Patents

Literature

146 results about "Sterilized milk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sterilized milk is created by heating milk through an ultra-high temperature process, also known as UHT. This process destroys microbes and bacteria found in the milk, increasing its shelf life. Sterilization requires heating the milk to temperatures up to 135 degrees Celsius, and packaging the milk in aseptic containers.

Methods of making sterilized milk compositions comprising native gellan gum

InactiveUS6663911B2Optimize para-cresol reductionFunction increaseMilk preparationFood preservationGellan gumSphingomonas elodea

Owner:CP KELCO U S INC

Method for producing ultrahigh pressure sterilizing milk

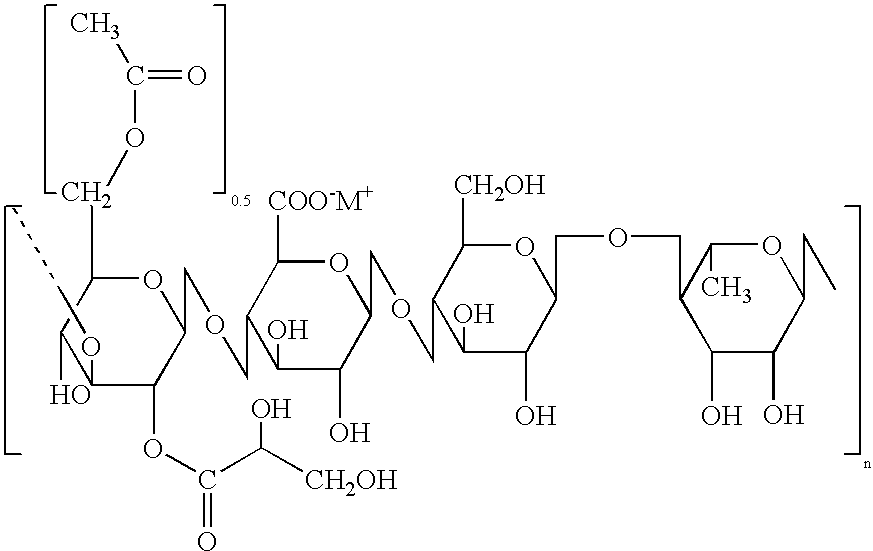

The invention discloses a method for producing ultrahigh pressure sterilizing milk. The method comprises the following steps of: (1) homogenizing the milk at the temperature of between 55 and 65 DEG C under the pressure of between 120 and 200 bars; (2) pasteurizing the milk in the step (1), and keeping the temperature of between 72 and 75 DEG C for 10 to 15 seconds; (3) cooling the milk in the step (2) to the temperature of between 2 and 6 DEG C within 5 to 30 seconds, and filling, wherein the residual volume of air of each filled package is less than or equal to 1 percent, and the percentage is the volume percentage that the residual volume of the air accounts for the each package; and (4) sterilizing the filled milk at the temperature of between 2 and 6 DEG C under the high pressure of between 500 and 800 MPa, and keeping the pressure for 5 to 15 minutes. By the method, the retention time of the milk at the high temperature is shortened, the heated temperature of the milk is reduced, and the fresh flavor and nutritive value of the milk are kept to the maximum degree; and the microbes in the milk treated by the sterilizing method do not exceed the standard easily within the normal quality guarantee period.

Owner:BRIGHT DAIRY & FOOD

Method for preparing yoghourt rich in gamma-aminobutyric acid (GABA)

ActiveCN102550670AHas nutritional valueImprove securityMilk preparationNutritive valuesBiotechnology

A method for preparing yoghourt rich in gamma-aminobutyric acid (GABA) relates to a method for preparing yoghourt and comprises the steps of resuscitating, purifying and activating lactobacillus plantarum NDC75017, lactobacillus bulgaricus 11057 and streptococcus thermophilus CICC 20379, respectively enlarging culture solutions and then mixing to obtain a leavening agent, and inoculating the leavening agent to sterilized milk to ferment. The GABA content in the yoghourt rich in GABA is 151.51mg / 100g. High-yield GABA bacterial strains and existing commonly-used bacterial strains are compoundedand then fermented to prepare the yoghourt rich in GABA, all the bacterial strains are food-grade lactic acid bacteria, and the safety is high. In addition, products have double effects, and the yoghourt rich in GABA integrates physiological efficacy of the GABA and health-care effect of yoghourt, namely the yoghourt rich in GABA is provided with special physiological efficacy of the GABA and thehealth-care effect of the yoghourt and is novel health-care yoghourt.

