Patents

Literature

944results about "Radiators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

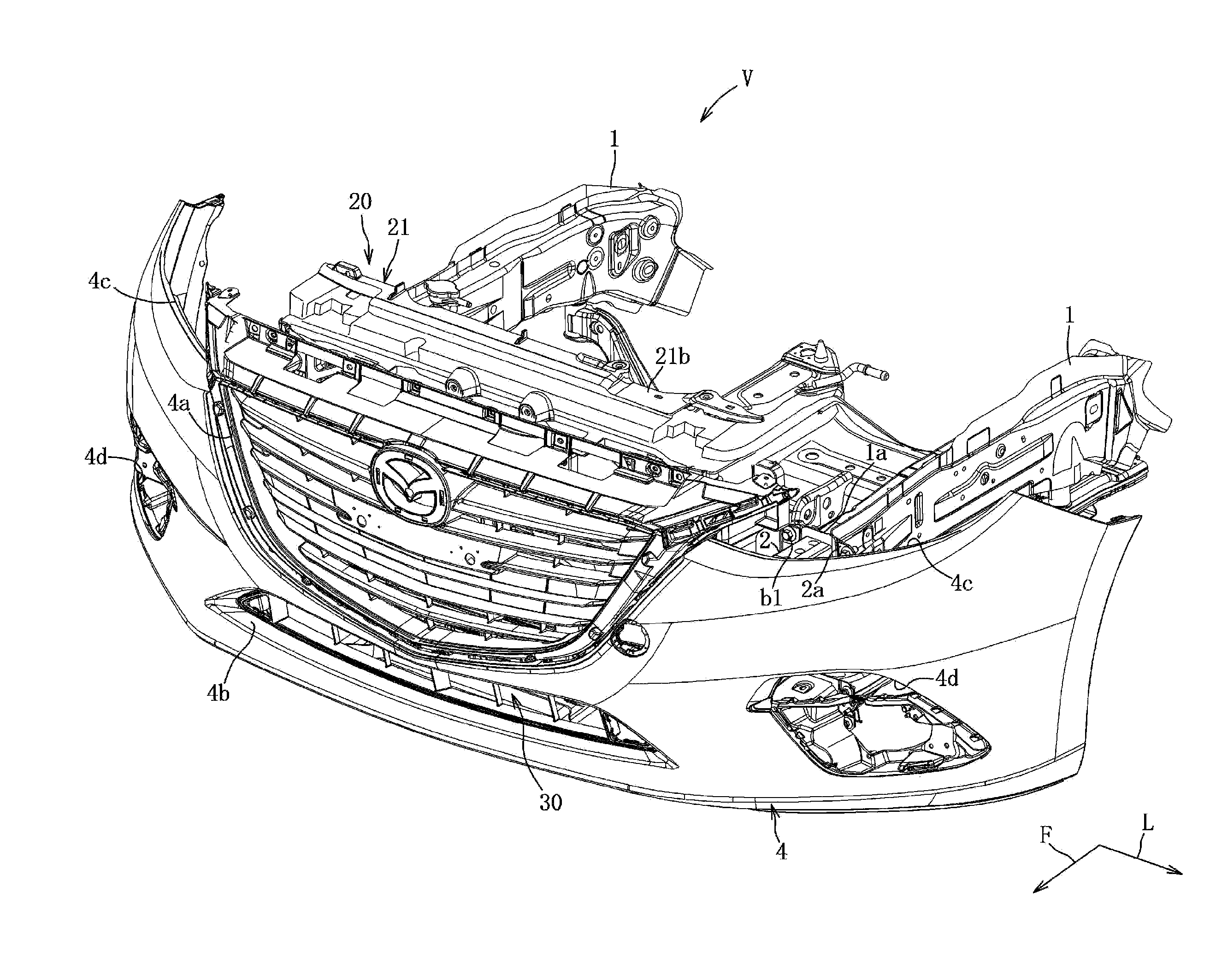

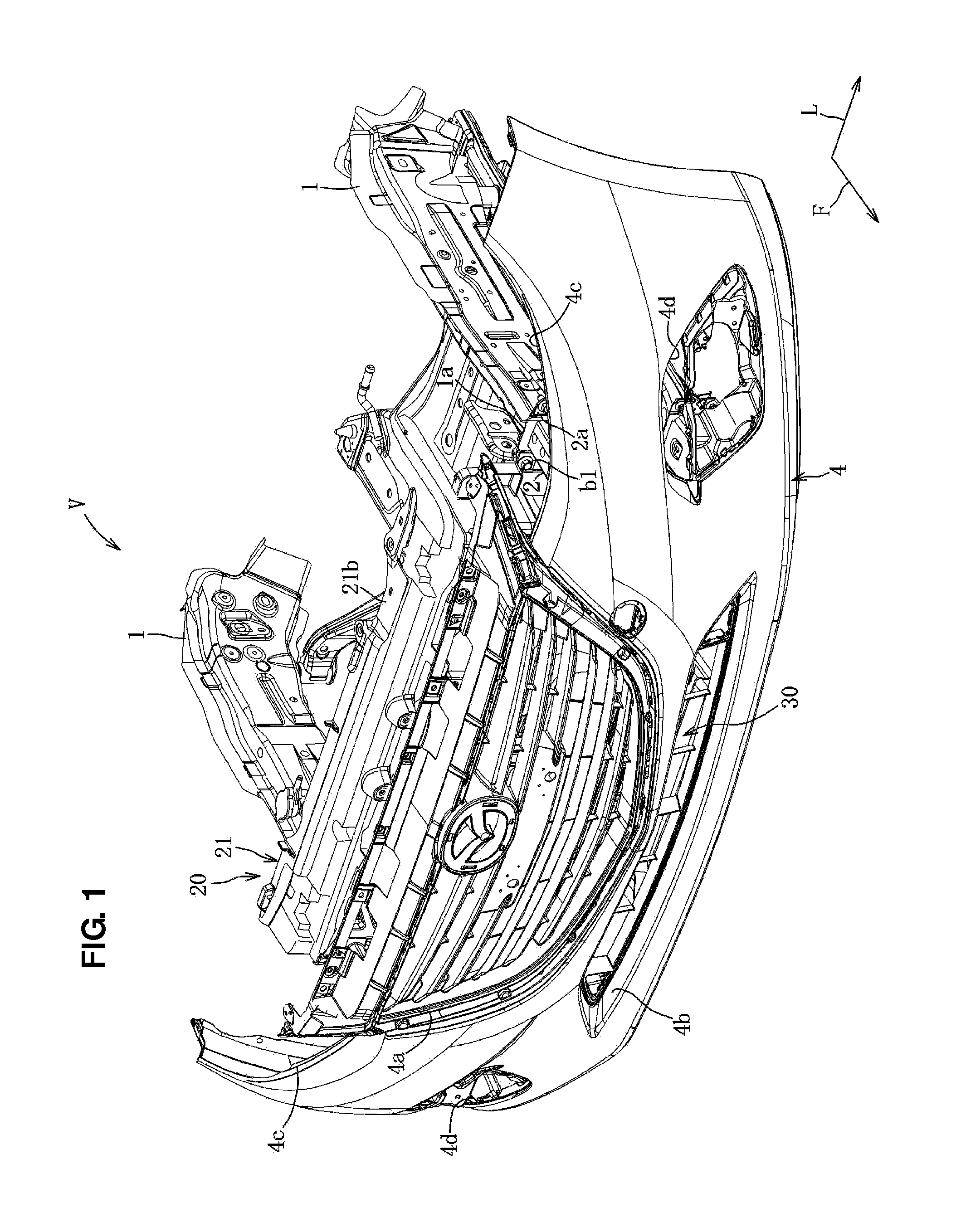

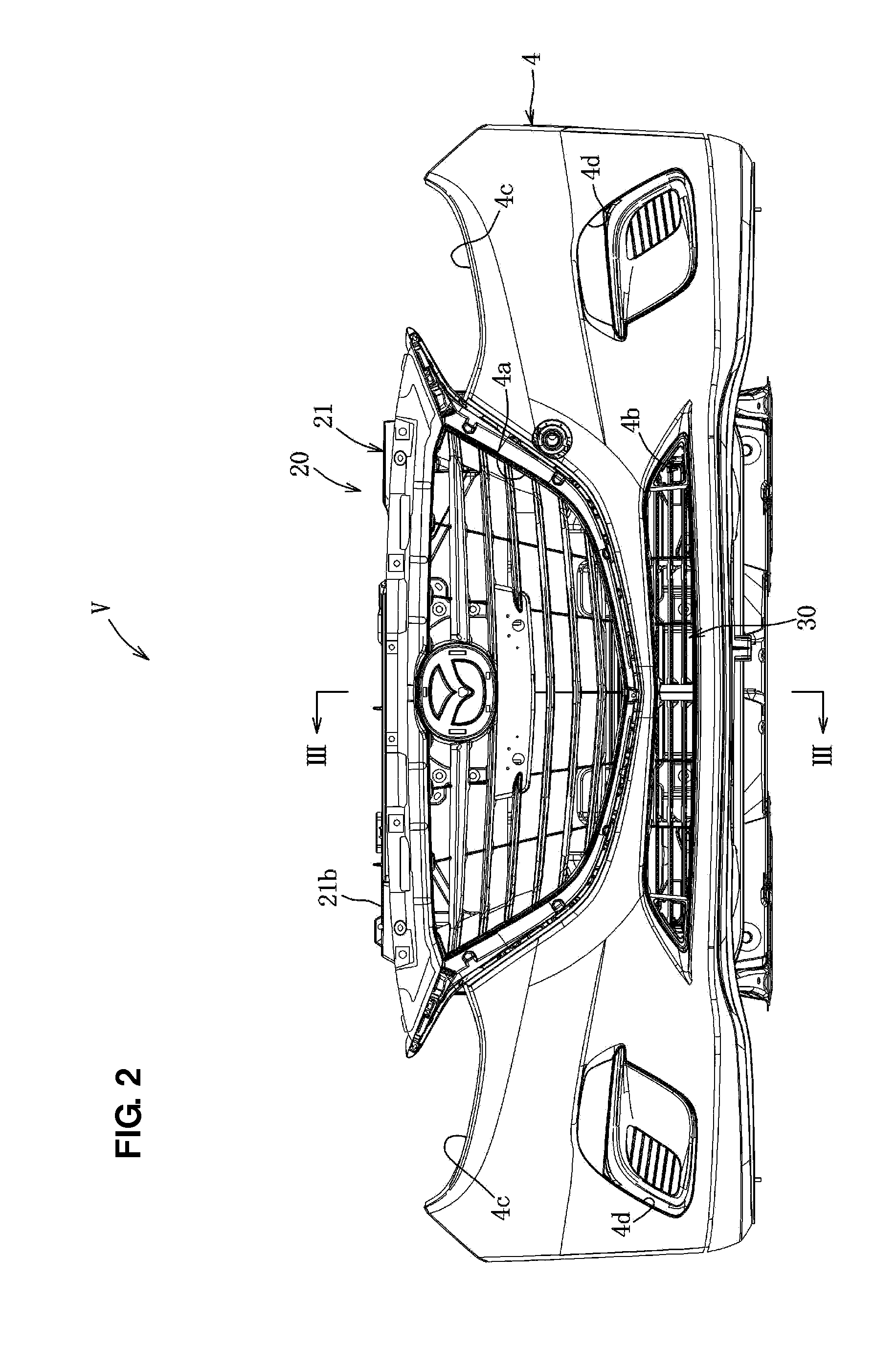

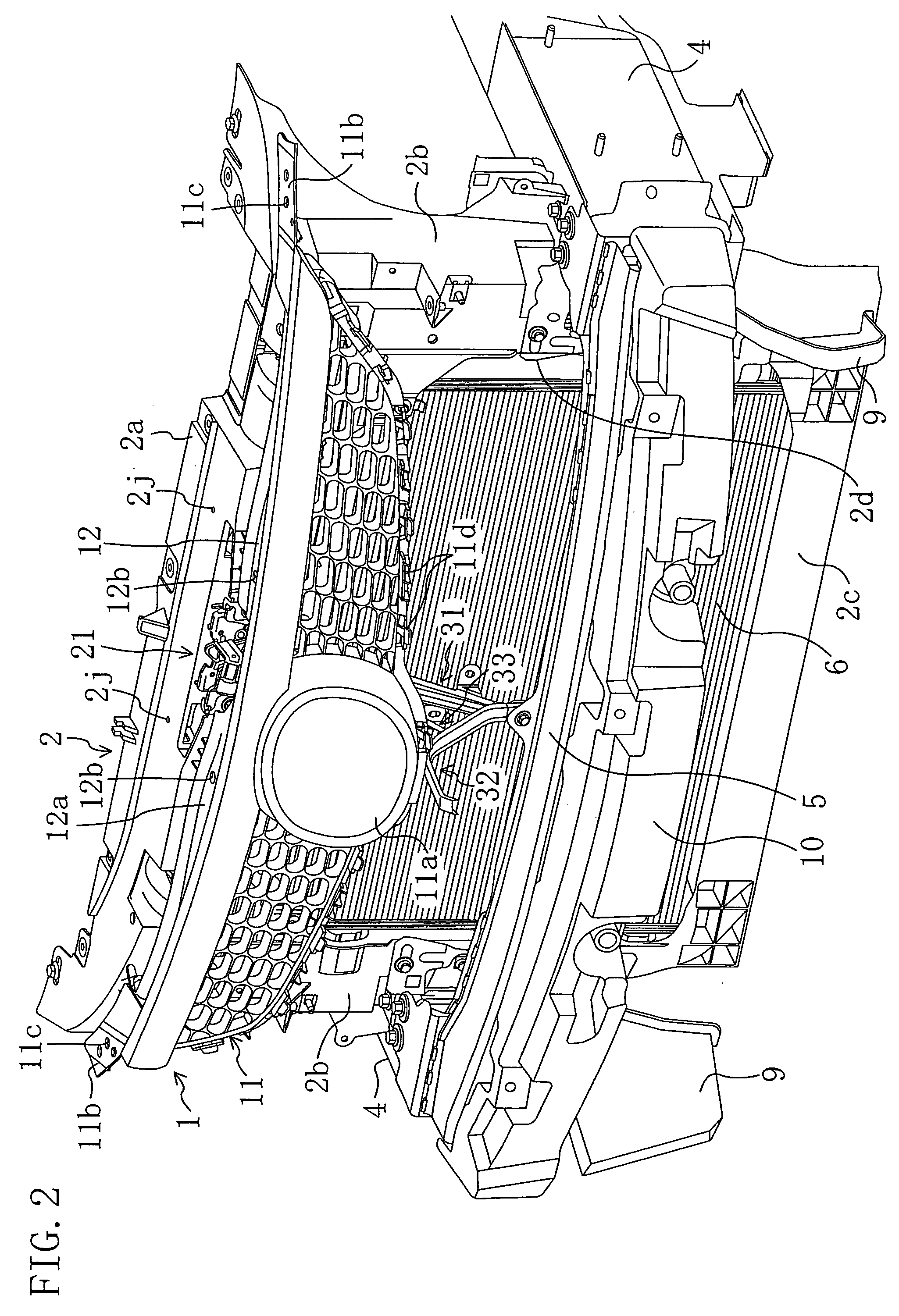

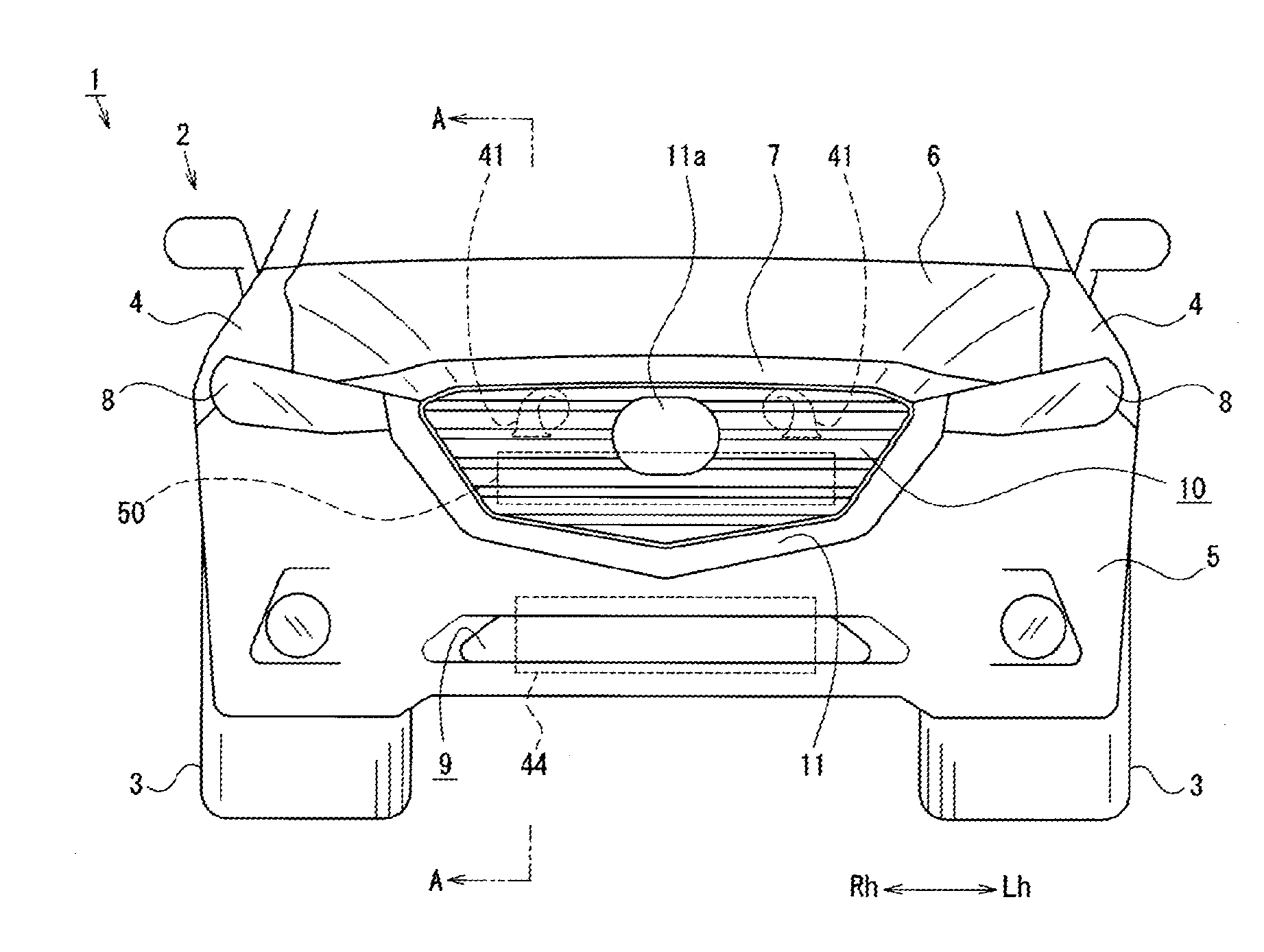

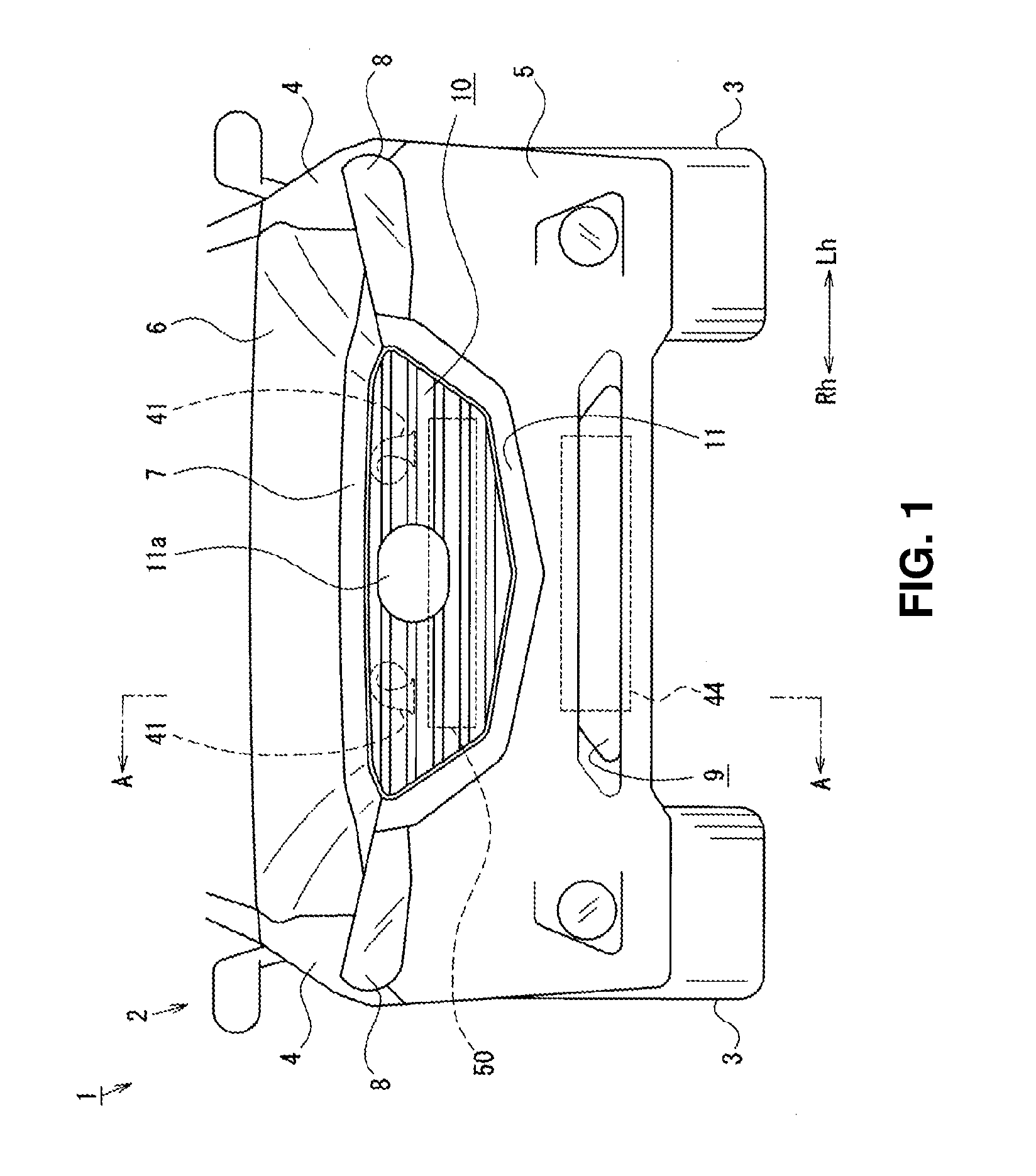

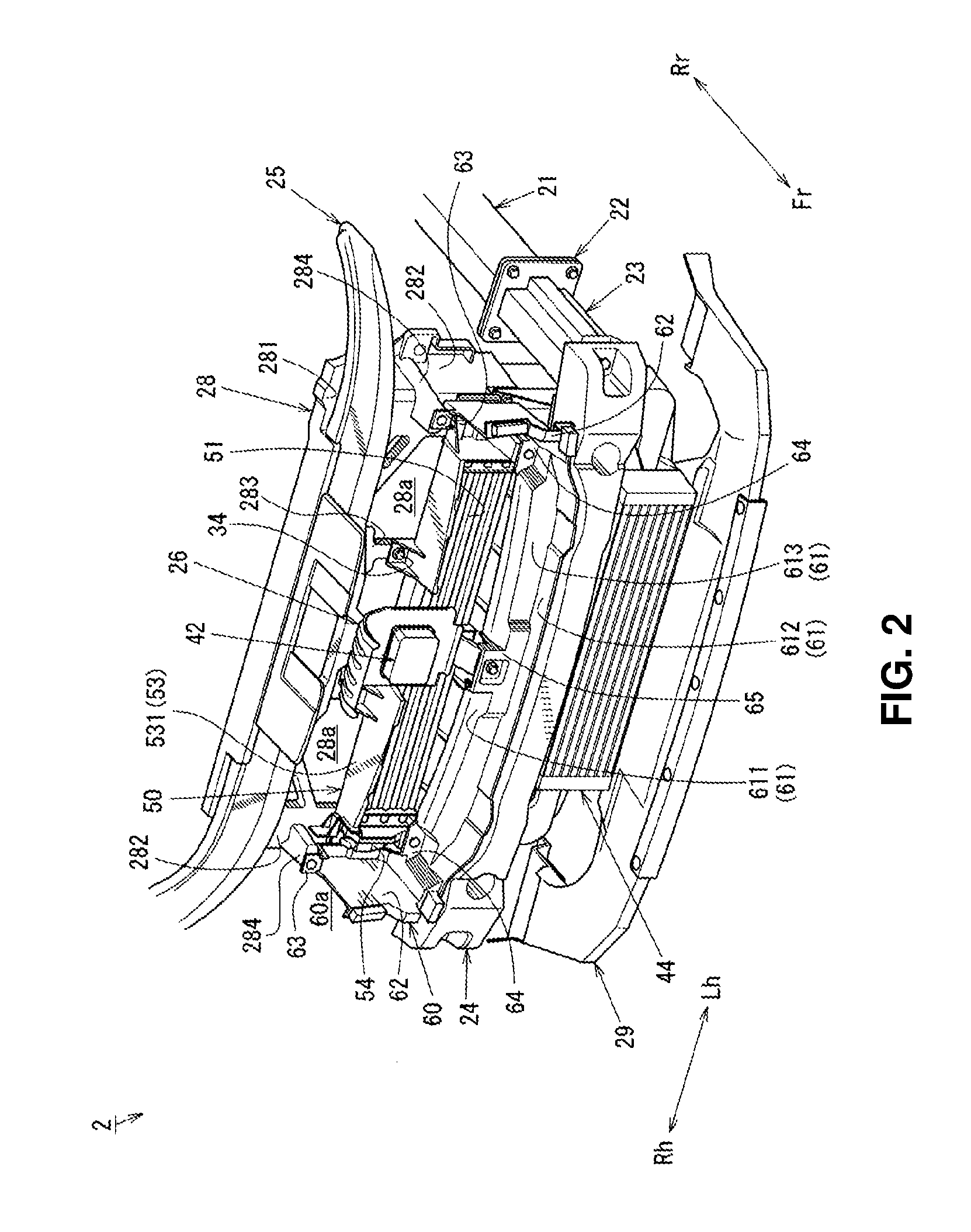

Grill shutter structure of vehicle

ActiveUS20140291056A1Ensuring fuel economyImprove fuel economyVehicle sub-unit featuresAutomatic initiationsWindow shutterEngineering

A grill shutter unit comprises a shutter unit provided in back of a traveling-air introductory port formed at a front end of a vehicle body and including shutter members, and a traveling-air guide member including a guide frame portion provided at an outer peripheral edge portion of the shutter unit and a seal portion provided to extend forward continuously from a front end of the guide frame portion and be made from soft synthetic resin having more flexibility than the frame portion, wherein the grill shutter unit is configured such that when the shutter members are closed, a seal portion of the traveling-air guide member is pressed against an outer peripheral wall face of the traveling-air introductory port by pressure of traveling air shut off by the shutter members closed.

Owner:MAZDA MOTOR CORP

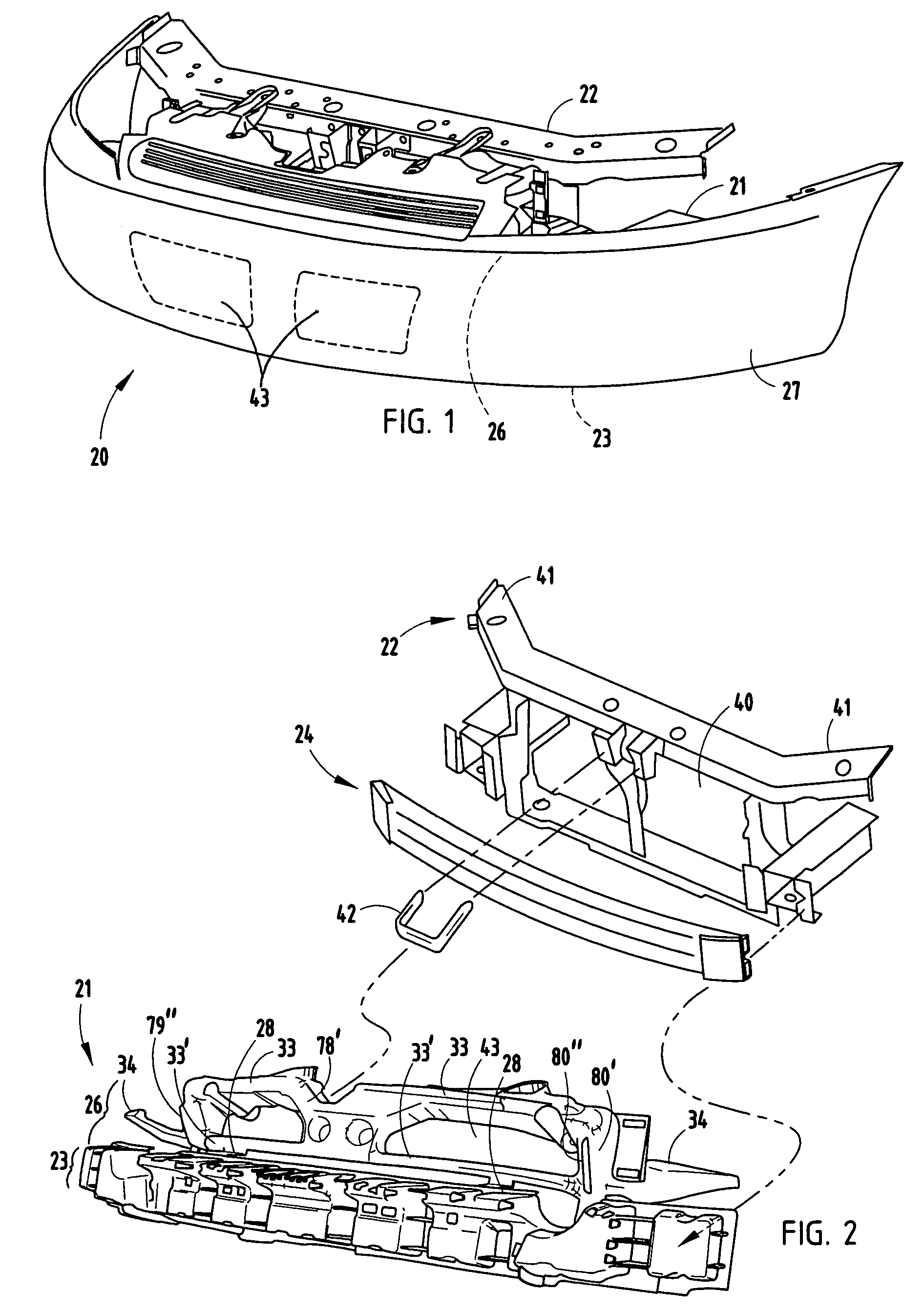

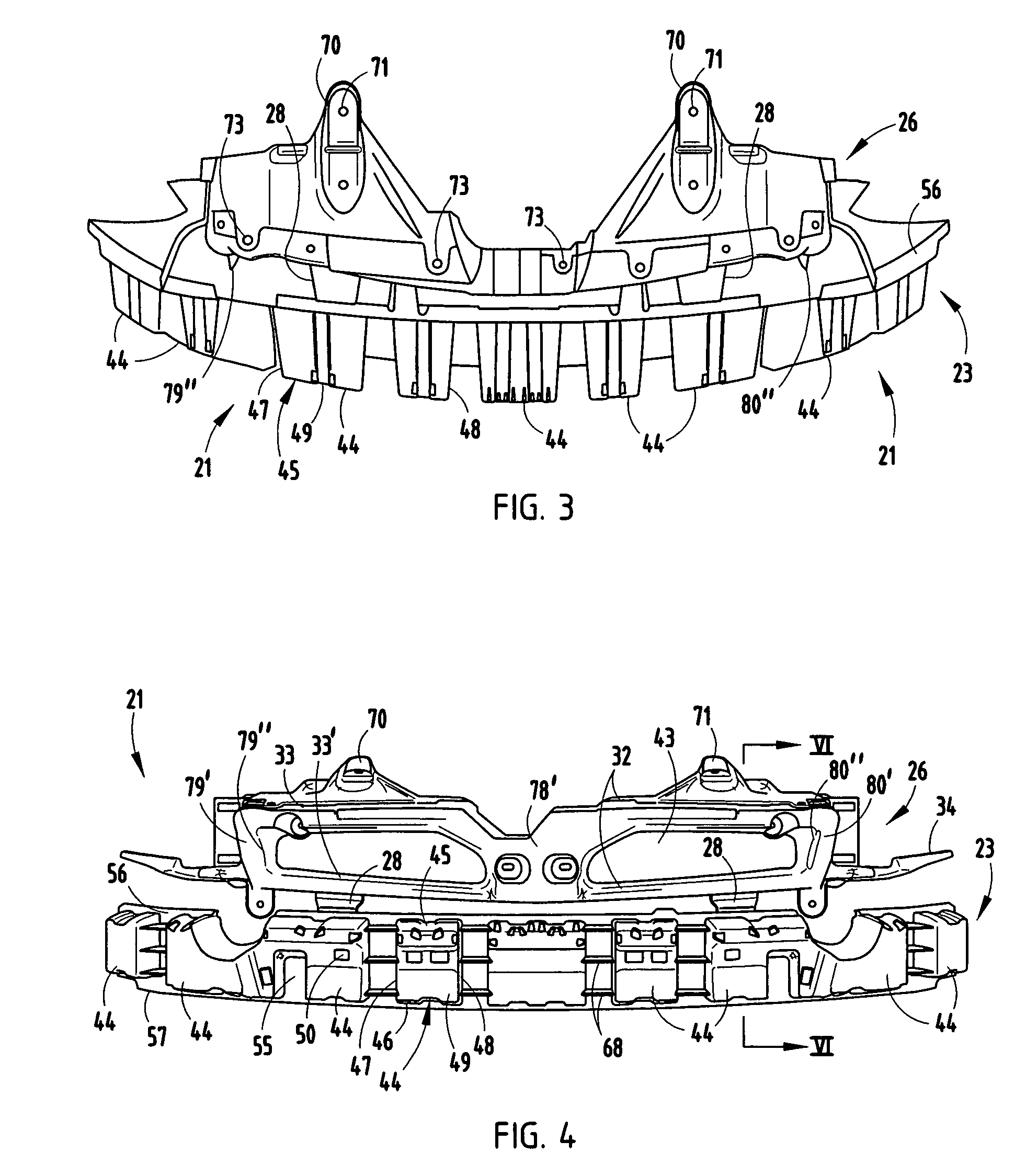

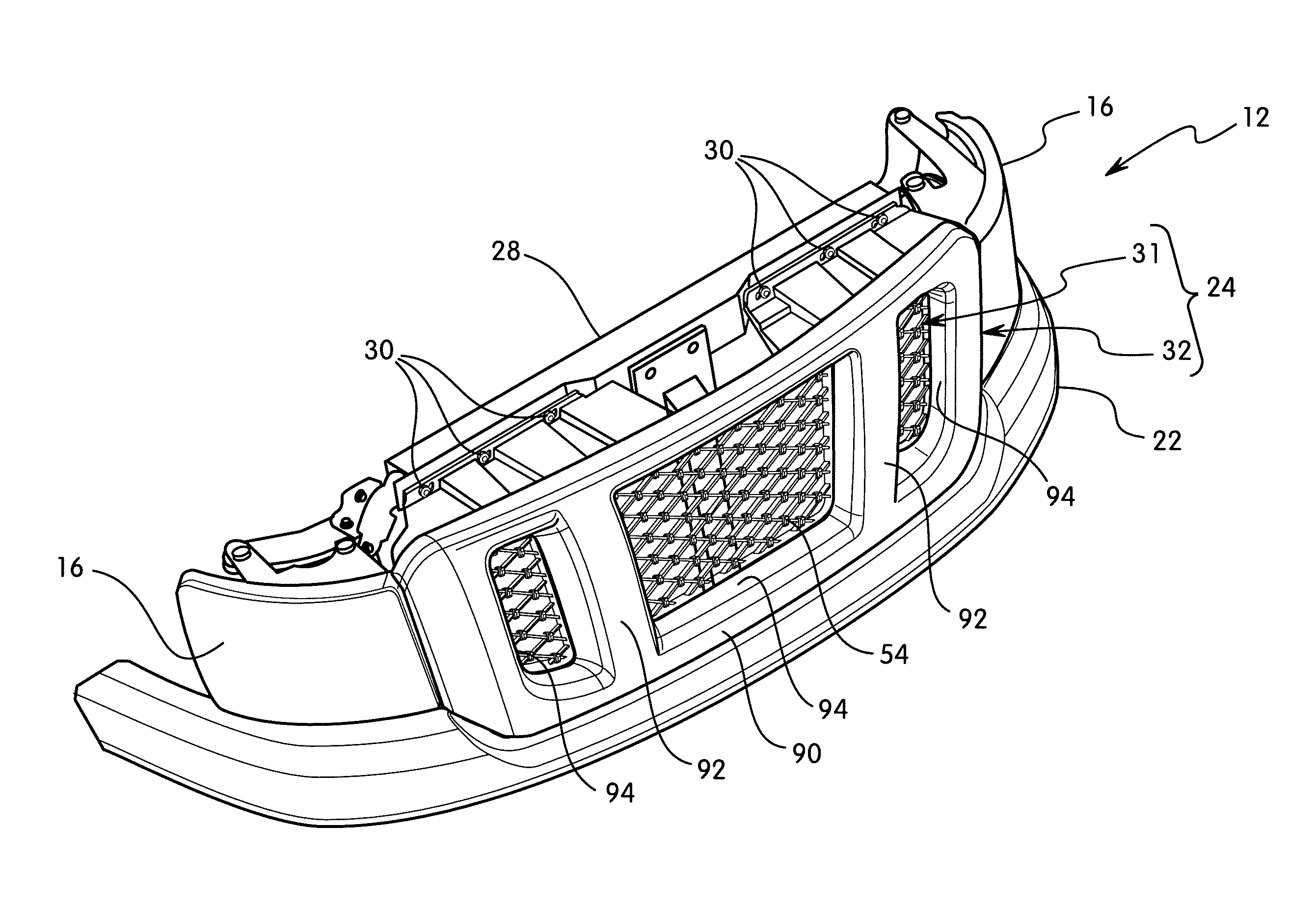

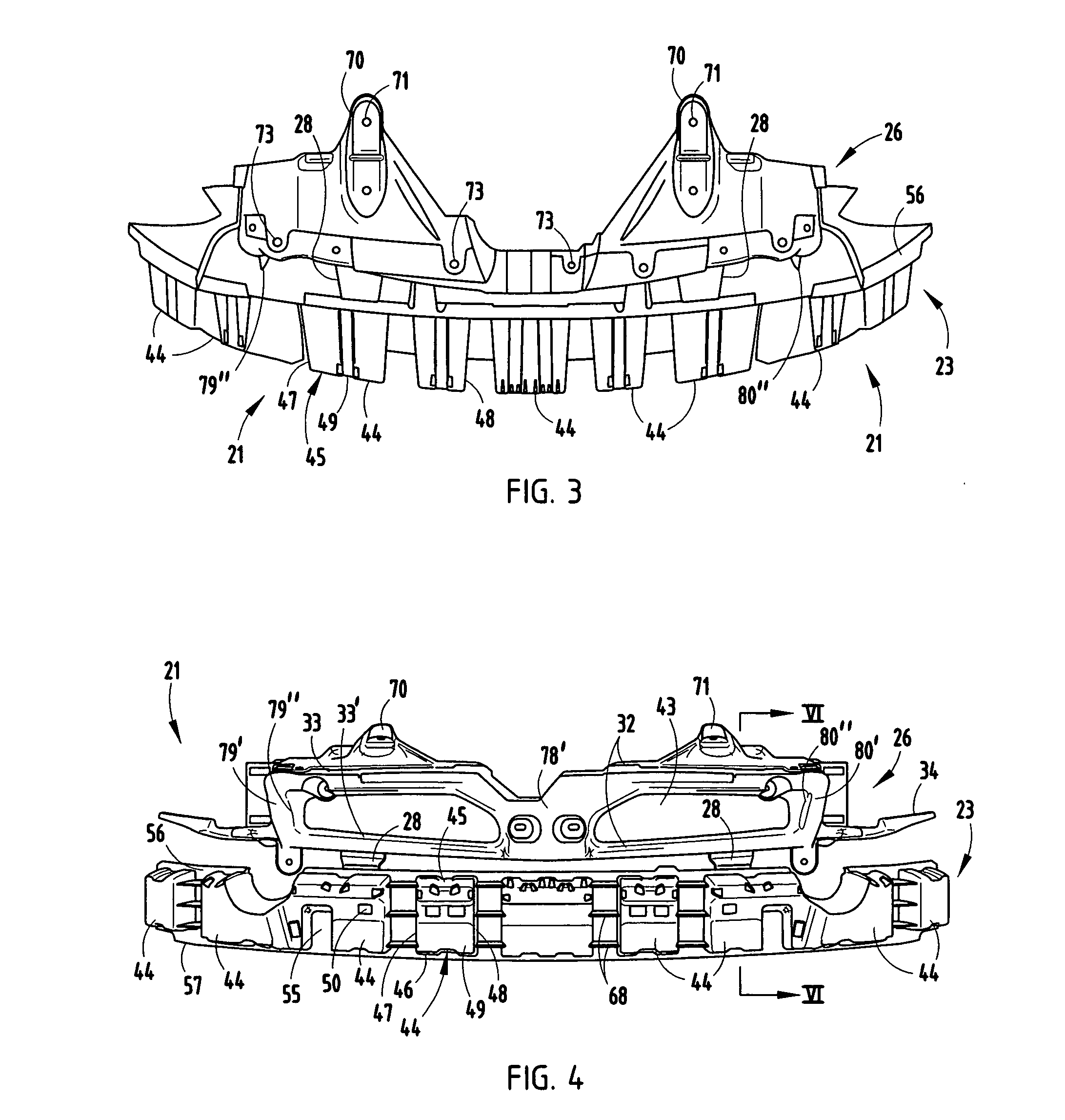

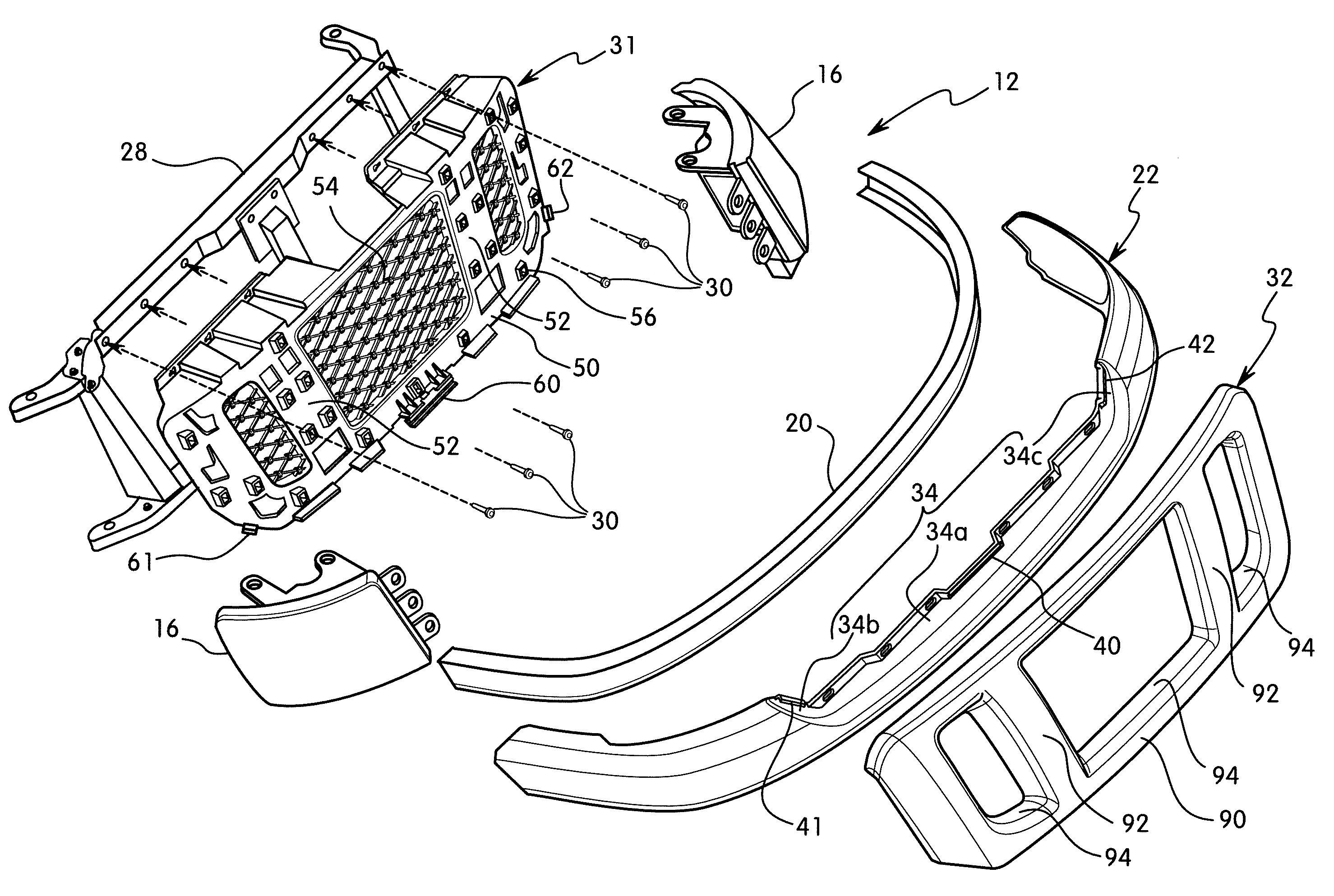

Integrated bumper energy absorber and fascia support component

ActiveUS6997490B2Facilitate simultaneous assemblyAvoid damageVehicle seatsDashboardsEngineeringPolymer

