Patents

Literature

395 results about "Industrial Oils" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oils which are used in industrial or commercial applications.

HVI-PAO in industrial lubricant and grease compositions

ActiveUS20070000807A1Good effectViscosity indexSolid fuelsLiquid carbonaceous fuelsViscosity indexWear resistance

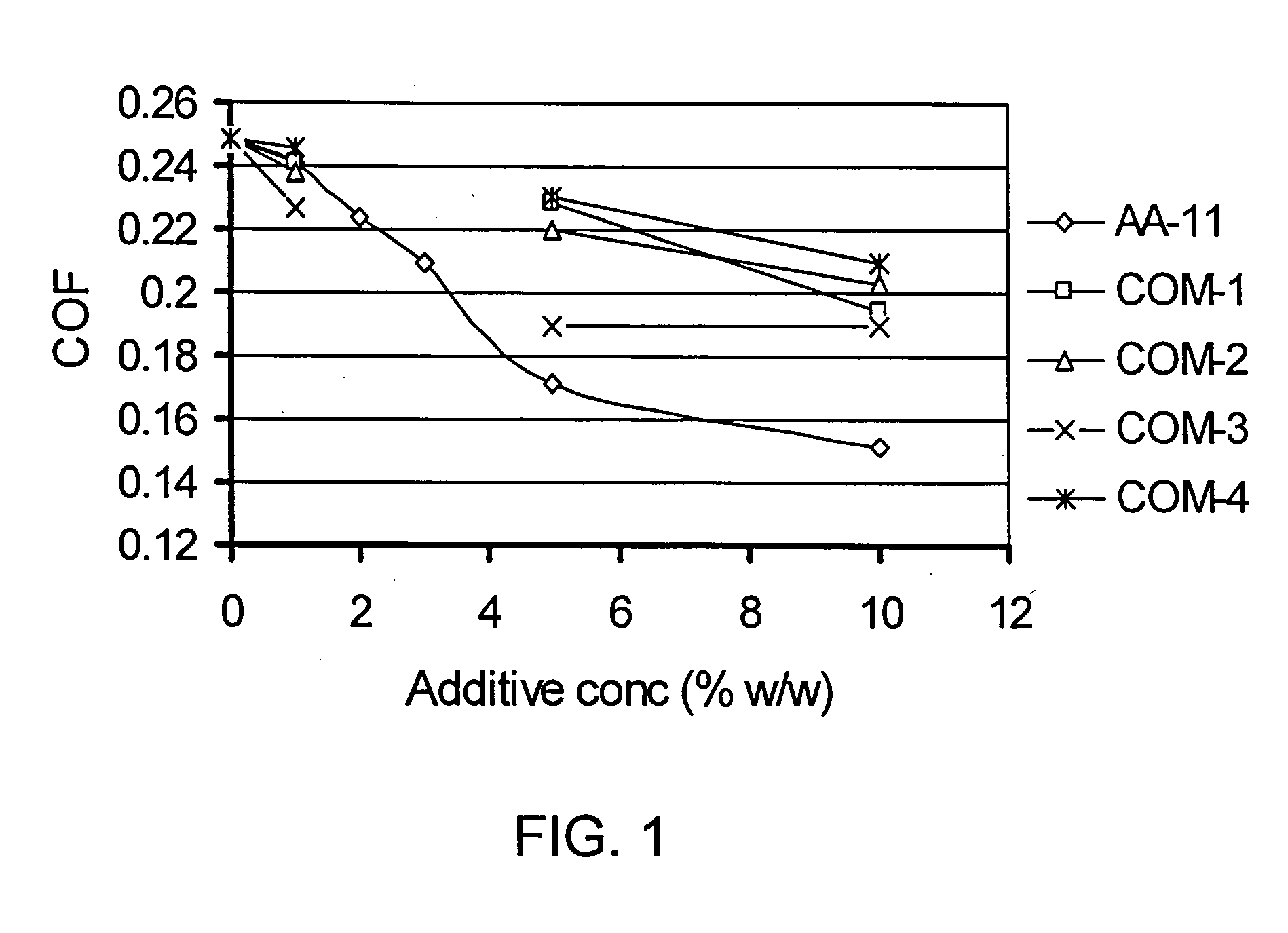

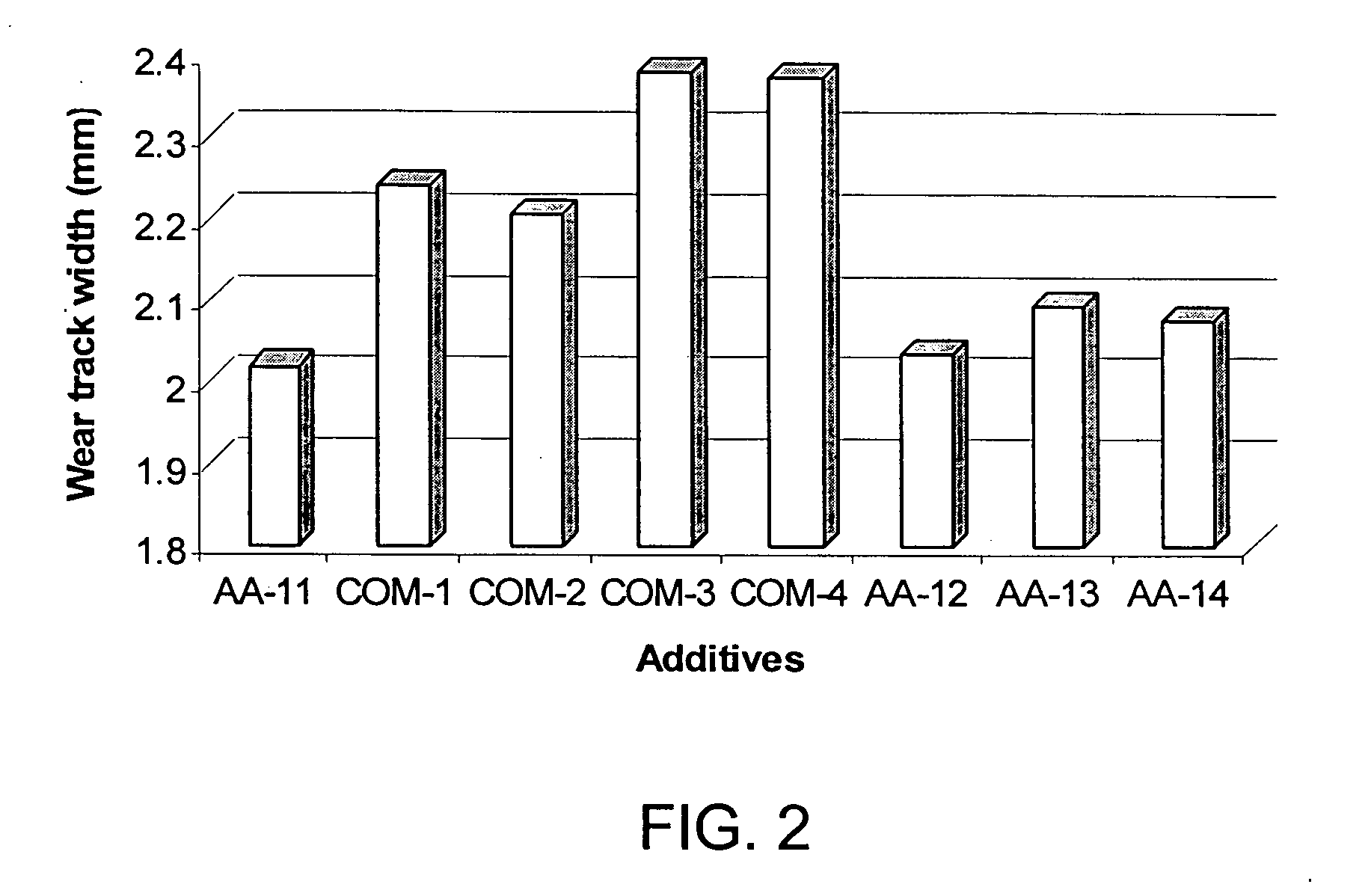

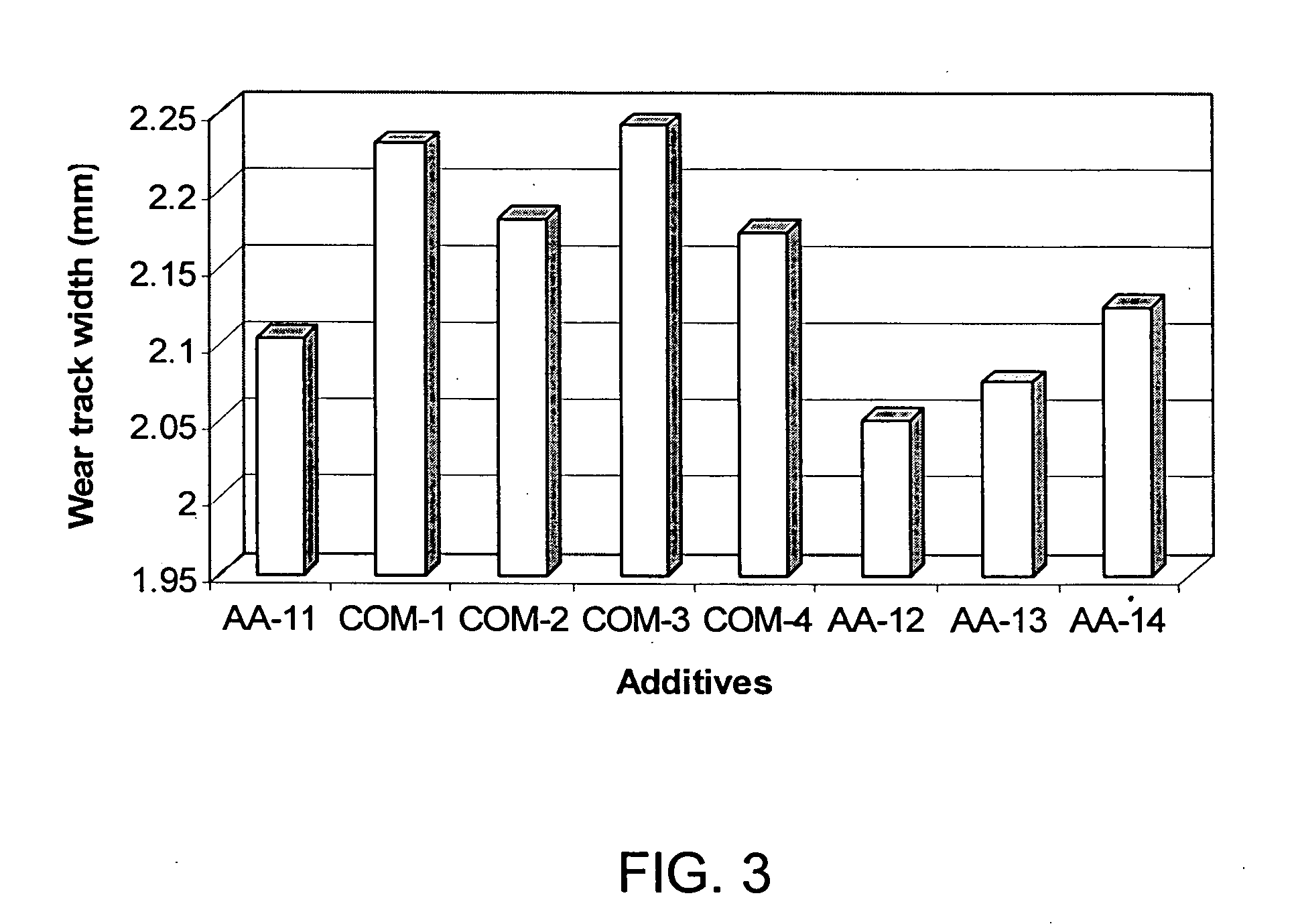

The invention relates to industrial lubricant and grease compositions containing high viscosity index polyalphaolefins (HVI-PAO). The use of HVI-PAOs in industrial oils and greases application provides advantages in improved shear stability, wear property, foam property, energy efficiency and improved overall performance.

Owner:EXXONMOBIL CHEM PAT INC

Determining method for surveying reserves of hypotonic clastic rock oil-gas reservoir

