Patents

Literature

62 results about "Laser-hybrid welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser-hybrid welding is a type of welding process that combines the principles of laser beam welding and arc welding. The combination of laser light and an electrical arc into an amalgamated welding process has existed since the 1970s, but has only recently been used in industrial applications. There are three main types of hybrid welding process, depending on the arc used: TIG, plasma arc or MIG augmented laser welding. While TIG-augmented laser welding was the first to be researched, MIG is the first to go into industry and is commonly known as hybrid laser welding.

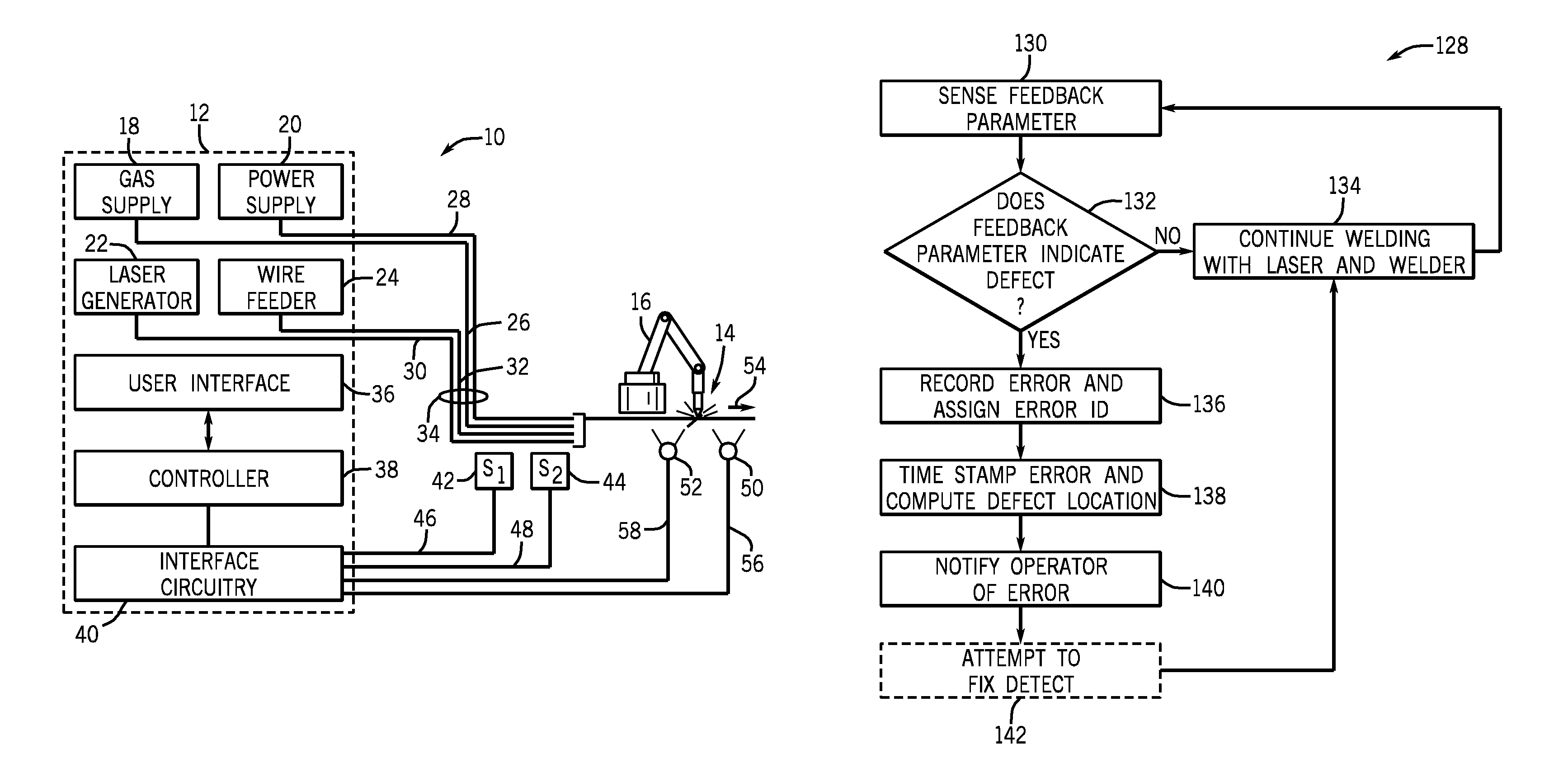

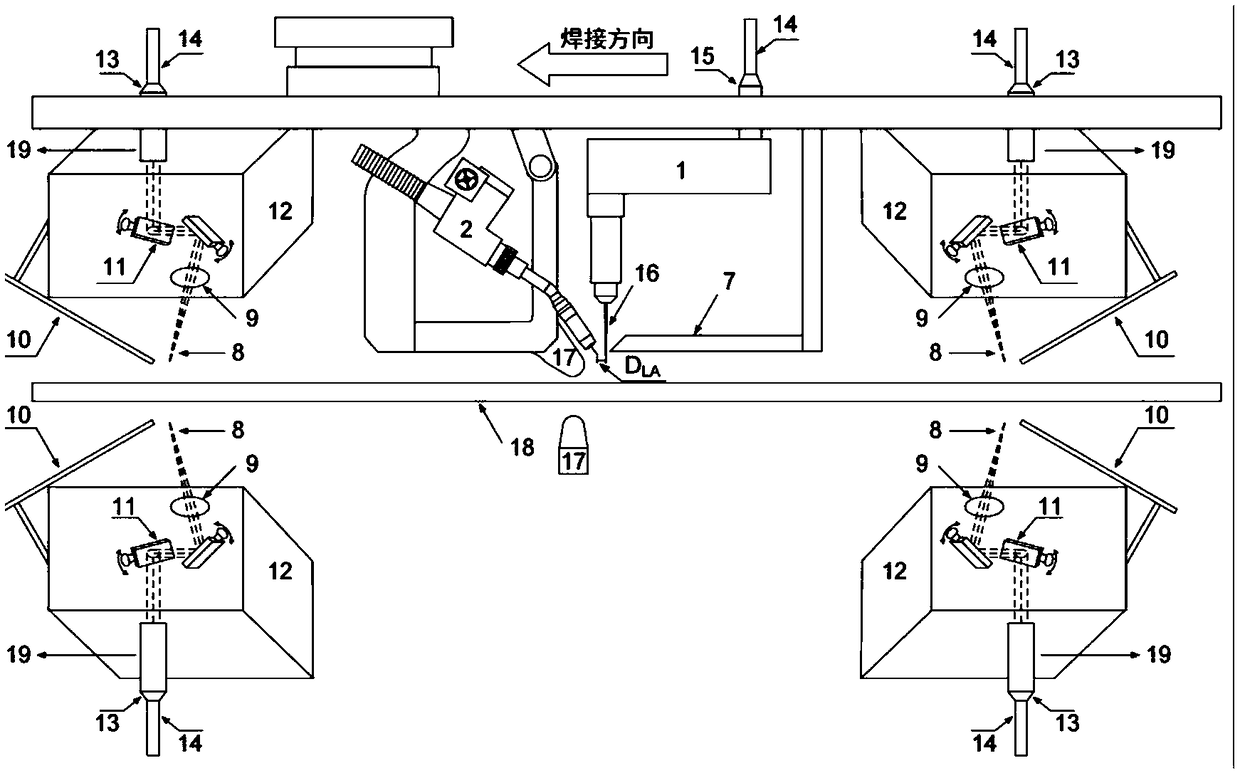

Weld defect detection systems and methods for laser hybrid welding

ActiveUS20100314362A1Welding/cutting auxillary devicesArc welding apparatusLaser-hybrid weldingPower flow

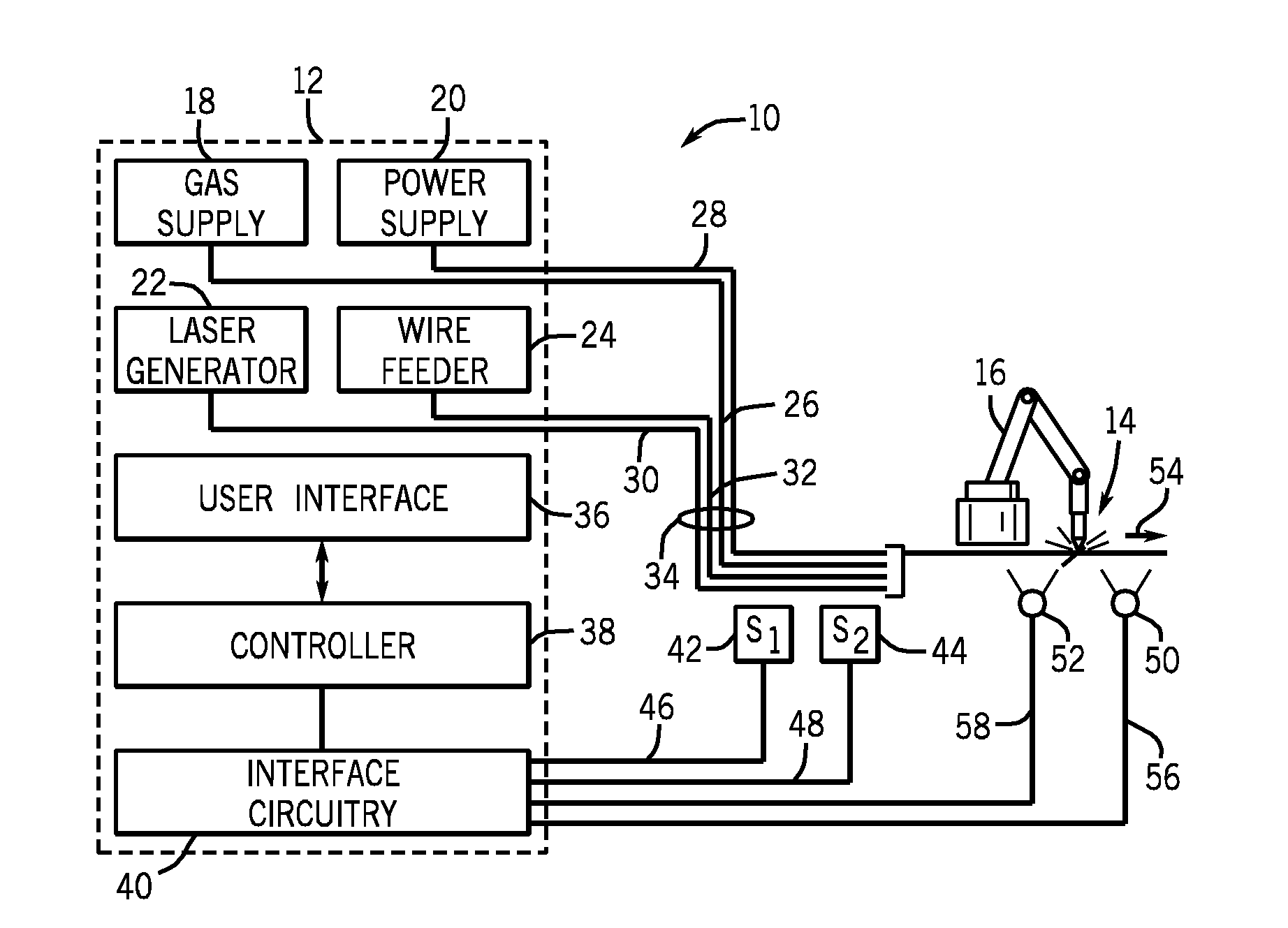

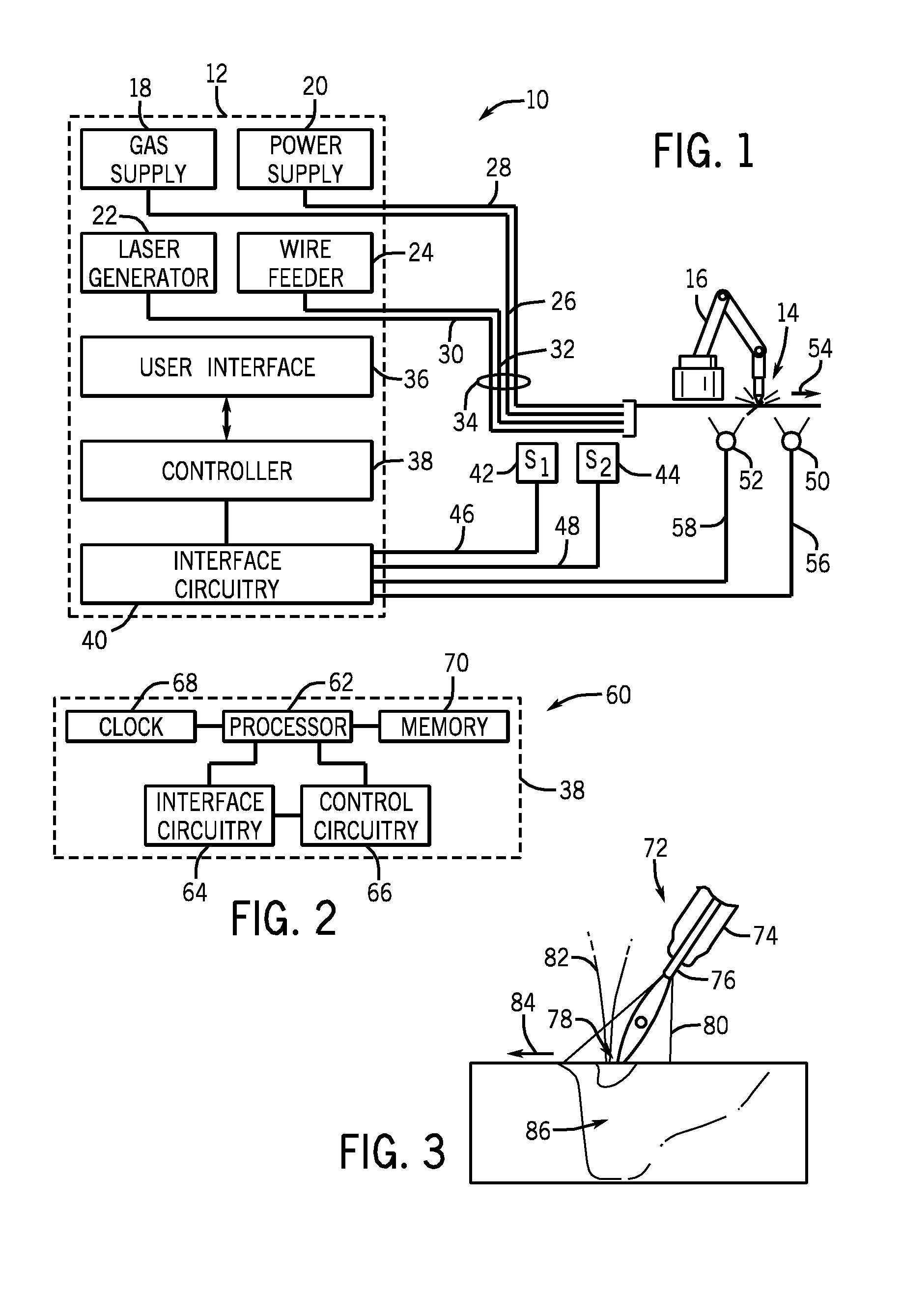

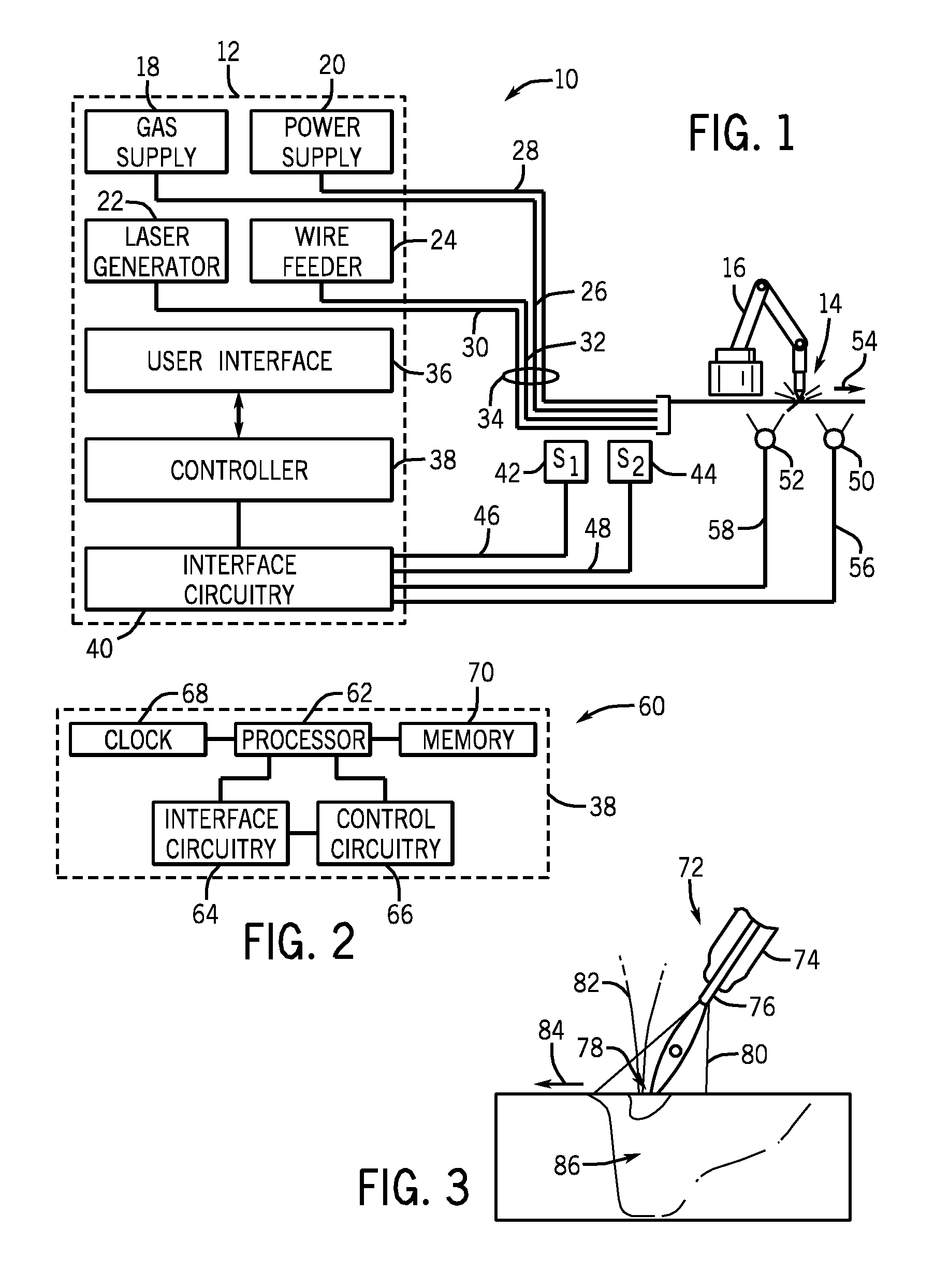

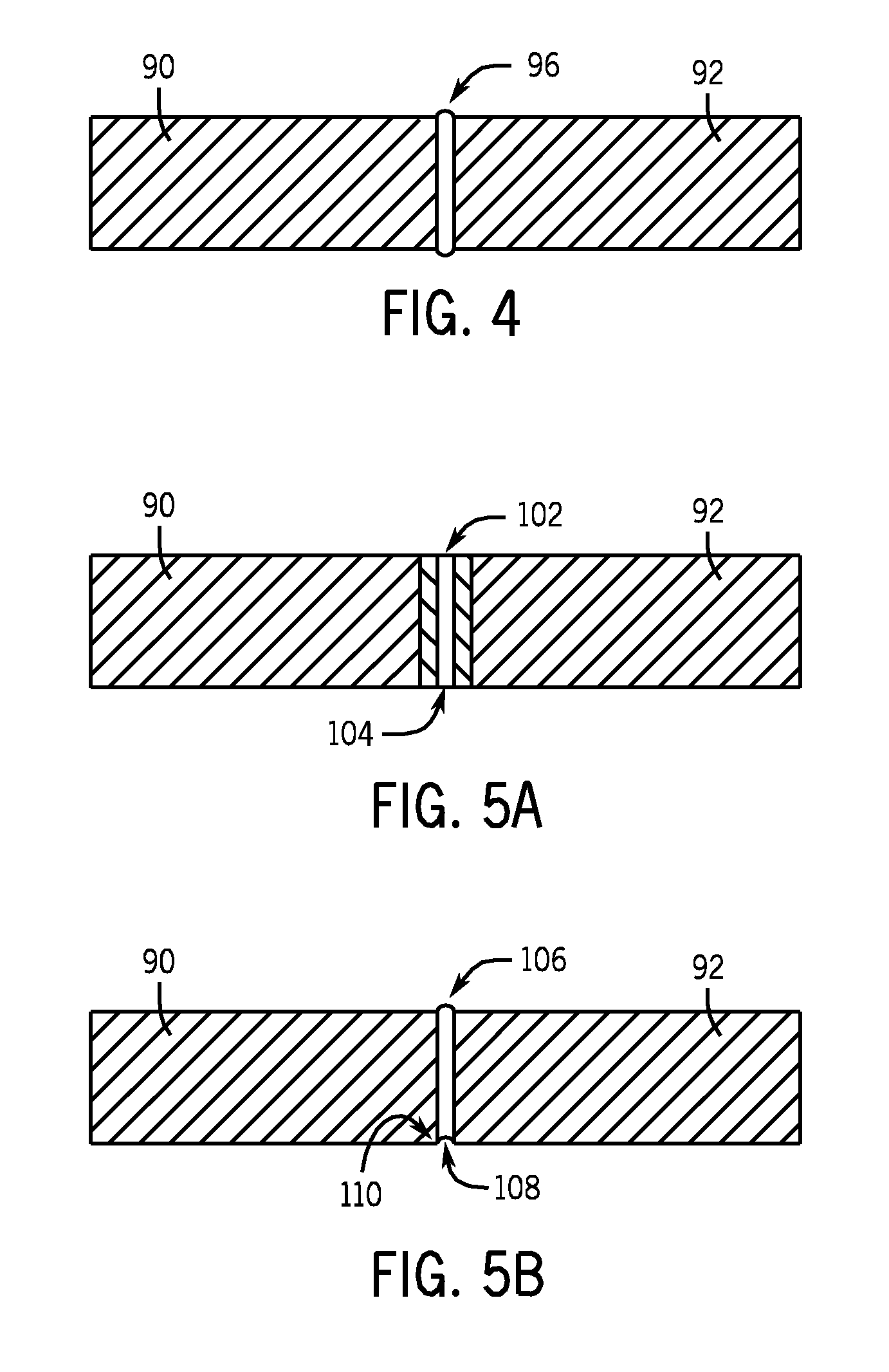

Laser hybrid welding systems adapted to identify and / or fix a weld defect occurring during a laser hybrid welding process are provided. Embodiments of the laser hybrid welding system may include one or more devices that provide feedback to a controller regarding one or more weld parameters. One embodiment of the laser hybrid welding system includes sensors that are adapted to measure the weld voltage and / or amperage during the welding process and transmit the acquired data to the controller for processing. Another embodiment of the laser hybrid welding system includes a lead camera and a lag camera that film an area directly in front of the weld location and directly behind the weld location.