Owner:湖北均瑶大健康饮品股份有限公司

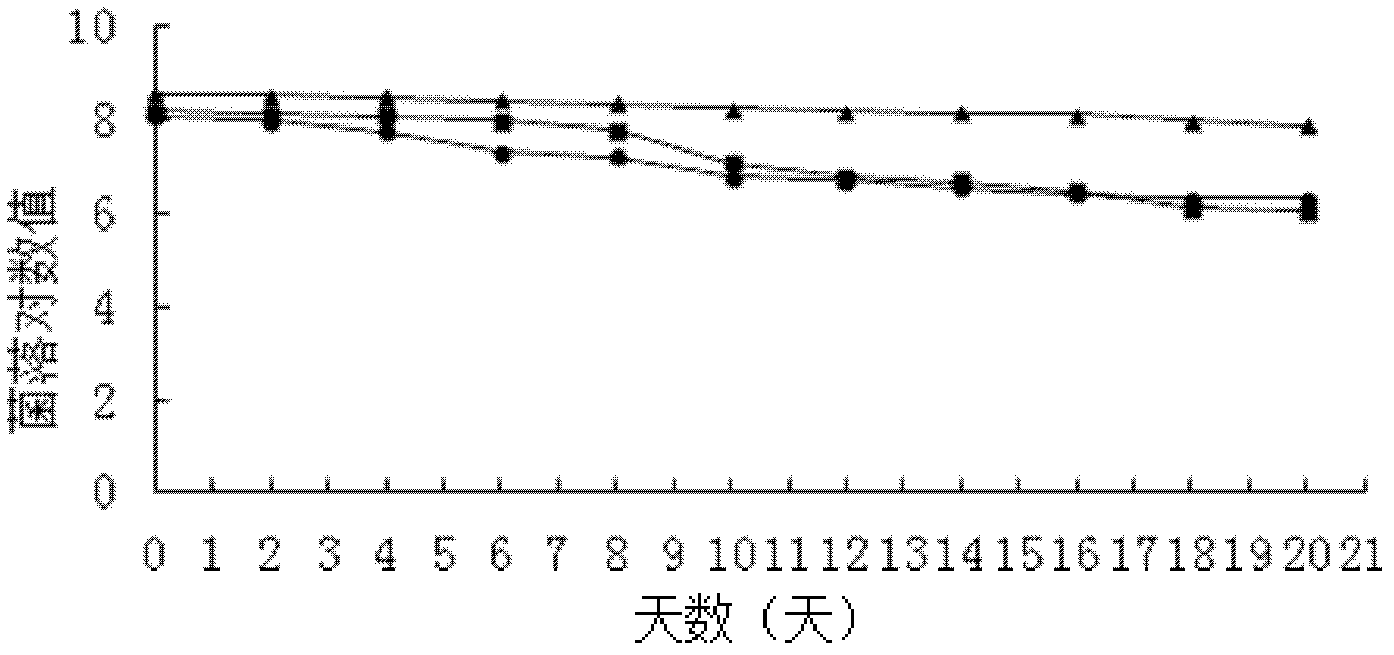

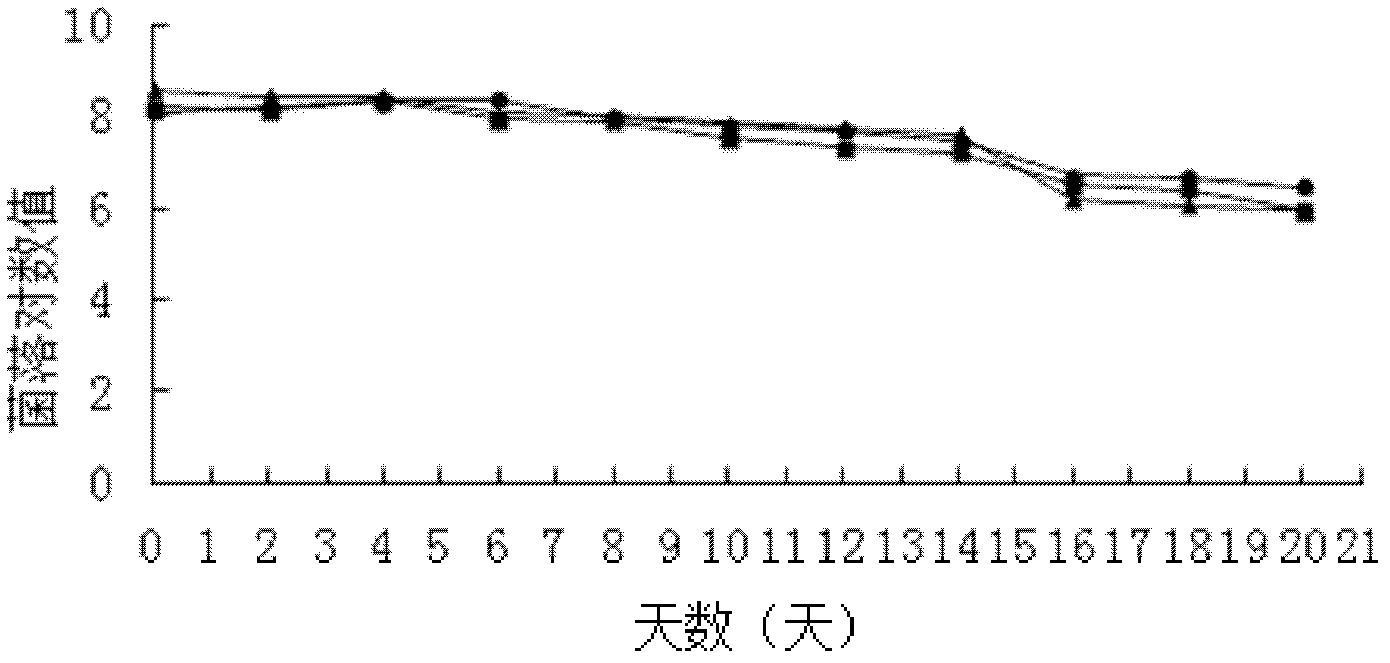

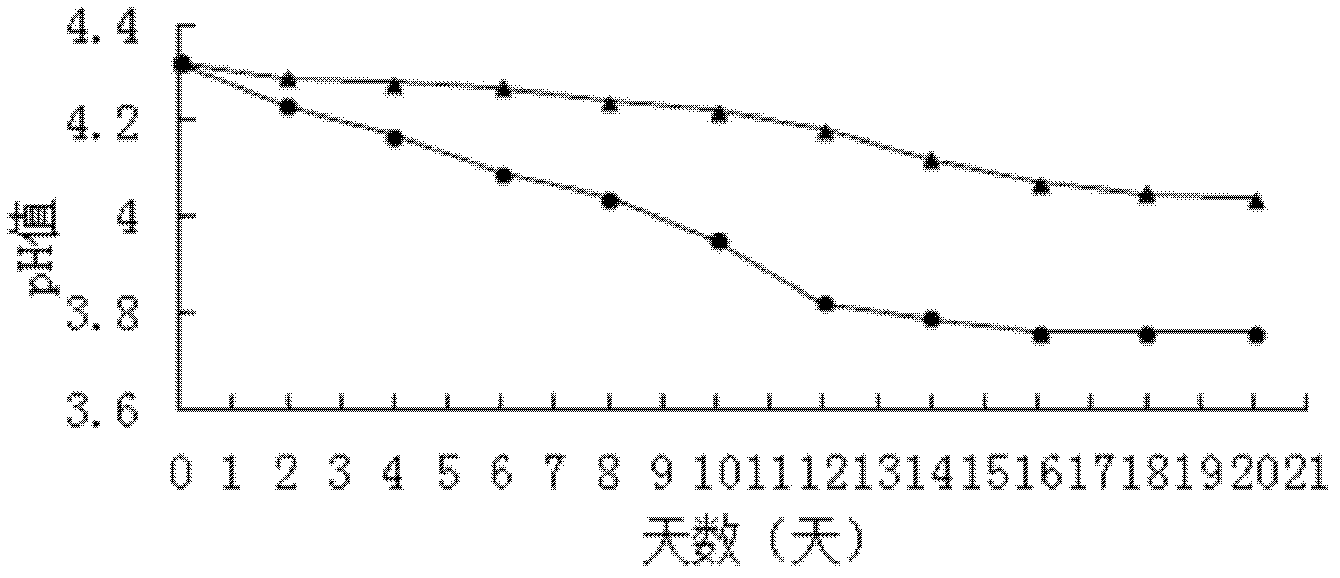

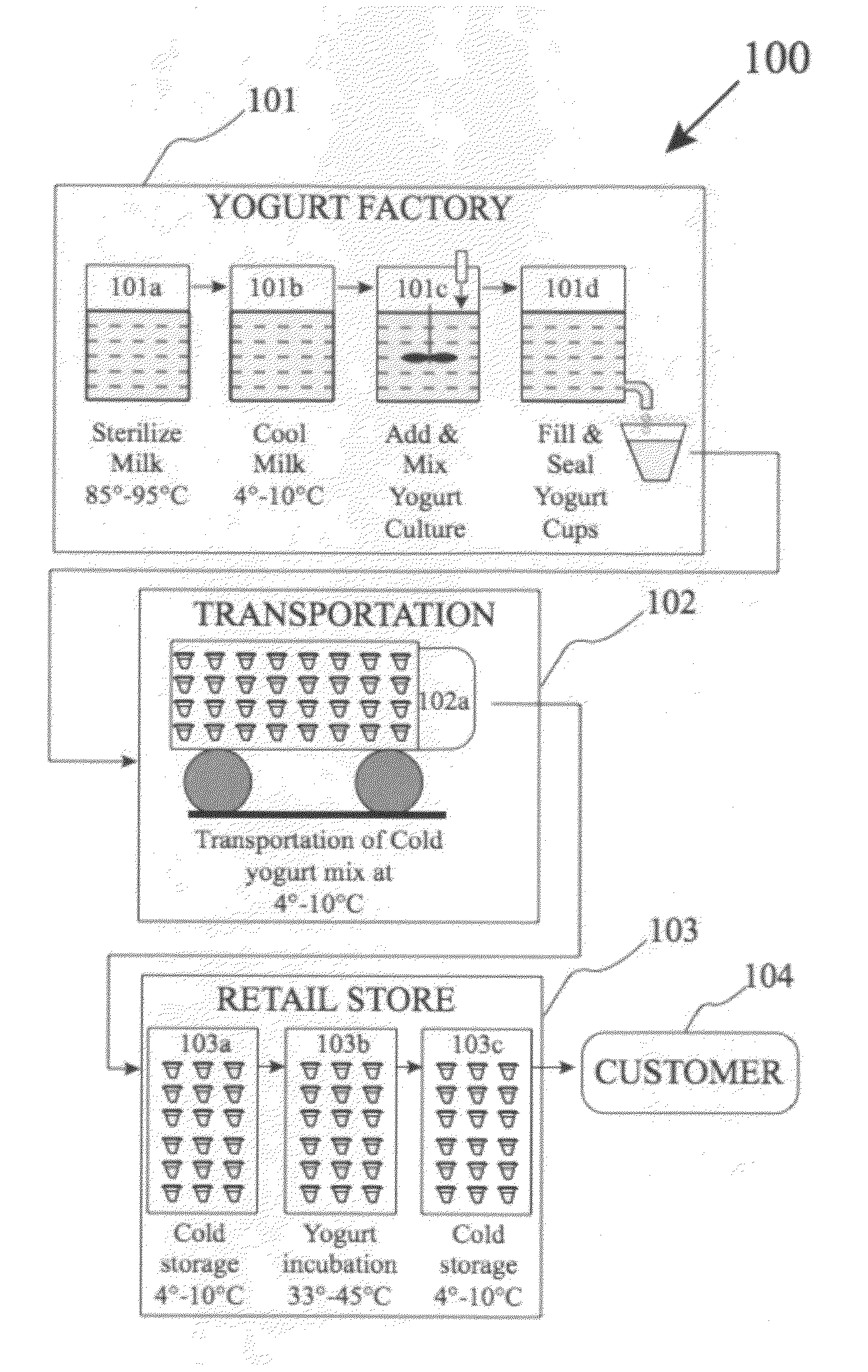

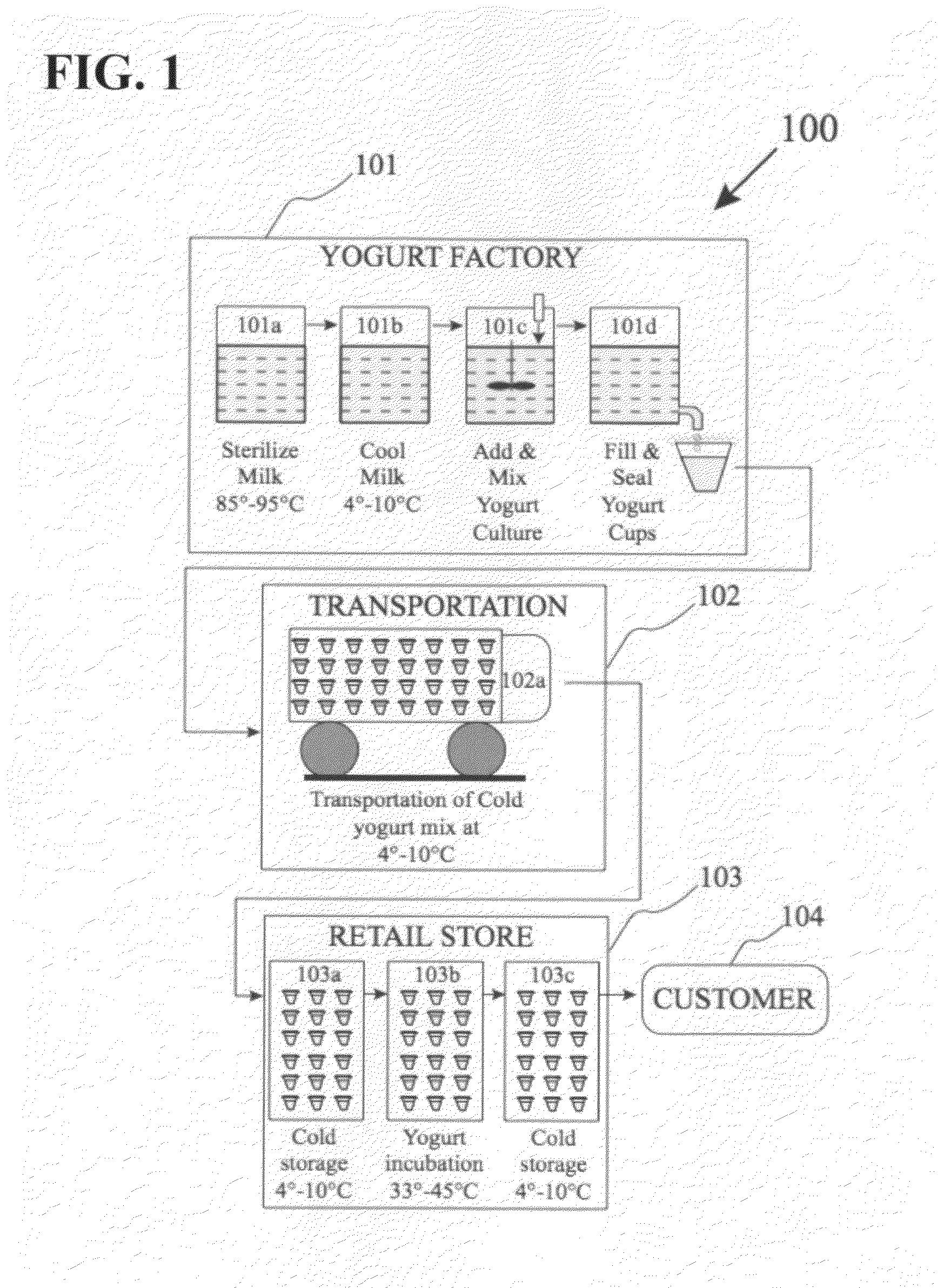

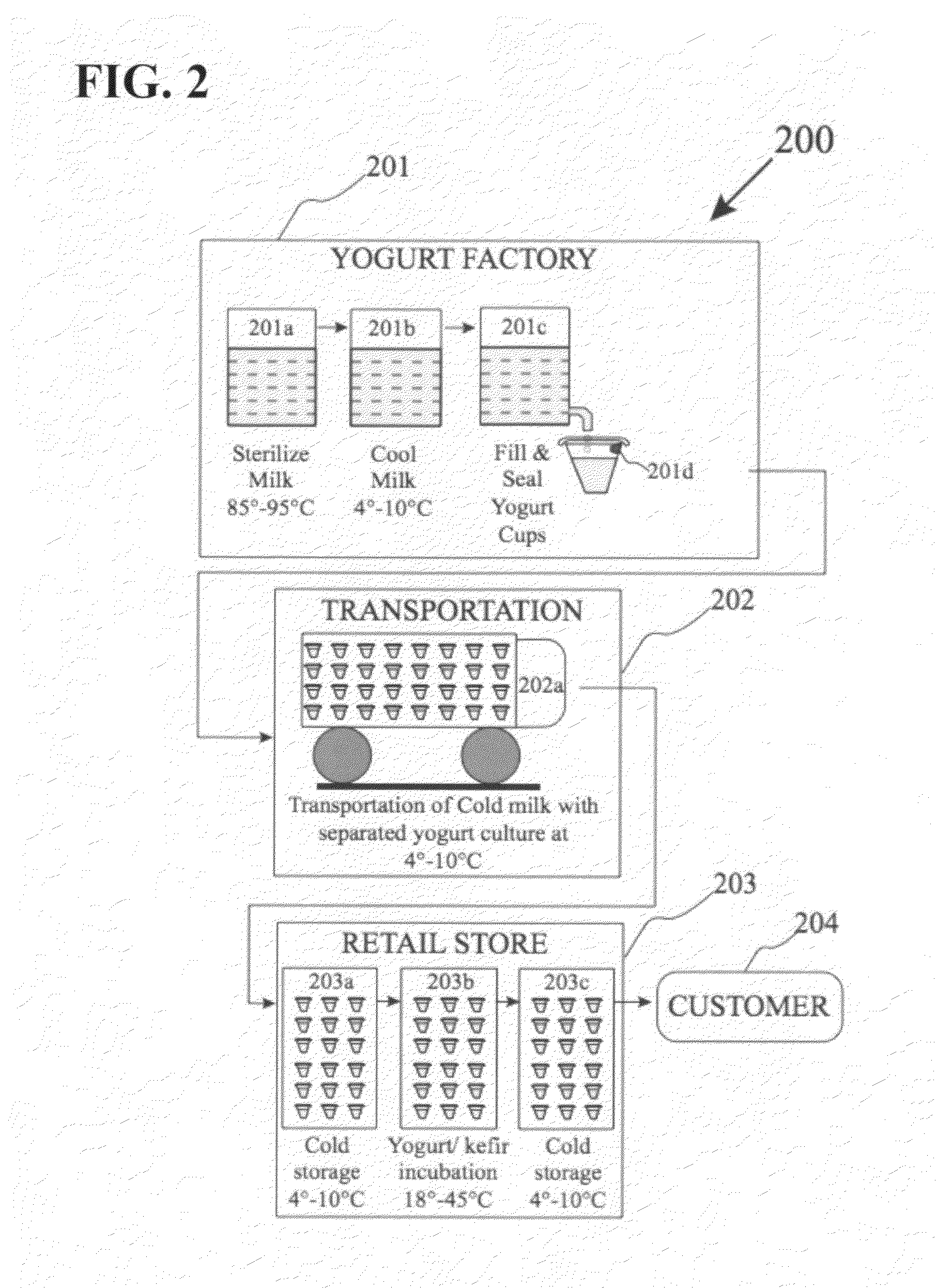

Process and system for delivering fresh yogurt or kefir

InactiveUS20110244077A1Improve textureFresh tasteMilk preparationButtermilkMicroorganismBiotechnology

A process for delivering to a retail location freshly prepared ‘Grade A’ yogurt or kefir with full undiminished concentration of probiotic microorganisms provides health benefits to customers. The yogurt manufacturing facility mixes cooled sterilized milk with a yogurt culture with low growth at 4° C. to 10° C. forming yogurt mixture fills and seals yogurt containers. Alternatively, the cold milk is separated from any yogurt or kefir culture in the yogurt container by a separation portion. The yogurt containers are then shipped cold to retail locations. The retail location stores yogurt containers at low temperature prior to incubation. When needed, the yogurt container is shaken to mix milk and separated yogurt or kefir culture. The yogurt containers are transferred to incubation oven for appropriate time to set yogurt or kefir, which is then refrigerated for sale to customers.

