Patents

Literature

77 results about "Aluminized steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminized steel is steel that has been hot-dip coated on both sides with aluminium-silicon alloy. This process assures a tight metallurgical bond between the steel sheet and its aluminium coating, producing a material with a unique combination of properties possessed neither by steel nor by aluminium alone. Aluminized steel shows a better behavior against corrosion and keeps the properties of the base material steel for temperature lower than 800 °C (1,470 °F). For example, it is commonly used for heat exchangers in residential furnaces, commercial rooftop HVAC units, automotive mufflers, ovens, kitchen ranges, water heaters, fireplaces, barbecue burners, and baking pans. This steel is very useful for heating things up because it transfers heat faster than most other steels.

Ceramic substrate for nonstick coating

InactiveUS20030059600A1Improve coating adhesionMore durableSynthetic resin layered productsPretreated surfacesFritAluminized steel

The present invention provides a new and useful nonstick coating for use on pure aluminum, alloys of aluminum, or aluminized steel surfaces. A nonstick coating according to the present invention includes a ceramic substrate disposed on an aluminum surface and a fluorocarbon polymer coating disposed on the ceramic substrate. The ceramic substrate, prior to firing, includes at least two layers: a first or bottom layer applied to the aluminum surface including an enamel ground coat; and a second or top layer applied over the enamel ground coat layer including a blend of one or more glass frits, non-ceramic refractory particles, and non-vitreous inorganic oxide particles. Upon firing, the ceramic substrate includes a continuous layer of vitreous enamel that is bonded to the aluminum surface. The exposed surface of the ceramic substrate has a micro-rough texture that is enriched with bonding sides for binder resins used in a fluorocarbon polymer primer layer. The ceramic substrate protects the aluminum surface from corrosion and mechanical damage and also protects the fluorocarbon polymer coating from abrasive wear.

Owner:FERRO CORP

Ceramic substrate for nonstick coating

InactiveUS6638600B2Easy to optimizeImprove adhesionSynthetic resin layered productsPretreated surfacesFritAluminized steel

The present invention provides a new and useful nonstick coating for use on pure aluminum, alloys of aluminum, or aluminized steel surfaces. A nonstick coating according to the present invention includes a ceramic substrate disposed on an aluminum surface and a fluorocarbon polymer coating disposed on the ceramic substrate. The ceramic substrate, prior to firing, includes at least two layers: a first or bottom layer applied to the aluminum surface including an enamel ground coat; and a second or top layer applied over the enamel ground coat layer including a blend of one or more glass frits, non-ceramic refractory particles, and non-vitreous inorganic oxide particles. Upon firing, the ceramic substrate includes a continuous layer of vitreous enamel that is bonded to the aluminum surface. The exposed surface of the ceramic substrate has a micro-rough texture that is enriched with bonding sides for binder resins used in a fluorocarbon polymer primer layer. The ceramic substrate protects the aluminum surface from corrosion and mechanical damage and also protects the fluorocarbon polymer coating from abrasive wear.

Owner:FERRO CORP

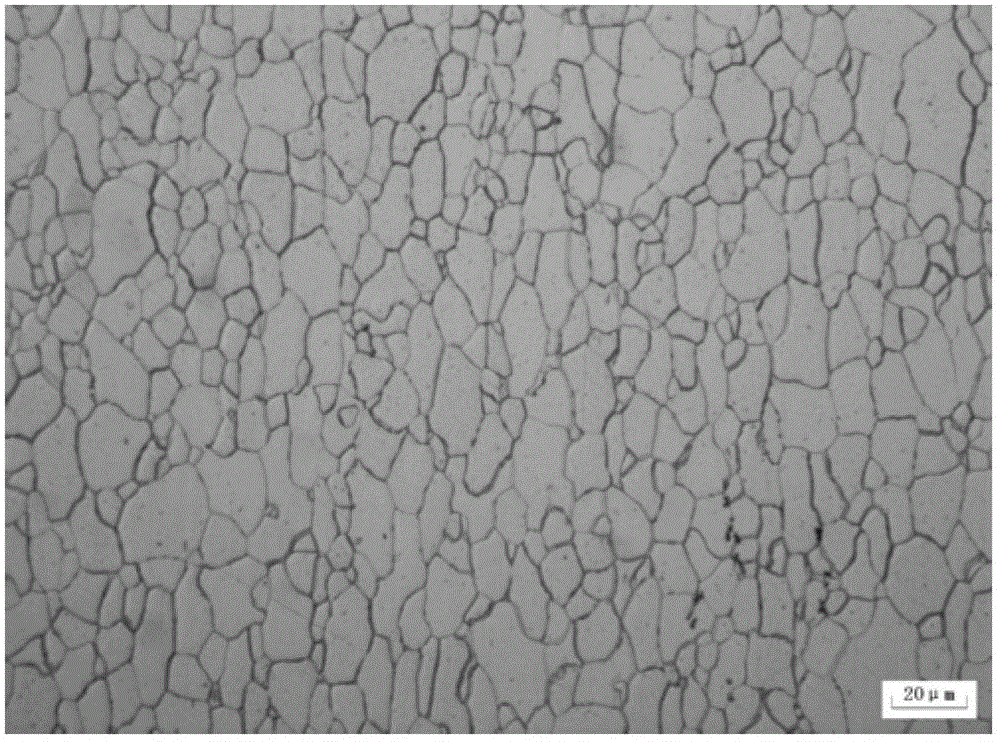

Method for producing cold-rolled sheet for surface coating and plating base plate

ActiveCN102716905ABright and clean surfaceGood formabilityHot-dipping/immersion processesMetal rolling arrangementsAcid washingContinuous annealing

The invention discloses a method for producing a cold-rolled sheet for a surface coating and plating base plate. A steel billet comprises the following compositions by weight percentage: at most 0.12 percent of C, at most 0.05 percent of Si, at most 0.60 percent of Mn, at most 0.04 percent of P, at most 0.04 percent of S, and the balance of Fe. The steel billet comprising the compositions is sequentially subjected to hot rolling, acid washing and cold rolling to obtain a cold-rolled steel coil, and then the cold-rolled steel coil is made into the cold-rolled sheet for the surface coating and plating base plate through a continuous annealing or galvanizing method. Continuous annealing coating and plating bases plate and galvanizing coating and plating base plates produced through the method for producing the cold-rolled sheet for the surface coating and plating base plate have a good formability, meanwhile also have a good surface quality and paintability, and can be used as base plates of high-grade electric galvanized sheets, prepainted steel sheets, tinning sheets and aluminized steel sheets.

Owner:SHOUGANG CORPORATION

Catalytic porcelain enamel coating composition

The present invention provides a new and improved porcelain enamel coating composition for use in forming a self-cleanable coating upon aluminized steel. The coating composition comprises a glass component having a composition comprising from about 30% to about 55% SiO2, from about 11% to about 20% TiO2, from about 0% to about 10% B2O3, from about 20% to about 40% alkali metal oxides, less than about 5% rare earth metal oxides, from about 0% to about 10% CaO, from about 0% to about 10% BaO, from about 0% to about 10% MnO, from about 2% to about 12% CuO, from about 0% to about 10% Sb2O3, from about 1.5% to about 10% Fe2O3, from about 0% to about 10% SnO2, from about 0% to about 10% P2O5, less than about 2% MoO3, and less than about 5% V2O5.

Owner:FERRO FRANCE S A R L

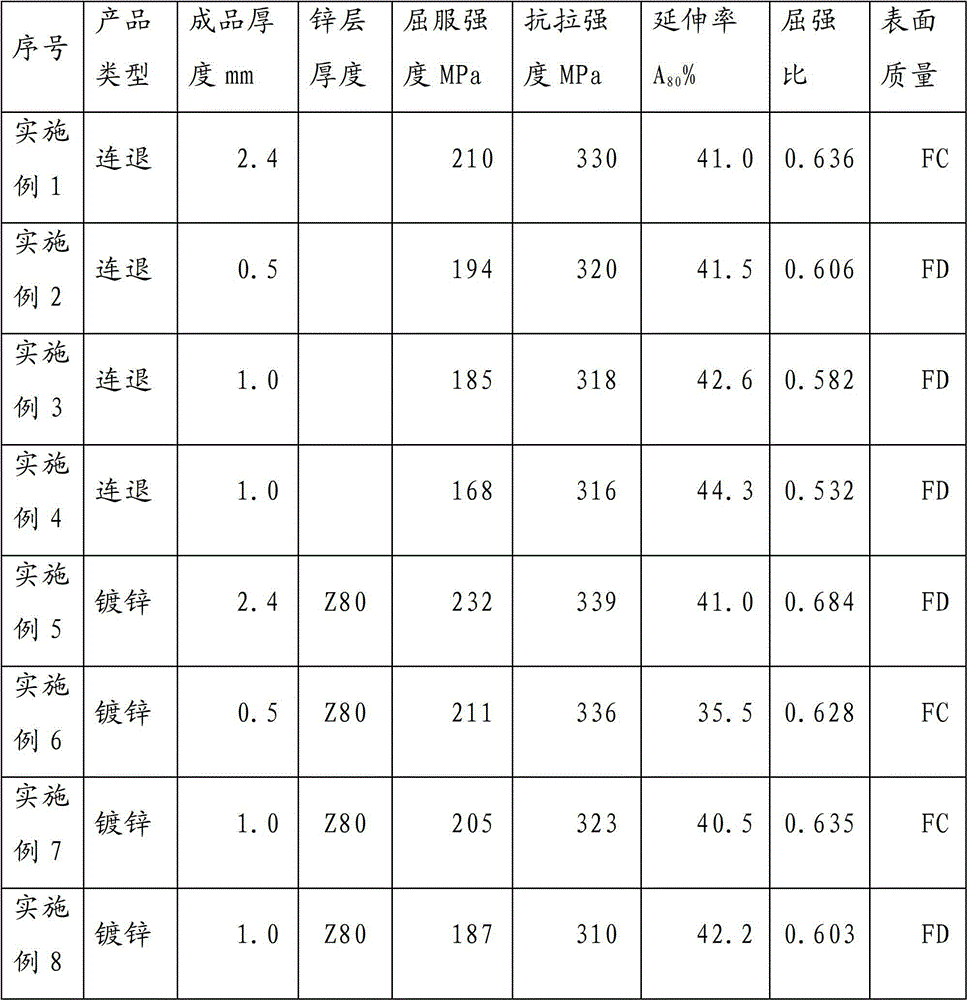

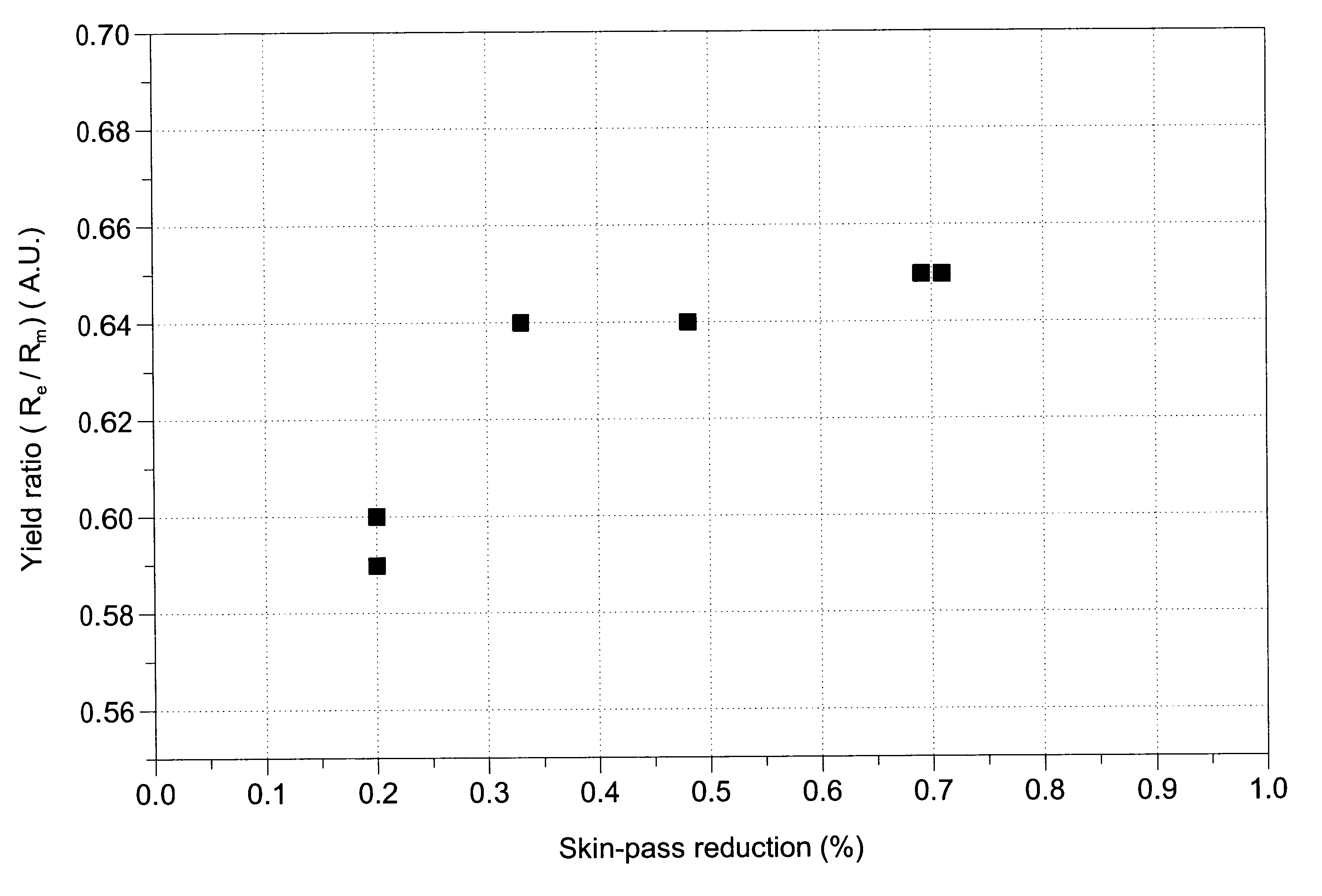

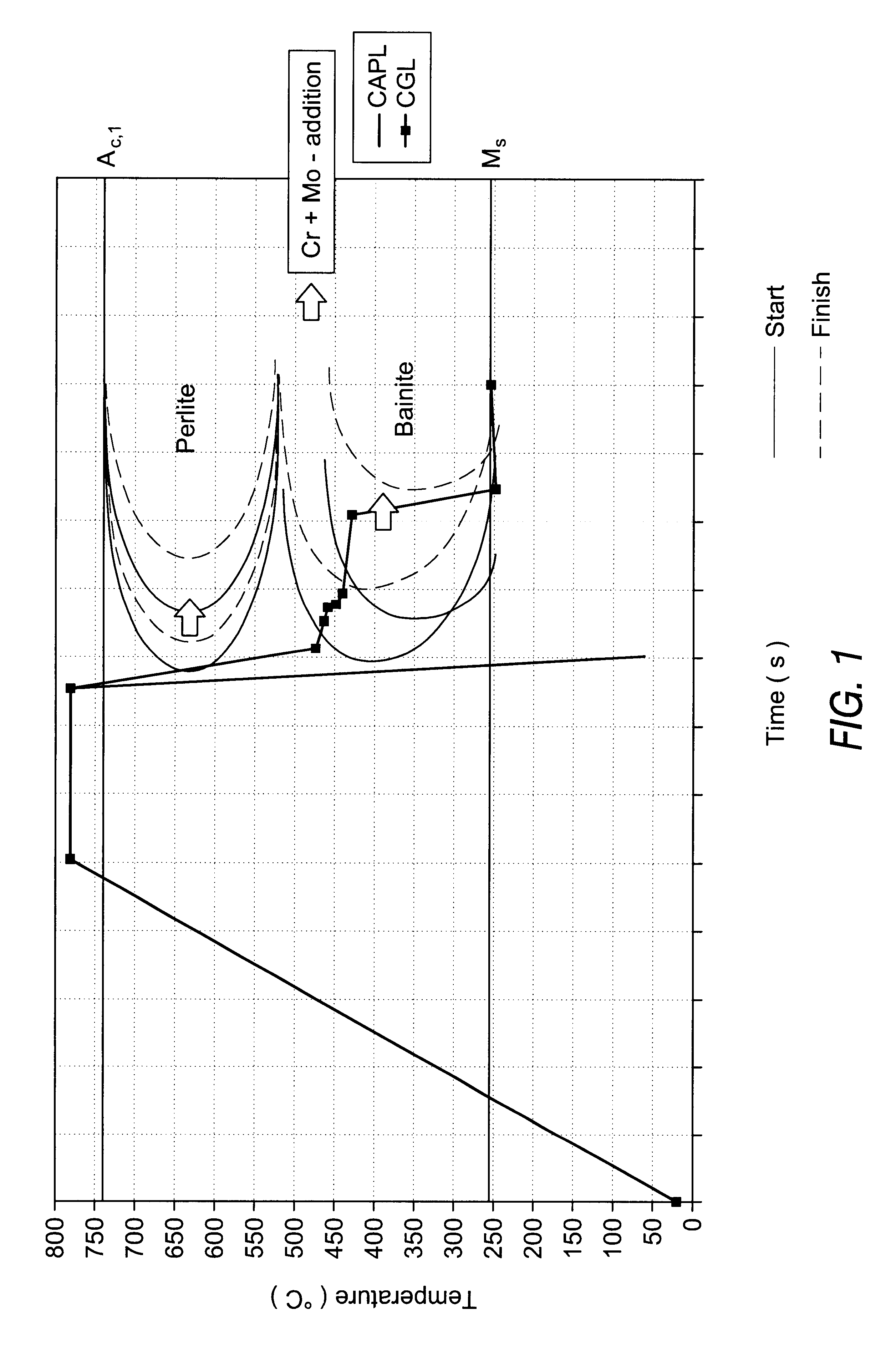

Method of production of cold-rolled metal coated steel products, and the products obtained, having a low yield ratio

