Patents

Literature

67 results about "Delayed coker" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

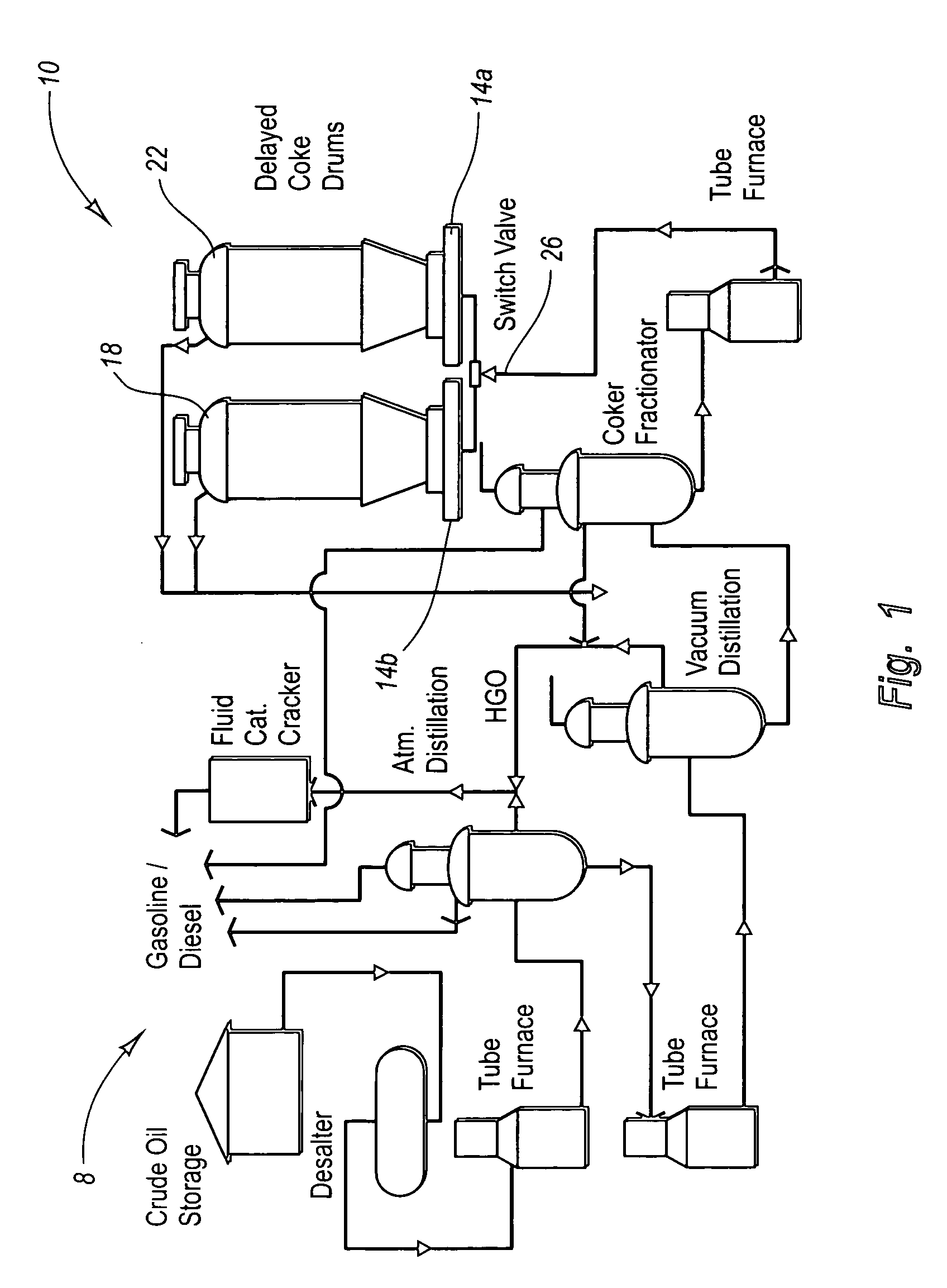

A delayed coker is a type of coker whose process consists of heating a residual oil feed to its thermal cracking temperature in a furnace with multiple parallel passes. This cracks the heavy, long chain hydrocarbon molecules of the residual oil into coker gas oil and petroleum coke.

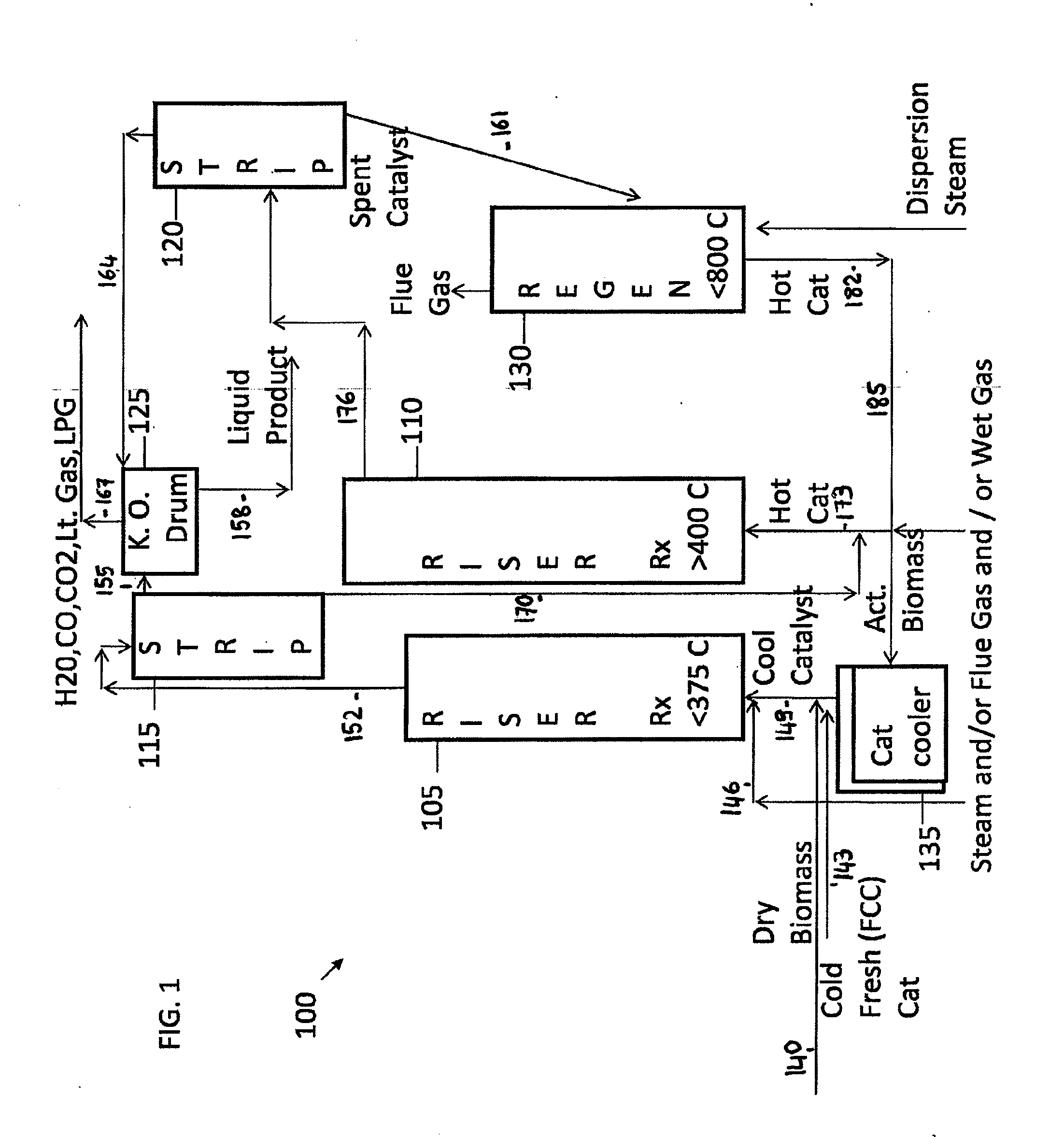

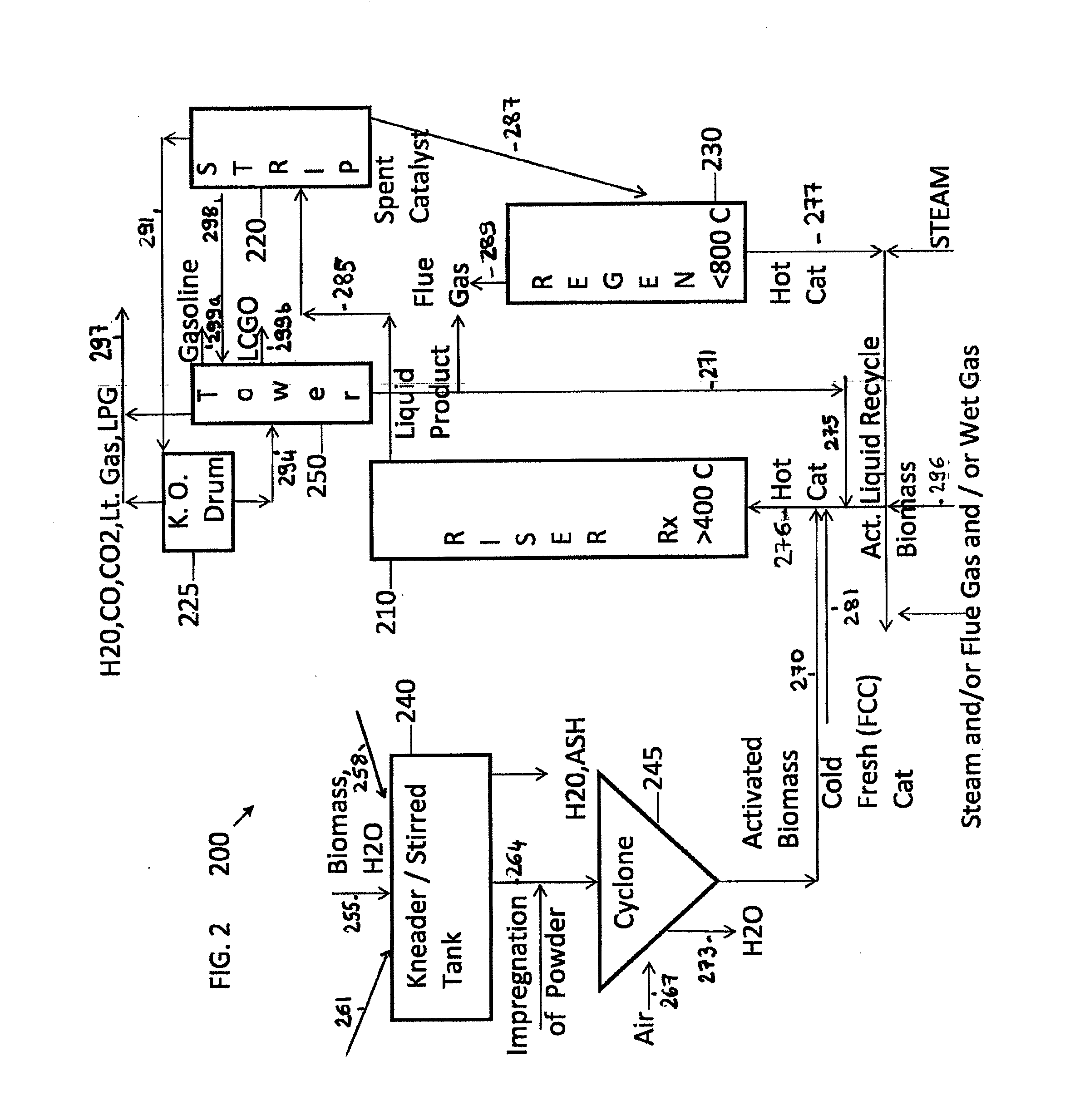

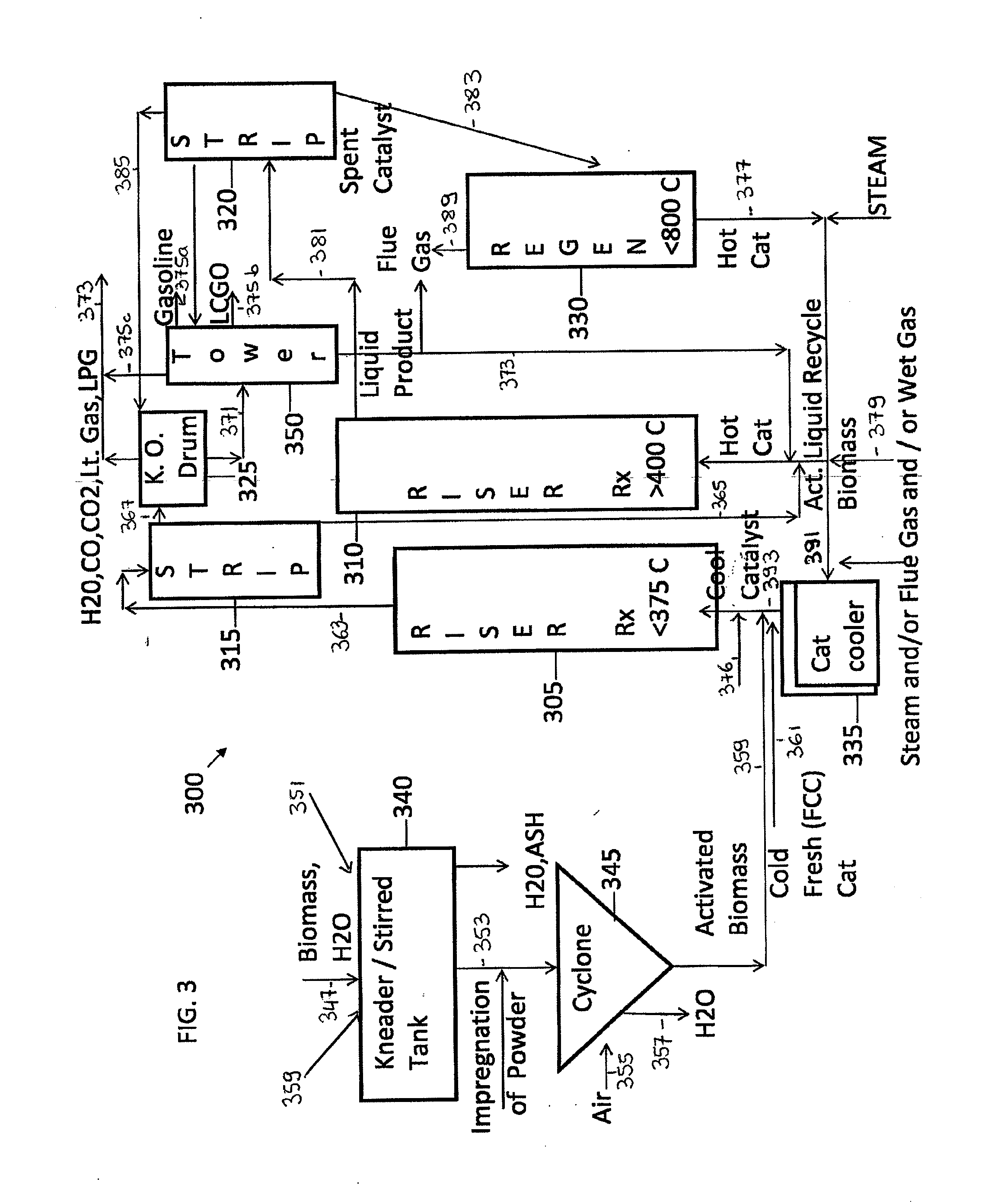

Methods for Co-Processing of Biomass and Petroleum Feed

ActiveUS20110154720A1Mitigate equipment cost and energy cost and degradationSpeed up the conversion processCatalytic crackingBiofuelsLiquid hydrocarbonsDelayed coker

A process for producing fuel from biomass is disclosed herein. The process includes torrefying biomass material at a temperature between 80° C. to 400° C. to form particulated biomass having a mean average particle size between 1 μm and 1000 μm. The particulated biomass is mixed with a liquid hydrocarbon to form a suspension, wherein the suspension includes from 1 weight percent to 40 weight percent particulated biomass. The suspension is fed into a unit selected from the group consisting of a pyrolysis reactor, a fluid catalytic cracking unit, a delayed coker, a fluid coker, a hydroprocessing unit, and a hydrocracking unit, and then at least a portion of the particulated biomass of the suspension is converted into fuel.

Owner:MARD INC

Process for the Conversion of Solid Particulated Biomass Materials

ActiveUS20110094147A1Mitigate equipment cost and energy cost and degradationSpeed up the conversion processCatalytic crackingBiofuelsLiquid hydrocarbonsBiofuel

A process for producing bio-fuel from biomass is disclosed herein. The process includes processing the mean particle diameter of the biomass by mechanical processing to a size ranging from 1 μm to 1000 μm to form particulated biomass. The particulated biomass is mixed with a liquid hydrocarbon to form a suspension, wherein the suspension includes between 1 weight percent to 40 weight percent particulated biomass. The suspension is heated to a temperature between 50° C. and 550° C. The heated suspension is fed into a unit selected from the group consisting of a pyrolysis reactor, a fluid catalytic cracking unit, a delayed coker, a fluid coker, a hydroprocessing unit, and a hydrocracking unit; and then at least a portion of the particulated biomass of the heated suspension is converted into fuel.

Owner:MARD INC

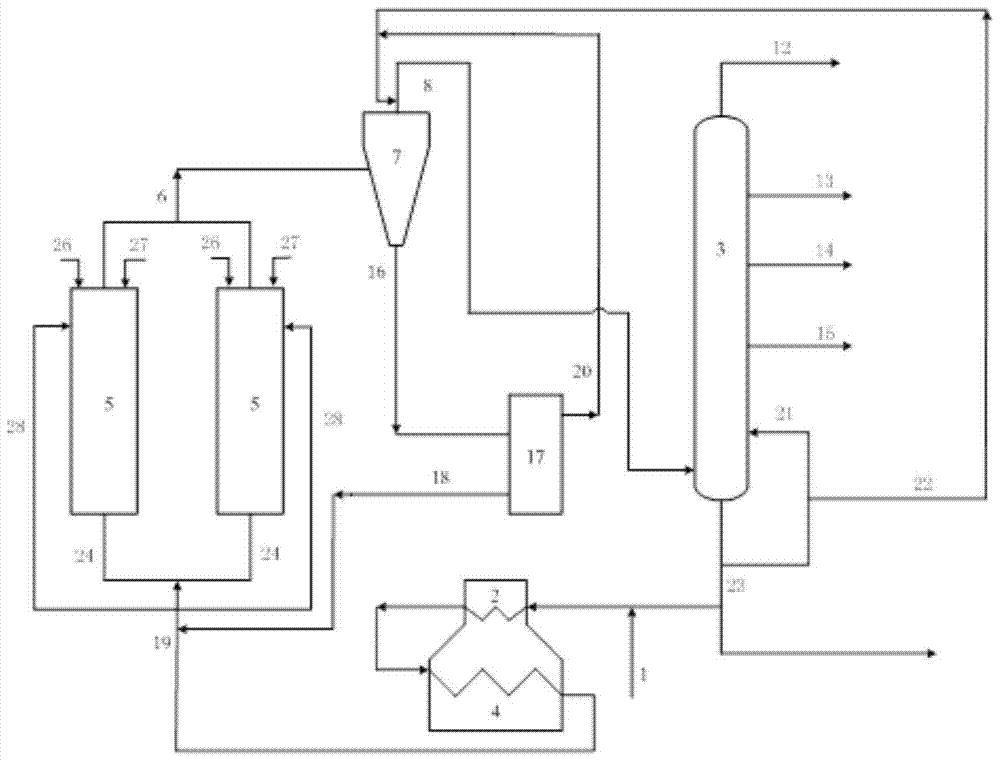

Method for producing needle coke by catalytic cracking-delayed coking combination process

ActiveCN103045301AFully integratedLow viscosityTreatment with plural serial stages onlyGasolineProcess engineering

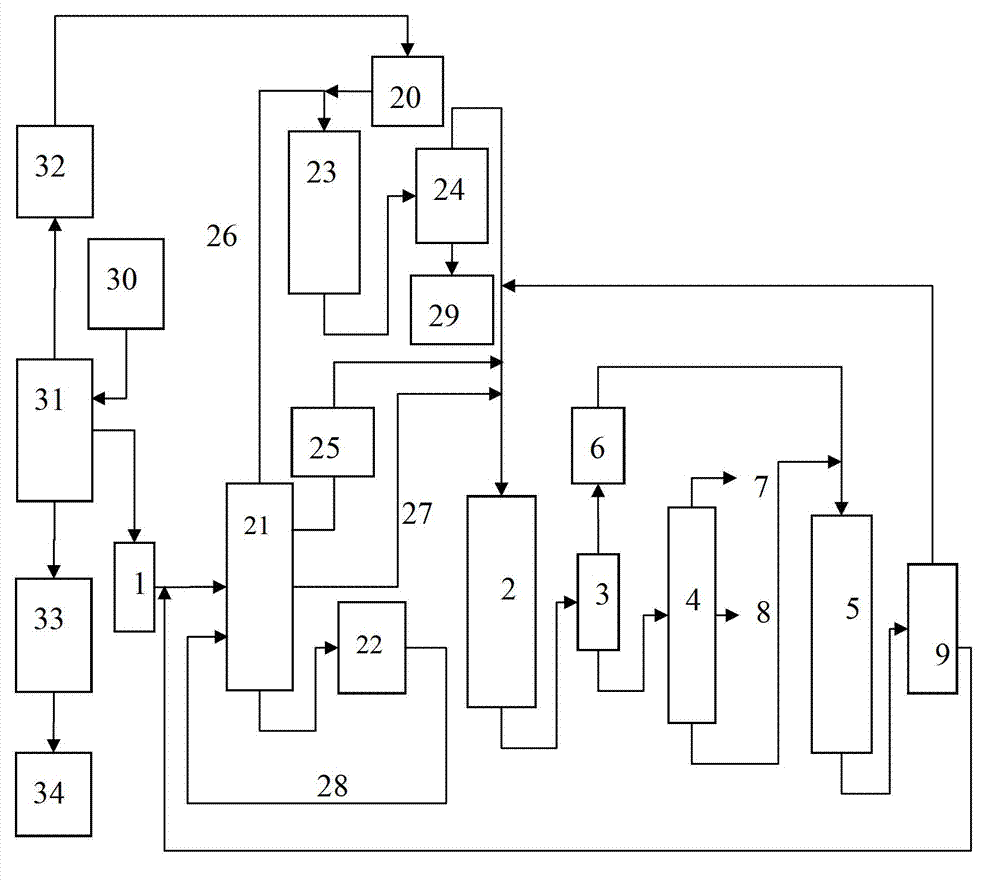

The invention discloses a method for producing needle coke by a catalytic cracking-delayed coking combination process, which comprises steps as follows: (1) raw oil enters a catalytic cracking unit to be subjected to catalytic cracking reaction, and generated oil enters a fractionating tower to be separated into gas, gasoline fraction diesel fraction and catalytic slurry oil; (2) the catalytic slurry oil obtained in the step (1) is filtered and enters a delayed coker, when the treatment amount of the delayed coker reaches 60-80% of the total treatment amount, the generated oil in the step (1) is separated to obtain gas and gasoline fraction, and the rest fraction is filtered to totally enter the delayed coker; and (3) when reaching the total treatment amount of the delayed coker, oil introduction is stopped, and the coke tower is switched to perform the coking scorching stage, so that the needle coke deposits on the tower bottom. The method can obtain the high-fiber-structure good-quality needle coke product while obtaining qualified catalytic cracking products.