Owner:ILLINOIS TOOL WORKS INC

Laser-hybrid welding with beam oscillation

InactiveUS7154065B2Arc welding apparatusWelding/soldering/cutting articlesLaser-hybrid weldingMetallurgy

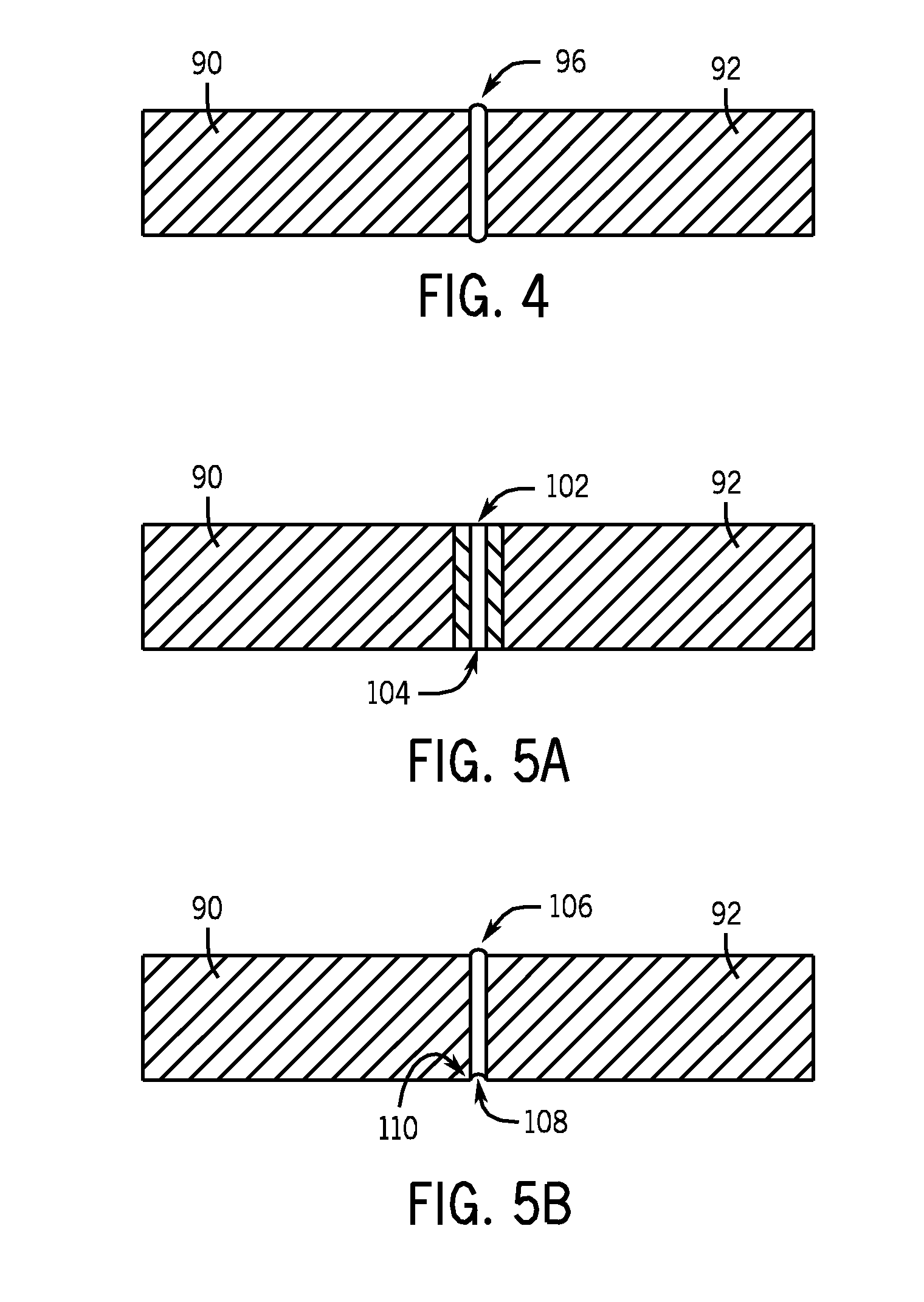

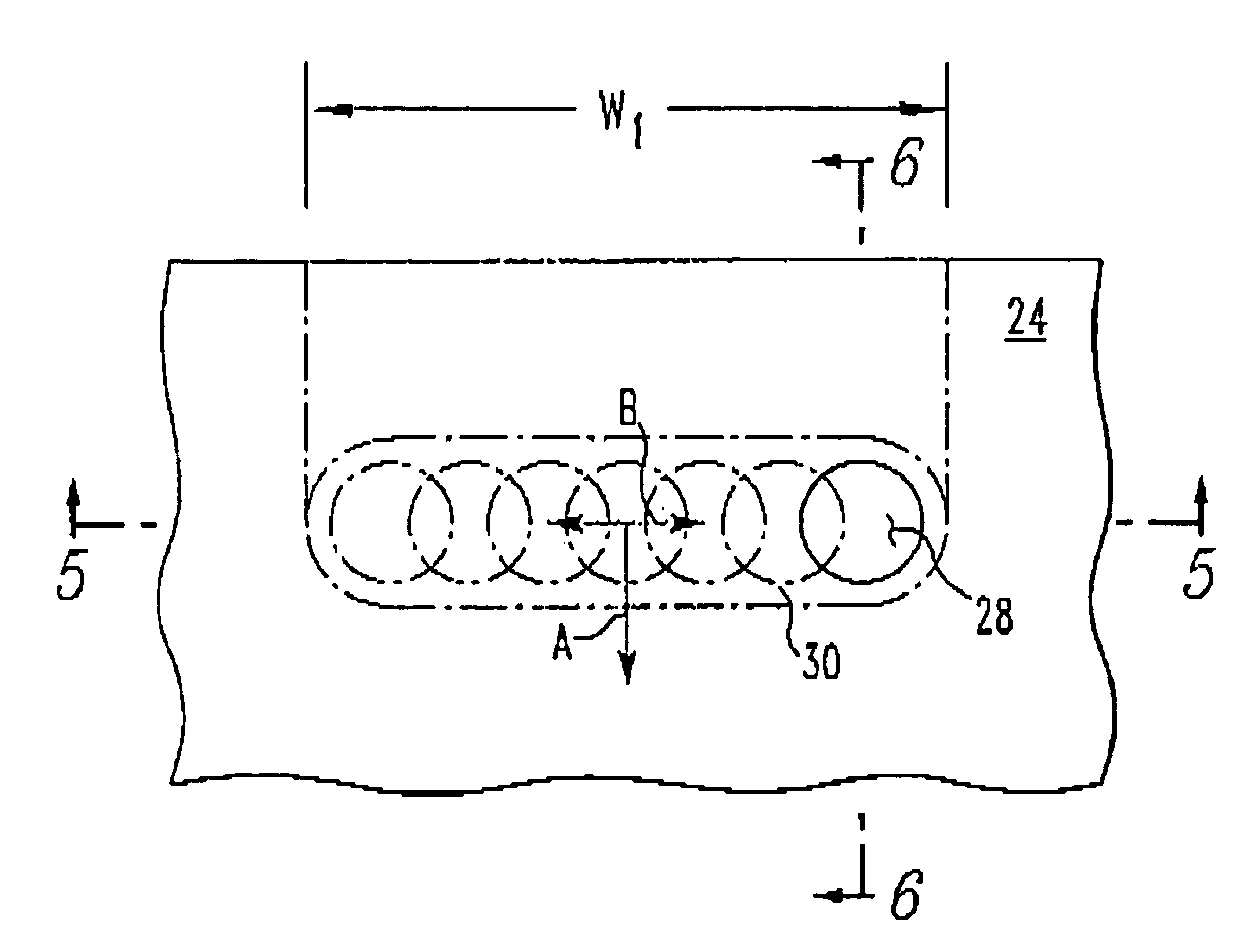

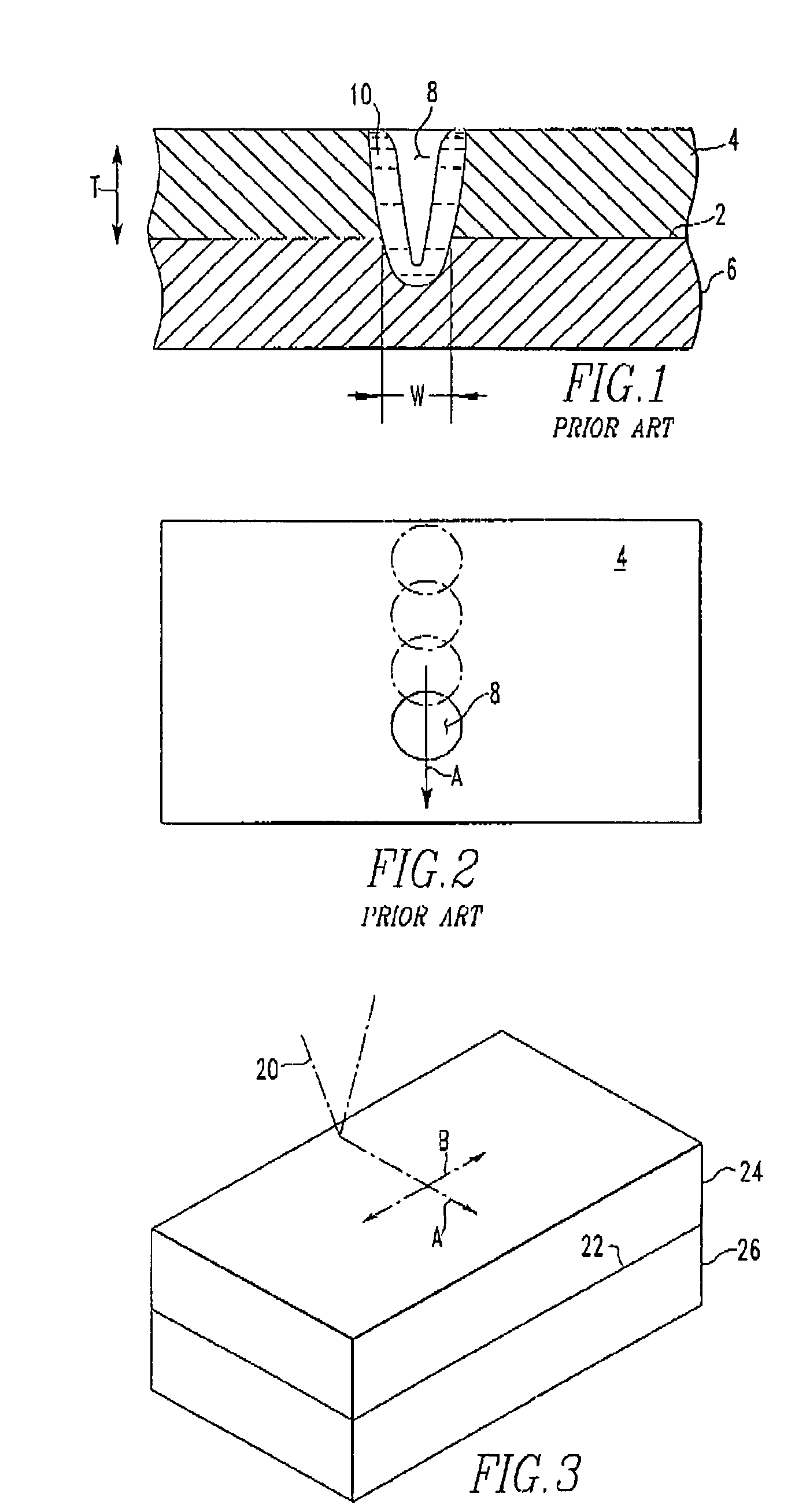

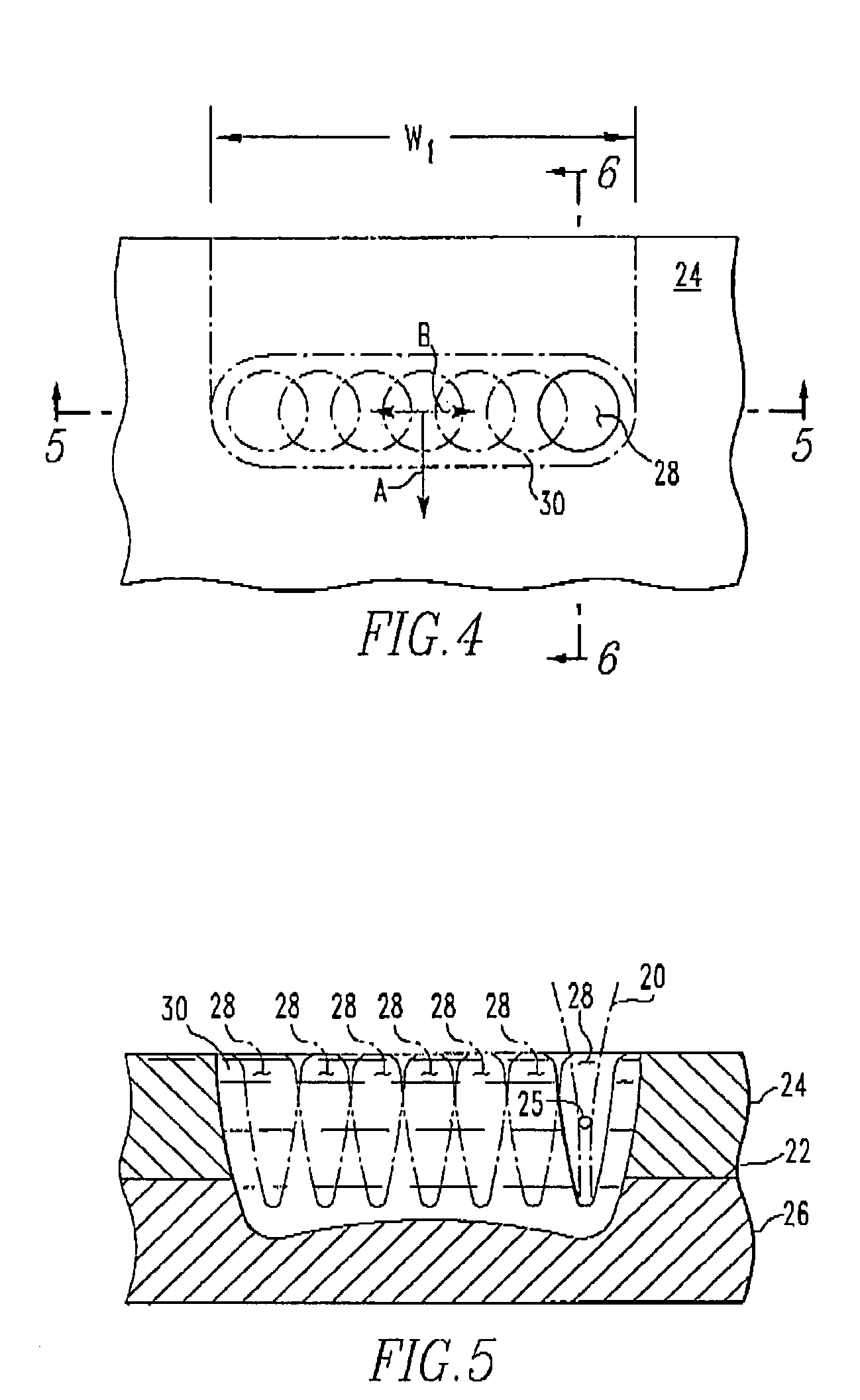

A method of welding metal components together including moving a laser beam in a first direction along an interface between a pair of metal components such that in the vicinity of the focused beam, metal from each component is vaporized to produce a keyhole in a pool of molten metal. The laser beam is oscillated in a direction different from (e.g., transverse to) the first direction such that the keyhole oscillates through the pool of molten metal and molten metal fills into the keyhole as the position of the keyhole changes.

