Patents

Literature

37results about How to "Good viscosity-temperature characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

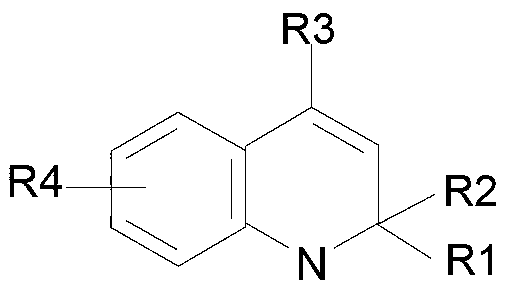

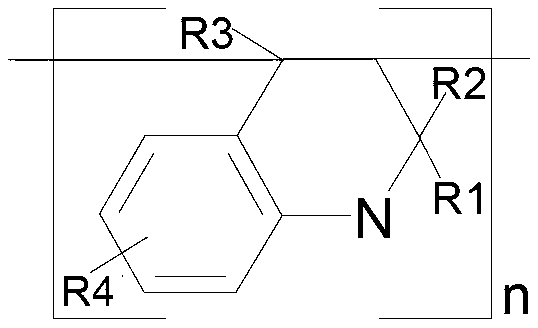

Air compressor oil composition and preparation method thereof

ActiveCN103194303AExtended service lifeImprove performanceHeat-exchange elementsLubricant compositionAntioxidantOxidation stability

The invention provides an air compressor oil composition and a preparation method thereof. The air compressor oil composition comprises polyether oil base oil or polyether oil and ester oil mixture base oil, a 2,2,4-trialkyl-1,2-dihydroquinoline antioxidant and a metal deactivator. Compared with the known air compressor oil composition, the air compressor oil composition has excellent oxidation stability, excellent comprehensive performance and a simple preparation method, and is particularly suitable for a screw air compressor.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

Method for producing pentaerythritol oleate under catalysis of granular solid superacid

InactiveCN102875374ANo pollutionHigh yieldOrganic compound preparationCarboxylic acid esters separation/purificationPentaerythritolAcid catalyzed

The invention discloses a method for producing pentaerythritol oleate under catalysis of granular solid superacid, and relates to a method for synthesizing ester base oil in biodegradable lubricating oil. The method comprises the following steps of: mixing pentaerythritol and oleic acid in a mass ratio of 1:(7.2-9.5), adding the granular solid superacid, and reacting at the temperature of between 140 and 240DEG C for 4 to 10 hours in the vacuum degree of 100-1,000Pa; filtering by using a 200-12,500 mesh filter screen or filter plate; and heating crude grease to the temperature of between 160 and 280DEG C, removing unreacted acid or alcohol, keeping the vacuum degree of the system ranging from 1 to 500Pa, and distilling under reduced pressure for 40 to 120 minutes to obtain the pentaerythritol oleate. The pentaerythritol oleate produced by the method has excellent low temperature fluidity, lubricity, viscosity-temperature characteristics, oxidation safety, cleanness and good biodegradability, and the method is an environment-friendly and high-efficiency production method having advantages of simple treatment, short production period, high esterification rate and high product yield.

Owner:SICHUAN SIPO CHEMICAL CO LTD

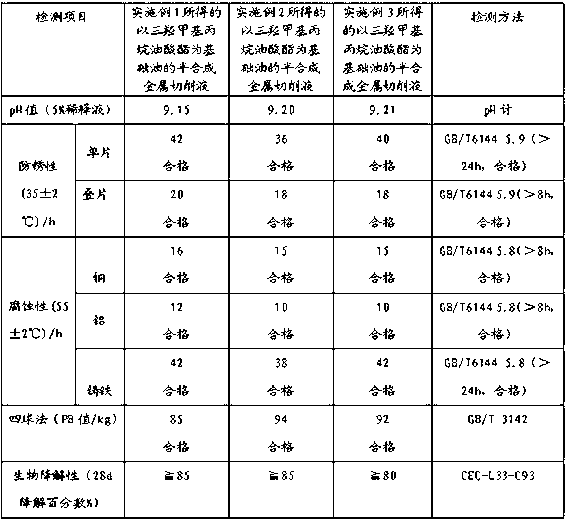

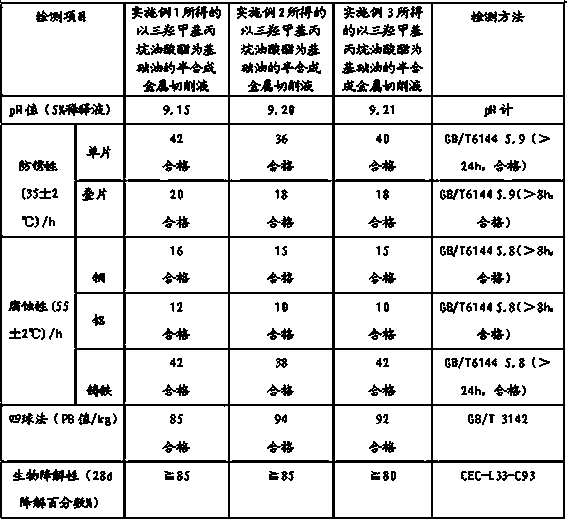

Semisynthetic metal cutting fluid with trimethylolpropane oleate serving as base oil and preparation method of semisynthetic metal cutting fluid

The invention discloses semisynthetic metal cutting fluid with trimethylolpropane oleate serving as base oil and a preparation method of the semisynthetic metal cutting fluid. The semisynthetic metal cutting fluid comprises the trimethylolpropane oleate, nonionic surfactants, anionic surfactants, antirust agents, cosolvents, extreme pressure agents, defoaming agents, bacteriacide and water. The preparation method of the semisynthetic metal cutting fluid includes: adding the extreme pressure agents into the base oil with uniform stirring so that solution A is obtained; then sequentially adding the defoaming agents, the antirust agents, the cosolvents and the bacteriacide into the water with uniform stirring so that solution B is obtained; and mixing the solution A with the solution B, and stirring while slowly dropwise adding the nonionic surfactants and the anionic surfactants so that a homogeneous and clarified micro-emulsion system, namely, the semisynthetic metal cutting fluid with the trimethylolpropane oleate serving as the base oil is obtained finally. The semisynthetic metal cutting fluid has good lubricity and biological degradability, has low-toxicity and low-harm to human bodies and the environment and is suitable for metal machining of most materials.

Owner:上海樱花化研化工科技有限公司

Synthesis method of poly alpha-olefin

ActiveCN107304237AImprove performanceAppropriate degree of branchingBase-materialsZiegler–Natta catalystSynthesis methods

The invention relates to a synthesis method of poly alpha-olefin. The synthesis method comprises the following steps: carrying out reaction on a C8-C12 olefin monomer for a certain time under the action of a Ziegler-Natta catalyst system; after the reaction is finished, adding a quenching agent, finishing reaction and stopping stirring, extracting heat by virtue of external circulation, lowering a system temperature to room temperature, then adding an initiating agent, introducing BF3, controlling a polymerization temperature, reacting for 0.5-3 hours, and then carrying out aftertreatment, so that a poly alpha-olefin oligomerization mixture is obtained.

