Patents

Literature

8315results about How to "Closely connected" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

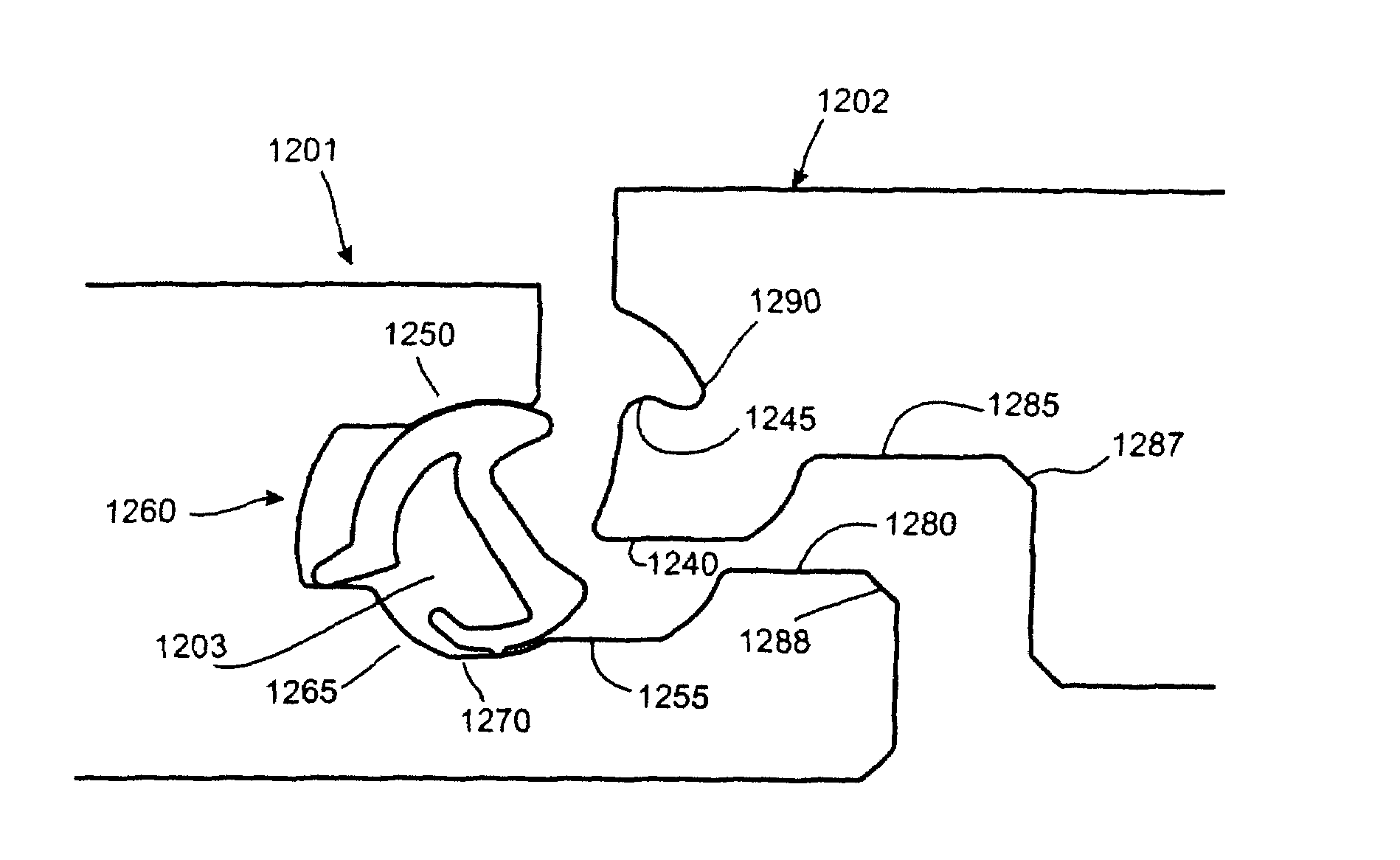

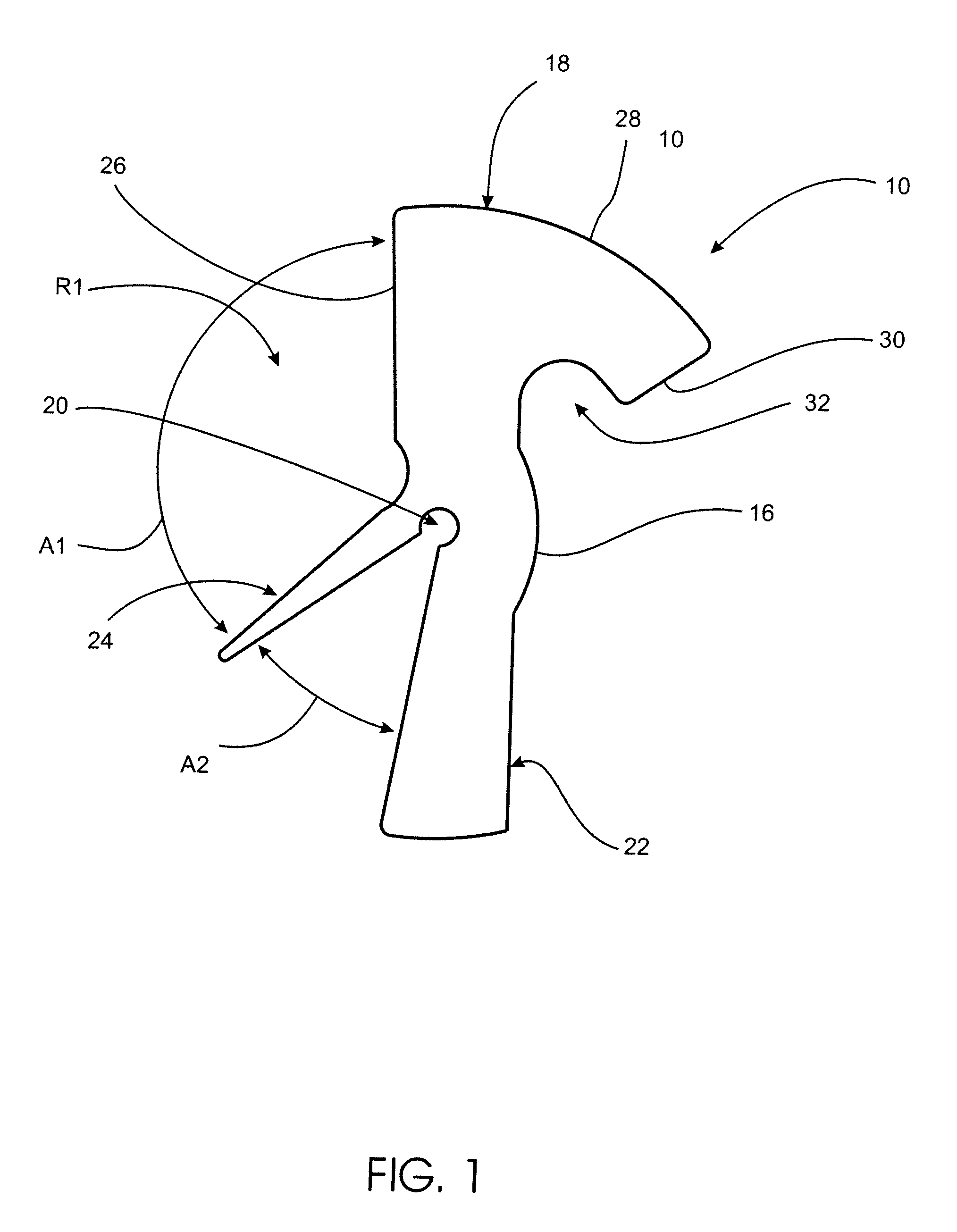

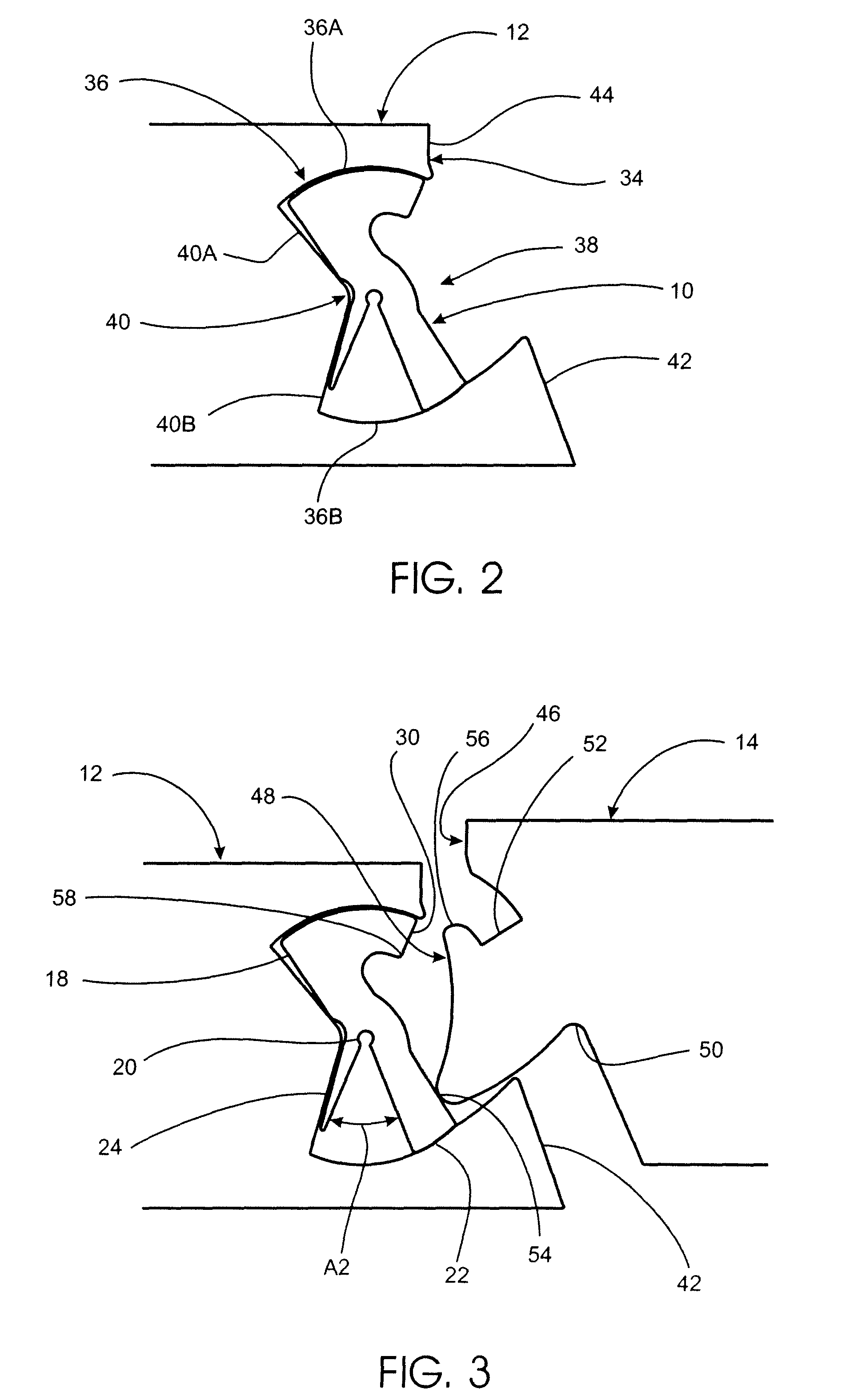

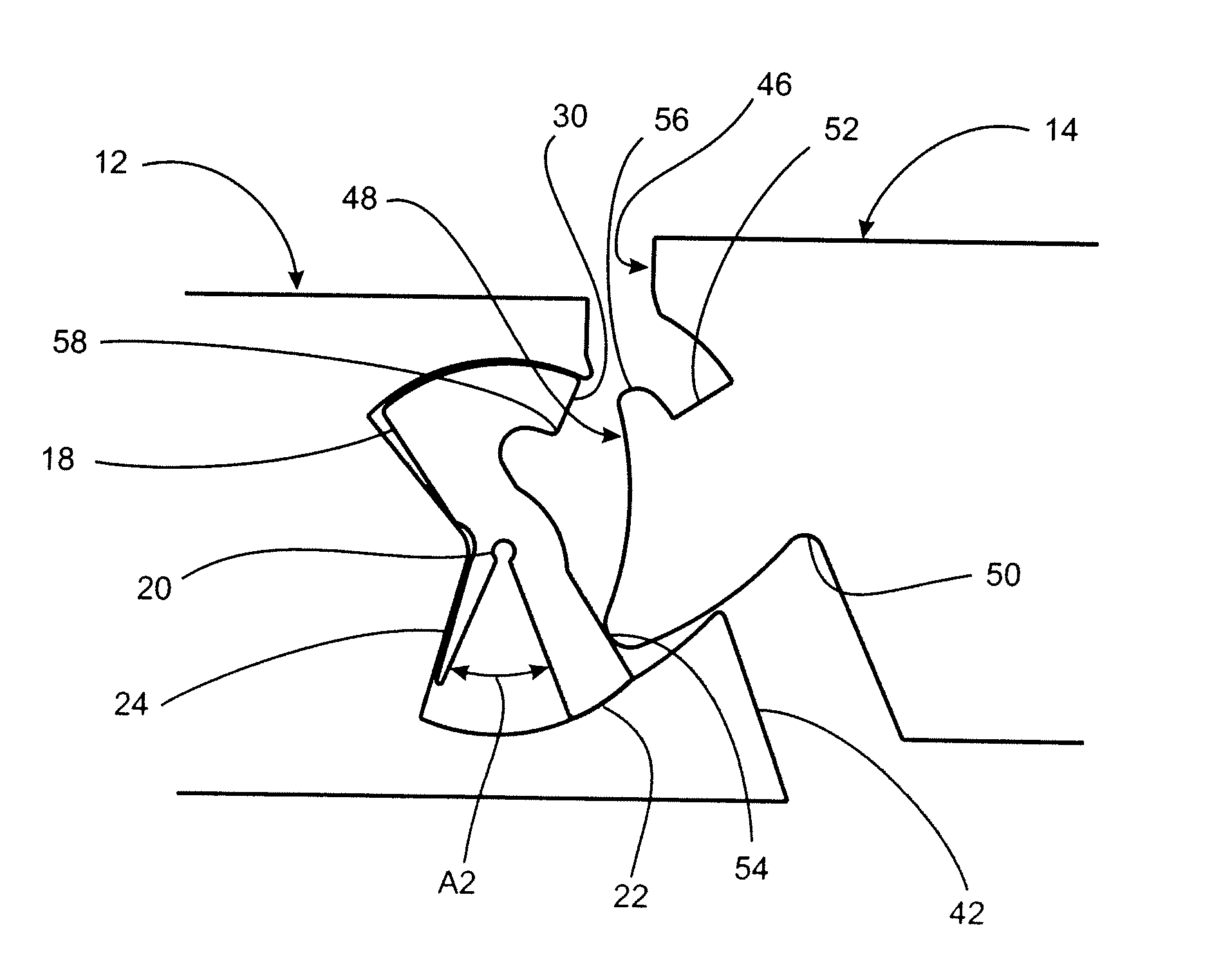

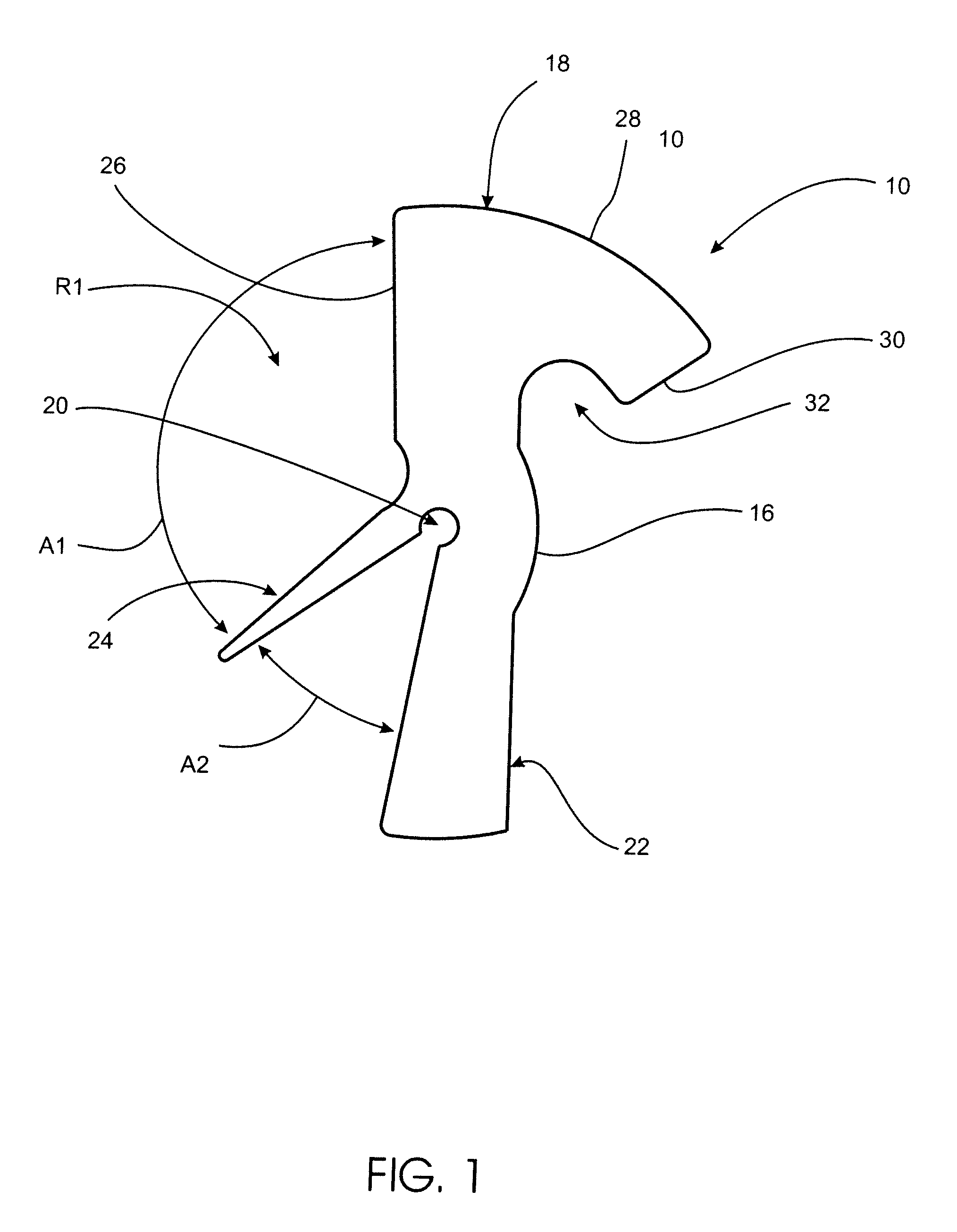

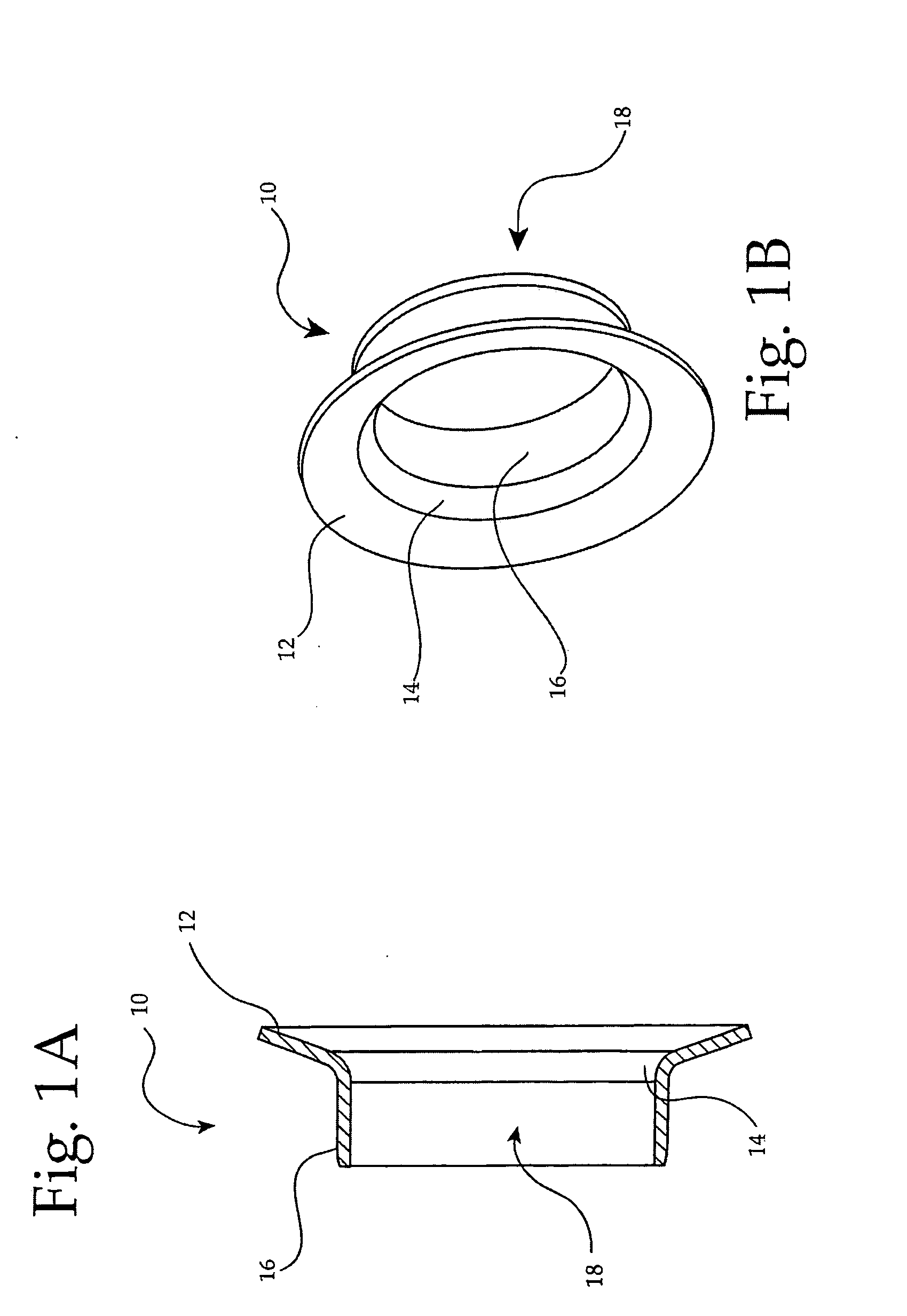

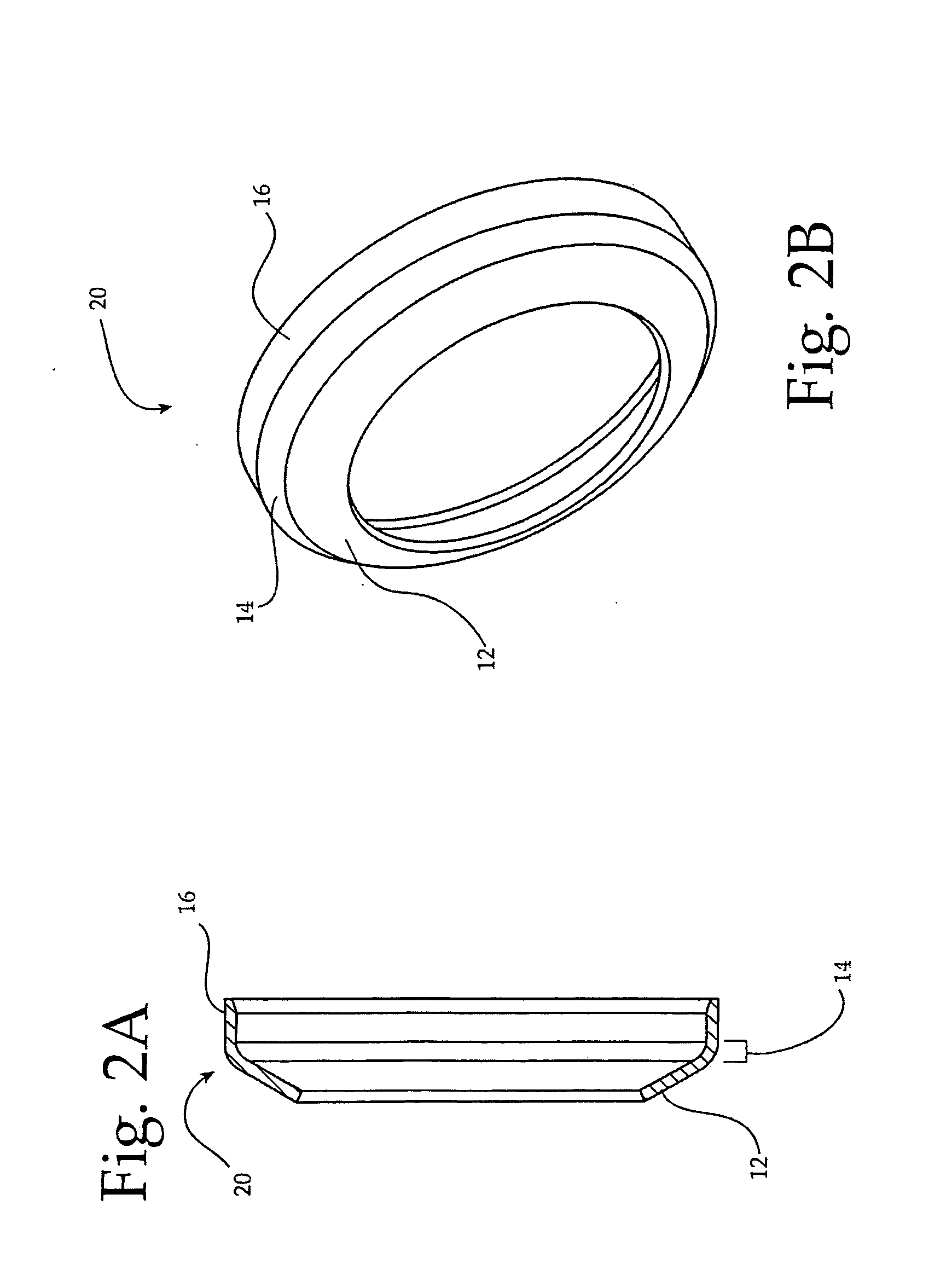

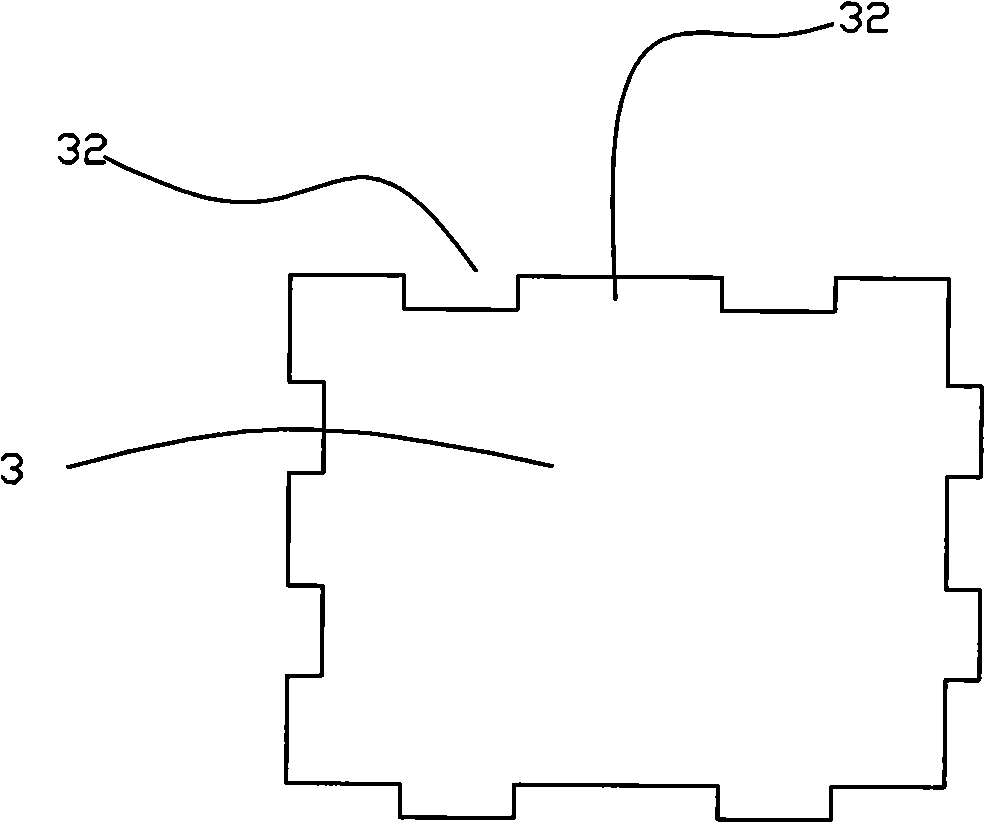

Flooring system

A joint for connecting two adjacent flooring panels together in a substantially vertical manner includes a rotatable locking member made of plastic, metal or another resilient material. The rotatable locking member is located within a groove or opening of one flooring panel and the second flooring panel has a tongue shaped to mate with the rotatable locking member. Upon installation, the rotatable member rotates and locks around the back of the tongue via a groove above the tongue. The rotatable locking member includes a resilient arm which is bent away from its initial rest position upon installation, so that when the rotatable locking member locks onto the tongue, the resilient arm is bent providing a biasing force which holds the panel securely in position.

Owner:INNOVARIS

Flooring system

A joint for connecting two adjacent flooring panels together in a substantially vertical manner includes a rotatable locking member made of plastic, metal or another resilient material. The rotatable locking member is located within a groove or opening of one flooring panel and the second flooring panel has a tongue shaped to mate with the rotatable locking member. Upon installation, the rotatable member rotates and locks around the back of the tongue via a groove above the tongue. The rotatable locking member includes a resilient arm which is bent away from its initial rest position upon installation, so that when the rotatable locking member locks onto the tongue, the resilient arm is bent providing a biasing force which holds the panel securely in position.

