Patents

Literature

1388 results about "Fluid catalytic cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

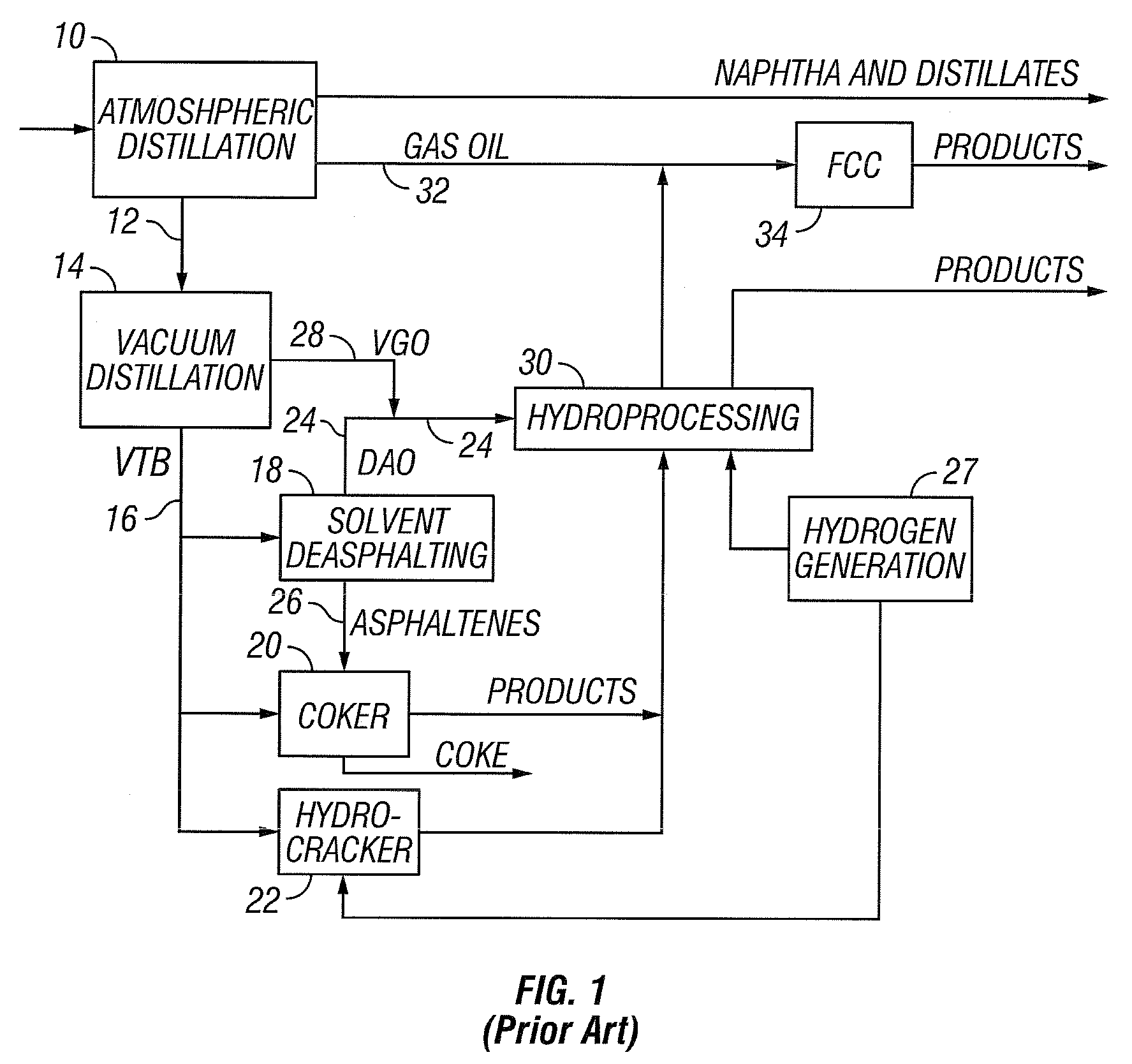

Fluid catalytic cracking (FCC) is one of the most important conversion processes used in petroleum refineries. It is widely used to convert the high-boiling, high-molecular weight hydrocarbon fractions of petroleum crude oils into more valuable gasoline, olefinic gases, and other products. Cracking of petroleum hydrocarbons was originally done by thermal cracking, which has been almost completely replaced by catalytic cracking because it produces more gasoline with a higher octane rating. It also produces byproduct gases that have more carbon-carbon double bonds (i.e. more olefins), and hence more economic value, than those produced by thermal cracking.

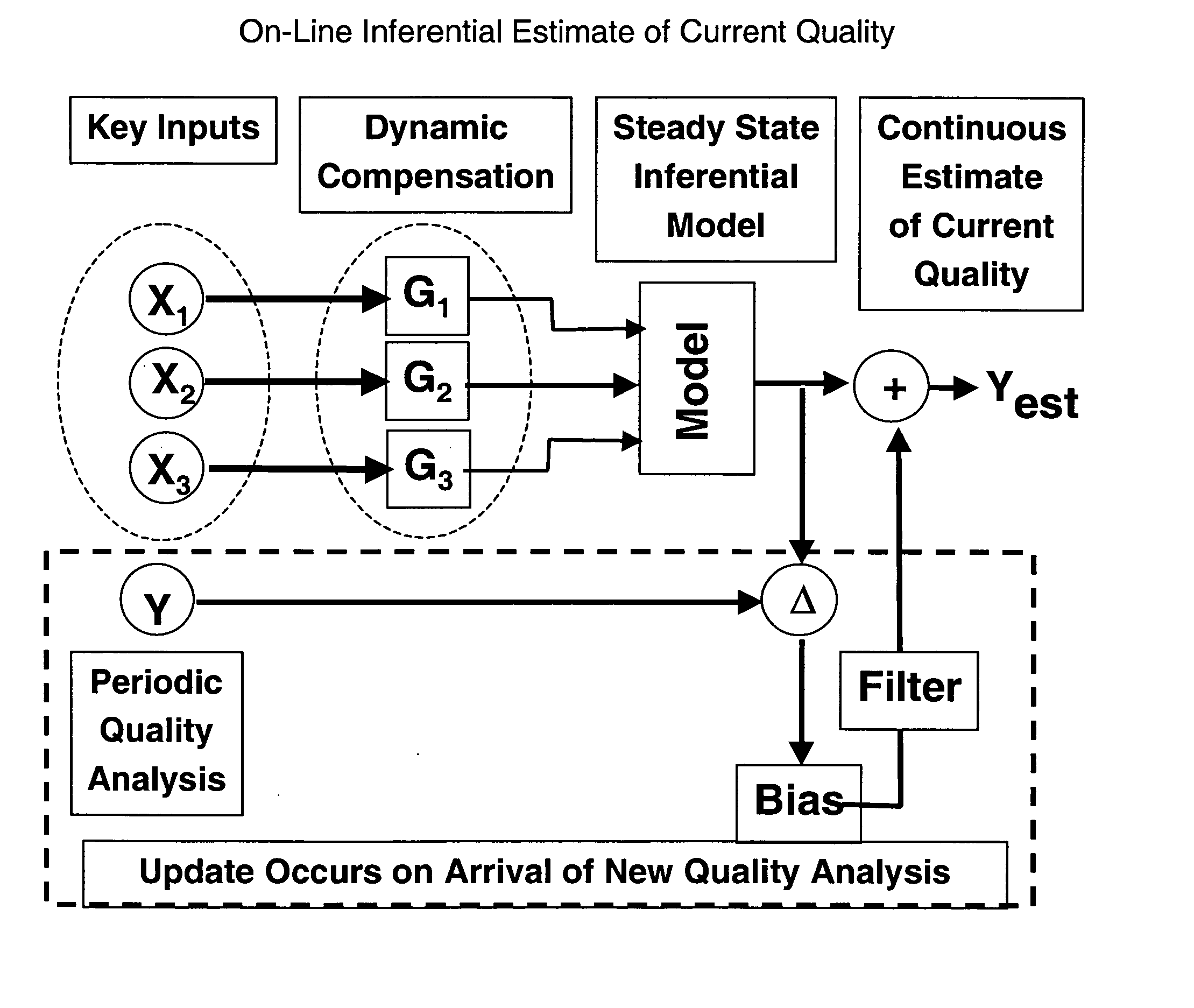

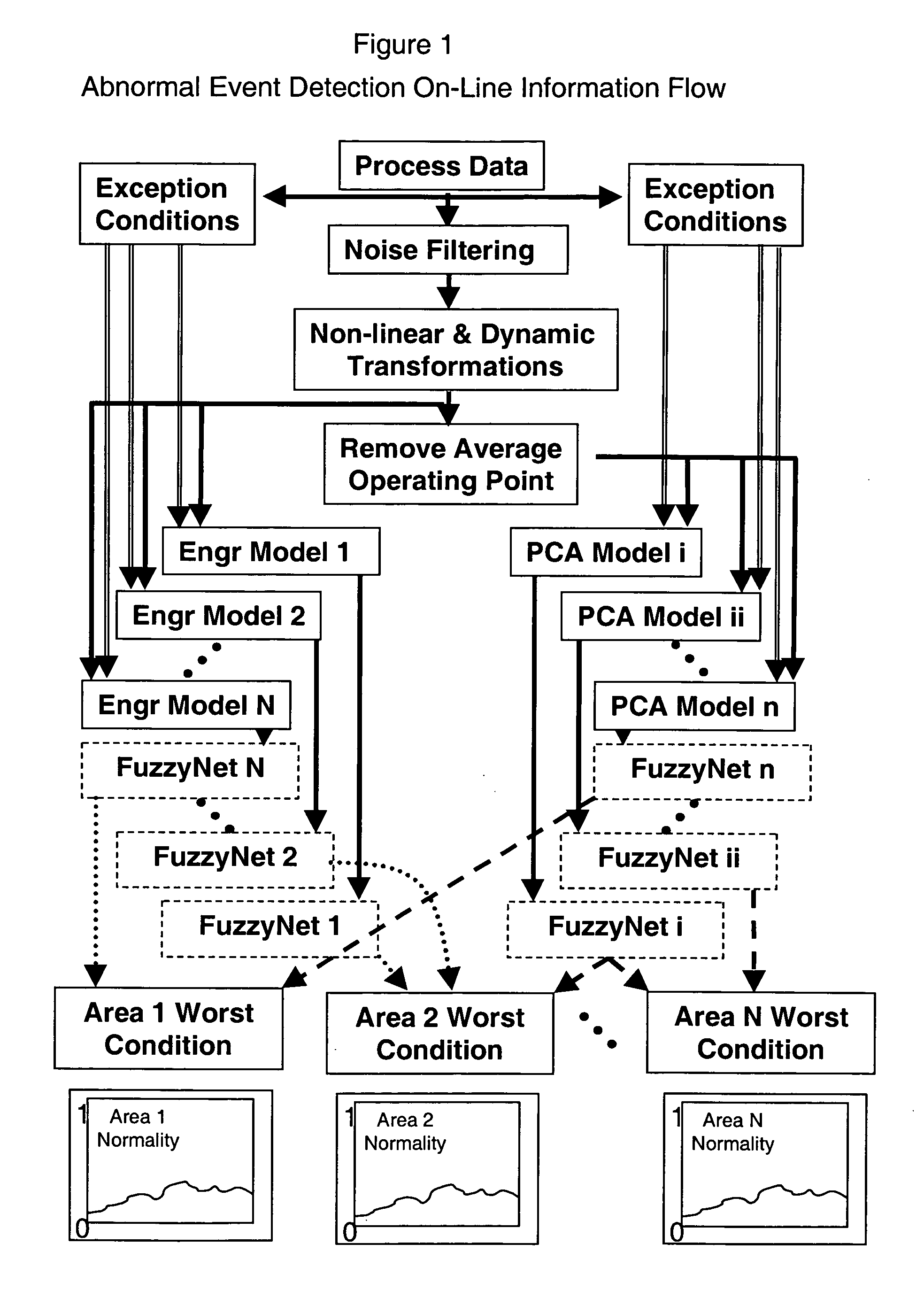

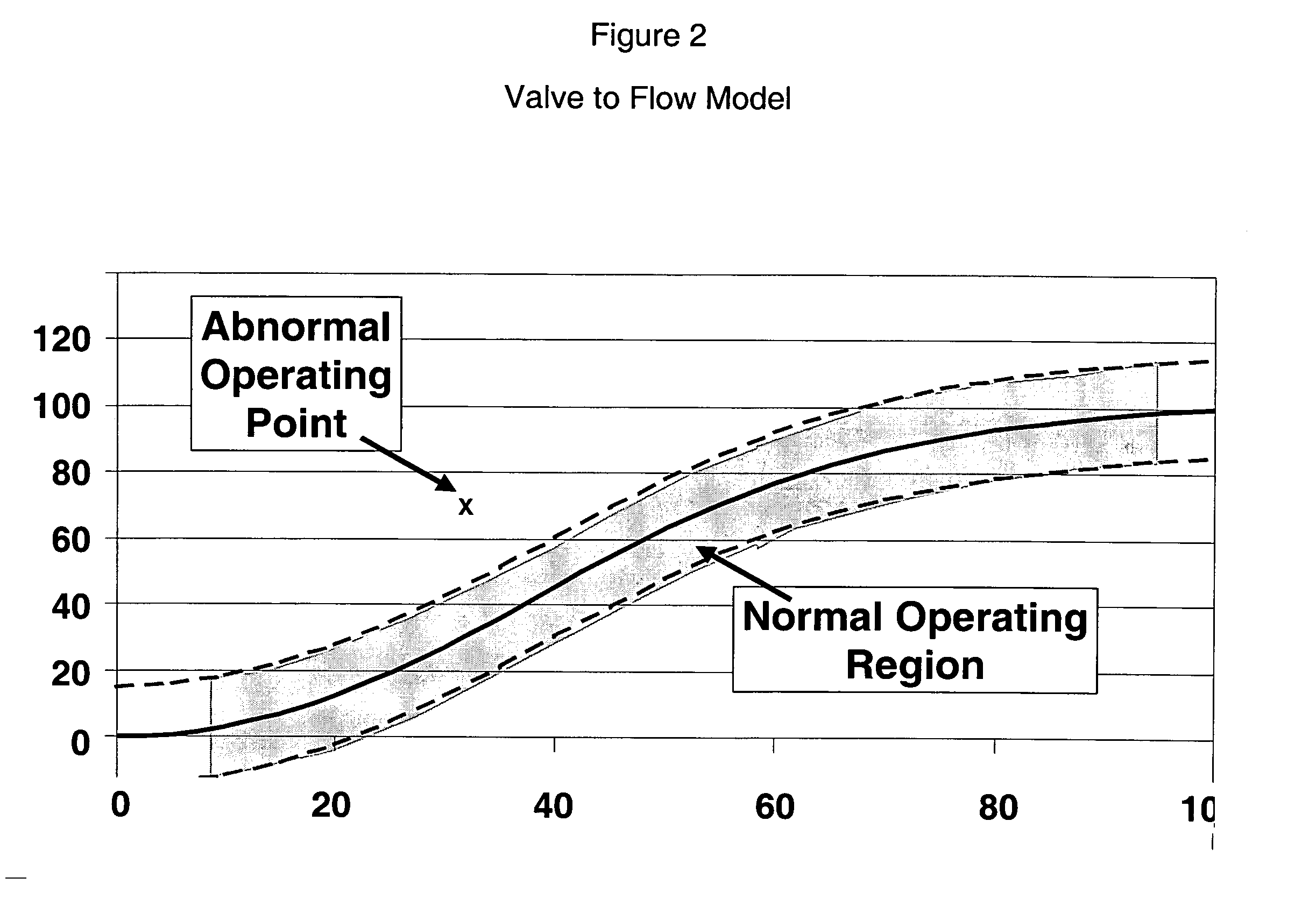

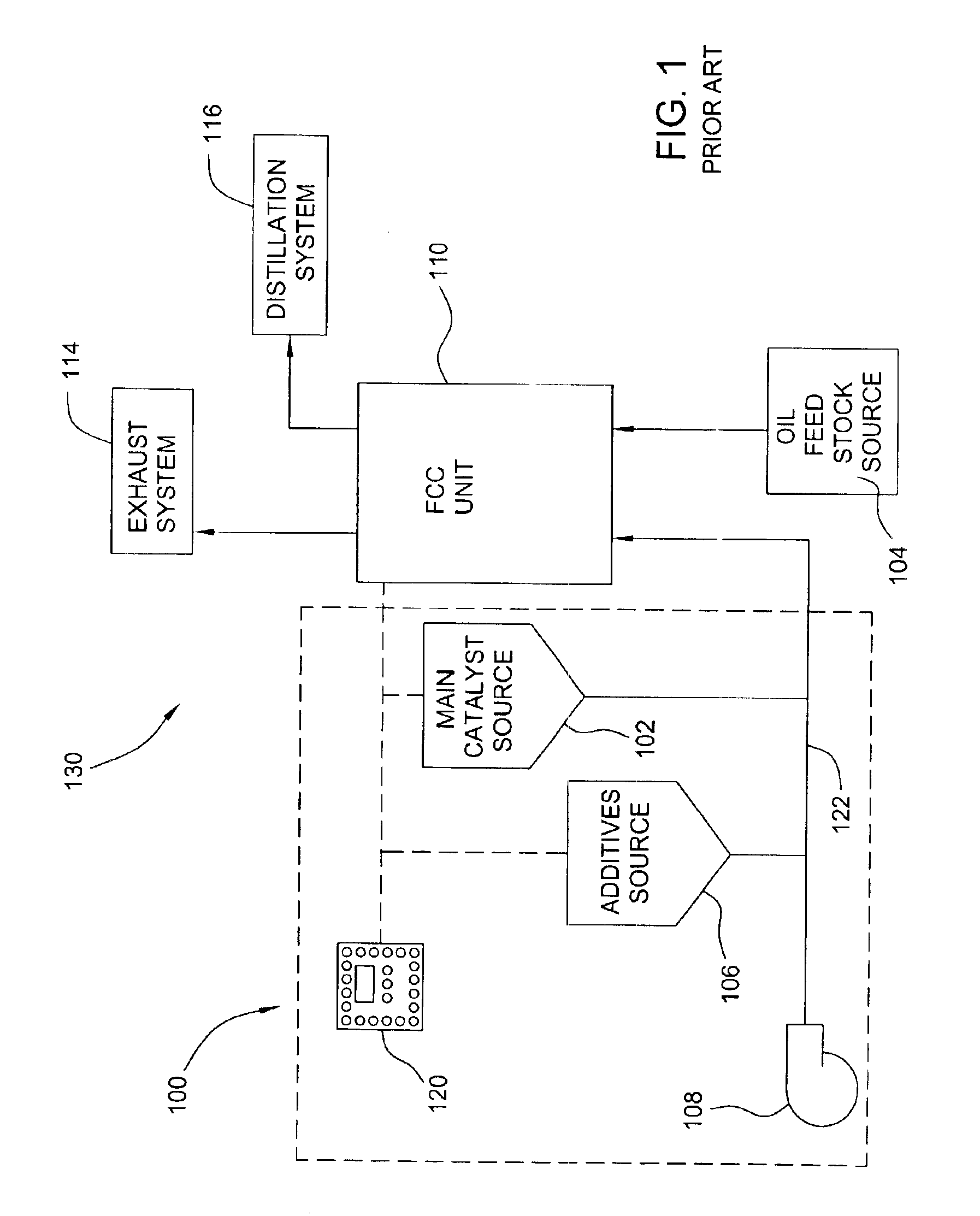

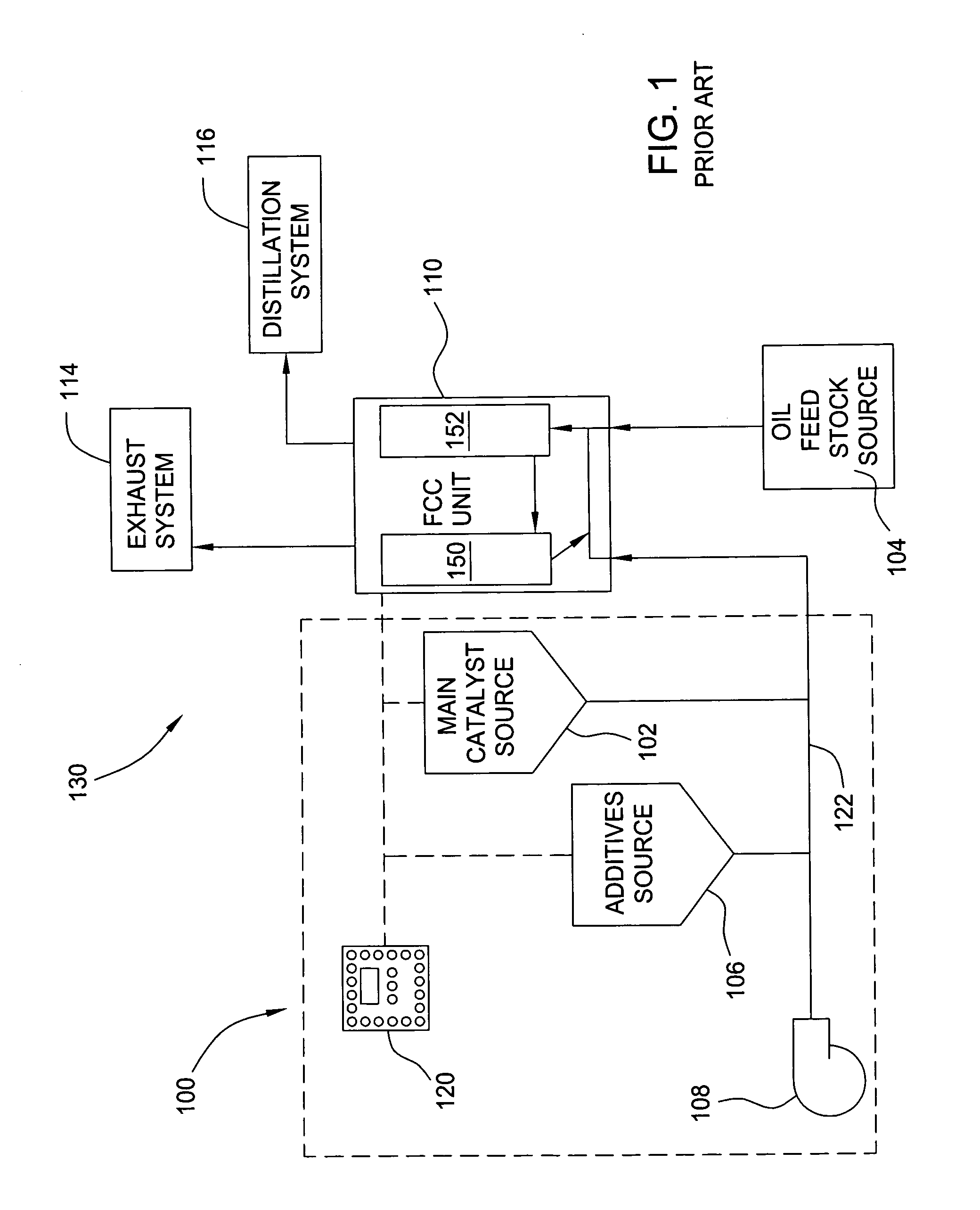

Application of abnormal event detection technology to fluidized catalytic cracking unit

ActiveUS20060073013A1PropellersSpecial data processing applicationsPrincipal component analysisCorrelation analysis

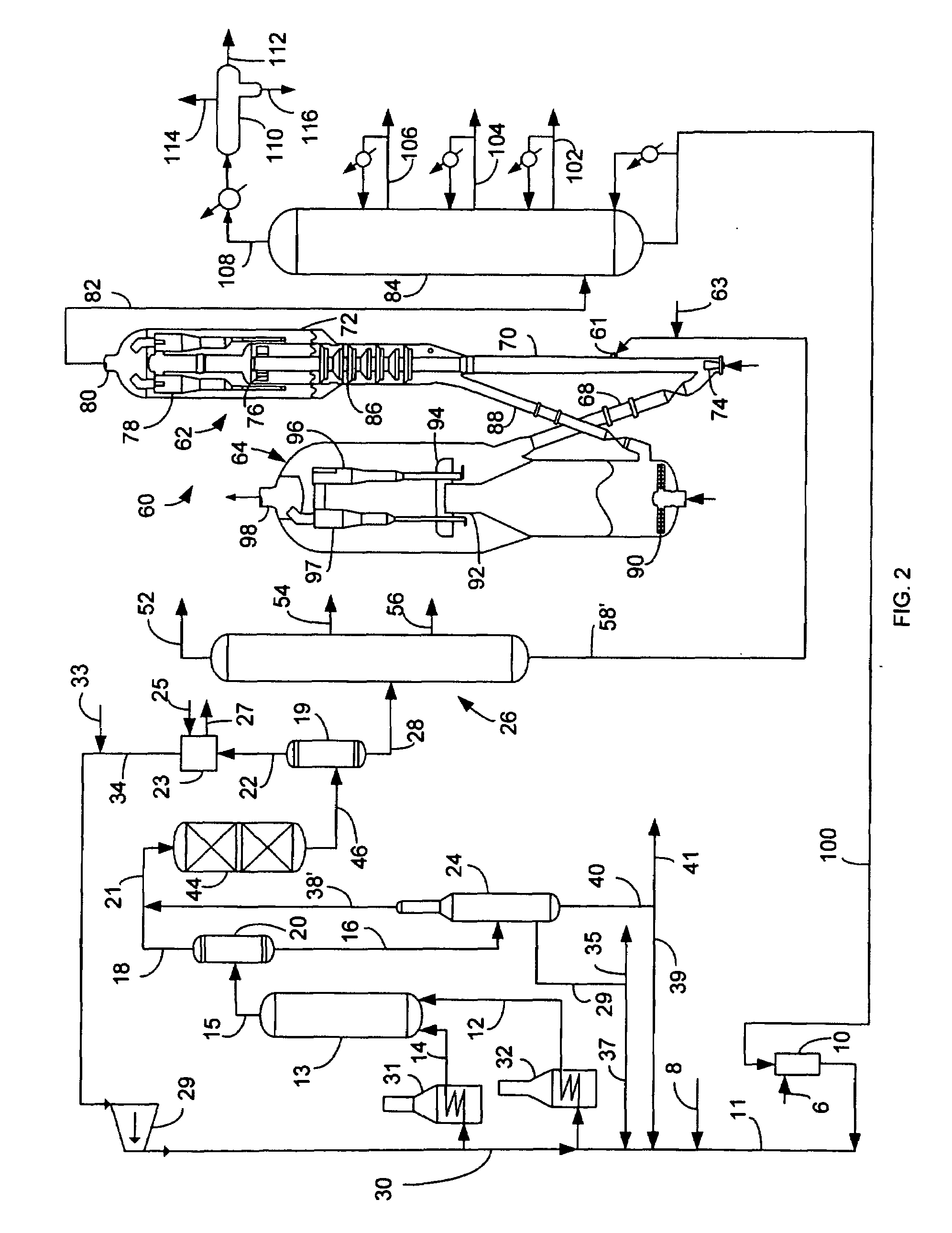

The present invention is a method for detecting an abnormal event for process units of a Fluidized Catalytic Cracking Unit. The method compares the operation of the process units to a statistical and engineering models. The statistical models are developed by principle components analysis of the normal operation for these units. In addition, the engineering models are based on partial least squares analysis and correlation analysis between variables. If the difference between the operation of a process unit and the normal model result indicates an abnormal condition, then the cause of the abnormal condition is determined and corrected.

