Polyimide nano-fiber aerogel, preparation method thereof and application of aerogel

A nanofiber and polyimide technology, applied in the field of polyimide nanofiber aerogel and its preparation, can solve the problems of polyimide aerogel application without reports of substantive content, and achieve high Effect of reusability, high reusability, rich source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention provides a kind of preparation method of polyimide nanofiber airgel, and this preparation method comprises the following steps:

[0045] (1) polyamic acid solution is provided;

[0046] The polyamic acid solution used in the present invention can be prepared by using solid polyamic acid and a solvent that can dissolve polyamic acid, or can be prepared by polymerizing dianhydride monomers and diamine monomers. The dianhydride monomer can be selected from any one or more of pyromellitic dianhydride, biphenyltetracarboxylic dianhydride, benzophenone tetraacid dianhydride, diphenyl ether tetraacid dianhydride, and the diamine monomer can be Select diaminodiphenyl ether, 4,4'-diphenyl ether diamine, p-phenylenediamine, 2-(4-aminophenyl)-5-aminobenzoxazole, 2-(4-aminophenyl) -Any one or more of 5-aminobenzimidazole, m-phenylenediamine and 4,4',-diaminobenzoanilide. Of course, other dianhydride monomers and / or diamine monomers that can be polymerized to produce...

Embodiment 1

[0081] Step 1: dissolving diamine monomer and dianhydride monomer in dimethylacetamide, and obtaining 25wt% polyamic acid solution by polymerization;

[0082] Step 2: Electrospinning is used to spin the polyamic acid solution into polyamic acid nanofibers with a diameter of 500nm; the parameters of the electrospinning equipment are voltage 20kV, distance 20cm, and needle No. 19;

[0083] Step 3: the polyamic acid nanofibers are evenly dispersed in the aqueous solution, the mass fraction of the polyimide nanofiber aqueous solution is 1 wt%, and freeze-dried to obtain the polyamic acid nanofiber airgel;

[0084] Step 4: imidize the polyamic acid nanofiber airgel at 350° C. for 1 hour in a nitrogen atmosphere to obtain a hydrophobic superelastic polyimide nanofiber airgel.

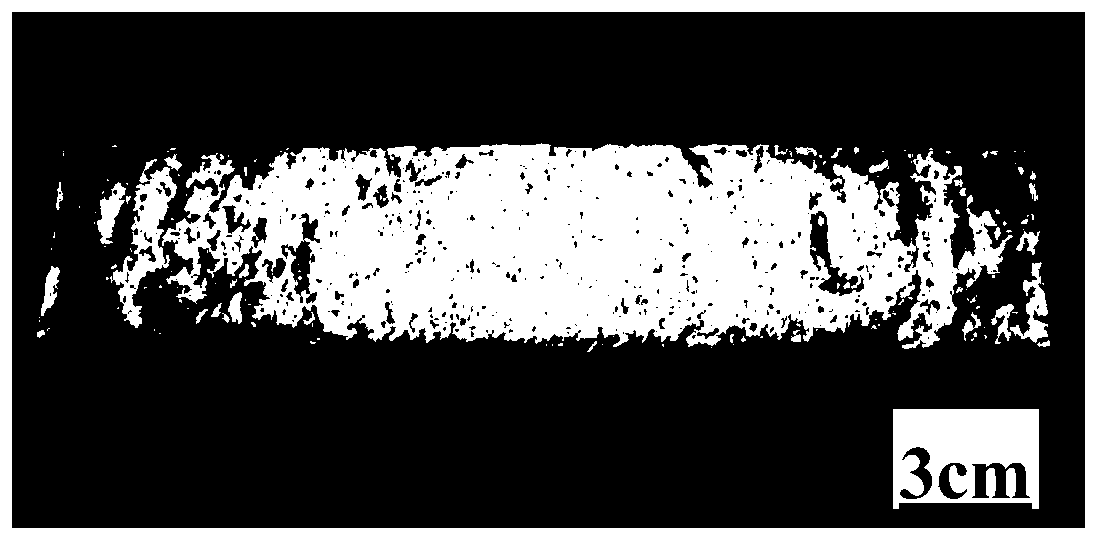

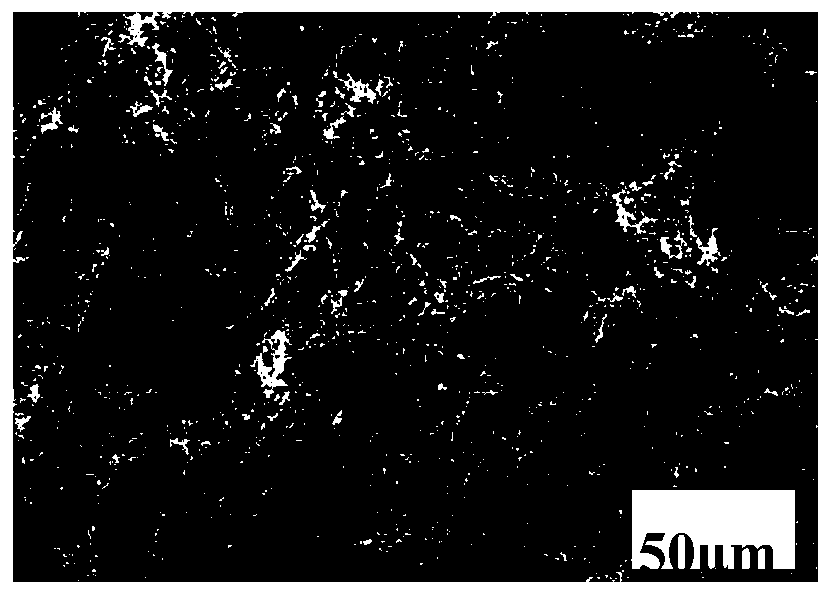

[0085] figure 1 with figure 2 A photograph of the material prepared by this method is shown. image 3 with Figure 4 SEM image of the material prepared for this method. Figure 5 Water contact angle plo...

Embodiment 2

[0089] Step 1: dissolving diamine monomer and dianhydride monomer in dimethylacetamide to prepare a 15wt% polyamic acid solution;

[0090] Step 2: Use electrospinning equipment to spin the polyamic acid solution into polyamic acid nanofibers with a diameter of about 500nm; the parameters of the electrospinning equipment are voltage 20kV, distance 20cm, and needle No. 19;

[0091] Step 3: the polyamic acid nanofibers are uniformly dispersed in the aqueous solution, the mass fraction of the polyimide nanofiber aqueous solution is 1 wt%, and the polyamic acid nanofiber airgel is obtained by freeze-drying;

[0092] Step 4: imidize the polyamic acid nanofiber airgel at 350° C. for 1 hour in a nitrogen atmosphere to obtain a hydrophobic superelastic polyimide nanofiber airgel.

[0093] The results showed that when the concentration of the polyamic acid solution was 15wt%, the diameter of the polyamic acid nanofibers prepared by electrospinning decreased, and the compressive strength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com