Patents

Literature

69 results about "Para-Cresol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Para-Cresol, also 4-methylphenol, is an organic compound with the formula CH 3 C 6 H 4 (OH). It is a colourless solid that is widely used intermediate in the production of other chemicals. ... p-Cresol is produced by bacterial fermentation of protein in the human large intestine.

Methods of making sterilized milk compositions comprising native gellan gum

InactiveUS6663911B2Optimize para-cresol reductionFunction increaseMilk preparationFood preservationGellan gumSphingomonas elodea

Owner:CP KELCO U S INC

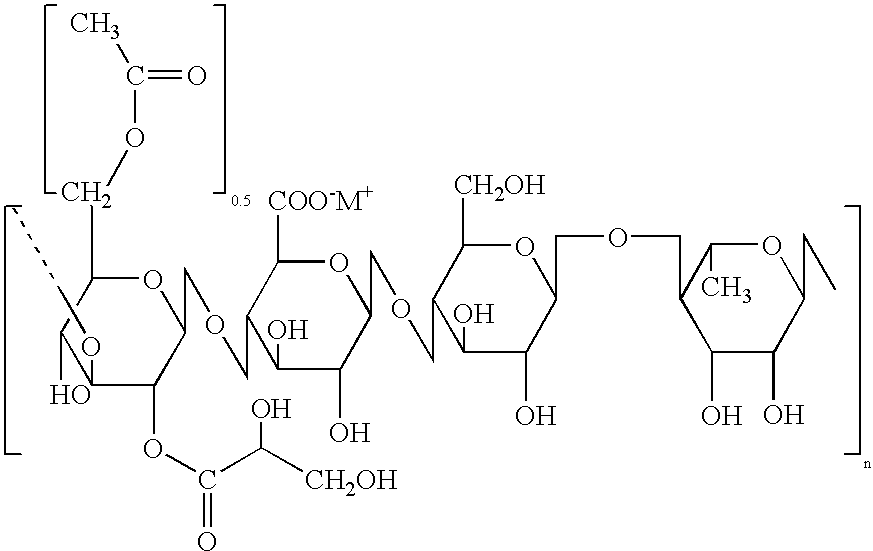

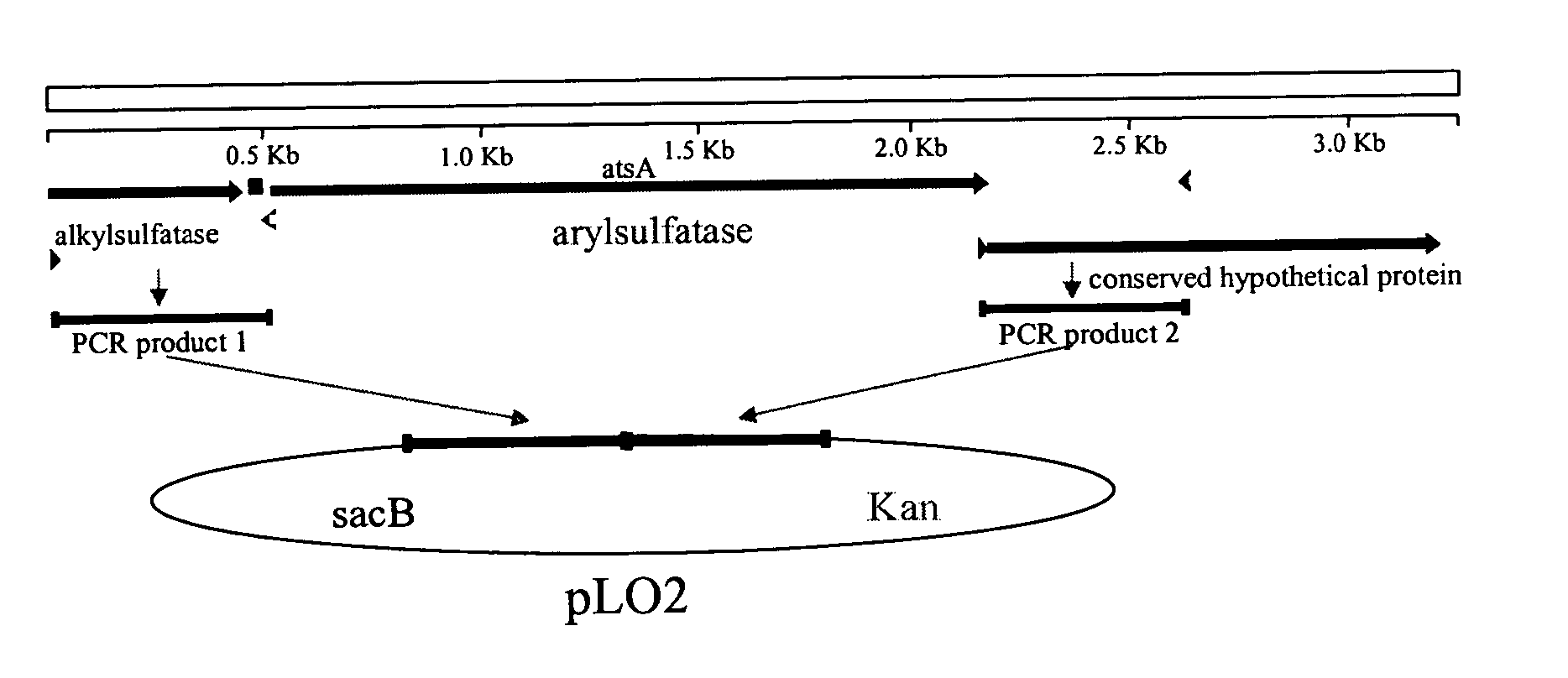

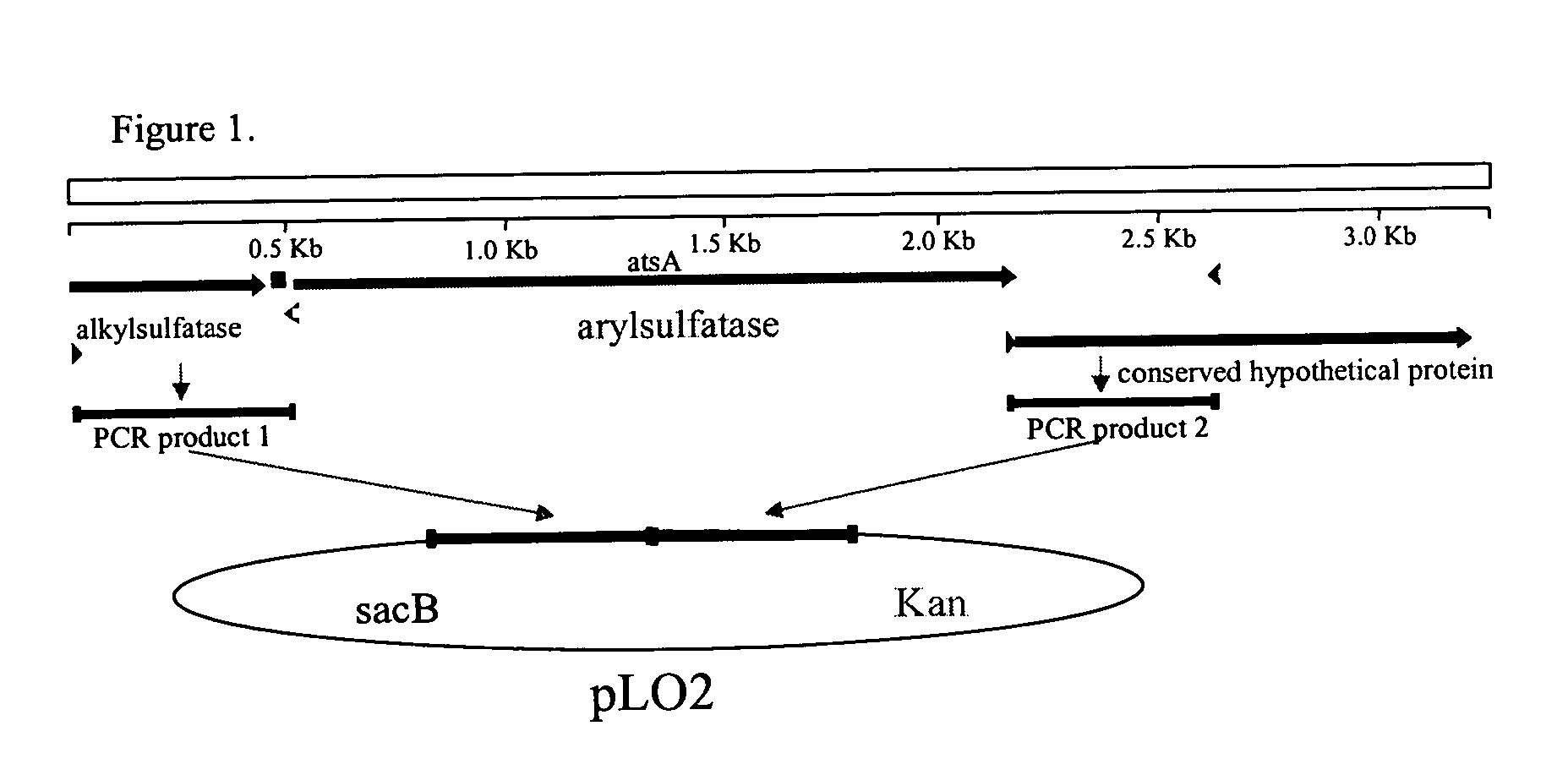

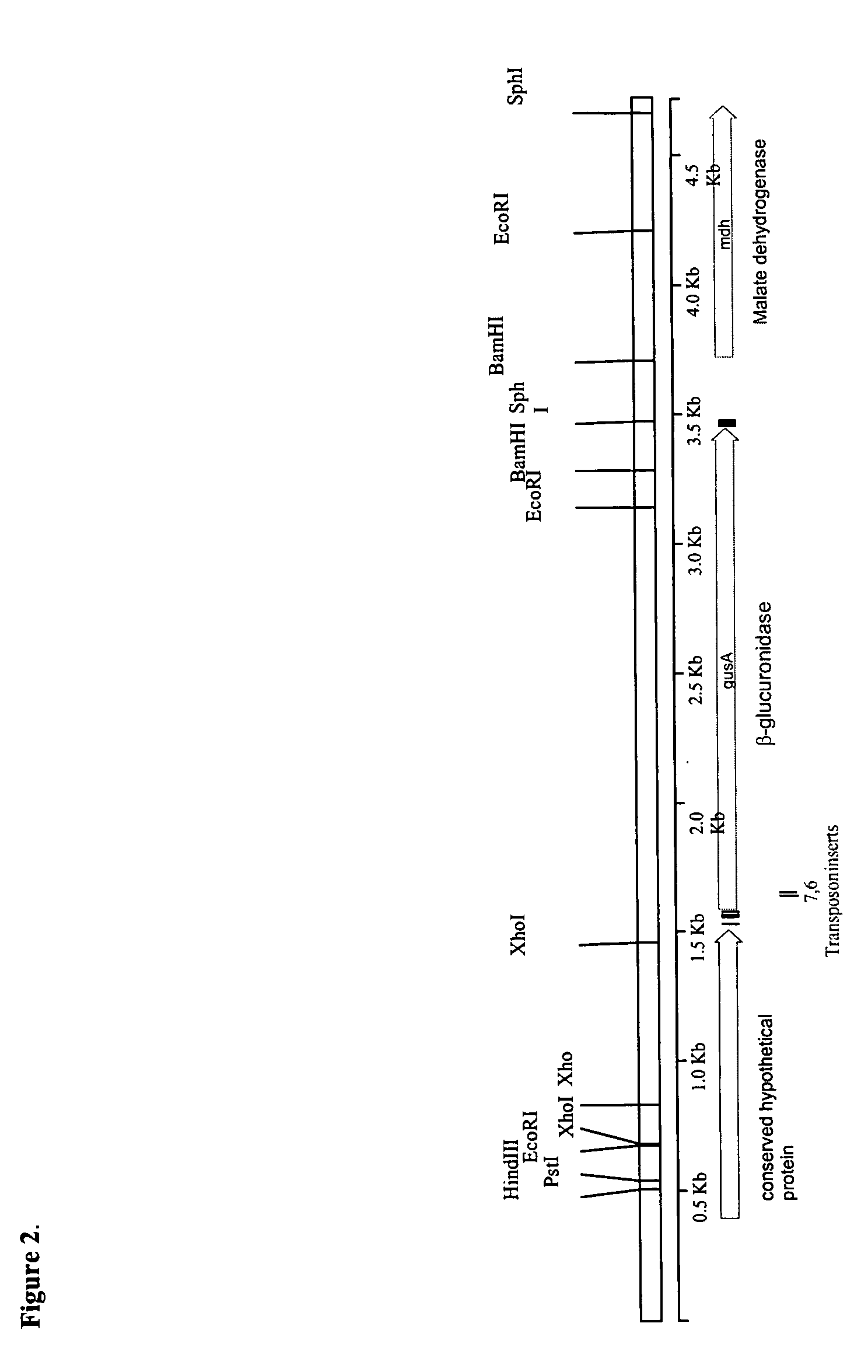

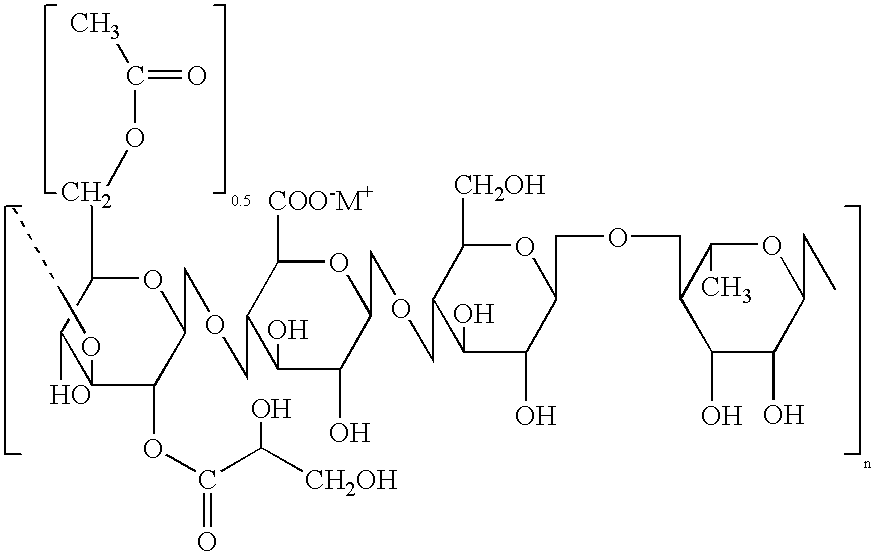

Genetically purified gellan gum

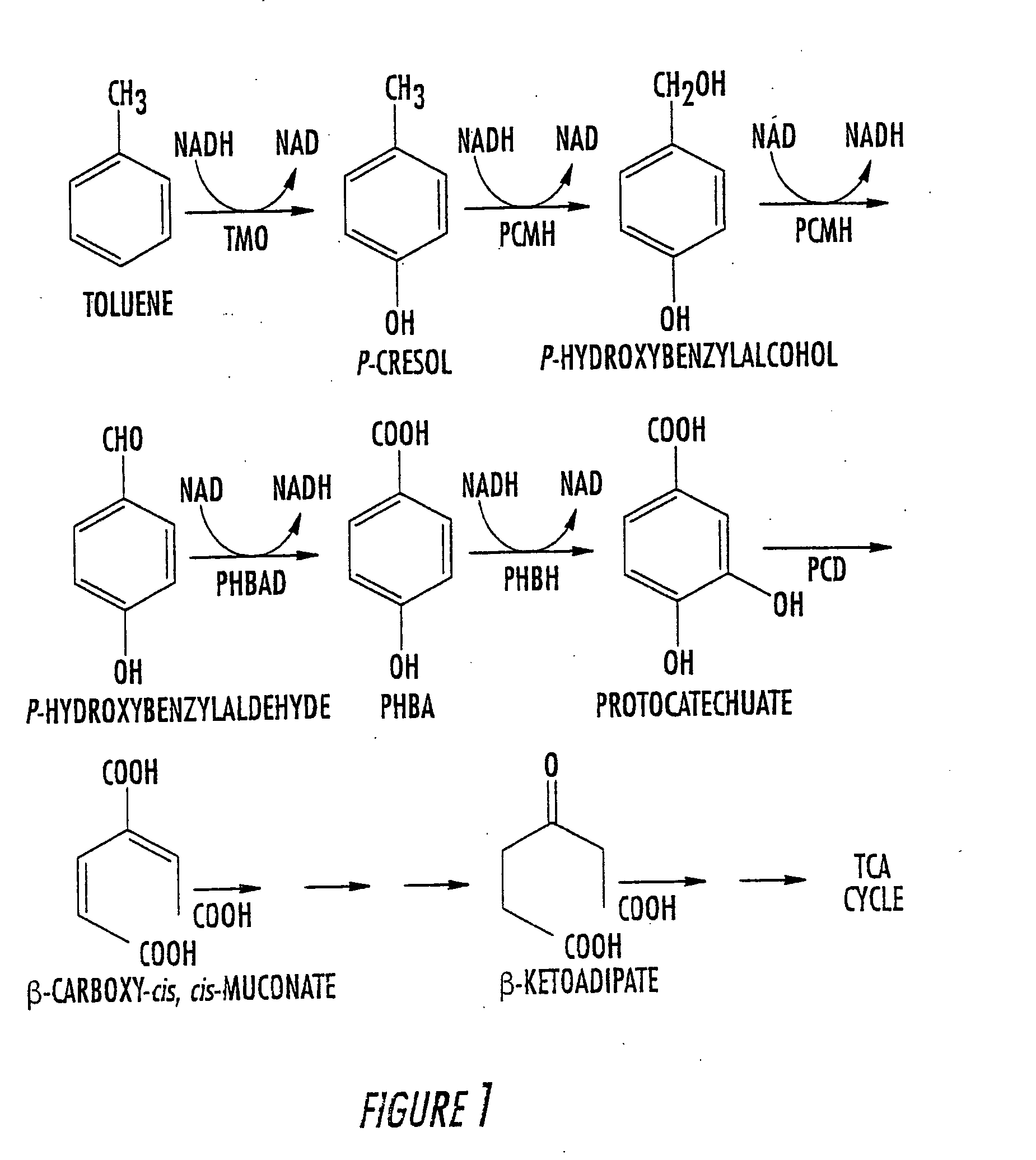

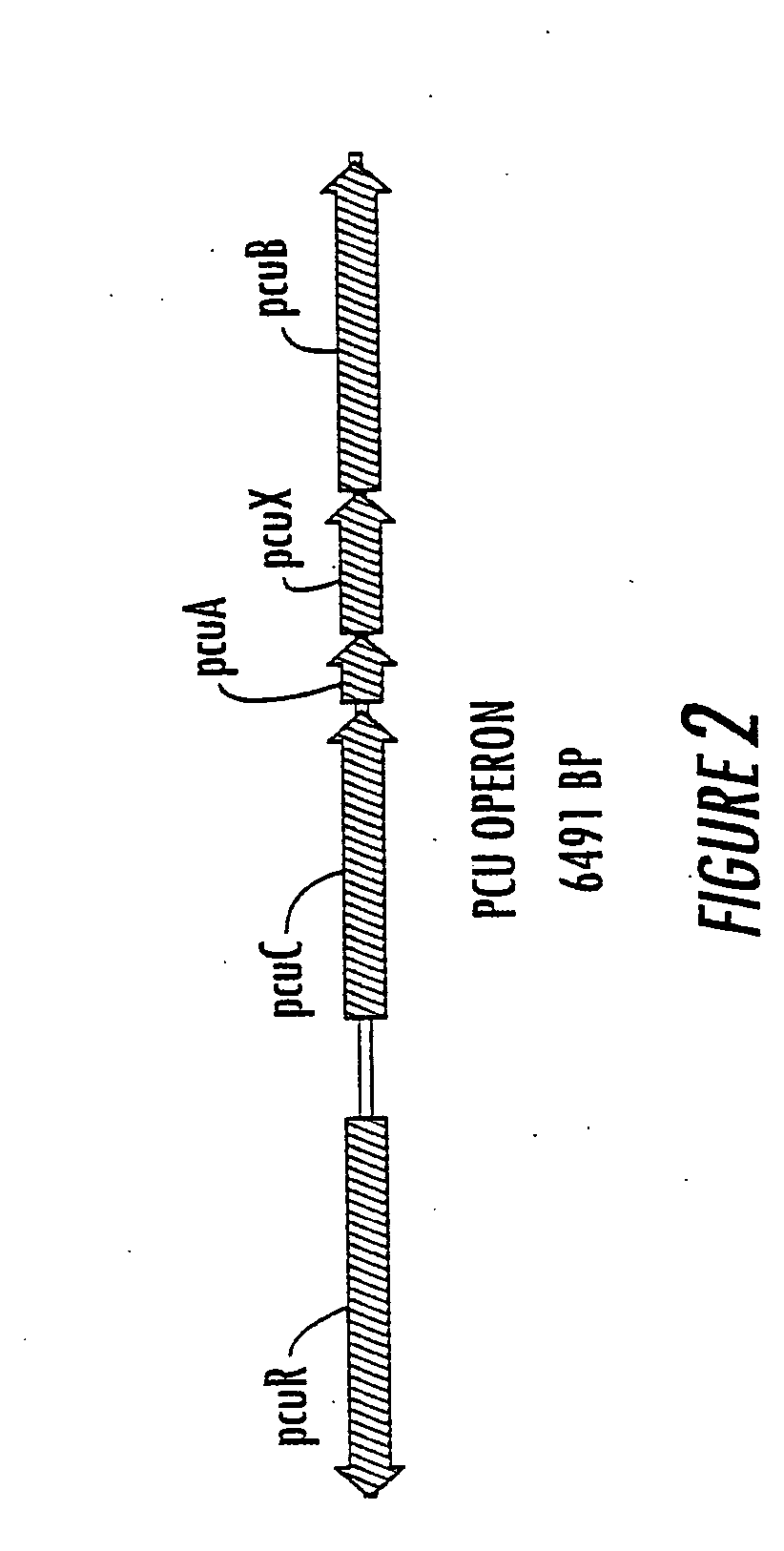

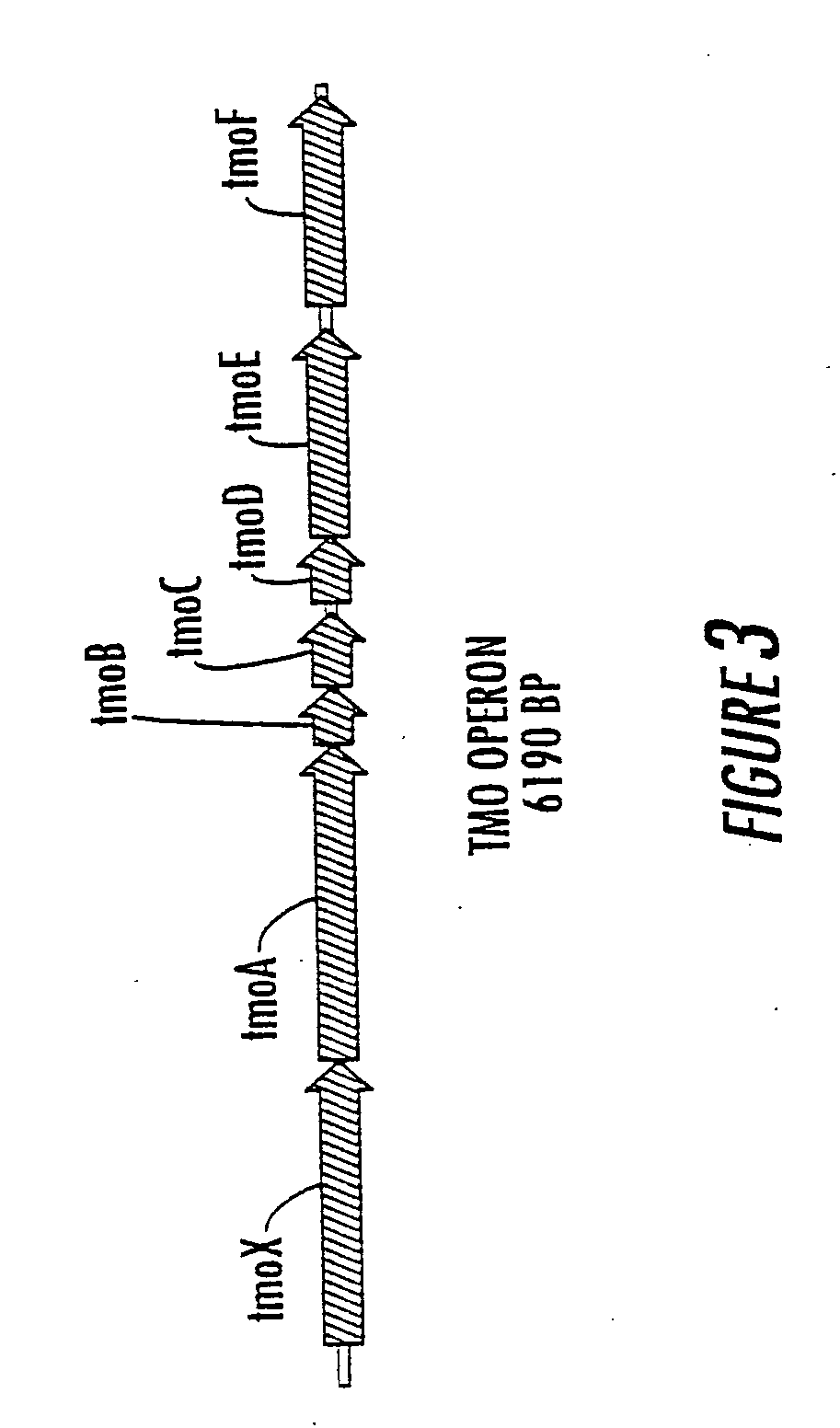

Mutational inactivation of proteins involved in para-cresol production in certain milk products results in improved taste and odor. The undesirable para-cresol forms over time as a result of enzymes produced by the bacterium that produces gellan gum. Since the gellan is typically used in a relatively