Patents

Literature

34results about How to "Reduced heat exchange capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

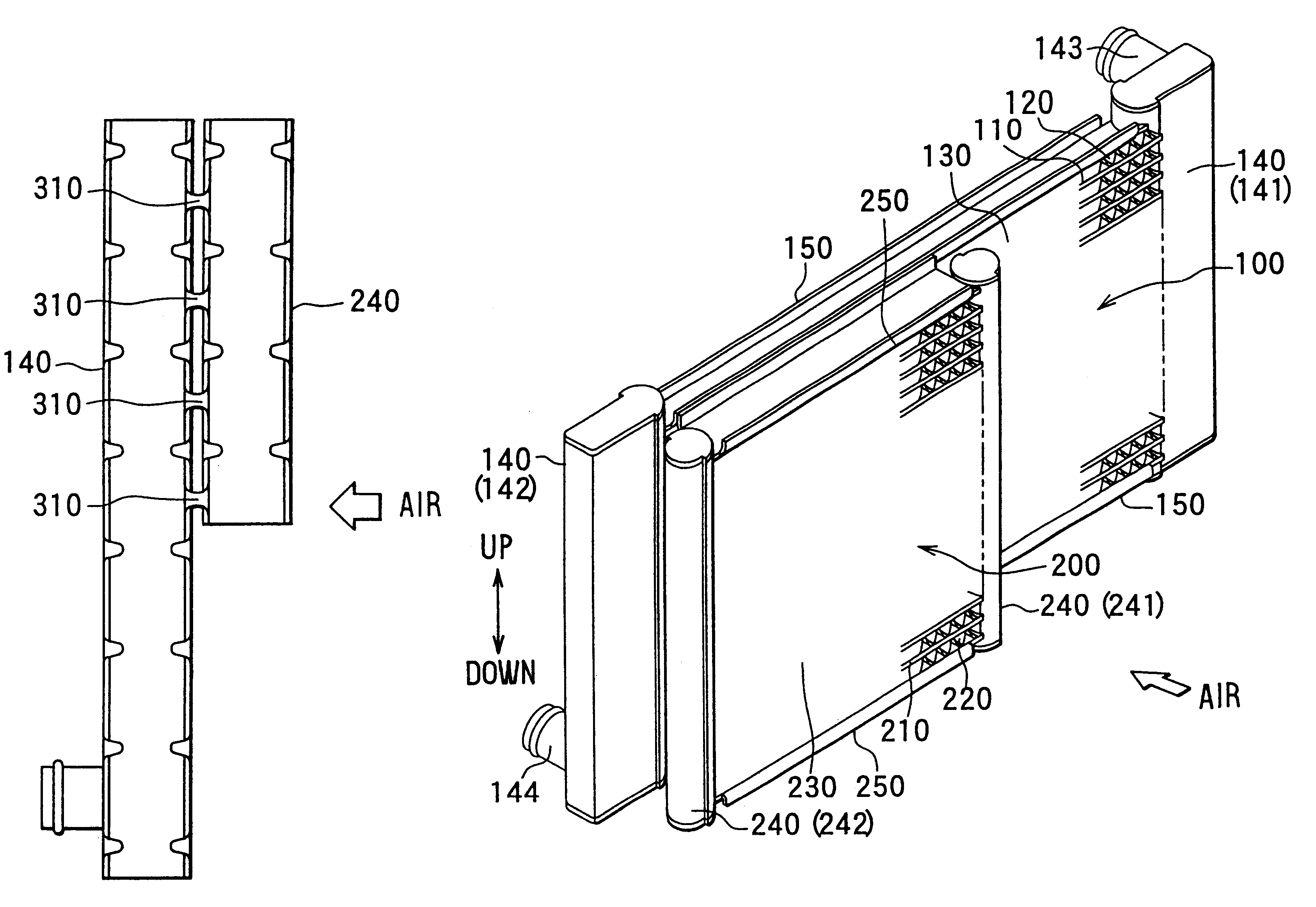

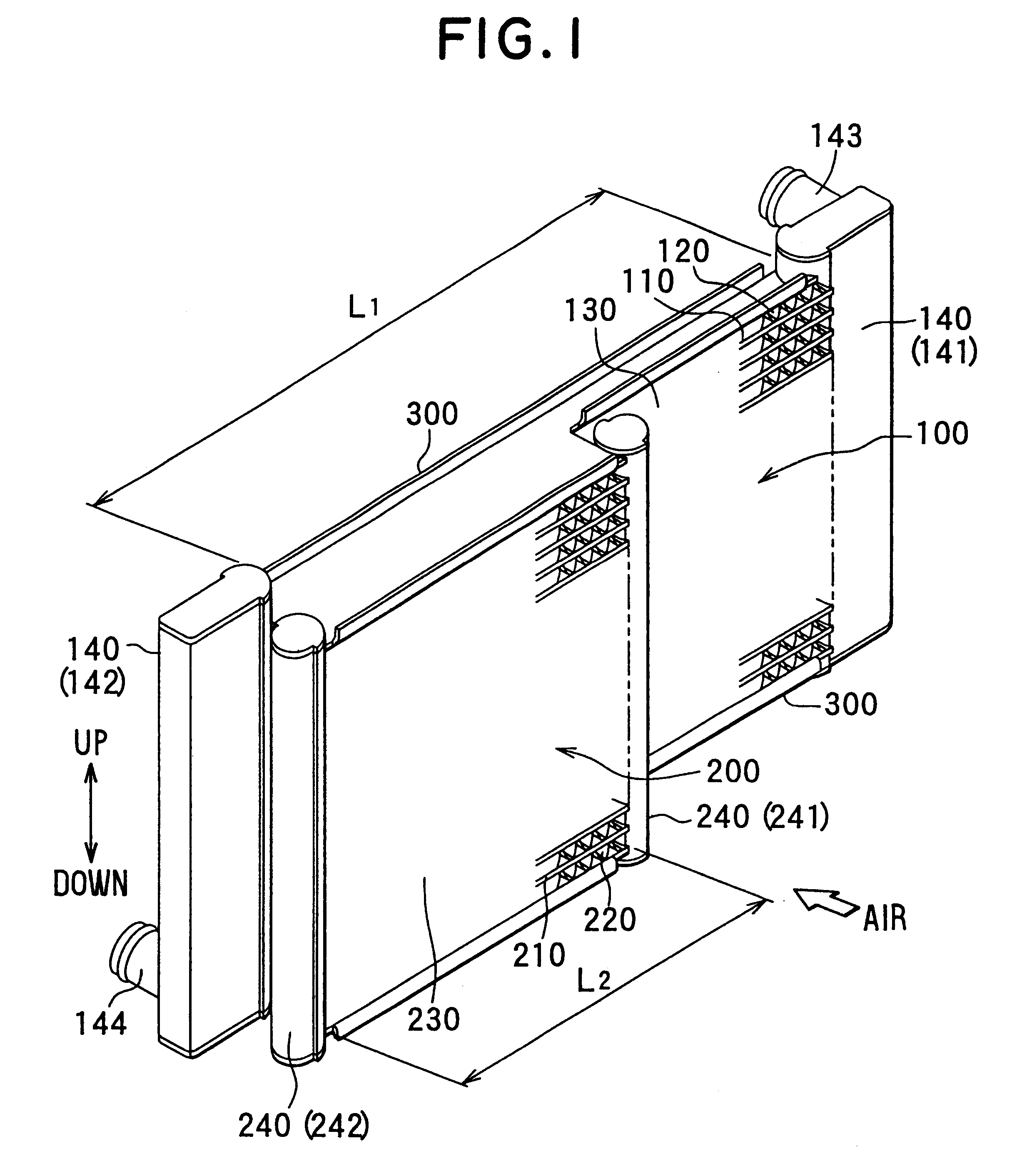

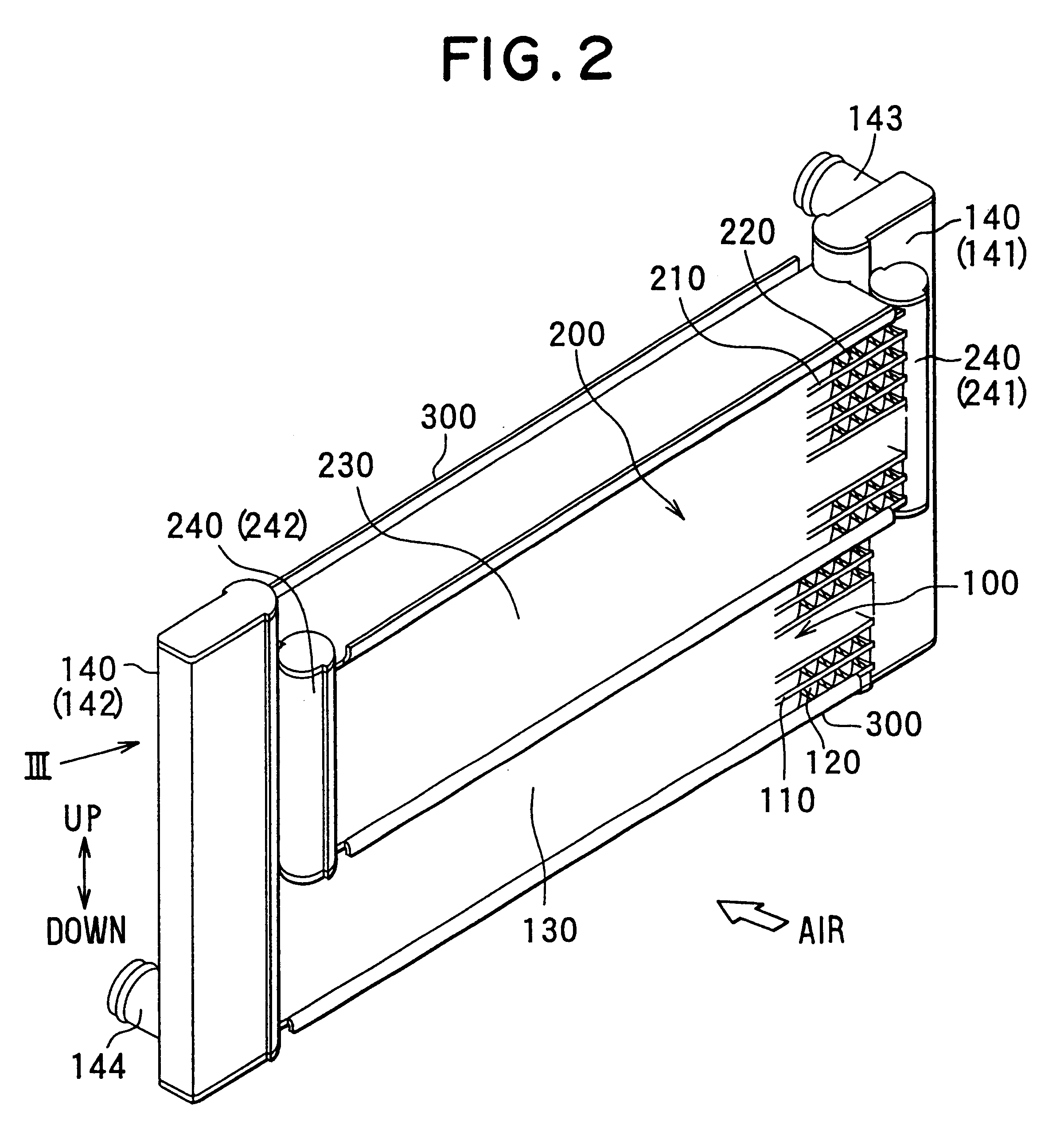

Double heat exchanger

InactiveUS6408939B1Reduced heat exchange capacityAvoid sizeHeat exhanger finsStationary conduit assembliesEngineeringHeat spreader

In a double heat exchange, a radiator and a condenser are integrated through a side plate for reinforcing the radiator and the condenser, and a longitudinal dimension of condenser tubes is made smaller than a longitudinal dimension of radiator tubes. Therefore, a core area of the condenser becomes smaller than that of the radiator. Thus, heat-exchanging capacity of the condenser is restricted from being increased more than a necessary capacity, and size and performance of the double heat exchanger are restricted from being increased more than necessary conditions.

