Glue cooling device without condensate water

A technology of cooling device and condensed water, which is applied in the field of dispensing machines, can solve problems such as water droplets on the surface of the shell, clogging dispensing equipment, and affecting dispensing operations, so as to reduce the contact area, prevent loosening and leakage of glue, and reduce heat dissipation. The effect of the exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

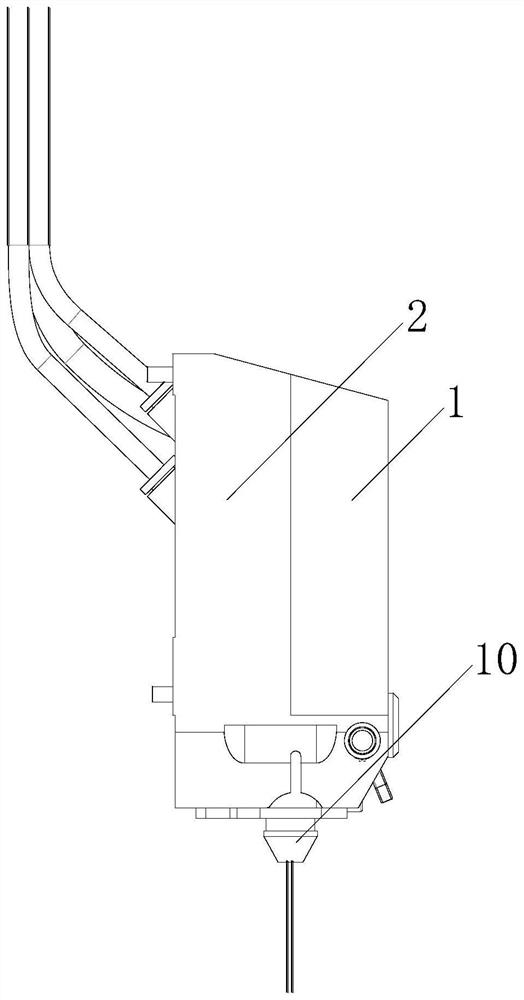

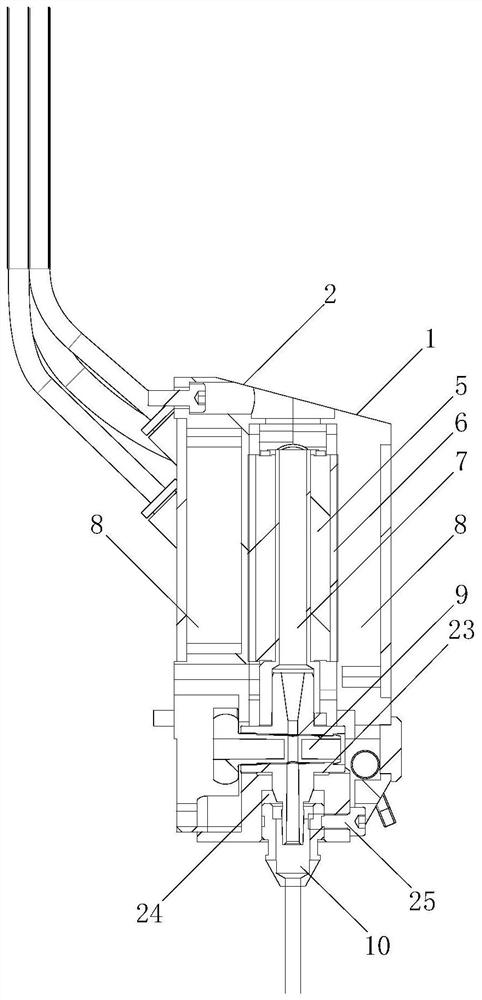

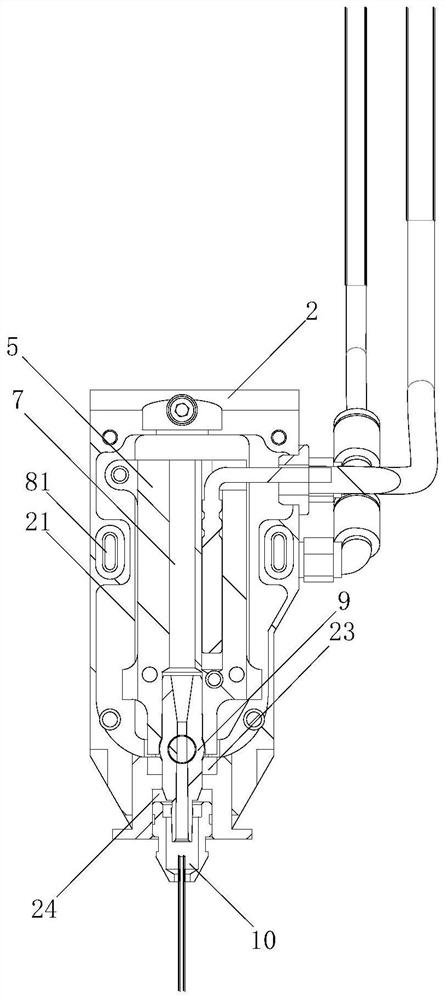

[0027] Embodiment 1: see Figure 1 to Figure 4 , a glue cooling device without condensed water, comprising a cooling device and a dispensing mixing tube 7 to be installed, the cooling device mainly consists of a housing, an internal cooling block 5, two cooling fins 6 and two cooling water tanks 8 , the internal cooling block 5 adopts a heat-conducting metal with excellent thermal conductivity, such as a copper block, and the cooling sheet 6 is a semiconductor cooling sheet, which has the advantages of small size and good cooling effect. The casing is composed of the front casing 1 and the rear casing The housing 2 is composed of the front housing 1 and the rear housing 2. The front housing 1 and the rear housing 2 are fixedly connected by screws. The inner sides of the front housing 1 and the rear housing 2 are provided with installation grooves 21 matching with the cooling water tank 8. The cooling The cooling surfaces of the fins 6 are respectively fixed on the front and ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com