Owner:PENN STATE RES FOUND

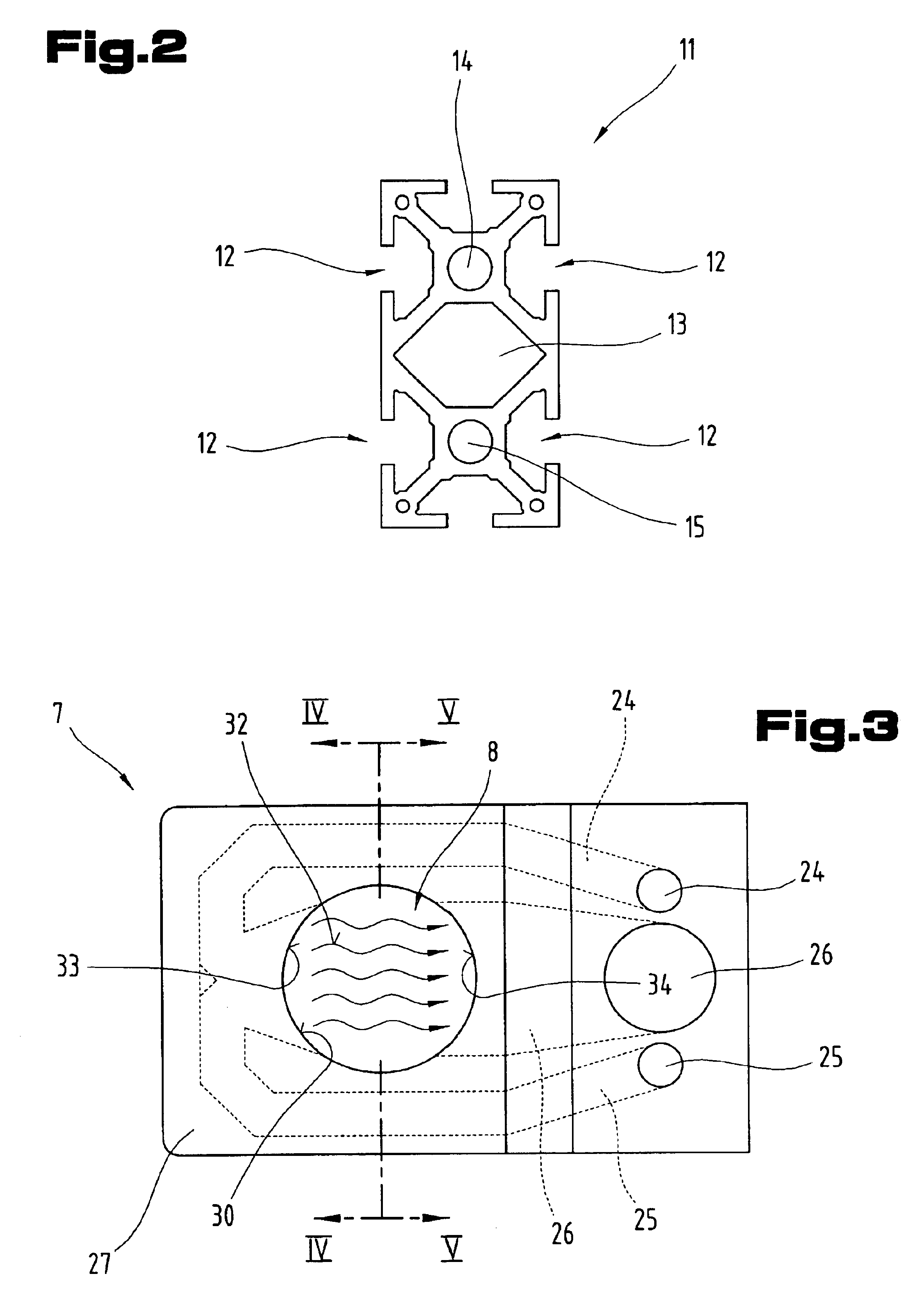

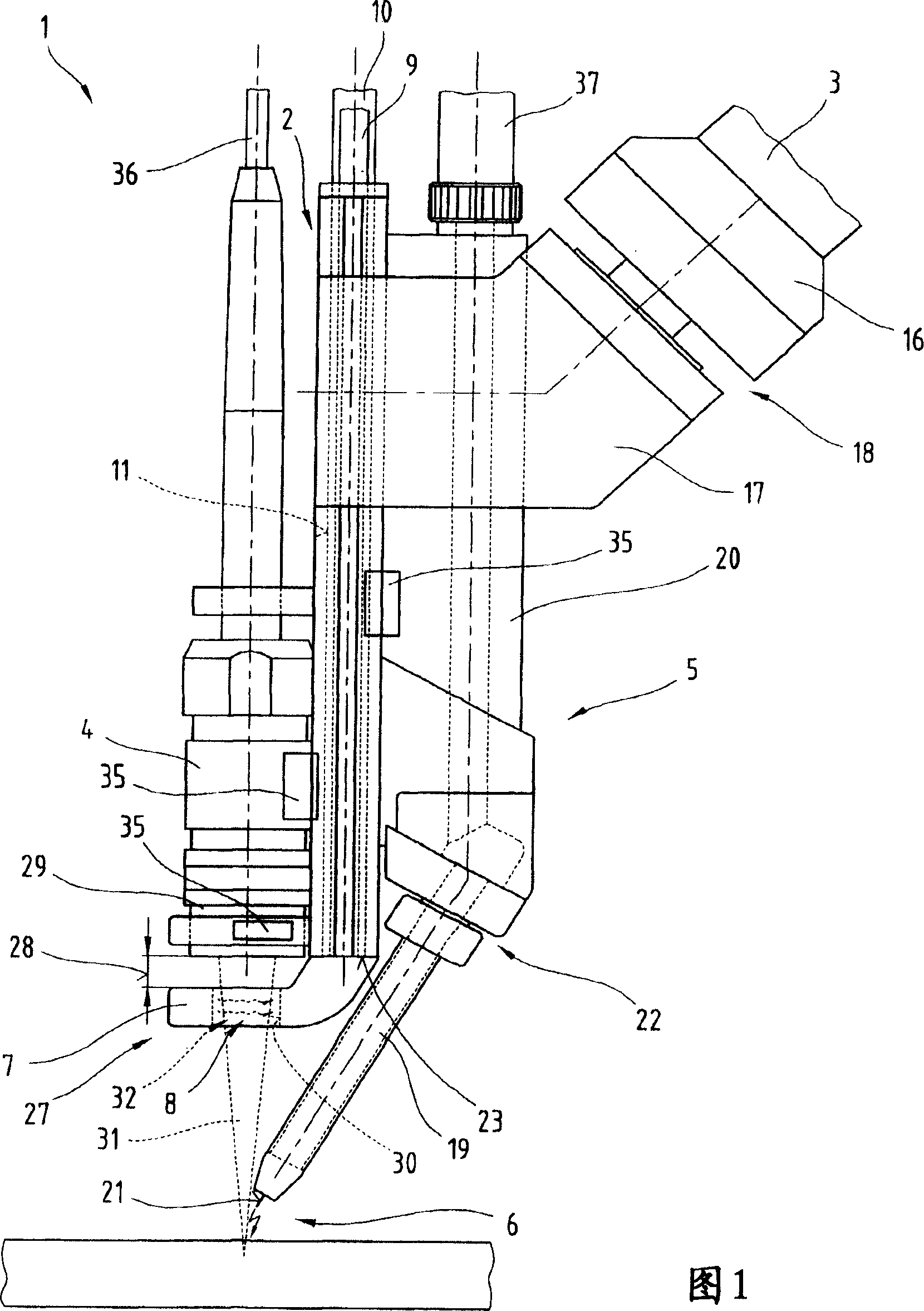

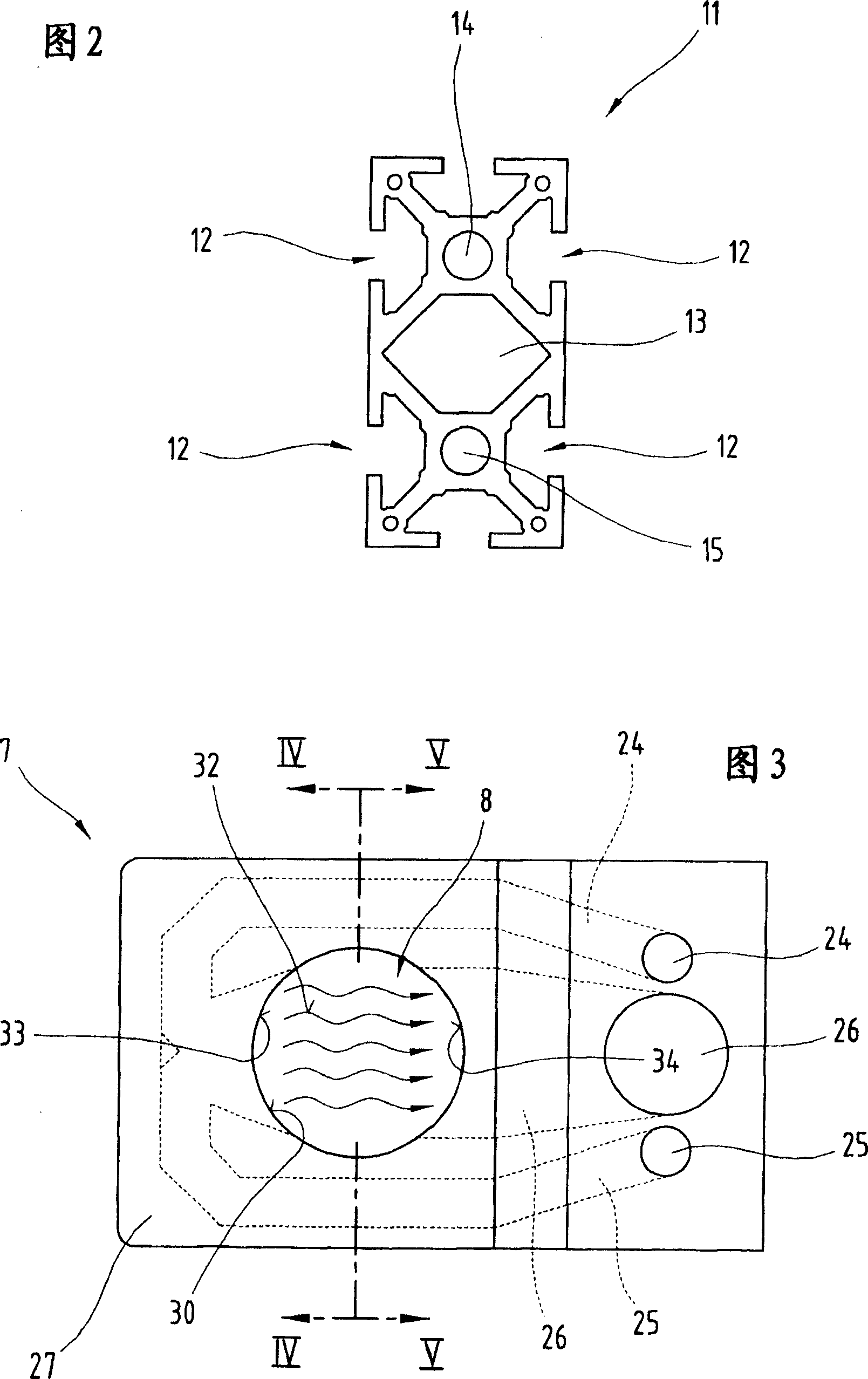

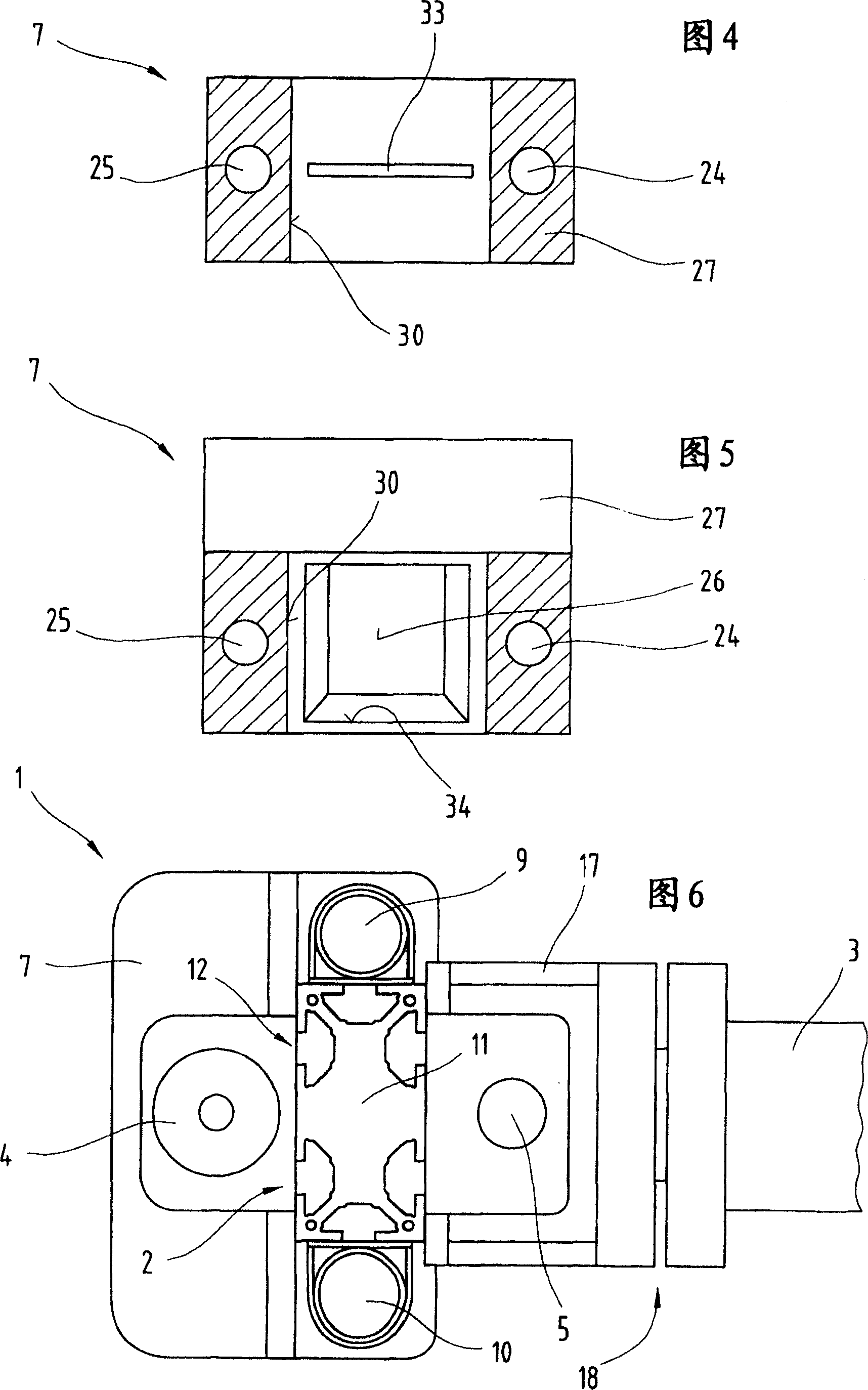

Device for a laser-hybrid welding process

InactiveUS6844521B2Small component sizeSimple structureSupport devices with shieldingWelding/cutting media/materialsLaser-hybrid weldingEngineering

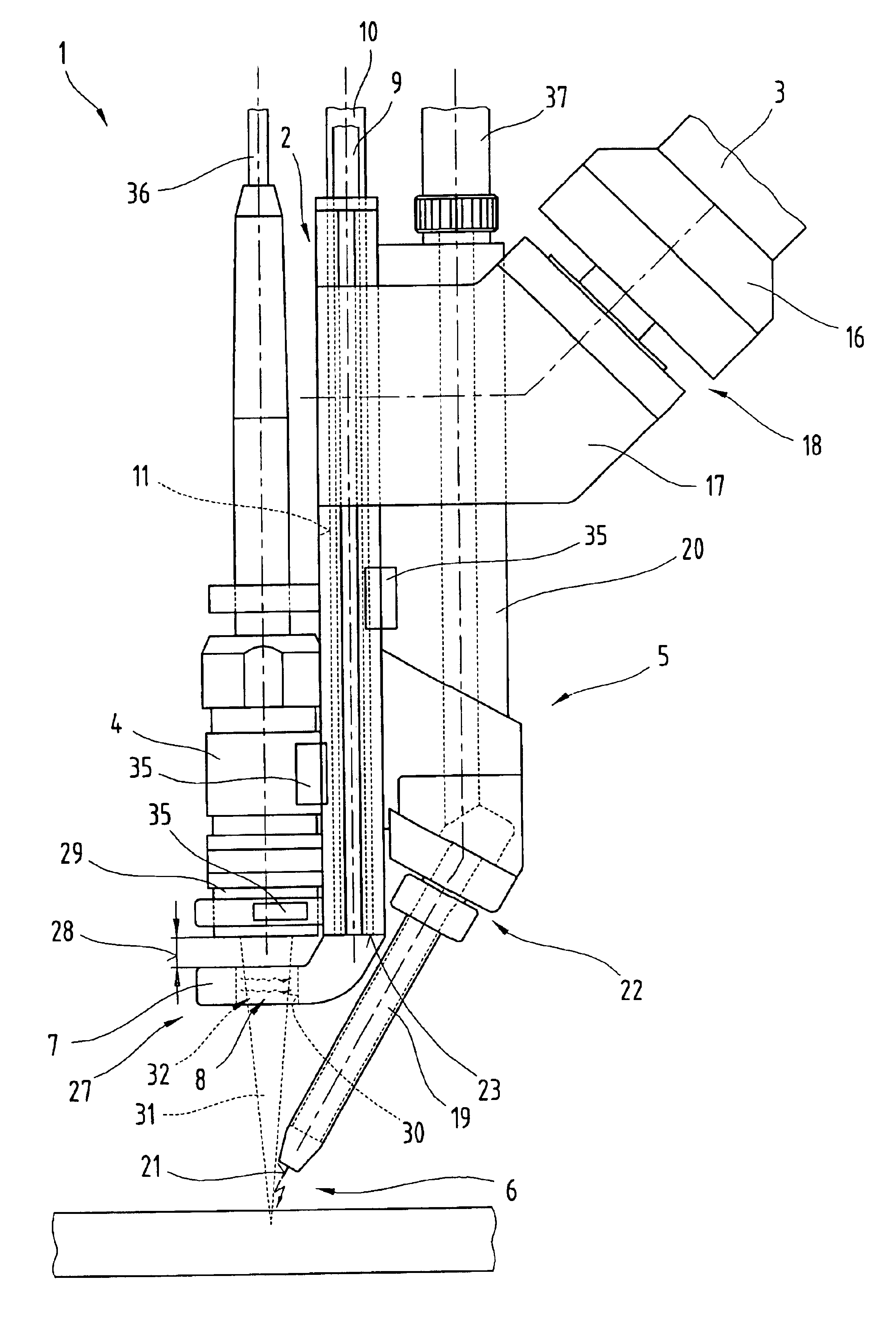

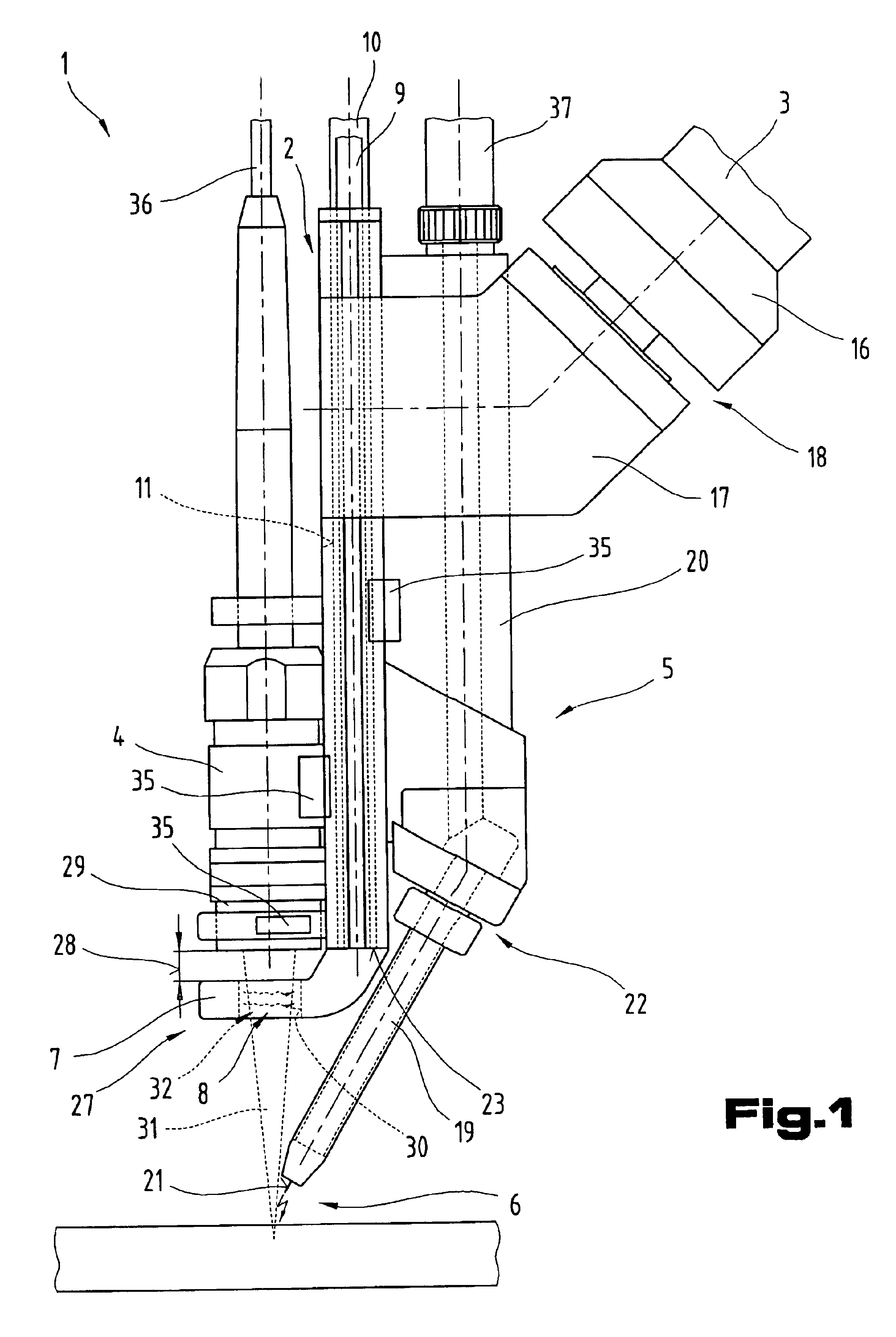

The invention describes an apparatus, in particular a laser hybrid welding head (1) for a laser hybrid welding process, in which a laser (4) or laser optics or an optical focussing unit and elements of a welding torch (5) for an arc welding process and / or a feed device for a welding wire as well as a device for generating a cross jet (8) connected by at least an incoming line (9) and an outgoing line (10) to a compressed air supply system, are mounted on at least one mounting element (2). The incoming line (9) and the outgoing line (10) carrying compressed air for the cross jet (8) are disposed between the two components, in particular the laser (4) and laser optics or the optical focussing unit and the elements of the welding torch (5) or feed device for the welding wire (21).