Owner:DENSO CORP

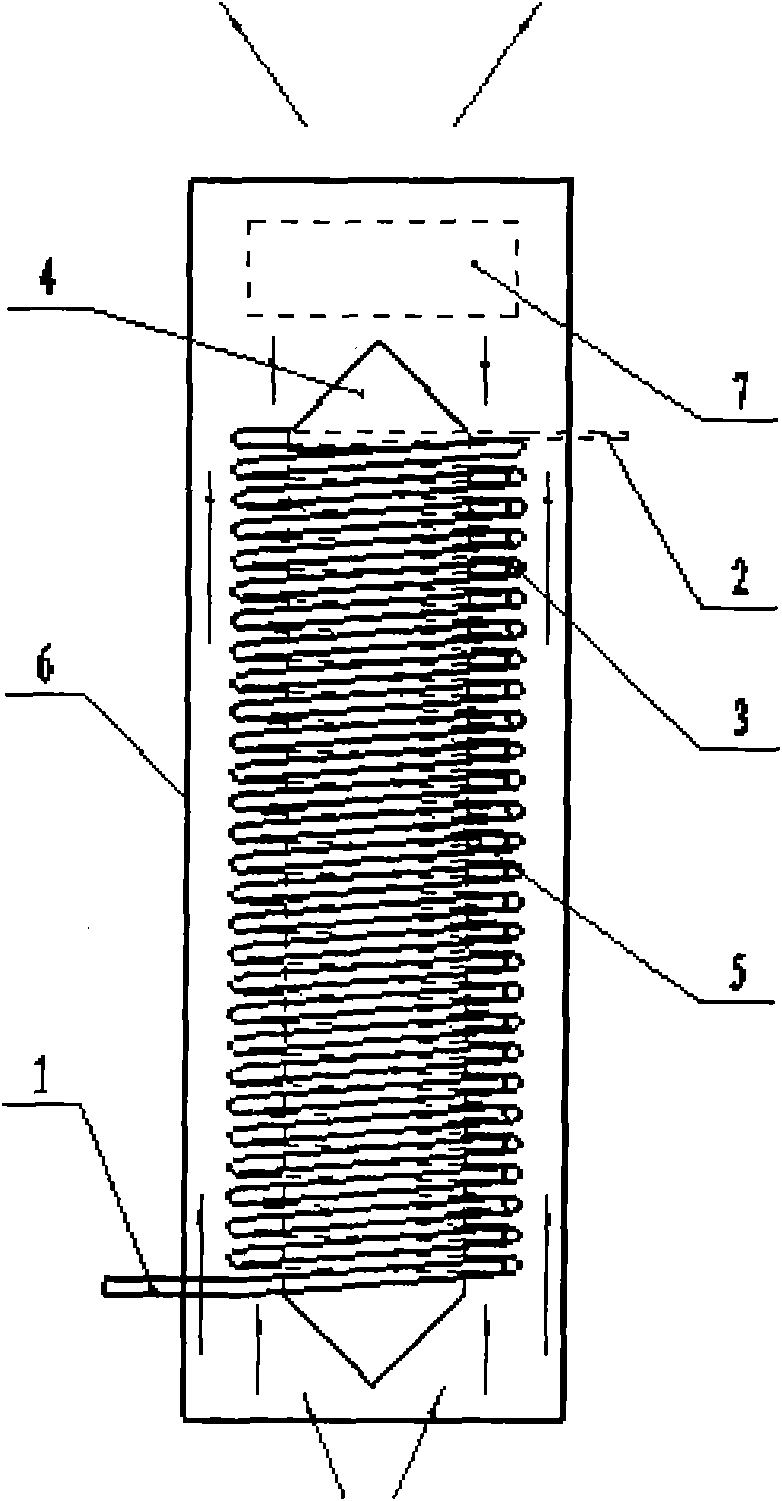

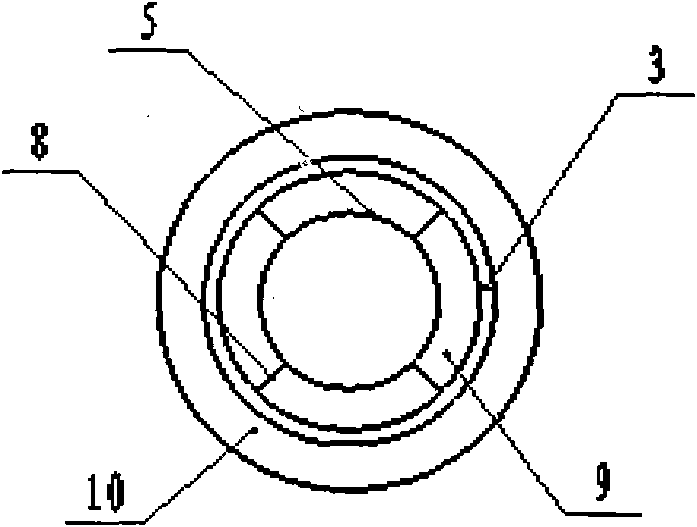

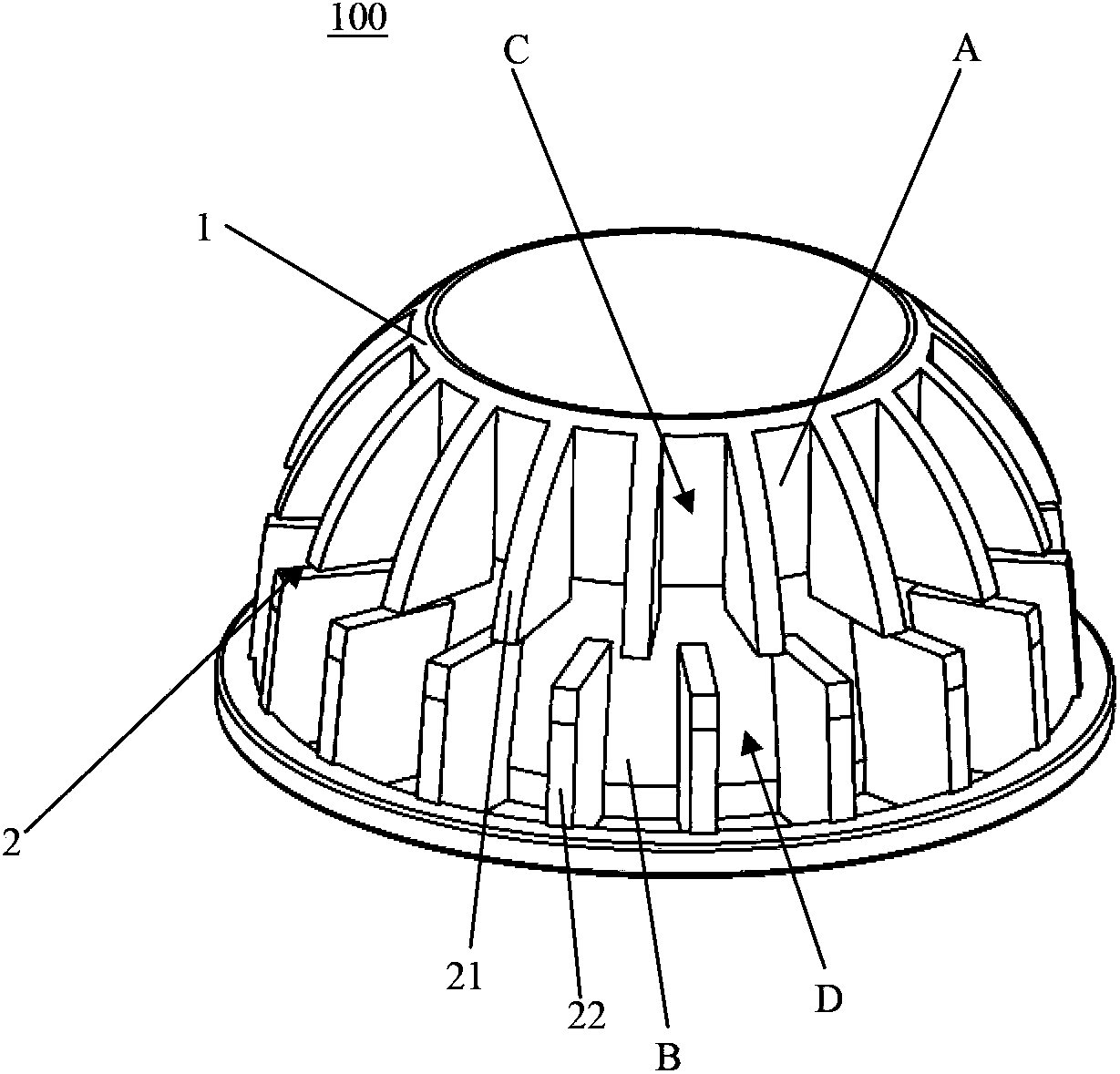

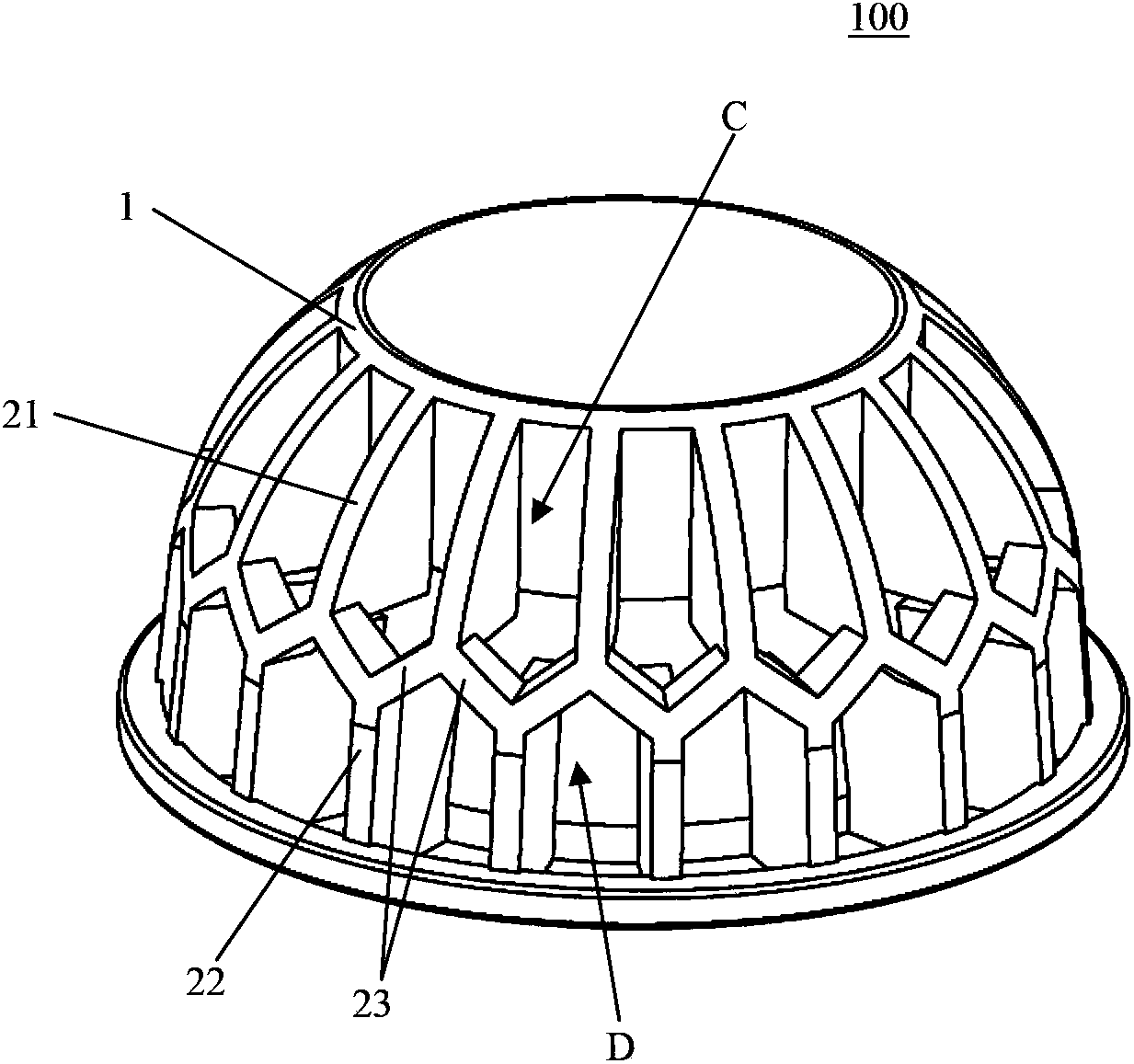

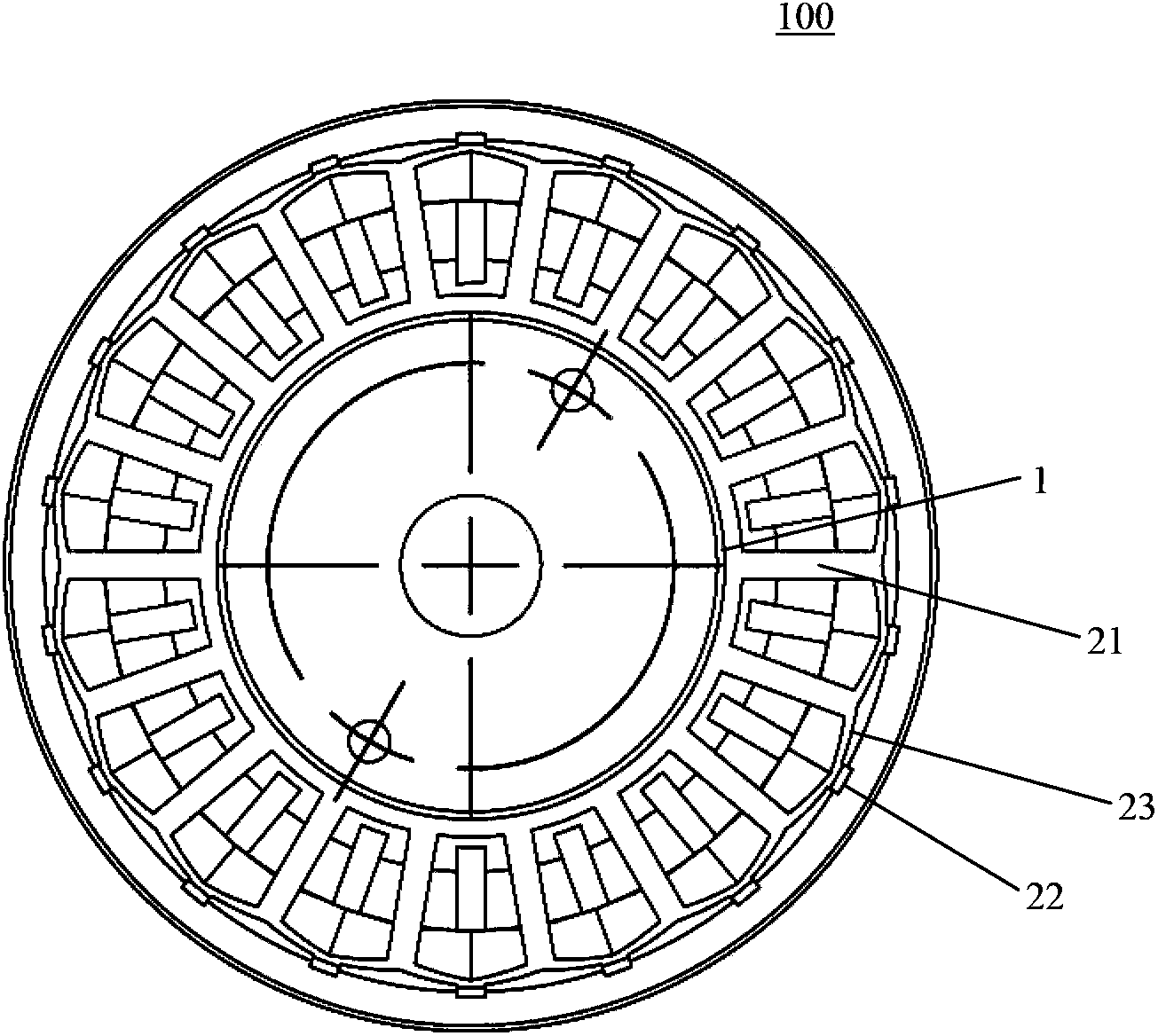

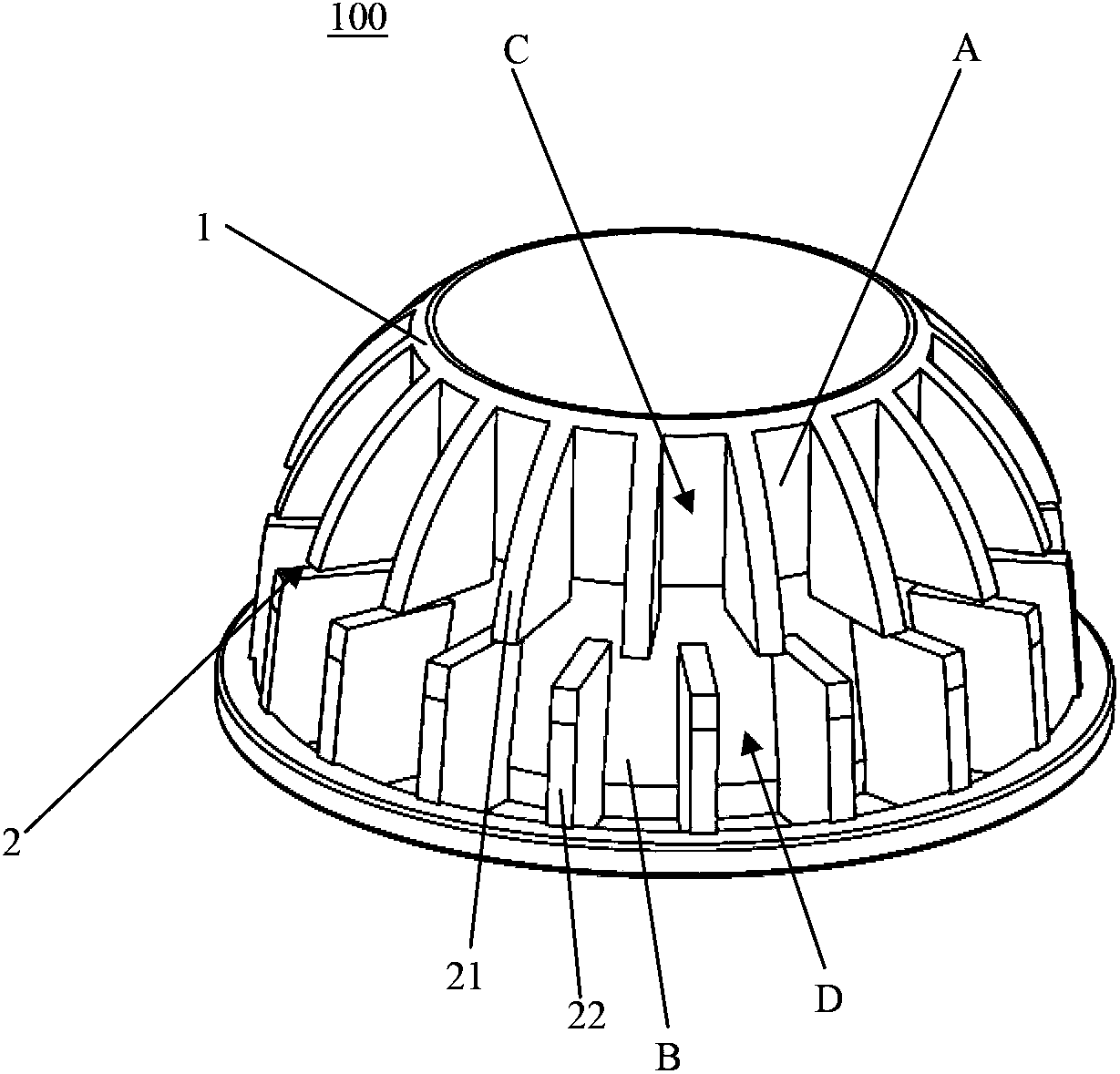

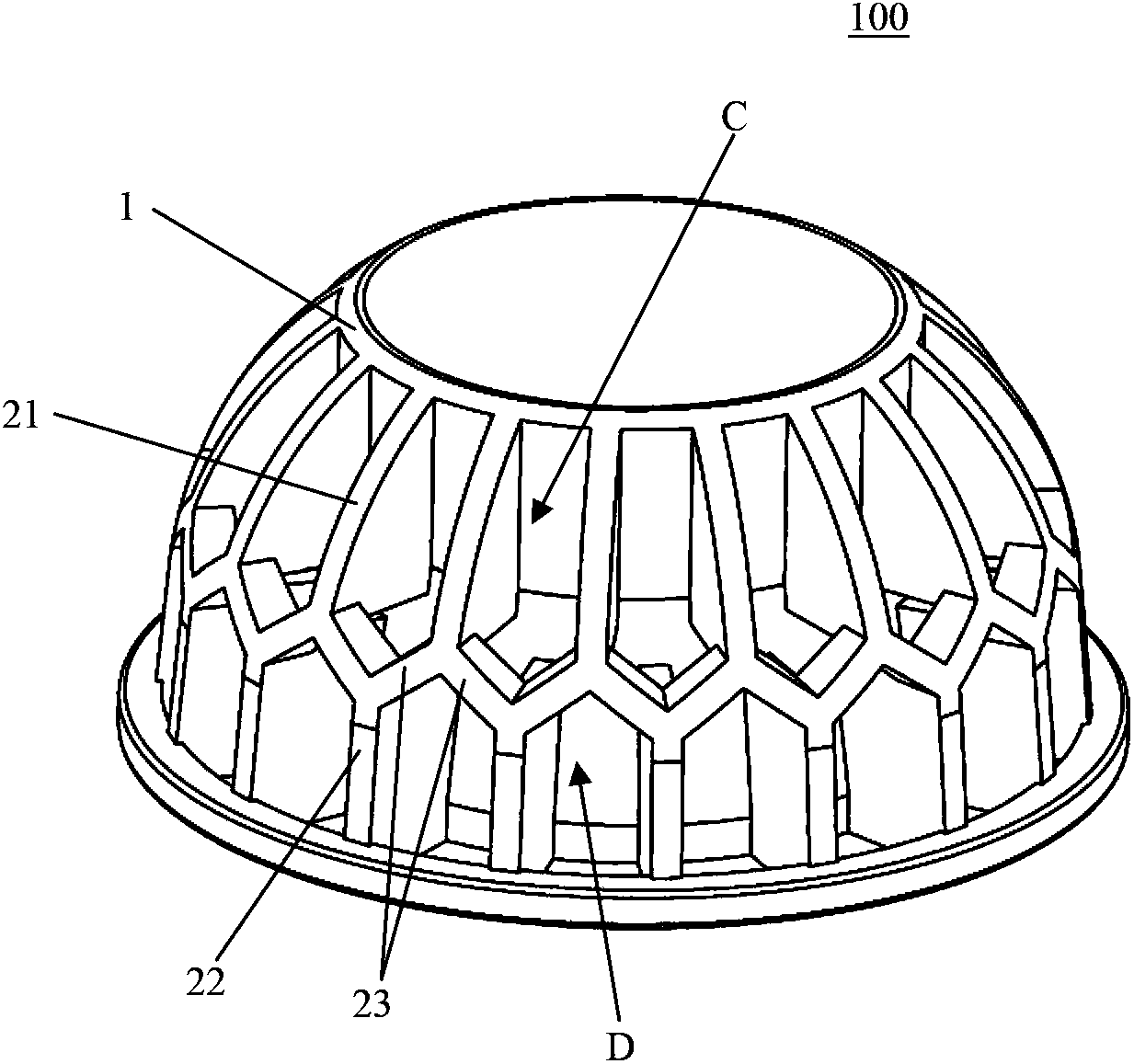

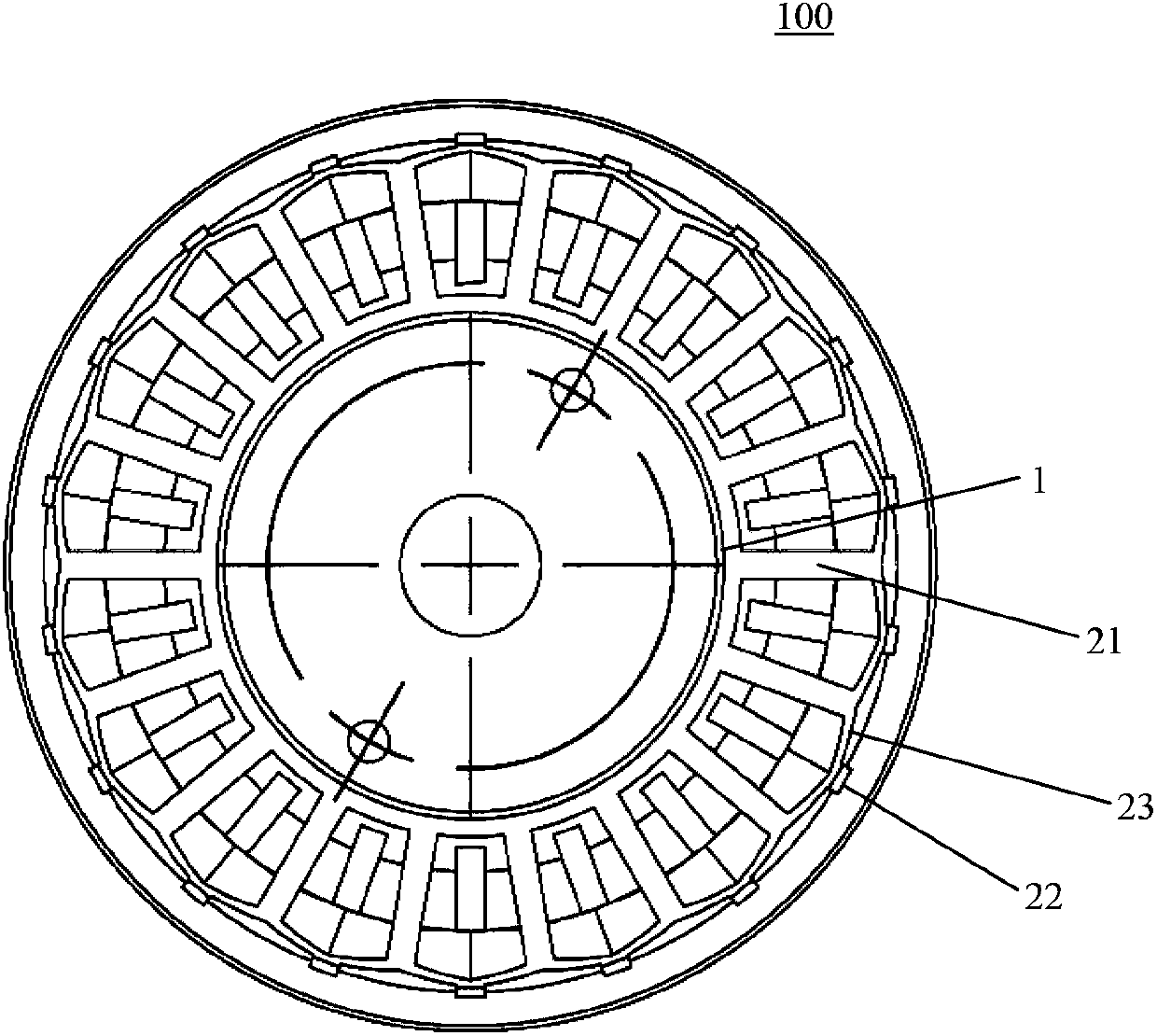

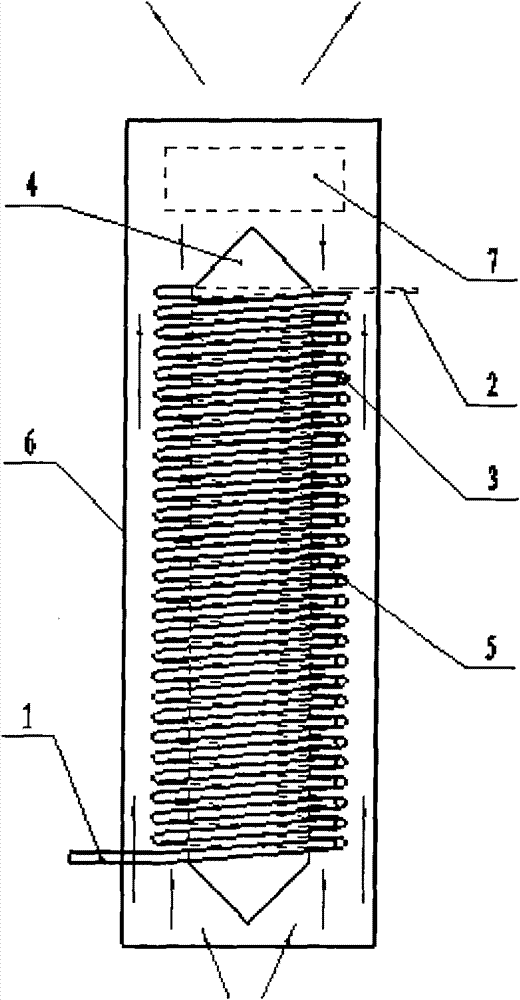

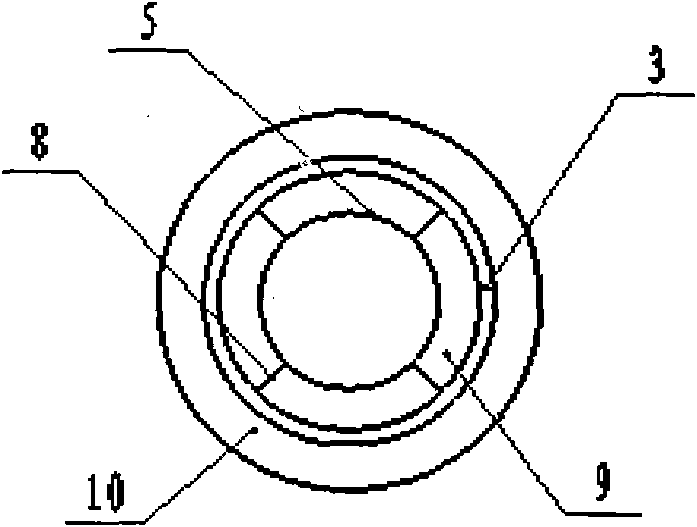

Heat exchanger with corrugated pipe coil structure provided with internal duct and external duct

InactiveCN101619944ASmooth heat convectionModularElectrolysis componentsChemical industryLiquid mediumEngineering

The invention discloses a heat exchanger with a corrugated pipe coil structure provided with an internal duct and an external duct, which comprises an inlet, an outlet, a corrugated pipe, a dome, an internal ring bushing, an external ring bushing, a fan and a bracket. When fluid media to be in heat exchange flow in the corrugated pipe in the heat exchanger from the inlet, form a turbulent flow in a pipe wall with a corrugated structure and carry out heat exchange with air in the internal duct and the external duct outside the corrugated pipe via the wall of the corrugated pipe, the fan discharges air in the internal duct and the external duct, and the fluid media are discharged from the outlet after the heat exchange performed in the corrugated pipe in a spiral way. The heat exchanger has the advantages of high heat exchanger effectiveness, simple structural technology, light weight, integration, and the like, and the fluid media in the pipe coil after the heat exchange have even temperature, thereby the heat exchanger can be used for heat exchange of air, liquid and air-liquid mixing substances. When the corrugated pipe adopts resistant materials, the heat exchanger can be used for heat exchange for corrosive liquid media.

Owner:南京容宇能源科技有限公司

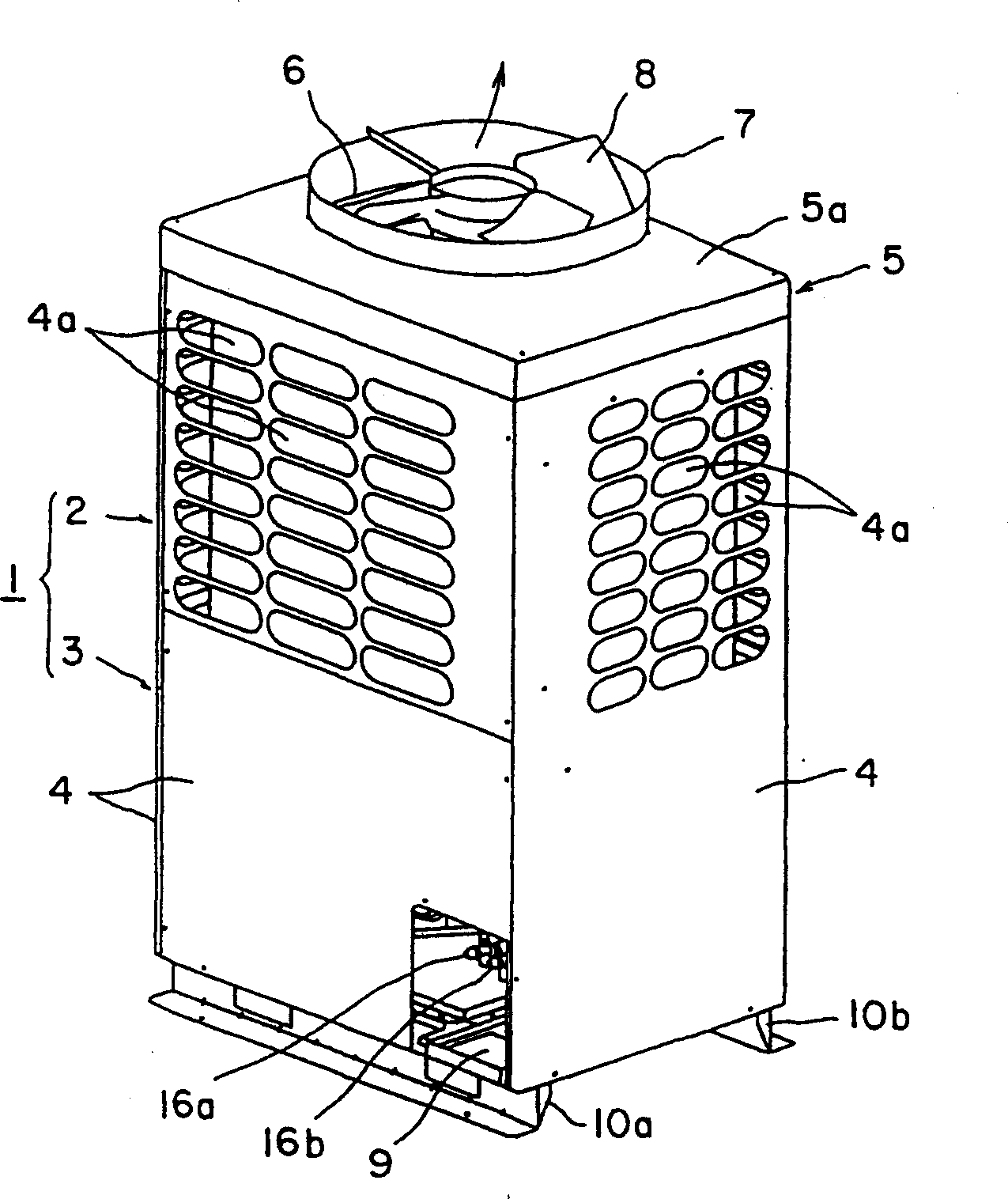

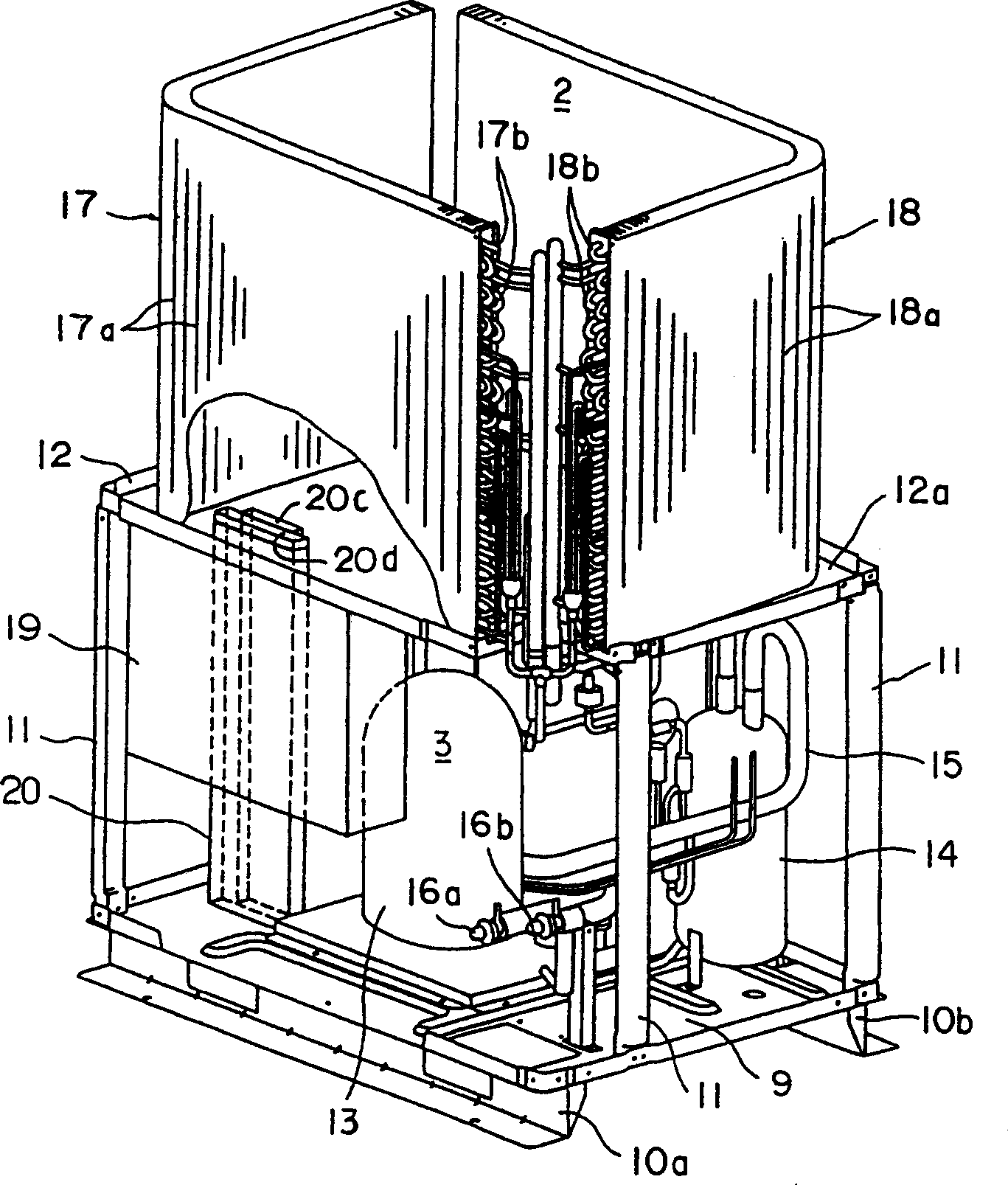

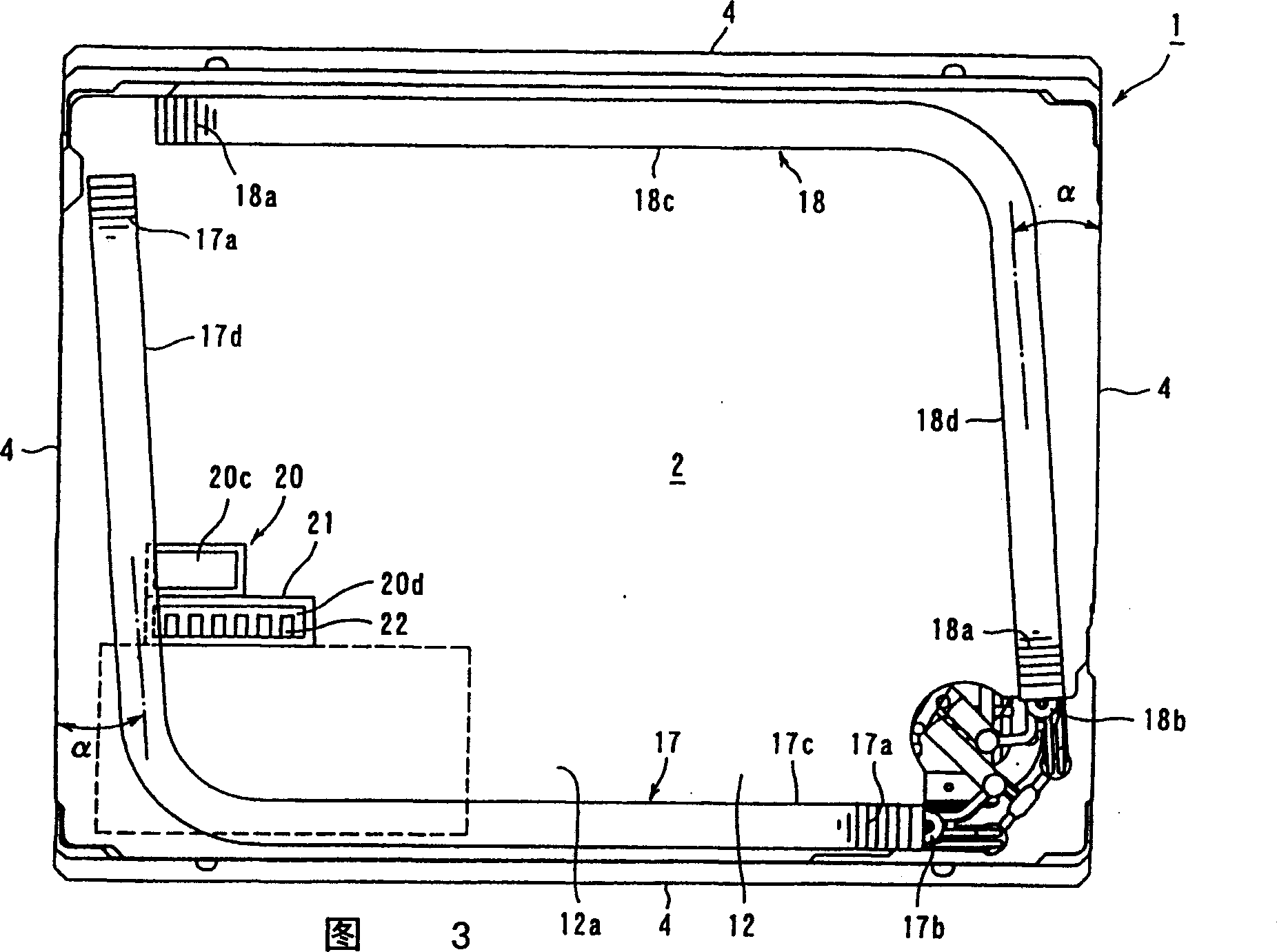

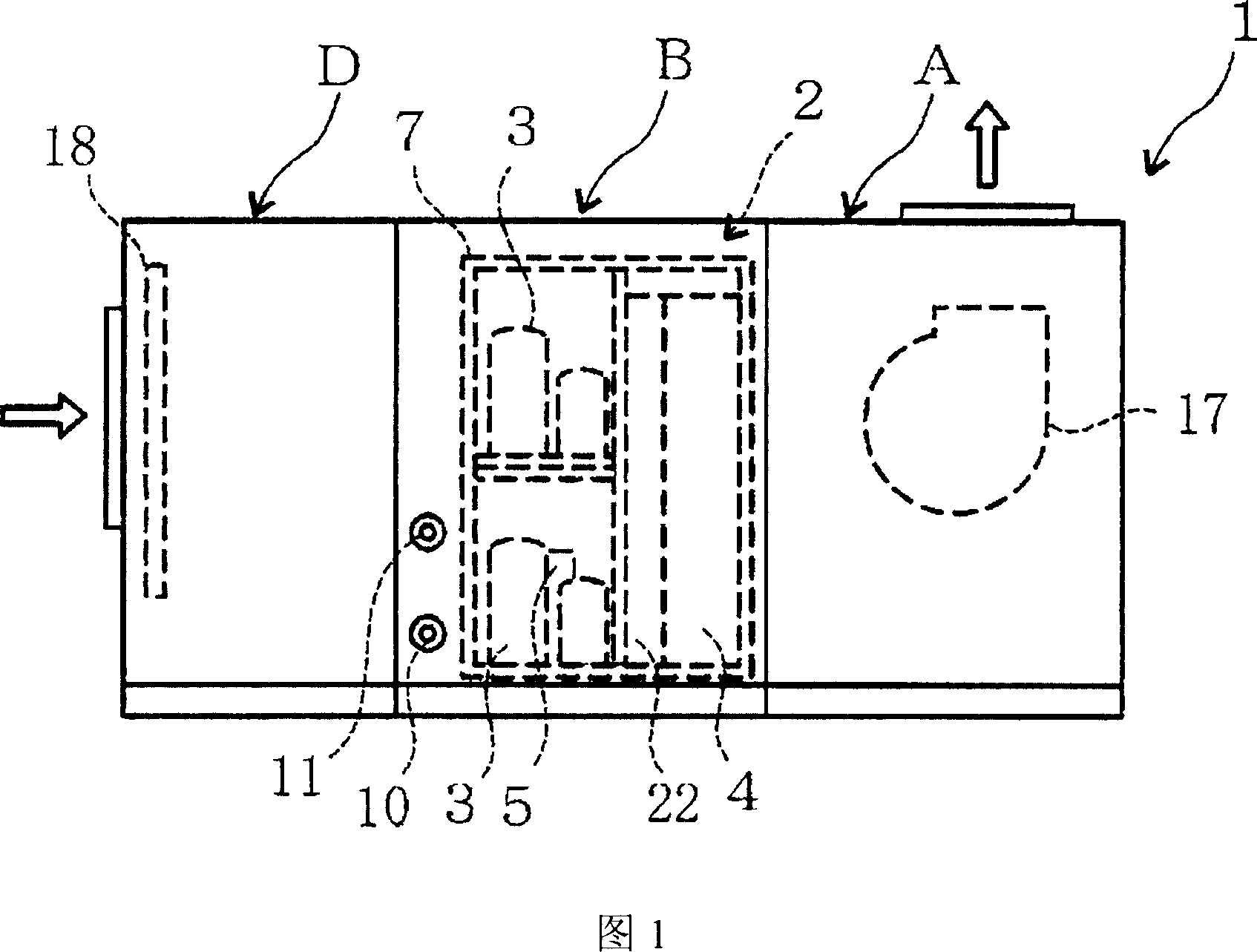

Outdoor unit of air conditioner

InactiveCN1358265AReduced heat exchange capacityAspiration Prevention and EliminationCondensate preventionLighting and heating apparatusHeat spreaderEngineering

An outdoor unit (1) of an air conditioner comprises a unit case having a rectangular shape in section and composed of side panels (4, 4, - - - ) in which a machine chamber (3) and a heat exchanger chamber (2) are defined so as to be vertically aligned in an installed state with the heat exchanger chamber being disposed above the machine chamber and being sectioned therefrom by means of a partition plate (12) which also acts as a drain plate or pan, and the side panels surrounding the heat exchanger chamber is formed with air suction ports (4a, 4a - - - ). The outdoor unit (1) further comprises a heat exchanger unit (17, 18) having four side wall sections at least opposing two of which are inclined inward by a predetermined angle with respect to inner surfaces of the side panels to which the air suction ports are formed. Thus, the outside air can be effectively and smoothly introduced inside the outdoor unit. The outdoor unit is also provided with a duct unit (20) arranged in the unit case in association with the drain pan (12) for effectively discharging drain, cooling electrical part such as heat sink (22) and improving the outer appearance of the outdoor unit.