InactiveUS6641931B2High strengthGood molding effectHot-dipping/immersion processesFurnace typesManganeseYield ratio

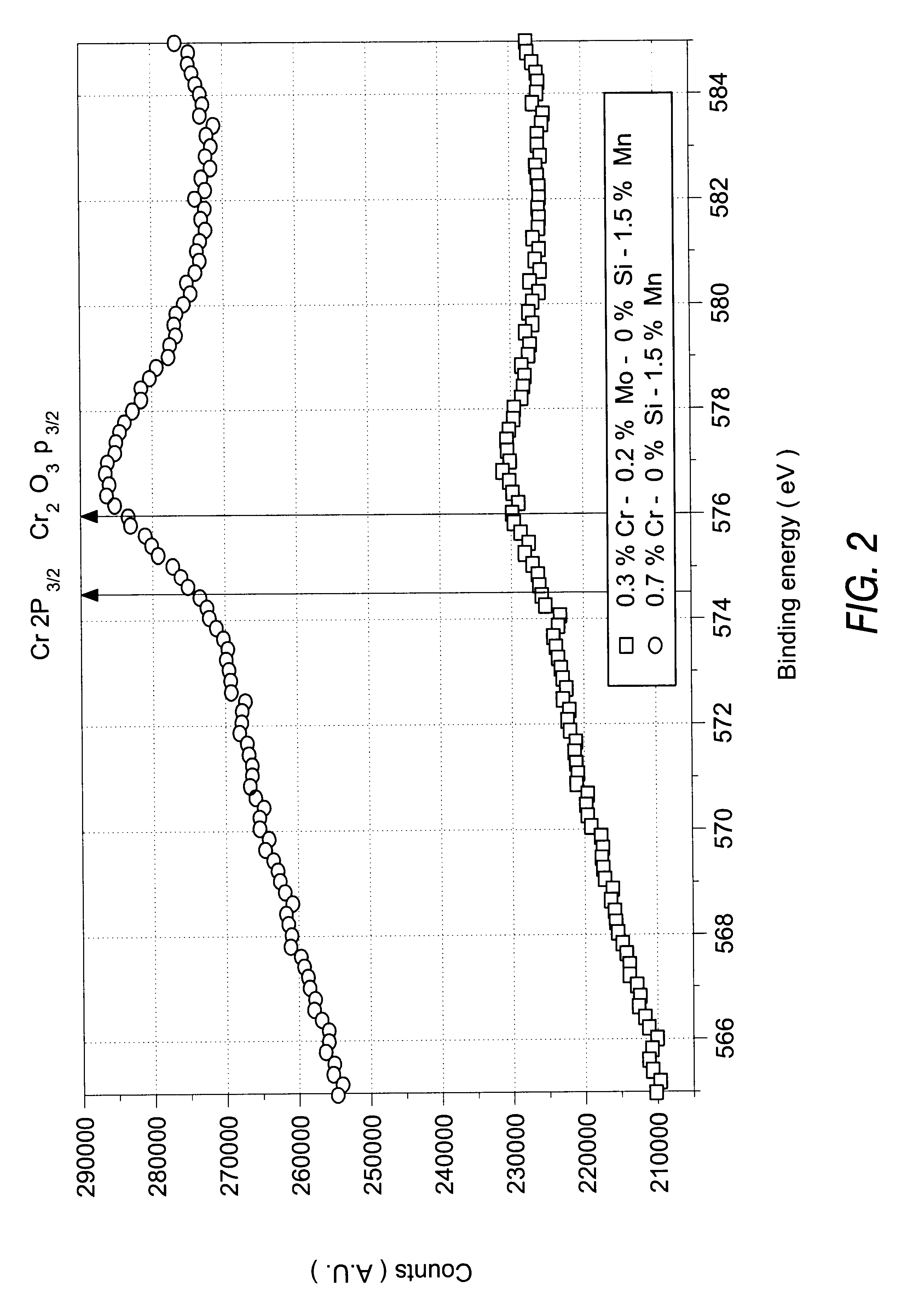

The present invention aims to produce a cold rolled metal coated multi-phase steel, characterized by a tensile strength of at least 500 MPa, a yield ratio (Re / Rm) lower than 0.65 in skinned conditions, lower than 0.60 in unskinned conditions, and with good metal coating adhesion behavior. In the case of the aluminized steel according to the invention, the steel also has superior resistance to temperature corrosion up to 900° C. and excellent mechanical properties at this high temperature. The hot metal coated steel product having a steel composition with a manganese content lower than 1.5%, chrome content between 0.2 and 0.5%, molybdenum content between 0.1 and 0.25%, and a relation between the chrome and molybdenum content as follows Cr+2 Mo higher than or equal to 0.7%, undergoes a thermal treatment in the hot dip metal coating line defined by a soaking temperature between Ac1 and Ac3, a primary cooling speed higher than 25° C. / sec and a secondary cooling speed higher than 4° C. / sec.

Owner:SIDMAR

Method for the preparation of aluminized steel sheets to be welded and then press hardened

ActiveUS20170266761A1Eliminate expensiveTime-consuming to eliminateArc welding apparatusVehicle componentsSheet steelMetal alloy

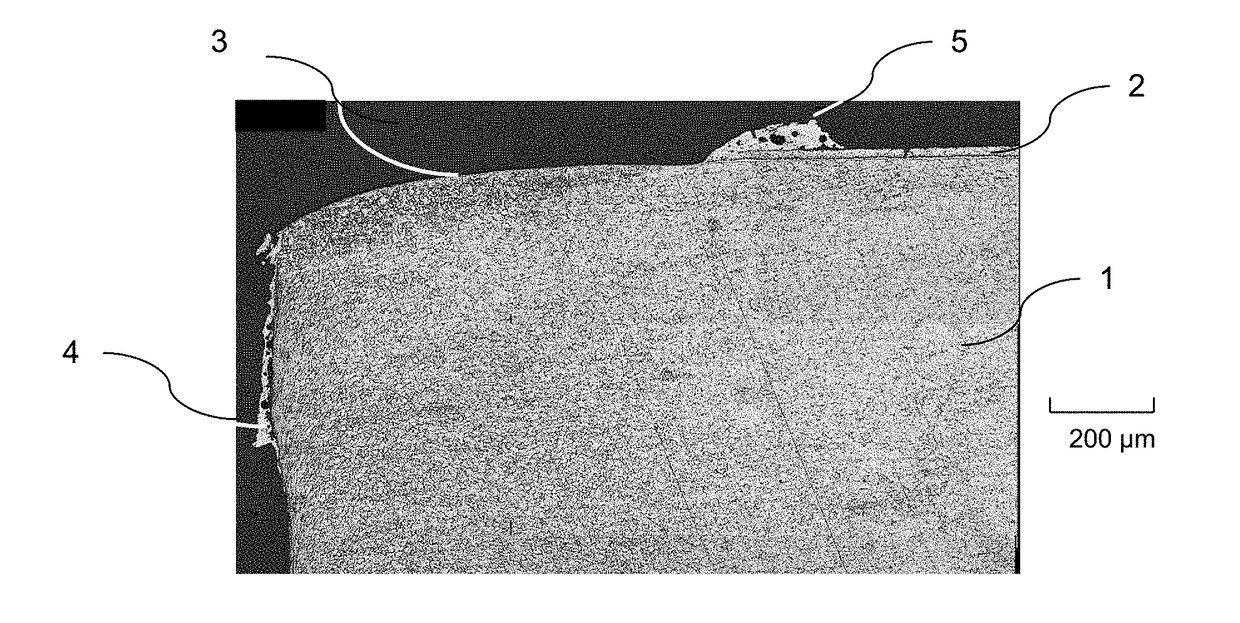

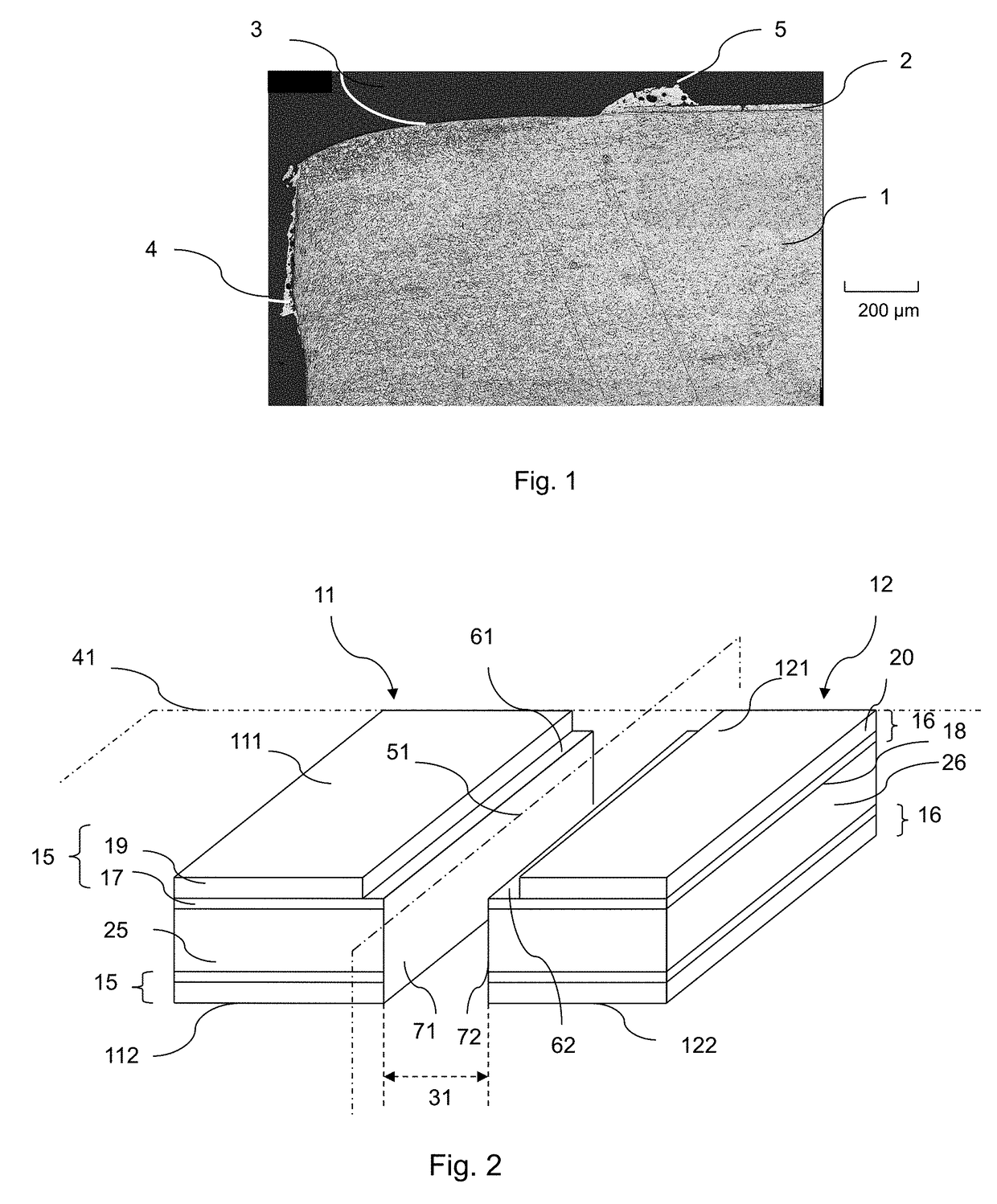

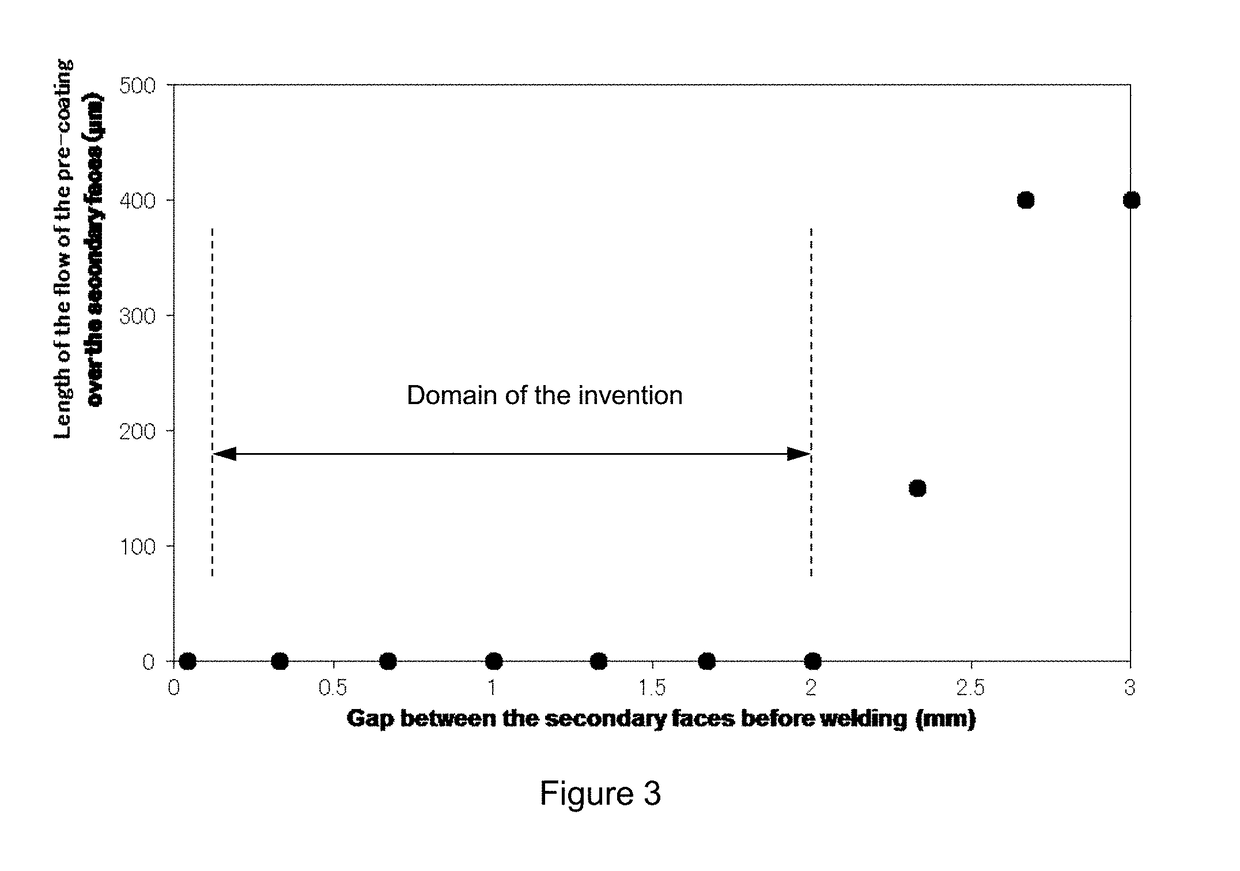

A method for the preparation of steel sheets for fabricating a welded steel blank is provided. The method includes procuring at least two pre-coated steel sheets, each having a pre-coating of an intermetallic alloy layer, topped by a layer of aluminum metal or aluminum alloy or aluminum-based alloy. The sheets have a principal face, an opposite principal face, and at least one secondary face. The sheets are positioned so a gap between 0.02 and 2 mm exists between the secondary faces. The secondary faces face each other. The positioning of the first and second sheets defines a median plane perpendicular to the principal faces. Layers of metal alloy are removed by melting and vaporization simultaneously on the principal faces, in a peripheral zone of the sheets, the peripheral zones being the zones of the principal faces closest in relation to the median plane.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