An integrated one-piece polymeric molded component includes an energy-absorbing section, a fascia-supporting beam section, and a plurality of connecting section connecting the energy-absorbing and fascia-supporting beam sections. The energy-absorbing section engages a front of a bumper beam and includes crush boxes configured to absorb impact energy during a vehicle crash. The connecting sections are strong enough to hold the energy-absorbing section and the fascia-supporting beam section together during assembly of the one-piece component onto a vehicle, but are flexible to allow collapse of the energy-absorbing section during a vehicle crash without damaging the fascia-supporting beam section. The beam section is channel-shaped and extends cross-car generally between headlamps of the vehicle, for providing added support structure to a front-end of the vehicle. The beam section includes air-redirecting ridges for optimal air flow and integral clips for wire management.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

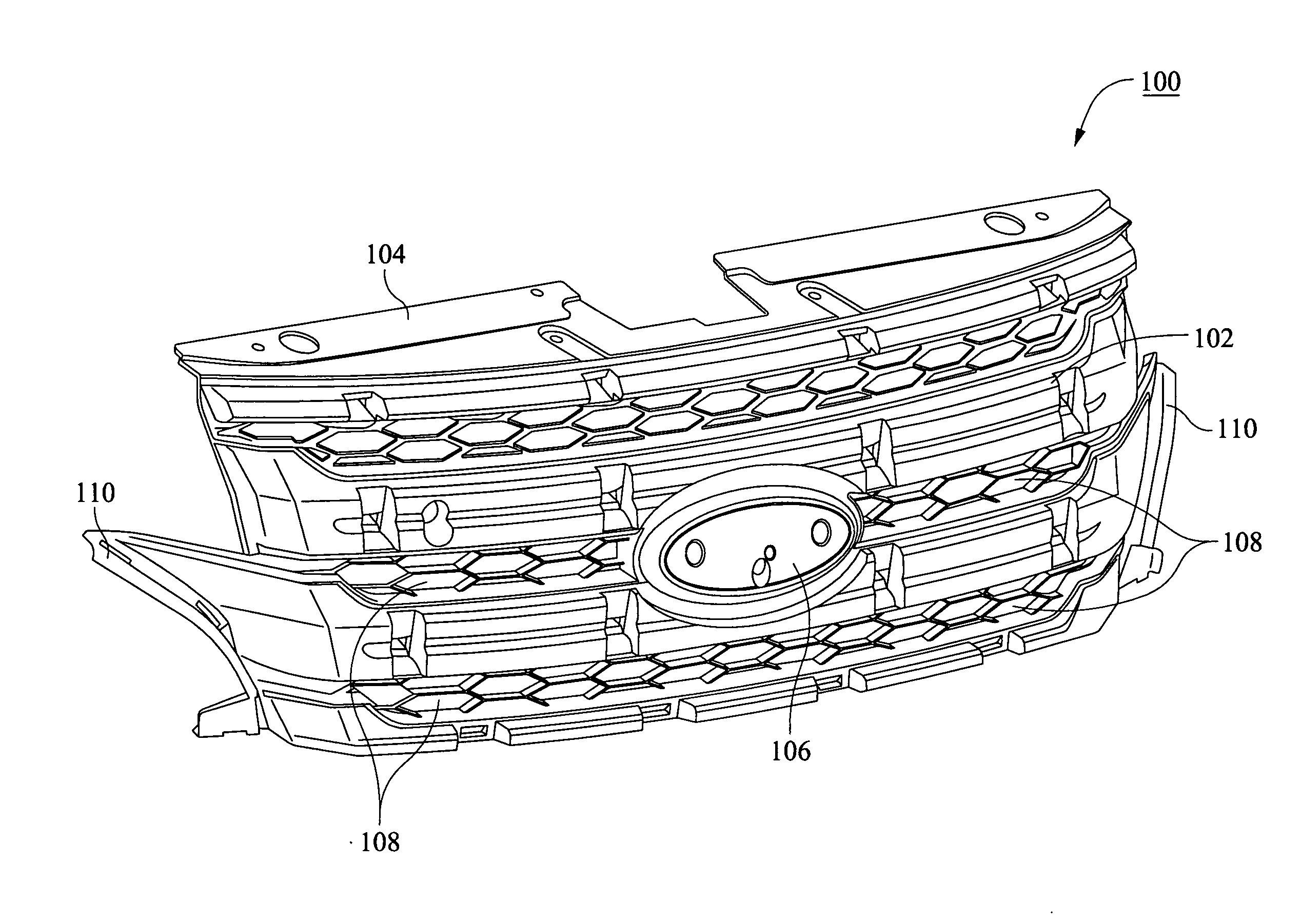

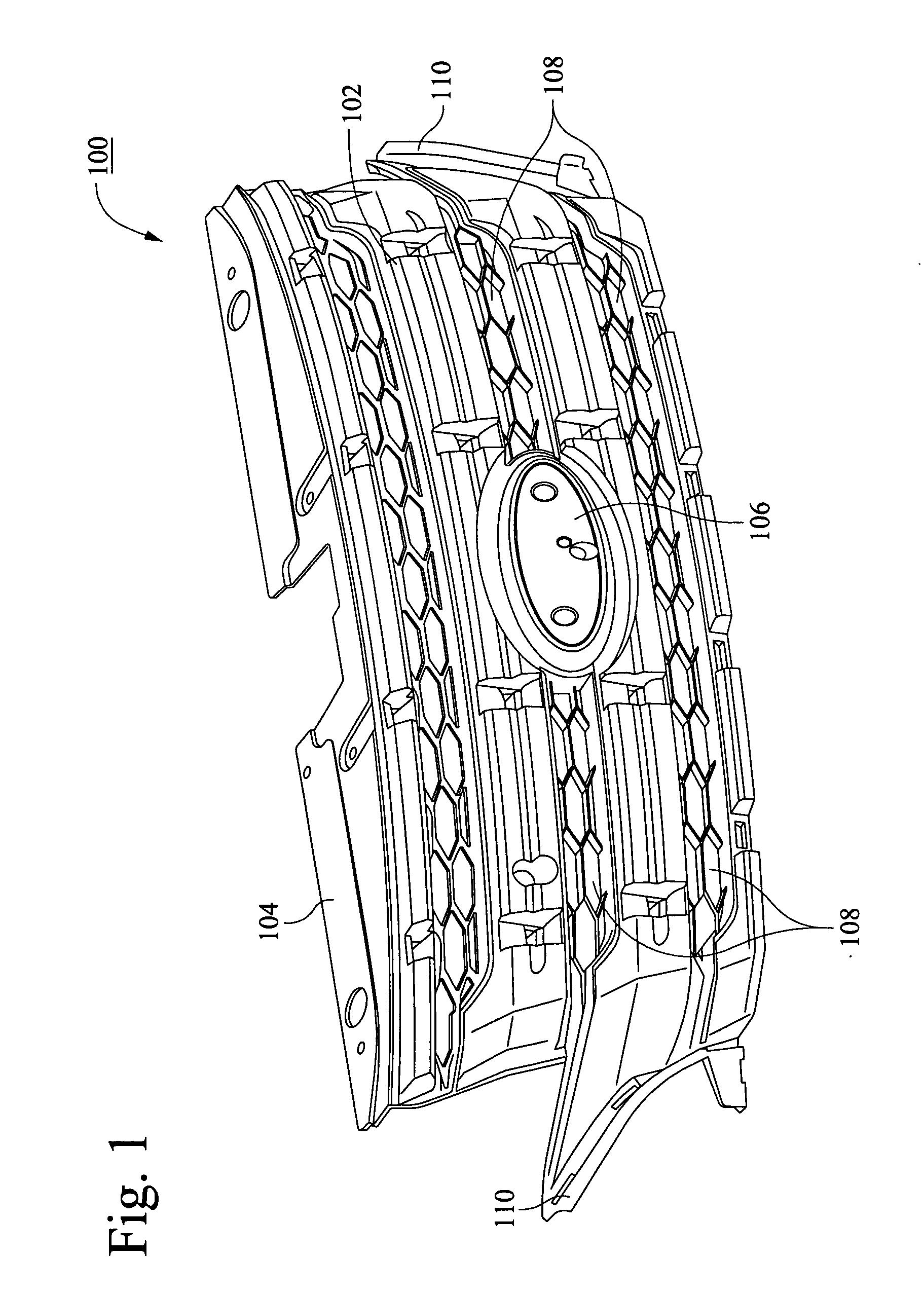

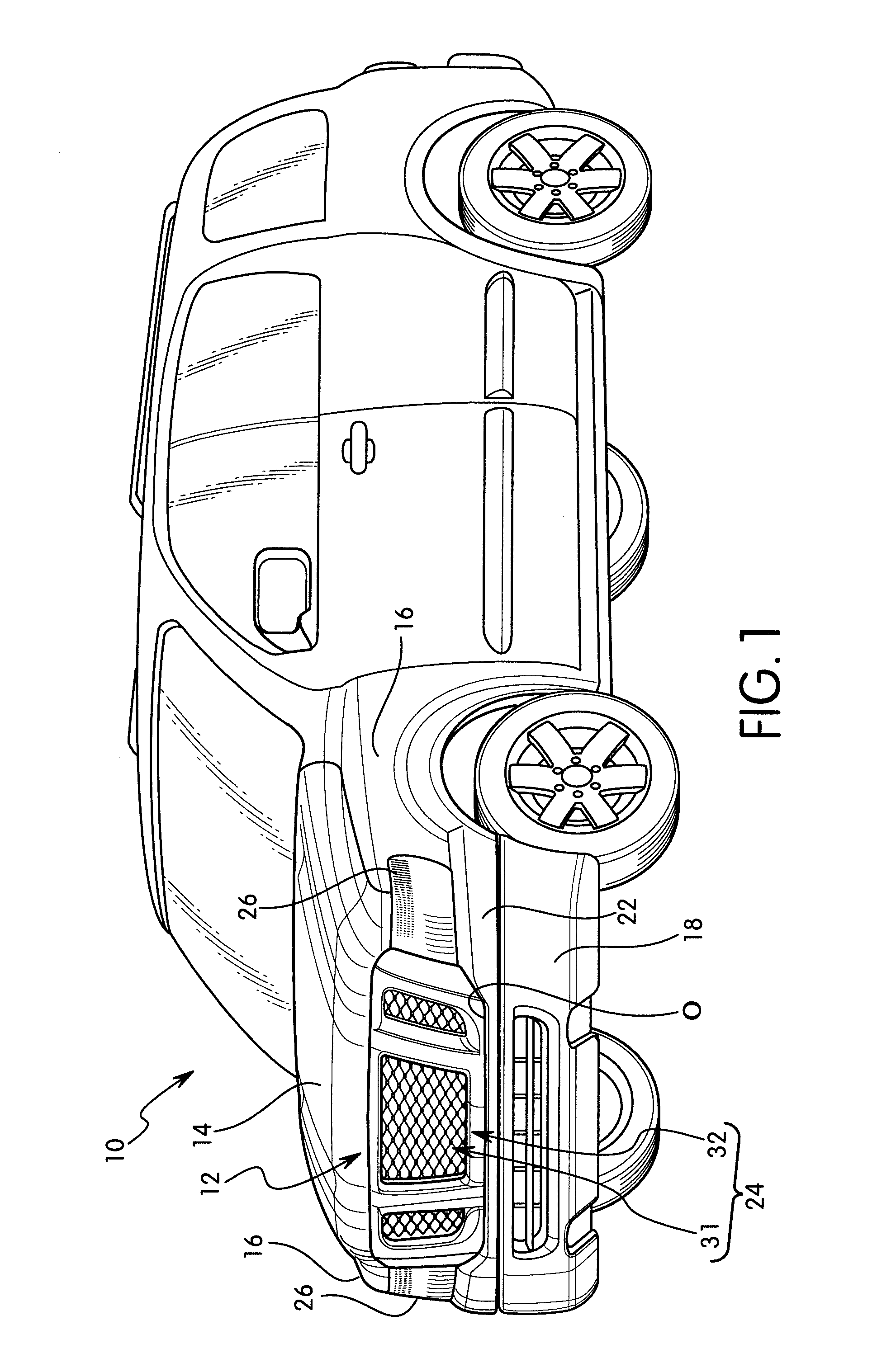

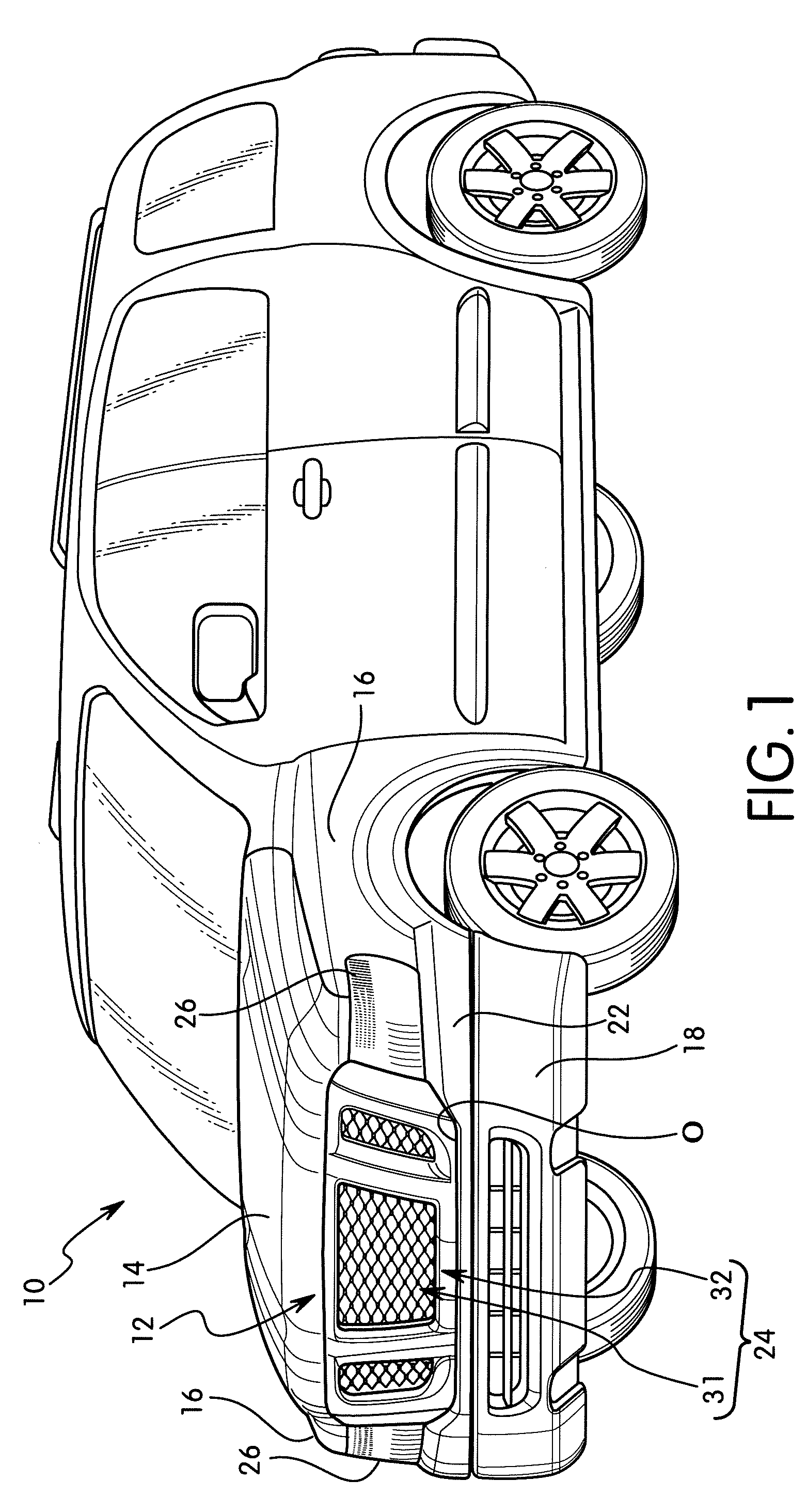

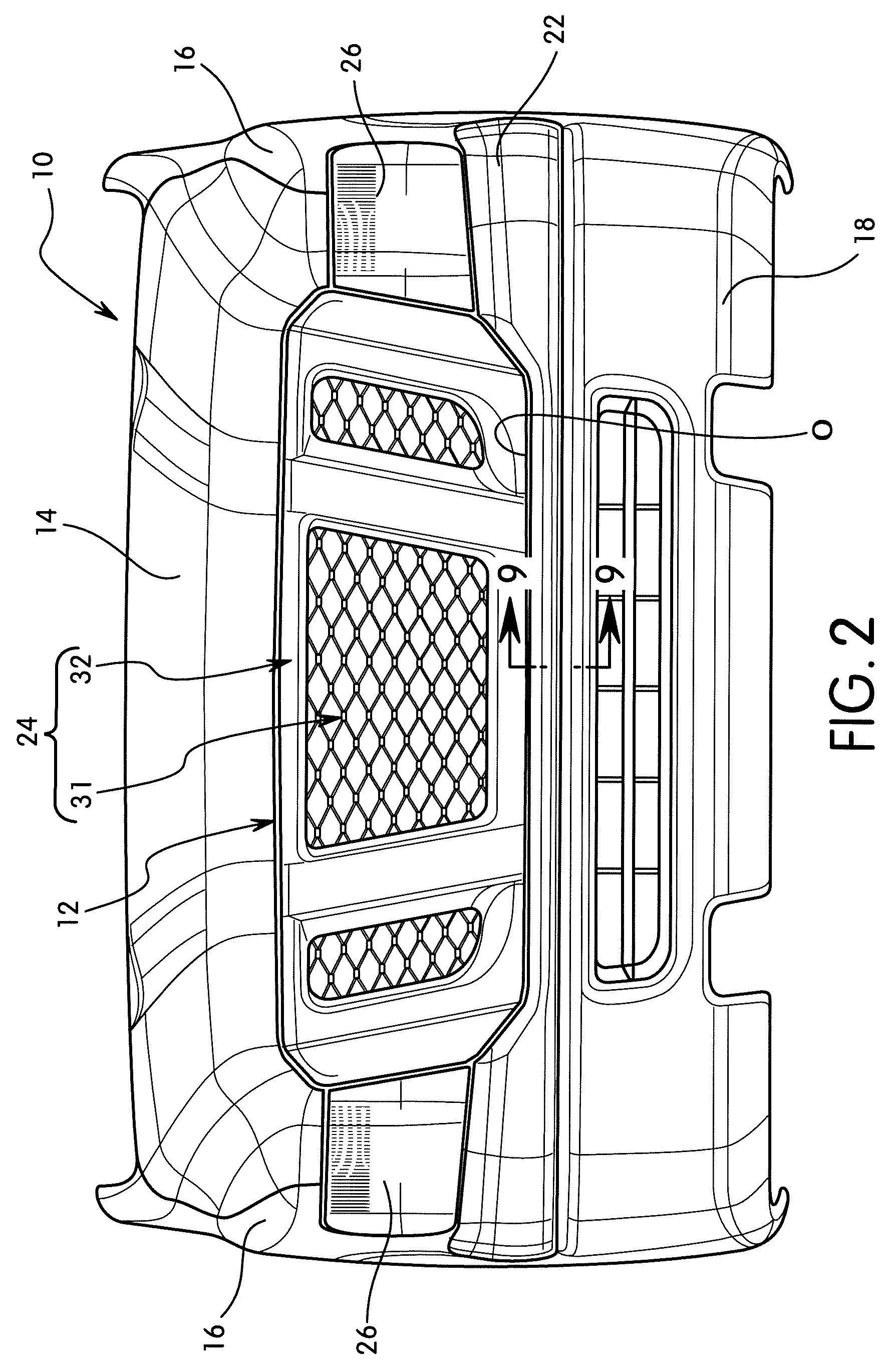

Vehicle grille including adjustable louvers, and/or method of making the same

InactiveUS20110005851A1Improve aerodynamic performanceReduce resistanceComponent optimizationRadiatorsWindow shutterFuel efficiency

In certain example embodiments of this invention, there is provided a grille for a vehicle (e.g., a car, truck, SUV, or the like). In certain example embodiments, the vehicle grille includes adjustable louvers. In certain example embodiments, the louvers are configured to change position relative to the grille (e.g., to rotate, slide, or otherwise move) when a predetermined condition is met (e.g., vehicle speed above / below a predefined threshold, wind speed above / below a predefined threshold, etc.). This configuration advantageously may result in better vehicle performance (such as, for example, better fuel efficiency), e.g., related to less drag and / or improved aerodynamics.

