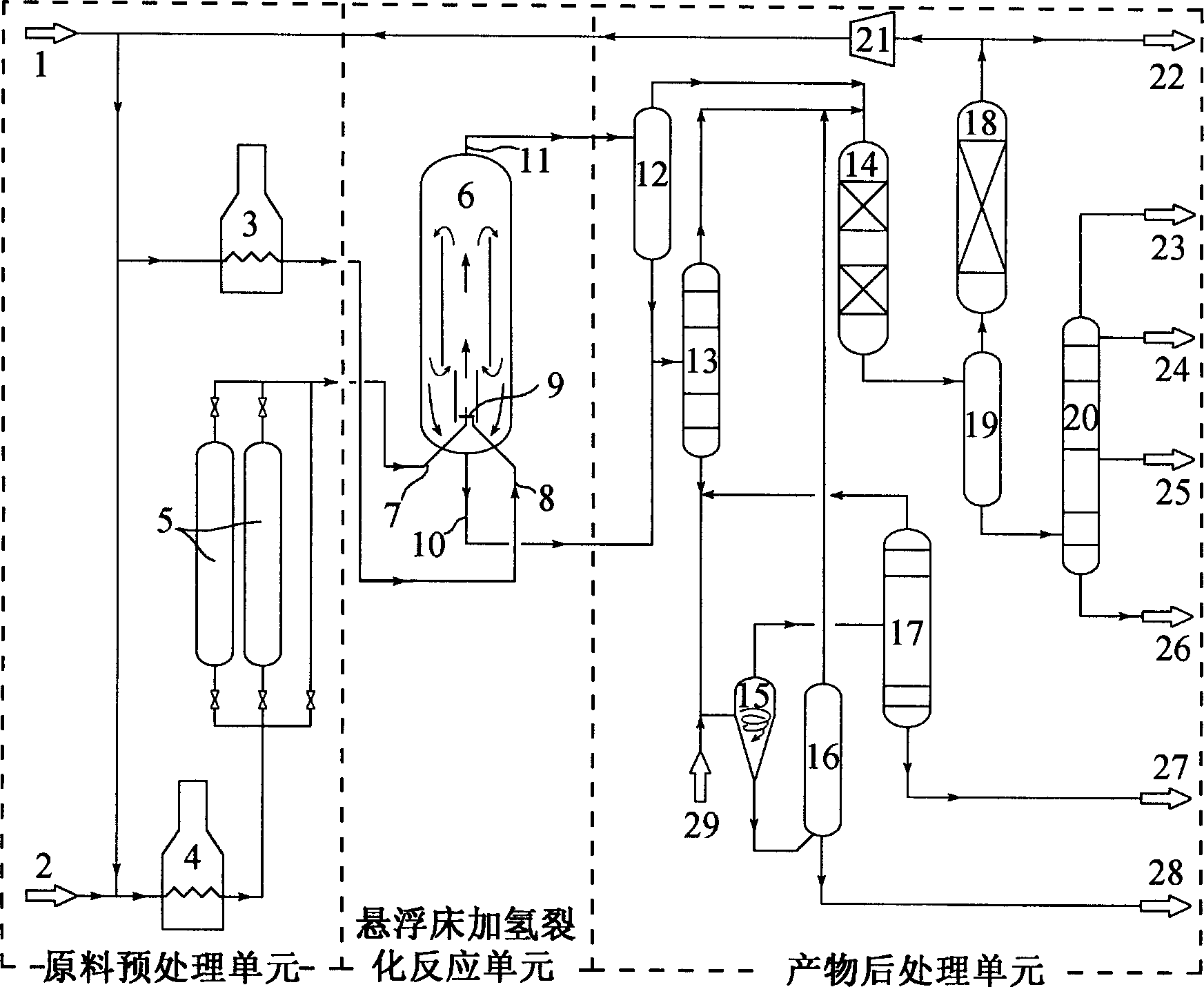

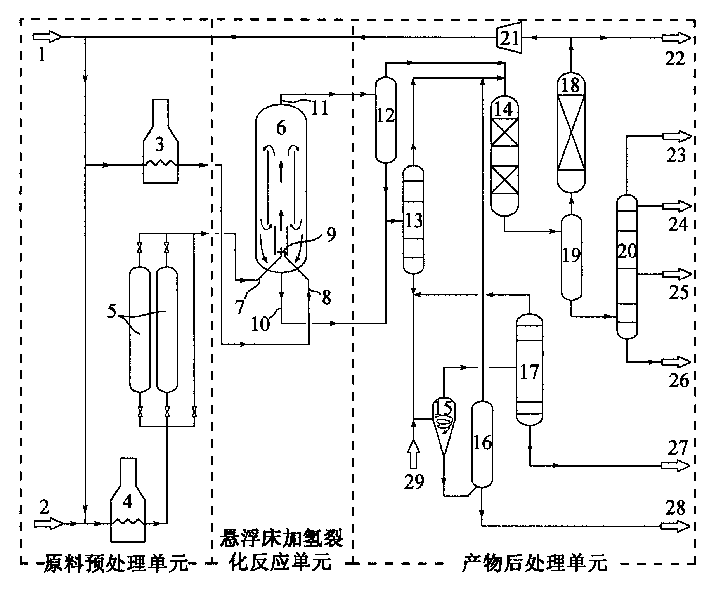

Suspension bed hydrocracking technique for producing gasoline with high octane number and diesel oil with high cetane number simultaneously

A high-octane gasoline, hydrocracking technology, applied in hydrocarbon oil cracking, petroleum industry, etc., can solve the problems of low cetane number of diesel oil, high olefin content of gasoline, low octane number of gasoline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Suspension bed hydrocracking process is often used in the treatment of heavy hydrocarbon raw materials, and the catalysts are usually aqueous solutions of transition elements such as Co, Mo, Ni, Fe, W, Mn, organic compounds, inorganic or organic complexes, and heteropolyacids. Salt, natural ore powder, coal powder, special soil powder, and spent catalyst powder from other processes. These said catalysts are dispersed in heavy hydrocarbon feedstocks, mostly in suspension. If the reaction bed is fixed, it is called a fixed bed; if the reaction bed is fluidized, it is called a fluidized bed. The reaction bed is in a suspended state, so it is naturally called a suspended bed.

[0031] Catalysts mainly play two roles in the suspension bed hydrocracking process: ① promote hydrogen transfer, generate hydrogen free radicals to inhibit the condensation of fused ring free radicals produced by cracking reactions, that is, inhibit the production of coke; ② serve as a medium for ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com