Owner:INNOVARIS

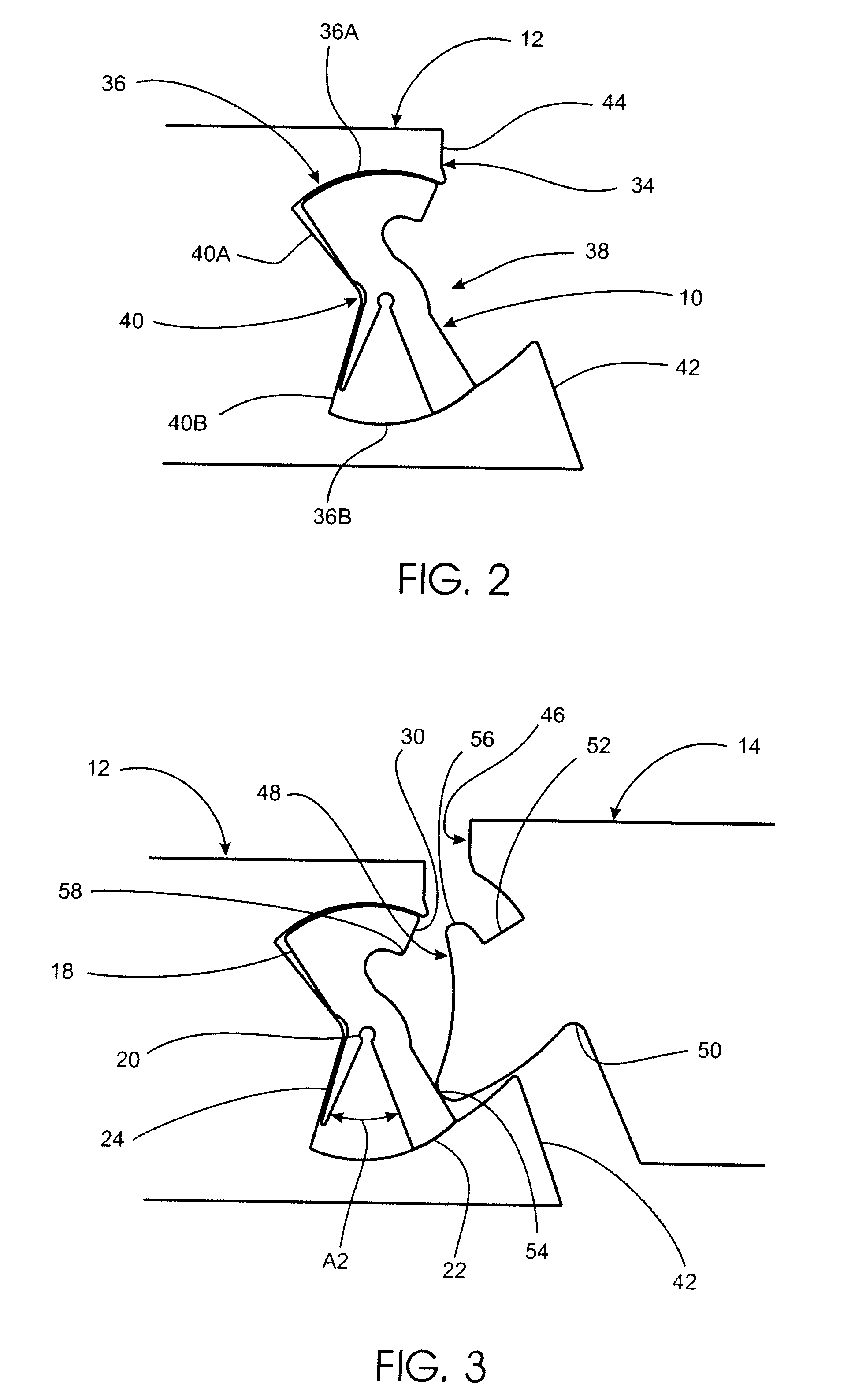

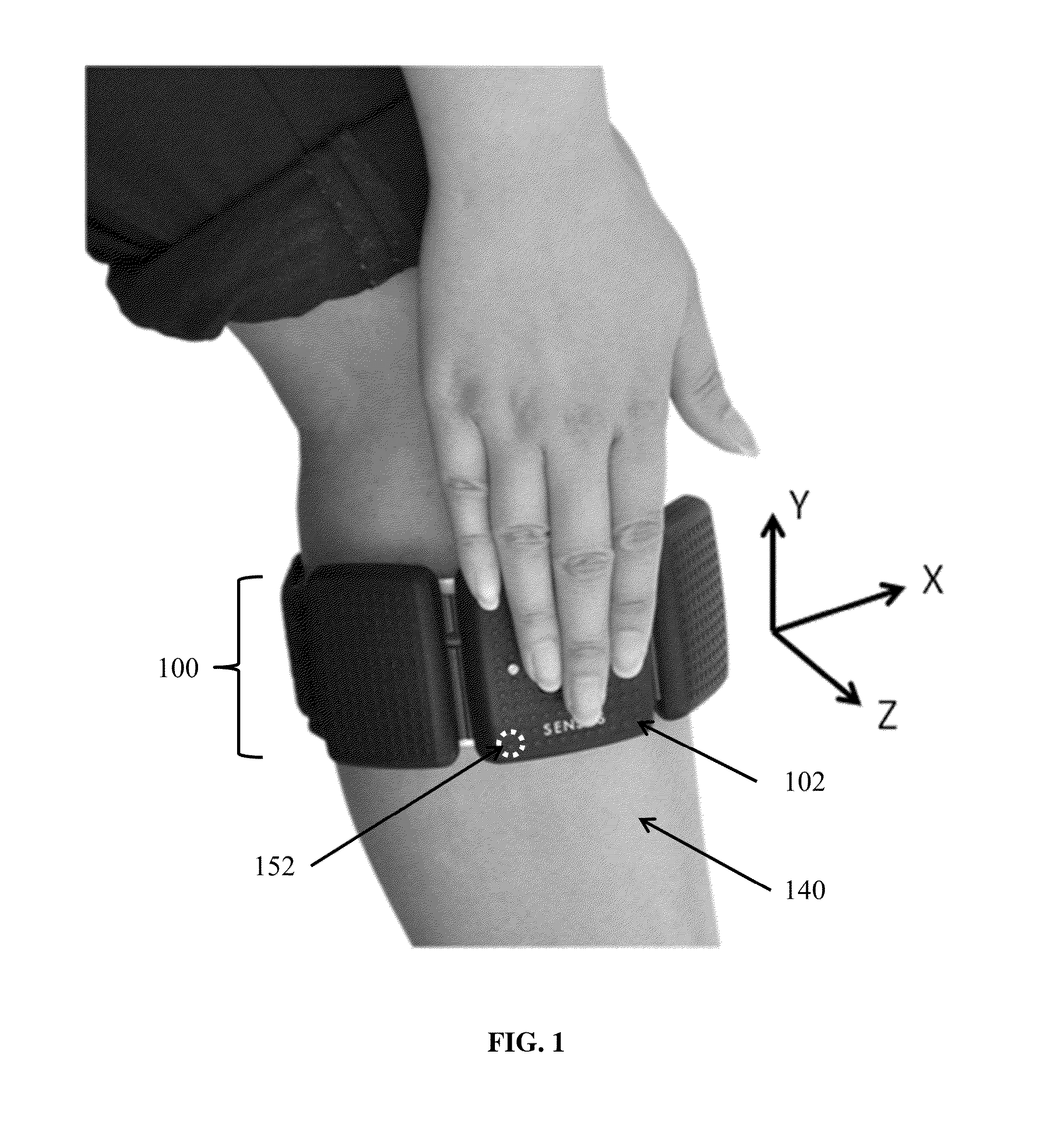

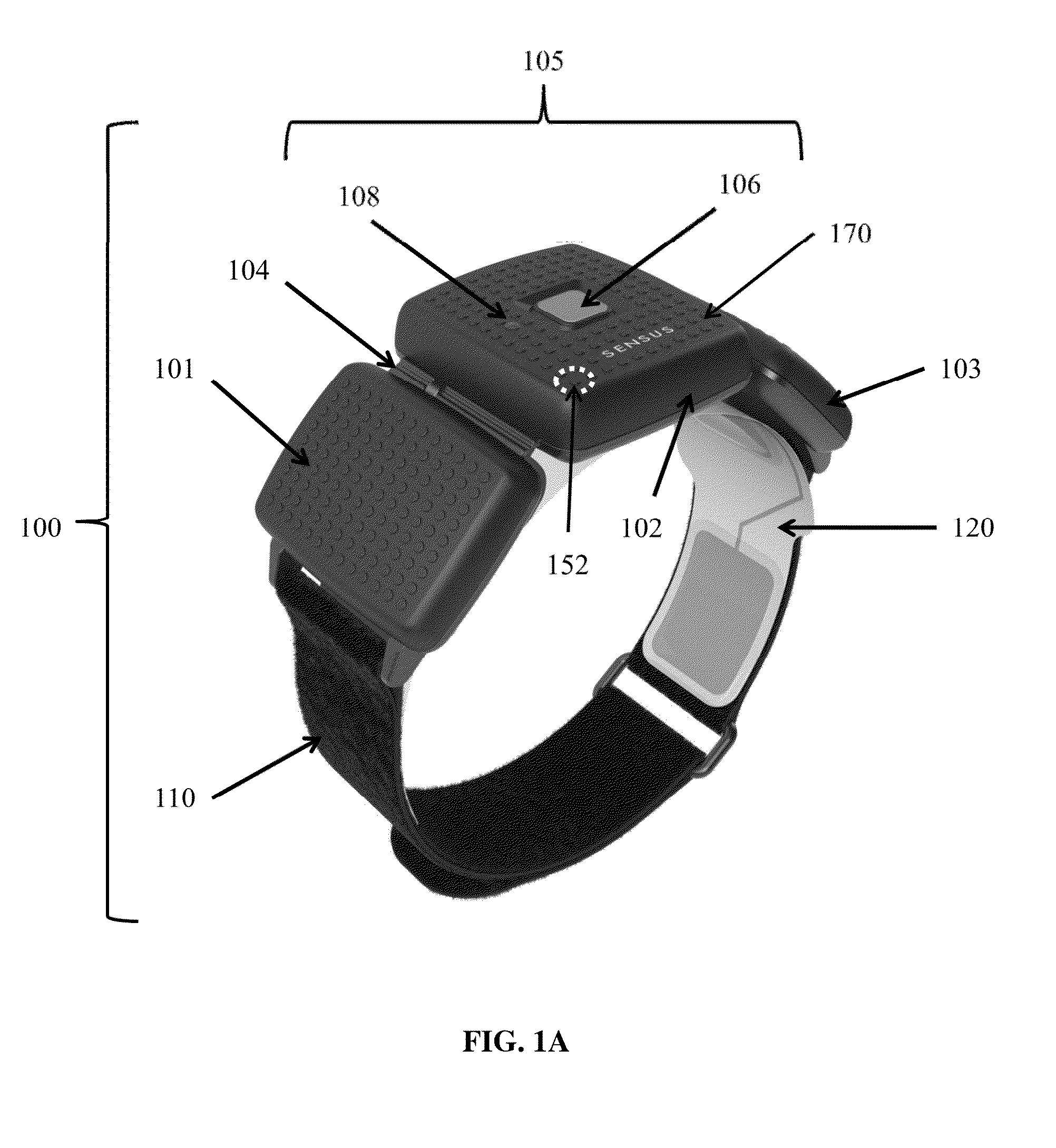

Transcutaneous electrical nerve stimulator with user gesture detector and electrode-skin contact detector, with transient motion detector for increasing the accuracy of the same

ActiveUS20140296935A1Eliminating “ false ” detectionClosely connectedElectrotherapyInertial sensorsElectricityMotion detector

Apparatus for transcutaneous electrical nerve stimulation in a user, the apparatus comprising:a housing;stimulation means carried by the housing for electrically stimulating at least one nerve;a pair of electrodes releasably mounted to the housing and connectable to the stimulation means for electrical stimulation of the at least one nerve;monitoring means for monitoring user gesture, electrode-skin contact integrity and transient motion;analysis means for analyzing the output of the monitoring means for determining user gesture, electrode-skin contact integrity and transient motion; andcontrol means for controlling the output of the stimulation means in response to the determined user gesture, electrode-skin contact integrity and transient motion.

Owner:NEUROMETRIX INC

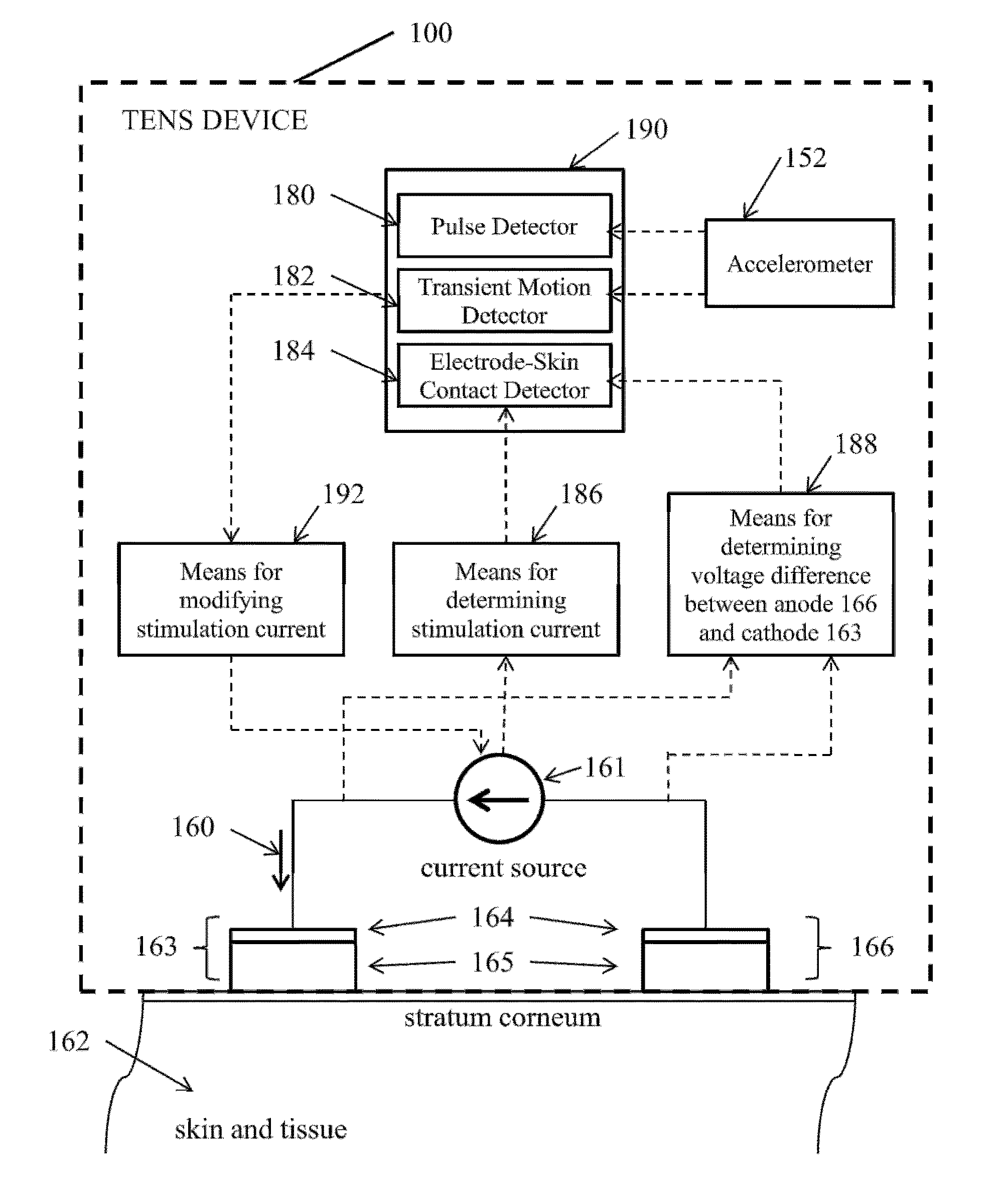

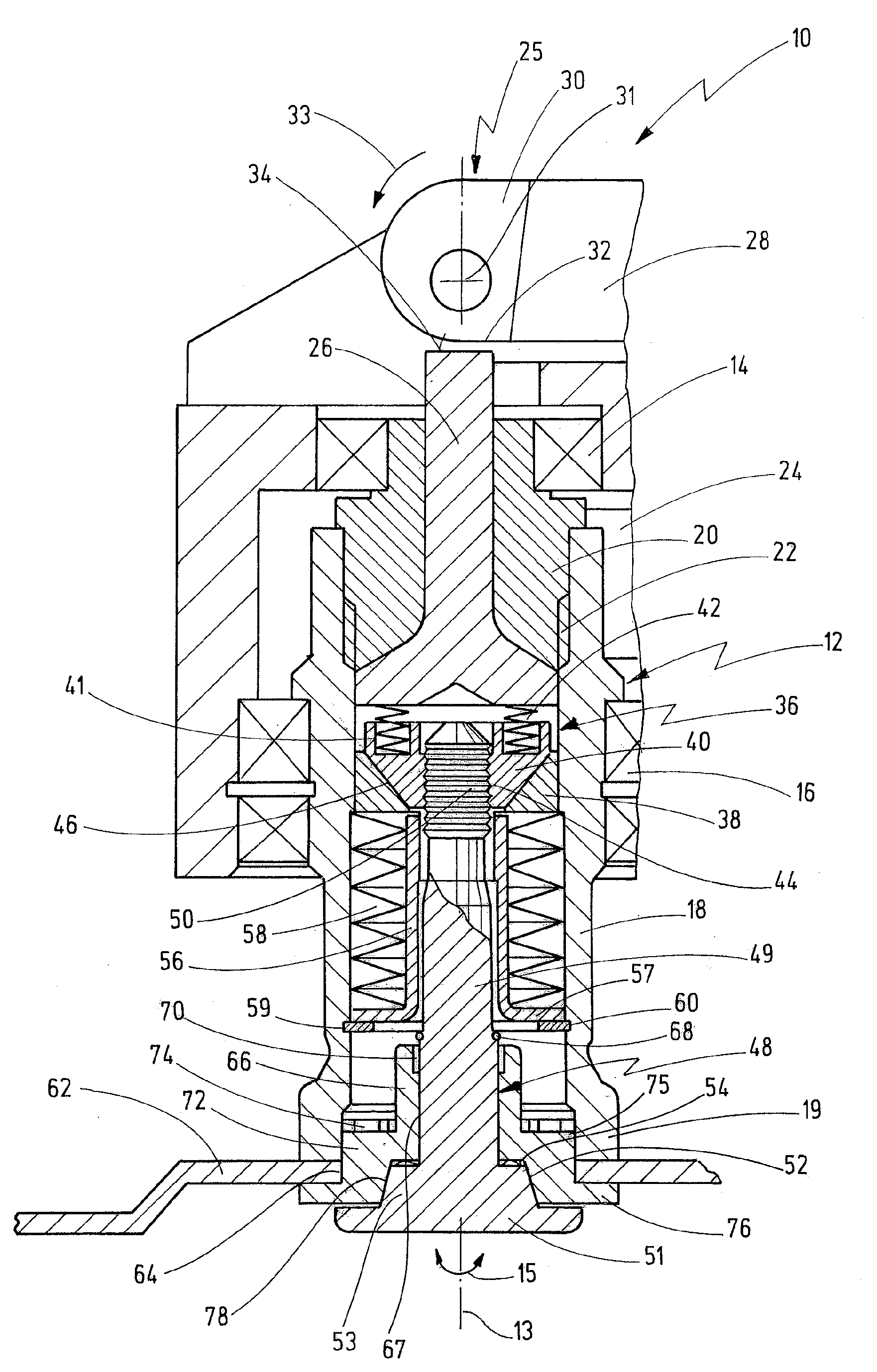

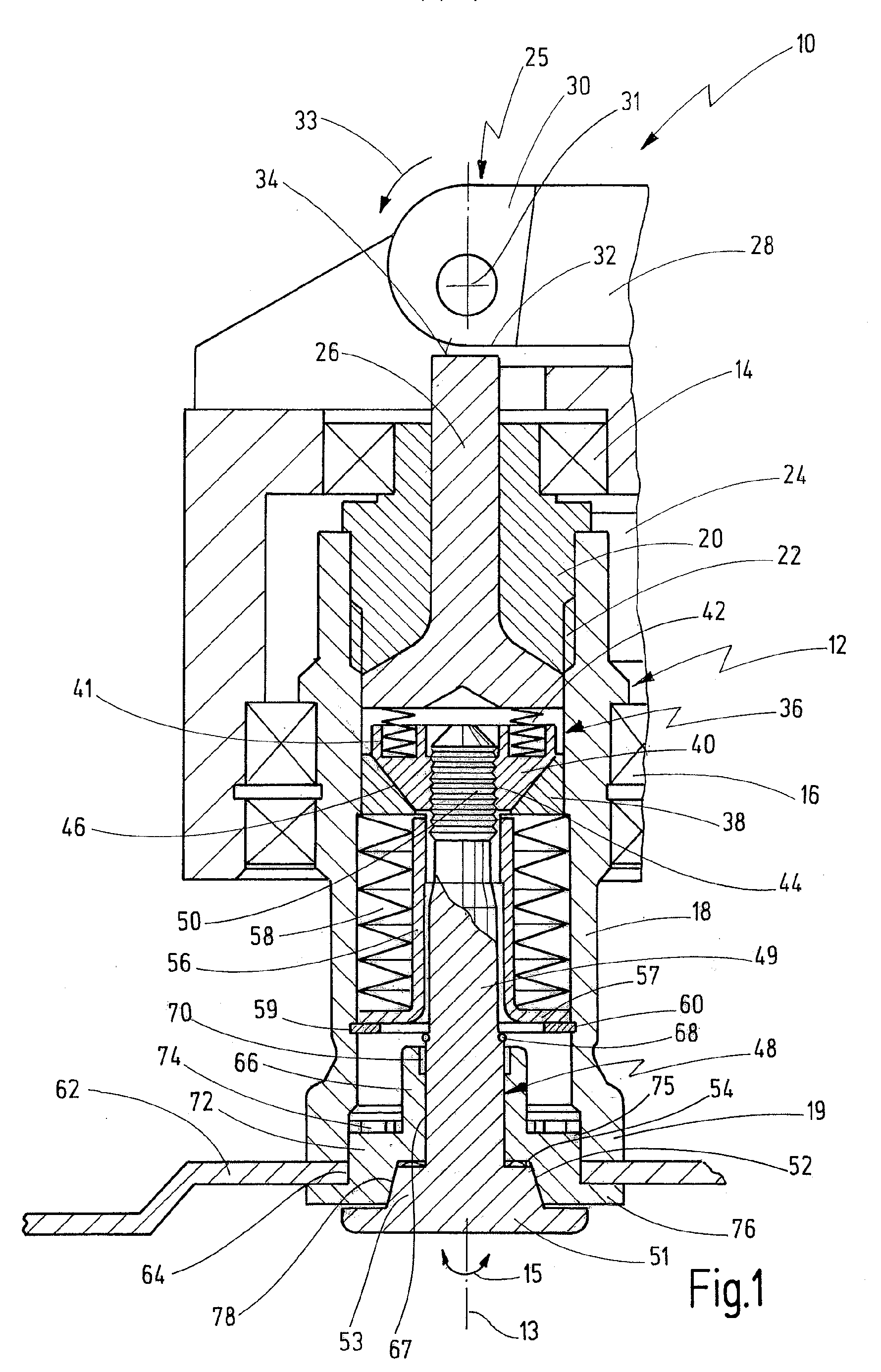

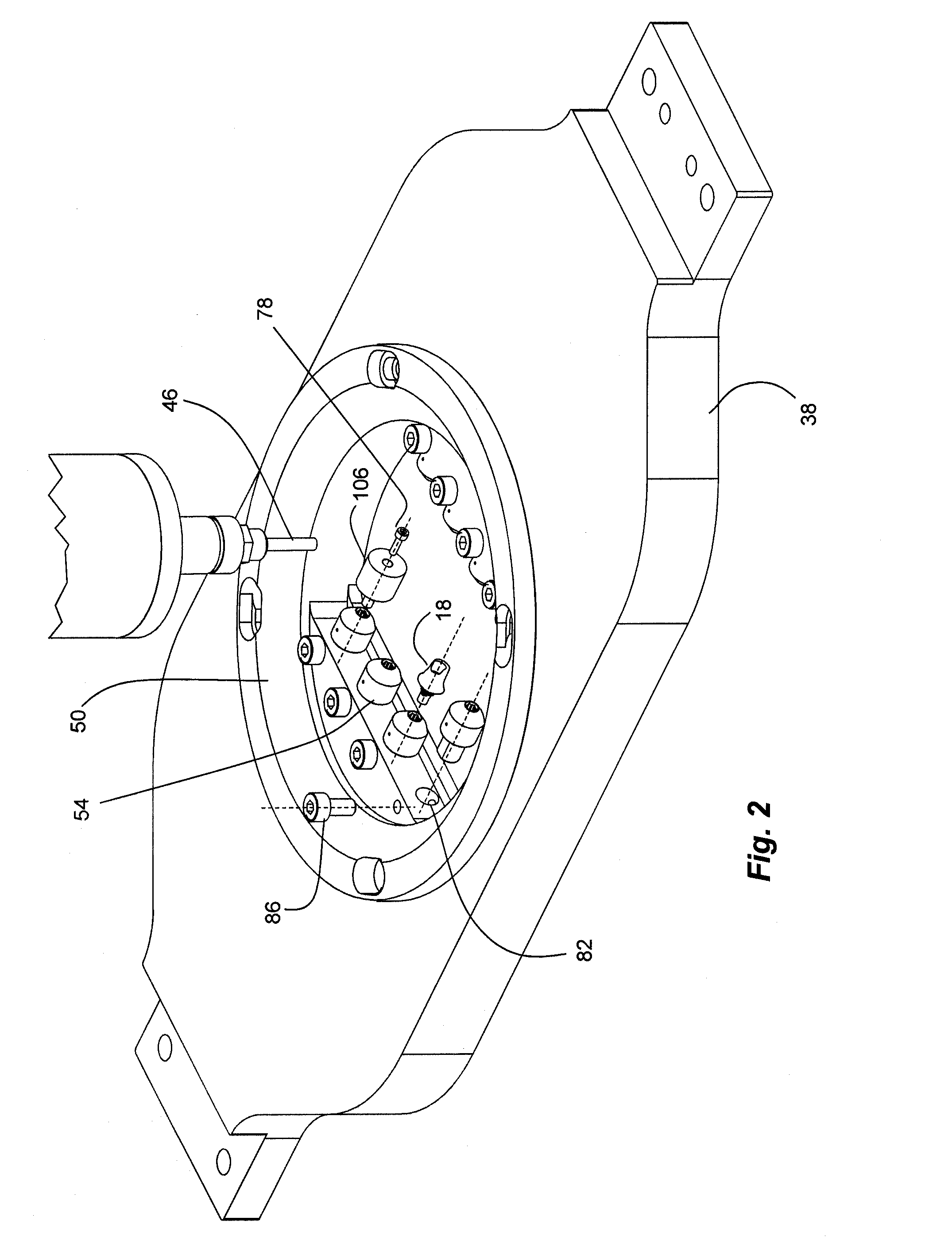

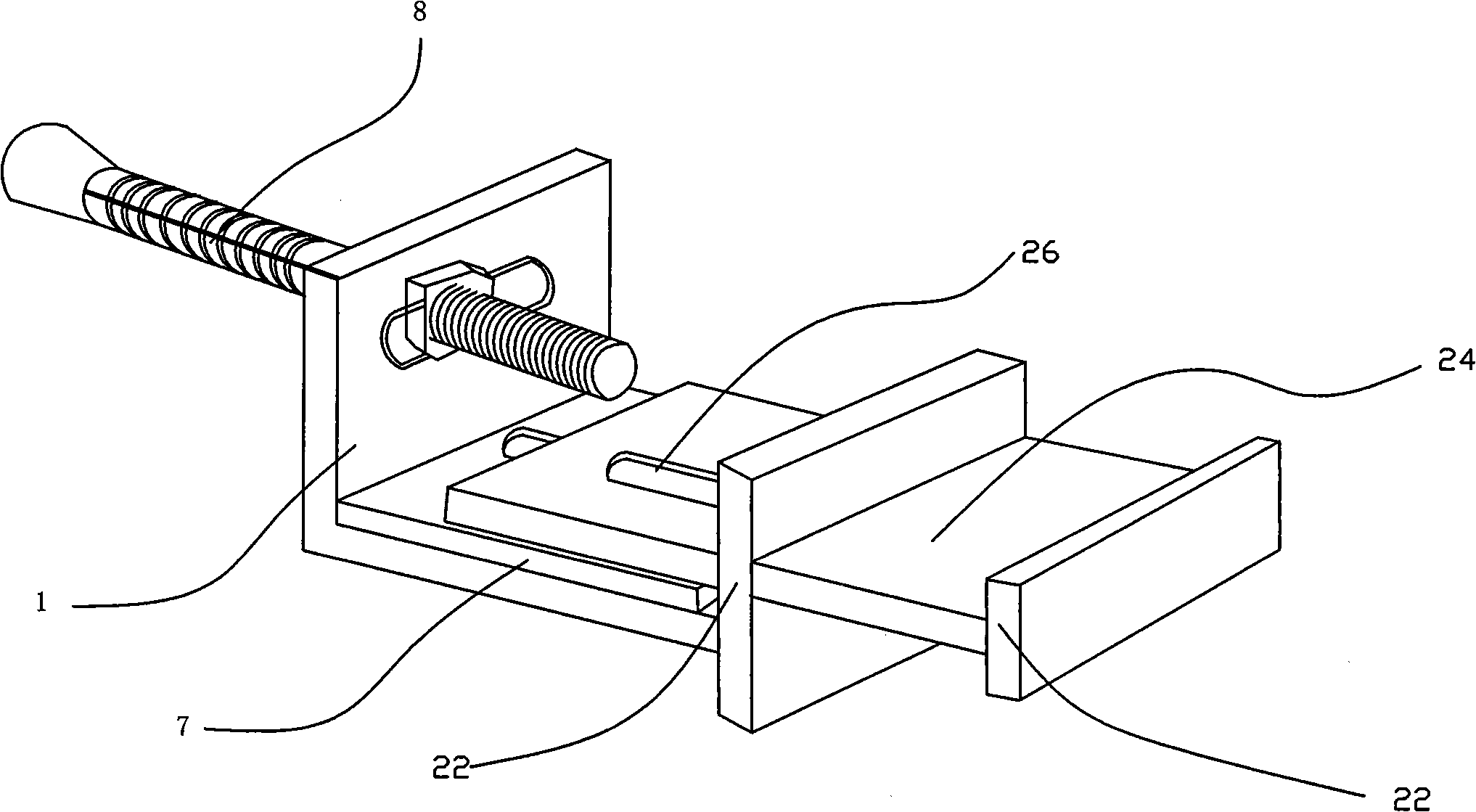

Power-Driven Hand Tool

ActiveUS20090023371A1Closer form-locking connectionFirmly connectedGrinding wheel securing apparatusPortable grinding machinesEngineeringHand tool

A power-driven hand tool comprises a drive spindle adapted to drive a tool, that can be driven to oscillate about its longitudinal axis, which tool can be fixed on a retaining section of the dive spindle by a securing element, and further comprises a displacing device that serves to displace the securing element between a releasing position in which the securing element can be released from the drive spindle and a clamping position in which the securing element is clamped on the retaining section by a spring element, the securing element comprising a clamping shaft adapted to be inserted into the securing element, which is axially fixed in the drive spindle for clamping the tool in the clamping position, and which can be detached in the releasing position. For clamping of the tool a split chuck is provided which is clamped on the retaining section by the securing element in the clamped position and is connected with the retaining section in form-locking engagement.

Owner:C & E FEIN

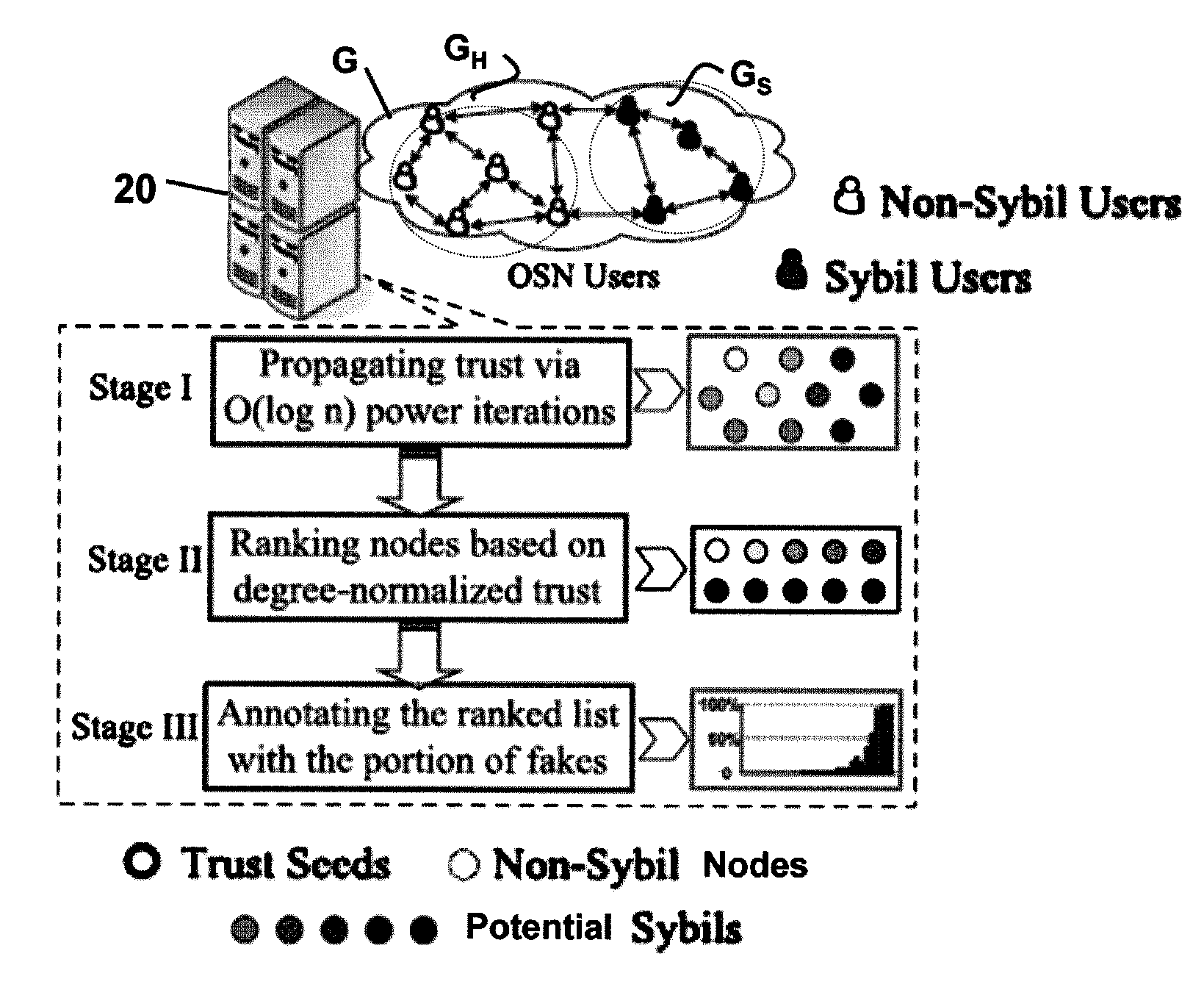

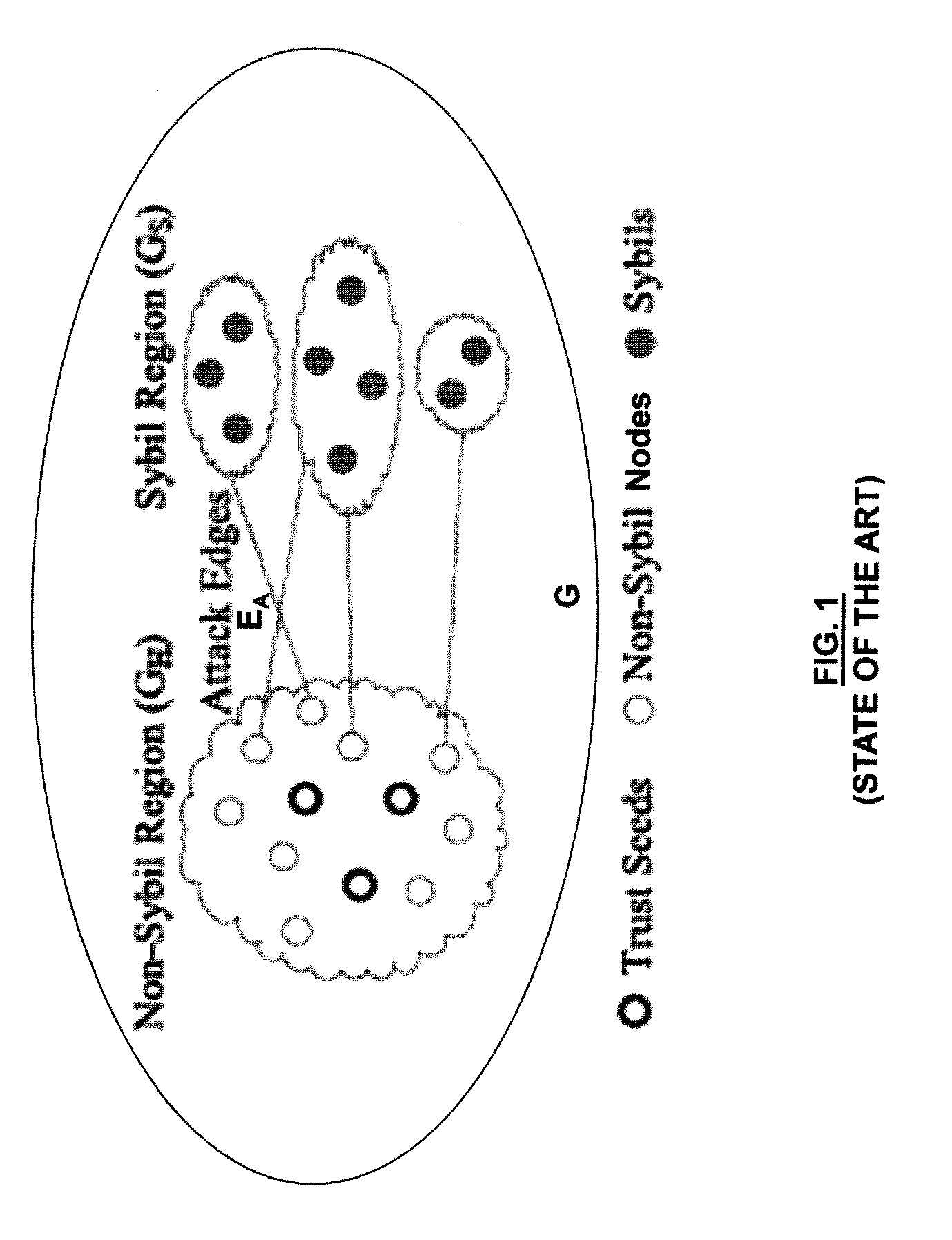

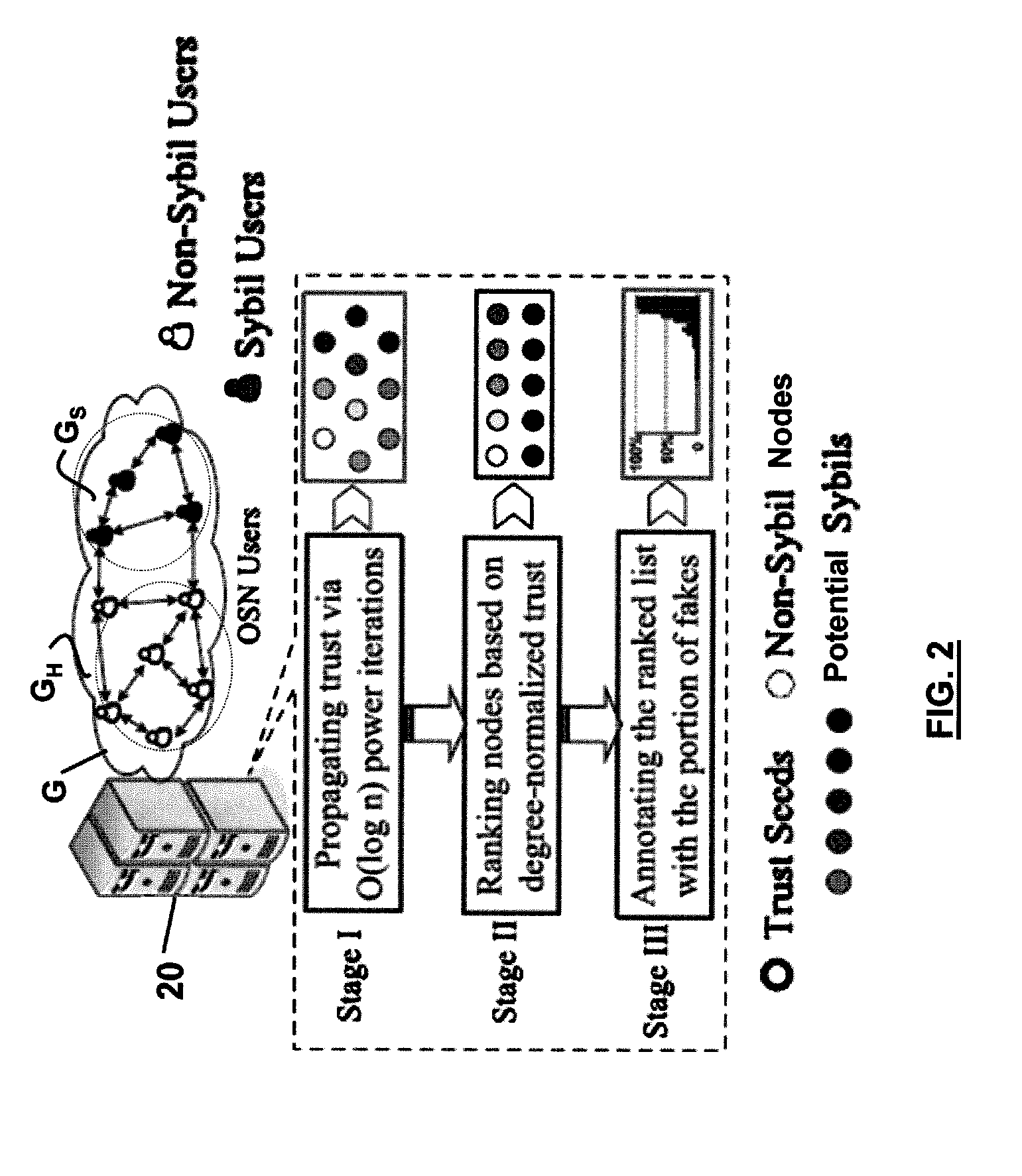

Method and system for detecting fake accounts in online social networks

InactiveUS20140317736A1Improve the level ofFirmly connectedMemory loss protectionError detection/correctionSocial graphTheoretical computer science

A system and method for detecting fake accounts in OSNs is proposed to aid the OSN provider 20 against fake users, wherein a social graph G of the OSN, with n nodes, a non-Sybil region GH and a Sybil region GS, is obtained and the following steps are performed:a trust value T(i)(v) is computed through i power iterations on each node v of the social graph G, i=0, 1, . . . O(log n)the power iterations distribute the trust value T(i)(v) from each node v to its neighbour nodes,after O(log n) power iterations, ranking nodes by a degree-normalized trustT^v=T(w)(v)deg(v)in order to obtain a ranked list of nodes,detecting fake accounts based on the obtained ranked listassigning intervals in the ranked list to a fake portion, determined by manual inspection means of the OSN provider, based on the degree-normalized trust of the nodes belonging to the intervals.