Owner:TOSHIBA CARRIER CORP

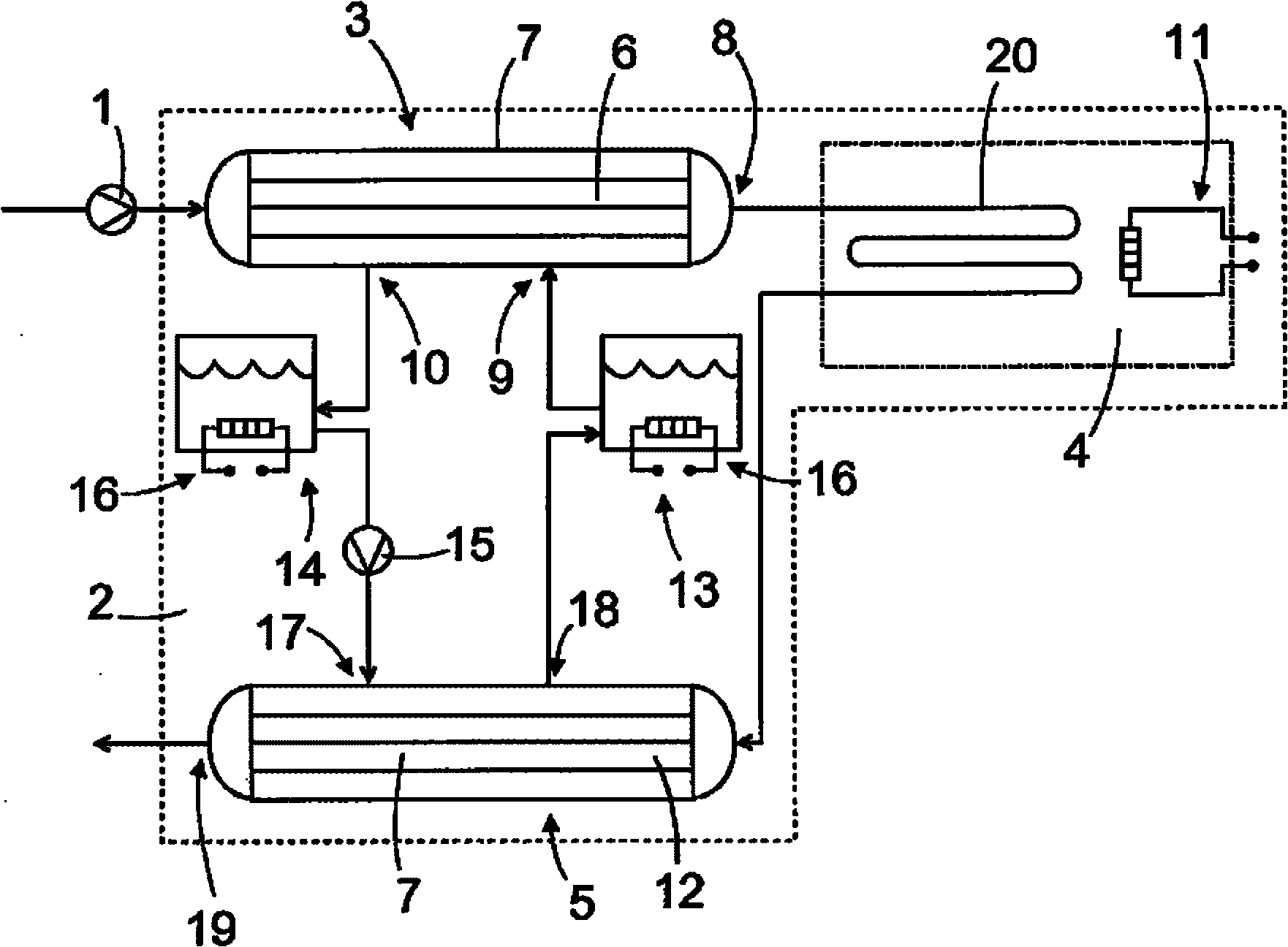

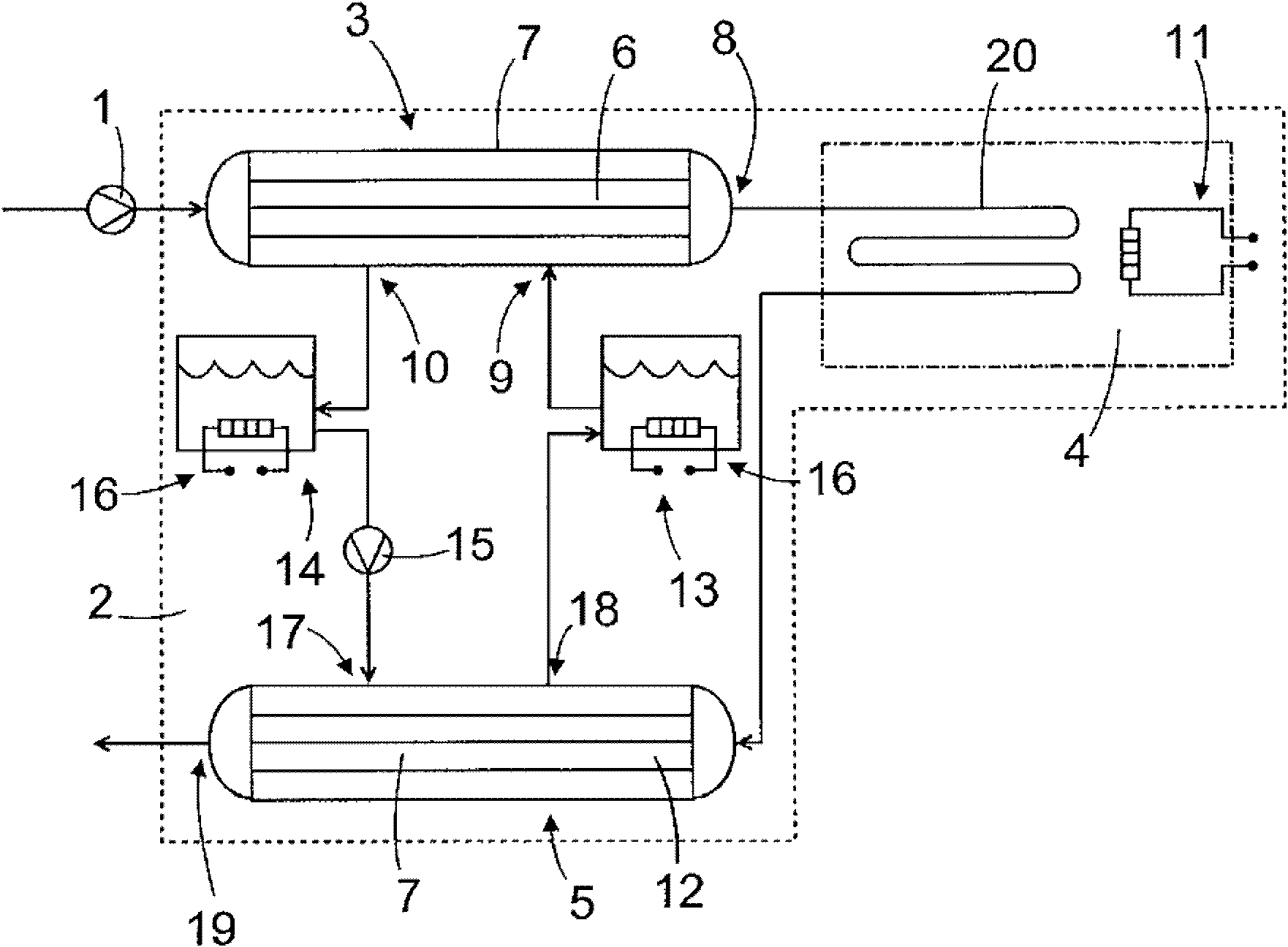

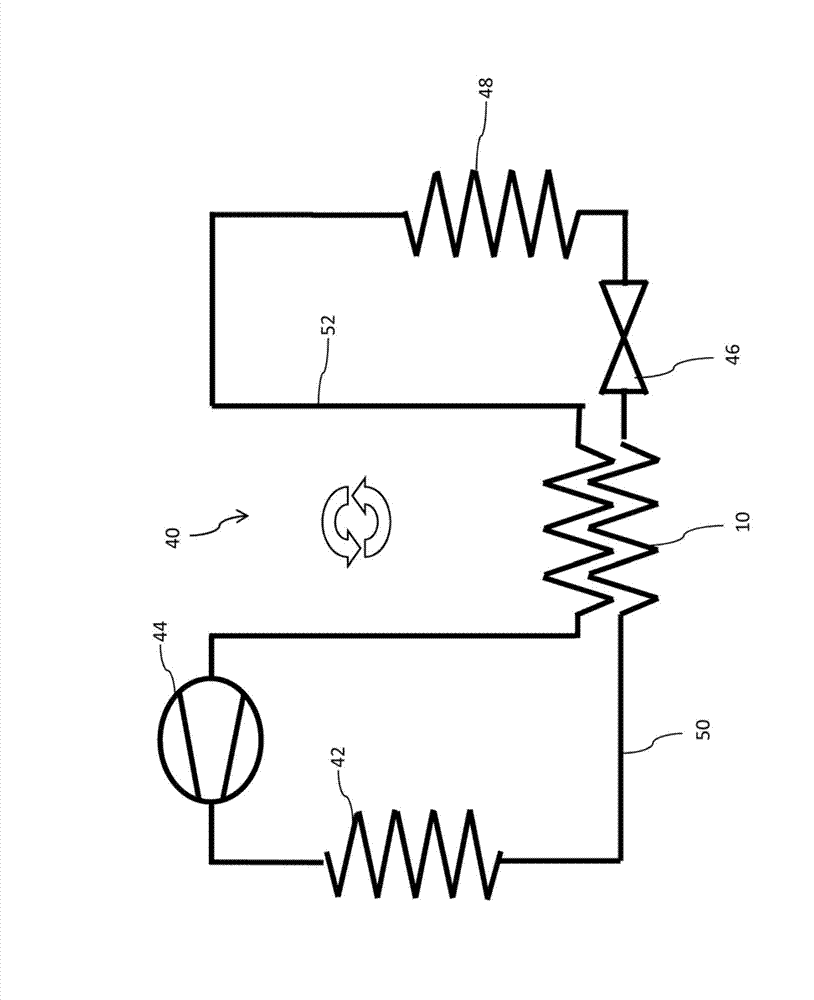

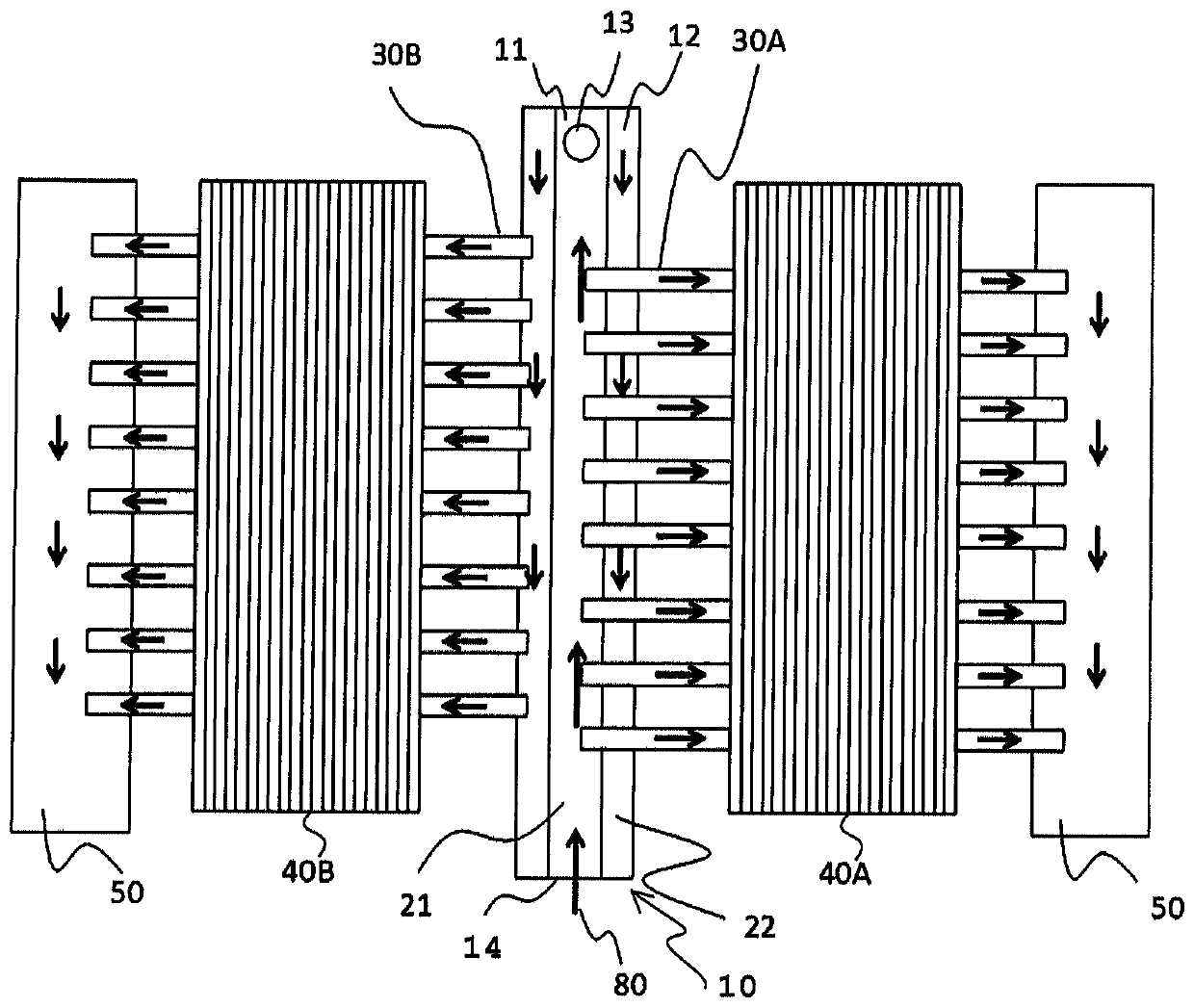

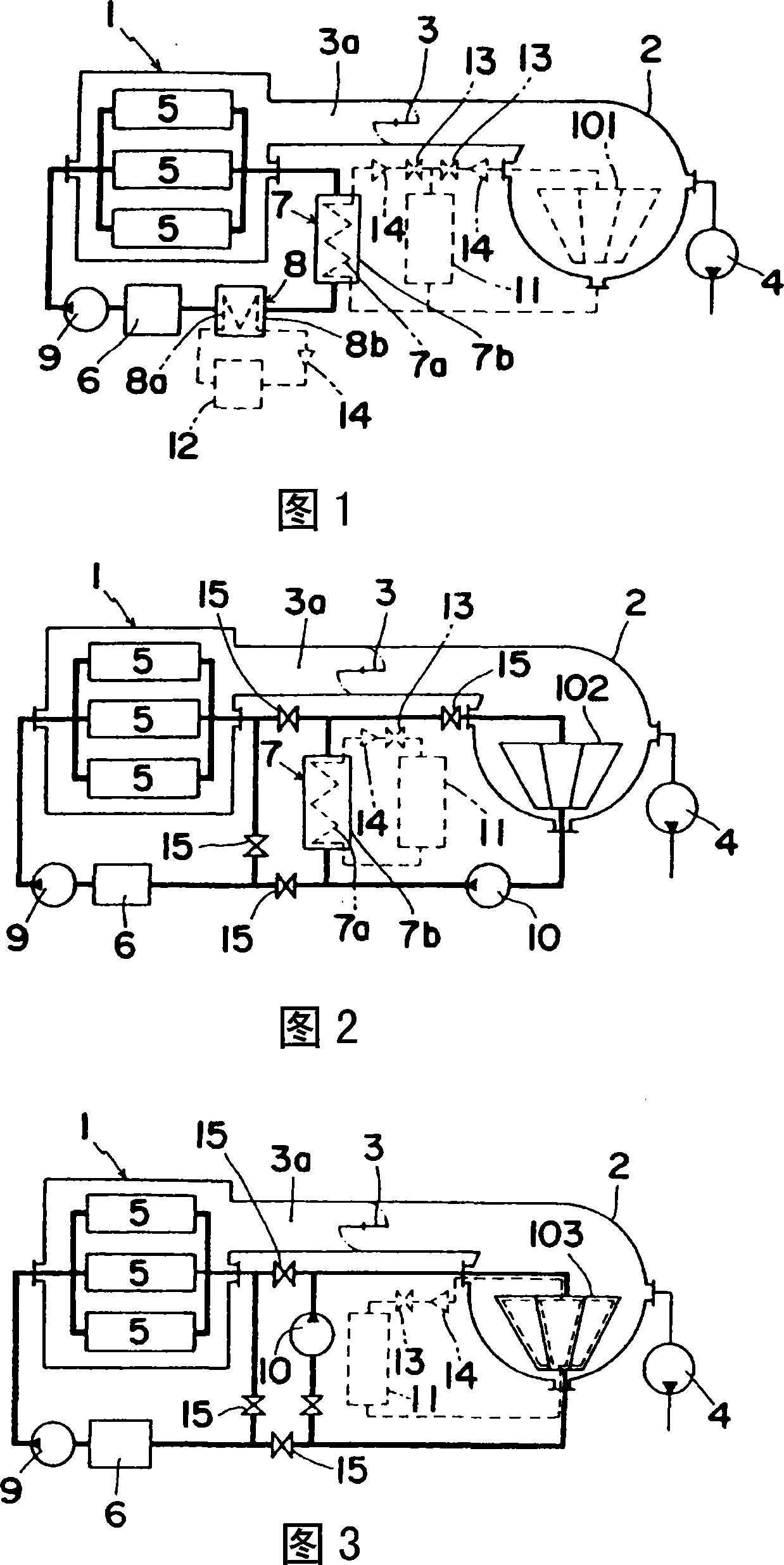

Methods, systems and applications for heat exchange

InactiveCN102264873AImprove heat exchange performanceAvoid accumulationPulp liquor regenerationHeat storage plantsThermal energyMolten salt

Disclosed are a method, a system and use for heat exchange in super-critical or near-critical water gasification process of biomass. The method comprises the steps of: heating a biomass in a first heat exchanger (6) by thermal energy of a heat transfer medium, reacting the biomass in said super-critical or near-critical water gasification process and producing reaction products, cooling the reaction products of the biomass in a second heat exchanger (12) by absorbing the thermal energy of the reaction products to said heat transfer medium, and circulating said heat transfer medium between the first heat exchanger (6) and the second heat exchanger (12), wherein molten salt is used as the heat transfer medium.

Owner:UPM-KYMMENE OYJ

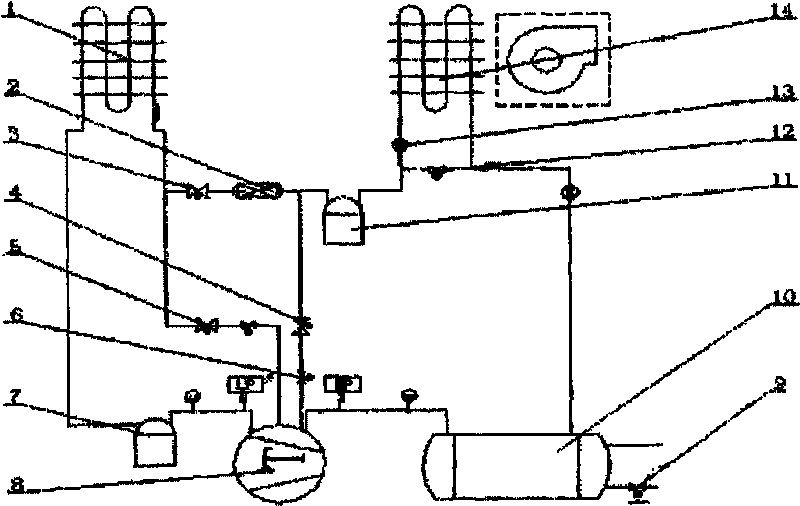

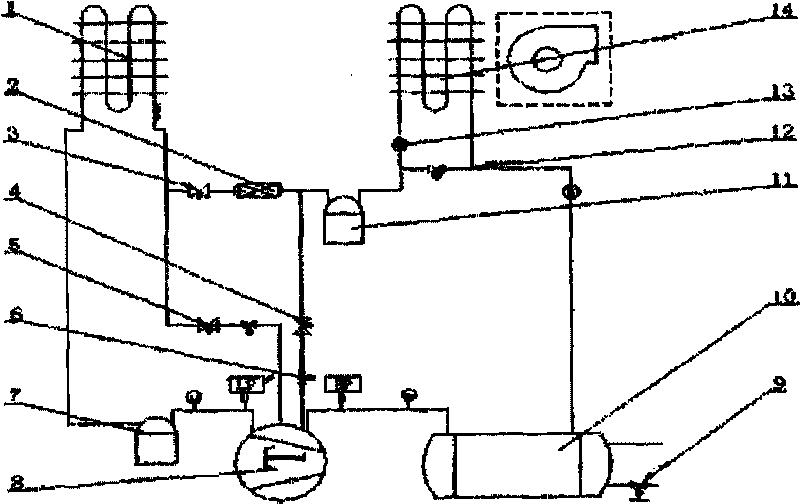

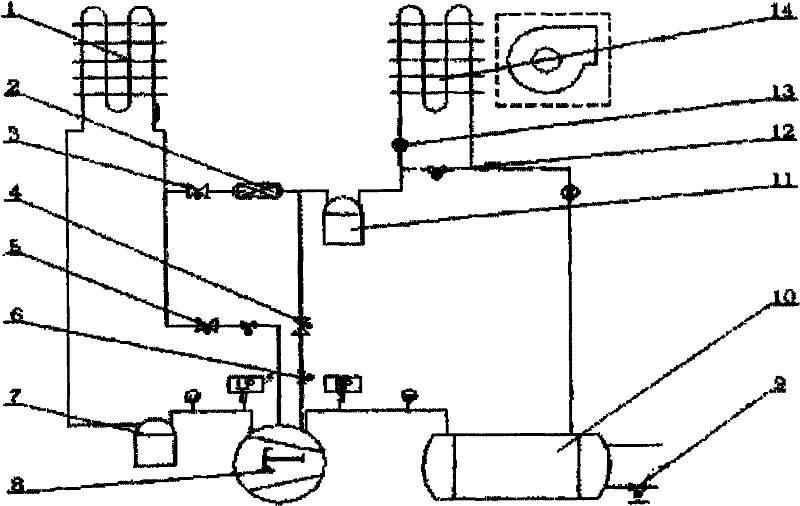

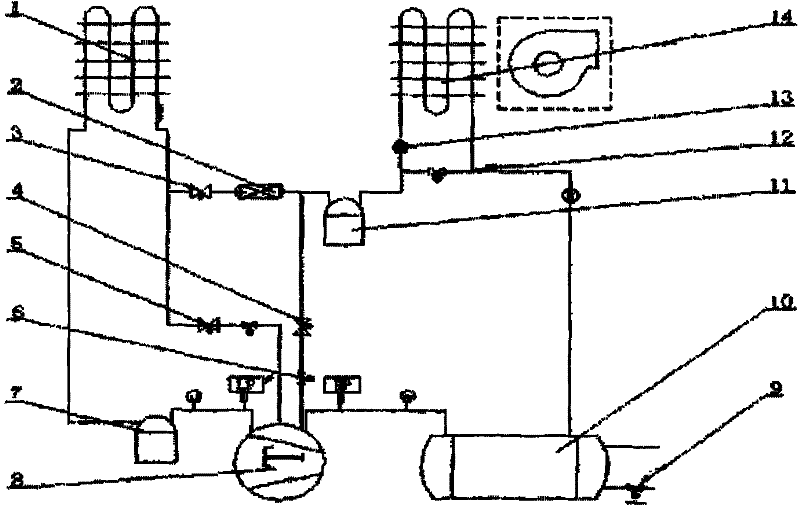

Wide temperature range type full fresh air temperature-adjustable dehumidifier

InactiveCN101737988AReduced heat exchange capacityEffective exhaustCompression machines with non-reversible cycleCorrosion preventionVapor–liquid separatorFrost

The invention relates to a wide temperature range type full fresh air temperature-adjustable dehumidifier, which is characterized in that an evaporator is connected with a gas-liquid separator; the gas-liquid separator is connected with a stepless adjustable screw compressor; the stepless adjustable screw compressor is respectively connected with a hot air bypass valve, an electromagnetic valve and a water-cooling condenser; the water-cooling condenser is respectively connected with a flow regulating valve and an air-cooling condenser; the air-cooling condenser is connected with a check valve; the check valve is respectively connected with a flow regulating valve and a liquid reservoir; and the liquid reservoir is respectively connected with a liquid spray valve and a drying filter. The invention has the following technical effects: 1. the dehumidifier can reduce the effective exhaust of the compressor and absorb heat of liquid refrigerant in the evaporator to decrease the heat exchanging ability of the evaporator; 2.the opening degree of the flow regulating valve can be automatically adjusted according to the predetermined outlet air temperature; 3. high temperature air enters the inlet of the evaporator to melt away frost on the evaporator; 4. when fresh air load is high and the overheating of a motor of the compressor is caused, the liquid refrigerant is sprayed on the motor to cool the motor.

Owner:TELLHOW SCI TECH CO LTD

Controllable heat exchanger for a motor vehicle air conditioning system

InactiveCN102767984AChange the heat exchange capacityAdapt or adjust heat exchange capacityVehicle heating/cooling devicesStationary tubular conduit assembliesPlate heat exchangerAutomobile air conditioning

A heat exchanger for a motor vehicle air conditioning system is provided. The heat exchanger includes an inner tube through which a heat exchanger medium can flow, an outer tube that at least regionally envelops the inner tube forming an intermediate space, and a regulating unit fluidically connected to the intermediate space. The regulating unit is configured to alter the flow resistance of the intermediate space as a function of the temperature of a heat exchanger medium that flows through the intermediate space.