unpurified form, the enzymes are added to the milk along with the gellan. Inactivation of the enzymes is a genetic means of eliminating the enzymes without requiring any additional purification or processing.

Owner:CP KELCO U S INC

BPA and polycarbonate made from renewable materials

Owner:SHPP GLOBAL TECH BV

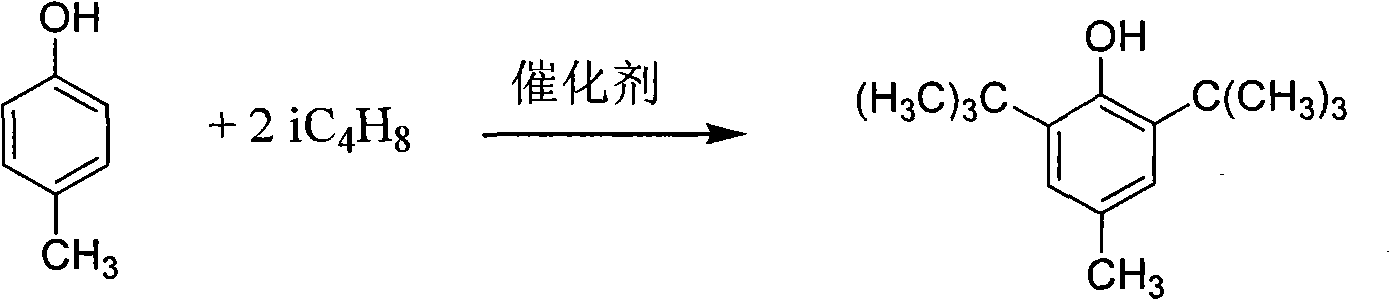

Processing technique of 2,6-ditbutyl-4-methylphenol

The invention mainly discloses a processing technique of 2,6-ditbutyl-4-methylphenol, which mainly comprises the steps of: alkylating methylphenol and isobutene and then neutralizing and washing the alkylated product. The processing technique of the 2,6-ditbutyl-4-methylphenol is characterized in that a catalyst with a usage amount of 0.3-1.5% mole percent of the methylphenol is added in the process of the alkylation of the methylphenol and the isobutene; the alkylated product after being washed is directed refined; methods of reduced pressure distillation and re-crystallization are jointly carried out in the refining process; and then the finished product of the 2,6-ditbutyl-4-methylphenol is obtained through offcentering and drying steps. The processing technique of the 2,6-ditbutyl-4-methylphenol has the advantages as follows: the yield of a course product of BHT (butylated hydroxytoluene) can reach 92% or higher with the adoption of methanesulfonic acid or sulfamic acid as a novel catalyst for the alkylation, and the purity of the pure product can reach 99% or higher through the joint of the reduced pressure distillation and the re-crystallization.

Owner:RUGAO JINLING CHEM

Methods of making sterilized milk compositions comprising native gellan gum

InactiveUS20020146499A1Lower levelHigh purityMilk preparationFood preservationPara-CresolPre treatment

The present invention relates to a method of making a sterilized milk composition comprising native gellan gum, wherein the native gellan gum has been pre-treated with a denaturing agent. The method comprises the step of pre-treating the native gellan gum with a denaturing agent such as a common oxidative agent or an alkaline caustic agent prior to mixing and sterilizing the native gellan in milk. Preferably, treatment with the denaturing agent results in reduction of para-cresol levels in the sterilized native gellan / milk composition to below 25 ppb after 12 months of storage, and most preferably, to levels where para-cresol is undetectable by taste. The present invention further relates to sterilized milk compositions and milk-based gellan food products.

