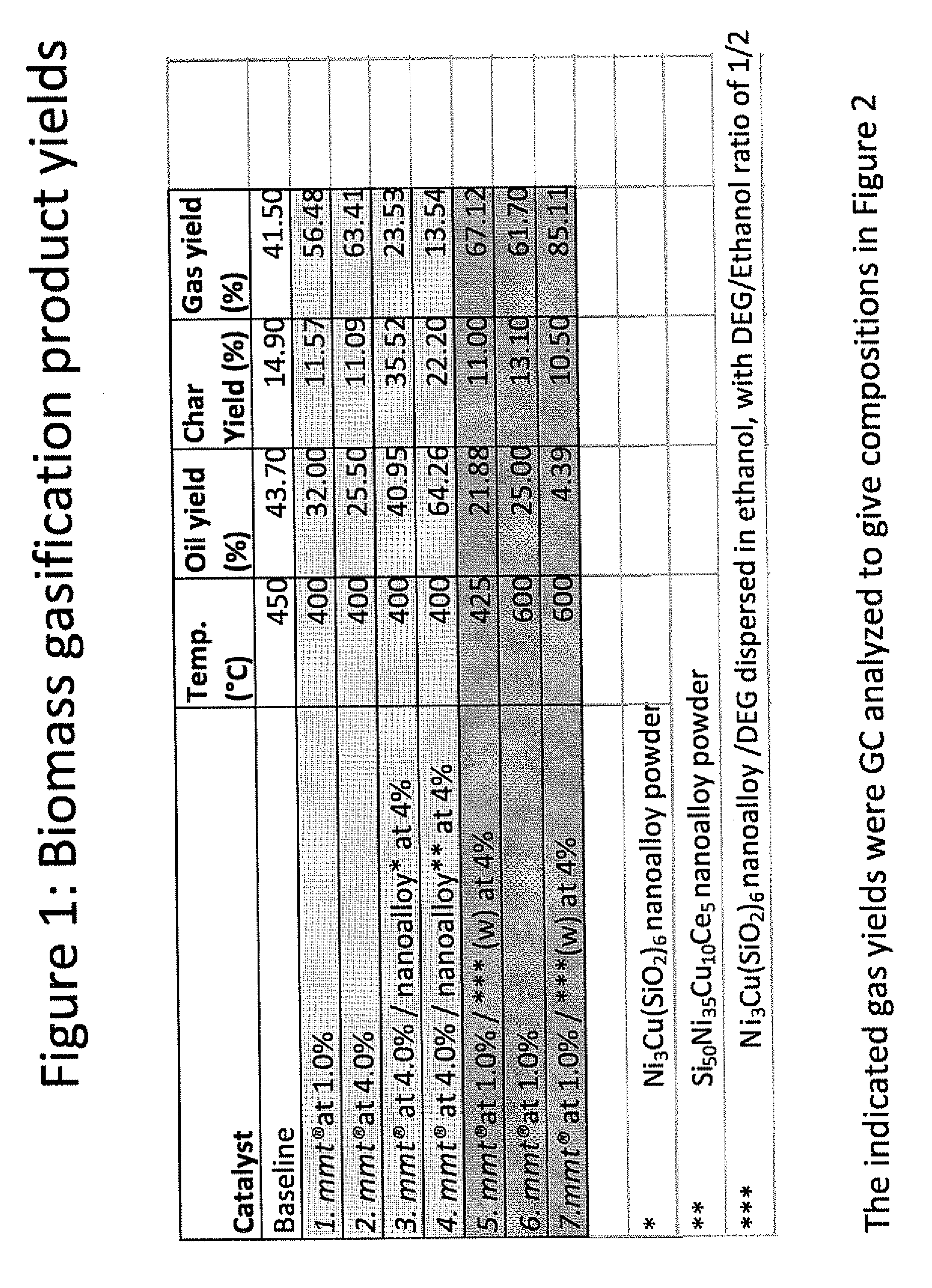

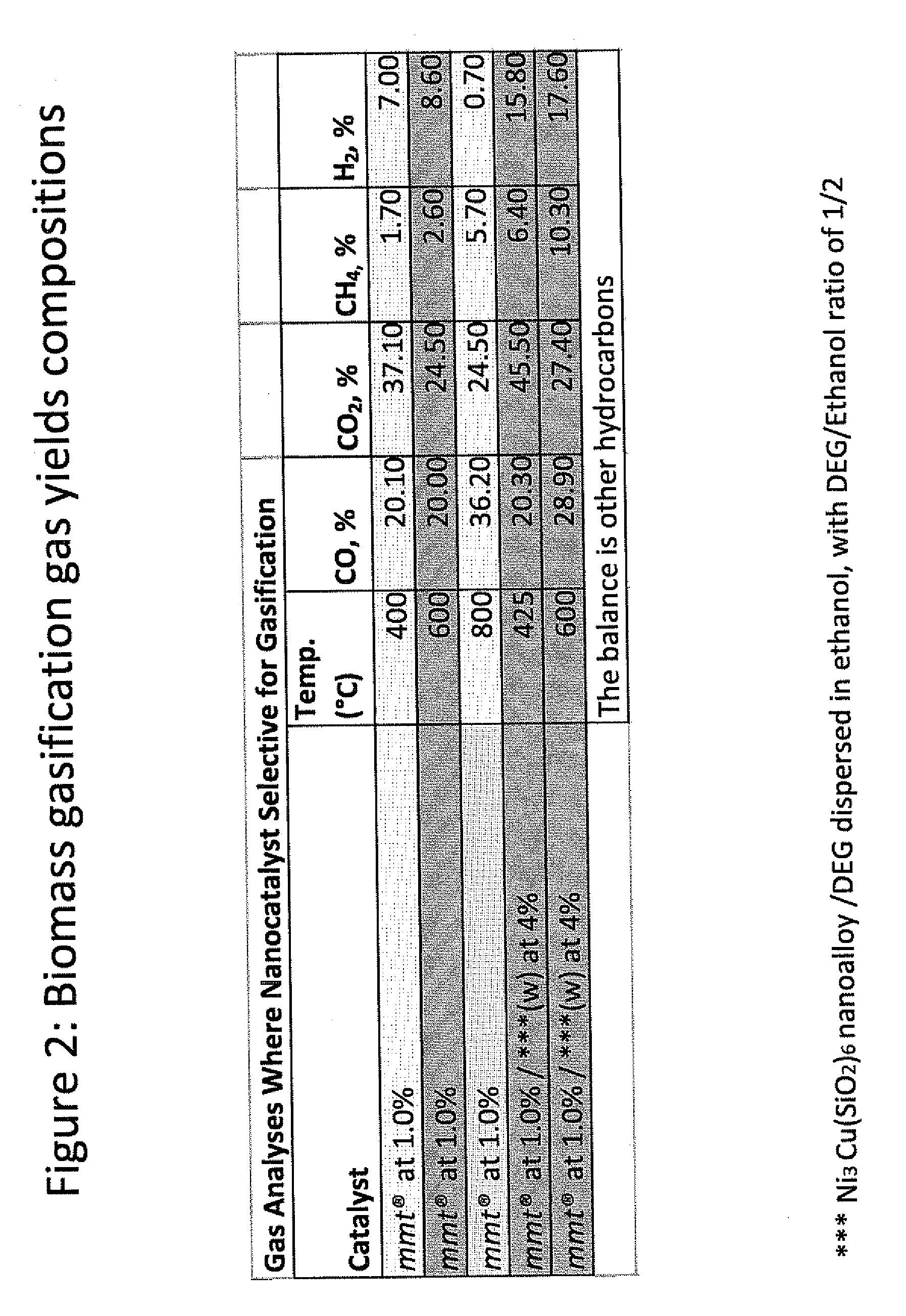

Nanoparticle Catalyst Compounds and/or Volatile Organometallic Compounds and Method of Using the Same for Biomass Gasification

InactiveUS20100299990A1Improve gasificationHigh gas yieldBiofuelsWaste based fuelNano catalystOil production

A nanocatalyst, dual catalyst and methods for improving the efficiency and output of a biomass gasification process are provided where the catalysts comprise a volatile organometallic compound(s) and / or a nanoalloy catalyst. By the catalyst and method, a very high biomass gasification conversion efficiency of over 85% can be achieved. The subject nanocatalyst cracks and gasifies lignin, which is generally inert in conventional gasification, at relatively low gasification temperatures. The subject disclosure also provides a means to increase gas yields and lower lignin content in the resulting product relative to conventional gasification. Alternatively, oil production may be increased, if desired. Moreover, the resulting gas may achieve a Fischer-Tropsch reactor favorable H2:CO ratio of about 9:1. The energy input to the gasification is correspondingly reduced to reduce costs and the environmental impact associated with the gasification process.

Owner:AFTON CHEMICAL

Method for reducing olefin sulfur content in gasoline

InactiveCN1521241AReduce sulfur contentReduce total hydrogen consumptionTreatment with hydrotreatment processesDehydrogenationAlkene