Owner:TELEFONICA DIGITAL ESPANA +1

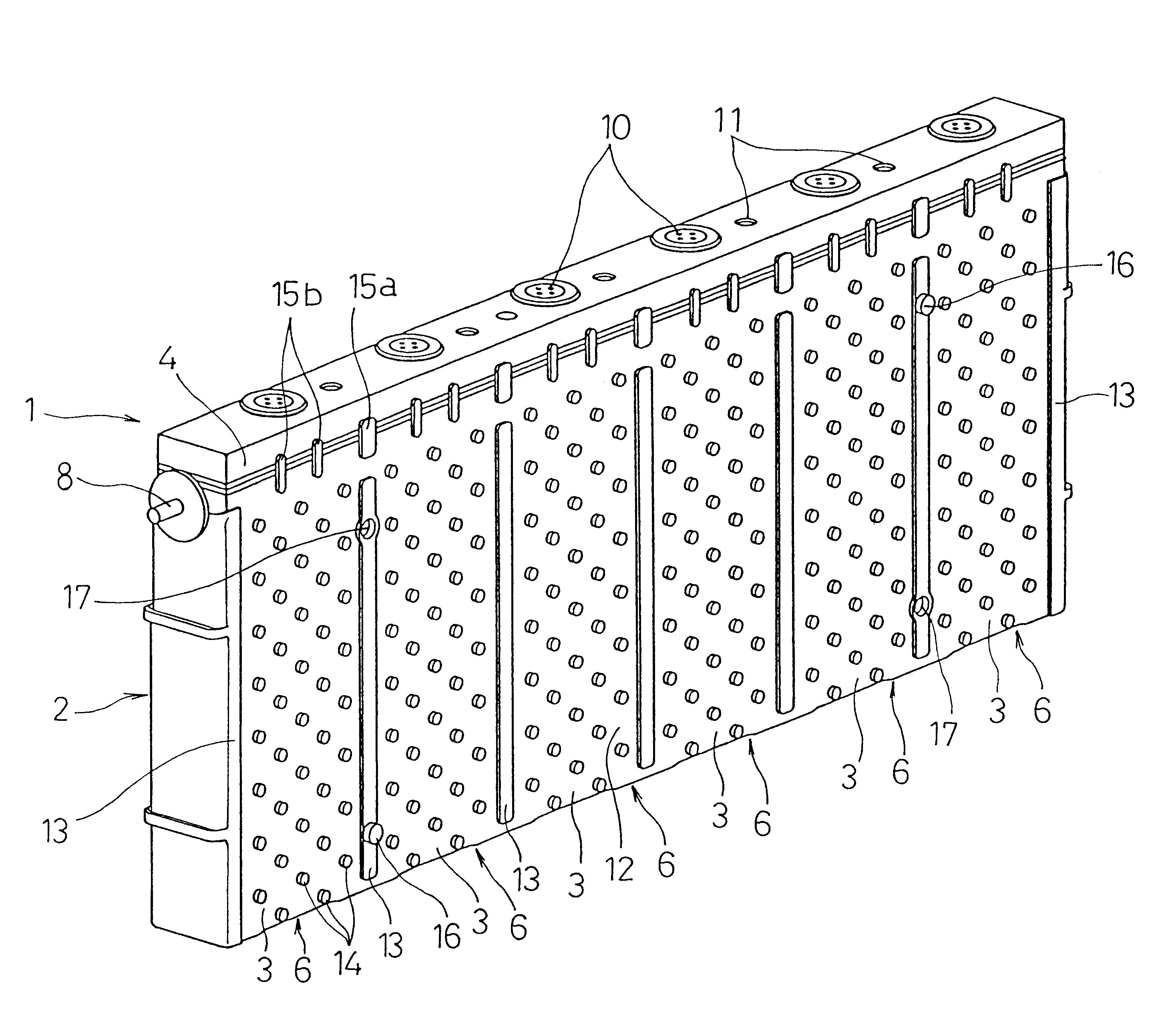

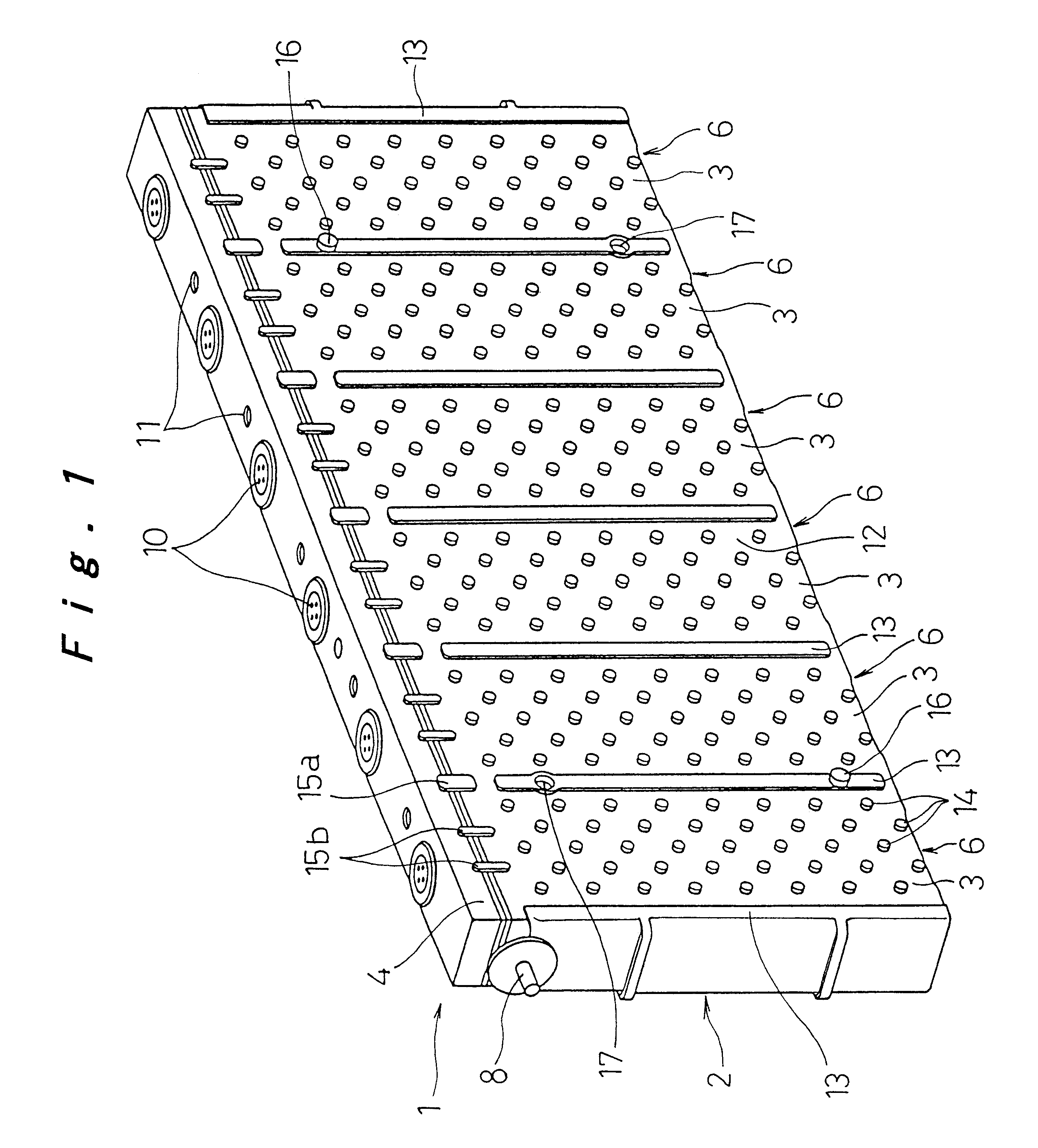

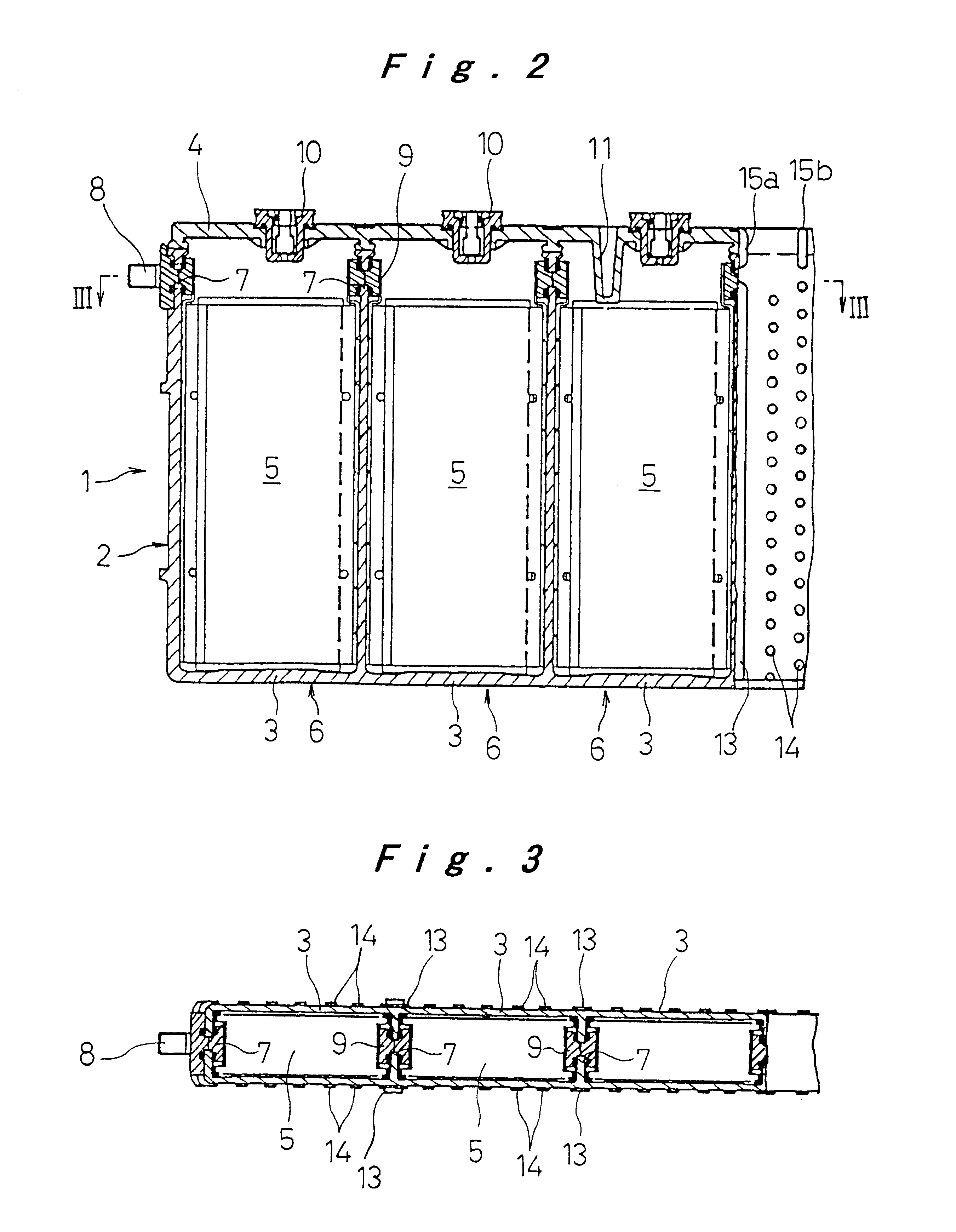

Battery module having a plurality of interconnected batteries

InactiveUS6555264B1Compact connectionImprove cooling effectPrimary cell to battery groupingFinal product manufactureEngineeringElectrical and Electronics engineering

A plurality of cells each encased in prismatic cell cases having short lateral walls and long lateral walls are arranged side by side, with adjacent short lateral walls being integral with each other, thereby constituting an integral battery case. The upper open ends of the plurality of prismatic cell cases are integrally closed by a single lid member. Each of the cells accommodates therein a group of electrodes stacked alternately upon one another parallel to the long lateral walls of the cell cases with intervening separators therebetween. Neighboring cells are connected in series at their abutting lateral opposite ends with each other.

Owner:PANASONIC CORP +1

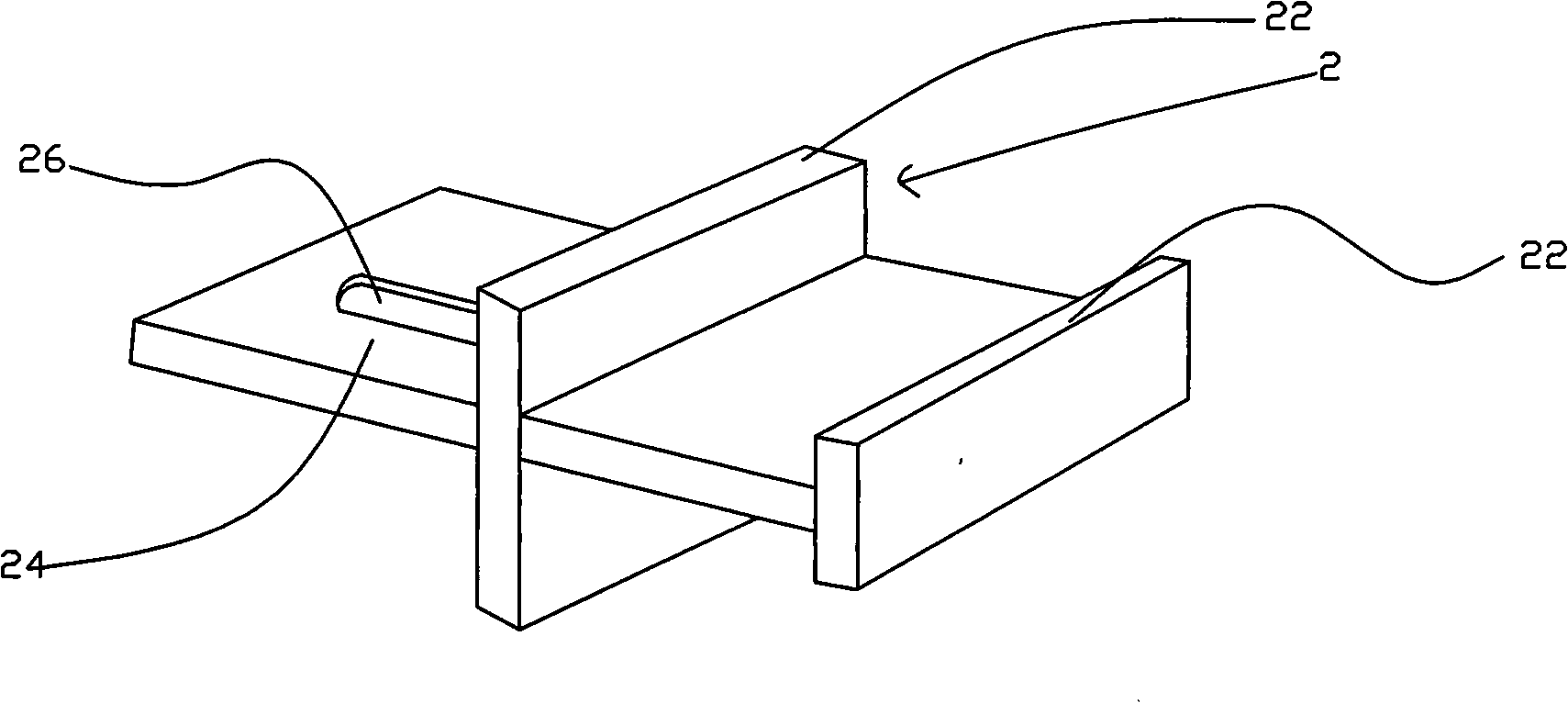

Pivoting connector assembly for connecting two members

ActiveUS8100600B2Maximum flexibilityClosely connectedScaffold connectionsLocks for portable objectsEngineeringMechanical engineering

Owner:BOSCH REXROTH AG +1

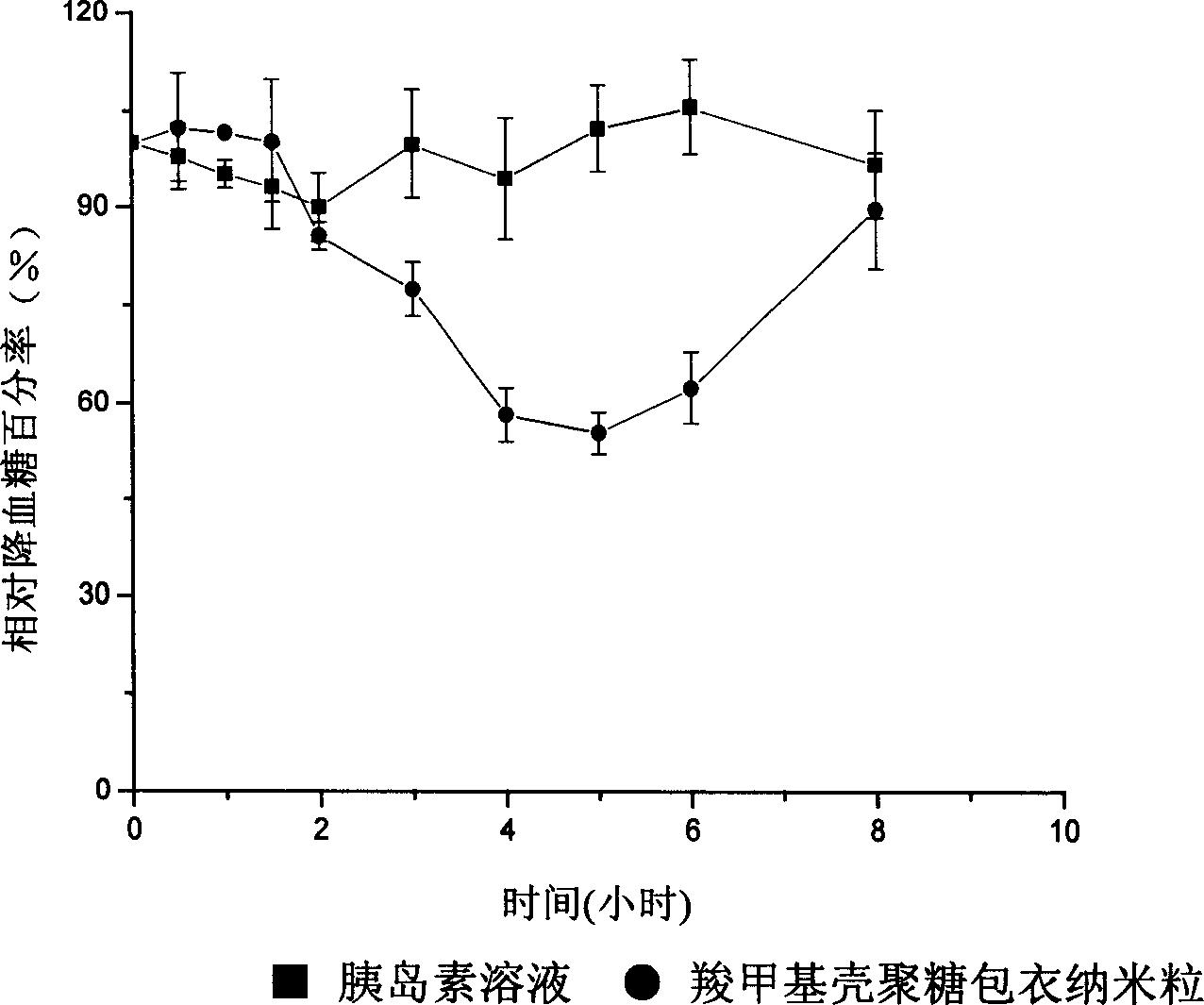

Interpenetrating network polymer type super porous aquogel, its prepn. method and application

InactiveCN1757662AOral administration is convenientHigh mechanical strengthPharmaceutical non-active ingredientsCarrier-bound/immobilised peptidesCross-linkFoaming agent

A super-porous aqueo-gel of an interpenetrating network polymer used for the orally applying system of protein polypeptide to suppress proteinase and break the close linking between epithelial cells contains two polymers: a cross-linked polymer and a cross-linked polyose polymer. Its preparing process includes such steps as mixing at least one unsaturated enylmonomer, at least one polyenyl cross-linking agent, a linear polyose polymer and a foaming agent to generate the super-porous aqueo-gel of semi-interpenetrating network polymer, and cross-linking with linear polyose.

Owner:FUDAN UNIV

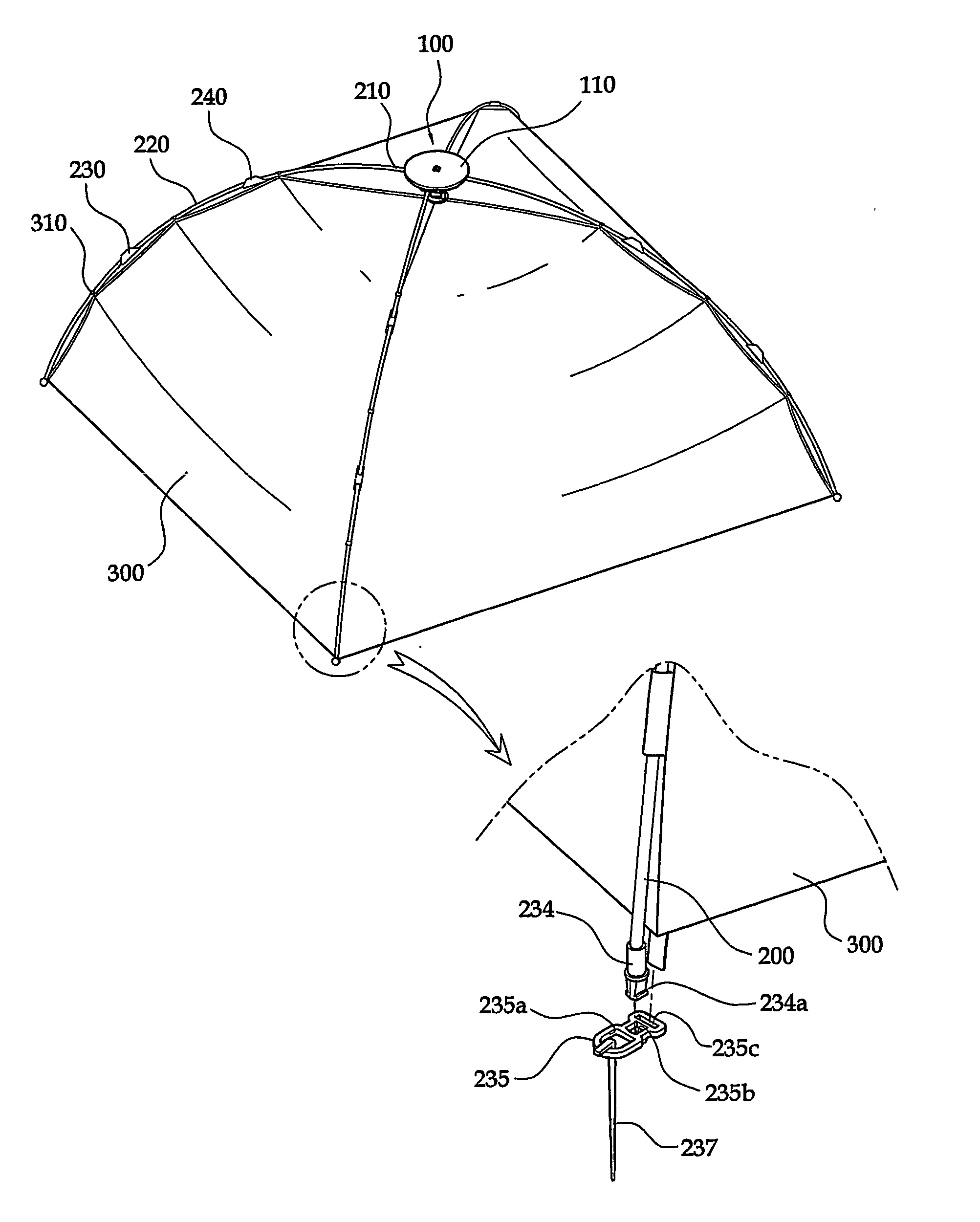

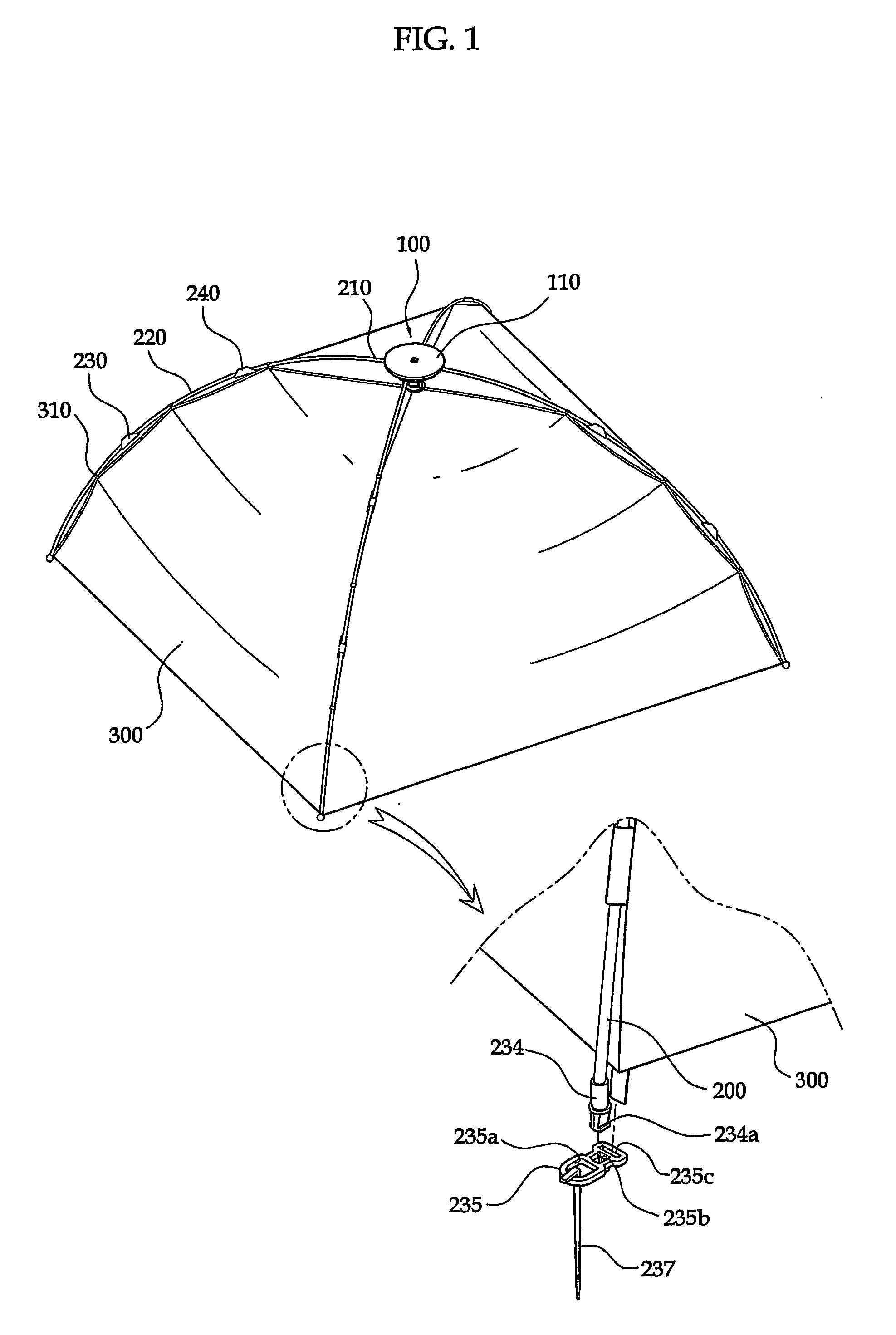

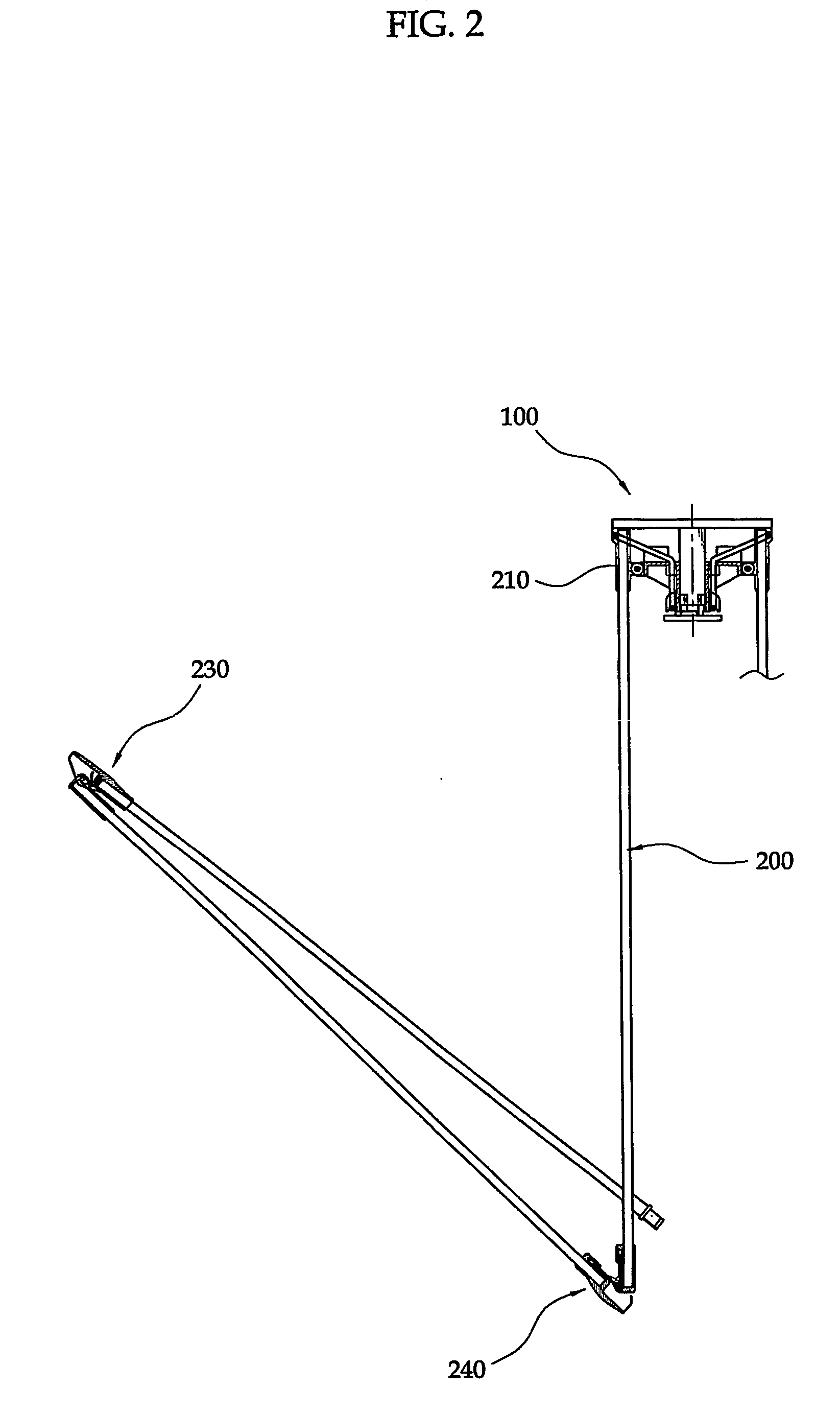

One-touch type foldable tent

The present invention relates to a one-touch type foldable tent, and in particular to an improved one-touch type foldable tent in which the poles are concurrently folded and unfolded based on an operation of a connection assembly. The connection assembly is provided at an upper center of the tent for folding and unfolding the poles, and the upper sides of the poles are hinged at the center connection assembly.

