Patents

Literature

2418 results about "Viscosity index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The viscosity index (VI) is an arbitrary, unitless measure of the change of viscosity with temperature, mostly used to characterize the viscosity-temperature behavior of lubricating oils. The lower the VI, the more the viscosity is affected by changes in temperature. The VI was originally measured on a scale from 0 to 100; however, advancements in lubrication science have led to the development of oils with much higher VIs.

Modified polyethylene compositions

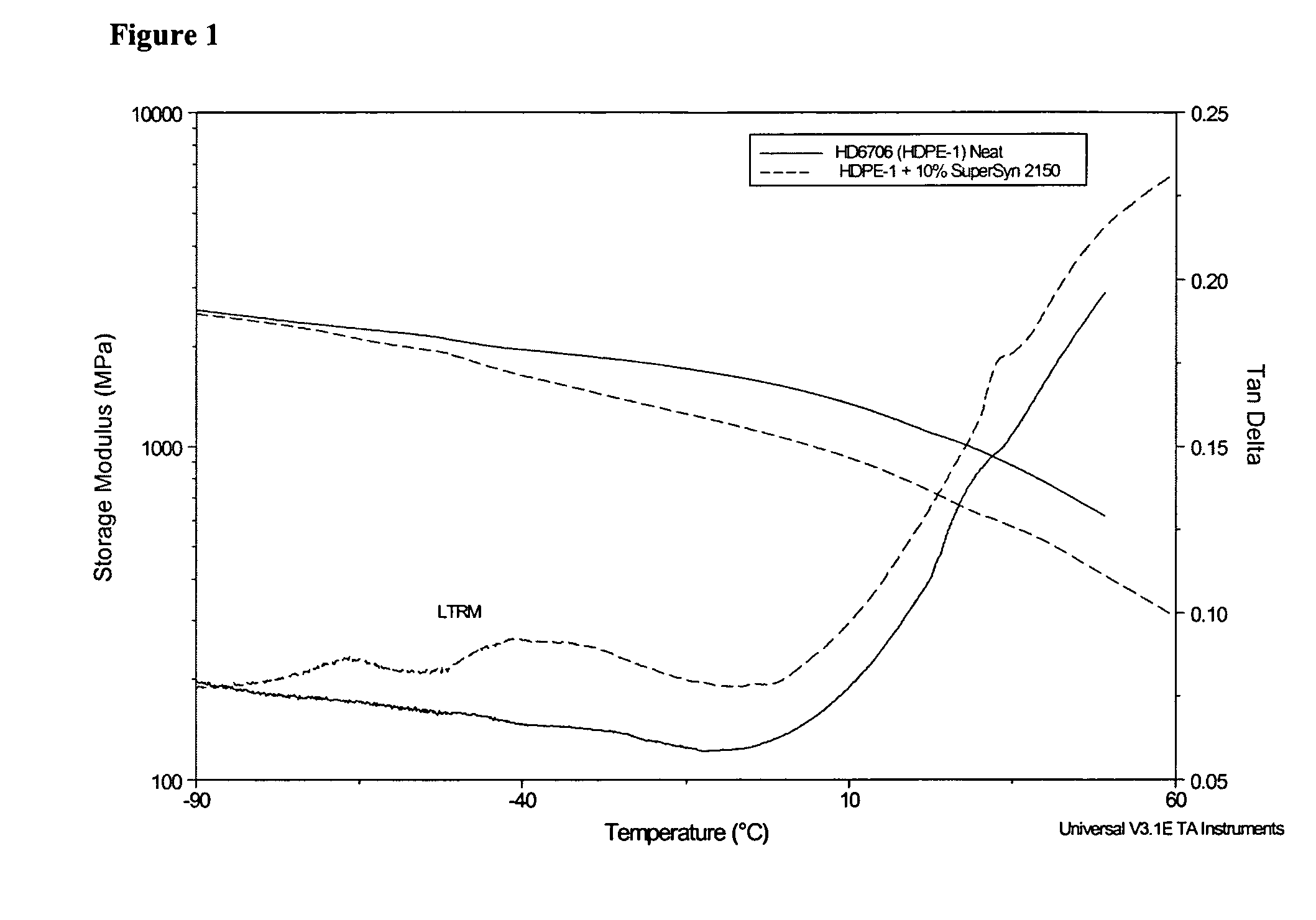

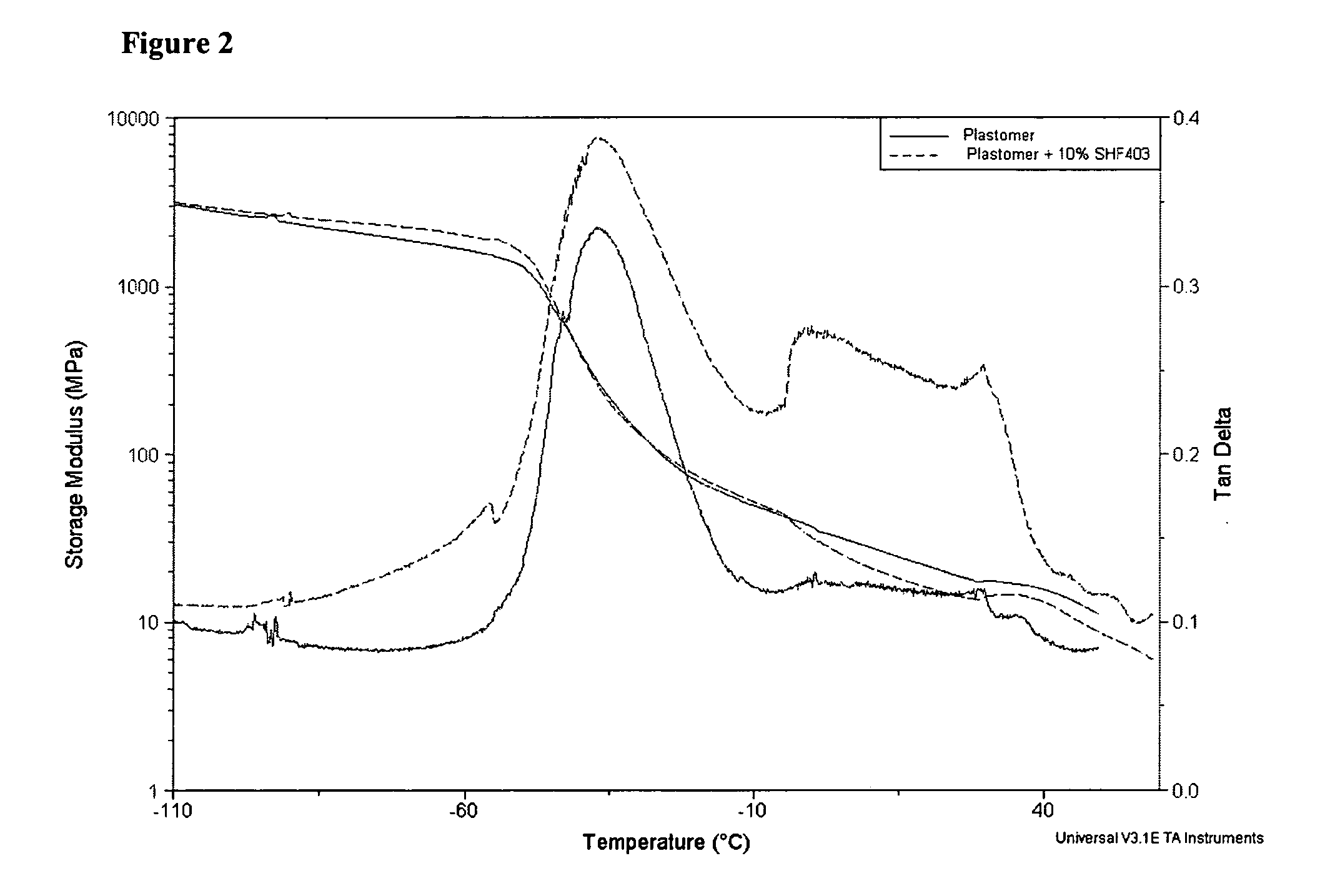

The present invention relates to a composition comprising more than 25 weight % (based on the weight of the composition) of one or more ethylene polymers having an Mw of 20,000 g / mole or more and at least 0.1 weight % of a liquid hydrocarbon modifier where the modifier has: 1) a viscosity index of 120 or more, and 2) an kinematic viscosity of 3 to 3000 cSt at 100° C., and 3) a pour point of −10° C. or less, and 4) a flash point of 200° C. or more; and wherein the modifier contains less than 5 weight % of functional groups selected from hydroxide, aryls, substituted aryls, halogens, alkoxys, carboxylates, esters, acrylates, oxygen, nitrogen, and carboxyl, based upon the weight of the modifier.

Owner:EXXONMOBIL CHEM PAT INC

Viscosity index improver for lubricant compositions

Owner:DOW GLOBAL TECH LLC

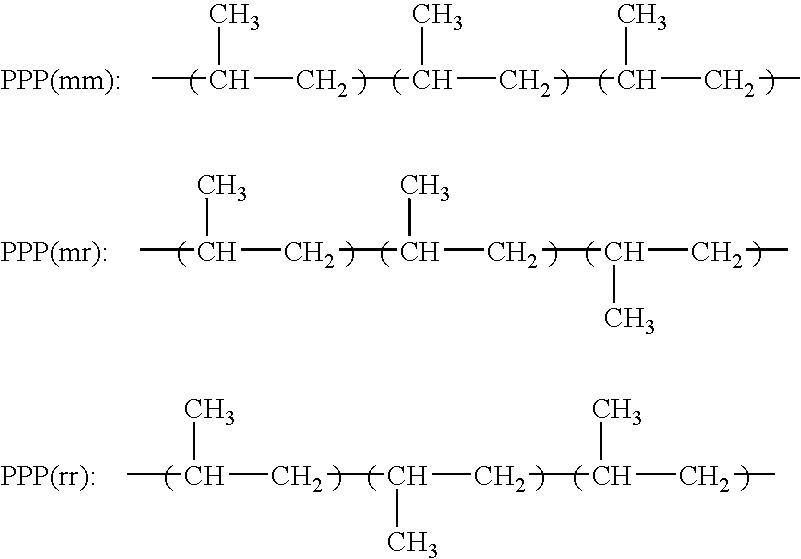

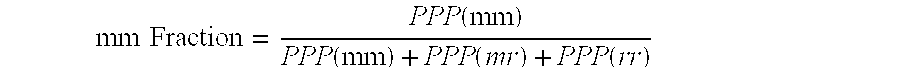

Plasticized polyolefin compositions

InactiveUS20060135699A1Monocomponent polyolefin artificial filamentArtifical filament manufacturePolyolefinPlasticizer