The process of lowering the olefin and sulfur contents in gasoline includes separating gasoline fractions into light fraction and heavy fraction, alkaline washing the light fraction, hydrogenating the heavy fraction to saturate its olefin while desulfurizing and denitrogenating, dehydrogenating, and finally mixing the treated light and heavy fractions to obtain gasoline product with relatively low olefin and sulfur contents and relatively high octane number. The said process can lower the the olefin and sulfur contents of gasoline while losing no octane number of gasoline and has high liquid yield. Hydrogen produced in the dehydrogenation may be used in hydrogenation to lower the total hydrogen consumption of the whole gasoline hydrogenating process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hydrocracking catalyst

ActiveCN104588085AHigh hydrocracking activityHigh oil selectivityMolecular sieve catalystsMolecular sieveActive phase

The invention discloses a preparation method of a hydrocracking catalyst. The method includes preparing nickel-aluminum precipitate by a normal precipitation method and tungsten-silicon-aluminum precipitate by a parallel-flow precipitation method, adding an organic amine in gelling process of any one step or two steps above, mixing the two precipitates, adding a molecular sieve suspension, and performing aging and forming to obtain the catalyst. The inventive method can control the distribution of different metals with hydrogenation activities, is conducive to forming a highly active phase between active metals tungsten and nickel, can improve the interaction between the active metals and a carrier, so that the hydrogenation activity and cracking activity of the obtained hydrocracking catalyst can be well coordinated, and the use performance of the hydrocracking catalyst is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