Owner:FRONIUS INTERNATIONAL GMBH

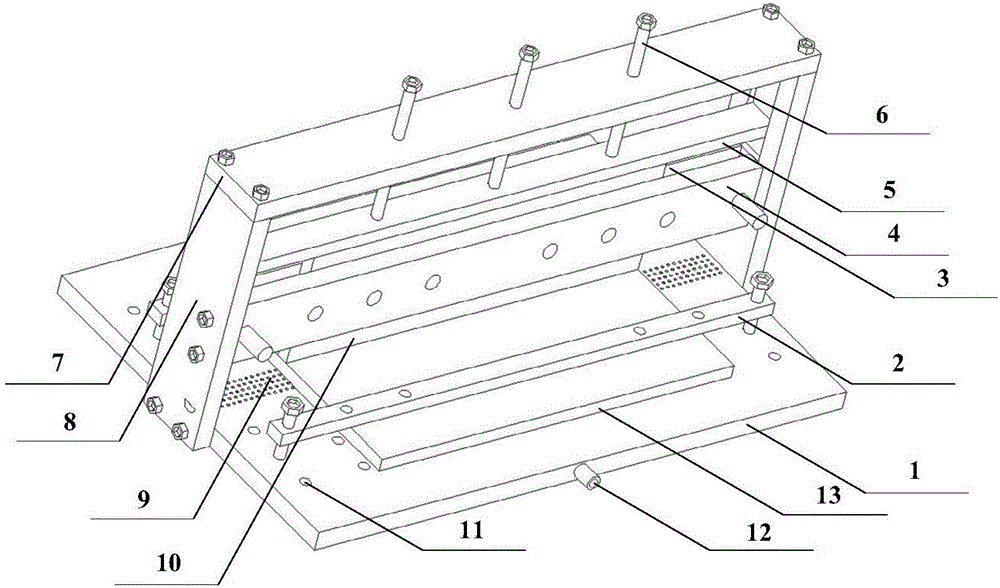

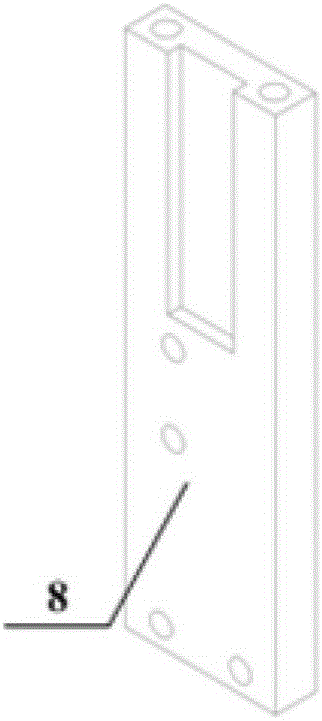

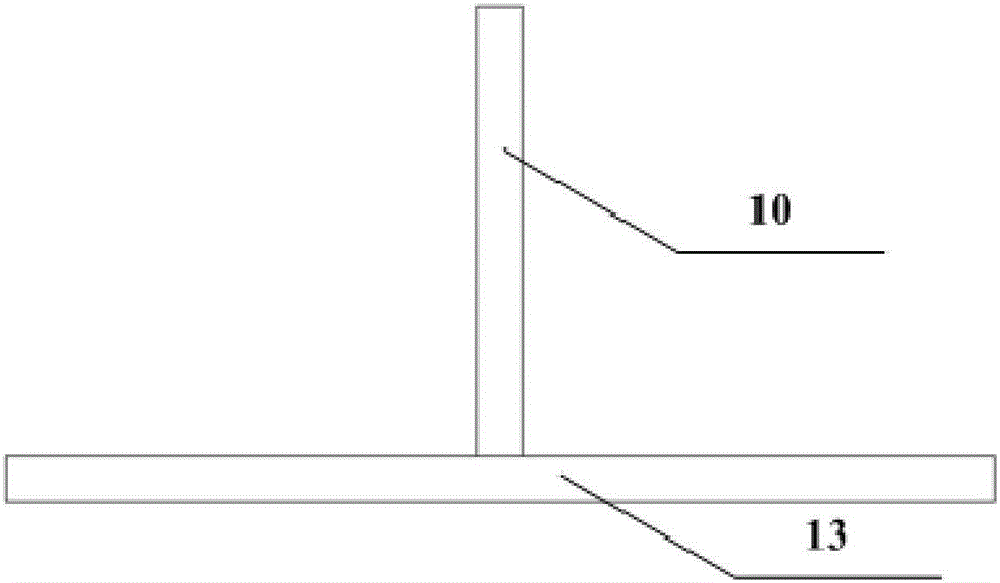

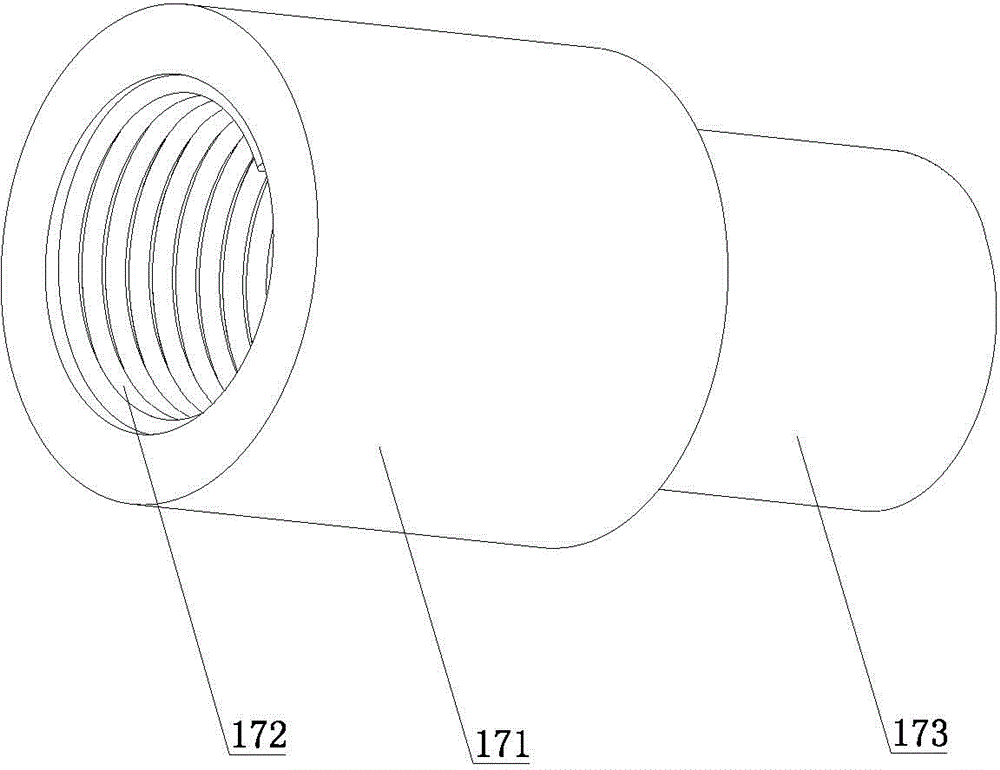

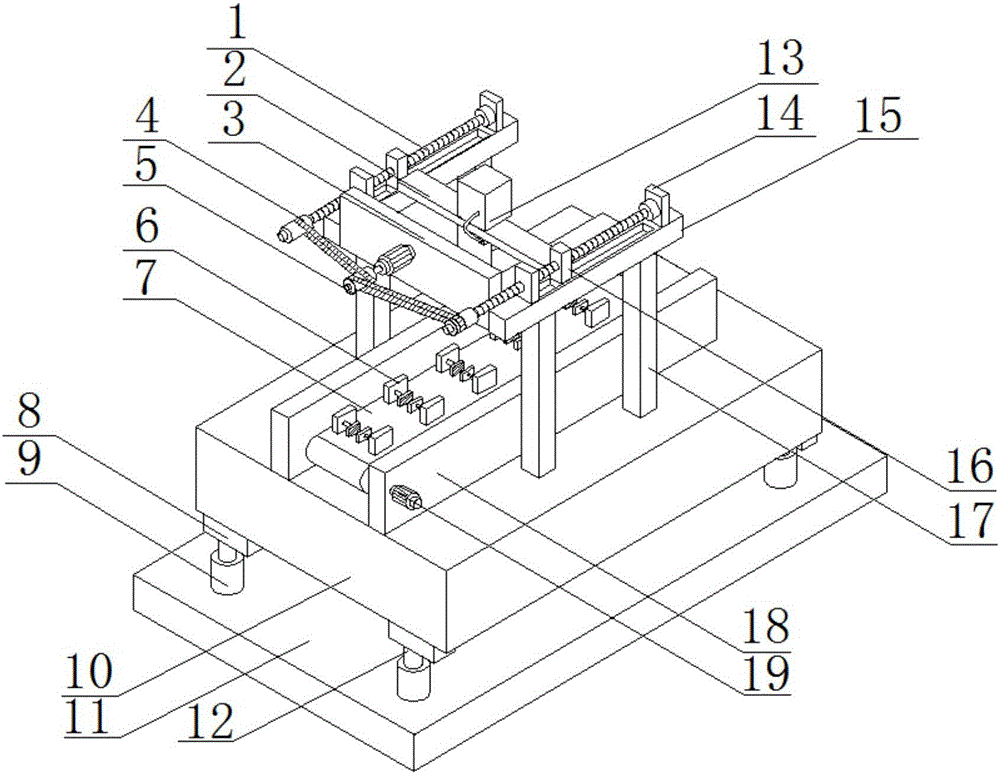

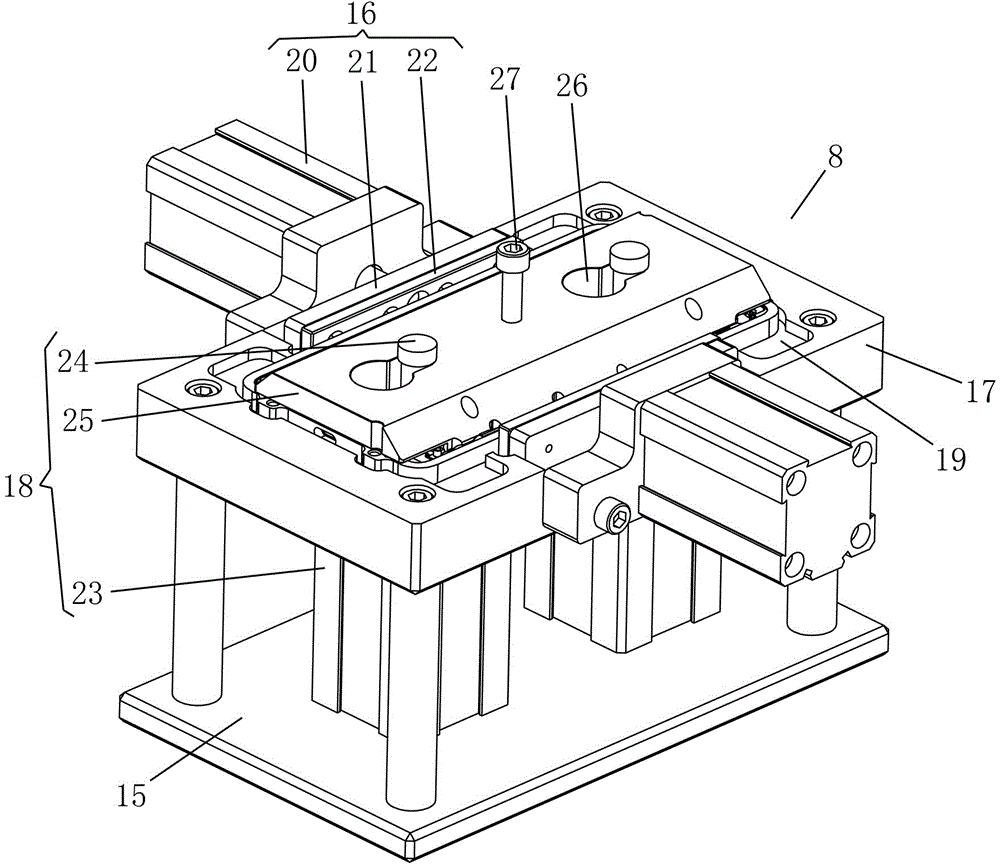

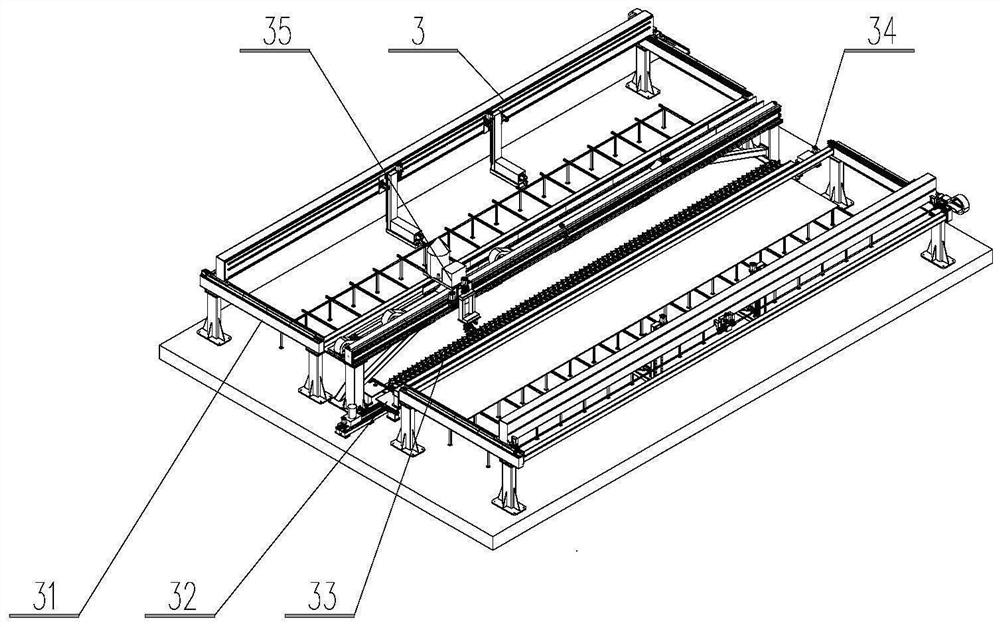

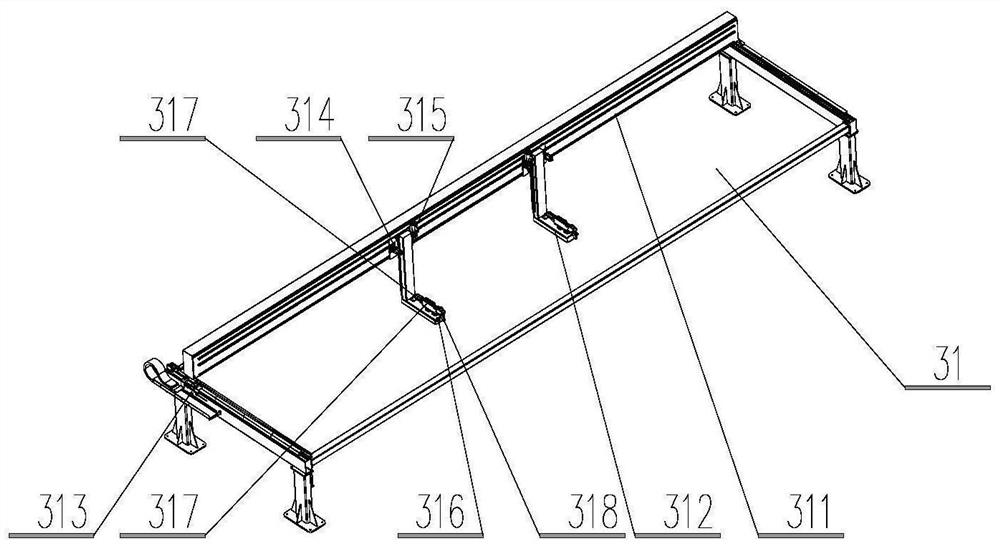

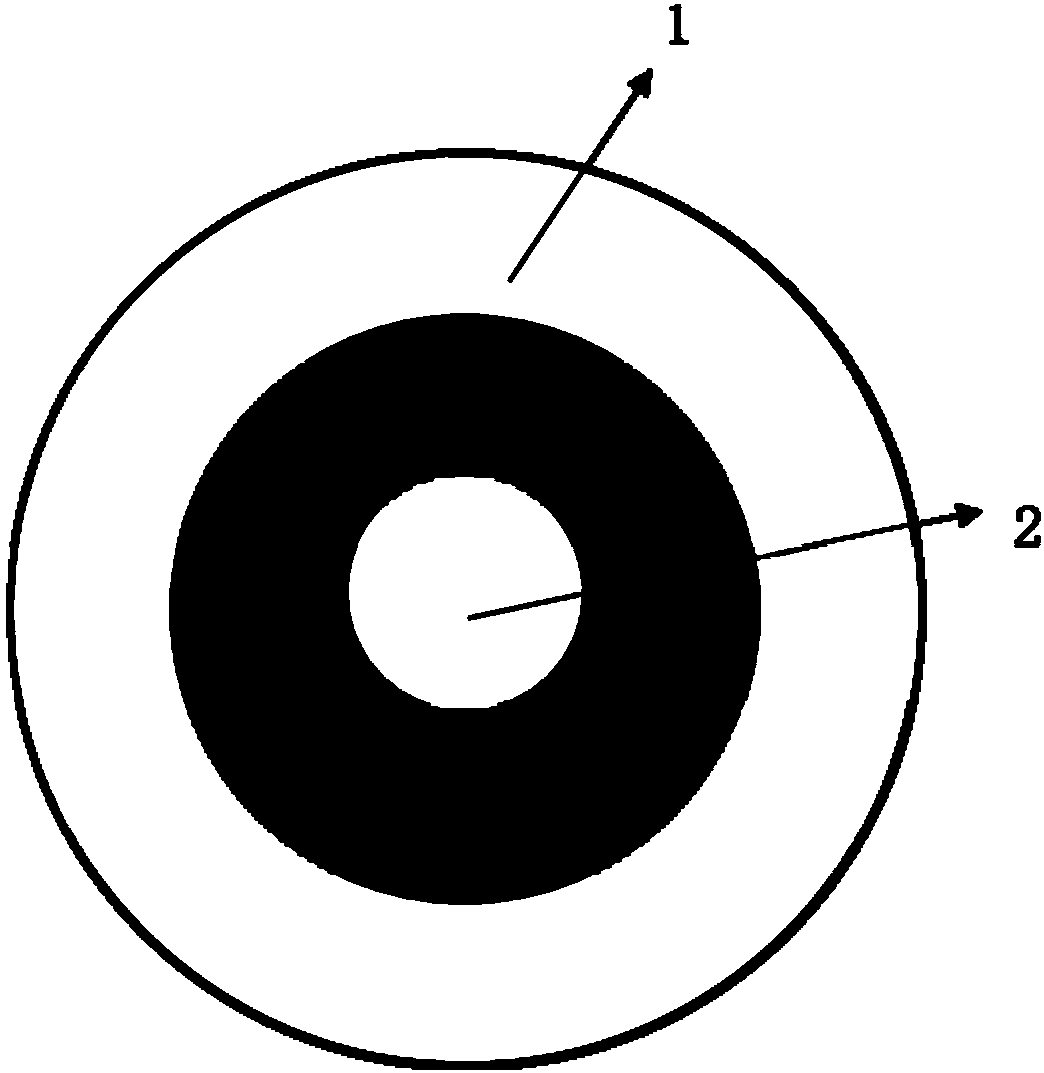

Clamp for laser hybrid welding of T-shaped connector

InactiveCN106425230AImproving the Precision of Laser Hybrid WeldingUniversally applicableWelding/cutting auxillary devicesAuxillary welding devicesLaser-hybrid weldingEngineering

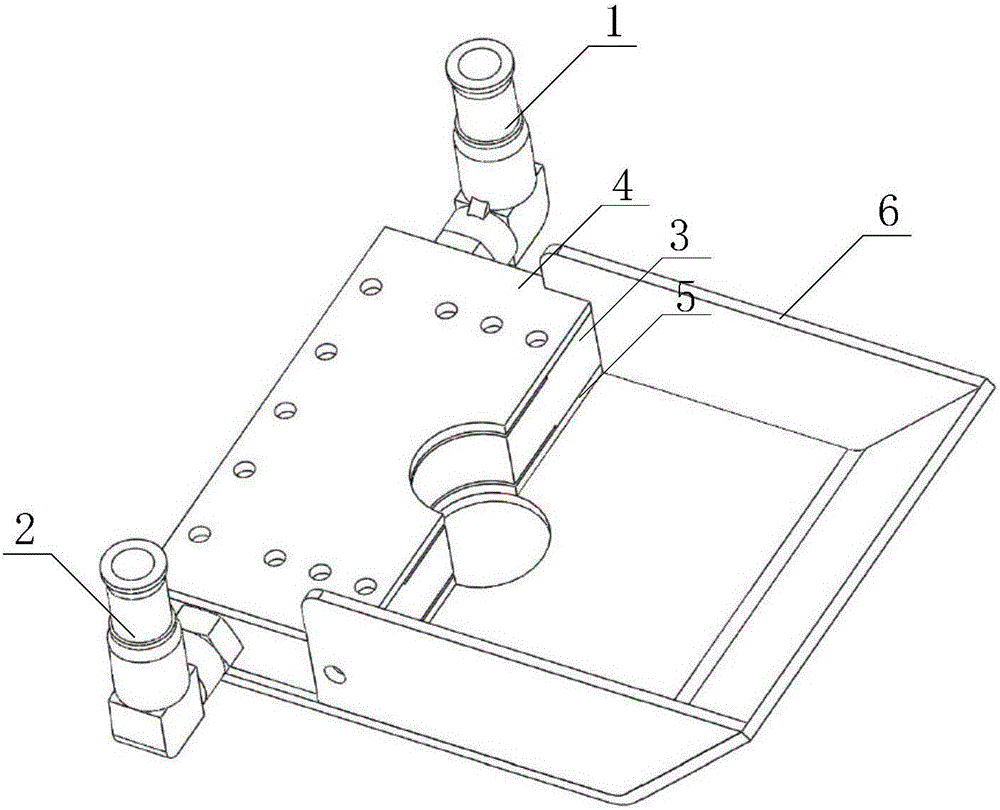

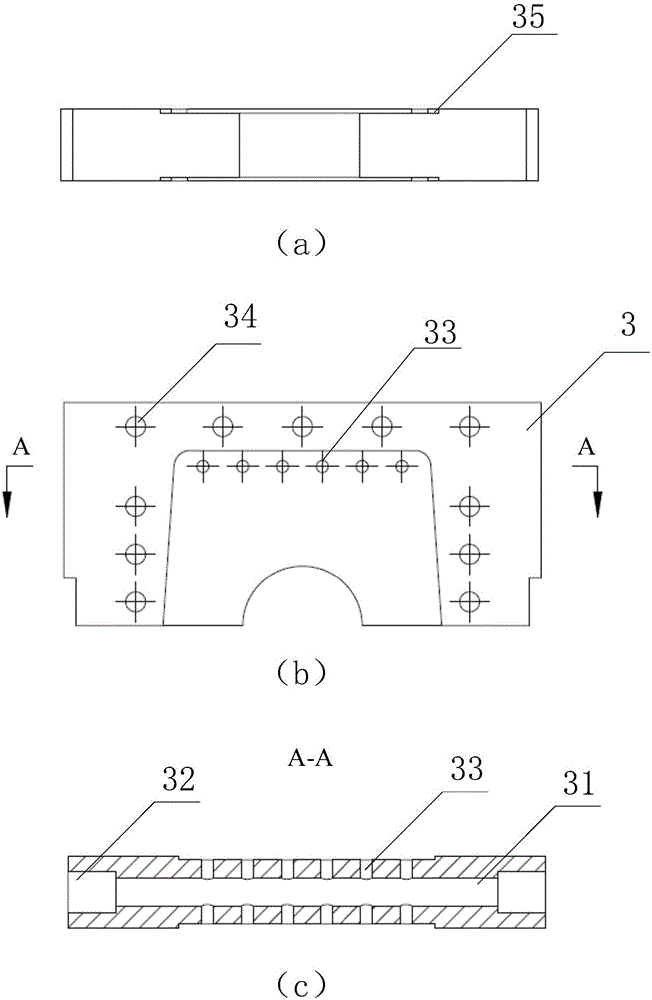

The invention discloses a clamp for laser hybrid welding of a T-shaped connector. The clamp for the laser hybrid welding of the T-shaped connector comprises a base, and frame body vertical beams which are positioned on the two sides of the base; a wing plate is placed on the base and is compressed on the base through a compressing device; the frame body vertical beams are mounted on the base; a first pressing plate is fixedly mounted on the frame body vertical beams; the side surface of the first pressing plate is perpendicular to the upper surface of the base; a web plate is clamped by the first pressing plate through the second pressing plate so that the web plate is vertically intersected with the wing plate; the first pressing plate is connected with the second pressing plate by bolts; a plurality of air holes are formed in the base; the air holes are communicated with a protective gas pipe. The clamp for the laser hybrid welding of the T-shaped connector disclosed by the invention meets the requirement on precision of welding piece assembling, and can ensure the assembling precision in welding, ensure the forming quality, and reduce welding deformation effectively.

Owner:JIANGSU UNIV OF SCI & TECH

Laser hybrid welding method and system

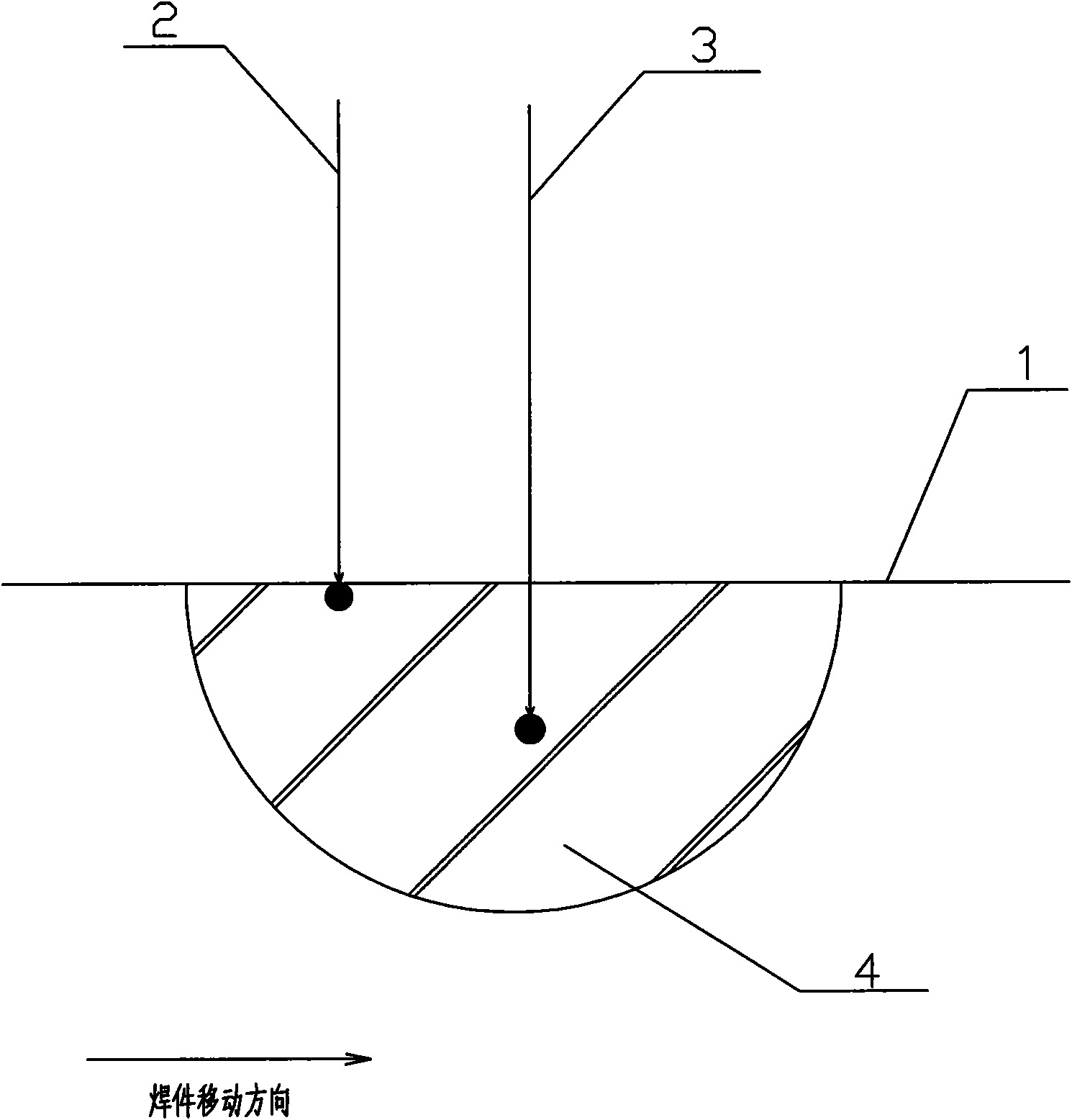

The invention discloses a laser hybrid welding method which comprises steps as follows: a laser with a first wavelength, which is used for increasing the absorptivity of a workpiece to be welded to a laser with a second wavelength, is transmitted; the laser with the second wavelength is transmitted; and the laser with the first wavelength and the laser with the second wavelength are synthesized into one laser beam, and simultaneously, the laser beam is focalized on the workpiece to be welded so as to weld the workpiece to be welded. Continuous laser of the laser with the first wavelength is used for illuminating the workpiece to be welded to achieve preheat, and simultaneously, pulse laser of the laser with the second wavelength is used for welding, so that the effect and the speed of high-efficiency laser welding can be achieved, the construction cost is lower, and the requirement for various aspects of heat dissipation, power consumption and the like can be reduced. Besides, the invention further provides a laser hybrid welding device adopting the laser hybrid welding method.