Owner:PETROCHINA CO LTD

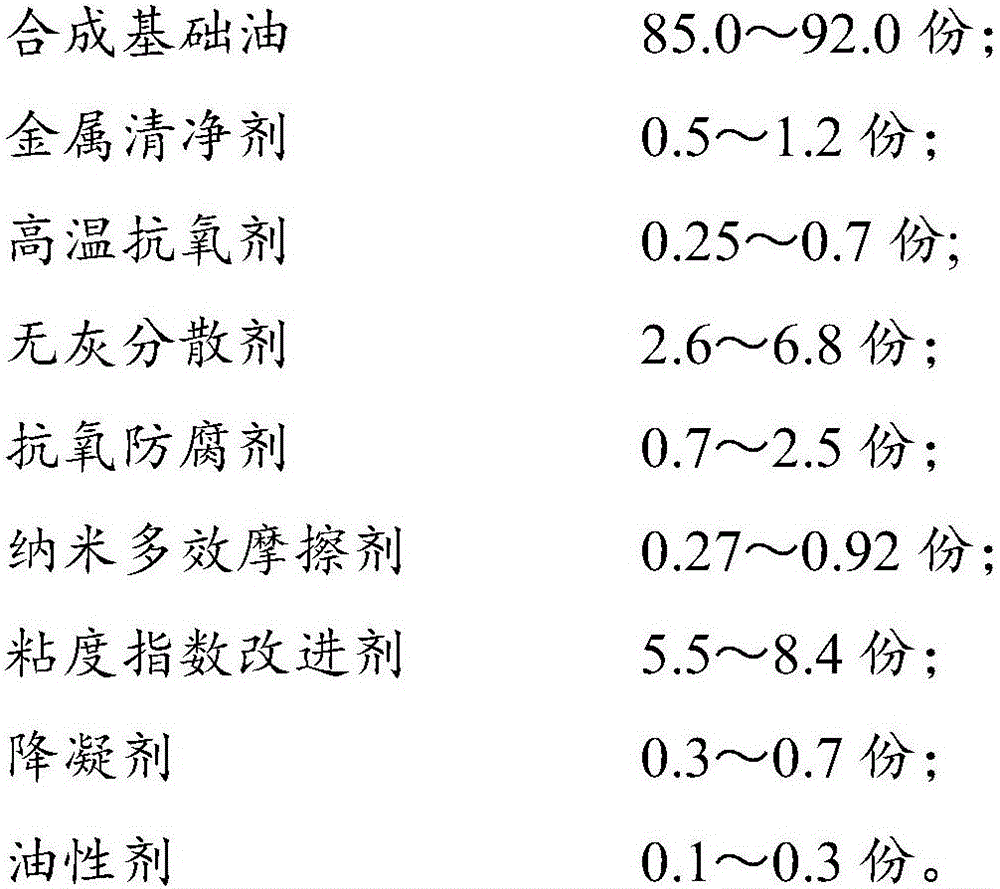

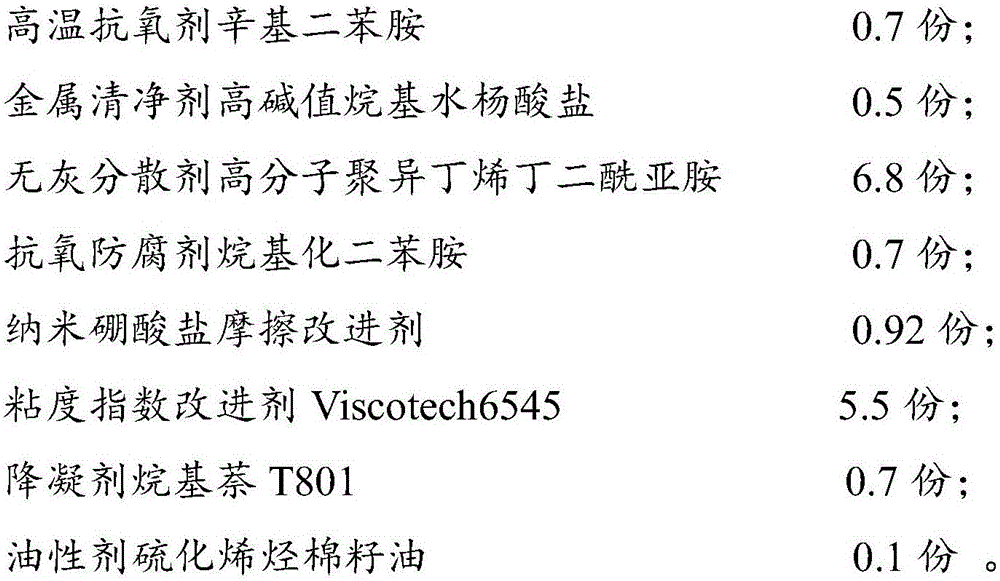

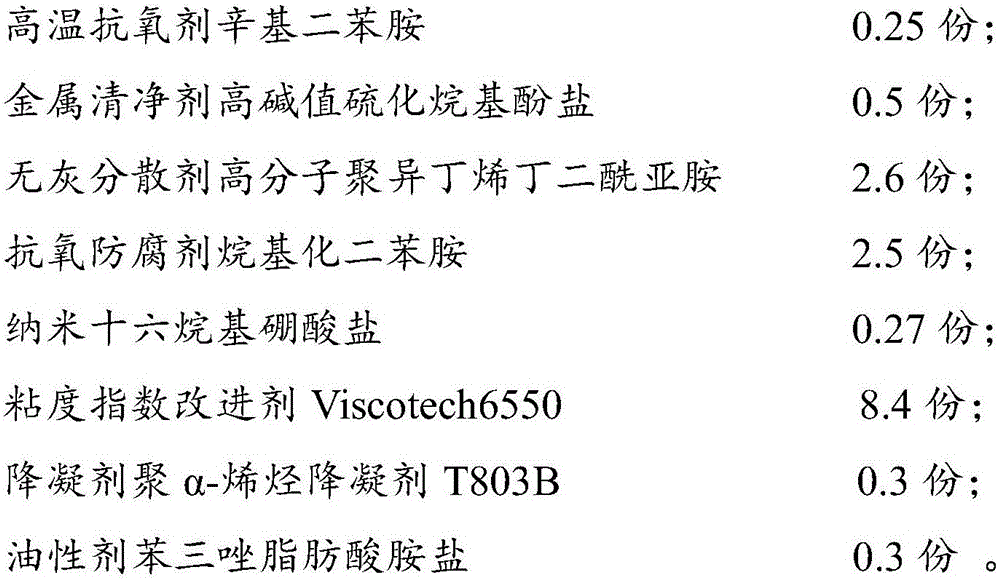

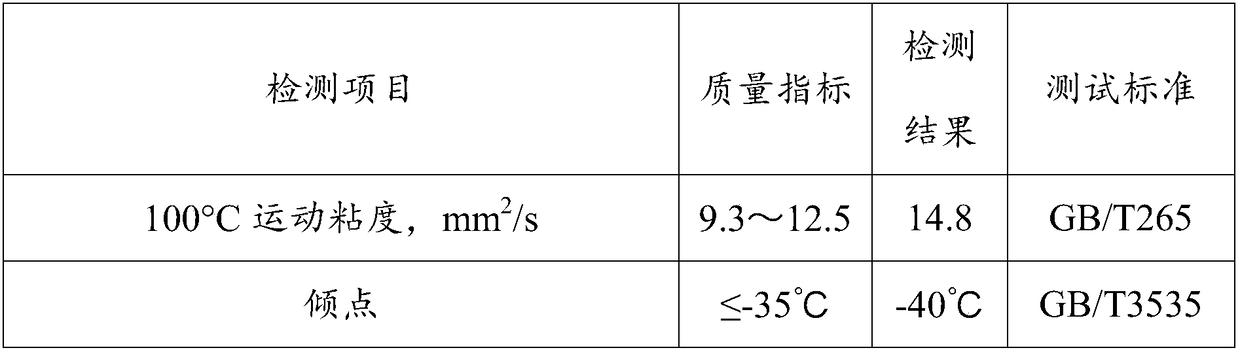

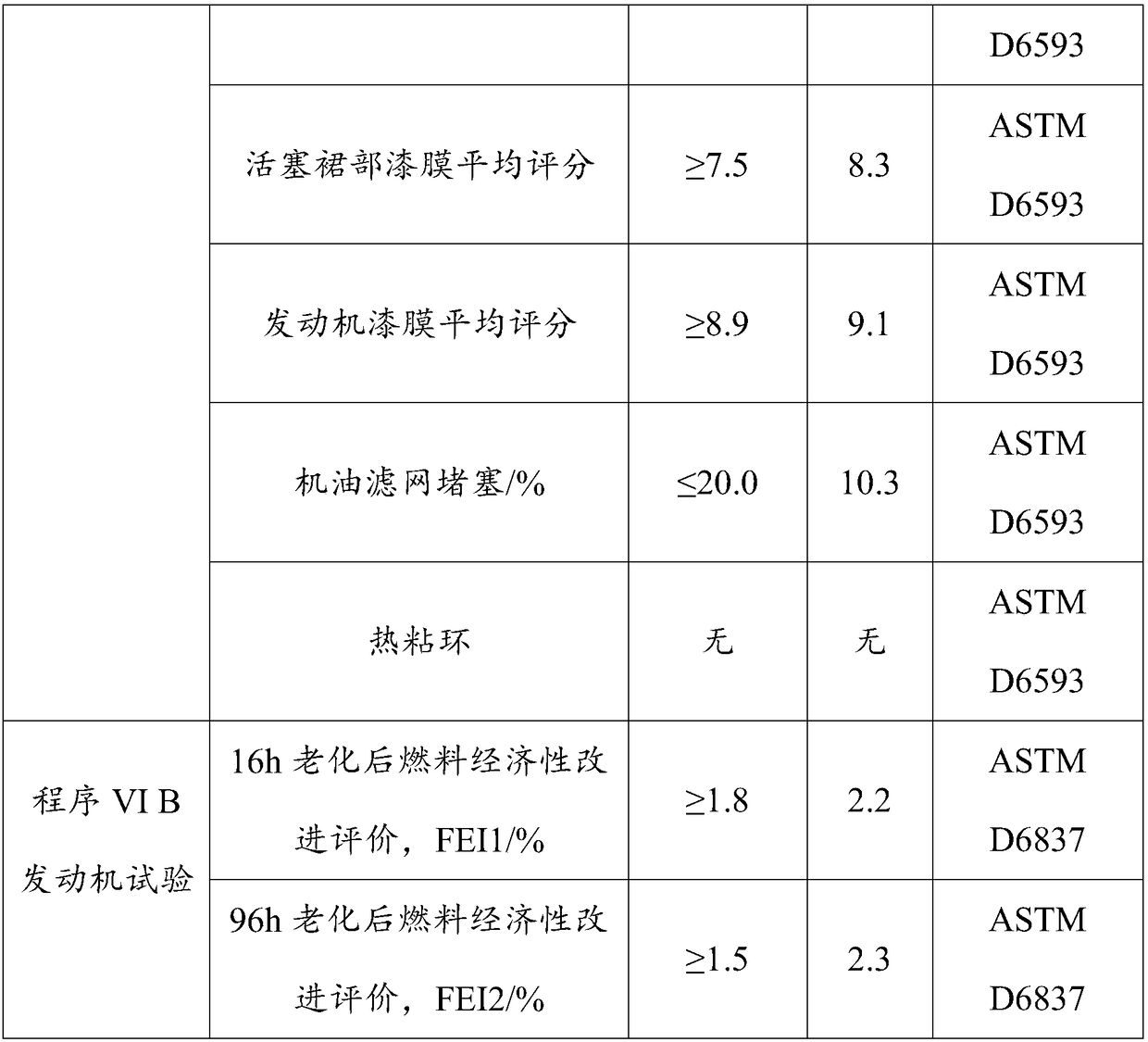

High-performance internal combustion engine oil capable of performing viscosity classification and preparation method thereof

InactiveCN105907447AGood energy saving and environmental protectionOutstanding anti-wear and anti-friction propertiesBase-materialsAntioxidantOil sludge

The invention discloses high-performance internal combustion engine oil capable of performing viscosity classification and a preparation method thereof. The internal combustion engine oil comprises synthesized base oil, high-temperature antioxidant, metal clearing agent, ash-free dispersing agent, anti-oxidation preservatives, nano multi-effect abradant, viscosity index improver, pour point depressant and oiliness agent. The high-performance internal combustion engine oil has the advantages that the internal combustion engine oil is outstanding in energy conservation and environment protection performance, excellent in wear resistance and friction resistance, good in fuel economy, excellent in low-temperature flowability, outstanding in high-temperature oxidation resistance and high in abrasion resistance; the influence of temperature on the viscosity change of the internal combustion engine oil is small, the internal combustion engine oil can flow under a low-temperature condition and keep proper viscosity in a high-temperature environment, and the internal combustion engine oil can reduce engine wear and prolong the service life of an engine; in addition, the internal combustion engine oil prepared by the method is high in extraction purity and cannot be easily oxidized and degraded into oil sludge and carbon deposition, and accordingly the oil change period of the internal combustion engine oil is long.

Owner:FUJIAN HEISHI LUBRICANTS LTD

Wind power generation lubrication system

InactiveCN101196175AHigh biodegradation rateGood viscosity-temperature characteristicsMachines/enginesWind energy generationWater sourceEngineering

The invention provides a lubricating method for wind power generator, which comprises a lubricant, a wind power generator. Compound lubricant is adopted; the main lubricating parts of the wind power generator include a gear box, a generator bearing, a crab system bearing and gear, a hydraulic brake system and a min bearing. Compared with the ordinary mineral grease, the adopted compound lubricant has the advantages of excellent viscosity-temperature characteristics and little impact due to temperature change, is able to ensure easy startup under low temperature and no loss under high temperature, thereby providing sufficient lubrication for the friction parts. In addition, with excellent stability of thermal oxidation and little loss in vaporization, the lubricant can be used for a long time under rigid working condition and climatic situation. Especially, with high biodegradation rate, the compound lubricant can be widely promoted as it results in no pollution to the soil and water source.

