Patents

Literature

1618 results about "Raw milk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Raw milk or unpasteurized milk is milk that has not been pasteurized, a process of heating liquid foods to decontaminate them for safe drinking. Proponents of raw milk have stated that there are benefits to its consumption, including better flavor, better nutrition, and the building of a healthy immune system. However, the medical community has warned of the dangers, which include a risk of infection, and has not found any clear benefit. The availability and regulation of raw milk vary around the world. In the US, some dairies have adopted low-temperature vat pasteurization, which they say produces a product similar to raw milk.

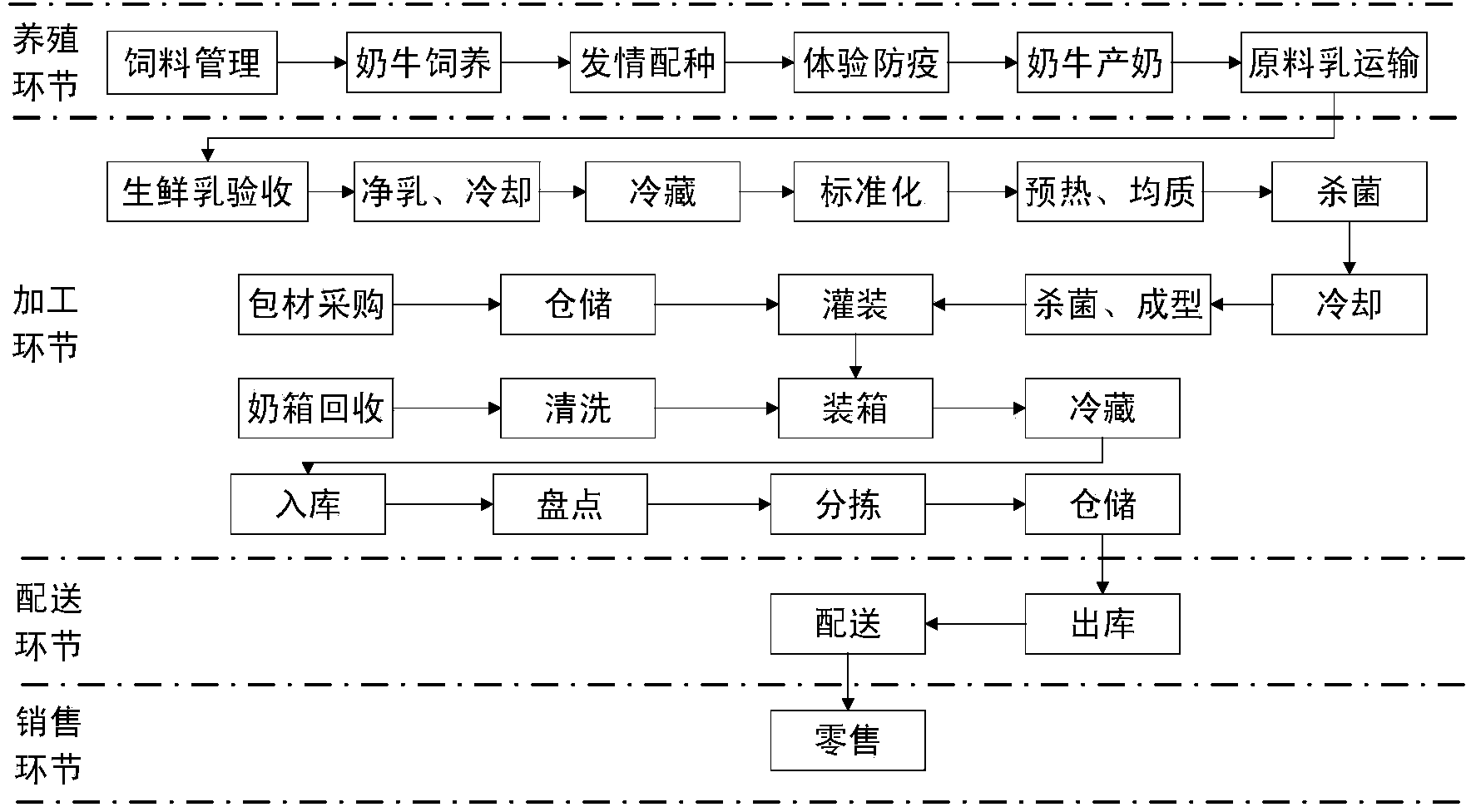

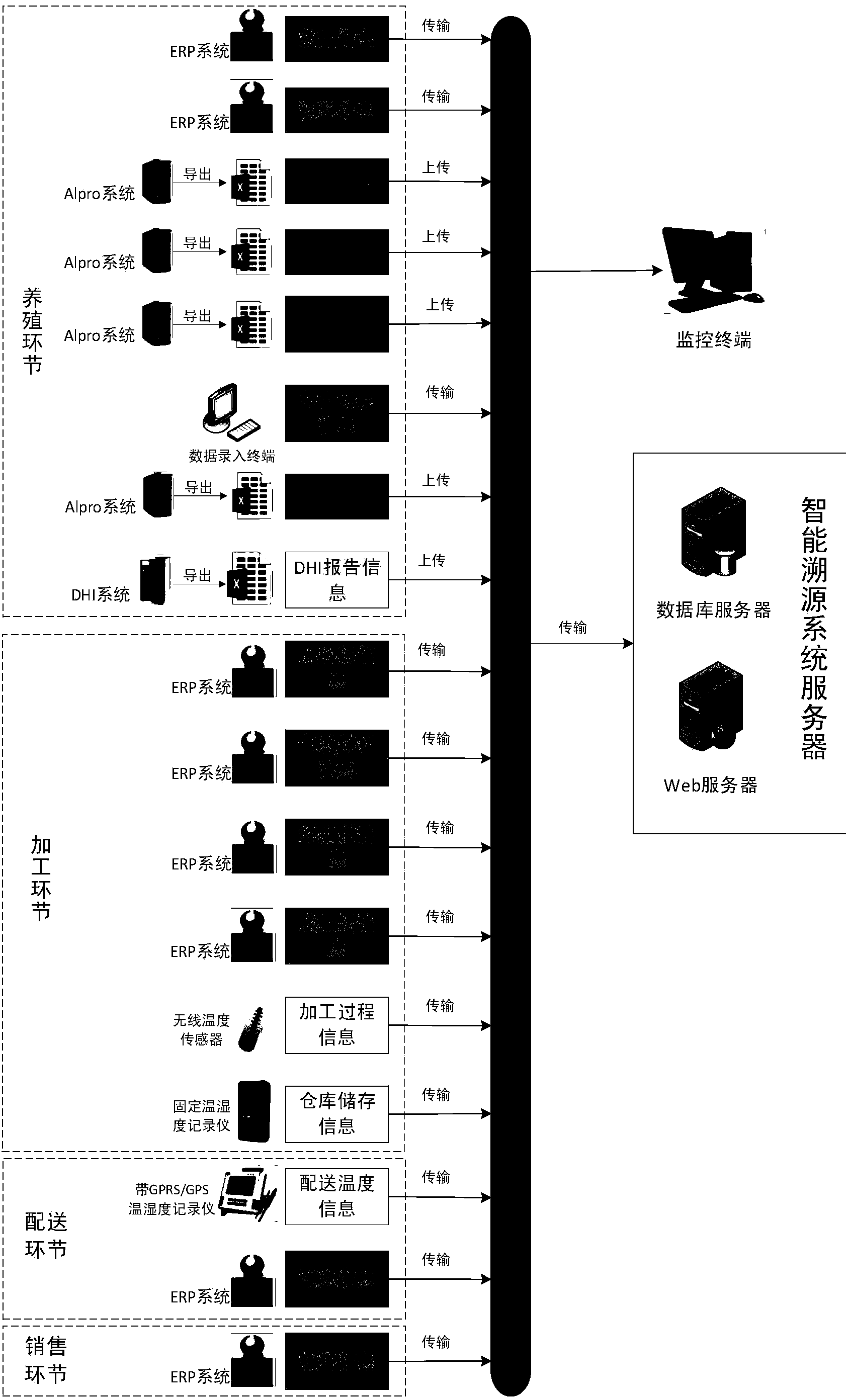

Dairy product quality safety full-life-circle intelligent traceability method based on Internet of things

The invention discloses a dairy product quality safety full-life-circle intelligent traceability method based on the Internet of things. The method comprises the following steps: the step S1 in which various cow breeding information is acquired in the breeding link; the step S2 in which various material and processing information is acquired in the processing link; the step S3 in which the raw milk and finished milk temperature information is acquired in the distribution link; the step S4 in which the order, customer and distribution information is acquired in the marketing link; the step S5 in which a traceability method in which a two-dimensional bar code and a traceability code are combined is adopted, wherein the two-dimension code is used on a large package, and the traceability code is used on a small package, and a traceability platform is established to perform traceability. According to the traceability method of the invention, an appropriate technology is selected when the enterprise actual situation is taken into account, and at the same time, the existing enterprise information system is used to acquire most of the traceability information, so that a lot of equipment and labor cost can be reduced. Additionally, the intelligent traceability system can be used to realize the visualization of the whole dairy product supply chain, so great utilization values can be provided for dairy product enterprises and supervision departments to facilitate the enterprises and the supervision departments to find problems timely, so that the loss can be effectively reduced.

Owner:SOUTH CHINA UNIV OF TECH +2

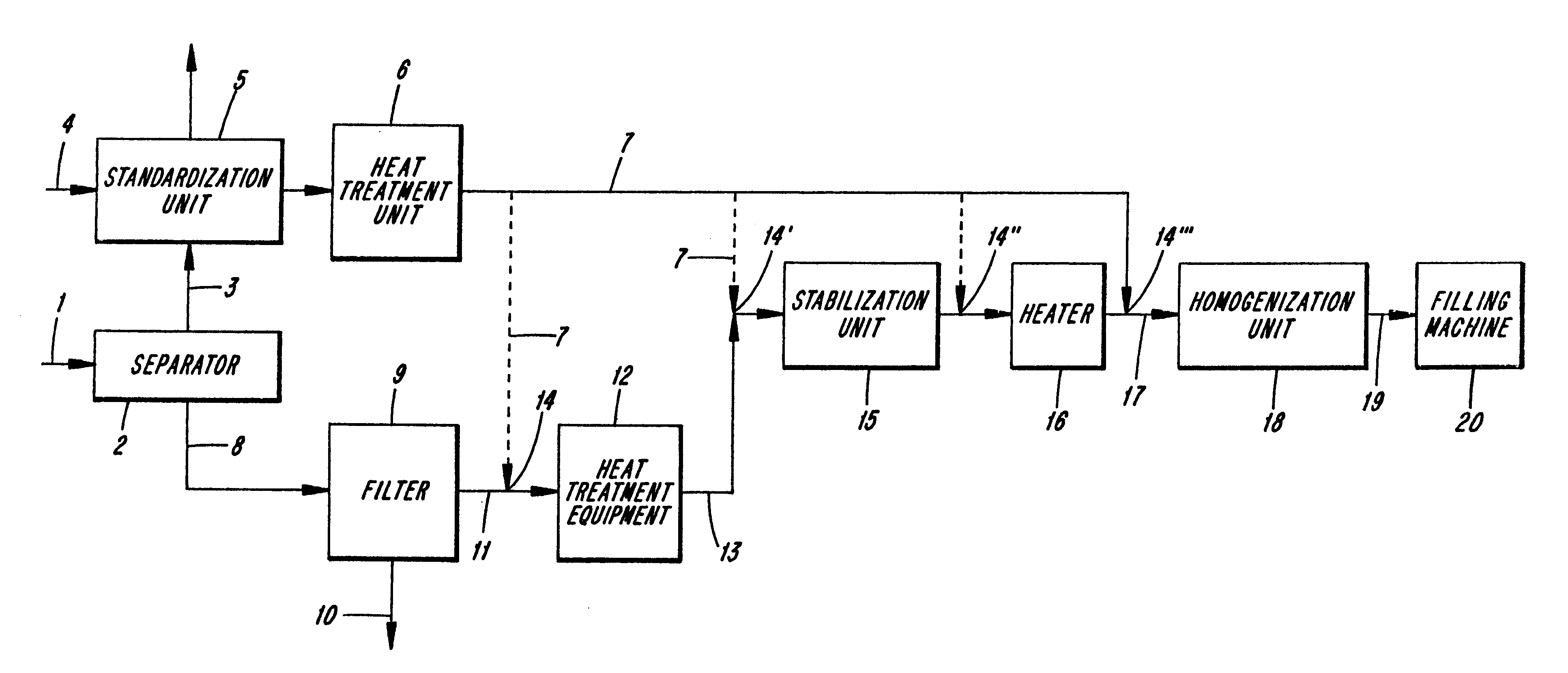

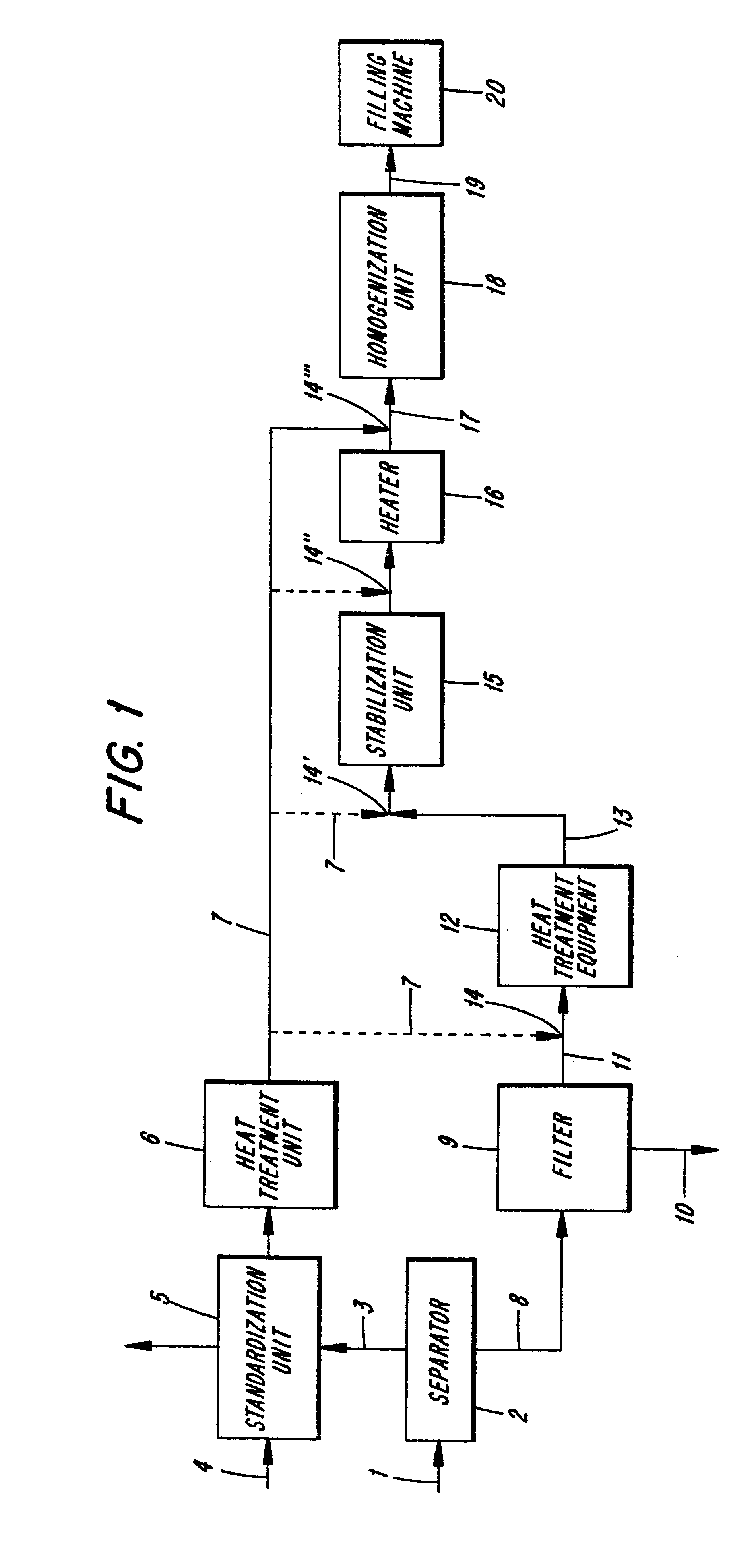

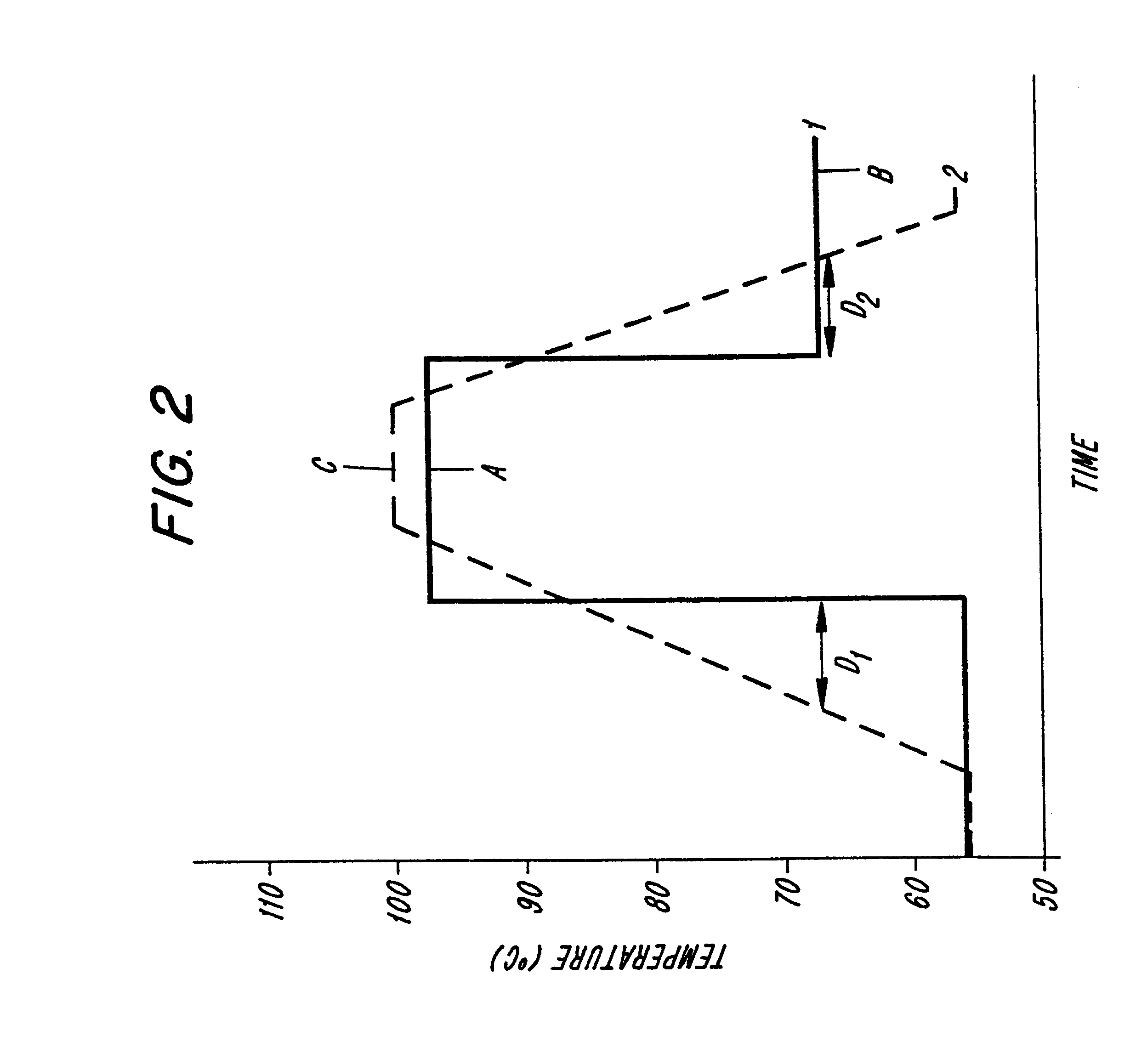

Method for producing sterile, stable milk

This invention is a method of producing a stable, sterile milk fraction comprising filtering a portion of raw milk, sterilizing the filter permeate at a temperature of from about 78° C. to about 121° C., stabilizing the sterile permeate at a temperature of from about 50° C. to about 121° C., and deactivating enzymes at a temperature of from about 50° C. to about 78° C. The stable, sterile milk fraction and milk products made therefrom have an improved flavor and a shelf life of at least about one month, preferably at least about three months, under ambient conditions. The sterile, stable milk fraction is free of heat resistant bacteria; is free of, or has a reduced number of, thermoduric bacteria; and has a reduced number of heat sensitive bacteria as compared to the raw milk portion.