Owner:INTELUME LASER SYST

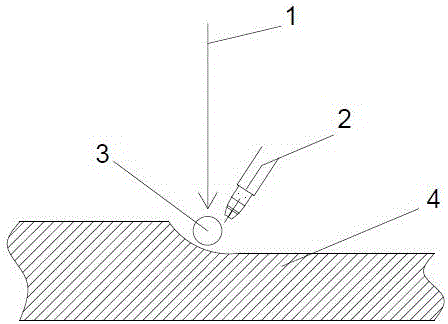

Micro-beam plasma arc/laser hybrid welding method

InactiveCN101992354AReduce reflectivityIncrease the effective heating depthPlasma welding apparatusLaser beam welding apparatusLaser-hybrid weldingAbsorption rate

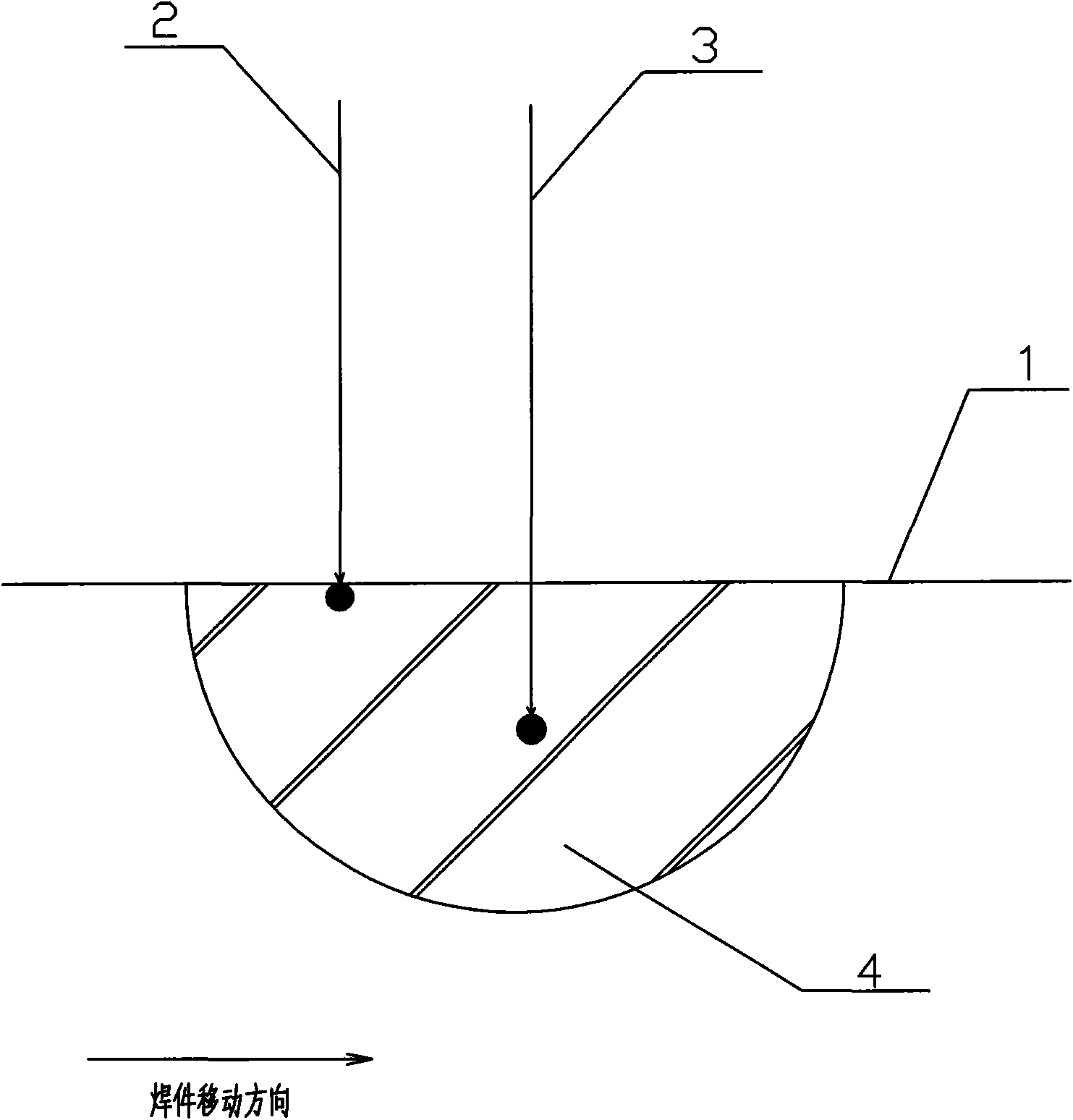

The invention relates to a micro-beam plasma arc / laser hybrid welding method, which comprises the following steps: fixing a micro-beam plasma arc transmitter and a laser beam transmitter, providing a workpiece which moves at a constant speed, and forming a mode of micro-beam plasma arc preposition; carrying out initial fusion on the surface of a welded part of the workpiece by micro-beam plasma arcs, then irradiating laser beams to the welded part, thereby deepening the depth of fusion of micro-beam plasma arc welding, and then completing the welding. The welding method of the invention can reduce the reflectance of aluminium alloys to lasers, and improve the absorption rate of aluminium alloys to laser energies, thereby improving the effective heating depth of laser, increasing the depths of fusion of weld joints and effectively reducing the widths of weld joints and heat affected zones; and finally, obtaining weldments which have the advantages of large depth of fusion, extremely small heat affected zone and beautiful appearance.

Owner:CRRC QINGDAO SIFANG CO LTD

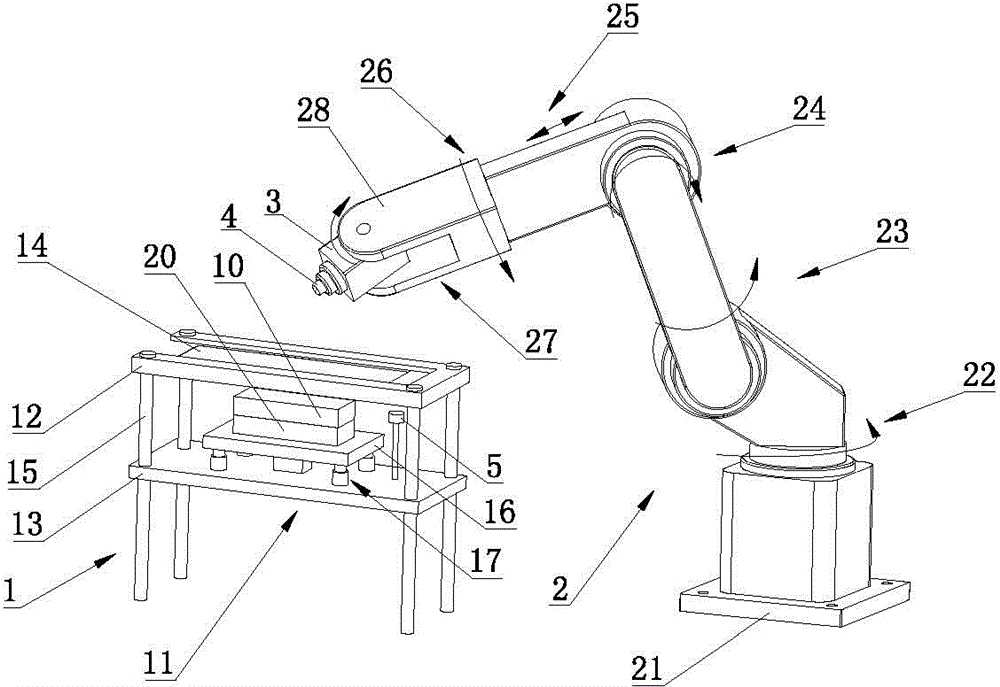

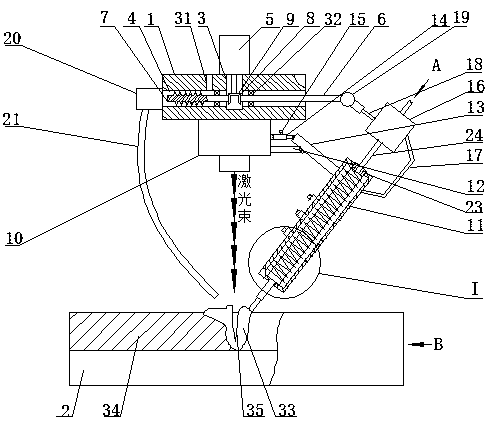

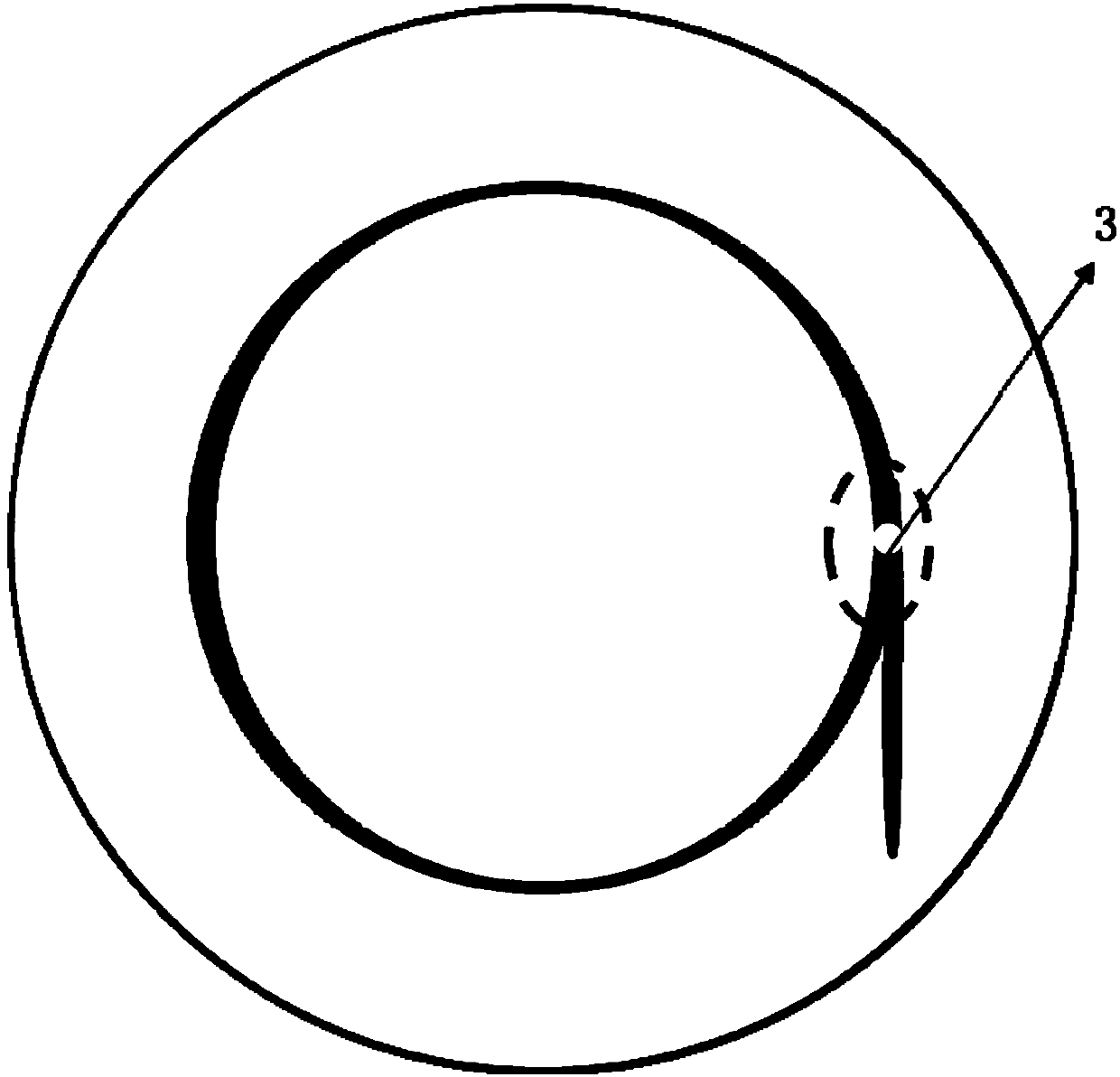

Active laser vision steady weld joint tracking system for laser-arc hybrid welding

ActiveCN109226967ATroubleshoot tracking errorsRealize automatic extractionImage enhancementProgramme-controlled manipulatorLaser-hybrid weldingEngineering

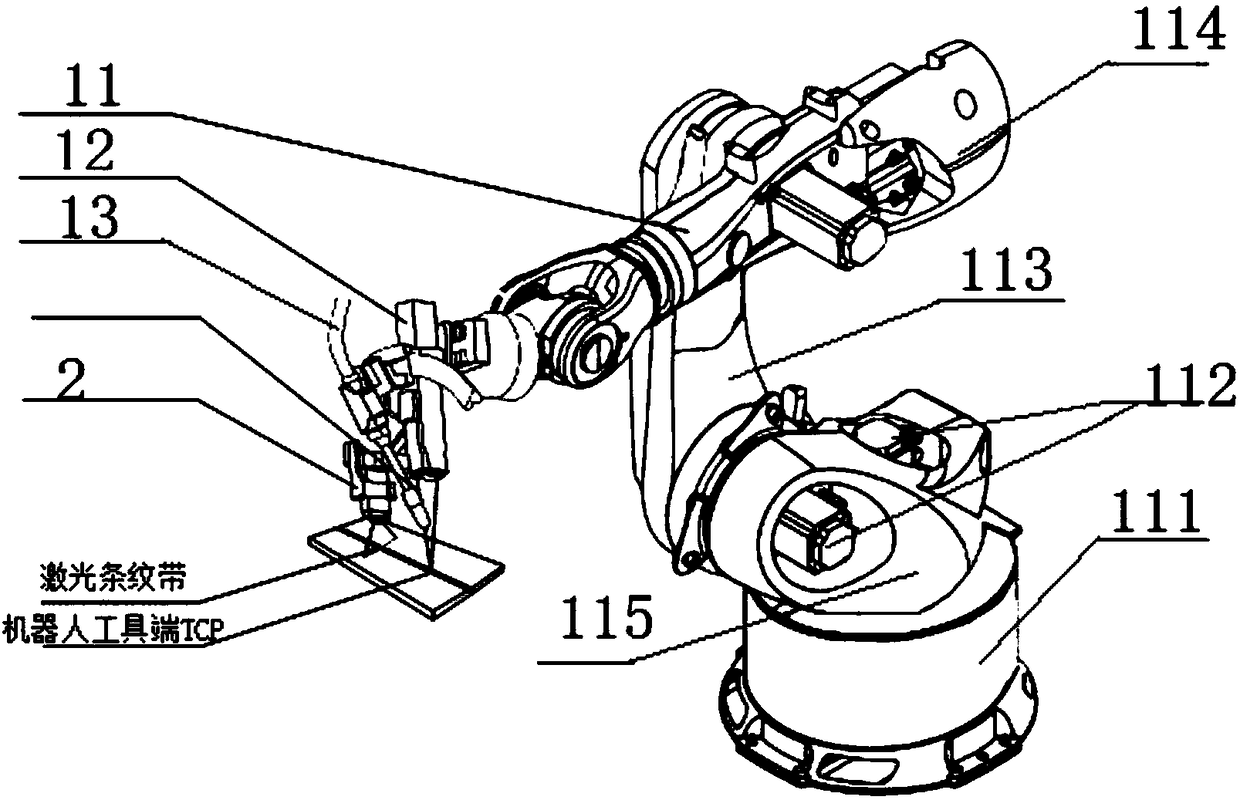

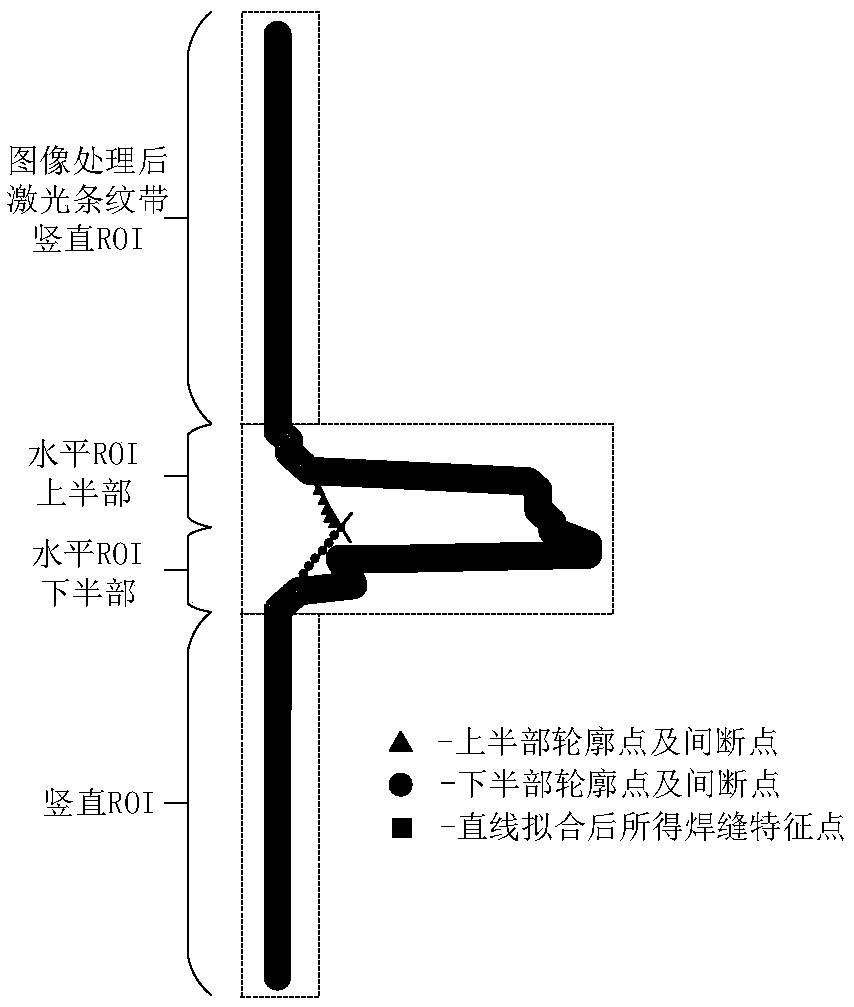

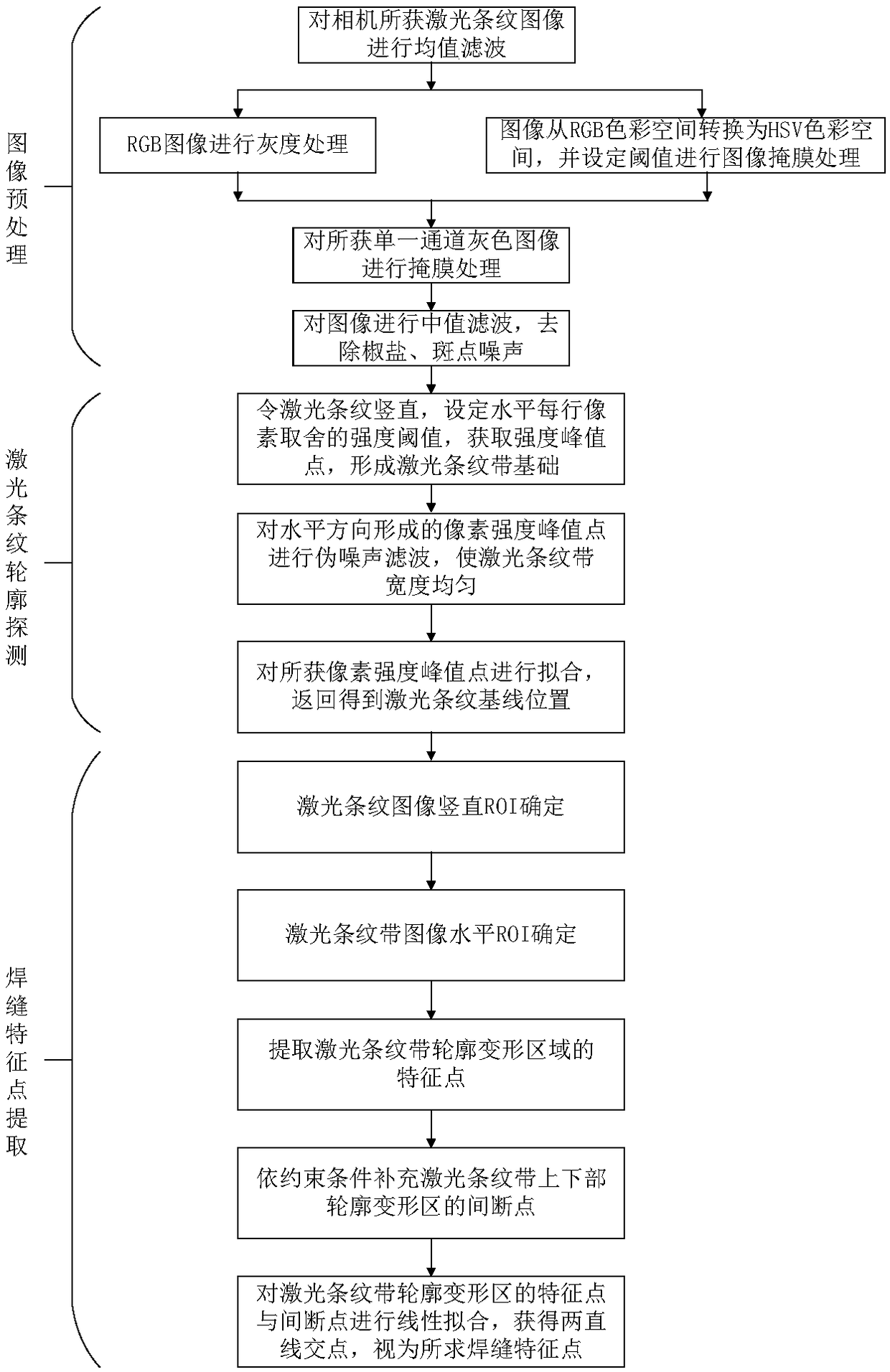

The invention discloses an active laser vision steady weld joint tracking system for laser-arc hybrid welding. The system comprises a laser-hybrid welding robot, an active laser vision system, a lasersource, an image processing system and a control system, wherein the active laser vision system and the laser source are both disposed on the laser-hybrid welding robot; the image processing system is disposed in the control system; and the laser-hybrid welding robot, the active laser vision system, the laser source, and the image processing system are all connected with the control system. The active laser vision steady weld joint tracking system solves the problem that during the traditional laser-arc hybrid welding, the arc light and the spattering interference causes the weld joint tracking system to generate excessive image noise, which ultimately affects the welding quality, the welding precision and efficiency, and solves the robot tracking errors caused by the weld joint feature point trajectory deviation during the teaching process, combines the weld joint image recognition with robot motion control to realize automatic extraction and accurate intelligent tracking of weld joint features.