Owner:苏州市南极风能源设备有限公司

Graphene-containing vegetable lubricant and preparation method thereof

InactiveCN106350167AReduce friction lossGood friction and lubrication propertiesLubricant compositionSucrosePolymethyl methacrylate

The invention discloses a graphene-containing vegetable lubricant. The graphene-containing vegetable lubricant is prepared from the following raw materials: castor oil, modified castor oil, liquid graphene, trimethyl citrate, N,N-dimethylacetamide, modified nano cerium vanadium oxide, modified sodium carboxymethylcellulose, sucrose ester, an organic molybdenum compound, dodecyl selenium, 4-hydroxy-4-methyl-2-pentanone, benzotriazole, polymethyl methacrylate, 1-butyl-3-vinyl imidazole hexafluoroantimonate, polyurethane, cyclohexane and an organic anti-aging agent. The graphene-containing vegetable lubricant disclosed by the invention has the advantages that the castor oil and other additives are combined, an environment-friendly vegetable lubricant is prepared, the balance of properties is achieved by controlling the types and quantity of the additives, the vegetable lubricant has better oxidation resistance and self-cleaning capability and also has good lubricating property, viscosity-temperature characteristic, low temperature fluidity, low volatility, corrosion resistance, anti-foam property and anti-emulsifying property, and the overall performance is good.

Owner:梁海东

Novel automobile damper oil

InactiveCN103740446AHigh viscosity indexImprove damping performanceLubricant compositionPhosphatePerformance index

The invention relates to a novel automobile damper oil, which is composed of the following substances: a mixture composed of one or more components selected from: polymethacrylate, polyisobutene, and a carbon-chain strengthening agent; a mixture composed of one or more components selected from fatty alcohol polyoxyethylene ether, chlorinated paraffin, and phosphate; a mixture composed of one or more components selected from fatty alcohol ester of styrene-maleic anhydride resin, alkenyl butanediamide acid salt, sween, and tween; a mixture composed of one or more components selected from diisooctyldiphenylamine, 2,6-ditertbutyl-4-methypheonl, and phenothiazine; polyoxyethylene-polyoxypropylene segmented polyether, polyoxyethylene-polyoxypropylene glycerin, plant oil, and the balance being basic oil. The damper oil prepared according to the technical scheme mentioned above has improved performance indexes such as the viscosity index, and the like; and the work life of the damper oil is prolonged at the same time.

Owner:NINGBO NANFANG SHOCK ABSORBER MFG

Method for preparing pentaerythrite oleic ester used in cold-rolling oil

InactiveCN102050735AReduce non-target componentsImprove performanceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzenePentaerythritol

A method for preparing pentaerythrite oleic ester used in cold-rolling oil belongs to the technical field of ester compound synthesis in organic chemistry. Pentaerythrite and oleinic acid are adopted as raw materials and p-toluenesulfonic acid or / and tributyl phosphate is / are adopted as catalyst; toluene or benzol is adopted as a water carrier, and esterification reaction lasting 4 to 6 hours is performed under the protection of high-purity nitrogen and under the temperature of 140 to 180 DEG C; after the reaction, continuous vacuumization lasting 40 to 60 mins is performed under the high-vacuum condition with a vacuity of 40 to 60Pa; and pentaerythrite oleic ester is obtained after the filtration of remains after vacuumizing. The pentaerythrite oleic ester prepared by adopting the method provided by the invention is specially used in cold-rolling oil, and has the advantages of excellent lubricity, temperature characteristics, annealing detergency and excellent mill housing cleanness.

Owner:LUOYANG XINZHONG PETROCHEM

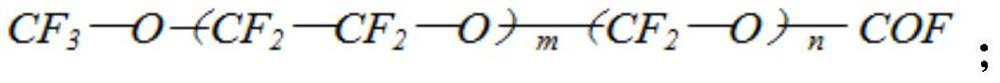

Perfluoropolyether grease for long-life high-temperature bearings and preparation method and application of perfluoropolyether grease

InactiveCN108715768AThe components are simpleSimple preparation processAdditivesPerfluoropolyetherEvaporation

The invention provides perfluoropolyether grease for long-life high-temperature bearings and a preparation method and application of the perfluoropolyether grease. The perfluoropolyether grease is prepared from, by weight, 60-80% of perfluoropolyether, 20-40% of a thickening agent and 0.01-0.5% of an additive. The chemical formula of perfluoropolyether is CF3-O-(CF2-CF2-O)m-(CF2-O)n-CF3, wherein mand n are respectively selected from integers between 1 and 500 independently; the additive is the combination of one or multiple of molybdenum disulfide, sodium nitrite, barium petroleum sulfonate and benzothiazole. Technical problems of coking and carbon deposition, too fast evaporation and failure to provide long-term lubrication protection under the high temperature working condition of the bearings are solved through the perfluoropolyether grease ; in addition, the perfluoropolyether grease is simple in preparation process and can be obtained at relatively low temperature.

Owner:CHINA PETROLEUM & CHEM CORP

Graphene-inorganic nonmetallic fiber containing plant composite engine oil

ActiveCN108795547AGood lubricityExcellent overall performanceCarbon compoundsAdditivesCvd grapheneWax

The invention discloses graphene-inorganic nonmetallic fiber containing plant composite engine oil and a preparation method thereof. The preparation method comprises the following steps: adding graphene-inorganic nonmetallic fiber, liquid graphene, 1-octyl-3-methylimidazolium tetrafluoroborate into castor oil, stirring, then adding 2,2,4-trimethyl-1,3-pentanediol-isobutyric benzoate, didodecylmethyl tertiary amine, dimethyl glutarate, 12-hydroxystearic acid, a demulsifying agent, 1-3 parts of an antifreezing agent, an antiseptic and antirust agent, 2,6-di-tert-butyl-4-methylphenol, sasol wax,zinc dipentyl dithiocarbamate, triethanolamine oleate, oxidized polyethylene wax and fatty acid polyethylene glycol ester, and stirring to obtain the graphene-inorganic nonmetallic fiber containing plant composite engine oil. The graphene-inorganic nonmetallic fiber containing plant composite engine oil has good lubricity, viscosity-temperature properties, low-temperature fluidity and corrosion resistance and other characteristics, and has good comprehensive performance.

Owner:颜凤生

Automobile shock absorber oil suitable for low temperature environment

InactiveCN103756758AHigh viscosity indexImprove damping performanceLubricant compositionCarbon chainChlorinated paraffins

The invention relates to an automobile shock absorber oil suitable for low temperature environment. The automobile shock absorber oil is prepared from following materials: one or a mixture prepared from a plurality of compounds selected from polymethacrylate, poly(propylene-co-ethylene), and a carbon chain enhancer; one or a mixture prepared from a plurality of compounds selected from fatty alcohol-polyoxyethylene ether, chlorinated paraffin, and phosphorus pentoxide; one or a mixture prepared from a plurality of compounds selected from fatty alcohol ester of phenylethylene-maleic anhydride resin, alkenyl butanediamide acid salt, span, and tween; polyoxyethylene polyoxypropylene polyether, polyoxypropylene-polyoxyethylene glycerin, plant oil, and the balance base oil. The automobile shock absorber oil is capable of maintaining stability at low temperature, so that better working performance is obtained.

Owner:NINGBO NANFANG SHOCK ABSORBER MFG

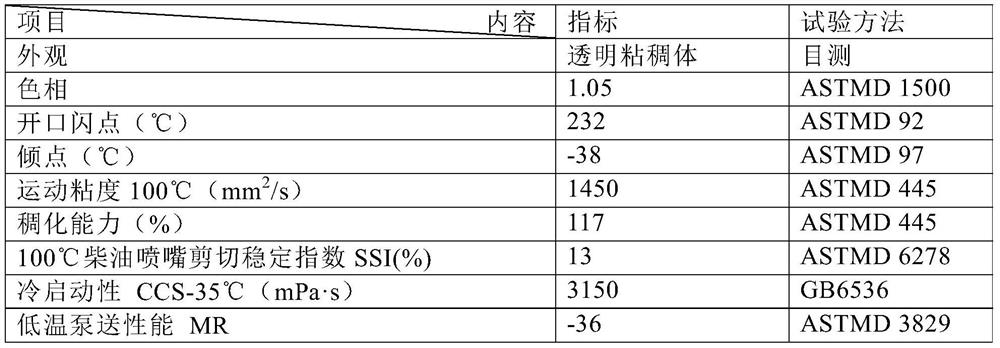

Synthetic method of lubricating oil base oil

ActiveCN111286385AIncrease carbon numberDosage controlLiquid hydrocarbon mixtures productionBase-materialsPolyolefinPtru catalyst

The invention discloses a synthetic method of lubricating oil base oil. The method comprises the following steps: simultaneously adding high-carbon olefin and ethylene into a high-pressure white steelpolymerization reaction kettle, adding a Ziegler-Natta catalyst into the reaction kettle, starting a reaction, and controlling conditions in a polymerization process; after the reaction is finished,pressing the material into a second reaction kettle through nitrogen (or cooling to room temperature in the same reaction kettle) while adding an AlCl3 catalyst into the material, and controlling theadding amount of the catalyst and the polymerization reaction conditions; and after the reaction is finished, emptying and depressurizing the reaction kettle, removing the residual catalyst from the obtained crude product through an alkali washing process, removing the unreacted high-carbon olefin through pressure reducing distillation, and carrying out structural characterization determination onthe product obtained after hydrogenation to determine branching degree, and carrying out performance test to determine indexes such as viscosity, viscosity index, pour point and the like of the product. According to the present invention, a complex raw material high-carbon olefin is adopted as a raw material, and the synthesized poly-alpha-olefin lubricating oil base oil has excellent viscosity-temperature performance and excellent low-temperature performance.