Owner:TETRA LAVAL HLDG & FINANCE SA

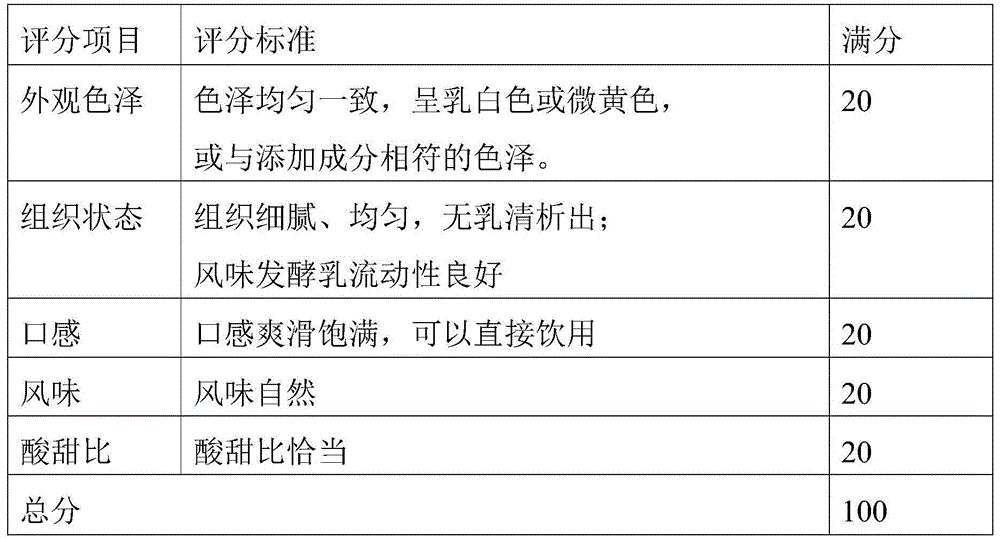

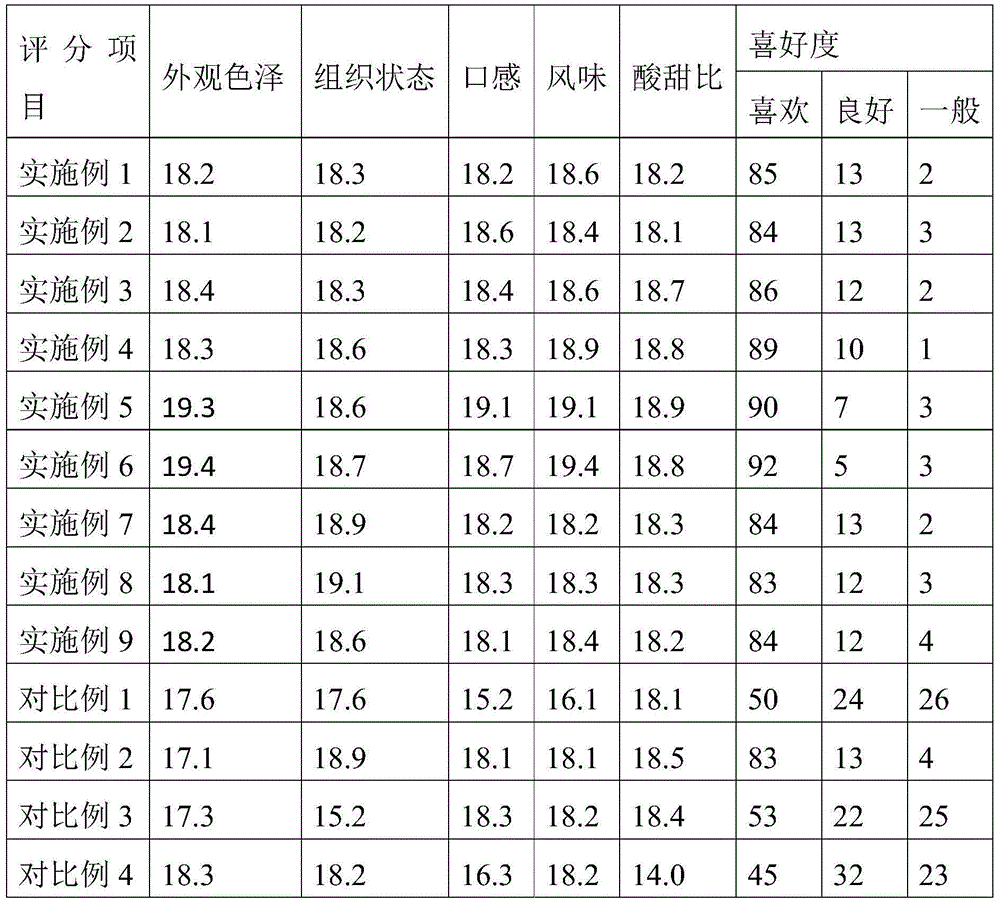

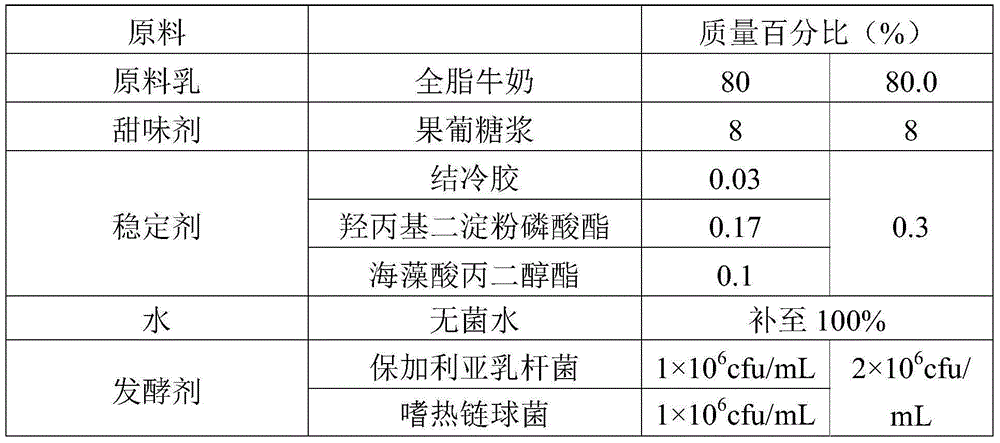

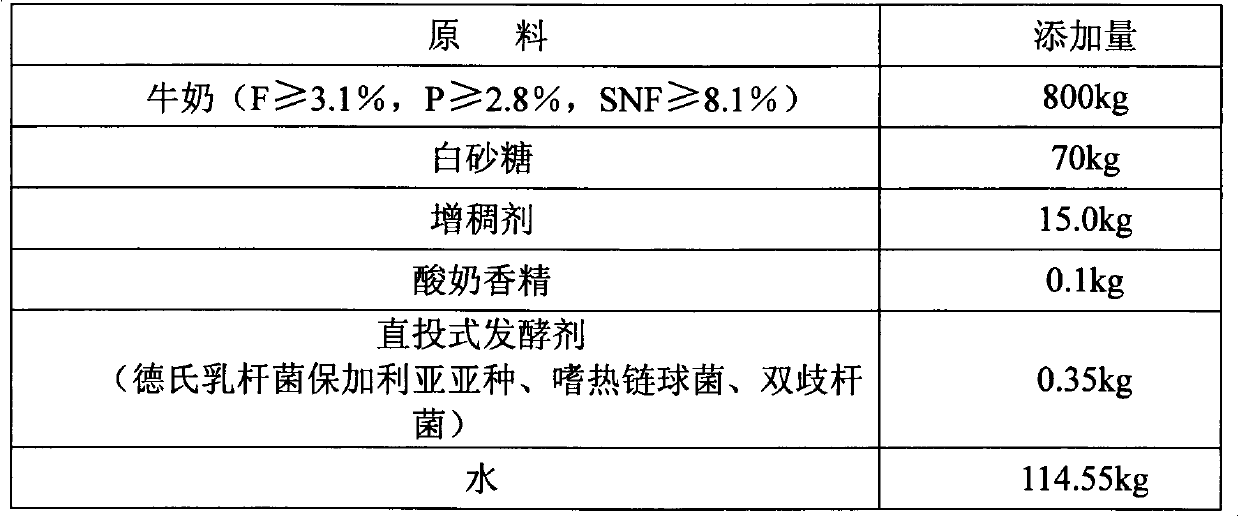

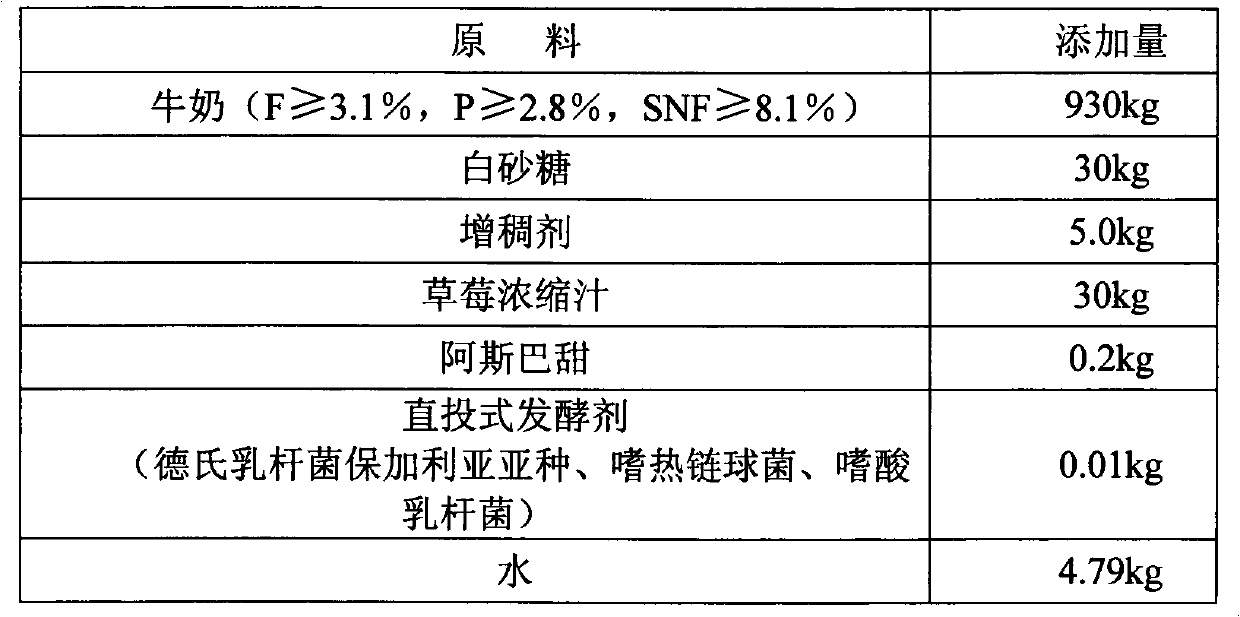

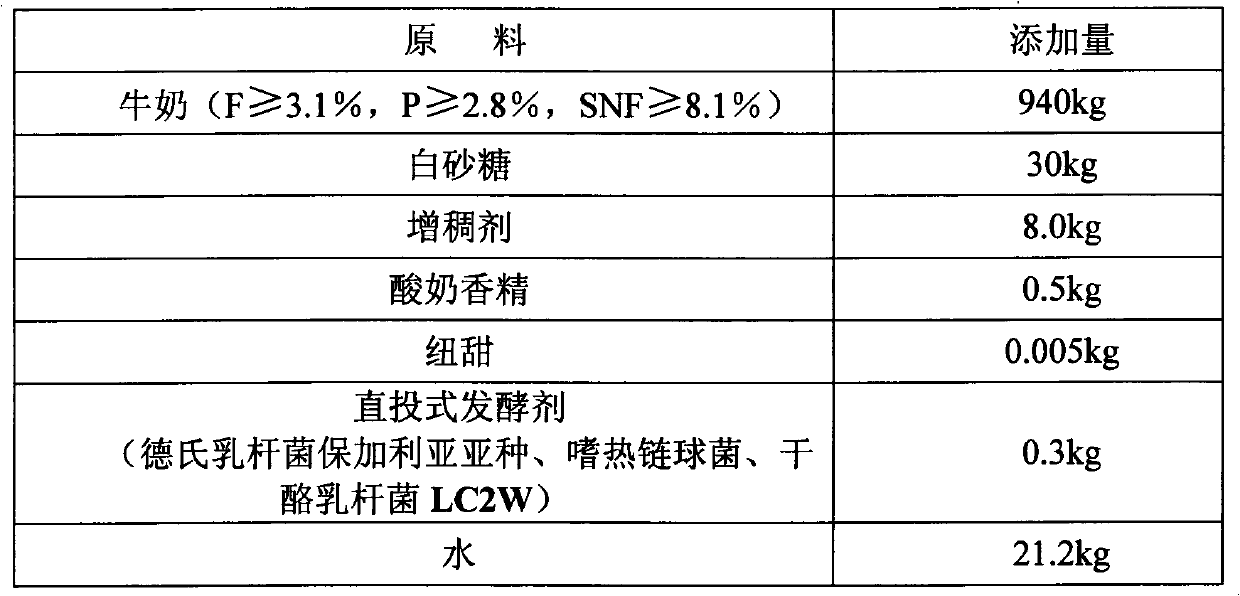

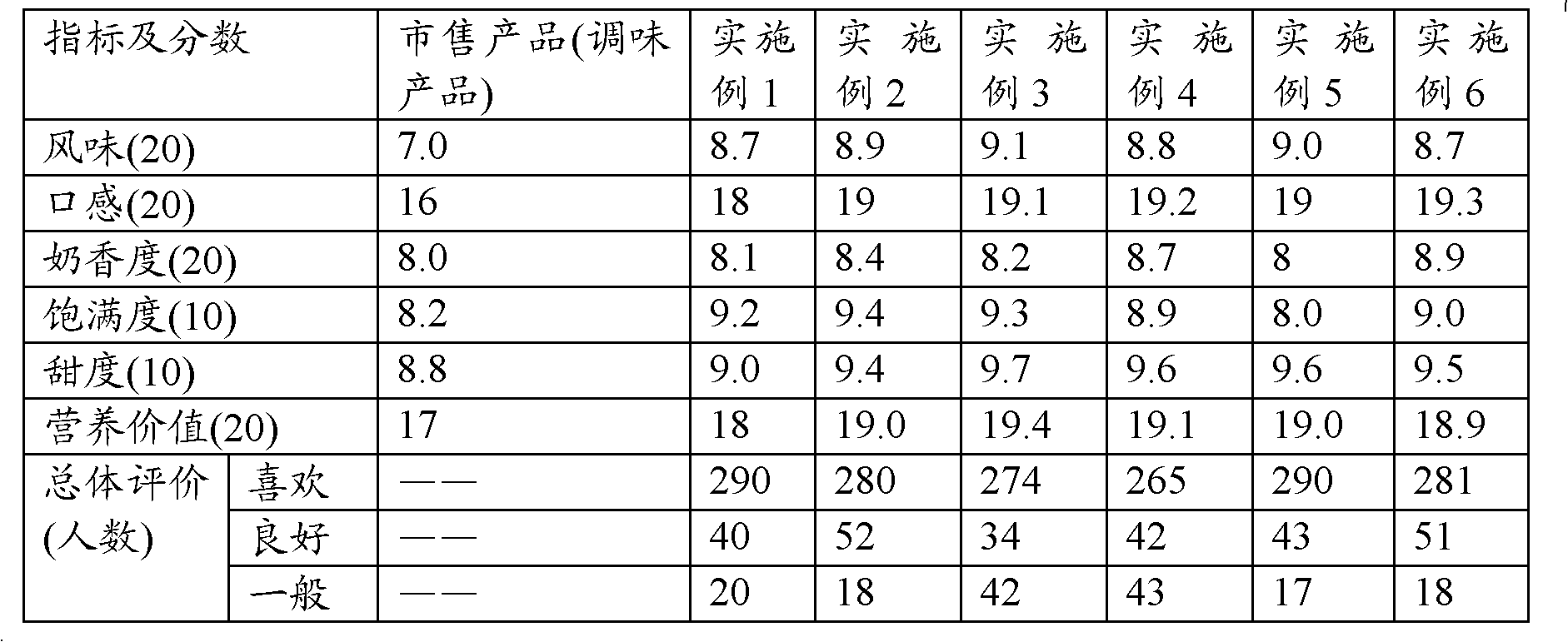

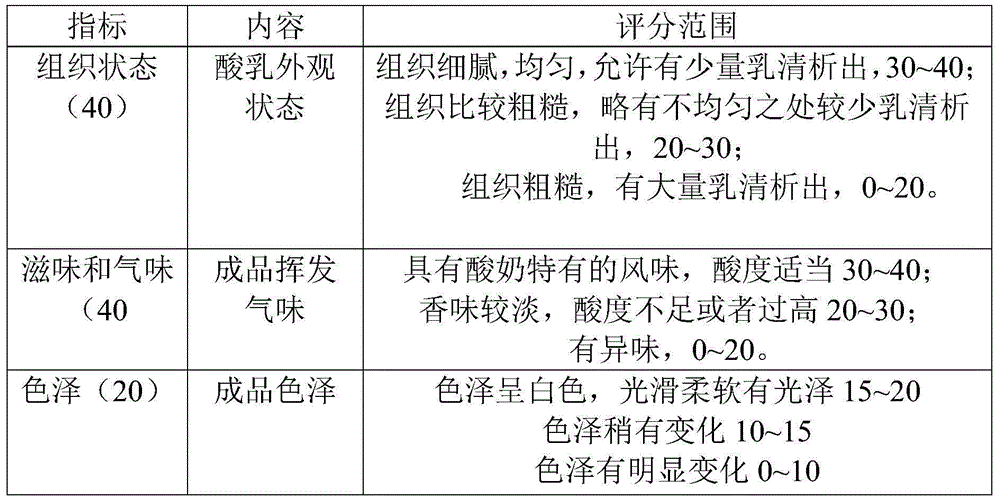

Normal-temperature drinking type yoghourt and preparation method thereof

The invention discloses normal-temperature drinking type yoghourt and a preparation method thereof. The normal-temperature drinking type yoghourt comprises the following raw materials in percentage by weight: 56.6%-60% of concentrated raw milk, 1*10<6>-7*10<9>cfu / mL of a fermenting agent, 0.03-0.5% of a stabilizing agent, a proper amount of a sweetening agent and a proper amount of water, wherein the stabilizing agent is selected from one or multiple of pectin, soybean polysaccharide and gellan gum, and the percentage is the mass percent of the stabilizing agent, accounting for the total mass of the normal-temperature drinking type yoghourt. The preparation method comprises the following steps: (1) homogenizing the concentrated raw milk and milk powder and sterilizing to obtain a sterilized liquid mixture A; (2) cooling, adding the fermenting agent for fermentation, overturning a jar by back pressure, homogenizing and cooling again; (3) uniformly mixing with the sterilized liquid mixture A, adjusting the acidity, homogenizing so as to obtain a liquid mixture B, wherein the liquid mixture A comprises the stabilizing agent, the sweetening agent and the water; and (4) sterilizing the liquid mixture B. The normal-temperature drinking type yoghourt and the preparation method disclosed by the invention have the advantages that the requirements of heat treatment for the viscosity of the yoghourt and the adding amount of the stabilizing agent are effectively reduced, the obtained normal-temperature drinking type yoghourt is good in fluidity and smooth in taste and has no obvious layering condition after being stored for 6 months under the normal temperature.

Owner:BRIGHT DAIRY & FOOD

Acidophilus milk and preparation method thereof

InactiveCN101715821ANutritional diversityComprehensive health functionMilk preparationPolygonum fagopyrumCereal grain

The invention relates to an acidophilus milk which comprises the following raw materials in parts by weight relative to total 1000 parts: 50-200 parts of nut, 0-200 parts of pulp, 0-200 parts of grain, 0-15 parts of albumen powder, 70-85 parts of white granulated sugar, 0.5-13.5 parts of stabilizing agent, 0-5 parts of edible essence and the balance of fresh milk. 0.02-0.08 activity unit / kilogram lactobacillus is used for fermenting. The nut is selected from filbert, a pine nut, almond, a Chinese chestnut, a pistachio nut, a sunflower seed, a walnut, anacardium occidentale, a lotus seed, peanut and / or armeniaca. The pulp is selected from coconut, strawberry, a yellow peach, blueberry, mulberry, tangerine, raisin, a grape, cherry, a mango, rubus corchorifolius and / or aloe vera gel. The grain is selected from barley, oat, wheat, rye, buckwheat, rice, wheat seed, broomcorn and maize. A preparation method of the acidophilus milk comprises the steps of inspecting raw milk, mixing, metering volume, homogenizing, sterilizing, cooling, vaccinally fermenting, adding, inspecting and refrigerating. The invention is convenient for the transport and storage of products and ensures the uniformity and completion of added substances.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

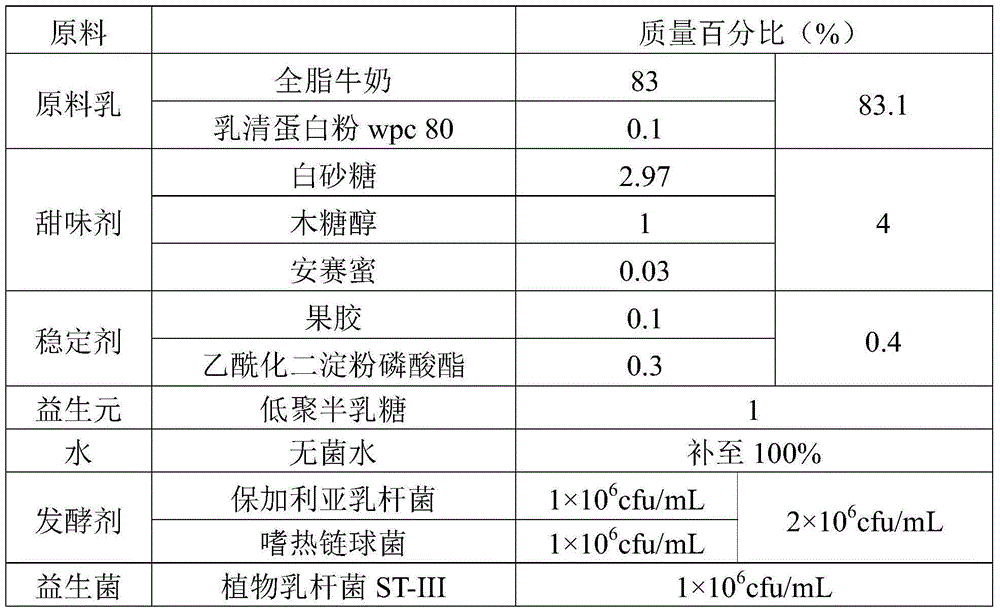

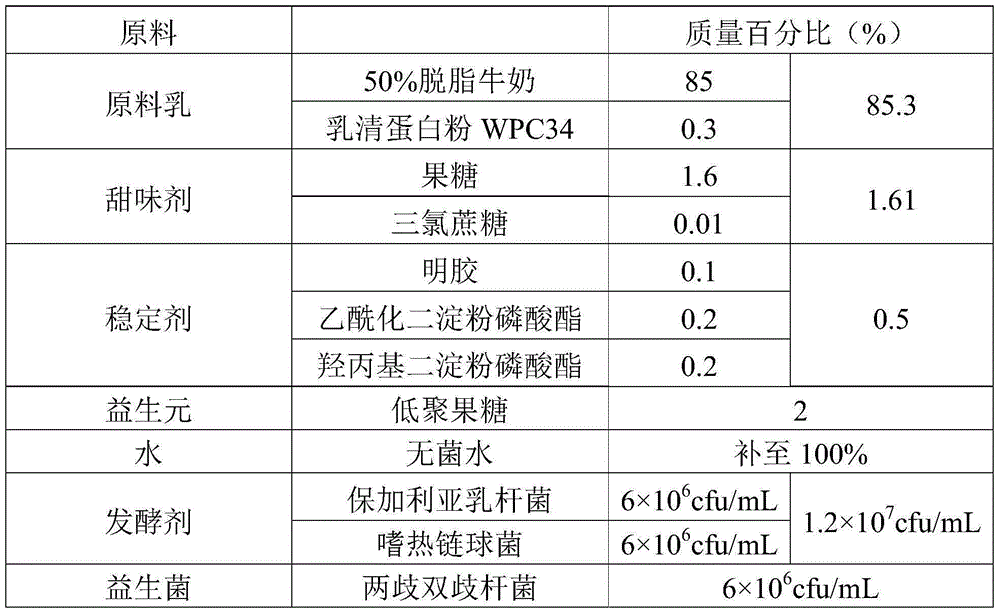

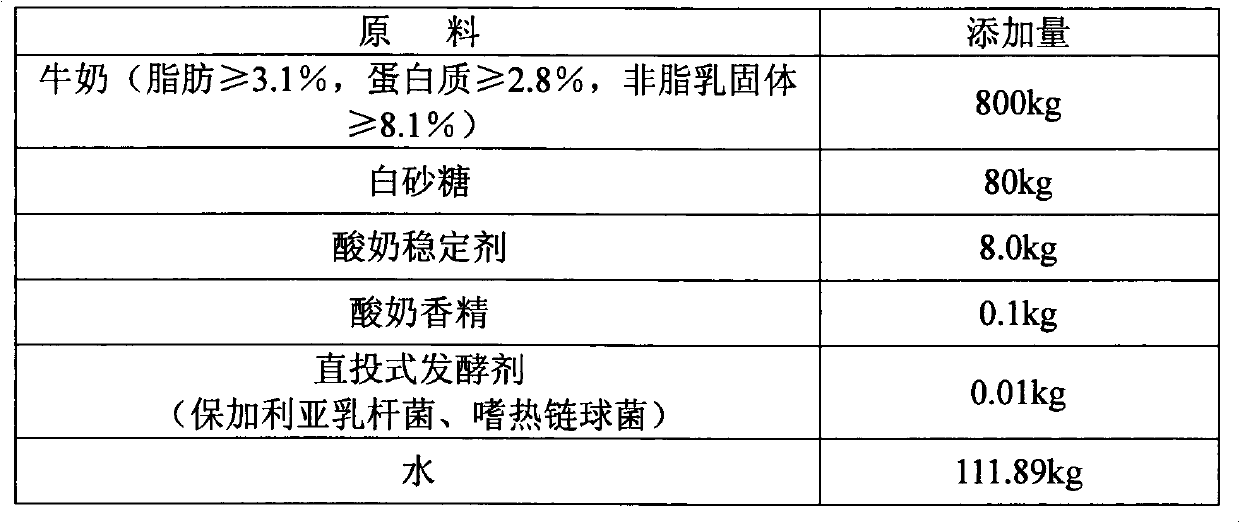

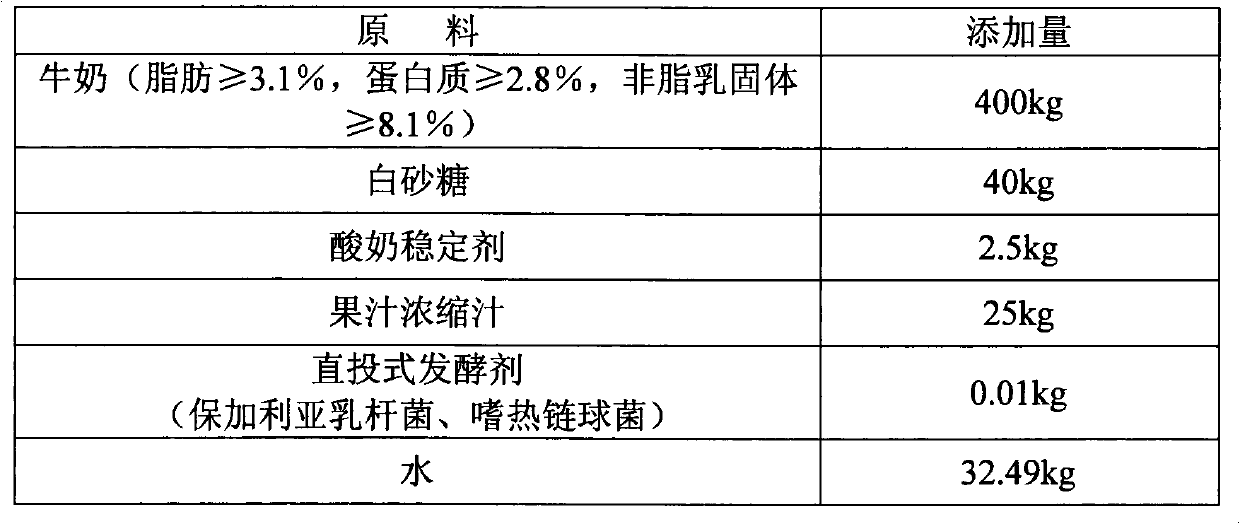

Normal-temperature set yogurt and preparation method thereof

The invention provides normal-temperature set yogurt and a preparation method thereof. Raw materials used in the preparation method comprise raw milk, a stabilizer, a sweetening agent and a leavening agent. The preparation method comprises steps as follows: (1), the raw milk, the stabilizer and the sweetening agent are uniformly mixed, homogenized, sterilized and cooled, and a mixed solution is obtained; (2), the leveling agent is inoculated to the mixed solution obtained in the step (1), and filling is performed; (3), the filling mixed solution obtained in the step (2) is fermented, cooled and processed under ultrahigh pressure of 300-600 MPa, and a finished product is obtained. After filling fermentation, a pasteurization heating processing technology commonly adopted in a normal-temperature yogurt production process is avoided, the normal-temperature set yogurt is produced and can be stored at the normal temperature, and the guarantee period is substantially prolonged.