Owner:EXXON RES & ENG CO

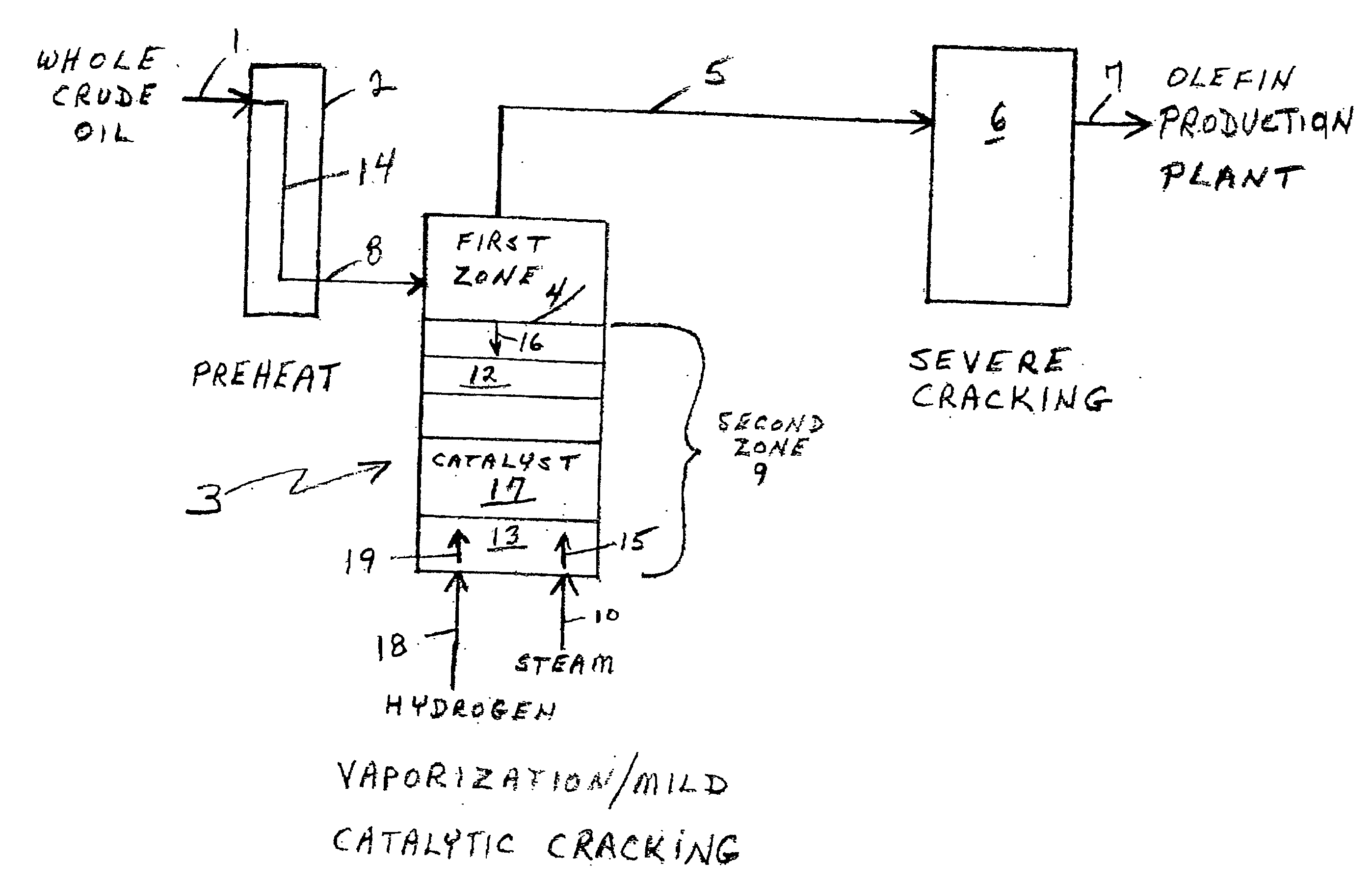

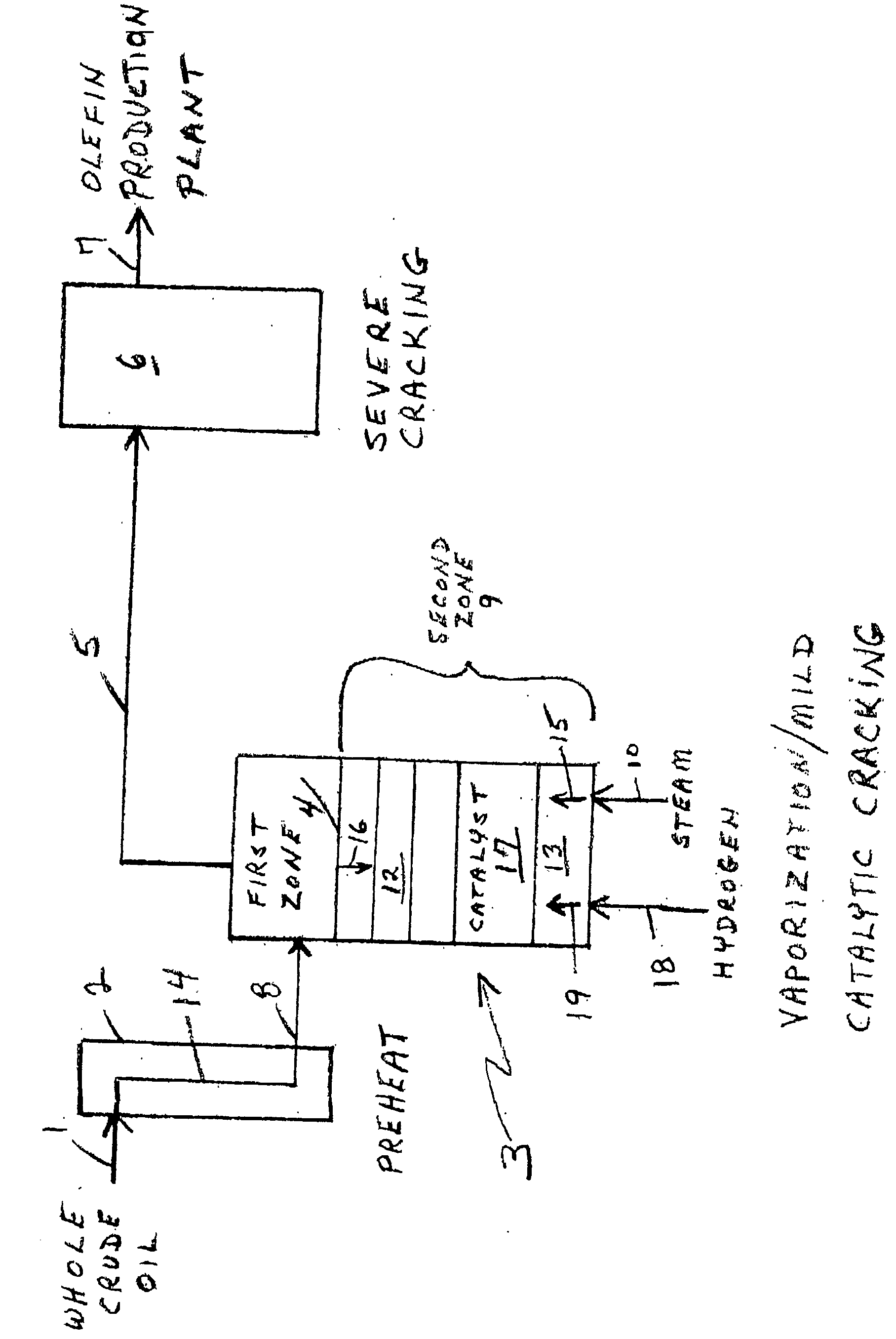

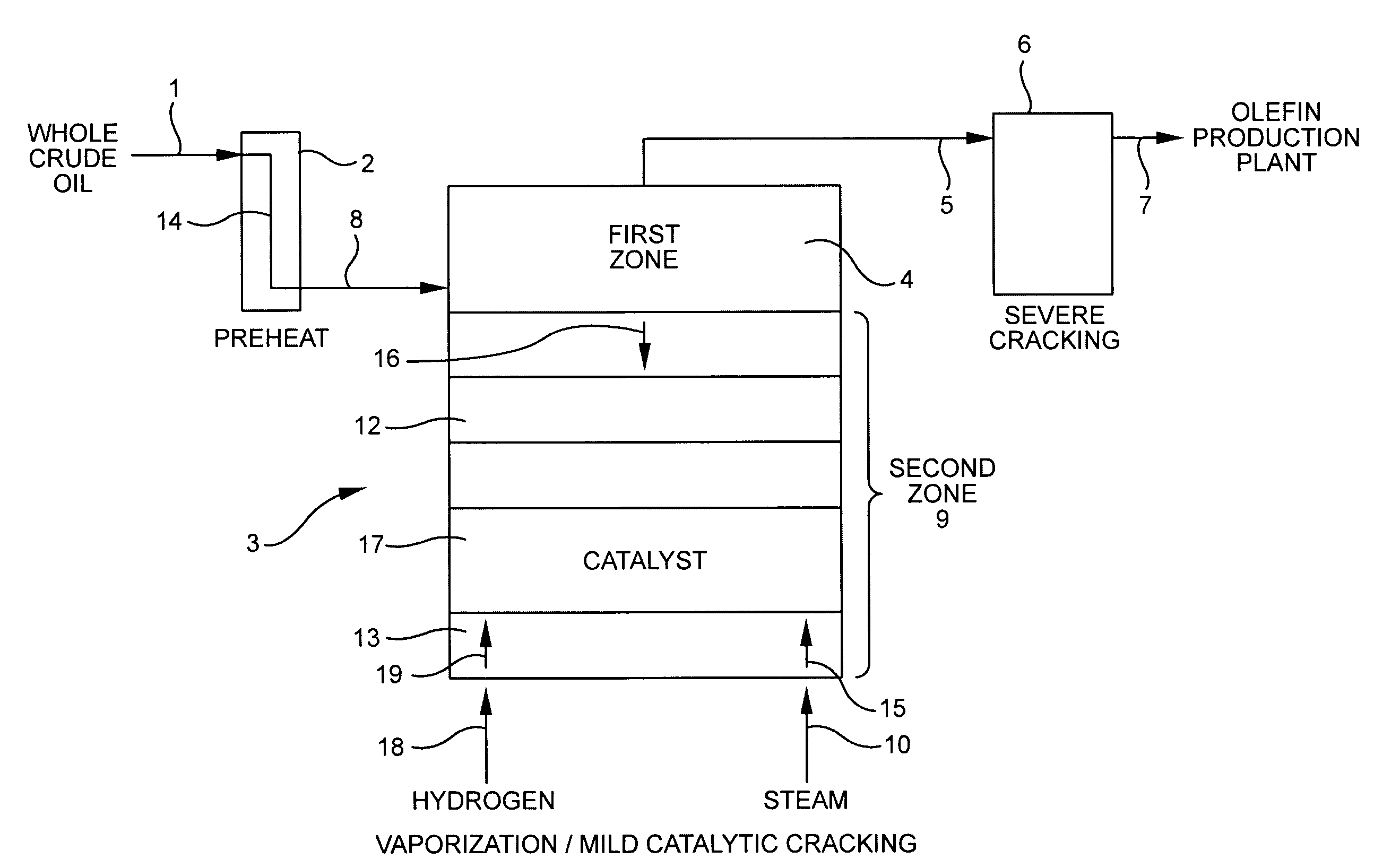

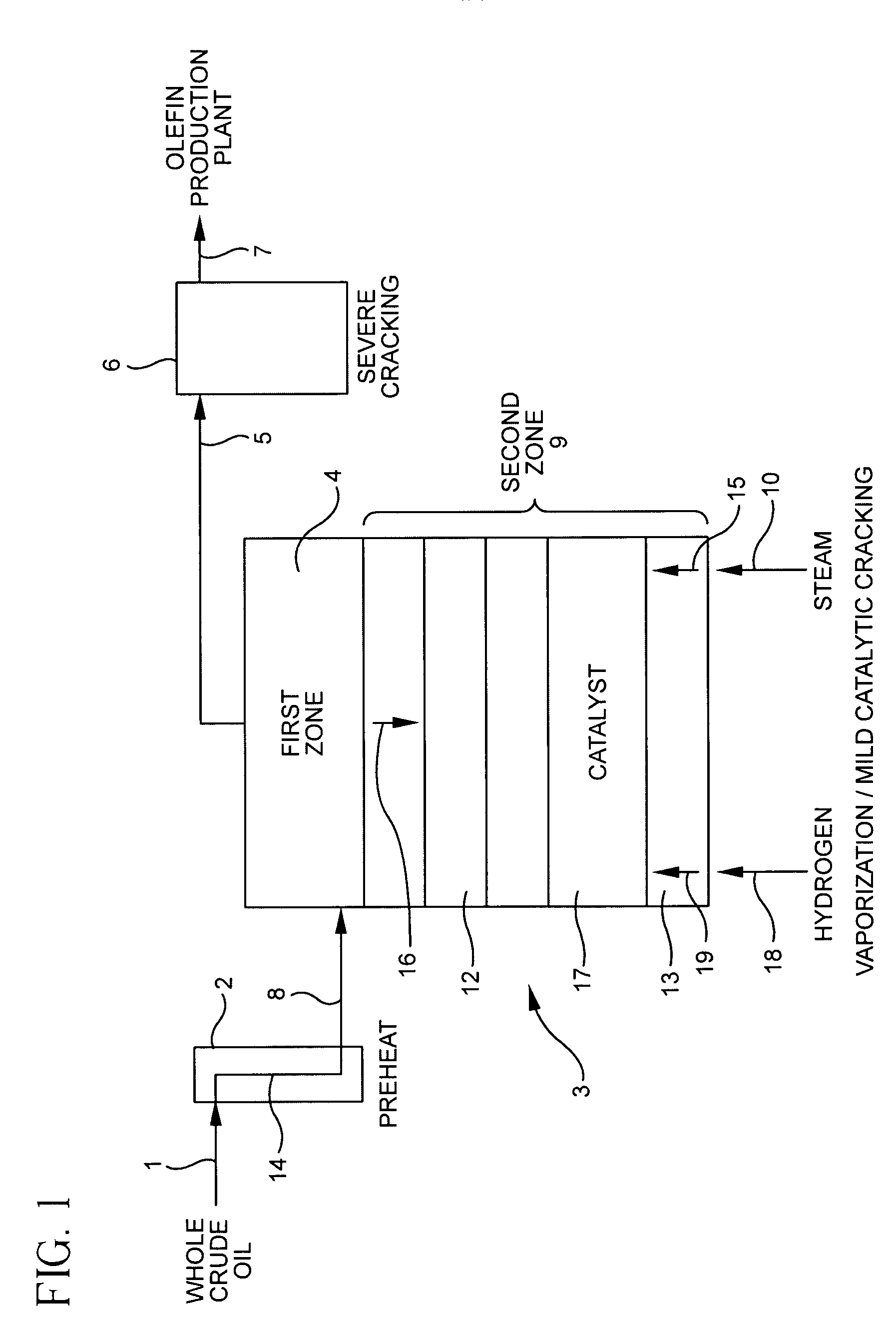

Olefin production utilizing whole crude oil and mild catalytic cracking

InactiveUS20040054247A1Lower temperature rangeImproved vaporizationThermal non-catalytic crackingCatalytic crackingChemistryPyrolysis

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild catalytic cracking conditions until substantially vaporized, the vapors from the mild catalytic cracking being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

Fluid cat cracking with high olefins prouduction

InactiveUS20020003103A1Increase productionMaximize lightThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaOrganic chemistry

The propylene production of a fluid catalytic cracking unit employing a large pore zeolite cracking catalyst, produces more propylene by adding a naphtha cracking riser and a medium pore zeolite catalytic component to the unit, and recycling at least a portion of the naphtha crackate to the naphtha riser. The large pore size zeolite preferably comprises a USY zeolite and the medium pore size is preferably ZSM-5. Propylene production per unit of naphtha feed to the naphtha riser is maximized, by using the 60-300.degree. F. naphtha crackate as the feed.

Owner:EXXON RES & ENG CO

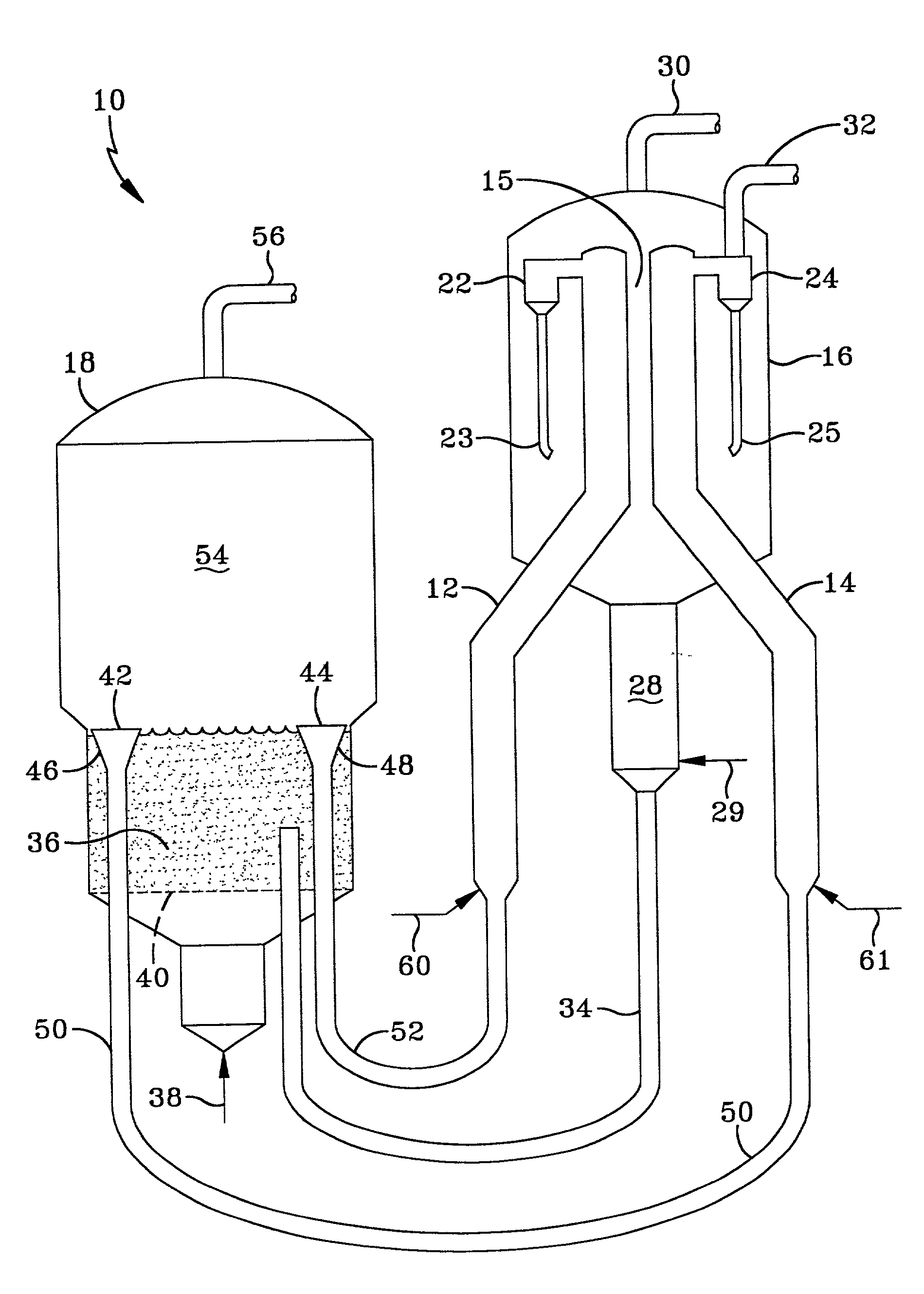

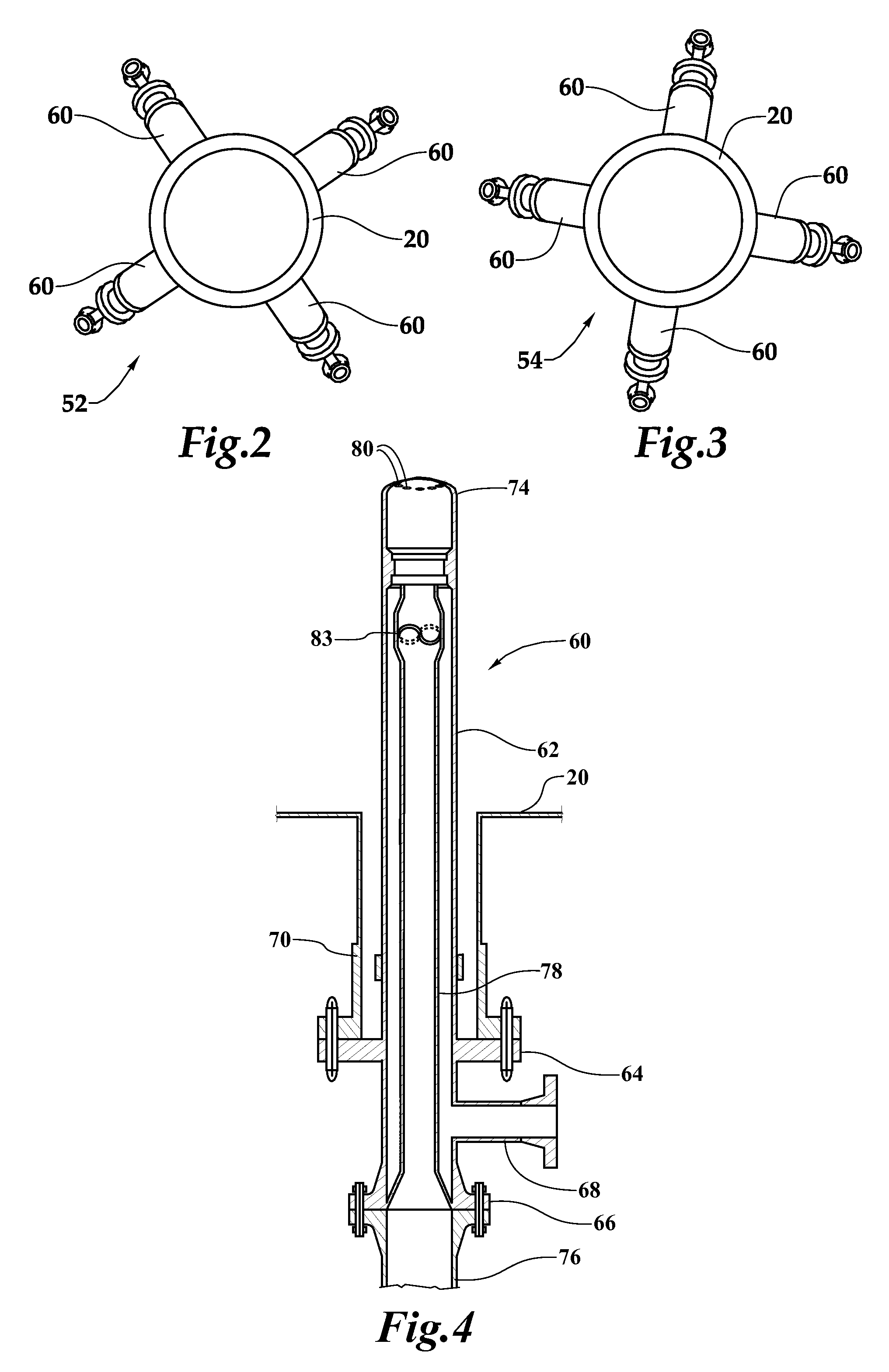

Fcc dual elevation riser feed distributors for gasoline and light olefin modes of operation

InactiveUS20070205139A1Increase flexibilityWiden the optionsCatalytic crackingFeed devicesHigh elevationPolymer science

A fluid catalytic cracking process includes feeding hydrocarbon into a riser in the presence of a catalyst, cracking the hydrocarbon in the riser in the presence of the catalyst to form a cracked stream, and separating the catalyst from the cracked stream. When in a gasoline mode, the hydrocarbon is fed through a first distributor into the riser, and when in a light olefin mode, the hydrocarbon is fed through a second distributor into the riser. The second distributor is positioned at a higher elevation than the first distributor.

Owner:UOP LLC

Olefin production utilizing whole crude oil and mild catalytic cracking

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild catalytic cracking conditions until substantially vaporized, the vapors from the mild catalytic cracking being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

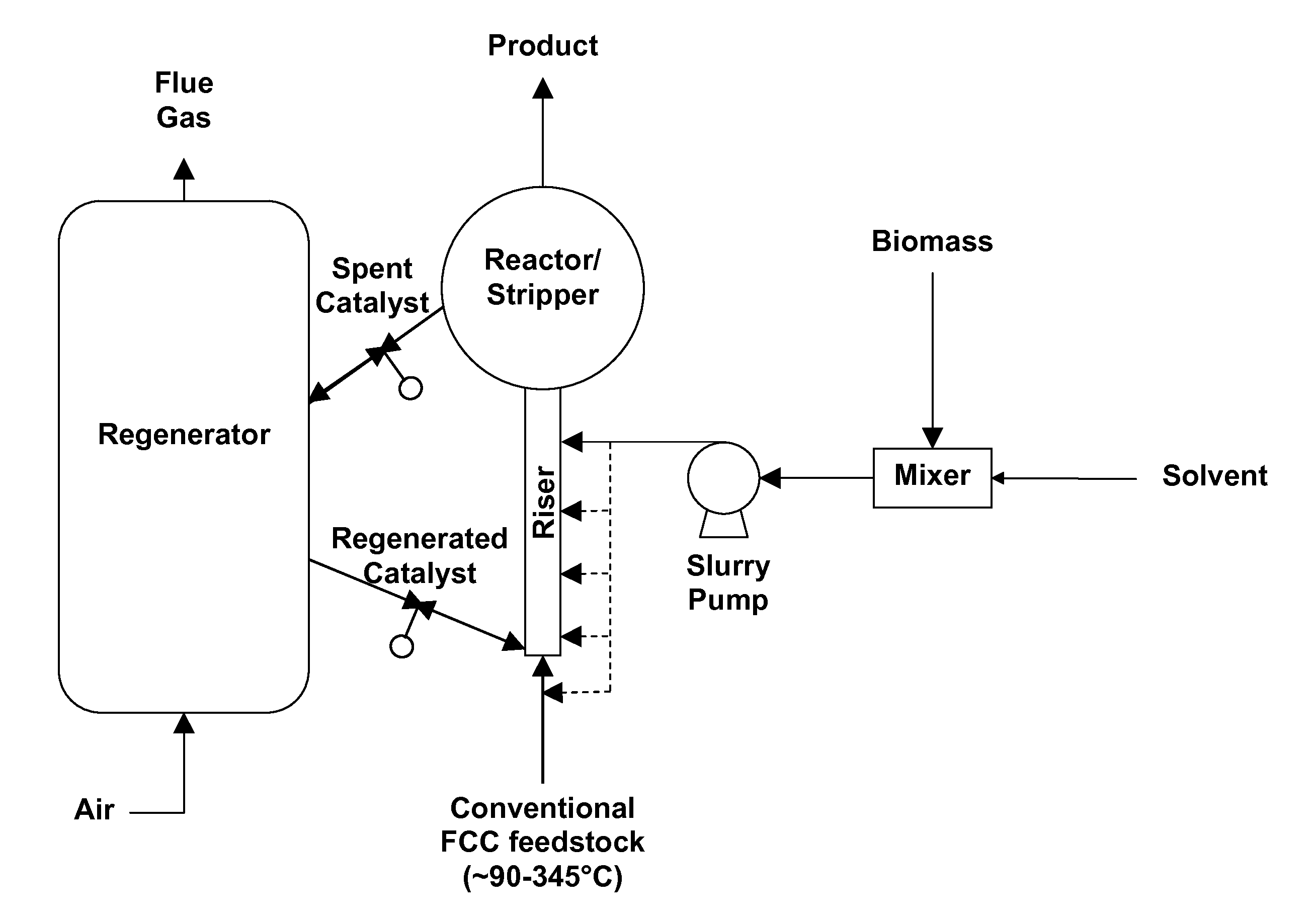

Integrated fcc biomass pyrolysis/upgrading

Owner:PHILLIPS 66 CO

Catalyst for fluidized catalytic cracking of heavy hydrocarbon oil and method of fluidized catalytic cracking