Owner:PETROCHINA CO LTD

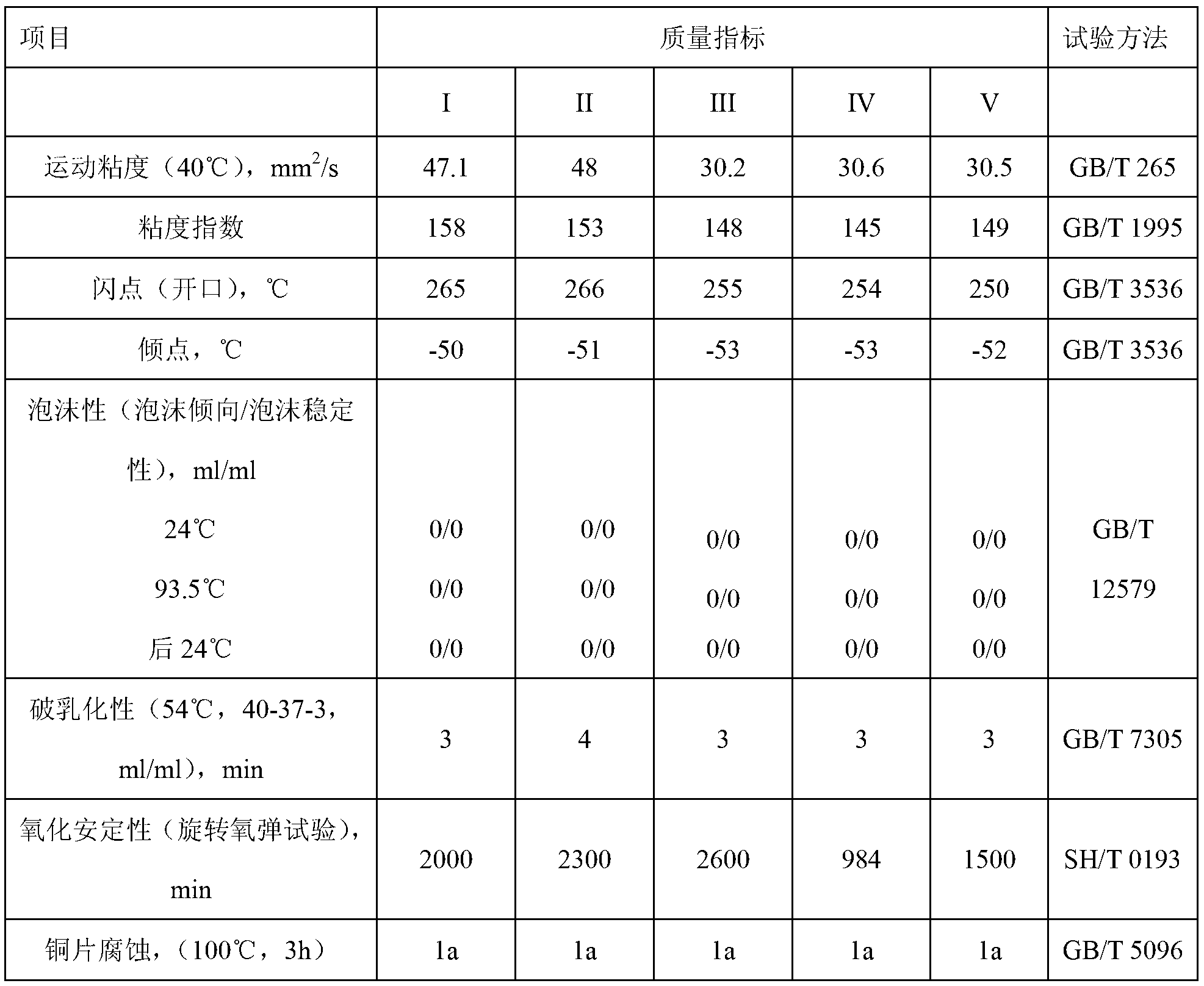

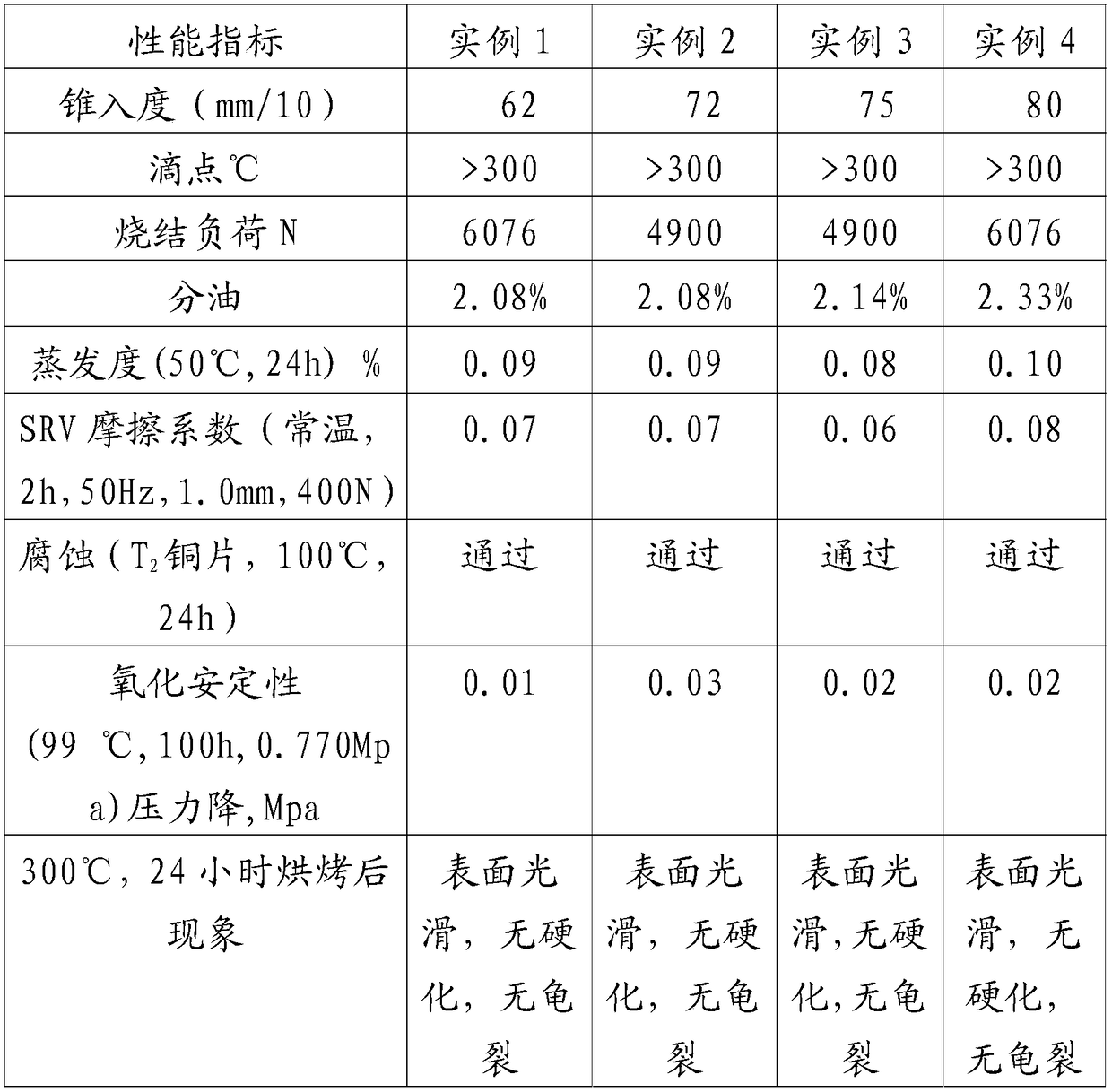

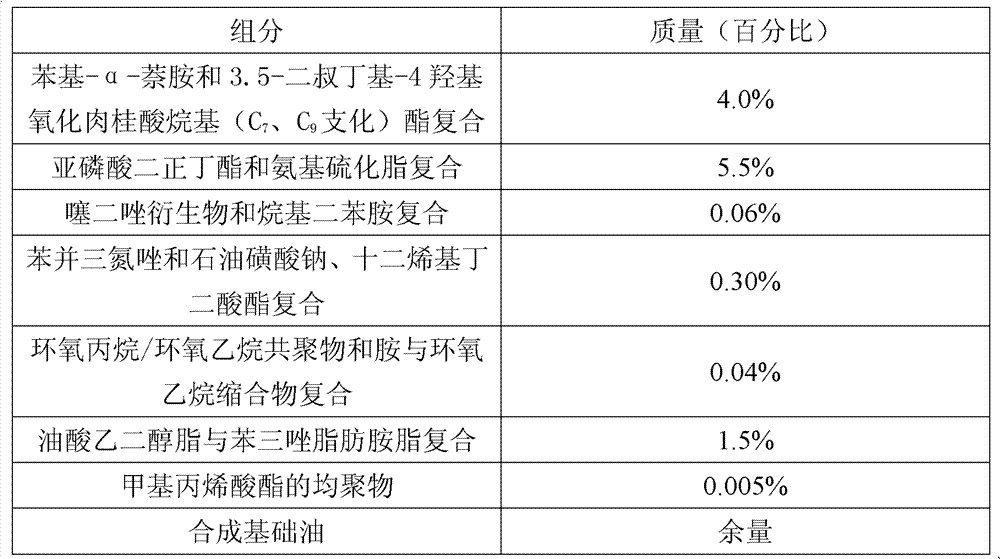

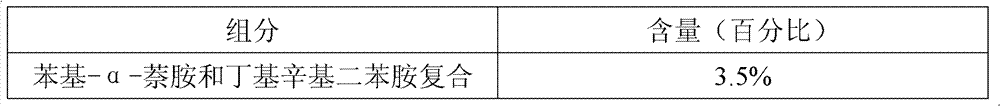

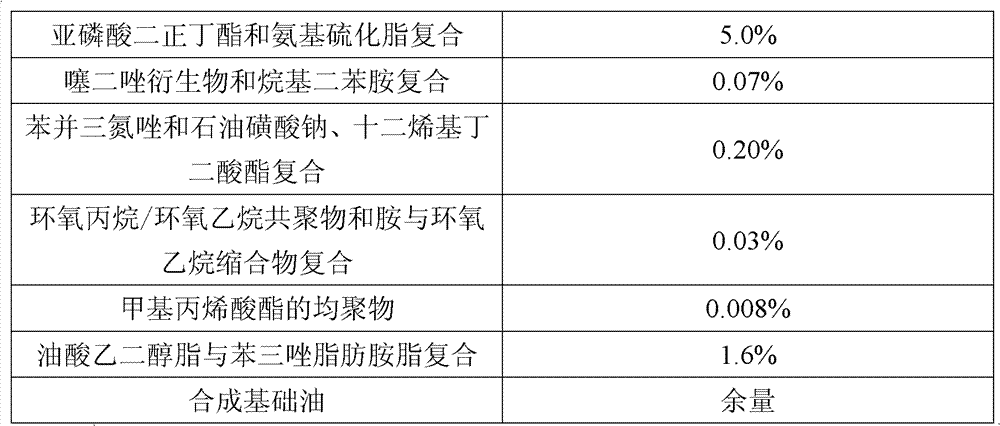

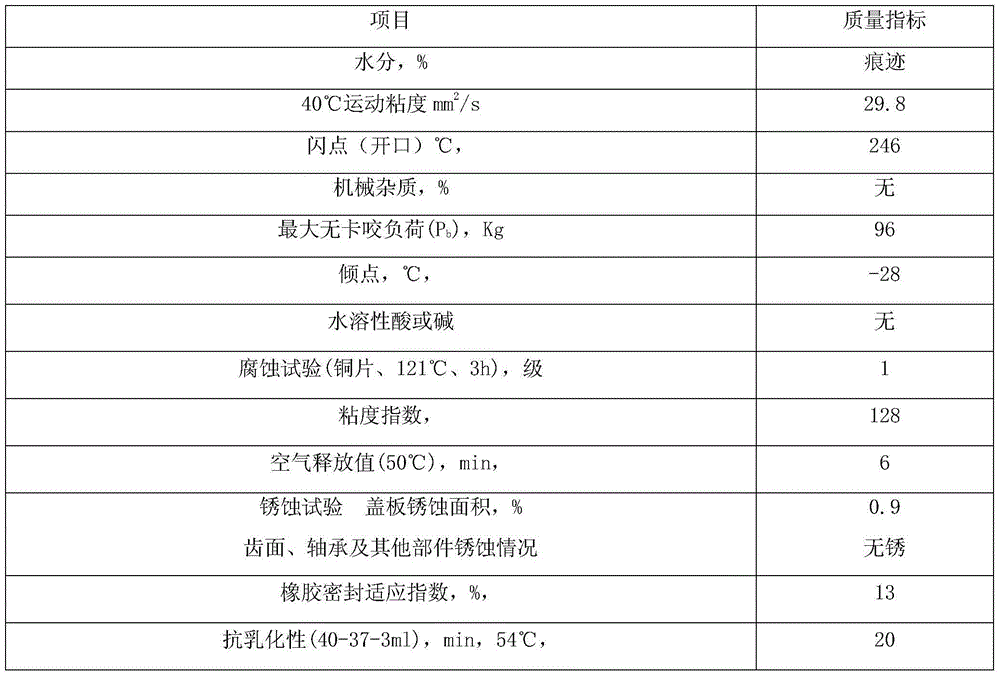

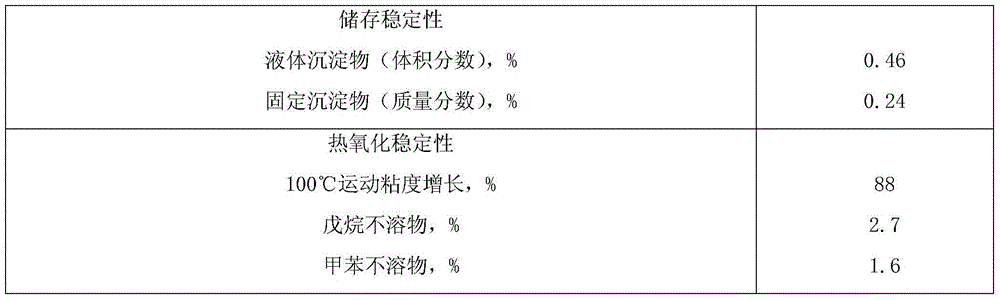

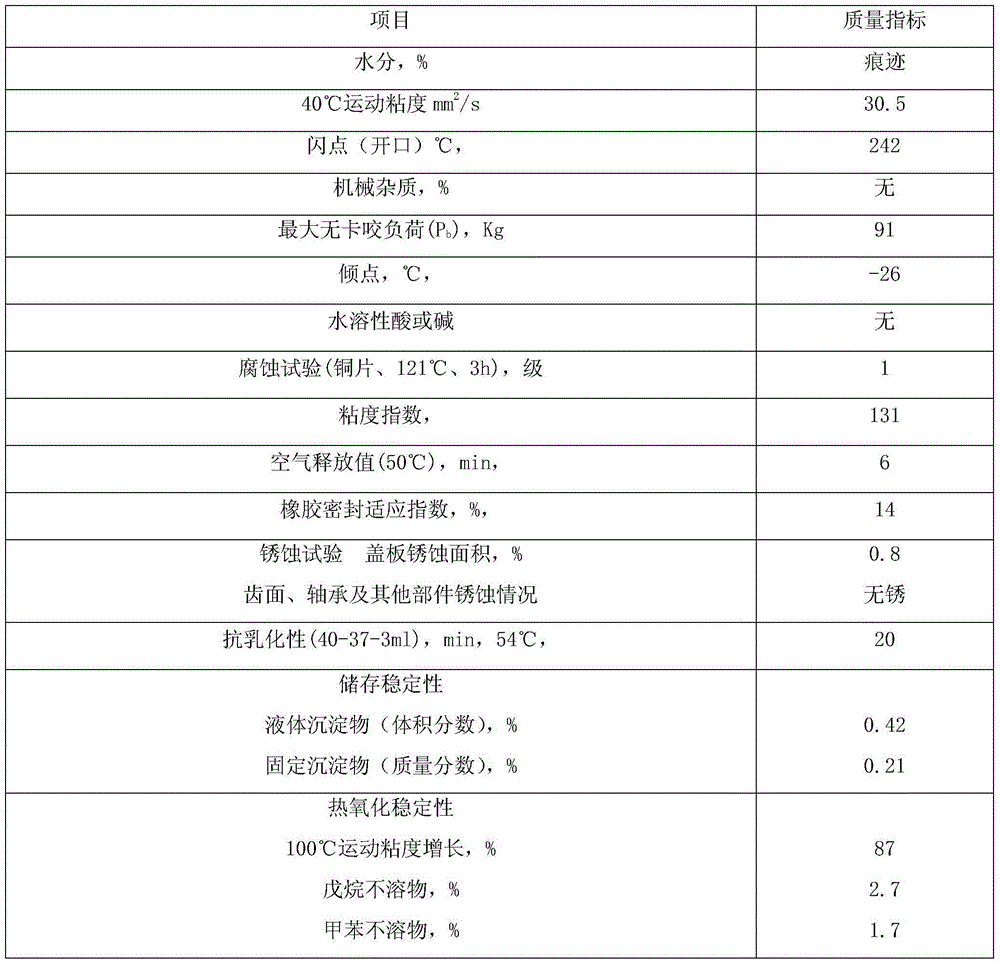

Lubricating-oil composition of speed reducing machine in gas turbine for ship

The invention discloses a lubricating-oil composition of a speed reducing machine in a gas turbine for ship. The lubricating-oil composition comprises the following components in percent by mass: 2-4% of antioxidant, 5-6% of antiwear agent, 0.1-0.4% of antirusting agent, 0.06-0.08% of metal passivating agent, 0.05-0.3% of demulsifying agent, 0.005-0.01% of anti-foaming agent, 1-2% of oiliness agent and the balance of base oil. The lubricating-oil composition has the obvious advantages that the comprehensive performance is good, and all performance indexes meet the use requirements; not only are the antioxygen, anticorrosion and antiwear performances good, but also the antirusting, anti-salt-fog and antifoaming performances are quite excellent; the lubricating-oil composition also meet the use requirements of the gas turbine for ship in the aspects of acid control capability, clean dispersity and rubber adaptability; and the base oil is compounded and synthesized by selecting diester and polyol ester which have excellent performance, so that the base oil assuredly has good heat stability, good viscosity-temperature characteristic, excellent low-temperature mobility, low volatility and good lubricity simultaneously.

Owner:GUANGXI UNIV

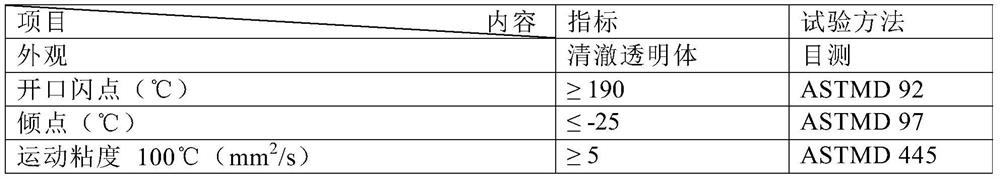

Base oil of cotton picker spindle lubricating grease