Owner:BRIGHT DAIRY & FOOD CO LTD

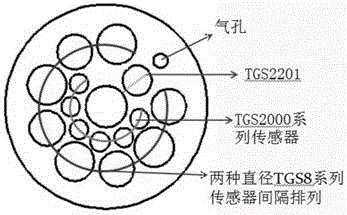

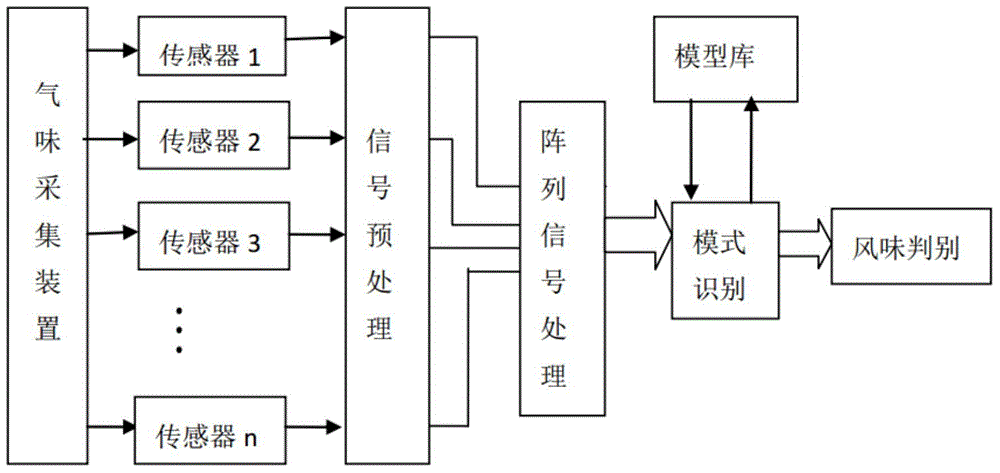

System and method for detecting milk freshness based on electronic nose

InactiveCN104792826AQuick checkReduce labor costsMaterial analysis by electric/magnetic meansGas detectorPrincipal component analysis

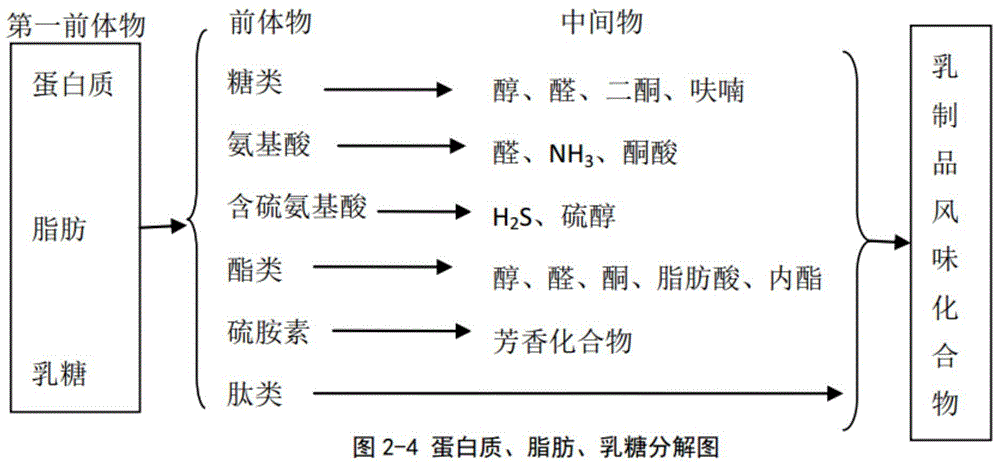

The invention discloses a system and a method for detecting milk freshness based on an electronic nose and aims to overcome the defects in quick detection of the raw milk freshness. The system comprises a flavor fingerprint information acquisition module, a signal preprocessing module, a character extracting and screening module and a pattern recognition module, wherein the flavor fingerprint information acquisition module is used for reading voltage signals responding to gas of a gas sensitive array into an internal memorizer in a digital manner, implementing real-time digital display and waveform display of the read data, and storing and recycling the displayed data; the signal preprocessing module is used for preprocessing the original signals by using a filter function, for example, removing noise of the original signals and extracting basic signals; the characteristic extracting and screening module is used for extracting characteristics of the filtered and de-noised signals and screening the characteristics according to a principal component analysis method; the pattern recognition module is used for training and identifying the detected samples according to a pattern recognition algorithm. The system and the method are used for quickly detecting the raw milk freshness based on the electronic nose and have guiding significance to control of flavor and quality of milk products. Compared with the conventional method, the method provided by the invention is more efficient and convenient, faster, and lower in manpower cost.

Owner:CHINA AGRI UNIV

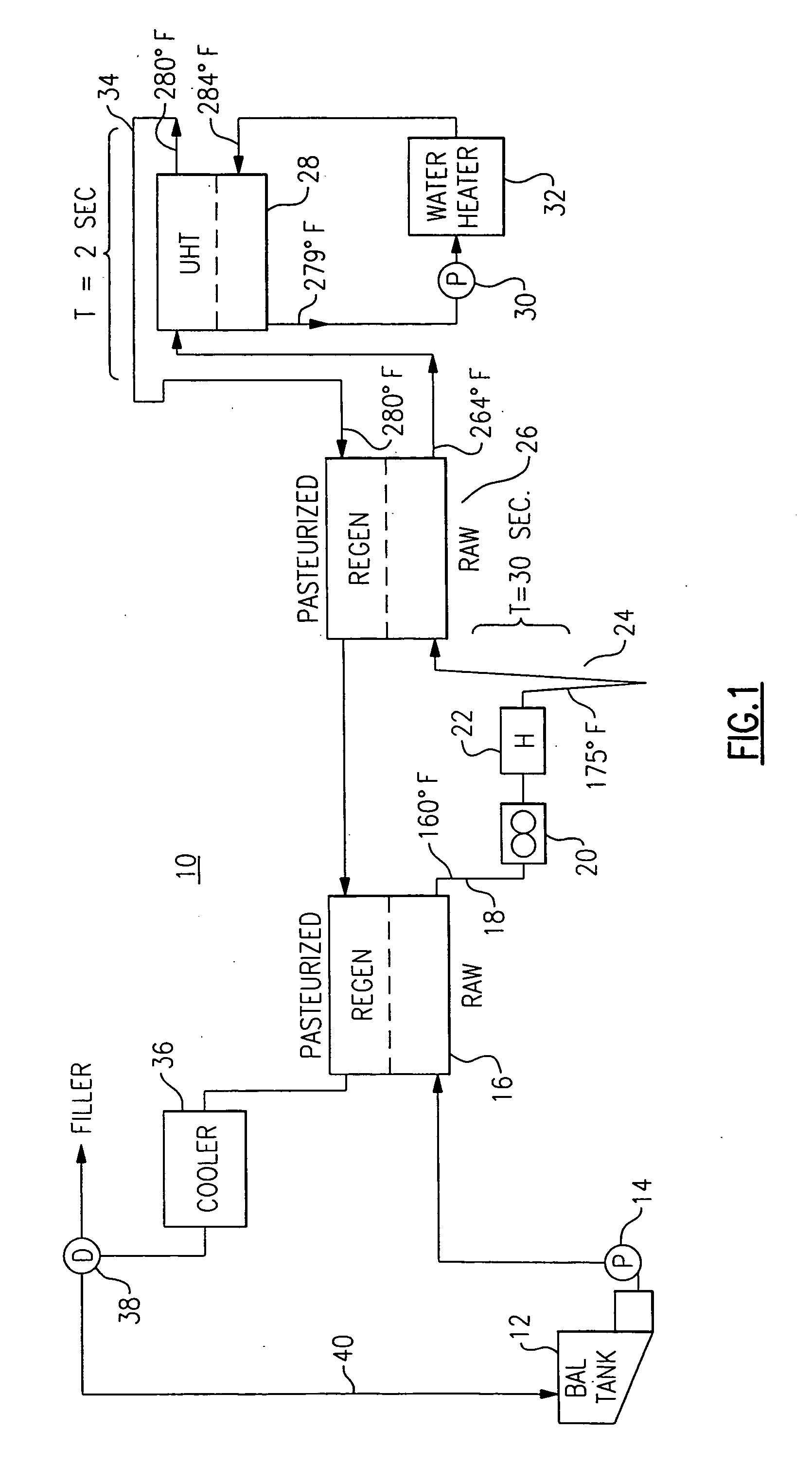

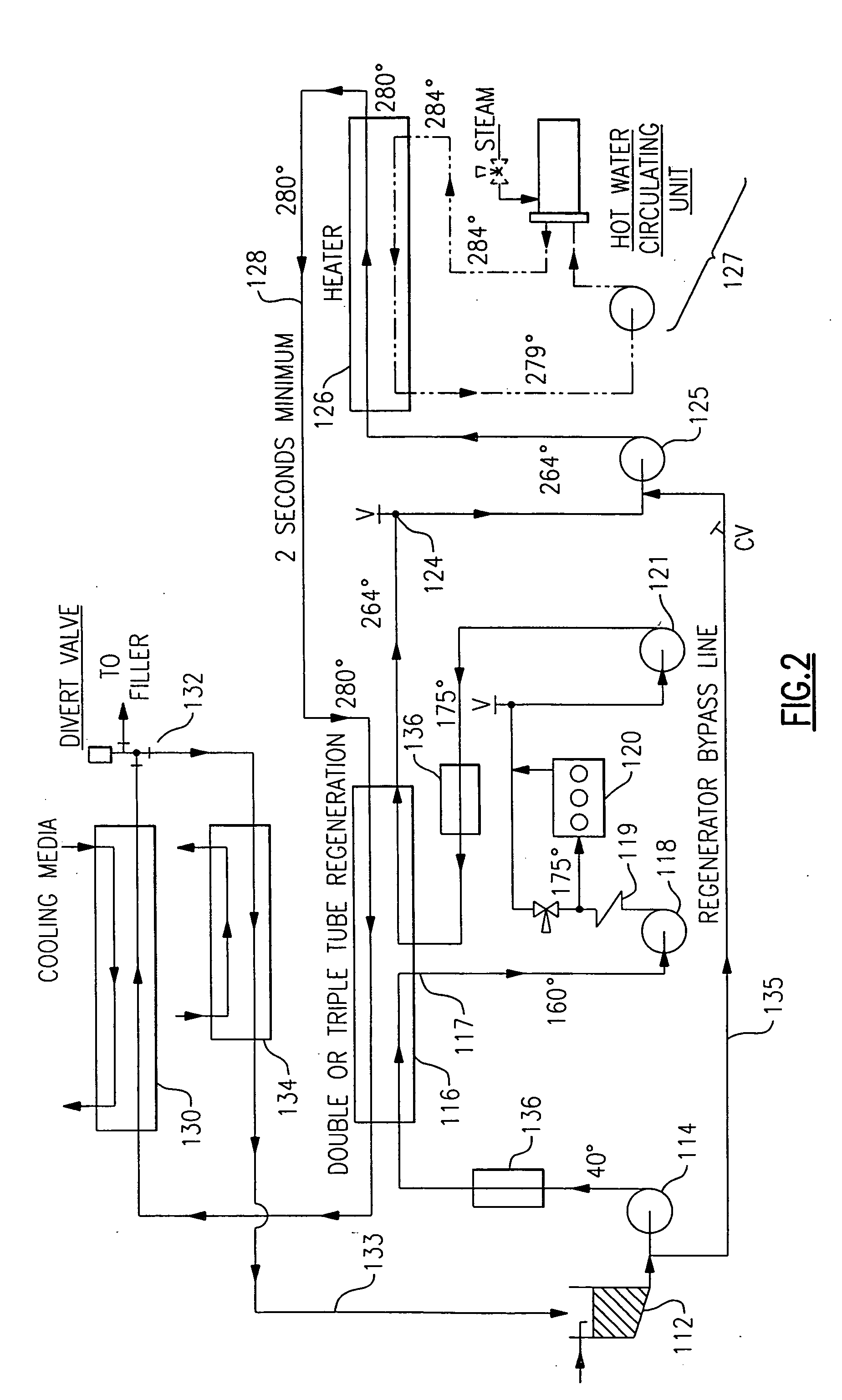

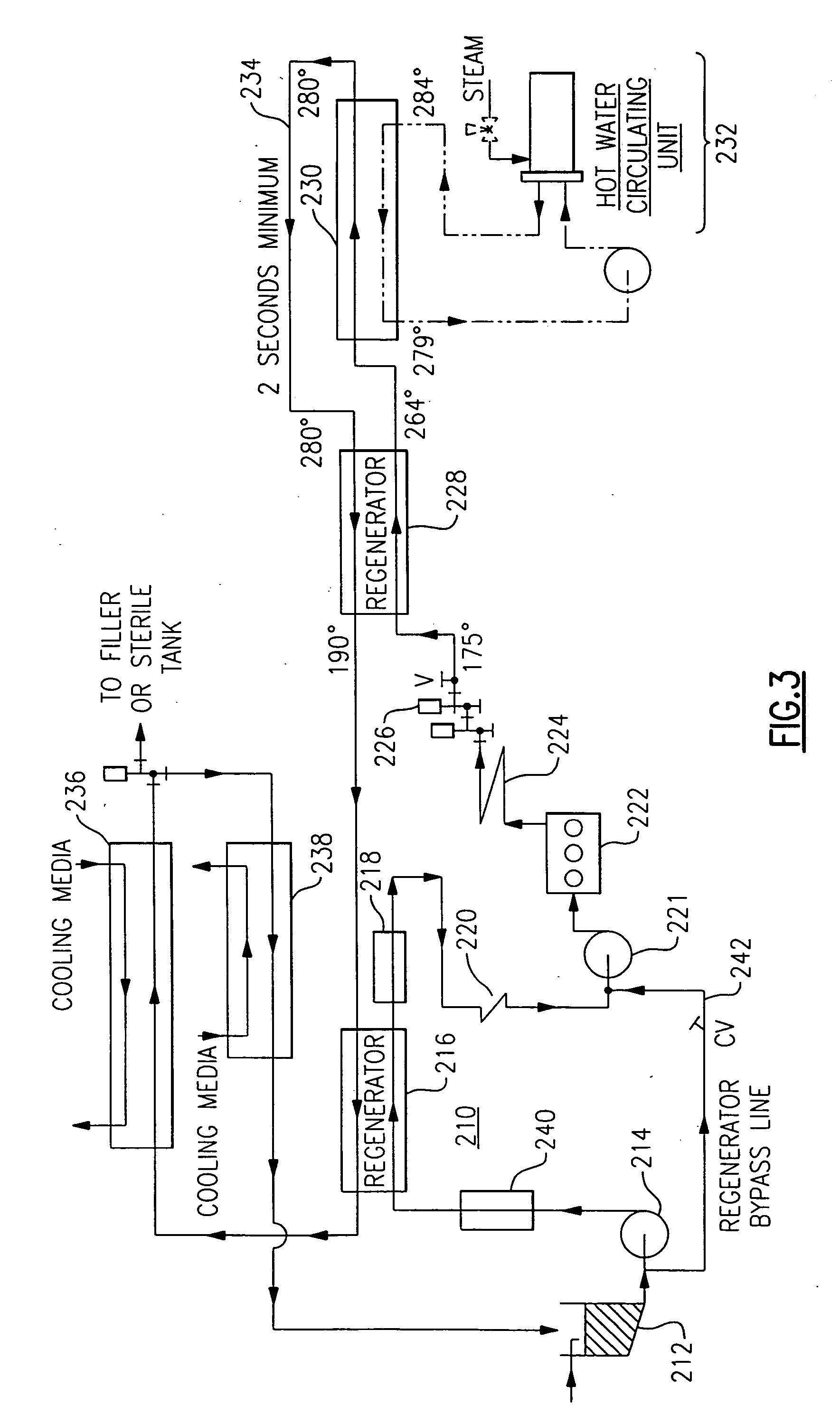

UHT pasteurizer with regeneration

ActiveUS20050112257A1Maximize efficiencyAvoid the tasteMilk preservationWort preparationWater flowProcess engineering

A pasteurization arrangement employs regeneration to bring raw milk or other liquid food product up to a few degrees below a UHT pasteurizing temperature. The product is first heated up by regeneration to about 175° F., and held at this temperature for about sixty seconds to denaturize proteins so that they do not deposit on the heat exchange walls of following stages. Then the product proceeds through a product-product regenerative heat exchanger where it emerges at about 264° and proceeds to a water-product heater to heat the product to 280° F. The water flows in counter current to the product. The temperature differential at any reference point in the heater and the regenerative heat exchanger is below 20°, and the ratio of rate of water flow to product flow in the heater is below about 3:1.

Owner:FELDMEIER EQUIP

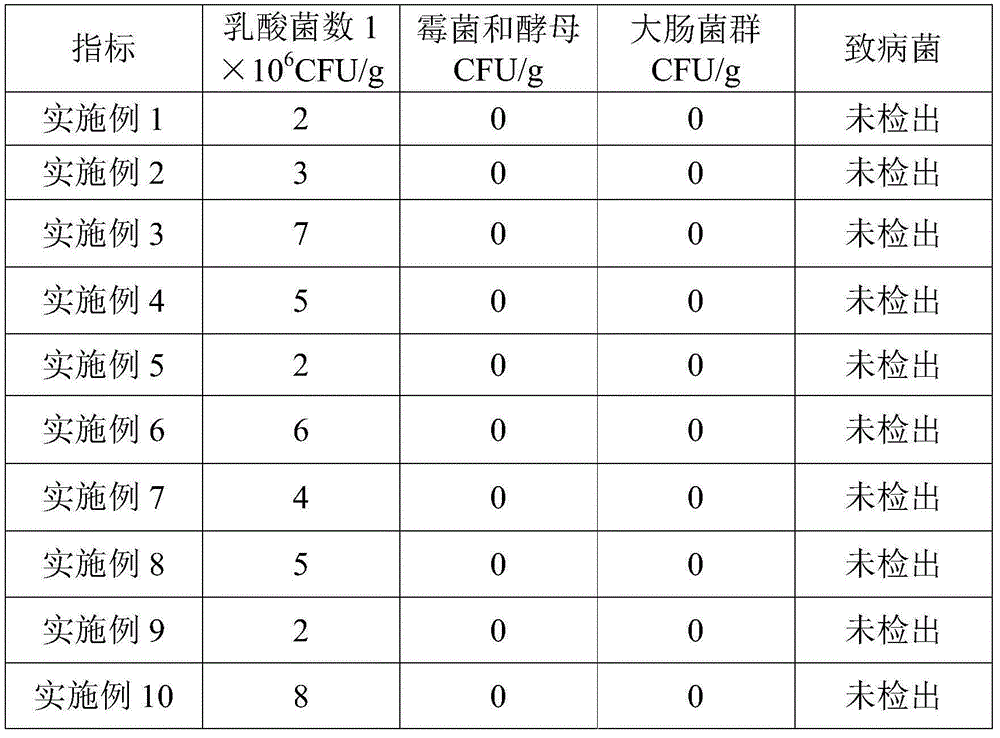

Set-style fermented yoghourt rich in probiotics and preparation method of yoghourt

InactiveCN102599245APromote proliferationIncrease the number ofMilk preparationFermentation starterTwo step

The invention discloses set-style fermented yoghourt rich in probiotics and a preparation method of the set-style fermented yoghourt. The method comprises the steps of adding a fermenting agent and a thickening agent into sterilized raw milk to form a feed liquid, and obtaining the yoghourt through fermentation, wherein the fermentation step adopts a two-stage combination fermentation process, and the process comprises two steps of performing middle-temperature fermentation at 30-37 DEG C for 3-6 hours in the front stage and performing hot fermentation at 42-45 DEG C for 1-3 hours in the back stage. The fermenting agent is a direct vat set fermenting agent, which includes lactobacillus bulgaricus, streptococcus thermophilus and probiotics; the inoculation quantities of the lactobacillus bulgaricus subsp. bulgaricus and streptococcus thermophilus are 1.0*10<6>-9.9*10<6>CFU / mL; the inoculation quantity of each of probiotics is 1.0*10<5>-9.9*10<5>CFU / mL. In the yoghourt prepared by the method disclosed by the invention, the viable bacteria count ratio of the probiotics is more than 1-3 orders of magnitude than that of the yoghourt prepared by the traditional fermentation method, and the quantity of the viable bacteria of the probiotics can reach 10<7>-10<9>CFU / mL.

Owner:BRIGHT DAIRY & FOOD CO LTD

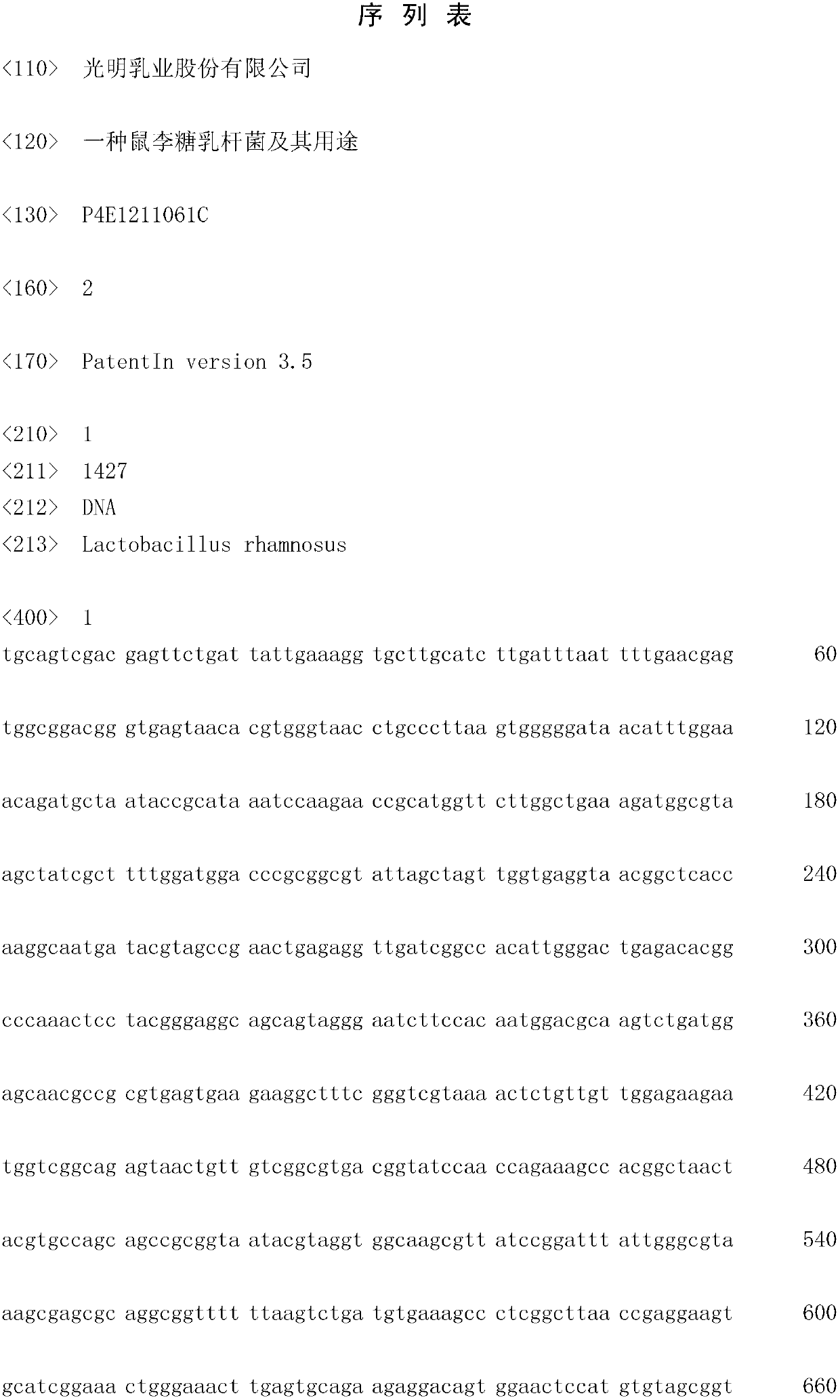

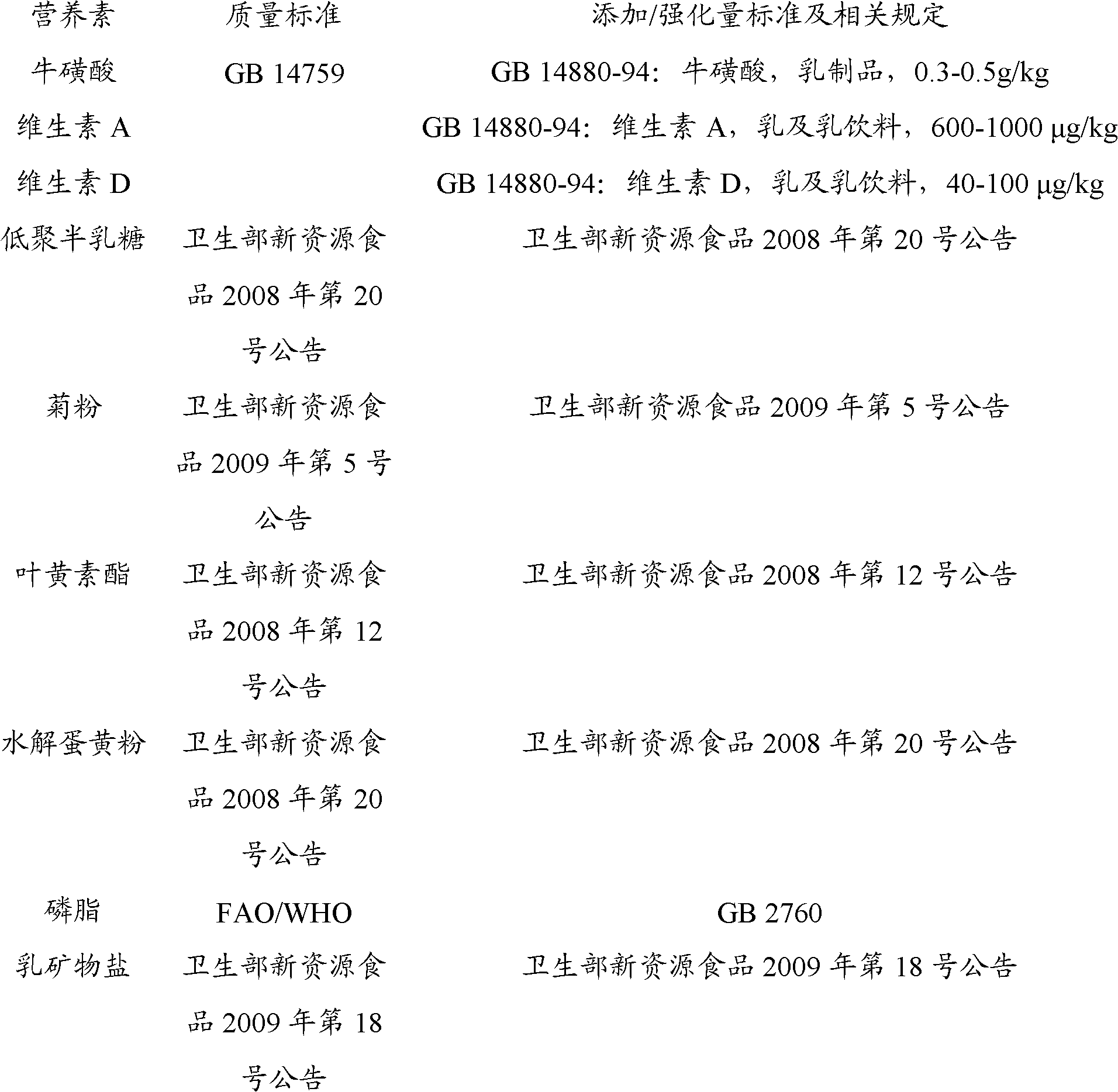

Lactobacillus rhamnosus and application thereof

The invention discloses lactobacillus rhamnosus and application thereof. The lactobacillus rhamnosus is preserved in the China General Microbiological Culture Collection Center (CGMCC) with a preservation number of CGMCC No.6430. Raw milk is used as a growth medium of the strain, and the monoamine oxidase inhibition rate of the obtained fermented milk can reach 52.4-78.8%. The lactobacillus rhamnosus can be used as a functional additive for producing beverages and dietary supplements with the functions of inhibiting the monoamine oxidase activity, fighting Parkinson's disease, easing depression or defying aging, and can also be applied to preparation of drugs for fighting Parkinson's disease or easing depression.