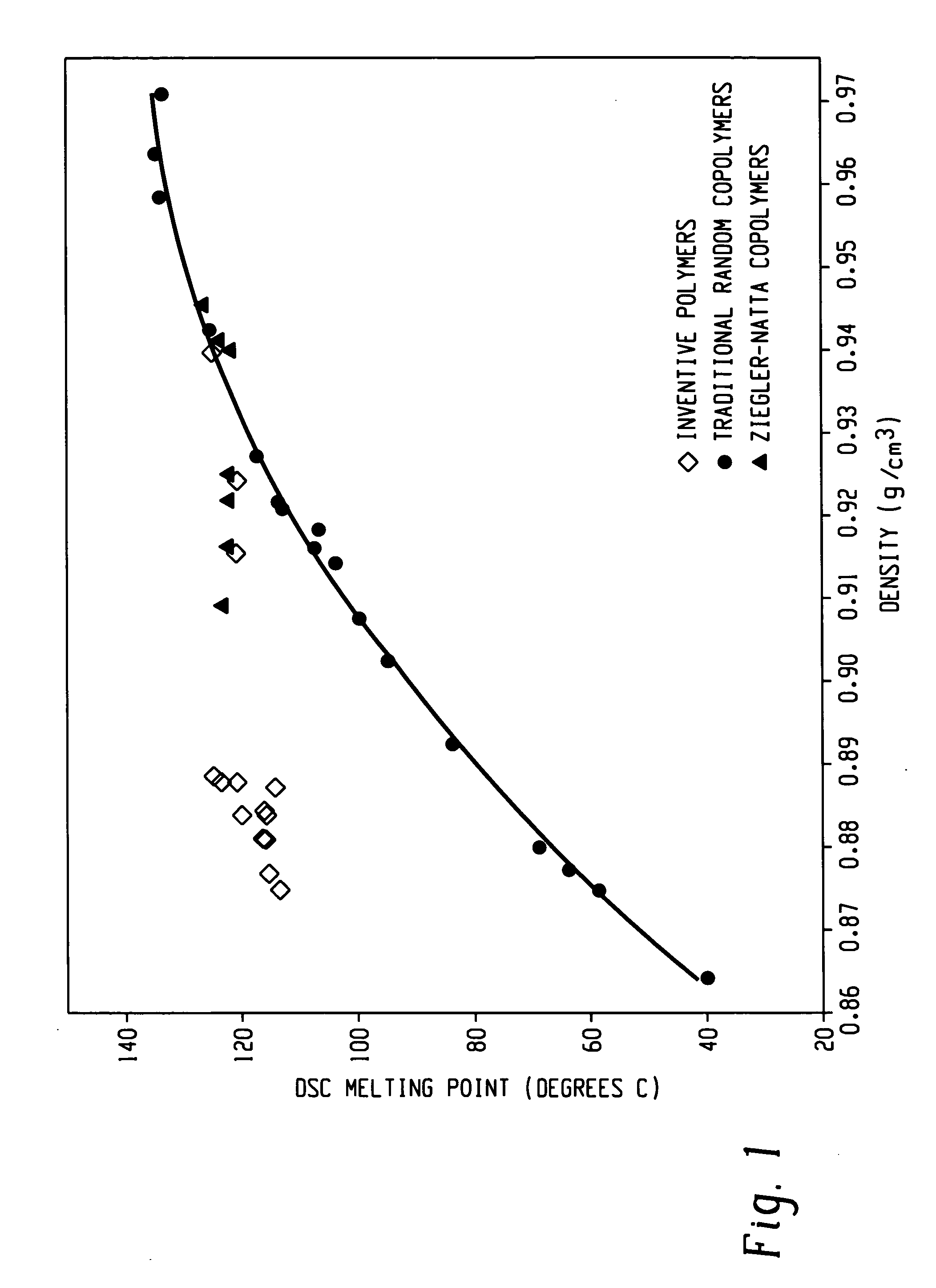

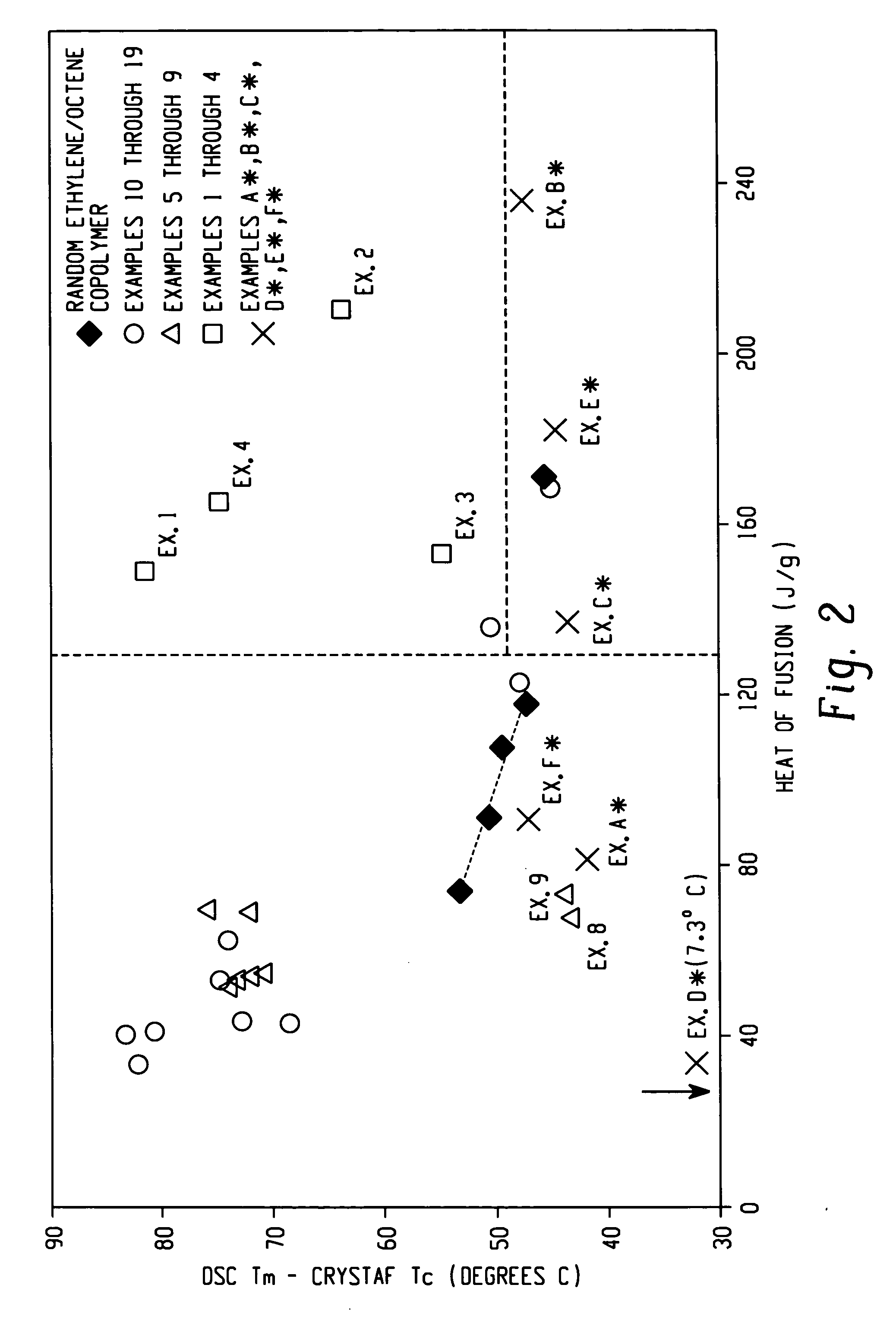

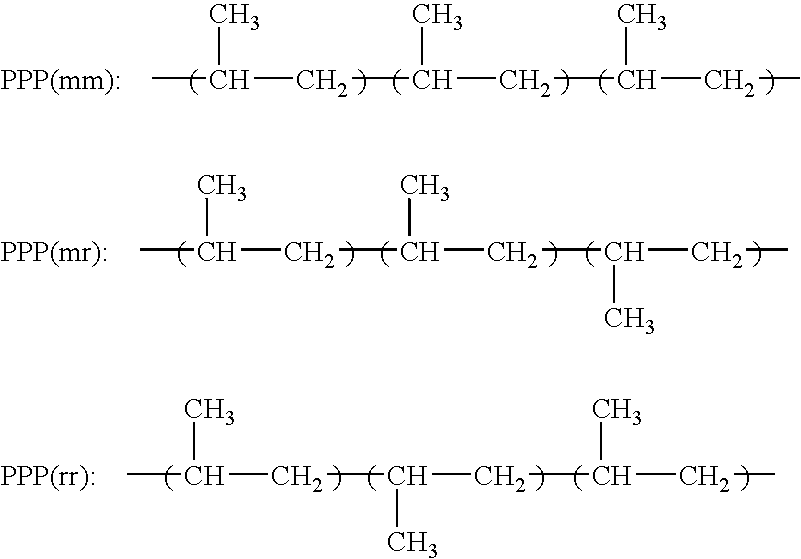

The present invention relates to a composition comprising 1) from 1 to 98 weight % of a first propylene polymer having a melting point of 100° C. or more, 2) from 5 to 98 weight % of a second propylene polymer having a heat of fusion of 70 J / g or less and a tacticity index of 75% or more, 3) from 0.5 to 75 weight % of a non-functionalized plasticizer (“NFP”) having a viscosity index of 120 or more, based upon the weight of the first polymer, second polymer, and the NFP, and articles therefrom

Owner:EXXONMOBIL CHEM PAT INC

Lubricating oil formulations

Lubricating oil compositions having excellent thermal and oxidative stability, wear control, copper corrosion control and compatibility with seal materials comprising a mineral oil having a) a Viscosity Index of greater than 110 and an aniline point of greater than 110 DEG C. and / or b) a linear+single ring paraffin content of greater than 68 wt %, and at least one polymer selected from olefin (co) polymer(s), polyalkyl (meth) acrylate(s) and mixtures thereof. The lubricating oil compositions are particularly useful as manual transmission and axle lubricants.

Owner:AFTON CHEM INTANGIBLES

Lubricating fluids with enhanced energy efficiency and durability

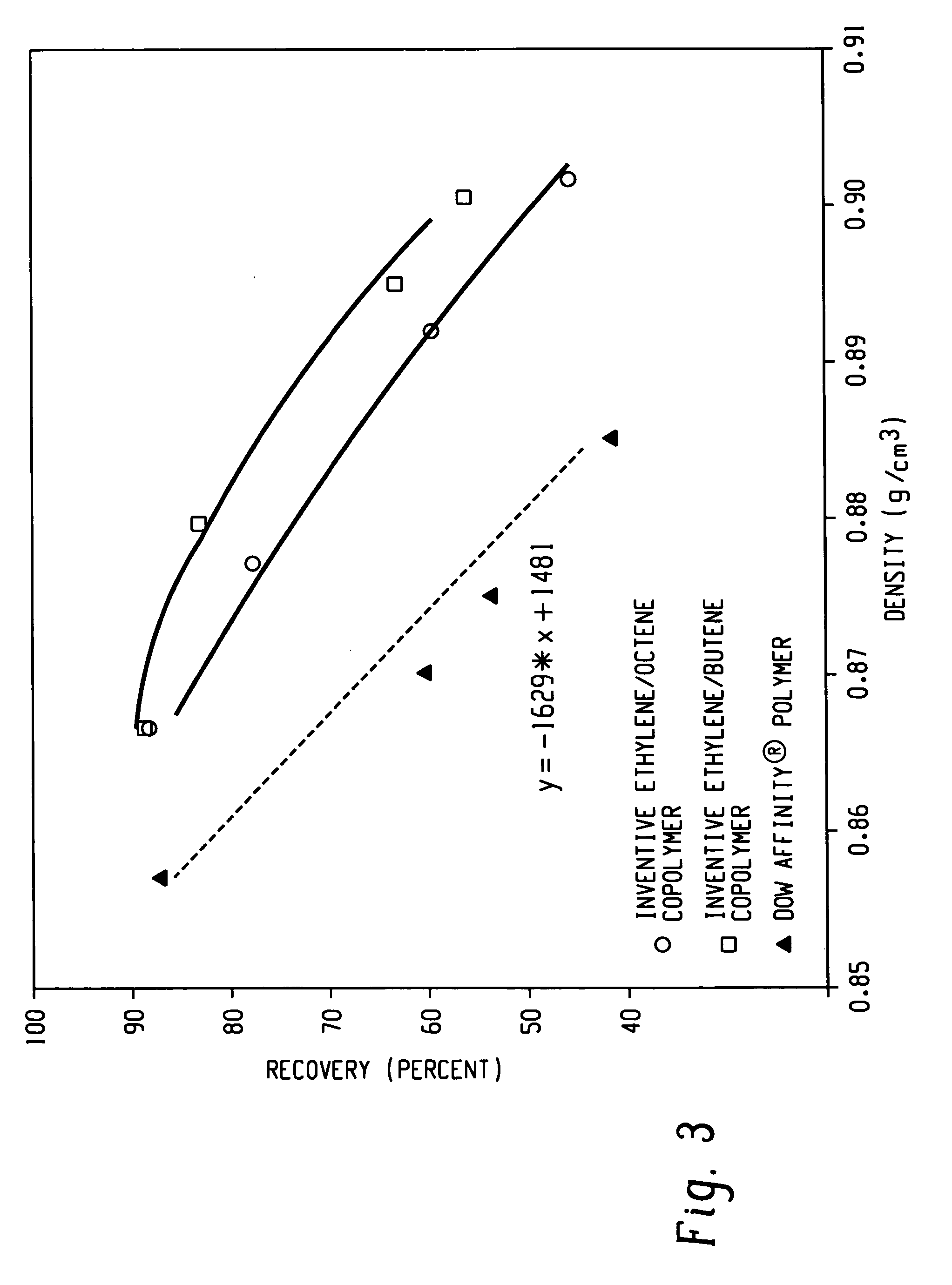

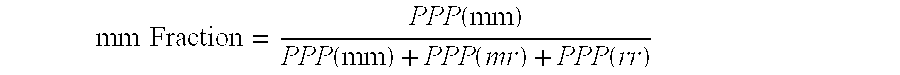

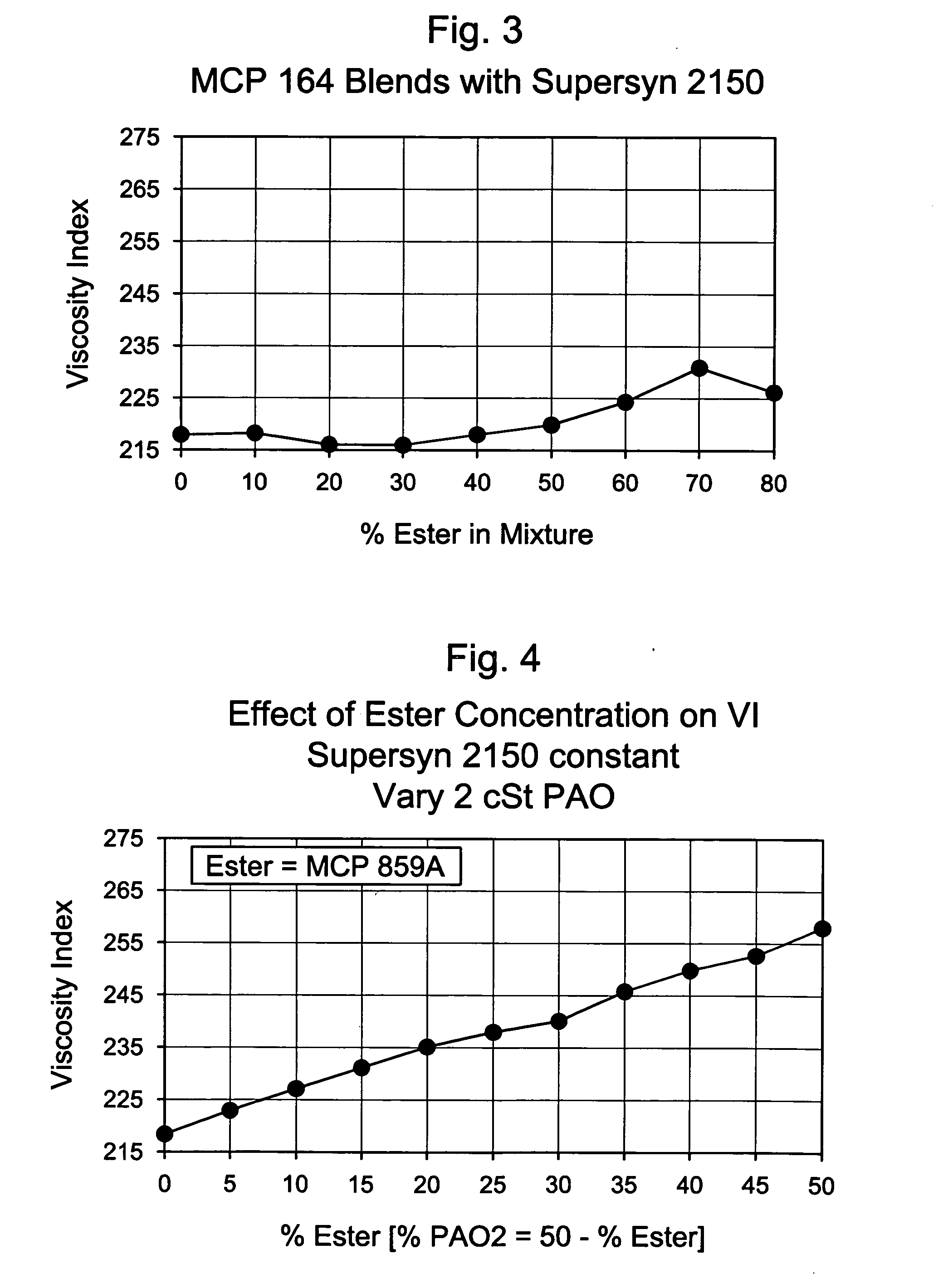

The present invention comprises novel lubricating compositions, automotive gear lubricating compositions, and fluids useful in the preparation of finished automotive gear lubricants and finished gear oils, and methods of preparation thereof. One embodiment of the present invention comprises a lubricating composition comprising a blend of a PAO having a viscosity of greater than or equal to about 40 cSt. at 100° C. and less than or equal to about 1,000 cSt. at 100° C. and an ester having a viscosity of less than or equal to about 2.0 cSt. at 100° C., wherein said blend of said PAO and said ester has a viscosity index greater than or equal to the viscosity index of the PAO.

Owner:EXXONMOBIL CHEM PAT INC

Production of high viscosity lubricating oil stock with improved ZSM-5 catalyst

InactiveUS6294077B1Low pour pointHigh viscosity indexMolecular sieve catalystsRefining to change hydrocarbon structural skeletonHydrogenParaffin oils