InactiveCN110499201AGood viscosity-temperature characteristicsMeet lubrication needsBase-materialsVegetable oilTemperature difference

Belonging to the technical field of lubricating compositions characterized by mixed ester, the invention in particular relates to a base oil of cotton picker spindle lubricating grease. The base oil of the cotton picker spindle lubricating grease comprises the following components: esterified modified epoxy vegetable oil, neopentyl glycol dioleate, isooctyl oleate and trimethylolpropane trioleate.The base oil of cotton picker spindle lubricating grease provided by the invention has good viscosity-temperature characteristics, and can meet the lubrication and sealing requirements of a cotton picker spindle bearing in a working environment with large temperature difference between day and night.

Owner:重庆化工职业学院

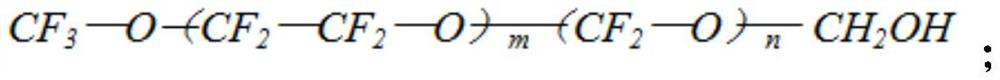

Straight-chain polyperfluoroether compound with hydroxyl-containing terminal group and preparation method thereof

ActiveCN111662443AGood viscosity-temperature characteristicsRegular molecular structurePolymer scienceStructural formula

The invention provides a straight-chain polyperfluoroether compound with a hydroxyl-containing terminal group and a preparation method thereof. The compound does not contain a branched chain structure, the molecular structure is neater, the compound is smoother, meanwhile, the compound has better viscosity-temperature characteristics, and the application range is wider. The straight-chain polyperfluoroether compound with the terminal group containing the hydroxyl group has a structural formula I shown in the specification; in the structural formula I, m is greater than or equal to 1, and n isgreater than or equal to 1.