Owner:BELFERMAN FELIX +1

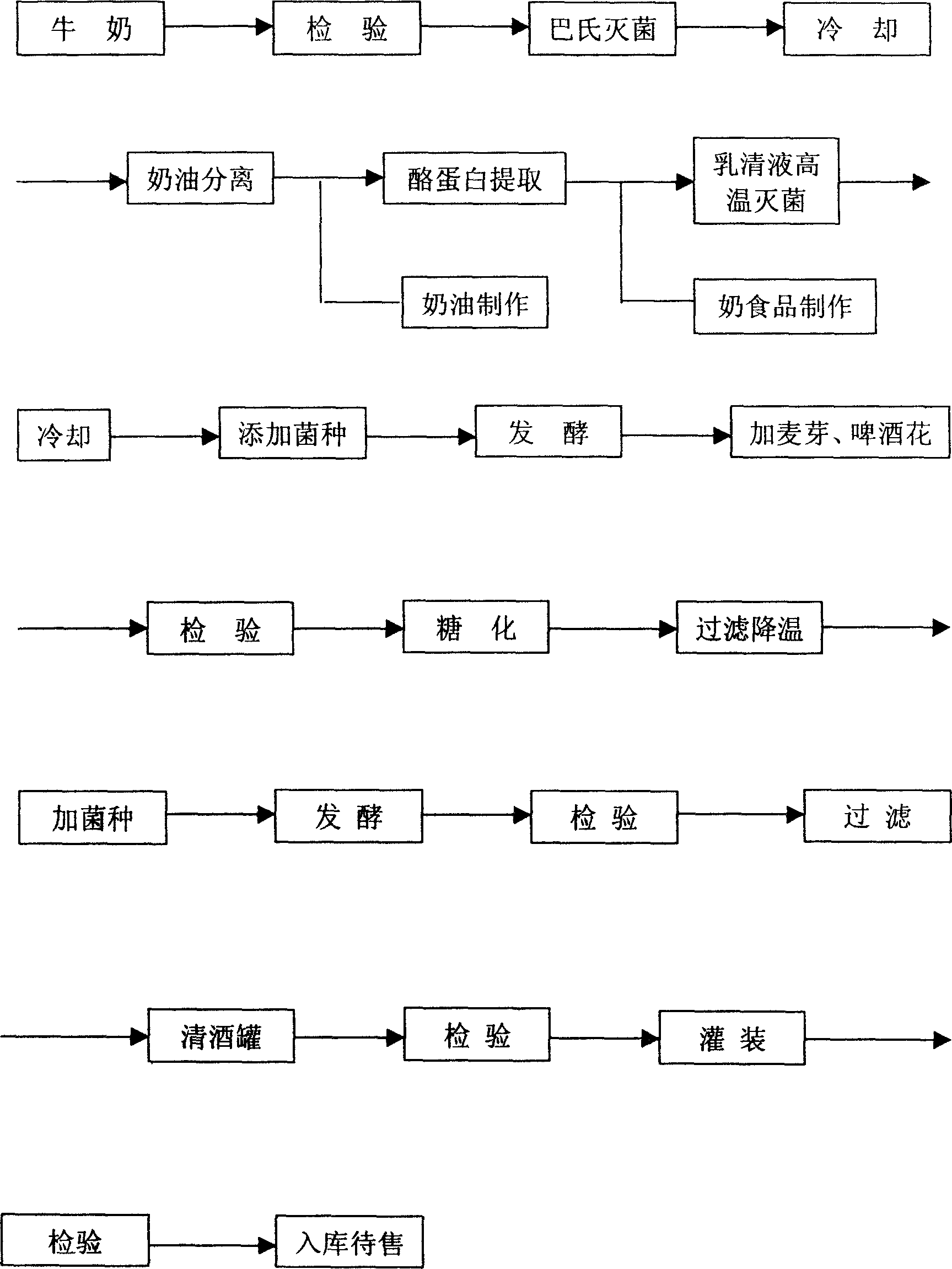

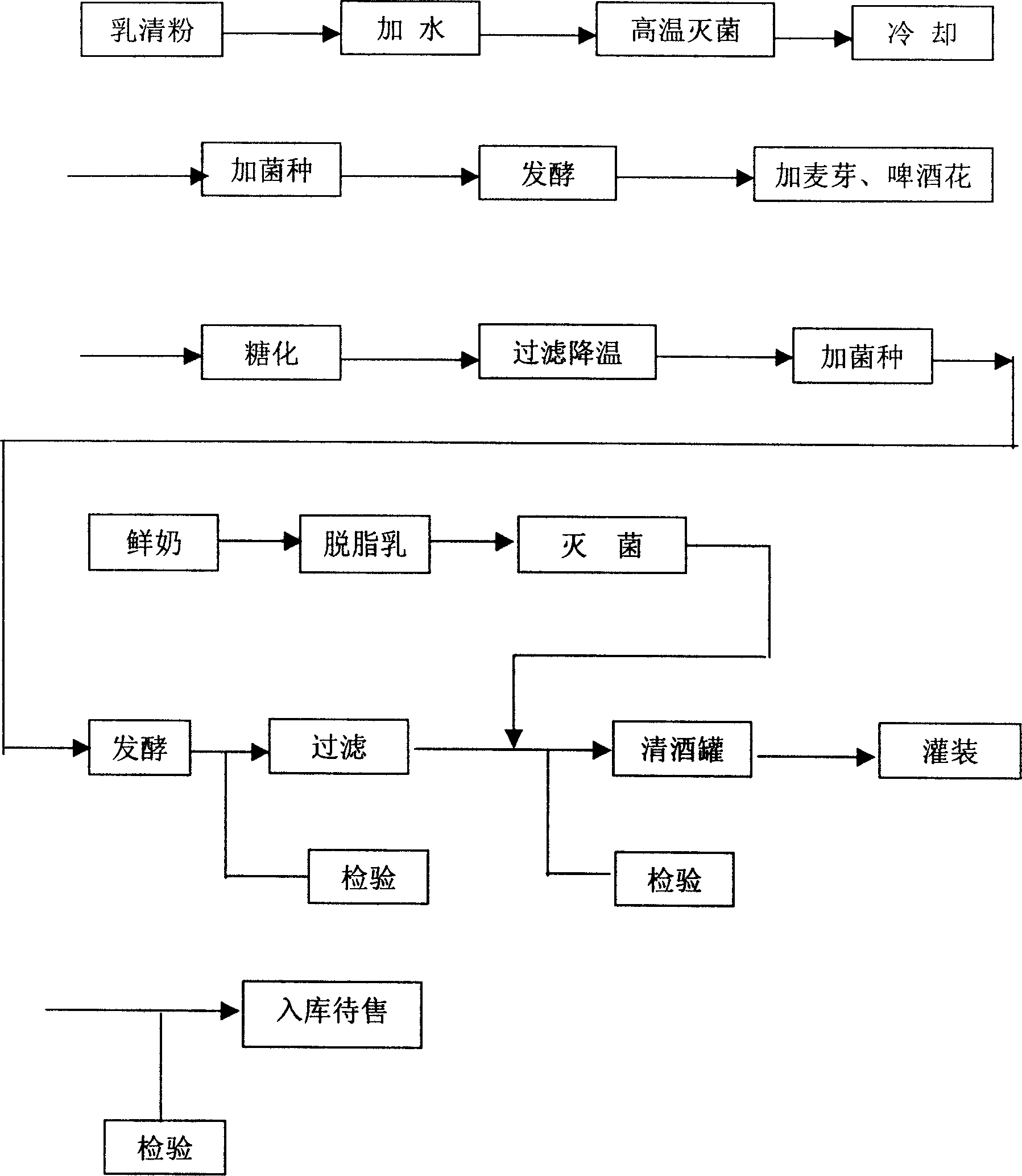

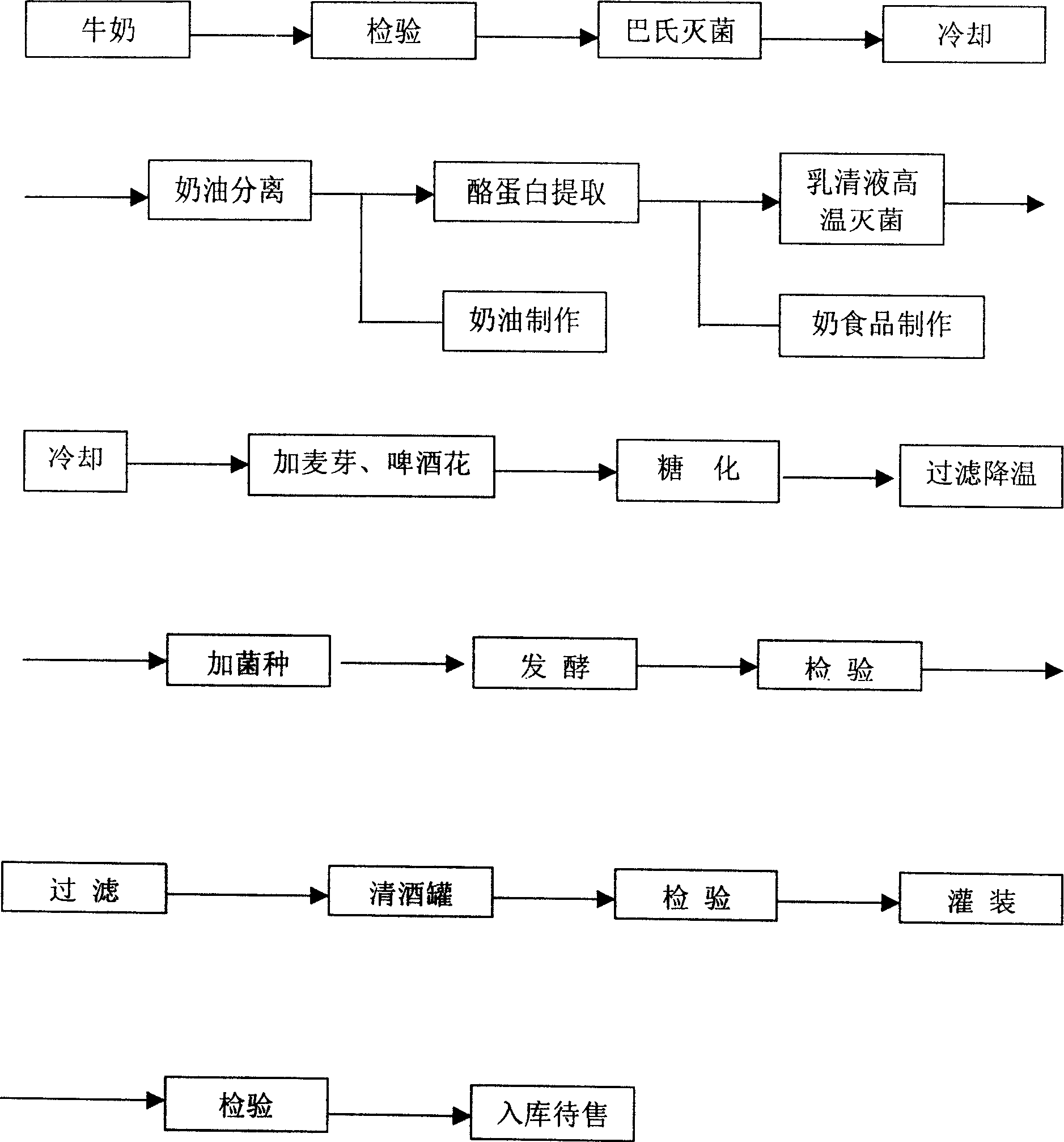

Formula of milk beer and making process

A milk beer is proportionally prepared from fresh milk whey, composite milk wine yeast, malt, beer hop, beer yeast, purified water and other auxiliaries through sterilizing milk, cooling, extracting casein, sterilizing whey liquid, cooling, fermenting, adding composite milk wine yeast, fermenting, adding malt and hop, saccharifying, fermenting, adding beer yeast and fermenting. Its advantages are refreshing milk smell, and rich nutrients including ammino acids, vitamines, carotene, etc.

Owner:王世新 +1

Method for improving yogurt coagulability through glutamine transaminase

InactiveCN105815446AImprove the coagulation effectPromote fermentationMilk preparationMicrofiltrationSterilized milk

The invention discloses a method for improving yogurt coagulability through glutamine transaminase, and belongs to the technical field of milk product processing. The method comprises the following technological steps of 1, raw milk microfiltration; 2, mixing, wherein 0.001-0.005 mg / kg of casoid flour is added into the raw milk, and the mass fraction of alpha-casein in the casoid flour is 70% or above; 3, homogenizing; 4, pasteurization; 5, inoculation, wherein the sterilized milk is inoculated with lactic acid bacteria, 0.001-0.005 mg / kg glutamine transaminase is added, and even mixing is performed; 6, fermentation. Compared with traditional set yogurt, by means of the method, the yogurt has better coagulability and smoothness, and whey precipitation is reduced.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

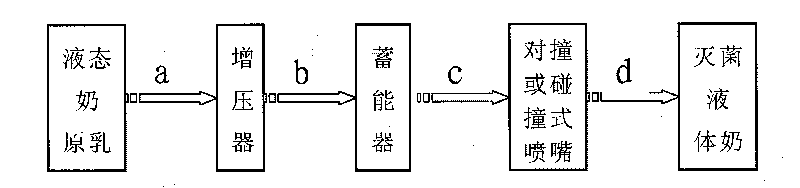

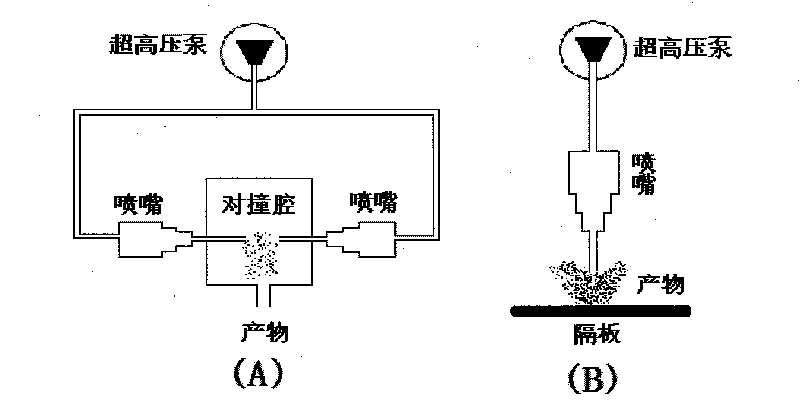

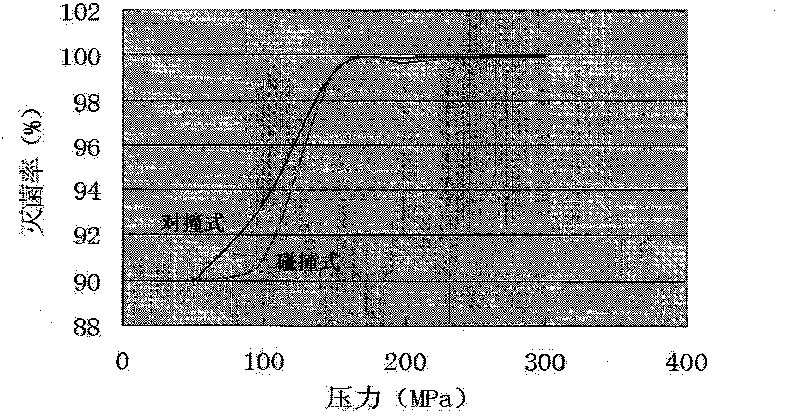

Low-temperature ultrahigh-pressure continuous sterilization method for liquid milk

InactiveCN101690515APreserve nutrientsConducive to the preservation of nutrientsMilk preservationWater buffaloLiquid state

The invention discloses a low-temperature ultrahigh-pressure continuous sterilization method for liquid milk, relates to liquid milk, and particularly relates to a method for sterilizing the liquid milk by adopting ultrahigh-pressure water jet. The method is characterized in that the liquid milk is subjected to the ultrahigh-pressure water jet treatment in a nozzle of coaxial equivalent clash type or collision type at the temperature of between 4 and 60 DEG C under the pressure of 50 to 400MPa; and the liquid milk overcomes the defects that the pasteurized milk has short shelf life and the instantaneous ultrahigh-temperature sterilized milk has large loss of nutrient components, and can preserve the nutrition, prolong the shelf life, save time and labor and reduce the energy consumption. The method is applied to sterilization of cow milk, yak milk, water buffalo milk and goat milk, and the sterilized milk is expected to become a new variety of the liquid milk, namely ultrahigh-pressure milk.