Owner:BRIGHT DAIRY & FOOD CO LTD

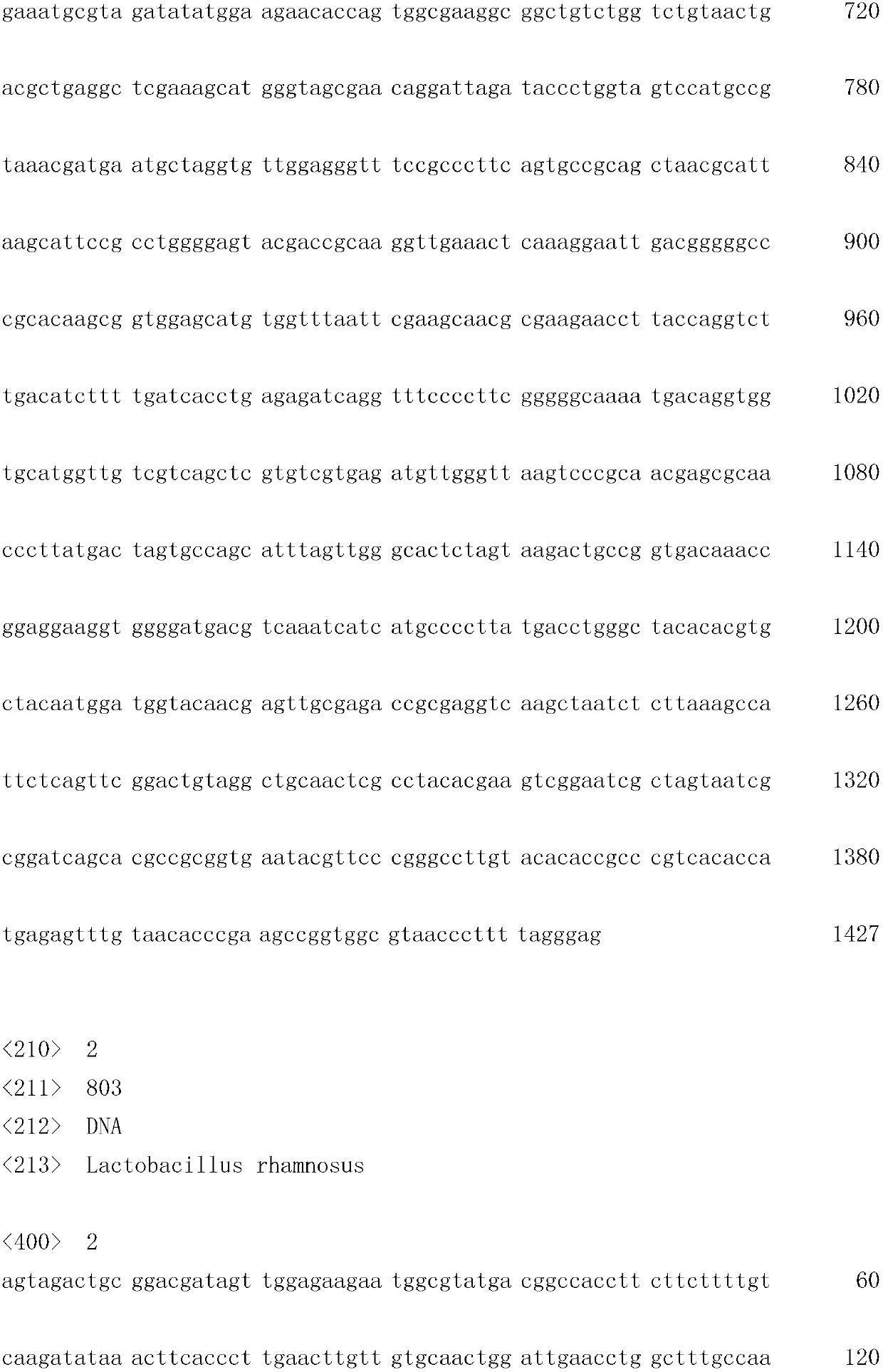

Liquid milk preparation method

InactiveCN103300143AExtended shelf lifeAvoid heat sterilization processMilk preservationAdditive ingredientLiquid state

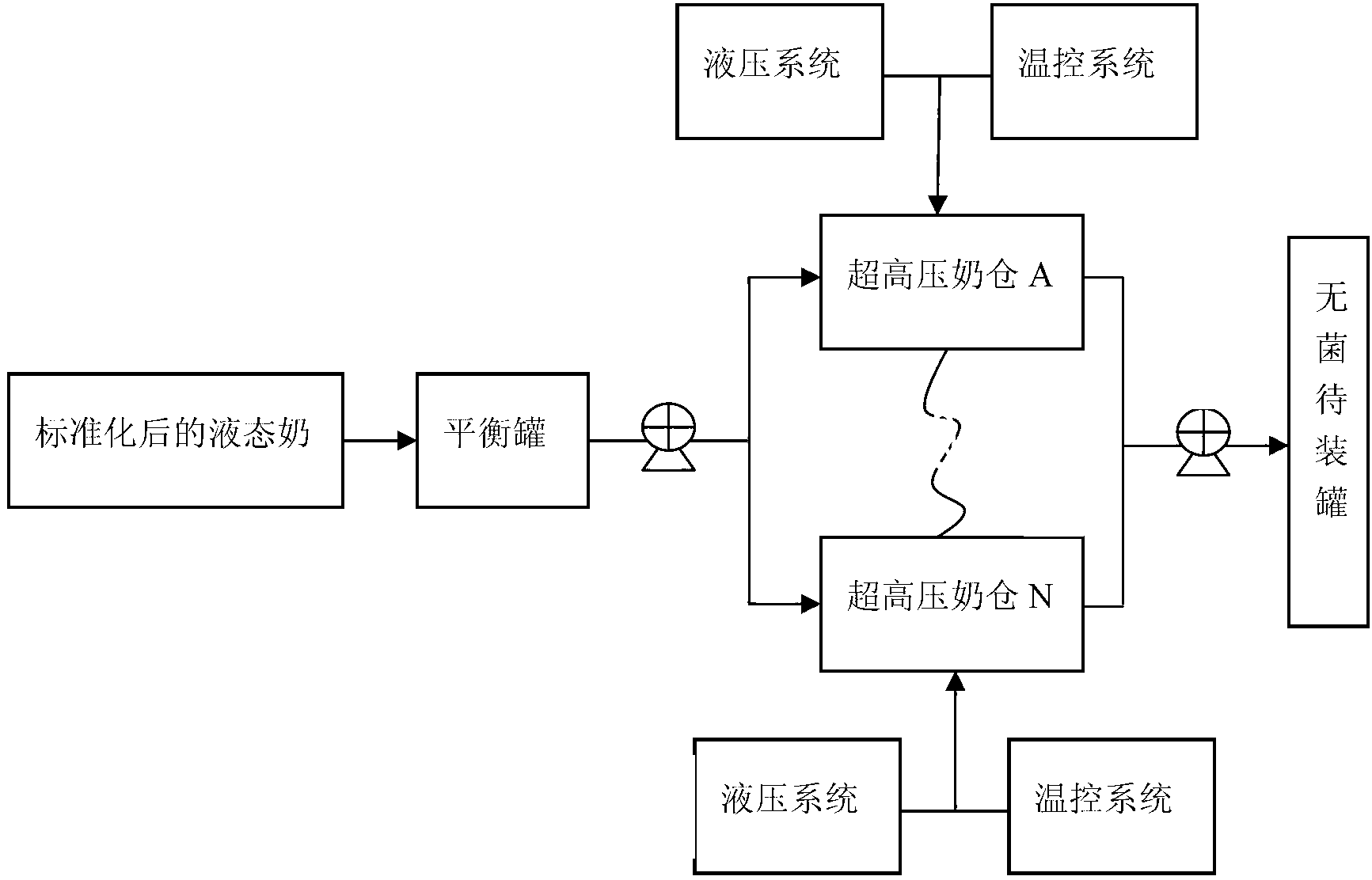

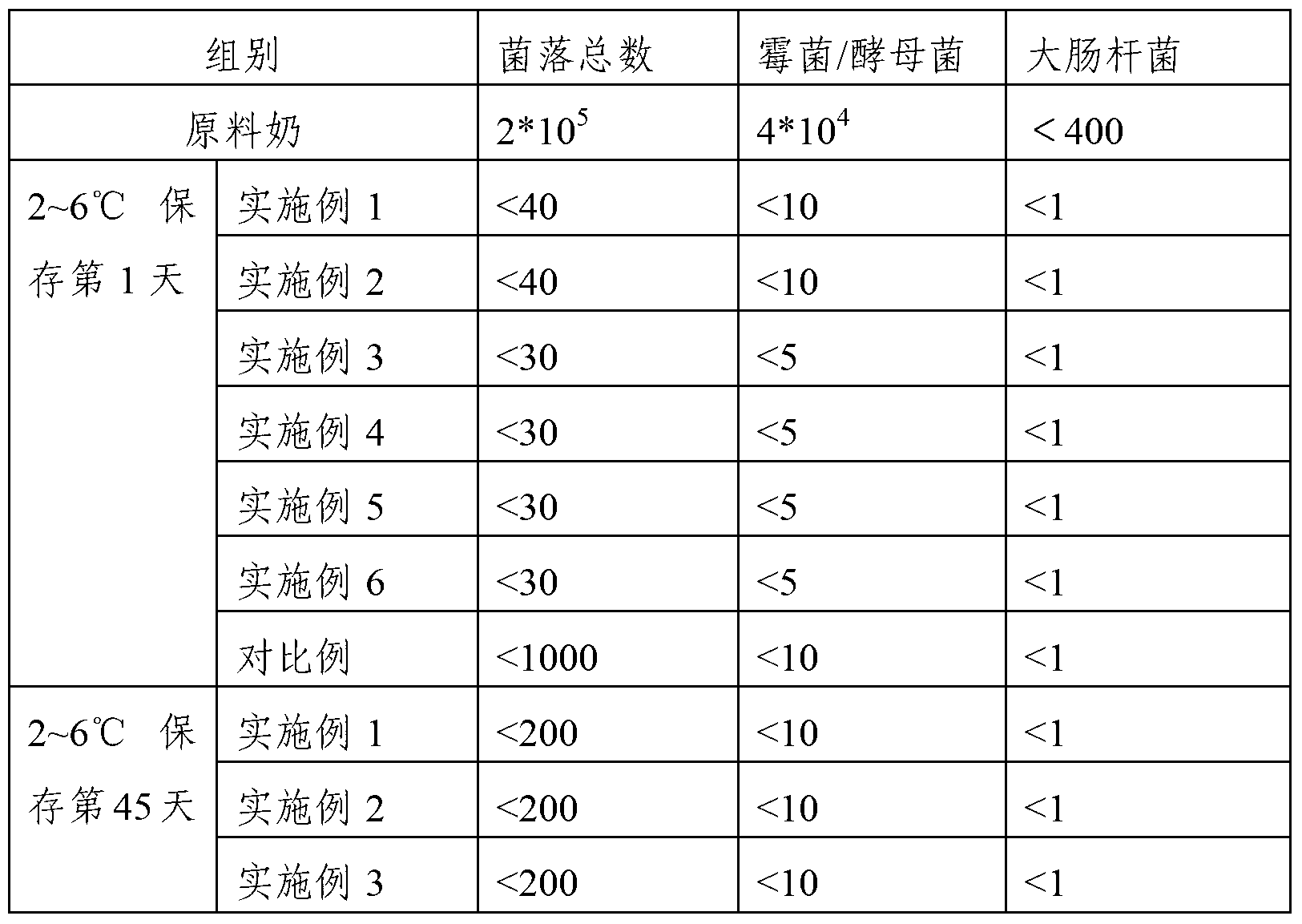

The invention provides a liquid milk preparation method. The method comprises the following steps of: 1, centrifugally separating a raw milk into skim milk and watery cream, and filtering the skim milk through a membrane; 2, standardly mixing the watery cream with the skim milk filtered by the membrane; 3, homogenizing the mixed milk of step 2 at 55 DEG C-65 DEG C under the homogenizing pressure of 160-220bar; and 4, carrying out ultrahigh pressure sterilizing on the homogenized milk under the ultrahigh pressure sterilizing pressure of 400-1000MPa for a pressure maintaining time of 5-20min. By utilizing an ultrahigh pressure long shelf-life liquid milk production method provided by the invention, a liquid milk thermization technology is avoided to the maximum extent, so that the energy consumption of industrial production is reduced, the active nutritional ingredients of the liquid milk can be completely reserved through a non-thermization technology, the shelf life of the liquid milk is prolonged to 45d, and the liquid milk is not easily deteriorated.

Owner:BEIJING SANYUAN FOOD

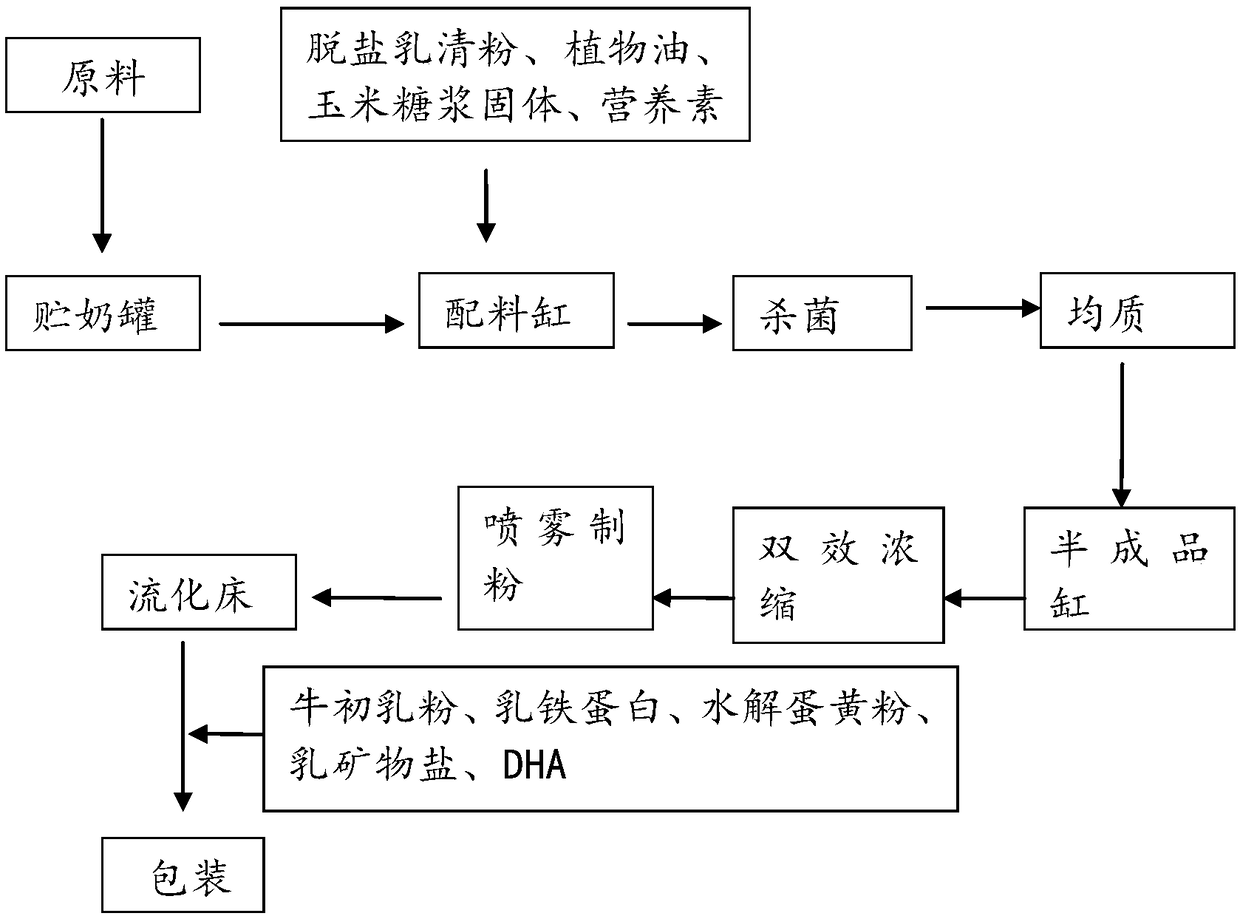

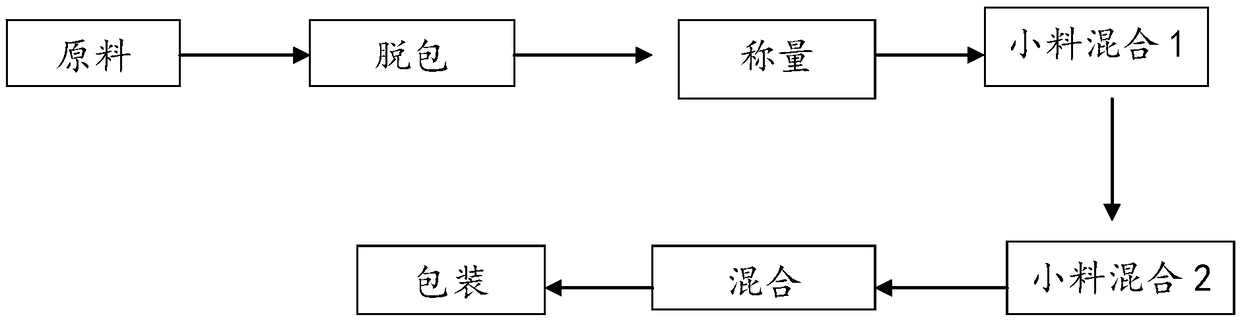

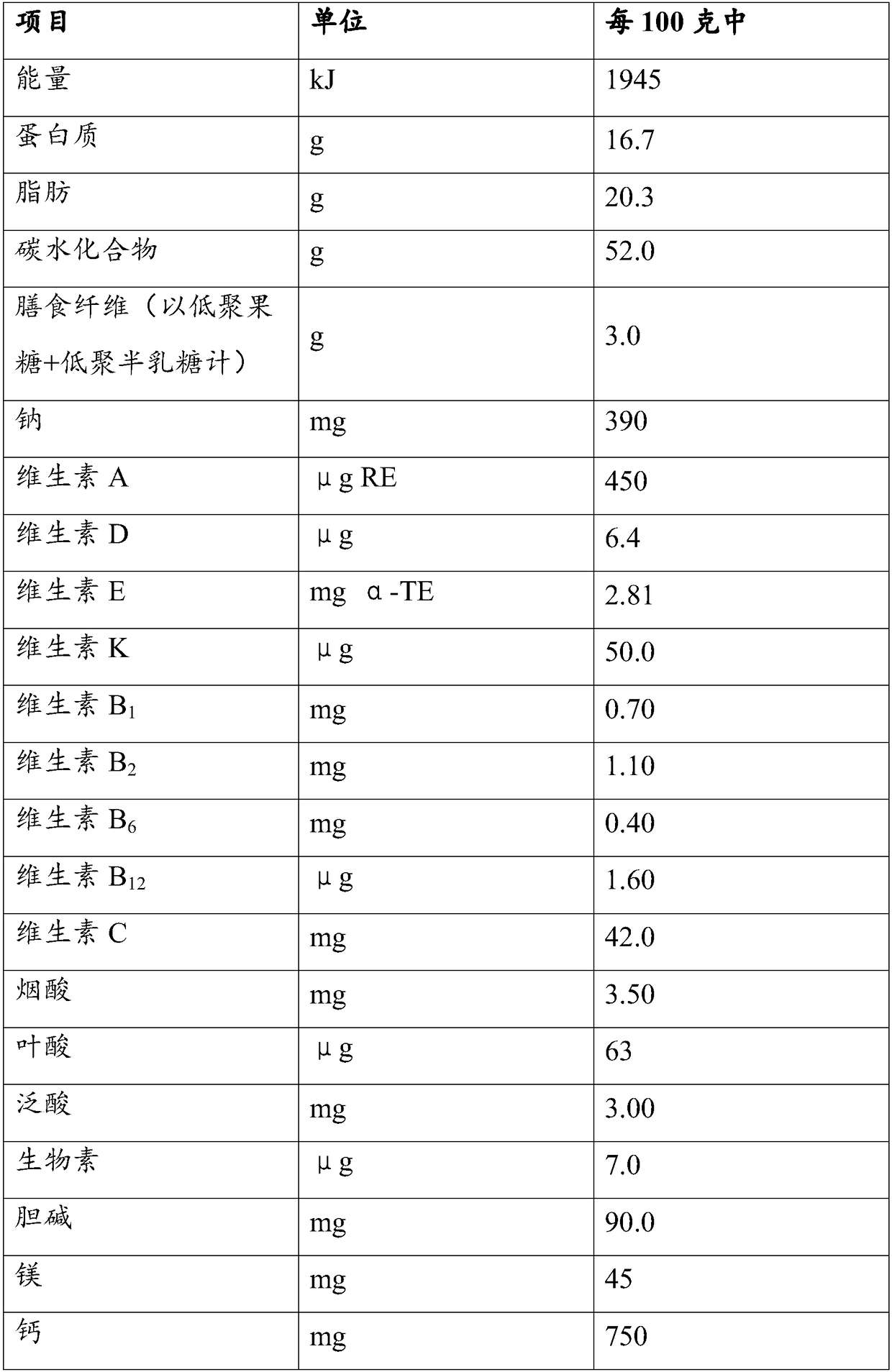

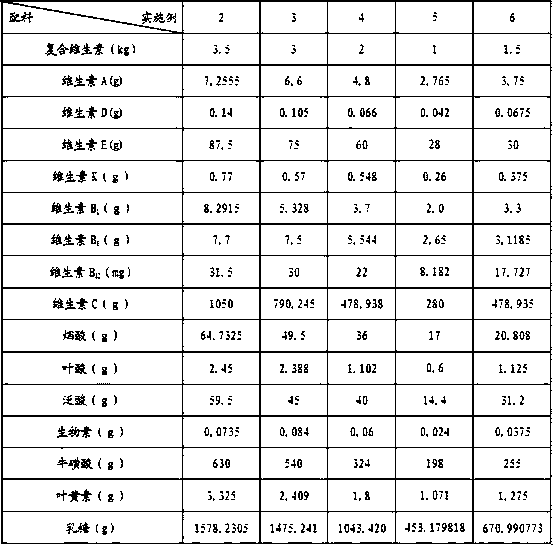

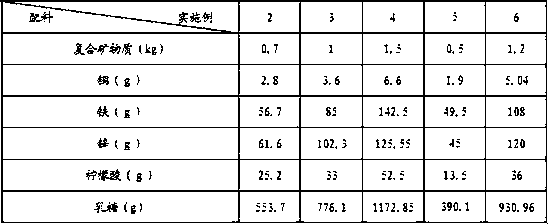

Formula milk powder assisting development of height of children and production method

The invention discloses formula milk powder assisting development of height of children. The formula milk powder consists of the following components of raw milk or whole milk powder, desalinated wheypowder, skimmed milk powder, solid corn syrup ( or maltodextrin ), whey protein powder, crystallized fructose, vegetable oil, fructo-oligosaccharide, anhydrous butter, galactooligosaccharide, docosa-hexaenoic, bovine coloctrum powder, milk mineral salt, hydrolyzed dried egg yolk, lactoferrin, phosphatide, vitamin A, vitamin D, vitamin E, vitamin K, vitamin B1, vitamin B2, vitamin B6, vitamin B12,vitamin C, magnesium, calcium, iron, zinc, selenium and the like. According to the formula milk powder assisting the development of the height of the children and a production method disclosed by theinvention, the products have the characteristics of ''supplementing, promoting and improving'', namely supplementing nutrition required by growth and development of Chinese children, promoting absorption of key nutrition for the development of the height, and improving immunity of the children, so that the height of the Chinese children is assisted to quickly grow.

