Vehicle front end structure

A technology for vehicles, gap structures, applied in the direction of superstructure, vehicle components, superstructure sub-assemblies, etc., can solve problems such as reduced maintainability, difficult to replace front panels and shields, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

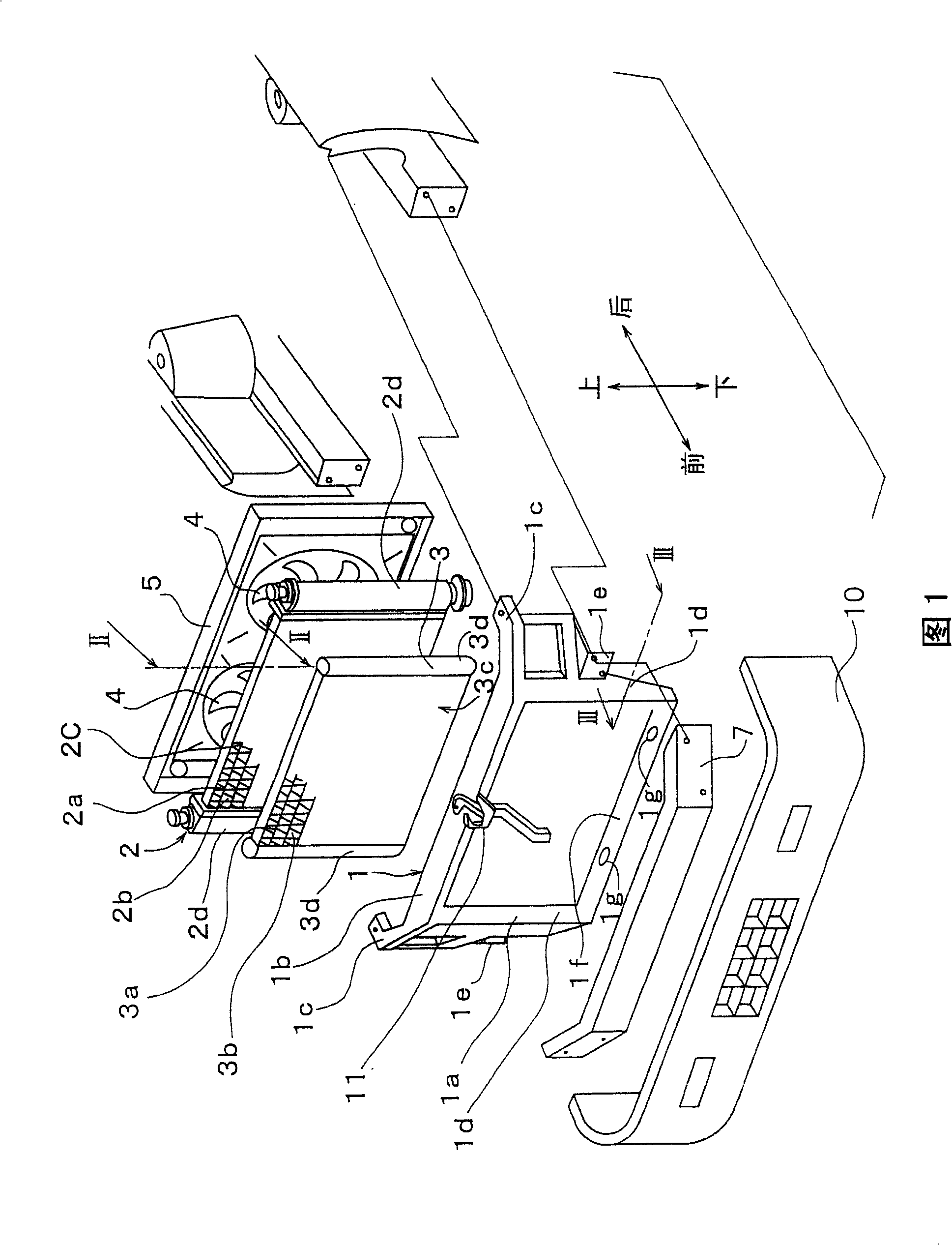

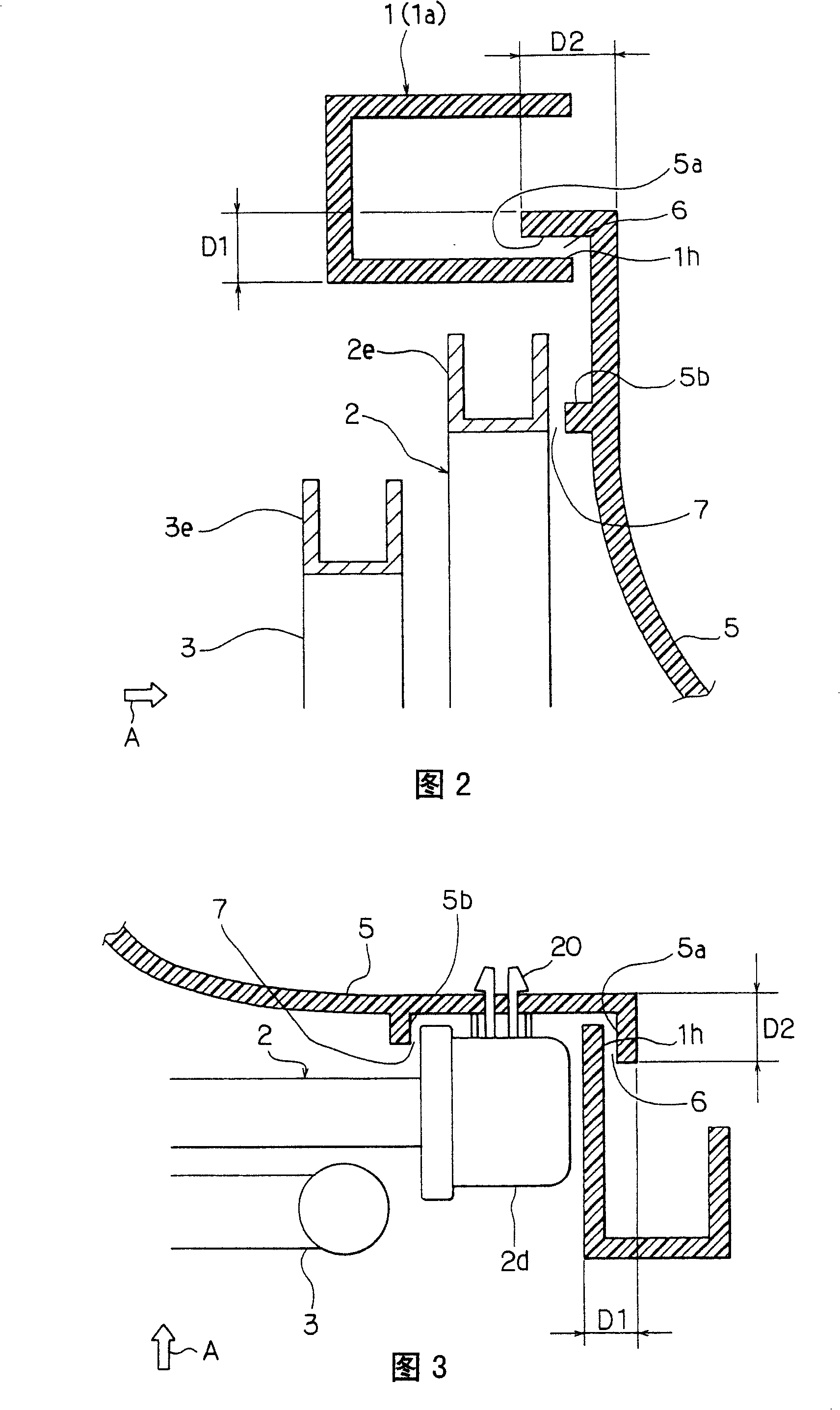

[0016] Referring to FIG. 1 , a front panel 1 is fixed to a vehicle body at a vehicle front end. The front panel 1 extends substantially in the left-right direction of the vehicle (the width direction of the vehicle). The front panel 1 includes a frame portion 1a, a first fixing portion 1c, and a second fixing portion 1e. The frame portion 1a has a substantially rectangular shape. The first fixing portion 1c extends from the longitudinal end portion of the upper beam portion 1b of the frame portion 1a toward the vehicle body side. The second fixing portion 1e is formed on the side column portion 1d of the frame portion 1a.