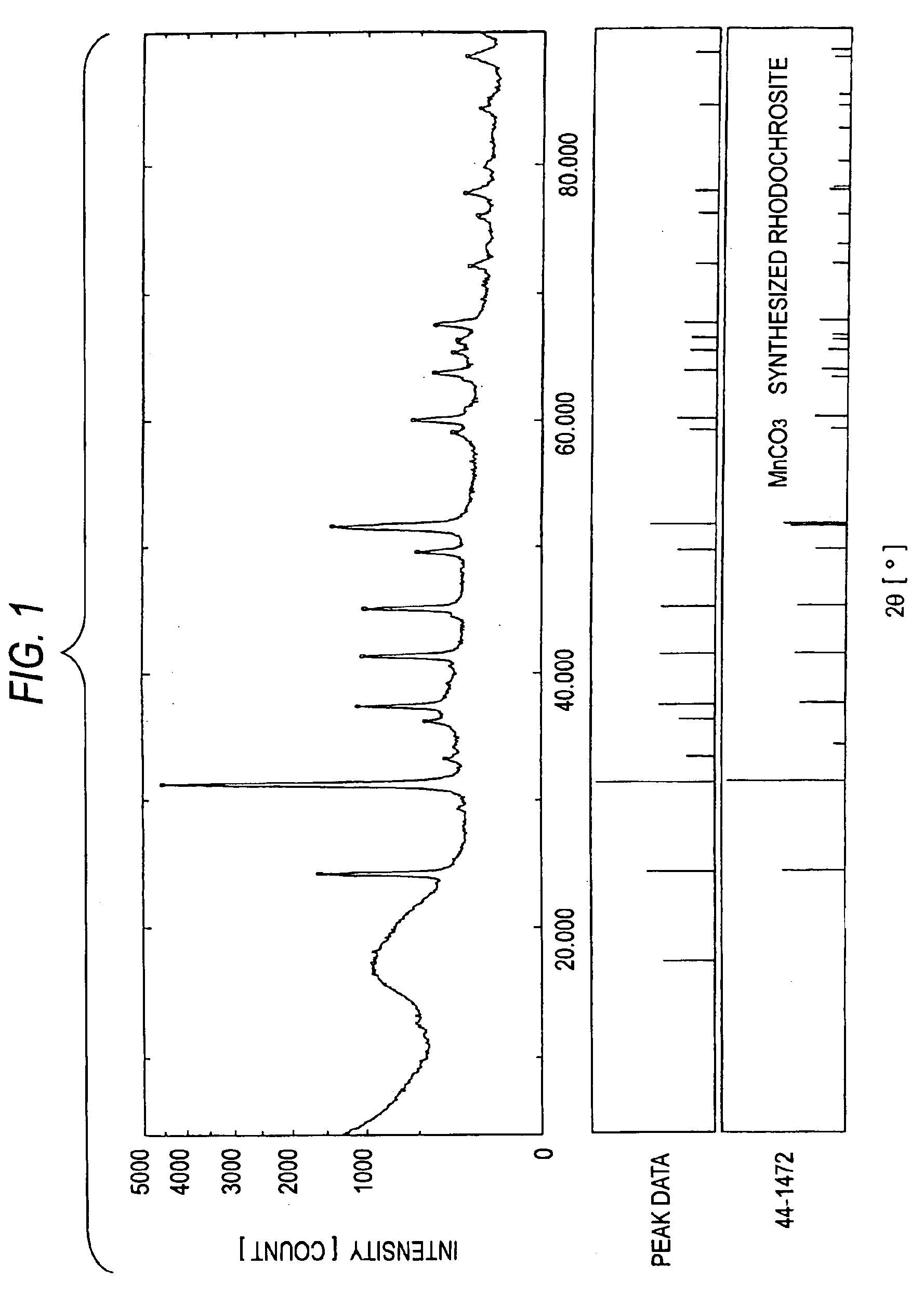

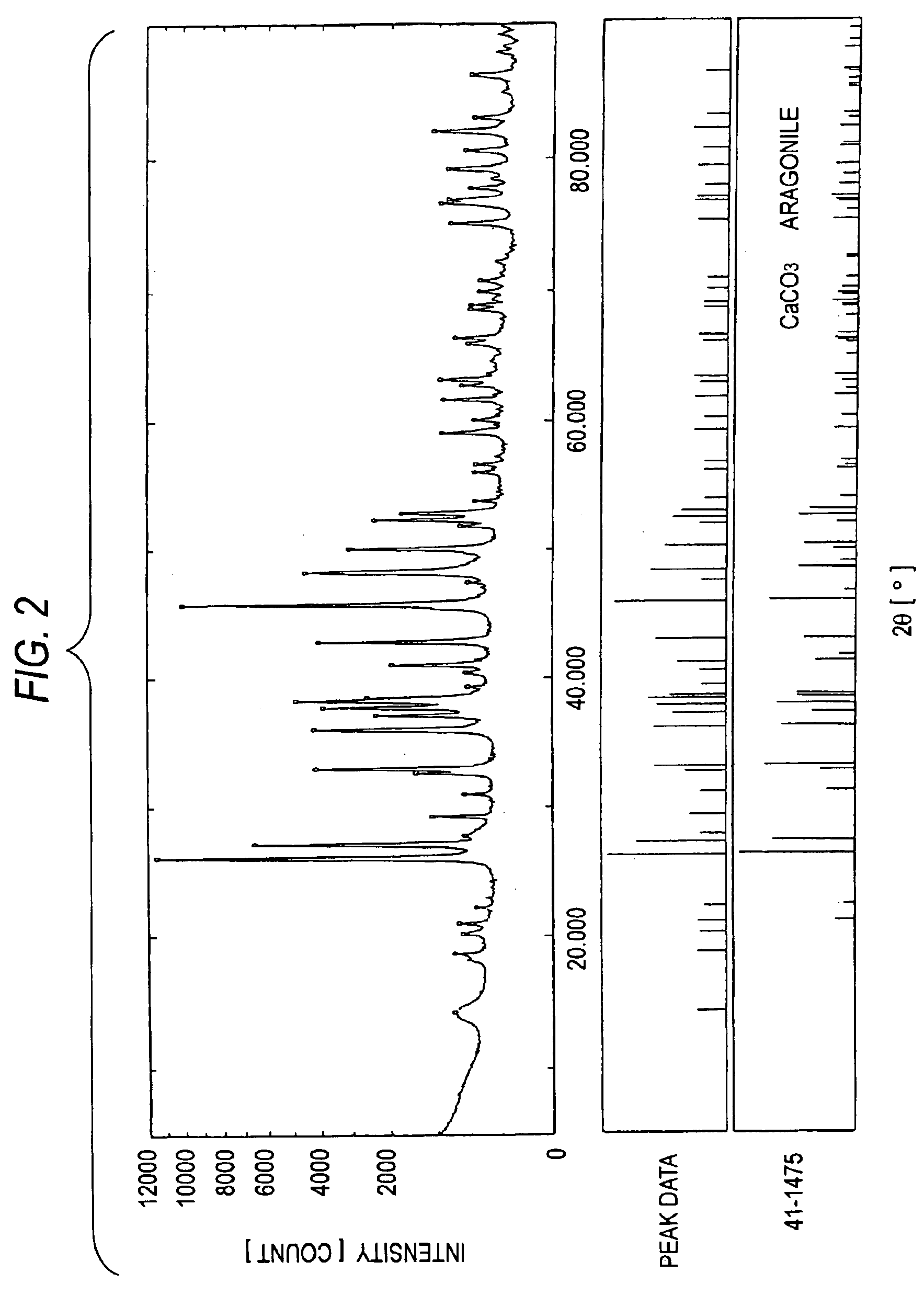

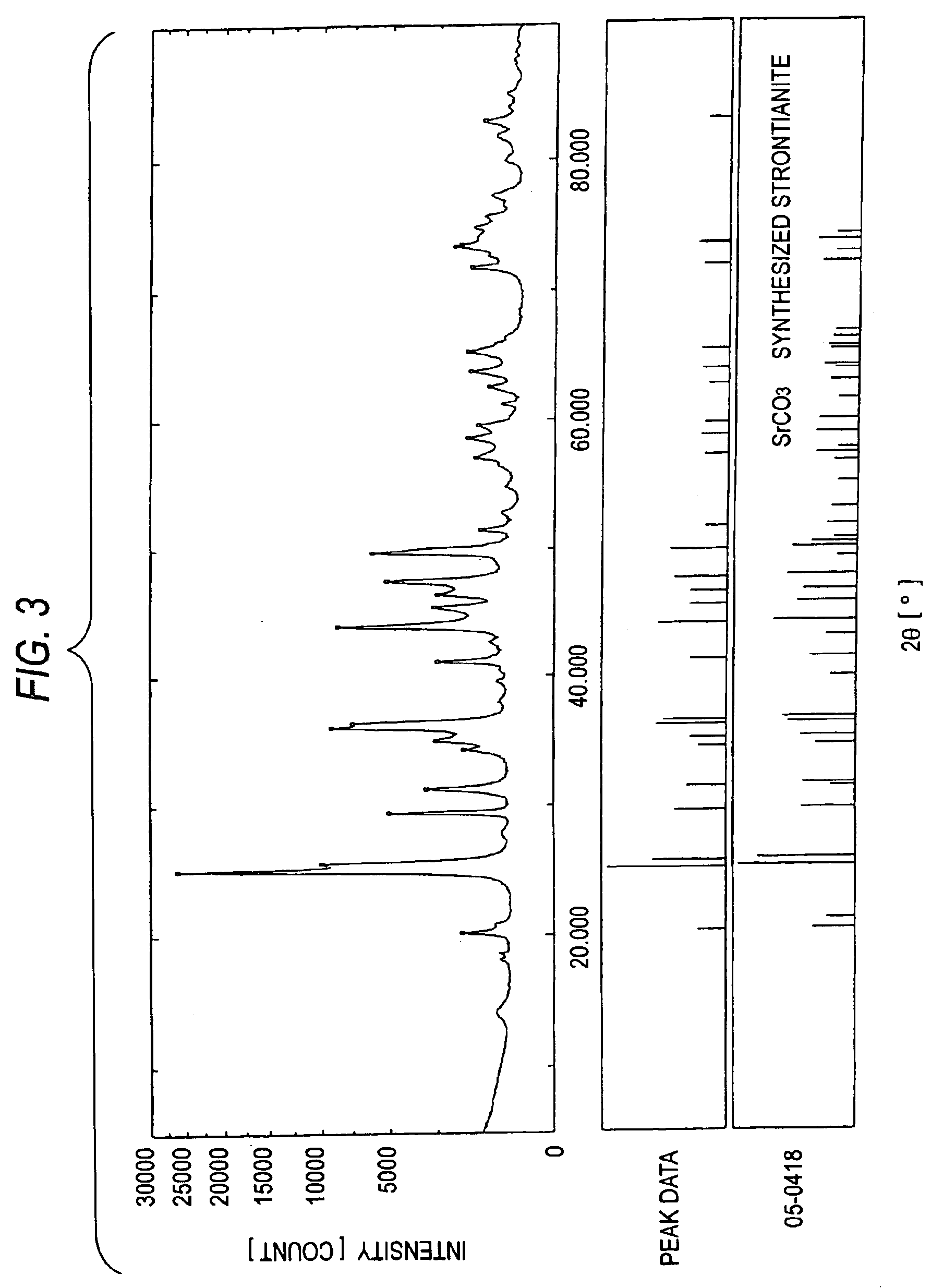

InactiveUS6916762B2Efficient inactivationReduce the amount requiredCalcium/strontium/barium carbonatesAluminium compoundsHydrogenOxide matrix

An FCC catalyst which not only deactivates catalyst poison metals, such as nickel, vanadium and the like, in feedstock oils, inhibits the generation of hydrogen or coke, has excellent cracking activity and bottom oil-treating ability, and can yield a gasoline and LCO fraction in high yields, but also retains the performances on a high level over long and has an improved catalyst life; and an FCC method using the catalyst. The FCC catalyst has a compound of a bivalent metal or of bivalent and trivalent metals showing an XRD pattern of a carbonate of the bivalent metal; an inorganic oxide matrix and the compound dispersed therein; or an inorganic oxide matrix and the compound dispersed therein together with a crystalline aluminosilicate zeolite, and relates to an FCC method in which at least one of the catalysts are used in combination with an FCC catalyst obtained by evenly dispersing a crystalline aluminosilicate zeolite in an inorganic oxide matrix.

Owner:GASOLINEEUM ENERGY CENT FOUND +1

Targeted hydrogenation hydrocracking

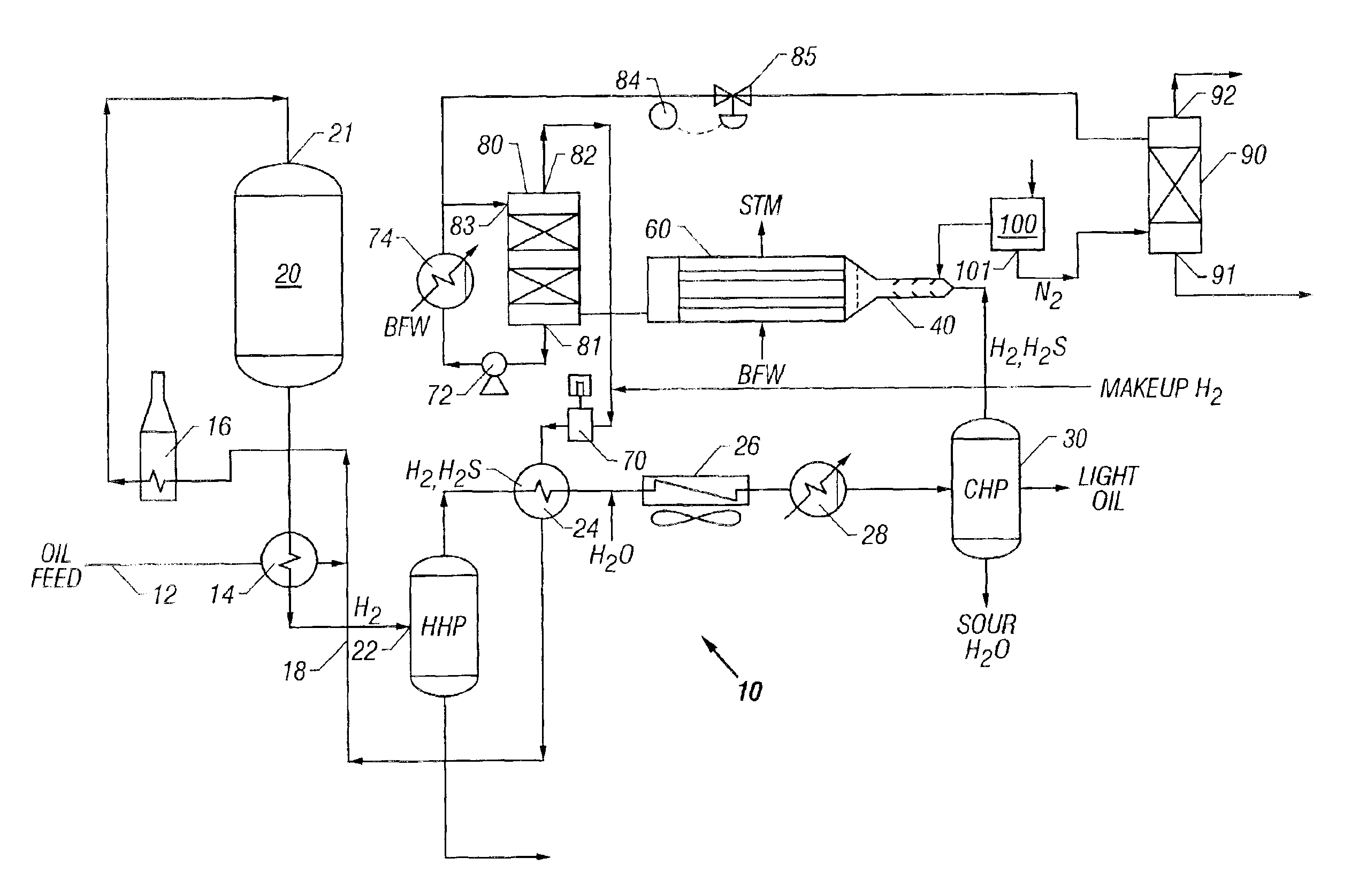

InactiveUS20090159493A1Hydrocarbon oil crackingTreatment with hydrotreatment processesProcess engineeringEngineering

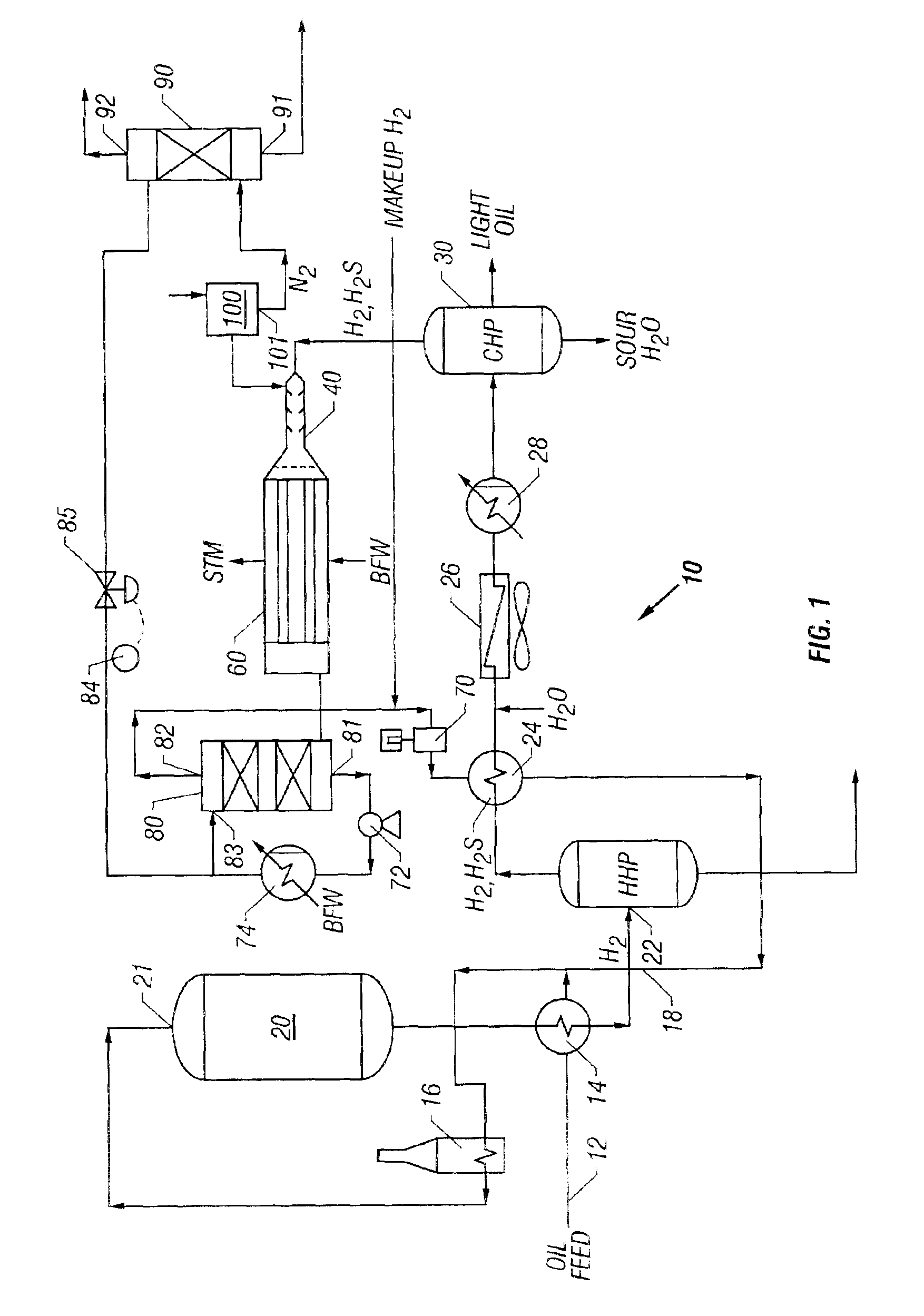

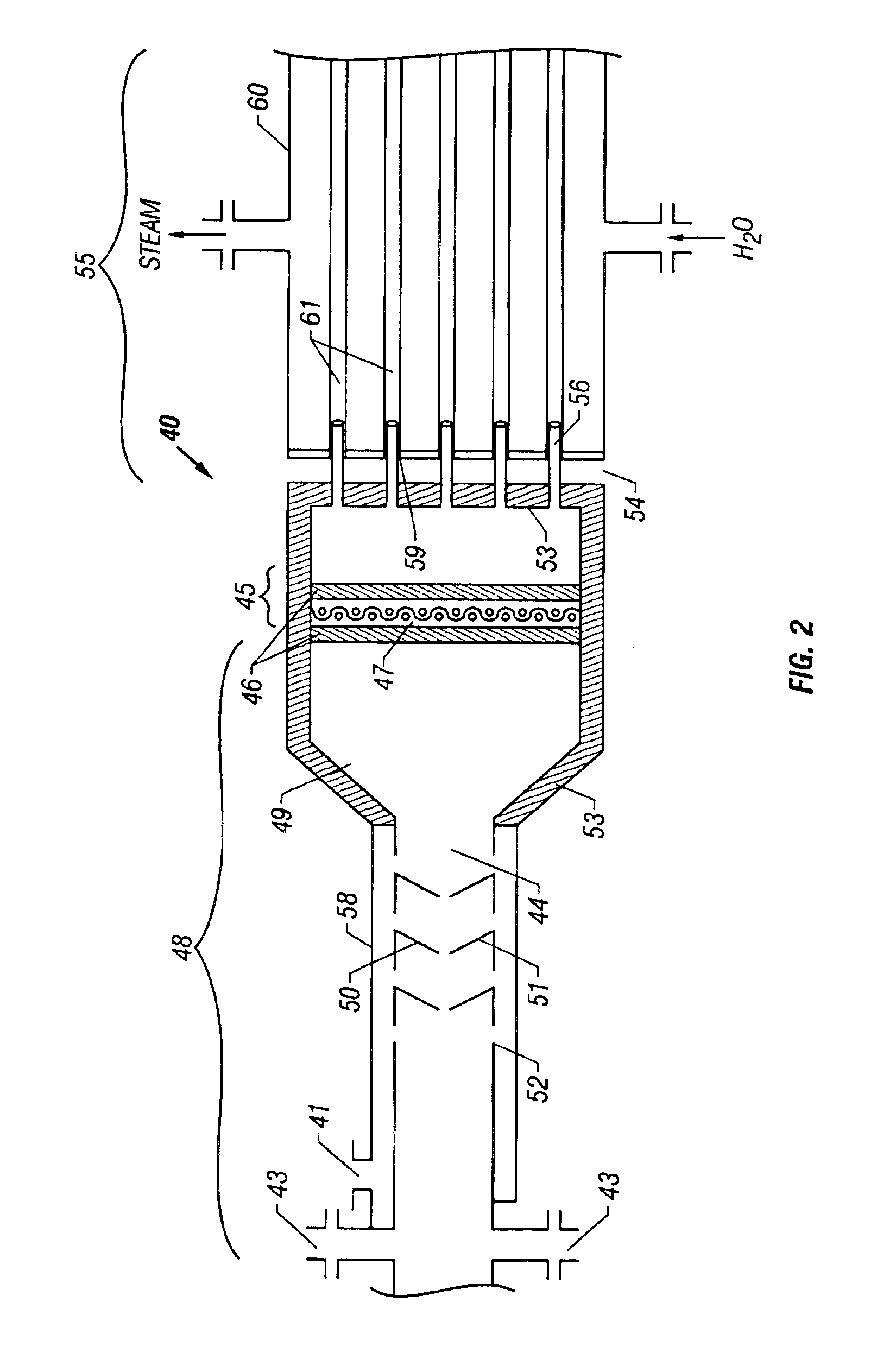

This invention is directed to a process scheme in which a partial conversion hydrocracking (HCR) unit, preferably preceded by a hydrotreating unit, feeds unconverted oil to a FCC (fluid catalytic cracking ) unit. Most refineries run the FCC unit at the full capacity for optimal asset utilization. During shutdowns of Residue Desulfurization unit(s) which feed an FCC unit, it is desirable to reduce the conversion in the FCC feed hydrocracker. In this way, the feed to FCC unit is maximized. Jet and Diesel products that conform to specifications may be produced during low conversion HCR operation. Furthermore, undesirable over-saturation of the unconverted oil (UCO) from the HCR unit feeding the FCC unit can be avoided. Excess hydrogen consumption can also be avoided. Normally, further aromatic saturation of the middle distillate products from a low conversion HCR is achieved in a separate, post treatment, unit.

Owner:CHEVROU USA INC

Gasoline sulfur reduction in fluid catalytic cracking

InactiveUS6852214B1Reduce sulfur contentLow sulfurCatalytic crackingMolecular sieve catalystsOxidation stateGasoline

The sulfur content of liquid cracking products, especially the cracked gasoline, of the catalytic cracking process is reduced by the use of a sulfur reduction additive comprising a porous molecular sieve which contains a metal in an oxidation state above zero within the interior of the pore structure of the sieve. The molecular sieve is normally a large pore size zeolite such as USY or zeolite beta or an intermediate pore size zeolite such as ZSM-5. The metal is normally a metal of Period 4 of the Periodic Table, preferably zinc or vanadium. The sulfur reduction catalyst may be used in the form of a separate particle additive or as a component of an integrated cracking / sulfur reduction catalyst.