Owner:TONGGAO ADVANCED MFG TECH TAICANG

Hybrid arc/laser-welding method for aluminized steel parts using gammagenic elements and a gas containing less than 10 % of nitrogen or oxygen

The invention relates to a hybrid laser / arc-welding method using an electric arc and a laser beam that are combined together within a single welding melt to which molten metal is supplied by melting a filler wire, wherein the welding melt is provided on at least one steel part including an aluminum surface coating, and a protective gas is used, characterized in that the filler wire contains at least 3 wt % of one or more gammagenic elements, in particular the gammagenic elements selected from C, Mn, Ni and N, and the protective gas consists of helium and / or argon with the addition of at least 10 vol % of nitrogen or oxygen. The method of the invention is particularly suitable for welding end-welded flanks used in the field of manufacturing automobiles or for tube welding.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

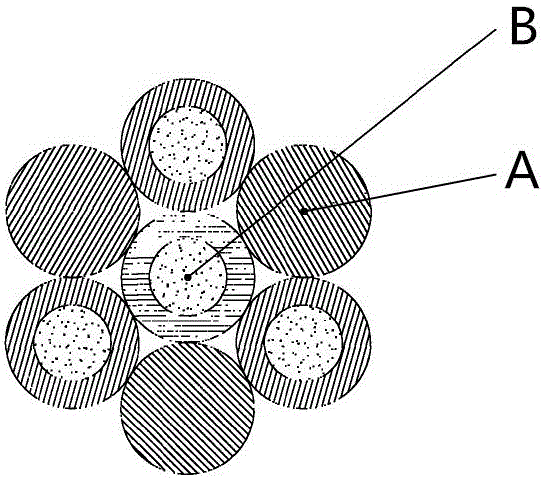

Laser-electric arc hybrid welding method capable of reducing aluminum alloy welding pores

InactiveCN106475684AInhibition formation rateSimple methodWelding/soldering/cutting articlesLaser beam welding apparatusLaser-hybrid weldingLiquid metal

The invention discloses a laser-electric arc hybrid welding method capable of reducing aluminum alloy welding pores and belongs to the field of laser hybrid welding. The method adopts a stranded welding wire for replacing a common aluminum alloy welding wire and adopts a laser-electric arc hybrid heat source for welding aluminum alloy. The stranded welding wire is adopted for mainly applying the specific rotary welding electric arc shape of the stranded welding wire, so that liquid metal in a molten pool flows in an eddy current type; and strong agitation is produced to fluid in the molten pool, and overflow of gas in molten metal and uniform distribution of beneficial elements in the molten pool can be benefited, so that weld defects are reduced, and the welding quality is improved. By adopting the welding method disclosed by the invention, production of welding pores can be effectively reduced, the operation is simple and convenient, and no extra complex equipment is adopted.

Owner:CHINA UNIV OF MINING & TECH

Weld defect detection systems and methods for laser hybrid welding

ActiveUS8552337B2Welding/cutting auxillary devicesArc welding apparatusLaser-hybrid weldingPower flow

Laser hybrid welding systems adapted to identify and / or fix a weld defect occurring during a laser hybrid welding process are provided. Embodiments of the laser hybrid welding system may include one or more devices that provide feedback to a controller regarding one or more weld parameters. One embodiment of the laser hybrid welding system includes sensors that are adapted to measure the weld voltage and / or amperage during the welding process and transmit the acquired data to the controller for processing. Another embodiment of the laser hybrid welding system includes a lead camera and a lag camera that film an area directly in front of the weld location and directly behind the weld location.

Owner:ILLINOIS TOOL WORKS INC

Shielding gas knife for laser hybrid welding

ActiveCN106271082ABlock smokePrevent splashLaser beam welding apparatusLaser processingLaser-hybrid welding

Owner:SHANGHAI JIAO TONG UNIV

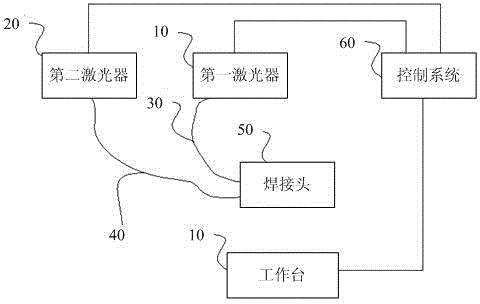

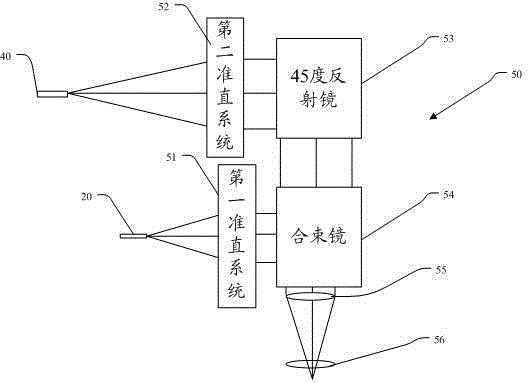

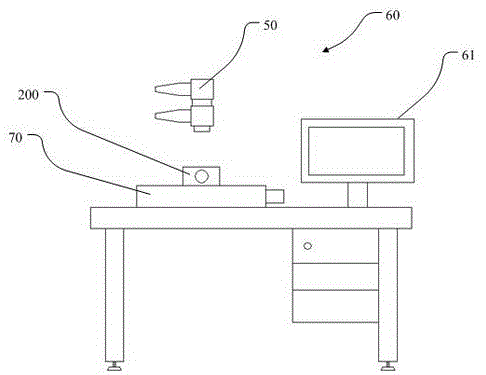

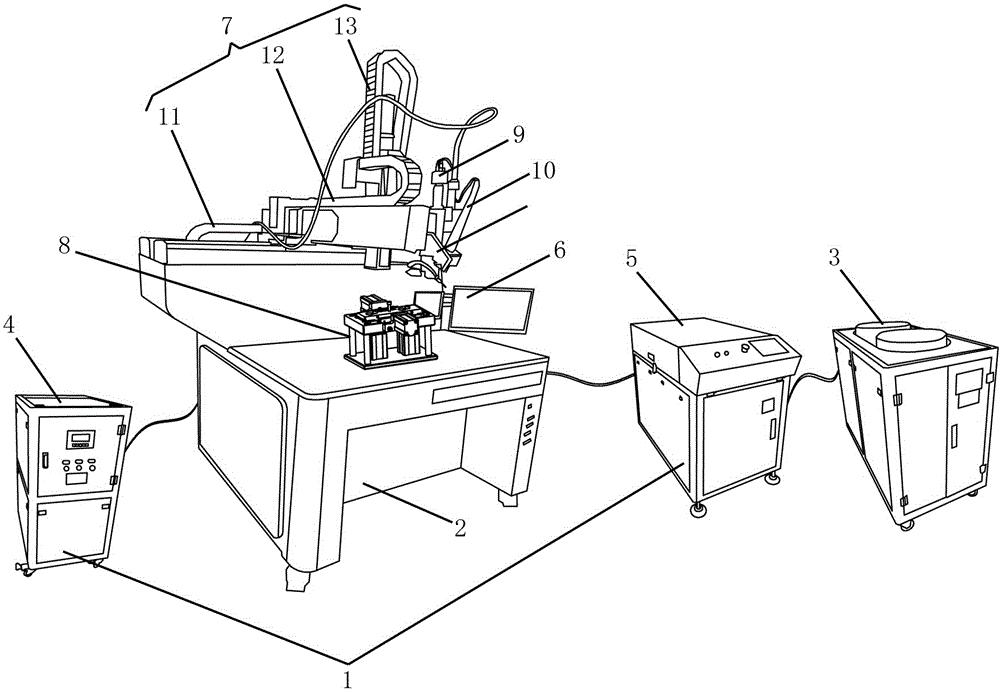

Plastic laser hybrid welding system

The invention relates to the technical field of laser welding, in particular to a plastic laser hybrid welding system. The plastic laser hybrid welding system comprises a welder bracket, a welding robot and a laser emitter and further comprises a multi-color light source device, wherein a clamp for clamping a welded component is arranged on the welder bracket, the laser emitter comprises a laser head, and both the laser head and the multi-color light source device are mounted on the welding robot. The clamp is used for clamping the welded component, ensures that the welded component can be fully bonded, and ensures the connecting firmness, the water tightness and the air tightness of the welded component. Two kinds of light are emitted by the laser head and the multi-color light source device under the control of the welding robot to carry out hybrid welding, and the welded component is prevented from being burnt by a laser light beam in the direction of a light path. Meanwhile, thermal stress and vibration stress produced by the welded component are reduced, the deformation of the welded component is prevented, and the welding quality is improved.

Owner:吴江市民福电缆附件厂

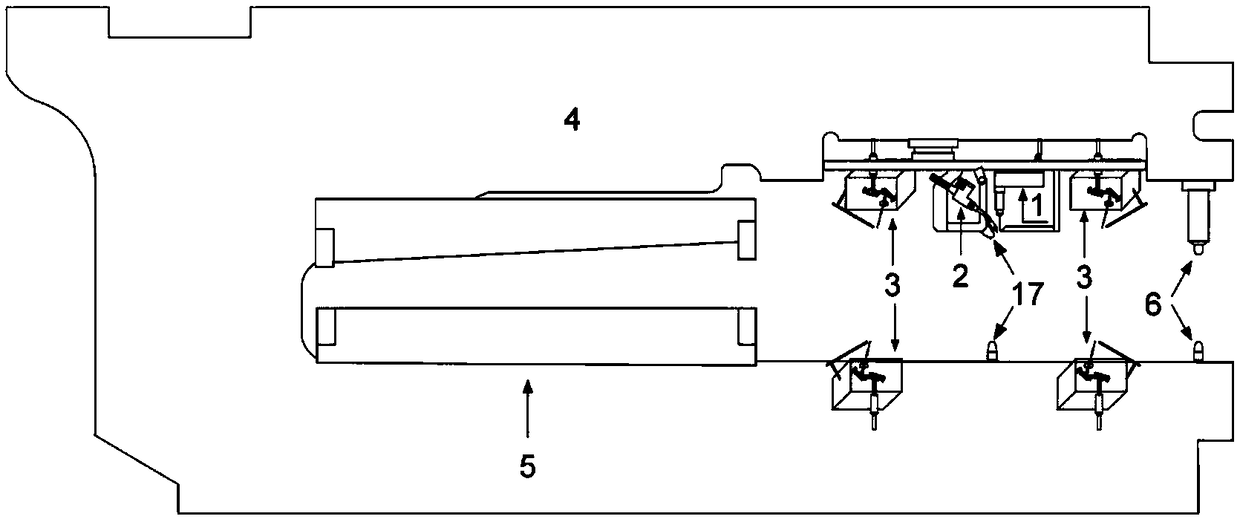

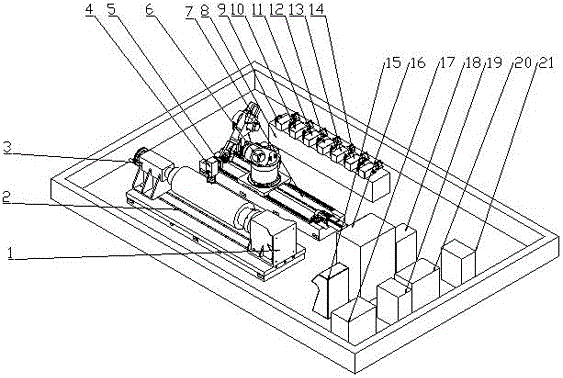

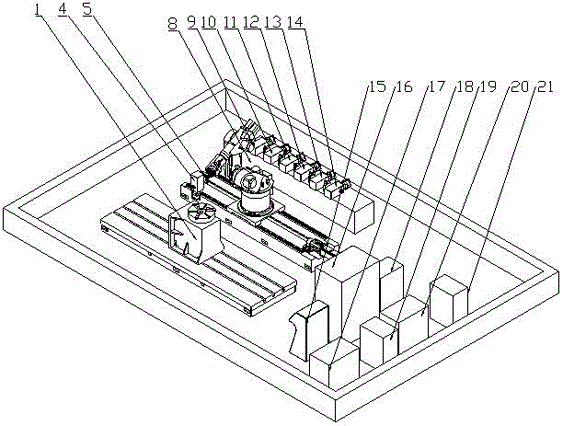

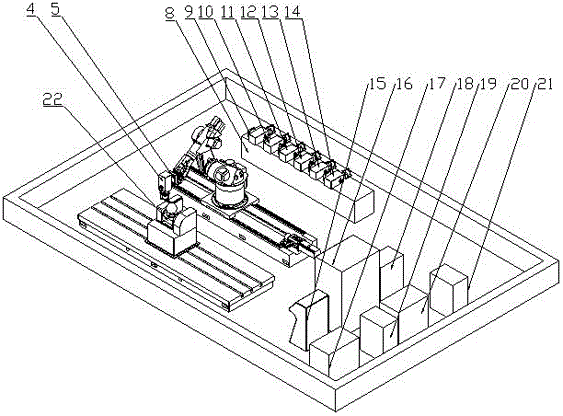

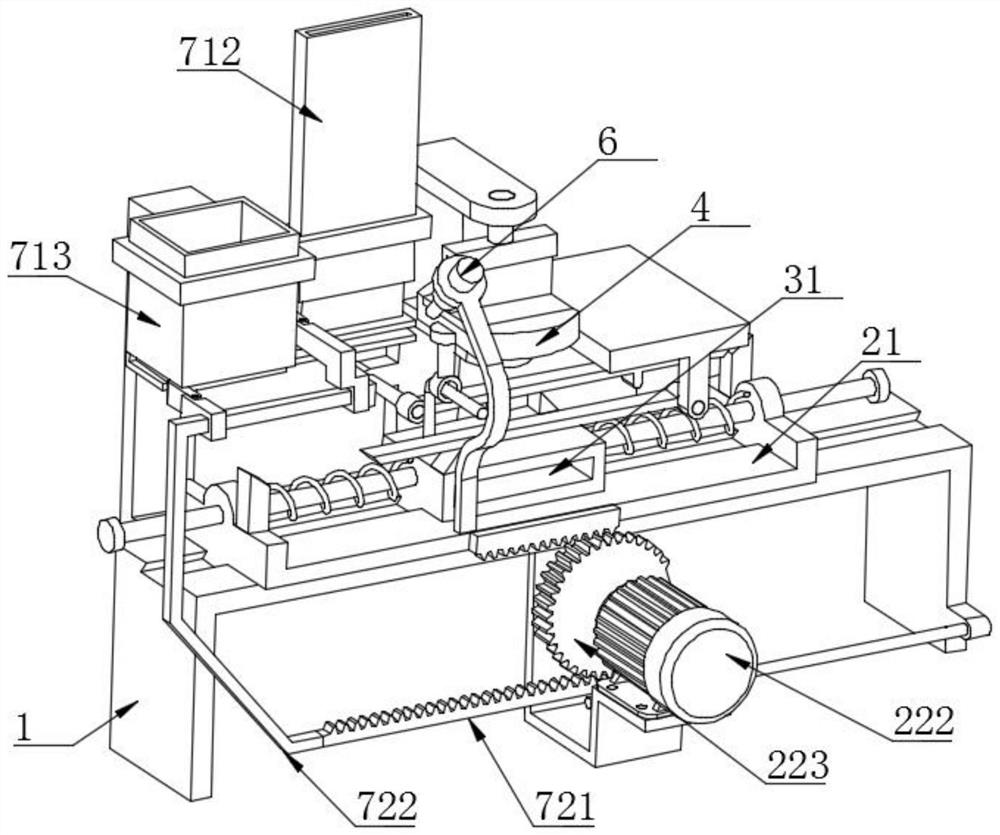

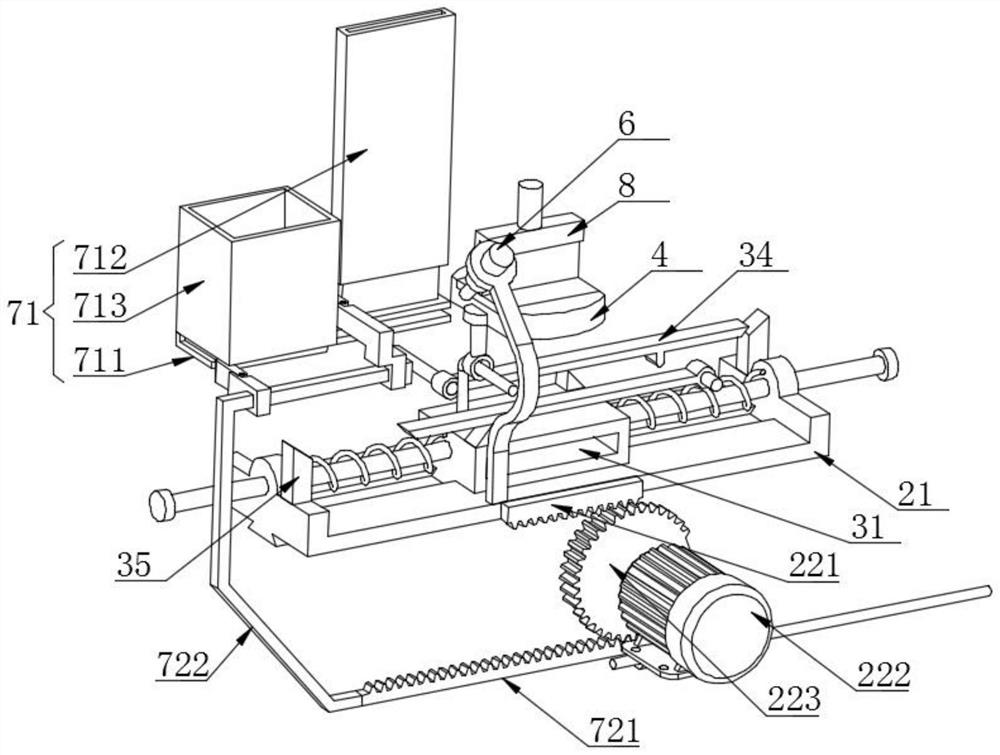

Cleaning and welding integration device for black volume endless rolling

ActiveCN109014943AImprove surface qualityImprove energy utilizationOther manufacturing equipments/toolsLaser beam welding apparatusMelting tankLaser-hybrid welding

The invention belongs to the technical field of hybrid welding and discloses a cleaning and welding integration device for black volume endless rolling. The cleaning and welding integration device comprises a hybrid welding module and a laser cleaning module. Hybrid heat source is formed by the hybrid welding module through laser and electric arc, and the hybrid heat source and the hybrid weldingmould cooperate on the surface of black coil steel to be welded to trigger the molten pool, meanwhile, the laser attracts the electric arc so that drift of arc root of the electric arc can be restrained; the laser cleaning module is used for partial cleaning of the upper and lower surfaces before and after welding of the joint of the black coil steel ; the hybrid welding module and the laser cleaning module are both arranged on the same support, and a integrative structure of cleaning-welding-cleaning is formed, therefore, that on-line cleaning and welding are conducted simultaneous is achieved. The invention further discloses a welding method of the cleaning and welding integration device for black volume endless rolling. According to the cleaning and welding integration device for the black volume endless rolling, metallurgical defects of air holes, inclusion and incomplete fusion in the welding process are prevented efficiently, seam quality and smooth after welding in the hybrid welding process are guaranteed, efficiency and stability of endless rolling are improved, and risk of strip breakage is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH +1