Owner:CHINA PETROLEUM & CHEM CORP +1

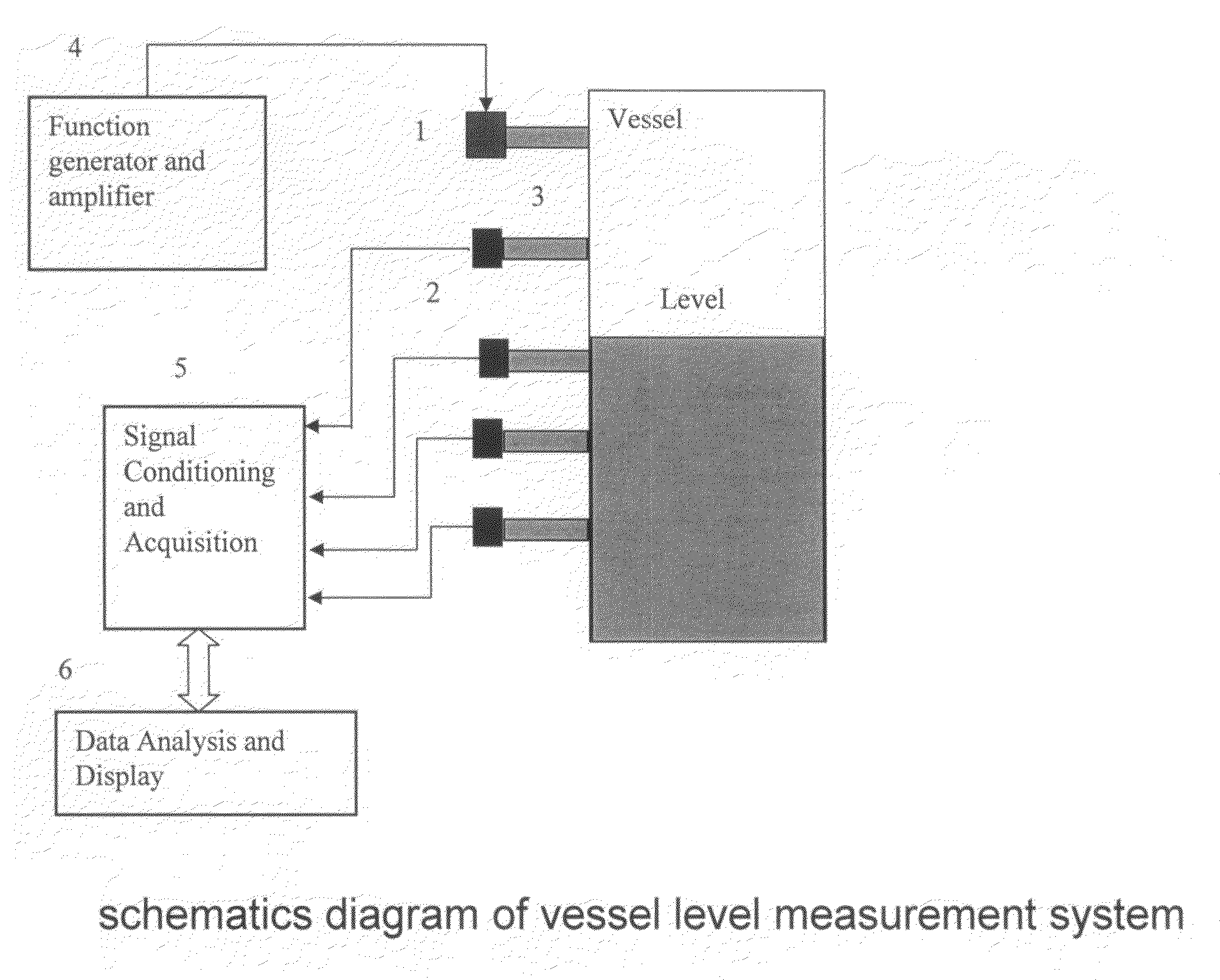

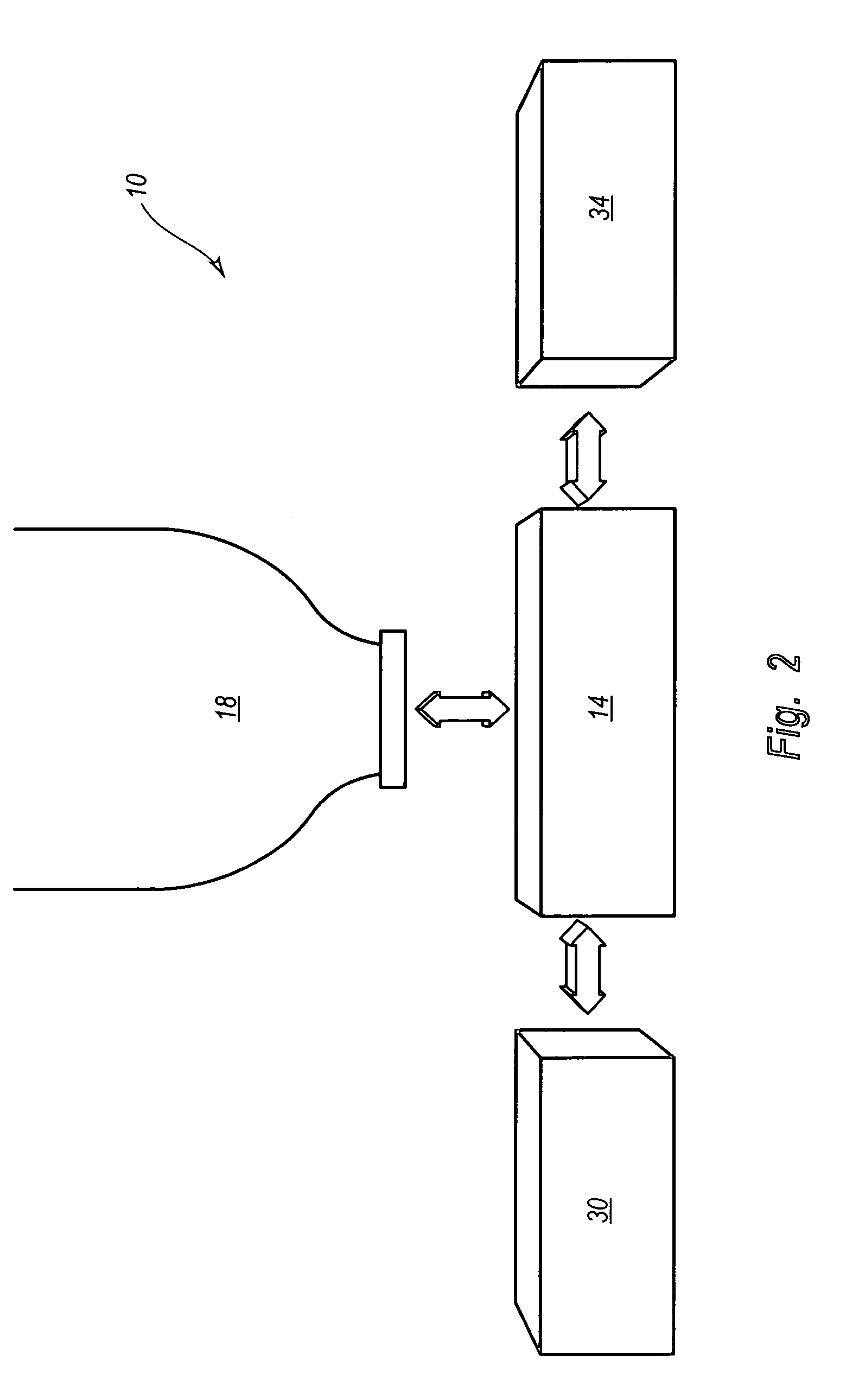

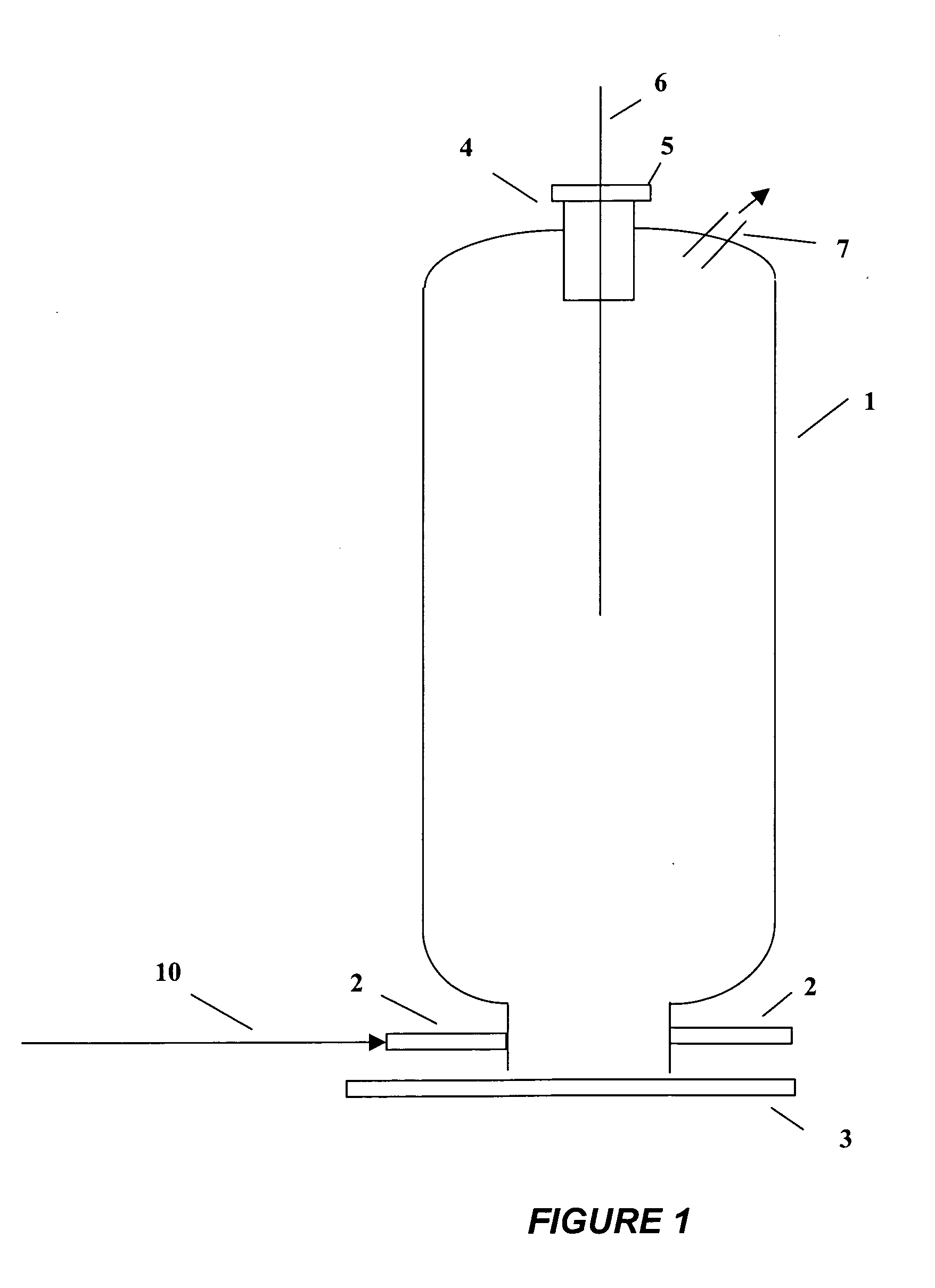

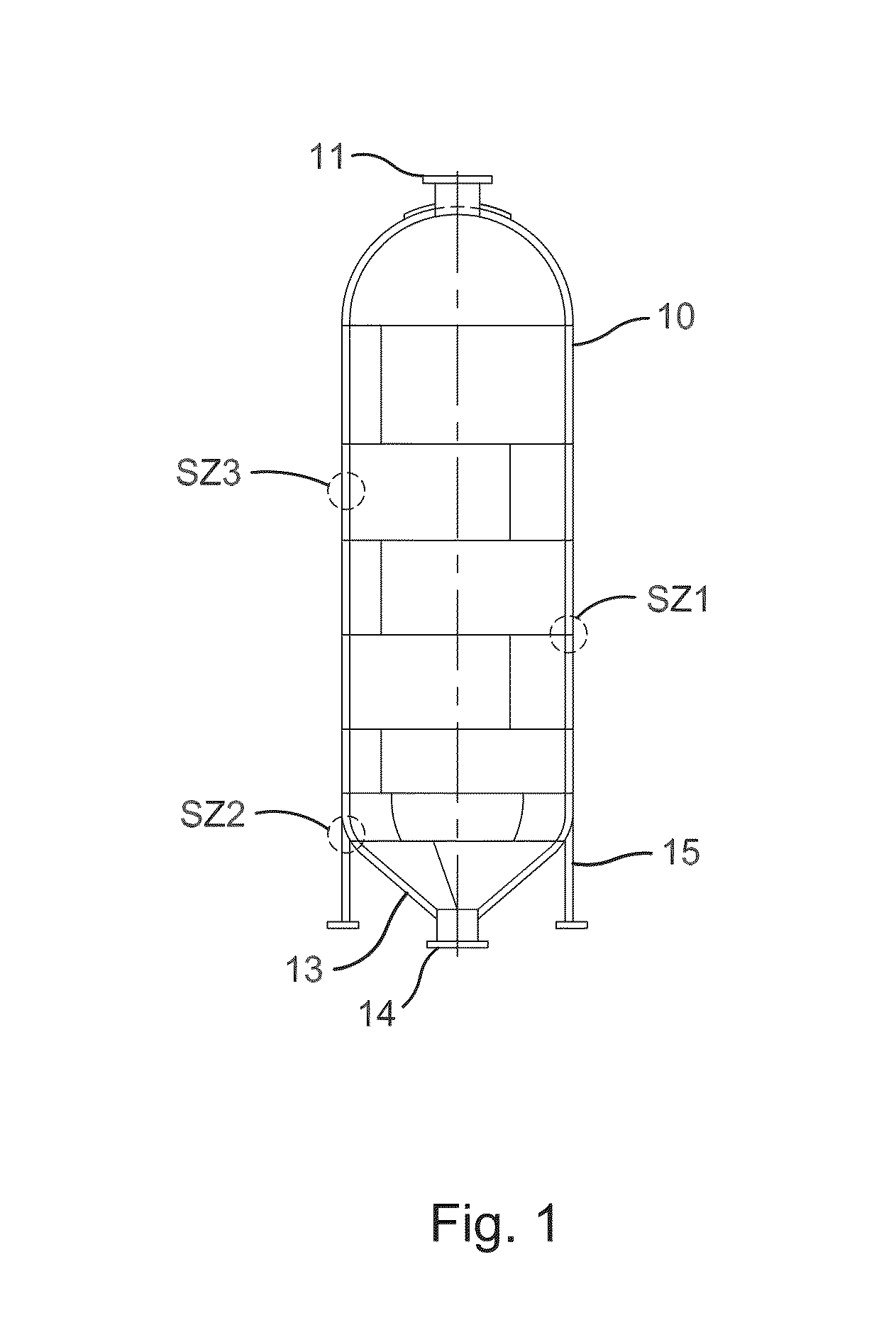

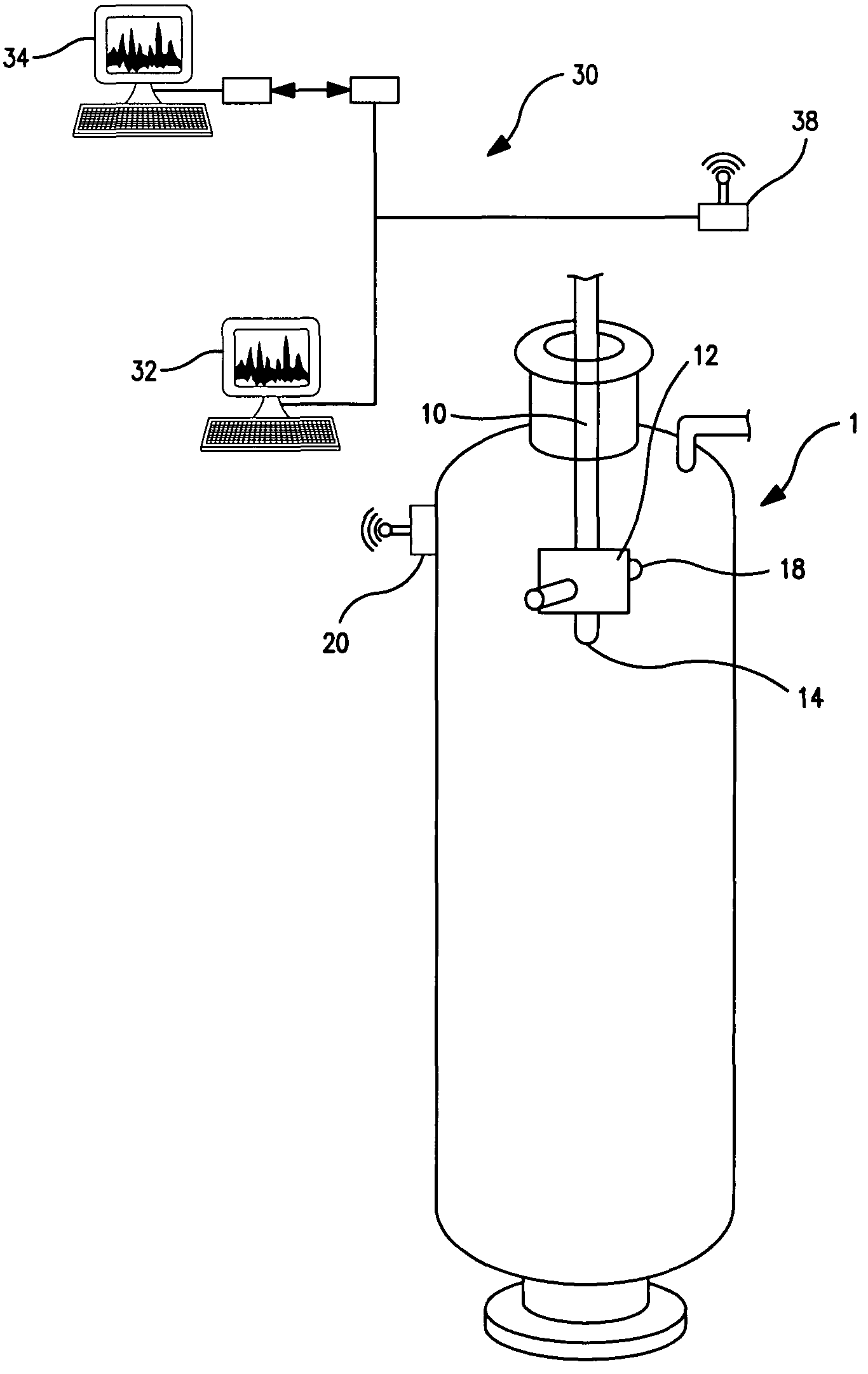

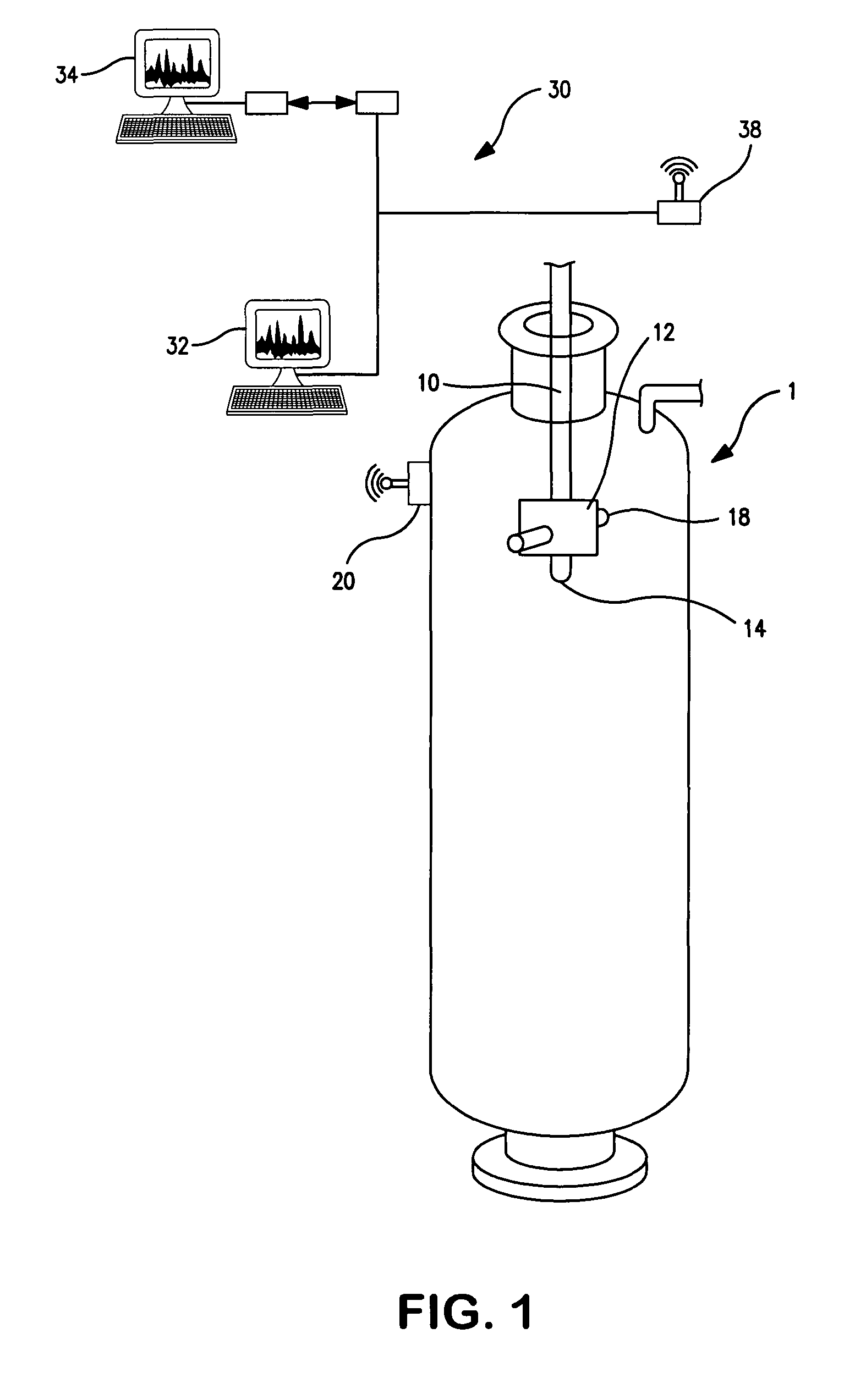

Method for measuring reactor bed level from active acoustic measurement and analysis