Owner:GUARDIAN GLASS LLC

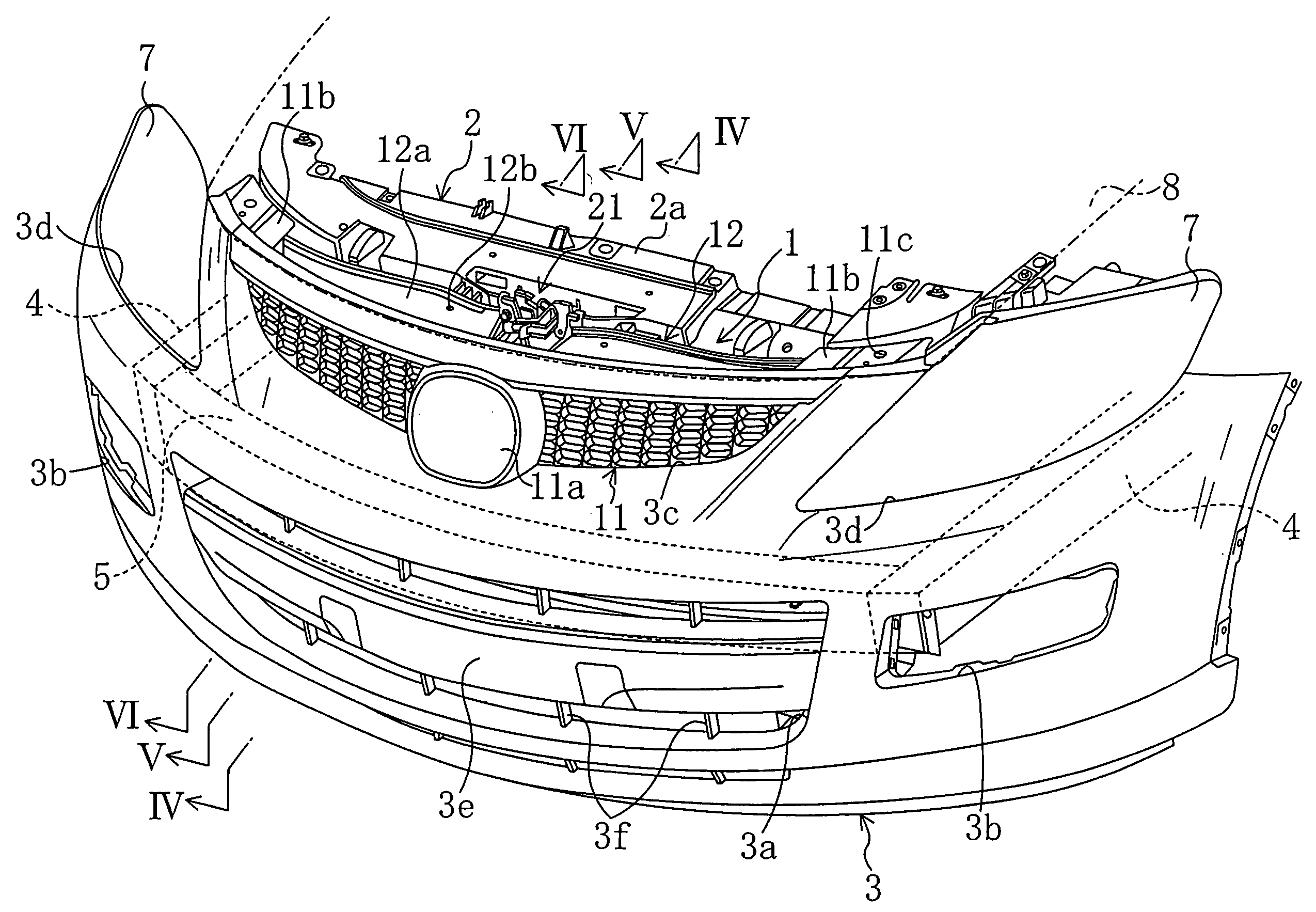

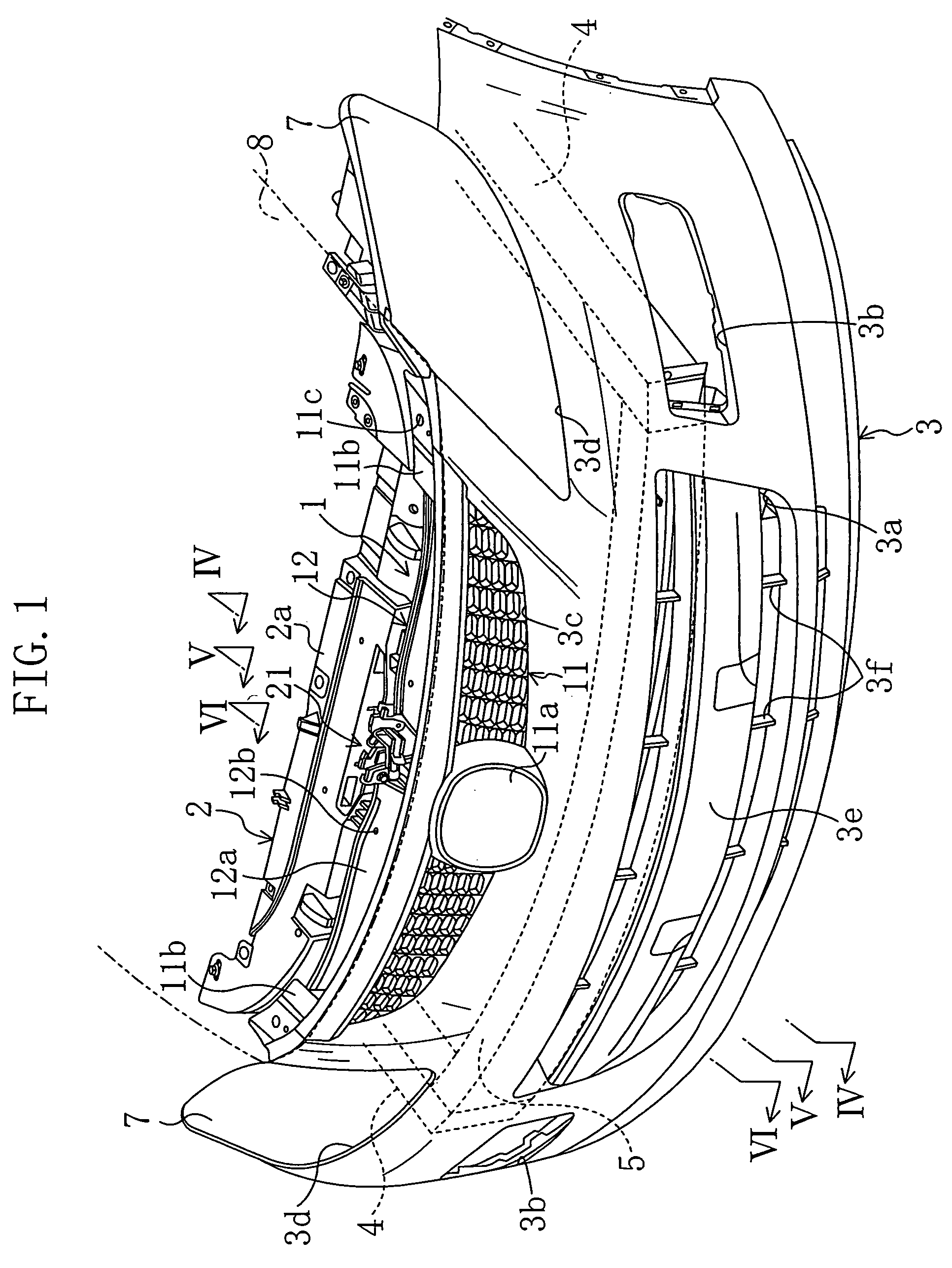

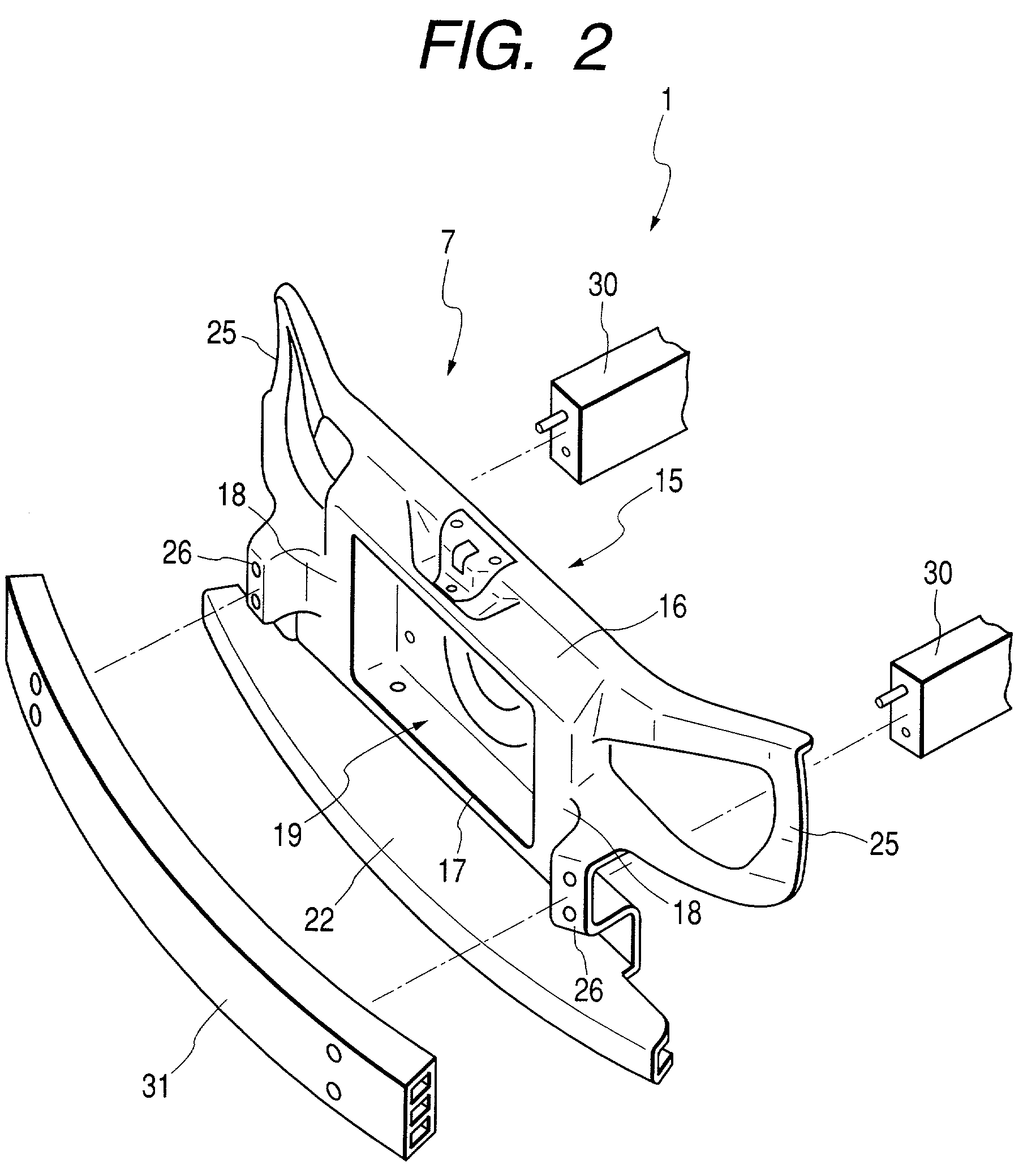

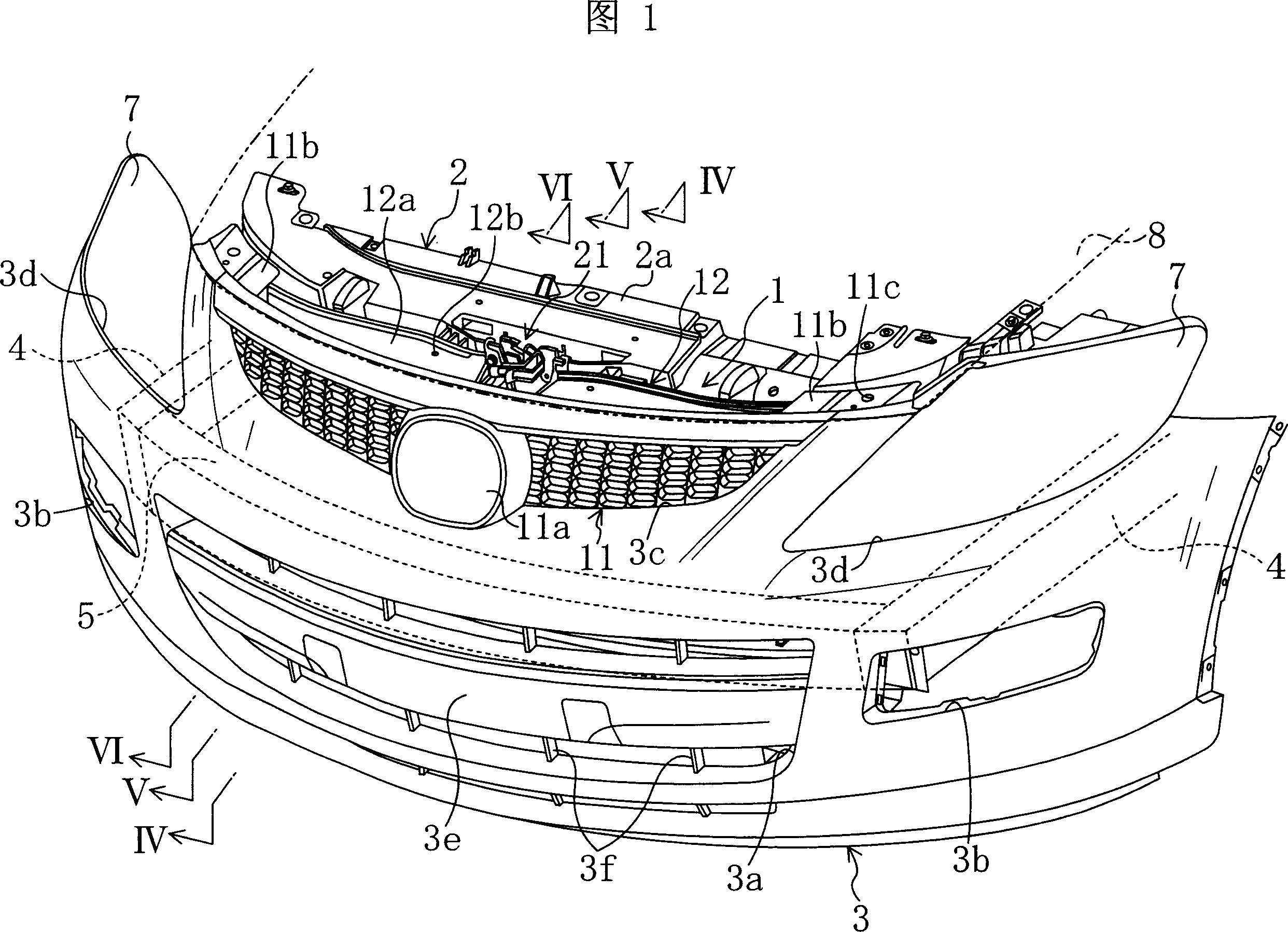

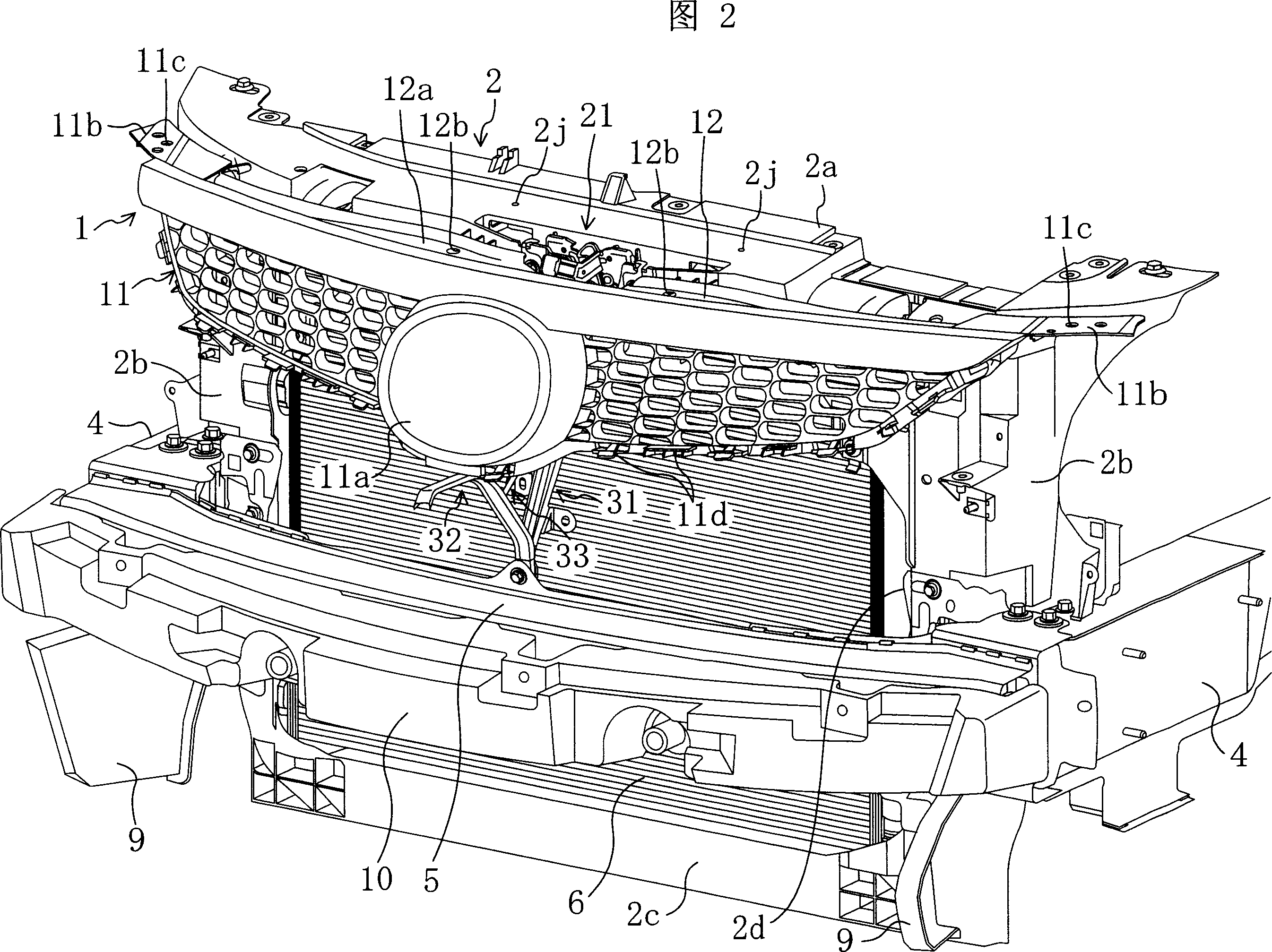

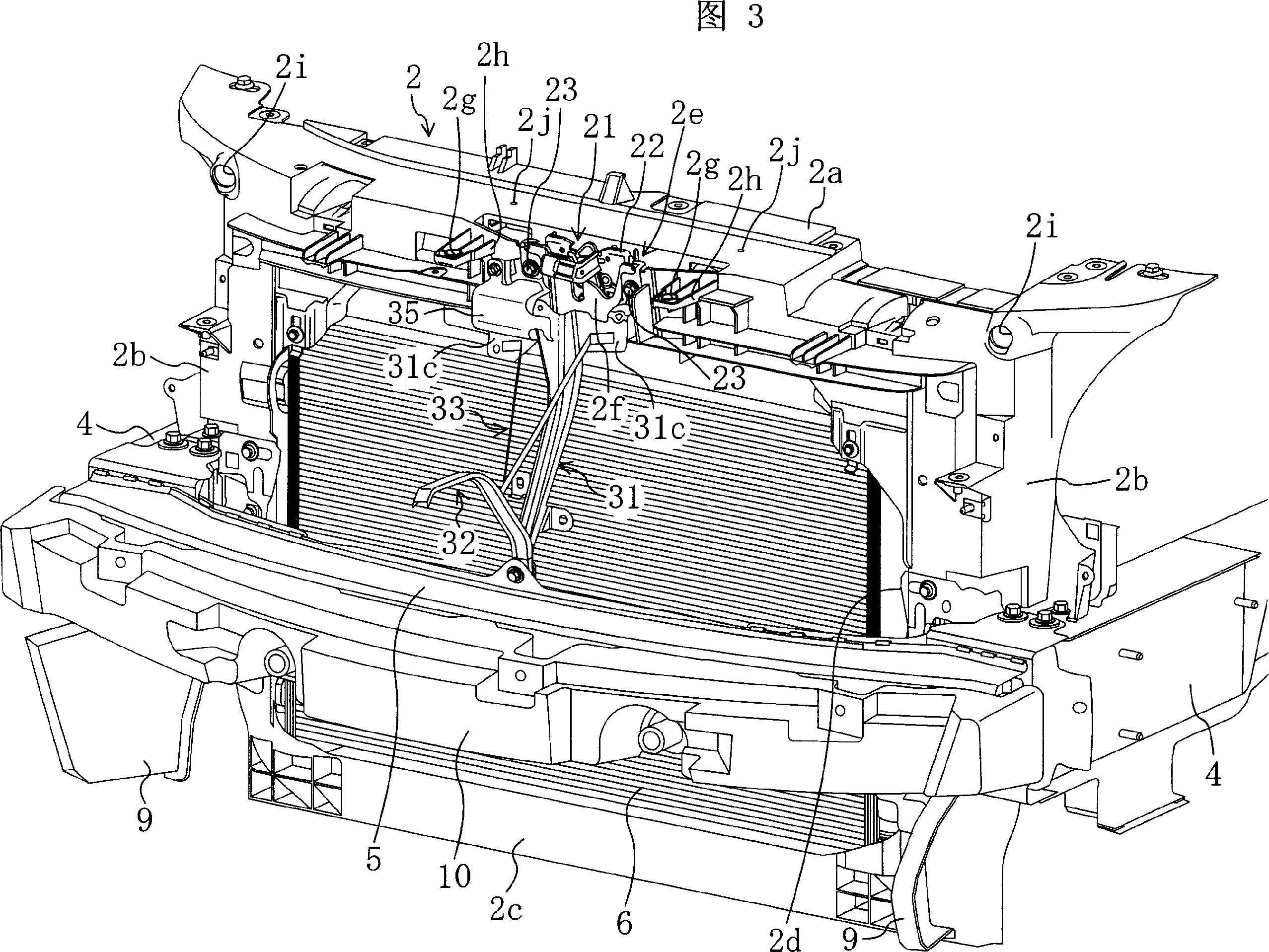

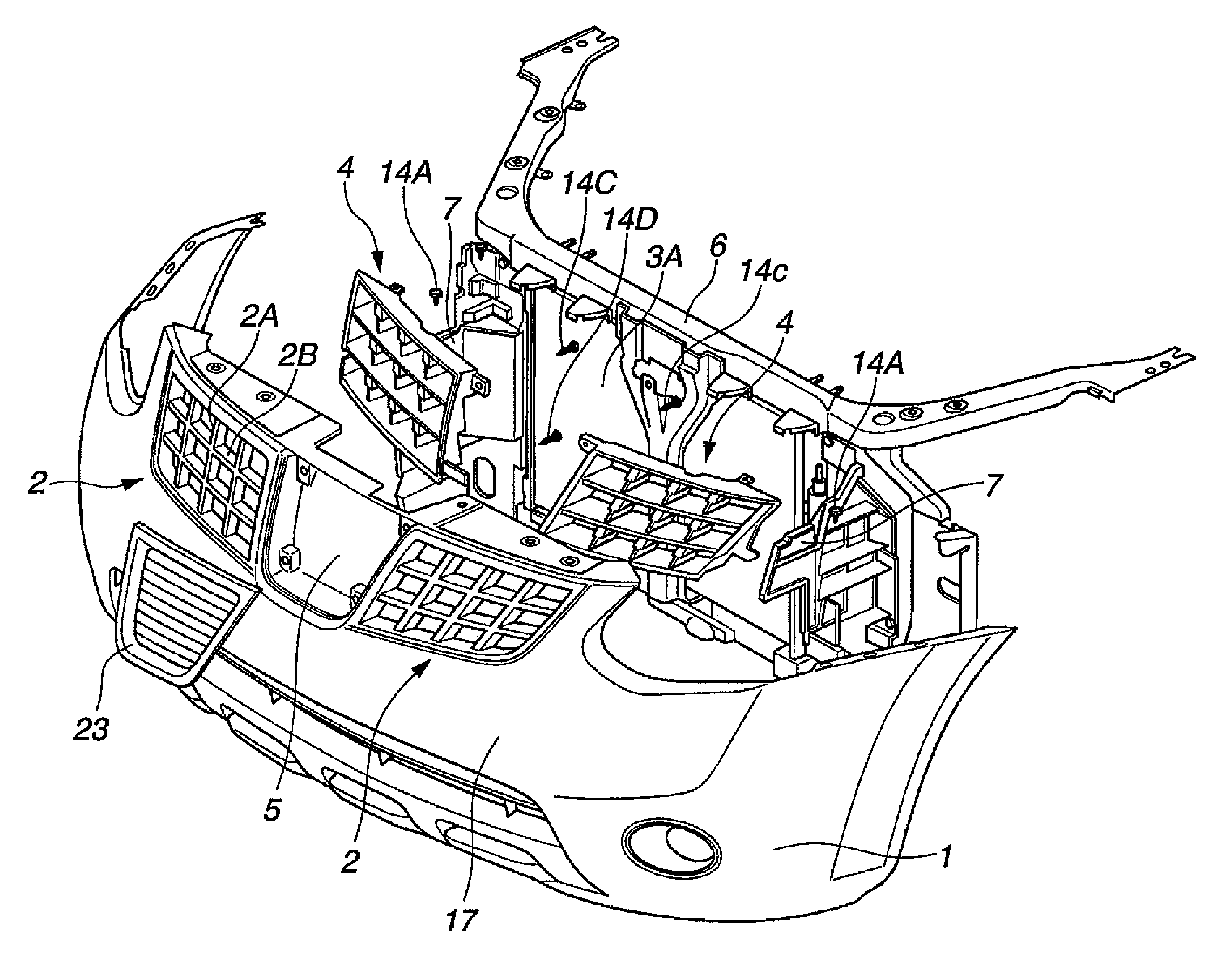

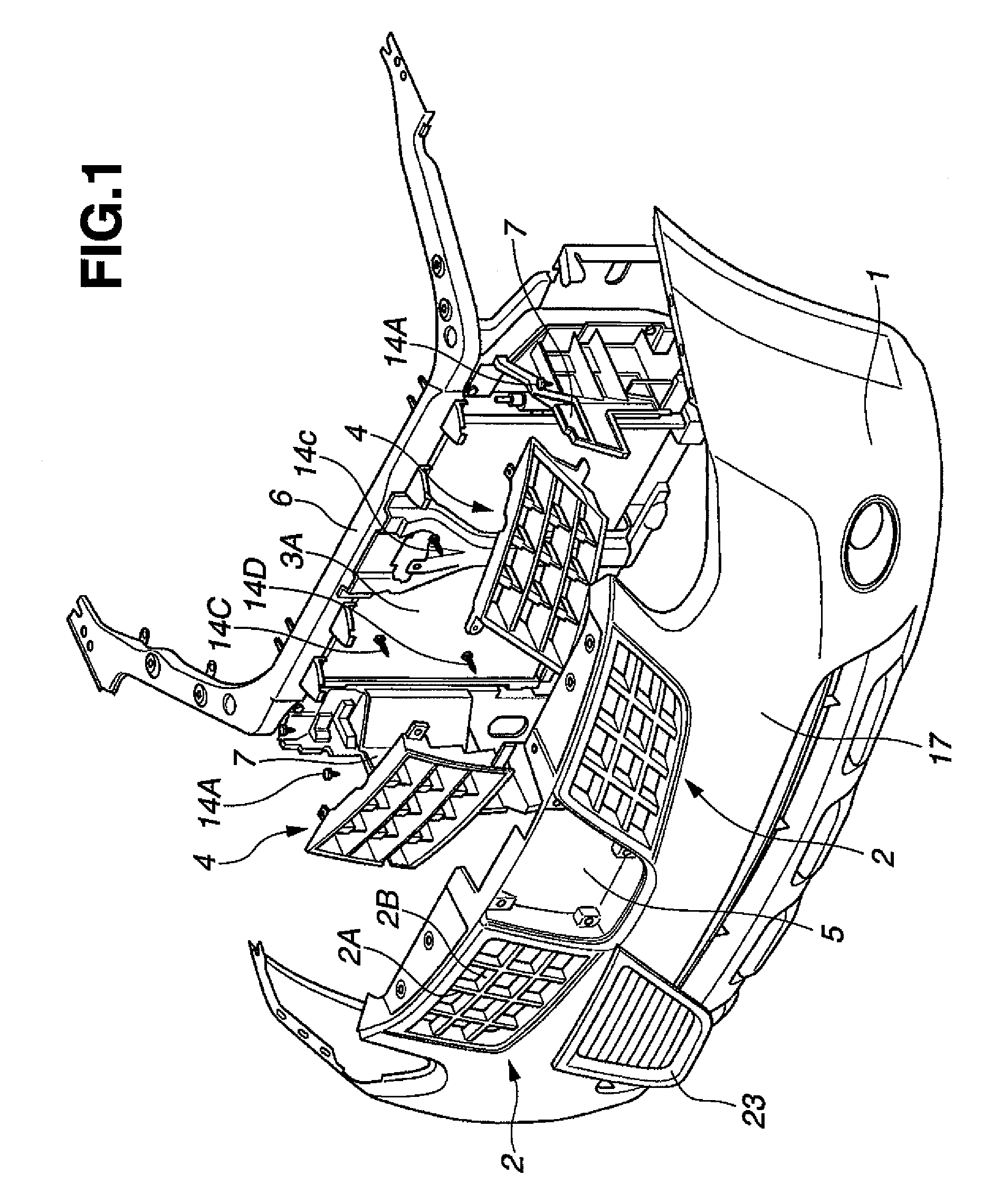

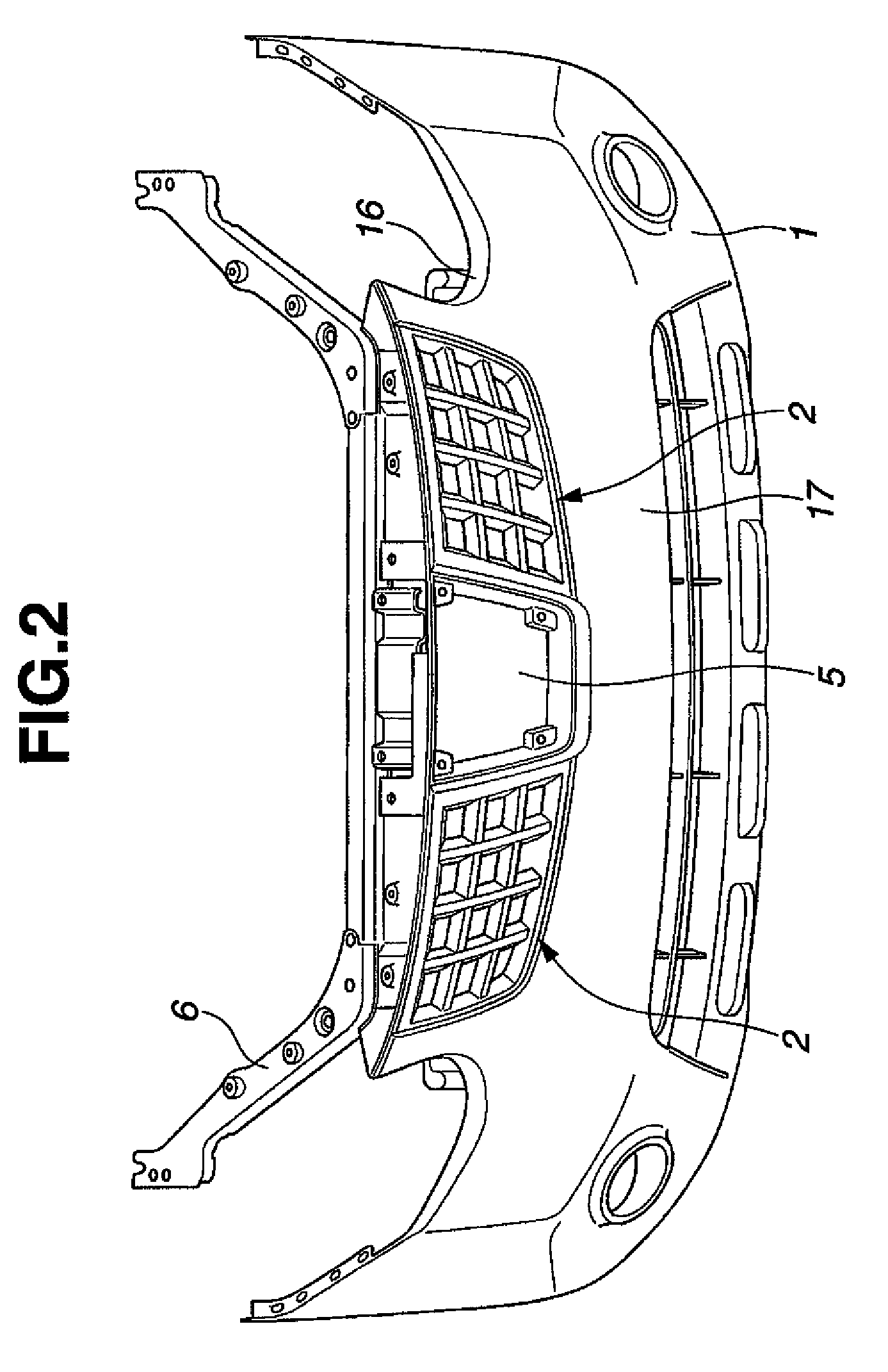

Vehicle front end structure

A front end structure for a vehicle comprises: a front bumper face; a shroud upper disposed to the rear of the front bumper face; a bumper beam disposed below the shroud upper to span the front ends of right and left front side frames; a center stay made of metal and spanning the shroud upper and the bumper beam; and a front grille supported at the upper side to the shroud upper and supported at the lower side to the front bumper face, the front grille is inclined so that the lower side is located frontwardly of the upper side, and the center stay is integrally provided with a grille support having a root end connected to the center stay and an abutment supporting part extending from the root end towards the bottom of the front grille to support the front grille from below. Alternatively, a front end structure for a vehicle comprises: a front bumper face; a shroud disposed to the rear of the front bumper face and including at least an upper part and right and left side parts; a front grille supported at the upper side to the shroud, supported at the lower side to the front bumper face and inclined so that the lower side is located frontwardly of the upper side; and a front grille support member including right and left mounting parts mounted to the right and left side parts of the shroud, respectively, and a shelf connecting the right and left mounting parts, formed to protrude frontward at a spanning part thereof connecting the right and left mounting parts and supporting the front grille from below.

Owner:MAZDA MOTOR CORP

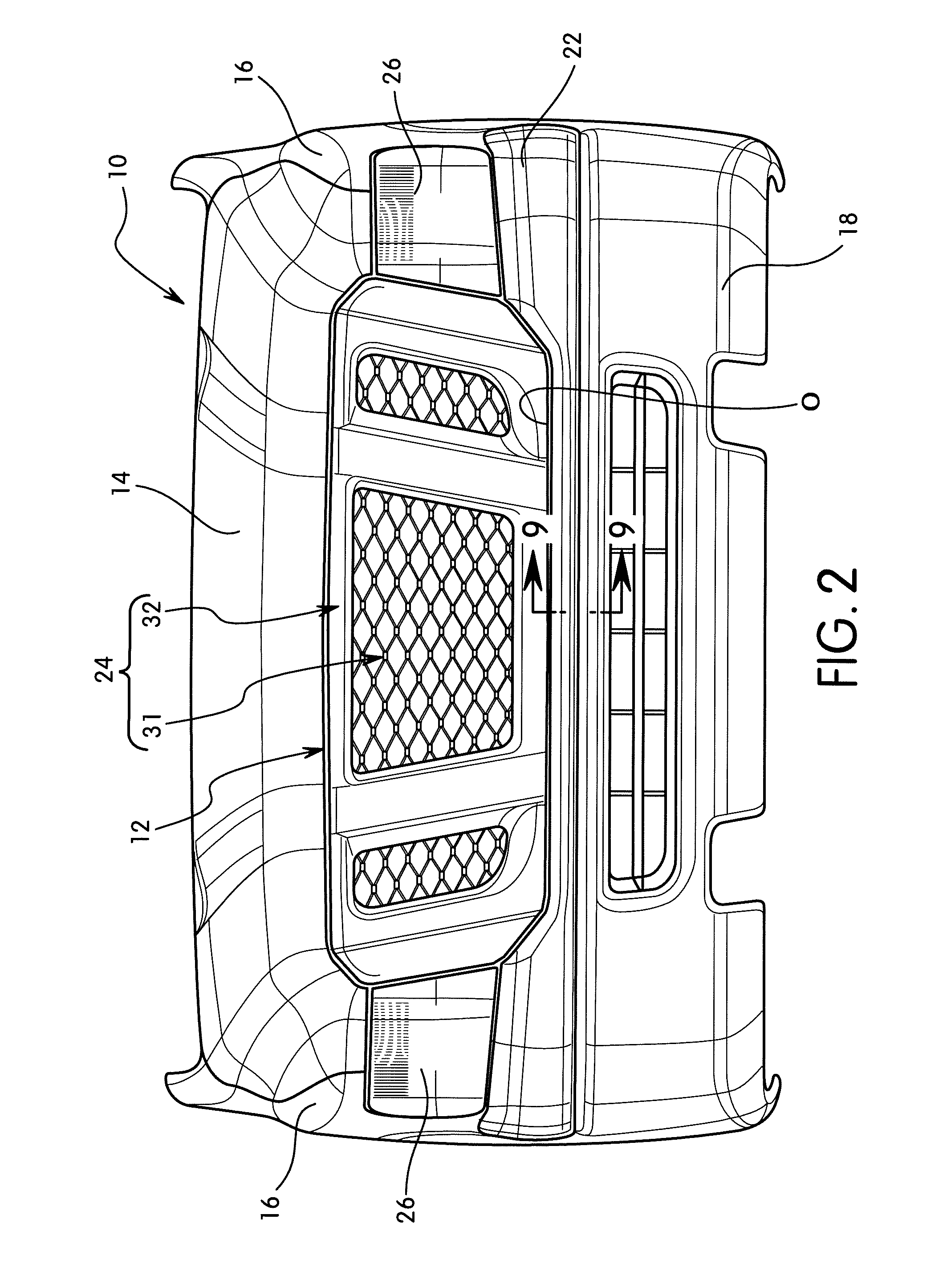

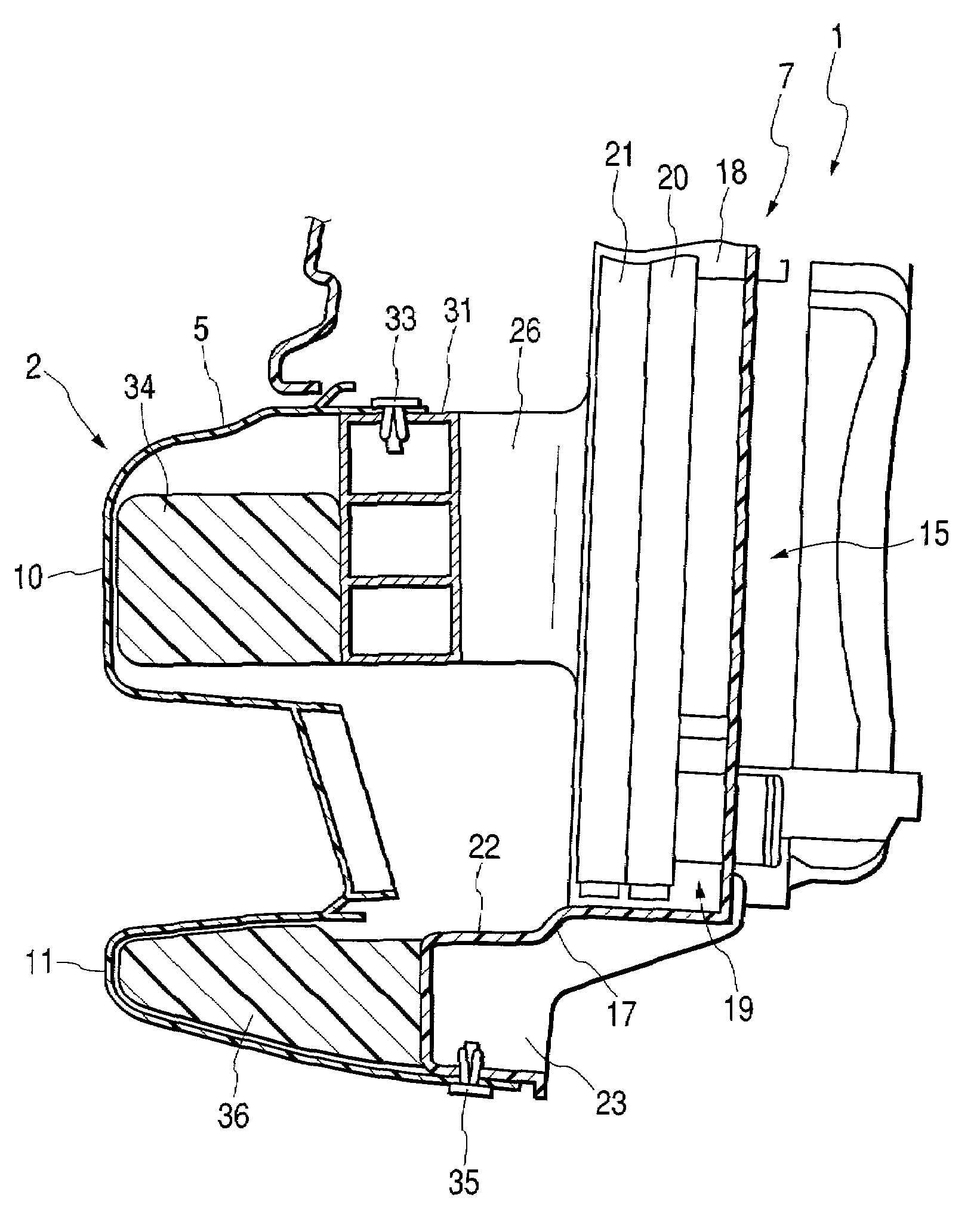

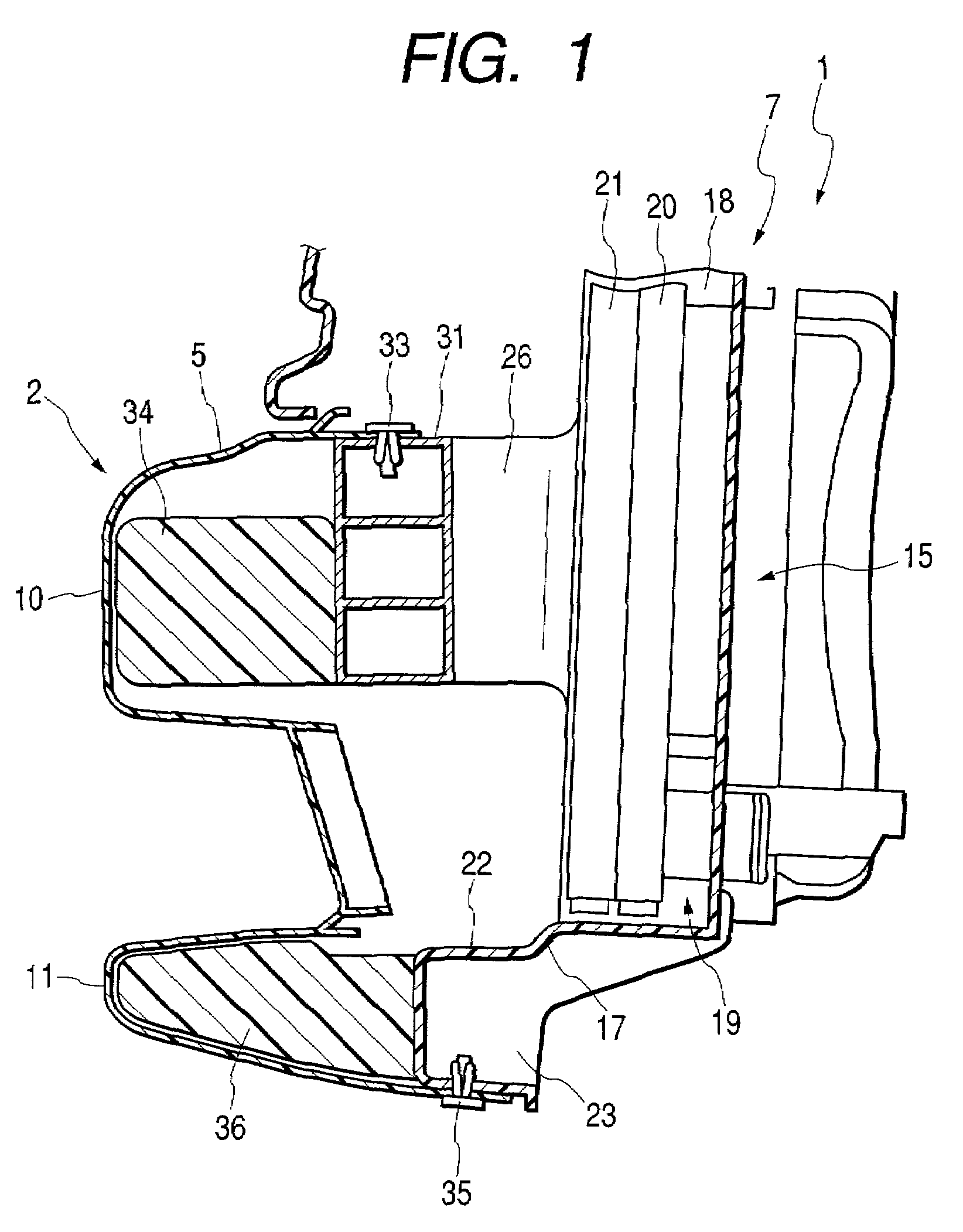

Vehicle end structure

ActiveUS20110204680A1Reduce exposureReduce vehicle qualityVehicle seatsSuperstructure subunitsEngineeringMechanical engineering

A vehicle end structure mainly includes a vehicle bumper fascia and a grille assembly. The vehicle bumper fascia includes a sill portion and a receiving member extending from the sill portion. The receiving member defines a channel with an opening extending in a forward vehicle facing direction. The grille assembly includes inner grille and outer grille members that are coupled together. The inner grille member has a support member formed at a periphery of the inner grille member. The support member is disposed in the channel of the receiving member to limit movement of the inner grille member in a direction normal to the forward vehicle facing direction. The outer grille member is disposed on a forward vehicle facing side of the inner grille member to conceal the support member from view in the first direction.

Owner:NISSAN MOTOR CO LTD

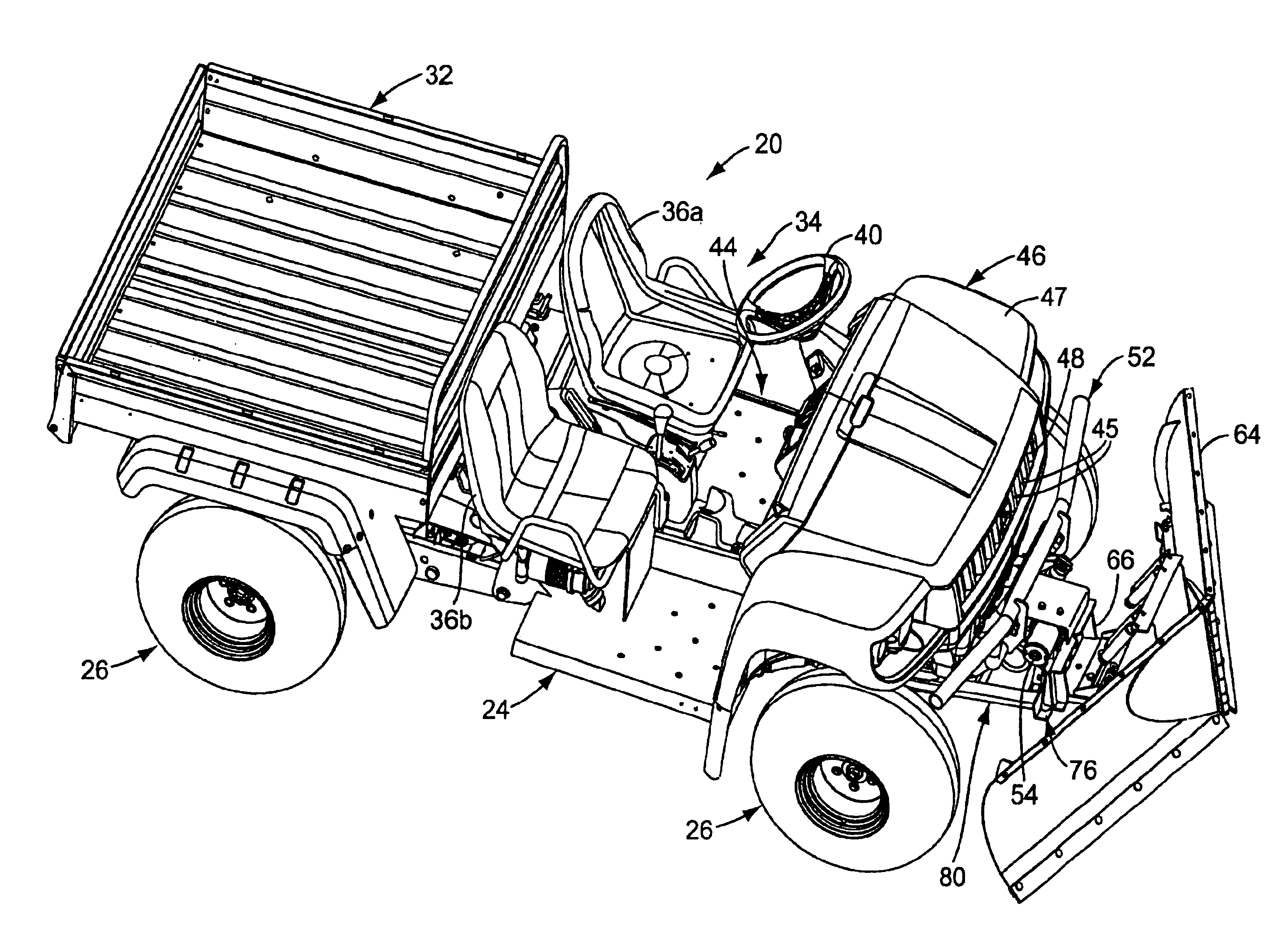

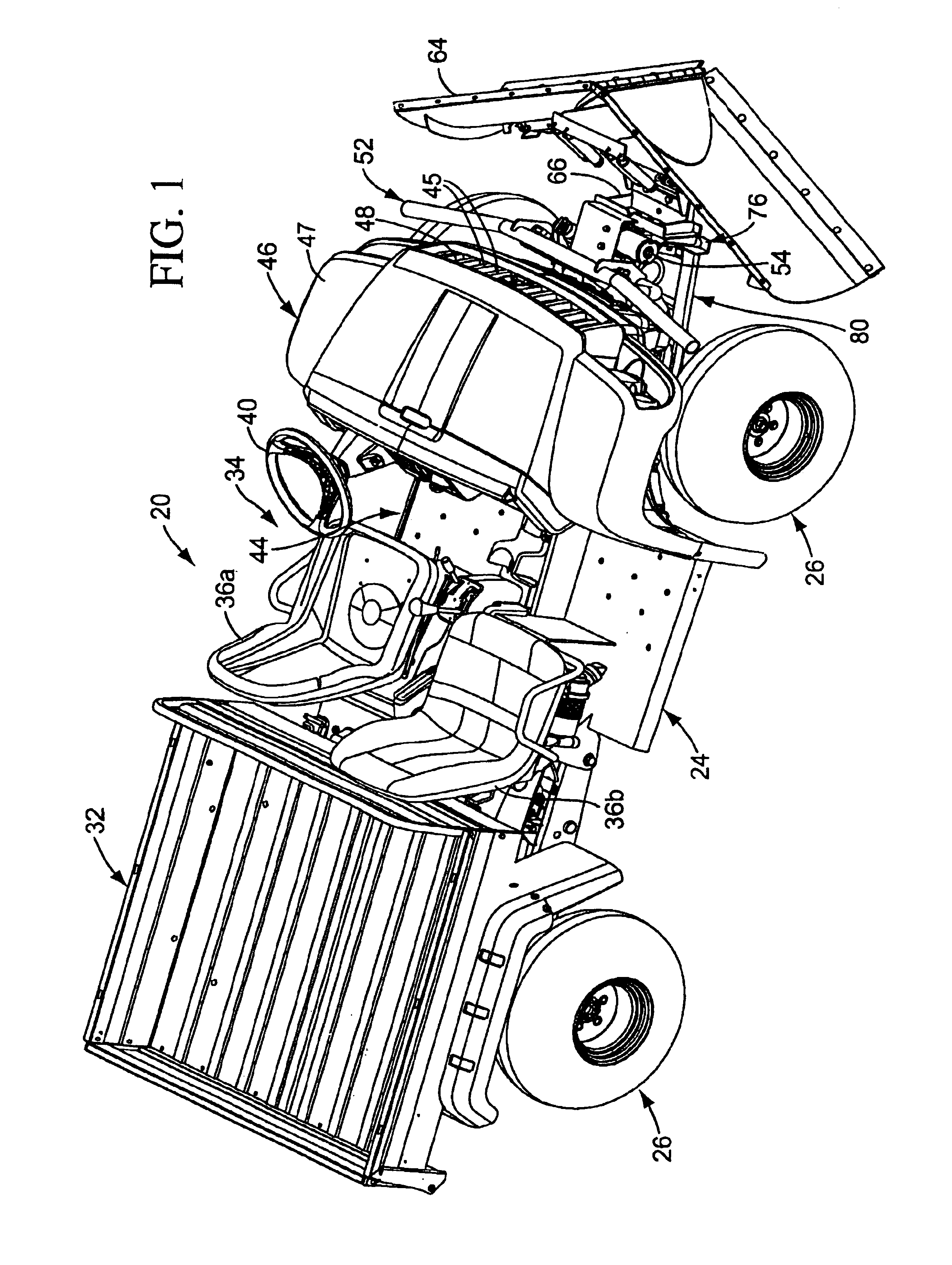

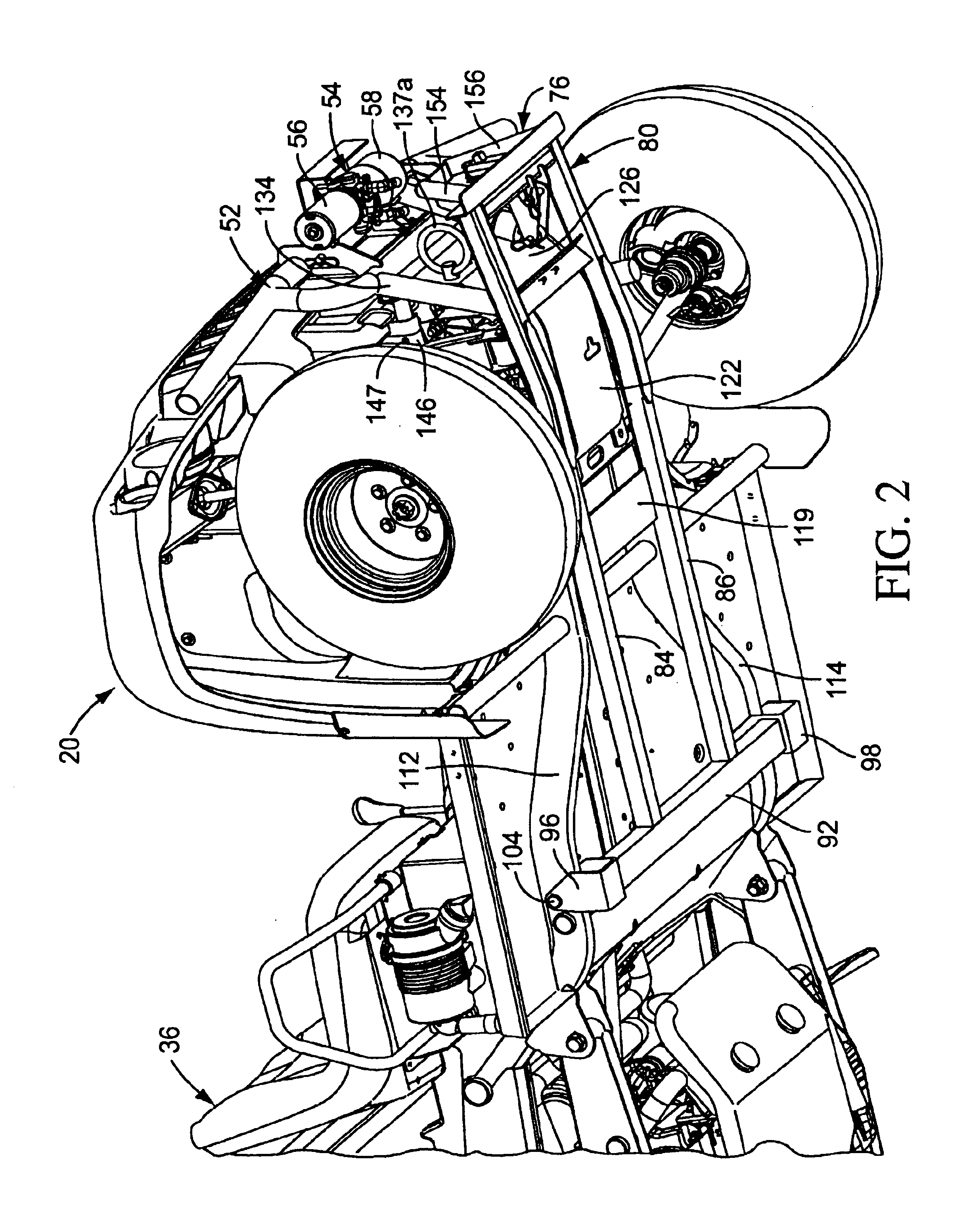

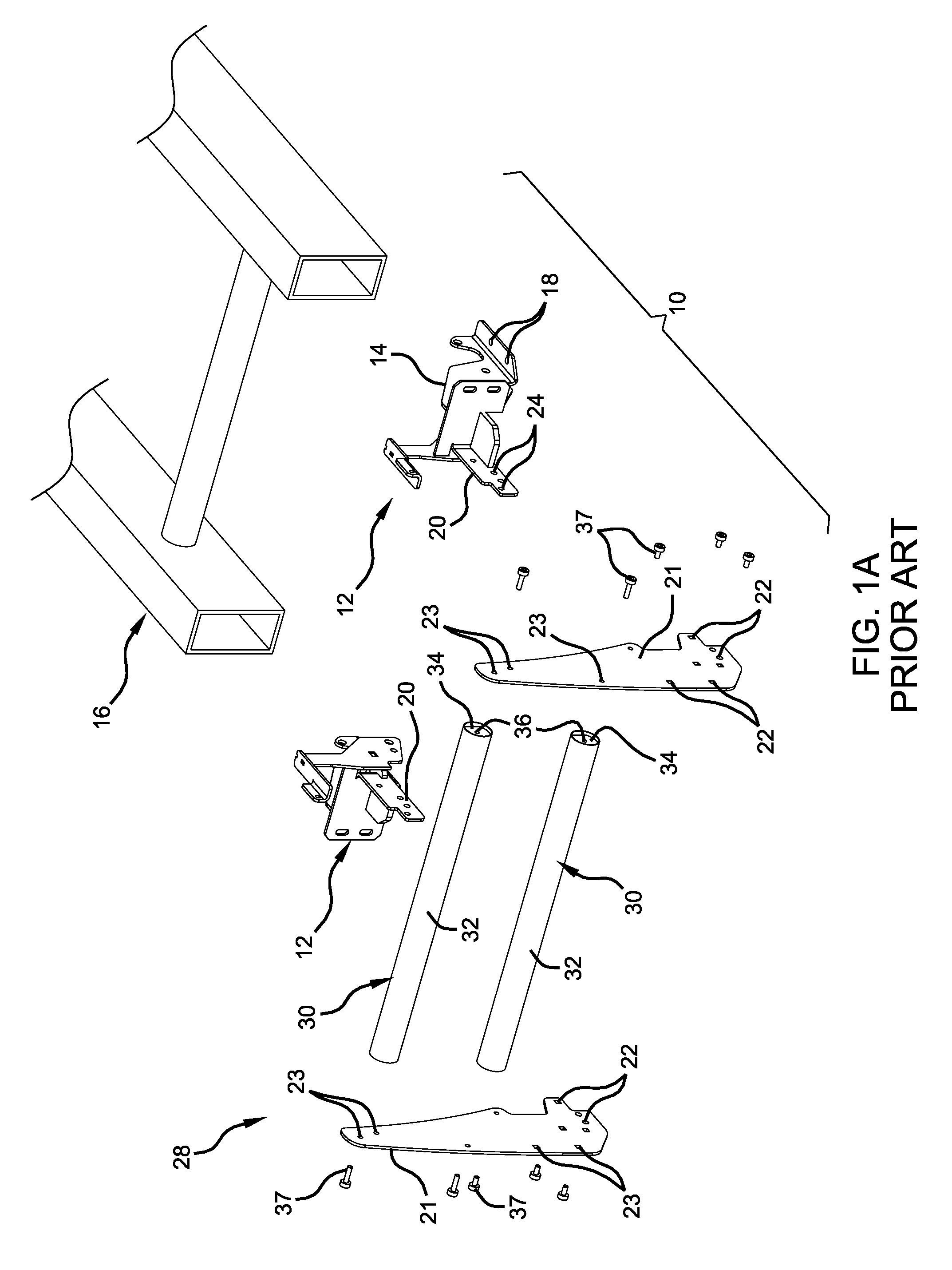

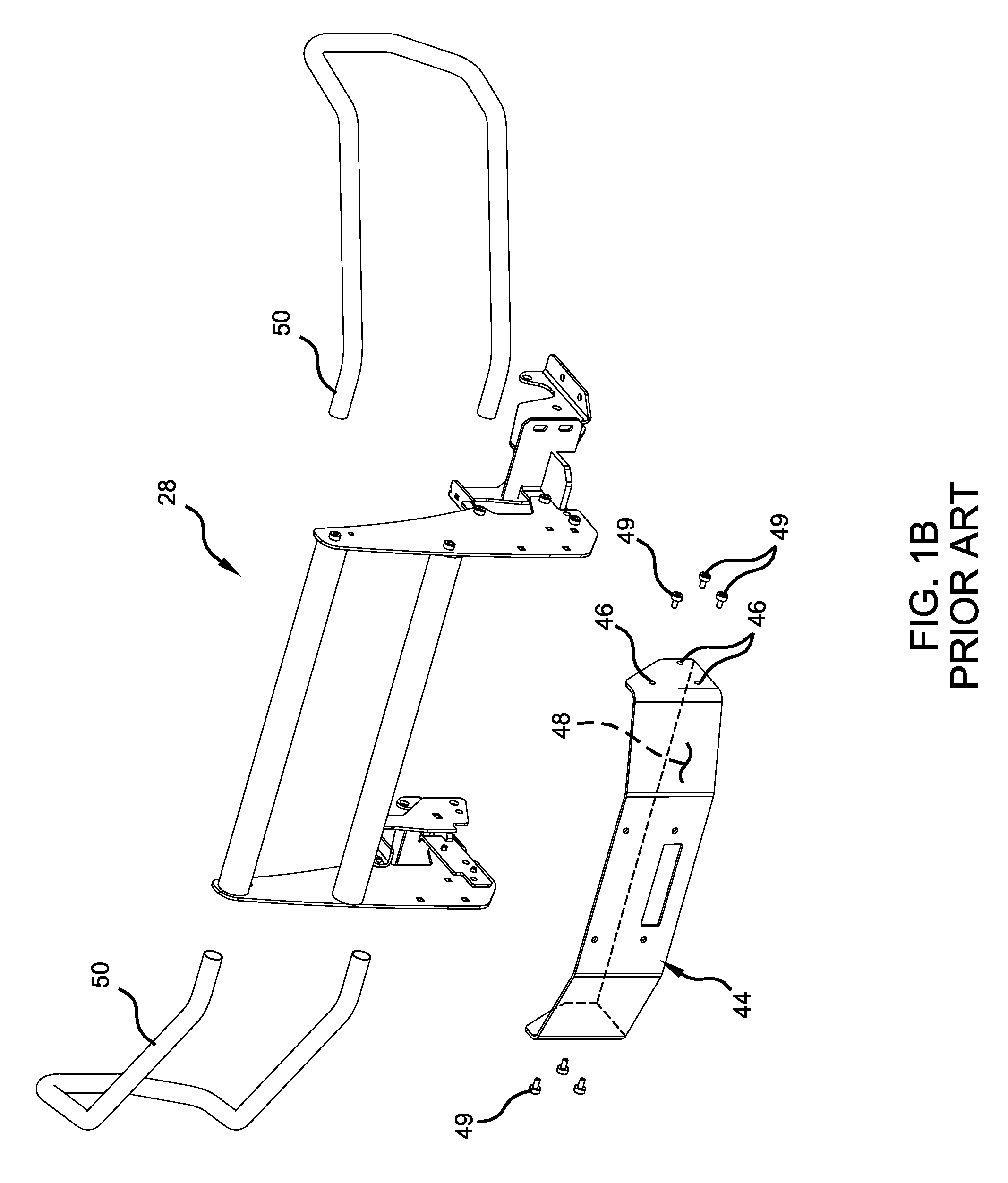

Bumper, skid plate and attachment system for utility vehicle

InactiveUS6925735B2Reduce gapProtect the frontMechanical machines/dredgersTractorsHydraulic cylinderSlide plate

A bumper assembly for a utility vehicle includes both front bumper structure for protecting the front of the vehicle, and skid plate structure to protect lower components of the vehicle from road or terrain hazards, as an integrated part. The bumper assembly includes a protective front structure extending substantially vertically in front of a front end of the vehicle hood, e.g., in front of the radiator of the utility vehicle. The bumper assembly also includes a protective bottom structure extending substantially horizontally beneath the chassis of the utility vehicle. The bumper assembly includes a front plate useful for locating attachments to the vehicle. An implement attachment arrangement includes an elongated structure pivotally connected at a rear of a chassis of the utility vehicle. The elongated structure is connected at a front end thereof to the bumper assembly via a hydraulic cylinder in order to make vertically adjustable the elevation of the front end of the elongated structure. The elongated structure provides an implement mounting bracket or coupling at a front end thereof. An implement having a compatible base is engageable to the implement mounting bracket.