Owner:上海育博营养食品有限公司

Preparation method of monascus sp. cheese and product thereof

ActiveCN103444878ABreakthrough understandingImprove immunityCheese manufactureNutritive valuesFlavor

The invention discloses a preparation method of monascus sp. cheese and a product of the monascus sp. cheese. The preparation method comprises the following steps: (1), sterilizing raw milk and then cooling to obtain treated milk, inoculating a lactic acid bacteria starter in the treated milk, adding chymosin when fermenting until pH is 6.0-6.5, curdling for 30-40min to obtain curd; (2), cutting the curd into blocks, stirring and discharging whey, adding salt in the curd after discharging the curd, and feeding into a mould after uniformly stirring; (3), carrying out or not carrying out pressing after feeding in the mould, overturning for 5-10 times at a frequency of 15-30min / times, and standing to ensure that the whey is discharged; and (4), cutting the curd into curd blocks, uniformly spraying a monascus fermentation liquor on the surface of the curd blocks, loading in a container, and curing to obtain the monascus sp. cheese. The monascus sp. cheese disclosed by the invention belongs to natural mould aged cheese; the quality and the flavor of the cheese are effectively improved by using the monascus sp., and the nutritional value of the cheese is increased; the preparation method is simple, convenient and easy to popularize and apply.

Owner:BRIGHT DAIRY & FOOD

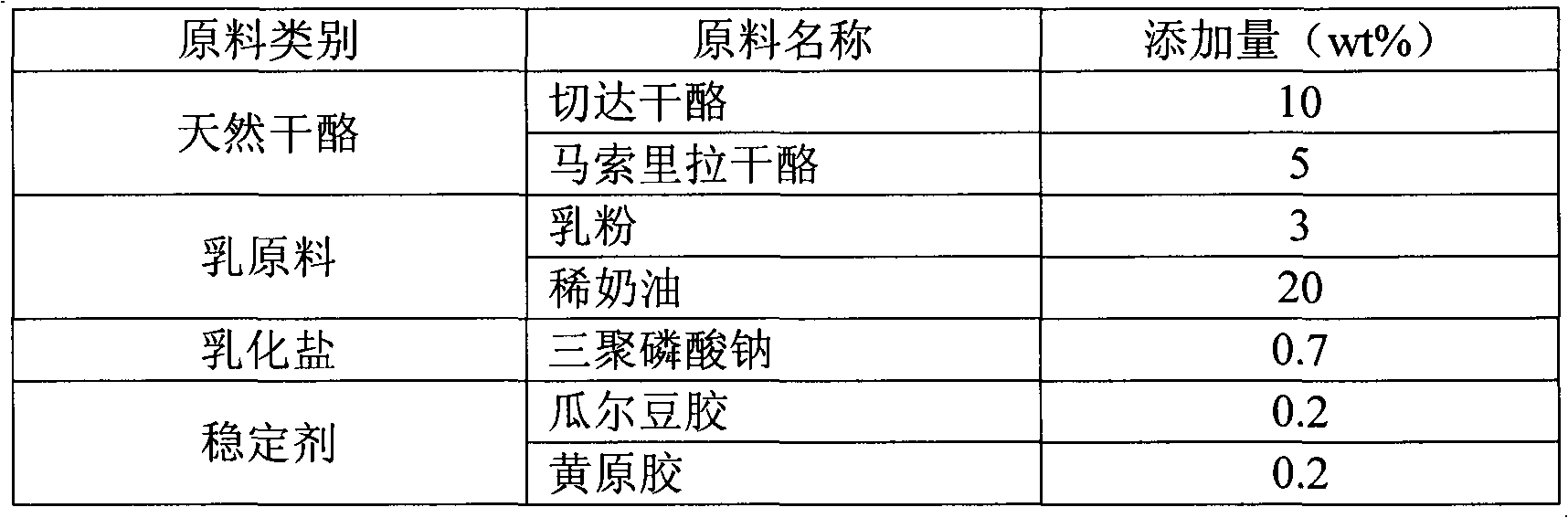

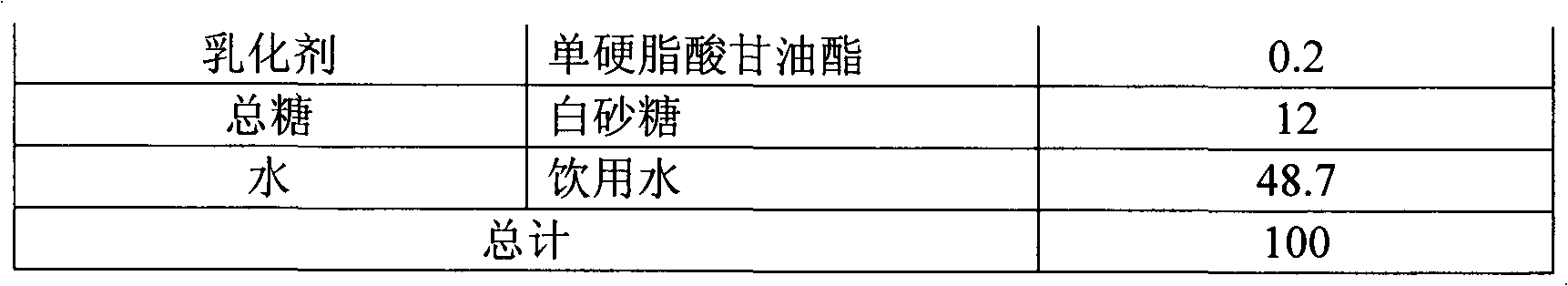

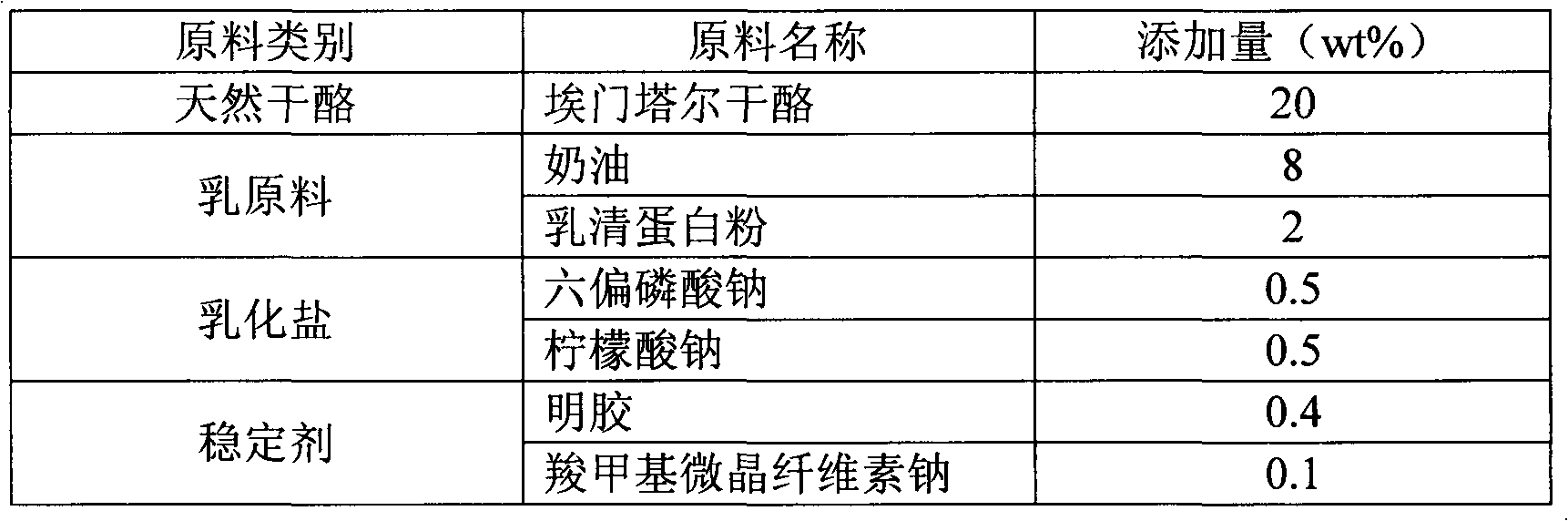

Cheese ice cream and preparation method thereof

InactiveCN102422969AOvercome rough tasteOvercome the problem of strong sandy feelingFrozen sweetsFlavorSugar

The invention discloses a raw material composition of cheese ice cream. The composition comprises the following components, by weight, 3-40% of natural cheese, 3-30% of raw milk, 0.5-1.5% of an emulsification salt, 0.2-2% of a stabilizer, 0.2-0.5% of an emulsifier, 10-25% of total sugar, and the balance water. The invention also discloses a preparation method of the cheese ice cream and the cheese ice cream prepared with the preparation method. By controlling the formula, the sterilization mode, the homogenizing mode, and the additional quick-frozen process of a freezing process of the cheeseice cream in the invention, problems of rough mouthfeel and strong sand-like feeling of the final ice cream, which are caused by the degradation or the denaturation coacervation of cheese proteins, the emulsification capability reduction and the hydratability reduction, are overcome. The cheese ice cream with fine texture, uniform tissue state and unique flavor, which is provided in the invention, allows the perfect combination of cheese and ice cream to be realized.

Owner:上海光明奶酪黄油有限公司

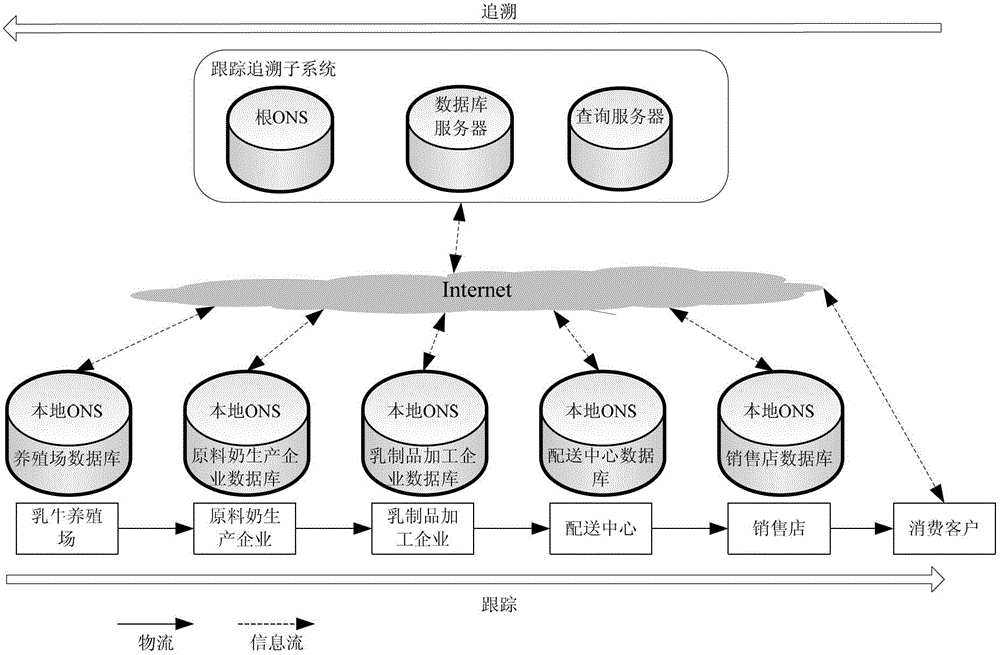

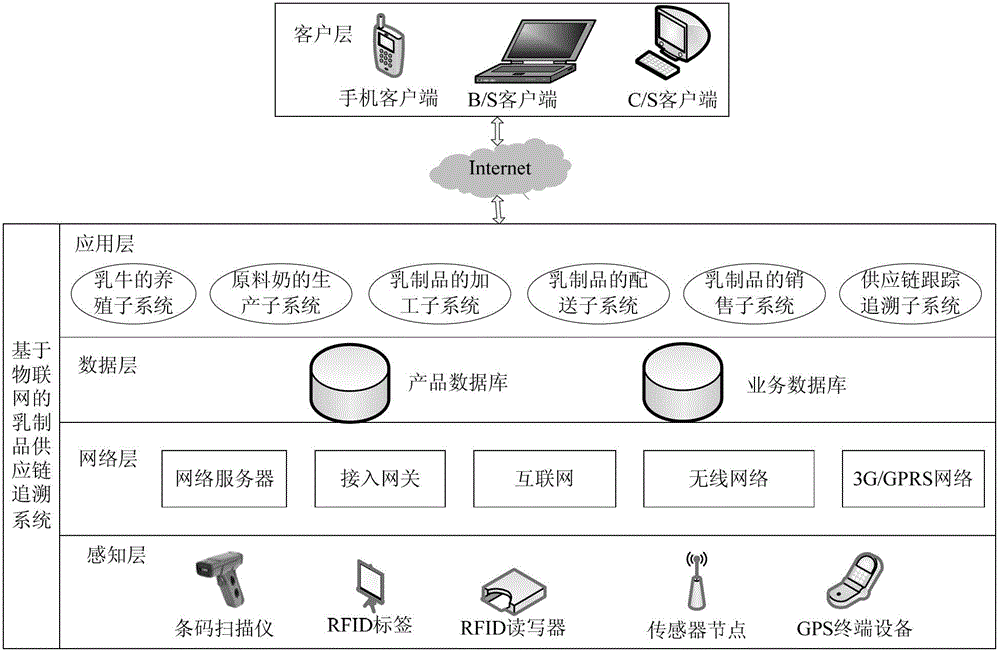

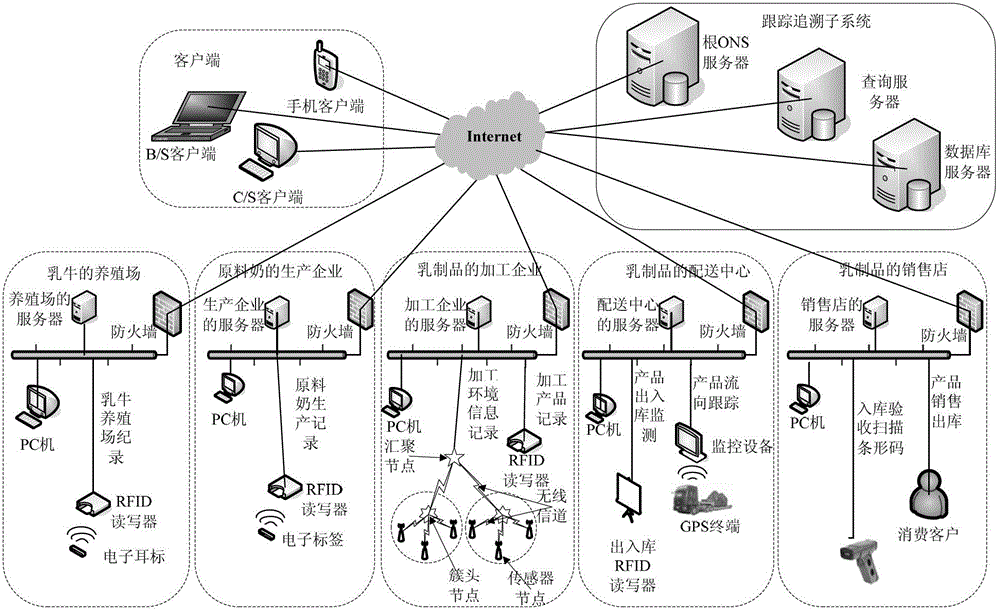

Tracking system and method of dairy product supply chain information based on Internet of Things

InactiveCN102722850ASolve the problem that the visualization of supply chain information cannot be truly realizedEnsure food quality and safetyData processing applicationsCo-operative working arrangementsThe InternetWireless sensor networking

The invention provides tracking system and method of dairy product supply chain information based on the Internet of Things. The system comprises a plurality of subsystems connected with each other through a network. The subsystems include a dairy cow farming subsystem, a raw milk production subsystem, a dairy product processing subsystem, a distribution subsystem, a sale subsystem and a tracking subsystem. The farming subsystem is used for acquiring and recording farming information of dairy cows. The production subsystem is used for acquiring and recording production information of raw milk. The processing subsystem is used for acquiring and recording processing information of dairy products. The distribution subsystem is used for acquiring and recording distribution information of the dairy products. The sale subsystem is used for acquiring and recording sale information of the dairy products. The tracking subsystem is used for collecting information related to aspects of farming, production, distribution, sale and the like and receiving search requests and returning to search results including upstream and / or downstream information. The bar code technology, RFID (radio frequency identification) technology, EPC (electronic product code) technology, wireless sensor network technology and GPS (global position system) technology are utilized to realize visualization of the dairy product supply chain information.