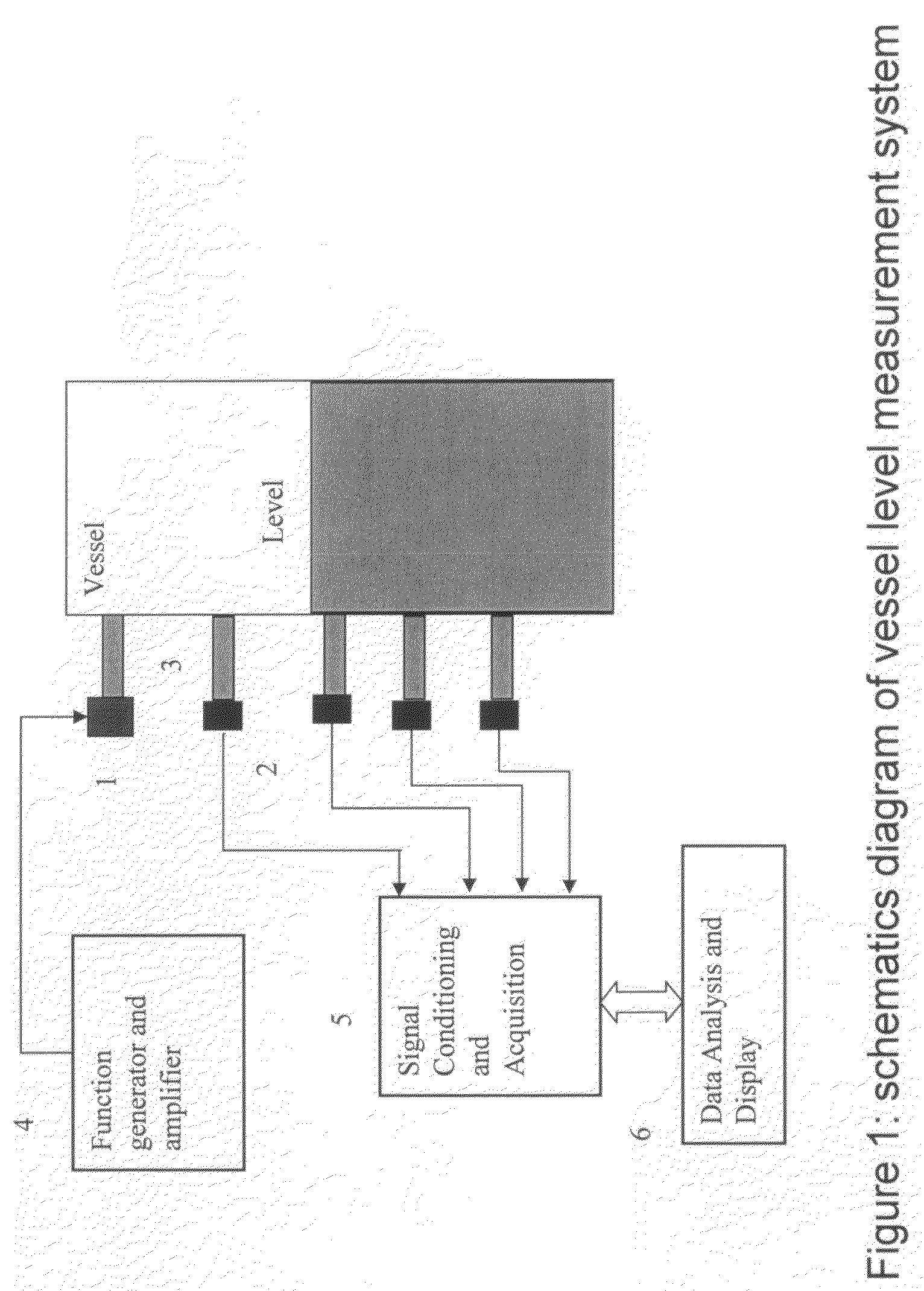

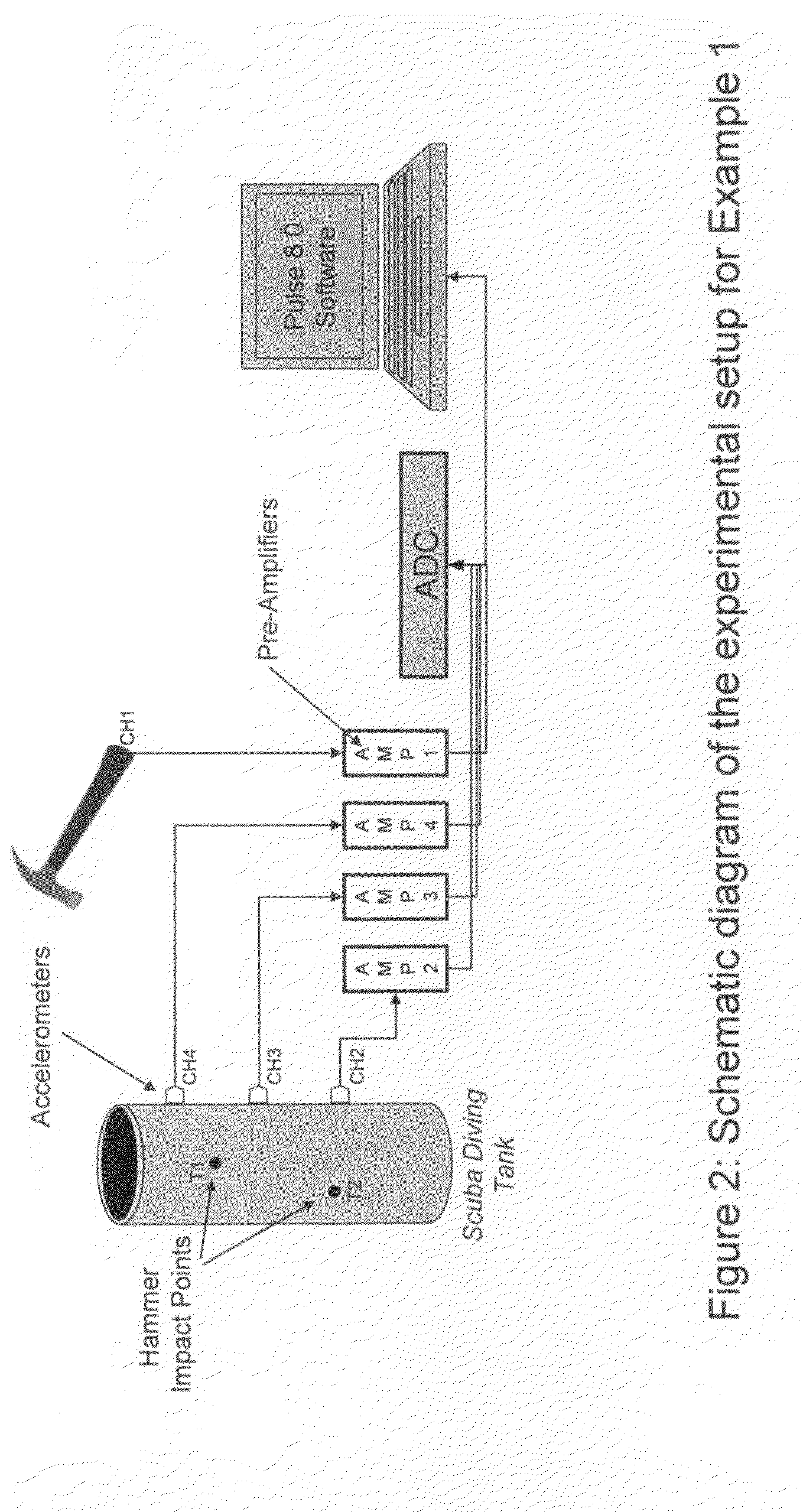

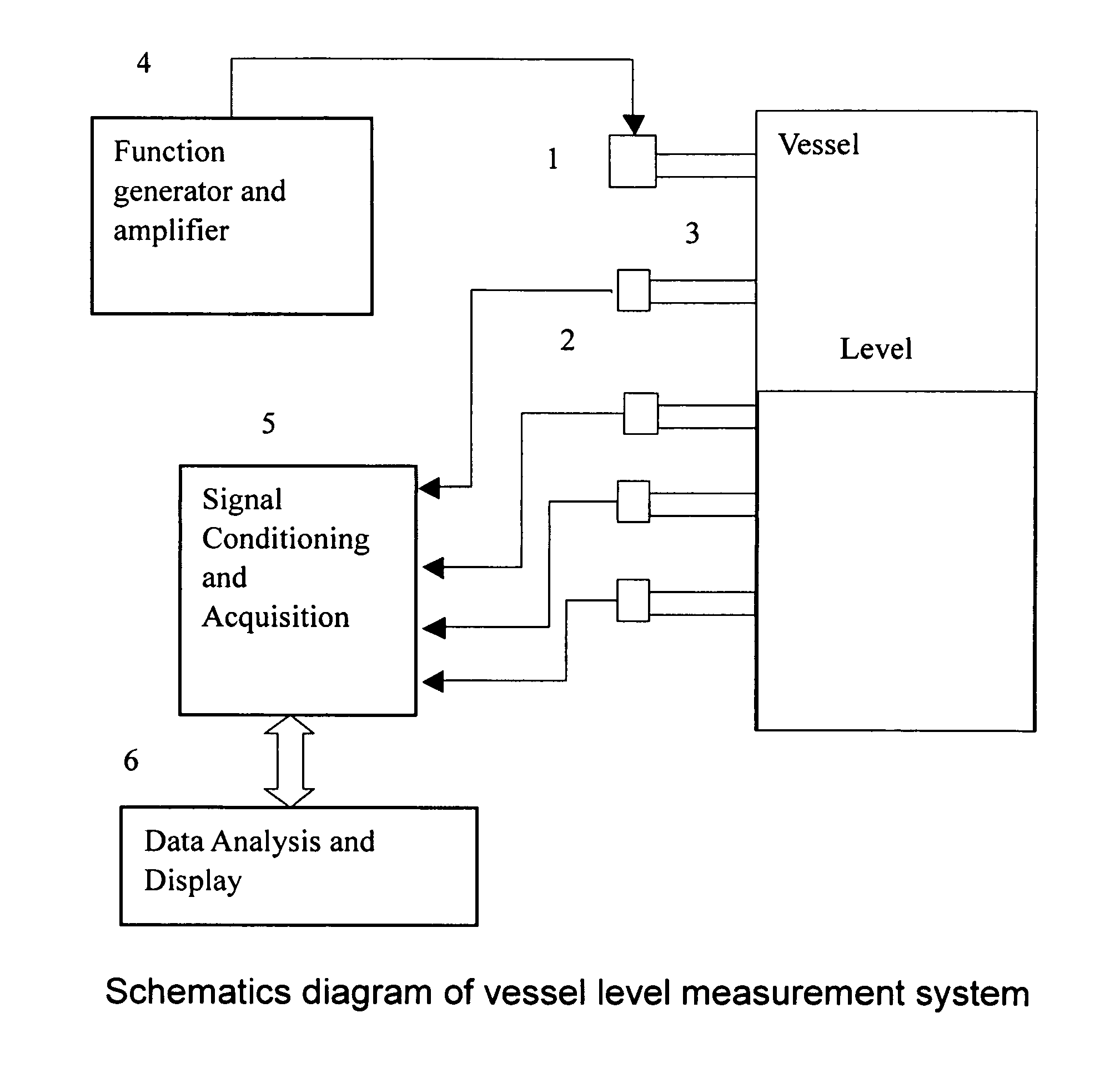

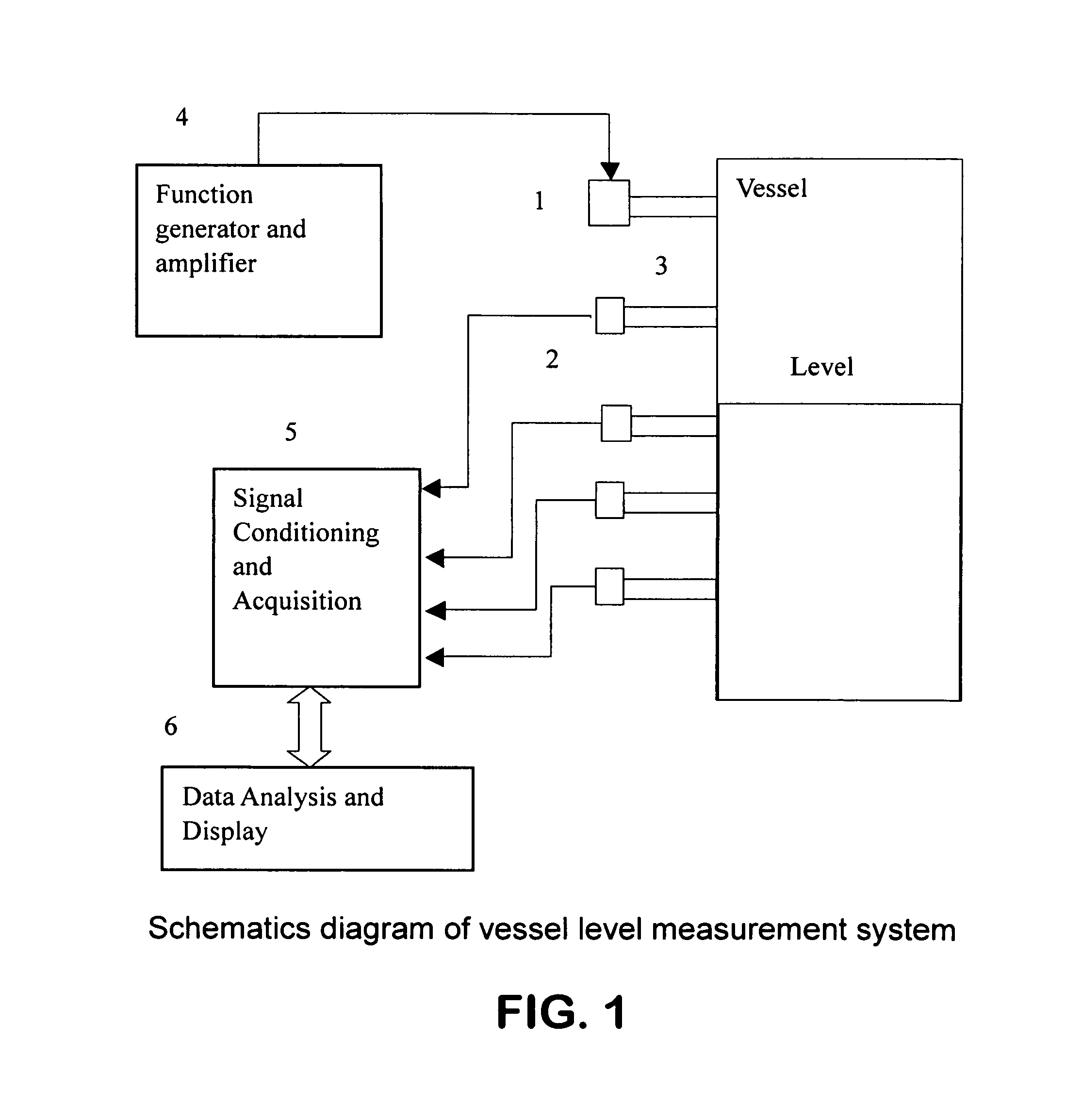

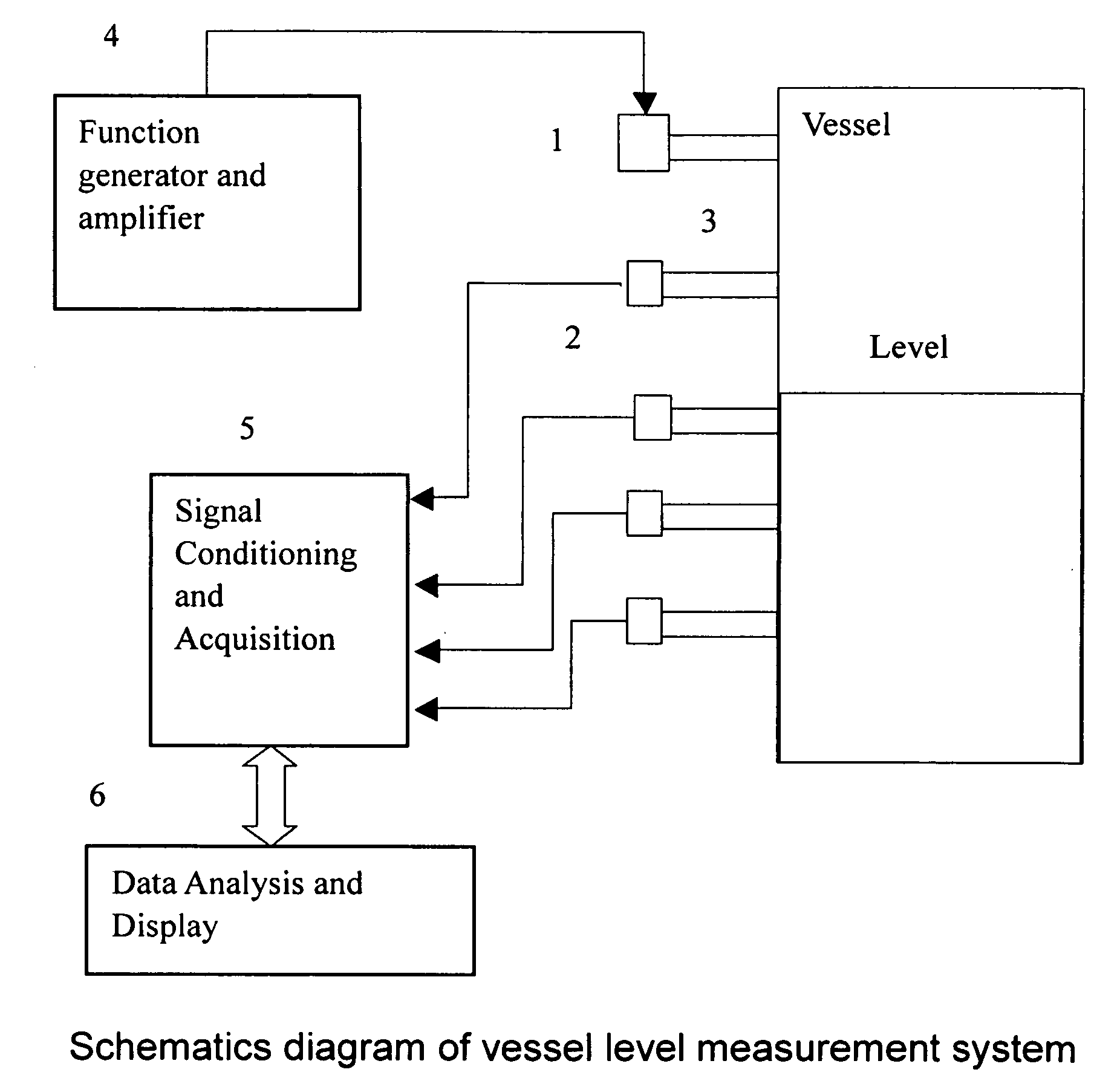

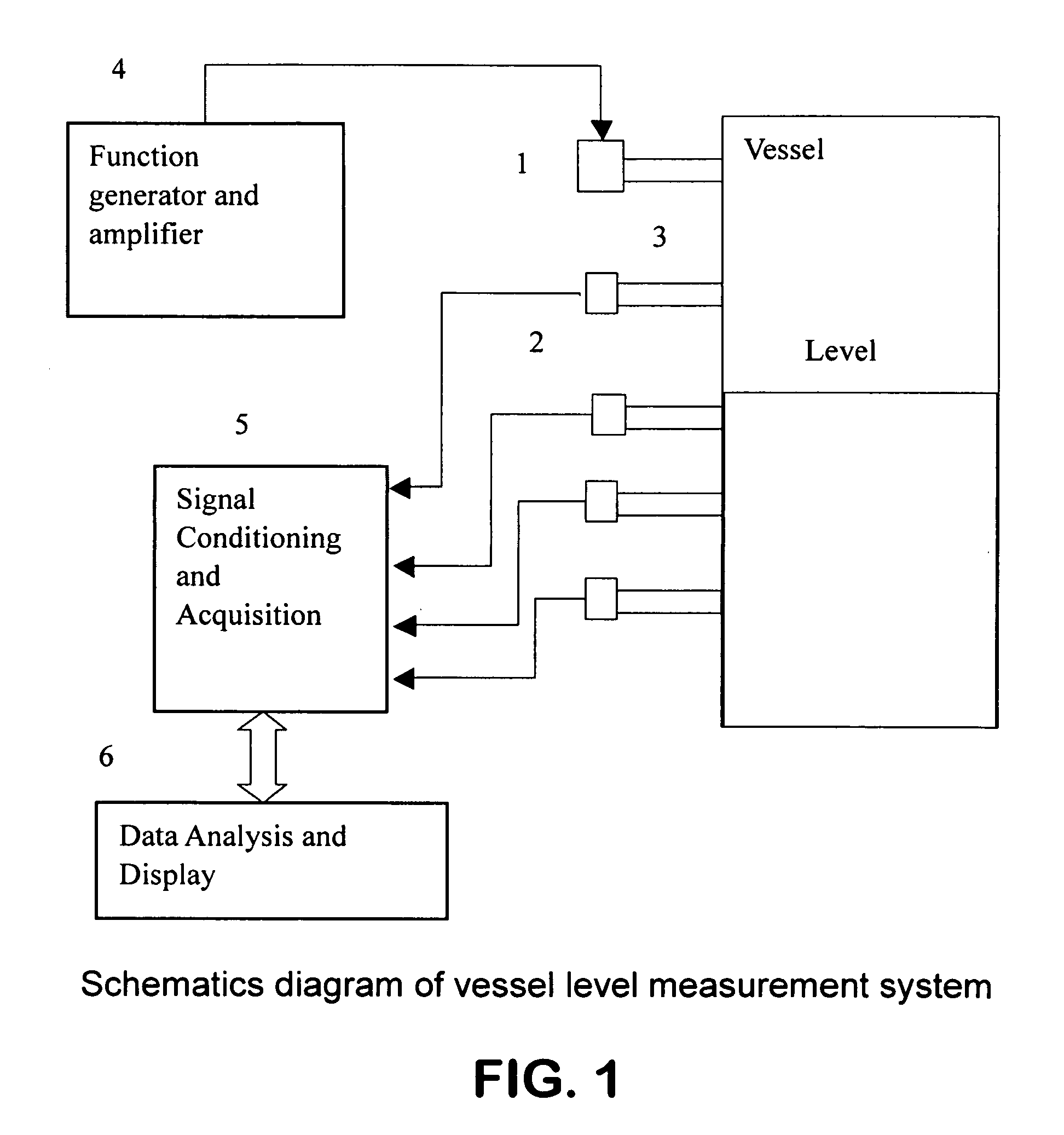

The present invention is a non-intrusive method to determine the fluid level in a vessel. In a preferred embodiment, the vessel is a delayed coker drum in a refinery. Waves are generated in the vessel from an outside source. For wall vibration generated in the frequency range of 1-20,000 Hz, accelerometers on the exterior wall of the vessel measures the frequency of the vibration modes of the vessel. The fluid level can be related to the frequency of the vibration mode.