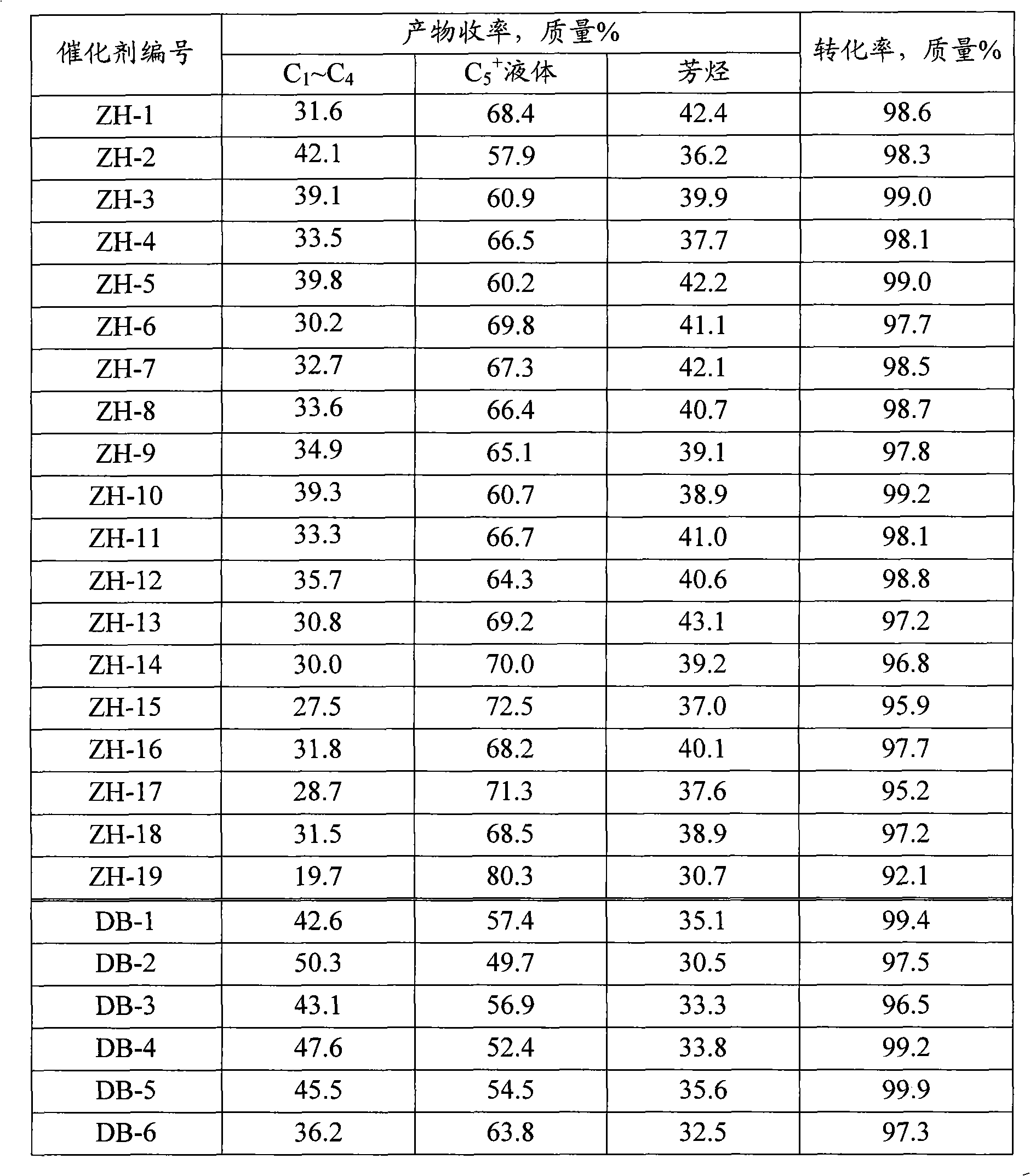

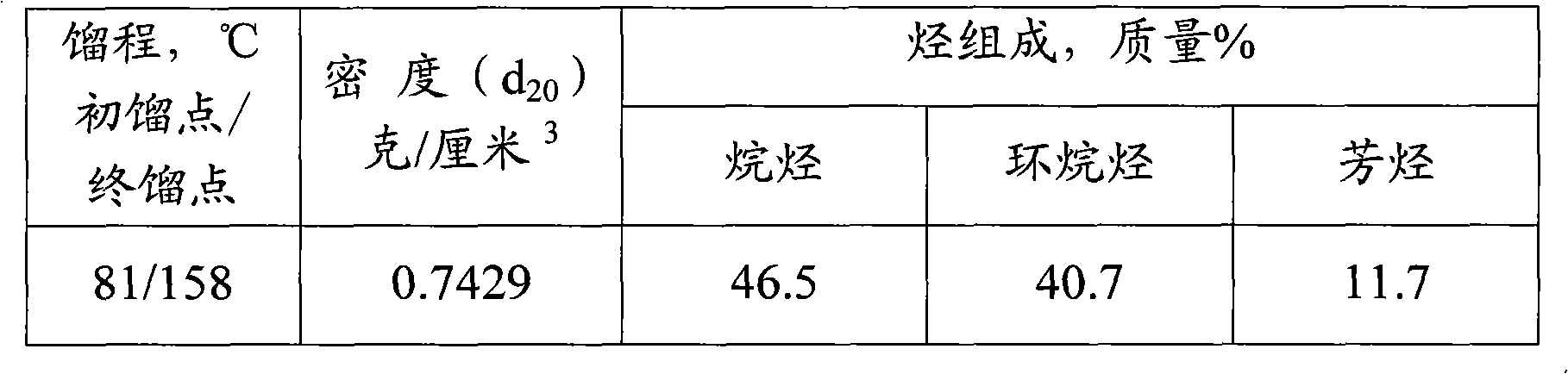

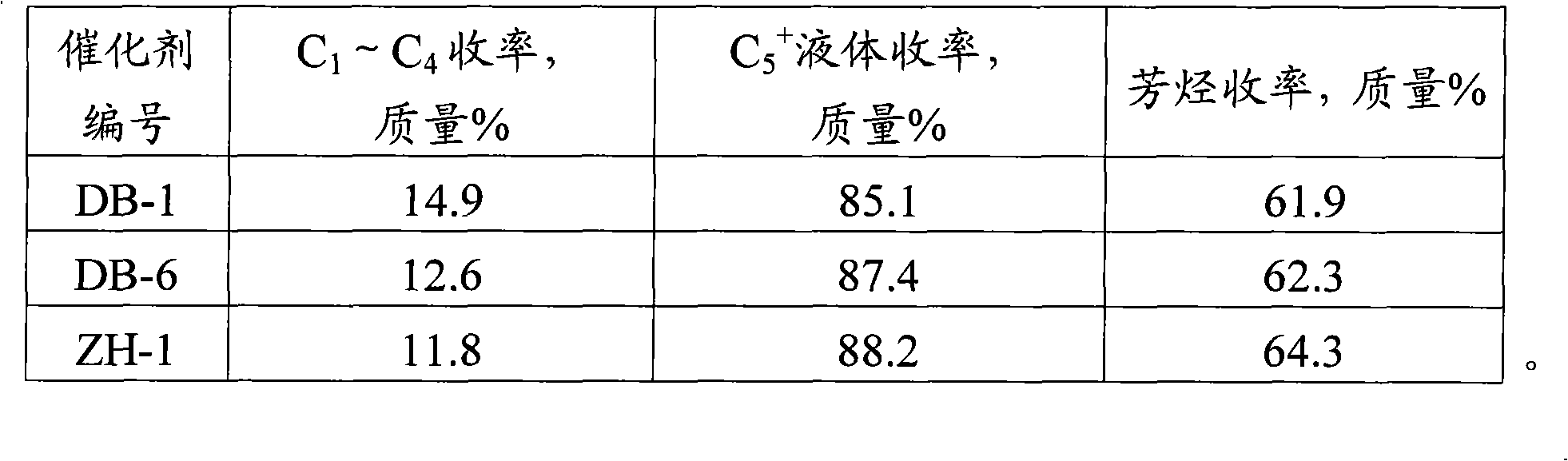

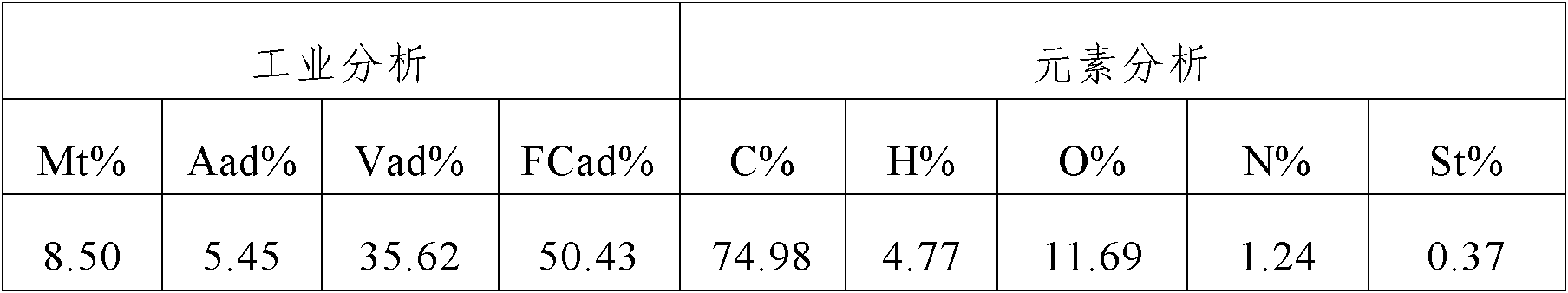

Bicomponent naphtha reforming catalyst and preparation method thereof

ActiveCN102029186AEasy to prepareSimple manufacturing methodMolecular sieve catalystsCatalytic naphtha reformingCatalytic reformingMolecular sieve