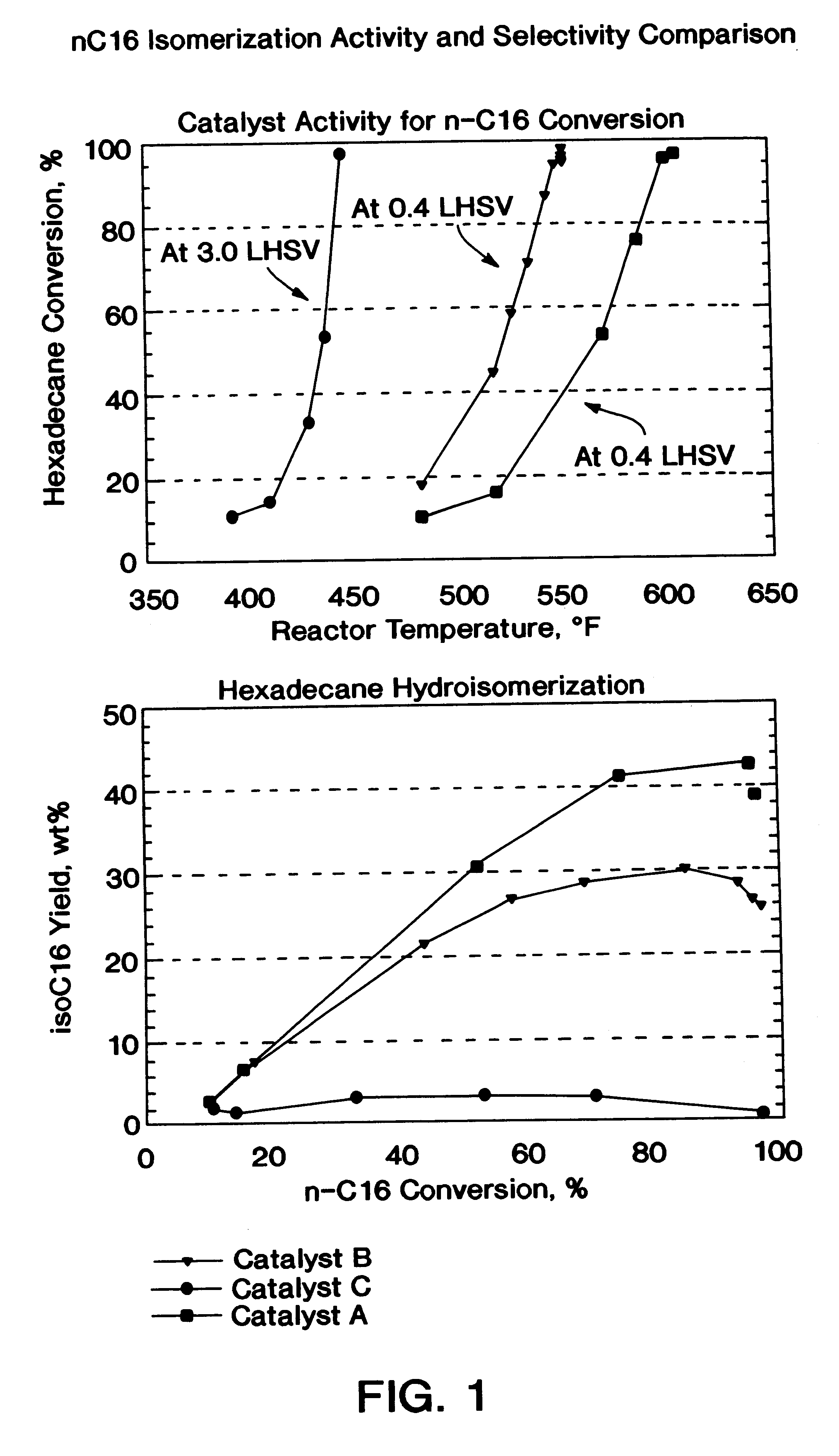

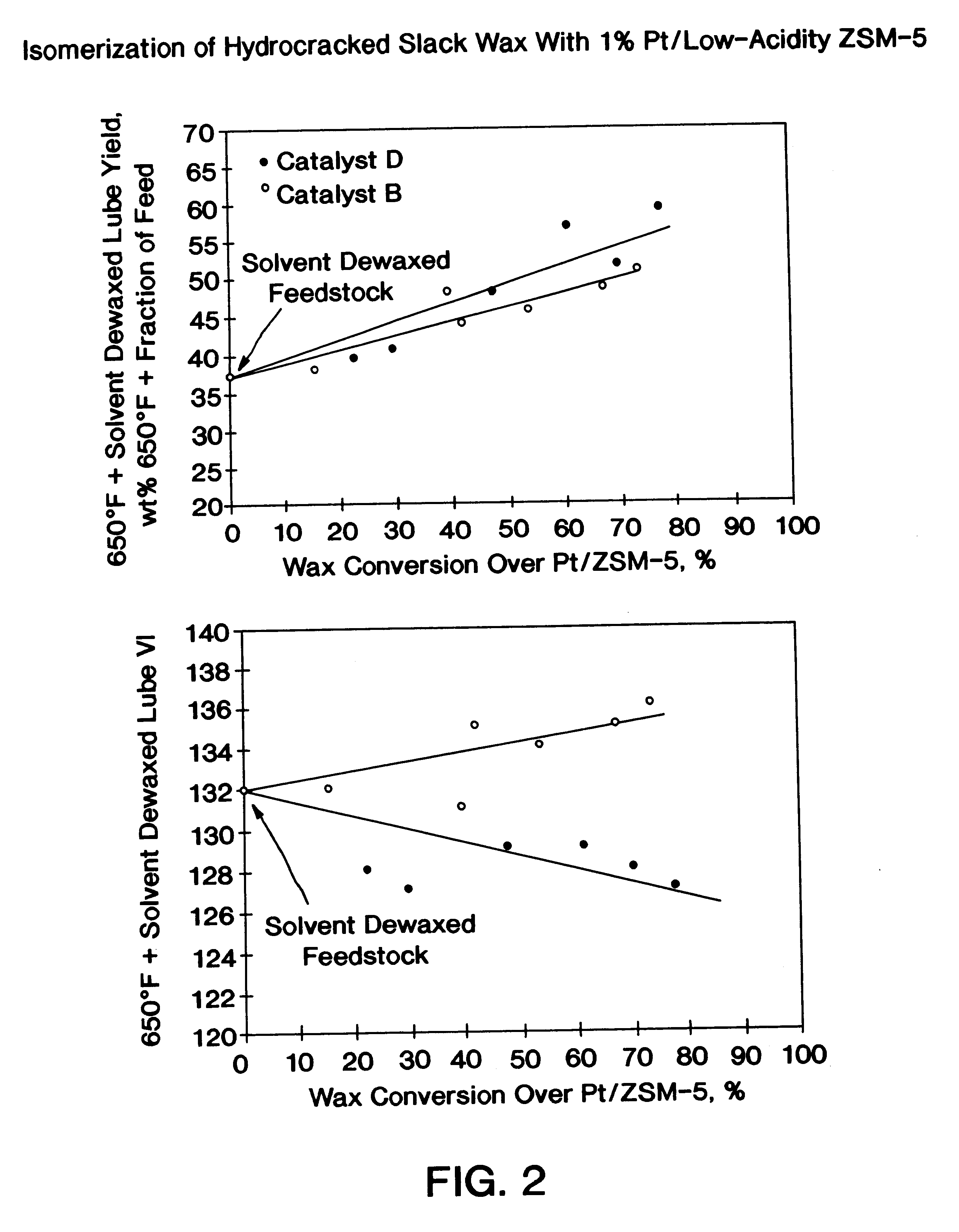

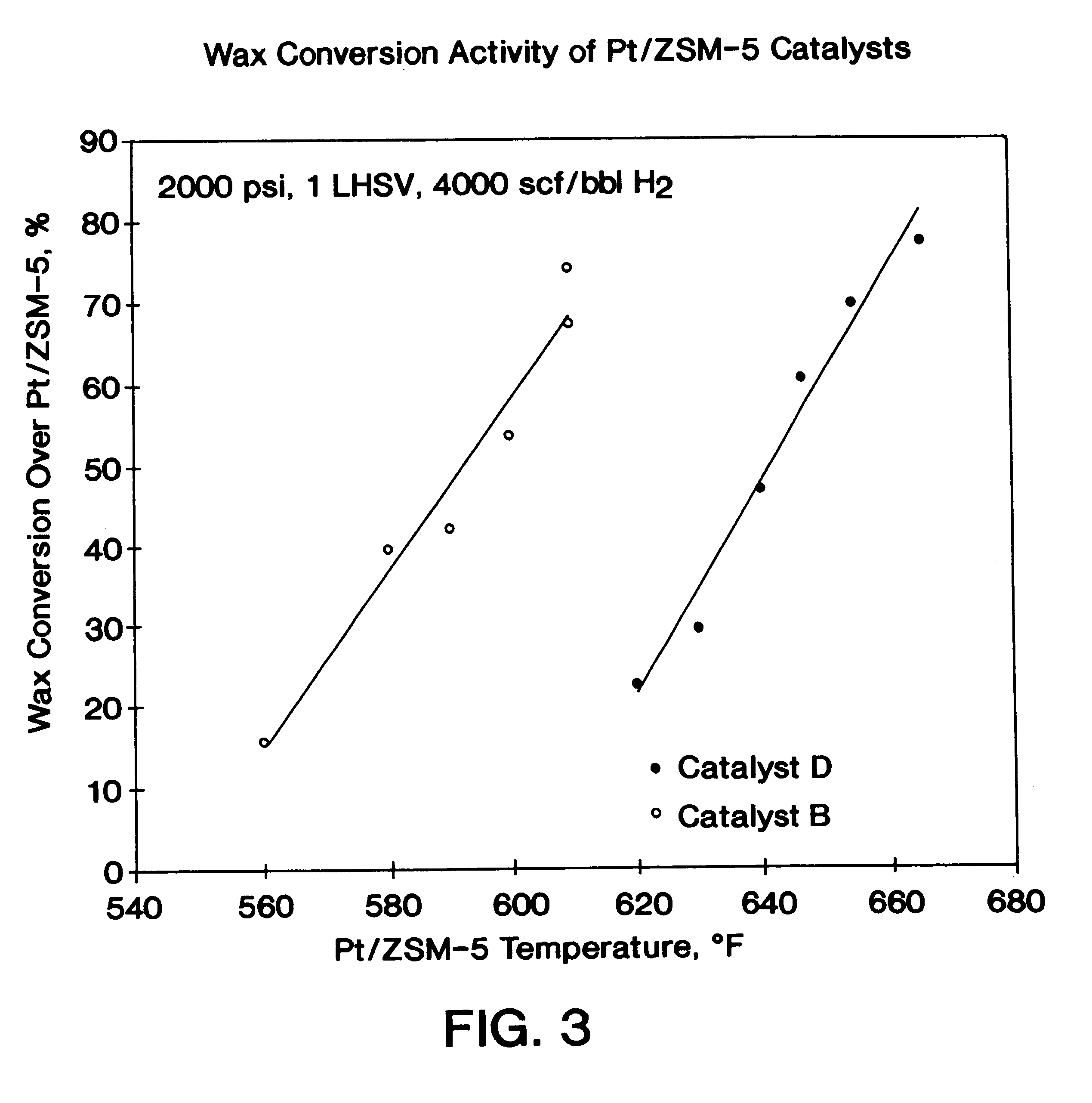

The present invention is a process for producing a high viscosity index and low pour point lubricating oil base stock which comprises catalytically converting a hydrotreated hydrocarbon lube oil feedstock containing waxy paraffins in the presence of hydrogen and in the presence of a low acidity ZSM-5 catalyst having a highly dispersed noble metal component. The ZSM-5 catalyst is subjected to controlled acidity reduction to an alpha value below 15 prior to incorporation of the noble metal component.

Owner:MOBIL OIL CORP

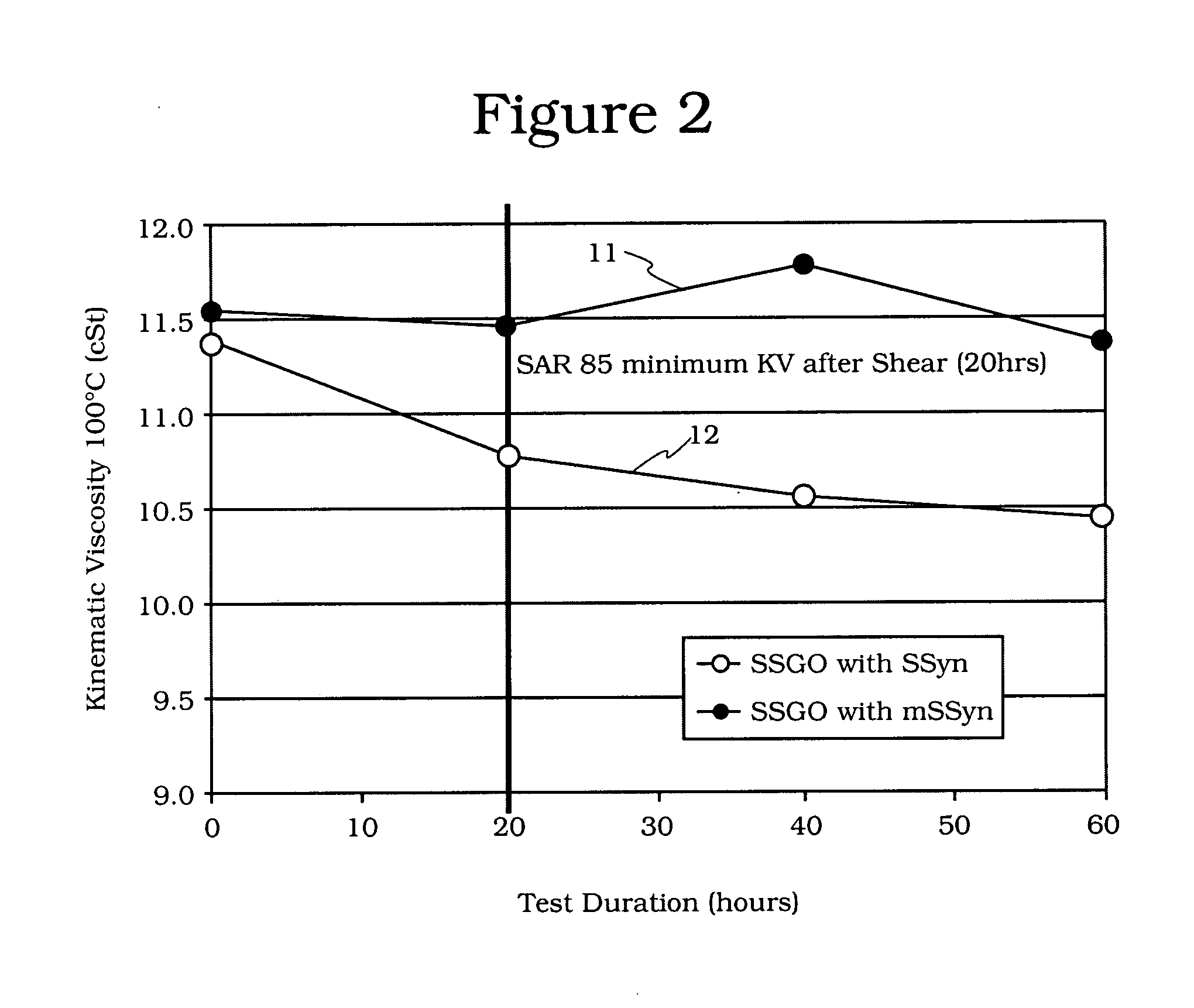

HVI-PAO in industrial lubricant and grease compositions

ActiveUS20070000807A1Good effectViscosity indexSolid fuelsLiquid carbonaceous fuelsViscosity indexWear resistance

The invention relates to industrial lubricant and grease compositions containing high viscosity index polyalphaolefins (HVI-PAO). The use of HVI-PAOs in industrial oils and greases application provides advantages in improved shear stability, wear property, foam property, energy efficiency and improved overall performance.

Owner:EXXONMOBIL CHEM PAT INC

Oligomerization of alpha olefins using metallocene-ssa catalyst systems and use of the resultant polyalphaolefins to prepare lubricant blends

ActiveUS20100317904A1Improve productivityHydrocarbon by hydrogenationAdditivesOligomerViscosity index

This disclosure provides for alpha olefin oligomers and polyalphaolefins (or PAOs) and methods of making the alpha olefin oligomers and PAOs. This disclosure encompasses metallocene-based alpha olefin oligomerization catalyst systems, including those that include at least one metallocene and an activator comprising a solid oxide chemically-treated with an electron withdrawing anion. The alpha olefin oligomers and PAOs prepared with these catalyst systems can have a high viscosity index combined with a low pour point, making them particularly useful in lubricant compositions and as viscosity modifiers.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

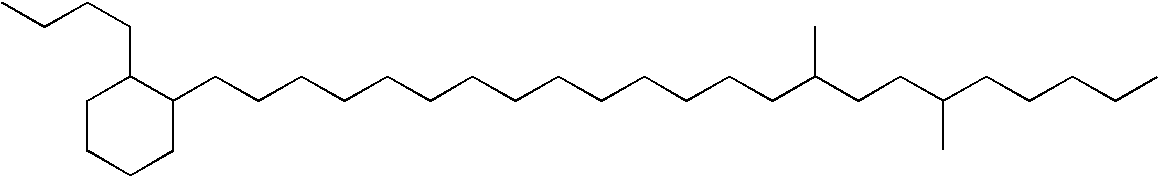

Base oil

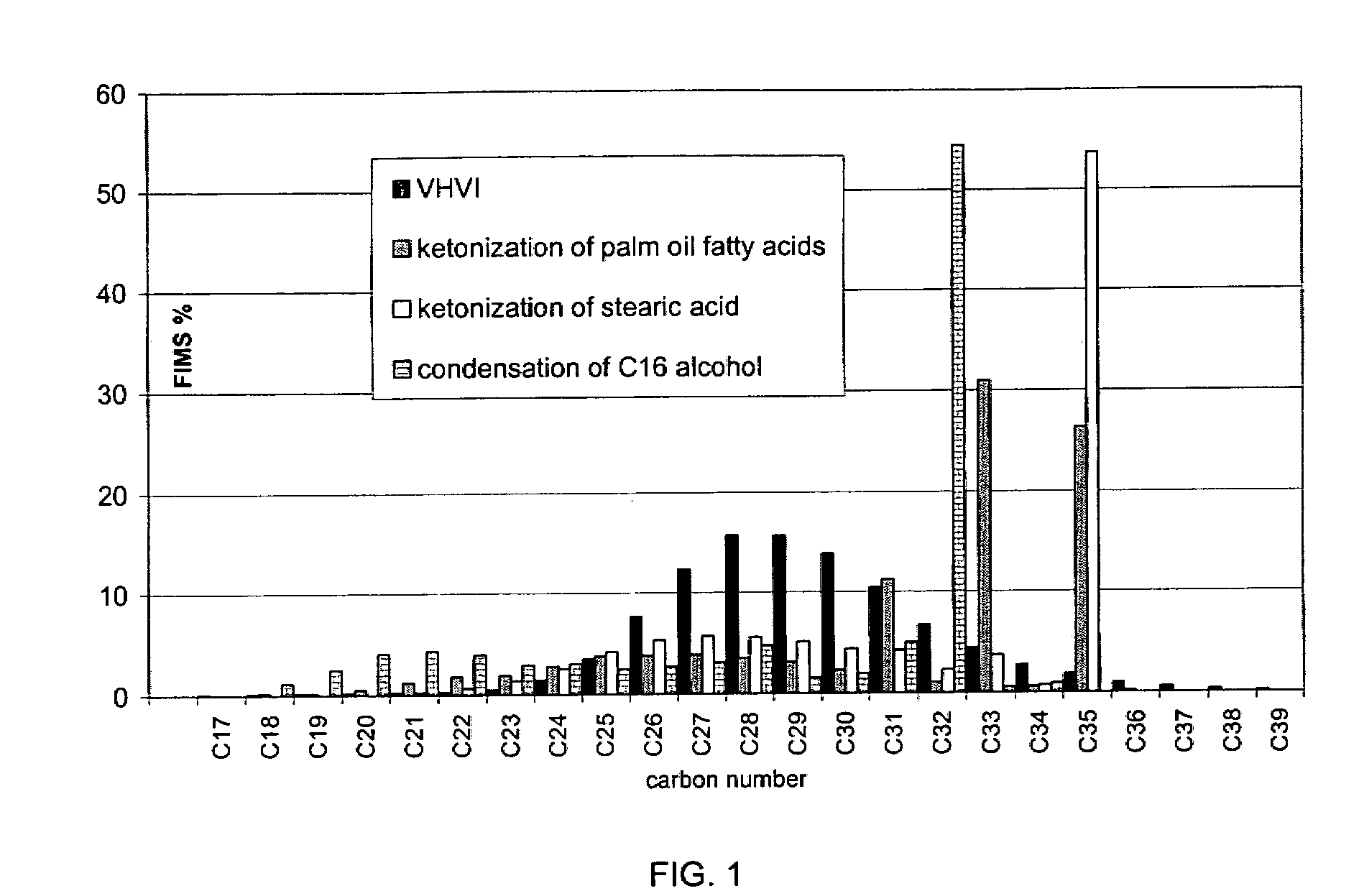

ActiveUS20070135663A1Improve technical effectReduce fuel consumptionHydrocarbon purification/separationLiquid carbonaceous fuelsCarbon numberViscosity index

The invention relates to a new base stock material. Specifically the invention relates to a saturated hydrocarbon composition and particularly to a composition based on biological raw materials, to be used as a high-quality base oil or to be used as a component in the production of a base oil having a high viscosity index and good low temperature properties. The composition contains saturated hydrocarbons and has a narrow carbon number range.