Owner:MOBIL OIL CORP +1

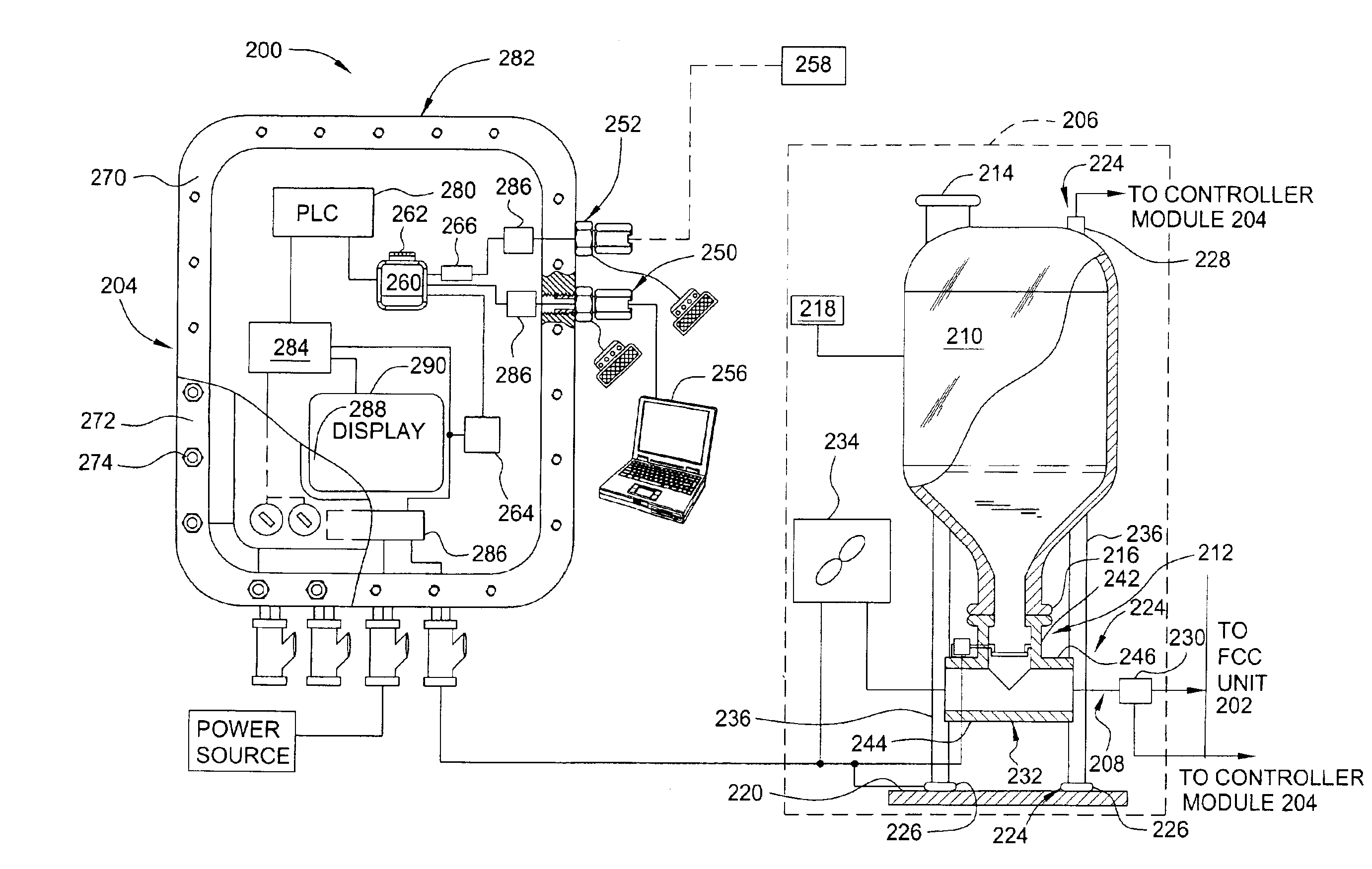

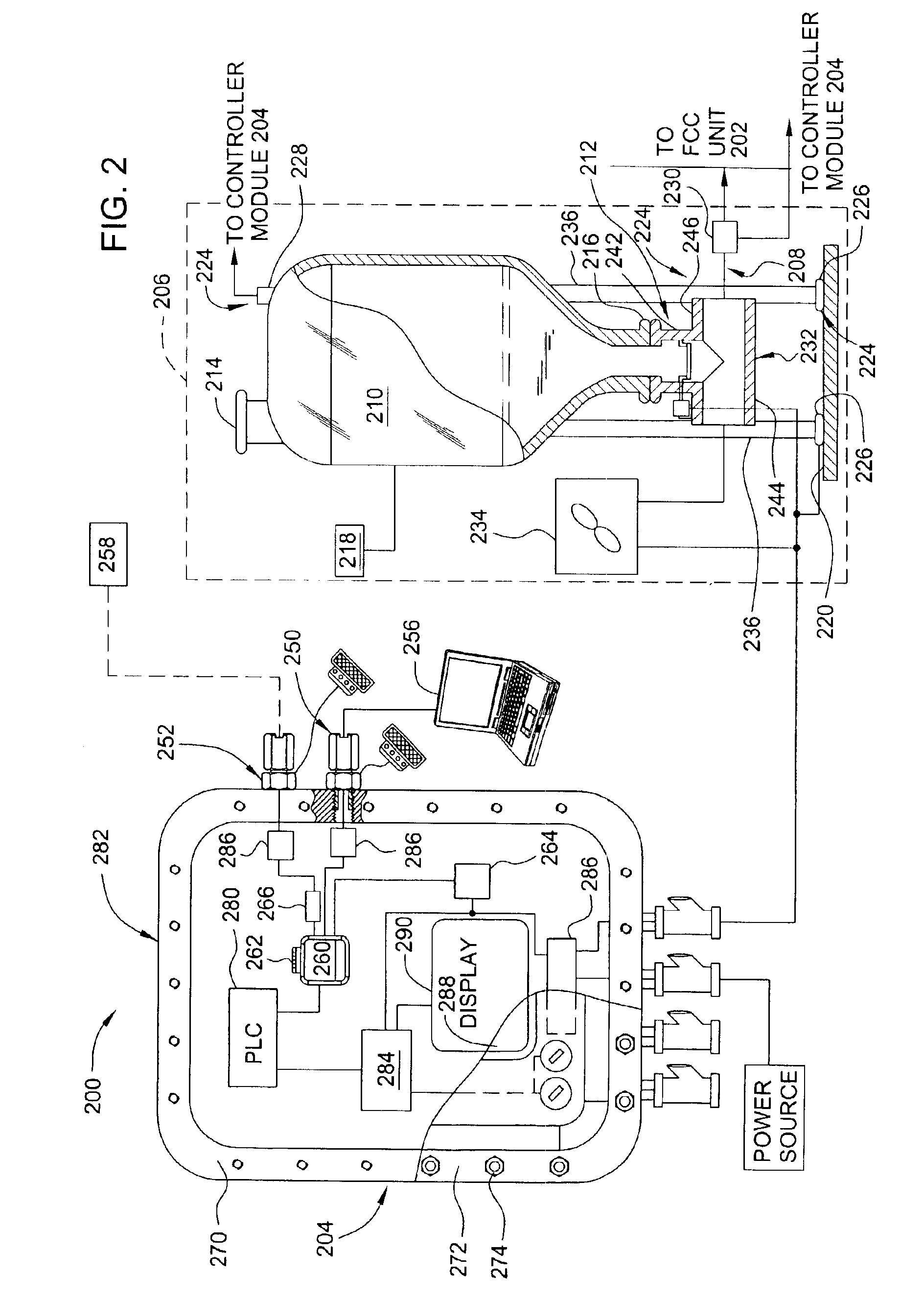

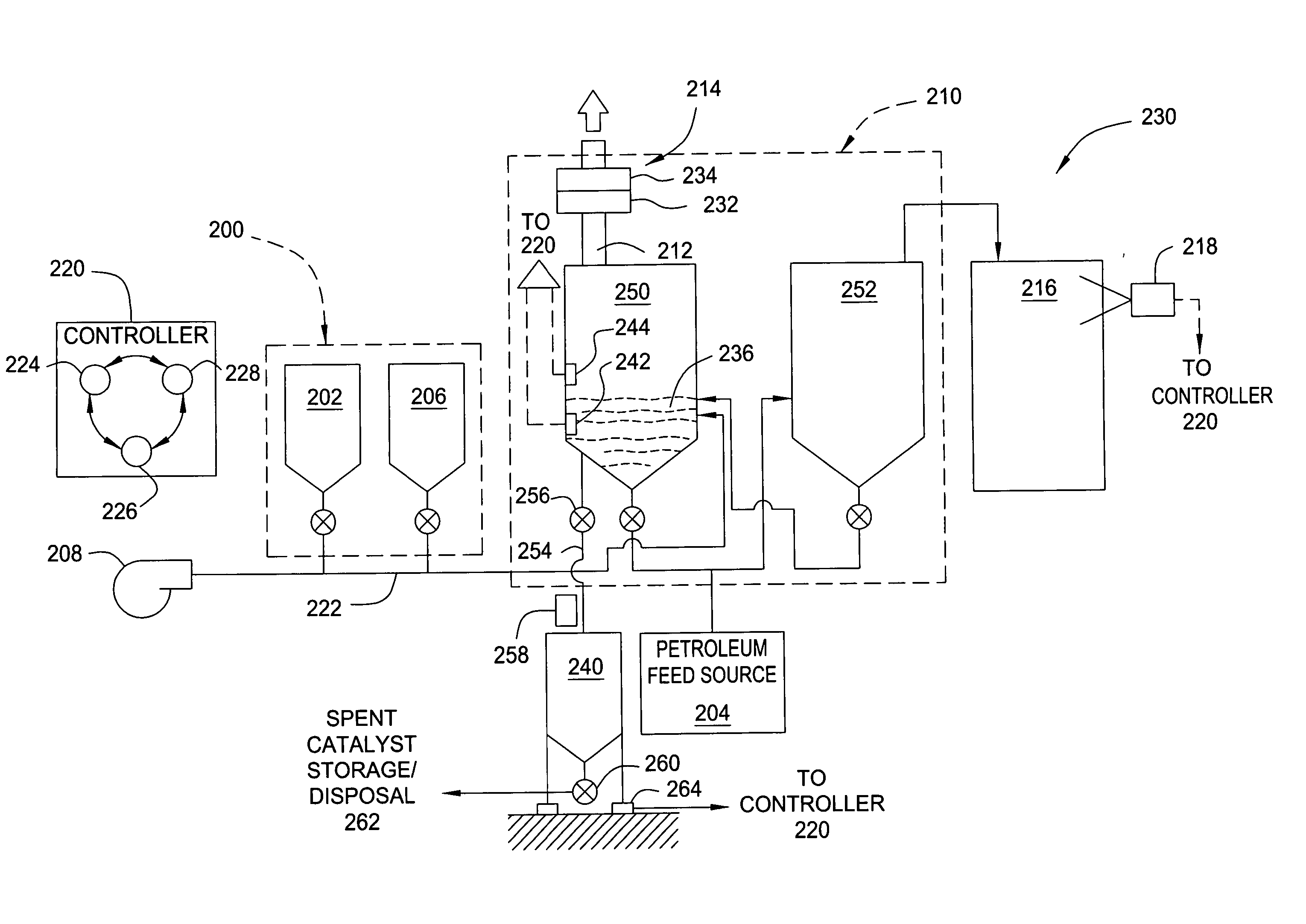

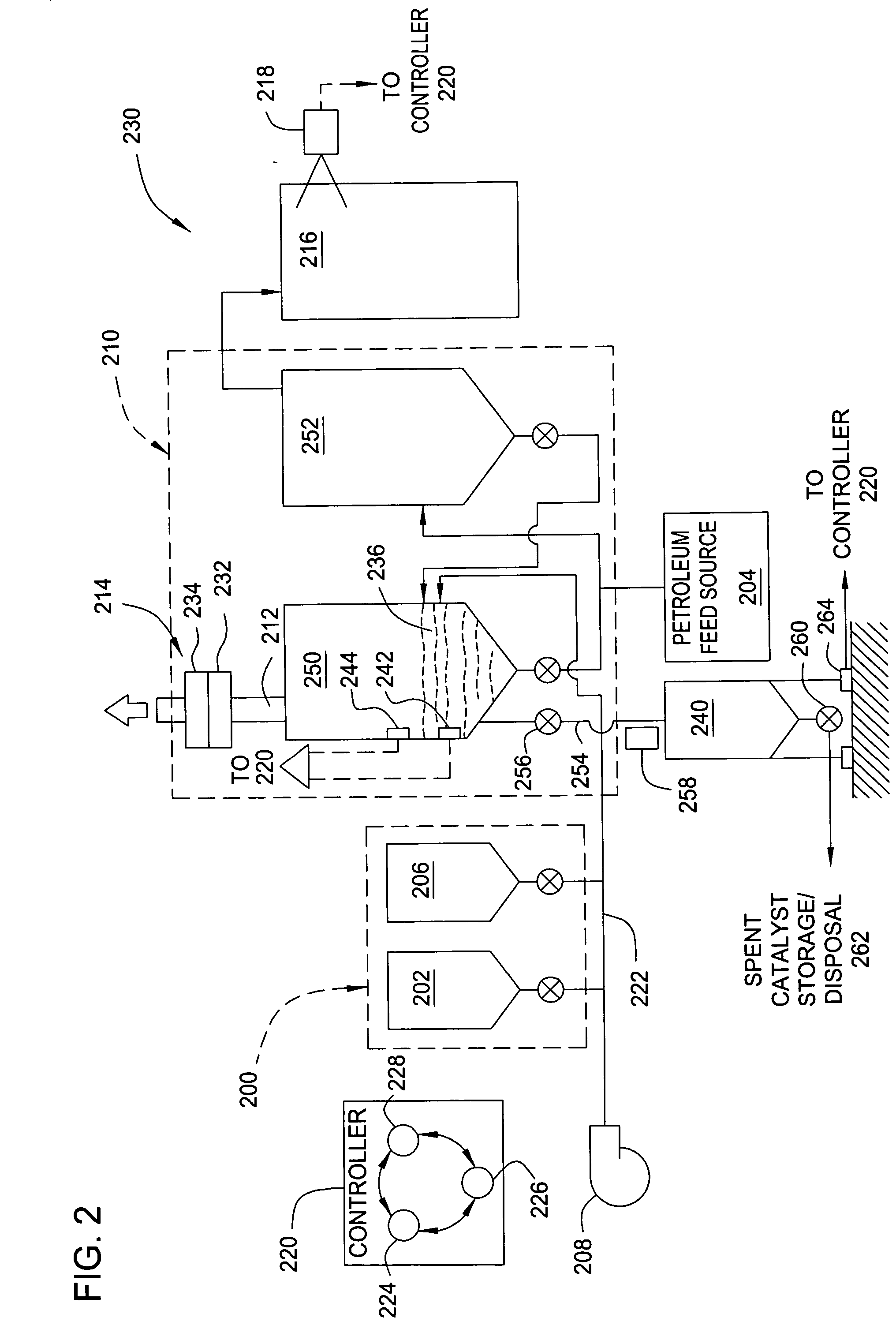

Method and apparatus for monitoring catalyst requirements of a fluid catalytic cracking catalyst injection system

InactiveUS6859759B2Catalytic crackingTesting/calibration apparatusPetroleum engineeringFluid catalytic cracking

A method and apparatus for monitoring catalyst requirements of a fluid catalytic cracking catalyst injection system is provided. In one embodiment, a method for monitoring catalyst requirements of a fluid catalytic cracking catalyst injection system includes the steps of communicating with a memory device of a control module of the catalyst injection system that is adapted to control the amount of catalyst injected into a fluid catalyst cracking unit and determining if catalyst inventory needs to be replenished. The method enables both suppliers and processors to remotely monitor inventory requirements and take appropriate action if inventories fall below a predefined level or reorder point.

Owner:JOHNSON MATTHEY PROCESS TECH

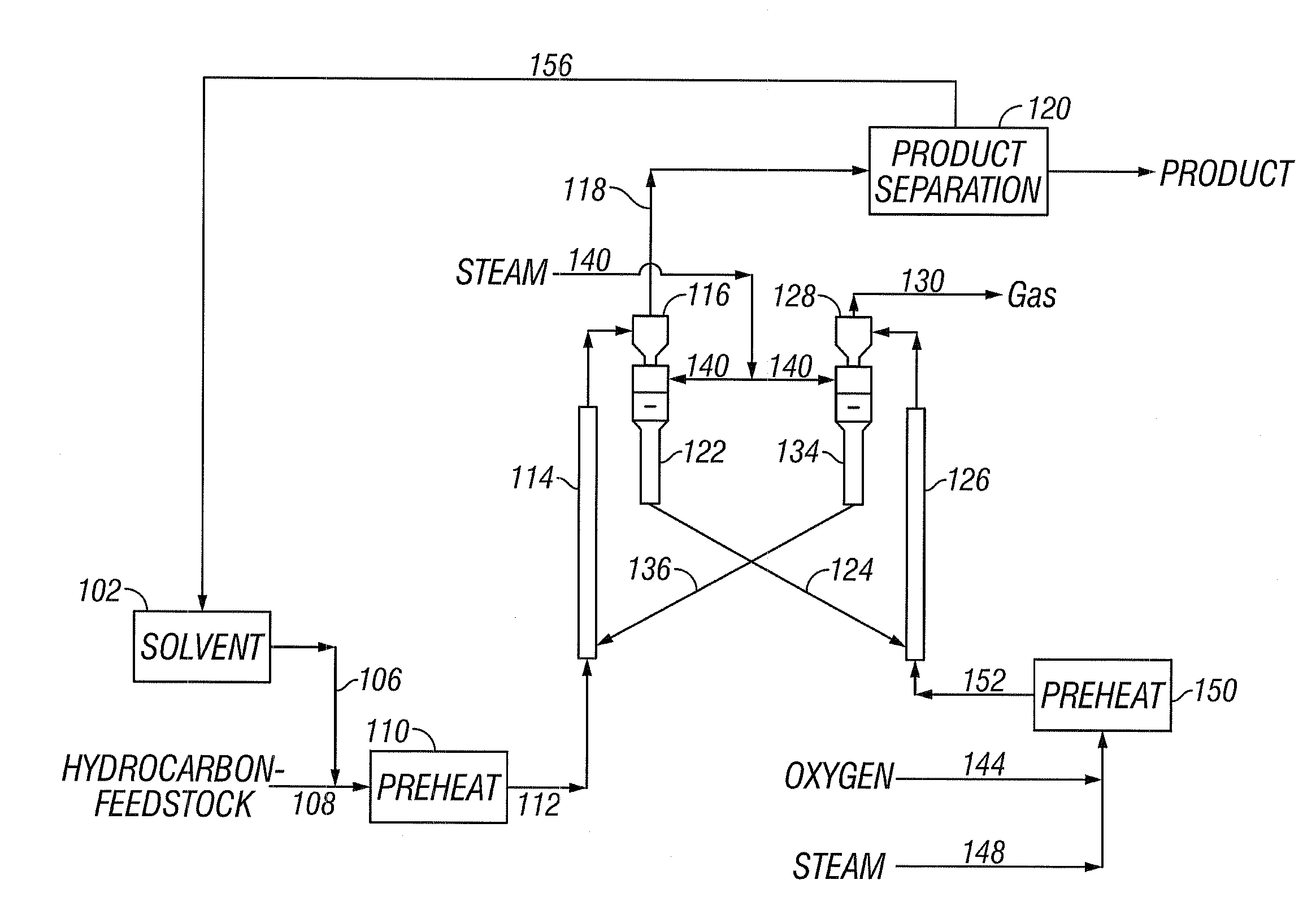

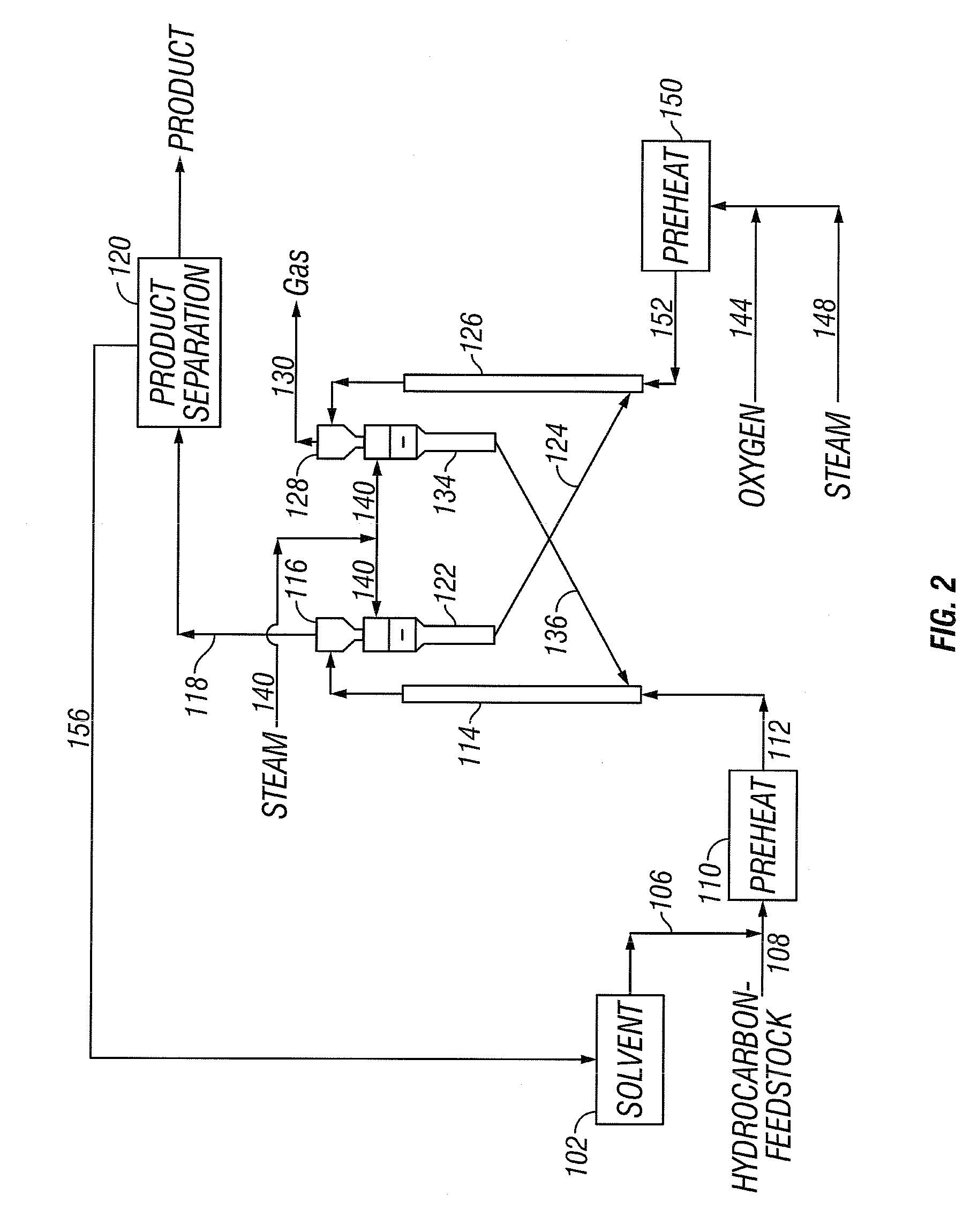

Supercritical hydrocarbon conversion process

ActiveUS7144498B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyReaction temperatureUnit operation

Supercritical conversion of hydrocarbons boiling above 538° C. (1000° F.) with a solvating hydrocarbon at a weight ratio of solvating hydrocarbon to high-boiling hydrocarbons of at least 2:1 and at conditions above the critical temperature and pressure of the high-boiling hydrocarbons-solvent mixture, in the presence of hot fluidized solids. The hydrocarbons are supplied to a reaction zone at a temperature below that of the hot solids supplied thereto, whereby the resulting hydrocarbons-solids suspension has a thermal equilibrium temperature corresponding to the reaction temperature. The conversion has high rates of sulfur, nitrogen and metals removal, nearly complete conversion to lower molecular weight products, high naphtha and distillate selectivity, and low coke formation. The supercritical conversion can replace crude distillation, vacuum distillation, solvent deasphalting, coking, hydrocracking, hydrotreating, and / or fluid catalytic cracking, and / or used in parallel with such unit operations for debottle-necking or increasing capacity.

Owner:KELLOGG BROWN & ROOT LLC

Catalytic cracking process for production of diesel from seeds of oleaginous plants

ActiveUS20080313955A1Production is possibleCatalytic crackingFatty acid chemical modificationEngineeringCracking reaction

The present invention comprises a thermocatalytic cracking process for the production of diesel oil from a charge of vegetable origin made from seeds of oleaginous plants in refineries possessing at least two FCC reactors. At least -one of such reactors processes heavy gas oil or residue under conventional conditions whilst at least one of such reactors processes the charge of vegetable origin made from seeds of oleaginous plants under conditions suitable, for production of diesel oil. Said process employs the same catalyst utilised in the fluid catalytic cracking process which, simultaneously, processes a conventional charge.The diesel, or biodiesel, oil produced by means of said process is of superior quality having a cetane number exceeding 40 given that the cracking reactions occur at low temperatures and the products obtained are less oxidised and consequently purer than products obtained by means of existing technology.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