Owner:BEIJING WUZI UNIVERSITY

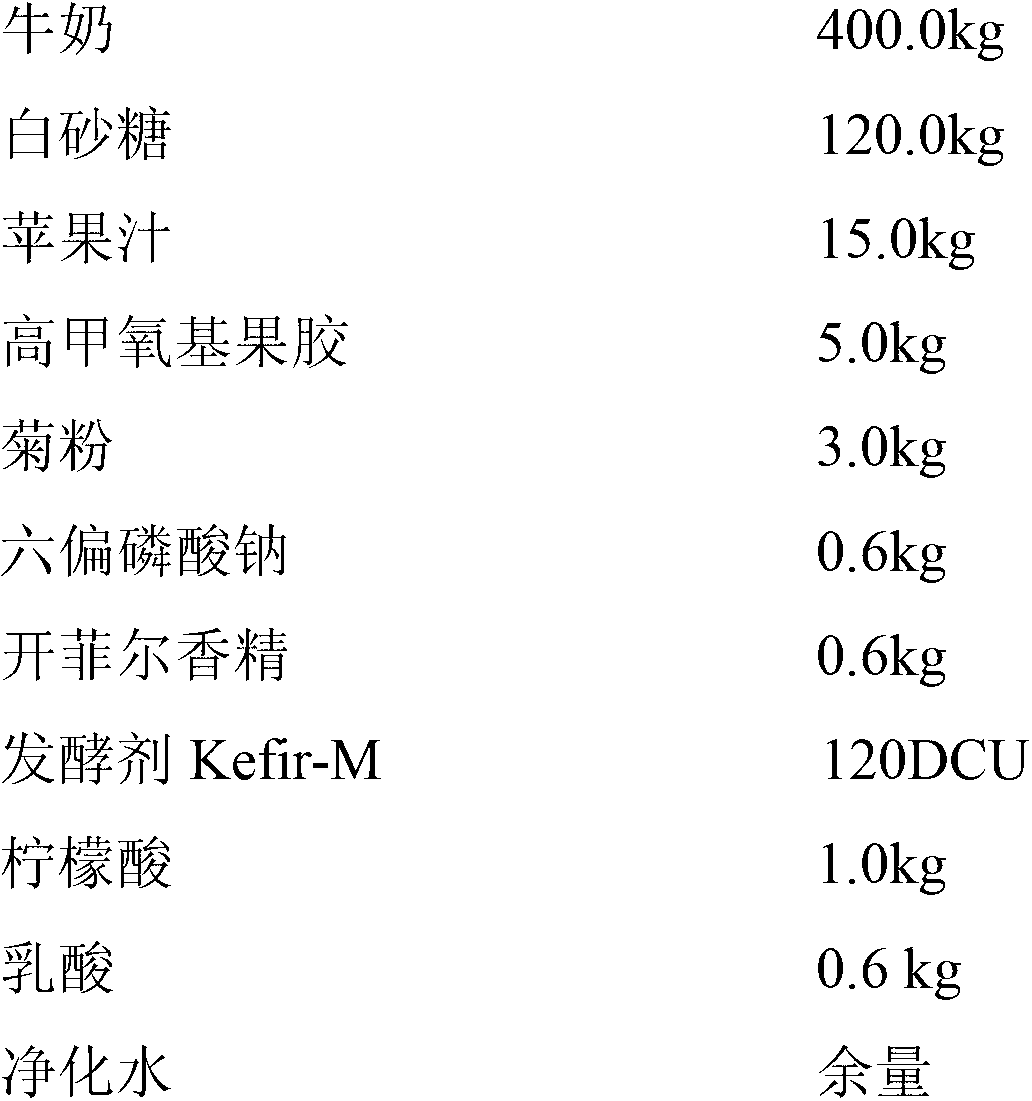

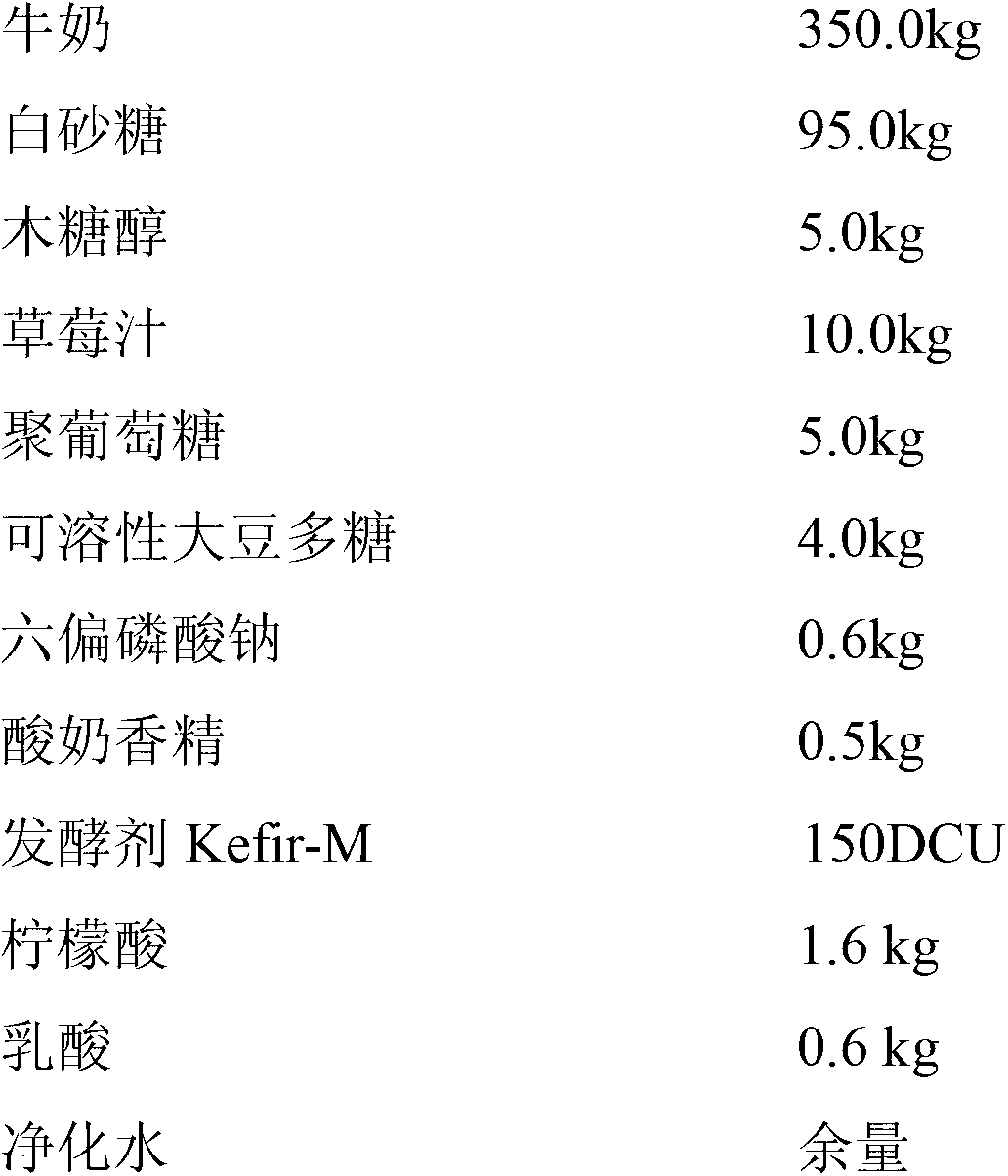

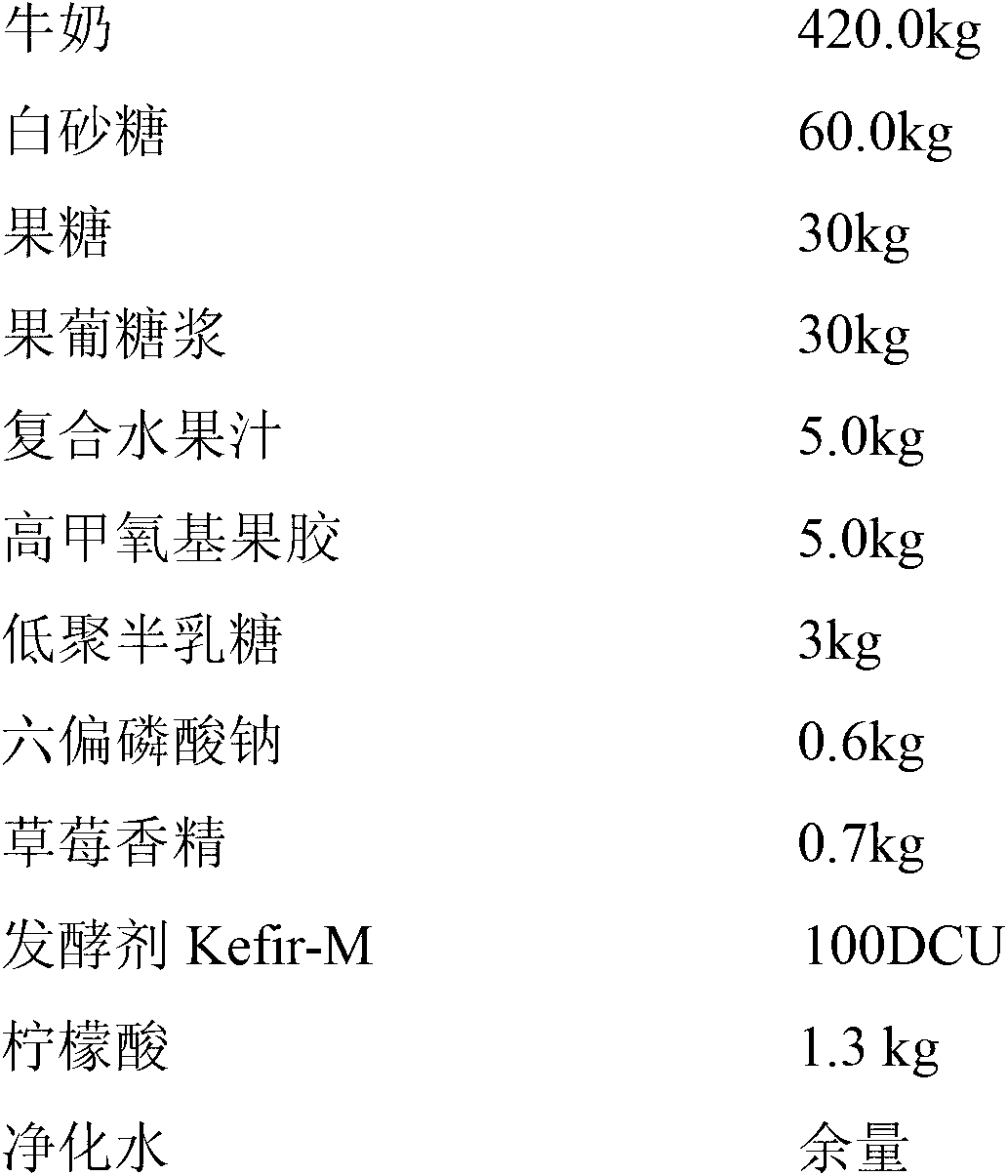

Kefir viable type sour milk beverage and production method thereof

The invention discloses a kefir viable type sour milk beverage and a production method thereof. The production method adopts a raw material formula which includes 1000 parts of raw materials: 350-450 parts of raw milk, 0.03-1 part of buffer salt, 3-6 parts of stabilizers, 0.1-120 parts of sweet substances, 2-5 parts of dietary fiber, 5-20 parts of fruit juice, 1-3 parts of acidity regulators, 0.4-0.8 parts of essence, 100-150 DCU of kefir leavening agent Kefir-M, and the balance water; and the production method includes steps: S1: 1) obtaining base materials after the raw milk is homogenized, sterilized, cooled for the first time, inoculated with the leavening agent, fermented, and cooled for the second time; and 2) dissolving the buffer salt in the water, adding a thickening agent, an emulsifying agent, the sweet substances, the dietary fiber and the fruit juice, mixing uniformly, sterilizing and cooling, and obtaining a solution B; and S2: mixing the base materials with the solution B uniformly, adding the acidity regulators and the essence, sterile homogenizing for the second time, cooling and filling. The kefir viable type sour milk beverage is gentle in flavor and stable in state, and has a certain health efficacy.

Owner:BRIGHT DAIRY & FOOD

Coconut yogurt and preparing method thereof

ActiveCN105028649APrevent browningMeet stability requirementsMilk preparationHigh-fructose corn syrupDietary fiber

The invention relates to a preparing method for coconut yogurt and coconut yogurt prepared through the method, and belongs to the technical field of fermented milk product processing. The preparing method for the coconut yogurt comprises the main steps that 3-5 g / L of whey protein powder, 1-2 g / L of modified dietary fiber, 0.4-0.8 g / L of acetylated distarch phosphate, 0.1-0.2 g / L of pectin, 1-4 g / L of fructooligosaccharide, 6-10 g / L of high fructose corn syrup and 70-90 g / L of white granulated sugar are dissolved in raw milk, mixed uniformly, then sterilized for 300 s at the temperature of 95 DEG C, cooled to 41 DEG C-43 DEG C, inoculated with ready-to-use starters such as Hansen YF-L904 and Danisco YM-C LYO, and fermented until acidity reaches over 70 degree T, in the mixing process, coconut syrup and / or coconut powder / or coconut jam containing pulp are / is added, and / or in the filling process, the coconut jam is added online. The problems that in the preparing process, coconuts are prone to browning, and the yogurt is prone to being contaminated by infectious microbes in the fermenting process are solved.

Owner:河北新希望天香乳业有限公司

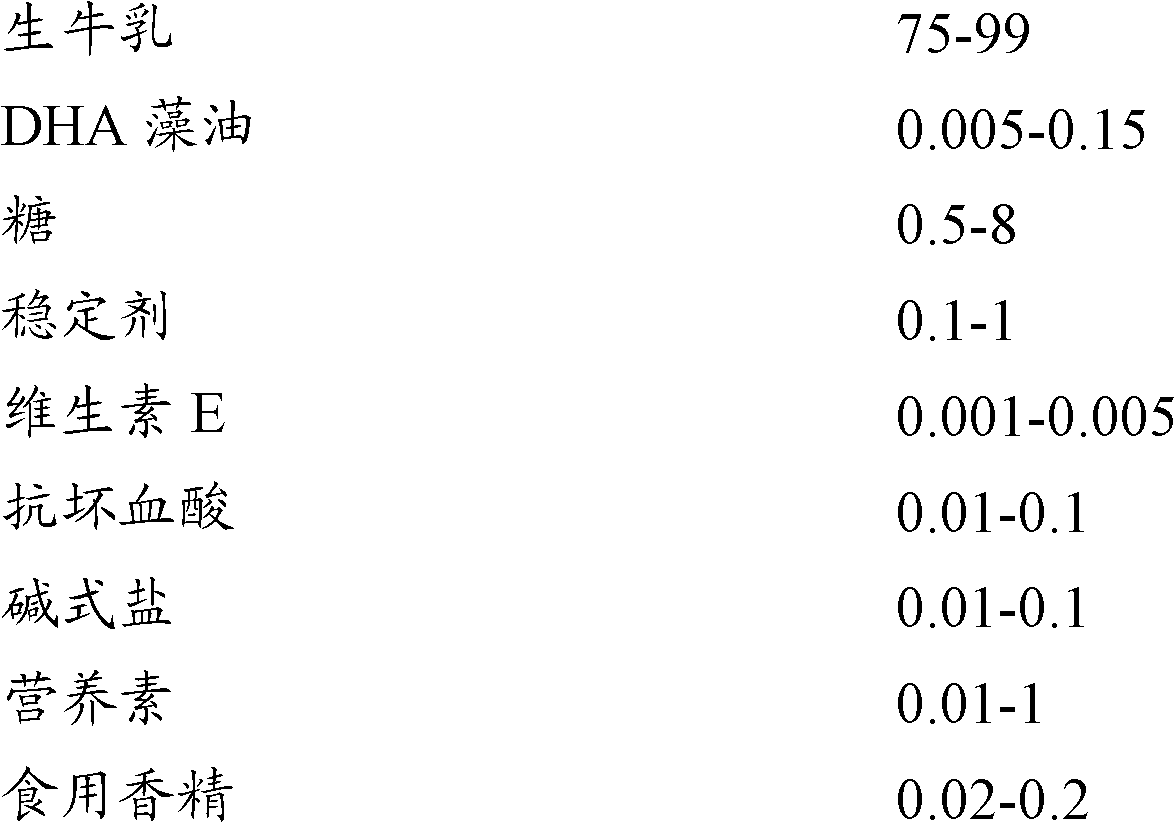

DHASCO (docosahexaenoic acid single cell oil)-contained modulated milk and production method thereof

The invention provides DHASCO (docosahexaenoic acid single cell oil)-contained modulated milk and a production method thereof. The raw material formula of the DHASCO-contained modulated milk comprises 75-99 weight parts of raw milk, 0.005-0.15 weight parts of the DHASCO, 0.001-0.005 weight parts of vitamin E, 0.01-0.1 weight parts of ascorbic acid and 0.01-0.1 weight parts of basic salt. In the DHASCO-contained modulated milk and the production method thereof, the ratio of each component is rationally screened, and the problem of the stability of the DHASCO in the modulated milk is solved, sothat the DHASCO can keep better flavor in the products, the products have no peculiar smell, and the product system is steady.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

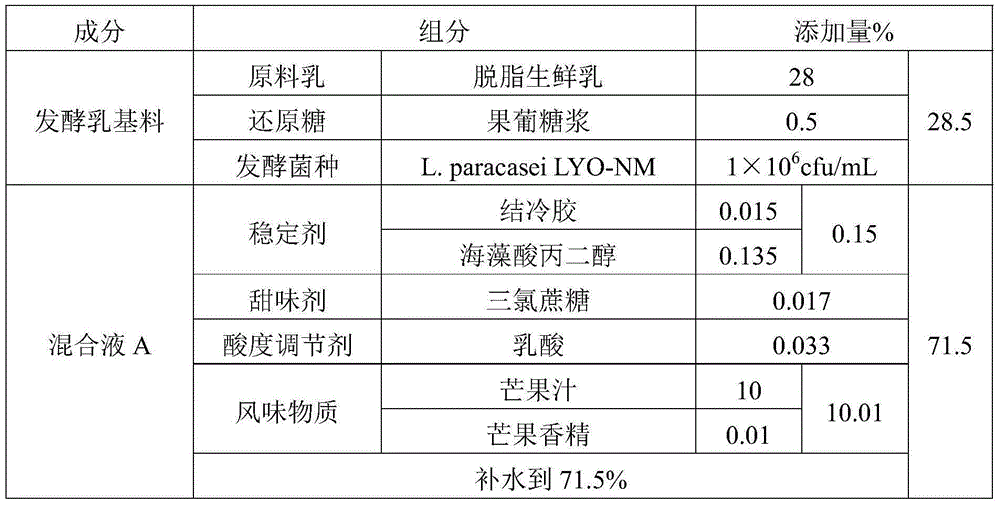

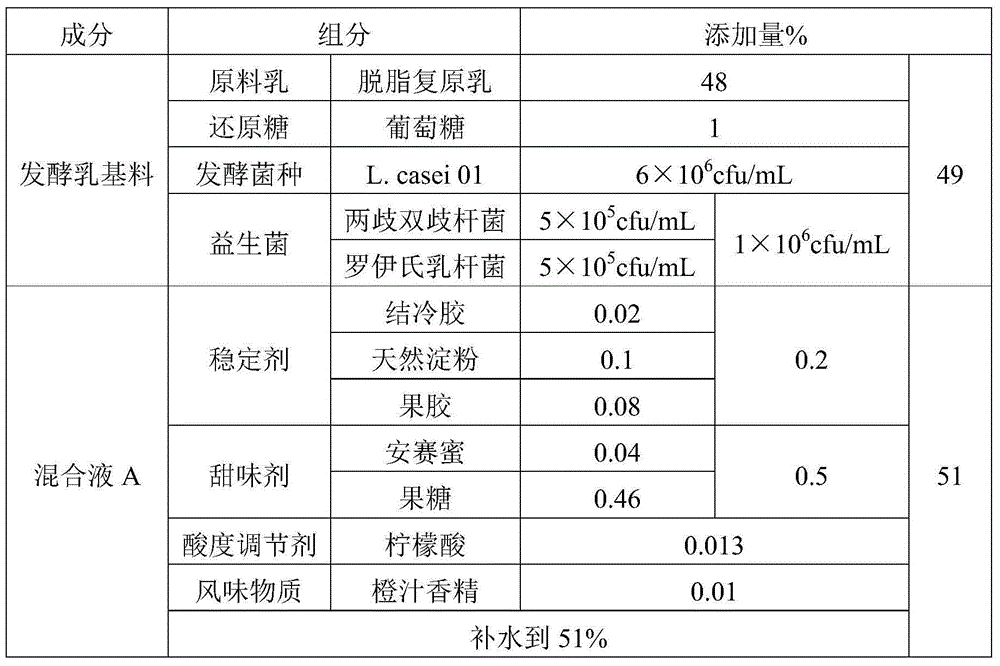

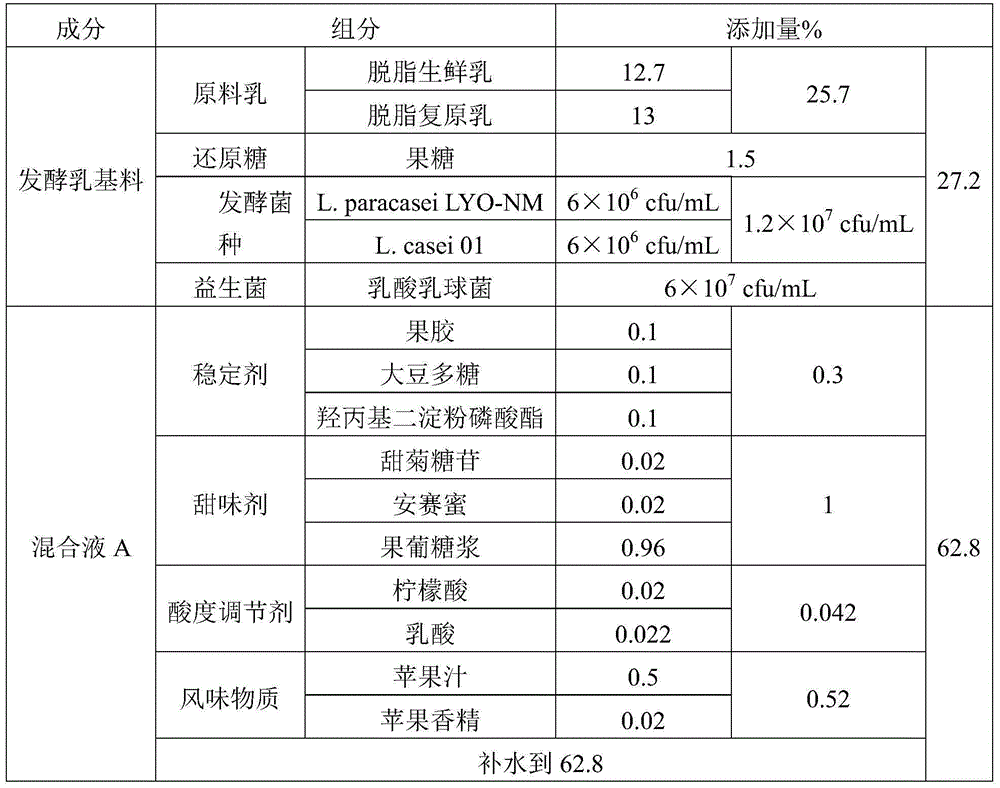

Normal-temperature fermented milk beverage and preparation method thereof

The invention discloses normal-temperature fermented milk beverage and a preparation method thereof. According to the preparation method, raw materials comprise components in percentage by mass as follows: 14%-48% of degreased raw milk, a leavening agent, 0.15%-0.6% of a stabilizer, 0.5%-4% of reducing sugar, a sweetening agent and the balance of water. The preparation method comprises steps as follows: (1), the degreased raw milk and the reducing sugar are mixed for a Maillard reaction; (2), the mixture is cooled, mixed with the leavening agent and fermented to the titration acidity of 160-220; (3), the mixture is uniformly mixed with a mixed solution A and then is homogenized and subjected to filling and ultra-high pressure processing under the pressure of 300-600 MPa, the normal-temperature fermented milk beverage is obtained, and the percentage represents mass percentage of a component accounting for the total mass of the normal-temperature fermented milk beverage; the mixed solution A comprises the stabilizer, the sweetening agent and the water. The prepared normal-temperature fermented milk beverage uses few stabilizers and has excellent effect of color, structure, taste, luster and stability.

Owner:BRIGHT DAIRY & FOOD

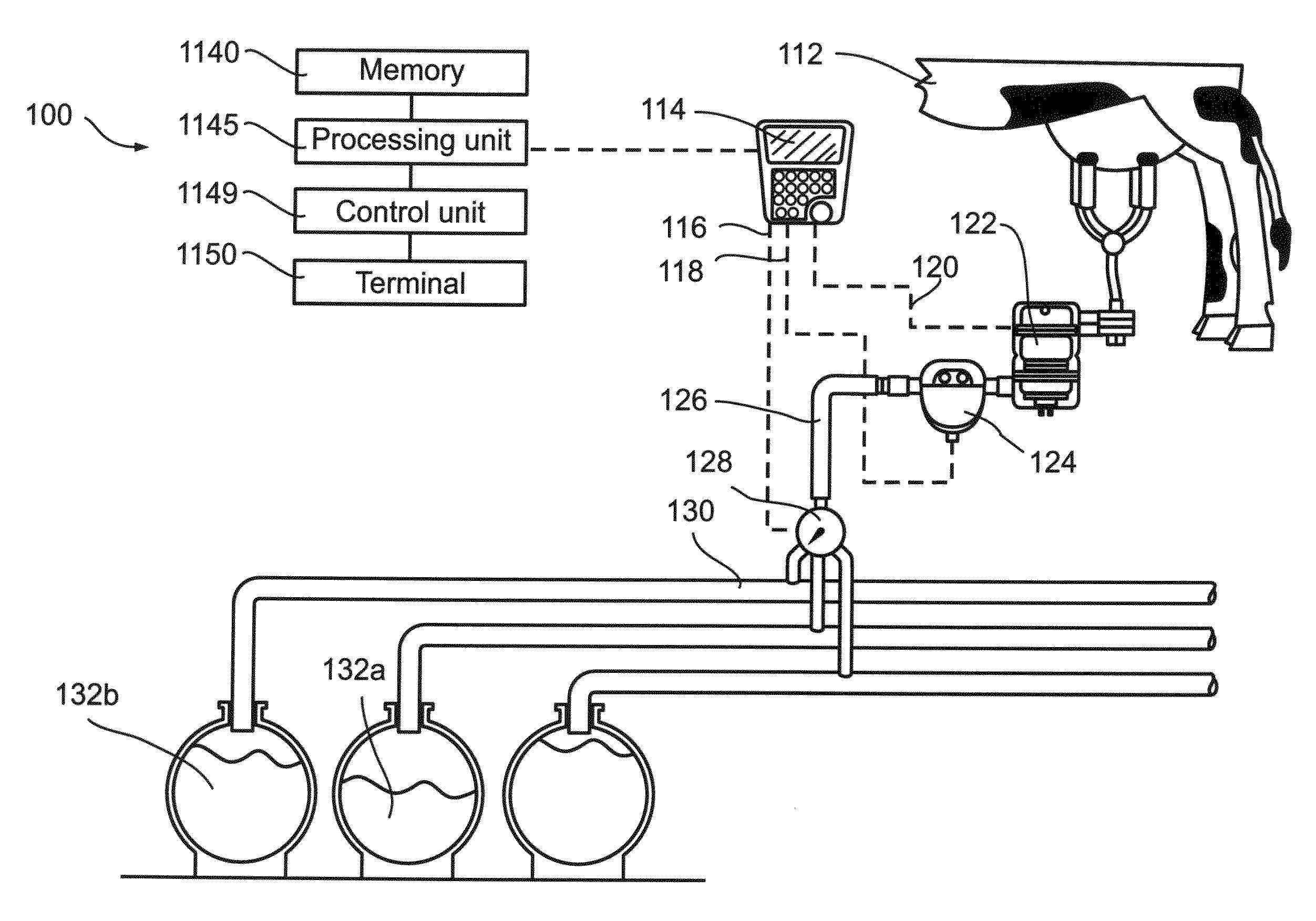

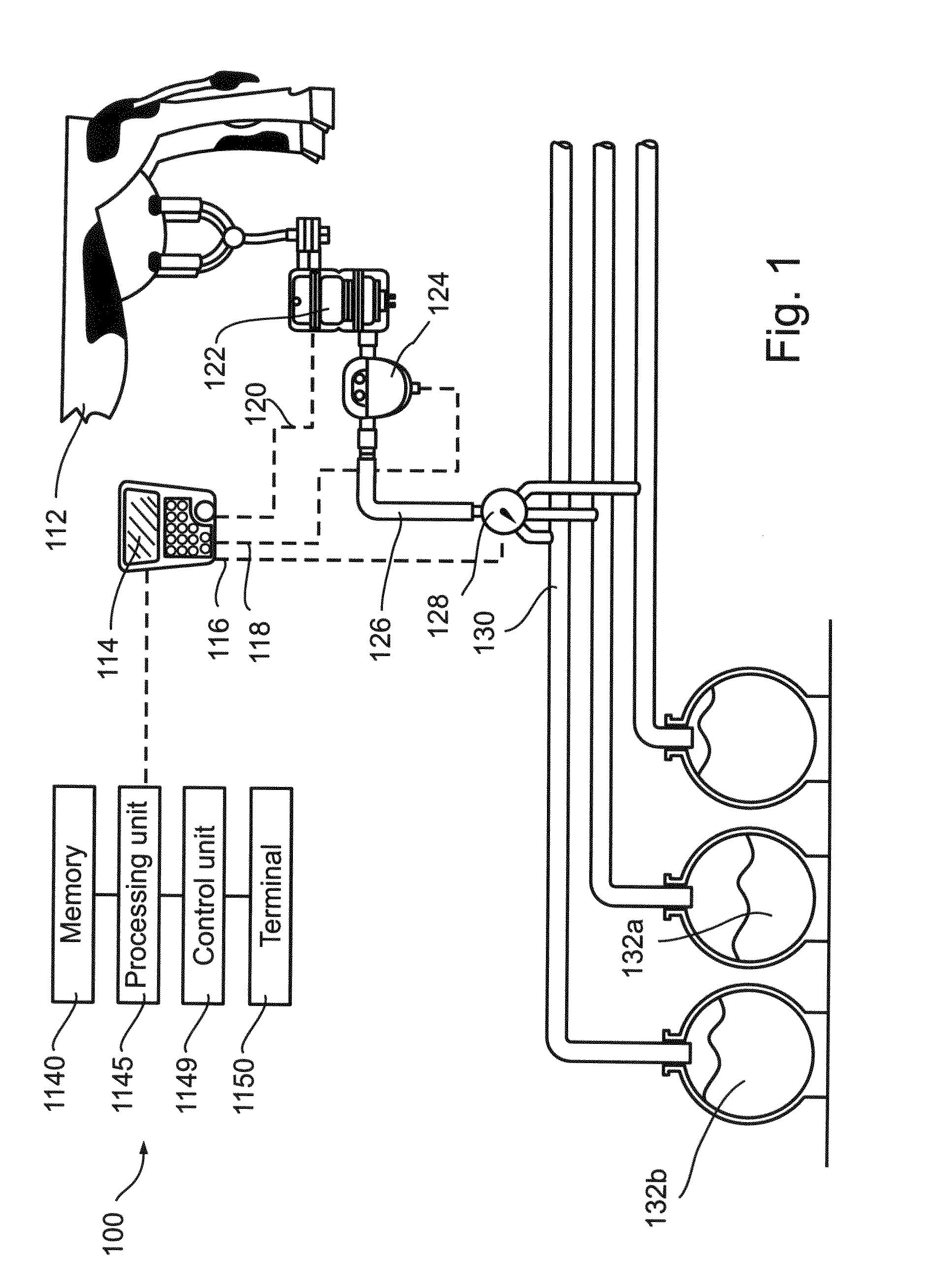

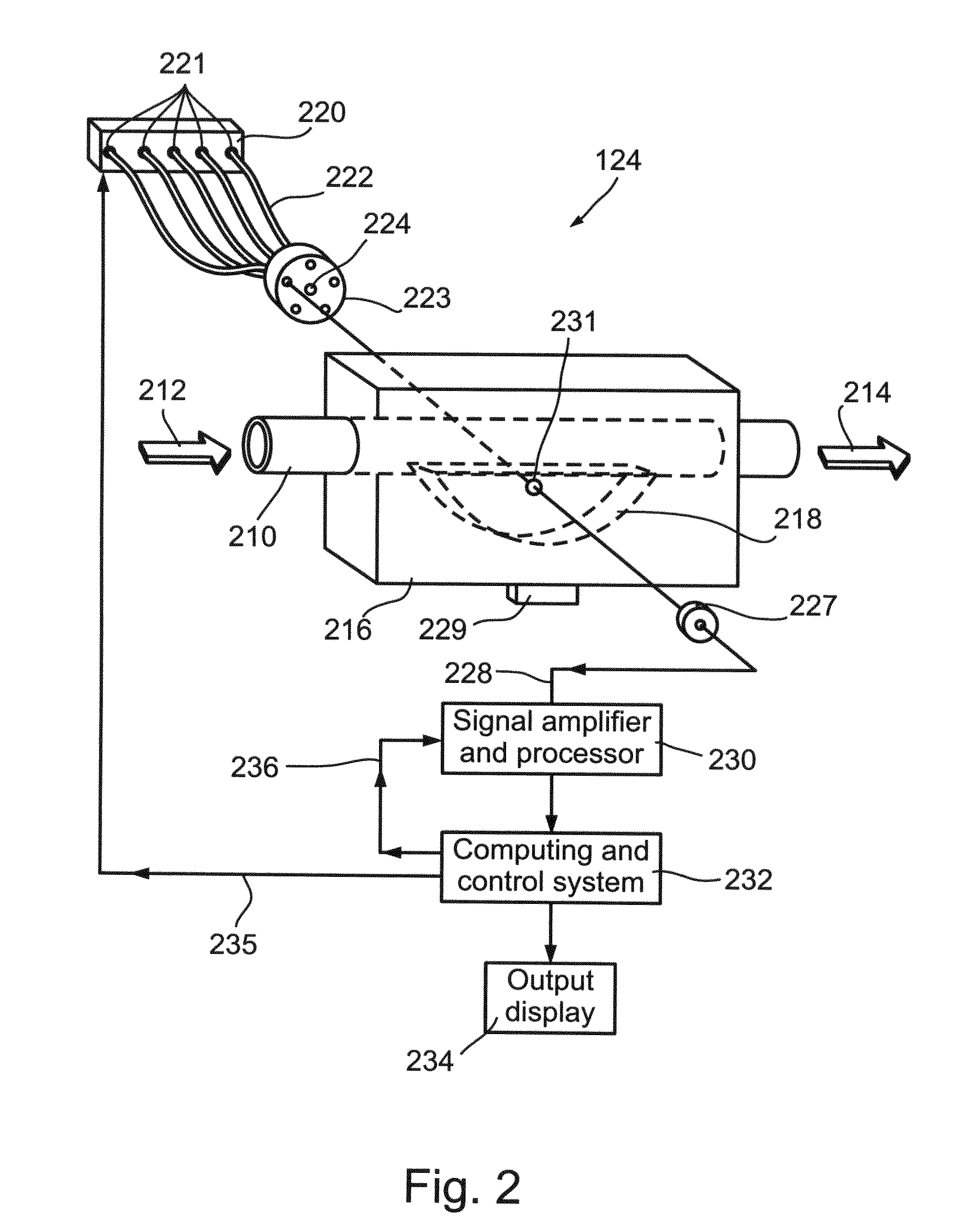

System and method for on-line analysis and sorting of milk coagulation properties

ActiveUS20090255473A1Radiation pyrometryMicrobiological testing/measurementOptical reflectionFluorescence

A method for on-line channeling of milk based on predicted coagulation properties where the method comprises sampling raw milk from a milk line between a milking station and a collection point, performing spectral analysis of one or more of optical transmission, optical reflectance, scatter and fluorescence on the raw milk sample, predicting at least one coagulation parameter on-line based on the spectral analysis, and channeling milk from the milking station on-line to one of a plurality of destinations based on the at least one coagulation parameter.