Owner:CP KELCO U S INC

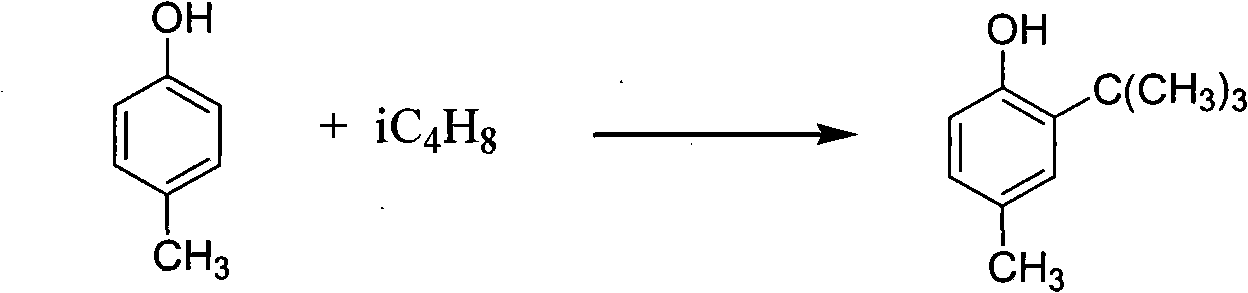

Method for fixed bed alkylation separation of m-cresol and p-cresol

InactiveCN104496759ASuppress generationReduce consumptionOrganic chemistryOrganic compound preparationFixed bedIt technology

Relating to the field of m-cresol and p-cresol separation and its technology, the invention discloses a new method of separating an m-cresol and p-cresol mixture to obtain high-purity m-cresol and p-cresol. The method takes a m-cresol and p-cresol mixed solution and isobutene gas as the raw materials, and employs a solid supported acidic ionic liquid as the catalyst to carry out alkylation reaction in a fixed bed, the obtained alkylation product is separated to obtain mono-t-butyl cresol, which is subjected to de-tert-butylation, thus obtaining the high purity m-cresol and p-cresol.

Owner:ANQING FULLTIME CHEM INDAL +1

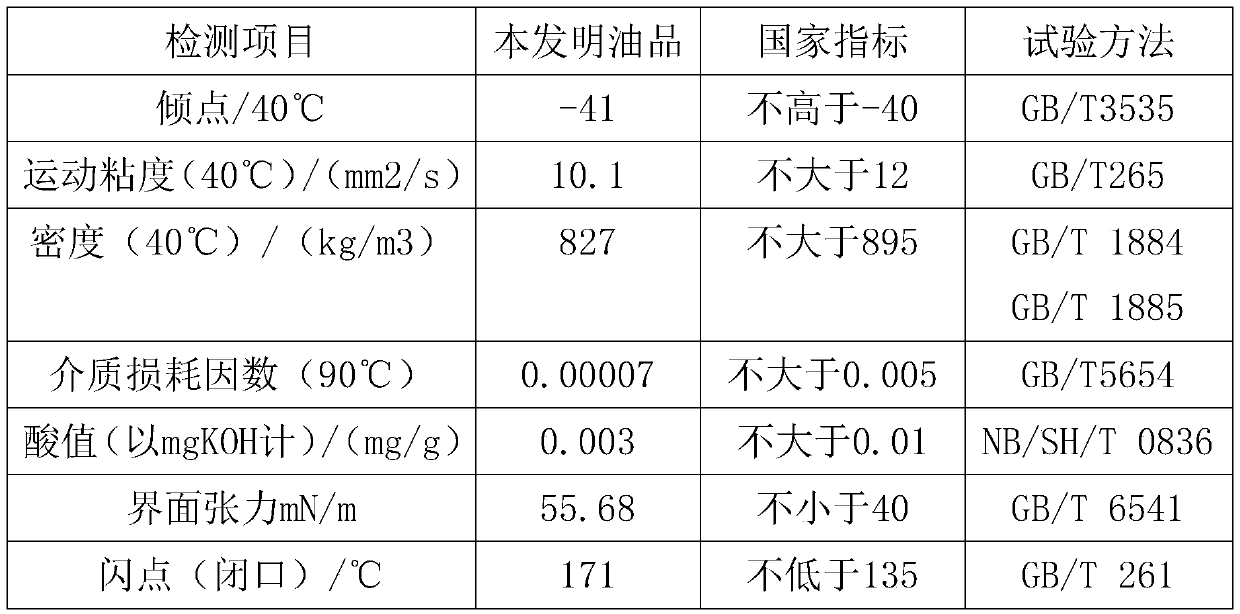

High-temperature overload transformer oil and preparation method thereof

The invention provides a high-temperature overload transformer oil, relating to the technical field of lubricating oil production. The high-temperature overload transformer oil is prepared from the following raw materials: 2-4 parts of hydroxy stearin, 2-4 parts of dibutyl phthalate, 3-5 parts of sulfurized calcium alkyl phenate, 2-4 parts of methyl acrylate, 80-90 parts of hydrogenated base oil, 1-3 parts of adsorbent, 2-4 parts of 2,6-di-tert-butyl-para-cresol and 2-4 parts of 2(2H-benzotriazolyl-2-yl)-6-dodecyl-4-methyl phenol. The power industry thermoelectric power generation equipment and material quality inspection indicates that the high-temperature overload transformer oil provided by the invention has the advantages of obvious use effect, high product quality, moderate kinematic viscosity, high flash point, excellent antioxidation and antiaging stability, high cleanness and transparency and favorable gassing property and is suitable for popularization and application.

Owner:ANHUI KAIAO NEW ENERGY CO LTD

Myllocerinus aurolineatus voss attractant and preparation method of lure of same

ActiveCN102125033AEasy to prepareImprove economyBiocidePest attractantsAntioxidantUltraviolet lights

The invention relates to a myllocerinus aurolineatus voss attractant and a preparation method of a lure of the same, belonging to the technical field of insect lures. The myllocerinus aurolineatus voss attractant comprises the following components: cis / trans-ocimene, cis-3-hexenyl acetic ester, 2,6-di-tert-butyl para-cresol and 2-hydroxyl-4-methoxy benzophenone. The preparation method of the lureof the myllocerinus aurolineatus voss attractant comprises the following steps of: preparing a lure carrier; preparing the myllocerinus aurolineatus voss attractant; and combining the lure carrier with the myllocerinus aurolineatus voss attractant. The myllocerinus aurolineatus voss attractant has reasonable compatibility and can effectively attract, collect, prevent and control the myllocerinus aurolineatus voss; the lure of the myllocerinus aurolineatus voss attractant can slowly and uniformly release the effective components by adopting compounded rubber as the lure carrier, thereby prolonging the persistent period; and added antioxidant and ultraviolet light adsorbent can well protect the components of the myllocerinus aurolineatus voss attractant from being subjected to oxygenolysis by factors, i.e. external air, light, ultraviolet rays, and the like. Thus the myllocerinus aurolineatus voss attractant disclosed by the invention is a persistent myllocerinus aurolineatus voss attractant.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Non-halogen red phosphorus flame-retardant heat shrinking tube and preparation method thereof

The invention provides a non-halogen red phosphorus flame-retardant heat shrinking tube. The heat shrinking tube comprises the following components in parts by weight: 100 parts of ethylene-acetate hexane copolymer, 90 to 110 parts of magnesium hydroxide, 5 to 20 parts of polyphosphazene, 1 to 3 parts of complex antioxidant, and 2 to 5 parts of lubricant, wherein the acetate hexane content of the ethylene-acetate hexane copolymer is 14-28 percent; the average grain size of the magnesium hydroxide is less than 4 mu m; the anti-oxidant is compounded of 2,2'-methylene-bis(6-tert-butyl-para-cresol) and 2-hydroxy-4-(octyloxy)benzophenone which are in a ratio of 5:1; and the lubricant is one or more of the following substances: polyethylene wax, zinc stearate and stearic acid. The non-halogen red phosphorus flame-retardant heat shrinking tube does not contain halogen, red phosphorous, lead, mercury, cadmium, hexavalent chromium or other toxic and harmful substances, the flame retardance can pass VW-1 test, the tensile strength is more than 10.9MPa, the elongation at break is more than 260 percent, the product surface is smooth, and the processing performance is excellent.

