Method for preparing TiO2 raw material for chlorination process from titanium-rich fine powder

A fine powder, chlorination technology, applied in the direction of titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of small particle growth, insufficient reaction, layering phenomenon, etc., and achieve short process flow and reaction time. , The effect of reducing the extrusion molding process and reducing the batching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

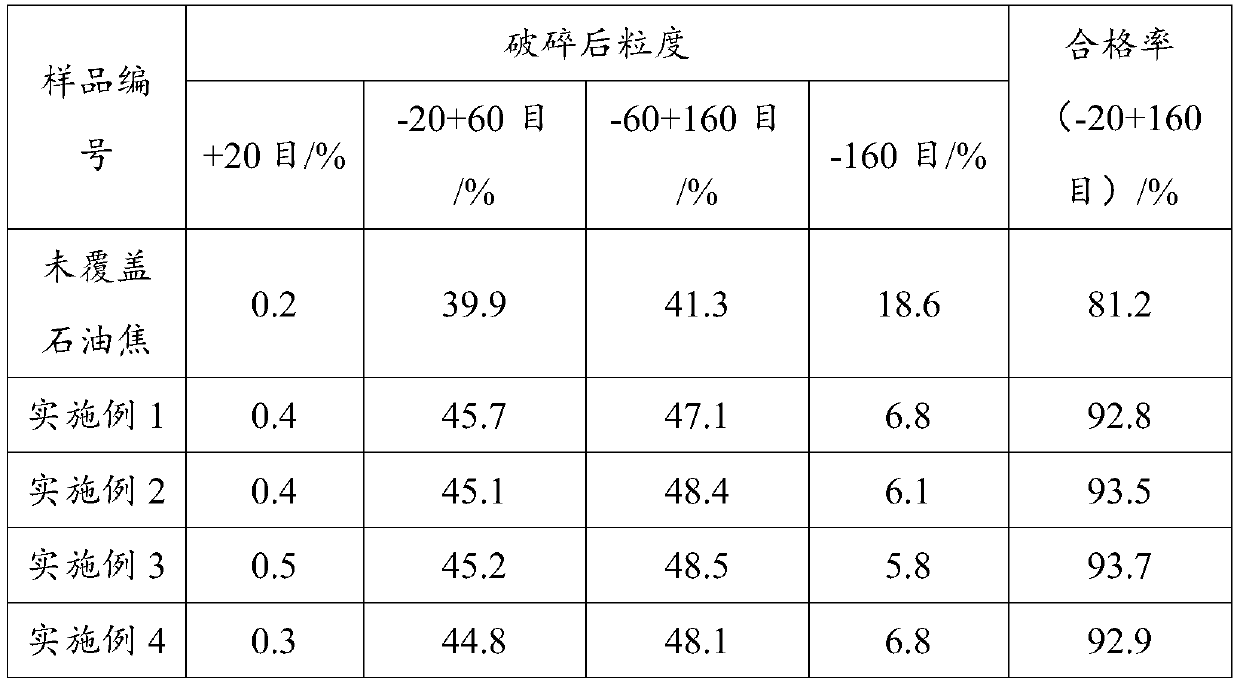

Embodiment 1

[0038] 1. Take low-concentration titanium liquid and hydrolyze it to prepare titanium-rich fine powder in the production process of titanium-rich materials, add 5% solid organic binder coal tar and 6% petroleum coke, and mix evenly at room temperature;

[0039] 2. Take the above-mentioned mixed materials in the hopper, cover the surface evenly with a layer of petroleum coke, the thickness of the petroleum coke is 1.5mm, and carry out low-temperature coking at 380°C for 4 hours;

[0040] 3. The material after low-temperature coking is crushed to a qualified particle size (20-60 mesh) by a roller mill, and the crushed material is subjected to high-temperature coking at 1000°C for 50 minutes, and after re-screening, chlorine with a particle size of 20-160 mesh can be obtained. Chemical method raw material, calculated yield, reaches 92.8%.

Embodiment 2

[0042] 1. Take low-concentration titanium liquid and hydrolyze it to prepare titanium-containing fine powder in the production process of titanium-rich materials, add a certain amount of 20% solid organic binder petroleum pitch and 18% petroleum coke, and mix evenly at room temperature;

[0043] 2. Take the above-mentioned mixed materials in the hopper, cover the surface evenly with a layer of petroleum coke, the thickness of the petroleum coke is 1.2mm, and carry out low-temperature coking at 410°C for 3 hours;

[0044] 3. The material after low-temperature coking is crushed to a qualified particle size (20-60 mesh) by a double-roller mill, and the crushed material is subjected to high-temperature coking at 900°C for 60 minutes. After re-screening, chlorine with a particle size of 20-160 mesh can be obtained. Chemical method raw material, calculated yield, reaches 93.5%.

Embodiment 3

[0046] 1. Take low-concentration titanium liquid and hydrolyze it to prepare titanium-containing fine powder in the production process of titanium-rich materials, add a certain amount of 15% solid organic binder coal tar pitch and 12% petroleum coke, and mix evenly at room temperature;

[0047] 2. Take the above-mentioned mixed materials in the hopper, cover the surface evenly with a layer of petroleum coke, the thickness of the petroleum coke is 1mm, and carry out low-temperature coking at 400 ° C for 3.5 hours;

[0048] 3. The material after low-temperature coking is crushed to a qualified particle size (20-60 mesh) by a double-roll mill, and the crushed material is subjected to high-temperature coking at 1100°C for 40 minutes, and after re-screening, chlorine with a particle size of 20-160 mesh can be obtained. Chemical method raw material, calculated yield, reaches 93.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com