Owner:NESTE OIL OY

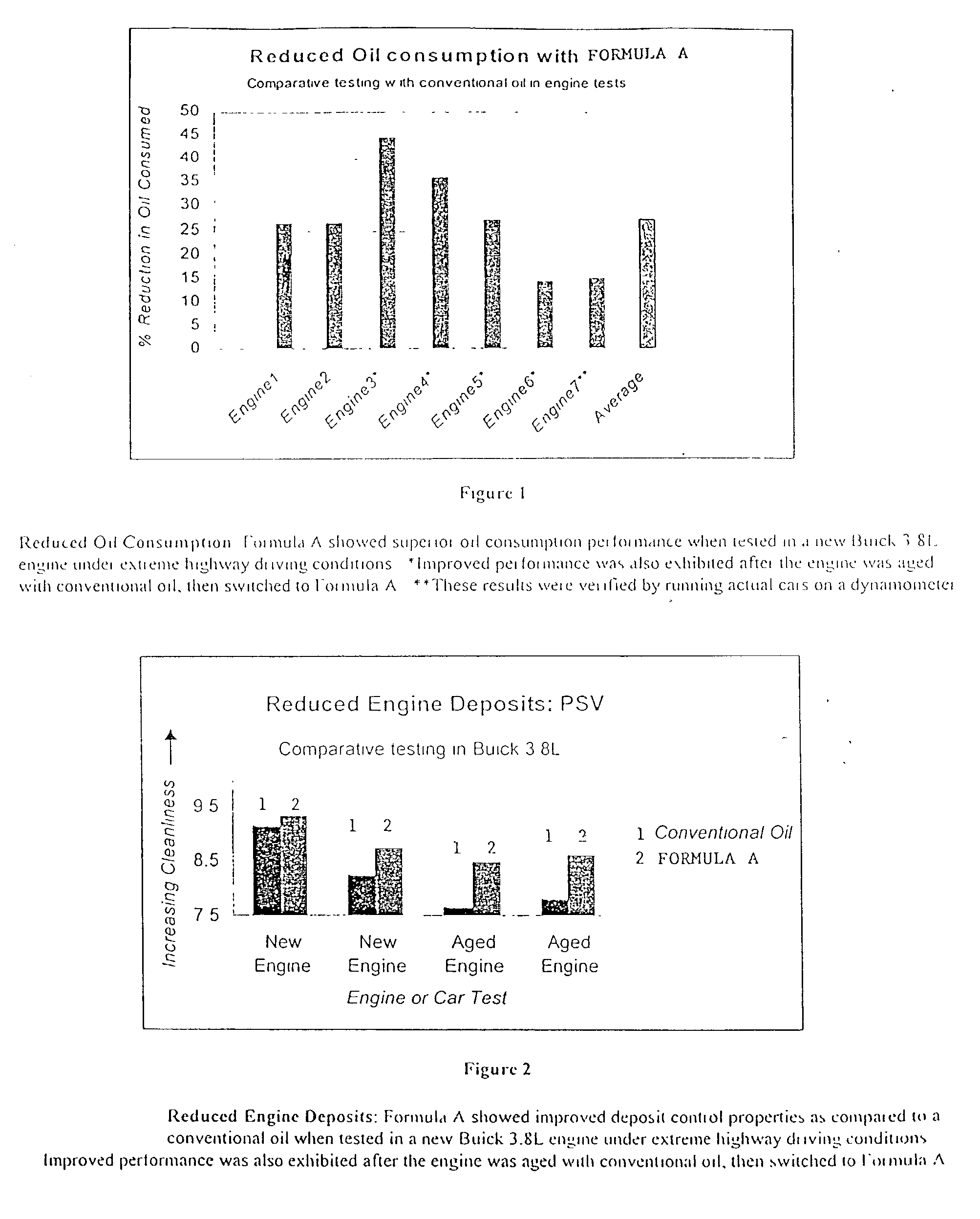

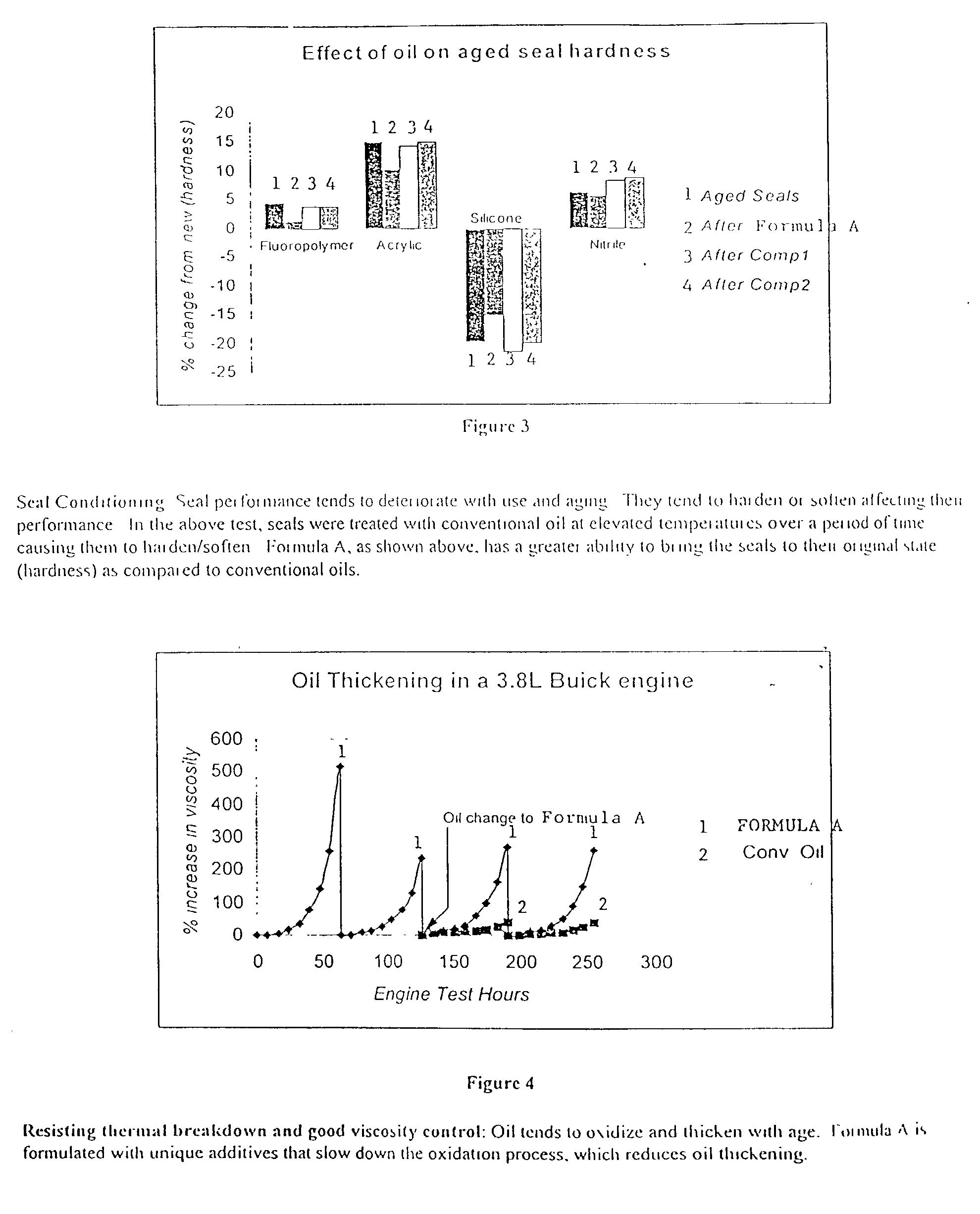

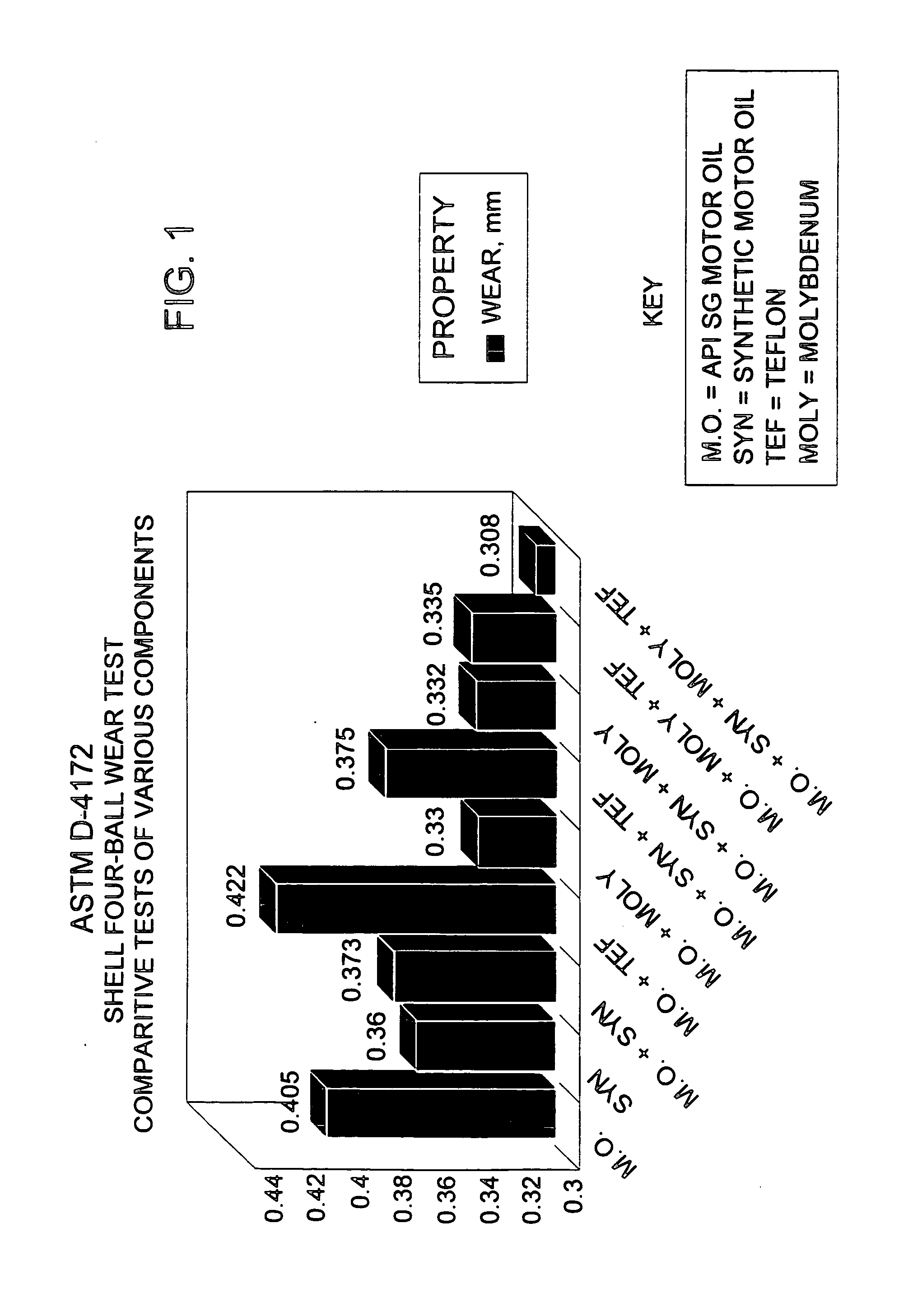

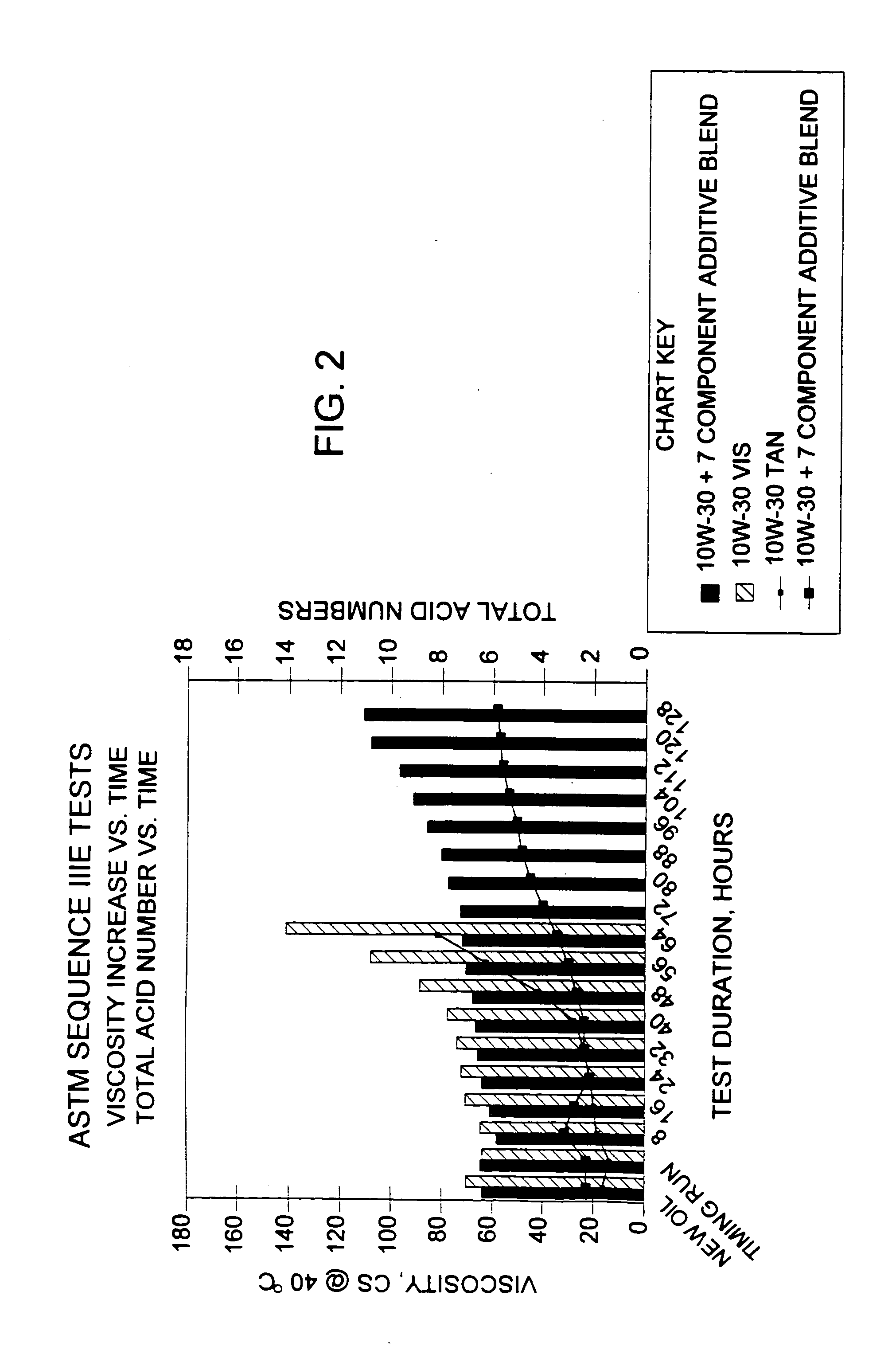

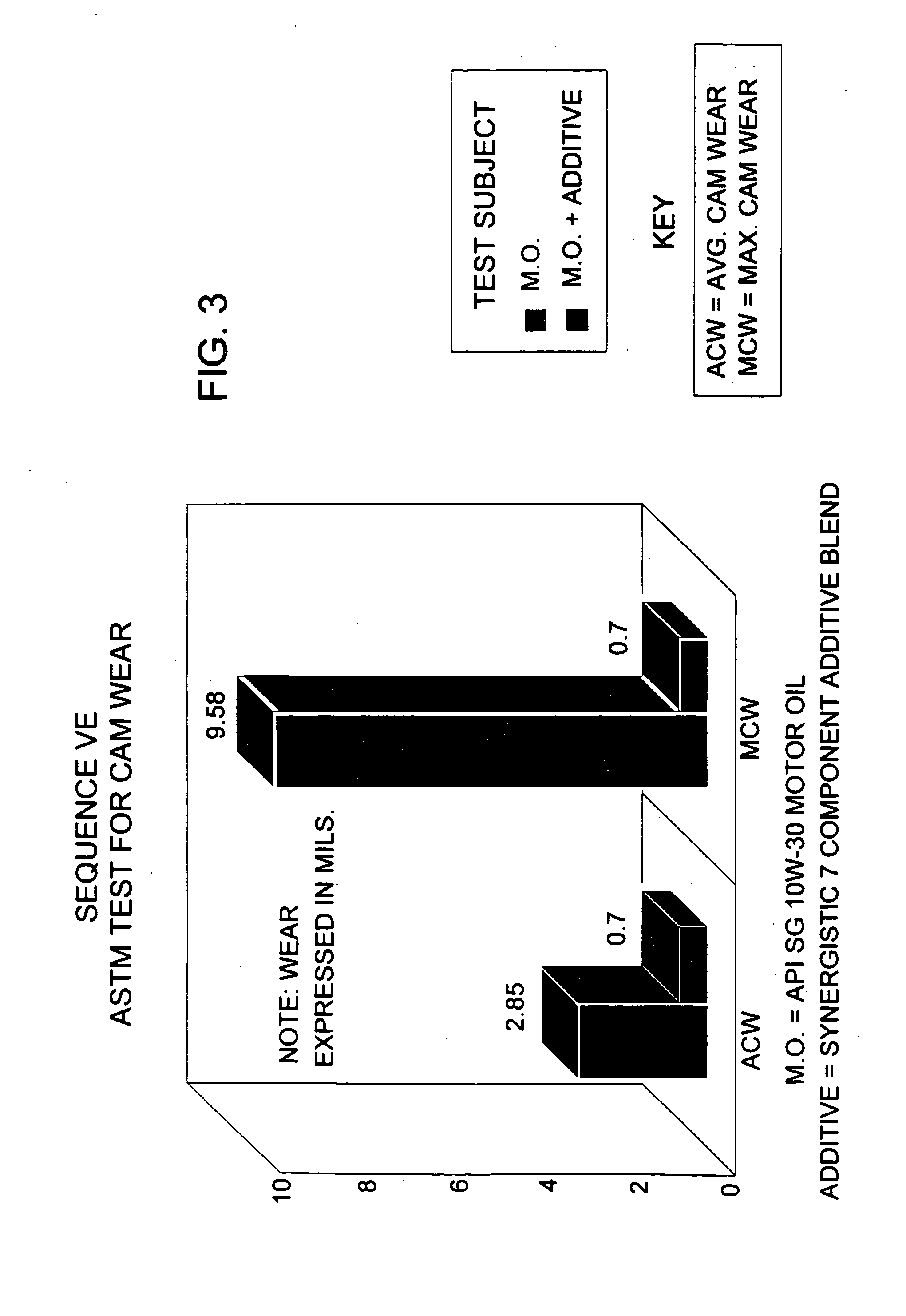

Lubricant and additive formulation

InactiveUS20030119682A1Improve the lubrication effectImprove engine performanceBiocideLiquid carbonaceous fuelsPolyolesterChemical composition