Owner:CHANGYUAN GRP

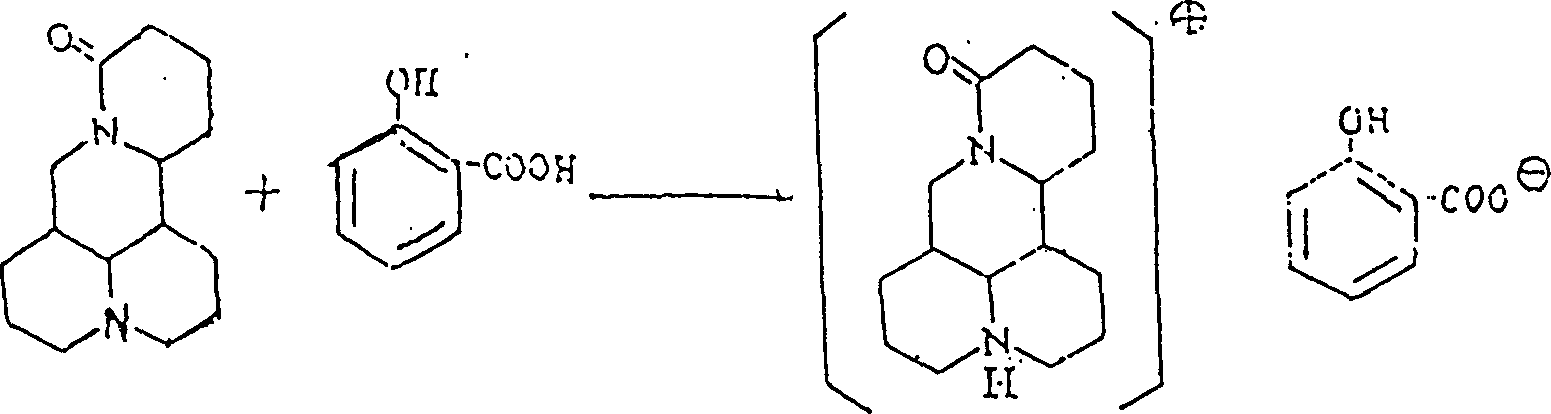

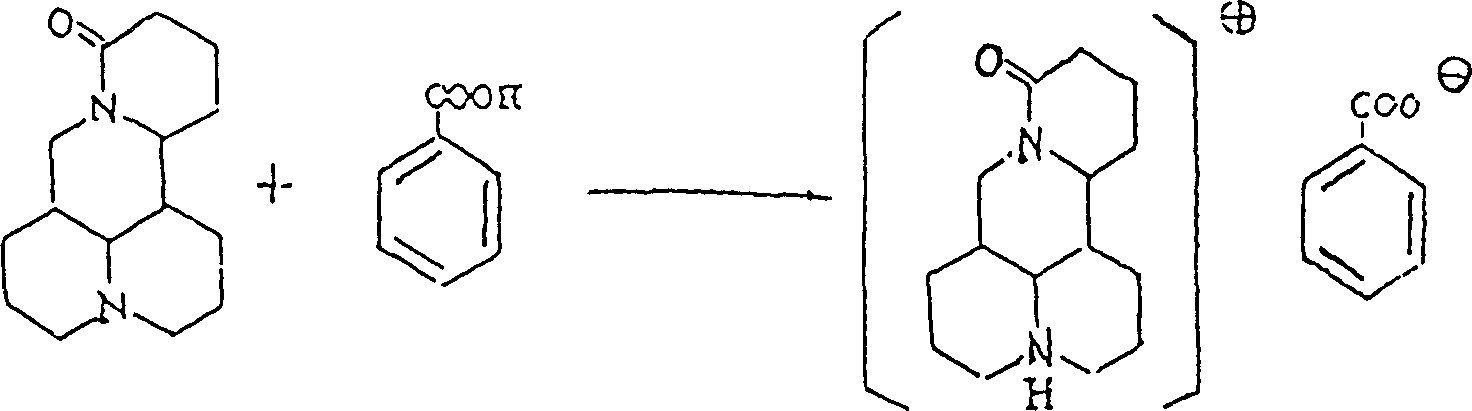

Medicine for treating tinea containing biological alkaline salt and preparation thereof

ActiveCN1644206ASignificant effectQuick effectAntimycoticsUnknown materialsFood scienceCurative effect

Owner:黄早堂

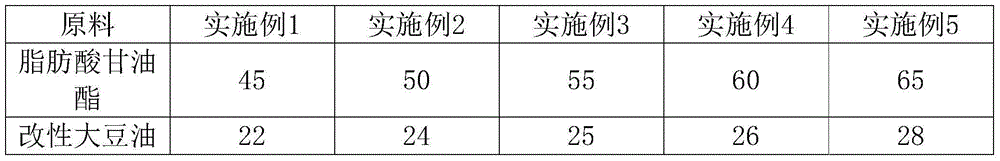

Antirust lubricant and preparation method thereof

InactiveCN104830491AHigh biodegradation rateHigh viscosity indexLubricant compositionVegetable oilPhosphate

The invention relates to the technical field of lubricants, particularly an antirust lubricant and a preparation method thereof. The antirust lubricant is composed of the following components in parts by mass: 45-65 parts of fatty glyceride, 22-28 parts of modified soybean oil, 5-10 parts of methyl silicone oil, 2-5 parts of corrosion inhibitor, 4-8 parts of non-ionic surfactant, 5-10 parts of sulfonate rust inhibitor, 4-8 parts of phosphate amine salt, 1.2-1.5 parts of antirust compound oil, 1.2-2.4 parts of sodium molybdate, 2-5 parts of polyethyleneglycol, 6-12 parts of glycerol, 0.02-0.06 part of 2,6-di-tert-butyl-para-cresol, 0.2-0.8 part of solid additive and 0.1-0.5 part of antioxidation preservative. By using the modified soybean oil as the base oil, the biodegradability is high. The antirust lubricant has the advantages of high viscosity index, favorable viscosity-temperature characteristics, favorable low-temperature fluidity, accessible raw materials and low cost. The antirust lubricant has excellent extreme pressure abrasion resistance since the vegetable oil polar molecules can form a protective film on the metal surface.

Owner:ZHANGJIAGANG SHANMU NEW MATERIAL TECH DEV

Environment-friendly hot-melt adhesive for paper-plastic compounding

InactiveCN104893615ALow costGood adhesionNon-macromolecular adhesive additivesStarch derivtive adhesivesMicrocrystalline waxButylated hydroxytoluene

The invention discloses an environment-friendly hot-melt adhesive for paper-plastic compounding, which is composed of the following components in parts by weight: 50-60 parts of wheat modified starch, 20-30 parts of PLA (polylactic acid) resin, 15-20 parts of terpene resin, 5-10 parts of microcrystalline wax, 2-6 parts of dibutyl phthalate, 0.5-1 part of 2,6-di-tert-butyl-para-cresol and 1-5 parts of talcum powder. By using the modified wheat starch as the main base material, the cost of the product is greatly lowered. The hot-melt adhesive has favorable bonding performance, and can be widely used for paper-plastic compounding packaging.

Owner:合肥卓元科技服务有限公司

Synthetic transformer oil composition

InactiveCN104673456ALow costGood thermal oxidation resistanceLubricant compositionUltravioletOxidation resistant

The invention discloses a synthetic transformer oil composition which is prepared from the following raw materials in parts by weight: 15-30 parts of paraffin base oil fraction, 5-10 parts of 2,6-di-tert-butyl-para-cresol, 10-20 parts of naphthene base oil, 2-4 parts of n-dodecylbenzene, 1-5 parts of benzotriazole, 2-5 parts of ultraviolet absorbent UV-P, 2-4 parts of coconut oil, 3-6 parts of anhydrous calcium chloride, 2-5 parts of ultraviolet absorbent, 3-7 parts of polybutylvinylether, 4-8 parts of dibutyl phthalate, 6-9 parts of sulfurized calcium alkyl phenate, 5-10 parts of methyl acrylate and 2-8 parts of pentaerythritol. The synthetic transformer oil composition has the advantages of excellent comprehensive properties, low kinematic viscosity, high flash point, excellent and stable oxidation resistance and moderate gassing property, and is capable of inhibiting the transformer oil flow from being electrically charged and enhancing the product quality and work efficiency.

Owner:QINGDAO KERUN PLASTIC MACHINERY

Photoresist resin composition

InactiveCN103329042AHigh sensitivityHigh resolutionPhotomechanical apparatusSemiconductor/solid-state device manufacturingResistSolvent

Provided is a photoresist resin composition having excellent sensitivity and resolution and high film retention, as well as other properties that are at least commensurate with those of the commonly used compositions. The photoresist resin composition contains a high-ortho-novolac phenol resin, a naphthoquinone diazide derivative, and a solvent, the high-ortho-novolac phenol resin being obtained by reacting an aldehyde and one or two compounds selected from meta-cresol, para-cresol, 3,5-xylenol, and 2,3,5-trimethylphenol in the presence of an acid catalyst at a temperature of 110-220 DEG C.

Owner:SUMITOMO BAKELITE CO LTD

Engine cleanser and preparation method thereof

InactiveCN105255606AClean thoroughlyEasy to makeOrganic non-surface-active detergent compositionsCleansers skinTG - Triglyceride

The invention provides an engine cleanser and a preparation method thereof. The engine cleanser is prepared from, by weight, 70-80 parts of 650SN base oil, 2-5 parts of para-cresol, 5-8 parts of lecithin, 7-10 parts of naphthenic acid, 15-20 parts of triglyceride and 20-30 parts of water. The 650SN base oil is heated to 60 DEG C to 70 DEG C, lecithin, naphthenic acid and glyceric acid are added, and even stirring is carried out. The water is heated to 60 DEG C to 70 DEG C, para-cresol is added, and even stirring is carried out. The two solutions are mixed and evenly stirred and are cooled to room temperature. The engine cleanser with the formulation can thoroughly remove deposited carbon in an engine, and is environmentally friendly, and the defects of an existing cleanser are overcome.

Owner:SHANGHAI CHANGYU COMM TECH CO LTD

BPA and Polycarbonate Made from Renewable Materials

ActiveUS20100152406A1Less carbon contentOrganic chemistryOrganic compound preparationDiacetone alcoholPolymer science

Bio-derived bisphenol A is made by combining bio-derived phenol and / or bio-derived acetone in the presence of a catalyst, The phenol or the acetone or both contain at least 0.5%, for example at least 1 weight % of bio-derived impurities. In the case of bio-derived phenol, these impurities may include one or more of 2-methylbenzofuran, 2-methoxyphenol, 2-methylphenol, 4-methylphenol (para-cresol) or 2-methoxy-4-methylphenol. In the case of acetone, the impurity may be ethanol, mesityl acetone and / or diacetone alcohol. This bio-derived BPA can be used in the production of polycarbonates with less fossil fuel-based carbon content.