Owner:CHINA PETROLEUM & CHEM CORP

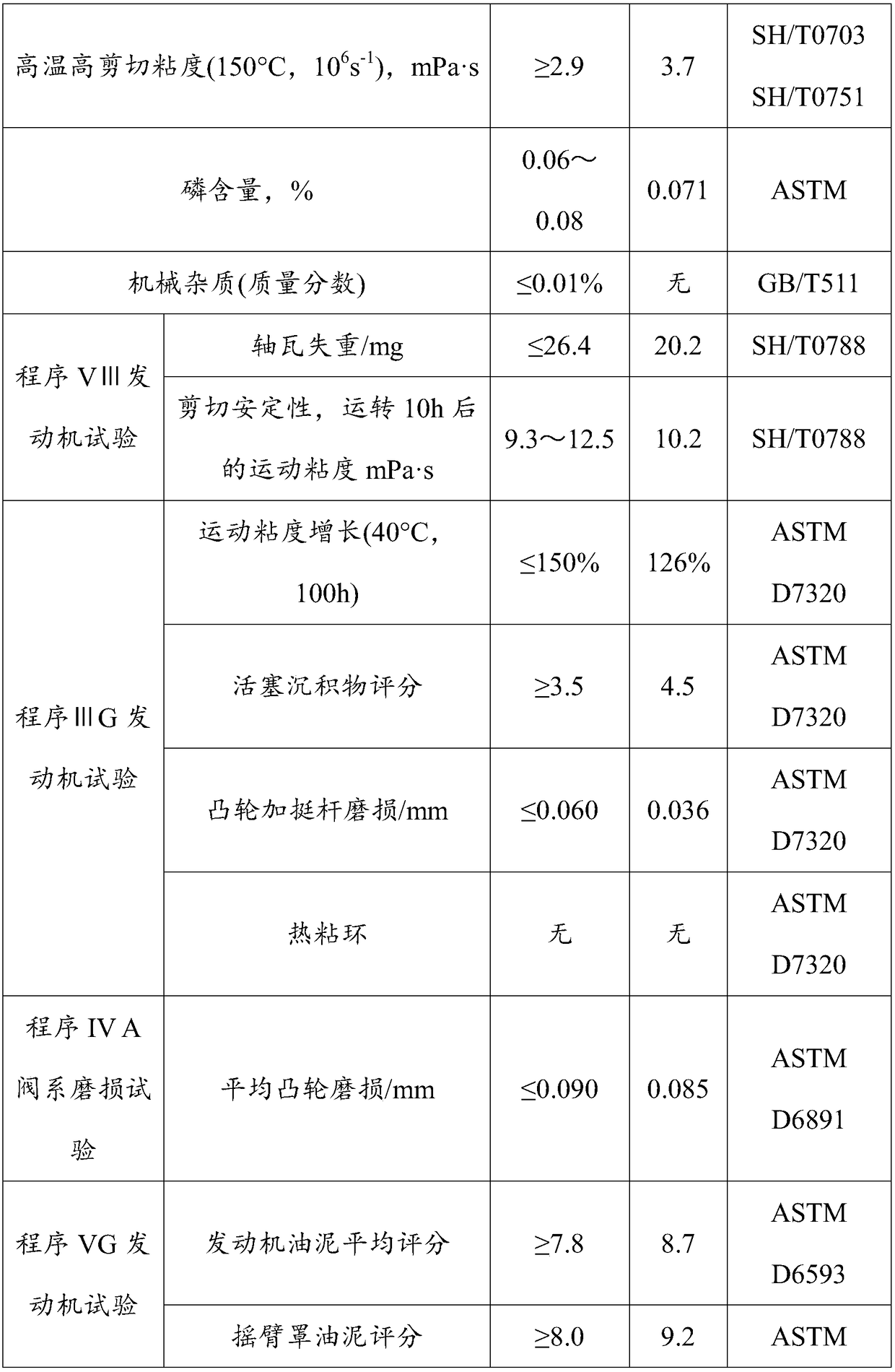

Powerful anti-friction energy-saving gasoline engine oil and production technology thereof

The invention discloses powerful anti-friction energy-saving gasoline engine oil and a production technology thereof. The powerful anti-friction energy-saving gasoline engine oil is prepared form thefollowing raw materials: synthetic base oil, a metal detergent, an ashless dispersant, an anti-oxidation and anti-corrosion agent, a nano-scale multi-effect abrasive, a viscosity index improver and apour point depressant. The production technology comprises the following steps: putting the synthetic base oil in a reaction kettle, starting stirring, and heating; putting the pour point depressant,the viscosity index improver, the anti-oxidation and anti-corrosion agent, the metal detergent and the ashless dispersant in sequence, and uniformly stirring; then putting the nano-scale multi-effectabrasive, and continuing to stir at a certain rotating speed by keeping the original temperature; finally, pumping the stirred materials to a storage tank, and standing for 1 hour, thus obtaining a finished product of the powerful anti-friction energy-saving gasoline engine oil. According to the powerful anti-friction energy-saving gasoline engine oil and the production technology thereof, disclosed by the invention, the production conditions are easy to control; fuel produced by the invention is good in economy and long in oil draining period, and excellent anti-abrasion and anti-friction performance, high-temperature oxidation resistance and low-temperature fluidity are obtained.

Owner:王兴民

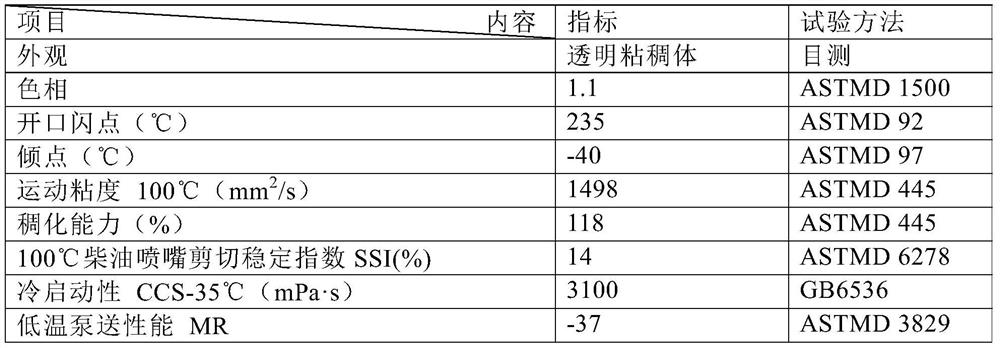

Synthetic method for high-grade lubricating oil PAO22 used for automobile engine

The invention provides a synthetic method for high-grade lubricating oil PAO22 used for an automobile engine. The synthetic method is characterized in that PAO22 base oil is synthesized from high-viscosity 1-decene monomers under the action of a catalyst and an assistant agent, wherein the catalyst is aluminum trichloride, and the assistant agent is acetylacetone. The invention provides a preparation method for the high-grade PAO lubricating oil used for the automobile engine and having high viscosity. When the total-synthesis lubricating oil in the invention is applied to the automobile engine, the service life of the automobile can be prolonged; the industrial catalyst used in the invention is cheap and easily avaialbe; the lubricating oil prepared in the invention can be used for preparation of high-grade lubricating oil and has good viscosity-temperature characteristics; reaction conditions are mild; the method is implemented at normal pressure; and the catalyst is easy to treat.

Owner:SHANGHAI OULEIFEN BIOLOGICAL TECH

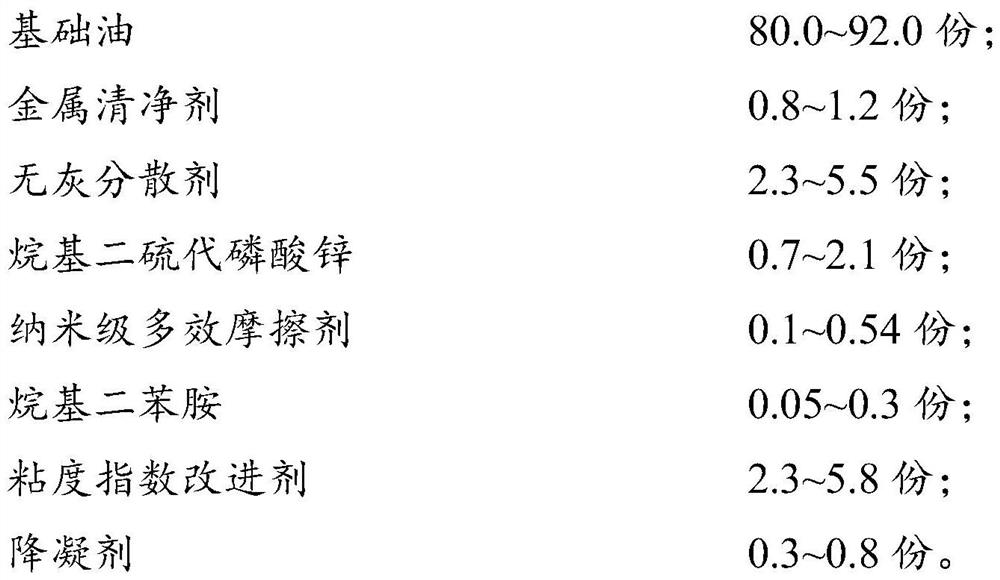

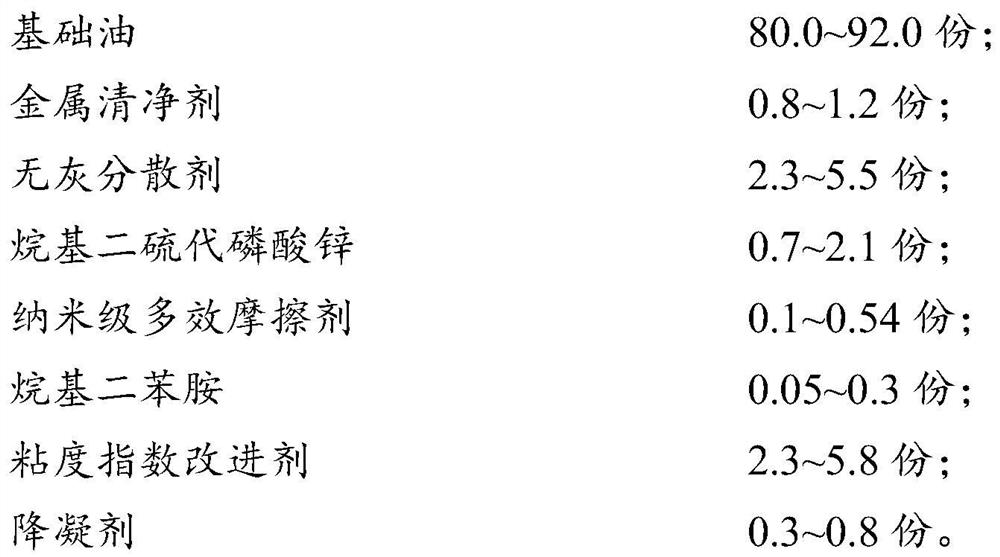

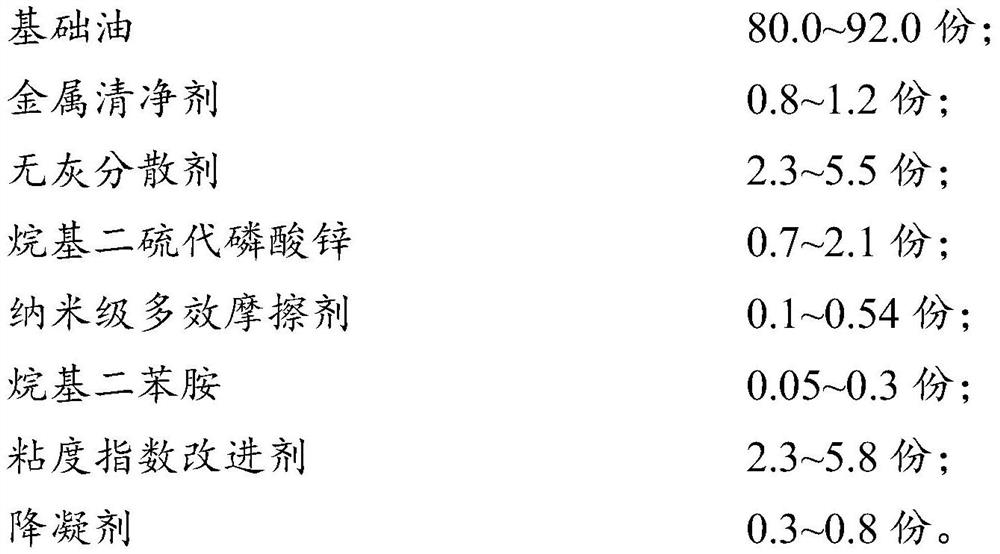

Internal combustion engine oil for crawler-type tank and preparation method of internal combustion engine oil

PendingCN113444563AImprove timelinessHarm reductionLubricant compositionFriction lossViscosity index

The invention provides internal combustion engine oil for a crawler-type tank and a preparation method of the internal combustion engine oil, and belongs to the technical field of vehicle engine lubricating oil. The internal combustion engine oil disclosed by the invention is prepared from the following raw materials in parts by weight: 80.0 to 92.0 parts of base oil, 0.8 to 1.2 parts of a metal detergent, 2.3 to 5.5 parts of an ashless dispersant, 0.7 to 2.1 parts of zinc alkyl dithiophosphate, 0.1 to 0.54 part of a nanoscale multi-effect abrasive, 0.05 to 0.3 part of alkyl diphenylamine, 2.3 to 5.8 parts of a viscosity index improver and 0.3 to 0.8 part of a pour point depressant. The internal combustion engine oil obtained by the invention is a novel lubricating material prepared on the basis of a nano material, and is an internal combustion engine oil which is outstanding in friction resistance, good in fuel economy, long in oil change period, ultralow in tail gas emission and capable of effectively reducing friction loss of an engine.

