Patents

Literature

42results about How to "Reduced and minimized amount" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

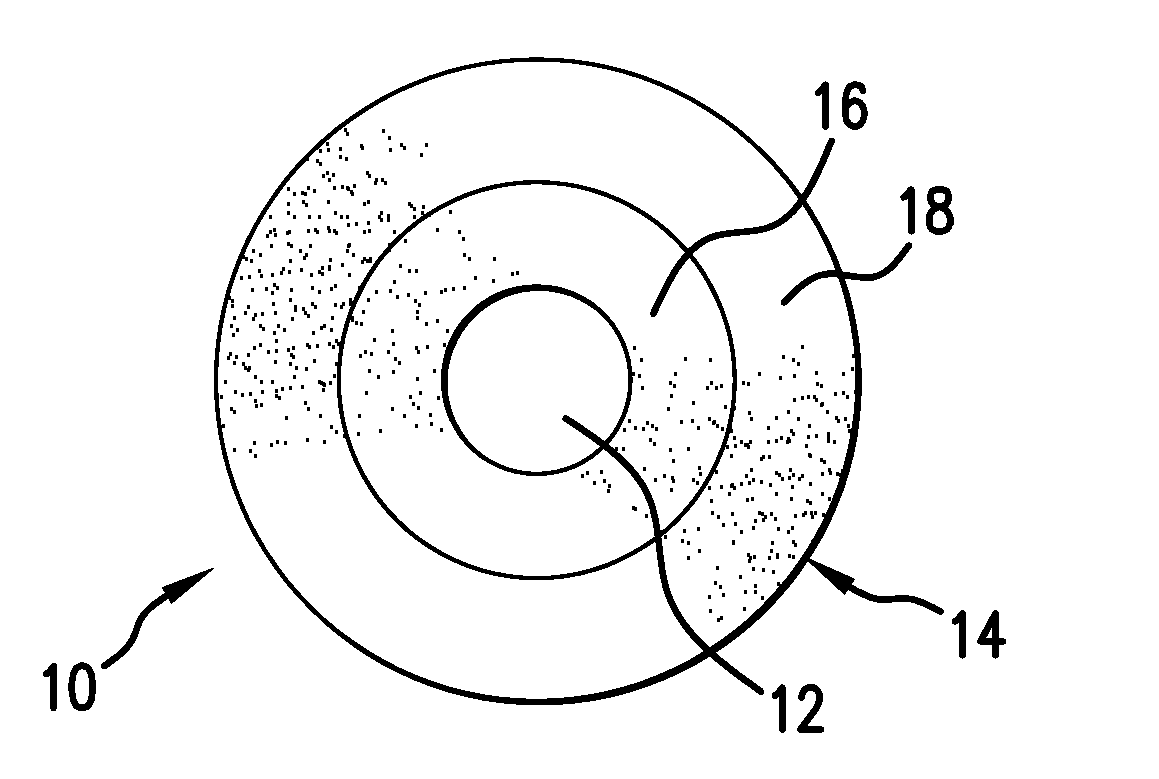

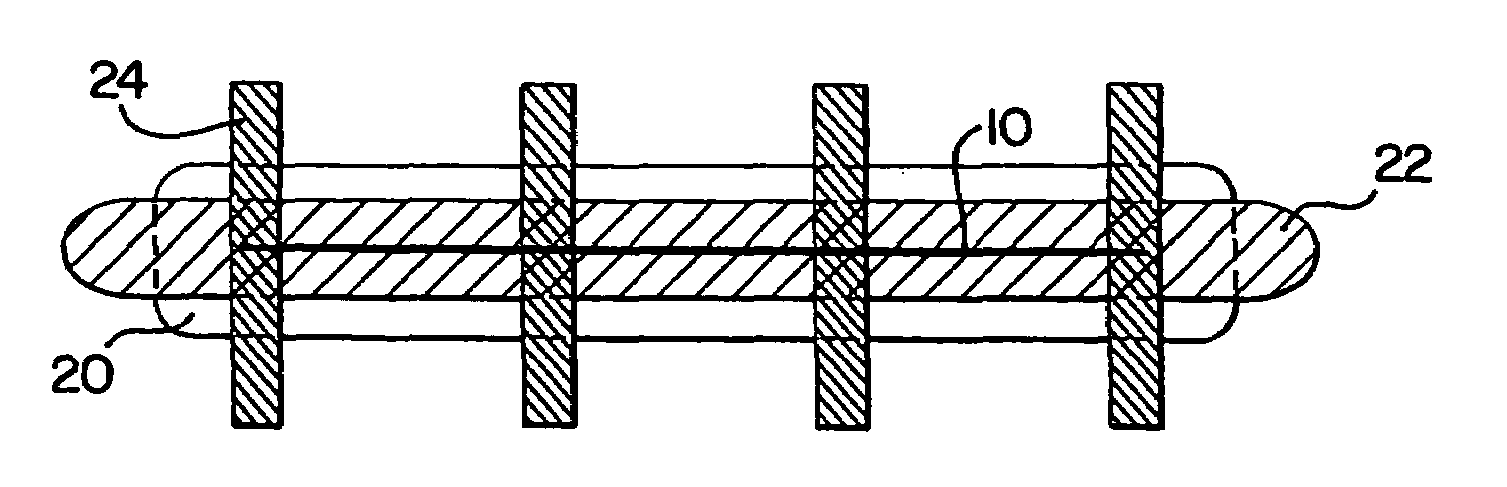

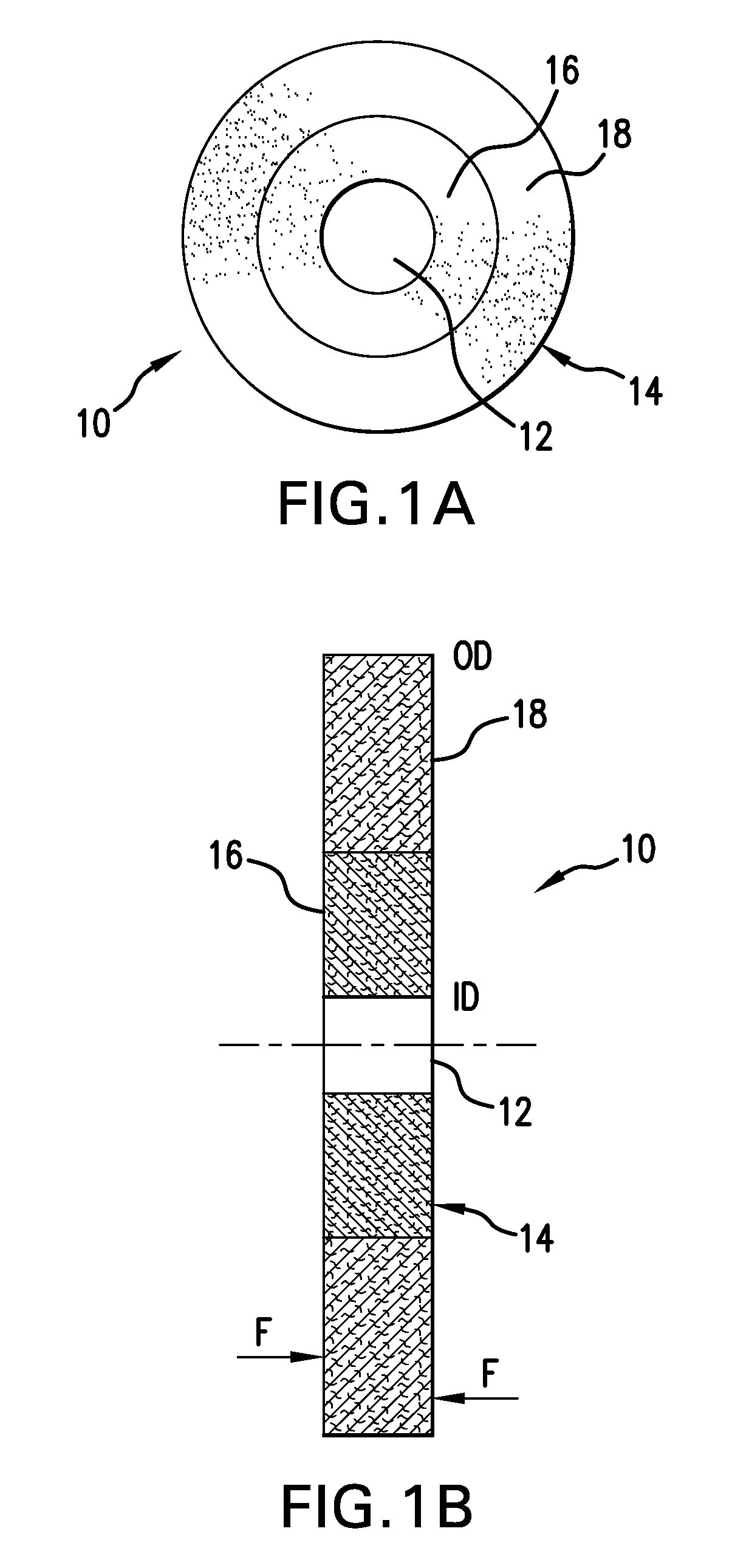

Reinforced Bonded Abrasive Tools

InactiveUS20100190424A1Improve performanceReduce the amount requiredPigmenting treatmentRevolution surface grinding machinesFiberFiberglass mesh

Bonded abrasive tools, e.g., grinding wheels, can be reinforced using, for instance, one or more fibreglass web(s) having a surface of glass per unit of at least 0.2. Alternatively or in addition, the fibreglass web has a thickness of 2 mm or less. The web can be designed to provide improved adhesion between the fibreglass reinforcement and the mixture employed to form the bonded abrasive tool. In some examples, the middle reinforcement at the neutral zone of the wheel can be eliminated or minimized.

Owner:SAINT GOBAIN ABRASIVES INC +1

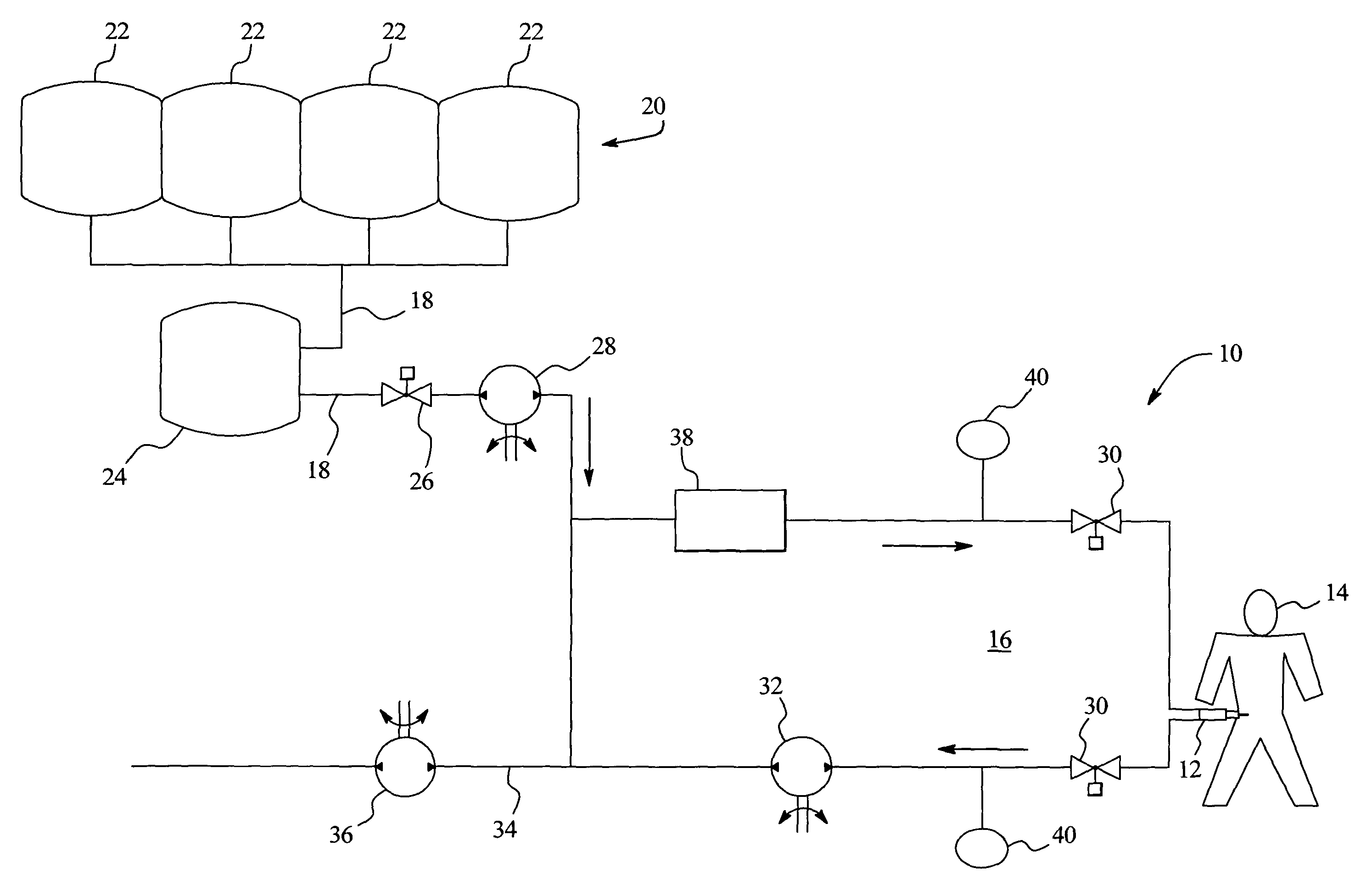

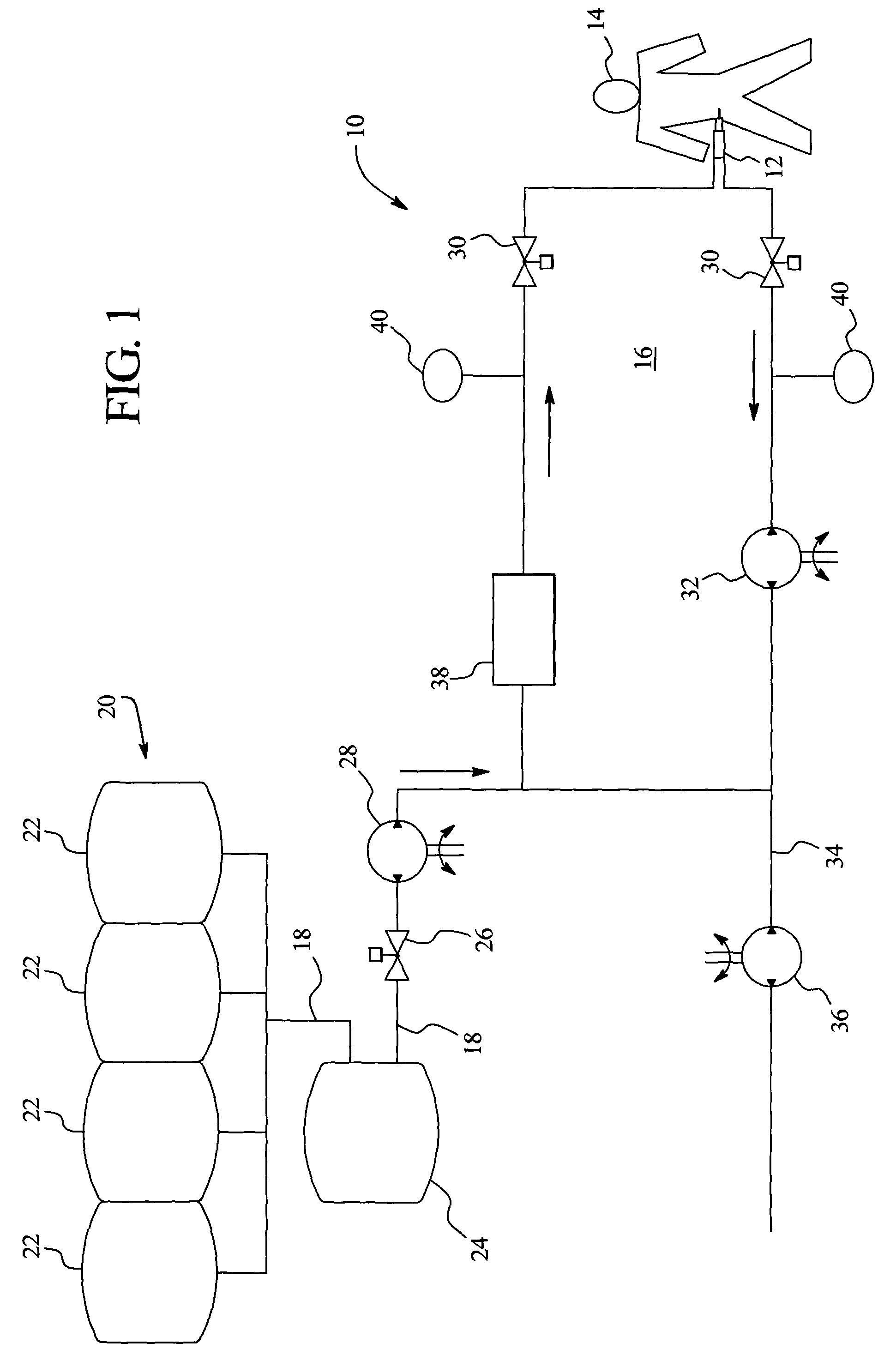

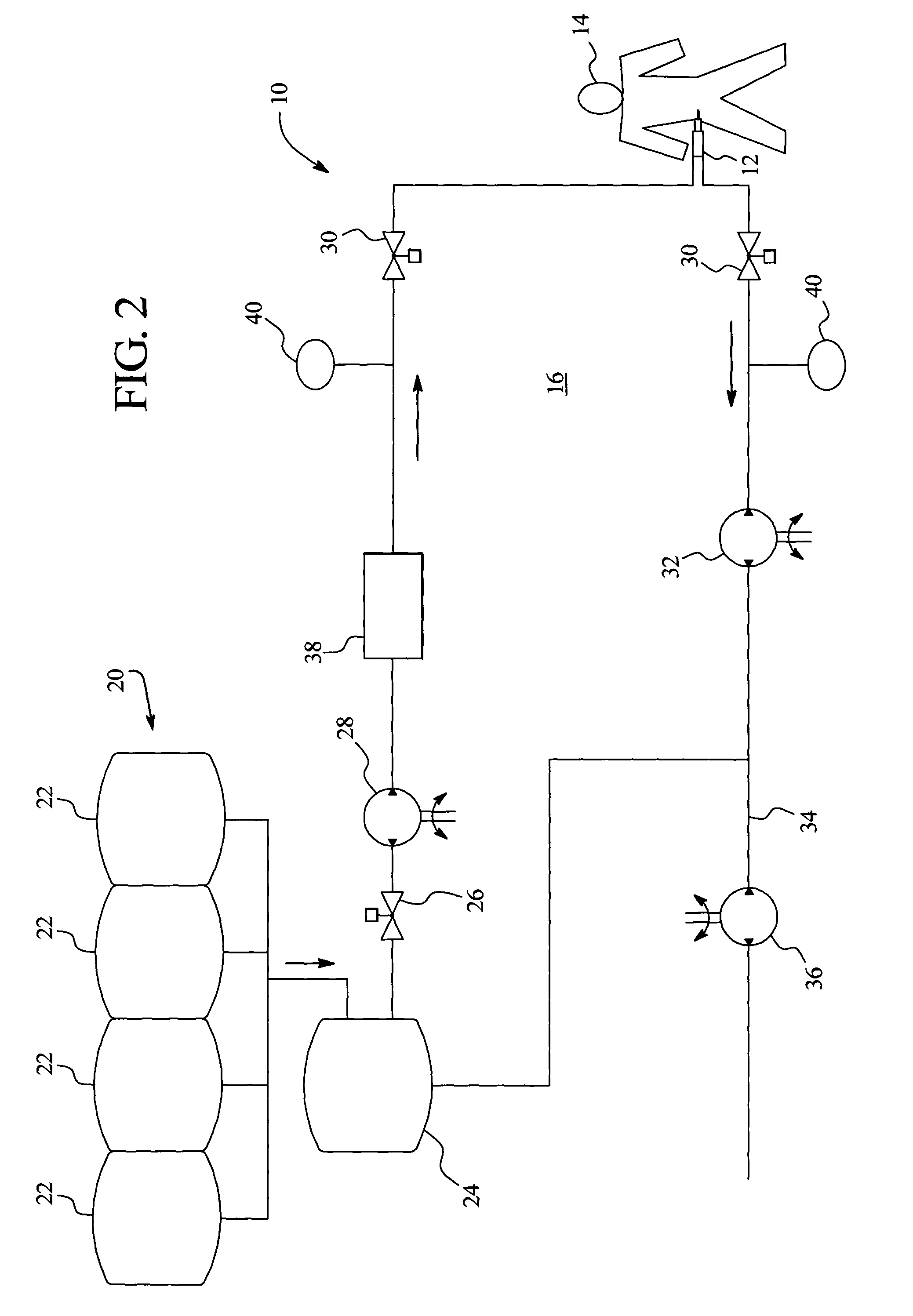

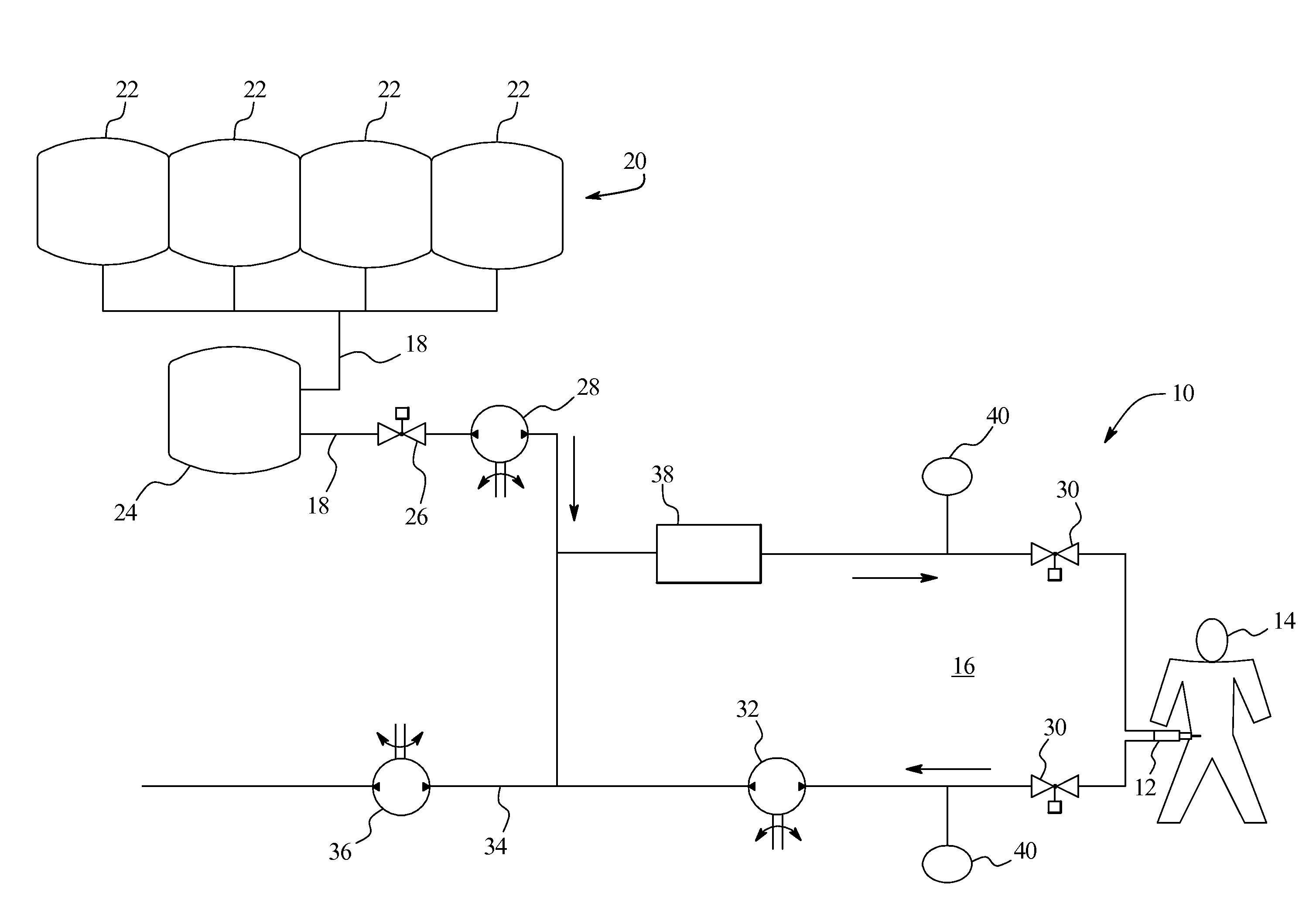

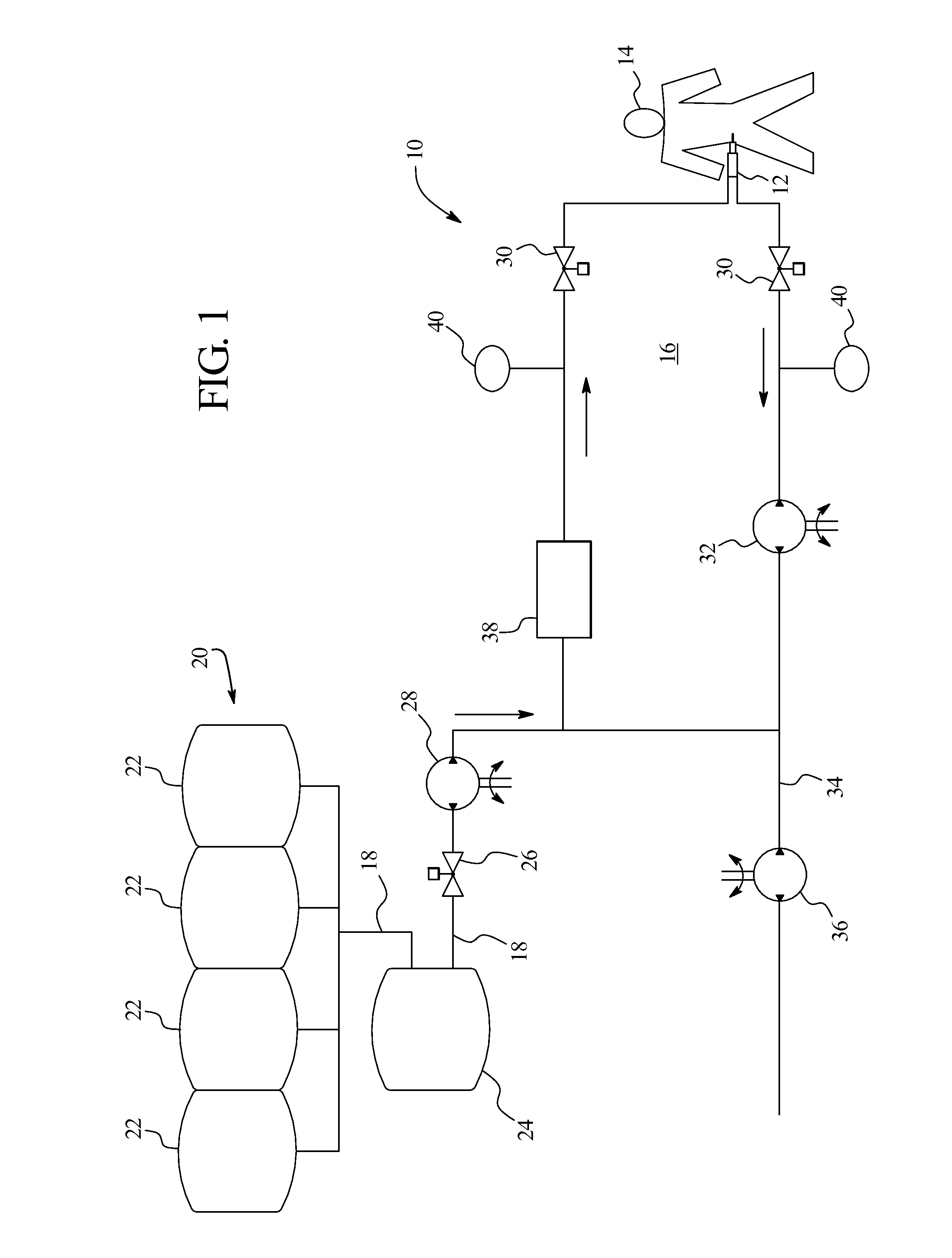

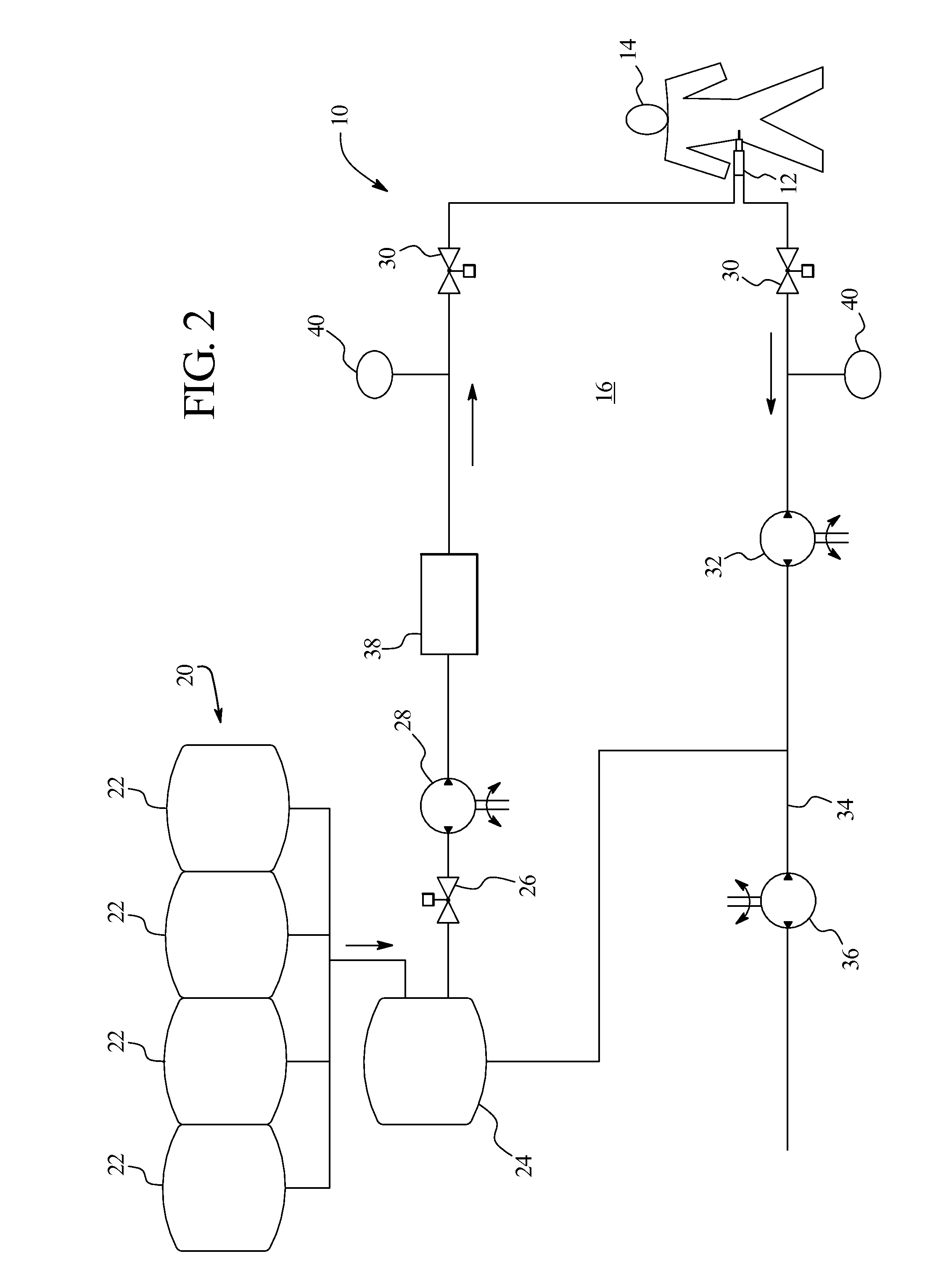

Systems and methods for performing peritoneal dialysis

ActiveUS7922686B2Strengthen the systemImprove methodPeritoneal dialysisProsthesisCycle rateContinuous flow

Systems and methods for providing multiple pass continuous flow dialysis therapy are provided. The present invention includes a fluid circuit connected to a patient via a catheter thereby defining a fluid loop along which a therapy fluid including a dialysate can be continuously circulated into, through and out of a peritoneal cavity of a patient to remove a therapeutically effective amount of excess water and solutes including uremic toxins. The feed rate and discharge rate of therapy fluid into the fluid loop can be controllably regulated in proportion to the circulation rate of fluid in the fluid loop such that the therapy fluid can pass a multiple number of times along the fluid loop prior to discharge.