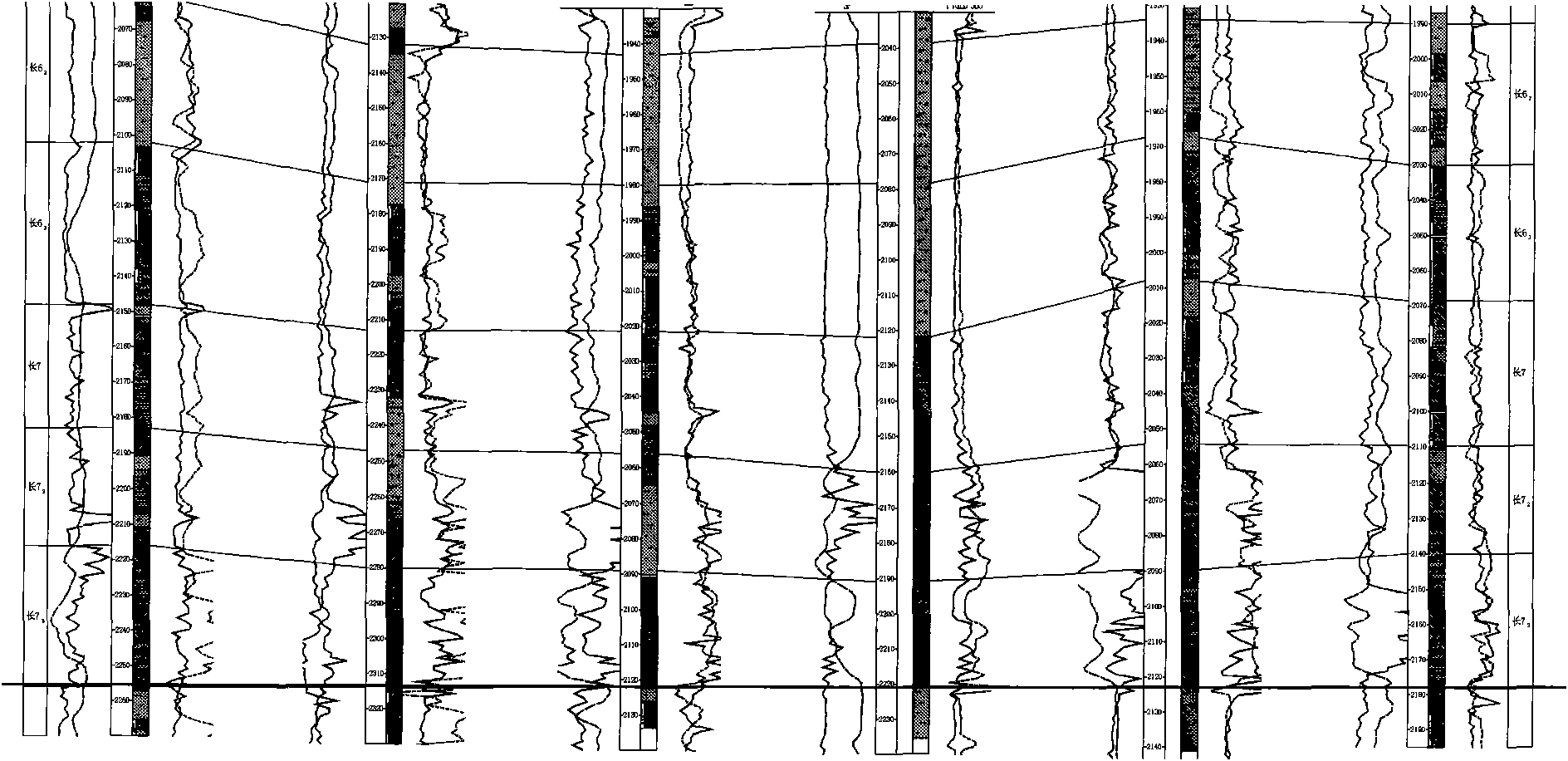

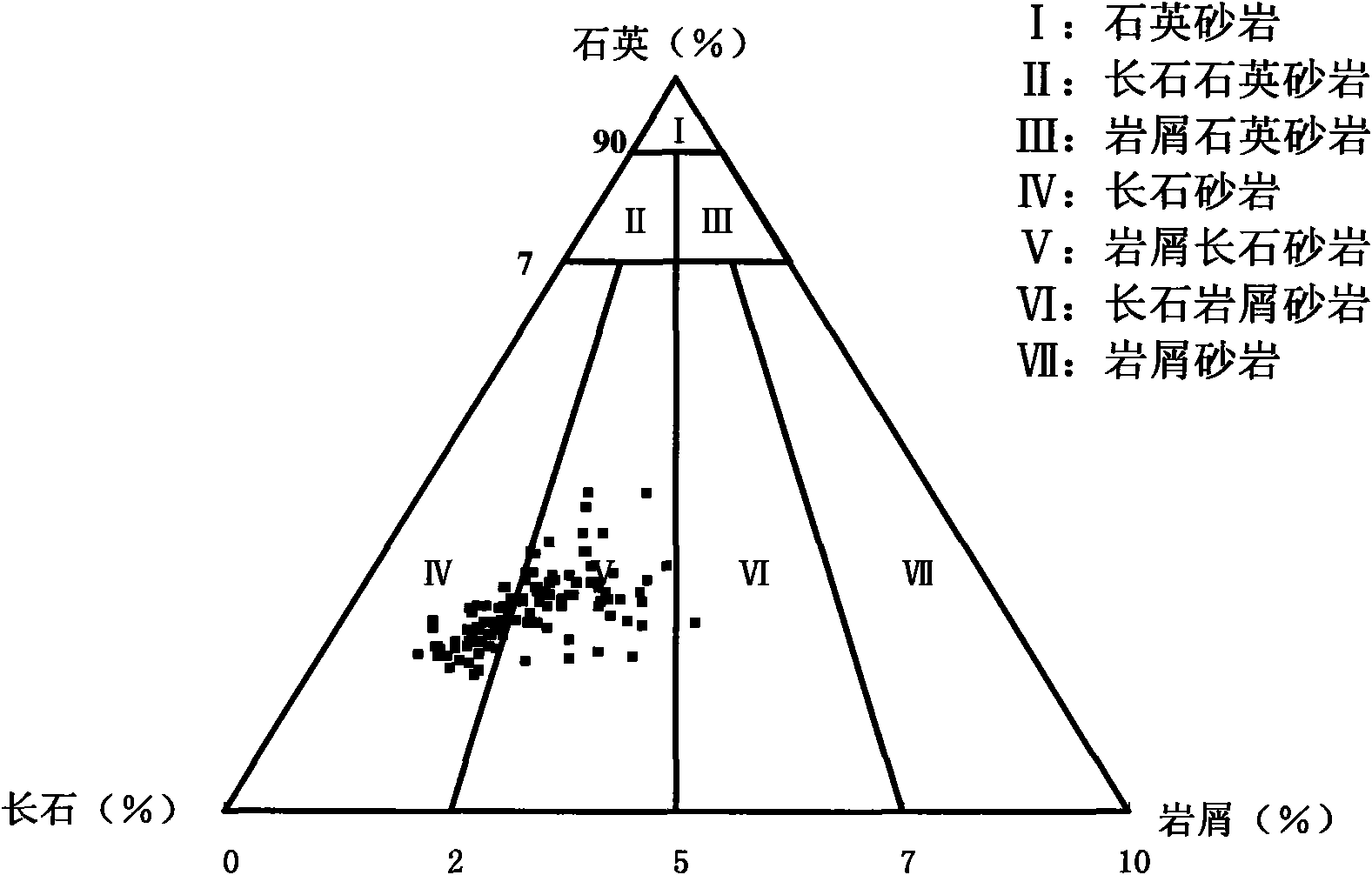

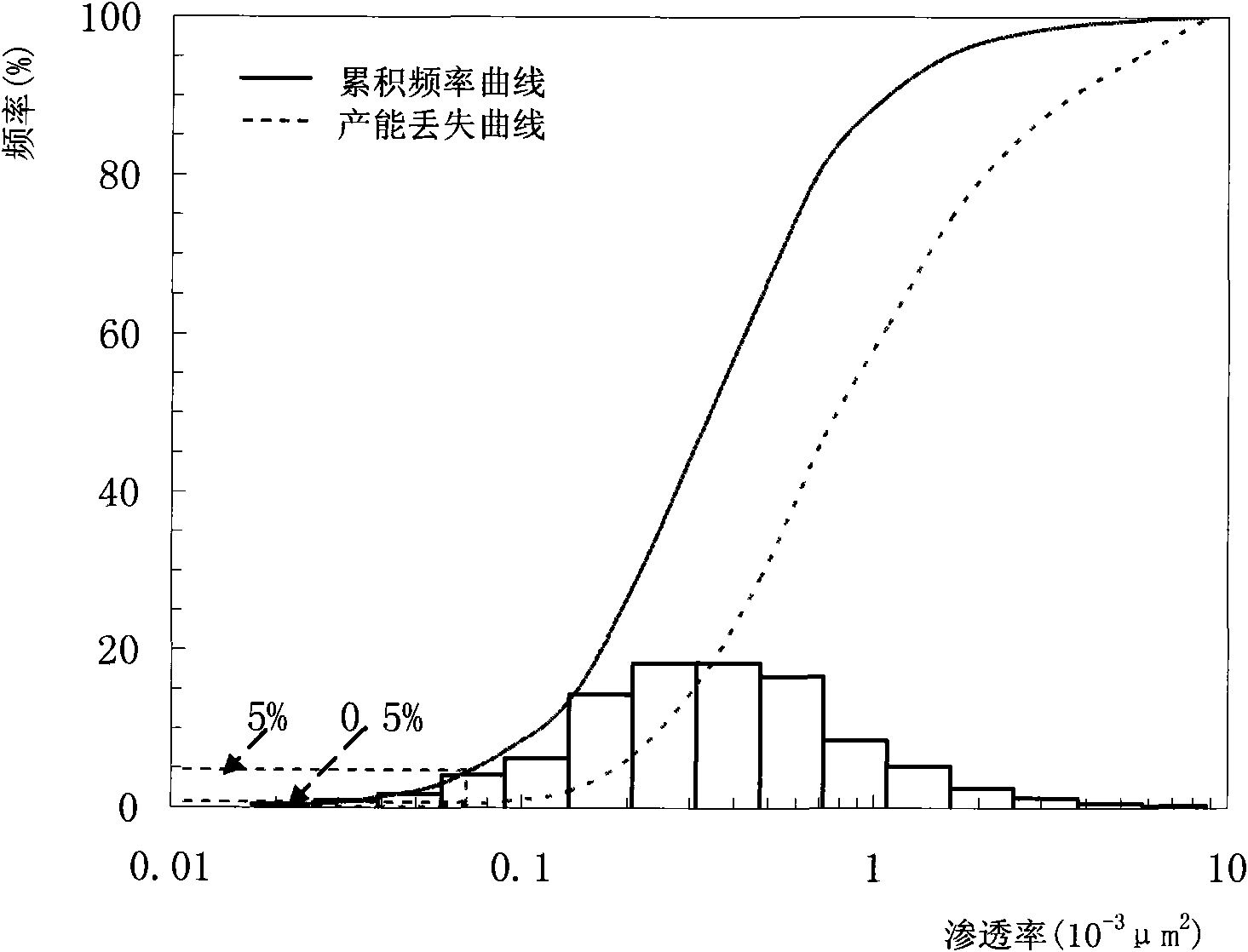

The invention relates to a determining method for surveying the reserves of hypotonic clastic rock oil-gas reservoir positioned on a clastic rock oil (gas) geological reservoir enrichment boundary, comprising the following steps of: carrying out statistical regression on the daily produced oil-gas data and water data of the traditional testing oil well and the traditional testing gas well and thecorresponding physical data, oil-bearing data and electrical data of an oil layer to determine the physical lower limit value, the oil-bearing lower limit value and the electrical lower limit value of an oil-gas layer, which correspond to industrial oil-gas flows; determining the minimum values of output and a sand body thickness according to the relationship between an effective thickness and test oil output and between the sand body thickness and test production; determining the area boundary of the oil-gas reservoir by using a sandrock thickness isoline method and an effective thickness isoline method; and calculating the reserves of the hypotonic clastic rock oil-gas reservoir. The invention solves the problem that the oil-bearing area of the traditional hypotonic clastic rock oil (gas) reservoir is extrapolated depending on artificial well points, is convenient to apply in the calculation of the reserves, can not only be used for more accurately calculating the reserves of oil (gas) reservoir, but also furthest save the exploration discovery workload and reduce the discovery cost of ton reserves, thereby enhancing the economic benefits of oil-gas exploration and development.

Owner:PETROCHINA CO LTD

Preparation method and application of ultra-hydrophobic and ultra-lipophilic paper-based separating material

InactiveCN102225273AImprove permeabilityReduce pollutionFiltration separationLiquid separationOil water emulsionSilicon dioxide

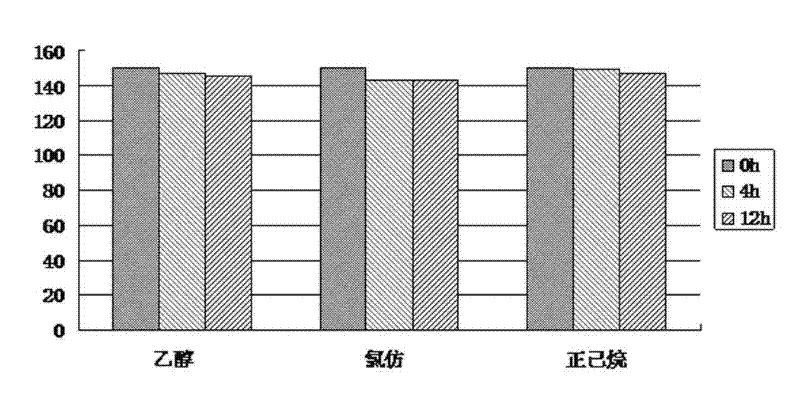

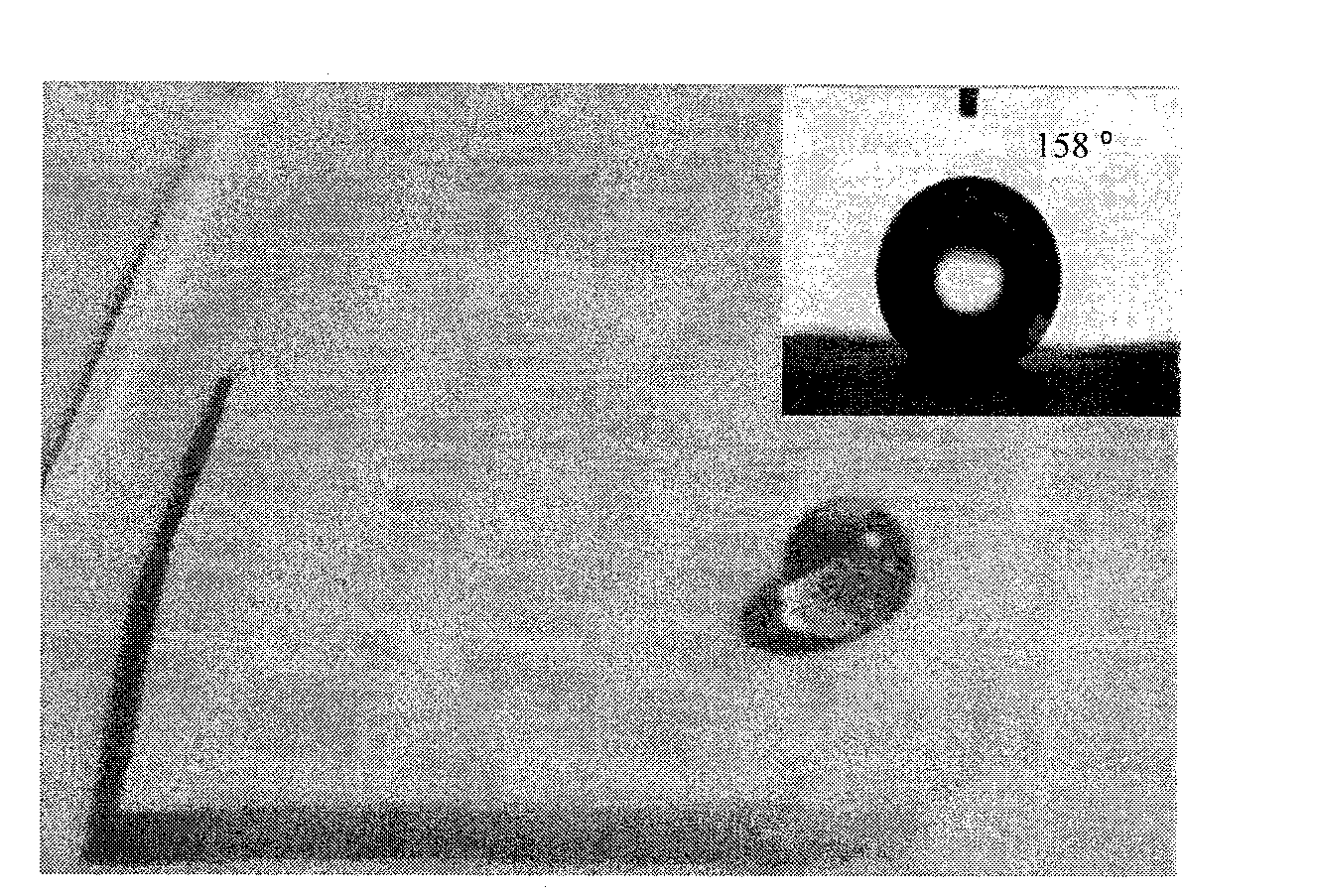

The invention relates to a preparation method and an application of an ultra-hydrophobic and ultra-lipophilic paper-based separating material. The preparation method comprises that: (1) a sol solution of silicon dioxide nano-particles with a particle size of 24 to 36nm is prepared with existing technologies; (2) the solution is modified with a silanizing reagent; (3) a piece of filter paper is immersed in the modified nano-particle solution for 10 to 20 seconds, and is naturally dried, such that an ultra-hydrophobic and ultra-lipophilic paper-based separating material is obtained. The surfaceof the material possesses micron-sized apertures. The contact angle between the separating material and the water surface is larger than 150 DEG. The material has a good ultra-hydrophobic performance, and is acid resistant and organic solvent resistant. The material can be used repeatedly, and can be used for absorbing oil stains floated on water surfaces. The material brings an excellent separating effect to oil-water mixtures, especially oil-water emulsion with high viscosity, and has wide application prospect in industrial oil-water separation and water area oil stain cleaning. According to the present invention, the preparation technology is simple, the requirement for equipment is low, the preparation condition is not restricted by region differences, and mass industrial production can be realized easily.