Owner:AFIMILK AGRI COOP

Additive-free high-protein yogurt and making method thereof

ActiveCN105010530AThe state of organization is smoothDelicate tissue stateMilk preparationSucroseLactase

The invention provides additive-free high-protein yogurt and a making method thereof. The method relates to raw materials including raw milk, single cream, a leavening agent and lactase. The method includes the steps that (1) the raw milk is degreased at the temperature of 40-50 DEG C, ultrafiltration and concentration are carried out after microfiltration sterilization, then the raw milk is mixed with the single cream, the protein content is made to be 4%-6% and the fat content is made to be 4%-7%; afterwards, homogeneity is performed, heat treatment is conducted for 5-10 minutes at the temperature of 90-95 DEG C, and cooling is conducted till the temperature is 38-45 DEG C; (2) 100-200 U / 1000 kg of leavening agent and 1000-3000 NLU / L of lactase are added to be stirred for 5-10 minutes, and the temperature rises to 38-45 DEG C so that filling can be conducted; (3) fermentation is carried out at the temperature of 38-45 DEG C and stops till the pH value is 4.4-4.55, curing is conducted for 12-24 hours after cold storage at the temperature of 2-6 DEG C is completed, and accordingly the additive-free high-protein yogurt is obtained. By the adoption of the method, the quality of the raw milk is greatly improved, the obtained yogurt is high in protein concentration and does not contain sucrose, and the yogurt further has good mouthfeel and flavors.

Owner:BRIGHT DAIRY & FOOD CO LTD

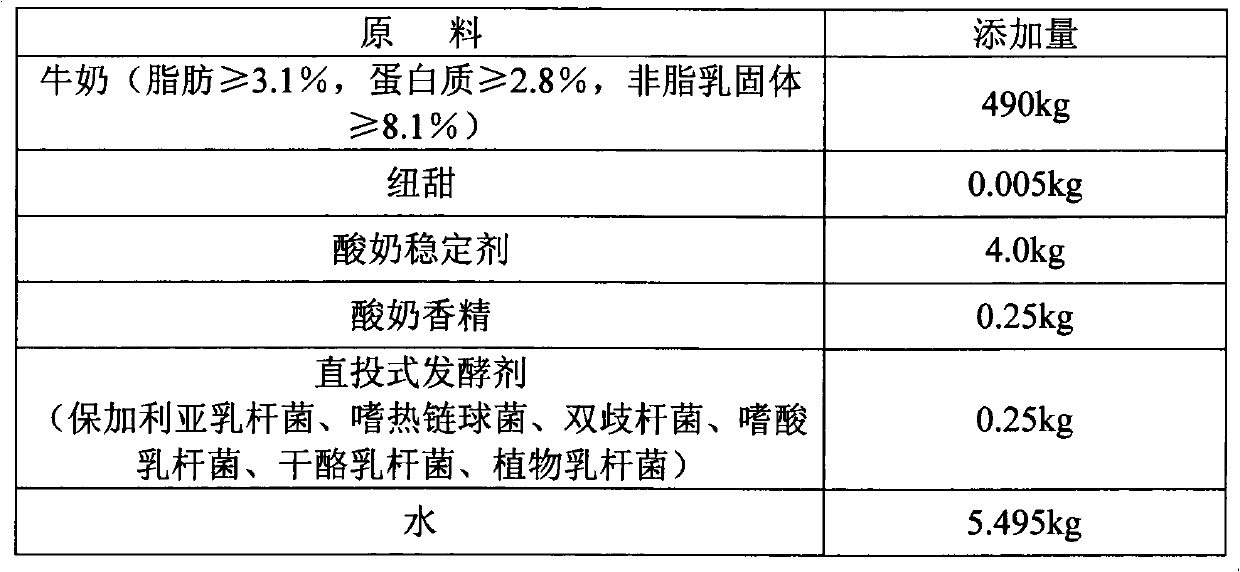

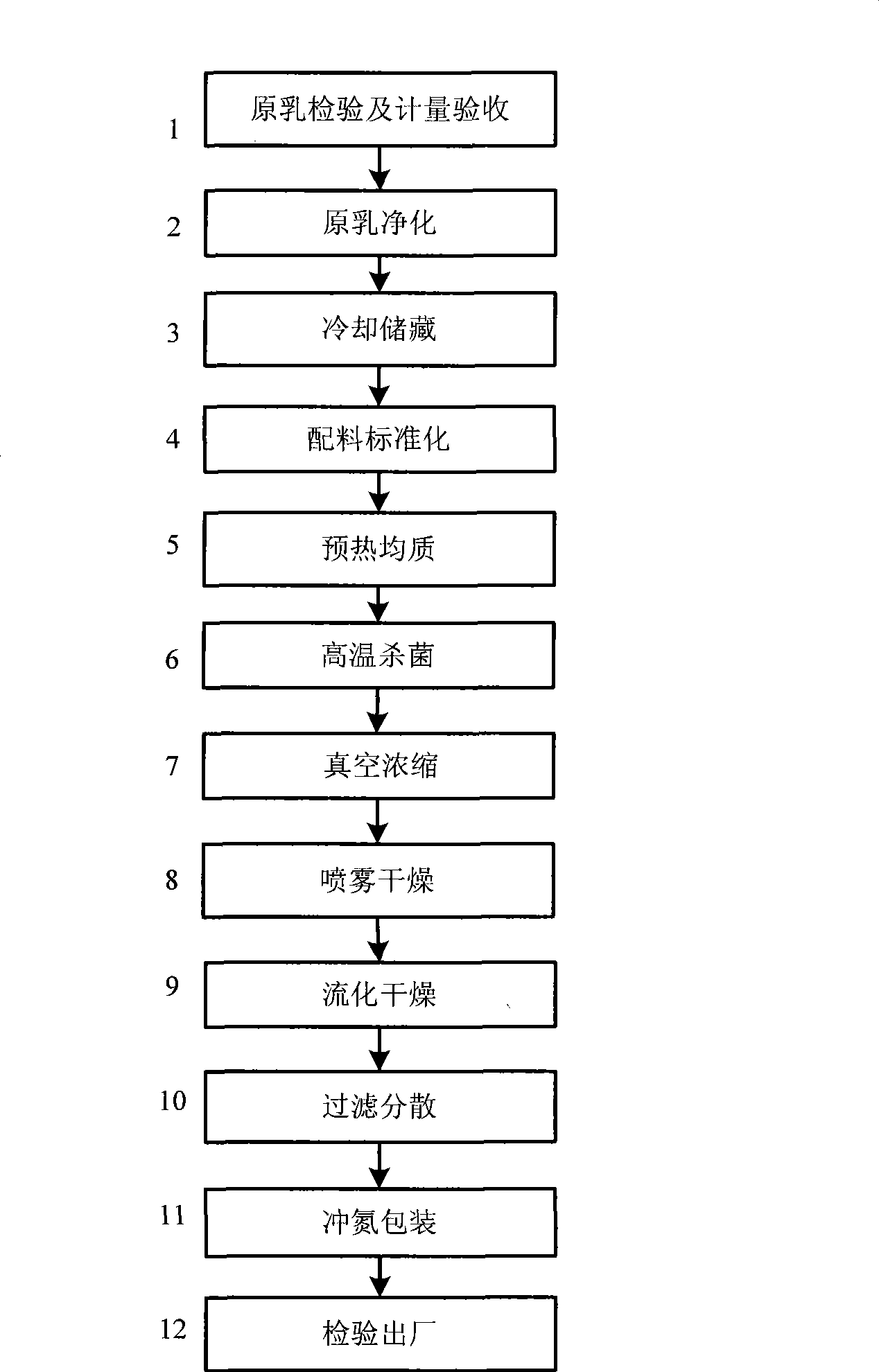

Yoghurt powder, yoghurt ice cream powder, preparation method and use method thereof

InactiveCN102986871AHigh viable countStrong bacterial activityMilk preparationFrozen sweetsFlavorIce cream

The invention discloses a yoghurt powder, a yoghurt ice cream powder, a preparation method and a use method thereof. The preparation method of the yoghurt powder comprises the steps of: 1, mixing 92-96wt% of raw milk and 4-8wt% of carbohydrate, homogenizing, sterilizing and cooling; 2, inoculating a strain, fermenting, and cooling, wherein the inoculating quantity is 1*10<8>-1*10<10>fu / g; and 3, spraying and drying until the water content in the powder is 10-20wt%, wherein the air inlet temperature is 120-150 DEG C, the exhaust air temperature is 40-50 DEG C, and the outlet temperature of the powder is below 35 DEG C; and fluidizing and drying at a temperature of 45-55 DEG C to ensure that the water content of the powder is below 2wt% to obtain the yoghurt powder. Contents of active probiotics in the yoghurt powder and the yoghurt ice cream powder are high, thus yoghurt ice cream which is prepared from the yoghurt powder and the yoghurt ice cream powder has a natural yoghurt flavor, is excellent in mouth feel and is rich in active probiotics, and has a wide market prospect. The preparation method is simple in process and low in cost, and is suitable for large-scale production.

Owner:BRIGHT DAIRY & FOOD

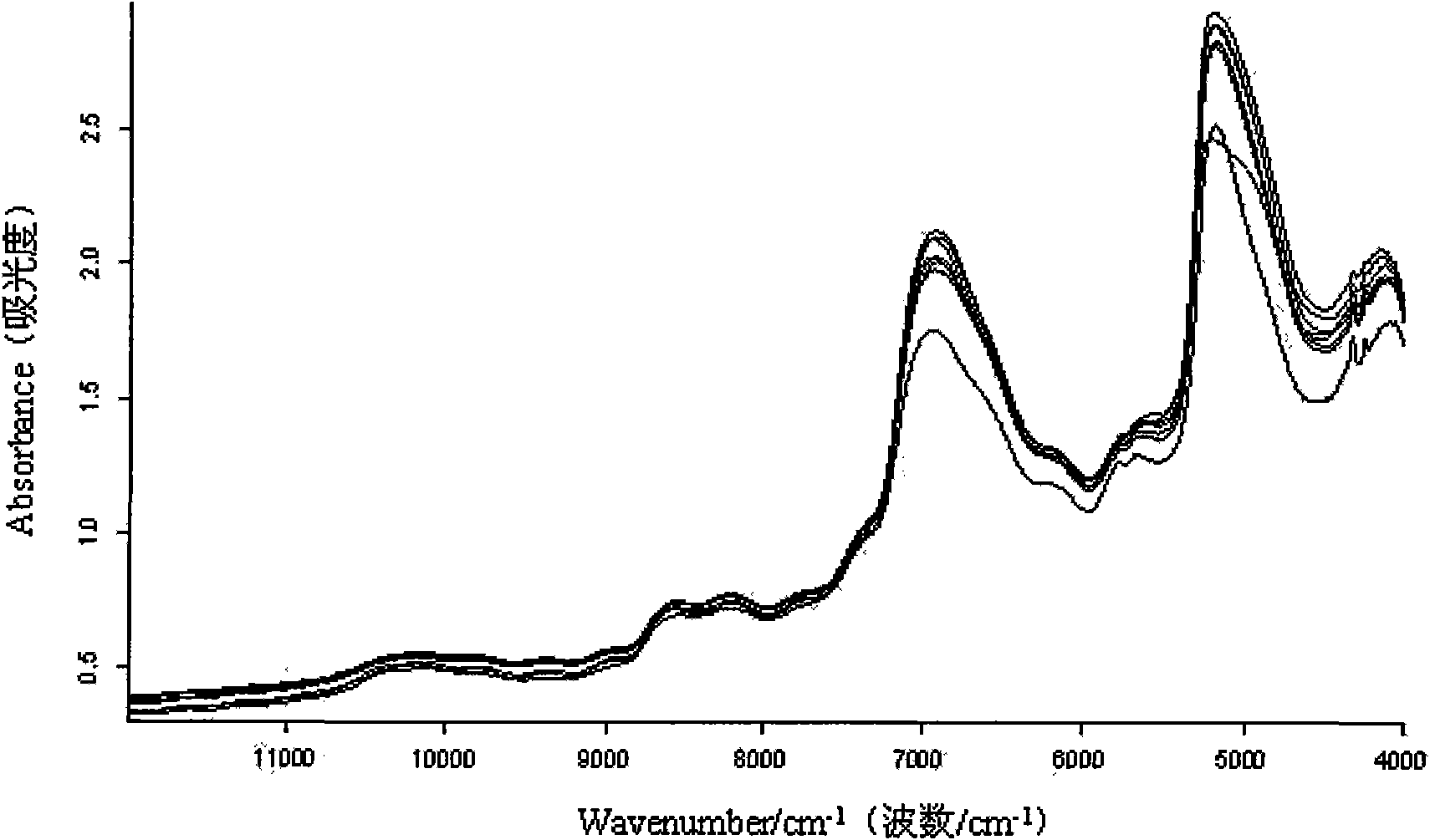

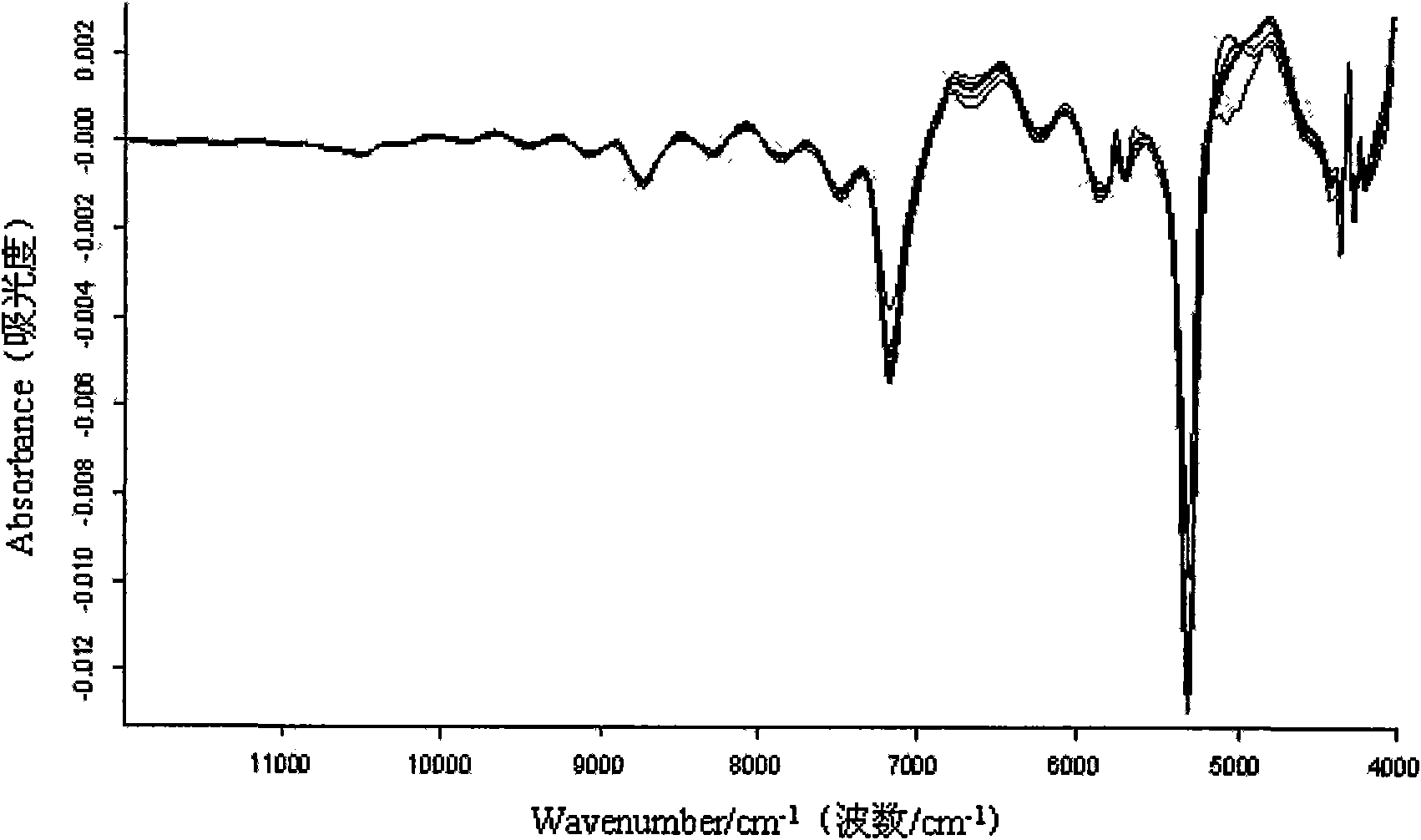

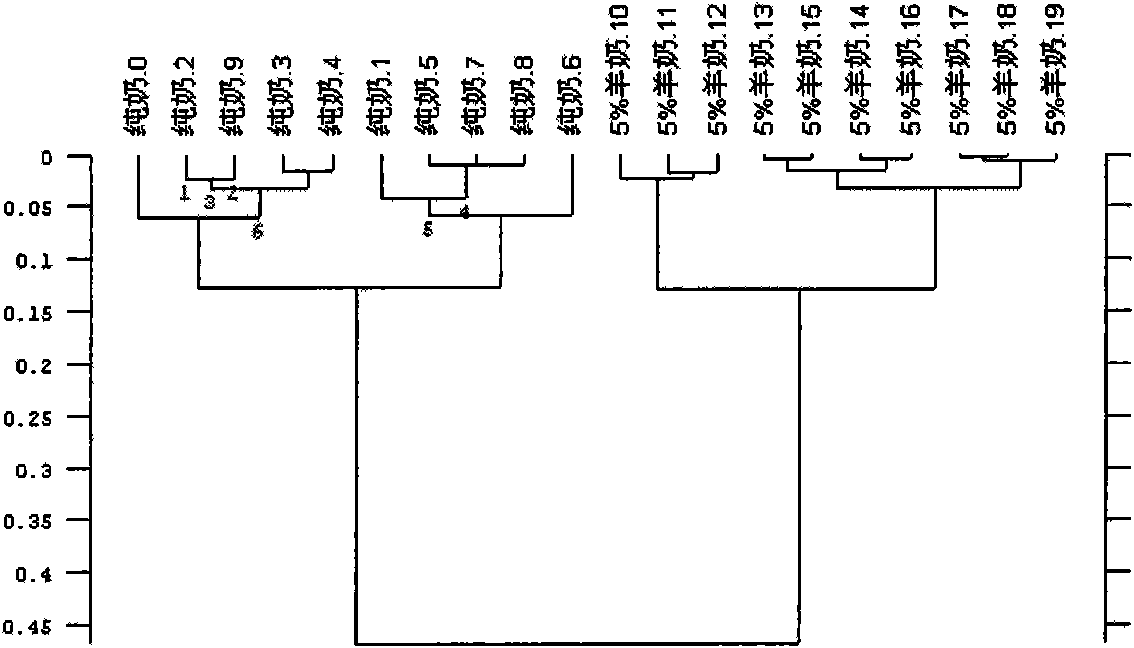

Method for distinguishing milk doped with ewe's milk by near infrared spectrum

InactiveCN101929951AReliable detectionColor/spectral properties measurementsSingle sampleMilk sample

The invention discloses a method for distinguishing milk doped with ewe's milk by a near infrared spectrum, and the method comprises the following steps: 1) selecting a milk sample; 2) collecting the near infrared spectrum; and 3) carrying out cluster analysis and establishing a qualitative distinguishing model, thus carrying out the cluster analysis on raw milk and adulteration milk and realizing qualitative judgment. By using the method, the milk doped with ewe's milk can be detected rapidly qualitatively and quantitatively; and when the weight percentage of the ewe's milk in the adulteration milk is greater than or equal to 5 percent, the accuracy of detection can reach 100 percent, and the detection time of a single sample is within 1 minute.

Owner:NORTHWEST A & F UNIV

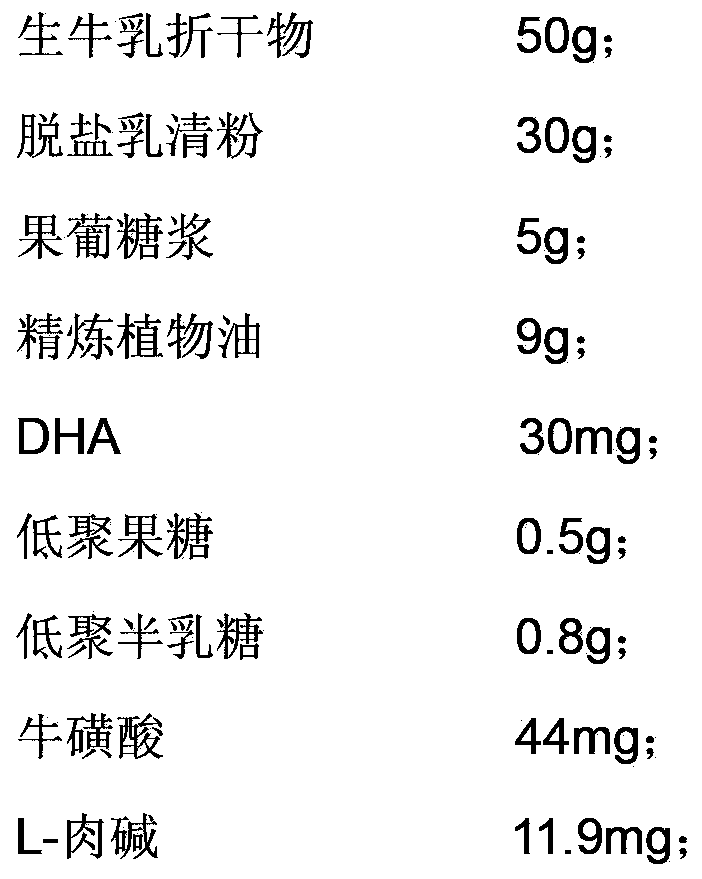

Child development formula milk powder and preparation method thereof

The invention discloses child development formula milk powder. DHA, phosphatidylserine and choline are combined to facilitate child brain development, lutein is added for protecting child eyesight, the components are reasonably combined with substances such as raw milk, various vitamins, mineral substances and dietary fiber (fructo-oligose and galactooligosaccharide) to give play to the synergistic effect, the effect of promoting comprehensive development of the brain, eyesight and the whole body of children of 3-7 years old is achieved, and the milk powder is good in taste and comprehensive in nutrient. The invention further provides a preparation method of the child development formula milk powder. The child development formula milk powder is obtained through the steps of raw milk inspection and acceptance, milk purification, pre-pasteurization, dosing, preheating, homogenizing, sterilization, condensation, spray drying, cooling and the like in sequence, the steps are simple, the process is easy to control, the nutritional ingredient losses are small, the method is applicable to preparing child formula milk powder, and the obtained milk powder is applicable to children of 3-7 years old.