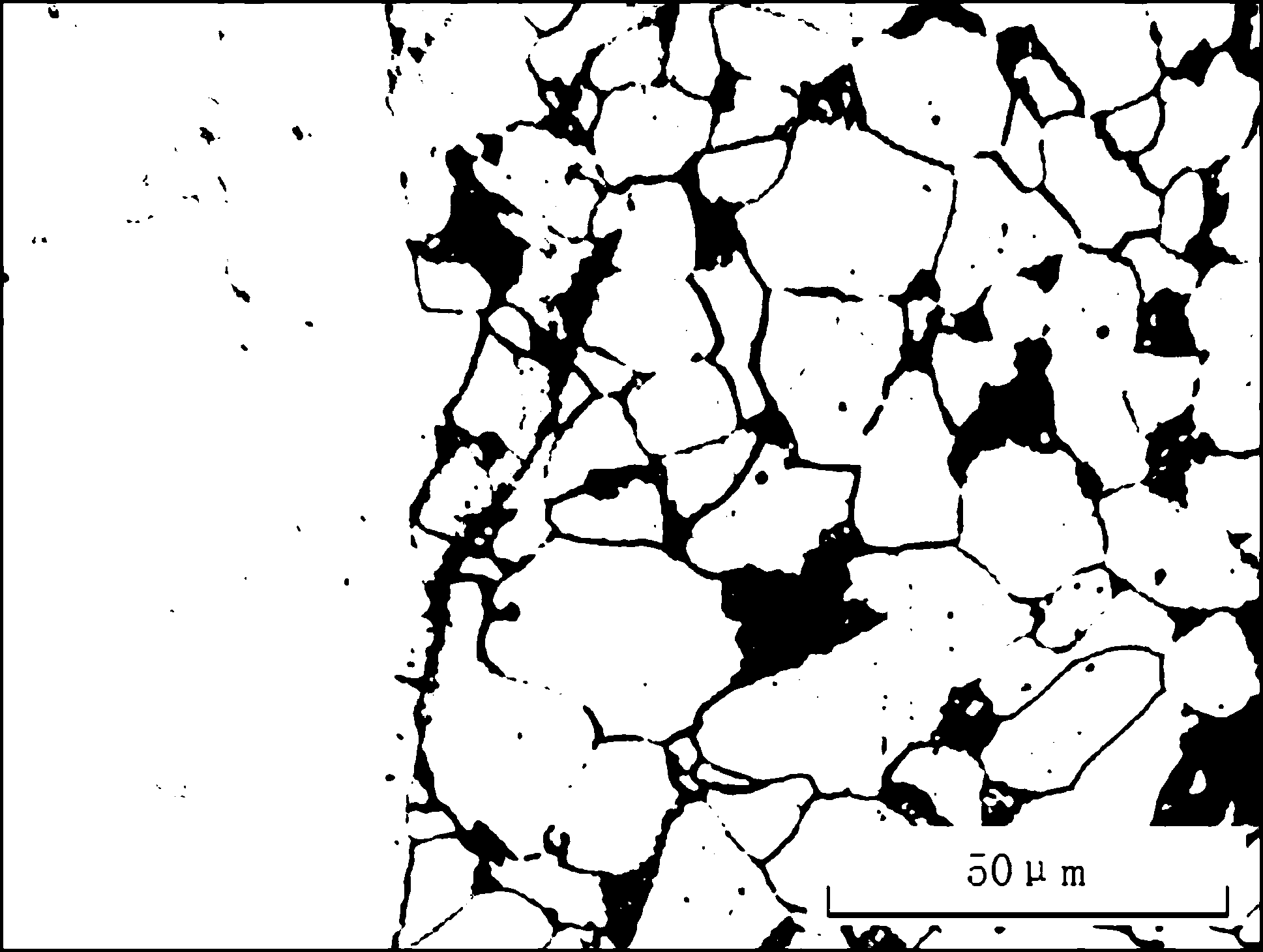

Aluminized steel and preparation method thereof

InactiveCN103320745AReduce concentrationEliminate the effects of hydrogen embrittlementSolid state diffusion coatingSurface layerThermal fatigue

The invention discloses aluminized steel comprising a steel workpiece, wherein a eutectic aluminized alloy layer and an aluminum layer are sequentially arranged on the surface layer of the steel workpiece from inside to outside, and the thickness of the aluminized alloy layer is 14-29 microns. A preparation method of the aluminized steel comprises the following steps: co-firing the steel workpiece to remove oil; pickling to remove rust; washing; carrying out surface activating; carrying out auxiliary infiltrating; drying; carrying out rapid induction aluminizing; immediately immersing the dried steel workpiece in molten aluminum heated to 680-700 DEG C in an induction manner, wherein the infiltration time is 2-3 minutes; and the aluminized steel is obtained by the steps. The aluminized steel disclosed by the invention has superior corrosion resistance, heat resistance, wear resistance and photo-thermal reflectivity, and meanwhile, the bending property of the aluminized steel can be improved, the surface brittleness of diffusion aluminized layers is eliminated and the thermal shock resistance and thermal fatigue resistance can be improved. The preparation method disclosed by the invention can be used for effectively controlling the thickness of the aluminized layer, shortening the technique preparation period, improving the efficiency and increasing the yield.

Owner:HUBEI PROVINCIAL COMM INVESTMENT FOUR ADVANTAGE STEEL TECH

Hybrid arc/laser-welding method for aluminized steel parts using gammagenic elements and a gas containing less than 10 % of nitrogen or oxygen

The invention relates to a hybrid laser / arc-welding method using an electric arc and a laser beam that are combined together within a single welding melt to which molten metal is supplied by melting a filler wire, wherein the welding melt is provided on at least one steel part including an aluminum surface coating, and a protective gas is used, characterized in that the filler wire contains at least 3 wt % of one or more gammagenic elements, in particular the gammagenic elements selected from C, Mn, Ni and N, and the protective gas consists of helium and / or argon with the addition of at least 10 vol % of nitrogen or oxygen. The method of the invention is particularly suitable for welding end-welded flanks used in the field of manufacturing automobiles or for tube welding.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

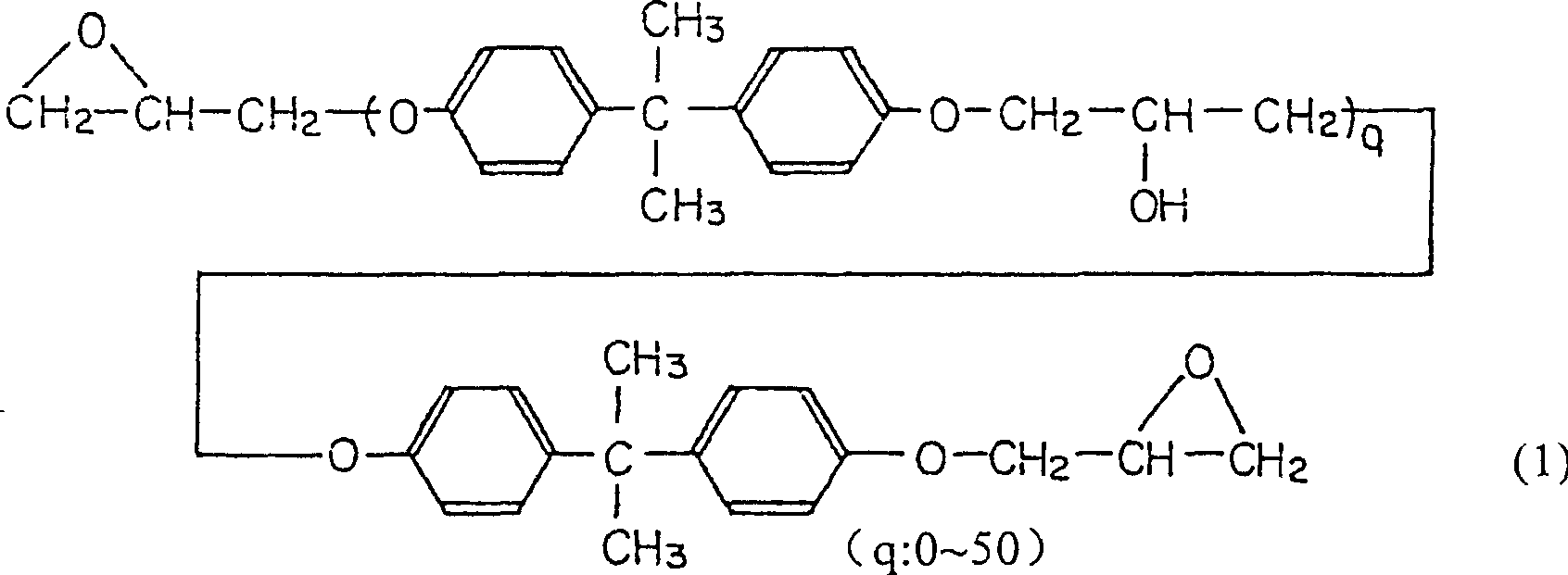

Surface treated steel plate excellent in corrosion resitance electroconductivity and appearance of coating film

PROBLEM TO BE SOLVED: To provide a surface-treated steel sheet having superior corrosion resistance in spite of containing no hexavalent chromium in a coating, and besides, having superior conductivity and coating film appearance.SOLUTION: The surface-treated steel sheet has a composite oxide coating on the surface of a galvanized or aluminized steel sheet, as the first layer, and an organic coating thereon as the second layer. The composite oxide coating includes (α) silica, (β) phosphoric acid and / or a phosphate compound, (γ) one or more metals selected among Mg, Mn and Al and (σ) a tetravalent vanadium compound, each in a predetermined amount. The organic coating includes a reaction product (X) of a film-forming organic resin (A) and an active-hydrogen-containing compound (B) formed of a hydrazine derivative (C), of which one part or all parts have active hydrogen; and a particular corrosion-preventing component (Y).

Owner:JFE STEEL CORP

Hybrid arc/laser-welding method for aluminized steel parts using gammagenic elements and a gas containing less than 10% of nitrogen or oxygen

The invention relates to a hybrid laser / arc-welding method using an electric arc and a laser beam that are combined together within a single welding melt to which molten metal is supplied by melting a filler wire, wherein the welding melt is provided on at least one steel part including an aluminum surface coating, and a protective gas is used, characterized in that the filler wire contains at least 3 wt % of one or more gammagenic elements, in particular the gammagenic elements selected from C, Mn, Ni and N, and the protective gas consists of helium and / or argon with the addition of at least 10 vol % of nitrogen or oxygen. The method of the invention is particularly suitable for welding end-welded flanks used in the field of manufacturing automobiles or for tube welding.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Method for finishing hot-dip coated steel sheet

InactiveCN101905240AImprove surface qualityQuality improvementHot-dipping/immersion processesRollsCoated surfaceSheet steel

The invention relates to a method for finishing a hot-dip coated steel sheet, comprising the step of rolling a hot-dip coated steel sheet by using a finishing roller, wherein the surface roughness of the finishing roller Ra is less than or equal to 1 Mum. The method is especially suitable for hot galvanized steel sheets and hot galvanized and aluminized steel sheets with zinc spangles on the coated surface. The method can ensure good shape, surface quality and coating performance of the hot-dip coated steel sheet and can ensure that zinc spangle profiles on the coating surface are clear and maintain good appearance decoration performance. In addition, the method is also suitable for finishing hot galvanized and aluminized steel sheets and facilitates the application of the hot galvanized and aluminized steel sheets to the electric appliance manufacturing industry and other industries having higher requirements for shape, surface quality and coating performance of the hot galvanized and aluminized steel sheets.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +2

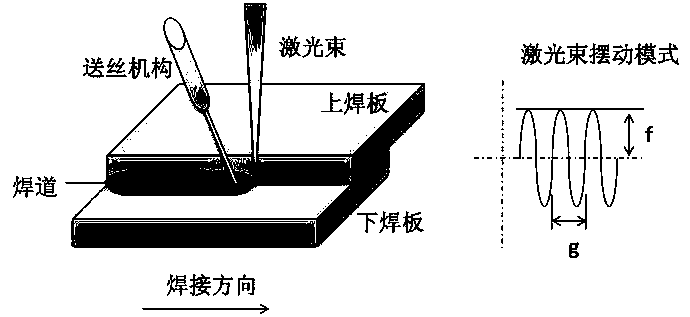

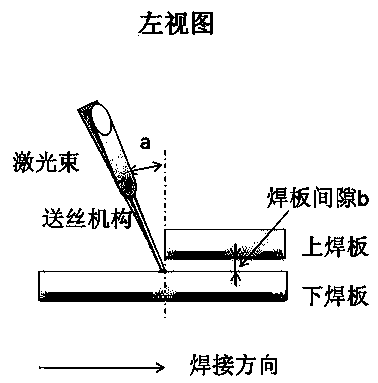

Overlap laser-arc hybrid welding of coated steel sheets

InactiveCN108857070ASolve the problem of stomataSolve defects such as inclusionsWelding/soldering/cutting articlesMetal working apparatusEngineeringAluminized steel

The invention relates to overlap laser-arc hybrid welding of coated steel sheets. Swinging lasers and a wire-feeding arc are combined; the power of a laser beam is 0.5-2 kW, the angle of inclination between the laser beam and the vertical direction of the steel sheets is 10-20 degrees, and the light spot diameter is 22-28 mm; the laser beam swings in the width direction of the welded sheets, the swing frequency is 150-200 HZ, and the swing range is 0.5-1.0 mm; the angle of inclination between an arc wire-feeding mechanism and the steel sheets is 20-30 degrees, and the arc voltage is 25-35 V; the dry extension of welding wires is 15-20 mm, the welding speed is 2.5-3.5 m / min, the space between the arc and the laser beam is 3-8 mm, and the space between the overlap steel sheets is 0.3-0.7 mm;and the diameter of the welding wires is smaller than or equal to 1.6 mm, and the welding wires contain, by weight percentage, 0.01-0.04% of S and 0.65-1.20% of Si. The method is suitable for overlapwelding of galvanized steel sheets and aluminized steel sheets, the efficiency is high, and the joint quality is good.

Owner:张家港创博金属科技有限公司

Ultra high strength hot dip aluminized steel plate and manufacturing method thereof

The invention provides an ultra high strength hot dip aluminized steel plate, which comprises the following components by weight: 0.20%-0.50% of C, 0.30%-2.00% of Si, 1.10-5.00% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, 0.02%-1.50% of Al, less than or equal to 1.50% of Mo, also contains at least one of 0.20%-1.00% of Cr and 0.20%-3.00% of Ni, also contains at least one of less than or equal to 0.10% of Nb and less than or equal to 0.25% of Ti, also contains at least one of less than or equal to 0.004% of Ca and less than or equal to 0.004% of Mg, and the balance Fe and inevitable impurity elements. Specifically, Cr+Mo and Ni+Mo are not less than 0.6%, and Nb+Ti is not less than 0.06%. The method includes: heating the steel plate on a continuous hot dip aluminizing line to 750DEG C-850DEG C, preserving the temperature at 750 DEG C-840DEG C, performing cooling to hot dip aluminizing temperature by a cooling speed of not greater than 20DEG C / s, then conducting hot dip aluminizing, discharging the plating solution, and then performing cooling at a speed of not greater than 20DEG C / s. The steel plate greatly enhances the plasticity and toughness of hot dip aluminized steel plate after hot stamping forming, and improves the comprehensive performance of the product.