Owner:GM GLOBAL TECH OPERATIONS LLC

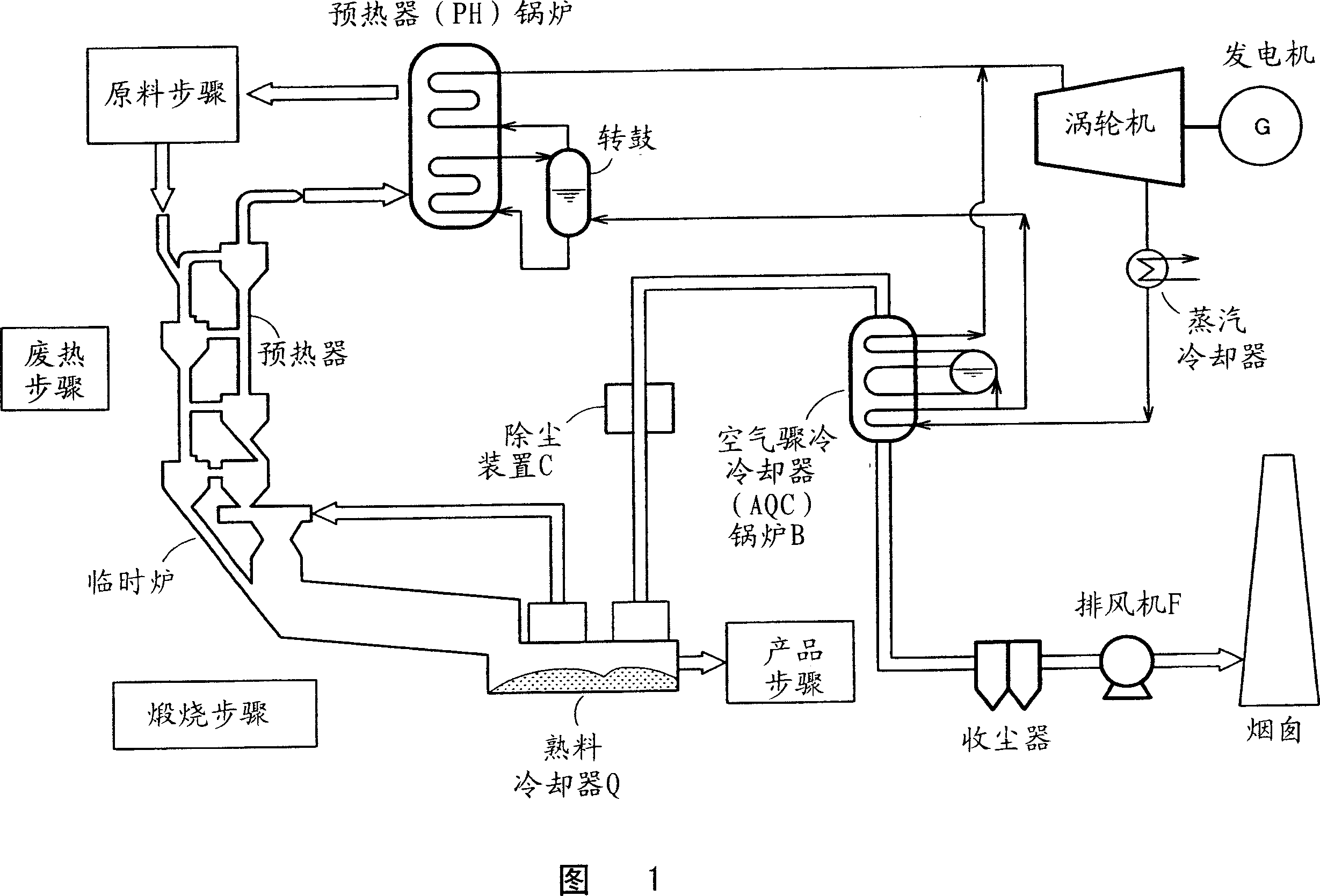

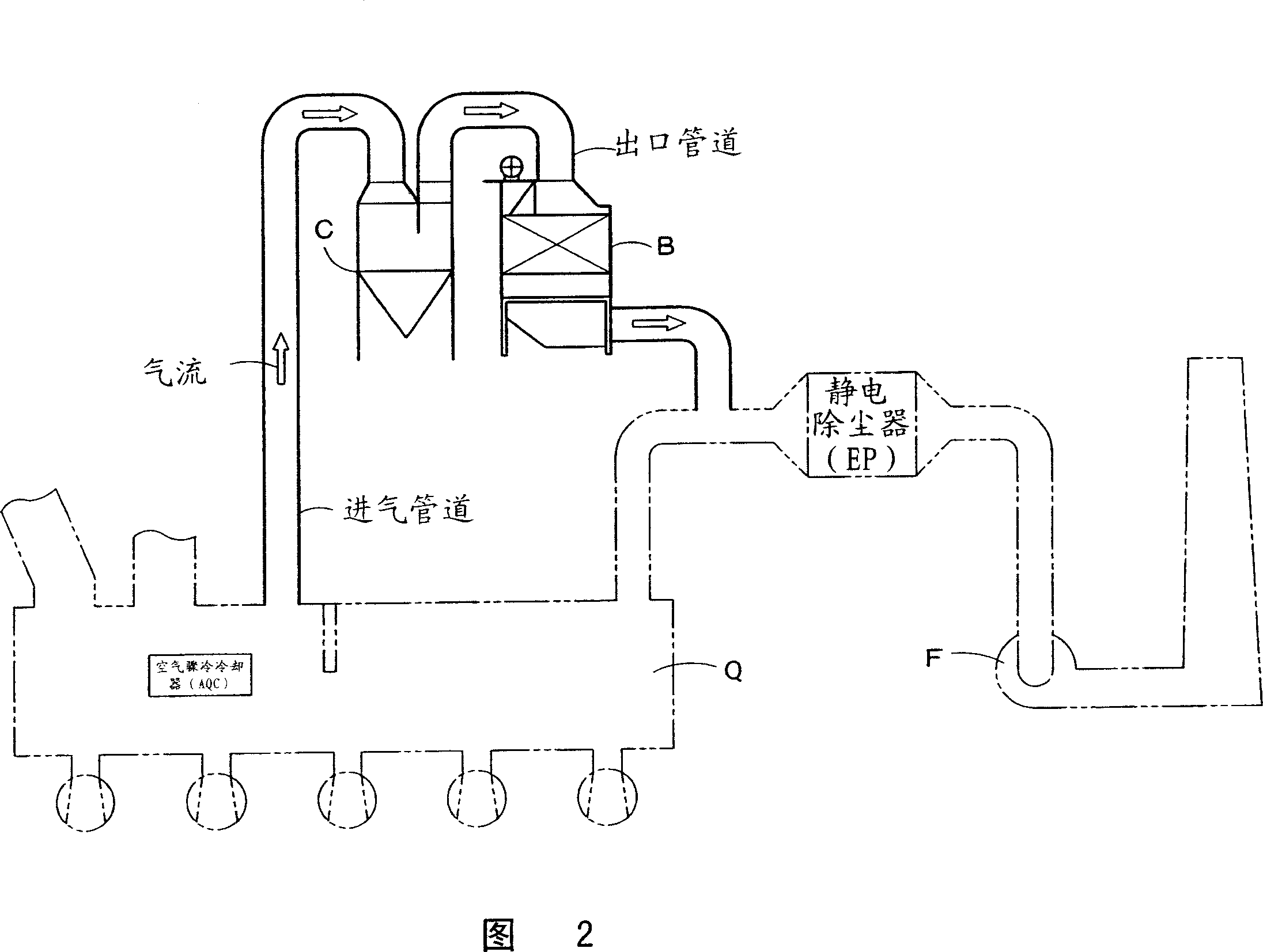

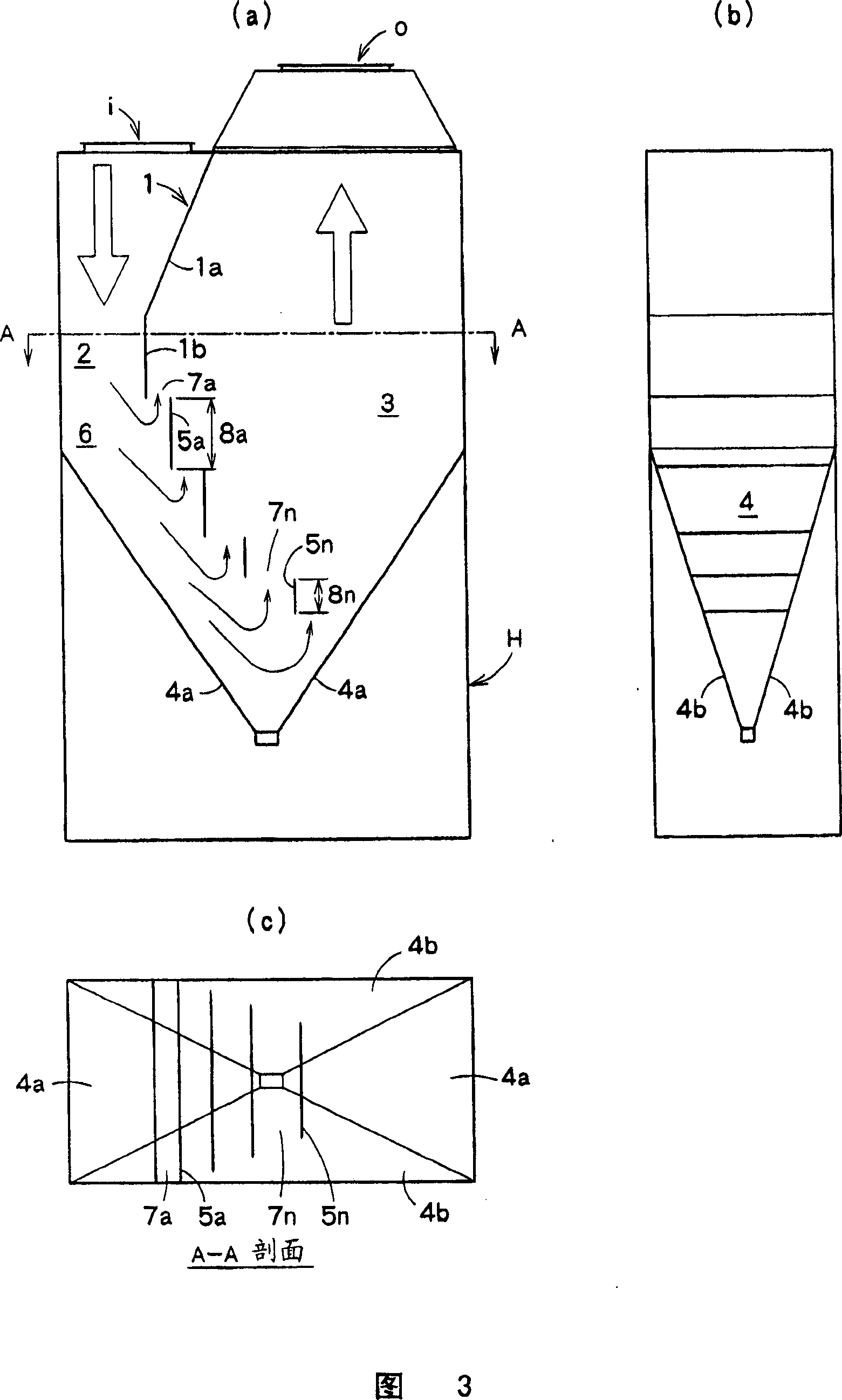

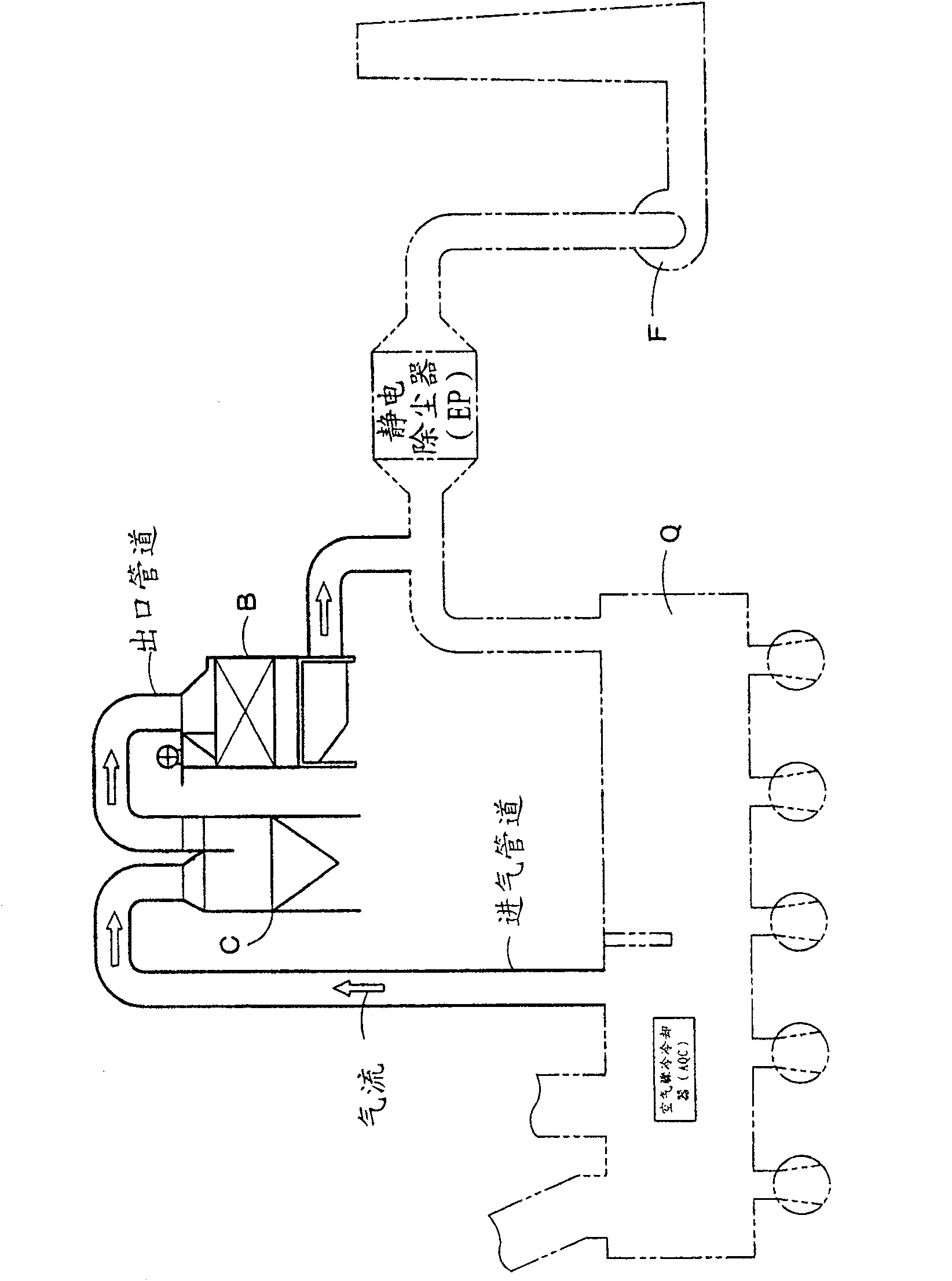

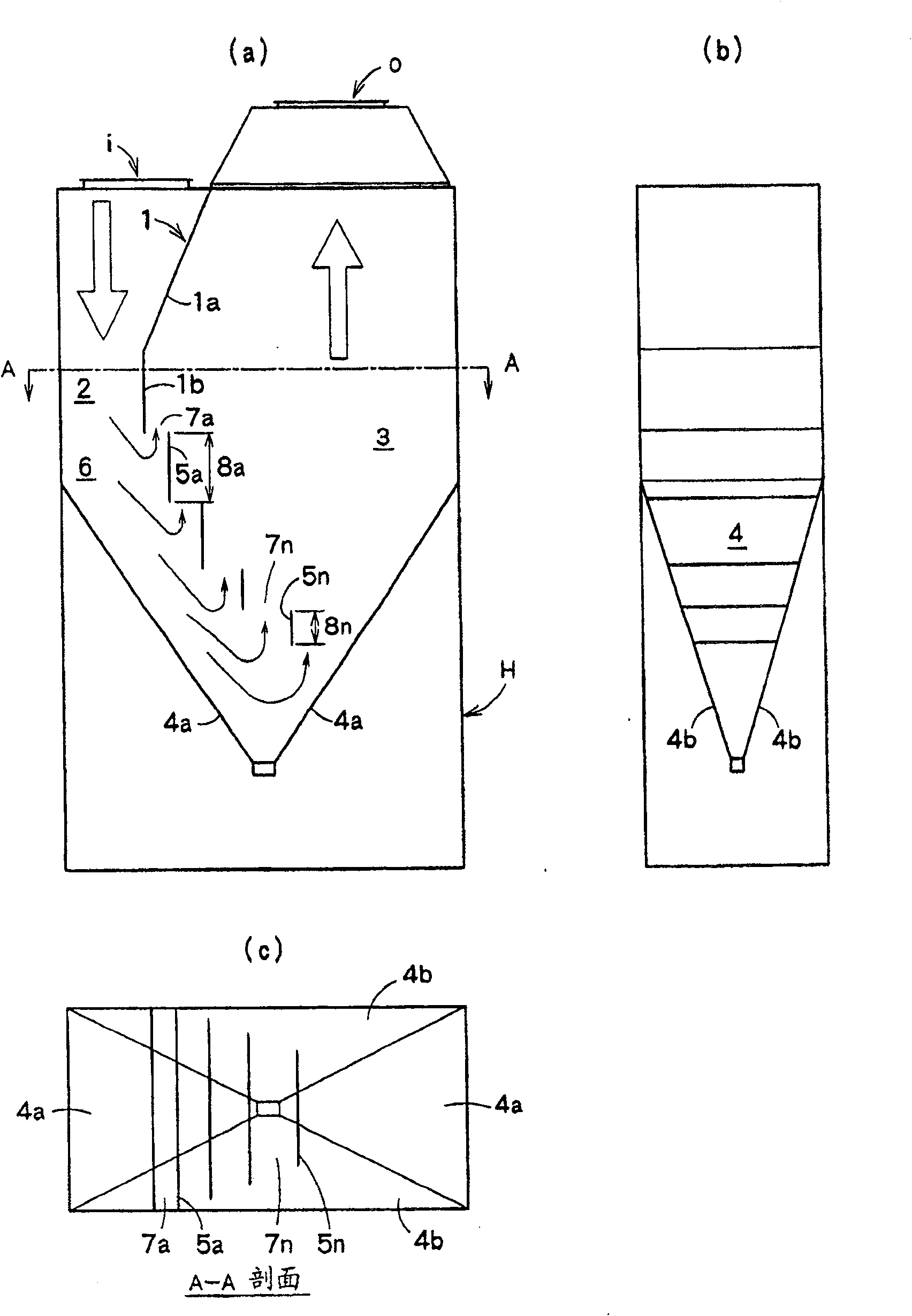

Reverse dust collector with eddy plate

ActiveCN101059313AInhibit wearAvoid damageEnergy industryClinker productionDust collectorWaste management

The invention provides a reverse rotation dedusting device, comprising a main unit. The main unit is a rectangle box. An ash hopper is arranged on the lower part of the main unit and comprises four inclined surfaces. The upper space of the main unit is divided into an air inlet chamber and a separation chamber through a baffle plate. The lower space of the main unit is provided with a plurality of vertical baffles basically along an inclined surface of the ash hoppers; a gas flow route is formed between all baffle plates and the inclined surfaces, in convenient for wide upstream side and a narrow downstream side. The baffle plate on the upstream side is long in the vertical direction; furthermore, the interval between all baffle plates has narrow upstream side and wide downstream side. The airflow in the gas flow route ascends along the baffle plate and is rectified on the upstream side through the baffle plate; the baffle plate is long in the vertical direction, so as to lead the airflow to be basically a lamellar flow and to flow into the separation chamber. The flowing speed of the airflow is restricted by flow resistance between the baffle plates, thus leading the flowing speed to be more uniform.

Owner:KAWASAKI HEAVY IND LTD

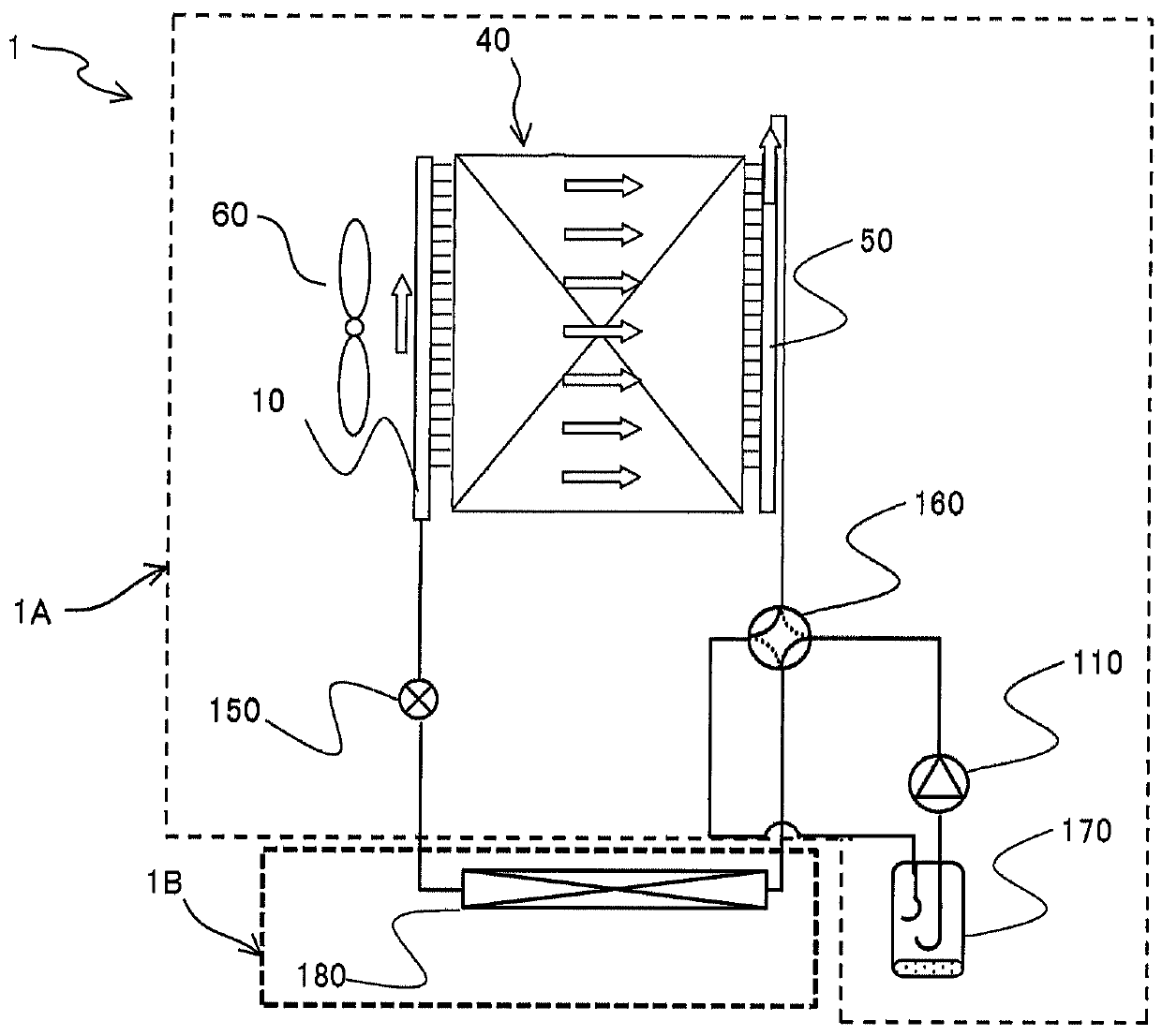

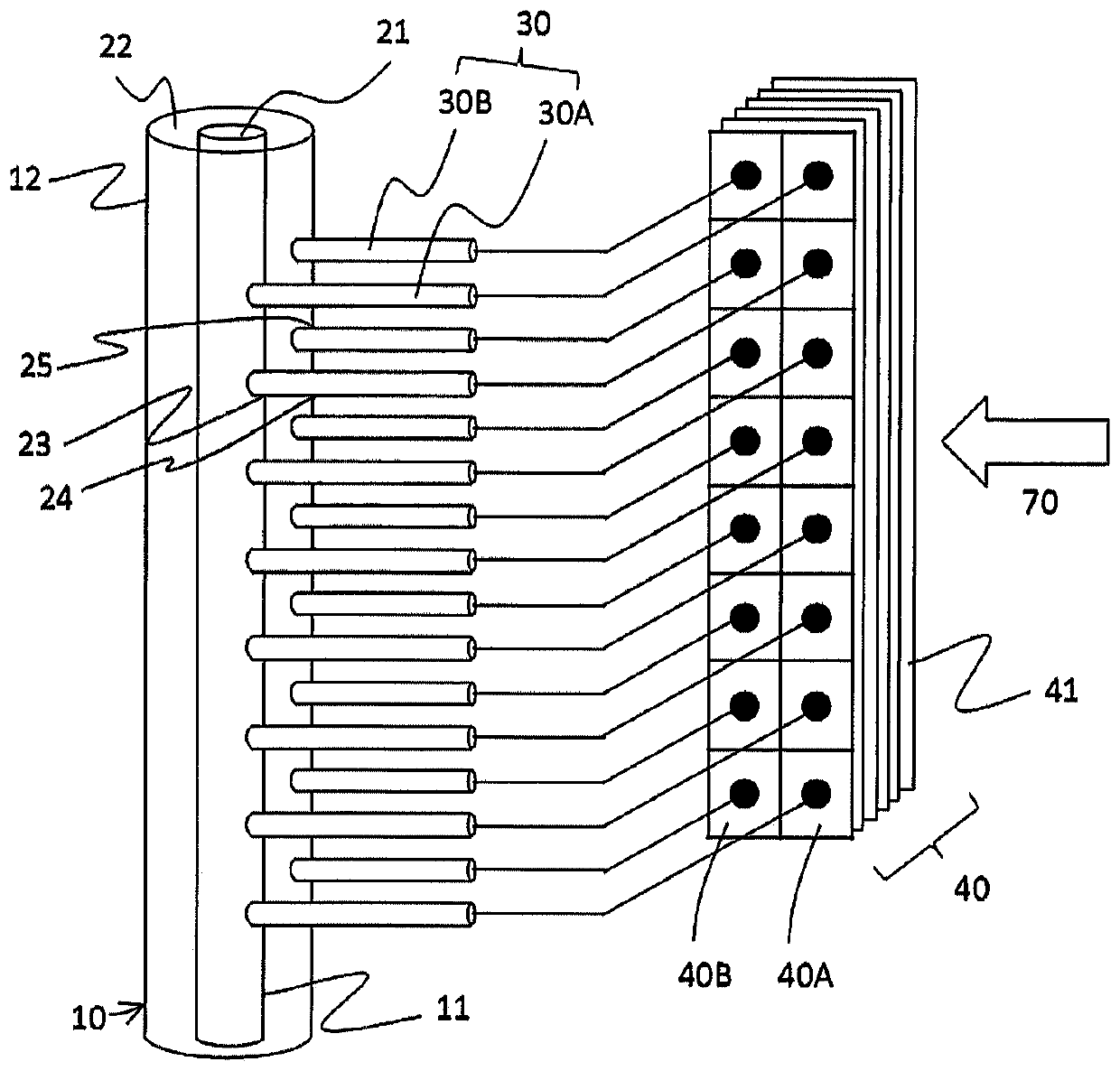

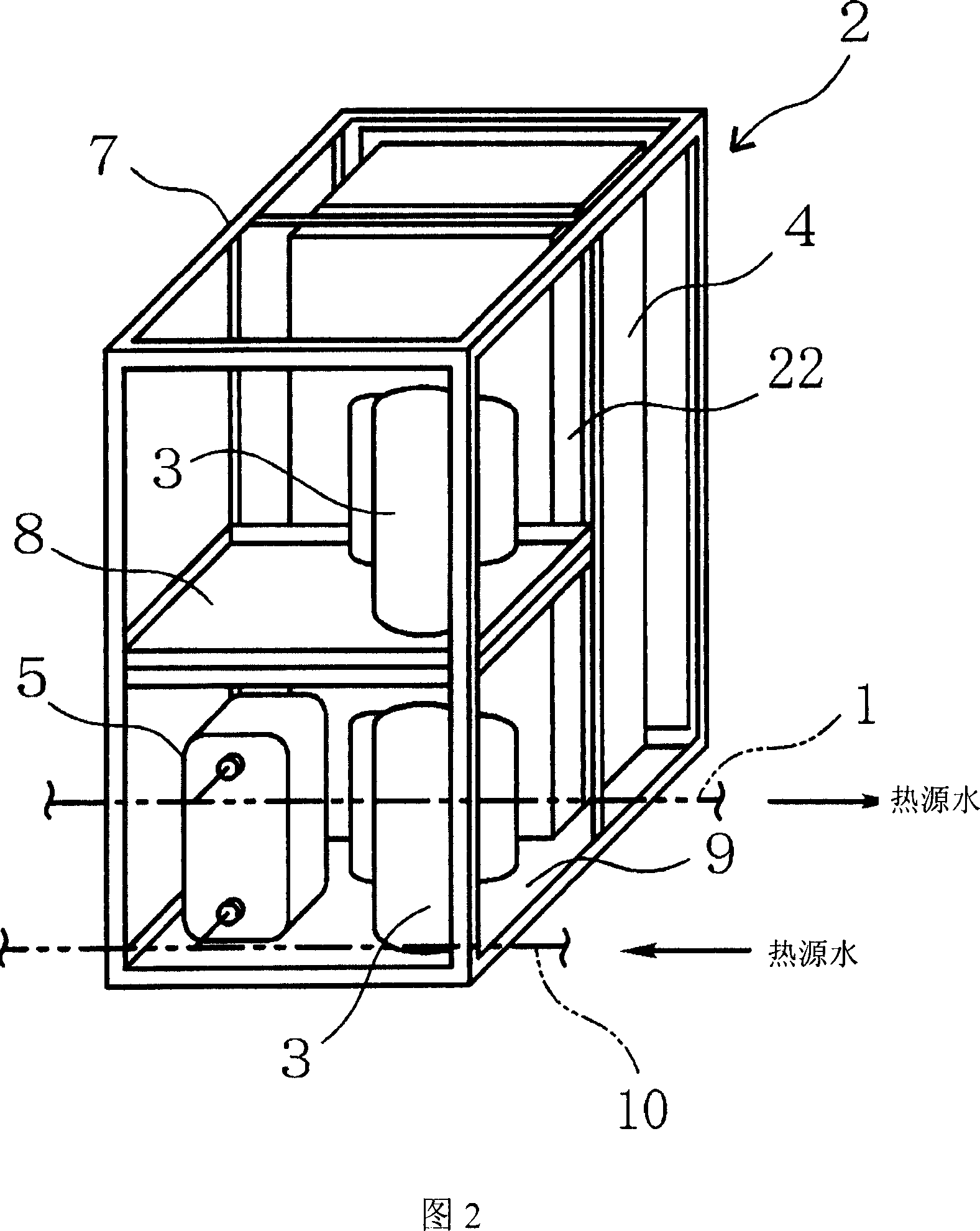

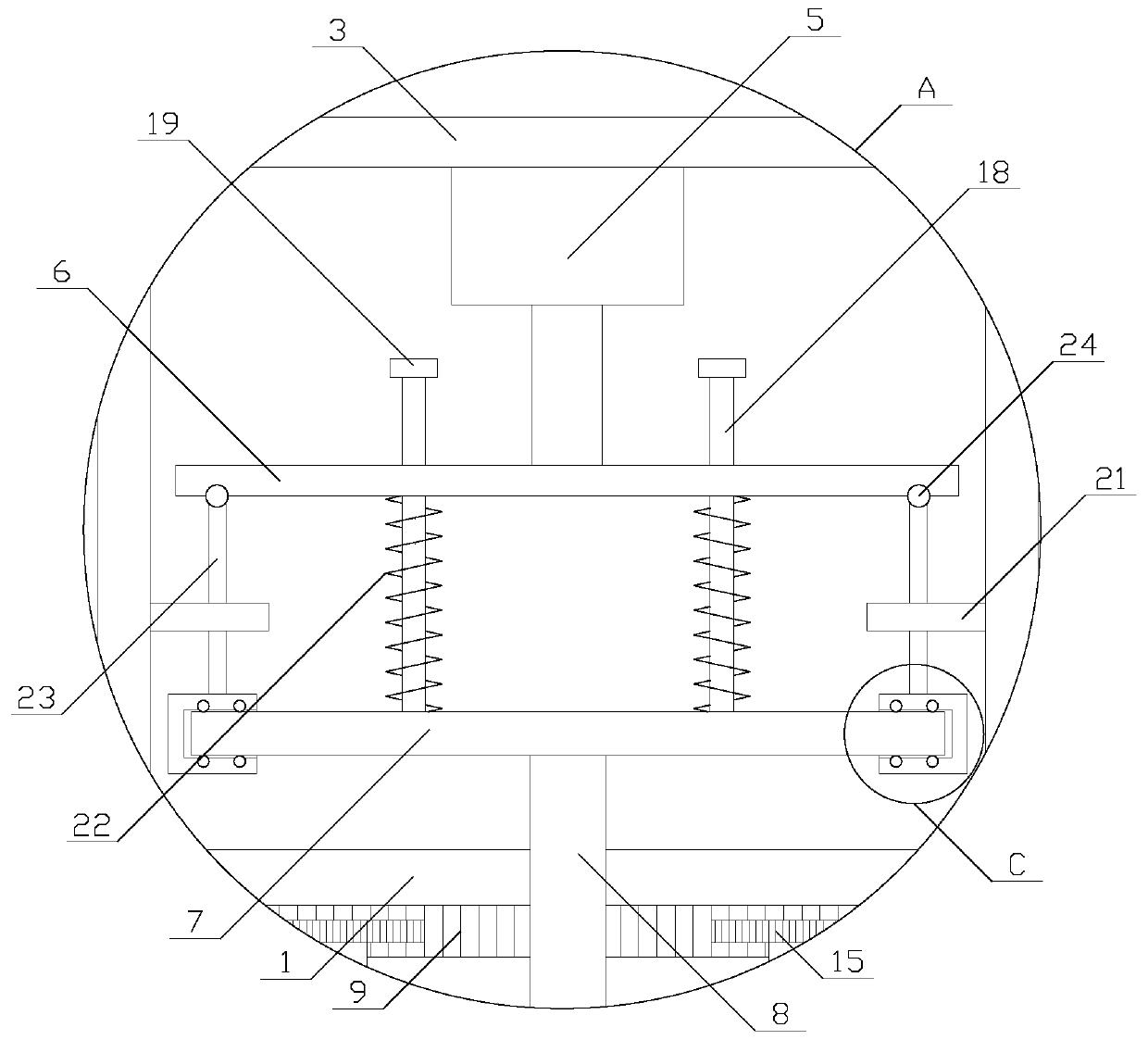

Heat exchanger and refrigeration cycle device

ActiveCN110832260AImprove heat exchange capacityReduced heat exchange capacityEvaporators/condensersStationary conduit assembliesRefrigerationRefrigerant

The heat exchanger comprises multiple heat exchanger cores and a distributor which distributes a refrigerant. Each of the heat exchanger cores includes multiple fins and multiple heat transfer pipes disposed side by side in the vertical direction. The multiple heat transfer pipes are connected to the distributor. The inside of the distributor is partitioned so as to have multiple refrigerant flowpaths, and is formed such that, when the refrigerant flows into one of the refrigerant flow paths, the refrigerant flows from the refrigerant flow path to another one of the refrigerant flow paths. The multiple heat transfer pipes of a heat exchanger core that is disposed on the windward side of the flow of air supplied to the heat exchanger among the multiple heat exchanger cores, are connected to the refrigerant flow paths located on the upstream side of the flow of the refrigerant in the distributor. The multiple heat transfer pipes of a heat exchanger core that is disposed on the leeward side of the flow of air supplied to the heat exchanger among the multiple heat exchanger cores, are connected to the refrigerant flow paths located on the downstream side of the flow of the refrigerantin the distributor.