Owner:JUNG IN YOUNG

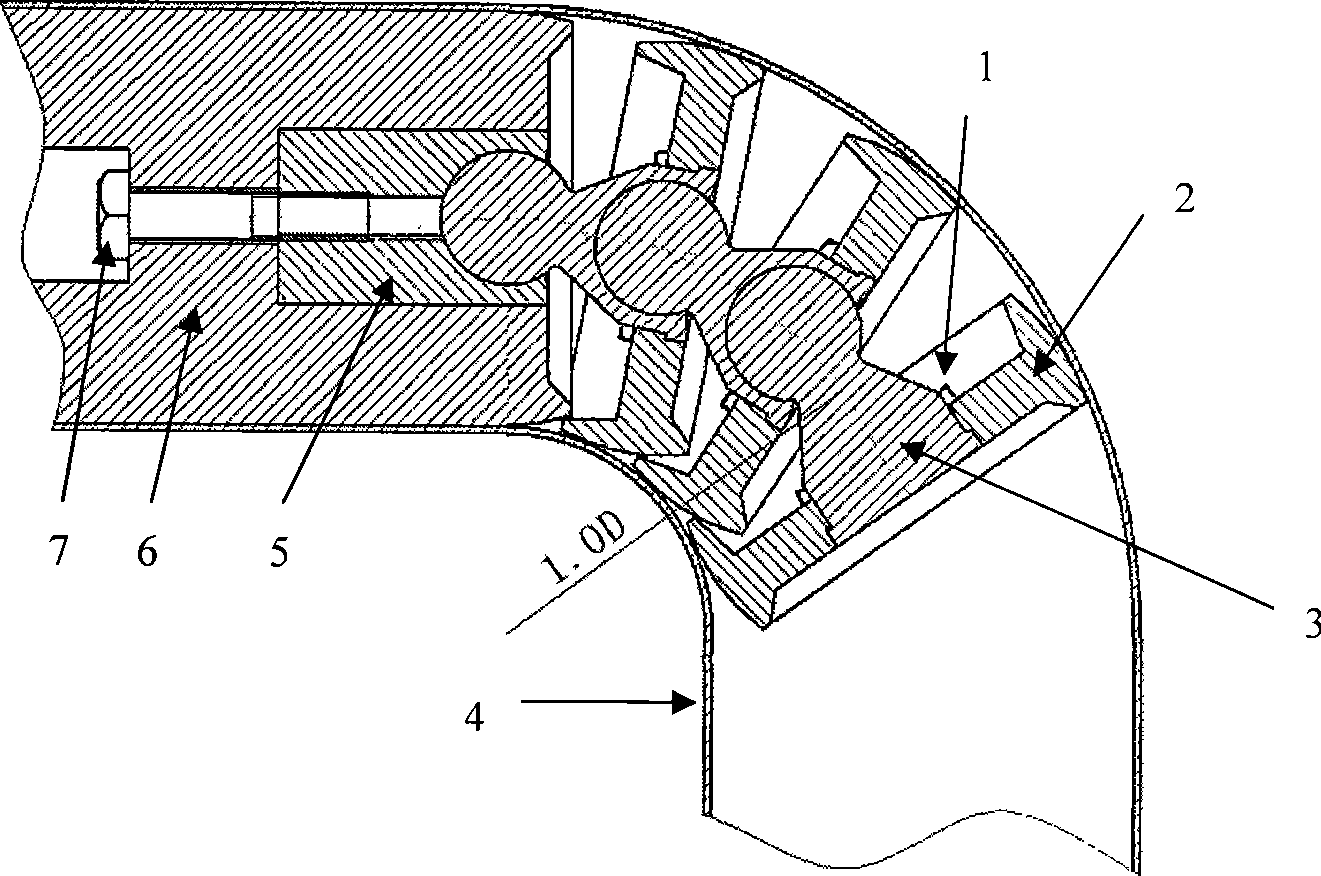

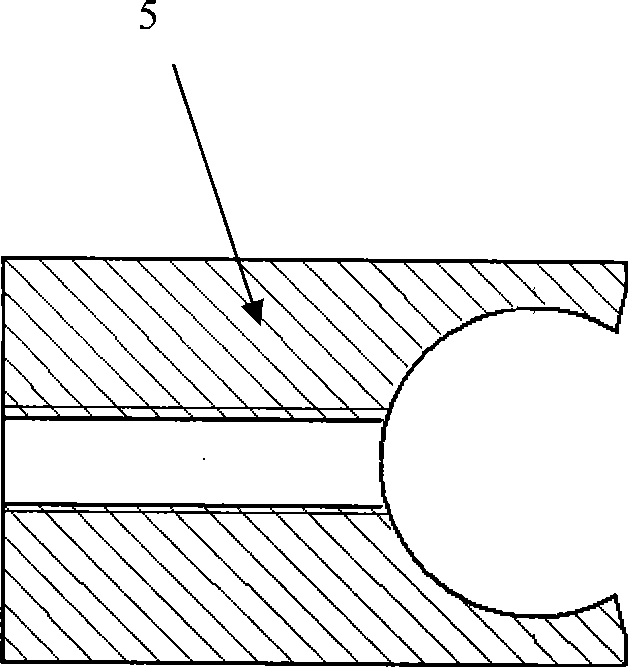

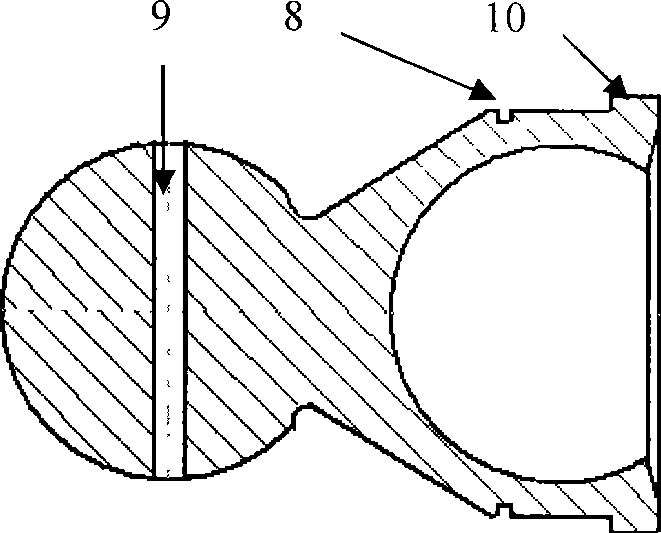

Flexible bend pipe core mould

The invention relates to a flexible syphon core mould, which comprises a core head body (6), a connecting shaft (5), ball joints (3), a positioning key (11), a core head sleeve (2) and an elastic clamp ring (1) which are in mechanical connection. The ball joints (3) are arranged in the core head sleeve (2) as core heads; a plurality of ball joints (3) are linked through the nested cooperation between balls and ball sockets and are axially positioned by the clamp ring (1) and the positioning key (11); and the outside diameter of each point on the surface of an outer circle of the core head sleeve (2) is equal to the diameter of the core head body (6) in order that each point of the outer surface of the core head sleeve (2) can be matched with the inner wall of a tube (4). In use, the core head sleeve (2) can freely rotate around the ball joints by the movable ball joint so as to meet the requirement for the bending and forming curvature of tubing. The flexible siphon core mould can smoothly bend a large-calibre thin-wall tube with the smallest relative bending radius of 1.0 decimeter, can control the ellipticity of the formed tubing within 5 percent and has the characteristics of compact structure, easy replacement of main wearing parts and strong universality.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

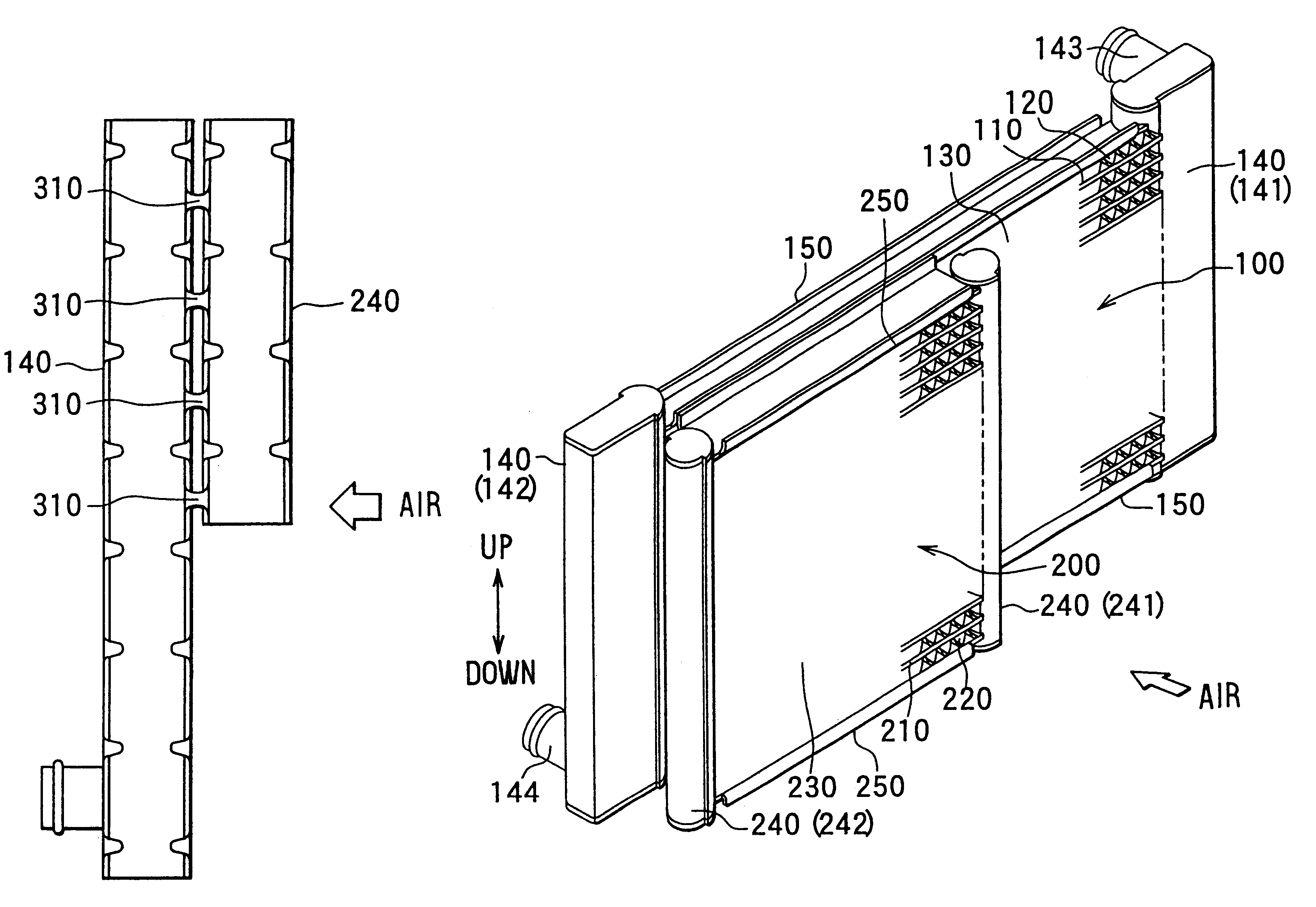

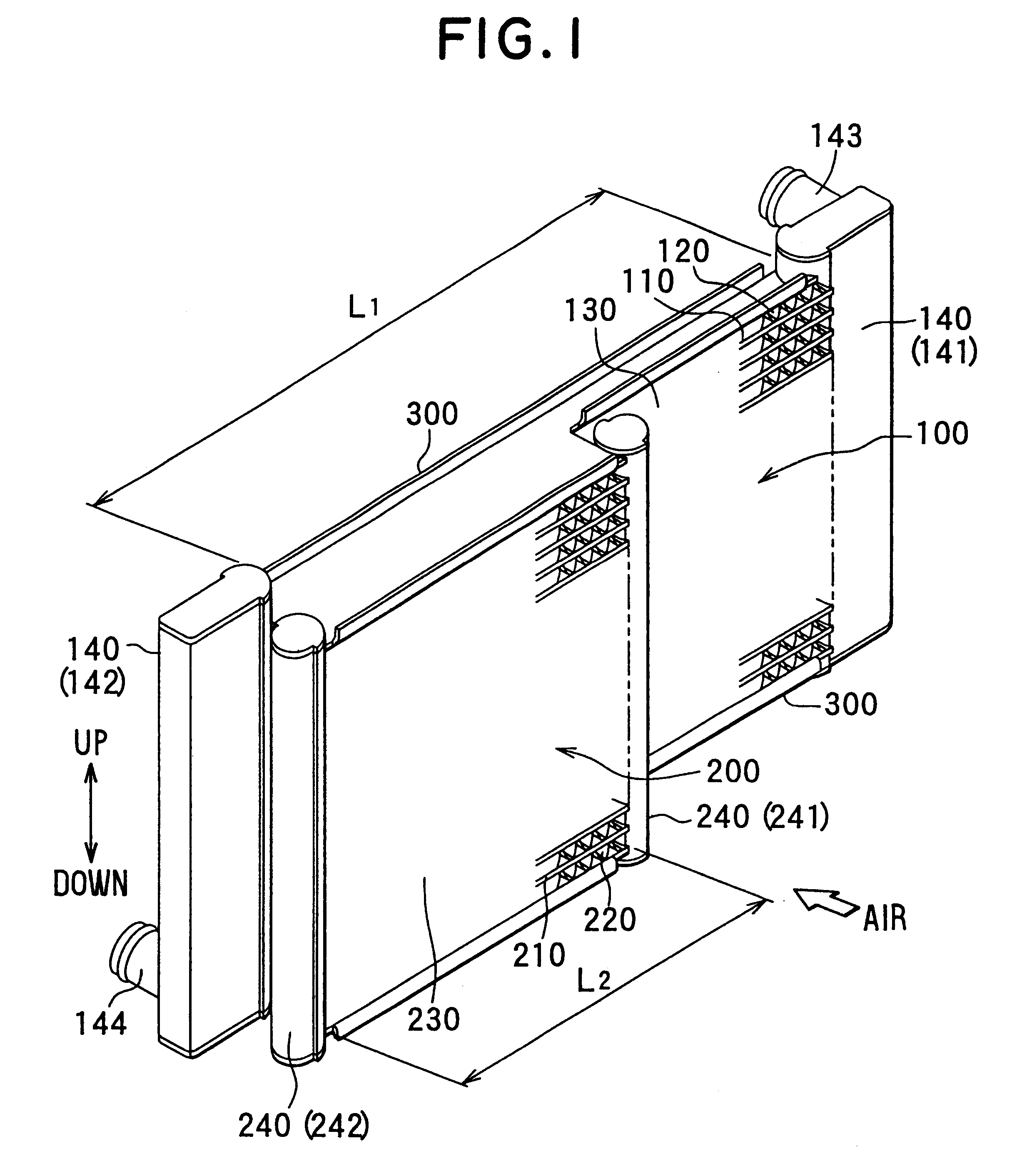

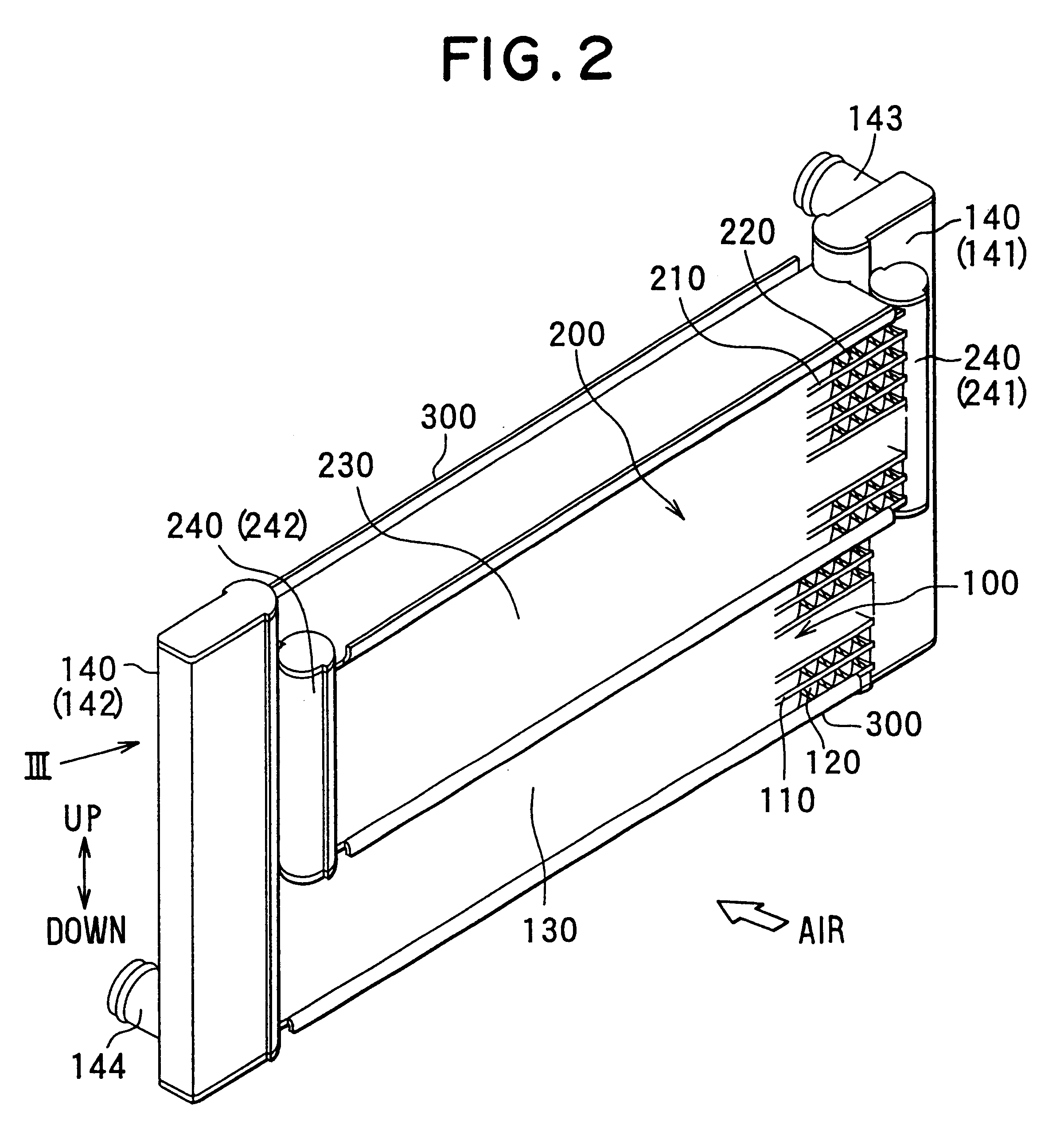

Double heat exchanger

InactiveUS6408939B1Reduced heat exchange capacityAvoid sizeHeat exhanger finsStationary conduit assembliesEngineeringHeat spreader

In a double heat exchange, a radiator and a condenser are integrated through a side plate for reinforcing the radiator and the condenser, and a longitudinal dimension of condenser tubes is made smaller than a longitudinal dimension of radiator tubes. Therefore, a core area of the condenser becomes smaller than that of the radiator. Thus, heat-exchanging capacity of the condenser is restricted from being increased more than a necessary capacity, and size and performance of the double heat exchanger are restricted from being increased more than necessary conditions.

Owner:DENSO CORP

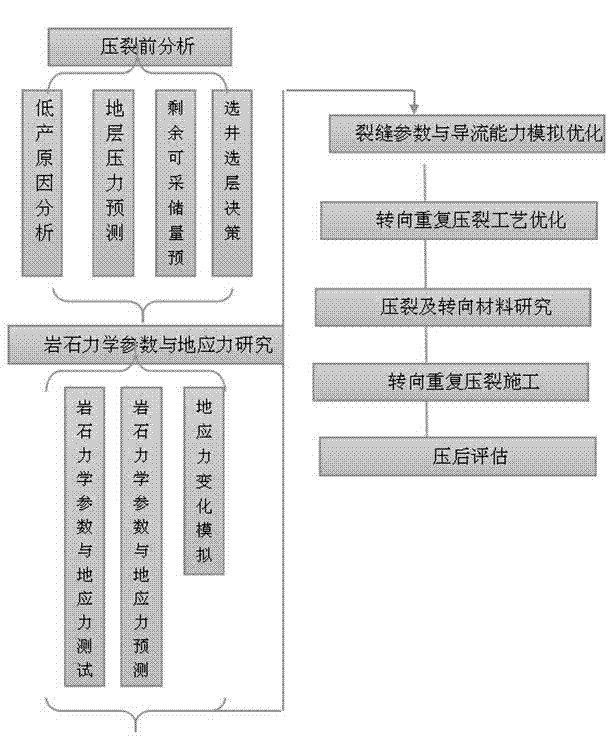

Low permeability gas reservoir turning repeated fracturing technological method

ActiveCN104727798ARealize integrationOptimum Fracturing Construction Pumping ProcedureFluid removalSealing/packingIntegrated designReservoir evaluation

The invention provides a low permeability gas reservoir turning repeated fracturing technological method. The specific technological method comprises the following steps of gas well initial fracturing failure or low-efficiency reason analyzing, reservoir stratum evaluating conducted before turning repeated fracturing, turning repeated fracturing well selection and stratum selection decision making, rock mechanical parameter and ground stress testing, turning repeated fracturing ground stress field changing simulating, fracture geometrical parameter and flow conductivity optimizing, turning repeated fracturing technology optimizing, fracturing liquid and turning agent studying, repeated fracturing constructing and evaluating conducted after repeated fracturing. The well selection and stratum selection decision making and residual gas detecting serve as verification systems of each other, fracturing design and fracture detecting serve as verification systems of each other, and a novel fracture turning agent is used in the low permeability gas reservoir turning repeated fracturing technological method. The integrated design of the low permeability gas reservoir turning repeated fracturing is achieved, and the low permeability gas reservoir turning repeated fracturing technological method has the advantages that the design links are macroscopically integrated, local innovation is achieved, linkage is close, mutual verification is achieved, the design is advanced, and the technological advantage is obvious.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

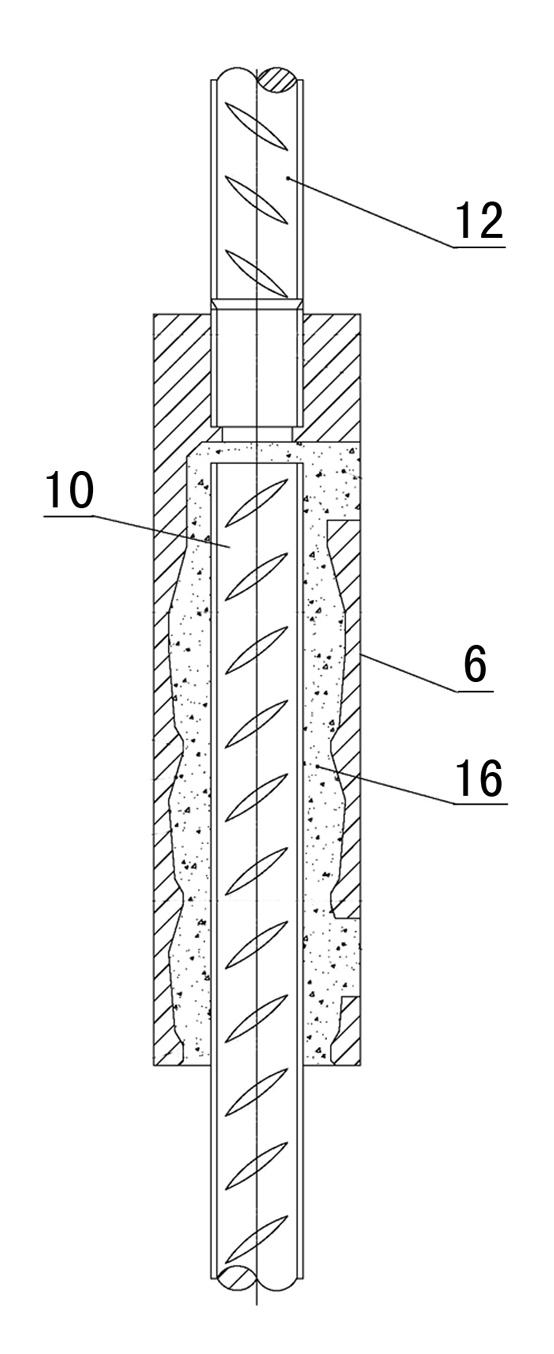

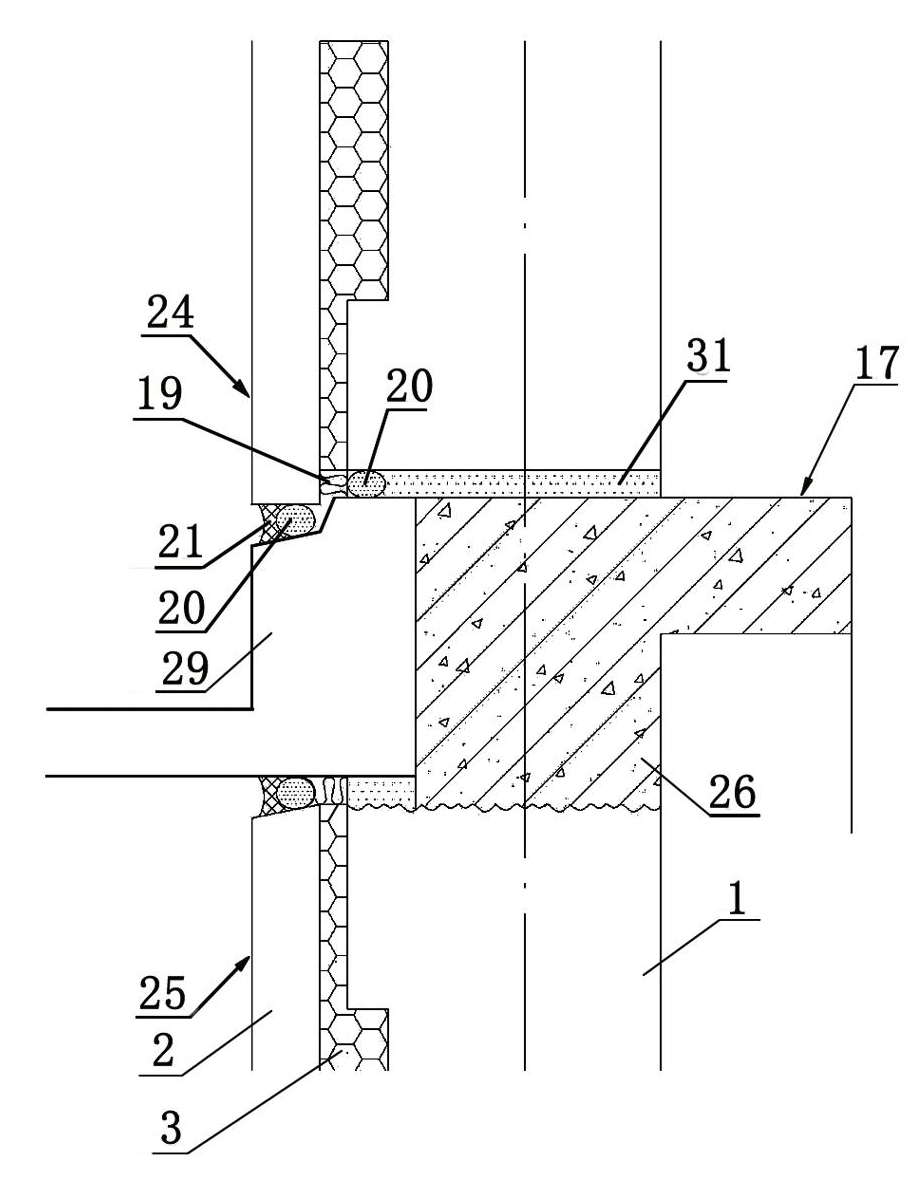

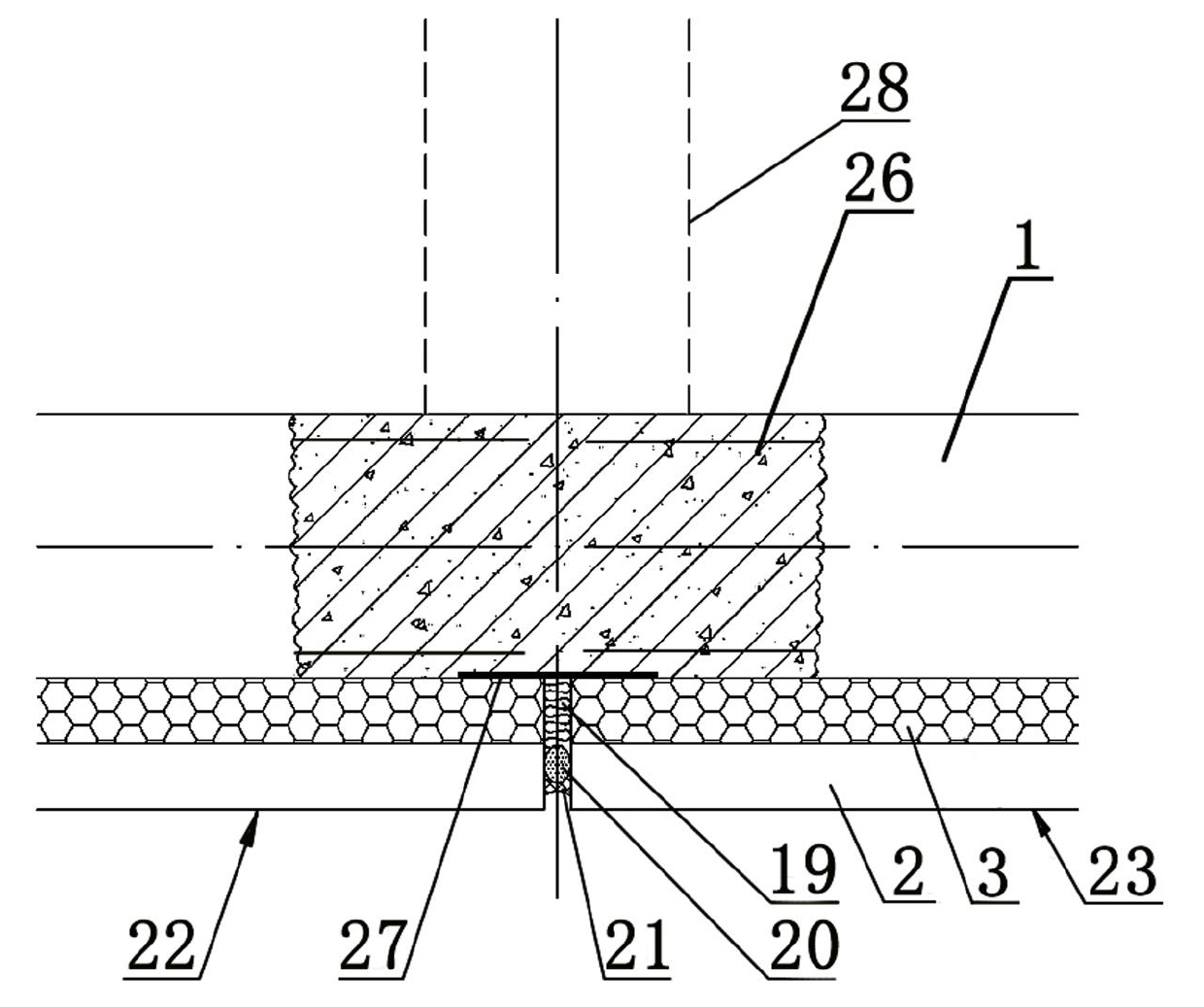

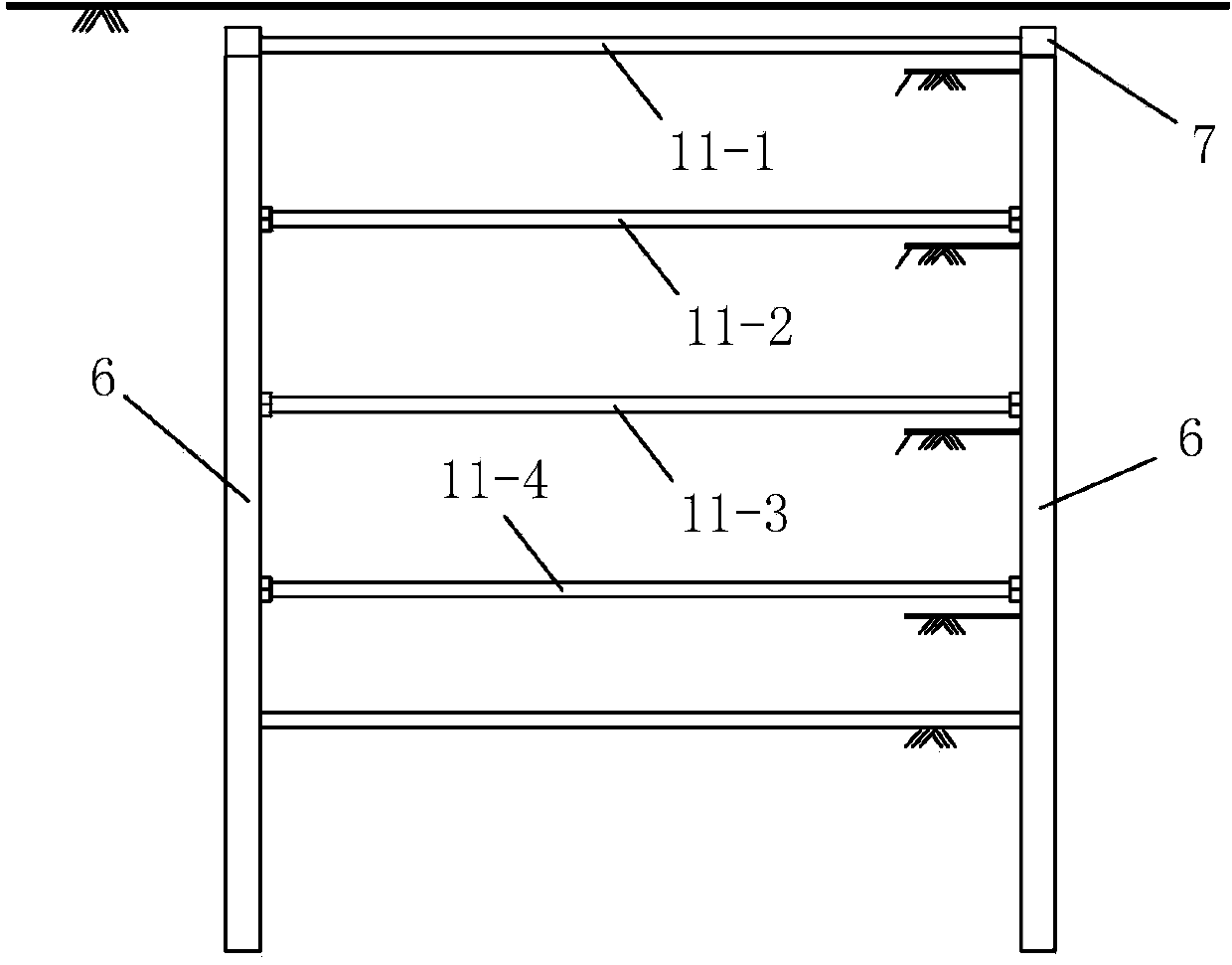

Assembled integral shear wall structure system and construction method thereof

ActiveCN101818527ALow costGuarantee the construction qualityWallsBuilding material handlingReinforced concretePolystyrene

The invention discloses an assembled integral shear wall structure system and a construction method thereof. Prefabricated composite wallboards are hoisted and assembled integrally at a construction site; a board body of the prefabricated composite wallboards comprises a structural layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; the insulating layer is an extruded polystyrene foam plastic board; steel meshes are arranged in the concrete of the protective layer; and anchor bolts in a dotted distribution are connected among the structural layer, the insulating layer and the protective layer. Vertical seams and horizontal seams of prefabricated composite walls adopt structural self-waterproofing, so that common quality problems such as leakage and cracks and the like in a traditional process are solved. The prefabricated composite walls simplify construction processes, speed up the construction, and lower the construction cost. Furthermore, products prefabricated in a factory have uniform specifications and unified quality, so that the construction quality of a building construction can be sufficiently guaranteed; the industrialization, standardization, and generalization of the building walls are realized; and the products can be widely applicable to the construction of reinforced concrete buildings in the construction industry.