Owner:ANGANG STEEL CO LTD

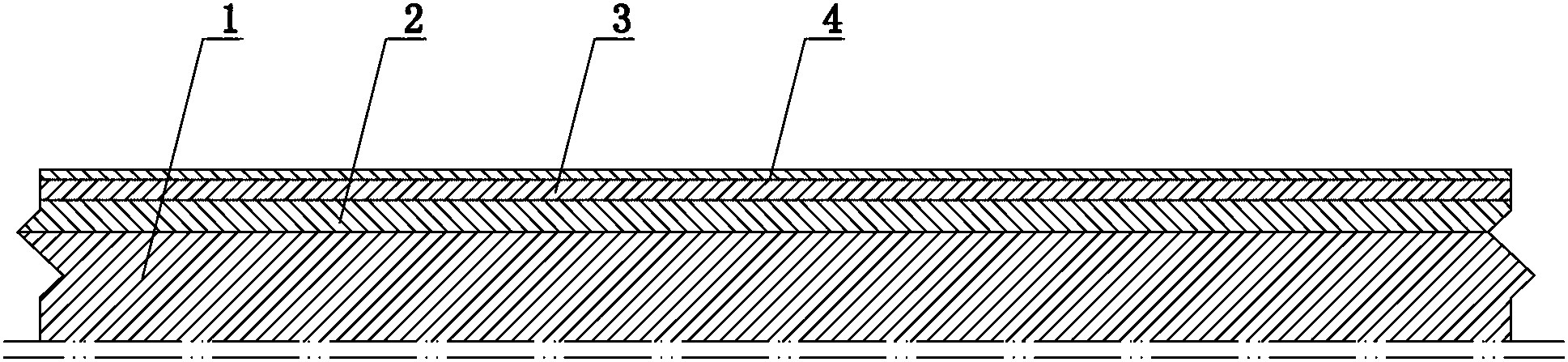

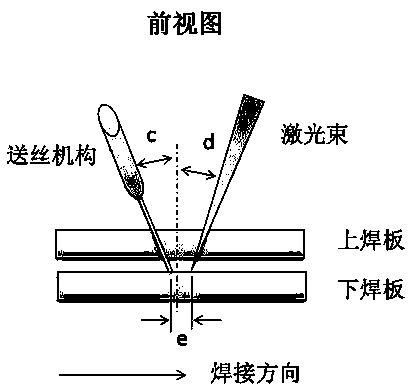

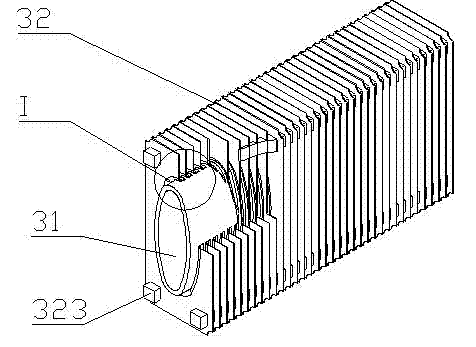

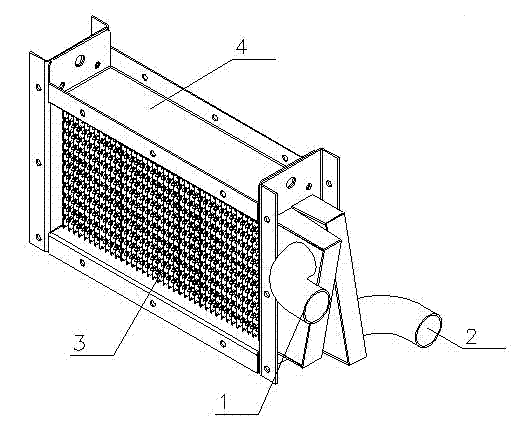

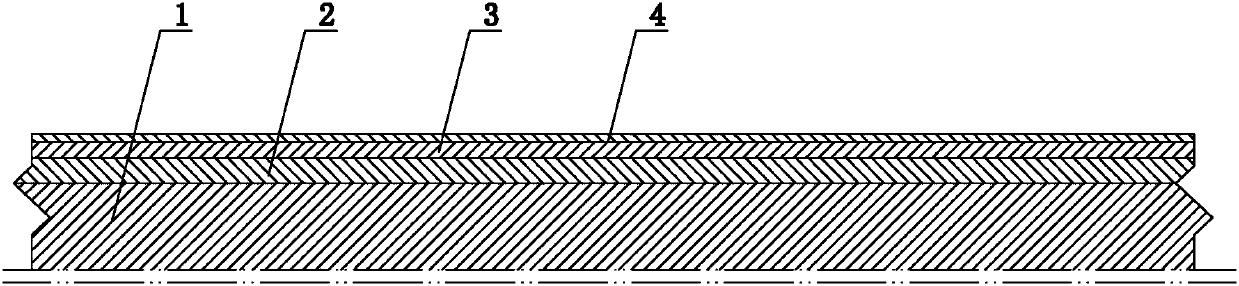

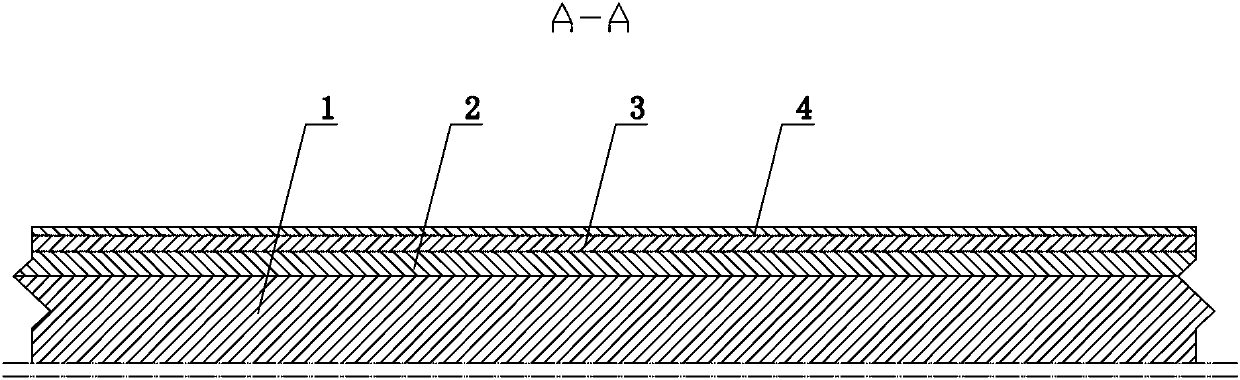

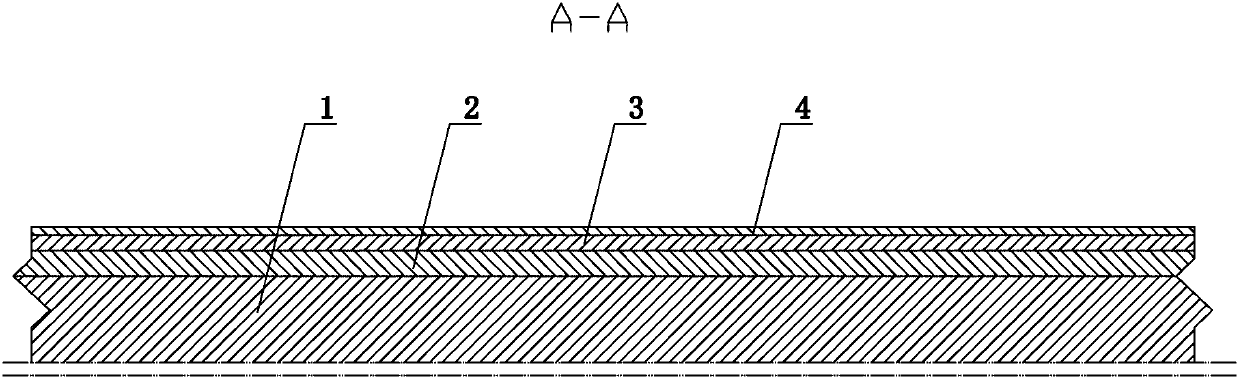

Steel-aluminum compounding finned tube and processing method thereof as well as heat exchanger manufactured by same

InactiveCN102393158ARealize continuous productionFacilitate continuous productionStationary conduit assembliesTubular elementsPunchingEngineering

The invention relates to a steel-aluminum compounding finned tube and a processing method thereof, as well as a water-air heat exchanger manufactured by the same. The steel-aluminum compounding finned tube provided by the invention is brazed by a parent tube and a plurality of fins, wherein the parent tube is of a complete aluminized steel compounding tubular product with an aluminum layer outer surface, and the fins are aluminium fins provided with through-tube openings in the middle and form curled edges at the through-tube openings. The processing method of the steel-aluminum compounding finned tube provided by the invention comprises the steps of: raw material preparation, punching sheet and tube penetration, finned tube cleaning, soaking with a soldering flux liquid, assembly of a stokehold fixture, brazing in a furnace and the like. The invention is capable of combining the advantages of the steel tube steel fin radiator and the aluminum pipe aluminum fin radiator so as to form a steel tube aluminum fin radiator, thus being favor of improving resistance to corrosion, protecting environment, ensuring strength of the heat exchanger finned tube and improving heat dissipation efficiency of the heat exchanger. Simultaneously, continuous production of a brazing process can be realized, the capacity and quality of the product can be improved and the production cost can be reduced.

Owner:BEIJING LONGYUAN COOLING TECH

Aluminized steel and preparation method thereof

InactiveCN103320745BReduce concentrationEliminate the effects of hydrogen embrittlementSolid state diffusion coatingThermal fatigueSurface layer

The invention discloses aluminized steel comprising a steel workpiece, wherein a eutectic aluminized alloy layer and an aluminum layer are sequentially arranged on the surface layer of the steel workpiece from inside to outside, and the thickness of the aluminized alloy layer is 14-29 microns. A preparation method of the aluminized steel comprises the following steps: co-firing the steel workpiece to remove oil; pickling to remove rust; washing; carrying out surface activating; carrying out auxiliary infiltrating; drying; carrying out rapid induction aluminizing; immediately immersing the dried steel workpiece in molten aluminum heated to 680-700 DEG C in an induction manner, wherein the infiltration time is 2-3 minutes; and the aluminized steel is obtained by the steps. The aluminized steel disclosed by the invention has superior corrosion resistance, heat resistance, wear resistance and photo-thermal reflectivity, and meanwhile, the bending property of the aluminized steel can be improved, the surface brittleness of diffusion aluminized layers is eliminated and the thermal shock resistance and thermal fatigue resistance can be improved. The preparation method disclosed by the invention can be used for effectively controlling the thickness of the aluminized layer, shortening the technique preparation period, improving the efficiency and increasing the yield.