Owner:DEERE & CO

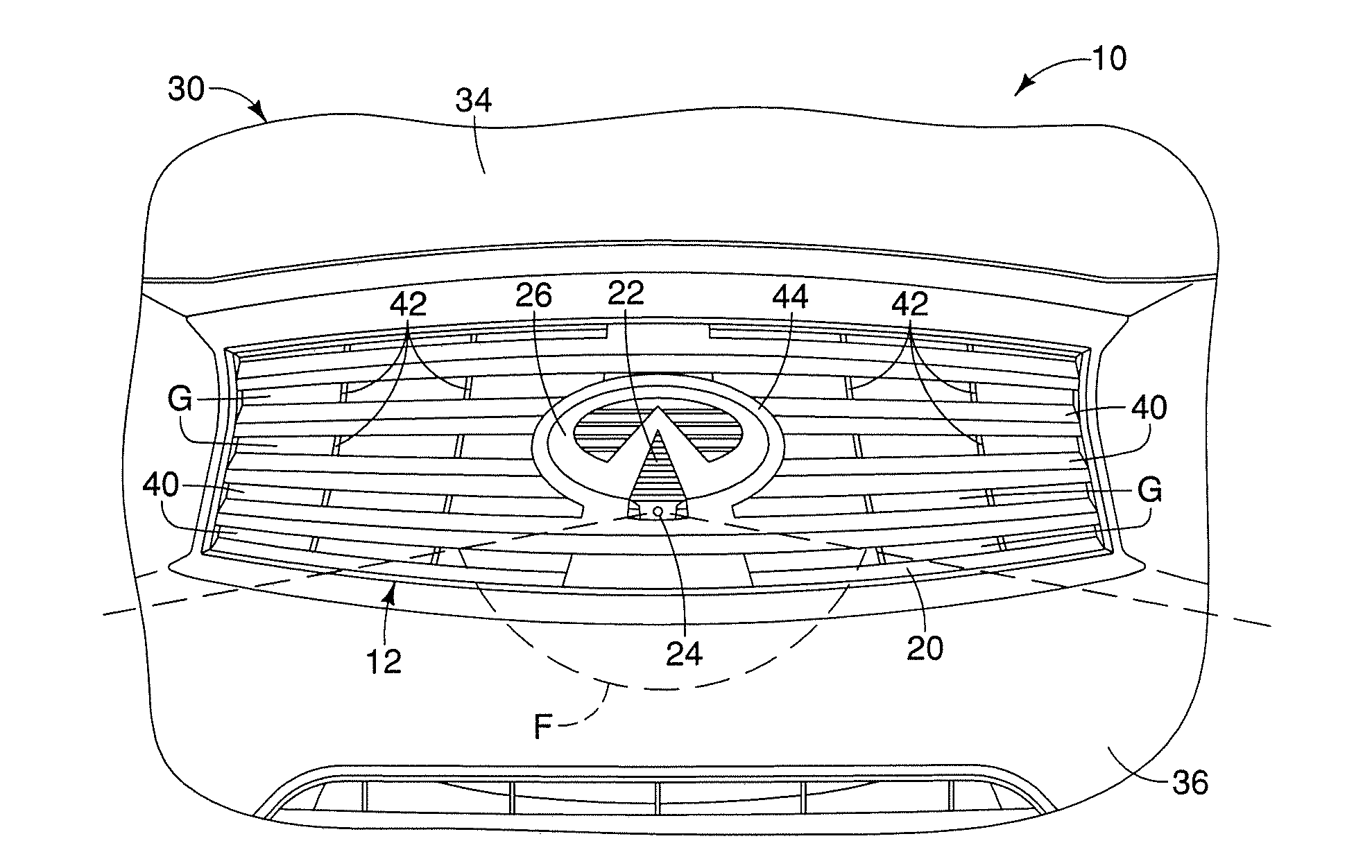

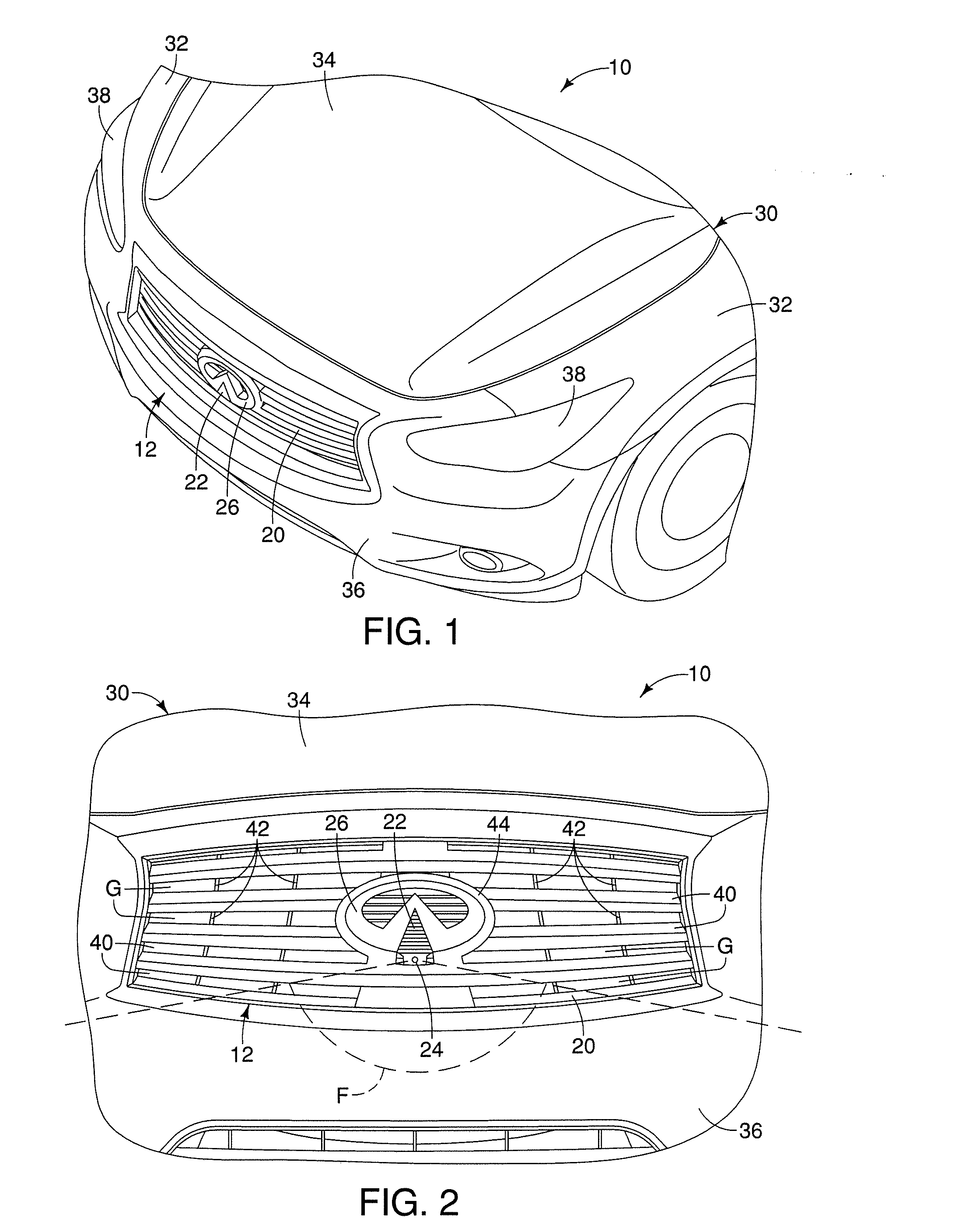

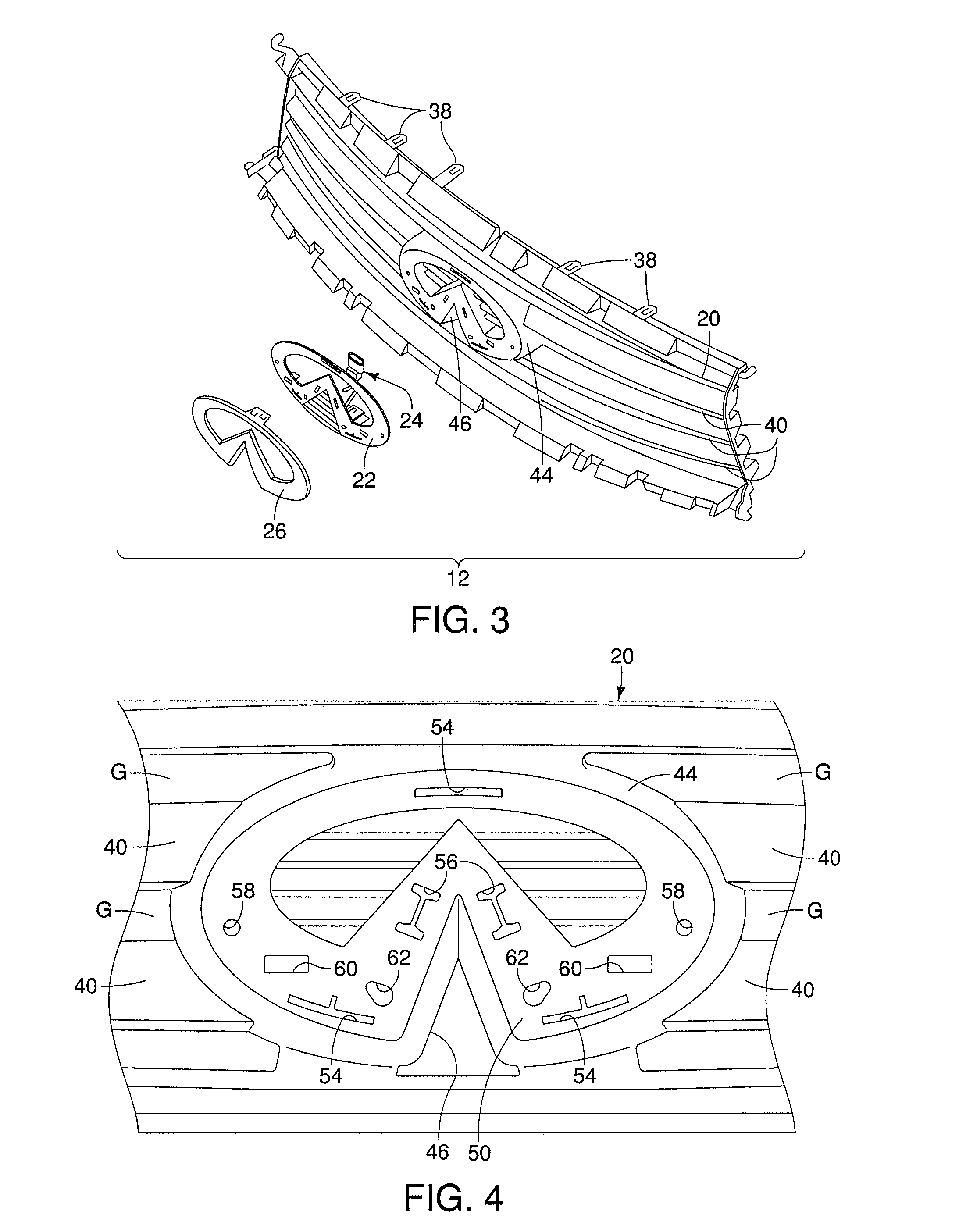

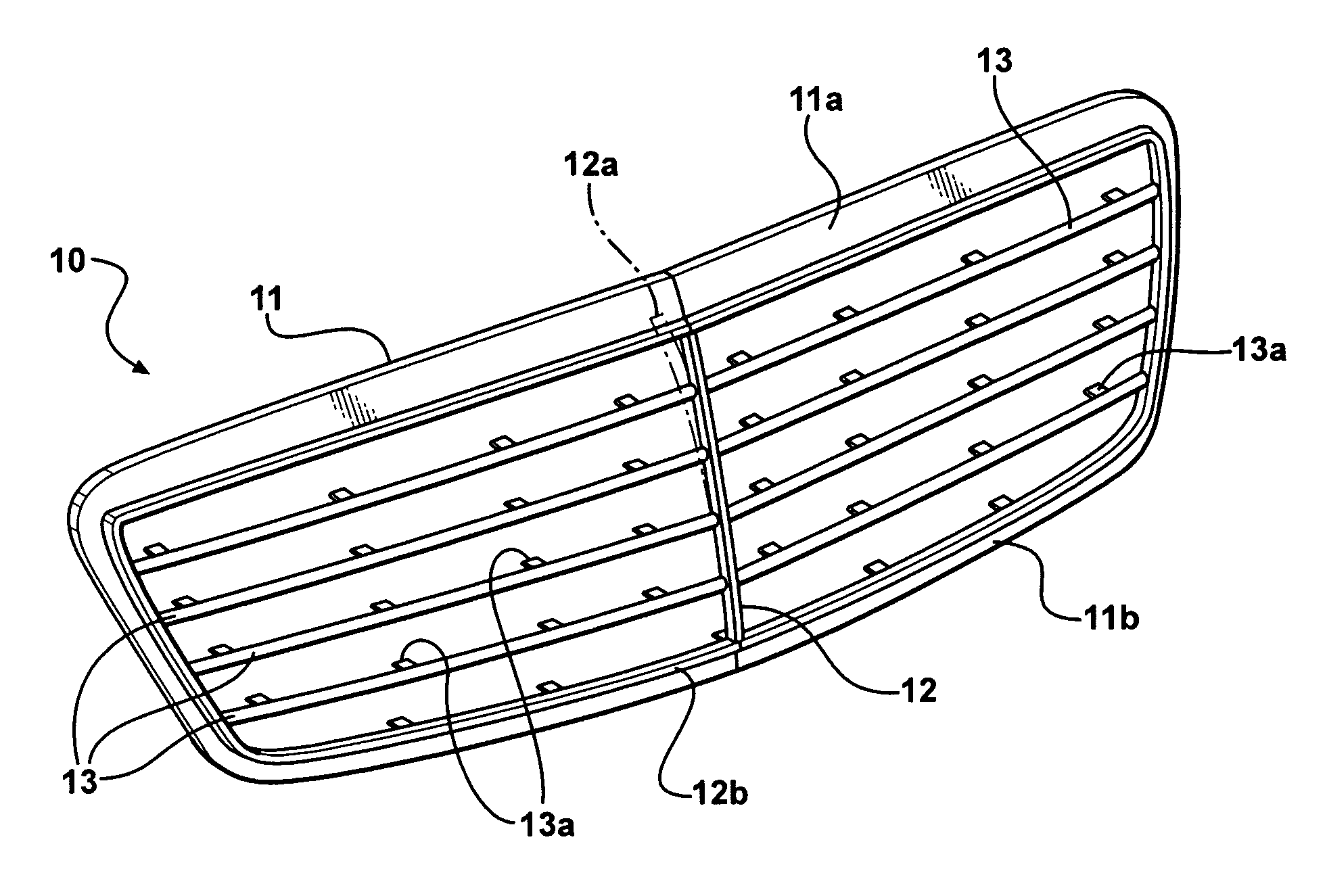

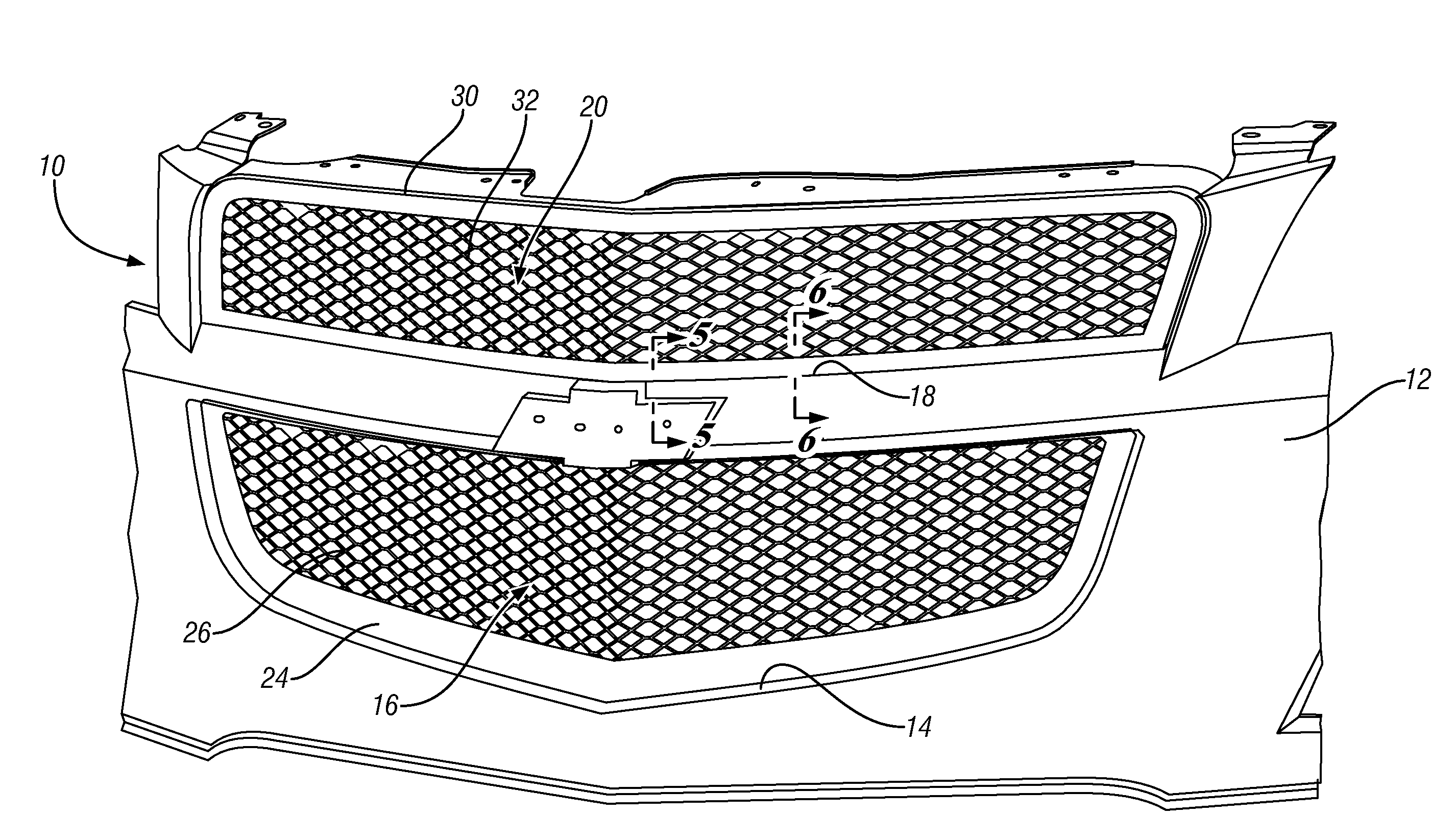

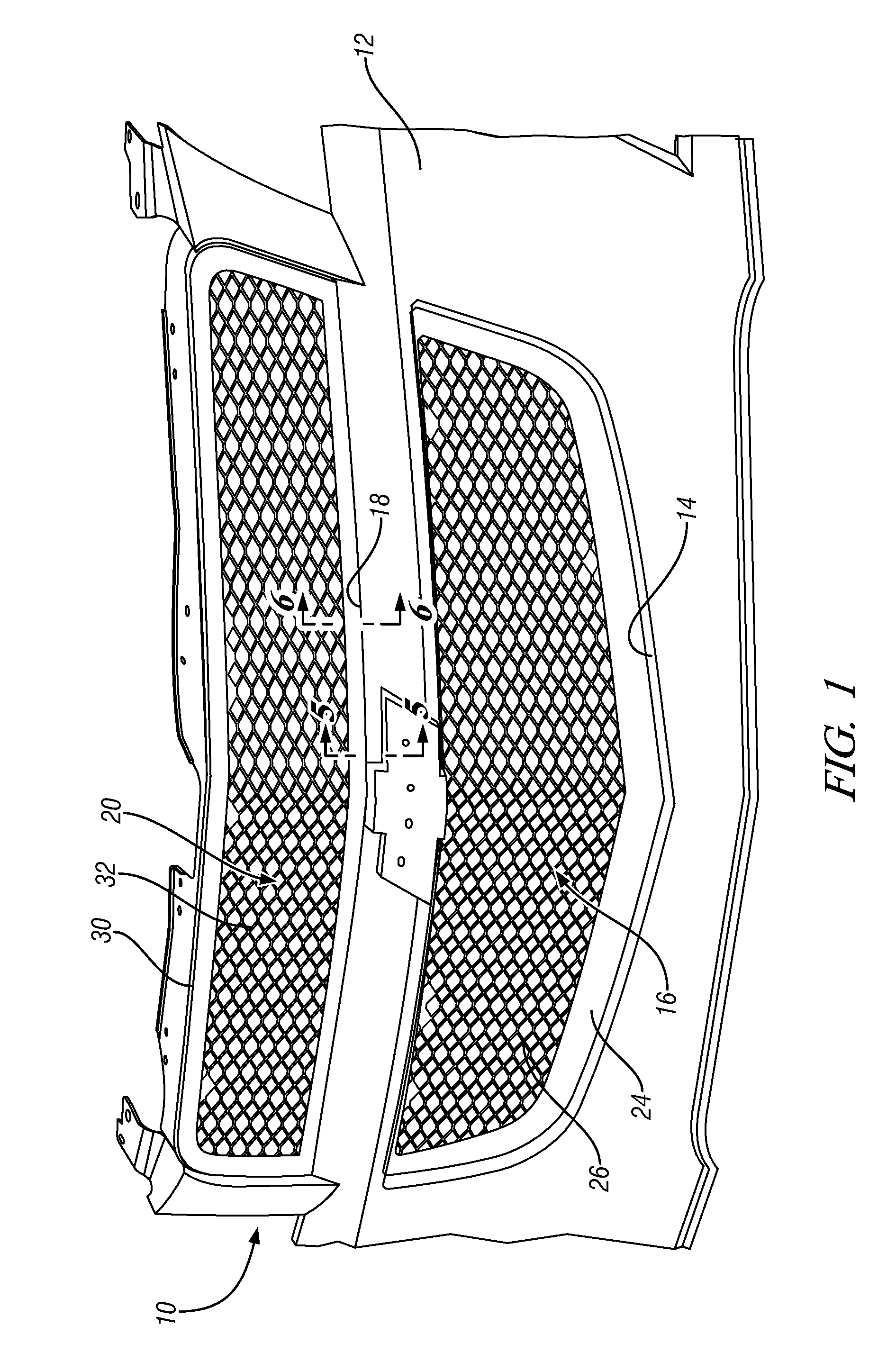

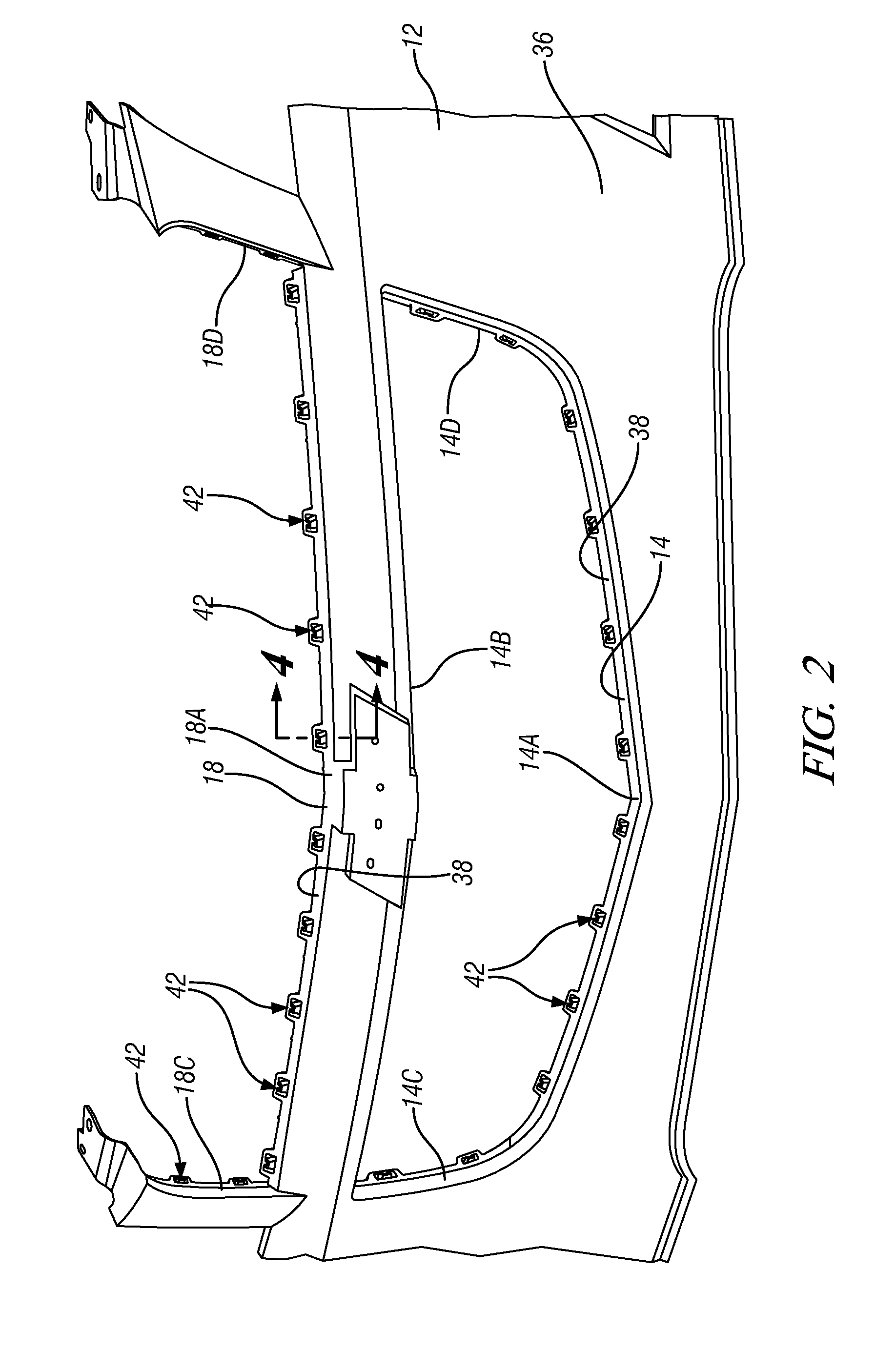

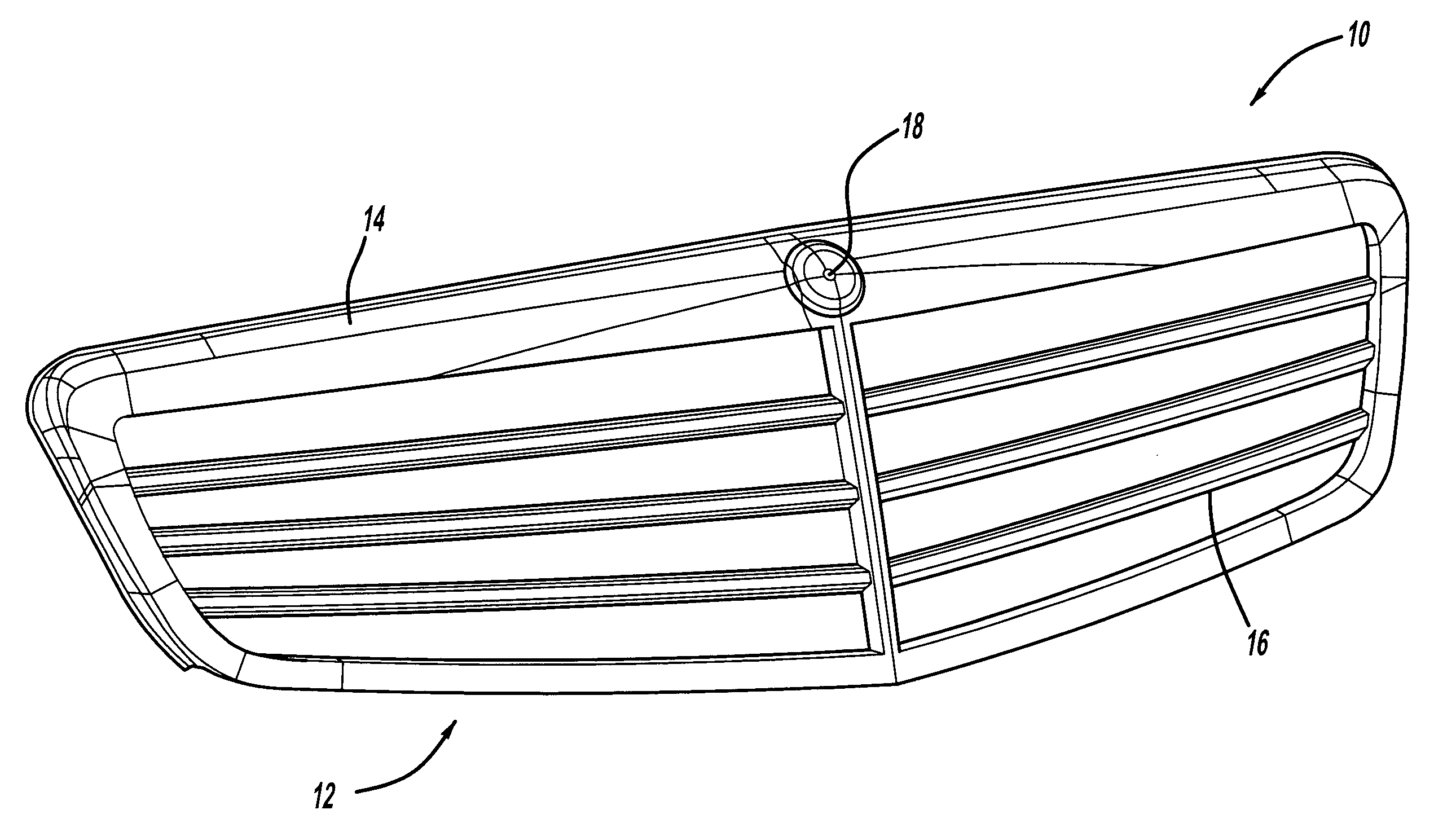

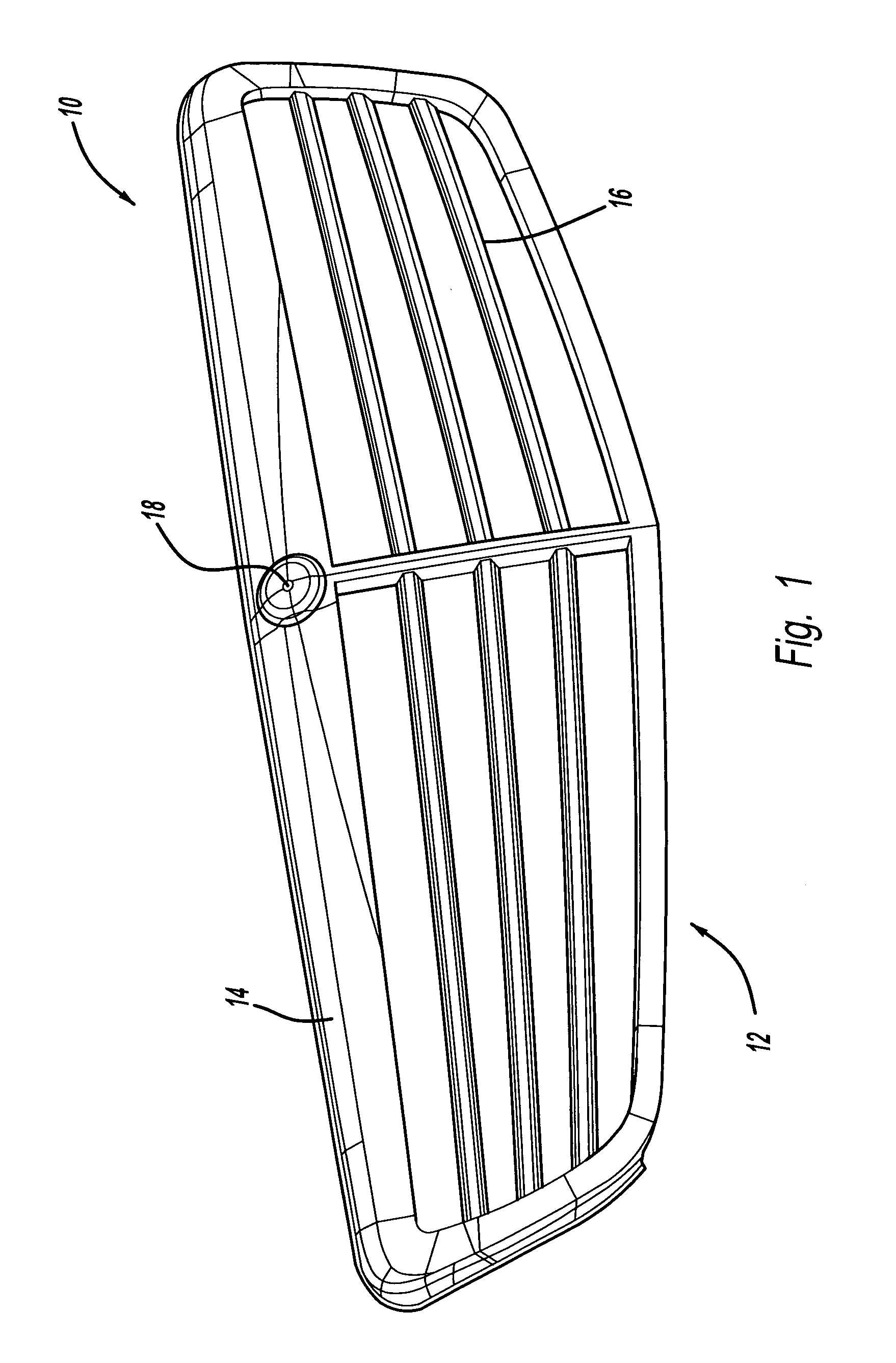

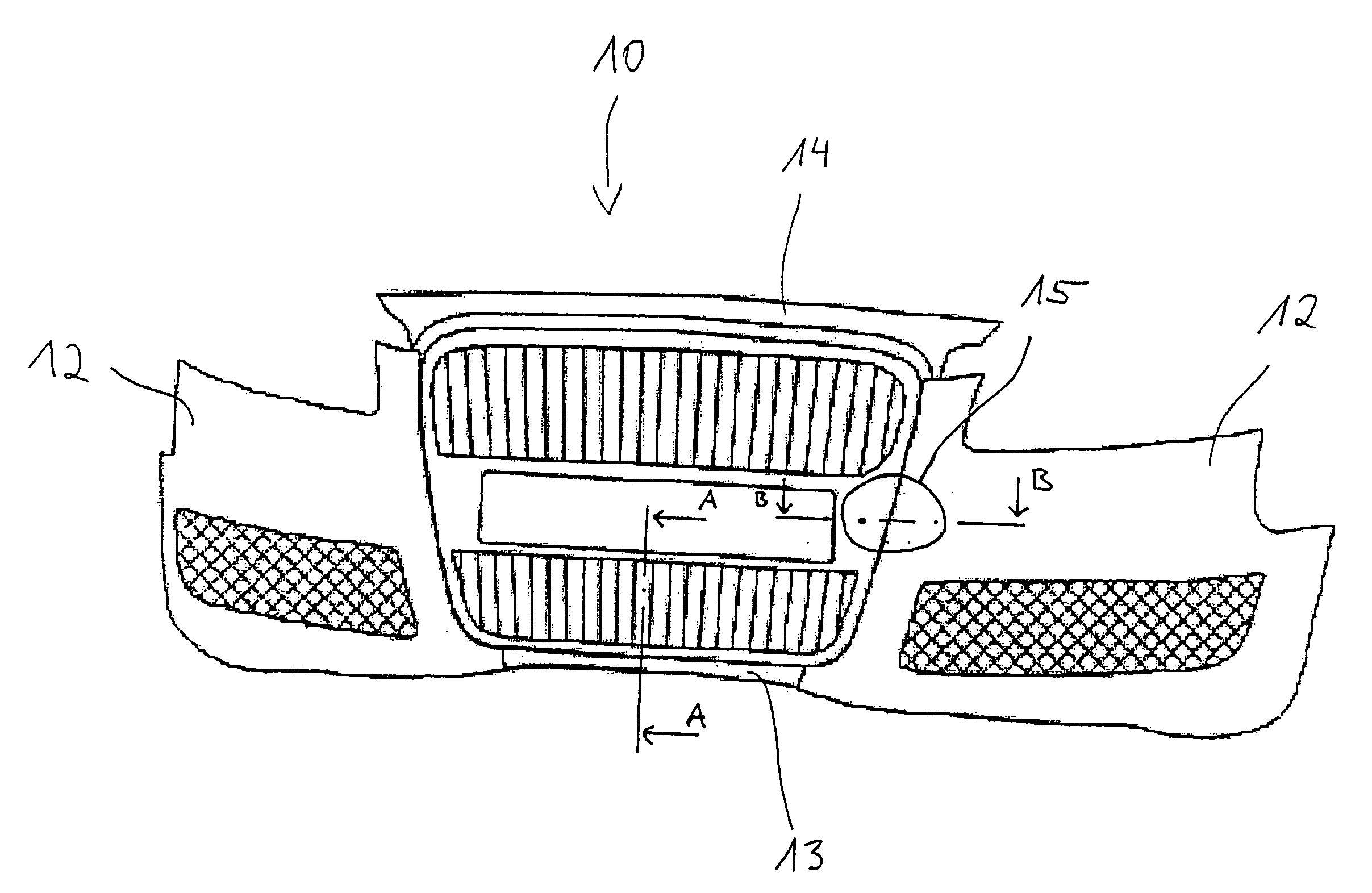

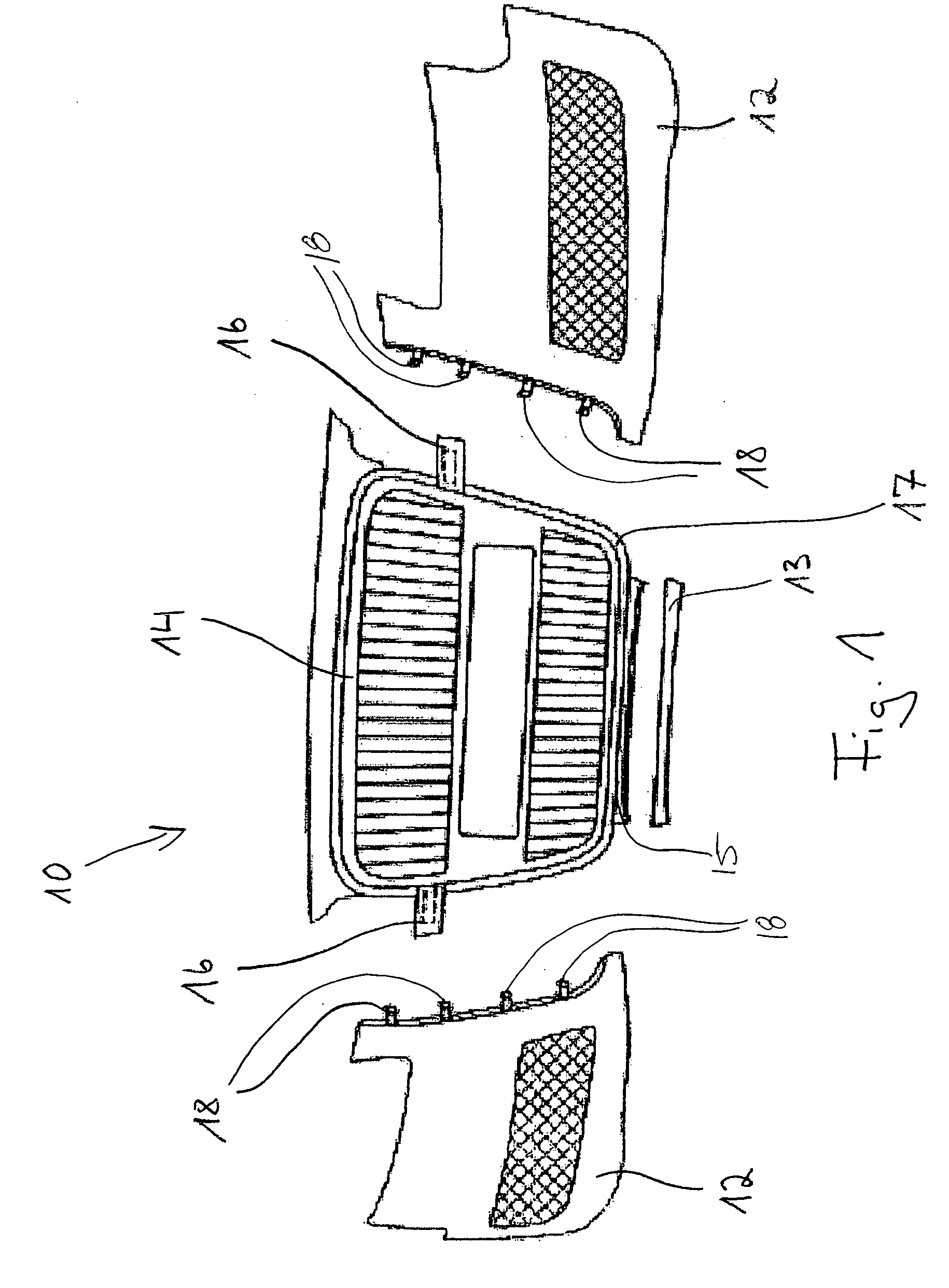

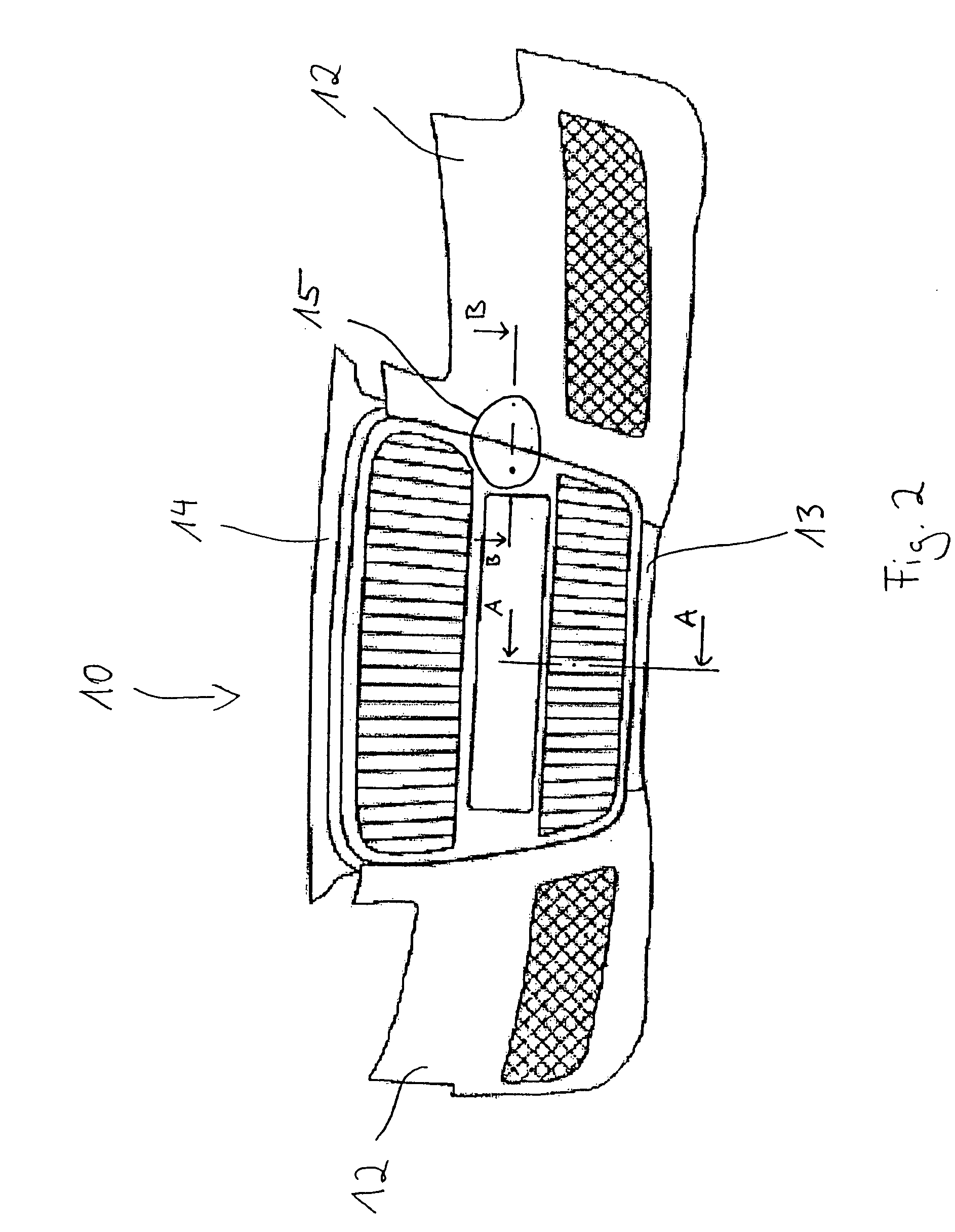

Vehicle front grille assembly

ActiveUS20130107046A1Color television detailsClosed circuit television systemsEngineeringMechanical engineering

A vehicle front grille assembly includes a vehicle grille, an emblem, a camera support and a camera. The vehicle grille includes an emblem mounting portion having a first mounting structure. The emblem includes an outer surface and an inner surface that is opposite the outer surface. The inner surface has a second mounting structure that directly mates with the first mounting structure of the emblem mounting portion. The camera support has an attachment portion and an extension portion. The attachment portion is sandwiched between the emblem mounting portion of the vehicle grille and the inner surface of the emblem. The attachment portion includes at least one opening and one of the first and second mounting structures extends through the at least one opening of the attachment portion. The camera is fixedly mounted to the extension portion of the camera support.

