Vehicle front end structure

A front structure, vehicle technology, applied in the direction of the radiator, etc., can solve problems such as detrimental to the appearance of the front of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

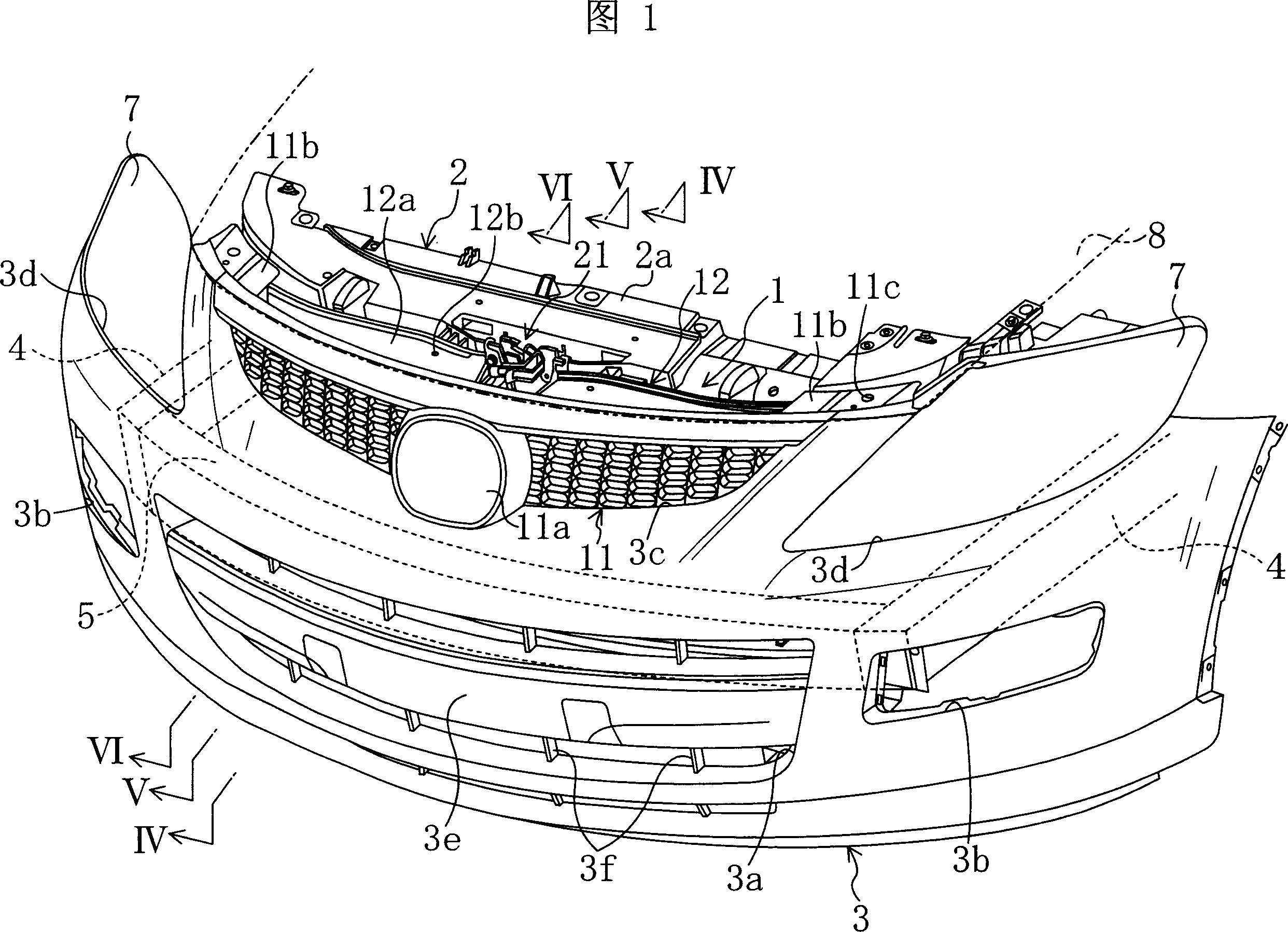

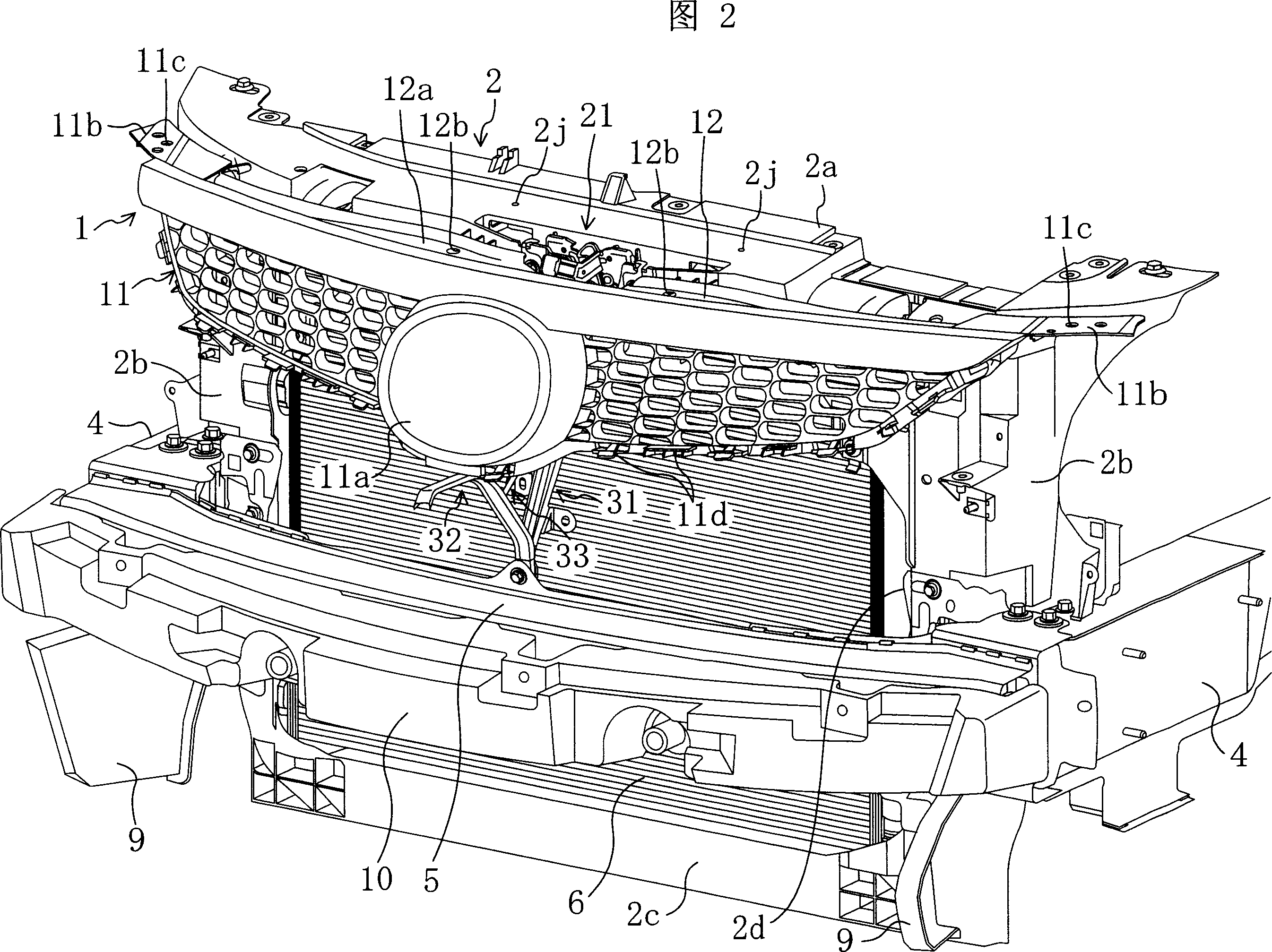

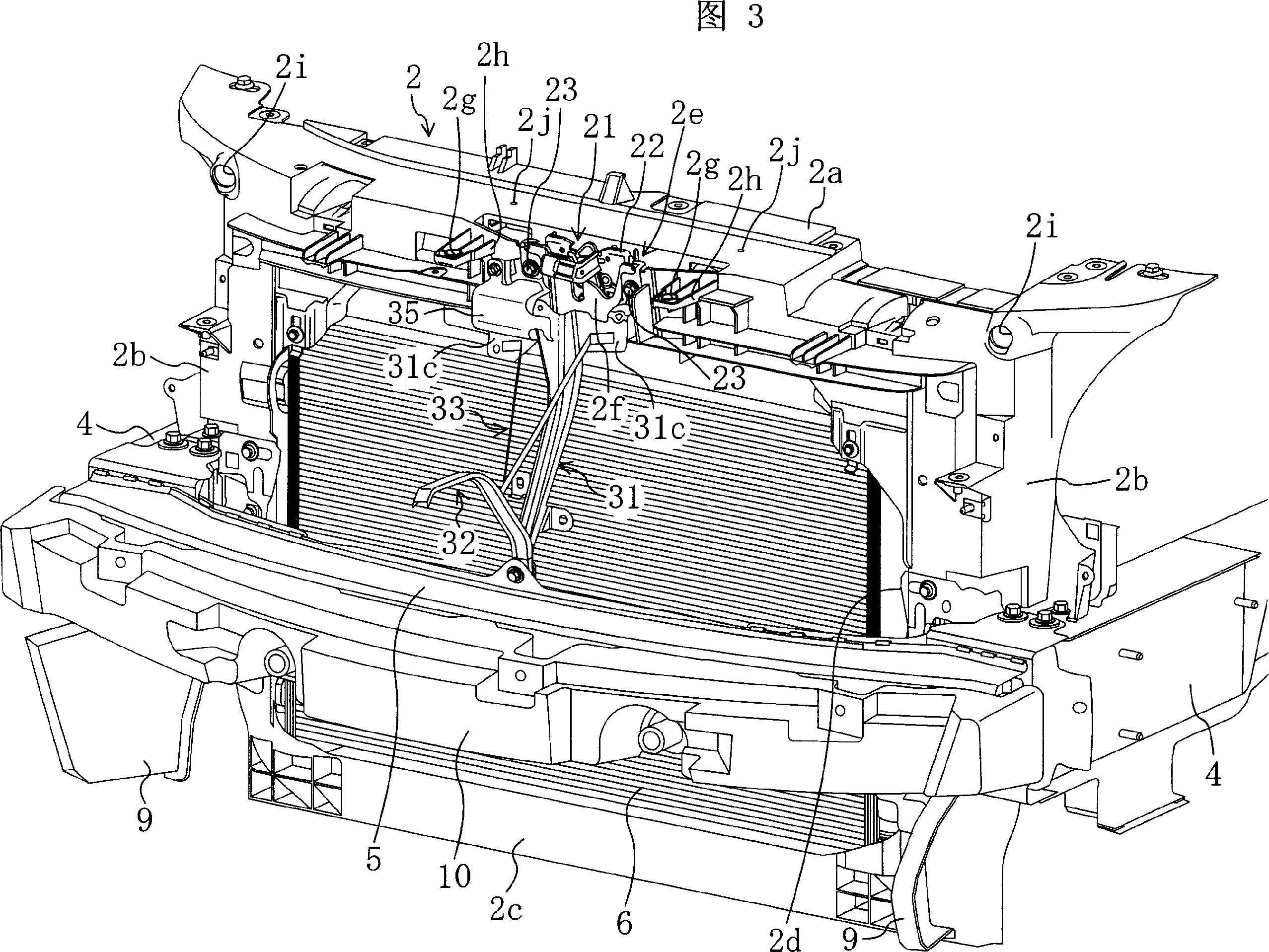

[0075] FIG. 1 shows a vehicle front structure according to a first embodiment of the present invention. That is, this FIG. 1 schematically shows the main components of the vehicle front such as the radiator grille 1, the radiator fixing frame 2, the bumper cover 3 (front bumper cover), and other parts (for example, the engine, etc.) ) is omitted.

[0076] The bumper cover 3 is formed of a resin plate-shaped member formed into a predetermined shape, and is disposed so as to cover the front portion of the vehicle. In addition, a bumper face opening 3a serving as a vent is provided at the lower center thereof, and fog lamp openings 3b, 3b for placing fog lamps are provided on the left and right of the bumper face opening 3a. In addition, in the upper part of the bumper