Owner:BAXTER INT INC +1

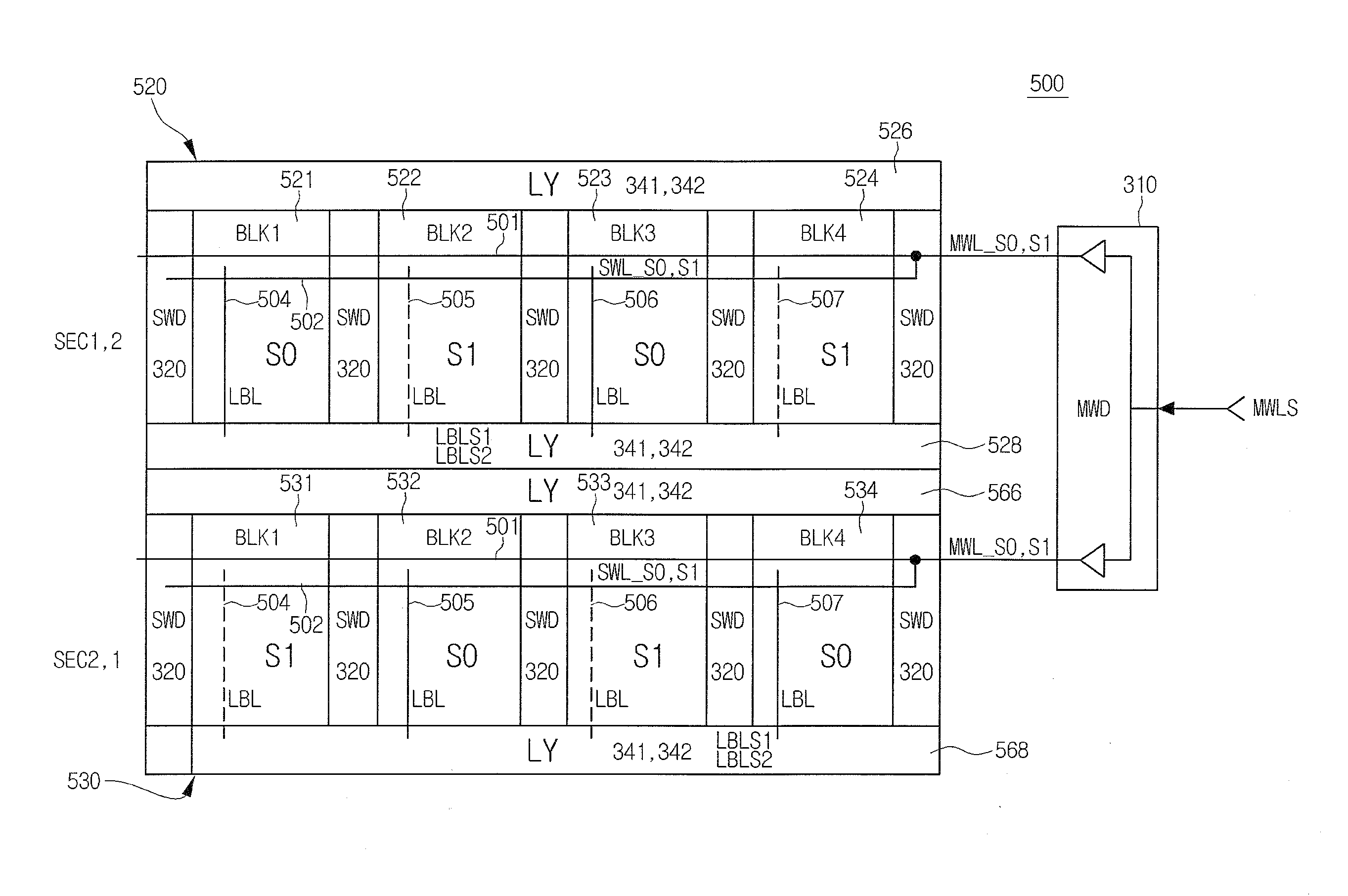

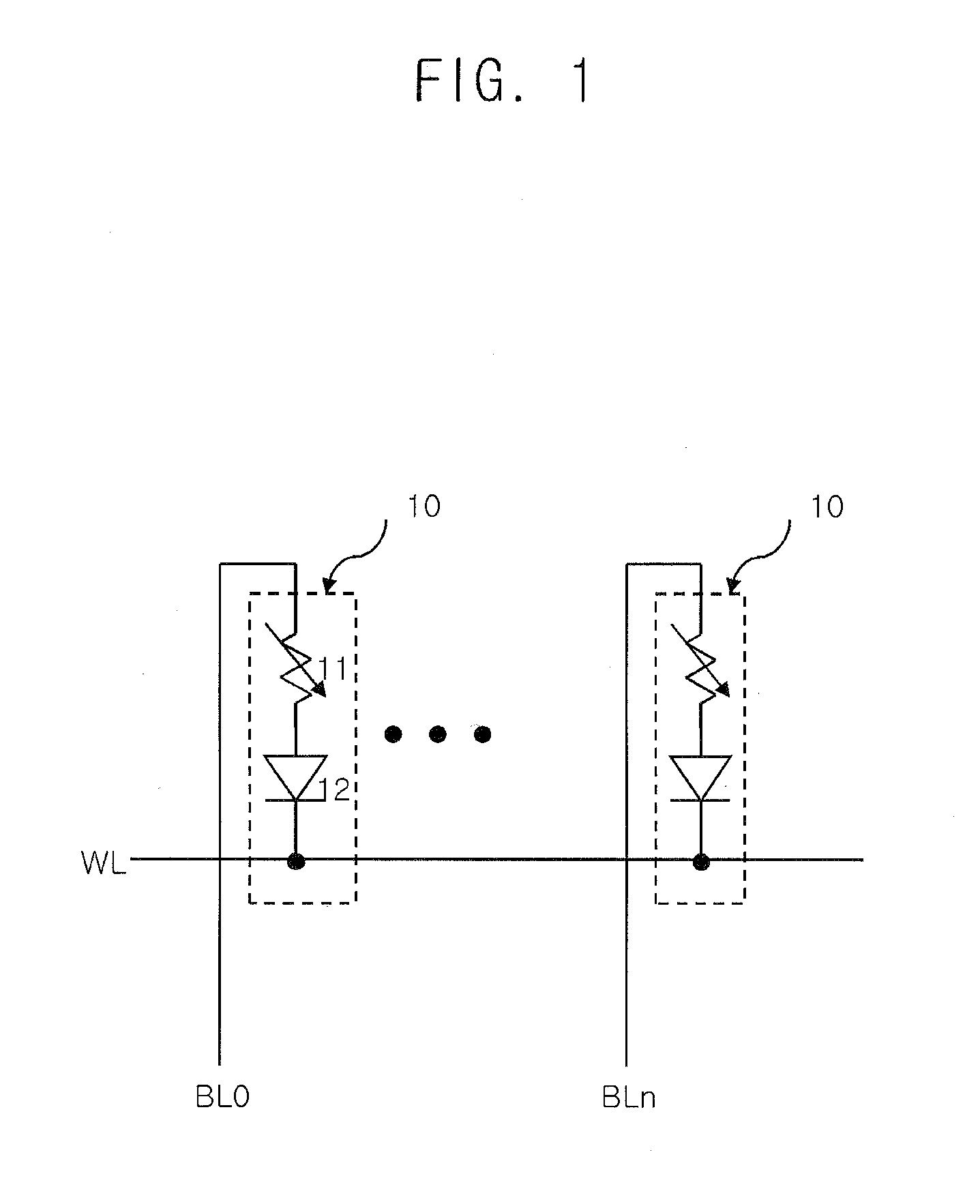

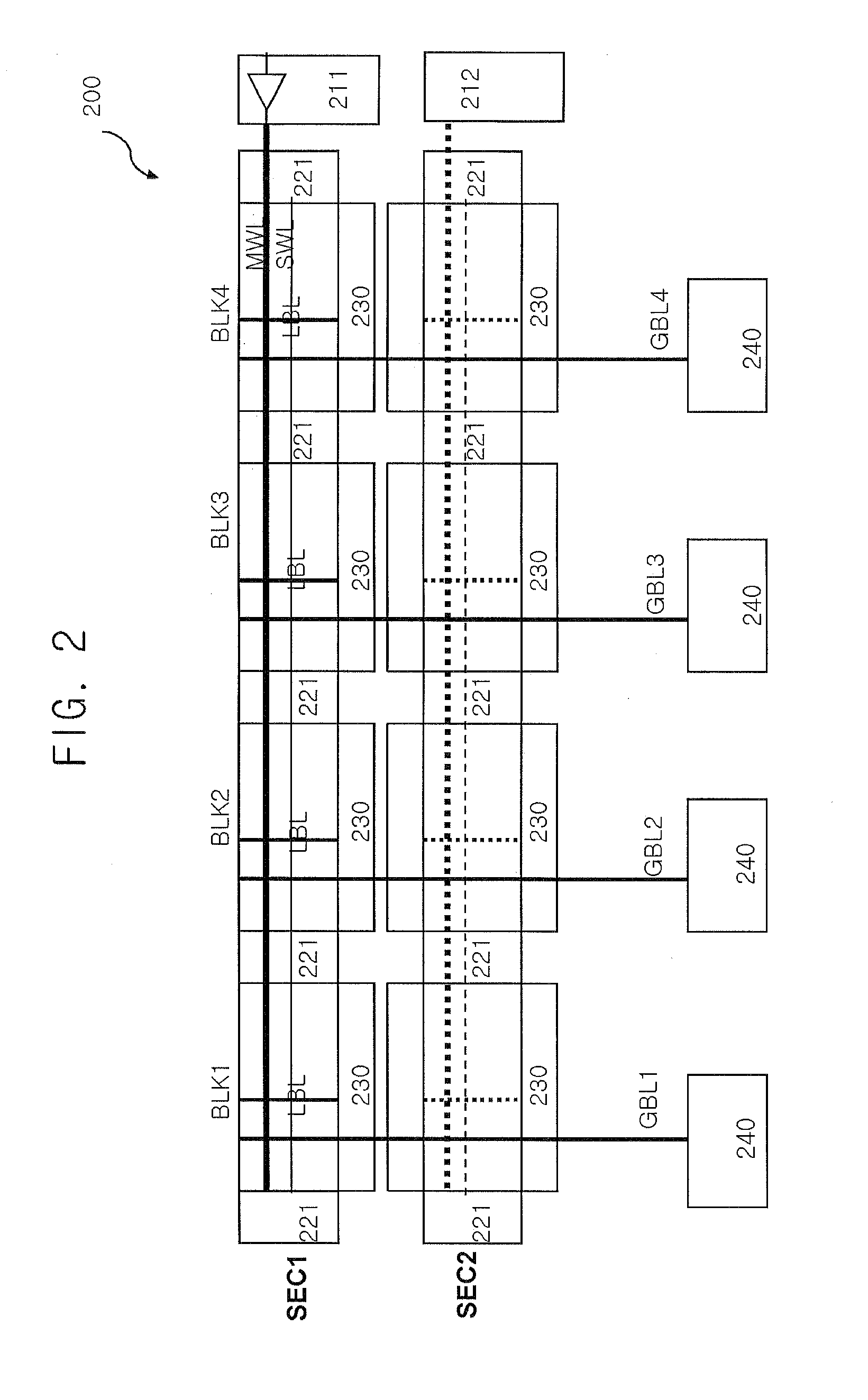

Semiconductor memory device using variable resistor

ActiveUS20100067279A1Quantity minimizationPrevent increase in word line voltageRead-only memoriesDigital storageBit lineComputer architecture

Example embodiments relate to a variable resistance semiconductor memory device including: a plurality of memory blocks belonging to different memory sectors and alternately arranged in a memory bank including the memory sectors so as to be adjacent to each other; and a line selecting unit simultaneously selecting word lines of the plurality of memory blocks and simultaneously selecting bit lines of the memory blocks belonging to the same memory sector among the plurality of memory blocks in an access operation mode.

Owner:SAMSUNG ELECTRONICS CO LTD

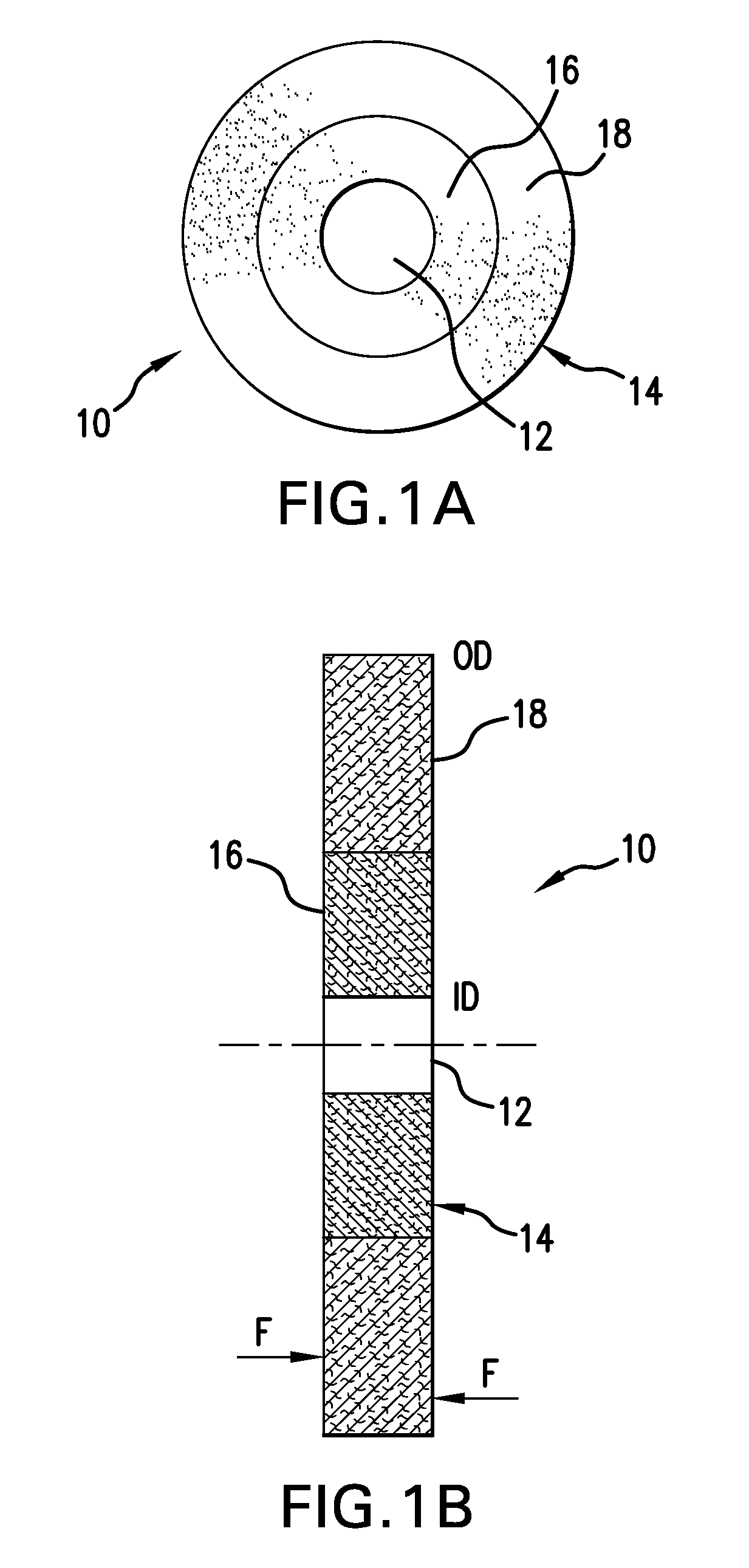

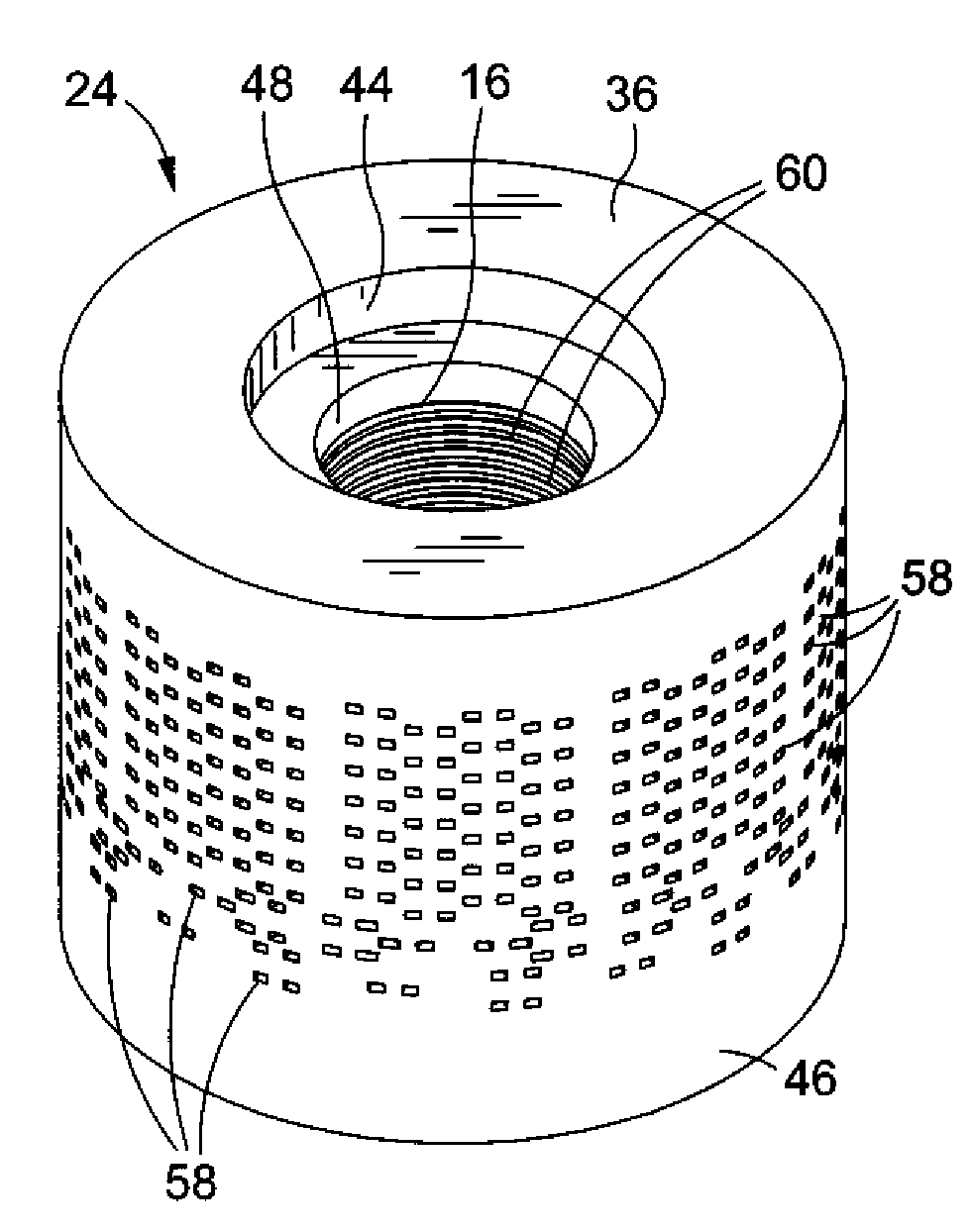

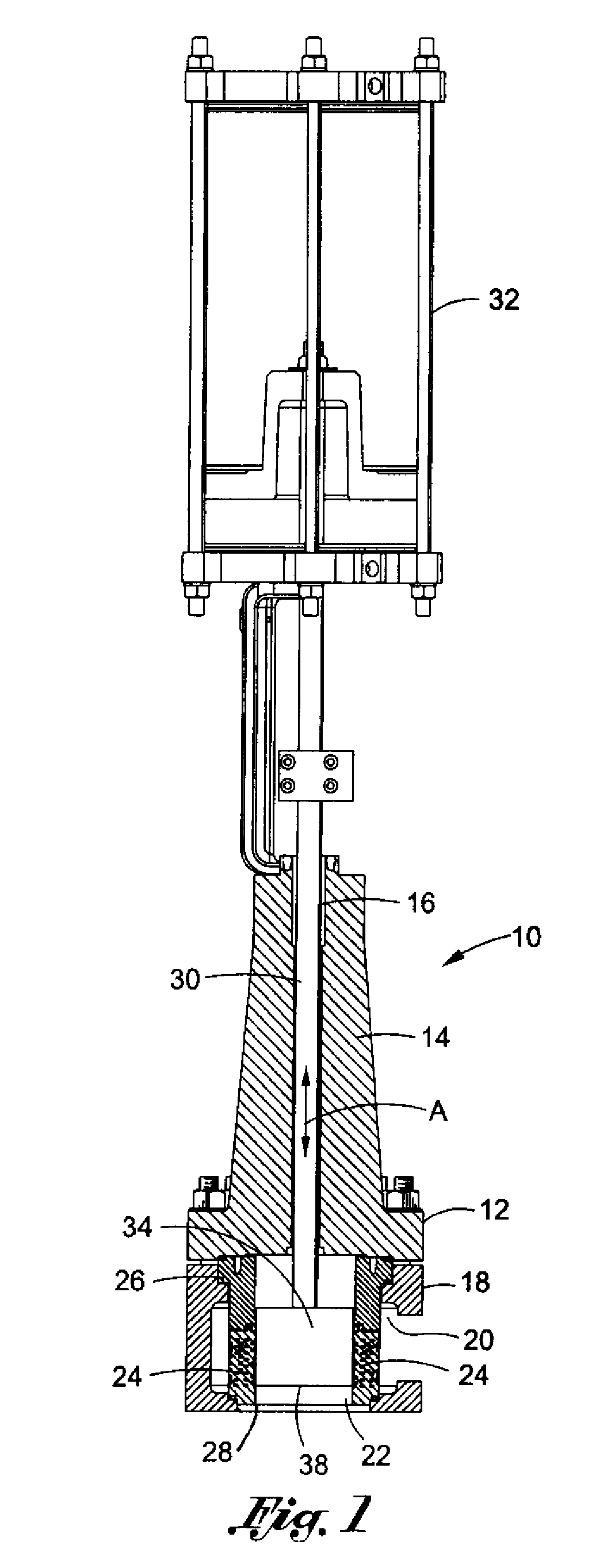

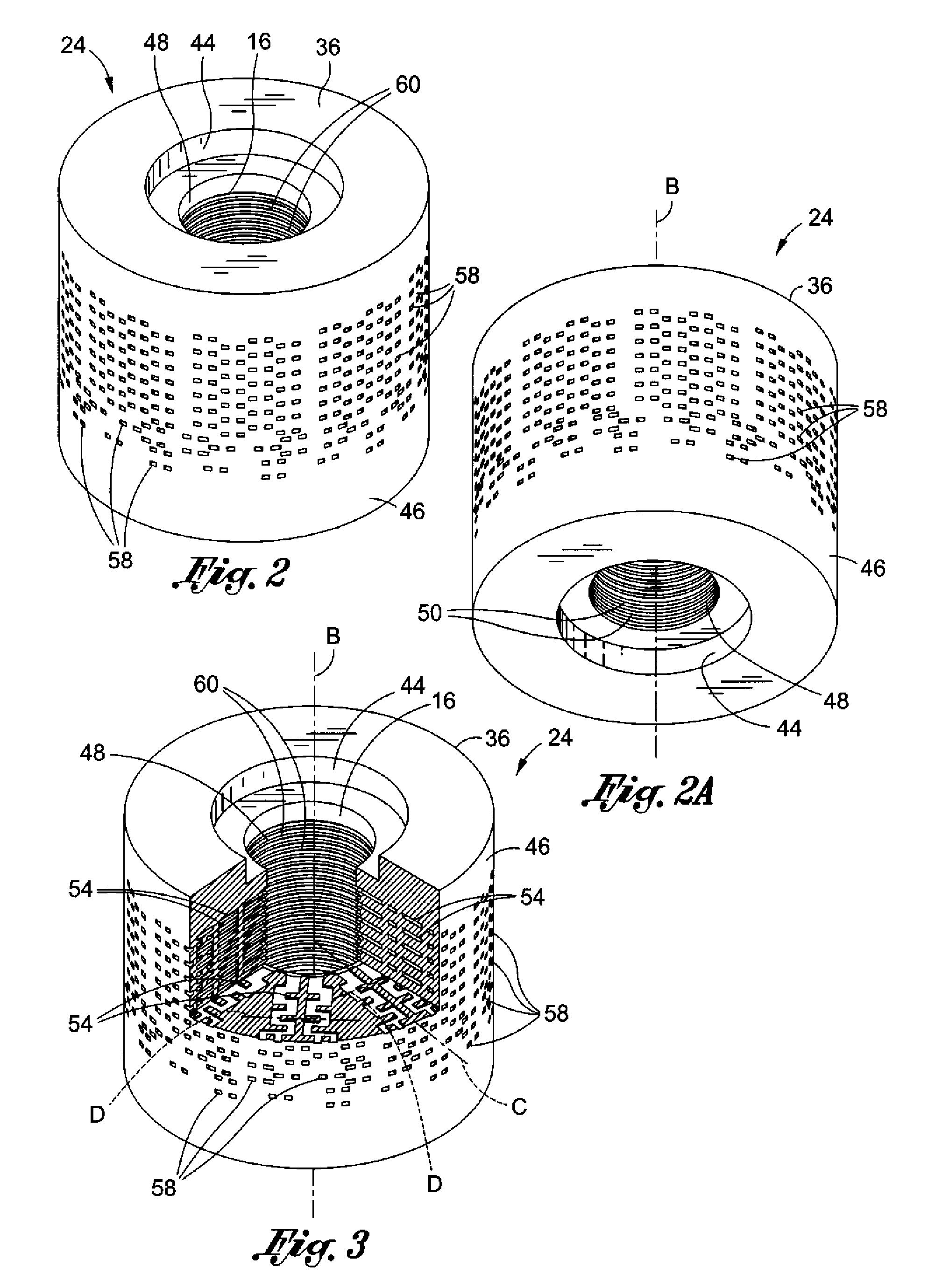

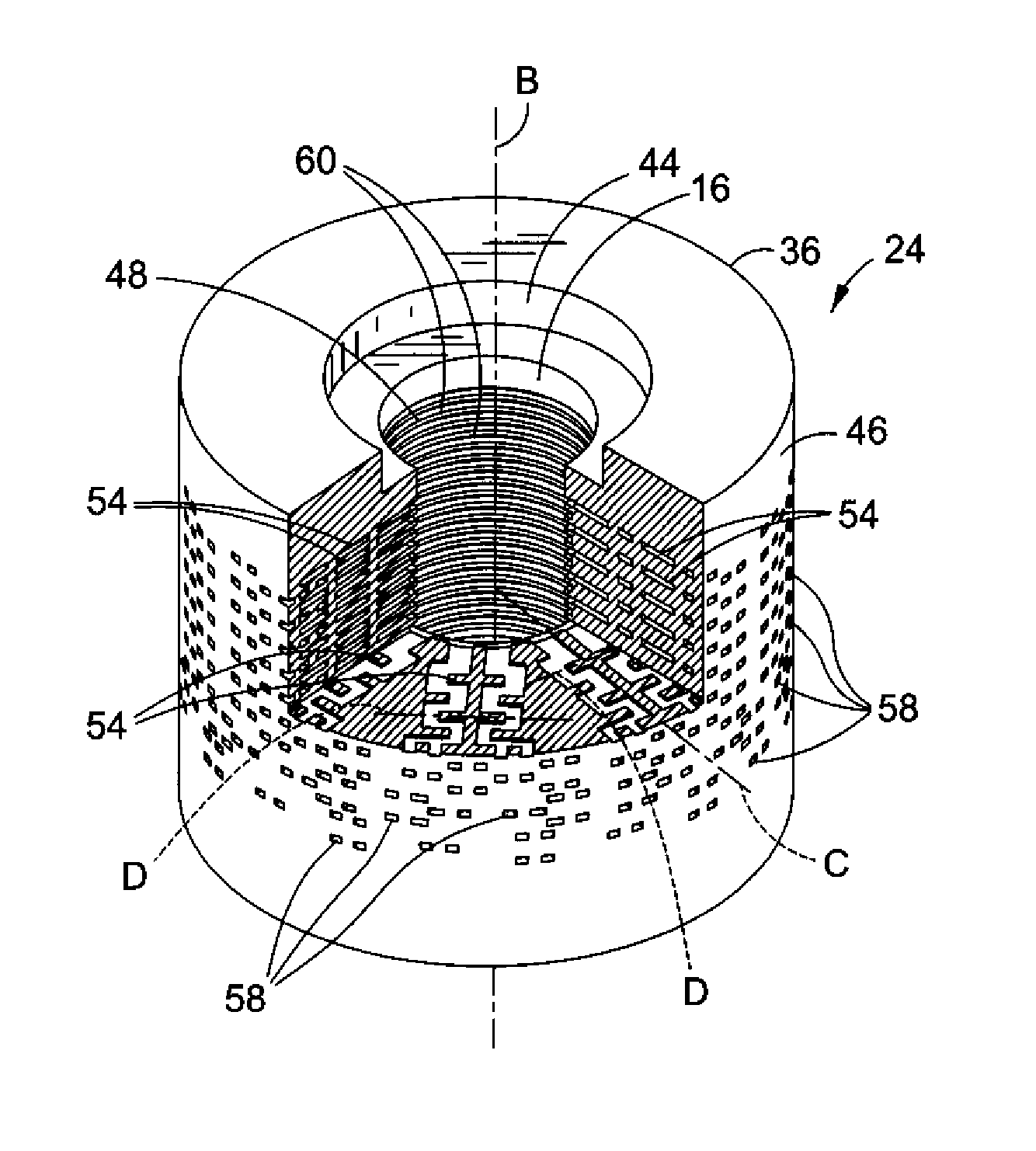

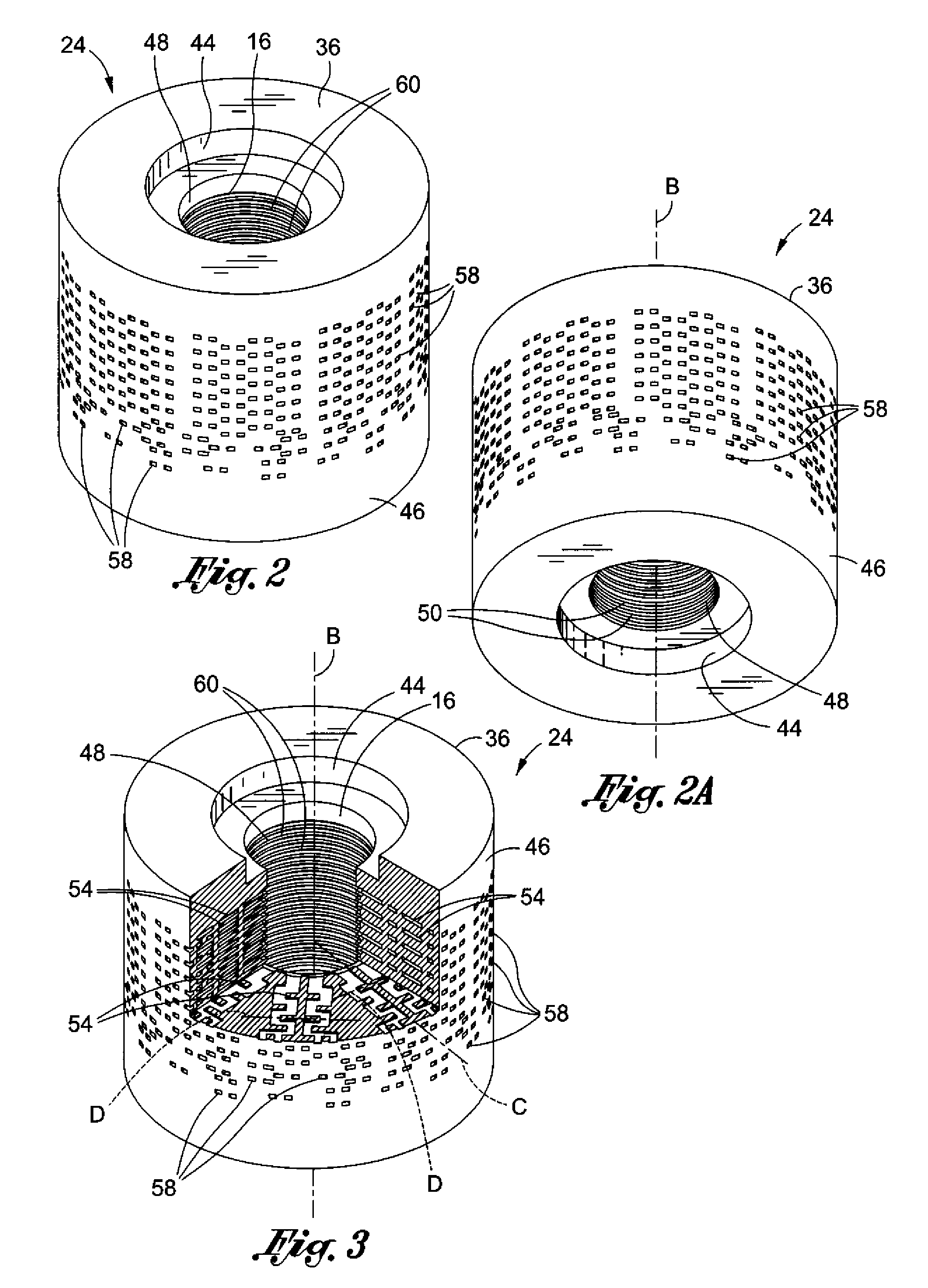

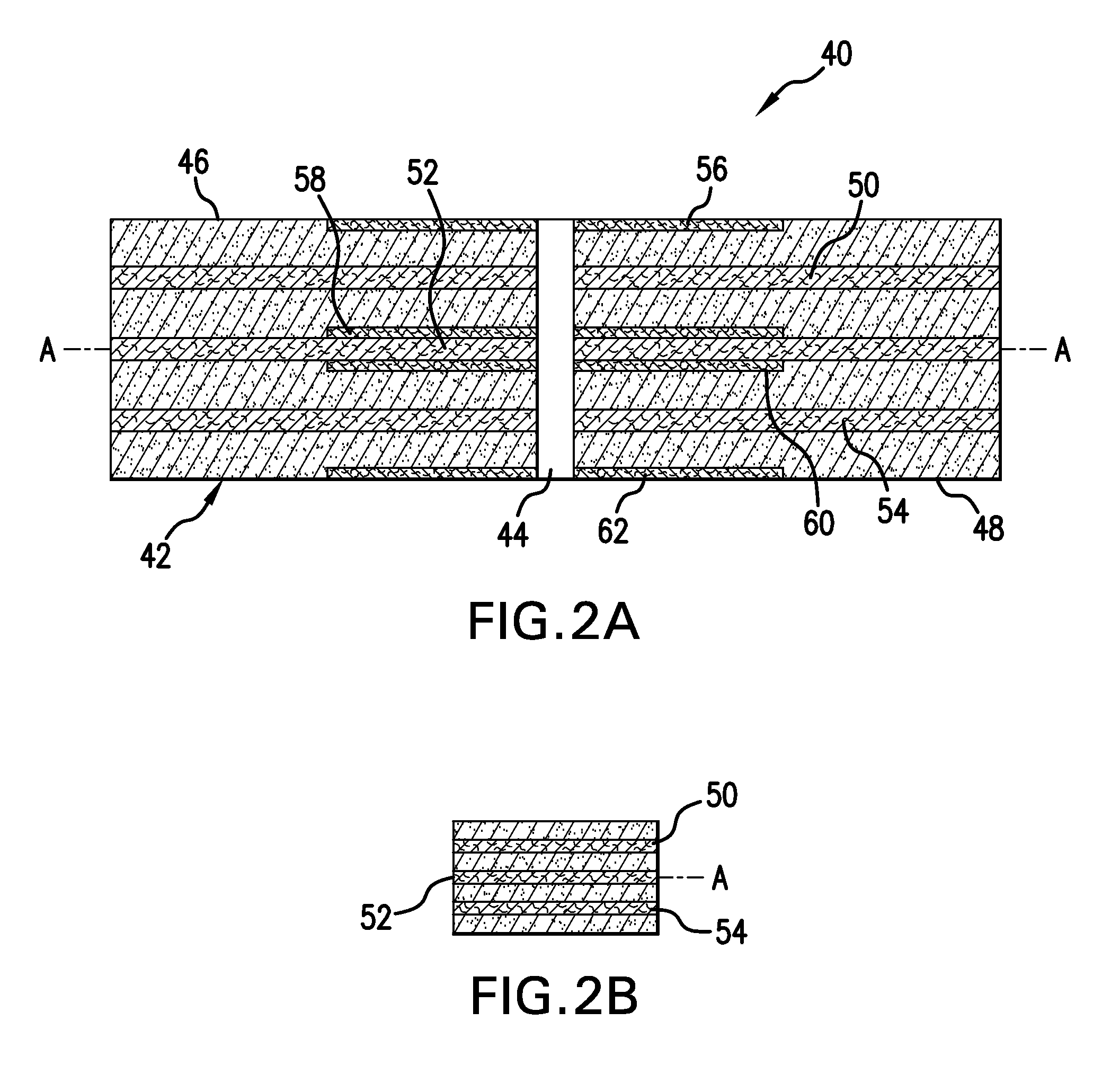

Direct metal laser sintered flow control element

ActiveUS20090183790A1Reduce velocity of fluidHigh degree of accuracyAdditive manufacturingValve members for absorbing fluid energyEngineeringMetallic materials

A flow control element comprises a cylindrical element body having a bore formed therethrough. The cylindrical element body may include inner and outer peripheral surfaces and define a plurality of tortuous flow passages which extend between the inner and outer peripheral surfaces. The flow control element is formed as a unitary structure wherein the flow passages are oriented along at least two axes. The flow control may be formed by direct to metal laser sintering wherein successive layers of powdered metallic material are solidified by applying laser energy to the selected portions until the flow element is formed as a unitary structure with a plurality of flow passages extending therethrough. The laser energy is selectively applied to the powdered metallic material according to a computer model of the flow control element.