Owner:HUBEI PROVINCIAL COMM INVESTMENT FOUR ADVANTAGE STEEL TECH

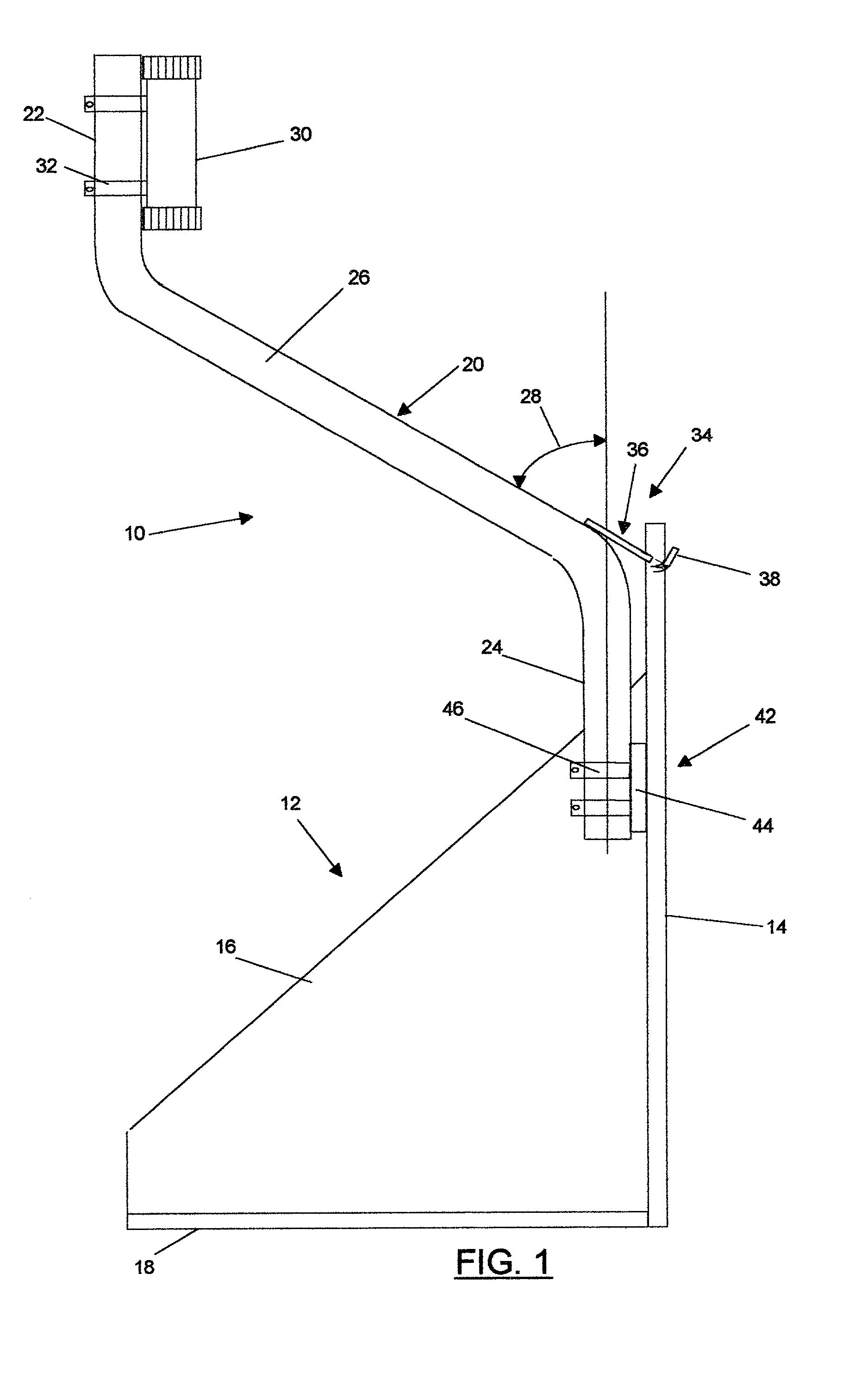

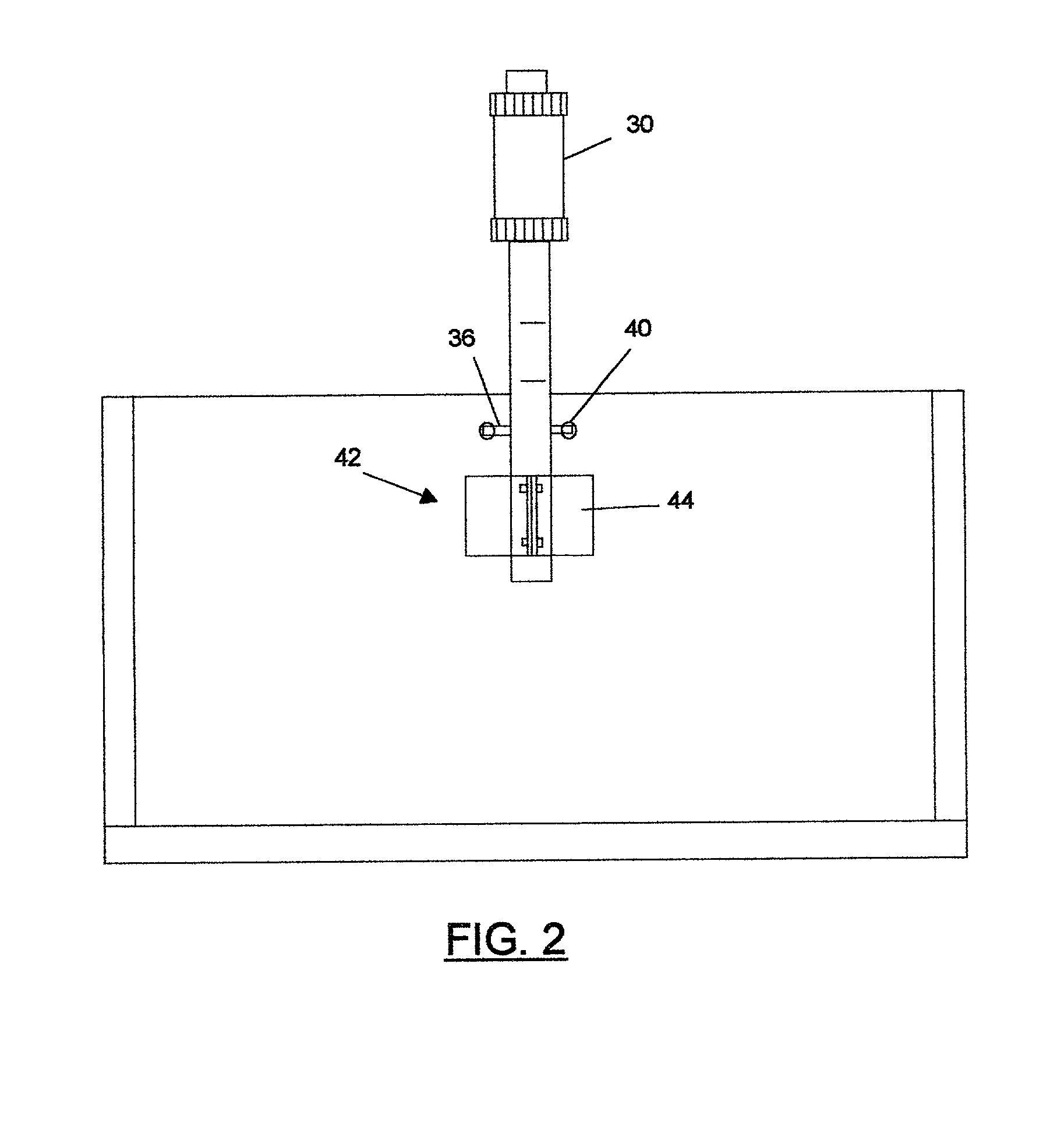

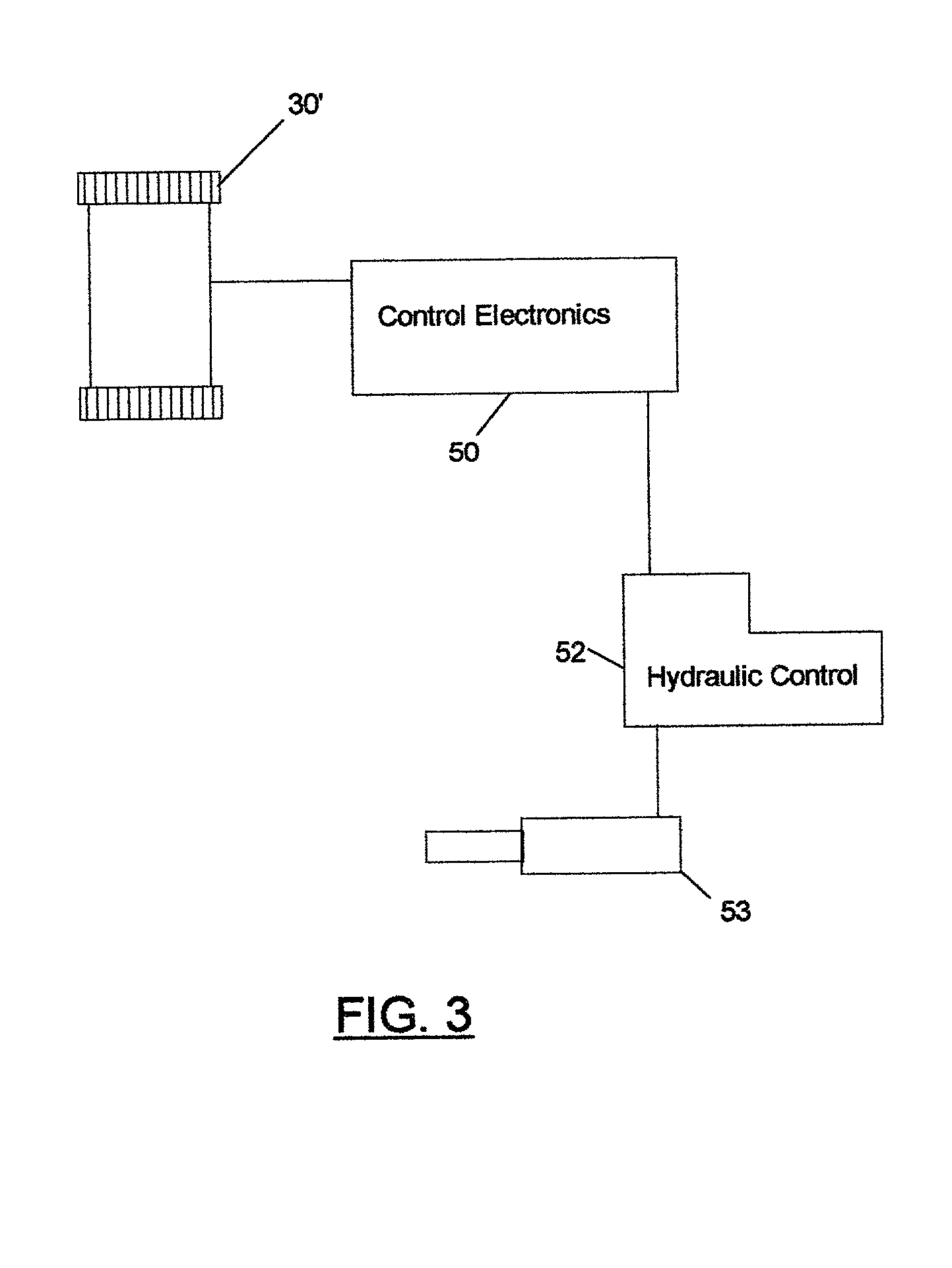

Excavation control mounting mast

InactiveUS20010045032A1Analogue computers for trafficMechanical machines/dredgersEngineeringAluminized steel

A mast assembly is adapted for attachment to an excavating apparatus such as a loader bucket of a skid steer vehicle such as a BOBCAT. The excavating apparatus includes a rear wall, a pair of side walls, and a bottom. The mast assembly includes a mast, which can be fabricated from any suitable relatively rigid and durable material, such as aluminized steel. The mast includes an upper portion and a lower portion connected by an angled portion angled to maintain the upper portion in an upright vertical position. A laser receiver is secured to the upper portion of the mast with a pair of adjustable securing straps. The laser receiver operates in a known manner to receive laser energy from a laser beacon to facilitate accurate positioning of the excavating apparatus. A first removable securing member, such as a hook arrangement or latch bracket, is affixed to the mast. The hook arrangement can include a pair of hooks which extend through a corresponding number of bores formed in the excavating apparatus. The latch bracket can include a pair of latch points that fit into an adapter plate. A second removable securing member, such as a magnet, is connected to the mast. The second securing member is attached to the mast by a pair of adjustable securing straps, or by a pivotable bracket. The magnet should have sufficient strength to secure the mast to the excavating apparatus such that the mast remains fixed during excavation.

Owner:KLEFFNER CHARLES P

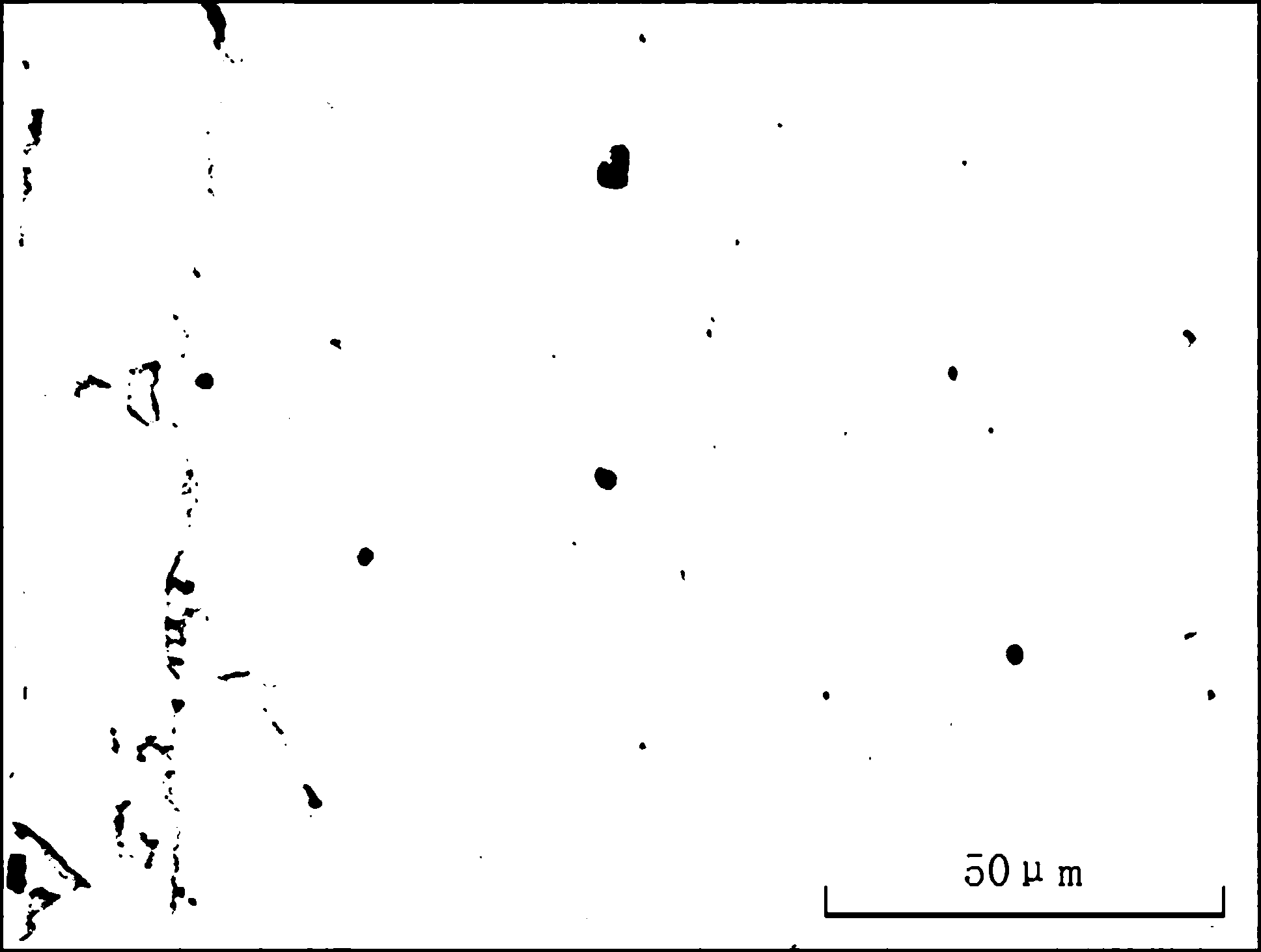

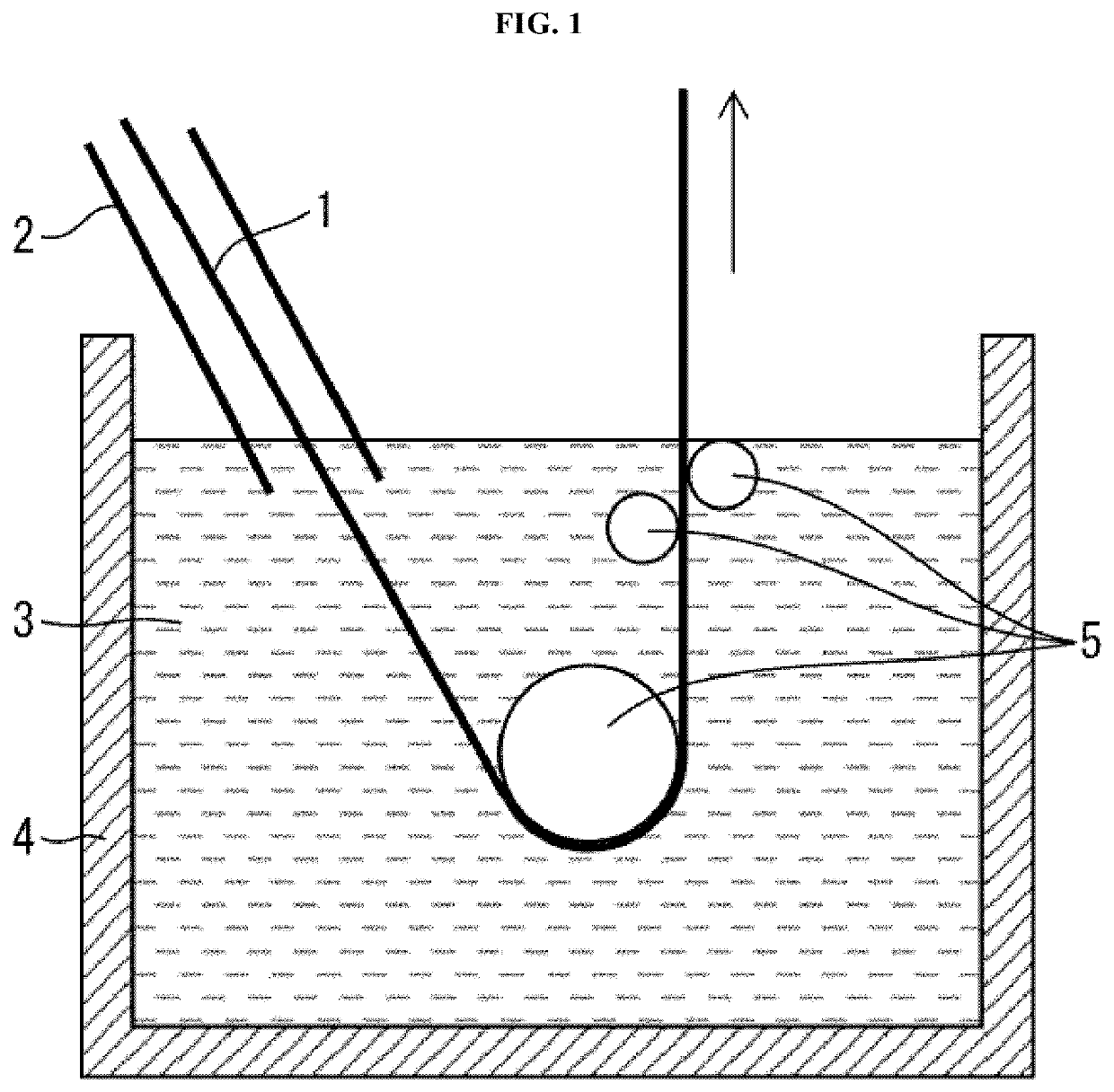

Ultrasonic frequency induction heating technology based quick hot-dipping aluminizing technology

InactiveCN104313533AReduce concentrationReduce consumptionSolid state diffusion coatingThermal fatigueHeat resistance

The invention provides an ultrasonic frequency induction heating technology based quick hot-dipping aluminizing technology. The technology comprises the following steps: oil removing, acid pickling for rust removal, washing, surface activation, auxiliary infiltration, drying, and ultrasonic frequency induction heating technology based quick aluminizing. The technology has the following advantages: concentration and consumption of a pickling solution are reduced, and a rust removal speed is greatly increased; the hot-dipping aluminizing temperature is low, and the aluminizing process is short; compared with a heating method of a traditional resistance aluminizing furnace, the induction heating method adopted enables the utilization rate of electrical energy to be improved over 20%, and enables the annual output to be increased over one time; compared with traditional diffuse type aluminizing steel material, the new aluminizing steel material prepared with the technology retains a pure aluminium layer and an iron-aluminium alloy layer under a columnar eutectic state, and has the effects of corrosion resistance, heat resistance, abrasion resistance and photo-thermal reflectivity; a fragility area on the surface is eliminated; bending performance and punch forming performance are greatly improved; resistance to heat shocks and resistance to thermal fatigue are improved over 10%.

Owner:WUHAN TIANCONG CREATIVE TECH

High-strength high-toughness hot-dip aluminized steel plate and manufacturing method thereof

ActiveCN105506470AIncreased comparative strengthSave energyHot-dipping/immersion processesSheet steelHigh intensity

The invention provides a high-strength high-toughness hot-dip aluminized steel plate. The steel plate comprises the following components in percentage by weight: 0.15%-0.65% of C, 0.50%-3.50% of Si, 1.10%-7.00% of Mn, less than or equal to 0.50% of P, less than or equal to 0.30% of S, 0.02%-5.00% of Al, and at least one of less than or equal to 0.50% of V, less than or equal to 0.20% of Ti, less than or equal to 0.20% of Nb and less than or equal to 0.005% of B, and the balance Fe and some inevitable impurity elements; the steel plate further contains at least one of less than or equal to 0.004% of Ca and less than or equal to 0.004% of Mg. A method for manufacturing the high-strength high-toughness hot-dip aluminized steel plate comprises the following steps: heating a steel plate on a continuous hot-dip aluminizing production line to a range of 750-950 DEG C and preserving heat of the steel plate at a temperature ranging from 750 to 950 DEG C; heating and preserving heat of the steel plate on the continuous hot-dip aluminizing production line at a temperature within an austenitic range, cooling the steel plate to a range of 680-700 DEG C before going into an aluminum-silicon plating solution, or slowly cooling the steel plate to a two-phase region of austenite and ferrite and then rapidly cooling the same to a range of 680-700 DEG C before going into the aluminum-silicon plating solution, and after the steel plate is taken out of the plating solution, carrying out rapid air cooling to a bainite transformation region, followed by rapid cooling to a temperature between an Ms point and an Mf point of steel. The stele has the yield strength of greater than 700MPa, the tensile strength of greater than 900MPa and the elongation of greater than 10%; and energy sources are saved.

Owner:ANGANG STEEL CO LTD

Hot-dip aluminizing technology for steel radiator

InactiveCN106244965AExtend your lifeImprove corrosion resistanceHot-dipping/immersion processesSolid state diffusion coatingOrganic acidSurface layer

The invention discloses a hot-dip aluminizing technology for a steel radiator, comprising the following steps: S1, degreasing before hot dipping; S2, rust removal before hot dipping; S3, assistant plating treatment; S4, hot-dip treatment; S5, diffusion treatment; and S6, treatment after aluminizing. According to the hot-dip aluminizing technology for a steel radiator, the surface of the steel radiator is aluminized such that a high-temperature-resistant alumina film is formed on the surface of the steel radiator and high-temperature molten aluminum can be immersed into the surface layer of the steel radiator to react with iron to generate a compact acid-and alkali-resistant aluminium oxide film. Thus, the internal iron is protected, and life of the steel radiator can be greatly prolonged. The hot-dip aluminized steel can be resistant to corrosion of multiple chemical mediums such as SO2, SO3, H2S, NH3, CO2, crude oil, seawater, organic acid and the like. The corrosion resistance of the hot-dip aluminized steel is several times even tens of times higher than corrosion resistance of non-aluminized carbon steel.

Owner:QUANJIAO SAIDELI MACHINERY

Oil removal agent for galvanized and aluminized steel plate

InactiveCN107313060APrevent mildewReduce pollutionMetallic material coating processesALLYL SUCROSEProtopine

A kind of degreaser for galvanized steel plate of the present invention is characterized in that, comprises the raw material of following parts by weight: Sodium carbonate: 0.1-5 part; Caustic soda: 0.01-1 part; Anionic surfactant: 10-1 part 20 parts; defoamer: 0.1-5 parts; polyaspartic acid: 1-5 parts; polyacrylic acid: 2-8 parts; complexing agent: 0.1-2 parts; water: 80-100 parts. The degreasing agent for galvanized steel sheets provided by the invention forms a dense protective layer on the surface of the material, overcomes the problem that the surface of galvanized materials is easily corroded, and effectively prevents the surface of the material from being damaged by primary battery corrosion or air oxidation. Mildew phenomenon, but also has a good degreasing effect, less pollution to the environment, no harm to the skin contact.