Owner:福建省黑狮润滑油研究中心

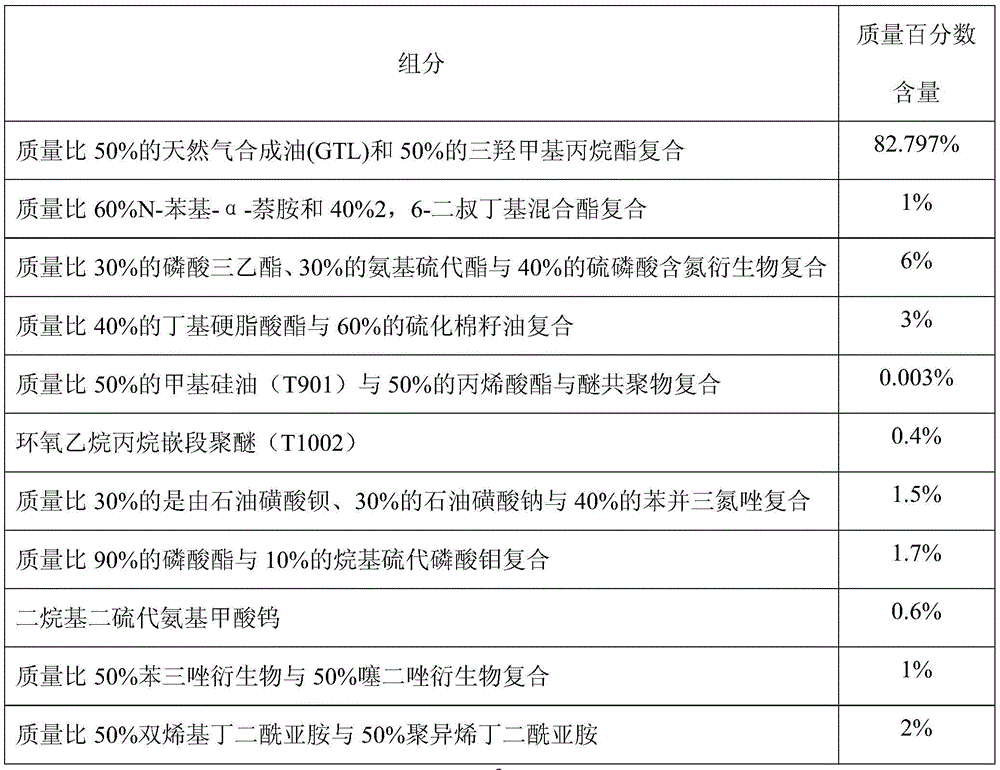

Spray supply mode cutting oil for metal material cutting processing

InactiveCN101717684BEasy to useImprove extreme pressure lubrication performanceAdditivesPhosphoric Acid EstersVegetable oil

Owner:DG ARMORINE ENERGY EFFICIENT & ECO FRIENDLY TECH

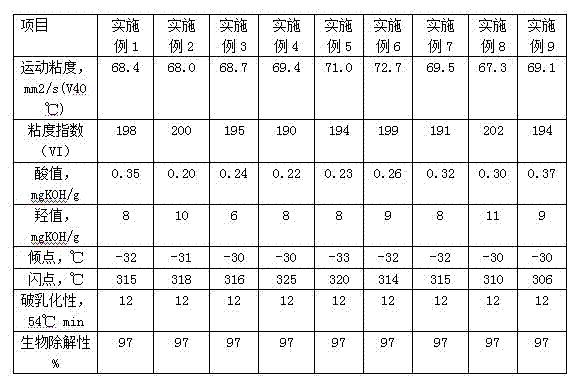

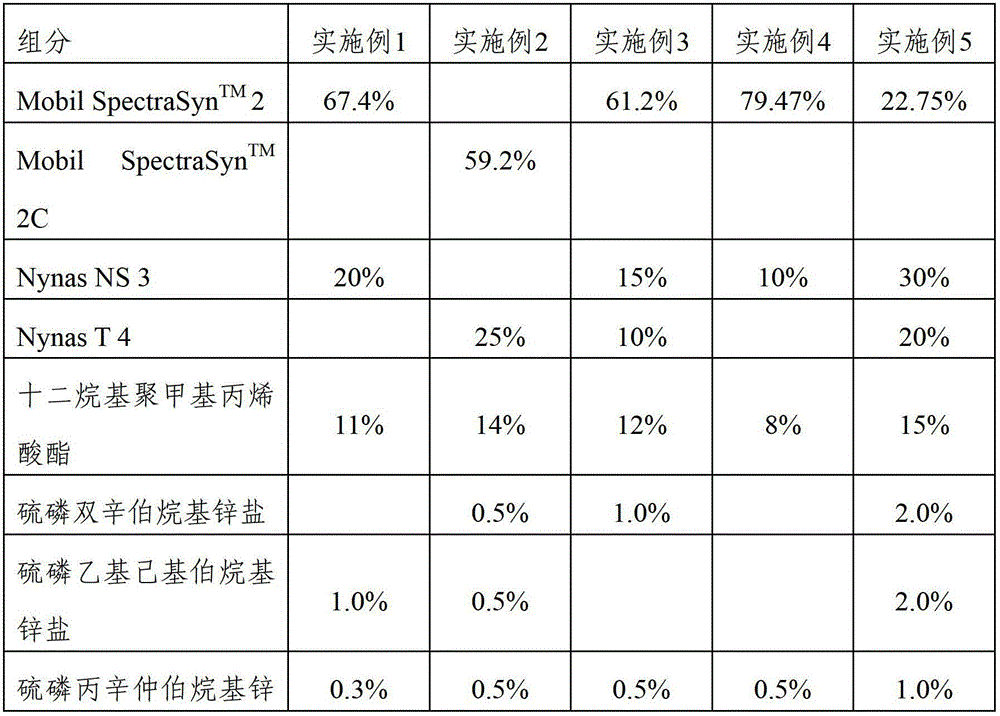

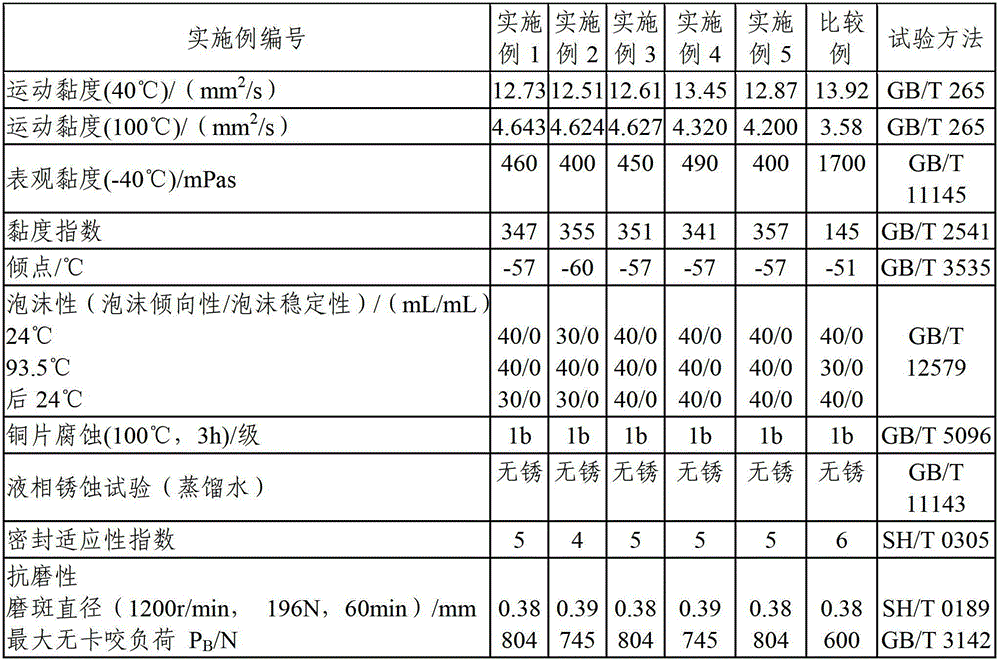

Shock absorber oil composition

ActiveCN103571589BCompatibility is reasonableGood viscosity-temperature characteristicsLubricant compositionFoaming agentViscosity index

The invention provides a shock absorber oil composition which consists of the following components in percentage by weight: 50-90% of poly alpha-olefin synthetic oil, 10-50% of cycloalkyl mineral oil, 8-15% of a polymethacrylate viscosity index modifier, 0.5-5% of an antiwear agent, 0.1-5% of an antioxidant, 0.01-2% of a rust-preventing agent and 0.001-0.05% of an anti-foaming agent. The shock absorber oil composition provided by the invention has the beneficial effects that compared with common shock absorber oil, the shock absorber oil provided by the invention has remarkable viscosity-temperature performance (the viscosity index is greater than 325), excellent low temperature performance (the pour point is less than -50 DEG C), excellent anti-foaming performance, good anti-oxidizing and rust-preventing performances and excellent antiwear performance. Meanwhile, the shock absorber oil composition has good adaptability to rubber. The product provided by the invention can be used for automotive, train and locomotive shock absorbers, and can satisfy the using demands such as all weather, long service life and universality.