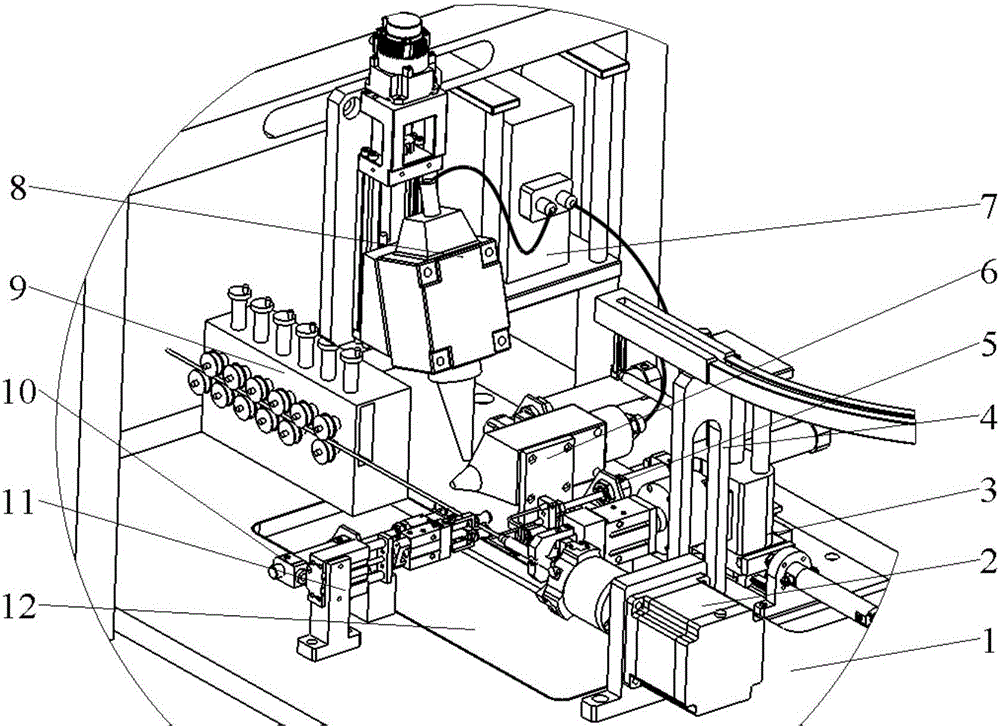

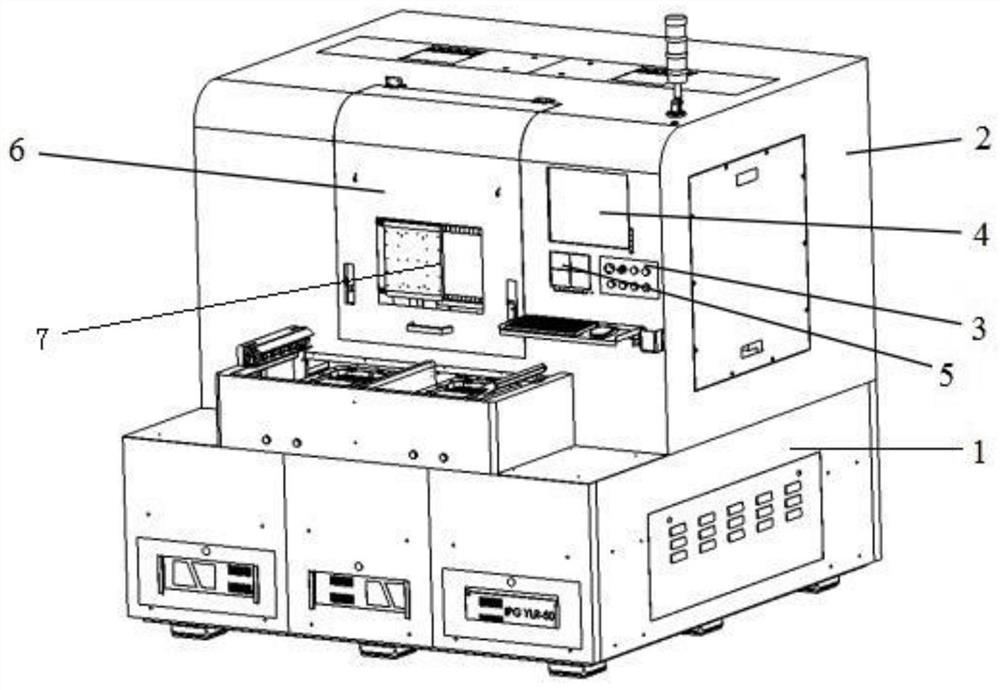

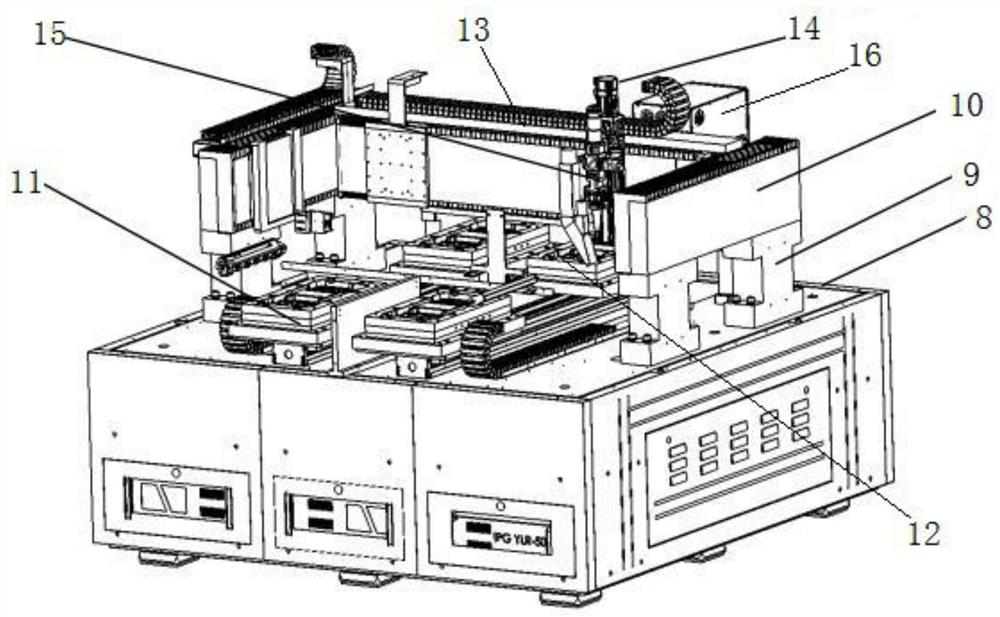

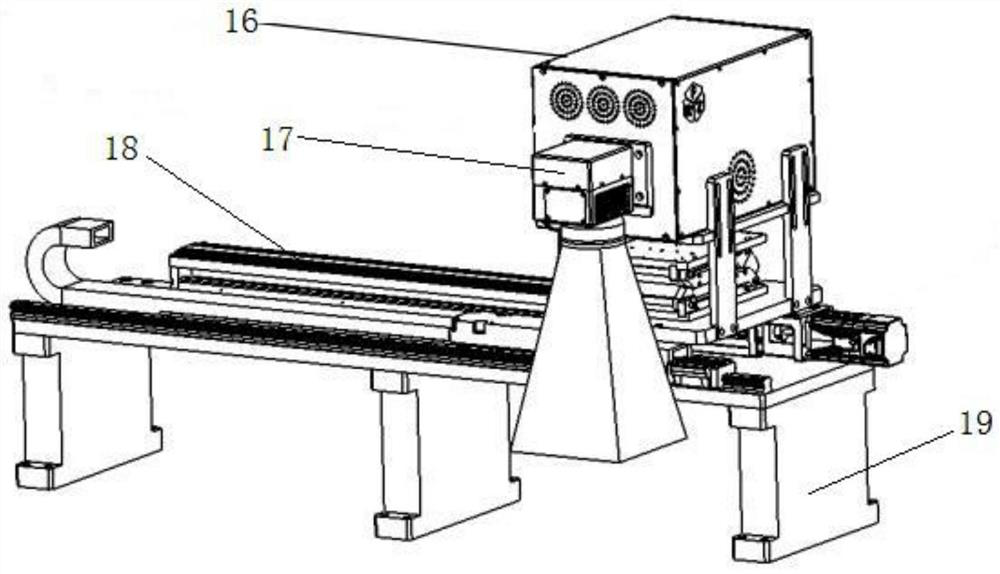

High-precision flexible laser processing system

ActiveCN106624350AQuick Auto SwitchQuick switchLaser beam welding apparatusLaser-hybrid weldingLaser processing

The invention discloses a high-precision flexible laser processing system. The high-precision flexible laser processing system can achieve up to seven types of 3D laser processing on the surfaces of various workpieces. The types of laser processing comprise laser cladding, laser welding, laser quenching, laser cutting, laser hybrid welding, laser micro-processing and laser cleaning. The high-precision flexible laser processing system is composed of a laser system, a mechanical motion forming system, a laser head base system, a control system and an auxiliary system. According to the flexible laser processing system, laser heads are installed on a robot arm in the mechanical motion forming system through a fast switch, the fast switch can be matched with a laser head base for use so that the laser heads can be switched quickly and automatically, and thus the functions of the high-precision flexible laser processing system can be switched rapidly.

Owner:NANTONG UNIVERSITY

Laser hybrid welding equipment

InactiveCN106392329ARealize automatic deliveryRealize the clamping effectLaser beam welding apparatusLaser-hybrid weldingEngineering

The invention discloses laser hybrid welding equipment. The laser hybrid welding equipment comprises an operation table for welding, a damping device is arranged at the lower end of the operation table, a conveying device used for conveying work-pieces to be welded is arranged in the middle of the upper end of the operation table and is provided with a plurality of work-piece clamping mechanisms, two parallel supporting rods are arranged on each of two sides of the conveying device, a connecting block is fixed to the upper ends of two supporting rods on one side, a moving mechanism is arranged on the two connecting blocks, a fixing device is arranged on the moving mechanism, and a welding equipment body is arranged on the fixing device. According to the laser hybrid welding equipment, automatic conveying and clamping of the work-pieces are realized through the conveying device and the clamping devices, three-dimensional moving of a laser welding gun and an arc welding gun is realized through a second electric sliding rail, a first air cylinder, a third drive device and the moving mechanism, the welding efficiency is improved, and the application range of laser hybrid welding is expanded. Thus, the laser hybrid welding equipment is suitable for being popularized.

Owner:QINGDAO BRANCH CO., LTD. OF MECHANICAL SCIENCE RESEARCH INSTITUTE

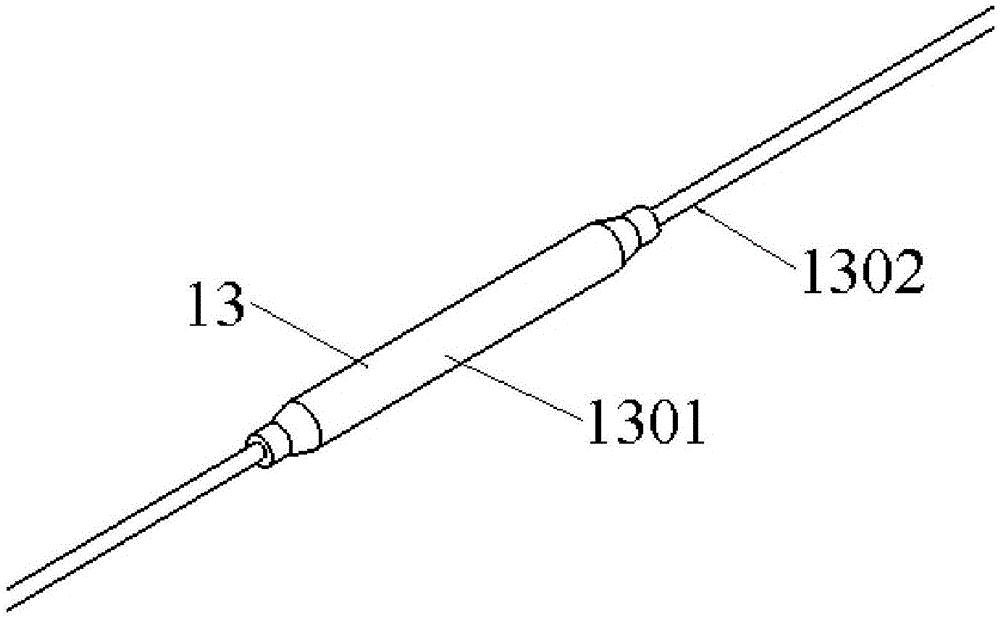

Preparation method and device of laser cutting and laser hybrid welding combined socketed pipe

ActiveCN106735936ASolid phase junctionSolve the problem of welding blockage caused by flowing into the copper pipeWelding/cutting auxillary devicesAuxillary welding devicesLaser-hybrid weldingStructural engineering

The invention provides a preparation method of a laser cutting and laser hybrid welding combined socketed pipe. The preparation method comprises the steps of clamping a hollow copper pipe; inserting one end of a hollow copper core into the hollow copper pipe; arranging a high-frequency induction heating coil; connecting an electronic optical shutter splitter to the output end of a laser; outputting welding laser beams, and performing fixed spot welding; outputting cutting laser beams so as to cut off the hollow copper core; outputting the welding laser beams so as to obtain laser circumferential welding seams of the side end of the socketed pipe; electrifying and preheating the high-frequency induction heating coil; after the preheating temperature reaches a set value, performing solid-phase coupling of socketed weld metal through an extrusion wheel; horizontally turning over the hollow copper pipe for 180 degrees; and then welding the other end of the hollow copper pipe. According to the preparation method, two techniques of laser welding and high-frequency induction welding are combined, so that the problem of welding blocking formed in a way that local molten materials flow into the copper pipe by adopting traditional simple high-frequency induction welding is effectively solved; the invention further provides a preparation device of the socketed pipe.

Owner:山东特车机械配件有限公司

Induction heating and laser hybrid welding device and method for thick plate welding

ActiveCN108747024AReduce welding defectsReduce laser energy inputLaser beam welding apparatusLaser-hybrid weldingThick plate

The invention relates to an induction heating and laser hybrid welding device for thick plate welding. The induction heating and laser hybrid welding device for thick plate welding comprise an installation plate and two welding plates, wherein a hole slot is formed in the middle of the top surface of the installation plate; first through holes are formed in the middles of the left end surface andthe right end surface of the installation plate; the inner ends of the first through holes communicate with the hole slot; a vertical micro servo motor is fixedly arranged at the upper end of the holeslot; the lower end of an output shaft of the servo motor is located in the hole slot; a first horizontal shaft is arranged in the first through hole in the right side; a second horizontal shaft is arranged in the first through hole in the left side; the inner ends of the first horizontal shaft and the second horizontal shaft are connected with the inner ends of the corresponding first through holes through sealing bearings; first bevel gears are fixedly arranged at the inner ends of the first horizontal shaft and the second horizontal shaft; a second bevel gear is fixedly arranged at the lower end of the output shaft of the servo motor; and the first bevel gears mesh with the second bevel gear. The induction heating and laser hybrid welding device for thick plate welding provided by theinvention has a wire feeding function and an air cooling function, only requires one motor for providing power, and is simple in structure, low in cost, and convenient to use.

Owner:长沙跃博机电科技有限公司

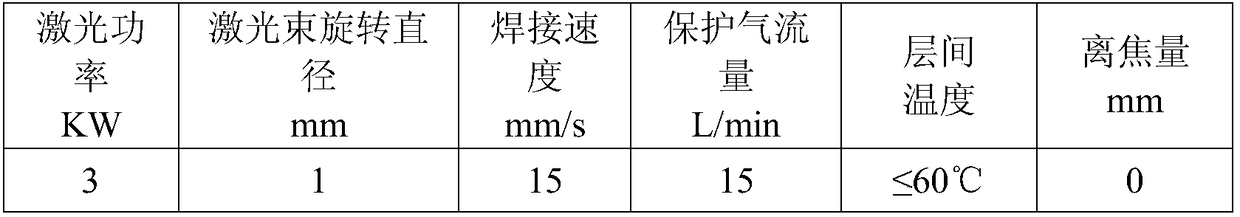

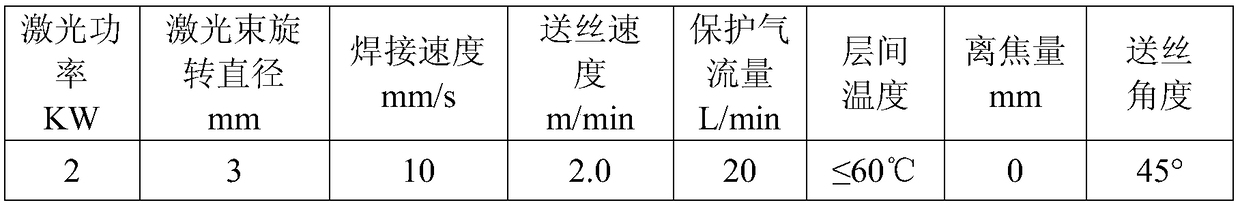

Laser hybrid welding technological method of high-strength magnesium alloy thick plate

PendingCN109483053AReduce adverse effectsBreak through the technical problems of weldingWelding/cutting auxillary devicesAuxillary welding devicesLaser-hybrid weldingWelding defect

The invention discloses a laser hybrid welding technological method of a high-strength magnesium alloy thick plate. The laser hybrid welding technological method comprises the following steps: 1, designing a welded joint: a groove of the welded joint adopts the double Y-shaped groove type with truncated edges; 2, preparing welding equipment: the welding equipment is composed of a semiconductor laser with the laser beam rotary function and a robot welding arm; 3, making preparation before welding; 4, carrying out truncated edge welding; and 5, groove welding. According to the laser hybrid welding technological method, the technology is simple, and through the welding method of truncated edge laser deep penetration welding and groove laser filler wire welding, the problem that the welding defects including a concave pit, an undercut and the like are likely to be formed on the surface of a welding seam is perfectly solved, the matching precision requirement of laser welding to the technological parameters including welding powder, welding speed, wire feed rate and wire feed angle and the like is lowered, the technological problem about fusion welding of a deformed high-strength magnesium alloy thick plate (20mm-50mm) is solved, excellent welding of the high-strength magnesium alloy thick plate is realized, the welding seam forming is level, smooth and artistic, the mechanical property of the welded joint meets the indicator requirement, the quality and property of the welded joint are greatly improved, and the laser hybrid welding technological method is suitable for weldingengineering structural components with various sizes.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Laser-hybrid-welding molding equipment for aluminum alloy mobile phone shell and molding process of laser-hybrid-welding molding equipment

InactiveCN106425094AFast productionIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlLaser-hybrid welding

The invention relates to laser-hybrid-welding molding equipment for an aluminum alloy mobile phone shell and a molding process of the laser-hybrid-welding molding equipment. The laser-hybrid-welding molding equipment comprises a laser device, a welding device and a cooling device; the laser device comprises a continuous type optical fiber laser device and a pulse type optical fiber laser device; the welding device is provided with a CNC numerical control device, a transmission mechanism and a clamping mechanism; the continuous type optical fiber laser device and the pulse type optical fiber laser device are respectively connected with the CNC numerical control device; a continuous type optical fiber laser head and a pulse type optical fiber laser head are mounted at the transmission mechanism; the cooling device is electrically connected with the pulse type optical fiber laser device. The laser-hybrid-welding molding equipment provided by the invention has the beneficial effects that a traditional continuous type optical fiber laser device and a traditional pulse type optical fiber laser device are combined on the welding device, the shell and a middle frame of a mobile phone are subjected to laser welding operation by adopting continuous type and pulse type laser simultaneously, metal structures are not changed, and meanwhile the laser welding operation is combined with metallurgy, so that the production speed is five times that of a traditional numerical control milling way or higher, the production efficiency is greatly improved, the production period is shortened, the machining cost is lowered, and high practicability is realized.

Owner:广东金三甲精密科技有限公司

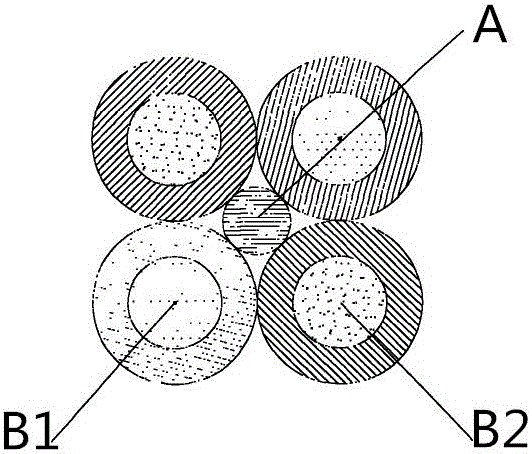

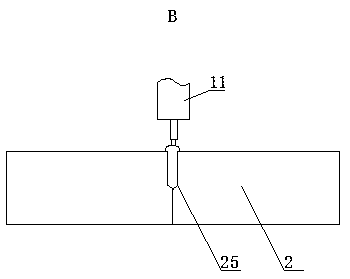

Method for improving optical fiber laser-MIG arc hybrid welding back forming

InactiveCN104028893AGuaranteed stabilityGuaranteed forming effectLaser beam welding apparatusLaser-hybrid weldingPower flow

The invention provides a method for improving optical fiber laser-MIG arc hybrid welding back forming. The method includes the following steps that (1) the minimum power Pd of an optical fiber laser device during single-laser welding and through welding is determined; (2) the minimum power Pf of the optical fiber laser device during optical fiber laser-MIG arc hybrid welding and through welding is set, the current of MIG arc welding is I, the ratio of Pd to Pf is determined according to the following formula that Pd:Pf=(1+a)*Pd*(1+bI / 120-b), a is 20-30%, when I is larger than or equal to 90A and when I is larger than or equal to 90 A and smaller than 120A, b is 0, and when I is larger than or equal to 120A, b is 1; (3) optical fiber laser-MIG arc hybrid welding is carried out according to the following welding mode that in the welding direction, an MIG welding point is in front, a laser welding point is at back, a heat source distance ranges from 1 mm to 2 mm, the lengthening quantity of a welding wire is 8-12 mm, a welding torque inclined angle is 55-60 degrees, and a welding gap is 0-0.5 mm. Hybrid welding is carried out according to the method, so that the back forming effect during single-side through welding of hybrid welding can be guaranteed, and meanwhile stability of MIG welding can be guaranteed.

Owner:武汉钢铁有限公司

Shipyard thin plate splicing butt-joint laser hybrid welding system

PendingCN112139659AIncrease productivityHigh speedLaser beam welding apparatusLaser-hybrid weldingPlate pressure

The invention discloses a shipyard thin plate splicing butt-joint laser hybrid welding system which is characterized in that a laser hybrid welding spliced plate pressure frame is arranged between a feeding platform and a discharging platform; the laser hybrid welding spliced plate pressure frame is composed of an adjustable liner plate, a grounding device, a piano key type pressing unit, a milling device, a recycling system and a welding device; the adjustable liner plate and the grounding device are arranged between two fixed gantries; the feeding platform pushes a thin plate to a welding station of the laser hybrid welding spliced plate pressure frame through a clamping frame, and spliced plates are automatically welded through the welding device and then sent out of the system throughthe discharging platform, so that the automatic line production of spliced plate butt joint is achieved. Compared with the prior art, the shipyard thin plate splicing butt-joint laser hybrid welding system provided by the invention integrates thin plate splicing, milling and welding, is simple in structure and good in compatibility, and is used for the spliced plate butt-joint automatic welding ofthe plane thin plates in the shipyard plate hull manufacturing and machining process, so that the production efficiency of thin plate splicing and welding can be greatly improved.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

Cross-jet guiding device for hybrid laser welding

InactiveCN101003108AAchieve automationSupport devices with shieldingLaser beam welding apparatusLaser-hybrid weldingLaser beams

The invention relates to a device, especially a laser-hybrid welding head, for a laser-hybrid welding process. A laser or a laser optical system or an optical focussing unit and elements of a welding torch for an arc-welding process or of a supply device for a welding wire, and a device for forming a cross jet which is connected to a pressurised air supply system by at least one feed line and one discharge line are located on at least one mounting element. Said feed line and said discharge line for the pressurised air of the cross jet are located between the two components, especially the laser or the laser optical system or the optical focussing unit and the elements of the welding torch or the supply device for the welding wire.

Owner:FRONIUS INTERNATIONAL GMBH

Bipolar plate laser hybrid welding equipment for hydrogen fuel cell

PendingCN112775542AGuaranteed pressing forceDoes not block the welding positionLaser beam welding apparatusCollectors/separatorsLaser-hybrid weldingHydrogen fuel cell

The invention discloses bipolar plate laser hybrid welding equipment for a hydrogen fuel cell. The bipolar plate laser hybrid welding equipment comprises a cabinet base, a protection cabinet, a cabinet door, a marble platform, a first marble portal frame, a first Y-axis linear module, a jig for fixing a bipolar plate, a second Y-axis linear module, a first X-axis linear module, a Z-axis linear module, a collimation laser welding head, a second portal frame, a second X-axis linear module, an optical fiber laser and a laser scanning galvanometer. A light outlet of the laser scanning galvanometer is vertically downward, and emitted laser is perpendicular to the upper end face of the bipolar plate on the jig. Compared with the prior art, high-efficiency machining of the bipolar plate can be achieved, and the laser welding yield of the bipolar plate can be remarkably increased.