Owner:HUNAN NORMAL UNIVERSITY

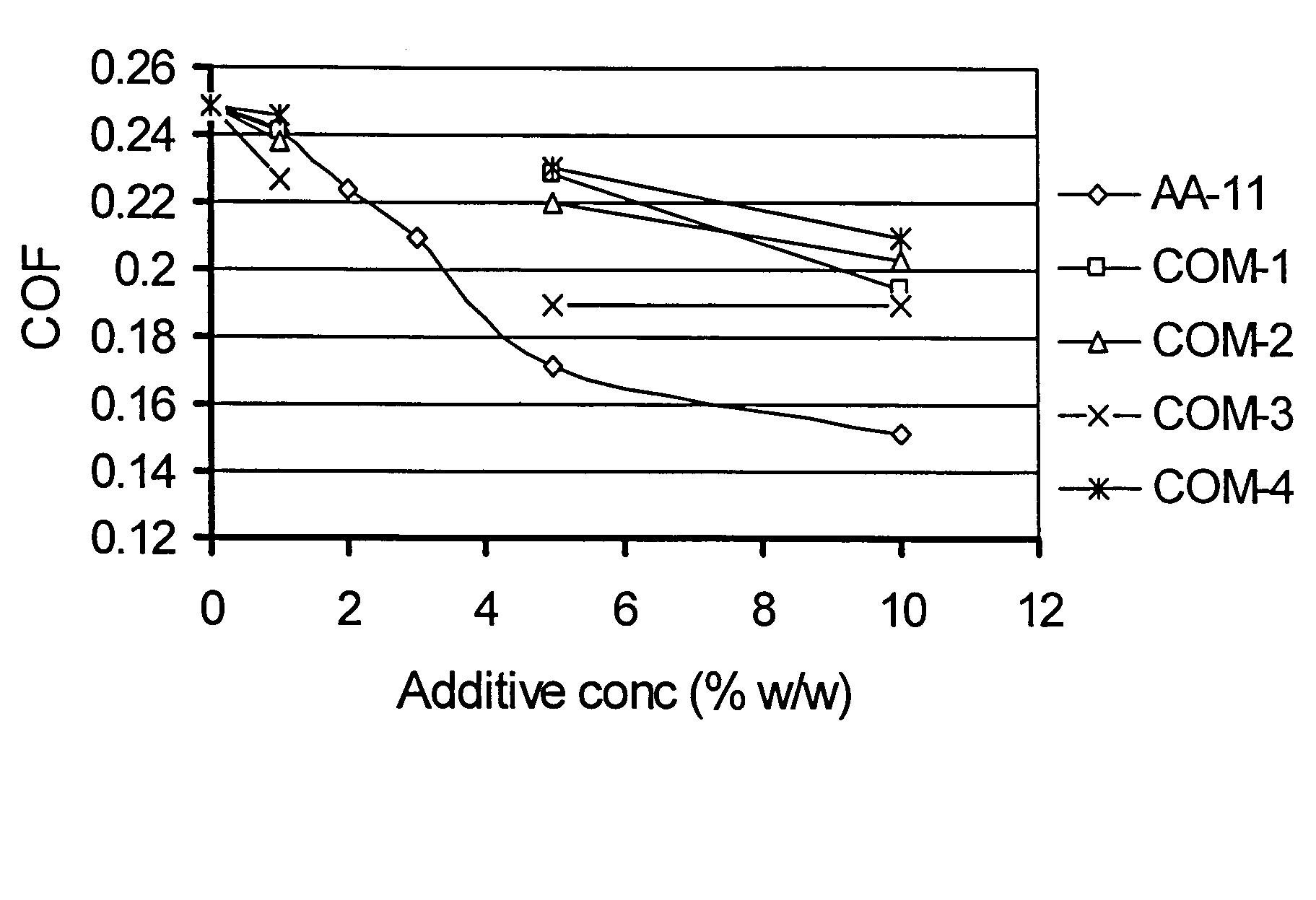

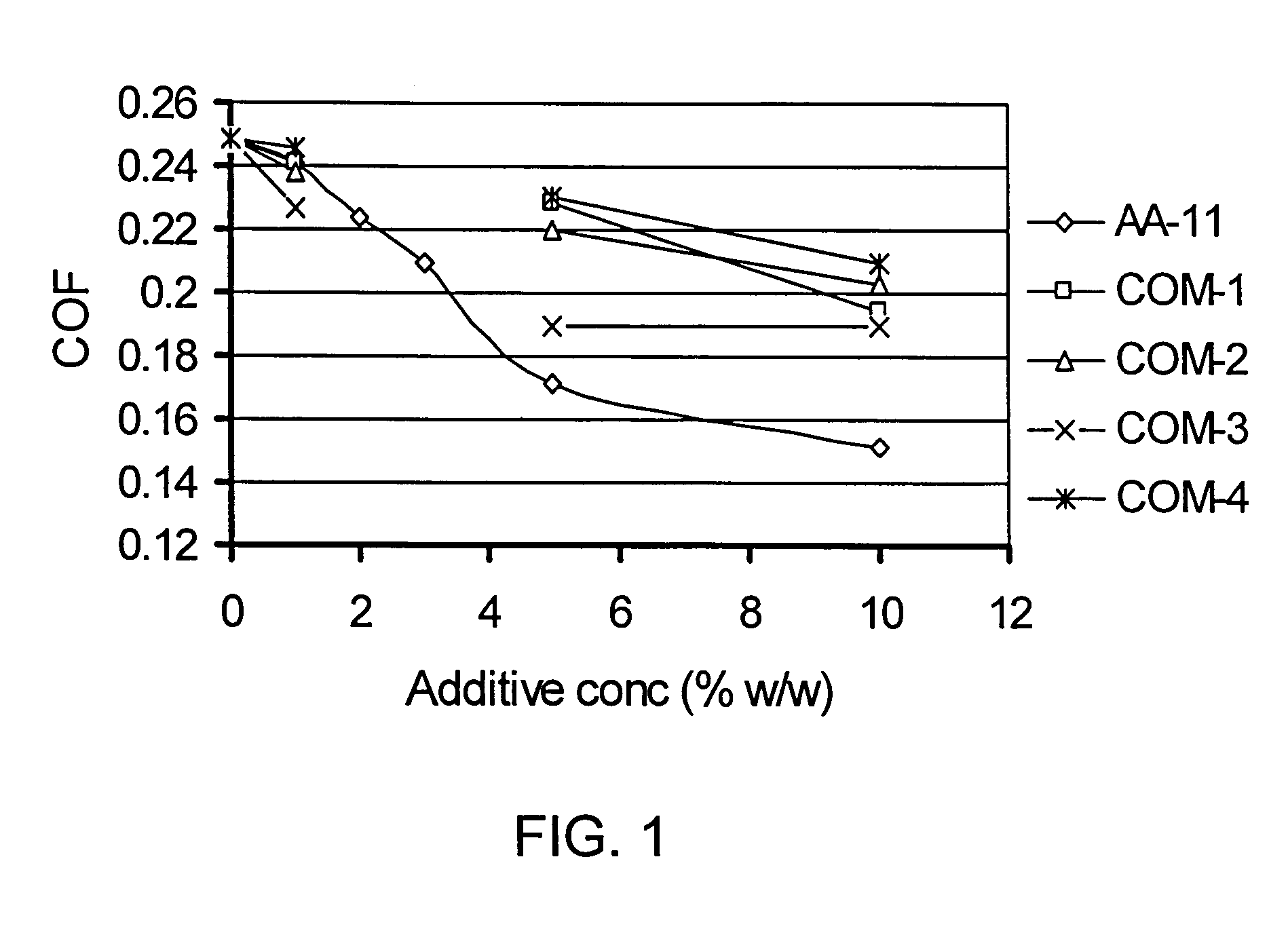

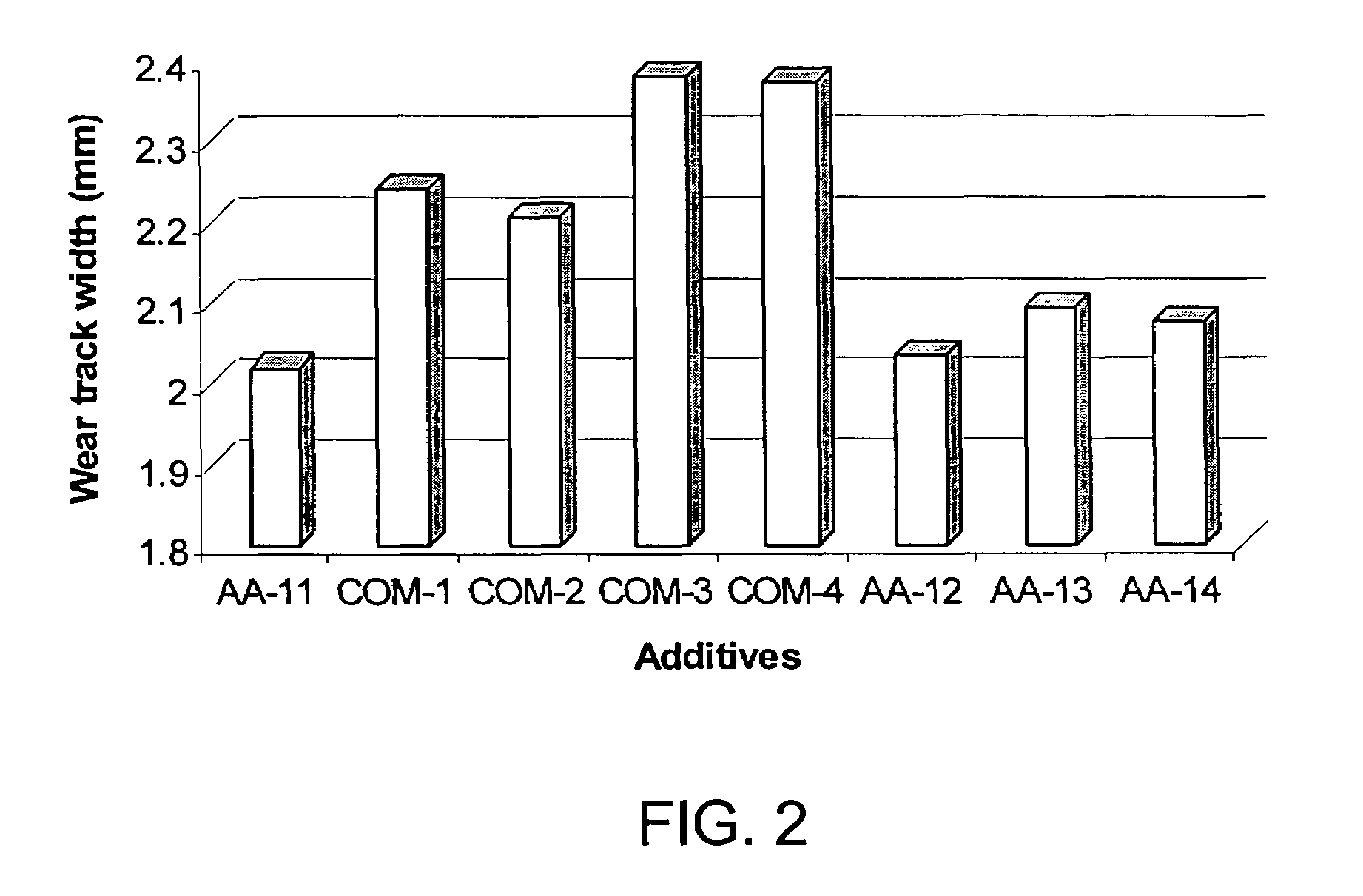

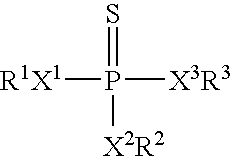

Poly(hydroxy thioether) vegetable oil derivatives useful as lubricant additives

InactiveUS20060009365A1Expand the marketReduce demandOrganic compound preparationSurface-active detergent compositionsThiolVegetable oil

A novel class of chemically-modified vegetable oils is prepared by reacting epoxidized triglyceride oils with thiols. The resultant poly(hydroxy thioether) derivatives have utility as antiwear / antifriction additives for environmentally-friendly industrial oils and automotive applications.

Owner:US SEC AGRI +1

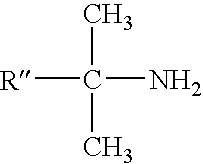

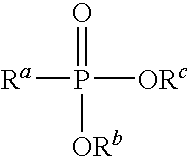

Lubricant compositions

ActiveUS20050090410A1Improve carrying capacityLiquid carbonaceous fuelsAdditivesCarrying capacityDiluent

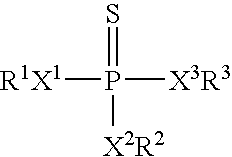

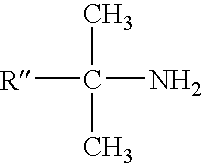

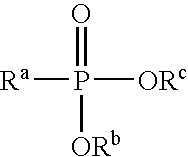

Lubricant compositions having improved load carrying capacity comprising an extreme pressure compound comprising a sulfur-containing compound, a load carrying capacity enhancing combination comprising a hydrocarbylamine compound and an alkylphosphorothioate compound, a friction modifier compound, and a diluent or base oil as applicable. These lubricant compositions can be used as industrial oils well-suited for the demands of geared device applications, such as in wind turbine gear-boxes and automotive gears and axles.

Owner:AFTON CHEMICAL

Agent for removing adhesive products

InactiveUS6689727B1No skin irritationGood removal effectCosmetic preparationsOrganic detergent compounding agentsChemistryAdhesive

Composition for removal of nail polish, plaster, adhesives, discolorations or other adhesive products on the skin and / or nails, which to at least 20% includes one or more esters of one or more natural oils, which further includes one or more synthetic esters, and which is substantially free from volatile solvents. The invention also refers to a composition of the same type for paintbrush wash and / or removal of industrial paint or other adhesive products on objects.

Owner:OLSSON BOZENA

Super hydrophobic-supper lipophilic polymer porous film, preparation method and application thereof

ActiveCN102794113AHigh mechanical strengthEfficient separationSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPolymer chemistryIndustrial Oils

The invention discloses a super hydrophobic-supper lipophilic polymer porous film, preparation method and application thereof. The surface of the polymer porous film is a micro nanometer structure, a nanometer level and / or micron / submicron level pore channel is arranged in the polymer porous film, the thickness of the film is controllable in the range of tens of nanometers to millimeters and the film is used for oil / water (including emulsified oil) separation. The preparation method comprises the following steps: adding a micromolecular additive into a macromolecular solution according to a certain proportion, spreading the obtained mixture solution on the surface of a substrate, and finally forming a film by a wet-method phase inversion technology. The oil immersion speed of the polymer porous film is quick and the film is not easily polluted, and the film has relatively high separation efficiency and flux for the oil-water mixture and the oil-water emulsion (or emulsified oil), and the film has other features such as convenient preparation technology, easy operation and low production cost. The film can be widely applied in various fields such as large-scale separation and purification of the industrial oil water (emulsified oil water) and large-scale filter and separation of organic liquid / water.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

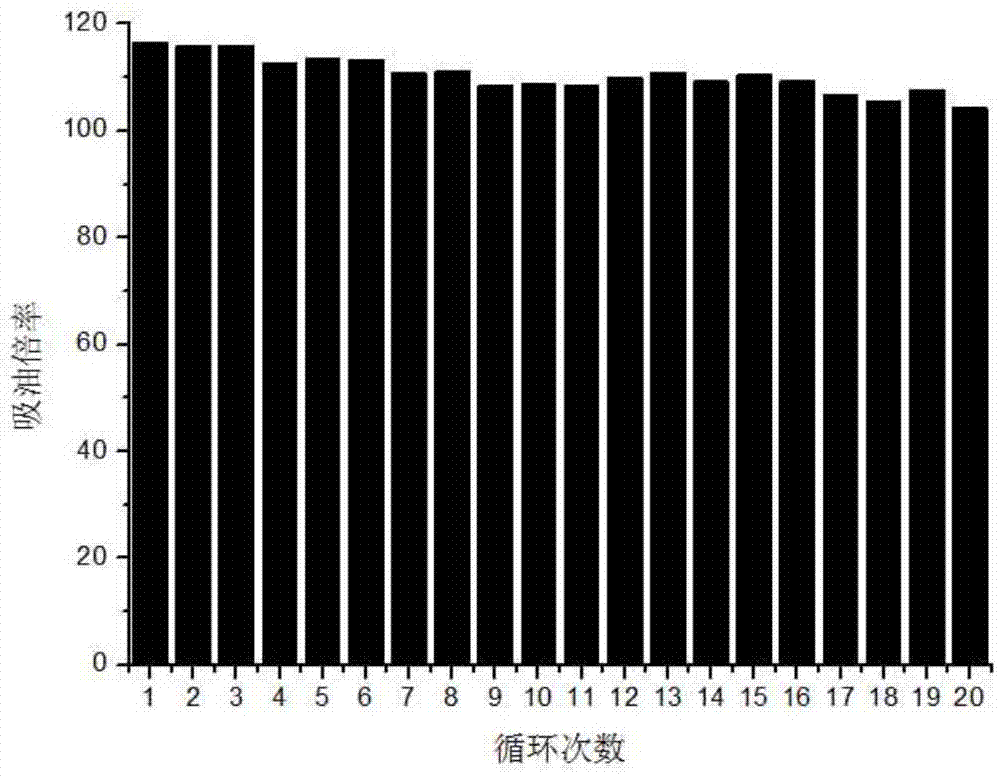

Preparation method of sponge with high oil-absorbing performance for oil-water separation

The invention relates to a preparation method of a sponge with a high oil-absorbing performance for oil-water separation. The preparation method comprises the following steps: processing the surface of polyurethane sponge skeleton by a modifier to obtain a hydrophobic modified layer, and then heating the processed sponge to activate the sponge so as to obtain oil-absorbing sponge. The modified sponge has an ultrathin hydrophobic modified layer, thus the characteristics of high porosity and high elasticity of polyurethane sponge are preserved, and at the same time the modified sponge has a high performance on absorbing oil. The prepared oil-absorbing sponge only absorbs the oil and does not absorb the water. The absorbed oil amount is tens to hundreds of the weight of the sponge. The oil can be absorbed by the sponge by simple squeezing. The sponge has the characteristics of low cost, simple and practical technology, and good reusability, can be produced massively, and is advantageously used in the fields such as water oil pollutant removal, petroleum exploitation, industrial oil pollutant separation, and the like.