The invention relates to a bicomponent naphtha reforming catalyst which comprises a molecular-sieve catalyst and an alumina catalyst, wherein the molecular-sieve catalyst is used for platinum exchange, the carrier of the alumina catalyst is alumina, the mass ratio of the molecular-sieve catalyst to the alumina catalyst is 1-9:9-1, the platinum content in the molecular-sieve catalyst on the calculating basis of a dry-basis molecular sieve is 0.1-2.0 percent by mass, the molecular sieve is a borosilicate molecular sieve or a low-aluminum borosilicate molecular sieve, and the alumina catalyst comprises the following active components with the content on the calculating basis of dry-basis alumina: 0.1-3.0 percent by mass of platinum-family noble metal, 0.1-5.0 percent by mass of VIIB-family metal and 0.5-10.0 percent by mass of halogen. The catalyst is applicable to naphtha catalytic reforming and has higher liquid yield and aromatics yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

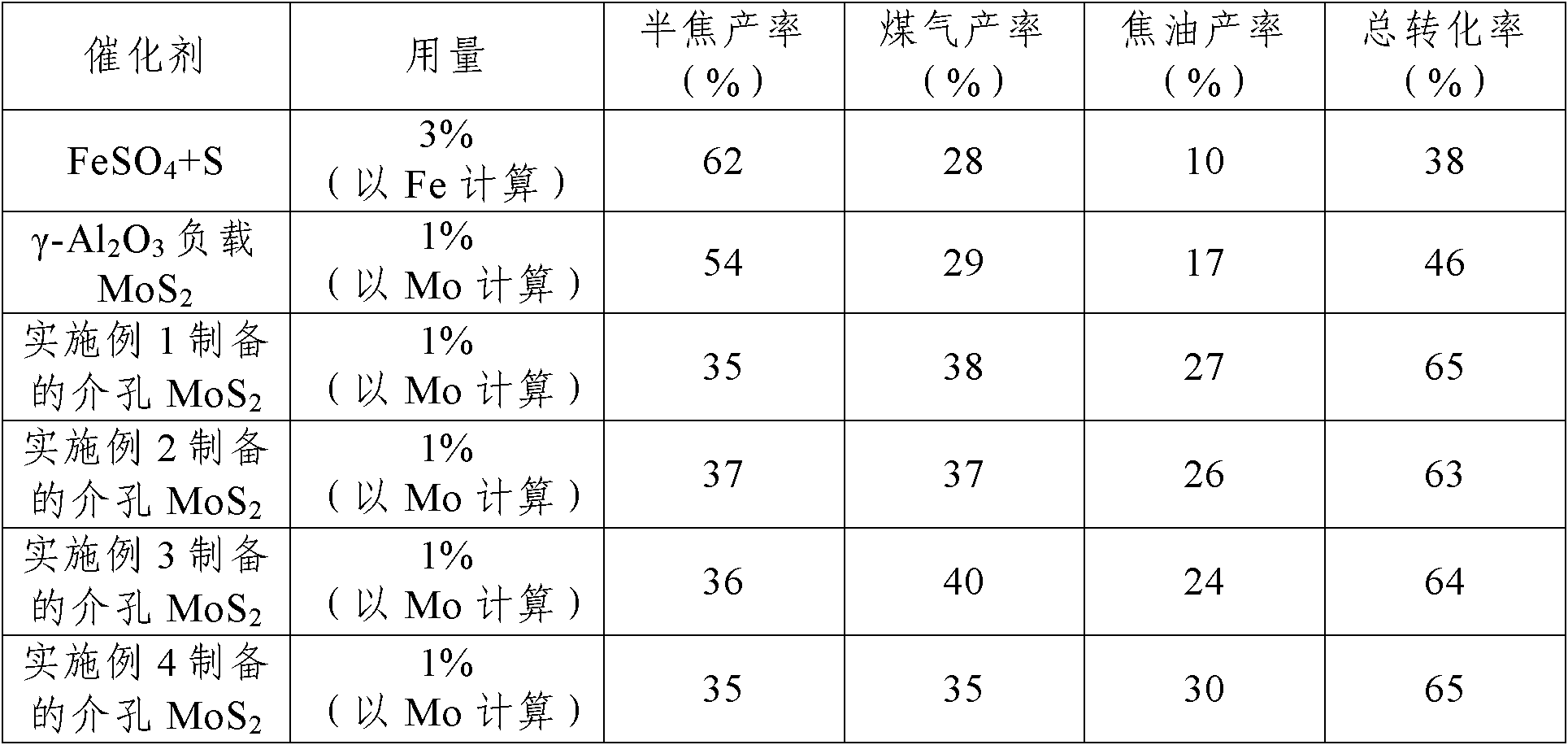

Method for synthesizing mesoporous molybdenum disulphide by taking mesoporous silica molecular sieve as hard template

InactiveCN102583546ADiffuse fullyAvoid Precursor Concentration EffectsMolybdenum sulfidesMesoporous silicaCoal pyrolysis

The invention discloses a method for synthesizing mesoporous molybdenum disulphide by taking a mesoporous silica molecular sieve as a hard template. The method comprises the following steps of: firstly, preparing a hydrochloric acid solution of alcohol amine; secondly, adding ammonium tetrathiomolybdate, standing at room temperature after stirred reaction, filtering, cleaning and drying in vacuumto obtain a precursor; thirdly, dissolving the precursor into water and absolute methanol, adding the mesoporous silica molecular sieve, and carrying out ultrasonography after stirred reaction to obtain a solid and liquid mixture; fourthly, placing the solid and liquid mixture into a muffle furnace after filtering, cleaning and drying, raising the temperature to 400-450 DEG C under the protectionof hydrogen, then, preserving the temperature for 1-2h, and cooling to the room temperature to obtain mesoporous molybdenum disulphide powder containing the mesoporous silica molecular sieve; and fifthly, cleaning 1-5 times by using an HF (Hydrogen Fluoride) aqueous solution and drying to obtain the mesoporous molybdenum disulphide. The mesoporous molybdenum disulphide synthesized by using the method provided by the invention is high in catalytic activity, the yield of tar obtained in coal pyrolysis reaction is high, and the using amount of catalysts is small, and no assistant is needed.

