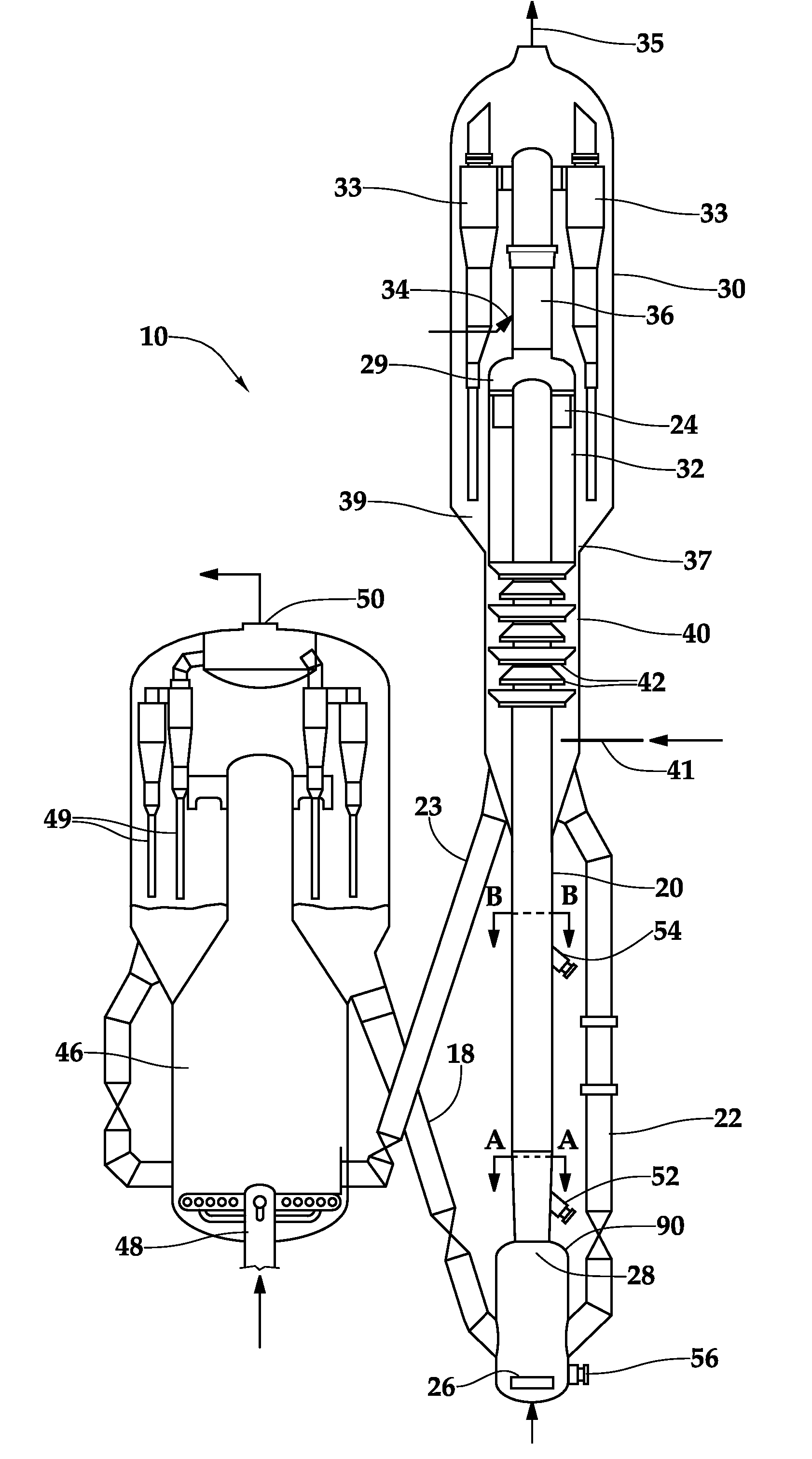

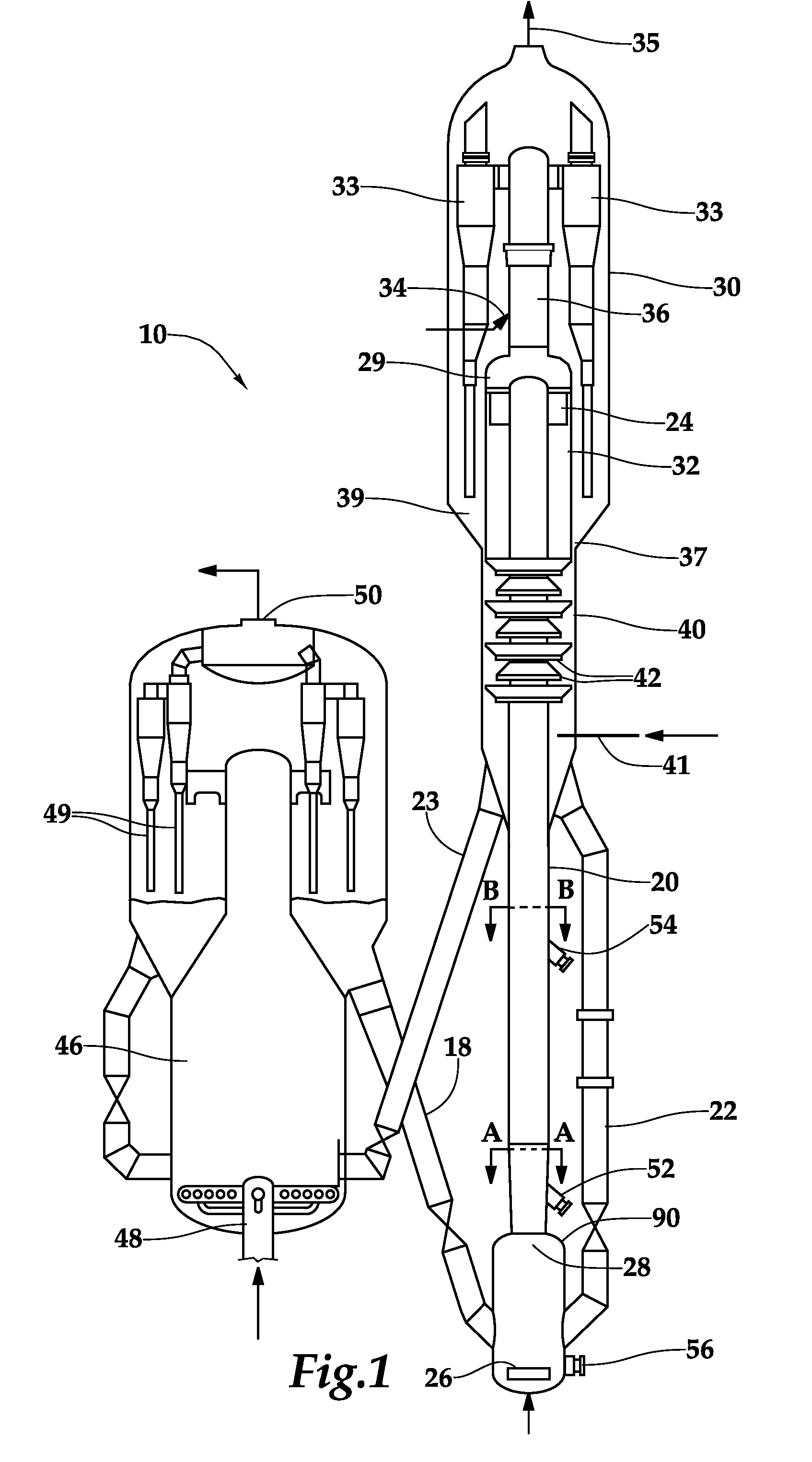

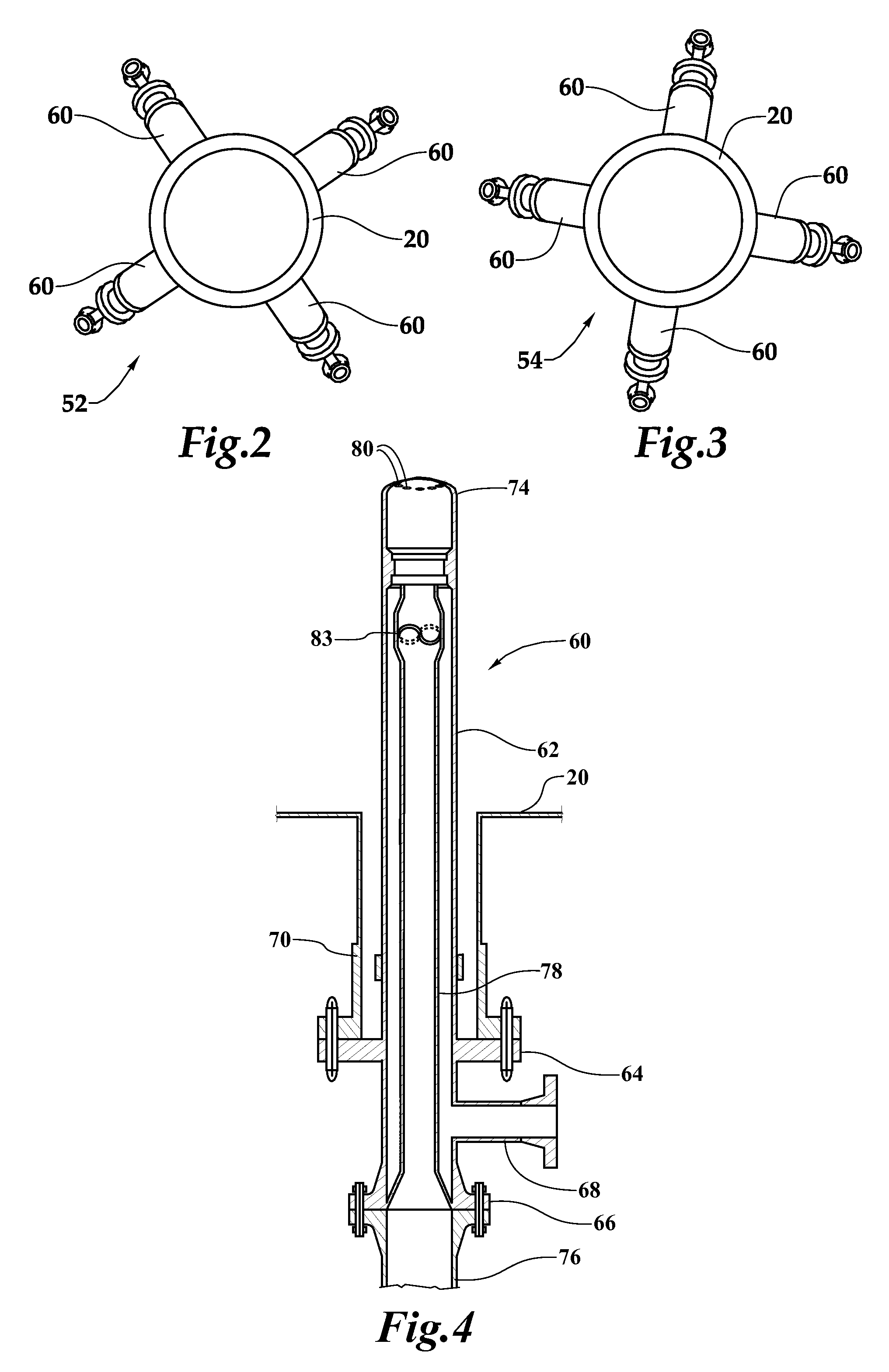

Fcc dual elevation riser feed distributors for gasoline and light olefin modes of operation

a technology of fcc and gasoline, which is applied in the direction of catalytic cracking, chemistry apparatus and processes, chemical/physical processes, etc., can solve the problems of affecting the steady state of operations, requiring the unit to be shut down, and affecting the production of valuable products, etc., to achieve the effect of enhancing flexibility and options

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0035]In an example of one embodiment of this invention, an FCC process of the present invention was simulated to run in gasoline mode under the conditions given for the present invention which produced a gasoline selectivity of 60 vol-% and a propylene selectivity of 8 vol-%. When the present invention was simulated to run in light olefin mode under the conditions given for the present invention it produced a gasoline selectivity of 33 vol-% and a propylene selectivity of 32 vol-%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com