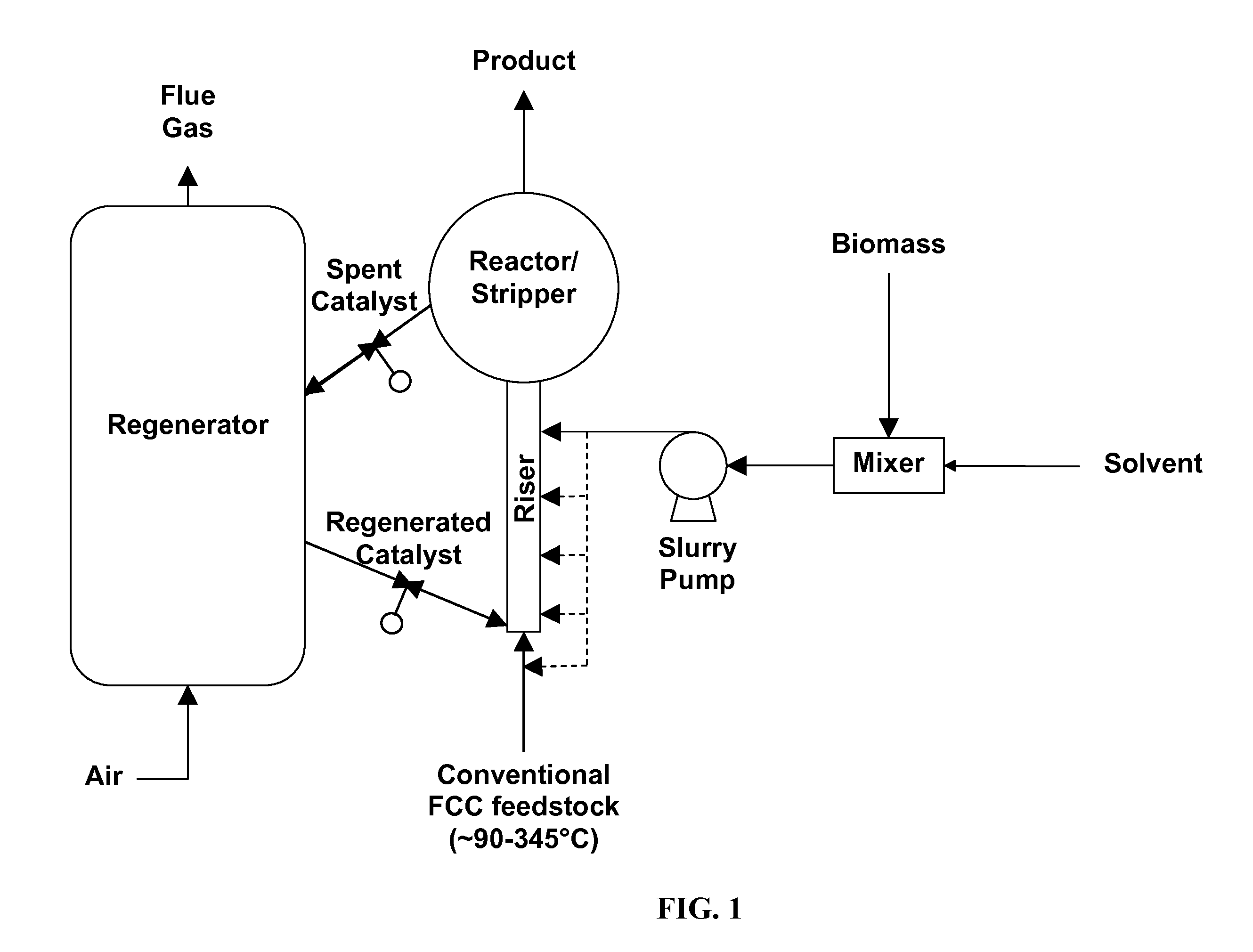

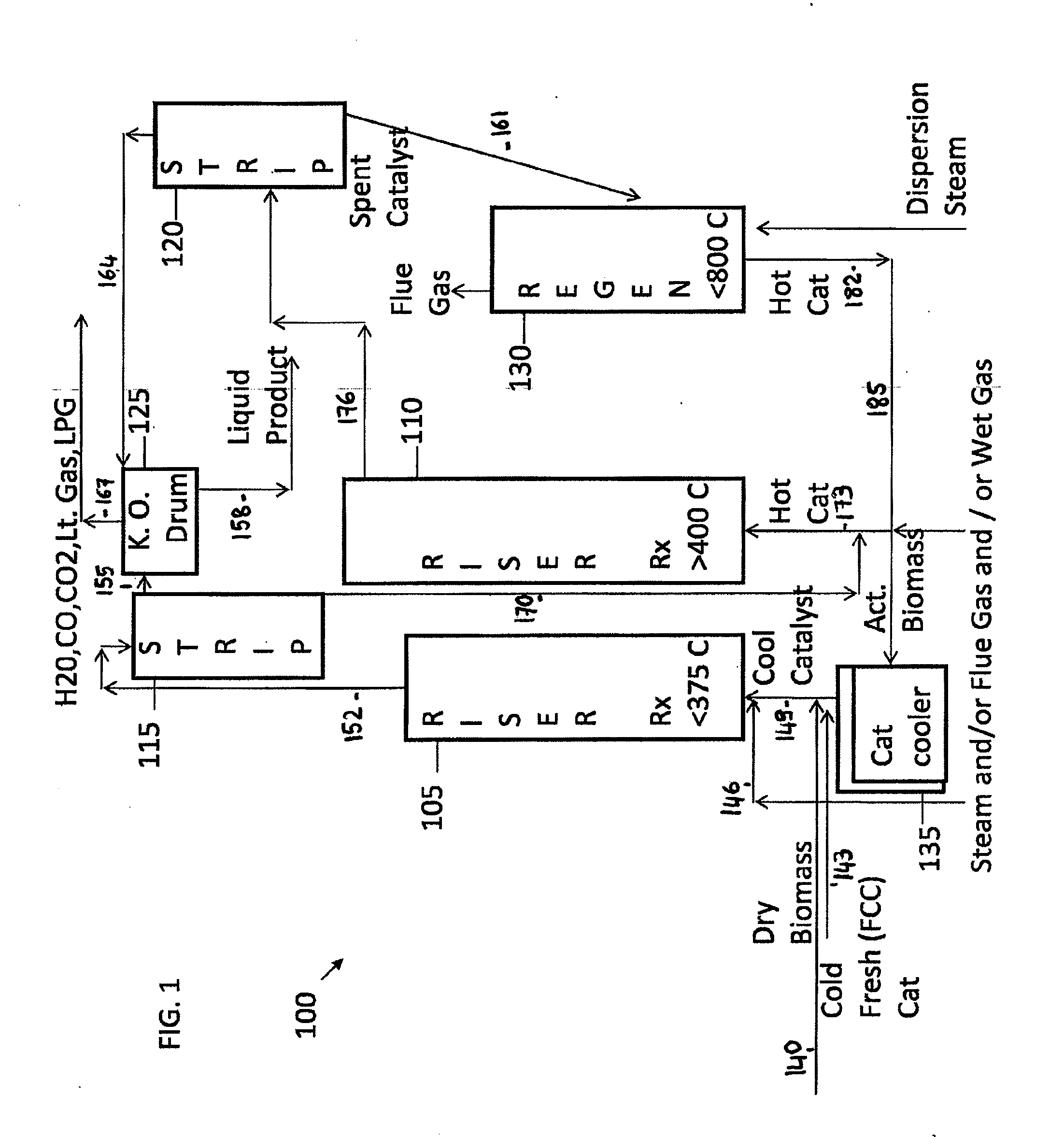

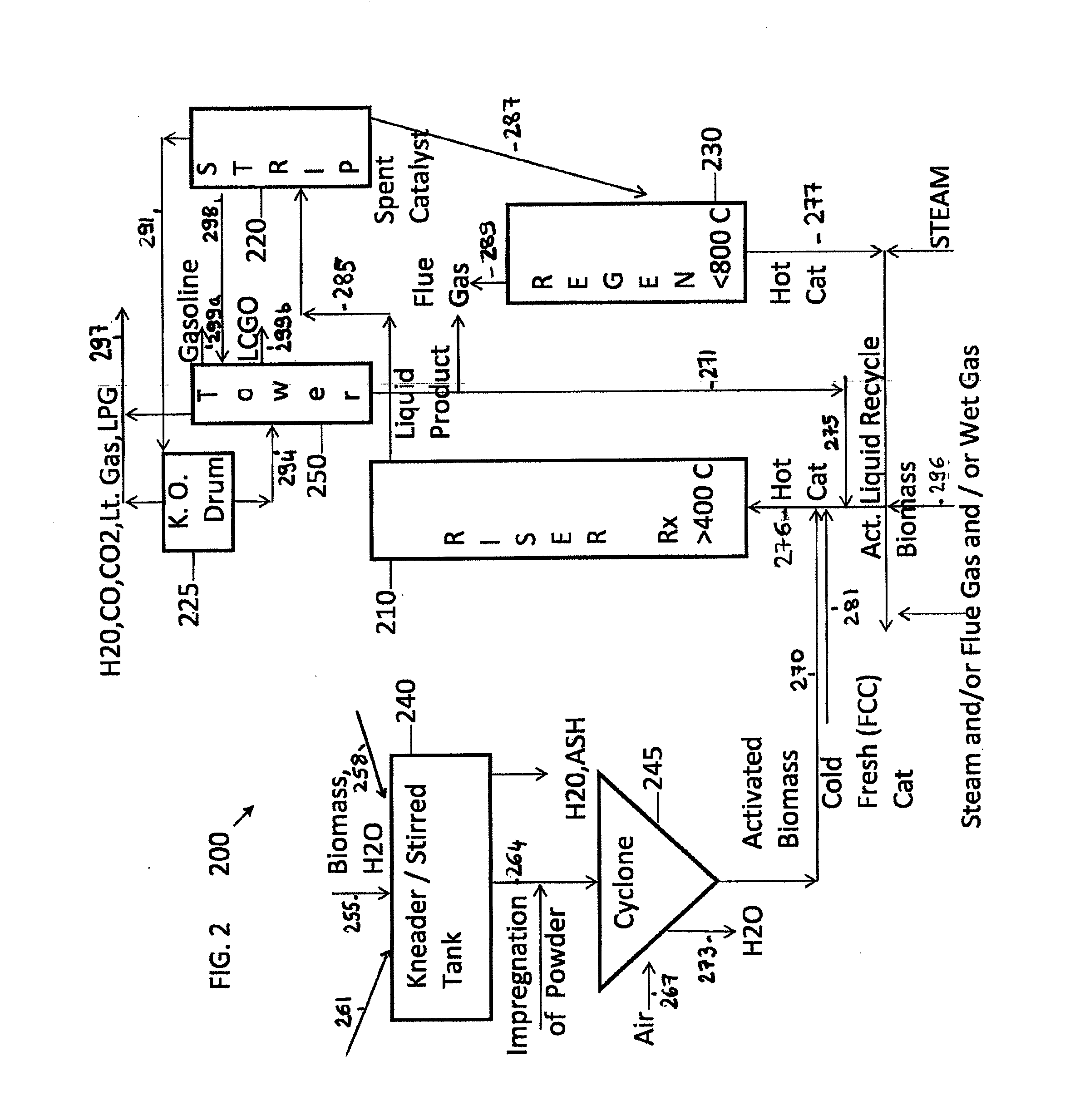

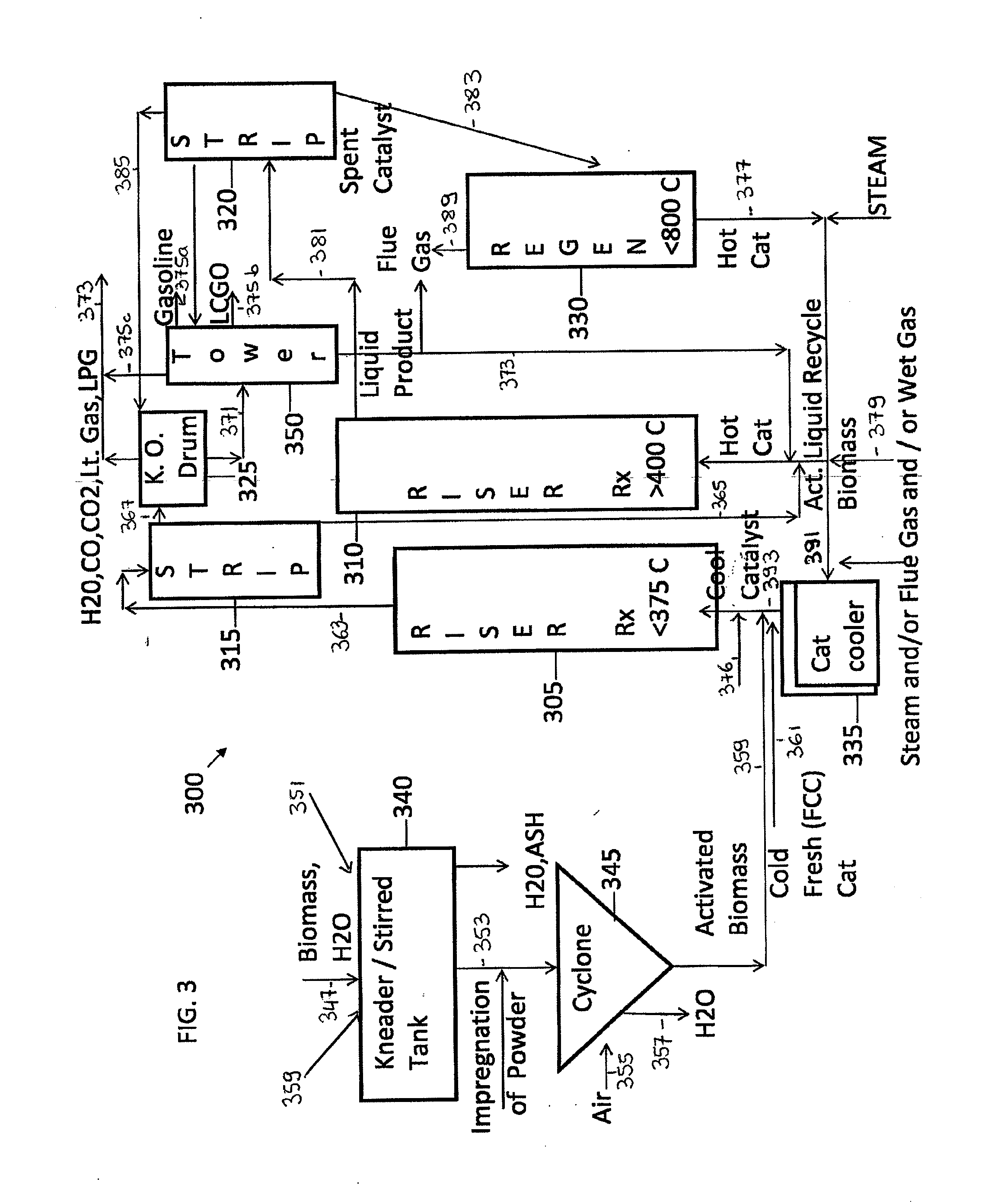

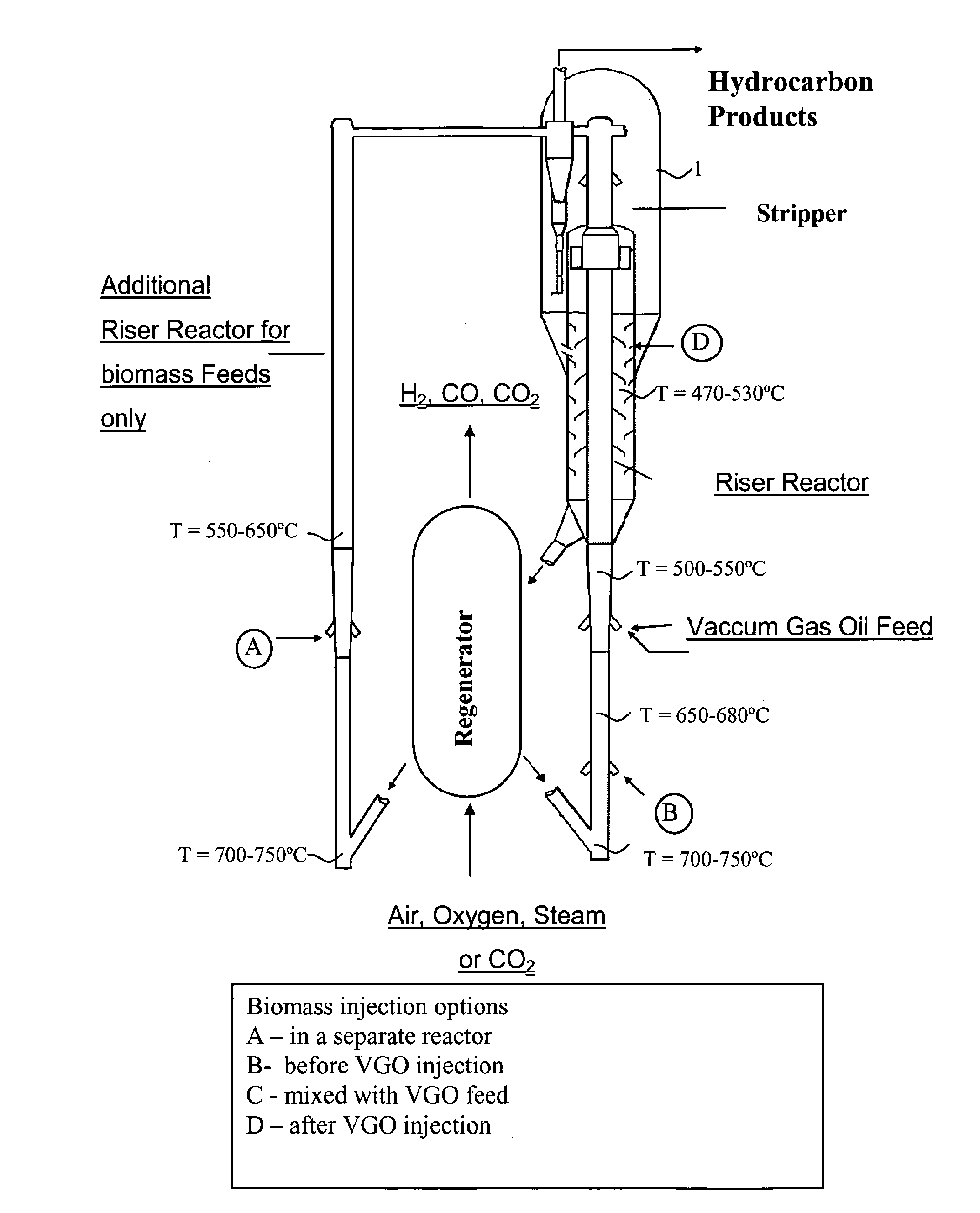

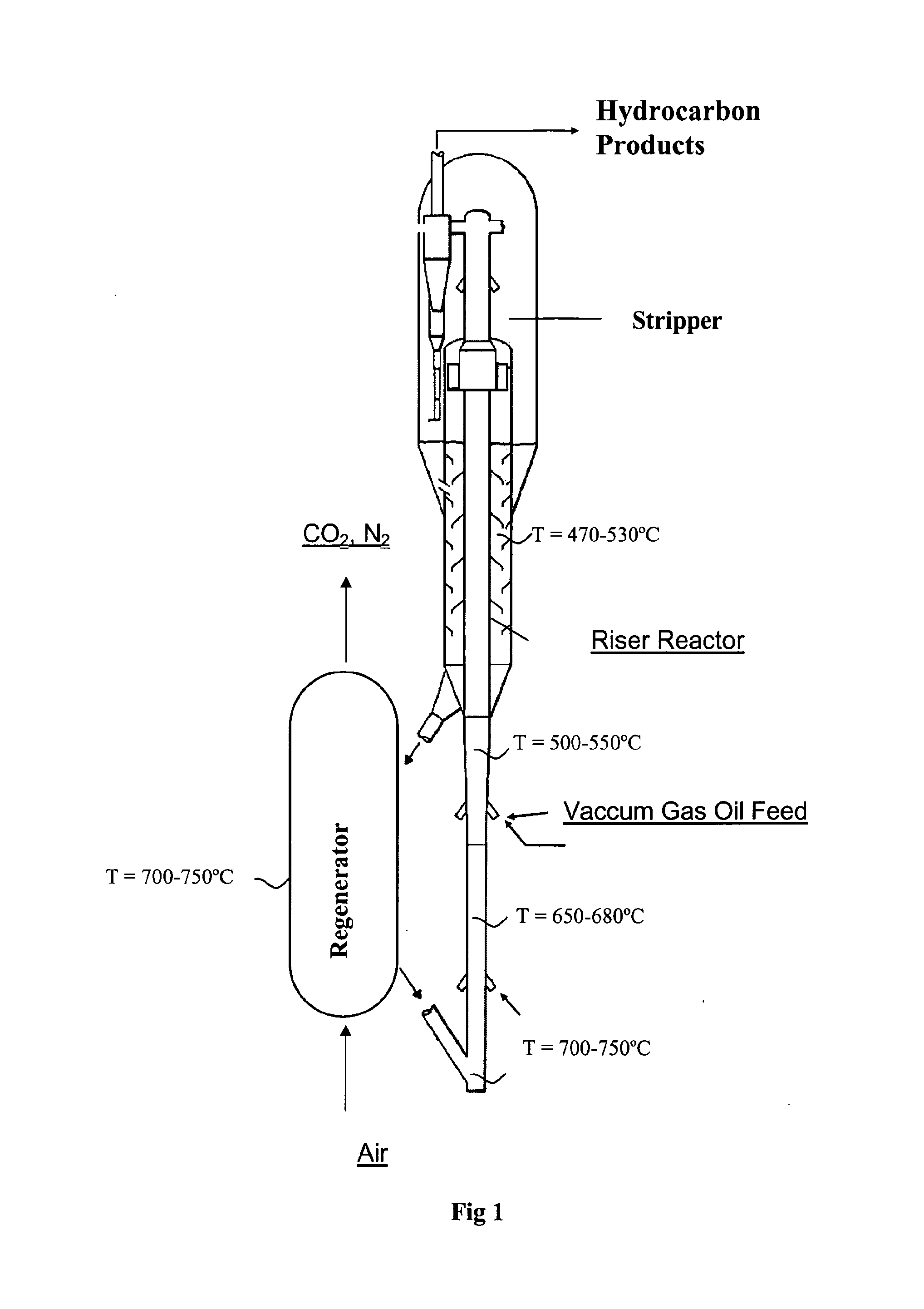

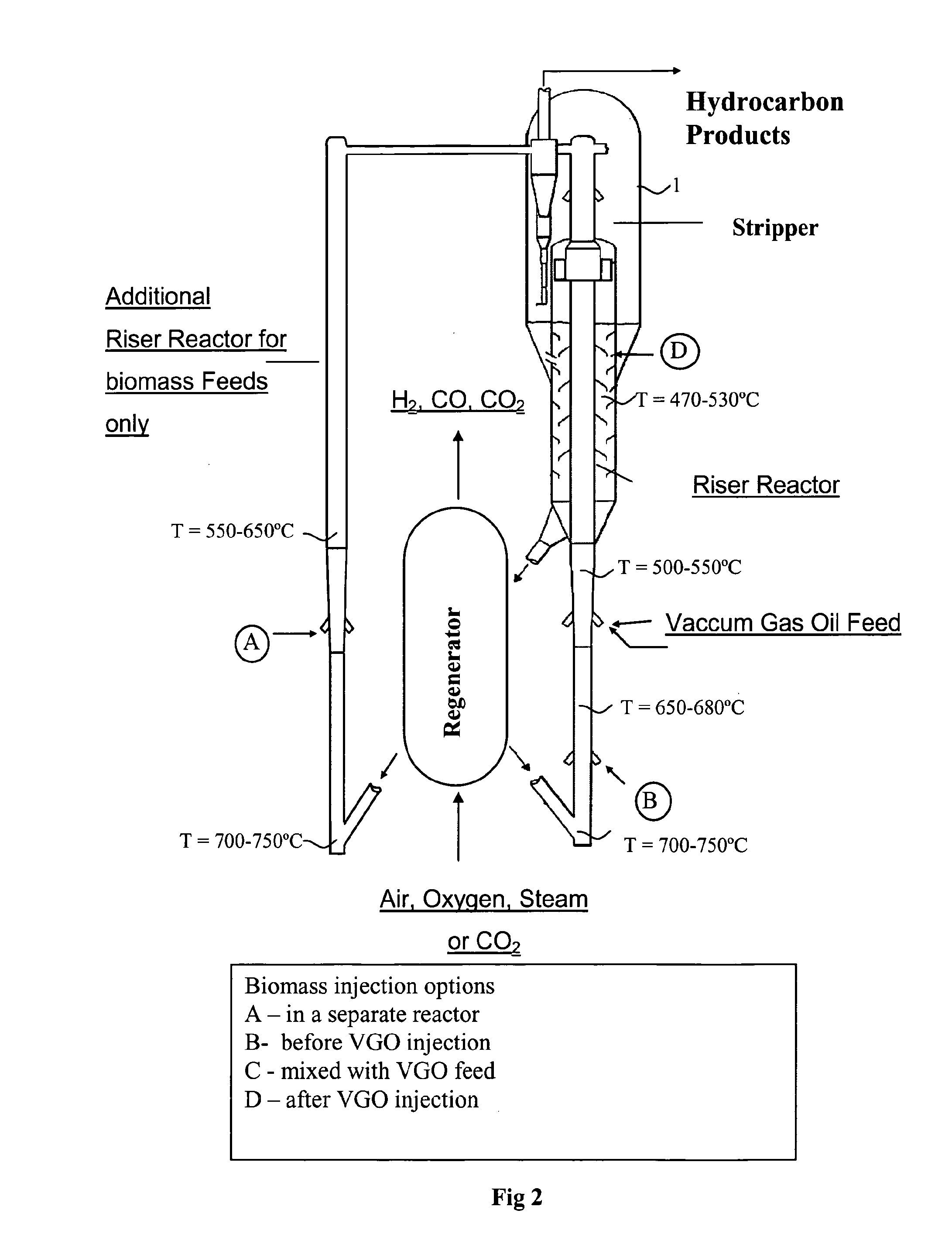

Methods for Co-Processing of Biomass and Petroleum Feed

ActiveUS20110154720A1Mitigate equipment cost and energy cost and degradationSpeed up the conversion processCatalytic crackingBiofuelsLiquid hydrocarbonsDelayed coker

A process for producing fuel from biomass is disclosed herein. The process includes torrefying biomass material at a temperature between 80° C. to 400° C. to form particulated biomass having a mean average particle size between 1 μm and 1000 μm. The particulated biomass is mixed with a liquid hydrocarbon to form a suspension, wherein the suspension includes from 1 weight percent to 40 weight percent particulated biomass. The suspension is fed into a unit selected from the group consisting of a pyrolysis reactor, a fluid catalytic cracking unit, a delayed coker, a fluid coker, a hydroprocessing unit, and a hydrocracking unit, and then at least a portion of the particulated biomass of the suspension is converted into fuel.

Owner:MARD INC

Fluid catalytic cracking of oxygenated compounds

ActiveUS20100222620A1Treatment with plural serial cracking stages onlyCatalytic crackingCompound aGlycerol

A process is disclosed for fluid catalytic cracking of oxygenated hydrocarbon compounds such as glycerol and bio-oil.In the process the oxygenated hydrocarbon compounds are contacted with a fluid cracking catalyst material for a period of less than 3 seconds.In a preferred process a crude-oil derived material, such as VGO, is also contacted with the catalyst.

Owner:MARD INC

Method for reliving FCC dead catalyst

ActiveCN101219396AIncreased microreactivityHigh selectivityMolecular sieve catalystsOrganic acidGasoline

The invention relates to a method to rehabilitate waste FCC (fluid catalytic cracking) catalyst, pertaining to recovery and resource regeneration field of waste catalyst. The invention reconstructs the frameword of catalyst through the synergistic effects of inorganic acid and organic acid, to construct developed micropores-mesoporous compound pore-channel structure system during the reconstruction process, and eliminates or passivates heavy metal of the waste catalyst, so as to dramatically increase the specific surface area of the rehabilitated catalyst; the eliminating rate of heavy metal can reach 30 percent, the micro reactor activity can be improved by more than 10 percent, and the invention has comparatively higher selectivity of liquefied gas and gasoline and lower yield ratio of coke.

Owner:QINGDAO HUICHENG PETROCHEM TECH

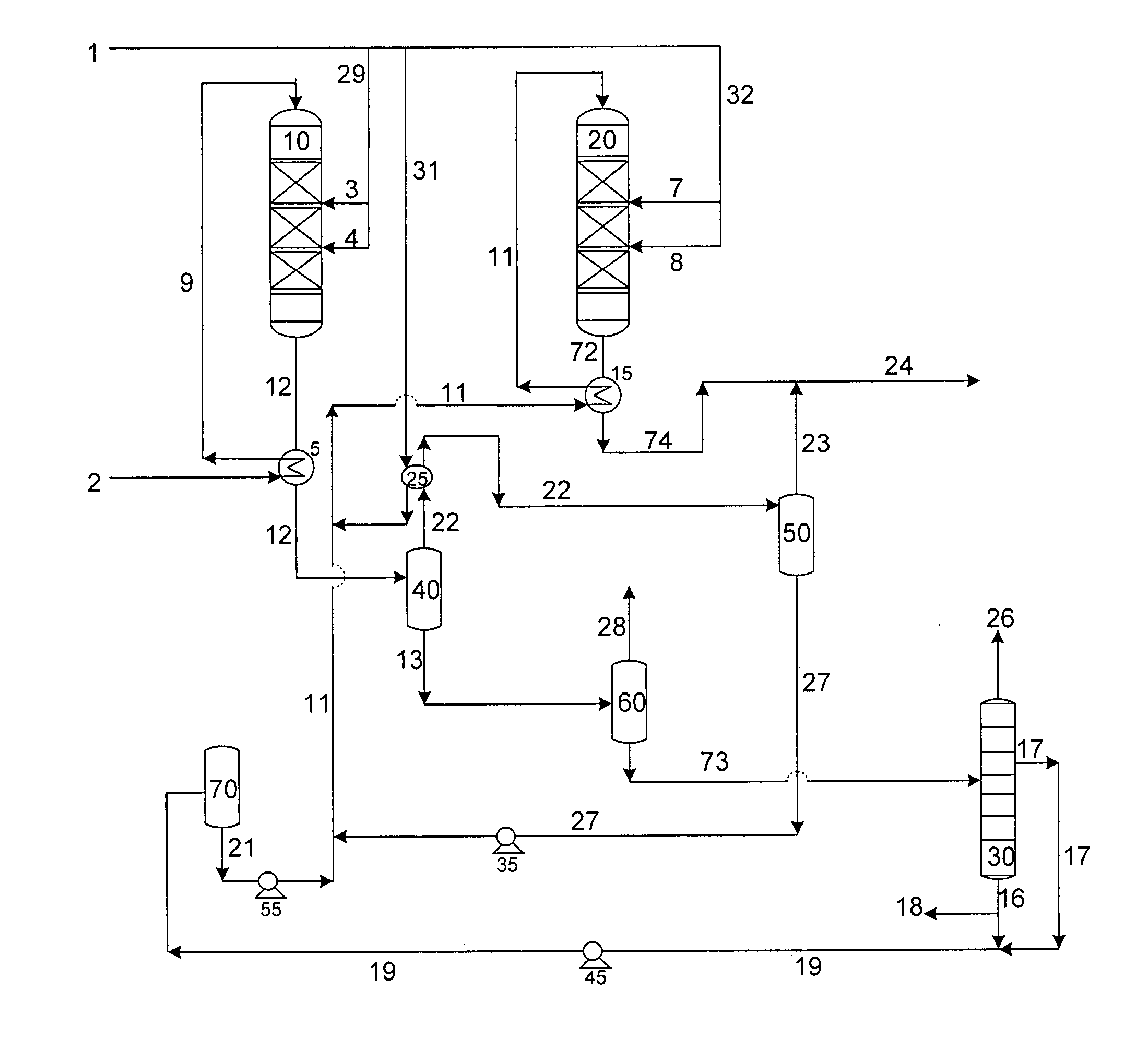

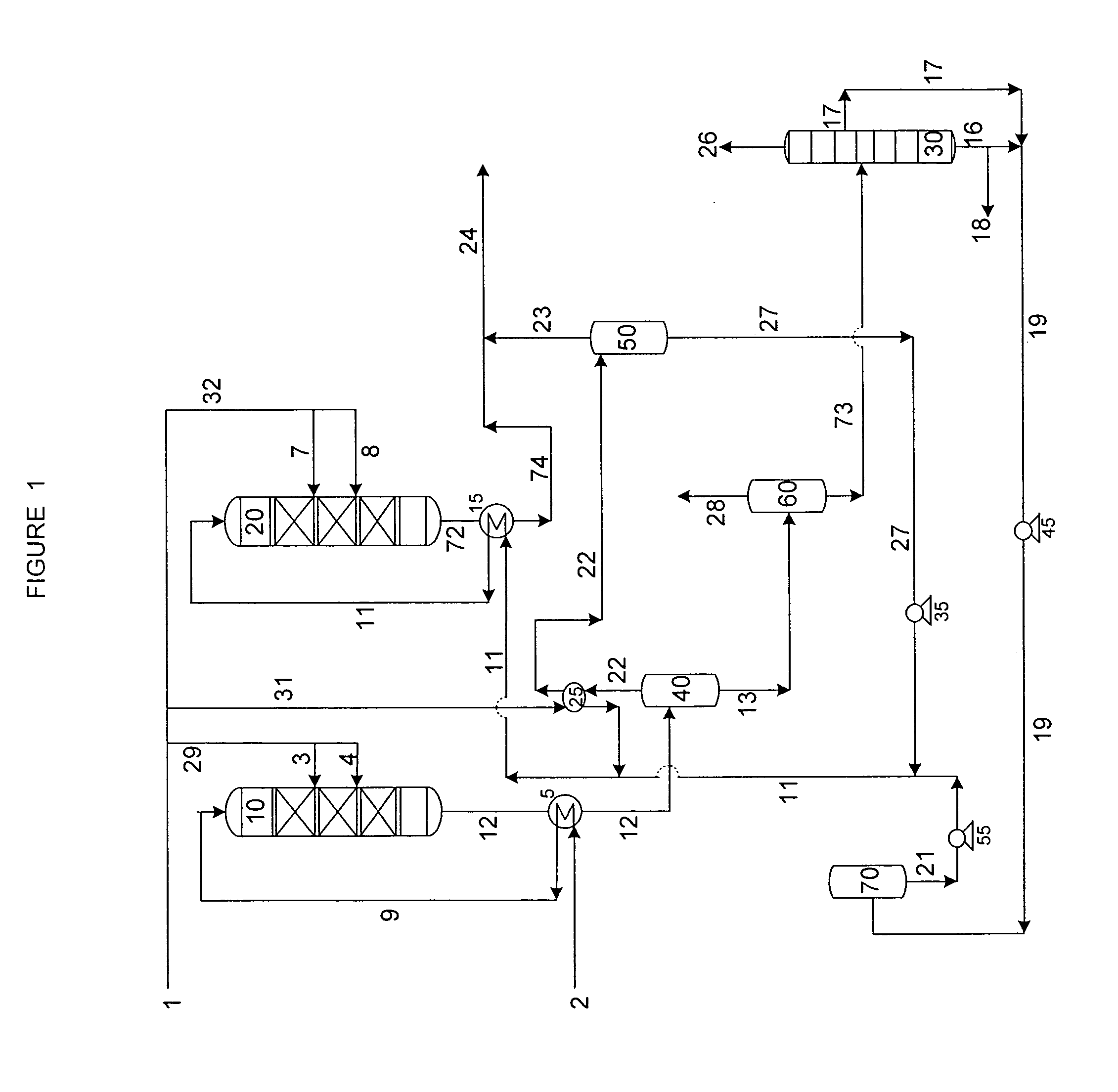

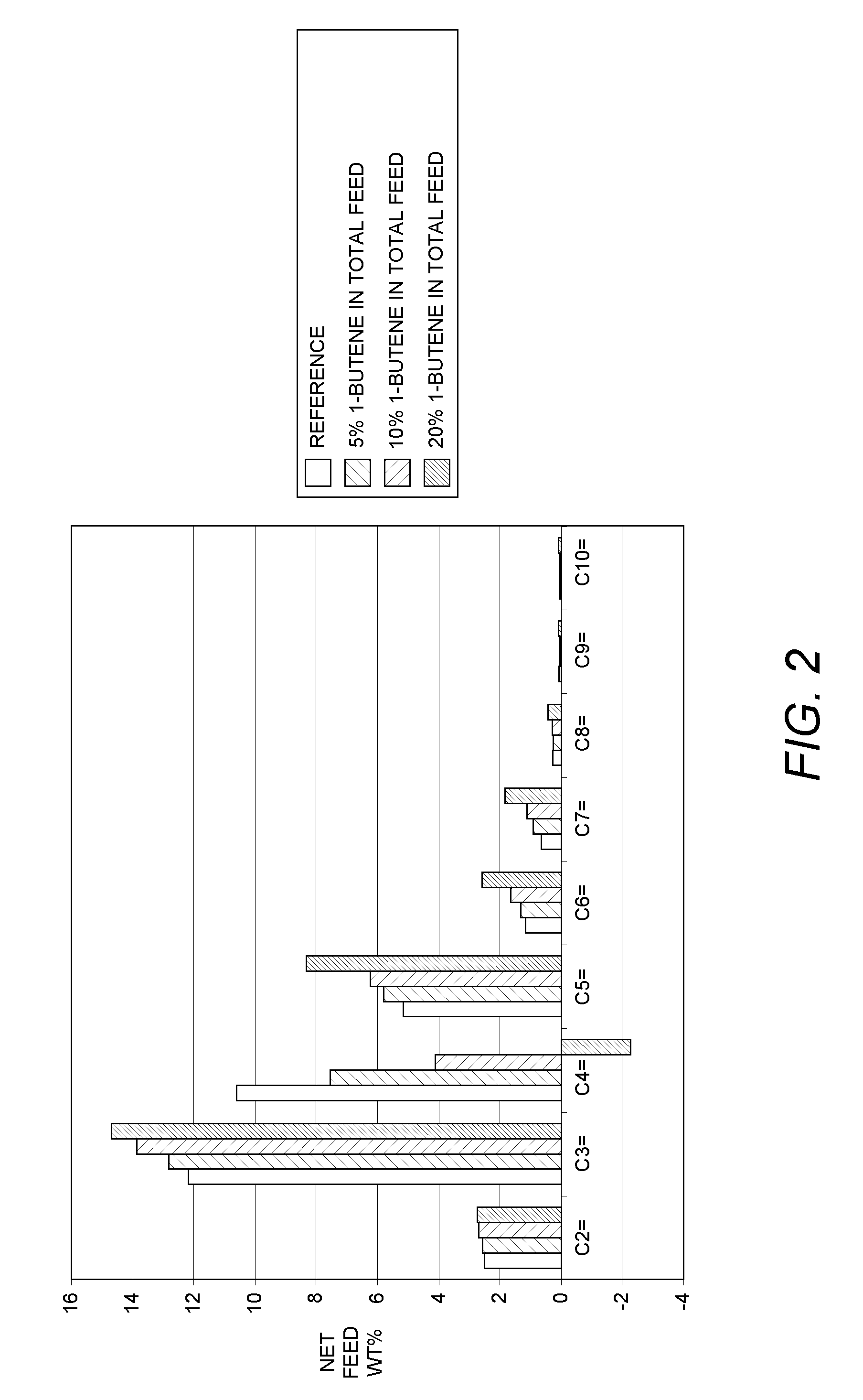

Two stage fluid catalytic cracking process for selectively producing C2 to C4 olefins