Owner:ASHLAND OIL INC +1

Synthesis of poly-alpha olefin and use thereof

InactiveUS7129197B2Improve oxidation stabilityImproved biodegradibilityOrganic chemistry methodsSolid fuelsHydrogenIsomerization

One or more oligomers of an olefin are prepared in the presence of a single-site catalyst. Preferably, the olefin is an α-olefin, and the oligomers are a poly-alpha-olefin (PAO). The PAO so prepared is completely or substantially free of tertiary hydrogen resulting from isomerization. Consequently, the PAO possesses improved biodegradability, improved oxidation resistance, and / or a relatively higher viscosity index. The PAO has many useful applications, such as a component of a lubricant.

Owner:SHELL OIL CO

Process To Produce Polyalphaolefins

The present invention relates to processes to produce liquid poly-alpha-olefins comprising:a) contacting in a reaction zone, in the presence of from 0 to 60 psi hydrogen, one or more C3 to C20 alpha-olefin monomers with a non-coordinating anion activator, a single bridged meso-metallocene transition metal compound having less than about 35 wt % racemic isomer, and a co-activator selected from the group consisting of alkyl aluminum compounds and alkyl alumoxanes, provided that when the alkyl alumoxane is present it is present in a molar ratio of less than 0.1:1 of alkylalumoxane to meso-metallocene, and provided that when the alkyl aluminum compound is present it is present at a molar ratio of alkyl aluminum to meso-metallocene of from 2:1 to 10,000 to 1, where the molar ratio of activator to meso-metallocene is from 10:1 to 0.1:1, andprovided that ethylene is not present at more than 30 volume % of the monomers entering the reaction zone, and provided that the alpha-olefin monomers in the feed components are present in at least 20 wt % or more based upon the weight of the meso-metallocene, non-coordinating anion activator, co-activator, monomers, and solvent or diluent, andwhere: i) the productivity of the process is at least 50,000 g of total product per gram of transition metal compound (where the total product is defined to be the total amount of product exiting the reactor, minus unreacted monomers and solvents); and ii) no more than 5% monomer is converted from olefin to alkane; andb) obtaining a liquid polyalphaolefin product having a pour point of less than 25° C., a KV100 of 2 to 6000 cSt, 20 weight percent dimer or less and a viscosity index of 60 or more.

Owner:EXXONMOBIL CHEM PAT INC

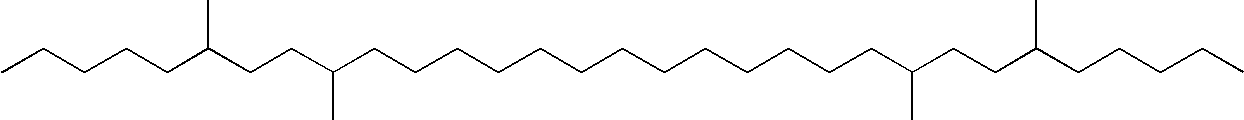

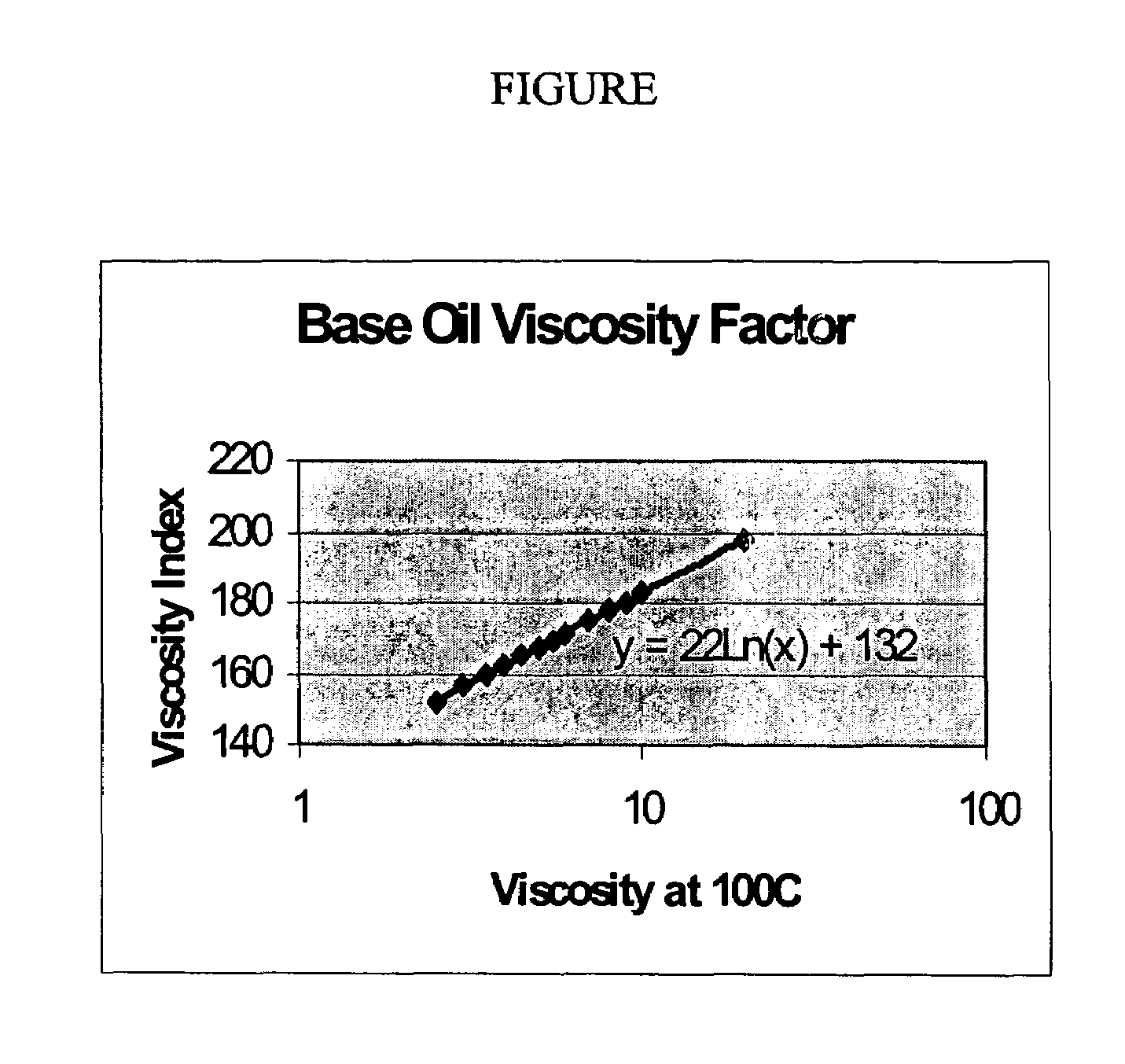

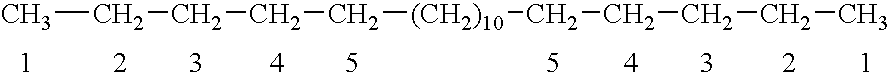

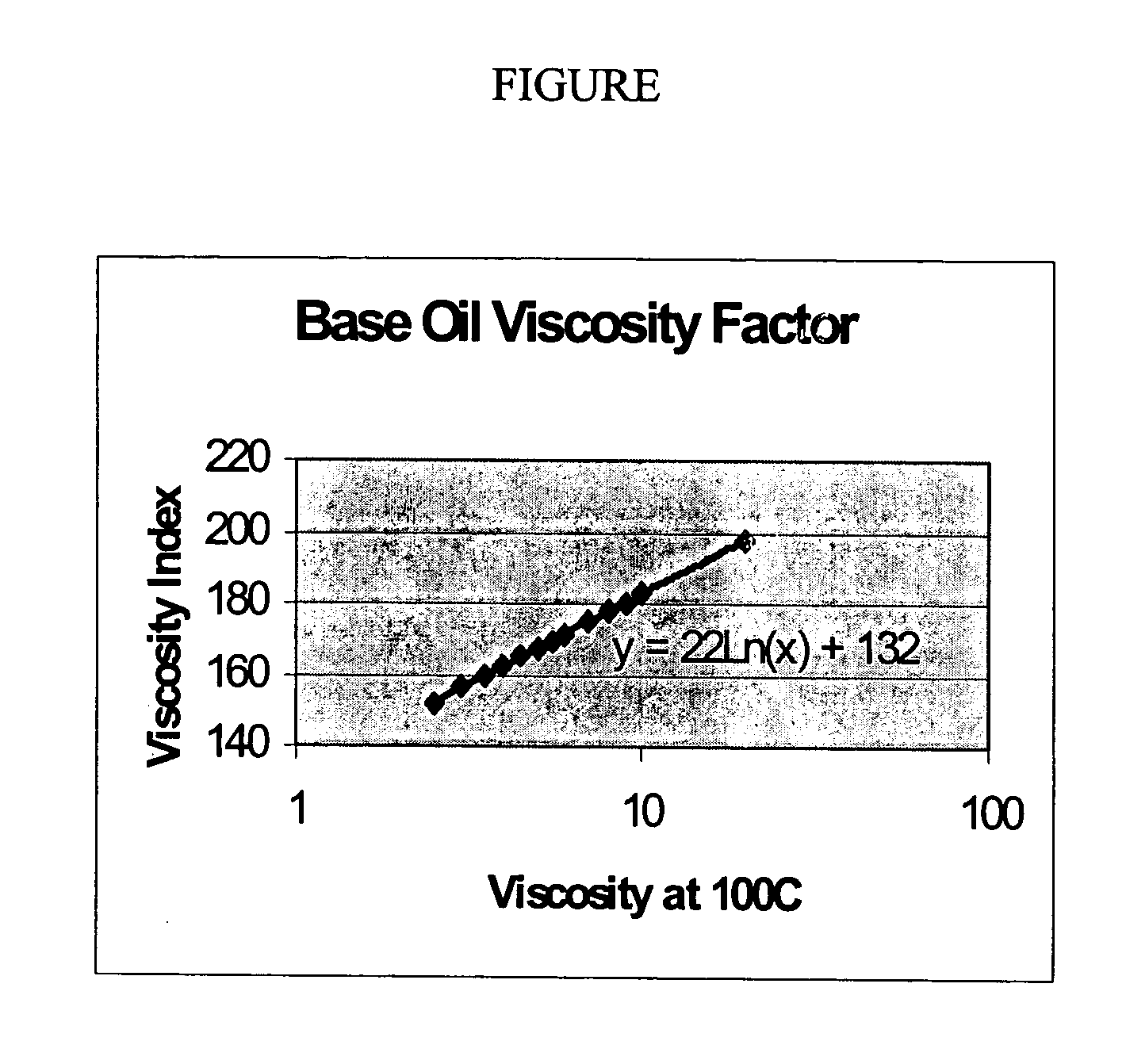

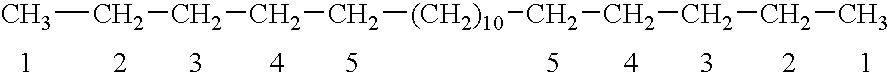

Processes for producing lubricant base oils with optimized branching

InactiveUS7018525B2Treatment with hydrotreatment processesHydrocarbon oils refiningViscosity indexBase oil

This invention relates to processes of producing lubricant base oils comprising paraffinic hydrocarbon components that have optimized branching. The lubricant base oils comprising paraffinic hydrocarbon components with optimized branching have low amounts of branching with the branching concentrated toward the center of the lubricant base oil molecules. The lubricant base oils comprising paraffinic hydrocarbon components with optimized branching have low pour points and extremely high viscosity indexes. The invention further relates to processes of producing commercial lubricants comprising the lubricant base oils comprising paraffinic hydrocarbon components with optimized branching from waxy feeds.

Owner:CHEVROU USA INC

Lubricating oil composition

ActiveUS20080248981A1Improve the level ofLow viscosity propertiesTin organic compoundsLiquid carbonaceous fuelsChemical compositionViscosity index

The lubricating oil composition of the invention comprises a lubricating base oil with a urea adduct value of no greater than 4% by mass and a viscosity index of 100 or higher, an ashless friction modifier at 0.01-10% by mass and a phosphorus-containing anti-wear agent at 0.01-0.2% by mass as phosphorus, based on the total amount of the composition.

Owner:JX NIPPON OIL & ENERGY CORP

Processes for producing lubricant base oils with optimized branching

InactiveUS20050077209A1Treatment with hydrotreatment processesHydrocarbon oils refiningViscosity indexBase oil

This invention relates to processes of producing lubricant base oils comprising paraffinic hydrocarbon components that have optimized branching. The lubricant base oils comprising paraffinic hydrocarbon components with optimized branching have low amounts of branching with the branching concentrated toward the center of the lubricant base oil molecules. The lubricant base oils comprising paraffinic hydrocarbon components with optimized branching have low pour points and extremely high viscosity indexes. The invention further relates to processes of producing commercial lubricants comprising the lubricant base oils comprising paraffinic hydrocarbon components with optimized branching from waxy feeds.

Owner:CHEVROU USA INC

Plasticized polyolefin compositions

InactiveUS20080227919A9Monocomponent polyolefin artificial filamentArtifical filament manufacturePolyolefinPlasticizer

The present invention relates to a composition comprising 1) from 1 to 98 weight % of a first propylene polymer having a melting point of 100° C. or more, 2) from 5 to 98 weight % of a second propylene polymer having a heat of fusion of 70 J / g or less and a tacticity index of 75% or more, 3) from 0.5 to 75 weight % of a non-functionalized plasticizer (“NFP”) having a viscosity index of 120 or more, based upon the weight of the first polymer, second polymer, and the NFP, and articles therefrom

Owner:EXXONMOBIL CHEM PAT INC

Lubricant and additive formulation

InactiveUS20050124504A1Improve the lubrication effectImprove engine performanceMaterial nanotechnologyAdditivesSuspended particlesNanostructure

A lubricant composition for use as a concentrate and motor oil having an enhanced thermal conductivity. One preferred composition contains a lubricant composition, nanomaterial, and a dispersing agent or surfactant for the purpose of stabilizing the nanomaterial. One preferred nanomaterial is a high thermal conductivity graphite, exceeding 80 W / m in thermal conductivity. Carbon nano material or nanostructures such as nanotubes, nanofibrils, and nanoparticles formed by grounding and / or milling graphite to obtain a mean particle size less than 500 nm in diameter, and preferably less than 100 nm, and most preferably less than 50 nm. Other high thermal conductivity carbon materials are also acceptable. To confer long-term stability, the use of one or more chemical dispersants or surfactants is useful. The graphite nanomaterials contribute to the overall fluid viscosity and providing a very high viscosity index. Particle size and dispersing chemistry is controlled to get the desired combination of viscosity and thermal conductivity increase from the lubricant. The resulting fluids have unique properties due to the high thermal conductivity and high viscosity index of the suspended particles, as well as their small size.