Owner:华筑(辽宁)建筑工程设计有限公司

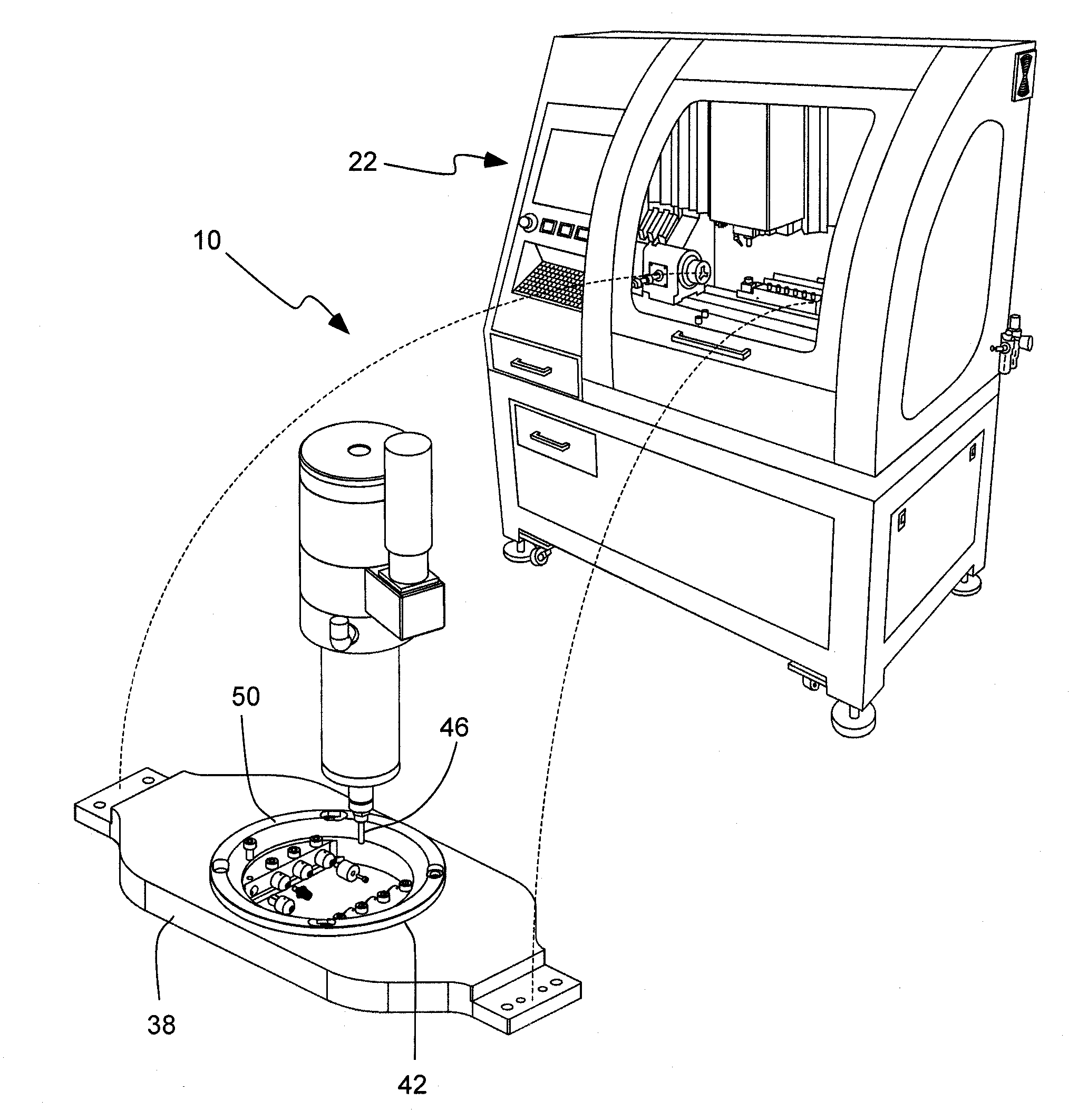

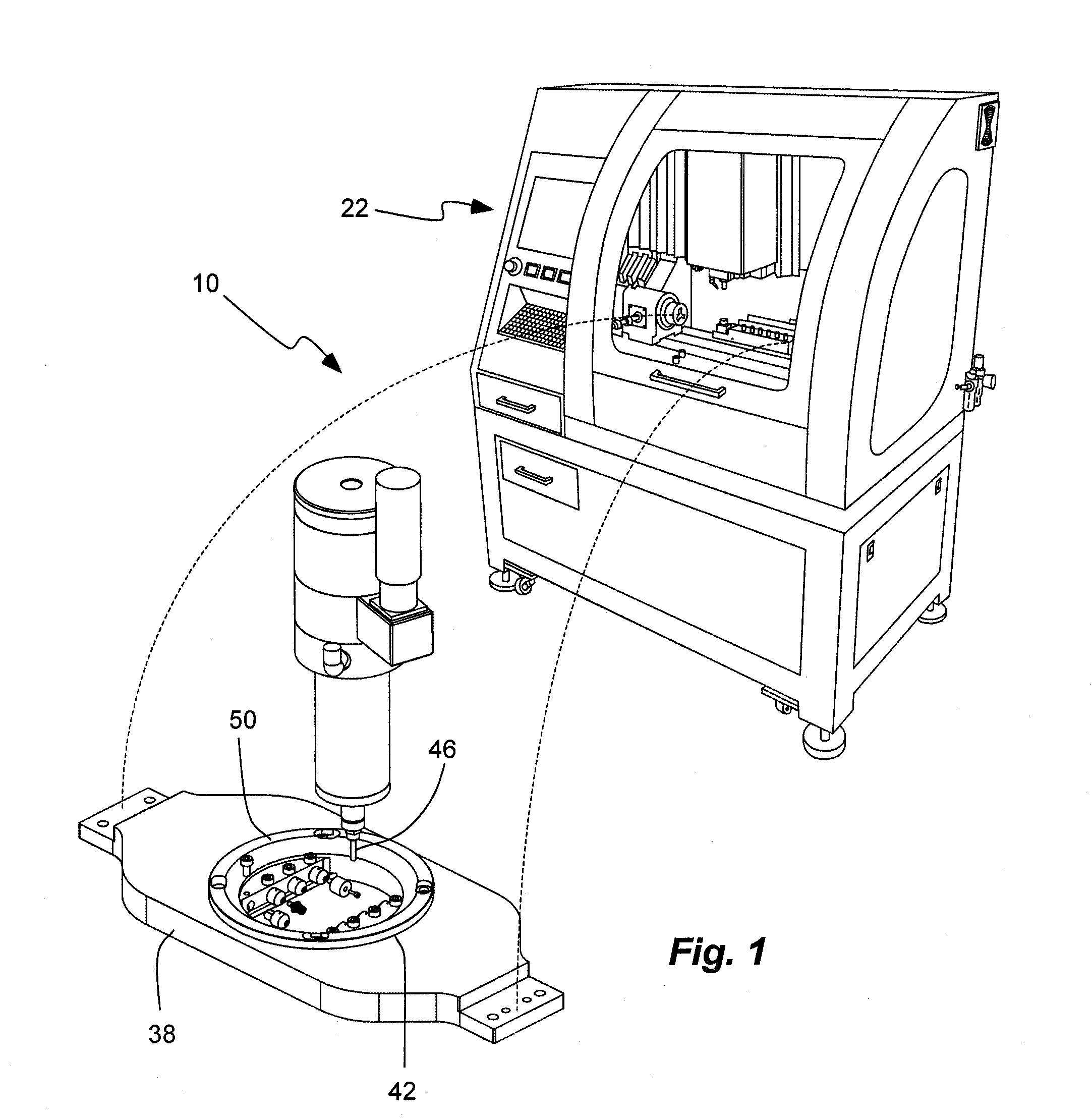

Method for fabricating a custom implant abutment

InactiveUS20120214133A1Facilitate precision millingSimple manufacturing processDental implantsTooth crownsCNC routerBiomedical engineering

A system and method for fabricating custom implant abutments uses an implant abutment connector to secure a partial blank with respect to a milling tool of a CNC milling machine. The implant abutment connector has an implant interface geometry of an implant. The partial blank can have a prefabricated implant abutment interface geometry of the implant abutment; and can thus mate with the implant, and the implant interface geometry of the implant abutment connector.

Owner:B & D DENTAL

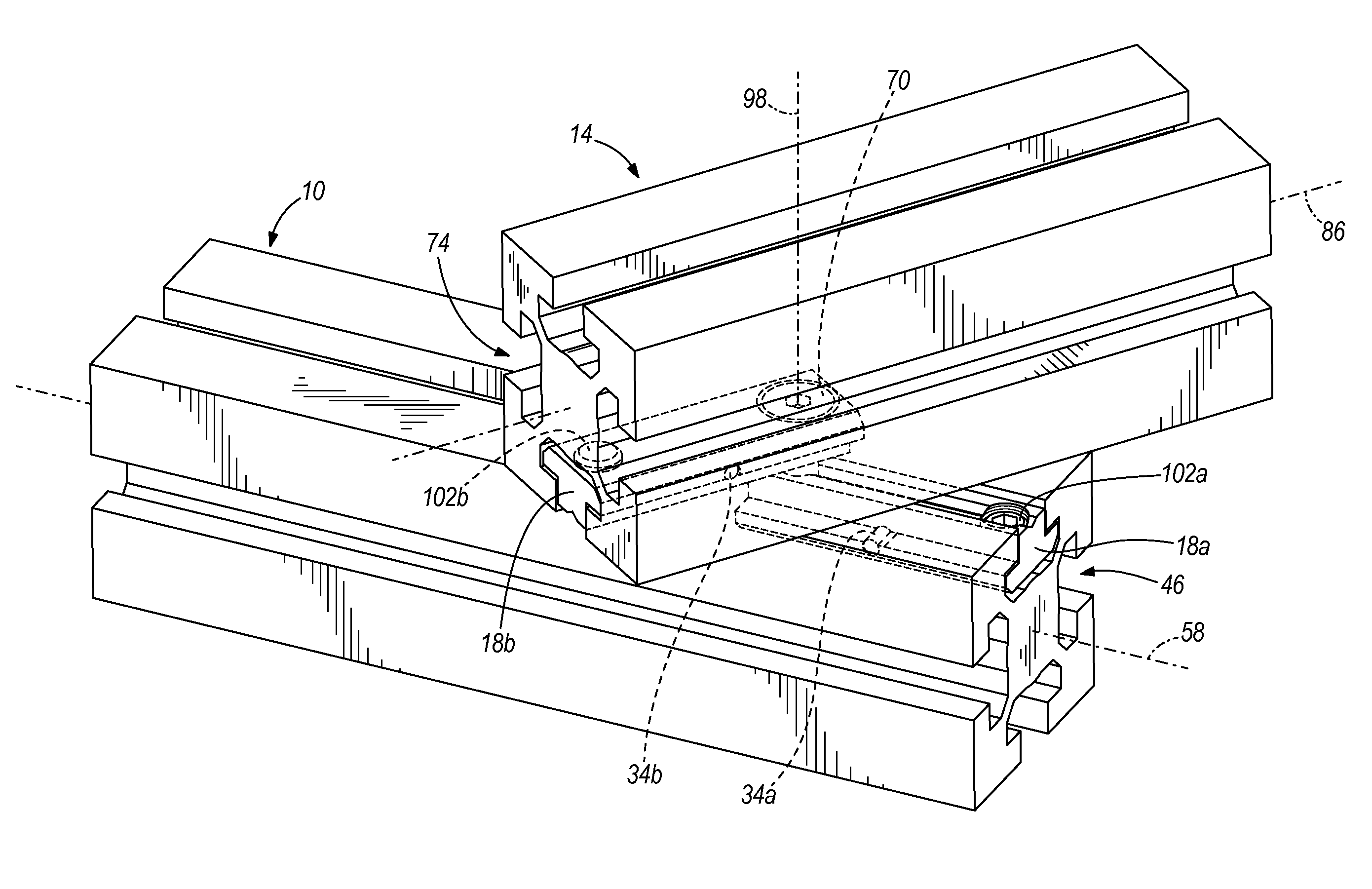

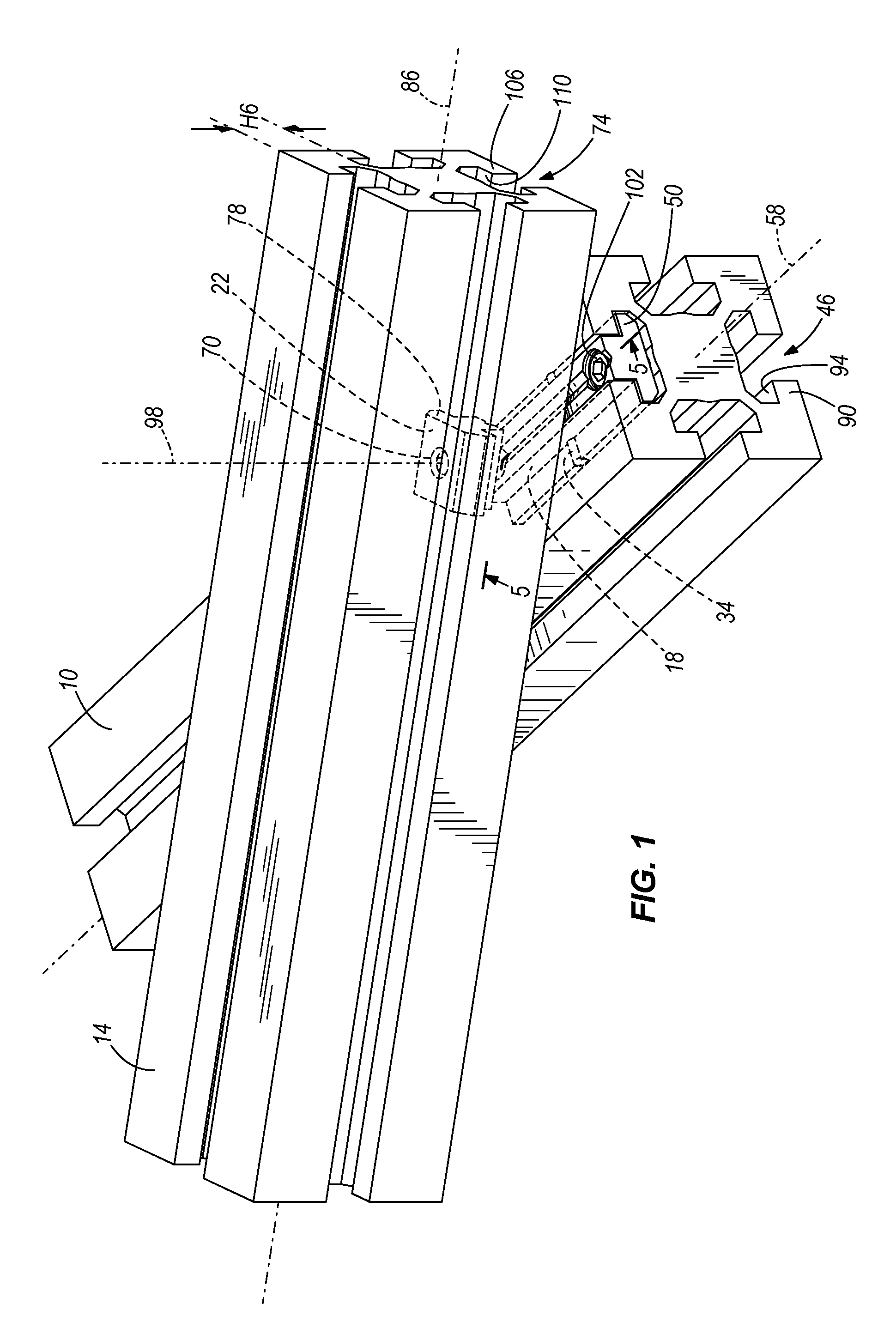

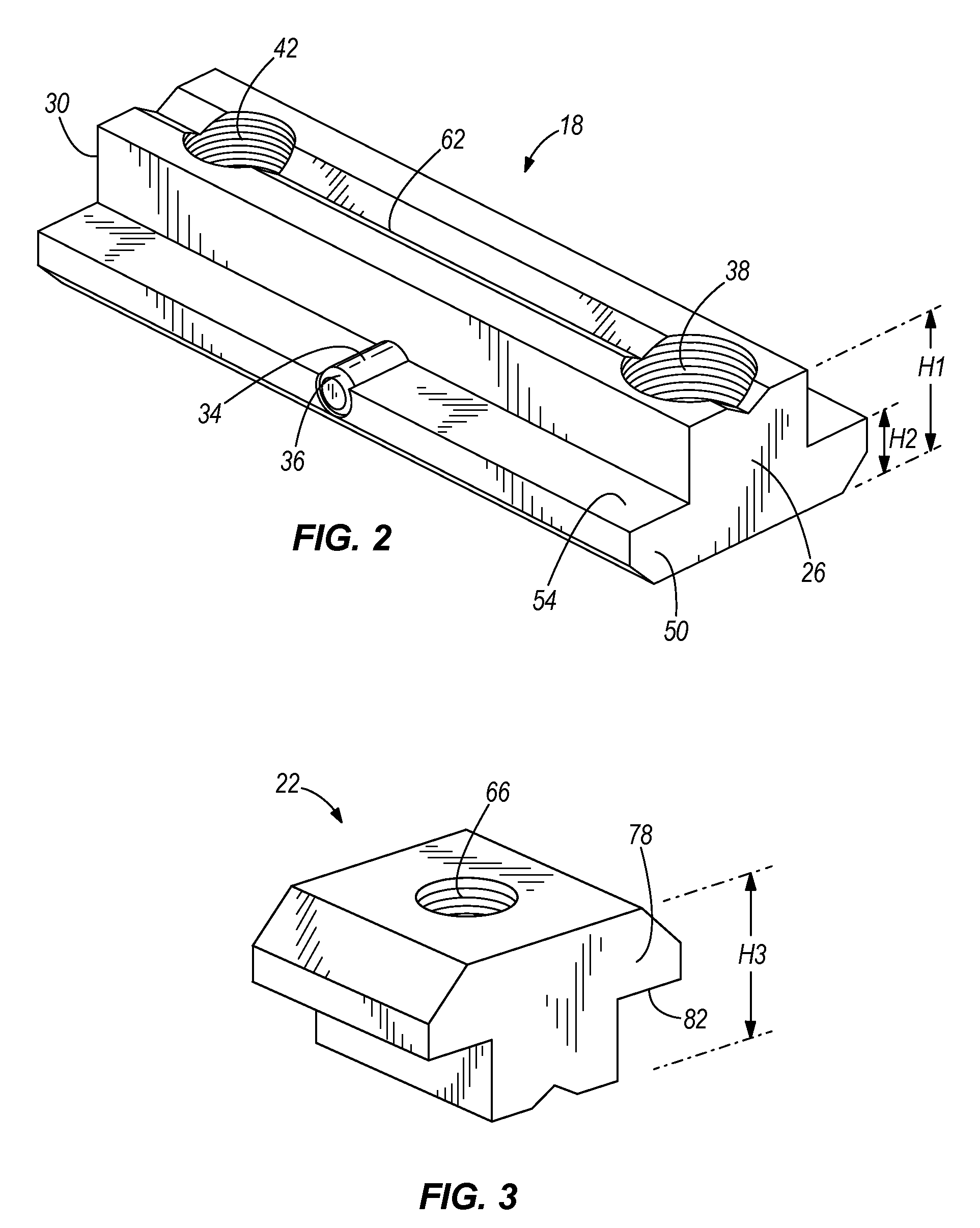

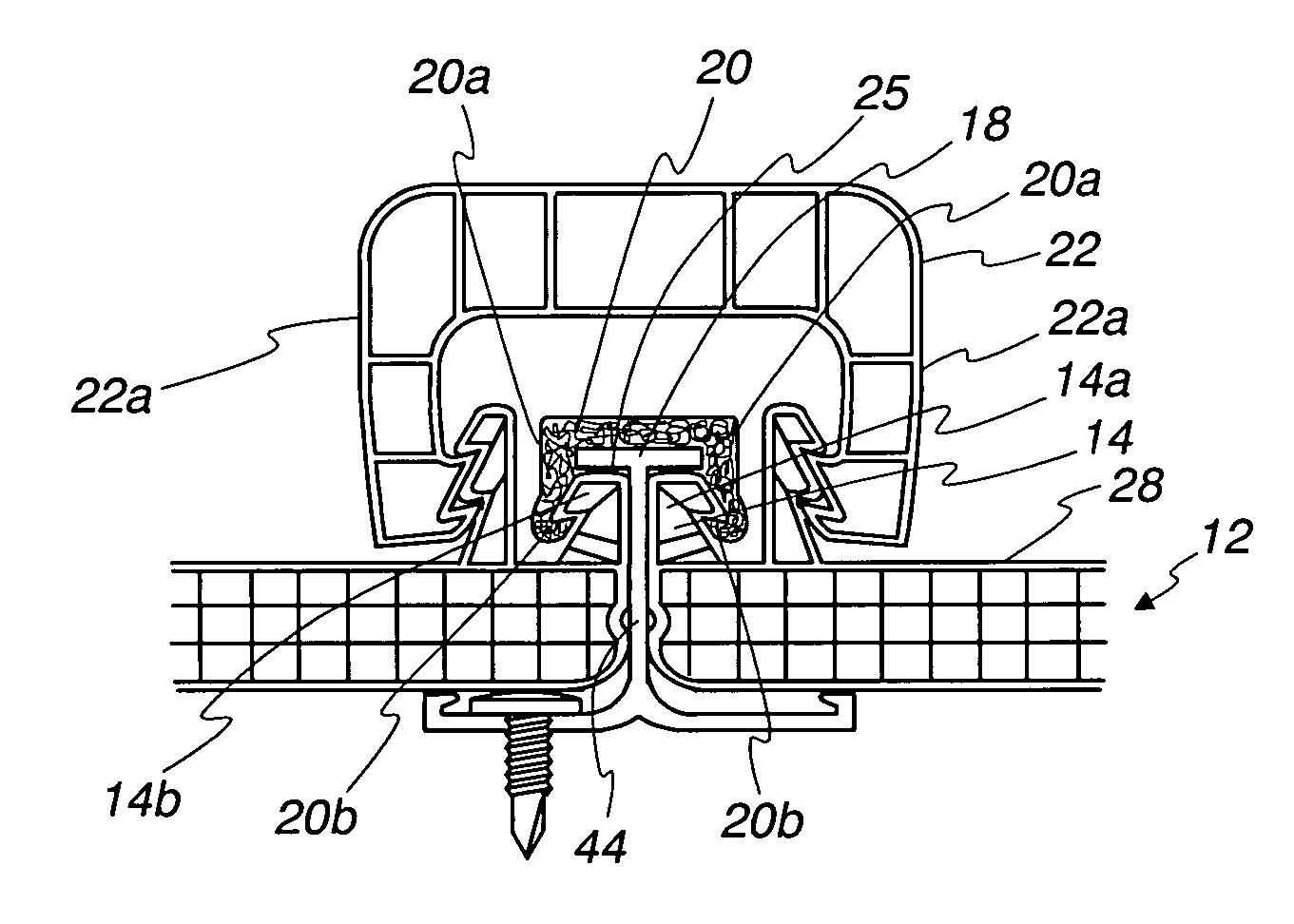

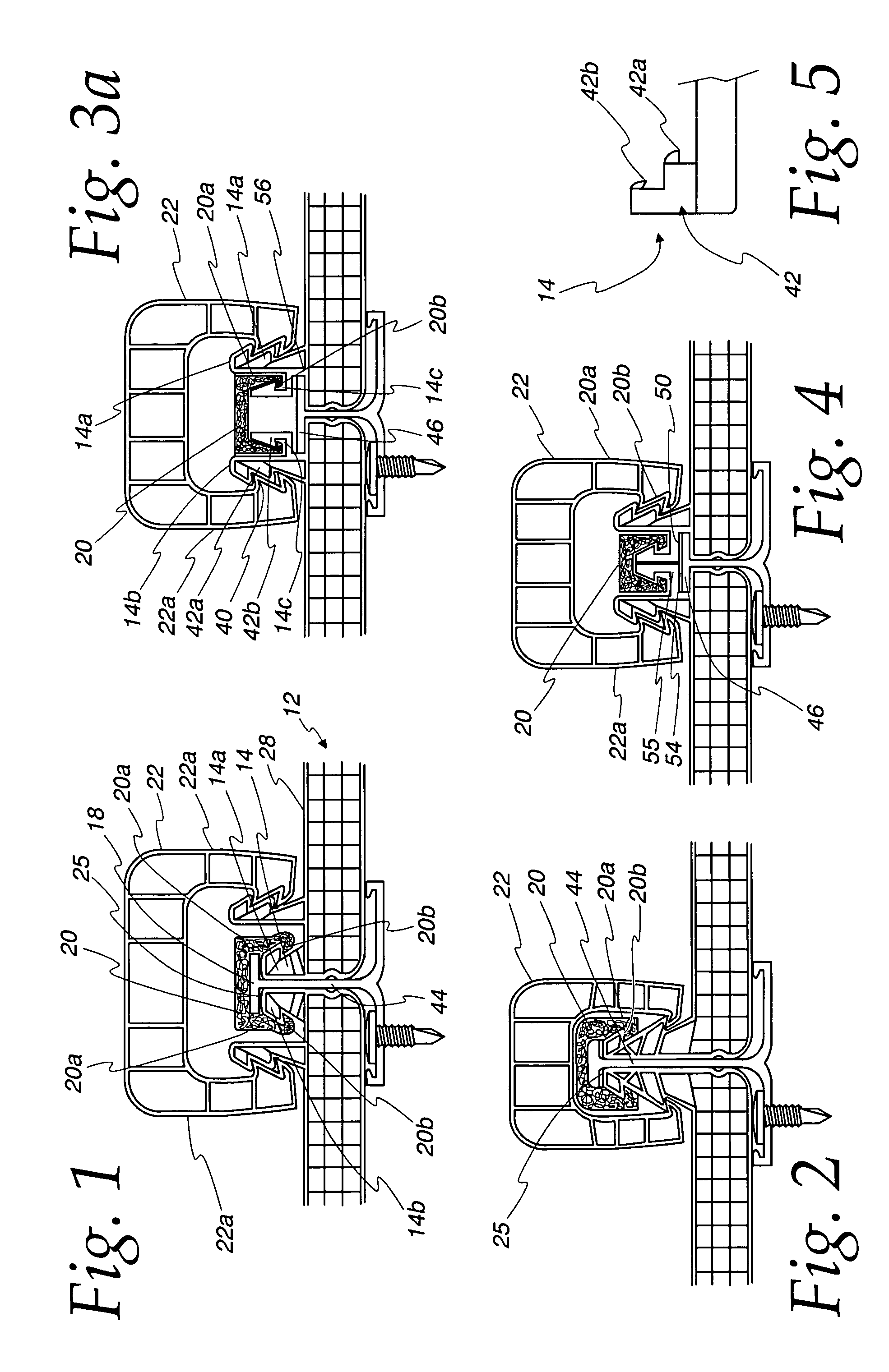

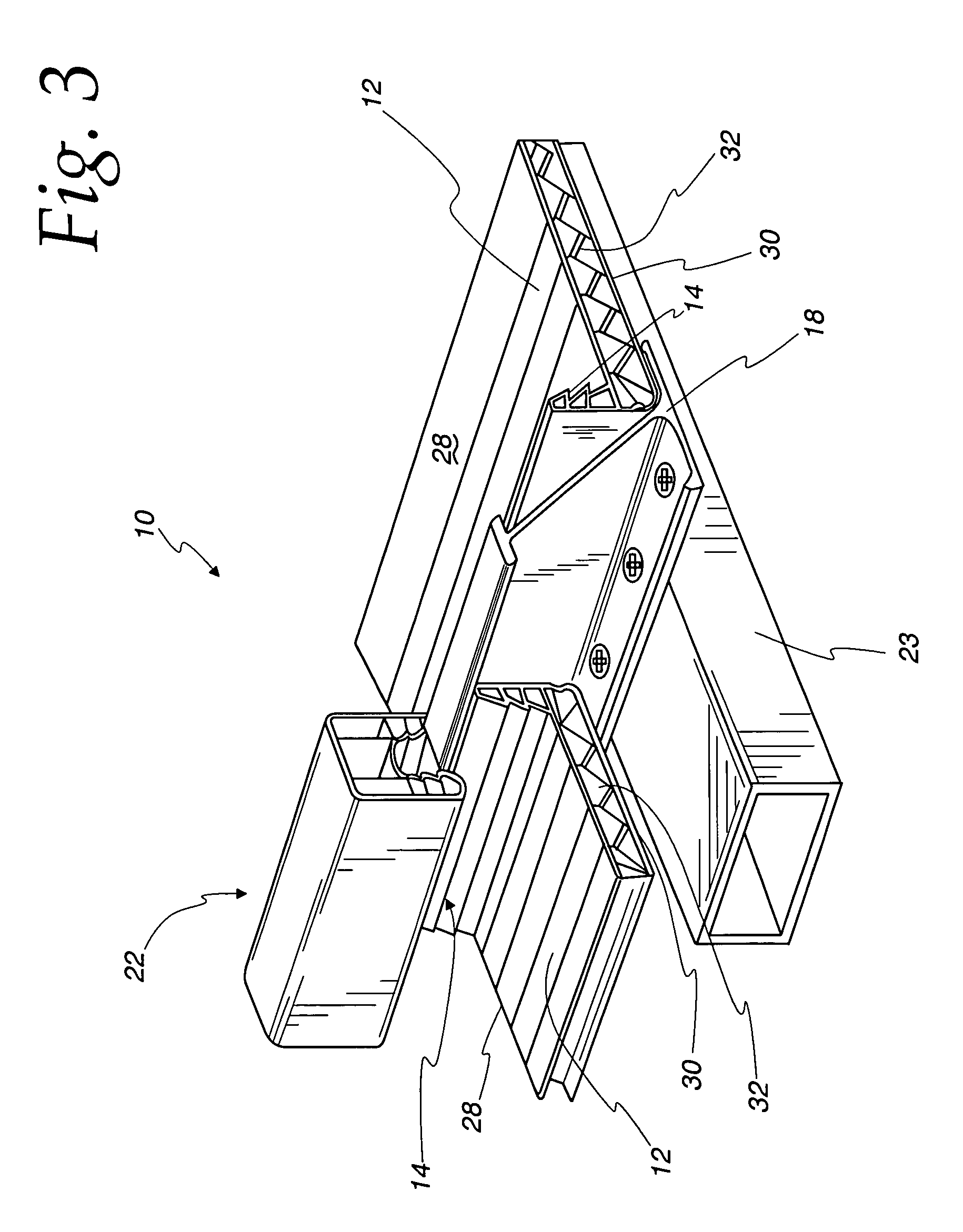

Light transmission panels, retaining clip and a combination thereof

ActiveUS7441379B2High retention rateEasy loadingRoof covering using slabs/sheetsBuilding roofsThick plateAdded resistance

A glazing panel system is provided with improved glazing panels, retention clips and / or U-shaped connectors. The retention clip may engage the glazing panels at locations lower than top ends of the upstanding seam flanges. In one embodiment, an internal U-shaped connector is positioned to engage the seam flanges while an external U-shaped connector covers the internal connector and the seam between adjacent glazing panels. The retention clips may be formed with an upper transverse portion that is movable relative to the base portion of the clip to accommodate panel expansion and contraction. Also, a thicker plate or portion may be provided at a top flange for the retention clip to provide increased resistance to uplift loads trying to bend the flange.

Owner:VIKON LLC

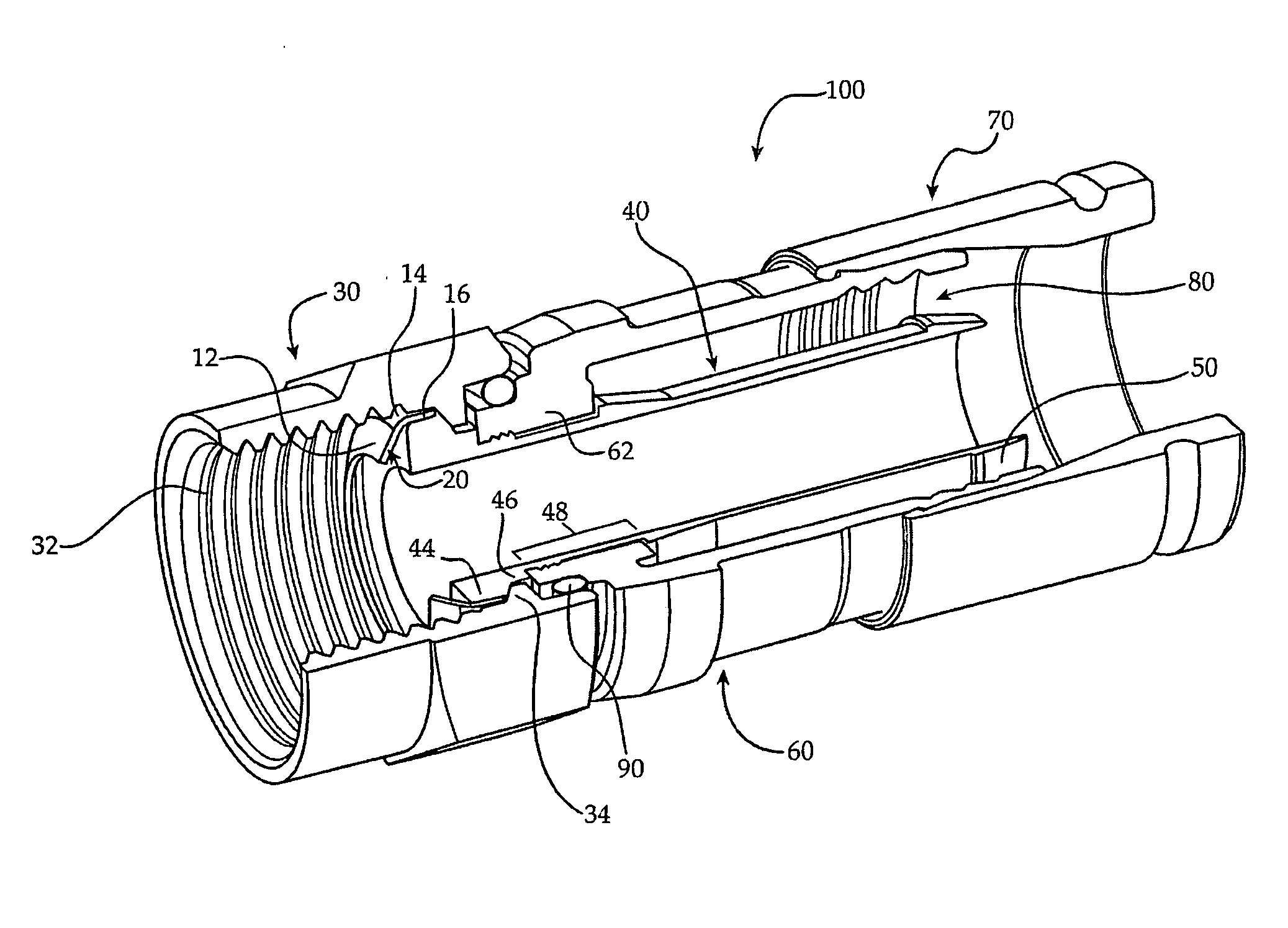

Flexible RF seal for coaxial cable connector

InactiveUS20080248689A1Closely connectedSave time and costLine/current collector detailsTwo pole connectionsCoaxial cableEngineering

The present invention incorporates a flexible seal into a typical coaxial cable connector. The seal comprises a flexible brim, a transition band, and a tubular insert with an insert chamber defined within the seal. In a first embodiment the flexible brim is angled away from the insert chamber, and in a second embodiment the flexible brim is angled inward toward the insert chamber. A flange end of the seal makes a compliant contact between the port and connector faces when the nut of a connector is partially tightened, and becomes sandwiched firmly between the ground surfaces when the nut is properly tightened. The present invention allows the connector to make a uniform RF seal on a port even with a range of tightening torques.

