Set-style fermented yoghourt rich in probiotics and preparation method of yoghourt

A technology of coagulated yogurt and probiotics, applied in milk preparations, dairy products, applications, etc., can solve the problems of insufficient number of viable probiotics and increase production costs, achieve good flavor and texture, promote proliferation, and increase the number Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Set type fermented yoghurt

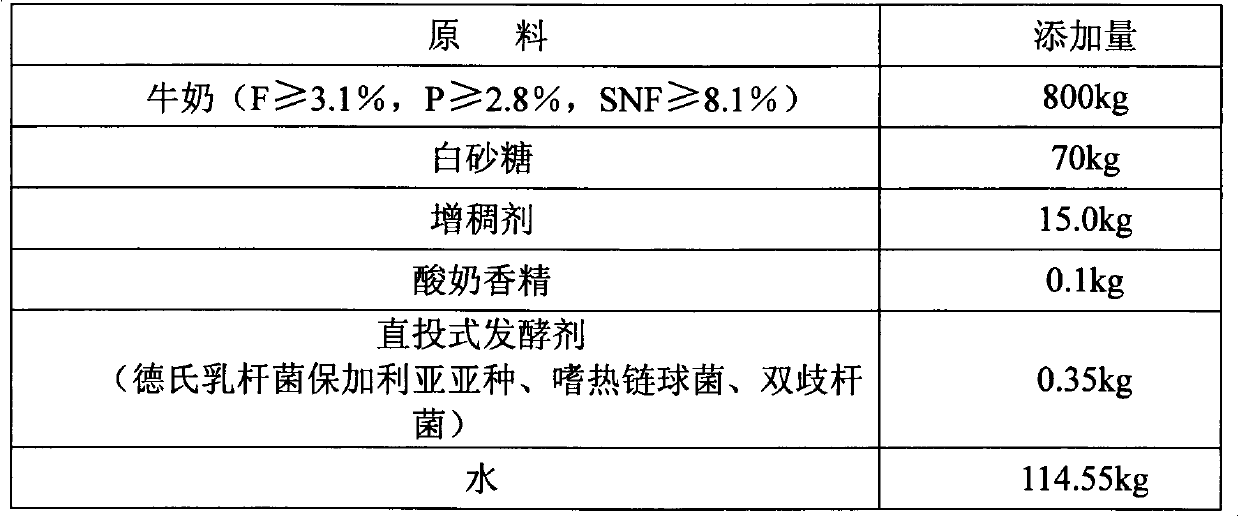

[0036] Product formula (calculated per ton of final product):

[0037]

[0038] The preparation method comprises the following steps:

[0039] (1) Pre-sterilize non-antibiotic milk with a fat of not less than 3.1% and a protein of not less than 2.8%, and store it in a cleaned and sterilized milk storage tank, and store it in cold storage (storage temperature: 2-6°C) before use;

[0040] (2) Heat the feed liquid obtained in step (1) to 40°C, add water, thickener, sweetener, and flavoring substances, and stir for 30 minutes at a stirring speed of 900 rpm to fully dissolve and evenly;

[0041] (3) Homogenize the feed liquid obtained in step (2), the homogenization temperature is 60°C, and the pressure is successively two-stage homogenization of 15MPa and 2MPa;

[0042] (4) Sterilize the feed liquid obtained in step (3), the sterilization temperature is 85°C, the sterilization time is 5min, cool to 40°C after sterilization, and st...