Owner:CHANGAN UNIV

Prepn process of catalyst for residual oil hydrocracking in suspension bed

The catalyst for residual oil hydrocracking in suspension bed is prepared with molybdenum ore dressing tailing or slag as material, and through wet oxidation and leaching with chemical reagent, filtering and other processing steps to obtain solution being used as the catalyst for hydrocracking in suspension bed. The catalyst is dispersed in heavy oil or residual oil, and in the presence of hydrogen, the inferior heavy oil or residual oil containing the catalyst is hydrocracked into light product. The catalyst has the features of low cost, environment friendship, high light product yield and others.

Owner:CHINA PETROLEUM & CHEM CORP +1

Suspension bed hydrocracking technique for producing gasoline with high octane number and diesel oil with high cetane number simultaneously

InactiveCN1446888AGood dispersionHigh catalytic activityHydrocarbon oil crackingDispersityOil processing

A suspension-bed hydrocracking process for preparing both the gasoline with high octane number and the diesel oil with high cetane number at same time includes adding the aqueous solution of alcohol,which contains catalytic active component and assistant and is used as high-dispersity catalyst, to heavy hydrocarbon as raw material, cracking to generate olefin while reaction of the olefin on alcohol to obtain the oxygen-contained compound with high octane number. and hydrocracking to obtain said diesel oil. Its advantages are high output rate and high quality of products.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

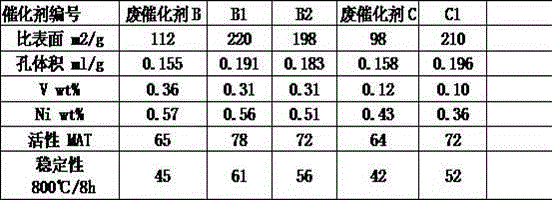

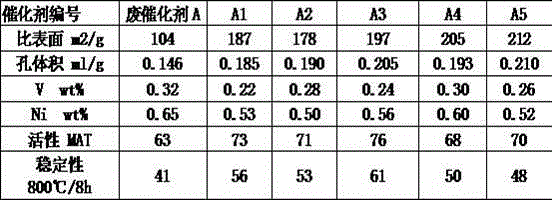

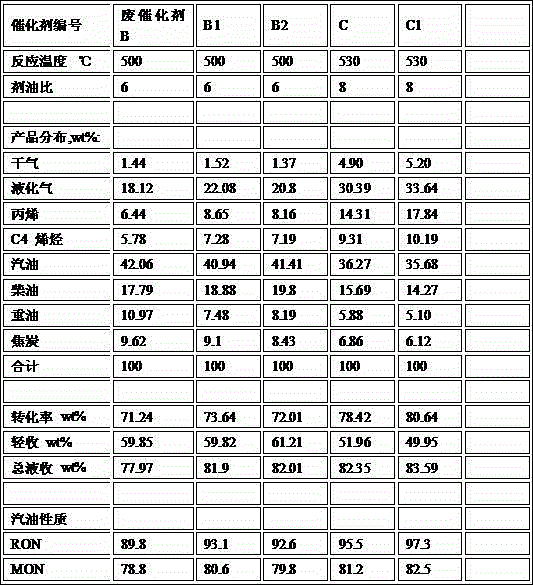

Revivification method for catalytic cracking waste catalyst

ActiveCN104815702AImprove liquid yieldReduce coke yieldCatalyst regeneration/reactivationPhosphoric acidChemistry

The invention relates to a revivification method for a catalytic cracking waste catalyst, which is characterized in that composite acid and ammonium salt are treated, and at least one of a supported rare earth treatment process and a phosphorus-containing acid treatment process is employed. a principle is characterized in that by improving a tunnel structure of the catalyst, composite acid is used for dredging the tunnel of the catalyst, a part of structure of molecular sieve is reconstructed through reaction and calcinations, acidity of the catalyst is adjusted by a rare earth compound-containing and / or phosphate-containing compound, so that waste catalyst performance can be recovered, the specific surface and activity of the recovered catalyst can be obviously increased, stability is obviously increased, good liquefied gas and low carbon olefin selectivity can be presented, green coke is reduced, liquid recovery is increased, gasoline RON is increased by 0.5-3 points, propylene and butylene yield can be respectively increased by more than 20-40% and 10-30%.

Owner:于向真

MEMS device, liquid ejecting head, liquid ejecting apparatus, manufacturing method of MEMS device, and manufacturing method of liquid ejecting head

ActiveUS20170066240A1Simple manufacturing processImprove productivityInking apparatusLiquid jetEngineering