Owner:SOUTHWEST JIAOTONG UNIV

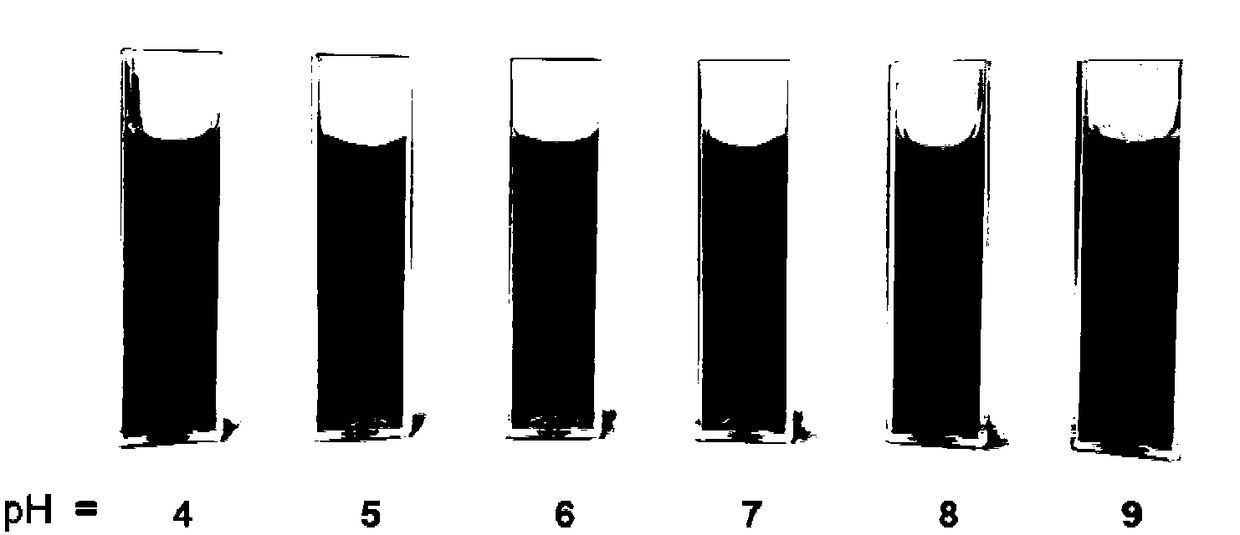

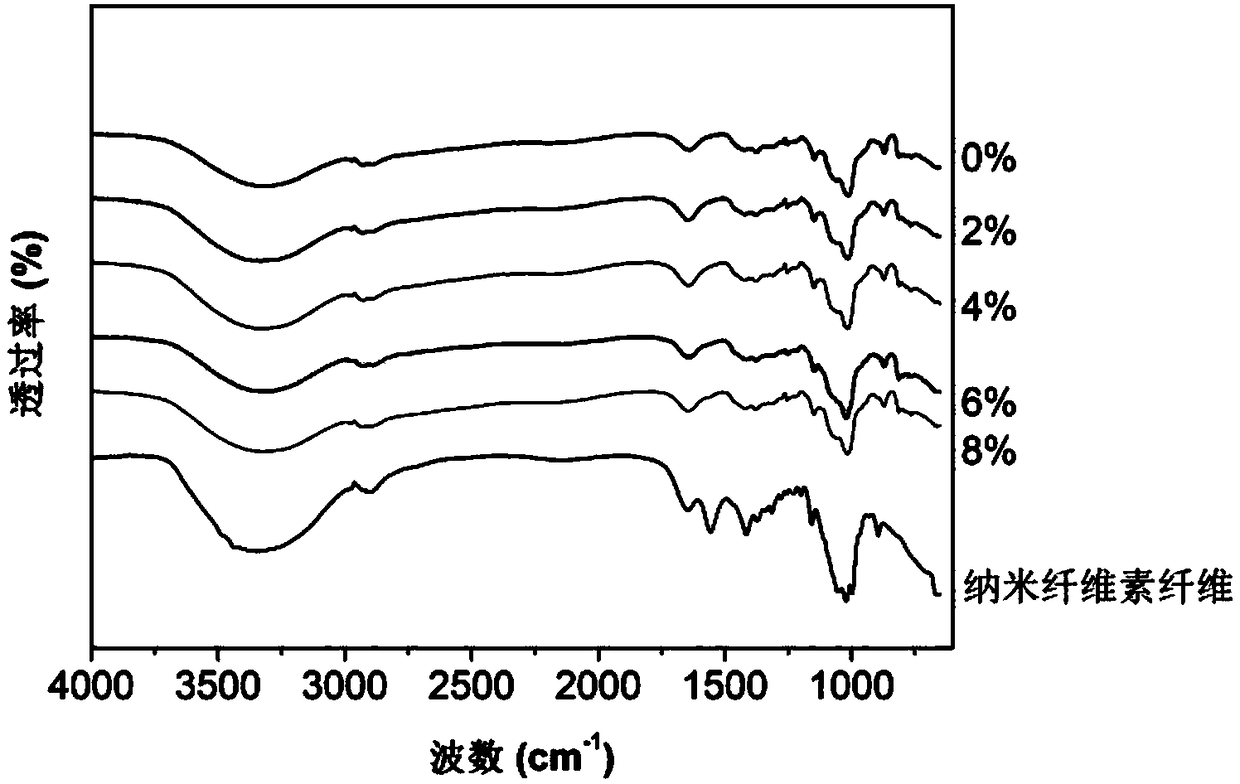

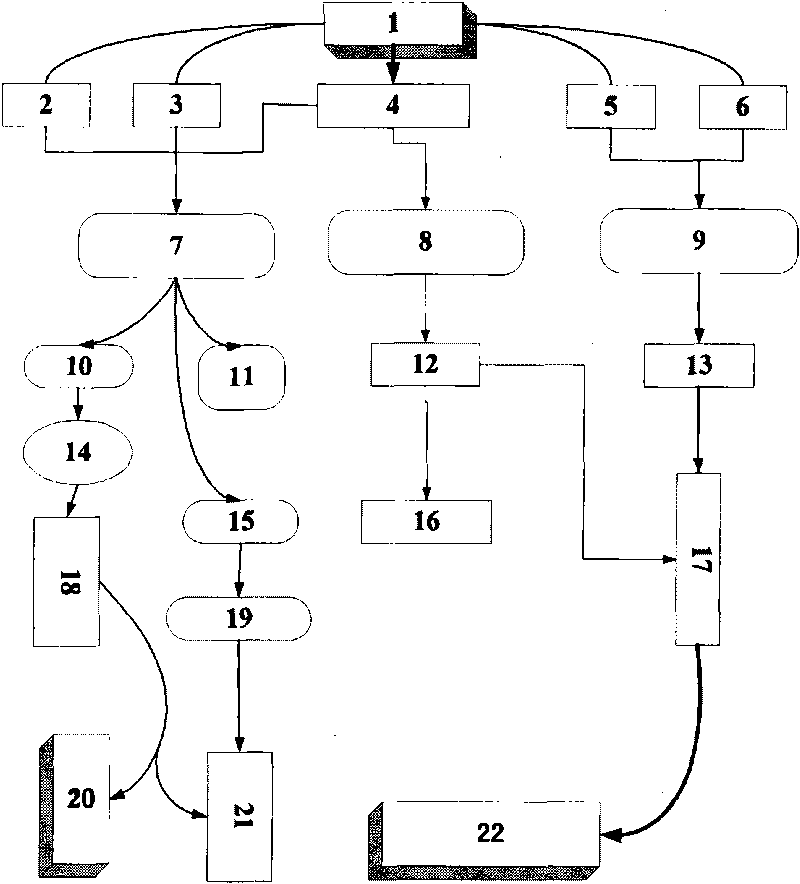

Food deterioration fast detecting material with pH discoloration responsiveness and preparation and use thereof

InactiveCN108586825AImprove mechanical propertiesQuick checkMaterial analysis by observing effect on chemical indicatorCellulose fiberUltimate tensile strength

The invention discloses a food deterioration fast detecting material with pH discoloration responsiveness and a preparation and use thereof. Polysaccharide gum is used as a food deterioration fast detecting material matrix. 1-50wt% of a edible softening and toughening agent, 2-8wt% of a nano-cellulose fiber solution reinforcing and toughening agent with a mass concentration of 5% and 0.1-2.5wt% ofa natural edible pH responsive substance are added into the material matrix so that the food deterioration fast detecting material with pH discoloration responsiveness is obtained. The food deterioration fast detecting material has good mechanical strength, degradability and pH sensitivity, meets the needs for rapid detection of food deterioration, can be used as a safe and environmentally-friendly food deterioration fast test material, is used for fast detecting the freshness of foods producing pH change such as fresh milk, sterilized milk, pasteurized milk, raw milk, brewed milk and other dairy products or fruits, cakes, meat, fish, etc. in the deterioration process, and has broad application prospects.

Owner:黄正农

Drinking type flavor fermented milk and making method thereof

The invention discloses drinking type flavor fermented milk and a making method thereof. The making method comprises the following steps of a, preparing 852.85-924.4 parts by weight of raw milk, taking 30% of the prepared raw milk, heating the taken raw milk to 45-50 DEG C, then putting 5-15 parts of whey protein powder in the heated raw milk, performing stirring to obtain a mixture, enabling the mixture to stand, performing hydration to obtain an emulsion 1, taking another 30% of the prepared raw milk, heating the taken raw milk to 50-55 DEG C, adding 0.5-2 parts of dried egg yolk, 10-40 parts of coffee cream, 60-90 parts of white granulated sugar in the heated raw milk, performing stirring to obtain a mixture, and cooling the mixture to 2-6 DEG C so as to obtain an emulsion 2; b, mixing the emulsion 1 with the emulsion 2, adding the residual raw milk, performing volume settling, and performing stirring so as to obtain milk liquid; c, heating the milk liquid to 65-70 DEG C, homogenizing the heated milk liquid, and then sterilizing the homogenized milk liquid; d, after the homogenized milk liquid is sterilized, cooling the sterilized milk liquid to 42-44 DEG C, inoculating 0.1-0.15 parts of a fermenting agent, performing stirring, and performing fermentation at a constant temperature; and e, through fermentation, changing the milk liquid into a base material, performing emulsion breaking on the base material, after emulsion breaking, shearing the emulsion broken base material by a shearing emulsification pump, and after shearing is completed, performing filling. Through the adoption of the drinking type flavor fermented milk and the making method thereof disclosed by the invention, the problem that food additives can be added in conventional drinking type flavor fermented milk is solved.

Owner:KUNMING XUELAN MILK

Red jujube yogurt and preparation method

InactiveCN101791008AKeep it authenticPromote digestion and absorptionMilk preparationFlavorHigh volume manufacturing

The invention relates to red jujube yogurt and a preparation method. The fruit material yogurt is prepared from pure fresh milk and concentrated red jujube juice in the weight ratio of 85-100:1-20 through homogenization, sterilization, cooling inoculated fermentation and filling. The preparation method comprises the following steps of: proportionally mixing the pure fresh milk and the concentrated red jujube juice, and uniformly stirring; heating the mixture to 60-70 DEG C, and homogenizing under the pressure of 18-20 MPa; continuously heating to 100-105 DEG C for sterilization; cooling the sterilized milk liquid to 42-46 DEG C, and fermenting inoculated lactobacillus for 4-5.5 h; stirring the fermented semi-finished product to obtain the finished product, packaging, and going on the market. The invention is prepared from the pure fresh milk used as a raw material, and the natural concentrated red jujube juice and the lactobacillus are added for fermentation; the red jujube yogurt has fresh quality and is rich in active lactobacillus, nutrients are digested and absorbed by the human body more easily, and meanwhile, the original taste and flavor of the red jujube yogurt are maintained; the red jujube yogurt is a healthy and fashionable tonic, the guarantee period can reach 15 days, and the red jujube yogurt is applicable to large-size production, storage and sales.

Owner:云南乍甸乳业有限责任公司

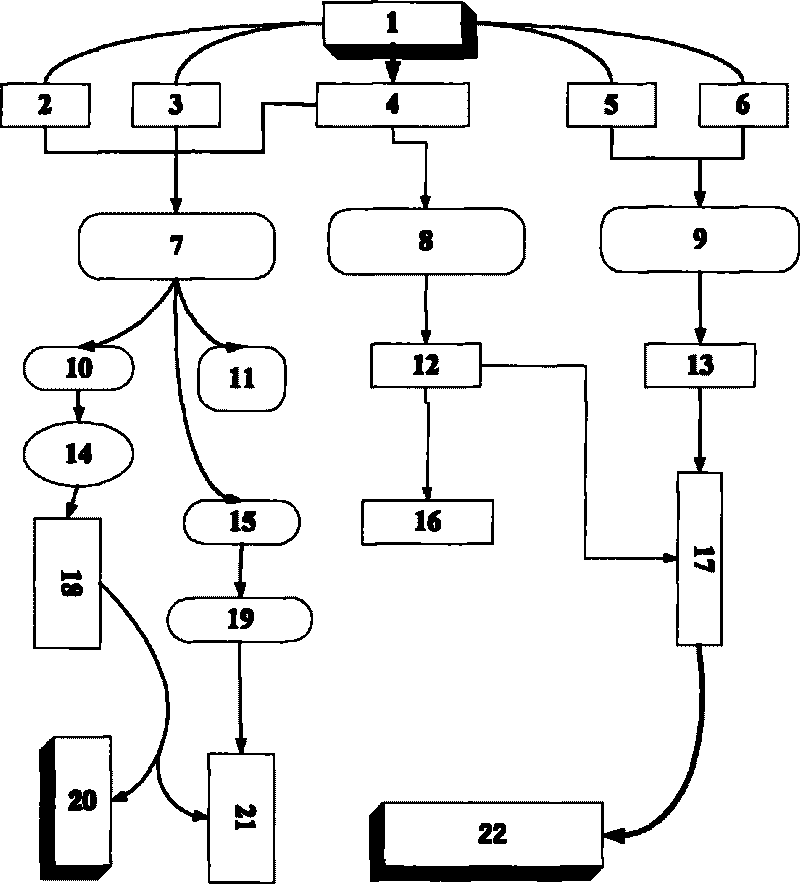

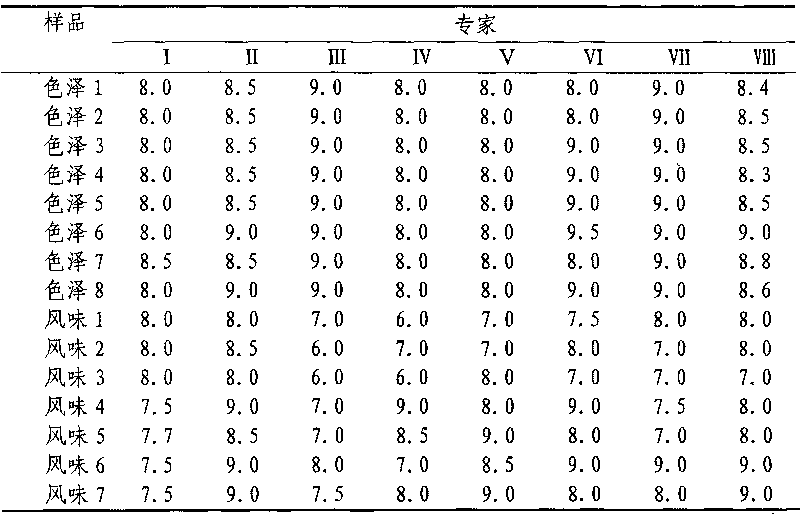

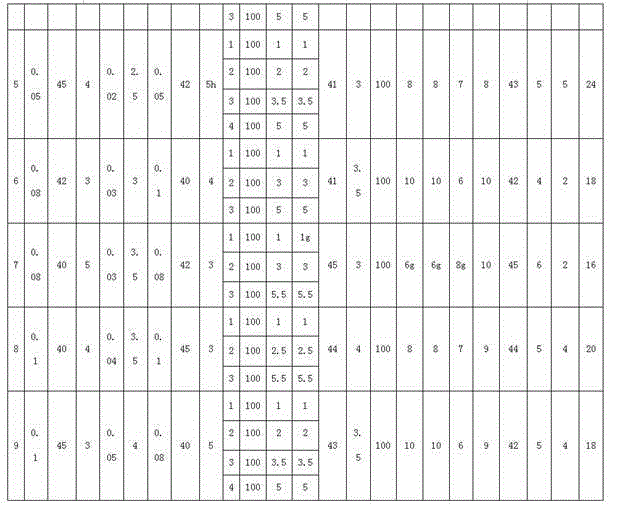

Method for quantitatively evaluating quality of dairy products

The invention relates to a method for quantitatively evaluating quality of dairy products and belongs to the field of food science. In the operational method, the mixing synthetic method is utilized to study the quantitative evaluation of the quality of UHT milk, sterilized milk, and fermented milk; three food quality evaluation indexes are selected, and the detection method is standardized; the standardized detection results are subjected to special so as to obtain the combined weightings of color, flavor and texture which are 0.280,0.385 and 0.334 for the UHT milk respectively, 0.240,0.383 and 0.378 for the sterilized milk respectively, and 0.239, 0.383 and 0.377 for the fermented milk respectively; and the index detection of each sample is subjected to positive and zero dimension treatment and mixing synthetic method statistical analysis, and finally the quantitative evaluation result of each sample is obtained. By comparing the evaluation result with the conventional marked evaluation result, the result obtained by the novel method is based on the strict mathematical statistics and realizes overall comprehensive quantization of various indexes, so that the randomness and the blindness are eliminated, and the defects of bigger influence of human factors and stronger randomness existing of the conventional evaluation method are effectively overcome.

Owner:SHANDONG AGRICULTURAL UNIVERSITY +1

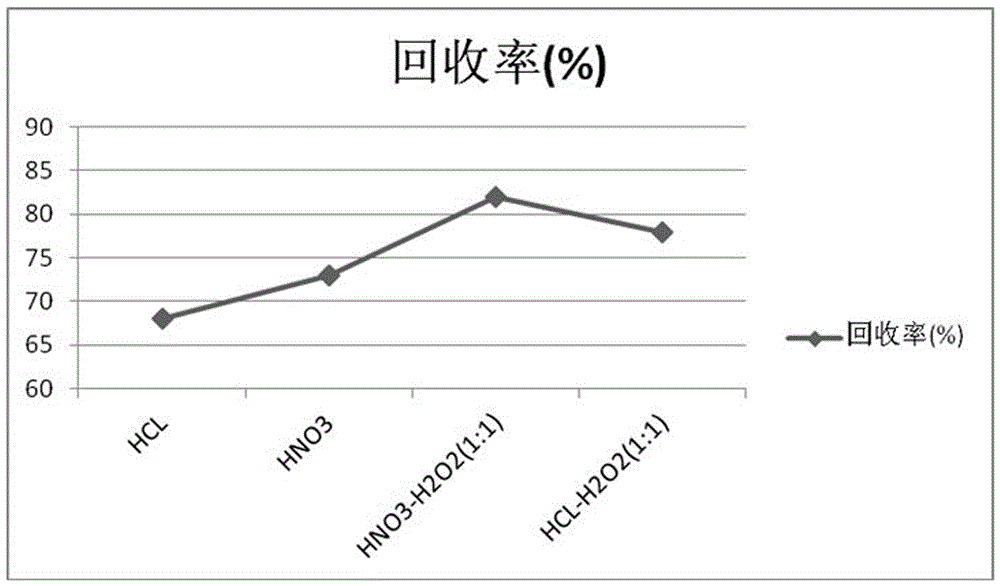

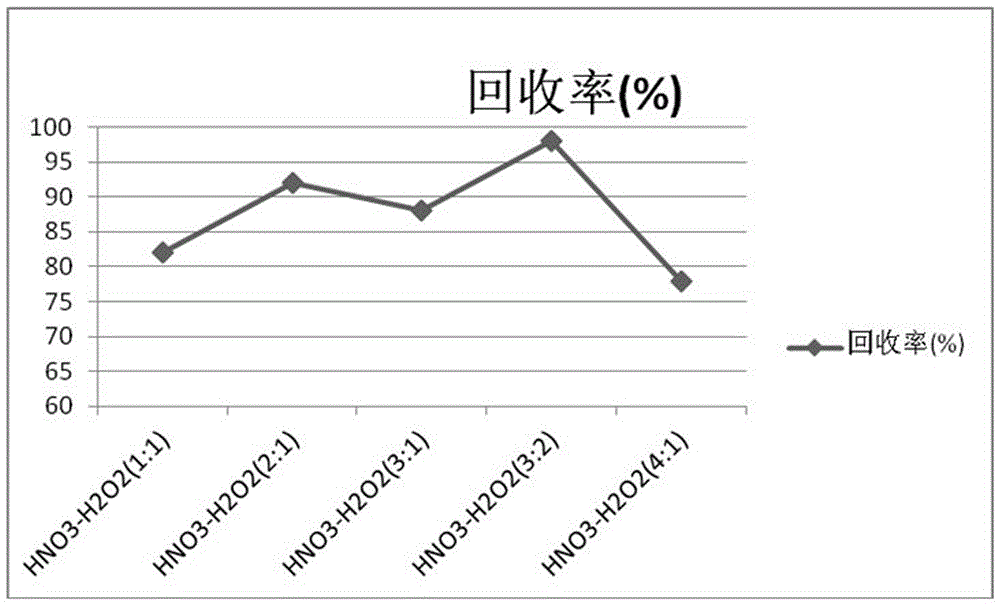

Method for rapidly determining lead and chromium in dairy products

InactiveCN105758812AShort processing timeReduce harmPreparing sample for investigationColor/spectral properties measurementsBatch processingContamination