Owner:NISSAN MOTOR CO LTD

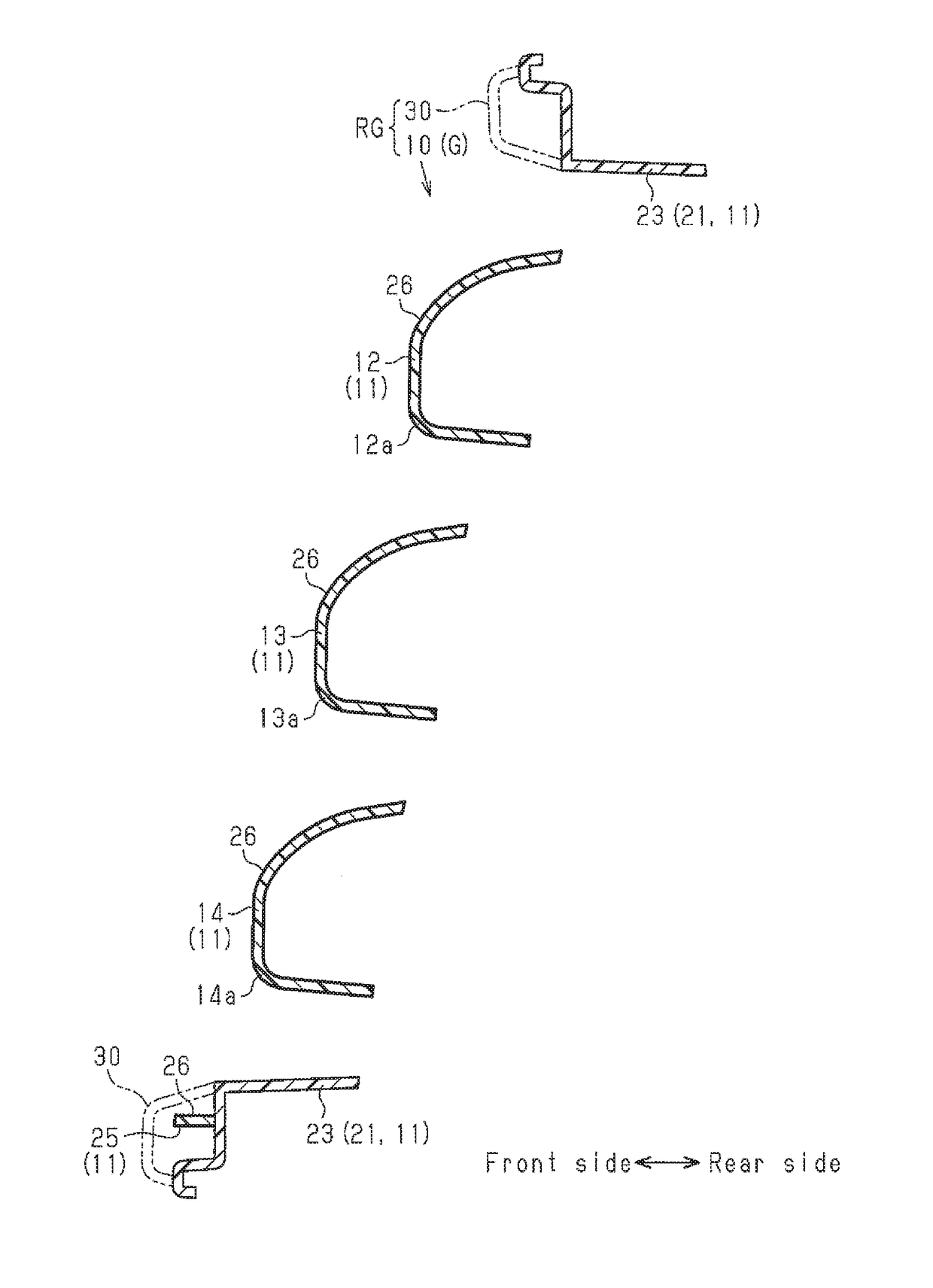

Plated resin product and method for manufacturing plated resin product

ActiveUS20170137954A1Lower aesthetic appealIncrease volumeElectrolysis componentsLiquid/solution decomposition chemical coatingEngineeringElectroplating

A plated resin product includes a resin base including main plated portions and an auxiliary plated portion and metal films respectively arranged on the main plated portions and the auxiliary plated portion. The main plated portions are arranged next to one another. One of the two main plated portions located at two ends in a direction in which the main plated portions are arranged includes an edge at a portion located at a side of the main plated portion that is far from an adjacent one of the main plated portions. The auxiliary plated portion is located farther from the adjacent main plated portion than the main plated portion including the edge and spaced apart from that main plated portion. The metal film on the auxiliary plated portion is located at a section of the auxiliary plated portion that is non-visible when the product is viewed from the front.

Owner:TOYODA GOSEI CO LTD

Radiator grille for mounting in a radiator grille arrangement and method of producing it

Owner:LUCIDITY ENTERPRISE +1

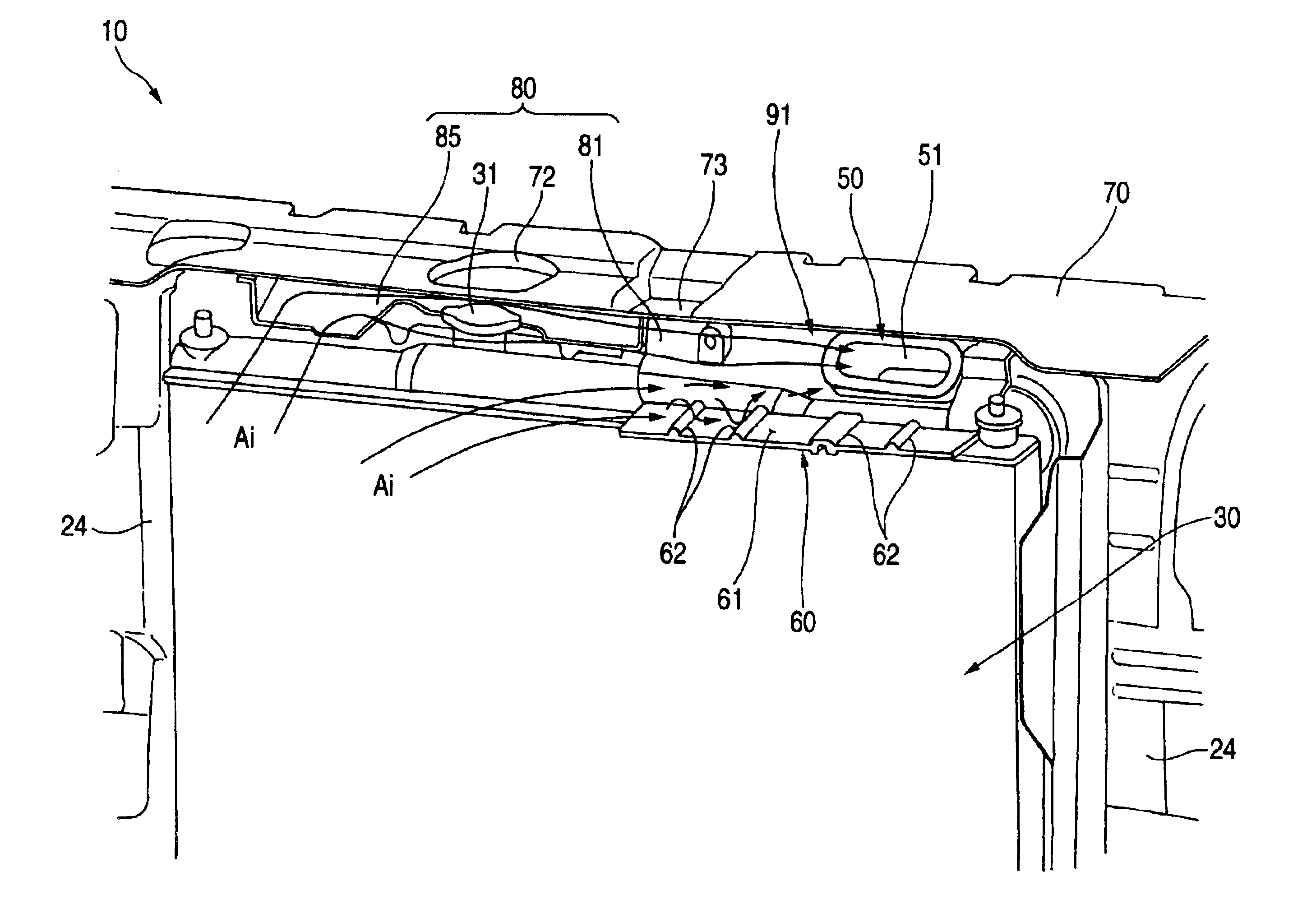

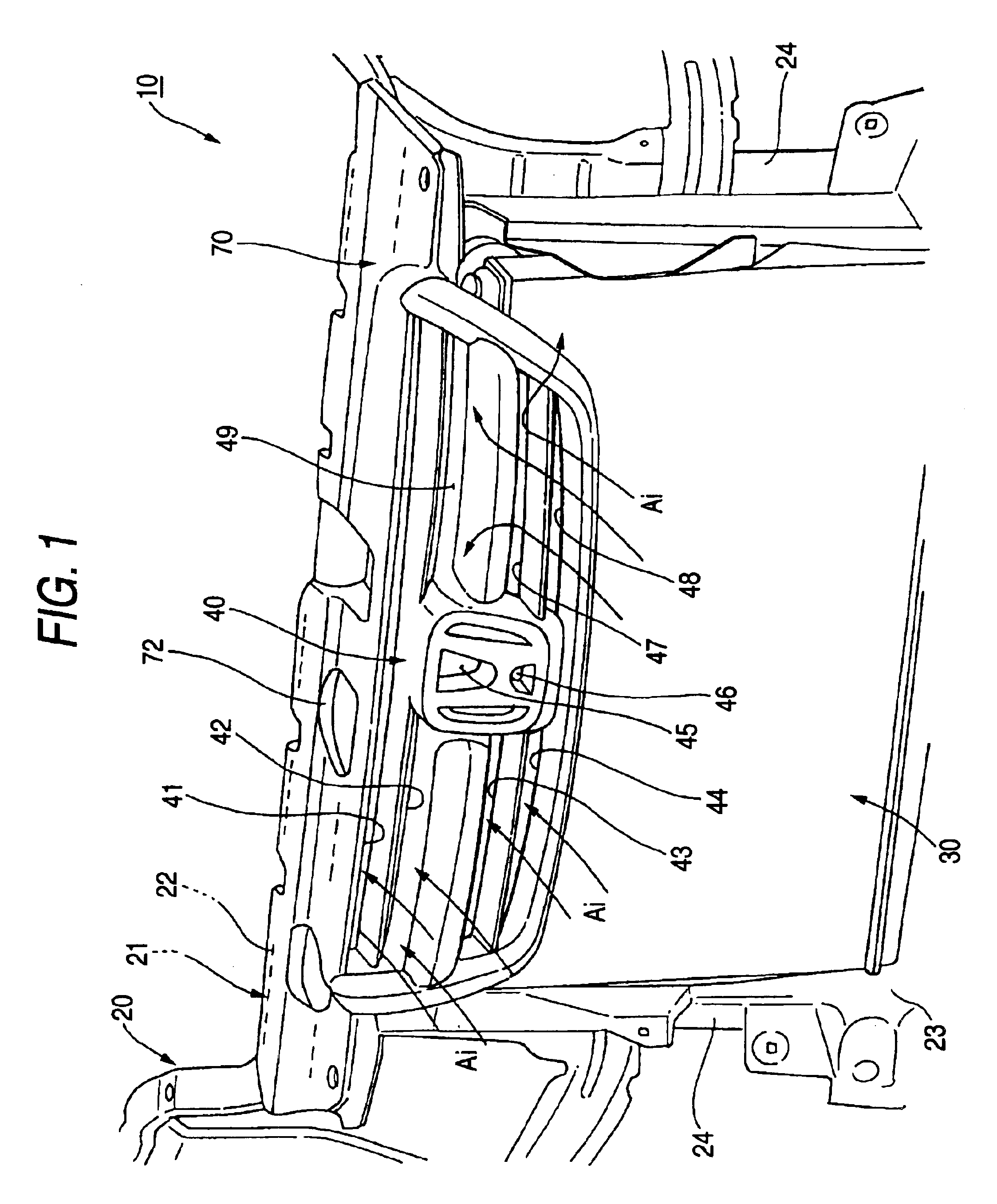

Air-intake structure around front grille for vehicle

InactiveUS6880655B2Good effectSimple structureVehicle seatsSuperstructure subunitsAerospace engineering

Owner:HONDA MOTOR CO LTD

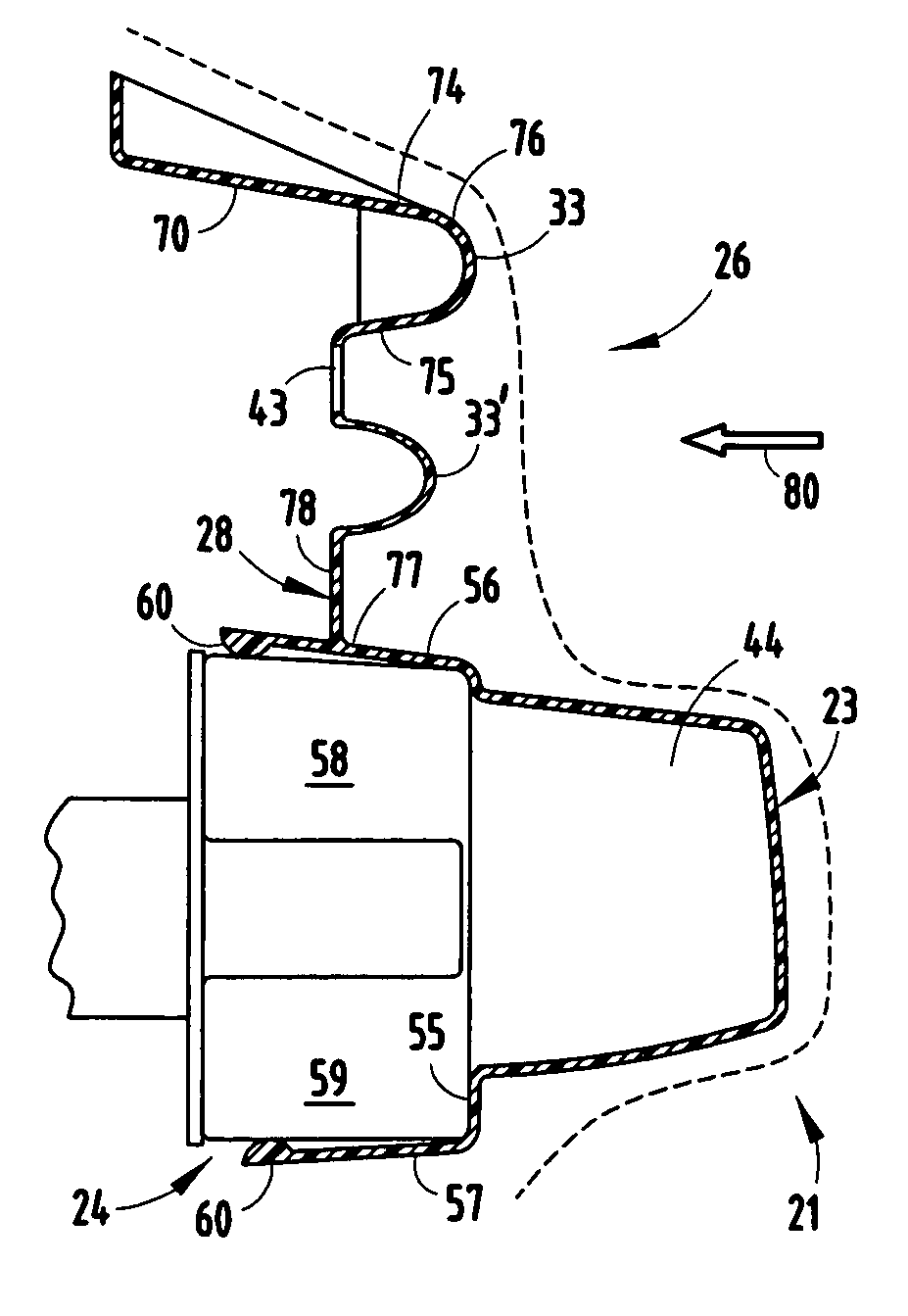

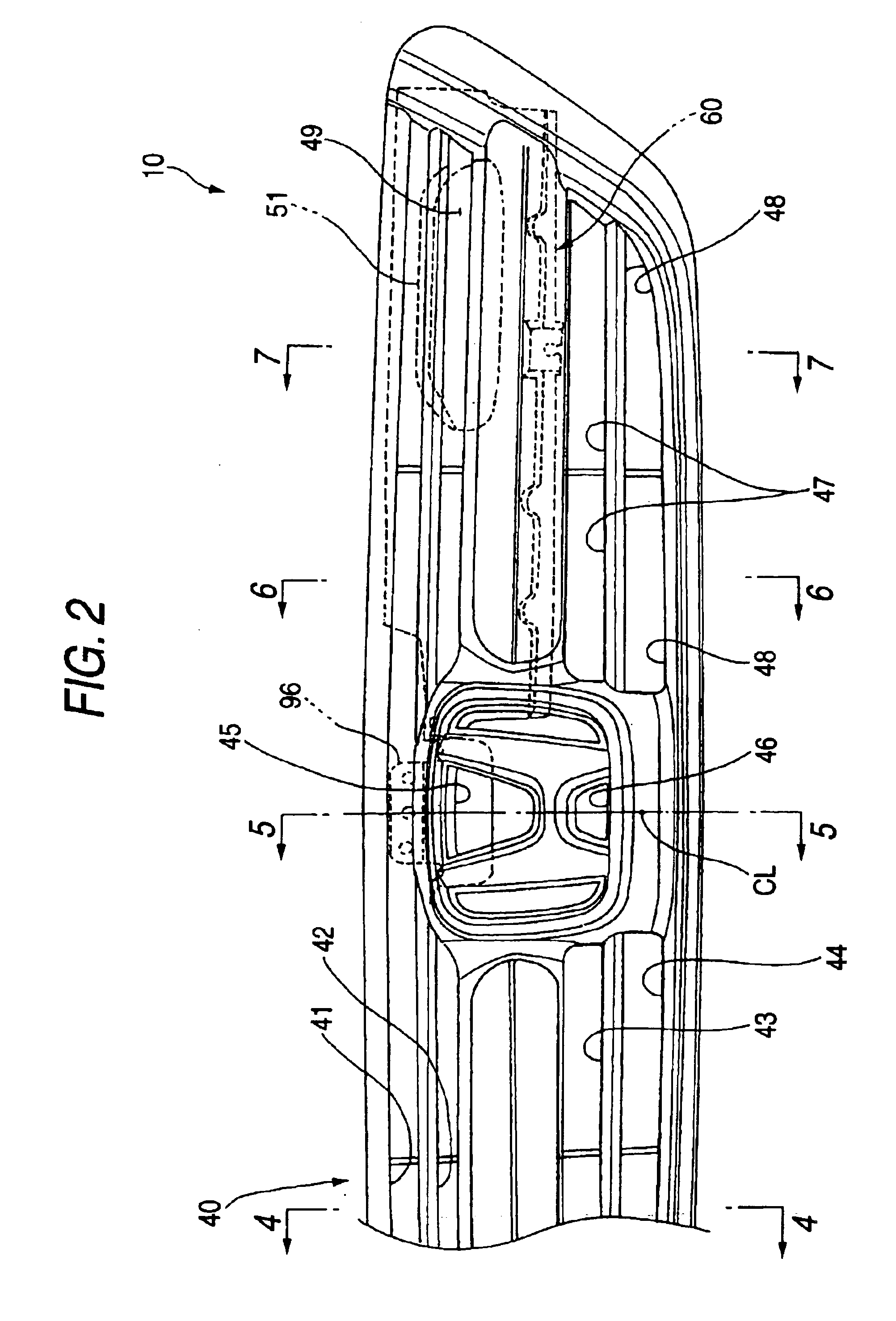

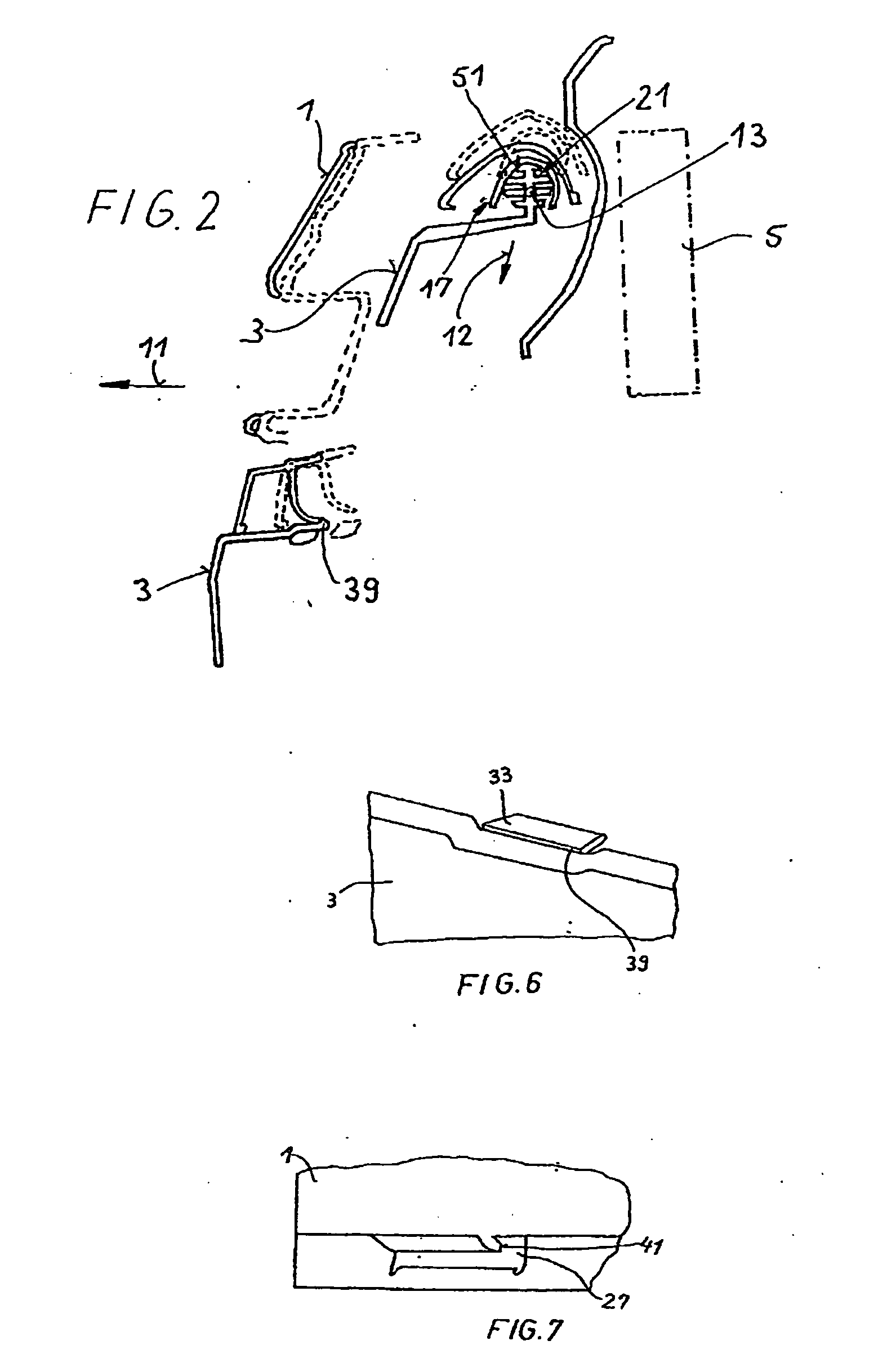

Vehicle Fascia and Grille Assembly

Vehicle fascia assembly includes a plastic fascia panel and a grille frame. The fascia panel has a grille opening defined by a flange extending rearward from the show surface toward the back side of the fascia panel. The flange has a plurality of flexure fingers at spaced intervals along the flange. The grille frame has a forward facing show surface and has a C-shaped channel molded around the outer edge of the show surface. Upon the assembly of the grille frame onto the backside of the fascia panel, the spaced apart channel legs fit onto the flange and the flexure fingers are biased and then engage with an abutment face on the grille frame, thereby attaching the grille frame onto the back side of the fascia panel without exposing the show surface of the fascia panel to injury by the grille frame during the assembly operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

Emblem for motor vehicle

InactiveUS20060237995A1Considerable costNot easy to be stolenVehicle seatsDashboardsSurface finishMultiple forms