Owner:MITSUBISHI ELECTRIC CORP

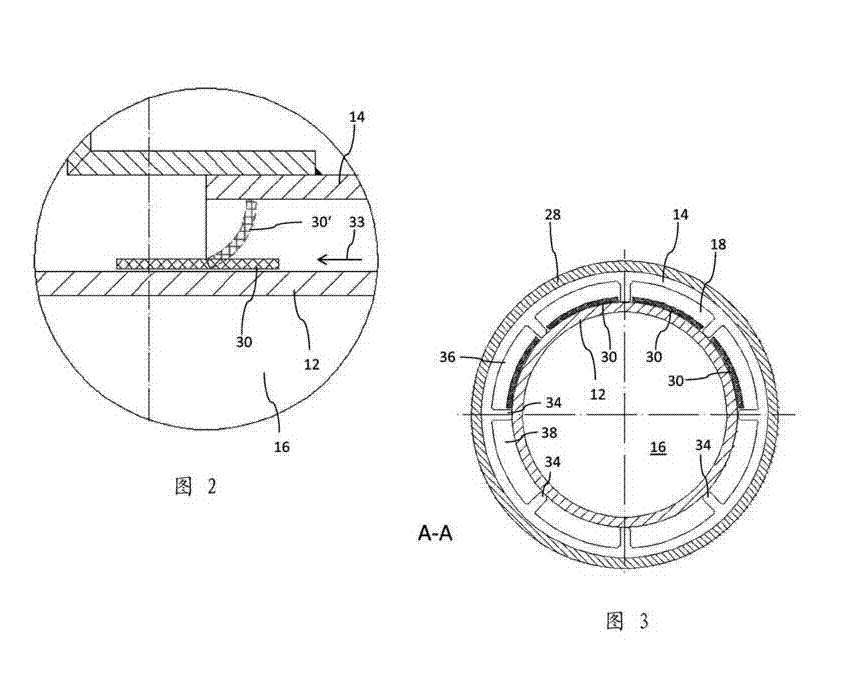

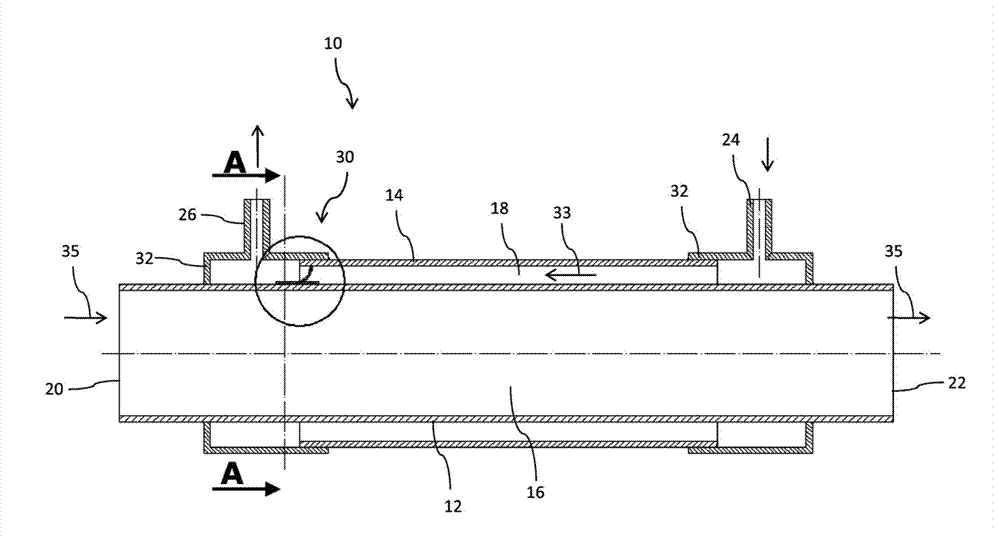

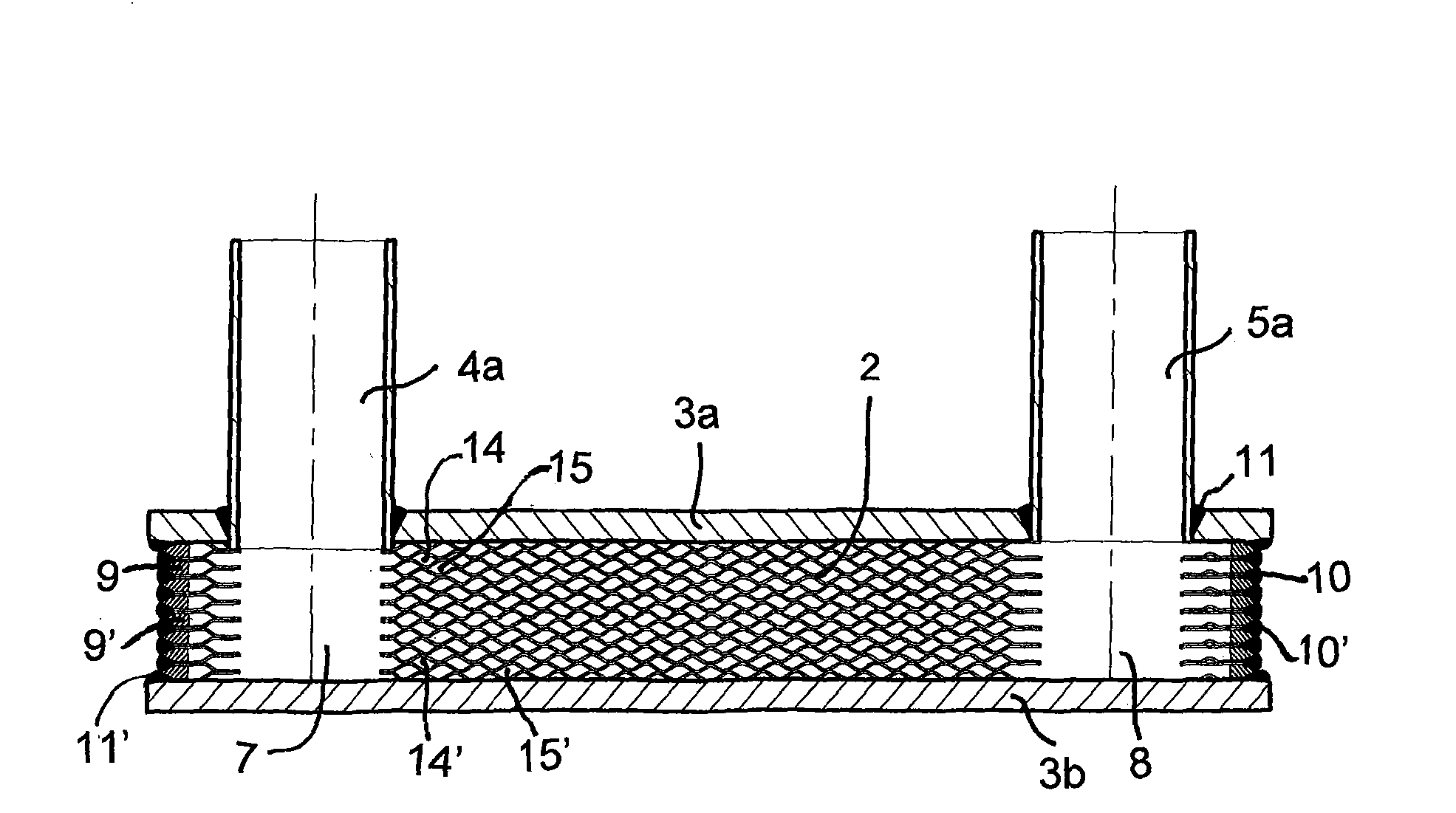

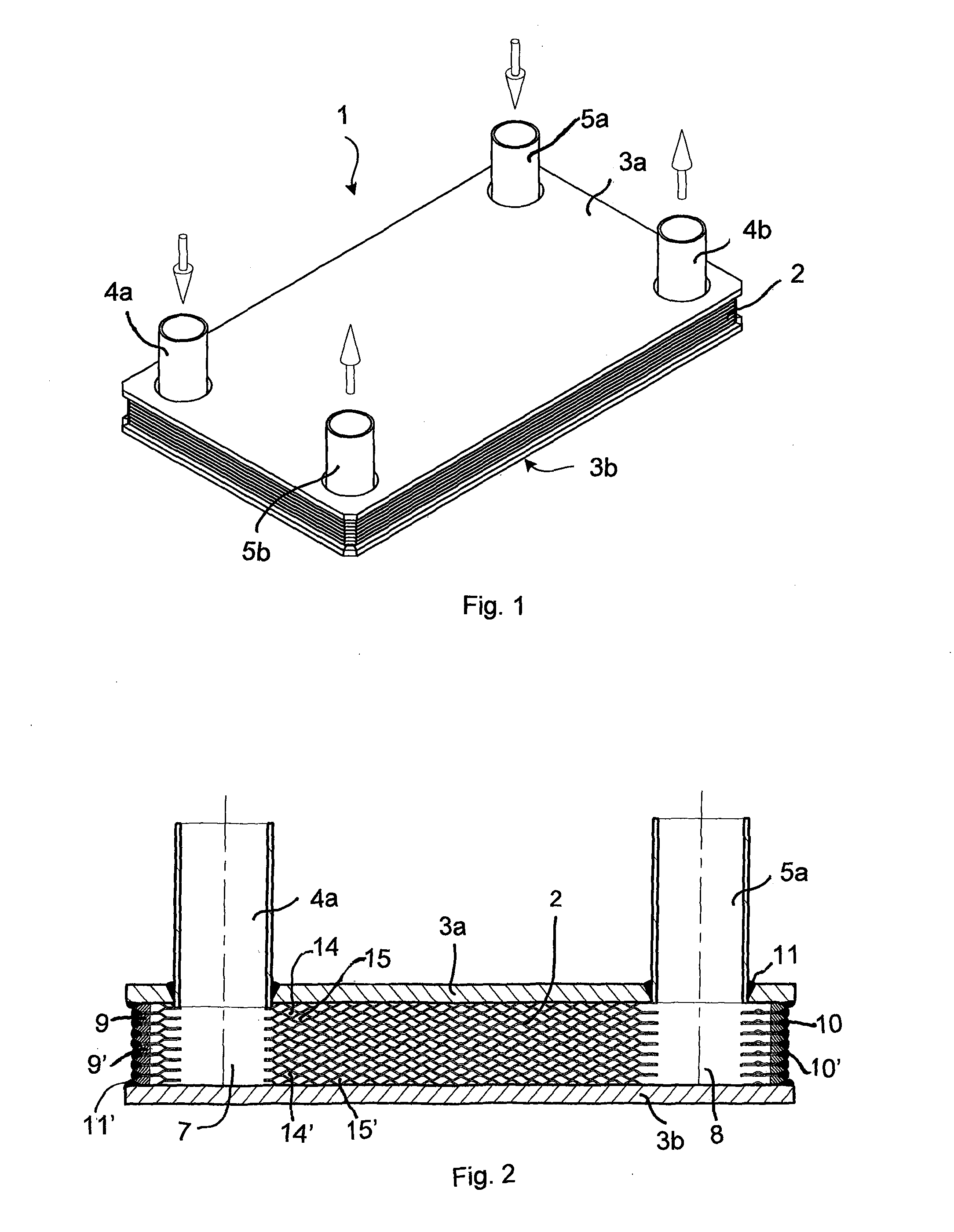

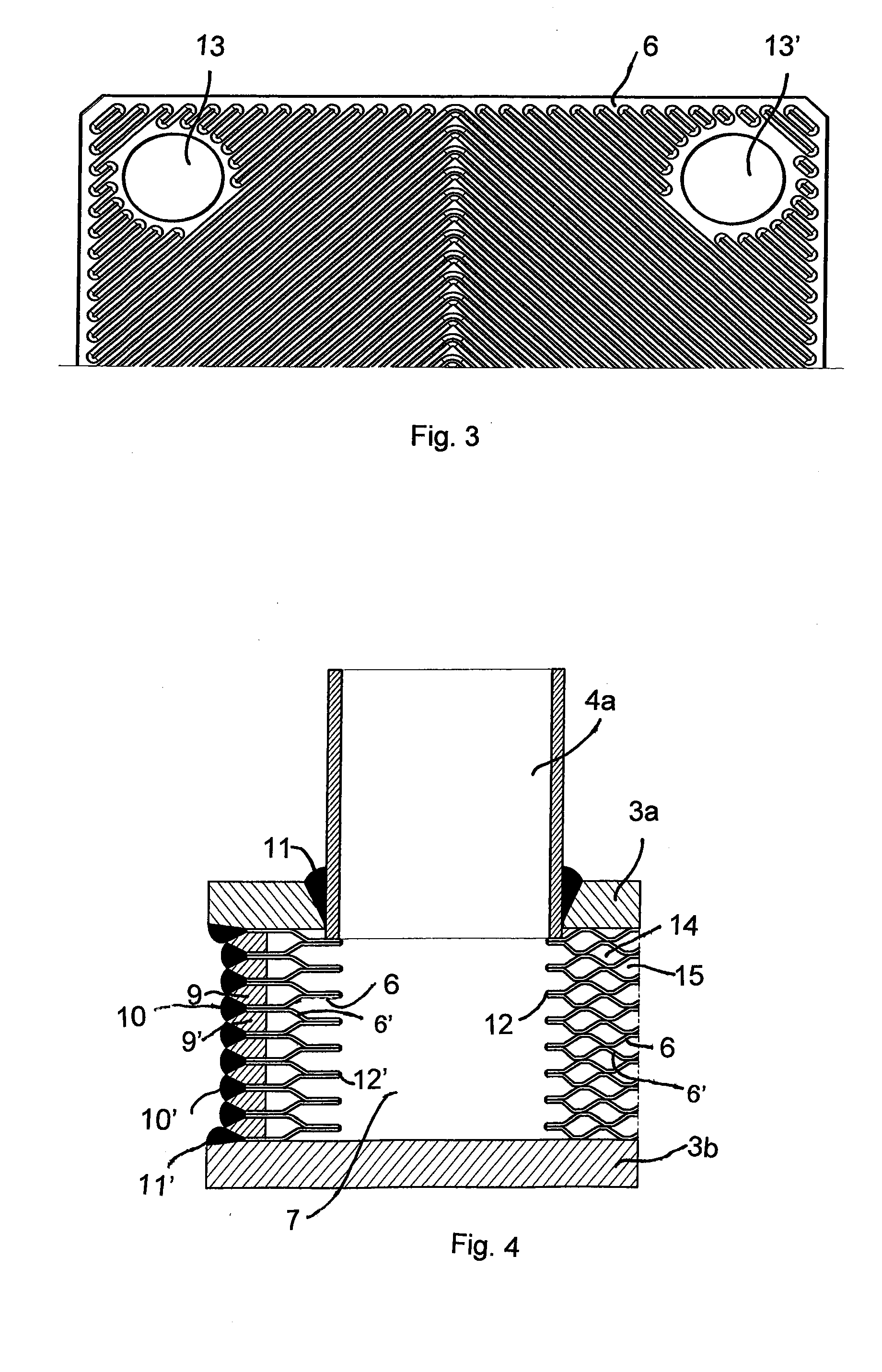

Plate heat exchanger and method for manufacturing a plate heat exchanger

InactiveUS20140326439A1Reduced heat exchange capacityImprove heat exchange effectReinforcing meansMetal-working apparatusEngineeringMechanical engineering

The invention relates to a plate heat exchanger, which comprises a plate pack formed by corrugated heat exchange plates with openings for the flow of a first and a second heat exchange medium. The outer shell of the plate heat exchanger (1) has been formed by arranging separate strips (9, 9′) in the outer edge of the plate pack (2) so that the outer surfaces of the strips (9, 9′) are substantially in the same plane with the outer edges of the heat exchange plates (6, 6′), and by welding the strips (9, 9′) and the outer edges of the heat exchange plates (6, 6′) to each other.

Owner:VAHTERUS OY

Radiating device and illuminating device with same

ActiveCN103423721AReduce manufacturing difficultyReduce manufacturing costPoint-like light sourceLighting heating/cooling arrangementsHeat sinkEngineering

Owner:LEDVANCE GMBH

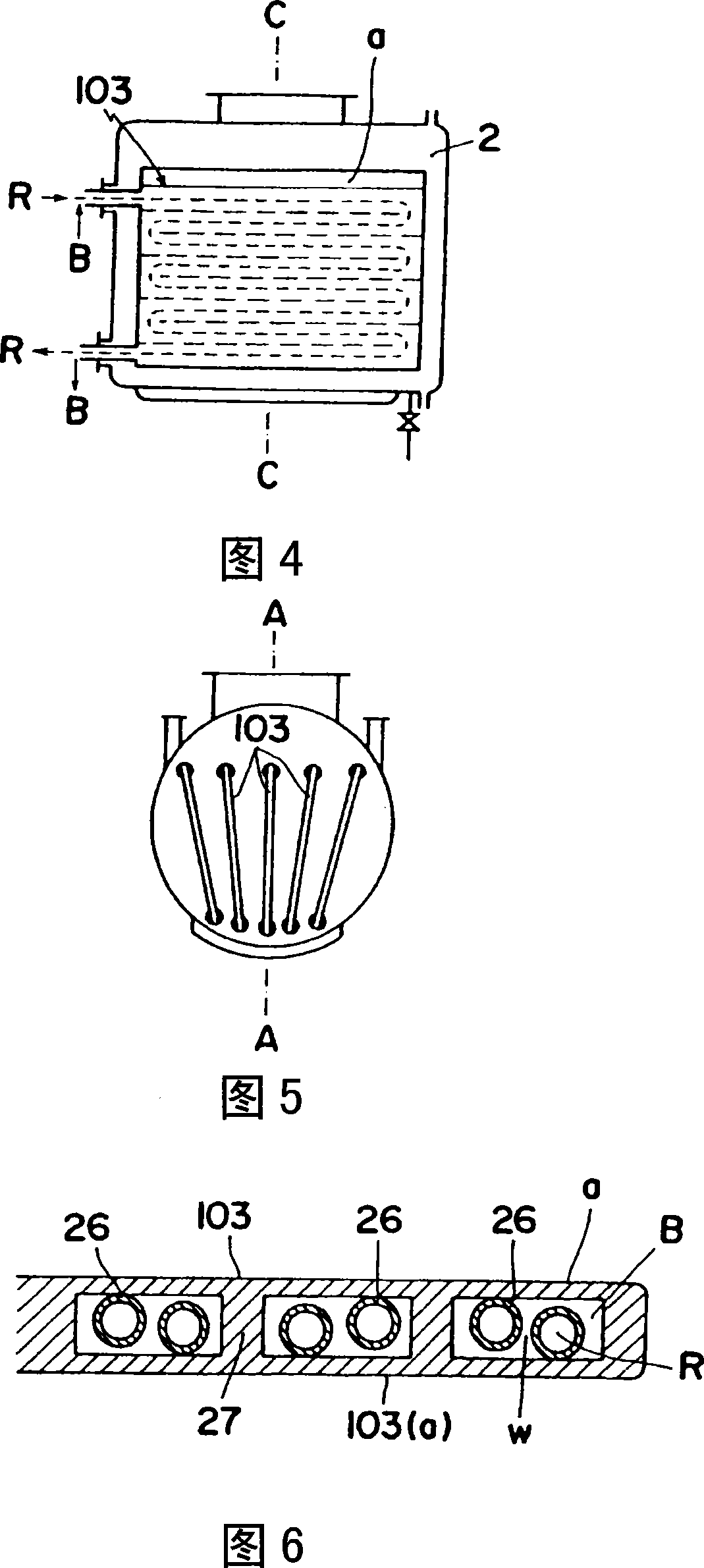

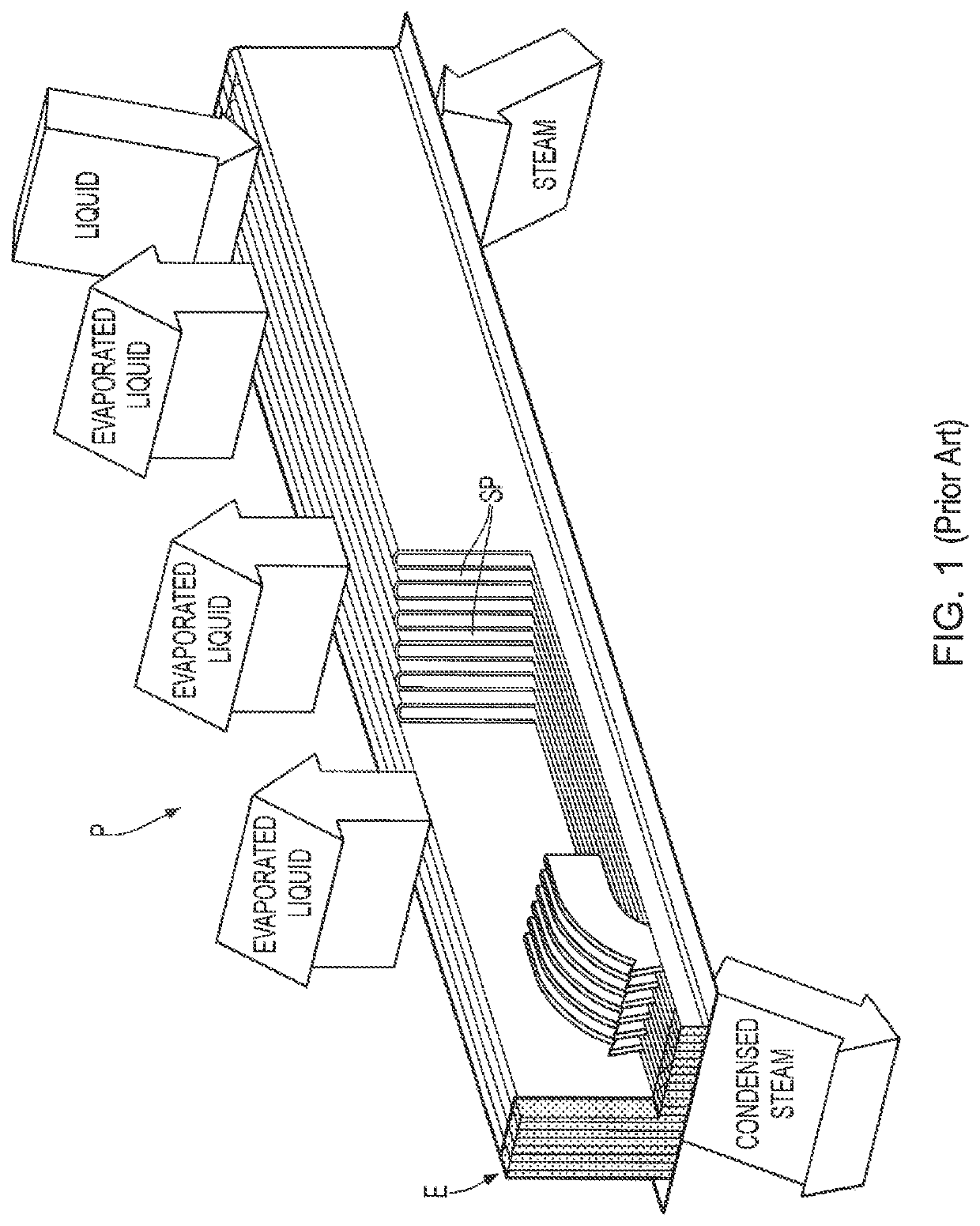

Steam condenser of vacuum plant

ActiveCN101498533AReduced overall heat transfer coefficientReduced heat exchange capacityEvaporators/condensersSteam condensationEvaporation

The invention relates to a steam condenser of a vacuum device. Compared with a steam condenser of a vacuum drying device, the steam condenser of a vacuum device can enhance the heat transfer performance and reduce the loss of the transmission temperature difference loss of a refrigerant and the vacuum steam of a condensing surface. A circular refrigerant evaporation tube inside the steam condenser of a vacuum drying device is changed from a smooth tube into a circular tube with an inner surface groove and then processed into a flat elliptical tube through deformation, one flat horizontal surface or two flat horizontal surfaces of a pair of flat horizontal surfaces is / are tightly attached to the inner wall surface of a channel of heat transfer medium fluid and is / are arranged in the channel to increase the tight attachment area of the inner wall surface of the channel of the heat transfer medium fluid inside a steam condensation plate and the elliptical refrigerant evaporation tube, and rods which can equidistantly generates turbulences are arranged along the elliptical refrigerant evaporation tube in the channel of the heat transfer medium fluid to confuse parallel flows of the outer surface of the elliptical refrigerant evaporation tube, thereby the heat transfer of convection films of the heat transfer medium fluid is promoted.