The invention belongs to the chemical detection analysis field and in particular relates to a technology for rapidly determining lead and chromium in dairy products by use of a microwave digestion-graphite furnace atomic absorption spectrometry. The method comprises the following steps: (1) preprocessing a sample; (2) preparing lead and chromium standard curve series solutions; (3) drawing lead and chromium standard curves; and (4) measuring the sample. Compared with the prior art, the method has the beneficial effects that the sample preprocessing time is short and is only 2.4h, the operation is simple, the harm to laboratory technicians can be reduced to the maximum extent due to use of microwave digestion, the environment is friendly, the whole microwave digestion process of the sample is performed in a closed environment, a small amount of target detection substances are volatized, the contamination of external substances is avoided, the detection result has high accuracy and good repeatability, lead and chromium in the dairy product can be measured simultaneously, and the method is suitable for the batch processing and measurement of samples, is suitable for determining the contents of lead and chromium in various samples such as raw milk, sterilized milk, modified milk, milk powder, fermented milk and the like, and has wide application range.

Owner:YUNNAN XINXIWANG DENGCHUAN DIEQUAN DAIRY

Liquid milk and preparation method thereof

InactiveCN104938635AIncrease nutritional contentHigh nutritional valueMilk preparationFlavorNutritive values

The invention provides liquid milk and a preparation method thereof. The preparation method comprises the following steps: (1) pre-treating fresh and raw milk to obtain pre-treated milk, wherein the pre-treatment step comprises impurity removing and homogenizing; (2) conducting first-time ultra-high pressure sterilization on the pre-treated milk obtained in the step (1) for 2-10 min at the pressure of 150-300 MPa to obtain first-time ultra-high pressure sterilized milk; (3) conducting second-time ultra-high pressure sterilization on the first-time ultra-high pressure sterilized milk obtained in the step (2) for 10-30 min at the pressure of 400-600 MPa to obtain the liquid milk. The method can effectively kill harmful microbes in fresh and raw milk, and meanwhile, maintain the relatively good taste and fresh flavor of fresh and raw milk, and the liquid milk obtained through sterilizing fresh and raw milk maintains the nutrient content and still has a relatively high nutritive value.

Owner:BRIGHT DAIRY & FOOD

Production process of rhamnose lactobacillus milk powder

ActiveCN101019577ABreak through the key technical problems of low survival rateMilk preparationFood preparationLactobacillus rhamnosusSterilized milk

The production process of rhamnose lactobacillus milk powder includes the first instantaneous high temperature sterilizing of milk material and decompression concentrating to obtain concentrated milk; the subsequent inoculating rhamnose lactobacillus to high temperature sterilized milk, adding girasole powder and heat insulating culturing to obtain activated spawn; adding the activated spawn to the concentrated milk and homogenizing; and final spray drying to produce the rhamnose lactobacillus milk powder. The present invention has girasole powder as the rhamnose lactobacillus increasing agent to solve the technological problem of well preserving rhamnose lactobacillus in the high temperature spray drying.

Owner:陕西英童乳业有限公司

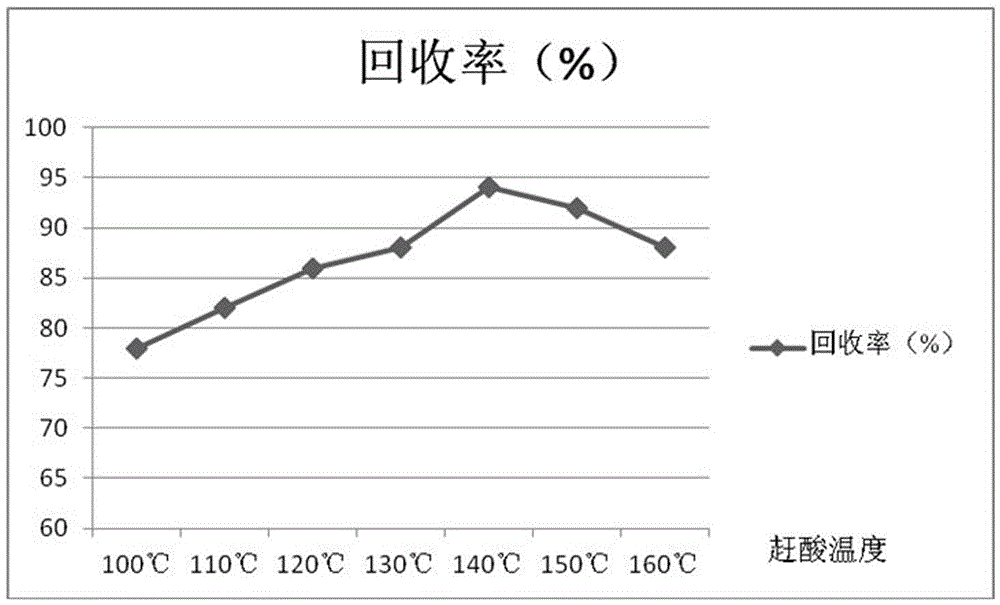

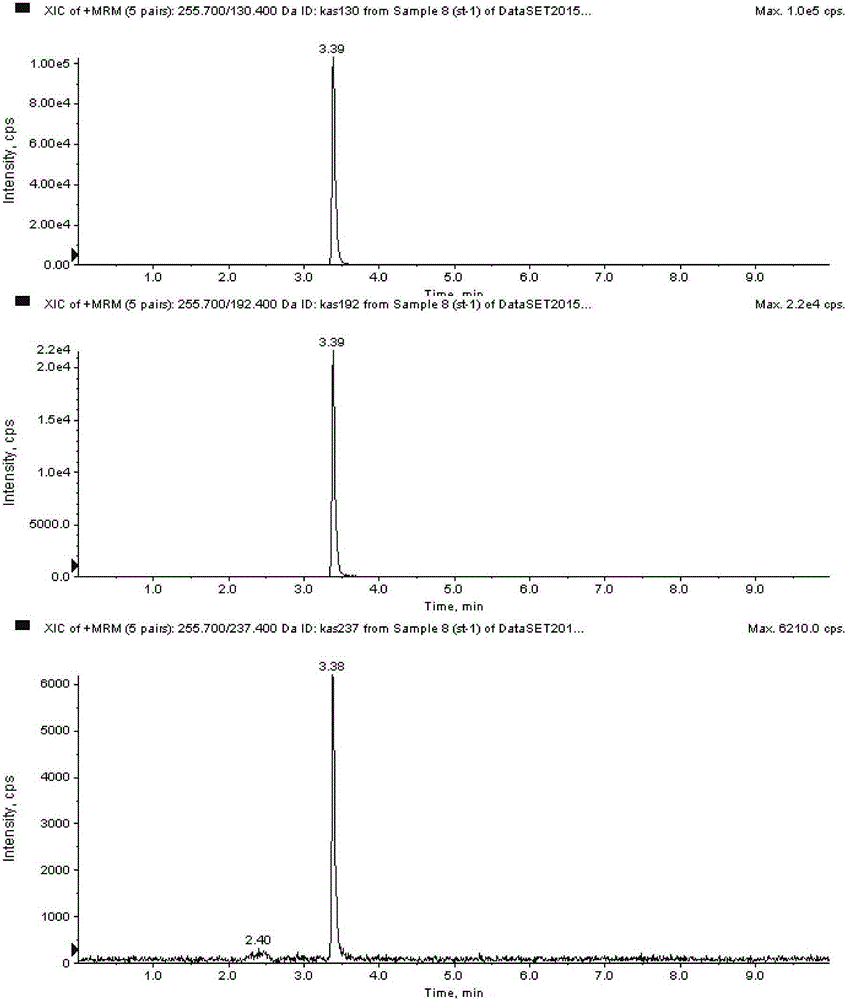

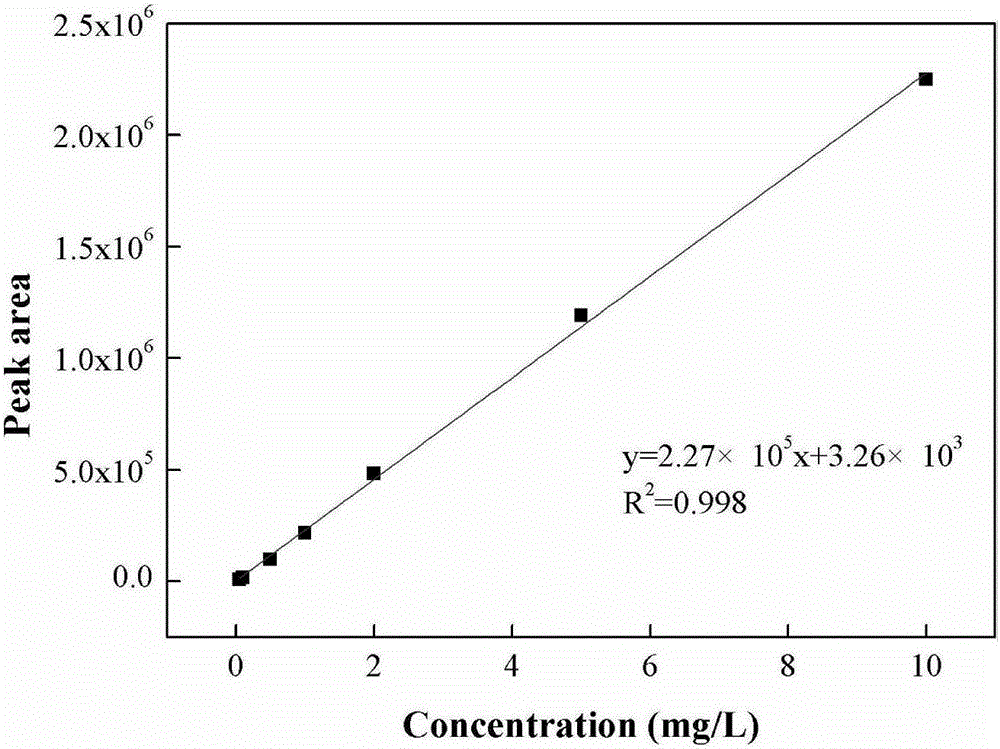

Method for testing furosine in dairy products

InactiveCN105203651AReduce preprocessing timeReduce processing timeComponent separationFiltration membraneBottle

The invention provides a method for testing furosine in dairy products. The method comprises the following steps: (1) sample preparation, (2) purification, and (3) liquid chromatography and tandem mass spectrum combination, wherein the sample preparation comprises the following steps: conducting pretreatment, heating at 115 DEG C for hydrolysis for 4 h, cooling, conducting dry filtration, and reserving a filtrate for determination; the purification comprises the following steps: putting 0.10 ml of a supernatant into a nitrogen blowing pipe, blow-drying by using a nitrogen blowing concentrator, enabling the volume to be 1.00 ml through a formic acid-ammonium formate buffer solution, fully and uniformly shaking, and transferring the mixture into a sampling bottle through a 1 mL injector filtering film to be subjected to liquid chromatography and tandem mass spectrum testing. The dairy products capable of being tested by the method comprise lactogenesis, reconstituted milk, pasteurized milk or ultra-temperature instant sterilized milk. According to the method, the pretreatment time is shortened, the recovery rate is greatly improved, the tandem mass spectrum is adopted in testing, and the specificity and the sensitivity are improved.

Owner:INSPECTION & QUARANTINE TECH CENT OF GUANGDONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Composite baterial milk products and preparation proess thereof

The present invention relates to a composite bacteria milk product and its preparation method. It is characterized by that the composite bacterial culture composed of a fungus (lactic acid kluyveromyces) and a life-benefiting bacterium (lactobacillus delbruckii bulgaricus subspecies) can be inoculated in the sterilized milk so as to obtain the invented milk product with uniform gel, palatable taste and several health-care functions of regulating stomach and intestine. Said invention can do not use any food additives.

Owner:陈克铨

Carrot and purple sweet potato mixed yogurt and preparation method thereof

InactiveCN104397175ATo make up for the single speciesImprove balanceMilk preparationPectinaseVegetable oil

The invention discloses a carrot and purple sweet potato mixed yogurt. The mixed yogurt comprises carrot and purple sweet potato. A preparation method comprises the following steps: step 1: pulping carrot and water according to the mass ratio of 1:(1-3), adding pectinase, adding vegetable oil and polyglyceryl fatty ester after enzymolysis, allowing the mixture to completely emulsify, performing vacuum suction filtration, and obtaining carrot juice; step 2: pulping purple sweet potato and water according to the mass ratio of 1:(1-3), adding pectinase into the purple sweet potato pulp, performing vacuum suction filtration after enzymolysis, and obtaining purple sweet potato juice; step 3: inoculating sterilized milk containing the carrot juice and the purple sweet potato juice with activated lactic acid bacteria starter, fermenting and acclimatizing into production strain; step 4: adding white granulated sugar into the milk containing the carrot juice and the purple sweet potato; step 5: inoculating the milk with the acclimatized strain, and fermenting to obtain finished products of yogurt. The yogurt has more health care efficacies, and simultaneously makes up the situation that the variety of the mixed yogurt in the market is single.