Owner:CHINA PETROLEUM & CHEM CORP

Crown gear central differential lubricant composition

InactiveCN104357188AModerate coefficient of frictionImprove anti-friction and anti-wear propertiesLubricant compositionDispersityHeat stability

The invention discloses a crown gear central differential lubricant composition which uses the composite of polyinternalolefins and isodecyl sebacate as base oil and is matched with multiple composite additives, including antioxidant, antiwear additive, oily agent, metal passivator, friction improver, antifoam agent, rust inhibitor, antioxidant preservative, demulsifying compound, dispersing agent and reinforcing agent. The lubricant composition has the advantages of proper friction factor, favorable friction and abrasion resistance, favorable heat stability, favorable viscosity retentivity, favorable viscosity-temperature characteristics, favorable clean dispersity, favorable heat dissipation property, favorable carrying capacity, high acid number controllability and high oxidation resistance, prevents corrosion, reduces the abrasion, shock load and vibrations, and can effectively provide hydraulic power.

Owner:GUANGXI UNIV

A kind of method of polymer modified lubricating oil

ActiveCN107573985BImprove liquidityGood viscosity-temperature characteristicsAdditivesPolymer sciencePolymer modified

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricant for extruding lead and lead alloy materials

Owner:GUANGXI UNIV

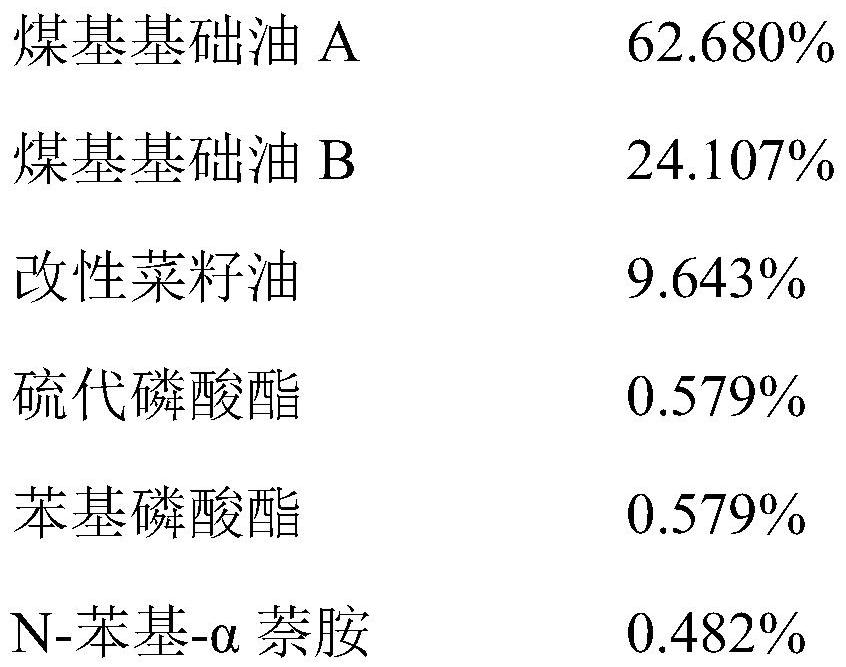

Coal-based anti-wear hydraulic oil and preparation method thereof

PendingCN113136256AImprove anti-wear performanceReduce device wearLubricant compositionAnoxomerPetroleum

The invention relates to hydraulic oil, in particular to coal-based anti-wear hydraulic oil and a preparation method thereof, and aims to solve the problems that in the prior art, the hydraulic oil is mainly prepared by adopting petroleum-based mineral oil as base oil and adding additives, wherein the performance improvement mainly lies in the updating of the types of the additives, and the improvement of the performance of the hydraulic oil is greatly limited. The invention provides coal-based anti-wear hydraulic oil. The coal-based anti-wear hydraulic oil is prepared from coal-based base oil A, coal-based base oil B, V-type base oil, an anti-wear agent, an antioxidant, an oiliness agent, an anti-rust agent and a composite anti-foaming agent; wherein the viscosity index of the coal-based base oil A is greater than 120, the kinematic viscosity at 40 DEG C is 40-50 mm2 / s, the pour point is lower than -30 DEG C, the saturated hydrocarbon content is greater than or equal to 99%, and the sulfur content is less than or equal to 0.0005%; the viscosity index of the coal-based base oil B is greater than 120, the kinematic viscosity at 40 DEG C is 30-35 mm2 / s, the pour point is lower than -30 DEG C, the saturated hydrocarbon content is greater than or equal to 99%, and the sulfur content is less than or equal to 0.0005%; and the V-type base oil is one or a mixture of two of modified rapeseed oil or alkyl naphthalene synthetic oil.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

Semisynthetic metal cutting fluid with trimethylolpropane oleate serving as base oil and preparation method of semisynthetic metal cutting fluid

The invention discloses semisynthetic metal cutting fluid with trimethylolpropane oleate serving as base oil and a preparation method of the semisynthetic metal cutting fluid. The semisynthetic metal cutting fluid comprises the trimethylolpropane oleate, nonionic surfactants, anionic surfactants, antirust agents, cosolvents, extreme pressure agents, defoaming agents, bacteriacide and water. The preparation method of the semisynthetic metal cutting fluid includes: adding the extreme pressure agents into the base oil with uniform stirring so that solution A is obtained; then sequentially adding the defoaming agents, the antirust agents, the cosolvents and the bacteriacide into the water with uniform stirring so that solution B is obtained; and mixing the solution A with the solution B, and stirring while slowly dropwise adding the nonionic surfactants and the anionic surfactants so that a homogeneous and clarified micro-emulsion system, namely, the semisynthetic metal cutting fluid with the trimethylolpropane oleate serving as the base oil is obtained finally. The semisynthetic metal cutting fluid has good lubricity and biological degradability, has low-toxicity and low-harm to human bodies and the environment and is suitable for metal machining of most materials.

Owner:上海樱花化研化工科技有限公司

A kind of engine oil additive composition and preparation method thereof

InactiveCN104830432BImprove antioxidant capacityImprove the lubrication effectAdditivesAntioxidantOil additive

The invention discloses an engine oil additive composition and a preparation method thereof. The formula of the engine oil additive composition is calculated in parts by weight: 20-40 parts of castor oil, 15-20 parts of boron nitrogen type modified castor oil, castor oil polyol 5-10 parts of ester, 5-10 parts of rust inhibitor, 5-10 parts of antioxidant, 5-8 parts of surfactant, 10-15 parts of organic molybdenum compound, 5-10 parts of dispersant, 2-5 parts of graphite powder 1 to 3 parts of metal deactivator, 2 to 5 parts of cleaning agent, 2 to 5 parts of nanometer metal powder concentrate, and 2 to 5 parts of viscosity index improver. The present invention prepares an environment-friendly engine oil additive composition by controlling the types and quantities of castor oil, modified castor oil, nanoparticles and other phosphorus-free additives. The additive has good lubricity, viscosity-temperature characteristics, low-temperature fluidity, and Corrosion resistance, anti-foaming and anti-emulsification capabilities, good comprehensive performance, and due to the addition of nano-materials and phosphorus-free additives, it increases anti-wear performance, prolongs the oil change period, reduces environmental pressure, and reduces adverse effects on the engine .

Owner:梁海东

Plant composite engine oil containing graphene-inorganic non-metallic fibers

ActiveCN108795547BImprove the lubrication effectPlay a repairing roleCarbon compoundsAdditivesBenzoic acidPolymer science

The invention discloses graphene-inorganic nonmetallic fiber containing plant composite engine oil and a preparation method thereof. The preparation method comprises the following steps: adding graphene-inorganic nonmetallic fiber, liquid graphene, 1-octyl-3-methylimidazolium tetrafluoroborate into castor oil, stirring, then adding 2,2,4-trimethyl-1,3-pentanediol-isobutyric benzoate, didodecylmethyl tertiary amine, dimethyl glutarate, 12-hydroxystearic acid, a demulsifying agent, 1-3 parts of an antifreezing agent, an antiseptic and antirust agent, 2,6-di-tert-butyl-4-methylphenol, sasol wax,zinc dipentyl dithiocarbamate, triethanolamine oleate, oxidized polyethylene wax and fatty acid polyethylene glycol ester, and stirring to obtain the graphene-inorganic nonmetallic fiber containing plant composite engine oil. The graphene-inorganic nonmetallic fiber containing plant composite engine oil has good lubricity, viscosity-temperature properties, low-temperature fluidity and corrosion resistance and other characteristics, and has good comprehensive performance.

Owner:颜凤生

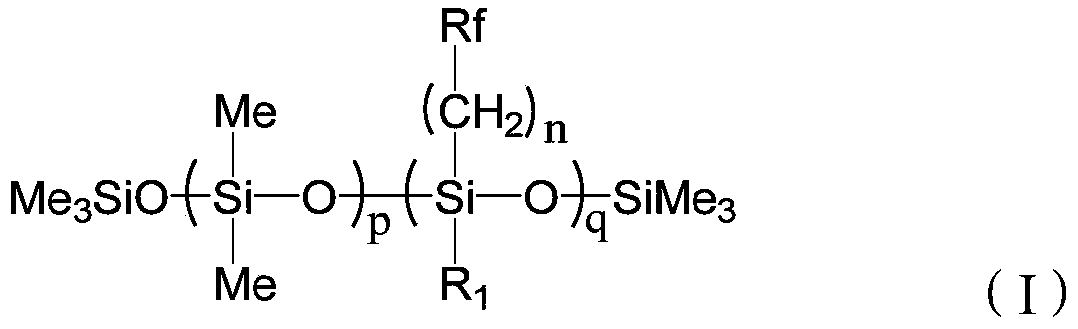

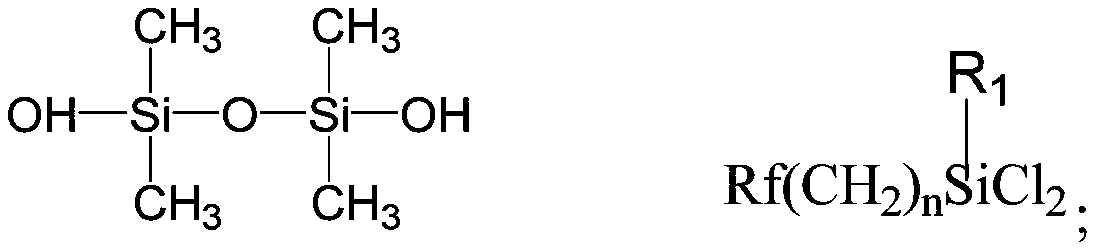

Perfluoroether-based polysiloxane and its preparation method and application

ActiveCN106883410BGood flexibilityGood viscosity-temperature characteristicsAdditivesBase-materialsPolymer sciencePerfluoroether

Owner:YICHANG COLLIN SILICON MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com