Aluminum-plated steel sheet for hot pressing with rapid heating, process for producing same, and method of hot-pressing same with rapid heating

一种快速加热、制造方法的技术,应用在制造工具、热浸镀工艺、照明和加热设备等方向,达到杜绝流挂、提高生产性、降低延迟破坏的风险的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0142] The present invention will be further specifically described below in conjunction with examples.

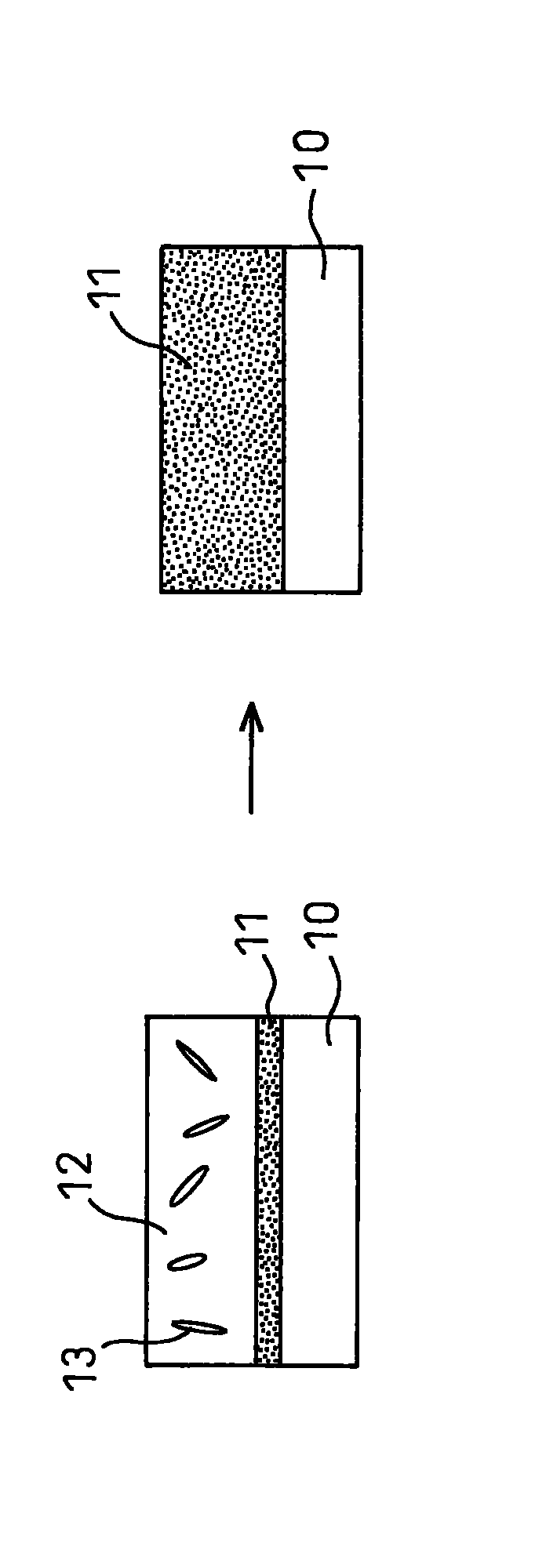

[0143] Hot-dip aluminum plating was performed using cold-rolled steel sheets (thickness 1.2 mm) having steel compositions shown in Table 1 that had undergone conventional hot-rolling and cold-rolling steps as materials. As hot-dip aluminum plating, a non-oxidizing furnace-reduction furnace type pipeline is used, and the amount of plating on one side is adjusted to 20 to 100 g / m by the gas wiping method after plating 2 , and then cooled. The plating bath composition at this time was Al-9%Si-2%Fe. The Fe in the bath comes from the plating equipment and steel strip in the bath and is inevitably introduced. The plating appearance was good, and non-plating and the like did not occur.