Owner:NANJING UNIV OF TECH

Steel for expandable casing for oil well and manufacturing method thereof

ActiveCN101812631APerformanceAvoid easy crackingTemperature control deviceFurnace typesNumerical controlAlloy

The invention discloses steel for an expandable casing for an oil well and a manufacturing method thereof, and the manufacturing method is applied to preparing the expandable casing for the oil well for petroleum and gas industrial oil. The steel alloy material of the expandable casing for the oil well comprises the following components in percentage by weight: 0.08 to 0.2 percent of C, 1 to 2 percent of Mn, 0.15 to 0.35 percent of Si, 0.02 to 0.06 percent of Al, less than or equal to 0.01 percent of P, less than or equal to 0.05 percent of S, less than or equal to 0.08 percent of N, 0.001 to 0.005 percent of Ca, and the balance of Fe. The method for preparing the expandable casing for the oil well comprises the following steps of: preparing hot rolled steel coils; producing straight seam resistance welded steel pipes by using the hot rolled steel coils; normalizing welding lines after welding; and finally, cutting into welded steel pipes, and machining API standard threads or special threads at two ends of each welded steel pipe by using a numerical control machine. The steel for the expandable casing for the oil well has the advantages of excellent comprehensive performance such as expansion deformation capacity, intensity, toughness, and the like, no defect of the welding lines and uniform and consistent performance with base metals.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

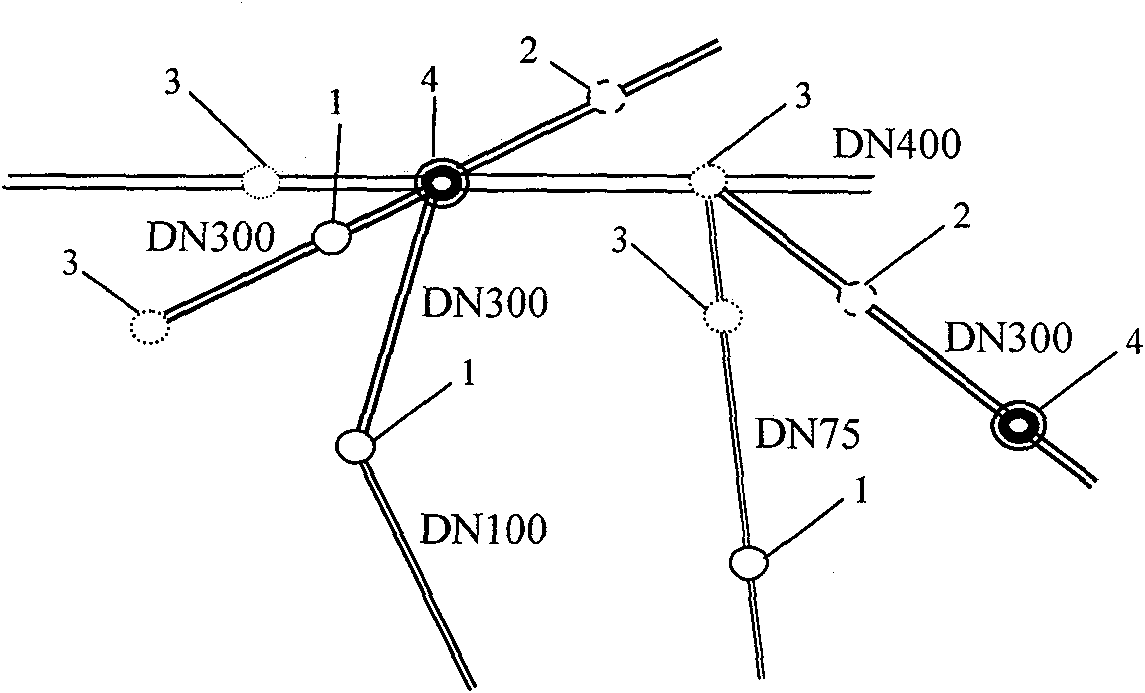

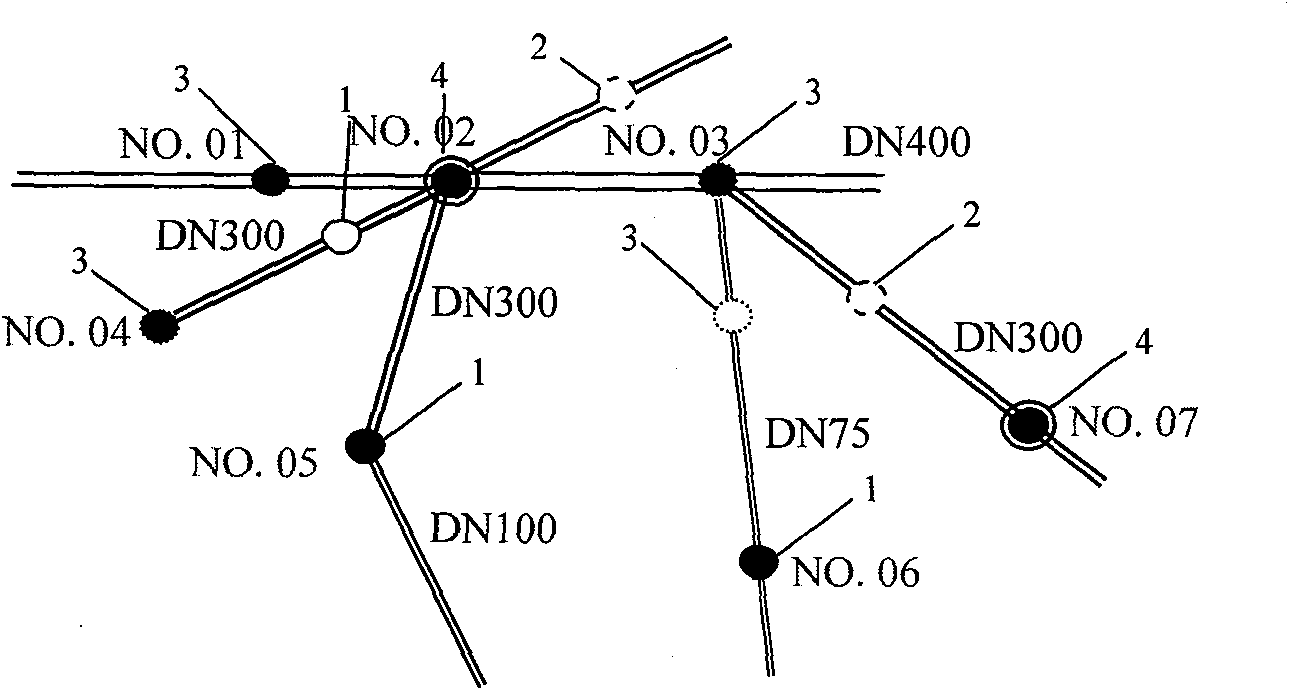

Leakage detecting method for urban water supply pipes

InactiveCN102072408AAvoid blind investigationAvoid heavy investigation workPipeline systemsUrban water supplyReclaimed water

The invention pertains to the technical field of leakage detection of pipes, and in particular relates to a leakage detection technology comprehensively utilizing a leakage noise recorder, a manual leakage listening detecting rod and the like, and an application method of the leakage detection technology to the urban water supply network. Based on the noise leakage detecting method of a leakage recorder, the signals of the leakage recorder are analyzed by a water supply network geographic information system (GIS) platform, and the key check area is determined; and further, the key check area is detected by comprehensively using the leakage recorder and the manual leakage listening detecting method so as to determine the leakage and locate the leakage point. The leakage detecting method combines the leakage detecting method by using the leakage recorder which has extremely high sensitivity on sound signals with the manual leakage listening detecting method, and is used for analyzing the leakage signals by utilizing the GIS platform, thereby not only effectively avoiding aimless check of a large-scale pipe network by using the manual leakage listening detecting method independently, but also avoiding a great quantity of misinformation signals by utilizing the leakage recorder independently and heavy check work caused thereby. The leakage detecting method not only can be used for detecting leakage of urban water supply networks, but also can be used for detecting leakage of pipes of urban reclaimed water supply networks, industrial oil pipes, industrial circulating cooling water pipes and the like.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI +1

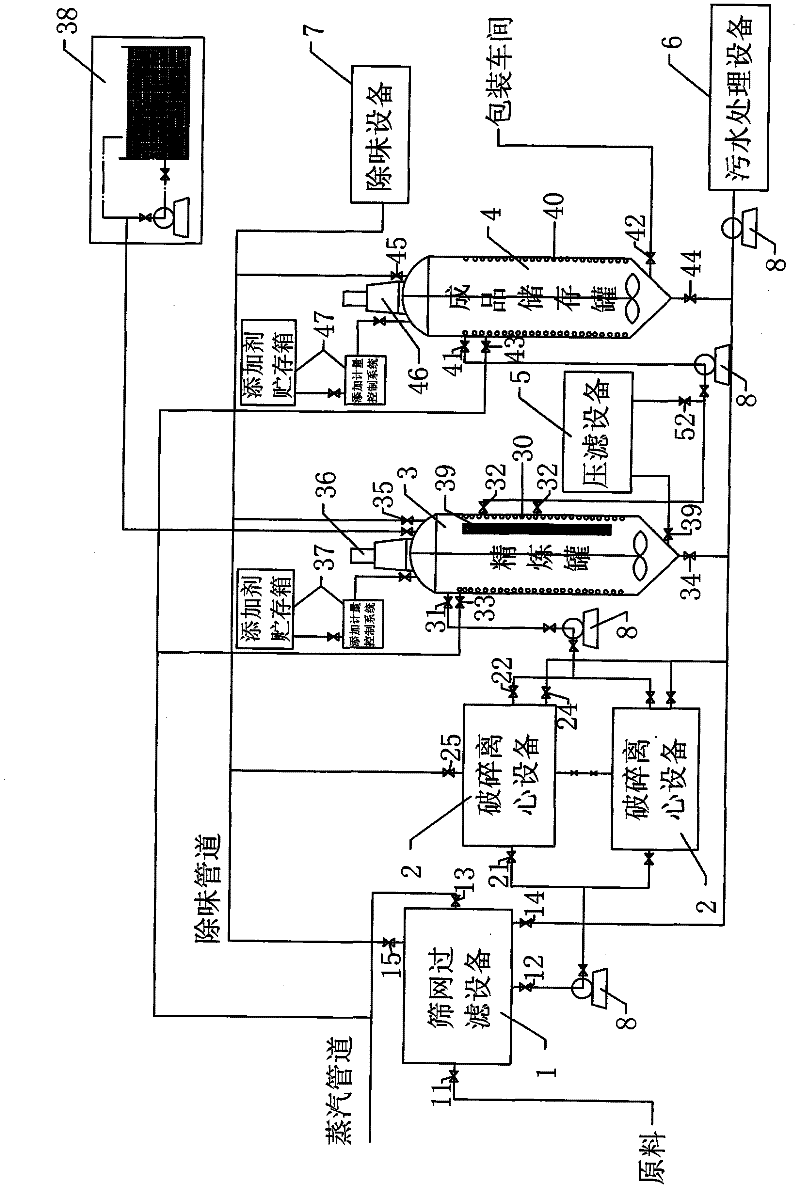

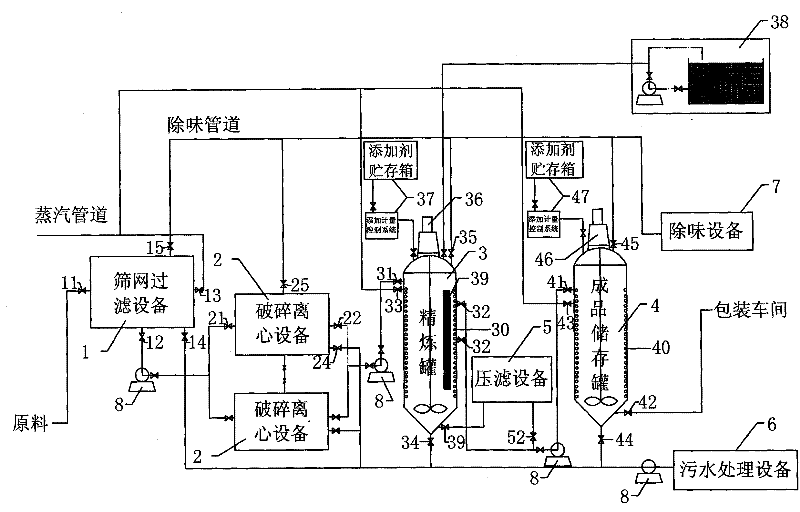

A method and system for treating waste kitchen waste oil

InactiveCN102295997AHigh purityIncrease productionFatty oils/acids recovery from wasteFatty substance recoveryCentrifugationWaste oil

The invention discloses a processing method of kitchen waste grease, comprising the following steps: a step of filtering with a sieve: filtering the recycled kitchen waste grease with the sieve at the temperature of 40-50 DEG C to preliminarily remove impurities; a step of crushing and separating: putting the filtered kitchen waste grease into a pipeline crusher to crush the residual impurities and soft solid materials in the raw materials, then carrying out centrifugation with a centrifuge to preliminarily separate grease raw material from water and residual impurities; and a step of refine refining grease: putting the grease raw material obtained by centrifugation into an oil-water separation device for oil-water separation to separate out purified grease. The invention also discloses aprocessing system of kitchen waste grease. According to the invention, the industrial grease products with high purity and high yield can be produced with low energy consumption, easiness and feasibility.

Owner:严正华

HVI-PAO in industrial lubricant and grease compositions

ActiveUS8399390B2High viscosityBig advantageSolid fuelsLiquid carbonaceous fuelsViscosity indexChemistry

Owner:EXXONMOBIL CHEM PAT INC

Ester glycosyl phase selective oleophylic gelator as well as preparation method and application thereof in oil gelatinization

InactiveCN104803850AEasy to separateTo achieve the effect of gellingFatty/oily/floating substances removal devicesPreparation from carboxylic acid halidesOil phaseRaw material

The invention discloses an ester glycosyl phase selective oleophylic gelator as well as a preparation method and application thereof in oil gelatinization. Mannitol and medium / long alkyl chain acyl chlorides are taken as raw materials, and the selective oleophylic gelator is prepared through O-esterification reaction. Due to the / long alkyl chain, the ester glycosyl phase selective oleophylic gelator disclosed by the invention can selectively enter an oil phase in an oil-water mixture, self-assembling can be achieved in the oil phase through the weak interaction of intermolecular hydrogen bonds, a physically crosslinked supramolecular structure can be formed, furthermore the oil phase is immobilized through interfacial tension and capillary action, then the oil phase has no mobility, and the effect of gelatinization can be achieved. The problems that a conventional similar gelator is complex in preparation process, high in catalyst cost, and low in gelatinization efficiency are solved, and the ester glycosyl phase selective oleophylic gelator has a relatively good application prospect in the fields of offshore overflow oil recycling and rapid industrial oil-containing wastewater separation.