Owner:ZHOUKOU NORMAL UNIV

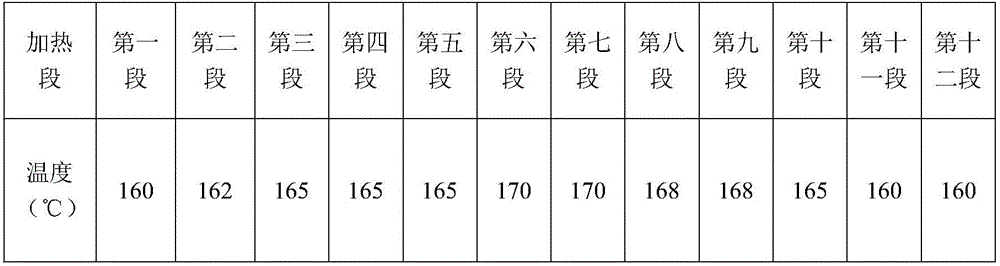

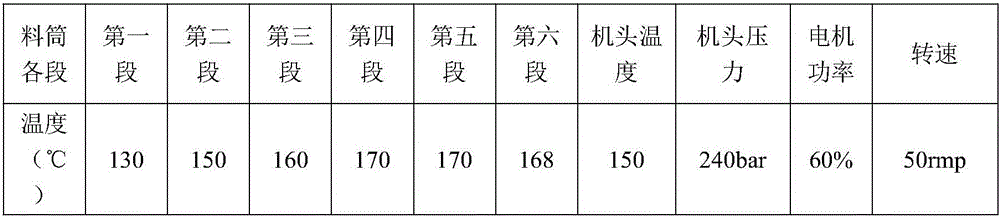

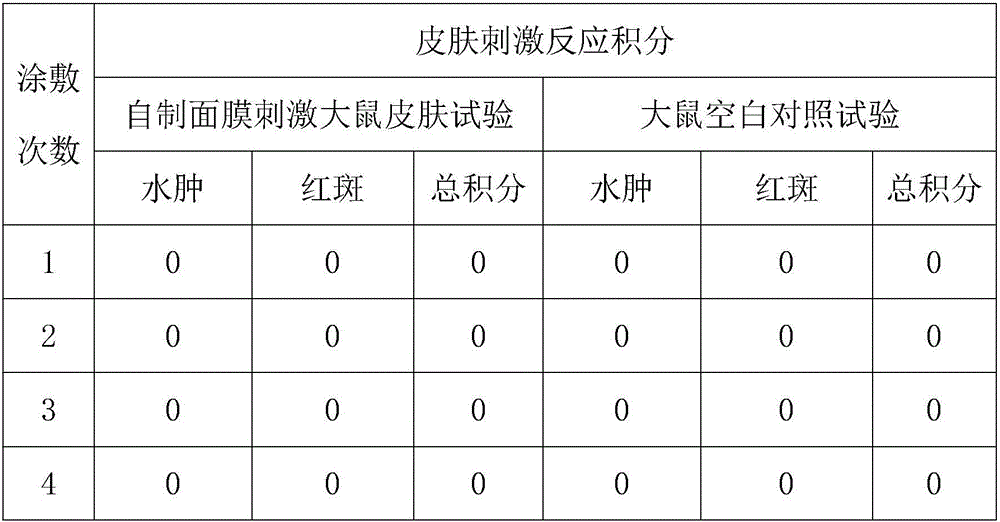

Compound factor synthesized transdermal absorption mask and manufacturing method

InactiveCN106821944ABreathability preventionAvoid allergiesCosmetic preparationsToilet preparationsPropolisLemon juice

A composite factor synthetic transdermal absorption mask and its production method. The invention utilizes the composite factor to accelerate the proliferation and division speed of human cells, replace aging dead cells, and increase the number of newborn cells, so as to achieve the mechanism of keeping the skin young. By selecting sterilized milk, Quail egg extract, grape seed extract, collagen polypeptide extract, snail secretion, hyaluronic acid, tomato juice seven substances, a self-made compound factor; then add propolis, lemon juice, angelica, ginseng, pearl powder, almonds , rice water, egg white, silver nanoparticles, seaweed particles, natural mineral water, aloe vera, glycerin to synthesize a high-efficiency transdermal absorption mask with antibacterial, anti-wrinkle, whitening, and moisturizing properties. At the same time, environmentally friendly materials are selected as the mask carrier. The invention has the characteristics of skin penetration, easy absorption, moisturizing, safety and environmental protection.

Owner:广州海梦科化妆品有限公司

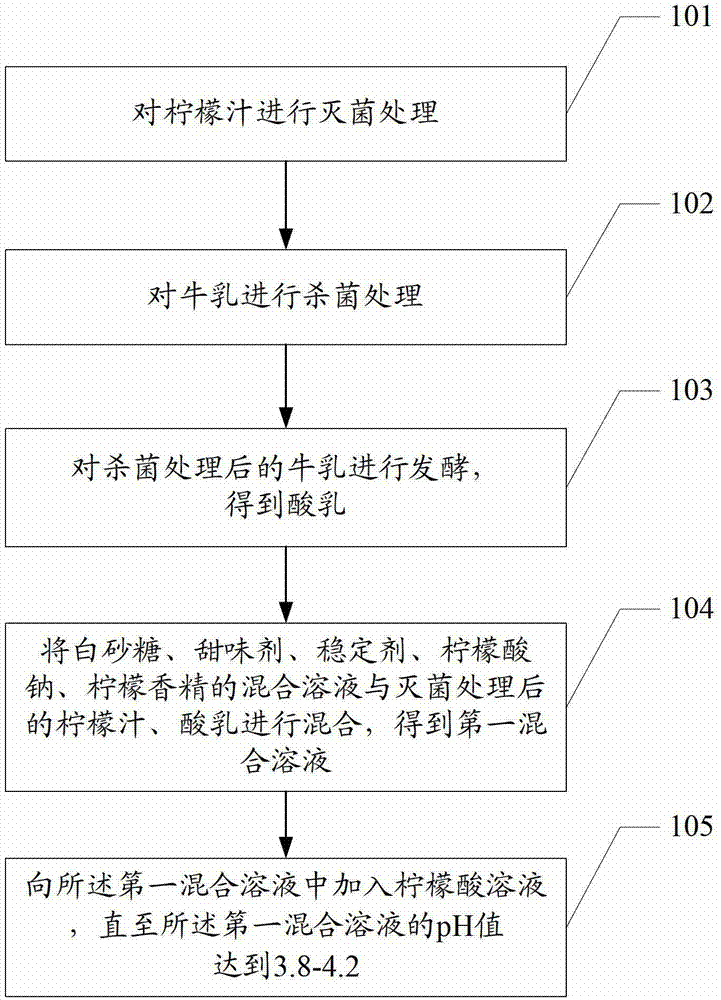

Lemon flavor beverage and preparation method thereof

InactiveCN102919357AHigh nutritional valueHigh in nutrientsMilk preparationSodium citrateLemon juice

The invention relates to the technical field of beverage preparation, in particular to a lemon flavor beverage and a preparation method thereof. The preparation method comprises the following steps: fermenting sterilized milk, stopping fermentation until the pH value of the fermented milk reaches 4.2-4.5, and obtaining acid milk, wherein the temperature of a fermentation environment is 40-44 DEG C; mixing a mixed solution of 55-65 parts of white granulated sugar, 5-7 parts of sweetener, 4-6 parts of stabilizer, sodium citrate and lemon essence with 80-120 parts of lemon juice and 25-350 parts of the acid milk by weight to obtain a first mixed solution; and adding a citric acid solution into the first mixed solution until the pH value of the first mixed solution reaches 3.8-4.2. Through the lemon flavor beverage and the preparation method thereof, the types of fruit flavored type milk beverages can be enriched.

Owner:SICHUAN HUATONG LEMON

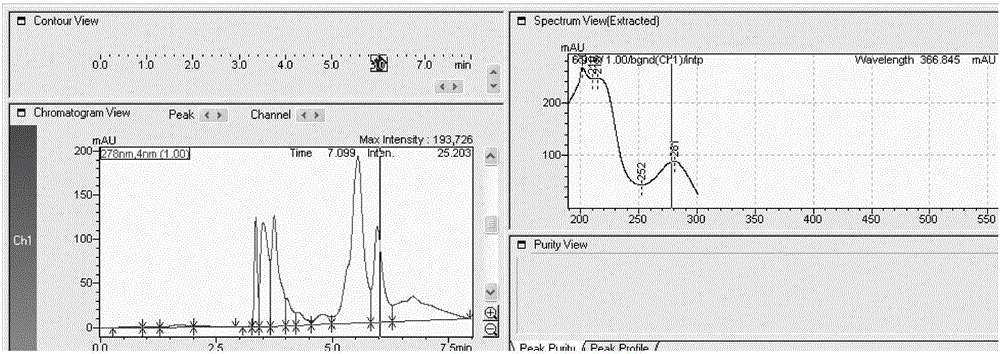

Method of identifying reconstituted milk and ultra-high temperature sterilized milk

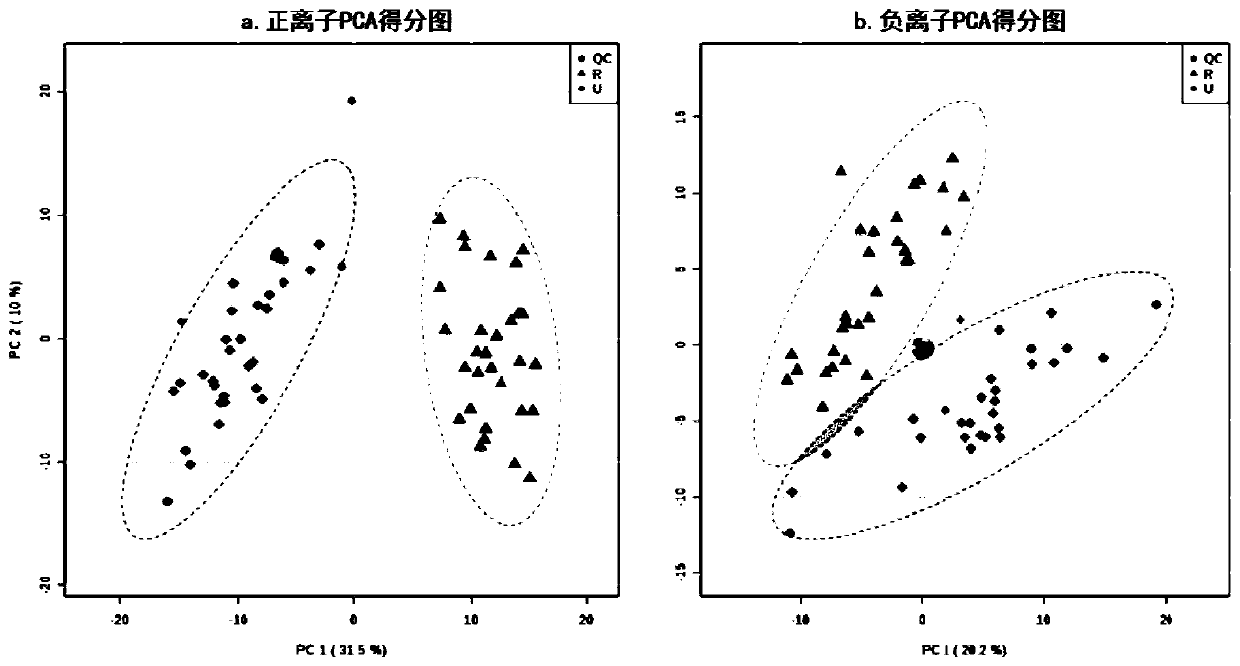

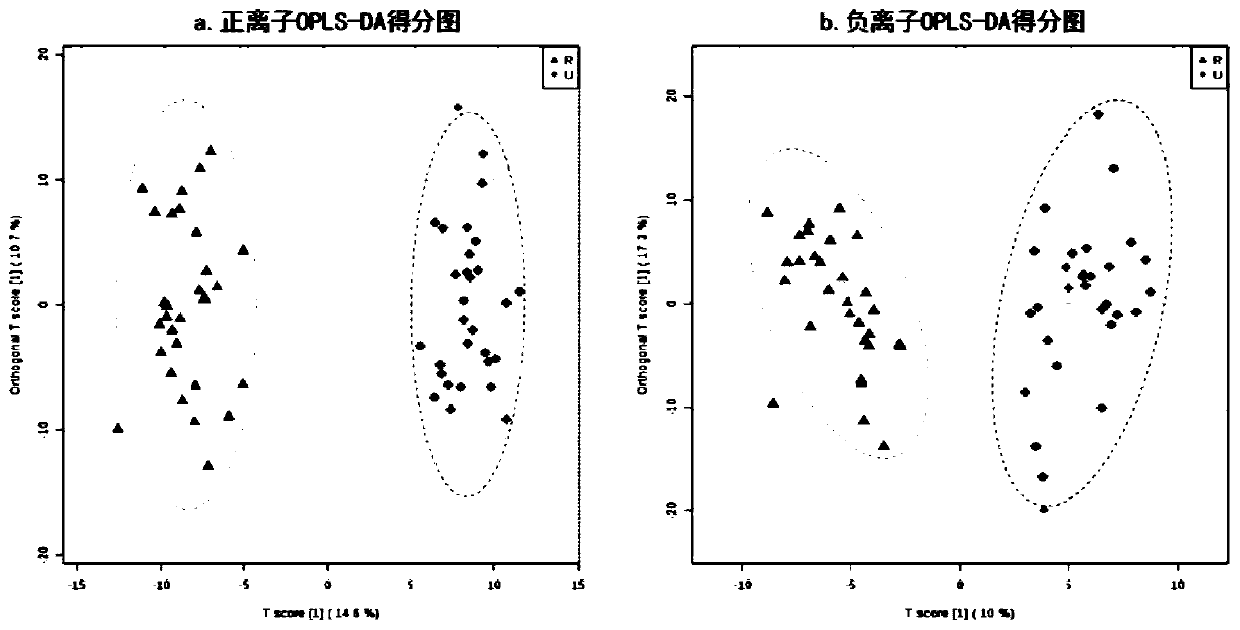

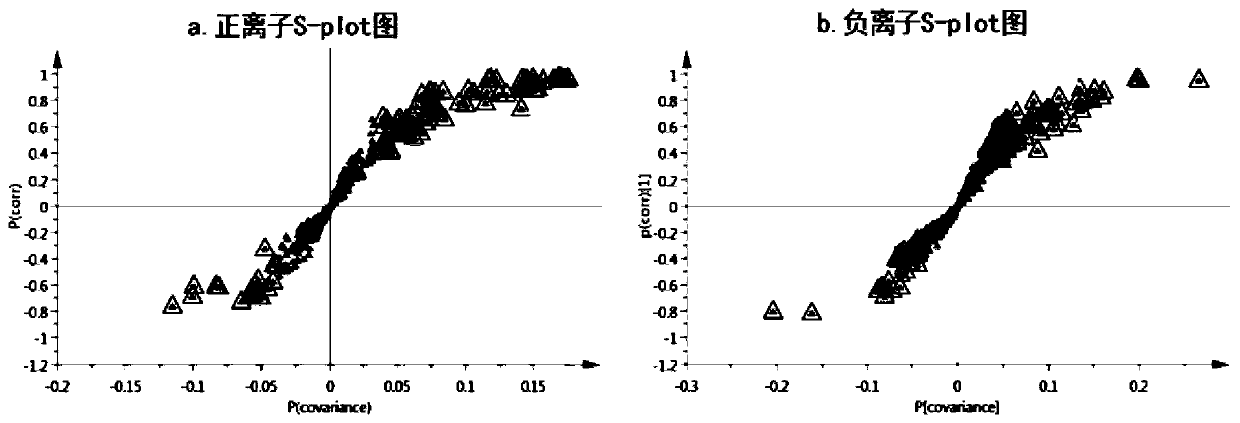

ActiveCN110470781AImprove accuracyComprehensive resolutionComponent separationNon targetedNon target

The invention relates to a method of identifying reconstituted milk and ultra-high temperature sterilized milk. The method comprises steps: a) non target metabonomics data of milk samples of reconstituted milk and ultra-high temperature sterilized milk are collected separately by adopting high performance liquid chromatography-high resolution mass spectrometry, and the characteristic information of the two is extracted respectively; b) an analysis model is built, the characteristic information is analyzed, and differential metabolites of the reconstituted milk and the ultra-high temperature sterilized milk are determined; c) a pseudo-target metabolomics detection method to identify reconstituted milk and ultra-high temperature sterilized milk is constructed to screen the differential metabolites in the step b), and the characteristic information of the differential metabolites is obtained; and d) based on the characteristic information of the differential metabolites obtained in the step c), a PCA-Class discriminant analysis model is constructed, and based on the PCA-Class discriminant analysis model, determination of a to-be-detected milk sample is realized. The method is convenient, sensitive and accurate, and can realize rapid and automatic discrimination of ultra-high temperature sterilized milk and reconstituted milk.