Owner:KYOWA VACUUM ENG

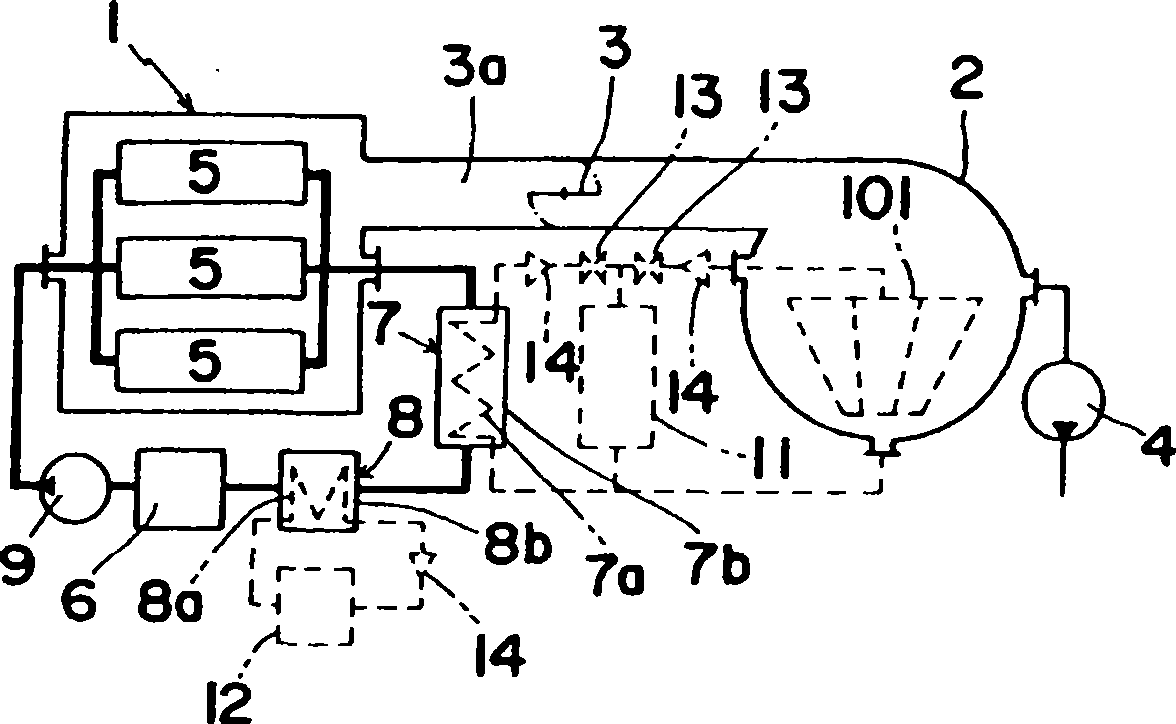

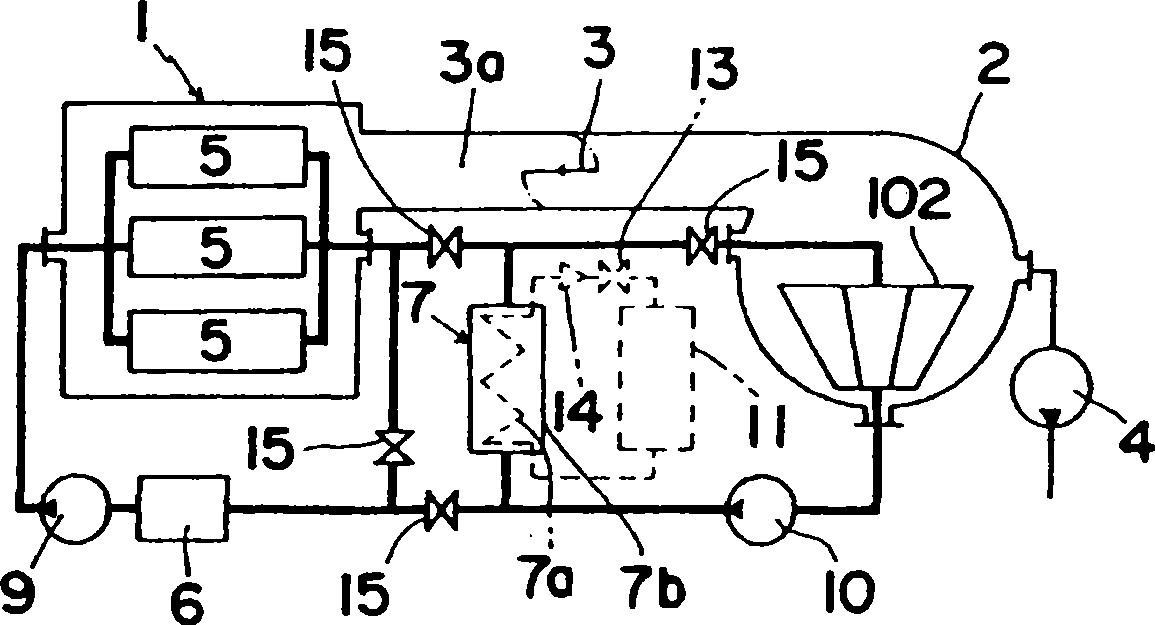

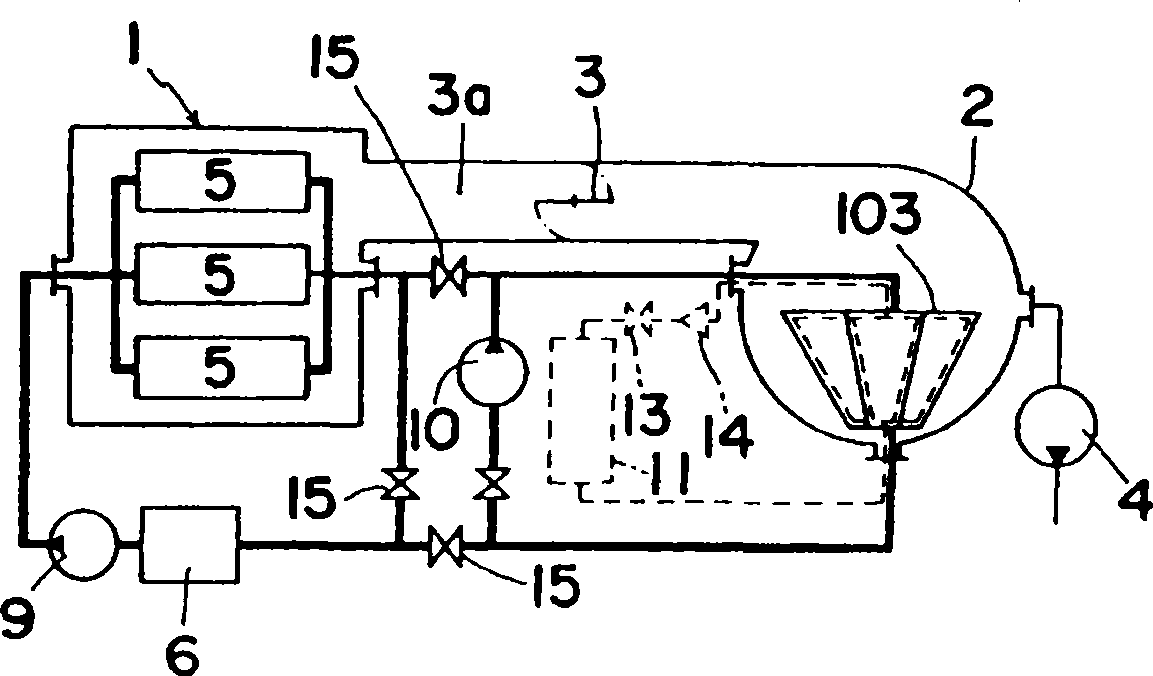

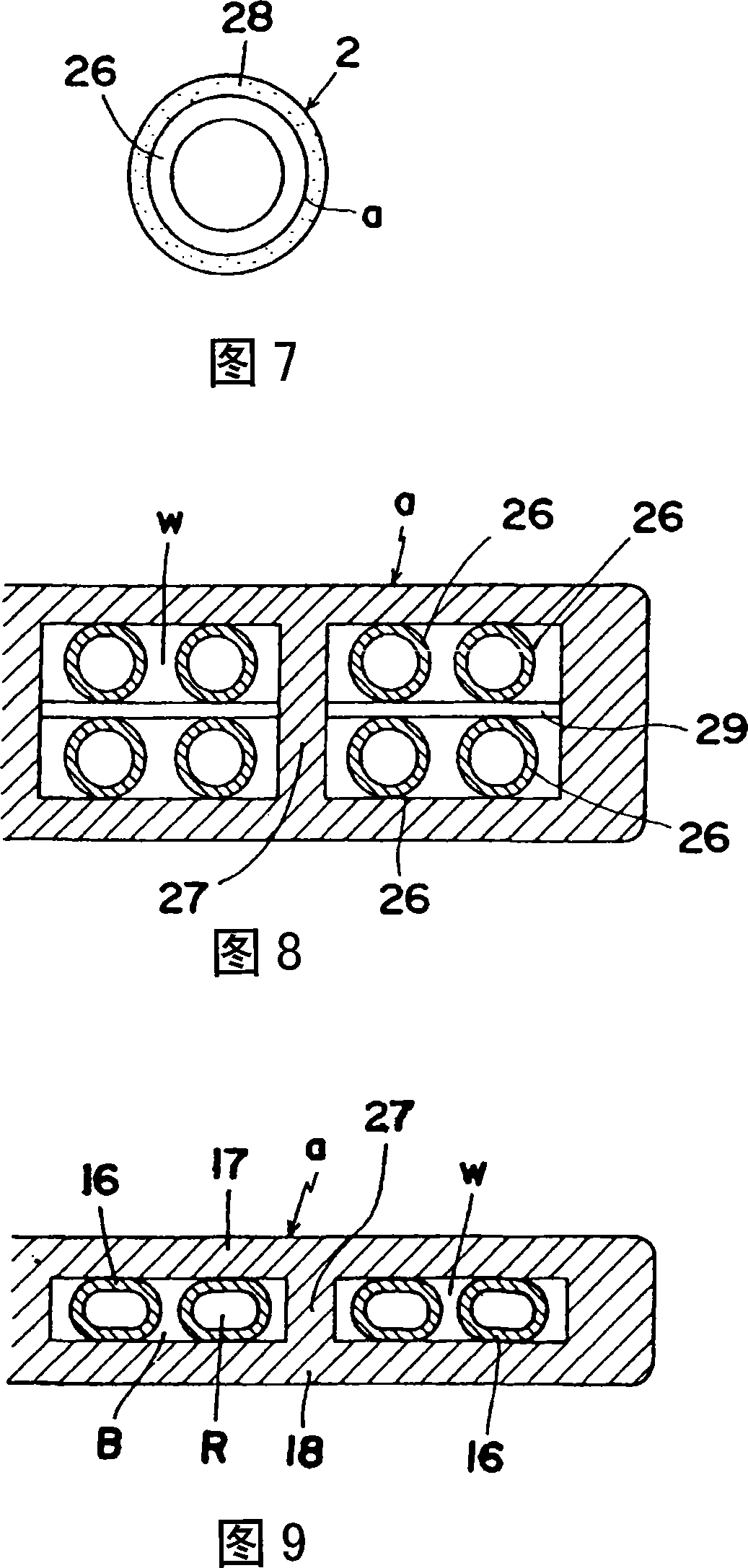

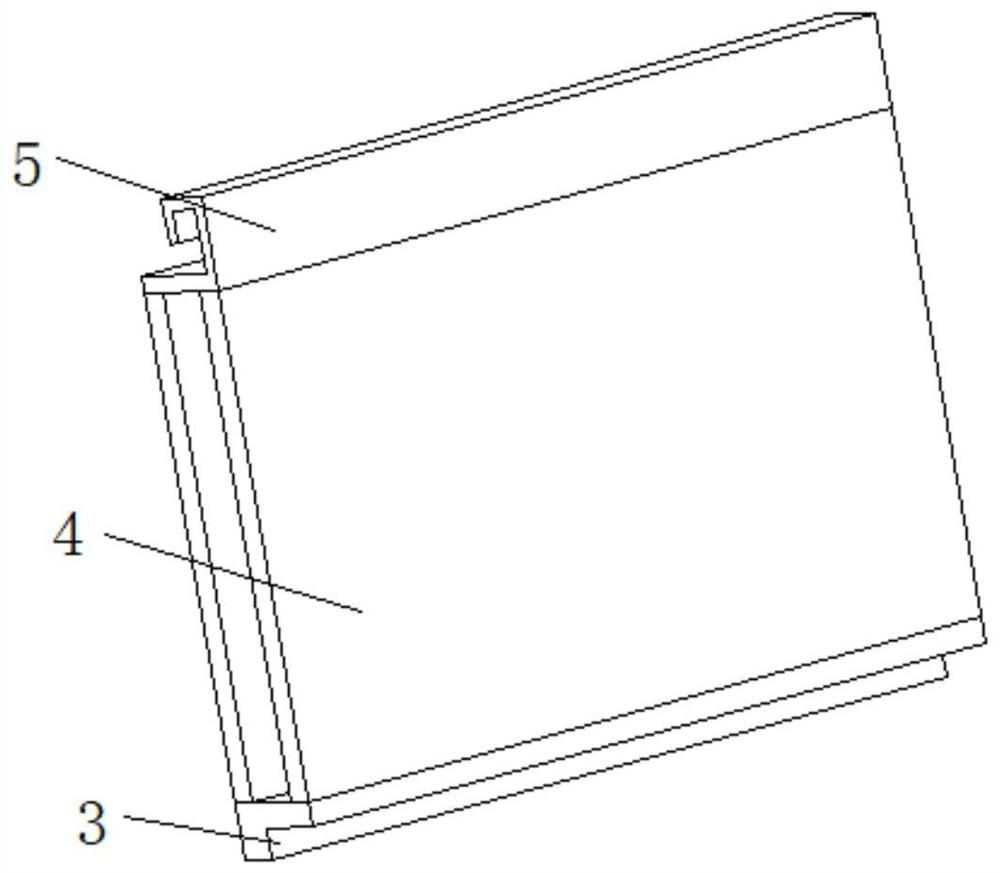

Water-cooling type air conditioner

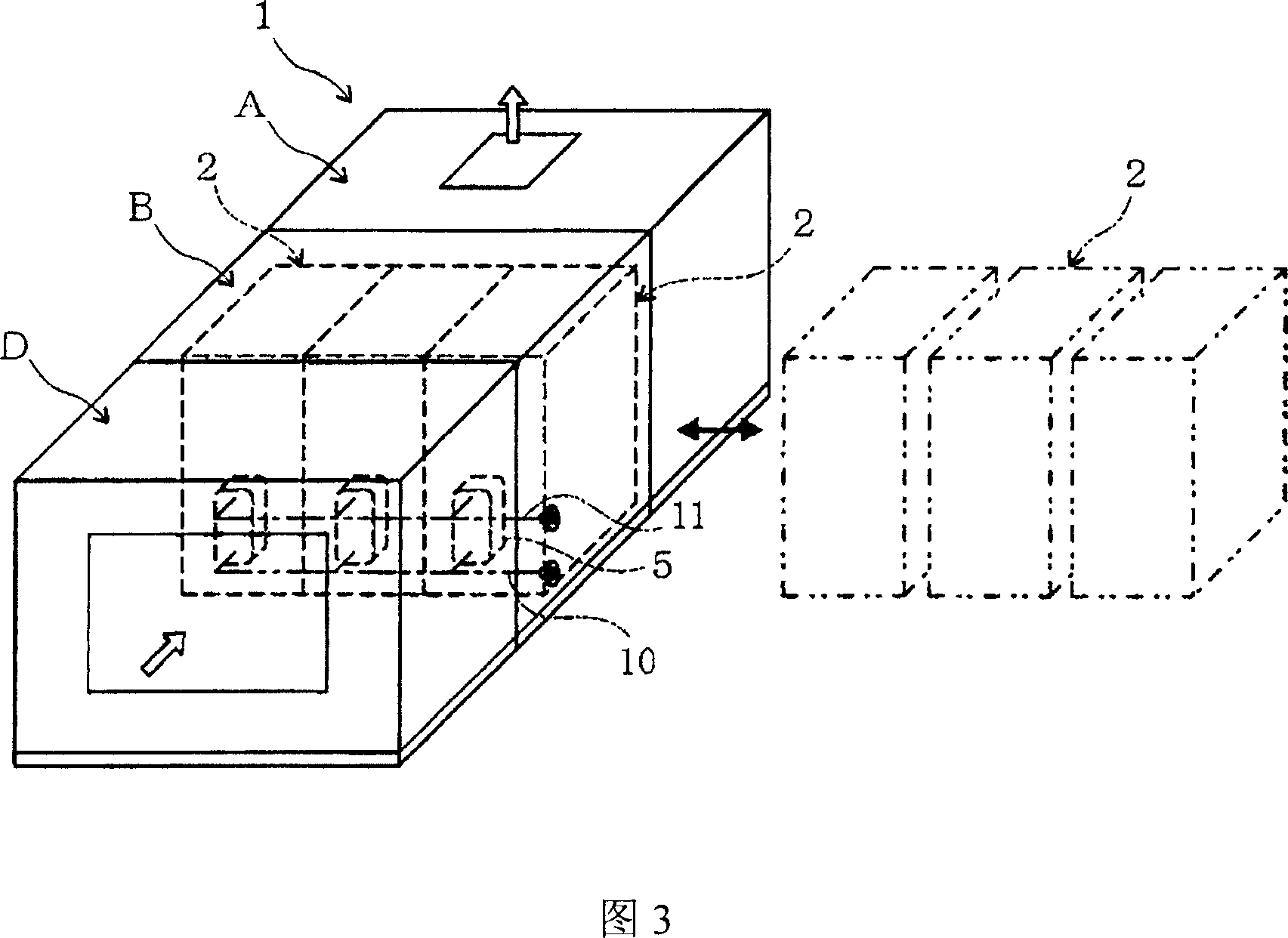

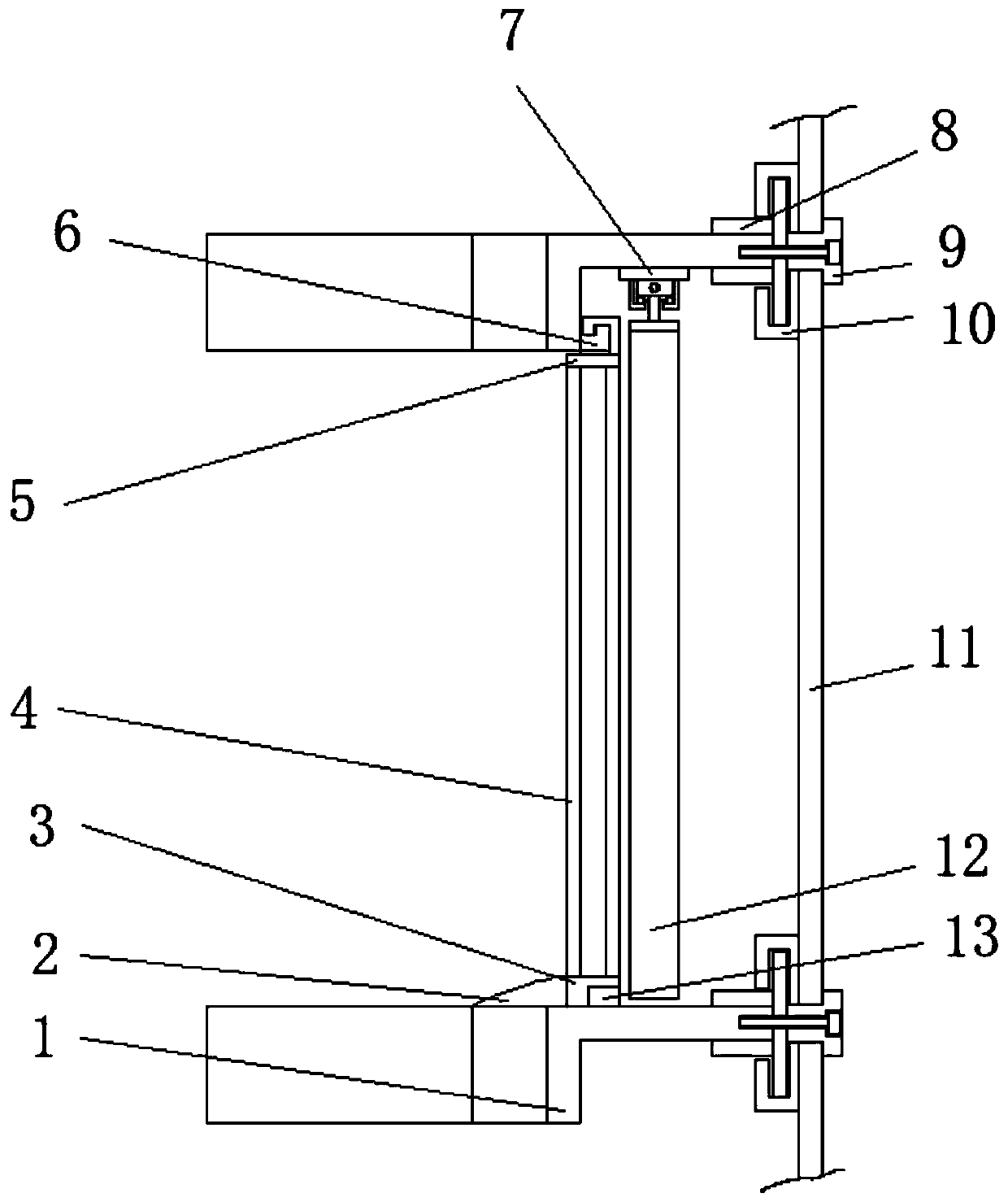

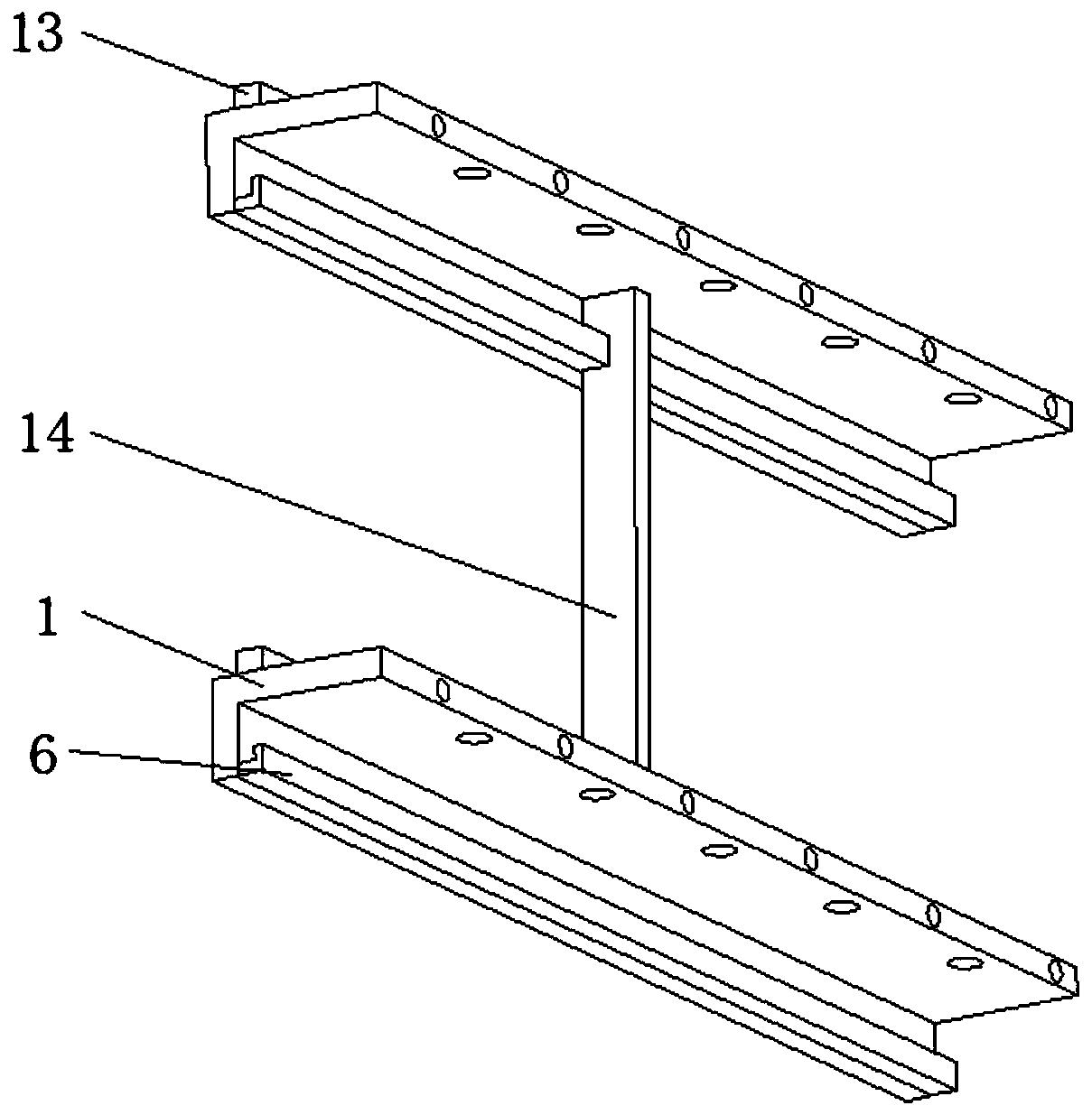

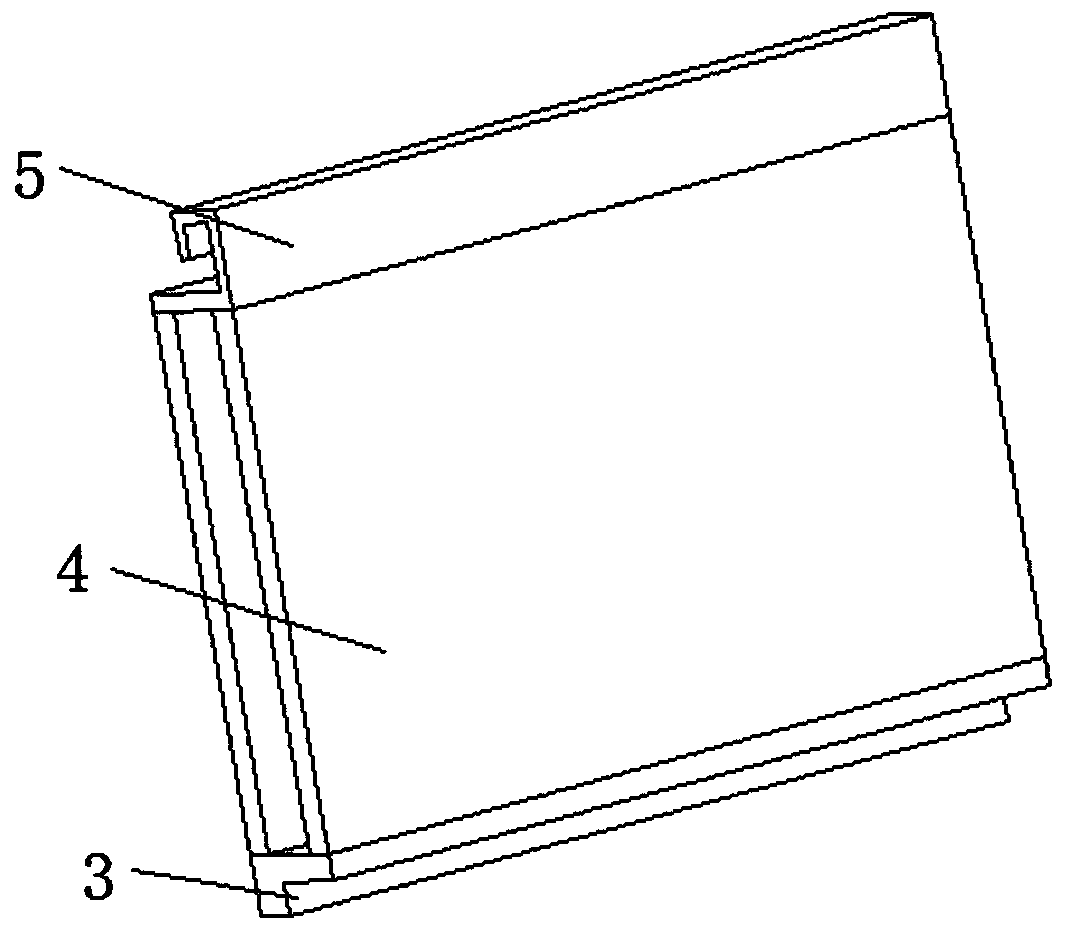

InactiveCN1967093AReduce in quantityGuaranteed large air volumeHeat pumpsAir conditioning systemsEngineeringHeat pump

A water-cooling heat pump type air conditioner comprises a housing (1) and a plurality of water-cooling heat pump units (2) which is opposite to the housing (1) and can be taken out or received freely. The water-cooling heat pump units (2) at least comprises a plurality of compressors (3), an air heat exchanger (4) and a water heat exchanger (5) for a plurality of compressors (3), a decompressor, and a frame (7) for arranging the parts. The compressors (3) arranged on the air entrance of the air heat exchanger (4) are arranged up-and-down separated. The thermal source water passageway of the water heat exchanger (5) can connect or separate freely with enter pipe (10) and discharge pipe (11) of the thermal source water arranged in the housing (1).

Owner:KIMURA KOHKI CO LTD

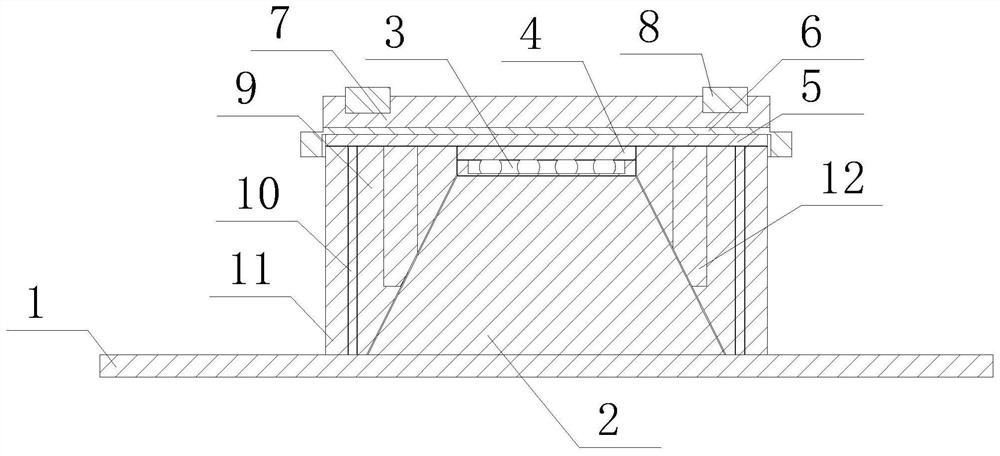

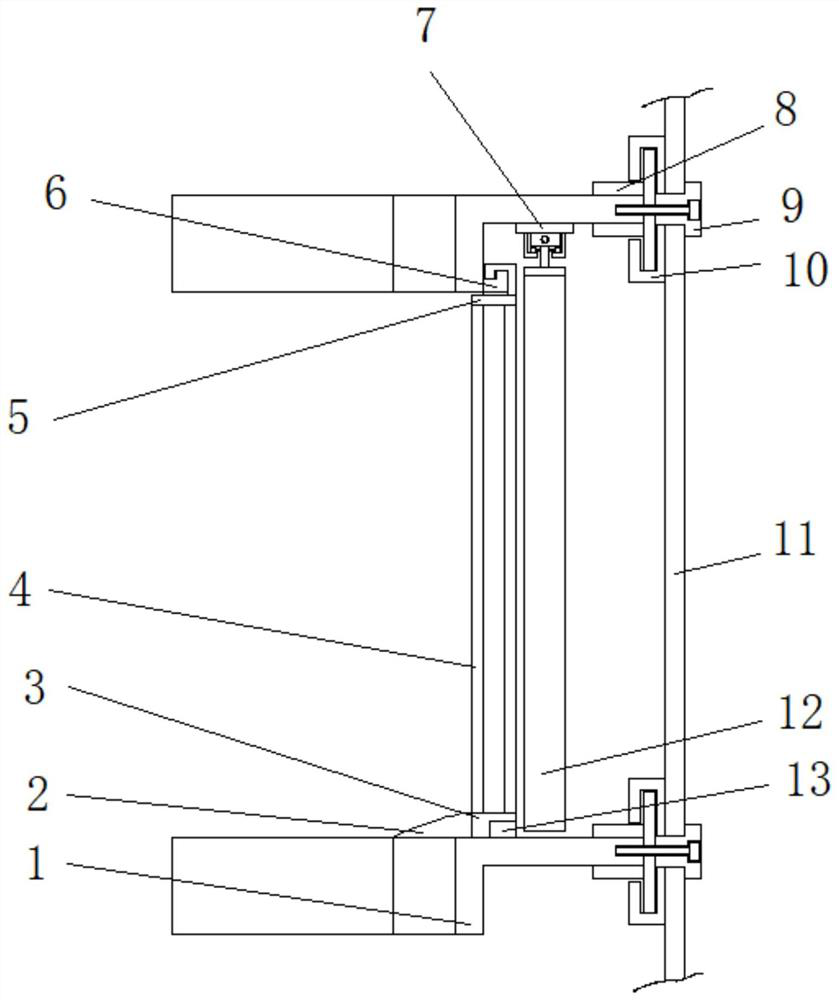

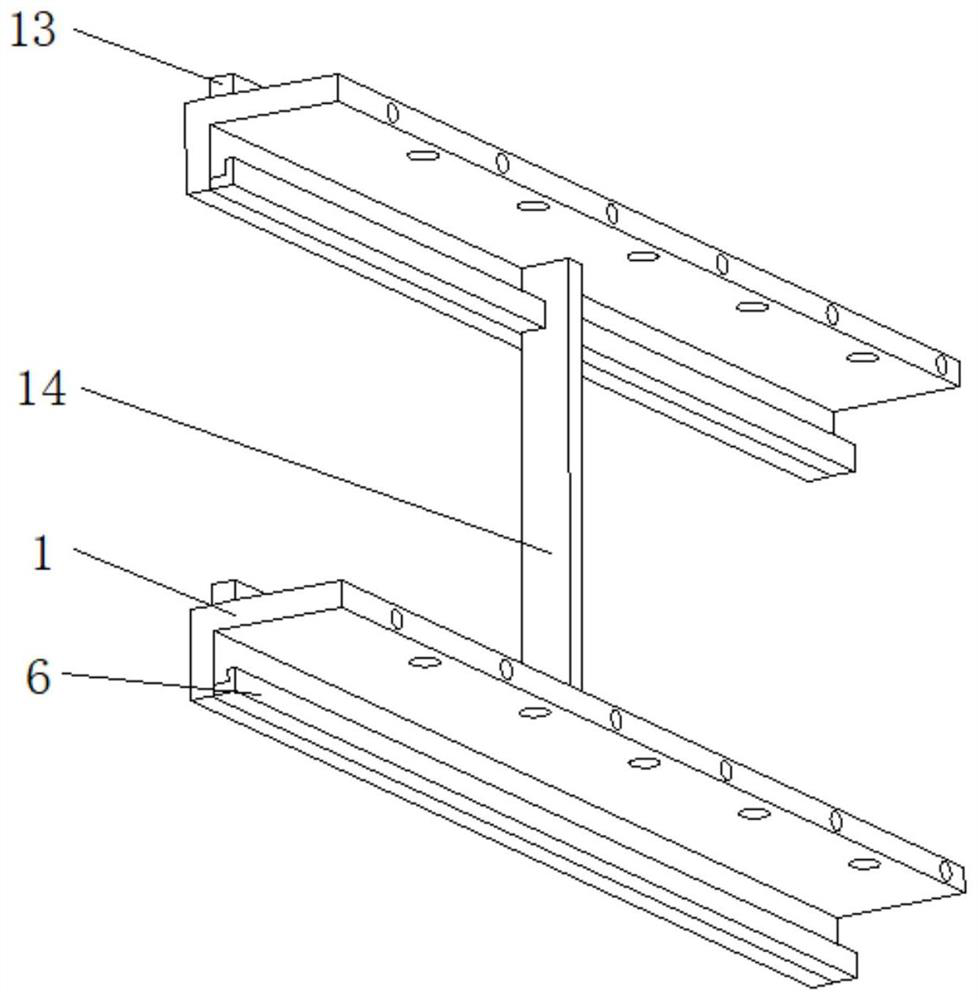

Energy-saving curtain wall

ActiveCN111441516AReduce heat exchangeReduce utilizationWallsBuilding insulationsMechanical engineeringCurtain wall

The invention belongs to the technical field of buildings, and particularly relates to an energy-saving curtain wall. For solving problems that a curtain wall is poor in heat insulation property, andthe energy-saving effect is commonly not ideal, the energy-saving curtain wall is provided and comprises supporting parts mounted on the outer side of a building floor, the ends of the supporting parts are provided with multiple thread holes, multiple mounting holes are formed in the tops of the supporting parts, multiple supporting keels are fixedly mounted between the supporting parts, mountingparts of J structures are fixedly mounted on the bottoms of the side faces of the supporting parts, a buffer cavity is mounted between an inner curtain wall mechanism and an outer curtain wall mechanism, an effective isolation effect is generated, indoor and outdoor heat exchange is reduced, the curtain wall is energy-saving and environment-friendly, meanwhile, an electric curtain rail capable ofbeing remotely controlled is mounted between the inner curtain wall mechanism and the outer curtain wall mechanism, a curtain is mounted in the curtain wall, utilization of the indoor space is reduced, the isolated curtain cannot become a combustion object, and the expanded risks caused when the fire happens can be greatly reduced.

Owner:山东腾翔建设集团有限公司

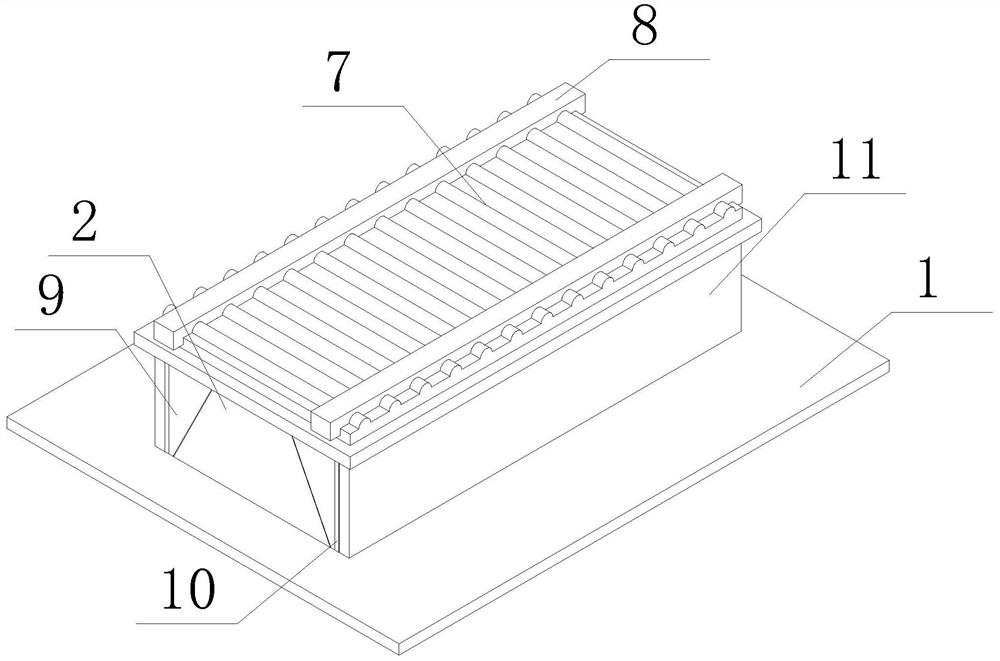

High-speed railway subgrade considering vibration reduction and freezing prevention

ActiveCN111945485AImprove antifreeze effectImprove the protective effectBallastwayEngineeringSubgrade

The high-speed railroad bed comprises a railroad bed body, a gravel layer is fixedly connected to the end, away from the ground, of the railroad bed body, a roadbed body is fixedly connected to the end, away from the railroad bed body, of the gravel layer, and a heat preservation layer is fixedly connected to the end, away from the gravel layer, of the roadbed body; the end, away from the roadbedbody, of the heat preservation layer is fixedly connected with a protective layer, and the end, away from the heat preservation layer, of the protective layer is fixedly connected with a shock pad. The high-speed railway subgrade has the advantages that the top ends of the subgrade body, the fixing layer, the damping material layer and the reinforcing layer are sealed by the heat preservation layer, so that the subgrade body is isolated from the outside by the heat preservation layer, and temperature conduction above the subgrade body and the heat preservation layer is isolated; therefore, theheat exchange capacity between the roadbed body and the outside is reduced, the anti-freezing capacity of the railroad bed can be effectively improved, and the protective performance of the railroadbed is improved.

Owner:中铁八局集团第二工程有限公司 +1

Steam condenser of vacuum plant

ActiveCN101498533BReduced overall heat transfer coefficientReduce deliveryEvaporators/condensersSteam condensationEvaporation