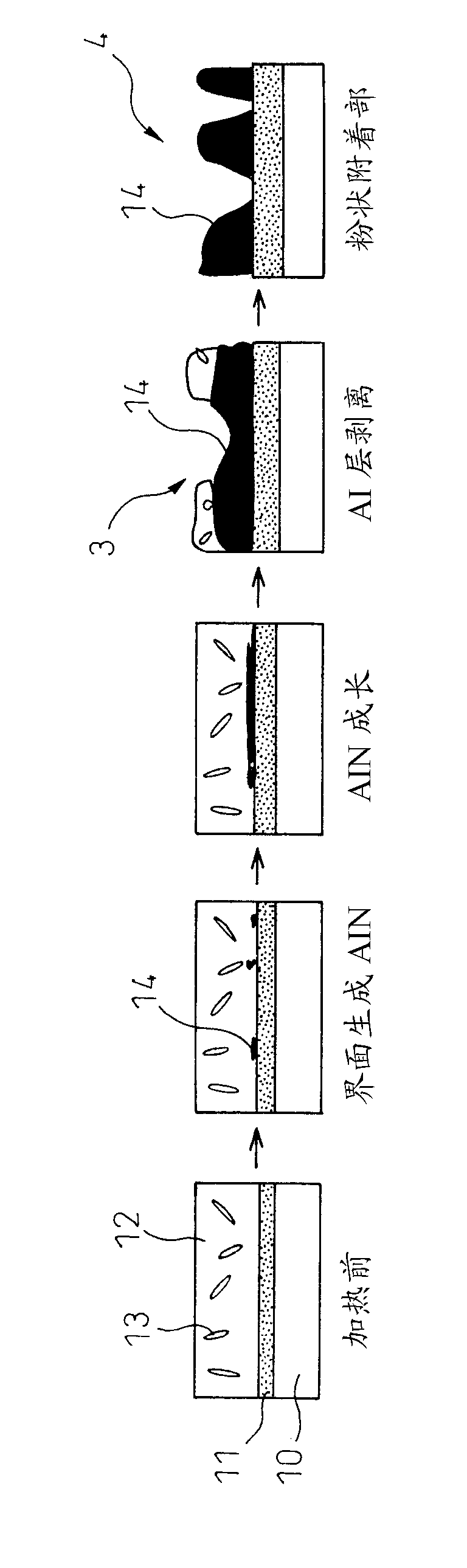

[0144] Then, the steel sheet was subjected to box annealing in a coiled state. Conditions of box annealing are set to air atmosphere, 540 to 780° C., and 1 to 100 hours. After annealing, a b...

Embodiment 2

[0156] In the same manner as in Example 1, cold-rolled steel sheets (thickness 1.2 mm) having various steel components shown in Table 3 were subjected to hot-dip aluminum plating. Make the coating weight 60g / m on one side 2 . These aluminum-coated steel sheets were heated at 620° C. for 8 hours using a box anneal.

[0157] Then, it heated to the attainment temperature of 900 degreeC by electric heating at the average temperature increase rate of 60 degreeC / sec, and then performed die hardening. Table 3 shows the results of measuring the hardness (Vickers hardness, load 10 kg) after quenching. It can be seen that if the amount of C in the steel is low, the hardness after quenching will decrease, so the amount of C is preferably 0.10% by mass or more. It should be noted that, at this time, no sagging occurred in any of the test pieces.

[0158] [Table 3] Steel composition (mass%) of sample material

[0159]

Embodiment 3

[0161] According to the method same as embodiment 1, to the cold-rolled steel plate (thickness 1.6mm) that has the steel composition shown in table 1, with single side 80g / m 2 Aluminum plating is implemented. Then, to the ZnO microparticle suspension (nanotek slurry manufactured by CI Chemicals Co., Ltd.), a water-soluble acrylic resin was added in a weight ratio of 20% relative to ZnO, and the amount of Zn was 1 g / m 2 The resulting solution was applied in a target amount, and then dried at 80°C. This material was annealed at 630° C. for 7 hours under box annealing conditions until the surface was alloyed. The L* value at this time was 52.

[0162] Using this sample, the temperature was raised to 900° C. by the energization heating method, and the holding time was not elapsed, followed by rapid cooling in the mold. The average temperature increase rate at this time was 60°C / sec. The post-coating corrosion resistance of the material thus produced was evaluated in the same m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com