Owner:苏州日新水性涂料有限公司

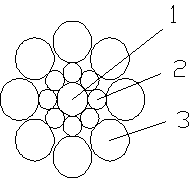

Steel wire rope special for elevator

InactiveCN103526619AIncrease elasticityStrong resistance to shock loadsTextile cablesCarbon fibersEngineering

The invention discloses a steel wire rope special for an elevator. The steel wire rope comprises a center strand, multiple inner layer strands and multiple outer layer strands, wherein the center strand, the multiple inner layer strands and the multiple outer layer strands are sequentially arranged from inside to outside. The center strand is made of carbon fibers, polyamide fibers and cotton fibers. The outer diameter of the center strand is larger than that of the inner layer strands, the inner layer strands are made of multiple aluminized steel wires, and the outer layer strands are made of multiple stainless steel wires. Through the mode, the steel wire rope has high elasticity and the impact load resistant capacity, and high requirements for the steel wire rope special for the elevator are fully met.

Owner:无锡市前洲康华染整设备厂

Method for manufacturing single-sided aluminium plating steel plate

The invention relating to a method of preparing aluminizing steel plates provides a method of preparing single-sided aluminizing steel plates for solving problems that the prior technique of preparing single-sided aluminizing steel plates has complex processes, high producing cost and low efficiency.The method of the invention comprises the following steps: 1. performing tight welding to the edges of two steel plates having a same size; 2. performing processes of oil removal, derusting, rinshing, assisted plating, drying and pre-heating to the steel plates with the edges tight-welded together, then aluminizing; 3. cutting the welded seam of the steel plates after being aluminized by using a cutting method to obtain two single-sided aluminizing steel plates. By using processes of welding, aluminizing and cutting, the single-sided aluminizing steel plates are produced without generating any influence on the other side, realizing single-sided aluminizing in real meanings and the operations are simple and the quality of the products are stable.

Owner:HARBIN INST OF TECH

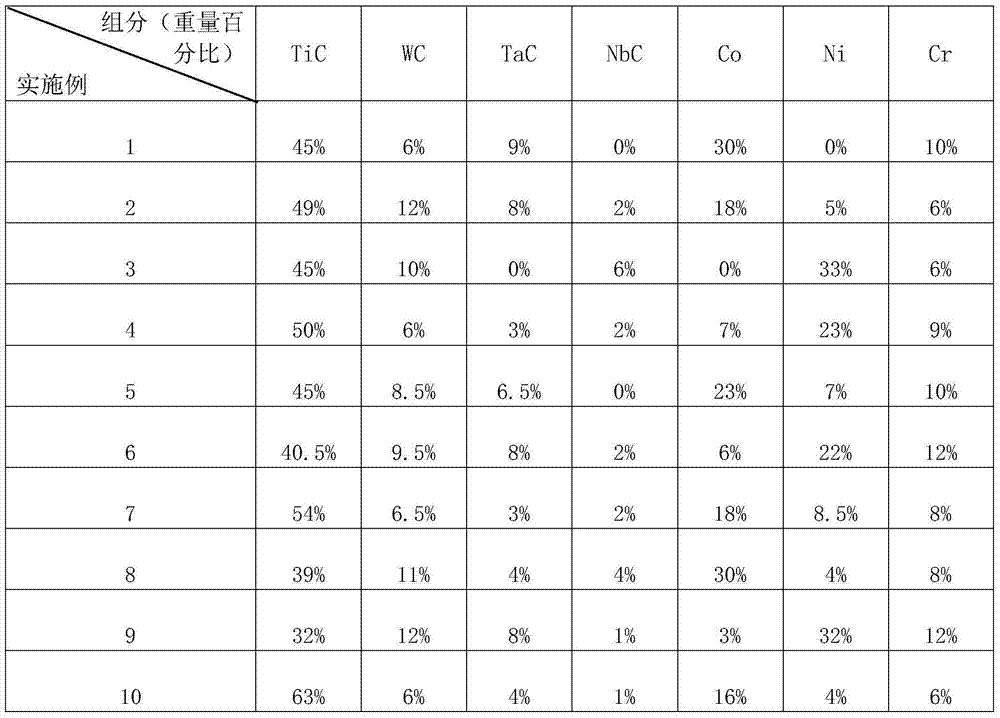

Corrosion-resistant roll and manufacturing method thereof

ActiveCN104120376AAvoid corrosionAvoid it happening againMolten spray coatingProduction lineSheet steel

The invention discloses a corrosion-resistant roll which is characterized by comprising a base and a corrosion-resistant coating coated on the base surface, wherein the corrosion-resistant coating is prepared by spraying a corrosion-resistant spraying powder. The corrosion-resistant roll can be widely used as a sink roll, guide roll or support roll in a hot-galvanizing or hot-aluminizing production line, and has favorable corrosion resistance. The corrosion-resistant layer on the roll surface has the advantages of favorable thermal shock resistance, low tendency to cracking or shedding and long service life, and the produced galvanized or aluminized steel plate and the like have higher quality.

Owner:SHANGHAI JUSN SURFACE TECH ENG

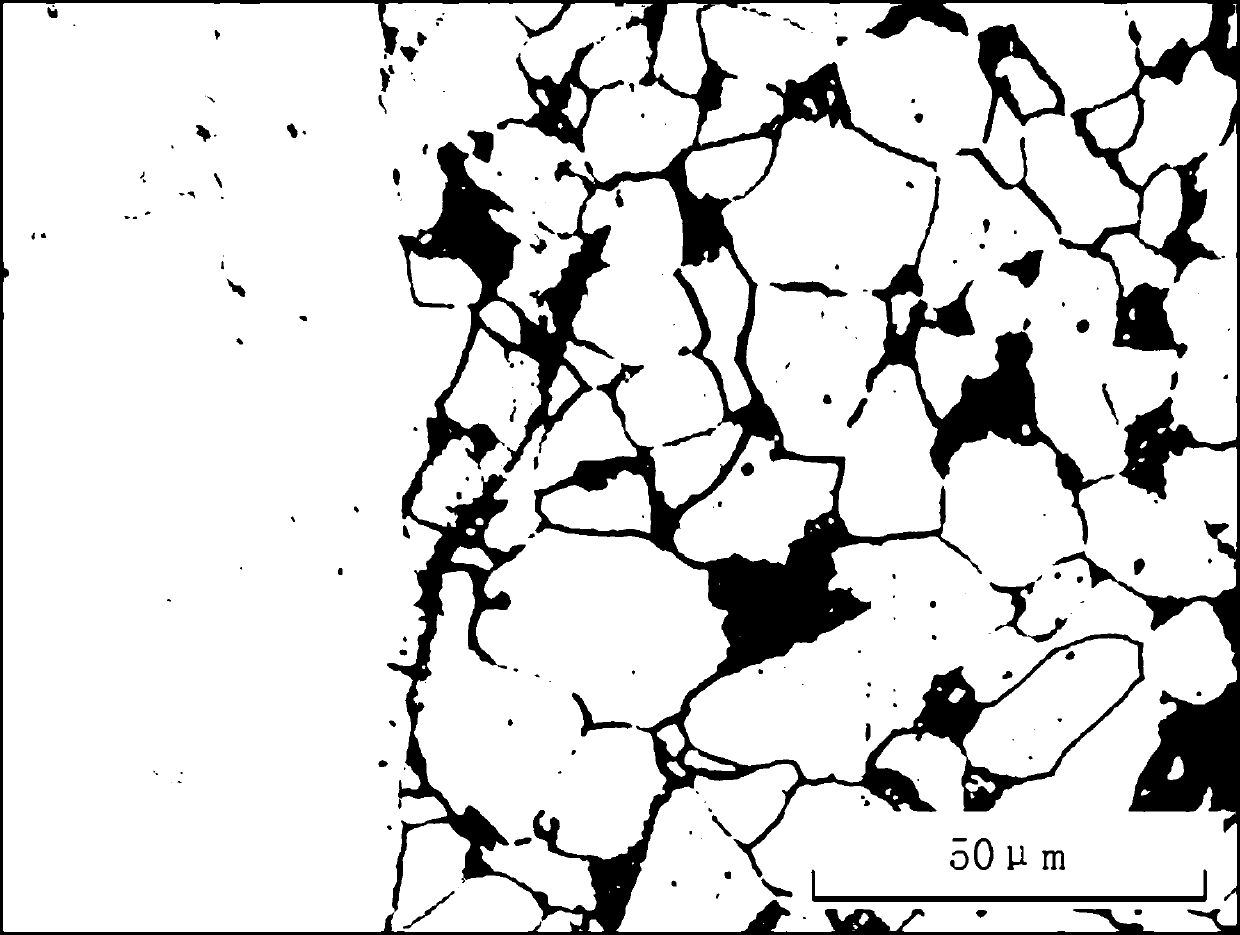

Aluminized steel fastener type scaffold steel pipe and preparation method thereof

InactiveCN103343613AImprove toughnessEliminate surface brittle zonesHot-dipping/immersion processesScaffold accessoriesMicrometerAlloy

An aluminized steel fastener type scaffold steel pipe comprises a scaffold steel pipe body. The scaffold steel pipe body is sequentially divided into a base body layer, an iron-and-aluminum alloy layer and an aluminum layer from inside to outside, the thickness of the iron-and-aluminum alloy layer is 14-29 micrometers, and the thickness of the pure aluminum layer is 15-100 micrometers. A preparation method of the aluminized steel fastener type scaffold steel pipe includes the following steps of using a common seamless or seamed steep pipe as a workpiece, drying and unoiling the workpiece, acid cleaning and removing rust, washing, activating the surface, promoting permeation, drying, and rapidly aluminizing in an induction mode. The scaffold steel pipe with the aluminized surface is acquired through the steps. The mechanical performance of the aluminized steel fastener type scaffold steel pipe can be guaranteed, the excellent corrosion resistant performance is possessed, the service life is long, and using cost of the scaffold steep pipe is reduced.