Owner:CONTROL COMPONENTS INC

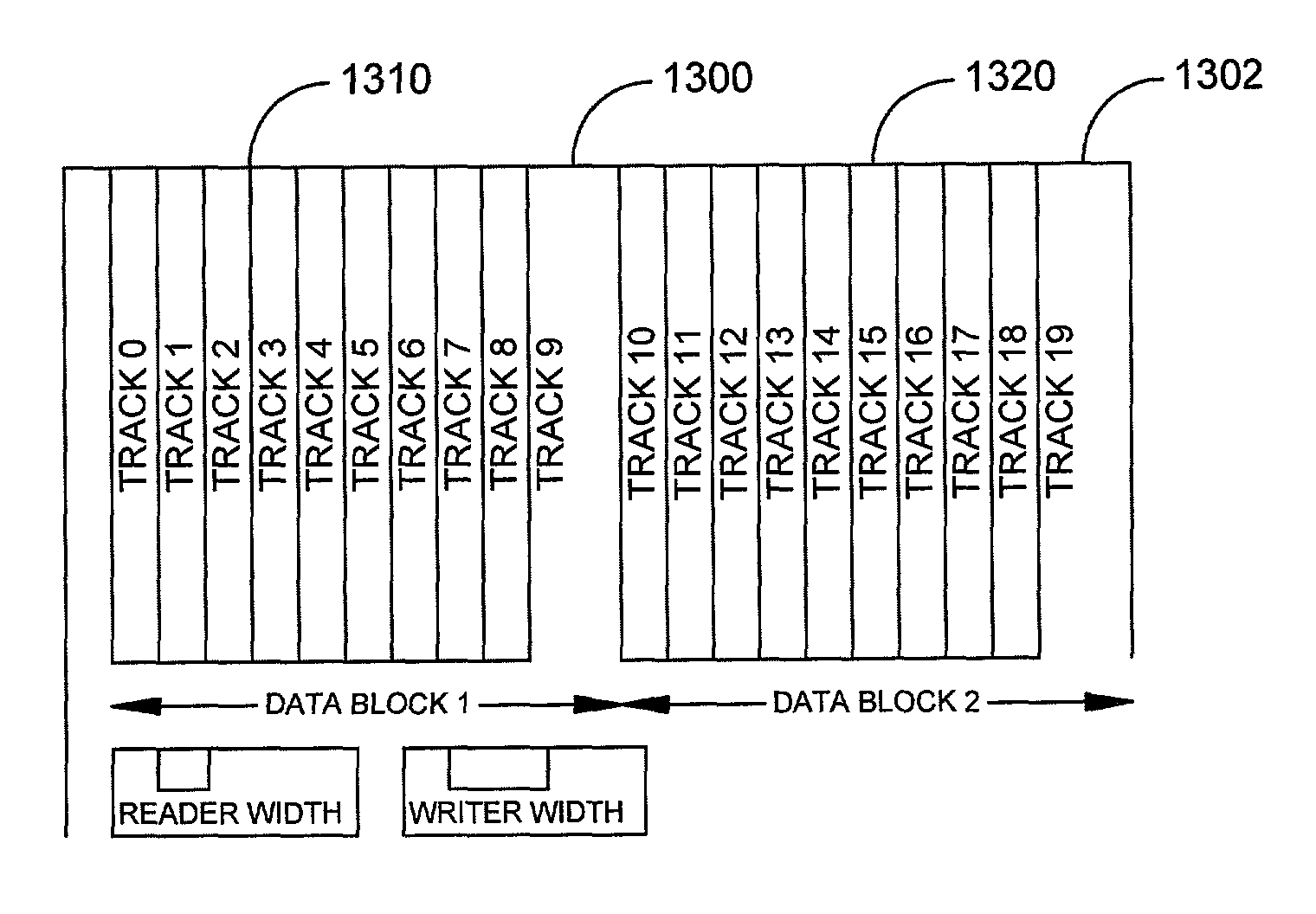

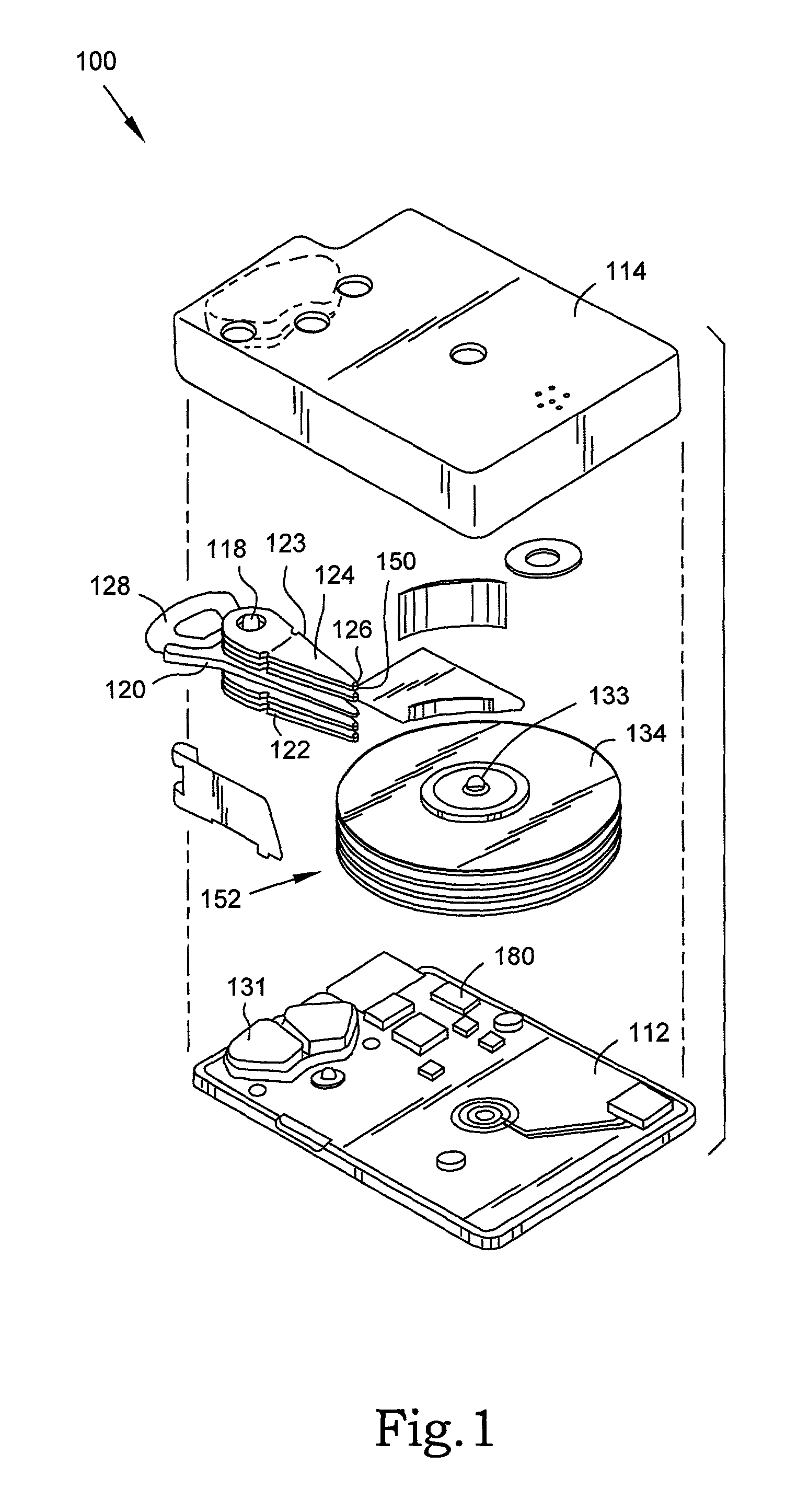

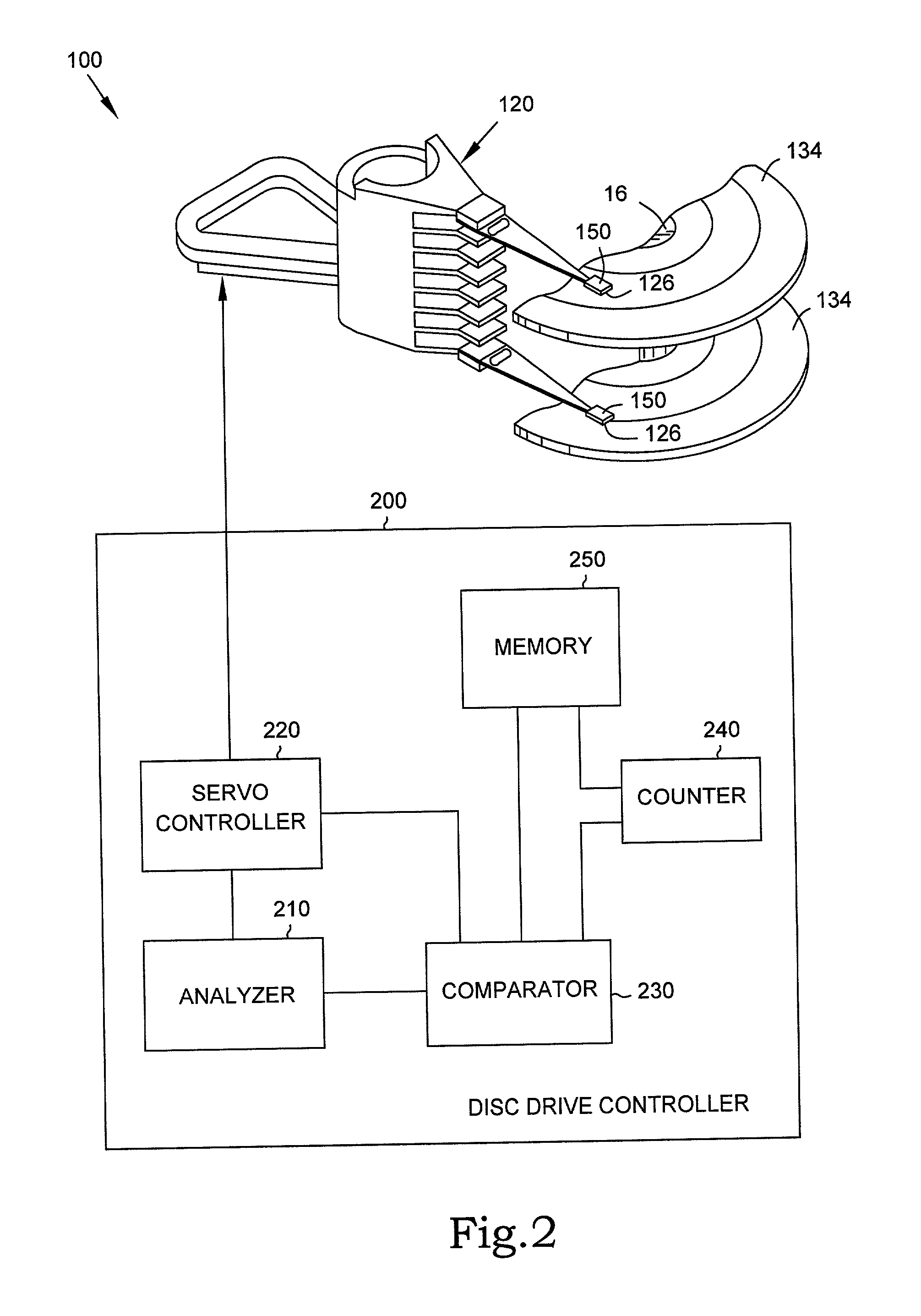

Method to achieve higher track density by allowing only one-sided track encroachment

InactiveUS7082007B2Reduced and minimized amountAccurate informationFilamentary/web carriers operation controlTrack finding/aligningTrack densityTransducer

A disc drive includes a transducer having a separate element for writing information and a separate element for reading information to and from the disc. In a disc drive designated to read and write long sequential records, the track misregistration budget is reduced to account for previously written tracks not being encroached on one side. An initial track is written. Subsequent tracks are written after a seek in one direction. The subsequent track is written so that the initially written track is overwritten to one side and leaves a track having a width substantially equal to the width of the read element. Records can be written into data bands of a selected number of tracks. A guard band is left between groups of data bands so that data on tracks in subsequent data bands are not overwritten.

Owner:SEAGATE TECH LLC

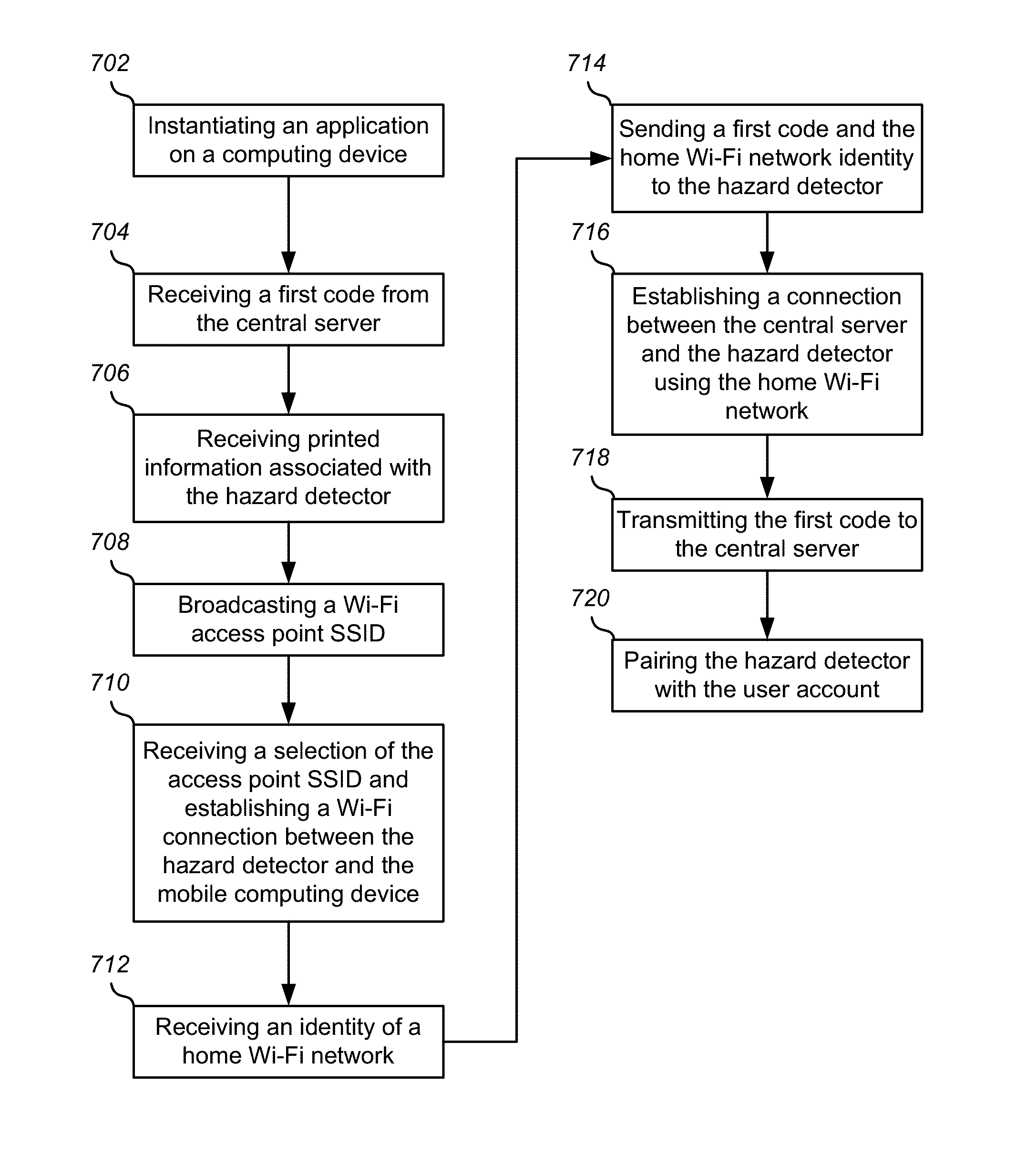

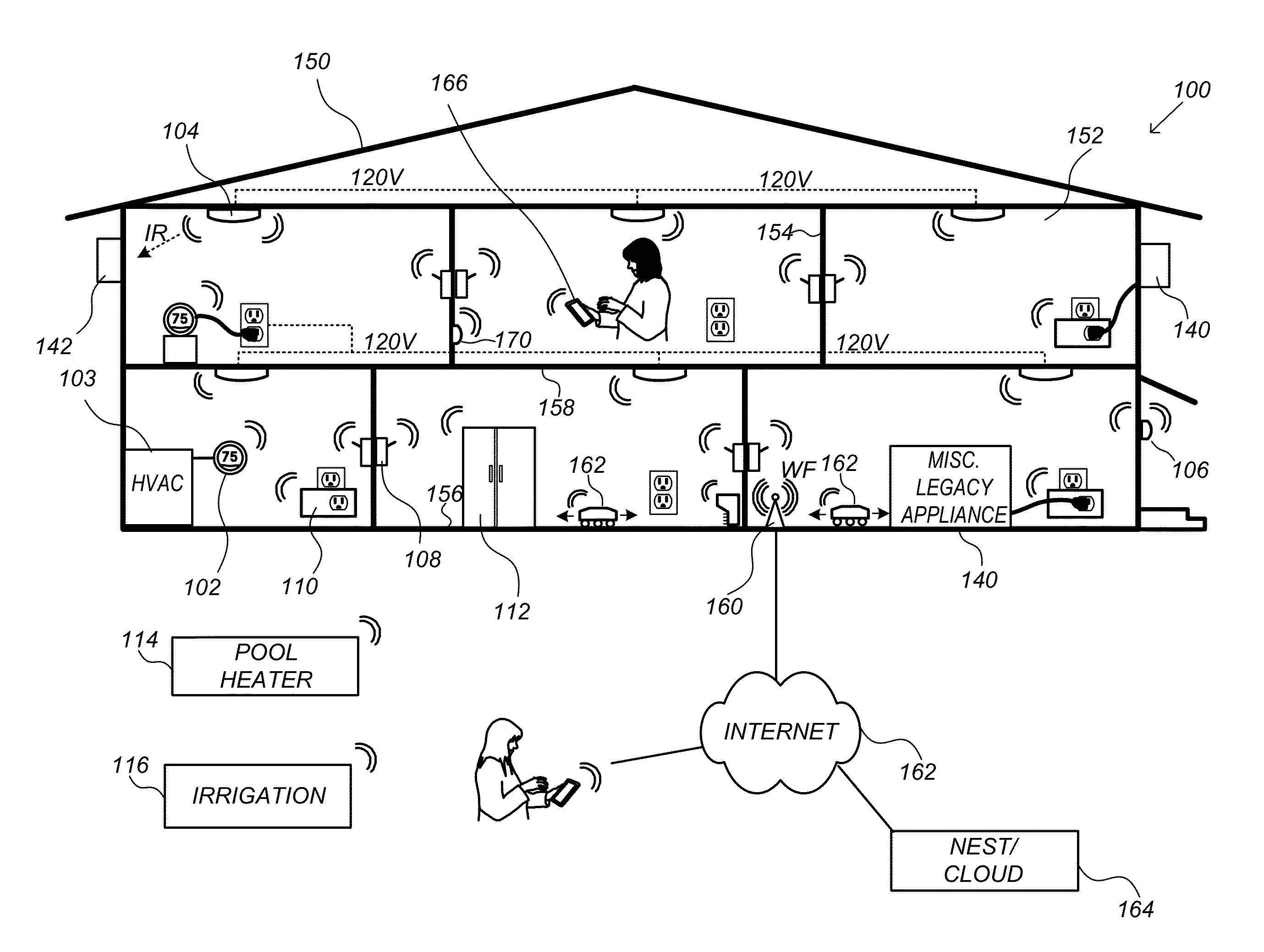

Hazard detection unit facilitating user-friendly setup experience

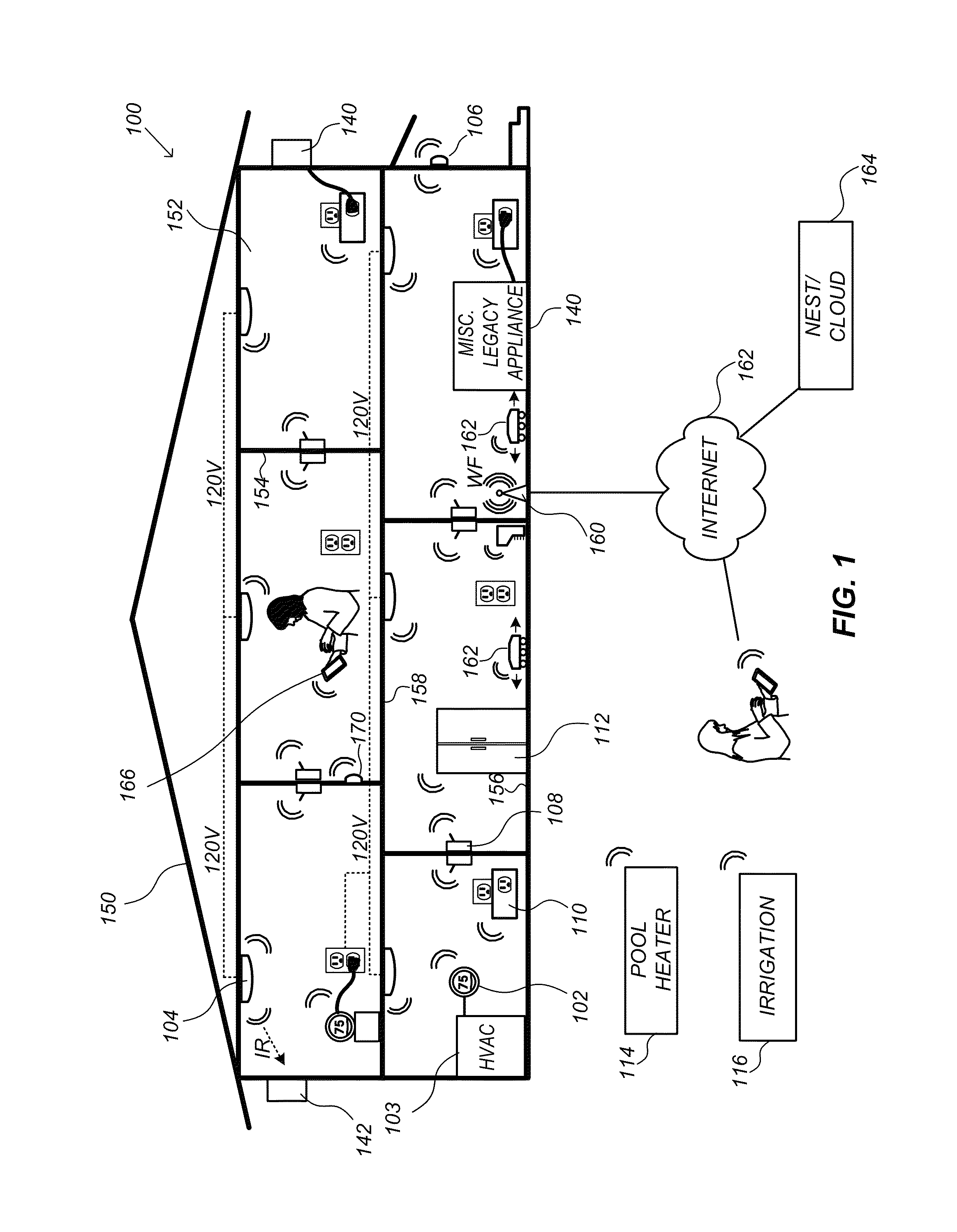

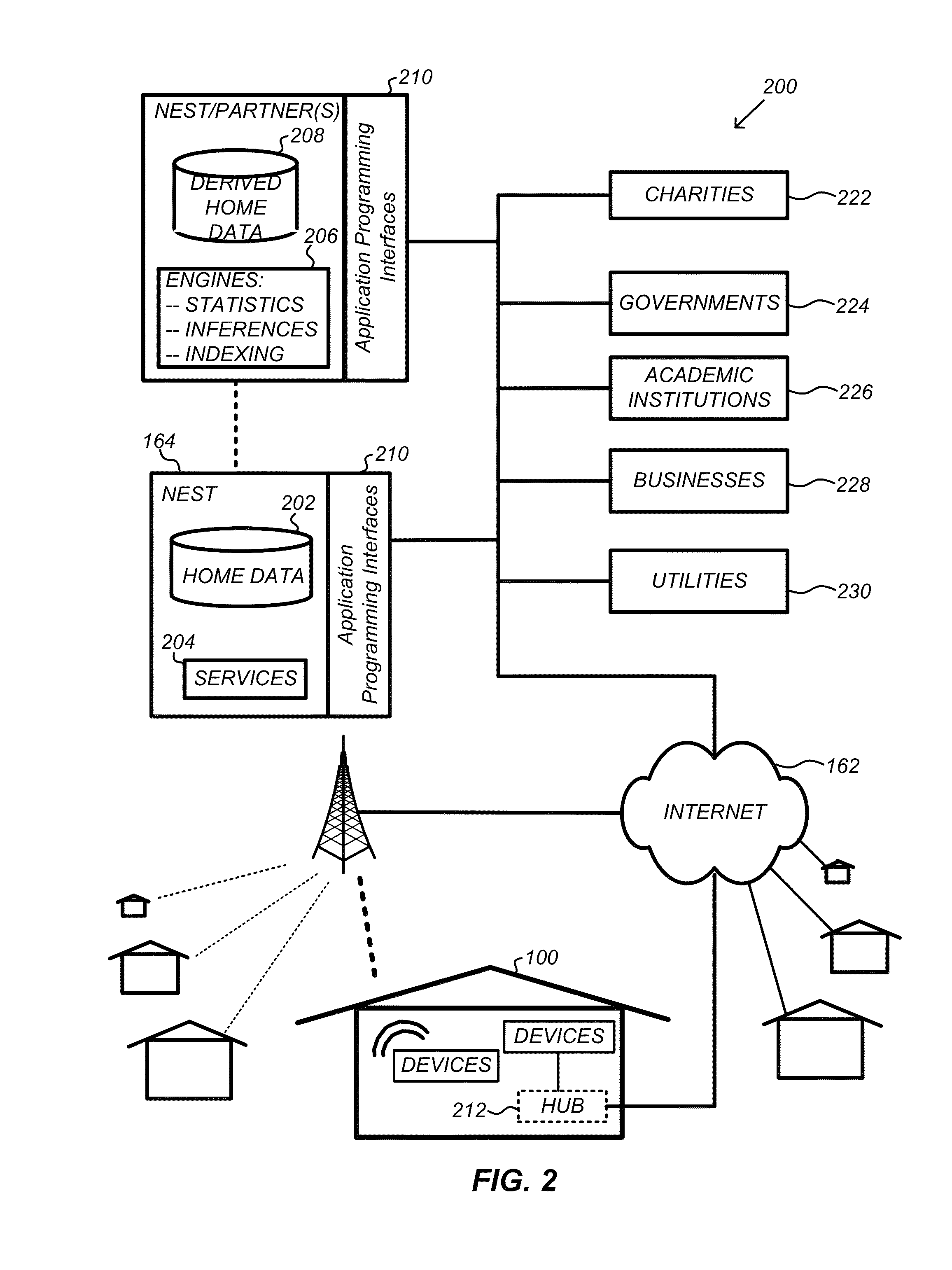

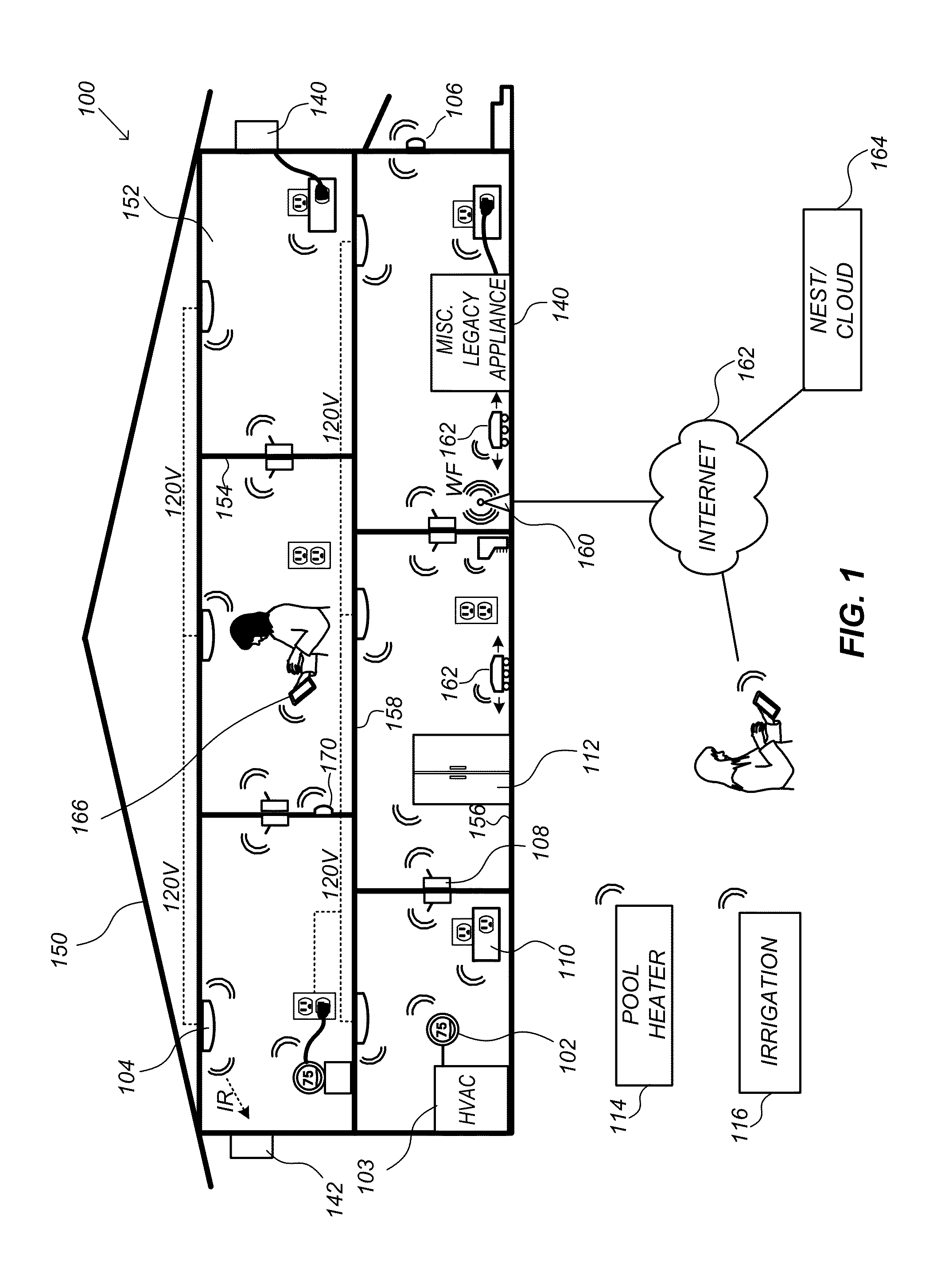

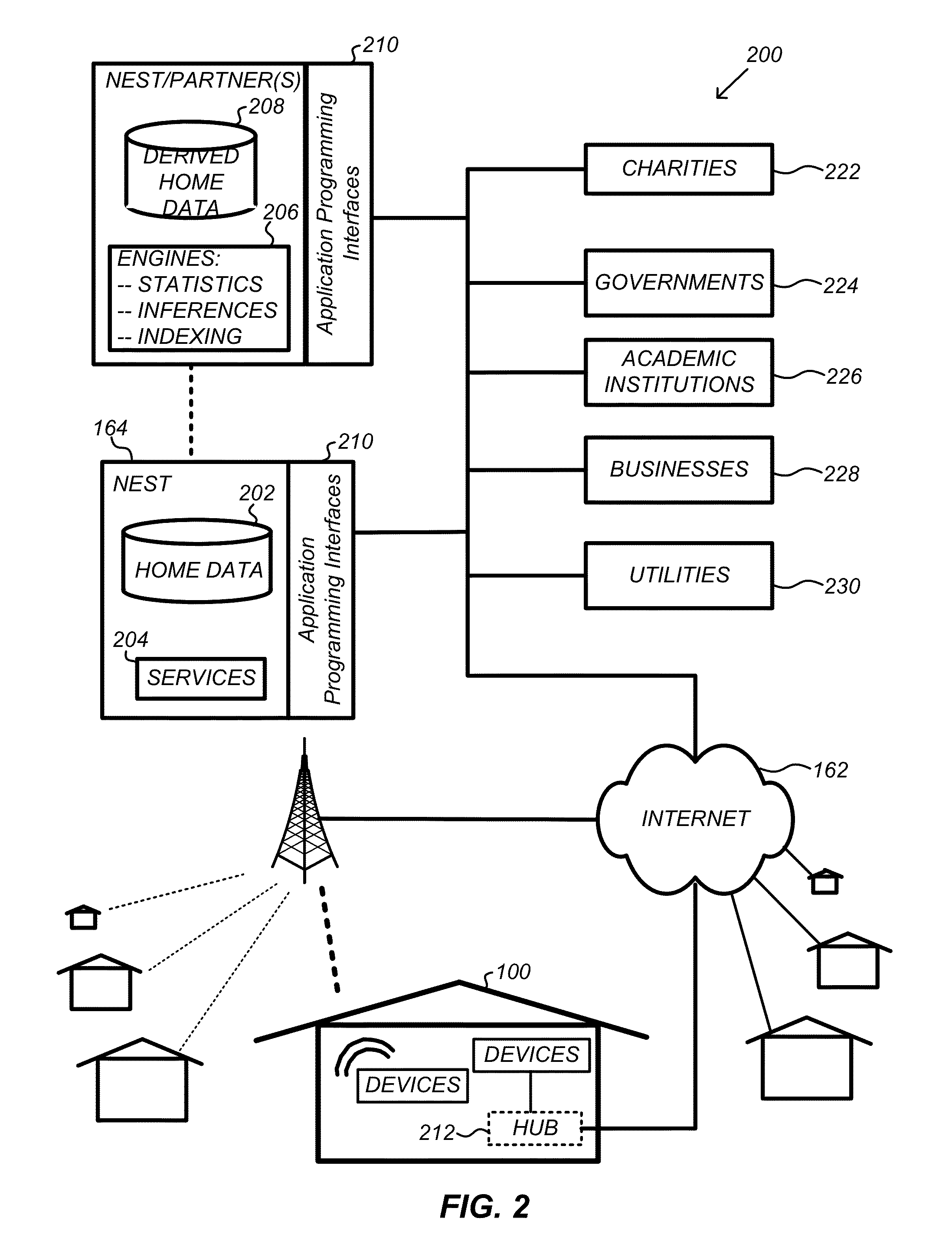

ActiveUS9049567B2Reduced and minimized amountEasy to configureParticular environment based servicesNetwork topologiesWi-FiThe Internet

A method for establishing a pairing between a hazard detector and an online account may include instantiating an application on a mobile computing device and receiving a first code from a central server. The application may receive a second code from printed material associated with the hazard detector. The hazard detector may broadcast a Wi-Fi access point, and the application may join the Wi-Fi access point. The application can be authenticated by the hazard detector using the second code, and the application can receive an identity of a home Wi-Fi network from a user. The application can then transmit the identity of the home Wi-Fi network to the hazard detector. The hazard detector can use the home Wi-Fi network to access the Internet and transmit the first code to the central server, where the central server can use the first code in completing the pairing process.

