Antirust lubricant and preparation method thereof

A technology of anti-rust lubricants and preservatives, applied in the direction of lubricating compositions, etc., can solve the problems of endangering the ecological environment and ecological balance, polluting land, rivers and lakes, and strong accumulation of ecological toxicity, so as to prolong the service life and biological The effect of high degradation rate and excellent extreme pressure and anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

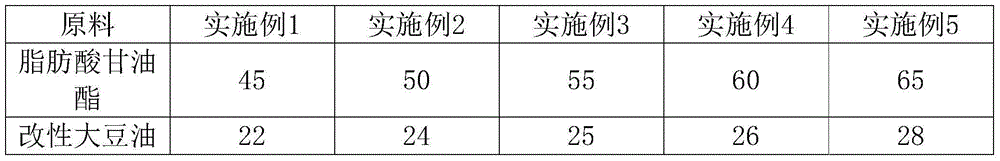

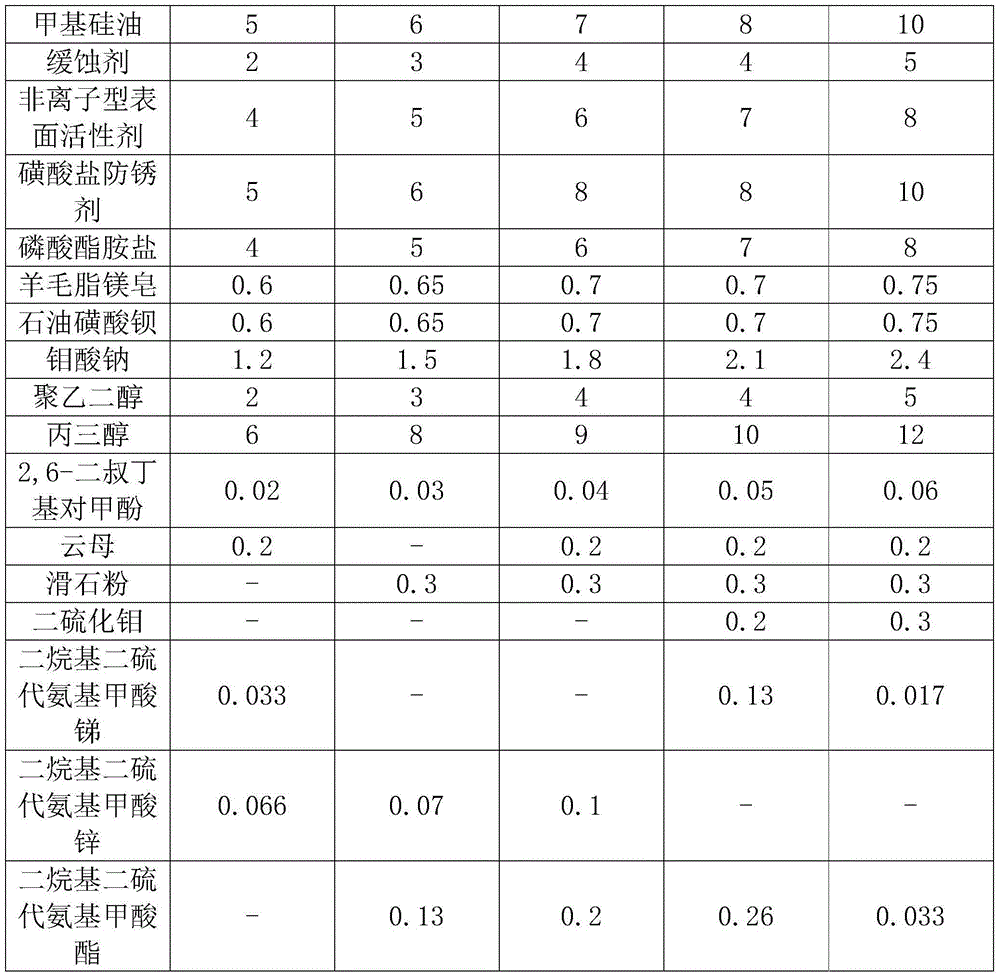

[0023] Embodiment 3 is the best implementation mode.

[0024] A method for preparing an anti-rust lubricant, the method is as follows: add fatty acid glycerides, modified soybean oil, and methyl silicone oil into a reaction kettle, heat to 45-48°C, stir and mix evenly, and then add corrosion inhibitors in sequence , sulfonate antirust agent, phosphate amine salt, antirust compound oil, sodium molybdate, ethanol, polyethylene glycol, glycerol, continue to stir for 50-55min, and finally add solid additives, anti-oxidation preservatives, non- The ionic surfactant continued to stir for 30-35 minutes to obtain the required anti-rust lubricant.

[0025] Table 2 is the technical indicator of the antirust lubricant of the present invention.

[0026] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com