[0017] Also, a radiator fixing portion 1g for fixing the radiator 2 is formed on the lower beam portion 1f and the upper beam portion 1b of the frame portion 1a. The heat sink 2 is elastically supported by the front panel 1 through an elastic support member (not shown) such as elastically deformable anti-vibration rubber. In this embodiment, the frame p...

no. 2 example

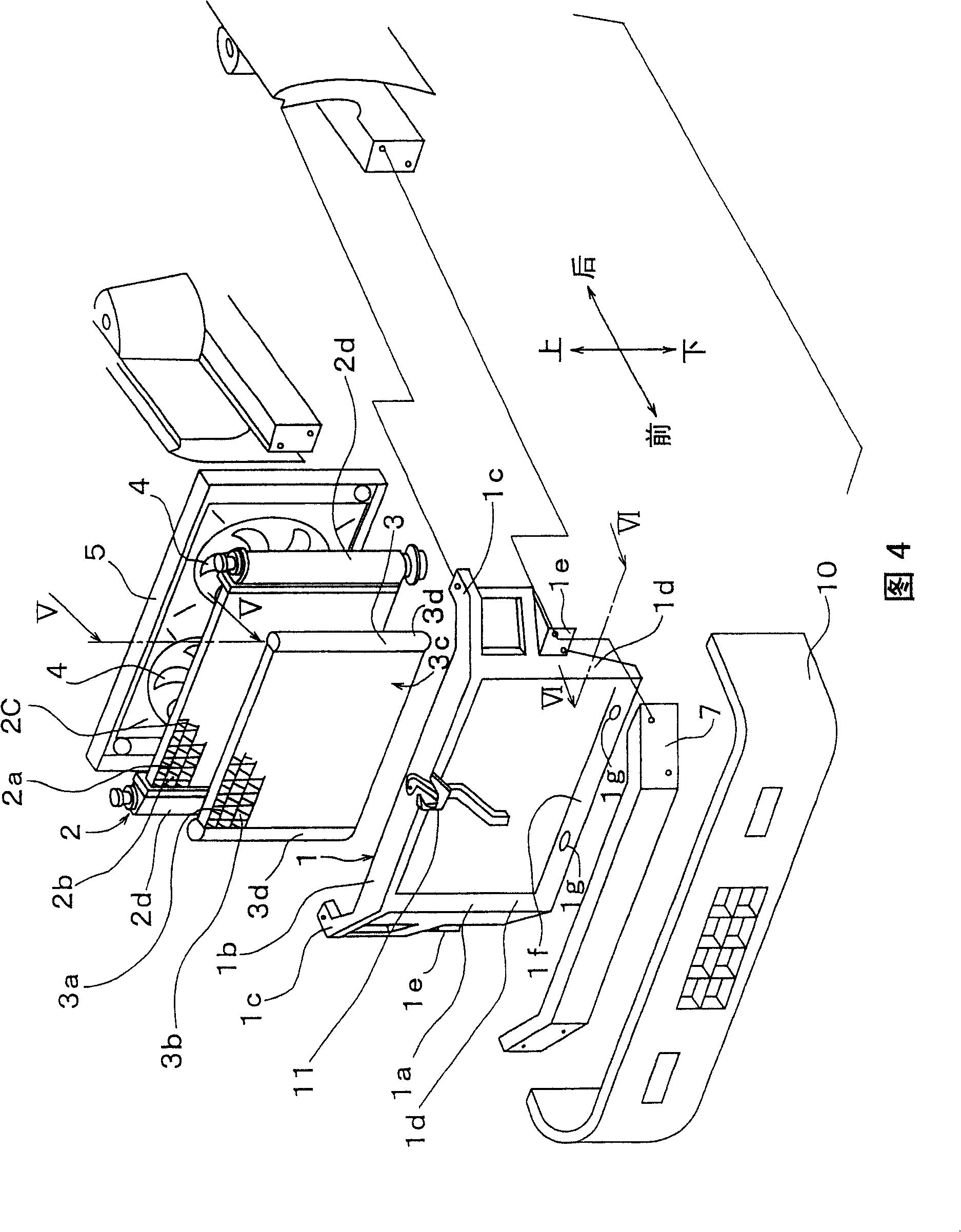

[0034] Referring to FIGS. 4 to 6 , the opposing shroud portion 5 a is formed at a position other than the position corresponding to the header tank 2 d of the radiator 2 . That is, the opposing shroud portion 5 a is formed at a position corresponding to the side plate 2 e of the radiator 2 .

[0035] The labyrinth gap structure 6 constituted by the opposing panel portion 1 h and the opposing shroud portion 5 a is not formed at a position corresponding to the header tank of the radiator 2 . Instead, the front panel 1 forms a sealing protrusion (second panel protrusion) 1j to form a labyrinth gap 12 between the header tank 2d and the front panel 1, as Image 6 shown.

[0036] and, if Figure 5 As shown, the front panel 1 forms a sealing protrusion (first panel protrusion) at a position corresponding to the side plate 2e on the front side of the radiator 2 (ie, the side opposite to the fan shroud 5 with respect to the radiator 2). 1k. The sealing protrusion 1 k forms a labyrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com