Owner:EXXON RES & ENG CO

Blending of resid feedstocks to produce a coke that is easier to remove from a coker drum

A method of blending delayed coker feedstocks to produce a coke that is easier to remove from a coker drum. A first feedstock is selected having less than about 250 wppm dispersed metals content and greater than about 5.24 API gravity. A second delayed coker feedstock is blended with said first resid feedstock so that the total dispersed metals content of the blend will be greater than about 250 wppm and the API gravity will be less than about 5.24.

Owner:EXXON RES & ENG CO

Production and removal of free-flowing coke from delayed coker drum

InactiveUS7727382B2Thermal non-catalytic crackingCoking carbonaceous materialsDelayed cokerEngineering

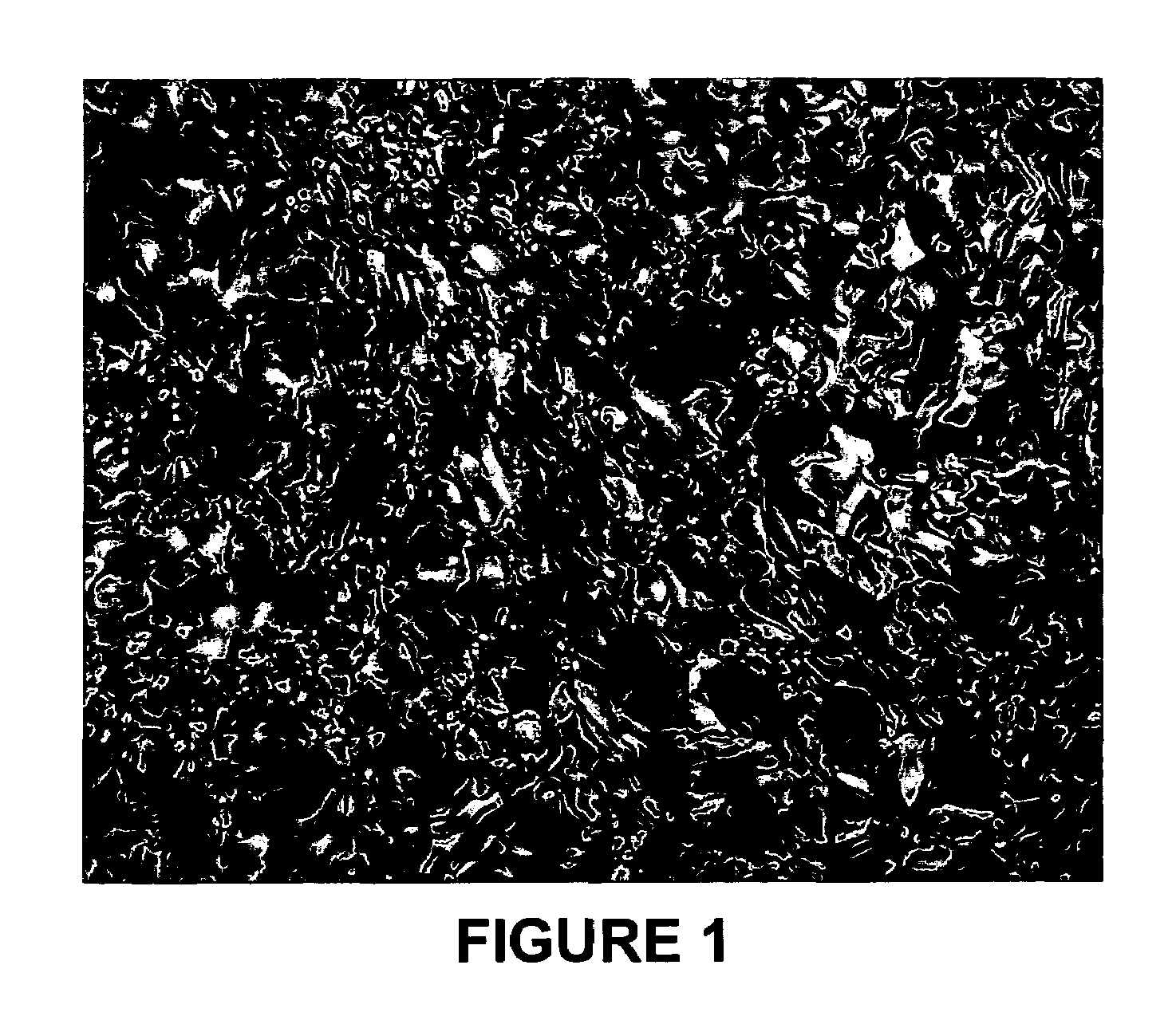

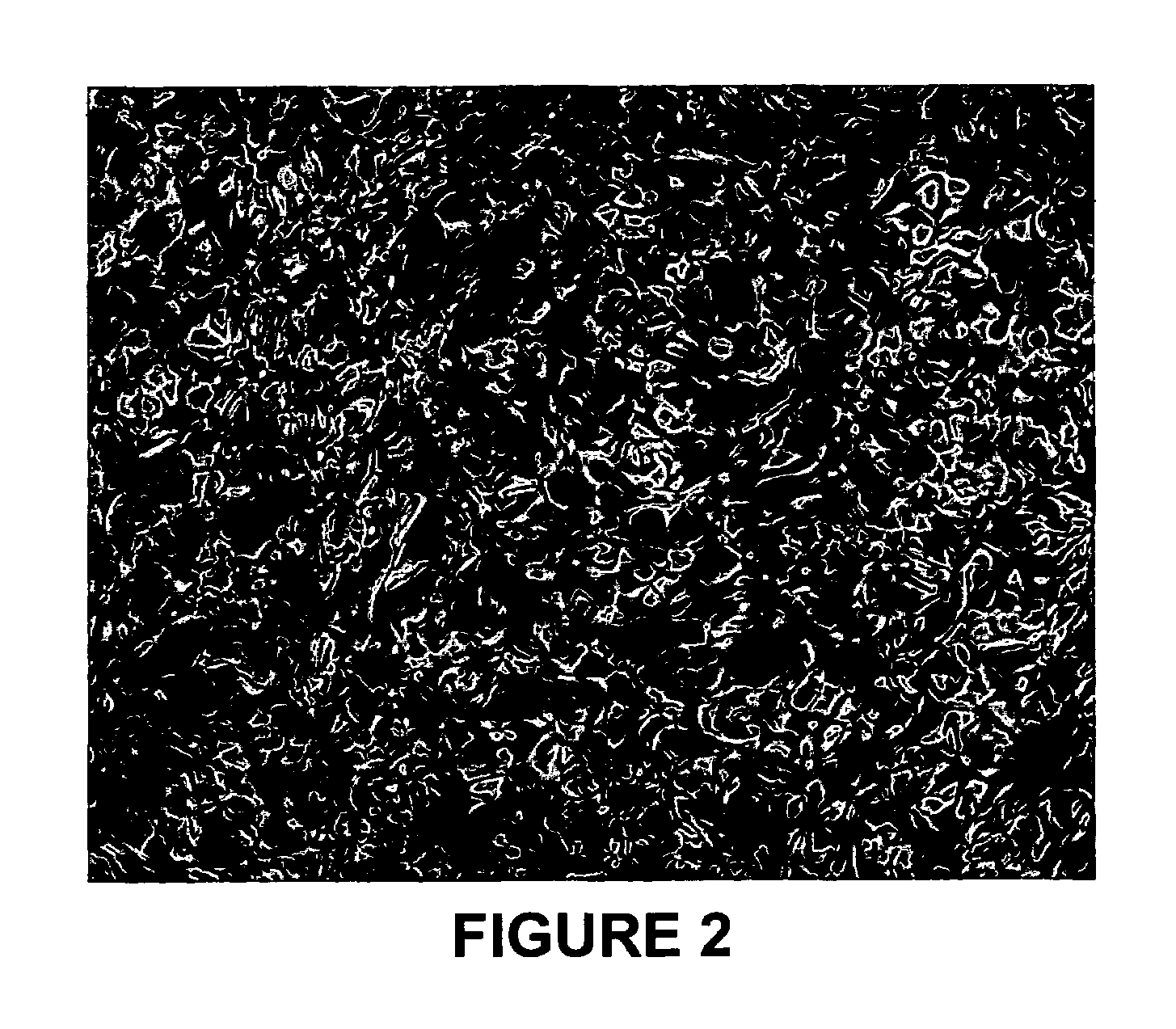

A method for producing and removing coke which has bulk morphology such that at least about 30 volume percent is free-flowing under the force of gravity or hydrostatic forces from a delayed coker drum. At the completion of the fill cycle, the coker drum, filled with hot coke, is cooled by steaming and then flooding it with water, thereby producing a coke / water mixture. The coke / water mixture is released from the coke drum through one or more drum closure / discharge throttling systems near the bottom of the coker drum.

Owner:EXXON RES & ENG CO

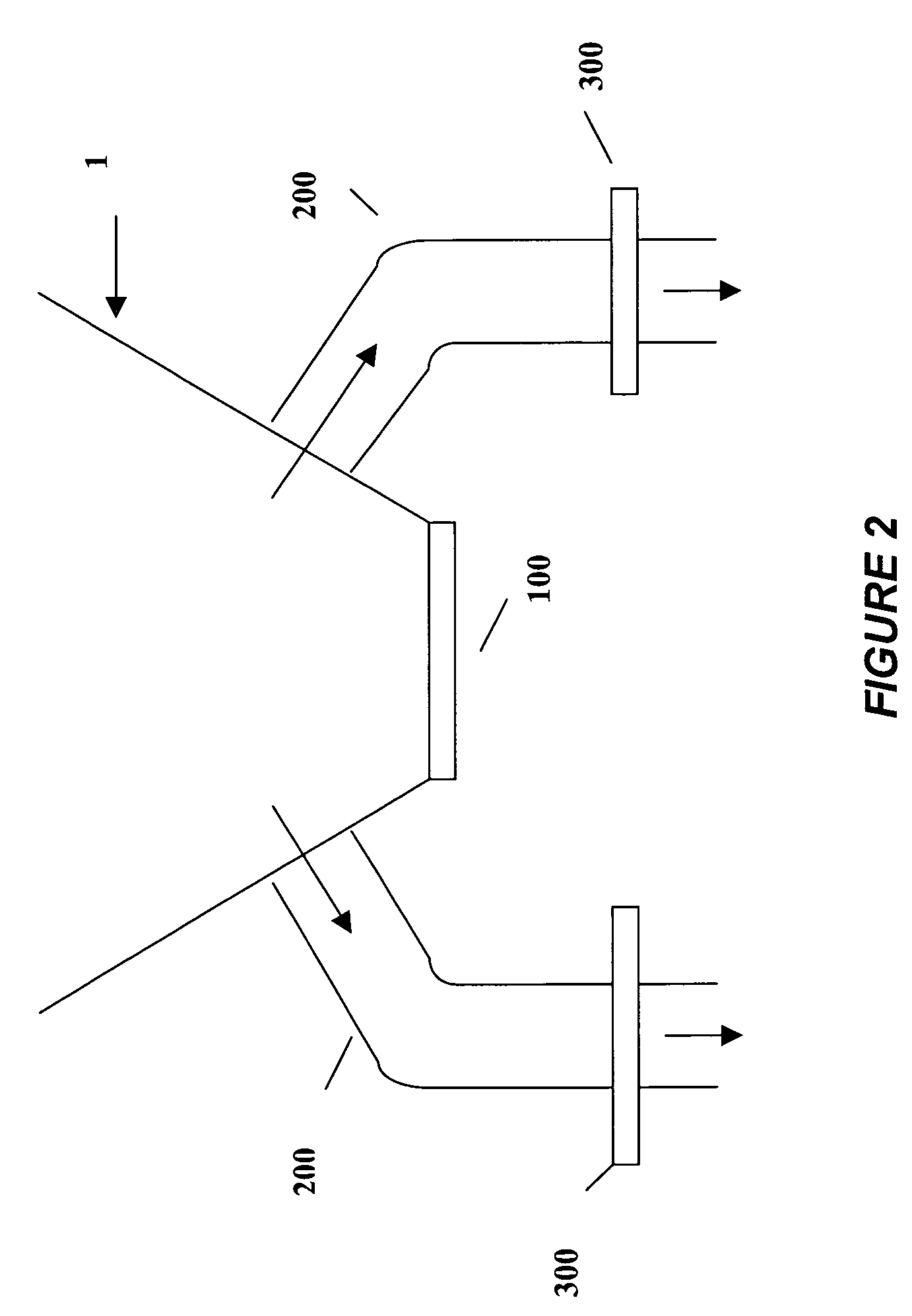

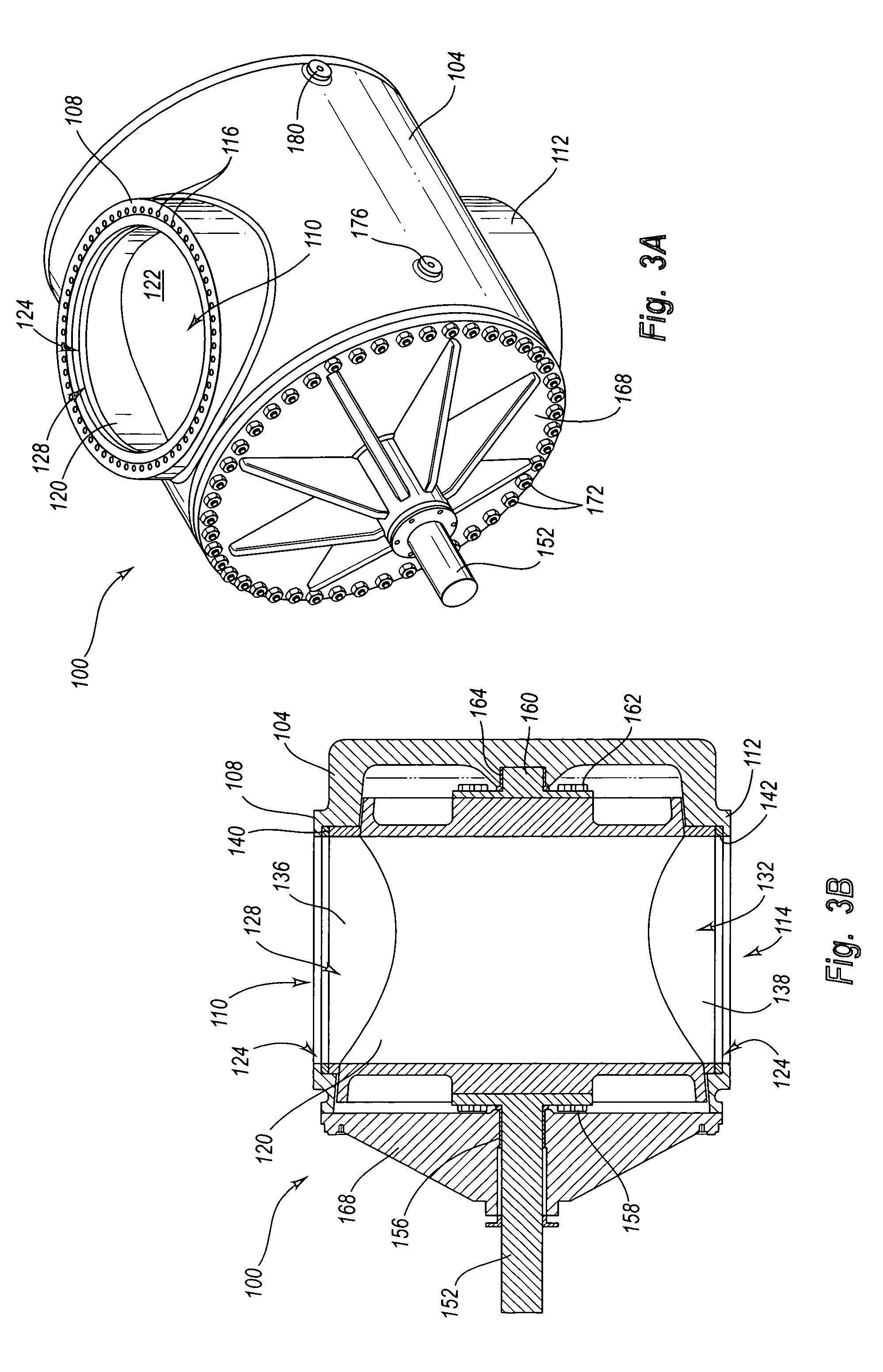

Systems and methods for providing continuous containment of delayed coker unit operations

ActiveUS20060076225A1Simplify decoking processLocation somewhat remoteDerricks/mastsDirect heating destructive distillationDelayed cokerCoker unit

The present invention relates to a safety system during the entire delayed coker operation. The present invention preferably comprises a coke drum; a first coke drum de-header system coupled to the bottom of the coke drum; a second coke drum de-header system coupled to the top of the coke drum; a containment system coupled to the second coke drum de-header system; and a remote switching system. Hence, the present invention provides system for cutting coke within a coke drum with increased safety, efficiency and convenience.

Owner:DELTAVALVE

Production and removal of free-flowing coke from delayed coker drum

InactiveUS20050269247A1Increase percentageThermal non-catalytic crackingCoking carbonaceous materialsThermodynamicsProcess engineering

A method for producing and removing coke which has bulk morphology such that at least about 30 volume percent is free-flowing under the force of gravity or hydrostatic forces from a delayed coker drum. At the completion of the fill cycle, the coker drum, filled with hot coke, is cooled by steaming and then flooding it with water, thereby producing a coke / water mixture. The coke / water mixture is released from the coke drum through one or more drum closure / discharge throttling systems near the bottom of the coker drum.

Owner:EXXON RES & ENG CO

Silicone defoamer to better control hydrocarbon foam and reduce silicon content of liquid hydrocarbon products

ActiveUS7427350B2Reduced and minimized amountEffectively controls foamThermal non-catalytic crackingHydrocarbon distillationKeroseneLiquid hydrocarbons

It has been discovered that crosslinked polydimethylsiloxane (PDMS) resins are useful defoamers and antifoamers for hydrocarbon-containing liquids, such as delayed coker feedstocks and feedstocks to preflash and atmospheric towers. These PDMS resins are crosslinked with either alkyl polysilicate or siloxane. The crosslinked PDMS resins may be used alone or together with linear PDMS, and are typically blended with a carrier such as kerosene for easier handling. Importantly, the use of crosslinked branched PDMS resins permit less total amount of polysiloxanes to be used, which reduces the silicon carryover in coker products and reduces poisoning of downstream catalysts.

Owner:BAKER HUGHES INC

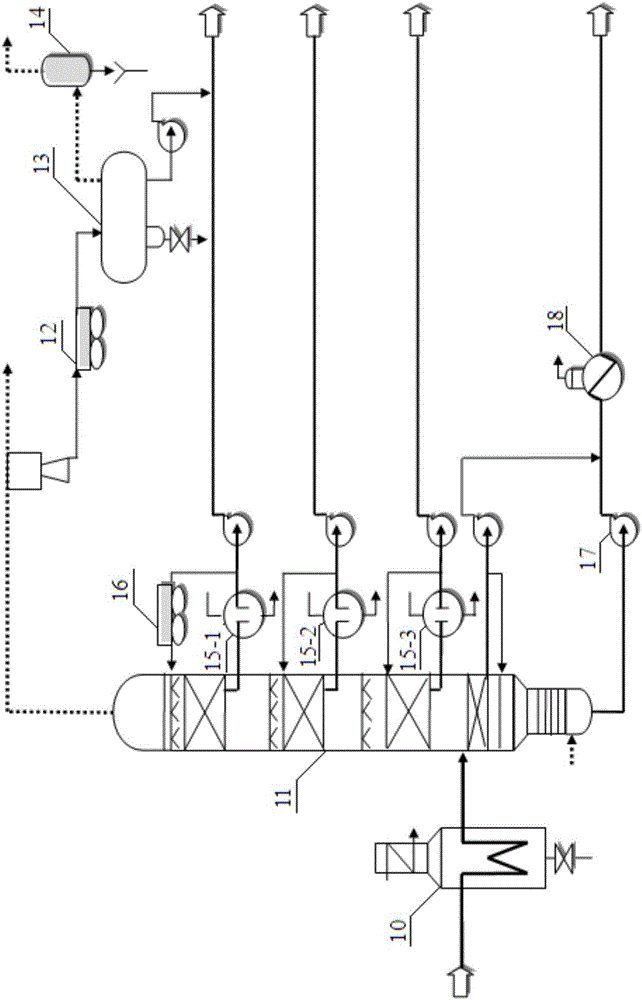

High-temperature coal tar hydrogenation, post-delayed coking and methanol preparation by utilizing coke oven gas combined technology

InactiveCN102634369ACombined CrossoverReduce pollutionOrganic compound preparationHydroxy compound preparationDelayed cokerCoking plant

The invention relates to a high-temperature coal tar hydrogenation, post-delayed coking and methanol preparation by utilizing coke oven gas combined technology. The combined technology comprises the following technologies: (1) a methanol preparation technology by utilizing coke oven gas, (2) a high temperature coal tar hydrogenation technology and (3) a needle coke preparation technology by utilizing a post-delayed coking technology. With the adoption of the combined technology provided by the invention, when a coking plant produces cokes, by-products coke oven gas and high-temperature coal-tar oil are produced, the coke oven gas is used as a raw material for manufacturing methanol, the by-product spread air escape of the methanol is used for preparing hydrogen through a pressure swing adsorption device and then the hydrogen is taken as the raw material for the high-temperature coal tar hydrogenation; the by-product maltha generated by the high-temperature coal tar hydrogenation enters a post-delayed coker, is used as the raw material for manufacturing the needle coke; each productive unit is connected with each step, and a circulation economic model with energy conservation and emission reduction is realized; and therefore, the composite cost is low, the air pollution of the coking plant to surrounding environment is reduced.

Owner:焦云

Adding substance for reducing furnace tube deposition coking and improving liquid yield of delayed coker

InactiveCN101113367AAvoid cleavage reactionsHigh yieldThermal non-catalytic crackingTreatment apparatus corrosion/fouling inhibitionAlcoholGasoline

An additive, which is used for delaying device coking, reducing the scaling and coking of furnace tubes and improving the yield of liquids, comprises the raw materials by the weights and portions of: 5-20 portions of ash-less nonmetal dispersant, 5-20 portions of pyrolysis initiator, 25-35 portions of inhibitor, 10-30 portions of antifoulant and 5-20 portions of solvent, wherein, the ash-less nonmetal dispersant is made by the methods that: alcohol amine and fatty acid are mixed by molecular ratio of 1:0.7-1.7, and stirred in the temperature of 170 DEG C-200 DEG C, water produced in the reaction is carried out by toluene or gasoline, and the reaction can be stopped when no more water is produced, and the ash-less nonmetal dispersant is obtained when the toluene or gasoline are steamed. When used in the coking delaying, the additive provided by the invention has the advantages of simple operation, good effects of reducing coke and scale, high general liquid yield, and good economical and technical benefits.