Embodiment 2

[0047] Embodiment 2 set type fermented yoghurt

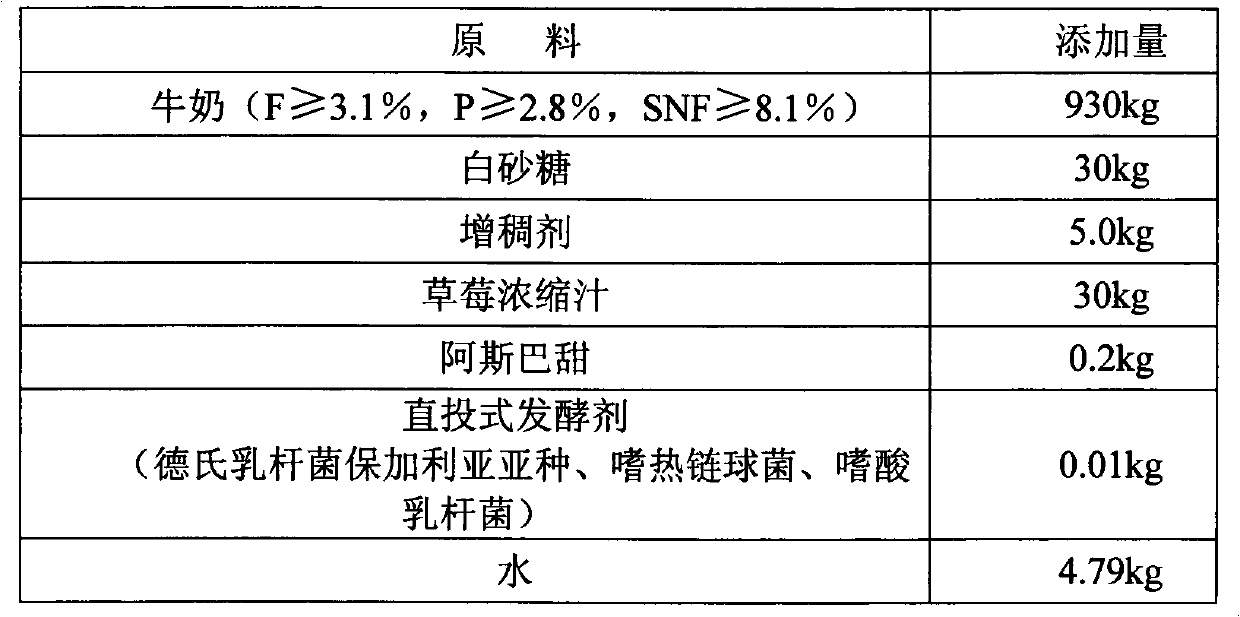

[0048] Product formula (calculated per ton of final product):

[0049]

[0050] The preparation method comprises the following steps:

[0051] (1) Pre-sterilize non-antibiotic milk with a fat of not less than 3.1% and a protein of not less than 2.8%, and store it in a cleaned and sterilized milk storage tank, and store it in cold storage (storage temperature: 2-6°C) before use;

[0052] (2) Heat the feed liquid obtained in step (1) to 55° C., add water, thickener, sweetener, and flavoring substances, and stir for 15 minutes at a stirring speed of 1800 rpm to fully dissolve and evenly;

[0053] (3) Homogenize the feed liquid obtained in step (2), the homogenization temperature is 70°C, and the pressure is successively two-stage homogenization of 18MPa and 5MPa;

[0054] (4) Sterilize the feed liquid obtained in step (3), the sterilization temperature is 95°C, the sterilization time is 5min, cool to 50°C after sterilization, ...

Embodiment 3

[0059] Embodiment 3 set type fermented yoghurt

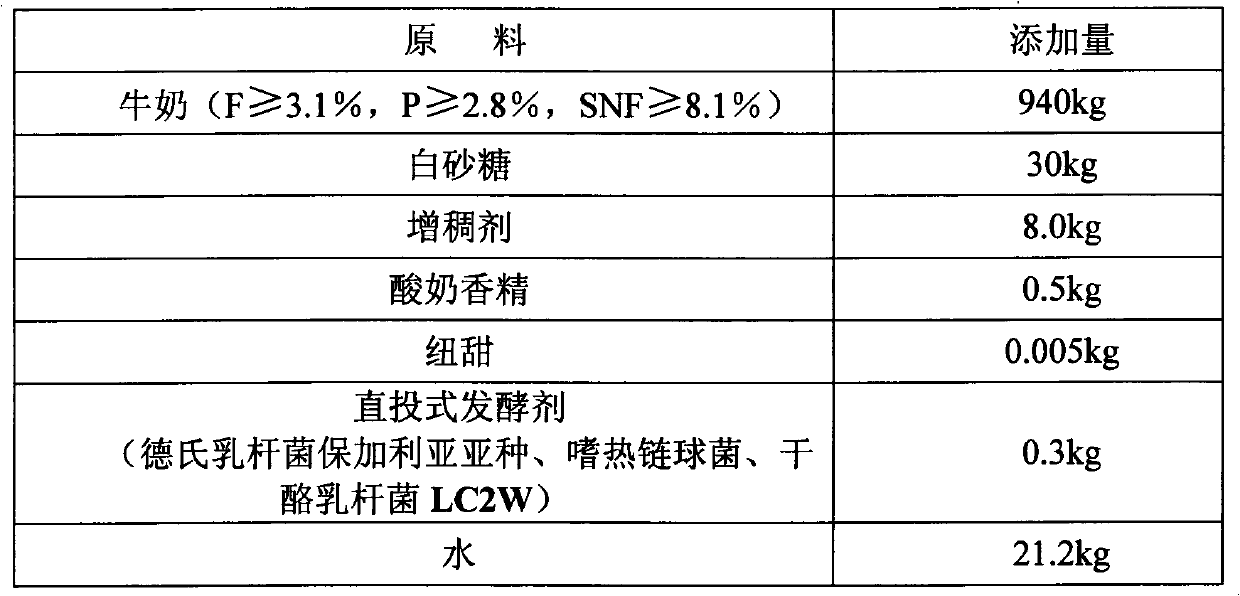

[0060] Product formula (calculated per ton of final product):

[0061]

[0062] The preparation method comprises the following steps:

[0063] (1) Pre-sterilize non-antibiotic milk with a fat of not less than 3.1% and a protein of not less than 2.8%, and store it in a cleaned and sterilized milk storage tank, and store it in cold storage (storage temperature: 2-6°C) before use;

[0064] (2) Heat the feed liquid obtained in step (1) to 55° C., add water, thickener, sweetener, and flavoring substances, and stir for 15 minutes at a stirring speed of 1800 rpm to fully dissolve and evenly;

[0065] (3) Homogenize the feed liquid obtained in step (2), the homogenization temperature is 68°C, and the pressure is successively two-stage homogenization of 17MPa and 3MPa;

[0066] (4) Sterilize the feed liquid obtained in step (3), the sterilization temperature is 90°C, the sterilization time is 8min, cool to 45°C after sterilization, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com