Owner:SHPP GLOBAL TECH BV

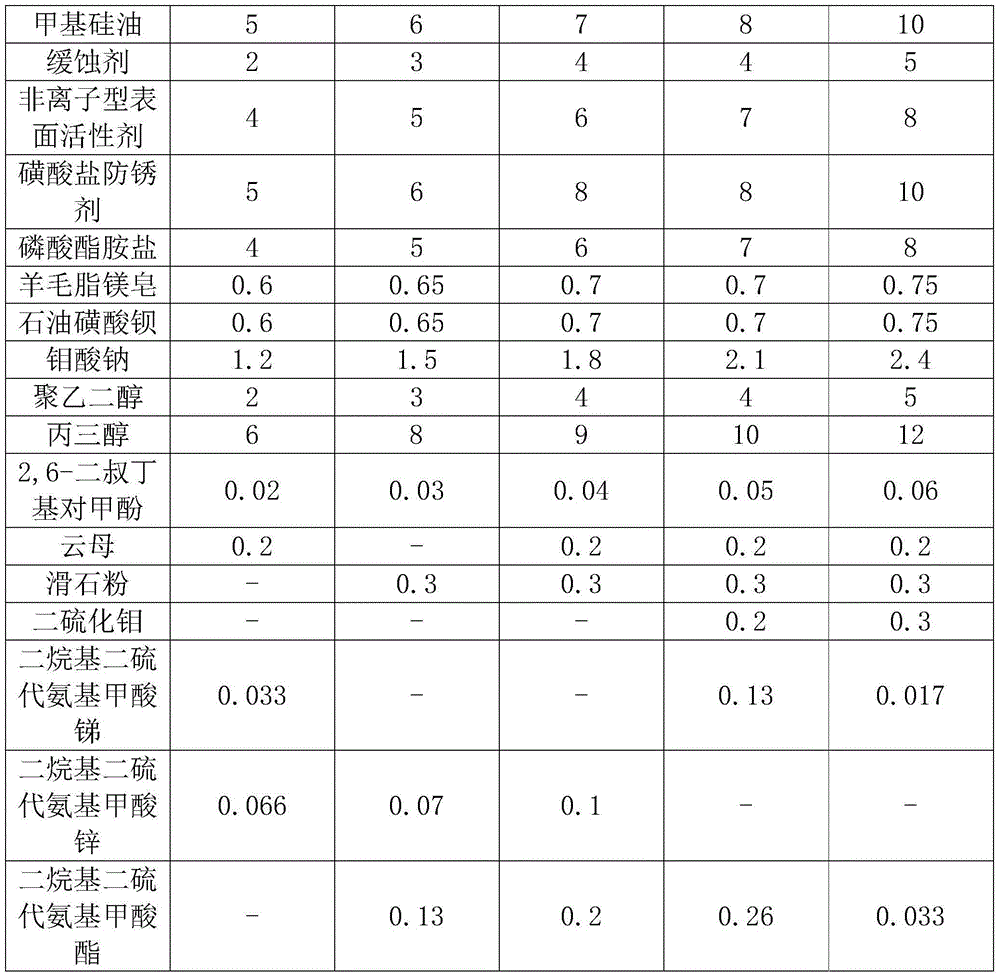

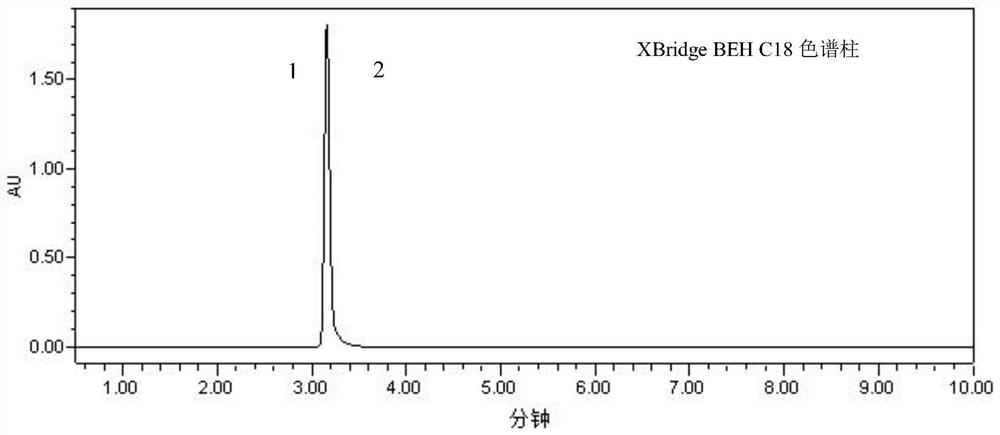

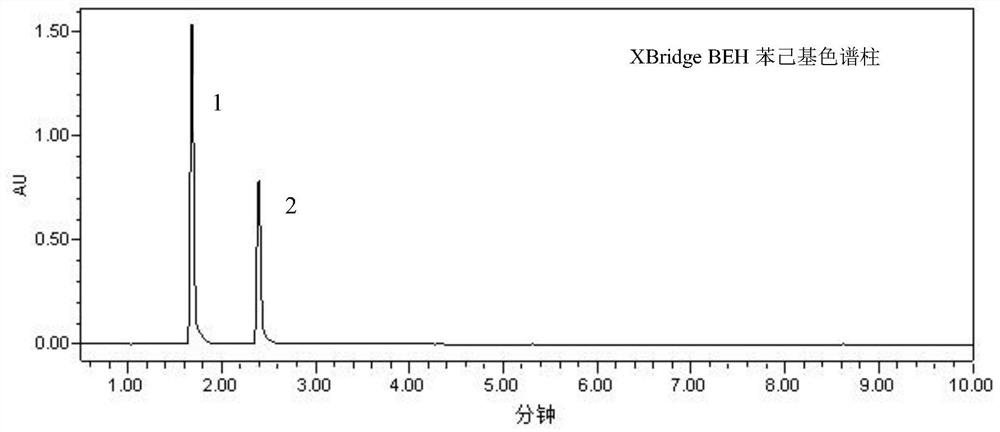

Method for separating and detecting m-cresol and p-cresol content through ultrahigh liquid chromatography and application thereof

The invention discloses a method for separating and detecting m-cresol and p-cresol content by adopting a phenyl column through ultra-high performance liquid chromatography. The method comprises the following steps of: adopting a chromatographic column taking triple bond bonding as a stationary phase, taking an organic phase-aqueous phase buffer solution as a mobile phase, and ensuring that the flow rate is 0.1-0.3 mL / min, wherein the detection wavelength is 210-400 nm; the column temperature is 10-40 DEG C; the sample size is 0.5-5 mu L; respectively carrying out ultrahigh liquid chromatography on standard samples with different concentration gradients and samples to be detected, establishing a linear regression curve, and substituting the peak area measured by the samples to be detectedinto the regression curve to obtain the contents of the cresol and the p-cresol in the samples to be detected. According to the method, the analysis time is greatly shortened, the operation is simpleand convenient, pre-column derivatization is not needed, and the purpose of product quality control can be quickly and accurately achieved. In addition, the solvent consumption is reduced, and the analysis cost is reduced.

Owner:RACHEM CHINA CO LTD +1

Liquid medicine for treating dermatophytosis and tinea pedis

InactiveCN101716337AEasy to makeCompatibility is scientific and reasonableAntimycoticsPeptide/protein ingredientsPropanoic acidArginine

The invention relates to liquid medicine for treating dermatophytosis and tinea pedis, aiming to effectively solve the problem of quick and efficient treatment of dermatophytosis and tinea pedis. A preparation method of the liquid medicine comprises the following step of: uniformly mixing 50-70 percent of active compound amino acid, 25-45 percent of vegetable acid and 3-8 percent of papain in percentage by weight, wherein the active compound amino acid is formed by uniformly mixing aspartic acid, threonine, glutamic acid, glycocoll, alanine, cystine, methionine, isoleucine, leucine, tyrosine, praline, arginine, histidine, lysine, phenylalanine, valine and water; the vegetable acid comprises acetic acid, methanoic acid, propionic acid, methyl alcohol, acetone, 2-furan aldehydes, 2-cyclopentenone, guaiacol, para-cresol, ob-cresol, o-cresol, ethyl guaiacol, furfural, flavone, maltol, vanillin and water; and the papain is papayotin. The only thing needed in the preparation of the liquid medicine is to mixing the components. The liquid medicine has reasonable matching, easy production, low cost and no toxic and side effects and is an innovation for treating the dermatophytosis and the tinea pedis.