Owner:KYOWA VACUUM ENG

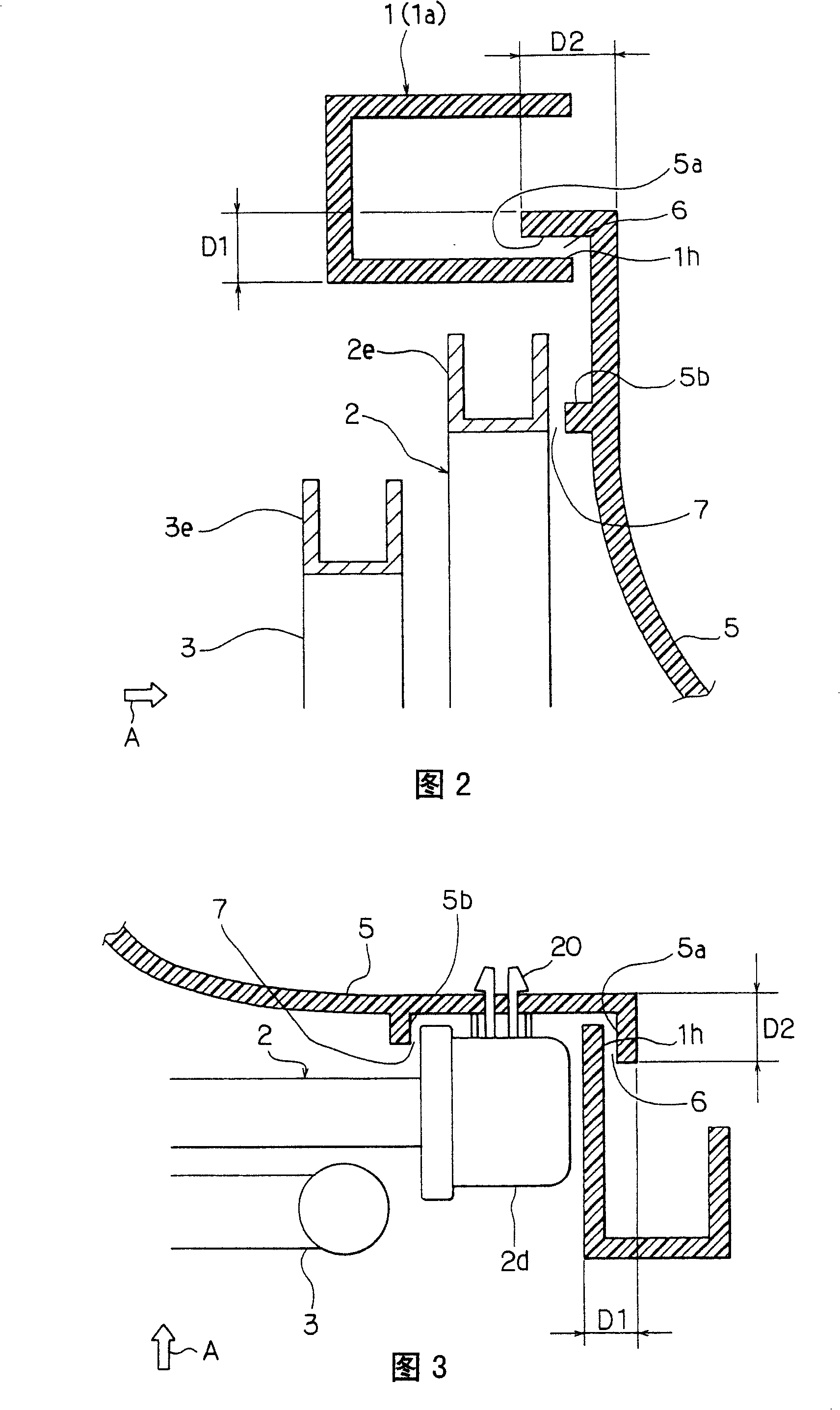

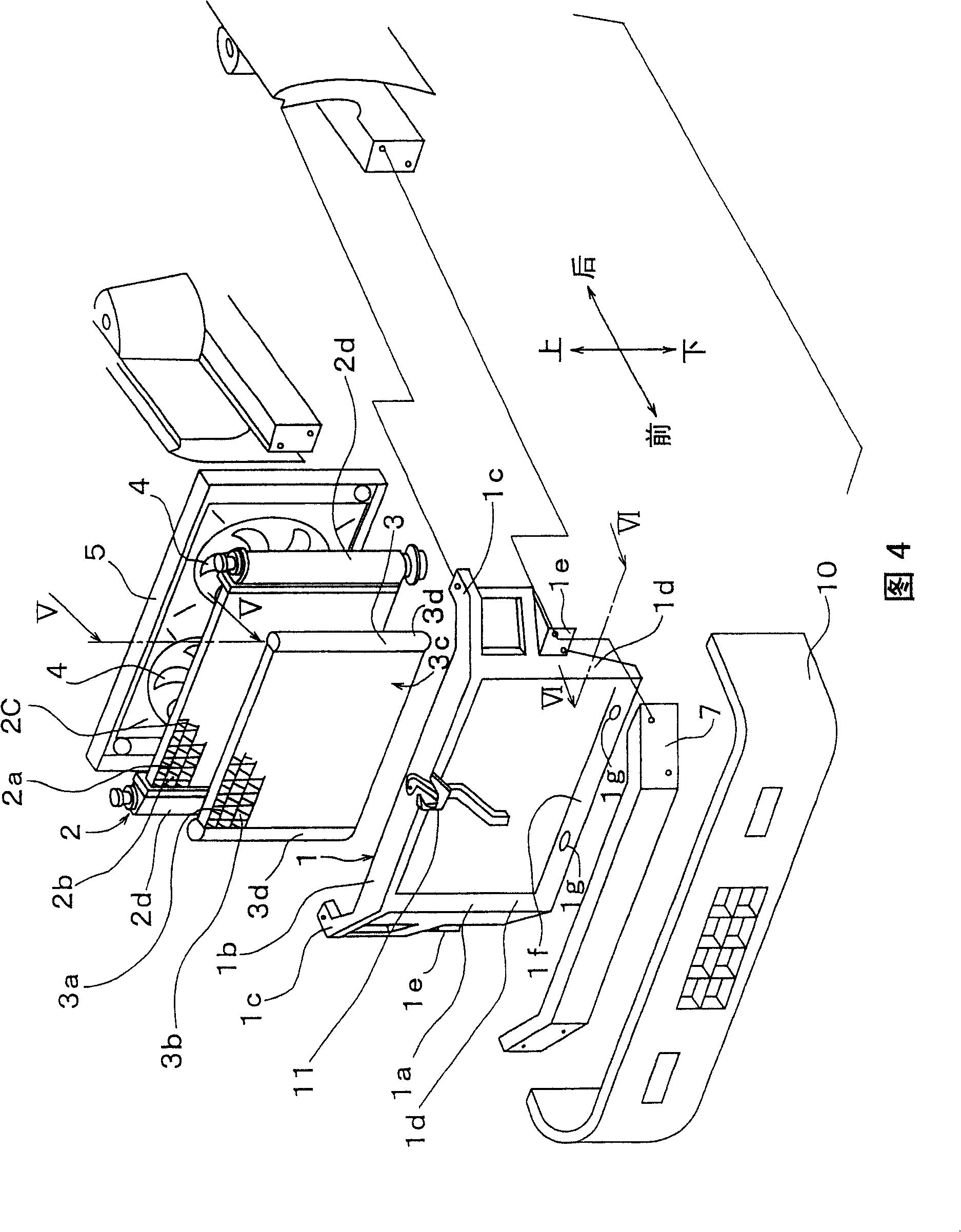

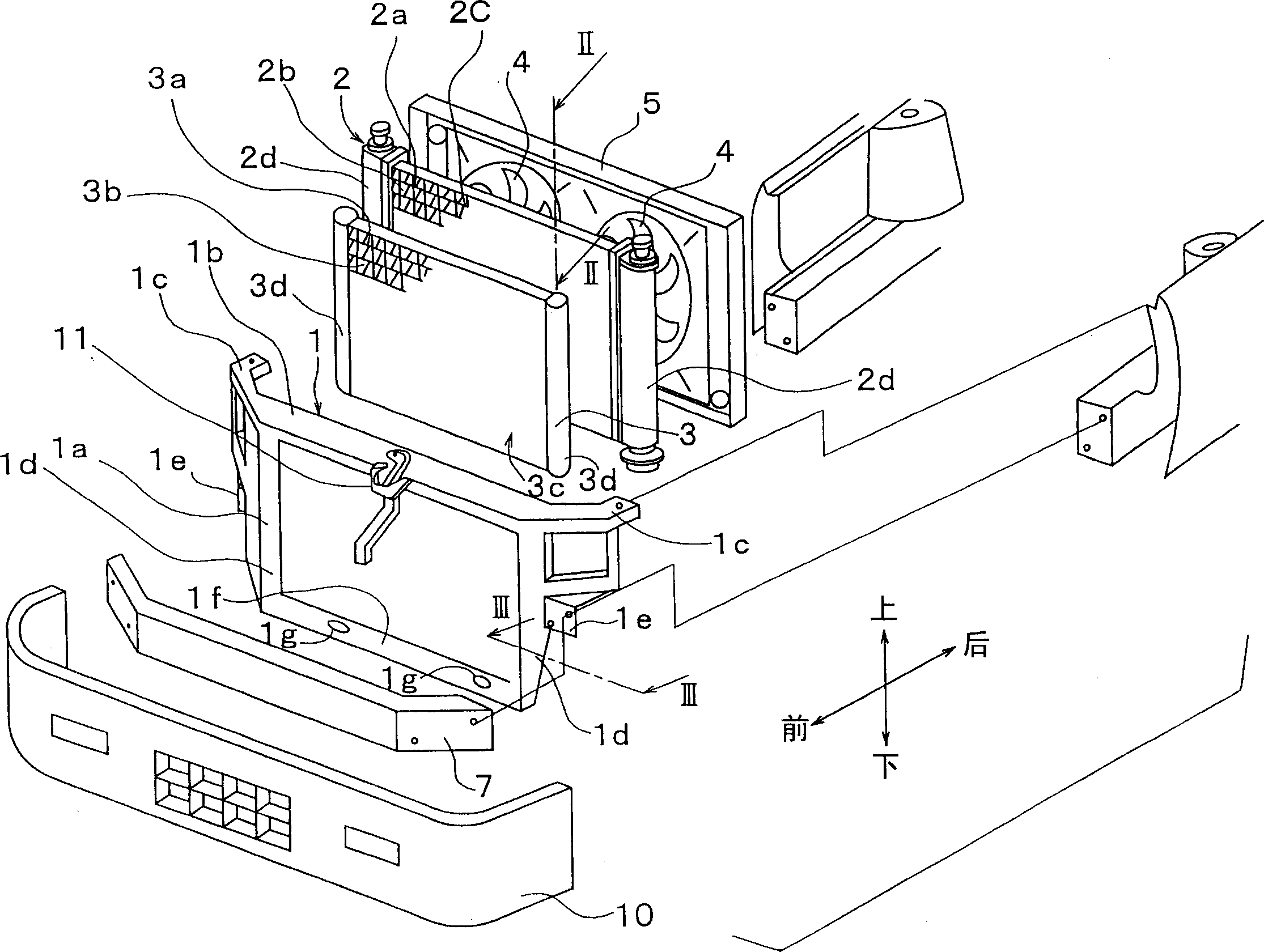

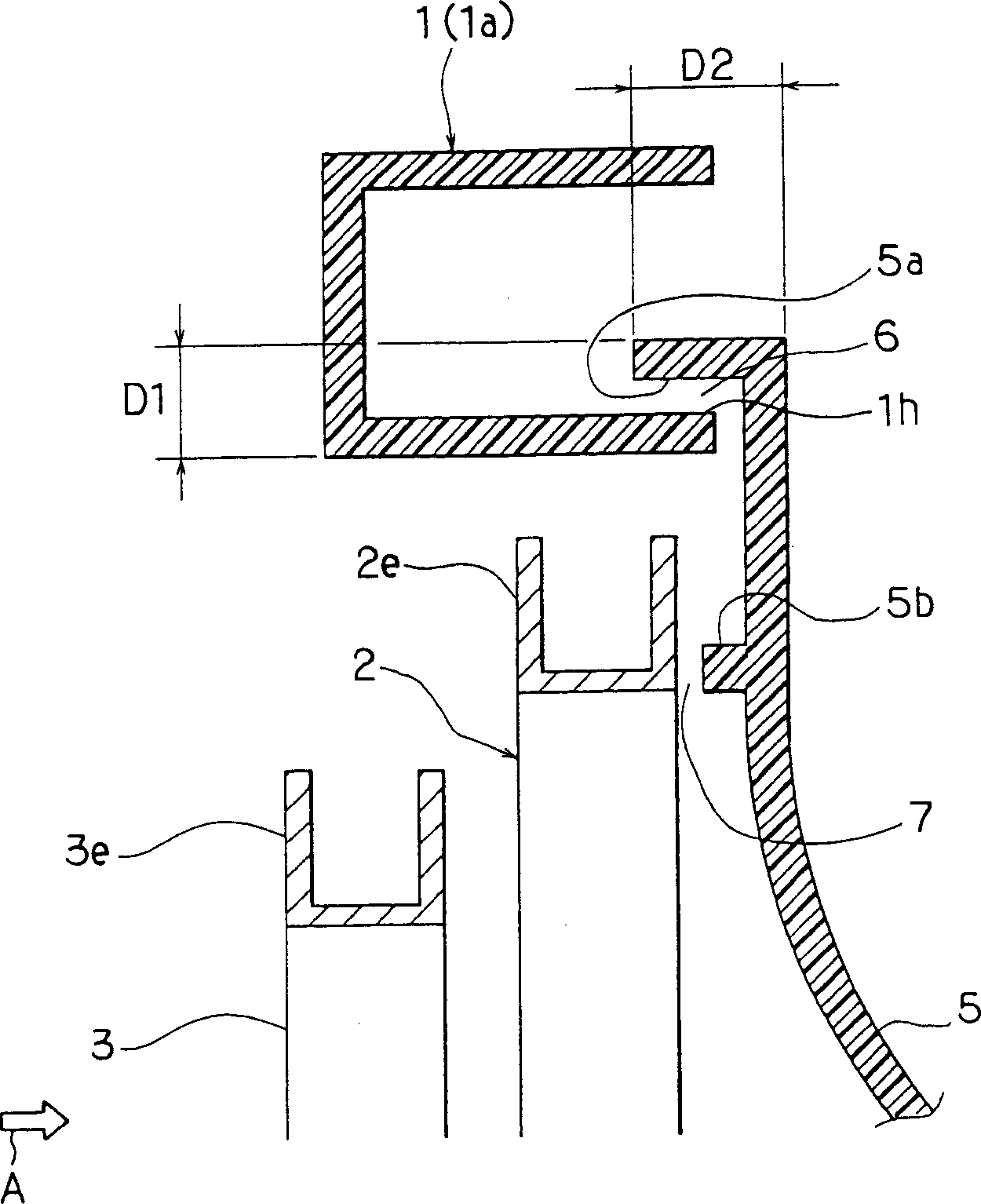

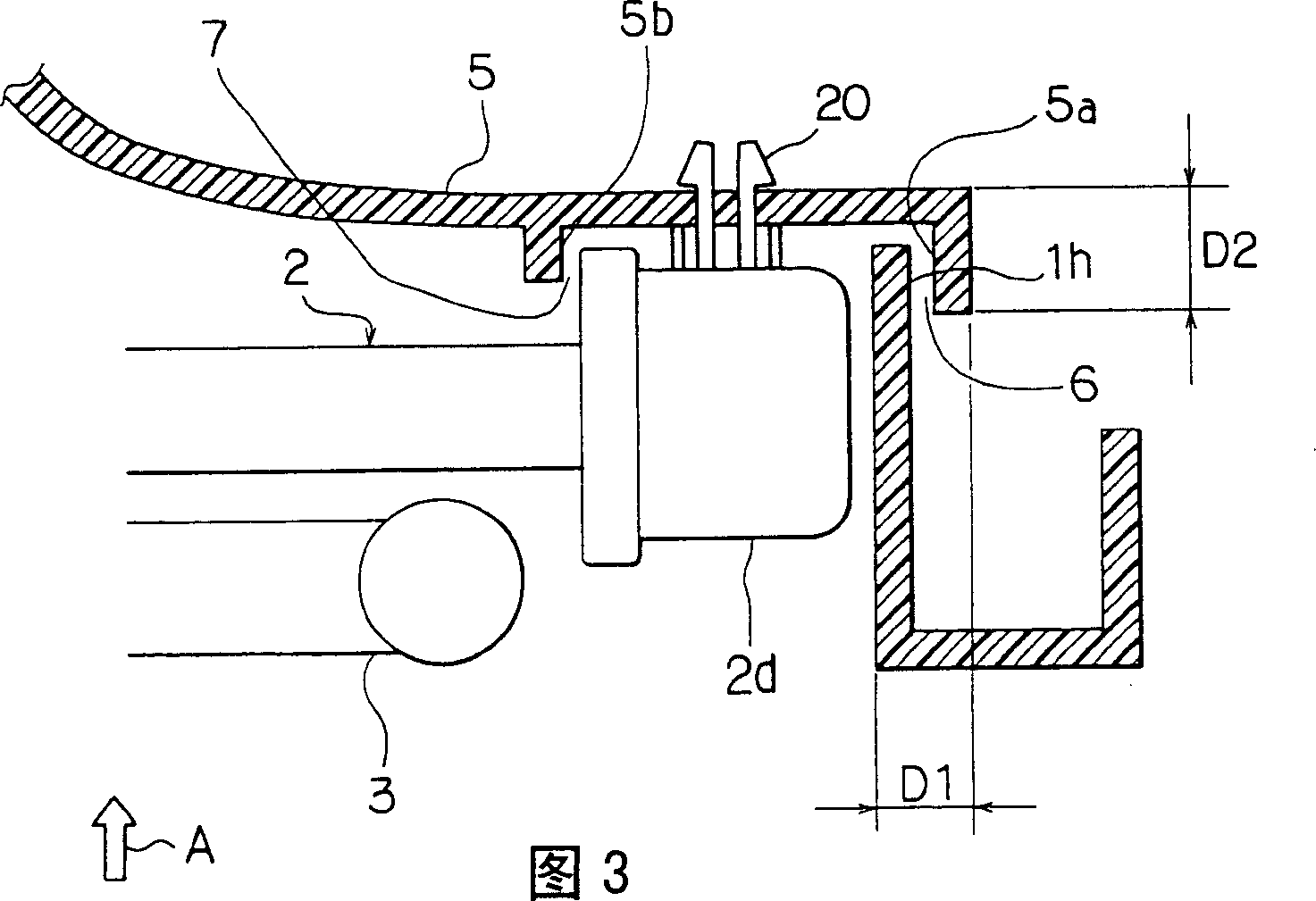

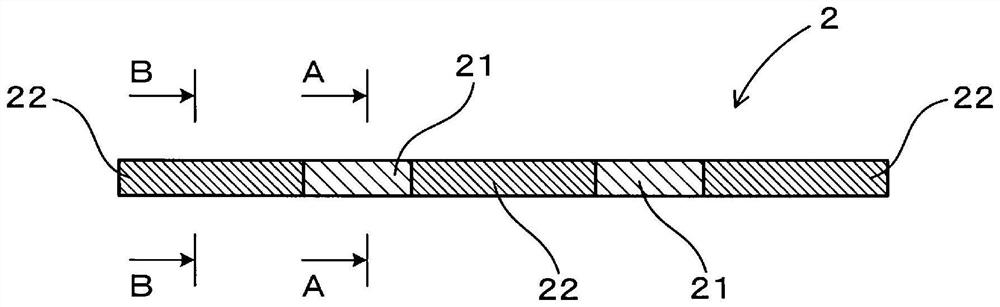

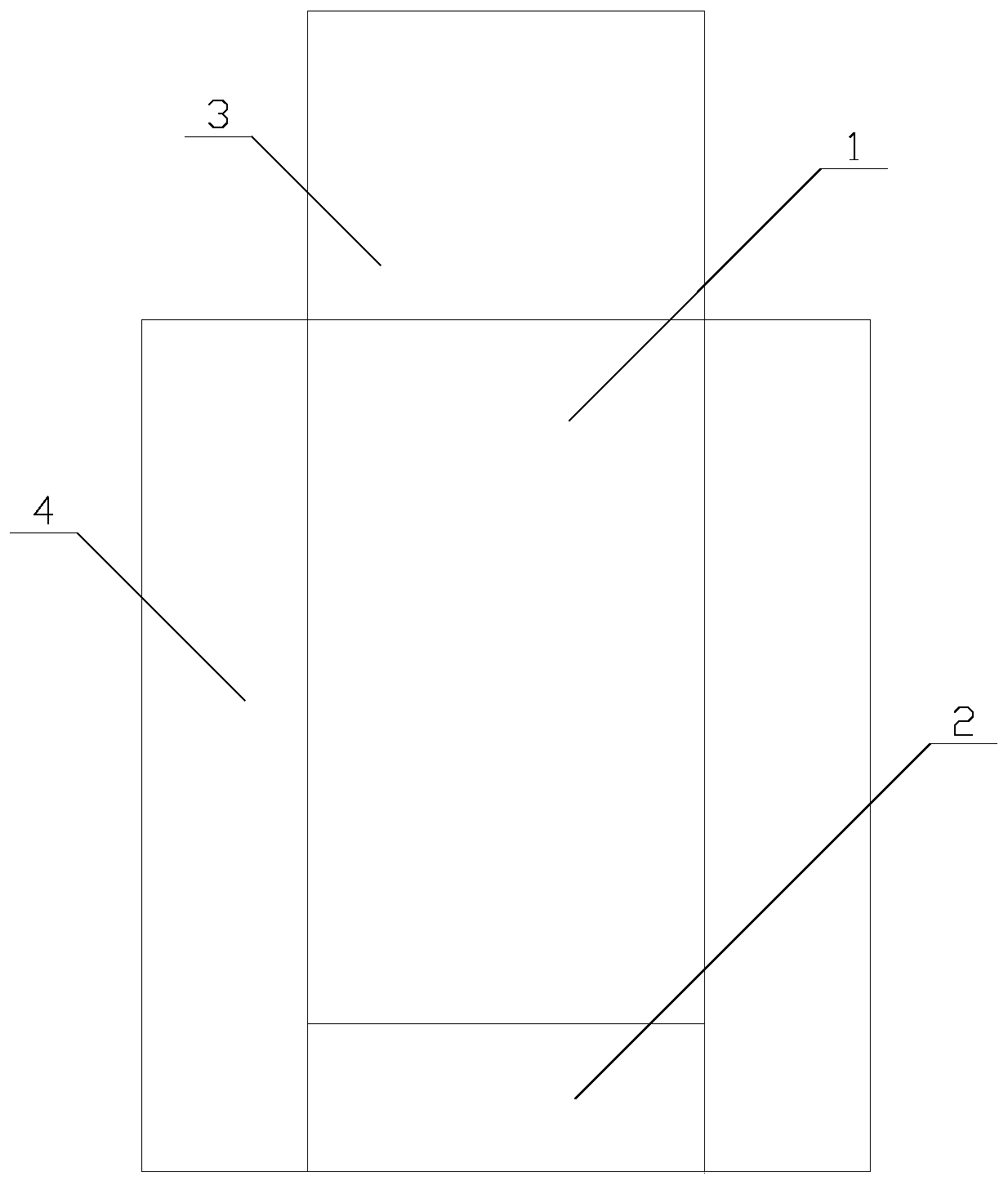

Vehicle front end structure

InactiveCN100434328CReduced heat exchange capacitySuppress gap leakageSuperstructure subunitsRadiatorsEngineeringFront panel

The invention discloses a vehicle front structure, which consists of front panel (1) and fan hood (5), wherein the labyrinth-type interstitial structure (6, 7, 12, 13) is formed between front panel (1) and fan hood (5), which inhibits air from leaking out of or entering into the space between front panel (1) and fan hood (5) against exchanging property reduction of heat-exchanger (2). The front panel (1) and fan hood (5) can be replaced or maintained independently.

Owner:DENSO CORP

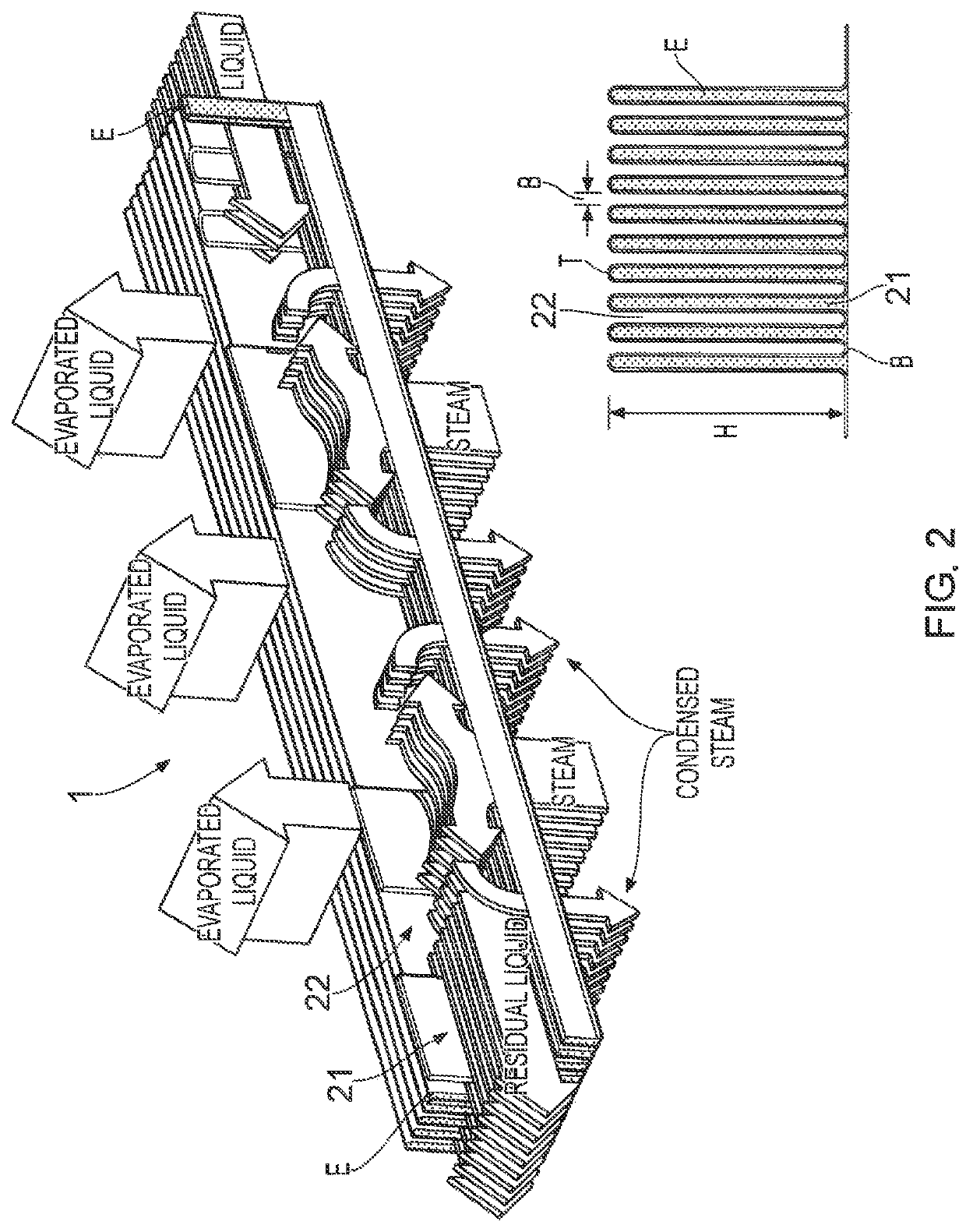

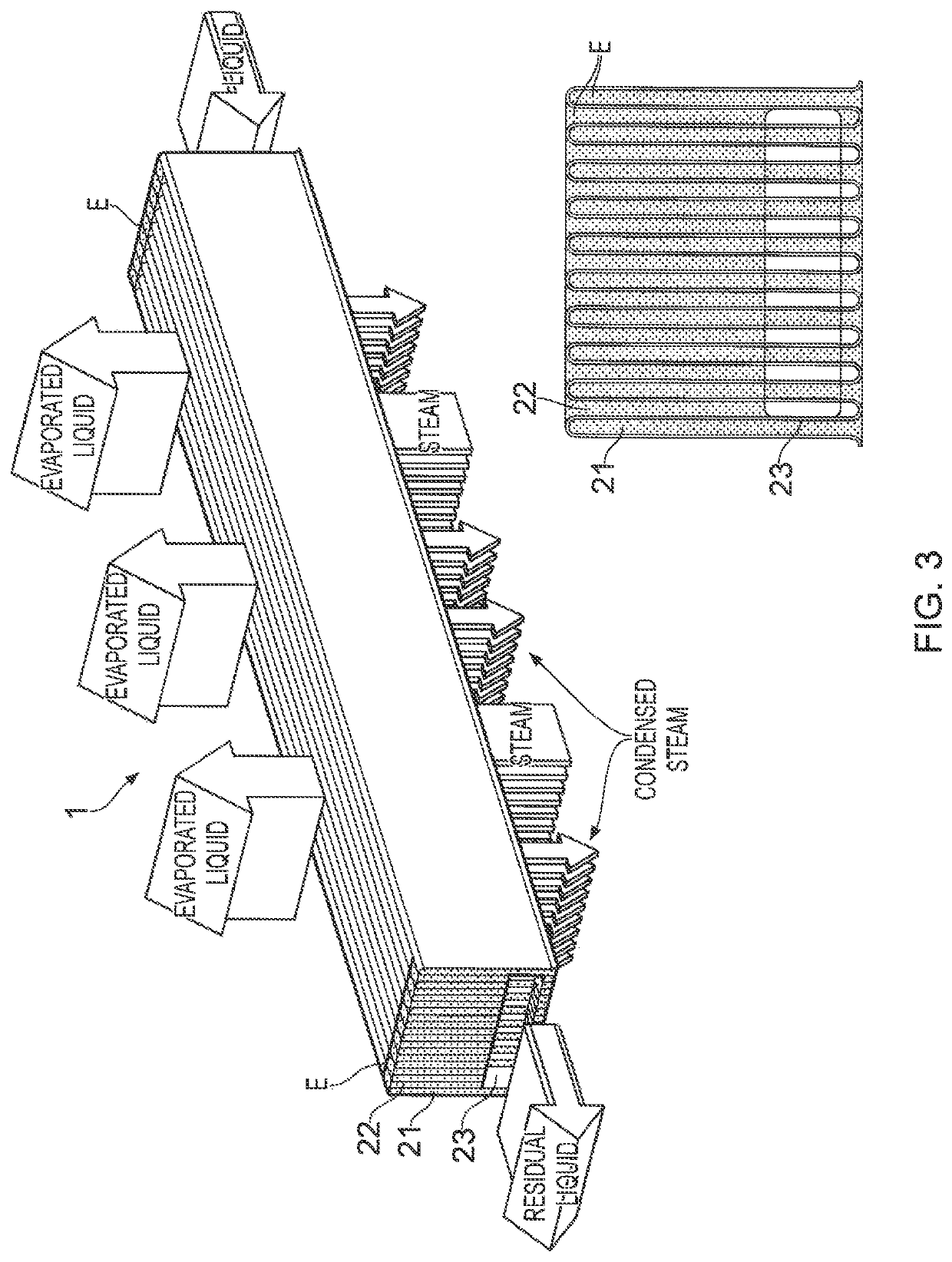

Device for heat exchange

ActiveUS10557670B2Degree of improvementHeat exchange efficiency of the sheet material over time is reducedHeat exchanger casingsLaminated elementsEngineeringMechanics

A sheet material is used for a heat exchange between a first fluid and a second fluid, and inducing a phase change in the fluids. Additionally, the sheet material is folded to form a plurality of slits to constitute flow paths of the fluids. Further, the slits for the first fluid, through at least one seal, are closed. Furthermore, the slits for the second fluid, through at least one seal, are fully or partly open for fluid outflow.

Owner:PLEAT AS

Heat dissipation device and lighting device with the heat dissipation device

ActiveCN103423721BLarge thermal resistanceImprove cooling effectLighting heating/cooling arrangementsSemiconductor devices for light sourcesHeat sink

Owner:LEDVANCE GMBH

Reverse dust collector with eddy plate

ActiveCN100581638CInhibit wearAvoid damageDispersed particle separationEnergy industryDust collectorWaste management

The invention provides a reverse rotation dedusting device, comprising a main unit. The main unit is a rectangle box. An ash hopper is arranged on the lower part of the main unit and comprises four inclined surfaces. The upper space of the main unit is divided into an air inlet chamber and a separation chamber through a baffle plate. The lower space of the main unit is provided with a plurality of vertical baffles basically along an inclined surface of the ash hoppers; a gas flow route is formed between all baffle plates and the inclined surfaces, in convenient for wide upstream side and a narrow downstream side. The baffle plate on the upstream side is long in the vertical direction; furthermore, the interval between all baffle plates has narrow upstream side and wide downstream side. The airflow in the gas flow route ascends along the baffle plate and is rectified on the upstream side through the baffle plate; the baffle plate is long in the vertical direction, so as to lead the airflow to be basically a lamellar flow and to flow into the separation chamber. The flowing speed of the airflow is restricted by flow resistance between the baffle plates, thus leading the flowing speed to be more uniform.

Owner:KAWASAKI HEAVY IND LTD

Heat exchanger with corrugated pipe coil structure provided with internal duct and external duct

InactiveCN101619944BSmooth heat convectionImprove cooling effectElectrolysis componentsChemical industryLiquid mediumEngineering

The invention discloses a heat exchanger with a corrugated pipe coil structure provided with an internal duct and an external duct, which comprises an inlet, an outlet, a corrugated pipe, a dome, an internal ring bushing, an external ring bushing, a fan and a bracket. When fluid media to be in heat exchange flow in the corrugated pipe in the heat exchanger from the inlet, form a turbulent flow ina pipe wall with a corrugated structure and carry out heat exchange with air in the internal duct and the external duct outside the corrugated pipe via the wall of the corrugated pipe, the fan discharges air in the internal duct and the external duct, and the fluid media are discharged from the outlet after the heat exchange performed in the corrugated pipe in a spiral way. The heat exchanger hasthe advantages of high heat exchanger effectiveness, simple structural technology, light weight, integration, and the like, and the fluid media in the pipe coil after the heat exchange have even temperature, thereby the heat exchanger can be used for heat exchange of air, liquid and air-liquid mixing substances. When the corrugated pipe adopts resistant materials, the heat exchanger can be used for heat exchange for corrosive liquid media.

Owner:南京容宇能源科技有限公司

Vehicle front end structure

InactiveCN1762751AReduced heat exchange capacitySuppress gap leakageSuperstructure subunitsRadiatorsEngineeringFront panel

The invention discloses a vehicle front structure, which consists of front panel (1) and fan hood (5), wherein the labyrinth-type interstitial structure (6íó7íó12íó13) is formed between front panel (1) and fan hood (5), which inhibits air from leaking out of or entering into the space between front panel (1) and fan hood (5) against exchanging property reduction of heat-exchanger (2). The front panel (1) and fan hood (5) can be replaced or maintained independently.

Owner:DENSO CORP

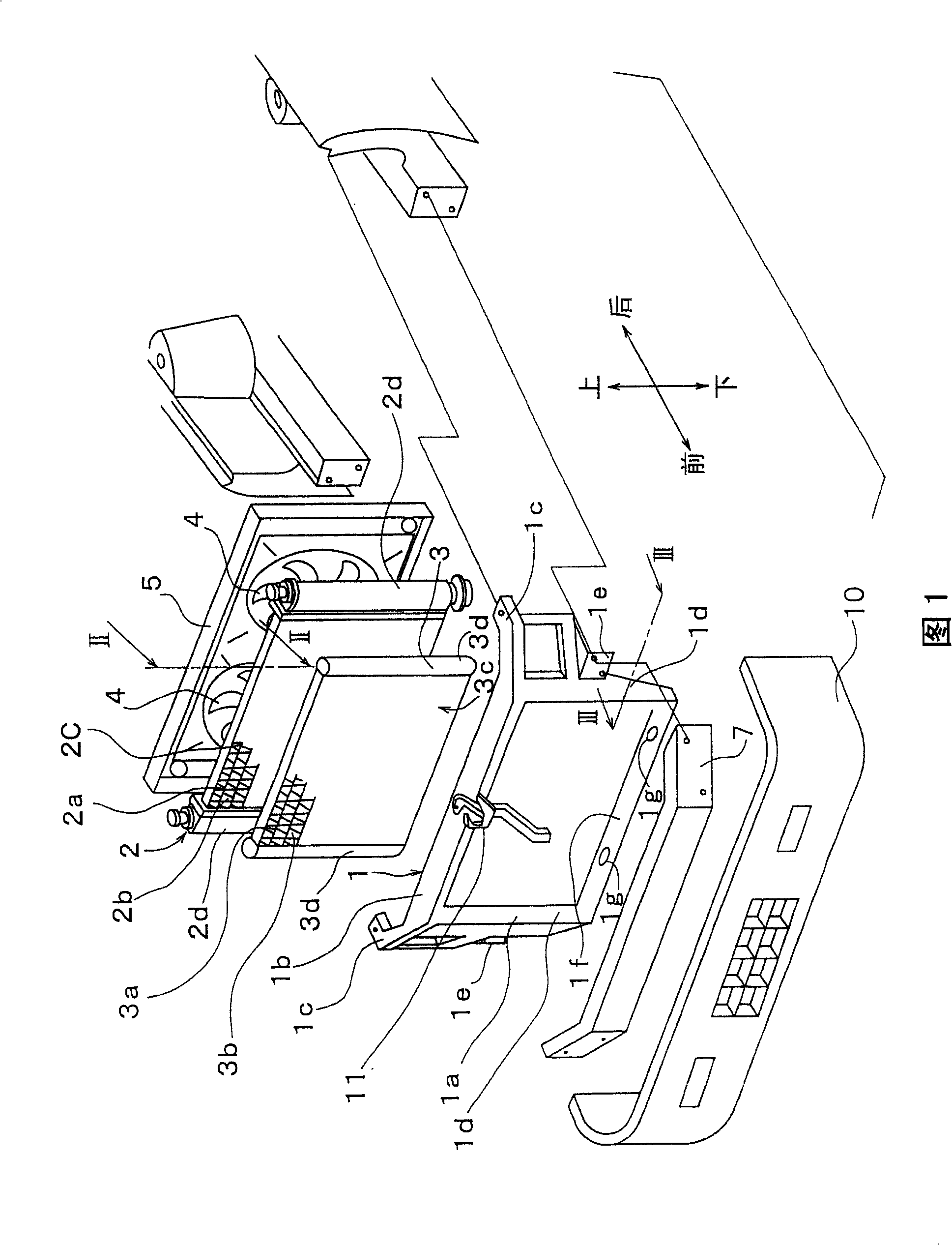

Heat transfer double-layer pipe, inner pipe for heat transfer double-layer pipe and manufacturing method of inner pipe

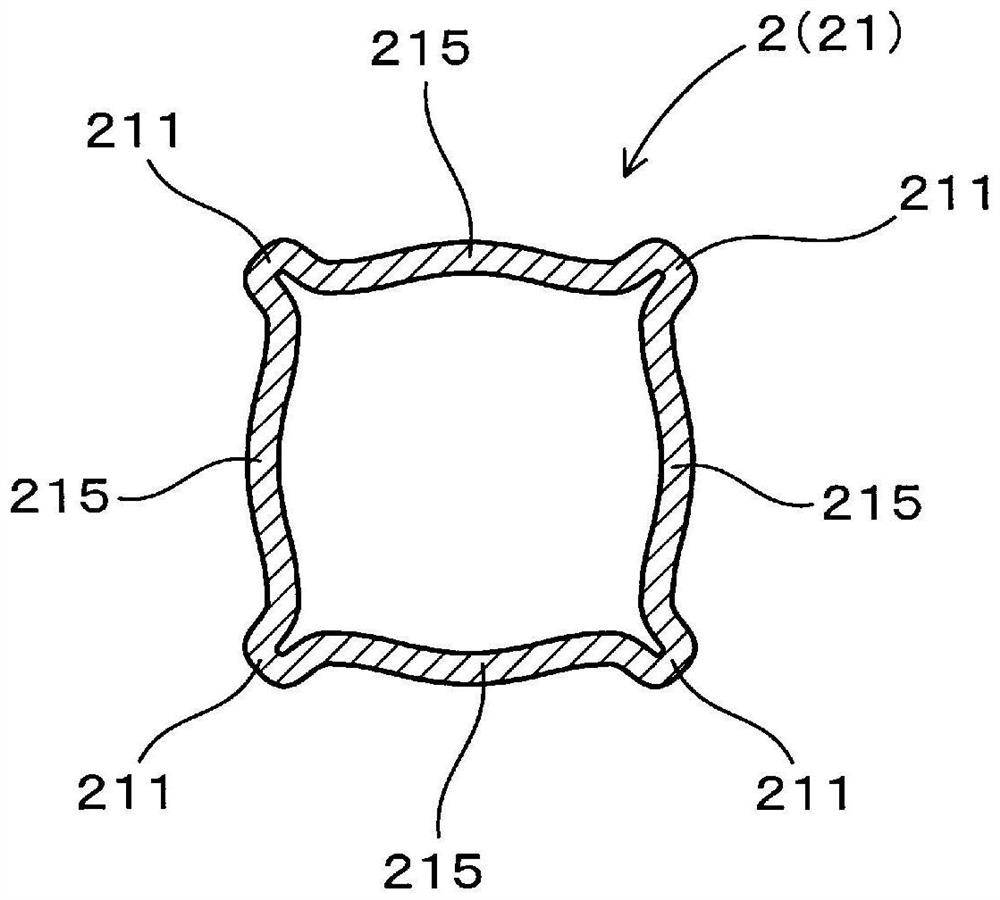

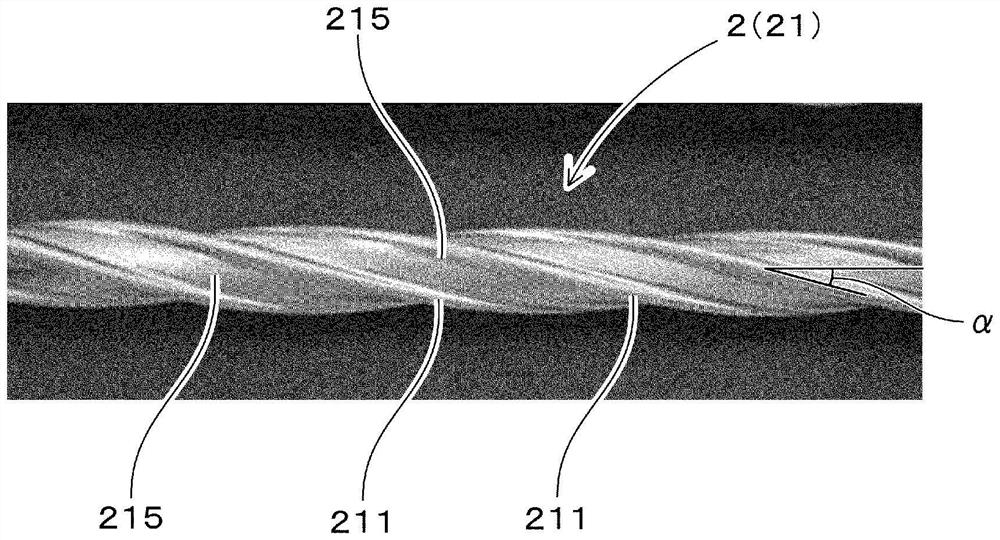

PendingCN114206640ANarrowing increaseIncreased pressure lossAir-treating devicesHeat exhanger conduitsEngineeringMechanical engineering

An inner tube (2) used in a heat transfer double-layer tube that exchanges heat between a fluid flowing inside the inner tube (2) disposed inside an outer tube and a fluid flowing between the inner tube (2) and the outer tube. The inner tube (2) has a first region (21) and a second region having different cross-sectional shapes, and the first region (21) has a plurality of first protrusions (211) protruding outward and has a first concave-convex shape in which the positions of the first protrusions (211) are displaced helically in the longitudinal direction. The second region has a plurality of second protrusions protruding outward at positions, the number of the second protrusions is larger than the number of the first protrusions, and the second region has a second concave-convex shape in which the positions of the second protrusions are displaced helically in the longitudinal direction.