InactiveUS7323099B2Treatment with plural serial cracking stages onlyCatalytic naphtha reformingPtru catalystNaphtha

A process for selectively producing C2 to C4 olefins from feedstock such as a gas oil or resid. The feedstock is reacted in a first stage comprising a fluid catalytic cracking unit wherein it is converted in the presence of a mixture of conventional large pore zeolitic catalyst and a medium pore zeolitic catalyst to reaction products, including a naphtha boiling range stream. The naphtha boiling range stream is introduced into a second stage where it is contacted with a catalyst containing from about 10 to about 50 wt. % of a crystalline zeolite having an average pore diameter less than about 0.7 nanometers at reaction conditions which include temperatures ranging from about 500 to about 650° C. and a hydrocarbon partial pressure from about 10 to about 40 psia (about 70 to about 280 kPa).

Owner:EXXONMOBIL CHEM PAT INC

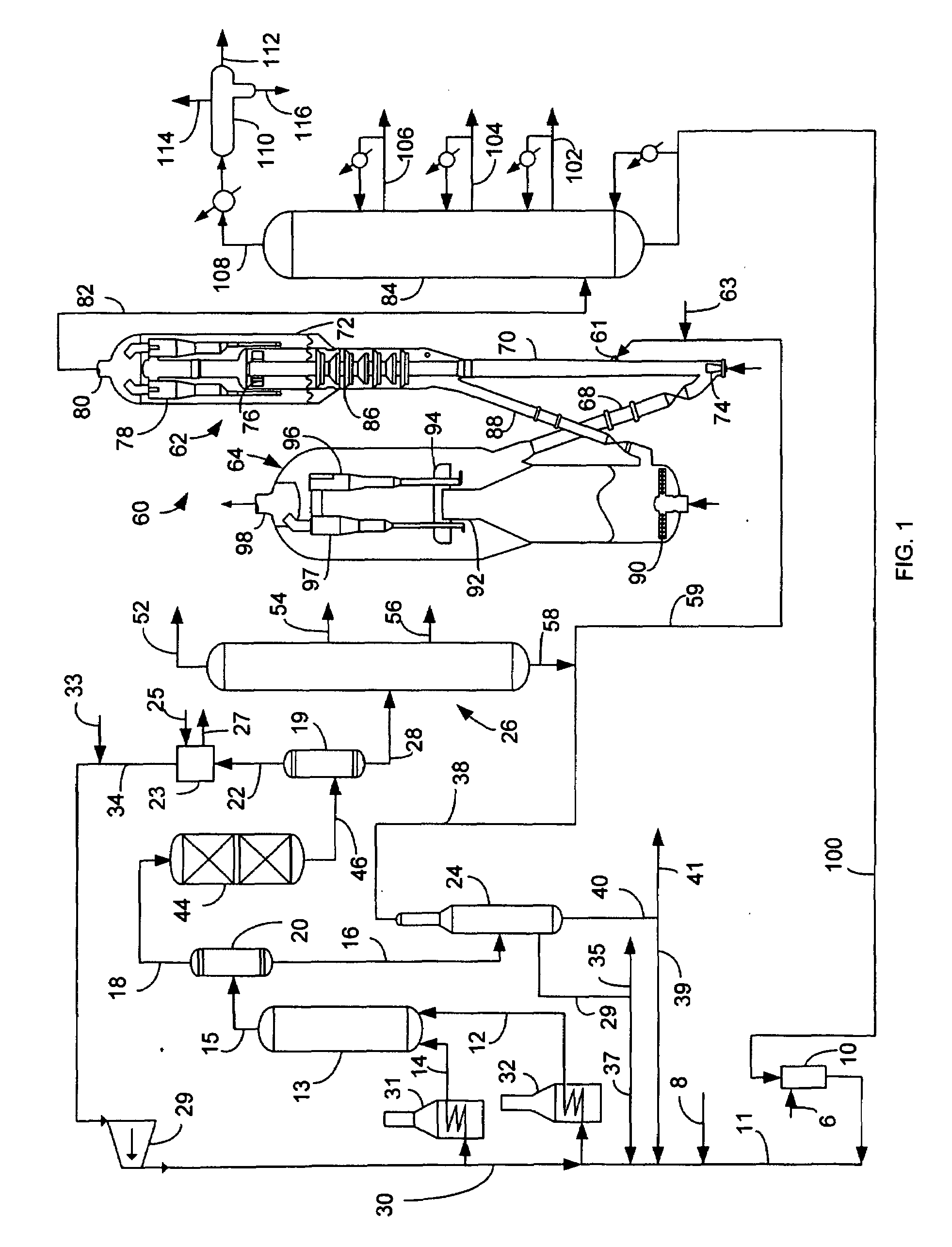

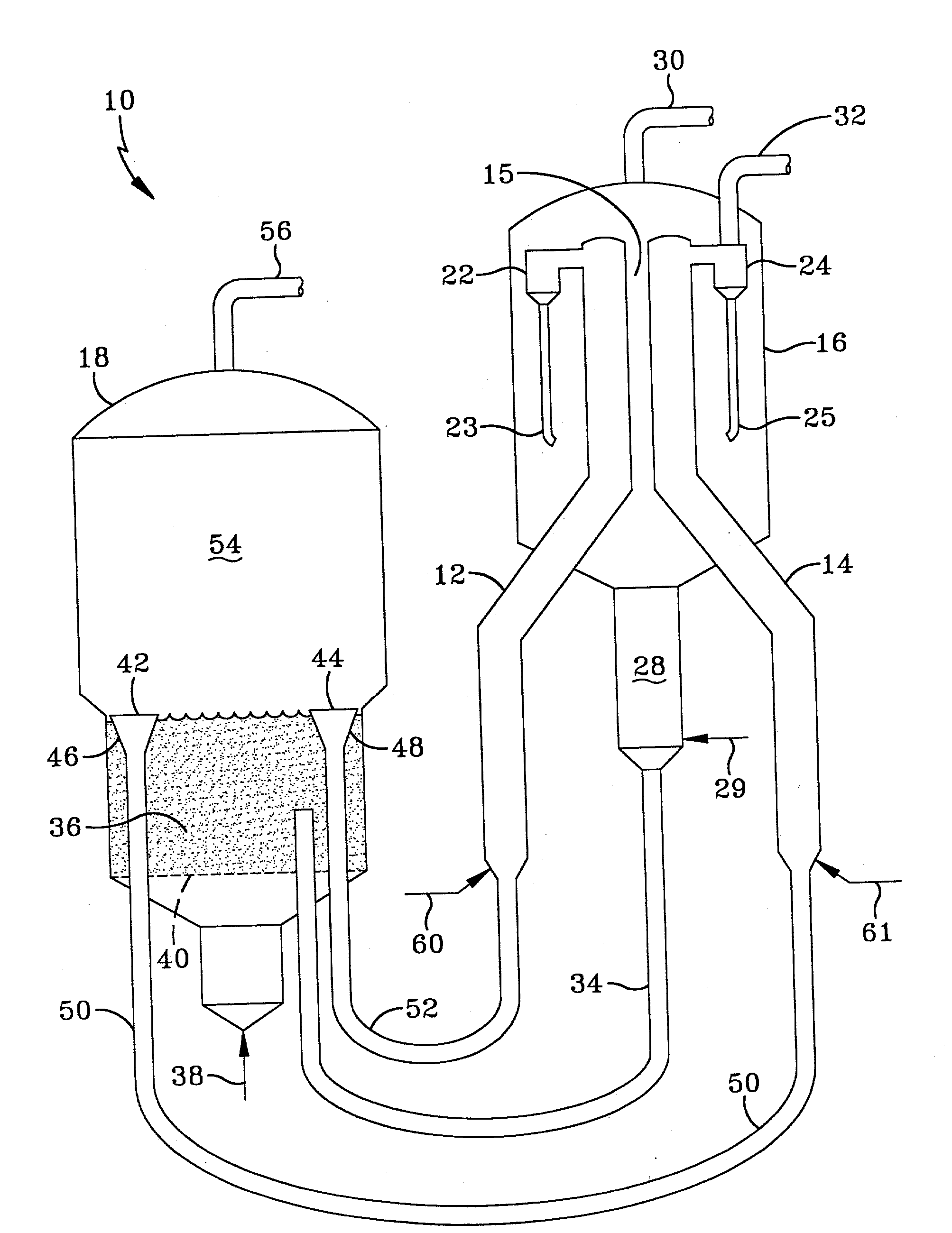

Process and Apparatus for Integrated Heavy Oil Upgrading

InactiveUS20090127161A1Improve performanceMaximize and optimize gasoline yieldCatalytic crackingHydrocarbon oil crackingParticulatesGasoline

A process and apparatus is disclosed for converting heavy hydrocarbon feed into lighter hydrocarbon products. The heavy hydrocarbon feed is slurried with a particulate solid material to form a heavy hydrocarbon slurry and hydrocracked to produce vacuum gas oil (VGO). A light portion of the VGO may be hydrotreated and subjected to fluid catalytic cracking to produce fuels such as gasoline. A heavy portion of the VGO may be recycled to the slurry hydrocracking reactor. FCC slurry oil may be recycled to the slurry for hydrocracking.

Owner:UOP LLC

Heavy oil and biomass hydrogenation coliquefaction treatment process

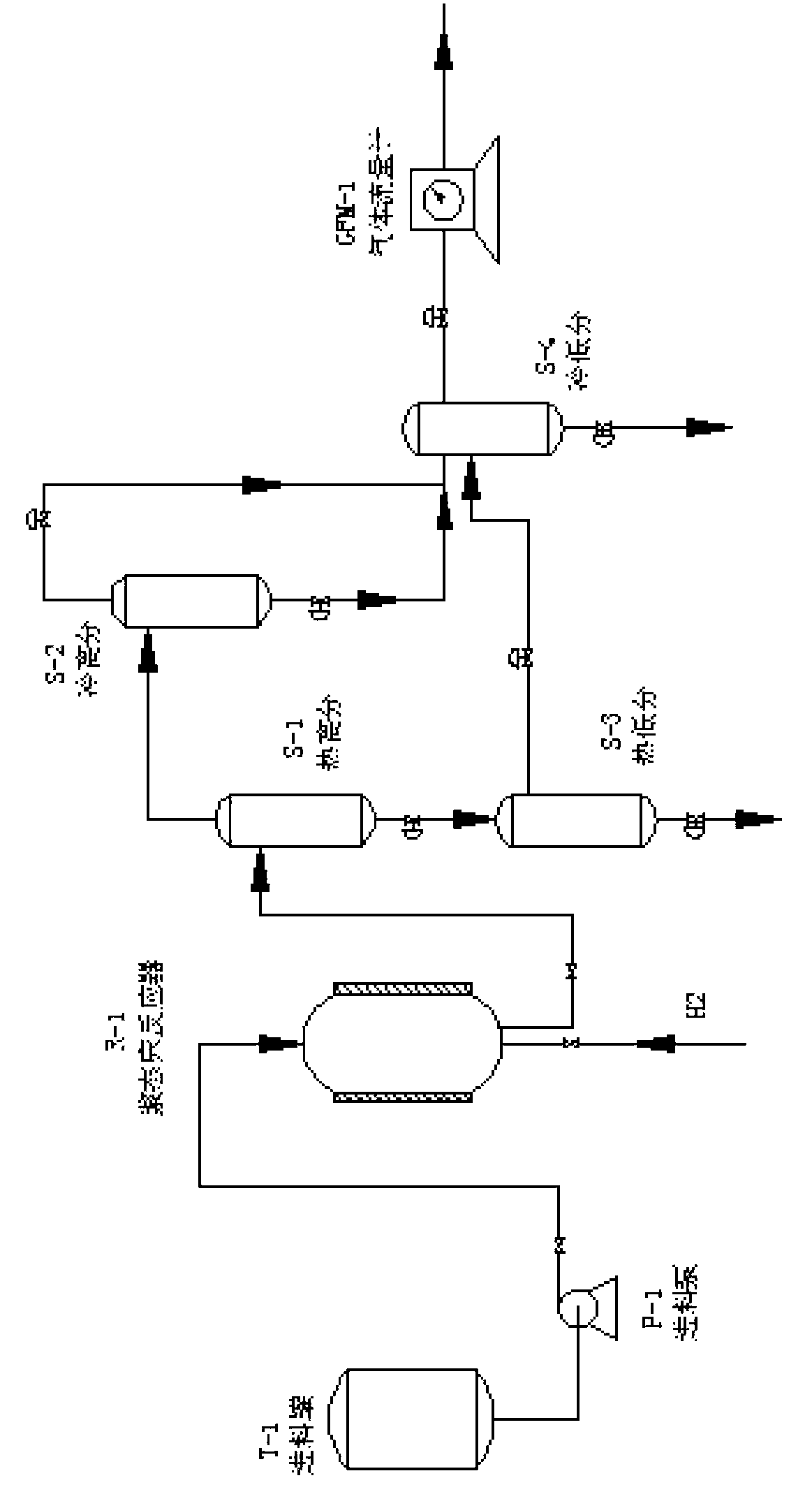

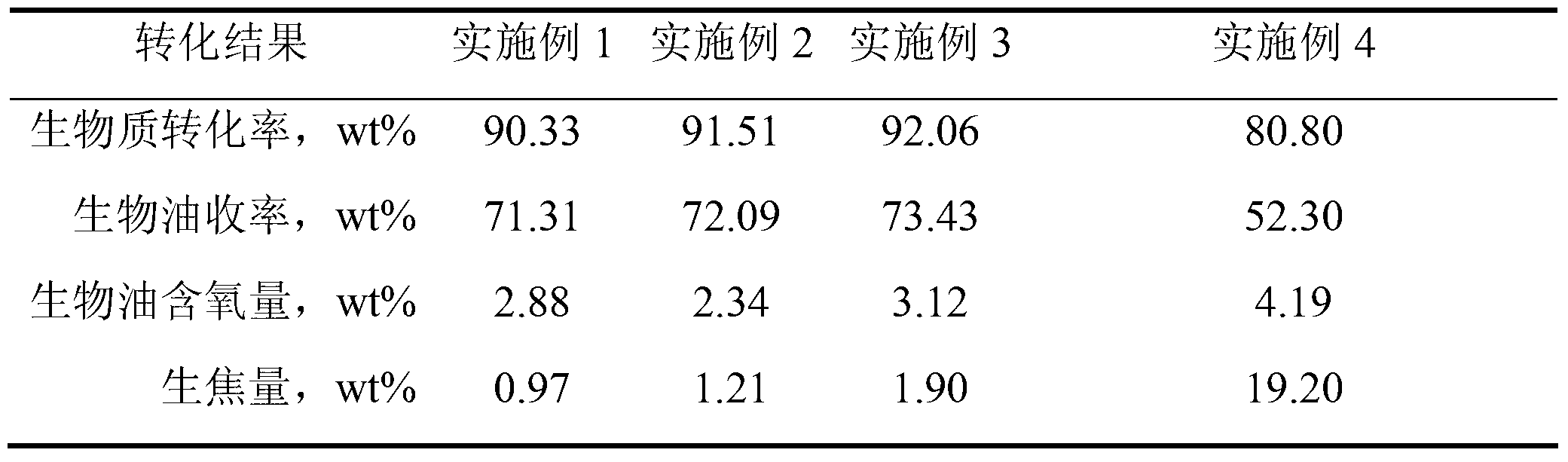

ActiveCN103242871AGood deoxidation effectUniform reaction temperatureBiofuelsHydrocarbon oil crackingDistillationHydrogen pressure

The invention relates to a heavy oil and biomass hydrogenation coliquefaction treatment process in which one or two of heavy oil and biomasses are used as raw materials in vacuum gas oil with the distillation range of 360-540 DEG C and FCC (Fluid Catalytic Cracking) oil slurry. In the process, an oil-soluble transition metal organic compound with hydrogenation activity is used as a catalyst, dimethyl sulfide is used as a vulcanizing agent, a full-back-mixing type empty barrel reactor is used as a slurry column hydrogenation reactor, the reaction temperature is uniform, and the structure is simple. By using the process, the conversion rate of the biomasses can be up to over 90wt% at lower hydrogen pressure of 4-8MPa and the temperature of 370-430 DEGC, and the yield of oil phases is up to over 70wt%. A dispersive hydrogenation catalyst adopted in the process can be used for greatly reducing the quantity of green cokes and taking a better deoxidization effect on the biomasses.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Short contact time catalytic partial oxidation process for recovering sulfur from an H2S containing gas stream

InactiveUS6946111B2Avoid contactExcess buildupHydrogenDispersed particle separationPartial oxidationSulfur

A process for removing sulfur from a H2S-containing gas stream is disclosed. A preferred embodiment of the process comprises incorporating a short contact time catalytic partial oxidation reactor, a cooling zone, and a condenser into a conventional refinery or gas plant process, such as a natural gas desulfurizer, a hydrotreater, coker or fluid catalytic cracker, in which sulfur removal is needed in order to produce a more desirable product. An H2S-containing gas stream is fed into a short contact time reactor where the H2S is partially oxidized over a suitable catalyst in the presence of O2 to elemental sulfur and water.

Owner:PHILLIPS 66 CO

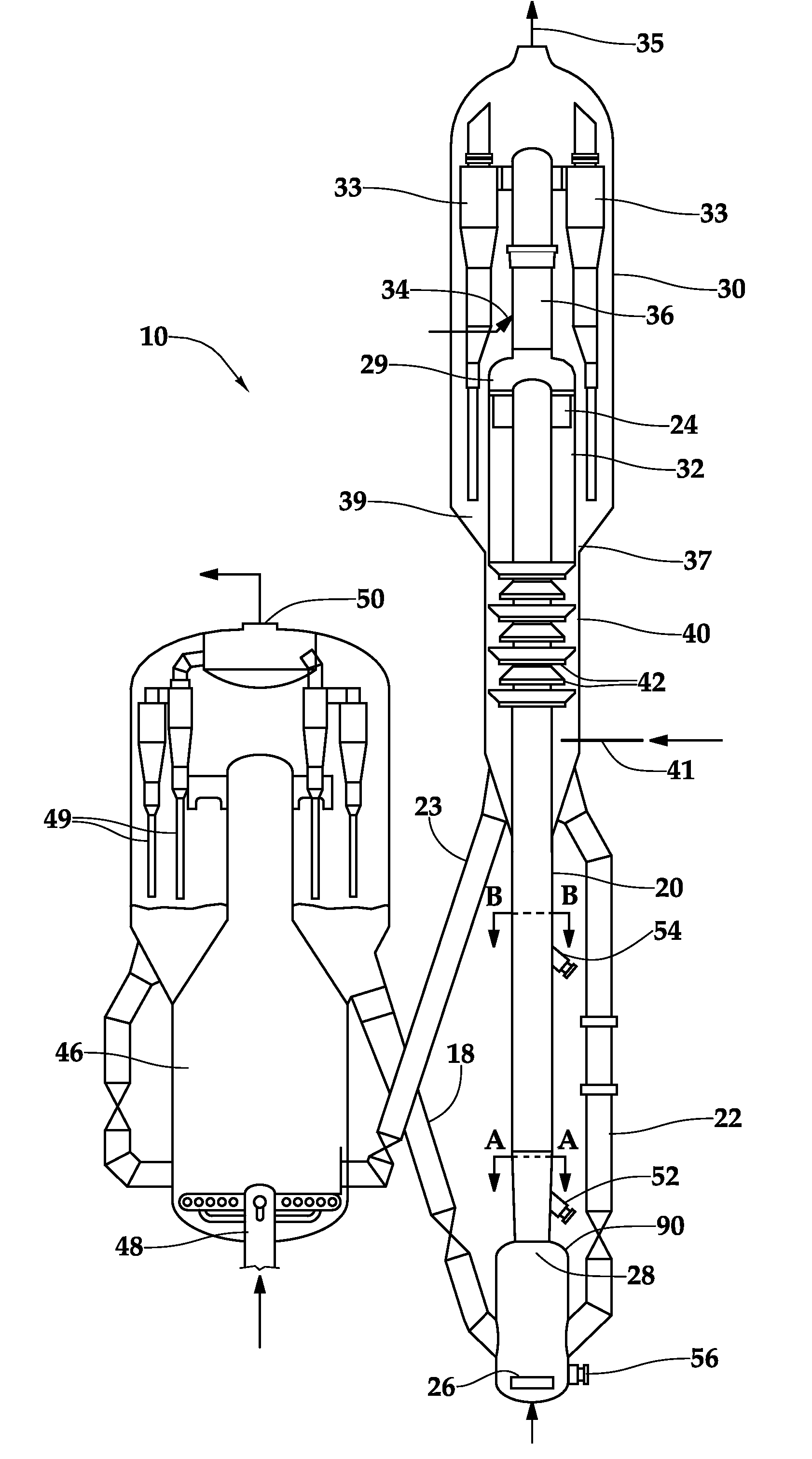

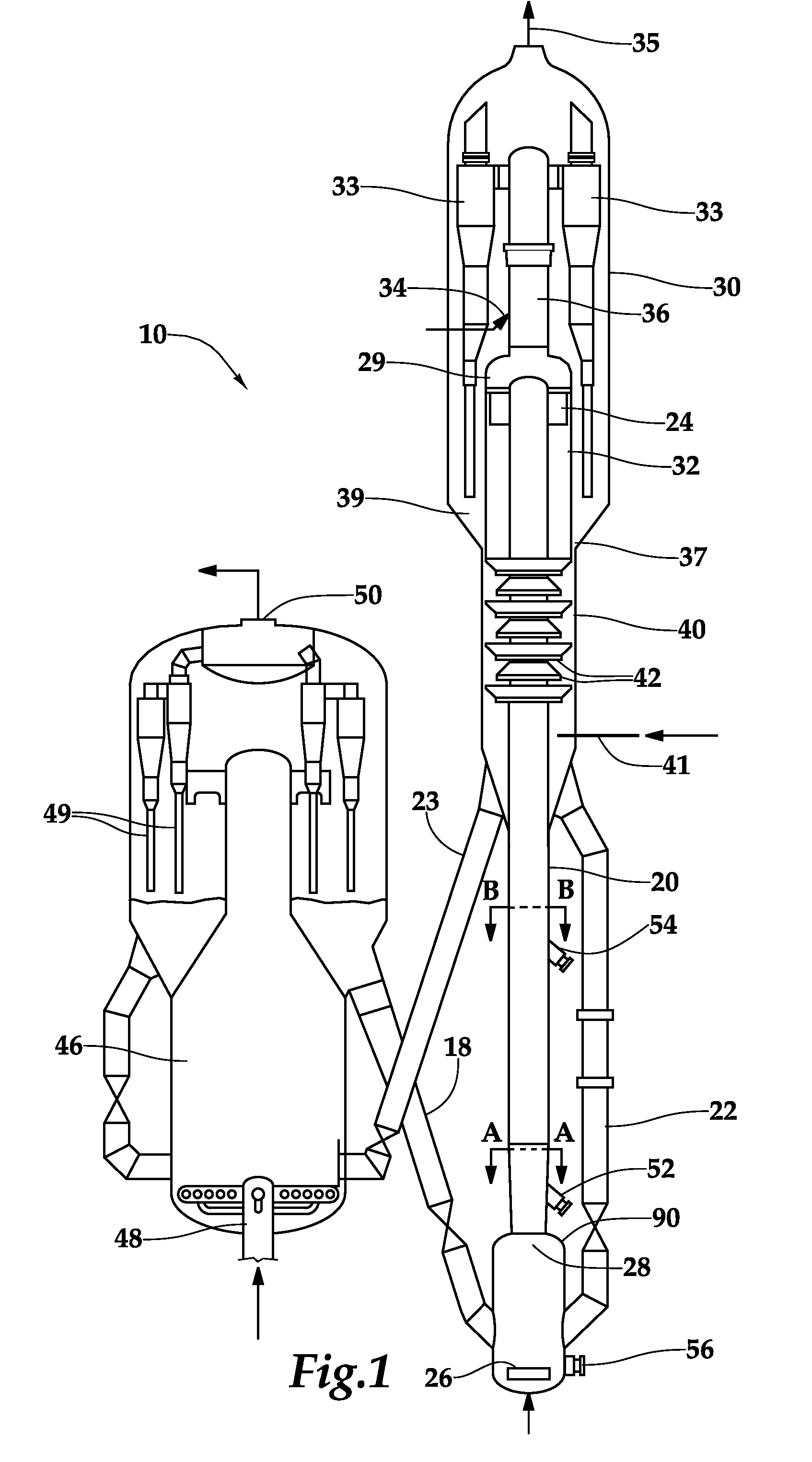

Fluid catalytic cracking system

ActiveUS20100158767A1Increase light olefin yieldReduce dwell timeTreatment with plural serial cracking stages onlyCatalytic crackingBoiling pointReaction zone

One exemplary embodiment can be a fluid catalytic cracking system. The system can include a reaction zone operating at conditions to facilitate olefin production and including at least one riser. The at least one riser can receive a first feed having a boiling point of about 180-about 800° C., and a second feed having more than about 70%, by weight, of one or more C4+ olefins.