Owner:INST OF QUALITY STANDARD & TESTING TECH FOR AGRO PROD OF CAAS

Method for predicting shelf-life stability of sterilized milk

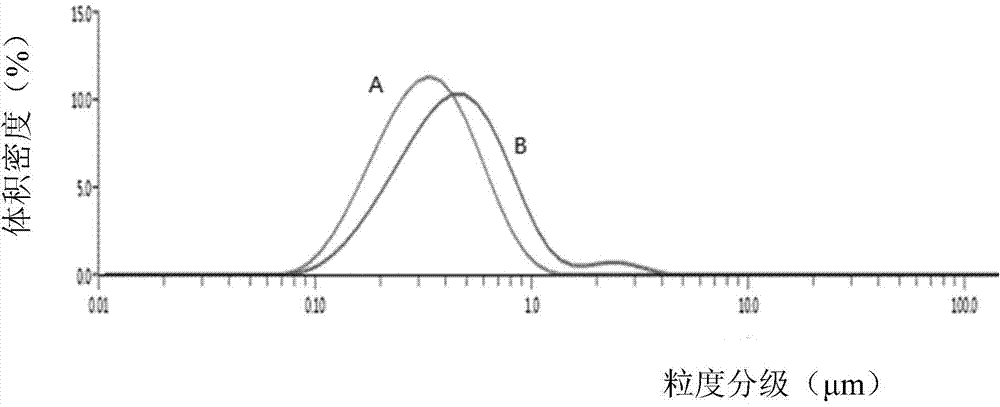

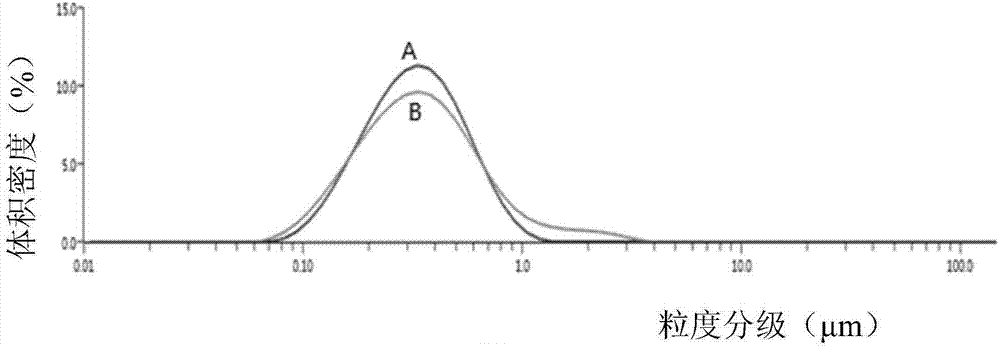

InactiveCN103940783AAccurate predictionScattering properties measurementsParticle size analysisSterilized milkChemistry

The invention discloses a method for predicting the shelf-life stability of sterilized milk. The method comprises the following steps: (1) scanning and measuring the average back scattering light change rate of the sterilizer milk within 22-26 hours in a stability analyzer under aseptic operation, and analyzing data of the average scattering light change rate to obtain an STI value; (2) judging the shelf-life stability of the sterilized milk according to the STI value, when the STI value is less than 1.5, judging that the sterilized milk is accordant with the shelf life of 6 months, when the STI value is more than or equal to 1.5 and less than 2, judging that the sterilized milk is not accordant with the shelf life of 6 months, and when the STI value is more than or equal to 2, judging that the shelf life of the sterilized milk is less than 150 days, wherein the temperature in the scanning and measuring process is 25-40 DEG C. By adopting the method, relevant analysis can be finished within 26 hours, and the shelf-life stability of the sterilized milk can pre-judged rapidly and accurately. The method is very convenient and practical.

Owner:BRIGHT DAIRY & FOOD CO LTD

Middle temperature inactivation ultrahigh temperature instantaneous sterilizing milk and its preparation method

The invention relates to milk and a preparation method, in particular to medium temperature inactivation ultrahigh temperature transient sterilization milk and a preparation method, and belongs to the technical field of milk beverage, food, human necessity (agriculture, light industry and medical industry). The preparation method for medium temperature inactivation ultrahigh temperature transient sterilization milk provided by the invention comprises conventional liquid milk production process, wherein, the medium temperature inactivation procedure is arranged between the UHT sterilization procedure and the sterile canning procedure. With medium temperature inactivation process, enzyme activity of the product provided by the invention is reduced, and therefore, the quality problem of UHT milk, such as bitter mass or caking, etc., can be reduced.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

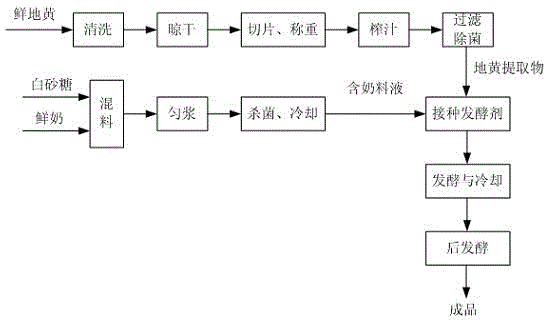

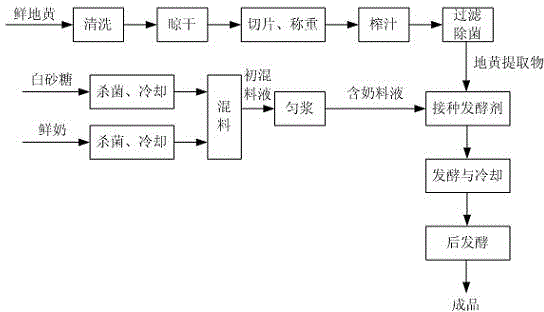

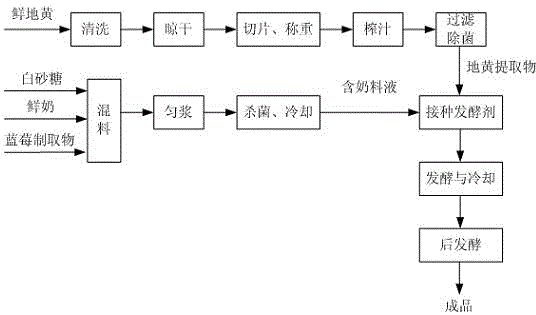

Rehmannia root functional yoghourt, rehmannia root blueberry functional yoghourt and preparation method thereof

InactiveCN103598331AEliminate dry eyesEliminate eye fatigueMilk preparationBlueberry extractFiltration

The invention relates to rehmannia root functional yoghourt, rehmannia root blueberry functional yoghourt and a preparation method thereof. Raw materials for the yoghourt comprise milk and a rehmannia root extract or milk, the rehmannia root extract and a blueberry extract, wherein a ratio of used rehmannia root to used milk is 1.7 kg 100 L to 2.5 kg 100 L, and a ratio of the used blueberry extract to used milk is 1 kg 7 L to 1 kg 12 L. The preparation method comprises the following steps carrying out heat sterilization on a milk-containing material liquid which is composed of milk or includes milk and blueberry as main raw materials; subjecting the rehmannia root extract with stable components to filtration sterilization; mixing the sterilized milk-containing material liquid with the sterilized rehmannia root extract; and adding a starter for fermentation so as to prepare the functional yoghourt. The rehmannia root functional yoghourt has a plurality of health care effects like removal of heat to promote salivation, cooling of blood and stopping of bleeding and is rich in nutritional components; the rehmannia root blueberry functional yoghourt has a plurality of health care effects like eye protection, prevention of cranial nerve aging, strengthening of the heart, resistance to cancers, softening of blood vessels and enhancement of human immunity besides the health care effects of the rehmannia root functional yoghourt.

Owner:HENAN NORMAL UNIV

Sour milk powder producing process

ActiveCN101019574ABreak through the key technical problems of low survival rateMilk preparationOther dairy technologySucroseVitamin B12

The sour milk powder producing process includes the first adding cane sugar into milk material, instantaneous high temperature sterilizing and concentrating to obtain concentrated milk; the subsequent inoculating thermophilic streptococcus and Lactobacillus bulgaricus to high temperature sterilized milk and heat insulating culture to obtain activated spawn; adding leucine, vitamin B12, glutamic acid and the activated spawn to the concentrated milk and homogenizing; and final spray drying similar to producing common milk powder. The present invention has leucine, vitamin B12 and glutamic acid as the high temperature protector to solve the technological problem of well preserving thermophilic streptococcus and Lactobacillus bulgaricus in the high temperature spray drying.

Owner:陕西英童乳业有限公司

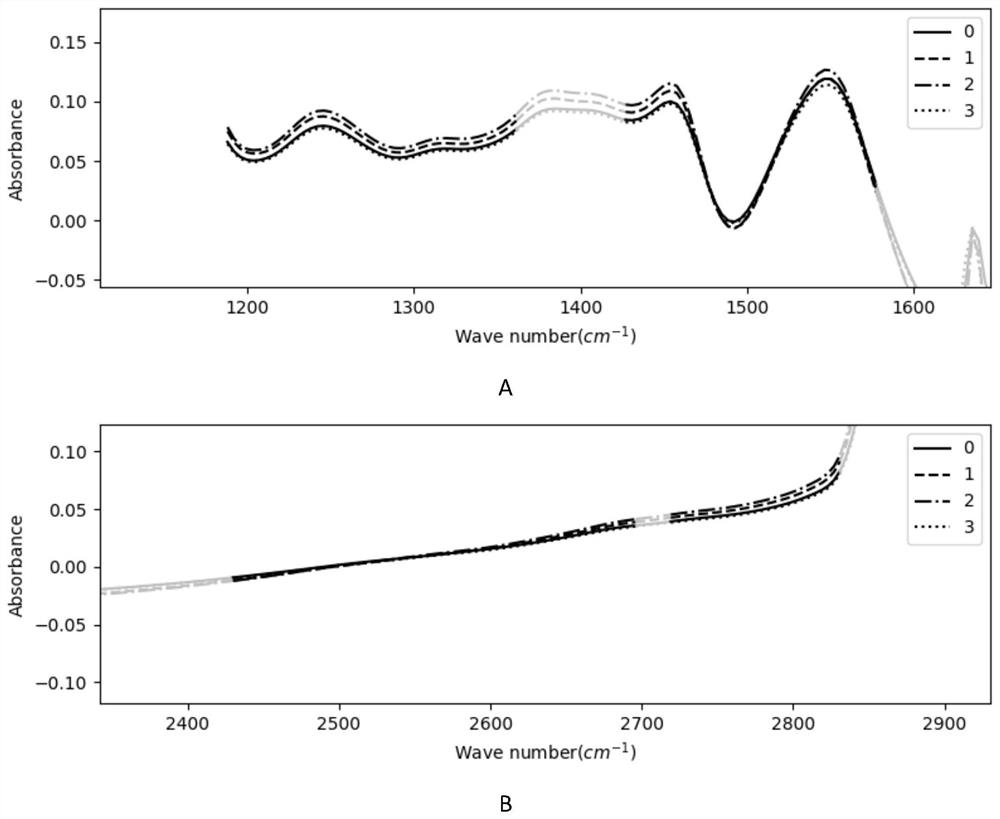

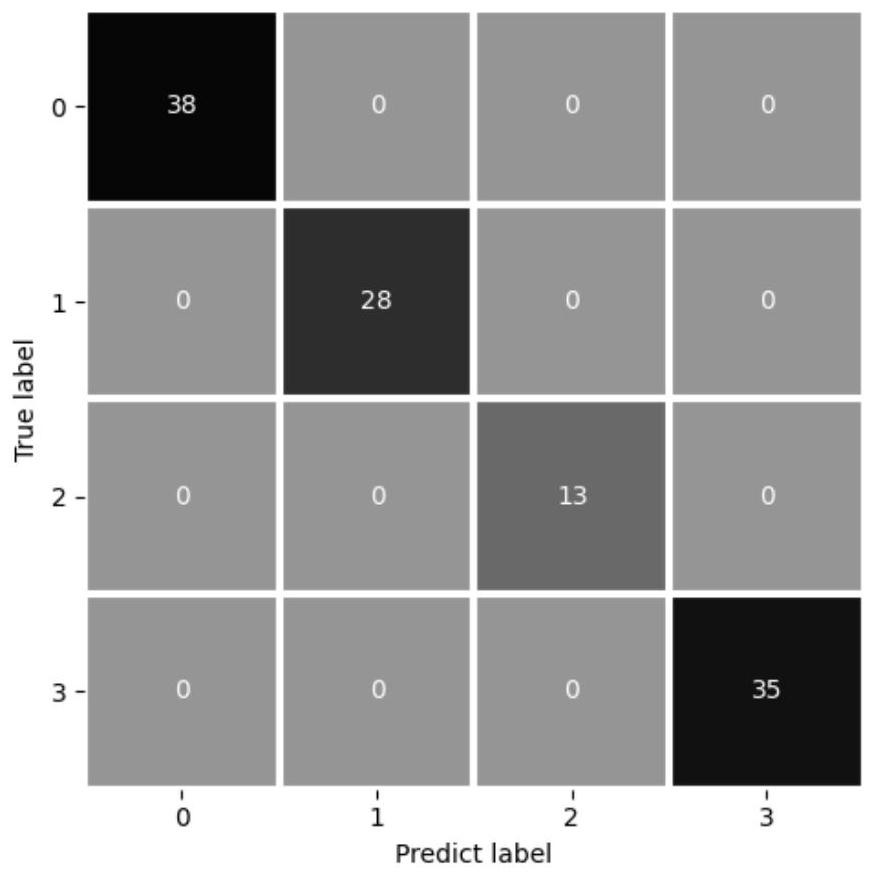

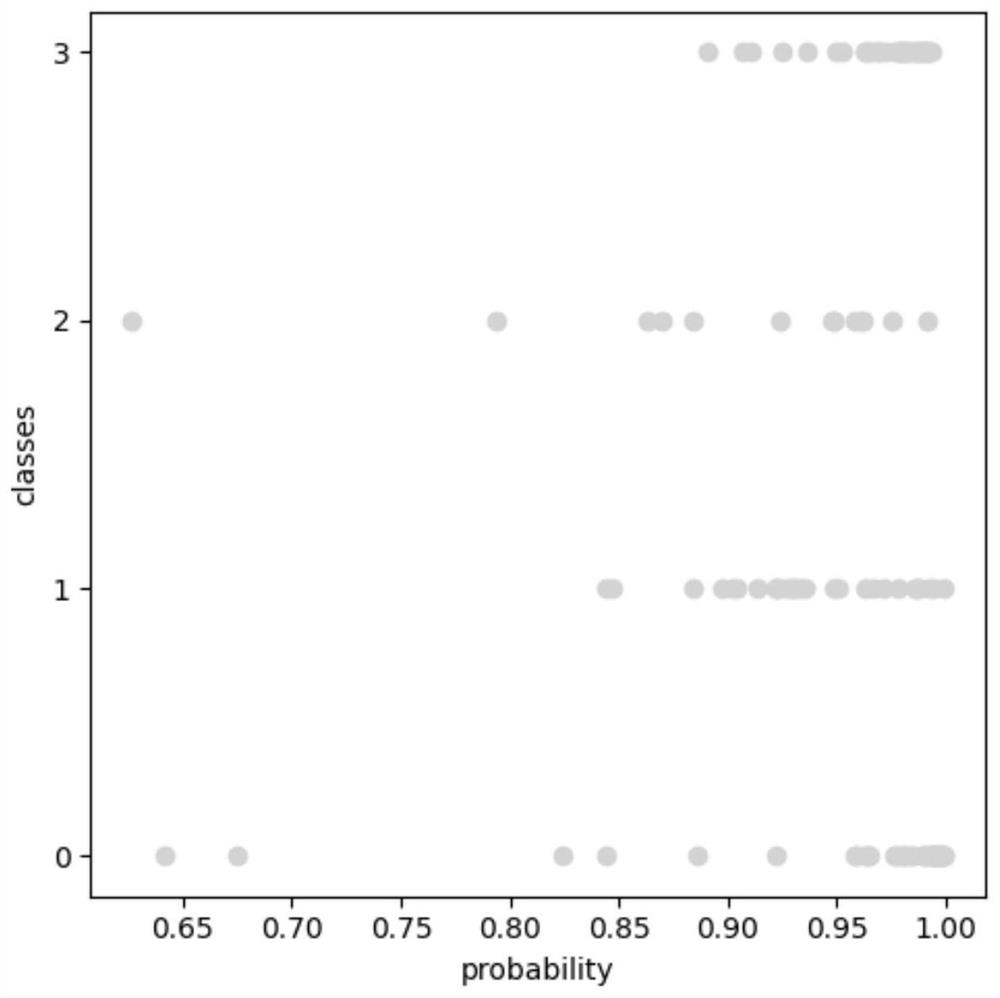

Rapid identification method for four kinds of high-temperature sterilized commercial milk