cover 3, a grill recess 3c for positioning the radiator grill 1 is formed in the central part, and opposite headlights are formed on the left and right sides of the grill recess 3c. Recesses 3d, 3d for positionin...

no. 2 example

[0121] 13 to 15 show a front view, a rear view, and a rear perspective view when the vehicle front structure according to the second embodiment of the present invention is used, respectively. Since the vehicle front structure involved in this second embodiment differs from the above-mentioned first embodiment only in the supporting structure of the radiator grille 1, the same symbols are marked for the same parts below, and only different parts are marked illustrate.

[0122] That is, in this embodiment, the front surface (surface) of the bumper holding piece 71 is bonded to the rear side of the bumper cover 3 to increase the rigidity of the bumper cover 3, and at the same time, it is held by the bumper. The sheet 71 supports the radiator grill 1 from below. The bumper holding piece 71 is supported by a holding piece supporting member 75 (grille supporting portion) extending forward and upward from the bumper beam side mounting portion 31 b of the center bracket 31 .

[0123...

no. 3 example

[0150] FIG. 19 shows a vehicle front structure according to a third embodiment of the present invention. That is, this FIG. 19 is a diagram briefly showing the main components of the vehicle front such as the radiator grille 1, the bumper cover 3 (front bumper cover part) and the engine cover 8. For other parts (for example, The illustrations of headlamps and fog lamps, etc.) are omitted. In addition, since the structure of the front part of the vehicle according to the third embodiment differs from the above-mentioned first and second embodiments only in the supporting structure of the radiator grille 1, the same reference numerals are assigned to the same parts in the following description. .

[0151] The above-mentioned bumper cover 3 is composed of a resin plate member formed in a predetermined shape to cover the front part of the vehicle, and a bumper cover opening 3a (opening) as an air vent is provided at the center of the lower side thereof. A lower side of the bumpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com