Owner:DECOMA GERMANY

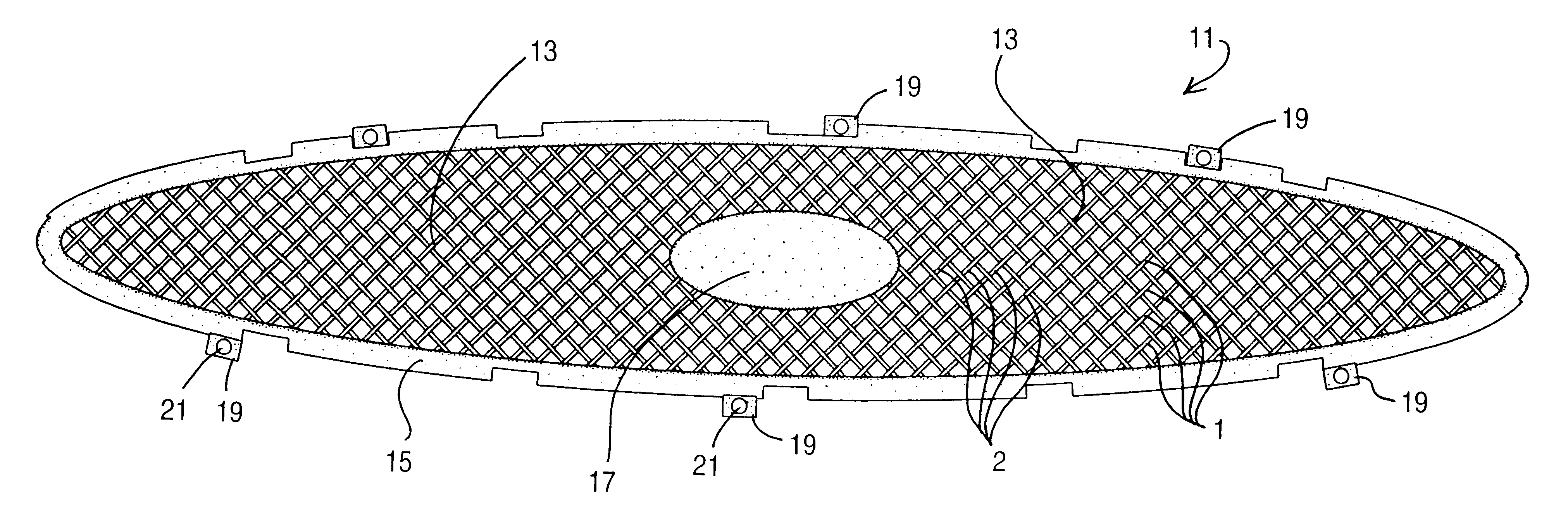

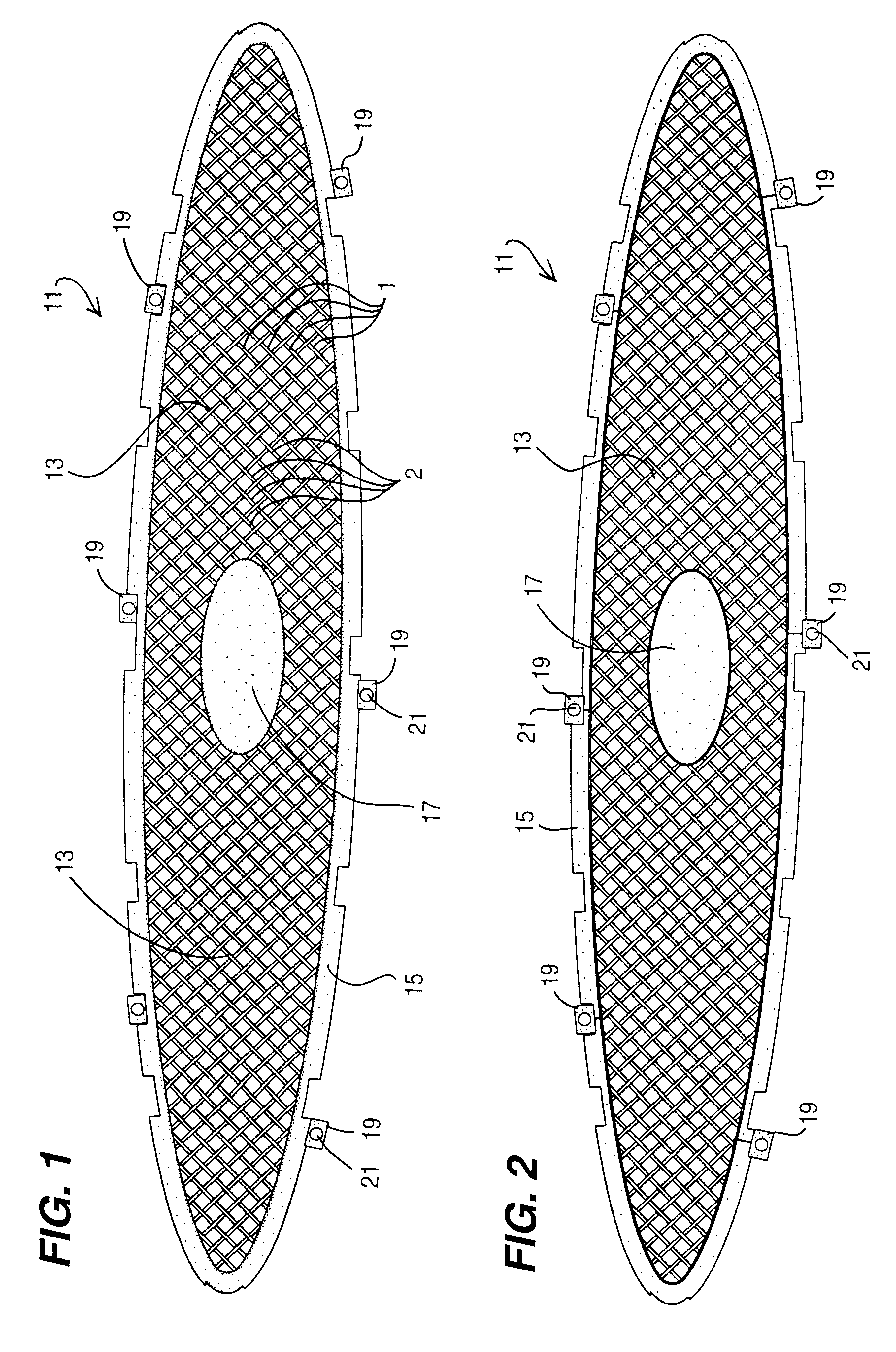

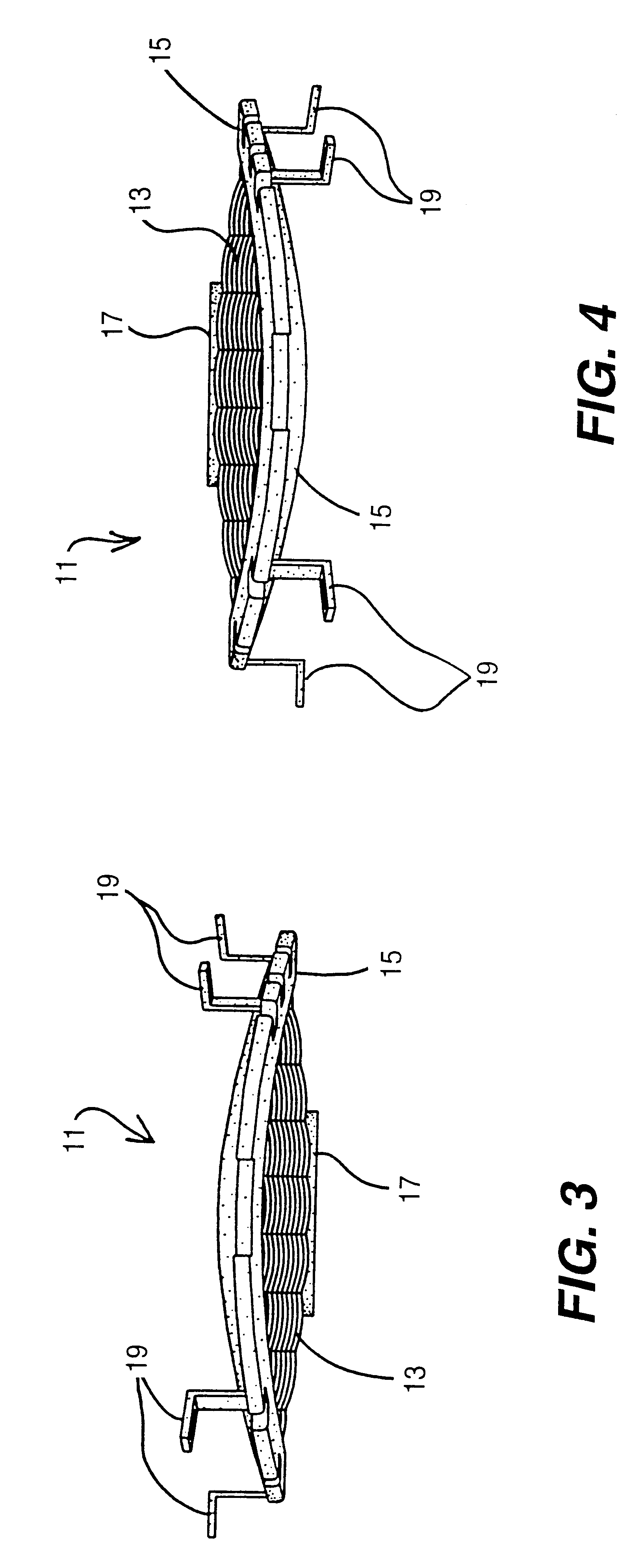

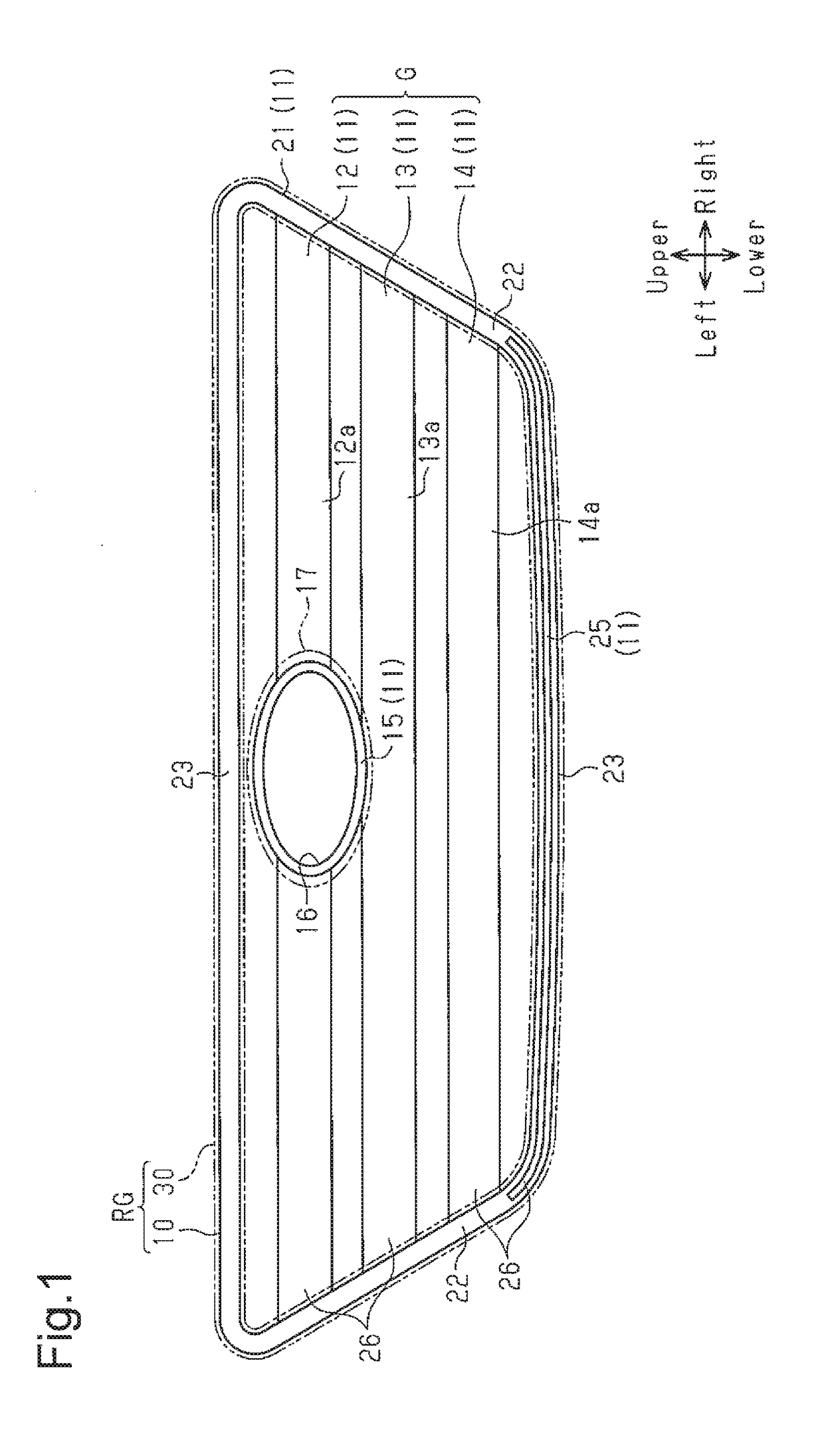

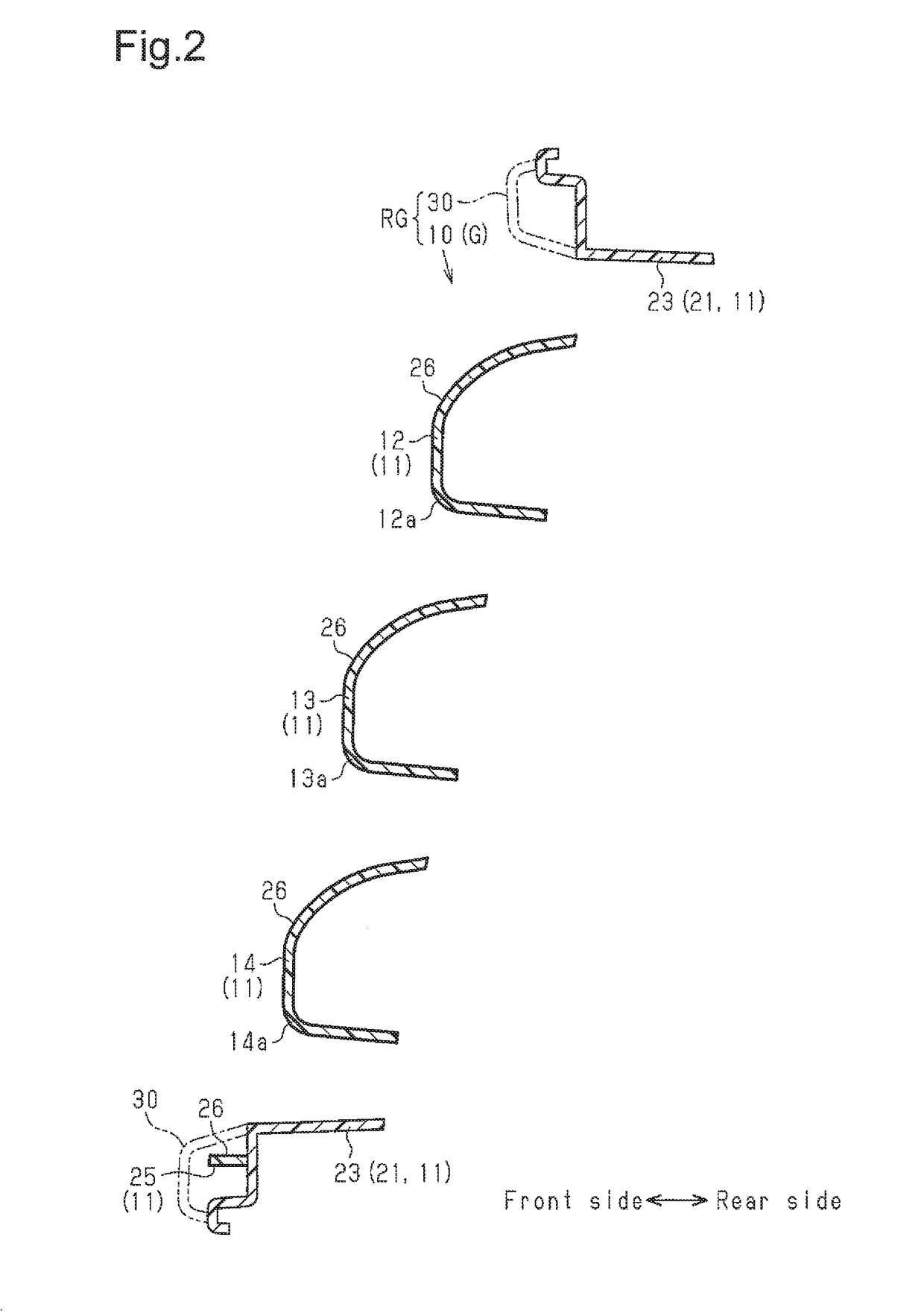

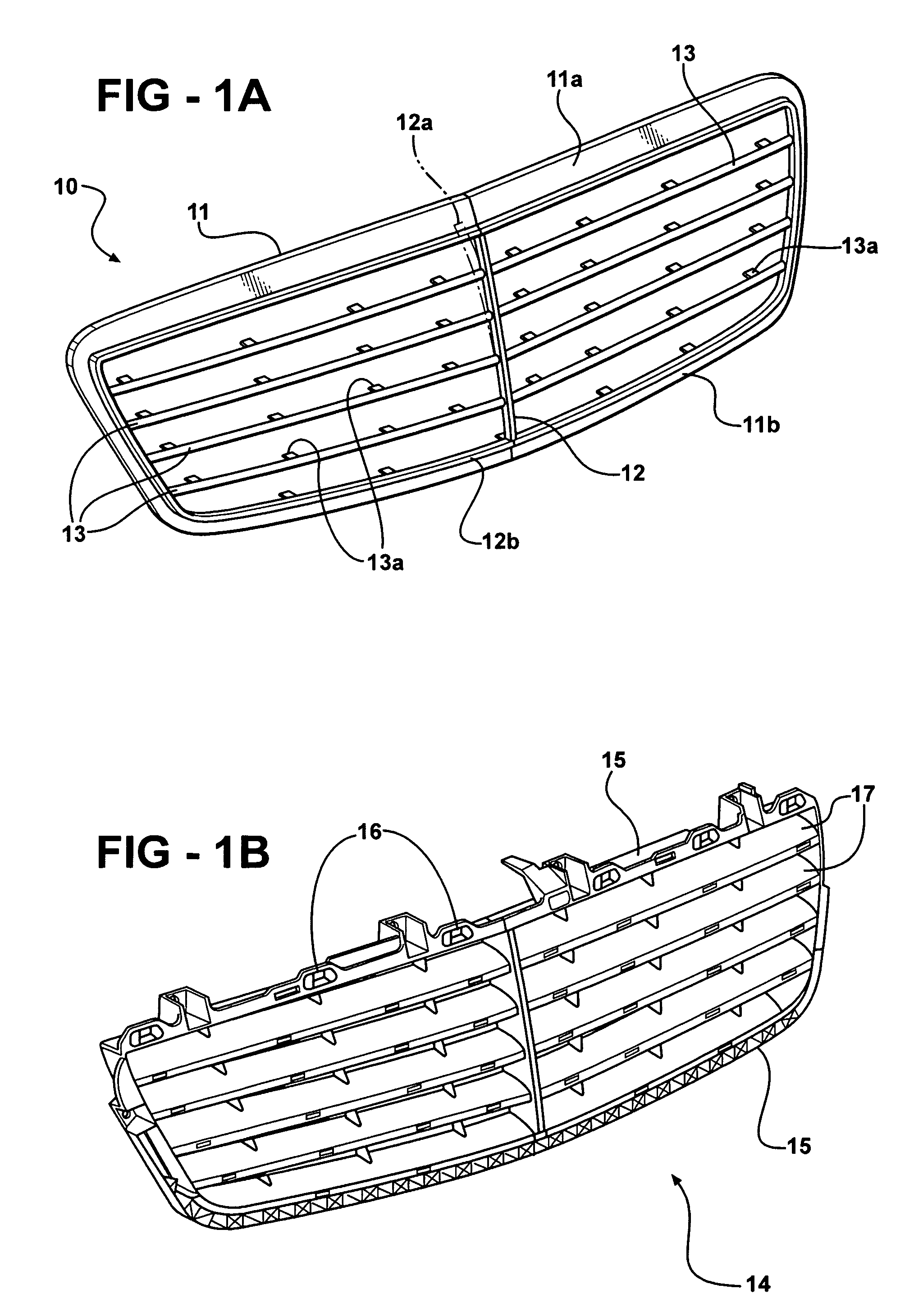

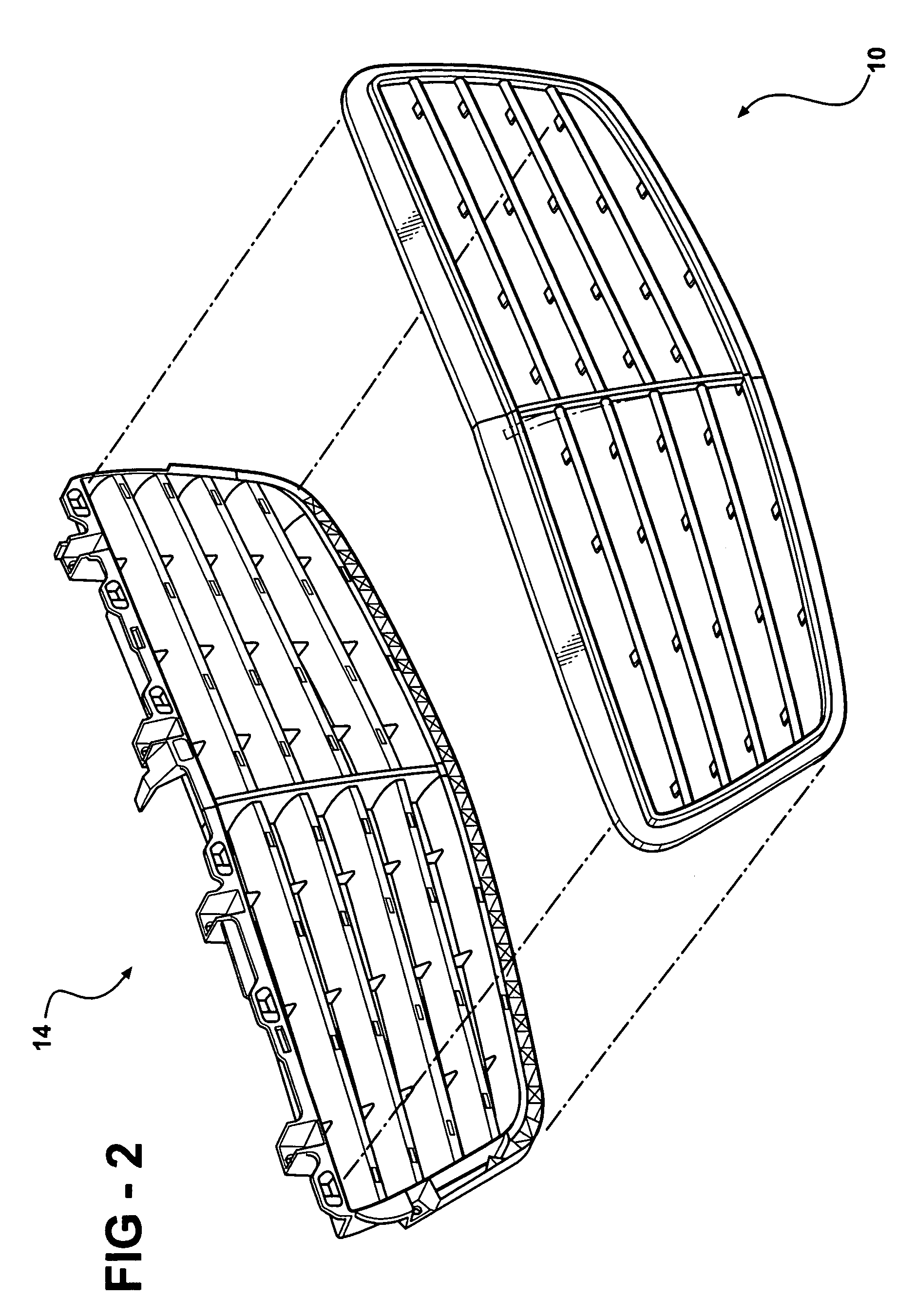

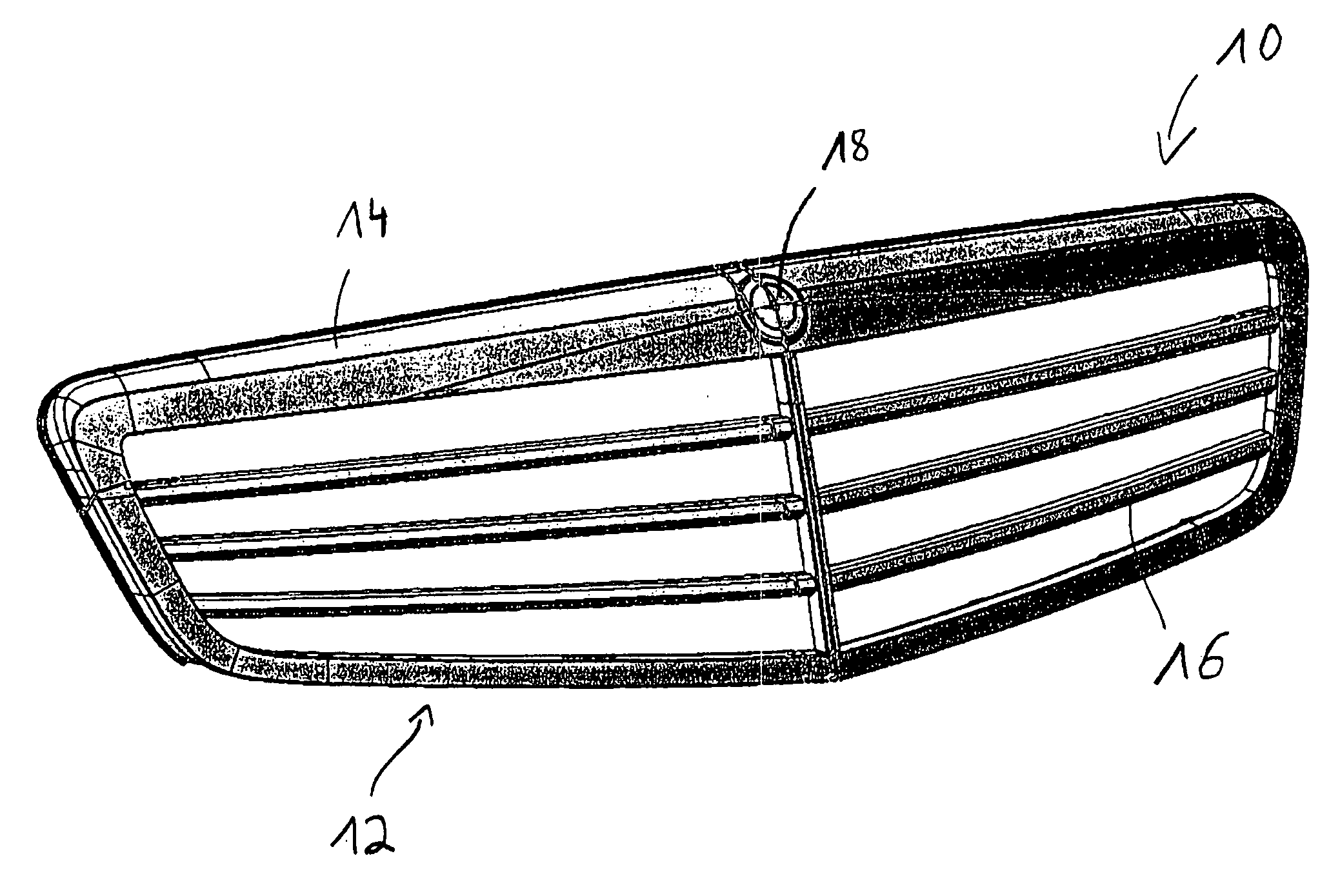

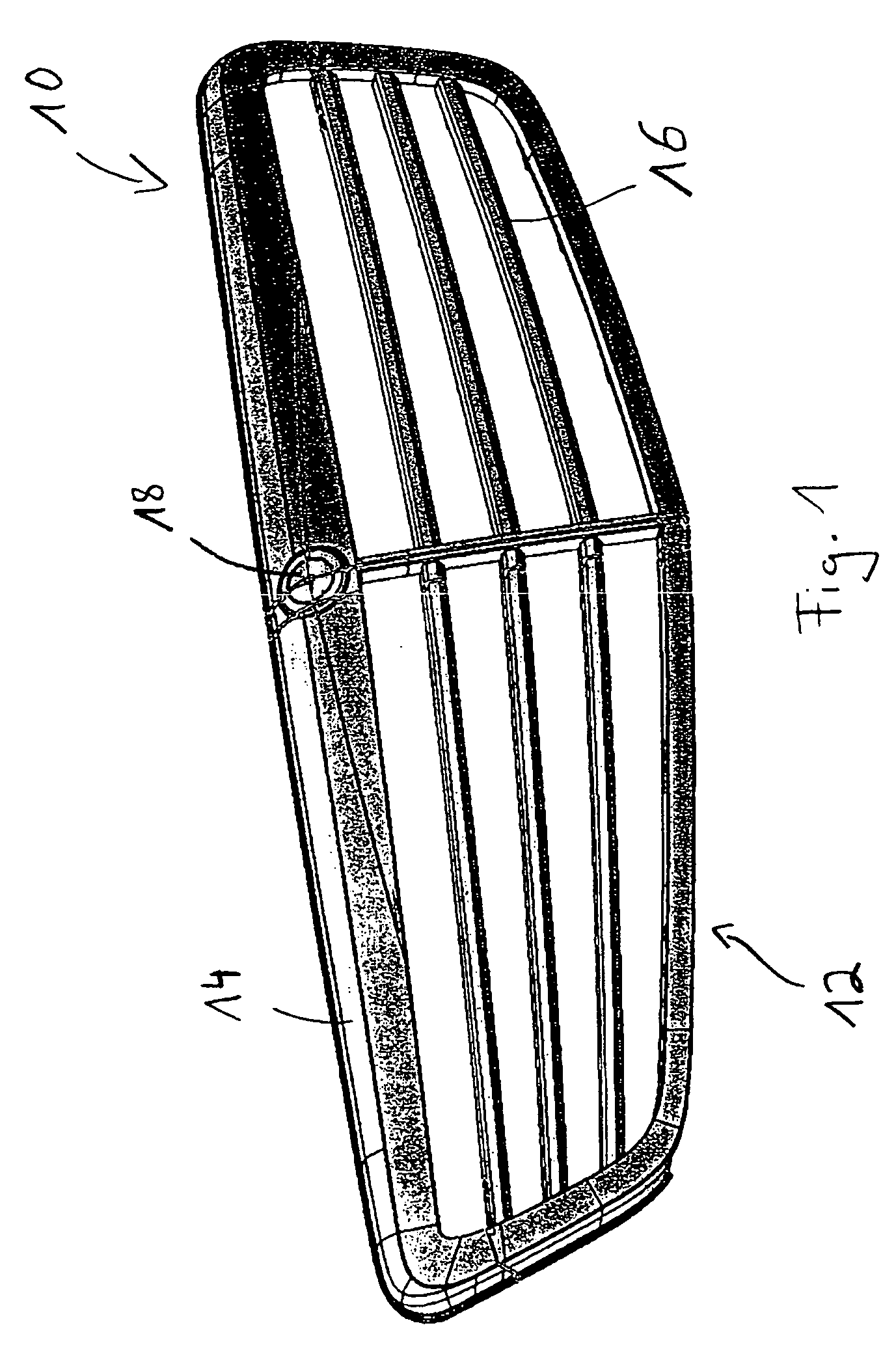

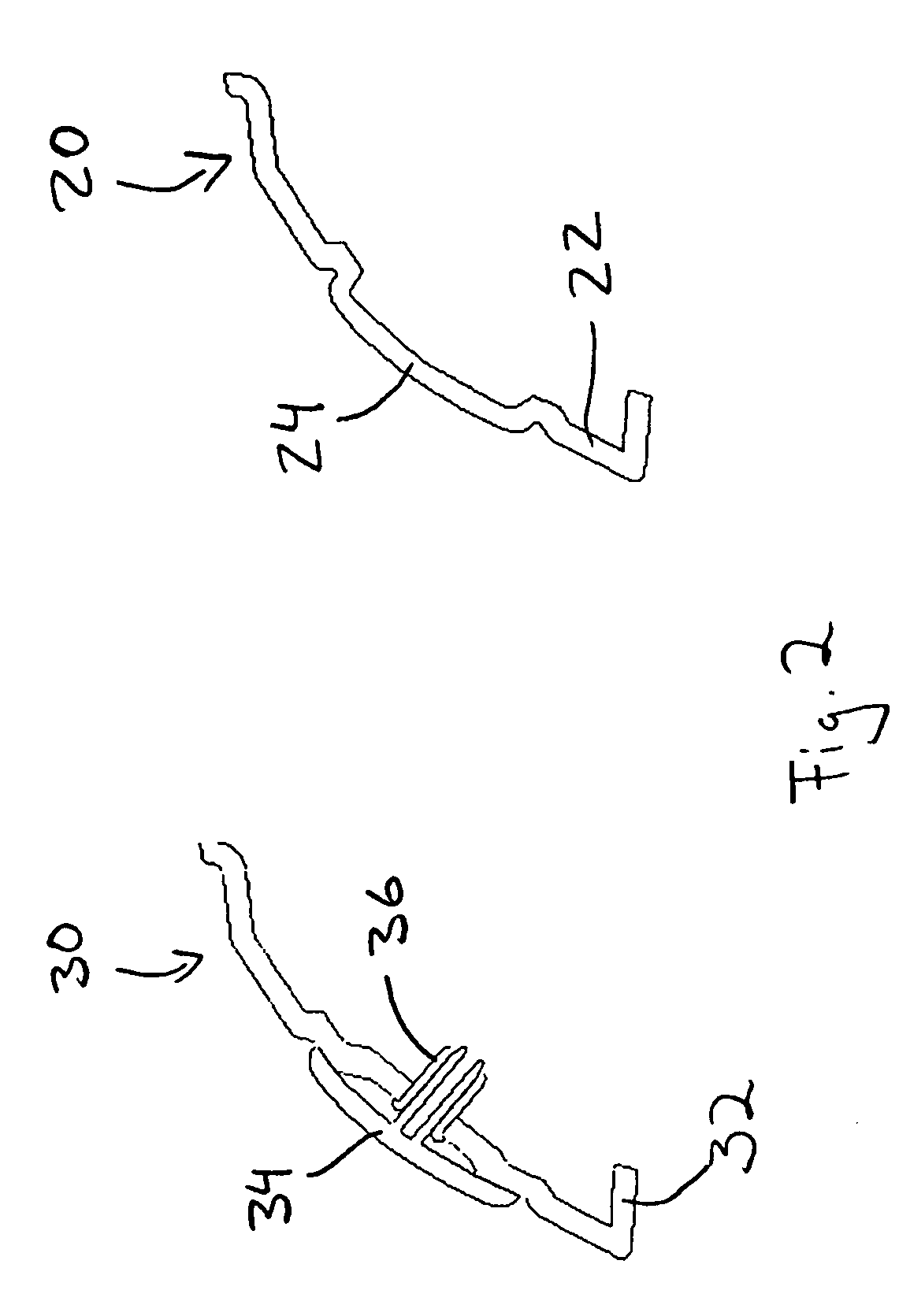

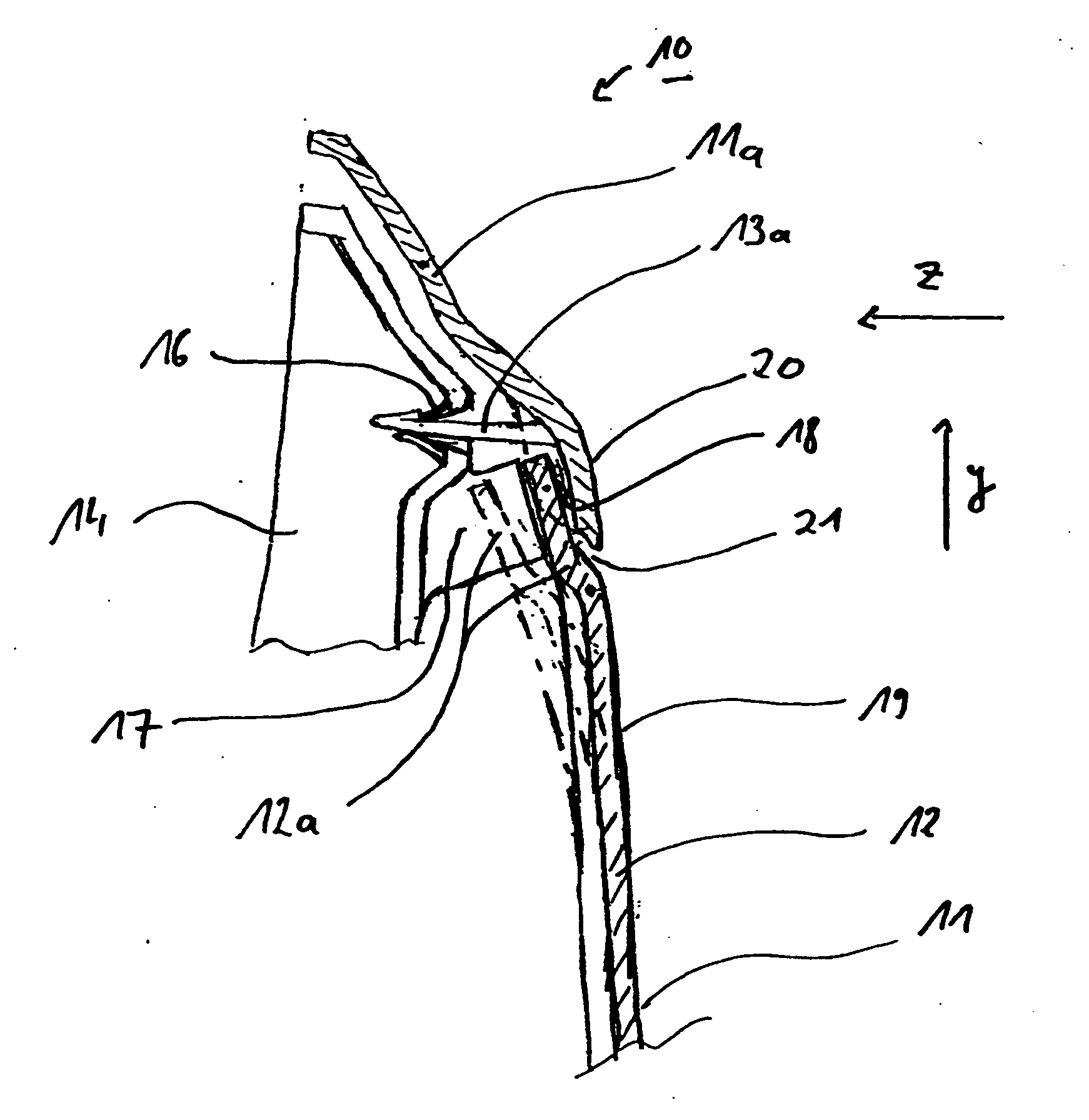

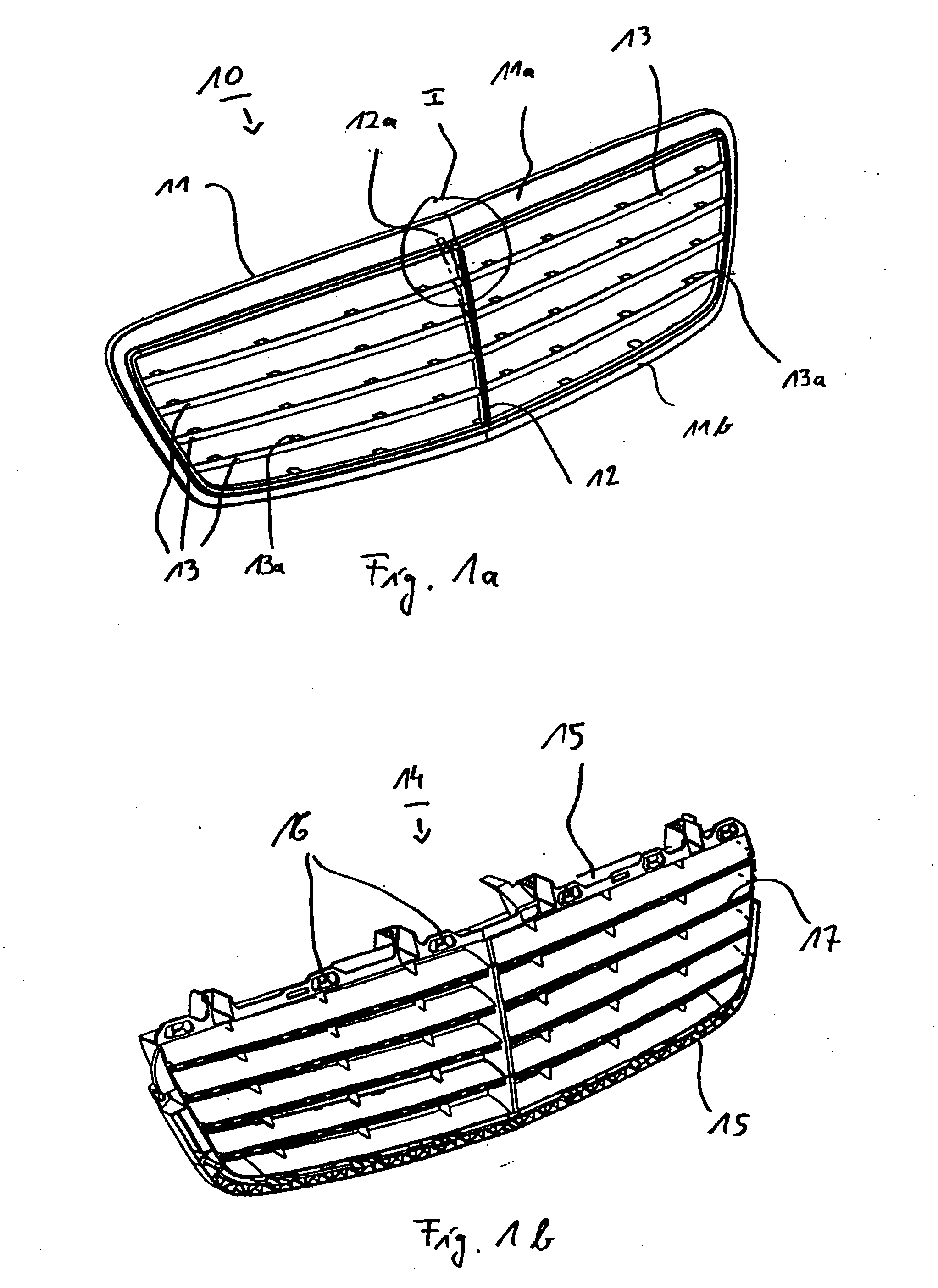

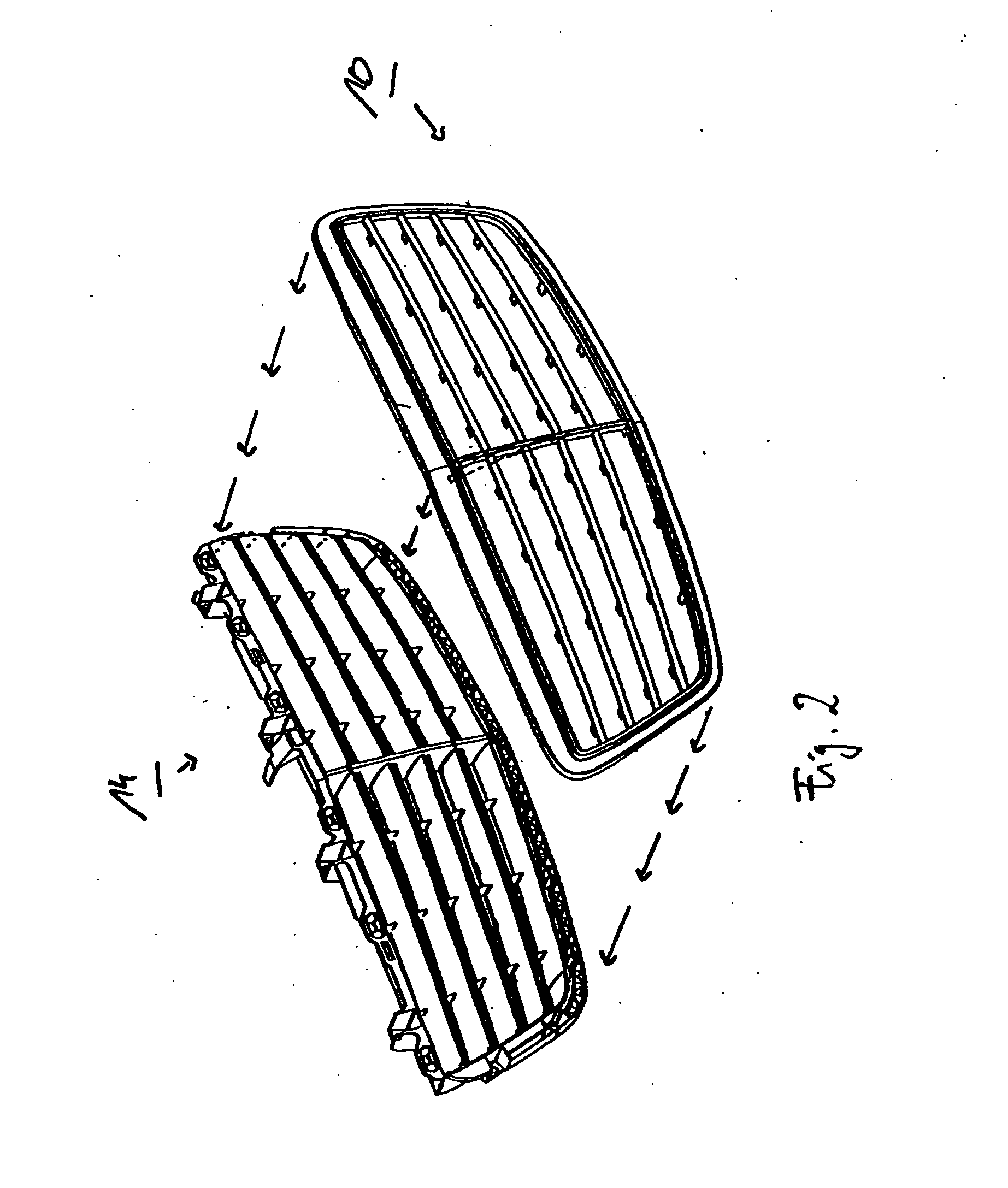

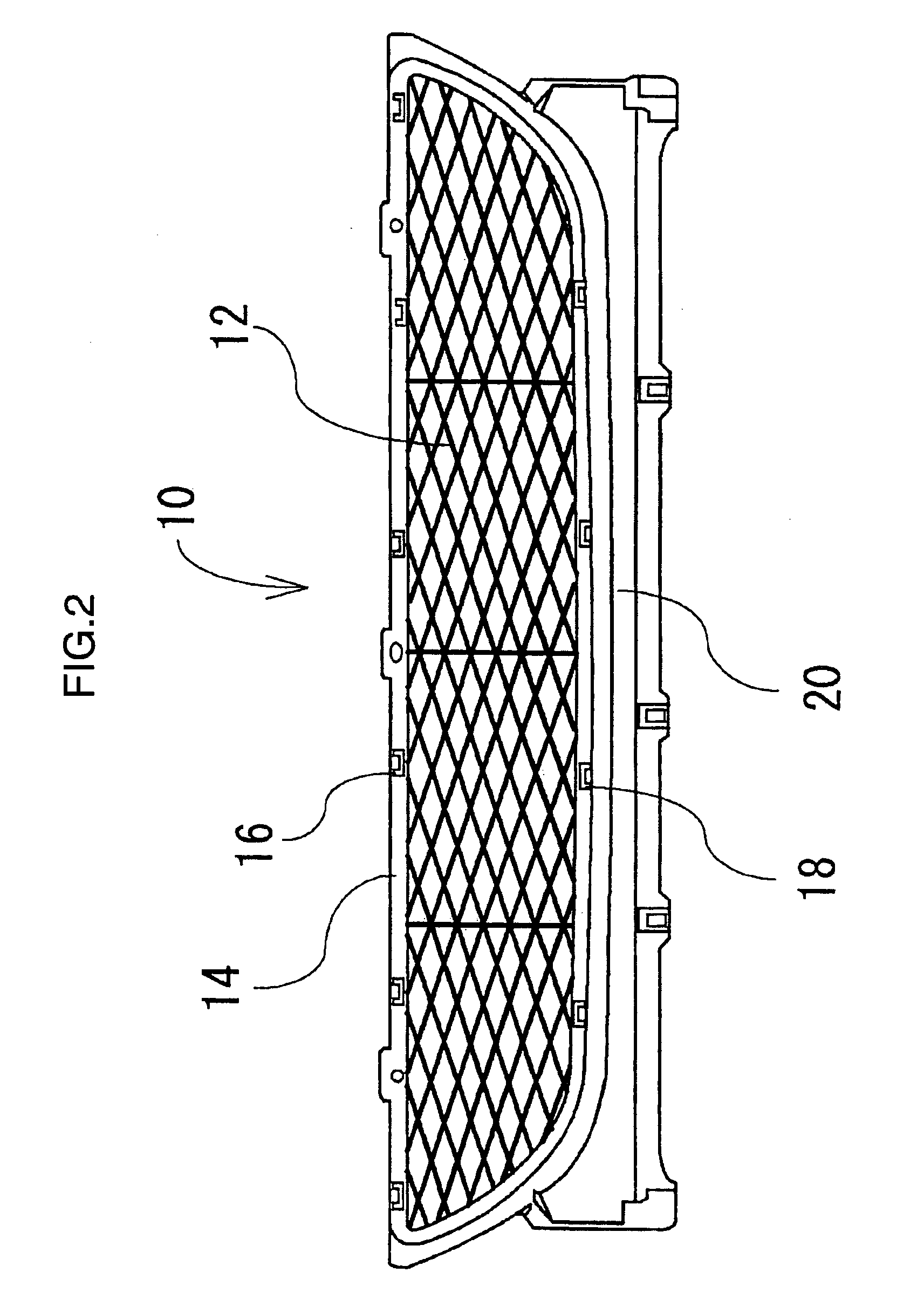

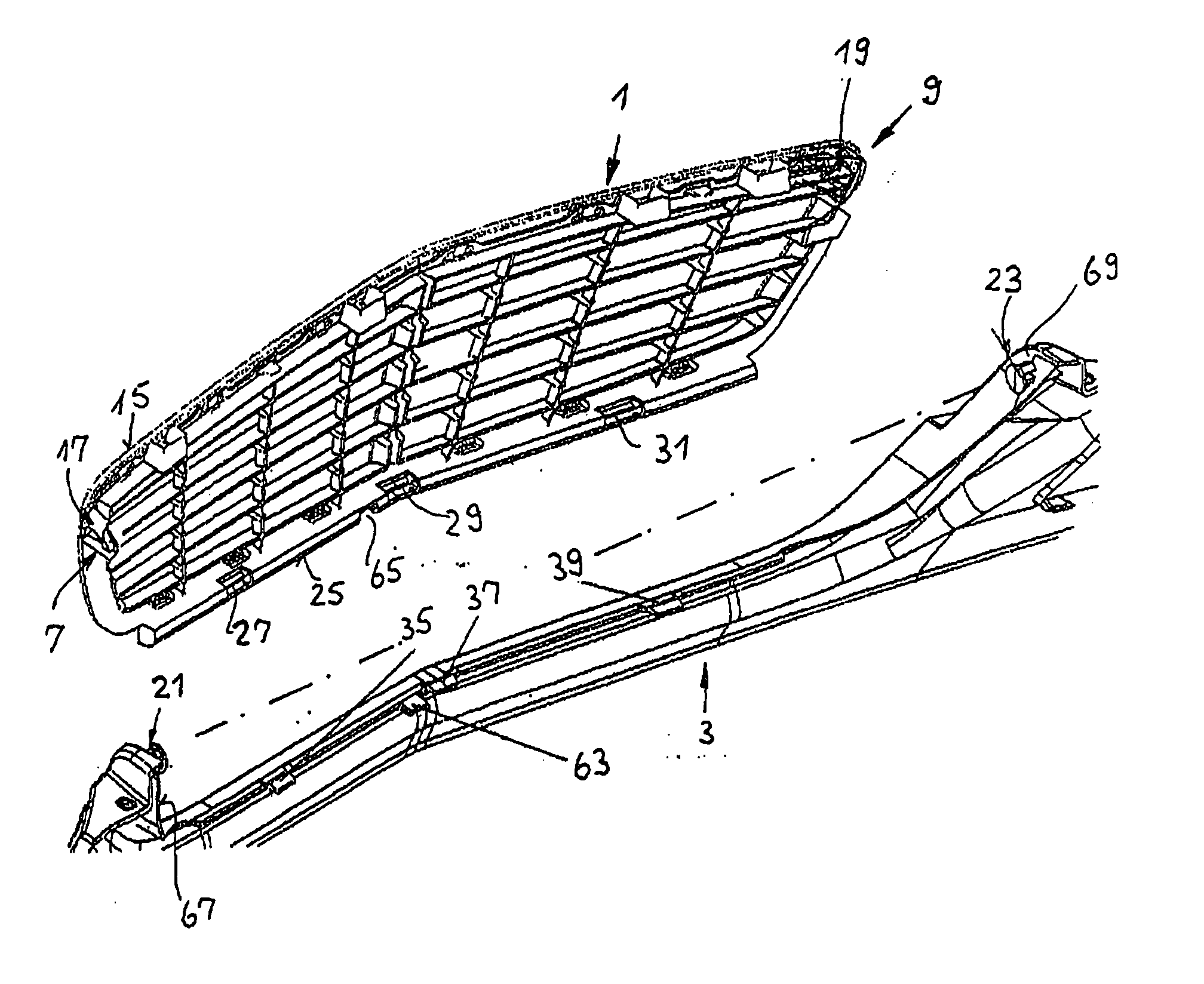

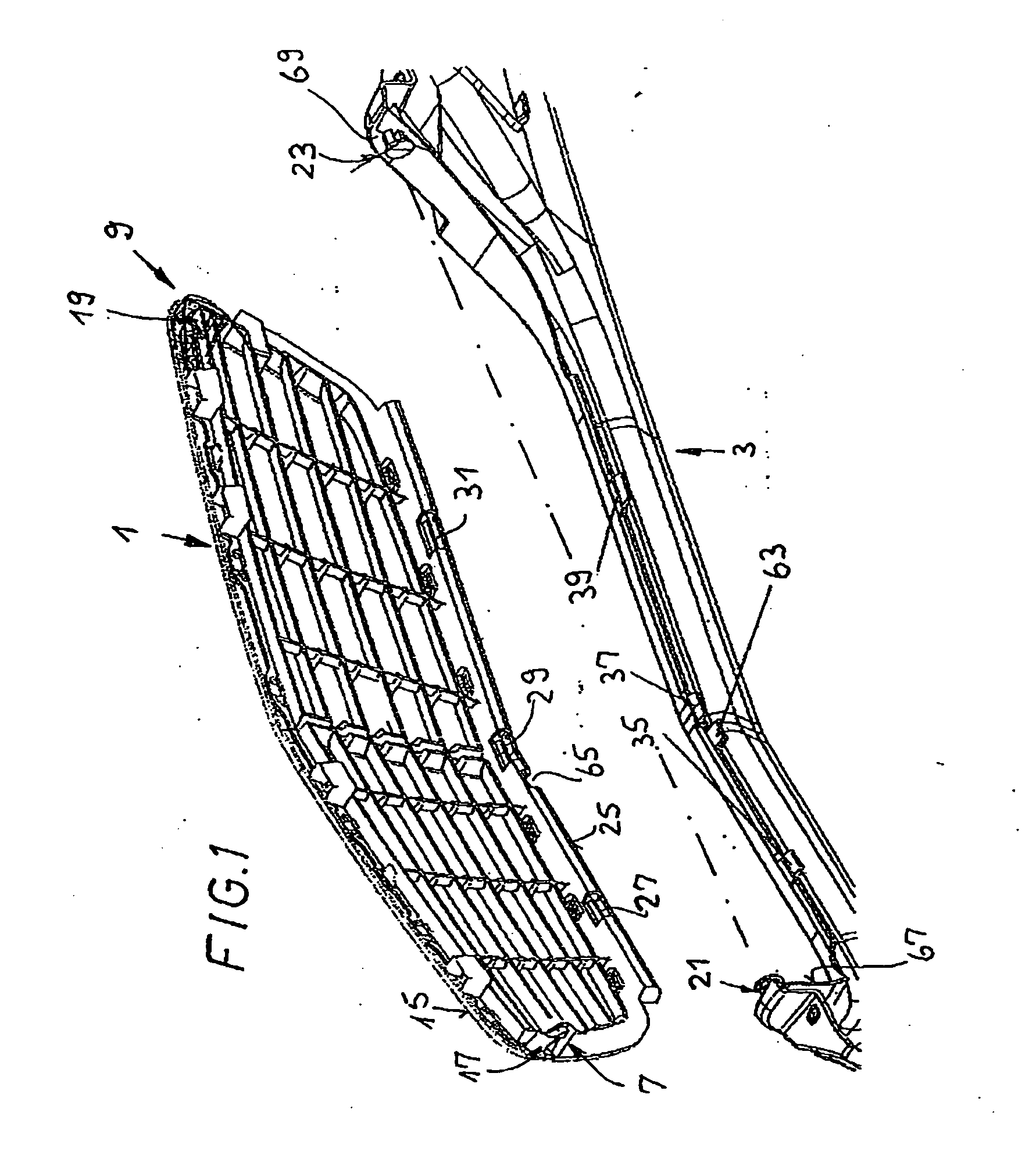

Radiator grille for mounting in a radiator grille arrangement and method of producing it

InactiveUS20050006928A1Reduce risk of damageVehicle seatsDashboardsMotorized vehicleMechanical engineering

A radiator grille (10) for mounting in a motor vehicle radiator grille arrangement and a method of producing same, includes radiator grille having a substantially rigid frame (11) and at least one bar element (12) arranged within the frame (11). The bar element includes at least one end (12a) which, in the unassembled state of the radiator grille (10), is spaced from a portion (18) of the frame (11) and in the mounted state of the radiator grille (10) is forced into contact with the portion (18). The end (12a) of the bar element (12) and the portion (18) of the frame (11) being movable relative to one another as a result of the external application of force.