Owner:UOP LLC

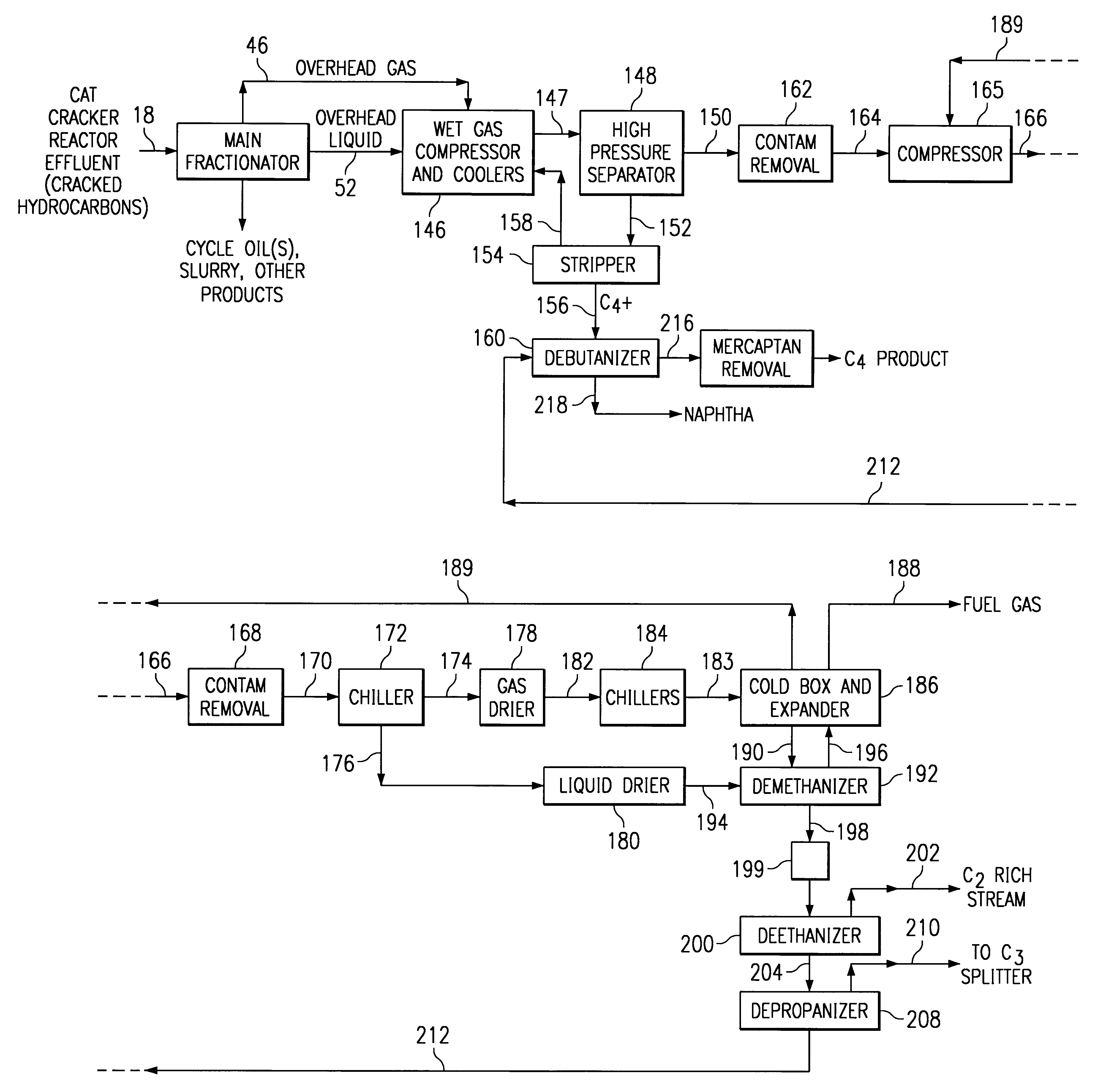

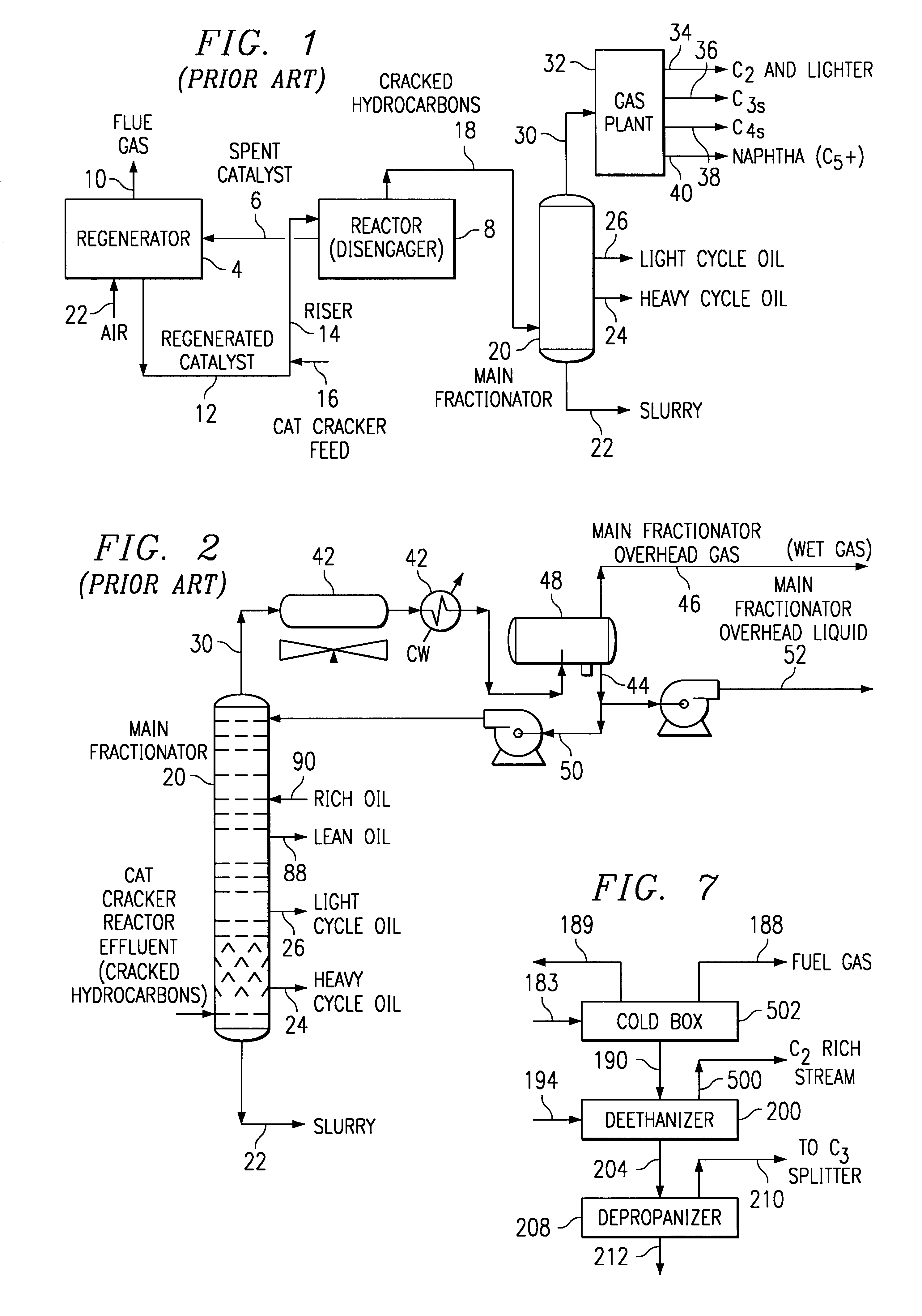

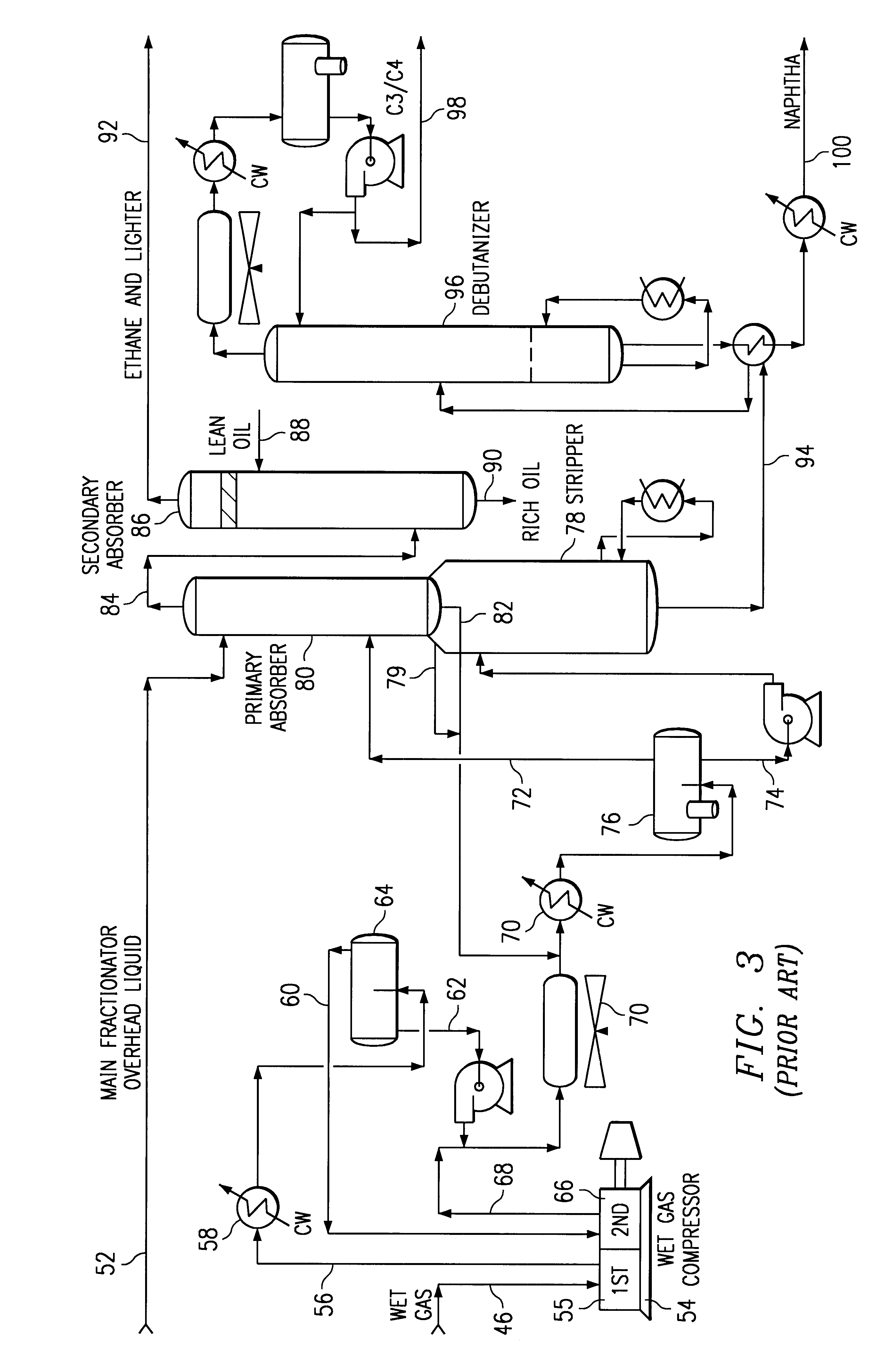

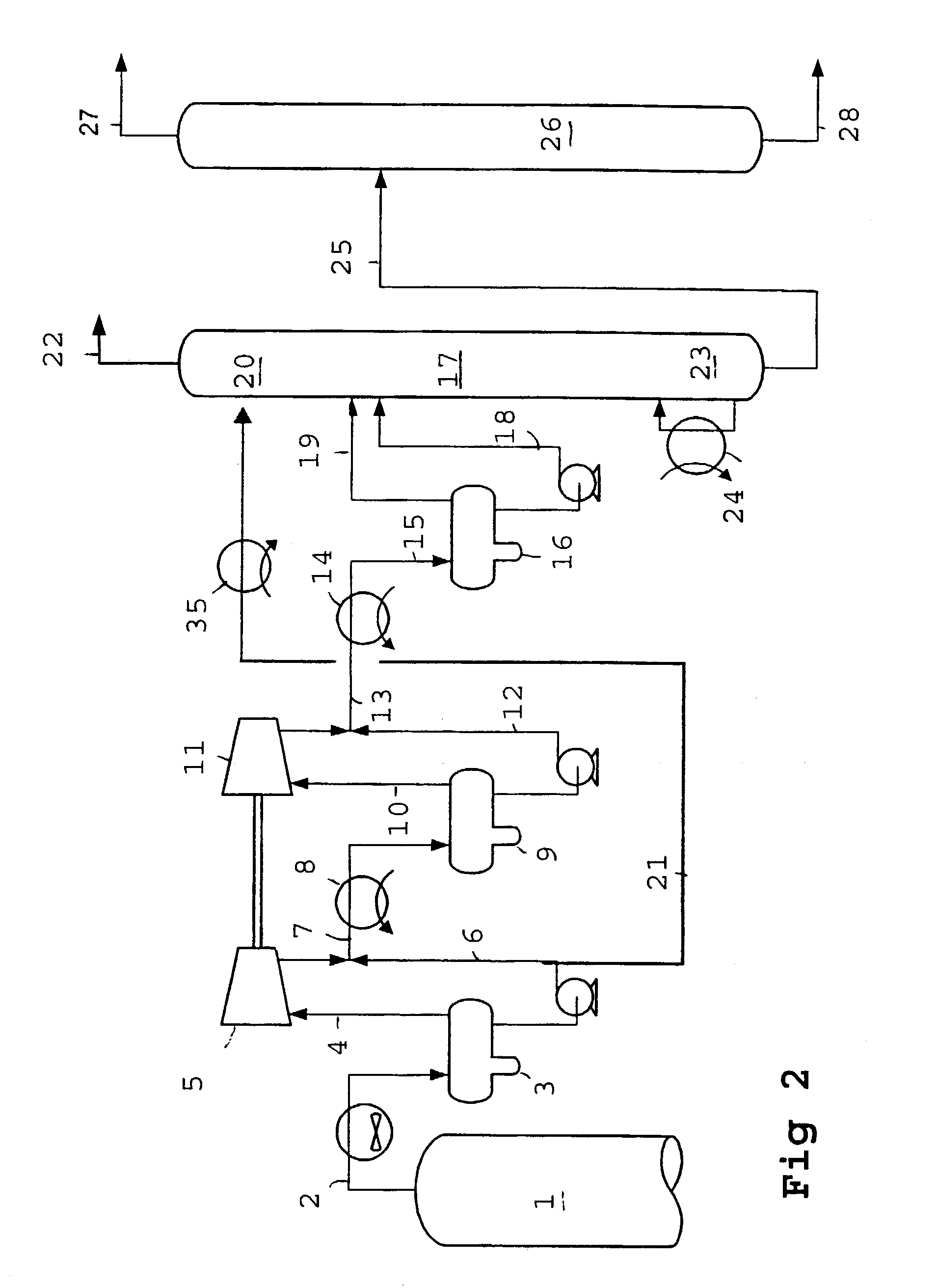

Cat cracker gas plant process for increased olefins recovery

The invention relates to a new process for more efficient separation and recovery of light olefins such as ethylene and propylene from a fluid catalytic cracking unit. The new process invention for recovering olefins from a mixture of cracked hydrocarbons from a fluid catalytic cracker comprises the steps of: (a) providing a mixture of cracked hydrocarbons including methane, ethylene, ethane, propylene, propane, butylene, butane and heavier hydrocarbons such as naphtha produced in a fluid catalytic cracker; (b) separating said mixture into (i) a first stream comprising substantially all of said ethane, ethylene, and methane and a major portion of said propane and propylene and (ii) a second stream comprising a portion of said butylene and butane, and a major portion of said heavier hydrocarbons; and (c) processing said first stream to recover the ethylene and propylene therefrom, and the details of such process described herein.

Owner:STONE & WEBSTER PROCESS TECH

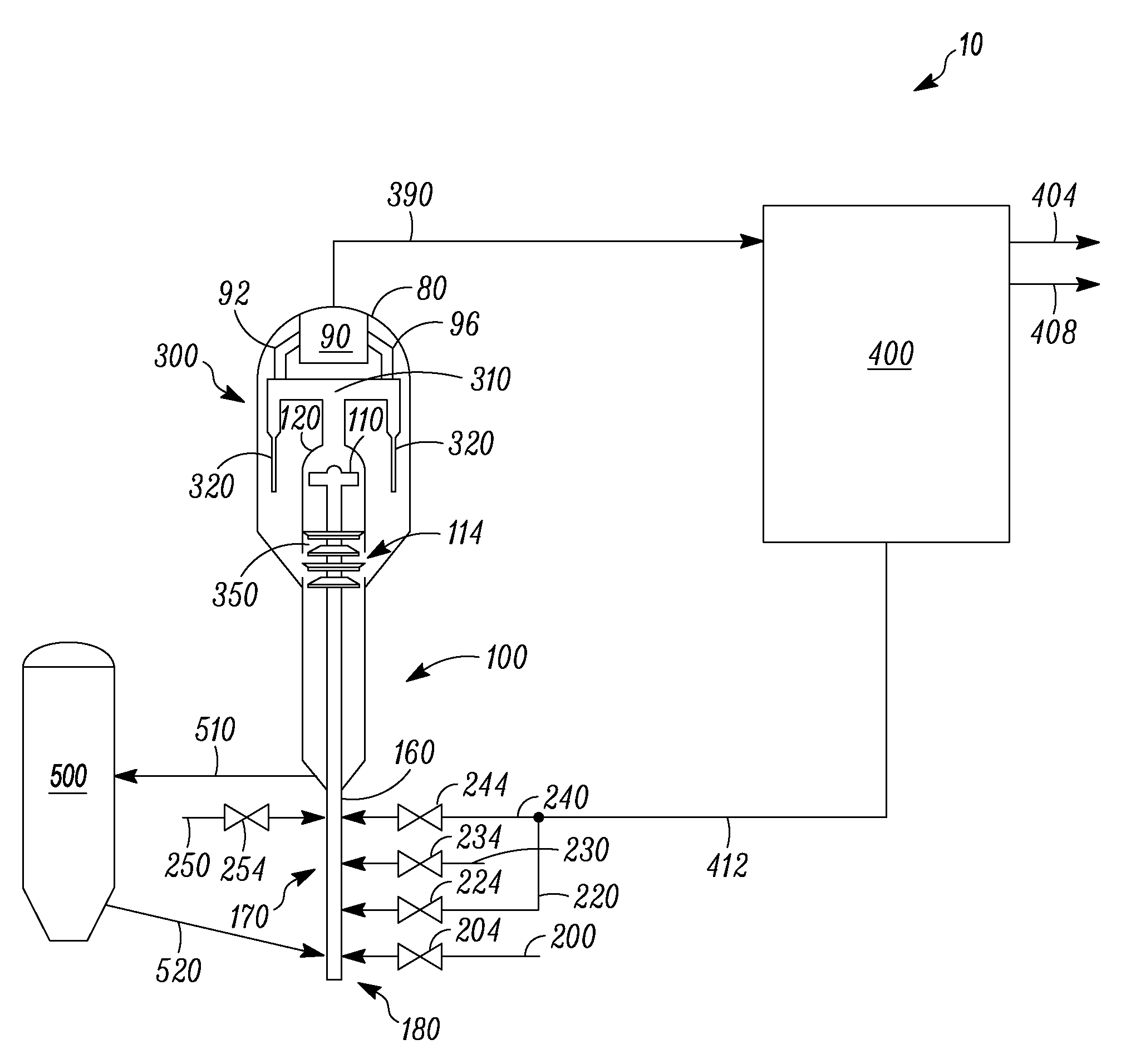

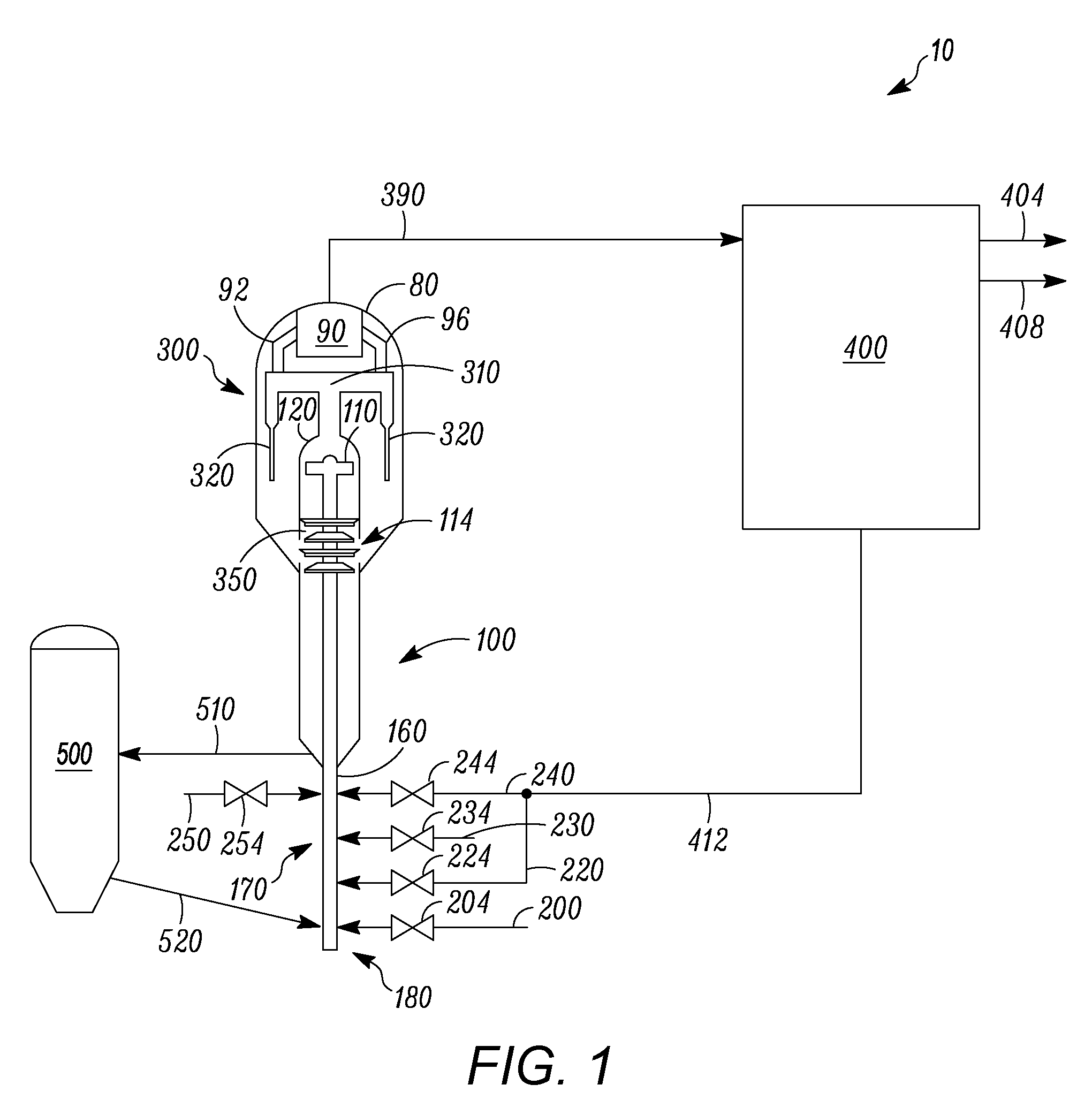

Catalyst withdrawal apparatus and method for regulating catalyst inventory in a fluid catalyst cracking unit

A catalyst withdrawal apparatus and method for regulating catalyst inventory in a fluid catalytic cracking catalyst (FCC) unit is provided. In one embodiment, a catalyst withdrawal apparatus for removing catalyst from a FCC unit includes a pressure vessel having a metering device coupled to a fill port. A heat dissipater is located adjacent the metering device and is adapted to cool catalyst entering the pressure vessel. A sensor is coupled to the pressure vessel arranged to provide a metric indicative of catalyst entering the pressure vessel through the metering device. In another embodiment, a method for regulating catalyst inventory in a FCC unit includes the steps of determining a change of catalyst present in a FCC unit, withdrawing catalyst from the FCC unit into an isolatable storage vessel coupled to the FCC unit, measuring the amount of catalyst disposed in the storage vessel, and removing the measured catalyst from the storage vessel.