Owner:TIANJIN UNIV

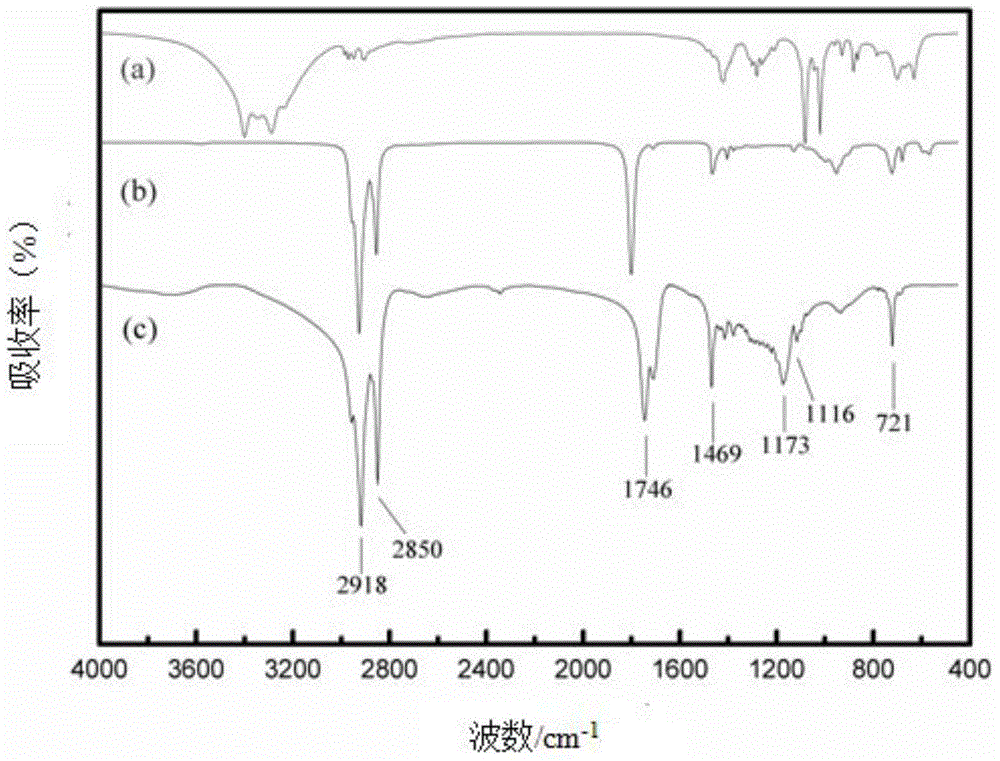

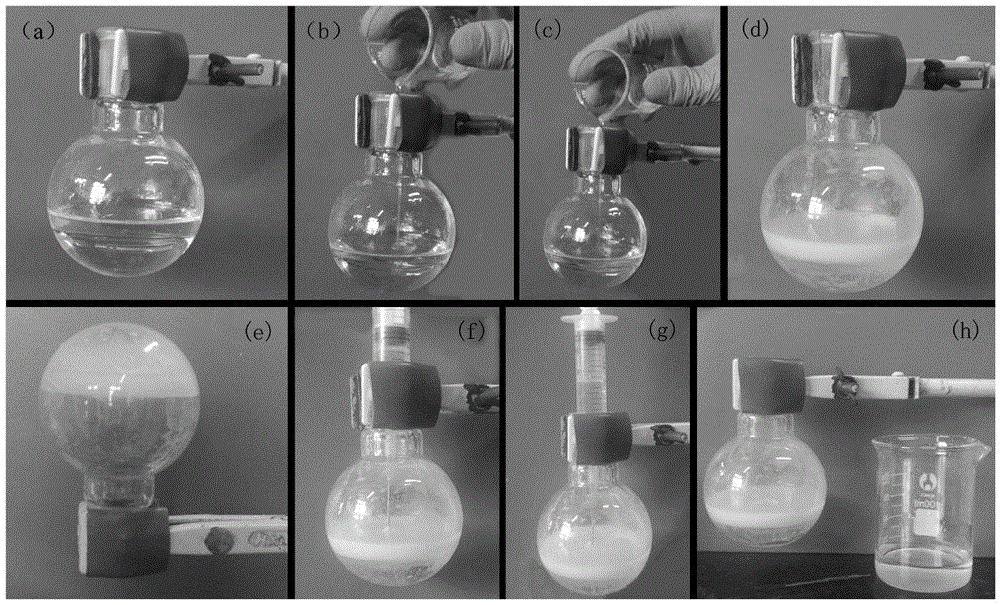

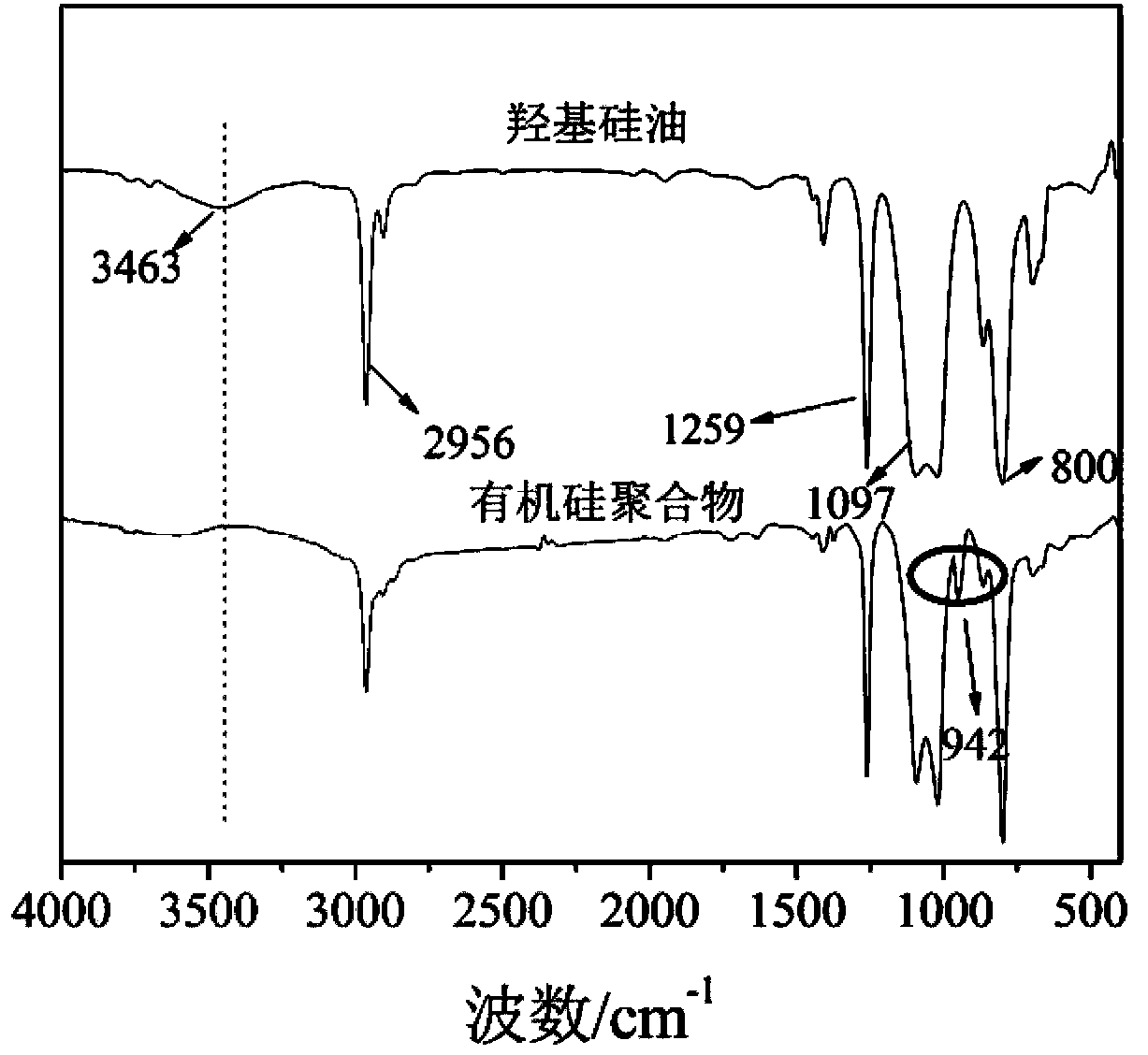

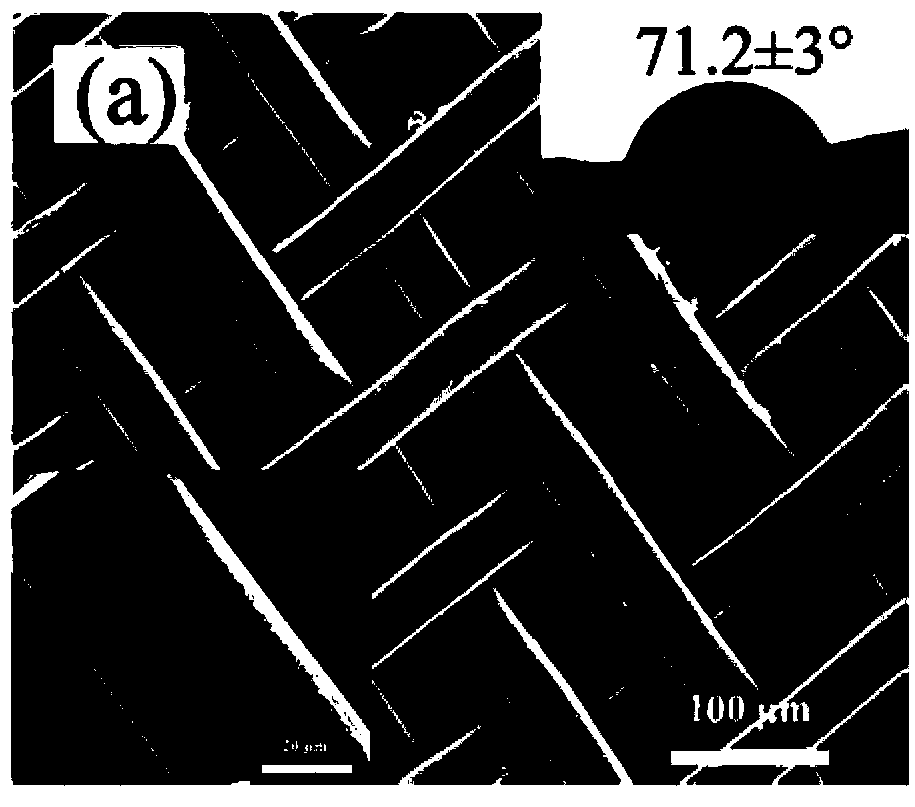

Super hydrophobic/super lipophilic filter cloth and preparation method thereof and application thereof in oil-water separation

InactiveCN103357196AHas super hydrophobic and super lipophilic propertiesEfficient separationLiquid separationFiberDip-coating

The invention discloses a super hydrophobic / super lipophilic filter cloth and a preparation method thereof and application thereof in oil-water separation. At room temperature, hydroxyl silicone oil, an organic tin catalyst and a titanate curing agent are dissolved in a toluene-ethanol mixed solvent to obtain organic silicon prepolymer; then a nano-silica toluene dispersion liquid is added into the prepolymer, after uniform mixing and dispersing, organosilicon / silica blend is obtained; and a 100-400 mesh polymer fiber filter cloth is put in the blend, and a super hydrophobic / super lipophilic cloth is prepared through a dip-coating-pulling manner. Compared with preparation technology of hydrophobic / super lipophilic materials in the prior art, the preparation method has the advantages of simple process and mild reaction conditions, the materials used are cheap and easily available, the prepared filter cloth has super hydrophobic and super lipophilic properties, can fast and effectively separate an oil-water mixture, and can be applied to the fields of sea crude oil leakage processing, industrial oil and water separation treatment and the like.

Owner:SOUTH CHINA UNIV OF TECH

Fuel oil additive

InactiveCN101643677AIncrease oxygen contentBoost octaneLiquid carbonaceous fuelsBiodieselDiesel locomotive

The invention discloses a fuel oil additive, which comprises the following components: 0.1 to 99.8 percent of dialkyl carbonate, 0 to 80 percent of ferrocene, 0 to 80 percent of benzotriazole, 0.1 to 80 percent of fatty alcohol and epoxyethane condensation compound, 0.05 to 50 percent of alkylphenol and epoxyethane condensation compound, and the like. The fuel oil additive can be widely used in gasoline of all grades, diesel oil, ethanol blended gasoline, biodiesel and heavy oil for various motor vehicles, marine diesel engines, diesel locomotives, industrial oil burning boilers and the like. The fuel oil additive has the advantages of improving the quality of fuel oil, increasing combustion efficiency, obviously saving oil, reducing harmful tail gases, strengthening the power of engines, protecting the engines, prolonging the service life of the engines, along with cleanness, no toxicity, small addition amount.

Owner:厦门市米基霖科技开发有限公司

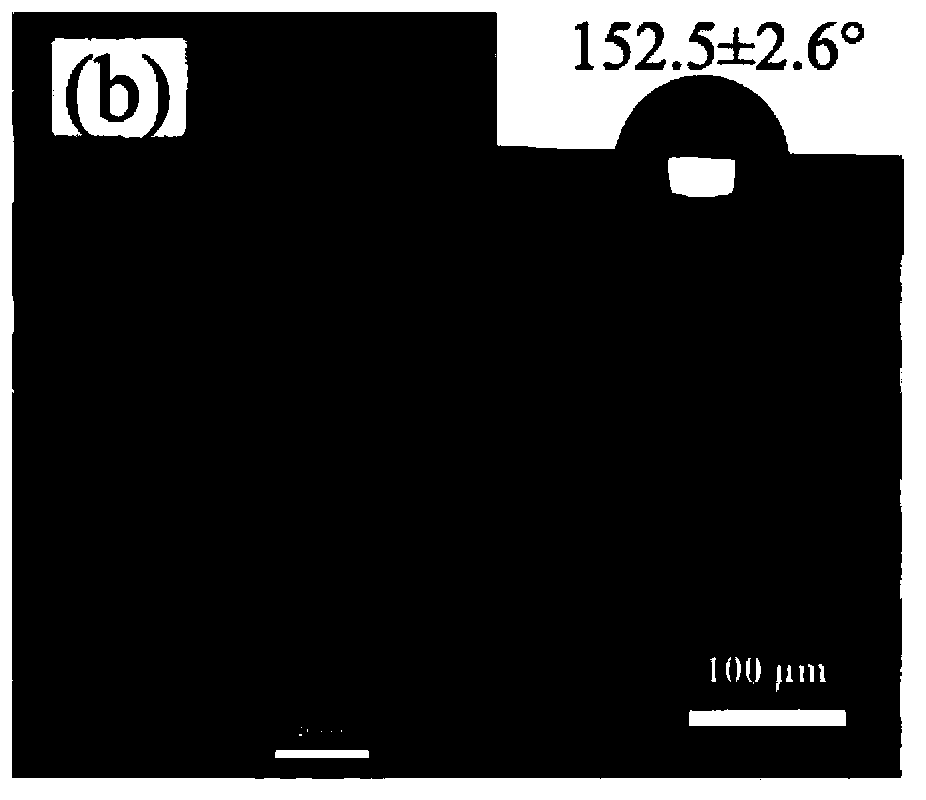

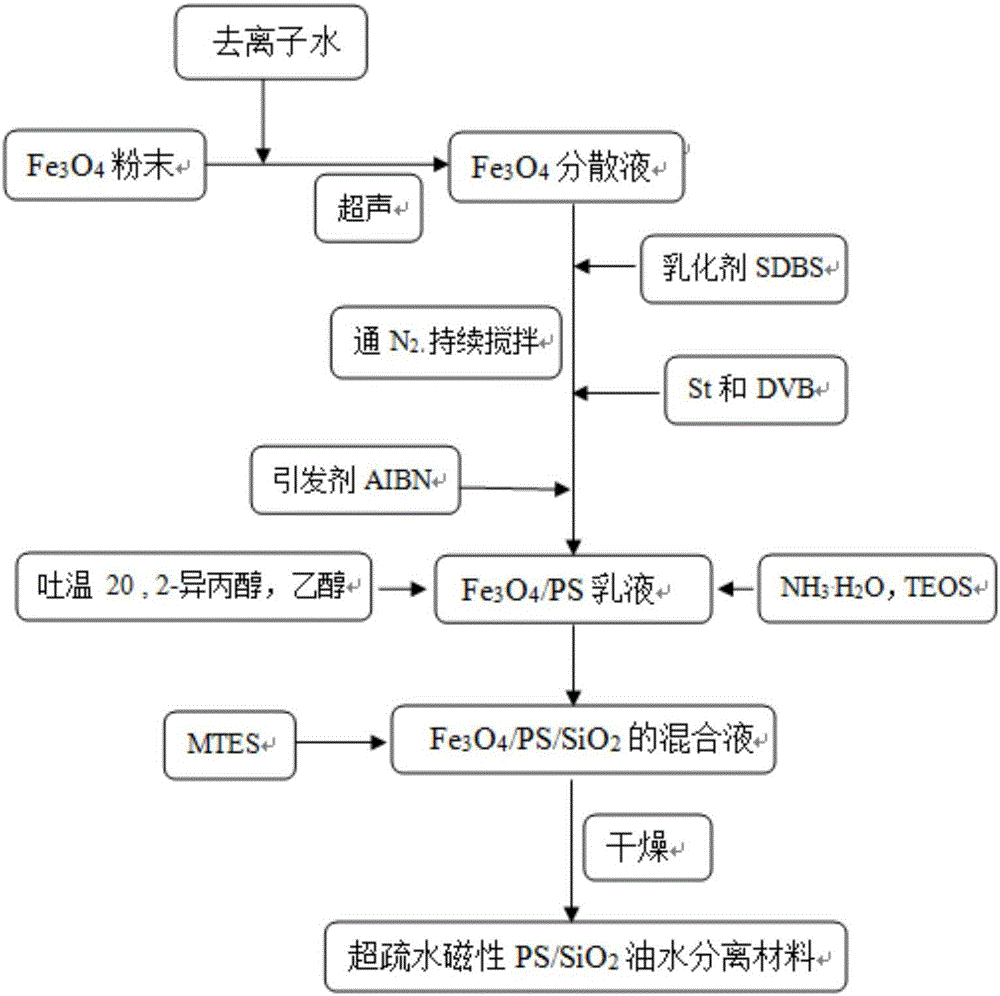

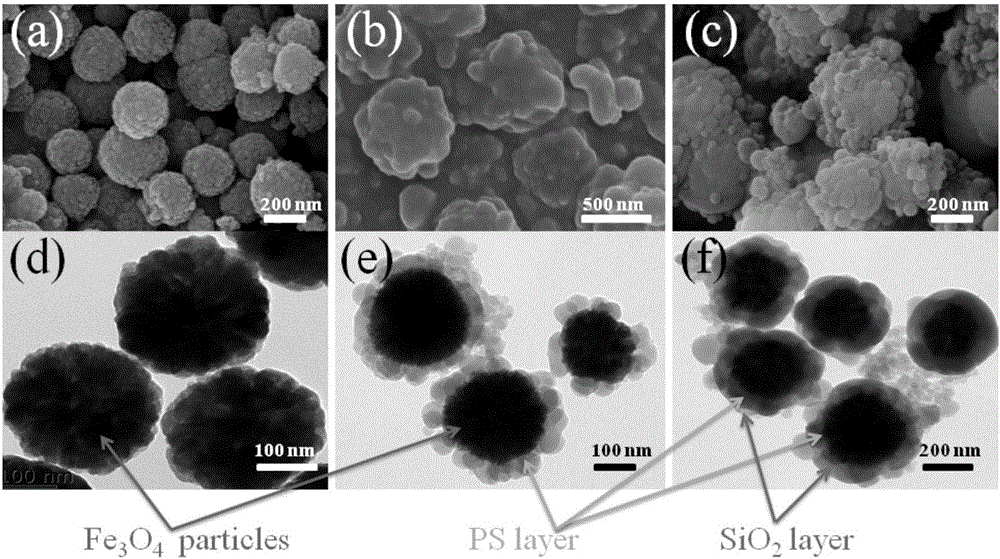

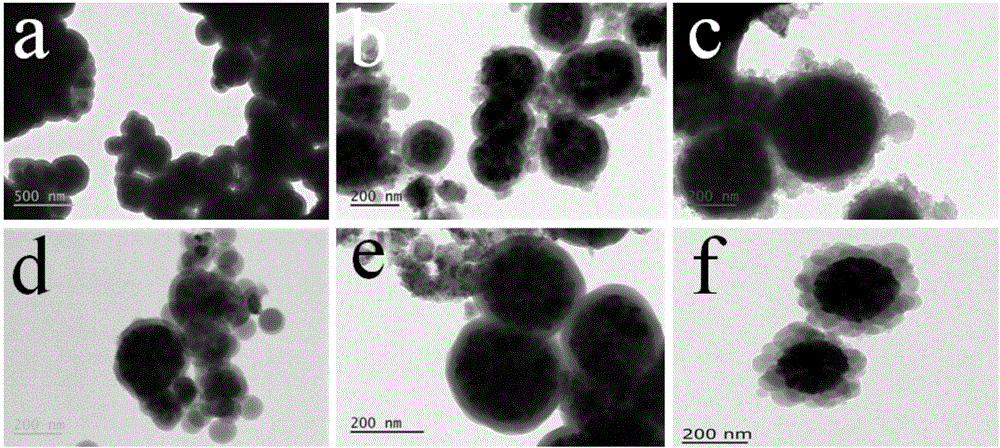

Super-hydrophobic and magnetic PS/SiO2 oil-water separation material and preparation method thereof