Owner:GOOGLE LLC

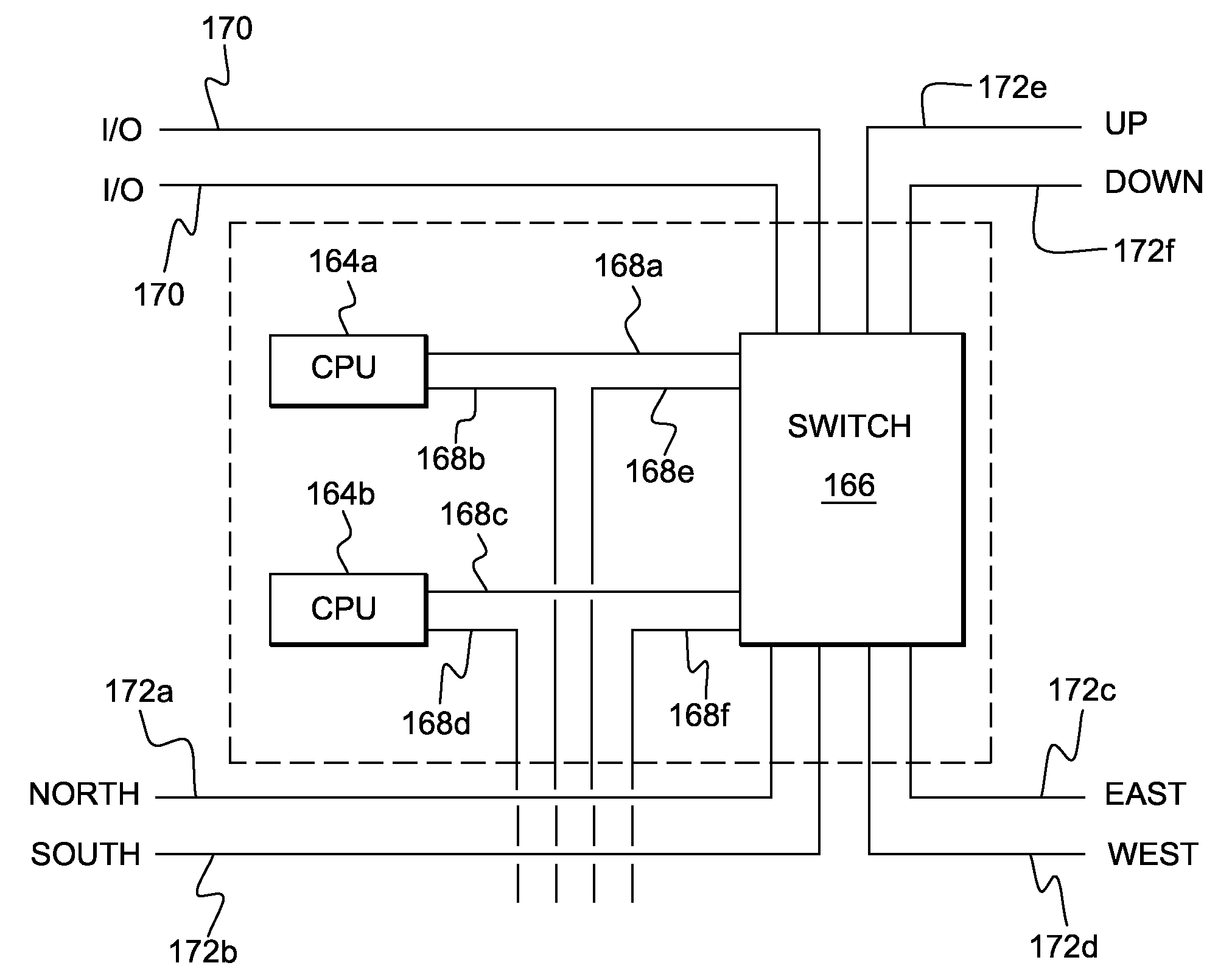

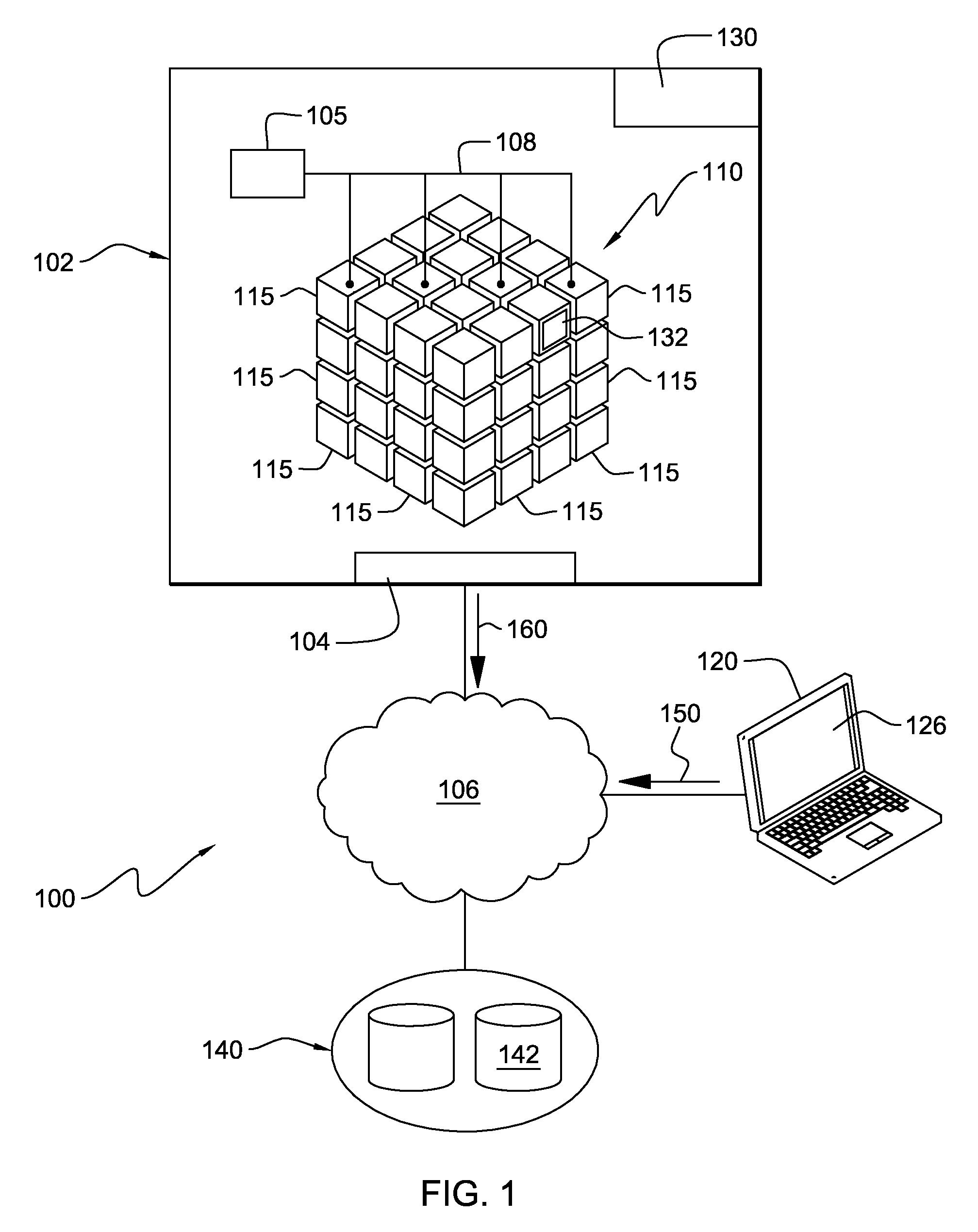

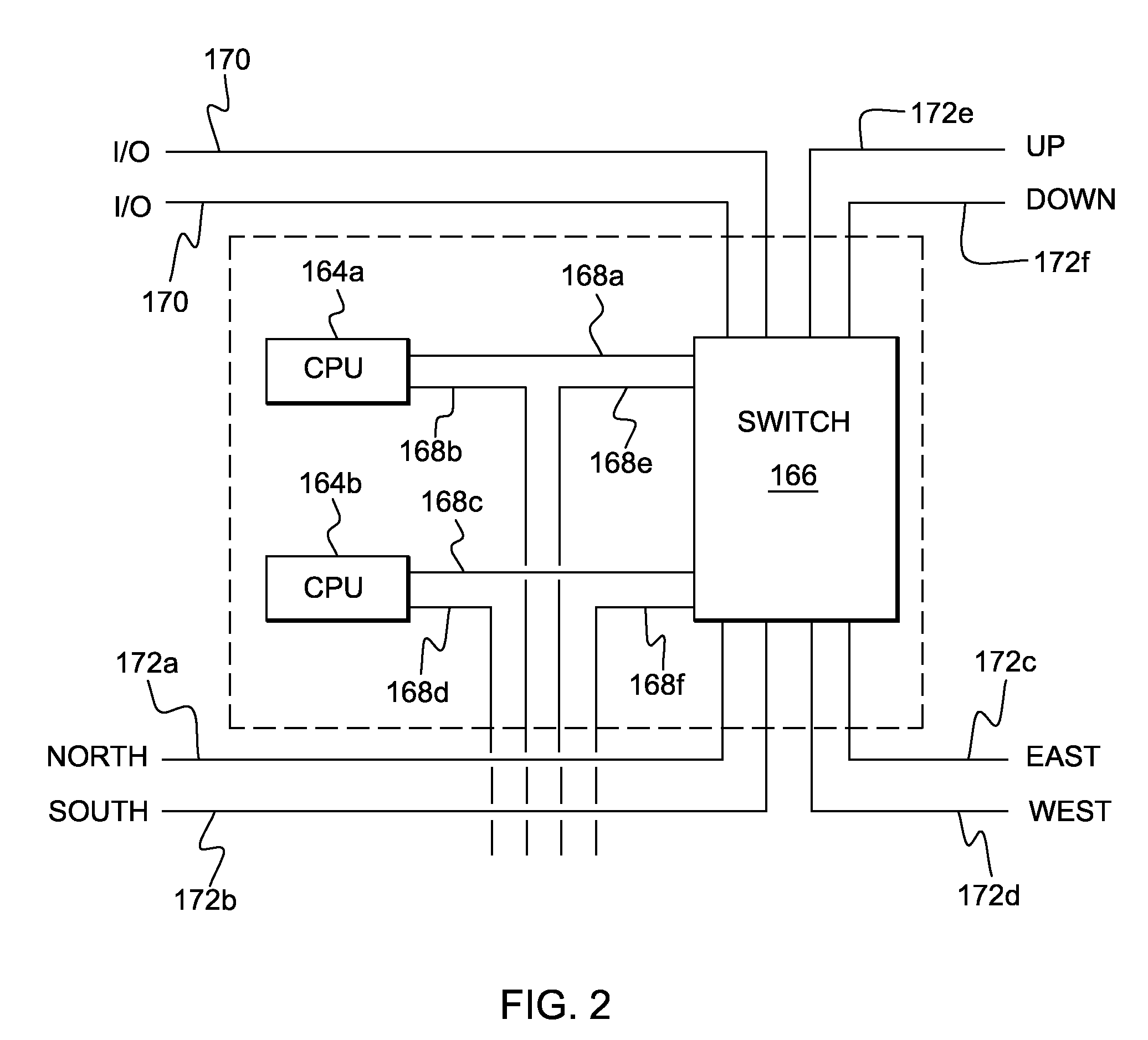

Methods and systems for migrating network resources to improve network utilization

ActiveUS20090193122A1Improve network utilizationReduced and minimized amountDigital computer detailsProgram controlTraffic capacityLock manager

A method and system are disclosed for migrating network resources to improve network utilization, for use in a multi-node network wherein nodes of the network share network resources. The method comprises the steps of identifying a group of nodes that share one of the network resources, and identifying one of the nodes satisfying a specified condition based on at least one defined access latency metric. The shared resource is moved to the identified one of the nodes to reduce overall access latency to access the shared resource by said group of nodes. One embodiment of the invention provides a method and system to synchronize tasks in a distributed computation using network attached devices (NADs). A second embodiment of the invention provides a method and system to reduce lock latency and network traffic by migrating lock managers to coupling facility locations closest to nodes seeking resource access.

Owner:IBM CORP

Systems and methods for performing peritoneal dialysis

InactiveUS20110144570A1Reduced and minimized amountPeritoneal dialysisProsthesisPeritoneal dialysisIntensive care medicine

Systems and methods for providing multiple pass continuous flow dialysis therapy are provided. The present invention includes a fluid circuit connected to a patient via a catheter thereby defining a fluid loop along which a therapy fluid including a dialysate can be continuously circulated into, through and out of a peritoneal cavity of a patient to remove a therapeutically effective amount of excess water and solutes including uremic toxins. The feed rate and discharge rate of therapy fluid into the fluid loop can be controllably regulated in proportion to the circulation rate of fluid in the fluid loop such that the therapy fluid can pass a multiple number of times along the fluid loop prior to discharge.

Owner:BAXTER INT INC +1

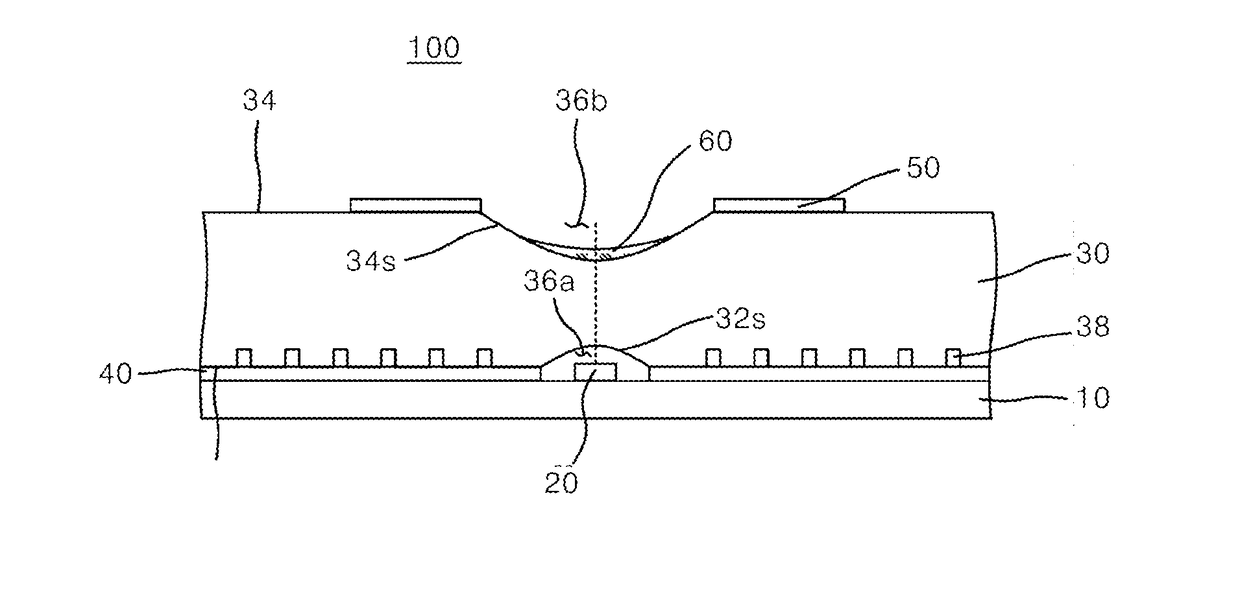

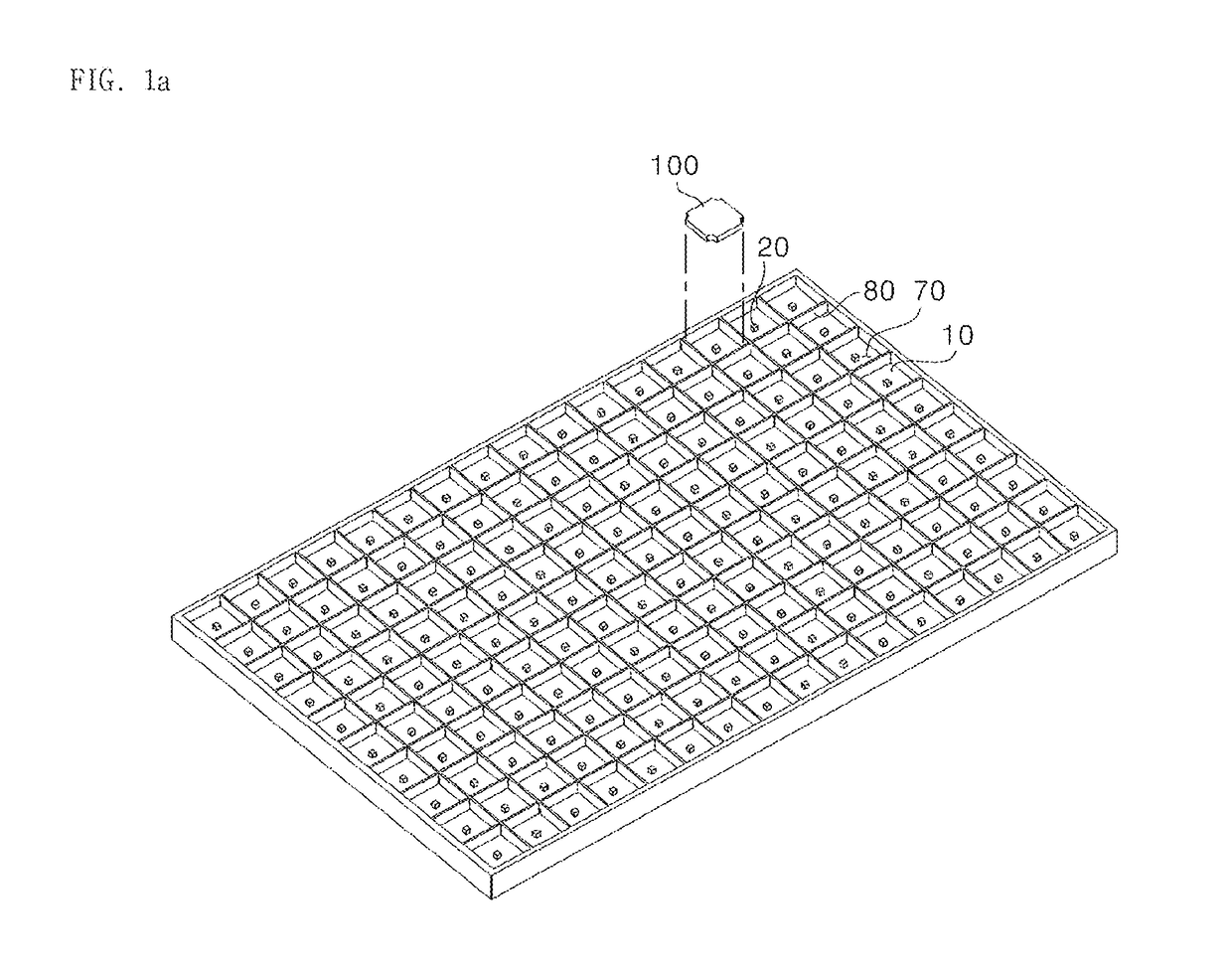

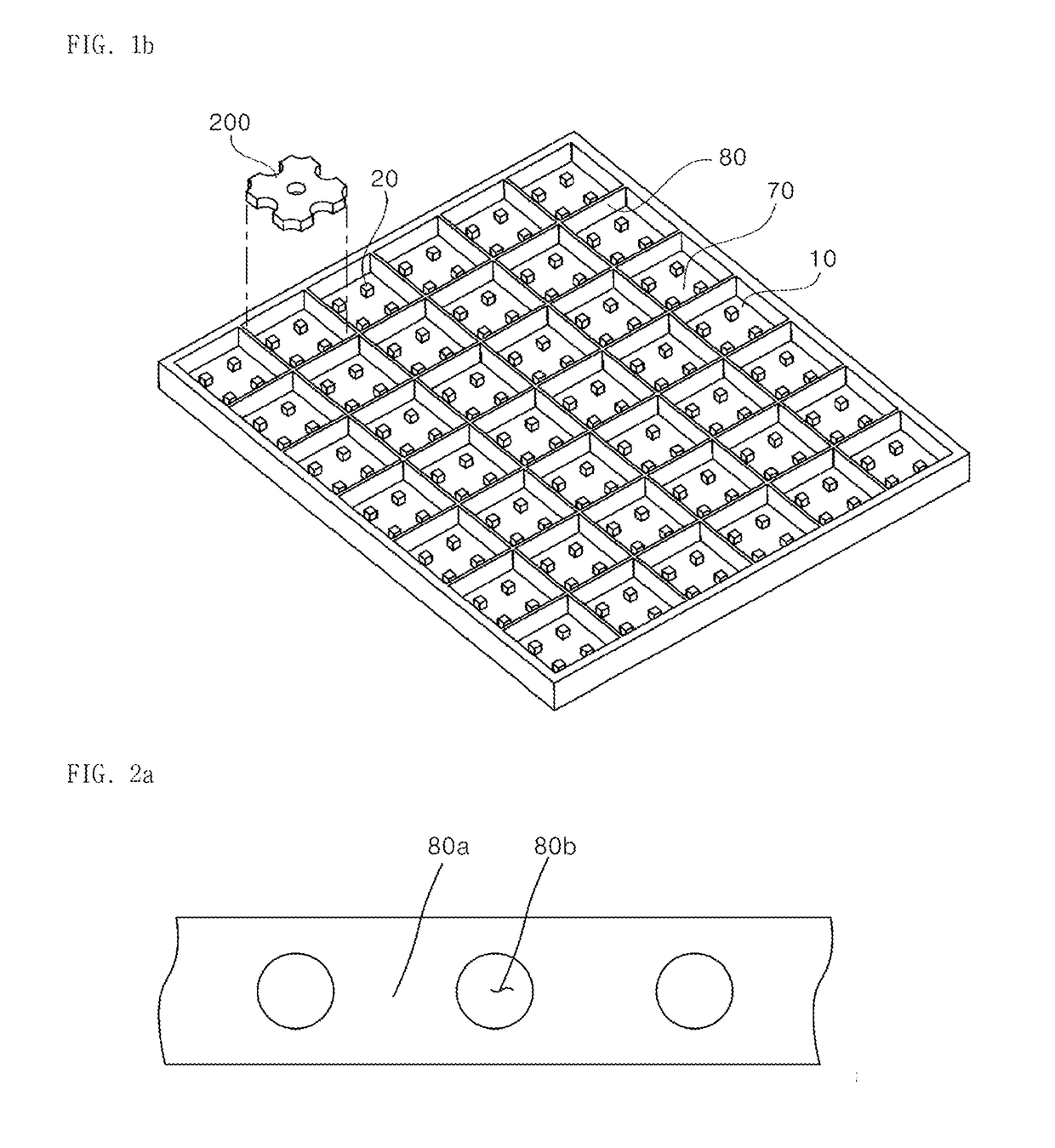

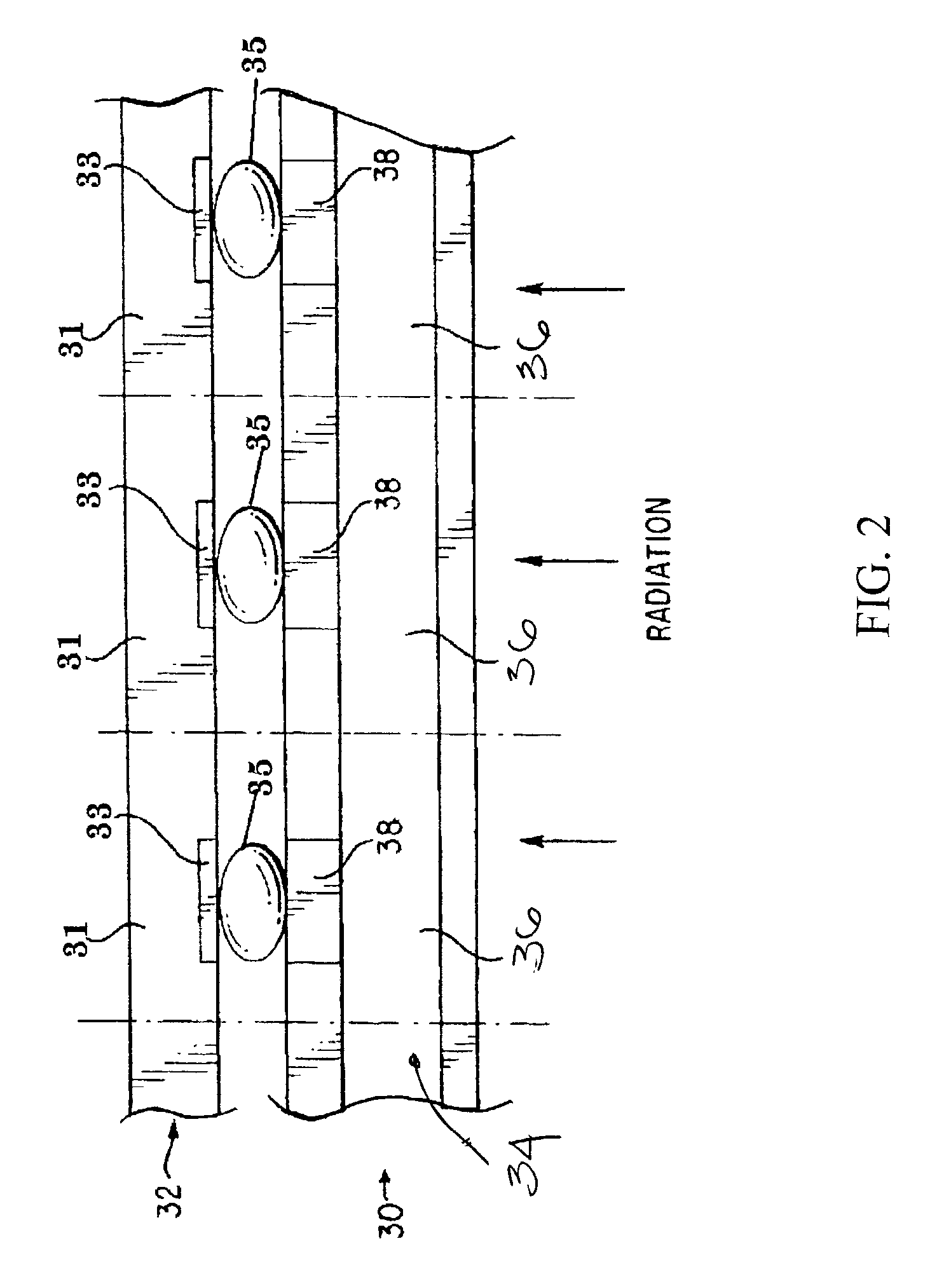

Backlight unit and luminous flux control member for local dimming

InactiveUS20180335559A1Suppress the white-spot phenomenonImprove abilitiesMechanical apparatusPlanar/plate-like light guidesLight guideLight beam

A backlight unit is disclosed which is capable of diffusing light emitted from a light source uniformly and suppressing white spot phenomenon. The backlight unit includes a light guide panel having a first surface and a second surface opposite to the first surface, a concaved light receiving region formed on the first surface, a light intensity adjusting recess formed on the second surface, a light intensity adjusting sheet disposed on the light intensity adjusting recess and the second surface around the light intensity adjusting recess. The backlight unit includes a substrate on which a plurality of light emitting devices are disposed, a plurality of luminous flux control members which are disposed on the substrate corresponding to the light emitting devices such that the light from the light source is uniformly transmitted upward, and a shade layer which is disposed between the luminous flux control members to reflect a portion of the light emitted through the luminous flux control member.

Owner:SEOHAN LITEK CO LTD

Hazard detection unit facilitating user-friendly setup experience

ActiveUS20150100618A1Reduced and minimized amountEasy to configureParticular environment based servicesNetwork topologiesWi-FiThe Internet

A method for establishing a pairing between a hazard detector and an online account may include instantiating an application on a mobile computing device and receiving a first code from a central server. The application may receive a second code from printed material associated with the hazard detector. The hazard detector may broadcast a Wi-Fi access point, and the application may join the Wi-Fi access point. The application can be authenticated by the hazard detector using the second code, and the application can receive an identity of a home Wi-Fi network from a user. The application can then transmit the identity of the home Wi-Fi network to the hazard detector. The hazard detector can use the home Wi-Fi network to access the Internet and transmit the first code to the central server, where the central server can use the first code in completing the pairing process.