Owner:ASHLAND LICENSING & INTPROP LLC

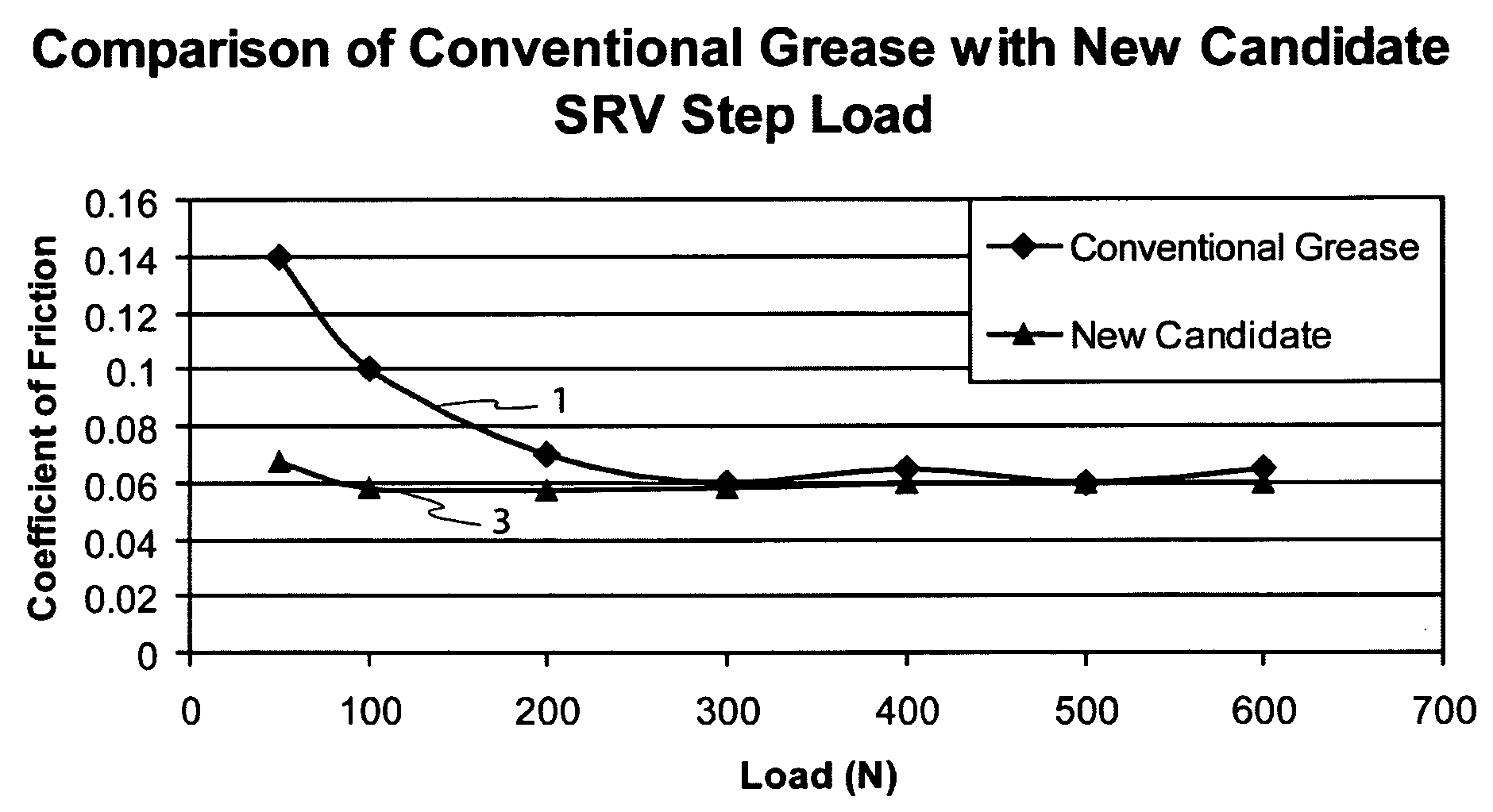

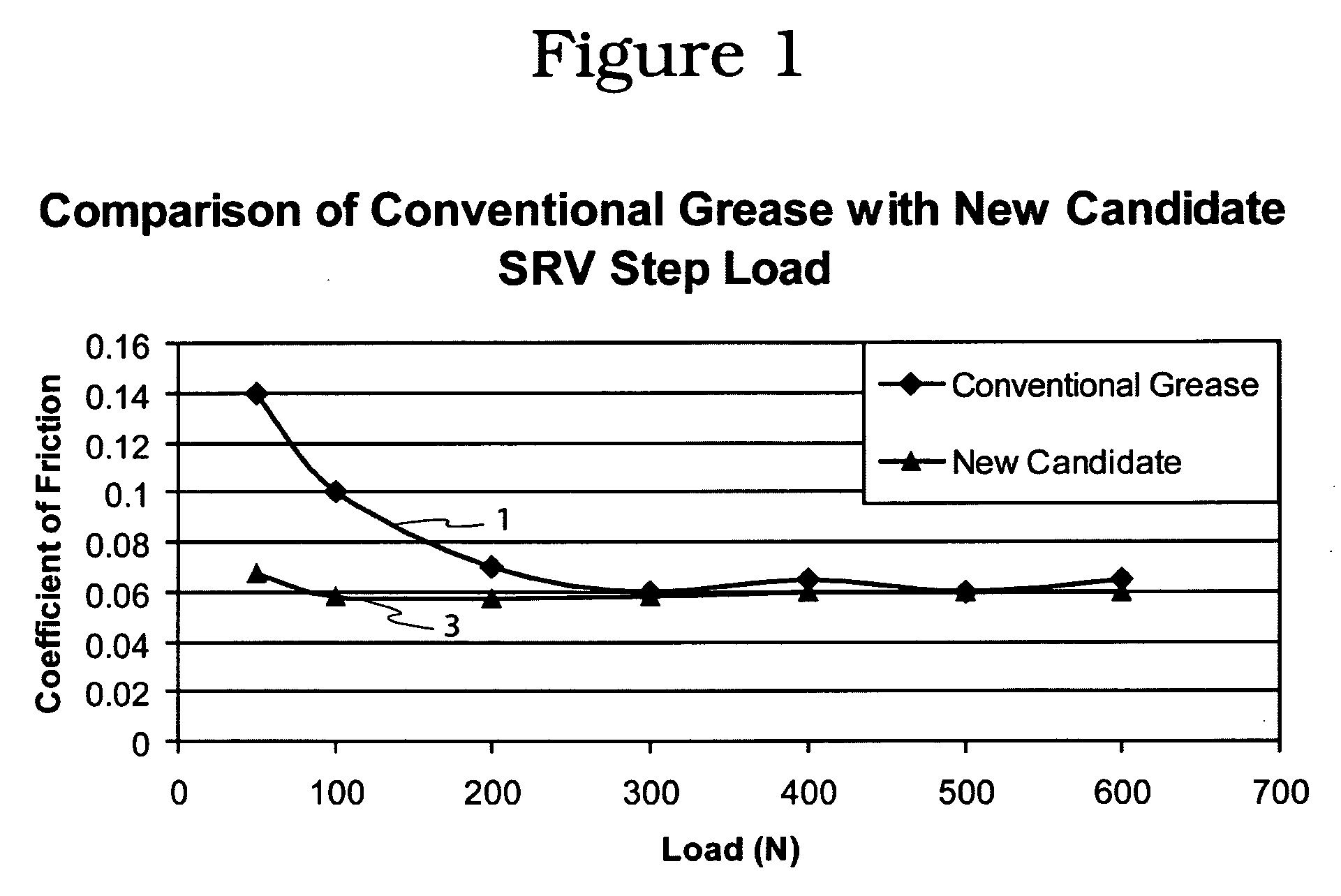

High viscosity index pao with polyurea thickeners in grease compositions

ActiveUS20090247441A1Improve friction performanceHigh indexThickenersAdditivesPolymer scienceBi modal

Owner:EXXON RES & ENG CO

Lubricating oil composition

ActiveUS20080234153A1Reduce wearReduce frictionLiquid carbonaceous fuelsAdditivesAfter treatmentChemical composition

The present invention provides a lubricating oil composition, which is capable to maintain sufficient low-friction (i.e. fuel saving performance) even when the lubricating oil is contaminated with soot and metal abrasion powder, which is excellent in durability with regard to anti-wear property and detergency, as well as oxidation stability, and which is capable to lower the ash content and to sufficiently maintain the performance of exhaust-gas after-treatment device for a long term. The lubricating oil composition comprises a lubricant base oil containing a base oil (X) of which % CP is 70 or more, % CA is 1 or less, viscosity index is 115 or more, and CCS viscosity at −35° C. is 3000 mPa·s or less, wherein the lubricant base oil, to total mass of the composition, contains following components (A)˜(D):(A) 0.01˜10 mass % of ashless friction modifier;(B) 0.01˜0.2 mass % of phosphorus-containing anti-wear agent as phosphorous content;(C) 0.01˜1 mass % of metallic detergent as metal content; and(D) 0.01˜0.4 mass % of ashless dispersant having 3000˜20000 of weight-average molecular weight as nitrogen content.

Owner:NIPPON OIL CORP

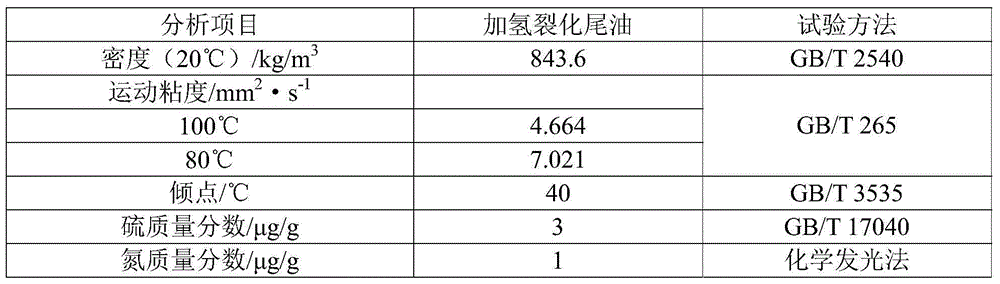

Hydroisomerization catalyst, preparation method and application thereof, and hydroisomerization method for hydrocracked tail oil

ActiveCN105582992AHigh catalytic activityHigh isomerization reaction selectivityMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveHalogen

The invention discloses a hydroisomerization catalyst, a preparation method and an application thereof. The preparation method comprises the following steps: a) providing a catalyst precursor containing a carrier, and a compound containing noble metals in the VIII group and a compound containing a second metal which are both supported on the carrier, wherein the two compounds hereinabove are both non-oxides, the second metal is one or more than two selected from the metal in the VB group, the metal in the VIB group, non-noble metal in the VIII group and lanthanum-series metals, the carrier containing mesoporous molecular sieve; and b) roasting the catalyst precursor in an atmosphere formed by a gas containing an oxidizing gas and a halogen-containing compound. The invention also discloses a hydroisomerization method for hydrocracked tail oil with the hydroisomerization catalyst. The hydroisomerization catalyst, when being used in the hydroisomerization for the hydrocracked tail oil, can be used for producing an isomerized product having high viscosity index and low pour point, which is suitable for being used as lubricant basic oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydraulic oil with excellent air release and low foaming tendency

ActiveUS20060131210A1Low air releaseImprove foam stabilityPositive displacement pump componentsTreatment with hydrotreatment processesCavitationHydraulic pump

This invention provides a hydraulic oil comprising: 1) a lubricant base oil having an average molecular weight greater than 475, a viscosity index greater than 140, and a weight percent olefins less than 10; and 2) an antiwear hydraulic oil additive package. The hydraulic oil of this invention has an air release by ASTM D 3427-03 of less than 0.8 minutes at 50 degrees C., and a sequence II foam tendency by ASTM D 892-03 of less than 50 ml. We describe a process for making the hydraulic oil of this invention, and a method of operating a hydraulic pump without pump cavitation using the hydraulic oil of this invention.

Owner:CHEVROU USA INC

Isomerization dewaxing catalyst and preparing method thereof

InactiveCN1488733AHigh reactivityHigh selectivityMolecular sieve catalystsPetroleum wax recoveryMolecular sieveIsomerization

The present invention discloses an isodewaxing catalyst for producing base oil of lubricating oil and its preparation method. Said catalyst contains a new-type phosphorus silicon aluminium molecular sieve with AEL structure and active metal component, and the surface acidity of said molecular sieve is strong, and its mesopore distribution is more. Said catalyst is used for isodewaxing reaction of lubricating oil fraction, and has the characteristics of low reaction temp. high base oil yield, low product pour point and high viscosity index.

Owner:CHINA PETROLEUM & CHEM CORP +1

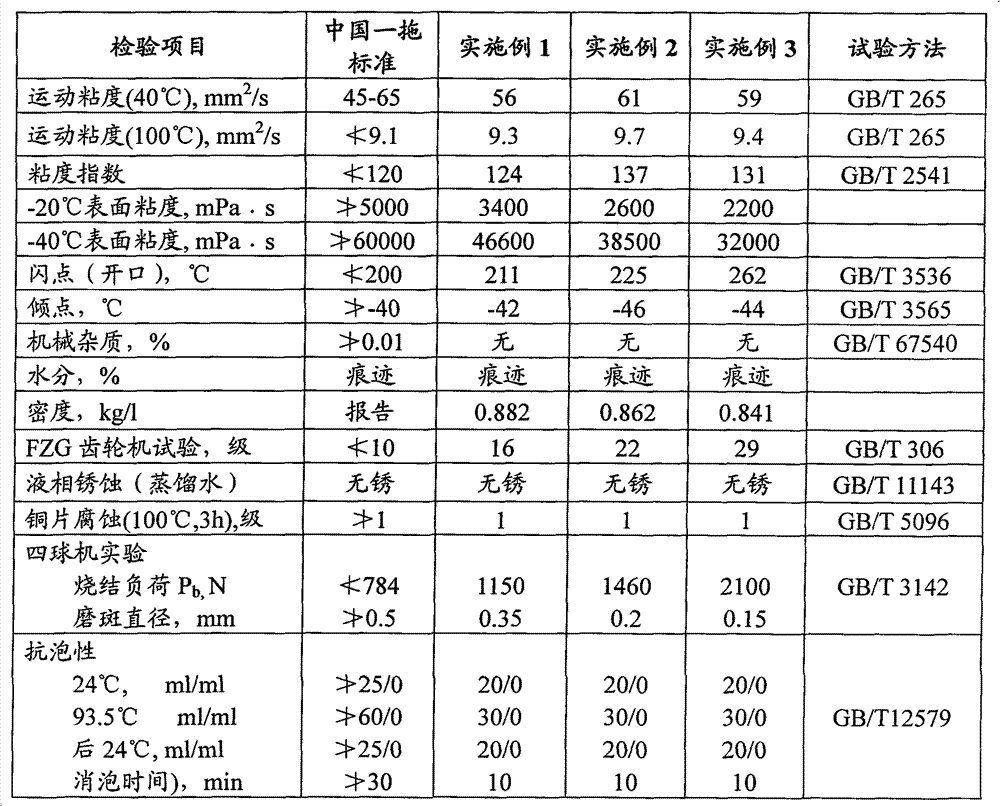

Hydraulic-transmission-braking three-use lubricating oil composition

InactiveCN102952617AAvoid wear and tearPrevent rustLubricant compositionFriction reductionTransmission brake

The present invention relates to a hydraulic-transmission- braking three-use lubricating oil composition, which is prepared by mixing the following raw materials, by weight, 85-98% of high viscosity index base oil, 0.1-5% of an extreme pressure wear resistance agent, 0.1-4% of an antioxidant, 0.1-3% of a metal deactivator / antirust agent, 0.1-5% of a friction modifier, and 0.1-2% of a dispersing agent. The hydraulic-transmission- braking three-use lubricating oil composition has beneficial effects of good low temperature fluidity, friction reduction, wear resistance, corrosion resistance, rust resistance, emulsification resistance and foaming resistance, and can meet requirements of universal hydraulic transmission oil used by large-medium-sized tractors and construction machinery so as to achieve complete lubricating protection on hydraulic parts, transmission parts, gear parts, power output parts and braking parts, such that a long service life is provided, equipment operation stability is easily improved, and energy saving and consumption reduction are provided.