Owner:SEIKO EPSON CORP

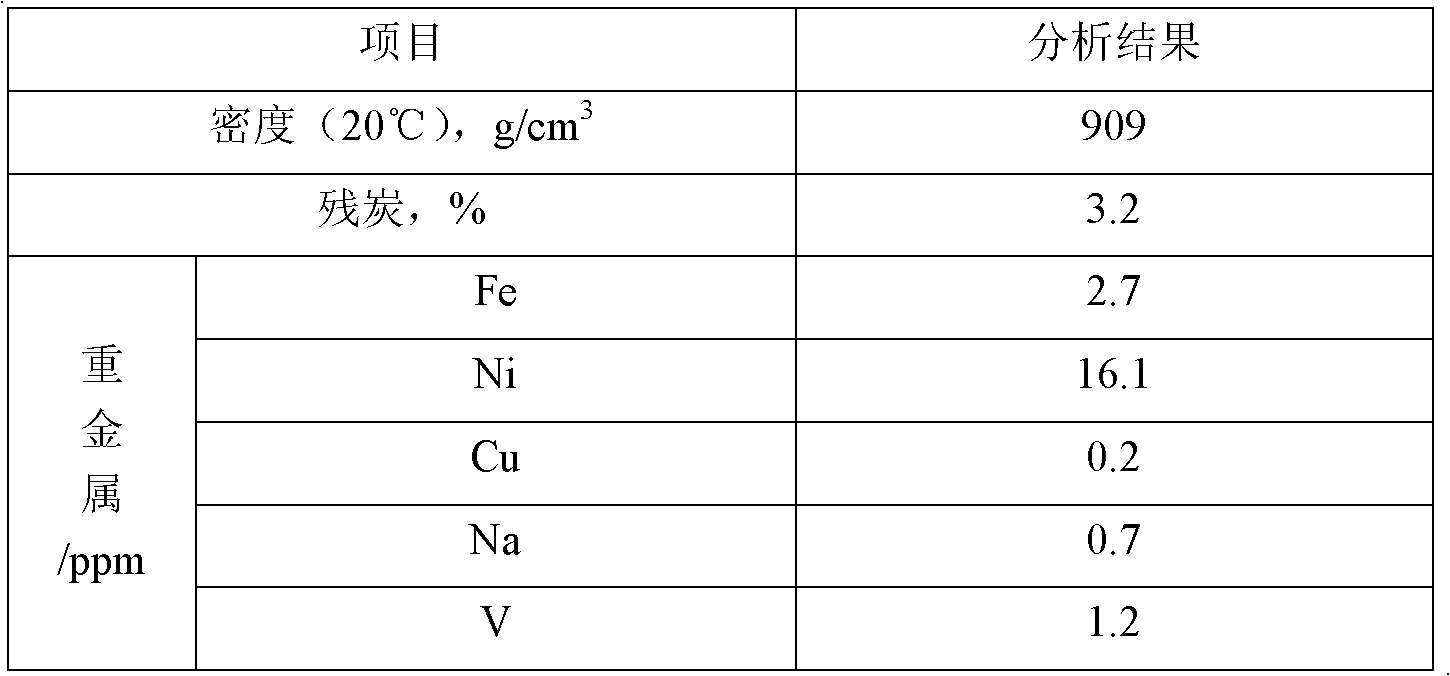

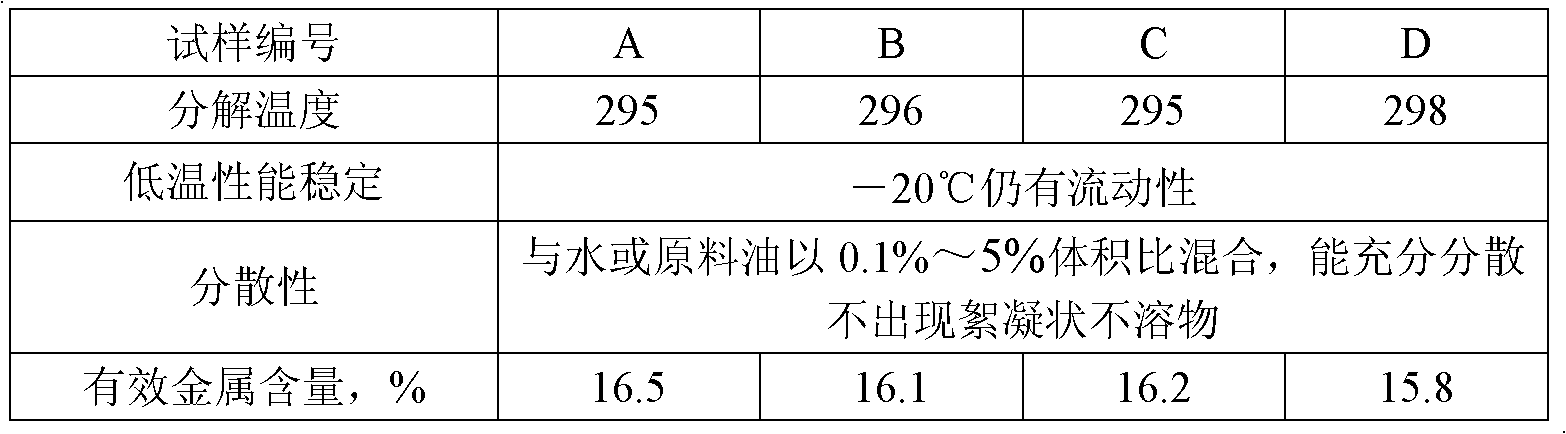

Preparation method and application of catalytic cracking metal passivant

ActiveCN101885980AHigh thermal decomposition temperatureHigh hanging antimony rateCatalytic crackingTreatment apparatus corrosion/fouling inhibitionRare earthAntimony trioxide

The invention relates to a preparation method and application of a catalytic cracking metal passivant. The preparation method comprises the following steps of: preparing raw materials in the following percentage by weight: 20%-45% of dispersing agents, 30%-50% of oxidants, 15%-30% of metal oxides, 10%-30% of solvents and 2%-5% of stabilizing agents; sequentially adding the oxidants and the metal oxides to the dispersing agents during preparation; increasing temperature to 50-90 DEG C within 2-4 hours, keeping the temperature for 1-5 hours and then cooling; adding the solvents and the stabilizing agents, and then filtering to remove impurities so as to obtain the metal passivant, wherein the dispersing agents are diethanol amine and / or triethanol amine; the oxidants are hydrogen peroxide of 30-50 percent and / or nitric acids of 66-68 percent; the metal oxides are one of diantimony trioxide, rare earth oxides and bismuth oxides or mixtures of more than two of the diantimony trioxide, the rare earth oxides and the bismuth oxides in any proportion; the solvents are one of water or alcohol solvents or mixtures of more than two of the water or the alcohol solvents in any proportion; and the stabilizing agents are methylcellulose compound solutions.

Owner:金浦新材料股份有限公司

Slurry bed hydrogenation catalyst, and preparation, design method and use thereof

ActiveCN104907078AHigh catalytic activityGood dispersionLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsActivated carbonRed mud

The invention discloses a slurry bed hydrogenation catalyst, and preparation, a design method and a use thereof; the catalyst includes the following components: a catalyst main body, molybdenum-containing red mud or hematite powder, a carrier and activated carbon; the molar ratio of a metal center Fe to the other metal center Mo in the red mud or hematite is 1:150 to 1:200, the mass ratio of the catalyst main body to activated carbon is 0.2:1 to 1.1:1, and the activated carbon has the pore size of 1-100 nm. The preparation method includes the following steps: firstly, preparing the molybdenum-containing red mud or hematite powder, then adding activated carbon with the particle size of 50-150 [mu]m into the molybdenum-containing red mud or hematite powder, mixing evenly, and thus obtaining the slurry bed hydrogenation catalyst. The slurry bed hydrogenation catalyst has the advantages of low cost, simple preparation method, and easy storage and transportation, can be discarded and has no need of recycling, is applied to heavy oil slurry bed hydrogenation, coal direct liquefaction and oil coal mixing, and achieves quite high residual oil / oil coal conversion rate and liquid yield.