Owner:GOOGLE LLC

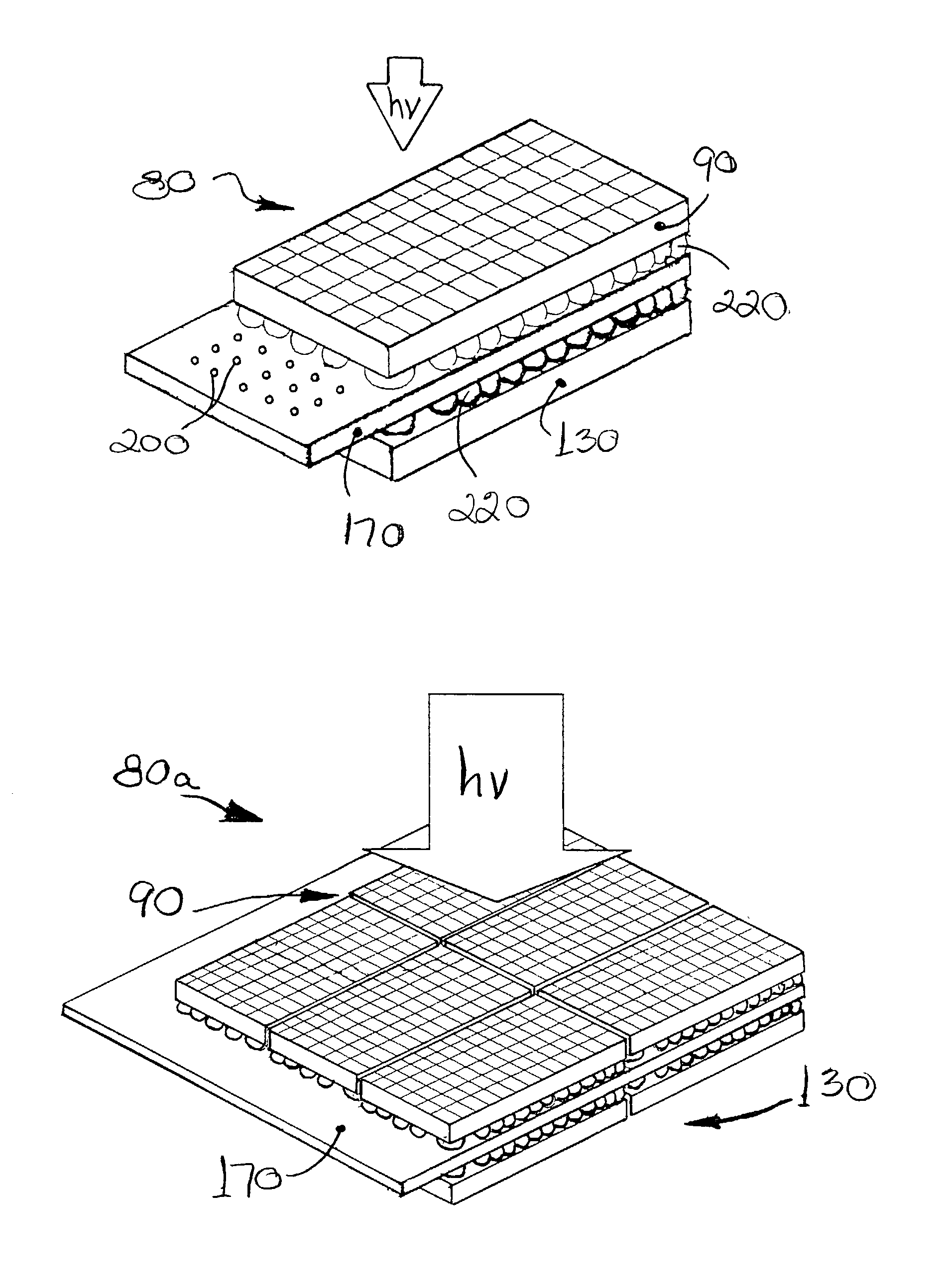

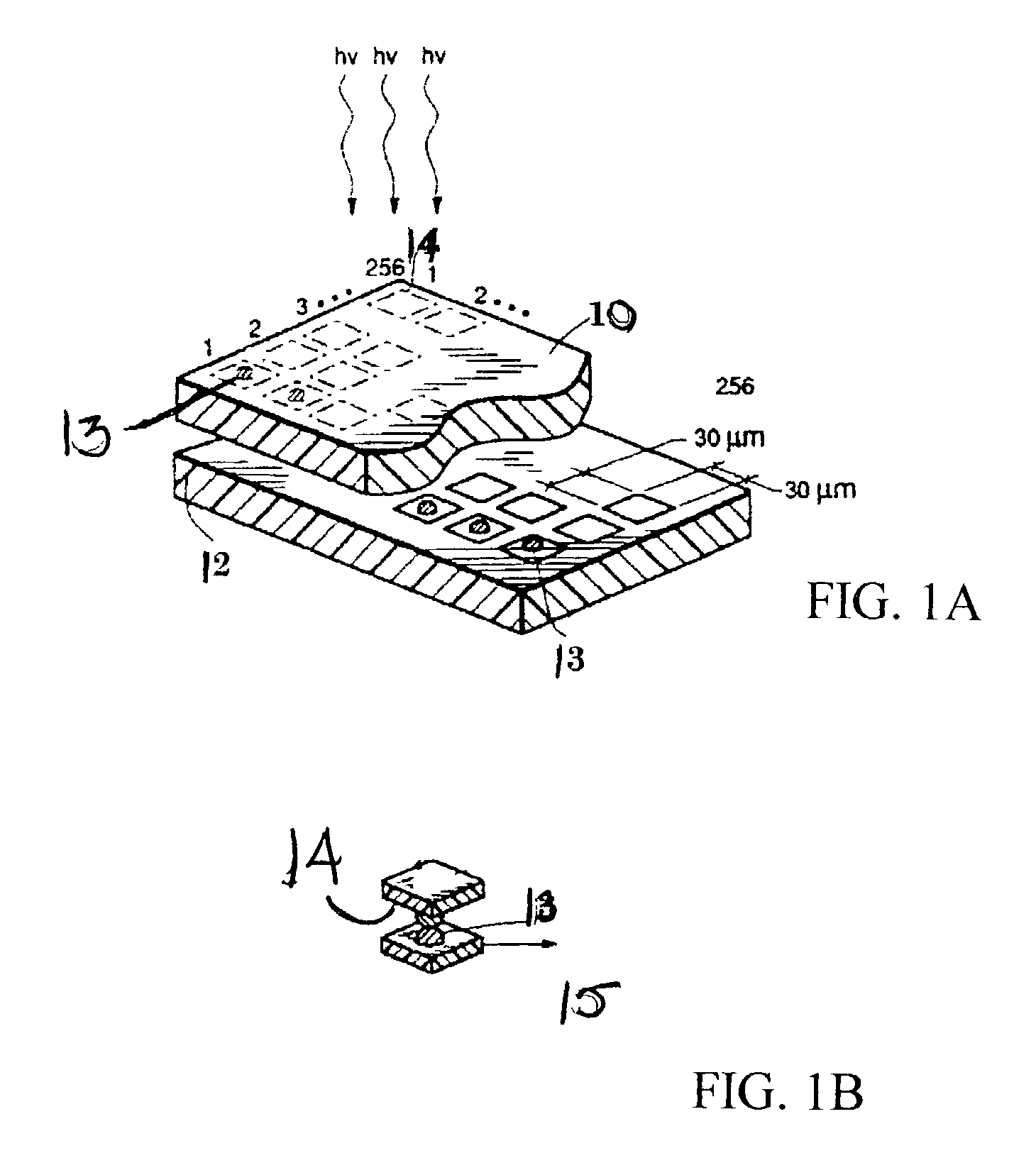

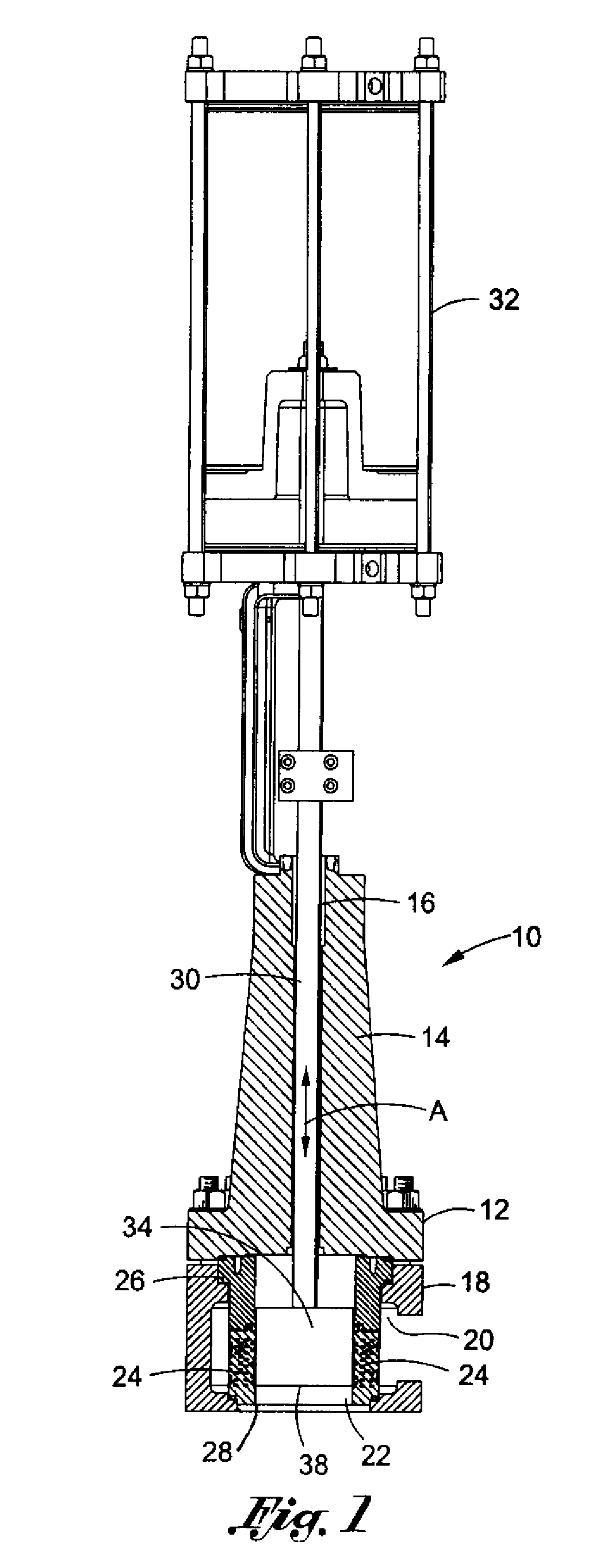

Radiation imaging device and system

InactiveUS7189971B2Big imageImprove image qualitySolid-state devicesMaterial analysis by optical meansElectricitySoft x ray

An x-ray and gamma-ray radiation energy imaging device has its semiconductor detector substrate and semiconductor readout / processing substrate both mounted on opposite sides of, and electrically communicating through, an intermediate substrate. The substrates are all substantially planar with the top plan perimeter of the semiconductor readout / processing substrate falling within the top plan shadow perimeter of the corresponding semiconductor detector substrate with which it electrically communicates. Additionally, all of the readout / processing circuitry contacts of the semiconductor readout / processing substrate are disposed on the surface of the semiconductor readout / processing substrate that electrically communicates with the intermediate substrate. Substantially all electrical communication to and from the semiconductor readout / processing substrate is routed through the intermediate substrate. The intermediate substrate is a printed circuit board or similar construct. The electrical contacts between the semiconductor substrates and the intermediate substrate are accomplished using bump-bonds, conductive adhesive bonds, conductive adhesive films or a combination thereof. One or two dimensional planar arrays of semiconductor readout / processing substrates and corresponding semiconductor detector substrates can be mounted on a single intermediate substrate using “tiling” techniques known in the art to form a mosaic radiation imaging device of increased active imaging area and reduced / minimized imaging dead area.

Owner:OY AJAT LTD

Direct metal laser sintered flow control element

ActiveUS8826938B2High precisionReduce fluid velocityAdditive manufacturingValve members for absorbing fluid energyDirect metal laser sinteringMetallic materials

A flow control element comprises a cylindrical element body having a bore formed therethrough. The cylindrical element body may include inner and outer peripheral surfaces and define a plurality of tortuous flow passages which extend between the inner and outer peripheral surfaces. The flow control element is formed as a unitary structure wherein the flow passages are oriented along at least two axes. The flow control may be formed by direct to metal laser sintering wherein successive layers of powdered metallic material are solidified by applying laser energy to the selected portions until the flow element is formed as a unitary structure with a plurality of flow passages extending therethrough. The laser energy is selectively applied to the powdered metallic material according to a computer model of the flow control element.

Owner:CONTROL COMPONENTS INC

Silicone defoamer to better control hydrocarbon foam and reduce silicon content of liquid hydrocarbon products

ActiveUS20050109675A1Reduced and minimized amountEffectively controls foamThermal non-catalytic crackingHydrocarbon distillationDefoamerChemistry

It has been discovered that crosslinked polydimethylsiloxane (PDMS) resins are useful defoamers and antifoamers for hydrocarbon-containing liquids, such as delayed coker feedstocks and feedstocks to preflash and atmospheric towers. These PDMS resins are crosslinked with either alkyl polysilicate or siloxane. The crosslinked PDMS resins may be used alone or together with linear PDMS, and are typically blended with a carrier such as kerosene for easier handling. Importantly, the use of crosslinked branched PDMS resins permit less total amount of polysiloxanes to be used, which reduces the silicon carryover in coker products and reduces poisoning of downstream catalysts.

Owner:BAKER HUGHES INC

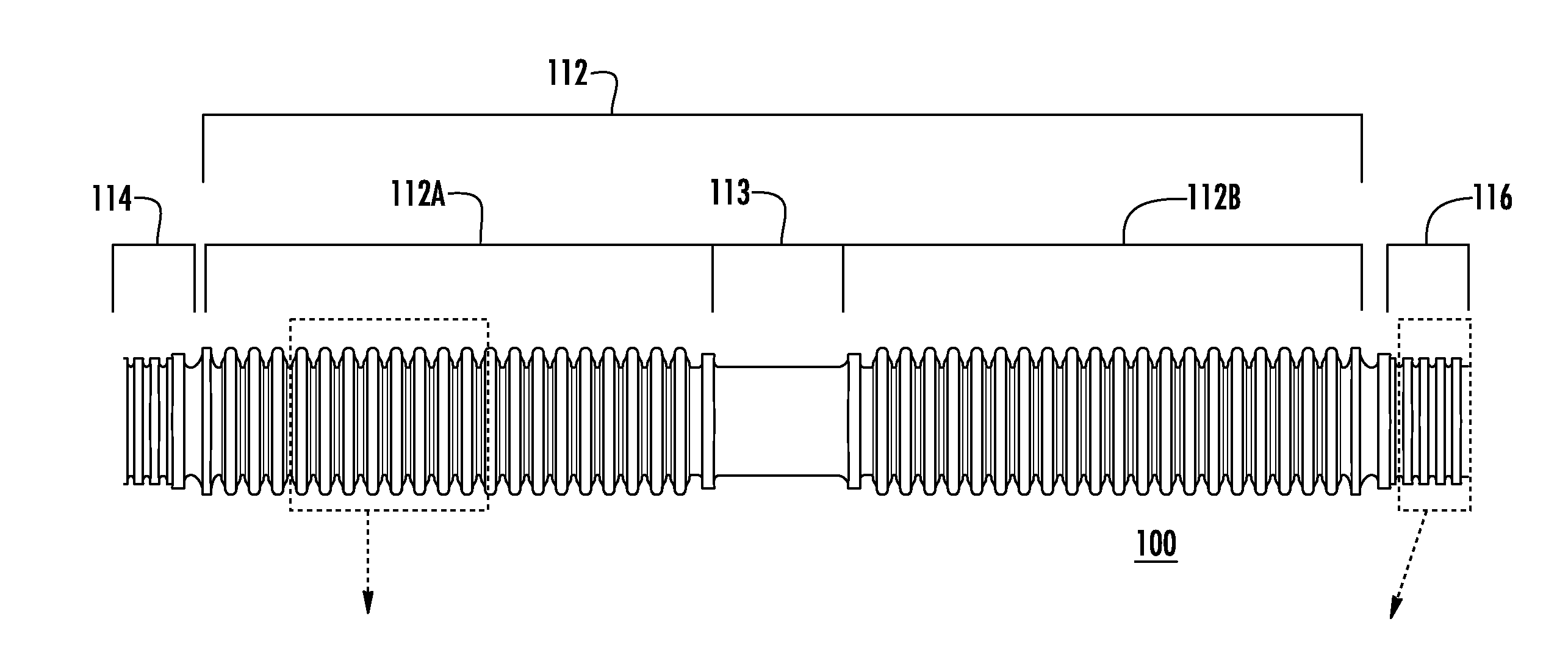

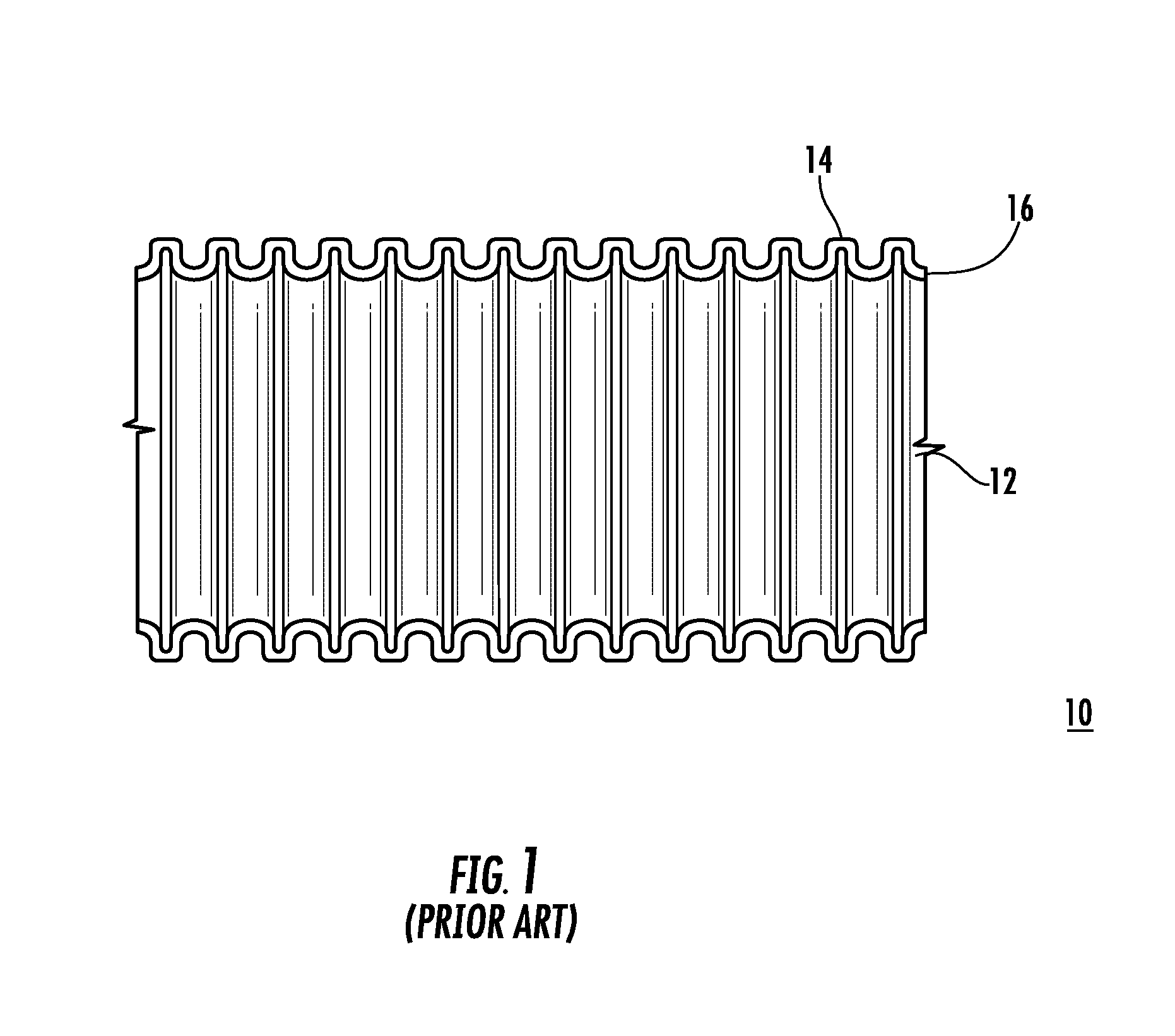

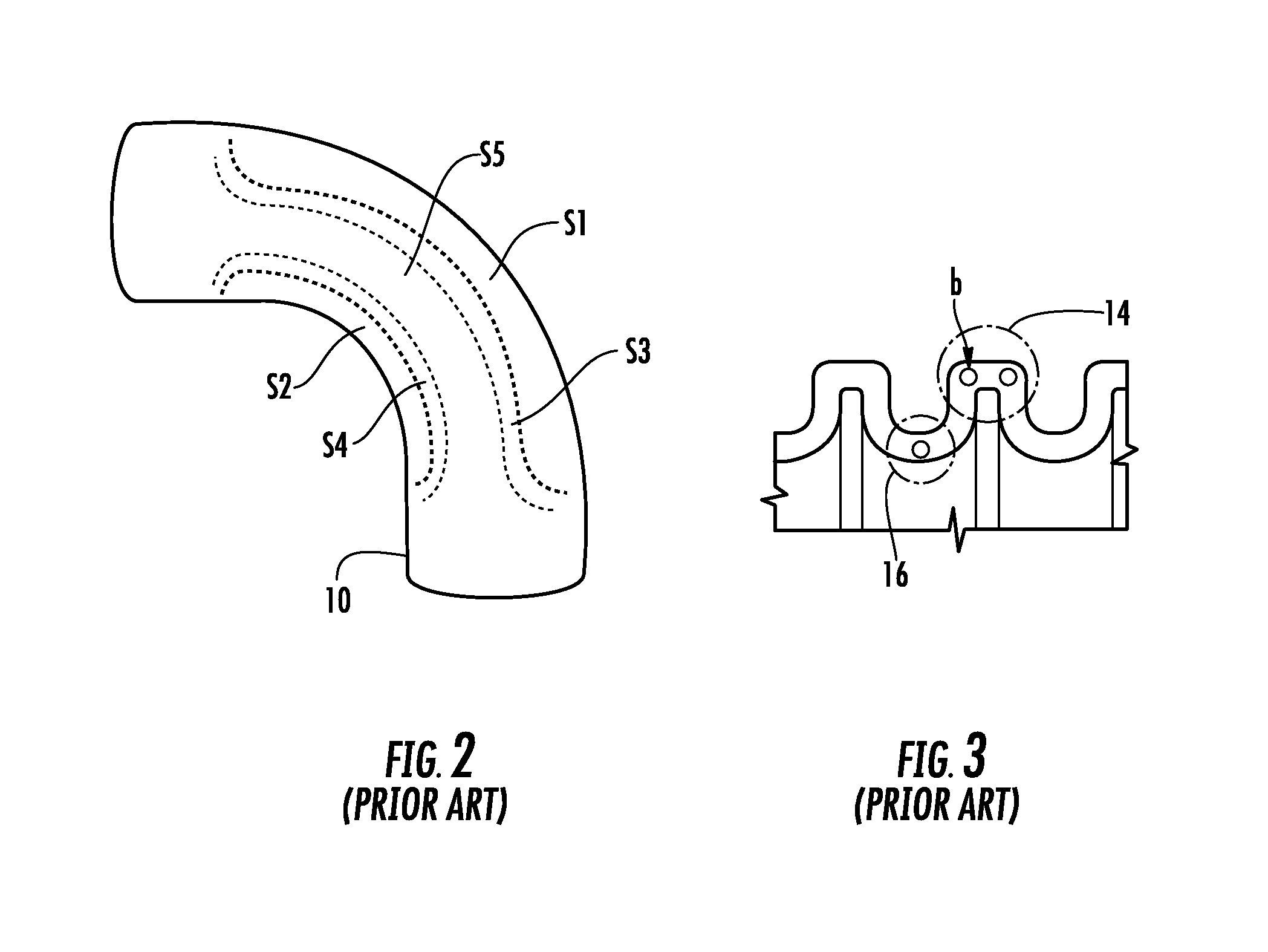

Drain hose for a washer

InactiveUS20120255329A1Precise alignmentAvoid distortionOther washing machinesFlexible pipesEngineeringHome appliance

A drain hose for a household appliance in which the drain hose includes a first open end, a second open end, and a continuous portion extending from the first open end to the second open end, wherein the continuous portion includes a first bending portion having a plurality of repeating profiles, wherein a cross-section of each profile includes a ridge and a trough, and wherein one of the ridge has three predetermined bending points, and the trough has two predetermined bending points.