Owner:FURUKAWA SKY ALUMINUM CORP

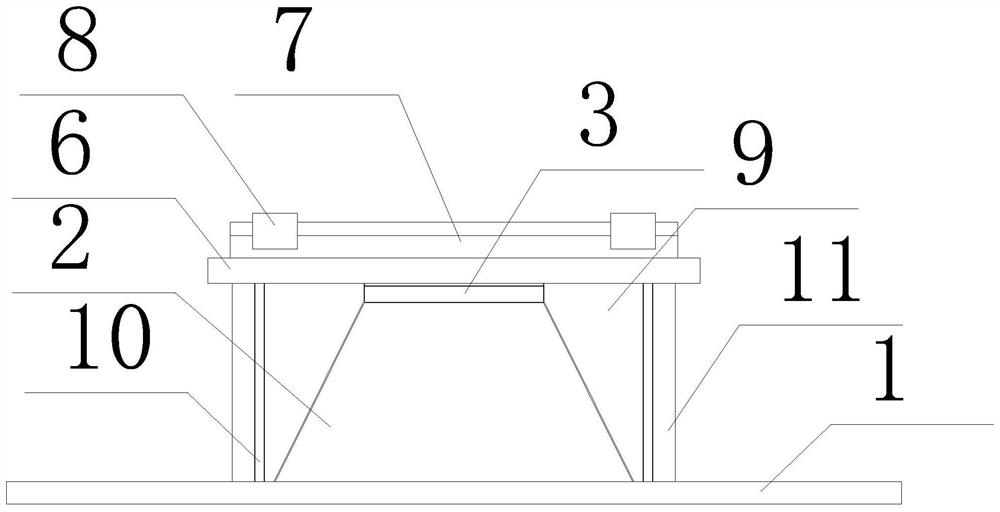

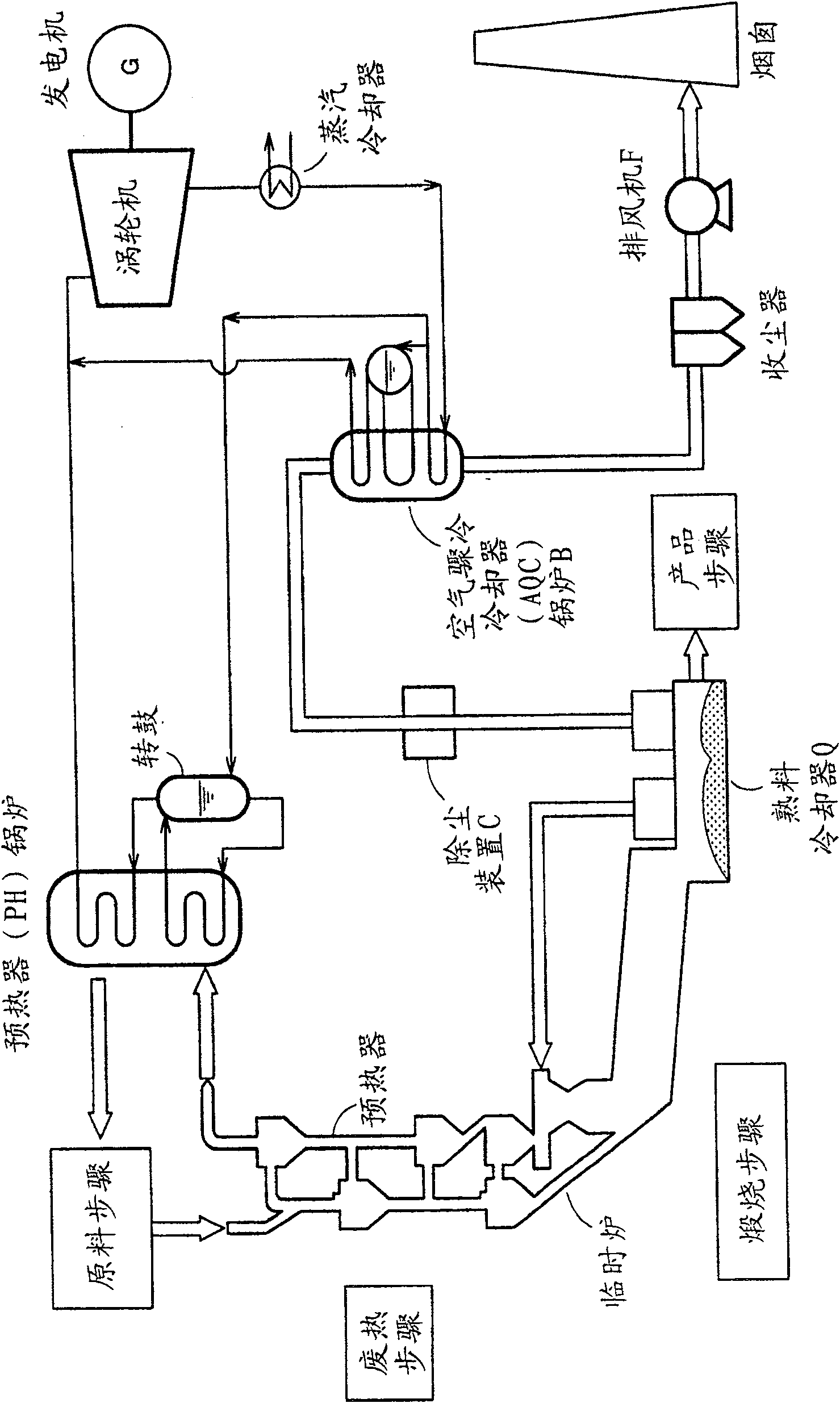

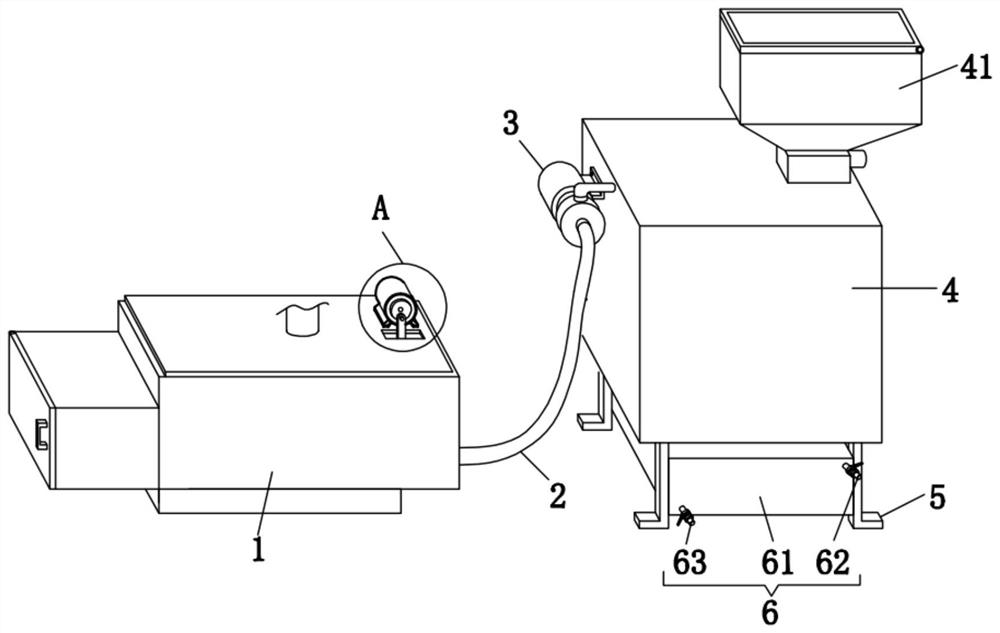

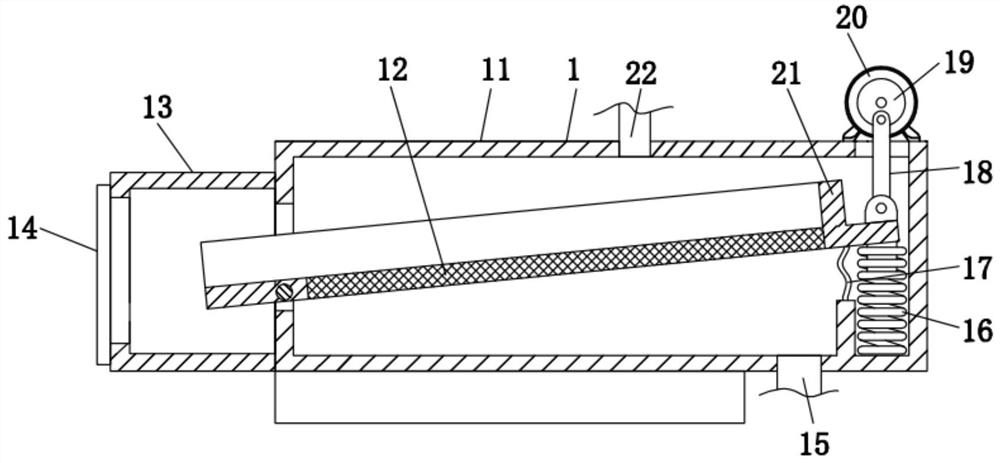

A waste heat recovery and utilization device and waste heat recovery method of automation equipment

ActiveCN111981875BIncrease temperatureReduce the temperatureGas treatmentDispersed particle filtrationToxic gasFlue gas

The invention discloses a waste heat recycling device for automation equipment, comprising: a filter mechanism, the output end of the filter mechanism is connected to one end of a conveying pipe, the other end of the conveying pipe is connected to the input end of a fan, and the fan is connected to the other end of the conveying pipe The output end is connected with a waste heat utilization mechanism 1, and the four corners of the bottom end of the waste heat utilization mechanism 1 are equipped with brackets, and the waste heat utilization mechanism 2 is installed between the four brackets. The invention can filter the flue gas impurities and toxic gases produced in the process of automation equipment through the filtering mechanism, and can preheat the fuel in the process through the waste heat utilization mechanism 1; the waste heat utilization mechanism 2 can not only reduce the flue gas The temperature can avoid impact on the environment, and the heat of flue gas can be used to provide hot water for platform production and life.

Owner:山东京清节能环保科技有限公司

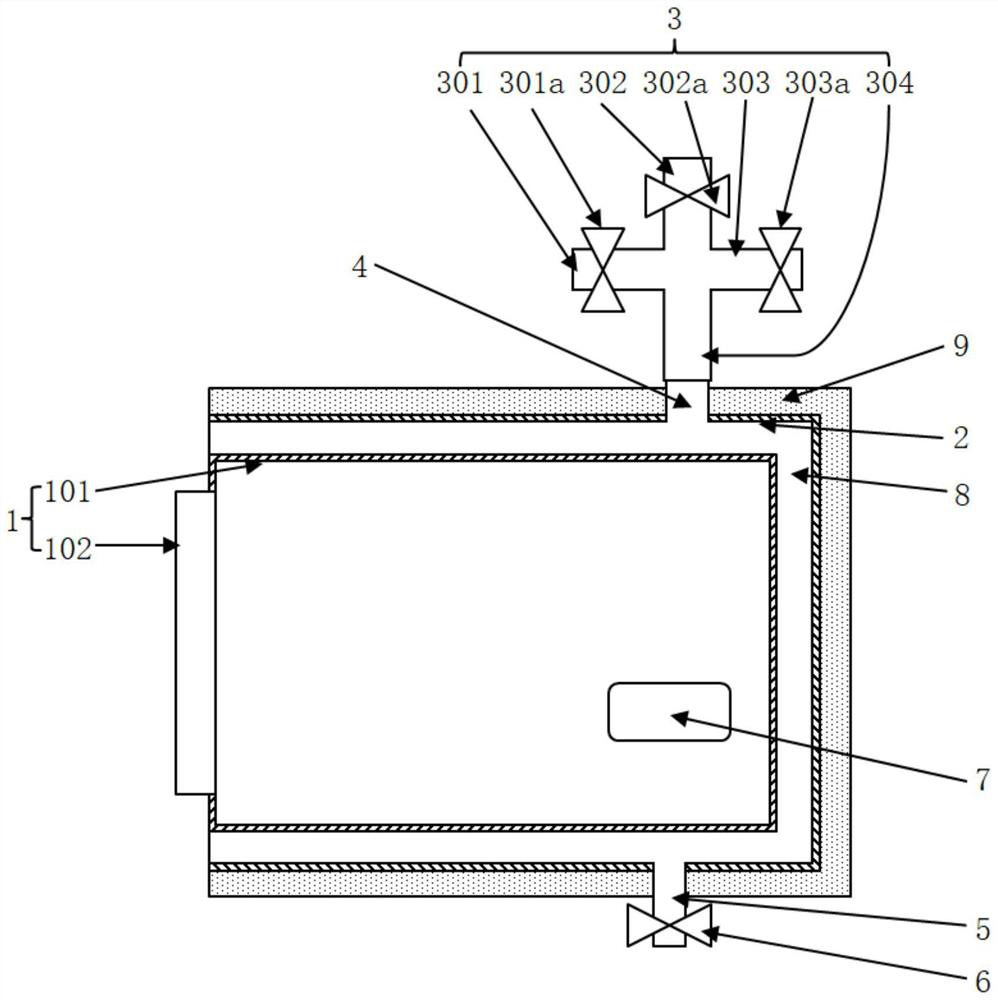

Heating furnace and working method thereof

PendingCN113970249AImprove heating efficiencySave energyMaintainance of heating chambersFurnace typesEngineeringHeat conservation

The invention provides a heating furnace and a working method thereof. The heating furnace comprises a furnace chamber, a furnace jacket layer and a multi-pass switching device, wherein the furnace jacket layer is arranged at the outer side of the furnace chamber, and a gap is formed between the furnace jacket layer and the chamber wall of the furnace chamber; and the multi-way switching device is fixedly connected with the outer wall of the furnace jacket layer, is communicated with the gap and is suitable for providing different media for the gap. The gap between the furnace jacket layer and the chamber wall provides a circulation space for media, and the multi-pass switching device communicated with the gap is arranged, so that one or more media can be introduced into the gap through the multi-pass switching device in the heating process, the heat preservation process and the cooling process of the heating furnace, the heating efficiency of the heating furnace in the heating process is improved, the heat loss of the heating furnace in the heat preservation process is reduced, the cooling efficiency of the heating furnace in the cooling process is improved, the energy of the heating furnace is saved, and the productivity of the heating furnace is improved.

Owner:安泊智汇半导体设备(上海)有限公司

An energy-saving curtain wall

ActiveCN111441516BReduce heat exchangeReduce utilizationWallsBuilding insulationsArchitectural engineeringMechanical engineering

The invention belongs to the technical field of buildings, especially an energy-saving curtain wall. Aiming at the problem that the curtain wall has poor heat insulation performance and therefore the energy-saving effect is generally unsatisfactory, the following scheme is proposed, including a support installed on the outside of the building floor. The end is provided with a plurality of threaded holes, and the top of the support is provided with a plurality of installation holes, a plurality of support keels are fixedly installed between the supports, and a J-shaped structure is fixedly installed on the bottom of the support. department. In the present invention, a buffer cavity is provided between the inner curtain wall mechanism and the outer curtain wall panel to produce an effective insulation effect, reduce indoor and outdoor heat exchange, save energy and protect the environment, and at the same time, an electric curtain that can be remotely controlled is installed between the inner curtain wall mechanism and the outer curtain wall panel Tracks and curtains are installed inside the curtain wall, which can reduce the use of indoor space, and the isolated curtains cannot become combustibles, greatly reducing the risk of fire expansion when a fire occurs.

Owner:山东腾翔建设集团有限公司

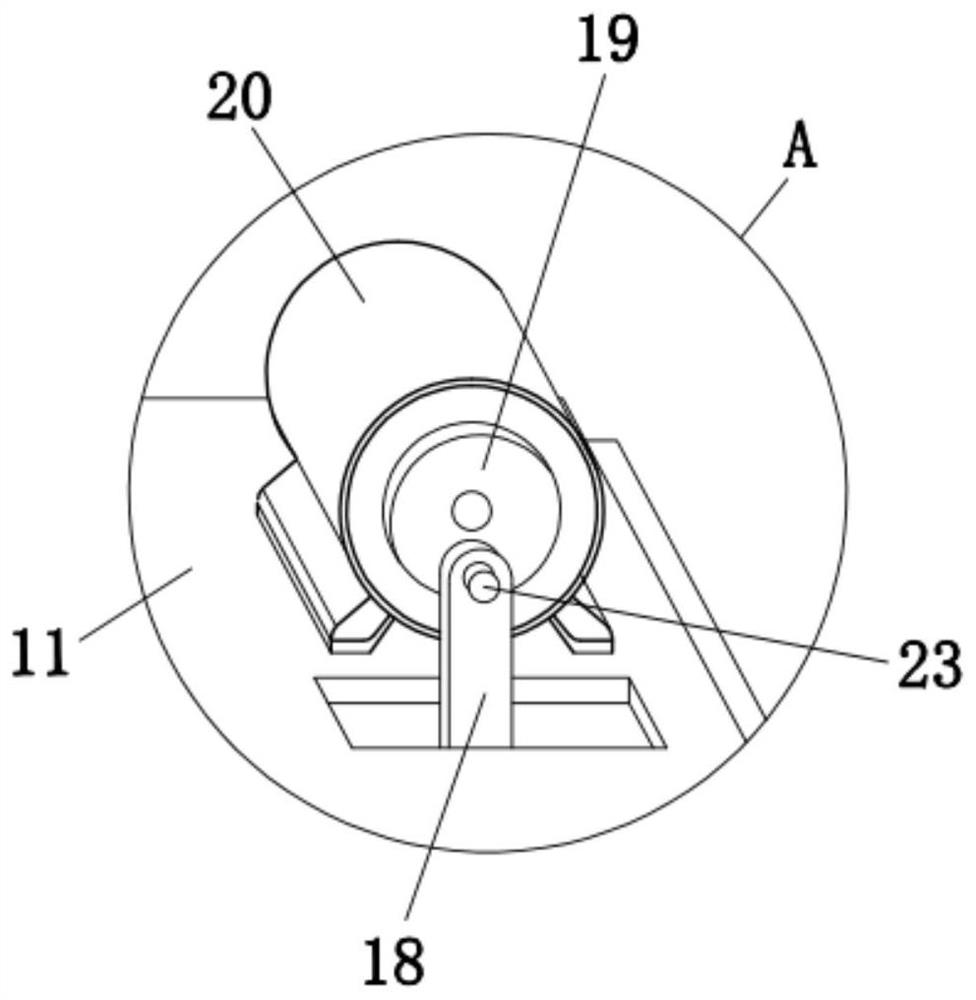

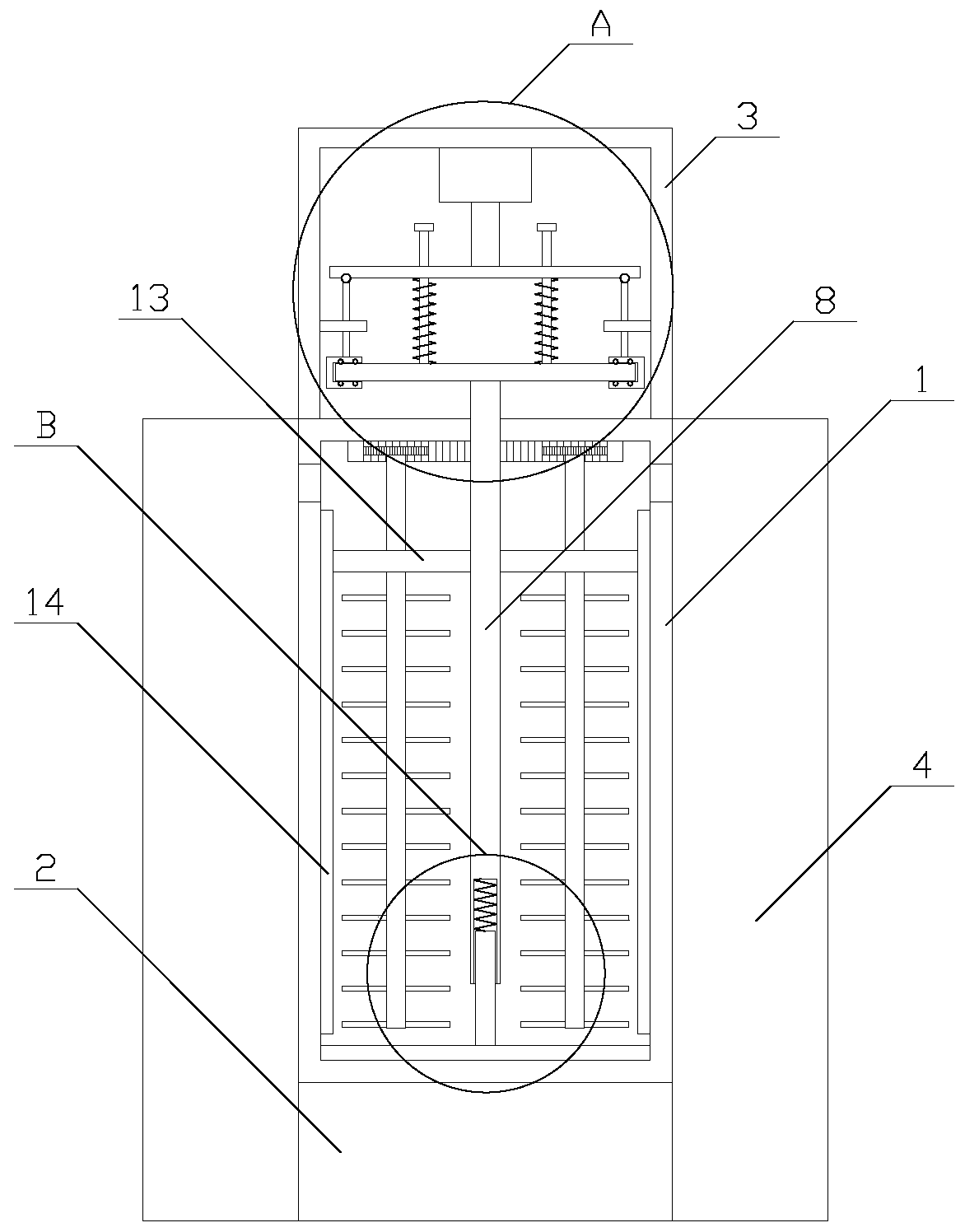

Easy-to-clean high-efficiency water purification equipment used for ships

InactiveCN109850966AImprove practicalityIngenious structureSeawater treatmentRotary stirring mixersDistillationDrive shaft

The invention relates to easy-to-clean high-efficiency water purification equipment for ships. The equipment comprises a main body, a heater, a power box and two water collecting tanks. The main bodyis in a cylindrical shape and is vertically arranged. The heater is arranged at the bottom of the main body. The two water collecting tanks are arranged on the two sides of the body respectively. Thewater collecting tank is communicated with the main body. The power box is fixed at the top of the main body. A stirring mechanism and a cleaning mechanism are arranged in the main body. The stirringmechanism comprises a power assembly, two stirring assemblies and two transmission assemblies. The power assembly comprises a power motor, a driving disc, a transmission disc, a transmission shaft andan inner gear. The equipment realizes the function of stirring seawater through the stirring mechanism, so that the heating uniformity of the seawater is improved, and the distillation efficiency isimproved. Moreover, through the cleaning mechanism, the function of removing salt crystals on the main body is achieved, the heat exchange capacity is prevented from being reduced due to salt crystals, and therefore the water making efficiency is reduced.

Owner:GUANGZHOU OUSHU ENVIRONMENTAL PROTECTION TECH CO LTD

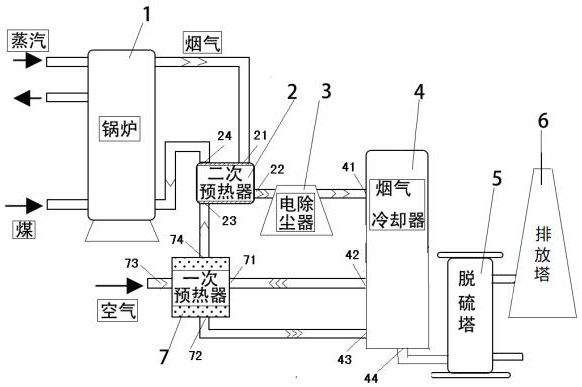

Flue gas waste heat secondary utilization process device

PendingCN114001558AReduce consumptionEmission reductionCombustion processIncreasing energy efficiencyFlue gasProcess engineering

The invention discloses a flue gas waste heat secondary utilization process device which is sequentially provided with a coal-fired (coal-fired or fuel-fired) boiler, a secondary preheater, a dust remover, a flue gas cooler, a desulfurizing tower and a flue gas emission tower according to a flue gas flow. And a heat exchange coil pipe is arranged in the primary preheater and is used for primary heat exchange of air and flue gas. The flue gas desulfurization device has the advantages of high waste heat utilization rate, reduction of fire coal consumption and good desulfurization effect.

Owner:NANTONG SHANJIAN GRAPHITE EQUIP

Glue cooling device without condensate water

PendingCN111905969AReduce contact areaReduce heat exchange effectLiquid surface applicatorsCoatingsAdhesive glueEngineering

The invention discloses a glue cooling device without condensate water. The glue cooling device comprises a cooling device body and a to-be-mounted dispensing mixing pipe, wherein the cooling device body is mainly composed of a shell, an internal cooling block, two refrigeration sheets and two heat dissipation water tanks, the refrigeration faces of the refrigeration sheets are fixed to the frontface and the back face of the internal cooling block respectively, the heat dissipation faces of the refrigeration sheets are tightly attached to the heat dissipation water tanks respectively, a fixedextension portion and limiting extension portions are arranged on the side face of the internal cooling block, a threaded hole is formed in the fixed extension portion, and the internal cooling blockis fixed to a rear shell body through a fastening screw matched with the threaded hole. Compared with the prior art, the structural stability of the internal cooling block in all directions is fullyconsidered, the contact area of the internal cooling block and the shell is greatly reduced while the coaxiality of components is guaranteed, the heat exchange effect between the internal cooling block and the shell is relieved, therefore, it is guaranteed that the shell is in a normal-temperature state, and the problem that condensate water drips from the surface of the glue cooling device is thoroughly solved.

Owner:成都苔岑智能设备有限公司

Wide temperature range type full fresh air temperature-adjustable dehumidifier

InactiveCN101737988BReduced heat exchange capacityEffective exhaustCompression machines with non-reversible cycleCorrosion preventionVapor–liquid separatorFrost

The invention relates to a wide temperature range type full fresh air temperature-adjustable dehumidifier, which is characterized in that an evaporator is connected with a gas-liquid separator; the gas-liquid separator is connected with a stepless adjustable screw compressor; the stepless adjustable screw compressor is respectively connected with a hot air bypass valve, an electromagnetic valve and a water-cooling condenser; the water-cooling condenser is respectively connected with a flow regulating valve and an air-cooling condenser; the air-cooling condenser is connected with a check valve; the check valve is respectively connected with a flow regulating valve and a liquid reservoir; and the liquid reservoir is respectively connected with a liquid spray valve and a drying filter. The invention has the following technical effects: 1. the dehumidifier can reduce the effective exhaust of the compressor and absorb heat of liquid refrigerant in the evaporator to decrease the heat exchanging ability of the evaporator; 2.the opening degree of the flow regulating valve can be automatically adjusted according to the predetermined outlet air temperature; 3. high temperature air enters the inlet of the evaporator to melt away frost on the evaporator; 4. when fresh air load is high and the overheating of a motor of the compressor is caused, the liquid refrigerant is sprayed on the motor to cool the motor.

Owner:TELLHOW SCI TECH CO LTD

Fin with zinc oxide whisker active agent coating and processing method thereof

InactiveCN100363704CStrong anti-corrosion activityLong-term maintenance of hydrophilic effectBiocidePretreated surfacesActive agentWhiskers

A method for preparing fin with whiskers active agent coating of zinc oxide includes coating an anticorrosion layer on aluminium foil surface and applying zinc oxide whiskers active layer on it with thickness ratio of anticorrosion layer to active layer as 1-5:1 , containing hydrophilic agent and whiskers active agent in whiskers active layer with weight ratio of hydrophilic agent to active agent as 100 : 1-10 , forming said active agent by weight ratio as 50-80 share of zinc oxide whisker , 5-25 share of nano zinc oxide , 5-25 share of nano titanium oxide and 10-40 share of sodium silicate carrier.

Owner:HISENSE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com