Owner:JOHNSON MATTHEY PROCESS TECH

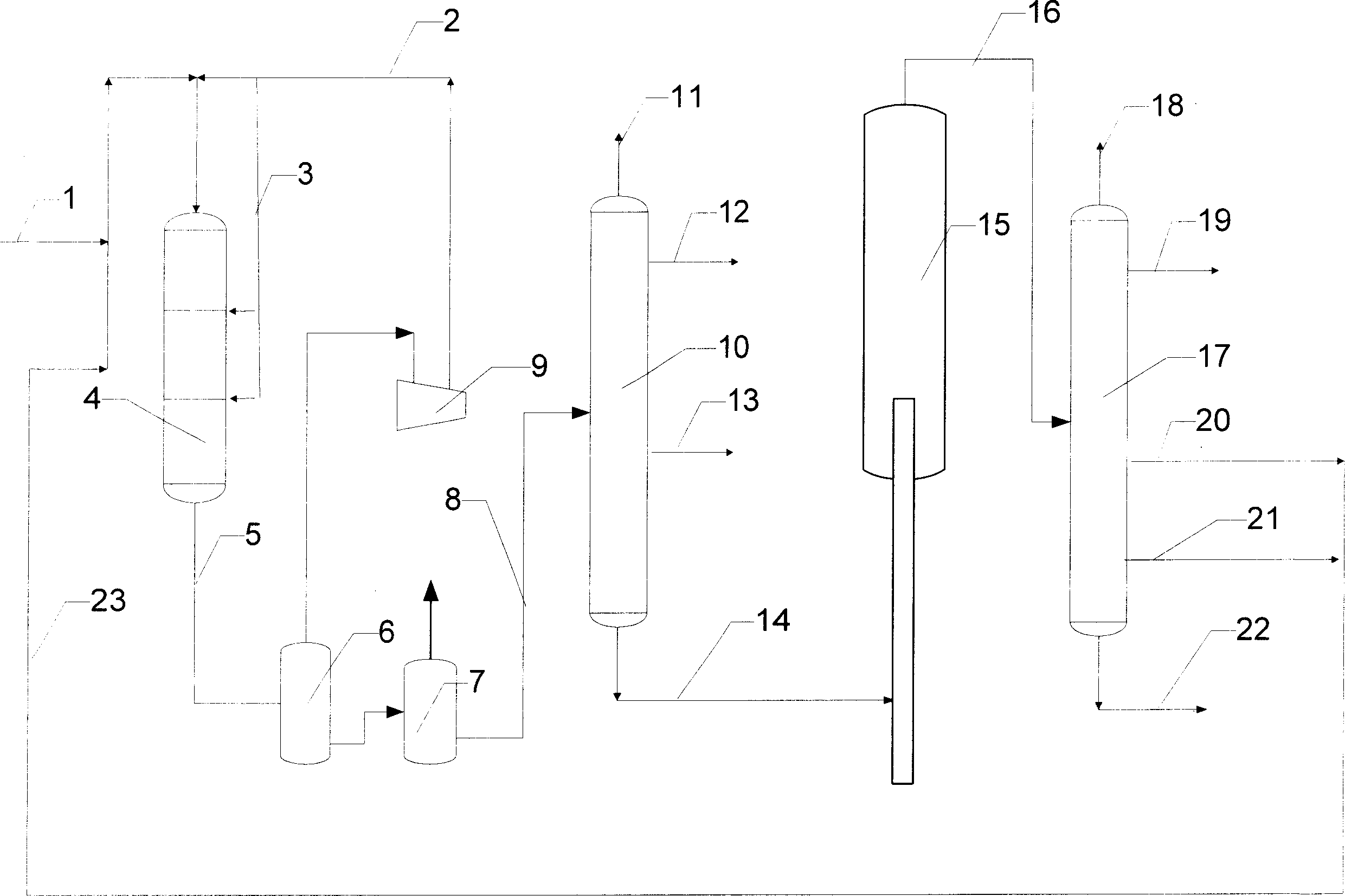

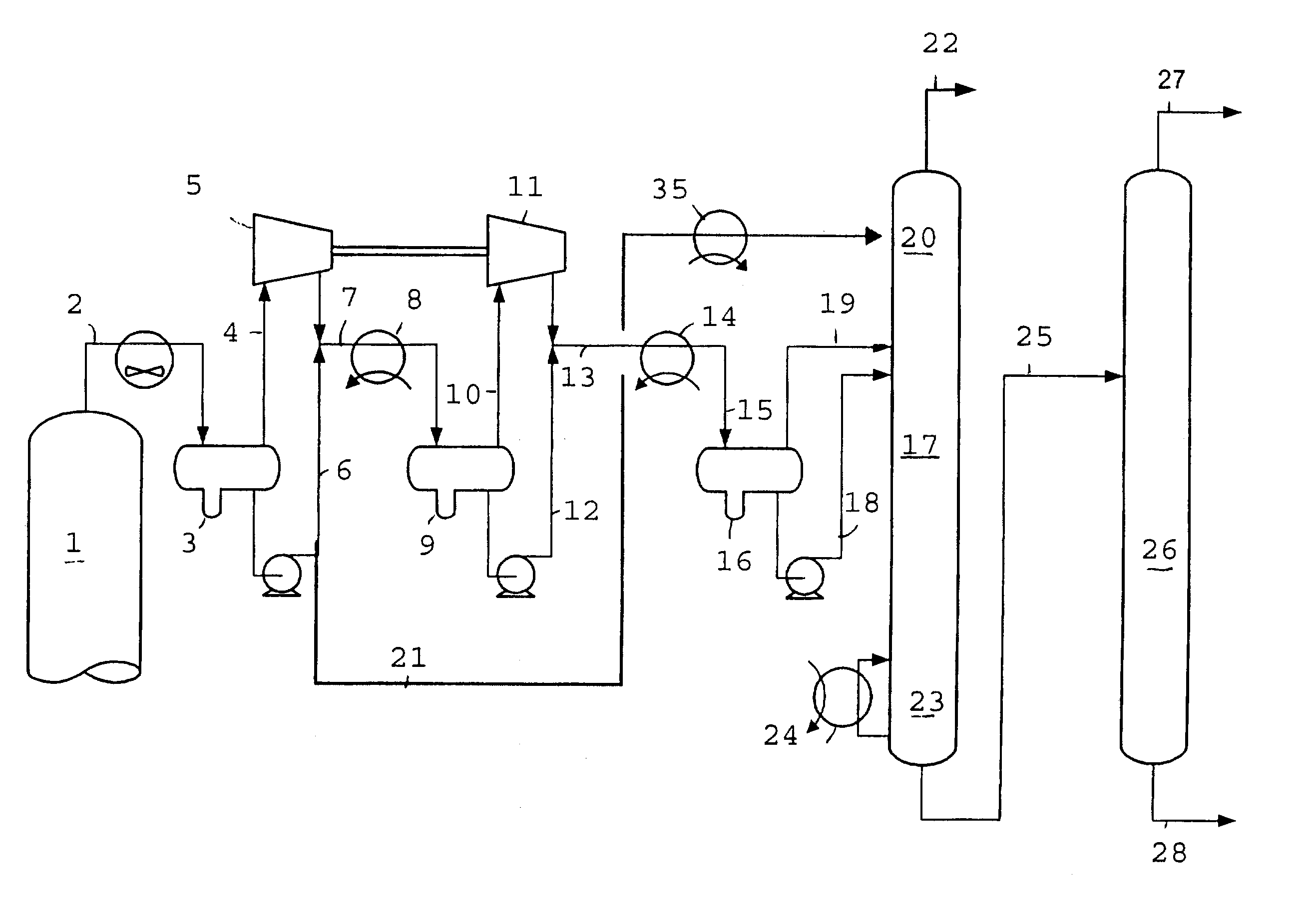

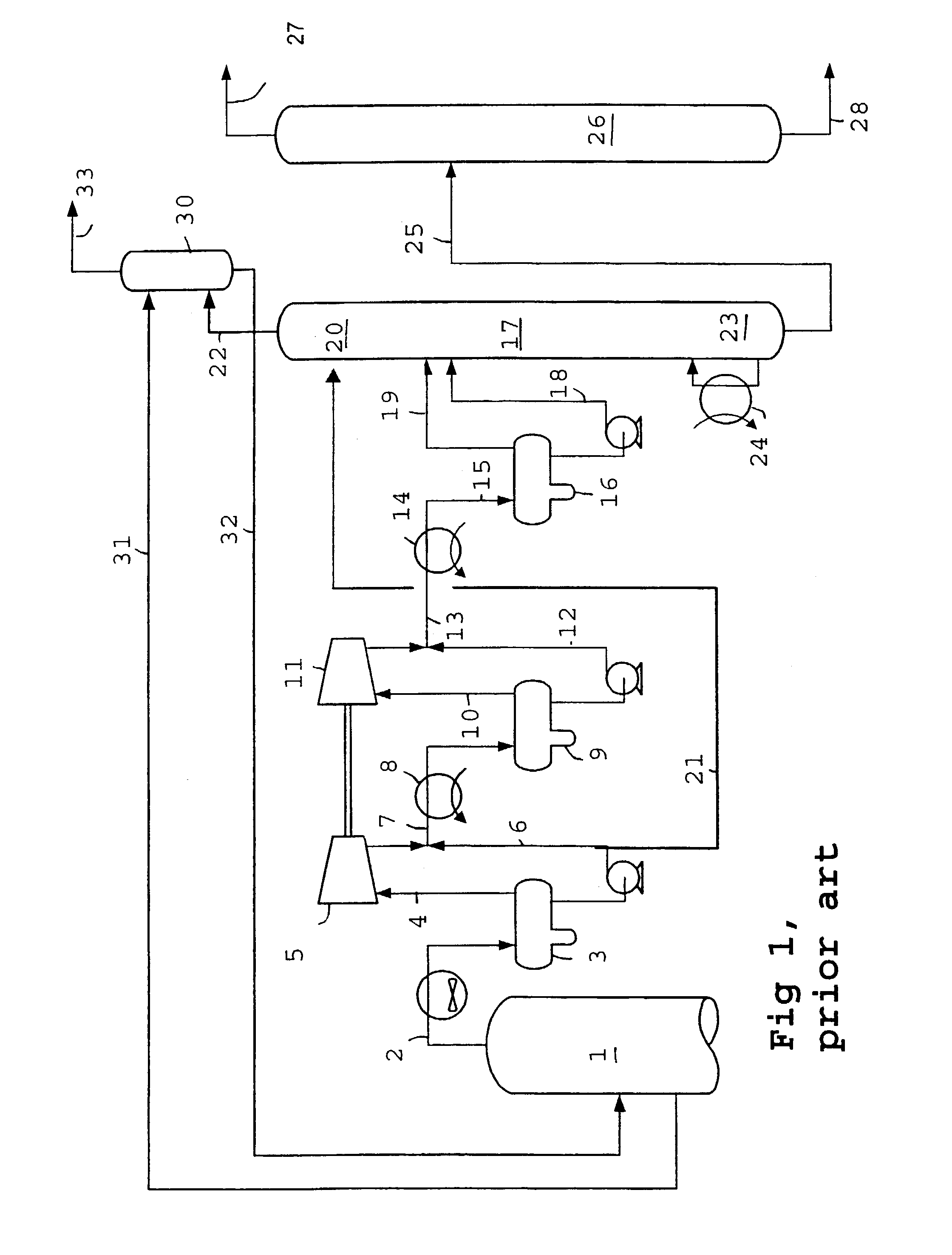

Two-way combined process of wax-oil hydrogenation treatment and catalytic cracking

A two-way combined process of wax oil hydro-process and catalytic crack is carried out by entering wax oil, catalytic cracking re-circulating oil and catalytic cracking diesel oil into hydro-processor, hydrogenation reacting under existence of hydrogen and hydrogenation catalyst, separating for reactant to obtain gas, hydrogenation naphtha oil, hydrogenation diesel oil and hydrogenation tail oil, entering hydrogenation tail oil into catalytic cracker, crack reacting under existence of catalytic cracking agent, separating to obtain dry gas, liquefied gas, catalytic cracking gasoline, catalytic cracking diesel oil and catalytic cracking re-circulating oil and oil slurry, and circulating for catalytic cracking diesel oil and catalytic cracking re-circulating oil to hydro-processor. It has higher recovery rate and cetyl value, less sulfur content, arene content and coke output.

Owner:CHINA PETROLEUM & CHEM CORP +1

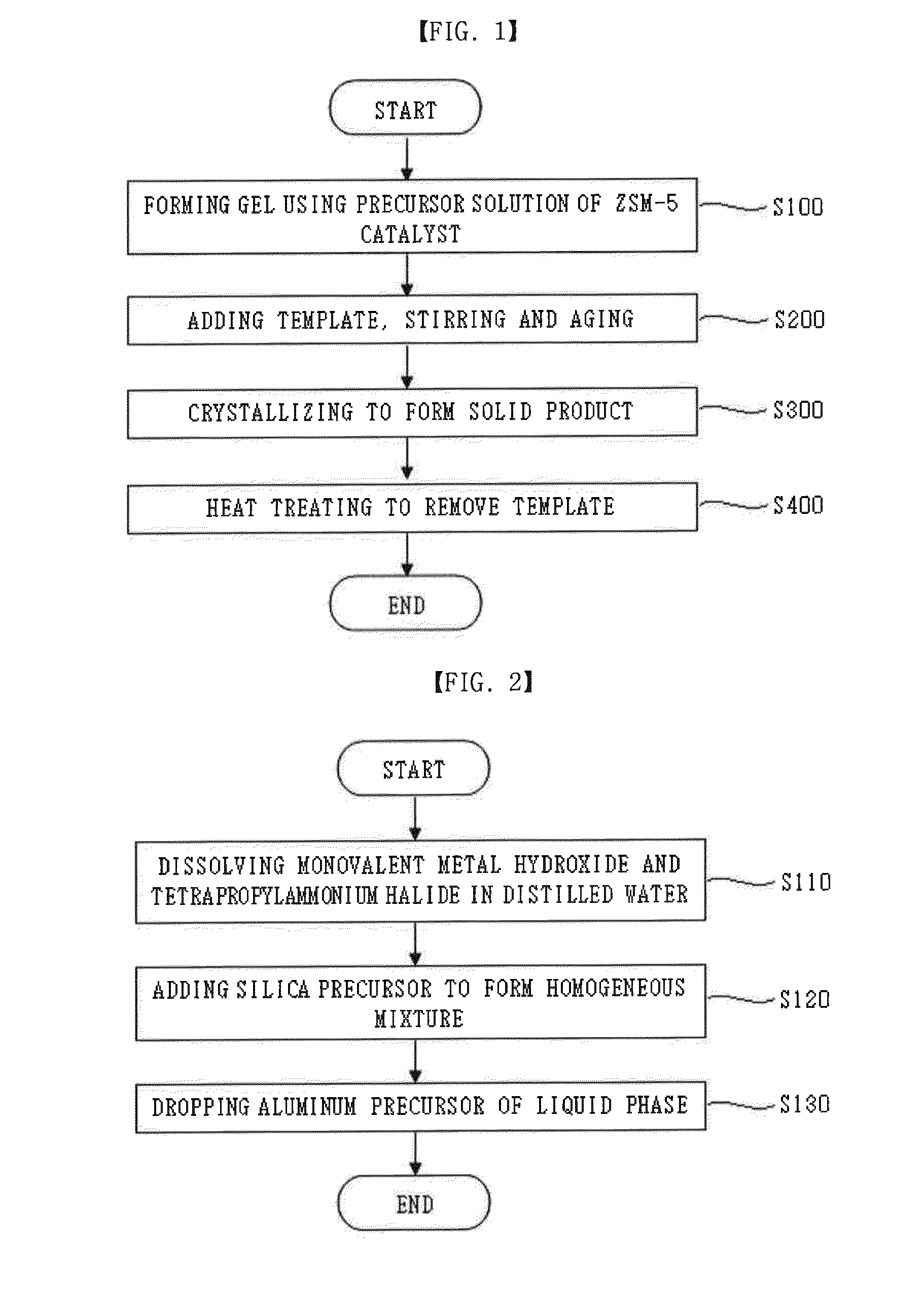

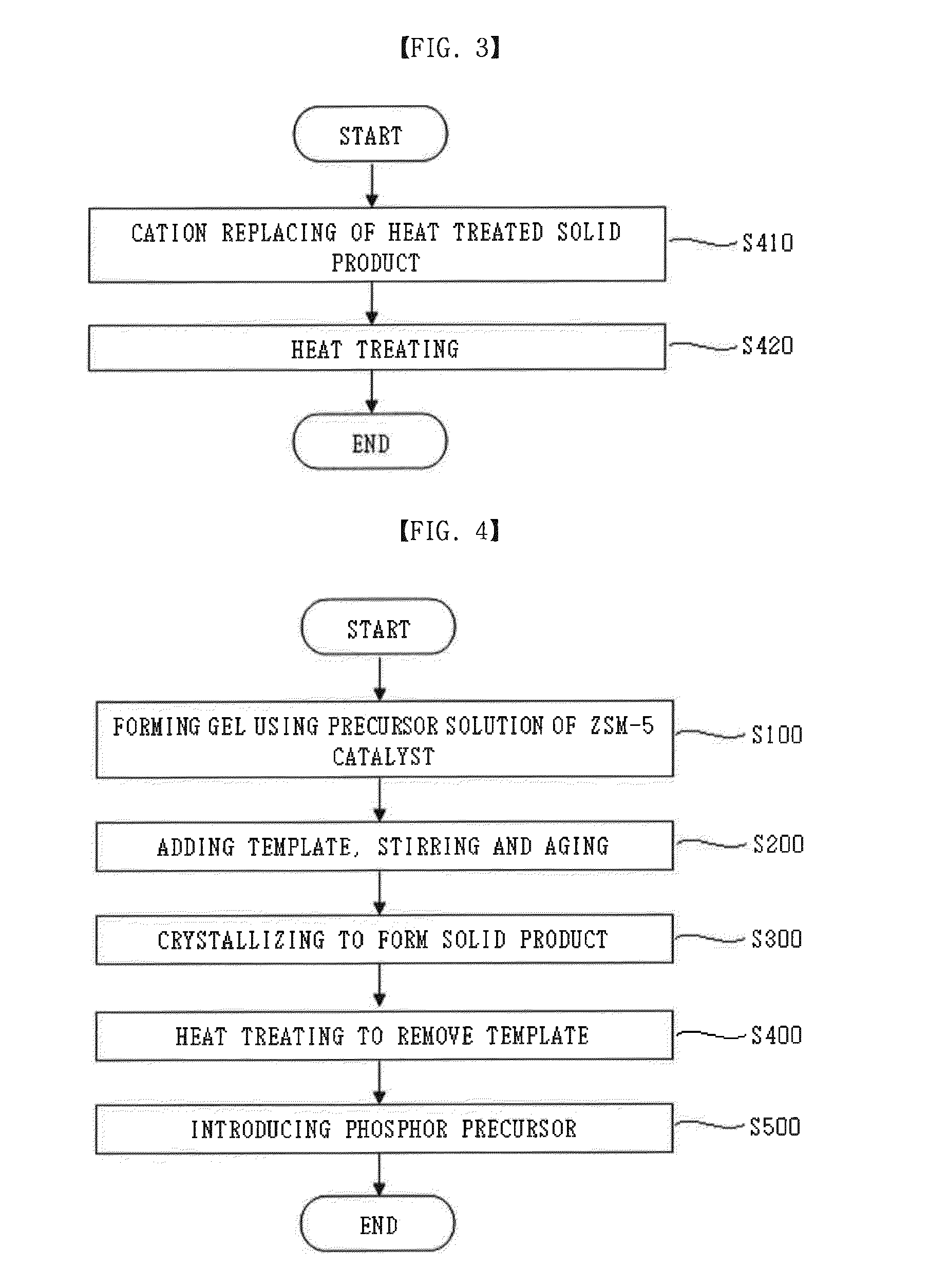

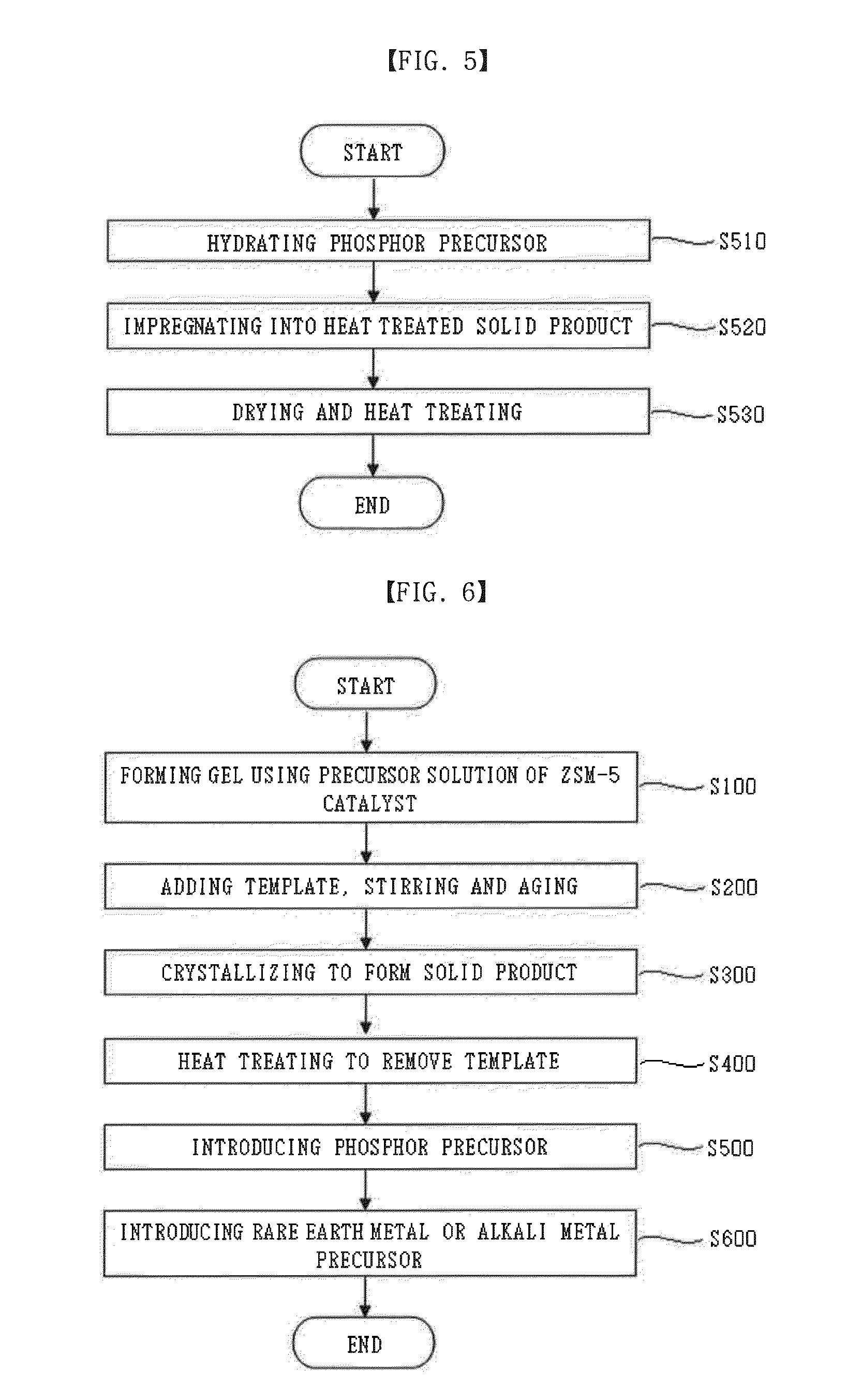

ZSM-5 catalyst with micropores and mesopores, preparation method thereof and production method of light olefins through catalytic cracking of hydrocarbons using the catalyst

InactiveUS20130085311A1Increase productionImprove featuresTreatment with plural serial cracking stages onlyCatalytic crackingHydrocarbon mixturesNaphtha

Provided is a method of preparing a ZSM-5 catalyst for preparing light olefins including ethylene and propylene through a catalytic cracking of a hydrocarbon mixture of C4 to C7 produced after a naphtha cracking. The method includes (a) forming a gel by aging a mixture solution including a silica precursor and an aluminum precursor; (b) adding a template possibly forming mesopores through a heat treatment, into the gel, stirring and then aging; (c) forming a solid product by crystallizing the aged mixture in step (b); and (d) heat treating the solid product to remove the template. The ZSM-5 catalyst may include micropores and mesopores and may have good physical and chemical properties along with a good pore property. The production yield of the light olefins may be increased.

Owner:HONAM PETROCHEM

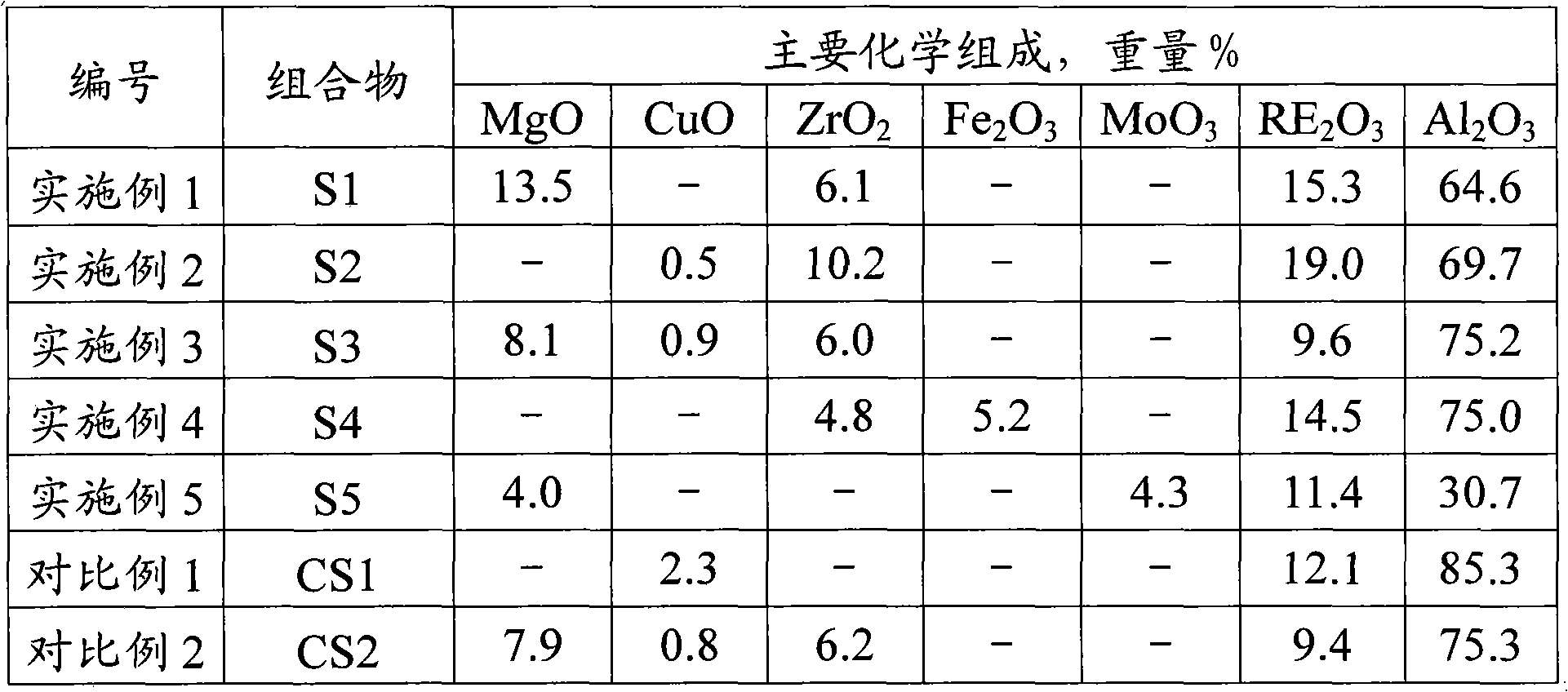

Composition for reducing discharge of NOx in regeneration flue gas of fluid catalytic cracking (FCC)

ActiveCN102371150AReduced activityReduce yieldCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementFlue gas

The invention provides a non-noble metal composition for reducing discharge of NOx in regeneration flue gas of catalytic cracking. The bulk density of the composition is no more than 0.65 g / ml, and the composition comprises, based on the weight of the composition, in terms of oxides, (1) 50 to 99 wt % of an inorganic oxide carrier, (2) 0.5 to 40 wt % of one non-noble metal or more non-noble metals selected from the group consisting of Group IIA, Group IIB, Group IVB and Group VIB, and (3) 0.5 to 30 wt % of a rare earth element. When the composition prepared in the invention is utilized in FCC, the discharge of NOx in regeneration flue gas can be substantially reduced, low yield of dry gas and coke is obtained, and distribution of FCC products is better.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking co-catalyst for producing diesel oil and its preparing method

InactiveCN1683474AReasonable hole structureReasonable strengthCatalytic crackingIn situ crystallizationSodium oxide

The catalytic cracking co-catalyst for increasing diesel oil yield is prepared through roasting kaolin at over 900 deg.c for in-situ crystallization. The co-catalyst contains type-Y zeolite in 5-20 wt%, as well as magnesia 0.5-3 wt%, RE oxide 0.5-5 wt%, and sodium oxide less than 0.6 wt%, and the zeolite has Si / Al ratio of 4.0-6.0. Adding certain amount of the catalytic cracking co-catalyst without altering the main catalyst in the oil refining apparatus can raise diesel oil yield of FCC catalyzed apparatus, improve product distribution, raise available catalyst utilization, and improve the activity stability of the catalyst system and heavy metal resistance.

Owner:PETROCHINA CO LTD

Use of low pressure distillate as absorber oil in a FCC recovery section

InactiveUS7074323B2Less equipmentImprove throughputThermal non-catalytic crackingCatalytic crackingNaphthaDistillation

A process for the recovery of gaseous products from the product mixture obtained by contacting a hydrocarbon feed with a catalyst in a fluid catalytic cracking process, wherein the liquid, obtained by separating the top product of main fractionators into gaseous and liquid fraction, when supplied to the absorber has a temperature of between about 8–25 DEG C. This liquid may be pre-saturated with gaseous top product from absorber; or also a high boiling fraction (cat cracker naphtha / light cycle oil) may be first separated from this liquid by distillation.

Owner:SHELL OIL CO

Fluid cat cracking with high olefins production

InactiveUS20020189973A1Maximize lightThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaOrganic chemistry

The propylene production of a fluid catalytic cracking unit employing a large pore zeolite cracking catalyst, produces more propylene by adding a naphtha cracking riser and a medium pore zeolite catalytic component to the unit, and recycling at least a portion of the naphtha crackate to the naphtha riser. The large pore size zeolite preferably comprises a USY zeolite and the medium pore size is preferably ZSM-5. Propylene production per unit of naphtha feed to the naphtha riser is maximized, by using the 60-300° F. naphtha crackate as the feed.

Owner:EXXON RES & ENG CO

Process for conversion of a cellulosic material

InactiveUS20130118059A1Less criticalEasy to useCatalytic crackingLiquid carbonaceous fuelsCelluloseSolvent

A process for conversion of a cellulosic material comprisinga) a liquefaction step, comprisingcontacting a cellulosic material with a liquid solvent at a temperature of equal to or more than 200° C.; orcontacting a cellulosic material with a liquid solvent at a temperature of equal to or more than 100° C. in the presence of a catalyst,to produce a final liquefied product;b) a catalytic cracking step, comprising contacting at least part of the final liquefied product with a fluidized catalytic cracking catalyst at a temperature of equal to or more than 400° C., to produce one or more cracked products.

Owner:SHELL OIL CO

Method of treating biomass, fuel for fuel cell, gasoline, diesel fuel, liquefied petroleum gas, and synthetic resin

ActiveUS20110113675A1Reduce amountStable processing efficiencyCatalytic crackingBiofuelsFuel cellsContact time

In processing of biomass by catalytic cracking in a fluidized catalytic cracker having a reaction zone, a separation zone, a stripping zone, and a regeneration zone, the feedstock oil containing the biomass is processed in the reaction zone using a catalyst containing 10 to 50 mass % of ultrastable Y-type zeolite under the conditions: outlet temperature of the reaction zone 580 to 680° C., catalyst / oil ratio 10 to 40 wt / wt, reaction pressure 1 to 3 kg / cm2 G, and contact time of the feedstock oil with the catalyst in the reaction zone 0.1 to 1.0 sec, and the catalyst is then treated in the regeneration zone under the conditions: regeneration zone temperature 640 to 720° C., regeneration zone pressure 1 to 3 kg / cm2 G, and exhaust gas oxygen concentration at the regeneration zone outlet 0 to 3 mol %.

Owner:NIPPON OIL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com