Owner:PPC BROADBAND INC

Dried hanging thermal insulation decorative curtain wall and mounting process thereof

InactiveCN101302782AReduce construction costsShorten construction timeCovering/liningsWallsThermal insulationKeel

The invention discloses a dry-hanging curtain wall for thermal insulation and decoration and an installation technique thereof, which essentially comprises a 'duplex F' shape installation hanging part; the radial frameworks and the zonal frameworks of the 'duplex F' shape installation hanging part are vertically arranged; a first layer of the radial frameworks with two or more than two layers is level to the zonal frameworks and the radial framework at the last layer is at a certain distance from the tail end of the zonal framework; the width and thickness of the radial frameworks at every layer can be equal or not. Insulation boards can be fixed in a point-typed installation and location method by the installation hanging part, thus overcoming the defects of the prior art, providing an installation technique of the thermal insulation and decoration curtain wall without installing the horizontal and the vertical joist, simplifying the installation procedure, saving the installation raw materials and cost and overcoming the defect that the rain leakage is easy to happen in the splicing seam of the insulation board adopting the traditional method.

Owner:SHENZHEN MINGYUAN BUILD MATERIALS TECH

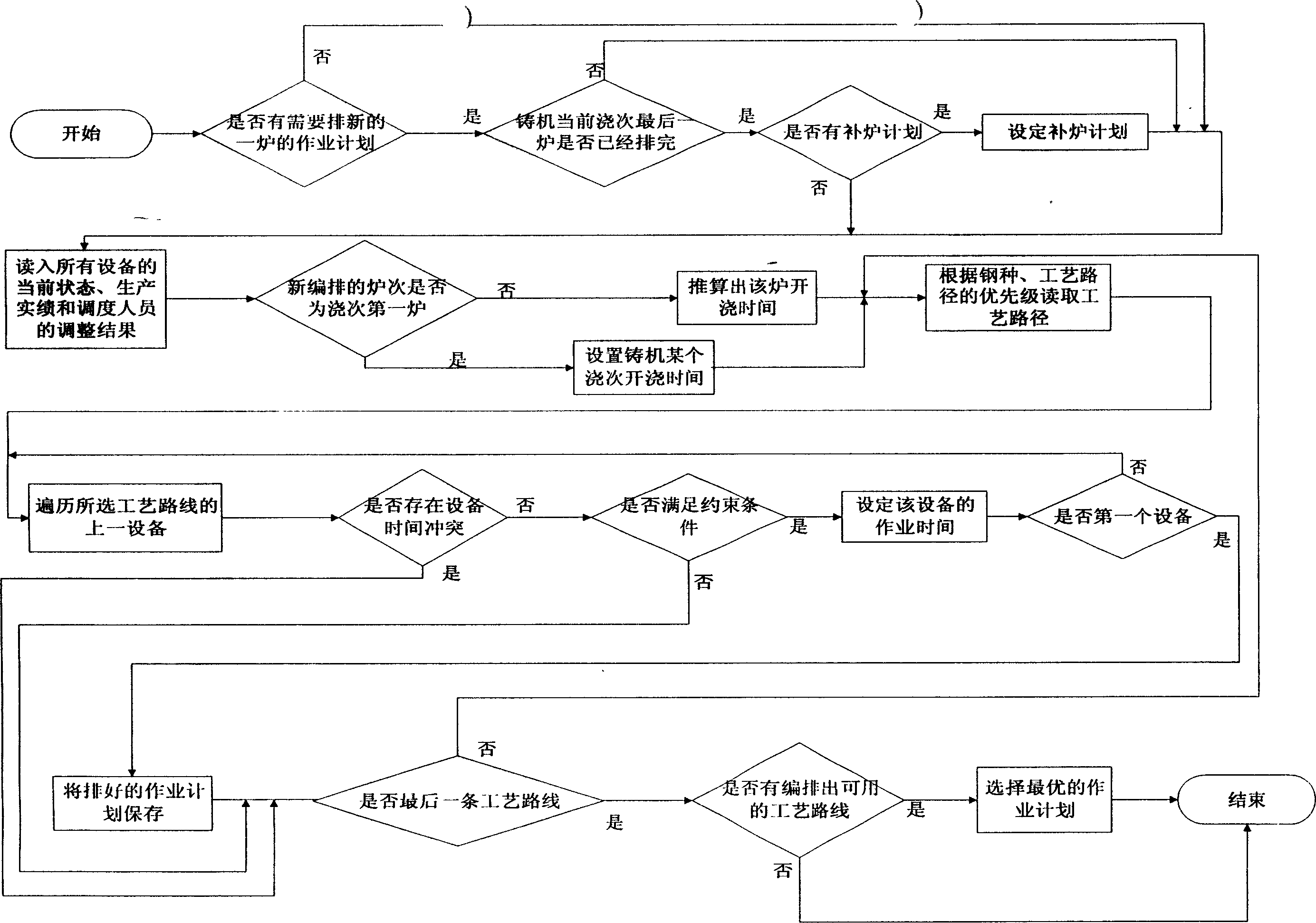

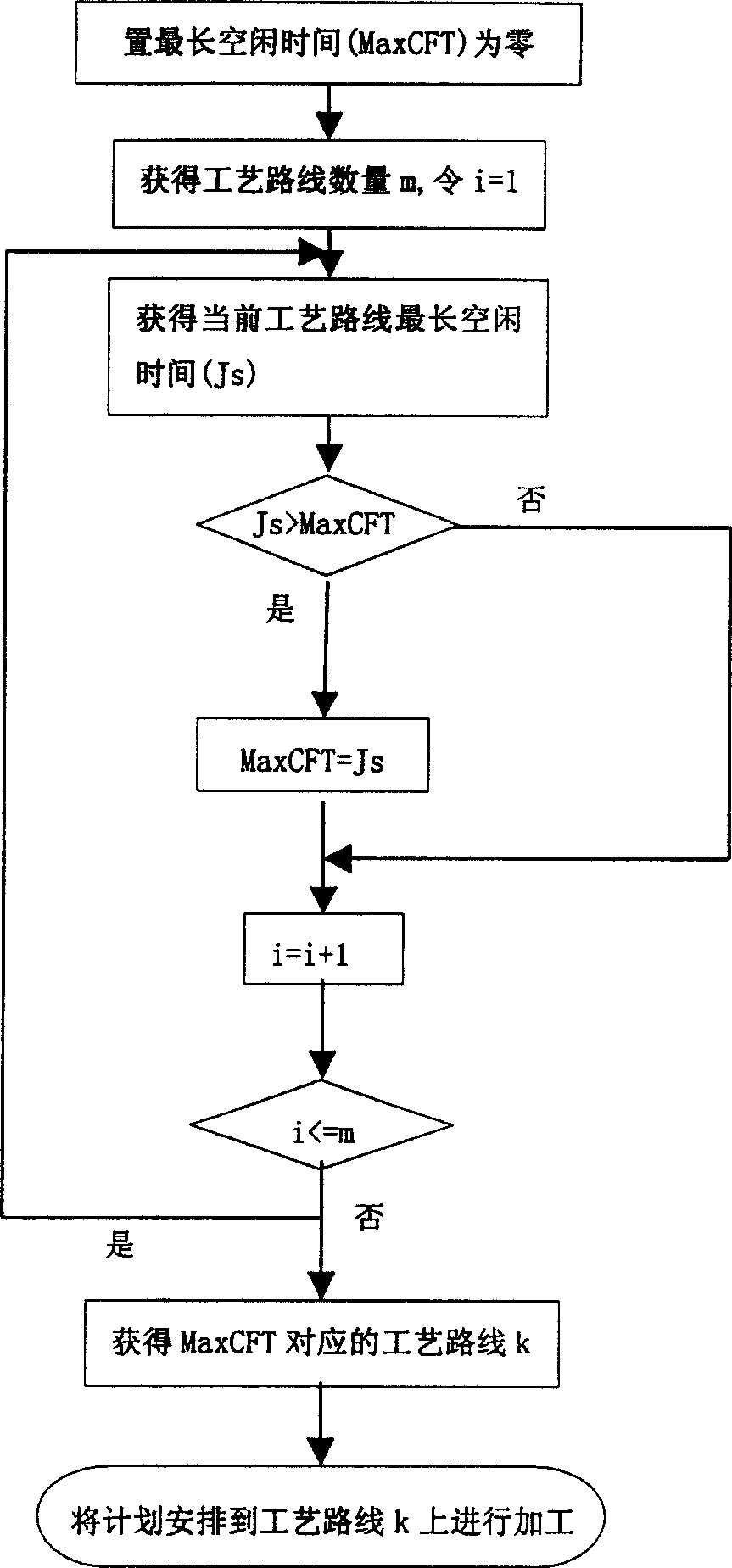

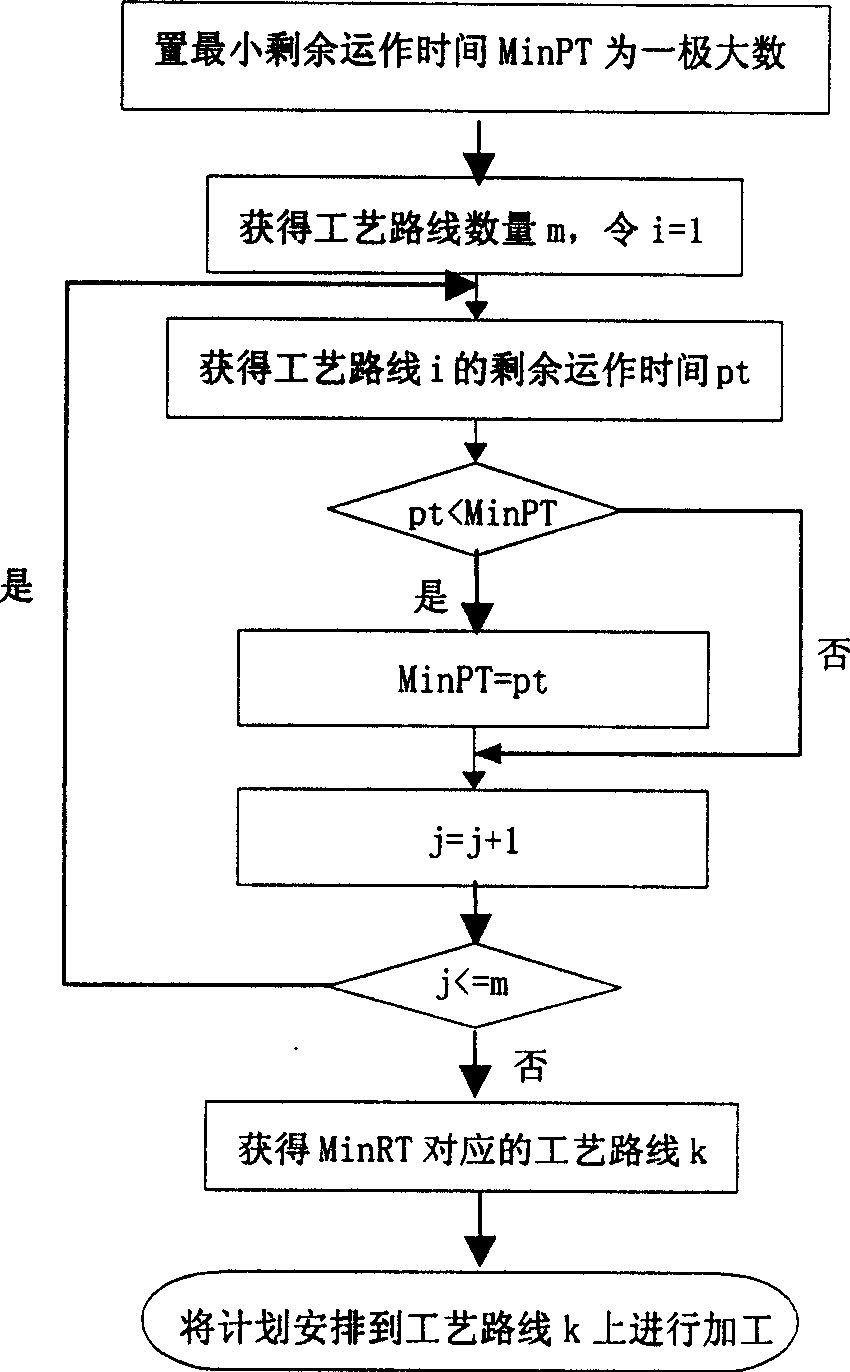

On-line dynamic dispatching method for continuous steel casting production

InactiveCN1614618AReduce cumulative time errorEasy production organizationSpecial data processing applicationsComputerized systemWorkstation

An on-line dynamic dispatching method for continuous production of steel making includes applying distributed computer system; working out a dynamic operation plan suitable for current production state by collecting data from site process and equipment, combining the set of dispatcher and using roll search mode; following the plan to carry out operation by operation station and feeding back regulation request to dispatching room for used as basis of next dispatch.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

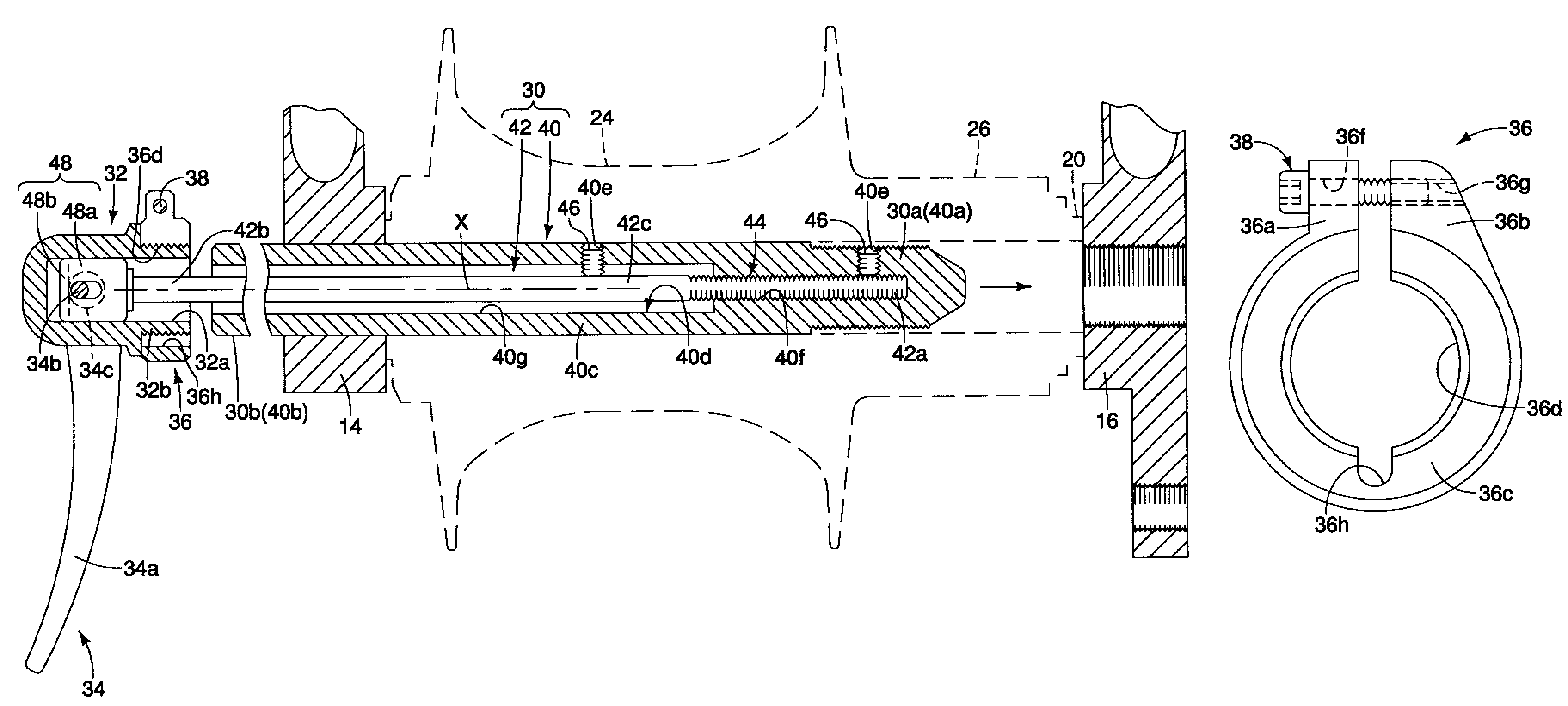

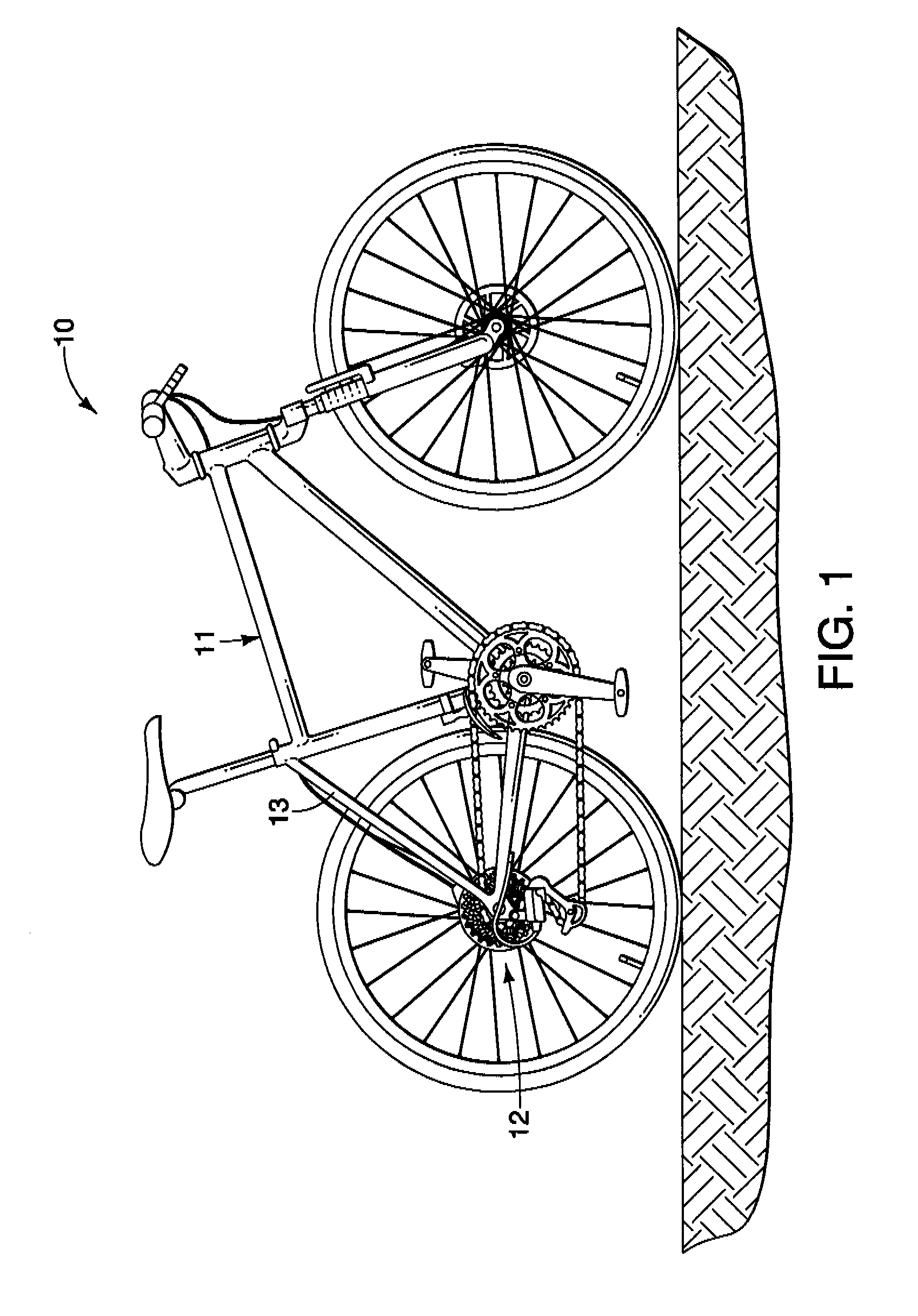

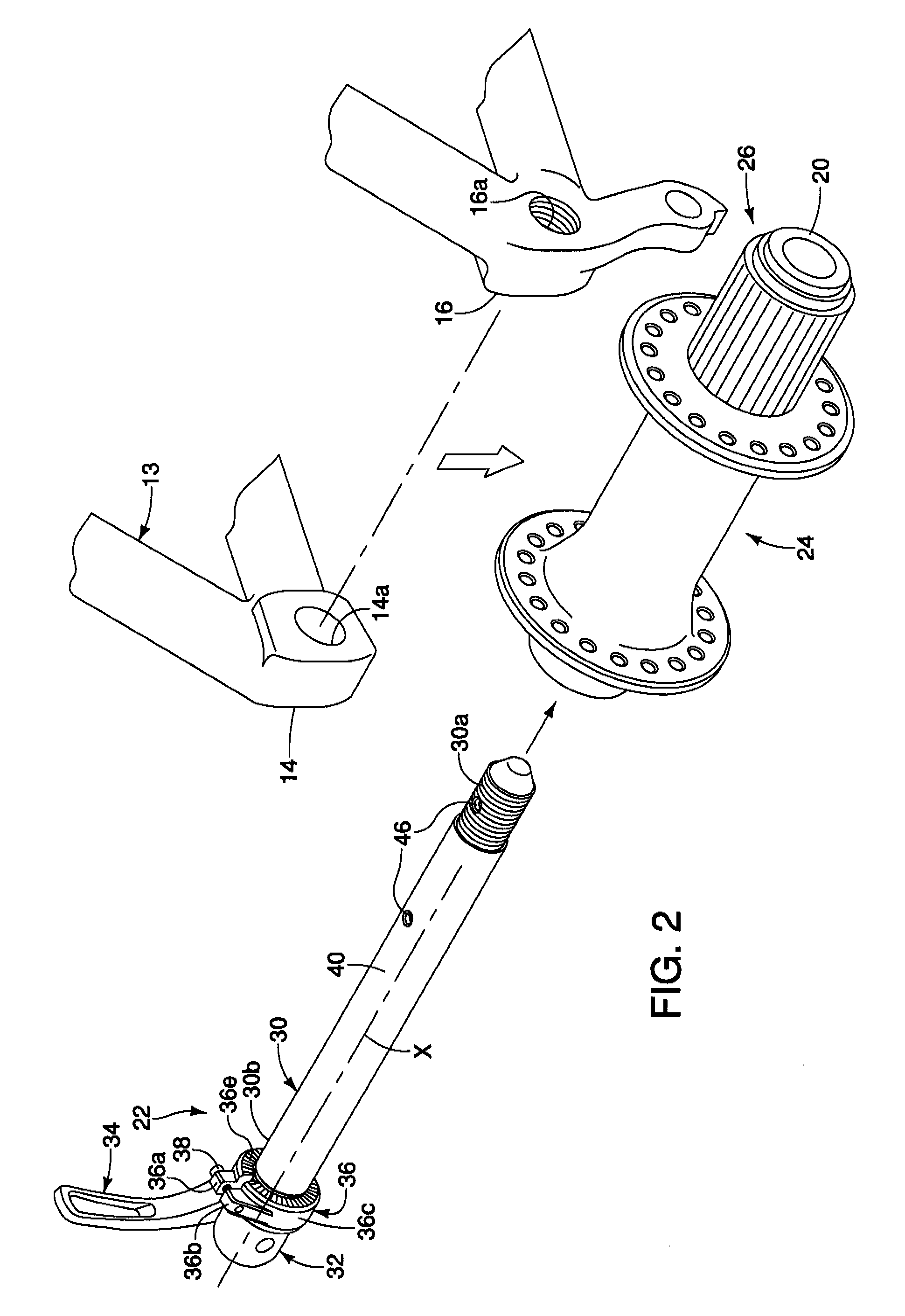

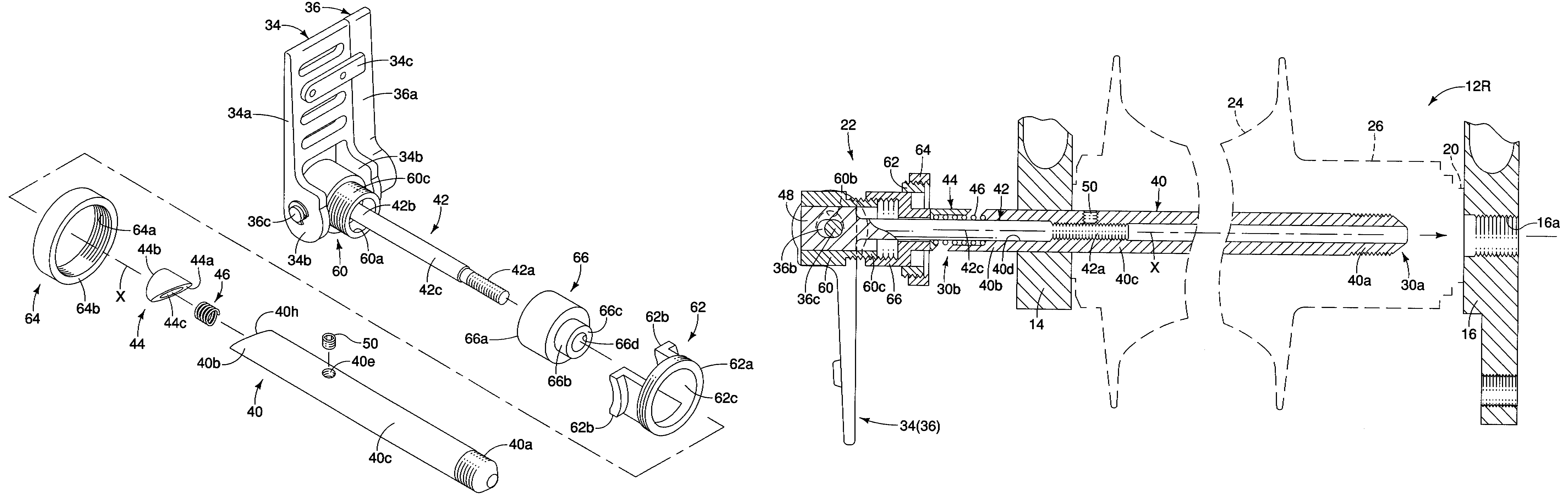

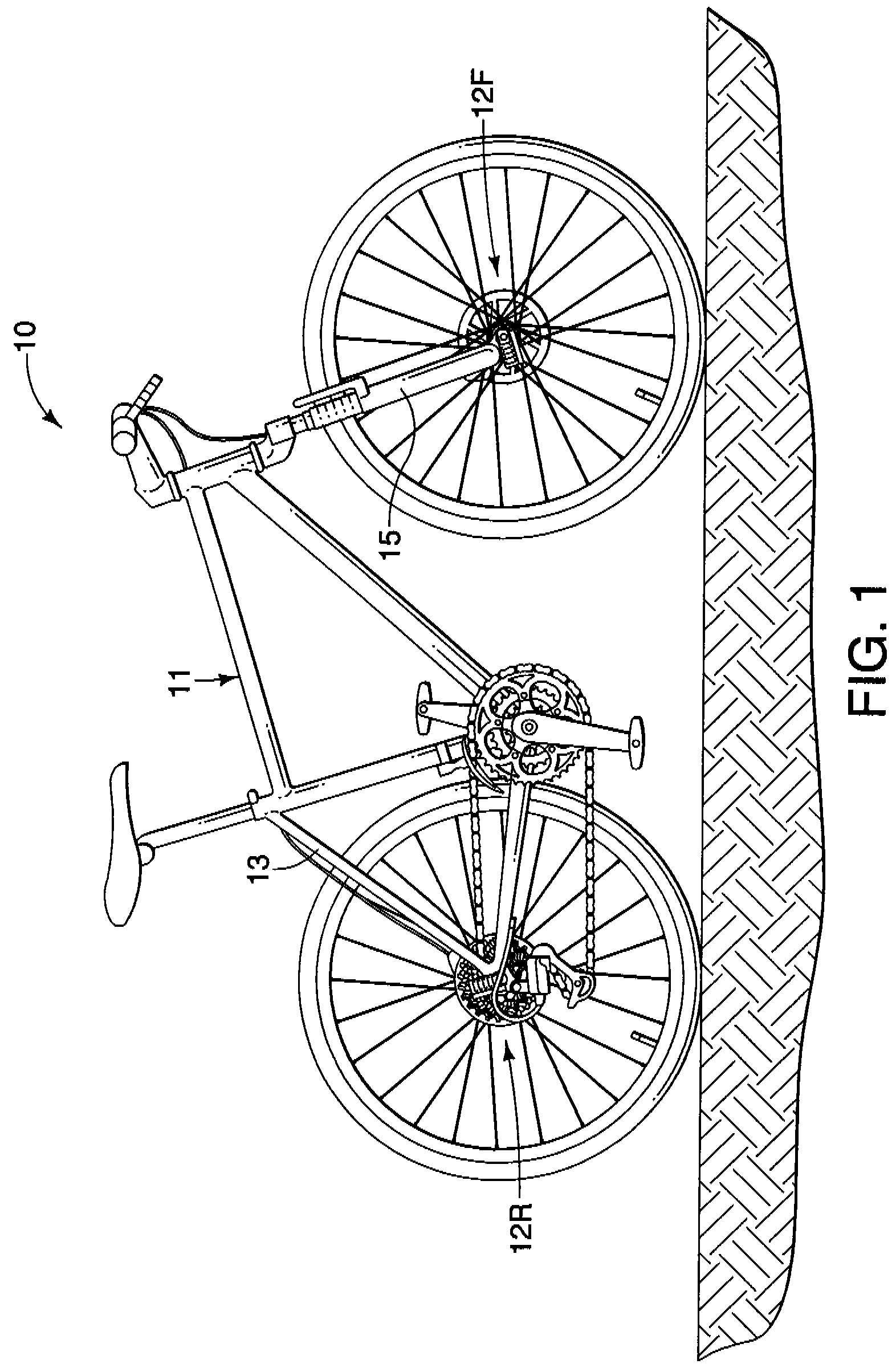

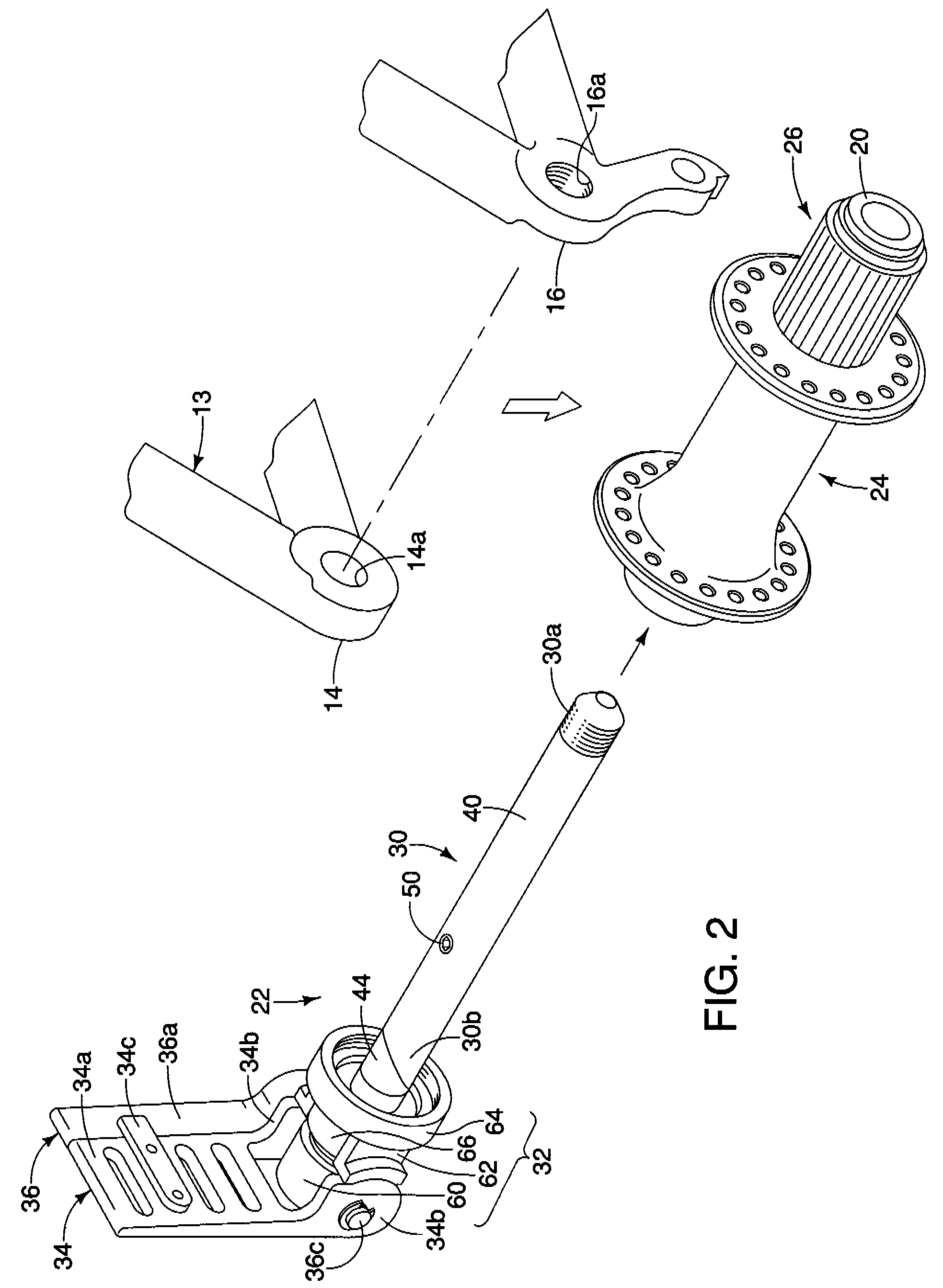

Bicycle wheel securing structure

ActiveUS7537291B2Easy to tightenClosely connectedHubsRod connectionsEngineeringMechanical engineering

A bicycle wheel securing structure includes a shaft member, a head member, a lever member and an adjustment member. The shaft member has a first threaded end and a second end with a center axis extending therebetween. The head member is disposed on the second end of the shaft member. The lever member is operatively mounted between the shaft member and the head member to move the shaft member in an axial direction relative to the head member in response to movement of the lever member. The adjustment member is axially adjustably coupled to the head member such that an axial position of an abutment surface of the adjustment member can be adjusted relative to the shaft member.