ActiveCN106277162AReduce usageSolve reunionFatty/oily/floating substances removal devicesOther chemical processesWater bathsNitrogen gas

The invention discloses a super-hydrophobic and magnetic PS / SiO2 oil-water separation material and a preparation method thereof. The oil-water separation material is a super-hydrophobic material adopting a core-shell structure, Fe3O4 is taken as a magnetic core, a PS layer is taken as an inner shell and a super-hydrophobic SiO2 layer is taken as an outer shell. The preparation method comprises the following steps: Fe3O4 is taken as the magnetic core, sodium dodecylbenzenesulphonate is added to a homogeneous dispersion of Fe3O4 firstly, the mixture is heated and stirred in water bath in a nitrogen atmosphere for a period of time, then styrene and divinylbenzene are added, and an emulsion polymerization reaction is performed under the action of 2,2'-azobis(2-methylpropionitrile); a crude product obtained through washing is re-dispersed in an ethanol and isopropanol mixed solution, the pH value is regulated, and silicon tetraacetate and methyltriethoxysilane are added slowly dropwise, and finally, the PS / SiO2 oil-water separation material with a rough surface is obtained. The prepared oil-water separation material has excellent hydrophobicity, lipophilicity, thermal stability and oil-water selectivity, is resistant to high temperature, resistant to acid and alkali corrosion, high in adsorption rate and high in recycling rate and can be used for treating industrial oil pollution.

Owner:NANJING UNIV OF SCI & TECH

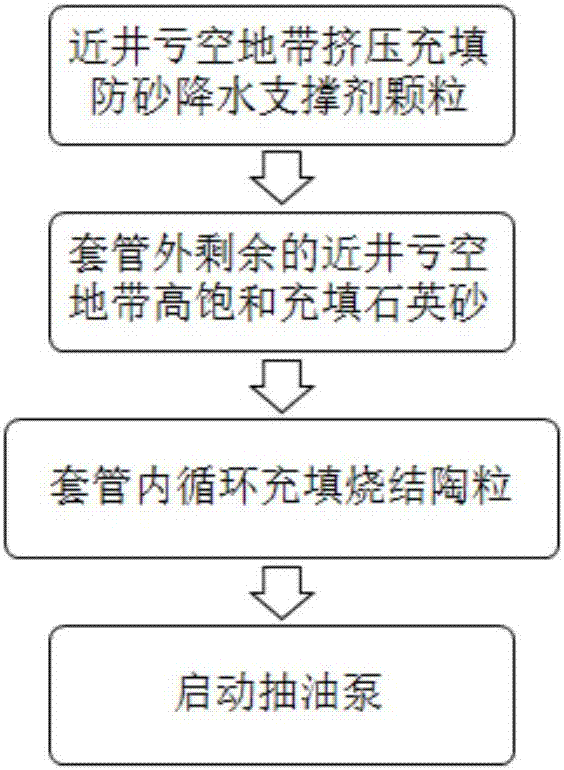

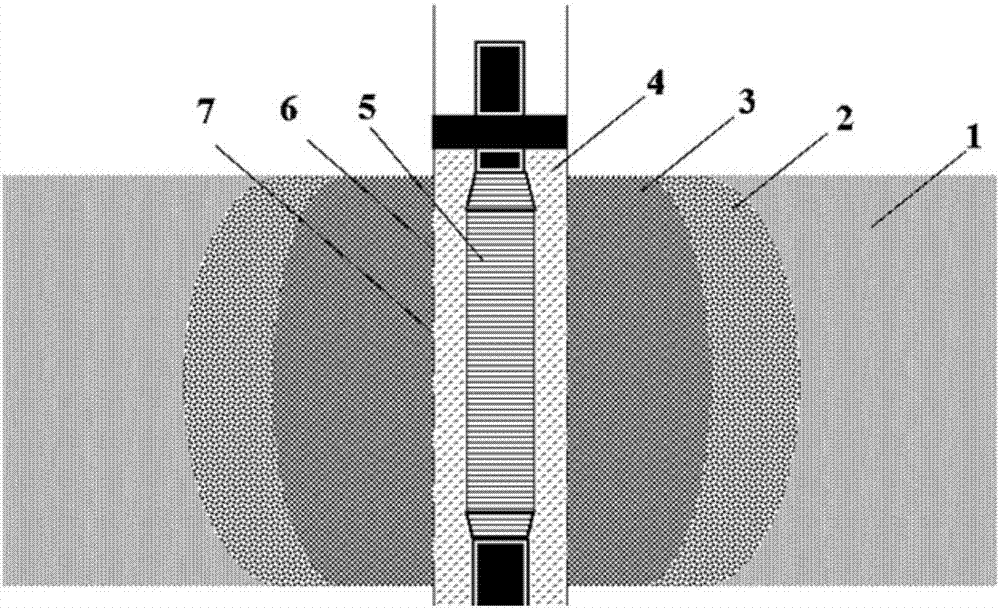

Multi-section-plug high-saturation filling water and sand controlling method for silty fine sand reservoir

InactiveCN107575187AStrong precipitation abilityHigh Sand Control StrengthFluid removalEngineeringOil water

The invention relates to a multi-slug high-saturation filling method for controlling water and sand in silt and fine sand reservoirs, belonging to the technical field of filling and sand prevention for oil and natural gas exploitation industries. The multi-stage sand retaining barriers are arranged in between, and the multi-stage sand retaining barriers include: the fourth-stage sand retaining barriers, the third-stage sand retaining barriers, and the second-stage sand retaining barriers arranged radially outwardly along the mechanical sand control screens and the first-stage sand retaining barrier; the first to third-stage sand retaining barriers respectively contain particles of corresponding particle sizes, and the present invention uses a four-stage sand retaining barrier formed by three-stage slugs, which solves the problem of single particle diameter in unconsolidated sandstone reservoirs. The sand control of gravel filling cannot meet the sand control requirements of oil wells with high water content in the late stage of silty sand reservoir exploitation. This method reduces the water content of oil wells and maximizes the silt and fine sand Production of wells with high water cut in reservoirs.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

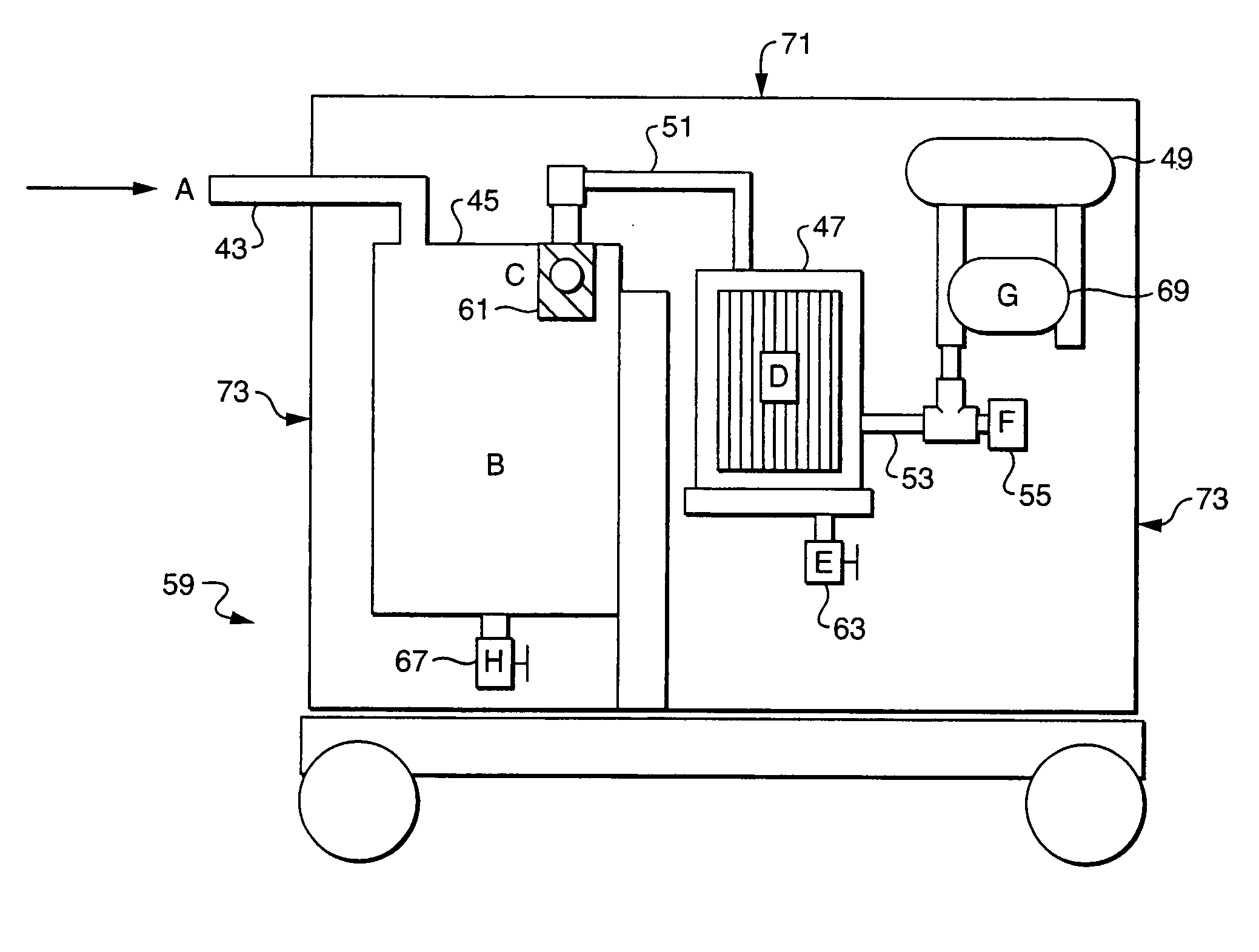

Manually controlled skimming of industrial oil contaminants

InactiveUS20050236311A1Easily and advantageously usedEasy to deployWaste water treatment from metallurgical processLoose filtering material filtersAir filtrationEnvironmental engineering

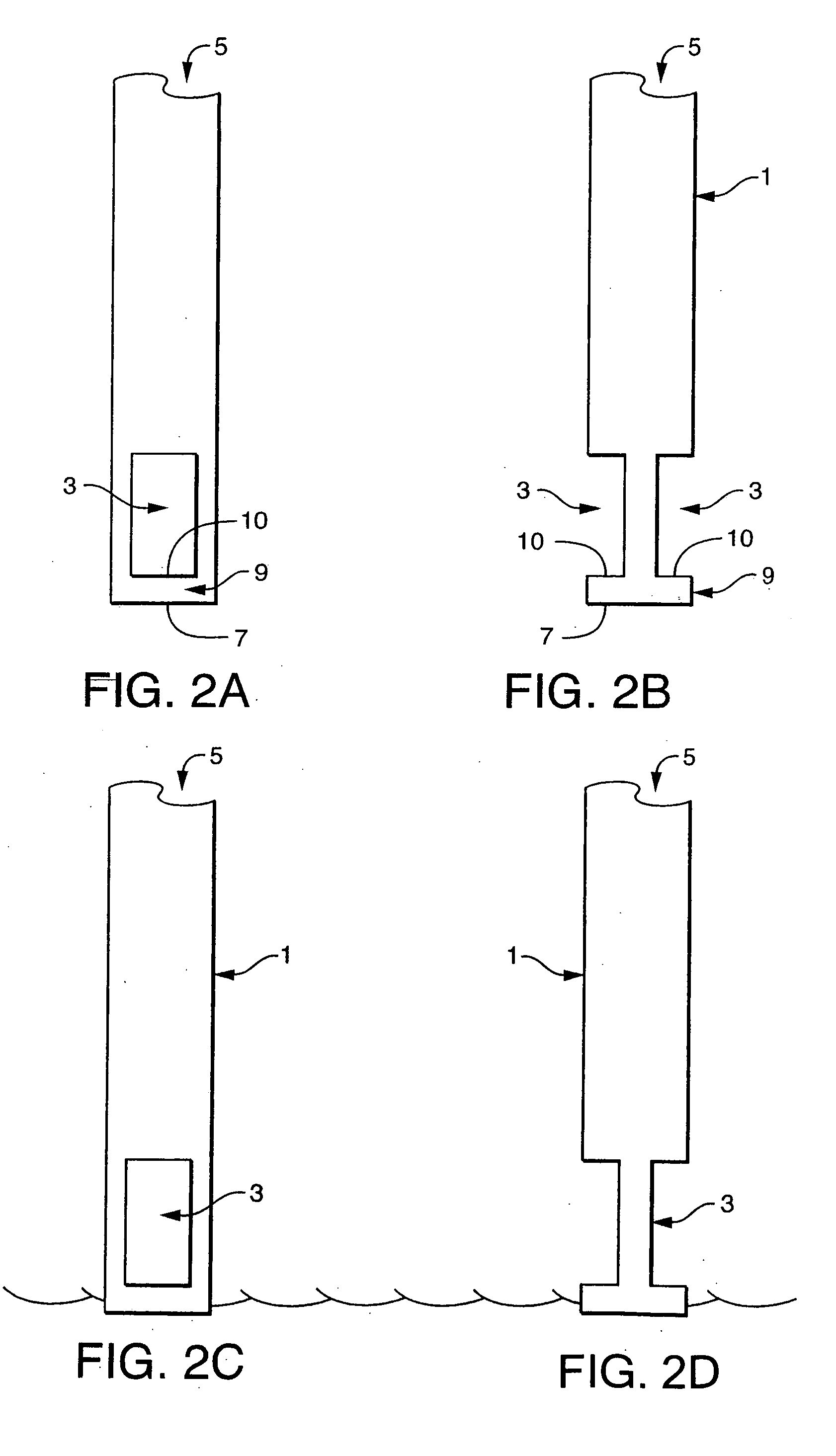

The present invention provides a method for removing an oil contaminant from a surface of an aqueous solution, comprising manually controlling a surface skimmer from a remote location to remove a layer or a batch of an oil contaminant from an oil-aqueous solution mixture by the skimmer, where the aqueous solution is contaminated by the oil as a result of an industrial process. The present invention also provides a system for carrying out the method, which comprises a surface skimmer, a collection means which is preferably a separator, a conduit connecting the skimmer to the collection means in an airtight fashion, and means for creating negative pressure in the skimmer, where the skimmer is capable of manual control from a remote location; in further embodiments, the system further comprises an air filtering means.