Owner:LUCIDITY ENTERPRISE +1

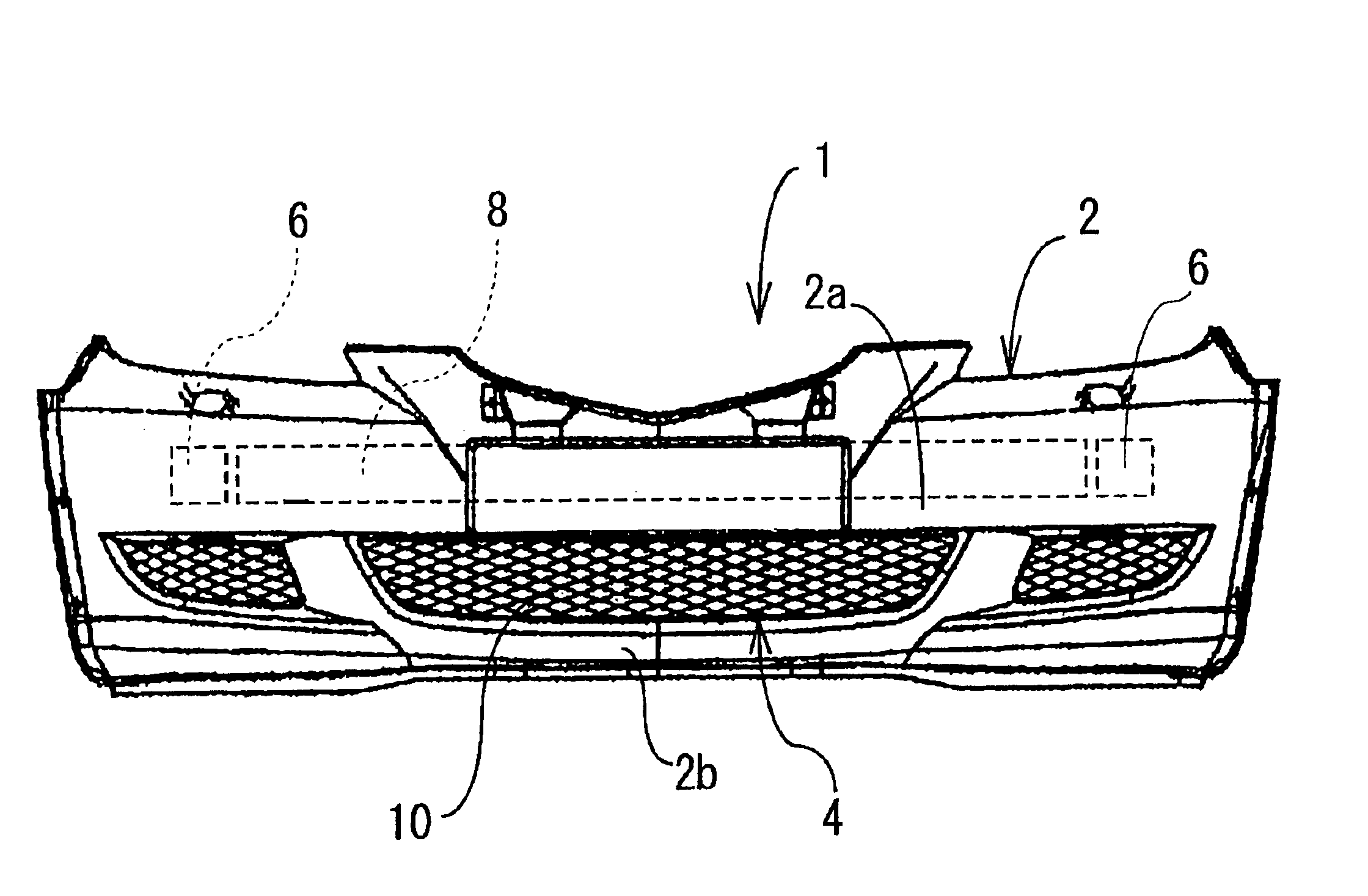

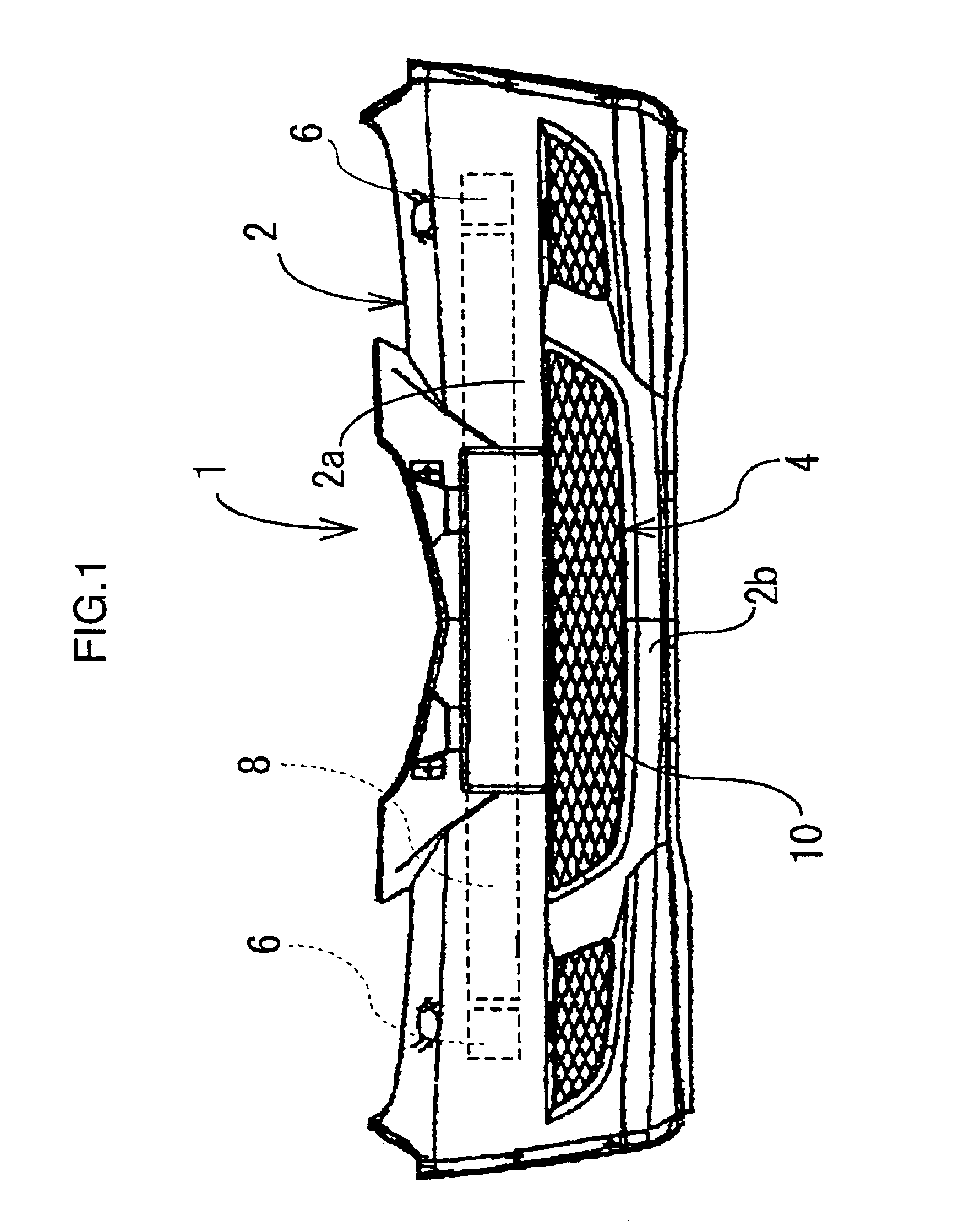

Automobile bumper structure

InactiveUS6886872B2Preventing pedestrianEasy to assemblePedestrian/occupant safety arrangementBumpersEngineeringMechanical engineering

An automobile bumper structure is provided which is capable of keeping down an increase in weight, strongly supporting a reinforcement member with a vehicle structure body behind it, preventing a pedestrian or the like from getting caught under a vehicle when the vehicle has hit the pedestrian or the like. In this automobile bumper structure, a bumper face 2 includes an opening portion 4, and a reinforcement member 20 is disposed behind and inside of a bumper lower face 2b which extends downward from this opening portion 4. Side-plane portions 22, an upper-plane portion 24, a front-plane portion 26 and a lower-plane portion 28 are formed in the reinforcement member 20. A vertical rib 32 is provided across the upper-plane portion 24, the front-plane portion 26 and the lower-plane portion 28. An extended portion 29 is united with the lower-plane portion 2 and extends rearward from it, and this extended portion 29 is connected to a cross member which is disposed behind a bumper structure body 1 and is also connected to an under cover.

Owner:MAZDA MOTOR CORP

Vehicle body front structure

InactiveUS7410018B2Simple structurePrecise absorptionPedestrian/occupant safety arrangementUnderstructuresEngineeringMechanical engineering

A lower member of a radiator core support includes a front end module formed so as to protrude forward, so that a protruding portion of the lower member is used as an impact absorbing frame member. A lower end portion of a bumper face may be superimposed fixedly on a lower surface of the protruding portion. A lower impact absorbing portion may be made of foamed resin and may be accommodated in the interior of a lower protruding portion, and this lower impact absorbing portion may be fixedly provided at a front end surface of the protruding portion.

Owner:SUBARU CORP

Emblem for motor vehicle

Owner:DECOMA GERMANY

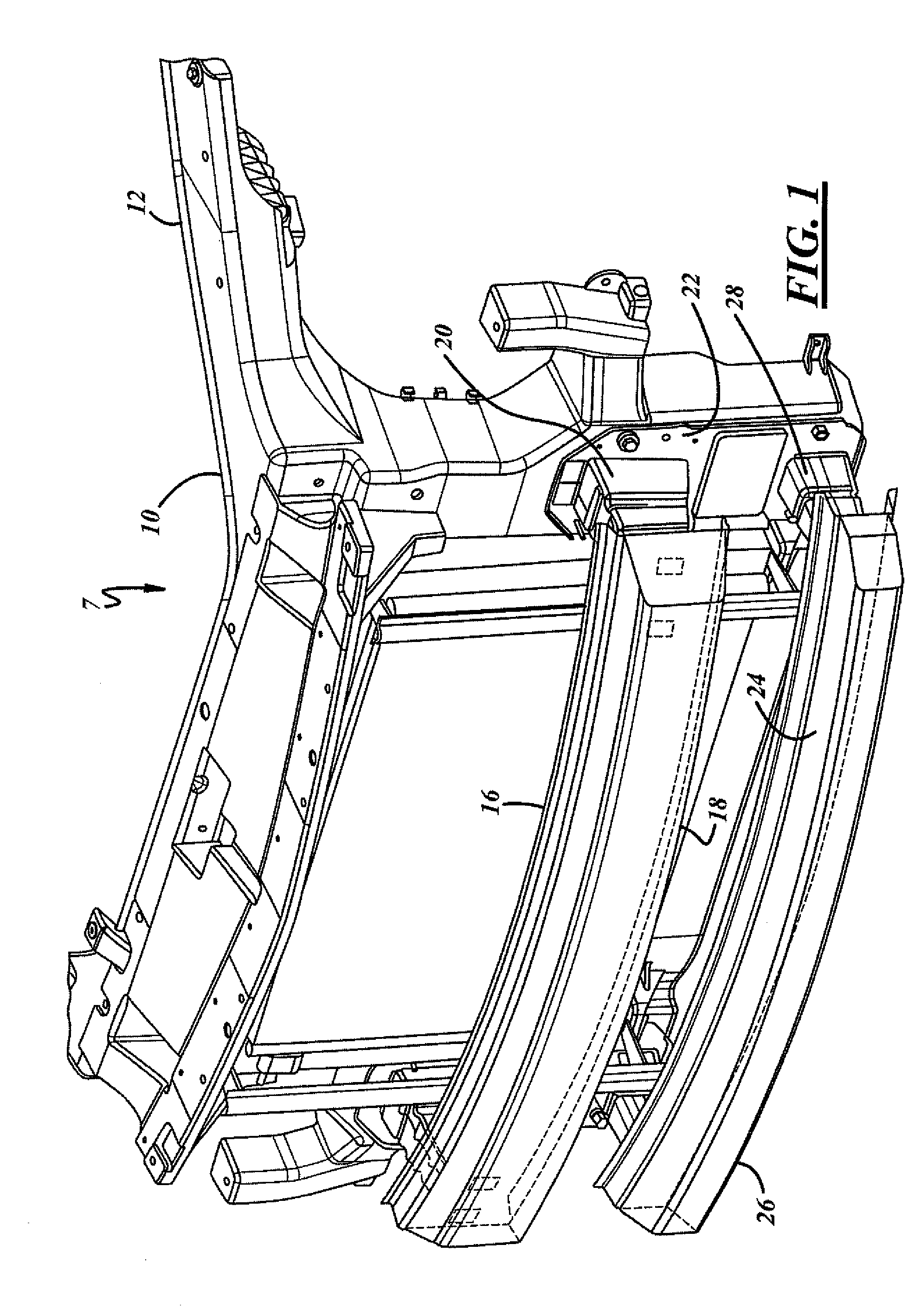

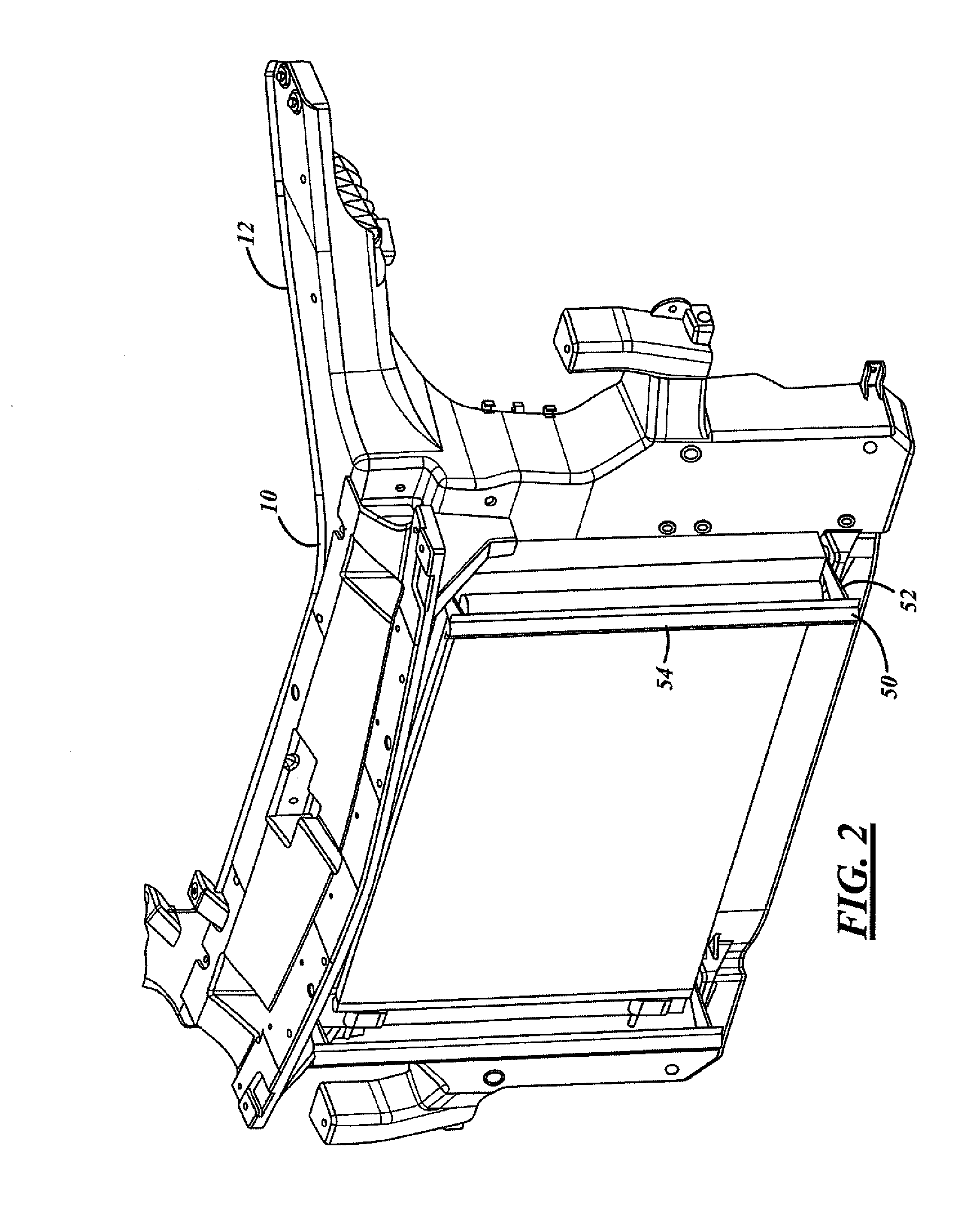

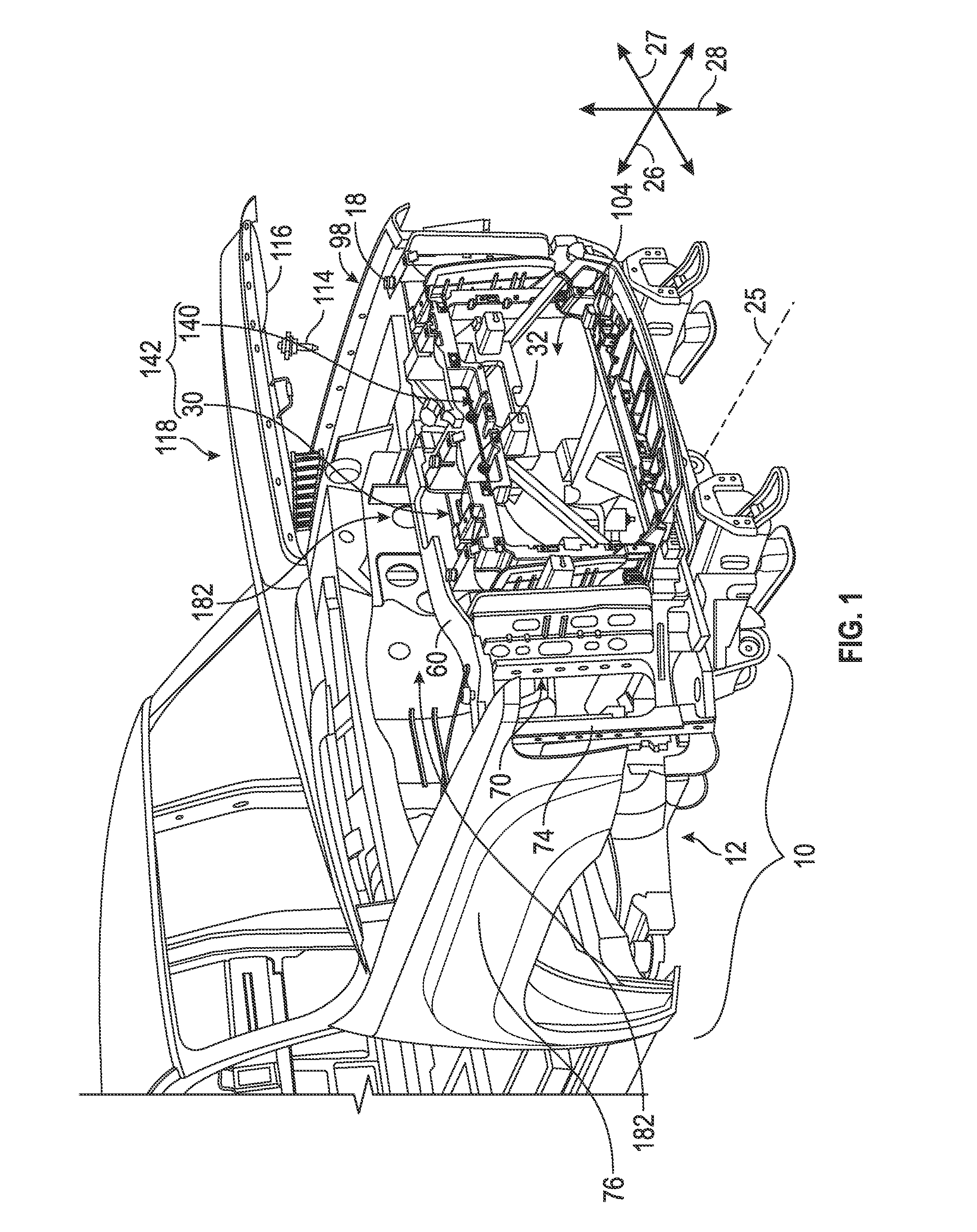

Front End Module with Breakaway Radiator

ActiveUS20080308333A1Material damage is minimized and eliminatedVehicle seatsUnderstructuresMobile vehicleMotorized vehicle

An automotive vehicle is provided which includes a structural member, a bumper movable with respect to the structural member upon an impact of said vehicle with an object, and a radiator for cooling fluid of a component of the vehicle, the radiator being mounted with the structural member. Movement of the bumper within predetermined limits causes the radiator to be dismounted with respect to said structural member minimizing material damage to the radiator.

Owner:MAGNA INTERNATIONAL INC

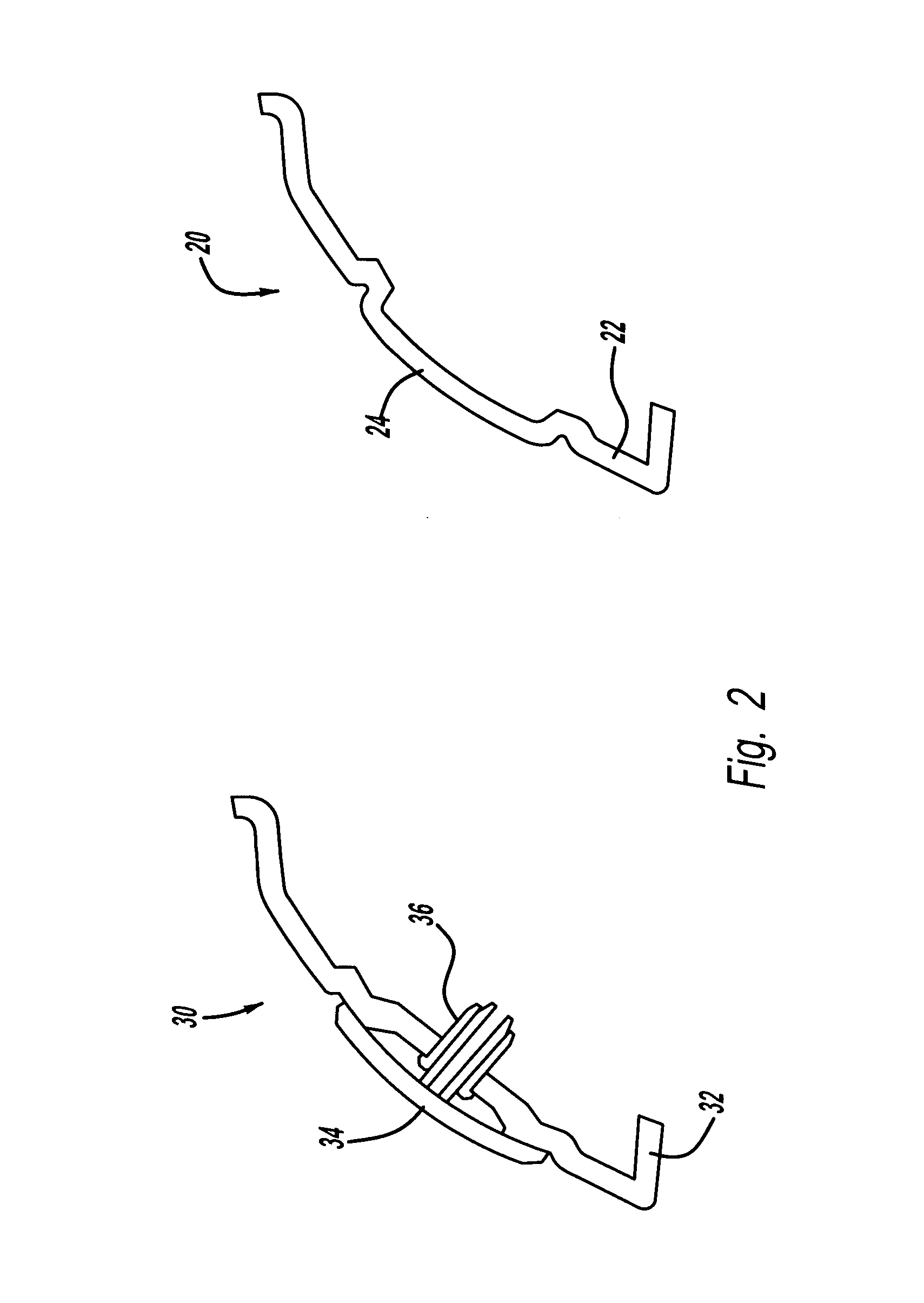

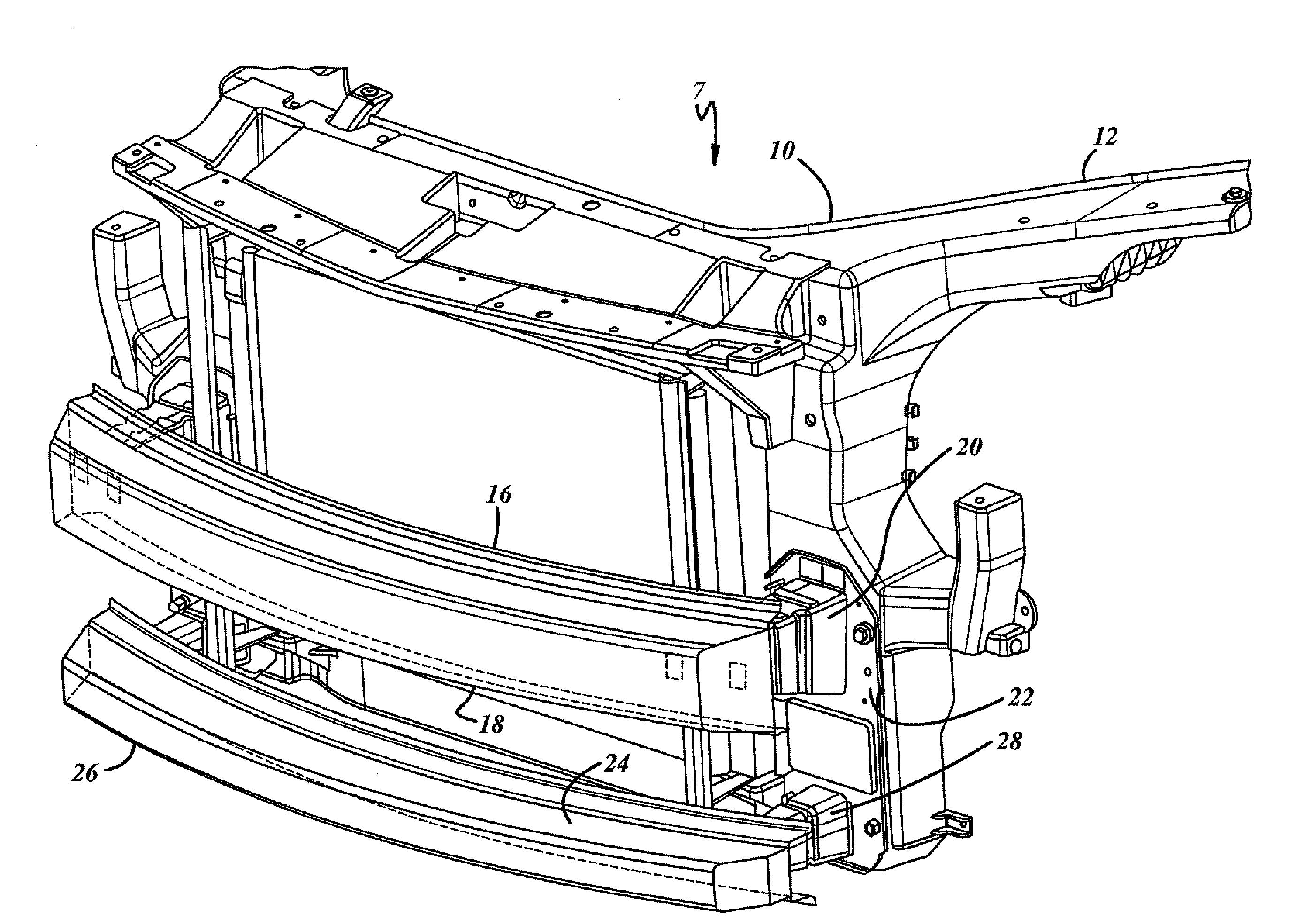

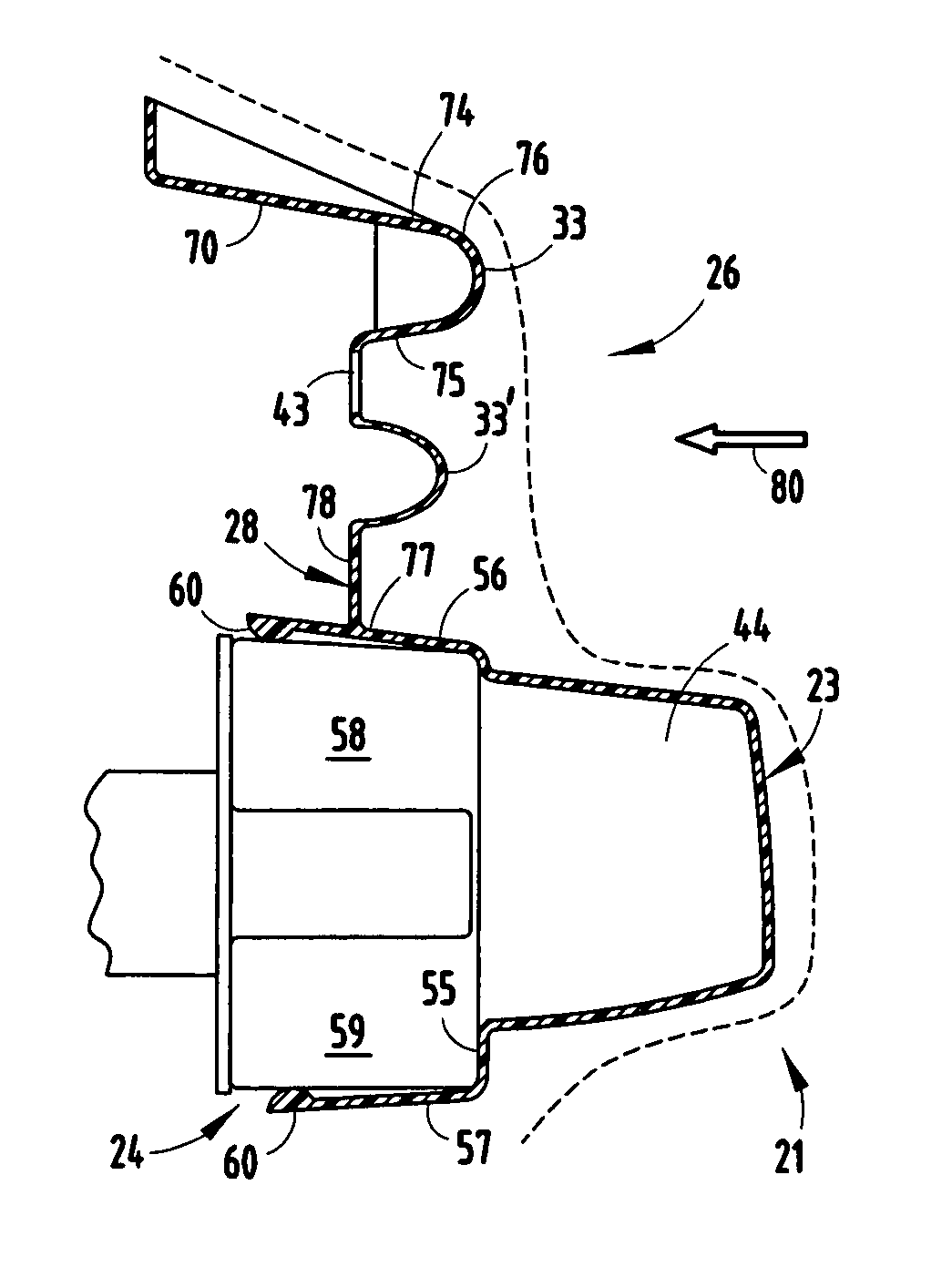

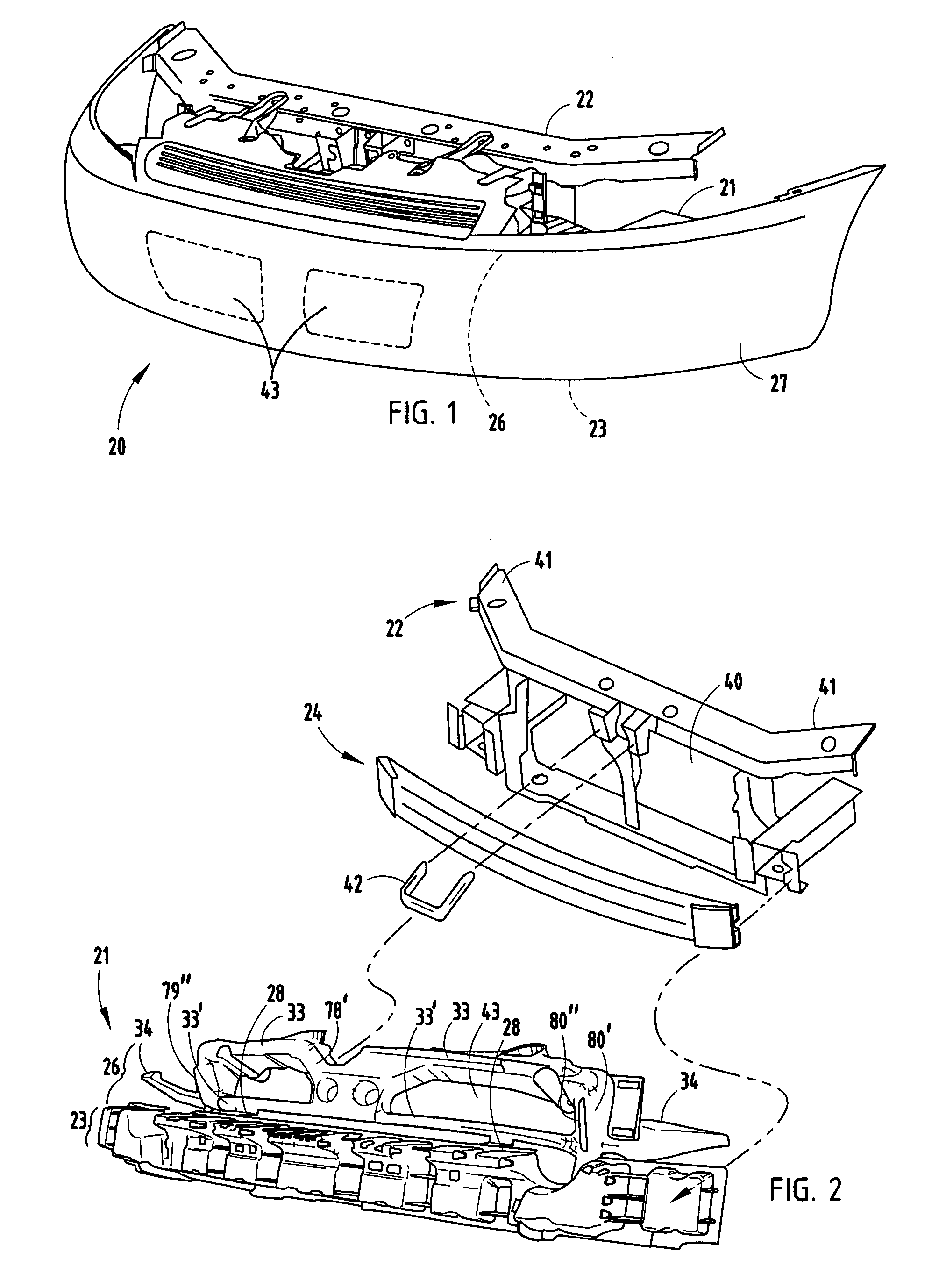

Integrated bumper energy absorber and fascia support component

ActiveUS20050017520A1Facilitate simultaneous assemblyAvoid damageBumpersRadiatorsEngineeringMechanical engineering

An integrated one-piece polymeric molded component includes an energy-absorbing section, a fascia-supporting beam section, and a plurality of connecting section connecting the energy-absorbing and fascia-supporting beam sections. The energy-absorbing section engages a front of a bumper beam and includes crush boxes configured to absorb impact energy during a vehicle crash. The connecting sections are strong enough to hold the energy-absorbing section and the fascia-supporting beam section together during assembly of the one-piece component onto a vehicle, but are flexible to allow collapse of the energy-absorbing section during a vehicle crash without damaging the fascia-supporting beam section. The beam section is channel-shaped and extends cross-car generally between headlamps of the vehicle, for providing added support structure to a front-end of the vehicle. The beam section includes air-redirecting ridges for optimal air flow and integral clips for wire management.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

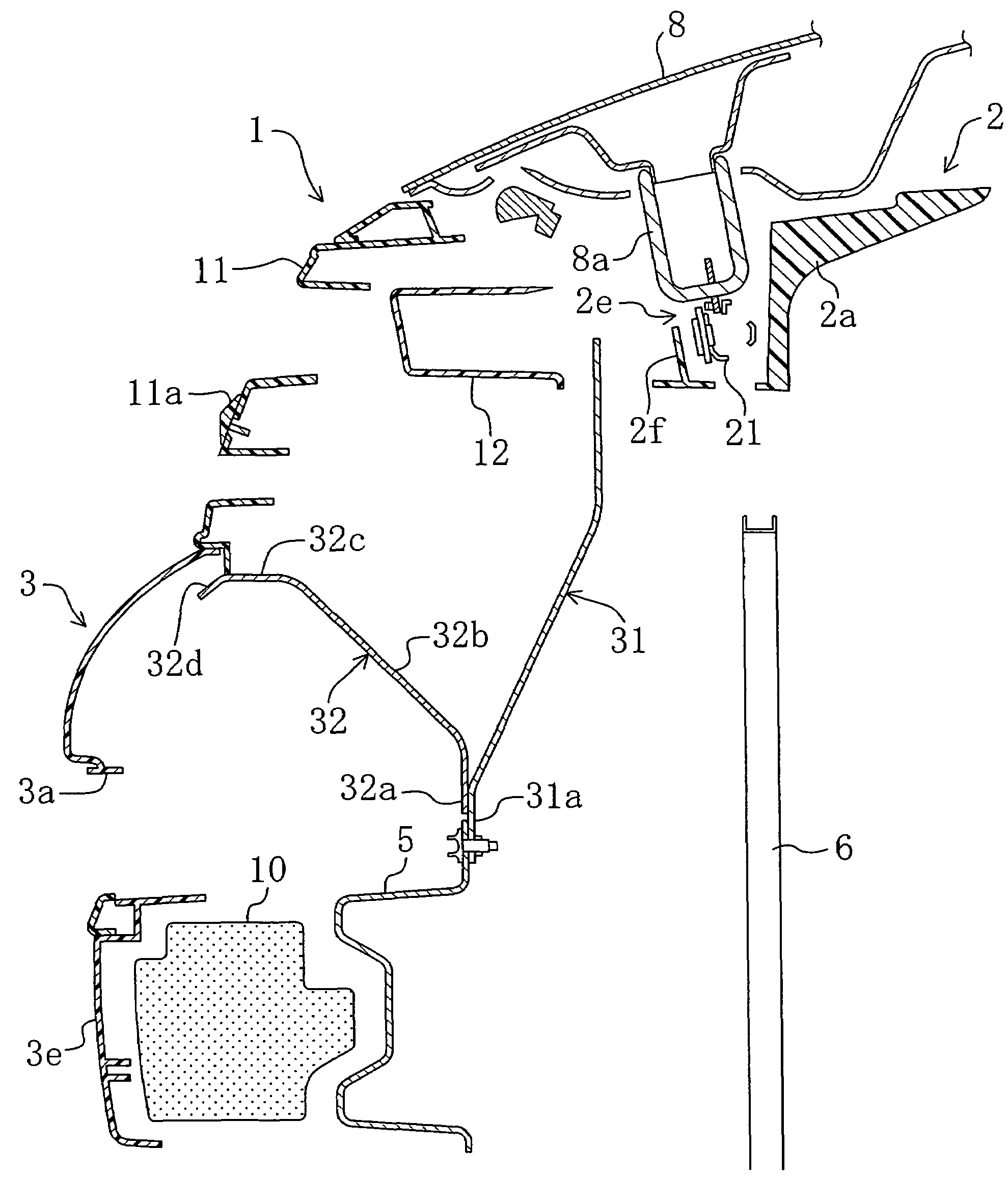

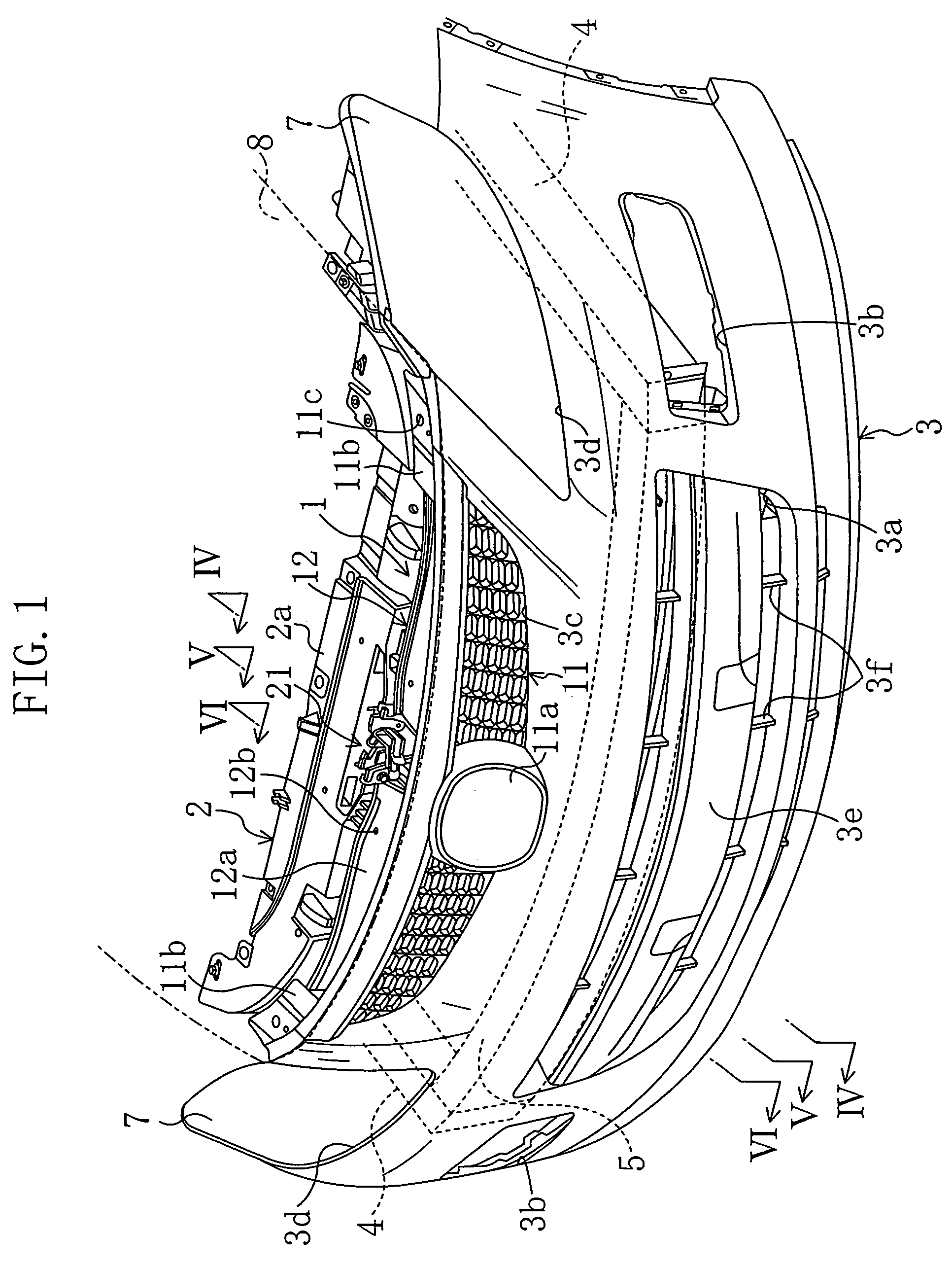

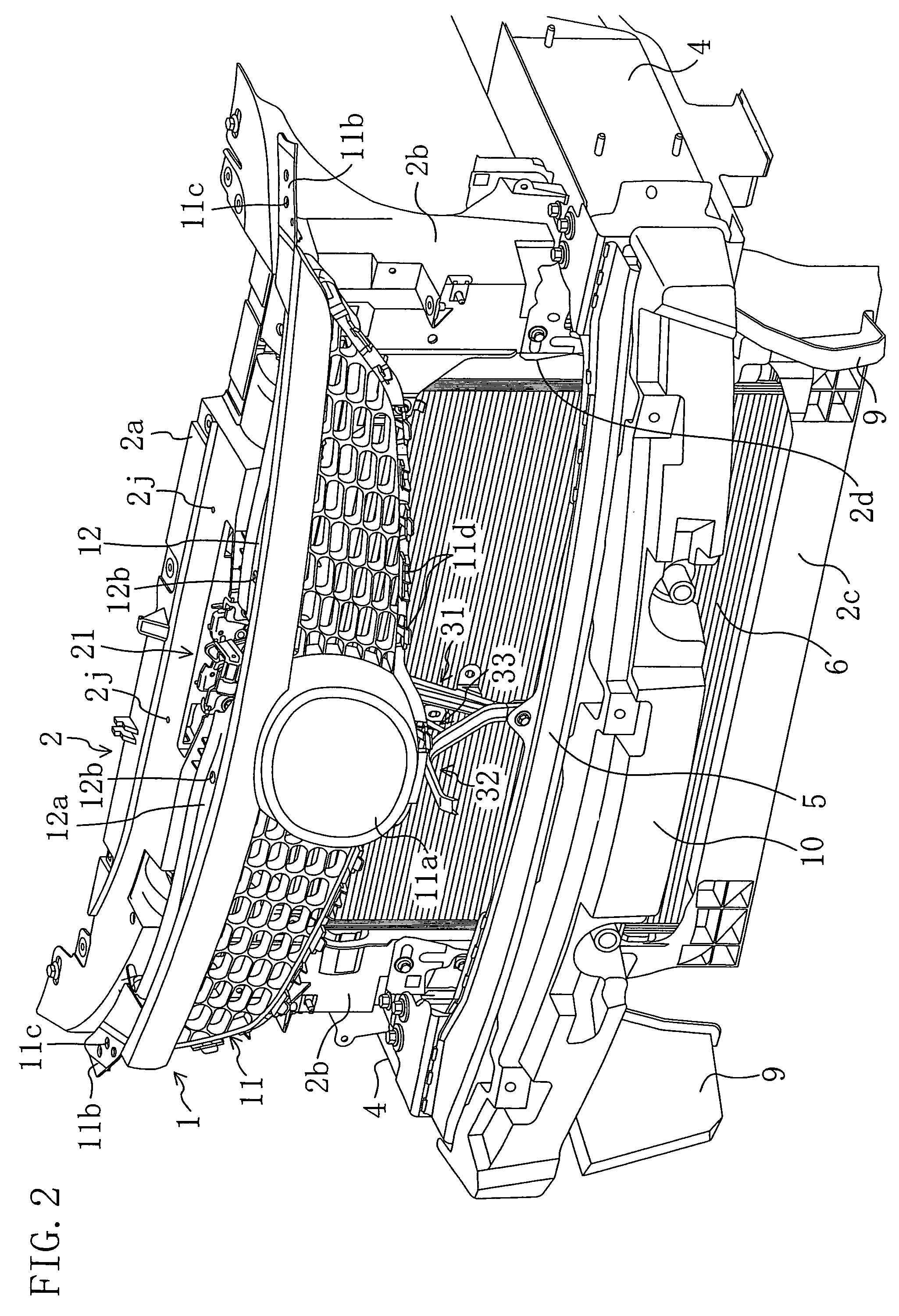

Vehicle front end structure

InactiveCN101020441APrevent saggingNo deterioration in assembly workabilityRadiatorsSection planeCoupling

The invention discloses a vehicle front part structure, and is to prevent a radiator grid from bending downwards due to the weight thereof in the vehicle front part structure with the large-scale radiator grid, which is tilted with the lower part ahead of the upper position and looks approximately cambered from above. A grid supporting component (32) is arranged on a central support (31) and integrated with the central support (31). The central support (31) bridging between the upper part (2a) of a radiator fixation frame and a bumper beam (5). The grid supporting component (32) is formed by folding a component, the section plane of which is rectangular with the left side open. The grid supporting component (32) consists of a coupling section (32a) coupled to the installation part (31b) of the central support (31) on the bumper beam; an elbow (32b) extending upwards and forwards from the coupling section (32a); a connecting part (32c) extending forwards from the front end of the elbow (32b) and supporting the radiator fixation frame(1) from below; and a guide part used to facilitate assembly of the radiator grid (1) onto the connecting part (32c).