Owner:苏州富润泽激光科技有限公司

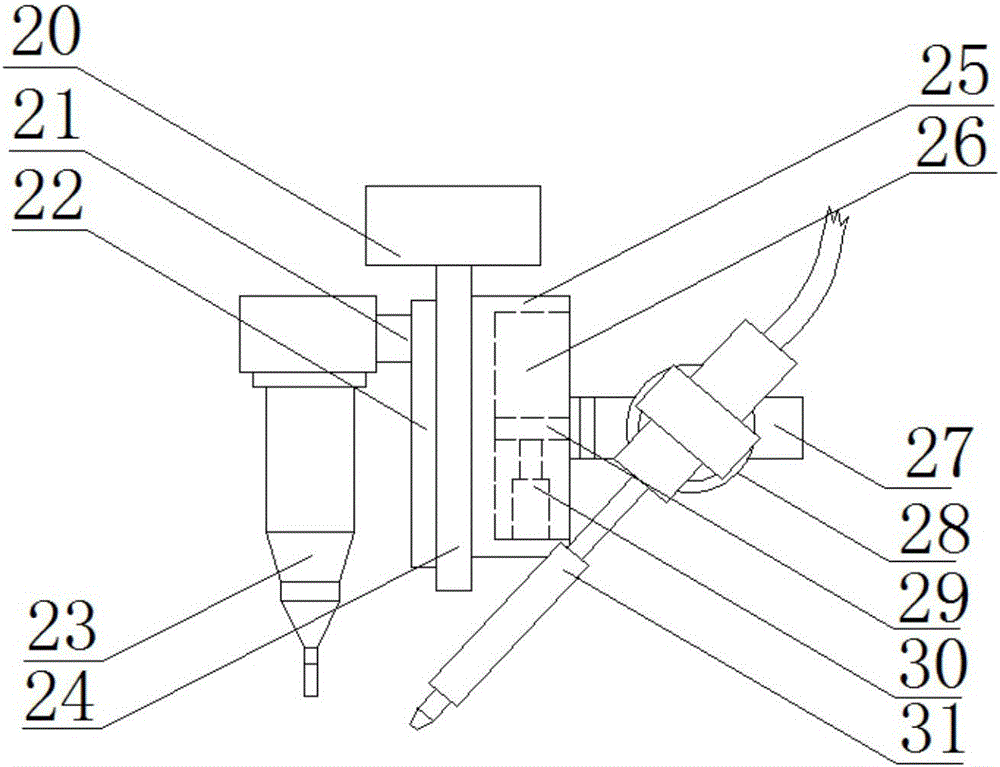

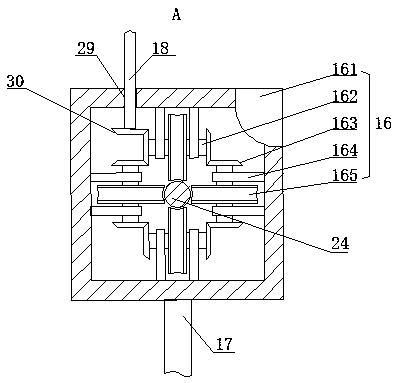

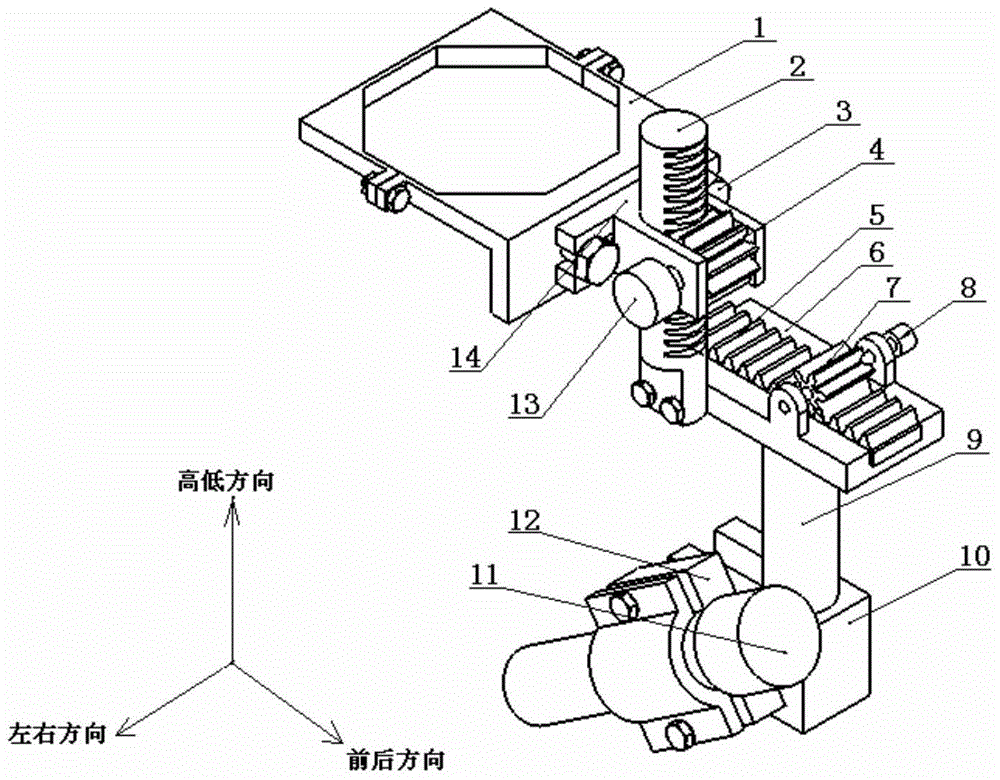

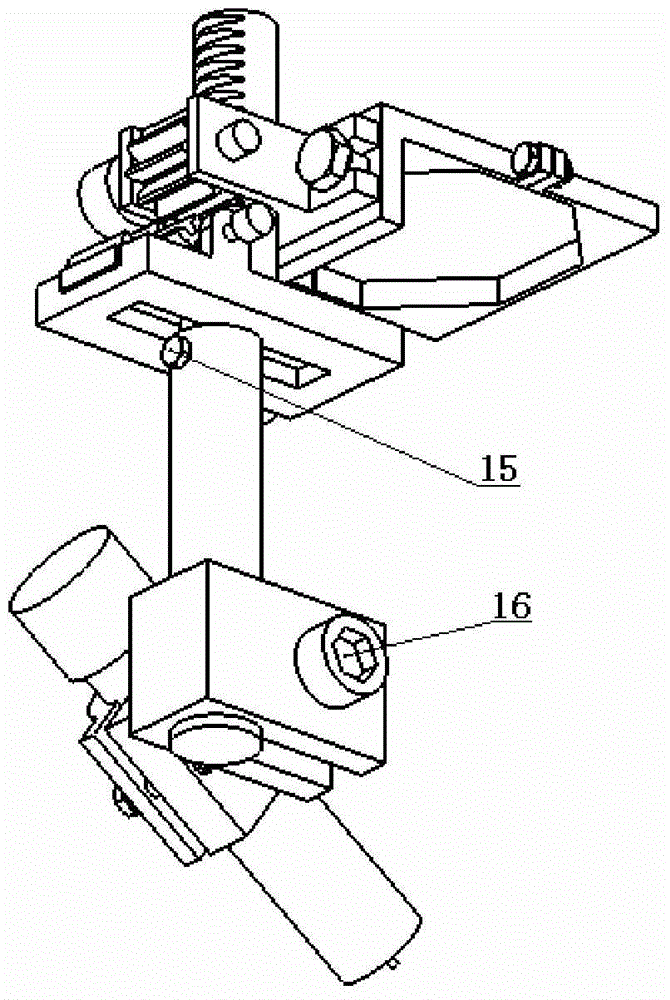

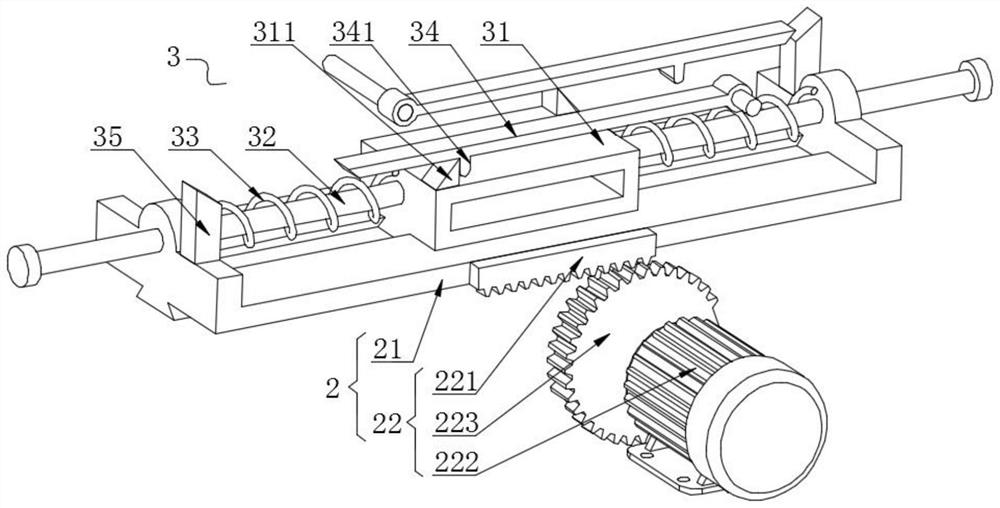

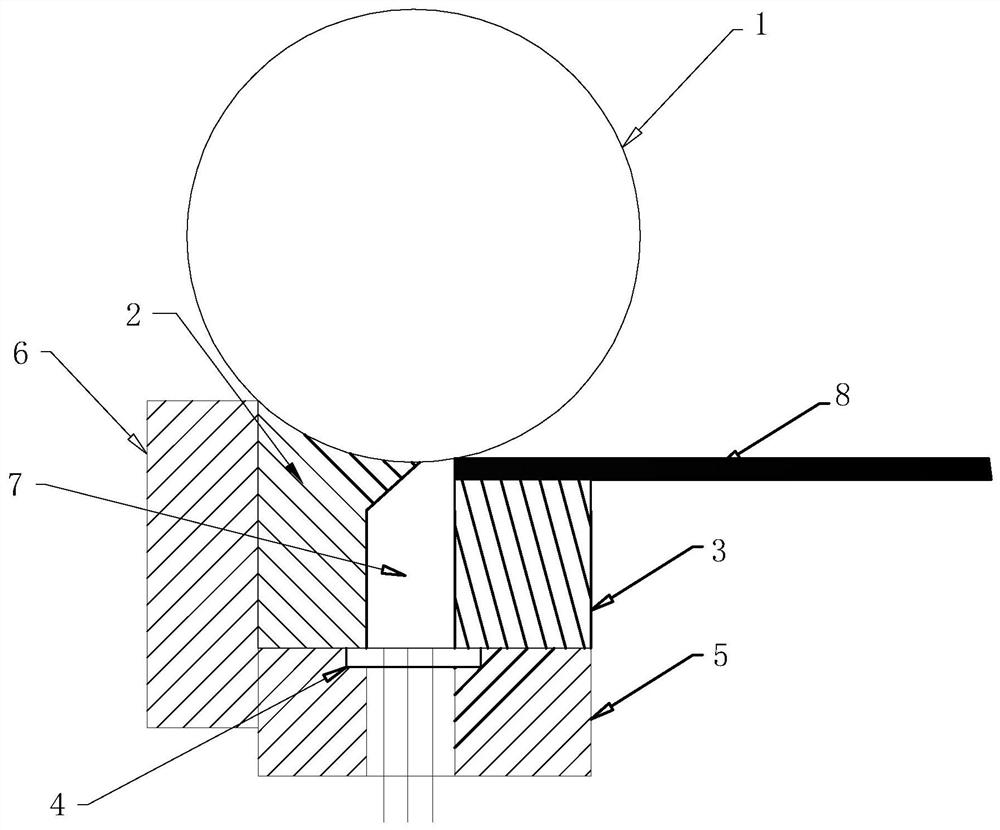

A welding torch adjustment device for laser arc hybrid welding

ActiveCN104942440BEasy to adjustSimple and fast operationLaser beam welding apparatusLaser-hybrid weldingThree-dimensional space

The invention discloses an adjustment device of a laser-electric arc combined welding gun. The adjustment device comprises a laser head clamping sleeve and the welding gun. The welding gun is connected with the laser head clamping sleeve sequentially through an angle adjustment mechanism, a front-and-back adjustment mechanism, an up-and-down adjustment mechanism and a left-and-right adjustment mechanism. The laser head clamping sleeve is connected with a laser welding head. The angle adjustment mechanism comprises a welding gun clamping sleeve, a guide column clamping sleeve, an angle adjustment guide column and an angle adjustment screw. The front-and-back adjustment mechanism comprises a sliding guide rail, a rack and a gear in the front-and-back direction, wherein the rack is meshed with the gear. The up-and-down adjustment mechanism comprises a sleeve base, a high-low-direction guide column with a rack and a high-low-direction gear, wherein the guide column is meshed with the gear. The left-and-right adjustment mechanism comprises a left-and-right adjustment screw, and the left-and-right adjustment screw penetrates through a long hole in the sleeve base to be fixed to the laser head clamping sleeve. Operation is easy and convenient, the structure is reasonable, manufacturing is convenient, the position of laser beams of the welding gun in three-dimensional space can be accurately adjusted, and the angle adjustable range is greatly expanded.

Owner:北京三帝科技股份有限公司

Continuous welding device for laser hybrid welding

InactiveCN113977086AEasy to weldImprove efficiencyLaser beam welding apparatusLaser-hybrid weldingPunching

The invention discloses a continuous welding device for laser hybrid welding, wherein the device is used for welding a metal plate I and a metal plate II which are mutually vertically arranged; and the invention particularly relates to the technical field of welding. The continuous welding device comprises a rack and a power assembly, and the power assembly comprises a sliding table sliding on the rack and a driving mechanism driving the sliding table to move in a reciprocating manner; the continuous welding device also comprises a rapid punching assembly arranged on the sliding table, the rapid punching assembly comprises a rapid punching table capable of sliding on the sliding table, and the sliding table can move in a reciprocating mode to drive the rapid punching table to advance; and the continuous welding device further comprises a welding table, the rapid punching table can drive the welding table to rotate when moving, and a welding gun used for welding the metal plate I and the metal plate II is fixedly mounted on the sliding table. On one hand, a welding seam A and a welding seam B are welded in sequence through left-right movement of the sliding table, and on the other hand, the positions can be switched after first-time welding, so that continuous welding and continuous welding are facilitated, and the efficiency is high.

Owner:LANDAHE INTELLIGENT EQUIP (SUZHOU) CO LTD

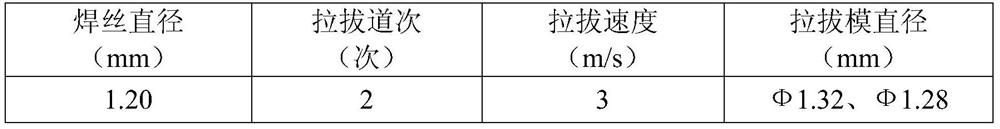

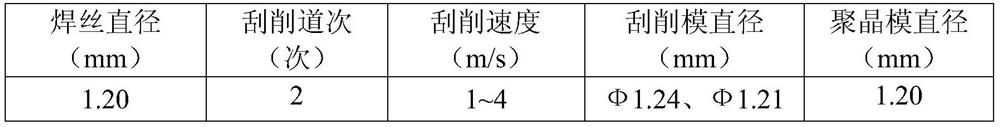

A kind of preparation method of magnesium alloy welding wire

ActiveCN109570826BSave energySolve the "bottleneckWelding/cutting media/materialsSoldering mediaLaser-hybrid weldingFusion welding

A preparation method of magnesium alloy welding wire, the steps are: ingot extrusion; wire billet cleaning; preheating; continuous extrusion: continuous feeding into the extruder, through the control of the extrusion speed and the adjustment of the temperature control system, to maintain The continuous extrusion temperature is between 380°C and 450°C; drawing; scraping; surface treatment. The preparation method of the present invention is not only simple in process and easy to operate, but also efficient in processing and low in economic cost, adopts continuous extrusion, greatly improves the processing performance of magnesium alloys, effectively solves the problem of joint connection of magnesium alloy welding wires, and can produce high-quality magnesium Alloy jointless welding wire can meet the quality requirements of fusion welding such as automatic MIG welding, TIG welding and laser hybrid welding, and is suitable for industrial production of high-quality magnesium alloy welding wire.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Hybrid arc/laser-welding method for aluminized steel parts using gammagenic elements and a gas containing less than 10 % of nitrogen or oxygen

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Laser-lateral CMT hybrid welding method

ActiveCN107717230AEasy spacing controlPrecise spacing controlLaser beam welding apparatusLaser-hybrid weldingElectric arc

The invention relates to a laser-lateral CMT hybrid welding method and relates to the field of material processing engineering. In order to solve the problems that defects are generated in the weldingprocess, and the depth of fusion is reduced, based on conventional laser-arc hybrid welding, a CMT welding gun is transversely arranged to weld a to-be-welded workpiece. By means of the hybrid methodin which the CMT welding gun is transversely arranged, the laser wire spacing can be precisely controlled within the range from 1 mm to 2 mm, the laser key hole stability is ensured, and blowhole defects are avoided. The laser-arc coupling effect is improved, after the method is adopted, the change of the spacing between the arc and the laser is small whether in the arc burning stage or in the arc transitory stage, a good coupling effect can be kept, and the aims of increasing the depth of fusion and improving the energy utilization rate are achieved.

Owner:HARBIN INST OF TECH

Laser continuous repair welding method

InactiveCN109648198AIncrease roughnessImprove laser absorption rateLaser beam welding apparatusLaser-hybrid weldingEngineering

The invention provides a laser continuous repair welding method which comprises the following steps of S1, picking defective batteries passing through a welding post; S2, carrying out secondary lasercleaning on the defective batteries; S3, re-placing the batteries subjected to secondary laser cleaning under the welding post, and carrying out laser welding, wherein a welding parameter and a welding trace are the same as a primary welding parameter; S4, carrying out secondary bright-dipping repair welding on the batteries through laser; and S5, if a repair welding effect is poor, repeating thesteps S1 to S4. The laser continuous repair welding method provided by the invention only uses existing equipment and process parameters and does not need to be readjusted so as to be simple and convenient. According to the repair welding method provided by the invention, a laser cleaning area includes a sealing nail welding bead area and exceptant areas, so that the roughness of the welding beadcan be improved, and the laser absorptivity during repair welding is improved; after laser repair welding, the welding bead is smooth and level in surface and good in sealability; and the welding efficiency is high, and the cost is low.

Owner:HANS LASER TECH IND GRP CO LTD

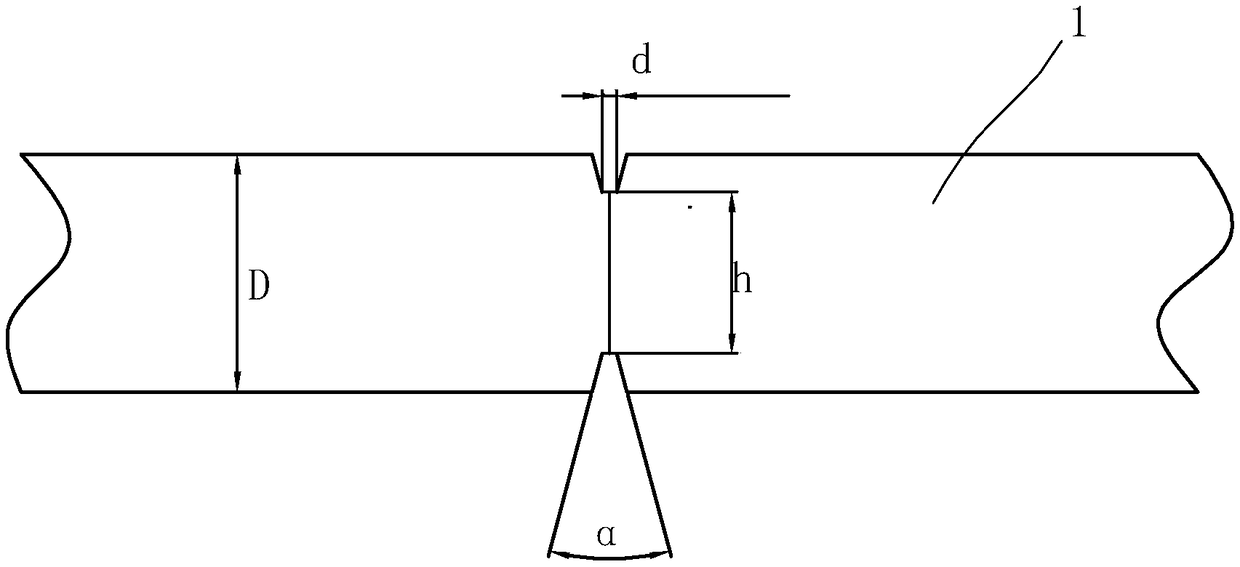

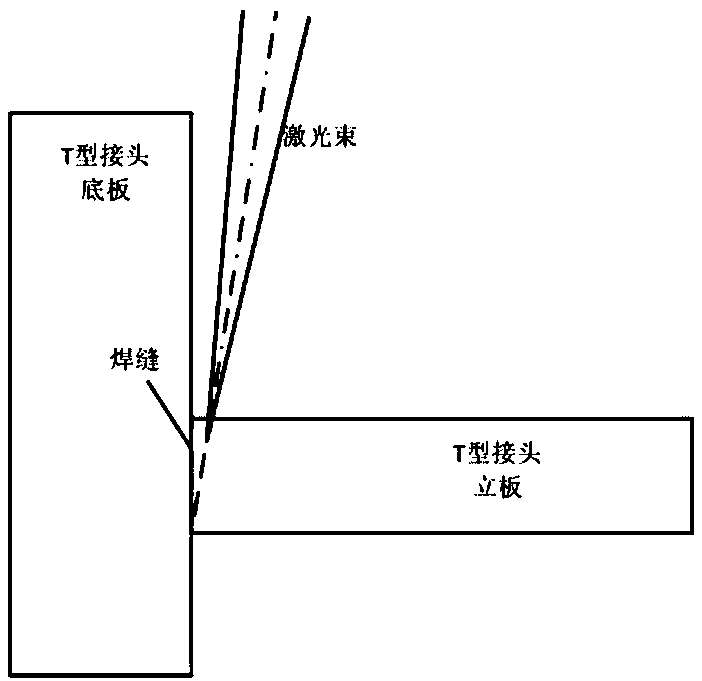

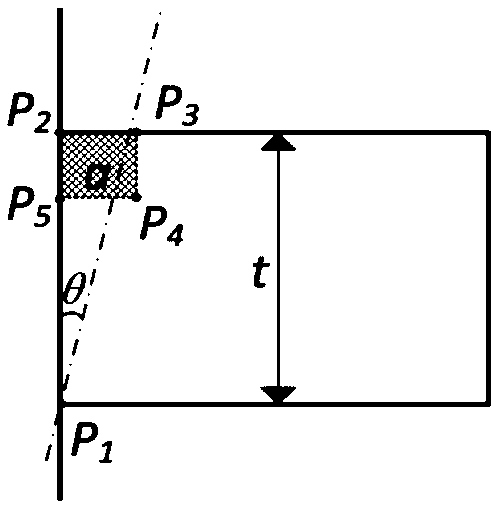

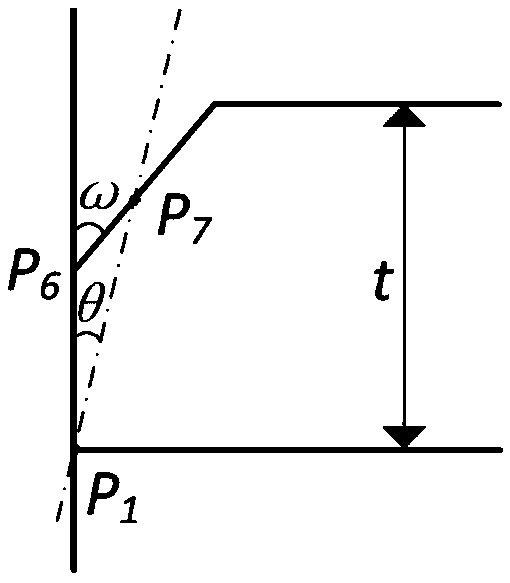

Laser incidence angle determining method for full penetration laser hybrid welding of T-shaped connector

ActiveCN109366010AImprove design efficiencyReduce dependenceLaser beam welding apparatusLaser-hybrid weldingOptical axis

The invention provides a laser incidence angle determining method for full penetration laser hybrid welding of a T-shaped connector, and relates to the professional technical field of laser welding. The problems that in the implementation process of an existing full penetration T-shaped connector, when the laser incidence angle is designed, a large number of process tests are adopted for the trial-and-error process, so that a large quantity of manpower and material resources are consumed are solved. The method includes the steps that the laser incidence angle is preliminarily calculated, wherein a laser beam comes in from one side of a vertical plate, the axis of the laser beam passes through the focal point position, at the root position of a weld joint, of the vertical plate and a bottomplate, the included angle between the axis of the laser beam and the surface of the bottom plate is the laser incidence angle theta, and the maximum value of the laser incidence angle theta is obtained; the size of a groove is designed, wherein whether the depth of penetration is larger than the distance, passing through the vertical plate, of lasers in the optical axis direction or not is judged, if yes, full penetration welding is achieved through square groove welding; if not, the truncated edge thickness and the groove angle of the groove are determined, and the distance, passing throughthe vertical plate, of the lasers in the optical axis direction is smaller than the depth of penetration of hybrid welding; and the laser incidence angle is obtained. By means of the method, the process design efficiency is improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com