Owner:TERRIEN RICHARD J +1

Valve plate matrix raw material component for cycloid hydraulic motor and copper infiltration process thereof

InactiveCN101540526AImprove the quality of copper infiltrationHigh densityManufacturing dynamo-electric machinesHydraulic motorHigh density

The invention relates to a valve plate matrix raw material component for a cycloid hydraulic motor and a copper infiltration process thereof. The valve plate matrix raw material component comprises the following components by the weight percent: 87.3-90.4 of atomized Fe powder of -100 meshes, 7.5-9.5 of Cu powder of -300 meshes, 0.35-0.7 of Ni powder of -250 meshes, 0.7-1.0 of Mo powder of -300 meshes, 0.4-0.8 of carbon powder of -325 meshes, 0.6 of zinc stearate of -325 meshes and 0.05-0.08 of No.20 industrial oil which are sufficiently mixed. Through pressing and molding, the obtained mixture is infiltered and sintered with a copper infiltration agent blank. An obtained product has high density, uniform air-tightness sealing holes and excellent mechanical performance and is suitable for batch production.

Owner:陕西华夏粉末冶金有限责任公司

Liquid state low calorie fat mixed triglyceride

The present invention discloses a method for producing low calorie oil which is liquid at normal temp. by general vegetable oil and adopting ester exchange process. Said invented product has reasonable fatty acid structure, and can provide enough fatty acid required for human body. It can be used as industrial oil and domestic edible oil.

Owner:北京市粮食科学研究院有限公司

Oil well sand washing plugging agent and plugging method

The oil well sand washing and plugging agent is re-compounded with component A of polymer and component B of cross-linking agent. The first recipe includes component A comprising guar gum powder, hydroxyl propyl guar gum powder, tonka bean gum powder, sesbania powder, hydroxyl propyl-hydroxyl methyl sesbania powder or hydroxyl propyl sesbania powder 10-70%, expansion preventing agent 0-10%, emulsifier 0.5-10% and industrial oil 20-60%; and component B comprising organoboron 30-70% and biological enzyme 10-60%. The second recipe includes component A of polyacrylamide latex 30-90% and component B of organoboron 10-70%. The present invention is used for oil well sand washing and plugging, and has simple construction, good operability, and high plugging effect.

Owner:SUNCOO PETROLEUM TECH

Poly(hydroxy thioether) vegetable oil derivatives useful as lubricant additives

InactiveUS7279448B2Expand the marketReduce demandOrganic compound preparationSurface-active detergent compositionsPolymer scienceVegetable oil

A novel class of chemically-modified vegetable oils is prepared by reacting epoxidized triglyceride oils with thiols. The resultant poly(hydroxy thioether) derivatives have utility as antiwear / antifriction additives for environmentally-friendly industrial oils and automotive applications.

Owner:US SEC AGRI +1

Lubricant compositions

ActiveUS7759294B2Improve carrying capacityLiquid carbonaceous fuelsAdditivesCarrying capacityDiluent

Owner:AFTON CHEMICAL

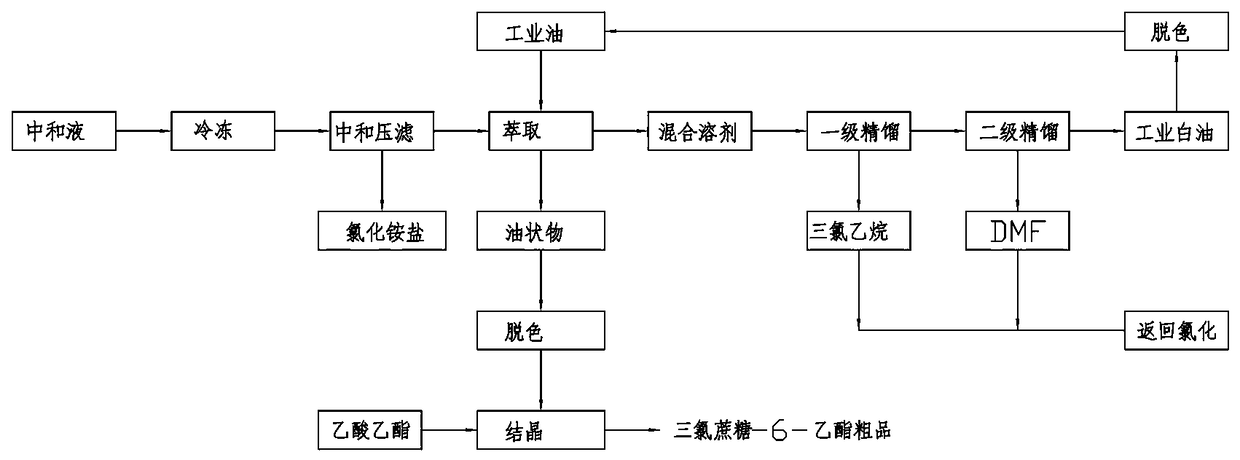

Method for separating solvents after chlorination and neutralization reaction of sucralose

ActiveCN109180748AAvoid lostEasy to separateEsterified saccharide compoundsSugar derivativesEthyl acetateSolvent

The invention relates to a method for separating solvents after a chlorination and neutralization reaction of sucralose. The method comprises the following steps: filtering a neutralized solution obtained after chlorination and neutralization, pumping the filtered neutralized solution into an extraction kettle, adding 10# industrial oil used as an extractant to extract the solvent trichloroethaneand DMF and make the solvents enter a supernatant, carrying out secondary reduced-pressure rectification on the supernatant, respectively separating the trichloroethane and DMF by using a boiling point difference, decolorizing high-boiling point industrial oil obtained after the secondary rectification with activated carbon to make the decolorized high-boiling point industrial oil directly reused,and directly reusing the trichloroethane and DMF obtained after the two-stage rectification in chlorination; and directly adding water to obtained lower oil to dissolve the lower oil, decolorizing and filtering the obtained solution, adding ethyl acetate, and performing freezing crystallization to obtain crude sucralose-6-acetate. The method has the advantages of simplicity, avoiding of the process of adding water to carry away the solvents during solvent recovery in traditional processes, reduction of the solvent recovery difficulty, improvement of the solvent recovery efficiency, energy consumption saving, great reduction of the production cost, and reduction of pollution.

Owner:ANHUI JINGHE IND

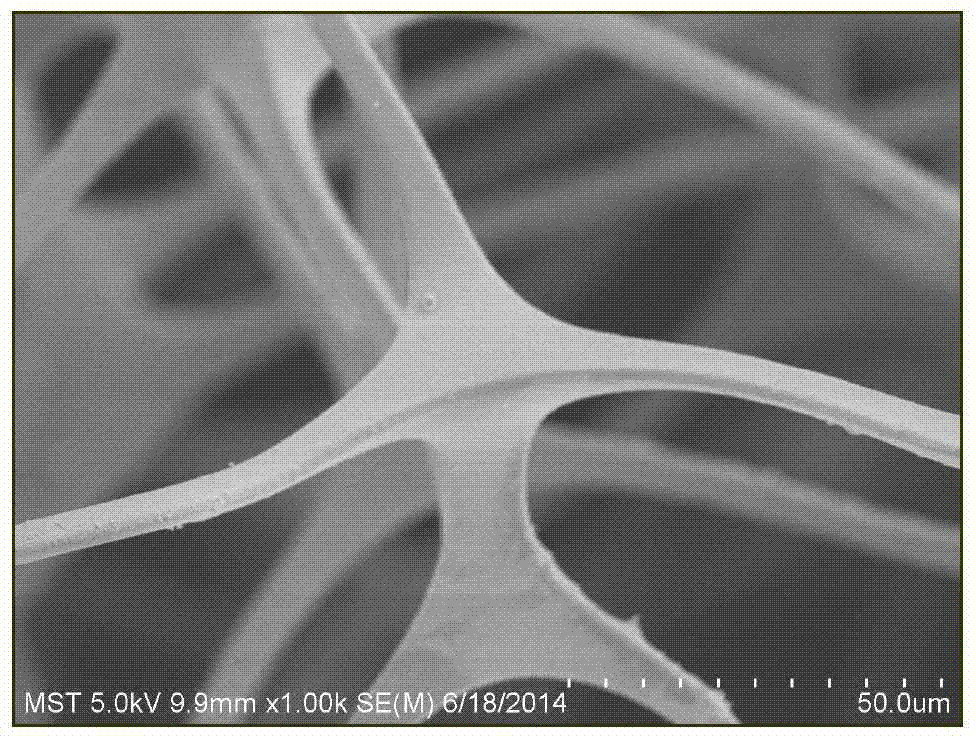

Polyimide nano-fiber aerogel, preparation method thereof and application of aerogel

ActiveCN109731533ALarge oil absorptionReusableLiquid separationColloidal chemistry detailsFiberFiltration

The invention relates to polyimide nano-fiber aerogel, a preparation method thereof and an application of the aerogel. The preparation method includes the steps: providing polyamide acid solution; preparing polyamide acid nano-fibers from the polyamide acid solution by an electrostatic spinning method; dispersing the polyamide acid nano-fibers in liquid, and freeze-drying the liquid containing thepolyamide acid nano-fibers to obtain the polyamide acid nano-fiber aerogel; performing imidization on the polyamide acid nano-fiber aerogel to obtain the polyimide nano-fiber aerogel. The polyimide nano-fiber aerogel has excellent mechanical flexibility, efficient oil-water separation for different oil and organic solvents, antifouling and self-cleaning characteristics and high reusability. A preparation process of the aerogel is simple and easy to implement, and raw materials are rich in source and low in cost. The aerogel can be used for the fields of large-scale separation and purificationof industrial oil and water (oil-water emulsion), large-scale filtration and separation of organic liquid / water and the like.

Owner:BEIJING JIAOTONG UNIV

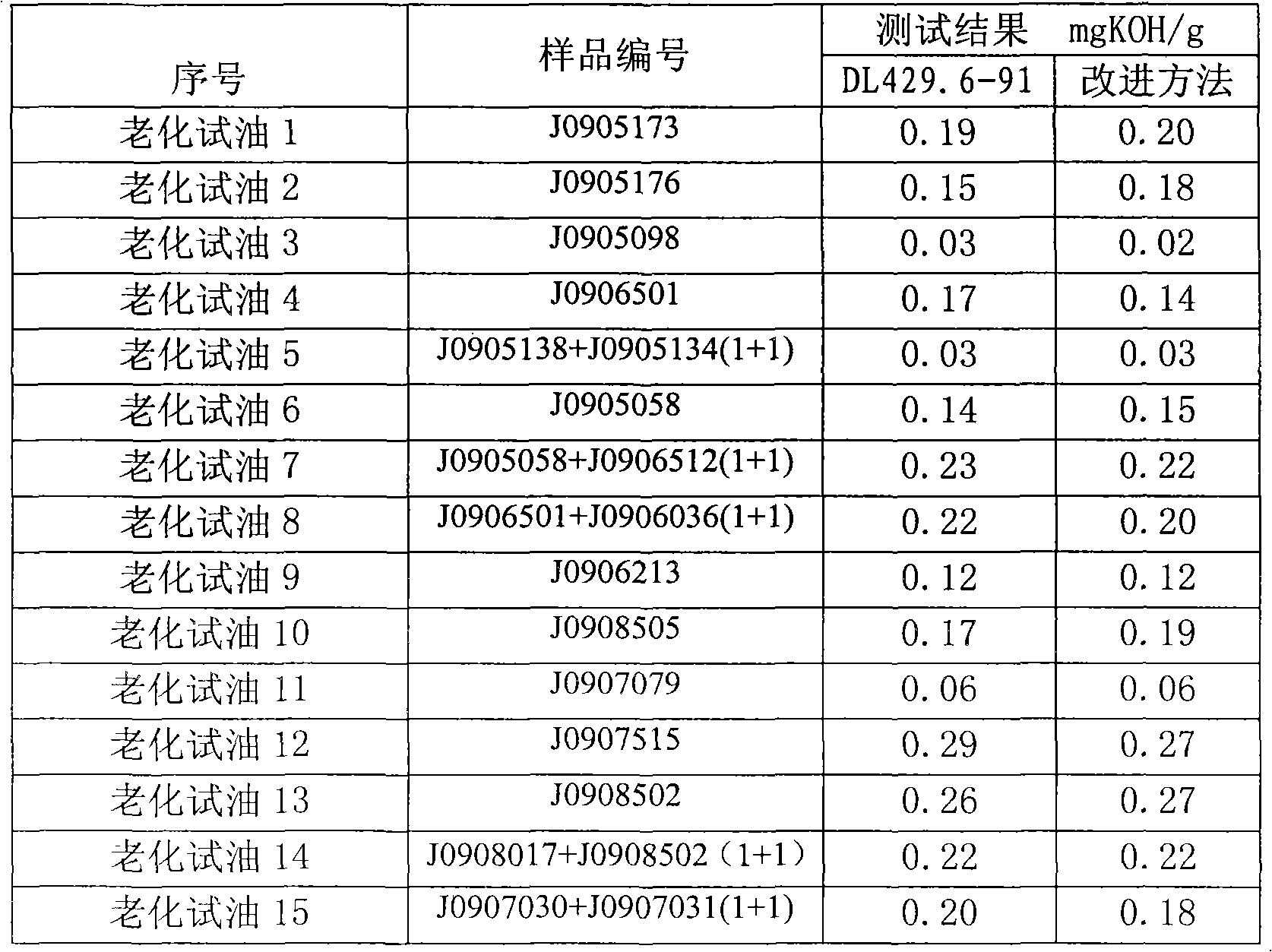

Method for testing aging degree of transformer oil

InactiveCN102033118AImprove consistencyLow toxicityAnalysis using chemical indicatorsChemical analysis using titrationBenzeneSolvent

The invention relates to industrial oil detection, in particular to a method for testing transformer oil. The method for testing the aging degree of the transformer oil comprises the following steps: 1) an oil sample test: accurately weighing 5.0 to 10.0g of aged test oil, adding 50ml of mixed solution of ethanol-petroleum ether, sufficiently and uniformly shaking, adding 0.5ml of alkali blue B indicator, and dripping KOH ethanol solution of which the concentration is 0.05mol / L until the color of the mixed solution is turned into light red; 2) a blank solvent test; and 3) calculation. In the method, benzene serving as solvent is abandoned, so the toxicity of the aging test is reduced, and the operation is simple and convenient.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