Owner:马照芳 +1

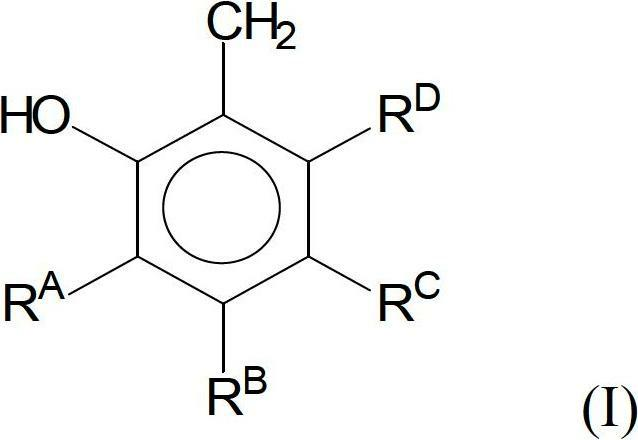

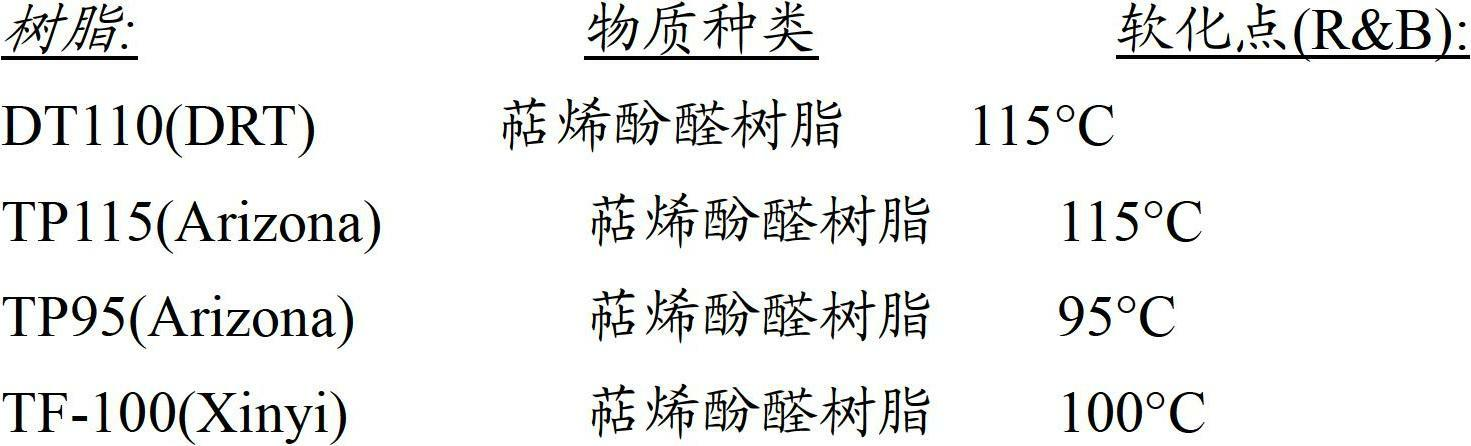

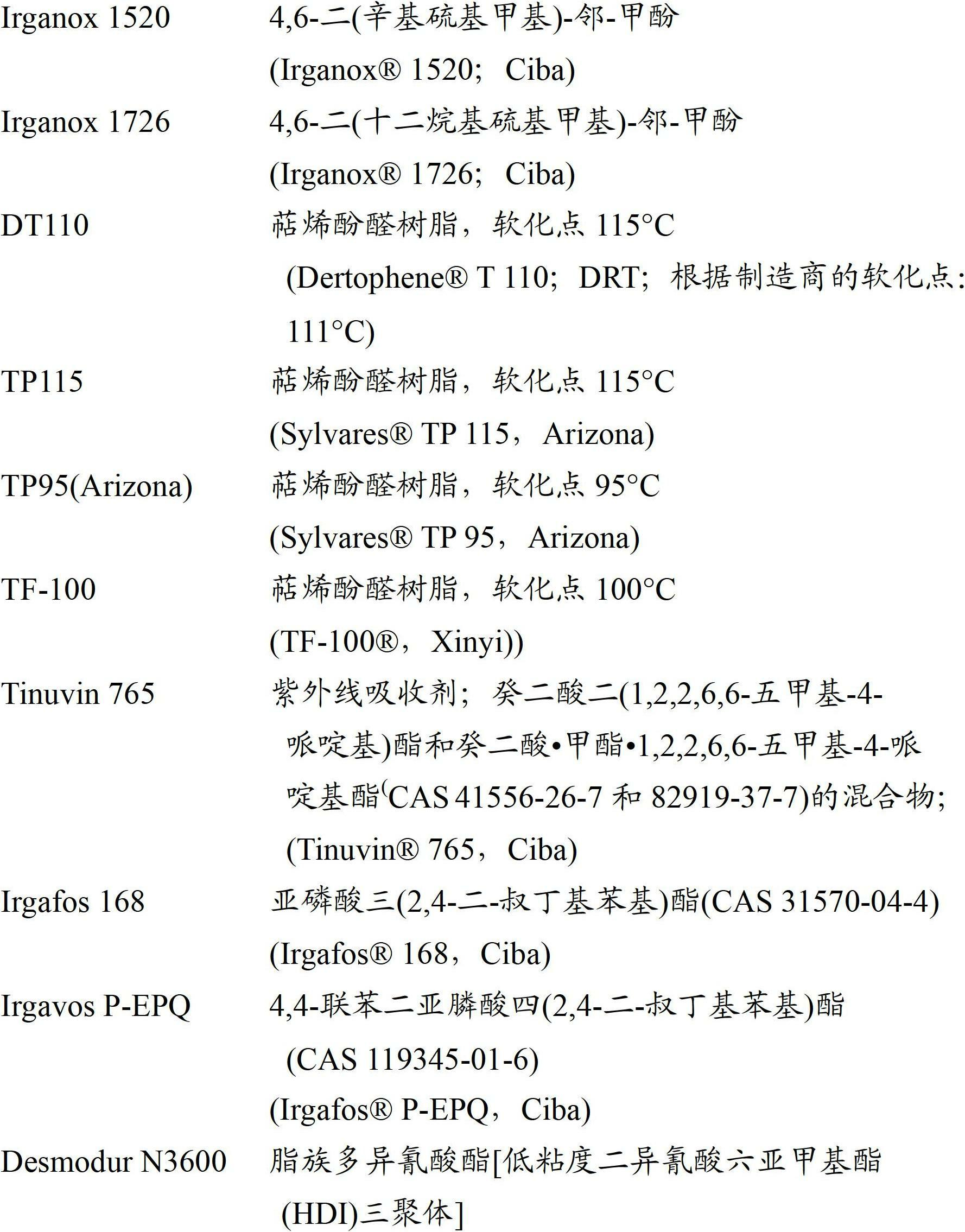

Method for stabilizing polyacrylate pressure-sensitive adhesives in admixture with adhesive resins

The invention relates to polyacrylate-based pressure-sensitive adhesives, containing at least one resin and at least one ortho, meta or para-cresol derivative, the aromatic ring thereof being substituted on at least two carbon atoms, wherein the substitutes are derivatives of thiols and / or thioethers. The invention further relates to adhesive tapes comprising at least one layer of said pressure-sensitive adhesive and to the use of said cresol derivatives as an antioxidant for polyacrylate pressure-sensitive adhesives.

Owner:TESA SE

Method for the production of p-hydroxybenzoate in species of Pseudomonas and agrobacterium

Owner:NORTH CAROLINA STATE UNIV

Hot-melt adhesive for cover binding

InactiveCN102796469AHigh bonding strengthFast curingNon-macromolecular adhesive additivesMacromolecular adhesive additivesParaffin waxRosin

The invention discloses a hot-melt adhesive for cover binding, which is prepared from 30-50 parts of ethylene-vinyl acetate copolymer, 10-30 parts of chlorobutylene resin, 10-20 parts of hydrogenated rosin, 10-20 parts of white oil, 10-20 parts of paraffin, 3-8 parts of barium sulfate, 5-8 parts of light calcium carbonate and 0.1-0.3 part of 2,6-di-tert-butyl-para-cresol. The adhesive film formed after being coated can adapt to the bending shape of the book back, can be kept round forever, has high adhesive strength and high curing speed, and can be used for binding continuously produced round hard covers.

Owner:WUJIANG QINGYI TEXTILE

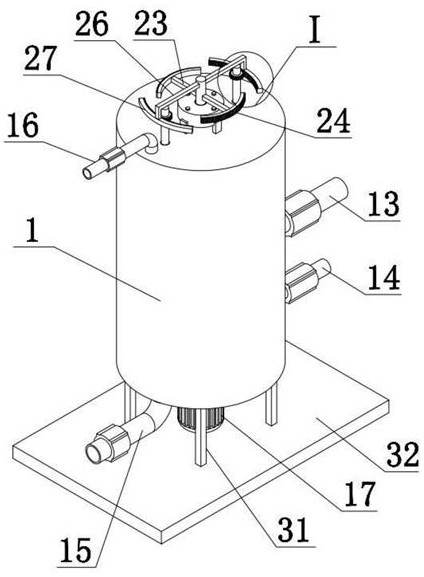

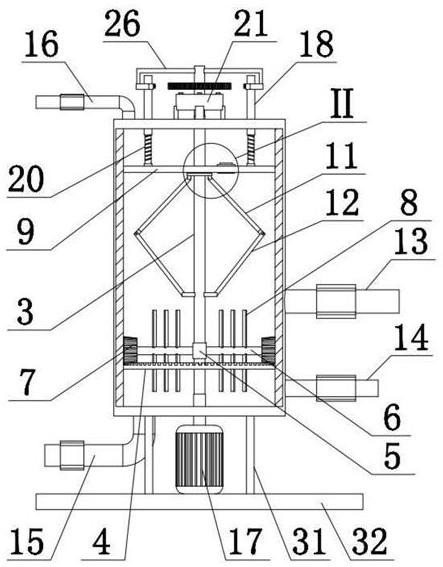

Continuous reaction device for alkylation of m-cresol and p-cresol

ActiveCN113209929AWell mixedIncrease reaction rateOrganic chemistryOrganic compound preparationElectric machineryStructural engineering

The invention provides a continuous reaction device for alkylation of m-cresol and p-cresol, and mainly relates to the technical field of reaction kettles. The continuous reaction device for alkylation of m-cresol and p-cresol comprises a reaction kettle, a first rotating shaft is mounted in a first through hole through a bearing, a plurality of obliquely-arranged blades are fixedly mounted on the periphery of a second rotating shaft, a pressure relief mechanism is arranged on one side of the top face of a sealing plate, and a circular ring is mounted on the bottom face of the sealing plate through a bearing. The two sides of the bottom face of the circular ring are hinged to one ends of first inclined rods correspondingly, the other ends of the first inclined rods are hinged to one ends of second inclined rods correspondingly, the other ends of the second inclined rods are hinged to the periphery of the first rotating shaft correspondingly, and the output end of the motor is fixedly connected with the lower end of the first rotating shaft. The reaction device has the beneficial effects that when the reaction device is used, the first rotating shaft rotates to drive the second rotating shaft, the blades, the first inclined rods and the second inclined rods to stir materials in the reaction kettle in different directions, so that the mixing efficiency of the materials is improved.

Owner:东营科宏化工有限公司

Glass-cloth-based adhesive tape

InactiveCN103242774AExcellent hot water resistanceGood moisture and heat aging resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesComposite filmAdhesive

The invention discloses a glass-cloth-based adhesive tape which comprises an adhesive and a base, wherein the adhesive is applied onto the base, and the base material is glass cloth; the adhesive contains the following components in percentage by mass: 45-60% of polyester resin, 15-17% of oligomer styrene resin, 8-10% of xylene resin, 6-8% of talcum powder, 1-2% of 2,6-di-tert-butyl-para-cresol and the balance of water. The composite-film-based adhesive tape, which is prepared from an ultralow-softening-point material, has the advantages of favorable hot water resistance, high damp-heat aging resistance and high flame retardancy, and can be easily peeled without leaving any adhesive trace on the premise of ensuring binding firmness. The peel strength of the adhesive tape is 200-300 N / m.