Owner:JUNLEBAO DAIRY GRP CO LTD

Preparation method of fermented yoghurt and prepared yoghurt

InactiveCN102599242AImprove utilization efficiencyReduce areaMilk preparationBiotechnologyProcess engineering

The invention discloses a preparation method of fermented yoghurt and prepared yoghurt. The preparation method comprises the steps of adding a fermenting agent into raw milk to ferment to obtain fermented yoghurt, and then cooling, wherein a tunnel rapid cooling technology is adopted by the cooling step: the obtained products pass through a cooling tunnel in a manner that the interval between the obtained products is 1-10cm, the tunnel cooling temperature is 0-10 DEG C, and the delivering speed of a tunnel rapid cooling device is 0.001-6.0m / s. The fermented yoghurt prepared by the process can be cooled quickly to 2-6 DEG C in 60-900s, so that the time of that the conventional fermented yoghurt needs post maturation treatment to recover viscosity is shortened, the better taste, the more quantity of viable bacteria and the more stable quality can be ensured, and the utilization efficiency of a refrigeration storage can be improved; in addition, the post acidification fermentation of the yoghurt can be inhibited effectively, and the problems that the stacking centre temperature cannot be reduced quickly, the post acidification degree is serious and the same batch of products have notable acidity differences after the conventional fermented yoghurt enters the refrigeration storage can be solved.

Owner:BRIGHT DAIRY & FOOD

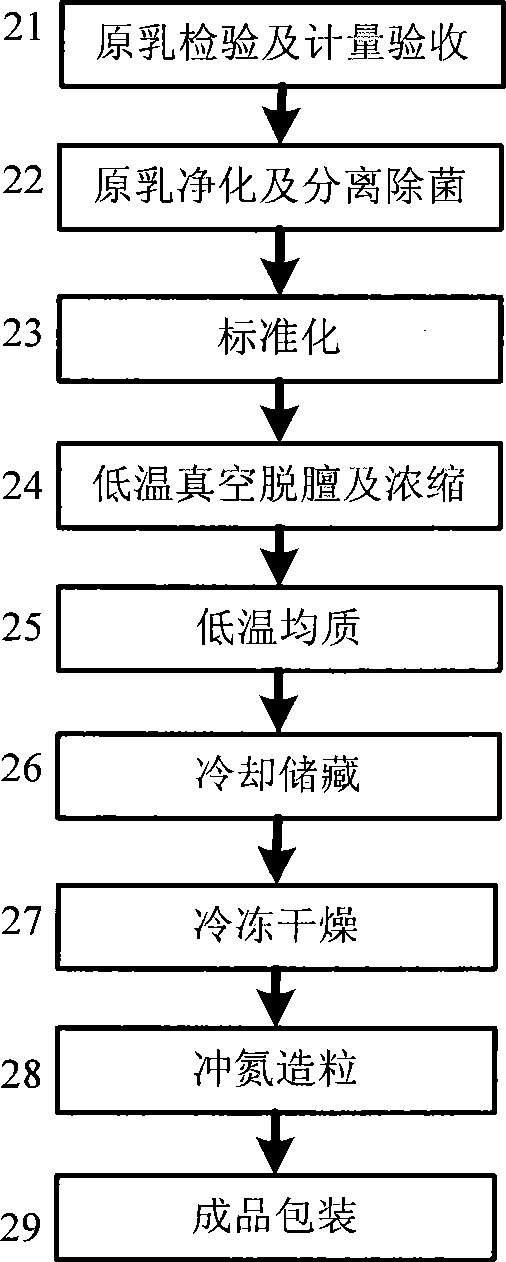

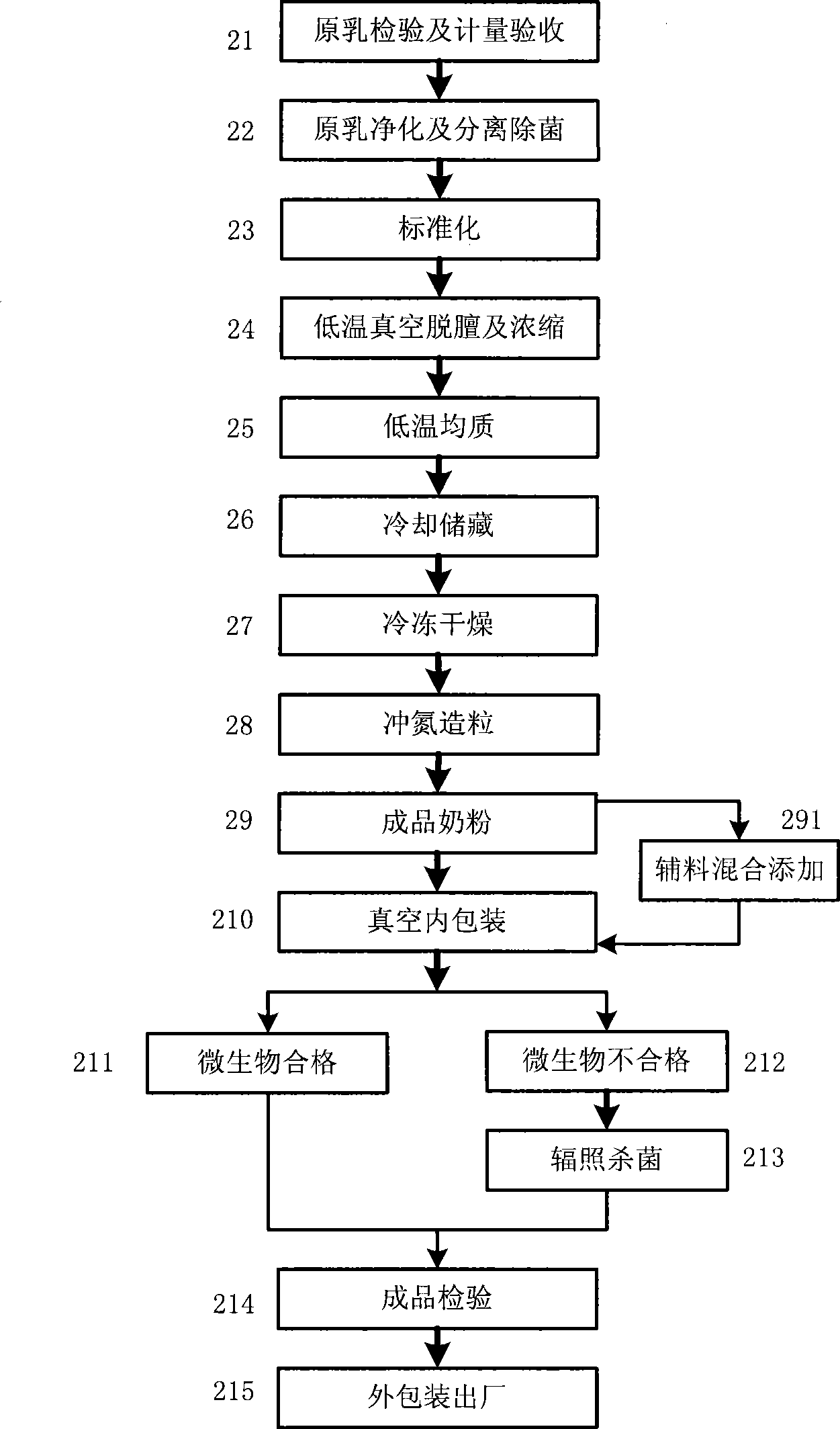

Production method of freeze-dried milk powder

ActiveCN101530129AKeep the natural flavorGuaranteed qualityMilk preparationOther dairy technologyFreeze-dryingHeat sensitive

The invention discloses a production method of freeze-dried milk powder. The method comprises the steps of: standardizing raw milk after purification, separation and sterilization to obtain standardized milk; implementing low-temperature vacuum mutton smell elimination and concentration of the standardized milk to lead the dry matter content in the obtained concentrated milk to account for at least 45 percent to 50 percent of the total weight of the milk; implementing homogenization of the concentrated milk, cooling and storing the concentrated milk after the homogenization; implementing freeze-drying treating of the concentrated milk after the treatment by the steps, thereby leading water which is frozen into solid state in frozen milk to be directly sublimated to gaseous state and separated from the frozen milk after that, leading the residual dry matters in the frozen milk to be shaped like powder and flakes and further forming the freeze-dried milk powder; the nitrogen filling and the method of crushing nitrogen for granulation are adopted to process the freeze-dried milk powder into even granules, and then a finished product is prepared by screening and separation. The method leads nutritional components in the raw milk to have no loss or damage and avoids the significant loss of heat-sensitive matters, active matters and other nutritional components in the raw milk caused by high-temperature sterilization, spray drying and other procedures in the existing milk powder production process.

Owner:张保钢

Ice cream and preparation method thereof

The invention discloses an ice cream and a preparation method thereof. The ice cream comprises 10-30 parts by weight of a sweetening agent, at least one of 0-35 parts by weight of fruit juice and jam, 0-10 parts by weight of edible fat, 0.1-0.8 part by weight of a stabilizing agent, 0-0.6 part by weight of an acidity adjusting agent, and 50-85 parts by weight of raw milk and dairy, wherein the content of solid contents in the ice cream is 33-36%, and the ice cream does not contain raw water. The ice cream disclosed by the invention has at least one of the following advantages of being rich in nutrition, good in flavor and mouth feel, and high in stability.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Method for preparing Kefir sour milk

The invention discloses a method for preparing Kefir sour milk which comprises water, sugar and sour milk prepared from the fermentation of two different Kefir grains; the preparing method comprises the follow steps: 1. raw milk is sterilized and then cooled to the temperature of 20 DEG C to 30 DEG C; 2. the two different Kefir grains are activated and cultured separately; 3. the activated and cultured Kefir grains with inoculum size of 2 percent to 5 percen are respectively inoculated to the sterilized raw milk; 4. the raw milk is fermented for 15 hours to 24 hours at the temperature of 20 DEG C to 30 DEG C; 5. the Kefir grains are filtered out to obtain two filtrates which are fermentation agents; 6. the two fermentation agents are mixed; 7. the mixed fermentation agents with the inoculum size of 2 percent to 5 percent are inoculated to the sterilized original milks and then fermented at the variable temperature ranging from 20 DEG C to 45 DEG C for 4 hours to 6 hours; and 8. the fermented milk are blended, homogenized and canned. With the adoption of the fermentation agents for fermenting at the variable temperature, the flavor of Kefir milk is well improved. The ferment time of the product is short, the yeasts in the mixed fermentation agents are more stable and the difference between flavors of Kefir sour milk prepared in different batches is small. The product has health-care functions of regulating beneficial bacteria in intestinal canals, lowering blood lipids, resisting tumors and the like, thus being a low-cost functional beverage.

Owner:于岚 +2

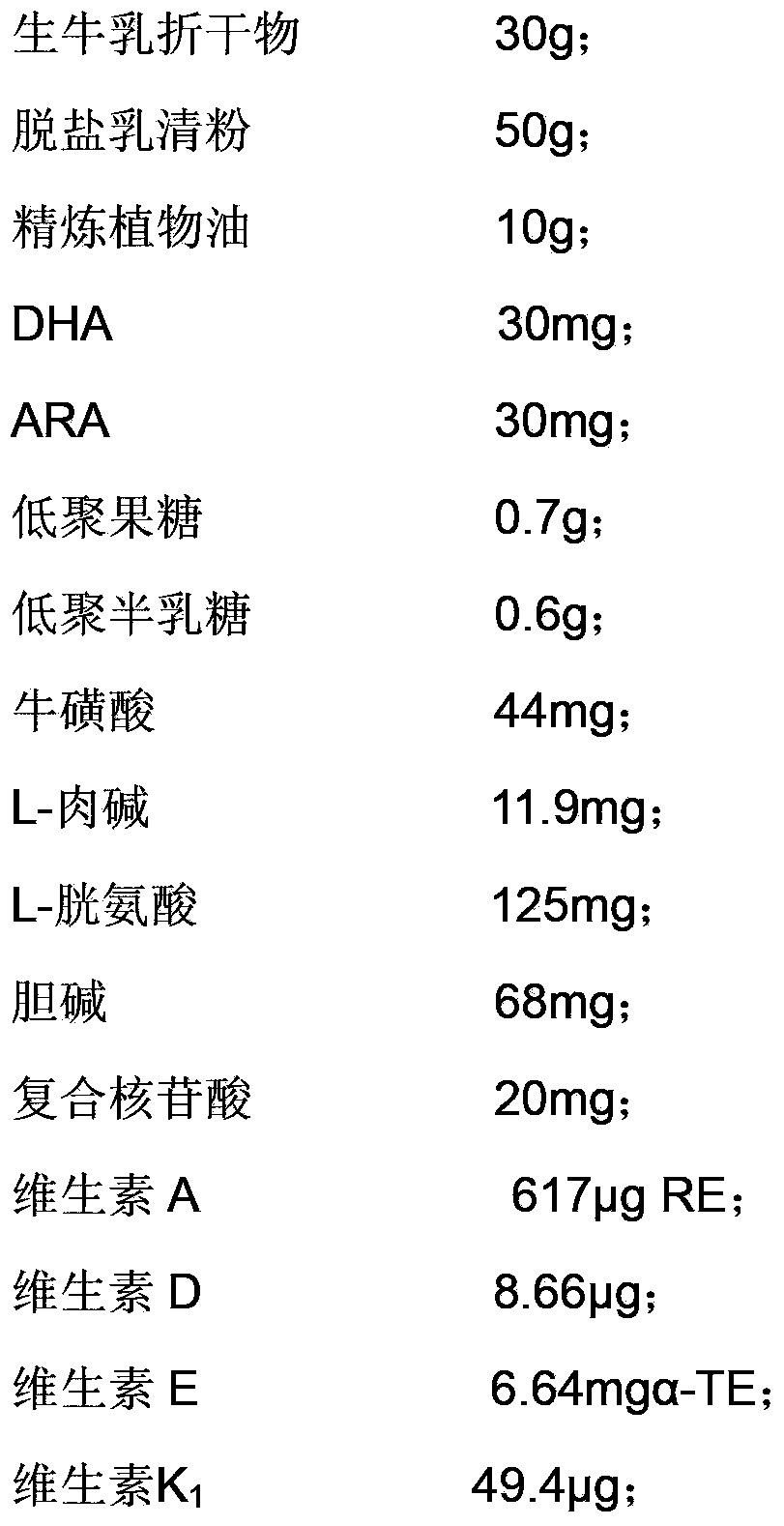

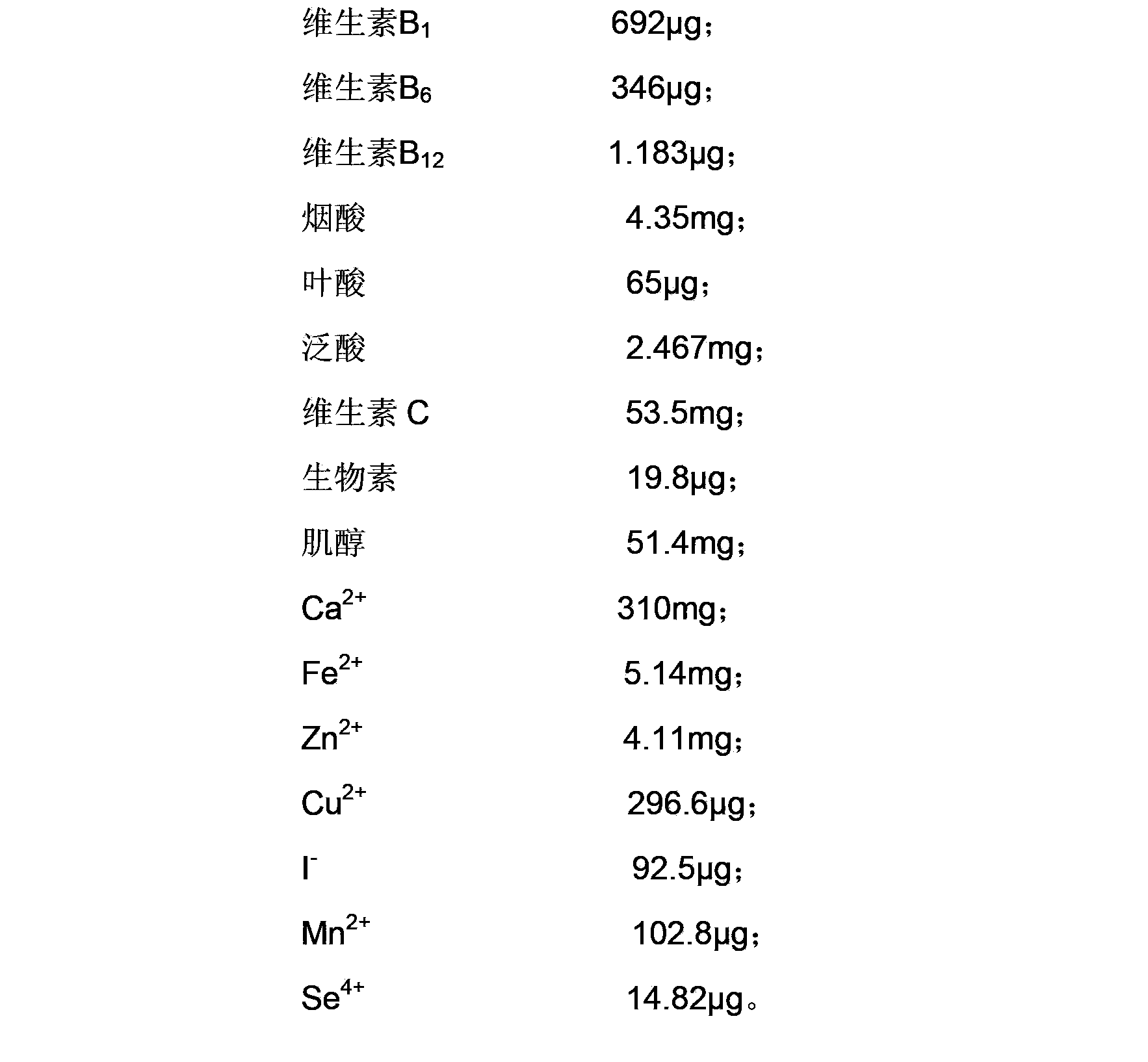

Dedicated infant formula for infant boys

ActiveCN103404595AMeet intellectual development needsDemand adaptationMilk preparationDocosahexaenoic acidVegetable oil

The invention provides a dedicated infant formula for infant boys, which comprises raw milk, demineralized whey powder, vegetable oil, docosahexaenoic acid (DHA), prebiotics, taurine, L-carnitine and / or L-carnitine salt, choline substances, composite nucleotide and mineral substances. The dedicated infant formula optimizes the ratio of intelligence nutrient substances (DHA, ARA, choline and the like), especially improves the content of the DHA and the like to be more suitable for the intelligence development requirement of the infant boys, optimizes the content of the prebiotics to be more in tune with the digestive absorption requirement of the infant boys, and further optimizes the ratio of energy substance, protein, fat, carbohydrate and the like to be more suitable for the requirement of the infant boys.

Owner:北安宜品努卡乳业有限公司

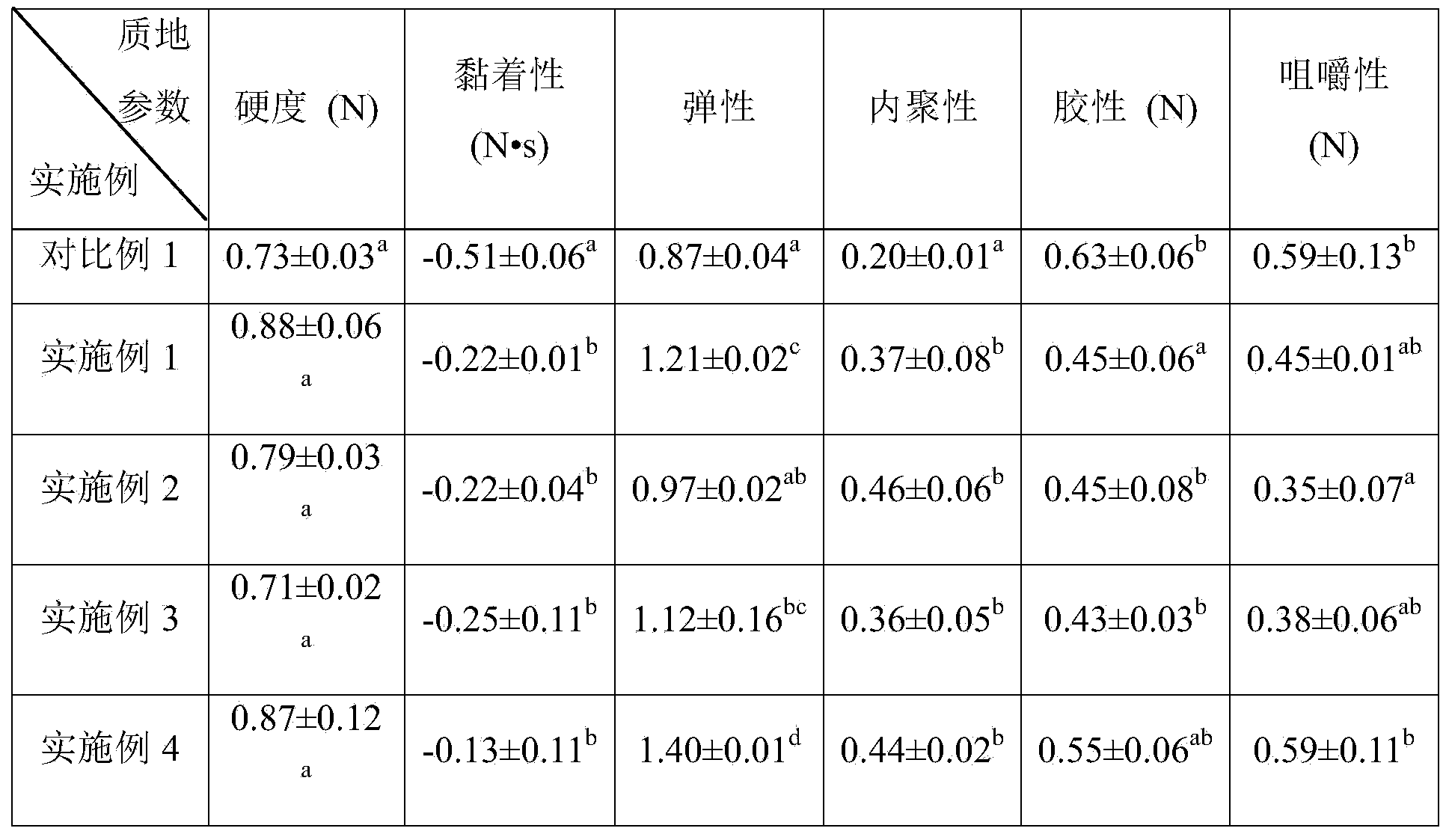

Low temperature fermenting Lactobacillus casei and method for preparing hard yark milk cheese from Lactobacillus casei

The invention discloses low temperature fermenting Lactobacillus casei and a method for preparing hard yark milk cheese from Lactobacillus casei. The Lactobacillus casei which has a preservation number of CGMCC4775 has a low temperature fermentation capability. The method for preparing the hard yark milk cheese from Lactobacillus casei comprises steps of raw milk sterilization, inoculation, fermentation, enzyme addition, milk curding, cutting, whey discharging, pile brewing, squeeze-molding, packaging, and maturation. The hard yark milk cheese, which is prepared in the invention, is milky in color and has the characteristics of rich milk fragrance, uniform quality and abundant nutrition, has the advantages of good hardness, good elasticity, good cohesiveness and good chewiness.

Owner:GANSU AGRI UNIV

Milky tea powder and preparing method thereof

InactiveCN101248818AAbundant resourcesLow costMilk preparationPre-extraction tea treatmentBrickPlate heat exchanger

The invention discloses milk-tea powder as well as a preparation method thereof, which is prepared by fresh milk, white sugar, non-dairy creamer, green brick tea, and solid essence powder according to a certain proportion. The preparation method comprises the following steps: A. comminution: the brick tea is comminuted into superfine tea powder; B. mixture: a proper amount of the fresh milk is taken and heated by a plate heat exchanger, via a water-powder mixer, the tea powder, the white sugar, the non-dairy creamer, and the solid essence powder are added and stirred circularly, and the rest raw milk is added; C. sterilization; D. concentration: the material is sterilized and concentrated by a double effect falling film vacuum evaporator to obtain the concentrated material; E. spray drying: the concentrated material is sprayed and dried by a high pressure pump; F. redrying by a fluidized bed to obtain the milk-tea powder. The milk-tea powder has reasonable formula, convenient drinking, easy method and simple technique, thereby minimizing the energy consumption in the milk-tea processing technique, shortening the productive time with enhanced stability of the milk-tea quality, and increasing the utility ratio of the tea in the milk-tea manufacturing process without waste and pollution.

Owner:NEW HOPE DAIRY HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com