Owner:MAOMING KEDA CHEM

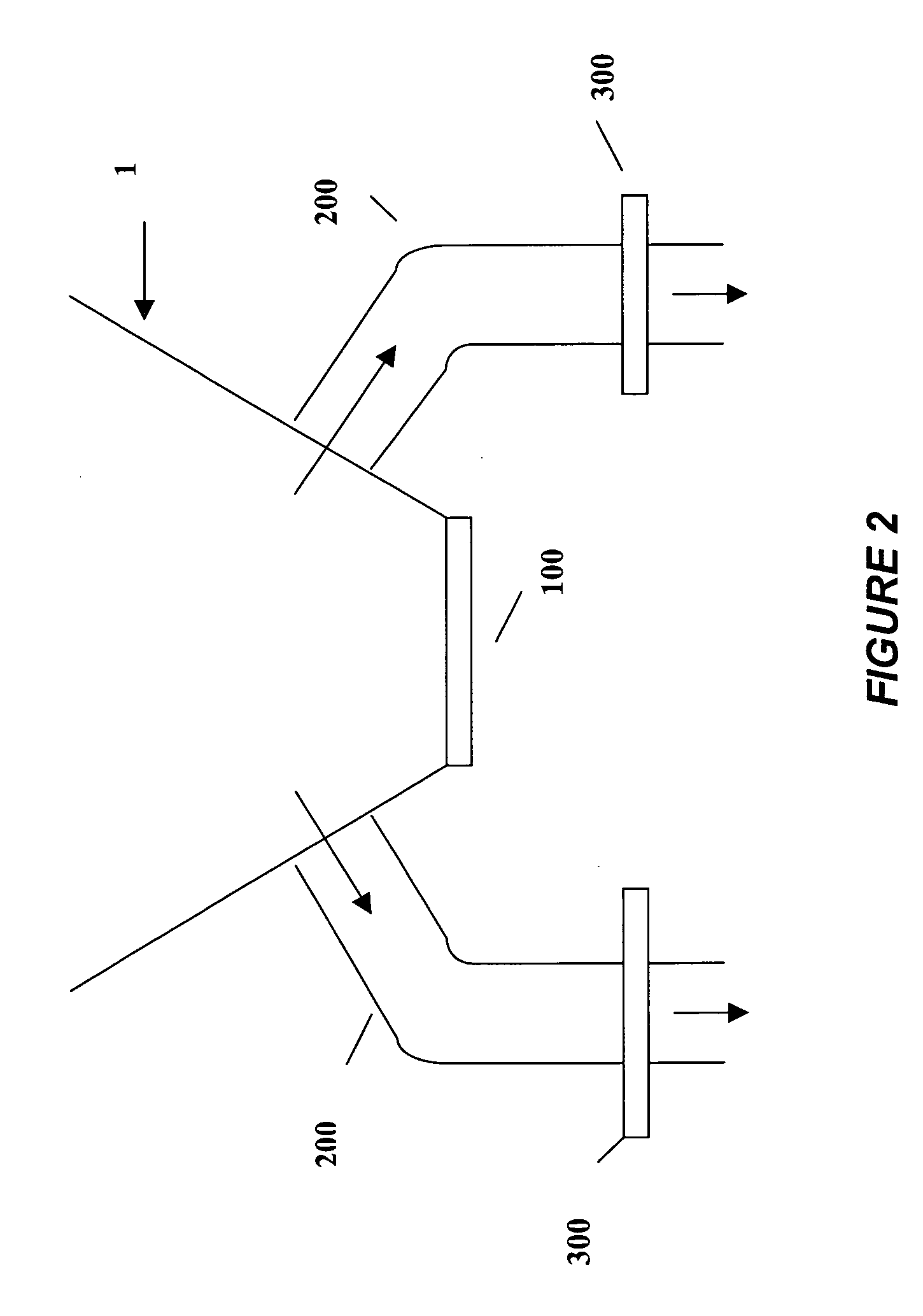

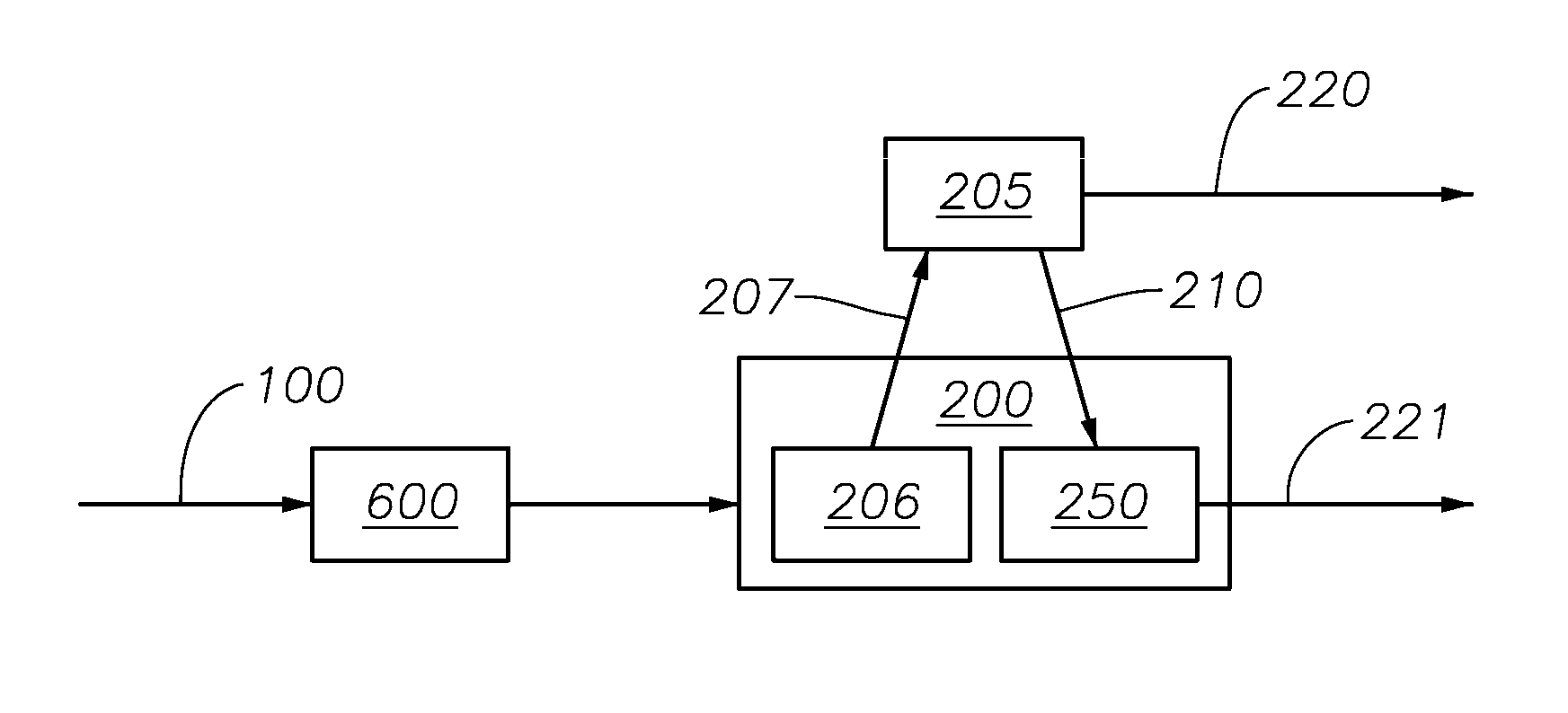

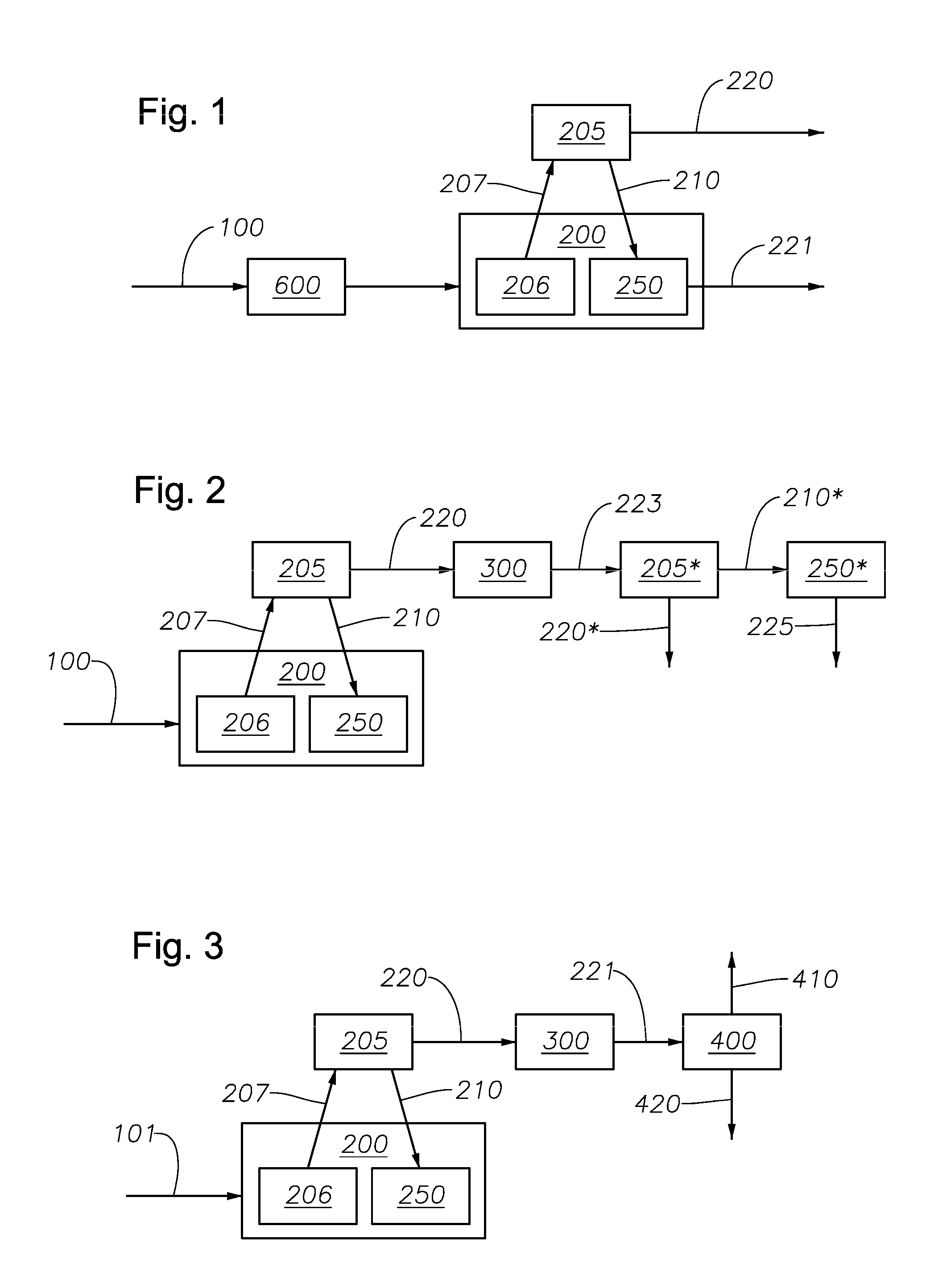

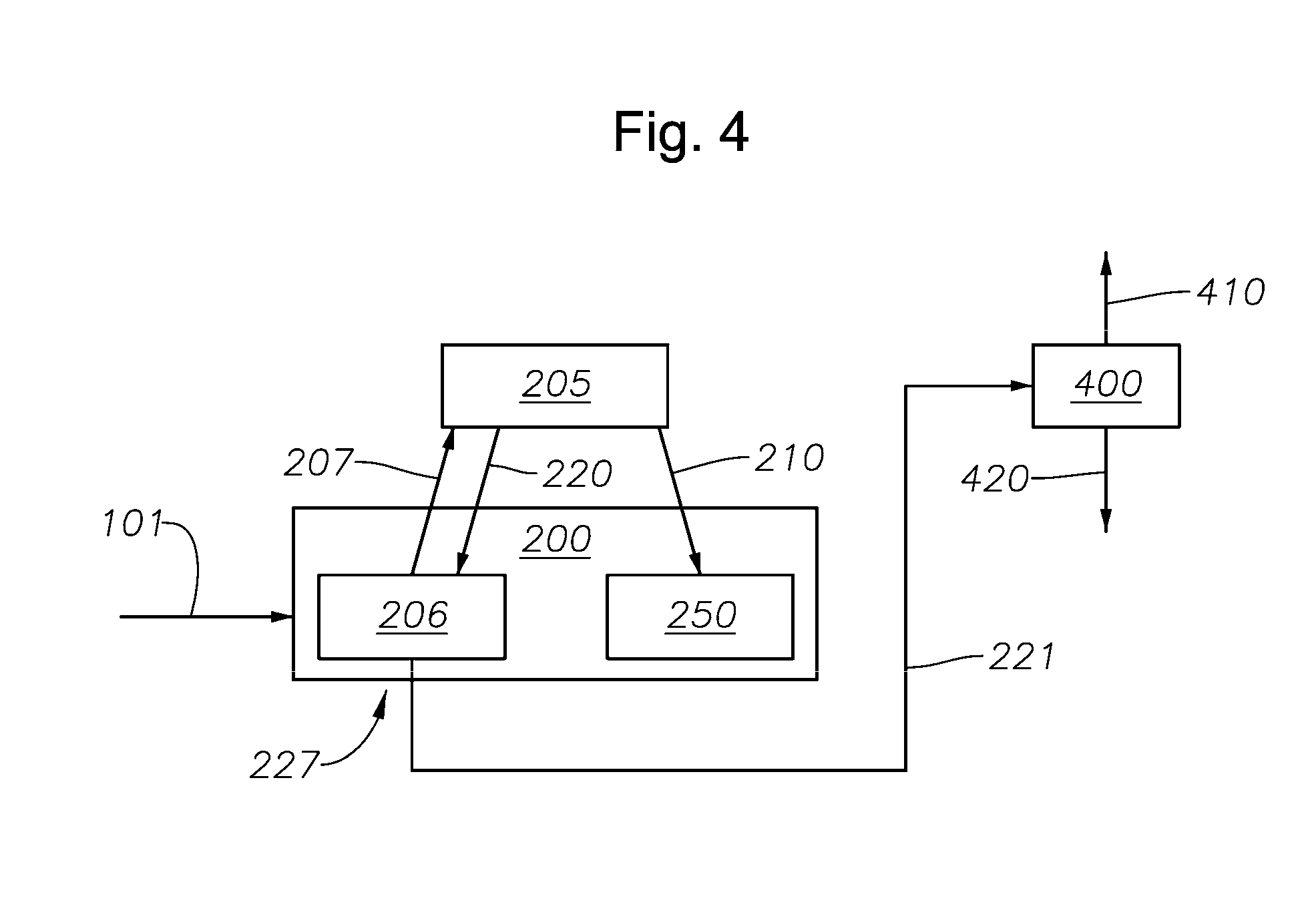

Integrated Process For Steam Cracking

ActiveUS20120006723A1Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyVisbreakerBoiling point

This invention relates to a process and system for cracking hydrocarbon feedstock containing vacuum resid comprising: (a) subjecting a vacuum resid to a first thermal conversion in a thermal conversion reactor (such as delayed coker, fluid coker, Flexicoker™, visbreaker and catalytic hydrovisbreaker) where at least 30 wt % of the vacuum resid is converted to material boiling below 1050° F. (566° C.); (b) introducing said thermally converted resid to a vapor / liquid separator, said separator being integrated into a steam cracking furnace, to form a vapor phase and liquid phase; (c) passing said vapor phase to the radiant furnace in said steam cracking furnace; and (d) recovering at least 30 wt % olefins from the material exiting the radiant furnace (based upon the weight of the total hydrocarbon material exiting the radiant furnace).

Owner:EXXONMOBIL CHEM PAT INC

Method for measuring reactor bed level from active acoustic measurement and analysis