InactiveCN113310936AFew bandsReduce computing costKernel methodsMaterial analysis by optical meansBiotechnologySpectral bands

The invention belongs to the field of dairy product analysis, and particularly relates to a rapid identification method for four kinds of high-temperature sterilized commercial milk. The four kinds of high-temperature sterilized commercial milk are pure milk, high-end milk, organic milk and A2-beta casein milk. The method comprises the steps of 1) collecting samples of four kinds of high-temperature sterilized milk; 2) scanning the samples in the mid-infrared spectrum range to obtain mid-infrared spectrum data; 3) preprocessing the original mid-infrared spectrum to remove abnormal values; 4) dividing the preprocessed data set into a training set and a test set according to a stratified sampling principle; 5) screening spectral bands for modeling; 6) combining different spectrum preprocessing methods and modeling algorithms, establishing an identification model, evaluating the model by using accuracy and a Kappa coefficient, and screening out an optimal preprocessing method and modeling algorithm combination to obtain an optimal model; and 7) verifying the model, and evaluating the generalization ability of the model.

Owner:HUAZHONG AGRI UNIV

Preparation method of concentrated sour milk

InactiveCN105767176ASmall heat capacityEasy to observeMilk preparationNutritive valuesAdditive ingredient

The invention discloses a preparation method of concentrated sour milk. The preparation method of the concentrated sour milk specially comprises the following steps: inspecting a raw material; and then, carrying out high-temperature sterilizing, cooling, inoculating, fermenting, centrifugal separating, adding of accessory ingredient, filling and refrigerating; the raw material is ultra-high-temperature sterilized milk; the ultra-high-temperature sterilized milk is low-fat sterilized milk and skimmed sterilized milk, or the ultra-high-temperature sterilized milk is whole-fat sterilized milk and skimmed sterilized milk; and fermentation bacteria utilized in the fermentation comprise Lactobacillus bulgaricus, Streptococcus thermophilus, Lactobacillus casei, Lactobacillus acidophilus and Bacillus bifidus. A large number of steps for treating fresh raw milk which are high in energy consumptions and investments are saved by utilizing the ultra-high-temperature sterilized milk as the raw material in the preparation method; many nutritive values are created and a shelf life of the concentrated sour milk is prolonged by high-speed centrifugal separation of casein and whey; and moisture is removed in form of whey in the technologic processes, so that heat capacities of final products are reduced. Thus, the products can be cooled naturally without using cooling equipment which is high in energy consumption.

Owner:LE MOO DAIRY HEFEI CO LTD

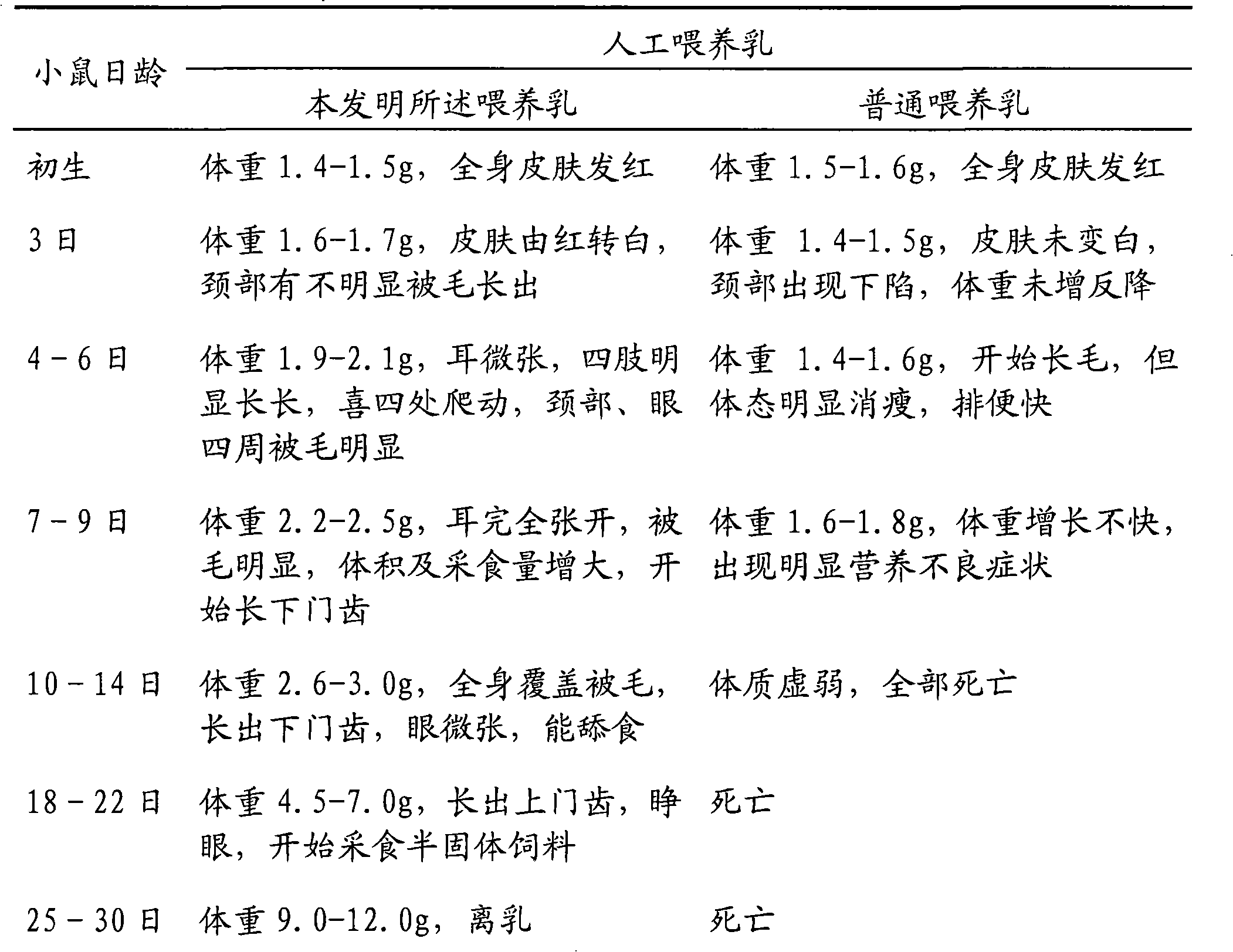

Germfree mice artificial milk and its preparation method

ActiveCN101283704AEasy to prepareImprove survival rateMilk preparationAnimal feeding stuffVitamin CFiltration

The invention discloses a milk for artificially feeding a germ-free mouse and a preparation method thereof. The milk contains, per 102 mL, 45.0-55.0 g of infant milk powder, 3.0-5.0 mg of vitamin B1, 0.7-0.9 mg of vitamin B2, 3.0-5.0 mg of vitamin B6, 30.0-50.0 Mug of vitamin B12, 11.0-13.0 mg of vitamin C, and water in balance. The preparation method of the milk comprises the following steps: sterilizing infant milk powder by irradiation, dissolving the sterilized milk powder in sterile water to make milk solution, dissolving vitamins B1, B2, B6, B12 and C in water to obtain vitamin solution, sterilizing by filtration, mixing the vitamin solution with the milk solution, and stirring thoroughly to obtain the milk for artificial feeding of germ-free mouse. The milk for artificially feeding the germ-free mouse has reasonable trophic structure and simple production process, increases the growth development level and survival rate of artificially-fed germ-free mouse, and reduces the cost of artificial feeding.

Owner:ARMY MEDICAL UNIV

Preparation method for red date yoghourt

InactiveCN105211289ARich in nutrientsNutrients are not destroyedMilk preparationBiotechnologySterilized milk

The invention provides a preparation method for red date yoghourt, which belongs to the technical field of food preparation. The preparation method comprises the following steps: (1) blending: a step of blending fresh milk with honey according to a ratio of 9: 1; (2) preheating: a step of preheating the blended fresh milk and honey at 40 to 55 DEG C for 5 to 10 min; (3) sterilization: a step of carrying out sterilization on the blended fresh milk and honey; (4) fermentation: a step of carrying out fermentation on the sterilized milk so as to form yoghurt; (5) mixing: a step of mixing the yoghurt with red date juice according to a ratio of 4: 1 so as to form the red date yoghurt, and subjecting the red date yoghurt to sterilization and cooling; and (6) filling: a step of subjecting the red date yoghurt to filling and carrying out finished product detection. The preparation method is simple, enables a great number of nutritional components to be obtained and does not destroy nutritional components of the yoghurt.

Owner:何笑飞

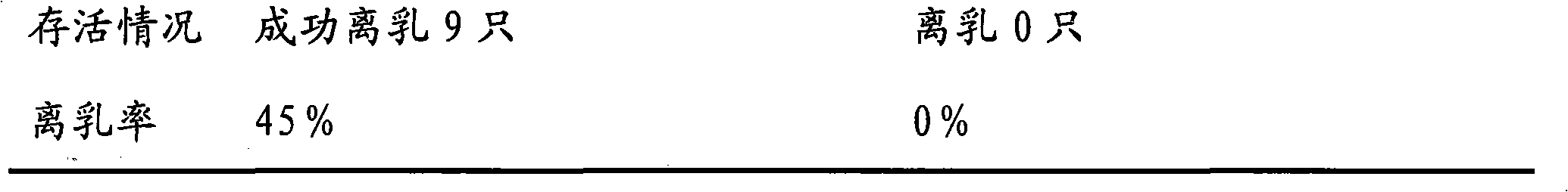

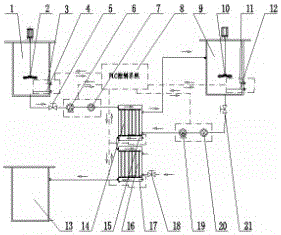

Hot water pasteurization device of fresh milk and automatic control method thereof

The invention discloses a hot water pasteurization device of fresh milk and an automatic control method thereof. The hot water pasteurization device comprises a raw material milk barrel, a hot water barrel, a raw material milk sterilizer, a sterilized milk cooler, a raw material milk metering pump, a hot water metering pump, a connecting pipe and a PLC control system. A thermocouple is used to determine temperatures of fresh milk and heated hot water, the metering pump is used to determine the control flows of the fresh milk and heated hot water, and the PLC automatically adjusts a flowing ratio of the fresh milk and heated hot water so that the automatic control method of setting a sterilization temperature and sterilization time is realized. The automatic control method realizes precise control of the sterilization temperature of 80 to 85 DEG C and the sterilization time of 13-15 seconds, improves bactericidal efficiency and effects, reduces a milk nutrition loss after sterilization, retains the flavor and taste of the sterilized milk and prolongs a shelf life and a storage period.

Owner:UNIV OF JINAN

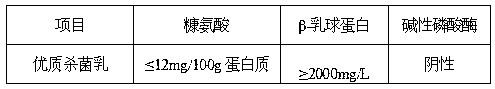

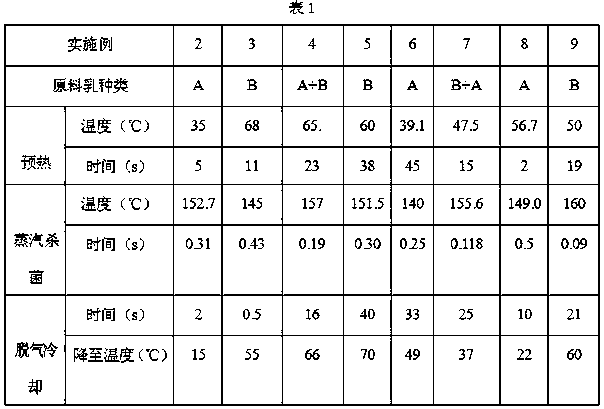

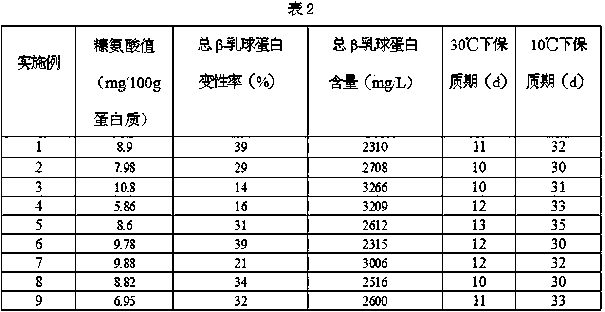

Sterilized milk preparation method

InactiveCN109042874AIncrease contentShort sterilization timeMilk preservationC constantUltimate tensile strength

The invention discloses a sterilized milk preparation method. The method is performed according to the following step sequence: preheating raw milk, directly steam sterilizing, instantly degassing andcooling, homogenizing and filling, wherein raw milk preheating time is 2 to 45 s, a temperature of the preheated raw milk is 35 to 68 DEG C, instant degassing and cooling time is 0.5 to 40 s, and a temperature of the cooled raw milk is 15 to 70 DEG C. According to the sterilized milk preparation method disclosed by the invention, a direct steam sterilizing mode is utilized, sterilizing time is shorter, the denaturation rate of active nutrient substances of milk is low, the heat treatment strength is low, and the milk can be stored under the normal temperature. After the milk is treated by thesterilized milk preparation method disclosed by the invention, a furosine value of the milk is smaller than 12 mg / 100 g protein, a beta-lactoglobulin content is larger than or equal to 2000 mg / L, shelf life is larger than or equal to 30 days, and shelf life under 30 DEG C constant-temperature storage is larger than or equal to 10 days. The sterilized milk preparation method is suitable for milk processing process.

Owner:JUNLEBAO DAIRY GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com