Owner:CATECH TECH

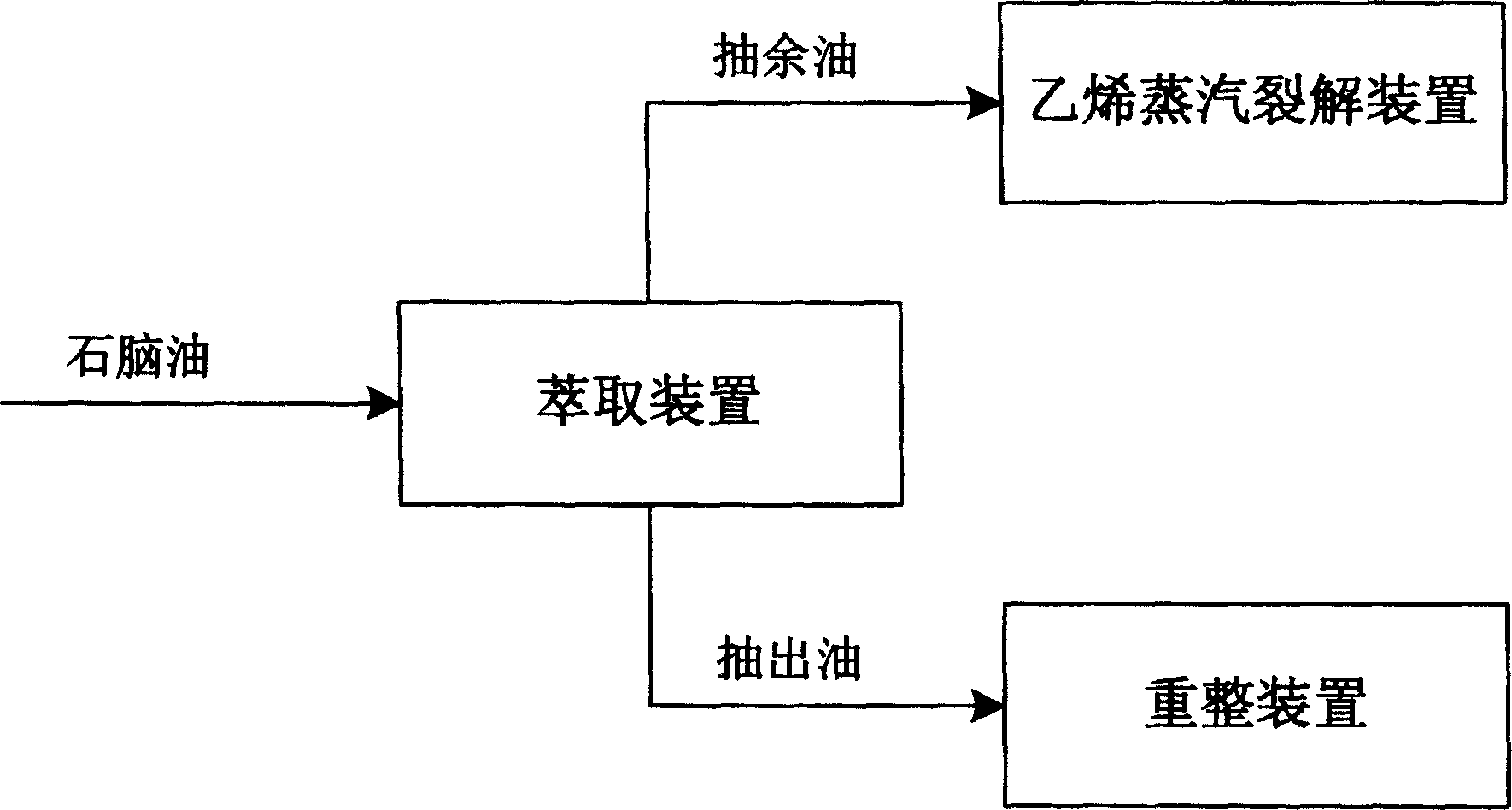

Recombinant processing method for naphtha

The naphtha reconstituting treatment process includes the following steps: extraction separating naphtha to obtain extract oil and raffinate oil; cracking the raffinate oil in an ethylene steam cracking unit; and reforming the extract oil in a reforming unit. Compared with available technology, the present invention has over 30 % raised arene yield and over 40 % raised ethylene yield.