Owner:MAZDA MOTOR CORP

Front bumper cover and radiator grille

InactiveUS20060249961A1Avoid deformationHigh level of occupancyVehicle seatsPedestrian/occupant safety arrangementEngineeringMechanical engineering

A front bumper cover is provided for an automotive vehicle. The front bumper cover includes a plurality of cover parts and a radiator grille having attachment points for fixedly securing the plurality of cover parts thereto. The radiator grille is adapted to mount to the vehicle thereby acting as a load-bearing element for supporting the front bumper cover.

Owner:DECOMA GERMANY

Vehicle end structure

ActiveUS8157303B2Reduce exposureTime consumingVehicle seatsSuperstructure subunitsMechanical engineeringEngineering

A vehicle end structure mainly includes a vehicle bumper fascia and a grille assembly. The vehicle bumper fascia includes a sill portion and a receiving member extending from the sill portion. The receiving member defines a channel with an opening extending in a forward vehicle facing direction. The grille assembly includes inner grille and outer grille members that are coupled together. The inner grille member has a support member formed at a periphery of the inner grille member. The support member is disposed in the channel of the receiving member to limit movement of the inner grille member in a direction normal to the forward vehicle facing direction. The outer grille member is disposed on a forward vehicle facing side of the inner grille member to conceal the support member from view in the first direction.

Owner:NISSAN MOTOR CO LTD

Auxiliary push bumper for motor vehicle

An auxiliary push bumper for a motor vehicle which is clamped to the original bumper by brackets attached to bumper guards on such push bumper. The push bumper is made of a plurality of bumper sections made of extruded aluminum whose ends are releaseably attached to the bumper guards for easy repair of the push bumper by replacement of a damaged bumper section. In one embodiment the push bumper includes a center section formed of an extruded aluminum u-shaped channel with an diagonal stiffening plate inserted into such channel. The center section is fastened at its opposite ends to a pair of bumper guards which may each be formed of a metal loop and a metal reinforcing plate attached to such loop and to the ends of the center section. A pair of curved side sections of the bumper are fastened at their inner end to the bumper guard plates and fastened at their outer end to the frame of the vehicle. A pair of side lights may be mounted on the bumper guards to transmit light beams from the sides of the vehicle. A second pair of front lights may be mounted on the center section of the bumper to project light beams from the front of the vehicle.

Owner:SETINA MFG

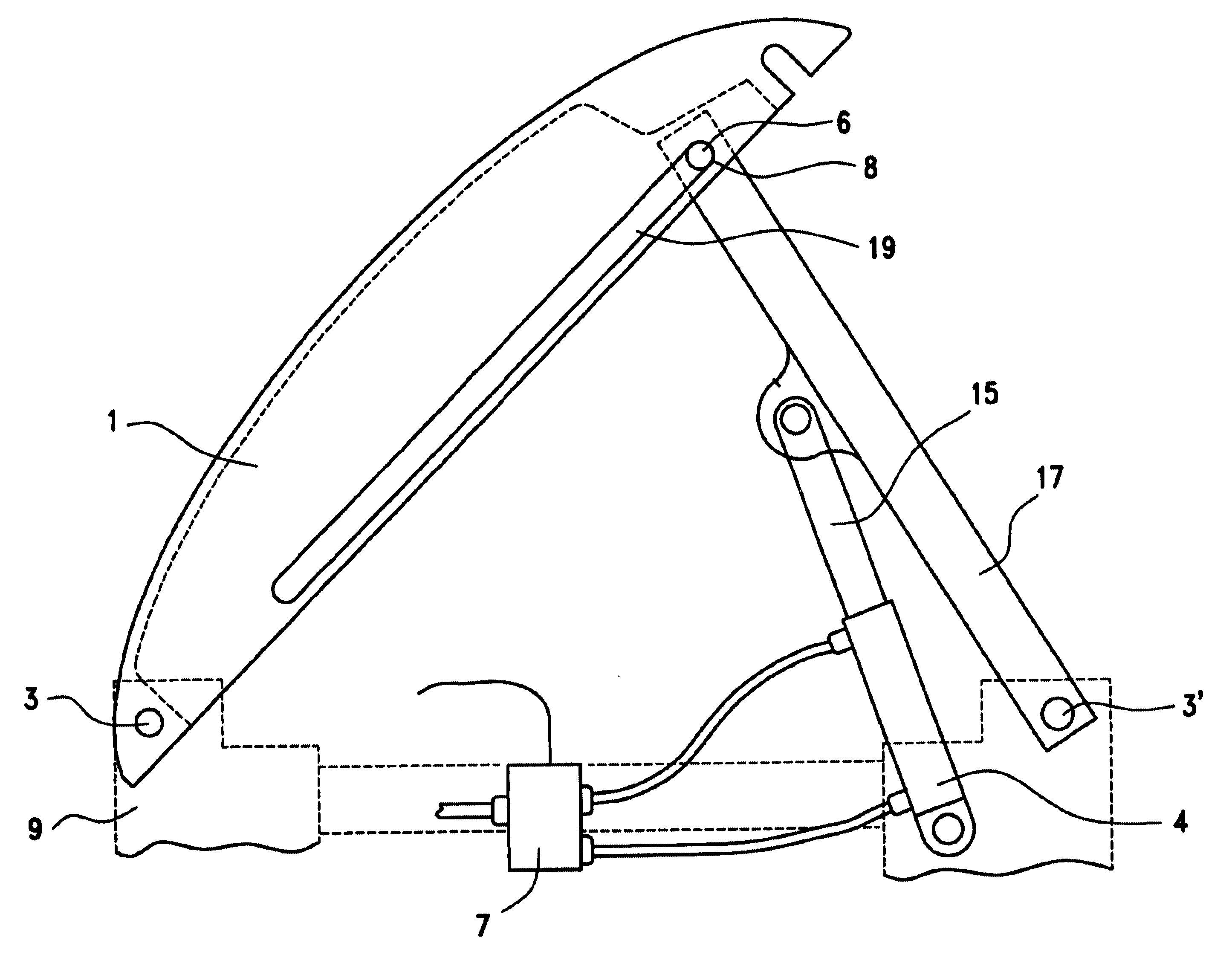

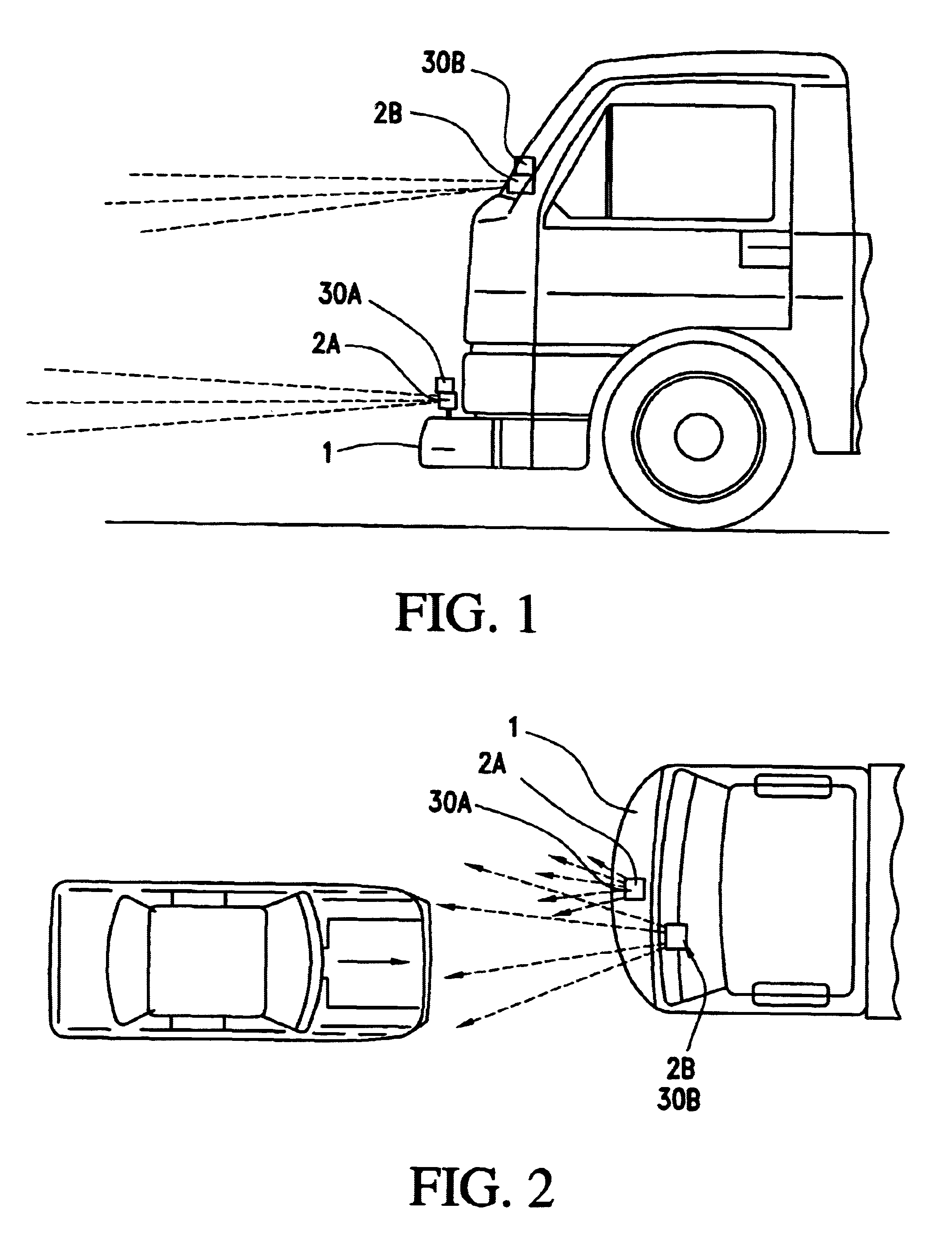

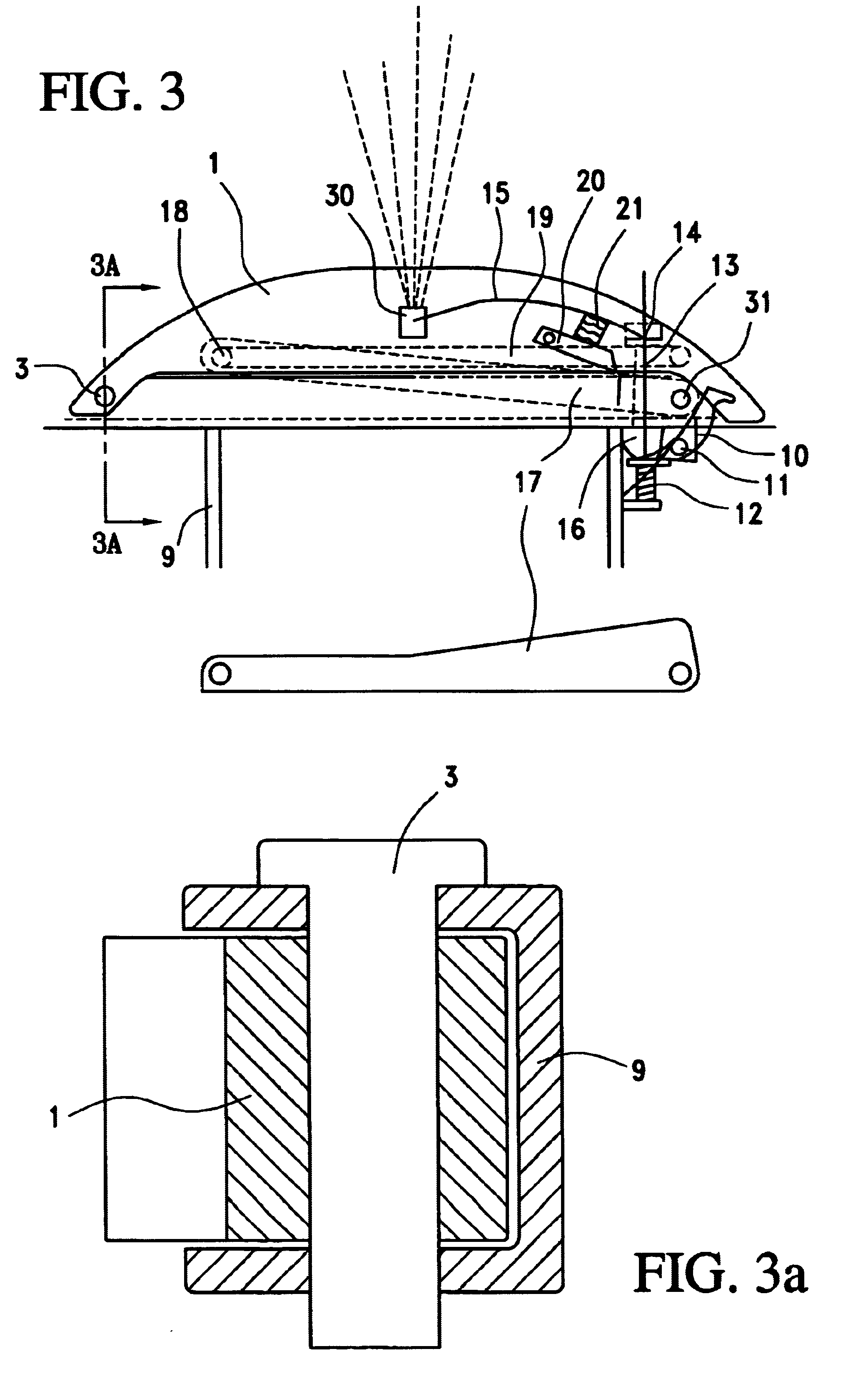

Collision safety device for vehicles

InactiveUS6623054B1Belt control systemsPedestrian/occupant safety arrangementMobile vehicleAutomatic braking

Device for motor vehicles designed to prevent traffic accidents or to reduce their injurious consequences. The extent of injuries in traffic accidents can be reduced significantly by employing the vehicle bumper (1) as a crumple (deformation) zone. A sensor (2) is used to record this distance from and speed relative to an obstacle in the direction of travel. When a collision is unavoidable, one end of the bumper (1) is projected outward by a propellant charge (13) so that, together with a strut (17, 22, 24), if forms a crumple zone ahead of the vehicle. The device can also be provided with a system to warn of dangerous traffic situations, and to brake the vehicle automatically or reduce its speed if the risk of a collision exists. In the case of trucks and buses, the bumper (1) may be deployed by means of a pneumatic cylinder (4) and valve (7), which are controlled by the vehicle's ordinary speedometer. The bumper remains depolyed above a certain threshold speed.

Owner:PALMQUIST EVERT

Grid member and vehicle front structure with the grid member

Owner:NISSAN MOTOR CO LTD

Mounting for a radiator casing in a motor vehicle

InactiveUS20050006913A1Simple and cheap fittingImprove protectionVehicle seatsDashboardsRotational axisMotorized vehicle

Owner:DECOMA GERMANY

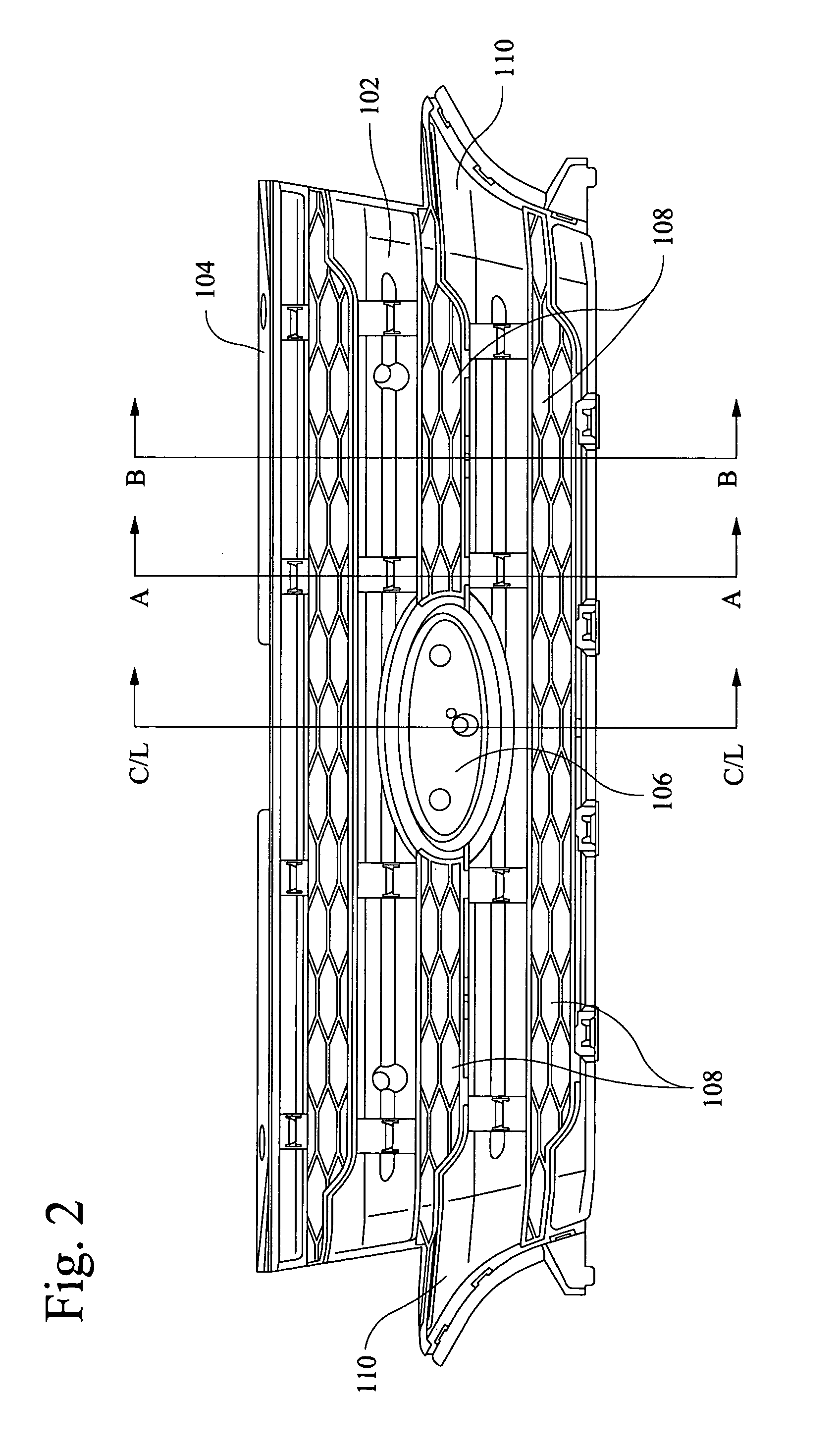

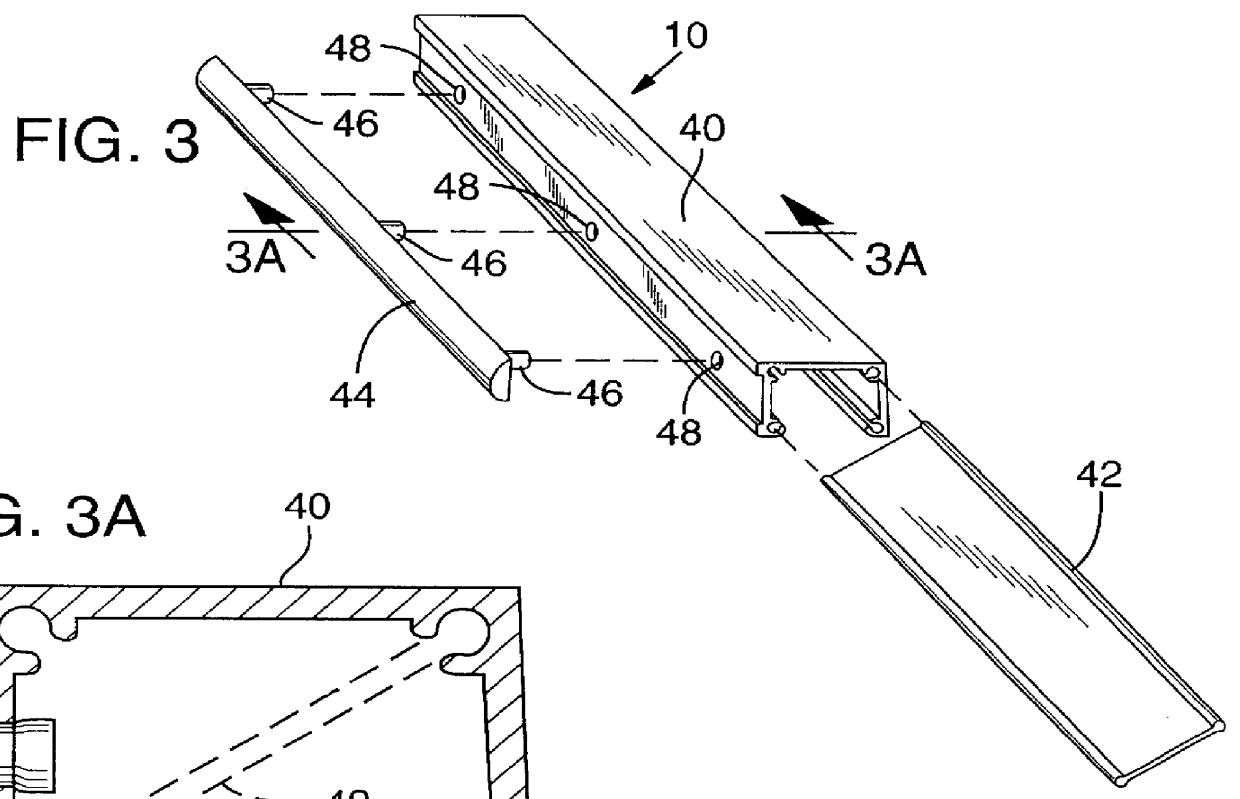

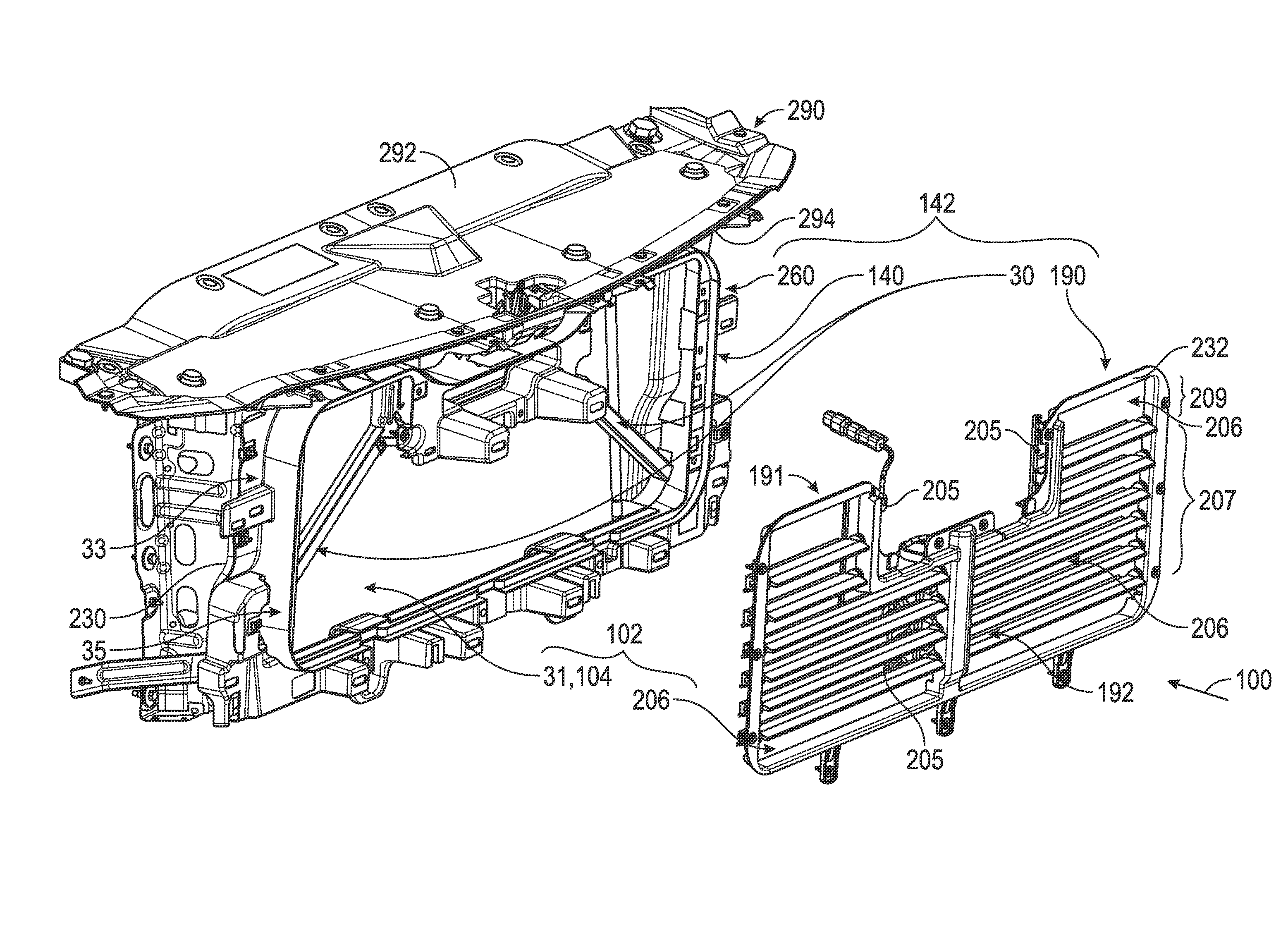

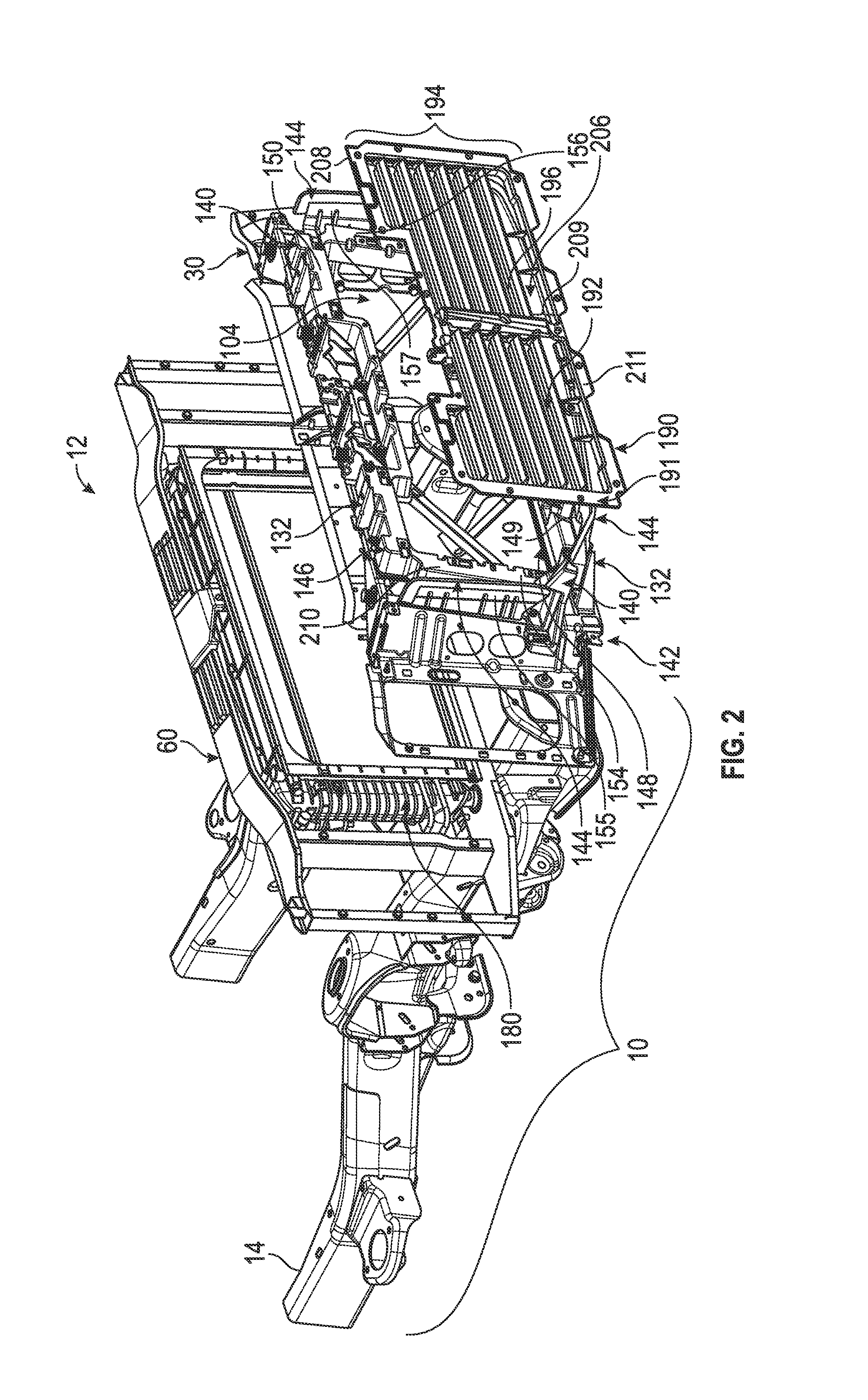

Front fascia or grill support structure and aerodynamic shutter assembly

A fascia support structure and aerodynamic shutter assembly for a vehicle includes a fascia support structure, comprising: a top portion comprising a substantially U-shaped body comprising a top fascia support member, a first side fascia support member and a second side fascia support member, the first side fascia support member having a first side baffle, the second side fascia support member having a second side baffle; and a bottom portion comprising a bottom baffle, the bottom portion attached to the first and second side fascia support members, the top portion and the bottom portion comprising a fascia support structure opening, at least one of the first side baffle, second side baffle or bottom baffle having a seal member disposed on a leading edge. The assembly also includes an aerodynamic shutter system comprising a shutter frame having a shutter frame opening and a plurality of rotatable shutters disposed therein.

Owner:GM GLOBAL TECH OPERATIONS LLC

Vehicle front end structure

Owner:MAZDA MOTOR CORP

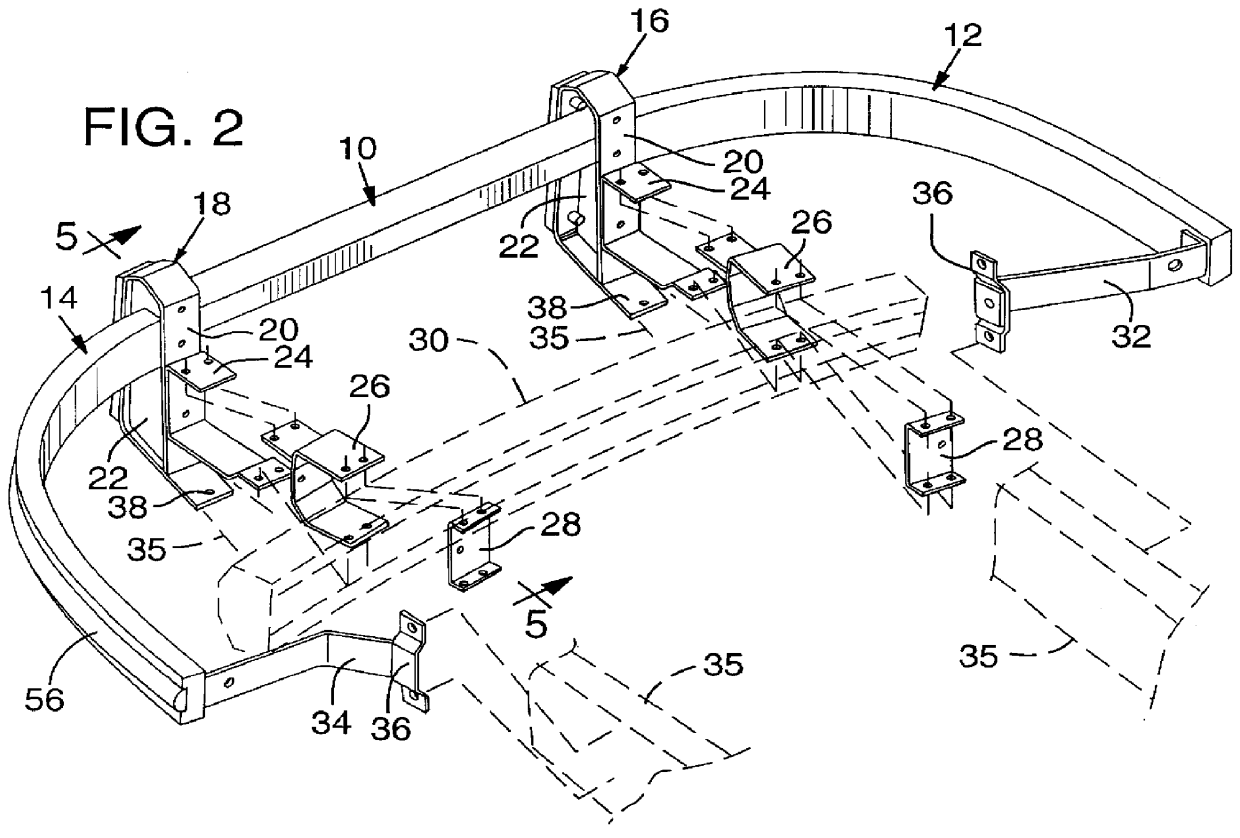

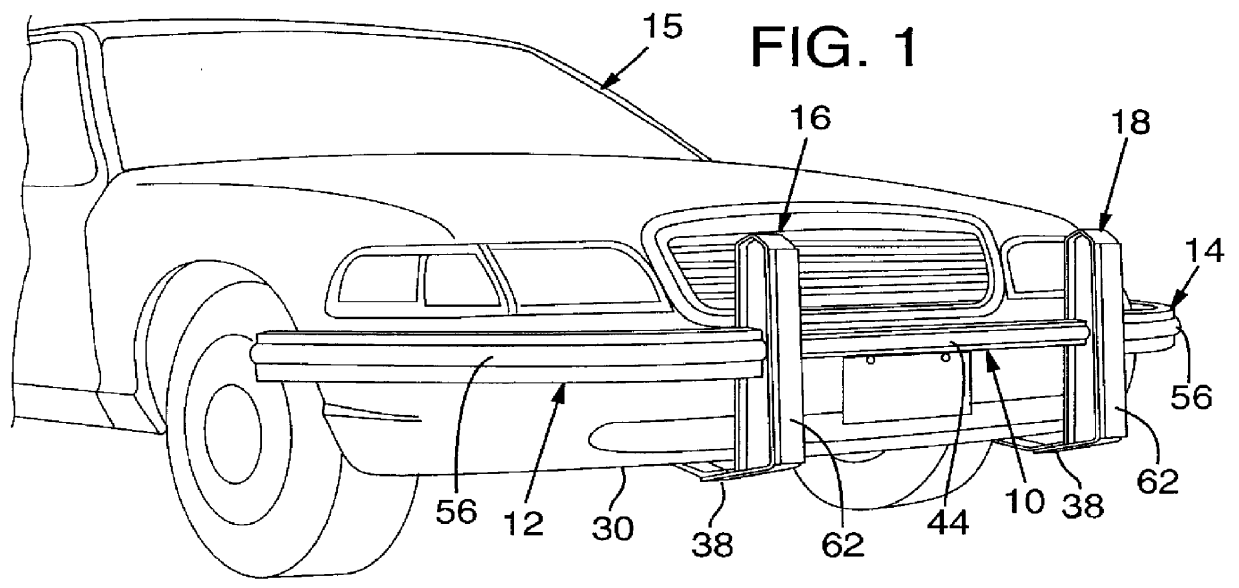

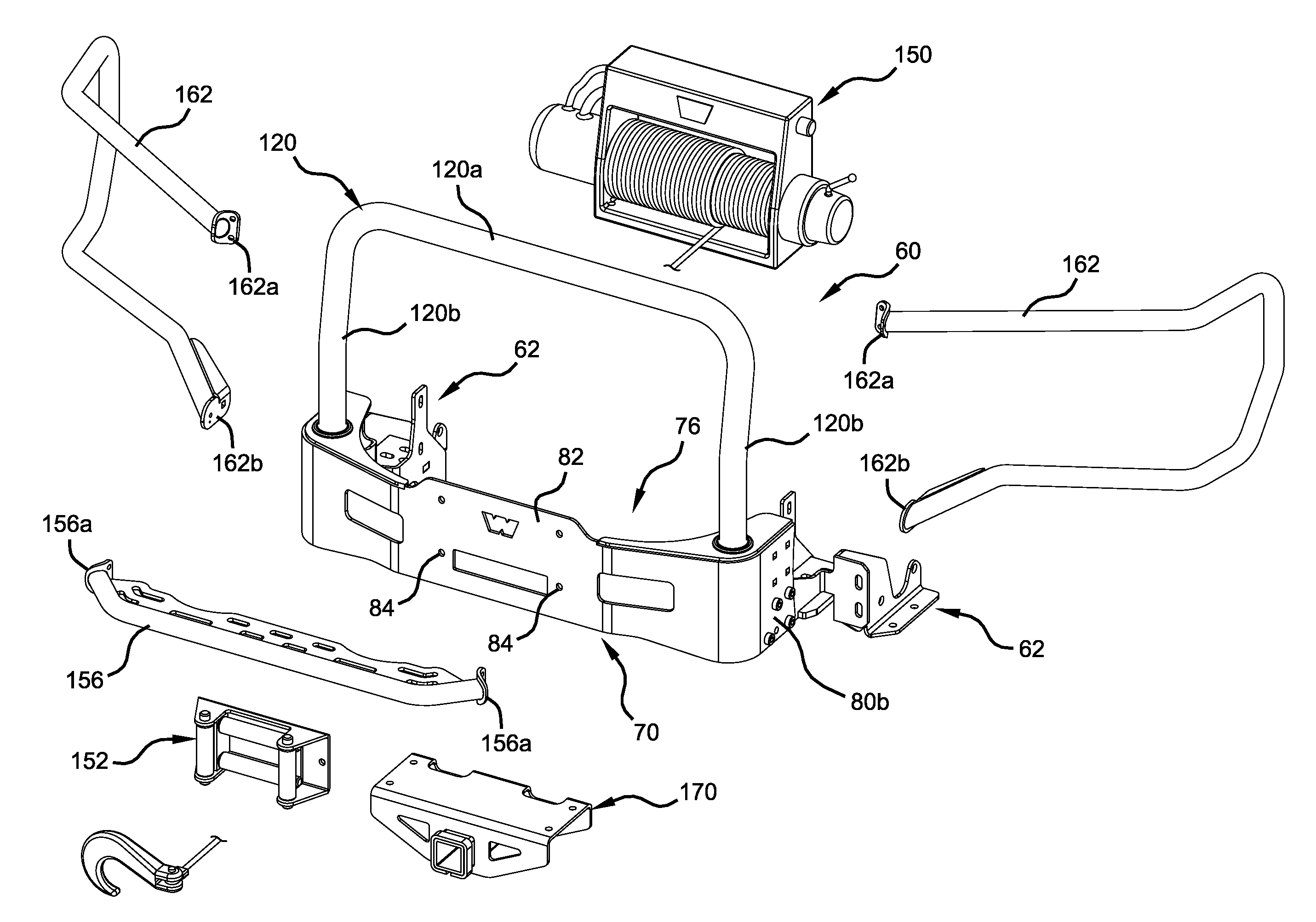

Winch Carrier and Grille Guard Mounting System

InactiveUS20110006553A1Simple interfaceImprove aestheticsMonocoque constructionsVehicle bodiesVehicle frameEngineering

An accessory mounting system for on-road and off-road passenger vehicles, such as light-duty trucks and SUV's is provided. The system attaches to a vehicle to serve as an extension of the vehicle frame to provide a secure mounting location for vehicle accessories, such as a winch, grille guards, headlamp guards, and lights. The system provides for the attachment of numerous accessory components without modification or replacement of an original equipment bumper.

Owner:WARN INDUSTRIES

Front air-rectifying structure of automotive vehicle

A shutter unit comprises plural flaps, a shutter frame member, and a second support portion to support an air guide member. The air guide member comprises a lower face portion positioned between an upper grille opening portion and the flaps, a first fixation portion fixed to a first support portion of a shroud member, and a second fixation portion fixed to a second support portion of the shutter unit. The lower face portion is configured such that the lower face portion in a state in which the second fixation portion is fixed to the second support portion is spaced apart upward from the shutter frame member.

Owner:MAZDA MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com