Owner:HUBEI PROVINCIAL COMM INVESTMENT FOUR ADVANTAGE STEEL TECH

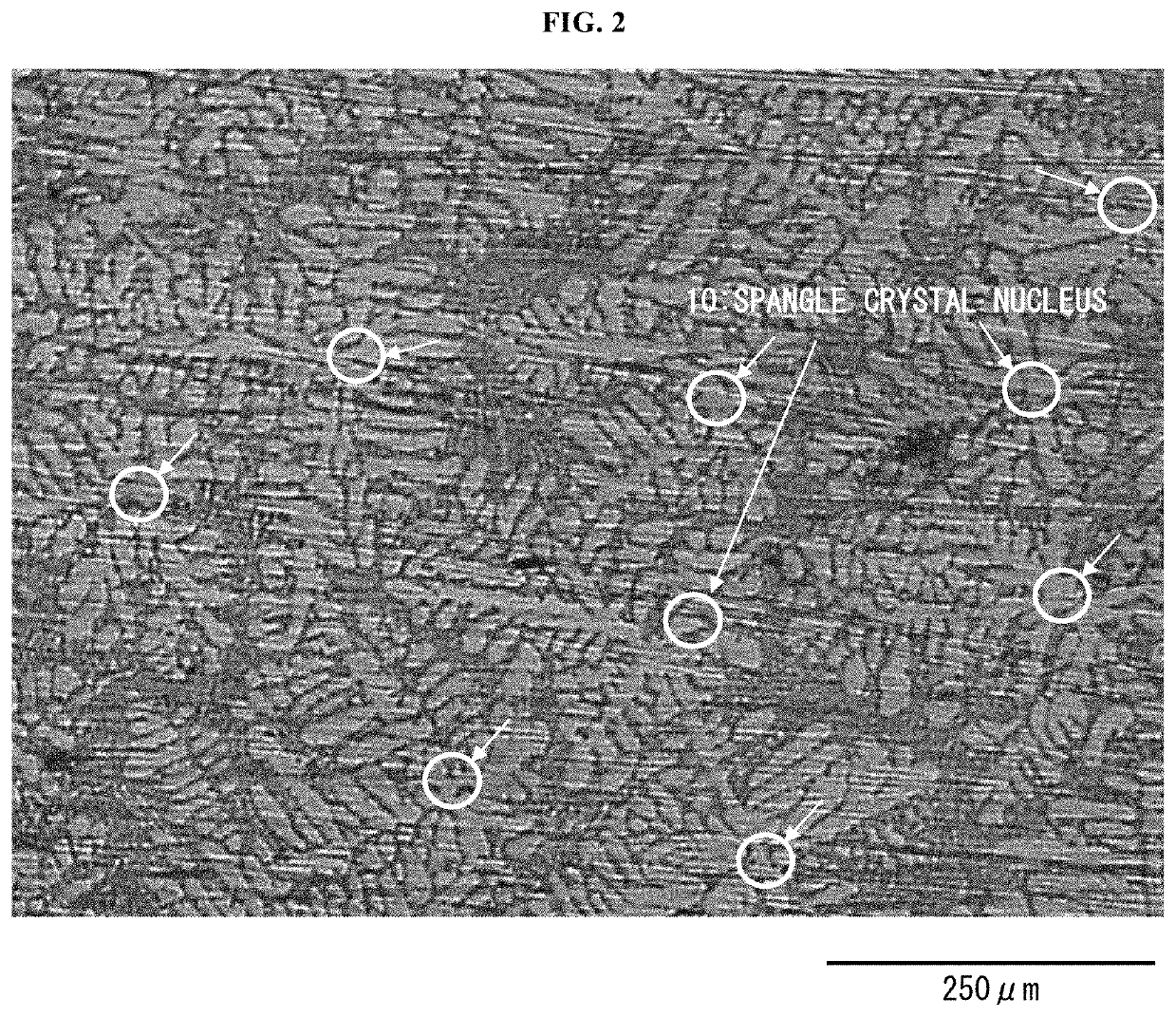

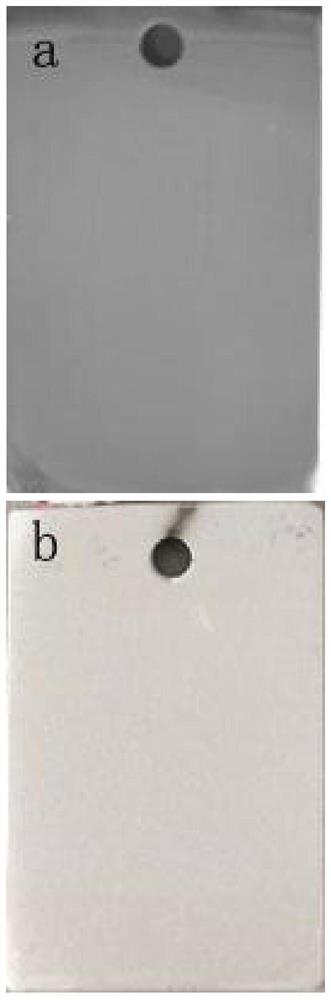

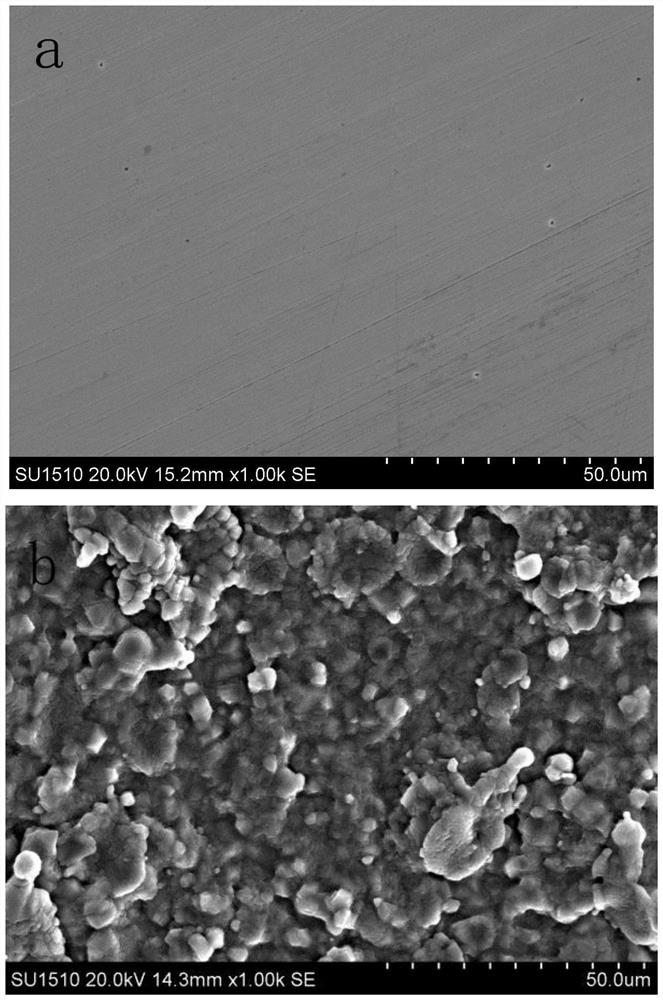

Hot-dip aluminized steel sheet and method of producing the same

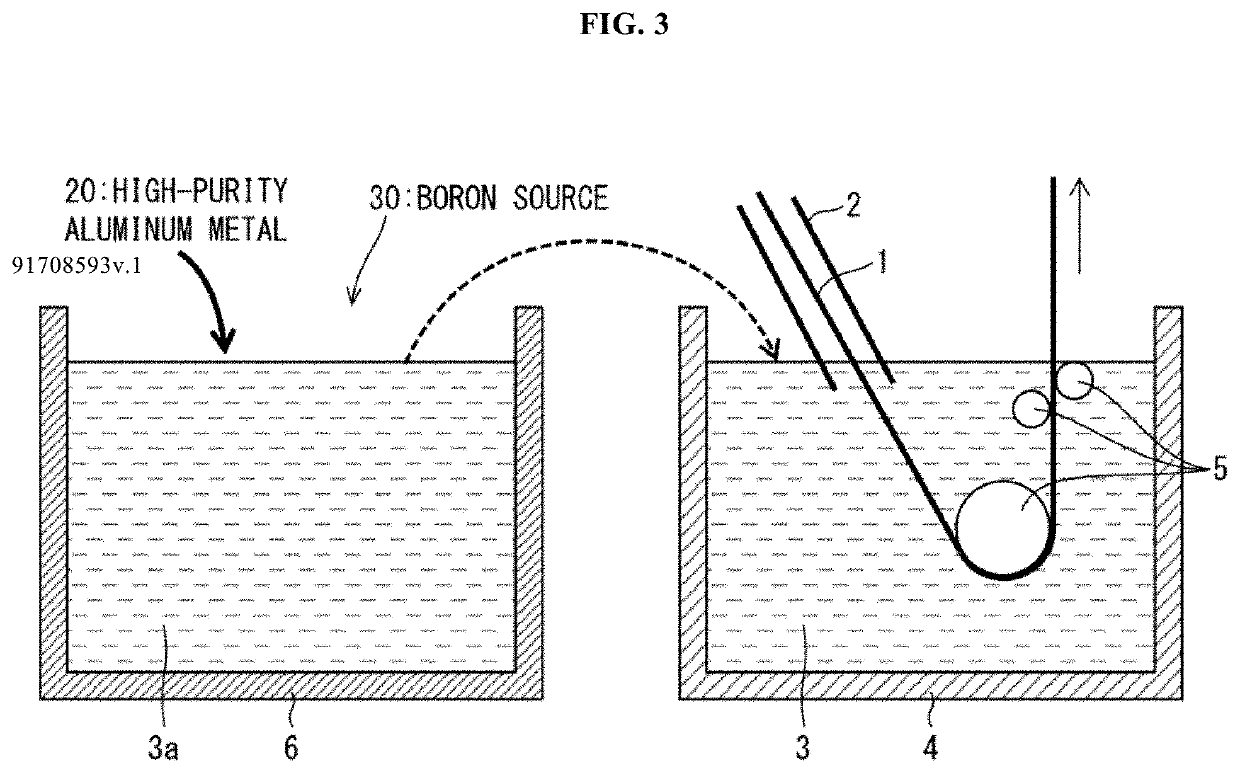

Provided is a hot-dip aluminized steel sheet with fine-sized spangles produced in a different way from conventional methods, and a method of producing a hot-dip aluminized steel sheet with fine-sized spangles in a different way from conventional methods. The hot-dip aluminized steel sheet includes: a substrate steel sheet; and an aluminum-based coating which is formed by a hot-dip method on the surface of the substrate steel sheet and in which the average B concentration is not less than 0.005 mass % and the sum of the average Ti concentration and the average V concentration is not more than 0.03 mass %.

Owner:NISSHIN STEEL CO LTD +1

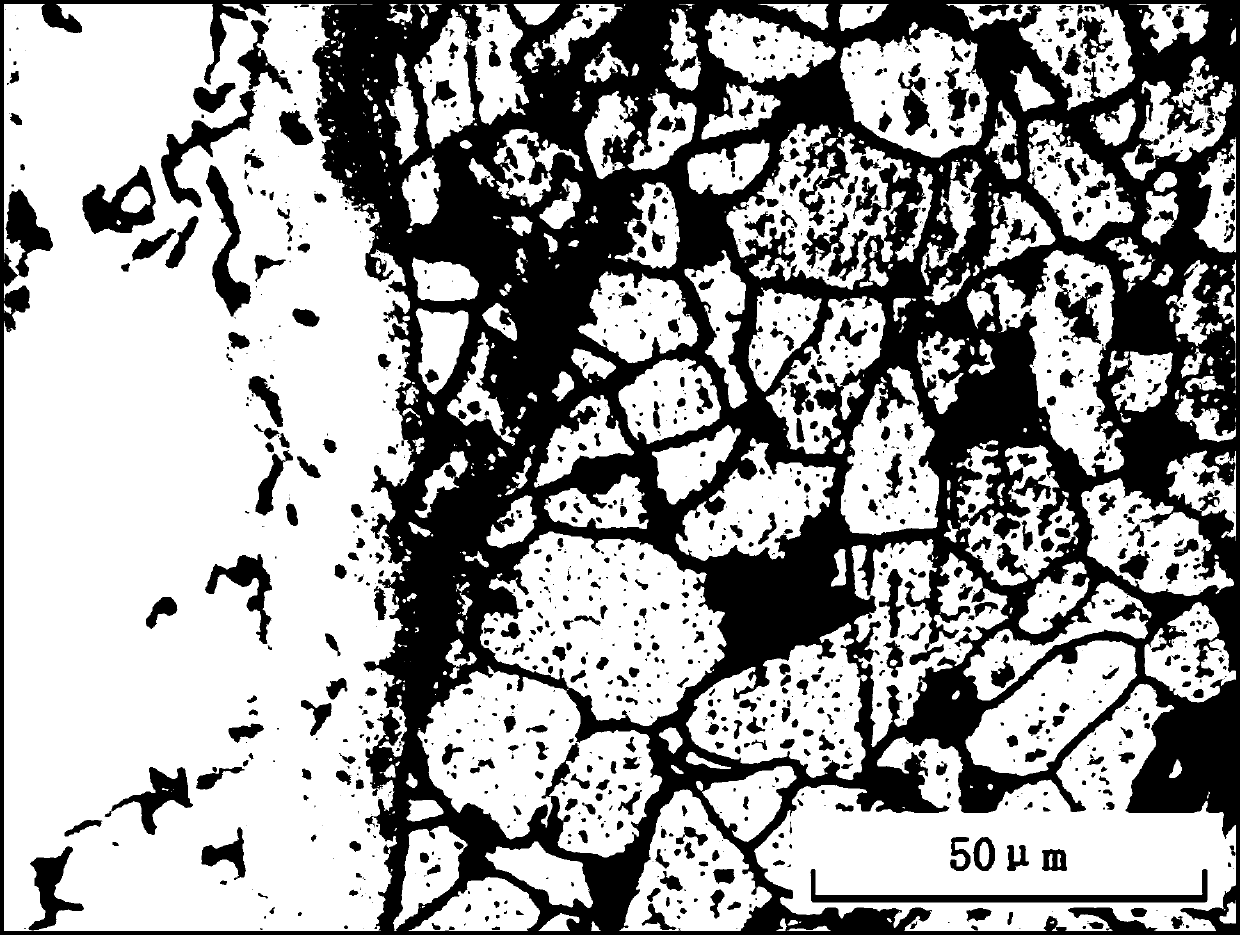

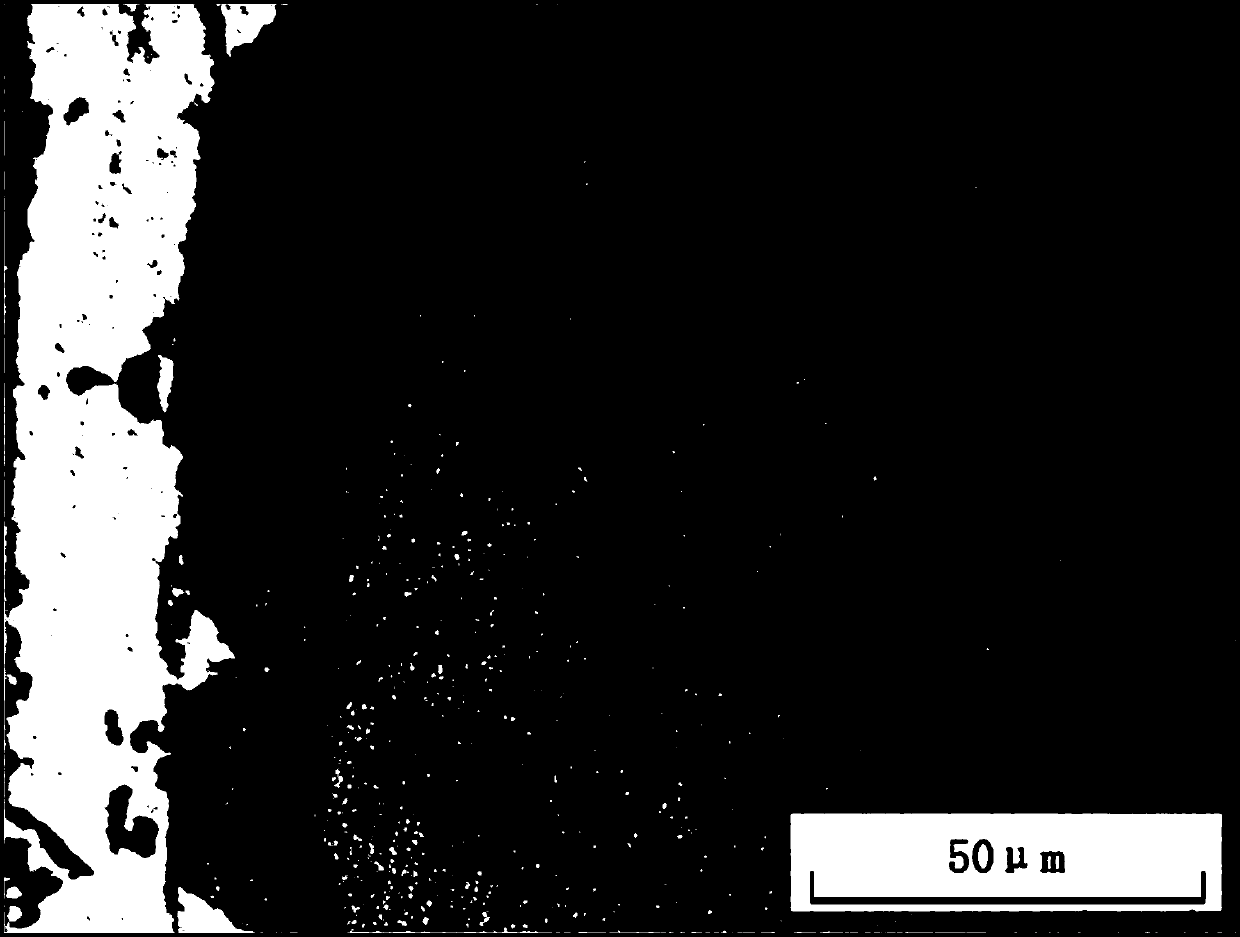

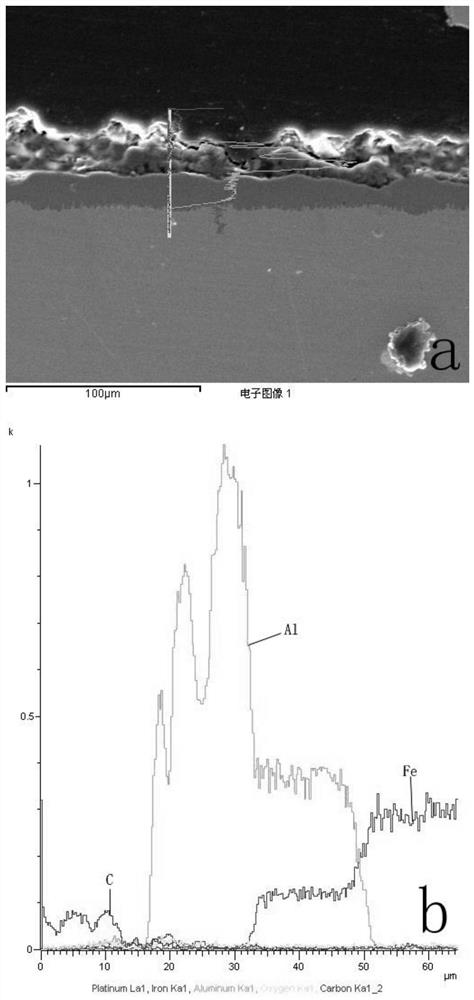

Hot dip aluminized steel material having excellent corrosion resistance and workability, and manufacturing method therefor

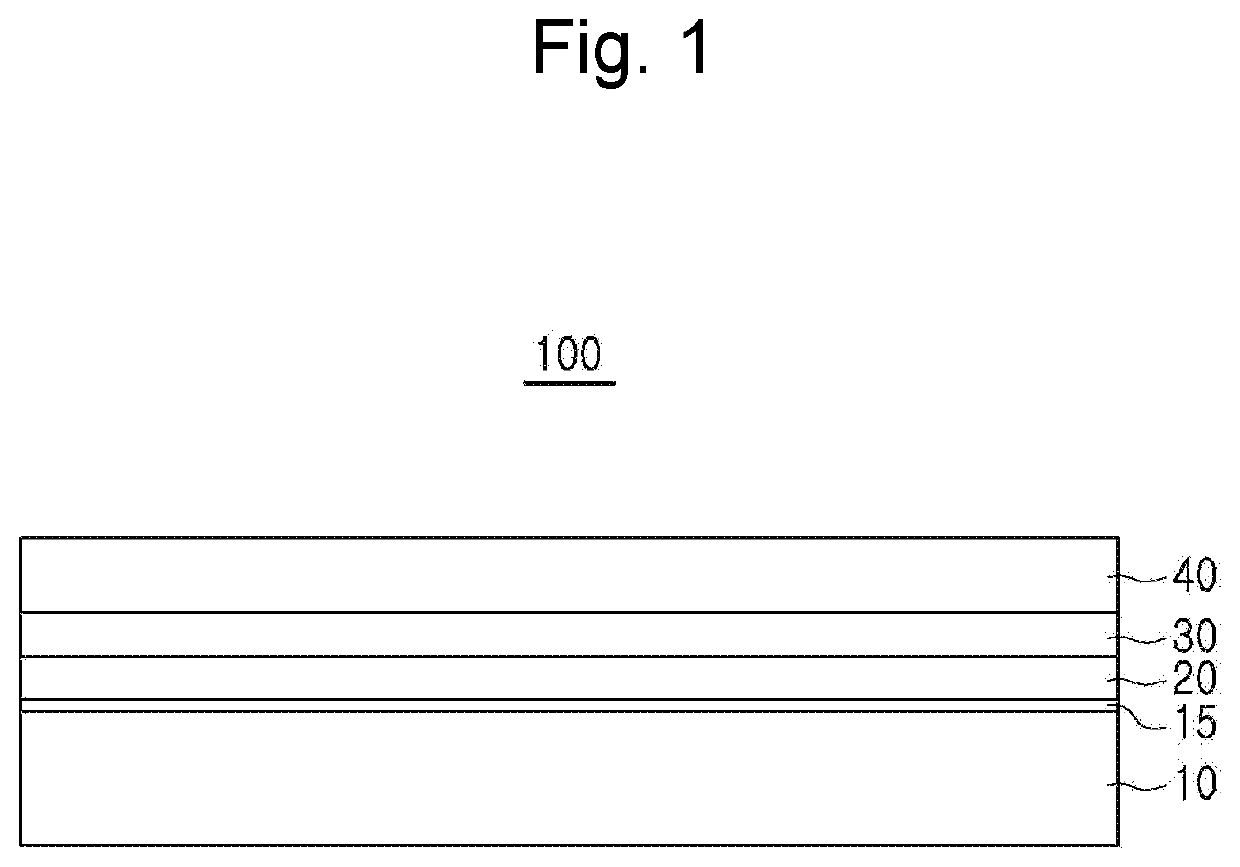

ActiveUS20190381764A1Improve corrosion resistanceEasy to processHot-dipping/immersion processesMetal layered productsSurface layerHardness

Provided is a hot dip aluminized steel material including a base steel and a hot-dip Al—Si-coated layer, wherein the surface layer of the base steel is provided with an Al-enriched layer in which 2 wt % to 20 wt % of Al is solid-solubilized, and an interface between the base steel and the hot-dip Al—Si-coated layer has a double-layer structured interfacial alloy layer having different hardnesses.

Owner:POHANG IRON & STEEL CO LTD

Aluminizing medium-free aluminizing method for surface of carbon steel

PendingCN111876727AReduce defectsShort aluminizing cycleVacuum evaporation coatingSputtering coatingEngineeringAluminized steel

The invention relates to an aluminizing medium-free aluminizing method for the surface of carbon steel. At present, aluminizing processes comprise a hot-dip aluminizing process, a chemical vapor aluminizing process, a powder aluminizing process and the like, a surface aluminizing medium is prone to bond in the most common powder aluminizing process, a aluminizing promoter ammonium chloride has irritation to skin and mucous membranes, and decomposed ammonia gas causes poisoning to the aluminizing process. The invention relates to an aluminizing technology without an aluminizing medium on the surface of carbon steel. The technology comprises the steps that (1) rust removal, oil removal and drying are carried out on the surface of the carbon steel; (2) the carbon steel is placed in an ion sputtering vacuum chamber, and the pressure and the temperature of the vacuum chamber are regulated and controlled within a certain range; and (3) an aluminized coating is prepared on the carbon steel inthe vacuum chamber under certain voltage and current. The aluminized layer is obvious in structure and excellent in corrosion resistance, and the aluminizing medium-free aluminizing technology for the surface of the carbon steel is non-toxic, pollution-free, low in energy consumption and easy to operate, and has a certain promoting effect on improving the corrosion resistance and high-temperatureresistance of aluminized steel.

