Coal-based anti-wear hydraulic oil and preparation method thereof

An anti-wear hydraulic oil, coal-based technology, applied in the field of hydraulic oil, can solve the problems of improving the performance of anti-wear hydraulic oil, and achieve the effect of reducing oxidized deposits, reducing device wear and high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

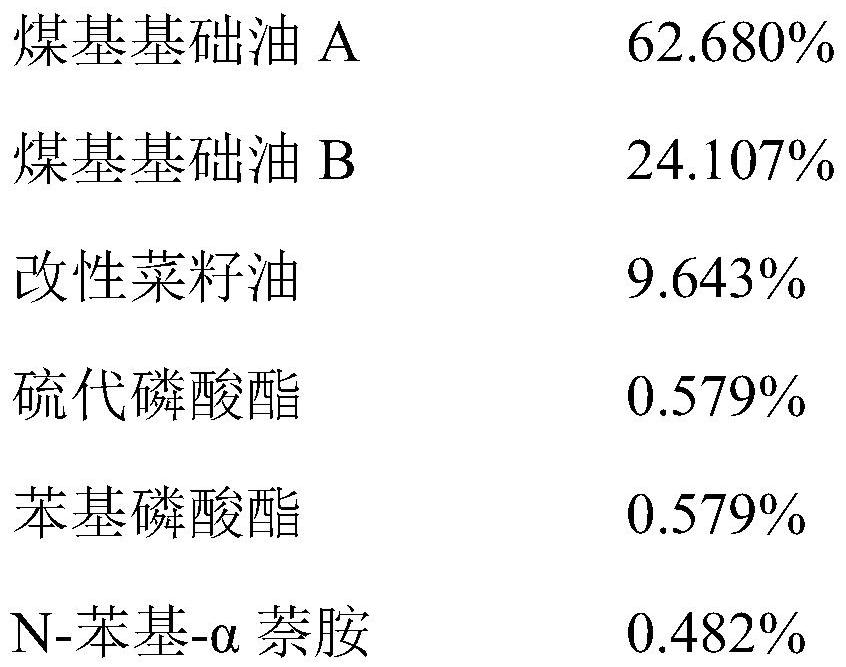

[0033] The formulation of No. 1 coal-based anti-wear hydraulic oil is as follows (mass percentage):

[0034]

[0035] Add coal-based base oil A, coal-based base oil B, and modified rapeseed oil into a three-necked flask according to the above ratio to form a mixed base oil, and then continue to add additives according to the above ratio, wherein the composite antifoaming agent is dimethyl silicone oil and The mass ratio of polyacrylate is 1:1. Use a water bath to raise the temperature of the mixture to 60°C and stir it at a constant temperature for 2 hours under magnetic stirring. Finally, the mixture is filtered with medium-speed quantitative filter paper and the filtrate is No. 1 coal-based anti- Grind hydraulic oil.

Embodiment 2

[0037] The formula of No. 2 coal-based anti-wear hydraulic oil is as follows (mass percentage):

[0038]

[0039] Add coal-based base oil A, coal-based base oil B, and alkylnaphthalene synthetic oil to a three-necked flask according to the above ratio to form a mixed base oil, and then continue to add additives according to the above ratio, wherein the composite antifoaming agent is simethicone The mass ratio of polyacrylate and polyacrylate is 3:2. Use a water bath to raise the temperature of the mixture to 60°C and stir it at a constant temperature for 2 hours under magnetic stirring. Finally, the mixture is filtered with medium-speed quantitative filter paper and the filtrate is No. 2 coal base Anti-wear hydraulic oil.

Embodiment 3

[0041] The formulation of No. 3 coal-based anti-wear hydraulic oil is as follows (mass percentage):

[0042]

[0043]

[0044] Add coal-based base oil A, coal-based base oil B, and modified rapeseed oil into a three-necked flask according to the above ratio to form a mixed base oil, and then continue to add additives according to the above ratio, wherein the composite antifoaming agent is dimethyl silicone oil and The mass ratio of polyacrylate is 3:2. Use a water bath to raise the temperature of the mixture to 50°C and stir it at a constant temperature for 1.5 hours under magnetic stirring. Finally, the mixture is filtered with medium-speed quantitative filter paper and the filtrate is No. 3 coal base Anti-wear hydraulic oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pour point | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com