Owner:EXXON RES & ENG CO

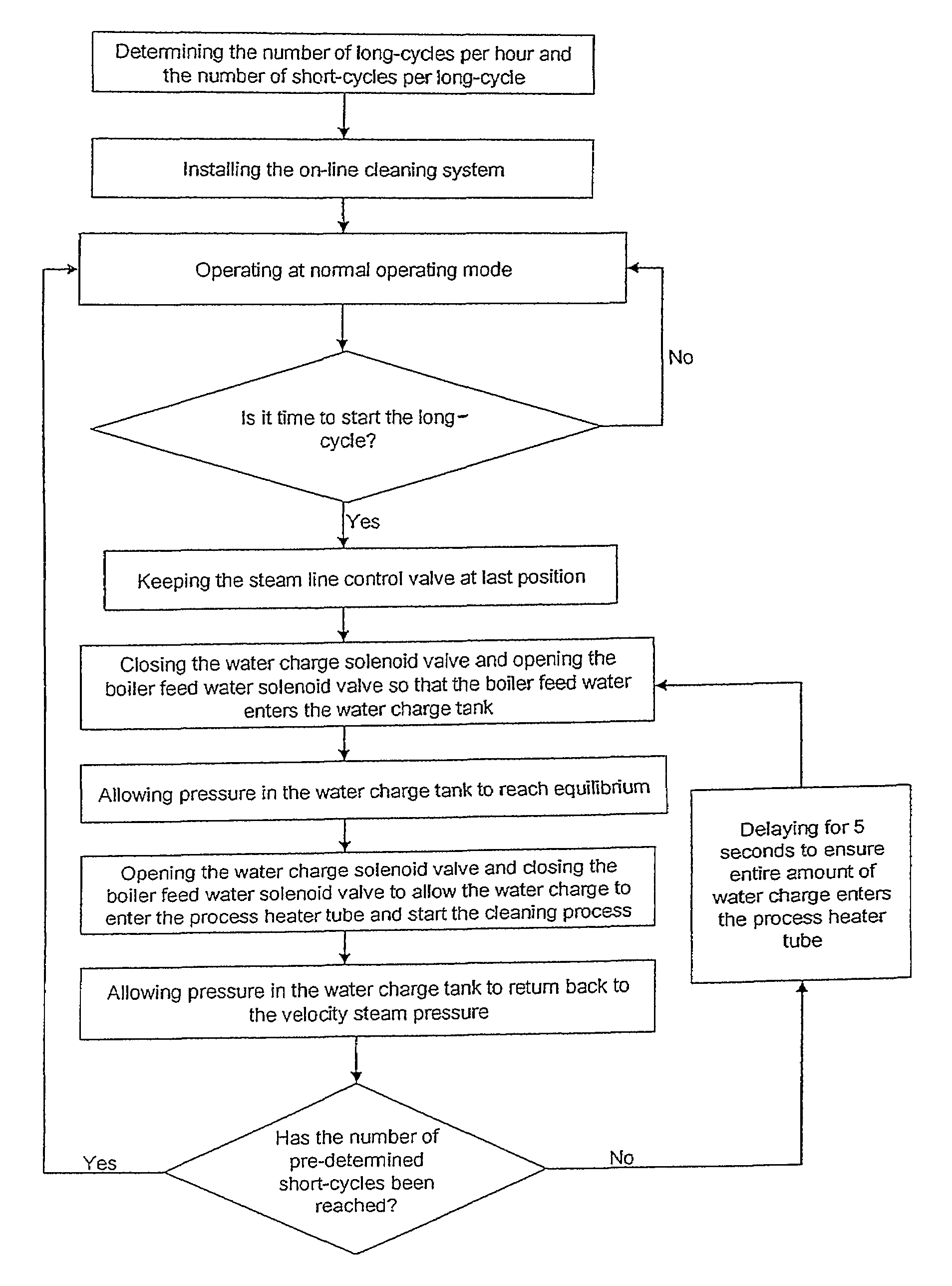

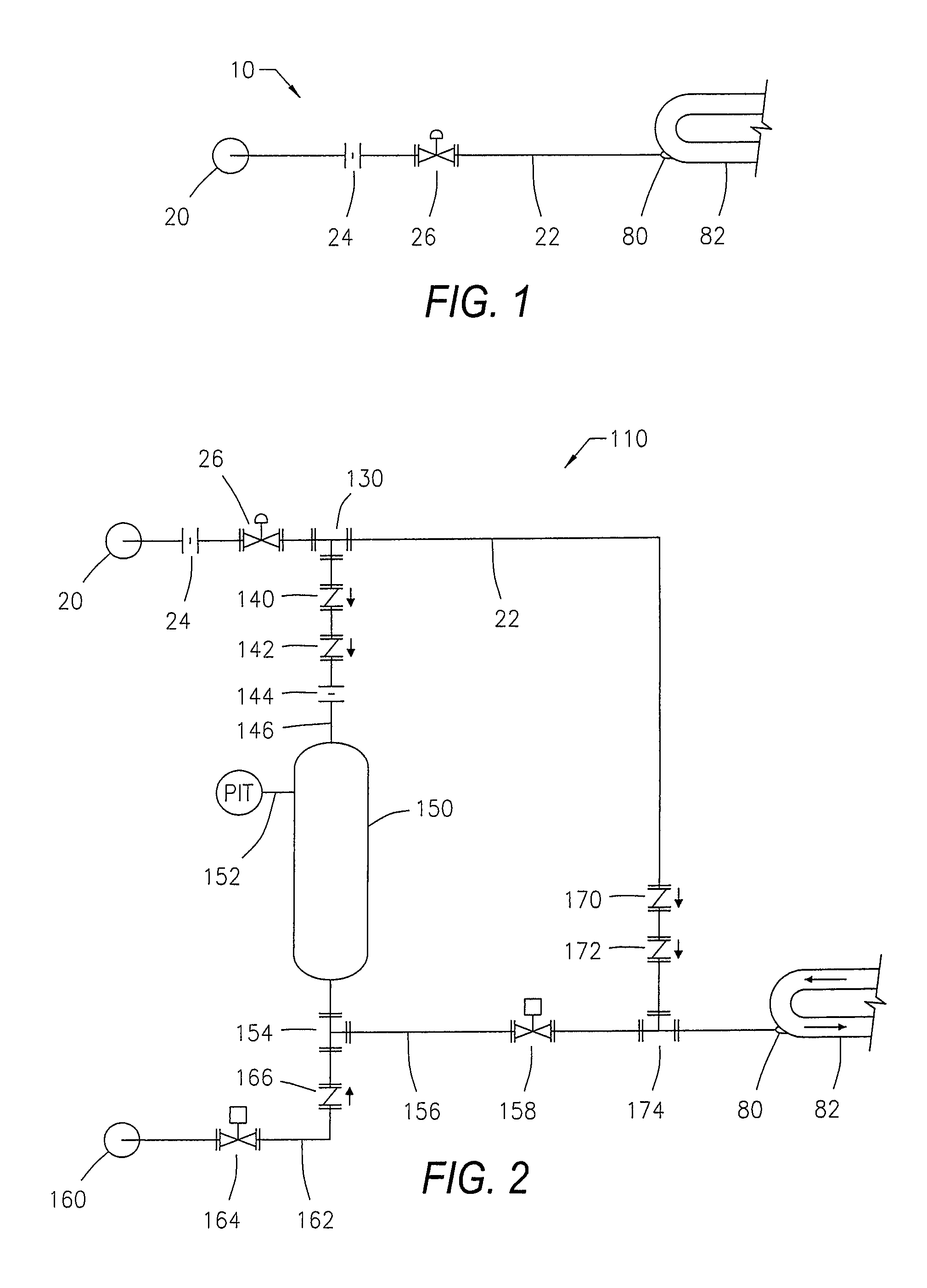

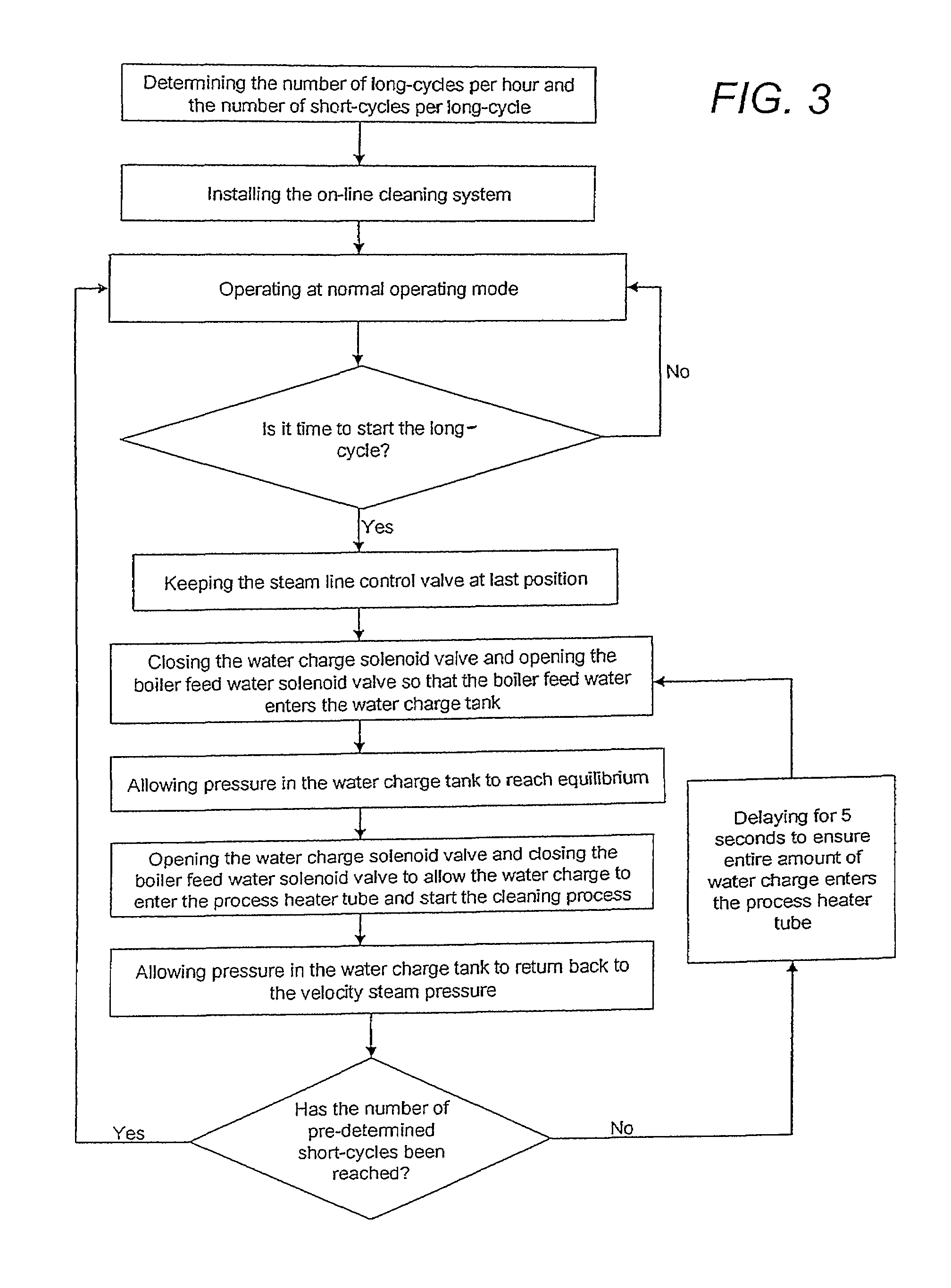

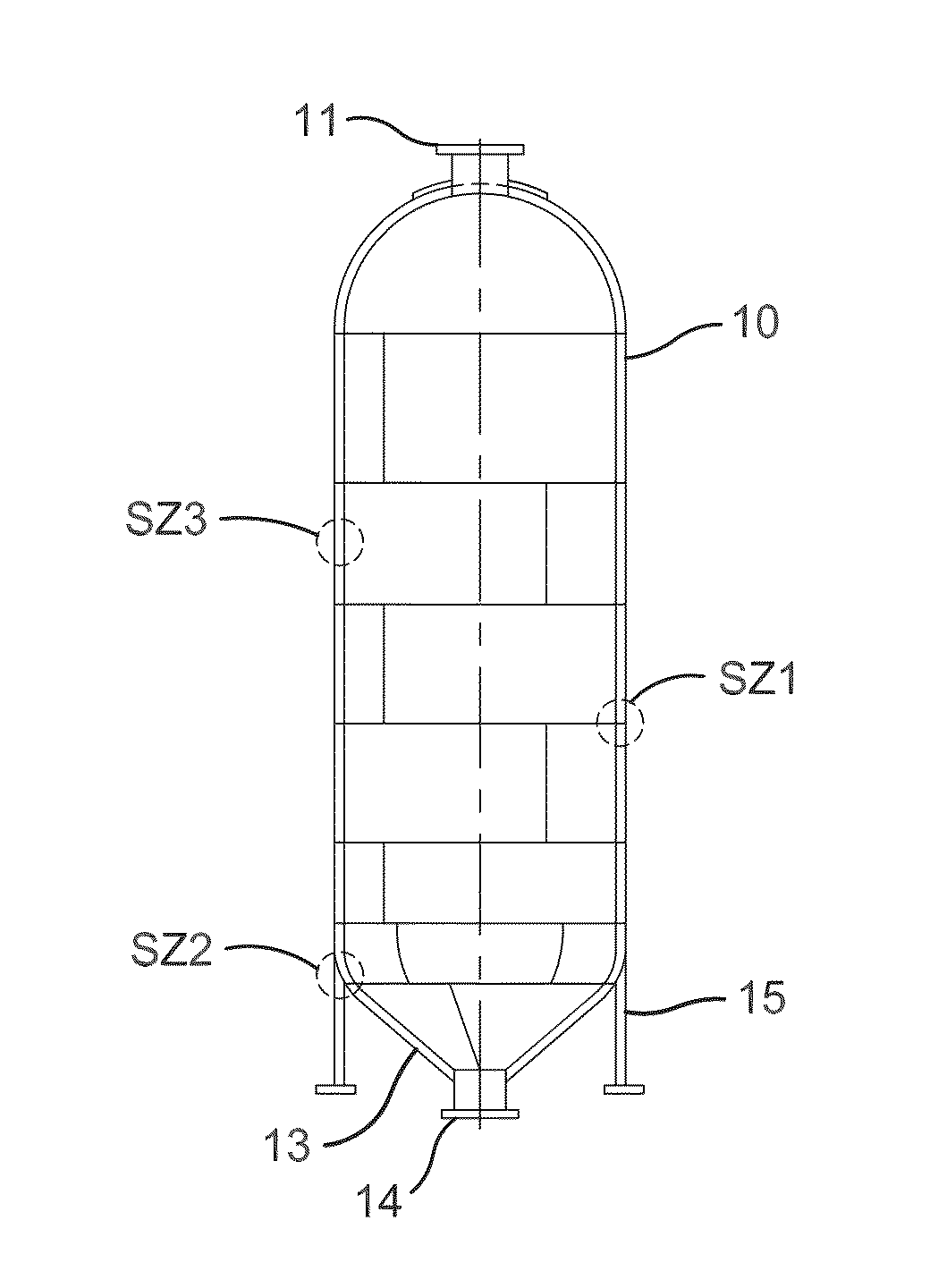

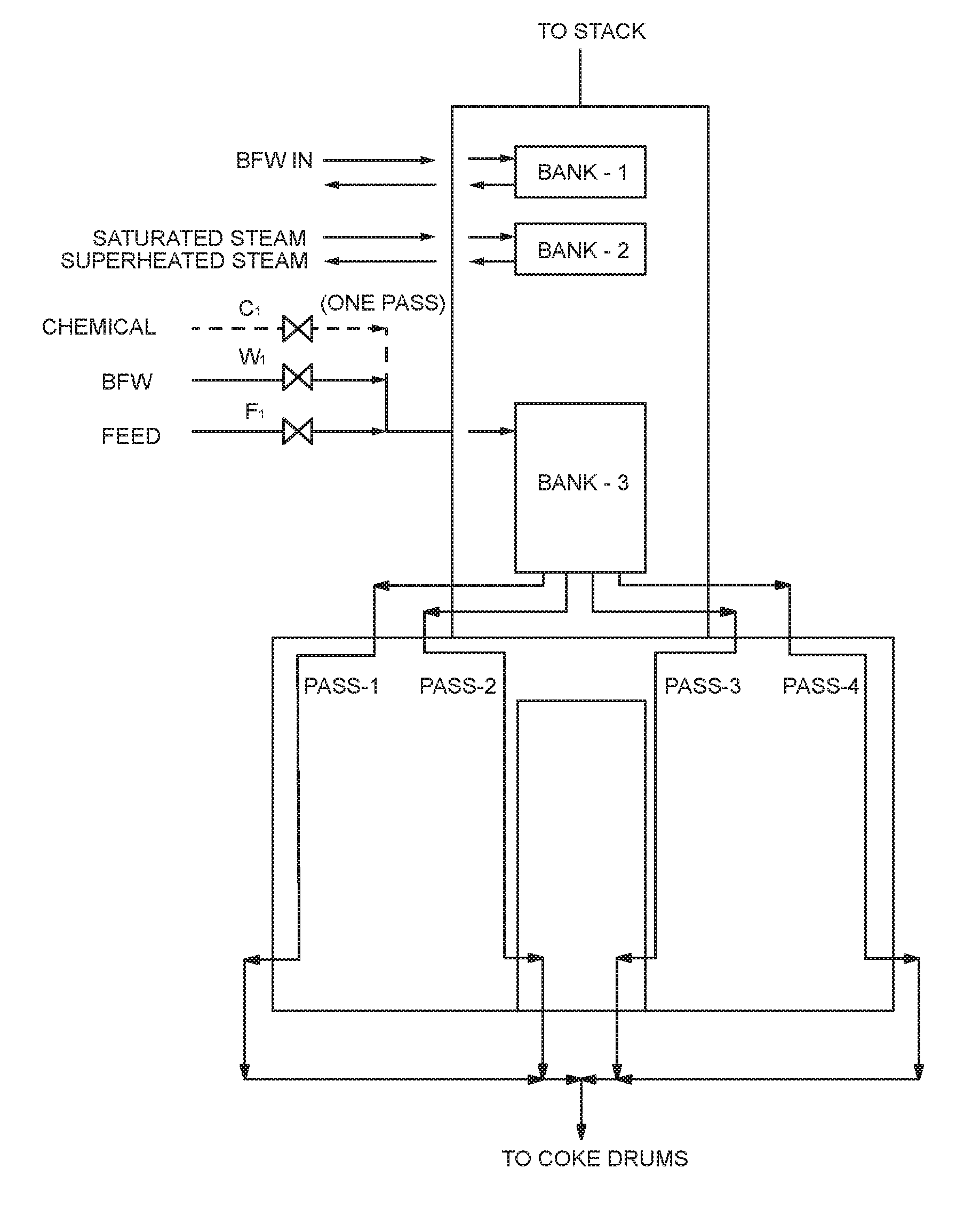

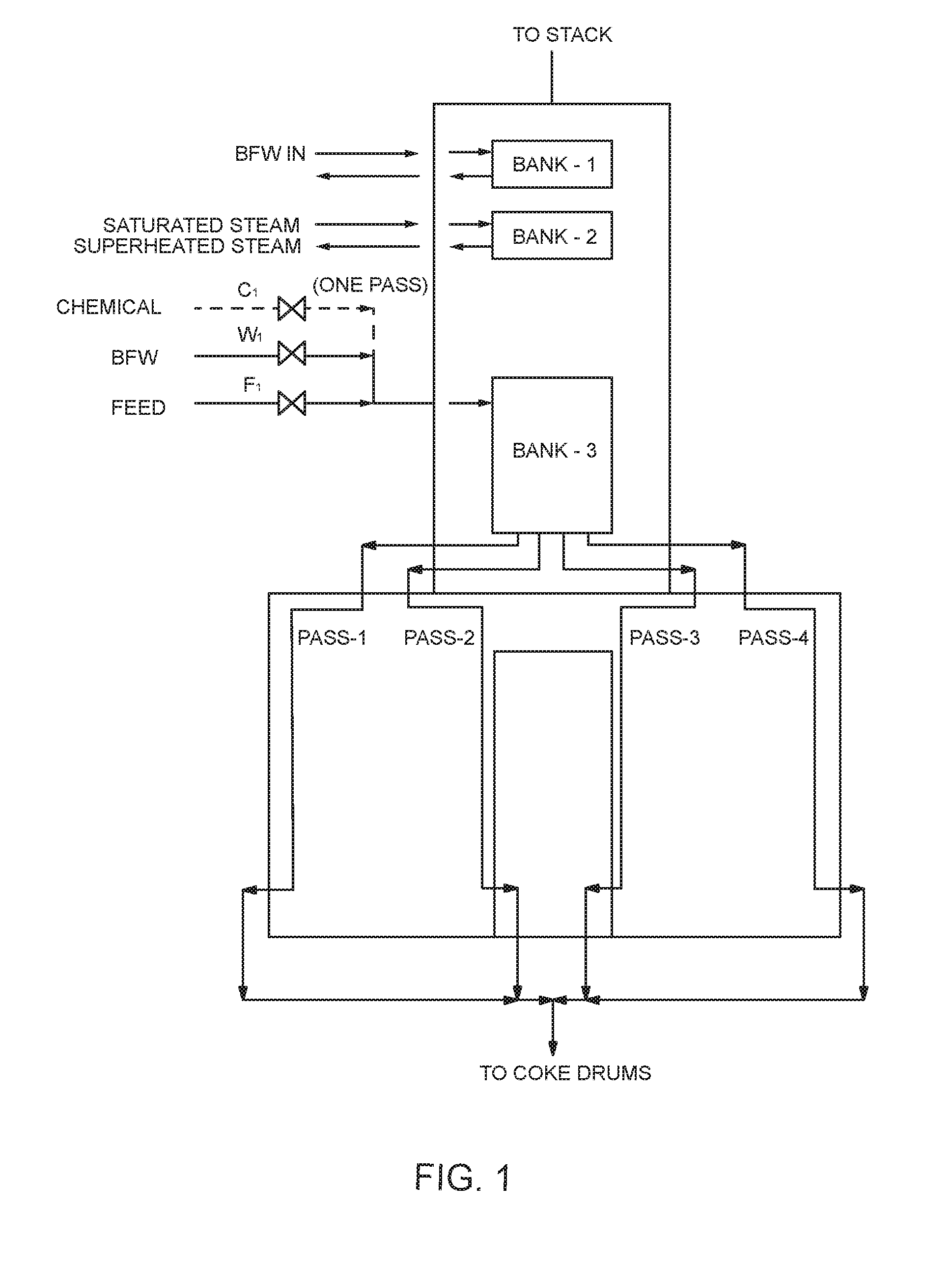

System and method for on-line cleaning of black oil heater tubes and delayed coker heater tubes

InactiveUS7670462B2Thermal non-catalytic crackingDirect heating destructive distillationWater flowEvaporation

A system and method whereby on-line cleaning of black oil heater tubes and delayed coker heater tubes may be effectuated by injecting a high pressure water charge through the tubes during normal process operations so as to prevent tube fouling and heater downtime. The high pressure water charge begins the on-line cleaning process once it enters the heater tube by undergoing intense boiling and evaporation. The cleaning occurs by two methods—a scrubbing action and a shocking action. The scrubbing action occurs because of the complete turbulence caused by the water charge's intense boiling within the heater tubes. The shocking action is caused by the expansion and contraction of the heater tubes resulting from the colder water charge flowing through the heater tubes which is then followed by the hotter process fluid flowing through the heater tubes.

Owner:GREAT SOUTHERN INDEPENDENT

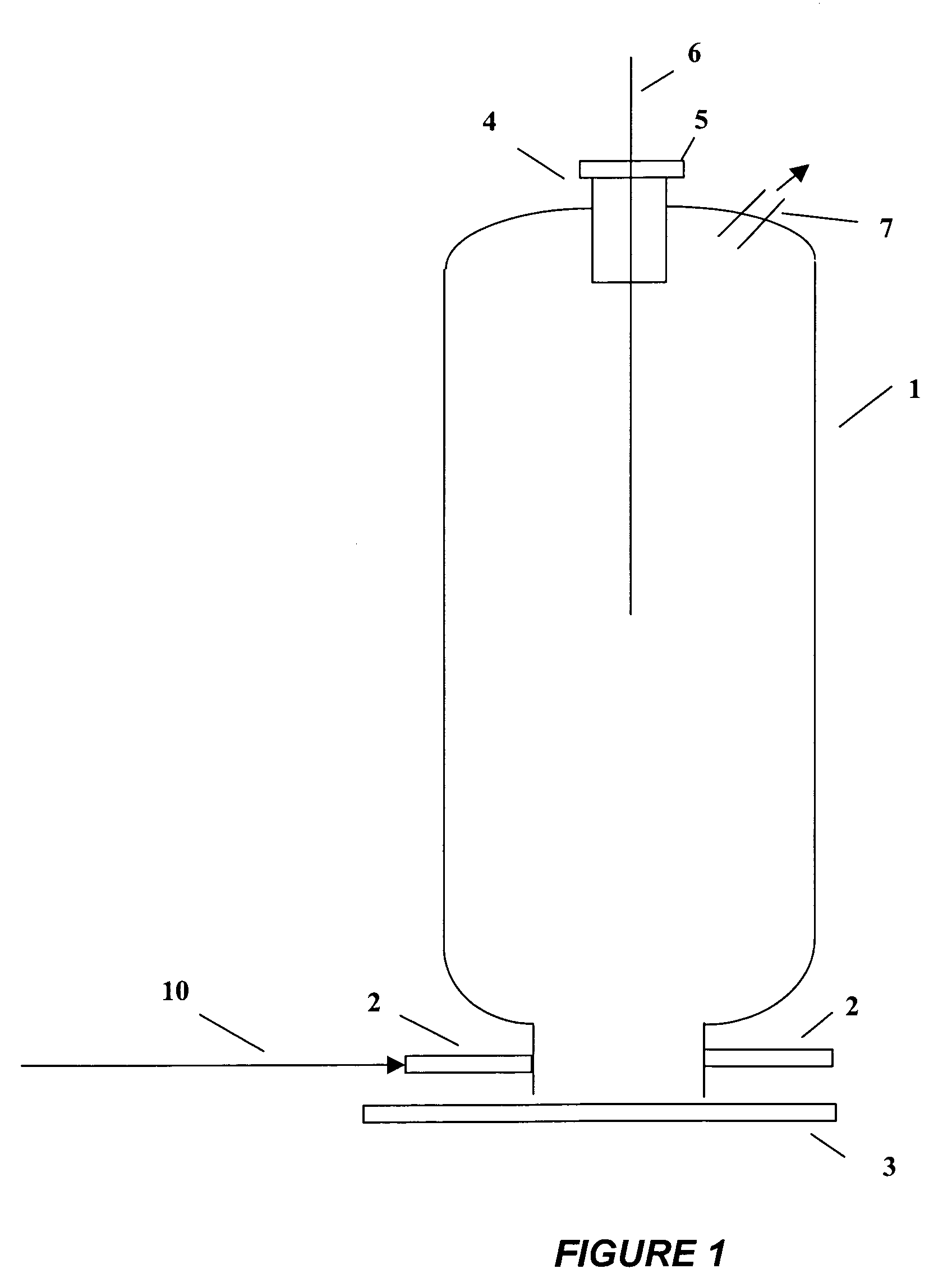

Internal lining for delayed coker drum

ActiveUS20150267122A1Relieve pressureReduce and minimize transient thermal stressThermal non-catalytic crackingCoke quenchingDelayed cokerEngineering

A delayed coking unit has a thermal shock-resistant, erosion-resistant internal lining to reduce thermally-induced mechanical stresses in the pressure boundary of the coke drum. The lining is effective to reduce or mitigate the transient thermal stress that occurs in the pressure boundary of the coke drum and to reduce or minimize the high thermal stress resulting from temperature differentials at the skirt-to-shell junction.

Owner:EXXON RES & ENG CO

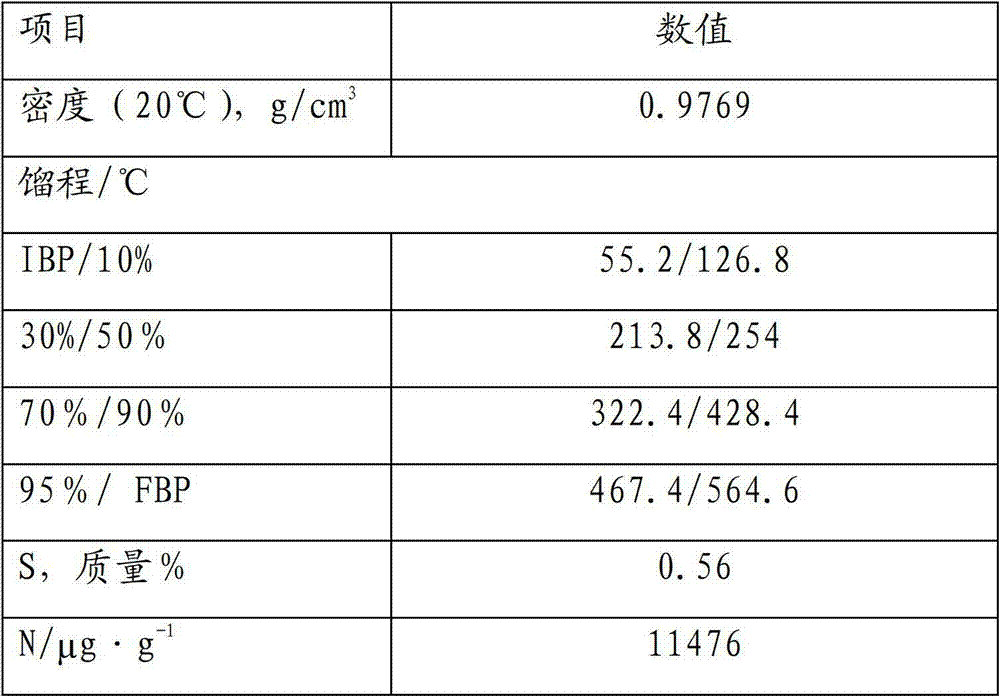

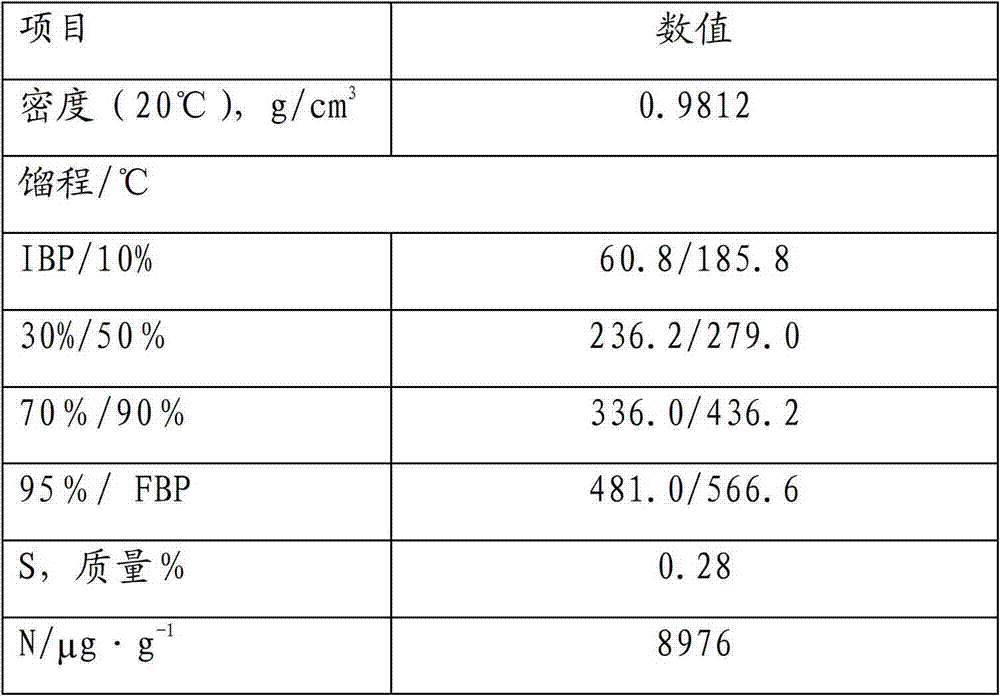

Process of used lubricant oil recycling

InactiveUSRE36922E1Thermal non-catalytic crackingLiquid hydrocarbon mixture productionSulfurNitrogen

A used lubricant oil recycling process is disclosed in which a used lubricating oil is injected to a delayed coker downstream of the coker furnace whereby the used oil is thermally cracked into hydrocarbon fuel products which are low in metal contaminants, sulfur and nitrogen. The used lubricant can be preheated in an independent heater to avoid a quenching effect of the process stream when added in an amount greater than about 3% by volume based on the entire volume of the feed.