Owner:NANCHANG HANGKONG UNIVERSITY

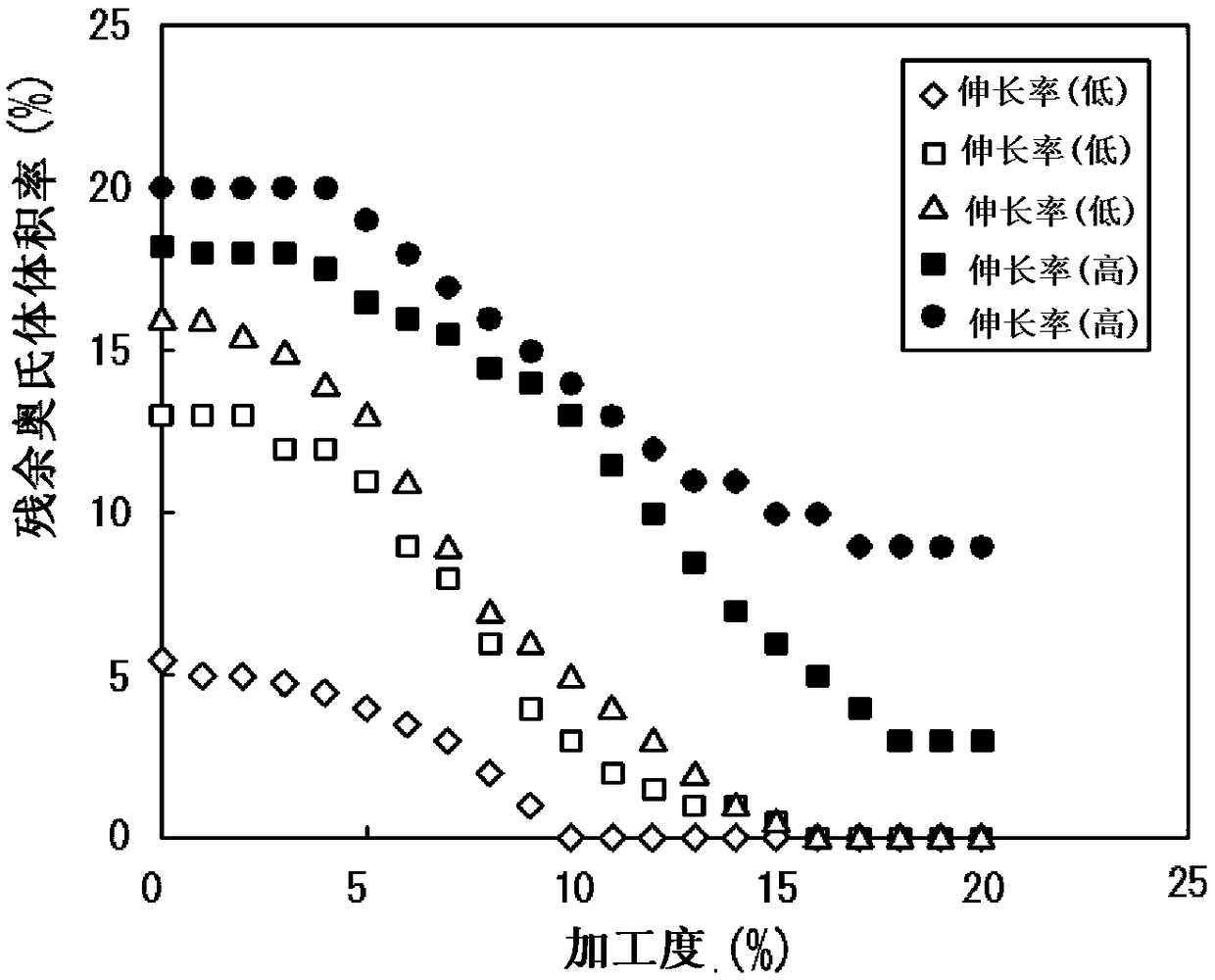

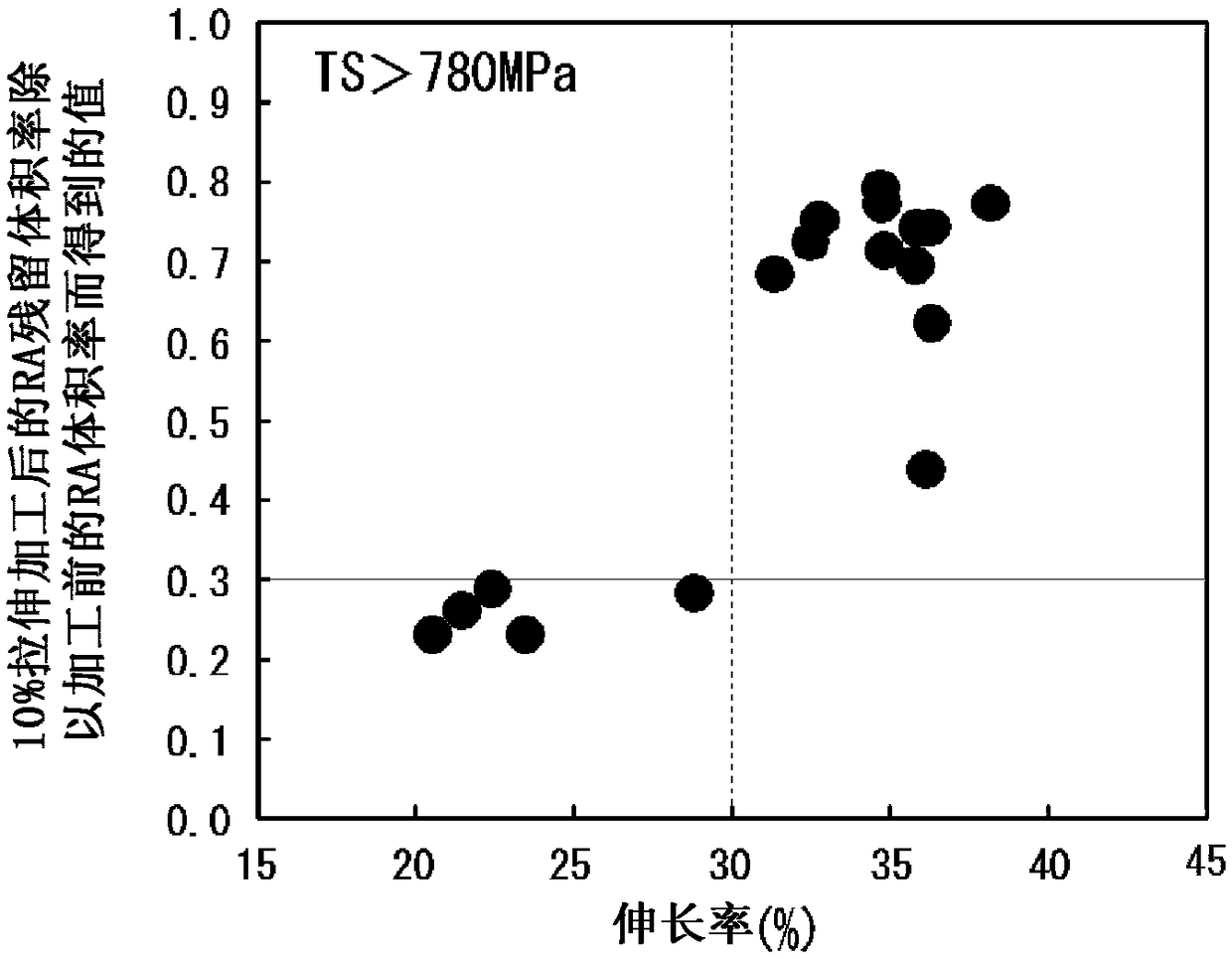

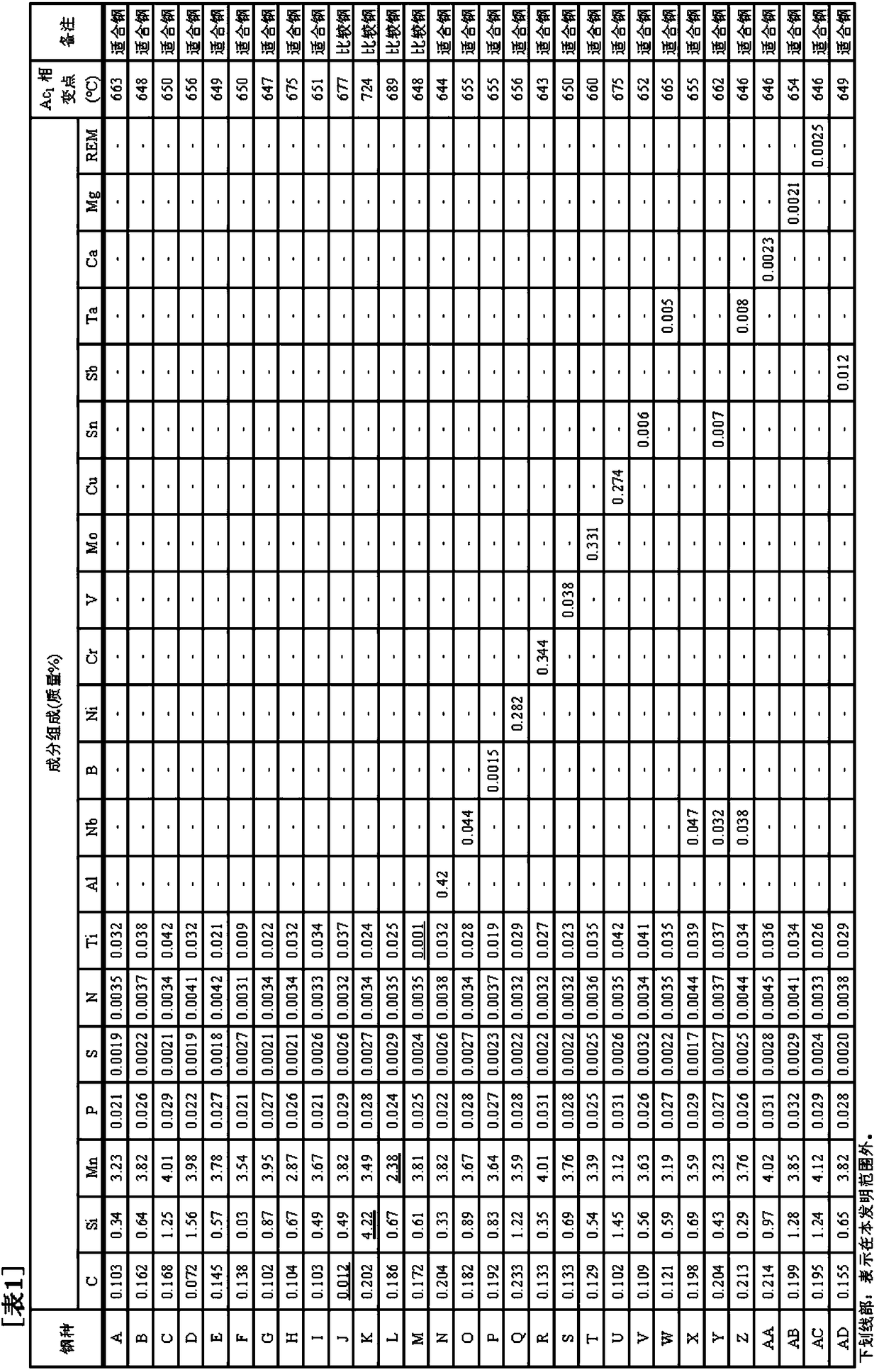

High-strength steel sheet, high-strength hot-dip galvanized steel sheet, high-strength hot-dip aluminized steel sheet, and high-strength electro-galvanized steel sheet, and their manufacturing methods

ActiveCN107148486BGood formabilityHigh Yield Ratio TypeHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

Consisting of a predetermined composition, the steel structure is polygonal ferrite: 35% to 80%, unrecrystallized ferrite: 5% and martensite: 5% to 25% in terms of area ratio , Retained austenite in terms of volume ratio: 8% or more, and the average grain size of the polygonal ferrite is 6 μm or less, the average grain size of the martensite is 3 μm or less, and the retained austenite The average grain size of the tenite is 3 μm or less, and the value obtained by dividing the Mn amount (mass %) in the retained austenite by the Mn amount (mass %) in the polygonal ferrite is 2.0 or more, Thereby, a high-strength steel sheet having a TS of 590 MPa or more and a YR of 68% or more having excellent formability and a high yield ratio can be obtained.

Owner:JFE STEEL CORP

Manufacturing technology for aluminized iron pan

InactiveCN103659162AImprove efficiencyImprove high temperature resistanceCooking vesselsSolid state diffusion coatingManufacturing technologyWarm water

The invention provides a manufacturing technology for an aluminized iron pan. The manufacturing technology comprises the first step of tensioning, wherein a prepared aluminized steel plate is placed on a hydraulic machine after being punched, pressurization is performed so that pressure can reach 10-12 MPa, and a pan body blank is formed, the second step of cutting edges, wherein the pressurized and formed pan body blank is placed on a barometric bead cutter, and redundant materials at the opening of the pan body blank are cut off, the third step of performing degreasing and cleaning, wherein the pan body is placed on a special cleaning line for the aluminum pan after the redundant materials at the opening are cut off, and drying is performed after degreasing, spraying with warm water and spraying and cleaning with clear water, and the fourth step of performing high-temperature thermal diffusion, wherein the dried pan body is placed into a high-temperature furnace with the temperature at 760 DEG C, high-temperature oxidation heat diffusion processing is carried out for 7-8 minutes, and the pan body is taken out of the furnace for wind cooling. Due to the adoption of the manufacturing technology for the aluminized iron pan, equipment and operation are simple, the technology is stable, the process is easy to control, cost is low, and meanwhile the manufacturing technology meets the requirements for environmental protection. Moreover, in the production process, an obvious pollution source will not be produced. Besides, the bonding strength between an aluminized layer and a base is increased, and the aluminized layer is prevented from peeling off and the like.

Owner:ZHEJIANG FOSCOM KITCHENWARE CO LTD

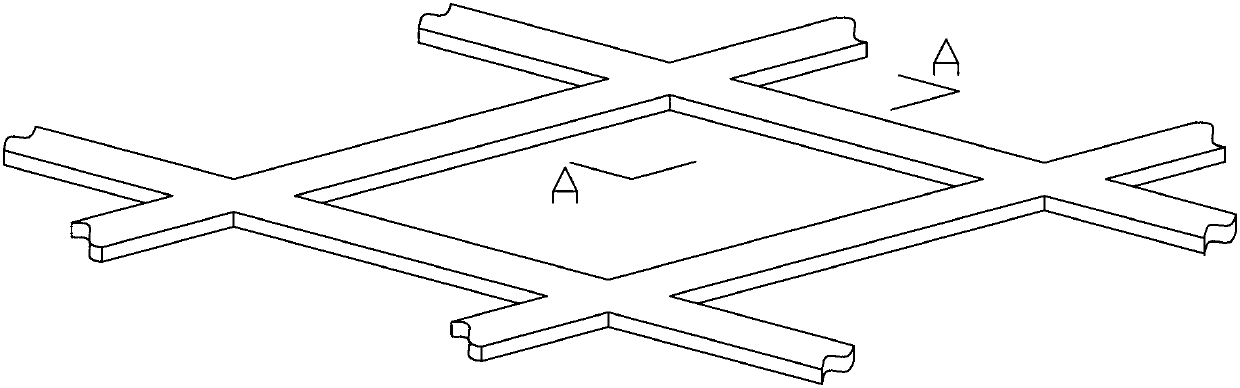

Aluminized steel sheet mesh and preparation method thereof

InactiveCN103342012AImprove toughnessEliminate surface brittle zonesLayered productsSolid state diffusion coatingPunchingSheet steel

The invention discloses an aluminized steel sheet mesh. The aluminized steel sheet mesh comprises a steel sheet mesh, wherein from inside to outside, the steel sheet mesh includes a substrate layer, an iron-aluminum alloy layer and an aluminum layer, and preferably the iron-aluminum alloy layer is 14-29 microns in thickness. A method for preparing the aluminized steel sheet mesh comprises the following steps of I, shaping a steel coil, a steel sheet or a steel strip into a steel sheet mesh work piece through punching and drawing; II, baking to remove oil; III, acid-pickling to remove rust; IV, washing; V, surface-activating; VI, permeation-promoting; VII, drying; VIII, implementing rapid inductive aluminizing; immediately immersing the dried work piece in molten aluminum which is heated to 680-700 DEG C by an inductive way for 2-3 minutes, thus obtaining a steel sheet mesh with surface aluminized. The preparation method can be used for not only guaranteeing the mechanical performance of the steel sheet mesh, but also ensuring excellent corrosion resistance and long service life; the preparation method can be used for greatly reducing the maintenance cost of the steel sheet mesh in later period.

Owner:HUBEI PROVINCIAL COMM INVESTMENT FOUR ADVANTAGE STEEL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com