Owner:BEIJING ALLUBE PETROCHEM

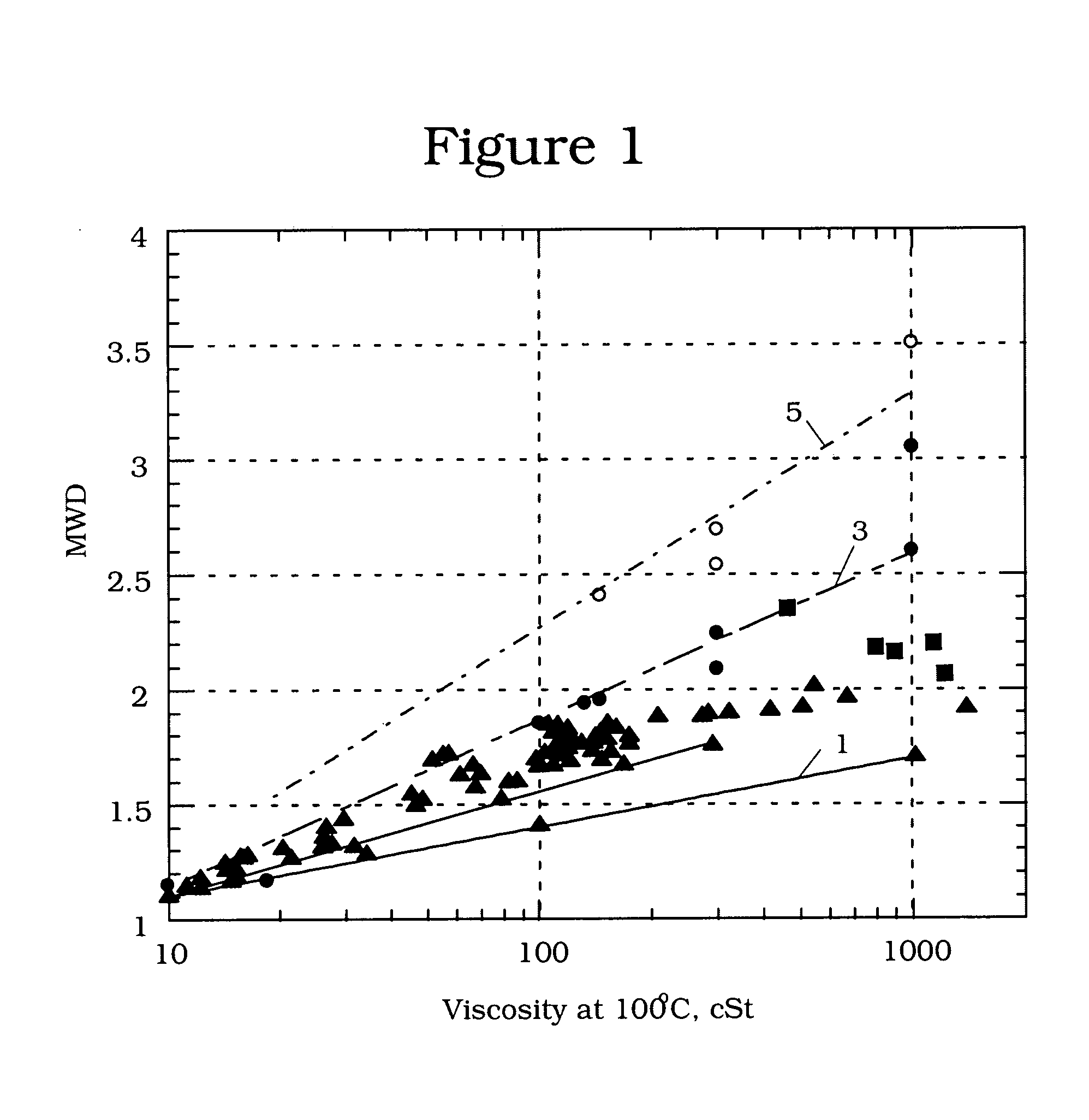

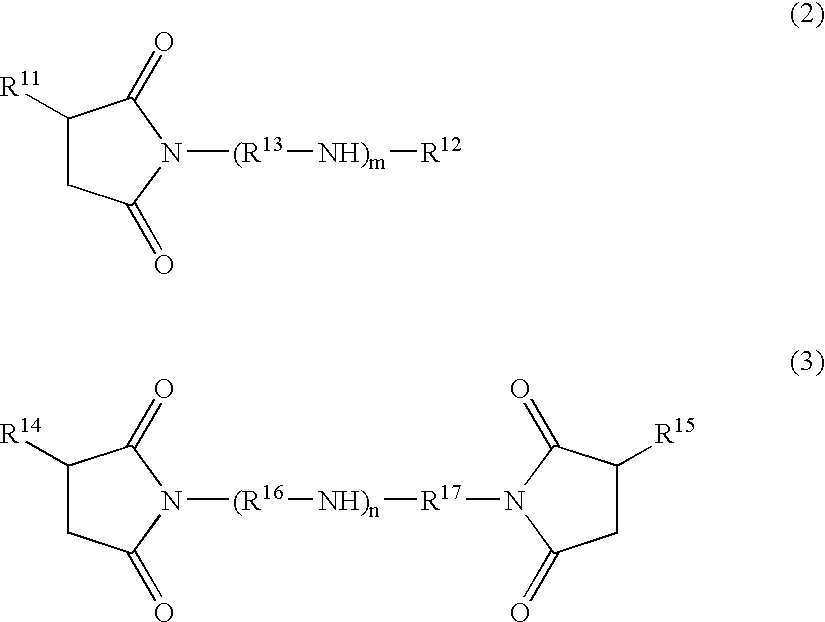

HVI-PAO bi-modal lubricant compositions

The invention relates to oil compositions containing metallocene catalyzed high viscosity index polyalphaolefins (HVI-PAO). In one embodiment the oil formulation comprises a metallocene catalyzed HVI-PAO with a viscosity greater than 125 cSt kv 100° C. and a viscosity index greater than 100, a second base stock with a viscosity of at least 2 cSt kv 100° C. and less than 60 cSt kv 100° C. wherein the second base stock is at least 60 cSt kv 100° C. less than the metallocene HVI-PAO, an ester with a viscosity of at least 2 and less than 6, the ester comprising more than 10 weight percent and less than 30 weight percent of the oil formulation, the oil formulation having a viscosity index of greater than 195. The use of metallocene catalyzed HVI-PAOs in a bimodal blend provides advantages in improved shear stability, and other properties related to shear stability.

Owner:EXXON RES & ENG CO

Lubricating oil composition for transmission

ActiveUS20070191239A1Improve fatigue lifeExcellent Low Temperature ViscosityOrganic chemistryAdditivesMeth-Viscosity index

Lubricating oil compositions for transmissions comprises (A) a lubricating base oil with a kinematic viscosity at 100° C. adjusted to 1.5 to 6 mm2 / s, composed of (A1) a lubricating base oil with a kinematic viscosity at 100° C. of 1.5 mm2 / s or higher and lower than 7 mm2 / s or (Al) the lubricating oil and (A2) a lubricating base oil with a kinematic viscosity at 100° C of 7 to 50 mm2 / s, blended with (B) a poly(meth)acrylate-based additive, so that the composition has a kinematic viscosity at 100° C. of 3 to 8 mm2 / s and a viscosity index of 95 to 200, (A) and (B) fulfill a specific requirement. The compositions achieve long fatigue life though having low viscosity.

Owner:NIPPON OIL CORP

Isomerization dewaxing catalyst and its prepn.

The present invention discloses one kind of isomerizing and dewaxing catalyst for lubricant oil production and its preparation. Specifically, SAPO-11 as acid component and organic matter are used tomodify prepared catalyst carrier and to protect the medium strength acid centers on the carrier, and the dried carrier is loaded with active metal component and high temperature roasted to release its protected acid centers and to produce the catalyst of the present invention. The catalyst is used for the isomerizing and dewaxing reaction of lubricant oil fraction in the presence of hydrogen, and has the advantages of high yield of lubricant oil base oil, low product pour point, high viscosity index and other advantages.

Owner:CHINA PETROLEUM & CHEM CORP +1

Co-oligomerization of 1-dodecene and 1-decene

InactiveUS6646174B2Quantity minimizationOrganic chemistry methodsLiquid hydrocarbon mixtures productionViscosity indexAlpha-olefin

A process for the co-oligomerization of 1-dodecene and 1-decene to produce a polyalphaolefin having a kinetic viscosity of 4 to 6 cSt at 100° C., a Noack weight loss of 4 to 9%, a viscosity index of 130 to 145, and a pour point of -60° C. to -50° C.

Owner:INEOS USA LLC

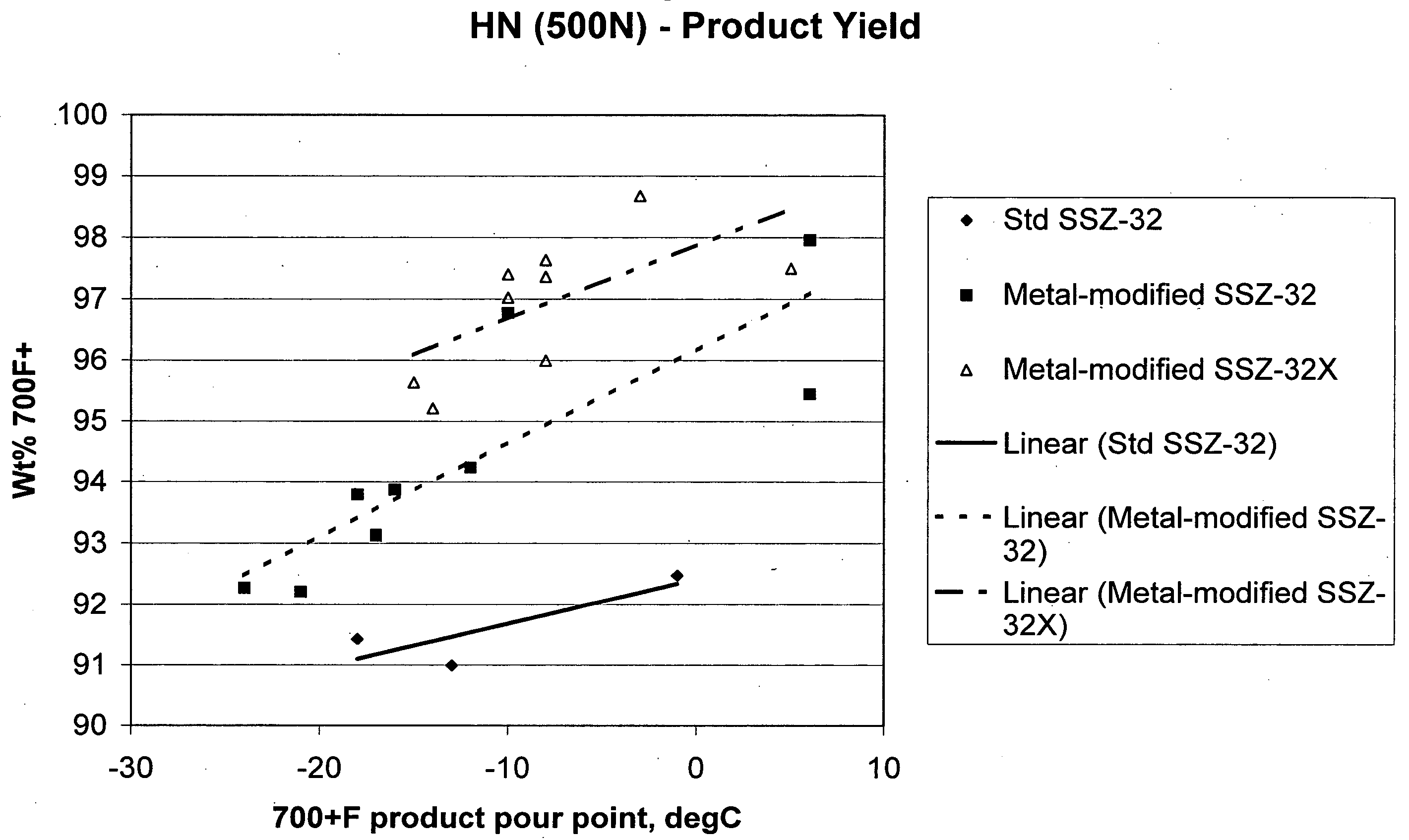

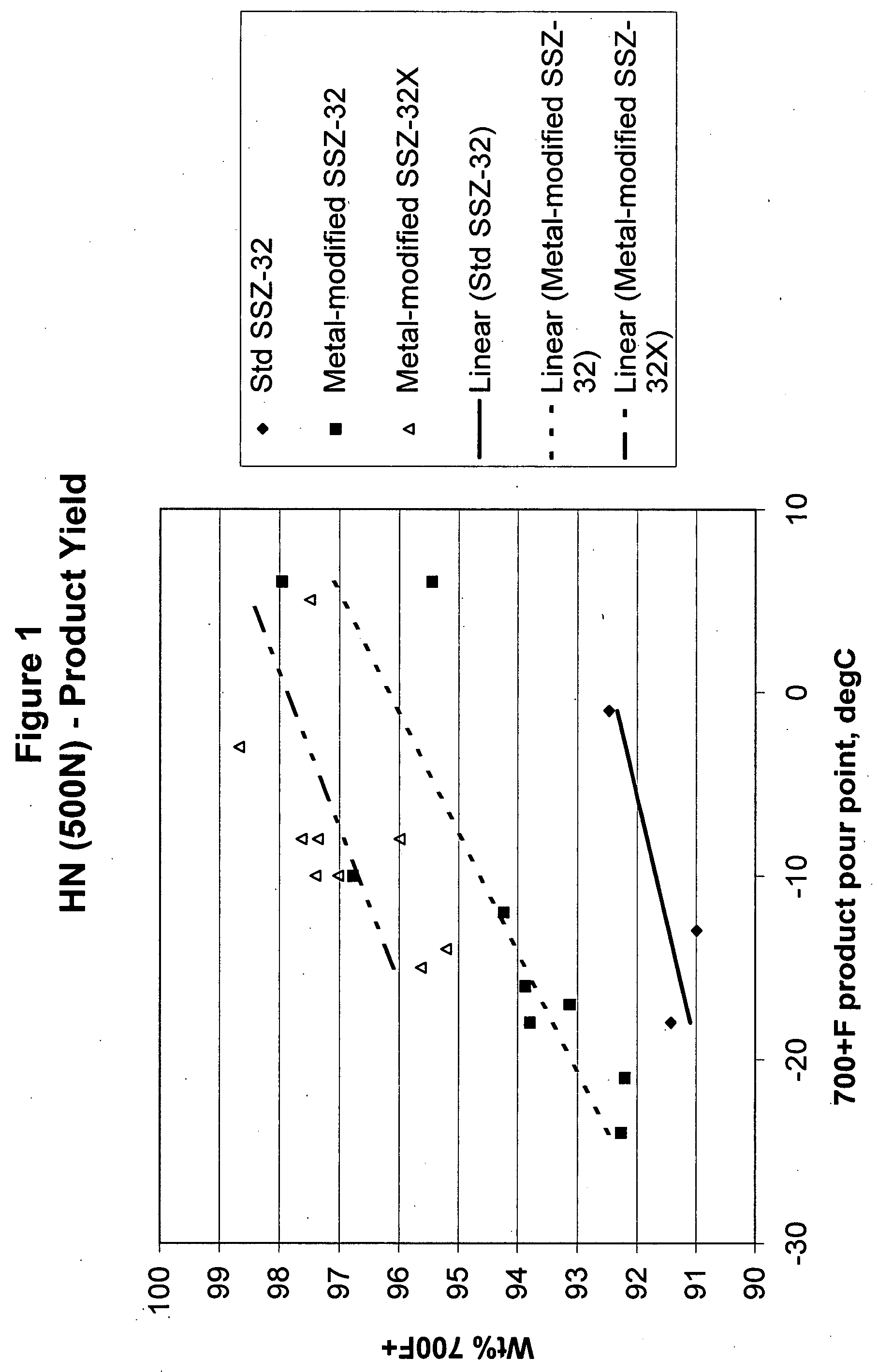

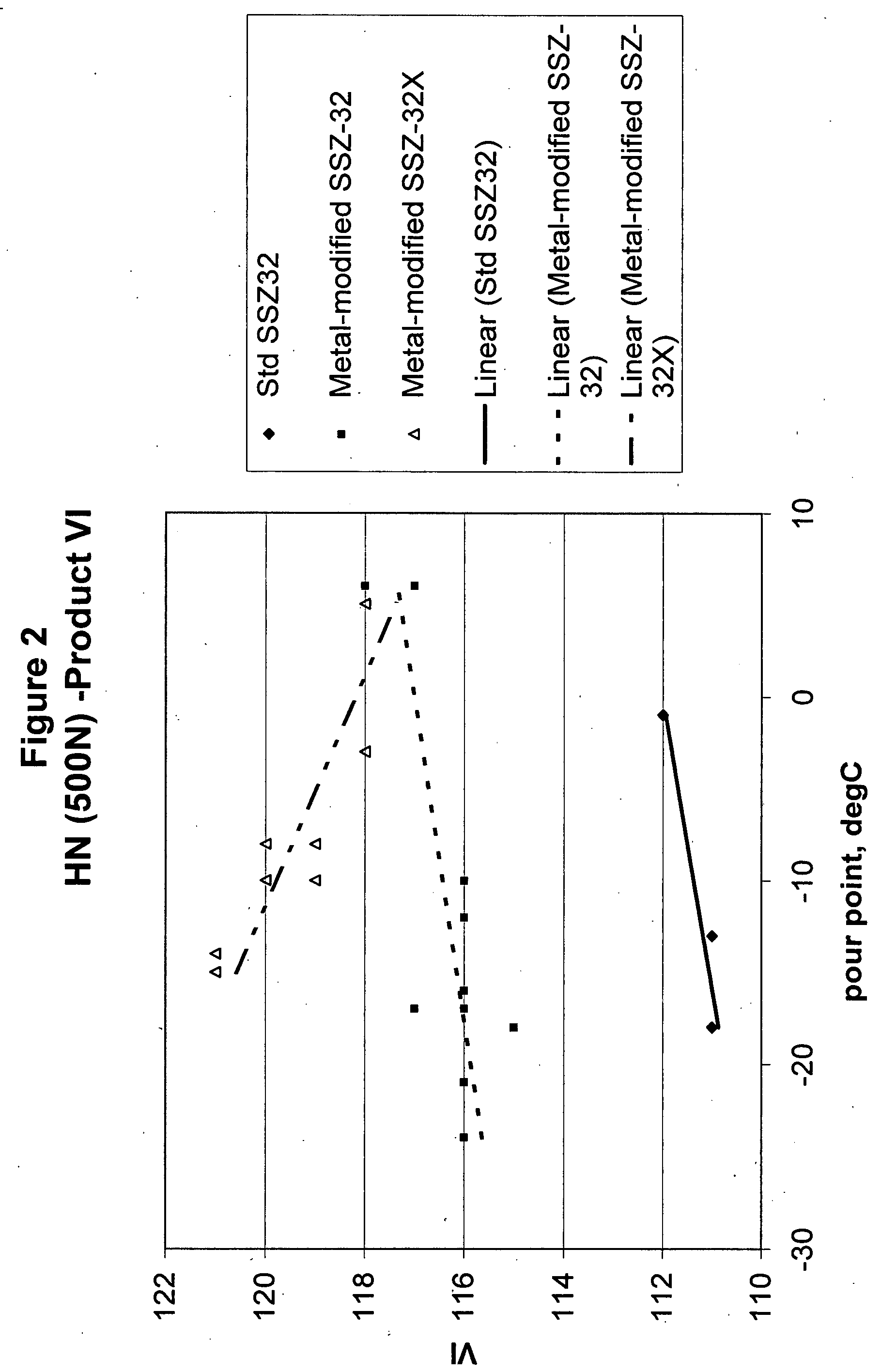

Isomerization process using metal-modified small crystallite mtt molecular sieve

InactiveUS20080083657A1Catalytic naphtha reformingTreatment with hydrotreatment processesMolecular sieveIsomerization