Owner:MOBIL OIL CORP

Integrated process for steam cracking

ActiveUS8399729B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyVisbreakerBoiling point

This invention relates to a process and system for cracking hydrocarbon feedstock containing vacuum resid comprising: (a) subjecting a vacuum resid to a first thermal conversion in a thermal conversion reactor (such as delayed coker, fluid coker, Flexicoker™, visbreaker and catalytic hydrovisbreaker) where at least 30 wt % of the vacuum resid is converted to material boiling below 1050° F. (566° C.); (b) introducing said thermally converted resid to a vapor / liquid separator, said separator being integrated into a steam cracking furnace, to form a vapor phase and liquid phase; (c) passing said vapor phase to the radiant furnace in said steam cracking furnace; and (d) recovering at least 30 wt % olefins from the material exiting the radiant furnace (based upon the weight of the total hydrocarbon material exiting the radiant furnace).

Owner:EXXONMOBIL CHEM PAT INC

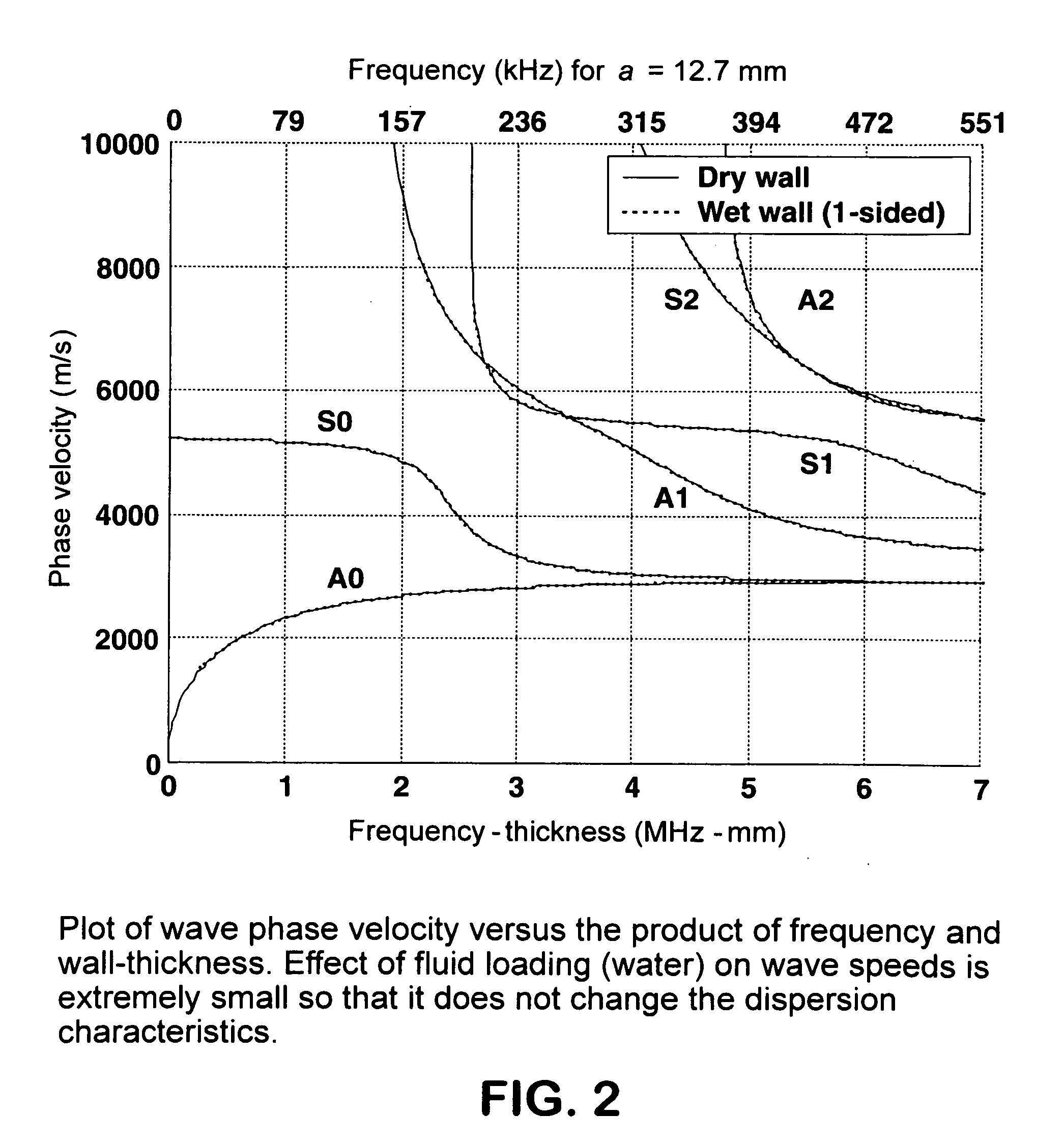

Method for measuring reactor bed level from active acoustic measurement and analysis

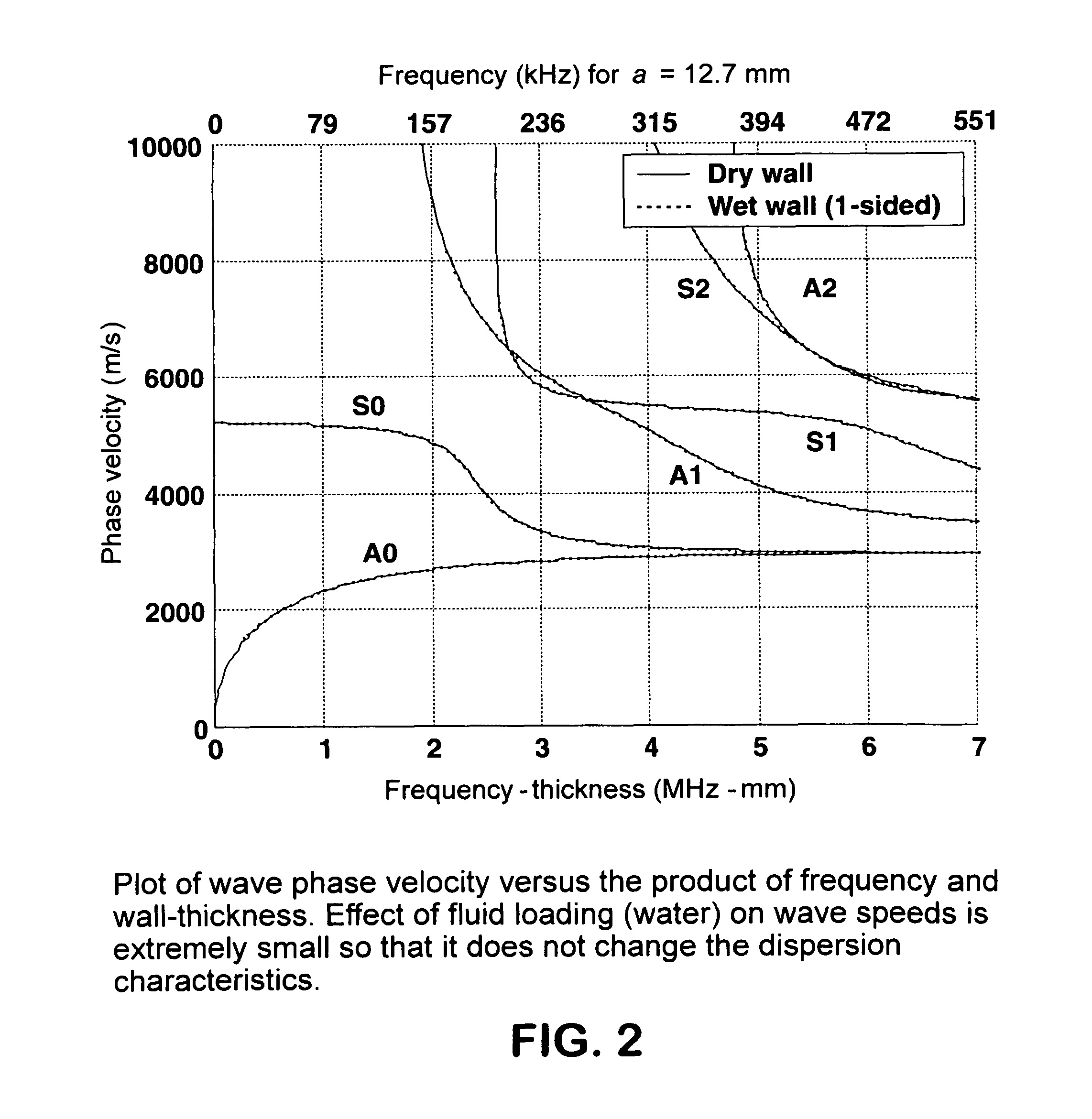

ActiveUS20090314080A1Machines/enginesLubrication indication devicesUltrasound attenuationAccelerometer

The present invention is a non-intrusive method to determine the fluid level in a vessel. In a preferred embodiment, the vessel is a delayed coker drum in a refinery. Waves are generated in the vessel from an outside source. For wall vibration generated in the frequency range of 1-20,000 Hz, accelerometers on the exterior wall of the vessel measures the attenuation of the vibration modes of the vessel. The fluid level can related to the attenuation of the vibration mode. For wall vibration generated in the ultrasonic range, the wave traveling in the vessel wall are guided waves. The guided wave will leak energy into the fluid inside the vessel and will attenuate depending on the fluid level. Ultrasonic receivers on the outside of the vessel measure the attenuation. The fluid level can be related attenuation of the ultrasonic waves.

Owner:EXXON RES & ENG CO

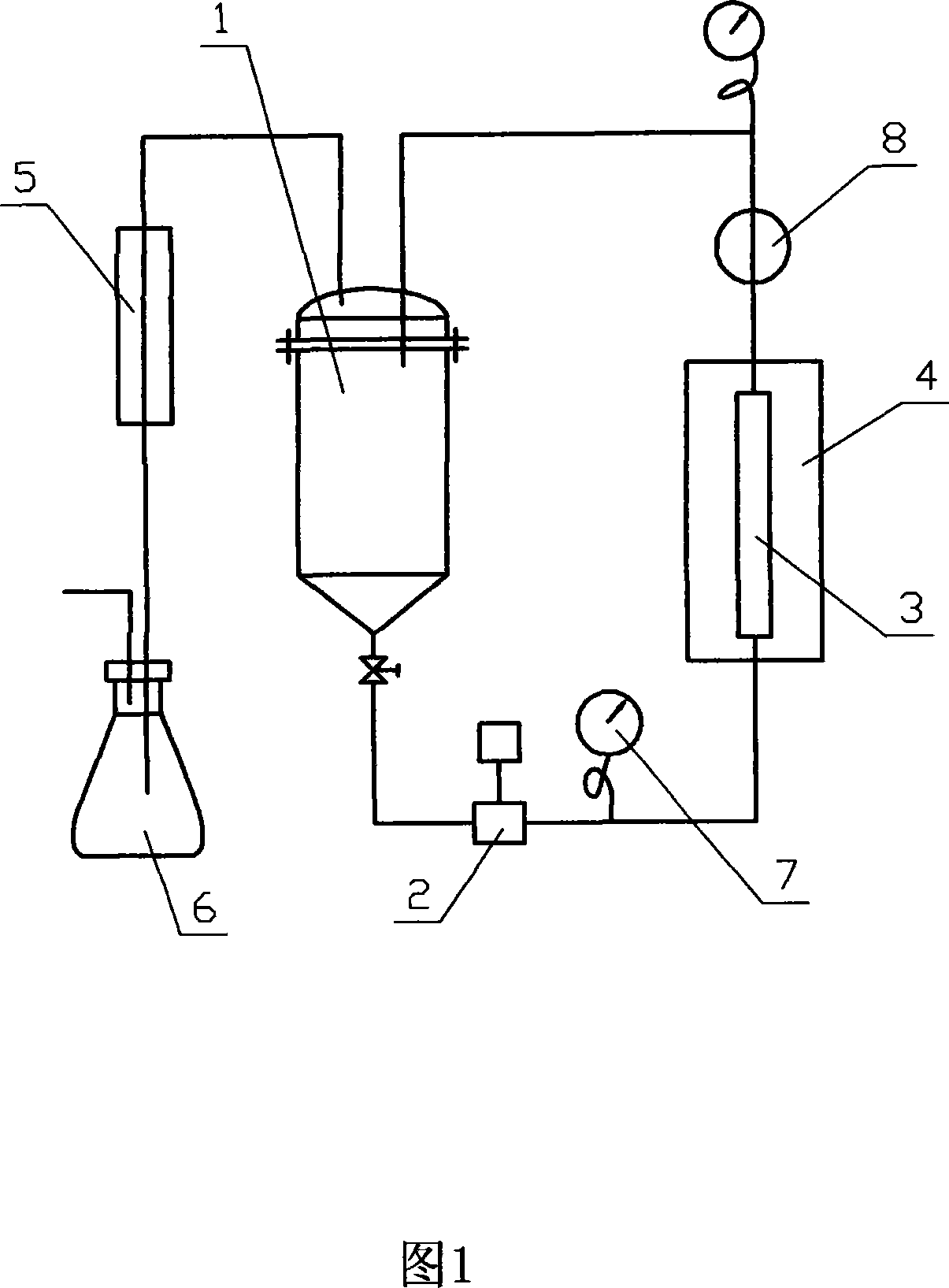

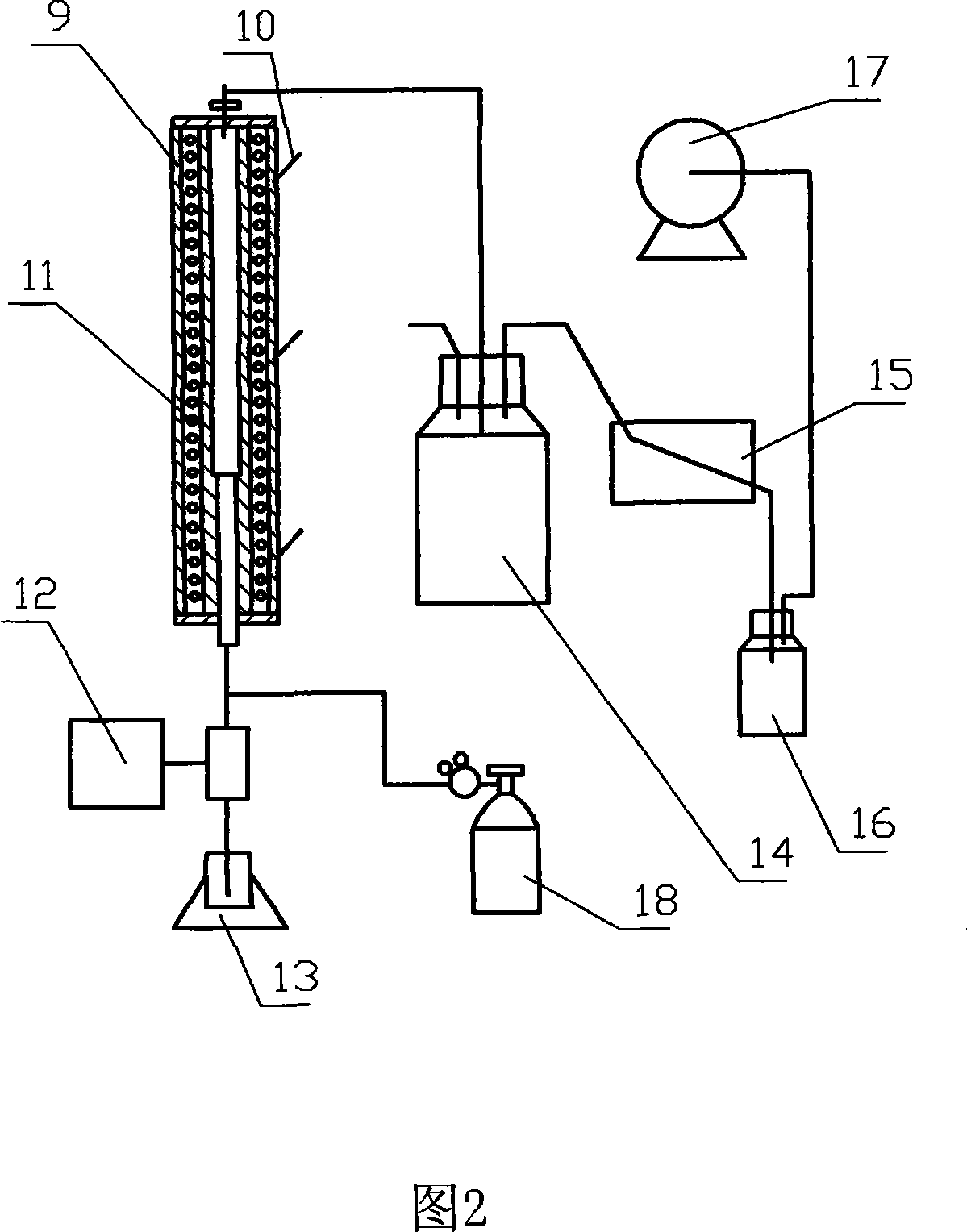

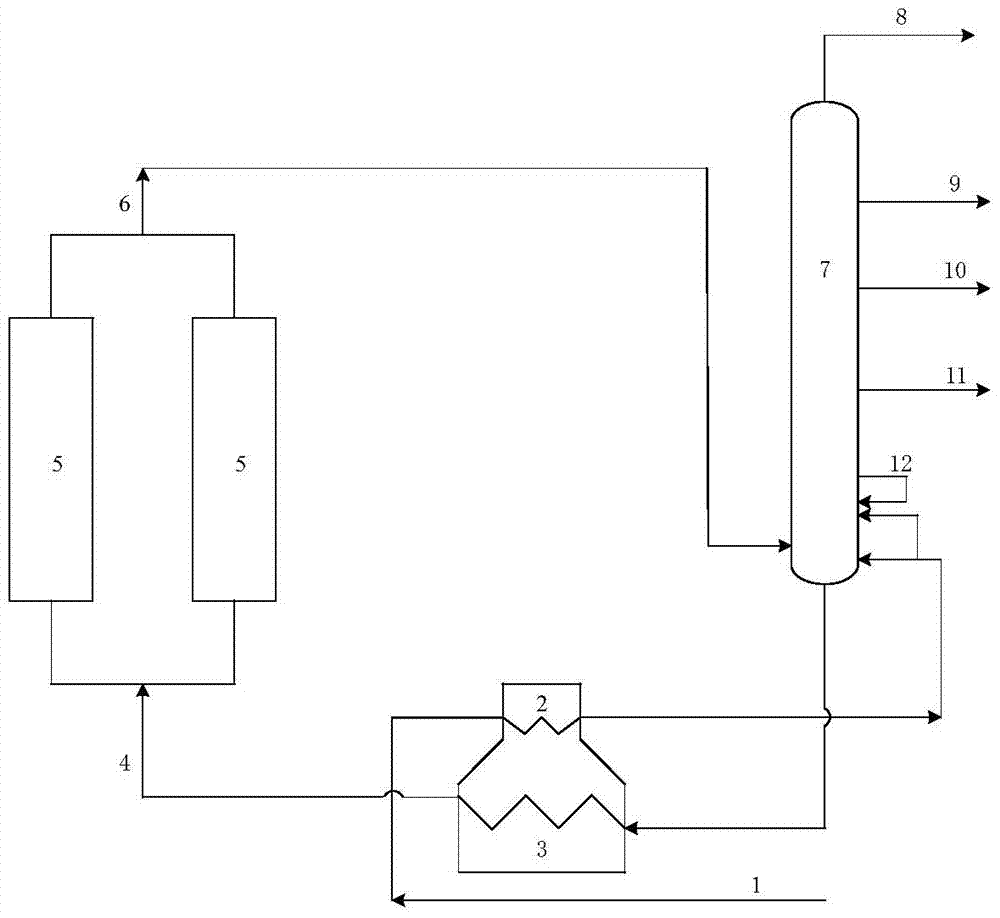

Method for processing delay coking liquid hydrocarbons with gas fractional distillation apparatus

InactiveCN101319149ASolve unqualifiedHydrocarbon distillationTreatment with plural serial refining stagesThiolLiquid state

The present invention discloses a method for producing propylene, propane and C4 fraction by pre-processing a liquid state hydrocarbon generated by a delayed coker and processing the liquid state hydrocarbon as a raw material of a gas fractionation plant. The method is comprises the following steps that: the coked liquid state hydrocarbon in which hydrogen sulfide is removed by an amine solution is subjected to sodafining and water washing to remove thiol and a small amount of water before entering a gas separation device; and then the liquid state hydrocarbon enters a COS hydrolyzer to desulfurate; afterward, hydrogen sulfide generated from the hydrolization is removed; and then the liquid state hydrocarbon enters the gas fractionation plant as a material to be processed.