Owner:BEIJING GRAND GOLDEN BRIGHT ENG & TECH

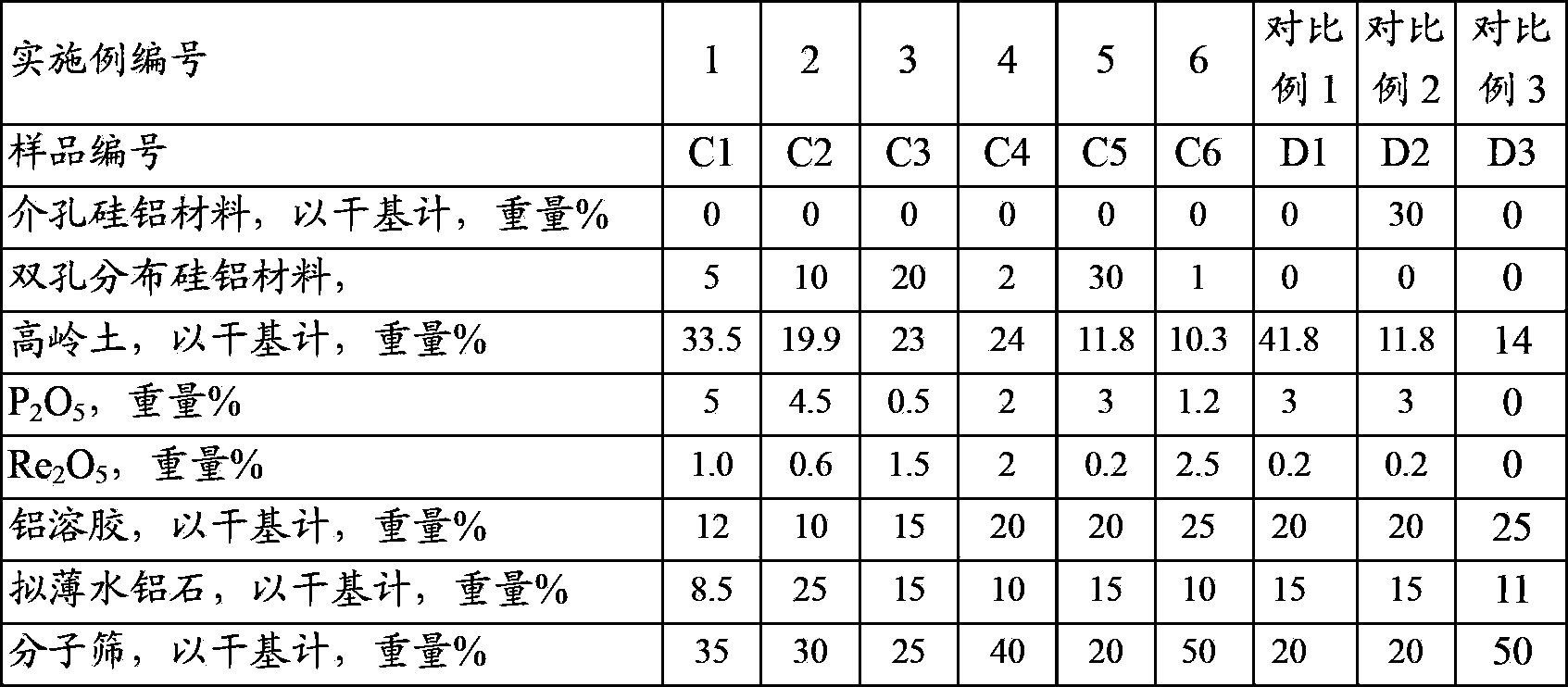

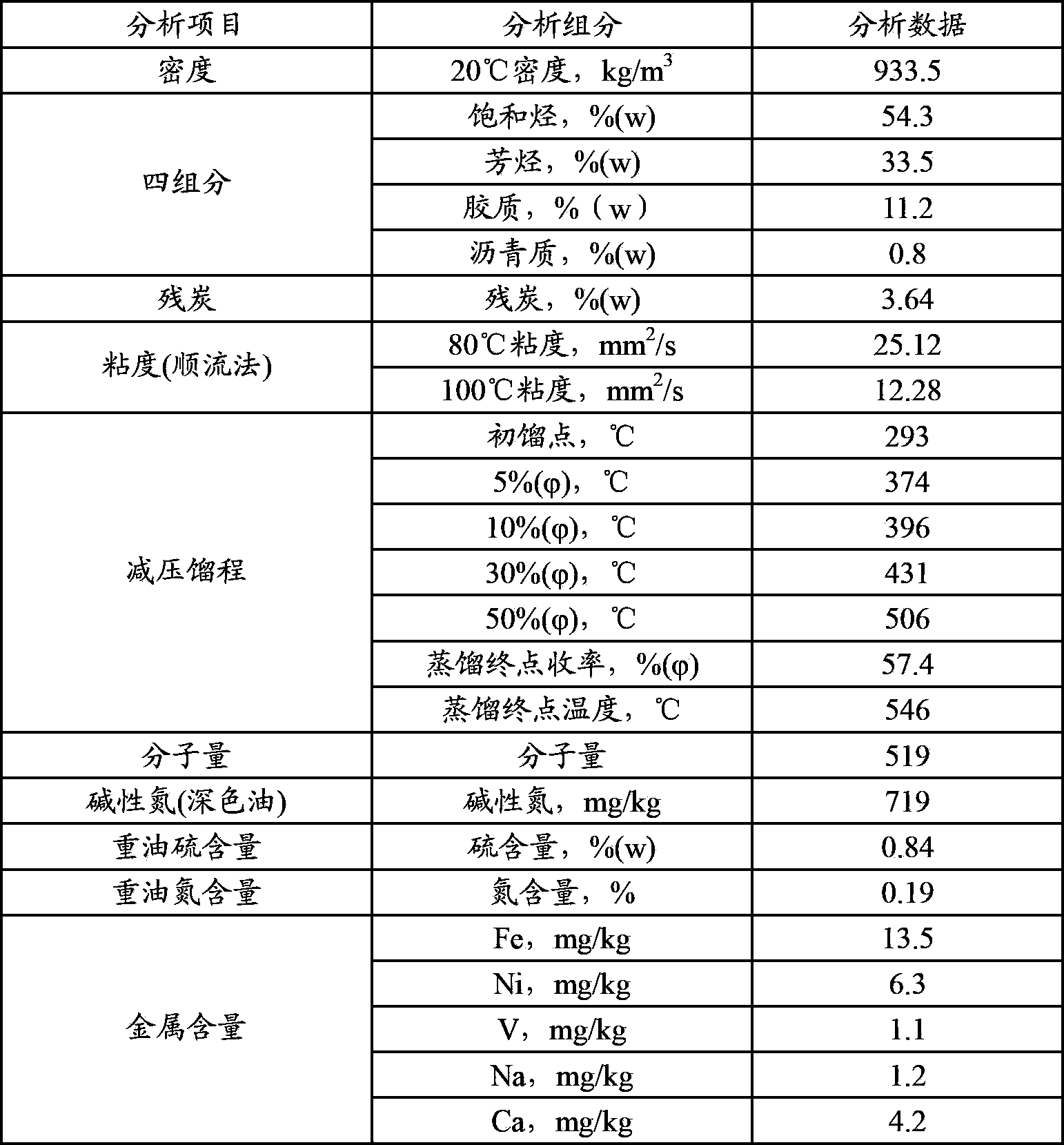

Catalytic cracking catalyst and preparation method therefor

ActiveCN103769192AGood resistance to metal pollutionHeavy oil cracking ability is strongCatalytic crackingMolecular sieve catalystsMolecular sieveGasoline

Provided are a catalytic cracking catalyst and a preparation method therefor. The catalyst contains a double-pore distributed silicon aluminum material and a molecular sieve. The probable pore diameters of the pores with smaller pore diameters of the silicon aluminum material are 2-10nm, and the probable pore diameters of the pores with larger pore diameters are10-25nm. With the total amount of the catalysts as a reference, by weight, the content of the double-pore distributed silicon aluminum material is 1-52%, the content of clay is 9-60%, the content of phosphorus is 0-8% in terms of P2O5, the content of rare earth metal is 0-3% in terms of Re2O3, the content of binding agents is 19-70%, the content of the molecular sieve is 20-70%, and the molecular sieve is a Y-type zeolite. The catalyst has high anti-metal-pollution ability, high heavy oil cracking ability and high liquid yield and can raise quality of gasoline in cracked products greatly.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com