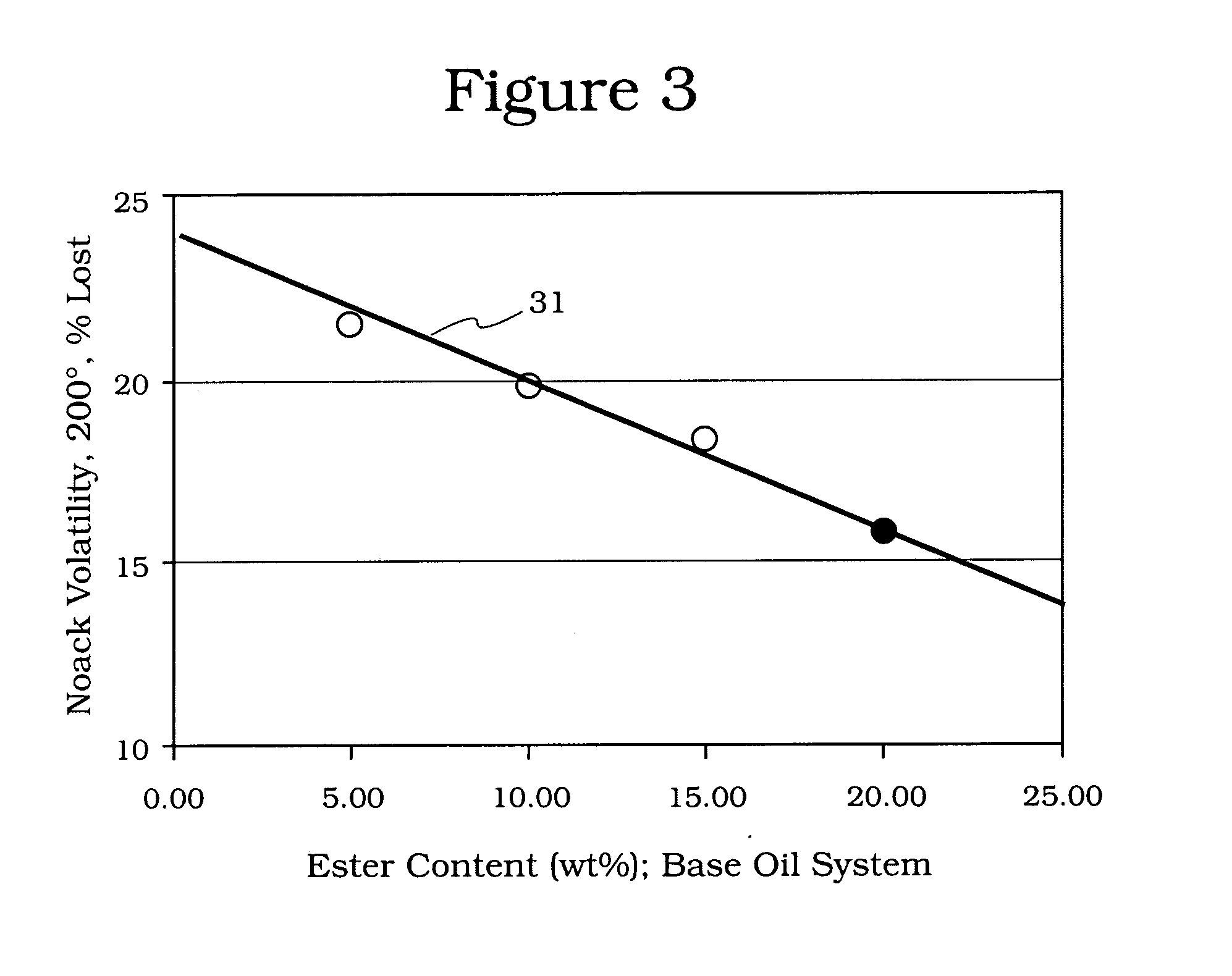

Dewaxing a hydrocarbon feed by isomerizing feed with catalyst comprising small crystallite molecular sieve having MTT framework, the catalyst containing at least one metal selected from the group consisting of Ca, Cr, Mg, La, Na, Pr, Sr, K and Nd, and at least one Group VIII metal. A dewaxing method to produce products boiling at 343° C. (650° F.) or higher with low pour points and high viscosity indexes wherein the line fit to the chart of the pour points and the viscosity indexes has a slope of zero or less. A dewaxing process, comprising isomerization dewaxing feed with a viscosity at 100° C. of 2.5 mm2 / s or greater over a metal-modified molecular sieve to produce products with low pour points and high viscosity indexes; the line fit to the chart of the pour points and the viscosity indexes has a slope of zero or less; and wherein the yield of products is high.

Owner:CHEVROU USA INC

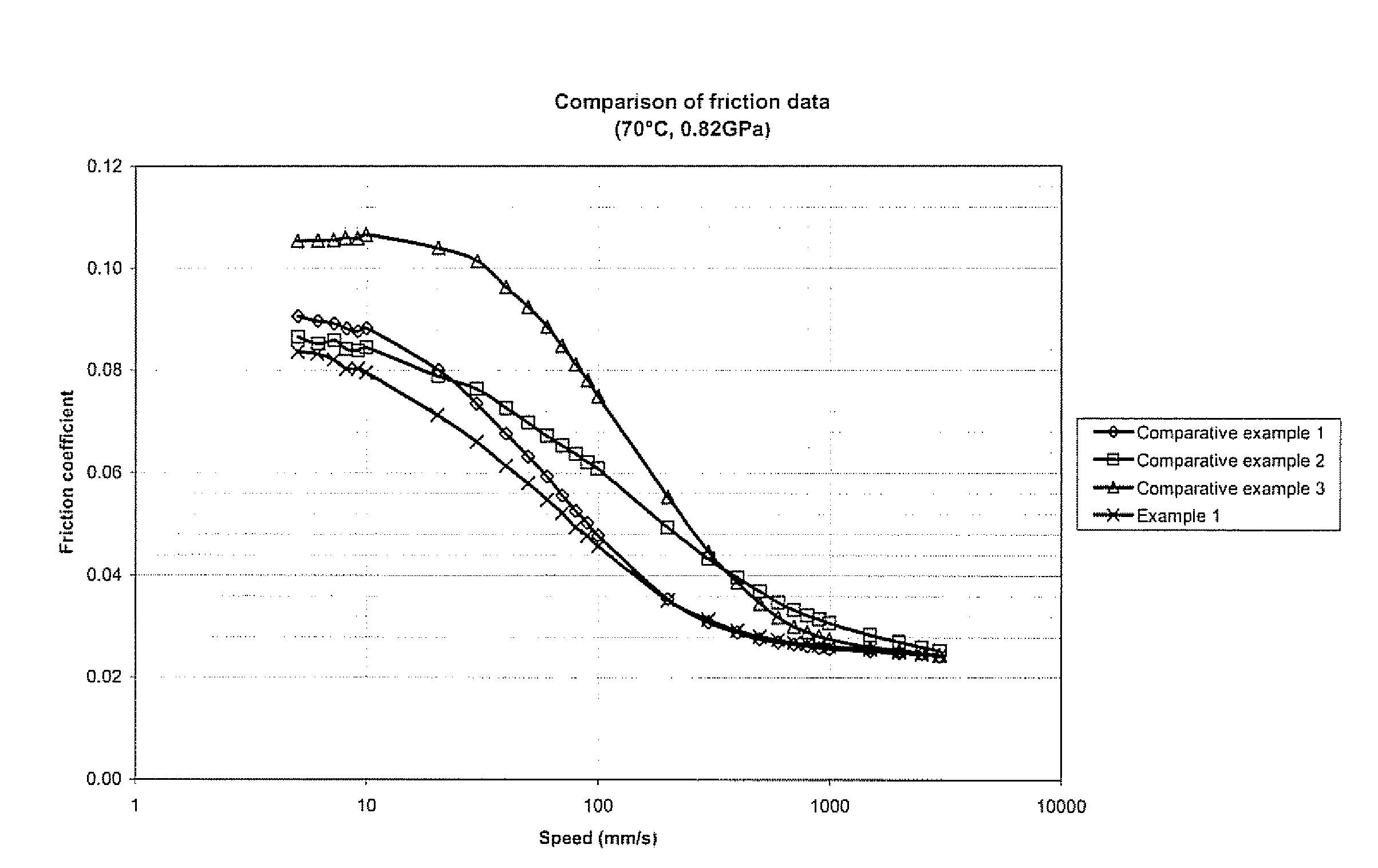

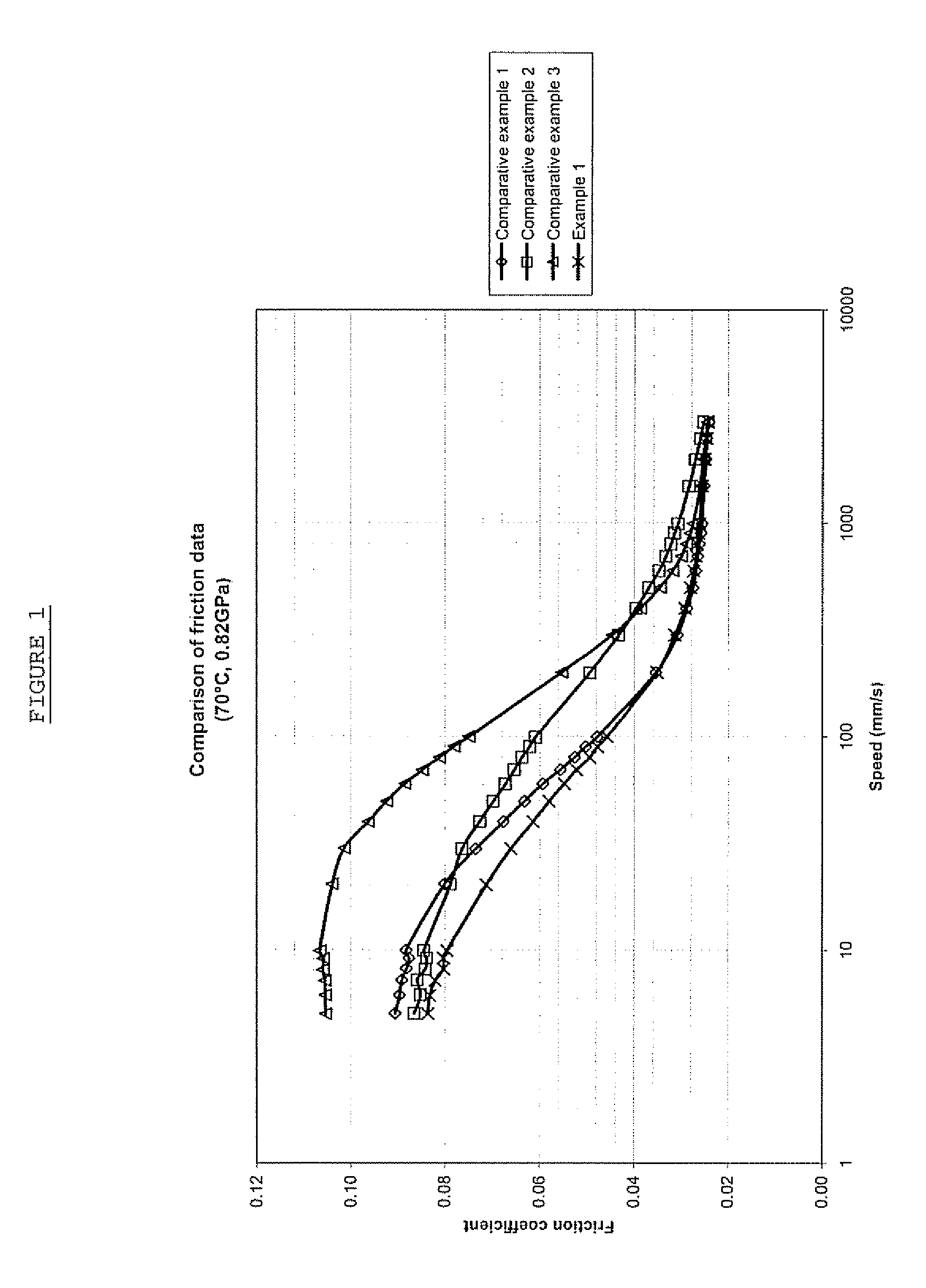

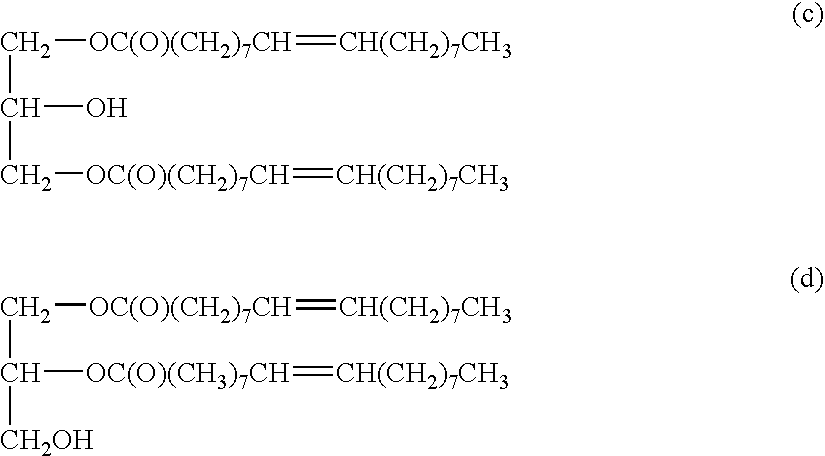

Lubricating oil composition

ActiveUS20080280795A1Good friction reductionImprove fuel economyOrganic chemistryAdditivesChemical compositionViscosity index

A lubricating oil composition comprising base oil, one or more glycerol esters selected from glycerol monooleate and / or glycerol dioleate, optionally in combination with glycerol trioleate, wherein said composition further comprises one or more dispersant-viscosity index improver compounds and an additive amount of one or more additional polyhydric alcohol esters; and a method of lubricating an internal combustion engine comprising applying said lubricating oil composition thereto.

Owner:SHELL USA INC

Lubricating oil for methanol fuel engine and preparation method thereof

InactiveCN101705144AAnti-agingResistance to emulsification damageAdditivesAntioxidantBULK ACTIVE INGREDIENT

The invention provides lubricating oil for a methanol fuel engine, which comprises the following components in percentage by weight: metal detergent 2.2-5.2, ashless dispersant 3.5-6.8, antioxidant and anticorrosion agent 0.5-1.6, high-temperature antioxidant 0.3-0.8, viscosity index improver 6-11, oiliness solvent 2.8-6, anti-foaming agent 120ppm, metal anti-rust agent 0.3-0.7, base oil 62.7-83, demulsifying agent 0.1-0.3, metal extreme pressure anti-wear agent 1.0-4 and pour point depressant 0.3-0.9. The lubricating oil of the invention has functions of preventing wear and rust of the engine, can prevent the active ingredients thereof from being extracted and emulsified by methanol and is particularly suitable for engines using M85 or M100 methanol gasoline as a fuel.

Owner:王恩臣 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com