Owner:SHIMANO INC

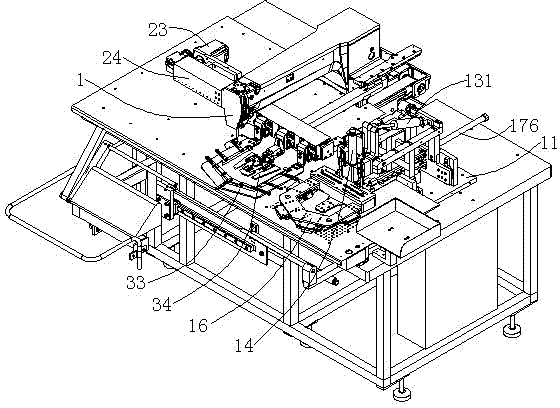

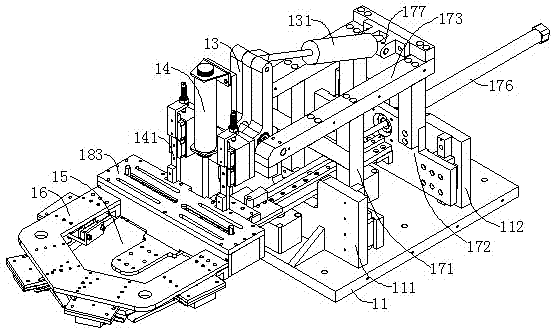

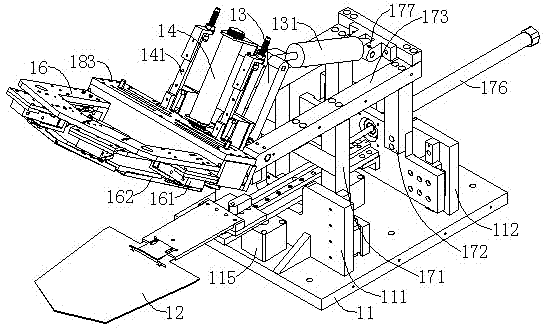

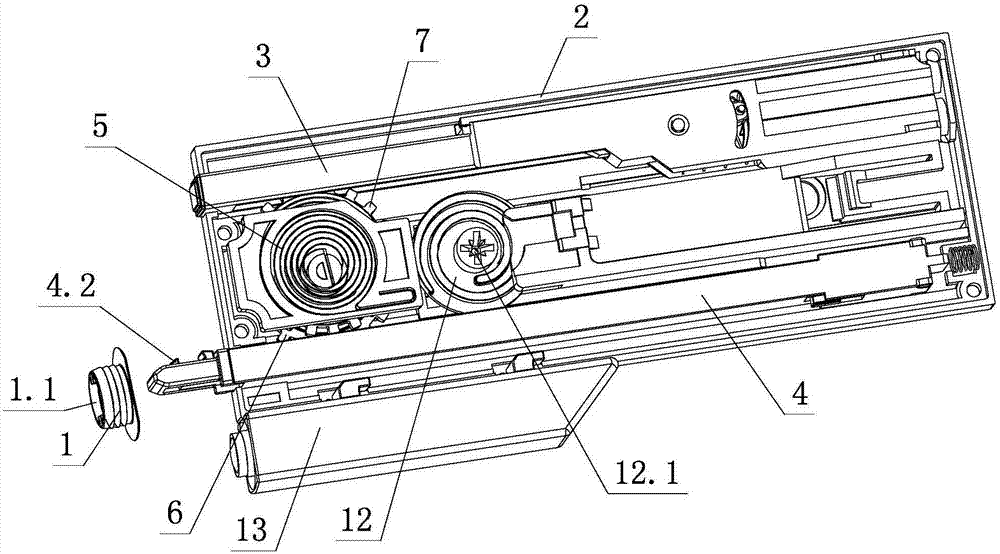

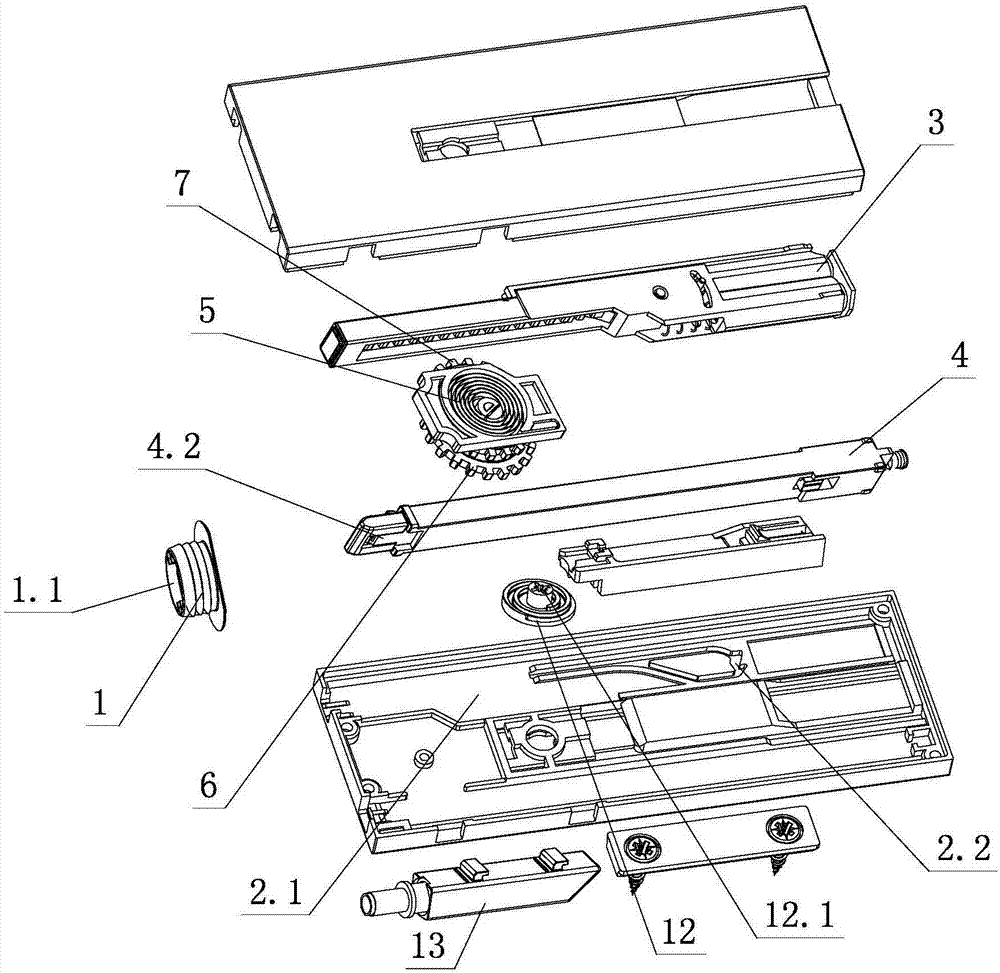

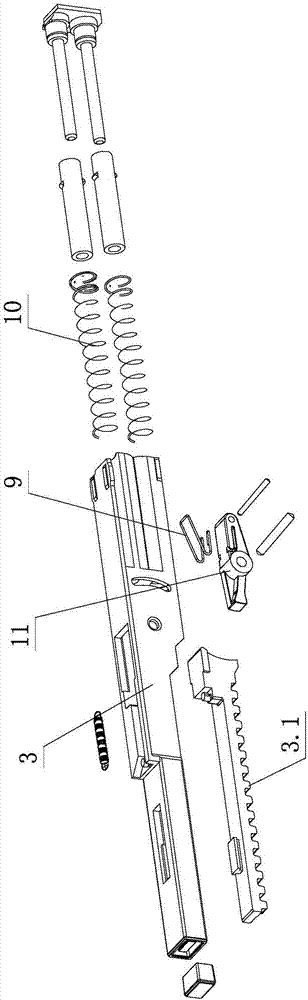

Full-automatic patch pocket machine

ActiveCN102899817ACompact structureSave installation spaceWork-feeding meansPressersEngineeringSewing machine

The invention discloses a full-automatic patch pocket machine which comprises a sewing machine head, a folding device, a pressing device and a feeding device, wherein the folding device comprises a mounting bracket which is capable of vertically moving and is arranged on a fixed base plate; a template for loading a pocket piece is arranged on the mounting bracket; the template can horizontally stretch relative to the mounting bracket; a pressing plate and a folding bracket are fixedly connected with a moveable bracket; the pressing plate is used for pressing by matching with the template; thefolding bracket is provided with a folding cylinder; a feeding mounting plate which is connected with the feeding device is arranged on the pressing device; an auxiliary pressing foot and a pressing frame are arranged on the feeding mounting plate; the auxiliary pressing foot is used for pressing the pocket piece on the template; the pressing frame is used for pressing cloth; pressing blocks are distributed on the periphery of the pressing frame; and the feeding device is used for driving the pressing device to send the pressed pocket piece and cloth to a sewing position of the sewing machinehead. The full-automatic patch pocket machine can be used for folding the pocket piece into a pocket and sewing on the corresponding cloth and solving the problems of complex pocket processing structure and low working efficiency of the prior art.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

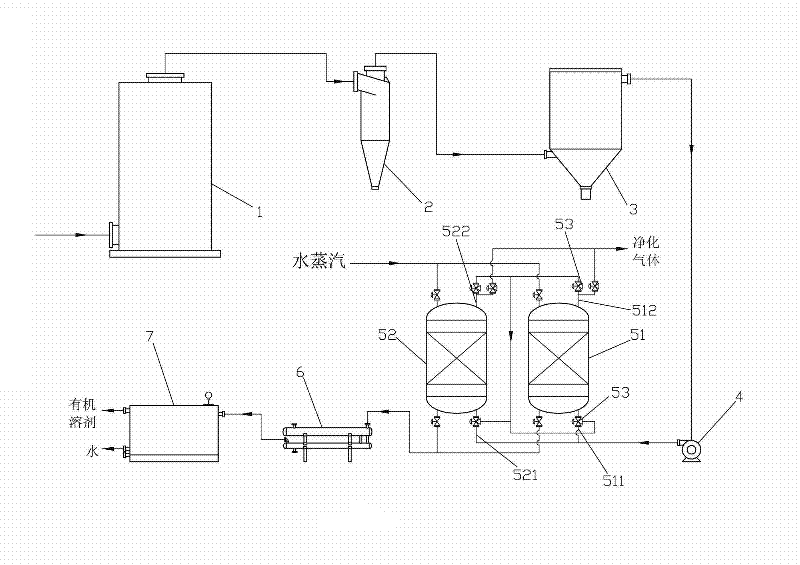

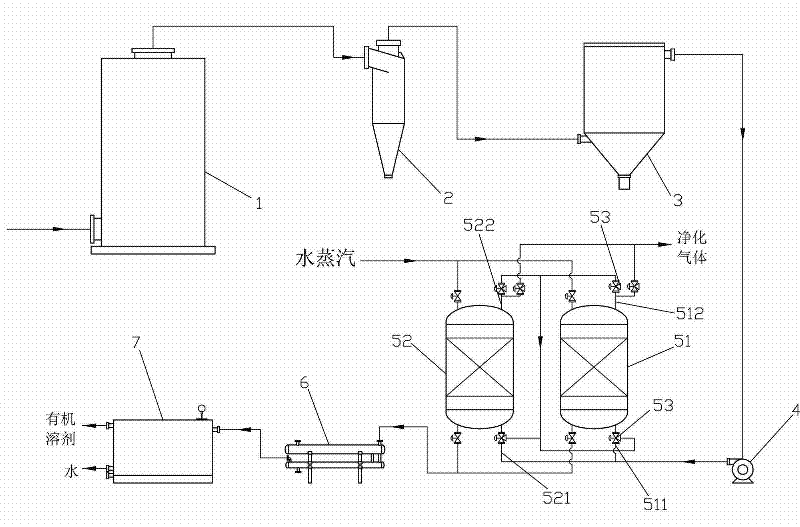

Recycling device for exhaust gas of painted organic solvent and method for recycling organic solvent

The invention discloses a recycling device for an exhaust gas of a painted organic solvent. The recycling device comprises a painting fog removing device, a fan, an absorbing jar, a condenser and an oil-water separator which are connected in turn, wherein the painting fog removing device comprises a gas collecting tank, a cyclone dust collector and a bag type dust collector; the gas collecting tank is used for temporarily storing the exhaust gas of the organic solvent; and the gas collecting tank, the cyclone dust collector and the bag type dust collector are connected in turn. All componentsof the recycling device are reasonably and compactly jointed; collection efficiency is high; and the painting fog is efficiently removed while a trouble in frequently exchanging filter cotton is avoided. The invention also discloses a method for utilizing the recycling device for the exhaust gas of the painted organic solvent to recycle the organic solvent. The method comprises the following steps: removing the painting fog; absorbing; desorbing steam; condensing; and separating oil from water, wherein the step of removing the painting fog is carried out by changing the painting fog into painting powder and then efficiently removing the painting fog. Compared with a traditional process, the method is more reasonable, compact and labor-saving.

Owner:中科天龙(厦门)环保股份有限公司

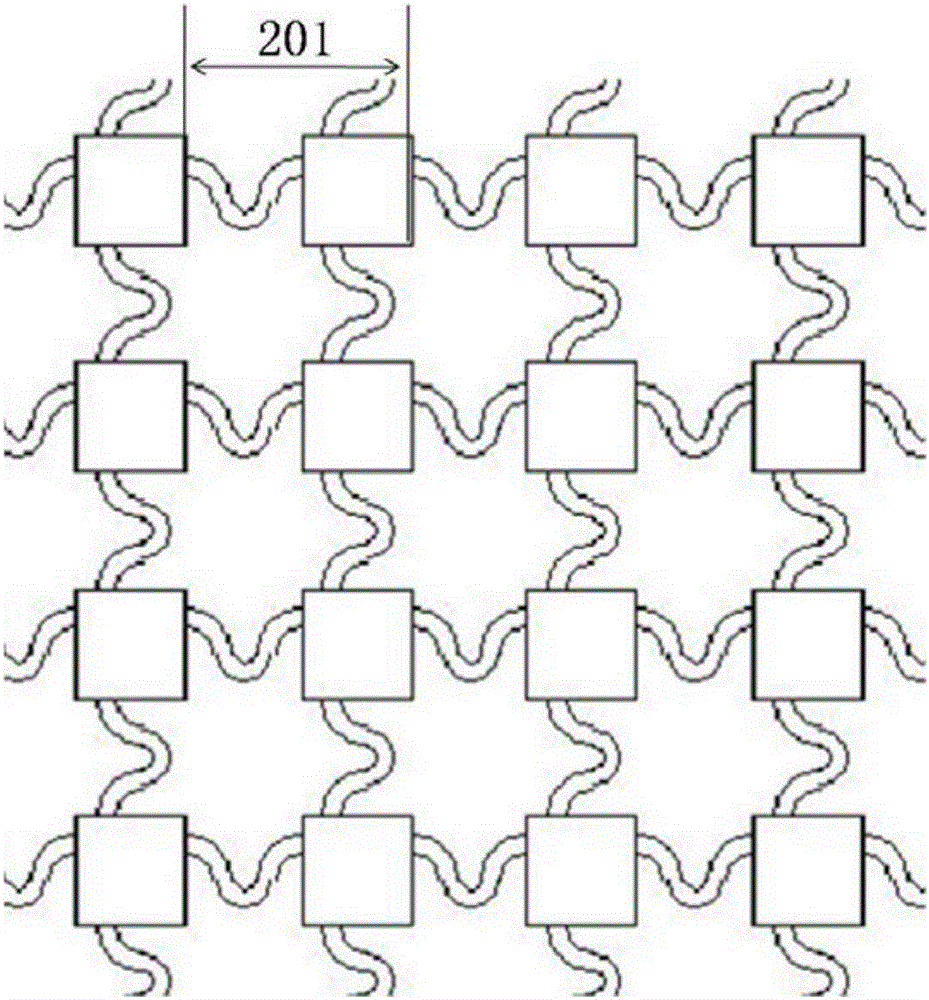

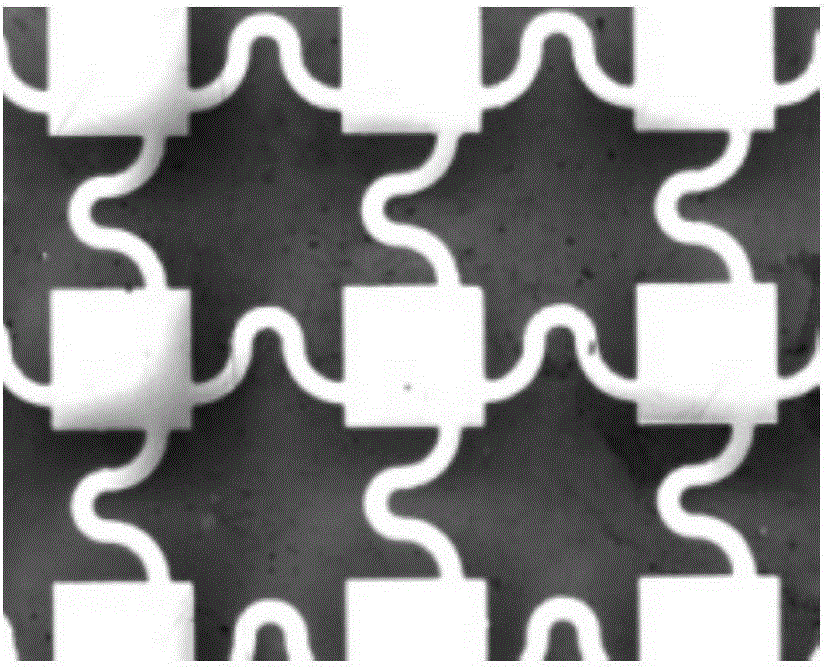

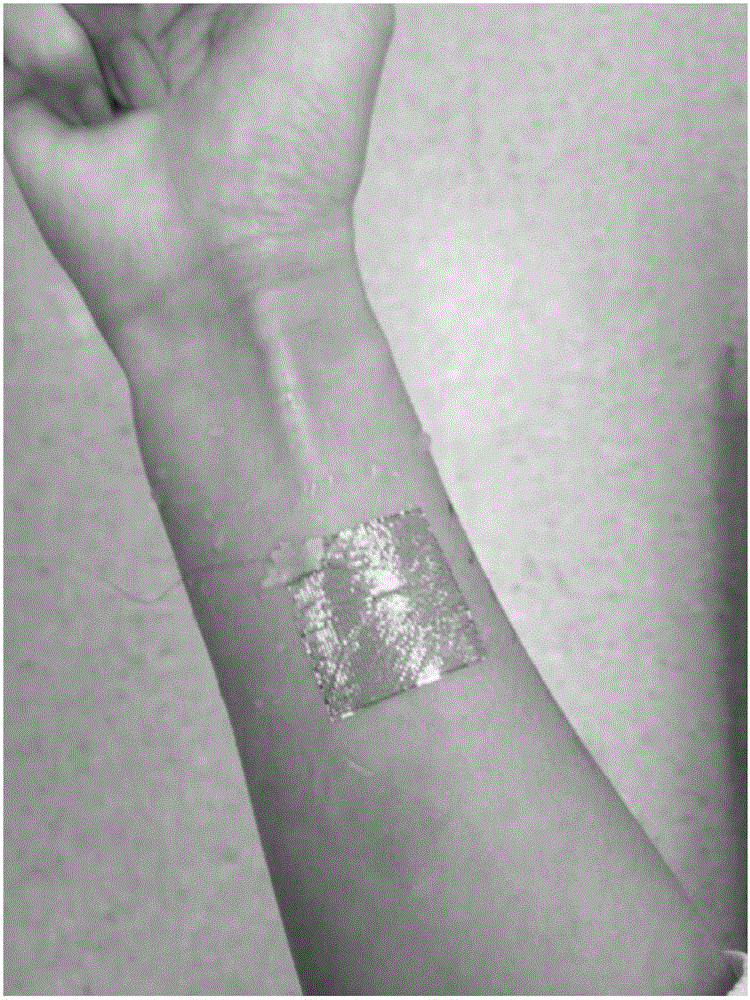

Method for manufacturing and using wearable flexible skin electrode

InactiveCN105326495AUndisturbedEasy to wearDiagnostic recording/measuringSensorsMicro nanoHuman body

The invention discloses a method for manufacturing and using a wearable flexible skin electrode. By fusion of the method and a novel micro-nano machining technology, the wearable flexible skin electrode is fixed to the skin surface through an ultrathin, nontoxic and high-biocompatibility skin adhesive without conductive adhesives, and the electrode can be well fused with the skin of a human body and is capable of moving along with stretching of the skin, high in comfort and less prone to shedding. Since the electrode is in directly close connection with the skin, low impedance, high sensitivity and high stability are achieved, and interference of limb movement is avoided. The electrode has waterproof and sweatproof functions and is capable of monitoring electric signals of the human body in large-amplitude motion. A human body electric signal detection device manufactured with the skin electrode has the advantages of small size, light weight, convenience in wearing, availability for long-term use, low cost and benefit of popularization for long-term health monitoring and acquisition of health big data of people in wide range.

Owner:杨军

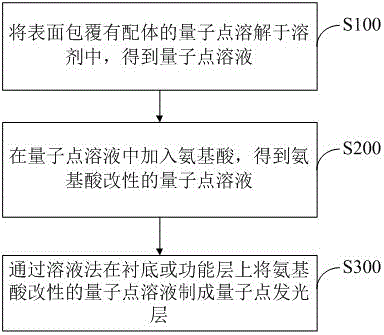

Quantum dot luminescent layer and preparation method thereof, and quantum dot light-emitting diode (QLED) and preparation method thereof

ActiveCN106601925AReduce surface defectsClosely connectedSolid-state devicesSemiconductor/solid-state device manufacturingElectron injectionQuantum dot

The invention discloses a quantum dot luminescent layer and a preparation method thereof, and a quantum dot light-emitting diode (QLED) and a preparation method thereof. The preparation method of the quantum dot luminescent layer comprises the following steps: dissolving a quantum dot whose surface is clad with a ligand in a solvent so as to obtain a quantum dot solution; adding amino acid in the quantum dot solution to obtain an amino modified quantum dot solution; and through a solution method, preparing the amino modified quantum dot solution into the quantum dot luminescent layer on a substrate or a function layer. According to the invention, the amino acid is added to the quantum dot solution, on one hand, the formed quantum dot luminescent layer is totally uniformly covered and is compact and flat; and on the other hand, through introduction of the amino acid, the quantum dot luminescent layer can be closely anchored on the substrate or the function layer below or above the quantum dot luminescent layer, the quantum dot luminescent layer is enabled to be closely connected with the substrate or the function layer, the interface stability and the interface property are maintained, surface defects of the quantum dot are passivated, the electron injection efficiency is effectively improved, the life of a QLED device is prolonged, and the stability of the QLED device is improved.

Owner:TCL CORPORATION

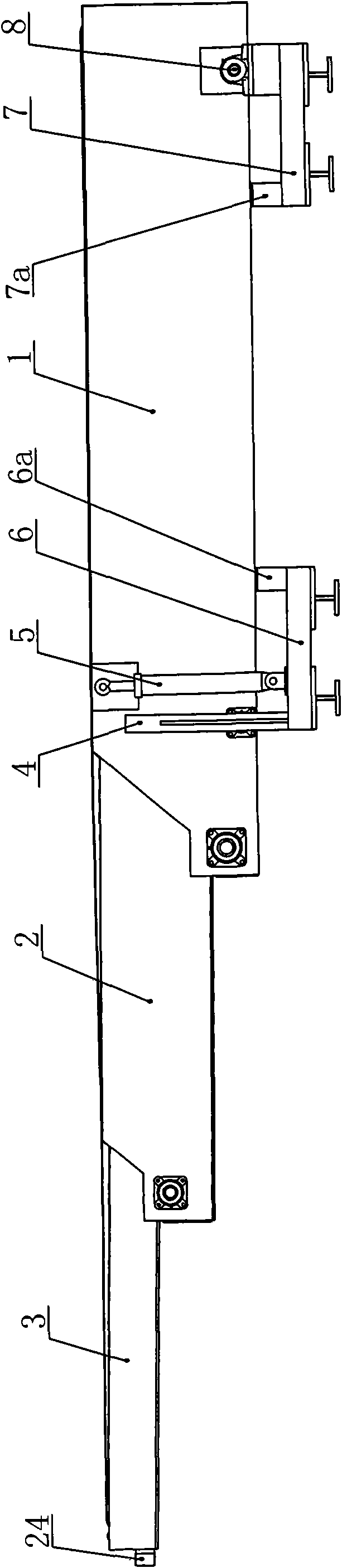

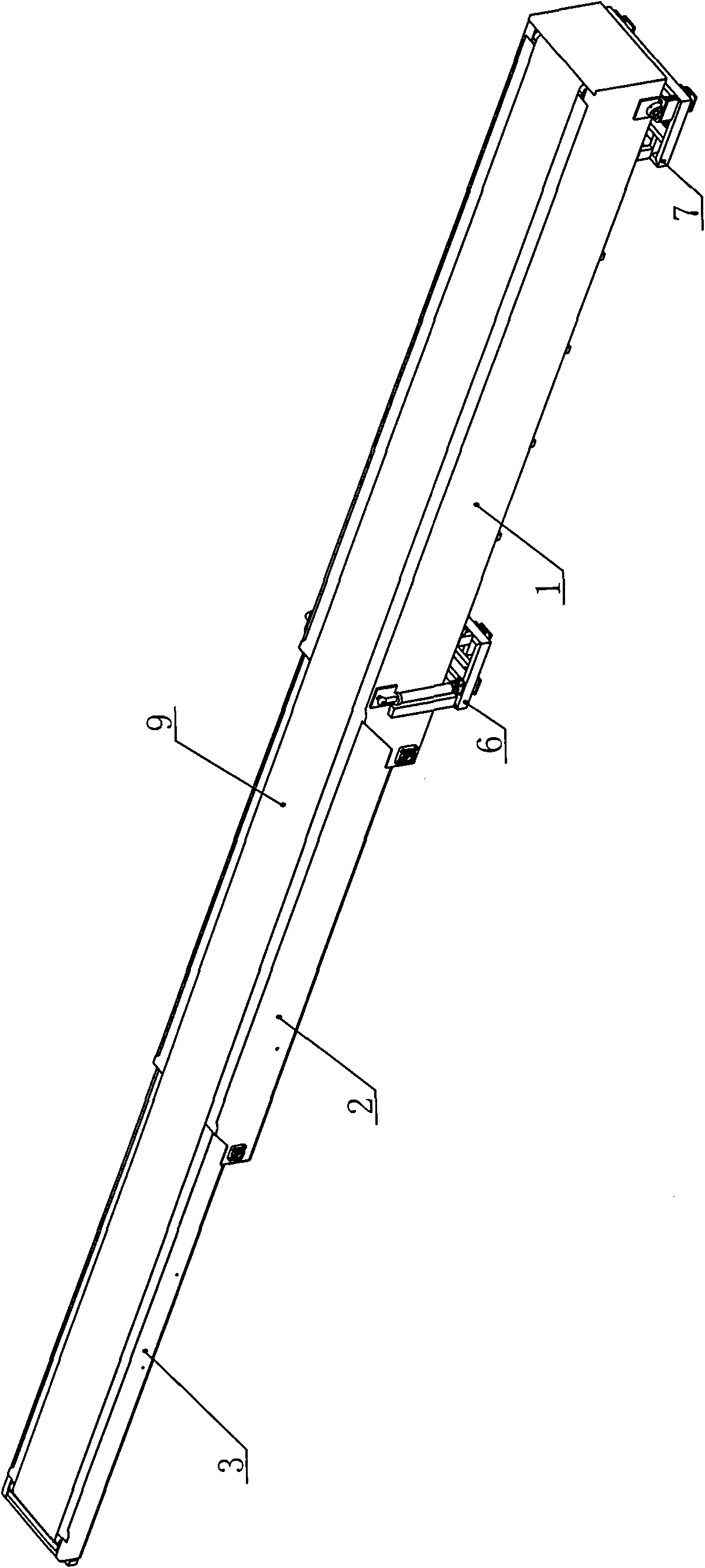

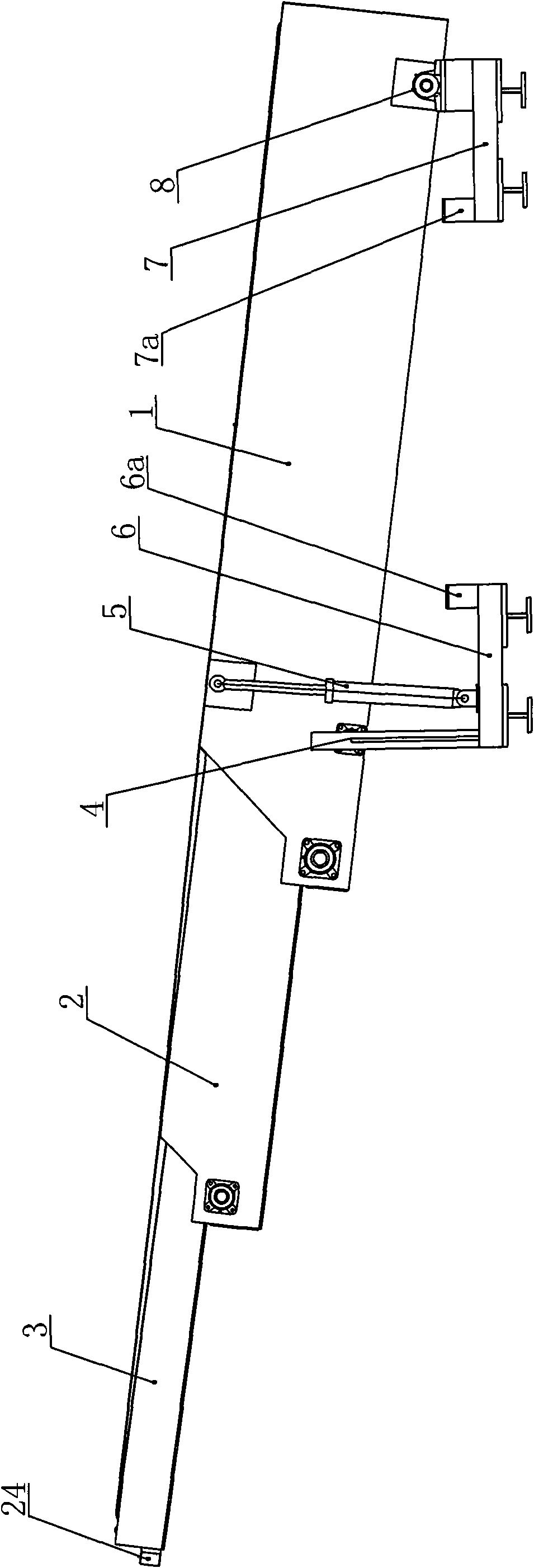

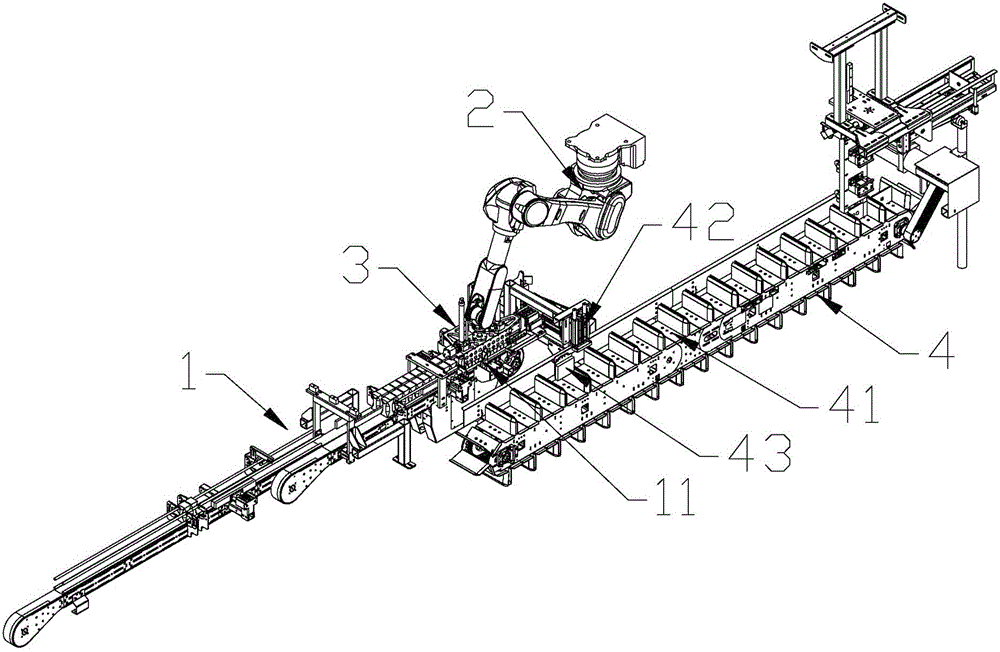

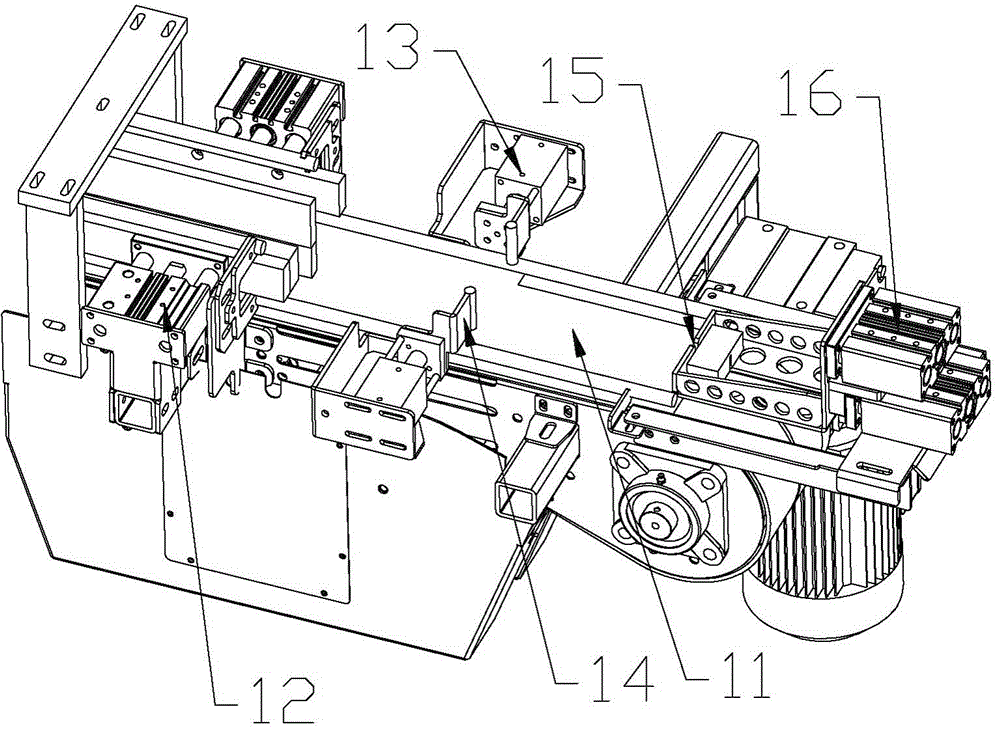

Telescopic bidirectional loading and unloading conveyor

ActiveCN101955068AIncrease contact areaAccurate connectionConveyorsControl devices for conveyorsEngineeringExpansion joint

The invention discloses a telescopic bidirectional loading and unloading conveyor, which belongs to the field of storage and logistics. The telescopic bidirectional loading and unloading conveyor comprises a base joint, a primary expansion joint, a secondary expansion joint, a belt conveying mechanism, a telescopic mechanism, and an elevator mechanism, wherein a front pedestal and a back pedestalare respectively arranged below the two ends of the base joint, and the back part of the base joint is hinged on the back pedestal; a lifting oil cylinder of the elevator mechanism is hinged on the front pedestal and a piston rod of the elevator mechanism is hinged on the front part of the base joint; the primary expansion joint is nested in the cavity of the base joint and can expand and contract along the base joint under the driving of the primary expansion joint; the secondary expansion joint is nested in the cavity of the primary expansion joint and can expand and contract along the primary expansion joint; the belt conveying mechanism comprises a conveying motor, a belt driven roller and a conveying belt; turnabout drums are respectively arranged at the front and back ends of the base joint, the primary expansion joint and the secondary expansion joint; and the conveying belt can be orderly wrapped on the belt driven roller and each turnabout drum to form a sealed conveying ring. The loading and unloading conveyor has the advantages of bidirectional conveying, convenient move, adjustable conveying height and distance, safety and reliability.