Owner:BSH HOME APPLIANCES CORP

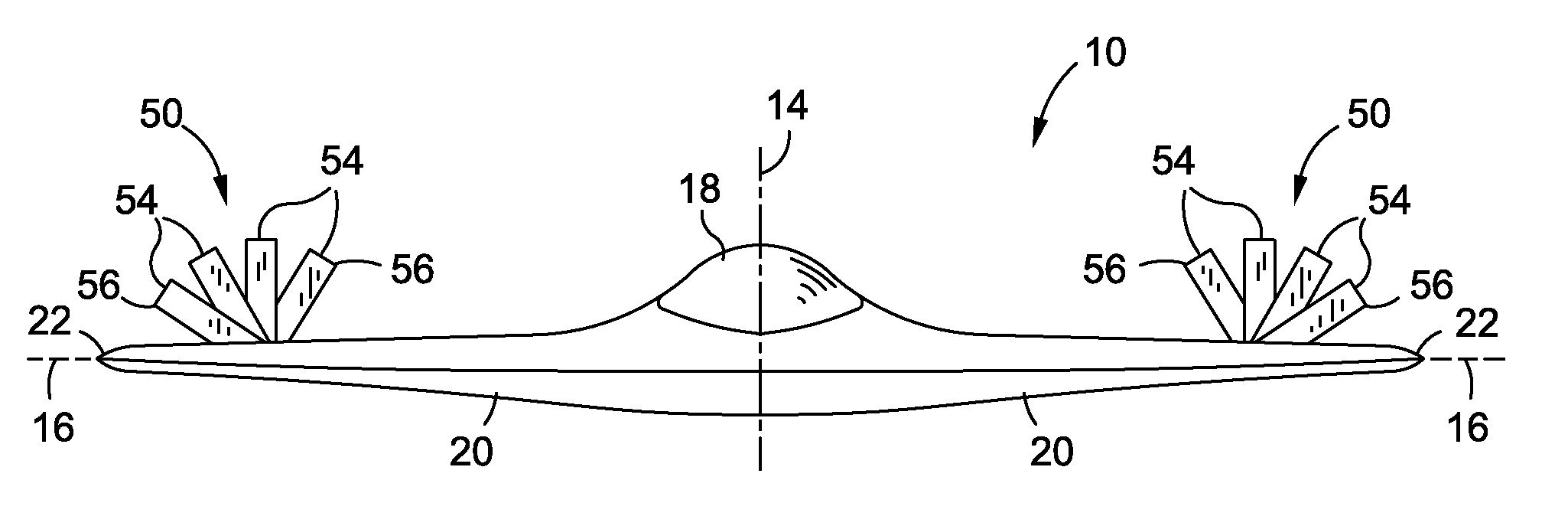

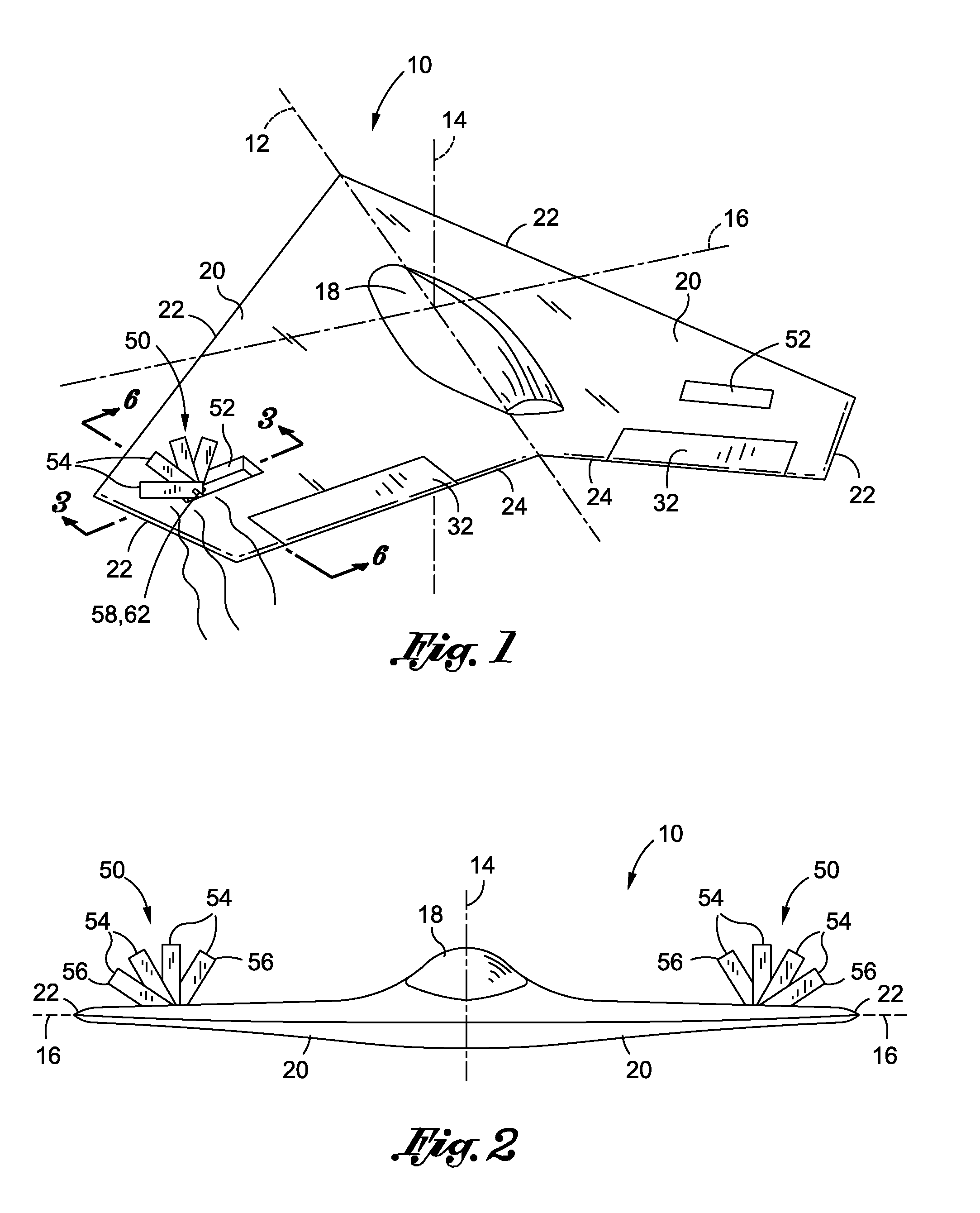

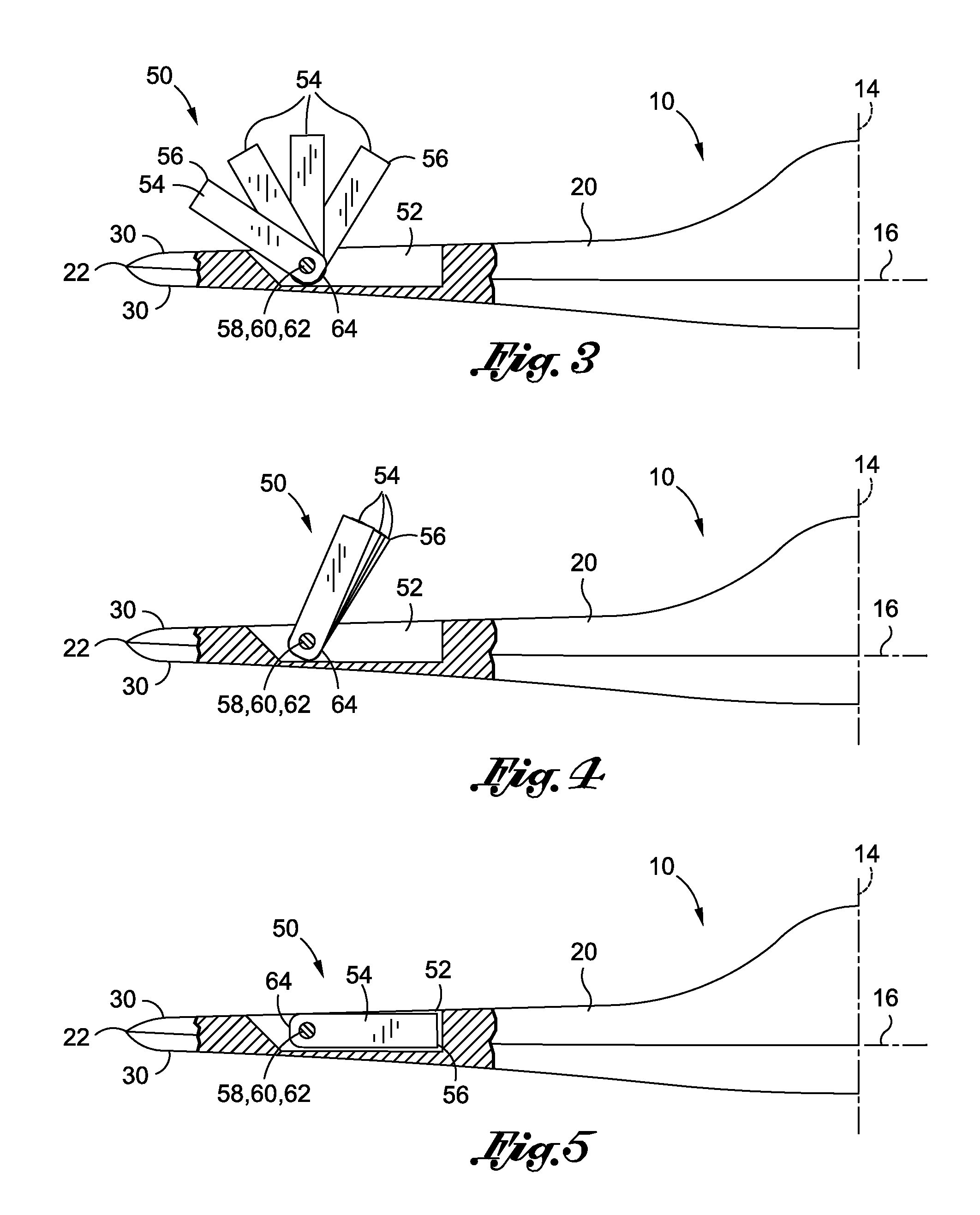

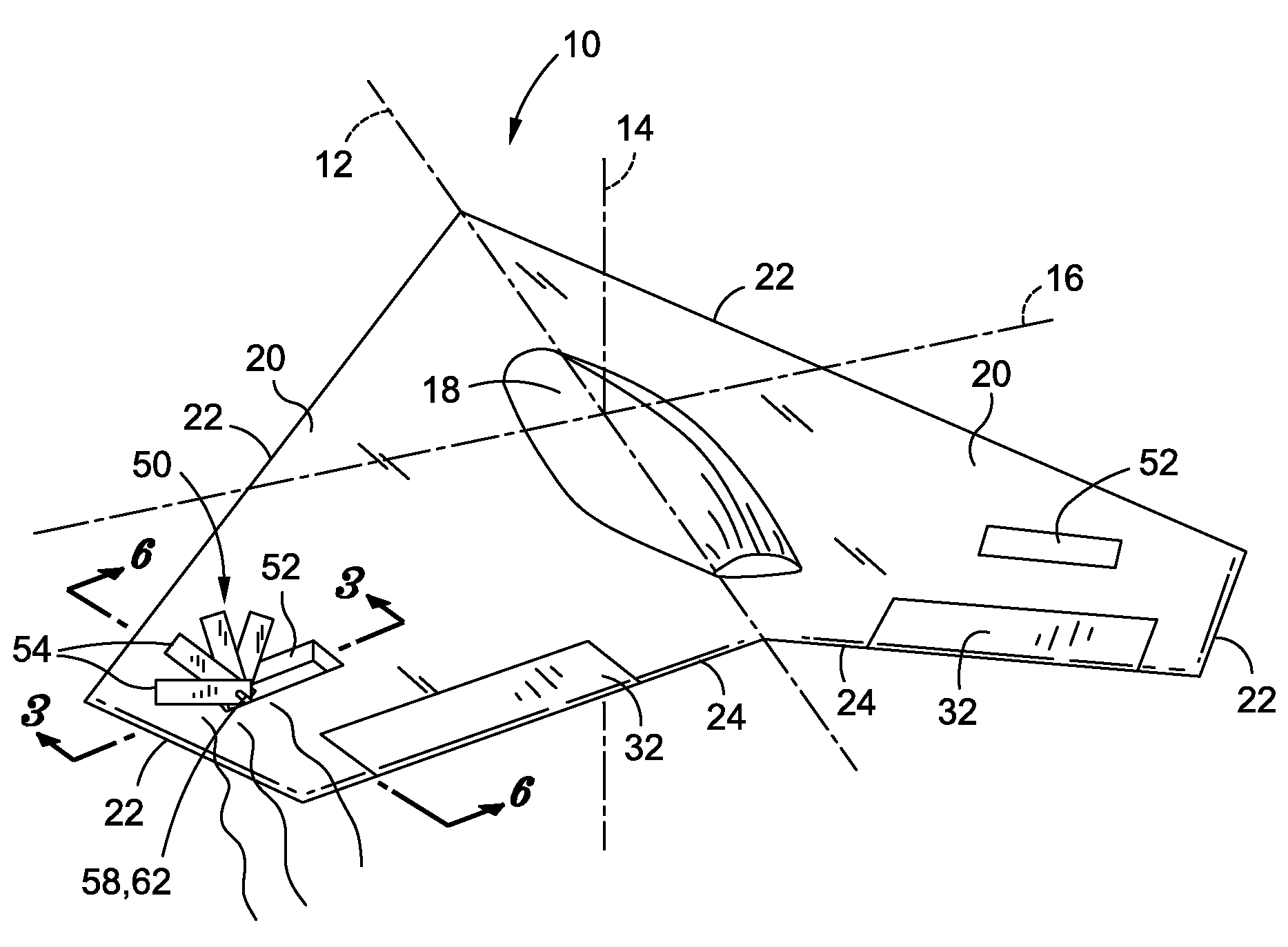

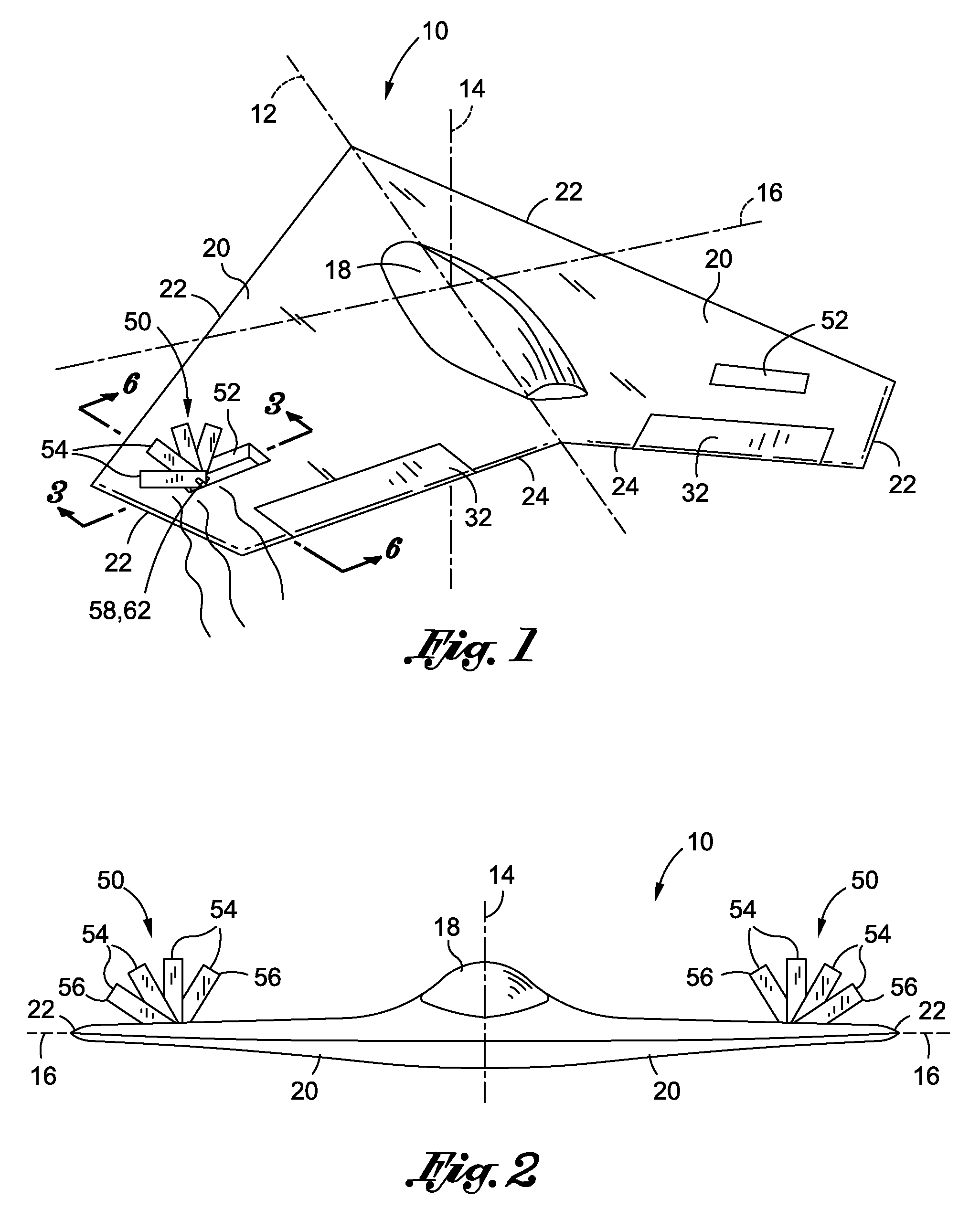

Aerodynamic fan control effector

ActiveUS20090230240A1Maximize net area of bladeFacilitate packaging and stowageInfluencers by generating vorticesAir braking surfacesActuatorAirplane

A fan control effector for an aircraft comprises at least one blade configured to be pivotably deployable in a radially outward direction from a retracted position to a deployed position such that the blade extends out of the aircraft. The fan control effector may be mounted in a symmetrical arrangement about a longitudinal axis on opposing wings of the aircraft. Furthermore, the fan control effector may comprise any number of blades for independent deployment outwardly from the wing. The blades are configured to be angularly deployable along a direction that is non-parallel to the longitudinal axis of the aircraft. The blades may be configured to be deployable sequentially from the wing starting with an initial deployment of an aft-most one of the blades.

Owner:THE BOEING CO

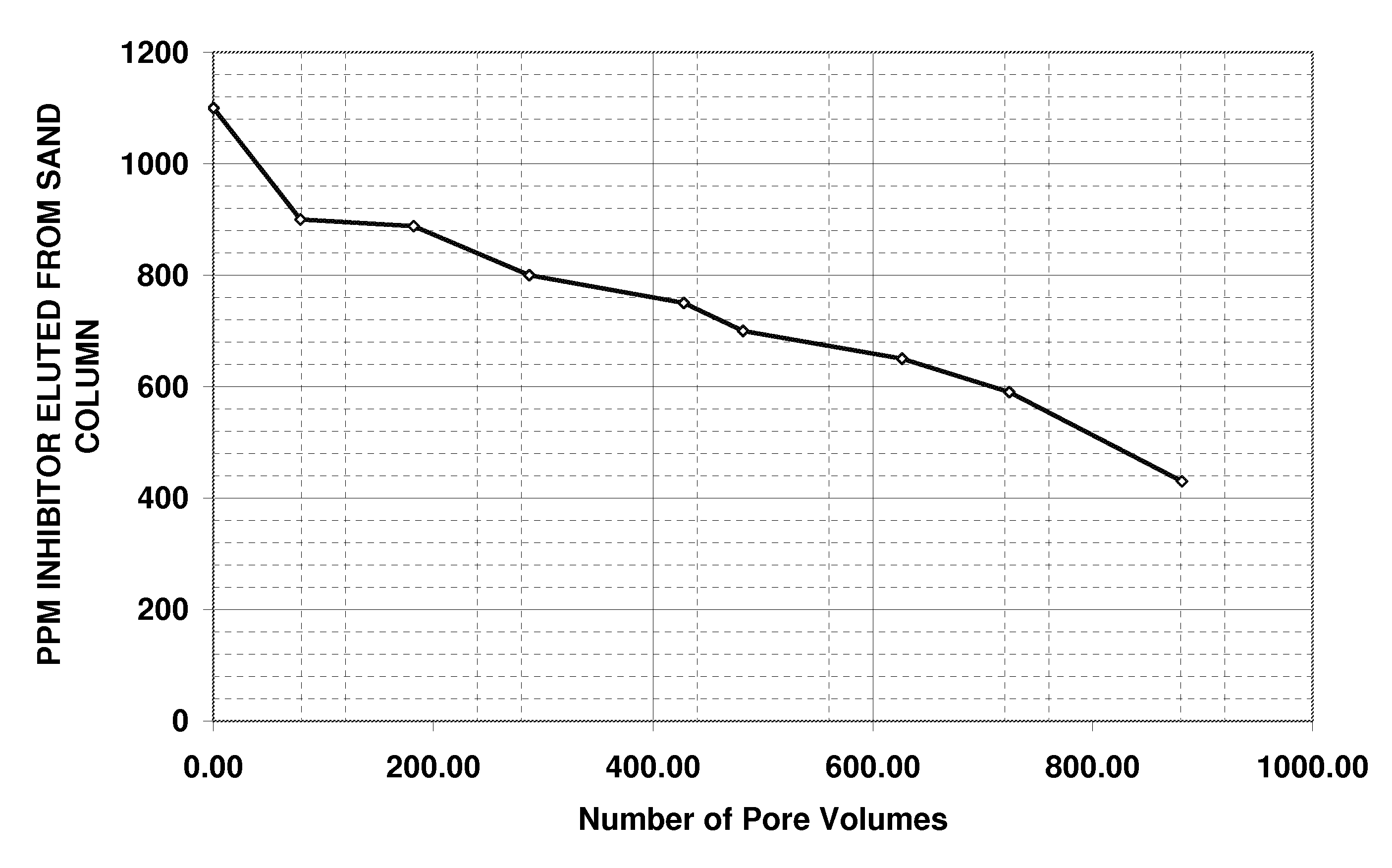

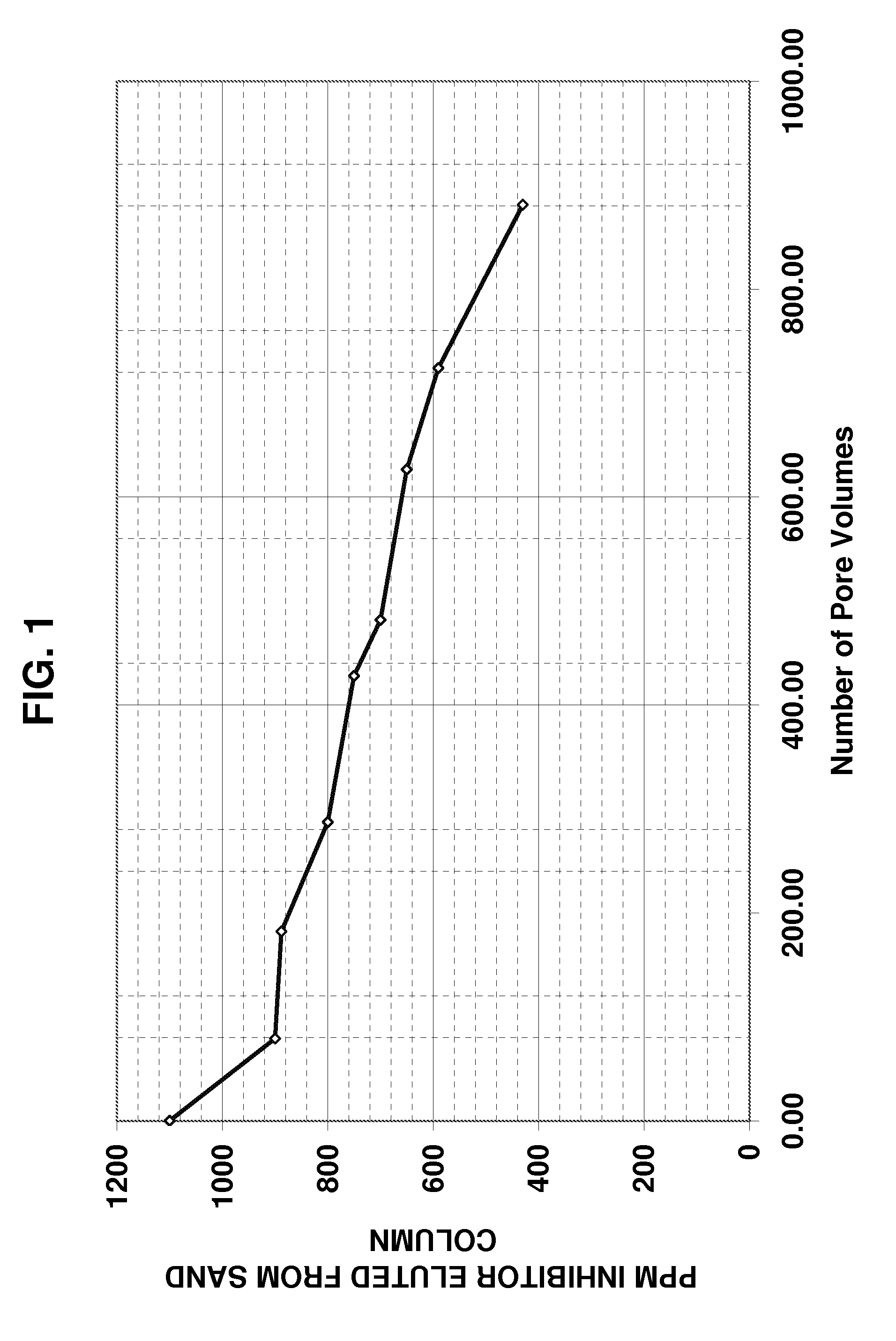

Method of minimizing or reducing salt deposits by use of a fluid containing a fructan and derivatives thereof

ActiveUS7977283B2Reduce the amount requiredReduced and minimized amountCleaning apparatusFluid removalSalt depositWater insoluble

The amount of crystallized salt in an oil and / or gas well may be minimized or reduced by use of a fructan, such as inulin, or a derivative as a salt block inhibitor. A preferred salt inhibitor is the salt of carboxyalkyl inulin such as a sodium salt of carboxymethyl inulin. The salt block inhibitor may be adsorbed onto a water-insoluble adsorbent.

Owner:BAKER HUGHES INC

Silicone defoamer to better control hydrocarbon foam and reduce silicon content of liquid hydrocarbon products

ActiveUS7427350B2Reduced and minimized amountEffectively controls foamThermal non-catalytic crackingHydrocarbon distillationKeroseneLiquid hydrocarbons

It has been discovered that crosslinked polydimethylsiloxane (PDMS) resins are useful defoamers and antifoamers for hydrocarbon-containing liquids, such as delayed coker feedstocks and feedstocks to preflash and atmospheric towers. These PDMS resins are crosslinked with either alkyl polysilicate or siloxane. The crosslinked PDMS resins may be used alone or together with linear PDMS, and are typically blended with a carrier such as kerosene for easier handling. Importantly, the use of crosslinked branched PDMS resins permit less total amount of polysiloxanes to be used, which reduces the silicon carryover in coker products and reduces poisoning of downstream catalysts.

Owner:BAKER HUGHES INC

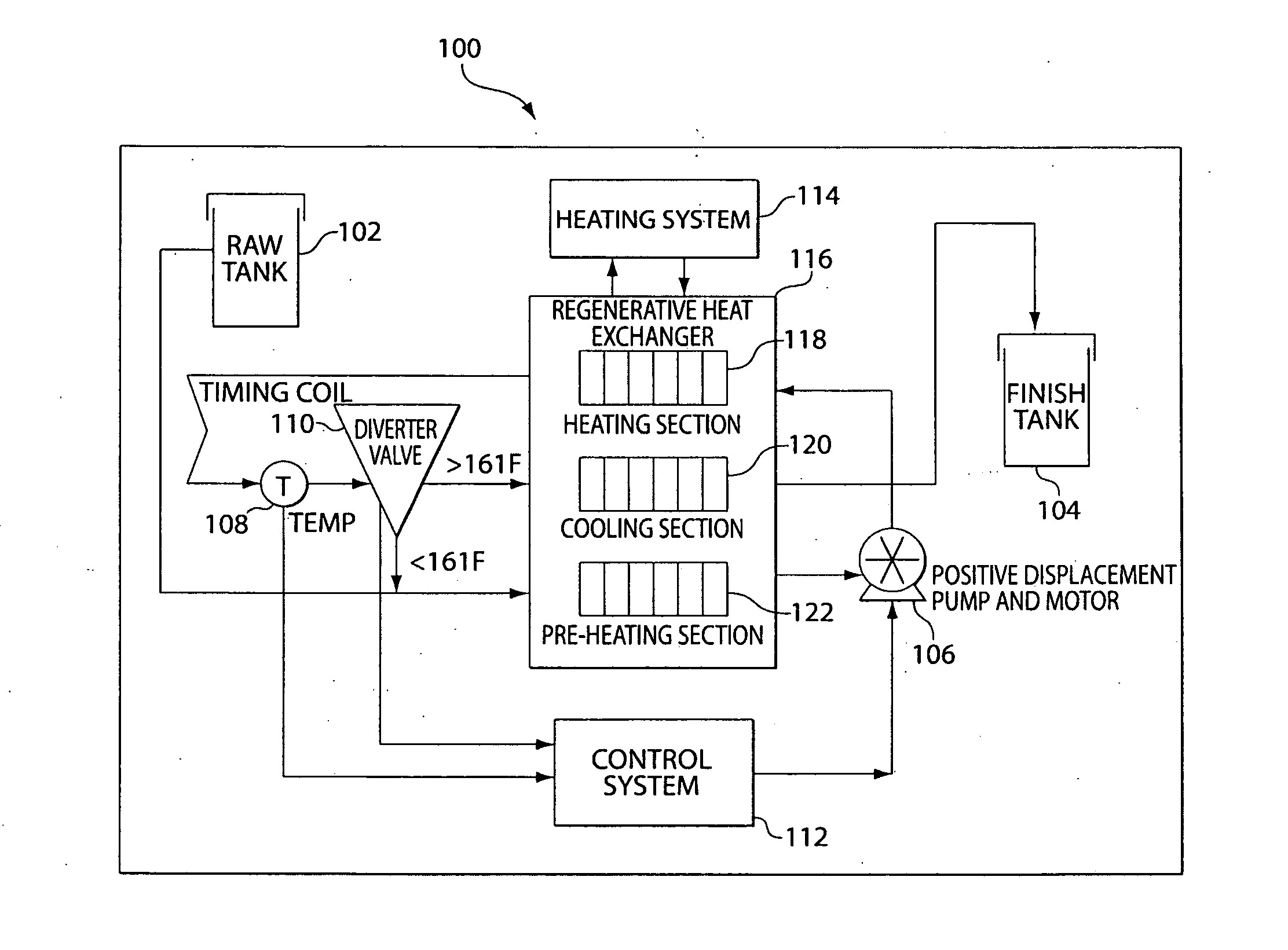

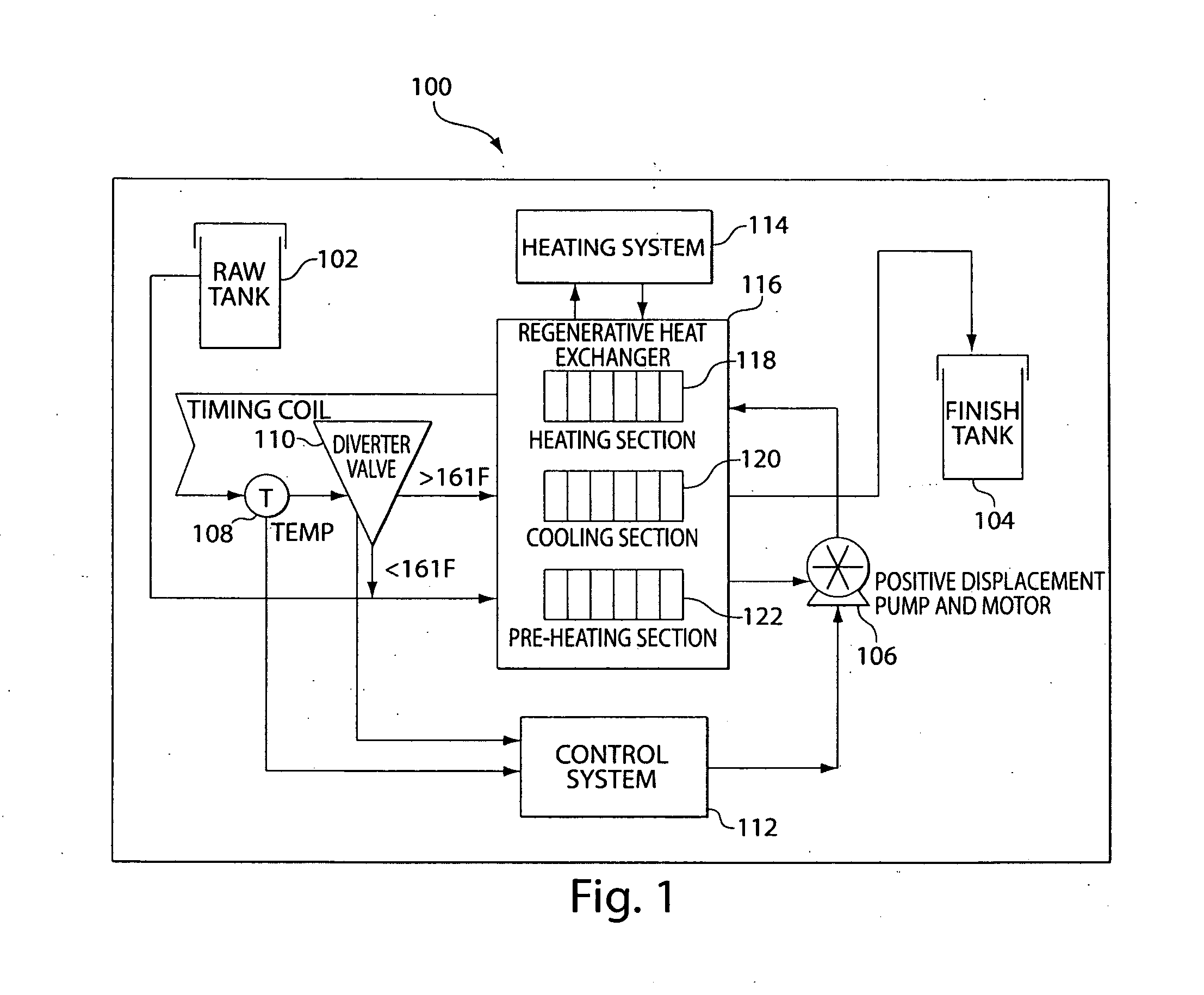

System and Method for Pasteurizing Milk

InactiveUS20110318463A1Lighter environmentLighter impactMilk preservationHollow article cleaningRaw milkEngineering

Systems and methods are provided for pasteurizing milk or other fluids, and for cleaning and disinfecting processing passageways prior to and after the milk processing. The disclosed pasteurization systems and methods have very low impact on the characteristics of raw, unpasteurized milk (e.g., texture, flavor, and / or nutritional value). For example, some systems and methods utilize a pump that operates at a very low flow rate (e.g., about 1 gallon per minute (GPM)) to prevent mechanical adulteration of the raw milk. Disclosed systems and methods for cleaning and disinfecting the fluid passageways also utilize a low-flow rate, and can use the same low flow pump that is utilized during pasteurization. A pressure pulser allows pressure to build up within the fluid passageways despite the low flow, and then releases the pressure to purge air from the passageways and to cause their interior surfaces to contact the cleaning fluid.

Owner:BOB WHITE SYST

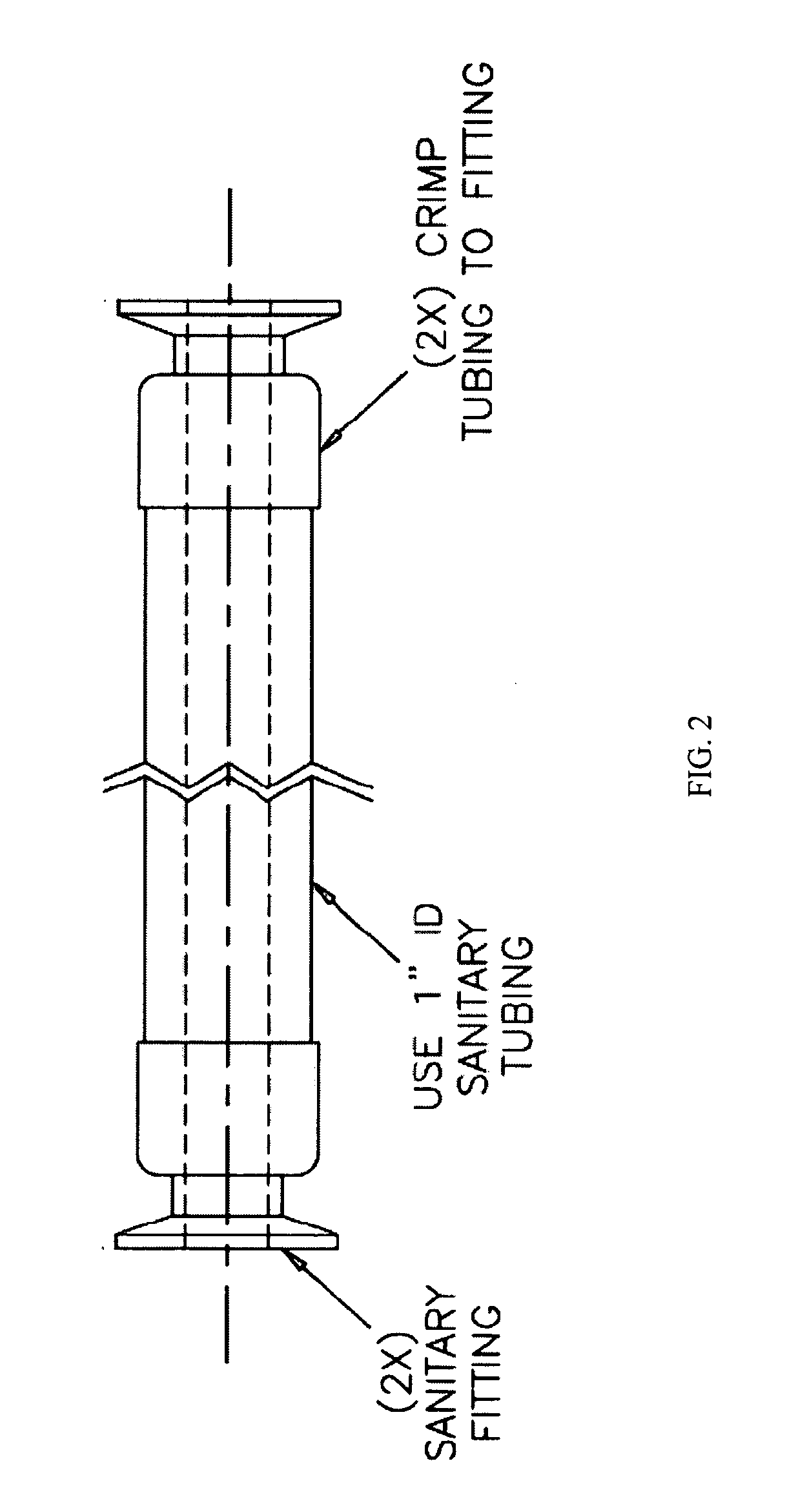

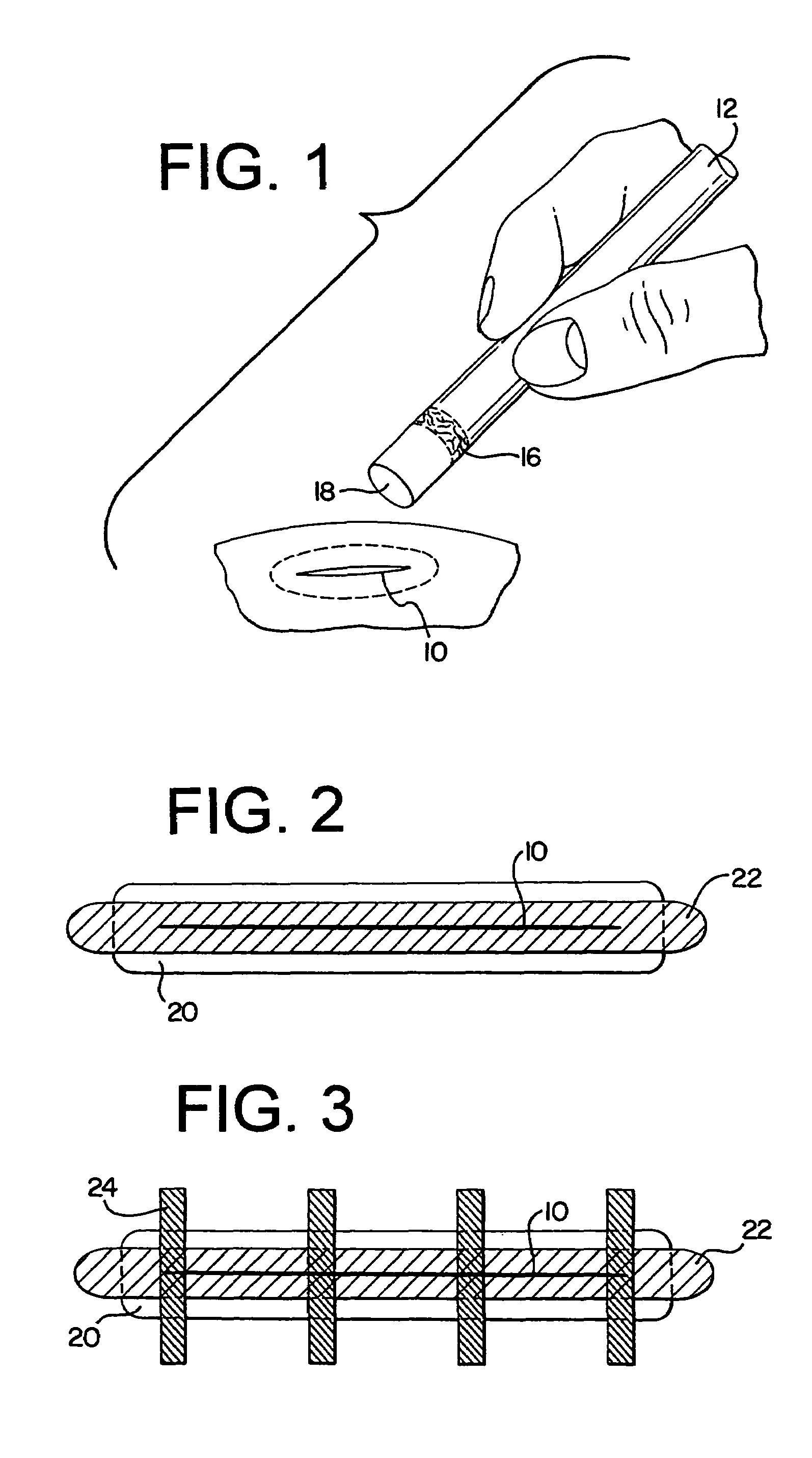

Dressing and method of treatment for a wound

InactiveUS20060029651A1Reduced and minimized amountSimple materialSurgical adhesivesAbsorbent padsMedicineAdhesive

A dressing and method for treating high-tension wounds. First and second layers of a 2-octyl cyanoacrylate 16 adhesive are applied to a short, high-tension wound, with the first and second layers covering the wound and extending to at least about 2.5 mm (0.0984 in.) from each side of the wound. The first layer is allowed to set and polymerize before the second layer of 2-octyl cyanoacrylate is applied. The second layer extends at least about 2.5 mm (0.0984 in.) beyond each edge of the first layer. In the case of a long, high-tension wound, a third layer is applied after the first and second layers are allowed to set and polymerize. The third layer is at least about 2.5 mm (0.0984 in.) wide and is substantially perpendicular to the first and second layers. The third layer may occur intermittently every 2.5 cm (0.984 in.) over the length of the wound, and preferably extends at least about 5 mm (0.197 in.) beyond the edge of the first layer.

