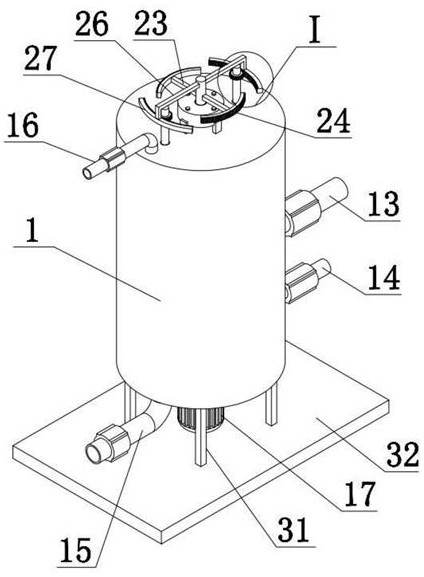

Continuous reaction device for alkylation of m-cresol and p-cresol

A reaction device and a cresol alkyl technology, which is applied in the field of a continuous p-cresol alkylation reaction device, can solve the problems of low mixing efficiency, inability to mix raw materials, and inconvenience for users to use, so as to improve work efficiency, The effect of improving the reaction rate and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

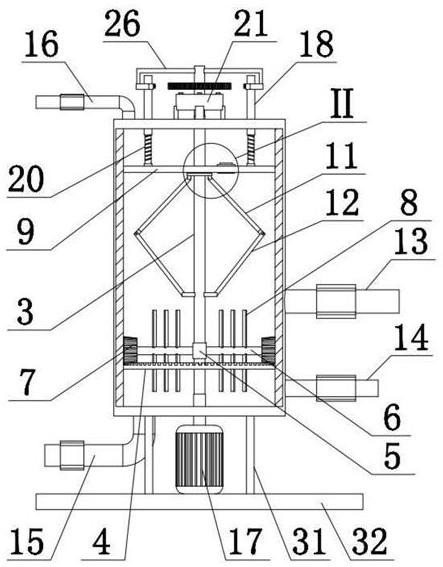

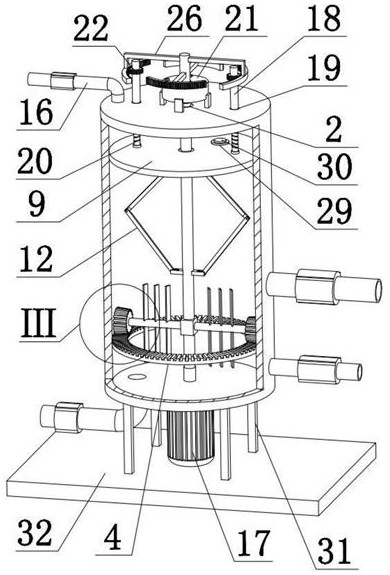

[0025] When the device is installed, several reactors are arranged side by side, such as Figure 7 Said, the discharge pipe on one of the reaction kettles is connected to the feed pipe on another adjacent reaction kettle through the first connecting pipe, and a water pump is set on the first connecting pipe to improve the delivery efficiency of the raw materials, Connect the exhaust pipe on one of the reactors to the inlet pipe on the other adjacent reactor through the second connecting pipe, and so on, connect several reactors in series for the continuous reaction of m-cresol alkylation , increasing its reaction rate. When the power supply of the motor is turned on during use, the output shaft of the motor drives the first rotating shaft connected to it to rotate synchronously. When the first rotating shaft rotates, the corresponding second rotating shaft is driven by the fixed block to rotate with the first rotating shaft as the axis. Under the mutual cooperation of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com