Owner:YANGZHOU SINO-EU IND ROBOT CO LTD

Bicycle wheel securing structure

InactiveUS7530645B2Easy to tightenClosely connectedHubsRod connectionsEngineeringMechanical engineering

Owner:SHIMANO INC

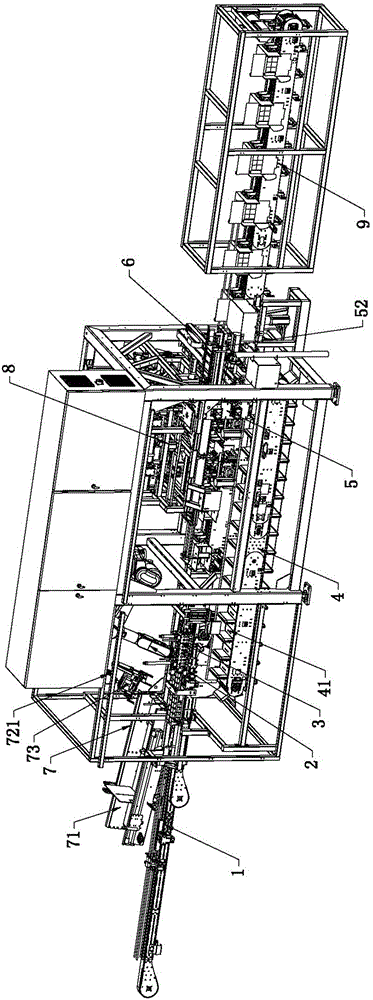

Automatic encasement system for Lilezuan milk bag gift boxes

ActiveCN104828288ASolve the problem that it is difficult to vertically transport automatic packingPrecise movement controlIndividual articlesEngineeringWorkload

The invention discloses an automatic encasement system for Lilezuan milk bag gift boxes. The automatic encasement system comprises a milk bag integration conveying line (1), a milk bag robot (2) and a milk bag unit conveying line (4), wherein a milk bag clamp (3) at the lower end of a manipulator of the milk bag robot (2) catches a milk bag unit on the milk bag integration conveying line (1) and pushes the milk bag unit into a corresponding milk bag unit separation slot (41) under the condition that the milk bag unit is in a horizontal state; then a small baffle plate insertion machine (5) inserts a small baffle plate into a middle clearance of the milk bag unit, and a horizontal pushing mechanism (6) is used for horizontally pushing the milk bag unit with the inserted small baffle plate into a packaging case already provided with a large lining plate on a packaging case conveying line (9); finally the packaging case already provided with the large lining plate, the small baffle plate and the milk bag unit is covered and encased to finish the whole automatic encasement process. According to the automatic encasement system for the Lilezuan milk bag gift boxes, the milk bag encasement operation is creatively changed from vertical encasement into horizontal encasement, so that the production operation is more stable, the maintenance is easy and convenient, and the workload can be reduced to the maximum extent.

Owner:苏州澳昆智能机器人技术有限公司

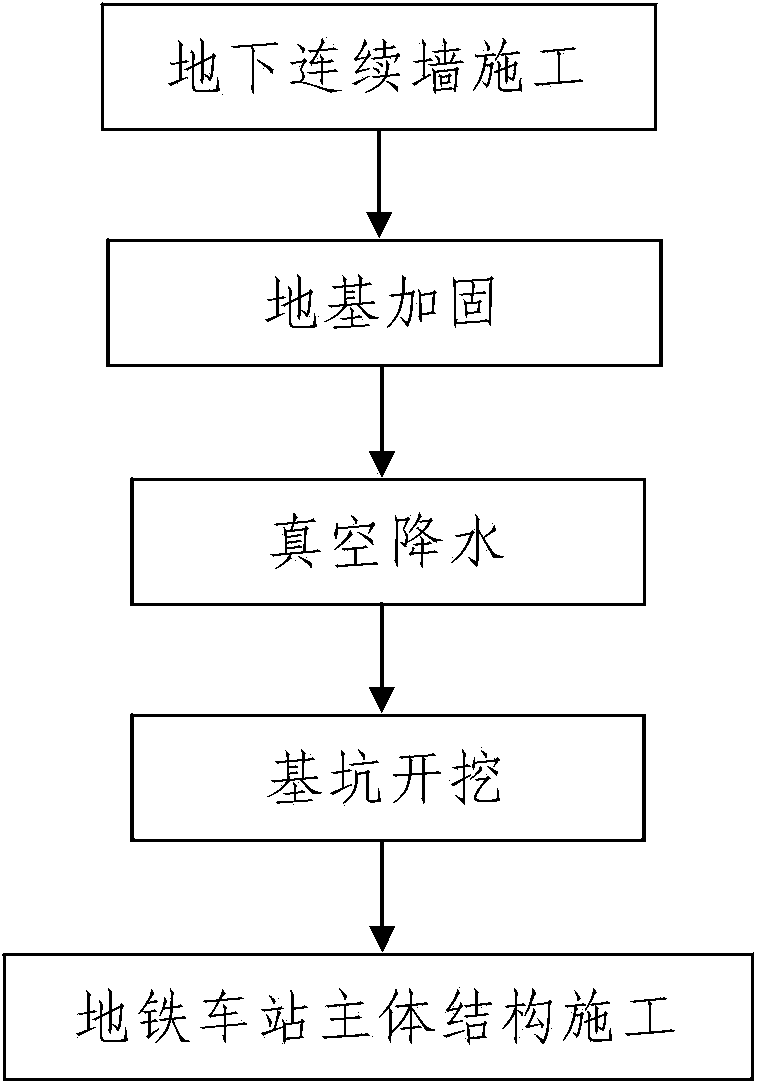

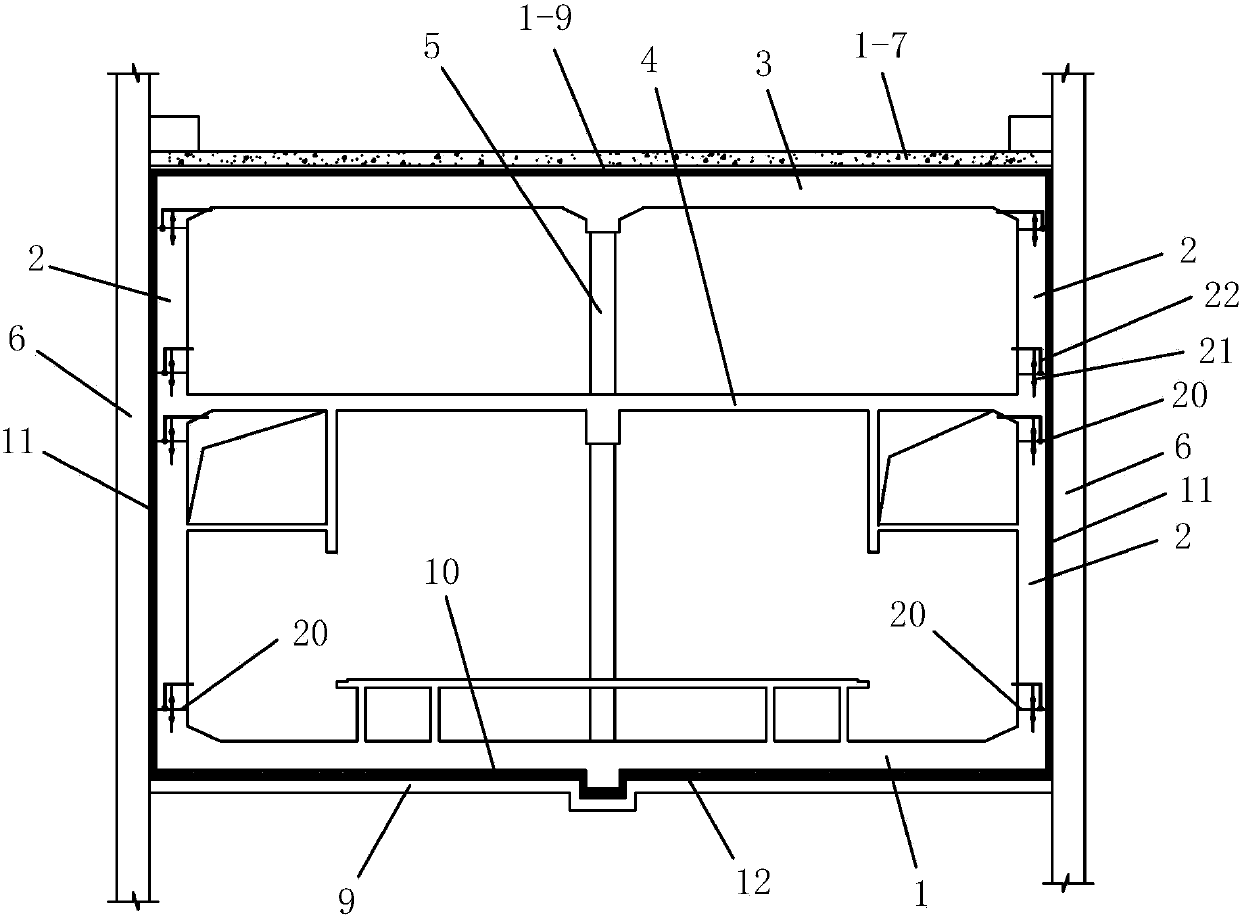

Peaty soft soil stratum subway station construction technology

ActiveCN103590425ASimplify construction stepsEasy constructionArtificial islandsProtective foundationSlurry wallReinforced concrete

The invention discloses a peaty soft soil stratum subway station construction technology. A main structure of a constructed subway station comprises base plates, side walls, top plates and middle plates distributed between the top plates and the base plates. Underground consecutive walls are arranged on outer sides of the two side walls. The base plates, the side walls, the middle plates and the top plates are all of a rebar concrete structure formed by pouring waterproof concrete. The subway station construction technology comprises the following steps: (1) underground consecutive wall construction, (2) foundation reinforcement, namely, three-shaft stirring piles are used for reinforcing the foundation of excavated foundation pits, (3) vacuum water falling, namely conducting vacuum well point water falling construction on the foundation pits needing excavating, (4) foundation pit excavation, namely, an open excavation method is used for conducting earthwork excavation on the foundation pits needing excavating with a plurality of excavating layers from top to bottom, (5) subway station main structure construction. The method is simple, convenient to realize, quick in construction speed, capable of being ensured in construction quality easily, and good in construction effect, and enables the subway station construction process of peaty soft soil stratum to be completed simply, quickly and with high quality.

Owner:中铁二十局集团第五工程有限公司

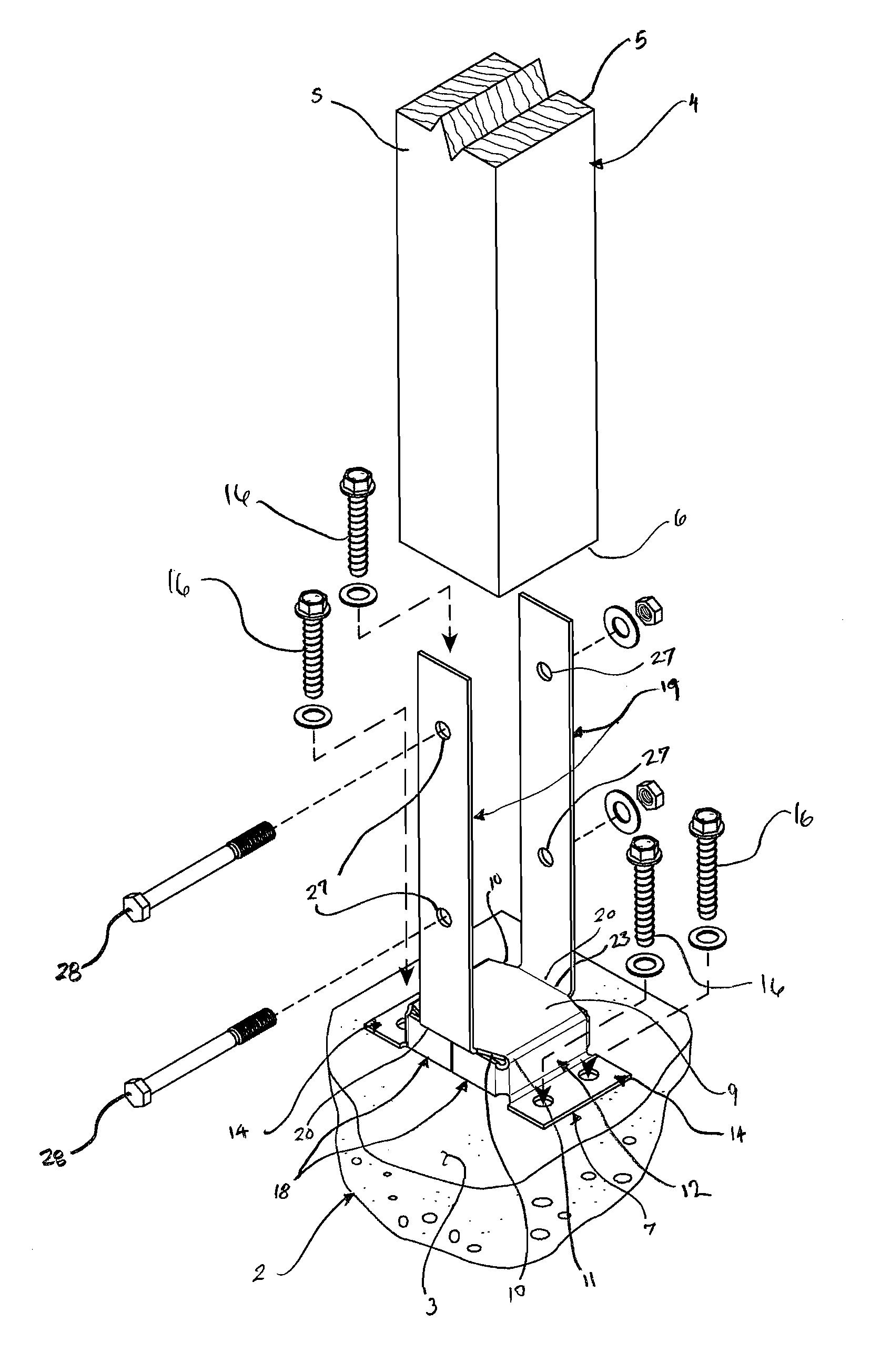

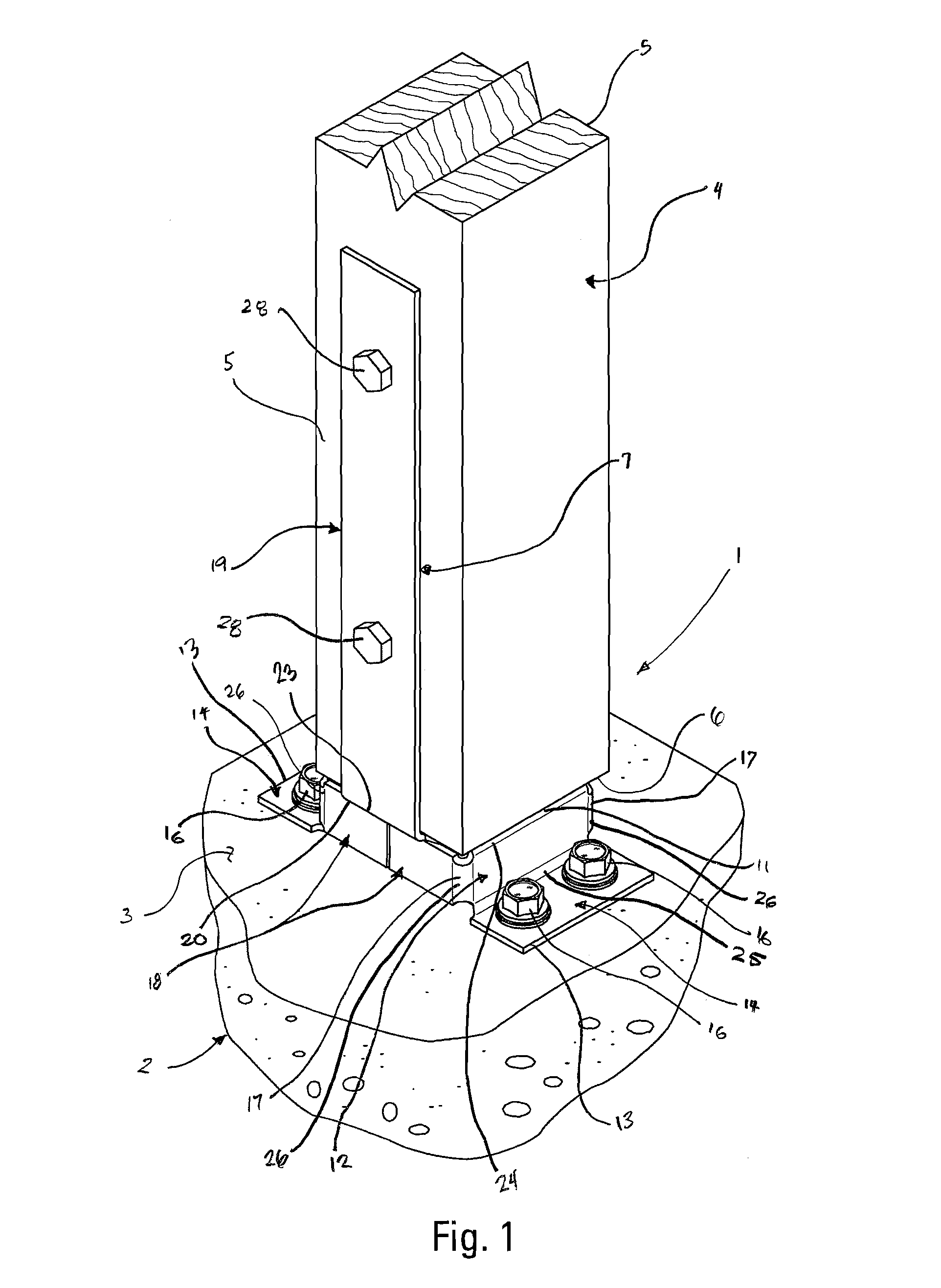

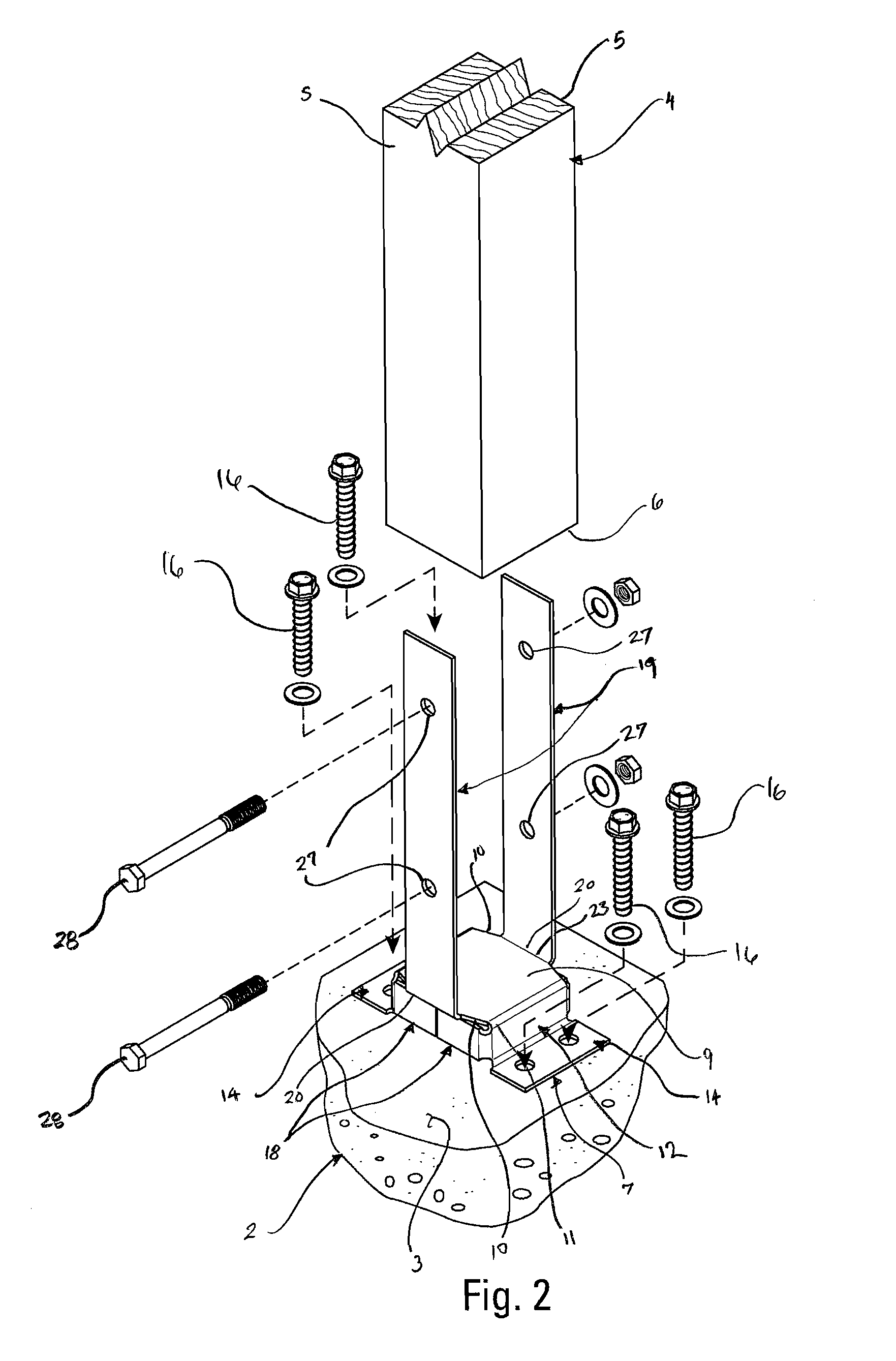

Single-piece standoff post base for retrofit

ActiveUS8959857B1Minimal costLess-expensive to manufactureFencingBuilding repairsArchitectural engineeringFastener

A post to foundation connection made with a connector that can be installed as a retrofit after the post is already in place, with fastener attachments that are made to either side of the post rather than under it. The connector can be slid into place below the post, between it and the foundation, after which it can be attached to the foundation and the post.

Owner:SIMPSON STRONG TIE

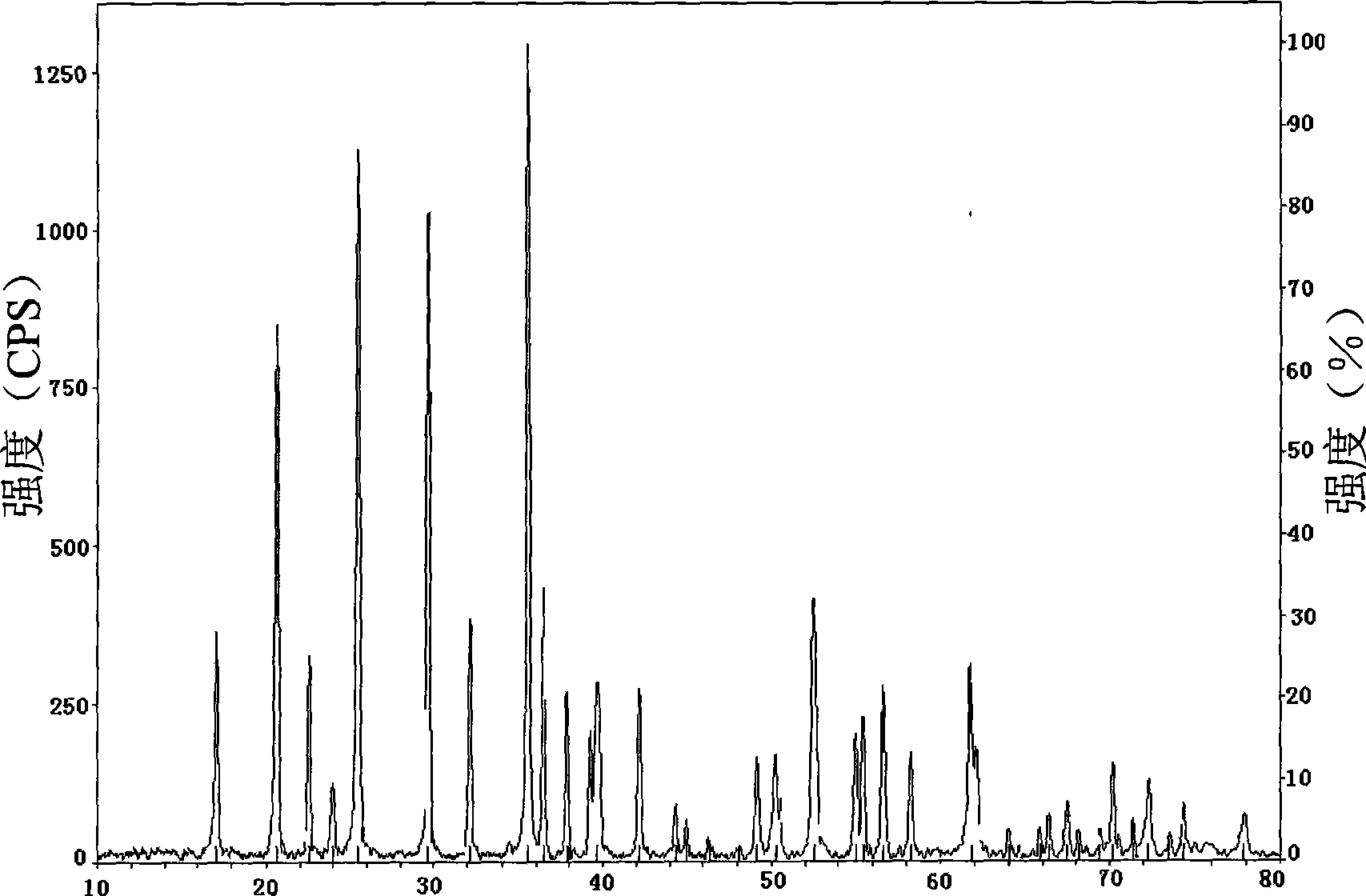

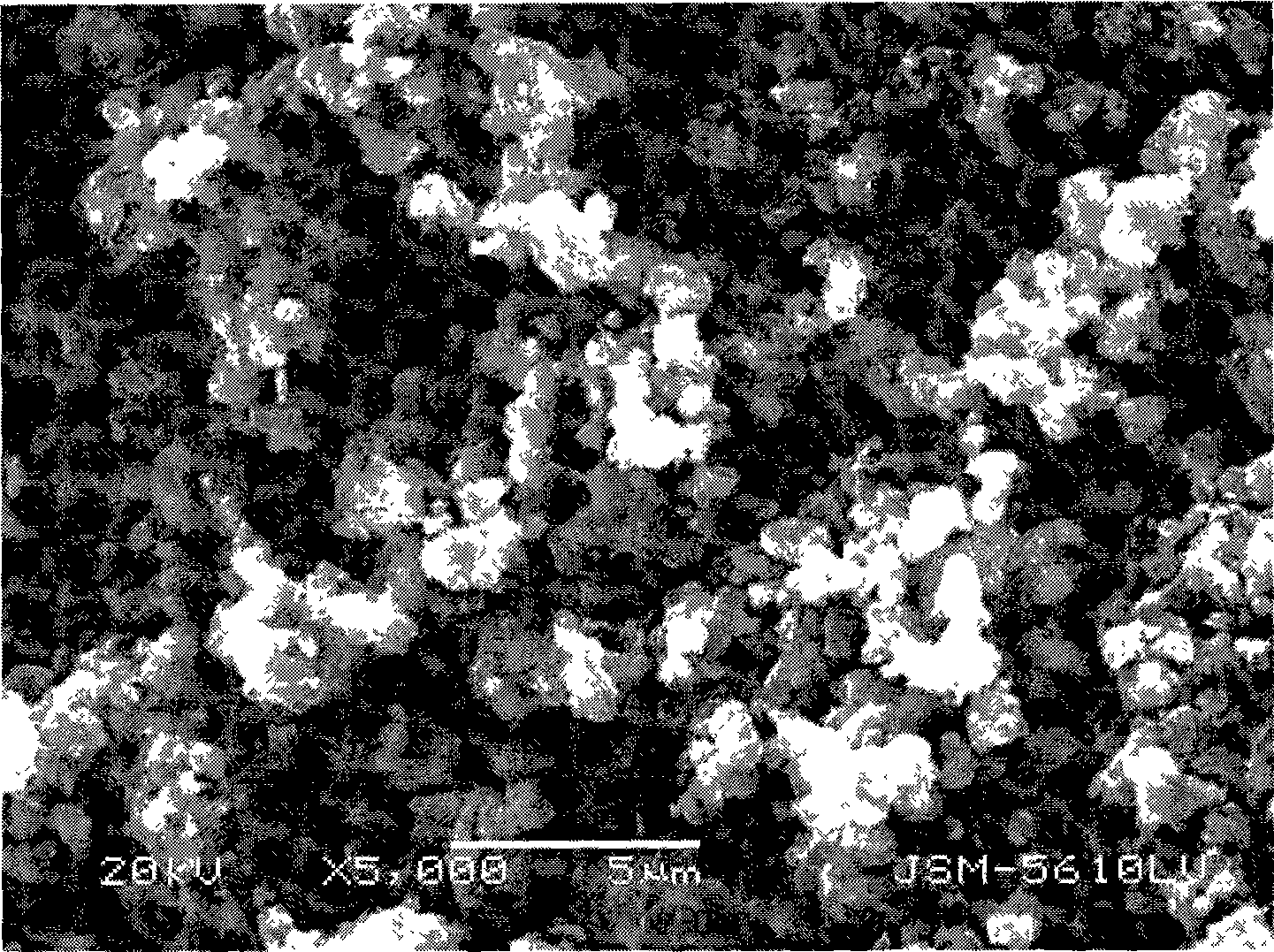

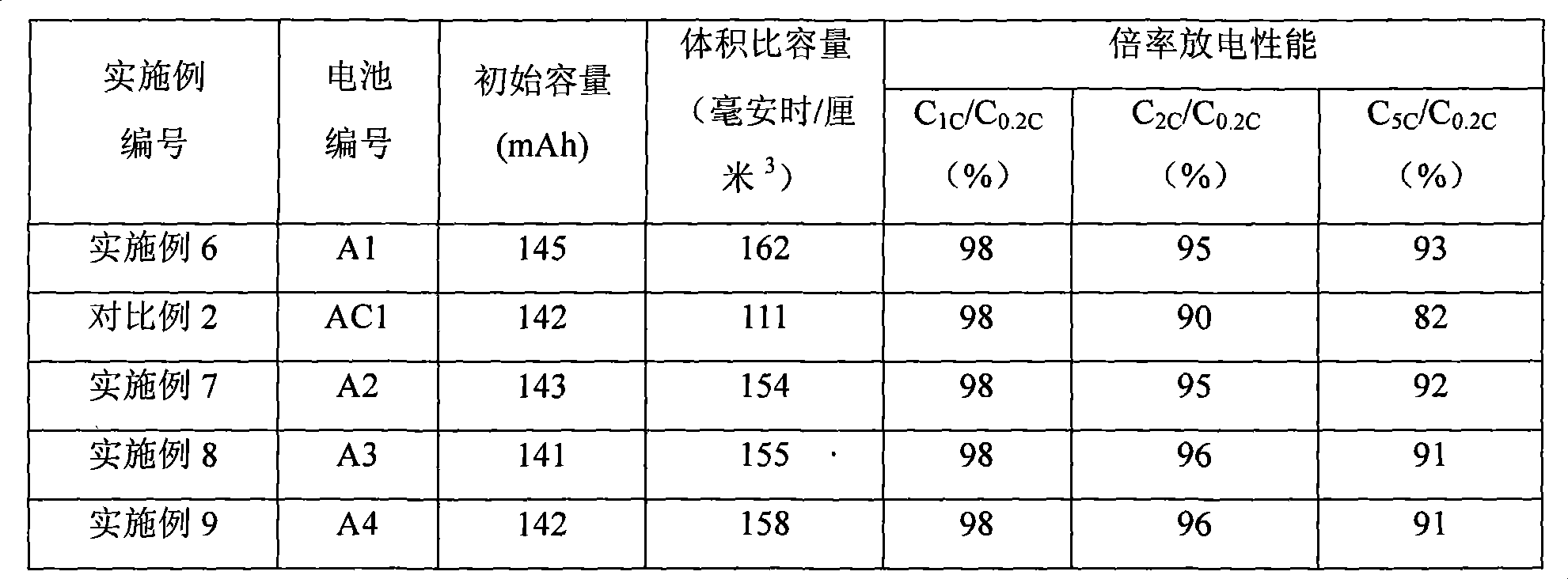

Preparing method of anode active material lithium iron phosphate for lithium ionic secondary cell

ActiveCN101399343AEasy to crushImprove high current charge and discharge performanceElectrode manufacturing processesSecondary cellsLithium iron phosphateBall mill

The invention provides a preparation method of lithium iron phosphate of a lithium-ion secondary battery positive electrode active material, the method comprises: a ferrous source compound, a phosphorus source compound, a lithium source compound and a carbon source compound are mixed, the first sintering is carried out on the obtained mixture under the protection atmosphere, products in the first sintering are ball-milled and dried, the second sintering is further carried out to obtain the lithium iron phosphate, wherein, the method further comprises the heating of the mixture at the temperature of 60-250 DEG C under the oxidation atmosphere before the first sintering or after the first sintering. The lithium iron phosphate which is obtained by adopting the method can have both high volume specific capacity and excellent high-current discharge performance.

Owner:TAICANG RONGCHI MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com