Owner:ZYMURGY

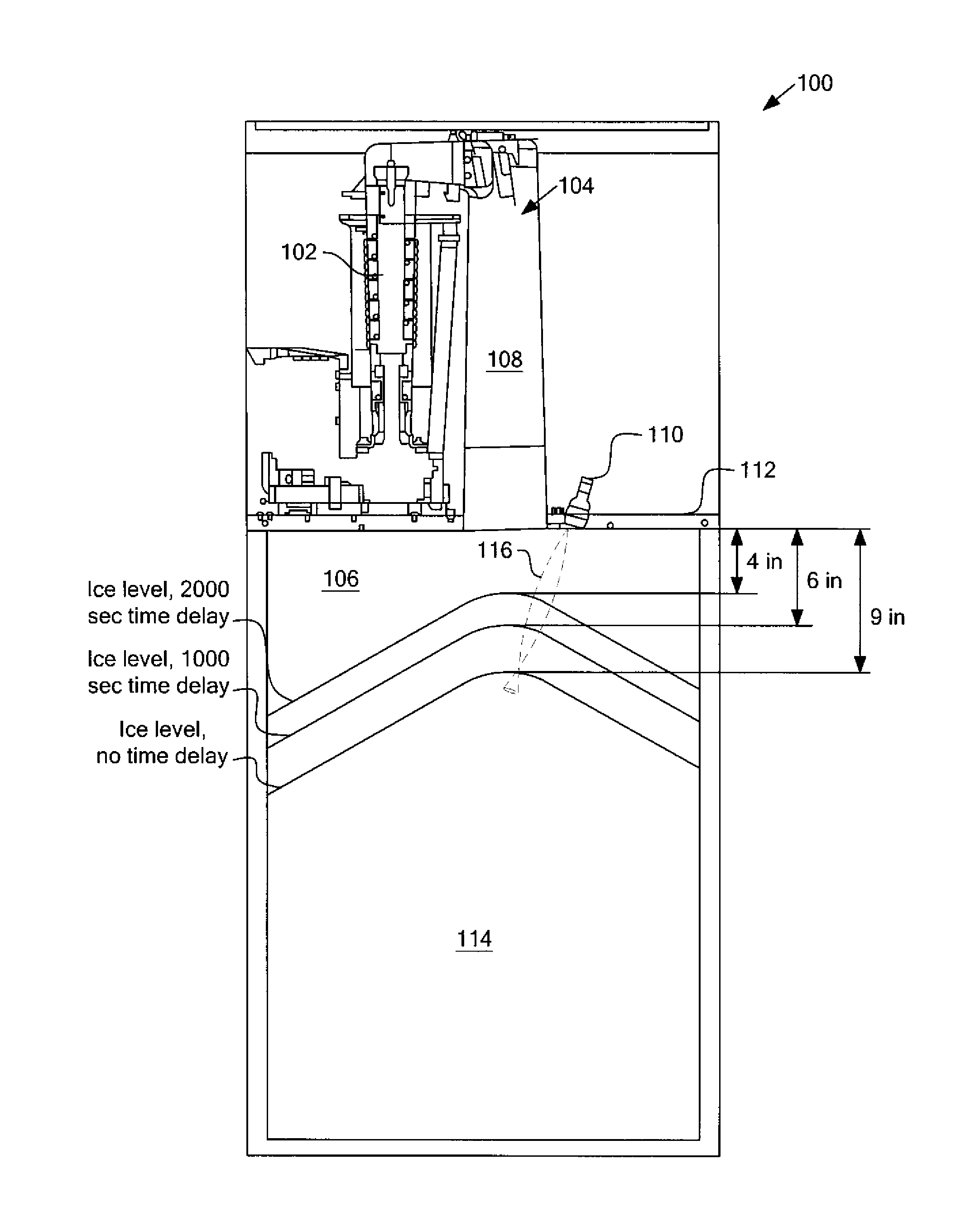

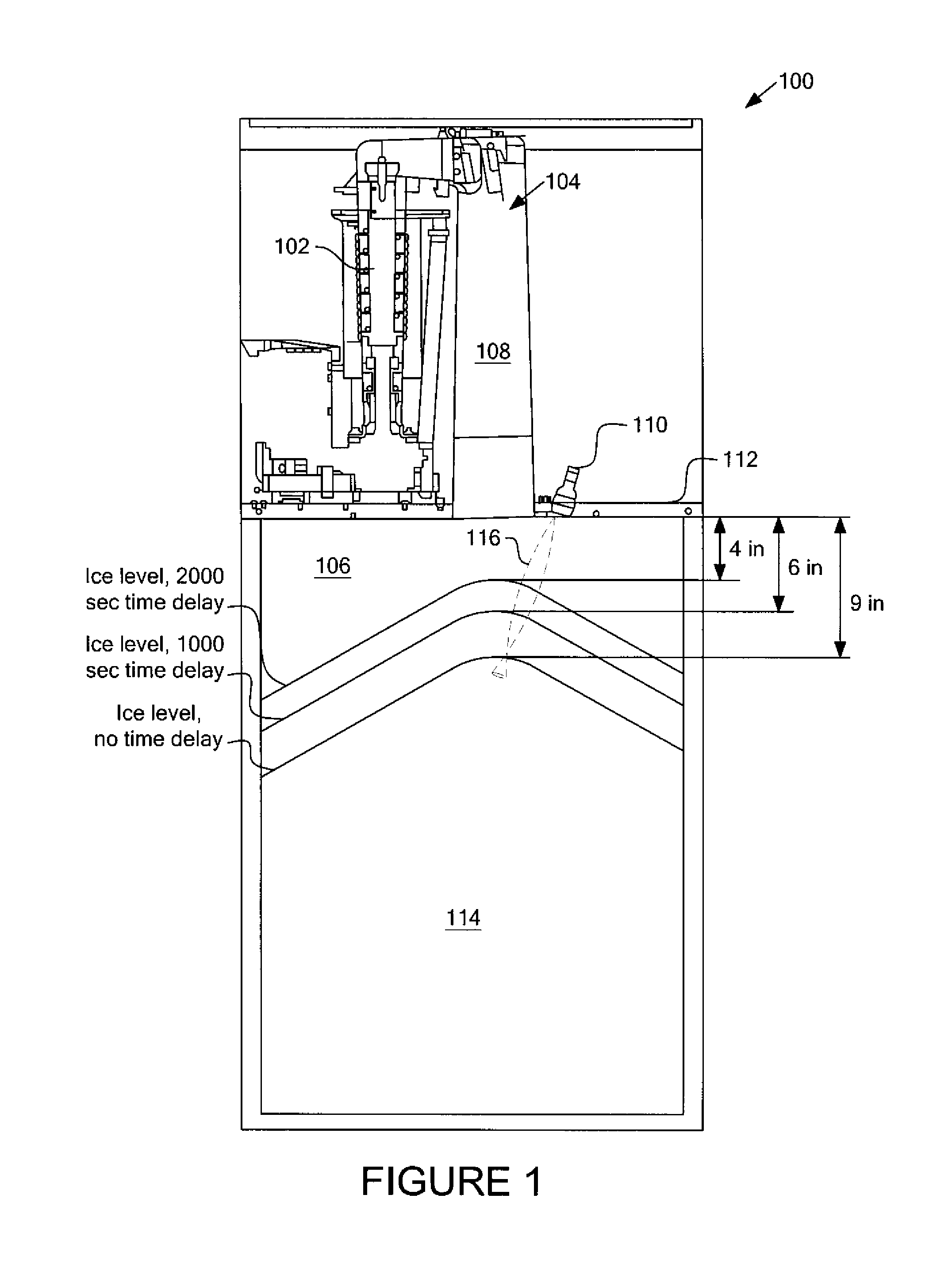

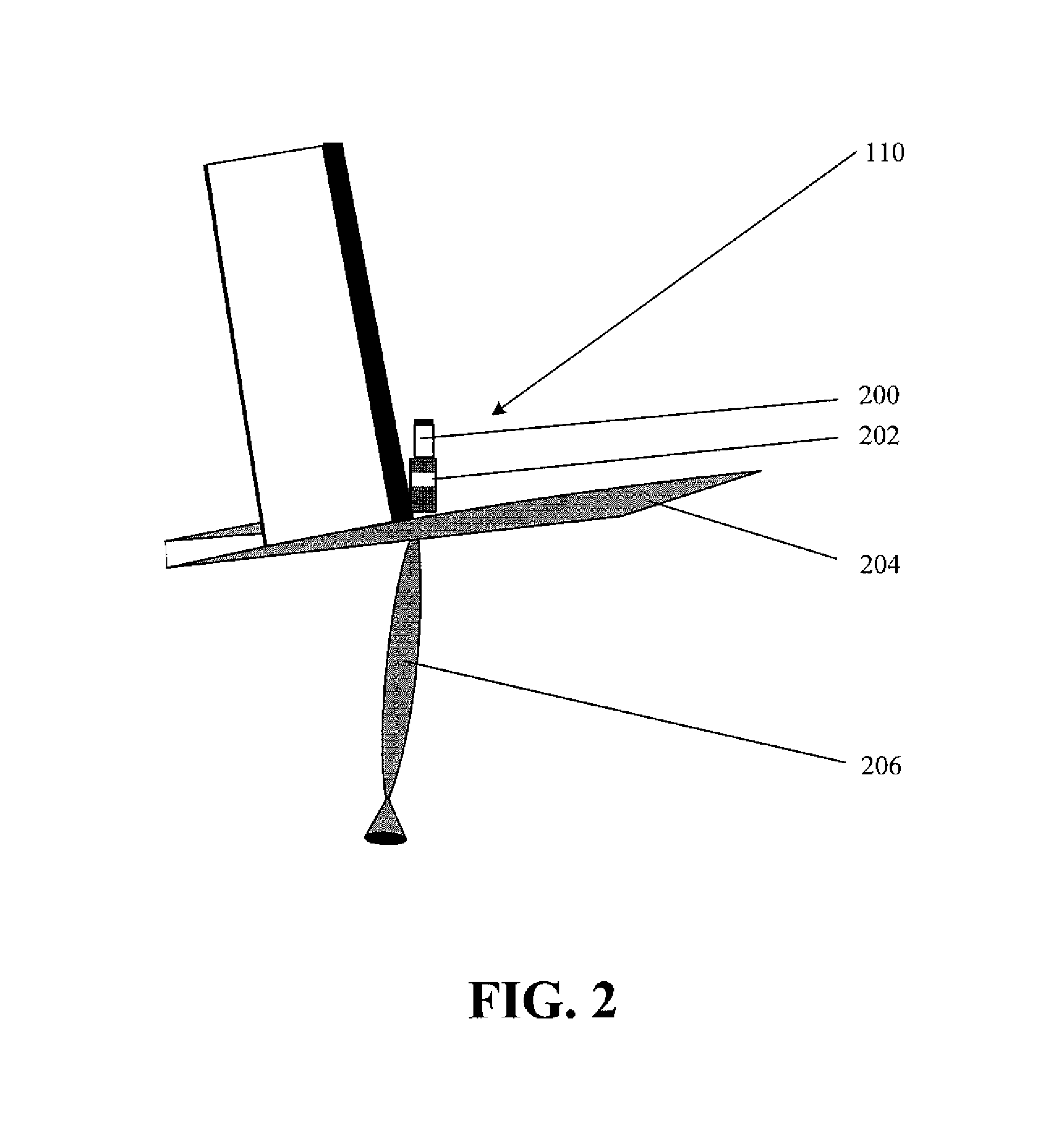

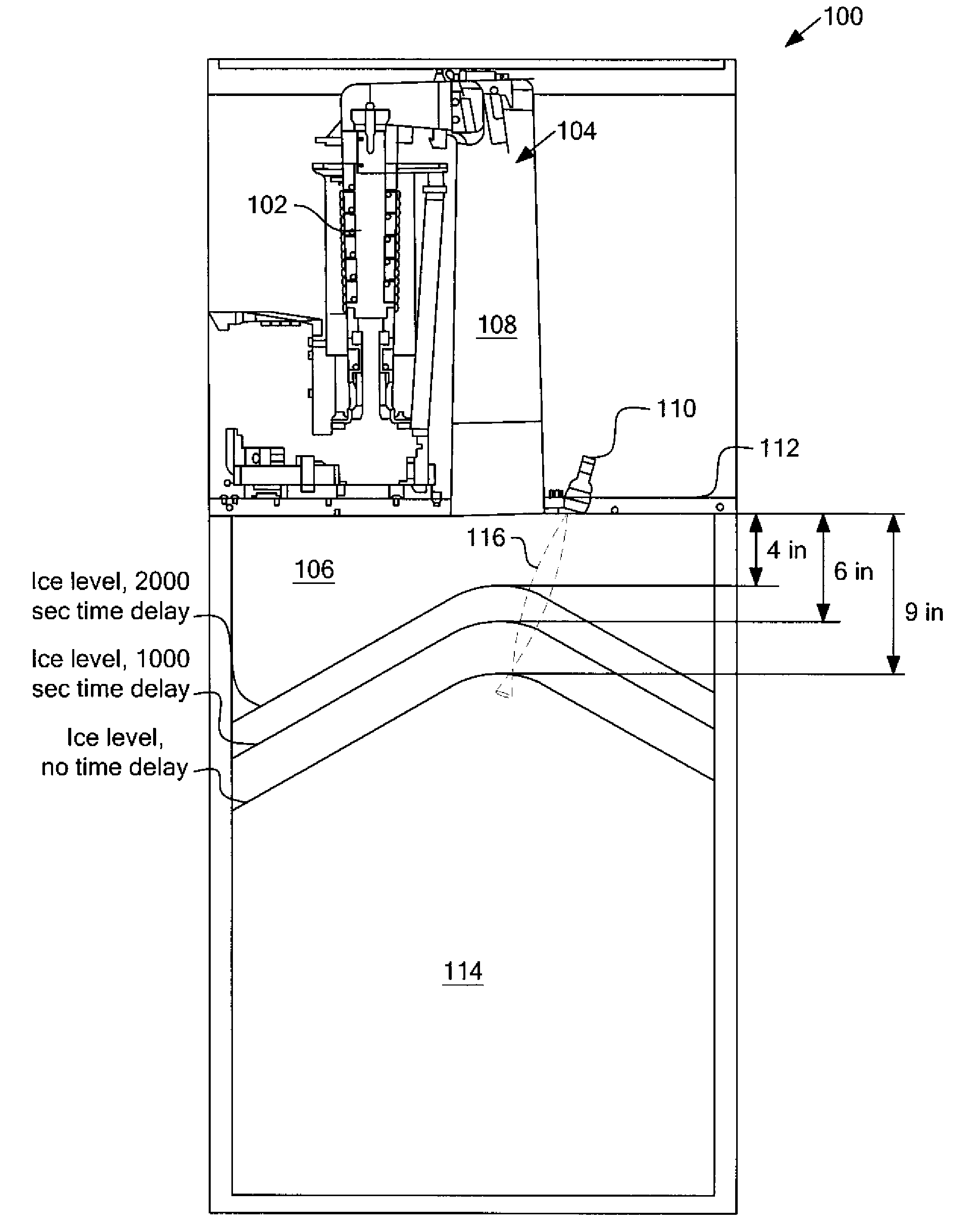

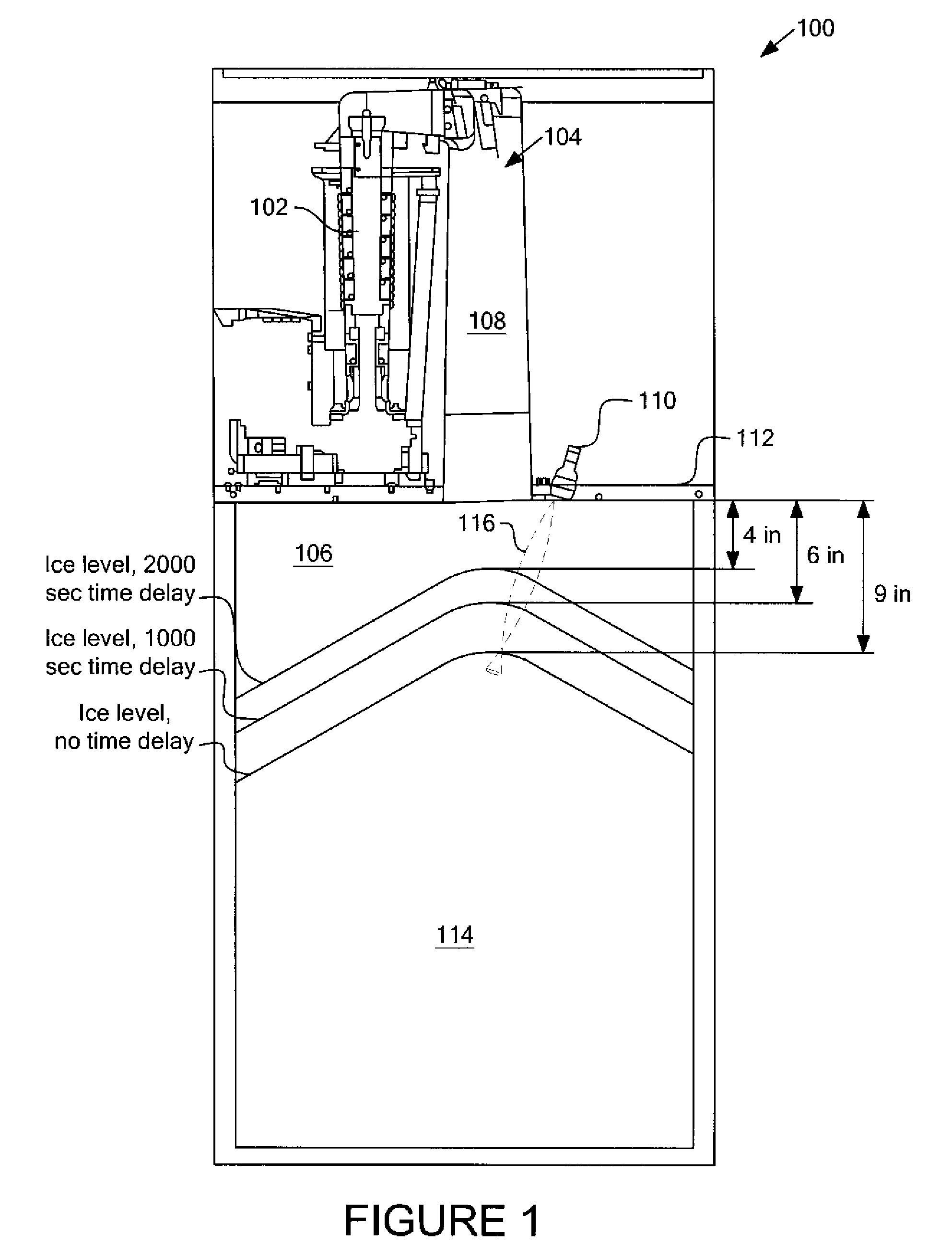

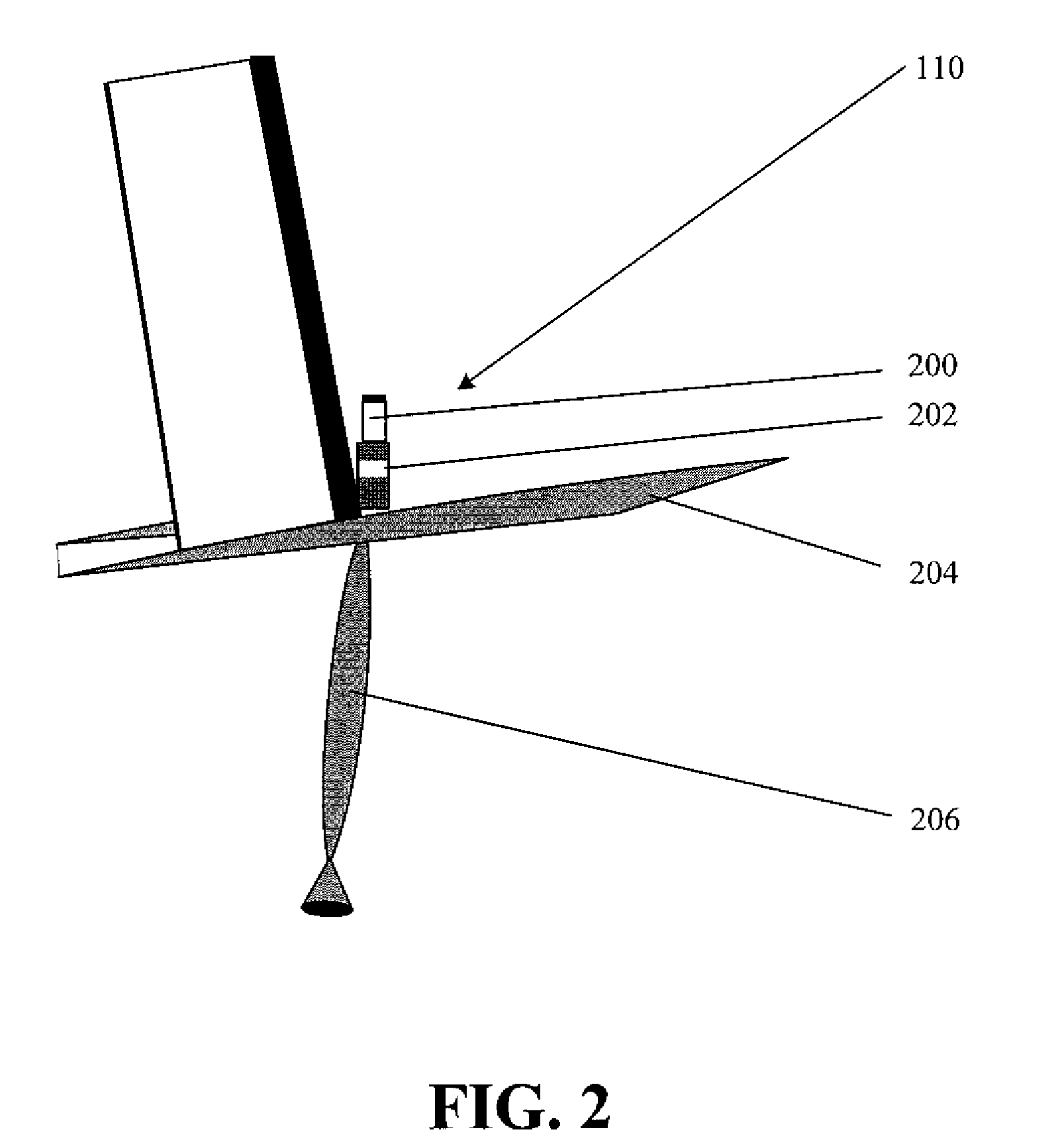

Systems and methods for providing an ice storage bin control sensor and housing

ActiveUS9188378B2Reduced and minimized amountReduce the possibilityLighting and heating apparatusIce productionIce storageEngineering

Embodiments of the invention can provide an ice storage bin control sensor and housing. In one embodiment, an ice storage bin can be provided. The ice storage bin can include at least one wall, an ice control sensor, and a housing section. The housing section can include an inner wall component operable to support at least a portion of the ice control sensor. The housing section can also include an outer wall component operable to support at least a portion of the ice control sensor. In addition, the housing section can include a cavity operable to receive the ice control sensor. Furthermore, the housing section can include a stop portion operable to maintain the position of the outer wall component or the inner wall component relative to the at least one wall of the ice storage bin, wherein at least a portion of the inner wall component is angled with respect to the stop portion, and at least a portion of the ice control sensor can be maintained at a predefined angle to the at least one wall within the ice storage bin.

Owner:HOSHIZAKI AMERICA INC

Systems and Methods for Providing an Ice Storage Bin Control Sensor and Housing

ActiveUS20080110186A1Protection from damageReduced and minimized amountLighting and heating apparatusIce productionIce storageEngineering

Embodiments of the invention can provide an ice storage bin control sensor and housing. In one embodiment, an ice storage bin can be provided. The ice storage bin can include at least one wall, an ice control sensor, and a housing section. The housing section can include an inner wall component operable to support at least a portion of the ice control sensor. The housing section can also include an outer wall component operable to support at least a portion of the ice control sensor. In addition, the housing section can include a cavity operable to receive the ice control sensor. Furthermore, the housing section can include a stop portion operable to maintain the position of the outer wall component or the inner wall component relative to the at least one wall of the ice storage bin, wherein at least a portion of the inner wall component is angled with respect to the stop portion, and at least a portion of the ice control sensor can be maintained at a predefined angle to the at least one wall within the ice storage bin.

Owner:HOSHIZAKI AMERICA

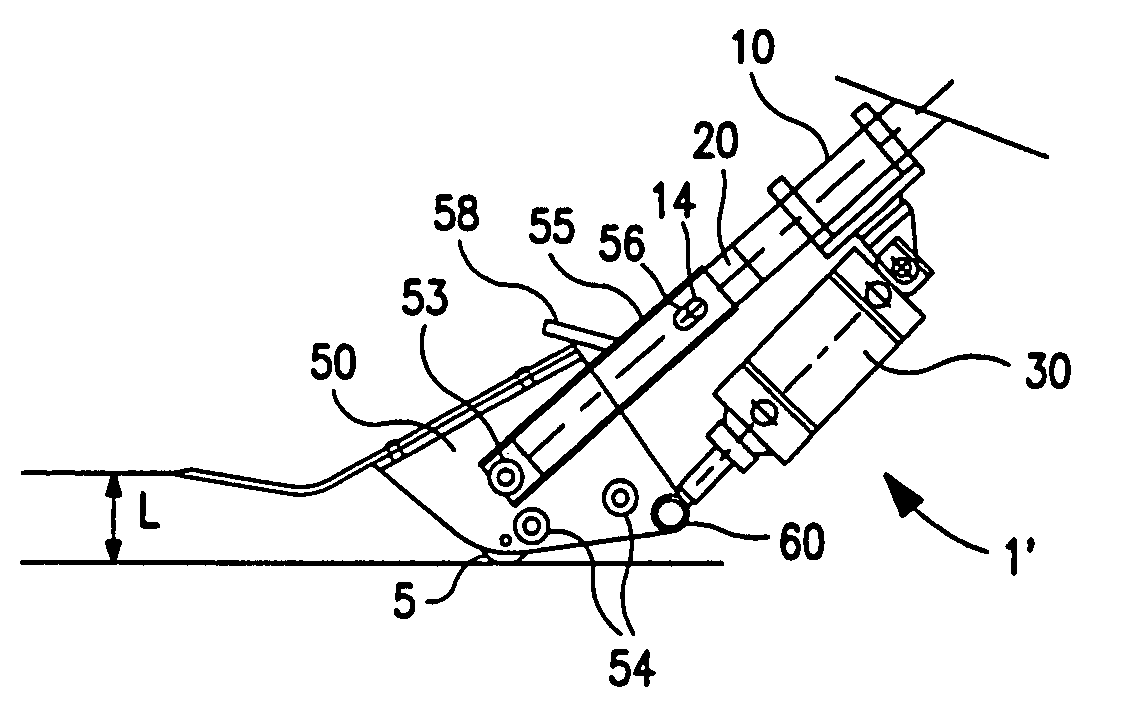

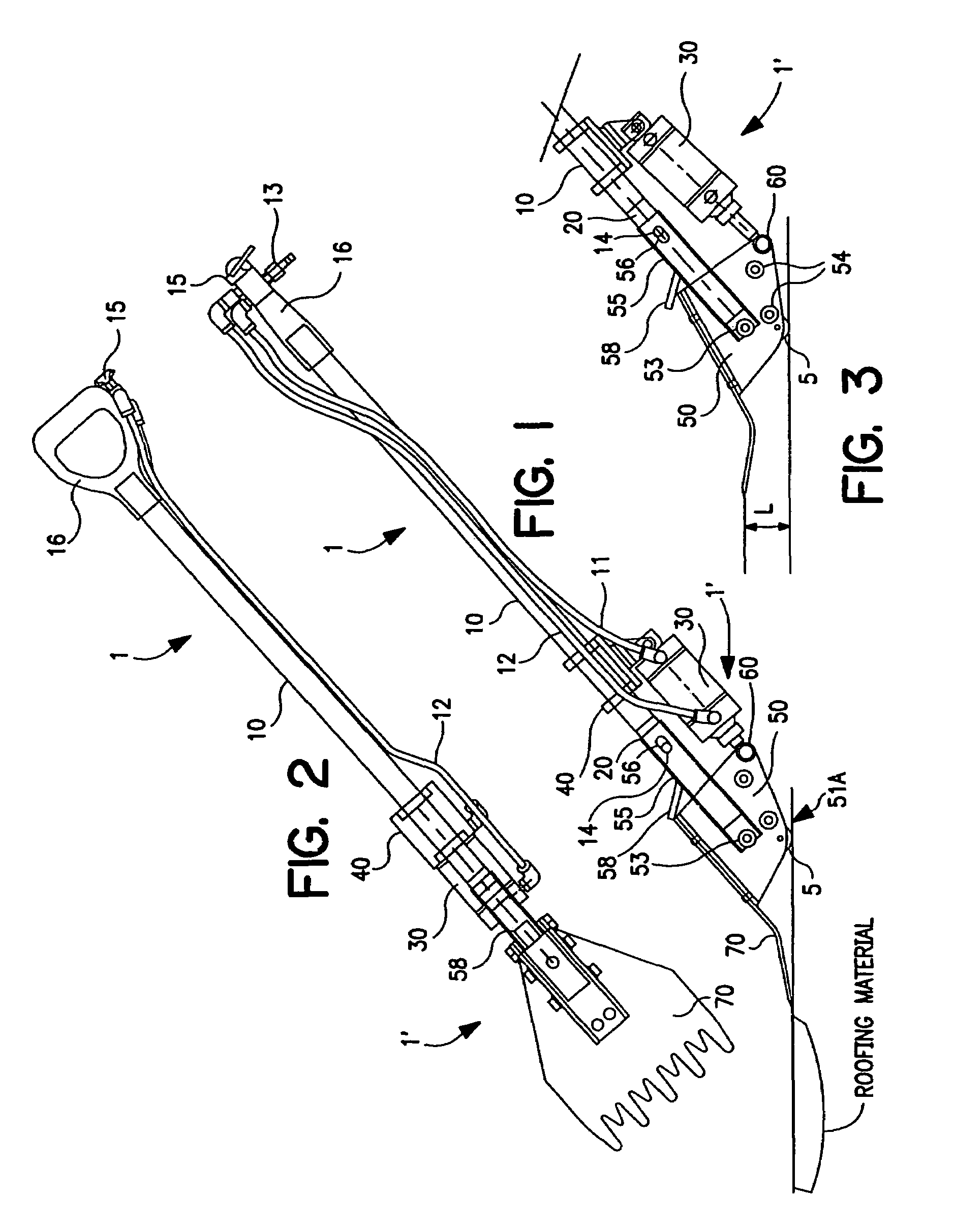

Apparatus for removing surface coverings and methods for using such apparatus

InactiveUS7401861B2Reduces and minimizes fatigueReduced and minimized amountHollow article cleaningOven incrustations prevention/removalLeading edgeEngineering

A apparatus for removing surface coverings, includes a shaft having a first end and a second end; a sleeve slidably mounted on the first end of the shaft; a clevis pivotably mounted on a first end of the sleeve; a drive mechanism for shifting a rod between a first rod position and a second rod position relative to the shaft; and a blade mounted on the clevis and extending away from the shaft. The clevis is secured to the rod, such that as the rod moves between the first rod position and the second rod position, the clevis pivots on the sleeve, and the sleeve slides on the shaft to shift a leading edge of the blade between a first edge position and a second edge position.