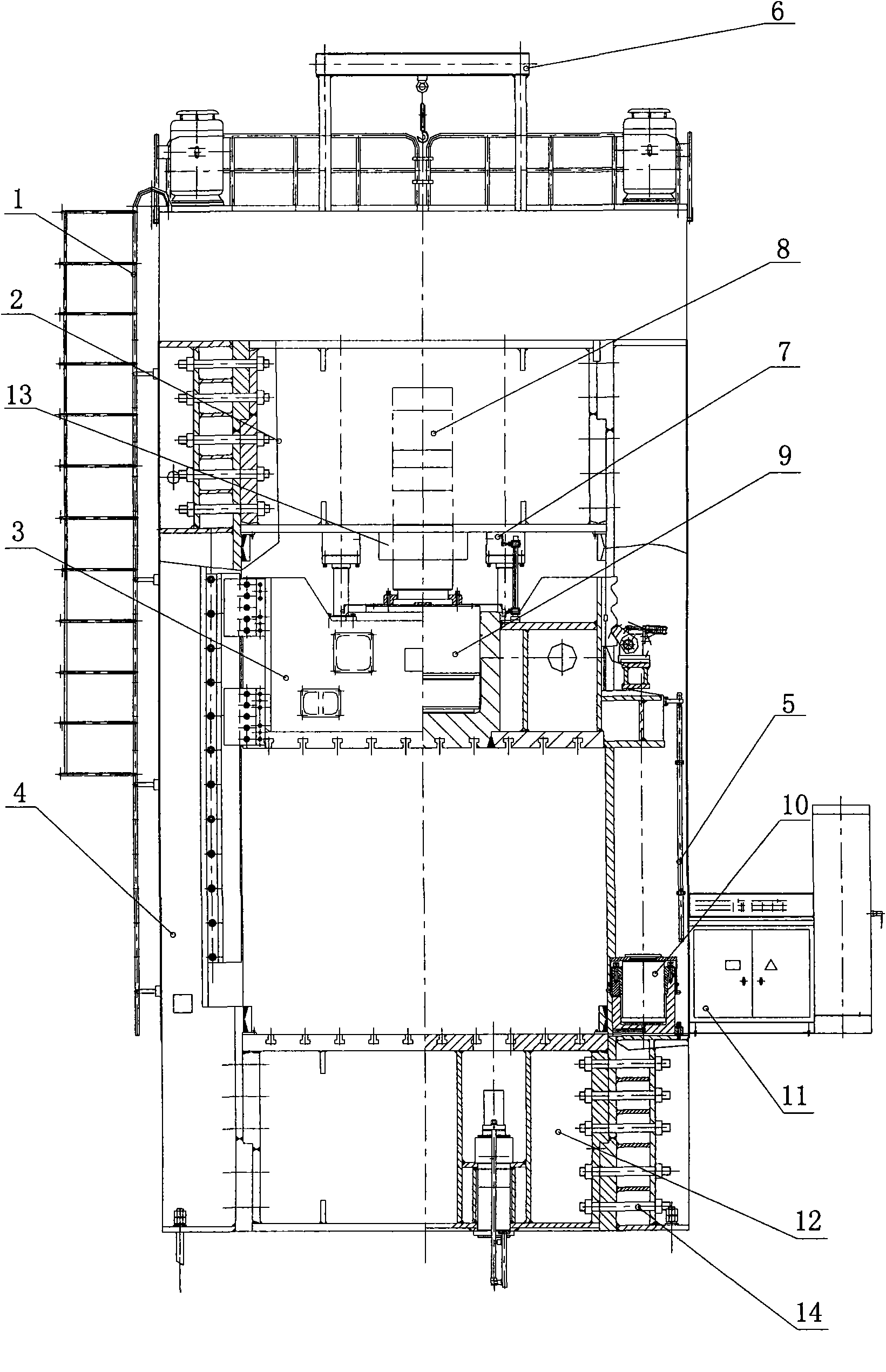

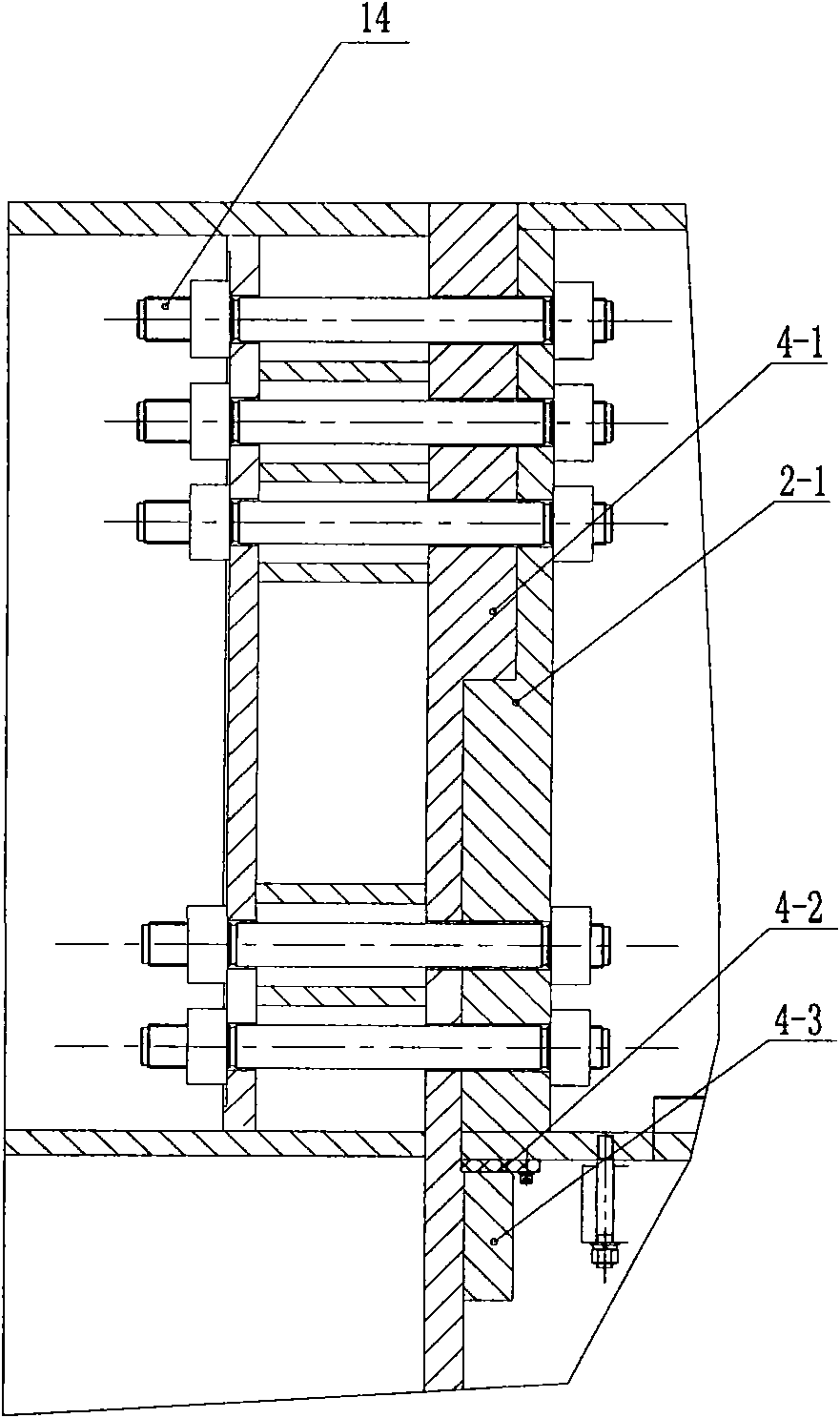

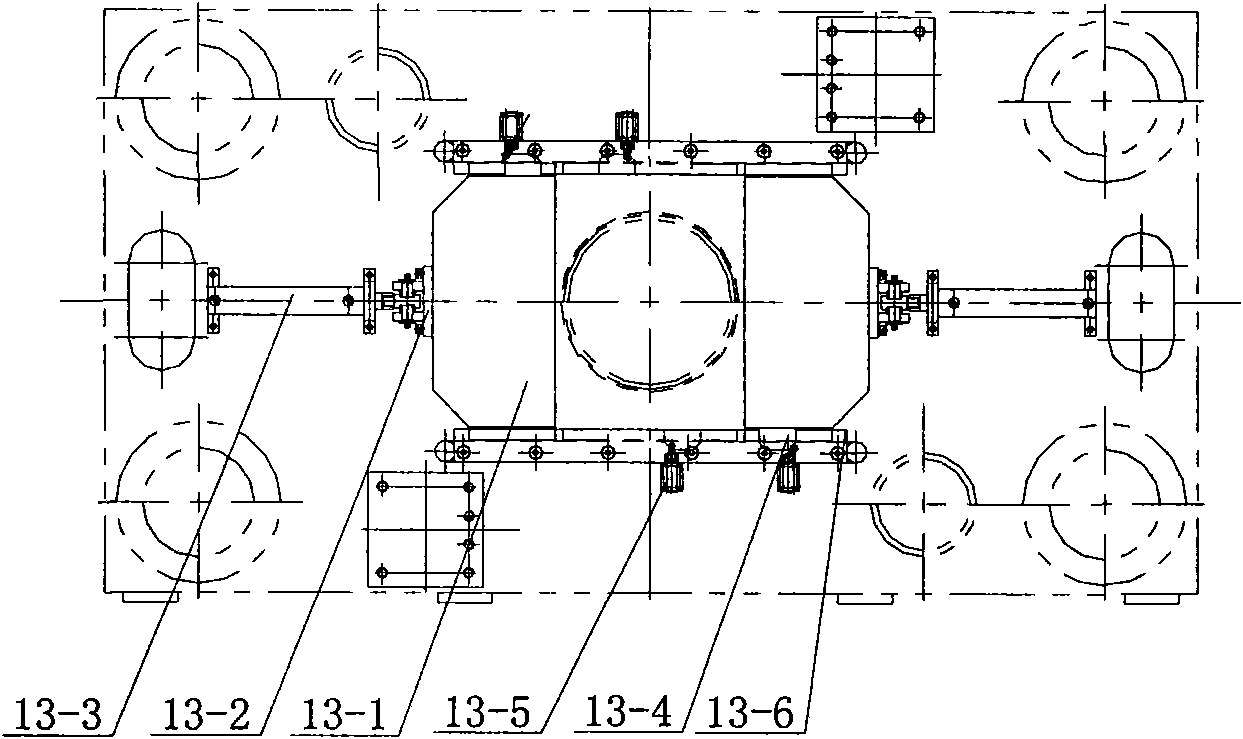

Combined framewrok non pull rod type glass product hydraulic press with adjustable stroke

The invention relates to a combined framework non pull rod type glass product hydraulic press with adjustable stroke, comprising a stand platform, a supporting post, an upper transverse beam, a main working oil cylinder, a slide block, a lower transverse beam and an electric control box which is mounted at the side of a machine body. The combined framework non pull rod type glass product hydraulicpress with adjustable stroke is characterized in that the internal side of the supporting post is provided with a shoulder; the upper transverse beam and the lower transverse beam are provided with shoulders, and the upper transverse beam and the lower transverse beam are fastened with the shoulder of the supporting post through the shoulders and bolt fastening components to form a gantry framework type machine body structure; and the lower plane of the upper transverse beam is provided with a gate device. The combined framework non pull rod type glass product hydraulic press with adjustablestroke has simple and reasonable structure as well as convenient installation and connection, lightens of the weight of a main machine, saves large amount of steel, greatly reduces the manufacture cost of the hydraulic press as the main working oil cylinder adopts a cylinder action type slide block structure inside which a plunger is totally mounted to result in the reduction of the length of an oil cylinder by approximate 4 / 5 and reduction of oil consumption of the hydraulic press by at least 4 / 5. The total power and the pump energy of the electric motor of the hydraulic press are below 50 percent of those of the traditional hydraulic press, the electric energy and industrial oil are obviously saved, and the production cost can be reduced for users.

Owner:TIANJIN TIANDUAN PRESS CO LTD

High-temperature resistance oil product oxidization resistance paint and preparation method thereof

InactiveCN101805530AHigh hardnessHigh densityFireproof paintsAnti-corrosive paintsWater dispersibleOxidation resistant

The invention provides high-temperature resistance oil product oxidization resistance paint and a preparation method thereof, which belong to the field of functional paint particularly applied to the aspect of oil product oxidation resistance under the condition of high temperature. Major ingredients of the paint comprise water-dispersible nanometer aluminum oxide, pigment, filling materials, potassium titanate whiskers, nanometer silver grains and one or two kinds of materials in methyltrimethoxysilane and methyl triethoxysilane. A coating layer prepared by the invention has the quality of the enamel surface, has advantages of fire resistance, high temperature resistance, high rigidity, high compactness and good weather resistance, and is completely harmless to human bodies. In addition, the invention can be used for effectively slowing down the oil product oxidation process. The edible oil can still maintain the nutritive and health quality through being placed in a high-temperature environment for a long time. The service life of the industrial oil can be prolonged.

Owner:SHANGHAI EXCILON NEW MATERIALS

Washable super-hydrophobic cotton fabric as well as preparation method and applications thereof

ActiveCN103952912ANon-stickyExcellent superhydrophobic propertiesLiquid separationVegetal fibresGlycidyl ethersOil water

The invention discloses a washable super-hydrophobic cotton fabric as well as a preparation method and applications thereof, which belong to the technical field of functional materials. The washable super-hydrophobic cotton fabric is obtained through the steps of washing a cotton fabric, and then sequentially soaking the cotton fabric in an acetone solution of epoxy resin, an aqueous solution of polyethyleneimine, an epoxidized silicon dioxide aqueous solution, and an n-hexane solution of stearic acid for treatment. The preparation method comprises the following detailed steps: 1. washing the cotton fabric; 2. soaking the cotton fabric in an epoxy resin solution; 3. soaking the cotton fabric in a polyethyleneimine solution; 4. soaking the cotton fabric in a modified sub-micro silicon dioxide aqueous solution in which 3-glycidyl ether oxyl propyl trimethoxysilane is dispersed; 5. repeating the steps 3 and 4; 6. soaking the cotton fabric in a stearic acid hydrophobically-modified solution and drying the cotton fabric. The washable super-hydrophobic cotton fabric is used for oil-water separation. The preparation method is simple in technology, low in cost, short in period and low in energy consumption and does not need special complicated equipment; the prepared super-hydrophobic cotton fabric is washable and capable of rapidly separating an oil-water mixture and can be applied to the fields of industrial oil-water separation and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

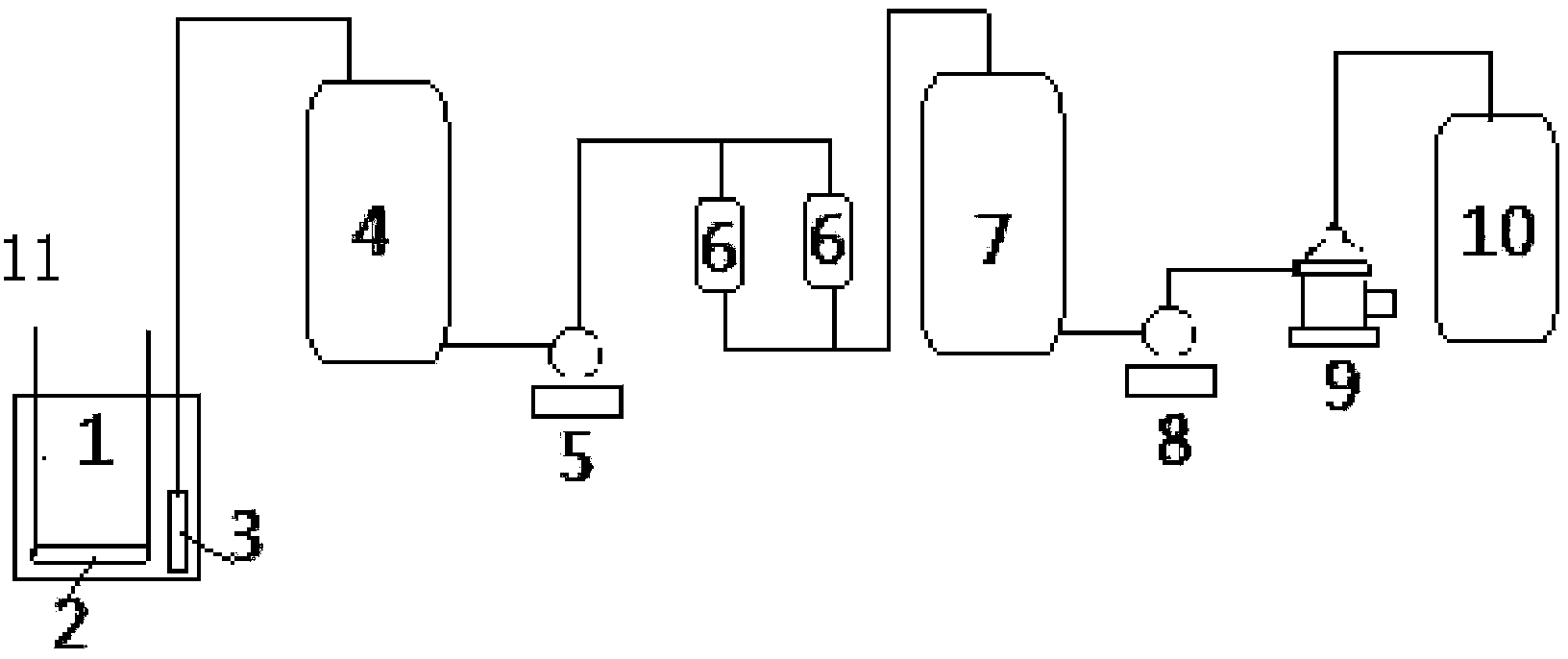

Process and system for recycling kitchen waste grease

InactiveCN104293488ASimple processLess investmentFatty oils/acids recovery from wasteFatty-oils/fats refiningOil and greaseOil water

The invention provides a process and a system for recycling kitchen waste grease. The system comprises a waste grease collecting tank, a grease preheating tank, a grease conveying pump, a filter, a grease heating tank, a centrifugal machine and a vapor source, wherein a heating coiler and the grease conveying pump are arranged in the waste grease collecting tank; the heating coiler is connected to the vapor source by virtue of a pipeline; the grease conveying pump is connected to the grease preheating tank by virtue of a pipeline; a bottom outlet of the grease preheating tank is connected to the filter by virtue of a pipeline and the grease conveying pump; the filter is connected to the grease heating tank by virtue of a pipeline; the bottom outlet of the grease heating tank is connected to the centrifugal machine by virtue of a pipeline and the grease conveying pump; and the centrifugal machine is connected to an industrial grease storage tank by virtue of a pipeline. According to the process and the system disclosed by the invention, the kitchen waste grease is heated and molten, and then heated and stirred, then, insoluble impurities of the kitchen waste grease are filtered out, and then the kitchen waste grease is heated and stirred to perform oil-water separation to obtain commercial grease. The process disclosed by the invention is simple, small in investment, high in efficiency and beneficial to large-scale production.

Owner:武汉百信环保能源科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com