Owner:孙海兵 +1

Processing method of tinpot oil

ActiveCN104650976AImprove conversion rateAvoid burnsTreatment with hydrotreatment processesLiquid productSlag

The invention relates to a processing method of tinpot oil, comprising the following steps: a, an oil-soluble catalyst and a heavy oil raw material are uniformly mixed and the mixture is then sent into a hydrogenation reactor to carry out a hydrogenation reaction under the existence condition of hydrogen; b, a liquid product obtained from the hydrogenation reaction enters a distiller to be cut into light oil and tail oil; c, the tail oil from the step b undergoes general hydrocyclone separation to obtain slag-removed tail oil and tailings; d, the slag-removed tail oil from the step c is sent into a delayed coker to undergo thermal cracking so as to obtain light distillate oil, dry gas and coke; and e, the tail oil from the step c is roasted and metal in the oil-soluble catalyst is recovered. By the above method, residual oil conversion rate is raised; green coke during the process is avoided; the problem that it is difficult to hydrotreat tail oil and metal in the catalyst cannot be recovered is solved; and the problem that coke obtained by coking of a high-sulfur raw material cannot be used is solved. Light distillate oil yield is raised by 10%. The technology is simple; the method is convenient to operate; investment is low; and the method is environmentally friendly.

Owner:PETROCHINA CO LTD

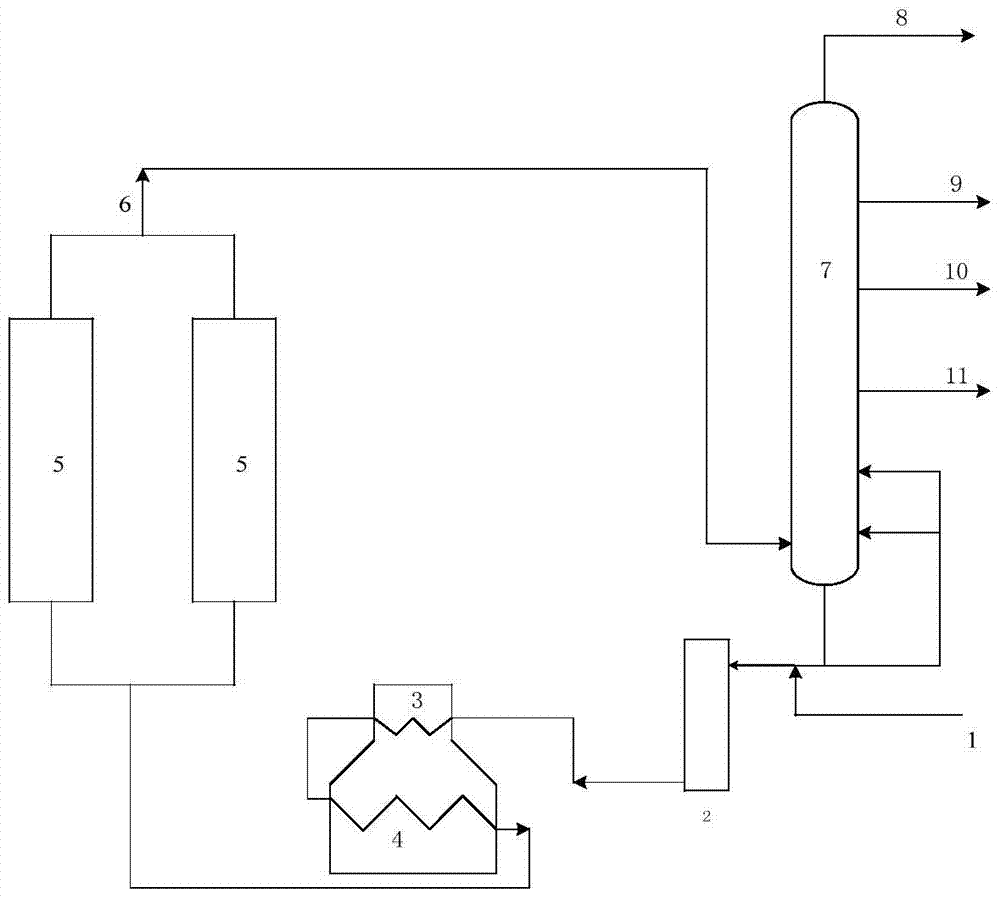

Deep processing method of non-caking coal or feebly caking coal

The invention discloses a deep processing method of non-caking coal or feebly caking coal, which comprises the following steps: performing medium-and-low-temperature carbonization reaction on non-caking coal or feebly caking coal to generate coal gas, semicoke and coal tar; treating the coal tar as follows: inputting the coal tar material, oil gas obtained through delayed coking reaction and a hydrocracking liquid-phase product into a distillation tower, and distilling out naphtha fractions, carbolic-oil-containing fractions, wax oil fractions and tower bottom oil; mixing the naphtha fractions with hydrogen, and inputting into a naphtha hydrofining reaction section; dephenolizing the carbolic-oil-containing fractions to obtain dephenolized oil, mixing with the wax oil fractions, and inputting into a hydrotreating reaction section; fractionating the hydrotreating reaction liquid phase into light fractions and heavy fractions, and performing hydrocracking on the heavy fractions; and inputting the tower bottom oil obtained through distillation into a delayed coker. Compared with the prior art, the method disclosed by the invention performs sufficient deep processing on coal, improves the yield of light fuel oil produced from coal tar, and simultaneously prolongs the service life of a catalyst in a hydrogenation device.

Owner:中铝能源有限公司

Blending of resid feedstocks to produce a coke that is easier to remove from a coker drum

InactiveUS20050284798A1Efficient formationThermal non-catalytic crackingLiquid organic insulatorsAPI gravityDelayed coker

A method of blending delayed coker feedstocks to produce a coke that is easier to remove from a coker drum. A first feedstock is selected having less than about 250 wppm dispersed metals content and greater than about 5.24 API gravity. A second delayed coker feedstock is blended with said first resid feedstock so that the total dispersed metals content of the blend will be greater than about 250 wppm and the API gravity will be less than about 5.24.

Owner:EXXON RES & ENG CO

A method of delayed coking

Owner:CHINA PETROLEUM & CHEM CORP +1

Optimized coke cutting method for decoking substantially free-flowing coke in delayed cokers

InactiveUS7815775B2Shorten the timeReduces the manpower required and the uncertainty inherentCoke oven safety devicesDirect heating destructive distillationDelayed cokerEngineering

A method for coke removal in delayed coker drums is provided. The method comprises the steps of draining from the drum of substantially free-flowing coke, performing a vibration signature analysis on the drum to identify whether and where any coke remains attached to the interior wall of the drum after the draining step, and cutting the coke from the areas identified by the signature analysis step.

Owner:EXXON RES & ENG CO

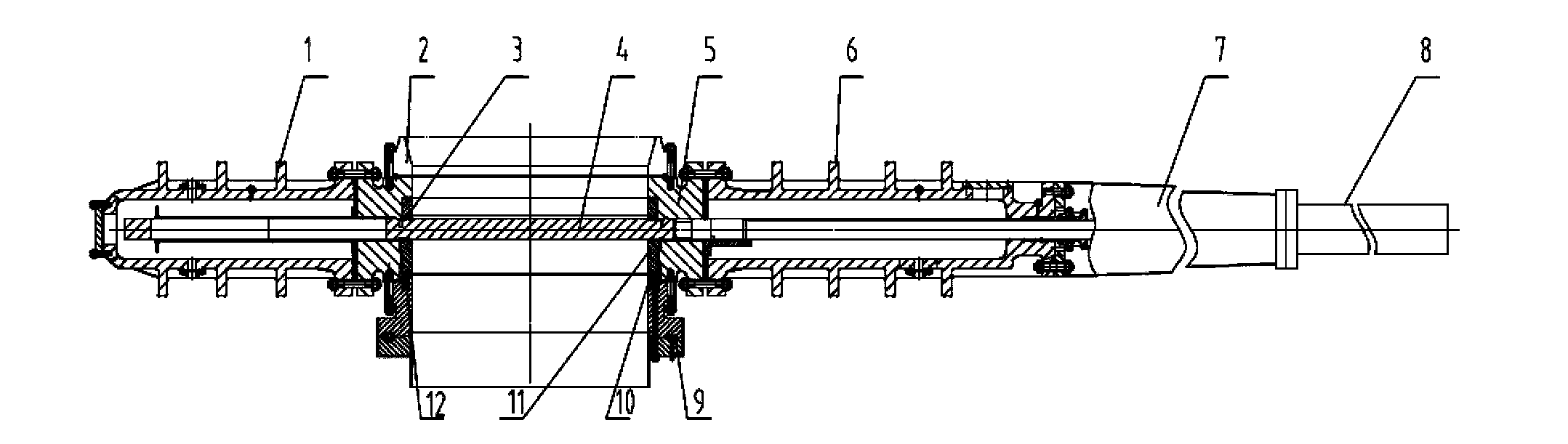

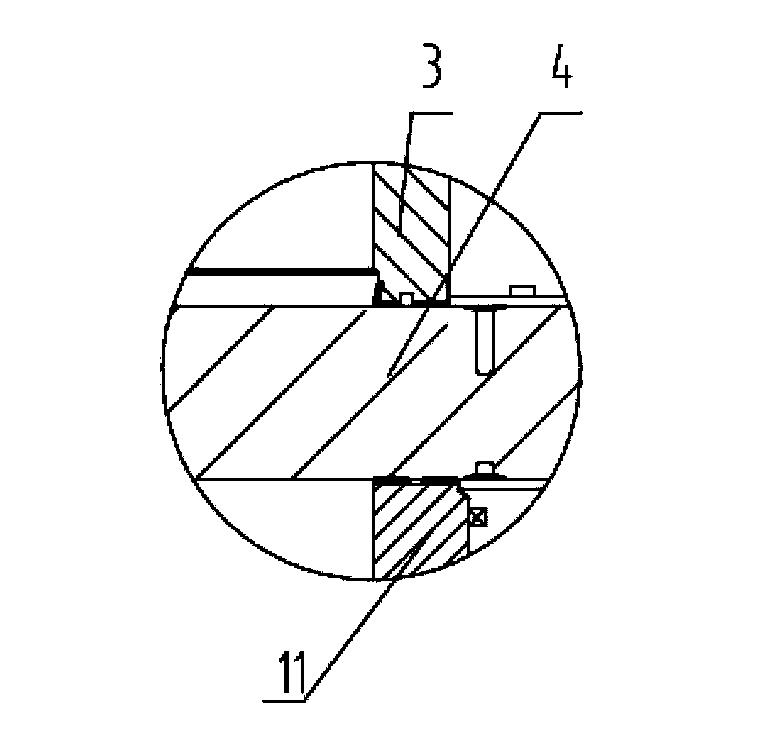

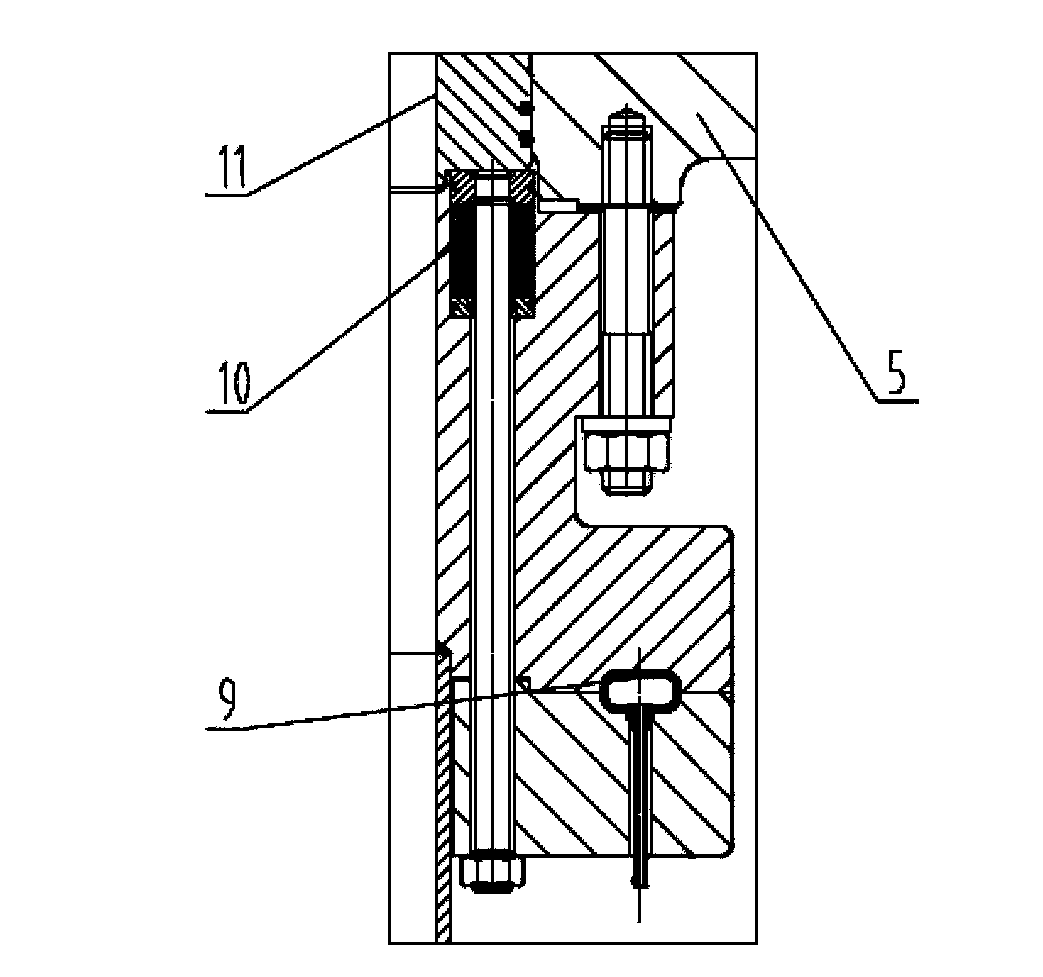

Valve for coke tower

The invention discloses a valve for a coke tower and belongs to the field of oil refining and chemical engineering devices. The valves are arranged on the top and at the bottom of the coke tower for a delayed coker. The valve comprises a valve body, a rear valve deck, a front valve deck, an upper valve seat, a lower valve seat, a valve plate, a support, a hydraulic oil cylinder, an unloading hydraulic ring and two sets of belleville springs. According to the structure, the valve has the advantages that after the valve is closed, the total seal specific pressure is quite large, and the sealing force can be adjusted, so that the sealing effect is greatly improved, and the steam consumption is low. In the process of action of the valve for the coke tower, the total seal specific pressure is relatively small after unloading, and therefore the abrasion of the valve plate, the upper valve seat and the lower valve seat is reduced. In the process of operation of the valve for the coke tower, steam is fed into the front valve deck and the rear valve deck, the pressure of the steam is 0.1 Mpa higher than the pressure of a medium, and therefore the auxiliary sealing function is achieved. In this way, through the measures, the valve for the coke tower has the advantages of being zero in medium leakage amount, high in sealing performance, and safe and reliable in overall structure.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Coking-prevention light oil yield increasing agent for delayed coker of oil refinery

InactiveCN102776027AHigh yieldStop cokingTreatment apparatus corrosion/fouling inhibitionActive agentFatty amine

The invention provides a coking-prevention light oil yield increasing agent for a delayed coker of an oil refinery. The coking-prevention light oil yield increasing agent comprises the following raw materials in percentage by mass: 35-37% of high-temperature-resistance antioxygen, 13-15% of high-temperature-resistance clearing agent, 10% of high-temperature-resistance dispersing agent, 5% of high-temperature-resistance metal deactivator, 5% of surfactant and 30% of solvent naphtha, wherein the high-temperature-resistance antioxygen is at least one of 2,6-di-tert-butyl catechol, 2,6-di-tert-butyl-p-cresol and 2.6-di-tert-butyl-ethylphenol, the high-temperature-resistance clearing agent is high-base-number linear alkyl benzene sulfonic acid calcium, the high-temperature-resistance dispersing agent is polyisobutylene bissuccinimide, the surfactant is fatty amine polyoxyethylene ether, the high-temperature-resistance metal deactivator comprises at least one of the following inorganic antimony compounds: antimony pentoxide, colloidal solution of antimony pentoxide, antimony pentasulfide, antimony sulfate, or the high-temperature-resistance metal deactivator comprises at least one of the following organic antimony compounds: stibium mercaptide, tricarboxylic antimony, triphenyl antimony, antimony diisopropyl dithiophosphate. The coking-prevention light oil yield increasing agent can be applied to the delayed coker of the oil refinery, the coking resistance rate is higher than 85%, and the yield of light oil is improved by over 1.5%.

Owner:关平

Desulfurization of naphtha blends

InactiveUS20160046881A1Minimize the octane lossLarge specific surface areaTreatment with hydrotreatment processesHydrocarbon oils refiningNaphthaHydrodesulfurization

A process for desulfurizing a delayed coker naphtha in a catalytic naphtha desulfurization process in which the feed comprising the delayed coker naphtha is passed over a silicon trap comprising a high surface area inert alumina of low metals content prior to being hydrodesulfurized in an olefin-retentive, catalytic naphtha hydrodesulfurization process. Unpromoted (no intentional metals content), inert alumina is preferred for the silicon trap since it will not affect the olefin-retentive qualities of the hydrodesulfurization catalyst and for maximal silicon capture, a high surface area alumina is employed.

Owner:EXXON RES & ENG CO

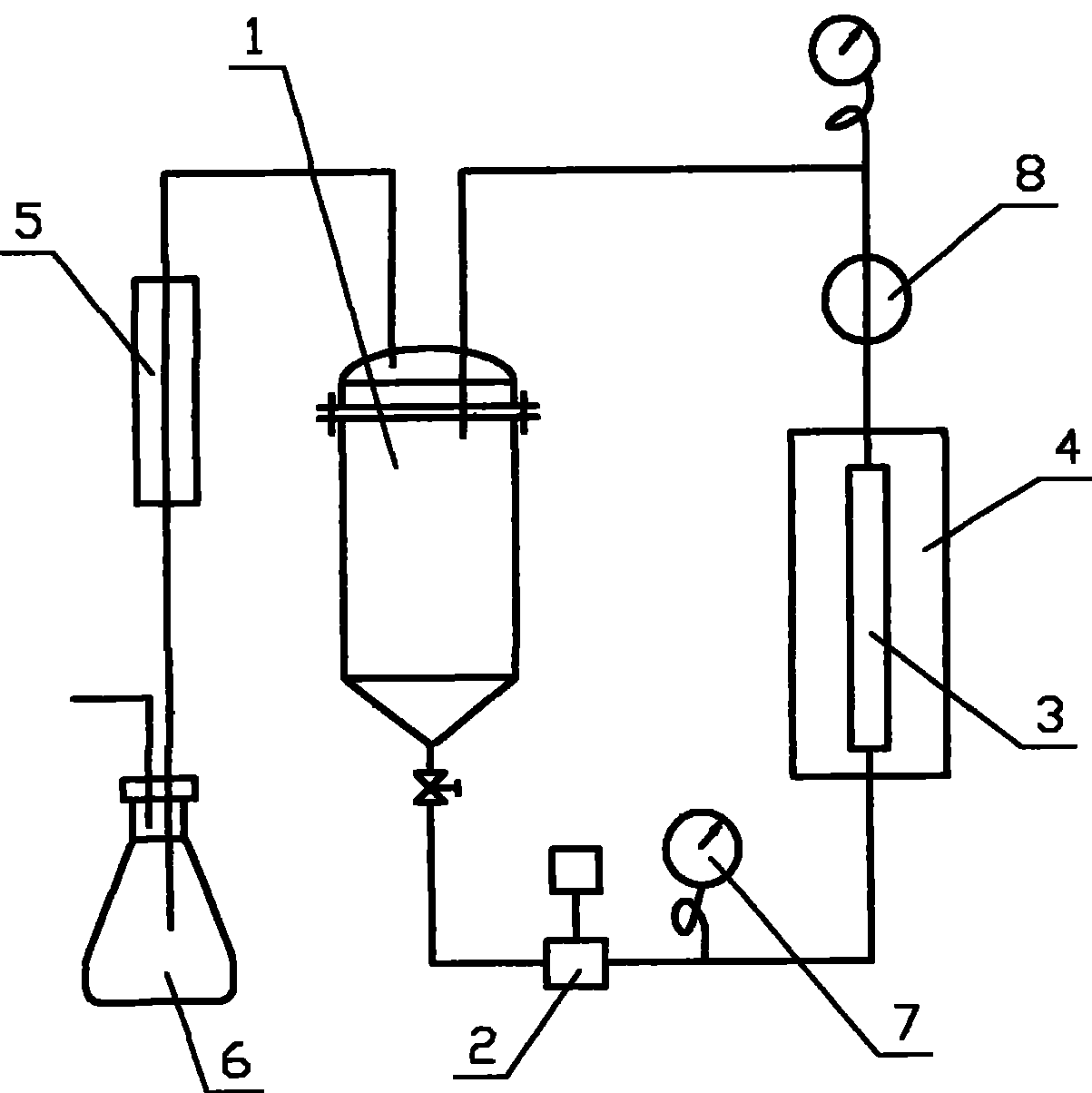

Delayed coker feed heater on-line steam-chemical decoking method

InactiveUS20160102253A1Increase speedLonger radiant coil lifeThermal non-catalytic crackingLighting and heating apparatusChemical mixturesEngineering

A process for decoking of delayed coker feed heater pass is disclosed. A chemical mixture containing a metal hydroxide and a metal carbonate is combined with steam to decoke the delayed coker feed heater pass.

Owner:SBT TECH

Adding substance for reducing furnace tube deposition coking and improving liquid yield of delayed coker

InactiveCN101113367BSimple and fast operationGood descaling and defocusing effectThermal non-catalytic crackingTreatment apparatus corrosion/fouling inhibitionLiquid productPhysical chemistry

An additive, which is used for delaying device coking, reducing the scaling and coking of furnace tubes and improving the yield of liquids, comprises the raw materials by the weights and portions of: 5-20 portions of ash-less nonmetal dispersant, 5-20 portions of pyrolysis initiator, 25-35 portions of inhibitor, 10-30 portions of antifoulant and 5-20 portions of solvent, wherein, the ash-less nonmetal dispersant is made by the methods that: alcohol amine and fatty acid are mixed by molecular ratio of 1:0.7-1.7, and stirred in the temperature of 170 DEG C-200 DEG C, water produced in the reaction is carried out by toluene or gasoline, and the reaction can be stopped when no more water is produced, and the ash-less nonmetal dispersant is obtained when the toluene or gasoline are steamed. When used in the coking delaying, the additive provided by the invention has the advantages of simple operation, good effects of reducing coke and scale, high general liquid yield, and good economical and technical benefits.

Owner:MAOMING KEDA CHEM

Deep processing method for shale oil

ActiveCN106221797AImprove utilization efficiencyImprove the level of deep processingTreatment with hydrotreatment processesHydrocarbon oils treatment productsDistillationCombined method

The invention relates to a shale oil deep processing combined process, in particular to a deep processing method for shale oil. The deep processing method aims at solving the technical problems that an existing method shale oil deep processing process is complex in technological process, low in light oil product yield and insufficient in processing depth. A raw material pretreatment unit, a reduced pressure distillation unit, a hydrofining unit, a delay coking unit and a product fractionation unit are involved in the shale oil deep processing combined method. The method that coked distillate returns to a hydrofining device for redistillation is adopted, and the raw material conversion rate and the yield of a diesel oil product are increased. Vacuum distillate, vacuum residuum and hydrogenated tail oil are mixed to serve as feed of a delayed coker, the yield of coking gas and coke is reduced, and the yield of coker diesel is increased.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com