Owner:PURCELL PATRICK W

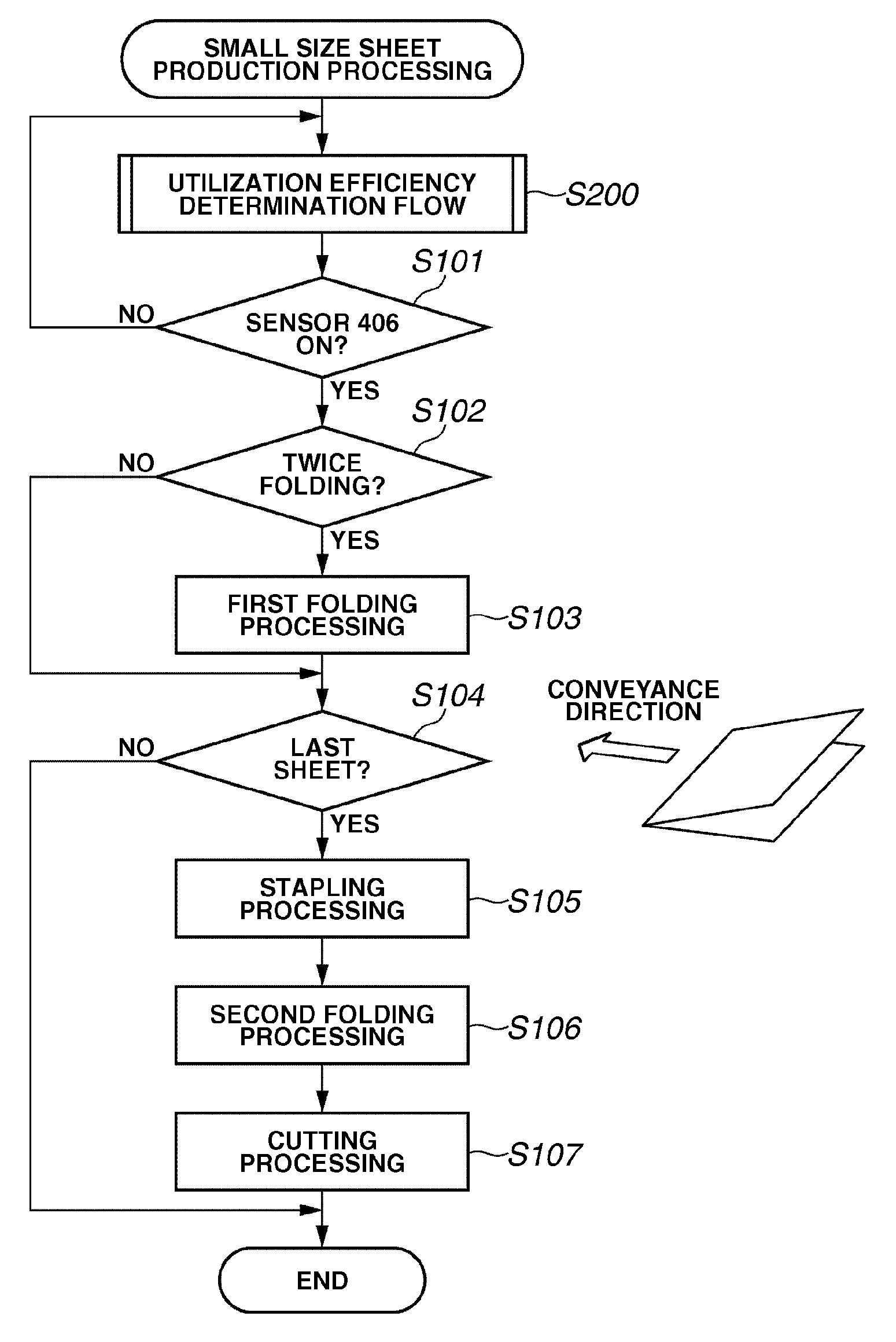

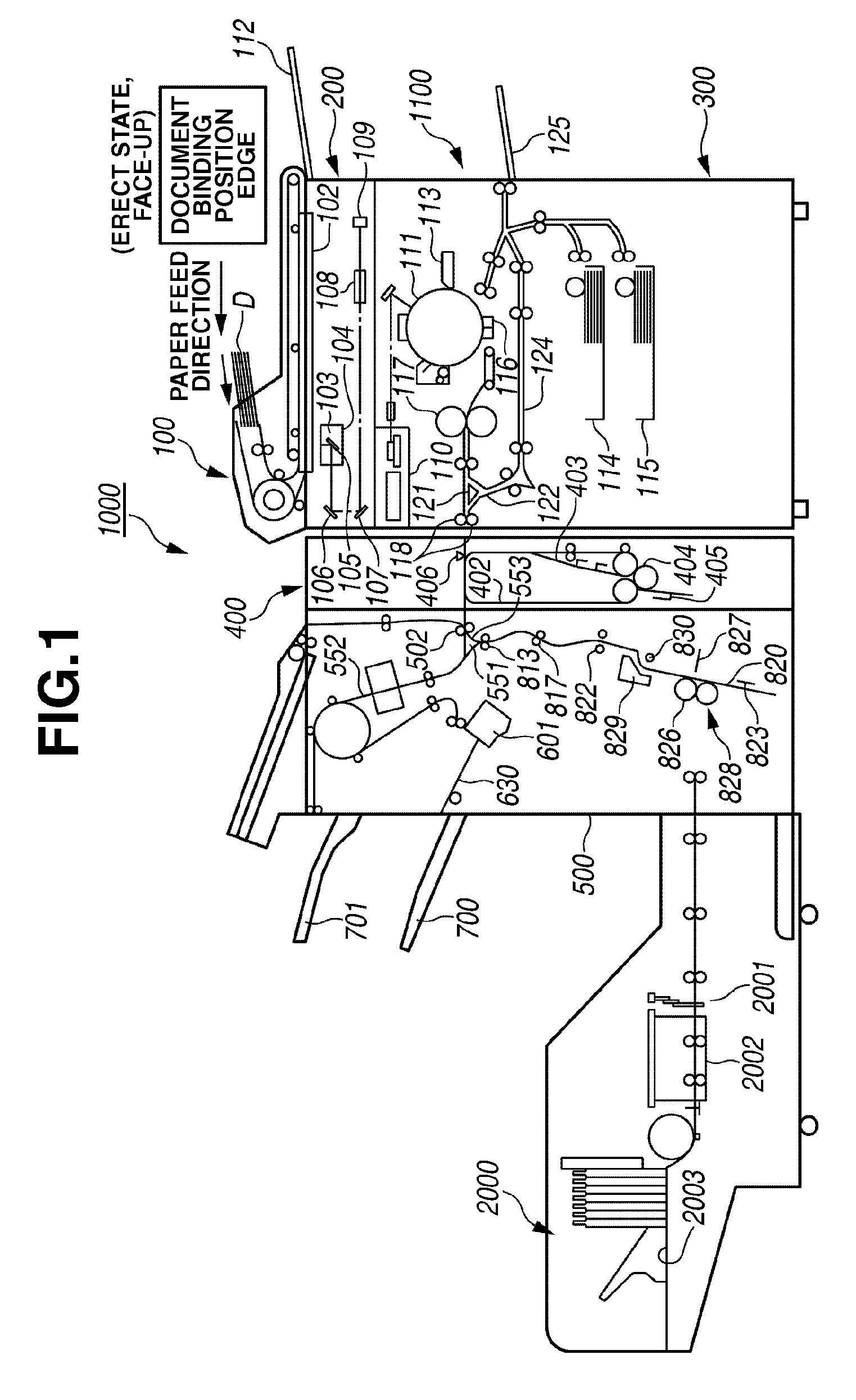

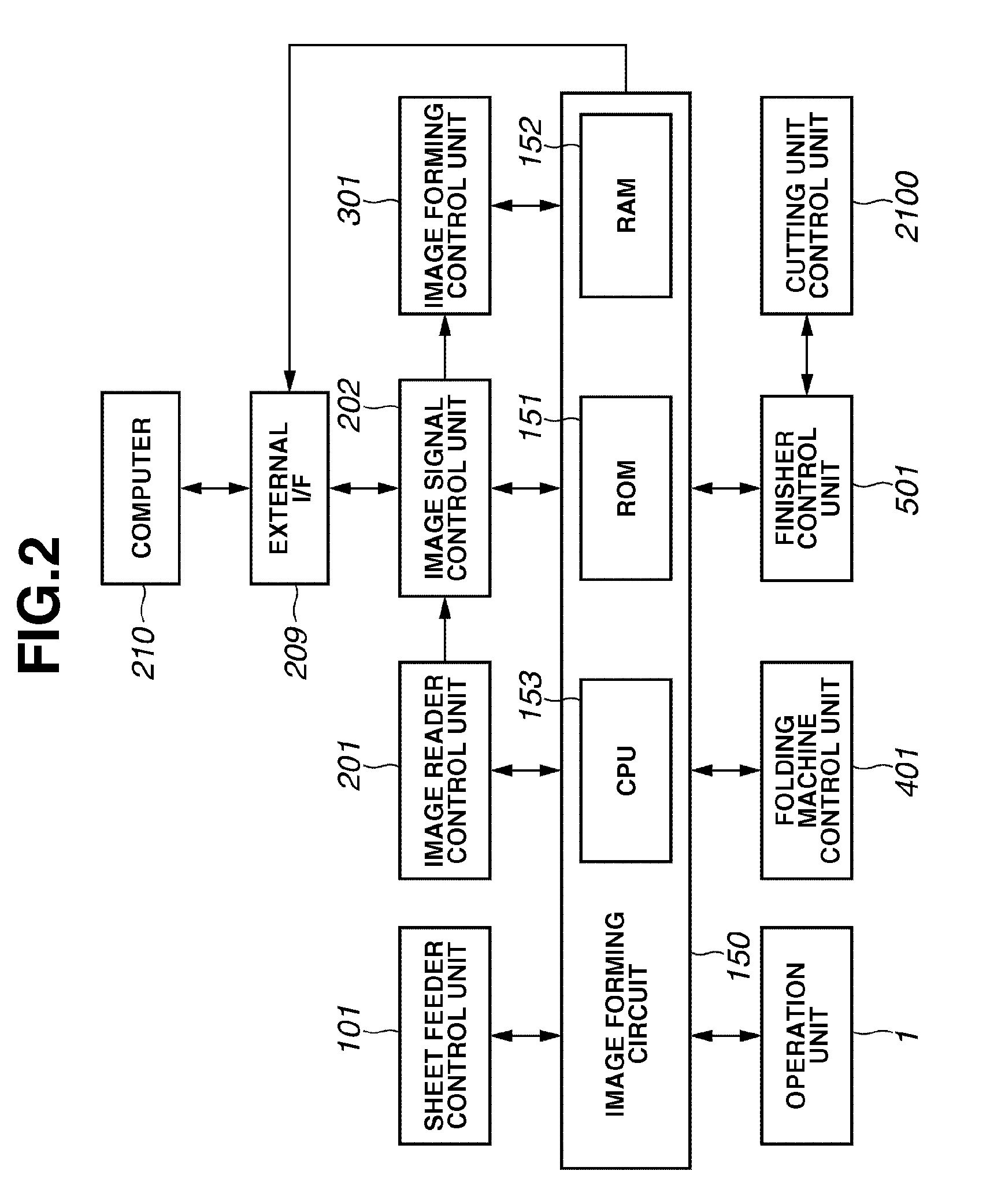

Sheet processing apparatus and method

InactiveUS7762537B2Reduced and minimized amountEasy to useMechanical working/deformationFunction indicatorsEngineeringSheet material

A sheet processing apparatus is operable to cut an edge portion of a sheet. The sheet processing apparatus is operable to calculate a sheet utilization efficiency based on an area of the sheet before cutting and an area of a sheet obtained by cutting the edge portion.

Owner:CANON KK

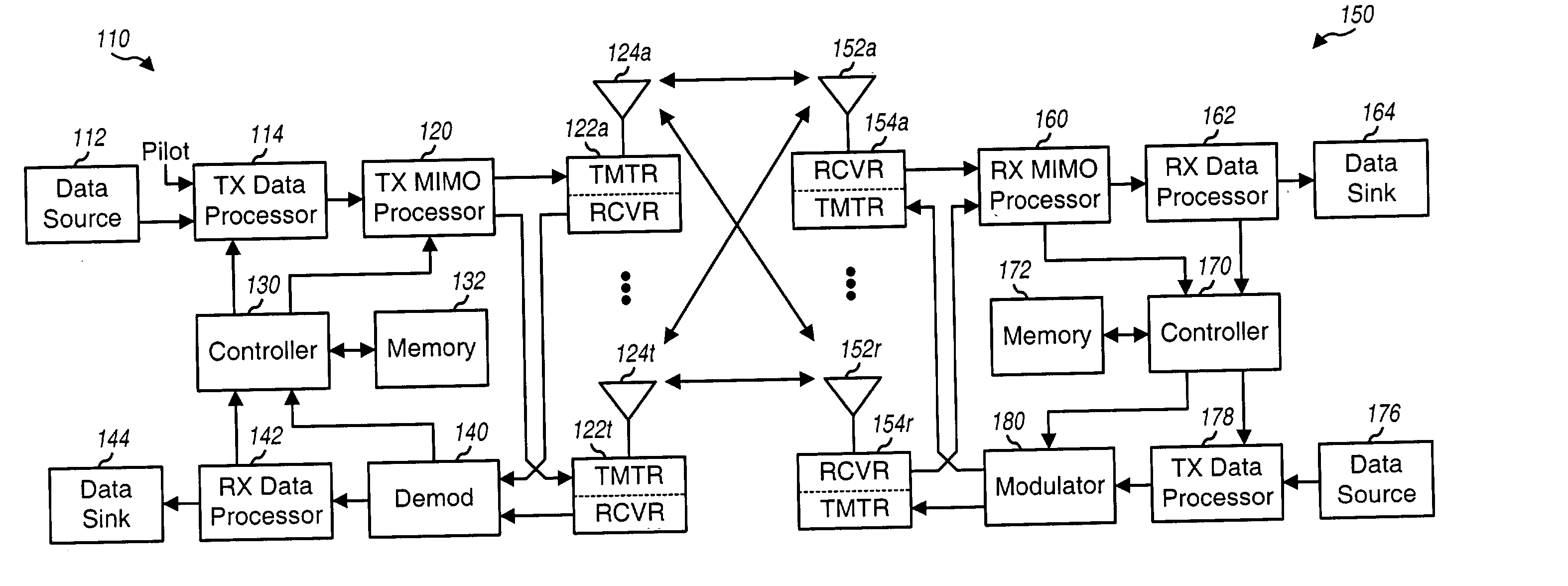

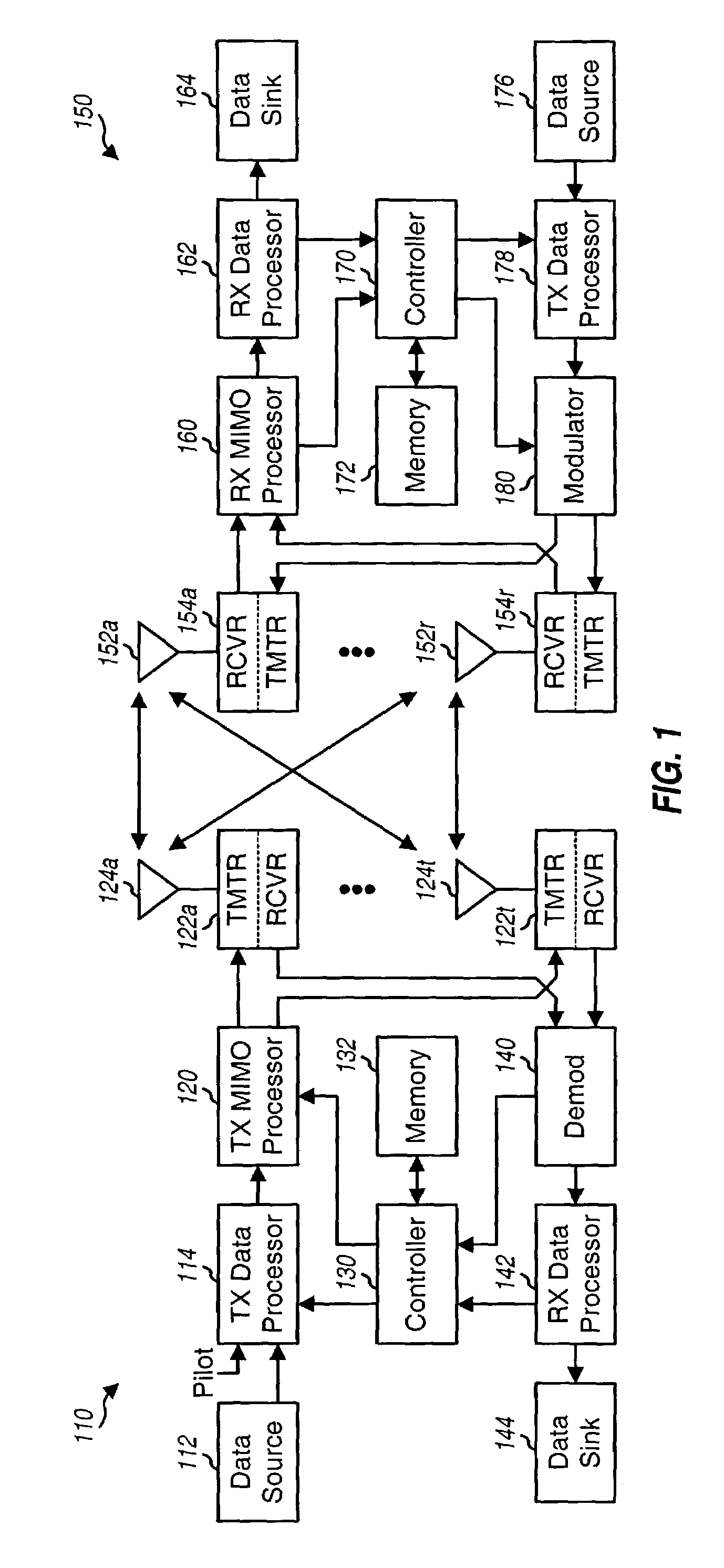

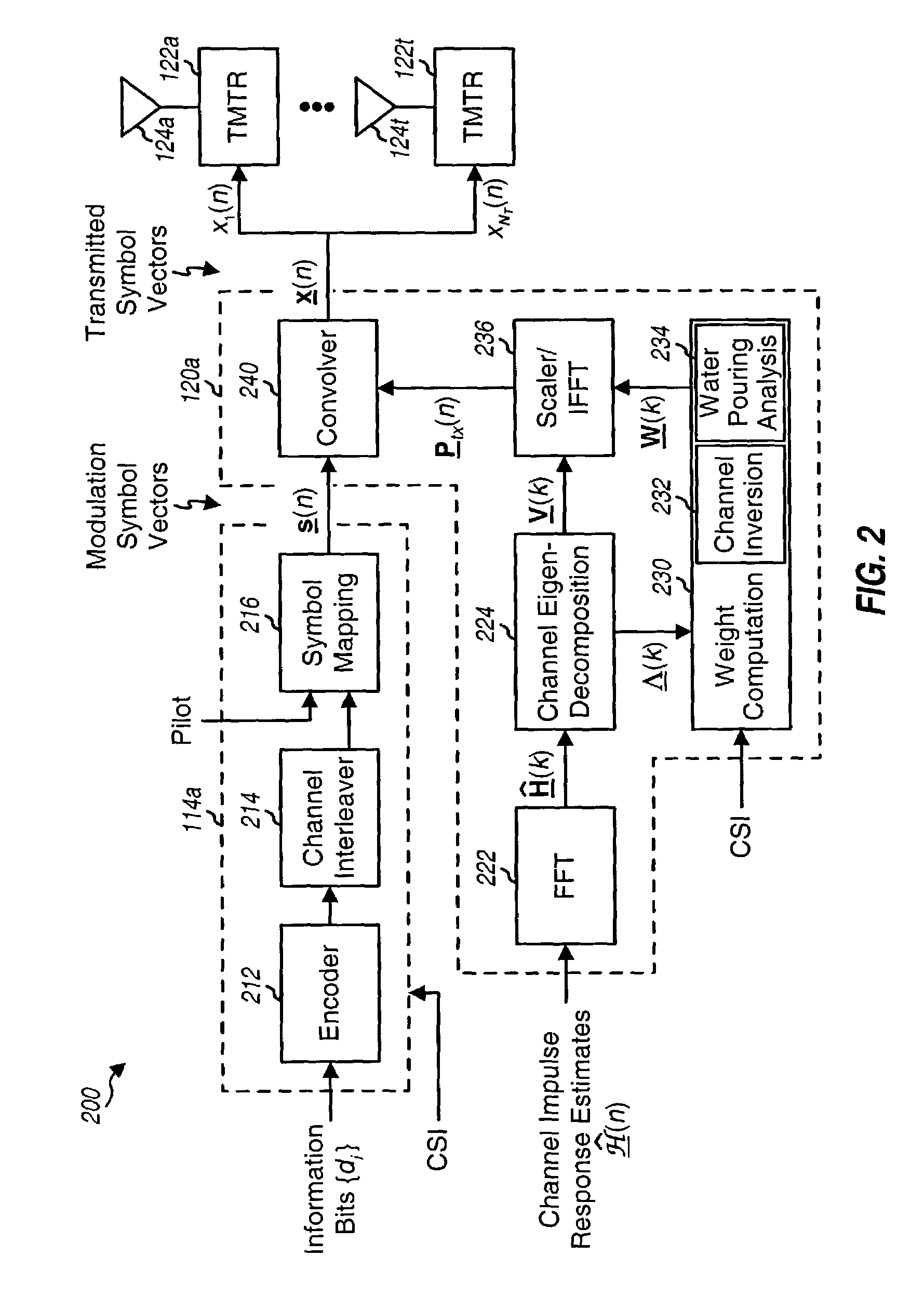

Signal processing with channel eigenmode decomposition and channel inversion for MIMO systems

InactiveUS7613248B2Improve performanceImprove throughputSpatial transmit diversityModulated-carrier systemsDecompositionTransmitted power

Techniques for processing a data transmission at a transmitter and receiver, which use channel eigen-decomposition, channel inversion, and (optionally) “water-pouring”. At the transmitter, (1) channel eigen-decomposition is performed to determine eigenmodes of a MIMO channel and to derive a first set of steering vectors, (2) channel inversion is performed to derive weights (e.g., one set for each eigenmode) used to minimize ISI distortion, and (3) water-pouring may be performed to derive scaling values indicative of the transmit powers allocated to the eigenmodes. The first set of steering vectors, weights, and scaling values are used to derive a pulse-shaping matrix, which is used to precondition modulation symbols prior to transmission. At the receiver, channel eigen-decomposition is performed to derive a second set of steering vectors, which are used to derive a pulse-shaping matrix used to condition received symbols such that orthogonal symbol streams are recovered.

Owner:QUALCOMM INC

Amine based additive composition for control and inhibition of polymerization of styrene, and method of use thereof

ActiveUS9334445B2Reduced and minimized amountControlling and inhibiting polymerizationOrganic compounds purification/separation/stabilisationHydrocarbon purification/separationNitro compoundChemical compound

The present invention relates to amine based additive composition for controlling and inhibition of polymerization of aromatic vinyl monomers including styrene comprising (a) one or more of nitroxide (i.e. nitroxyl) compounds; and (b) one or more of aromatic nitro compounds, characterized in that the said composition further comprises one or more of (c) amines, wherein said amine is selected from a group comprising (i) hydroxyl alkyl tertiary amines, (ii) tertiary alkyl amines, (iii) hydroxyl alkyl primary amine; and (iv) mixture thereof. In one embodiment, the present invention also relates to method of using presently provided composition. In another embodiment, the present invention also relates to method of controlling and inhibiting polymerization of aromatic vinyl monomers including styrene by employing presently provided composition. In still another embodiment, the present invention also relates to method of preparation of presently provided composition.

Owner:DORF KETAL CHEM (I) PTE LTD

Dressing for treatment of short wounds located in high tension areas

InactiveUS7482504B2Reduced and minimized amountIncrease the difficultySurgical adhesivesPlastersAdhesiveButyl cyanoacrylate

A dressing and method for treating high-tension wounds. First and second layers of a 1-butyl cyanoacrylate 16 adhesive are applied to a short, high-tension wound, with the first and second layers covering the wound and extending to at least about 2.5 mm (0.0984 in.) from each side of the wound. The first layer is allowed to set and polymerize before the second layer of 1-butyl cyanoacrylate is applied. The second layer extends at least about 2.5 mm (0.0984 in.) beyond each edge of the first layer. In the case of a long, high-tension wound, a third layer is applied after the first and second layers are allowed to set and polymerize. The third layer is at least about 2.5 mm (0.0984 in.) wide and is substantially perpendicular to the first and second layers. The third layer may occur intermittently every 2.5 cm (0.984 in.) over the length of the wound, and preferably extends at least about 5 mm (0.197 in.) beyond the edge of the first layer.

Owner:ZYMURGY

Aerodynamic fan control effector

InactiveUS7997538B2Area maximizationReduced and minimized amountInfluencers by generating vorticesAircraft stabilisationAerodynamics

Owner:THE BOEING CO

Additive composition for control and inhibition of polymerization of aromatic vinyl monomers, and method of use thereof

ActiveUS9228126B2Reduced and minimized amountControlling and inhibiting polymerizationOrganic compounds purification/separation/stabilisationHydrocarbon purification/separationNitro compoundPhotochemistry

The present invention relates to an improved additive composition for control and inhibition of polymerization of aromatic vinyl monomers including styrene comprising one or more of aromatic nitro compounds and one or more of aliphatic tertiary amines. In one embodiment, the present invention also relates to method of use of presently provided composition. In another embodiment, the present invention also relates to method of controlling and inhibiting polymerization of aromatic vinyl monomers including styrene by employing presently provided composition. In still another embodiment, the present invention also relates to method of preparation of presently provided composition.

Owner:DORF KETAL CHEM (I) PTE LTD

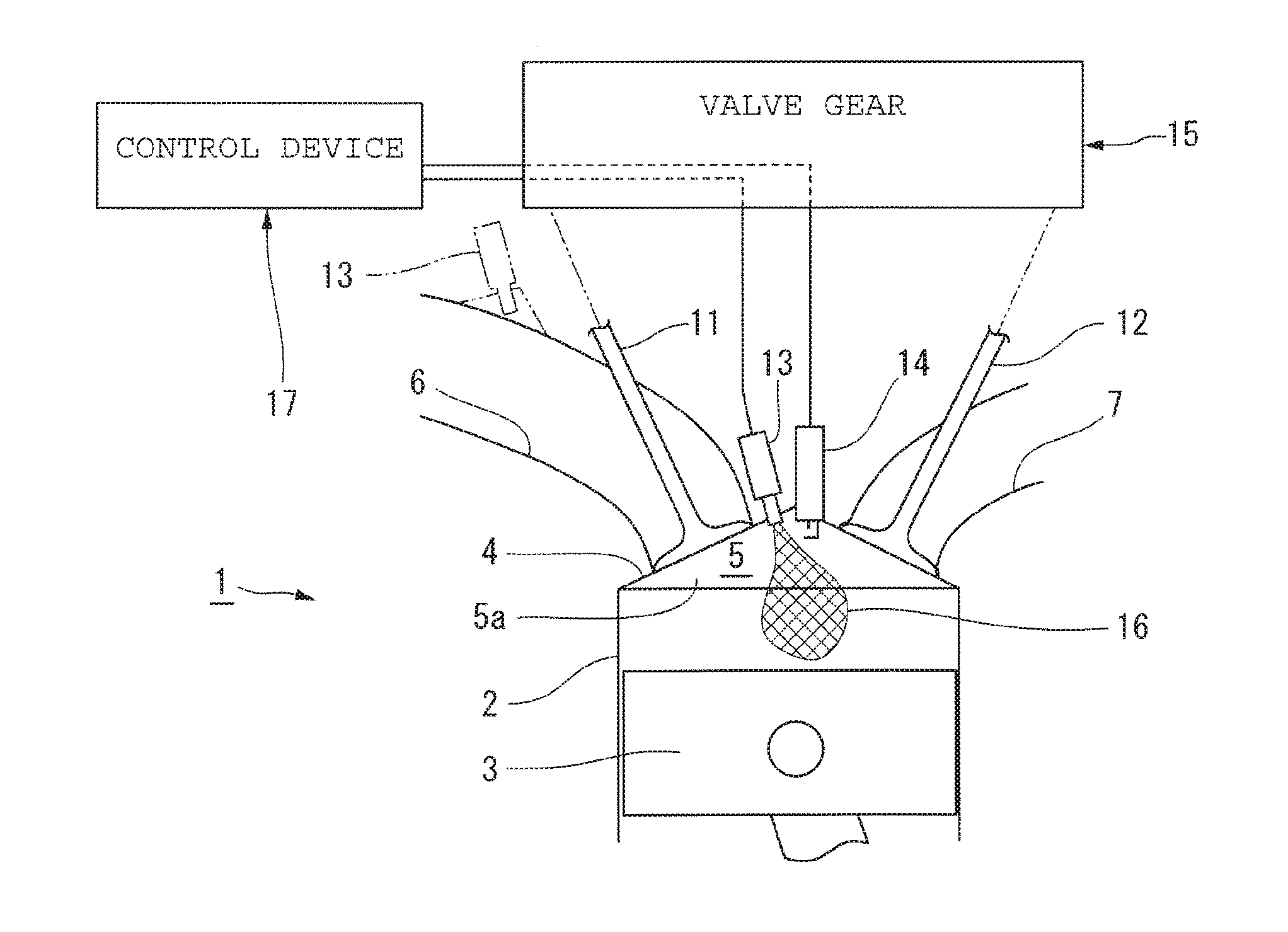

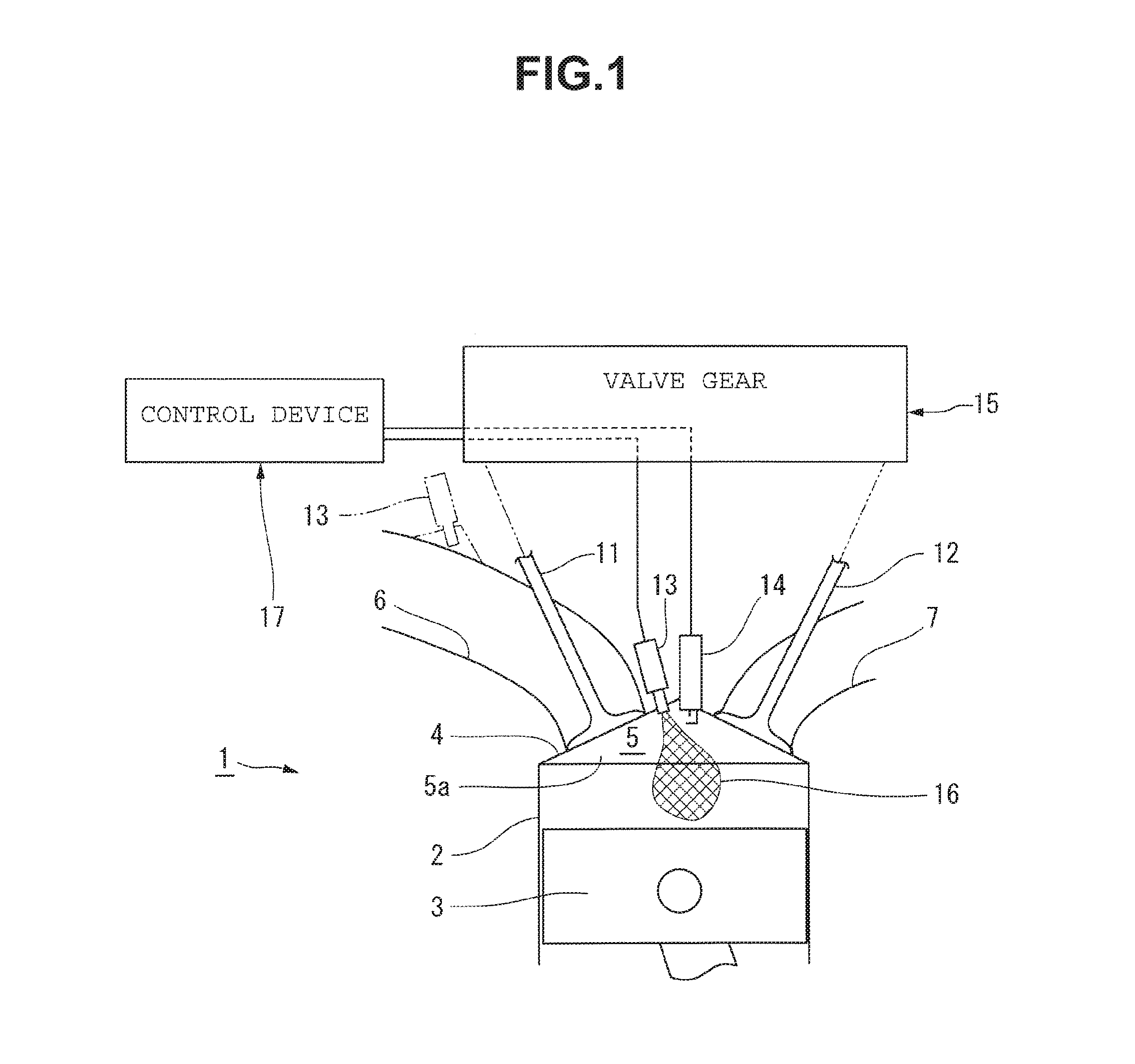

Six-stroke engine and method of operating six-stroke engine

InactiveUS20160169125A1Improve thermal efficiencyVery high cooling effectValve drivesCylinder headsTop dead centerCylinder head

A six-stroke engine includes a cylinder, a piston, a cylinder head, a combustion chamber, an intake port, an exhaust port, an intake valve, an exhaust valve, a fuel injector, and an ignition plug. The six-stroke engine includes a valve gear that operates the intake valve and the exhaust valve to execute an intake stroke, a compression stroke with ignition, an expansion stroke with combustion, an exhaust stroke, an expansion stroke without combustion, and a compression stroke without ignition. The valve gear opens, only for a predetermined period of time while the piston is located at top dead center, at least one of the intake valve and the exhaust valve within a period from the exhaust stroke to the intake stroke. A valve overlap state is produced at least once within the period from the exhaust stroke to the intake stroke.

Owner:YAMAHA MOTOR CO LTD

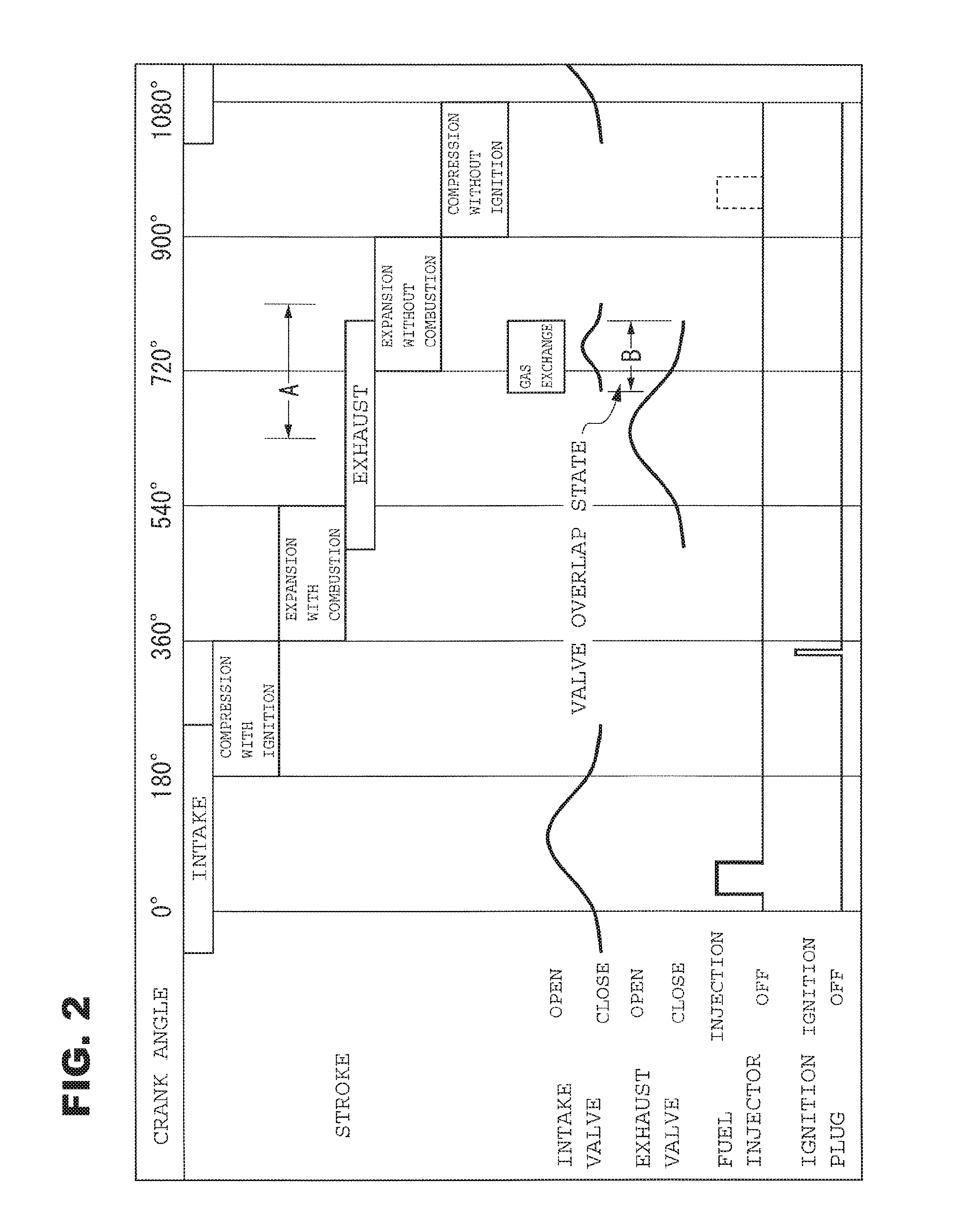

Reinforced bonded abrasive tools

InactiveUS8641481B2Optimally configuring characteristicImprove adhesionRevolution surface grinding machinesBonded abrasive wheelsGlass fiberFiberglass mesh

Bonded abrasive tools, e.g., grinding wheels, can be reinforced using, for instance, one or more fiberglass web(s) having a surface of glass per unit of at least 0.2. Alternatively or in addition, the fiberglass web has a thickness of 2 mm or less. The web can be designed to provide improved adhesion between the fiberglass reinforcement and the mixture employed to form the bonded abrasive tool. In some examples, the middle reinforcement at the neutral zone of the wheel can be eliminated or minimized.

Owner:SAINT GOBAIN ABRASIVES INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com