Owner:SUZHOU HUAZHOU TAPE

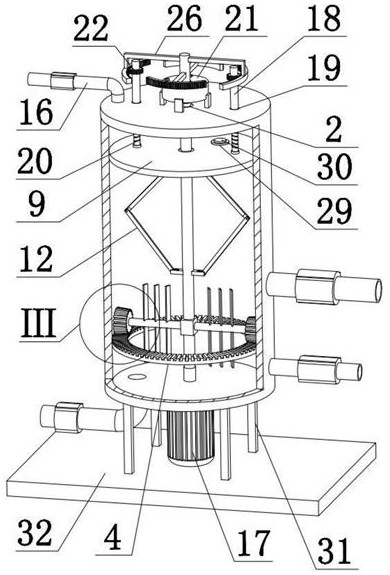

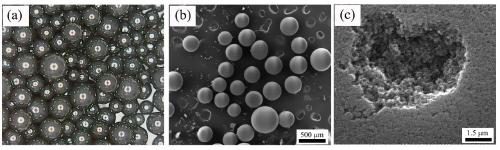

Nitrogen-rich carbon sphere adsorbent for whole blood perfusion and preparation method thereof

PendingCN111111616AHelp formPlay the role of heat resistance and non-meltingOther blood circulation devicesOther chemical processesMicrosphereDrug poisoning

The invention provides a nitrogen-rich carbon sphere adsorbent for whole blood perfusion and a preparation method thereof. The adsorbent disclosed by the invention is prepared by carrying out pre-oxidation and carbonization treatment on nitrogen-containing copolymer microspheres with a cross-linked porous structure. The prepared nitrogen-rich carbon sphere adsorbent for whole blood perfusion is good in hydrophilicity, high in blood compatibility and suitable for whole blood perfusion; the prepared nitrogen-rich carbon sphere adsorbent for whole blood perfusion is high in mechanical strength and high in use safety. The prepared nitrogen-rich carbon sphere adsorbent for whole blood perfusion can be applied to the fields of drug poisoning, liver failure, renal failure, immune adsorption and the like, and has relatively high adsorption and removal performance on protein-bound toxoid (such as indol sulfate, p-cresol sulfate, bilirubin, bile acid and the like).

Owner:刘云晖

Improved electric wire insulating varnish

Improved electric wire insulating varnish comprises raw materials in parts by weight as follows: 9-15 parts of aluminum hydroxide, 3-8 parts of modified phenolic resin, 10-15 parts of epoxy resin, 2-8 parts of polyvinyl formal resin, 4-9 parts of cresol, 4-6 parts of xylene, 5-8 parts of amino resin, 1-5 parts of polyvinyl alcohol, 2-7 parts of meta para cresol, 2-4 parts of mica, 3-5 parts of fire resistant fiber and 4-8 parts of propylene glycol. The improved electric wire insulating varnish has the benefits that the improved electric wire insulating varnish has good insulation capacity and has certain flame retardancy, and is widely applied to electric wires, cables and the like.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

Lactobacillus acidophilus KBL409 strain and application thereof

The invention relates to a lactobacillus acidophilus KBL409 strain and an application of the lactobacillus acidophilus KBL409 strain. The Lactobacillus acidophilus KBL409 strain (registration number KCTC 13518BP) according to the present invention alleviates renal inflammation and the concentration of uremic substances (such as blood urea nitrogen, creatinine, p-cresol and the like) in blood to protect the kidney, and exhibits the effects of proteinuria alleviation, renal mitochondrial function recovery and renal fibrosis inhibition. And therefore, the compound can be effectively applied to improvement of renal function and prevention and treatment of nephropathy (including chronic nephropathy).

Owner:KO BIOLABS INC

High-viscosity high-pressure antiwear hydraulic oil

InactiveCN104673443AImprove shear stabilityStrong demulsification abilityLubricant compositionAntioxidantHigh pressure

The invention discloses a high-viscosity high-pressure antiwear hydraulic oil which is prepared from the following raw materials in parts by weight: 30-50 parts of base oil, 8-16 parts of diisodecyl sebacate, 4-8 parts of polymethacrylate (PMA), 3-9 parts of dustless dithiophosphate, 2-14 parts of thiadiazole derivative, 3-6 parts of arylamine antioxidant, 1-6 parts of sulfonate, 2-4 parts of high-base-number sulfurized calcium alkyl phenate, 6-12 parts of vulcanized isobutylene, 2-8 parts of pentaerythritol ester, 7-10 parts of vulcanized isobutylene, 2-4 parts of di-n-butyl phosphite and 1-6 parts of di-tert-butyl-para-cresol. The high-viscosity high-pressure antiwear hydraulic oil has the advantages of favorable demulsibility, favorable hydrolytic stability, favorable heat stability, favorable filterability, outstanding wear resistance and obvious energy-saving effect.

Owner:QINGDAO KERUN PLASTIC MACHINERY

Rosin modified resin and production method thereof

The invention relates to a rosin modified resin and a production method thereof. The production method of the resin comprises the following steps: A, dissolving 95-100 kilograms of grade-one rosin, then transferring into a reaction kettle, adding 0.5-0.8 kilogram of 6-tert-butyl-3-methylphenol, performing steam blowing for 30 minutes when the temperature reaches 190-200 DEG C, and performing vacuum dehydration for 0.5 hour; B, when the temperature rises to 220-230 DEG C, adding 0-0.3 kilogram of di-tert-butyl-para-cresol and phosphite composite stabilizer, turning on condenser cooling water, dropwisely adding 10-15 kilograms of glycerol, performing constant-temperature esterification reaction for 6 hours when the temperature rises to 265 DEG C, then sampling, and assaying the acid value; C, after the assayed acid value is qualified, blowing the resin in the kettle for 1 hours with a steam jet; D, after the blowing operation is finished, further performing vacuum dehydration for 3 hours with a Roots pump; and E, performing nitrogen gas protection, cooling, granulating, and packaging. The rosin modified resin provided by the invention is light and transparent in color, low in smell and wide in application range.

Owner:ZHEJIANG XINSONG RESIN

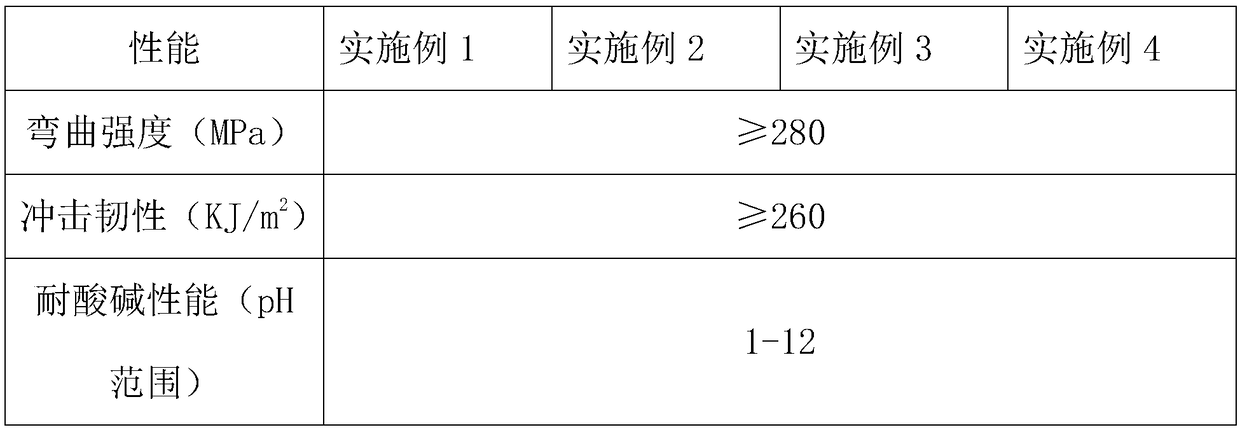

Production process of high-strength high-toughness glass-fiber-reinforced septic tank

The invention discloses a production process of a high-strength high-toughness glass-fiber-reinforced septic tank. The production process comprises the following steps: uniformly mixing styrene and 2,6-ditert-butyl para-cresol, and adding the mixture into an unsaturated polyester resin; sequentially adding a vinyl ester resin, an initiator, calcium hydroxide, polyoxyethylene castor oil and zinc stearate to be uniformly mixed; adding magnesium oxide, and uniformly mixing to obtain premix; adding reinforced fibers into the premix, uniformly kneading in a kneading machine, feeding into an extruder for extrusion, pouring into a mold, performing mold curing and molding, and demolding, thereby obtaining the high-strength high-toughness glass-fiber-reinforced septic tank. According to the production process of the high-strength high-toughness glass-fiber-reinforced septic tank provided by the invention, the produced septic tank has high strength and high toughness, also has corrosion resistance, and is long in service life and excellent in processability.

Owner:安徽汇创新材料有限公司

Nano water-resistant paint

The invention discloses a nano water-resistant paint which is prepared from the following raw materials in parts by weight: 71-80 parts of silicone-acrylic emulsion, 1-2 parts of polyvinyl pyridine, 2-3 parts of locust bean gum, 1-2 parts of N-ethyl-ortho-para-toluene sulfonate, 10-13 parts of nano calcium carbonate, 1-2 parts of zinc borate, 4-6 parts of fluorapatite, 0.1-0.2 part of succinic acid, 2-3 parts of butyl epoxy oleate, 1-2 parts of sodium sulfite, 0.1-0.3 part of ethylene glycol monobutyl ether, 1-2 parts of glycerol triglyceride, 0.5-1 part 2,6-di-tert-butyl-para-cresol, 4-5 parts of film formation assistant and 14-20 parts of deionized water. The nano raw material added into the water-resistant paint can effectively enhance the compatibility among the raw materials, enhances the leveling property of the coating surface, and has the advantages of favorable smoothness, high hardness, wear and scratch resistance, favorable leakage resistance and high weather resistance.

Owner:ANHUI SUNROAD ENVIRONMENT PROTECTIVE NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com